Patents

Literature

975results about How to "Won't overflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

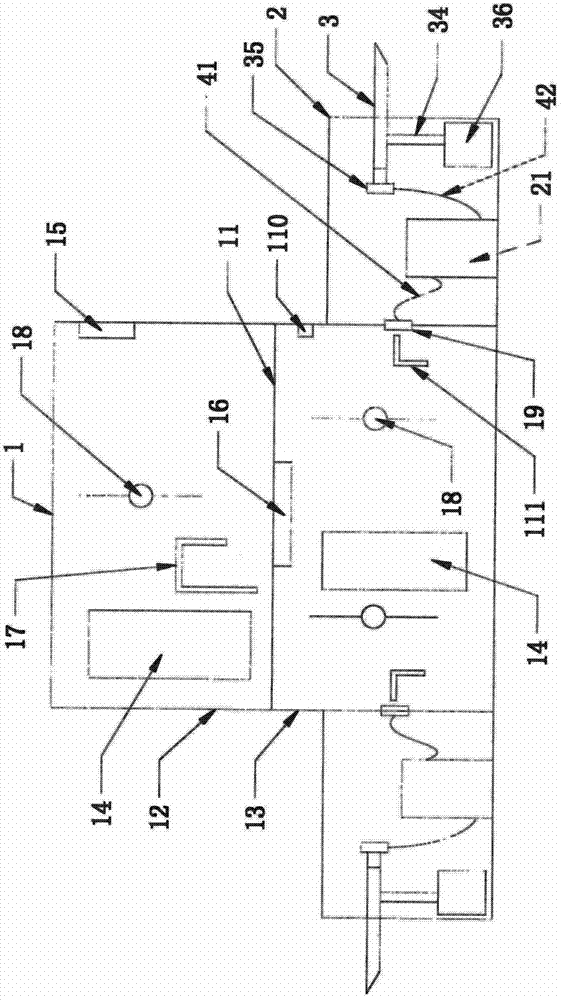

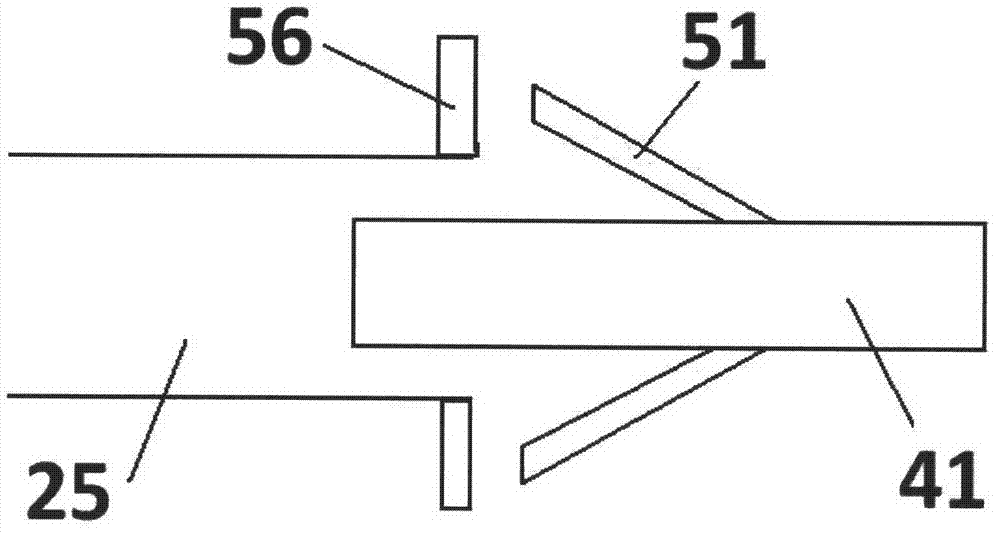

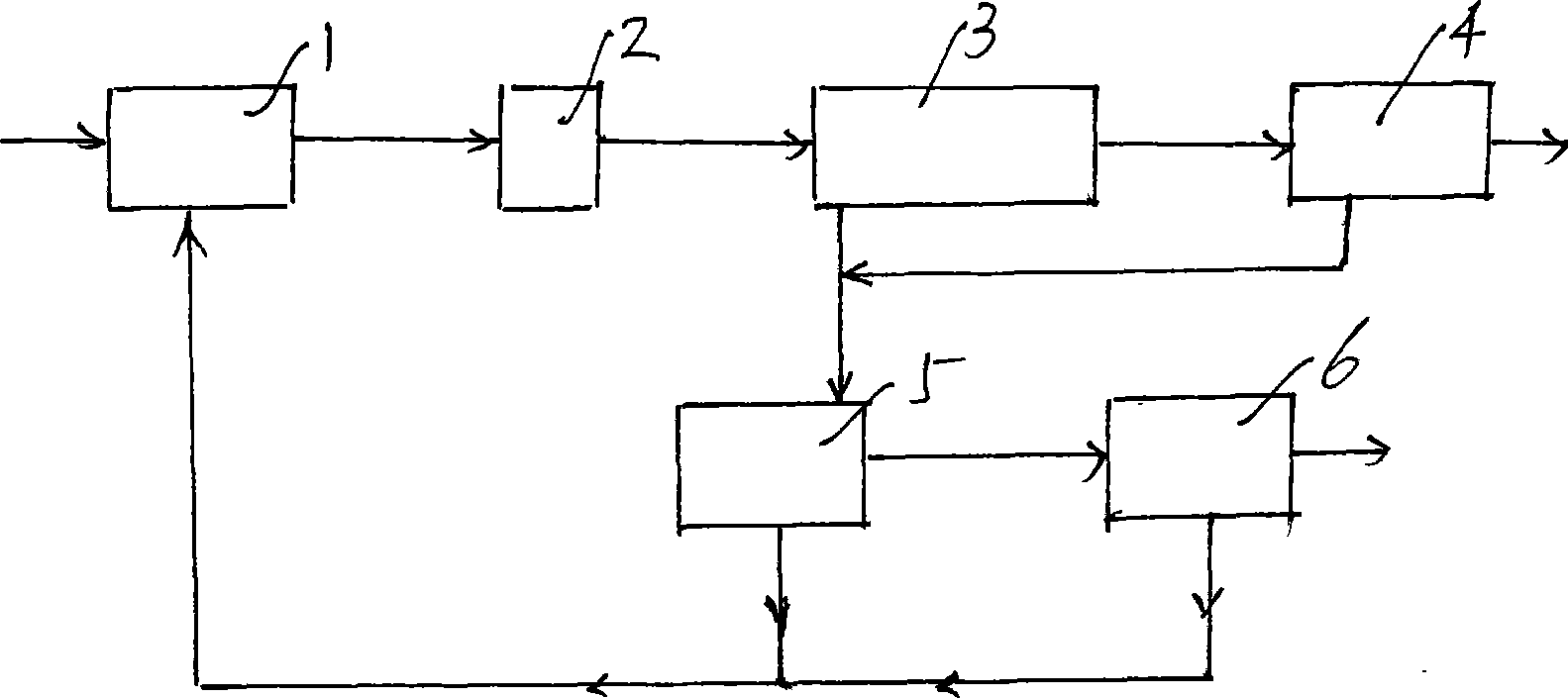

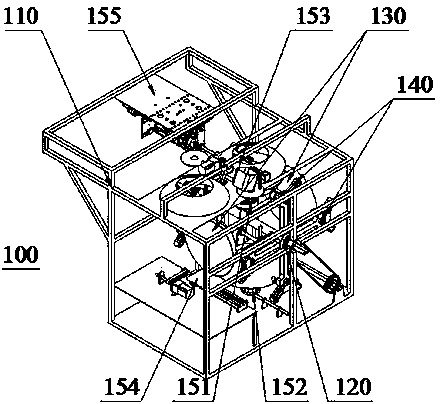

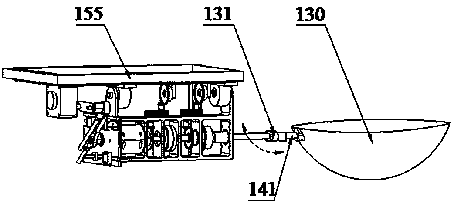

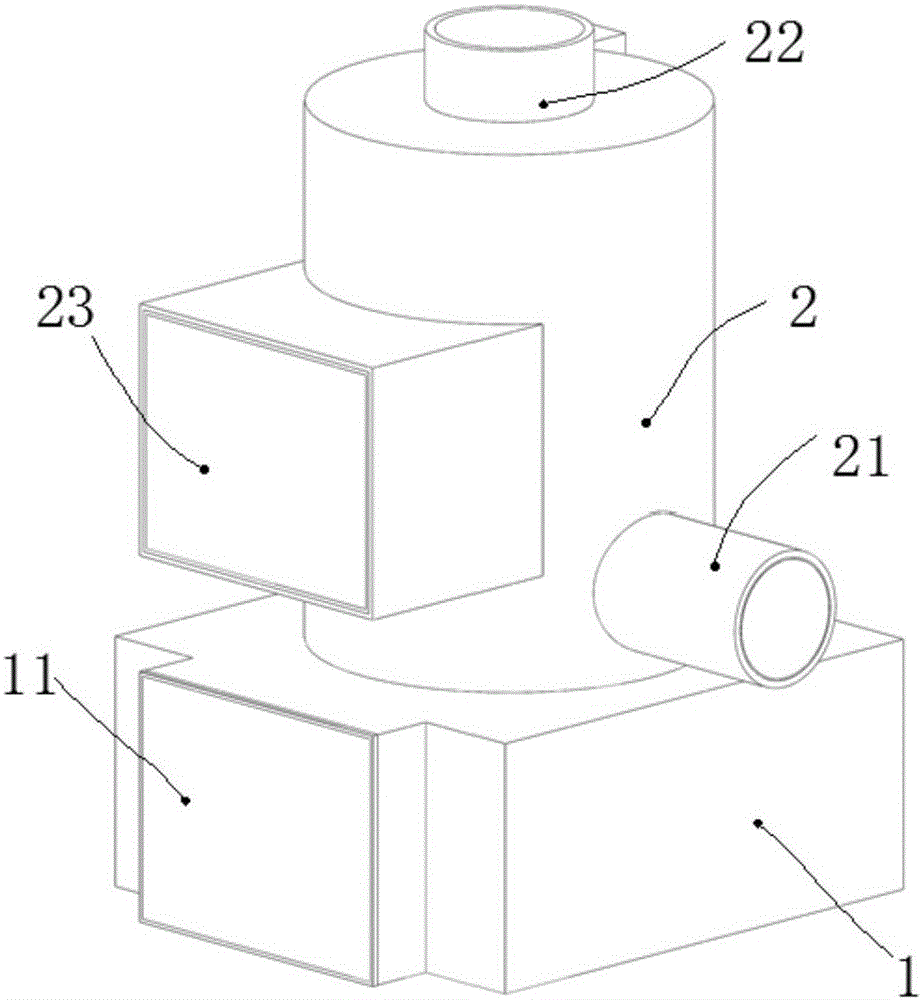

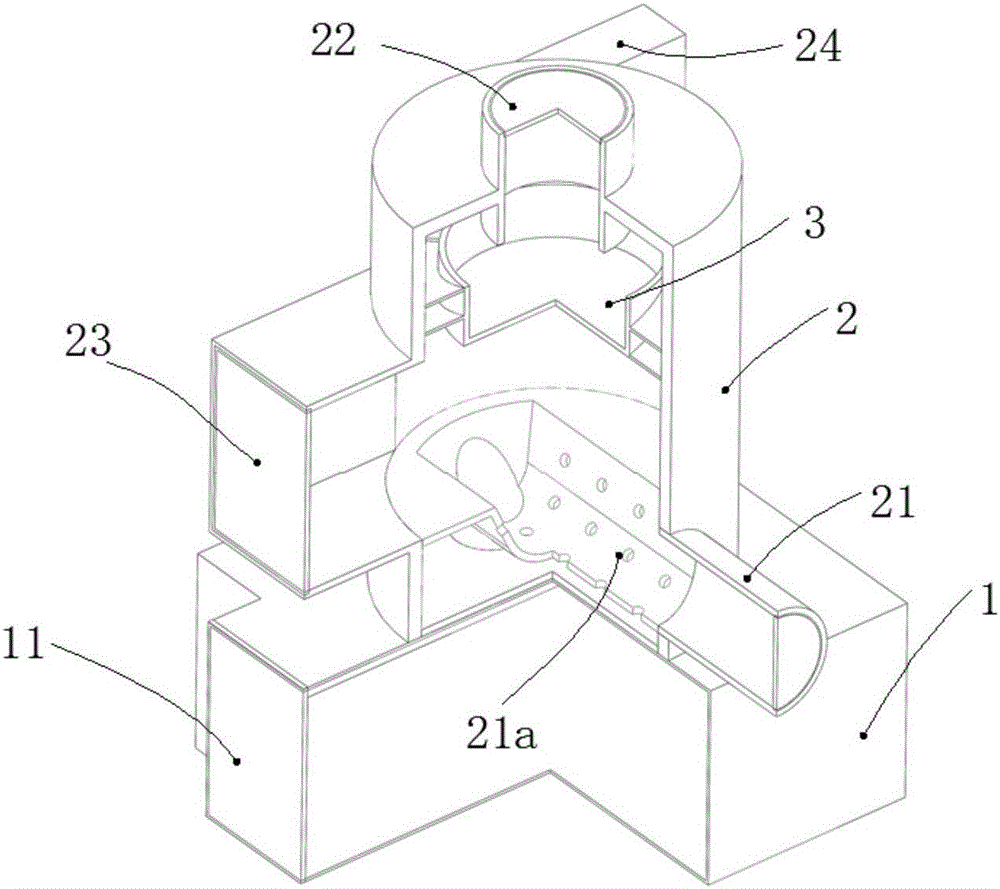

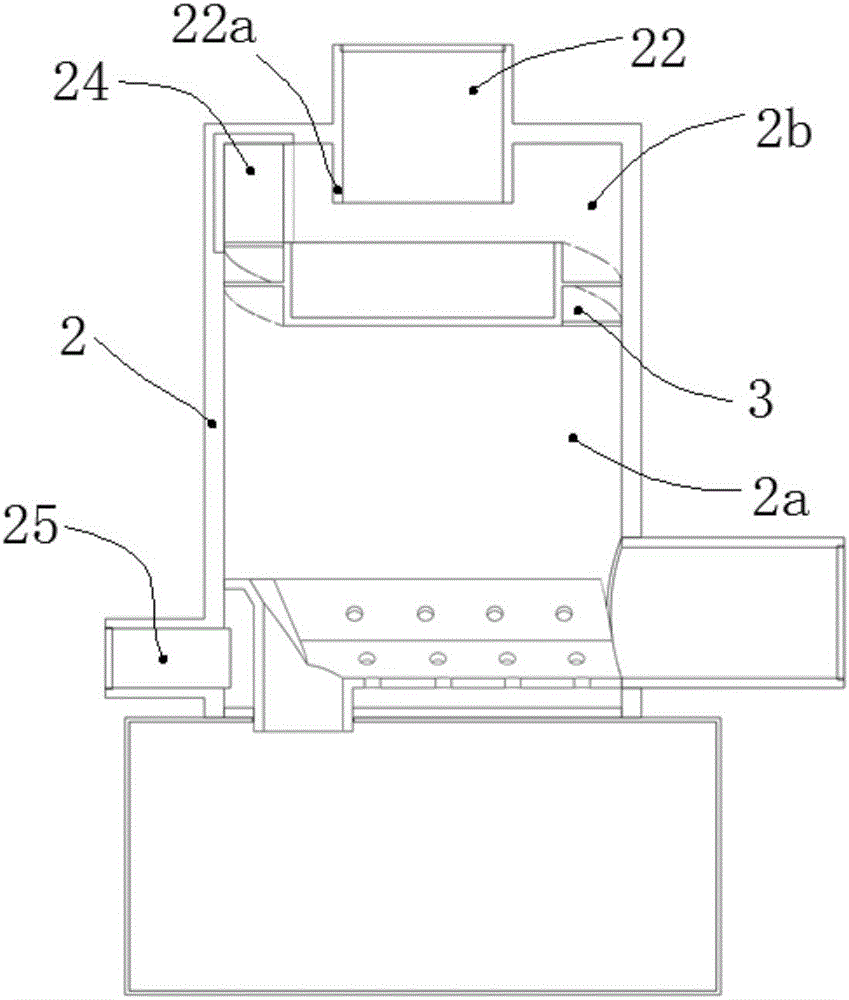

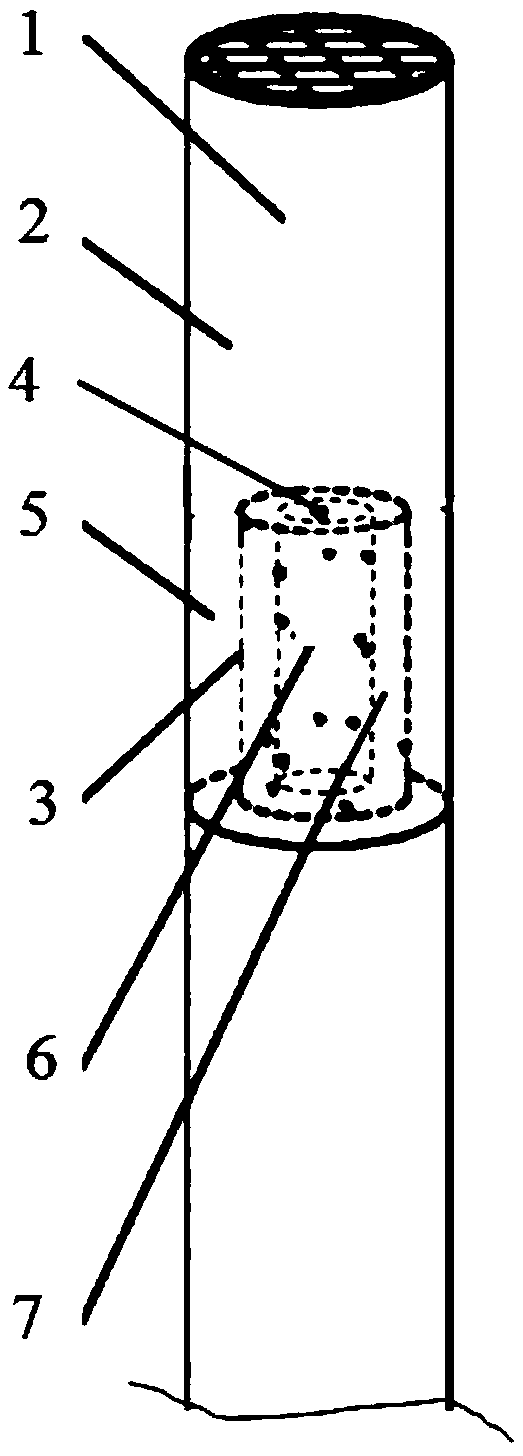

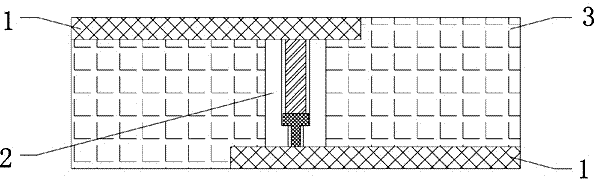

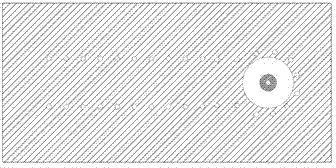

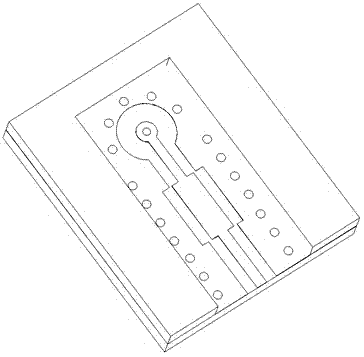

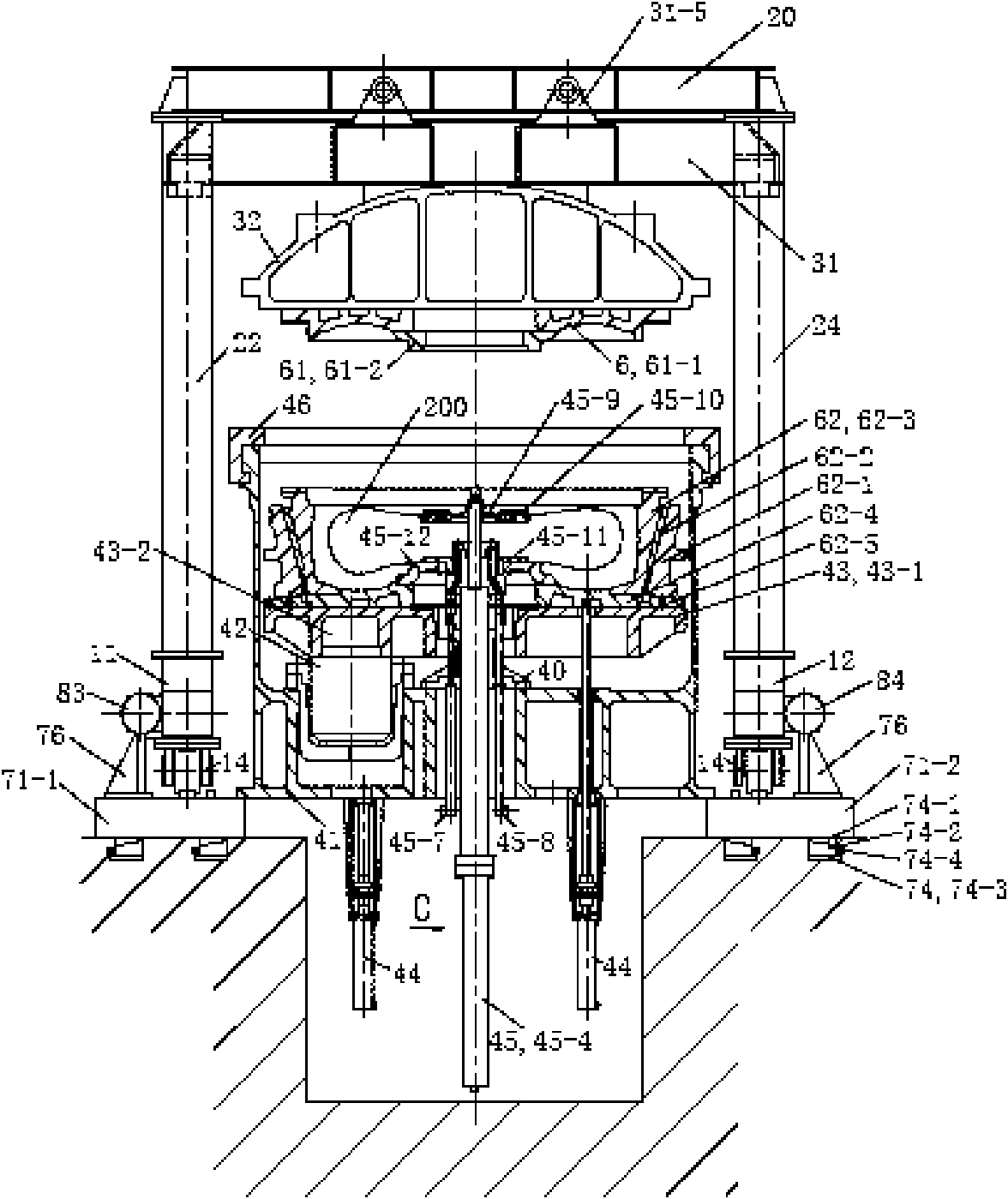

Down filling machine

ActiveCN102808245AStable outputHighly stable suedeUpholstery manufactureOakum treatmentEngineeringUltimate tensile strength

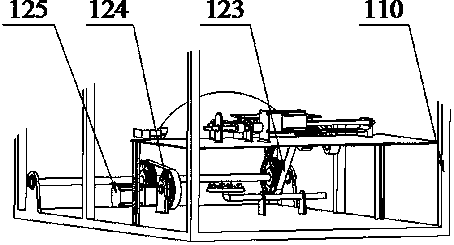

The invention discloses a down filling machine, which comprises a down storage box, weighing cabinets, down filling pipes and a programmable controller, wherein the down storage box is provided with at least two weighing cabinets; at least two weighing boxes are arranged in each weighing cabinet; the total number of the weighing boxes is equal to the total number of down outlets of the down storage box; each weighing cabinet is provided with at least one down filling pipe; the total number of the weighing boxes in each weighing cabinet is dual, and the number of the down filling pipes is a half of the total number of the weighing boxes. According to the down filling machine, the close full-automatic down filling can be carried out, the labor intensity is reduced, the production efficiency is improved, and the production cost is decreased. The down filling machine has the advantages of reasonable design, simple structure, low cost and good practicability. The down storage box of the down filling machine has stable down output, so that the down filling consistence and the down filling precision are ensured; a weighing process of the weighing boxes is independent, precise and effective; the down filling pipes cannot fill the down to airtight cutting pieces; working conditions of the multiple weighing boxes are alternatively changed and one down filling pipe is used for outputting, so that the down filling efficiency is further improved.

Owner:CHANGSHU BEALEAD AUTO MACHINERY

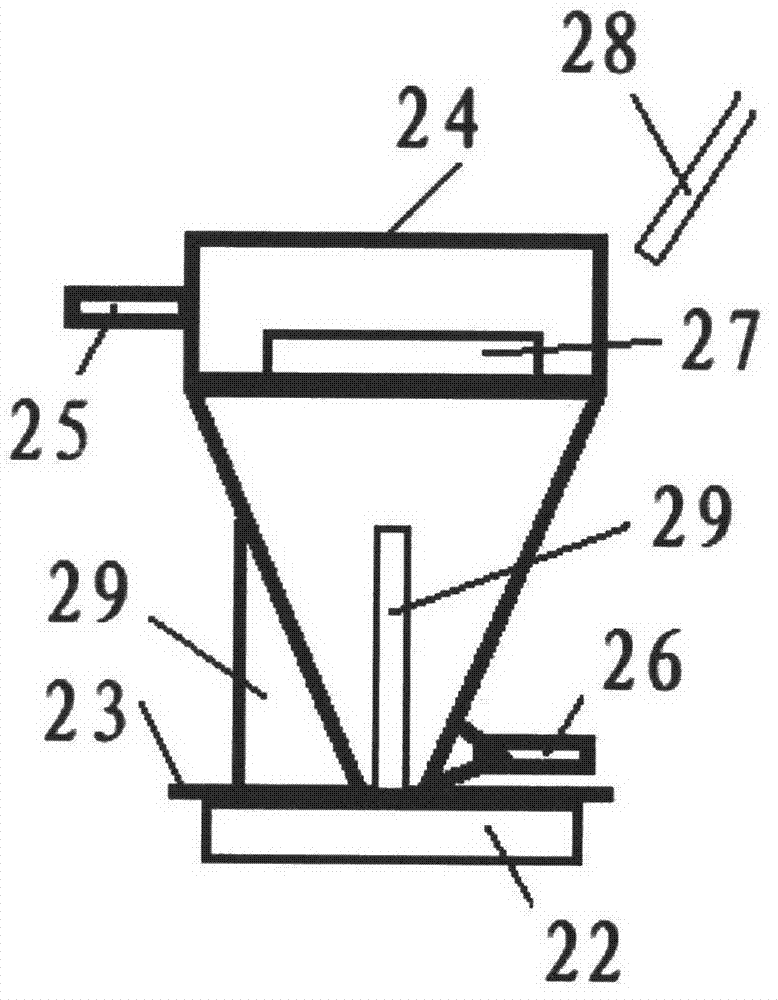

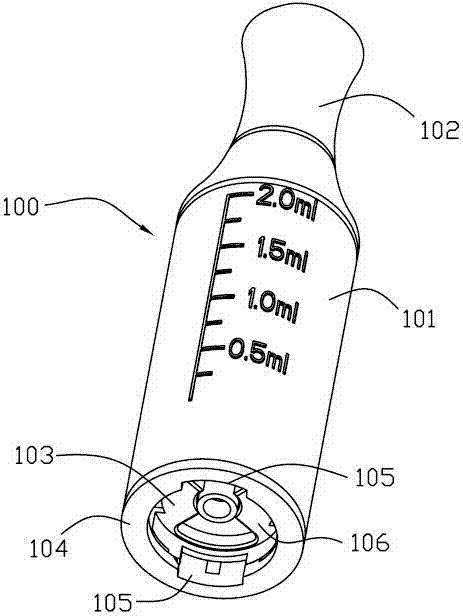

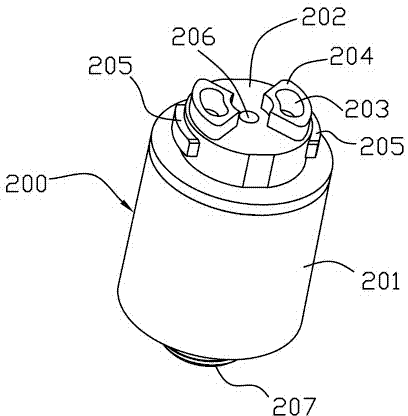

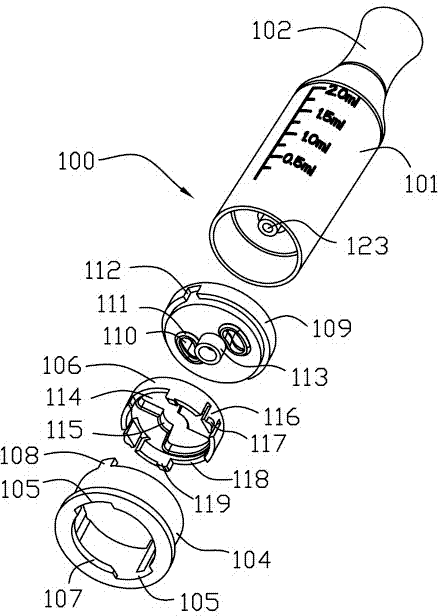

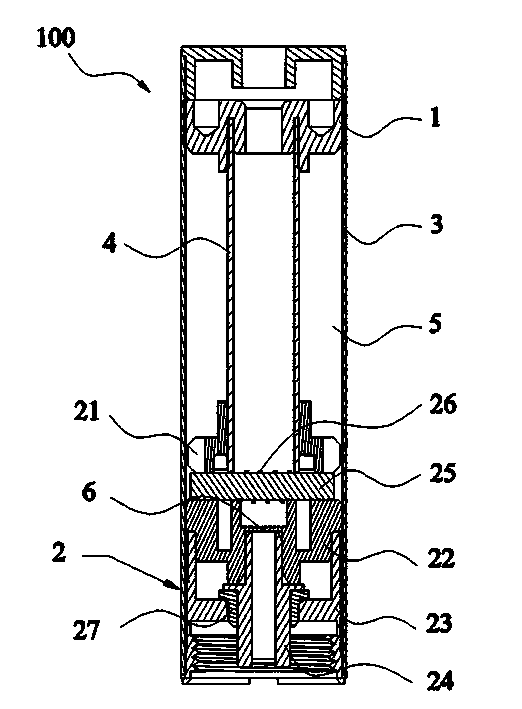

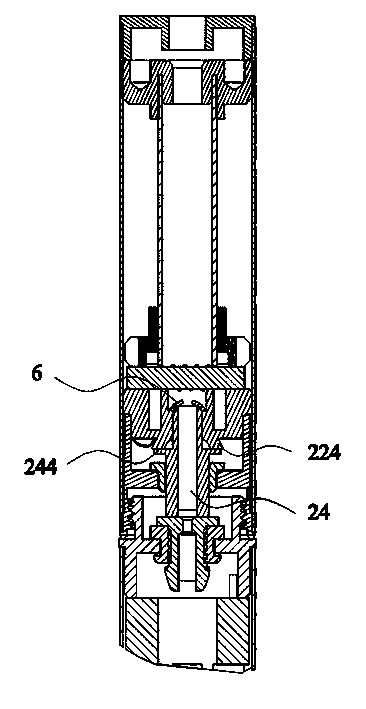

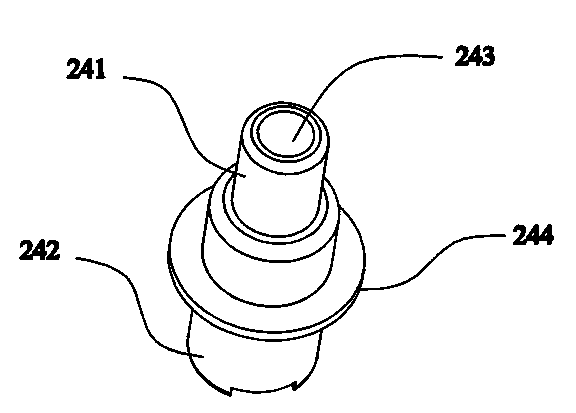

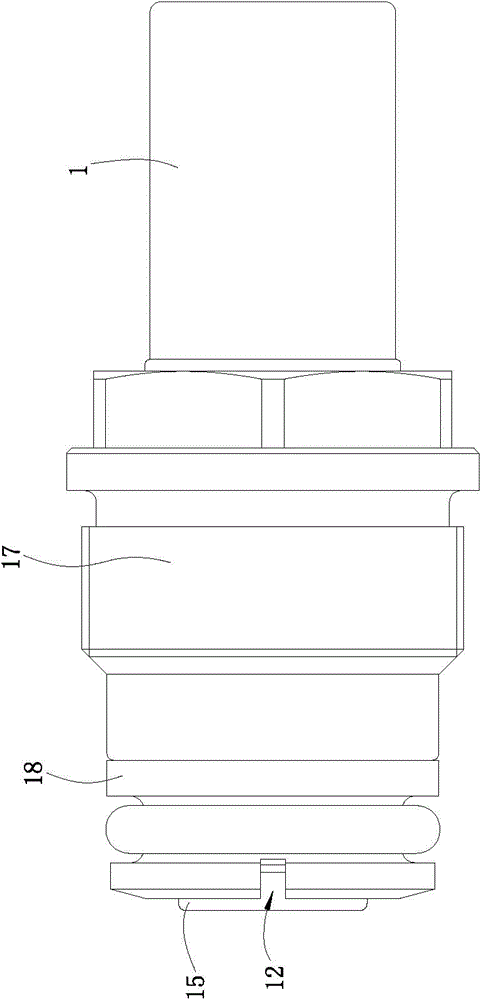

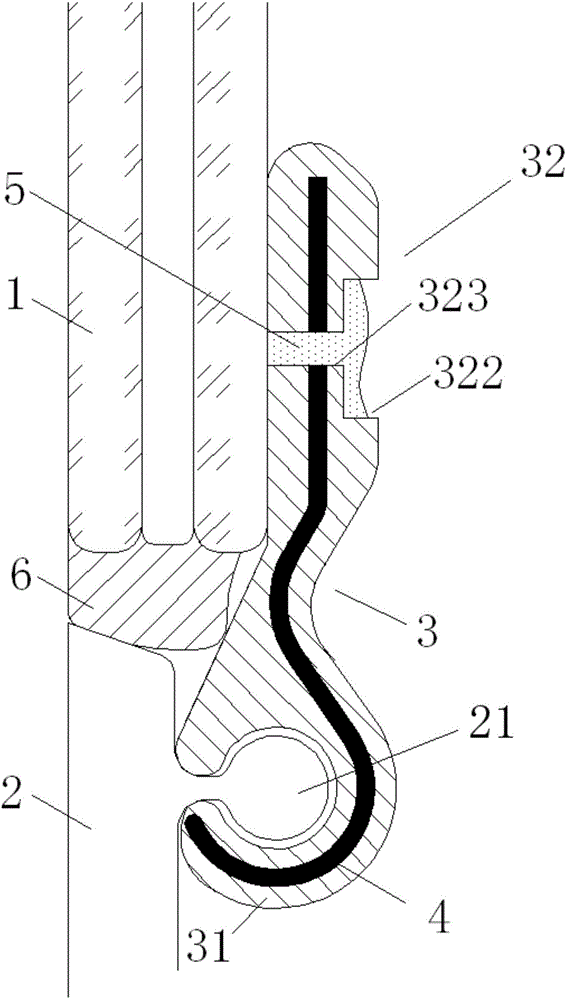

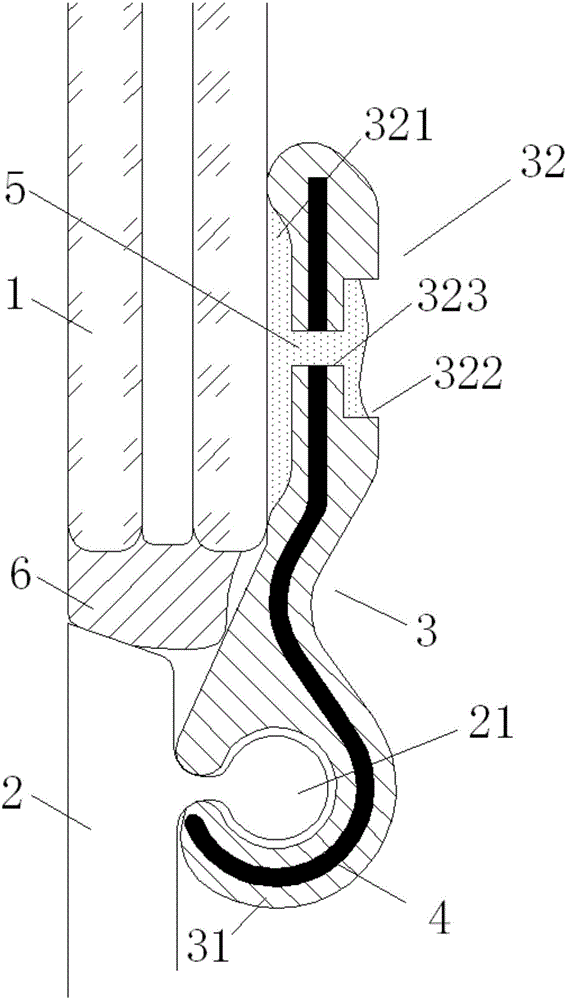

Atomizer, electronic cigarette and liquid storage device suitable for being replaced

PendingCN104738816AWon't overflowImprove experienceRespiratorsTobacco pipesElectronic cigaretteElectron

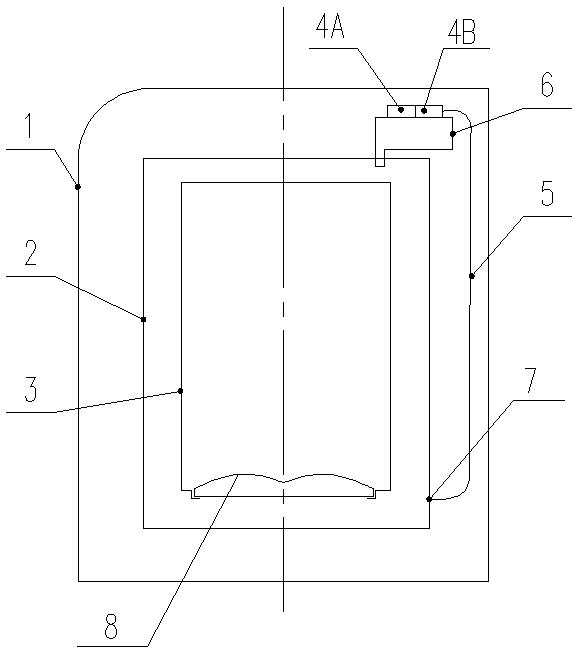

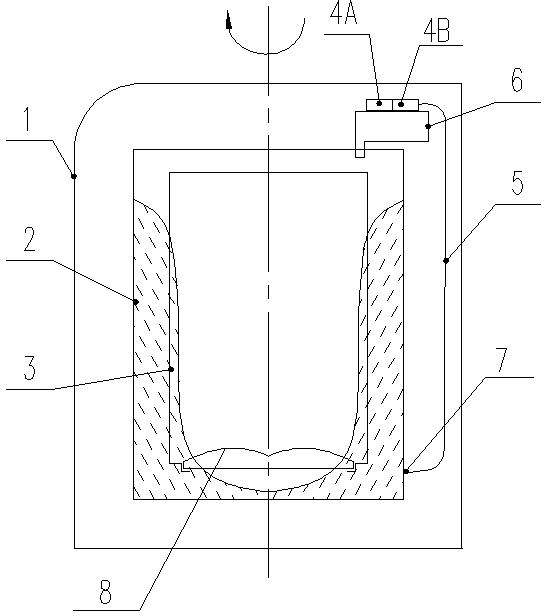

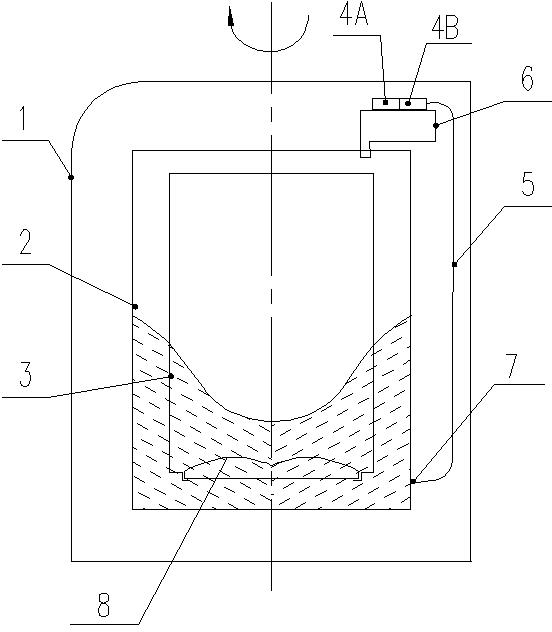

The invention discloses an atomizer, an electronic cigarette and a liquid storage device suitable for being replaced. The atomizer comprises the liquid storage device and an atomization assembly, wherein the atomization assembly comprises an atomization cavity and an atomization unit arranged in the atomization cavity and is provided with a connecting part used for being connected with the liquid storing device, a liquid inlet communicated with the atomizing cavity is formed in the connecting part, a sealing piece with a liquid outlet is arranged at the opening end of the liquid storage device, and the connecting part is suitable for being inserted in the opening end of the liquid storage device and then is rotated by a certain angle so that the connecting part and the liquid storage device can be connected through buckles; when the connecting part and the liquid storage device are connected through the buckles, the liquid outlet and the liquid inlet ate communicated, and when the connecting part and the liquid storage device are separated, the connecting part can drive a rotating part so that the liquid outlet can be blocked. The electronic cigarette with the atomizer guarantees that no tobacco liquid overflows from the liquid storage device in any state, and a consumer can obtain a good using experience.

Owner:SHENZHEN FIRST UNION TECH CO LTD

Low-odor low-VOC (volatile organic compound)-content styrene polymer composition and preparation method thereof

ActiveCN103044793AOvercome the shortcomings of not being able to directly add to raw materialsWon't overflowPolymer scienceAntioxidant

The invention discloses a low-odor low-VOC (volatile organic compound)-content styrene polymer composition and a preparation method thereof. The composition is prepared from the following components in percentage by weight: 70-99% of styrene polymer, 0.5-29% of strippant master batch and 0.01-1% of antioxidant. The preparation method comprises the following steps: preparing a strippant master batch, mixing the components in a high-speed mixer, adding the mixture into a screw extruder, carrying out melt extrusion, and granulating. The invention has the advantages of simple production technique and lower production cost, and effectively lowers the order and VOC content of the styrene polymer; and the prepared styrene polymer composition can be used in the field of materials with strict environmental requirements in packaging materials, daily necessities, home appliances, OA, toys, sports equipment, shoe materials, cables, instruments and meters, electronic components and equipment, construction materials and automobile materials.

Owner:CHENGDU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +2

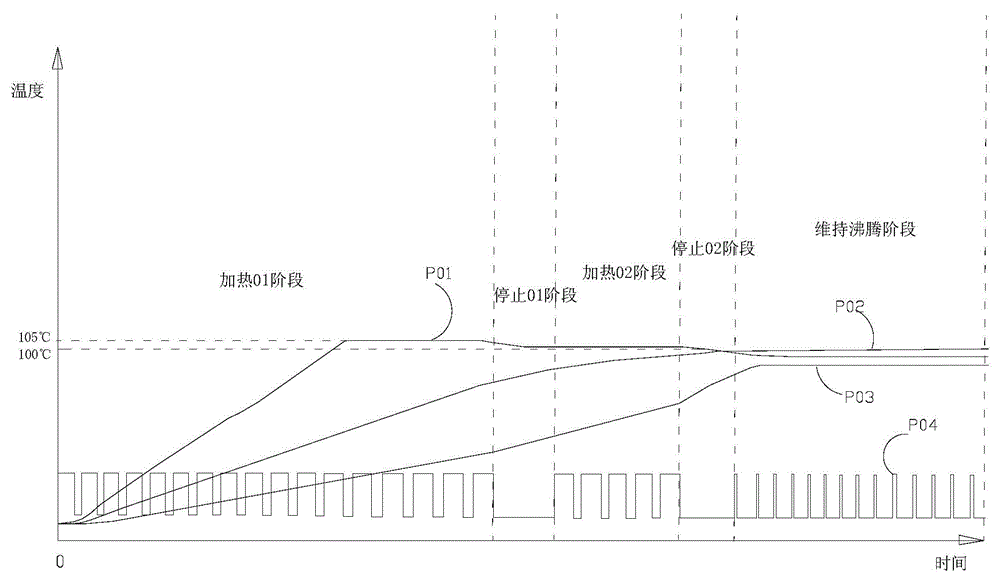

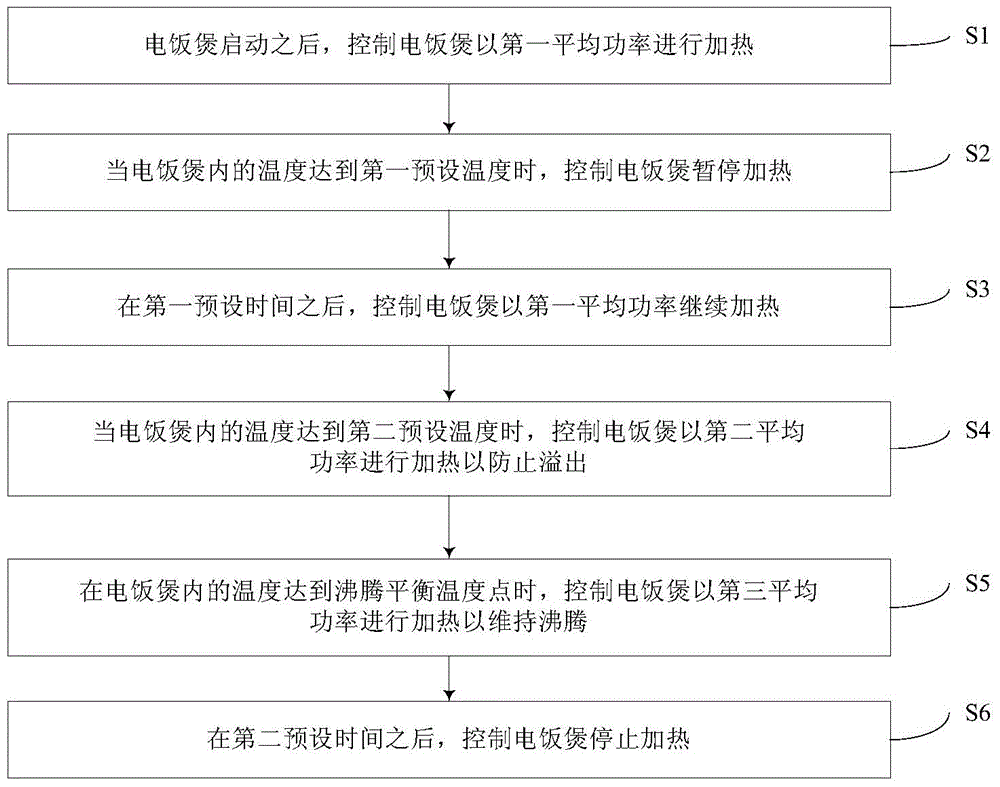

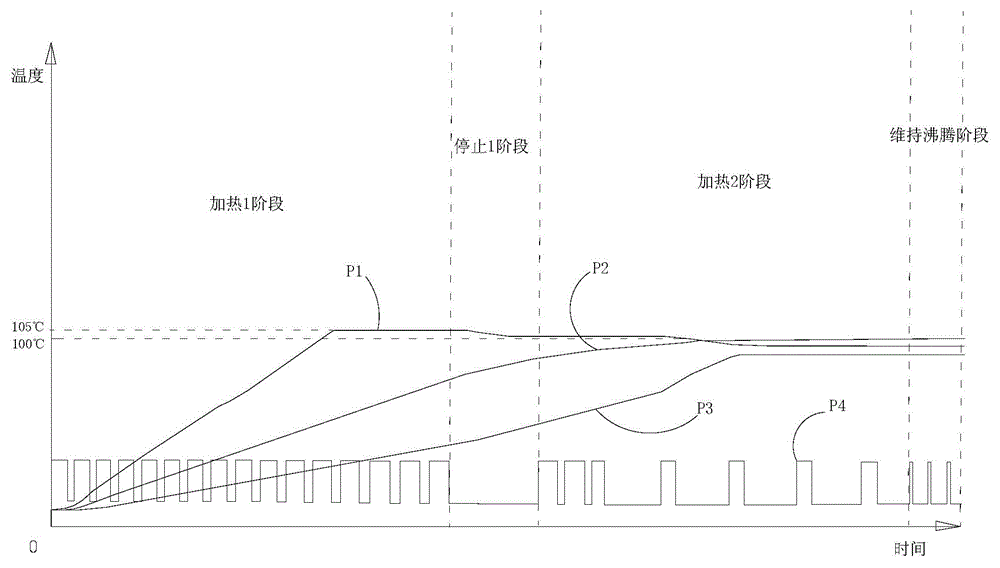

Electric cooker and control method thereof

ActiveCN105078233AWon't overflowAccurate temperatureBoiling over preventionTemperature controlEngineering

The invention provides an electric cooker and a control method thereof. The control method comprises the following steps: after the electric cooker is started, the electric cooker is controlled to be heated at the first average power; when the temperature in the electric cooker reaches a first preset temperature, heating of the electric cooker is controlled to be stopped temporarily; first preset time later, the electric cooker is controlled to be continuously heated at the first average power; when the temperature in the electric cooker reaches a second preset temperature, the electric cooker is controlled to be heated at the second average power, wherein the first preset temperature is larger than the second preset temperature, the power regulation ratio of the second average power is smaller than that of the first average power and the power regulation cycle of the second average power is larger than that of the first average power; when the temperature in the electric cooker reaches a boiling balance temperature point, the electric cooker is controlled to be heated at the third average power so as to keep boiling; and second preset time later, heating of the electric cooker is controlled to be stopped. According to the electric cooker and the control method thereof, the fact that the electric cooker reaches boiling temperature and material in the electric cooker does not overflow can be guaranteed and temperature control is more accurate.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

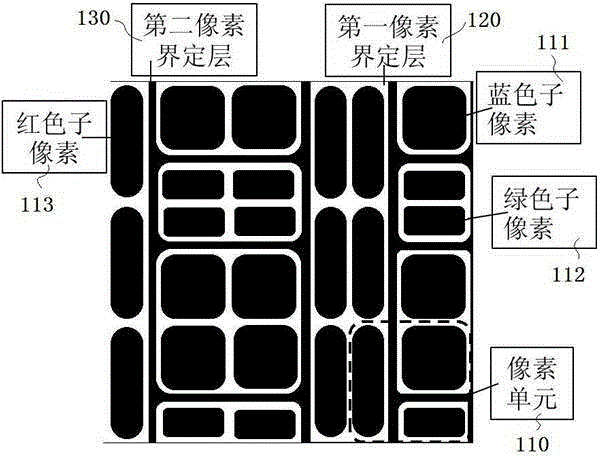

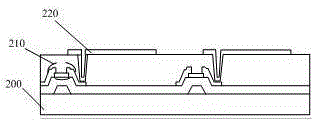

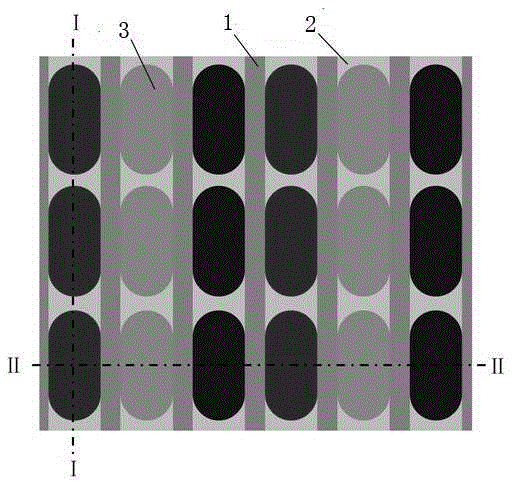

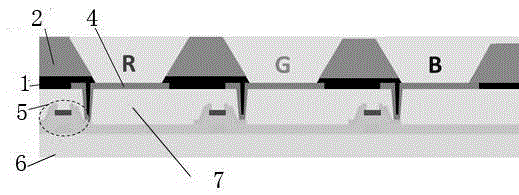

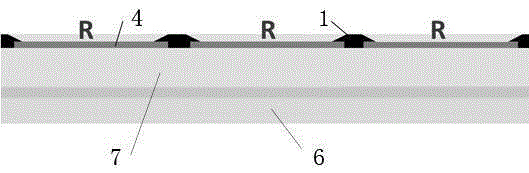

Pixel defining layer structure and manufacturing method thereof, display panel, and display apparatus

InactiveCN105206643ASmall sizeWon't overflowSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceComputer science

The invention discloses a pixel defining layer structure and a manufacturing method thereof, a display panel, and a display apparatus. The pixel defining layer structure comprises a first pixel defining layer and a second pixel defining layer disposed on the first pixel defining layer, wherein the first pixel defining layer is provided with multiple first openings in one-to-one corresponding to the luminescence area of each sub pixel, and the second pixel defining layer is provided with multiple second openings shared by an area formed by connecting sub pixels having the same color. Through the pixel defining layer structure provided by the invention, the multiple sub pixels having the same color are combined together for simultaneous printing so that the deposition area of ink is increased by multiple times. Therefore, the dimension of each sub pixel can be effectively reduced, at the same time, it is ensured that the ink does not overflow due to too small area of the sub pixels, and finally, a printing type high-resolution display device is prepared.

Owner:TCL CORPORATION

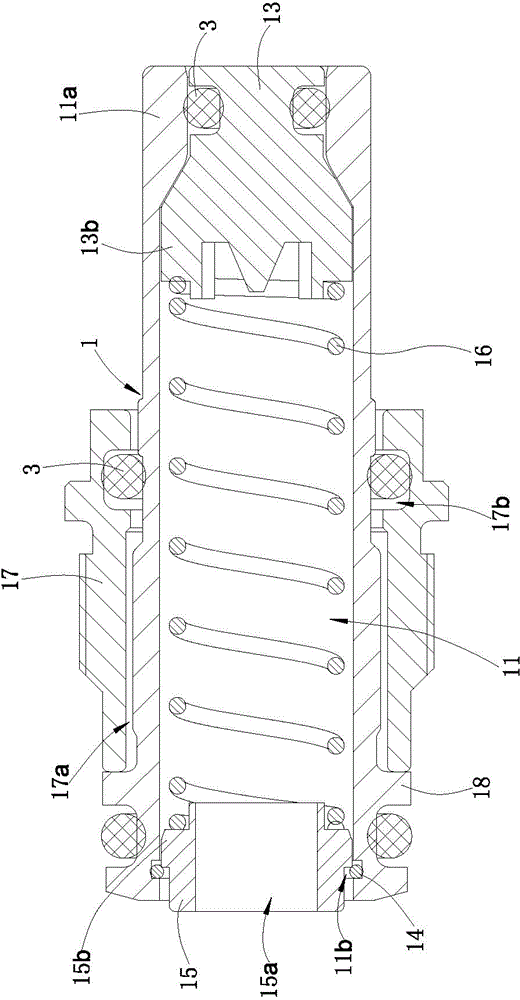

Electronic cigarette atomizer and electronic cigarette

ActiveCN103504478AEasy to useRemove aversionOhmic-resistance electrodesMedical devicesTarEngineering

The invention provides an electronic cigarette atomizer. The electronic cigarette atomizer comprises an atomization assembly, wherein an electrode ring which can move relative to a thread bushing in the axial direction is arranged in the atomization assembly. The electrode ring comprises a front end and a rear end, wherein the front end is connected with a fixing sleeve in a sleeved mode, the rear end is fixed into the thread bushing through an insulating ring, an oil leakage prevention structure is arranged between the front end and the fixing sleeve or between the rear end and the insulating ring, and the oil leakage prevention structure can be opened or closed when the electrode ring moves. The oil leakage prevention structure is opened when the electronic cigarette atomizer is used, the oil leakage prevention structure is closed when the electronic cigarette atomizer is not used, and therefore tobacco tar can be effectively prevented from leaking outward, and resentment of consumers is eliminated. The invention further provides an electronic cigarette with the electronic cigarette atomizer.

Owner:SHENZHEN FIRST UNION TECH CO LTD

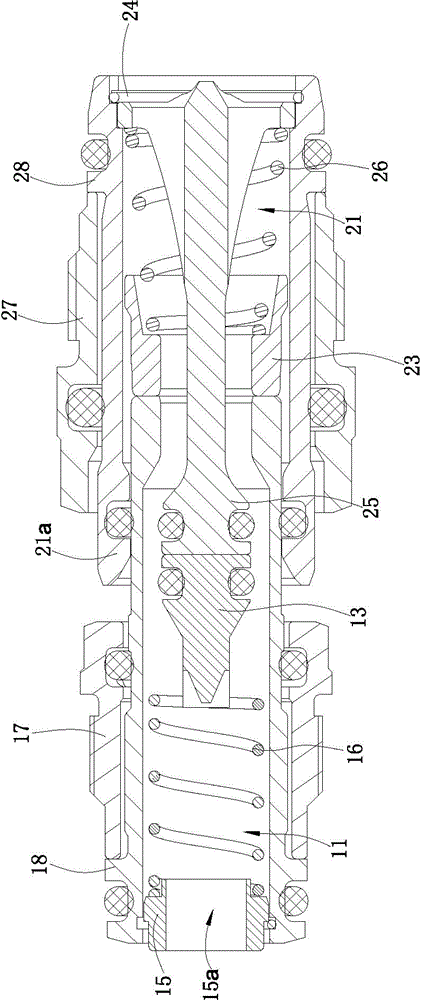

Floating blind-mating flow connector

ActiveCN103557392AImprove sealingExtended service lifeJoints with fluid cut-off meansEngineeringMechanical engineering

The invention discloses a floating blind-mating flow connector which comprises a socket and a plug matched with the socket, wherein a first flow guide hole is formed in the plug; a first snap ring, a valve bush, a first spring and a first valve core are arranged in the first flow guide hole; the valve bush is provided with a first bumping shoulder matched with the first snap ring; a first spring is arranged between the valve bush and the first valve core; a third flow guide hole is formed in the socket; a second snap ring groove is formed in the lateral wall at the front end of the third flow guide hole; a second snap ring, a flow guide post, a second ring and a second valve core are arranged in the third flow guide hole; the second snap ring is placed in the second snap ring groove; a third bumping shoulder matched with the second snap ring is arranged a the front part of the flow guide post; a fifth flow guide hole is formed in the third bumping shoulder; the second spring is arranged between the third bumping shoulder and the second valve core. According to the invention, both the socket and the plug can be used singly; the sealing effect is excellent and jamming is avoided when the socket and the plug are used together, so that, the fluid in the socket and the plug is enabled to run off quickly and the service life of the socket and the socket is prolonged.

Owner:中国电子科技集团公司第四十研究所

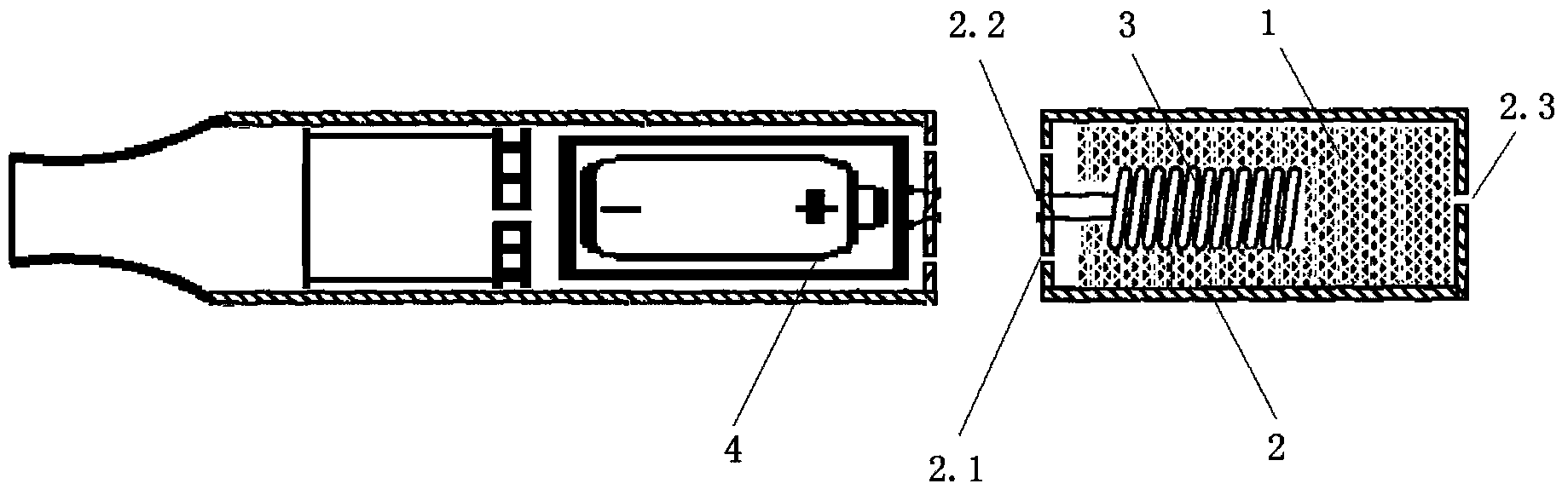

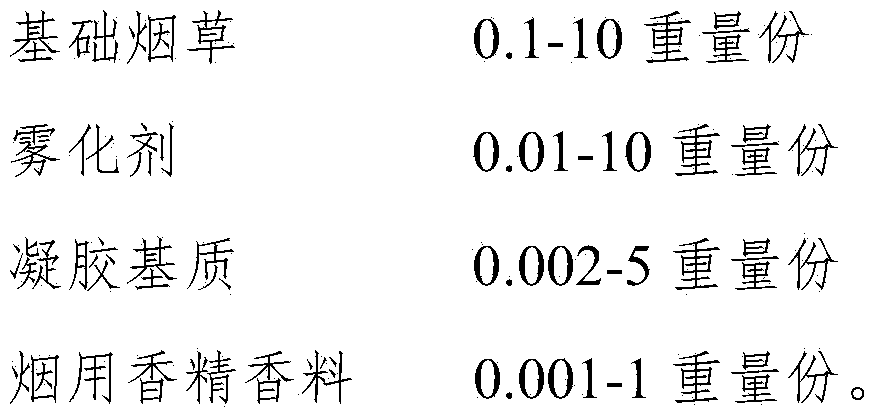

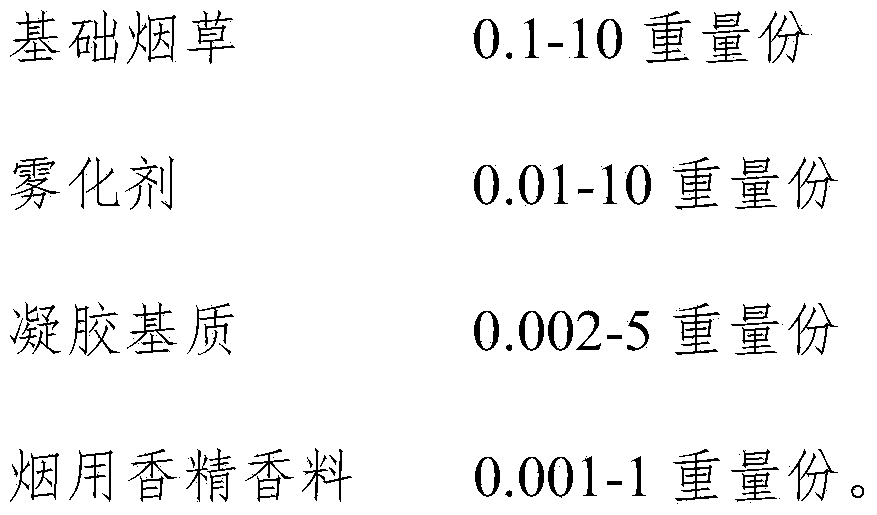

Gel type disposable electronic cigarette cartridge with electric heating wire arranged internally and with liquid fixed and preparation method thereof

The invention discloses a gel type disposable electronic cigarette cartridge with an electric heating wire arranged internally and with liquid fixed and a preparation method thereof. The gel type disposable electronic cigarette cartridge comprises an insulating case, and a smoke release hole is formed in one end of the insulating case. The gel type disposable electronic cigarette cartridge is characterized in that the electric heating wire is arranged inside the insulating case, a metal contact connected with the electric heating wire is arranged on the outer side of the end, provided with the smoke release hole, of the insulating case, the insulating case is filled with tobacco gel, the tobacco gel is formed by uniformly mixing and stirring basic tobacco, basic gel and tobacco flavors and fragrances, the basic tobacco is one of tobacco shreds, recombined tobacco and tobacco powder or a mixture of the tobacco shreds, the recombined tobacco and the tobacco powder, and the basic gel is formed by stirring and dissolving a gel base material and a fogging agent. The gel type disposable electronic cigarette cartridge has the advantages that spillage does not occur easily, and preservation is convenient.

Owner:HUBEI CHINA TOBACCO IND

Treatment process for desulfurized wastewater

InactiveCN101486517ASmall footprintLow construction costSludge treatment by de-watering/drying/thickeningWaste water treatment from gaseous effluentsFlocculationWastewater

The invention discloses a desulfurized wastewater treatment process. Firstly, NaOH or lime milk is added into the acidic desulfurized wastewater so as to adjust the pH value to be 8 to 9; then, the desulfurized wastewater is pumped into an electric flocculation treatment device by a pumpp, effluent after electric flocculation treatment enters an inclined pipe settling tank so as to be further treated, and then the treated wastewater reaching the standard is discharged or reused. The scruff discharged by the electric flocculation treatment device and the settled sludge discharged by the inclined pipe settling tank enter a sludge thickening tank so as to be further concentrated; the concentrated sludge is pumped into a sludge dewatering machine so as to be dried; and the dried sludge is shipped out for disposal, and the supernatant in the thickening tank and the filter-press fluid in the dewatering machine flow back to a regulating reservoir. The treatment process is characterized by simple flow and good treatment effect.

Owner:JIANGSU JINGYUAN ENVIRONMENTAL PROTECTION

Continuous cooking mechanism and method for controlling same

ActiveCN103720345AHigh level of cookingReduce the burden onCooking vessel supportEngineeringStability of motion

The invention relates to the field of automatic cooking equipment, and provides a continuous cooking mechanism and a method for controlling the same. The continuous cooking mechanism comprises a framework, a plurality of pots, a heating mechanism, a cleaning mechanism, an automatic cooking mechanism, a pot alternating mechanism and cooking limiting mechanisms. The pots are used for cooking, the heating mechanism is used for heating the pots, the cleaning mechanism is used for cleaning the pots, the pots can move in heating procedures under the control of the automatic cooking mechanism, the pot alternating mechanism is used for driving the pots to be sequentially alternated at different stations, and the cooking limiting mechanisms are used for supporting the pots when the pots move in the heating procedures and are fixed relative to the framework at least when positioned at heating stations. The continuous cooking mechanism and the method have the advantages that shortcomings in the prior art can be overcome, the continuous cooking mechanism is small in occupied space, complicated cooking functions can be stably realized, and continuous operation can be carried out; the cooking limiting mechanisms are fixed onto the framework in the heating procedures, the pots move in the cooking limiting mechanisms, and accordingly can be effectively supported by the cooking limiting mechanisms, and the movement stability of the pots can be guaranteed.

Owner:李夏

Novel liquid injection and activation process for lithium ion batteries

InactiveCN102315417ASpeed up entrySmooth entrySecondary cells charging/dischargingCell component detailsElectrical batteryPre-charge

The invention relates to a novel liquid injection, infiltration and pre-charging process for lithium ion batteries. The process comprises the following steps: (S1) carrying out vacuum operation on a lithium ion battery before liquid injection, injecting a predetermined amount of electrolyte, and filling a proper amount of film forming additive gas into the battery after injection of electrolyte is finished; (S2) employing the manner of cyclical fluctuation negative pressure infiltration, wherein, fluctuation of negative pressure is expressed with a waveform function instead of a simple first grade linear function; (S3) carrying out formation under the conditions of changing negative pressure and changing temperature, wherein, the negative pressure and temperature both increase gradiently with time, a charging current is not constant and varies in a manner of small gradient increase. The invention enables a predetermined amount of electrolyte to be rapidly absorbed by anode and cathode materials and diaphragms of the battery, and absorption time is short while full absorption is realized, thereby improving the utilization rate of the electrolyte and shortening time for liquid injection; addition of a proper amount of film forming additive gas is beneficial for the formation of SEI membranes and enables inreversible capacity loss of the battery in initial charge to be reduced; the method of pre-charging brought forward in the invention enables uniform and stable SEI membranes to form on the surface of electrodes, thereby improving safety performance and electrochemical performance of lithium ion batteries; the process is simple and is easy to control, investment cost for equipment used in the process is low, and the process is easy to realize.

Owner:HUNAN UNIV

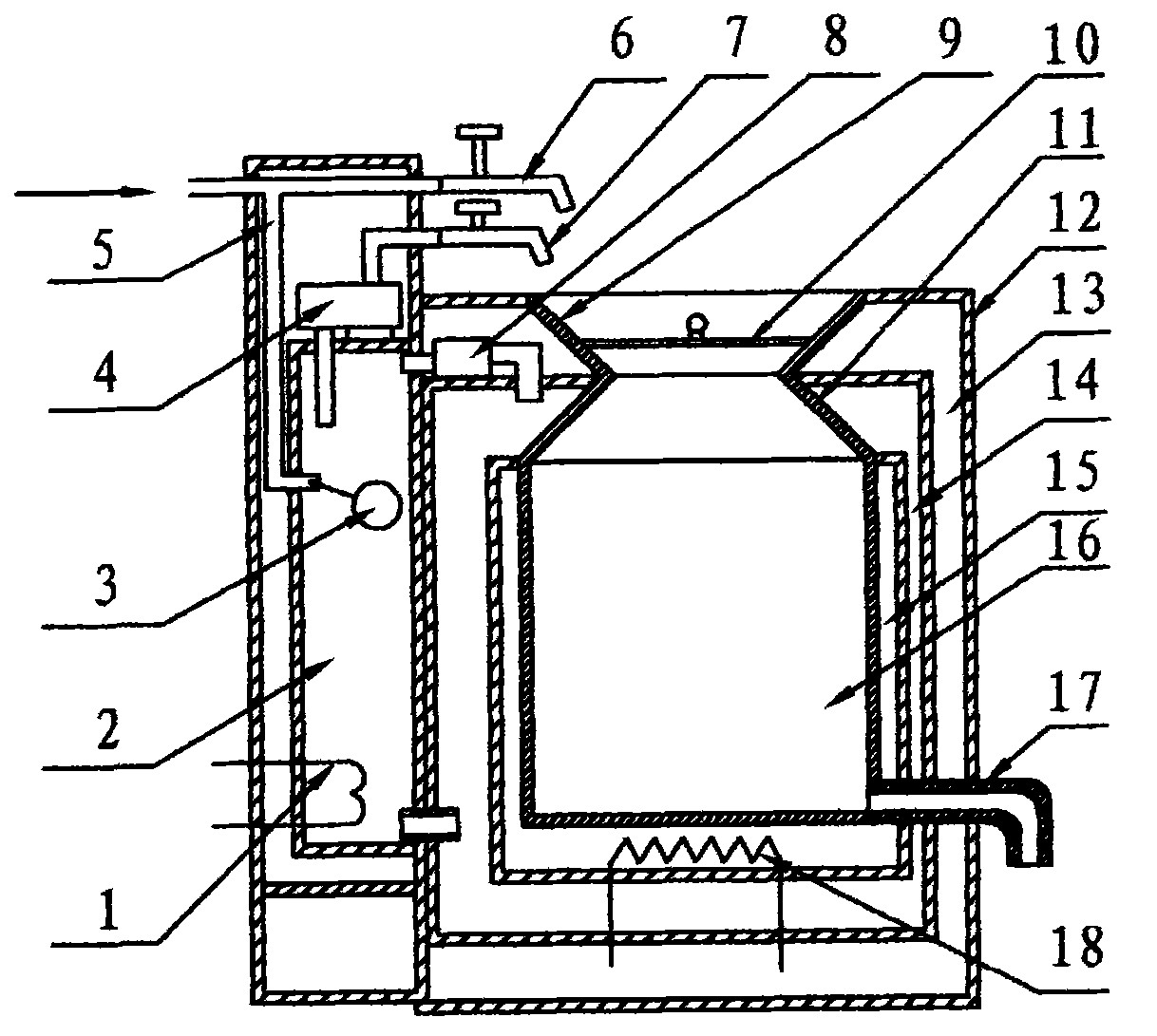

Sterilizing, disinfecting and mildew-proof barrel-cleaning washing machine and barrel-cleaning control method thereof

InactiveCN102628205AAvoid depositionEnsure normal dischargeOther washing machinesControl devices for washing apparatusImpellerInlet valve

The invention discloses a sterilizing, disinfecting and mildew-proof barrel-cleaning washing machine which comprises a shell, wherein an external water-storing barrel and an internal washing barrel are arranged in the shell; a water inlet box, a draining valve, a clutch, a program controller and a power supply part are arranged in the shell; a water inlet valve is arranged on the water inlet box; an ozone generating device is mounted on the water inlet box; an air outlet end of the ozone generating device is communicated with the bottom of a side wall of the external barrel through an ozone pipeline; the ozone generating device is connected with the program controller and the power supply part; and the draining valve and the clutch are respectively arranged and are respectively controlled by the program controller. The invention also discloses a barrel-cleaning control method of the washing machine. The sterilizing, disinfecting and mildew-proof barrel-cleaning washing machine is simple in structure and convenient in use; the internal barrel, the external barrel, the space between the internal and external barrels and the space under an impeller are cleaned and are sterilized and disinfected by using ozone; when water is discharged, the impeller is started to rotate positively and negatively by the washing machine so as to prevent line scraps and dirt in water from depositing at the bottom of the external barrel and internal barrel and on the impeller; the discharging of the line scraps and dirt is ensured; and the barrel-cleaning function is achieved.

Owner:HENAN XINFEI ELECTRICAL EQUIP

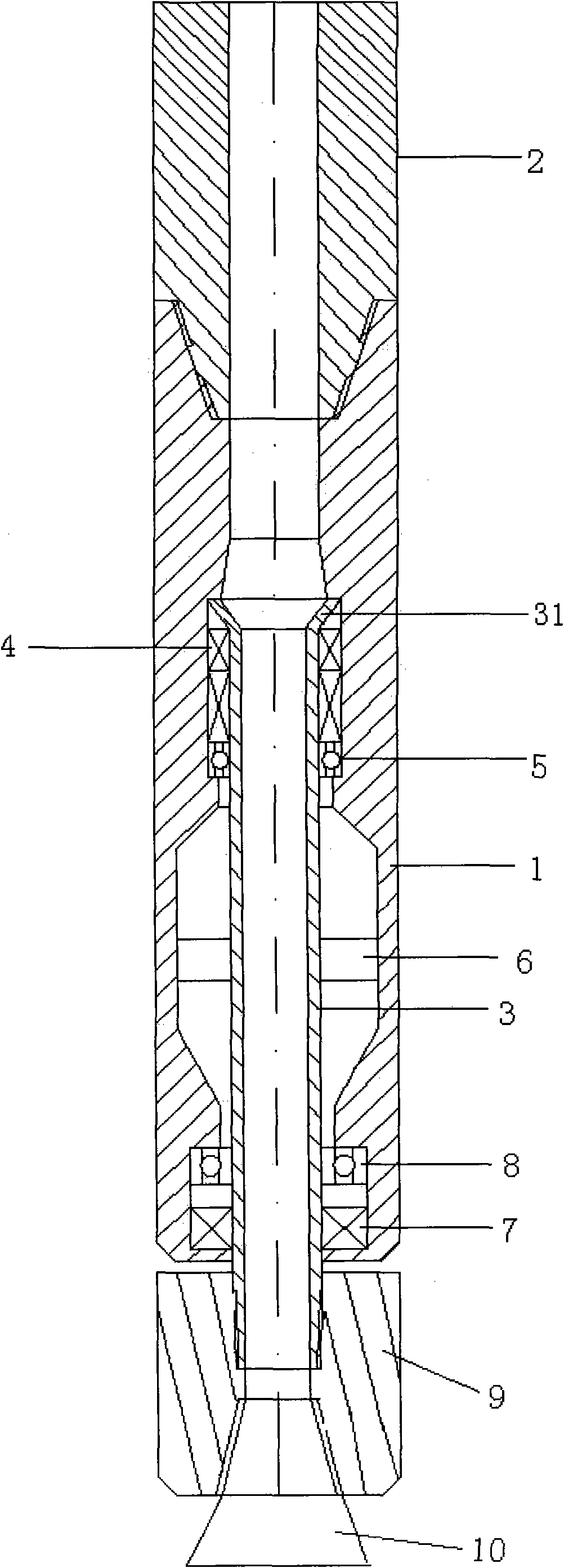

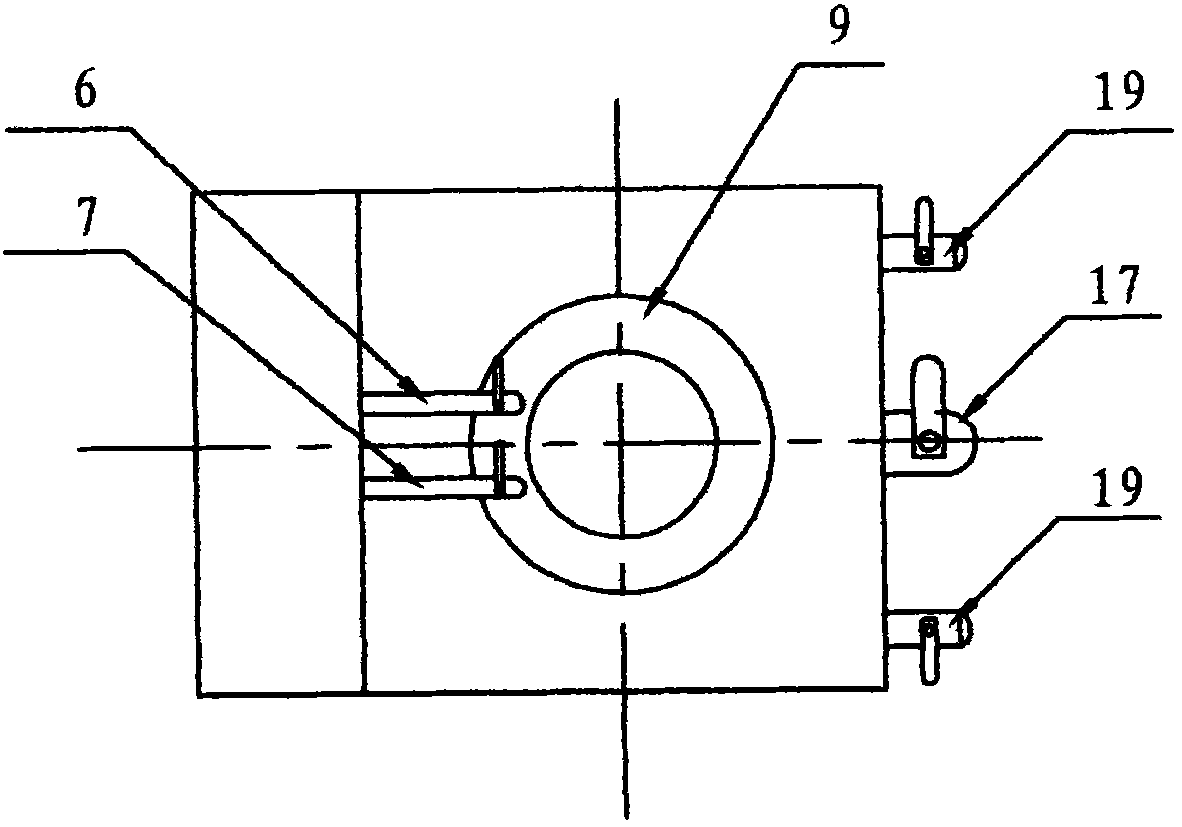

Oriented rotational guide drilling tool

ActiveCN101586440AAvoid damageExtended service lifeConstructionsDirectional drillingDrill bitEngineering

The present invention relates to an oriented rotational guide drilling tool which comprises a hollow housing with two through ends. The housing is communicated with a hollow drill collar through an upper female buckle. The lower end of the housing is inserted with a hollow mandrel. The cup-shaped port on the upper end of the hollow mandrel clings to the inner wall of the housing. The upper outer wall of the mandrel which clings to the cup-shaped port is sequentially sleeved and fixed with an upper floating sealing assembly and an upper floating bearing for supporting the mandrel from up to bottom. The mandrel penetrates an eccentric mechanism which is installed and fixed on the inner wall of the housing. The lower end of the mandrel extends out from the housing and is sequentially connected with a hollow rotating head and a drill. The outer wall which is in the lower chamber of the casing and clings to the mandrel is sequentially sleeved with a lower sealing assembly and a lower fixing bearing from up to bottom. The lower sealing assembly and the lower fixing bearing are fixedly connected with the inner wall and the mandrel of the housing. The oriented rotational guide drilling tool of the invention not only has high control precision, but also has a simple structure and therefore can be widely applied for various strata with different mechanic characteristics of surface.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Biomass cyclone dust removal burner

ActiveCN105864745AIncrease burn rateImprove combustion effectSolid fuel combustionAir/fuel supply for combustionCycloneCombustion chamber

The invention discloses a biomass cyclone dust removal burner. The biomass cyclone dust removal burner is characterized in that a cyclone dust removal burner is arranged at the upper part of a furnace body and at the lower end of a furnace body fire outlet, the cyclone dust removal burner divides the furnace body into a lower burning chamber and an upper burning chamber, a secondary air supply tube consistent with the spiral direction of the cyclone dust removal burner is arranged in the upper burning chamber, the cyclone dust removal burner consists of a concave barrel and S-shaped helical blades arranged outside the concave barrel, the head ends and the tail ends of the S-shaped helical blades are connected at intervals, and the helical angles of the S-shaped helical blades are 15-30 degrees. The biomass cyclone dust removal burner can keep dust particles formed after burning in the upper burning chamber and further enhances the wall-attaching dust collection effect under the centrifugal action, so that the burning effect, the dust removal performance and the fire purity of the burner are remarkably improved, the dust emission concentration is less than or equal to 5 mg / m<3>, the fume blackness reaches Ringelmann 0 grade, dust larger than 30 micrometers cannot overflow, a smoke-free and dust-free effect can be basically achieved, and the specifications of the biomass cyclone dust removal burner are higher than those of like products in the prior art.

Owner:郭征旭 +1

High-heat-resistance high-rigidity environmentally-friendly polystyrene resin composition and preparation method thereof

The invention discloses a high-heat-resistance high-rigidity environmentally-friendly polystyrene resin composition and a preparation method thereof. The polystyrene resin composition contains the following components in percentage by weight: 59-99 percent of polystyrene resin, 0.5-30 percent of SMA (Styrene-Maleic Anhydride) resin, 0-10 percent of stripping agent master batch and 0.01-1 percent of antioxidant, wherein the stripping agent master batch consists of a matrix and a stripping agent. The preparation method has the advantages of simple production process, reduced production cost and capabilities of effectively improving heat resistance and rigidity of polystyrene resin without reducing mechanical property thereof and meanwhile reducing smell and VOC (Volatile Organic Compound) content of the polystyrene resin; and the prepared polystyrene resin composition can be used in the fields of materials with strict requirements on heat resistance and environmental friendliness in packaging materials, daily articles, household appliances, OA (Office Automation), toys, electronic parts and components and equipment, building materials and automobile materials.

Owner:WUHAN JINFA TECH CO LTD

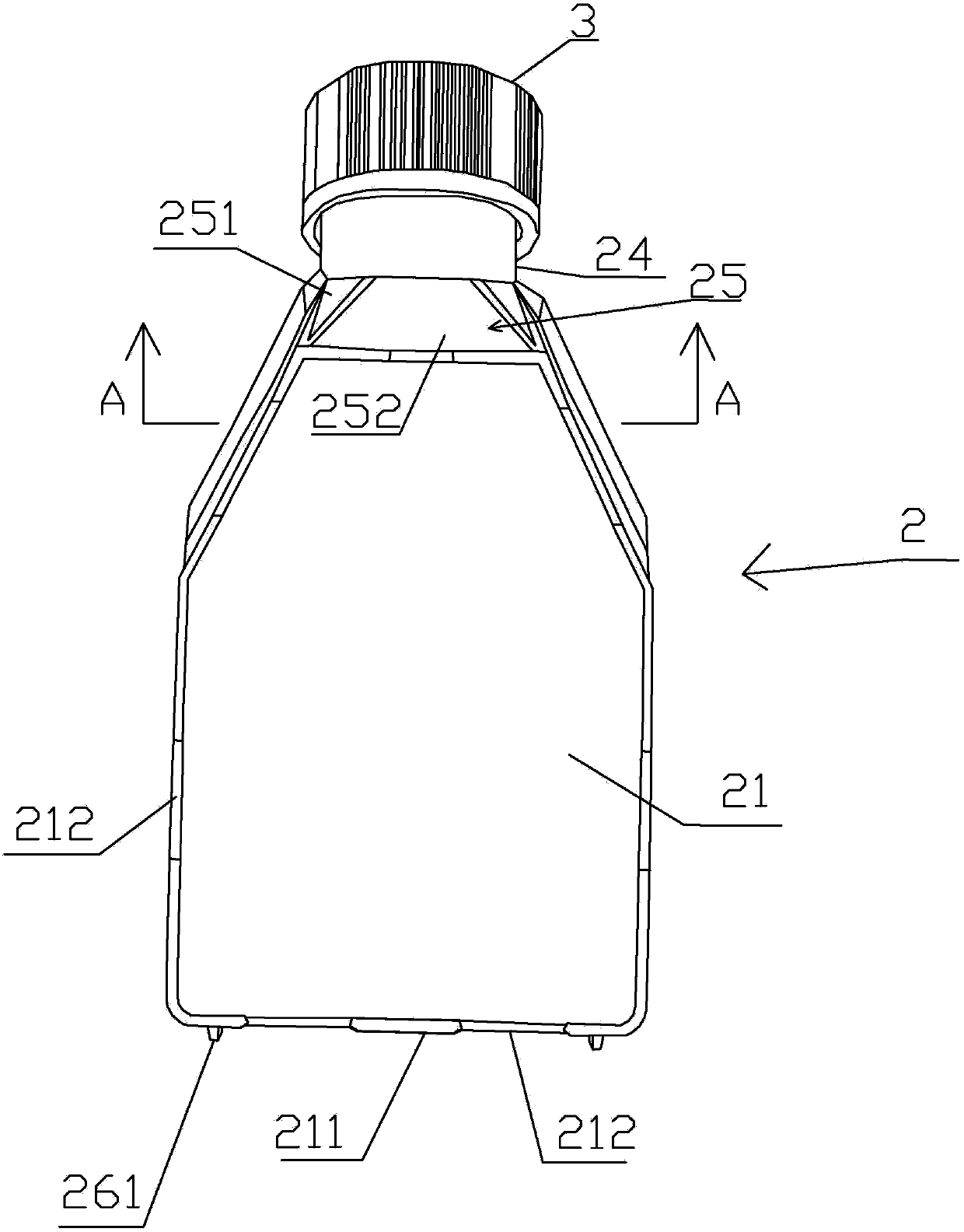

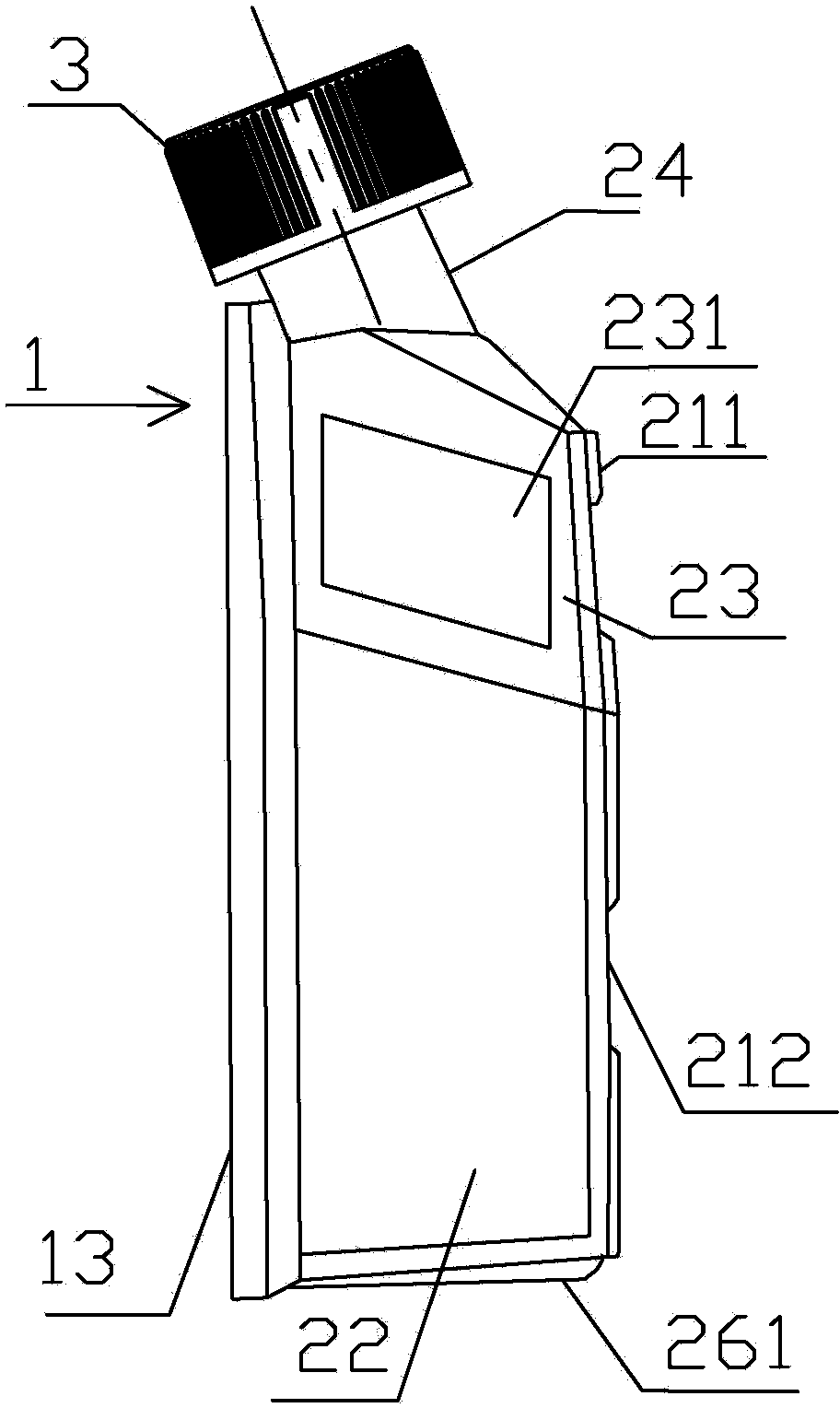

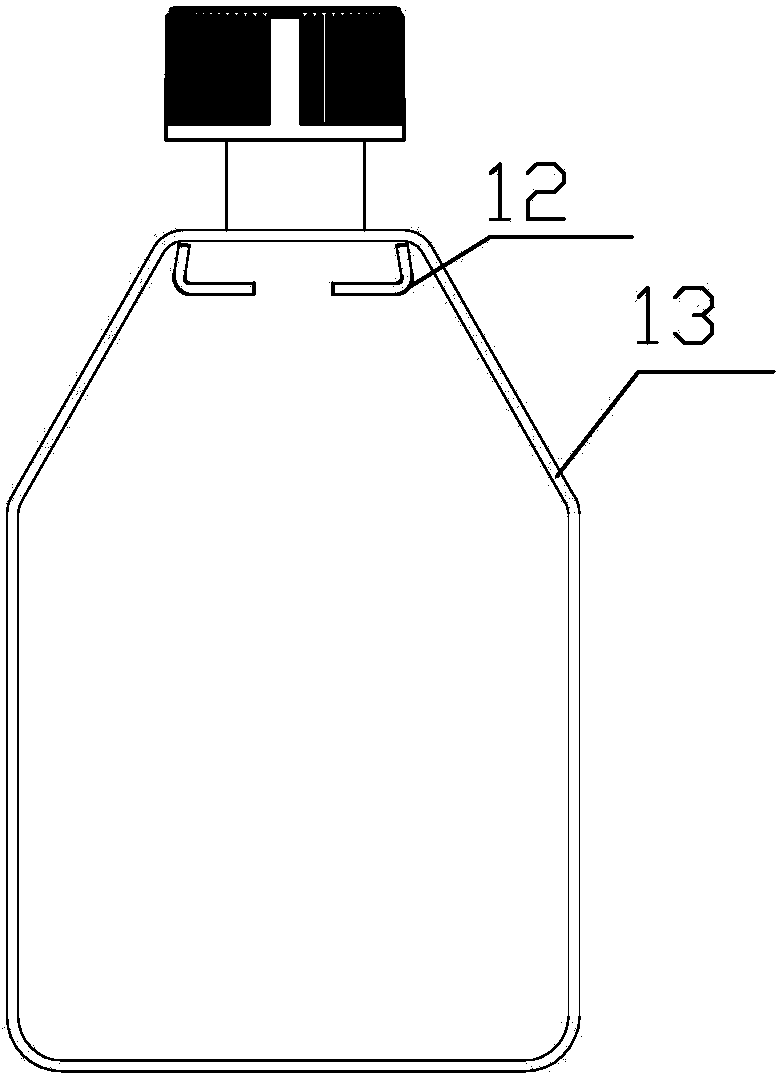

Cell culture bottle

InactiveCN103436441ASave spaceEasy to manageBioreactor/fermenter combinationsBiological substance pretreatmentsCell extractionPipette

The invention discloses a cell culture bottle. A clamping edge of a front panel of the cell culture bottle can be clamped and positioned between a clamping groove and a flanged edge of a back panel of another cell culture bottle; and thus, a plurality of culture bottles can be stored and moved in a piling mode, thereby saving the space of an incubator and facilitating the management. The joint of the cell culture bottle comprises two triangular plates and a trapezoidal plate, and the included angle formed by the trapezoidal plate and the front panel is 130 degrees; the lower side panel, bottom panel and upper side panel tilt towards the inner side of the bottle body, the bottleneck tilts towards the back panel, and a certain inclination angle is set; and when the cell culture bottle is arranged flatly, a pipette or cell scraper can touch all positions of the culture bottom surface, thereby facilitating the collection of cells, and preventing the culture bottle from generating dead area where cells can not be easily extracted. The invention solves the following problems: the plurality of cell culture bottles can not be easily managed and stored, the cell culture bottle generally has difficulty in cell extraction, and dead extraction areas can be easily generated.

Owner:ZHEJIANG SORFA MEDICAL PLASTIC

Cigarette filter rod with zeolite fragrance beads and cigarette zeolite fragrance bead preparation method

The invention discloses a cigarette filter rod with zeolite fragrance beads and a cigarette zeolite fragrance bead preparation method. The cigarette filter rod comprises the zeolite fragrance beads, the zeolite fragrance beads take zeolite as a carrier, adsorb essence suitable for cigarette and are provided with open adsorption holes, and the adsorption holes adsorb the essence. According to the cigarette filter rod, the zeolite fragrance beads serve as solid fragrance beads and are used in cigarette filter rod, zeolite has open adsorption holes and high adsorption capacity, fragrant substances can be stably released when cigarettes are smoked after densely covered adsorption holes of the zeolite adsorb the essence, and stable fragrance can be acquired when the cigarettes are smoked.

Owner:SHANGHAI JUHUA TECH

Cigarette filter rod containing aromatic silica gel beads and preparation method of aromatic silica gel beads for cigarettes

InactiveCN107836749AStrong adsorption performanceImprove stabilityTobacco smoke filtersCigarette filterSilica gel

Owner:SHANGHAI JUHUA TECH

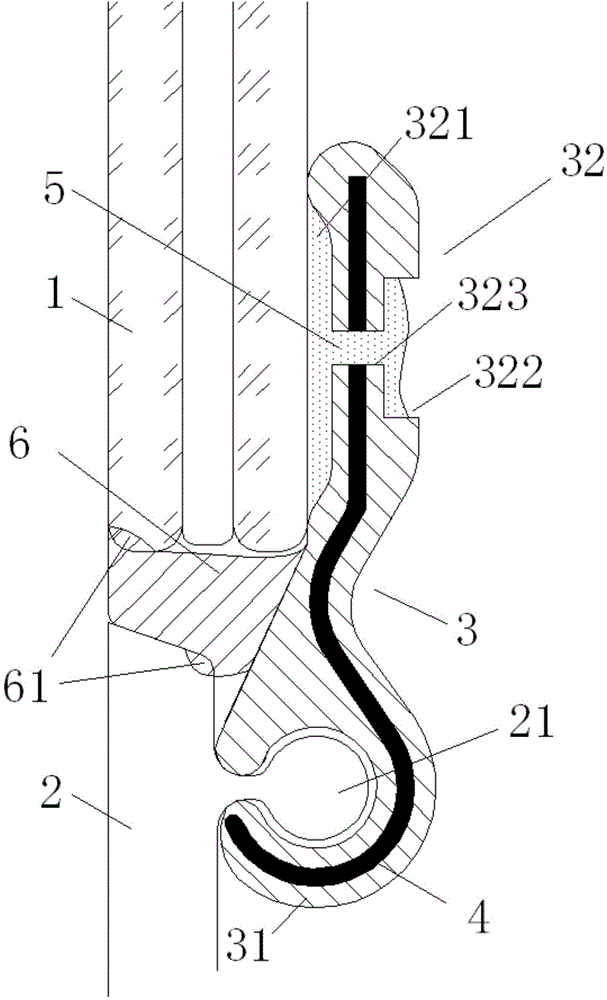

Sealing system of vehicle window glass

InactiveCN104085282AUniform bondingHigh bonding strengthEngine sealsVehicle sealing arrangementsEngineeringWindshield

The invention relates to a sealing system, in particular to a sealing system of vehicle window glass. The sealing system of the vehicle window glass is used for connecting a windshield with a water tank cap. The sealing system of the vehicle window glass comprises the windshield, the water tank cap, a hook-shaped sealing piece and a sealing lip, wherein the cross section of the hook-shaped sealing piece is in a hook shape. The hook-shaped sealing piece comprises a maintaining portion and an elastic arm. The outer side of the maintaining portion adheres to the inner side of the windshield. The elastic arm is tightly buckled with a rib of the water tank cover in a sealed mode. The sealing lip is tightly arranged between the lower edge of the windshield and the upper edge of the water tank cap in a matched mode and is flush with the outer surface of the windshield and the outer surface of the water tank cap. The sealing system of the vehicle window glass is characterized in that a glue containing groove used for containing an adhesive or a self-adhesive tape is formed in the outer side of the maintaining portion, a glue storage groove is formed in the maintaining portion, and at least one row of through holes which are longitudinally arranged along the maintaining portion are formed between the glue containing groove and the glue storage groove. The sealing system of the vehicle window glass has the advantages that the adhesive strength is improved, and the production cost is reduced.

Owner:FUYAO GLASS IND GROUP CO LTD

Radio-frequency vertical transformation circuit based on fuzz button

InactiveCN104733824AImprove reliabilityRealize three-dimensional vertical interconnectionCoupling devicesRadio frequency signalEngineering

The invention provides a radio-frequency vertical transformation circuit based on a fuzz button. The radio-frequency vertical transformation circuit comprises circuit wafers, a metal structure piece and a similar coaxial connector. The circuit wafers include the upper circuit wafer and the lower circuit wafer which are arranged at the upper end and the lower end of the metal structure piece respectively, are in electrical contact with the upper end and the lower end of the metal structure piece respectively and are the same in structure, and inputting and outputting of radio frequency signals are achieved. The similar coaxial connector is embedded into the metal structure piece, and the upper circuit wafer is in vertical circuit connection with the lower circuit wafer. The similar coaxial connector comprises an outer ring insulating layer and an internal vertical connecting circuit. The internal vertical connecting circuit comprises a fuzz button end and a fixed cap end which are electrically connected. Compared with the prior art, the radio-frequency vertical transformation circuit is simple in structure, excellent in performance, high in reliability and convenient to install; the structural mode of being matched with the fixed cap end is adopted to the similar coaxial connector based on the fuzz button, it can be guaranteed that the fuzz button can not be pressed to overflow at the fixed cap end, and therefore the reliability of the whole vertical transformation circuit is improved.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

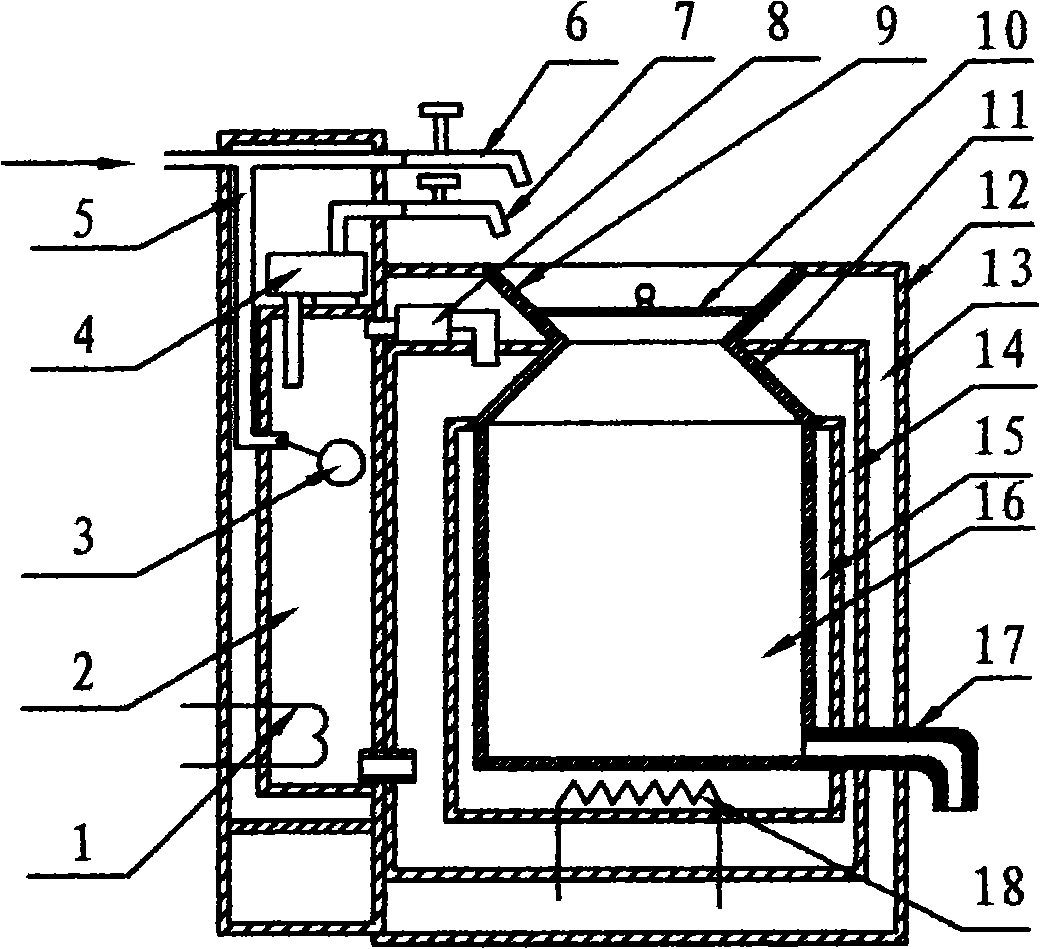

Congee cooking device

InactiveCN101862112AFast heat transferImprove cooking efficiencyStorage heatersCooking vesselsProcess engineeringEngineering

The invention relates to a congee cooking device, which comprises a congee cooking device body, a boiling water tank, a shell panel and a circuit control device. The pot opening of the congee cooking device body adopts a conical opening structure, so that the phenomenon of boiling overflow in the process of boiling the congee is avoided and the full-automatic congee cooking is realized. The congee cooking device body is provided with a heat exchange water sandwich layer which is communicated with the boiling water tank; the heat exchange water and water stored in the boiling water tank perform circular heating after the cooking of food is finished and the power is turned off, and the stored water in the boiling water tank is heated into boiling water by high temperature waste heat of a heat-conducting medium. The congee cooking device solves the problems that in the conventional congee cooking, a sandwich pot is manually operated, the efficiency is low, and the potential safety hazard exists. The congee cooking device fully realizes full-automatic cooking of the food, particularly cooking of congee and other foods, also can cook soup, stew fowl and the like, and has multiple purposes. The congee cooking device realizes congee cooking automation, reduces the operation cost, provides free boiling water by using the waste heat simultaneously, and is low-carbon, energy-saving and environment-friendly.

Owner:蔡钟坤

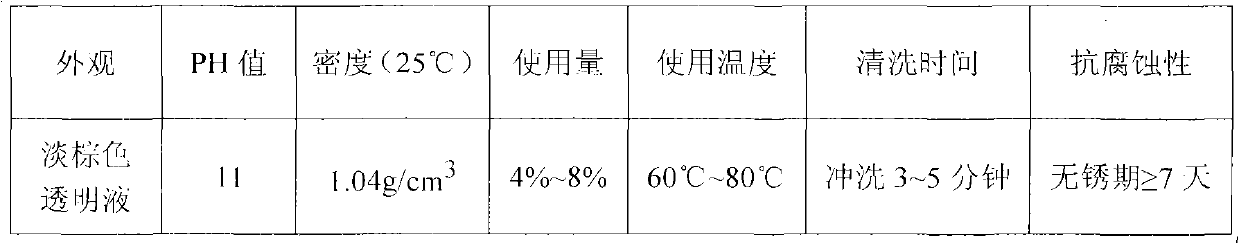

Efficient multipurpose metal cleaning agent

The invention discloses an efficient multipurpose metal cleaning agent, which is prepared from alkylphenol polyoxyethylene, fatty alcohol-polyoxyethylene ether, alkylolamide, oleic acid, triethanolamine, ethylene glycol monobutyl ether, anhydrous sodium metasilicate, sodium metaborate, sodium molybdate, organic silicon defoamer and water according to certain percentage by weight. The cleaning agent has quick oil removing and stain removing speed, and the cleaned surface has better corrosion inhibition capability, thus the cleaning agent is a low-foaming and basically non-toxic green product. When the aqueous solution, for which the working temperature is 60-80 DEG C and the dosage of the cleaning agent is 5%, is used for washing a steel piece for 3-5 minutes, the surface of the steel piece is clean, and the rust-free cycle of the steel piece is not less than 7 days.

Owner:郭良生 +1

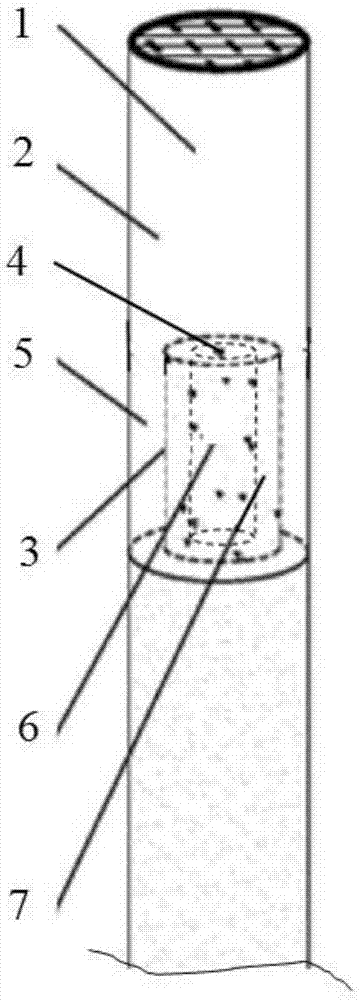

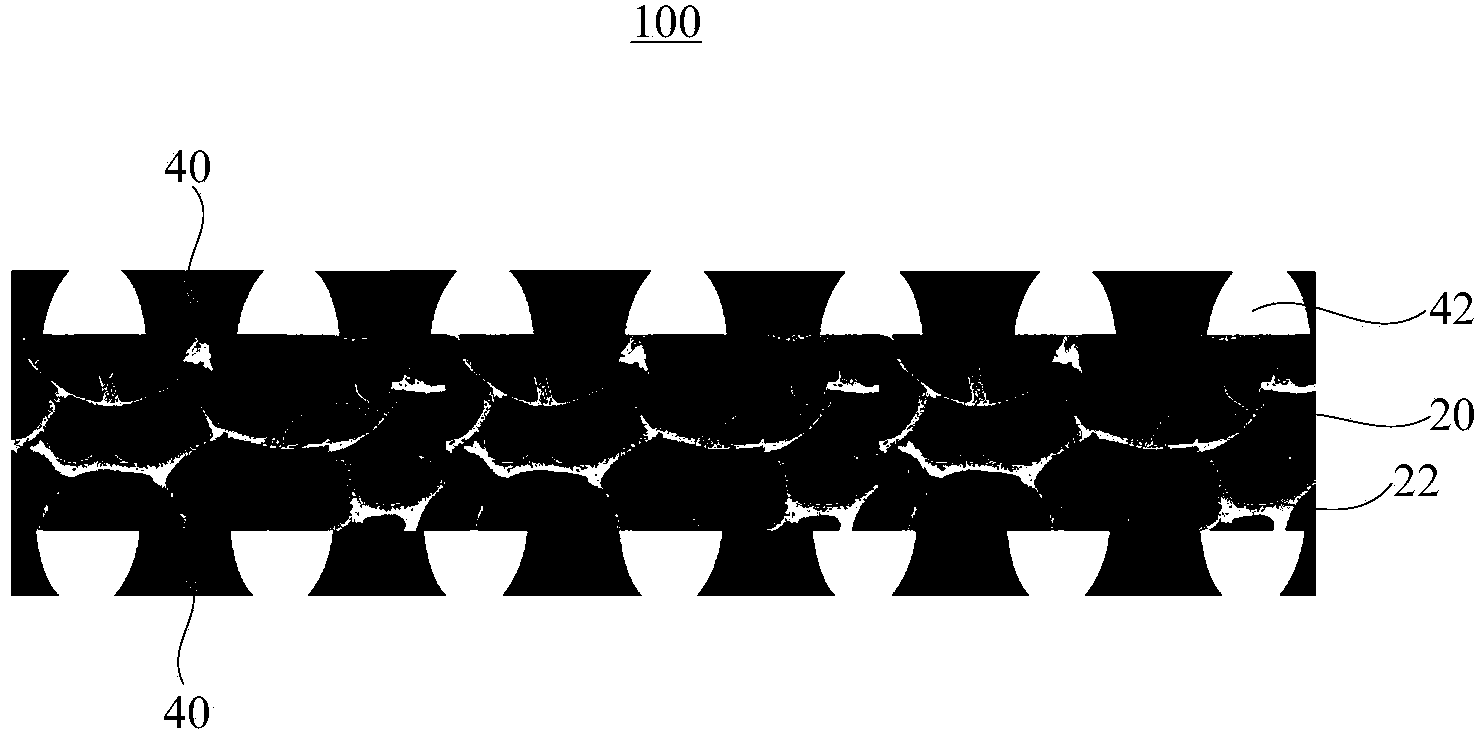

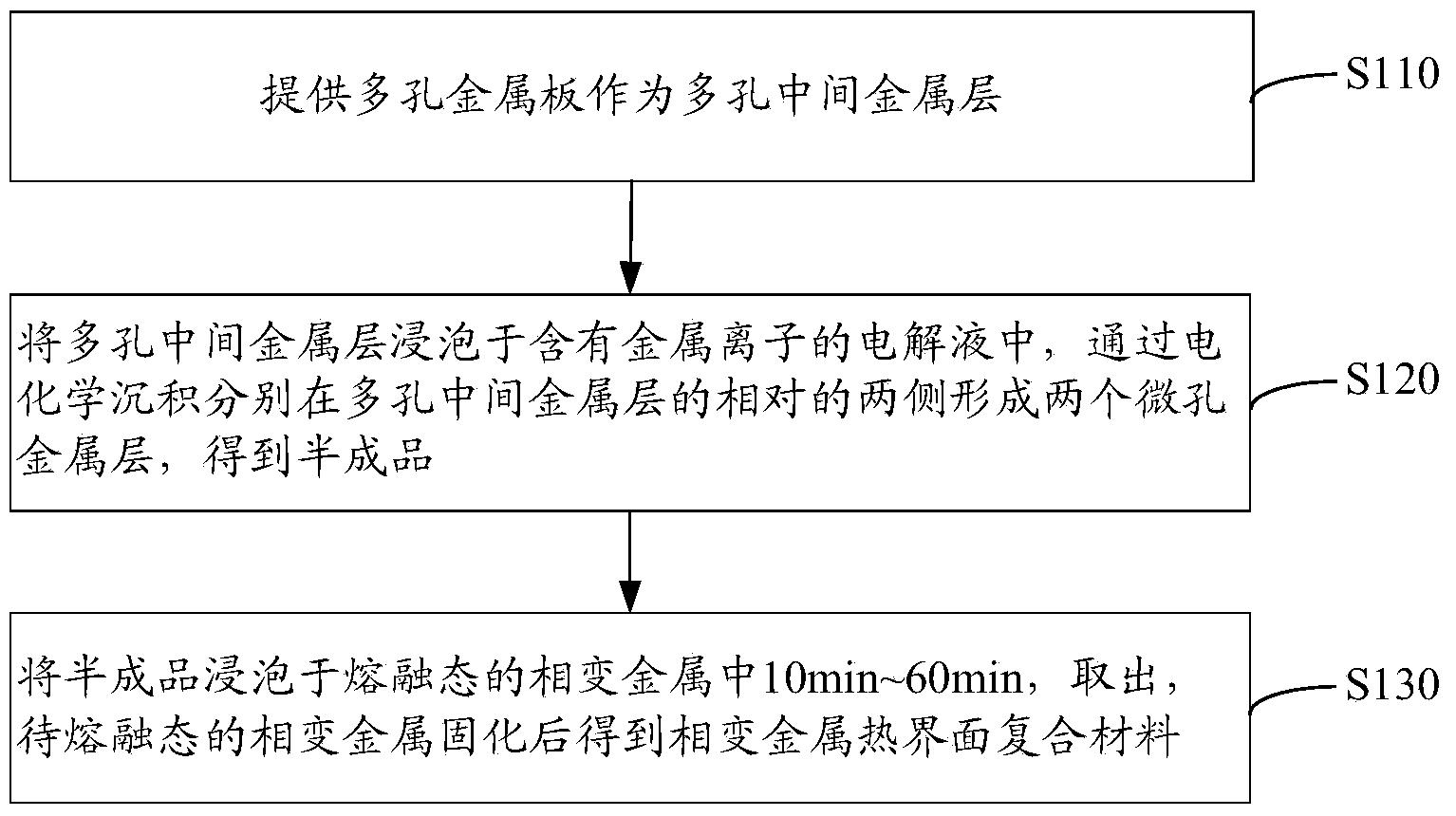

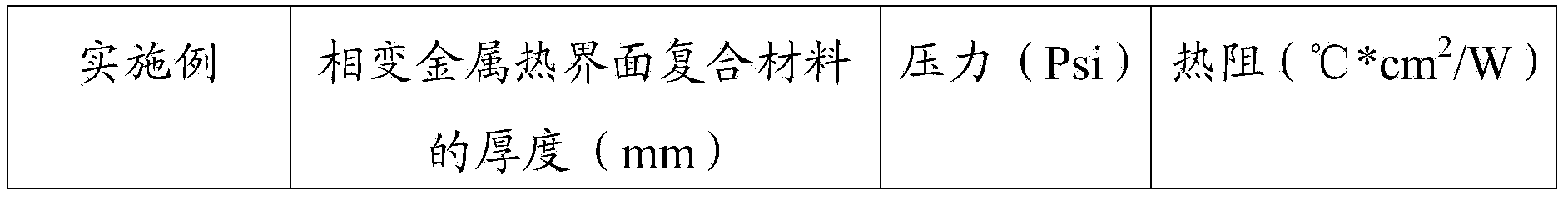

Phase-change metal thermal interface composite material and preparation method thereof

ActiveCN103862742AWon't overflowSuppress overflowSemiconductor/solid-state device detailsSolid-state devicesMolten statePhase change

The invention relates to a phase-change metal thermal interface composite material and a preparation method thereof. The phase-change metal thermal interface composite material comprises a porous middle metal layer, two microporous metal layers respectively arranged at two opposite sides of the porous metal layer, and phase-change metal, wherein the the porous middle metal layer and the two microporous metal layers are filled with the phase-change metal. The composite material has the advantages that the porous middle metal layer serving as a structure supporting layer can bear certain pressure to ensure that the phase-change metal in a molten state cannot be extruded and overflown and the phase-change metal can run through up and down to ensure that the phase-change metal thermal interface composite material has the low thermal resistance and the high heat-conducting property; the phase-change metal can be effectively prevented from being overflown by adopting the two microporous metal layers, after being molten and expanded, the phase-change metal can be oozed from micropores of the microporous metal layers to effectively fill up gaps in the composite material and no hole occurs in the using process.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

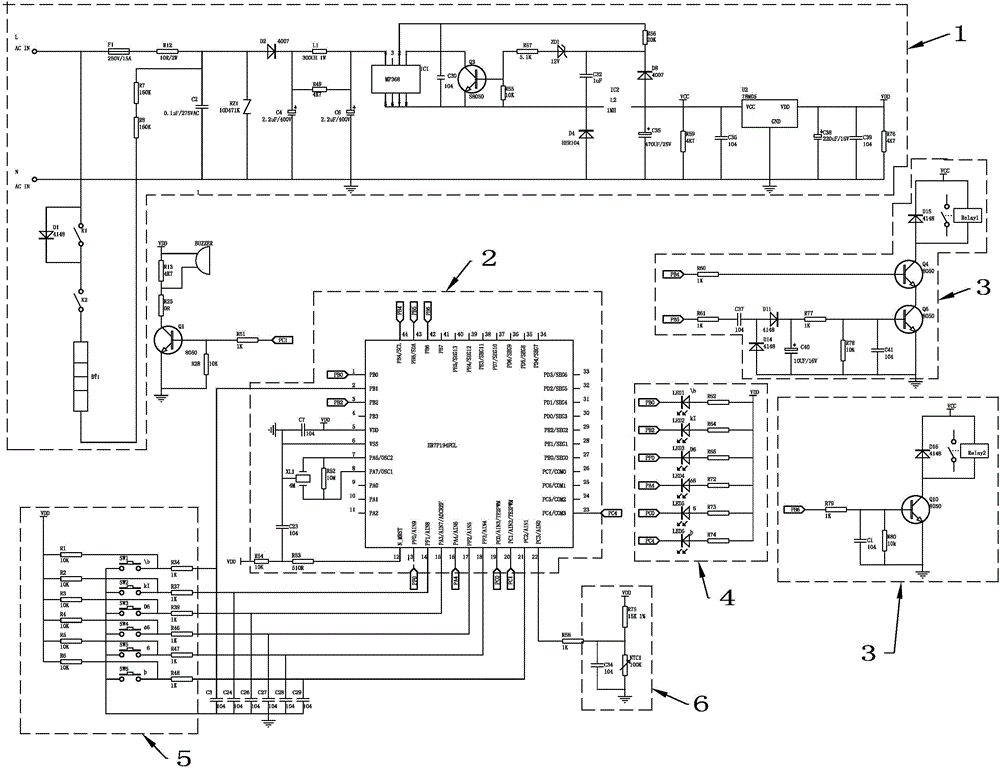

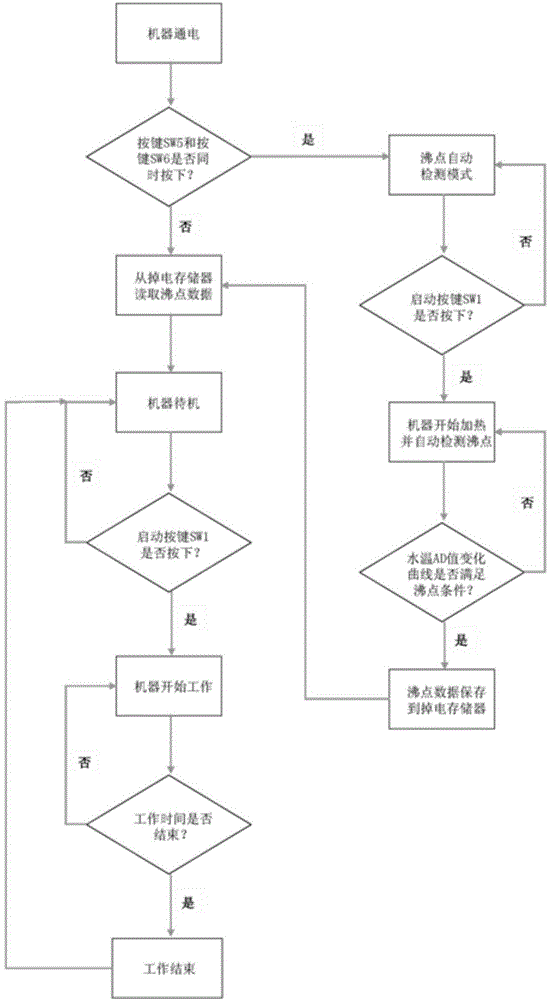

Intelligent circuit of kitchen appliance and method for identifying boiling temperature therefrom

InactiveCN104597944APrevent overflowAvoid placing food cooked in kitchen appliances from spillingTemperatue controlElectricityNegative temperature

The invention discloses an intelligent circuit for automatically identifying the boiling temperature of water at the altitude where a kitchen appliance locates and a method for identifying the boiling temperature. The intelligent circuit includes a power source module, a single chip control module, a heating relay drive module, and an LED (light-emitting diode) lamp drive module, wherein it further includes a key module, a NTC (negative temperature coefficient) temperature detecting module and a power failure memory. The kitchen appliance adopting the intelligent circuit is able to exactly detect the boiling temperature of water at the zone where the kitchen appliance locates and automatically store the boiling temperature in an electrical storage regardless of any altitude; thus when the kitchen appliance with the intelligent circuit is used every time in future, the circuit can immediately close a heating device of the kitchen appliance when the temperature of the food cooked in the kitchen appliance reaches the boiling temperature. Therefore, the intelligent circuit can prevent food cooked in the kitchen appliance from overflowing for excessive heating.

Owner:SHENZHEN BUYDEEM TECH CO

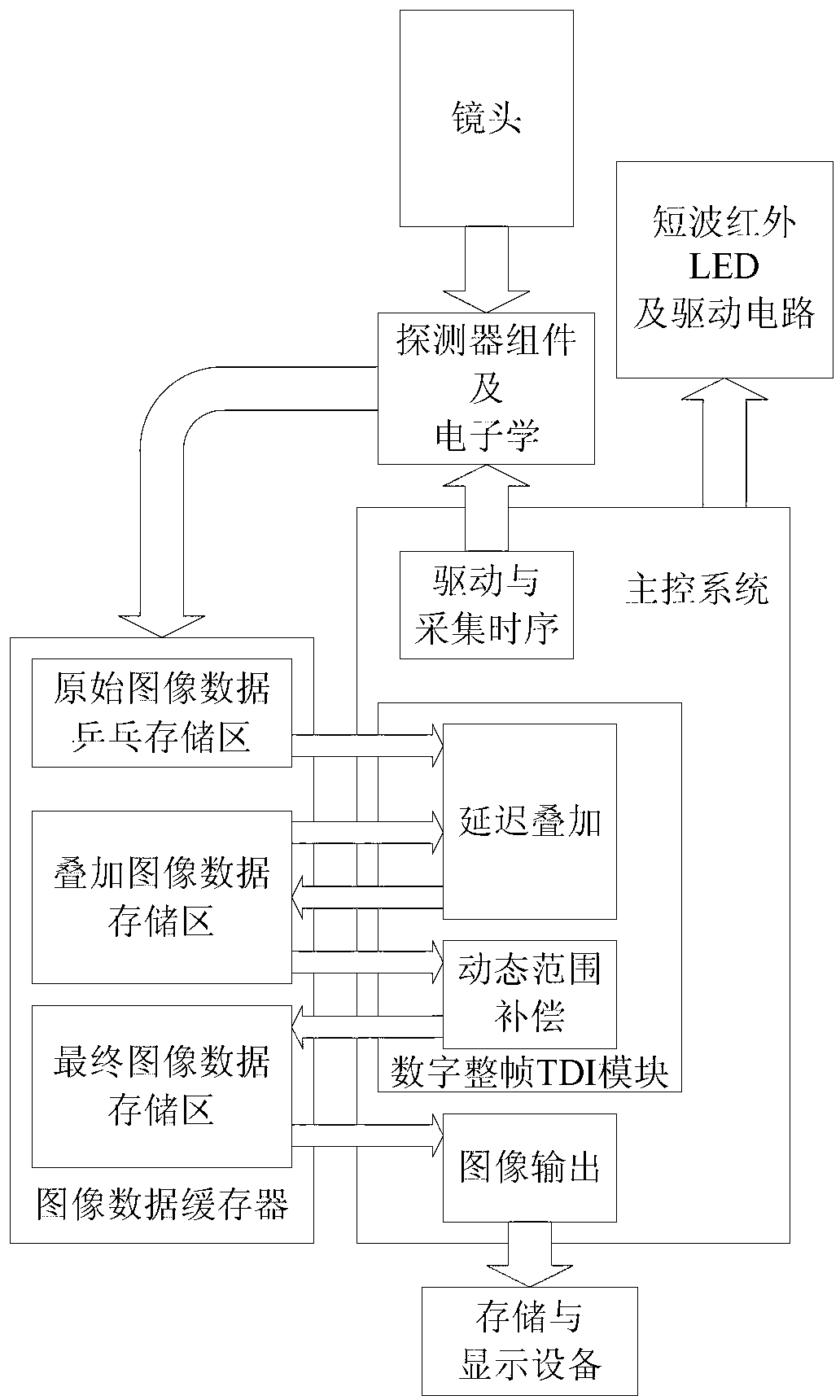

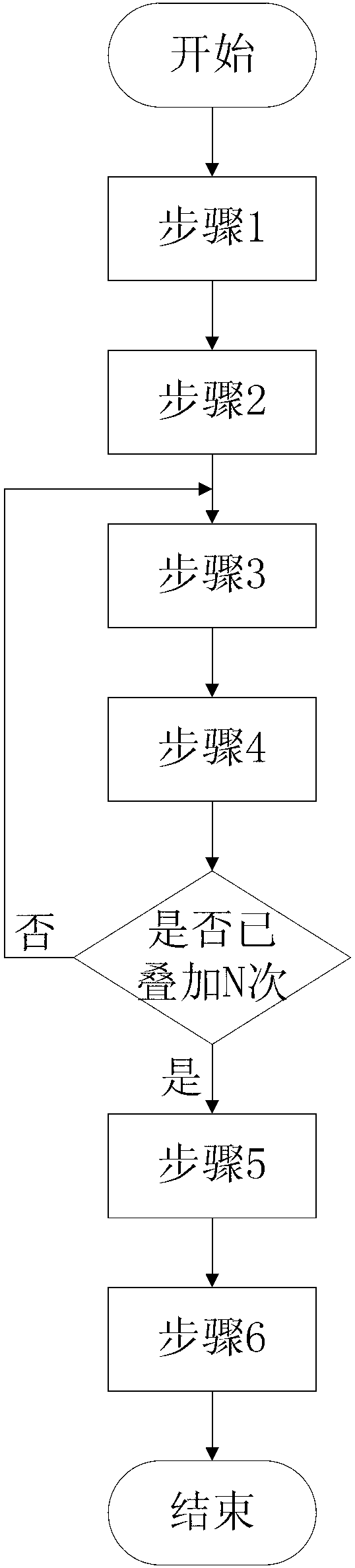

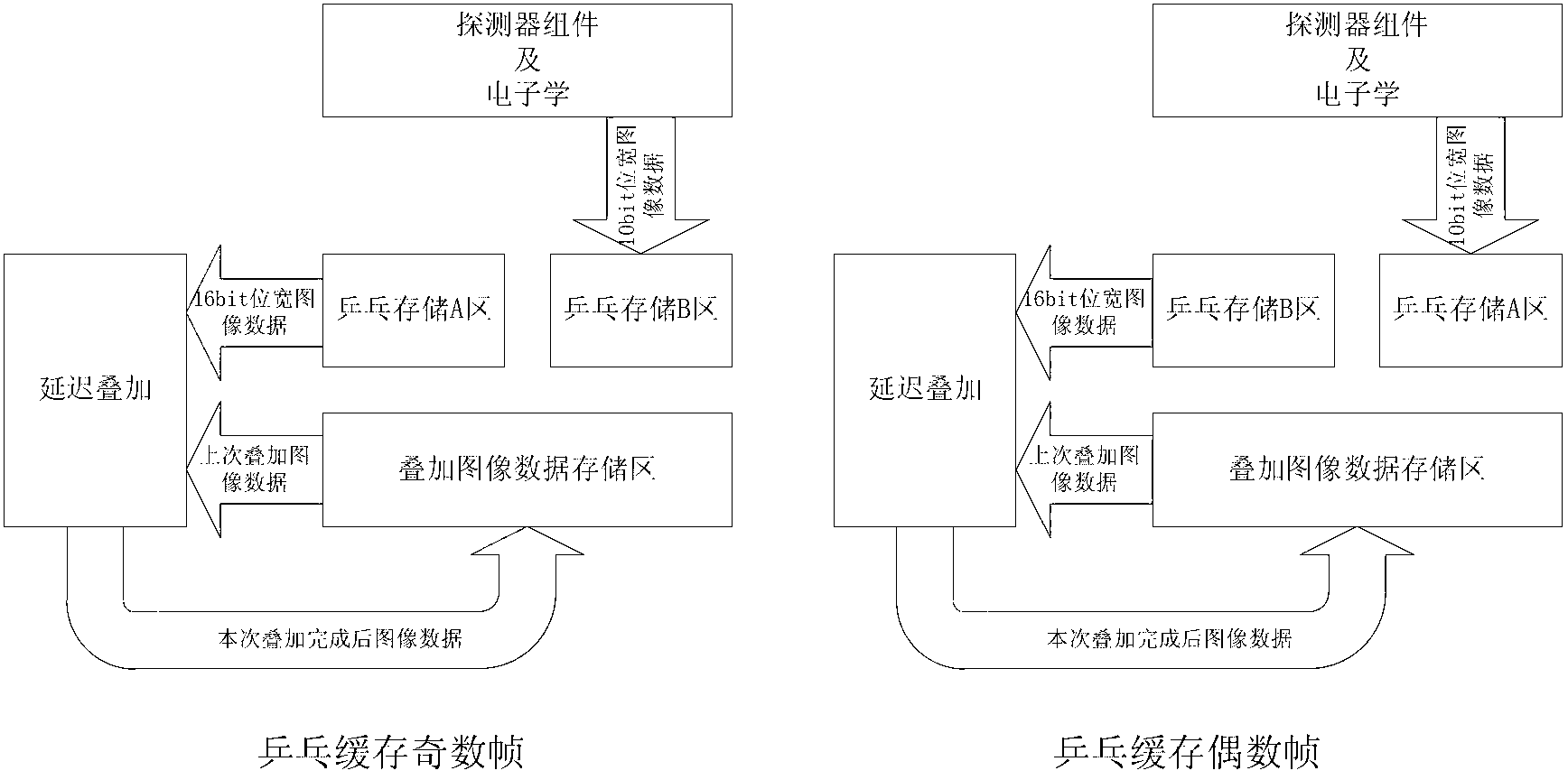

Gazing type digital trandport driver interface (TDI) short wave infrared glimmering imager and imaging method

ActiveCN103024299AWill not saturateWon't overflowTelevision system detailsColor television detailsCamera lensFrame time

The invention discloses a gazing type digital trandport driver interface (TDI) short wave infrared glimmering imager and an imaging method. The imager comprises a short wave infrared camera lens, a short wave infrared light-emitting diode (LED) lamp, a detector assembly and a driving acquisition circuit, an image data buffer, a master control system with a digital whole-frame TDI module and a storing and displaying device. The digital whole-frame TDI module performs whole-frame time delay integral computation on image data output by a detector on a digital domain in real time. Night monitoring of a foundation platform is mostly simple and reliable gazing imaging, so that signal to noise ratio cannot be improved by adopting the existing alignment scanning TDI technology. The digital whole-frame TDI technology is suitable for gazing imaging, can achieve high TDI levels, remarkably improves glimmering imaging quality, and can flexibly adjust dynamic range of images. The gazing type digital TDI short wave infrared glimmering imager and the imaging method are suitable for night security and protection monitoring requiring certain concealment and vehicle-mounted or handheld night patrol application of dangerous areas.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

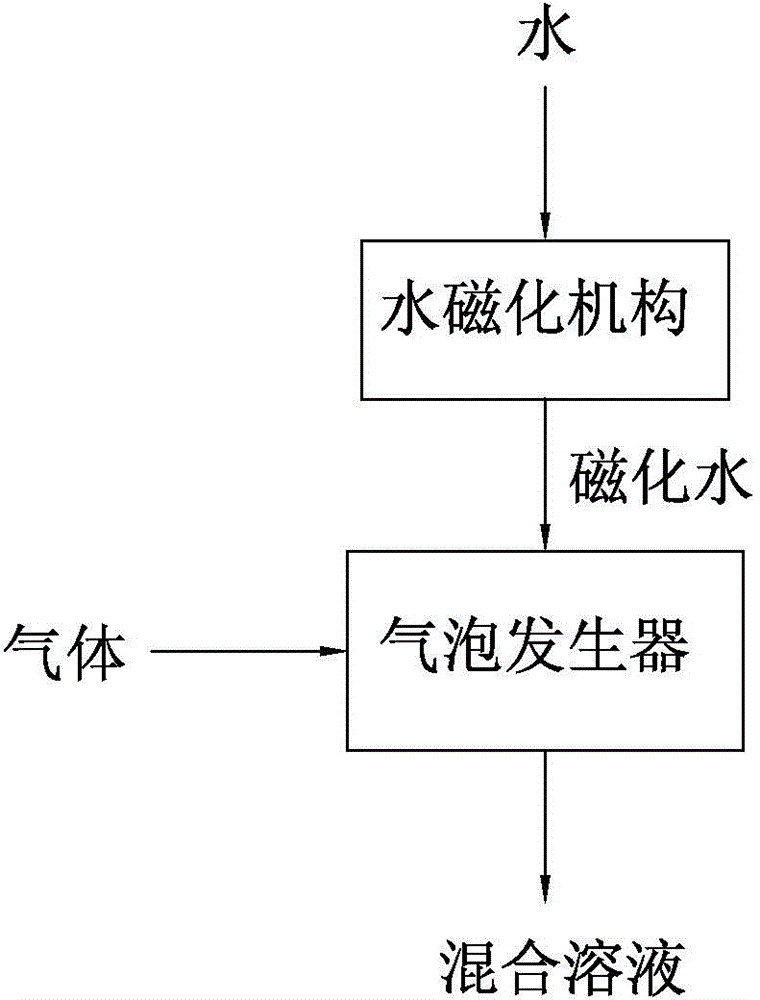

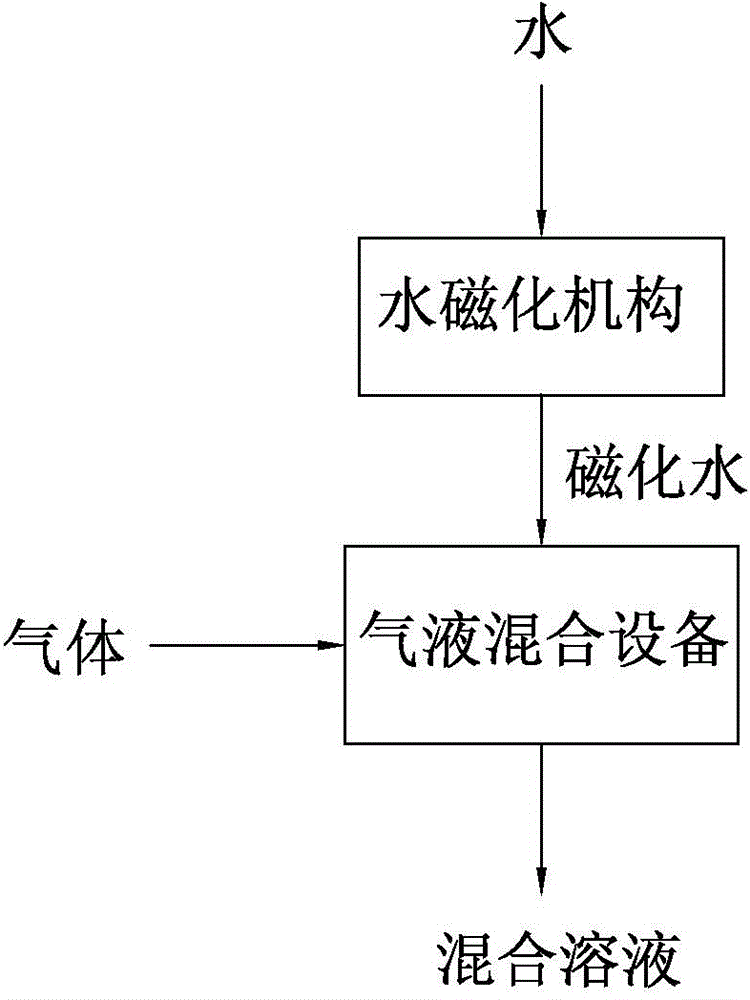

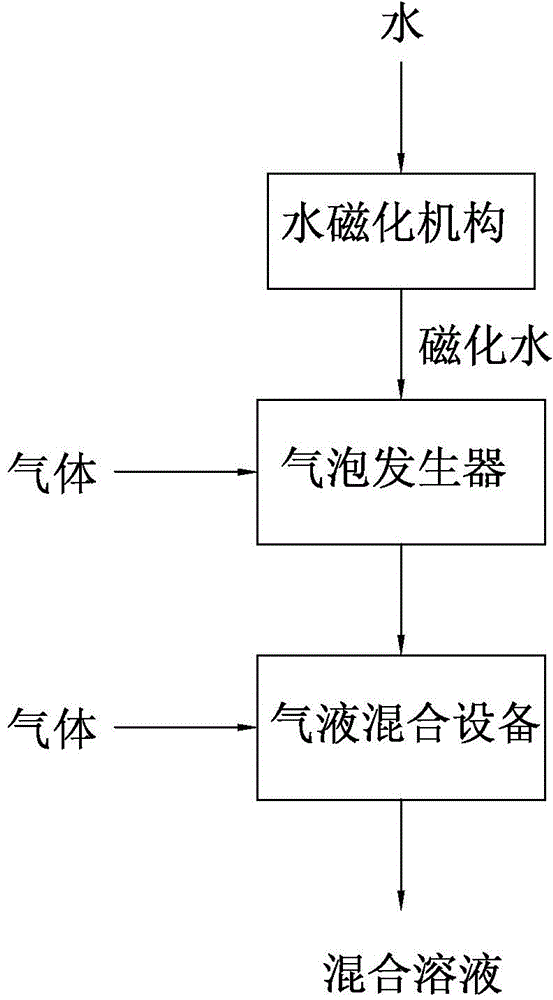

Gas-liquid mixing system and gas-liquid mixing method

InactiveCN104624070AImprove dissolution rateAvoid overflow situationsTransportation and packagingWater/sewage treatment by magnetic/electric fieldsMagnetizationEngineering

The invention relates to a gas-liquid mixing system and a gas-liquid mixing method. The gas-liquid mixing system comprises a water magnetizing mechanism and a gas-liquid mixing mechanism, wherein a water inlet of the gas-liquid mixing mechanism is connected to the output end of the water magnetizing mechanism. The gas-liquid mixing method comprises the following steps: after water is magnetized, feeding gas and the magnetized water into the gas-liquid mixing mechanism according to a given ratio so as to mix a gas and a liquid. The magnetization of water is realized by virtue of the water magnetizing mechanism which is installed on the front end of the gas-liquid mixing mechanism, and the molecular structure of the magnetized water is changed, so that the dissolving rate of the gas in the magnetized water is greatly improved, the dissolving rate of ozone gas in the magnetized water is 2 to 3 times of that in the non-magnetized water, and thus the gas-liquid mixing effect realized by micro bubbles formed in a high-speed swiveling manner after the magnetized water enters the gas-liquid mixing mechanism can be greatly improved, the situation that large bubbles overflow can be effectively avoided, and the dissolving rate of the gas can be effectively improved at an optimum water temperature.

Owner:于小波 +1

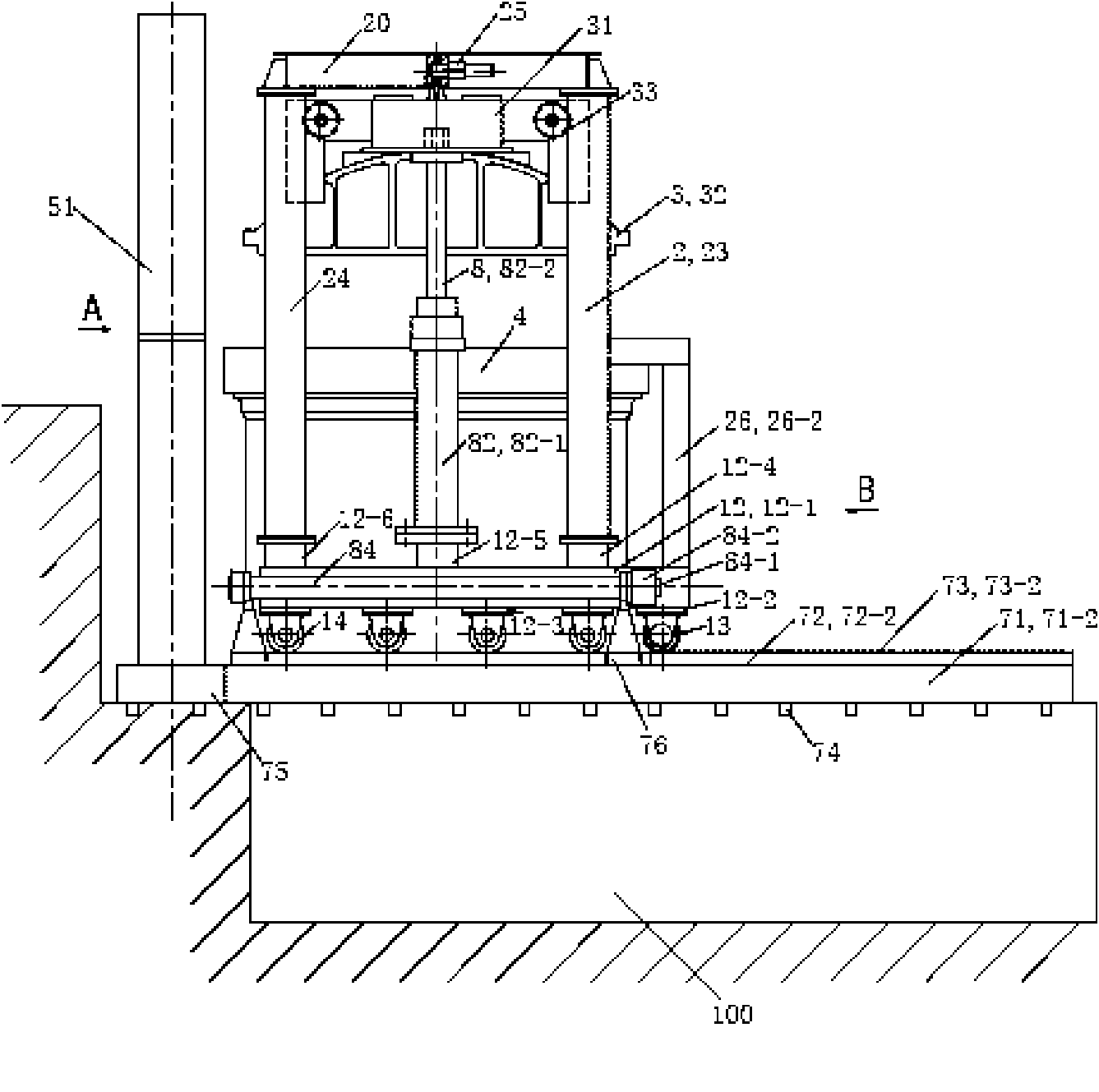

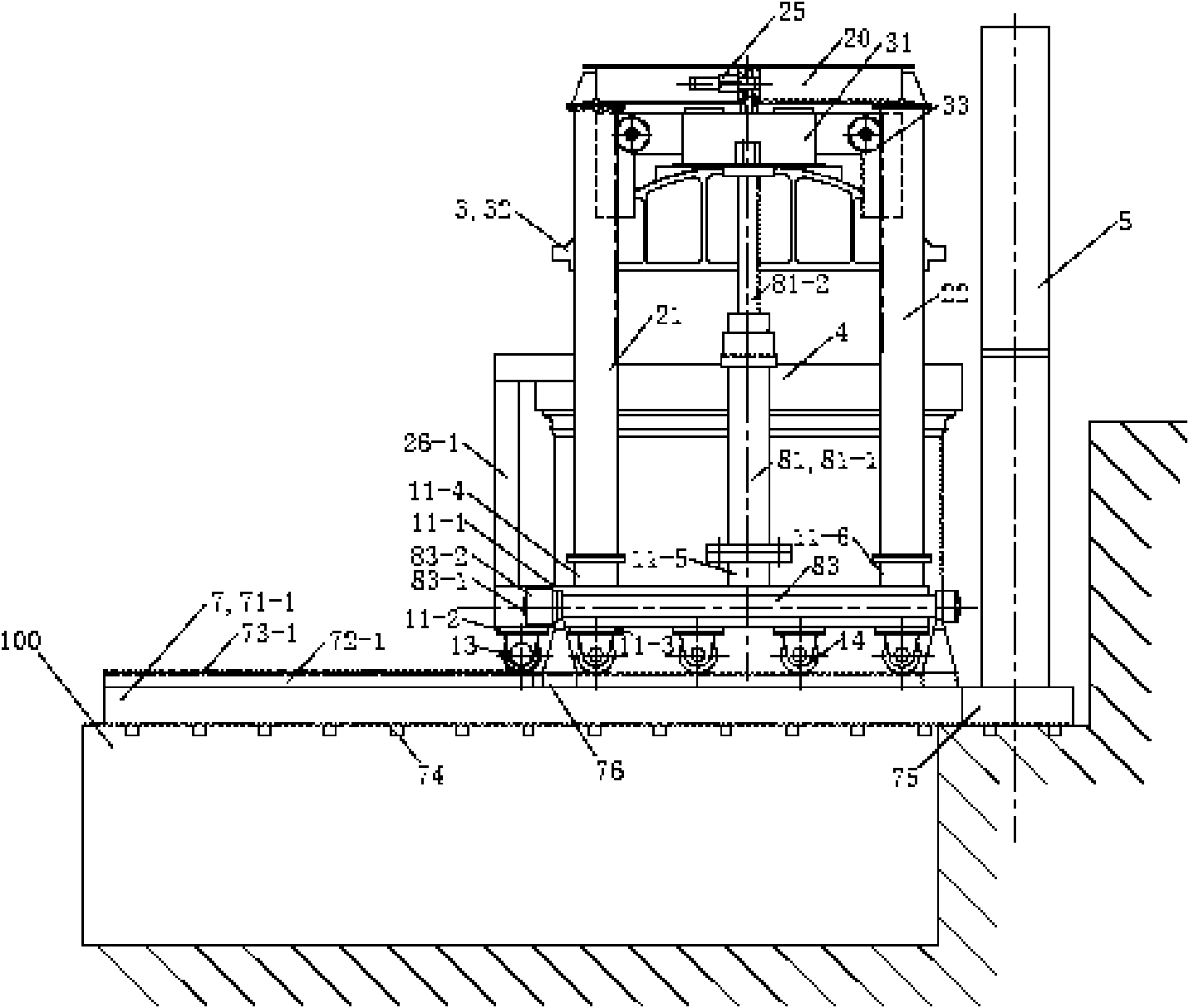

Translational vulcanizer

The present invention relates to a translational vulcanizer, including a translational mechanism, a translational frame, an upper vulcanizing chamber, a lower vulcanizing chamber, a device for assembling and disassembling a tyre, a radial parting mould, a stand body, a second stand, a switching mould oil cylinder and a translational oil cylinder. The translational frame and the switching mould oil cylinder are arranged on the translational mechanism, the upper vulcanizing chamber is arranged on a piston rod of the switching mould oil cylinder, the lower vulcanizing chamber is arranged on the stand body, and the device for assembling and disassembling the tyre is arranged on the second stand. The radial parting mould is divided into an upper mould and a lower mould, the lower mould is arranged in the lower vulcanizing chamber, and the upper mould is fixed below the upper vulcanizing chamber. Left and right supports of the translational mechanism are provided with three to five wheeled kinematic mechanisms locating below the support separately, and each wheeled kinematic mechanism is arranged on a wheeled guide rail fixed on the supports locating on the right and left sides of a stand component. the vulcanizer is used for vulcanizing a giant engineering tyre, has a stable and smooth operation by employing the wheeled kinematic mechanism, is not easy to break a movable member, reduces the cost and time for maintenance, and has a long service life.

Owner:江苏华瑞重工机械有限公司

Pixel defining structure, manufacturing method for same, display panel and display apparatus

InactiveCN105404038AIncreased deposition areaWon't overflowSolid-state devicesNon-linear opticsComputer scienceHigh definition

Owner:TCL CORPORATION

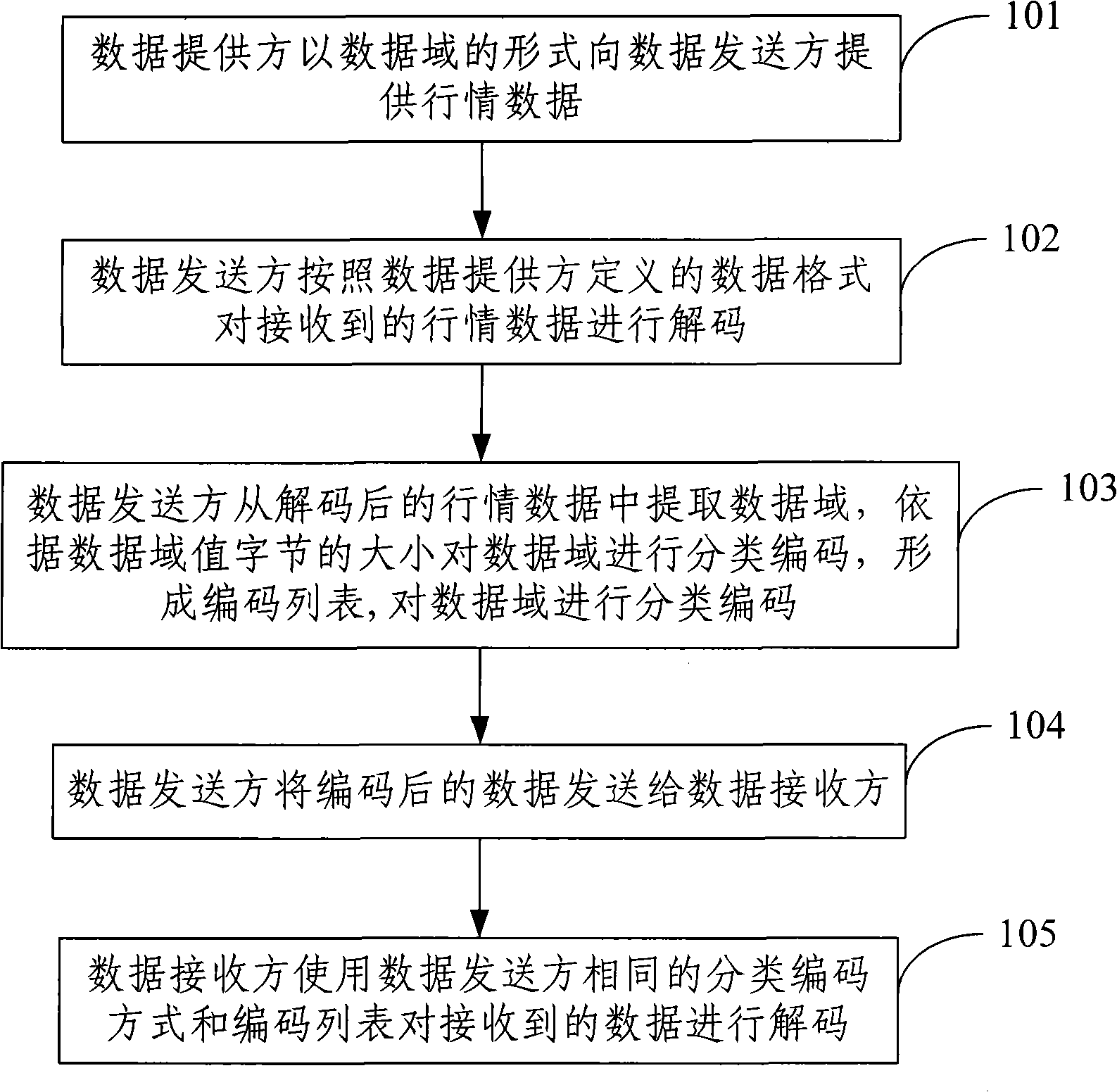

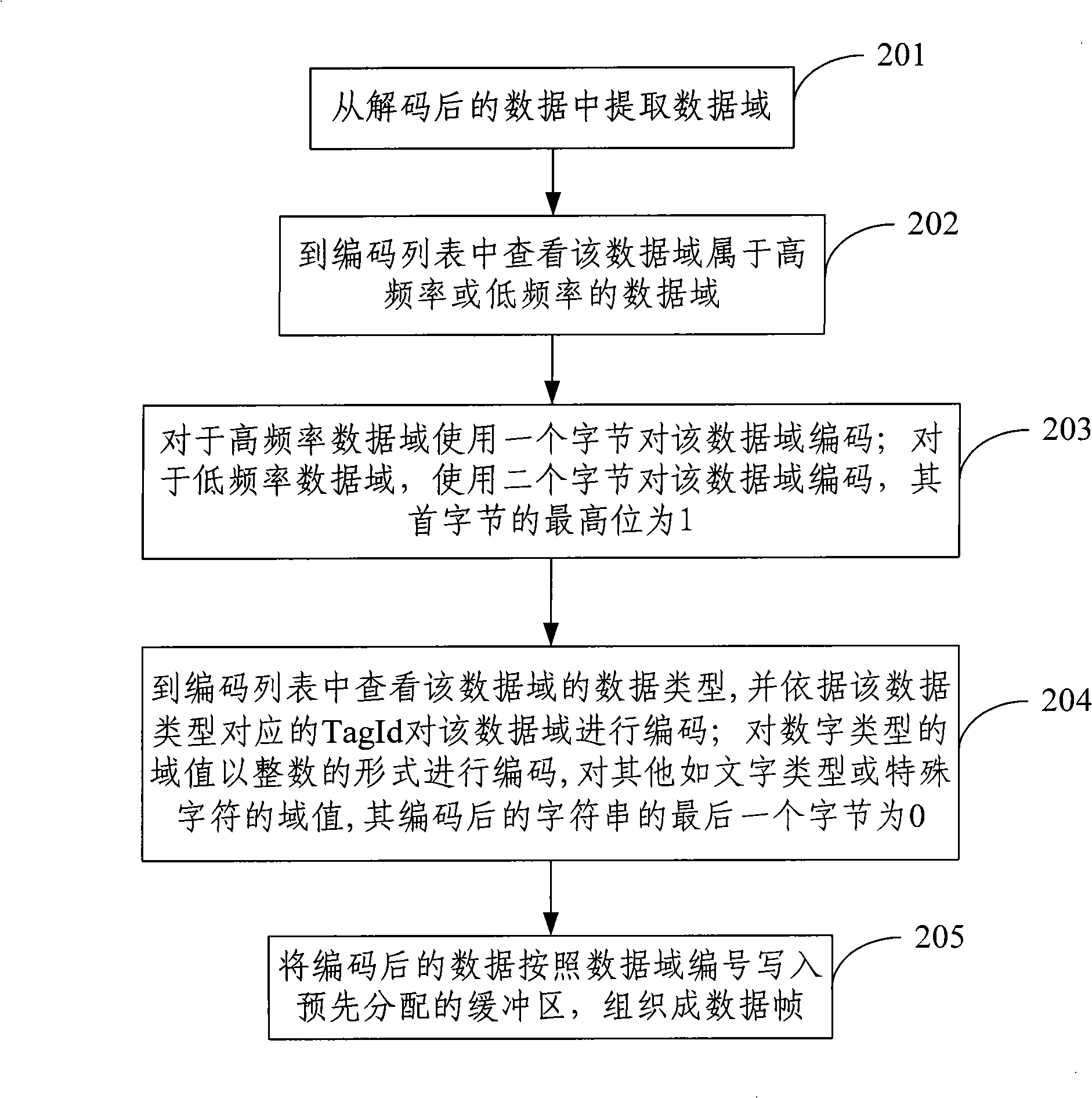

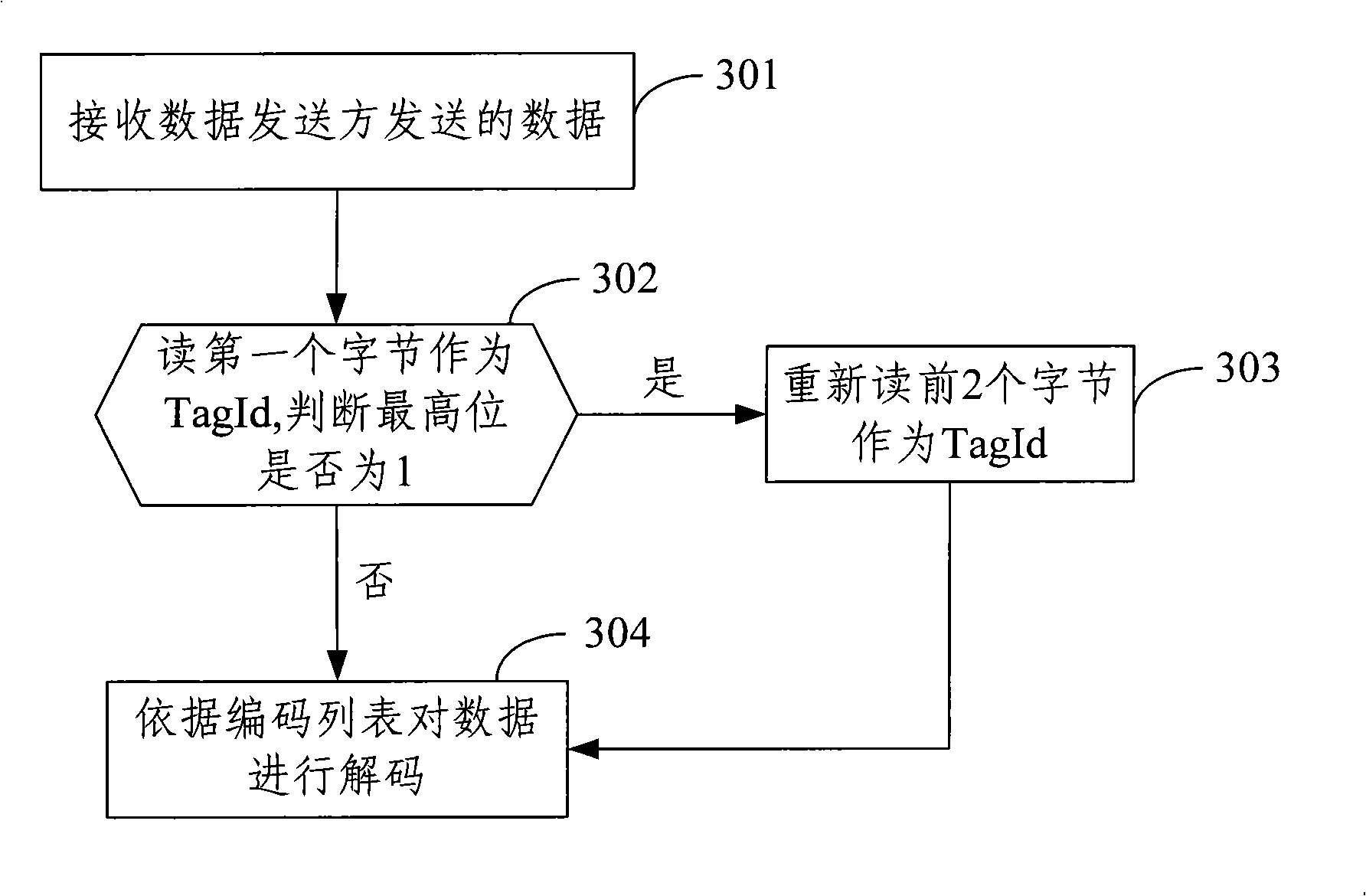

A transmission method and system for securities market data

The present invention discloses a method for transmitting the data of the stock quotation. A data provider provides the quotation information to a data transmitter with a form of data field. The invention is characterized in that the method comprises the following procedures: decoding the received quotation data by the data transmitter according to a data format defied by the data provider; extracting a data field from the decoded quotation data by the data transmitter, sorting the data field according to the magnitude of the byte of the data field value to form an encoding list, and executing code number sorting to the data field; transmitting the coded data to the data receiver by the data transmitter; and decoding the received data with a data field sorting coding mode and a coding list which are same to the data transmitter by the data receiver. The invention also discloses a coding system of the stock quotation data. The invention increases the adaptability to the variation of the data format of the quotation data and increases the speed of the data updating of the user terminal.

Owner:北京中企开源信息技术有限公司

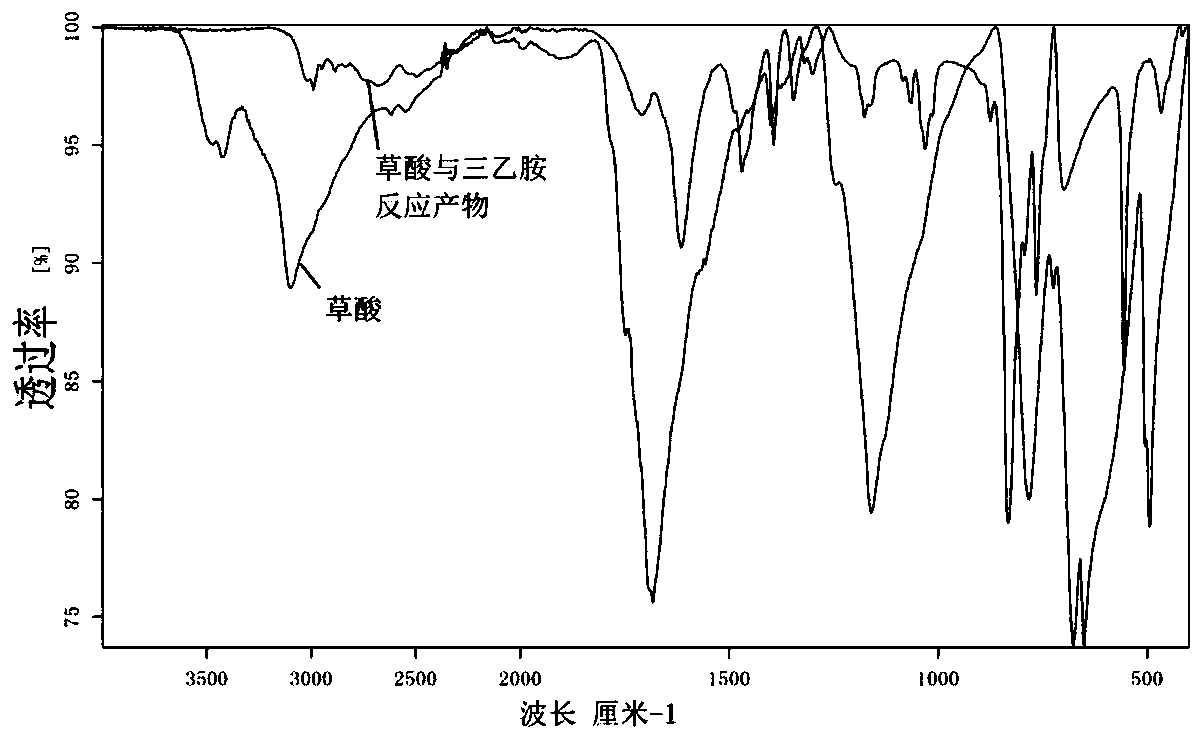

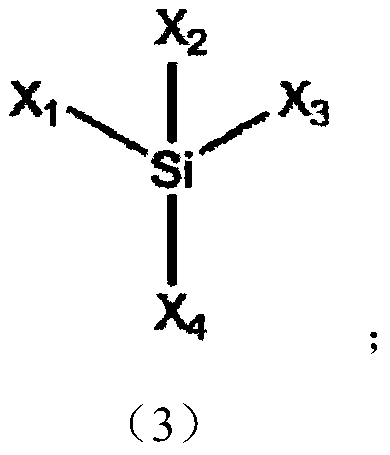

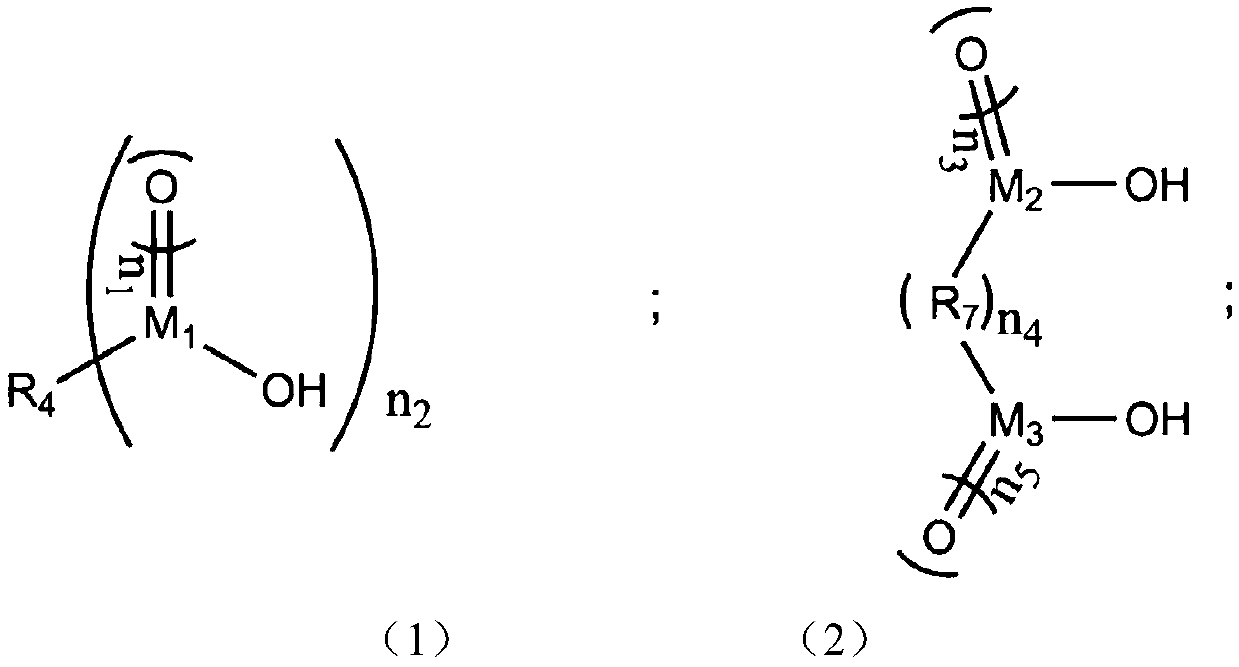

Preparation method of silicon-based ester compound, silicon-based ester compound, electrolyte containing silicon-based ester compound and secondary battery

ActiveCN111217850AHigh yieldHigh purityGroup 4/14 element organic compoundsSecondary cellsElectrolytic agentOrganic acid

The invention relates to a preparation method of a silicon-based ester compound, the silicon-based ester compound, an electrolyte containing the silicon-based ester compound and a secondary battery. The preparation method of the silicon-based ester compound comprises the following steps: adding organic alkali and organic acid into a solvent and carrying out reacting to obtain an intermediate, andthen, adding halogenated silane to react with the intermediate to obtain the silicon-based ester compound, wherein the intermediate is ionic liquid. The preparation method provided by the invention can relieve the problems of long reaction time, difficult treatment of byproducts, complex operation caused by step-by-step reaction, high cost, difficult industrial scale-up production and the like inthe existing synthesis method.

Owner:微宏先进材料公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com