Process for specially-shaped electrolytic conductive material

A technology of conductive material and processing technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of low production efficiency, high production cost, long production process flow, etc., to achieve short production process, excellent product quality, Excellent surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

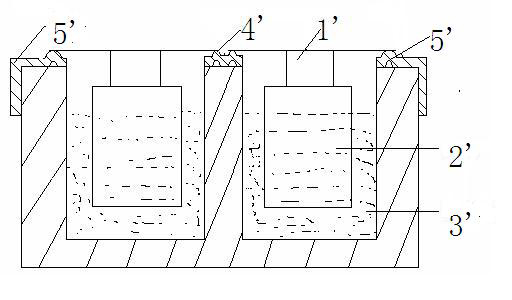

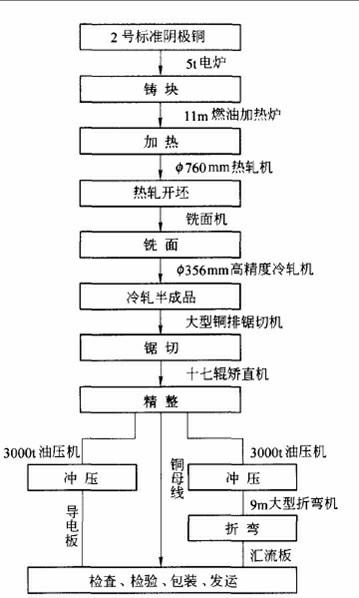

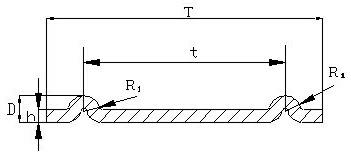

[0018] The processing technology of a special-shaped conductive material for electrolysis in this embodiment includes the following steps: 1) Using the No. 1 cathode copper specified by the national standard, the high-purity cathode copper with a copper content of not less than 99.99% is used as a raw material. The temperature is 1150°C±10°C, the hydraulic pressure of the crystallizer is 0.2-0.4MPa, the outlet water temperature of the crystallizer is controlled at 35°C-50°C for melting and heat preservation, and copper liquid refining technology is adopted in a vacuum state, and the vacuum state adopts wood charcoal Covered with graphite phosphorus sheet to achieve vacuum during melting. Using an online degassing and deoxidizing device, the copper liquid is filled with inert gas argon or nitrogen, and the controlled graphite shaft and rotor are used as a stirring device to press argon or nitrogen into the copper liquid and break it into tiny bubbles to make it Uniformly disper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com