Patents

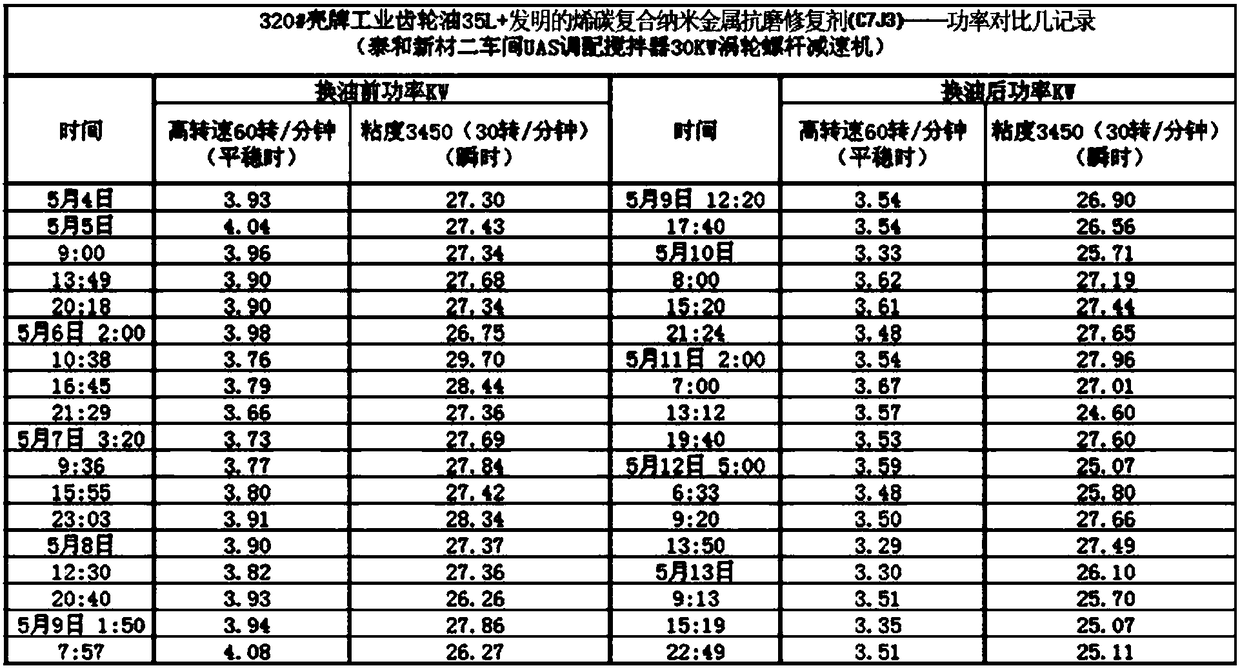

Literature

1014results about How to "Extended replacement cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing ethandiol by catalyzing epoxyethane hydration

InactiveCN1463960AHigh activityGood choiceBulk chemical productionPreparation by hydrolysisEpoxideEnergy consumption

The present invention relates to process of catalytic hydration of ethylene epoxide to prepare glycol and aims at solving the problems of available corresponding process. The said process is especially suitable for low water ratio operation, and has the features of very low heat energy consumption and power consumption, high activity, selectivity and stability of catalyst, and low production cost. The said process may be used in industrial production of glycol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing ethandiol by catalytic hydration of epoxyethane

InactiveCN1204103CHigh activityGood choiceBulk chemical productionPreparation by hydrolysisEthylene oxideHigh activity

The present invention relates to process of catalytic hydration of ethylene epoxide to prepare glycol and aims at solving the problems of available corresponding process. The said process is especially suitable for low water ratio operation, and has the features of very low heat energy consumption and power consumption, high activity, selectivity and stability of catalyst, and low production cost. The said process may be used in industrial production of glycol.

Owner:CHINA PETROLEUM & CHEM CORP +1

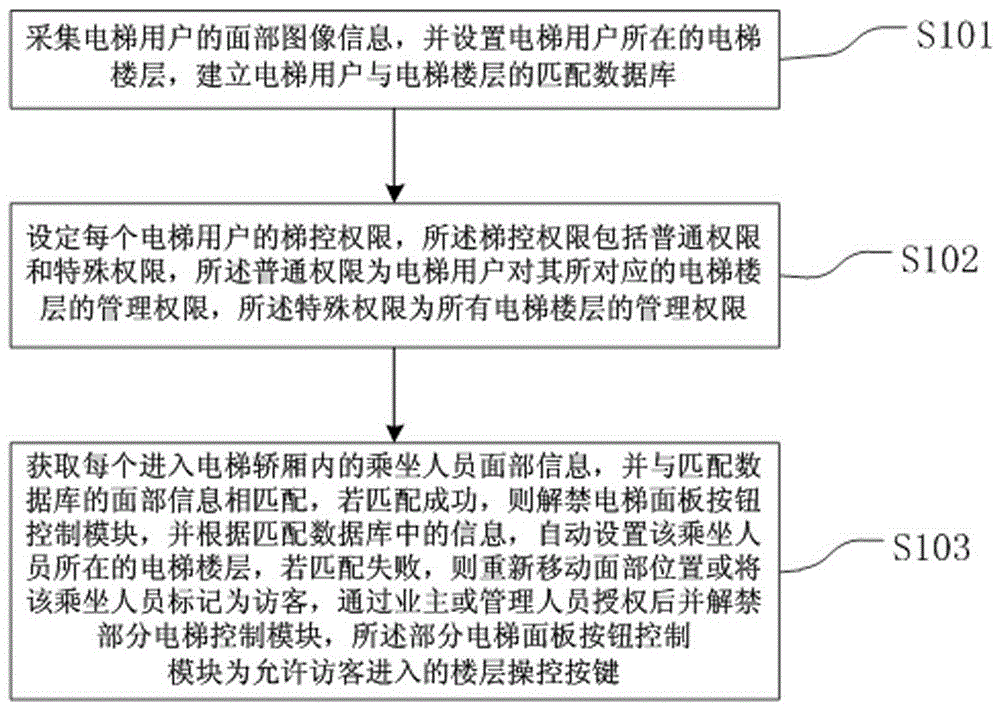

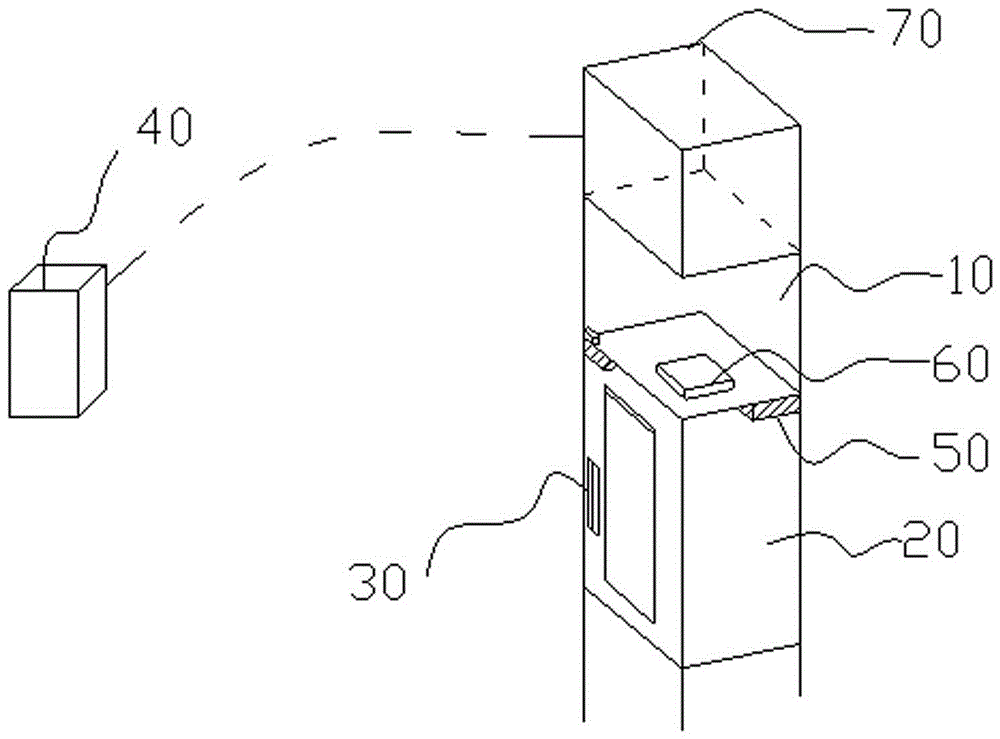

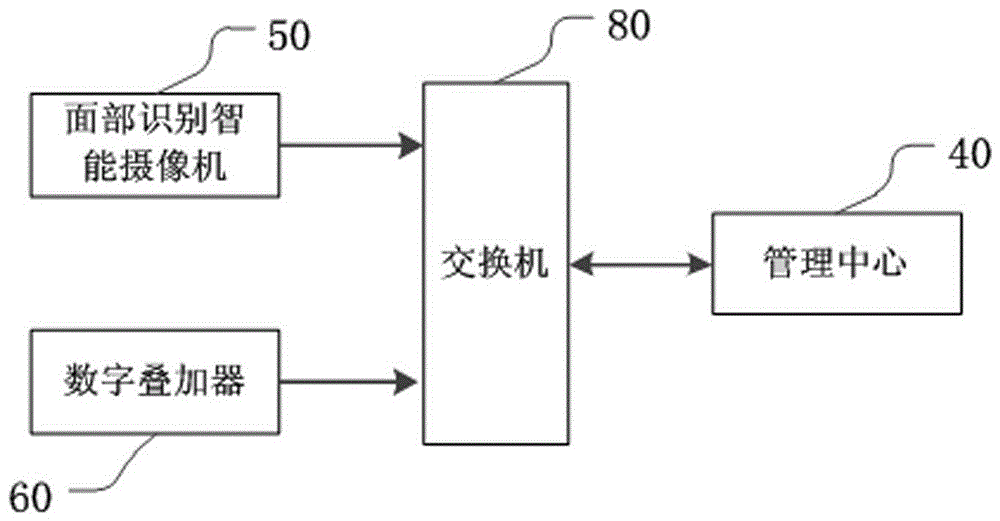

Elevator control method and system based on face recognition

InactiveCN106698118AHigh degree of humanizationImprove security levelElevatorsComputer moduleElevator control

The invention discloses an elevator control method based on face recognition. The elevator control method includes the steps that face image information is collected, and a matched database is established; the elevator control authority of each elevator user is set; and face information of each person entering an elevator is obtained and is matched with the face information in the matched database, and whether the ban on an elevator panel button control module is lifted or the ban is put on the elevator panel button control module is judged according to whether matching succeeds or not. According to the elevator control method, face recognition of elevator persons can be achieved, authority distribution is conducted on the elevator persons typed in the database, the visitor authority of each floor can be set, and the safety grade of a building is improved; and meanwhile, face recognition is adopted, and face recognition is more convenient and faster compared with traditional card reading and fingerprint recognition.

Owner:成都焦点合安物联网有限公司

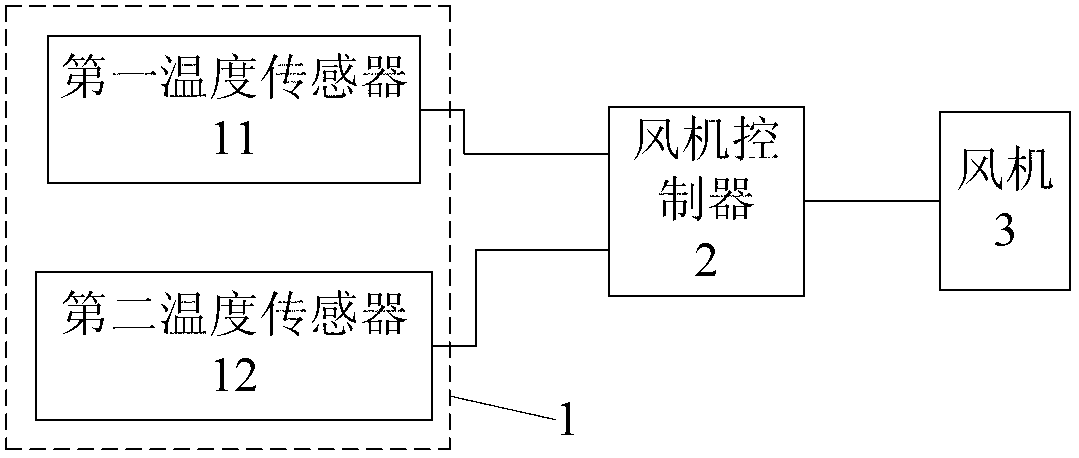

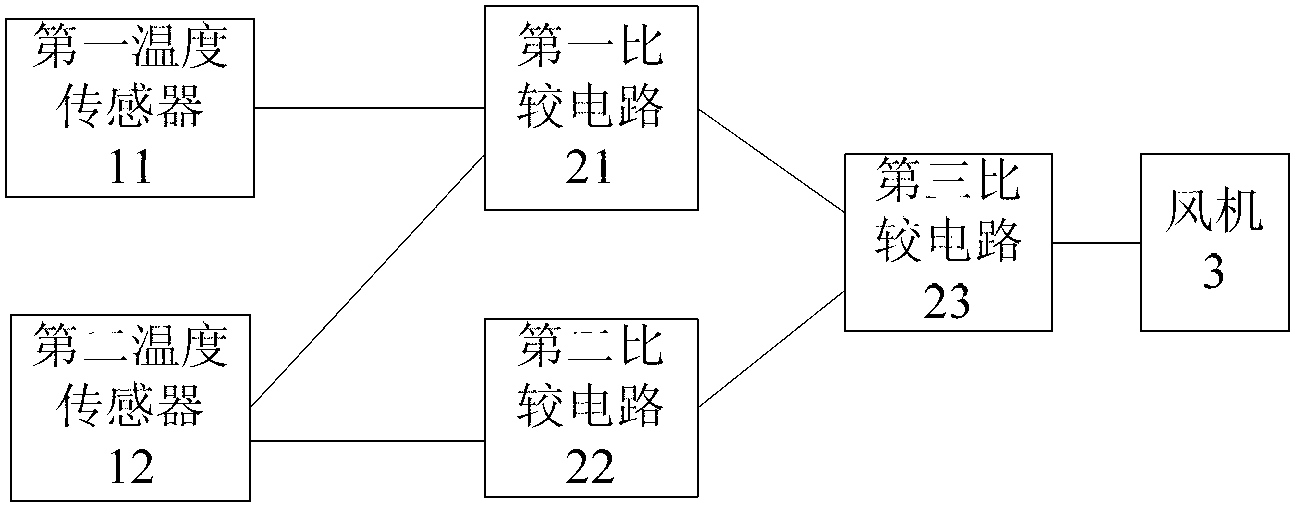

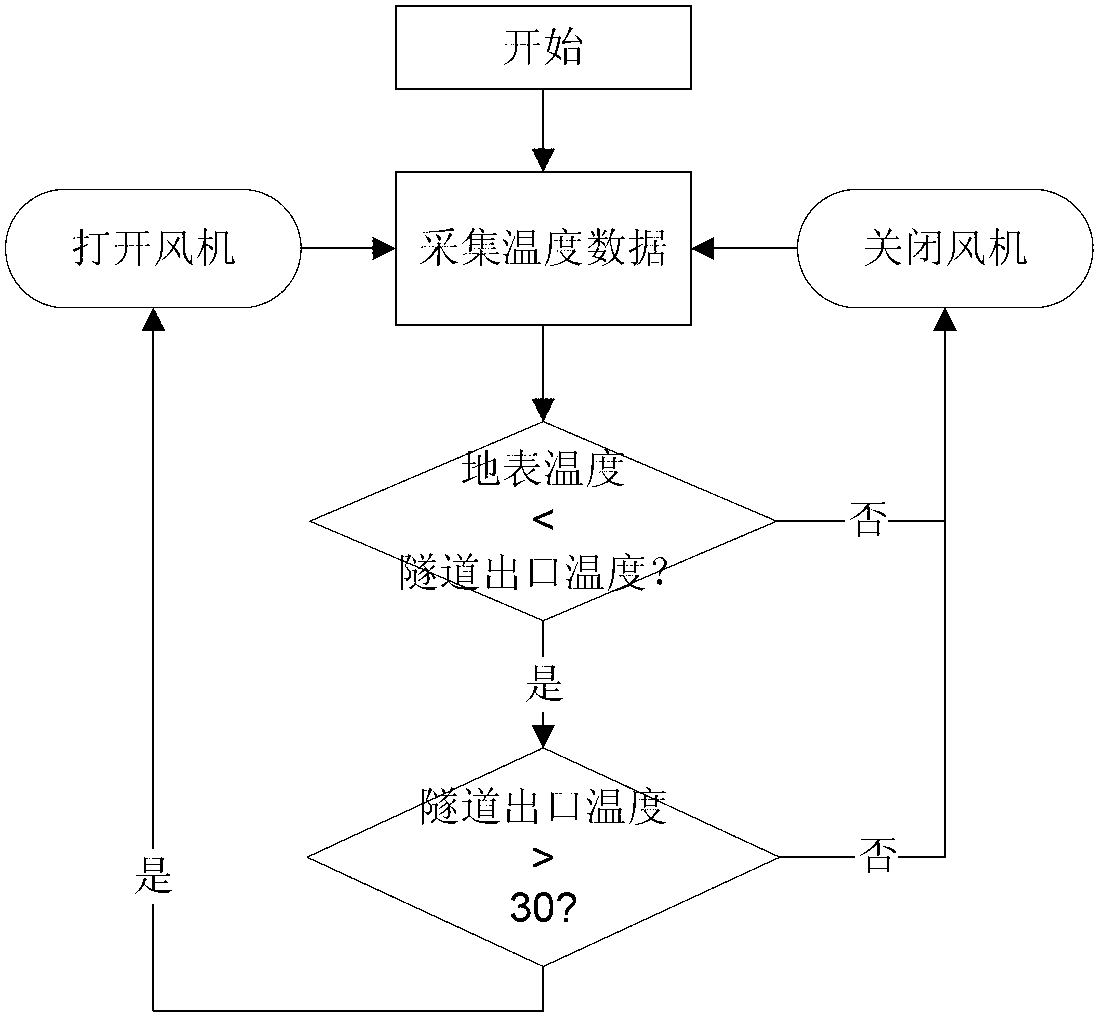

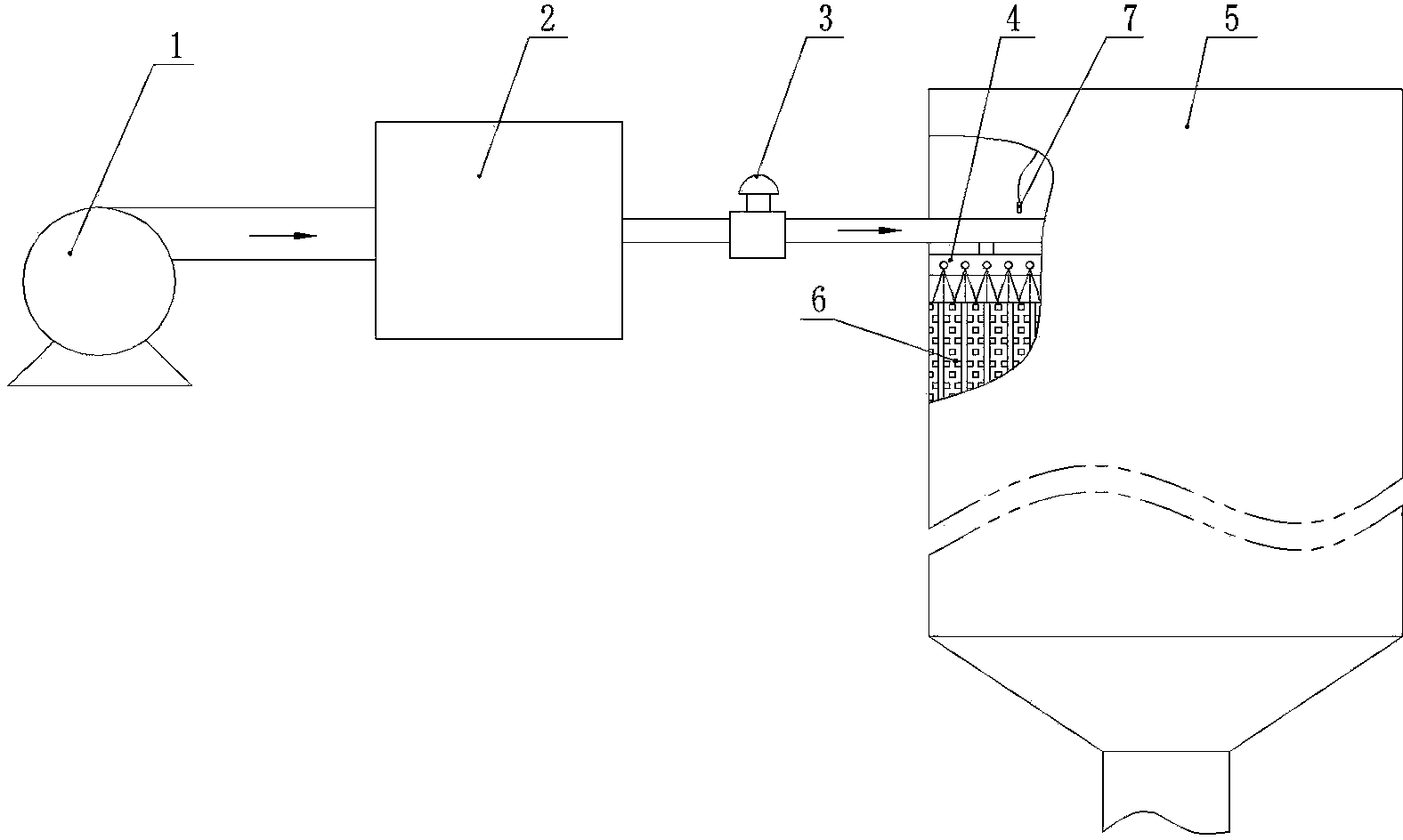

Device and method for intermittently ventilating cooling cable tunnel

InactiveCN103235612AGood ventilation and cooling effectExtended replacement cycleTemperatue controlEngineeringCooling effect

The invention relates to a device and a method for intermittently ventilating and cooling a cable tunnel. The device comprises a temperature acquisition assembly, a fan controller and a fan which are sequentially connected with one another. The method includes that the temperature acquisition assembly measures the temperature of the inside of the cable tunnel and the temperature of an external atmospheric environment in real time and transmits the temperature of the inside of the cable tunnel and the temperature of the external atmospheric environment to the fan controller; and the fan controller intermittently starts or stops the fan according to current temperature conditions to cool the cable tunnel. Compared with the prior art, the device and the method have the advantages of good ventilating and cooling effects, capabilities of saving energy and advantageously prolonging the replacement cycle and the service life of the fan in the tunnel, and the like.

Owner:STATE GRID CORP OF CHINA +1

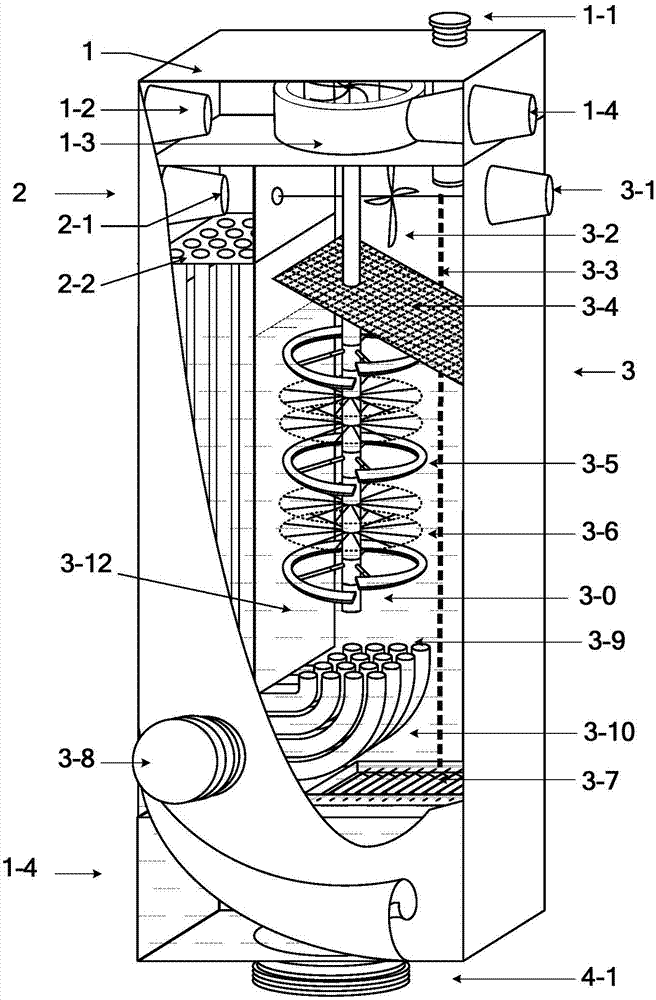

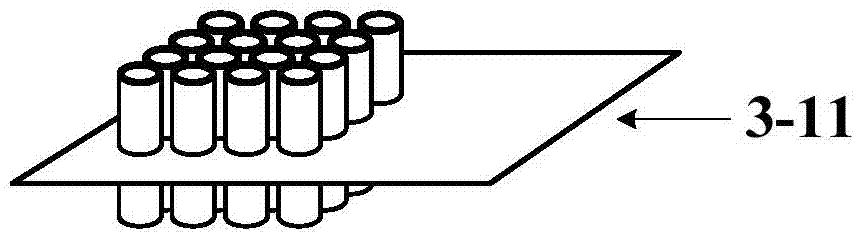

Device for eliminating haze and atmospheric pollutant

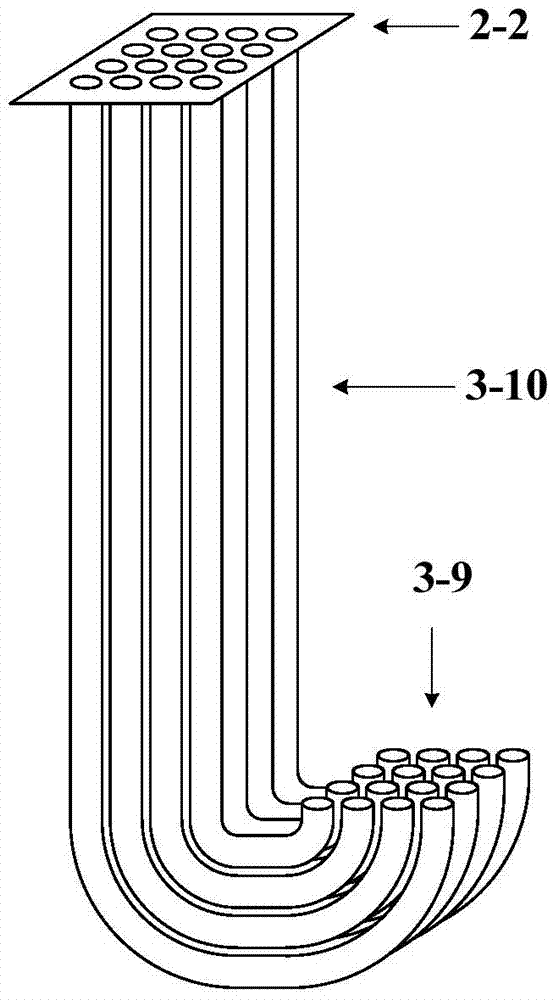

ActiveCN103933832AExtra running costEasy to useHuman health protectionUsing liquid separation agentSorbentCapillary Tubing

The invention discloses a device for eliminating haze and atmospheric pollutants. Appropriately preheated atmosphere with pollutants flows through a capillary tube array and is introduced into a liquid adsorbent, the pollutants in the atmosphere inside formed bubbles are adsorbed or dissolved by the surface of the liquid inside the bubble, and then atmosphere purification is achieved. The purification is applicable to atmospheric suspended grains of various diameters, and pm2.5 purification can be thoroughly achieved. To enhance the purification effect and the use convenience, the device is provided with function components such as a stirring rod with a bubble cutting steel wire and a spiral belt, and a waste liquid sucking chamber. The device can be separately used and can be also used with other devises in series. The device can be mounted on various carrying tools such as a vehicle, and due to the position change, the haze cleaning places can be changed at appropriate time, and the movement airflow of the carrying tool can be used as the power for eliminating the haze. The device can be used for purifying air at fixed points. When the device is used together with dust cleaning equipment, pm2.5 purification in polluted enterprises can be achieved. With special liquid adsorbent, the device can be used in special purification and professional equipment.

Owner:石博天

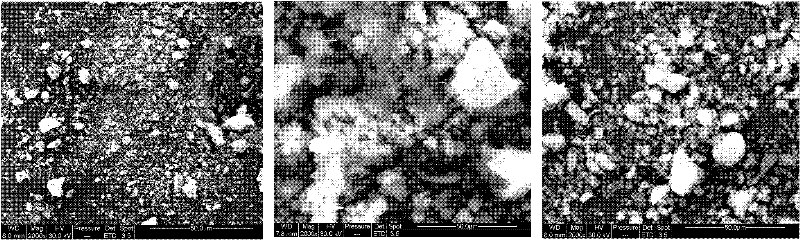

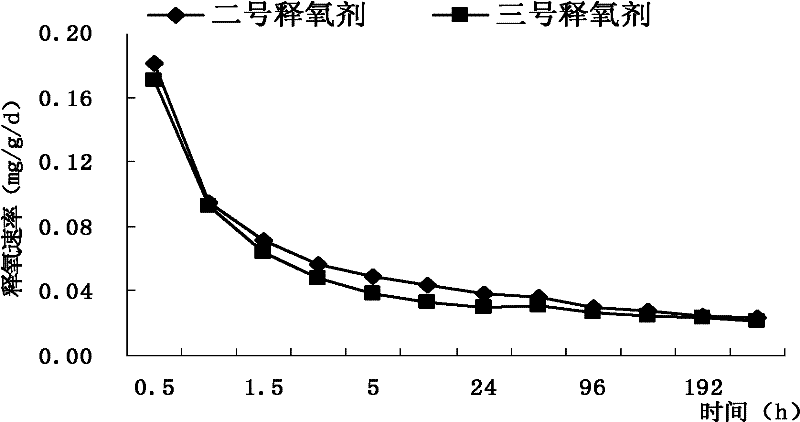

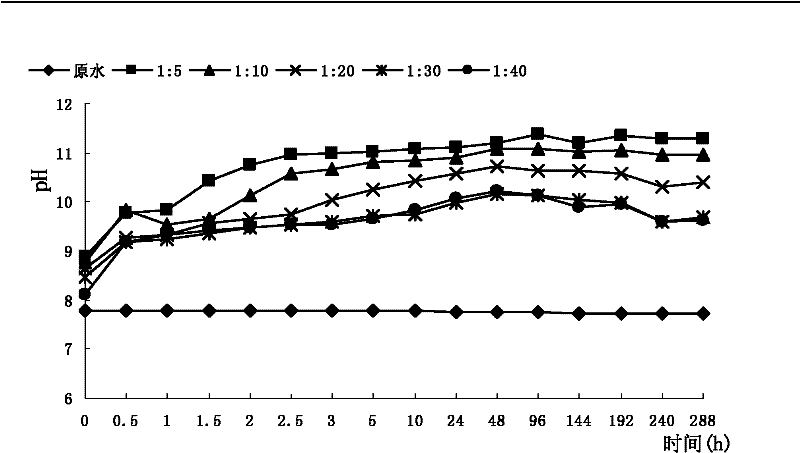

Oxygen-release material for ground water in situ aerobic bioremediation, and preparation method for the same

InactiveCN102336467AImprove structural propertiesReduce porosityTreatment using aerobic processesSustainable biological treatmentSodium BentoniteRelease time

The invention discloses an oxygen-release material for ground water in situ aerobic bioremediation, and a preparation method for the same, belonging to the field of oxygen-release material. The oxygen-release material is composed of the following component parts by weight: 11-14 parts of edible calcium peroxide by weight, 10 parts of sodium bentonite by weight, 1-3 parts of monopotassium phosphate by weight, 2-6 parts of ammonium sulfate by weight, 15 parts of river sand by weight and the coagulant (the rest), wherein total weight of the above materials is 70 parts by weight. The preparation method comprises the following steps of: weighing the calcium peroxide, the sodium bentonite, the monopotassium phosphate and the ammonium sulfate, fully mixing and uniformly dispersing the weighed materials; adding the cement and the river sand, adding water after mixing the cement and the river sand uniformly to prepare the mixture into a massive material, and naturally drying by air. The oxygen-release material has high total oxygen-release quantity and smooth oxygen-release speed, effectively prolongs the oxygen-release time, and improves the change cycle of the oxygen-release filler. The pH value and nutrient substances, such as N, P and the like in the water all meet the requirements on growth of aerobic microorganisms.

Owner:BEIJING UNIV OF TECH

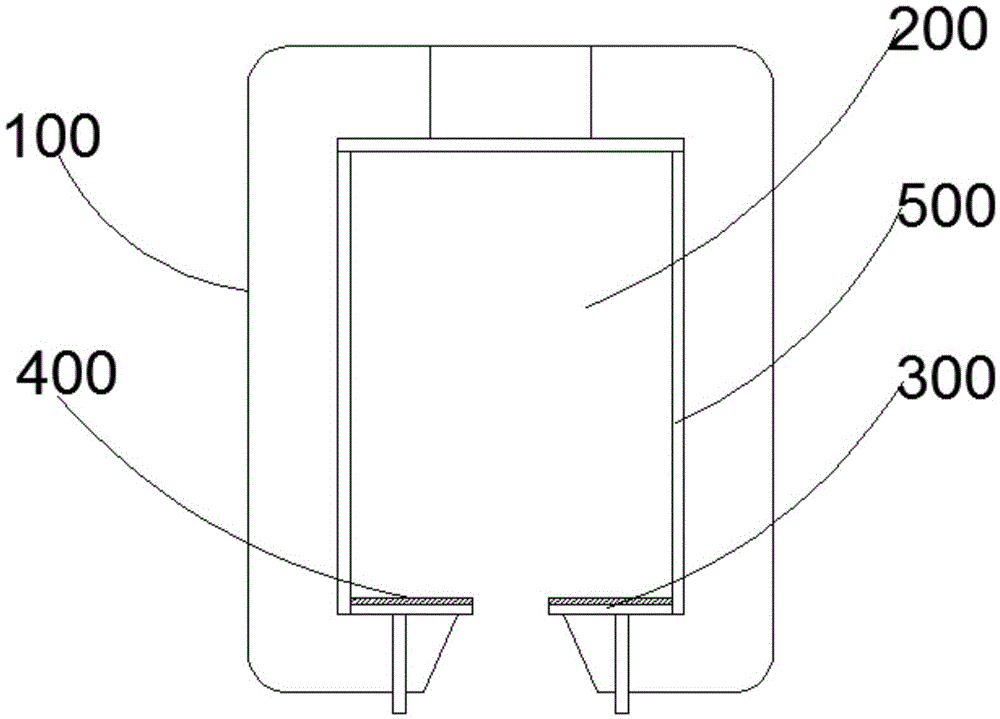

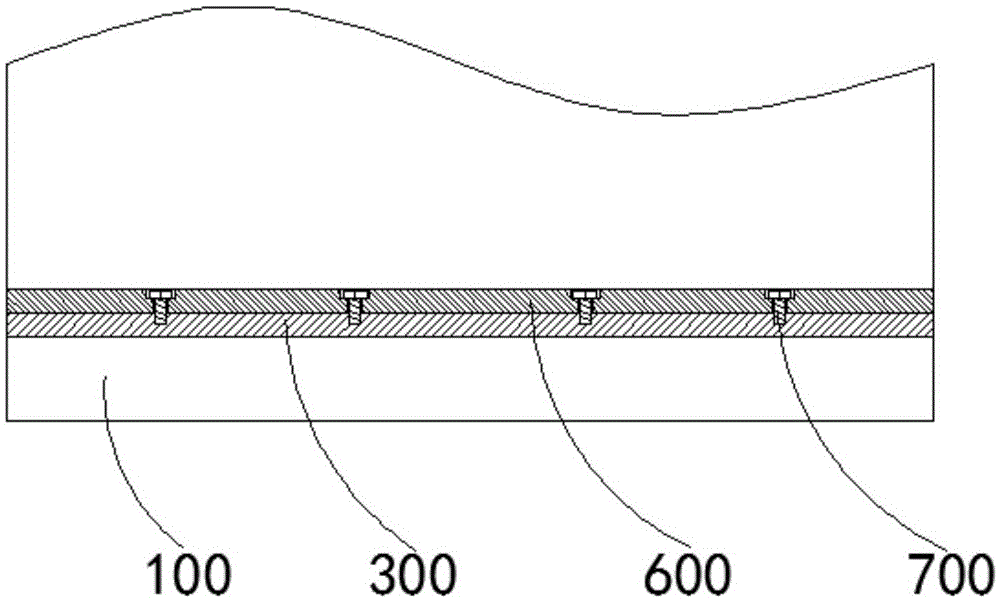

Suspension type monorail track and trolley bus

The invention provides a suspension type monorail track and a trolley bus and belongs to the field of communication and transportation. The suspension type monorail track comprises a track beam. A walking cavity is formed in the track beam. The bottom of the walking cavity is a walking face. The side face of the walking cavity is a guide face. A wear-resisting and tackifying layer is arranged on the walking face. A wear-resisting layer is arranged on the guide face. According to the suspension type monorail track and the trolley bus, the structure of additionally arranging the wear-resisting and tackifying layer on the walking face and additionally arranging the wear-resisting layer on the guide face is adopted, in this way, wear-resisting performance of the track beam can be effectively improved, and the period for replacing the track beam is prolonged greatly; moreover, adhesive force between a walking part of a vehicle and the walking face is increased, which is beneficial for enhancing the ability of a track system to adapt to terrain of a large ramp; meanwhile, by means of the wear-resisting and tackifying layer capable of being replaced or laid again, convenience of maintaining the track is improved, cost of maintaining the track is reduced, and the defects in the prior art are effectively overcome.

Owner:SOUTHWEST JIAOTONG UNIV

Preparation method of metal corrosion inhibitor

The invention relates to a preparation method of a metal corrosion inhibitor. Fatty acid and polyamine are used as initiative raw materials in the method, and the novel metal corrosion inhibitor is synthesized by amidation, quaternization and substitution reaction. The corrosion inhibition rate of the metal corrosion inhibitor prepared by the method is more than 99 percent, the corrosion inhibitor is easily biodegraded, the pH value of the corrosion inhibitor is 6 to 8 and close to neutrality, and the corrosion inhibitor is convenient to transport and use.

Owner:大庆高新区华龙祥化工有限公司

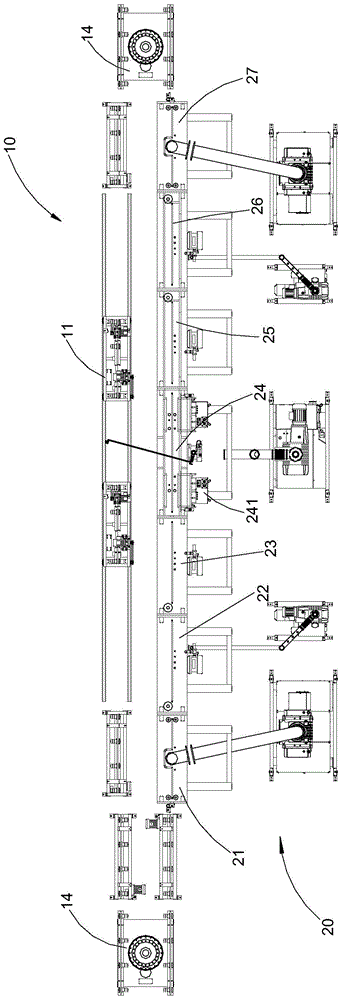

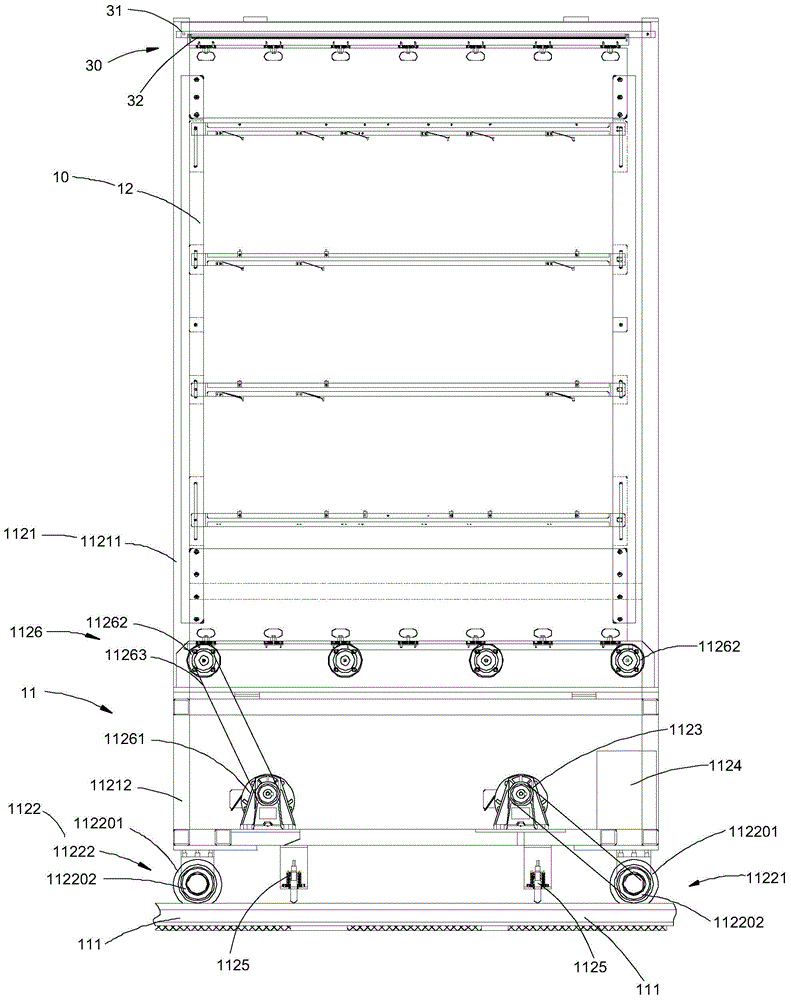

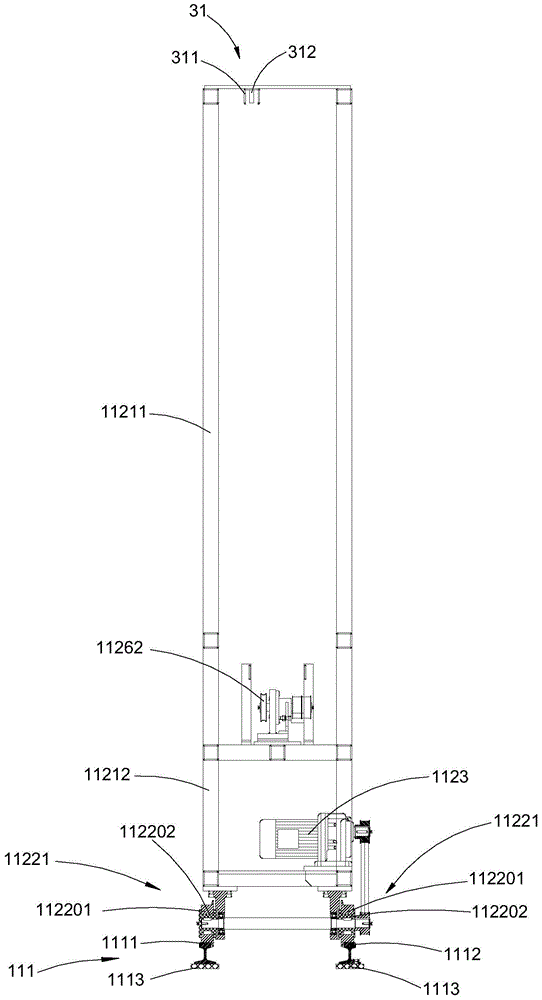

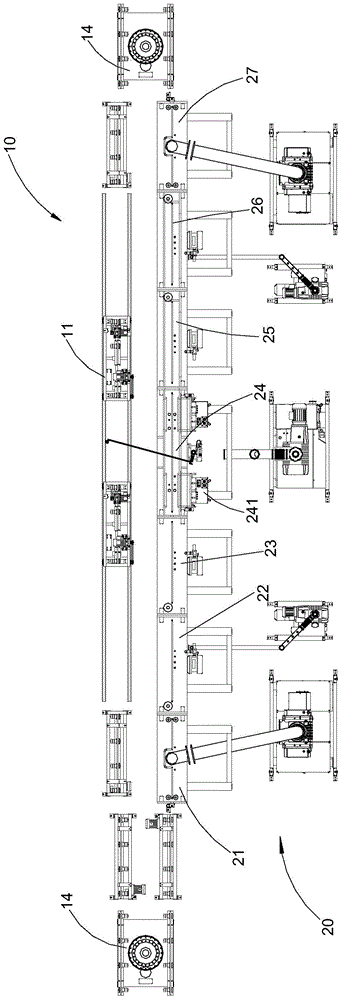

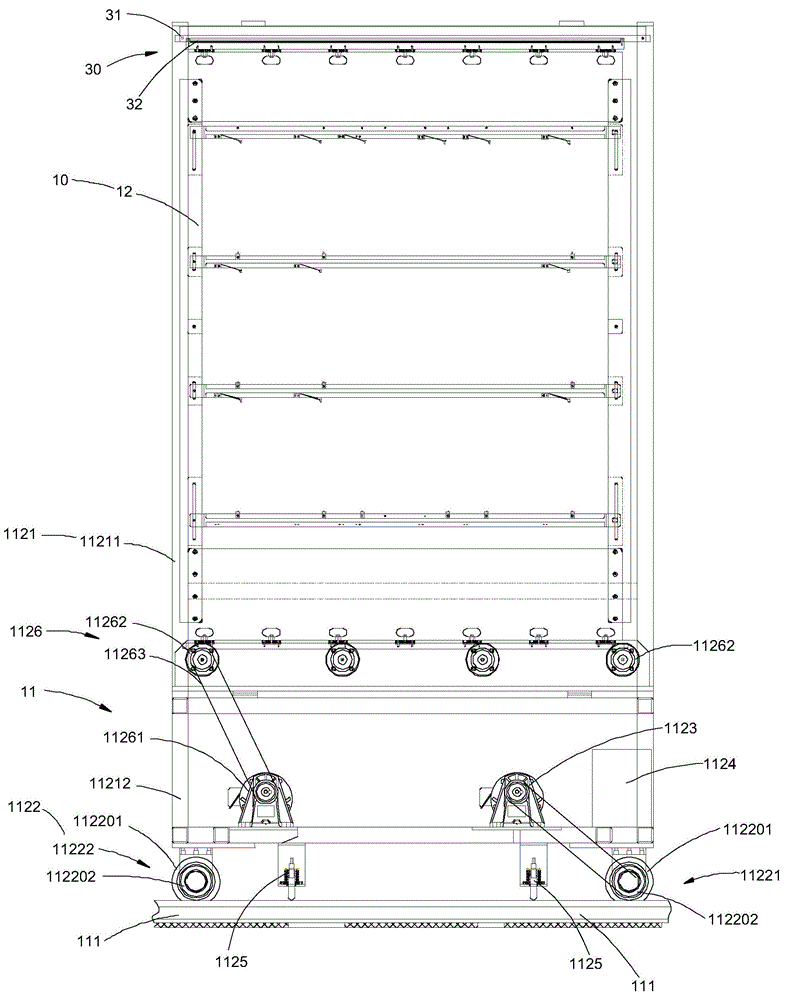

Vertical vacuum sputtering coating production line

ActiveCN104004999ASmall footprintHigh economic valueVacuum evaporation coatingSputtering coatingSputteringProduction line

The invention discloses a vertical vacuum sputtering coating production line. The vertical vacuum sputtering coating production line comprises a transmission assembly line and a coating assembly line, wherein the coating assembly line is connected with the transmission assembly line. The transmission assembly line comprises a rail, at least one transmission trolley and at least one substrate carrying device. The transmission trolley runs on the rail and transmits the substrate carrying device. The coating assembly line comprises an inlet cavity, an inlet transition cavity, an inlet buffer cavity, a coating cavity, an outlet buffer cavity, an outlet transition cavity and an outlet cavity. Compared with the prior art, the transmission assembly line and the coating assembly line are connected end to end to form an annular assembly line, so that the occupied area is saved; intelligent control is adopted for substrate transmission in the whole coating production line, so that manpower and material resources are saved, and production efficiency is improved; all cavities in the coating assembly line are replaced or added according to requirements of products, so that the whole coating production line meets the requirements of various coating processes; andthe service life is prolonged, resources are saved, and therefore the vertical vacuum sputtering coating production line has quite wide application prospects.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

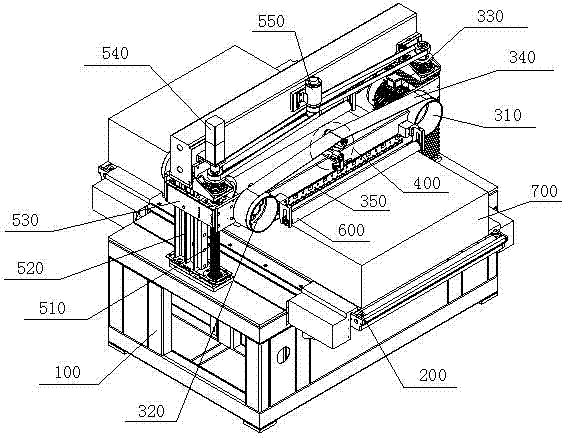

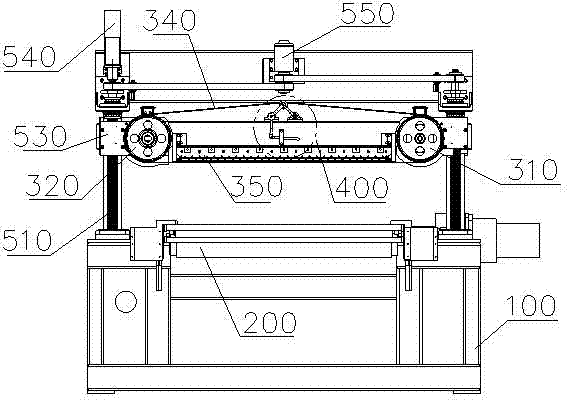

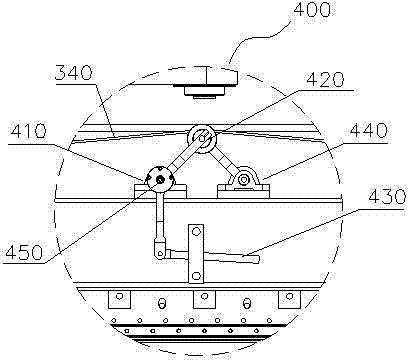

Automatic grinding device

The invention discloses an automatic grinding device. The automatic grinding device comprises a working table, a conveyor belt and at least one grinding mechanism, wherein the conveyor belt is arranged on the working table, and the grinding mechanism is arranged above the conveyor belt. The grinding mechanism comprises a driving wheel, a driven wheel, a grinding motor and an abrasive belt, wherein the driving wheel and the driven wheel are arranged on the two sides of the conveyor belt respectively, the grinding motor is connected with the driving wheel and supplies power to the driving wheel, and the abrasive belt winds the surface of the driving wheel and the surface of the driven wheel. The abrasive belt winds the driving wheel and the driven wheel and makes contact with grinded materials to form a grinding plane. The automatic grinding device is high in grinding efficiency, good in grinding effect, high in accuracy, and especially suitable for grinding different materials.

Owner:徐成炳

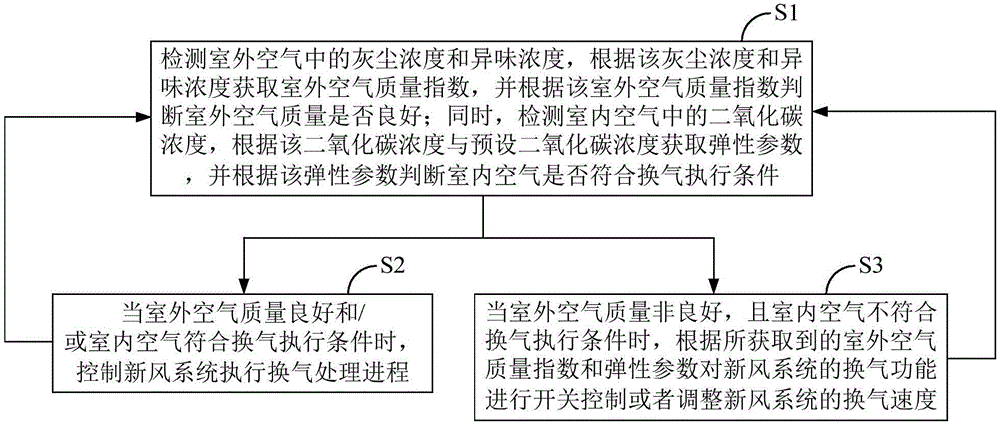

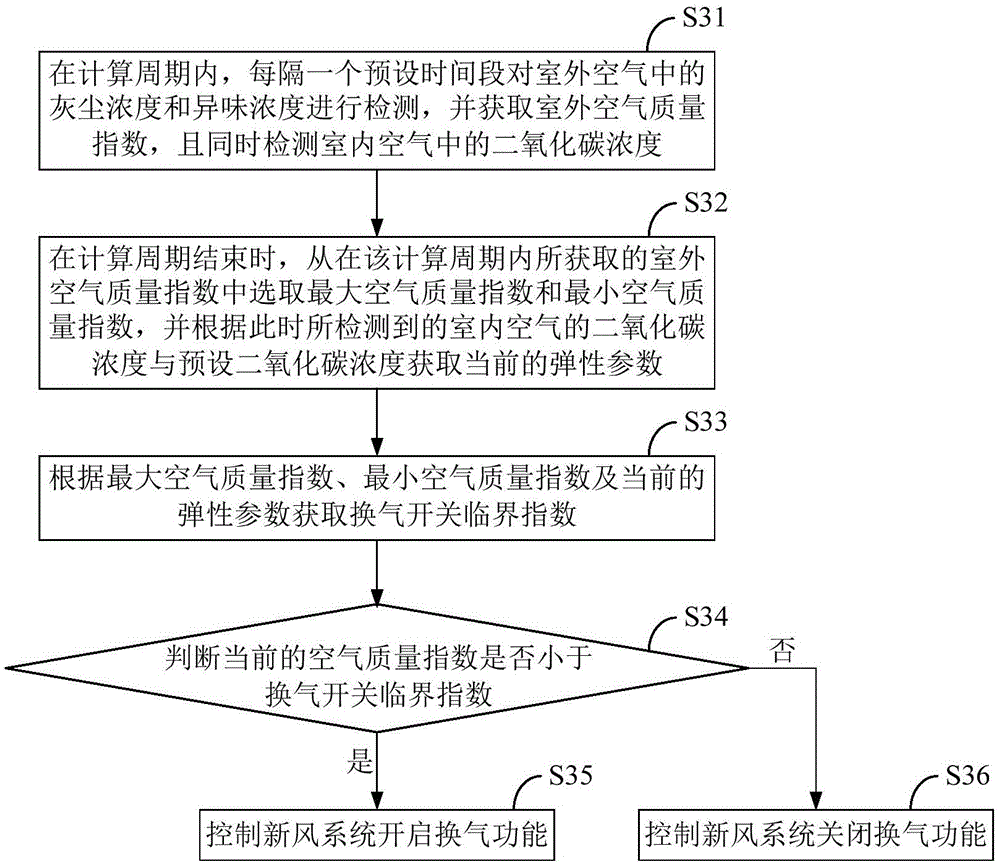

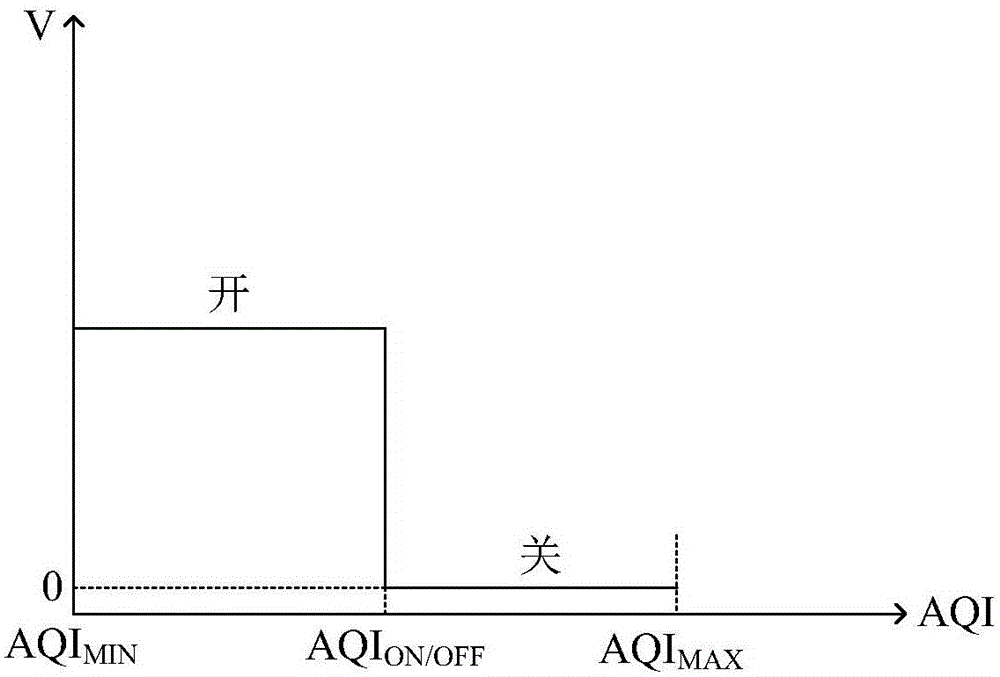

Fresh air system and air change control method and device thereof

ActiveCN105157157AExtended service life and replacement intervalsReduce maintenance costsSpace heating and ventilation safety systemsLighting and heating apparatusAir changeCarbon dioxide

The invention belongs to the technical field of air conditioner control and provides a fresh air system and an air change control method and device thereof. An outdoor air quality index is obtained by detecting the dust concentration and odor concentration of outdoor air, and whether the outdoor air quality is good is judged. Meanwhile, an elastic parameter is obtained according to a detected indoor carbon dioxide concentration and a preset carbon dioxide concentration, and whether indoor air meets air change execution conditions is judged according to the elastic parameter. When the outdoor air quality is very good and the indoor air does not meet the air change execution conditions, on-off control over the air change function of the fresh air system is conducted or the air change speed of the fresh air system is controlled according to the obtained outdoor air quality index and the elastic parameter. Accordingly, the air change function of the fresh air system can be regulated and controlled. In this way, the air change function is not performed in a whole course when the fresh air system operates. The service life or replacement cycle of a dust removal component and an odor removal component is prolonged. Furthermore, the maintenance cost of the fresh air system is lowered.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Dynamic balance correcting method for fan

InactiveCN102323009AReduce calibration timeSave manpower and material resourcesStatic/dynamic balance measurementMaterial resourcesEngineering

The invention discloses a dynamic balance correcting method for a fan, which can be used for shortening the correcting time. The method comprises the following steps of: firstly, determining an imbalance point of the fan and measuring the radial vibration offset delta caused by imbalance of the fan by using a vibration measurer; secondly, computing allowed imbalance degree and allowed residual imbalance amount of the fan, wherein the allowed imbalance degree eper of the fan is equal to (G*1000) / (n / 10), and the allowed residual imbalance amount m of the fan is equal to (eper*M) / (r*2); thirdly,computing the imbalance amount of the fan, wherein the imbalance amount m'' of the fan is equal to (m / 0.13)*delta; and lastly, balancing. After the method is adopted for correcting the dynamic balance of the fan, the correcting time can be shortened greatly, the fan restores running within a very short period of time, normal performance of production is ensured, a large quantity of manpower and material resources are saved simultaneously, and the production running cost is lowered. The method is suitable to be popularized and applied in the fan repair field.

Owner:SICHUAN CHUANWEI GRP CO LTD +1

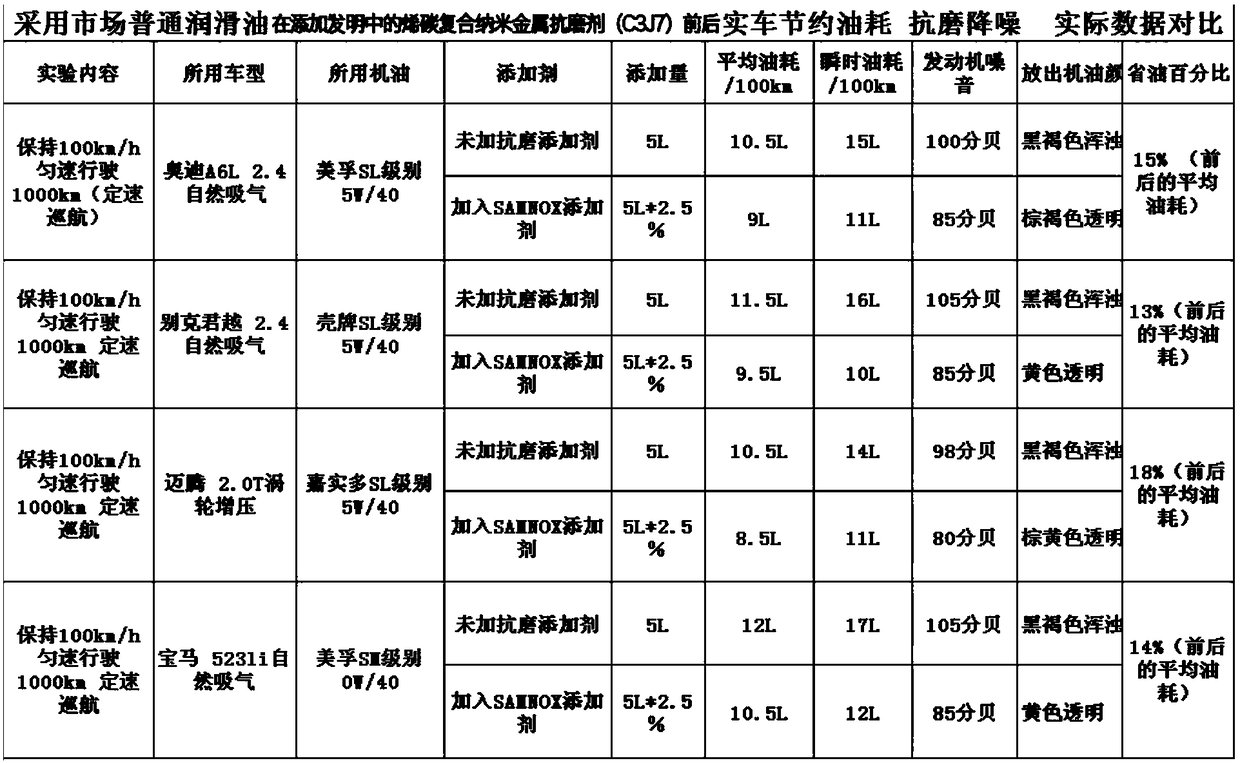

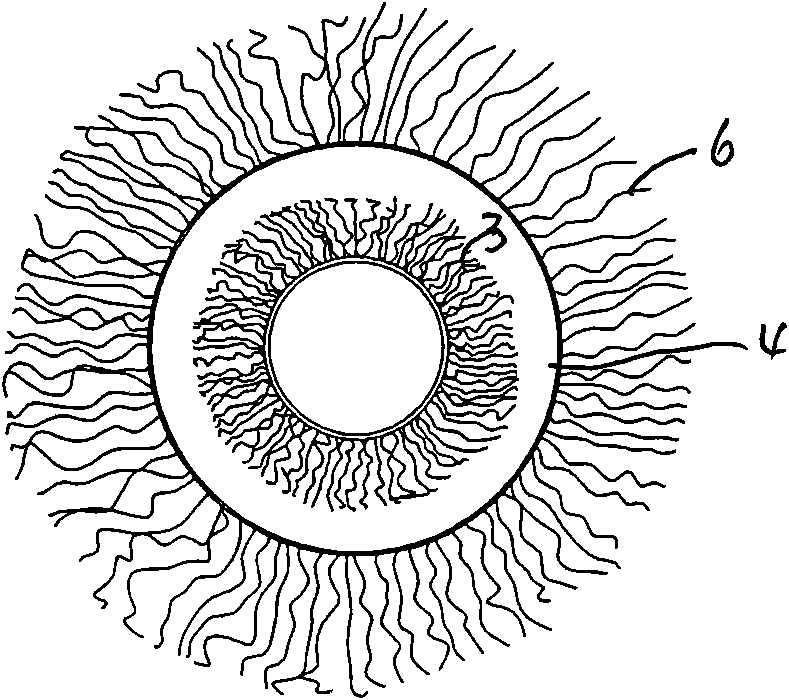

Olefinic carbon compound nanometer soft metal wear-resistant self-repairing material with surface modification, and preparation method thereof

ActiveCN108148652AImprove anti-wear performanceAchieve super lubricityAdditivesWear resistantLubrication

The invention relates to an olefinic carbon compound nanometer soft metal wear-resistant self-repairing material with surface modification, and a preparation method thereof. A nanometer olefinic carbon material with wear-resistant performance and a nanometer metal material with an abrasion repairing function are subjected to in-situ composite preparation with a sol-gel method, so that the materialhas dual functions of abrasion resistance and reduction and abrasion self-repairing, and the advantage complementation mechanism of the synergetic effect and the performance of different types of nanometer materials is performed. The olefinic carbon compound nanometer soft metal wear-resistant self-repairing material prepared with the preparation method can be used for realizing the breakthroughof 'exponential increase of wearing resistance under extreme pressure', 'zero abrasion of metal friction' under an extreme pressure situation is broken through, true super lubrication under the extreme pressure situation is realized, traditional sulfur-phosphorus-containing liquid lubrication performance and application technologies are subjected to revolutionary changes due to the occurrence of olefinic carbon compound wear-resistant energy-saving materials, the material does not contain caustic organic sulfur and phosphorus compound, wear-resistant performance is improved, and wear reductionenergy saving performance is also improved.

Owner:烟台华恒节能科技有限公司

Material for aluminum electrolysis crust-breaking hammer

The invention relates to a material for an aluminum electrolysis crust-breaking hammer, which is characterized by comprising the following components in percentage by weight: 0.5%-3.0% of carbon, 3.5%-10.0% of manganese, 0.5%-1.0% of silicon, less than 0.05% of phosphorus, less than 0.05% of sulphur, 5.0%-20.0% of chromium, less than 0.05% of Ni and the balance of ferrum. The material for the aluminum electrolysis crust-breaking hammer is an iron alloy material and is prepared by using a lost foam casting or sand casting process. In the invention, The manganese content in the material for the crust-breaking hammer is increased and the chromium content is optimized, thereby the material effectively improves the strength and wear resistance of the aluminum electrolysis crust-breaking hammer, prolongs the service life of the hammer, extends the replacement period, reduces the production cost and effectively relieves the labor intensity.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for treating polymer-containing sewage of oil field

ActiveCN101993177AEasy to separateExtend the filter cycleMultistage water/sewage treatmentSludgeBacillus cereus

The invention relates to the improvement of a method for treating polymer-containing sewage of an oil field. The method is characterized in that microorganisms are formed by mixing bacillus cereuses, bacillus megateria, bacillus subtilis, candida lipolytica, bacillus brevis and pseudomonas fluorescens; after microorganism aerobic degradation, post filter treatment is carried out; obligate microorganisms are used for degrading oil and organic pollutants bonded on polymers, thereby improving the separability of surplus inorganic substances and polymer-containing substances; and meanwhile, the degradation of the oil and the organic pollutants creates a condition for subsequently prolonging the filter period of a filter material. The invention has the advantages of simple process, simplified flows, convenient running and management, good treatment effect, low treatment and running cost (0.65-0.7yuen / ton of water, which is 2 / 3 of that of conventional treatment), no need of adding any drug,no treatment secondary pollution and stable treatment effect, can guarantee that treated yield water can stably reach 5.5.2, has small sludge quantity and does not need a sludge treatment system, thereby solving the treatment problem of polymer-containing sewage of an oil field.

Owner:JIANGSU BODA ENVIRONMENTAL PROTECTION

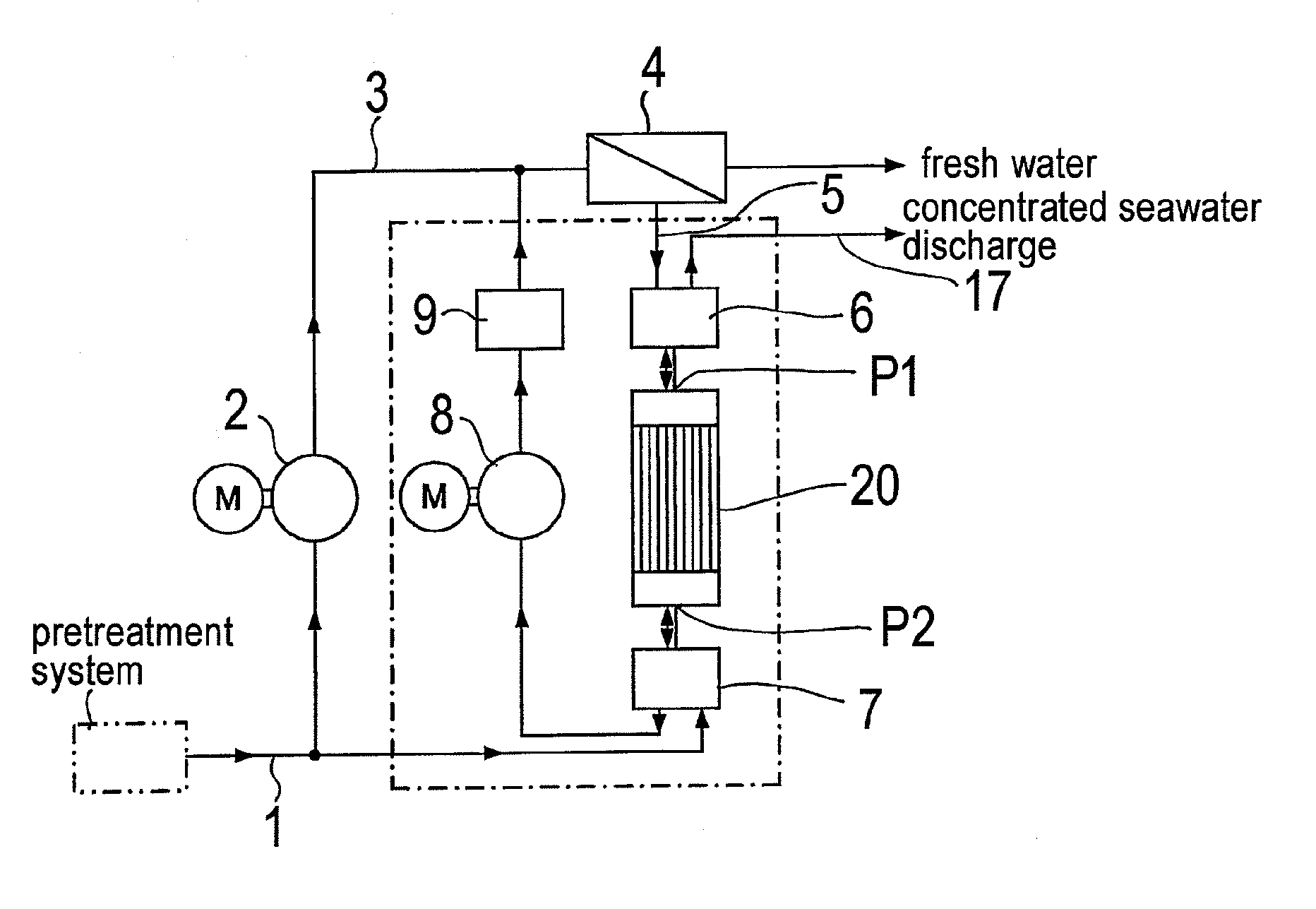

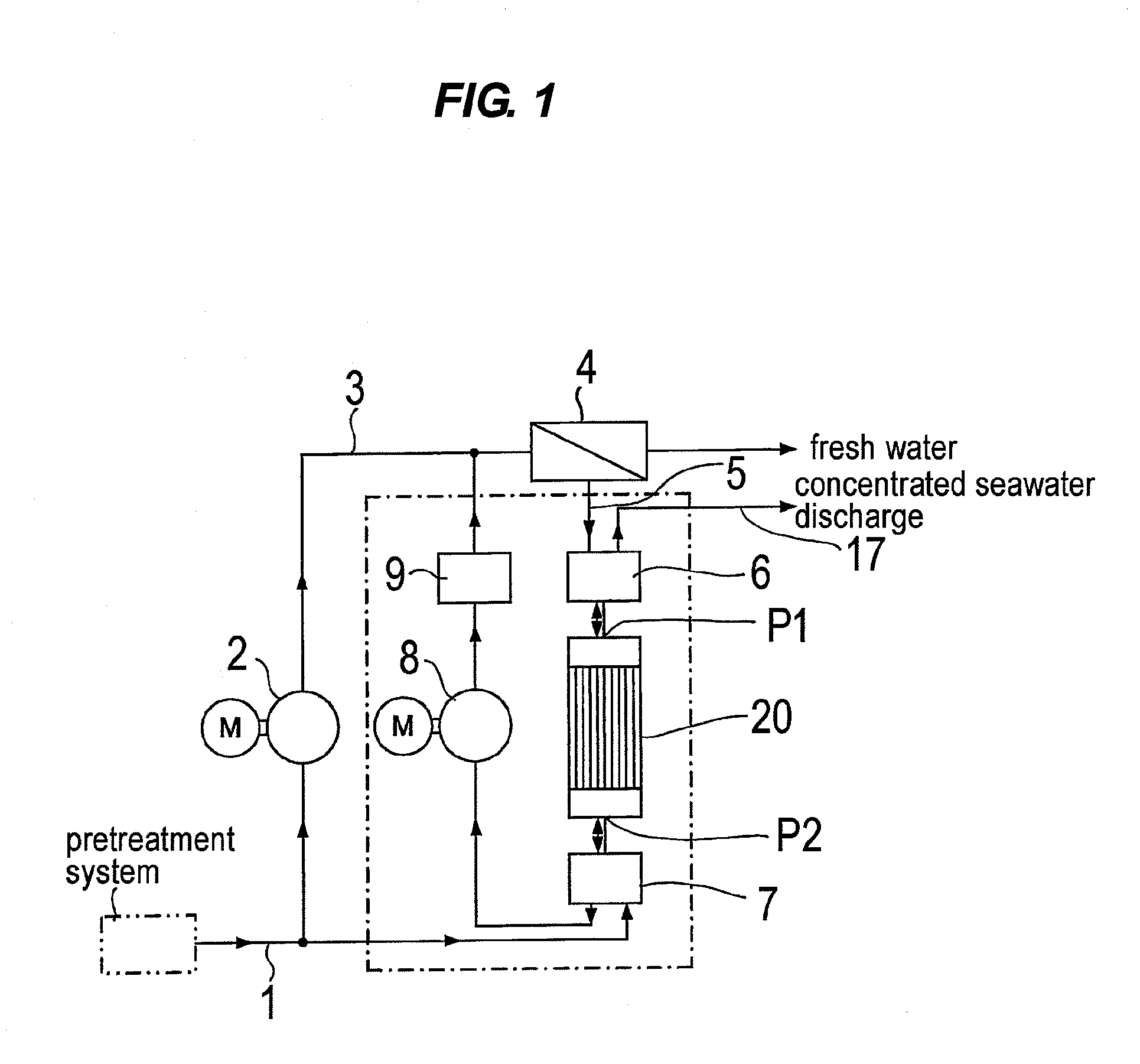

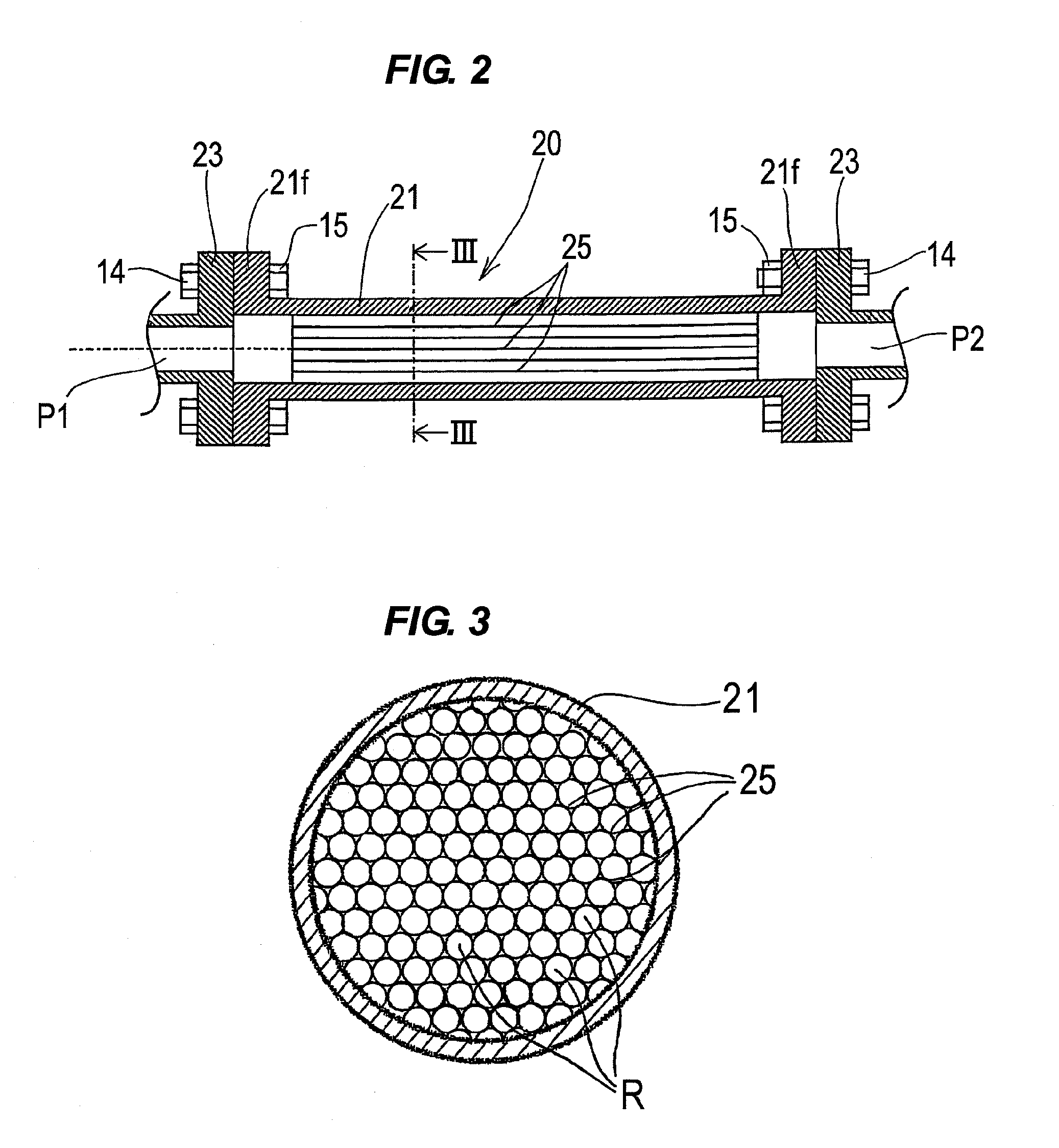

Seawater desalination system and energy exchange chamber

ActiveUS20120061309A1Manufacturing cost be reduceSuppress mixingMembranesGeneral water supply conservationPistonSeawater

A seawater desalination system which can solve a problem of wear of a sliding member and can suppress mixing of concentrated seawater and seawater by making an energy exchange chamber no-piston configuration is provided.In a seawater desalination system for producing fresh water from seawater by passing the seawater pressurized by a pump through a reverse-osmosis membrane-separation apparatus (4) to separate the seawater into fresh water and concentrated seawater, an energy exchange chamber (20) for utilizing pressure energy of the concentrated seawater discharged from the reverse-osmosis membrane-separation apparatus (3) as energy for pressurizing part of the seawater is provided. The energy exchange chamber includes a concentrated seawater port (P1) for introducing and discharging the concentrated seawater, a seawater port (P2) for introducing and discharging the seawater, and a plurality of partitioned fluid passages (R) provided in the chamber to allow the concentrated seawater port (P1) and the seawater port (P2) to communicate with each other.

Owner:EBARA CORP

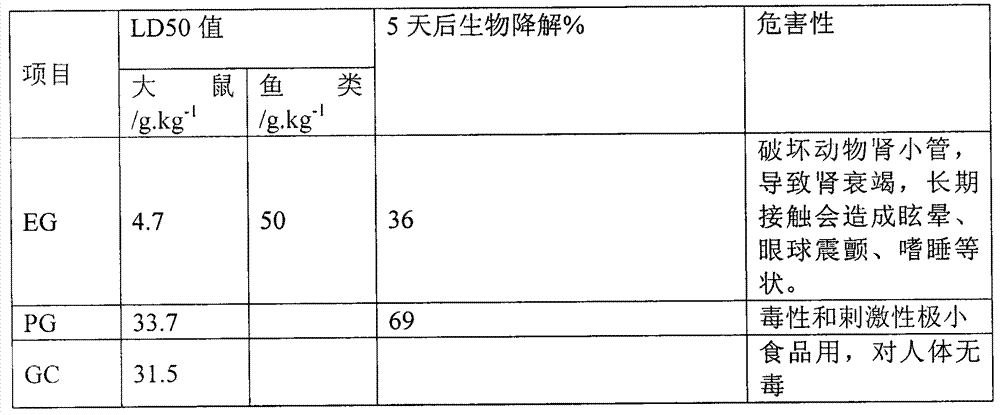

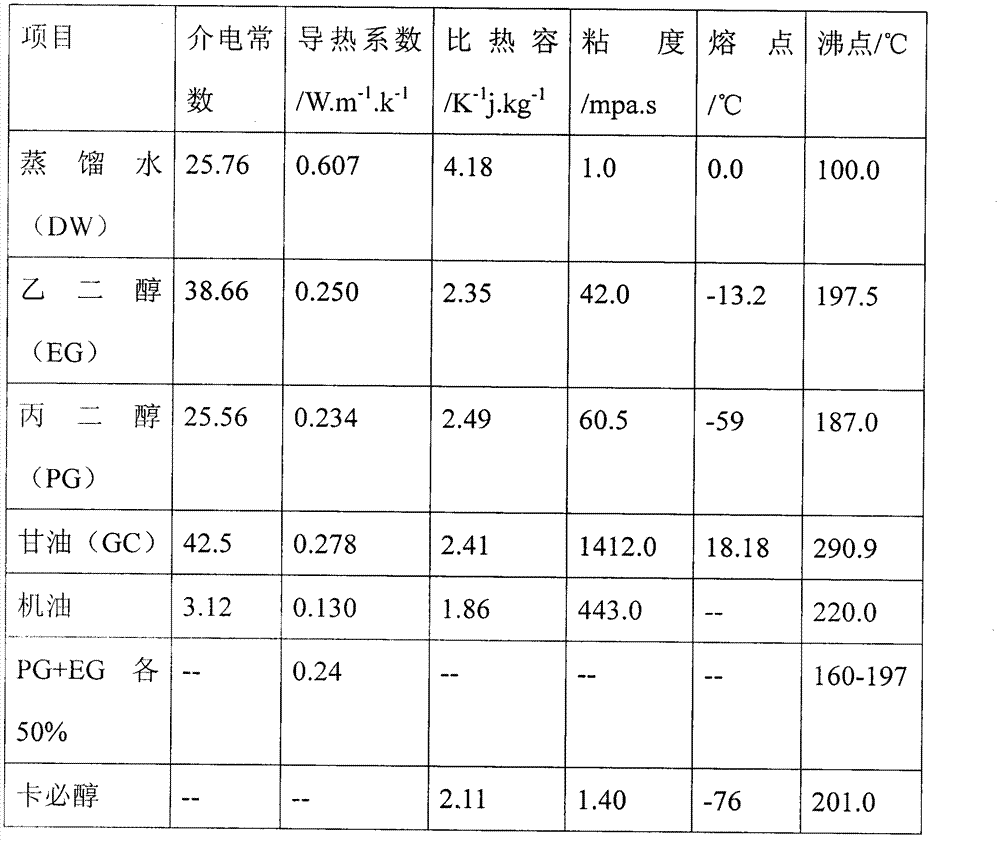

Nano long-acting liquid coolant

InactiveCN104263326AReliability benefitsHigh boiling pointHeat-exchange elementsFluorescenceCarbon nanotube

The invention discloses a nano long-acting liquid coolant. The nano long-acting liquid coolant comprises the following components of a base liquid which is composed of diatomic alcohol and a diluent, metal nanoparticles with a particle size of 3-100nm or carbon nano tube particles with a tube diameter of 8-100nm and length of 100-600nm, a dispersing agent, a corrosion inhibition additive, a pH regulator and a fluorescence colorant. The nano long-acting liquid disclosed by the invention is high in heat conductivity coefficient, good in heat transfer performance, good in liquidity and low in cost.

Owner:陈德全

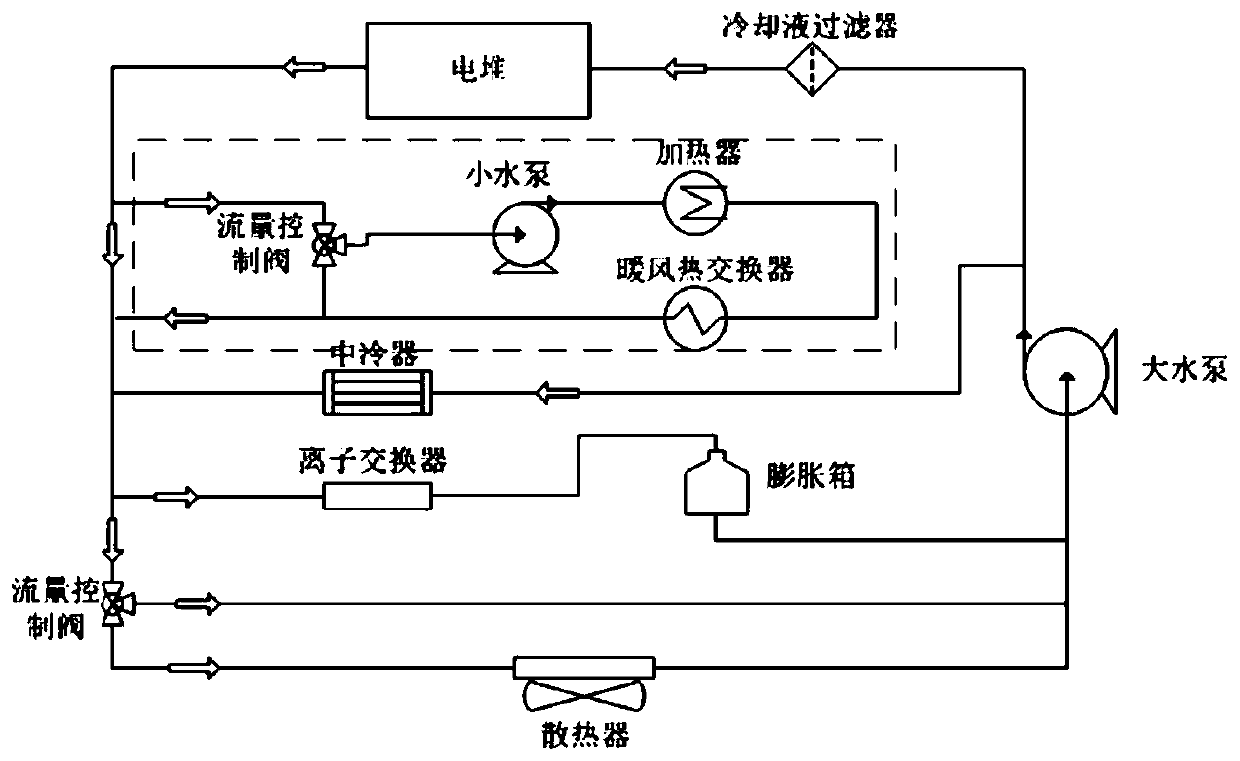

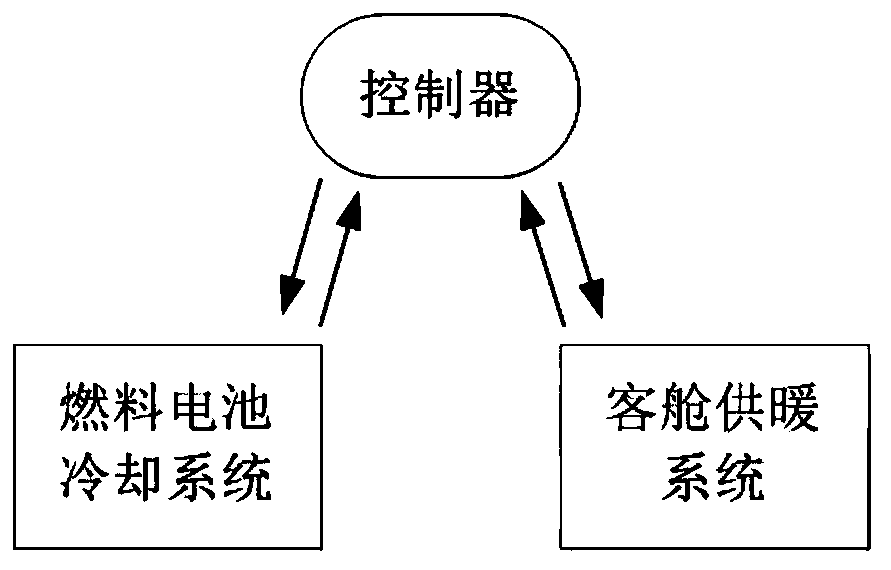

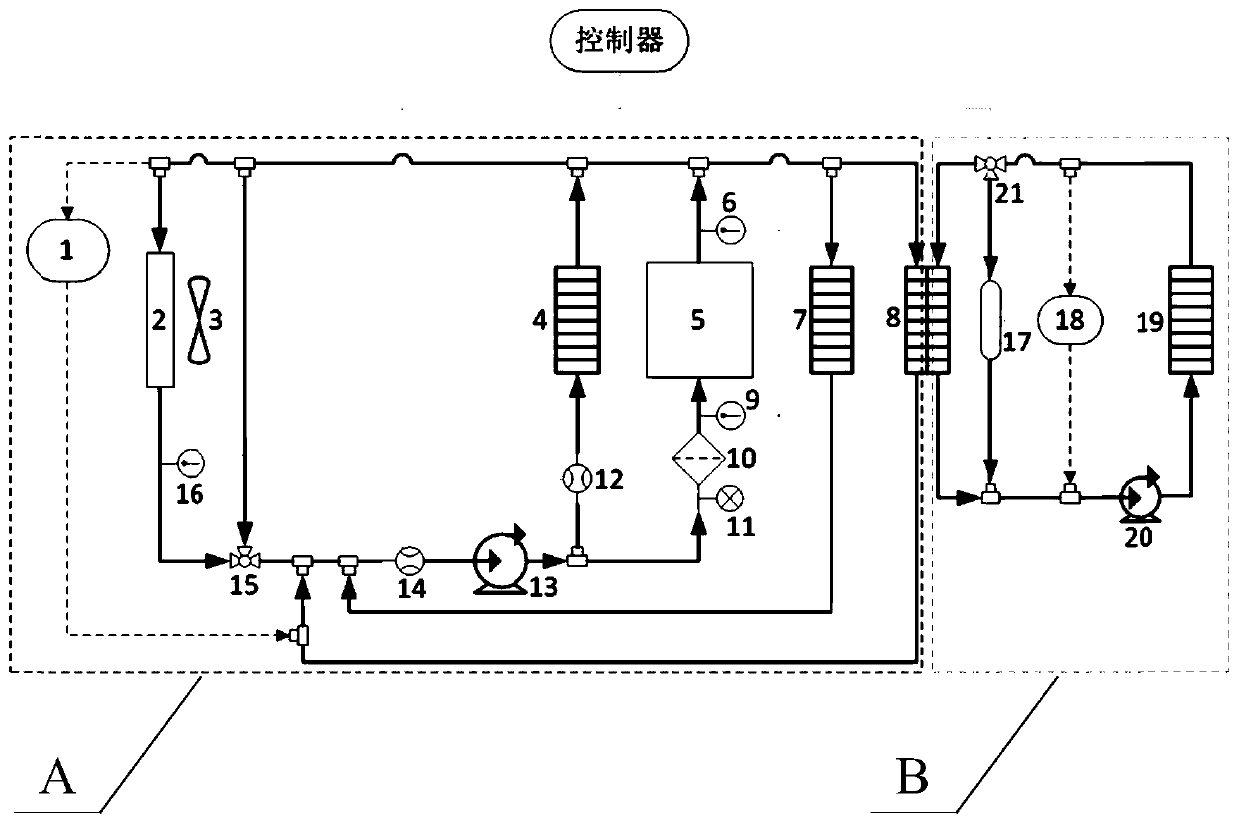

Thermal cycle management system for vehicle fuel cell

PendingCN111129541AExtended replacement cycleReduce raiseAir-treating devicesVehicle heating/cooling devicesFuel cellsCooling fluid

A thermal cycle management system for a vehicle fuel cell includes a stack cooling circuit, a cabin heating circuit, and a controller; the stack cooling circuit includes a first water pump, a deionization and filter assembly, a stack, and a cabin heat exchanger. The first water pump is arranged on a main loop of the stack cooling loop and used for providing circulating power for the galvanic pilecooling loop; the deionization and filter assembly is connected in series behind the first water pump and is used for removing ions and impurities in the cooling liquid; the stack is connected in series behind the deionization and filter assembly and is used for generating electric energy; the cabin heat exchanger is connected in series behind the stack and used for exchanging a part of heat generated by the stack to the cabin heating loop. According to the thermal cycle management system of the vehicle fuel cell, an integrated scheme of integrating the ion exchanger and the cooling liquid filter is adopted, the system performance is guaranteed, and the number of parts is reduced.

Owner:GUANGXI YUCHAI MASCH CO LTD

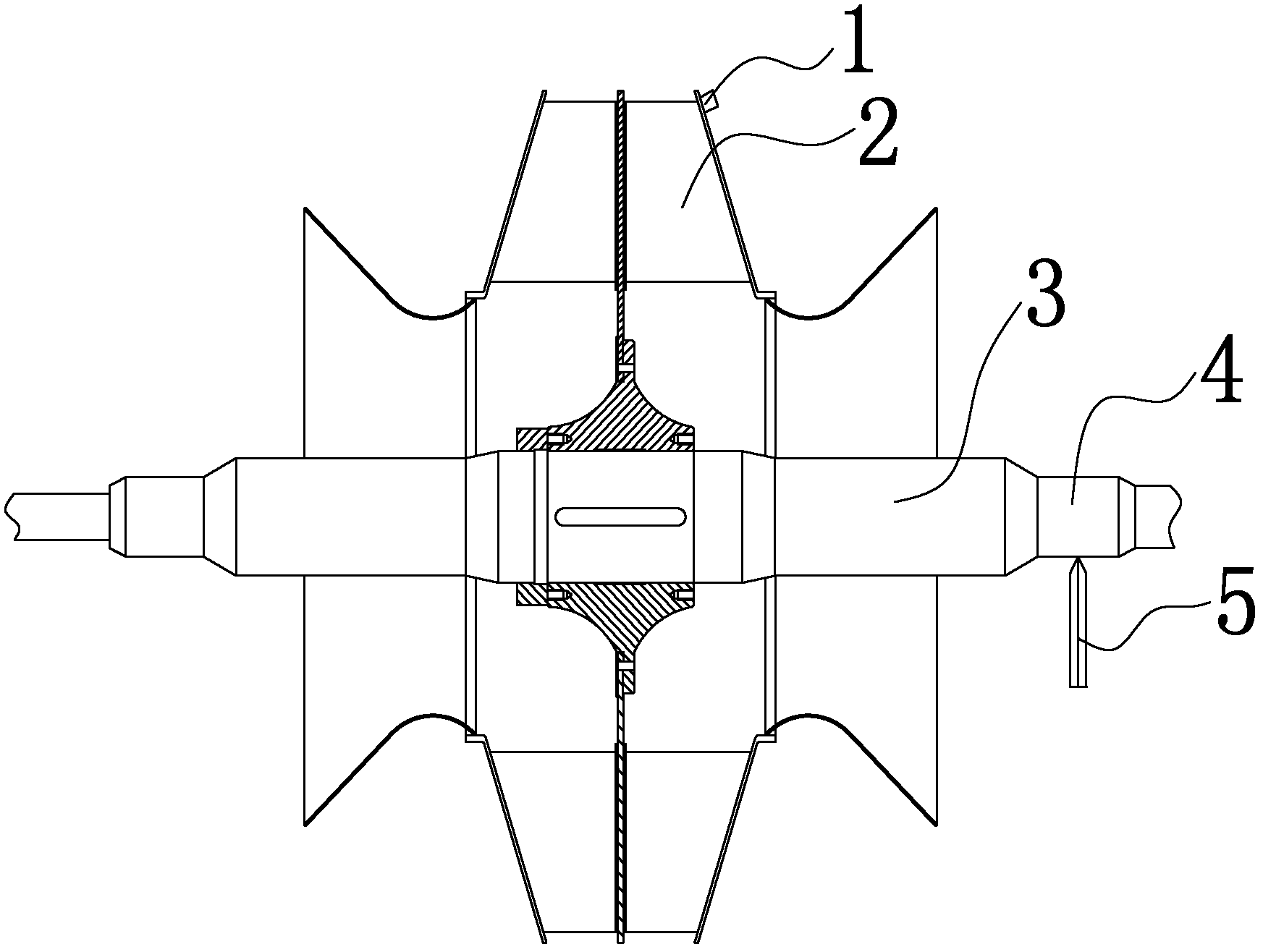

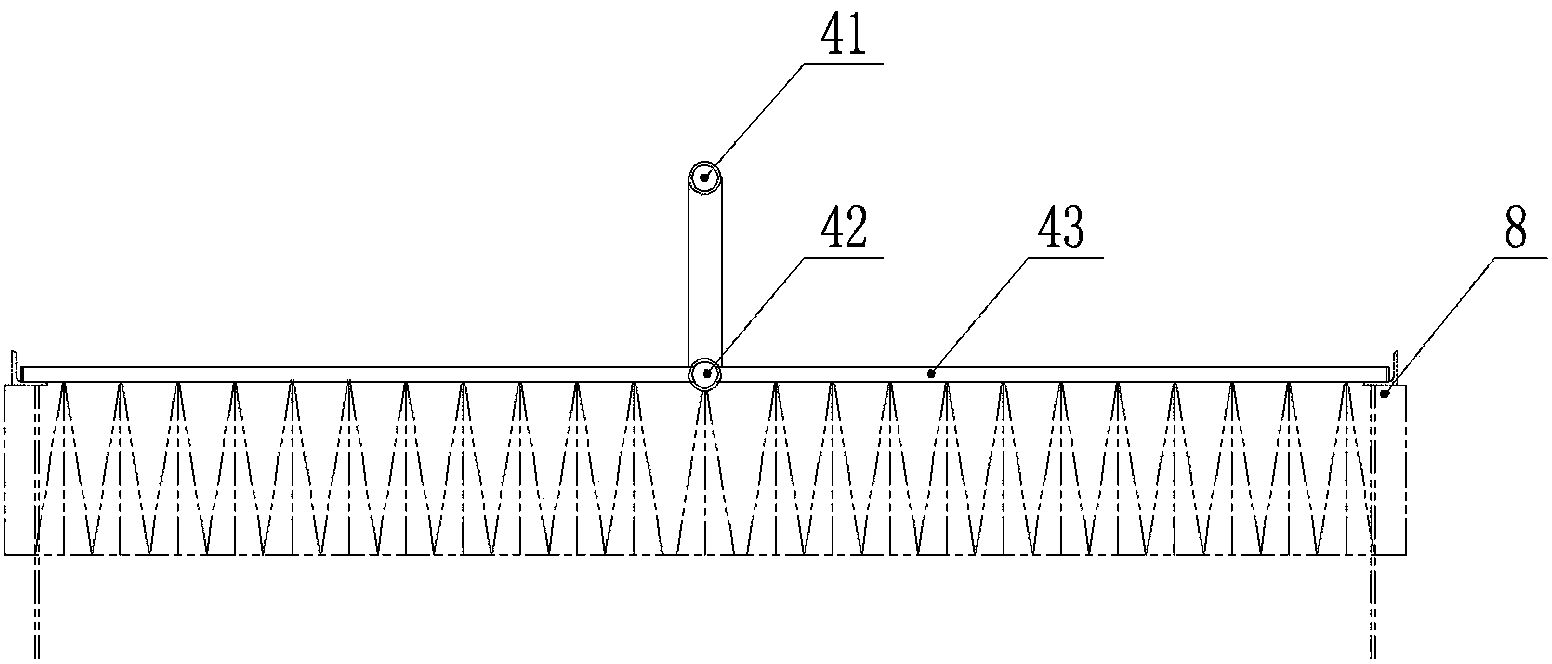

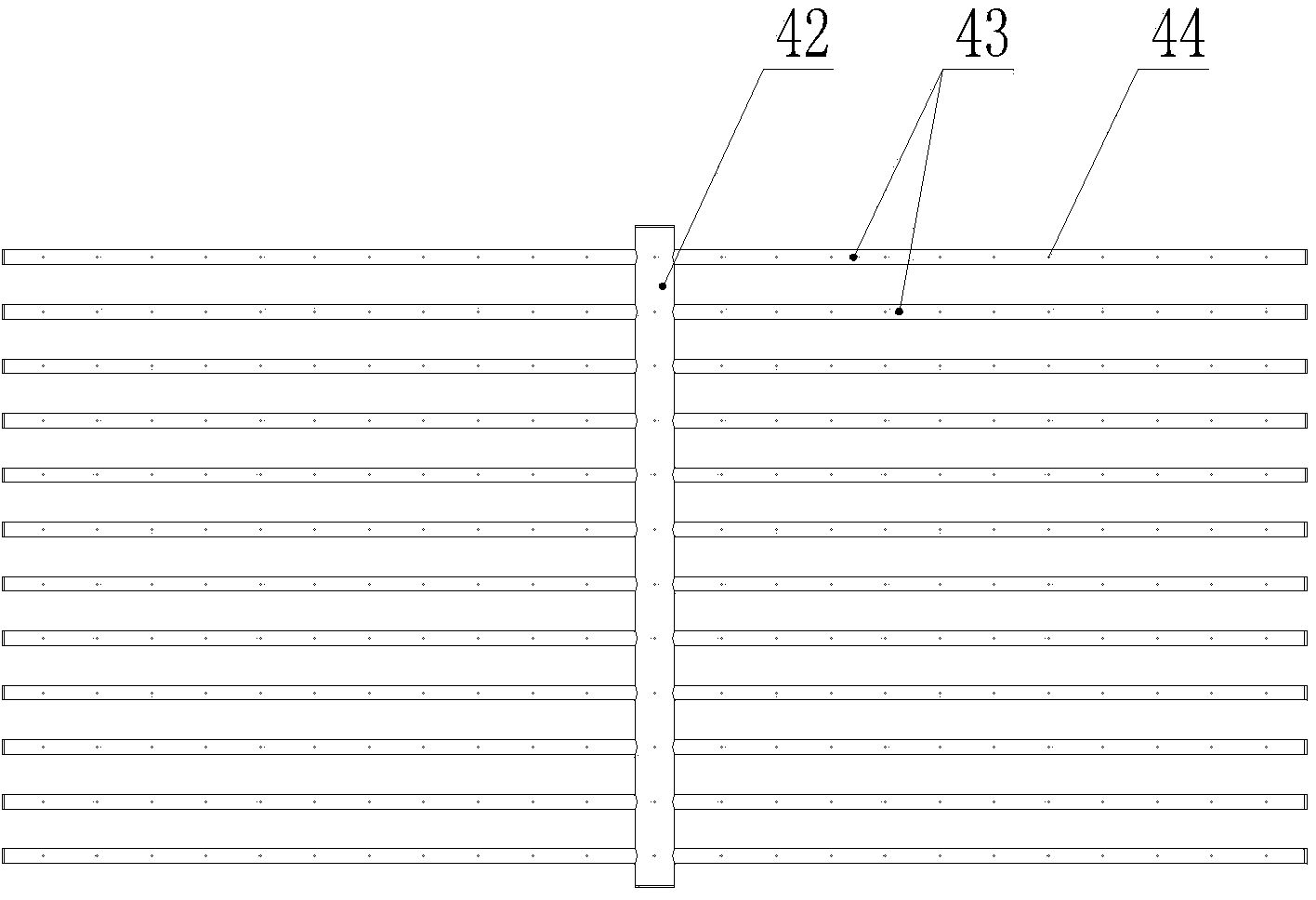

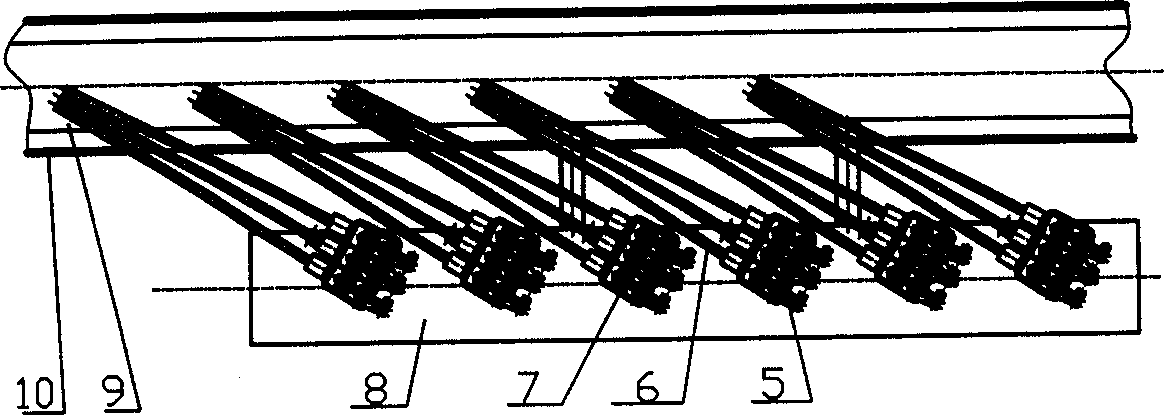

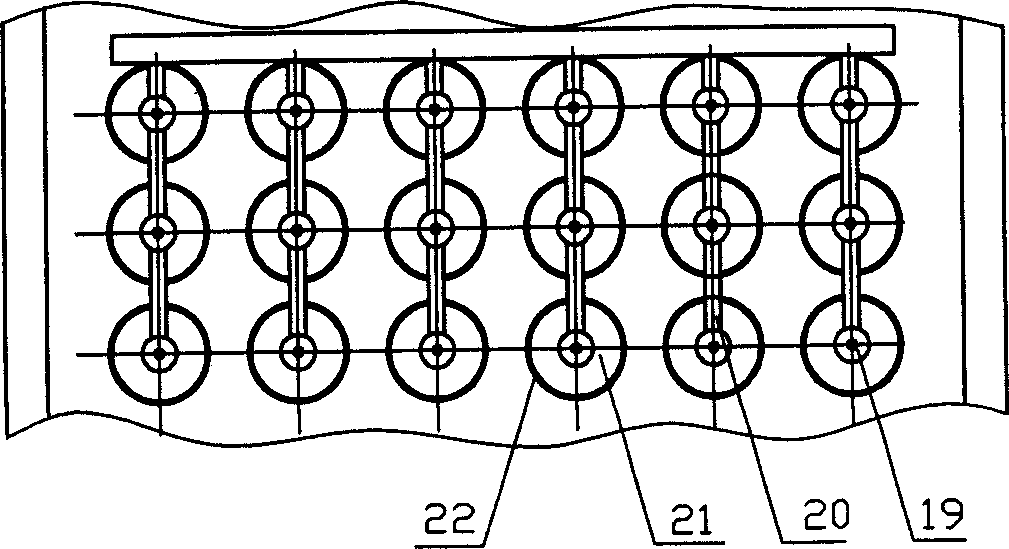

Dust blowing device for selective catalytic reduction (SCR) denitration reactor

InactiveCN103432904ASoot blowing forceThorough cleaningDispersed particle separationBuffer tankSolenoid valve

The invention discloses a dust blowing device for a selective catalytic reduction (SCR) denitration reactor. The dust blowing device comprises an air compressor, a buffer tank, a solenoid valve and jet pipe network unit module which are communicated in sequence; the jet pipe network unit module is positioned on catalyst units positioned in the SCR denitration reactor and jet pipes in the jet pipe network unit module are in one-to-one correspondence with the catalyst units. In the dust blowing device, a dust blowing air source is provided for the jet pipe network unit module by utilizing the air compressor; compressed air is stored and released by utilizing the buffer tank; the opening and the closing of the buffer tank is controlled by utilizing the solenoid valve; the jet pipes which are in the jet pipe network unit module and are in one-to-one correspondence with the catalyst units blow away dust in a manner of being dead against catalysts. The dry compressed air serves as a dust blowing medium, so that the normal work of the catalyst in a dry state is guaranteed. The dust blowing device has no vibration, no high temperature, no dead angle or no gathered dust residue, and has a large coverage surface when the gathered dust is cleaned by the compressed air; the service life of the catalysts is prolonged; the replacement cycle of the catalysts is prolonged; the denitration efficiency is effectively improved; an energy resource is saved.

Owner:HUNAN LUNAN DESULFURIZATION & DENITRATION TECH

Vacuum coating production line

ActiveCN104018130ASmall footprintHigh economic valueVacuum evaporation coatingSputtering coatingProduction lineAssembly line

The invention discloses a vacuum coating production line which comprises a conveying assembly line and a coating assembly line, wherein the coating assembly line is connected with the conveying assembly line; the conveying assembly line comprises a rail, at least one conveying trolley and at least one mounting device; and the conveying trolley operates on the rail, and the mounting devices are conveyed by the conveying trolley; the coating assembly line comprises an inlet cavity, an inlet transition cavity, an inlet buffer cavity, a coating cavity, an outlet buffer cavity, an outlet transition cavity and an outlet cavity. Compared with the prior art, the conveying assembly line and the coating assembly line are connected end to end to form an annular assembly line, the occupied area is saved, substrate transmission in the whole coating production line is intelligently controlled, manpower and material resources are saved, the production efficiency is improved, each cavity in the coating assembly line is replaced or increased according to the product needs, the whole coating production line meets the requirements of multiple coating processes, the service life is prolonged, and the resources are saved. Therefore, the application prospect is wide.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

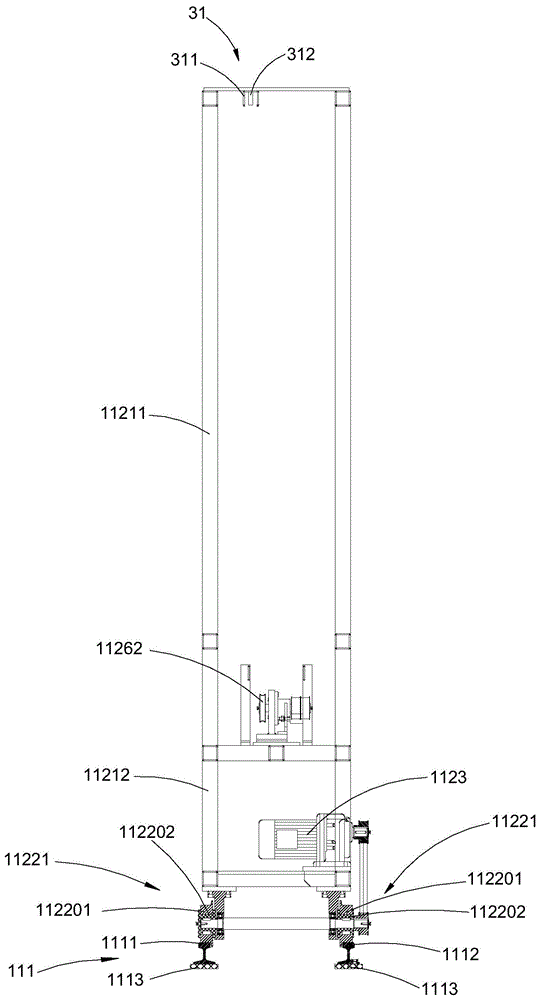

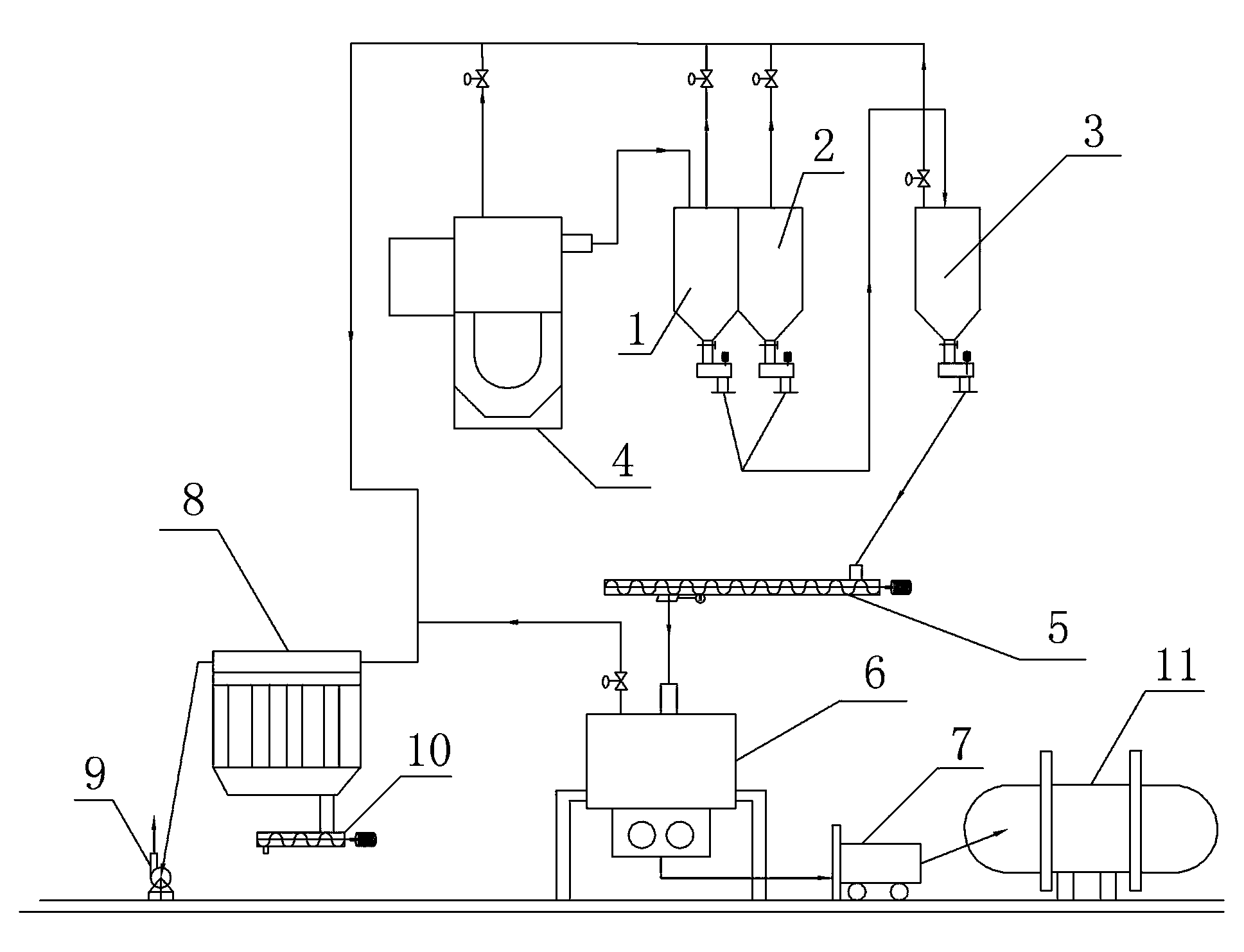

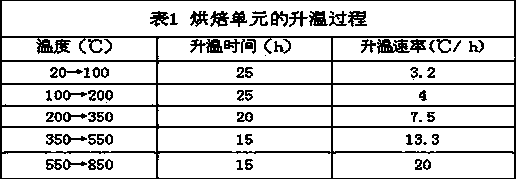

Resourceful treatment system and treatment method of aluminum ashes

The invention discloses resourceful treatment system and treatment method of aluminum ashes, and aims at solving the technical problems that the aluminum ashes in the prior art are low in recovery rate, complicated in process, and easy to pollute environment. The system comprises an aluminum ash separation unit, a burdening unit, a molding unit and a baking unit. The method comprises the following steps: adding hot aluminum ashes to a hot aluminum ash separator; separating out metallic aluminum and low-aluminum ashes; evenly mixing and stirring the obtained low-aluminum ashes and a binder according to the mass ratio of 10:1 to 10:2; pressing the mixed materials into an anode steel claw protection ring blank and demolding; sintering and sizing the obtained anode steel claw protection ring blank and then obtaining an anode steel claw protection ring. By adopting the resourceful treatment system and treatment method, integrated treatment of the aluminum ashes can be achieved, the treating processes of the aluminum ashes are simplified, the resourceful treatment system and treatment method are simple and convenient to operate, energy-saving and environmentally friendly, waste emission can be greatly reduced, regeneration and cyclic utilization of resources are fully achieved, and the problem of innocent treatment of the aluminum ashes is solved.

Owner:ZHENGZHOU JINGWEI TECH & IND

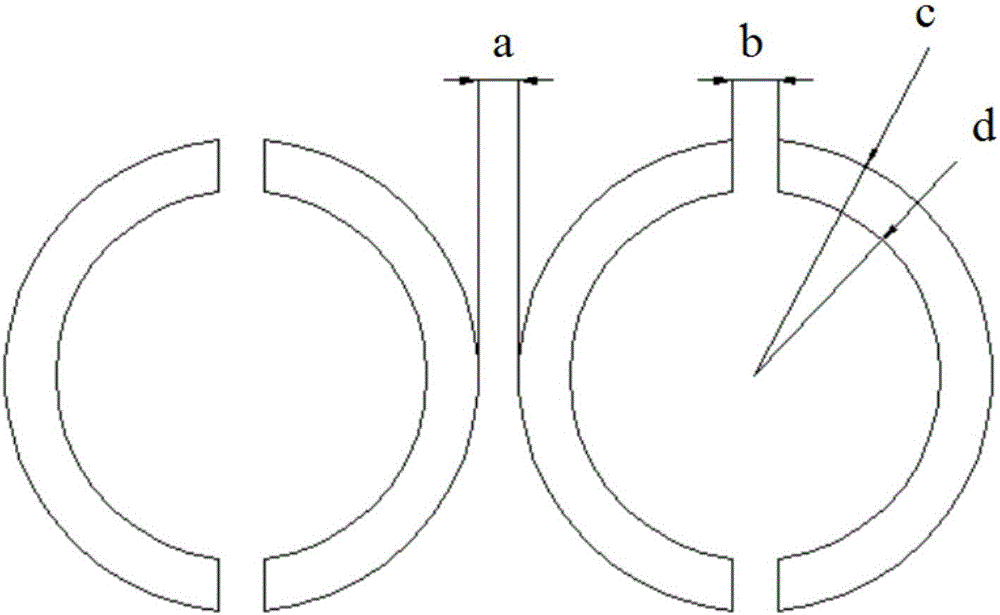

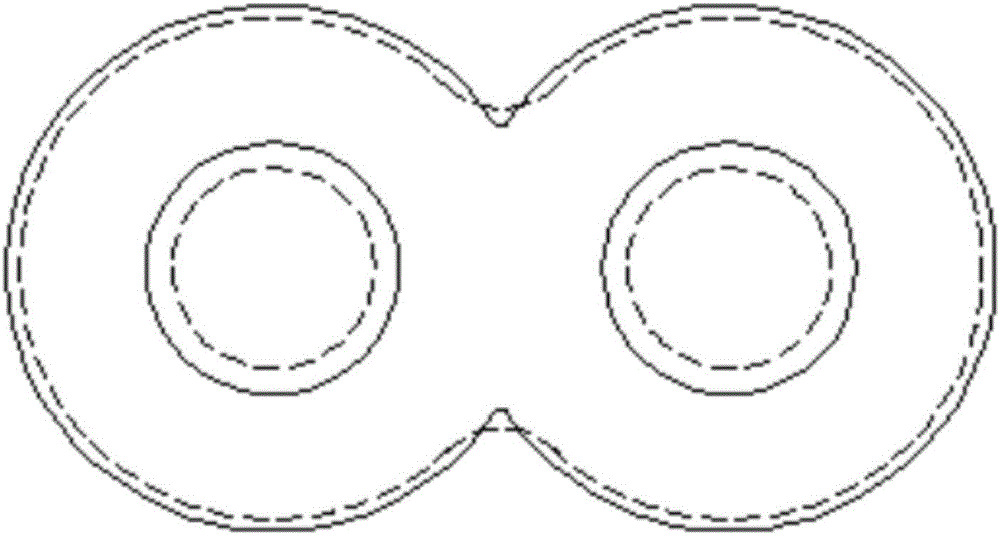

8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and preparation method thereof

ActiveCN106801265AReduce extrusion swelling effectImprove featuresMelt spinning methodsMonocomponent polyesters artificial filamentYarnFiber

The invention belongs to the polyester spinning field and relates to an 8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and a preparation method thereof. A spinning melt contains saturated fatty acid metal salt and modified polyester, wherein the mass ratio of saturated fatty acid metal salt to modified polyester is (0.0005-0.002) to 1; saturated fatty acid metal salt is fatty acid metal salt, the carbon atomic number is 12-22, the melting point is 100-180 DEG C, and the kinetic viscosity is less than or equal to 1Pa.s; a molecular chain of modified polyester comprises a terephthalic acid chain segment, a glycol chain segment and a rigid structure chain segment, and the molar ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02-0.05) to 1; and the die swell ratio of the spinning melt is 1.23-1.33, and the after-filtration pressure during the spinning is 85-125kg / cm<2>. The prepared 8-shaped hollow polyester fiber FDY has relatively high degree of hollowness and relatively good shape-preserving effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

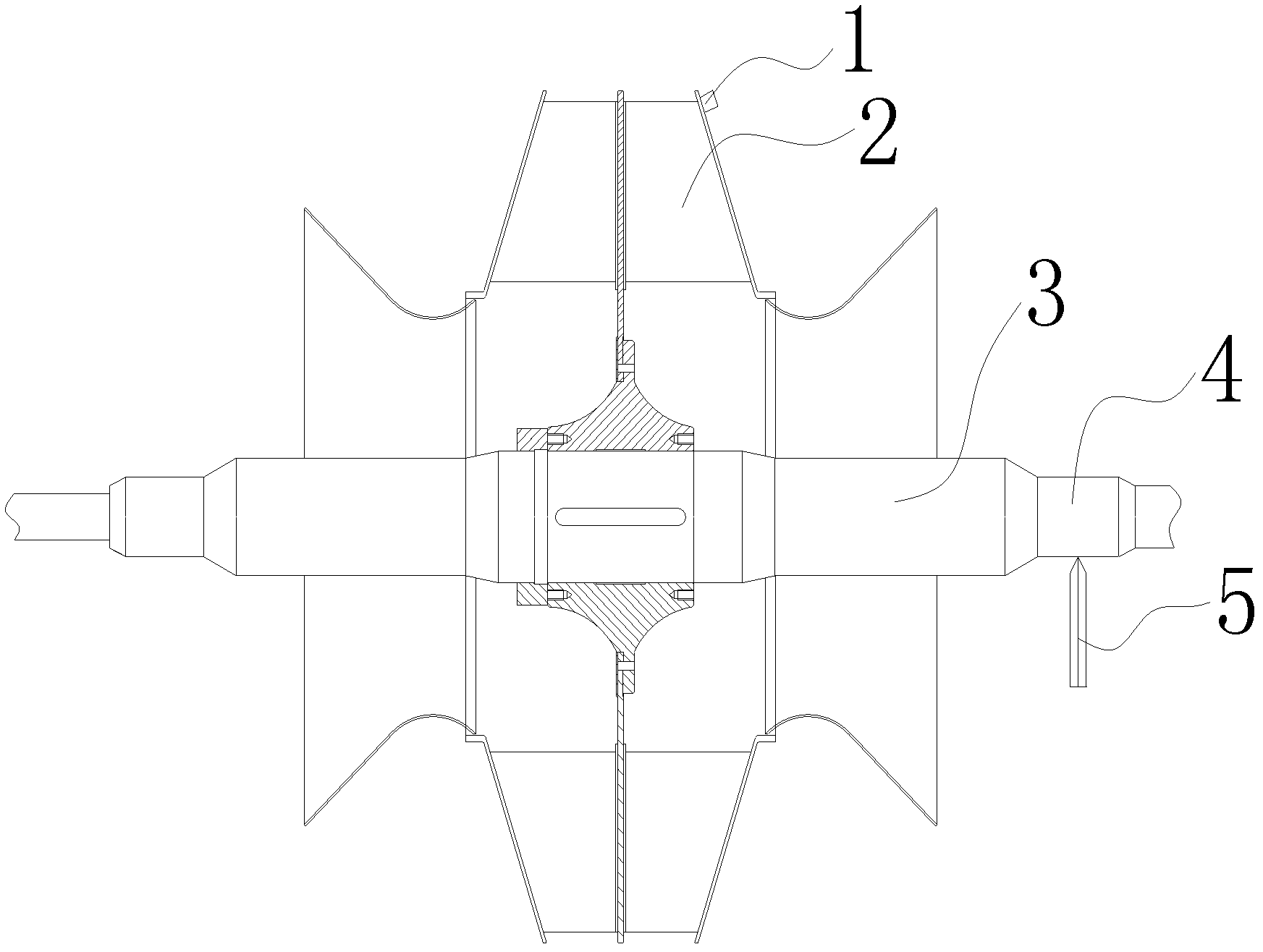

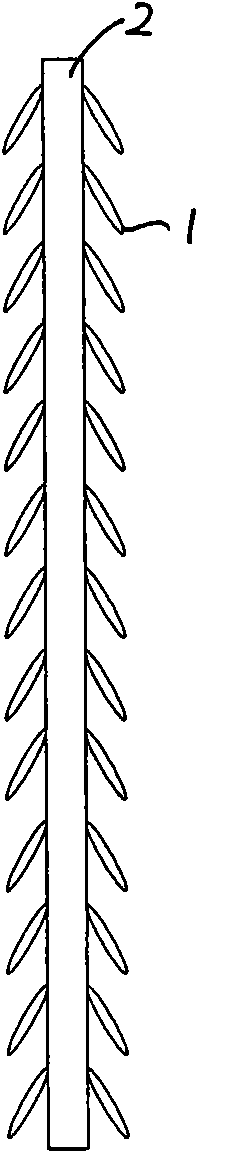

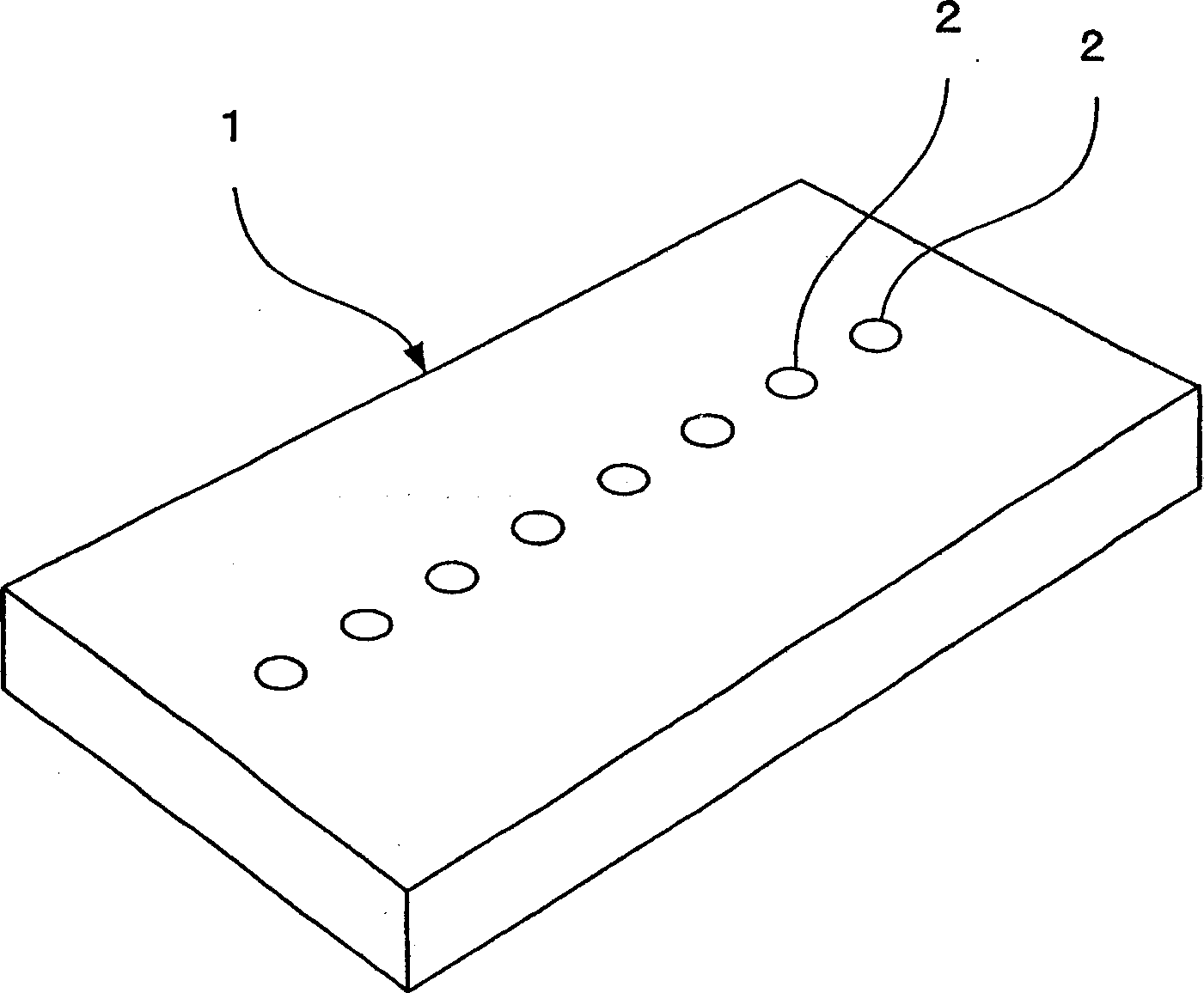

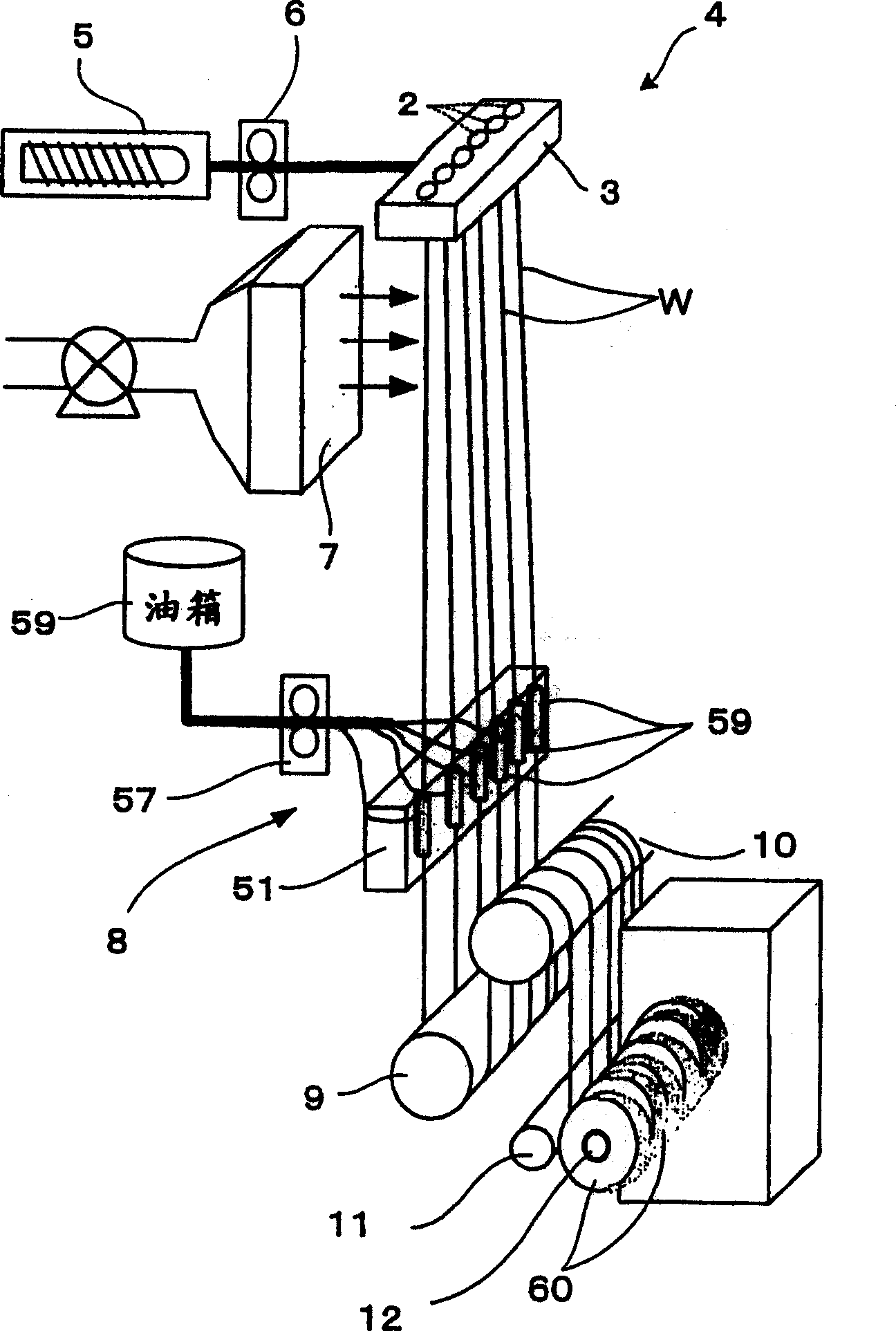

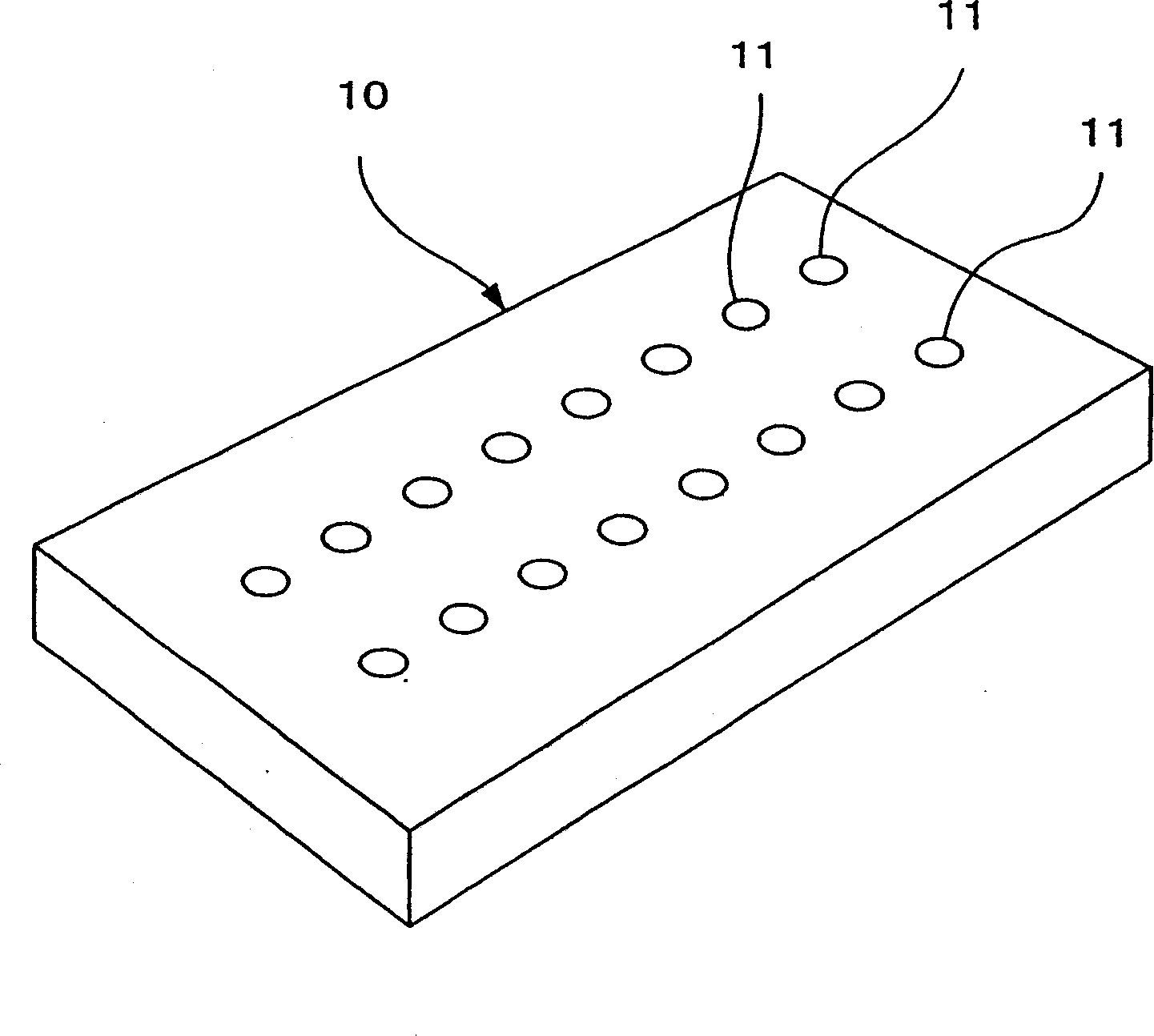

Spinneret, oiling device, production device and production method for synthetic fibers

InactiveCN1608149AExtended replacement cyclePrevent incomplete dischargeMonocomponent polyurethanes artificial filamentSpinnerette packsFilter mediaGuide wires

The present invention relates to a spinning head for synthetic fibers, an oiling device, a spinning device and a manufacturing method thereof. The spinning head (1) comprises a single row of spinning holes (2). The filaments discharged from the spinning hole (2) of the spinneret (1) avoid twisting and are wound up to the take-up roll (12) by means of an oiling device (8) and guide devices (9, 10). In the spinning head (20), a groove (24) may be formed to extend in a radial direction and have its center located in the spinning hole (23). A molten polymer filtered by the filter medium (22) can enter the spinning hole (23) through the slot (24). The oiling device (31) may include an oiling device (8) and a guide element (9), and the cooperation of the two elements prevents incomplete oiling.

Owner:TOYO TOYOBO CO LTD

Pouring material for cement kiln tertiary air duct

The invention relates to a pouring material for a cement kiln tertiary air duct. The pouring material comprises aggregate and a matrix material according to a weight ratio of 2-8: 1-3. The aggregate has particle sizes of 1-10mm and the matrix material has the particle sizes of 0.1-0.5mm. The aggregate comprises, by weight, 28-50 parts of fused magnesia, 25-45 parts of modified white alundum, 5-15 parts of zirconium mullite and 8-20 parts of magnesium aluminate spinel. The matrix material comprises magnesia powder, silicon oxide fine powder, mullite powder, alumina fine powder and andalusite. The pouring material utilizes appropriate aggregate and the matrix material and has wear resistance and corrosion resistance, a uniform degree of expansion and good thermal shock stability. Through use of a fiber additive, pouring material integrality is improved, and pouring material flexural performances and anti-erosion performances are improved. The cement kiln tertiary air duct has the advantages of long service life, long replacement period, small production cost and high production efficiency under bad conditions.

Owner:长兴兴鹰新型耐火建材有限公司

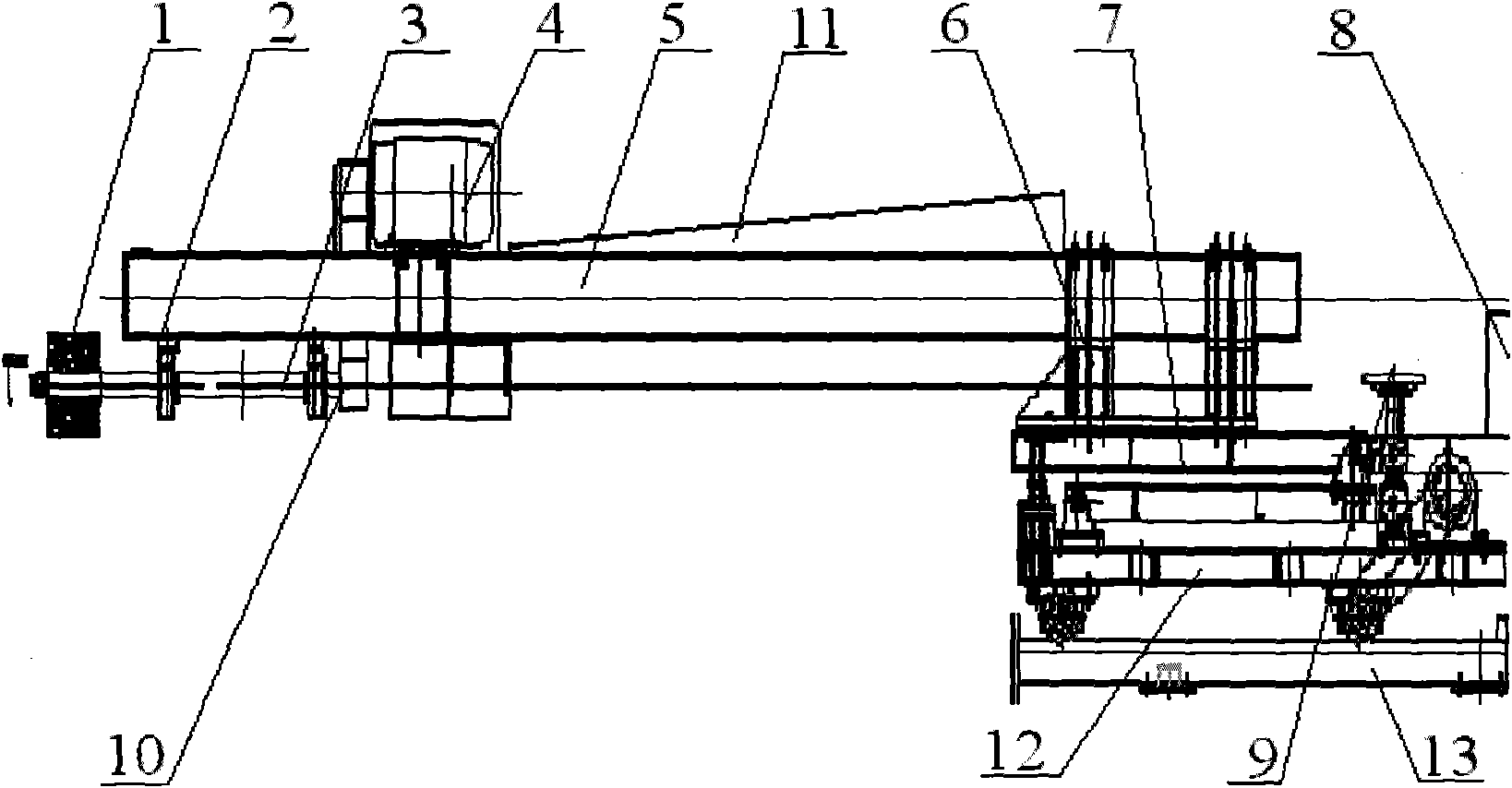

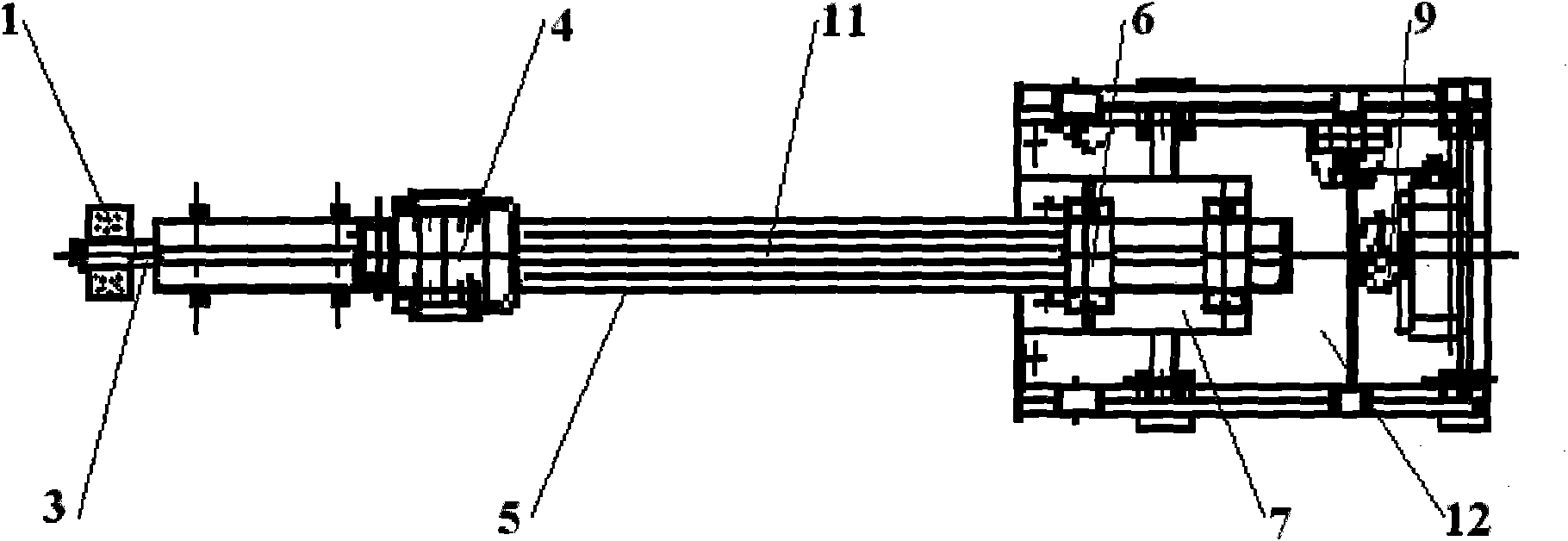

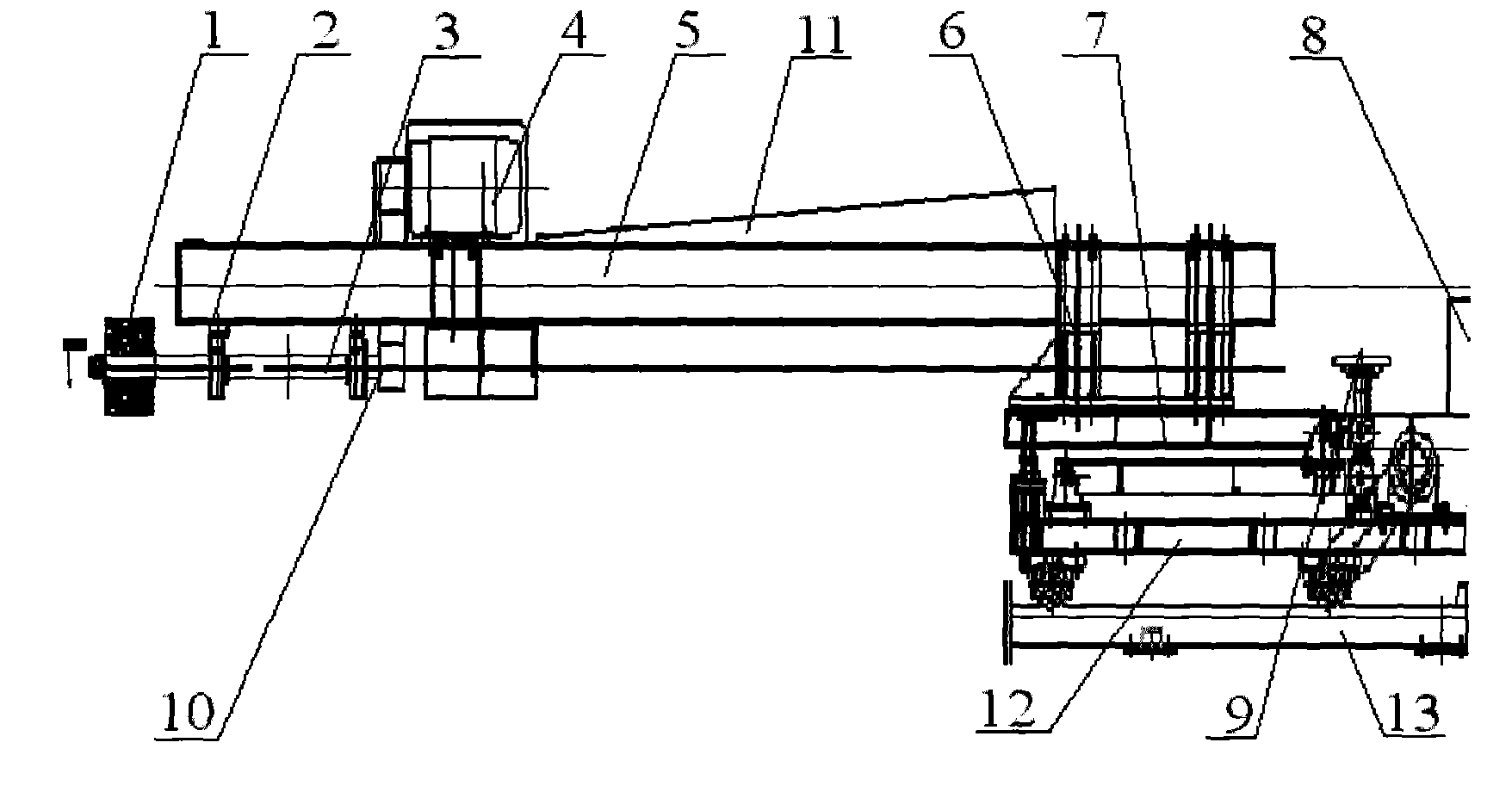

Grinding and driving mechanism of inner grinder of large-diameter cast iron pipe production line

ActiveCN101797706ASimple structureShorten the lengthRevolution surface grinding machinesEngineeringCast iron pipe

The invention discloses a grinding and driving mechanism of an inner grinder of a large-diameter cast iron pipe production line. The mechanism is provided with a grinding rod shaft bracket connected to a connecting seat of the inner grinder, and a grinding rod shaft is arranged on the front part of the grinding rod shaft bracket extending into a cast iron pipe through a bearing block, wherein the axis of the grinding rod shaft is longitudinally parallel to the grinding rod shaft bracket; and a driving motor is fixed on the grinding rod shaft bracket and connected with the grinding rod shaft through a belt transmission mechanism. The adoption of the technical scheme simplifies the structure of the inner grinder, decreases the length of the grinding rod shaft and reduces the number of supporting bearing blocks of the grinding rod shaft; in addition, the weight of the equipment mechanism is lightened, and under the condition that the power of a grinding electromotor keeps unchanged, the grinding time is reduced, and the replacement period of the grinding rod shaft is prolonged, thereby reducing the inventory of spare parts, greatly improving the production efficiency and reducing the production cost.

Owner:WUHU XINXING DUCTILE IRON PIPES

On-line roll grinding method for carbon jacket hearth roll

ActiveCN102776347AExtended replacement cycleImprove pass rateFurnace typesHeat treatment furnacesEnergy consumptionFurnace temperature

The invention provides an on-line roll grinding method for a carbon jacket hearth roll. According to the invention, for great accretion, temperature of each furnace segment is set to be 20 to 25 DEG C higher than normal temperature, a transitional coil which has been used less than 4 times and has a thickness of 0.5 to 0.7 mm is put in a furnace, tension in the furnace is eliminated, the roll is allowed to revolve for 8 to 12 min in a manner of combined inching after revolution for 4 to 5 min, then heating is carried out so as to control furnace temperature, and the above mentioned procedures are repeated for 3 cycles; for fine accretion, temperature of each furnace segment is set to be 10 to 15 DEG C higher than normal temperature, a transitional coil which has been used less than 4 times and has a thickness of 0.35 to 0.5 mm is put in a furnace, tension in the furnace is eliminated, and the roll is allowed to revolve for 1 to 3 min. According to the invention, accretion in the carbon jacket hearth roll can be rapidly removed; for the fine accretion, it is guaranteed that no accretion occurs any longer within 16 h after removal of the fine accretion; for the great accretion, it is guaranteed that no accretion occurs any longer within 30 h after removal of the great accretion; and therefore, an operating rate of a unit and rolling yield of products are greatly improved, and production cost and energy consumption are reduced.

Owner:ANGANG STEEL CO LTD

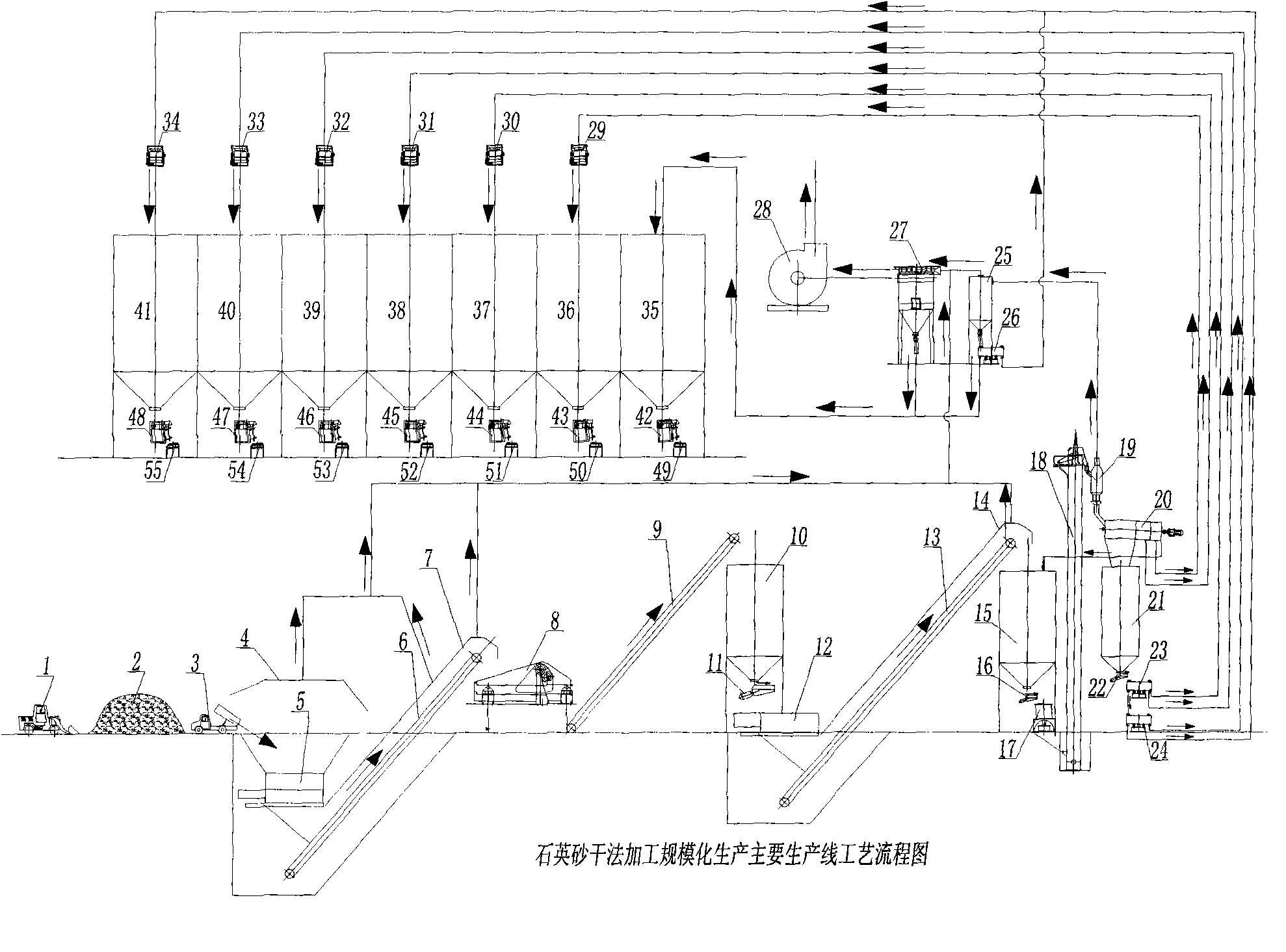

Dry process scale continuous production process of quartz sand

InactiveCN102211854AIncrease productionReduce manual labor intensityGas current separationGlass shaping apparatusProcess scaleProcess engineering

The invention discloses a dry process scale continuous production process of quartz sand, which comprises the process steps of quartz ore breaking and crushing, product grading, packaging and transportation, dust pollution treatment and the like. In the process step of the quartz ore breaking, a two-grade screening type breaker is adopted, and a cleaning dewatering screen and a broken stone drying tower are arranged between two grades of screening and breaking; in the process step of quartz ore crushing, a single-stage HK type sand making machine is adopted, and single-group production or multi-group parallel production can be performed from the HK type sand making machine to the finished product delivery after screening and grading. In the process step of product grading, the mode combining air classification and sieve classification is adopted, namely the process step of single-stage air classification, single-stage drum screen classification and two-stage rotation movable screeningmachine classification is adopted, wherein the air classification adopts negative pressure classification to realize comprehensive functions of separation and dust removal. In the process step of packaging and transportation, a production process in which a plurality of machine sets are connected in parallel is adopted, and the same product is collected and conveyed to a finished product storage bin by the same conveyor to realize the integration of packaging and shipping.

Owner:李立和 +1

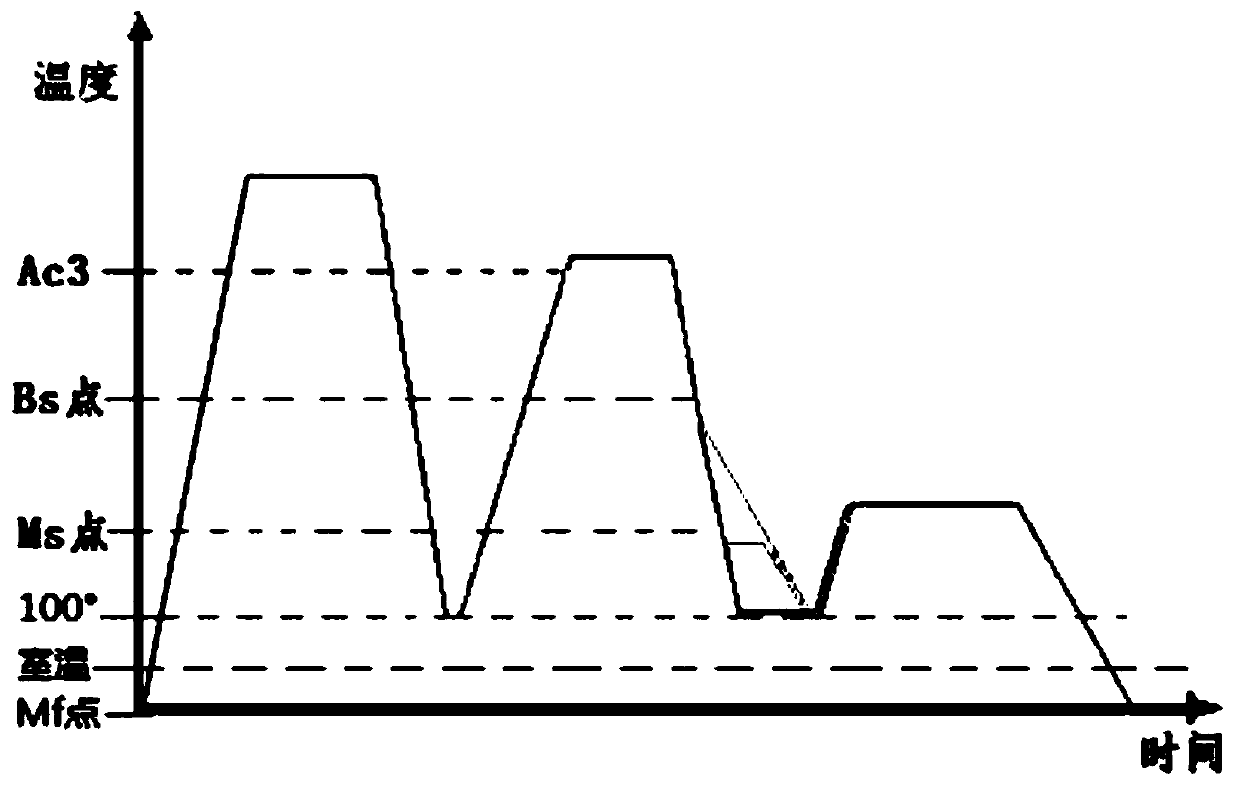

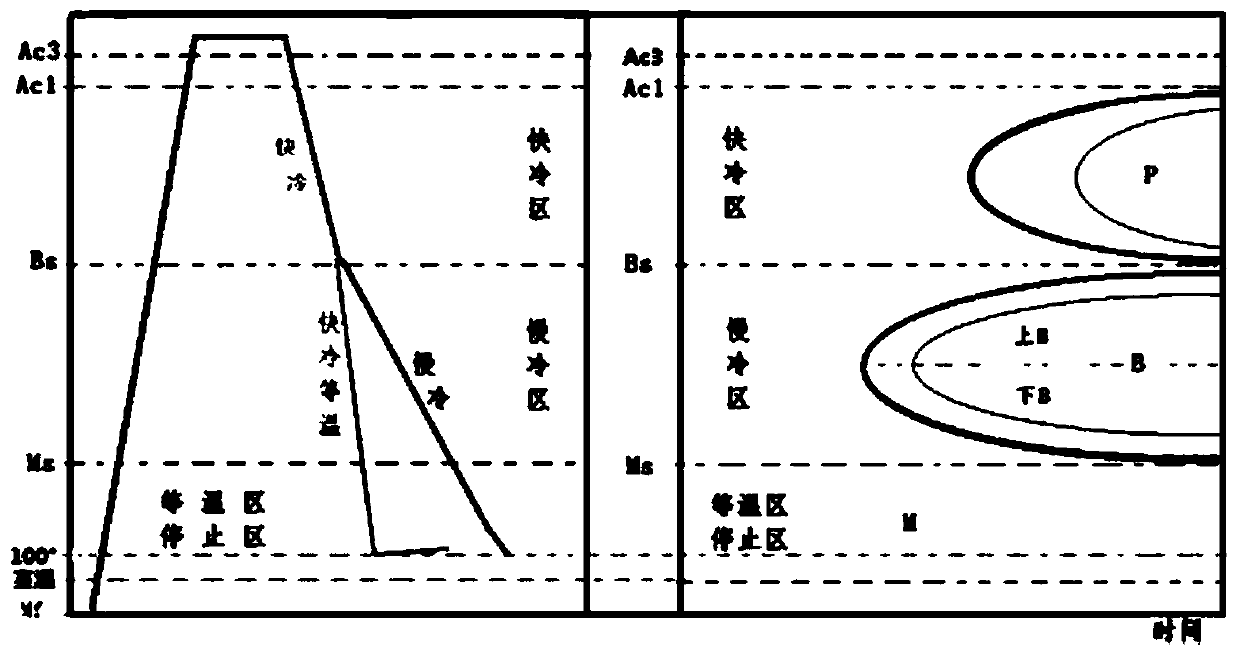

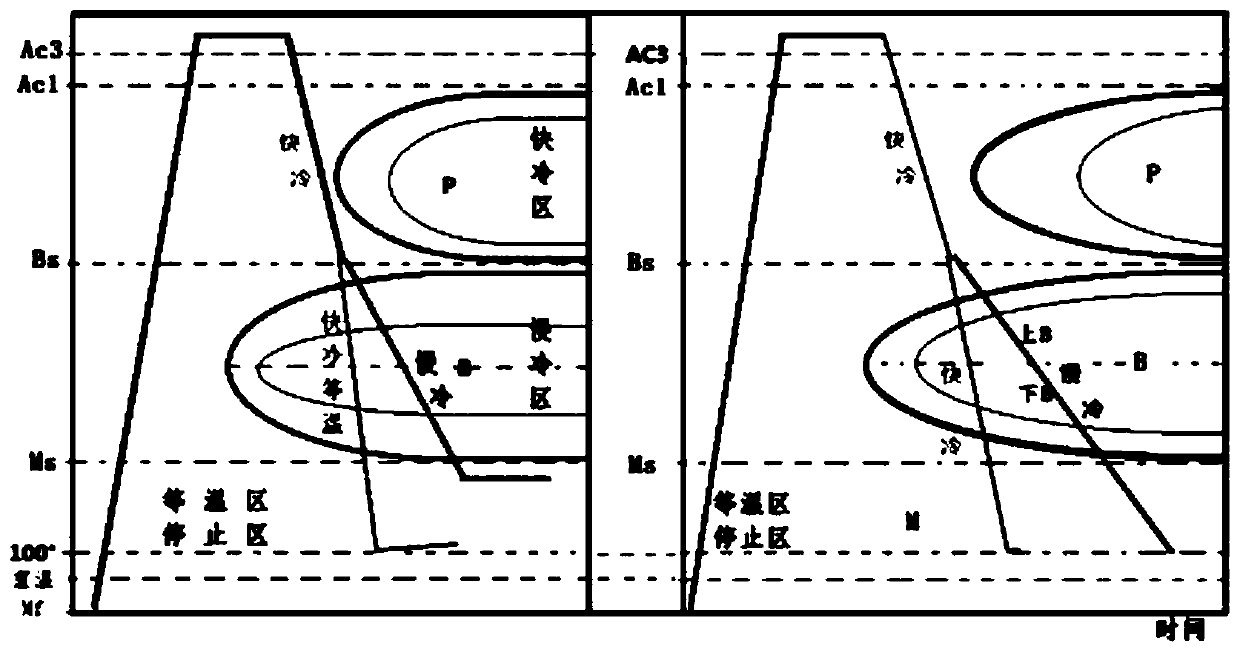

Preparation method for bainite, martensite and austenite complex-phase corrosion-resistant steel

The invention discloses a preparation method for bainite, martensite and austenite complex-phase corrosion-resistant steel. The preparation method is characterized in that a few multi-alloy elements are added to mutually restrain, i.e., a structure range is obtained by widening an upper bainite structure, a thermal treatment way adopts quick-cooling from austenite to a BS point, upper and lower bainite strcutures are obtained by adopting slow-cooling temperature-varying at a medium temperature, and a martensite residual-austenite structure is obtained at equal temperature within a low-temperature range. The whole process is used for continuously producing to obtain wear-resisting steel which consists of upper and lower bainites, martensite and austenite, and the wear-resisting steel resistimpact and cutting abrasion under various environments as well as corrosion. The production process simplifies the process of controlling cooling speed, and facilitates the preparation method for thebainite, martensite and austenite complex-phase corrosion-resistant steel which is simple in large-scale control, is good in quality and is high in wear resistance.

Owner:紫荆浆体管道工程股份公司

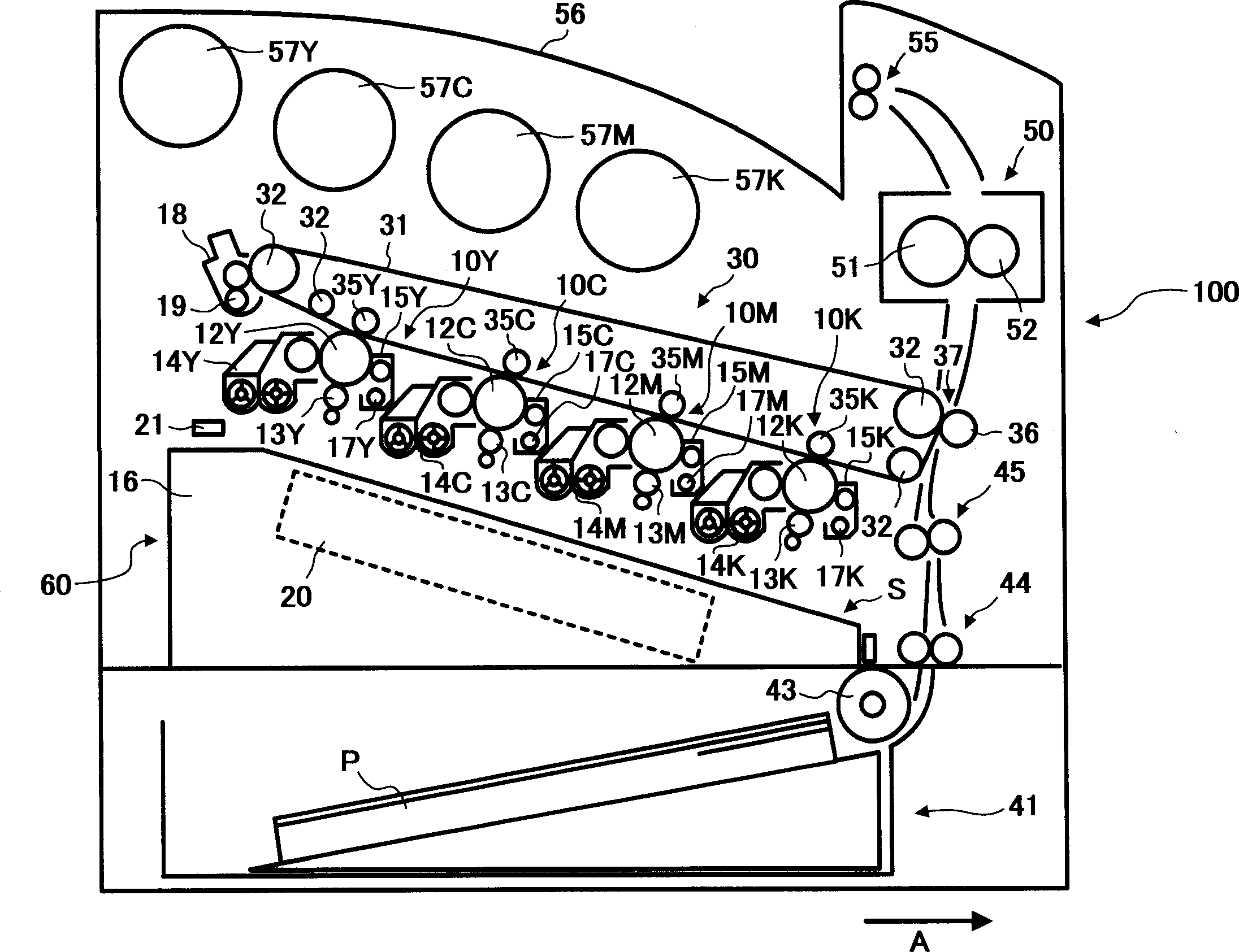

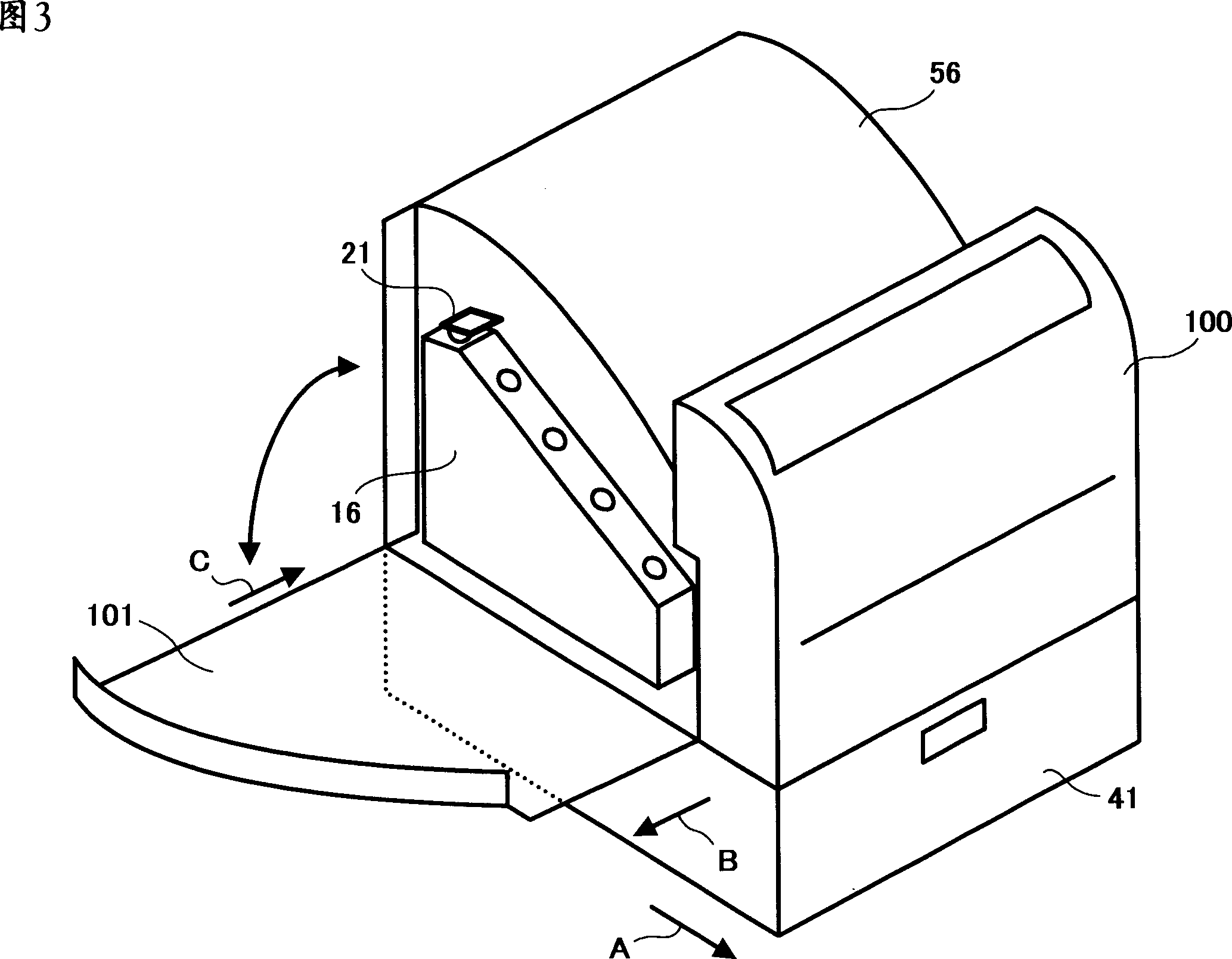

Waste toner recovering apparatus and image forming apparatus

InactiveCN1493932AEfficient fillingExtended replacement cycleElectrographic process apparatusImage formationEngineering

Owner:RICOH KK

One-spindle three-spinning viscose filament semicontinuous centrifugal spinning process and its spinning machine

ActiveCN1814865AImprove efficiencyAcid bath reaction conditions are the sameArtificial thread manufacturing machinesArtificial filaments from viscoseDecompositionCandle

This invention discloses a semi-continuous centrifugal filature technology and a spinning machine for producing viscose filaments, which applies a viscose filament semi-continuous centrifugal spinning technology for shaping one-ingot three-silks in a tube including that the solidification and decomposition of the glue and acid bath react in the way of shaping in the tube, in which, there are three viscose measure outlets for each ingot, three sets of candle filters, three nozzles, three shaping tubes and three centrifugal jars, which applies the new technology and new type of glu supply and winding device to realize the filament production efficiency 2-3 times of that of the original R535A(B) type.

Owner:YIBIN GRACE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com