Resourceful treatment system and treatment method of aluminum ashes

A treatment system and treatment method technology, which is applied in the aluminum ash resource treatment system and treatment field, can solve the problems of destructive impact on the environment, large waste of metal aluminum, and low recovery rate, so as to reduce waste discharge and solid waste discharge , The effect of cleaning the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

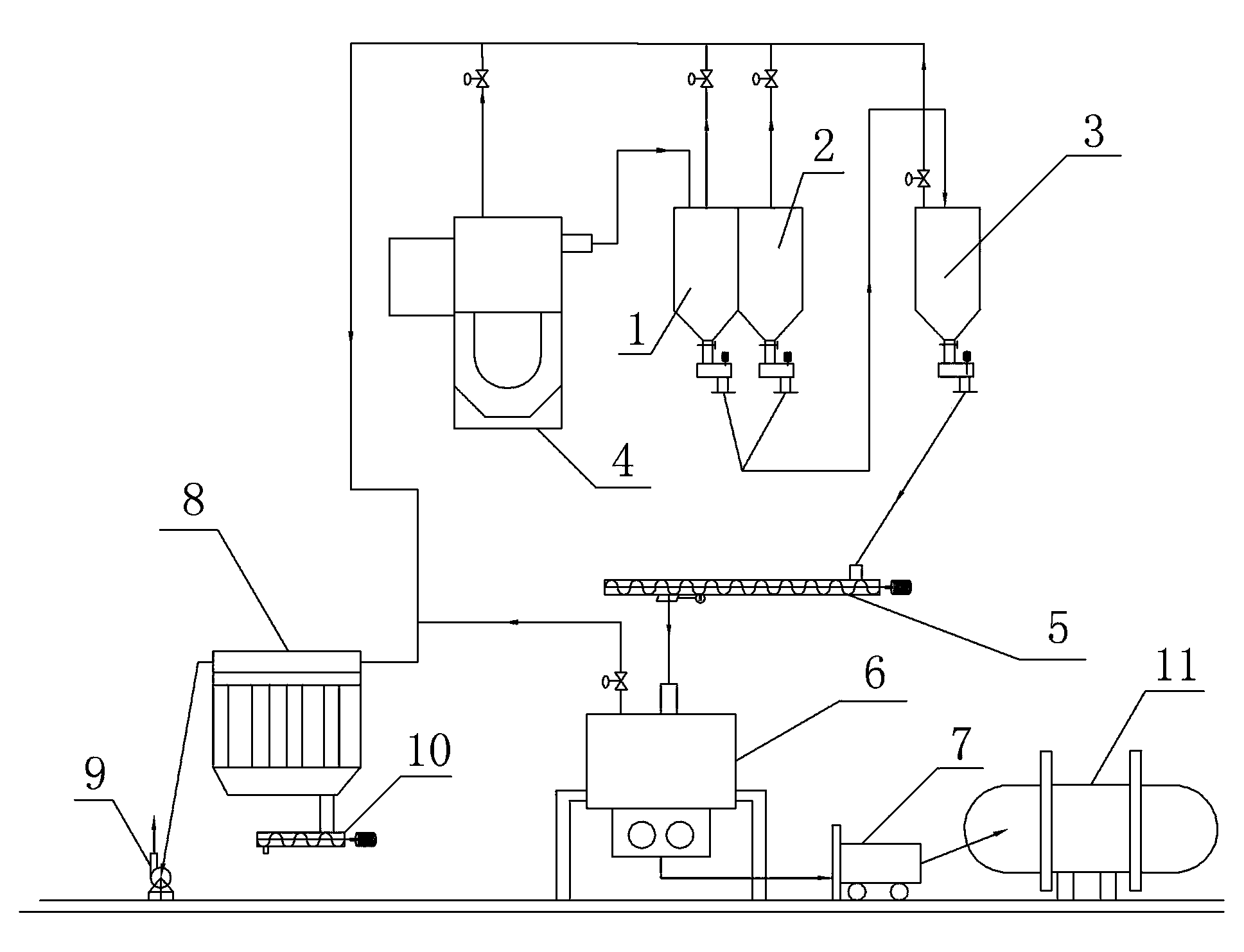

[0023] Embodiment 1: a kind of aluminum ash recycling processing system, such as figure 1 As shown, it includes an aluminum ash separation unit, a batching unit, a molding unit and a baking unit. The batching unit includes a low-aluminum aluminum ash silo 1, a binder silo 2 and a stirring silo 3. The low-aluminum aluminum ash The bin 1, the binder bin 2 and the mixing bin 3 are all provided with a weighing device and a discharge valve, and the outlets of the low-aluminum aluminum ash bin 1 and the adhesive bin 2 are respectively connected to the The feeding port of the stirring silo 3 is correspondingly connected, and a stirring device is arranged in the stirring silo 3; the aluminum ash separation unit includes a hot aluminum ash separator 4 and a feeding mechanism, and the hot aluminum ash separator 4 The ash discharge port communicates with the low-aluminum aluminum ash silo 1 through the feeding mechanism; end is correspondingly communicated with the discharge port of th...

Embodiment 2

[0028] Embodiment 2: An aluminum ash recycling processing method using the aluminum ash recycling processing system, comprising the following steps:

[0029](1) Add the hot aluminum ash cleaned from the melting and casting furnace to the hot aluminum ash separator to obtain separated metal aluminum and low-aluminum aluminum ash, and the obtained low-aluminum aluminum ash is transported to the low-aluminum aluminum ash Ash silo;

[0030] (2) Open the discharge valves of the low-aluminum aluminum ash silo and the binder silo, and add the low-aluminum aluminum ash and the binder into the stirring silo at a mass ratio of 10:1, Mix and stir evenly; the binder is composed of aluminum stearate, high manganese cement and quicklime, wherein the mass percentage of each component is: aluminum stearate 40%, high manganese cement 40%, quicklime 20%;

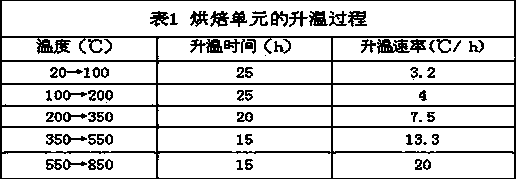

[0031] (3) Start the feeding mechanism, transport the mixed material obtained in step (2) to the pressing and demoulding mechanism of the m...

Embodiment 3

[0034] Example 3: The difference from Example 2 is that in step (2), the low-aluminum aluminum ash and the binder are mixed in a mass ratio of 10:2; the mass percentage of each component of the binder is: stearin Acid aluminum 32%, high manganese cement 45%, quicklime 23%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com