Patents

Literature

917results about How to "Realize one machine with multiple functions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

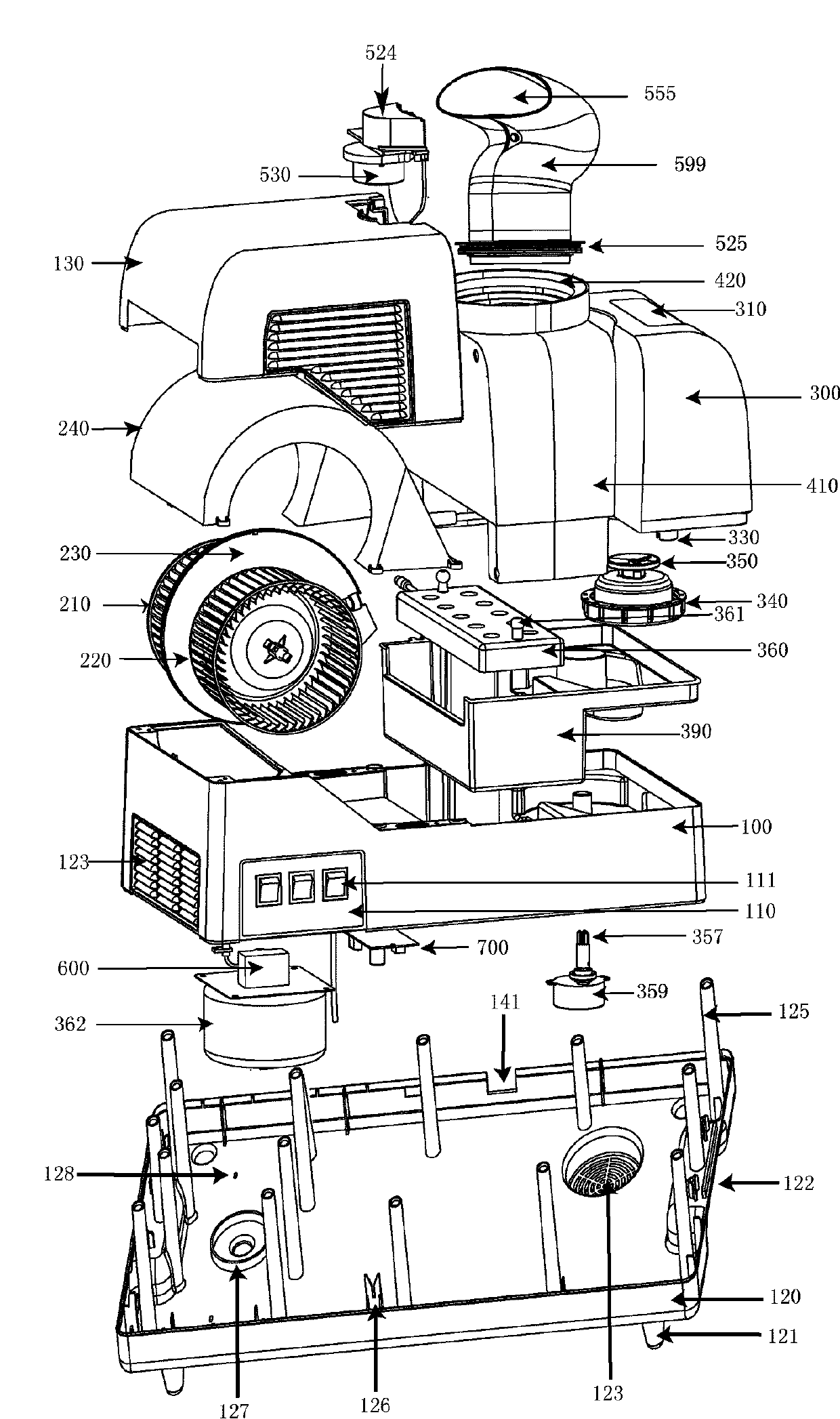

Efficient automatic dust-removing and intelligent ventilation system and automatic dust-removing method

InactiveCN101832612AGuarantee heat dissipation safetyImprove cooling effectSpace heating and ventilation safety systemsLighting and heating apparatusControl systemTime-sharing

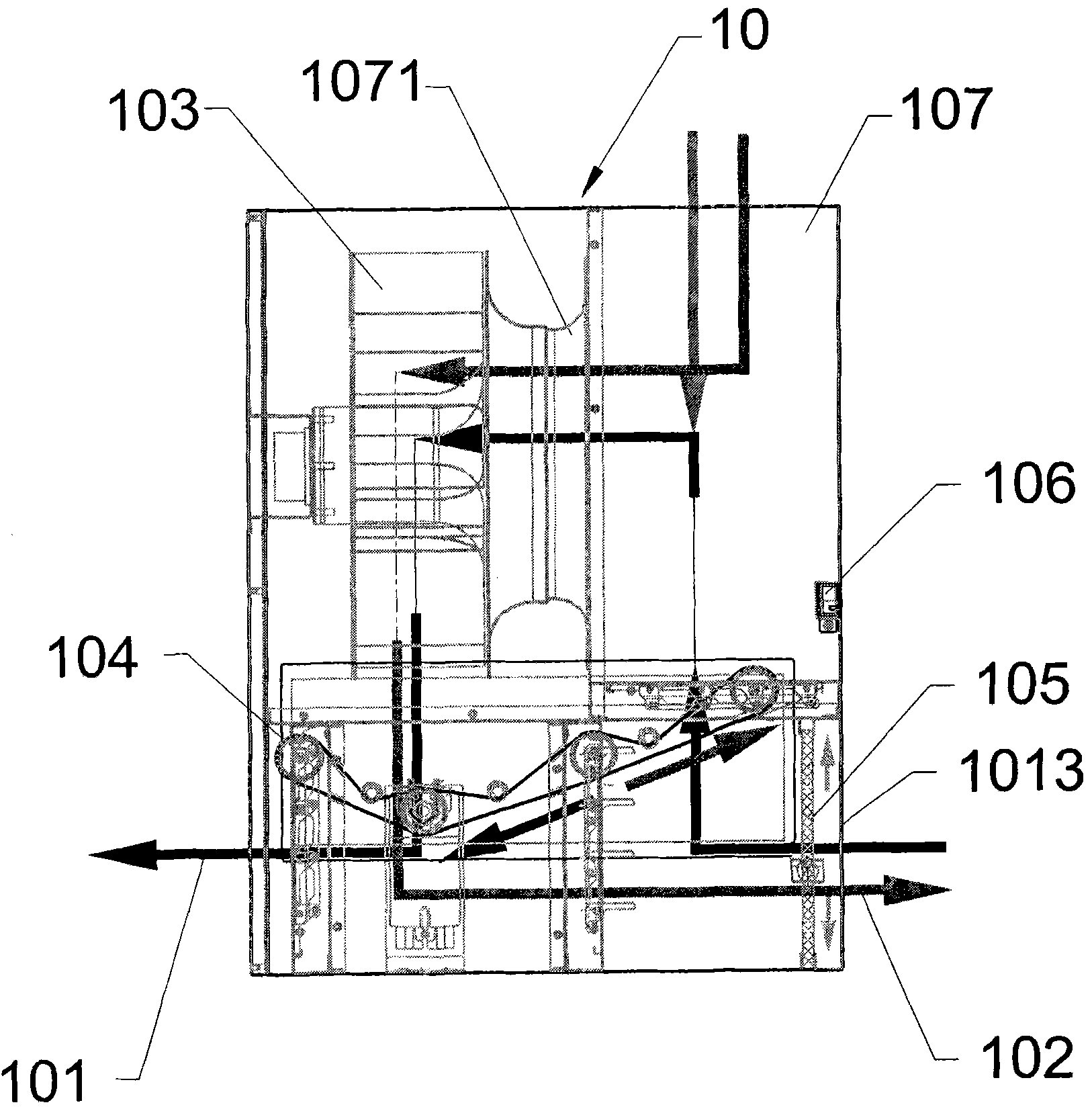

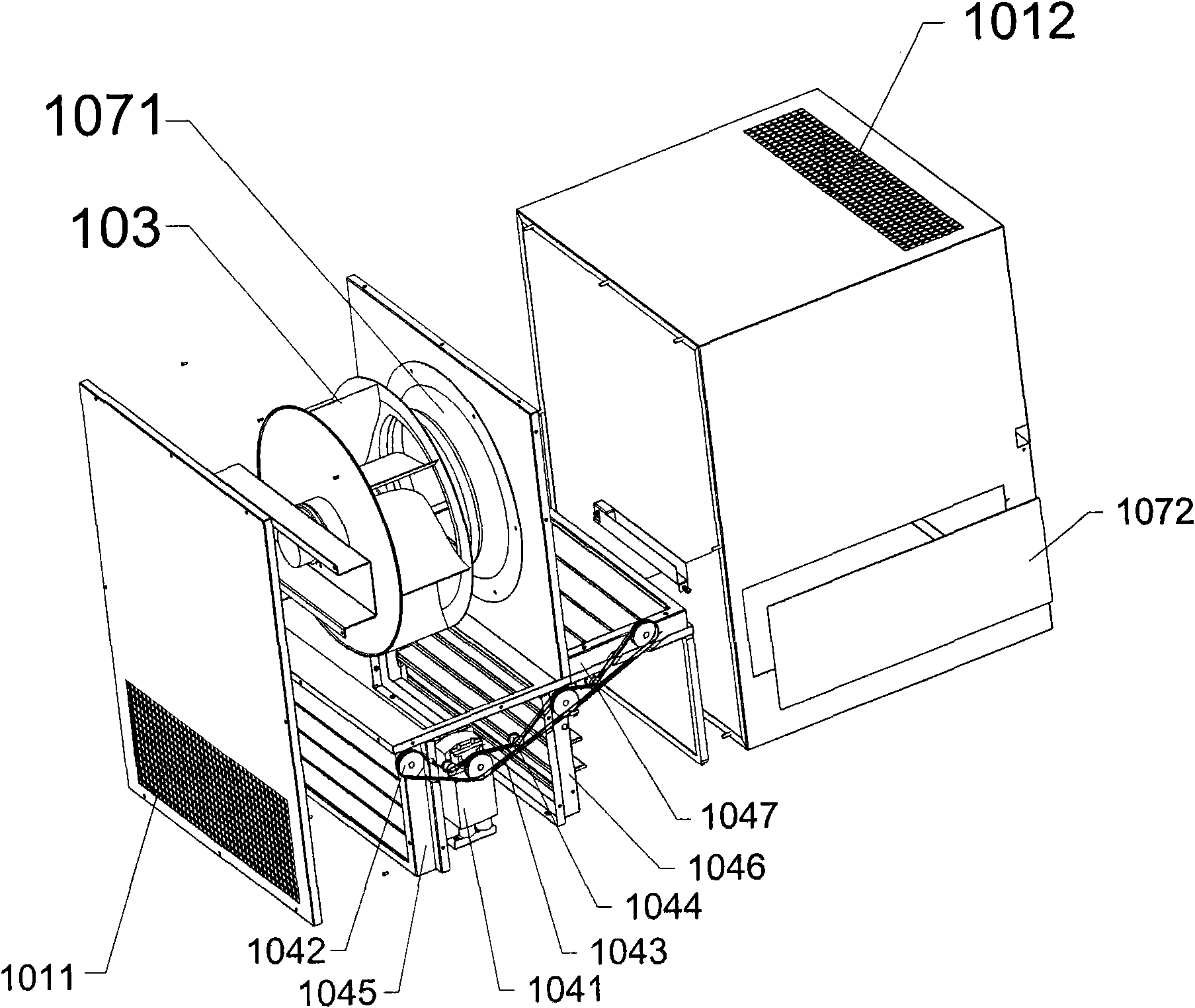

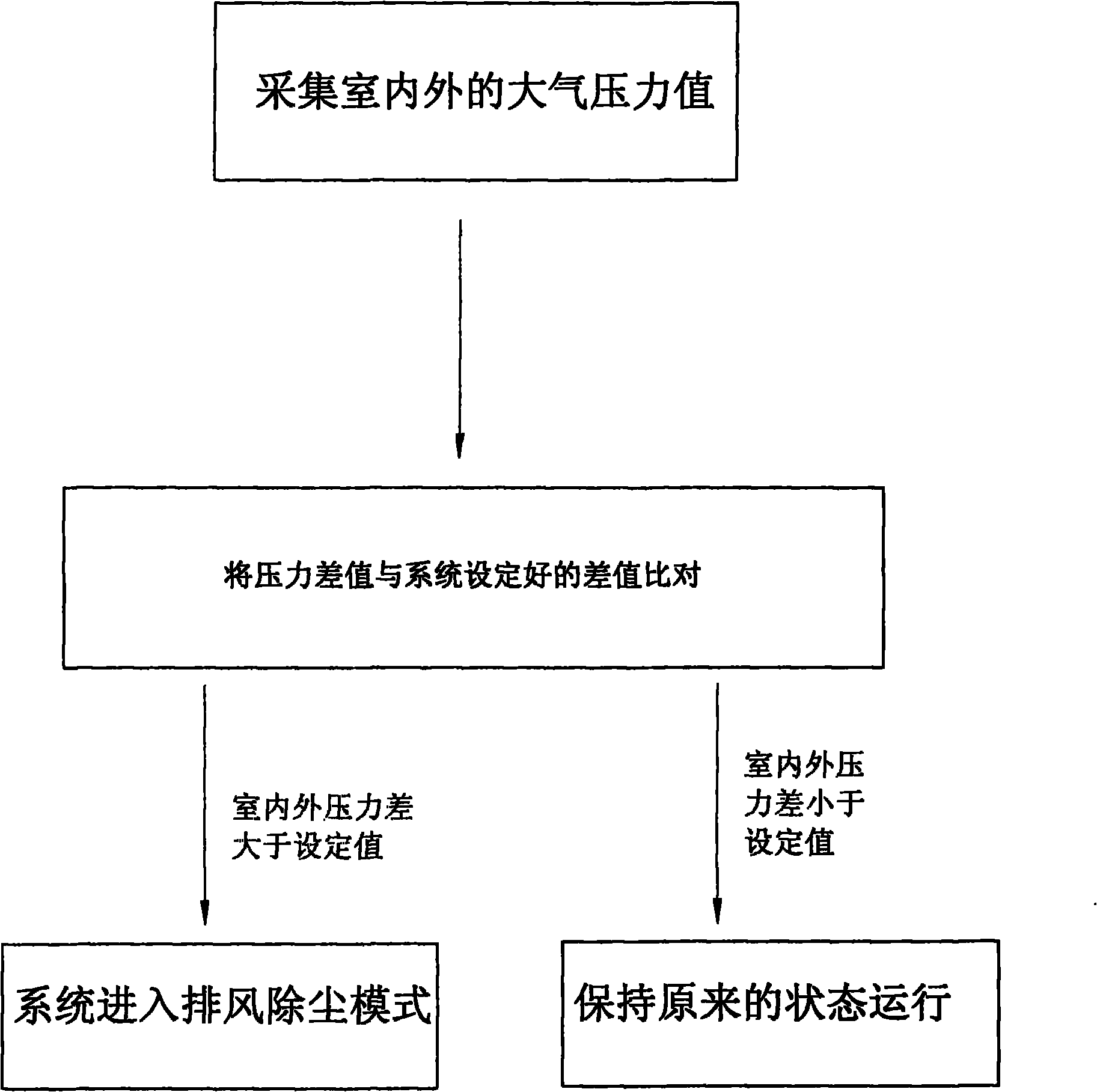

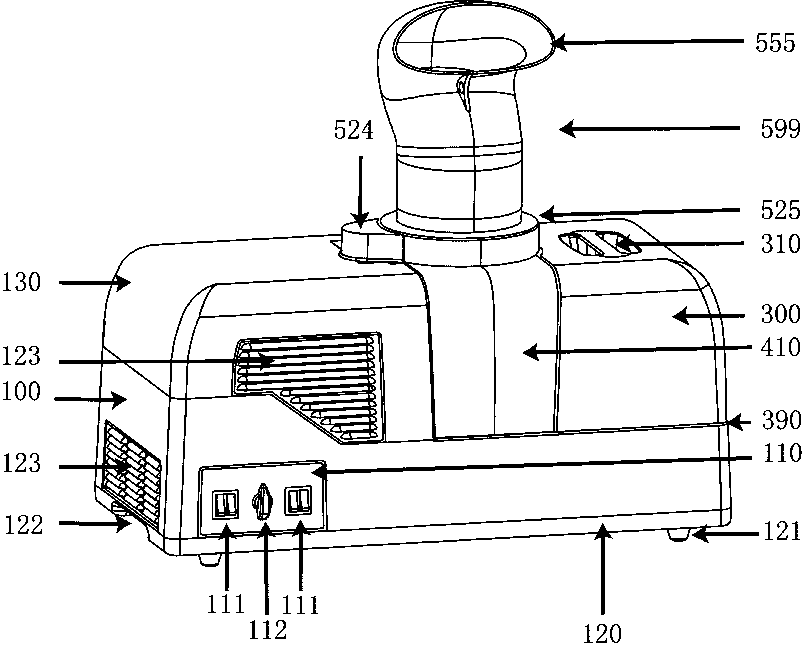

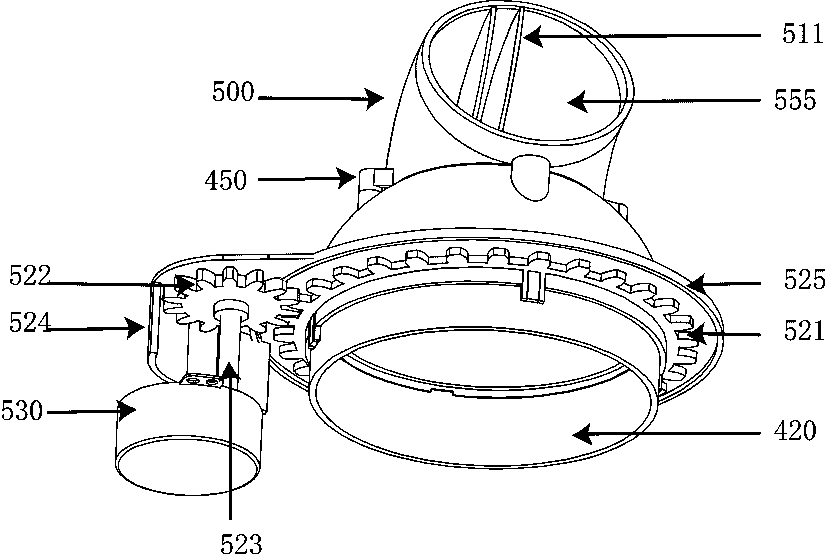

The invention relates to the ventilation system field, in particular to an efficient automatic dust-removing and intelligent ventilation system and an automatic dust-removing method. The system comprises an intelligent energy-saving ventilation system housing component and a fan, wherein the intelligent energy-saving ventilation system housing component comprises a dual duct, a dust-discharging duct, a throttle actuating mechanism, a dust screen, a temperature and humidity sensor and a distributed pressure sensor, wherein the temperature and humidity sensor and the distributed pressure sensor are connected with a control system, and the control system drives the throttle actuating mechanism to realize time-sharing and smooth transition of the dual duct and the dust-discharging duct. The beneficial effects of the invention are as follows: the fans of the air feeder unit can be used for several purposes such as air supply and dust removing, thus reducing the equipment cost; the self-cleaning of the filtering screen can be realized, thus prolonging the service life of the filtering screen, reducing replacement frequency and lowering maintenance cost; and by turning on / off the automatic dust-removing and intelligent ventilation system, the normal operation of the devices in an equipment room can be ensured.

Owner:SHENZHEN ZHONGXING SINDI TECH CO LTD

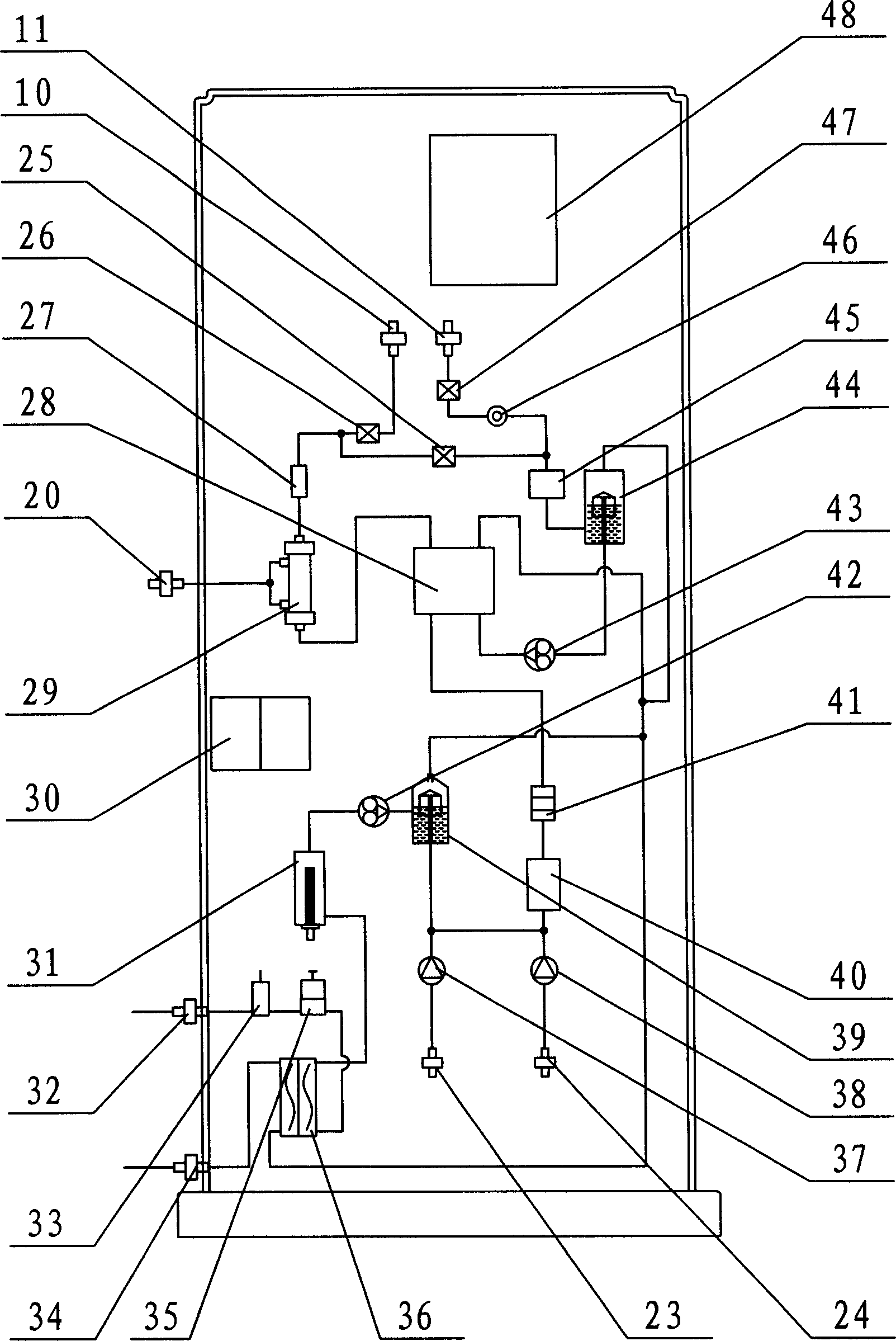

Medical hemodialysis filter

ActiveCN1830494AAvoid air embolismSolve unstable flowHaemofiltrationDialysis systemsHemodialysisGear pump

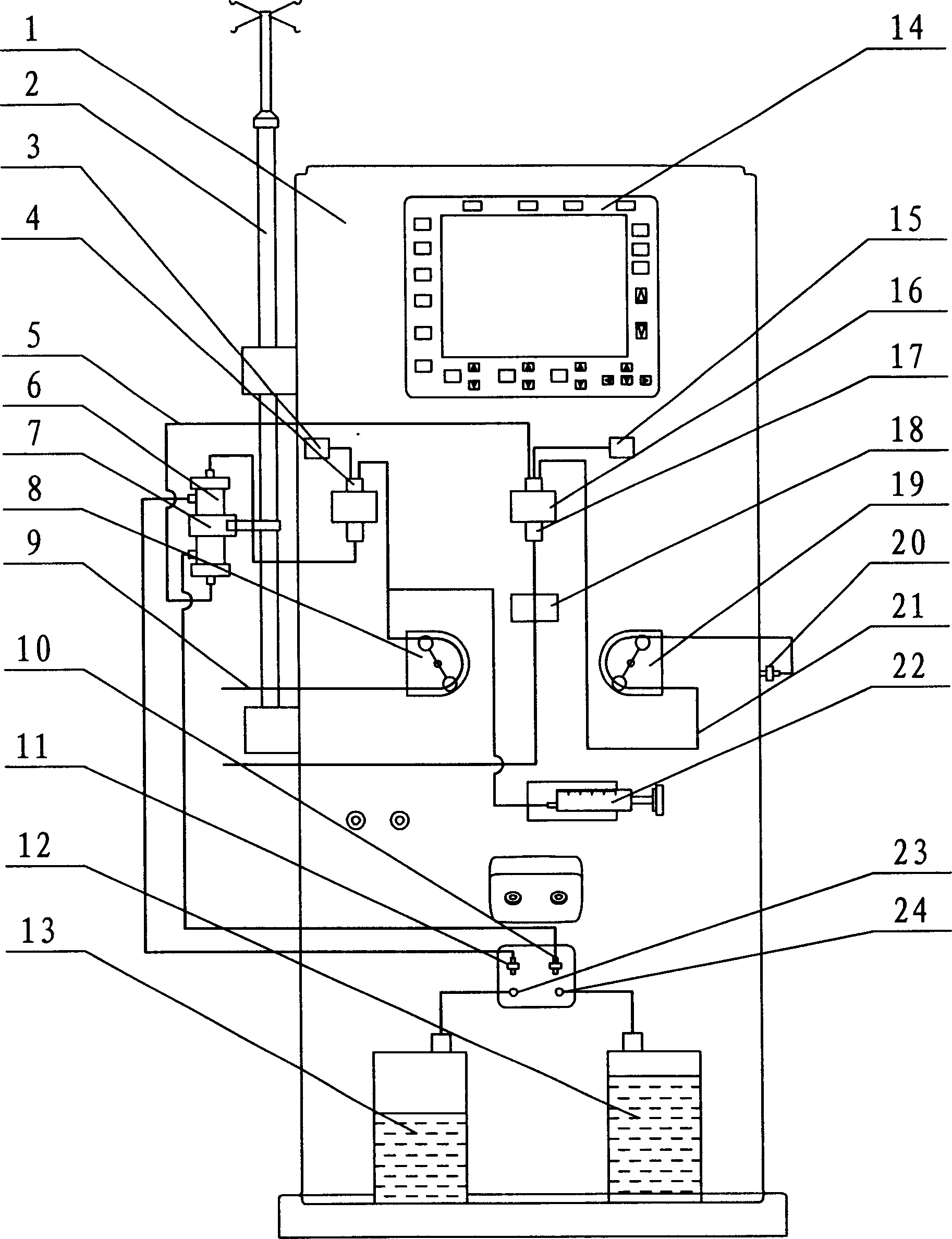

A medical filtering machine for the hemodialysis is composed of main body with console panel, blood loop consisting artery loop and vein loop, liquid-supplementing loop, water channel system and operation-control system. Said water channel system consists of reverse osmosis jointer, heat exchanger, heater, gear pump, deaerating unit, two concentrated liquid pumps, mixer, ion concentration monitor, volume balance and ultrafiltration unit, and endotoxin filter.

Owner:SWS HEMODIALYSIS CARE CO LTD

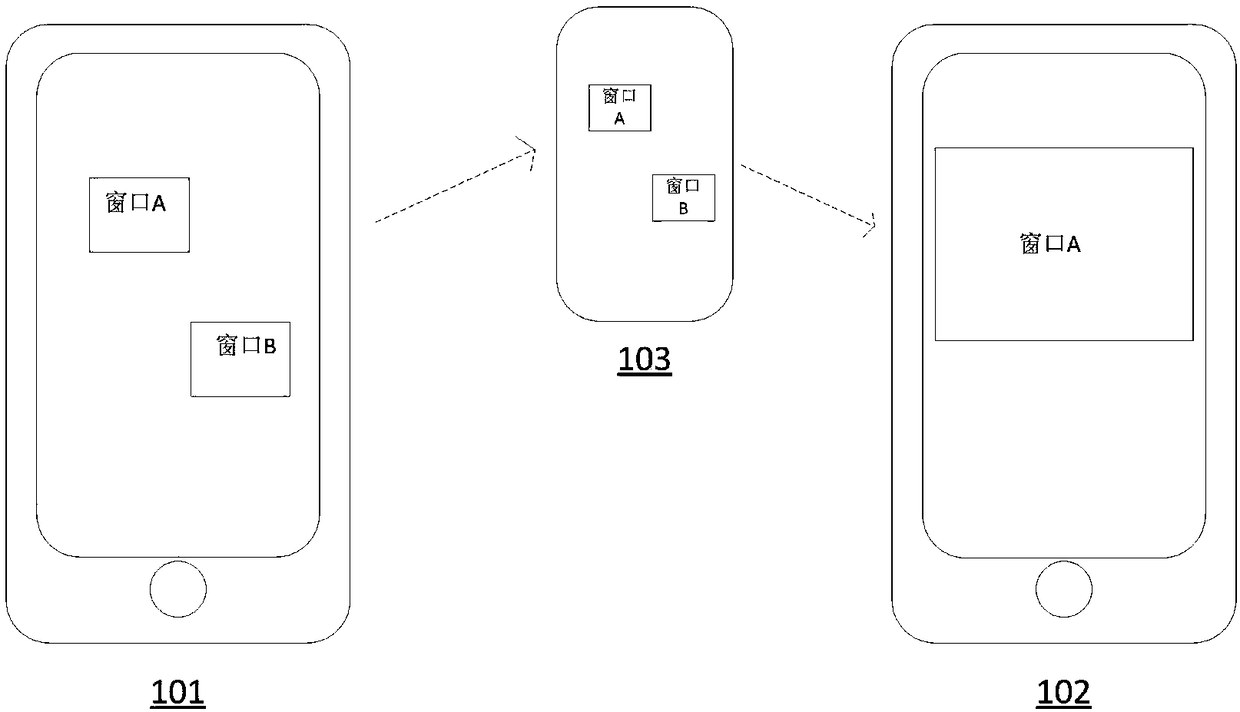

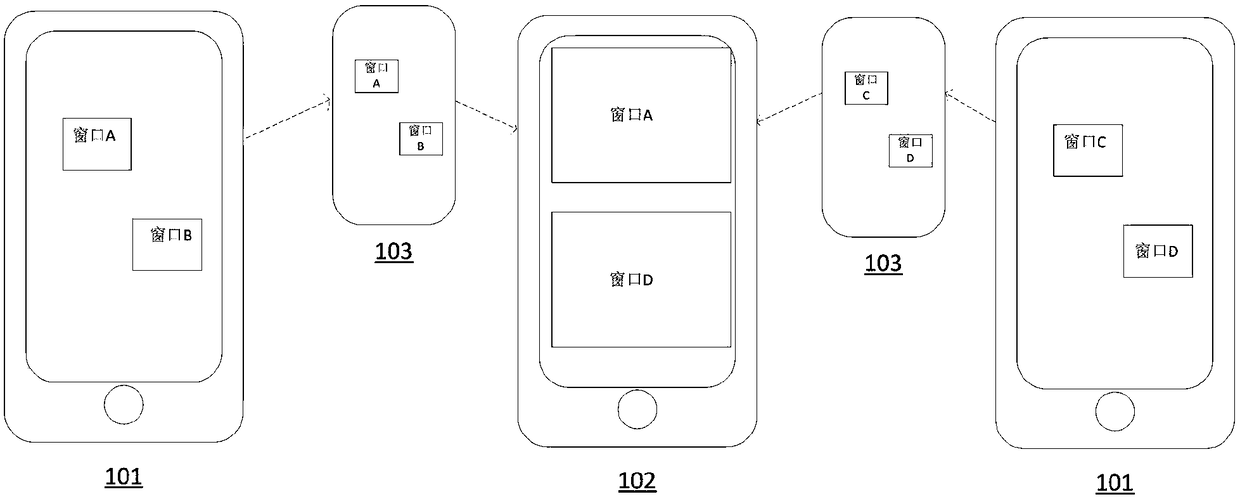

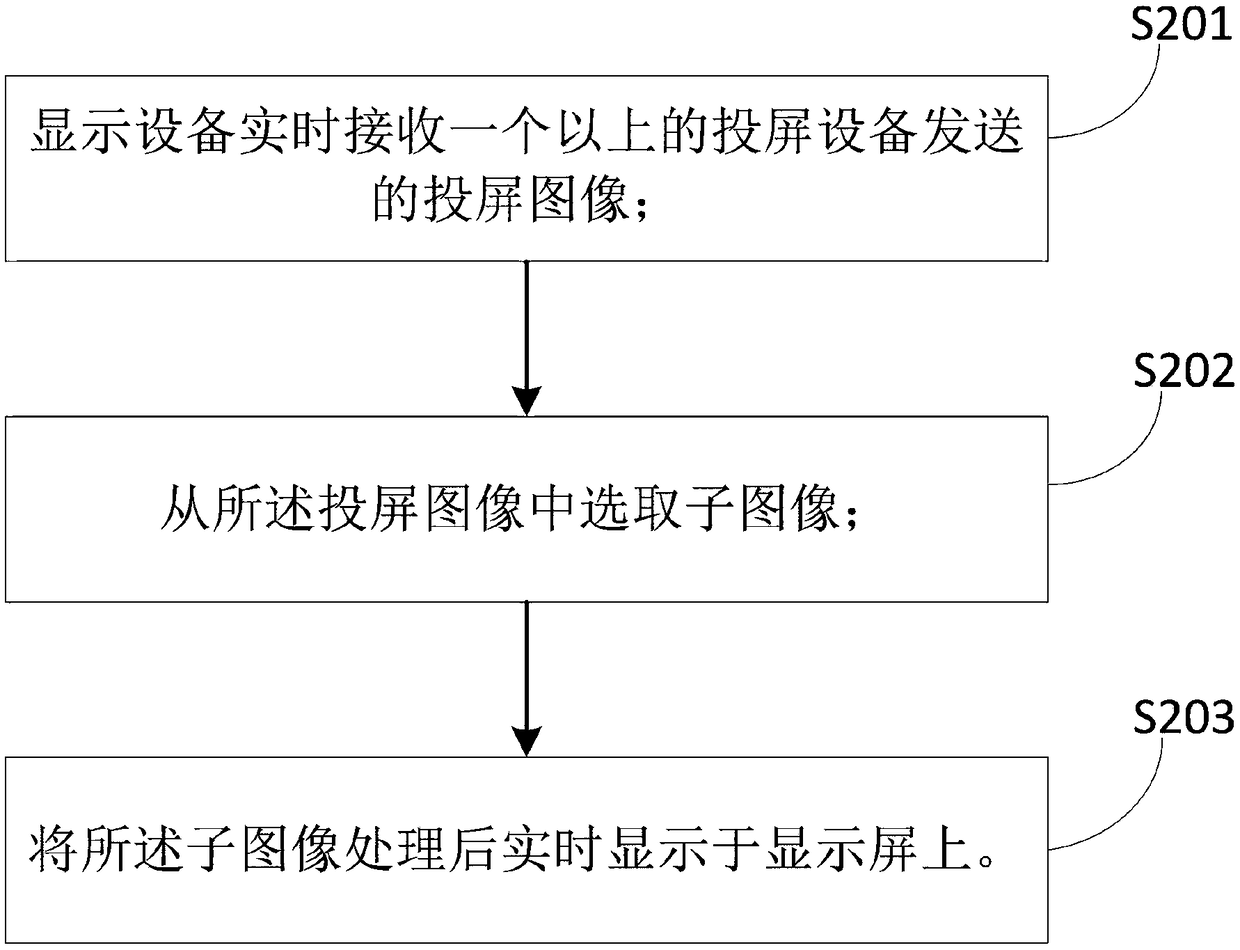

Screen projection display method, system, and storage medium

ActiveCN109508162AReduce data processingImprove the display effectExecution for user interfacesDigital output to display deviceProjection imageComputer graphics (images)

The invention relates to the technical field of image display, and provides a projection screen display method, a system and a storage medium. The method comprises the following steps: receiving projection screen images sent by more than one projection screen device in real time; Selecting a sub-image from the projection image; processing and displaying The sub-image on the display screen in realtime. different from the prior art, the projection screen device only needs to send a complete projection screen image, and the display device selects sub-images from the projection screen image for display, and the display device can display the sub-images after processing, so that the image projection screen display is more flexible, and the image projection screen display has better display effect and better versatility.

Owner:FUJIAN STAR NET EVIDEO INFORMATION SYST CO LTD

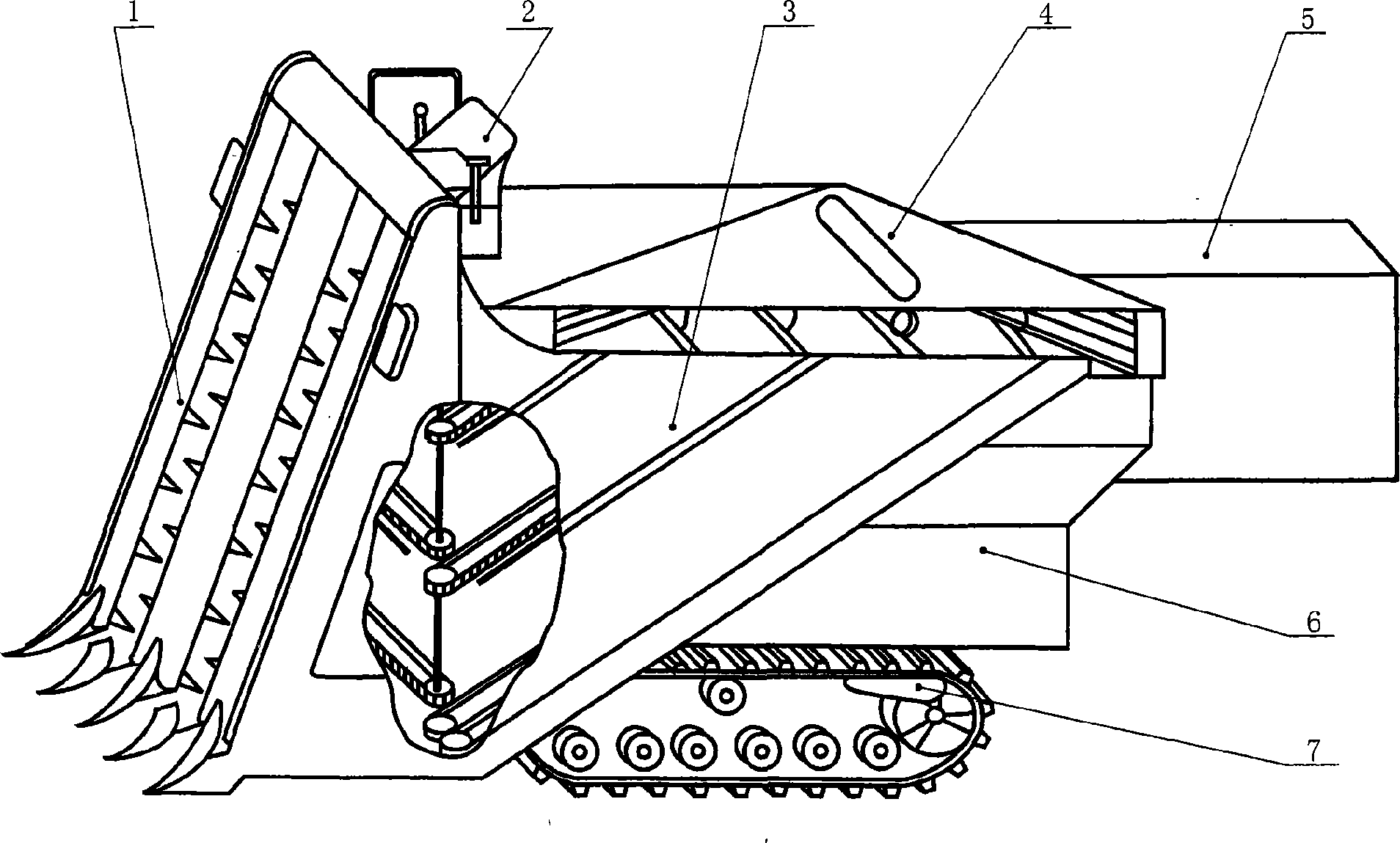

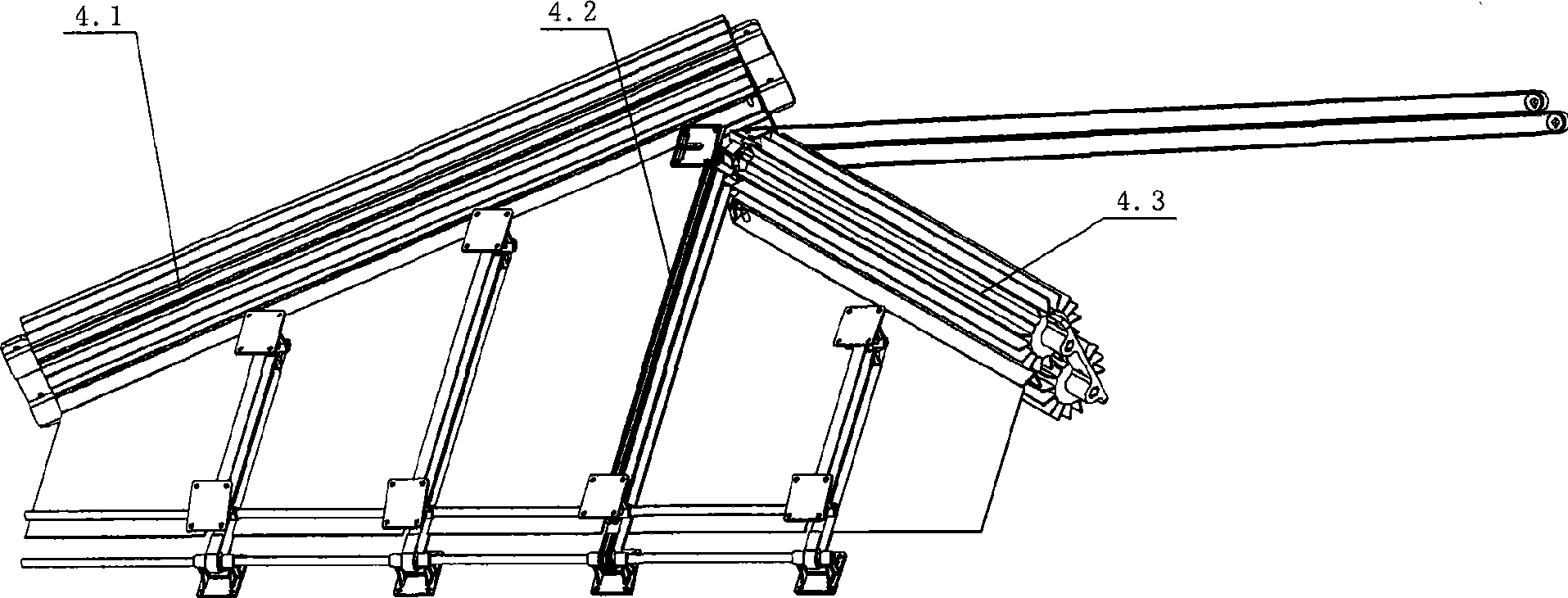

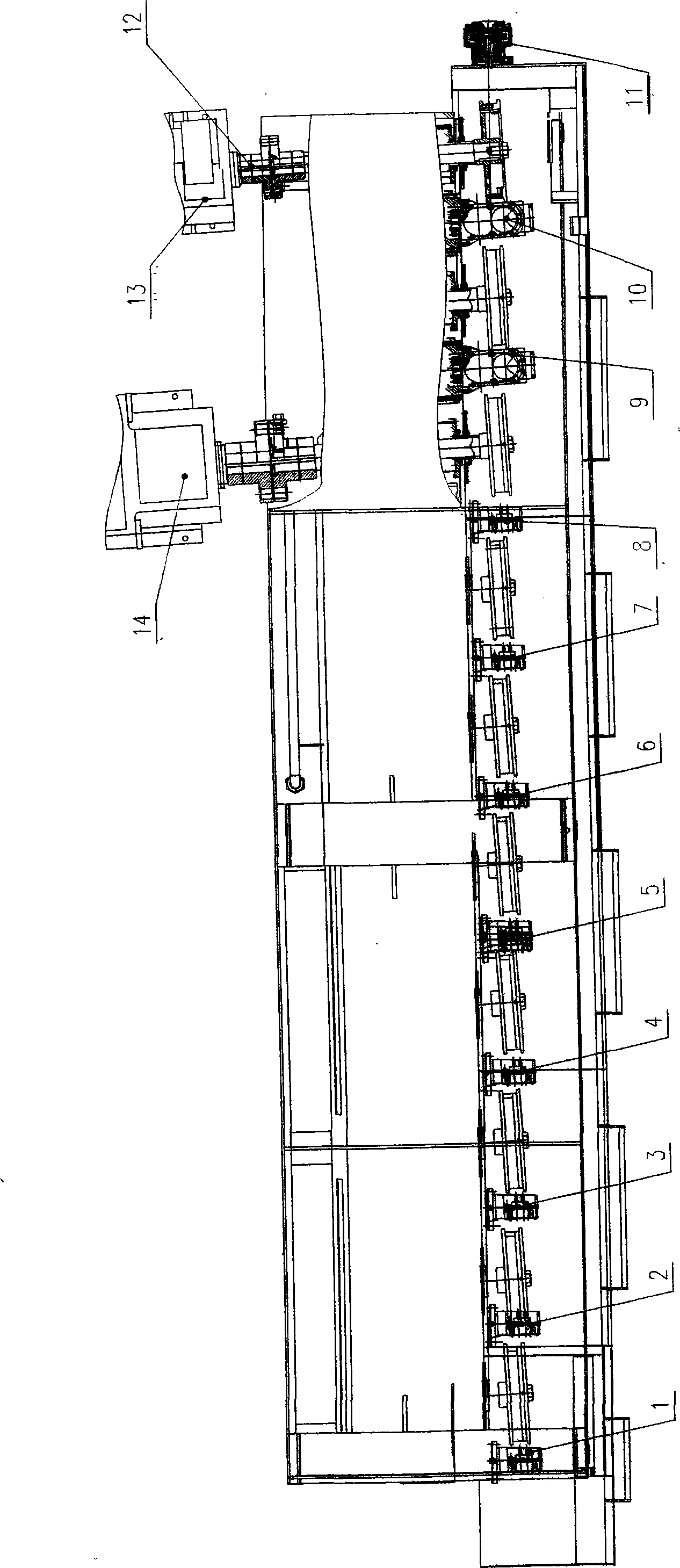

Ramie combine harvester

InactiveCN101518182AReduce impurityIncrease productivityHarvestersMechanical fibre separationEngineeringMechanical equipment

The invention relates to a ramie combine harvester which is applicable to combining harvest of ramie, namely completes ramie cutting and fiber primary processing by one time continuously, belonging to agricultural mechanical equipment. The ramie combine harvester consists of a vertical cutting table, an operating mechanism, a middle conveyor, a two-way automatic ramie removing machine, a mechanism which integrates ramie bin, power and transmission mechanism and a walking device. A bottom plate part is universal with a half head-feed grain combine harvester. A holding conveying belt is a synchronous belt; and the outer surfaces of the two belts are coupled with a longitudinal convex-concave bar groove, one belt at the inner side is a fixed support and the other belt is an elastic pressing support. The two-way ramie removing machine has two sets of ramie removing mechanisms at the front and back which are arranged in a reversed-V shape. After being cut, the ramie stalks are conveyed in a vertical and lateral mode, conveyed by a holding base part in a rotatable and upward mode, continuously fed into two sets of ramie removing mechanism for processing the base part and the tip part in a horizontal mode and the obtained ramie stalks are wound at a ramie blocking pin with an extruding and scratching machine at the tail ends of the ramie removing mechanisms, and the fiber is drawn, thus realizing removing of skin, skeleton and glue. The mechanical equipment has high production efficiency and good ramie removing quality and thoroughly solves the scutching difficulty which restricts the development of the ramie industry.

Owner:咸宁市农业机械化研究所

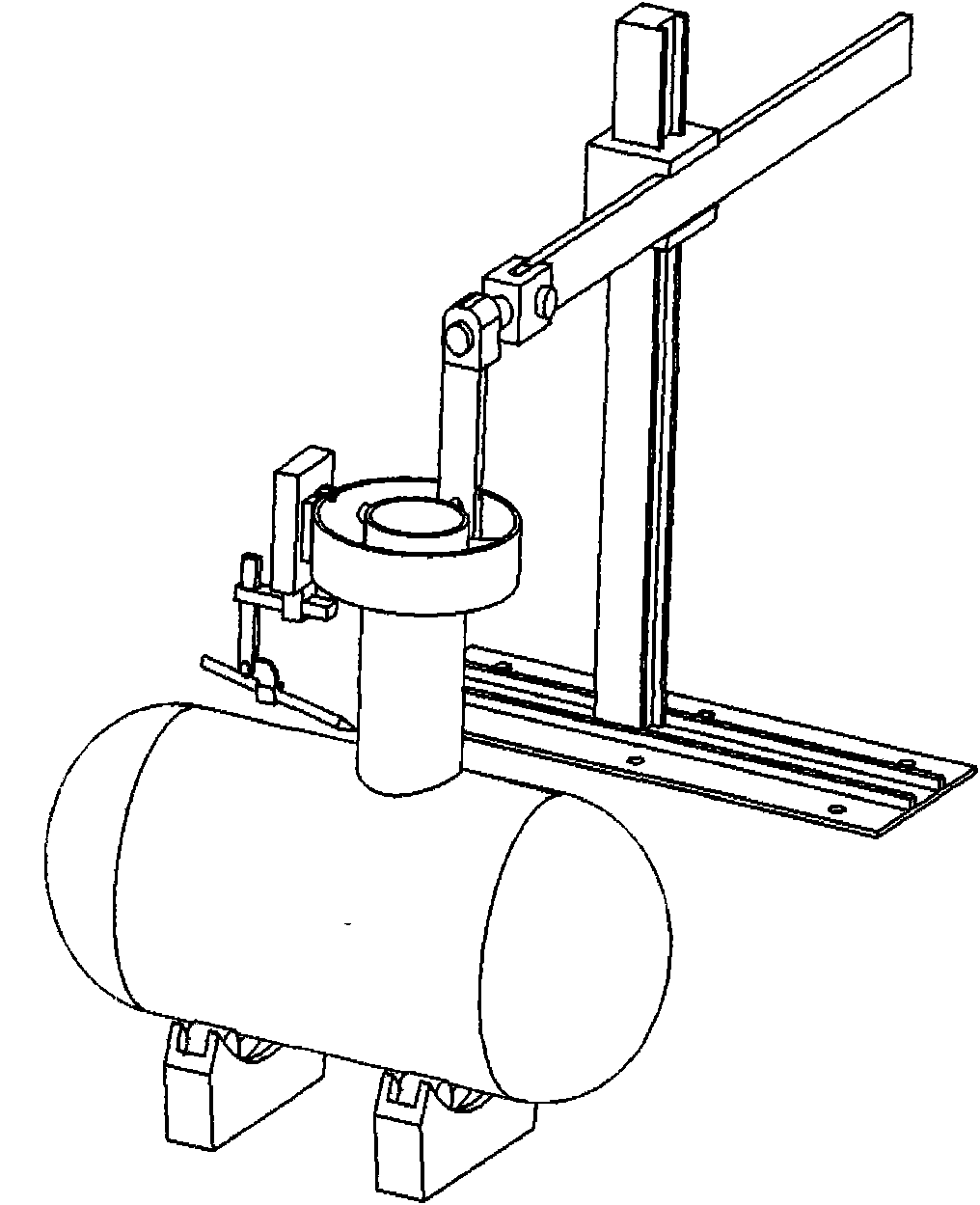

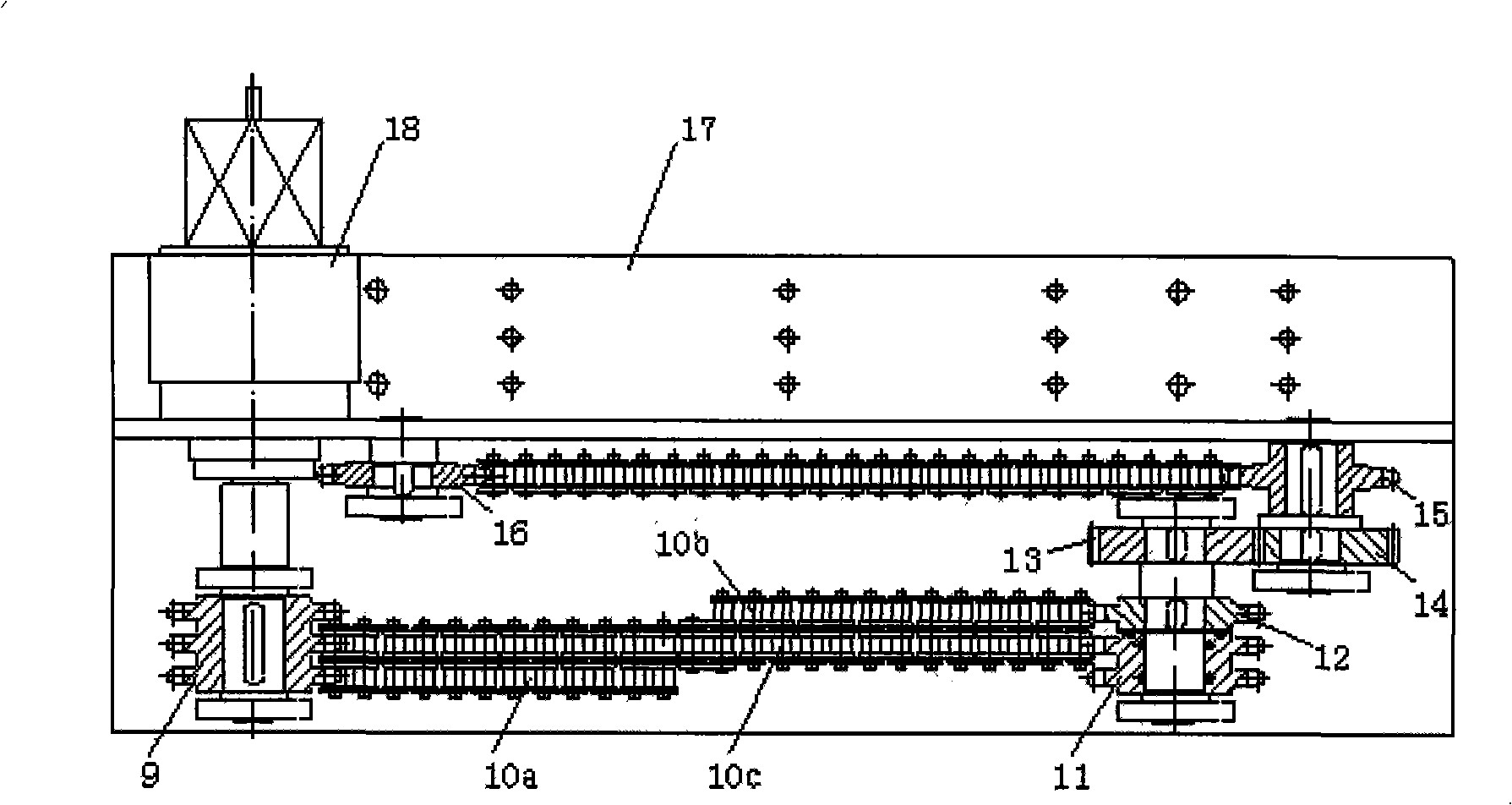

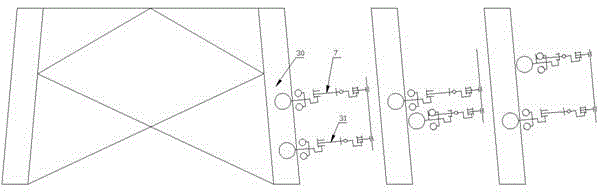

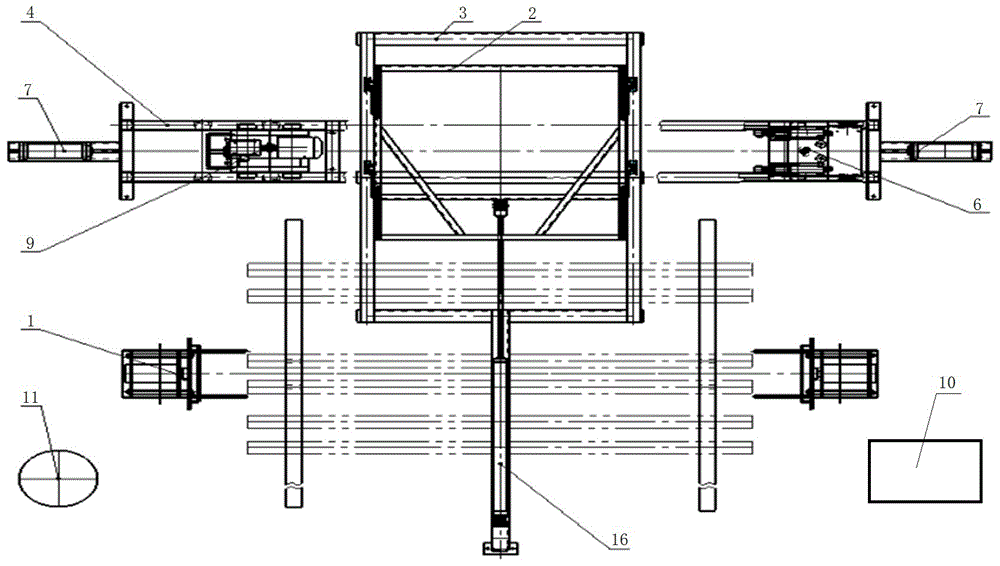

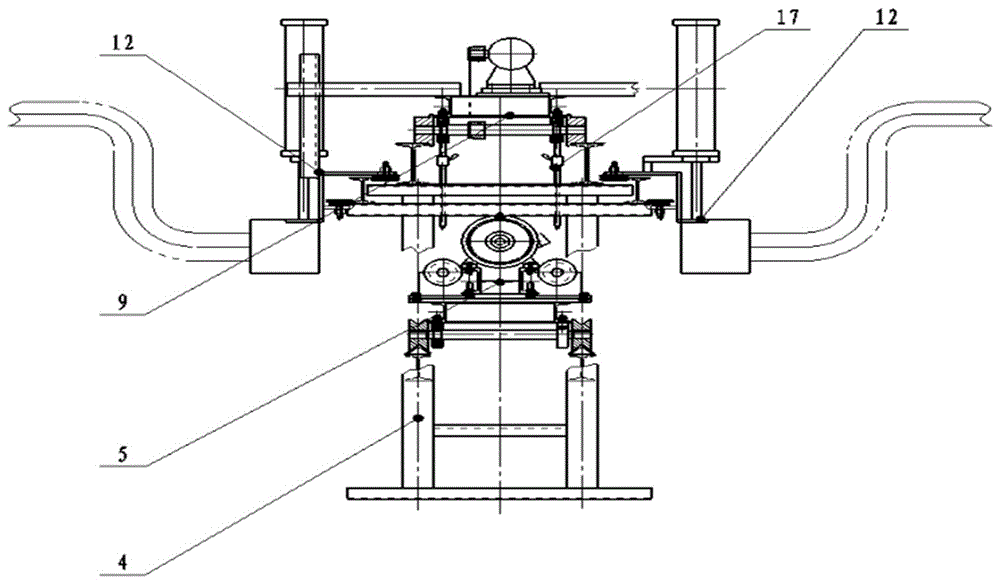

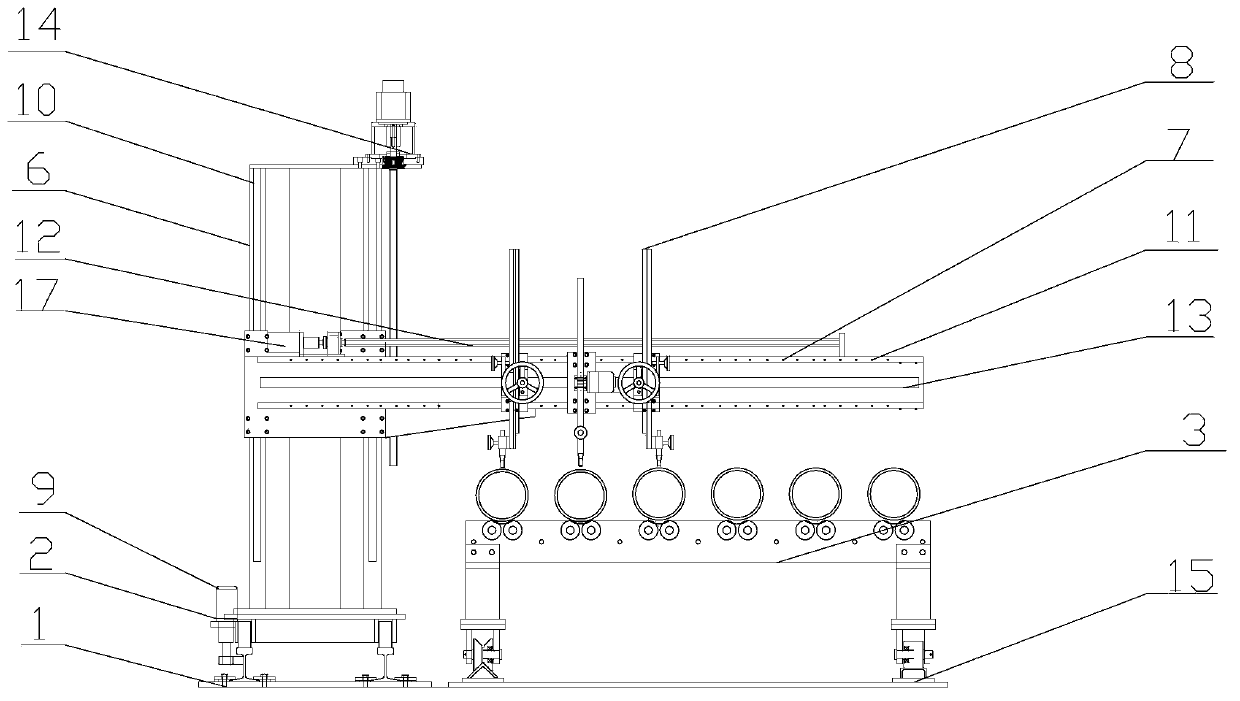

Opening-nozzle saddle-shaped seam welding equipment

ActiveCN101786210ASimple and compact structureRealize one machine with multiple functionsWelding/cutting auxillary devicesAuxillary welding devicesSeam weldingSaddle shape

The invention relates to opening-nozzle saddle-shaped seam welding equipment, which mainly comprises a cross-shaped automatic operation machine (1), a welding head track (2), a welding head (3) and a cylinder body workpiece (4). An axial moving device (11) of the cross-shaped automatic operation machine (1) is connected with a corresponding basic part; a vertical lifting arm (12) of the cross-shaped automatic operation machine (1) is assembled together with a transverse moving arm (13) by taking the axial moving device (11) as the base and is connected with the welding head track (2) through a suspension arm (17); and the welding head (3) is connected with the welding head track (2) through a locking mechanism (31) and can run along a ring-shaped track (21). The equipment achieves the function of multiple purposes, namely can perform gas cutting or plasma cutting on a saddle-shaped bevel pipe end and a pipe hole, and can perform high quality welding between the bevel pipe end and the pipe hole after an actuating mechanism is replaced; and in addition, the equipment has a compact and simple structure and is very suitable to be used on a construction site.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Automatic spraying robot outside of tube

InactiveCN101293237AAchieve mechanical propertiesFully automatedLiquid surface applicatorsSpraying apparatusWork qualitySystem structure

The invention relates to a spray finishing machine for pipe outer walls, which can meet the requirement of corrosion protection spray finishing of the outer walls of various straight pipes. A mechanical body consists of a spray finishing mechanism which can swing back and forth, a straight line running mechanism and a body frame, wherein, the spray finishing mechanism which can swing back and forth is composed of an incomplete chain transmission system and can lead a spraygun to swing back and forth around the outer wall of the pipe; the running mechanism is in a wheel type or a caterpillar type and can lead a robot to do continuous or interval straight line running along the pipe; the body frame consists of a lower part and an upper part, and can realize the quick assembly and disassembly of the robot through a quick dismantling handle. Different working devices can be installed on a general mechanical port of the robot to fulfill different pipe maintenance tasks such as descaling, deashing, measuring and welding, etc. at the exterior of the pipe. The spray finishing machine has simple system structure, high reliability and easy guarantee of working quality; the technique can replace the manual way to realize the automation of the maintenance working way such as corrosion protection spray finishing at the exterior of pipes.

Owner:JIANGSU UNIV

Line patrol robot capable of climbing poles and towers and climbing method

InactiveCN104477272ARealize one machine with multiple functionsEasy to log in and outApparatus for overhead lines/cablesVehiclesArm lengthsAttitude control

The invention relates to a line patrol robot capable of climbing poles and towers. A structure of a double-arm line patrol robot is adopted, and two mechanical arms are arranged on the same side of the robot. Each mechanical arm has three degrees of freedom and is capable of moving up and down along the arm length direction, rotating in the direction of a vertical plane of the mechanical arms, rotating along a horizontal plane of a robot body and integrally moving along a rail on the robot body; the upper portion of each mechanical arm is provided with two half rollers capable of opening and closing along the corresponding mechanical arm. The line patrol robot is capable of climbing poles and towers to inspect faults of the poles and the towers and capable of conveniently getting on and off lines to complete power transmission line inspection tasks. Further, obstacle crossing ways of the robot on power transmission lines are simple, posture control of the robot is easy, and accordingly patrol efficiency can be improved, and autonomous intelligence of the robot can be improved.

Owner:WUHAN UNIV

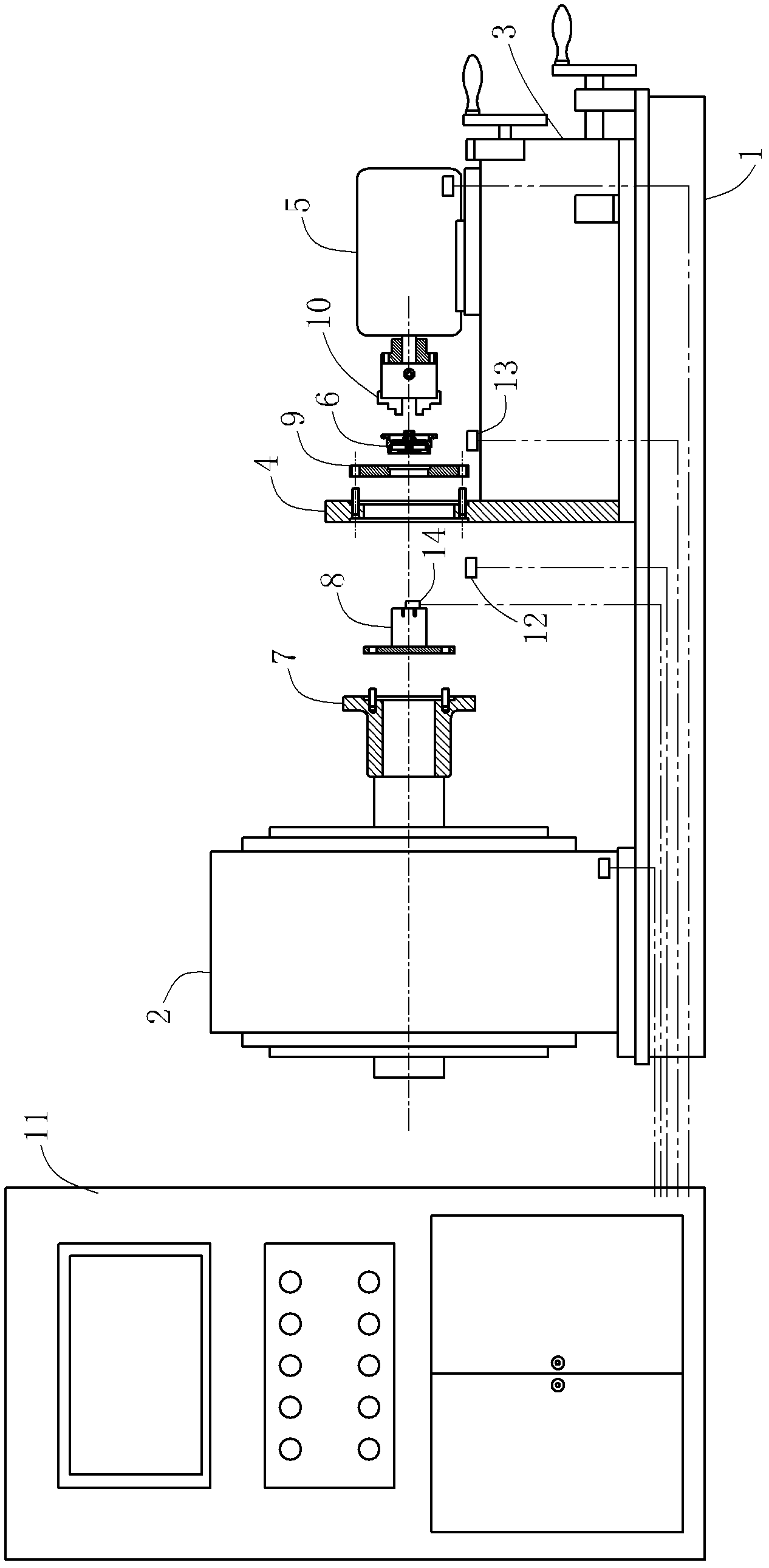

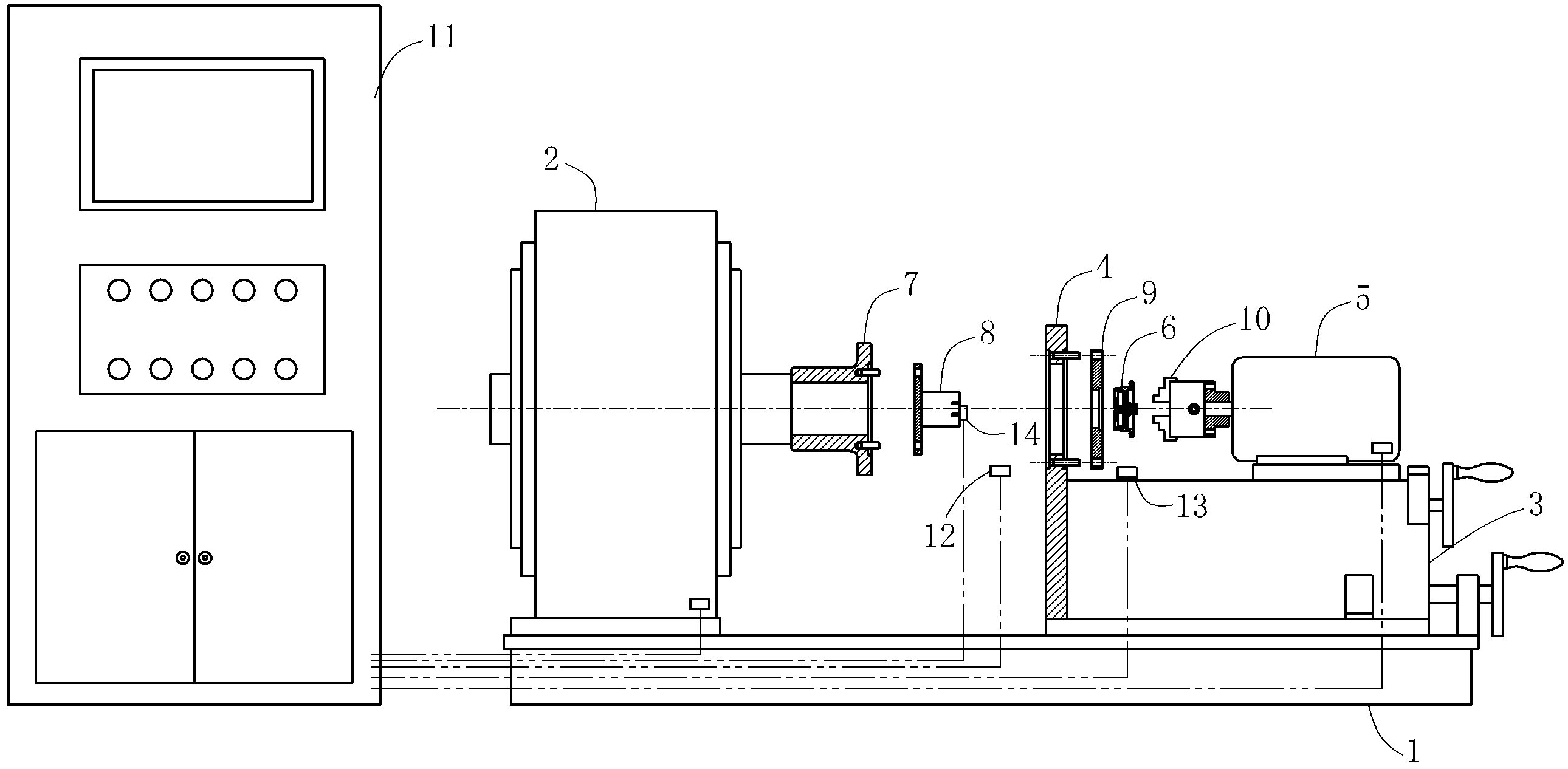

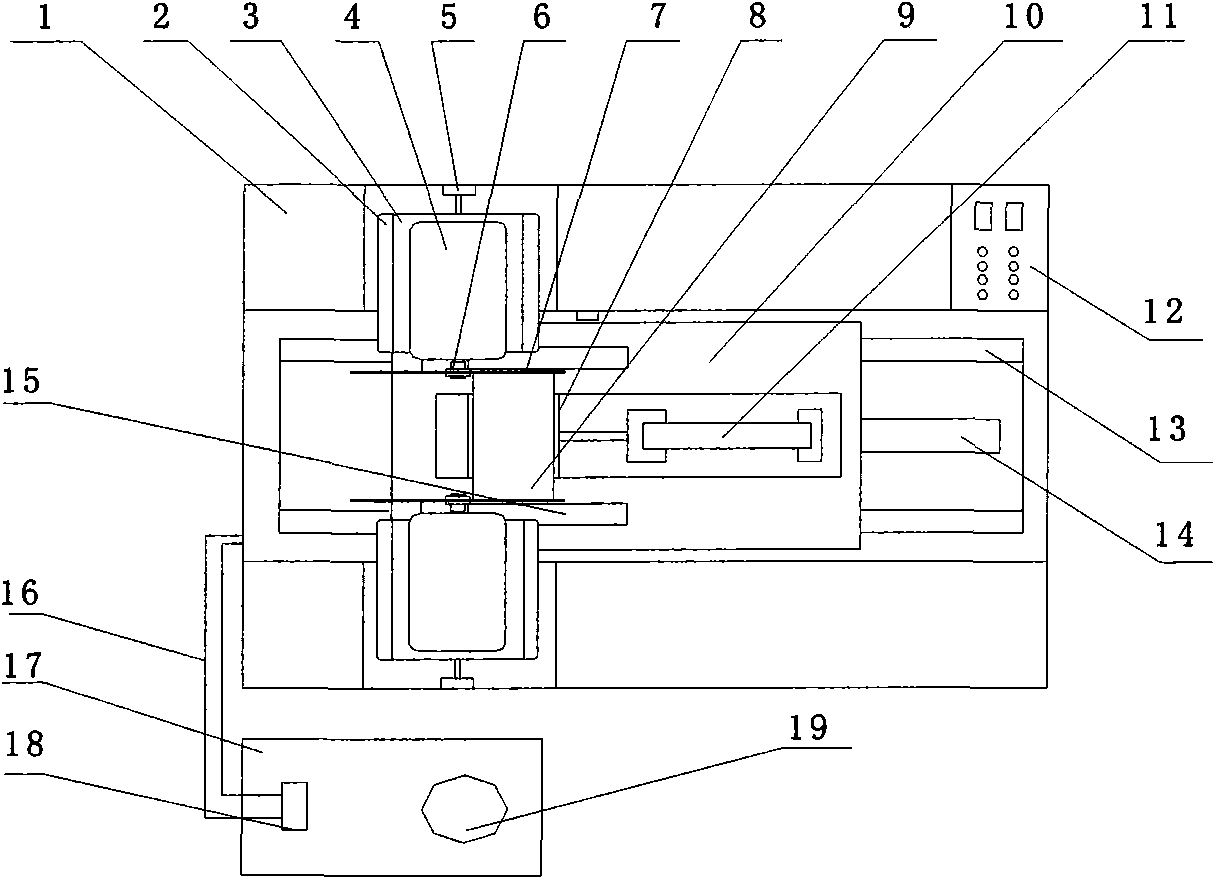

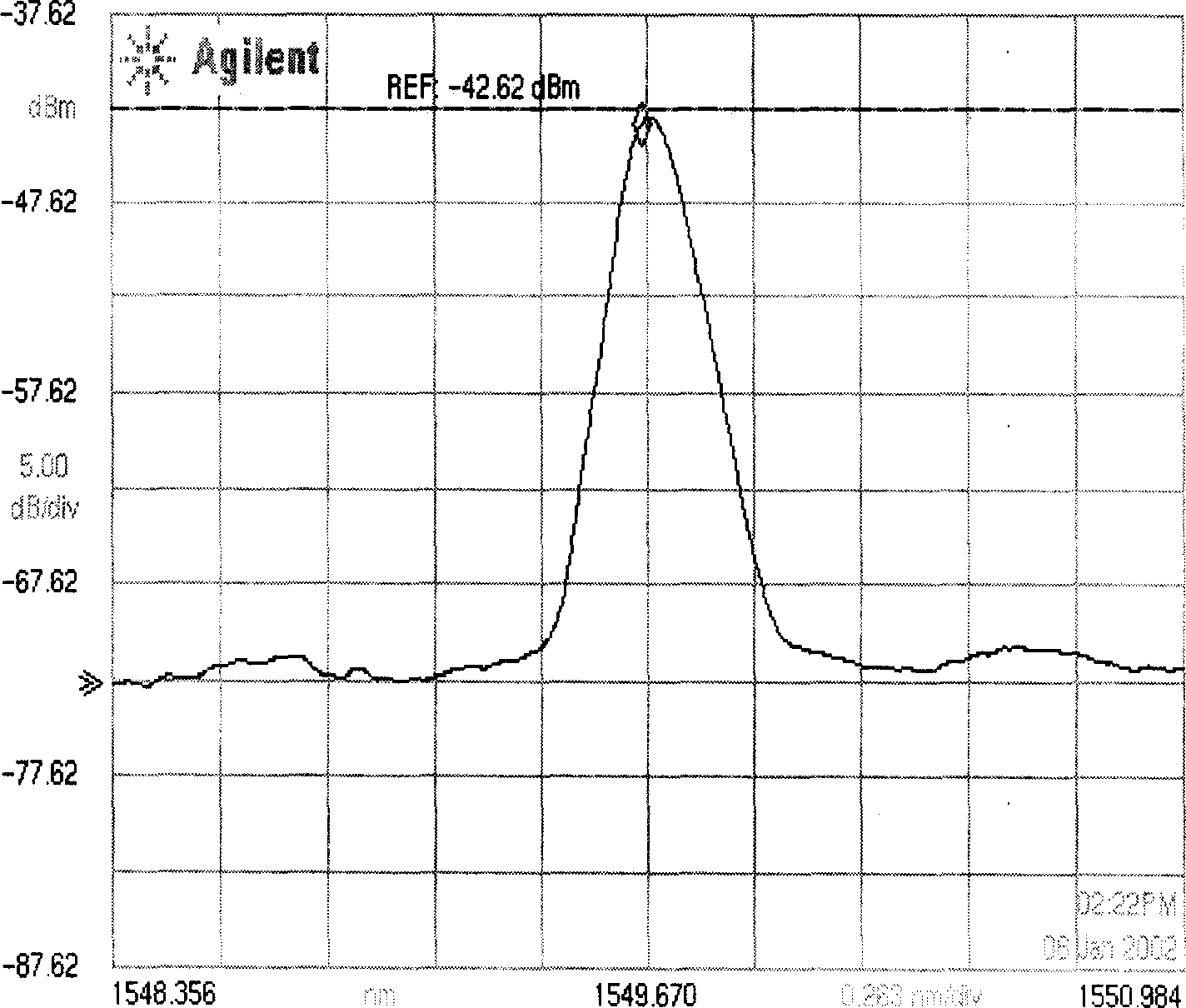

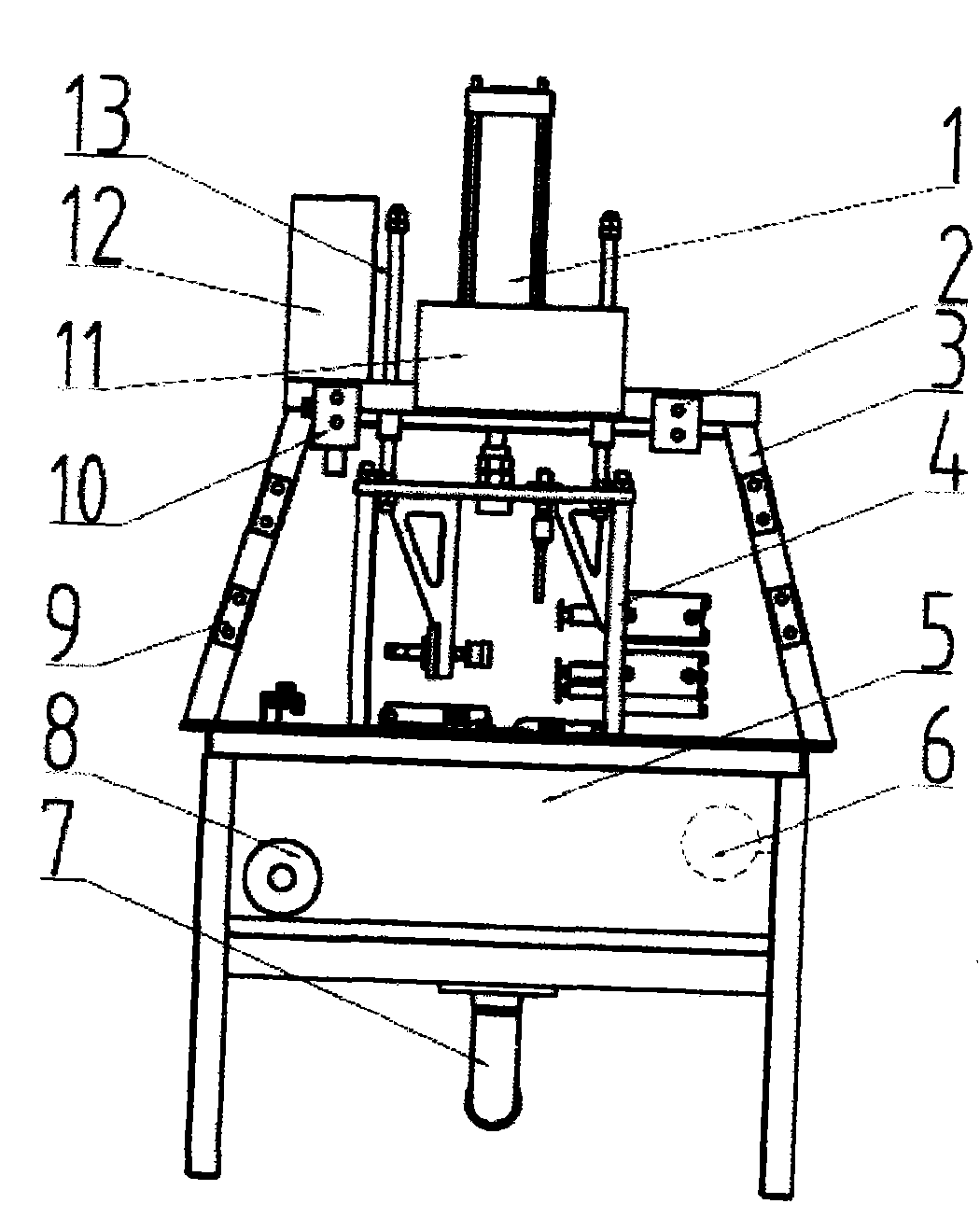

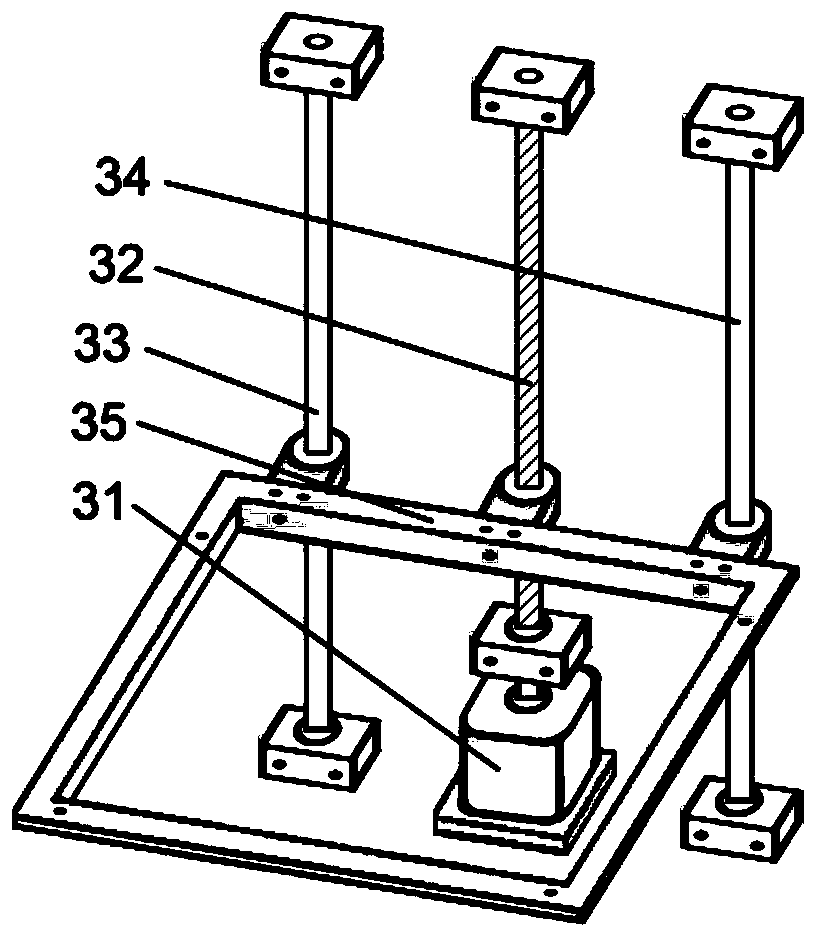

Comprehensive experiment table for performance parameters of harmonic reducer of robot

InactiveCN102494892ADetection of torque-life parametersAccurate Torque-Life ParametersMachine gearing/transmission testingReduction driveHarmonic

The invention discloses a comprehensive experiment table for performance parameters of a harmonic reducer of a robot, which belongs to the technical field of harmonic reducers and comprises a base, a load application device, a sliding seat, a servo motor and a control unit, wherein the load application device is mounted on the base, an input end of the load application device is connected with a flexible gear of the harmonic reducer, the sliding seat is slidably mounted on the base, slides towards the load application device and is provided with a fixing support for fixing a rigid gear of the harmonic reducer, the servo motor is slidably mounted on the sliding seat and slides towards the fixing support, a power output shaft of the servo motor is connected with a wave generator of the harmonic reducer, and the control unit is used for processing information and recording parameters and is connected with the servo motor and the load application device. The comprehensive experiment table is convenient in operation, is capable of truly and accurately detecting the performance parameters of the harmonic reducer, and is widely applied to detecting the performance of the harmonic reducer.

Owner:SHANDONG SHKE MACHINERY MFG

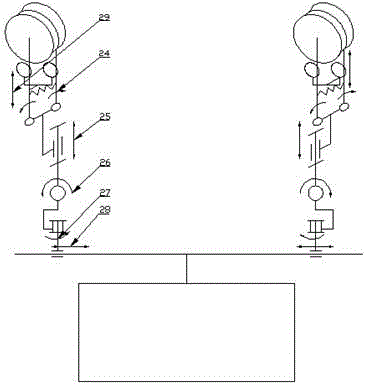

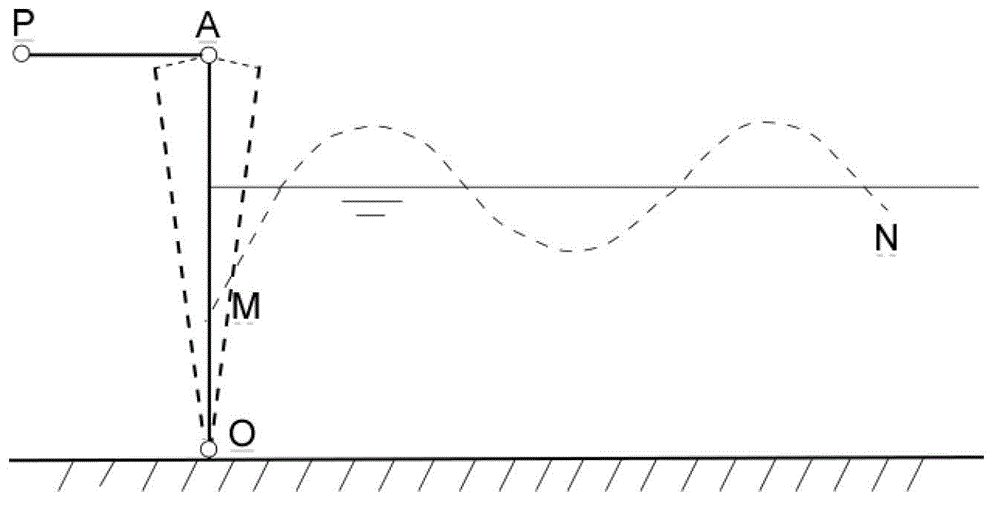

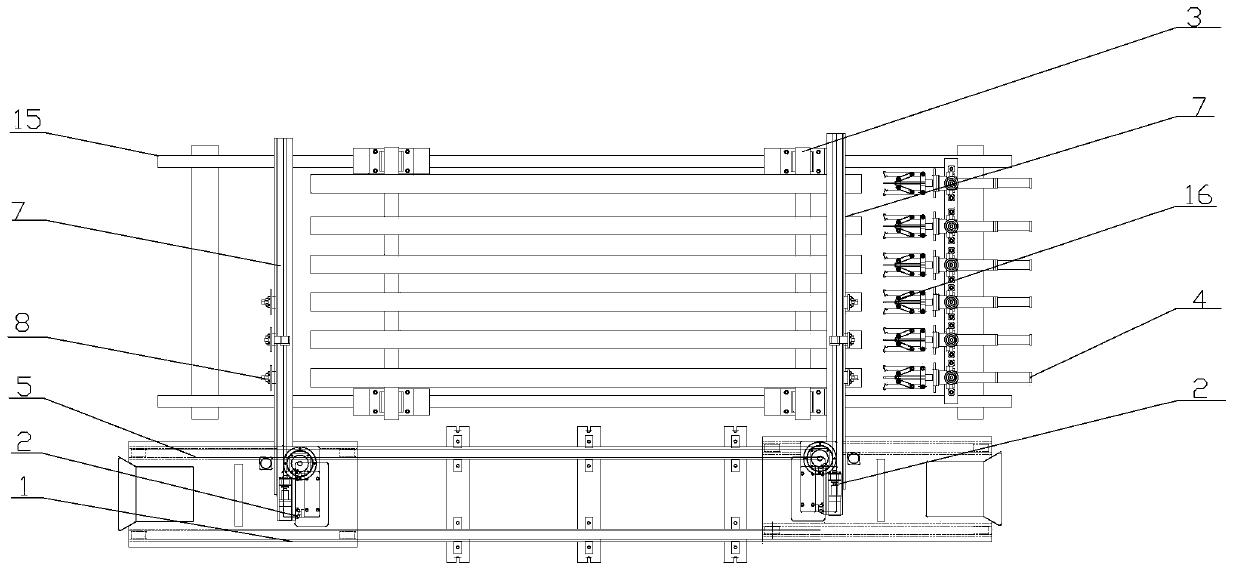

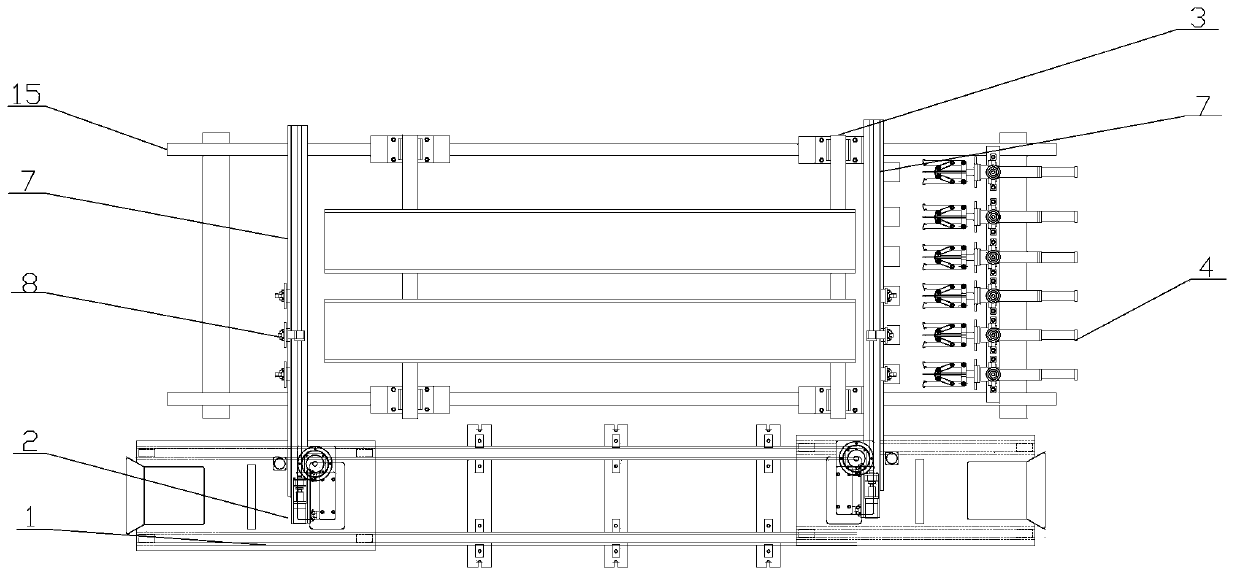

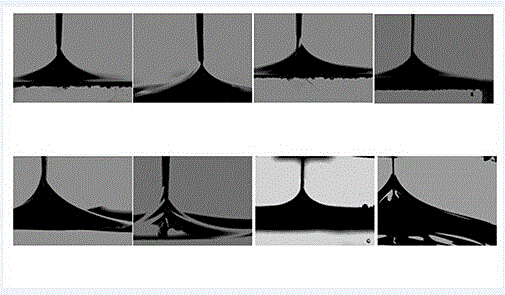

Wave generation device used for experiment

InactiveCN102865995ARealize one machine with multiple functionsStable structureHydrodynamic testingHydraulic modelsEngineeringCam

The invention relates to a wave generation device used for an experiment. The wave generation device used for the experiment comprises a control unit, a wave generation unit and a bracket, wherein the bracket is mainly composed of slide ways, a middle cross beam, a rotating wheel support plate, a belt wheel axle and a framework structure; the wave generation unit is mainly composed of multiple groups of wave generation structures; each group of the wave generation structures is mainly composed of two wave pushing plates, a push rod, four box type linear bearings, a connecting rod, a cantilever rod, a rotating wheel, a belt wheel and a triangle belt; the rotating wheel is formed by mutually engaging a cam and a concave wheel; the bearing, the connecting rod and the four box type linear bearings slide synchronously respectively along two adjacent slide ways; the other end of the connecting rod is connected to the cantilever rod while the other end of the cantilever rod is fixed on the concave wheel; the rotating wheel is fixed on the rotating wheel support plate; two ends of the triangle belt are respectively connected with the rotating wheel and the belt wheel; and two adjacent wave pushing plates of wave generation structures in different groups are connected through holes and grooves. The wave generation device used for an experiment, disclosed by the invention, has the advantages of a steady structure, high precision, strong wave generation capability, and extremely high practicability as well as generalization performances.

Owner:TSINGHUA UNIV

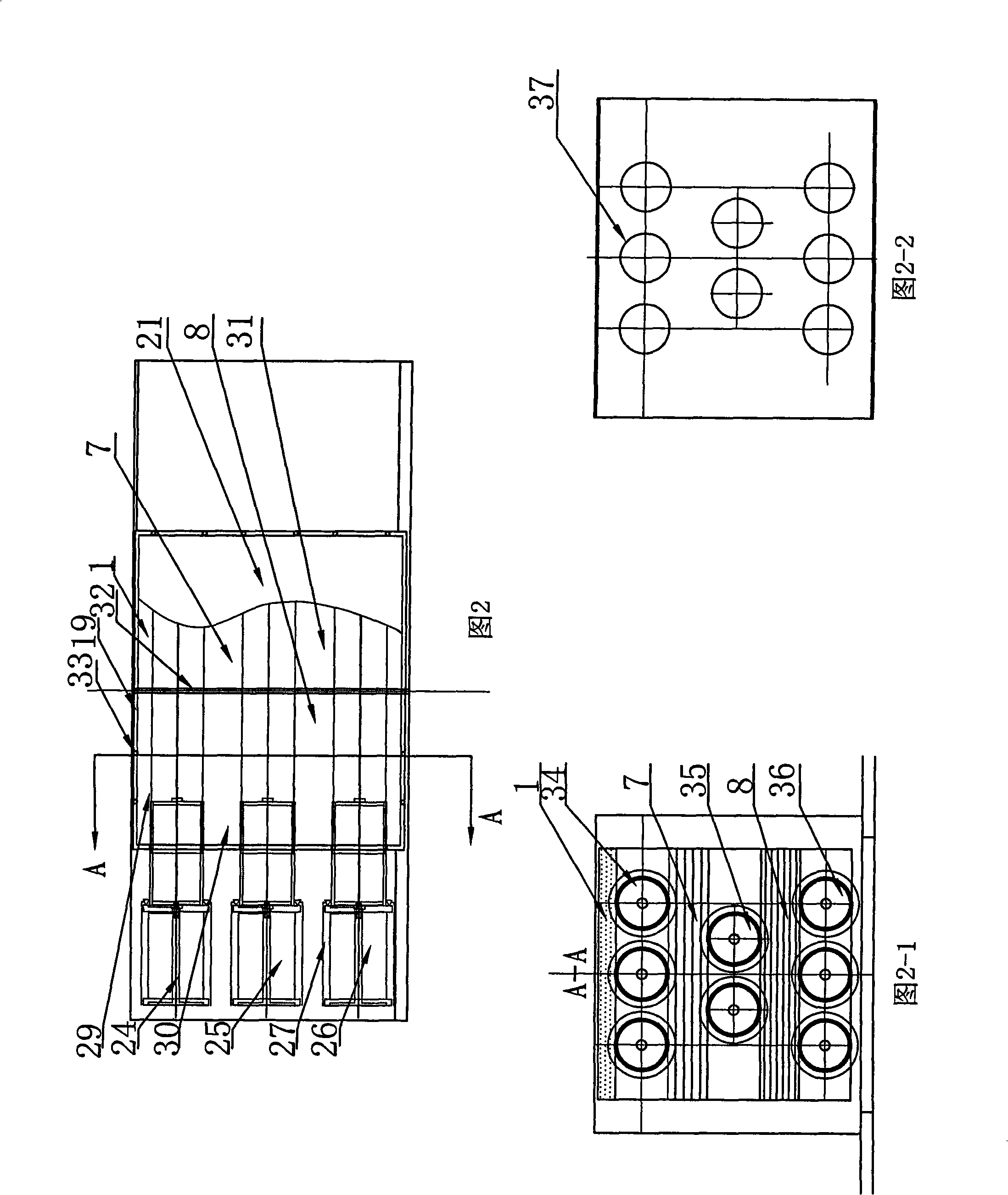

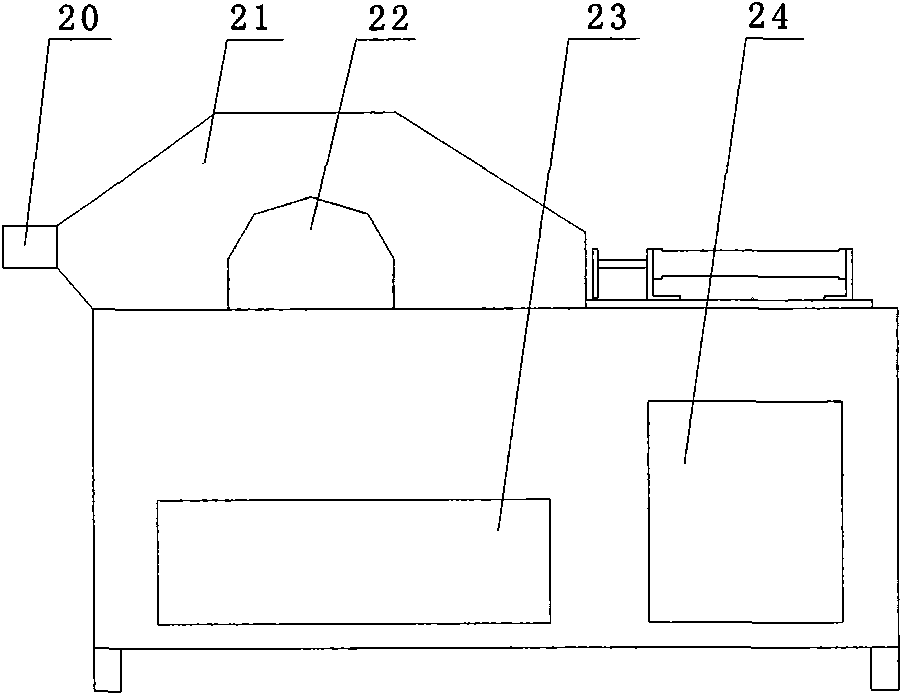

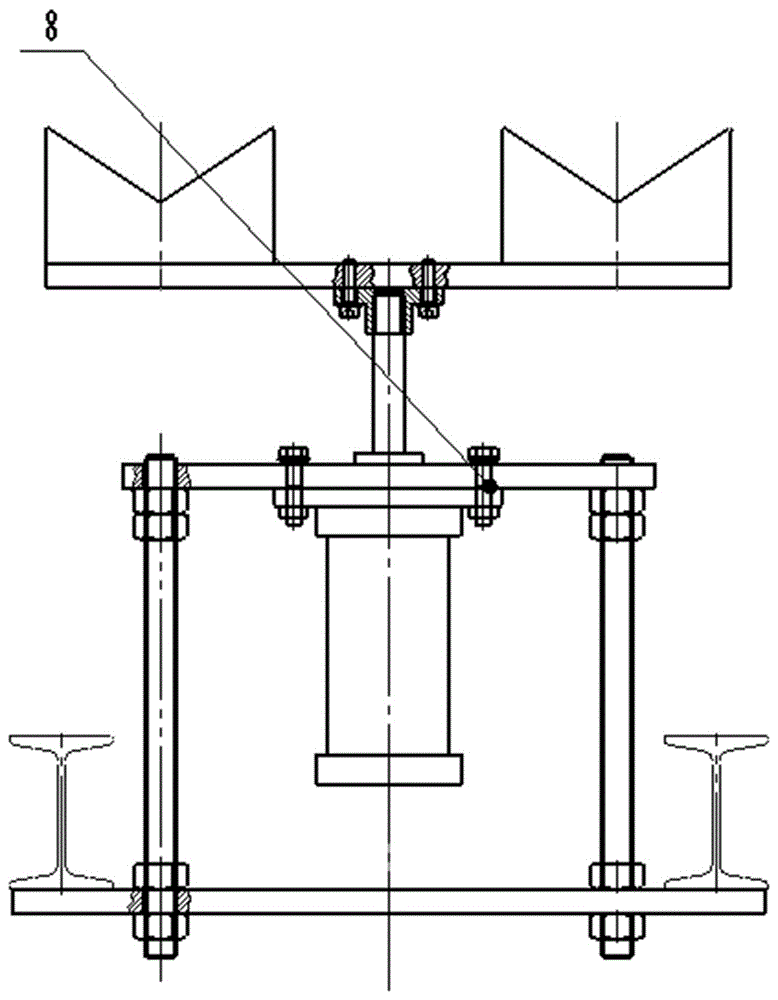

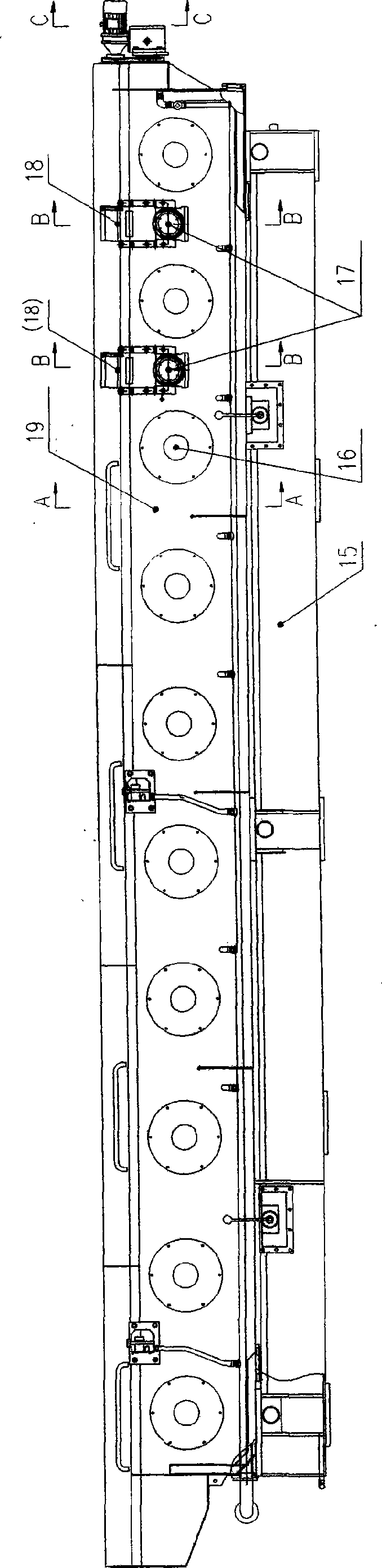

Split type multi-roller multi-component high-gradient vibration magnetic separator in permanent magnetism

InactiveCN101402069AHigh mechanical strengthEasy to replaceHigh gradient magnetic separatorsMagnetic separatorEngineering

The invention relates to a permanent magnetic midsplit type multi-roller multivariate high gradient vibration magnetic selector, which comprises a stander (12), a magnetic selection box body arranged above the stander (12) through a vibration reduction spring set (18), a plurality of permanent magnetic rollers arranged inside the magnetic selection box body, a feed hopper (22) positioned on the top of the magnetic selection box body and a feed discharging passage (17) positioned on the bottom of the magnetic selection box body. The vibration magnetic selector is characterized in that the permanent magnetic rollers are made from magnetic materials with different magnetic strengths; according to a two-dimensional matrix form, the plurality of the permanent magnetic rollers are arranged to construct a multivariate sorting magnetic field; the permanent magnetic rollers made from the magnetic material of the same type are positioned on the same plane; according to the magnetic strengths, the permanent magnetic rollers with different magnetisms are in deltaic alternate arrangement sequentially from top to bottom along the flowing direction of the materials; magnetic concentrating medium grooves with the same specification are arranged between the adjacent permanent magnetic roller layers in different layers and above the upper layer of the permanent magnetic roller layers; and the inside of each groove is provided with magnetic concentrating media with different types.

Owner:HENAN POLYTECHNIC UNIV

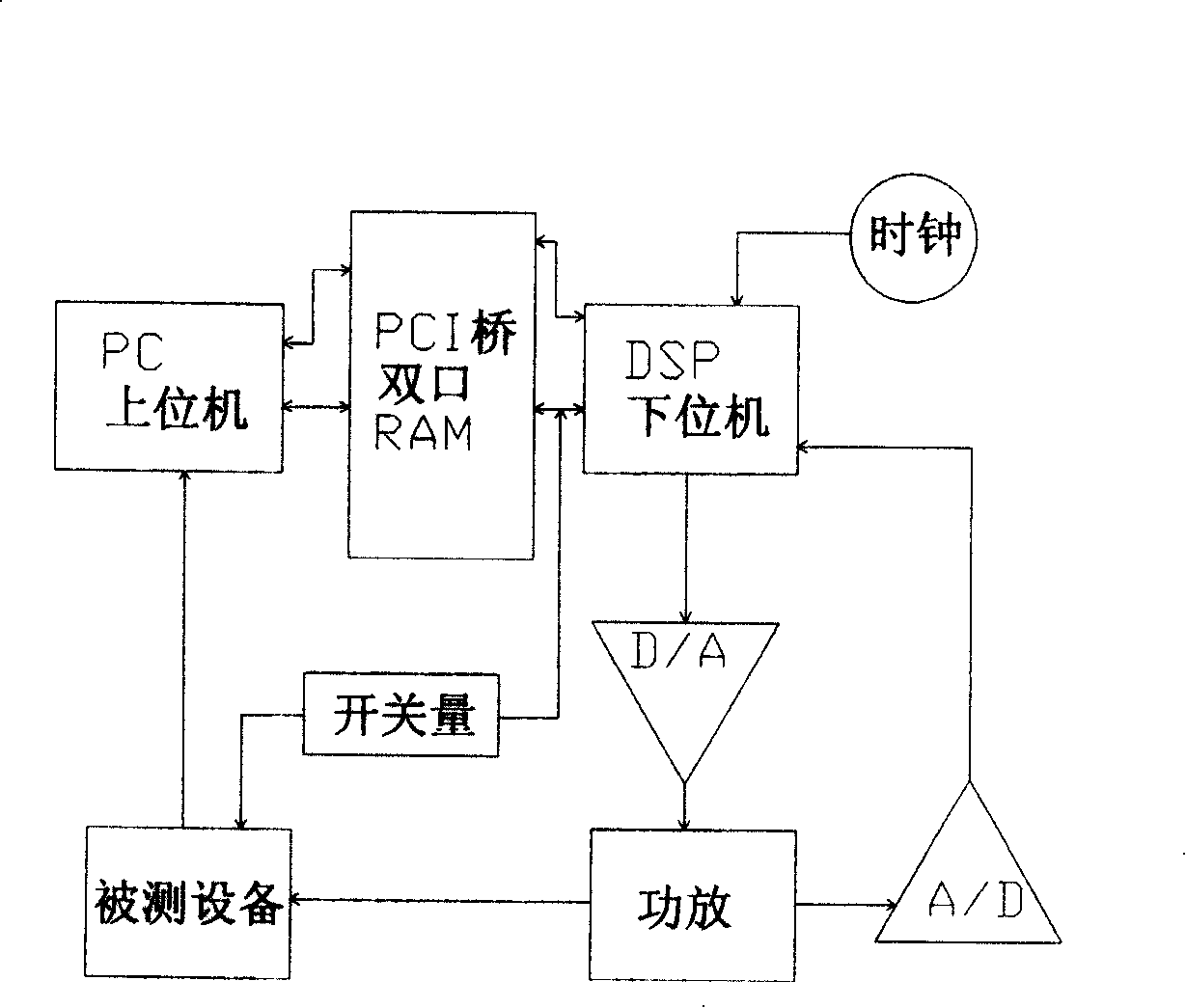

Electric power apparatus integrated automated detection system

InactiveCN101241155ARealize transmissionEasy to upgradeCircuit arrangementsElectrical testingElectric power systemElectric power equipment

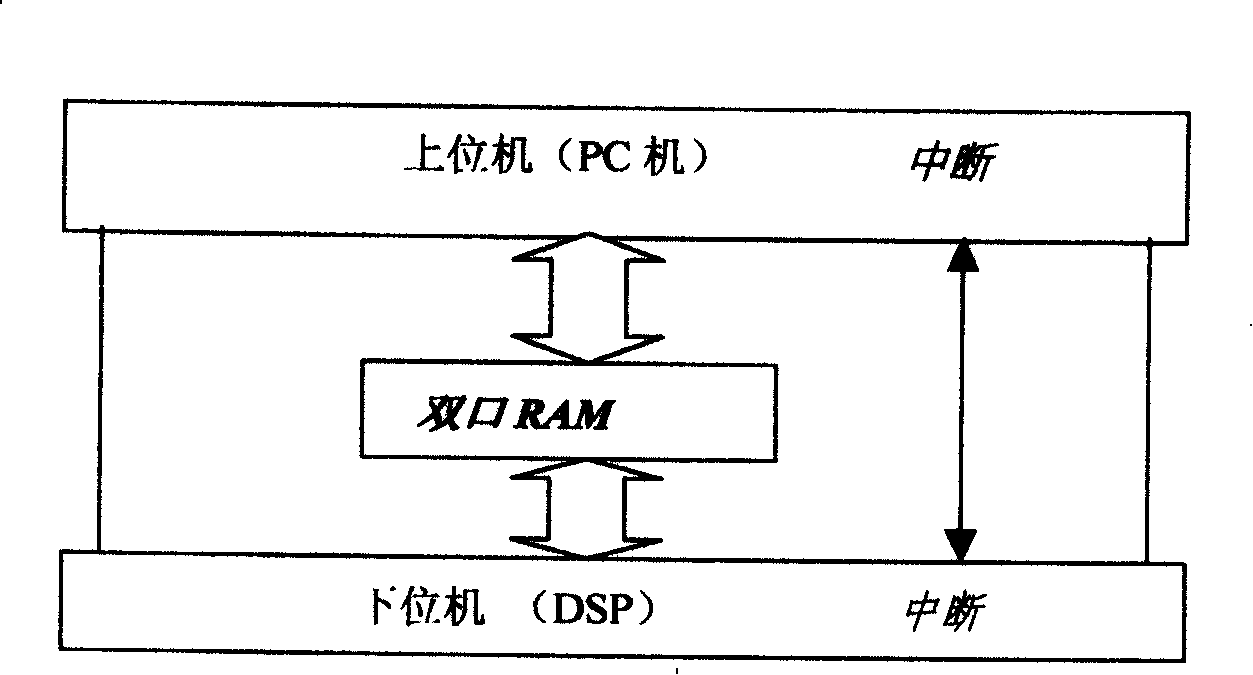

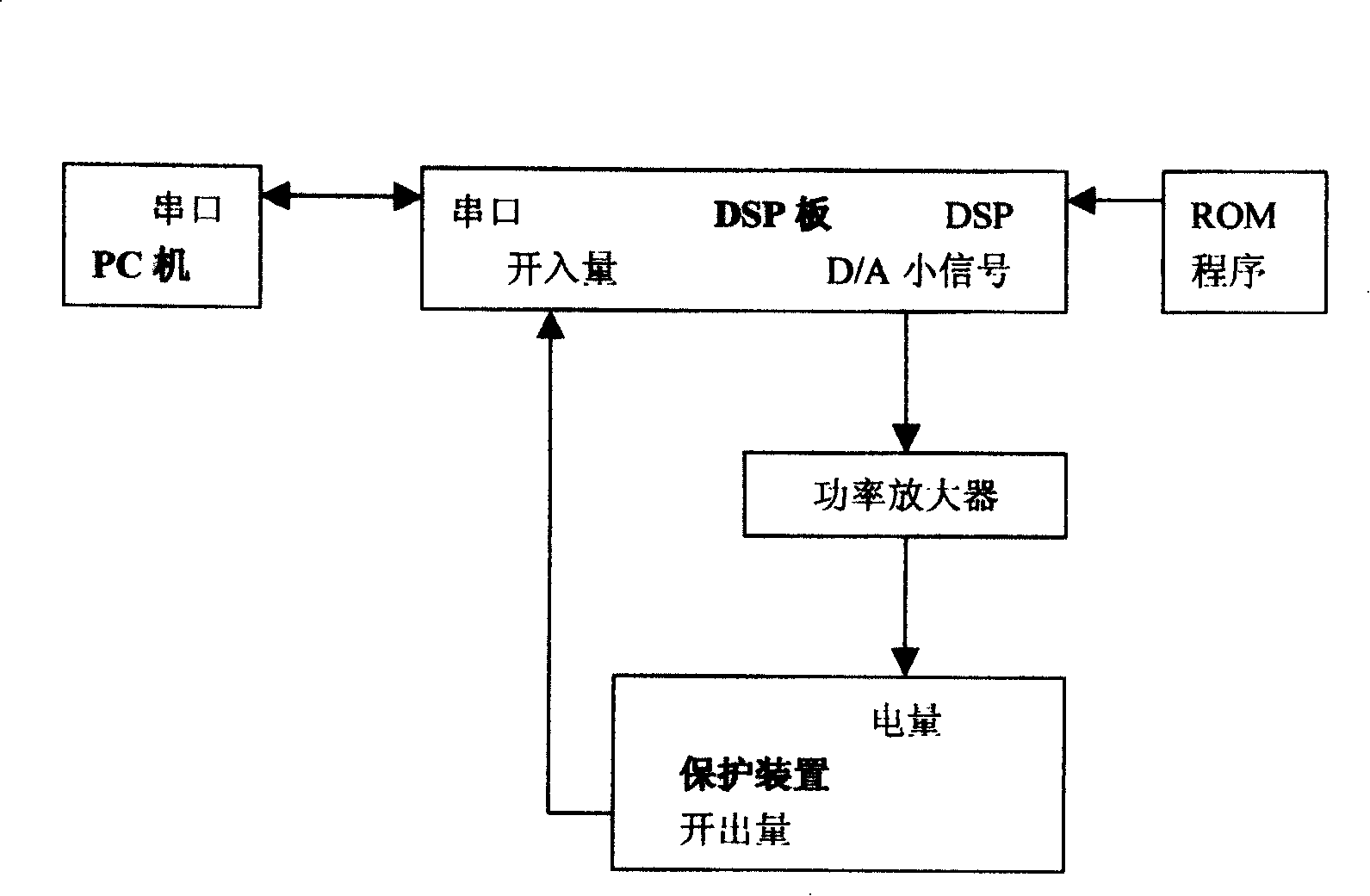

The present invention provides an integration automatization examining system of electric power equipment which relates to fields of integration automatization examining of electric power system, which comprises of host computer PC, lower computer DSP, power amplifier. A PCI bridge with dual-port RAM is connected between host computer PC and lower computer DSP, a sampling circuit connected with analog-to-digital converter in series is placed between power amplifier and lower computer DSP. Parameters and orders are input to host computer PC, selected program downloaded by PC is transferred to DSP, data current is passed through memorizer of DSP, and examining task is carried by DSP. The present invention changes former mode of customization examining device and realizes a multi-use machine, makes the upgrade operation of program convenient, can transfer large current data, and has high precision. The present invention can finish all kinds of protection functional testing of remote control, remote examining, remote signaling of on-line examining and inspection, can communicate with device to be measured, and display testing result on testing report automatically. The report employs Word document, so it's convenient operation by users.

Owner:扬州奥瑞科技有限公司

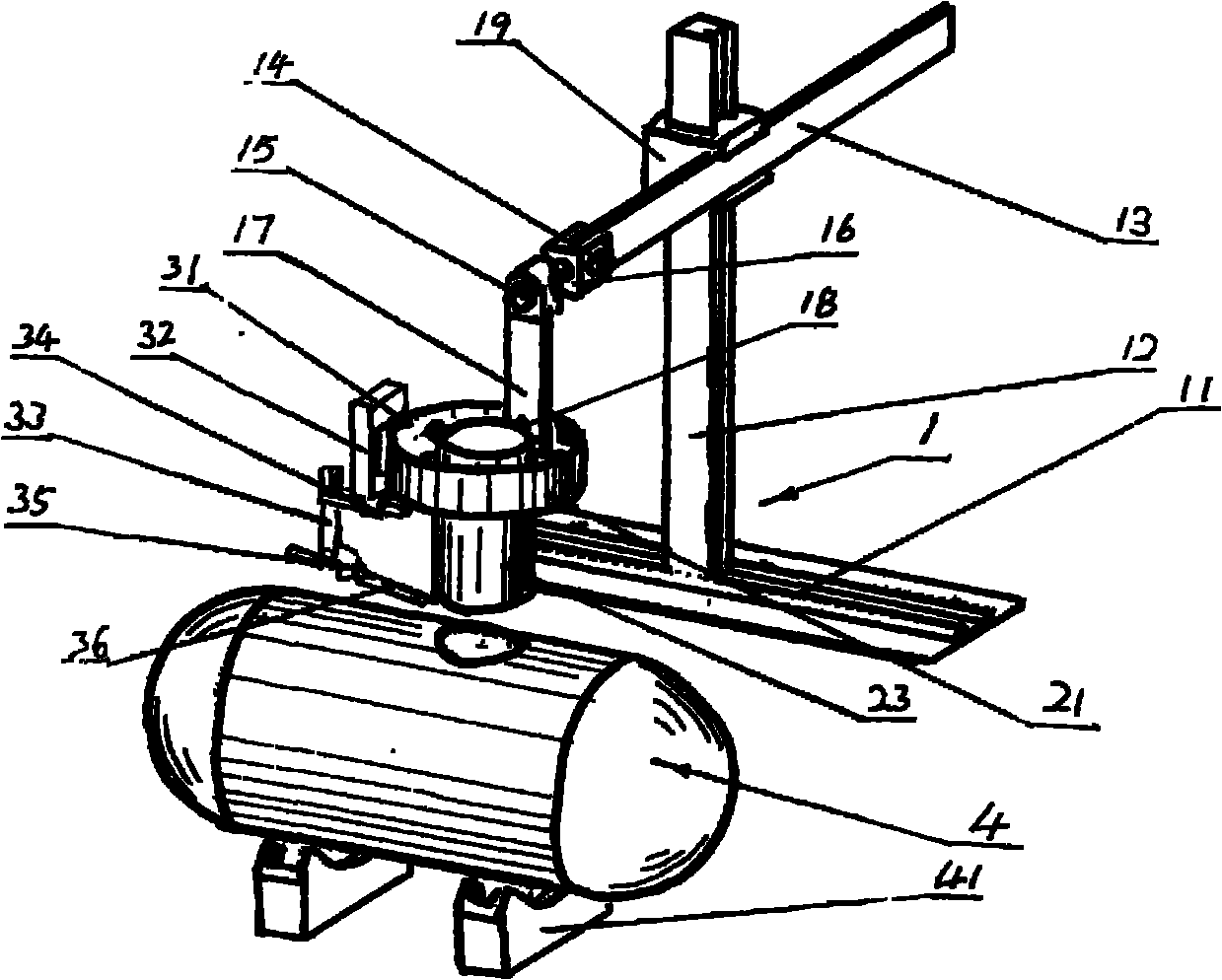

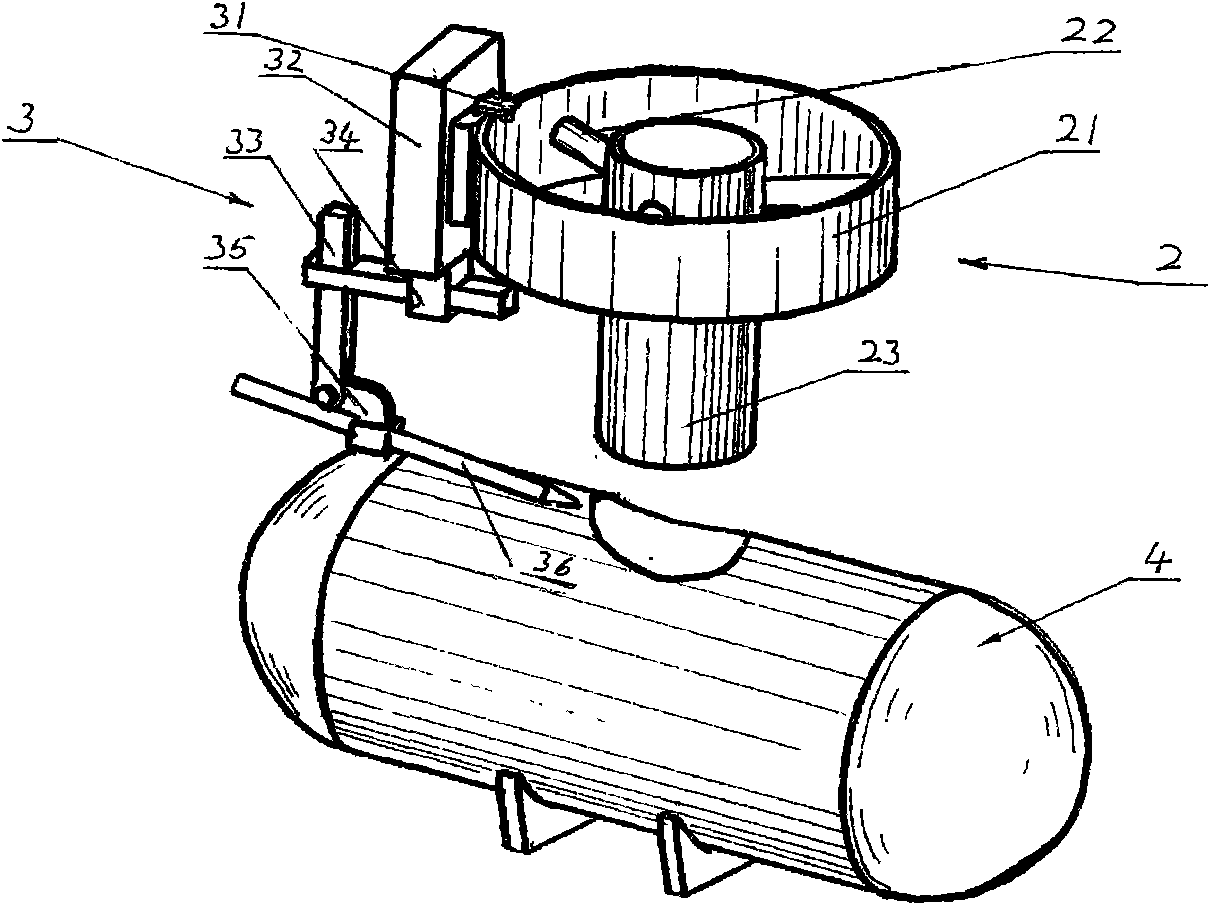

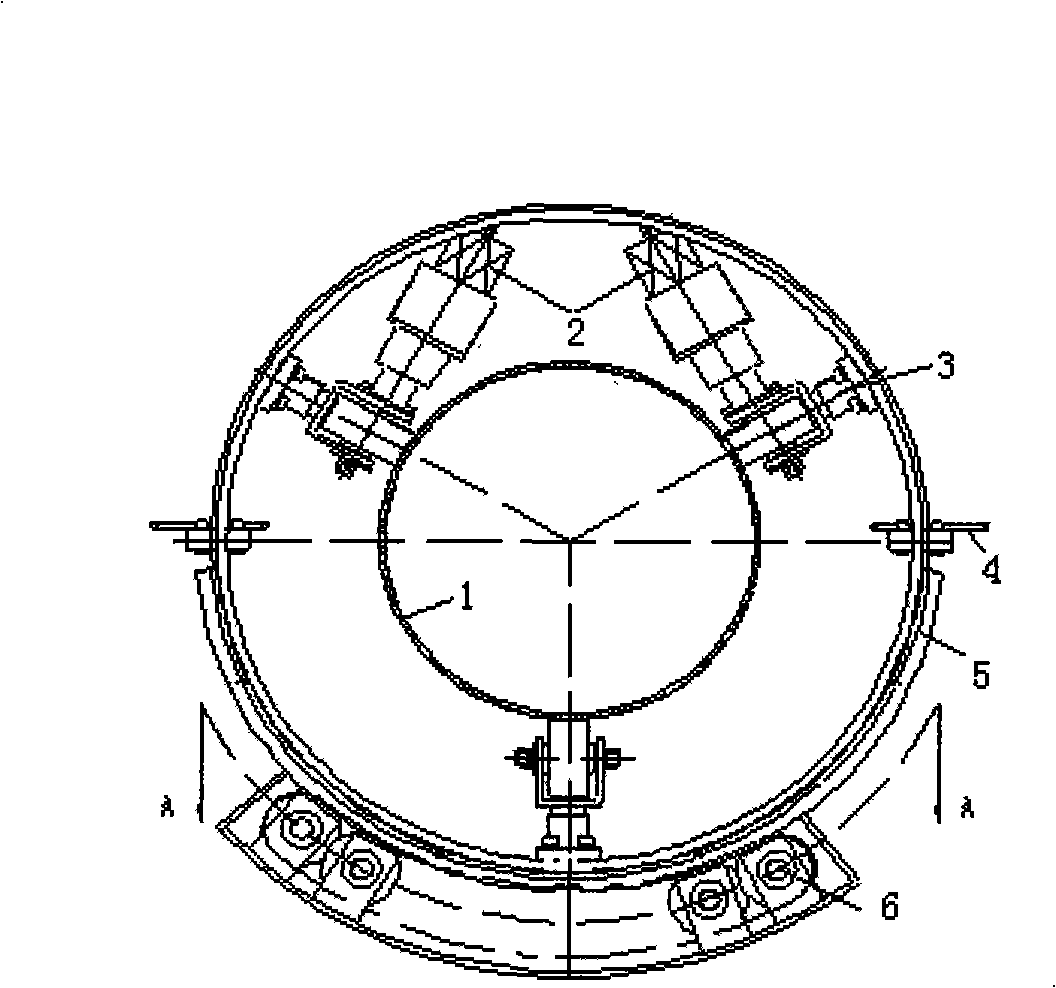

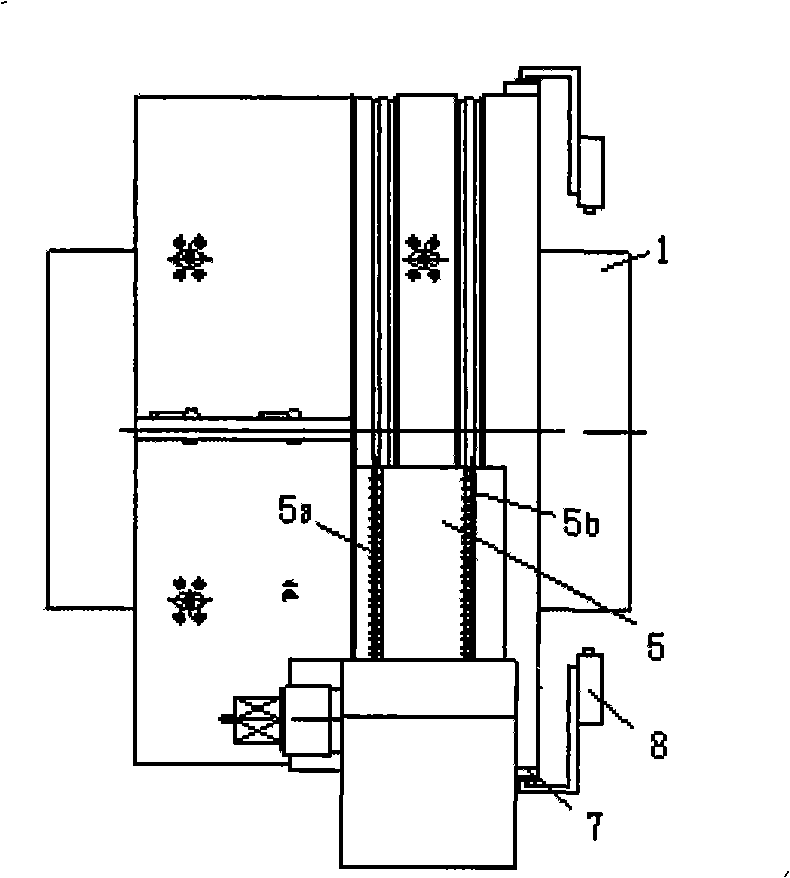

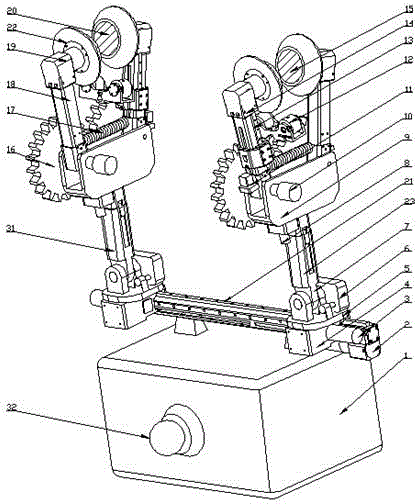

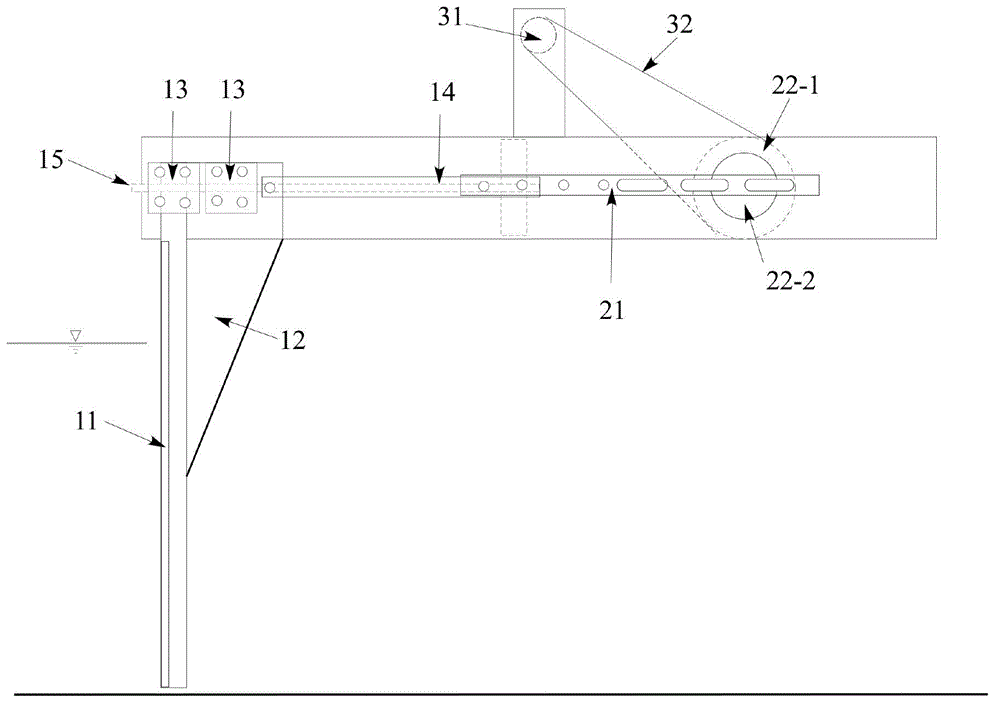

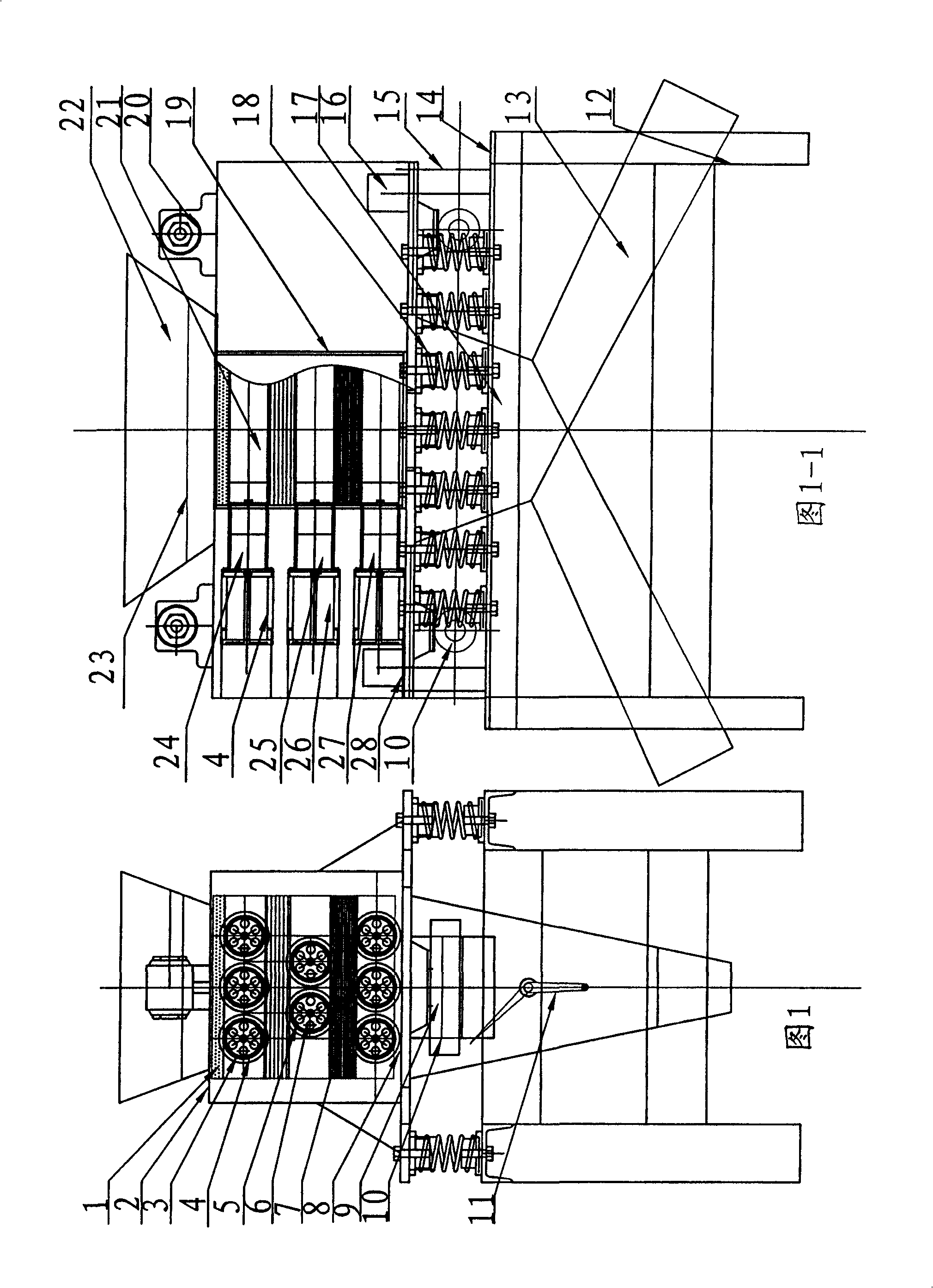

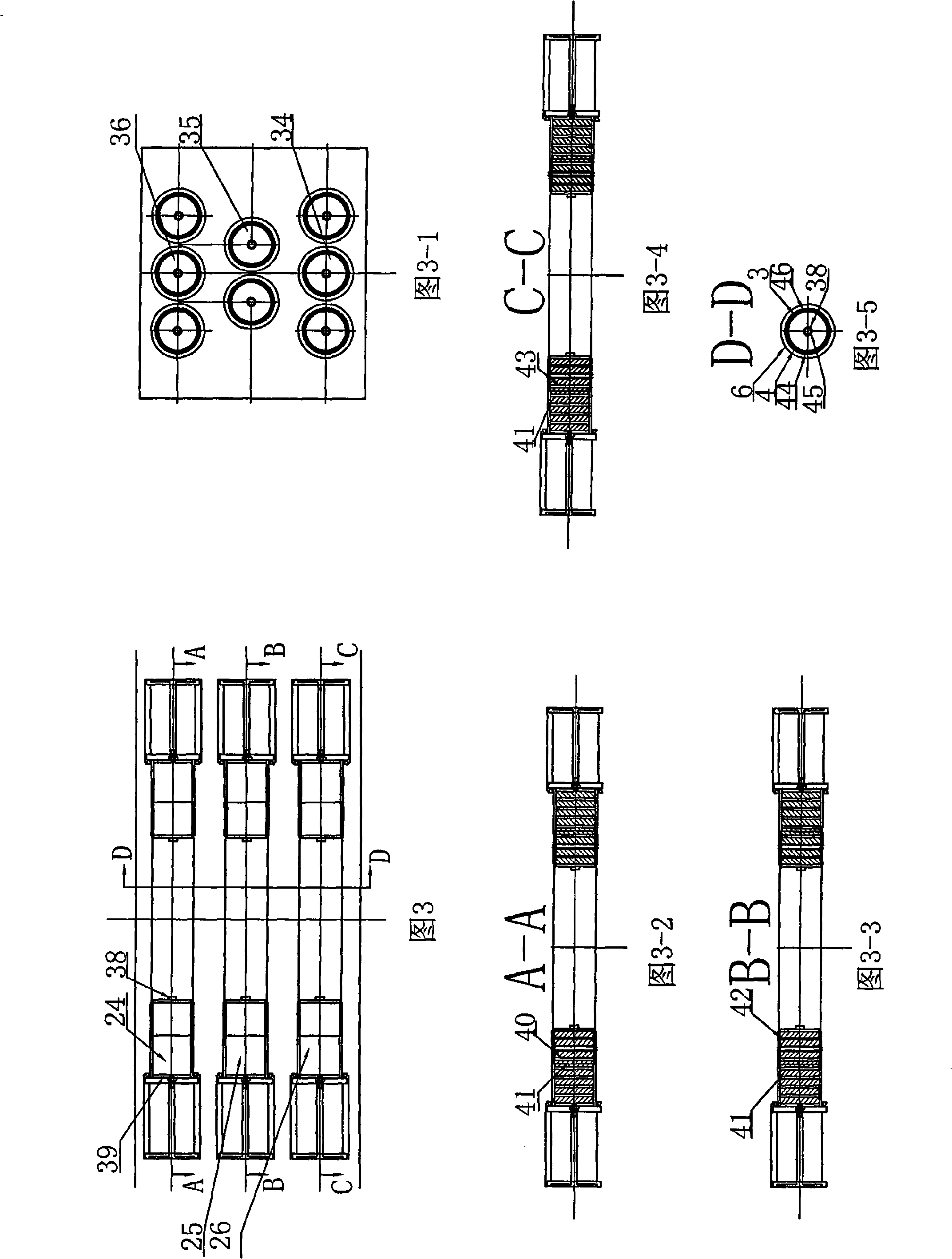

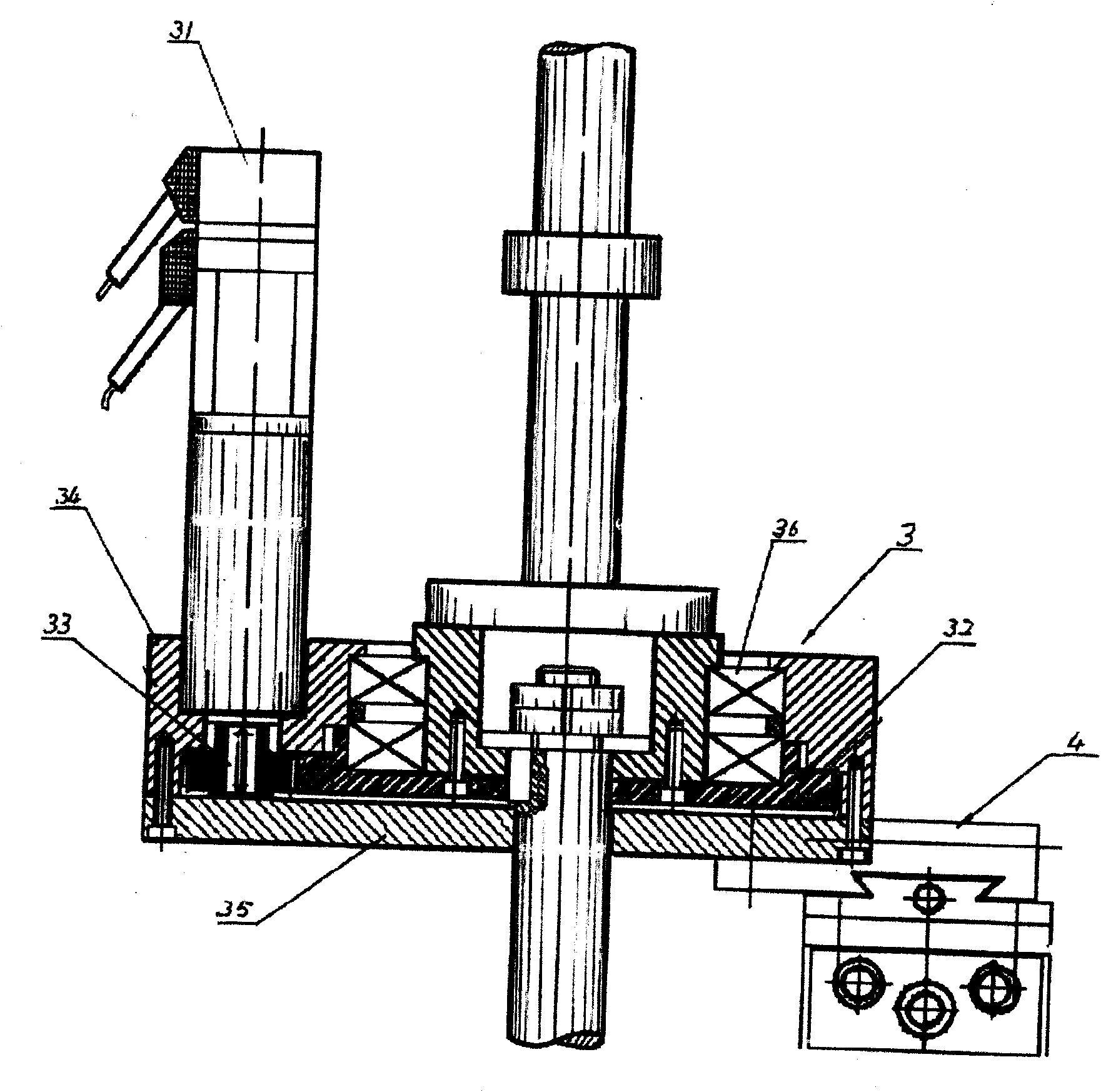

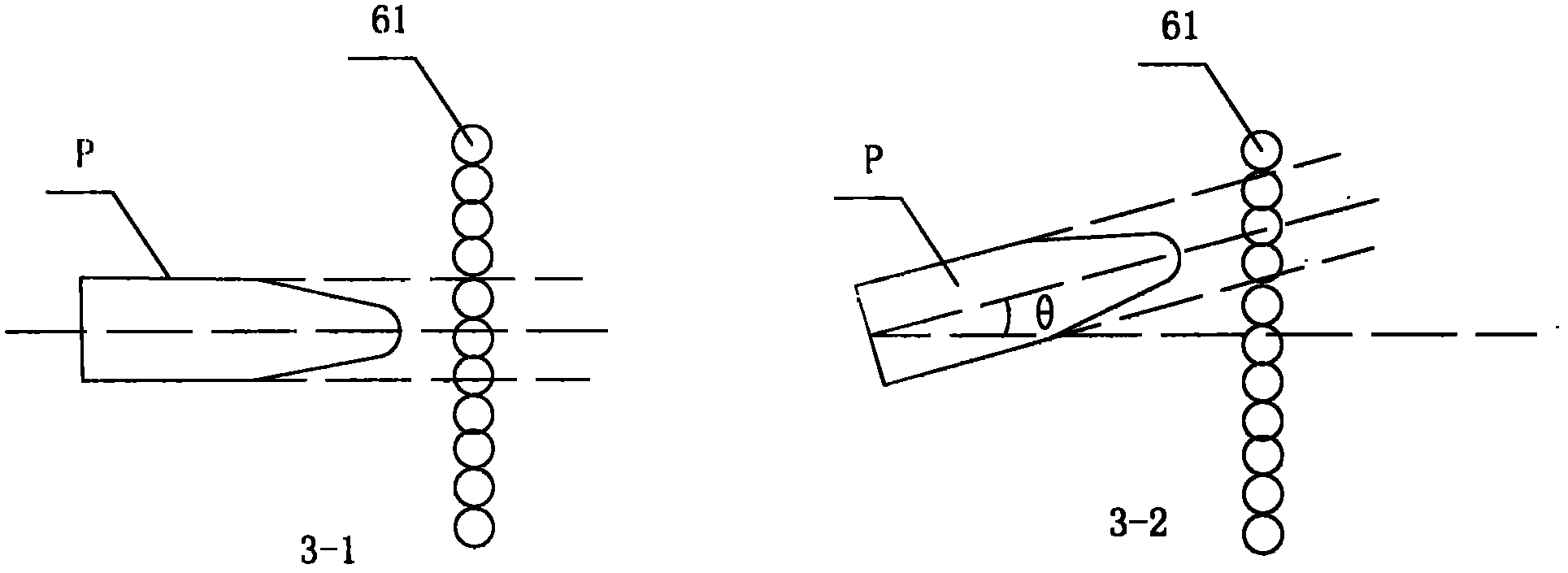

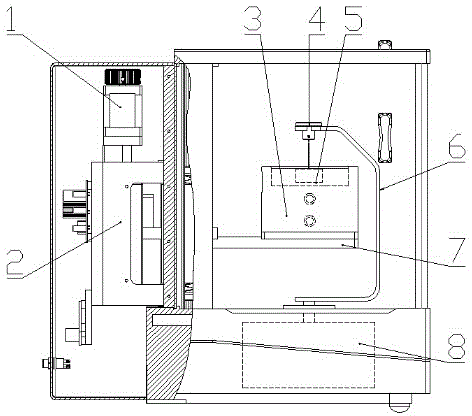

Portable integrated machine for opening tube connecting and saddle-shaped weld joint welding

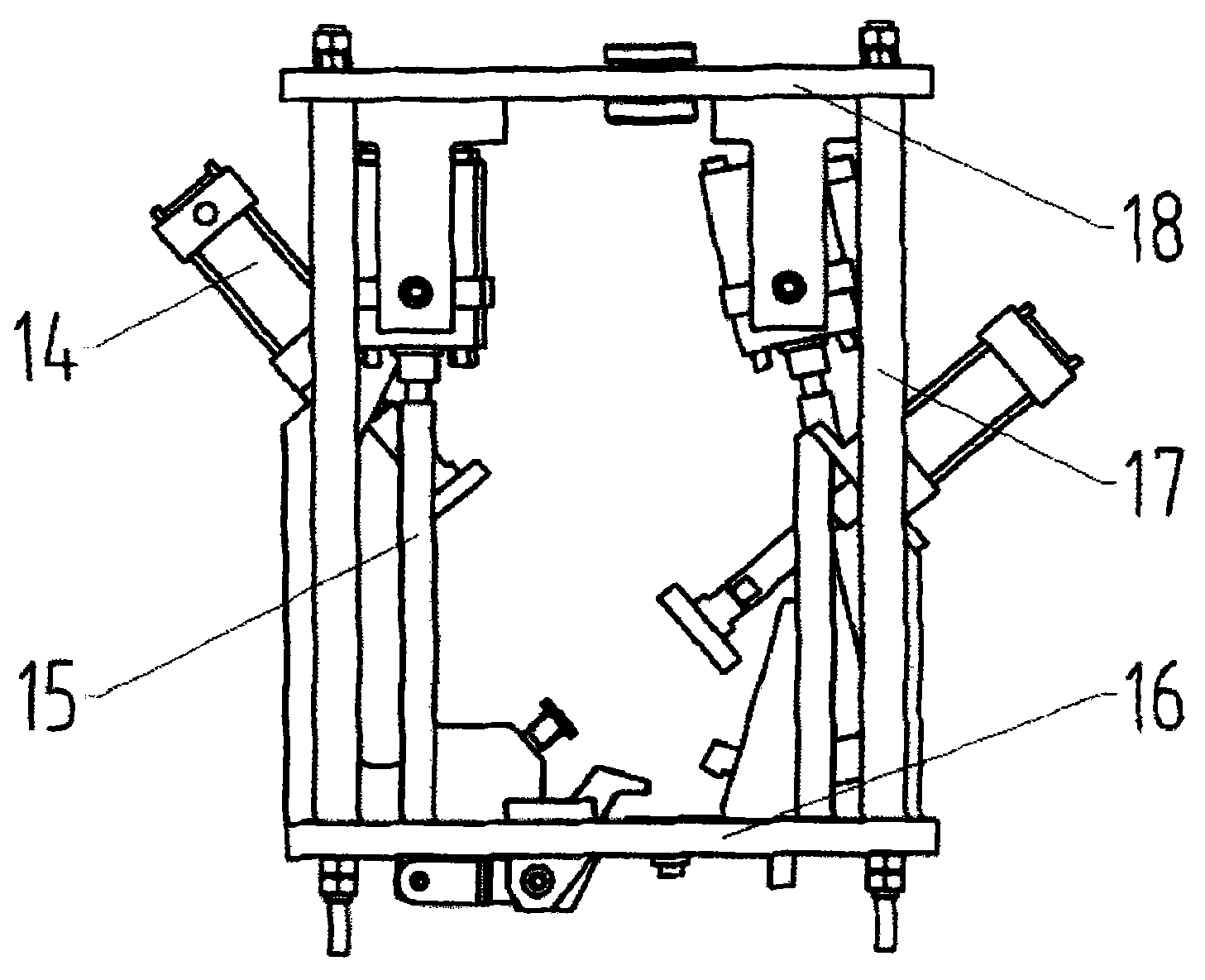

InactiveCN102248332AImprove system flexibilityPrevent the nozzle from tiltingWelding/cutting auxillary devicesAuxillary welding devicesSaddle shapeEngineering

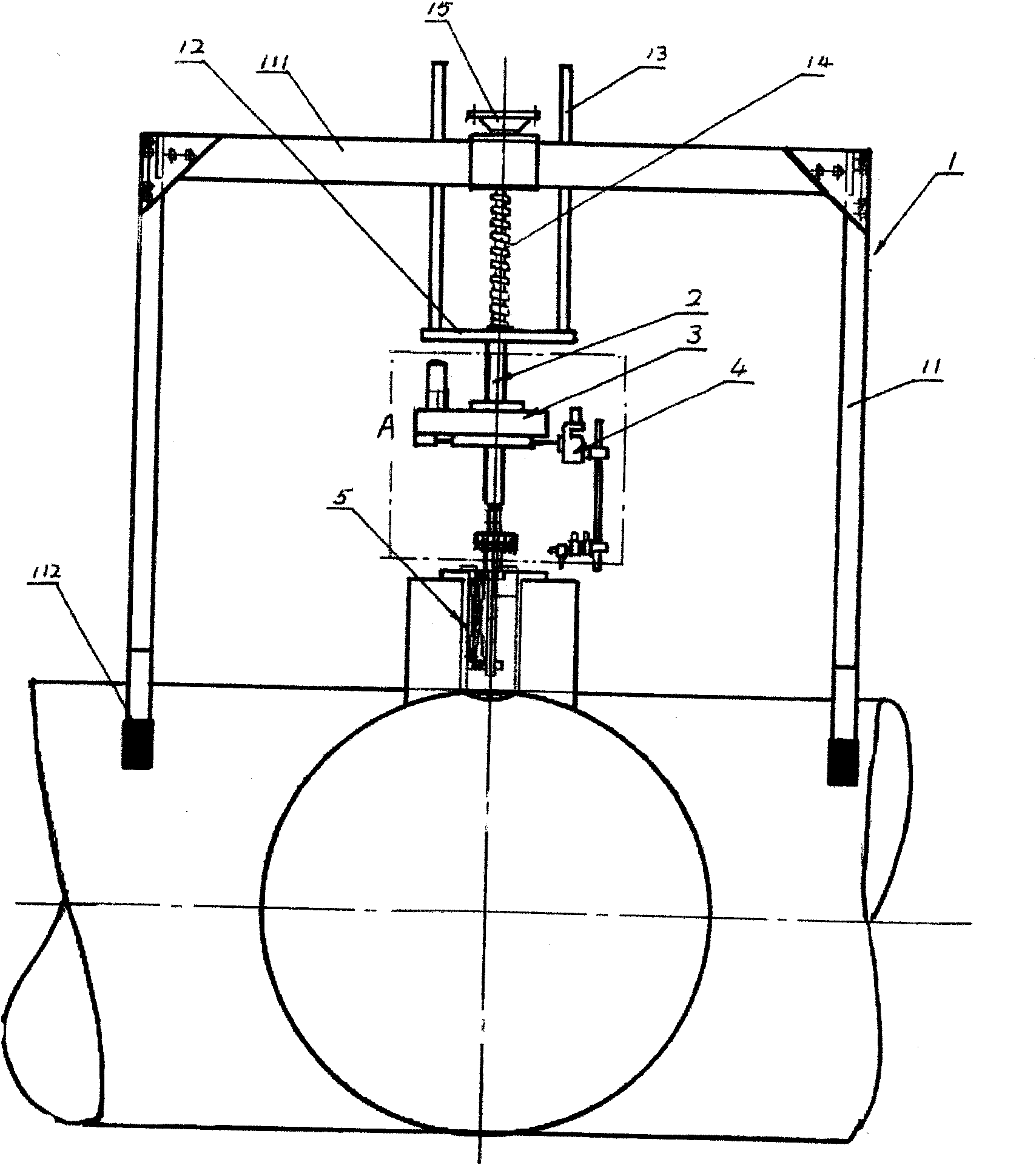

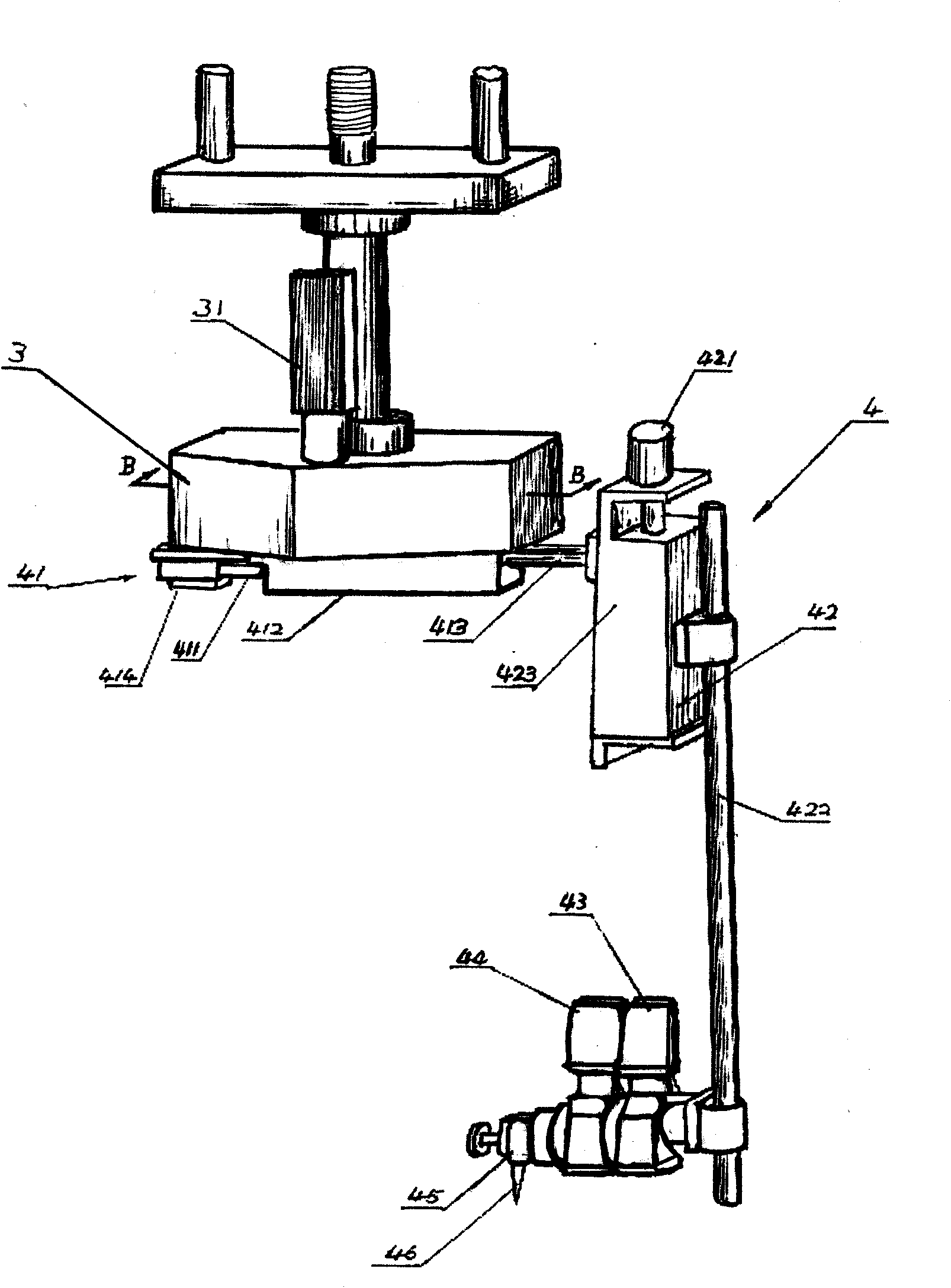

The invention relates to a portable integrated machine for opening tube connecting and saddle-shaped weld joint welding, mainly comprising a hanging bracket (1), a main shaft (2), a rotating disk (3), a welding head (4) and a pipe-expansion mechanism (5), wherein a magnetic base (112) is arranged at a support part of the hanging bracket (1); the rotating disk (3) mainly comprises a big gear wheel (32) fixedly connected with the main shaft (2) and a rotating motor (31) fixedly connected with an outer disk (34); a pinion (33) at an end part of the rotating motor (31) is meshed with the big gear wheel (32); a circular movement of the welding head (4) around the main shaft (2) can be realized through the rotating disk (3); and the rough and accurate positioning of a welding gun (46) can be realized through regulating mechanisms such as welding gun radial direction, height, pose, swing, clamping and the like so that the opening tube connecting and saddle-shaped weld joint welding are realized. According to the invention, the flexibility of a system is enhanced and the vector superposition of multidimensional movements can be accurately carried out so that the quality of a technical process is guaranteed; and the portable integrated machine has the advantages of simple and compact structure, low cost as well as simpleness and easiness in use, maintenance and repair.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Honeycomb ceramic dry green body dual-blade cutting machine

InactiveCN101579887ANo deformationNo damageCeramic shaping apparatusWorking accessoriesControl systemElectric machinery

The invention relates to a honeycomb ceramic dry green body dual-blade cutting machine, which consists of a cutting device, a linear working table, a hydraulic system, a dust collector and a control system, wherein the cutting device adopts a dual-blade structure, and two parallel round diamond blades are connected with a main shaft driven by one or two motors respectively; and the linear working table conveys a green body to the cutting device and consists of a green body clamping device and a green body conveying device provided with a travel switch for controlling motion. The green body clamping device consists of a cylinder, a green body clamp and a green body liner plate and is used for clamping and cutting a dry green body, and the clamping degree of the green body is controlled by adjusting the pressure of compressed air with a pressure adjusting valve so that a finished product after cutting is not deformed and damaged; and the green body conveying device drives the working table to perform linear feeding motion under the control of the hydraulic system and the travel switch.

Owner:JIANGSU GAOCHUN CERAMICS +1

Medicine application device and medicine application method

ActiveCN104663633ABroaden your optionsResidue reductionInsect catchers and killersAgricultural sciencePesticide residue

A device for applying a pesticide and a method for applying same, in which the pesticide is present in the form of a pesticide solution that can be atomized; the pesticide solution is atomized by ultrasonic oscillation; and providing a dynamic air flow to the atomized pesticide solution, so as to take the atomized pesticide solution away and to apply it in the environment where the application target is located. The pesticide particles applied by the device for applying a pesticide have a small particle size and a concentrated particle spectrum, which can be effectively absorbed by the target, and thus it is difficult to cause pesticide residues and waste. The rapid spread of a biologically active pesticide in a natural state can be achieved, so as to make the effective biological equivalent weight of the biologically active pesticide reach the maximum quantity in a relatively short period of time.

Owner:北京中知领见科技有限公司

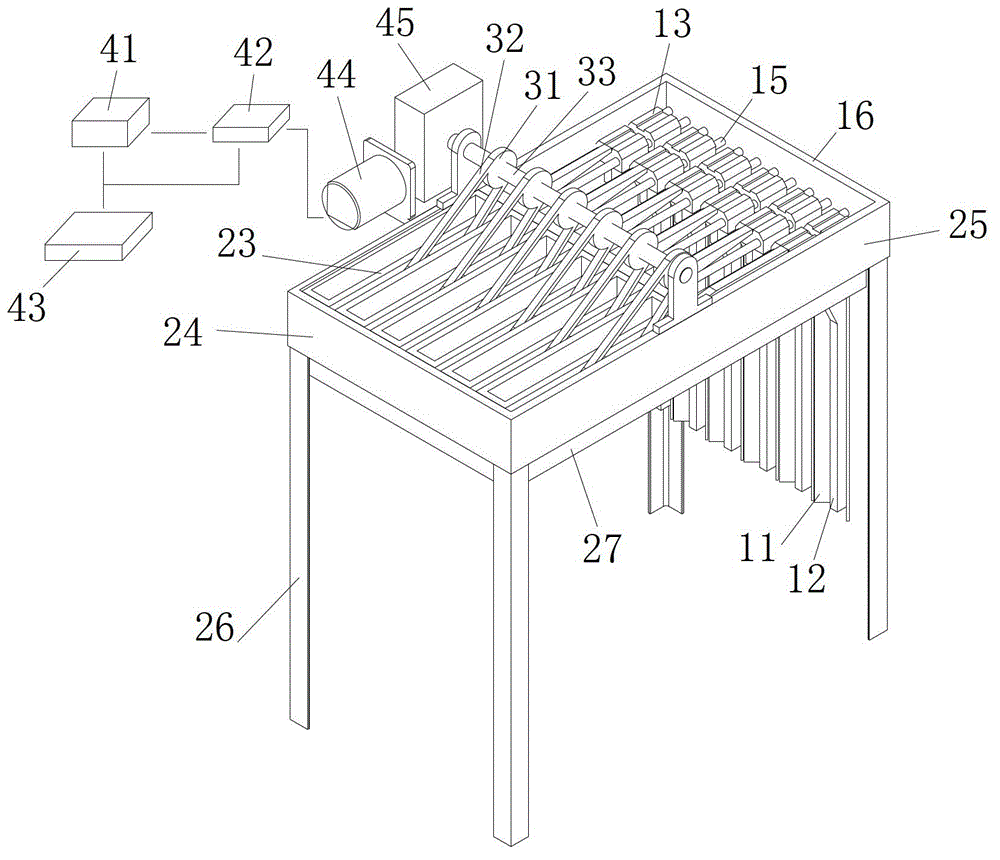

Full-automatic double-station device for spraying paint on outer surfaces of cast iron pipes

ActiveCN106111401AUniform paint thicknessQuality improvementLiquid surface applicatorsSpraying apparatusAutomatic controlEngineering

The invention relates to a full-automatic double-station device for spraying paint on the outer surfaces of cast iron pipes. A bracket is mounted on the ground. A guide rail is arranged at the upper part of the bracket. A paint spraying trolley and dust removing trolleys are mounted on the guide rail and can move along the guide rail. The paint spraying trolley is connected with the dust removing trolleys. Another guide rail used for allowing a primary tip trolley and a secondary tip trolley to travel is arranged in the middle of the bracket. Pneumatic devices are connected with the tail parts of the primary tip trolley and the secondary tip trolley. A trolley guide rail is arranged under the bracket. A pipe feeding and discharging stepping trolley is mounted on the trolley guide rail, and is connected with a stepping trolley cylinder and a duplex cylinder, which are mounted on the bracket. Automatic aligning devices are arranged in front of the bracket, are parallel to the bracket, and are connected with a pneumatic system. The full-automatic double-station device can be used for spraying paint on cast iron pipes which are 3 m long and have different external diameters, and adopts automatic control, the labor condition and the operation environment are improved, the labor intensity of workers is effectively reduced, the paint sprayed cast iron pipe is high in quality, and high in precision, and the working efficiency is improved effectively.

Owner:侯马市风雷管模制造股份有限公司

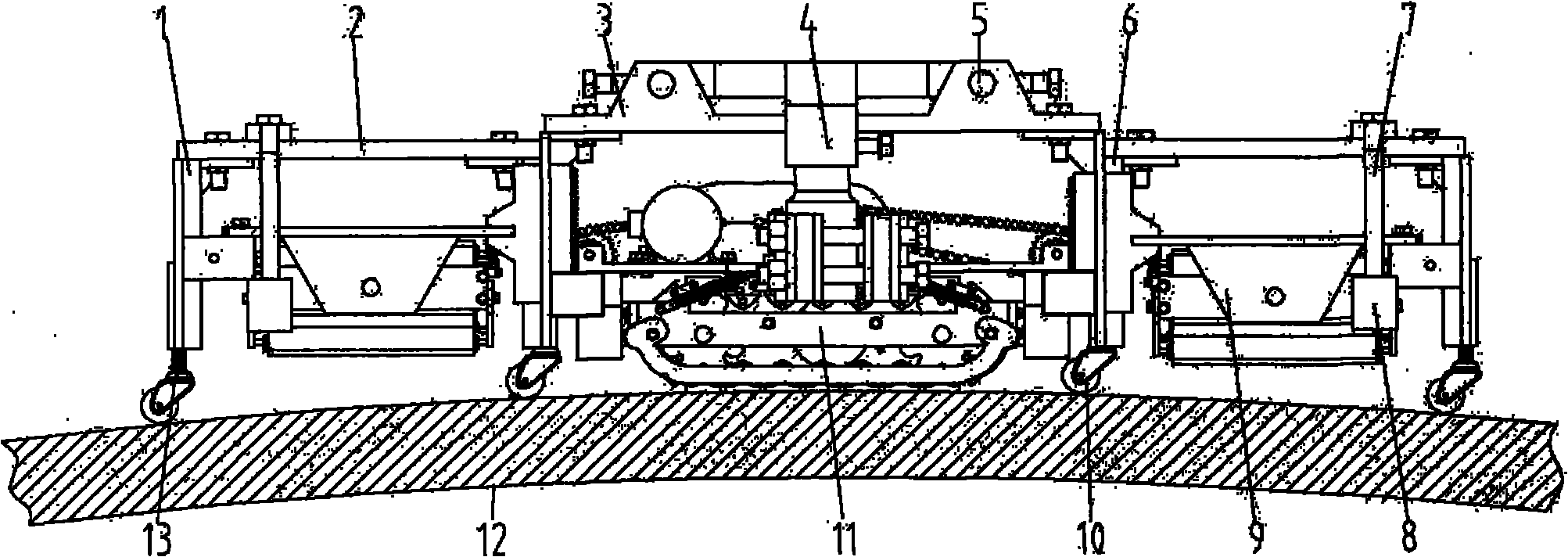

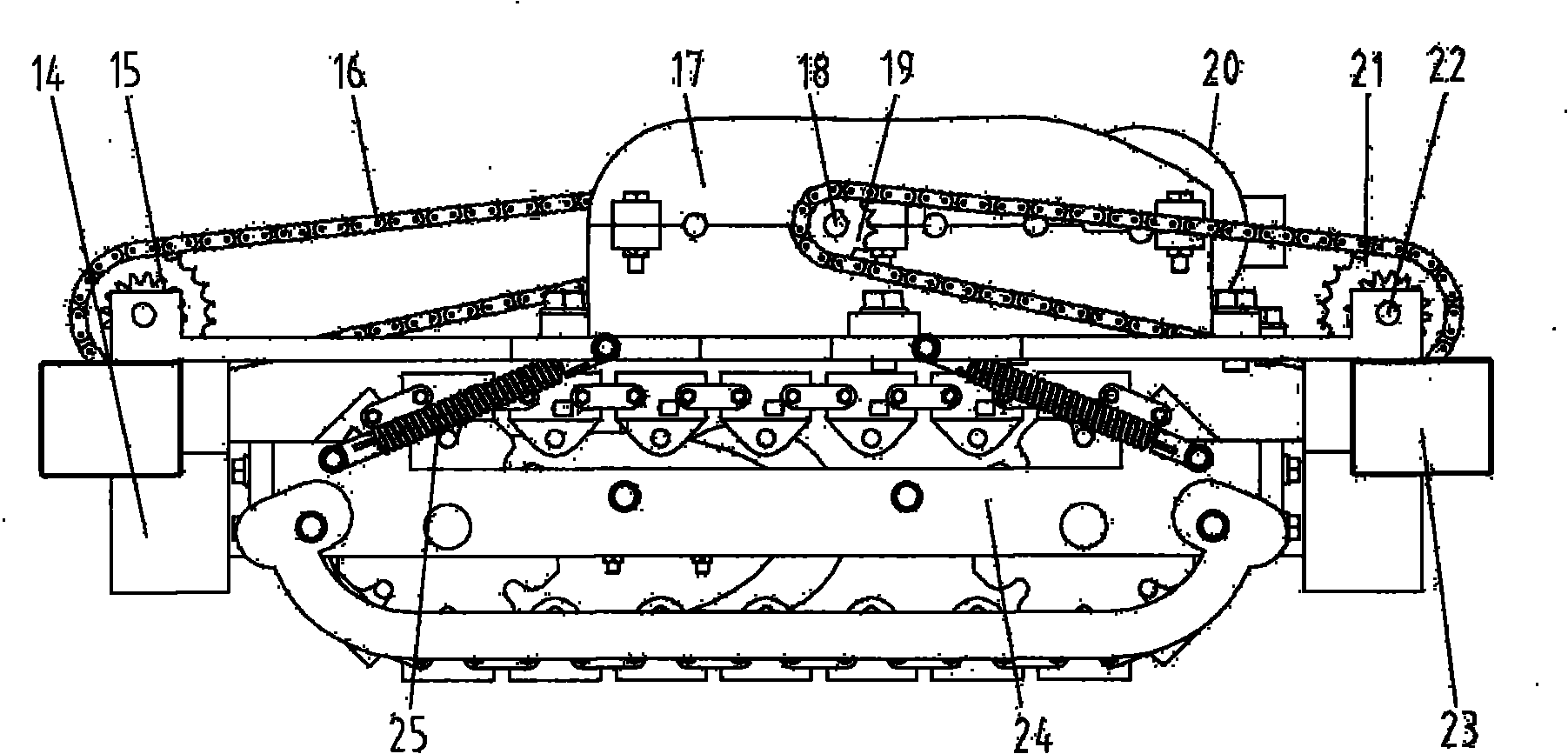

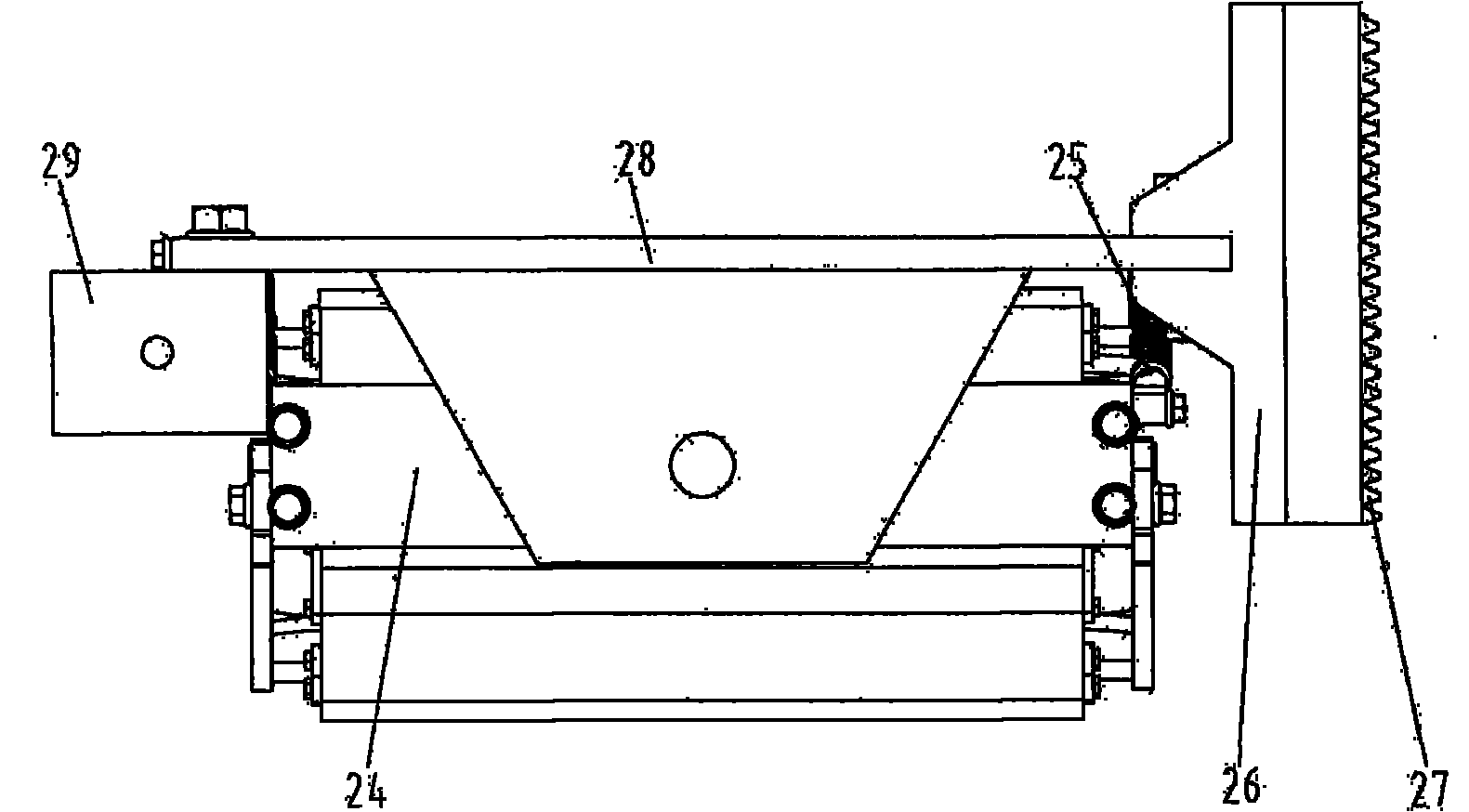

Robot operated on surface of oil storage tank

InactiveCN102079339ASolve the problem of easy disconnectionRealize one machine with multiple functionsEndless track vehiclesOil storageRust

The invention discloses a robot operated on the surface of an oil storage tank. The robot consists of a robot body machine frame, a traveling system and a lifting system. The robot travels on the surface of the oil storage tank by means of the absorption of two groups of electromagnetic caterpillars of which the traveling directions are mutually vertical and the adsorption forces are adjustable; and the two groups of electromagnetic caterpillars of which the traveling directions are mutually vertical switch work to steer. Operation appliances, such as a welding machine, a sand-blasting gun, a spray gun, a flaw detector and the like, can be selectively arranged on a public mounting platform of the robot according to operation needs. When the robot works, the corresponding operation appliances are arranged on the robot and the robot travels on the surface of the oil storage tank to replace a worker to finish works high above the ground, such as welding, removing rust, spraying paint, detection and the like so that the problems of high risk, low efficiency and poor finished quality during manual works high above the ground are solved.

Owner:TONGZHOU DONGSHENG TEXTILE MACHINERY

Cantilever type numerical control plasma flame structural steel three-dimensional cutting machine

ActiveCN103418881AImprove running stabilityImprove cutting accuracyWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlEngineering

The invention discloses a steel sheet cutting device, and particularly relates to a cantilever type numerical control plasma flame structural steel three-dimensional cutting machine used for cutting steel pipes. The cutting machine comprises two parallel Y-axis guide rails, two movable numerical control cutting main machines arranged on the Y-axis guide rails, a wheel overturning material frame used for storing steel pipes, and a pneumatic clamping dividing device arranged at one end of the wheel overturning material frame. Each numerical control cutting main machine comprises a walking cart, a stand column, a cantilever and a cutting gun, wherein the walking cart is driven by a Y-axis servo motor to move along the Y axis, and the stand column is provided with two parallel Z-axis guide rails. The cutting machine has the advantages that the grooving operation of the steel pipes and large-scale H-steel cutting operation can be achieved at the same time, one cutting machine can be used for multiple purposes, automatic cutting efficiency is high, operation is stable, and operation is simple and convenient.

Owner:QINGDAO EAST STEEL TOWER

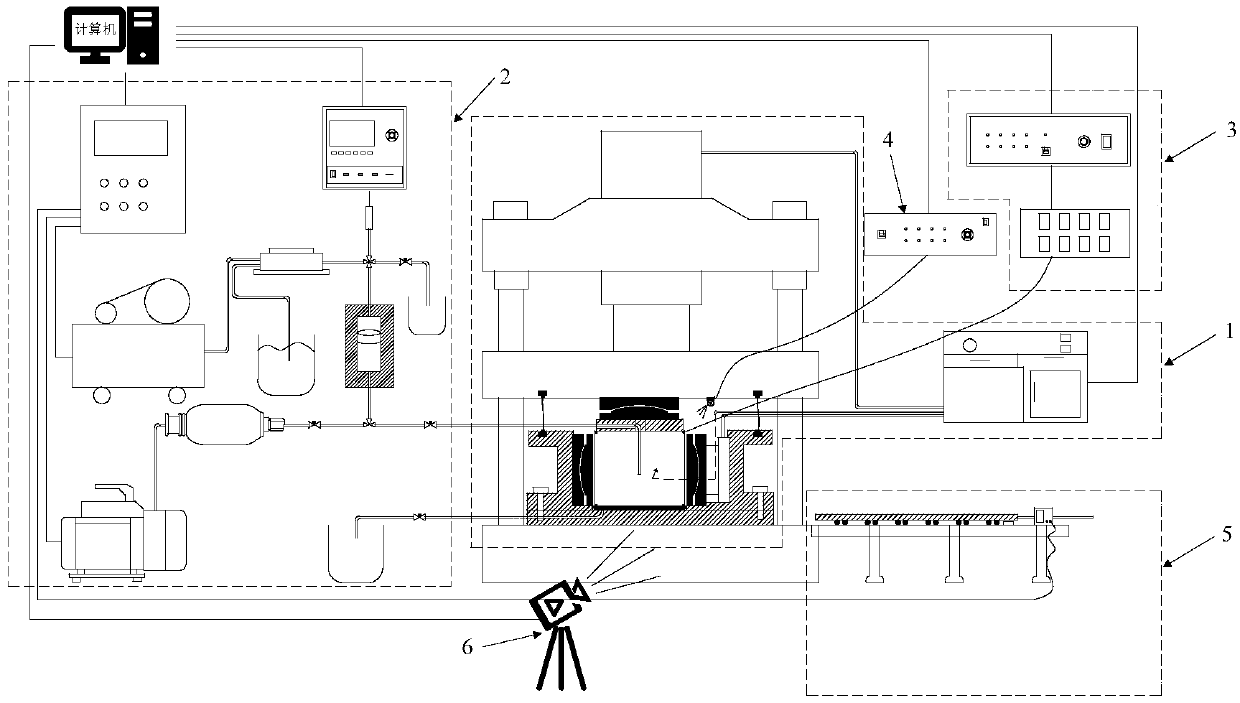

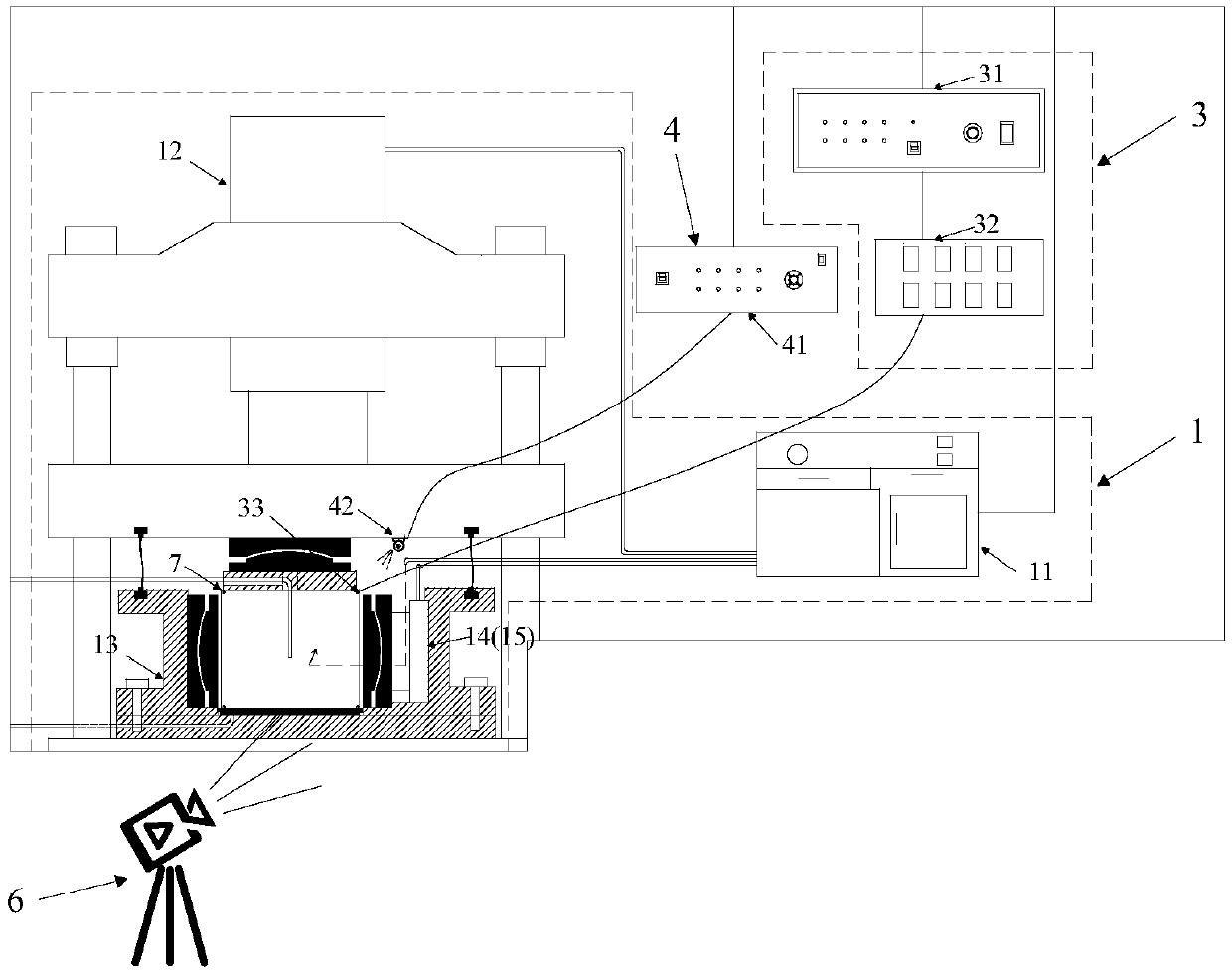

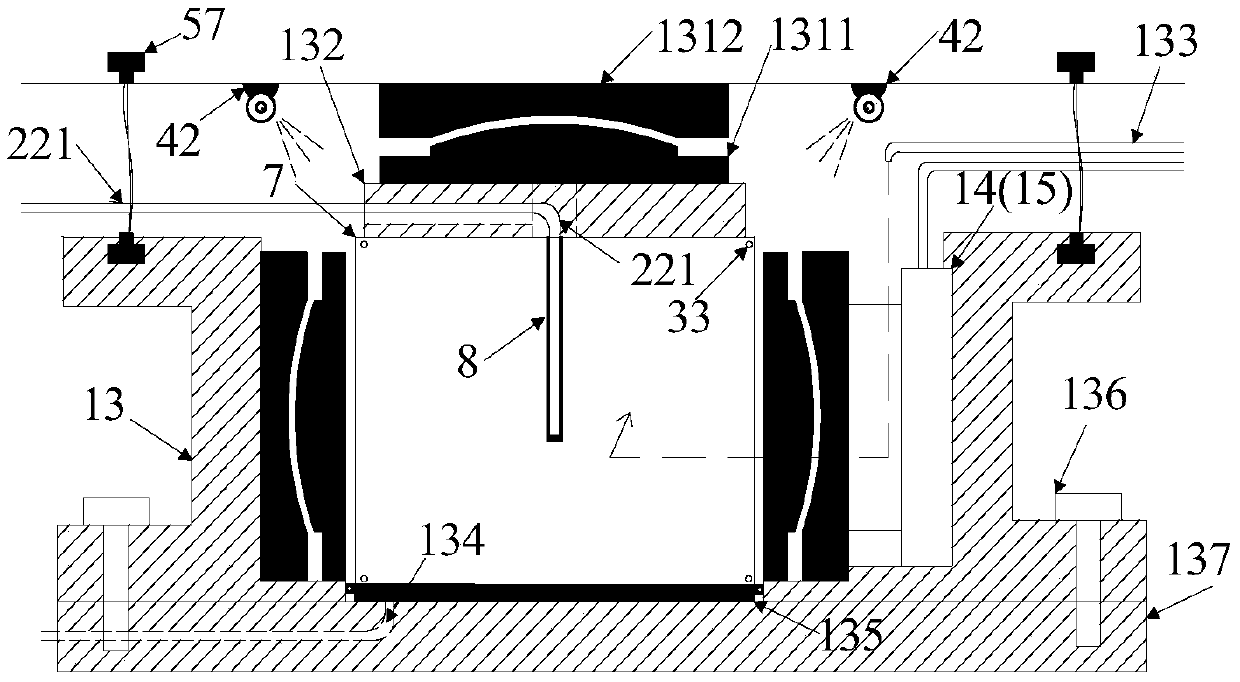

Large-size true triaxial hydraulic fracturing simulation test device and test method

PendingCN109540688ADoes not affect accuracyImprove reliabilityMaterial strength using tensile/compressive forcesTest sampleAcoustic emission

The invention discloses a large-size true triaxial hydraulic fracturing simulation test device and a test method. The test device comprises a large-size true triaxial loading module, a hydraulic servopumping module, an acoustic emission positioning module, an infrared monitoring module, a sample loading and unloading module and a computer, wherein a loading plate is formed by combining an inner plate and an outer plate which are matched with each other through a spherical surface. The test method comprises the following steps of manufacturing and loading a test sample, and performing hydraulic fracturing simulation test, sample unloading, data processing and analysis and the like. The device and the method for a hydraulic fracturing simulation test of shale have the following advantages that the accuracy of a test result is not influenced by the sample processing size and the parallelism deviation, so that the requirements for the sample size processing precision are reduced, and thetest reliability is improved; a loading condition of the shale in a triaxial loading chamber in a test process can be monitored in real time; the fracturing conditions of the multi-size samples can bemet; and a high-speed camera is matched for a uniaxial hydraulic fracturing simulation test, the dynamic expansion rule of hydraulic cracks can be observed directly, and multiple purposes of one machine can be realized.

Owner:LIAONING TECHNICAL UNIVERSITY

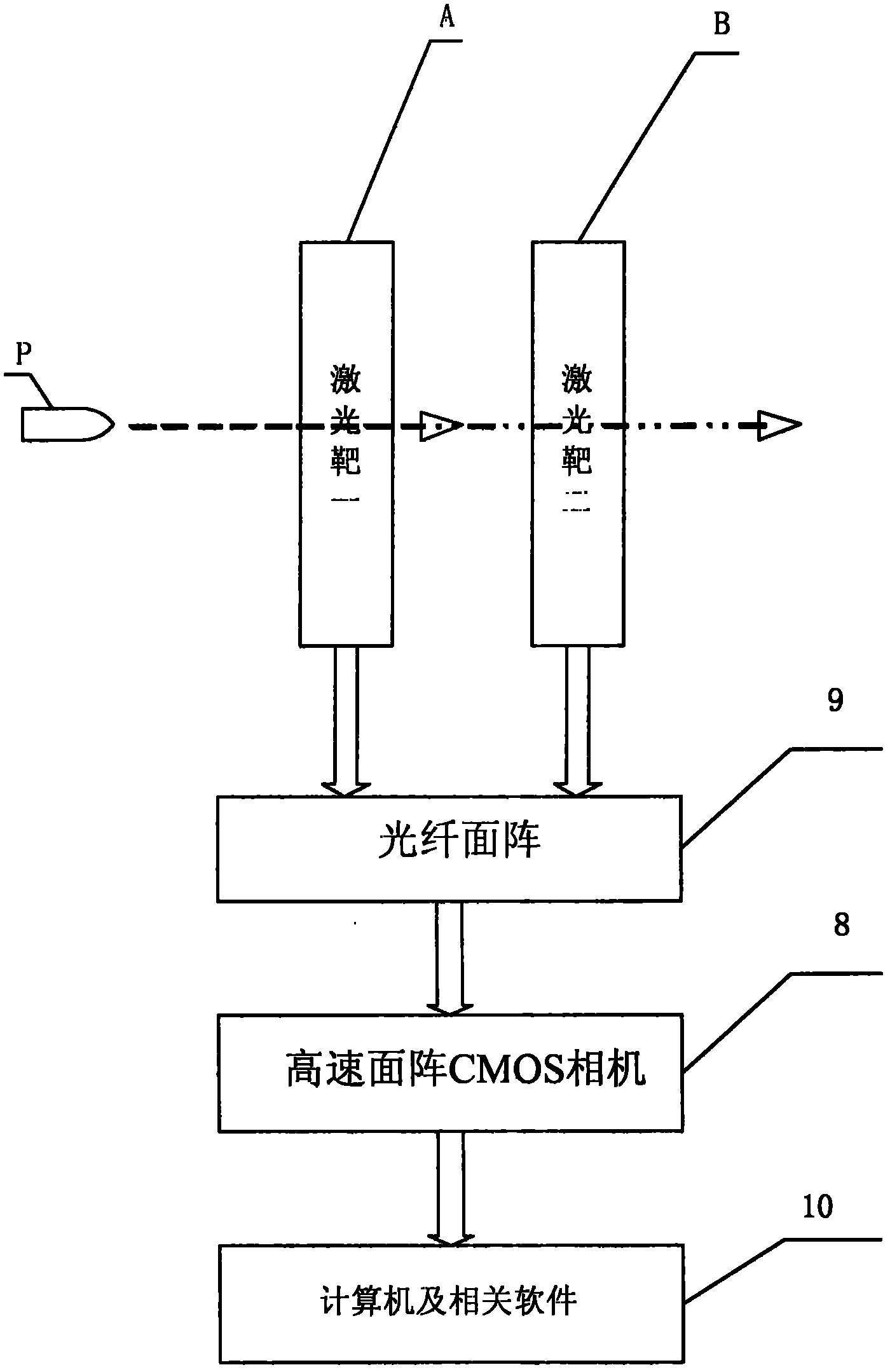

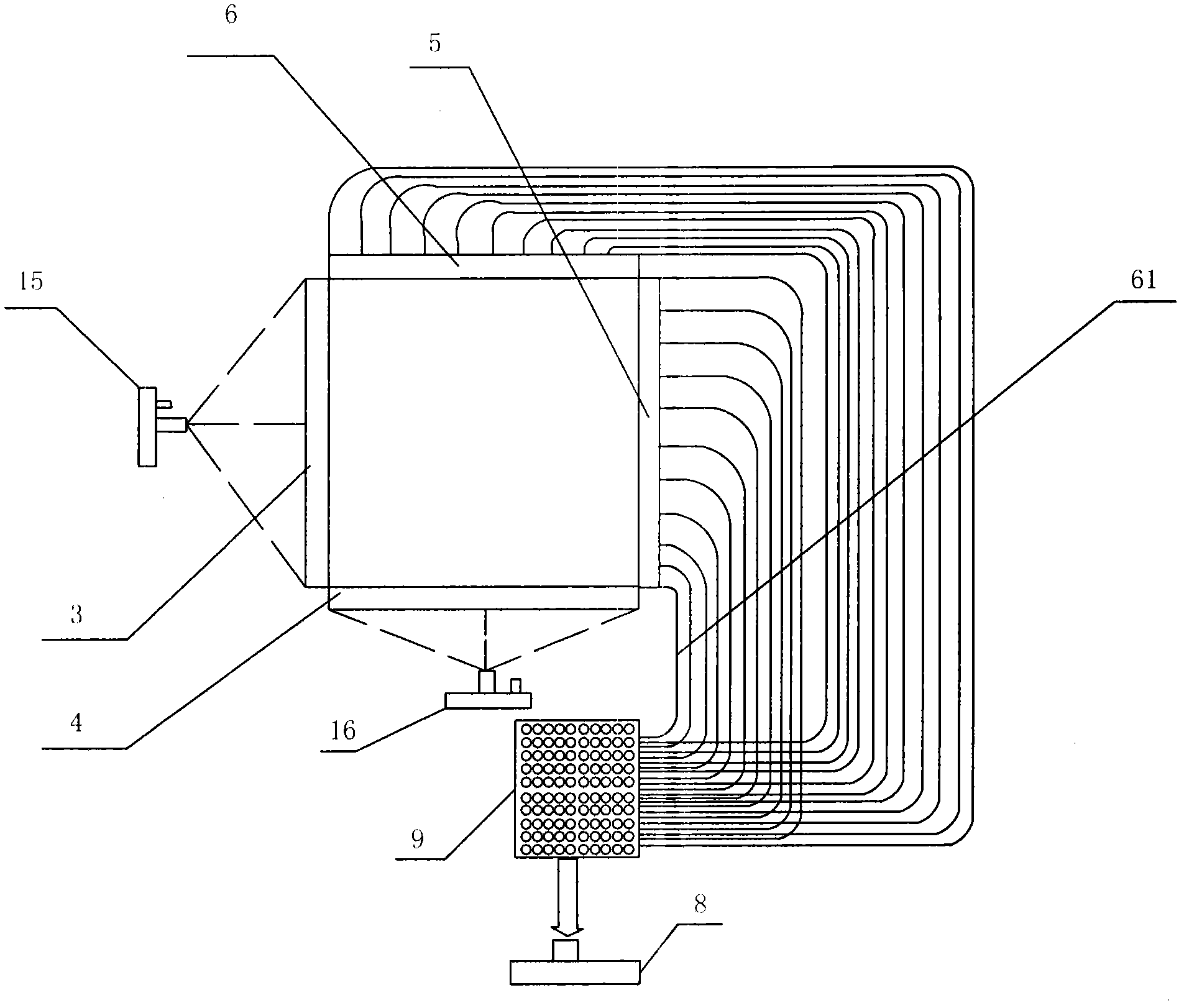

Measurement system for motion parameters of high-speed motion object

InactiveCN102135393AEasy to operateAccurate measurementWeapon testingContinuous measurementLaser target

The invention discloses a measurement system for motion parameters of a high-speed motion object. The measurement system comprises a laser target (A) and a laser target (B), wherein two coplanar parallel laser screens are formed in the laser target A and the laser target B respectively; the direction of propagation of the two parallel laser screens is perpendicular to each other; the laser target (A) and the laser target (B) are connected with an optical fibre face array (9) through optical fibres; when passing through the parallel laser screens, the motion object blocks a part of laser screens to make luminous flux in the optical fibre face array changed; the variable quantity is acquired by an optical signal acquisition device and transmitted to a computer (10); and the parameters such as a speed, coordinates, and scattering and motion gestures when the motion object passes through the screens can be obtained by processing an acquired image and displayed on a display. The measurement system is low in cost, simple in operation and high in precision and can carry out all-day continuous measurement.

Owner:ZHONGBEI UNIV

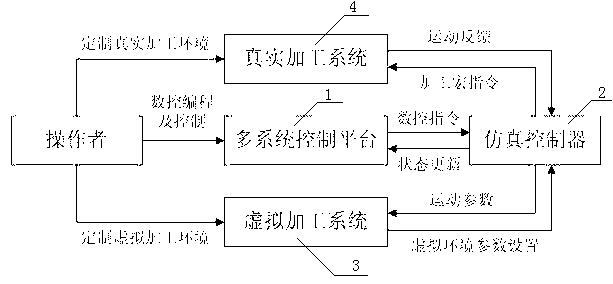

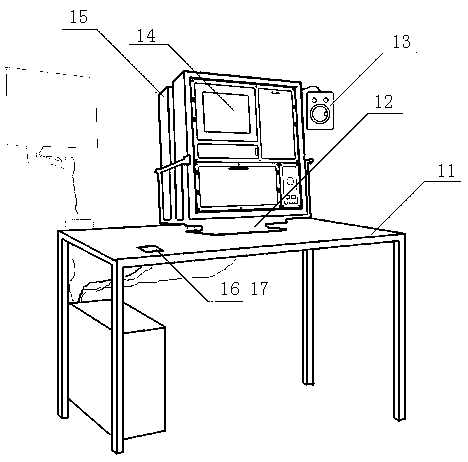

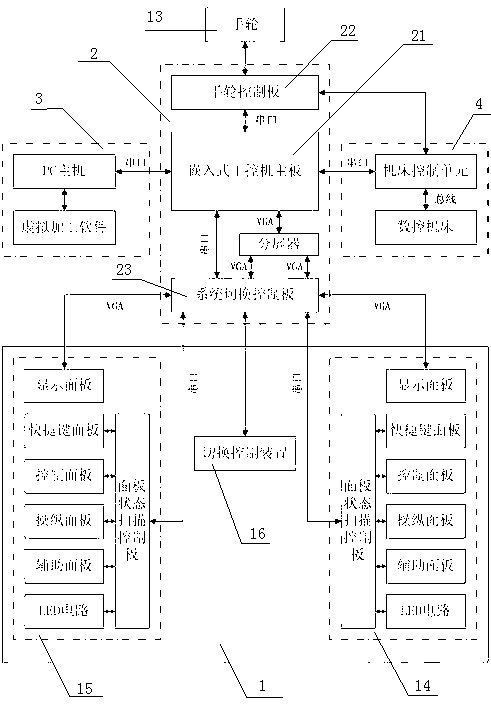

Method and system for simulating multisystem synchronous numerical-control processing

InactiveCN103236217ALearn about the training experienceSolve repair machining simulation problemsEducational modelsVirtual machiningControl system

The invention relates to a method and a system for simulating multisystem synchronous numerical-control processing, and belongs to the field of simulating training of numerical-control processing. The method comprises the following steps of customizing a virtual processing environment by a virtual processing system by an operator, and customizing a real processing environment by a real processing system; selecting a numerical-control system panel through a multisystem control platform to carry out numerical-control programming and controlling, encoding a numerical-control instruction, sending to a simulation controller, and enabling the simulation controller to simulate and calculate; on one hand, sending movement parameters of a cutter to the virtual processing system to complete virtual processing; and on the other hand, sending a processing macro instruction to the real processing system, so as to control a machine tool to complete the practical processing of blanks or repairing pieces. The method and the system have the advantages that the design concept is advanced, the function is practical, the cost is low, the deployment is convenient, the system compatibility is good, the group training method is flexible and variable, the processing process is visual and accurate, the human-computer interaction is good, the operation reality of a user is high, the user experience can be obviously changed, and the like.

Owner:PLA ARMORED FORCE TECH COLLEGE

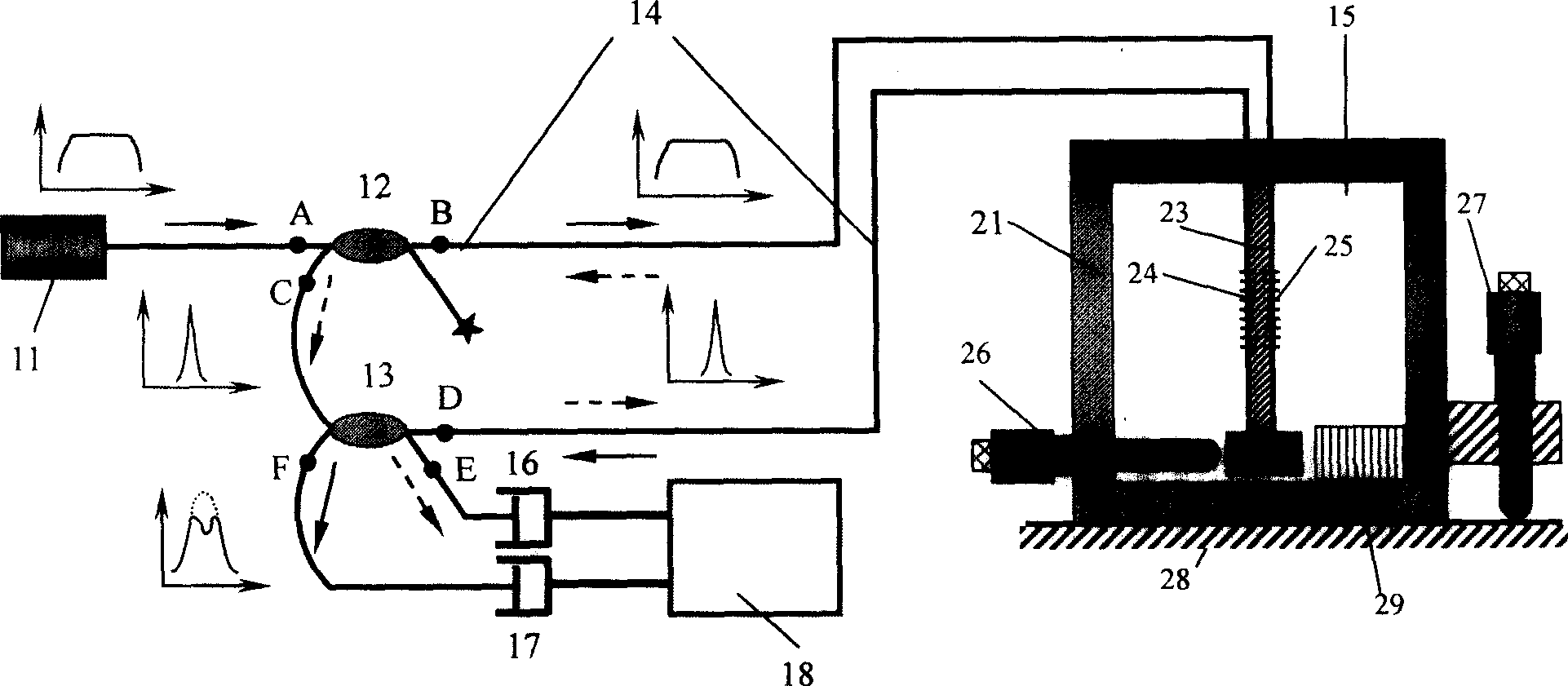

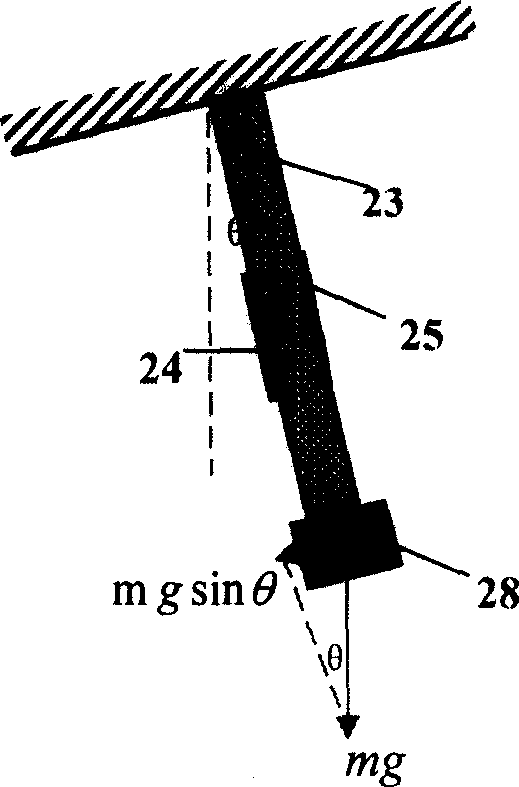

Optical fiber grating multi-parameter comprehensive sensing experimental apparatus

InactiveCN1605835ASimple structureNovel structureConverting sensor output opticallyCantilevered beamGrating

The present invention is multi-parameter comprehensive fiber grating sensing experiment instrument as one kind of physical and detection technology teaching instrument. The instrument includes measuring unit, sensing unit and fiber coupling link. The sensing unit includes frame, equal-thickness isosceles triangle cantilever beam fixed inside the frame, gravitational pendulum fixed to the bottom of the cantilever beam, two fiber gratings with the same parameters adhered symmetrically on two sides of the cantilever beam, micro displacement meter fixed horizontally to one side of the frame, micro obliquity meter fixed vertically on the other side of the frame and electromagnetic coil fixed inside the bottom of the frame. The instrument may be used in detecting current, obliquity, vibration and displacement, performing various fiber experiment, etc. and is suitable for use in relevant teaching experiments.

Owner:TSINGHUA UNIV

Leak detection equipment

InactiveCN102081005AClearly show defect locationImprove interchangeabilityDetection of fluid at leakage pointCouplingControl valves

The invention discloses leak detection equipment, belonging to the technical field of tightness detection, and solving the problem of poor interchangeability of the existing leak detection equipment. The leak detection equipment is mainly characterized by being composed of a rack, tightness detection equipment and a water tank, wherein the rack is provided with a power supply control box, a lifting cylinder, a guide bar, an air source processing triple piece, a reducing valve and a control valve; the tightness detection equipment is provided with a pneumatic sealing mechanism, a pneumatic clamping mechanism and a connecting hole matched with the lifting cylinder and the guide bar, wherein the pneumatic clamping mechanism and the pneumatic sealing mechanism are connected with the control valve via a pressure hose and a quick coupling; and the lower end of the rack is connected with the water tank via a zouma hole and a bolt. The leak detection equipment is convenient in assembling and disassembling operation, is reliable in operation, has low cost and good interchangeability, can realize one machine with multiple functions, can definitely display the defect position of leaked workpiece, is mainly used for tightness detection for the auto parts, such as an aluminium alloy intake manifold, a cylinder body, a cylinder cover, an oil pan, an oil filter seat and the like.

Owner:XINXING HEAVY IND HUBEI 3611 MECHANICAL

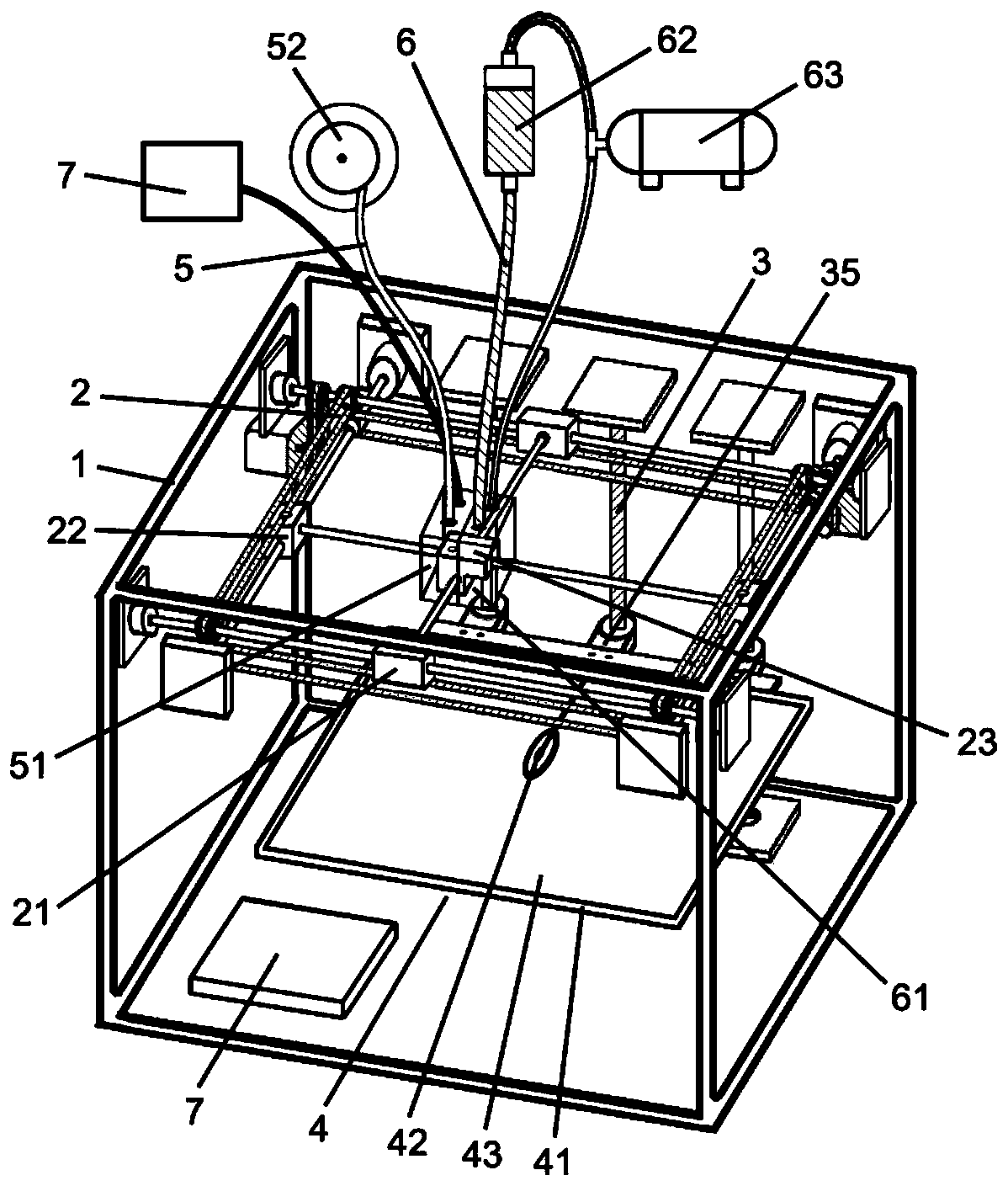

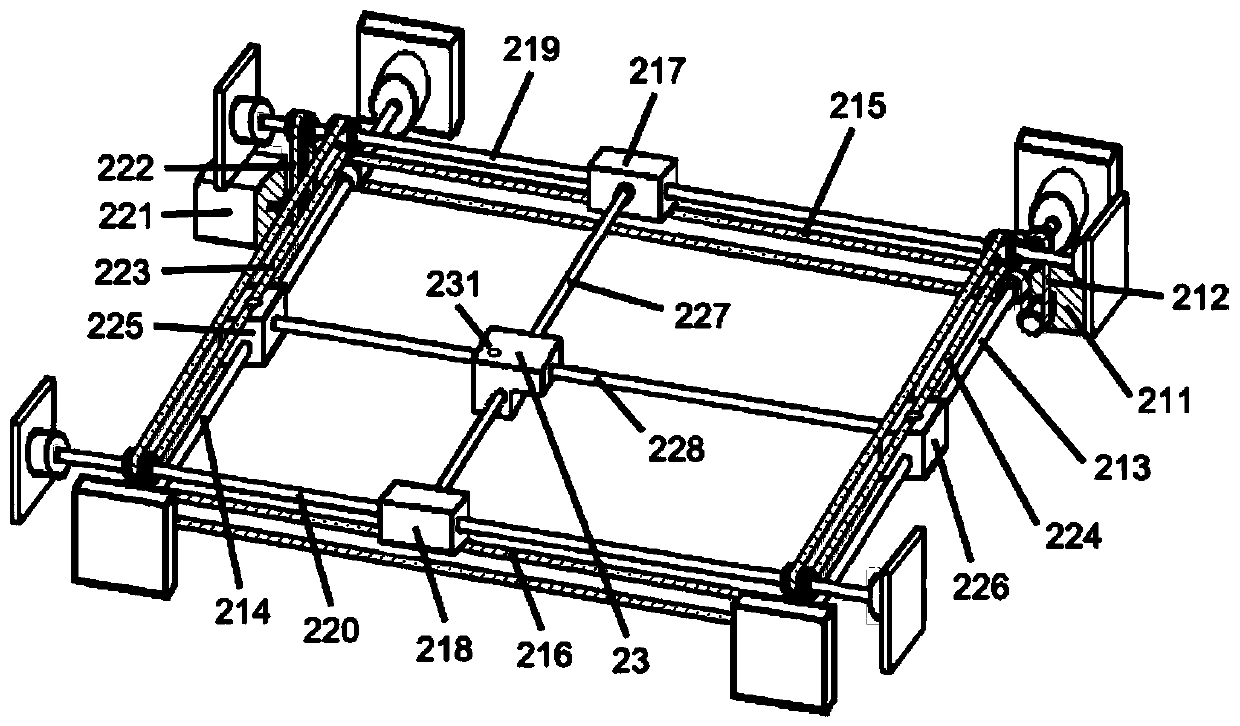

Solid material and liquid material combined dual-nozzle 3D printer and printing method thereof

PendingCN110614767A3D printing realizedRealize one machine with multiple functionsAdditive manufacturing apparatusIncreasing energy efficiencyThroatEngineering

The invention discloses a solid material and liquid material combined dual-nozzle 3D printer and a printing method thereof. The dual-nozzle 3D printer comprises a frame, an XY side moving module, a Zaxis moving module, a carrying plate, a solid material printing unit, a liquid material printing unit and a master control module, wherein the solid material printing unit comprises a solid printing head module and a wire feeding module; the upper end of a wire feeding throat pipe of the solid printing head module penetrates through a fixed plate of a cooling module to communicate with a wire feeding channel in the XY side moving module; and the lower end of the wire feeding throat pipe extends into a circular through hole of a metal heating block to communicate with a solid nozzle. An articlecombining the solid material with the liquid material can be printed, or a solid material article or a liquid material article is individually printed, and dual-component liquid materials are mixedlyprinted, a feeding module and a printing speed of the liquid material are flexibly controlled, and the combined dual-nozzle 3D printer and the printing method are suitable for performing 3D printingon multiple materials comprising a thermosensitive or thermoset liquid material.

Owner:SOUTH CHINA UNIV OF TECH

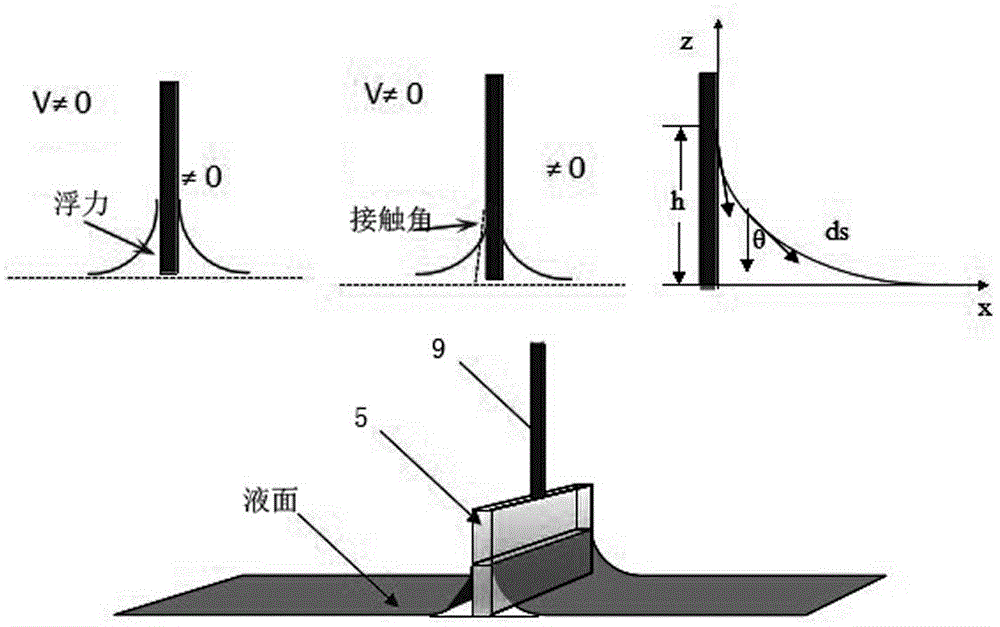

Interface tension and contact angle test device and method based on analytical balance

InactiveCN104406892AImprove test accuracyRealize one machine with multiple functionsSurface tension analysisPetrochemicalLift system

The invention discloses an interface tension and contact angle test device and method based on an analytical balance. The device comprises a lifting system, a lifting system bracket, a constant-temperature sample pool, a sample table and a weighing system, wherein the weighing system comprises a platinum plate, a platinum plate bracket, a hook bracket, a sample bracket and the analytical balance; one side of the sample table is fixedly mounted at the output end of the lifting system; the constant-temperature sample pool is mounted on the sample table; the platinum plate is arranged in the constant-temperature sample pool and mounted at the top end of the sample bracket through the platinum bracket and the hook bracket; the bottom end of the sample bracket is mounted on the analytical balance. The device can be widely applied to the industry fields of daily chemicals, pesticides, petrochemical engineering, surfactant research, fire control, electricity and the like, and has a very high promotion value.

Owner:上海梭伦信息科技有限公司

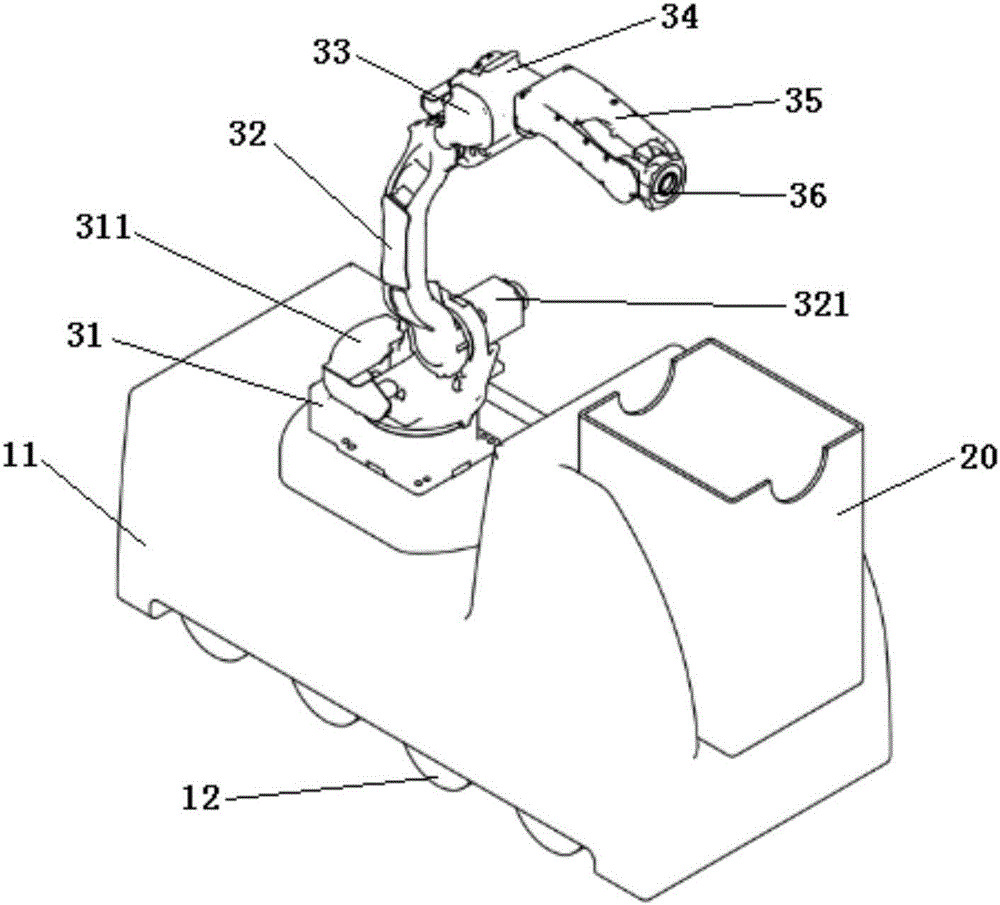

Transfer robot

InactiveCN106239471AImprove work efficiencyExpand the scope of activitiesGripping headsEngineeringMaterial storage

The invention discloses a transfer robot, comprising an AGV(Automatic Guided Vehicle), a grabbing arm and a main controller, wherein the AGV comprises a body and a transfer chassis, the main controller is arranged in the body, and a material storage box and an automatic positioning mechanism are arranged on the body; the grabbing arm comprises a base, a first connecting arm, a second connecting arm, a third connecting arm, a fourth connecting arm and a fifth connecting arm sequentially in rotating connection, wherein one end of each connecting arm is connected with the base in a rotating mode, the base is fixedly arranged on the AGV, a grabbing mechanism is arranged on the fifth connecting arm, the grabbing mechanism comprises a pneumatic grabbing head and a sucking disc which can be switched automatically, and a visual acquisition mechanism is arranged at the upper end of the grabbing mechanism; and the grabbing mechanism, the transfer chassis, the grabbing arm, the visual acquisition mechanism and the positioning mechanism are electrically connected with the main controller respectively. By effectively combining fixed point material placement and automatic movement together, the working efficiency is improved, the activity range is enlarged, the transfer robot can automatically grab and transfer objects, and the transfer robot is good in safety and high in reliability.

Owner:SHANGHAI DIANJI UNIV

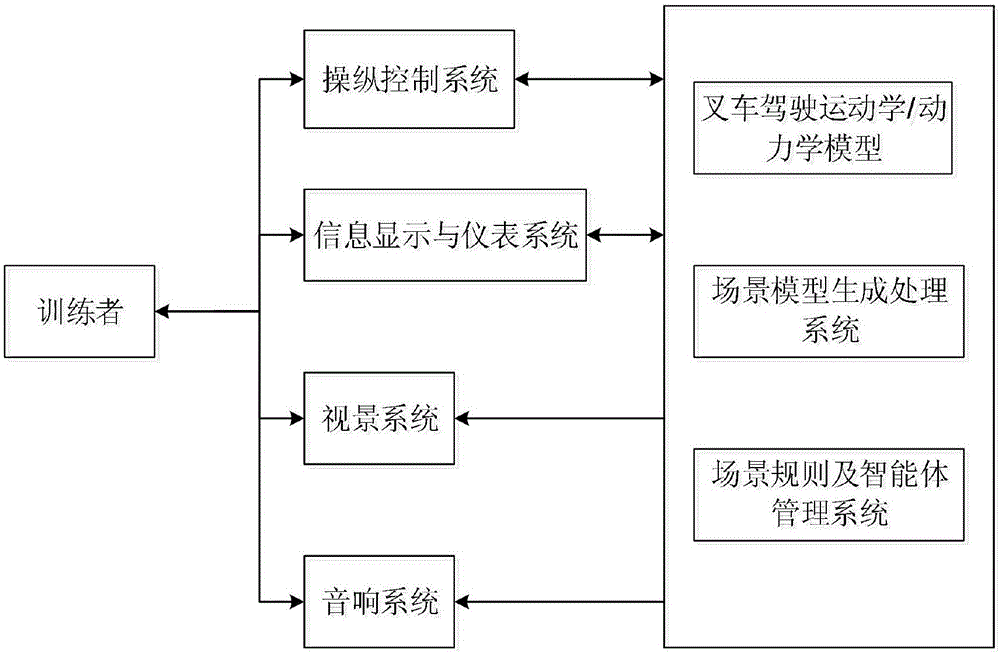

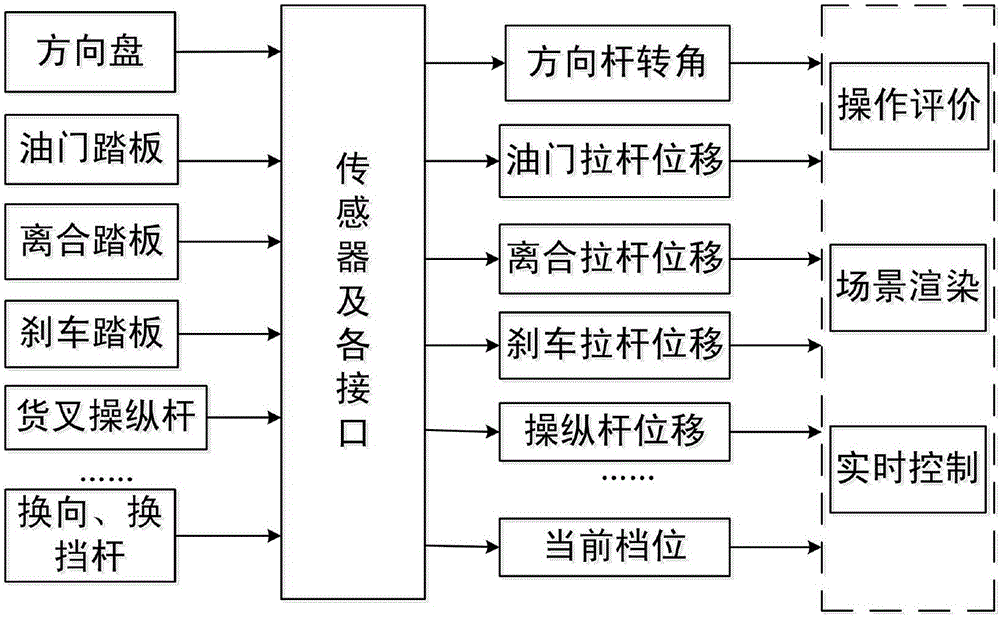

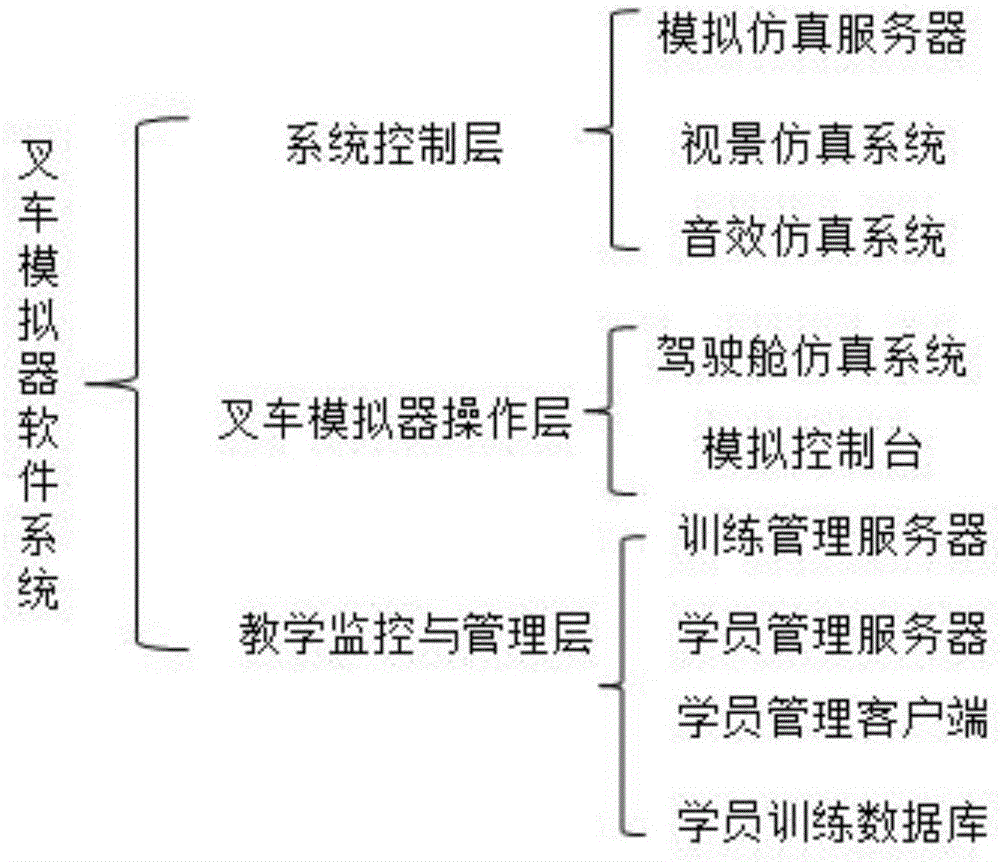

Forklift operation training simulator

InactiveCN106652642ARapid responseAvoid registrationCosmonautic condition simulationsSimulatorsTraining periodSoftware system

The invention relates to a forklift operation training simulator. A main structure of the forklift operation training simulator comprises hardware equipment and a software system. The hardware equipment comprise a simulation cab, an steering control system, an instrument system, a multimedia computer, an audio system, an instructor control panel and the like. The software system comprises an operation platform and is used for real-time working environment animation generation of the computer, dynamic forklift driving simulation, sound simulation, operation evaluation, data management, network control and the like. The forklift operation training simulator has the advantages that a whole training period of a student can be shortened greatly, the student is enabled to finish training tasks in a short time, sudden incidents which rarely happen during practical training can be simulated conveniently, accurate-judging ability, good psychological quality and the ability of handling emergency circumstances correctly of the student can be cultivated, and training quality is improved.

Owner:武汉科码软件有限公司

Technology and apparatus for manufacturing shaped conductor

InactiveCN101510455AMeet the requirements of flow productionOut of line fastDrawing diesSingle bars/rods/wires/strips conductorsFiberEngineering

The invention relates to a shaped conductor manufacturing technique and a device thereof, wherein, the manufacturing technique comprises payingoff step, lead-forming step and lead-drawing step and is characterized in that the lead-forming step adopts the technique of combing drawing and rolling; the section of a lead is shaped by rolling; the sectional area of the lead meets requirement by drawing; the device comprises a payingoff device, a shaped conductor forming device and a lead-drawing device which are sequentially arranged, wherein, the shaped conductor forming device is provided with a shaped groove roller device. The technique ensure the quality of products, greatly improves producing efficiency and meets the production requirement of compound carbon fiber aluminum stranded conductors required by ultra-high and super-high power transmission.

Owner:德阳东佳港智能装备制造股份有限公司

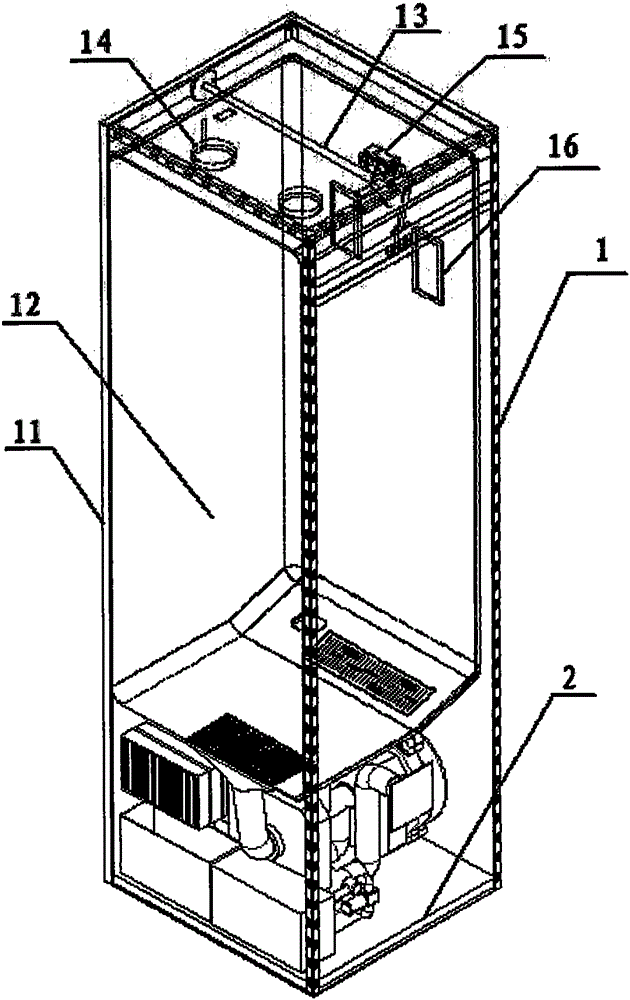

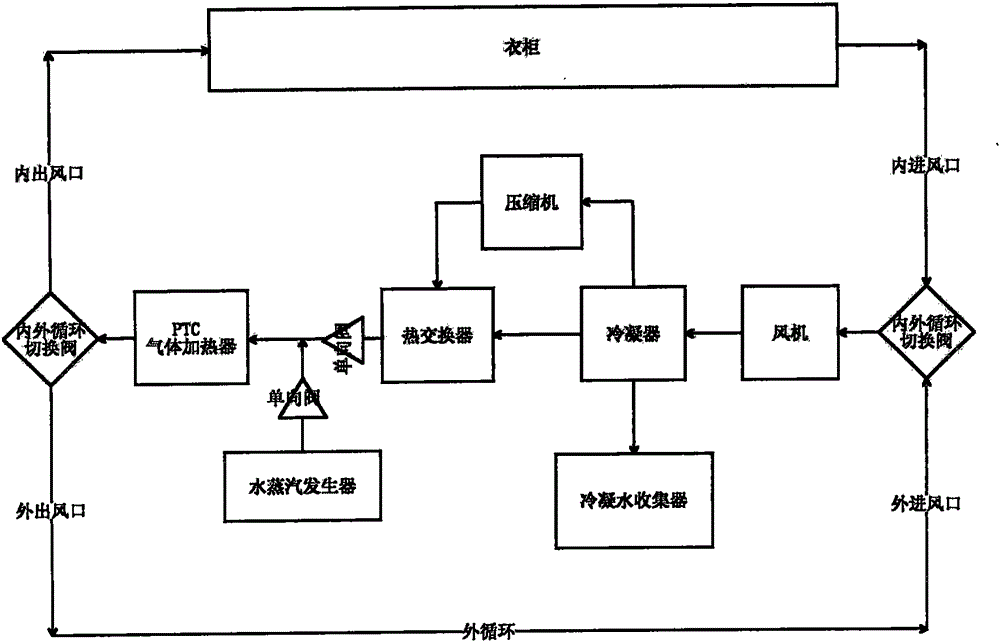

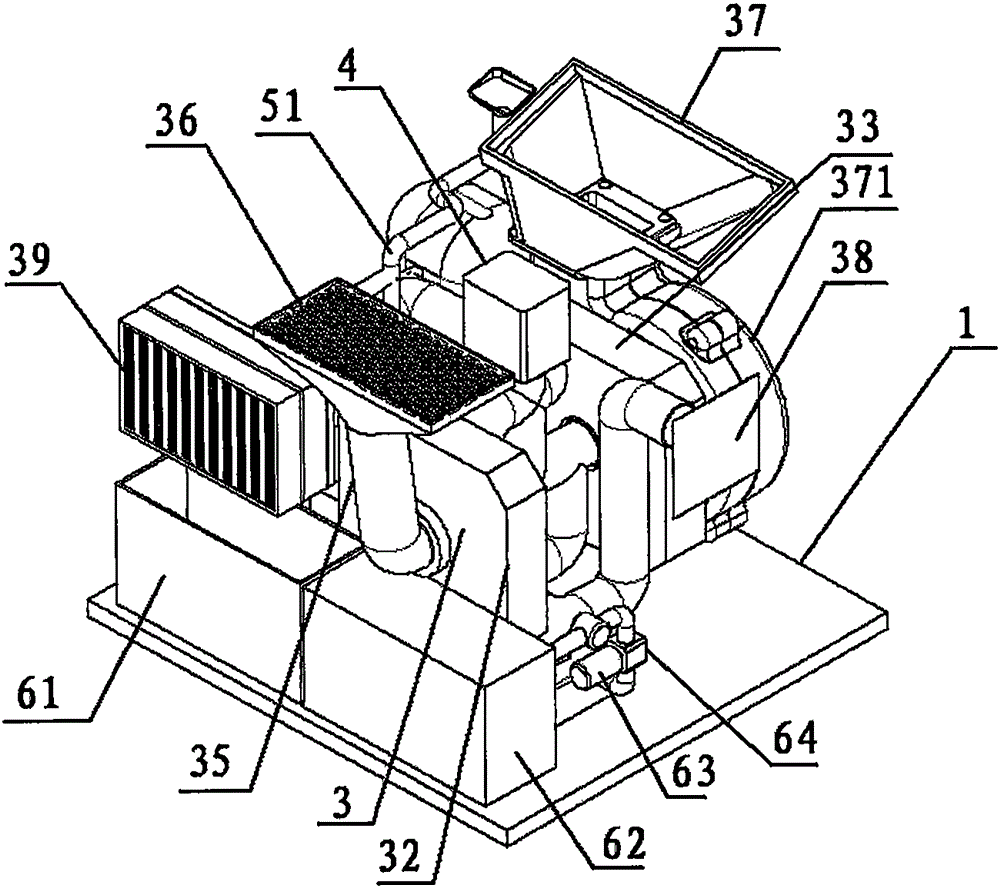

Multifunctional clothes care machine

InactiveCN105063979AClothing carePlay a jobIroning apparatusTextiles and paperElectrical and Electronics engineeringIon

The invention discloses a multifunctional clothes care machine. The multifunctional clothes care machine comprises a clothes cabinet (1) and a care box (2), wherein the care box (2) is arranged at the bottom part of the clothes cabinet (1); the clothes cabinet comprises a cabinet door (12) and a hollow cabinet body; the multifunctional clothes care machine is characterized in that a clothes hanging mechanism (13) and shaking mechanisms (14) enabling the clothes hanging mechanism (13) to shake are arranged in the cabinet body; the shaking mechanisms (14) are connected with the clothes hanging mechanism (13); the care box also comprises a heat circulation system (3), a gas circulation system (35) and a humidifying system. According to the multifunctional clothes care machine disclosed by the invention, by controlling the opening and the closing of internal and external air inlets and air outlets, the multifunctional clothes care machine having the functions of clothes caring, dehumidifying, humidifying, air purifying, negative ion generating and the like can be realized, and the multifunctionality is realized.

Owner:骆能文

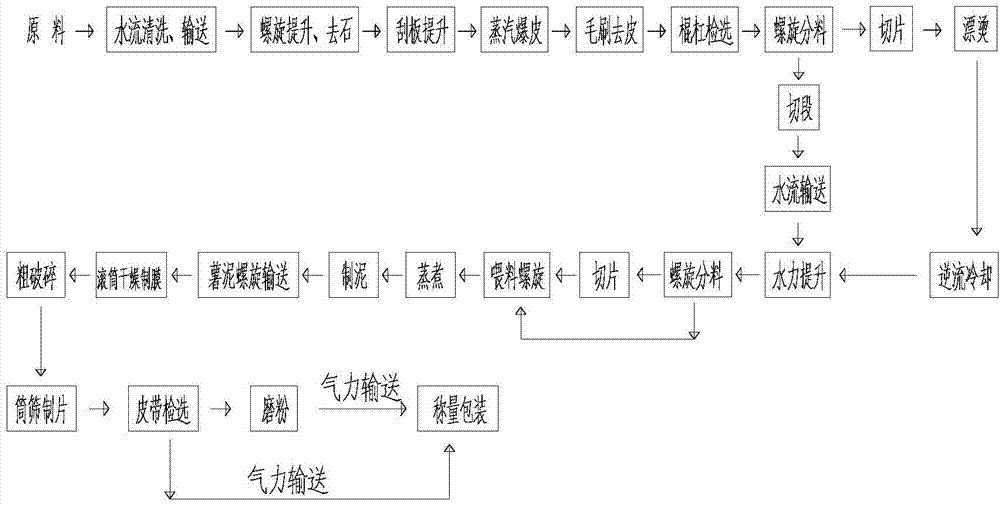

Preparation technology of potato whole powder

The invention discloses a preparation technology of potato whole powder. The preparation technology comprises the steps of conveying a raw material by water flow, and then feeding the raw material to a cleaning and stone-removing procedure and a peeling procedure sequentially; after the raw material is treated by the peeling procedure, cutting the raw material into pieces; and feeding the cut raw material to subsequent working procedures of cooking, mashing, roller drying and film preparation, crushing and packaging sequentially. The raw material of the potato whole powder is one in purple sweet potatoes, sweet potatoes and purple potatoes, and the cut raw material pieces have the length of 70-100 mm; the purple potatoes are sliced after being cut into pieces, and the purple potato slices sequentially enter the subsequent working procedures of cooking, mashing, roller drying and film preparation, crushing and packaging; the purple potato slices have the thickness of 10-30 mm. After the preparation technology is adopted, the generality of the potato processing technology can be improved, and the combination of preparation technologies of different potato materials can be realized; therefore, the utilization rate of a whole powder device and the whole powder quality are improved, and the aims that one machine in a processing enterprise serves multiple purposes, and the products are diversified can be achieved.

Owner:山丹县芋兴粉业有限责任公司

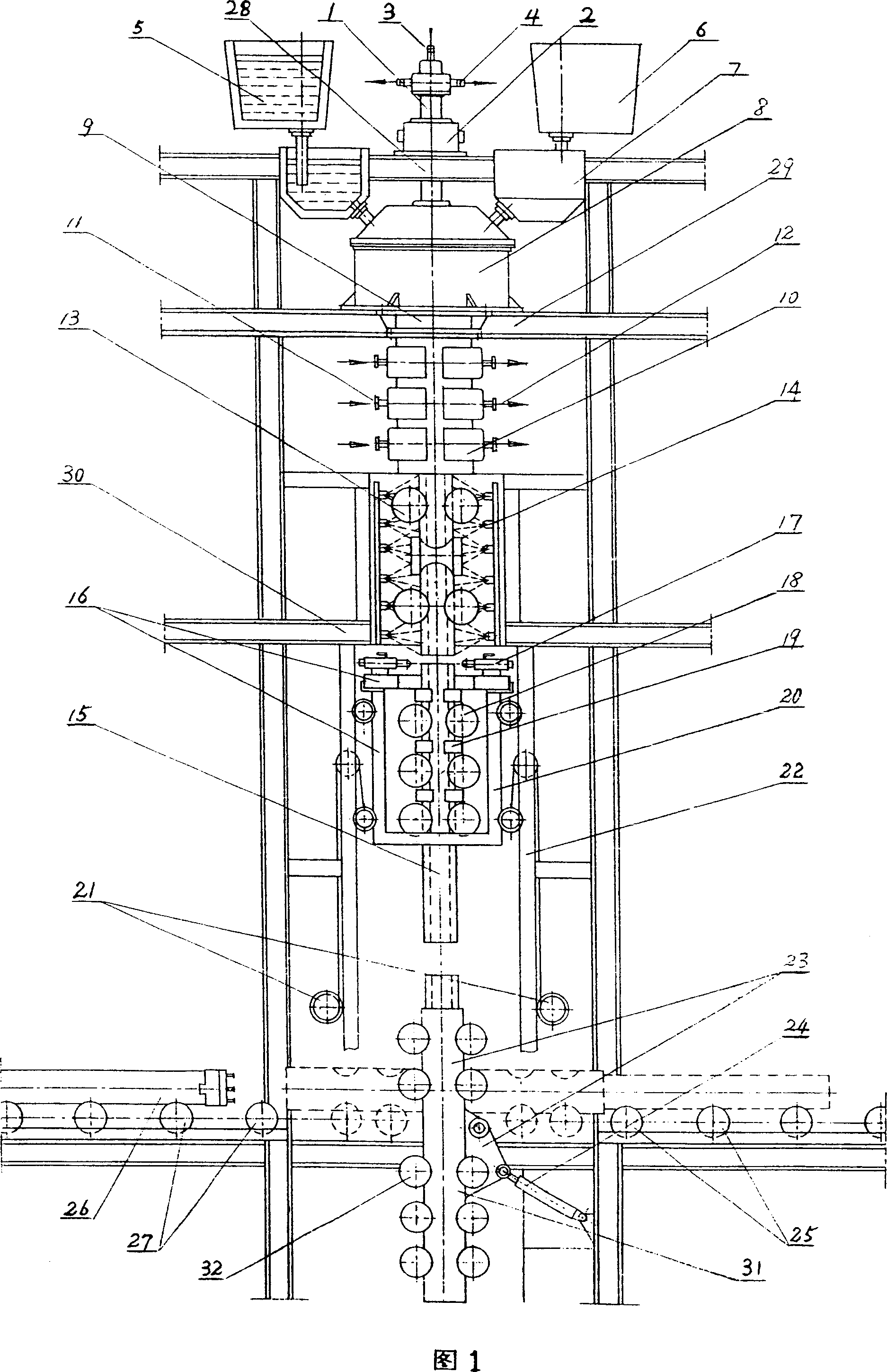

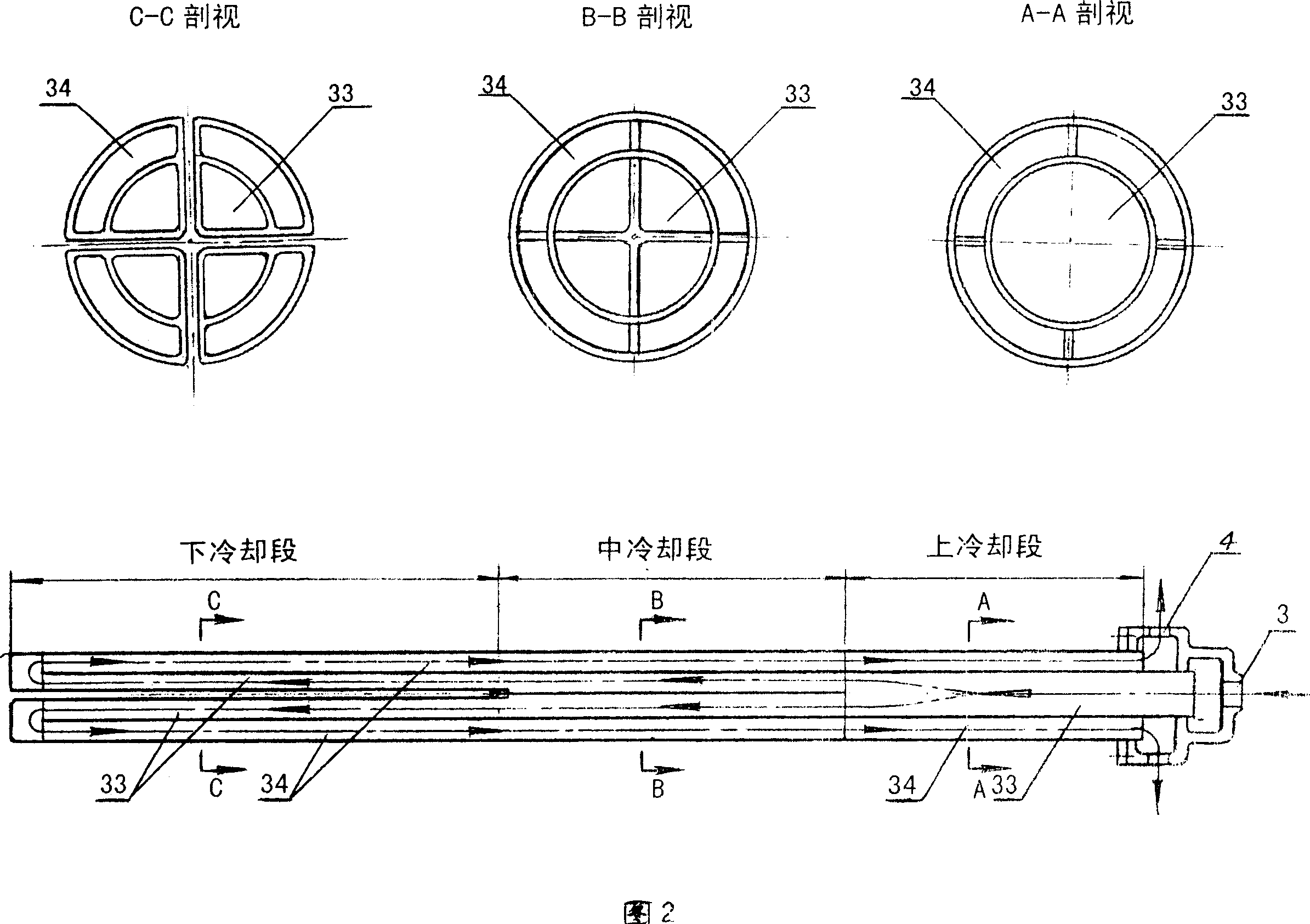

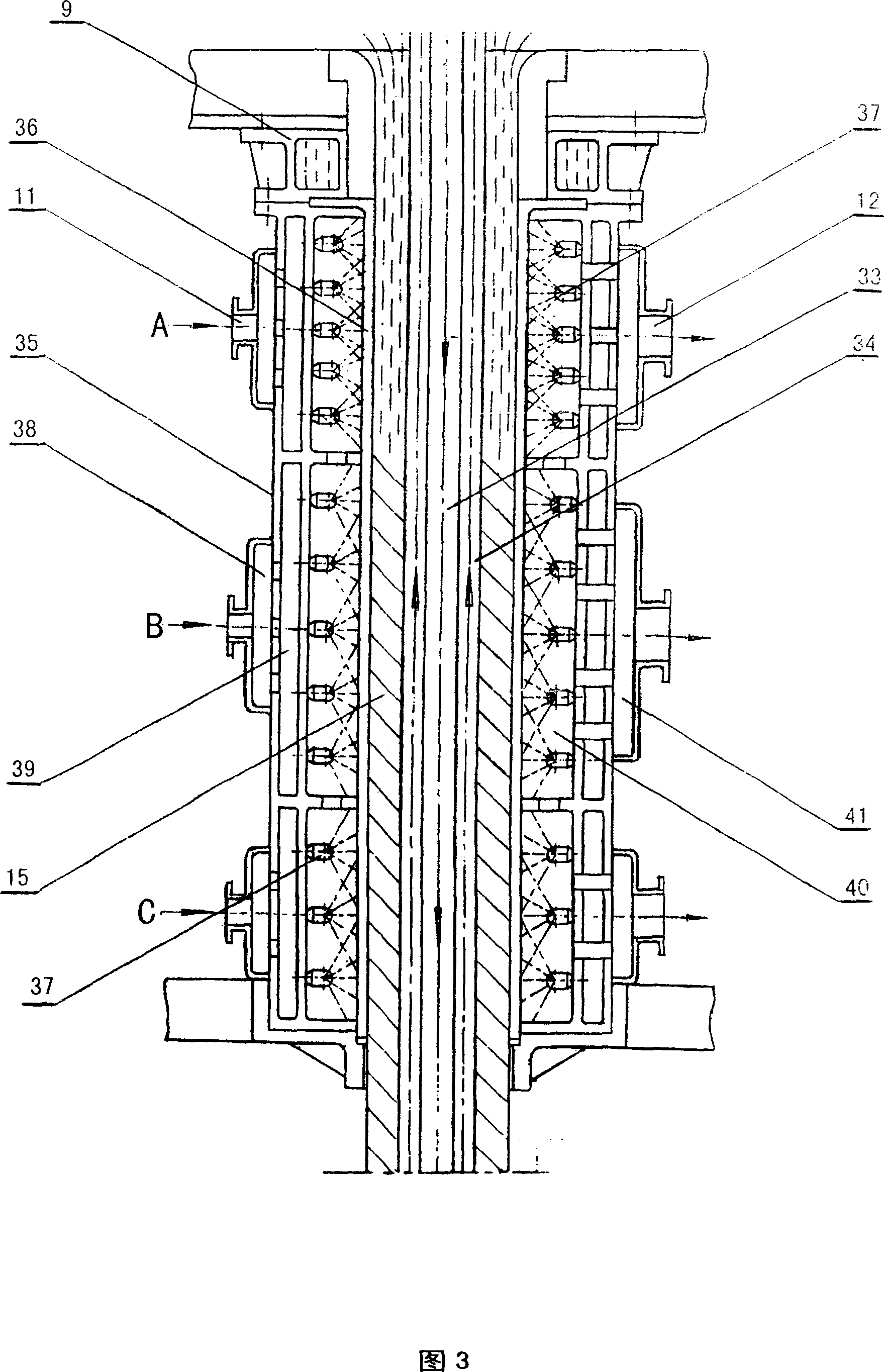

Vertical continuous casting machine for seamless steel pipe blank

The present invention relates to a vertical seamless steel pipe hollow pipe billet continuous casting machine. It is characterized by that it utilizes combination of internal crystallizer and external crystallizer to produce hollow pipe billets with various specification. Said continuous casting machine consists of internal crystallizer, external crystallizer, carryover pinch roll, dummy ingot cutting car and turnover roller way equipment. Said invention also provides their connection mode and concrete operation method of said continuous casting machine.

Owner:李铁铎

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com