Vertical continuous casting machine for seamless steel pipe blank

A seamless steel pipe and hollow pipe technology, applied in the field of vertical seamless steel pipe hollow billet continuous casting machine, can solve the problems of increasing equipment investment, process interruption, and elongated production process, so as to reduce equipment investment and reduce Production cost and the effect of shortening the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

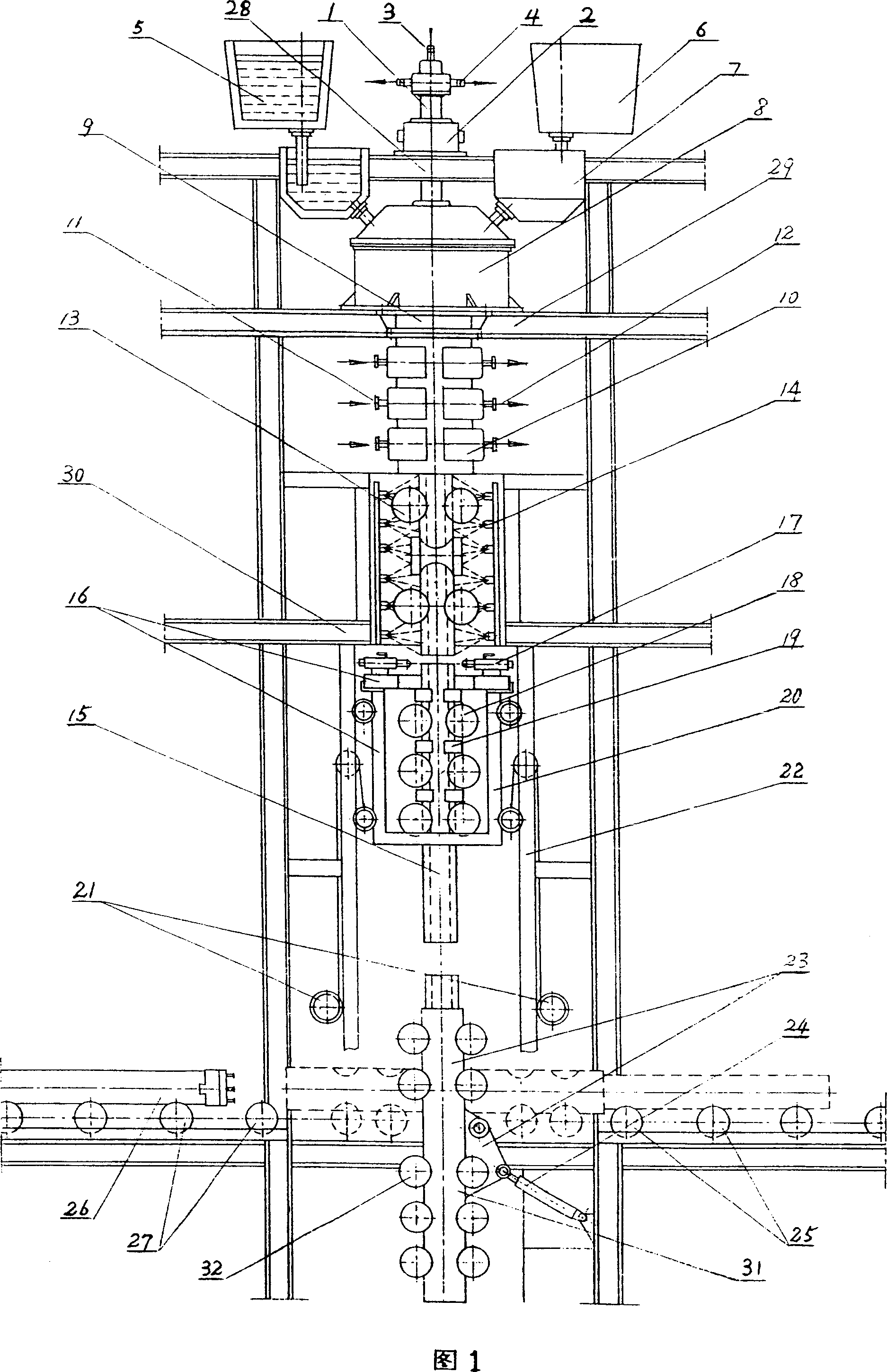

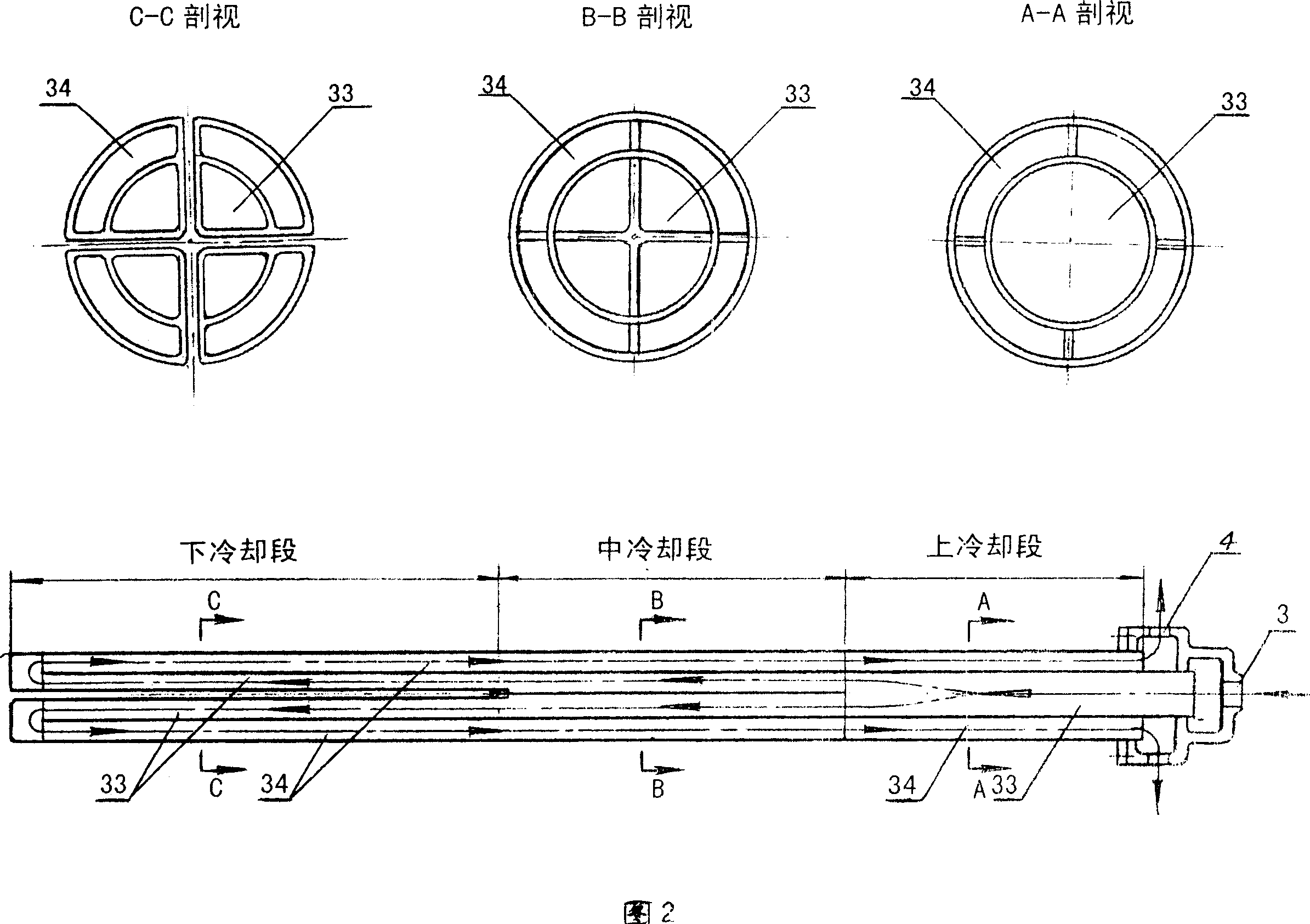

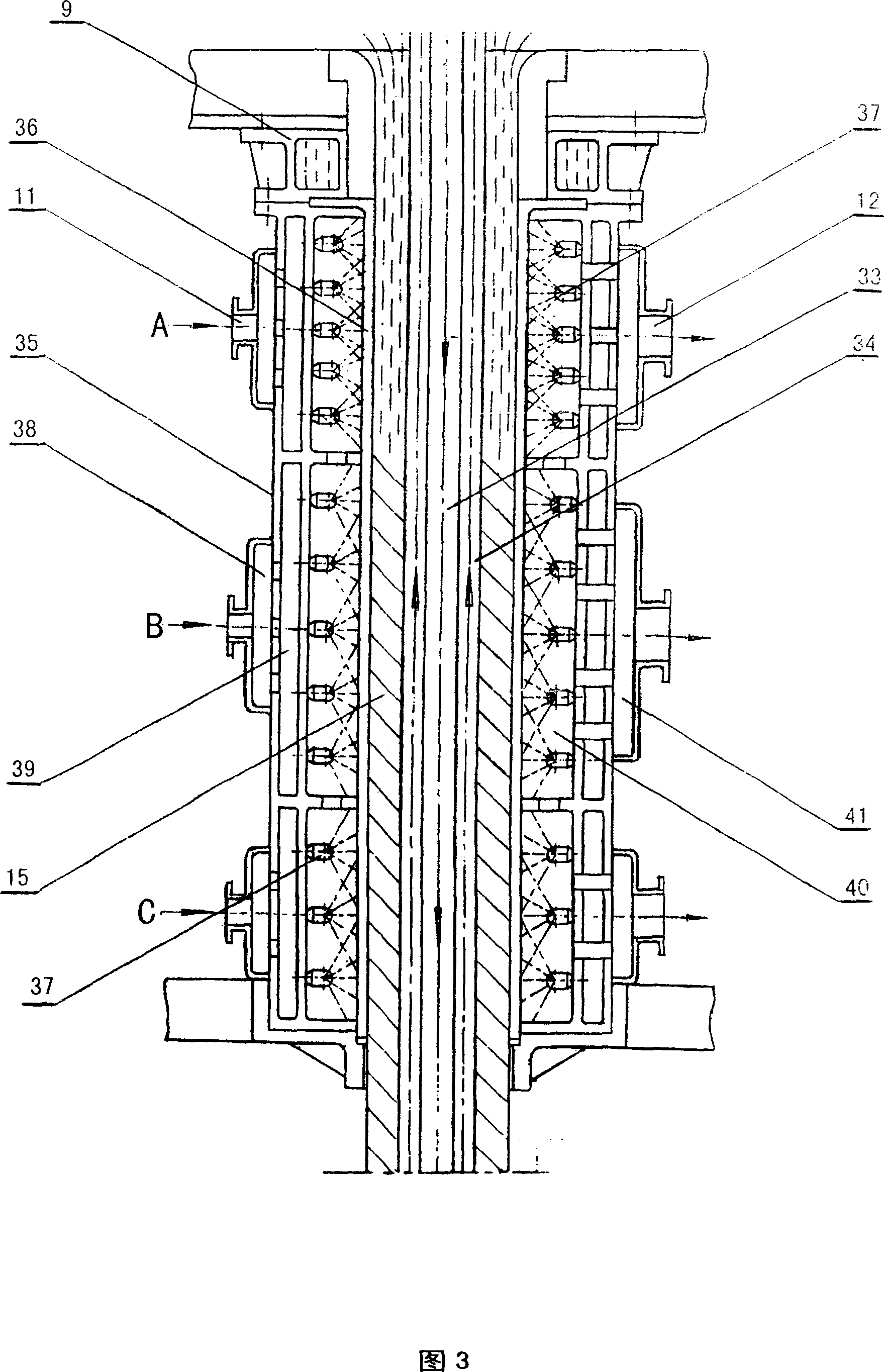

[0033] specific implementation plan

[0034] (See Figure 1) When producing a large-diameter hollow billet, the dummy bar is first sent into the crystallizer 10 through the fetching roller table 27, the turning roller table 23 and the pinch roller 18, and then the annular crystallization chamber is sealed. The molten steel 5 is injected into the tundish 8 through the ladle 6 and the casting tank 7, and the molten steel rotates continuously in the crystallizer under the action of the tangential impact force, and at the same time, it is forced to cool by the cooling walls of the inner and outer molds and rapidly crystallizes into a shell , the molten steel first contacts the dummy head and solidifies with it. At this time, the dummy bar 26 moves down slowly under the traction of the traction roller 13. When the tube blank is pulled out of the crystallizer, the spray device 14 sprays soda on the tube blank. 15, during the traction process, the tube blank is subjected to secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com