Congee cooking device

A technology for cooking porridge and a body, which is applied in the field of porridge cooking devices, can solve the problems of increased manufacturing cost, unenvironmental protection, increased labor intensity, etc., and achieves the effects of reducing production and use costs, maintaining aroma and taste, and shortening heating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

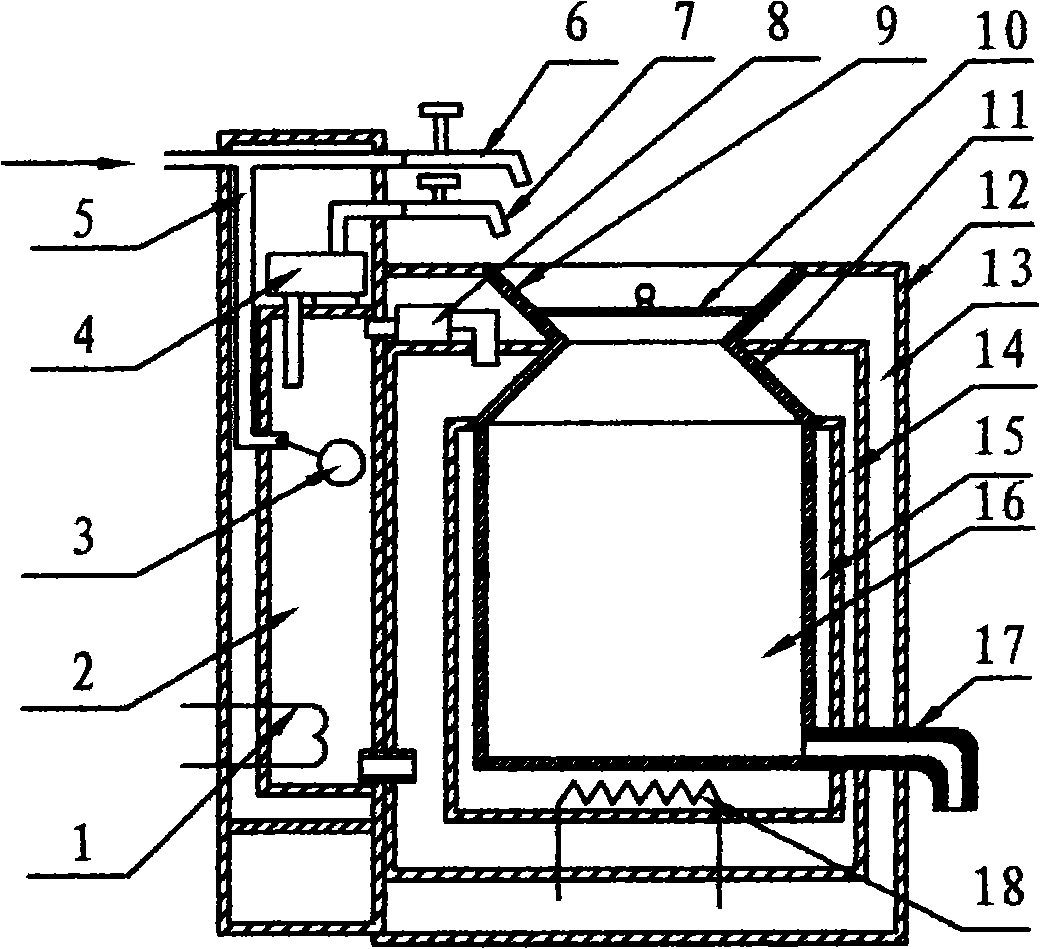

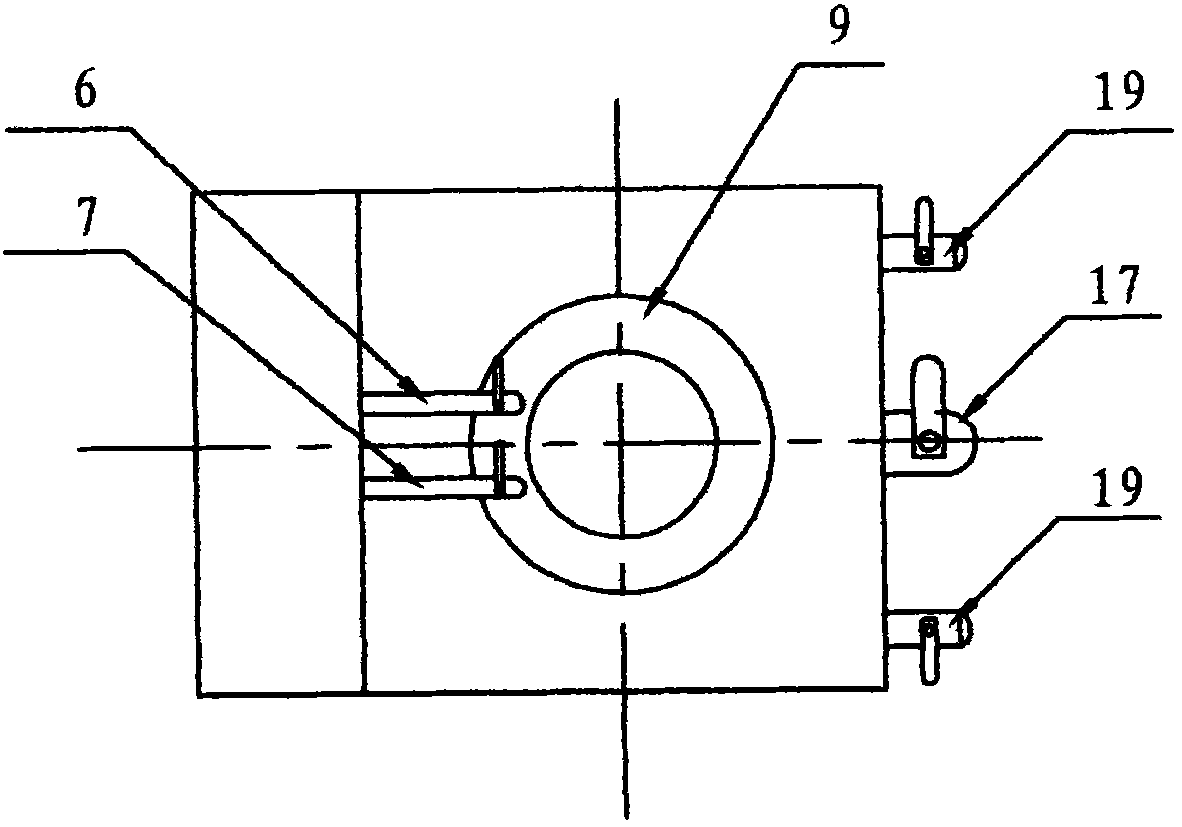

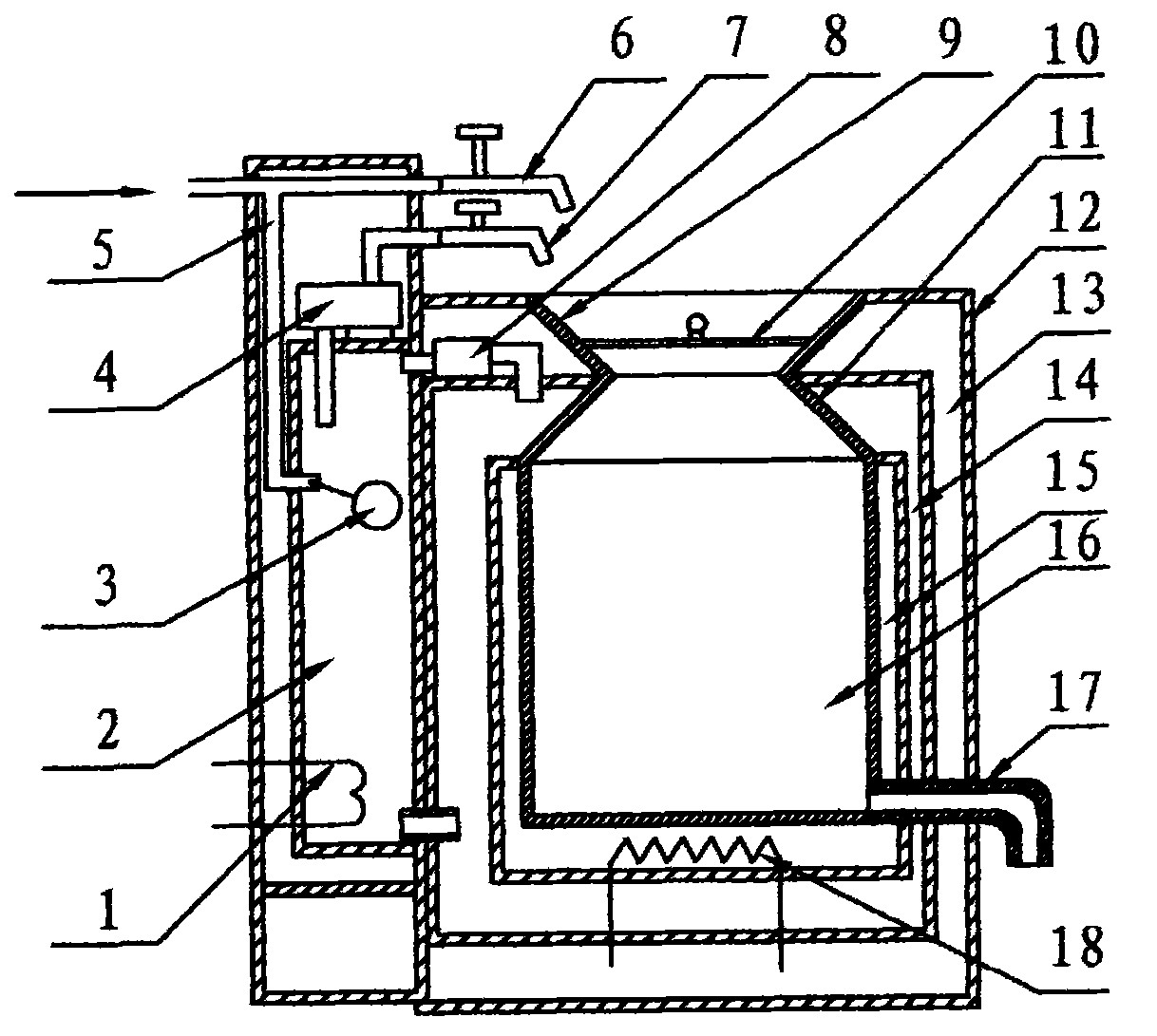

[0028] As shown in the accompanying drawings, a fully automatic multifunctional porridge cooker includes a shell panel 12, an inner container 16, a boiling water tank 2, a heat conducting medium interlayer 15, a water exchange interlayer 14, and a heater 18. In this embodiment, the boiling water tank 2 is arranged behind the main body of the porridge pot; the main body of the porridge cooking pot is provided with a loam cake 10 and a porridge outlet valve 17; A float switch 3 and an auxiliary heating element 1 are set; a solenoid valve 8 is set between the water exchange interlayer 14 and the boiling water tank 2; a hot water pump 4 is set on the upper part of the boiling water tank 2; Water tap 7, porridge outlet valve 17, water tap 19 are set on the front bottom.

[0029] Tap water is connected to float switch 3 and cold water faucet 6 through tap water pipe 5.

[0030] In this embodiment, the electric heat conduction oil medium solution is adopted, the electric heater 18 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com