Patents

Literature

55results about How to "Solve harmless disposal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Municipal solid waste harmless treatment method

InactiveCN106196081ASave waterSolve harmless disposalGas treatmentDispersed particle filtrationSocial benefitsWaste collection

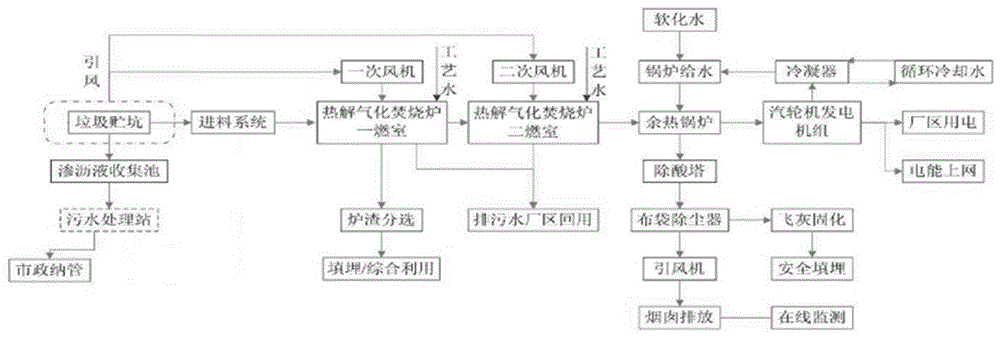

The invention aims to provide a municipal solid waste harmless treatment method. The purposes of harmless treatment of municipal solid waste and recycling of waste can be achieved effectively. According to the technical scheme, the municipal solid waste harmless treatment method comprises the following steps of (1) waste collection, (2) thermal pyrolysis, (3) waste heat utilization, (4) smoke treatment, (5) ash treatment, (6) fly ash treatment and (7) percolate treatment. The method is unique and scientific, saves energy, reduces emission, effectively achieves harmless treatment of municipal solid waste and is extremely great in economic and social benefits.

Owner:河南华泰粮油机械股份有限公司

Gas field produced wastewater reduction and harmless treatment methods

InactiveCN106395926ASolve harmless disposalReduce volumeWaste water treatment from quariesGeneral water supply conservationEconomic benefitsWastewater

The invention discloses gas field produced wastewater reduction and harmless treatment methods. According to the methods, water is separated from gas field produced wastewater with a desalting process, concentrated gas field produced water is formed, and the volume of the gas field produced water is reduced; meanwhile, the invention also discloses a further concentrated gas field produced wastewater harmless treatment method. With the adoption of the treatment method, defects in existing gas field produced wastewater treatment methods are overcome, the problem of harmless treatment on the gas field produced wastewater can be effectively solved, the problem of pollution environment caused by the gas field produced wastewater can be effectively solved, gas production aids and useful substances in the gas field produced wastewater can be effectively recovered, the cost and the energy consumption for recovery of the gas production aids and useful substances from the gas field produced wastewater can be greatly reduced, and the transportation volume, the transportation cost and the treatment energy consumption and expense of the gas field produced wastewater can be greatly reduced; the method has the advantages of being easy to implement, safe, reliable, wide in application, easy to popularize and the like; the economic benefit and the environmental protection benefit are remarkable.

Owner:BEIJING UNITY BENEFICIAL TECH CO LTD

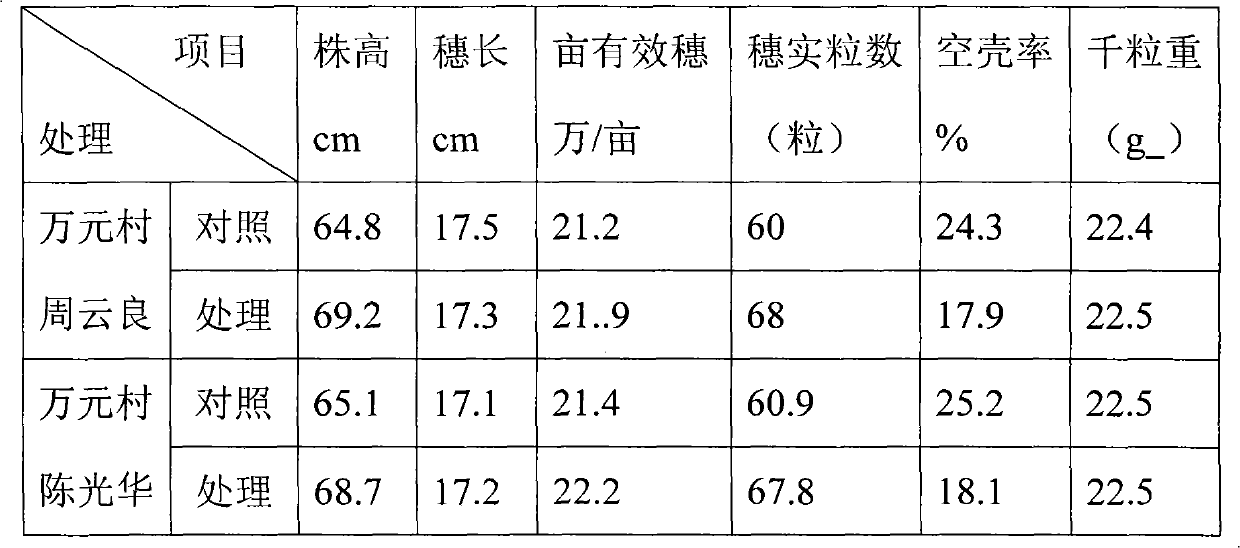

Resourceful treatment system and treatment method of aluminum ashes

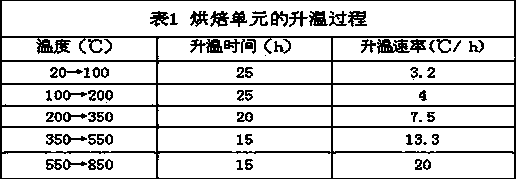

The invention discloses resourceful treatment system and treatment method of aluminum ashes, and aims at solving the technical problems that the aluminum ashes in the prior art are low in recovery rate, complicated in process, and easy to pollute environment. The system comprises an aluminum ash separation unit, a burdening unit, a molding unit and a baking unit. The method comprises the following steps: adding hot aluminum ashes to a hot aluminum ash separator; separating out metallic aluminum and low-aluminum ashes; evenly mixing and stirring the obtained low-aluminum ashes and a binder according to the mass ratio of 10:1 to 10:2; pressing the mixed materials into an anode steel claw protection ring blank and demolding; sintering and sizing the obtained anode steel claw protection ring blank and then obtaining an anode steel claw protection ring. By adopting the resourceful treatment system and treatment method, integrated treatment of the aluminum ashes can be achieved, the treating processes of the aluminum ashes are simplified, the resourceful treatment system and treatment method are simple and convenient to operate, energy-saving and environmentally friendly, waste emission can be greatly reduced, regeneration and cyclic utilization of resources are fully achieved, and the problem of innocent treatment of the aluminum ashes is solved.

Owner:ZHENGZHOU JINGWEI TECH & IND

Method for recovering heavy metal in electrolytic manganese passivating wastewater

InactiveCN101643263ASolve harmless disposalReduce manufacturing costWaste water treatment from metallurgical processWater/sewage treatmentElectrolysisWastewater

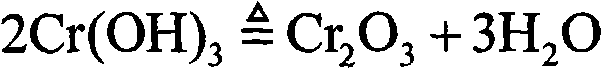

The invention relates to a method for recovering heavy metal in electrolytic manganese passivating wastewater. The method mainly comprises the following processes: firstly, regulating the pH value ofthe electrolytic manganese passivating wastewater by alkali, then adding carbonate into the electrolytic manganese passivating wastewater, filtering after finishing the reaction, regulating the pH value of the solution to 8-12, then adding peroxide and filtering after finishing the reaction; afterwards, regulating the pH value of the solution to 2.0-7.0 and adding quinary-sulfocarbonate to processsexavalent chromium. The invention can recover and utilize manganese and chromium ions in the electrolytic manganese passivating wastewater in a resource way and also can eliminate the generation ofdangerous solid wastes. Compared with the prior art, the invention also has the advantages of low production cost, easy operation, continuous operation and convenient realization of industrialized production.

Owner:CHONGQING UNIV

Complex enzyme preparation for sewage treatment and application method thereof

InactiveCN101898830AEasy to handleMonitor effluent qualityTreatment with aerobic and anaerobic processesCelluloseEutrophication

The invention relates to a complex enzyme preparation for sewage treatment. The complex enzyme preparation is compounded by mixing complex enzyme and mineral water, wherein the weight ratio of the complex enzyme to the mineral water is 1:9-50; and the complex enzyme contains the following components in volume content: 50 to 80 mg / L of bromelain, 50 to 80 mg / L of papain, 15 to 30 mg / L of L-aspartase, 15 to 30 mg / L of glutathione, 100 to 150 mg / L of yeast extract and 50 to 80 mg / L of cellulose. The complex enzyme preparation improves the treatment capability of a sewage plant, reduces the running cost, basically achieves zero release of residual organic sludge, prevents environmental secondary pollution of the sewage treatment, improves the self-purification capability of yielding water of the sewage plant, prevents secondary pollution of the yielding water, prevents secondary eutrophication of the yielding water, and radically solves the problem of environmental protection in operation of the sewage treatment plant.

Owner:麦广鸿 +2

Organic bacterium fertilizer taking sludge as raw material and preparation method thereof

InactiveCN106946630ASolve harmless disposalSolve processing problemsSewage/sludge fertilisersLiquid/slurry treatmentMicroorganismDenitrifying bacteria

The invention provides application of biological floc to harmless treatment of sludge, organic bacterium fertilizer and a preparation method thereof. The formula of the organic bacterium fertilizer is prepared from the following raw materials: sludge, the biological floc and zymophyte, wherein the biological floc comprises composted straw powder, a first microorganism bacterium agent, nitrifying bacteria and denitrifying bacteria; the first microorganism bacterium agent comprises first bacillus subtilis and selective actinomyces; the preparation method comprises the following steps: step (1): composting and fermenting; step (2): turning over and supplementing water; step (3): fermenting again; and step (4): granulating. The biological floc is applied to waste sludge from a municipal sewage treatment plant and the waste sludge is subjected to the harmless treatment to prepare organic fertilizer; stacking, pollution and waste problems of agriculture wastes can be rapidly solved and recycling of resources can also be realized; and the prepared organic bacterium fertilizer also has unexpected fertilizer efficiency.

Owner:上海安而信环保科技有限公司

Gas field sewage harmless treatment method

InactiveCN105523596ASolve harmless disposalSolve the pollution of the environmentWaste water treatment from quariesGeneral water supply conservationSocial benefitsSewage treatment

The invention discloses a gas field sewage harmless treatment method comprising the following steps: water content in the gas field sewage is evaporated with a ventilation method, such that gas field sewage is turned harmless. With the method, defects of existing gas field sewage treatment methods are overcome; a gas field sewage harmless treatment problem can be effectively solved; a gas field sewage environment pollution problem can be effectively solved; gas production auxiliary agents and useful substances in the gas field sewage can be effectively recycled; cost and energy consumption for recycling the gas production auxiliary agents and useful substances in the gas field sewage can be greatly reduced; and gas field sewage transportation volume, transportation cost, treatment energy consumption and treatment cost can be greatly reduced. The method is safe and reliable, and has the advantages of easy implementation, wide application, easy popularization and the like. The method provides significant economic and social benefits.

Owner:BEIJING UNITY BENEFICIAL TECH CO LTD

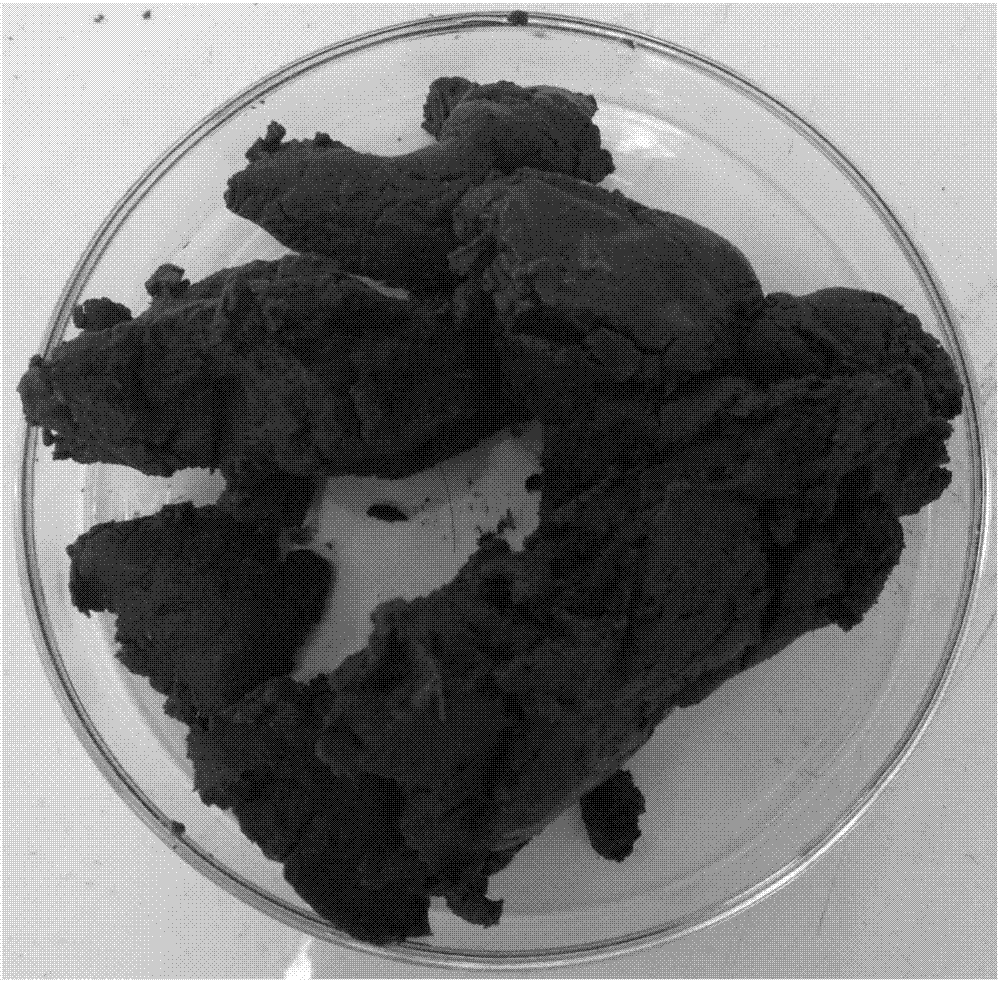

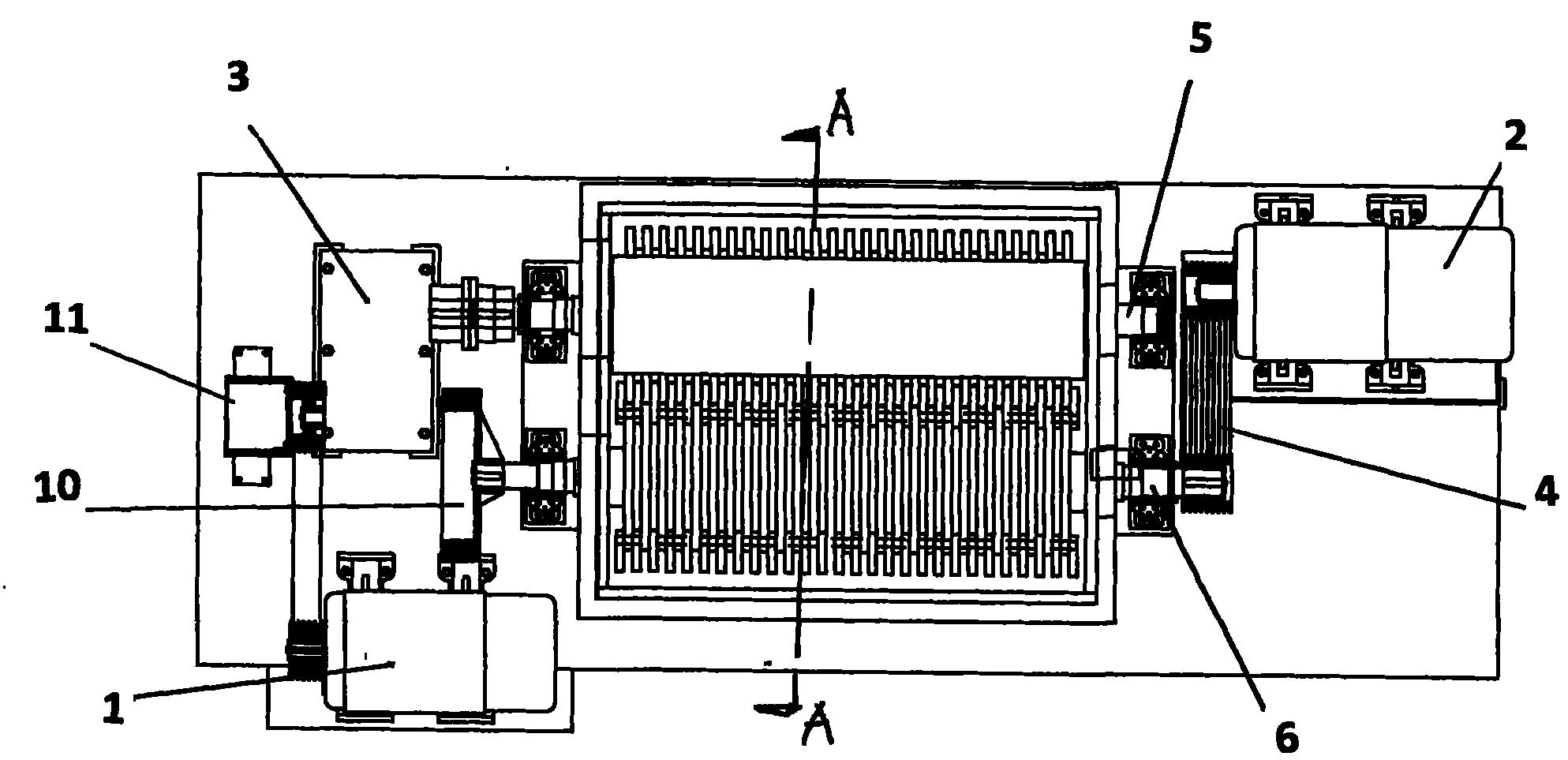

Environment-friendly animal carcass harmless fermentation treatment machine

InactiveCN105964665AGood effectSmall footprintSolid waste disposalTransportation and packagingElectric heatingTreatment effect

The invention discloses an environment-friendly animal carcass harmless fermentation treatment machine. The environment-friendly animal carcass harmless fermentation treatment machine comprises front wheels, front roll rings, a machine base, crushing cutters, a feeding door, a screw propelling blade, an electric heating element, an insulating material, rear wheels, rear roll rings, a temperature sensor, discharging push plates, an electric control device, a small gear, a speed reducer, a motor, a large gear, a roller and a discharging port. The front wheels and the rear wheels are arranged on the machine base. The front roll rings are fixed to the front end of the roller, and the rear roll rings are fixed to the rear end of the roller. The crushing cutters are arranged in the roller. The screw propelling blade is arranged behind the crushing cutters. The electric heating element and the insulating material are arranged on the outer surface of the roller. The discharging push plates are arranged in the roller. The large gear is arranged on the outer surface of the rear end of the roller. The temperature sensor is arranged between the large gear and the rear roll rings. The discharging port is formed in the middle position of the rear end face of the roller. The environment-friendly animal carcass harmless fermentation treatment machine has the beneficial effects that the animal carcass harmless treatment effect is good, the occupied area is small, operation is easy, and cost is low.

Owner:SICHUAN JUYE ENVIRONMENTAL PROTECTION TECH

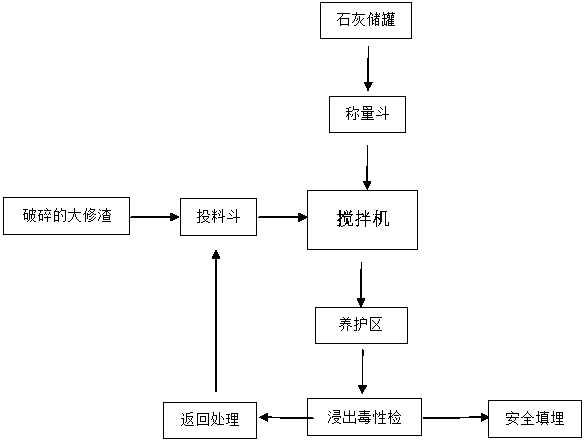

Wet-process harmless treatment method for electrolytic bath overhaul residue

InactiveCN105617596ASolve the problem of harmless treatment of overhaul slagRealize resource utilizationChemical protectionElectrolysisHypochlorite

The invention discloses a wet-process harmless treatment method for electrolytic bath overhaul residue. The wet-process harmless treatment method for electrolytic bath overhaul residue comprises a cyanogen removal process and a fluorine removal process, wherein in order to enable cyanides in the overhaul residue to react with hypochlorite released by bleaching powder in water as soon as possible while being dissolved in water, in the cyanogen removal process, the overhaul residue is premixed with the bleaching powder to shorten a reaction time, a pH value is controlled to be between 9 and 12, a reaction temperature is not greater than 50 degrees, and an available chlorine content of the bleaching powder is not less than 28%; and in the fluorine removal process, calcium hydroxide needs to be added at first, and then hydrochloric acid is added, and after a fluorine removal agent (calcium hydroxide) is added, the final pH value of reaction solution is controlled to be 6-7, and the content of Ca(OH)2 in the industrial calcium hydroxide is not less than 92%. The wet-process harmless treatment method for electrolytic bath overhaul residue, which is disclosed by the invention, belongs to solid waste treatment projects; the technical scheme is advanced and reasonable, low in investment, and high in implementation property; the purpose of harmless treatment for overhaul residue of enterprises is effectively solved; the treated overhaul residue is finally produced into cement bricks, and cannot generate any waste water and waste residue; and resource realization is effectively realized, and good economic benefits and social benefits are achieved.

Owner:HENAN ZHONGFU IND

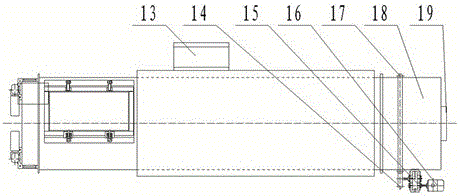

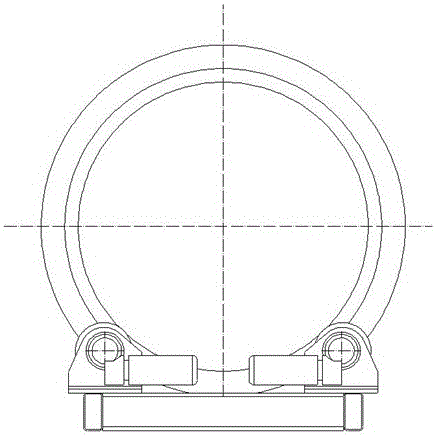

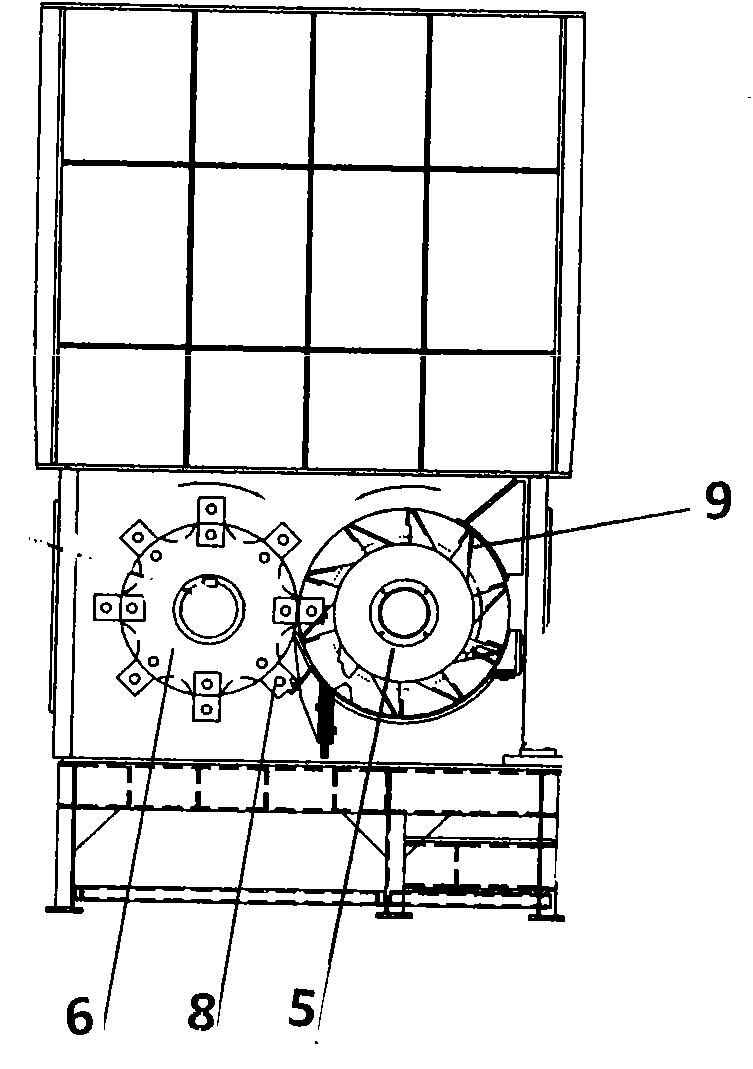

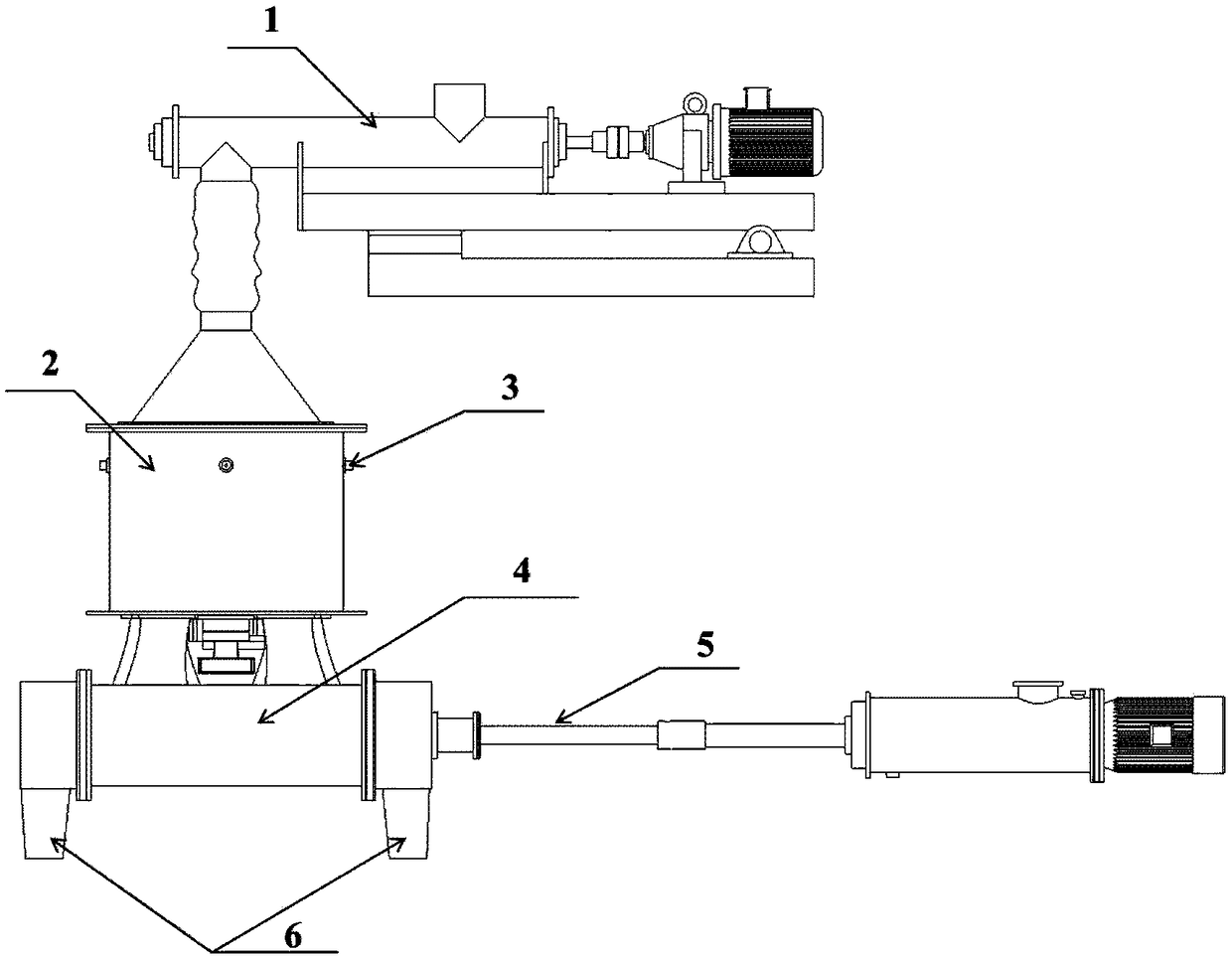

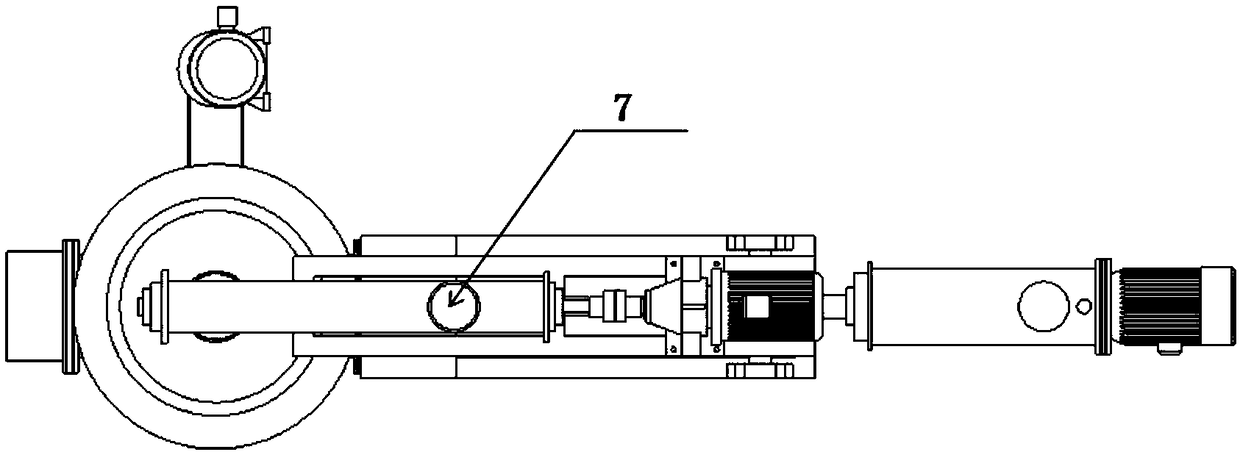

Combined functional rod-toothed crusher

InactiveCN101804372AReduce crushing powerImprove production and efficiencyGrain treatmentsElectrical controlElectric machinery

The invention relates to a combined functional rod-toothed crusher, which comprises a material feeding bucket, a crushing system, a base part and an electric control part, wherein the crushing system comprises a high-speed rod-toothed rotor and a low-speed rod-toothed rotor. The invention is characterized in that a plurality of groups of rotating fly cutters or fixed cutters are arranged on the high-speed rod-toothed rotor, sawtooth-shaped grooves are formed on the back corner surface of the cutter teeth in linear distribution on the low-speed rod-toothed rotor for forming multi-edge cutter teeth, energy storage fly wheels are arranged on the high-speed rod-toothed rotor, and the motor end of the high-speed rod-toothed rotor is also provided with a brake. The invention has the characteristics of reasonable design structure, double-roll differential opposite rotation, high crushing efficiency, high qualification rate of sieved materials and low energy consumption. The problem that the lathe spindle rotation can easily and suddenly stop while turning in the double-toothed roll crushing process in the prior art is solved.

Owner:SHENYANG HENGXING MACHINERY

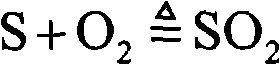

Method for comprehensively treating waste iron oxide desulfurizer and chromium slag

The invention discloses a method for comprehensively treating waste iron oxide desulfurizer and chromium slag so as to solve the problems that the conventional waste iron oxide desulfurizer contains FeS, the treating process is complex, the safety is low, the investment is high, the running expense is high and certain defects are existent in the conventional chromium salt detoxifying method. The method comprises two steps of pre-treating and mixing for reaction. According to the method, the two wastes are skillfully treated by each other and interact with each other to achieve the purpose of treating wastes with wastes; harmless treatment on the waste iron oxide desulfurizer and the chromium slag is effectively achieved while no other additive is used, so that the treatment cost is effectively reduced; the method is simple in process and convenient to operate, and has the characteristics of energy conservation, economy and environmental protection; the method is of important significance for solving the problem of the treatment of the waste iron oxide desulfurizer and the chromium slag, and especially can be used for effectively treating the chromium slag to effectively reduce harm of the chromium slag to the environment.

Owner:李平

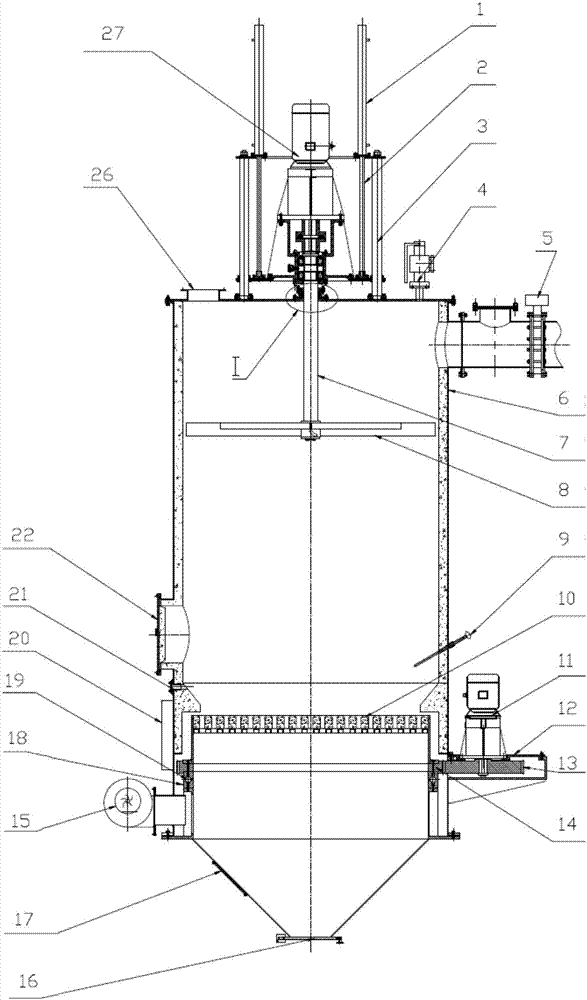

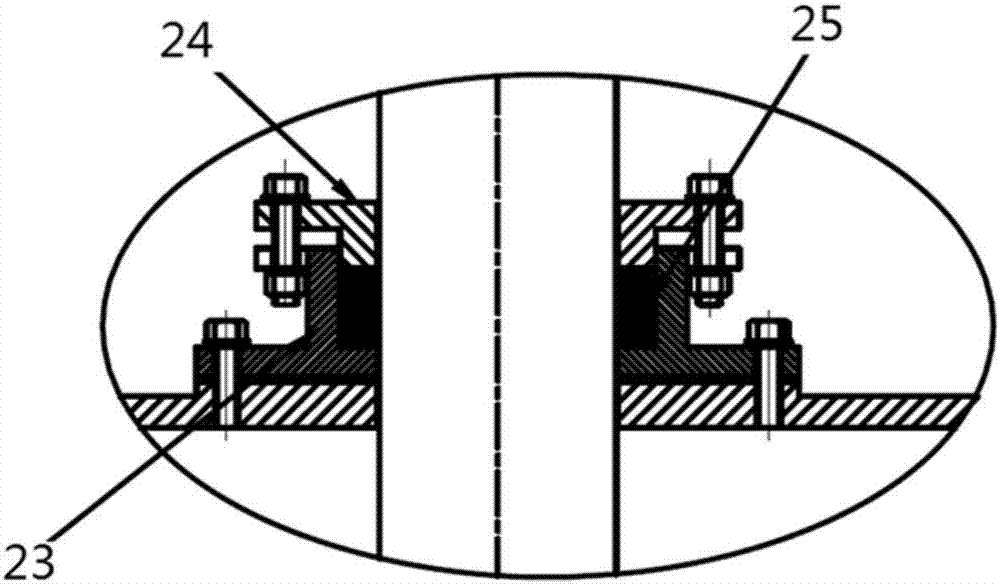

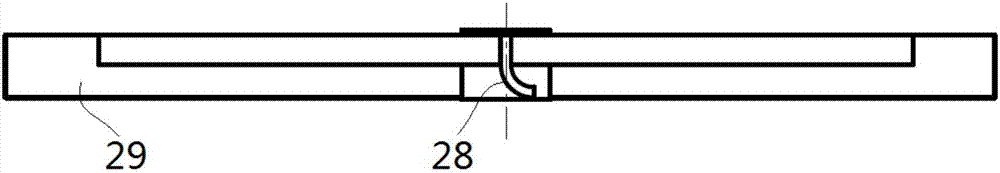

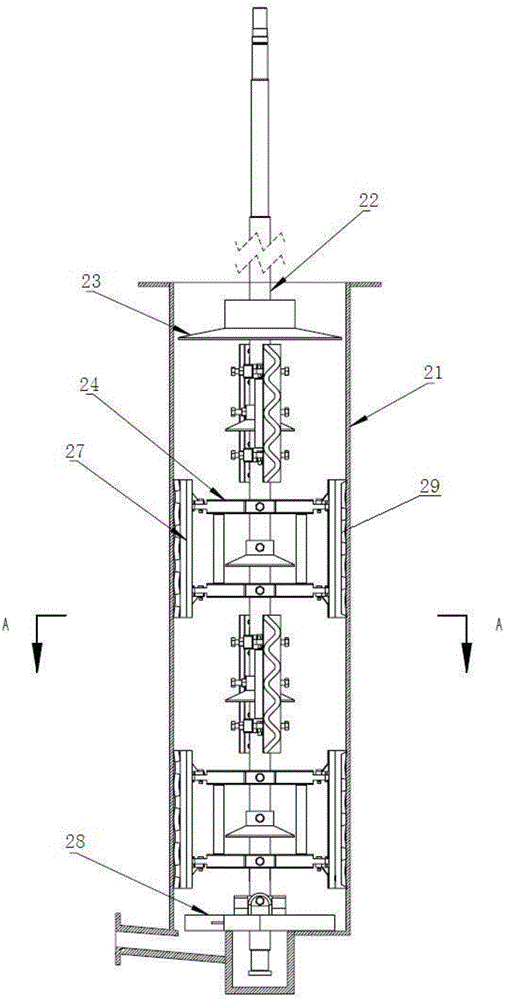

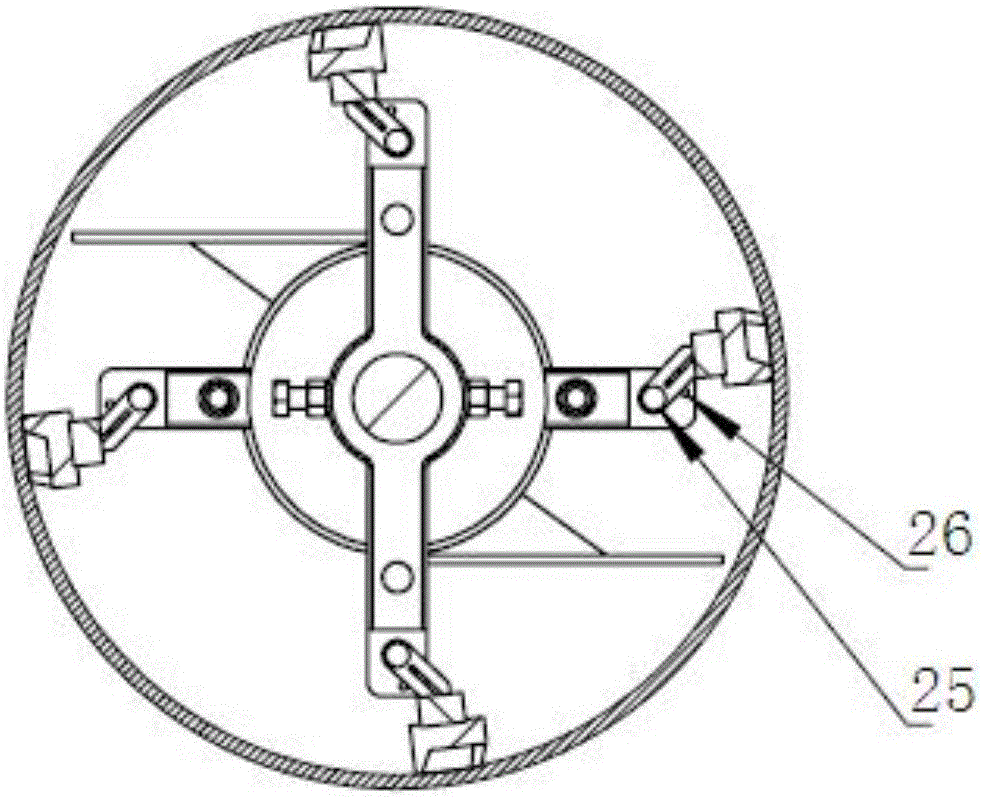

Internal rotary gasifier and domestic waste treatment technology

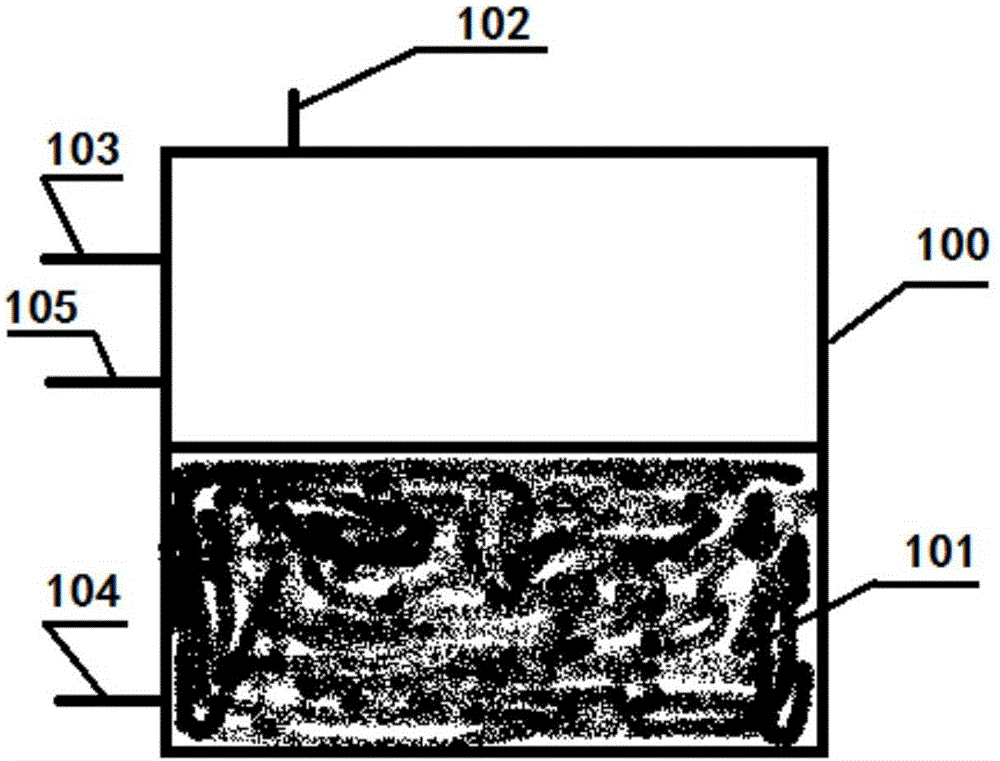

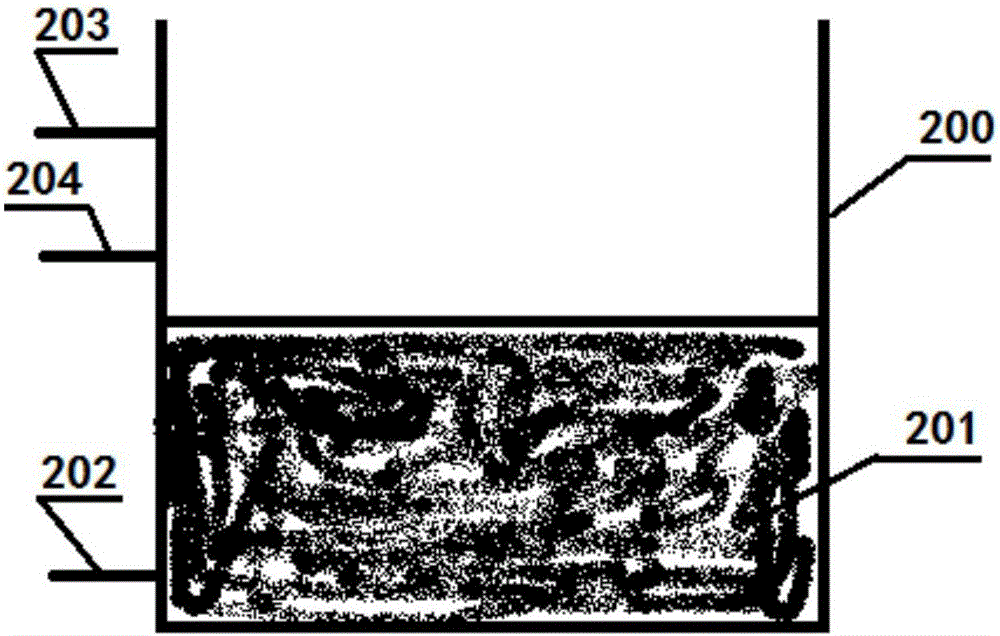

InactiveCN107011945ASolve harmless disposalRealize automatic slag dischargeGasifier feeding meansCombustible gas productionMaterial balancePhysical health

The invention discloses an internal rotary gasifier and a domestic waste treatment technology. The internal rotary gasifier comprises a gasifier body and a material balancing and pressing structure, wherein a feeding hole is formed in the top of the gasifier body and an ash outlet is formed in the bottom of the gasifier body; an air outlet is formed in the upper part or the top part of the gasifier body; the material balancing and pressing structure is arranged in the gasifier body and is used for uniformly dispersing a material from the feeding hole into a gasifier cavity and pressing the material which is uniformly dispersed into the gasifier cavity; the material balancing and pressing structure is fixedly connected with the bottom end of a rotating shaft which partially extends outside relative to the top of the gasifier body; and a lifting device for driving the rotating shaft to move up and down along the axial direction and a rotating device for driving the rotating shaft to horizontally rotate are arranged at the top end of the rotating shaft. The problem of increasing municipal domestic wastes can be solved, the environment is not polluted, meanwhile, the problem of pollution of dioxin to land and air is also solved, and the physical health of people is greatly protected.

Owner:HUNAN YUANYANG COAL MACHINE MFG

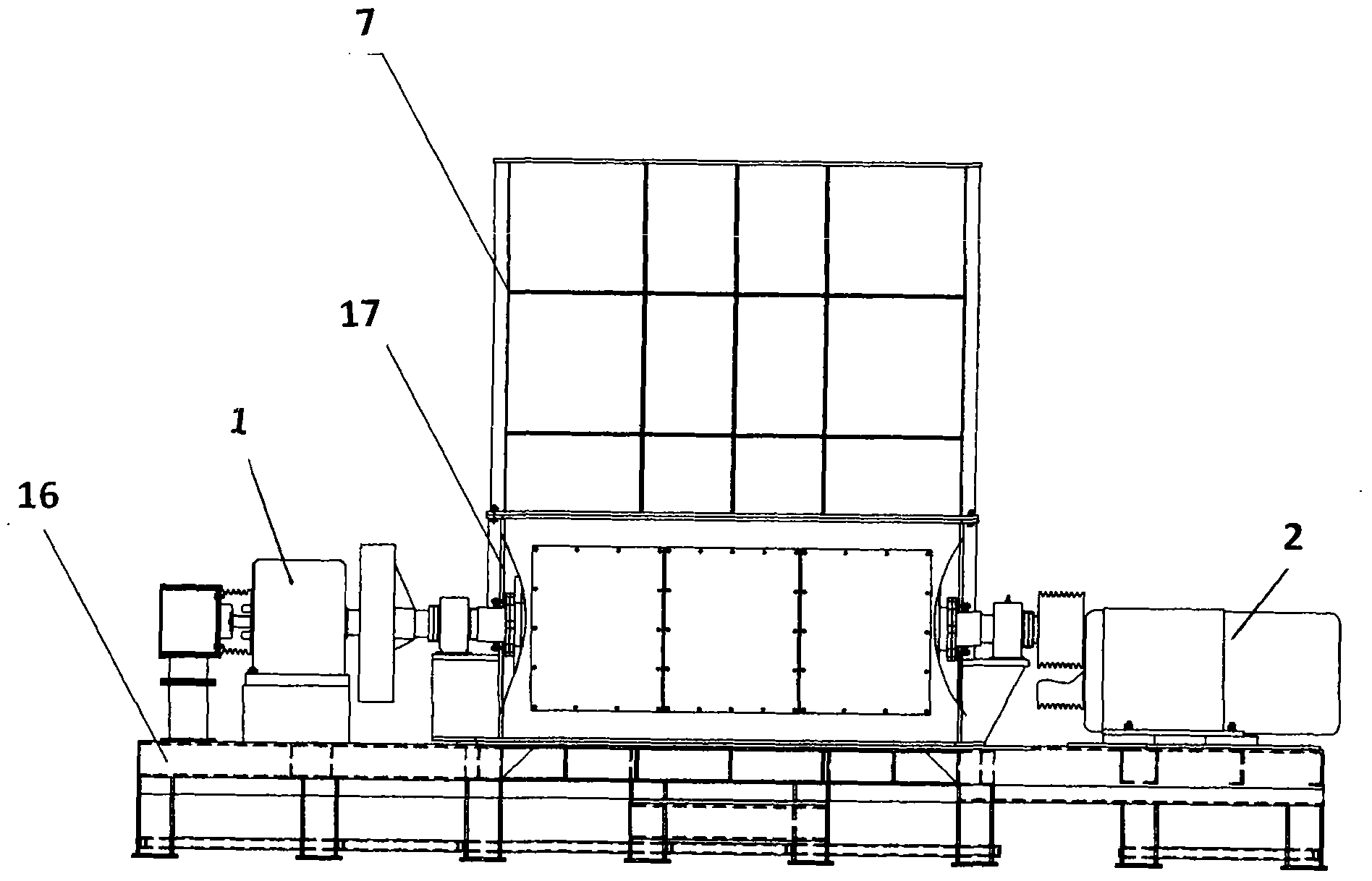

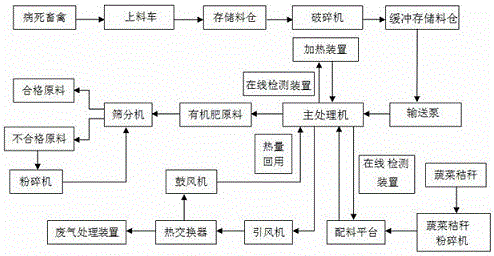

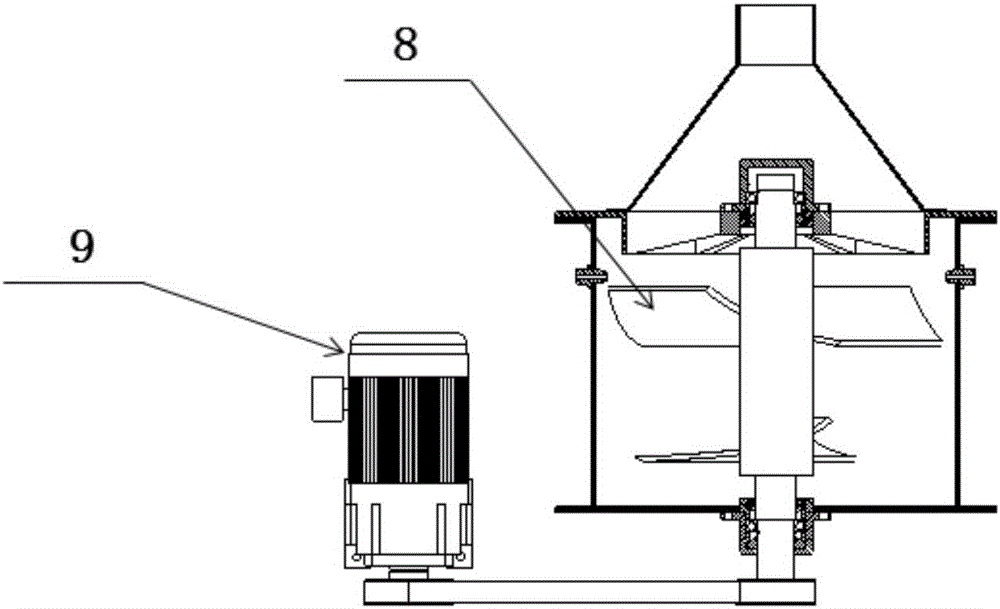

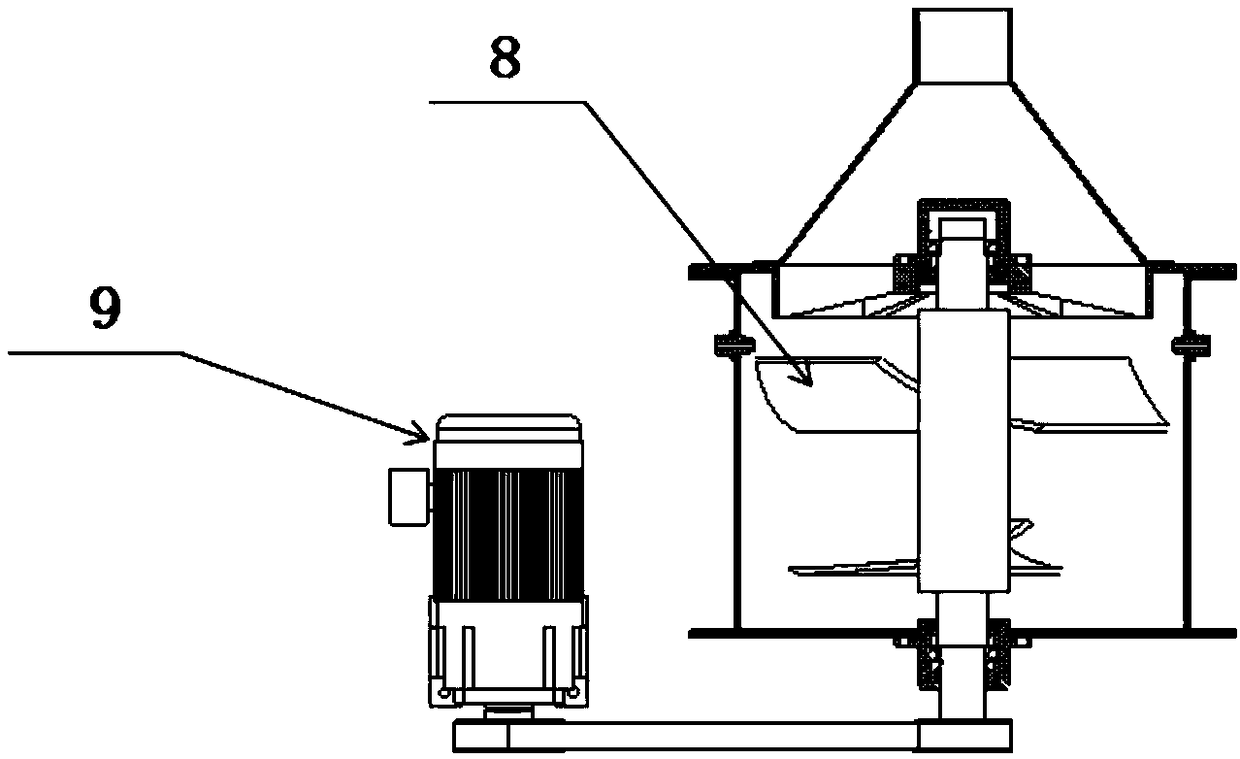

Industrial dead livestock/poultry treatment system and treatment method

InactiveCN106431535ASolve harmless disposalLess investmentBio-organic fraction processingAnimal corpse fertilisersBacterial agentLivestock

The invention provides an industrial dead livestock / poultry treatment system and a treatment method. The problem in industrial dead livestock and poultry harmless treatment in a country region can be effectively solved. The industrial dead livestock / poultry treatment system comprises a charging vehicle, a storage bin, a breaker, a buffer storage bin, a main treatment machine, a conveying pump, a vegetable straw pulverizer, a dosing platform, a sieving machine and a heat recovery device, wherein the storage bin is butted with the charging vehicle; the breaker is connected with a discharge port of the storage bin; the buffer storage bin is connected with an outlet of the breaker; the main treatment machine is used for performing function change treatment on the dead livestock and poultry; the conveying pump is connected with the buffer storage bin and the main treatment machine; the dosing platform is used for matching the pulverized vegetable straw with a biological bacterial agent and conveying to the main treatment machine; the sieving machine is connected with an outlet of the main treatment machine and used for sieving the treatment product of the main treatment machine; and the heat recovery device is communicated with the main treatment machine and used for treating the high-temperature waste gas generated in the treatment process of the main treatment machine.

Owner:SHANDONG ACADEMY OF AGRICULTURAL MACHINERY SCIENCES

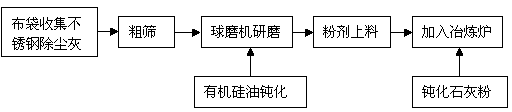

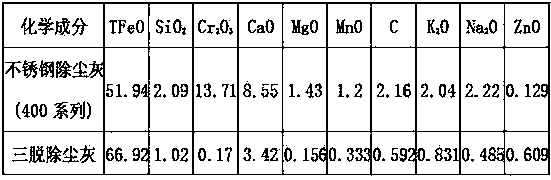

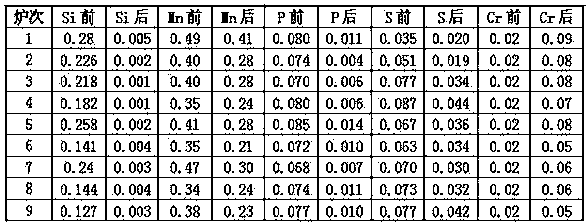

Smelting process of recycling chromium by combined-injection dephosphorizing using stainless steel precipitator dust

ActiveCN104212975ASolve harmless disposalSave or replace usageProcess efficiency improvementSmelting processMolten steel

The invention relates to the technical field of stainless steel smelting and discloses a smelting process of recycling chromium by combined-injection dephosphorizing using stainless steel precipitator dust. The process comprises the following main technical processes: coarsely screening the collected stainless steel precipitator dust; performing seal grinding, drying and passivating on moist caking particles with a ball mill ; feeding the passivated stainless steel precipitator dust and the passivated lime powder to two powder injection system stock bins; and injecting the powder by an injection pipeline of a smelting furnace into the molten steel within a steel ladle for combined-injection dephosphorizing of the molten steel pretreatment. The process can save or replace the dosage of solid materials like oxide scale, efficiently solve the problem of harmful treatment of the stainless steel precipitator dust, recycle chromium from the metal elements in the stainless steel precipitator dust to the molten steel for stainless steel smelting, realize recycling of chromium-containing stainless steel waste, and reduce the production cost. By using the method of the invention, the environment pollution is reduced and the aims of energy conservation and emission reduction are realized.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

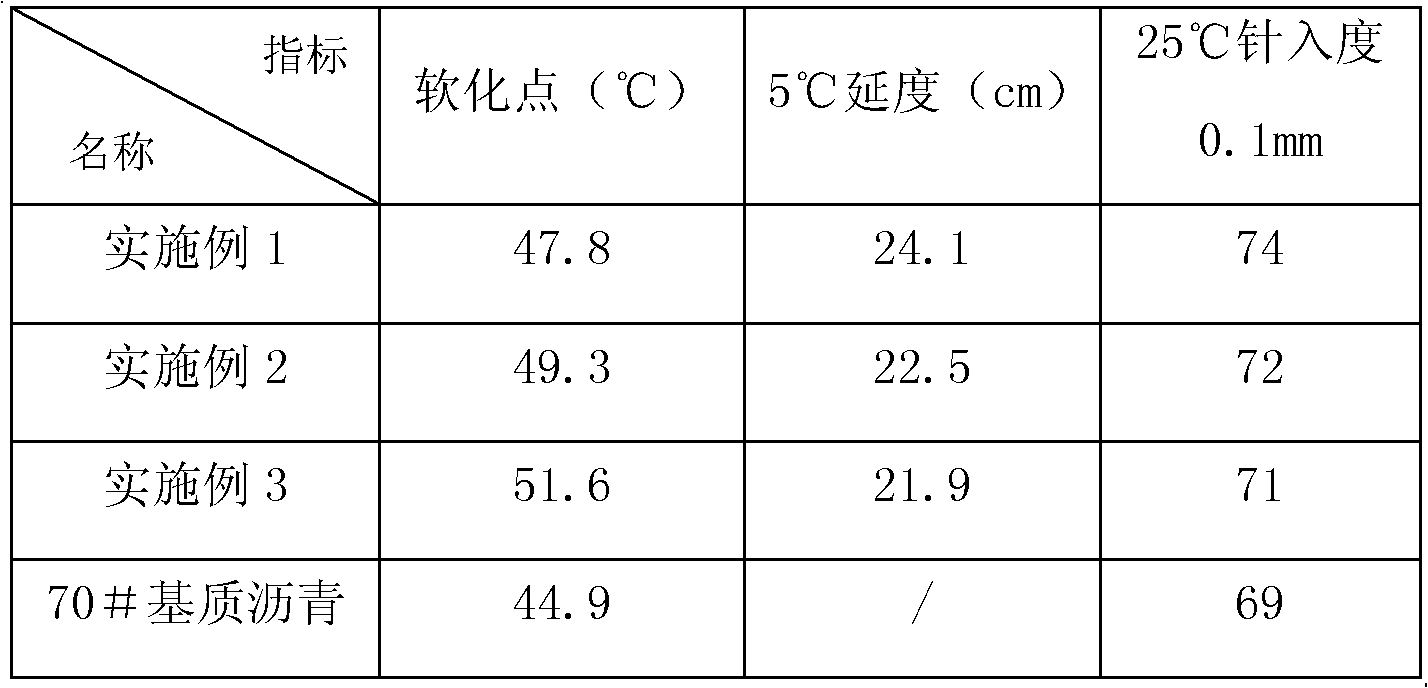

Asphalt modifier and preparation method thereof

InactiveCN102634217ACause secondary pollutionSolve harmless disposalBuilding insulationsChemical industryPolymer science

The invention relates to asphalt modifier and a preparation method thereof, belonging to the field of chemical industry. The invention aims to provide an asphalt modifier which can improve the comprehensive perforamnce of asphalt. The asphalt modifier provided by the invention is prepared from the following components in part by weight: 0.1-0.5 part of mixed silane, 0.02-0.05 part of surfactant and 0.5-0.9 part of tire rubber powder, wherein the mixed silane is a liquid-solid mixture with liquidity obtained by wet dust collection in the synthesis process of methyl chlorosilane monomer.

Owner:LUZHOU NORTH CHEM IND

Method for pretreating waste incineration fly ash before melting

ActiveCN106217925AEfficient processingSolve the problem of harmless disposalPress ramPre treatmentSmall footprint

The invention discloses a method for pretreating waste incineration fly ash before melting. The method comprises the following steps: firstly, mixing fly ash with membrane filtration concentrate of waste leachate and stirring into a muddy mixing body; and secondly, performing extrusion molding on the mud-like mixing body obtained in the first step into a strip-columnar raw material of an electric arc furnace. According to the method disclosed by the invention, the membrane filtration concentrate of the waste leachate and the fly ash are mixed and stirred; and loose fly ash is combined together by using the cohesiveness of the membrane filtration concentrate of the waste leachate and is processed and molded into the strip-columnar raw material of the electric arc furnace, so that the high-efficiency treatment process of the fly ash in a melting furnace can be guaranteed, the difficult problem about harmless treatment of the membrane filtration concentrate of the waste leachate is solved, the measure of using waste to treat waste is realized, and multiple purposes by one method are achieved. The method has the advantages of simple flow, compact structure, small occupied area, less investment, high operation efficiency and the like; and remarkable environmental benefits and economic benefits are obtained.

Owner:TIANJIN TEDA ENVIRONMENTAL PROTECTION

Baking-free lightweight insulating brick and preparation method thereof

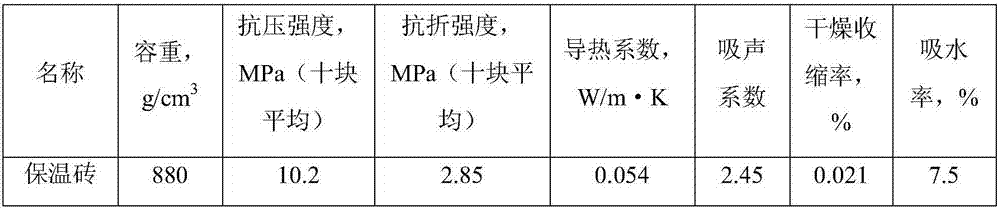

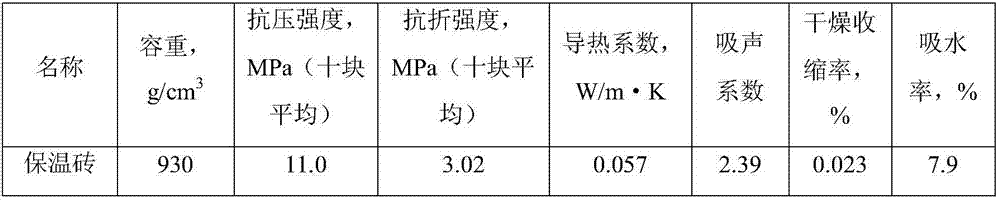

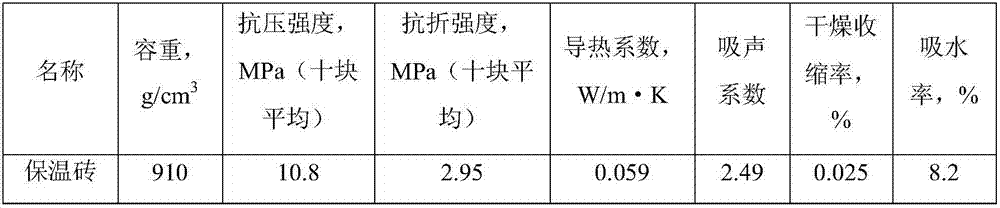

InactiveCN107399940ASolve secondary pollutionSimple processSolid waste managementThermal insulationScrap

The invention discloses a baking-free lightweight insulating brick and a preparation method thereof. The insulating brick comprises the following components in percentage by mass: 30-70% of mineral wool wastes, 10-35% of cement, 0-22% of fly ash and 5-10% of water. The preparation method comprises the following steps: burdening, namely preparing the mineral wool wastes, cement, fly ash and water according to a ratio; stirring, adding the mineral wool wastes, cement, fly ash, adding water according to a ratio for stirring 10-20 minutes so as to obtain a mixture; making a blank, vibrating and forming the mixture so as to obtain a brick blank; and curing, namely curing the brick blank at a normal temperature, thereby obtaining the baking-free lightweight insulating brick. According to the preparation method disclosed by the invention, the mineral wool production wastes and short fibers can be made into the baking-free brick, and the baking-free brick is small in investment, simple in process, low in volume-weight, good in thermal insulation properties, high in sound absorption and low in production cost.

Owner:ANGANG STEEL CO LTD

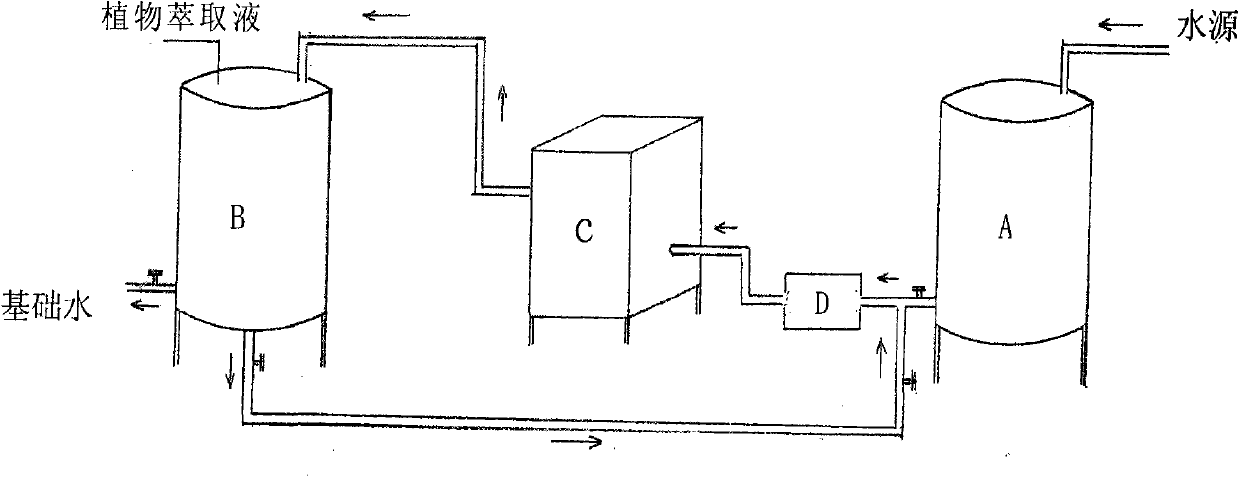

Organic fertilizer and natural shade composting method thereof

InactiveCN101905984AAvoid pollutionThe generation of solutionBio-organic fraction processingOrganic fertiliser preparationLivestock manureCompost

The invention provides an organic fertilizer and a natural shade composting method thereof. The composting method comprises the following steps of: adding curing solution prepared from plant extracts into composting raw materials containing a mother fertilizer; and performing low-temperature aerobic fermentation on the plant extracts to prepare an organic fertilizer, wherein the plant extracts are prepared by performing extraction, concentration, fermentation and antagonism treatment on a plurality of plants; the curing solution is prepared by blending the plant extracts and basic water; the mother fertilizer is obtained by spraying the fertilizer curing solution onto the excrements, serving as the raw materials, of pigs and yarding and turning the excrements up and down; and the pigs are fed by an environmentally-friendly dry odorless pig-keeping method. The natural shade composting method has the advantages of realizing odorless, zero-emission and pollution-free composting, saving the cost, improving the production efficiency, solving problems on the harmless treatment of agricultural wastes and livestock manure and improving the quality of the organic fertilizer. The organic fertilizer prepared by the method has the advantages of no odor, deodorization function, no secondary fermentation, stable quality, high organic matter content, high fertilizer efficiency, low heavy metal content, high germination percentage and the like.

Owner:杨兆松

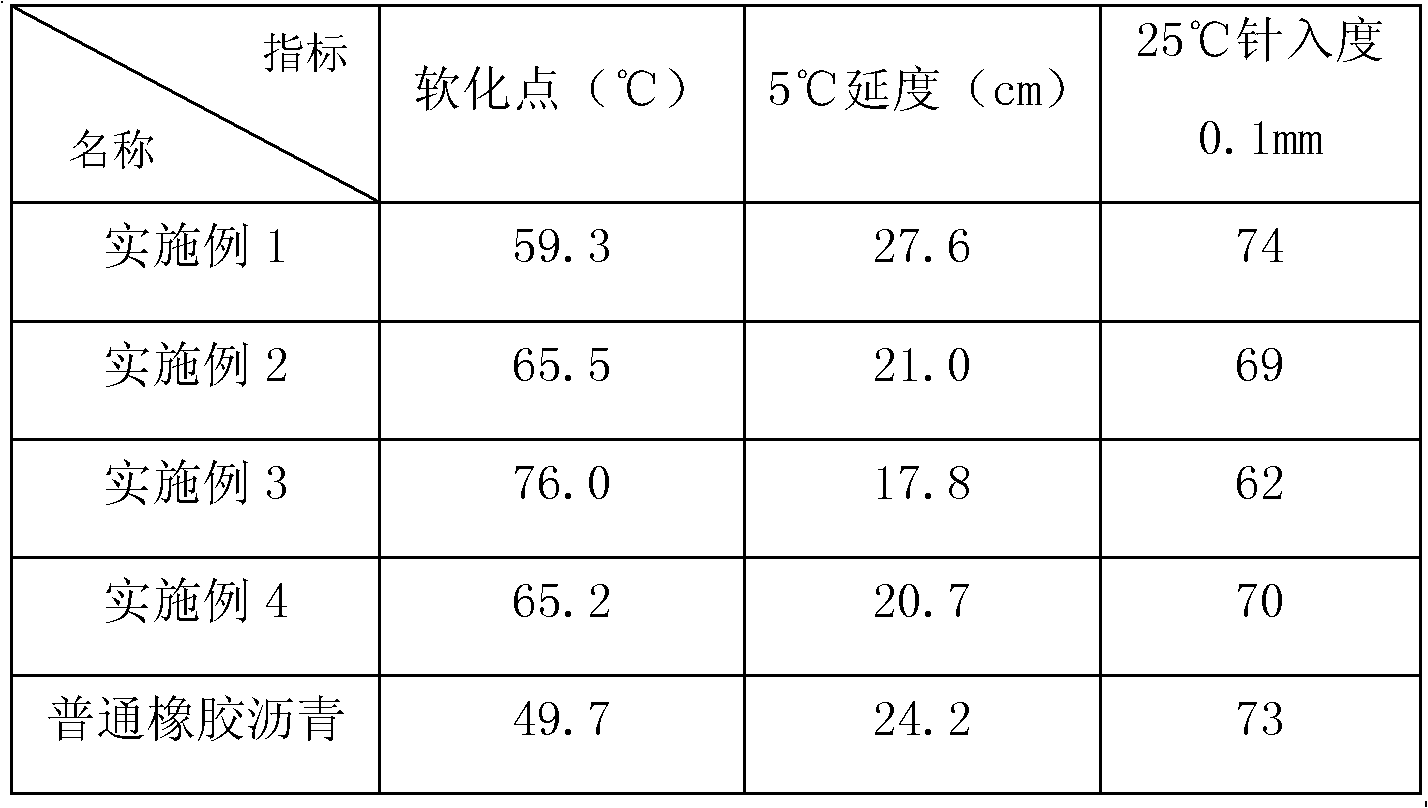

Modified rubber asphalt and preparation method thereof

InactiveCN102634216ASolve harmless disposalImprove performanceBuilding insulationsChemical industryPolymer science

The invention relates to modified rubber asphalt and a preparation method thereof, belonging to the field of chemical industry. The invention aims to provide modified rubber asphalt with good comprehensive perforamnce. The modified rubber asphalt provided by the invention is prepared from the following components in part by weight: 0.01-0.1 part of mixed silane and 1 part of rubber asphalt, or 0.01-0.1 part of mixed silane, 0.6-0.7 part of matrix asphalt and 0.3-004 part of tire rubber powder, wherein the mixed silane is a liquid-solid mixture with liquidity obtained by wet dust collection in the synthesis process of methyl chlorosilane monomer.

Owner:LUZHOU NORTH CHEM IND

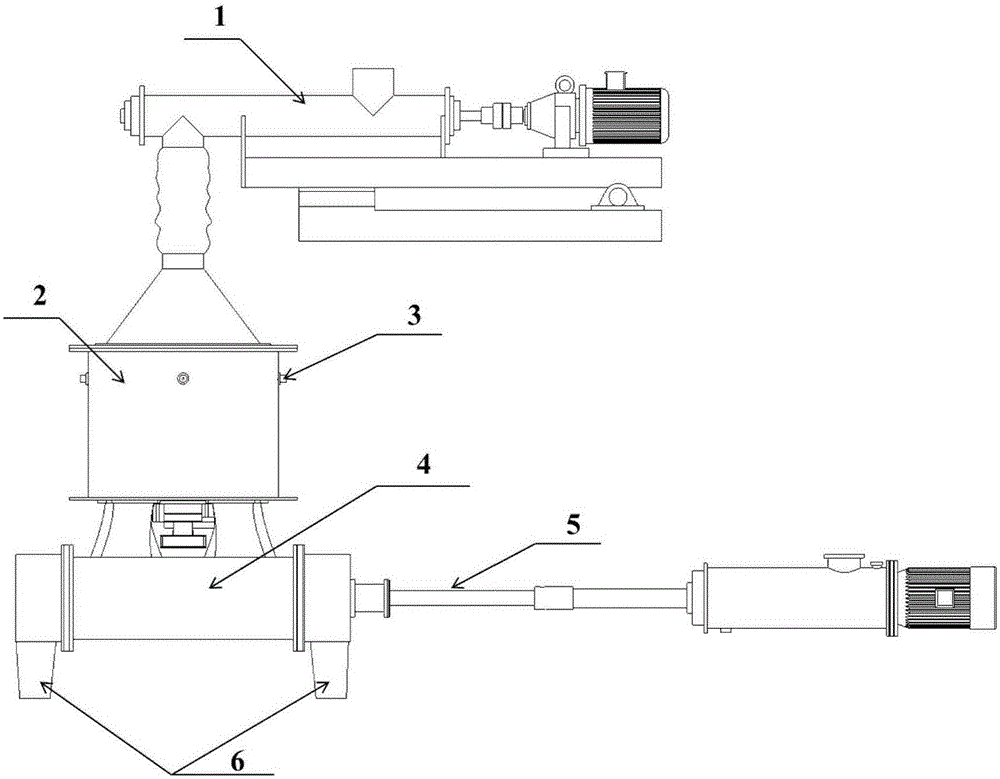

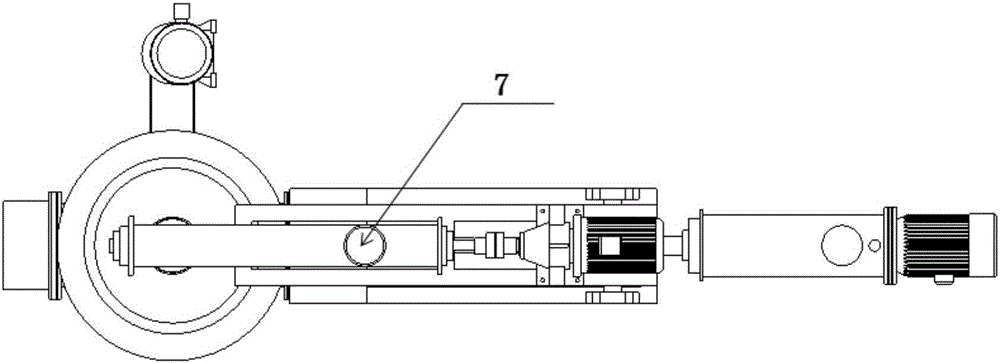

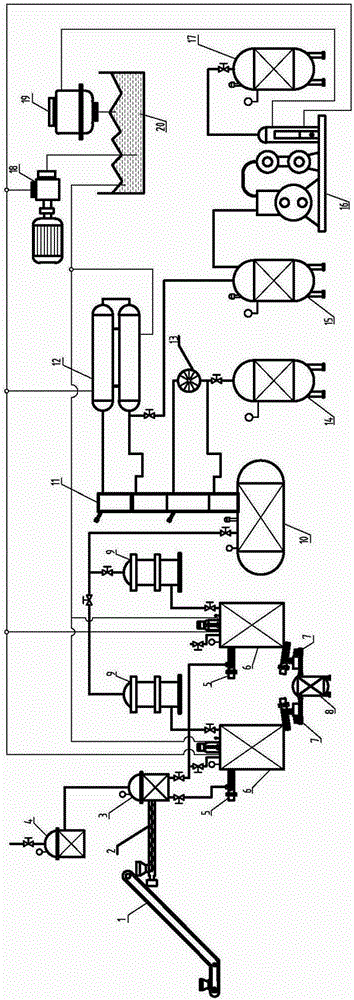

Harmless waste plastic treatment equipment and method

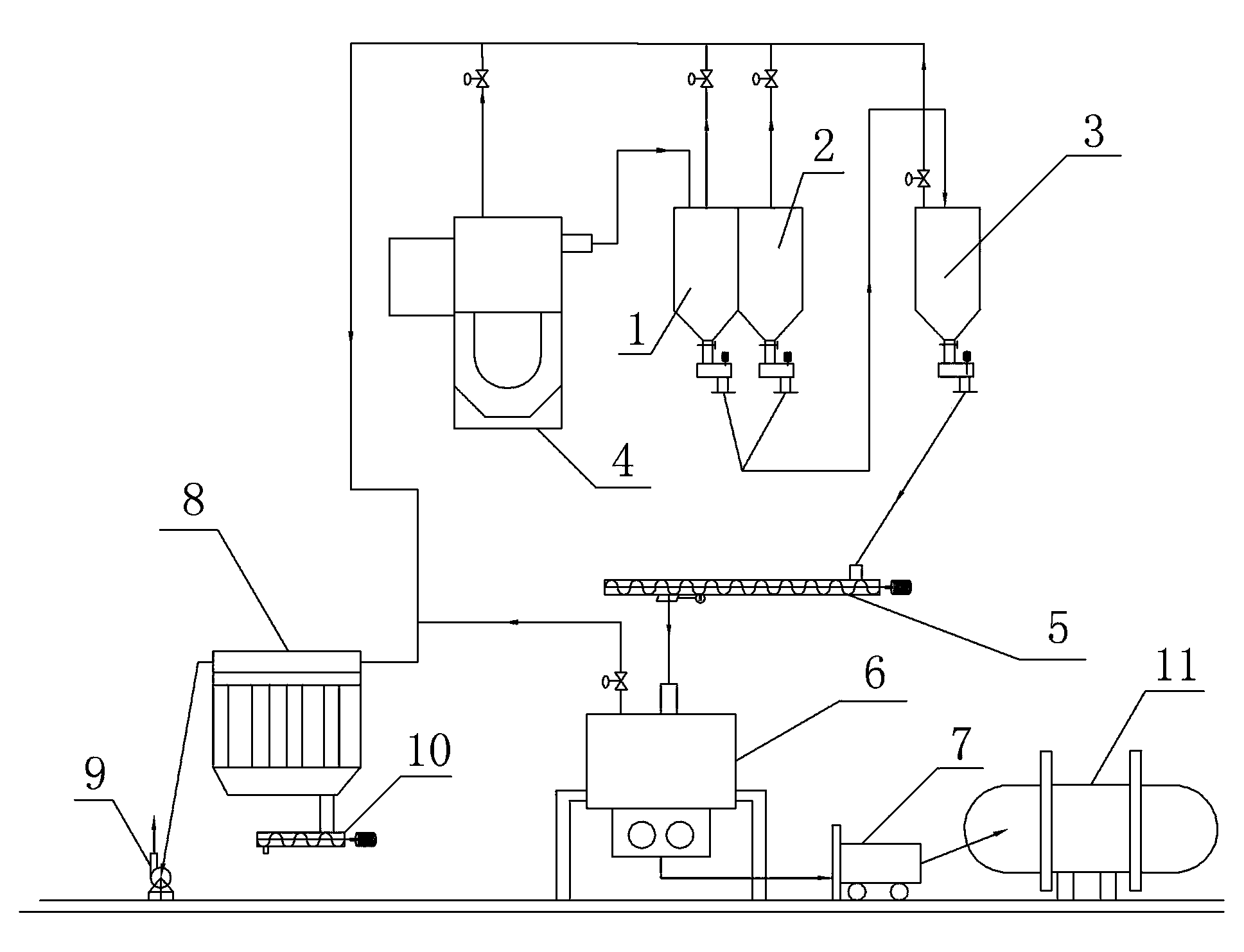

ActiveCN106118707ACause secondary pollutionSolve the problem of harmless disposalLiquid hydrocarbon mixture productionHydrocarbon oils treatment productsRefluxReboiler

The invention relates to harmless waste plastic treatment equipment which comprises a belt conveyor 1, wherein the belt conveyor 1 is connected with a large screw feeder 2; the large screw feeder 2 is connected with a dechlorination shunt 3; the bottom of the dechlorination shunt 3 is connected with a small screw feeder 5; the small screw feeder 5 is connected with a pyrolysis kettle 6; the bottom of the pyrolysis kettle 6 is connected with a carbon outlet system 7; the carbon outlet system 7 is connected with a carbon powder collection tank 8; a catalytic transforming tower 9 is connected with the pyrolysis kettle 6; an air outlet of the catalytic transforming tower 9 is connected with a reboiler 10; a fractionating tower 11 is arranged on the reboiler 10; air outlets and reflux inlets are formed in the fractionating tower 11; the upper air outlet is connected with an inlet of a condenser 12; an outlet of the condenser 12 is connected with the upper reflux inlet of the fractionating tower 11 and a gasoline storage tank 15; the lower air outlet is connected with an inlet of an air cooler 13; an outlet of the air cooler 13 is connected with the lower reflux inlet of the fractionating tower 11 and a diesel storage tank. According to the equipment disclosed by the invention, a fully sealed structure is adopted, emission of any waste gas, waste water and waste residue is avoided during operation, and secondary environmental pollution is avoided.

Owner:徐效奇

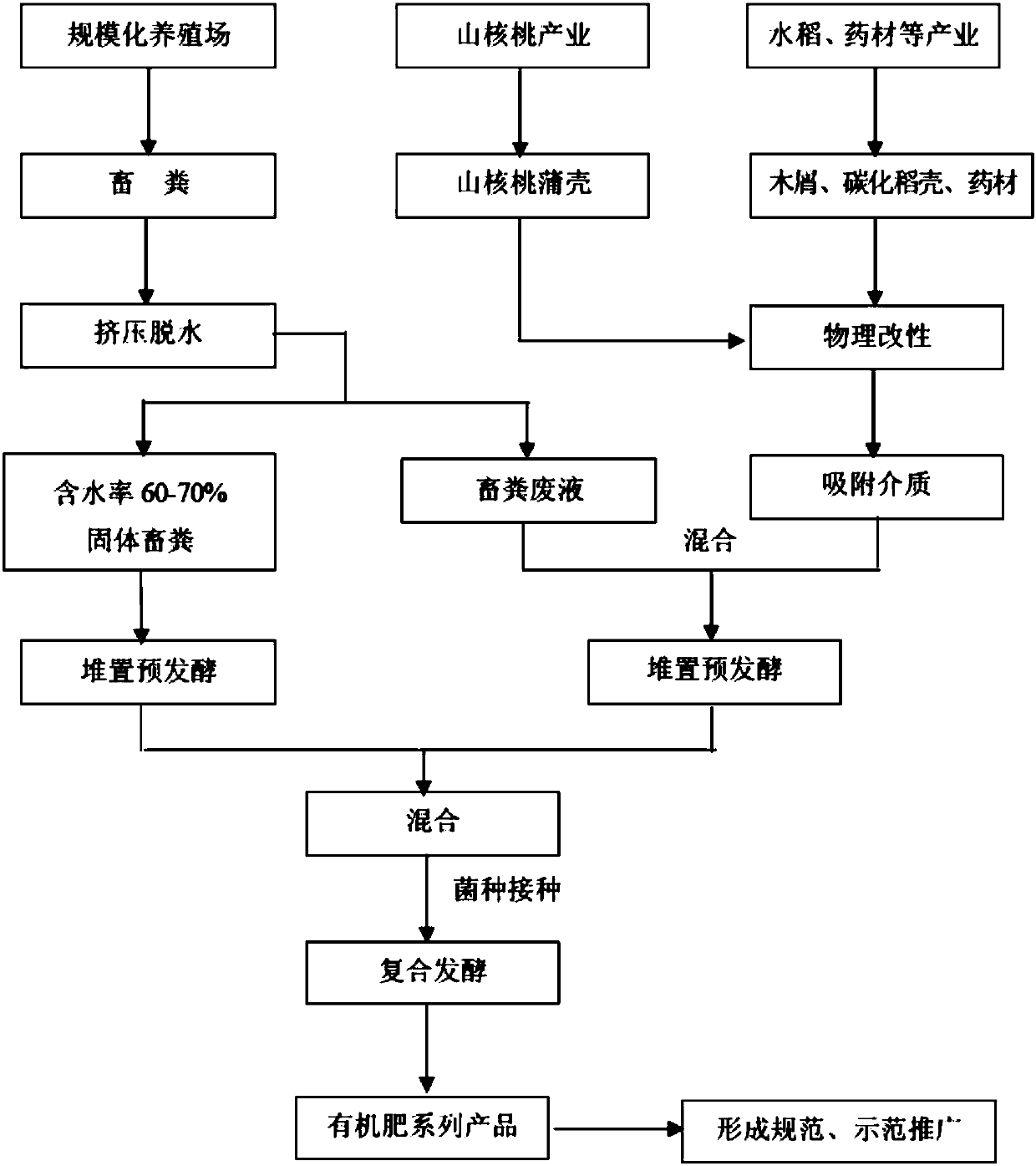

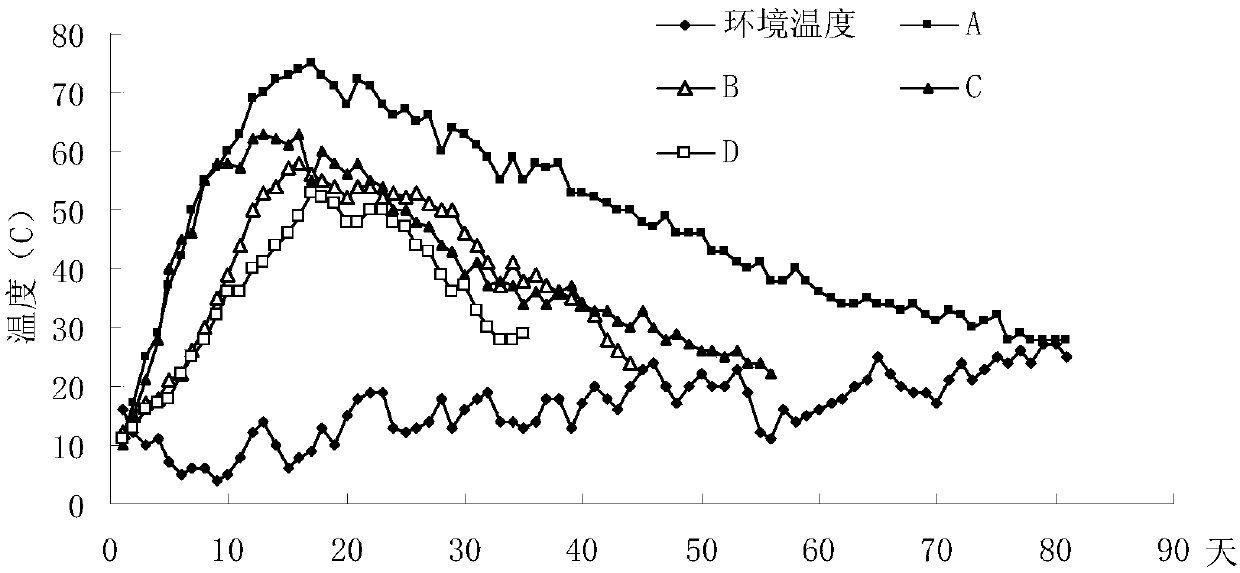

Animal manure treatment production technology for substrate or organic fertilizer raw material

InactiveCN107686398AEfficient use ofSolve harmless disposalBio-organic fraction processingExcrement fertilisersLiquid wasteFermentation

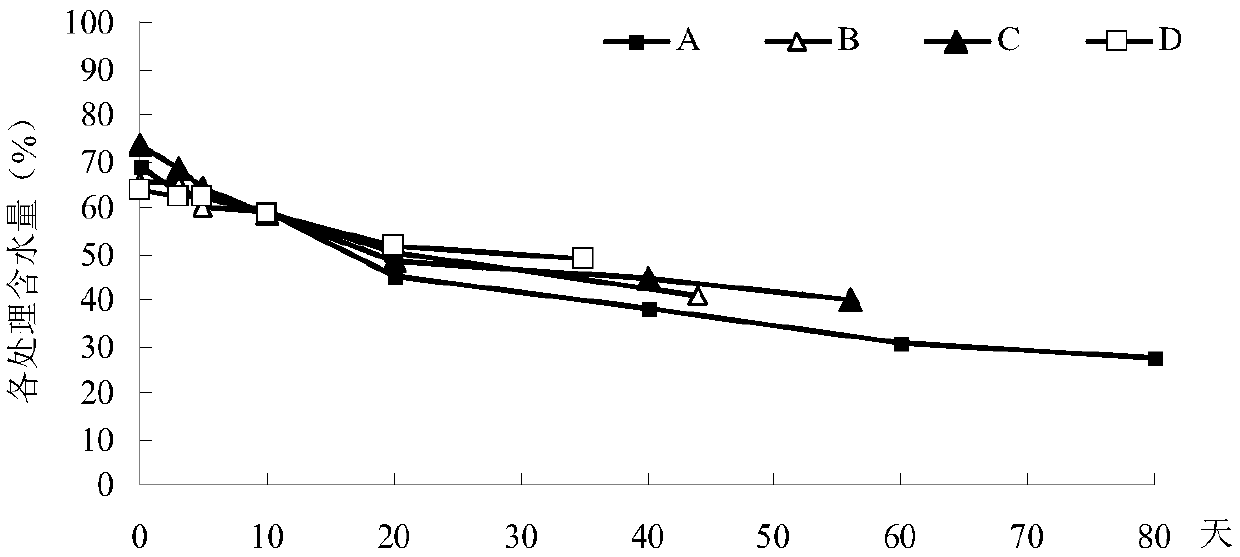

The invention discloses an animal manure treatment production technology for a substrate or an organic fertilizer raw material. The technology comprises the following steps of: (1) dehydrating animalmanure to form solid animal manure with a water content of 55-60% and animal manure waste liquid, and performing physical modification on agricultural wastes to form an adsorption medium, (2) stackingthe solid animal manure with the water content of 55-60% for pre-fermentation, mixing the livestock waste liquid and the adsorption medium for stacking and pre-fermentation, and (3) mixing two pre-fermented products obtained in step (2), and inoculating with a fermentation strain for compound fermentation. An animal manure solid-liquid separation technique is adopted to extrude the animal manureto form a solid and the liquid. The animal manure solid is directly stacked for the fermentation, and the liquid and dry wood dust are mixed to directly form a solid with a water content meeting fermentation requirements, and then mixed with the extruded animal manure solid for the direct fermentation. With the adoption of a 'parallel unification' technology, the fermentation efficiency of the animal manure is significantly improved by adjusting and controlling a water content of an animal manure ferment.

Owner:HANGZHOU JINHAI AGRI CO LTD

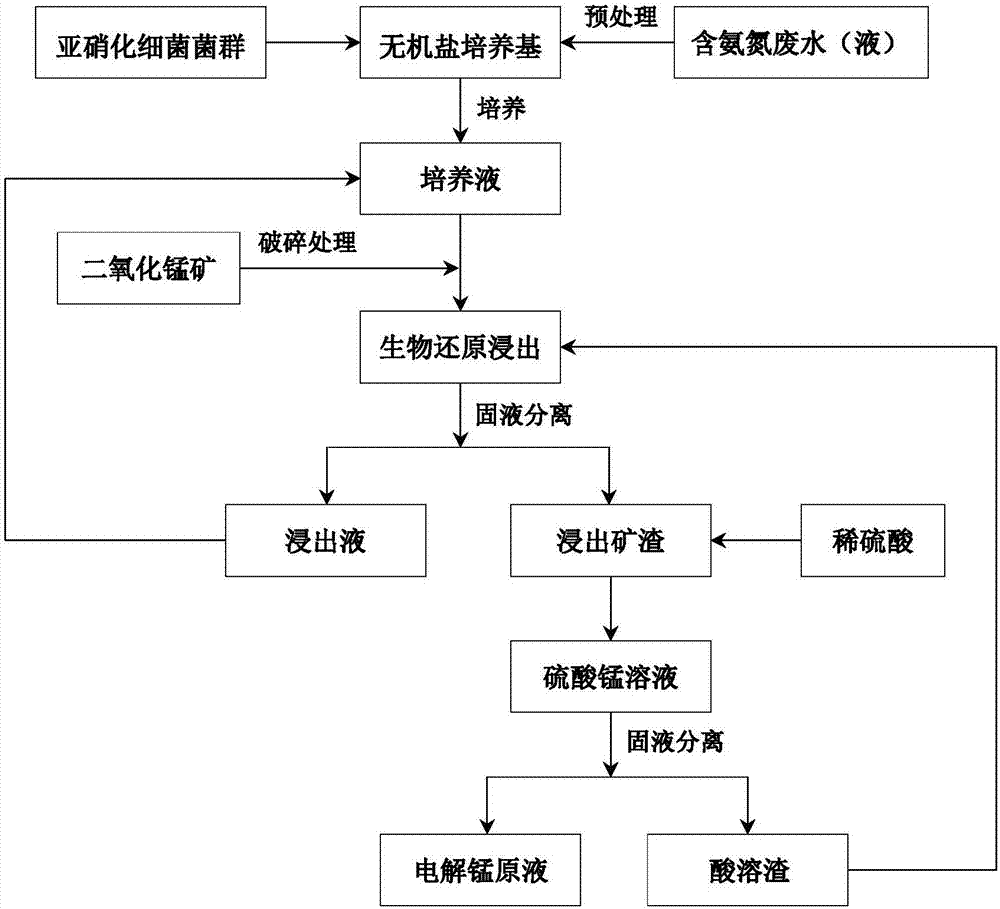

Method for digesting manganese in manganese oxide ore through reduction with nitrosobacteria and dissolution and dilution with dilute acid

InactiveCN107119188AAchieve reductive dissolutionSolve harmless disposalPhotography auxillary processesReduction ActivityElectrolysis

The invention relates to a method for digesting manganese in manganese oxide ore through reduction with nitrosobacteria and dissolution and dilution with dilute acid, and belongs to the technical field of novel biological metallurgy techniques for recovery of manganese resources in manganese ore. According to the method, low-grade manganese dioxide ore is reduced through a strong reducer hydroxylamine-like substance, namely an intermediate product generated while high ammonia nitrogen waste water / liquid is oxidized with nitrosobacteria, and then bivalent manganese is dissolved and diluted in a dilute acid solution so that a manganese sulfate saline solution for electrolytic manganese metal production can be obtained. Mn4+ in the manganese dioxide ore is reduced into Mn2+ through the high reduction activity intermediate product generated during aerobic oxidation of the high ammonia nitrogen waste water / liquid through the nitrosobacteria as well as related inoculants and enzyme systems, and the manganese sulfate saline stock solution for electrolytic manganese production is obtained through acidolysis with dilute acid. The novel bioleaching technique not only completely eliminates the problem of high fe-based / sulfenyl impurities in a traditional sulfur / iron-oxidizing bacterium bioleaching solution, but also achieves innocent treatment of the high ammonia nitrogen waste liquid. The novel microorganism hydrometallurgy technique has the beneficial effects of being simple, convenient to implement, environmentally friendly and capable of achieving resource recycling.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

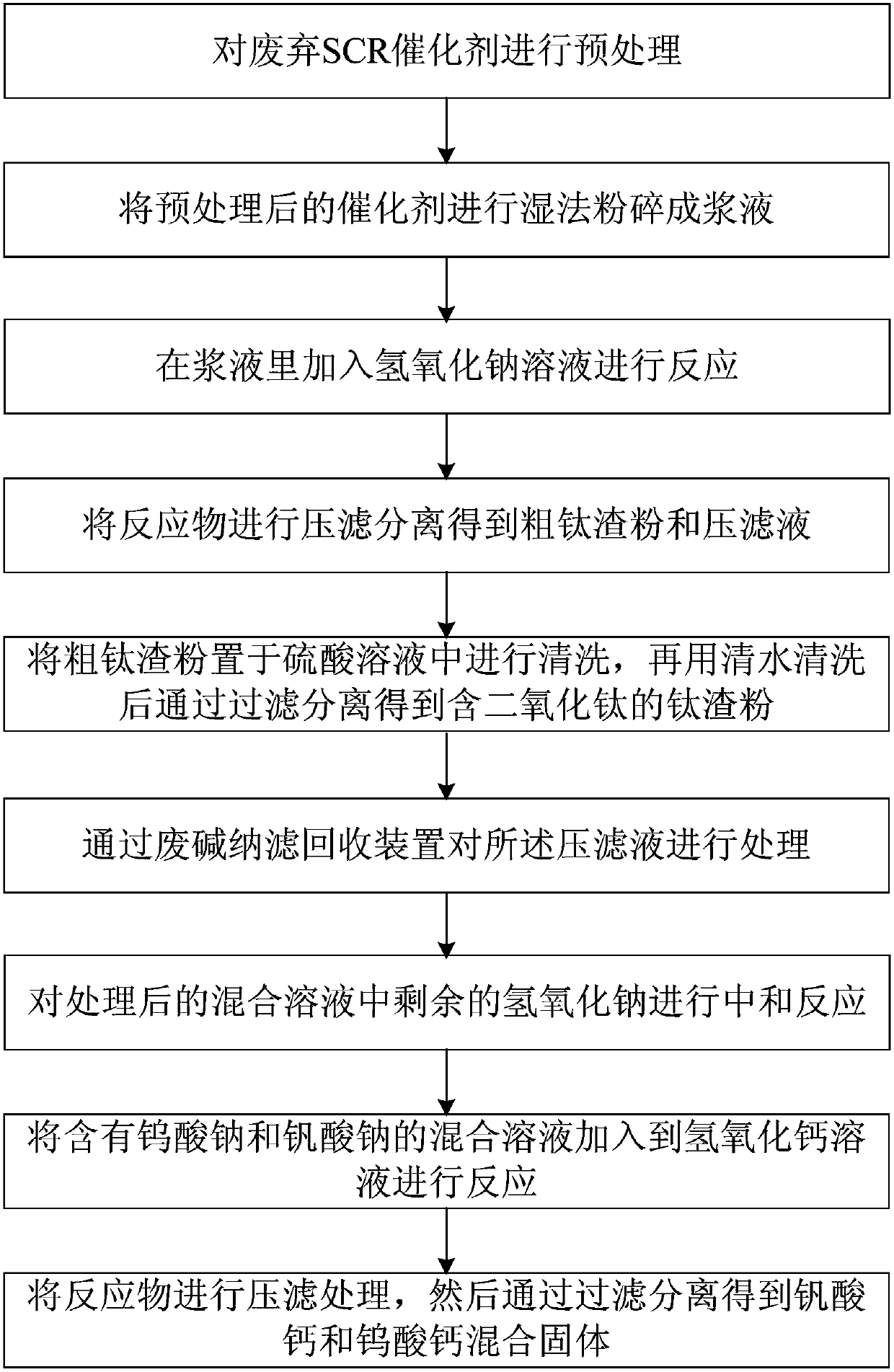

A method for extracting titanium slag, tungsten and vanadium salts from waste scr catalyst

ActiveCN106119544BSolve harmless disposalLow investment requirementProcess efficiency improvementPtru catalystCALCIUM HYDROXIDE SOLUTION

The invention provides a method for extracting titanium slag, tungsten and a vandic salt from a waste SCR catalyst. The method comprises the steps that the waste SCR catalyst is preprocessed and crushed into slurry by use of a wet method; a sodium hydroxide solution is added into the slurry for reaction; coarse titanium slag power and compression filtrate are obtained by filter-pressing and separating the slurry by use of a plate-and-frame filter press; the coarse titanium slag power is placed into a sulfuric acid solution for cleaning, cleaned with clear water, and then filtered and separated for obtaining titanium slag powder containing titanium dioxide; and the compression filtrate is treated through a waste alkali nanofiltration recovery device, the compression filtrate containing sodium tungstate and sodium vanadate is added into a saturated calcium hydroxide solution for reaction, products from the reaction are subjected to filter pressing, and then calcium vanadate and calcium tungstate mixed solid bodies are obtained through filtering and separating.

Owner:安徽思凯瑞环保科技有限公司

A method for pretreatment of waste incineration fly ash before melting

Owner:TIANJIN TEDA ENVIRONMENTAL PROTECTION

Nutrient and nontoxic culture medium of pot plant and preparation method thereof

InactiveCN103229704ASolving Fertilization ProblemsSolve harmless disposalAnimal housingCultivating equipmentsNutrientBiology

The invention discloses a nutrient and nontoxic culture medium of a pot plant and a preparation method thereof. The preparation method includes: autoclaving and then mixing an SPF-grade (specific pathogen free-grade) or sterile-grade mice bedding material and a cake material; and subjecting the mixed material to sealed fermentation, sun-baking, crushing, filtering and uniform mixing with ferrous sulfate to obtain the nutrient and nontoxic culture medium of the pot plant. The weight ratio of the SPF-grade or sterile-grade mice bedding material and the cake material is (3-5):(1.5-2.5). According to the nutrient and nontoxic culture medium of the pot plant and the preparation method thereof, the SPF-grade or sterile-grade waste animal bedding material is utilized for providing the nutrient and nontoxic culture medium for the pot plant, so that environmental friendliness, low cost and easy operation are achieved and mass production and marketing can be facilitated.

Owner:EAST CHINA NORMAL UNIVERSITY

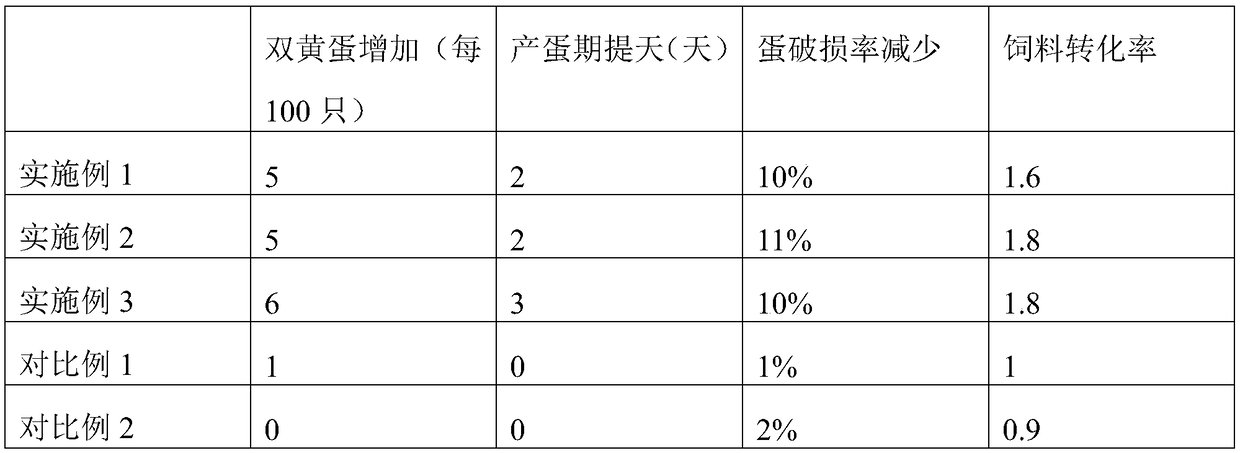

Method for fermenting and drying straw laying hen fodder

InactiveCN109221763ASolve harmless disposalLignin freeFood processingAnimal feeding stuffBiotechnologyCorn flour

The invention relates to a method for fermenting and drying a straw laying hen fodder. The method comprises the following steps: selecting maize straws, sorghum straws and soybean straws; smashing straws, thereby acquiring straw powder; soaking the straw powder in hot water; boiling the straw powder in a sulfite solution; soaking the straw powder in a sodium hydroxide solution; fermenting the straw powder; uniformly stirring corn flour, soybean cake powder, wheat bran, sweet potato powder, peanut cake powder, shell powder, soybean oil, table salt, fish meal, bone meal, healthcare sand and fermented straw powder in parts by weight; drying; preparing a glue solution; putting dried fodder into an inlet of a pelletizer, and meanwhile, utilizing a plurality of spraying pipes uniformly arrayed along horizontal direction and vertically arranged on a cylinder wall of a cylinder to spray the prepared glue solution in the form of mist into the pelletizer, thereby coating the glue solution on thesurface of the fodder; packaging. According to the invention, the straws are reasonably pretreated, are fermented and are finally prepared into the straw fodder, so that the problem of harmless disposal of agricultural waste straws can be solved.

Owner:甘宗琳

Stabilization landfill process of fluoride

InactiveCN109759415ASolve harmless disposalEfficient removalSolid waste disposalAluminium chlorohydrateSlag

The invention discloses a stabilization landfill process of fluoride. The stabilization landfill process of fluoride comprises the following steps of 1) adding 20-30 times of water into solid waste residue according to the weight of the solid waste residue, and soaking for 1-3 hours; 2) adding 2%-6% of calcium compound, and uniformly stirring; 3) adding 0.5-1.2% of aluminum compound, and uniformlystirring to prepare slurry; and 4) curing for 8-14 days in a landfill curing zone to form a cured body. According to the stabilization landfill process of the fluoride, calcium chloride hexahydrate and polyaluminum chloride (PAC) are adopted as a fluorine removal agent, the fluoride in overhaul slag can be effectively stabilized and cured, so that the cured body formed by the method can leach thetoxic fluoride to meet the requirement of safe landfill.

Owner:克拉玛依沃森环保科技有限公司

Method for recovering heavy metal in electrolytic manganese passivating wastewater

InactiveCN101643263BSolve harmless disposalReduce manufacturing costWaste water treatment from metallurgical processWater/sewage treatmentElectrolysisManganese

The invention relates to a method for recovering heavy metal in electrolytic manganese passivating wastewater. The method mainly comprises the following processes: firstly, regulating the pH value of the electrolytic manganese passivating wastewater by alkali, then adding carbonate into the electrolytic manganese passivating wastewater, filtering after finishing the reaction, regulating the pH value of the solution to 8-12, then adding peroxide and filtering after finishing the reaction; afterwards, regulating the pH value of the solution to 2.0-7.0 and adding quinary-sulfocarbonate to process sexavalent chromium. The invention can recover and utilize manganese and chromium ions in the electrolytic manganese passivating wastewater in a resource way and also can eliminate the generation ofdangerous solid wastes. Compared with the prior art, the invention also has the advantages of low production cost, easy operation, continuous operation and convenient realization of industrialized production.

Owner:CHONGQING UNIV

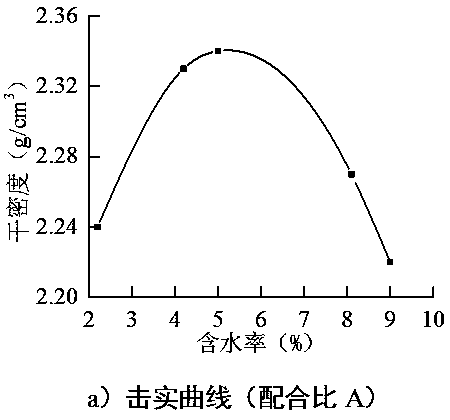

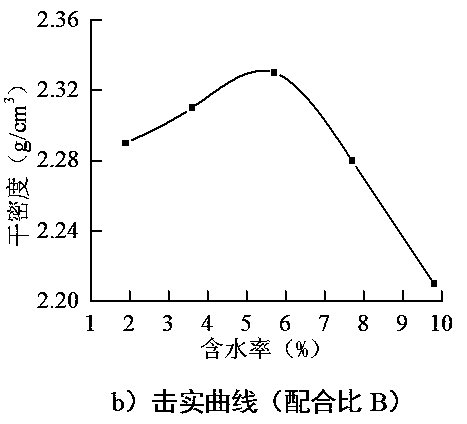

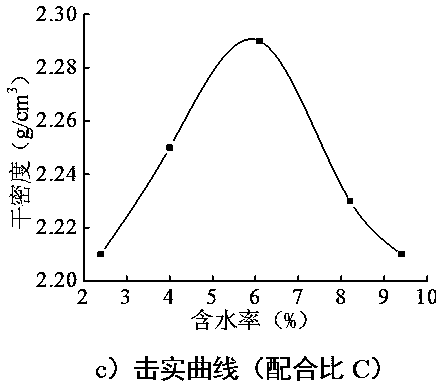

An application method of treated oil-based rock debris in an inorganic stable road base

InactiveCN109853312AReduce dosageReduce construction costsRoadwaysSolid waste managementEnvironmental indexMass ratio

The invention discloses an application method of treated oil-based rock debris in an inorganic stable road base, which is characterized by comprising the following steps: (1), treating the oil-based rock debris by adopting a waste oil-based mud rock debris resource recovery technology LRET and a thermal analysis technology, and after the detection of various treated environmental indexes is qualified, standing by; (2), checking a subbase layer before a base layer is constructed, and removing pumice stones and sundries; (3), mixing the mixture according to the following mass ratio: 52% of gravel, 12% of sand, 3-5% of cement and 31-33% of oil-based rock debris; and (4), filling the mixture on the subbase layer in a layered manner and compacting the same to finally form the road base layer. The method can be used for harmless and resourceful treatment of the oil-based rock debris; the mixture can be used as an admixture of the road base layer, thus meeting the strength requirement of theroad base layer, and effectively reducing the cement consumption required in road construction and reducing the construction cost.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

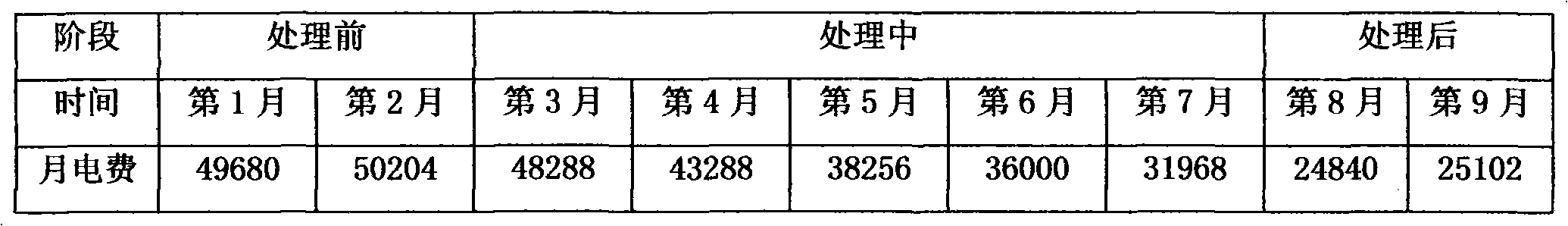

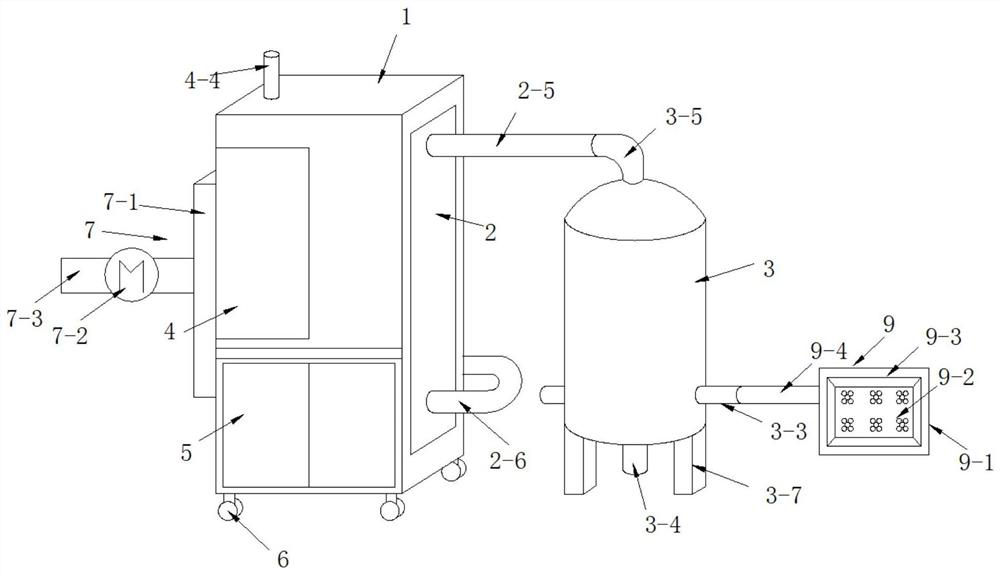

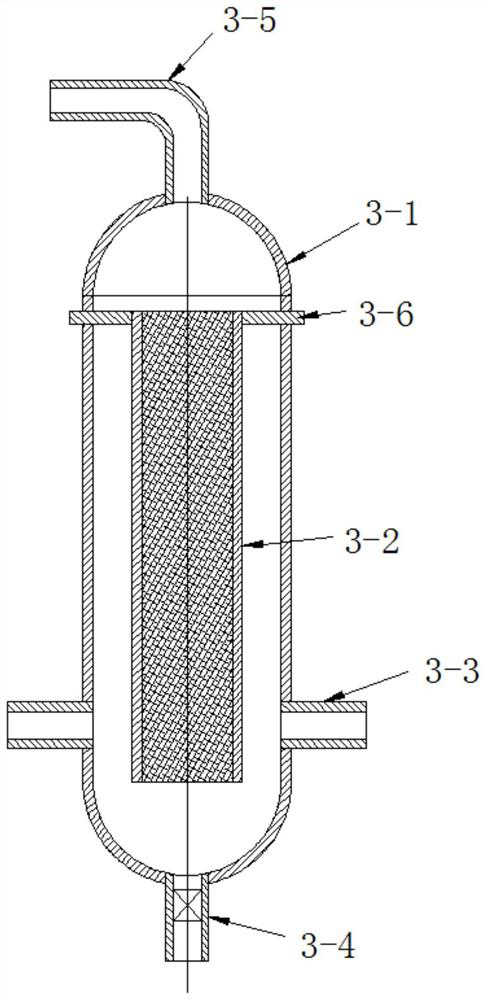

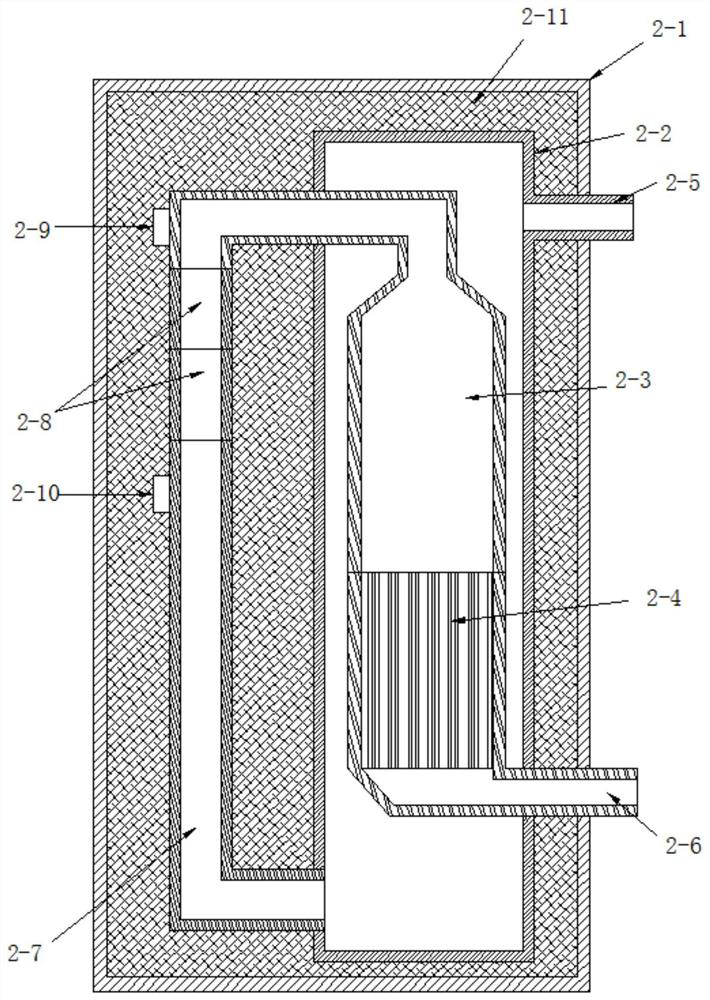

Smoke smell treatment system

InactiveCN111888927ASolve harmless disposalAvoid harmCombination devicesGas treatmentElectrical controlTemperature treatment

The invention relates to the technical field of smoke treatment, in particular to a smoke smell treatment system. The system comprises a box body, a moxa smoke treatment unit, a preprocessor, a high-temperature treatment and cooling unit and an electrical control box, wherein the moxa smoke treatment unit, the high-temperature treatment and cooling unit and the electrical control box are all arranged in the box body; the preprocessor is connected with the moxa smoke treatment unit; and the moxa smoke treatment unit is connected with the high-temperature treatment and cooling unit. According tothe invention, problems in harmless treatment of moxa smoke generated in the moxibustion treatment process are solved, the harm of moxa smoke to moxibustion treatment practitioners is avoided, the influence of the moxa smoke on the environment is reduced, contribution is made to the traditional Chinese medicine cause, and practicability and safety are both improved.

Owner:王友锋 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com