Patents

Literature

2292results about How to "Short production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of dark tea production process

ActiveCN102273527AReduce time for fermentation processIncrease productionPre-extraction tea treatmentBlack teaAspergillus niger

The invention relates to a production technology of black tea, in particular to the technical field of the black tea. The production technology of the black tea comprises the following working procedures: green removing, twisting, piling, drying at first time, steaming, compacting, fermenting and drying 2, wherein pulp filling is carried out on a tea leaf raw material before the green removing working procedure, and the mass ratio of water to tea leaf is 6-9% in the pulp filling process; and artificially adding inoculated strains between the steaming working procedure and the fermenting working procedure, wherein the artificially inoculated strains are one or more of Eurotium cristatum, candida albican and aspergillus niger. By adopting the production technology provided by the invention,time of a fermentation technology in the production process of the black tea is reduced, production efficiency is improved, and yield of the black tea is increased; meanwhile, the problem that the traditional black tea production technology is controlled by experience and level of a tea making master worker is solved, the time for producing the black tea by utilizing the technology is short, the produced black tea has good consistency, strong taste, pure fragrance, red-yellow soup colour and brown and bright leaf edge.

Owner:HUNAN XIANGFENG TEA

Resistance welding superposition technology for PCB thick copper lines

ActiveCN101534612AIncreasing the thicknessInhibit sheddingNon-metallic protective coating applicationProduction scheduleCooking & baking

The invention discloses a resistance welding superposition technology for PCB thick copper lines, comprising the steps of: at first, printing resistance welding ink on the surface of a PCB and forming a first resistance welding layer via screen printing resistance welding; and pre-drying while remaining 75 DEG C and semi-hardening the first resistance welding layer after cooling; then printing the resistance welding on the first resistance welding layer once again in order to form a second resistance welding layer; pre-drying once again while remaining 75 DEG C and semi-hardening the first resistance welding layer and the second resistance welding layer after cooling; eventually, hardening the resistance welding layer and the second resistance welding layer completely subsequent to the segmented baking of the semi-hardened PCB. The invention requires only one-time resistance welding pattern transfer and high-temperature baking by the superposition printing on the thickness of the resistance welding, which increases the thickness of the resistance welding layer, thickens, in particular, the thickness of the resistance welding layer at corners of the lines, and avoids the problems of resistance welding blistering and falling in thermal impact procedures of post-processing procedure, and meanwhile, using the inventive technology shortens production procedure dramatically, speeds up production schedule and lowers production cost.

Owner:SHENZHEN BOMIN ELECTRONICS

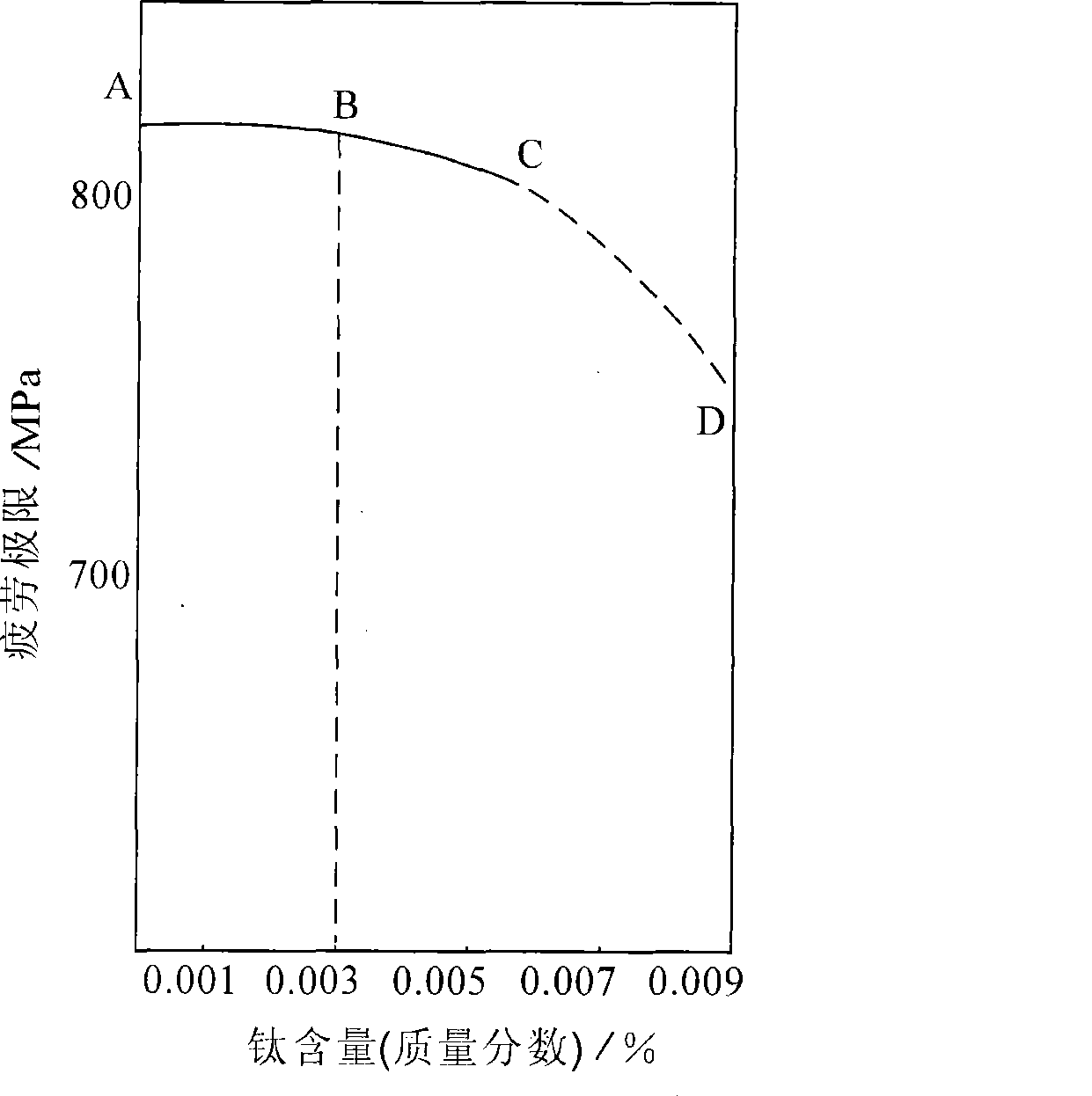

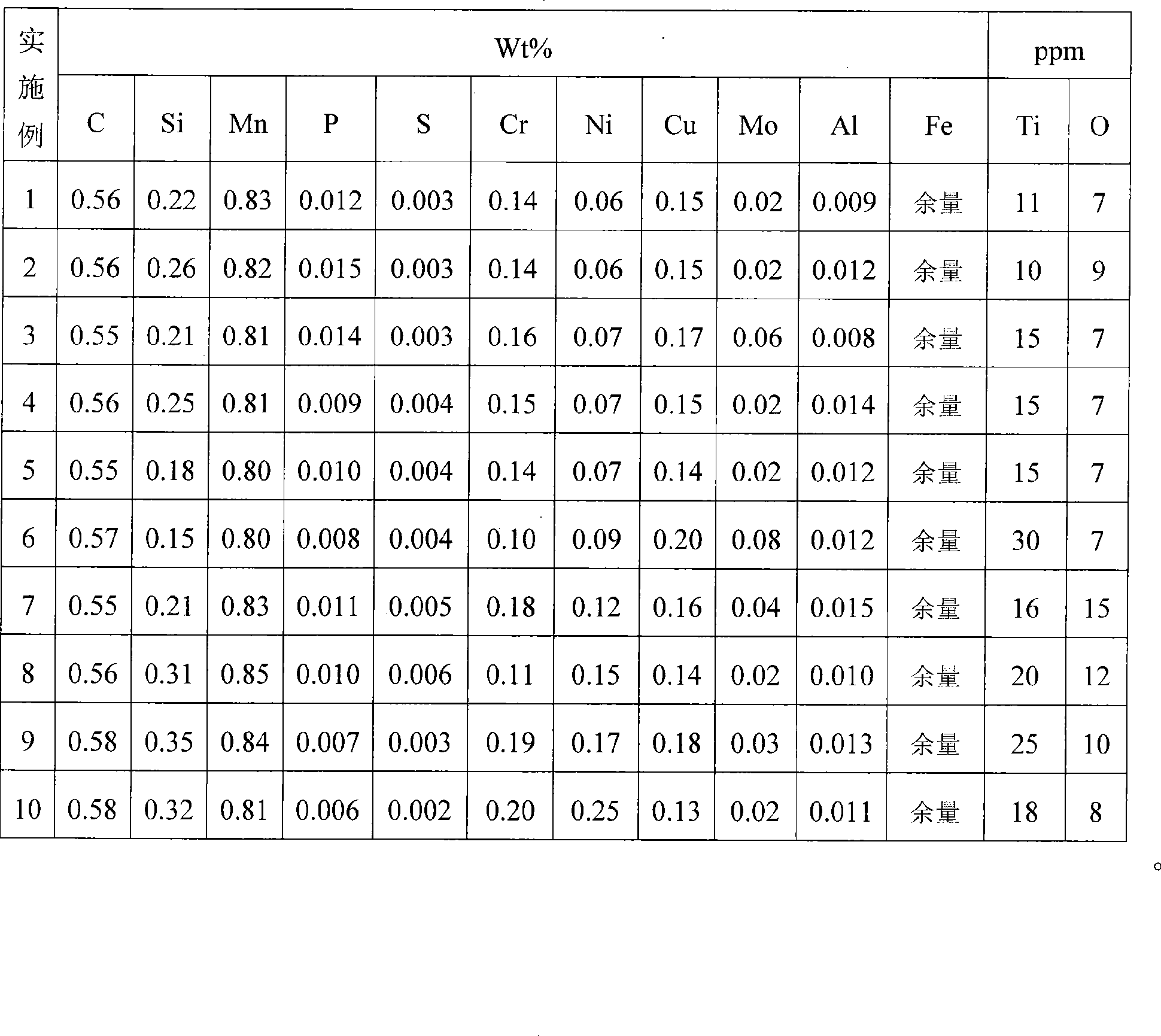

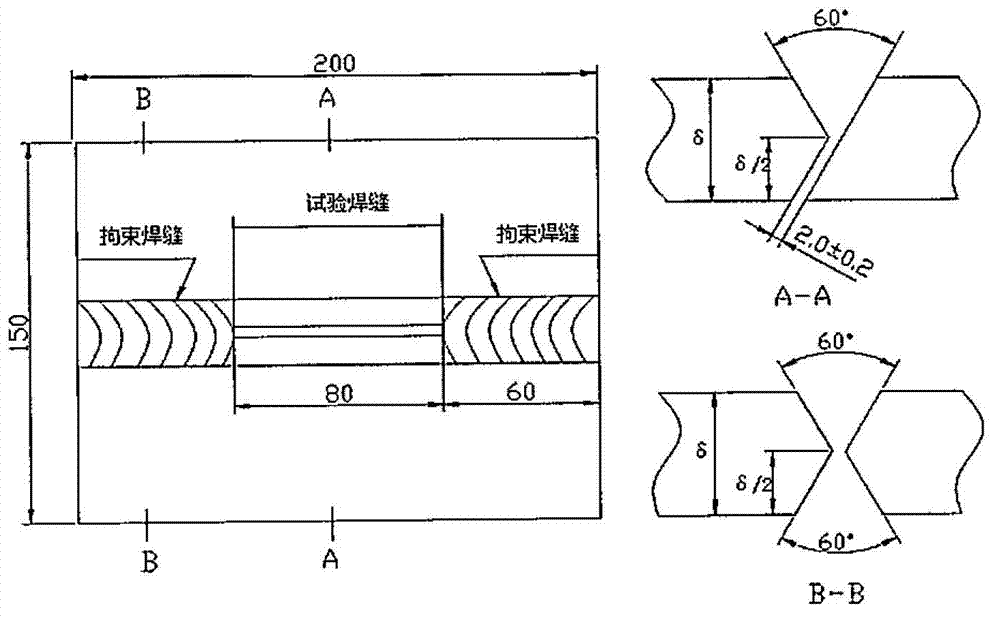

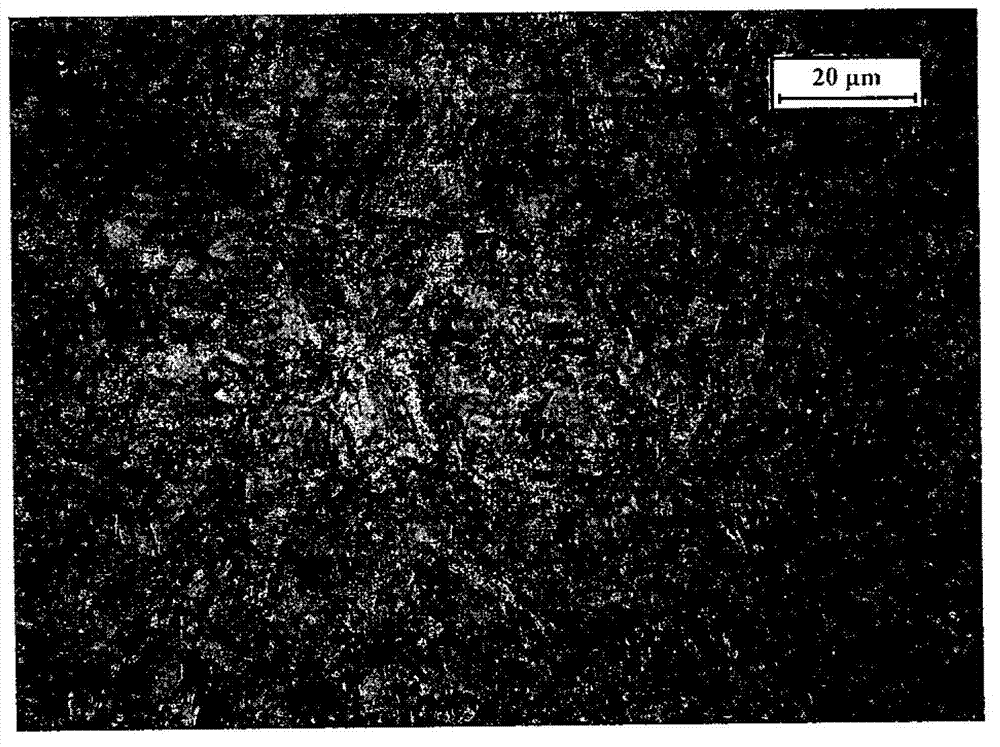

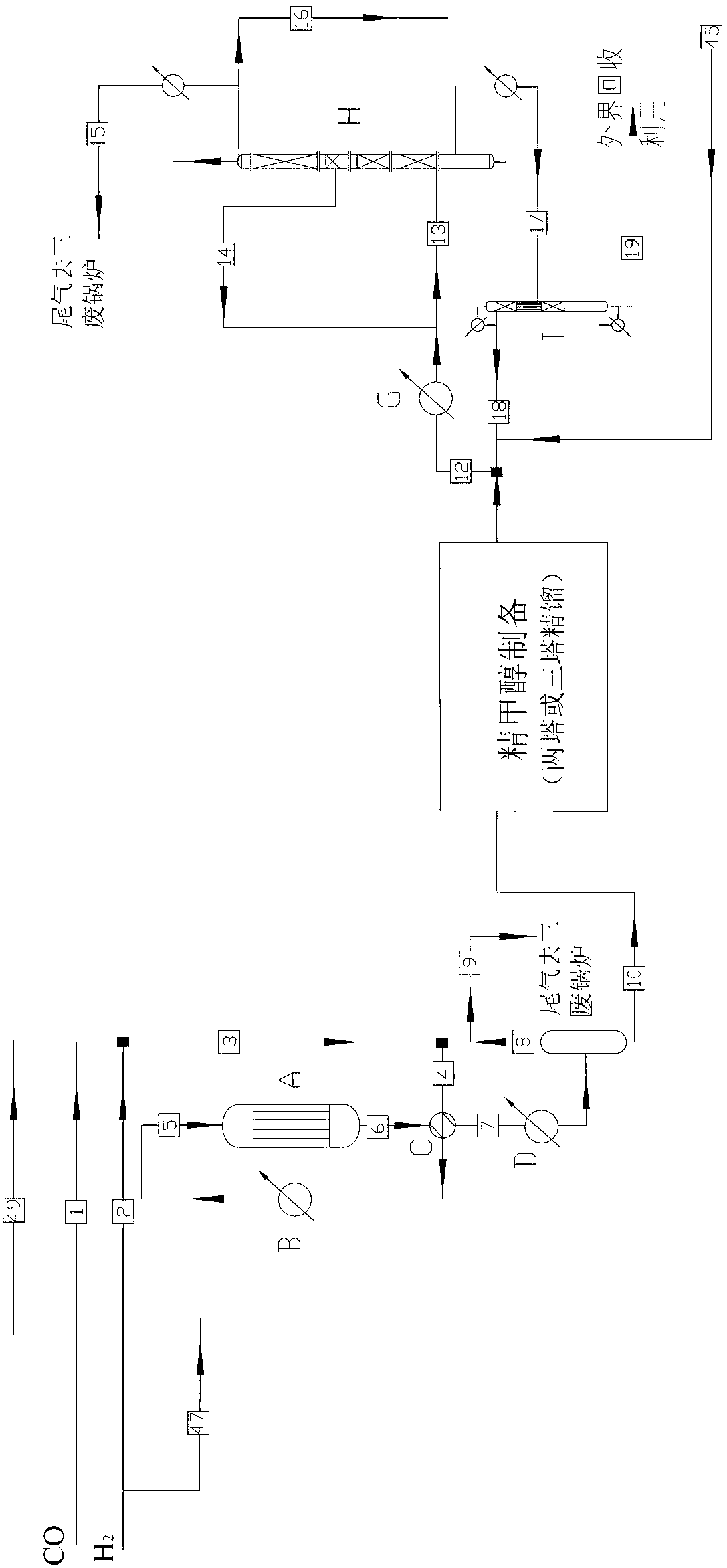

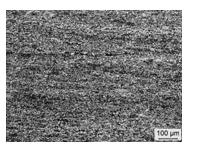

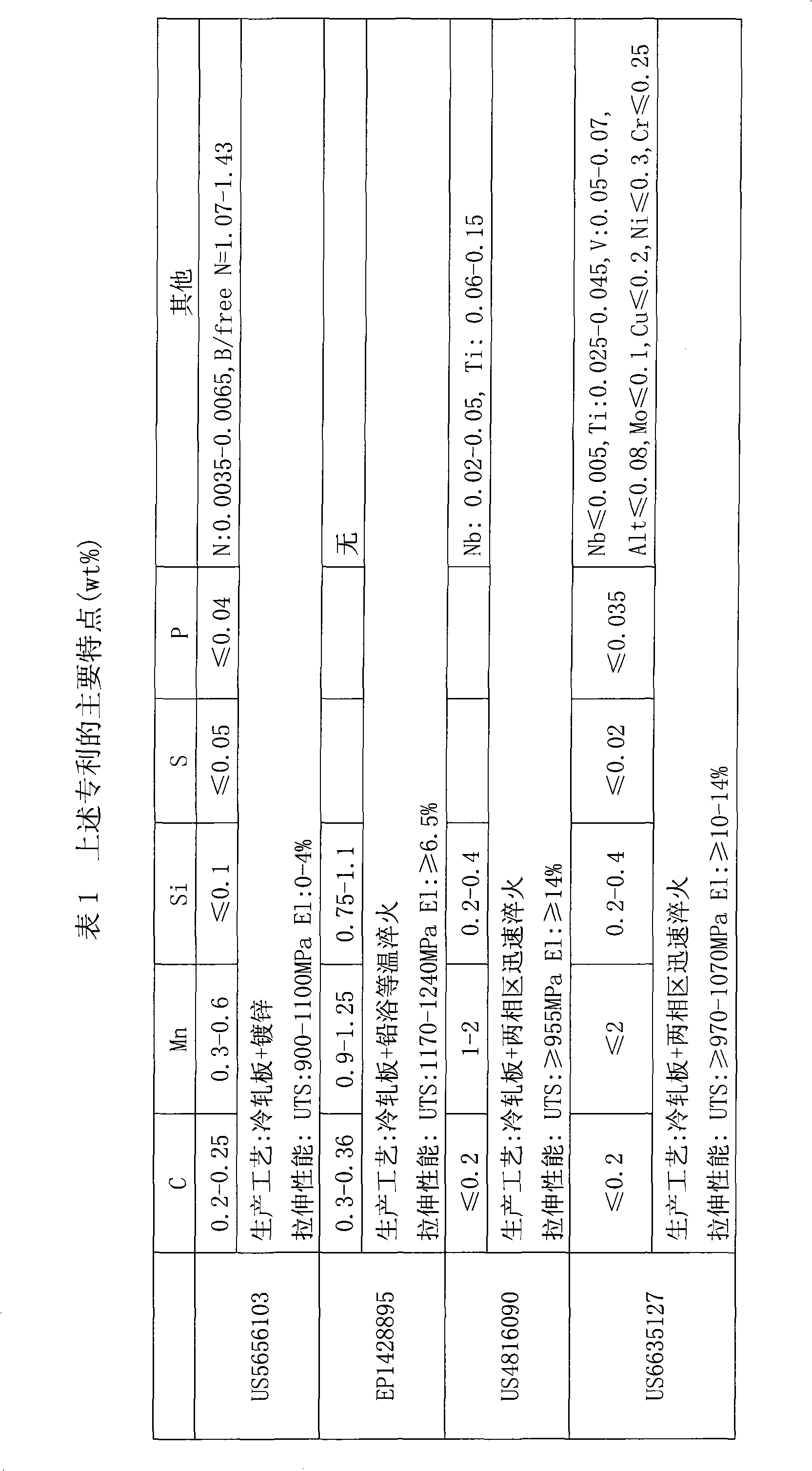

Low-cost high-purity medium carbon bearing steel for automobile hub and manufacturing method thereof

The invention discloses a manufacturing method of low-cost and high-purity medium-carbon bearing steel used for automobile hubs; the manufacturing method comprises the following steps: (a) the mass percentage of the components of the bearing steel is as follows: C: 0.55 percent to 0.58 percent, Si: 0.15 percent to 0.35 percent, Mn: 0.80 percent to 0.85 percent, P: less than or equal to 0.030 percent, S: less than or equal to 0.015 percent, Cr: 0.10 percent to 0.20 percent, Ni: less than or equal to 0.25 percent, Cu: less than or equal to 0.20 percent, Mo: less than or equal to 0.08 percent, Al: 0.008 percent to 0.015 percent, Ti: less than or equal to 30ppm, O: less than or equal to 15ppm, and the rest are Fe and inevitable impurities; (b) smelting, electric furnace initial melting+ ladle furnace refined melting+ vacuum degassing; (c) continuous casting into steel billet; (d) rolling. Compared with the prior art, the technological process has obviously shorter process and lower production cost; the impact resistance, torsion resistance, wear resistance and fatigue endurance of the produced automobile hub bearing are good.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

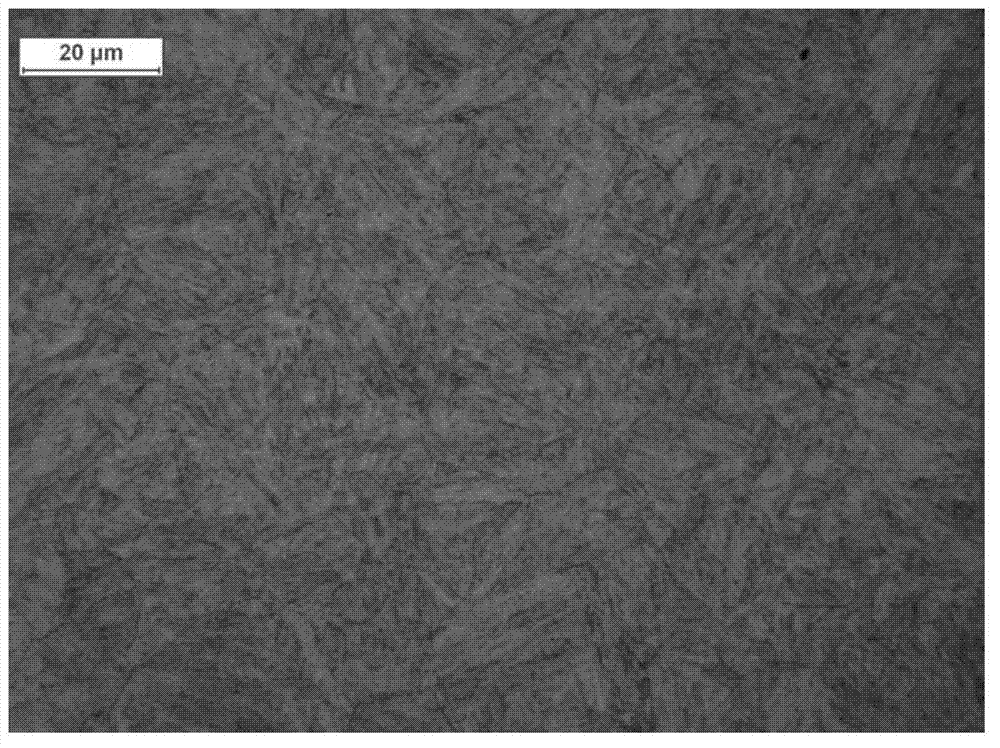

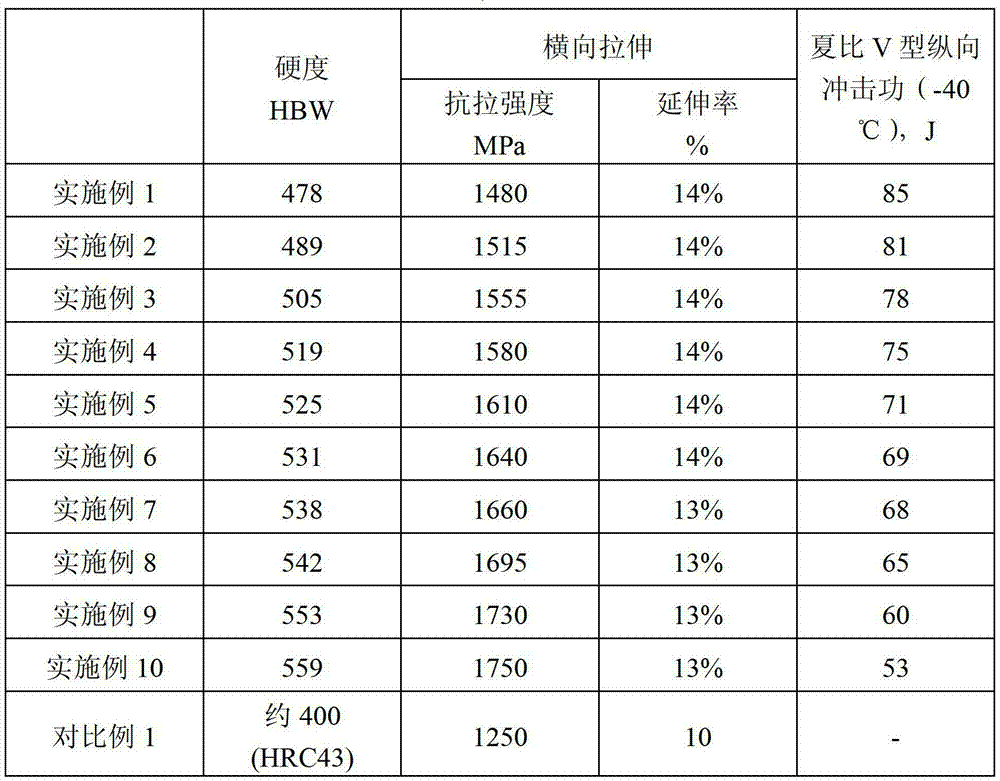

Super-strength high-toughness wear resistant steel plate and production method thereof

ActiveCN102876969AStrong mechanical propertiesGood mechanical propertiesFurnace typesQuenching agentsWear resistantHigh intensity

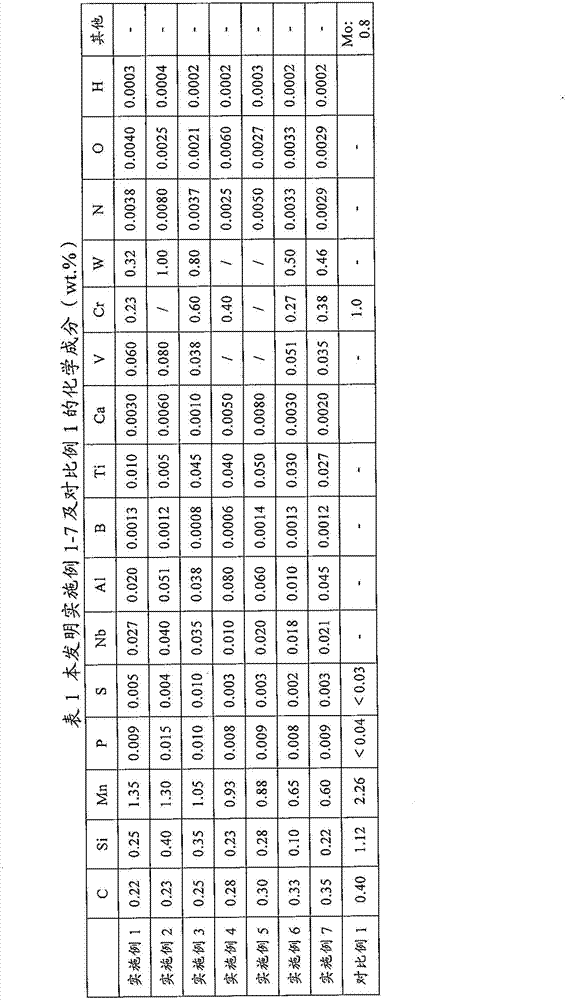

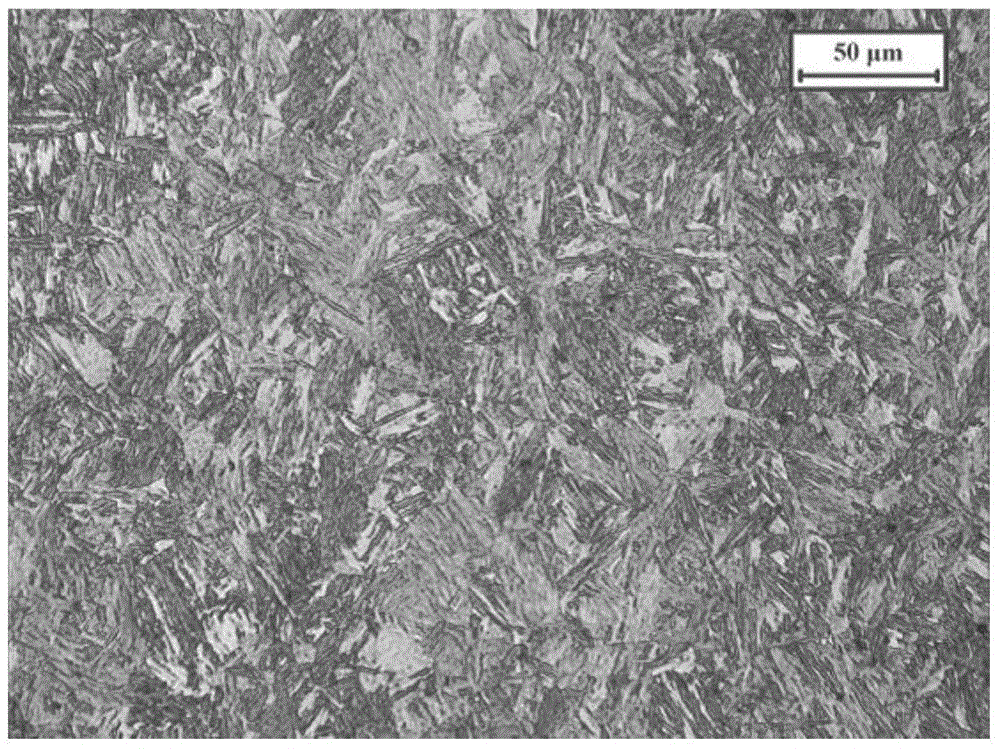

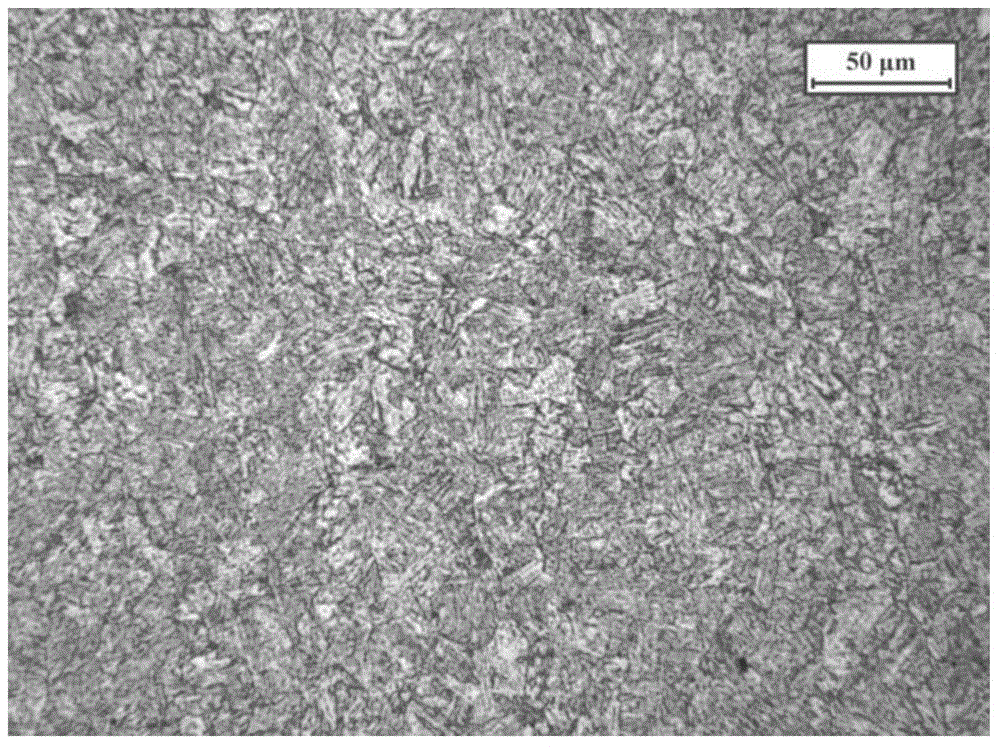

The invention provides a wear resistant steel plate, comprising the following chemical components (wt%): 0.22-0.35% of C, 0.10-0.40% of Si, 0.60-1.35% of Mn, not more than 0.015% of P, not more than 0.010% of S, 0.010-0.040% of Nb, 0.010-0.080% of Al, 0.0006-0.0014% of B, 0.005-0.050% of Ti, 0.0010-0.0080 wt% of Ca, not more than 0.080% of V, not more than 0.60% of Cr, not more than 1.00 wt% of W, not more than 0.0080% N, not more than 0.0060% of O, not more than 0.0004% of H and the balance of Fe and inevitable impurities, wherein Nb+Ti is not less than 0.025% and not more than 0.080%, and Al+Ti is not less than 0.030% and not more than 0.12%. The production method of the wear resistant steel plate comprises the steps of smelting, casting, rolling and directly cooling after rolling. The wear resistant steel plate obtained through the components and the process has the advantages of high intensity, good low temperature toughness, and excellent mechanical processing performance, and is suitable for easily abrasive devices in engineering and mine machinery, such as a grab bucket, a scraper conveyer and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Low-alloy high-strength high-toughness steel plate and manufacturing method thereof

InactiveCN104480406AUniform compositionImprove surface qualityMetal rolling arrangementsAlloyHardness

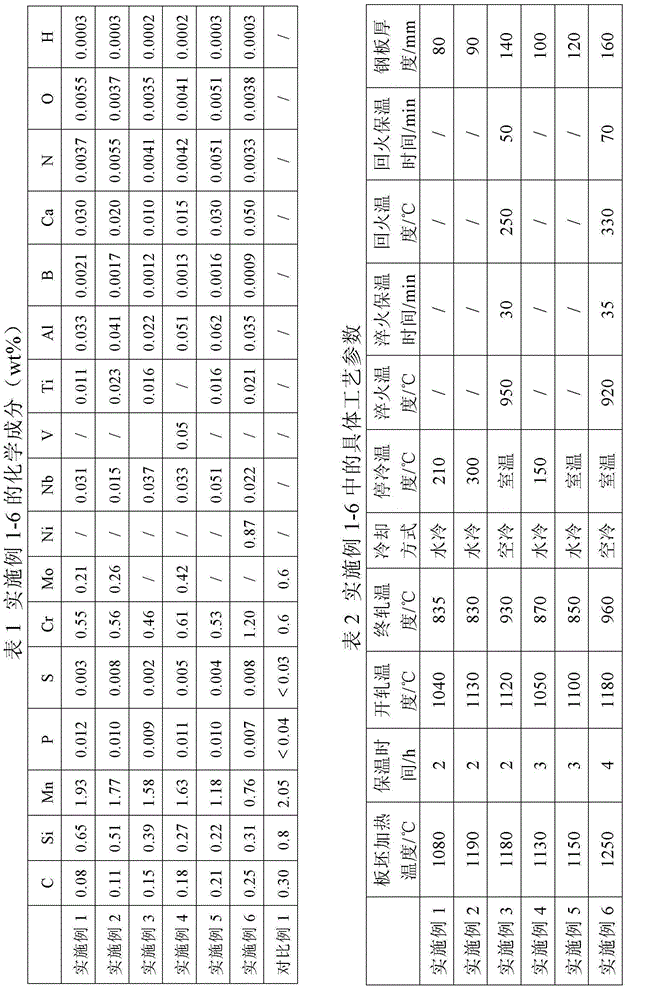

The invention relates to a low-alloy high-strength high-toughness steel plate and a manufacturing method thereof. The low-alloy high-strength high-toughness steel plate comprises the following components in percentage by mass: 0.08-0.25% of C, 0.10-1.00% of Si, 0.50-2.00% of Mn, less than 0.020% of P, less than 0.010% of S, 0.10-2.00% of Cr, 0-1.00% of Mo, 0-2.00% of Ni, 0.010-0.080% of Nb, at most 0.10% of V, at most 0.060% of Ti, 0.0005-0.0040% of B, 0.010-0.080% of Al, 0.010-0.080% of Ca, at most 0.0080% of N, at most 0.0080% of O, at most 0.0004% of H, and the balance of Fe and inevitable impurities. 0.20%<=(Cr / 5+Mn / 6+50B)<=0.55%, 0.02%<=(Mo / 3+Ni / 5+2Nb)<=0.45%, and 0.01%<=(Al+Ti)<=0.13%. The Brinell Hardness of the steel plate is 390-460 HB, the yield strength is 900-1100 MPa, the tensile strength is 1100-1400 MPa, the elongation percentage is 11-15%, the -40 DEG C Charpy V-notch longitudinal impact work is greater than or equal to 40J, and the plate thickness can reach 100mm above. Thus, the steel plate implements matching of high strength, high hardness and high toughness, and has favorable machining properties.

Owner:BAOSHAN IRON & STEEL CO LTD

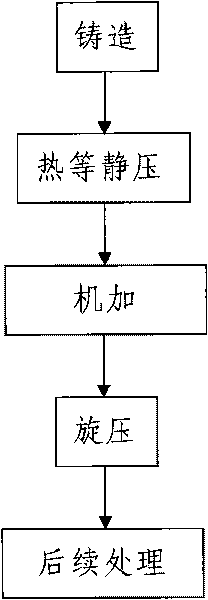

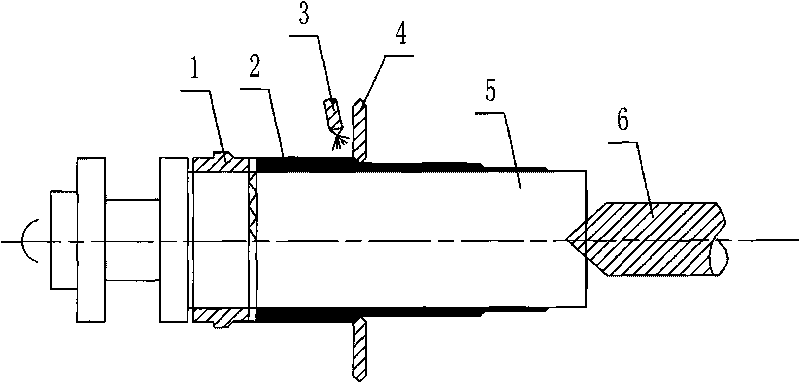

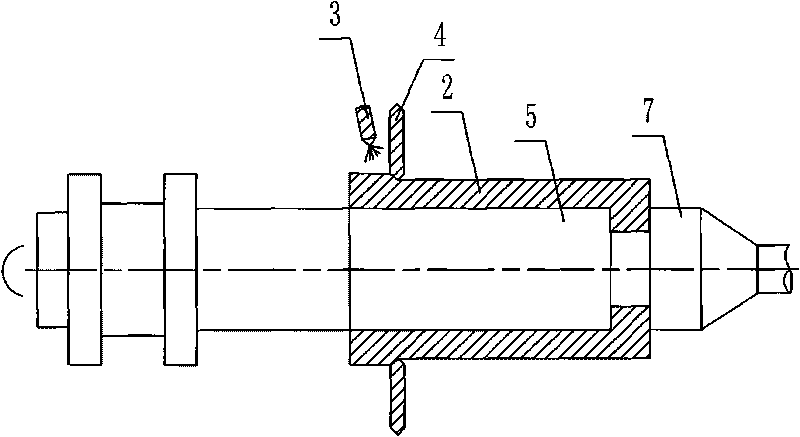

Manufacturing method of large-calibre seamless titanium alloy barrel body

InactiveCN101733641AWide range of sizesEasy to prepareOther manufacturing equipments/toolsTitanium alloyMachining

The invention discloses a manufacturing method of a large-calibre seamless titanium alloy barrel body, which comprises the steps of: 1, casting: casting titanium alloy raw materials into a large-calibre titanium alloy barrel blank by using a vacuum smelting furnace and through a vacuum smelting method; 2, hot isostatic pressing: performing the hot isostatic pressing for the large-bore titanium alloy barrel blank in an inert protective atmosphere by using a hot isostatic pressing device; 3, mechanical machining: processing a chamfer angle for spinning at the head of the large-bore titanium alloy barrel blank after the hot isostatic pressing by using mechanical processing equipment to obtain a spinning barrel blank; 4, spinning: thermally spinning the mechanically processed spinning barrel blank with the total deformation rate not less than 60% for many times by using spinning equipment to obtain a large-bore seamless titanium alloy thin-wall barrel body; and 5, subsequent treatment. The production process has short process flow, high yield, low cost, high utilization rate of materials and easy realization, and the defects of the large-bore seamless titanium alloy barrel body, such as complex process, high cost, low yield and the like of the traditional production process can be effectively solved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

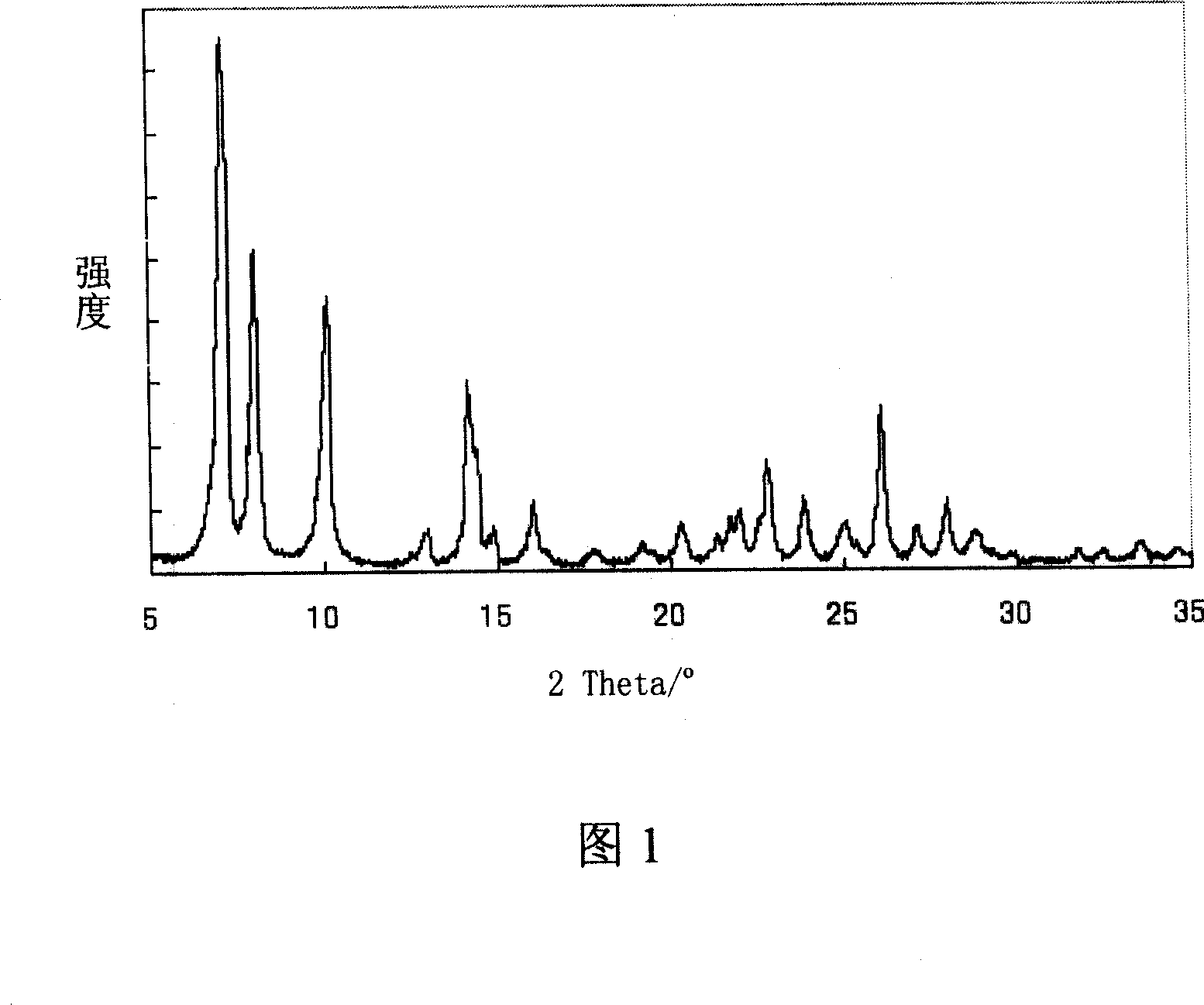

Preparation method of Ti-MWW molecular sieve

InactiveCN101012062AHigh catalytic activityShort production processCrystalline aluminosilicate zeolitesMolecular sieveInorganic Chemical

The invention discloses a making method of Ti-MWW molecular sieve in the inorganic chemical synthetic technical domain, which comprises the following steps: introducing surface activator in the crystallizing course of Ti-MWW molecular sieve; making raw powder of Ti-MWW molecular sieve; proceeding acid disposal; sintering; obtaining the product.

Owner:EAST CHINA NORMAL UNIV

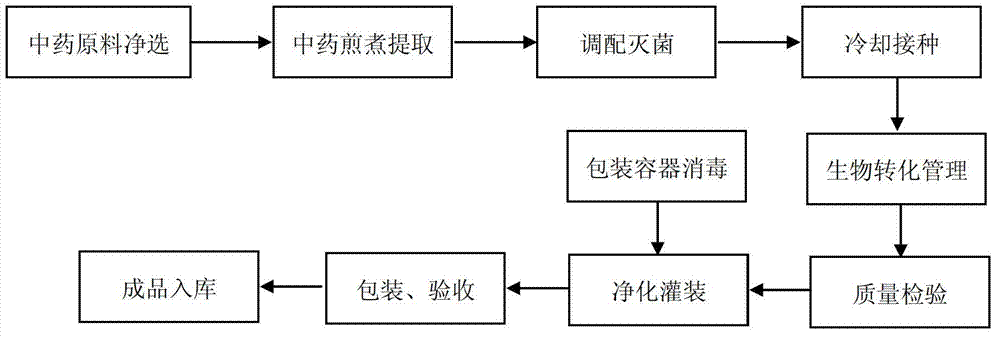

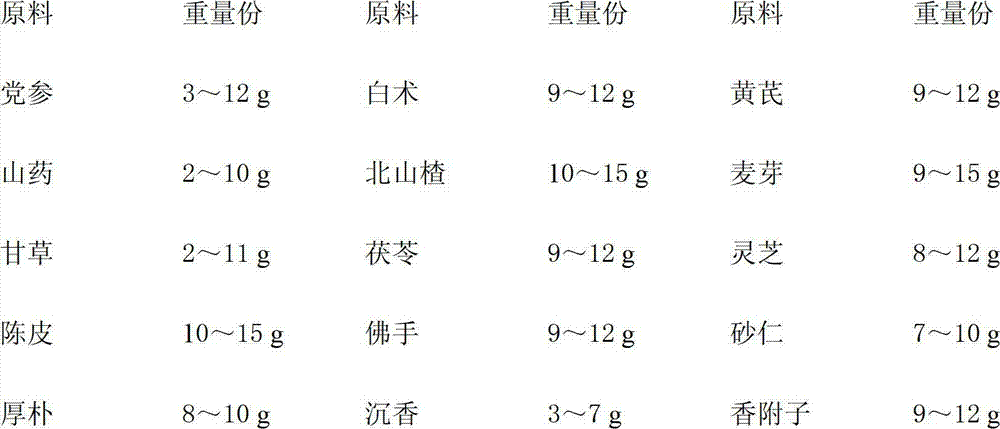

Baokangling multi-element probiotics oral liquid for treating digestive system disease and preparation method thereof

ActiveCN102727819AEliminates or quickly relieves bloatingEliminate or quickly relieve stomach painDigestive systemPharmaceutical delivery mechanismDrug biotransformationEssential nutrient

The invention discloses a baokangling multi-element probiotics oral liquid for treating a digestive system disease and a preparation method of the oral liquid, wherein the oral liquid is comprised of Radix Codonopsis, Atractylodes Rhizoma, Astragalus mongholicus, Rhizoma Dioscoreae, Crataegus pinnatifida, Fructus Hordei Germinatus, Radix Glycyrrhizae, Poria cocos, Ganoderma lucidum, pericarpium citri reticulatae, Fructus citrus sarcodactylis, Fructus Amomi, Cortex Magnoliae Officinalis, Lignum Aquilariae Resinatrm, Cyperus rotundus, Fructus Lycii, Angelica sinensis, Radix Salviae Miltiorrhizae, bletilla striata, unshelled Ascidia, Radix Bupleuri, Radix Paeoniae alba, Corydalis yanhusuo, Radix Glehniae, Polygonatum odoratum, Fructus Schizandrae, Rhizoma Coptidis, peeled Semen Raphani, Semen Lablab Album, Panax notoginseng powder, Fructus Aurantii Immaturus, Radix Aucklandiae, Coix seed, endothelium corneum gigeriae galli, Fructus Corni, lotus seeds and Lindera aggregate. The above traditional Chinese medicinal materials are decocted according to a certain weight ratio and subjected to probiotics fermentation so as to obtain the multi-element probiotics oral liquid. The oral liquid has unique treating effect proven by clinical application. The traditional Chinese medicines are decomposed from macromolecules to micromolecules through biotransformation, so that the effects of absorbing quickly and taking effect instantly are obtained; furthermore, the secondary components and invalid components of the traditional Chinese medicines are converted into the essential nutrient substances incapable of synthetizing by themselves in the human body, so that the curative effect is improved. The application range of the oral liquid is broadened and the quality guarantee period is prolonged.

Owner:湖北药王生物科技有限公司

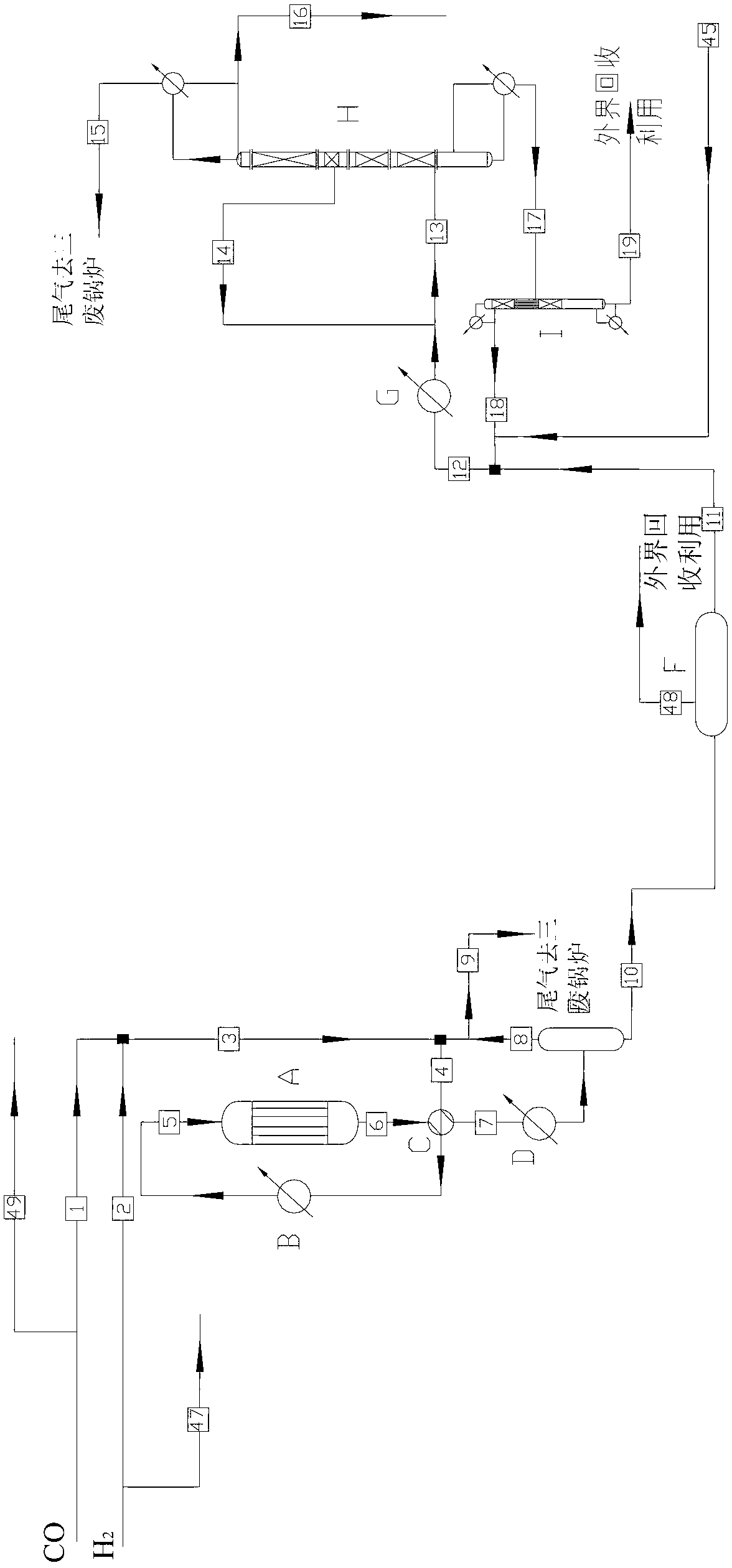

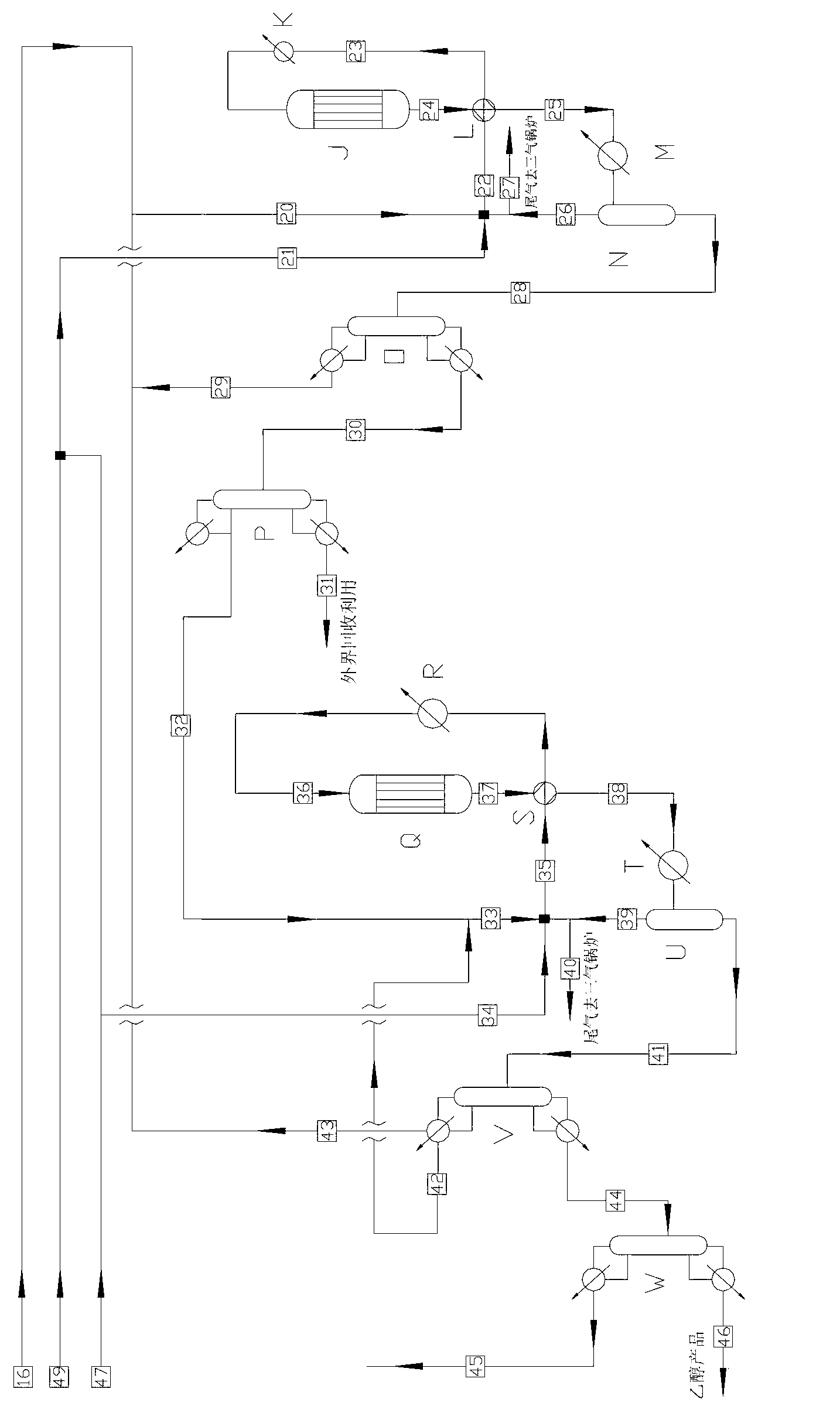

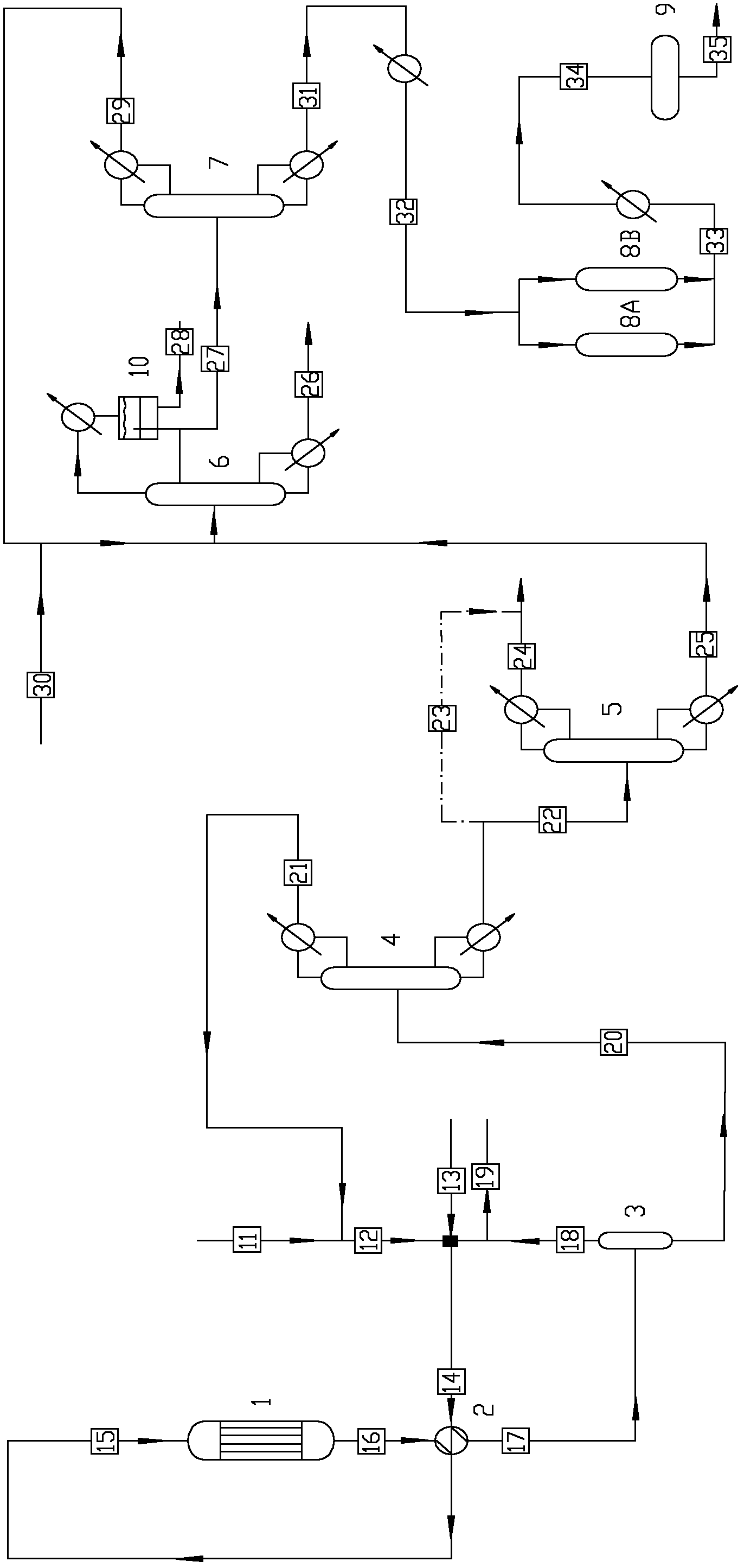

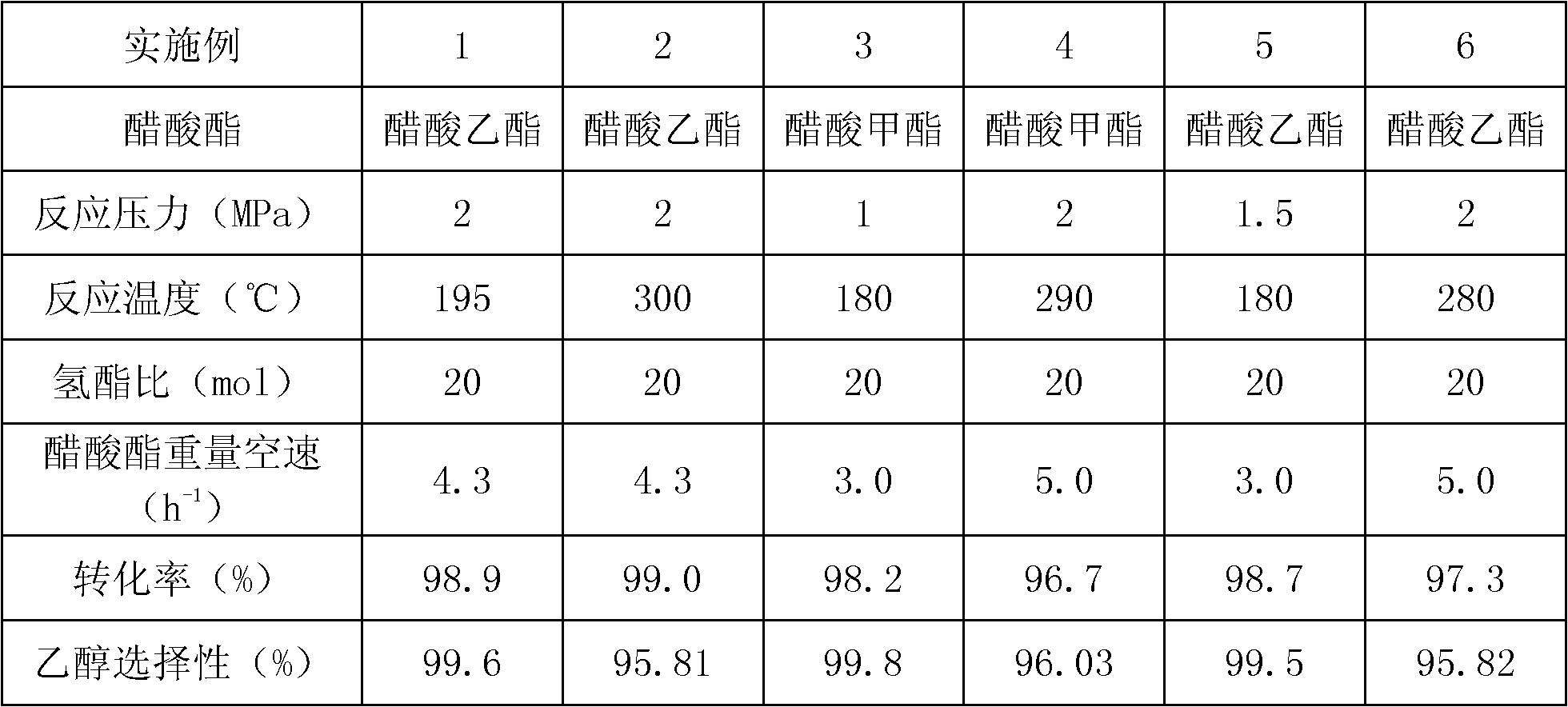

Process for indirectly producing alcohol with synthetic gas and application of process

ActiveCN103012062AReduce energy consumptionMild reaction conditionsOrganic compound preparationHydroxy compound preparationHydrogenMethyl acetate

The invention relates to a process for indirectly producing alcohol with synthetic gas. The process comprises the steps that the synthetic gas formed by mixing industrial carbon monoxide with hydrogen is taken as a raw material to synthesize methanol; methanol is dehydrated to prepare dimethyl ether; dimethyl ether, carbon monoxide and hydrogen are mixed for carbonylation reaction to prepare methyl acetate; methyl acetate is purified and hydrogenated; a hydrogenated product is purified; and an alcohol product is obtained. An adopted catalyst, the process and a device have the characteristics of high conversion per pass and high effective utilization rate of reaction heat; the load of separating a crude product is reduced greatly; the production flow is shortened; and the production energy consumption is reduced greatly.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

Method for synthesizing nano ZSM-23 molecular screen

InactiveCN101214971AShort production processLow costCrystalline aluminosilicate zeolitesSoluble glassIsopropylamine

A synthetic method of Nanosized ZSM-23 zeolites belongs to the technical field of synthesis of inorganic chemistry. Firstly preparing reaction mixture from sodium metaaluminate or aluminum sulfate, silicasol or soluble glass, sodium hydroxide and isopropylamine, then hydrothermal crystallizing the reaction mixture, at last obtaining the Nanosized ZSM-23 zeolites through conventionally filtering, washing, drying and sintering the hydrothermal crystallized reaction mixture. The synthetic method has the advantages that average diameter of the cross sections of crystal grains of the synthesized ZSM-23 zeolites is not more than 100 nm, the specific surface area is comparatively high, production flow is short, the cost is low, and the method is favorable for industrial production and application.

Owner:EAST CHINA NORMAL UNIV

Low-alloy high-performance wear-resistant steel plate and manufacturing method thereof

ActiveCN103205627AImprove performanceHigh hardnessFurnace typesQuenching agentsChemical compositionWear resistant

The present invention provides a low-alloy high-performance wear-resistant steel plate and a manufacturing method thereof. The steel plate comprises the following chemical compositions (wt%) of 0.21-0.32% of C, 0.10-0.50% of Si, 0.60-1.60% of Mn, 0.0005-0.0040% of B, 0-1.50% of Cr, 0-0.80% of Mo, 0-1.50% of Ni, 0-0.080% of Nb, 0-0.080% of V, 0-0.060% of Ti, 0.010-0.080% of Al, 0.0010-0.0080% of Ca, 0-0.0080% of N, 0-0.0080% of O, 0-0.0004% of H, 0-0.015% of P, and 0-0.010% of S, wherein the following relationships are satisfied: 0.20%<=(Cr / 5+Mn / 6+50B)<=0.55%, 0.02%<=(Mo / 3+Ni / 5+2Nb)<=0.45%, 0.01%<=(Al+Ti)<=0.13%, and the balance is Fe and inevitable impurities. The low-alloy high-performance wear-resistant steel plate manufactured by the above compositions and through a TMCP process has high strength and hardness, good toughness and excellent wear resistance, and is suitable for easy-to-wear parts in various mechanical equipments.

Owner:BAOSHAN IRON & STEEL CO LTD

Processing method of whole-grain instant porridge

The invention discloses a processing method of whole-grain instant porridge. According to the method, whole-grain flour is subjected to pretreatment, and the whole-grain instant porridge can be prepared through extrusion forming primary Alpha treatment, low-temperature drying and high-temperature secondary Alpha treatment. The instant porridge prepared by the method has the moisture content being lower than 10 percent and the Alpha degree being high than 95 percent. The processing method disclosed by the invention is simple, convenient and feasible, the continuous degree of the processing process is high, the prepared whole-grain instant porridge has good rehydration effect and can be rehydrated within 3 to 4 minutes through being immersed by hot water, various kinds of nutritional ingredients of the original whole grain are maintained, the mouth feeling is excellent, the eating by customers is convenient, and the storage time of products is prolonged.

Owner:SCI RES INST OF NAT FOOD & STRATEGIC RESERVES ADMINISTATION

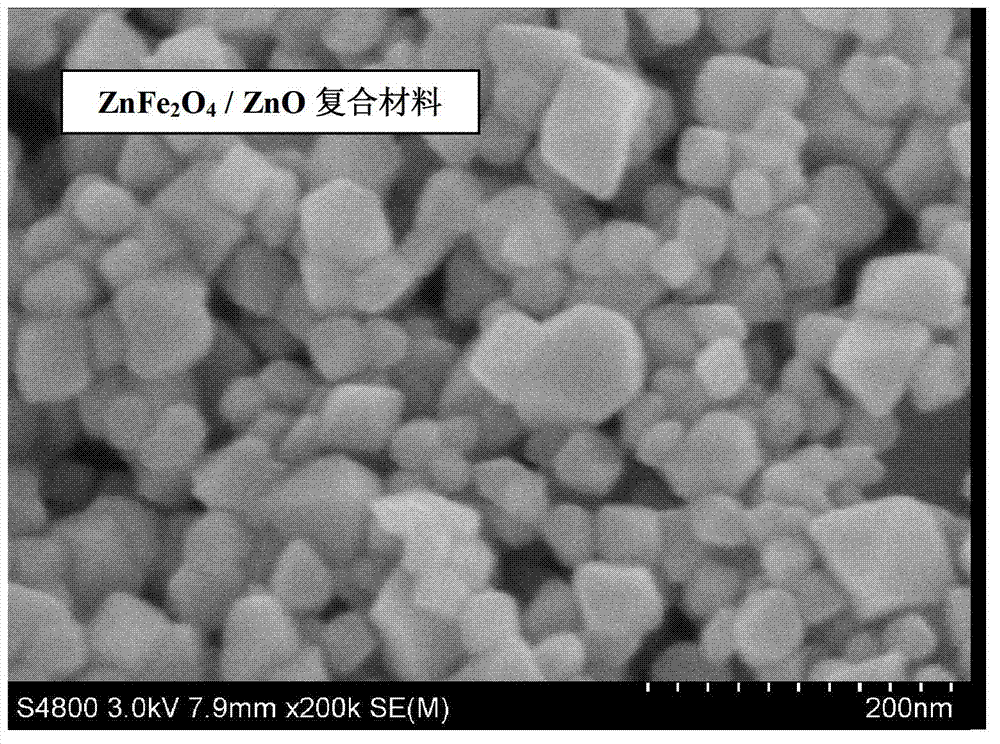

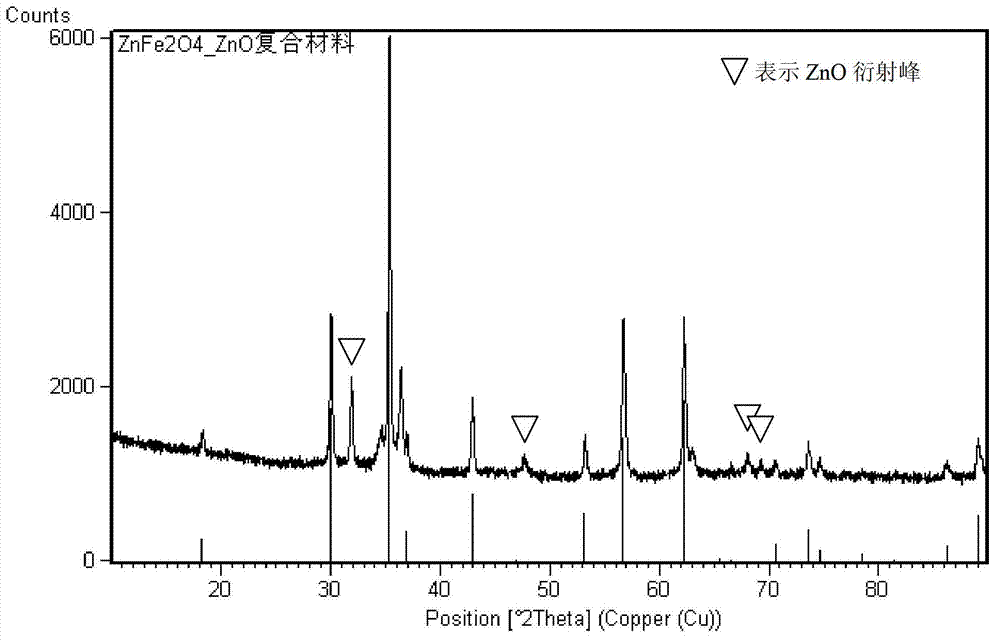

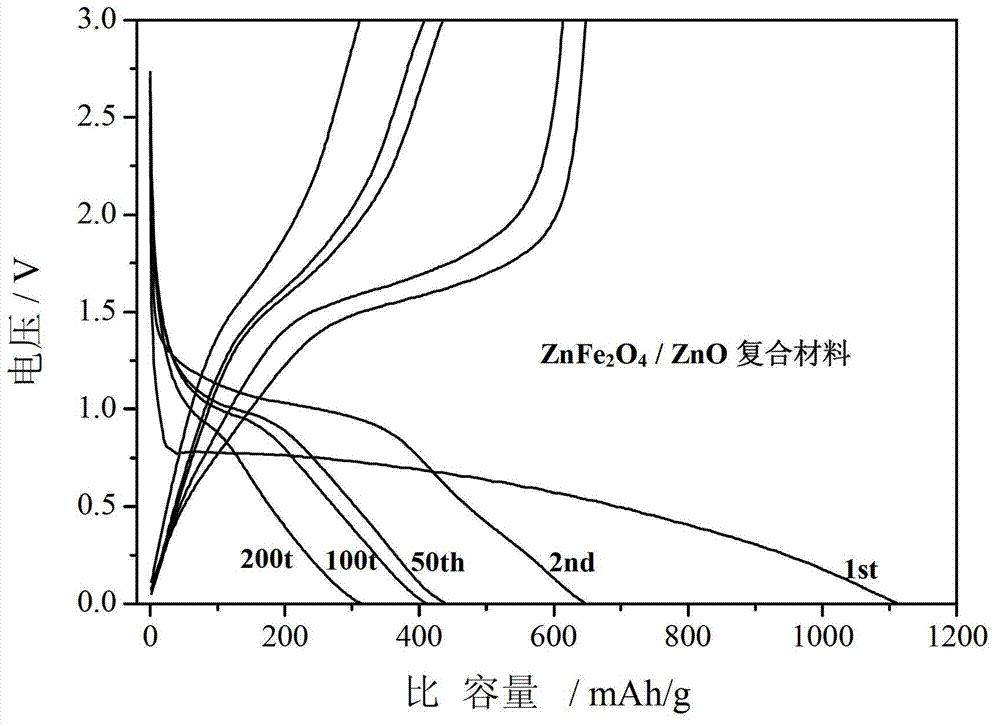

Zinc-ferrite-based nanometer composite as well as preparation method and application thereof

The invention relates to a ZnFe2O4-based nanometer composite. The zinc ferrite-based nanometer composite is a ZnFe2O4 / MO nanometer composite in which MO is a metal oxide. The ZnFe2O4-based nanometer composite comprises secondary particles formed by aggregating ZnFe2O4 nanoparticles with spinel structures and MO nanoparticles; and the metal oxide is ZnO, Fe2O3, CoO, NiO, CuO, MnO, TiO2, CrO3 and / or VO2. Compared with the prior art, the zinc-ferrite-based nanometer composite has the beneficial effects that the ZnFe2O4-based nanometer composite provided by the invention has high capacity and high cycle stability as a negative electrode material of a lithium ion battery, and the electrochemical performance of pure-phase ZnFe2O4 is greatly improved; the particles are uniform in size and good in dispersion; and a preparation method of the composite is simple, a production process is short without severe conditions, the cost is low, and the industrialization is easy.

Owner:BTR NEW MATERIAL GRP CO LTD

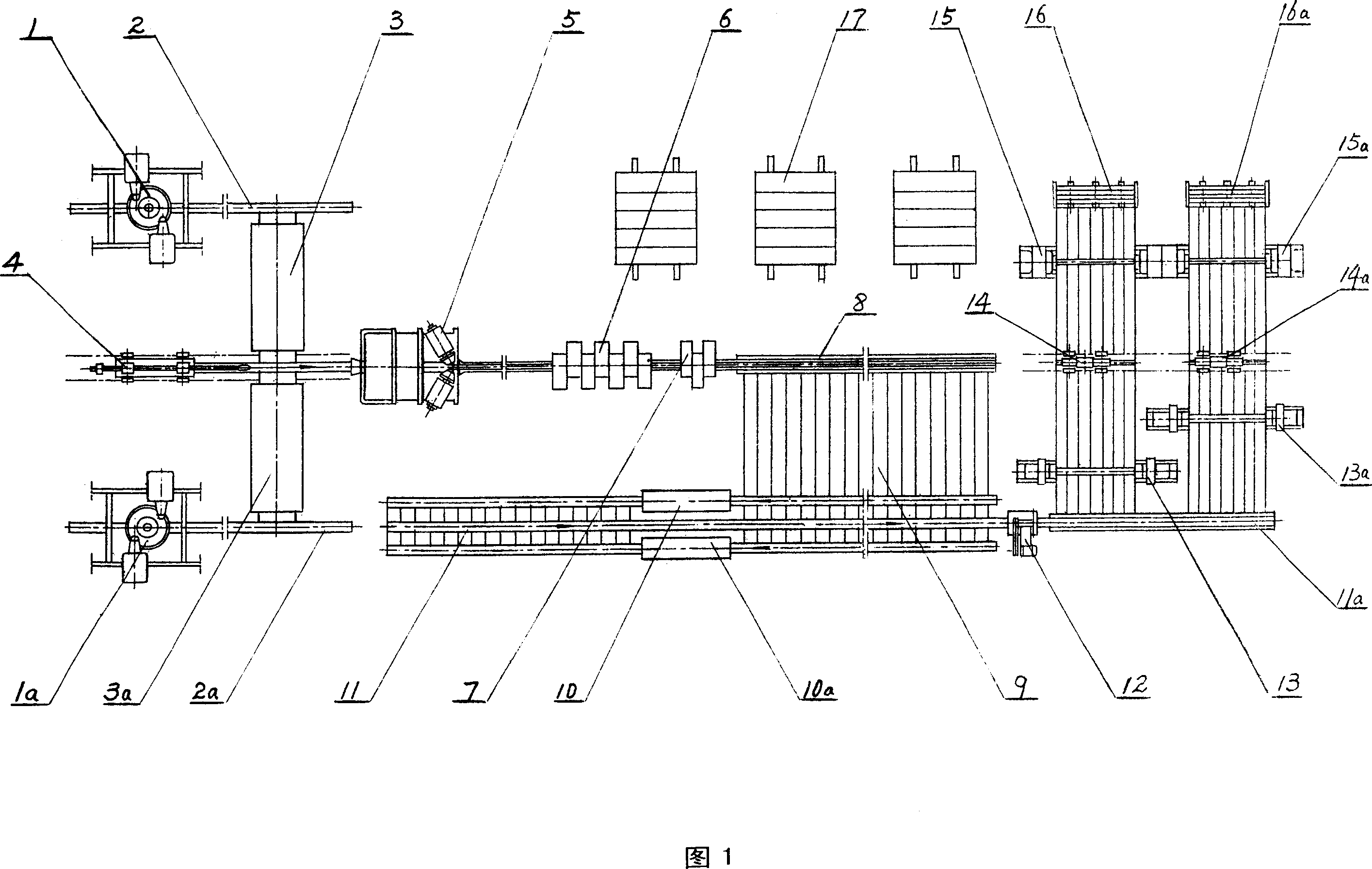

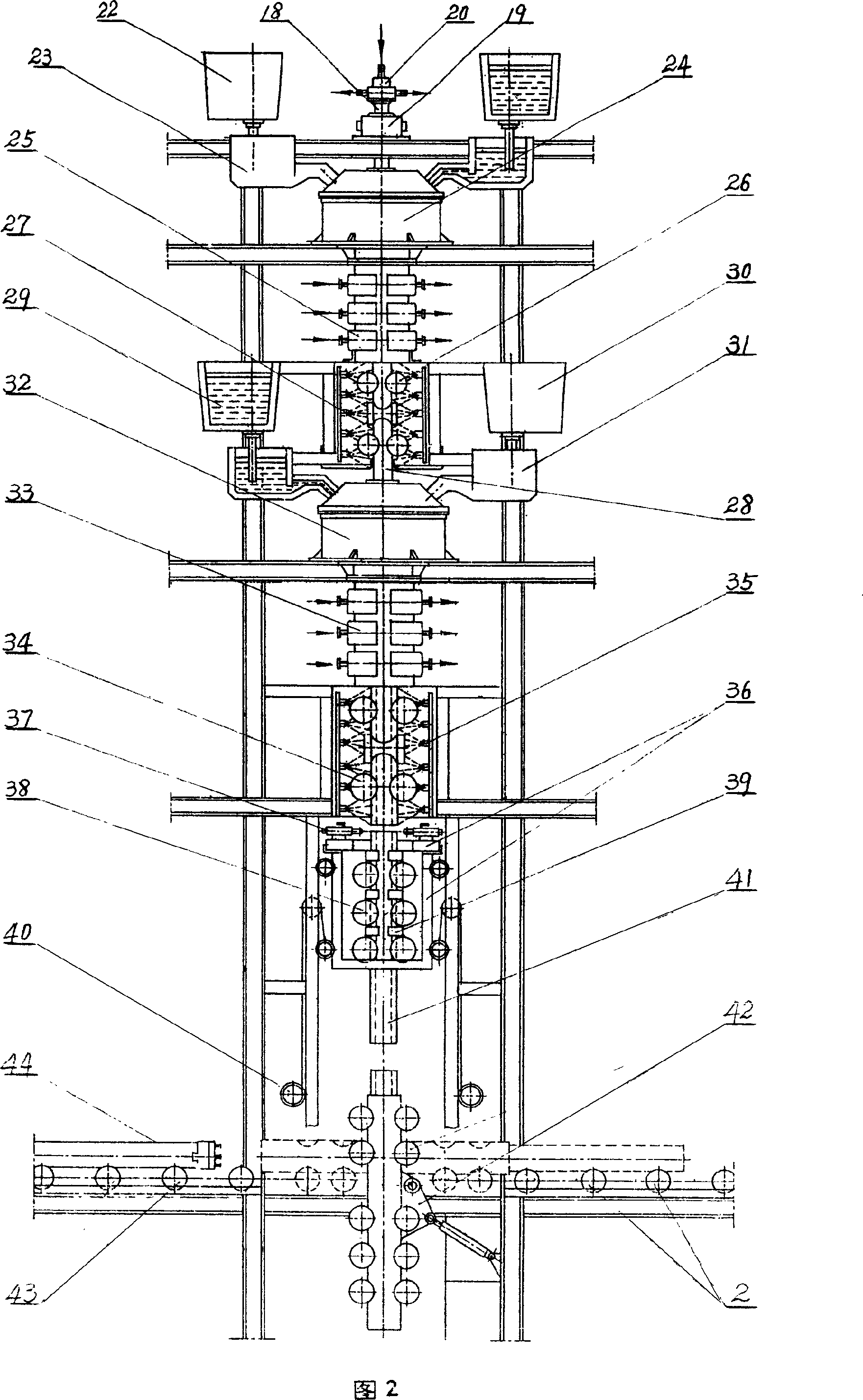

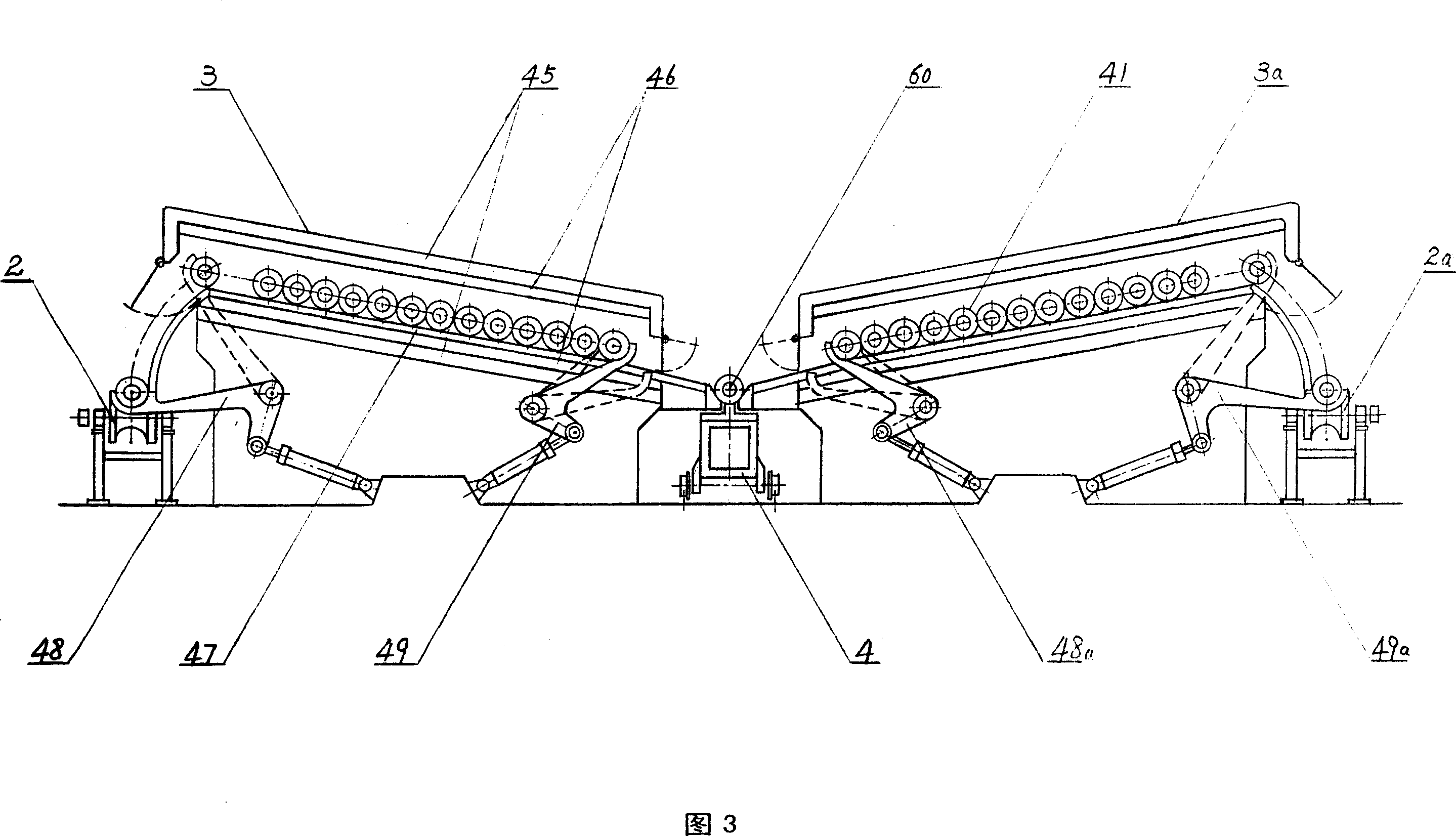

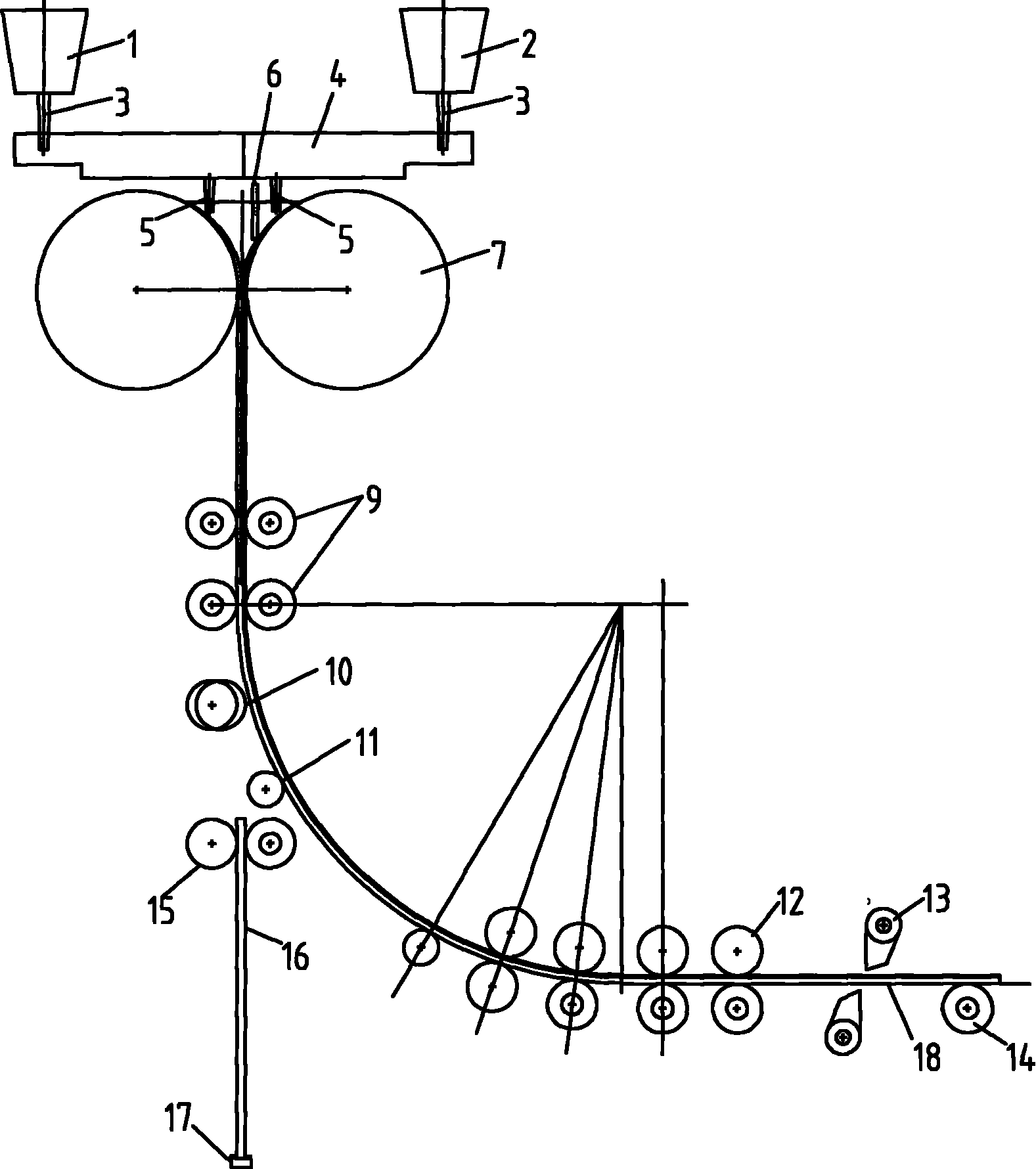

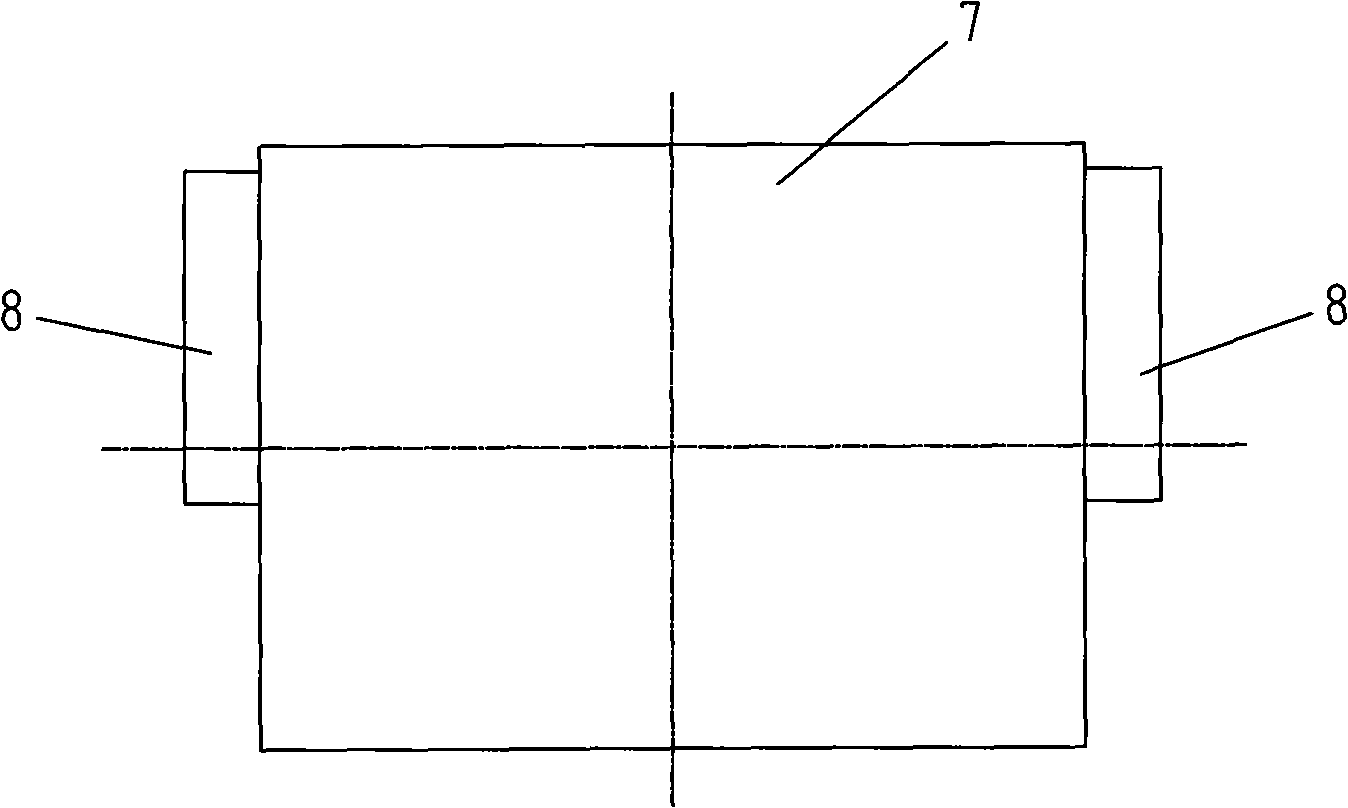

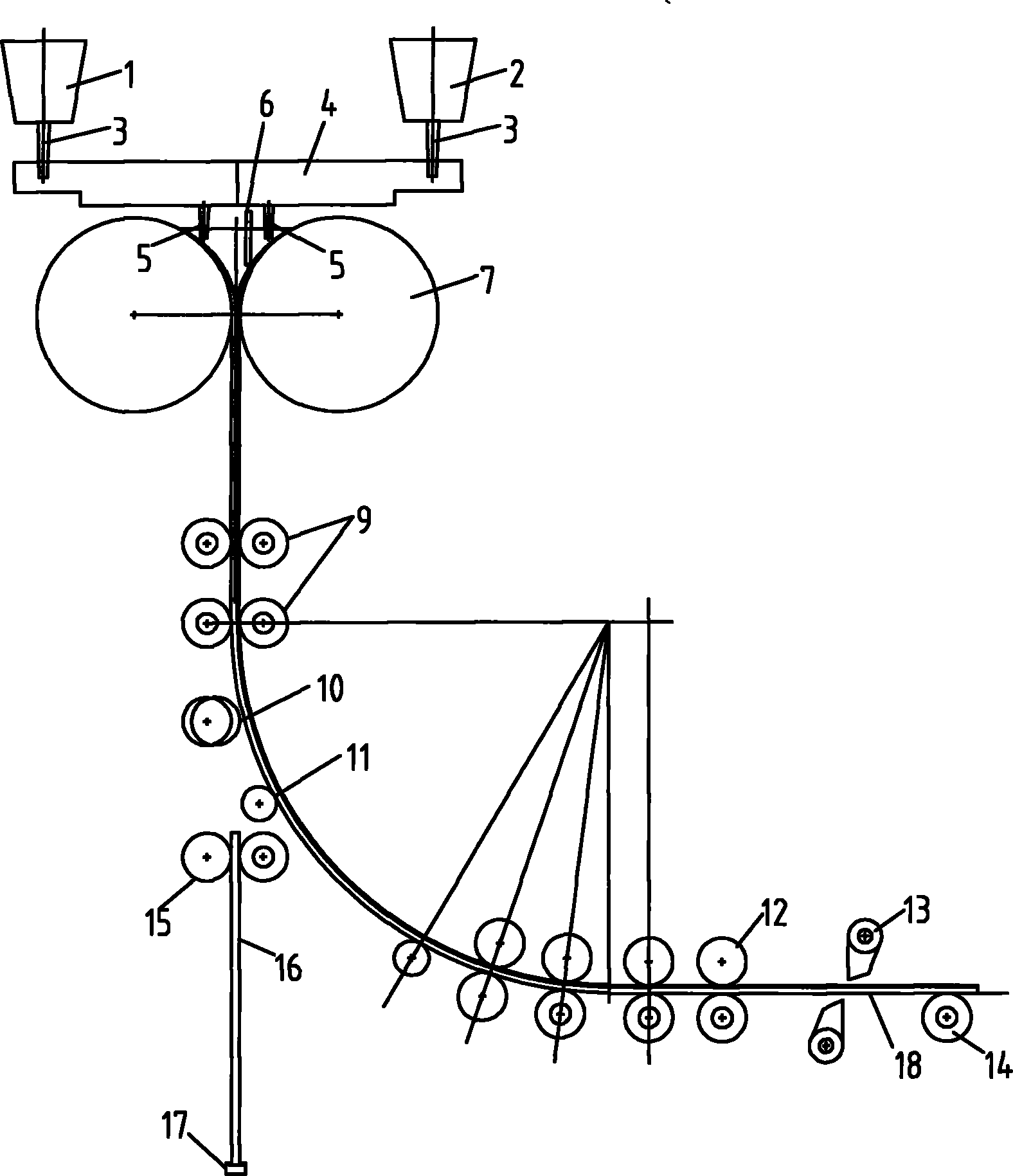

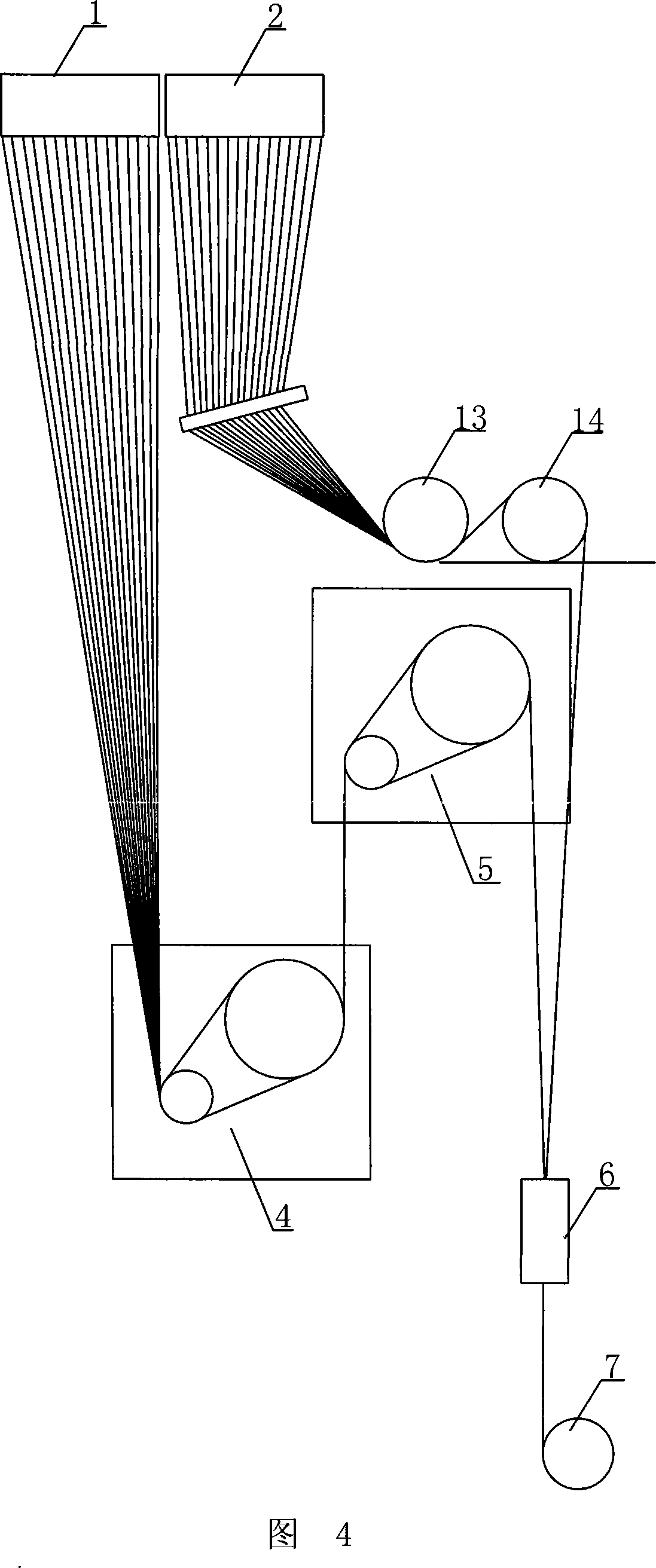

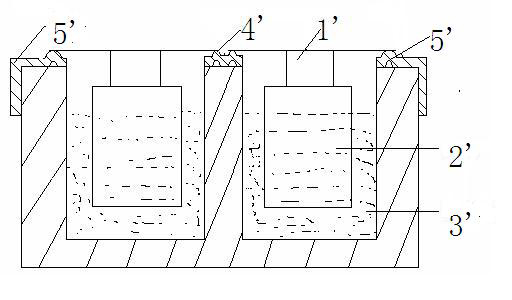

Continuous casting, continuous solling production method and apparatus for stainless steel seamless composite pipe

InactiveCN101024229AShort production processReduce equipment investmentMetal rolling arrangementsSteel tubeEnergy source

The invention relates to stainless steel seamless composite tube continuous casting tandem rolling producing method and device. Its features are that it uses two parallel vertical type hollow bloom continuous casting machines to directly cast out stainless steel composite hollow bloom, cut the high temperature tube blank into given size, and put into sloping bottom die casting furnace to adjust temperature; then the tube blank is taken out to sent into roller trio planet skew rolling mill, tension reducing mill, sizing mill to form finished tube; the finished tube is processed cooling, strengthening, scaling, packing. The invention can shorten production flow, reduce device investment, save energy sources, and increase production efficiency and steel tube rolling quality.

Owner:李铁铎

Method for producing steel plate of petroleum storage tank by using direct quenching process

The invention discloses a method for producing a steel plate of a petroleum storage tank by using a direct quenching process. The invention provides a chemical composition of special petroleum storage tank steel and adopts a direct quenching process. The method comprises the following steps of: heating a steel blank to 1100 to 1280 DEG C, rolling into a steel plate in re-crystallization and non-recrystallization stages; carrying out on-line quenching operation under the conditions that the temperature of the steel plate is between 780 DEG C and 900 DEG C, the average cooling rate ranges from 25 DEG C / s to 60 DEG C / s, the cooling terminal temperature is less than or equal to 350 DEG C, and performing off-line tempering on the steel plate subjected to quenching. Compared with the conventional high-energy-consumption hardening process based on the combination of off-line tempering and tempering, the method provided by the invention has the advantages of short production flow and low energy consumption and the prepared steel plate has good general mechanical properties and high heat input welding property. The yield strength of the steel plate is more than 490 MPa and the tensile strength of the steel plate is more than 610 MPa. In case of high heat input welding (less than or equal to 400 KJ / cm), a welding heat affected zone maintains excellent low-temperature toughness, and the mean value of work done by impact at -20 DEG C is more than 50 J.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD +1

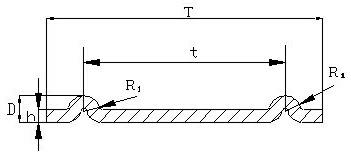

Economical high-strength binding strip steel with tensile strength more than or equal to 1,000 MPa, and manufacturing method thereof

The invention discloses economical high-strength binding strip steel with tensile strength more than or equal to 1,000 MPa, and a manufacturing method thereof. The steel comprises the following components in percentage by weight: 0.25 to 0.42 percent of C, 1.0 to 2.0 percent of Mn, less than or equal to 0.45 percent of Si, less than or equal to 0.04 percent of S, less than or equal to 0.04 percent of P, less than or equal to 0.08 percent of Al, and the balance of Fe and inevitable impurities. The manufacturing method comprises a steelmaking process for clean steel smelting controlled in inclusion forms, a hot rolling process, a cold rolling process and a bluing-annealing process. The manufacturing method can realize the clean production of high-strength binding strip steel, reduces production processes, improves the production efficiency, and can obtain the economical high-strength binding strip steel with well matched strength and plasticity and the tensile strength more than or equal to 1,000 MPa while significantly reducing production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

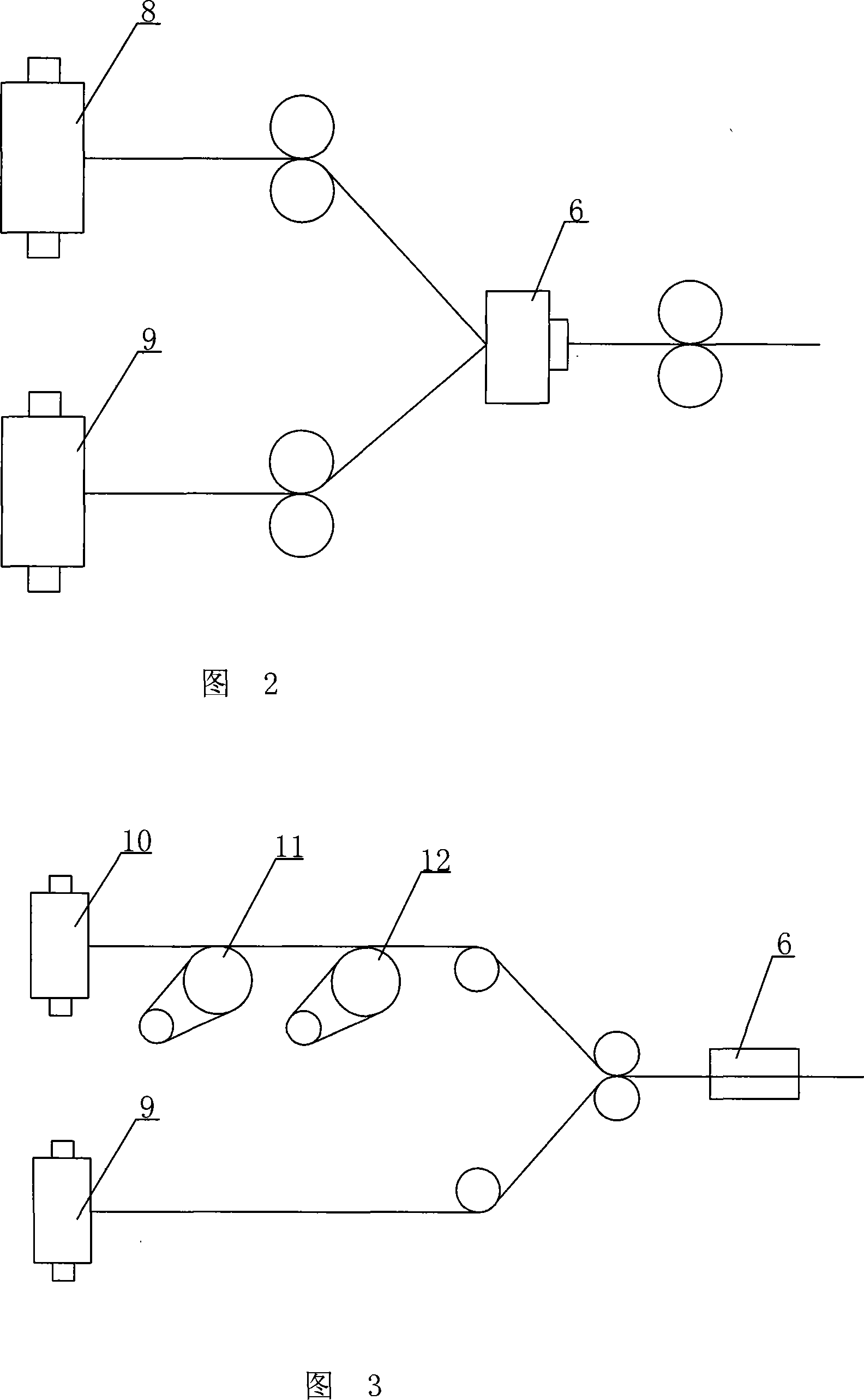

Method for producing color composite polyester yarn through one step

The invention discloses a method for producing a color composite polyester yarn through one step. Spinning positions are utilized to divide different areas, and the synchronous different-path spinning of pre-oriented yarns (POY) and fully-drawn yarns (FDY) and strand combined yarn networking are compounded together, so that four processing links of stock solution coloring, spinning, drawing and networking are completed through a one-step method. The production technological process is short, the production efficiency is high, energy consumption and loss are small, pollutant discharge is reduced, and the method is ecological and environmental-friendly.

Owner:ZHEJIANG HUAXIN ADVANCED MATERIALS

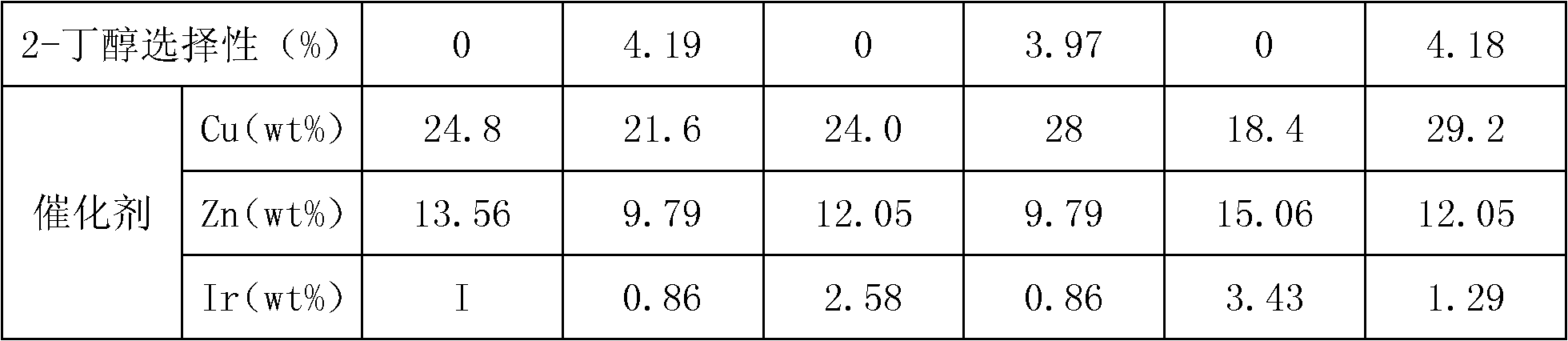

Process for producing alcohol and selectively co-producing 2-butanol by utilizing acetate and matching process system thereof

ActiveCN102659513AHigh selectivityHigh activityOrganic compound preparationHydroxy compound separation/purificationProcess systemsSec-Butanol

The invention relates to a process for producing alcohol and selectively co-producing 2-butanol by hydrogenising acetate and a matching process system thereof. After industrial acetate is hydrogenised and purified, a product is rectified, purified and dehydrated, thereby obtaining alcohol and co-producing 2-butanol. Cu-Zn-M is taken as an active component of a catalyst adopted in the process, wherein M is selected from the compound of one and more of Ir, Mn, W, Ru and Zr. 2-butanol is selectively co-produced by adjusting the reaction temperature. The catalyst, process and device adopted by the invention have the characteristics of high activity, high selectivity, high yield, strong market adaptability, less equipment investment, environmental protection, simpleness in preparing process, economical and practical properties, and the like. Meanwhile, conversion per pass is high and reaction heat is effectively utilized, so that the load for separating rough products is greatly relieved, the production flow is shortened and the energy consumption of production is also greatly reduced.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

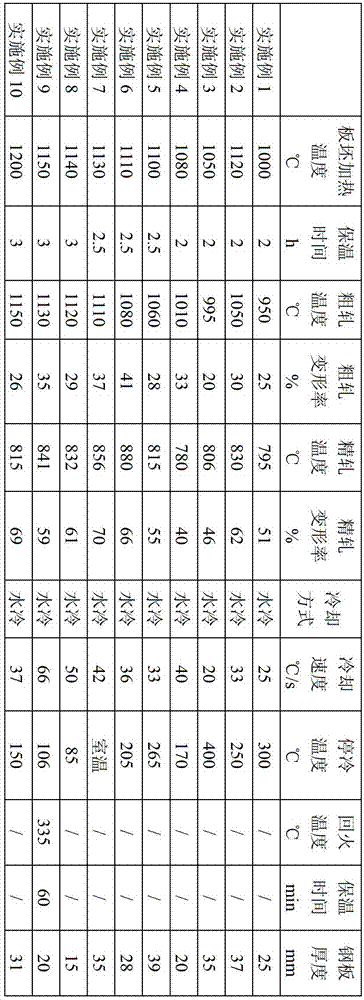

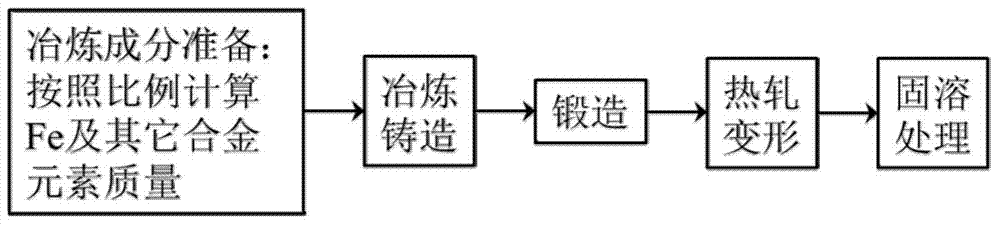

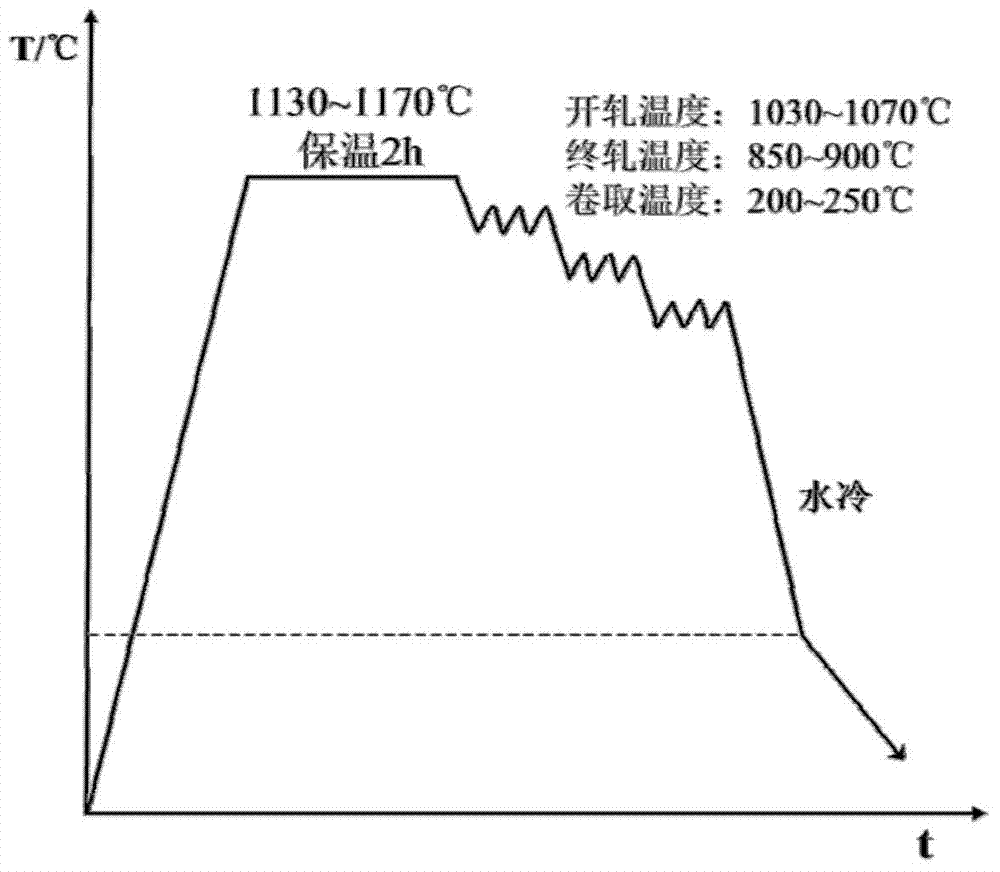

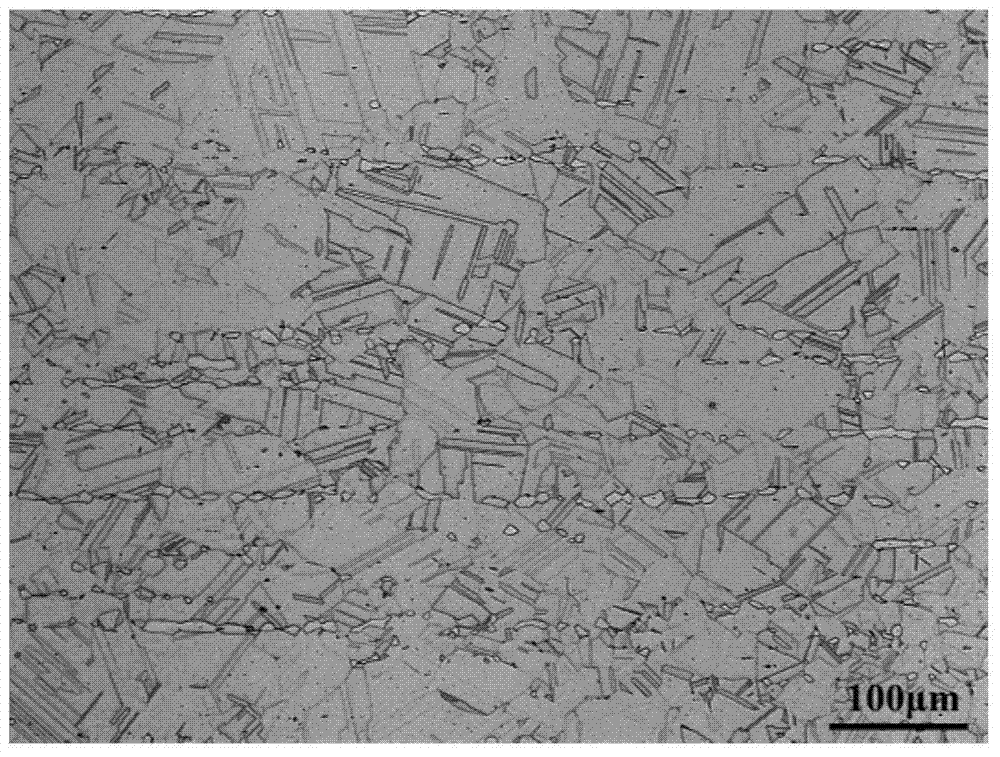

Low-density and high-toughness automobile-used steel board and preparation process

The invention belongs to the field of metal materials, and relates to a novel high strength steel board low in density, high in strength and good in anti-corrosion performance, in particular to component design and a preparation method of the novel automobile-used steel. The automobile-used steel board is characterized by comprising the following specific chemical compositions by mass percentage: 0.60-0.70 percent of C, 0.30-0.40 percent of Si, 10.0-15.0 percent of Mn, 5.0-10.0 percent of Al, less than 0.005 percent of P, less than 0.003 percent of S and Fe and unavoidable impurities in balancing amount. The preparation process comprises the following steps: performing smelting according to the chemical compositions, and forging casting blank material into a steel blank; heating the steel blank to 1,130-1,170 DEG C, keeping the temperature for 2 hours, and performing multi-pass hot-rolling deformation, wherein the rolling starting temperature ranges from 1,030-1,070 DEG C, the rolling stopping temperature ranges from 850-900 DEG C, the accumulated deformation amount ranges from 80 percent to 85 percent, and the rolling temperature is from 200 DEG C to 250 DEG C; after hot rolling, further performing solution treatment of the steel board, keeping the temperature at 1,000-1,050 DEG C for 0.5-1 hour, and performing water quenching treatment; taking a dual-phase organization combining austenite and ferrite, and obtaining the lower density and high toughness automobile-used steel board.

Owner:UNIV OF SCI & TECH BEIJING

Continuous casting method of liquid-phase composite slab

The invention provides a continuous casting method of a liquid-phase composite slab. A continuous casting device comprises a composite casting system, a roll type crystallizer, a pinch and bending device, a withdrawing-straightening device, a shearing device and a dummy bar system. A base material metal pouring ladle and a composite material metal pouring ladle pour metal solution into a roll type crystallizer molten pool formed by crystallizing rolls and side seal plates via submerged nozzles. An intermediate diaphragm separates the molten pool into a base material dissolved cavity and a composite material dissolved cavity. The base material metal solution and the composite material metal solution are respectively solidified into slab shells on the crystallizing rolls, the crystallizing rolls synchronously rotate in the reverse direction and the metal slab shells move downward along with rotation of the crystallizing rolls. The base material metal liquid interacts with the composite material metal solid-liquid interface to realize metallurgical fusion and composition of the interface, and is bonded into the composite slab at the exit of the roll crystallizer. The composite casting slab is transferred by pinch rolls and bent into arc by a bending roll, and then enters the withdrawing-straightening section through a guide roll to be horizontally straightened. The composite casting slab keeps on moving forward to the roll way in a shear zone to be cut to length by swinging shears and then is moved out.

Owner:CHINA FIRST HEAVY IND +1

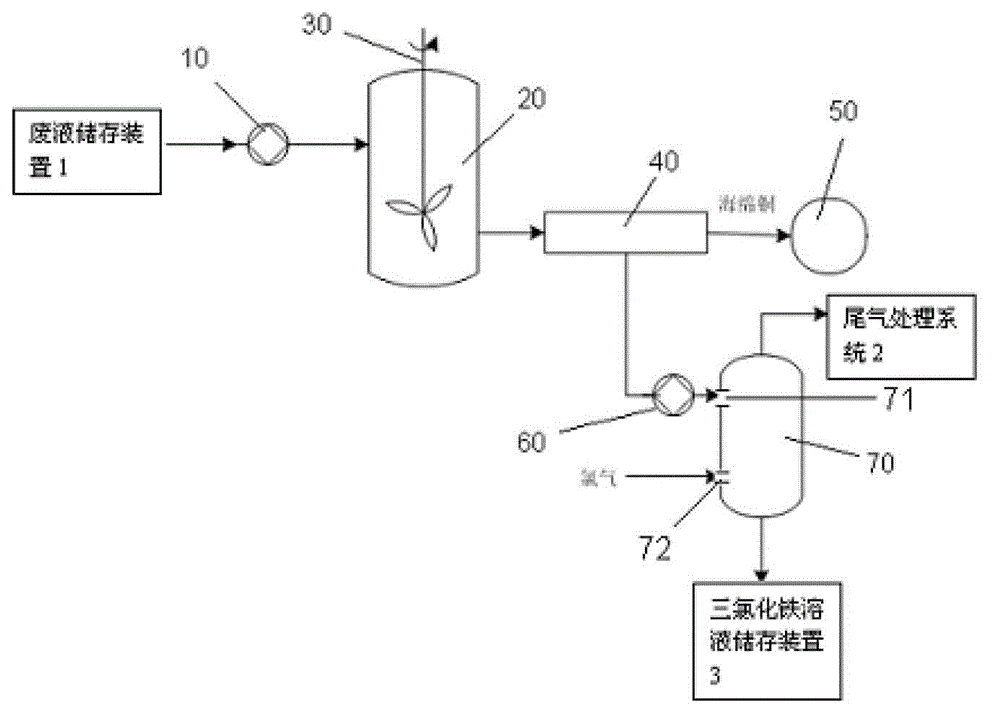

Method for recycling acidic copper-etching waste solution

InactiveCN102912352AAchieving "zero" emissionsShort production processLiquid wastePhysical chemistry

The invention discloses a method for recycling acidic copper-etching waste solution. The method comprises the following steps of: step 1, recovering copper form the acidic copper-etching waste solution, filling the acidic copper-etching waste solution in a reaction kettle, adding reduced iron while stirring so as to replace copper ions in the etching solution and separate out spongy copper, and performing solid-liquid separation treatment so as to obtain a spongy copper product having a water content of 50% and the solution containing lots of ferrous ions after the replacement; and step 2, preparing ferric trichloride from the solution after copper extraction: adjusting the solution according to the ferrous ion content and the pH value of the ferrum-containing solution after the replacement in the step 1, and then charging chlorine and reacting the ferrous ions with the chlorine to generate ferric ions, so as to prepare an effluent treatment agent, namely, ferric trichloride. The method disclosed by the invention is short in production flow, simple in process, low in energy consumption, wide in adaptability, capable of reutilizing all the remainder effective cost of the waste solution after the copper extraction while effectively extracting copper powder in the etching waste solution, and capable of realizing zero-discharge of the acidic etching waste solution of a printer circuit board and effectively protecting environment.

Owner:SHANGHAI LVCHENG ENVIRONMENTAL PROTECTION TECH

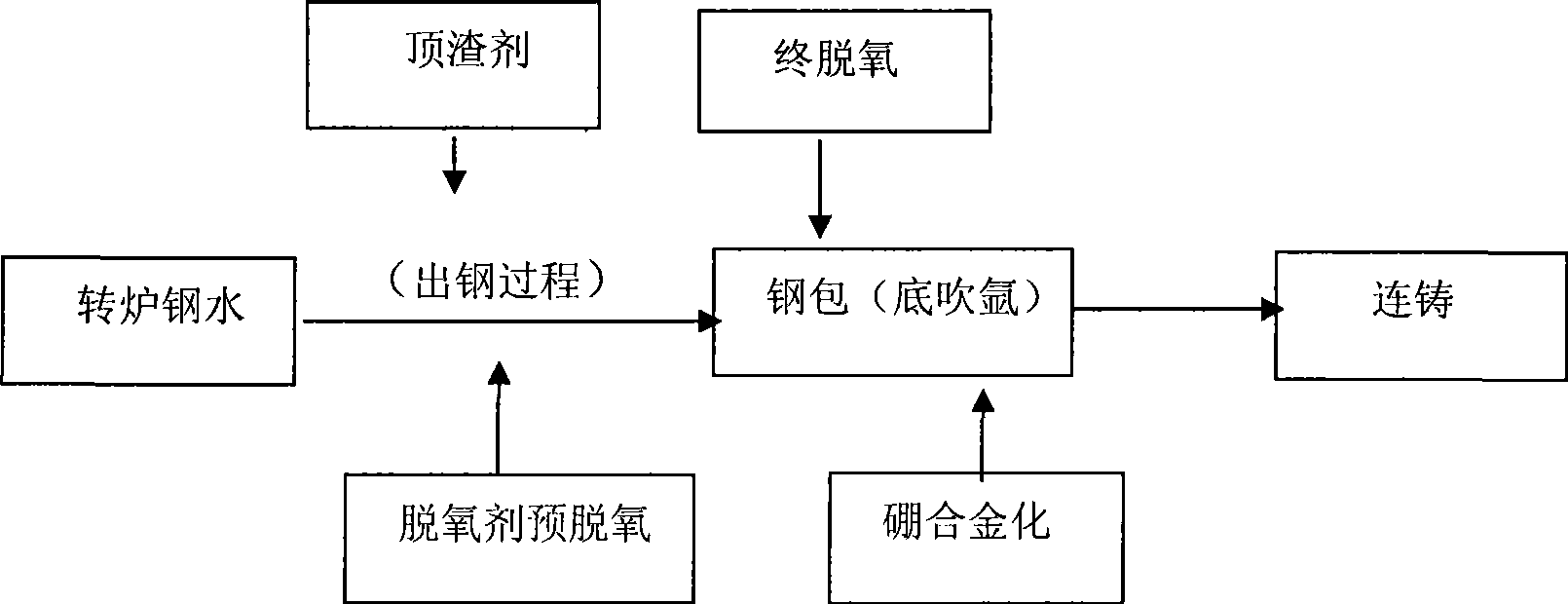

Method for producing boron steel by converter

InactiveCN101503746AAvoid stickinessAvoid water-prone mouthsManufacturing convertersAlloyMolten steel

The invention provides a method for producing boron steel in a converter, which is characterized in that argon subaeration is performed on a ladle in the whole process; a deoxidizer and alloys required by steel grades are begun to be added into the ladle for preliminary deoxidation and alloying under the condition of 1 / 4 tapping, and simultaneously a desulfurizer is added for desulfurization treatment; aluminum is added into the ladle in an argon blowing station for final deoxidation, and ferroboron is added into the ladle when the [O] is controlled to be between 0.0020 and 0.0040 percent; and the ferroboron is coated by an aluminum sheet and added into molten steel. The method has the advantages that: firstly, the method saves the refining procedure of an LF furnace and a vacuum furnace and has low production cost, short production procedure and high production efficiency; secondly, the pourability of the molten steel is good; thirdly, no requirement is put forward as for acid-soluble aluminum in the steel, so that the method solves the problems of pastiness of the molten steel, easy bonding of water gaps, reduction of the steel quality and the like caused by the increase of Al2O3 inclusion due to high acid-soluble aluminum; and fourthly, the recovery rate of boron can reach 60 to 75 percent and the wave range of the yield is small. Moreover, the method has good application prospect.

Owner:新余钢铁股份有限公司

Method for producing pale disproportionated rosin with high content dehydroabietic acid and P-camphogen simultinuously

InactiveCN1616570APrevent browningPrevent oxidationNatural resin purificationNickel catalystDistillation

The process of producing pale disproportionated rosin with high dehydroabietic acid content and paracymene simultaneously includes the following steps: rinsing turpentine to eliminate impurity, dissolving turpentine in turpentine oil to form turpentine solution, catalytic disproportionating turpentine in solution in the presence of Pd / C catalyst, filtering and decompression distillation to obtain pale disproportionated rosin with high dehydroabietic acid content and disproportionated turpentine oil containing paracymene in 20-60 %, and distilling disproportionated turpentine oil to obtain paracymene and pinane. Or, the rinsed turpentine as material may be re-crystallized to purify and catalytically disproportionated to prepare pale disproportionated rosin containing high dehydroabietic acid in 72-82 %. The Pd / C catalyst may be replaced with skeletal nickel catalyst.

Owner:GUANGXI UNIV

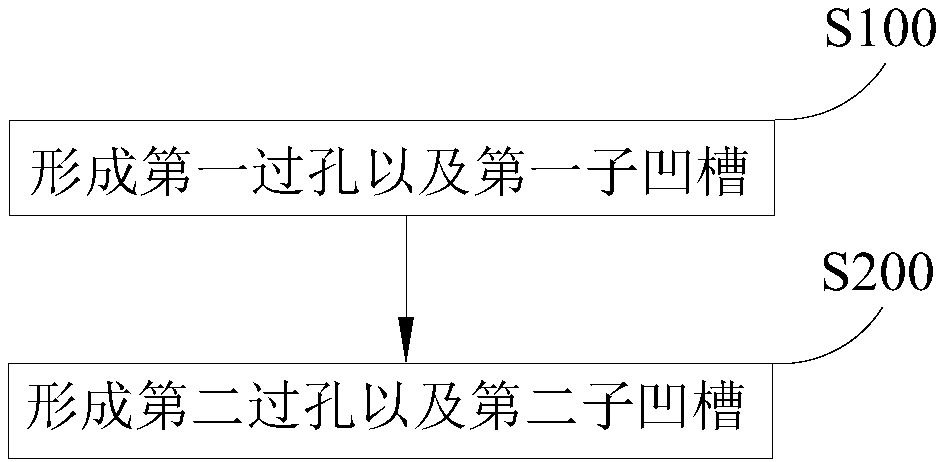

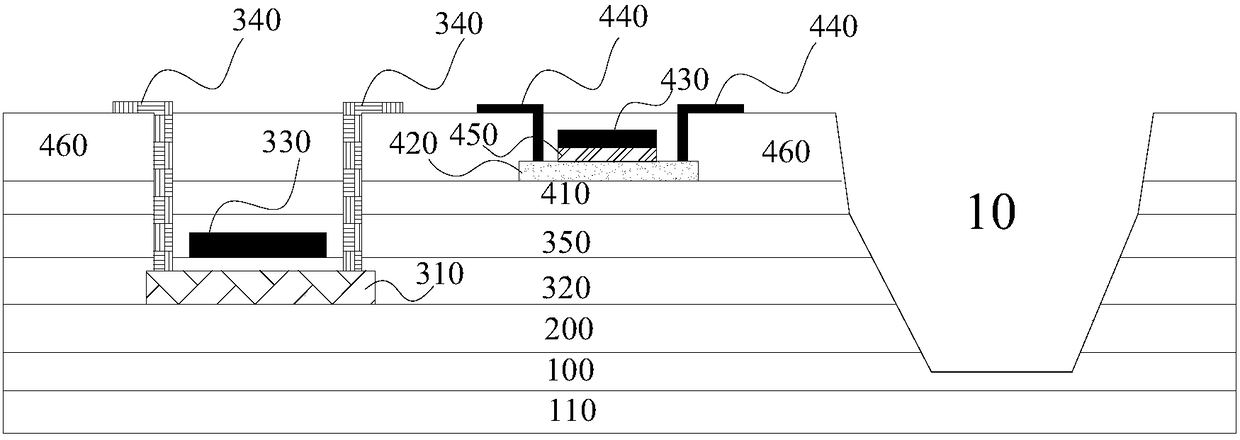

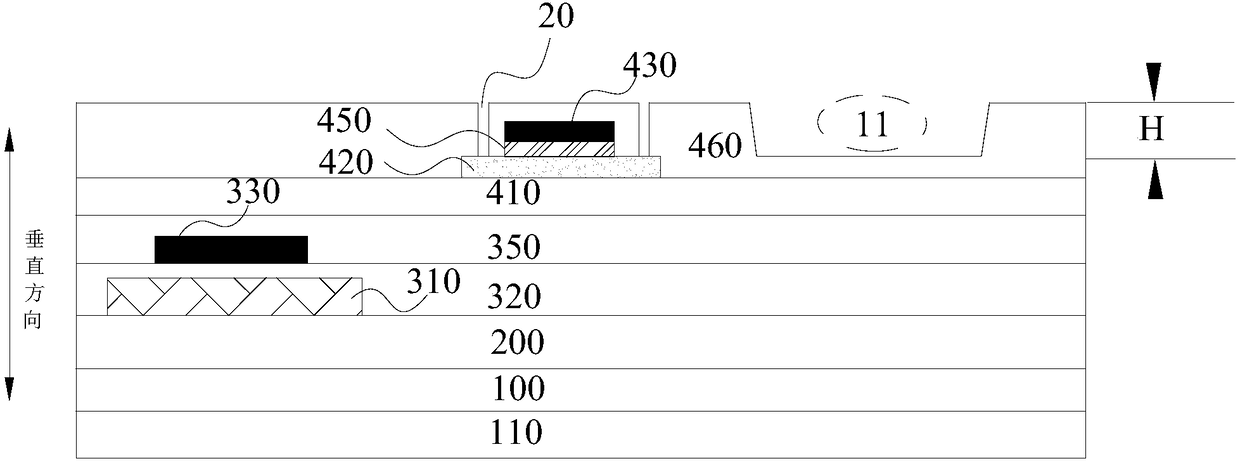

Array substrate and preparation method thereof, and display device

ActiveCN108376672AImprove voltage compensation capabilityIncrease pixel capacitanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceComposition process

The invention discloses an array substrate and a preparation method thereof, and a display device. A base of the array substrate is provided with a first film transistor and a second film transistor and a groove arranged in a wiring region, wherein the groove comprises a first sub groove and a second sub groove. The method comprises steps that a first through hole and the first sub groove are formed through employing the one-time picture composition process; the second through hole and the second sub groove are formed through employing the one-time picture composition process. The method is advantaged in that a problem of active layer over-etching due to difference in depth of the two through holes when the two through holes are formed synchronously is solved, and prolongation of the production process is avoided.

Owner:BOE TECH GRP CO LTD

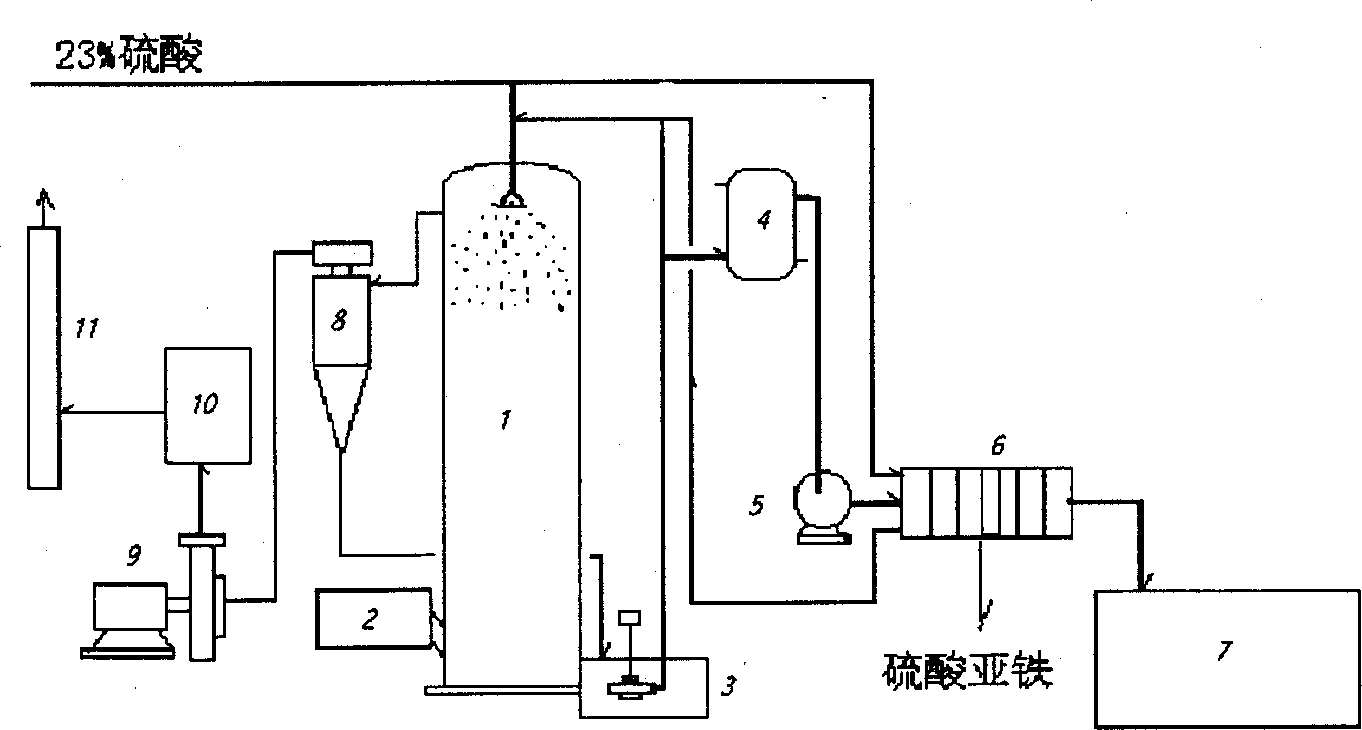

Process for concentrating diluted sulfuric acid and removing impurities

InactiveCN1376633AReduce recycling production costsLess investmentSulfur-trioxide/sulfuric-acidNuclear chemistryImpurity

A process for concentrating diluted sulfuric acid while removing impurities includes such steps as counter-current contact between hot air and atomized diluted sulfuric acid in drying-concentrating tower for heating, evaporating and concentrating, cooling, and separating the educed or deposited impurities for sulfuric acid. Its advantages are low cost and simple process.

Owner:SICHUAN LOMON CORP

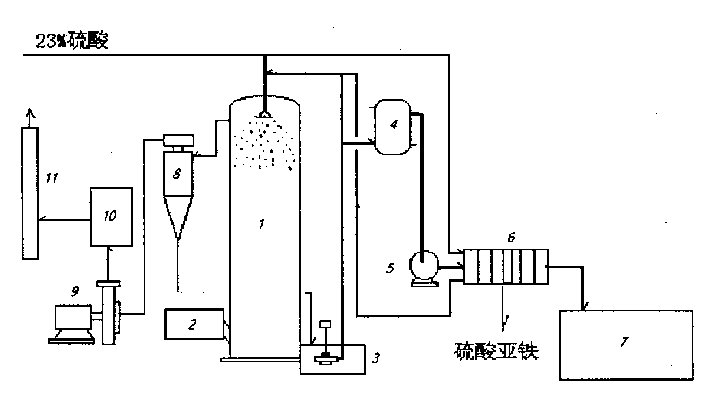

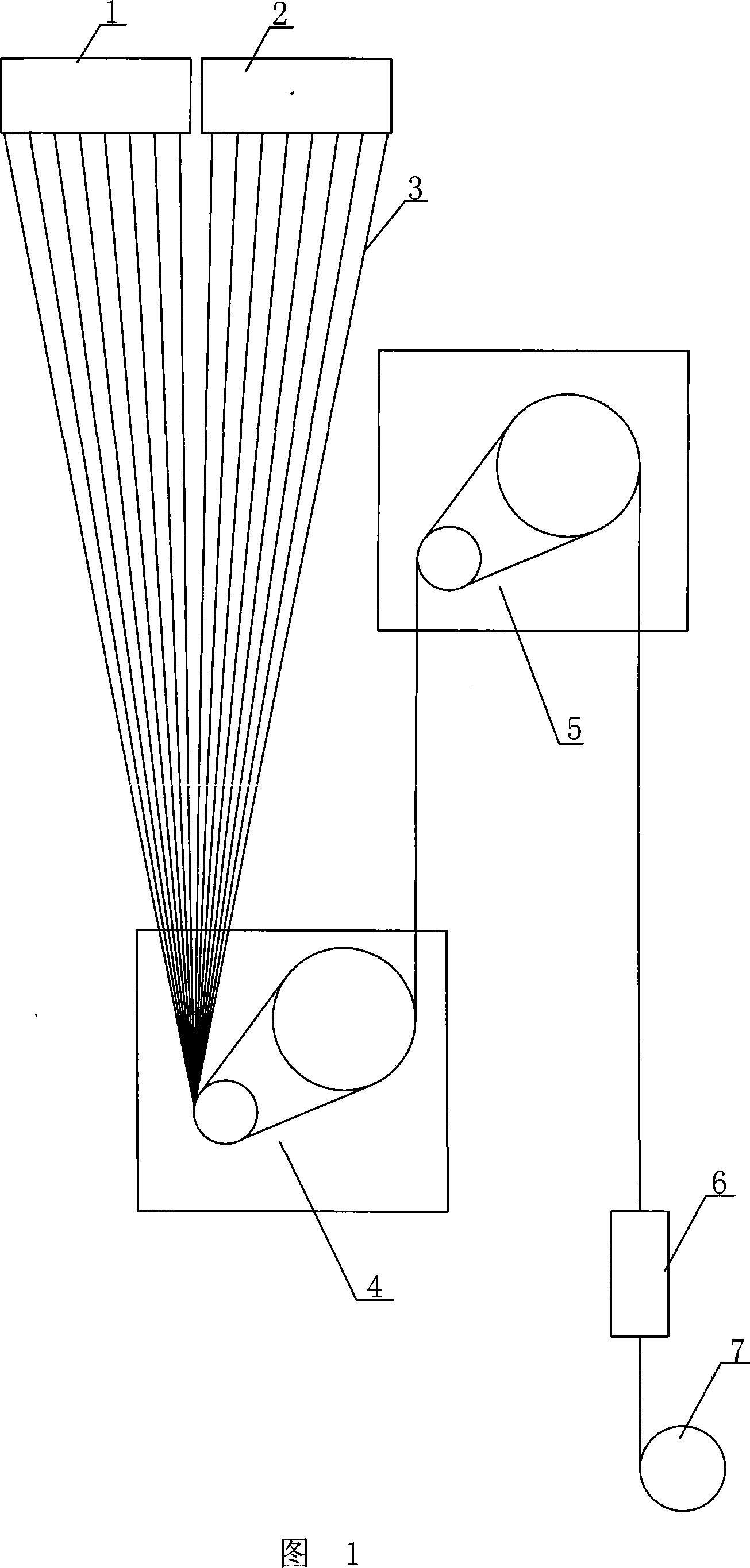

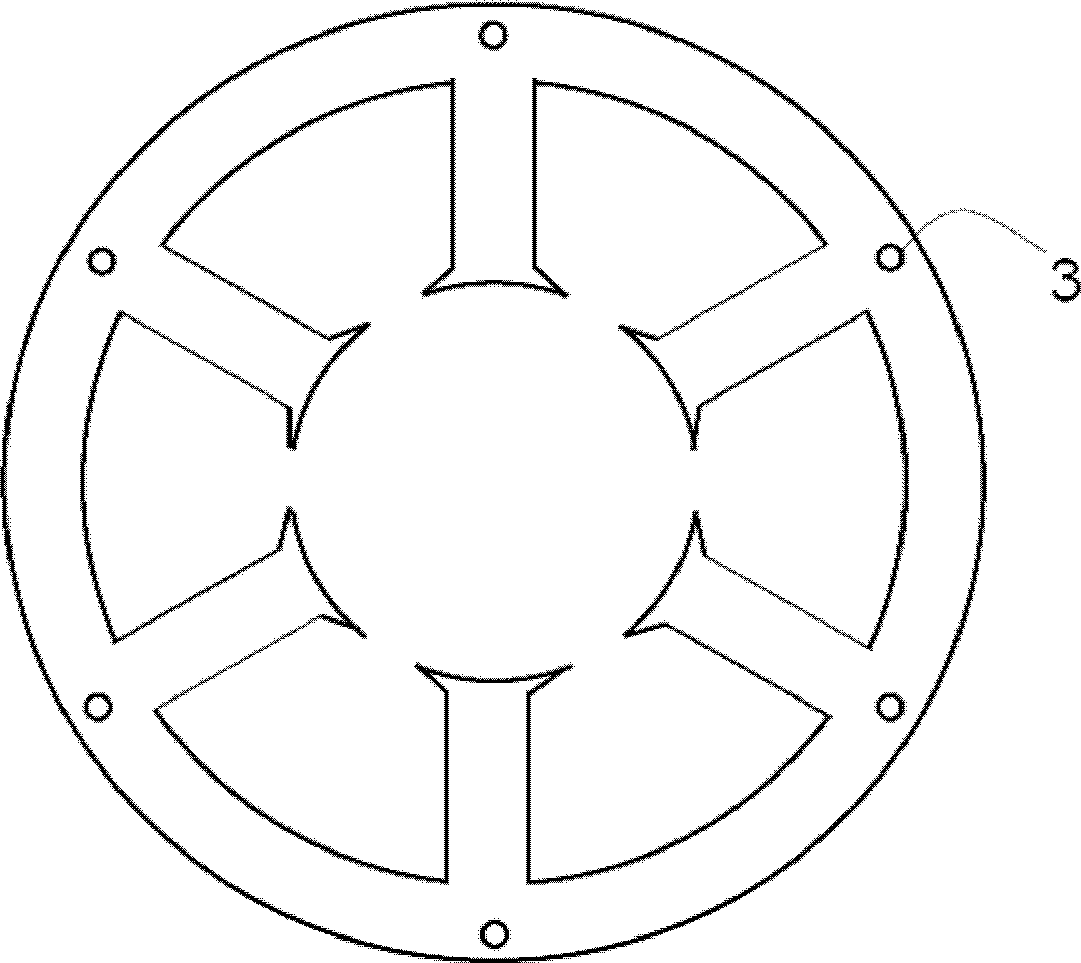

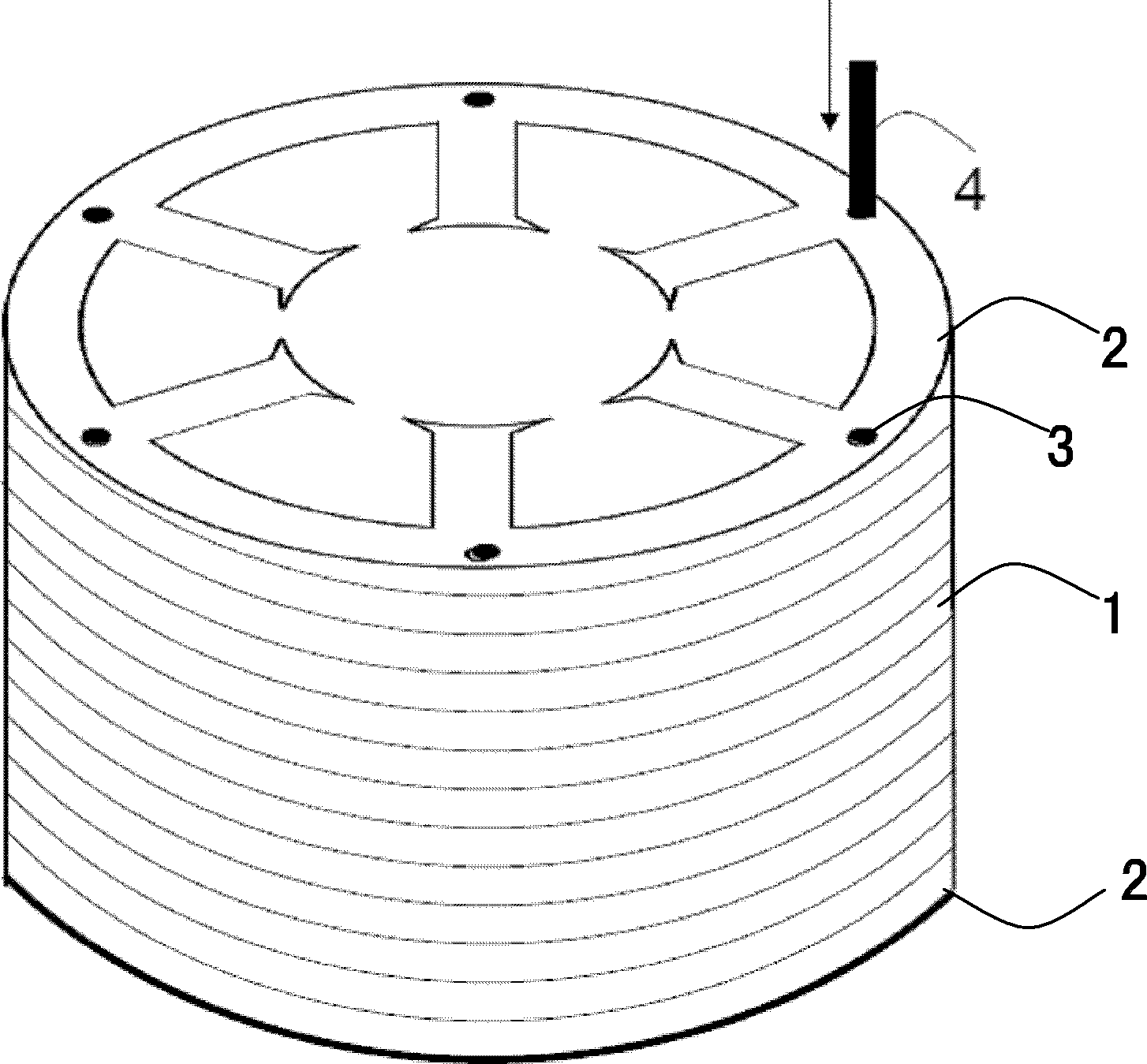

Method and device for manufacturing fully drawn yarn/pre-oriented yarn stranding composite yarn by one-step process

ActiveCN101200826AReduce consumptionSolve technical problemsSpinnerette packsFilament manufactureEngineeringRaw material

The invention discloses a one-step preparation method of stranding composite yarn of fully drawn yarn / pre-oriented yarn and a device thereof. The method includes that an FDY filament device is adopted to haul part tow on the back of a spinning box to two clod godet rollers to obtain POY yarn. The left tow is hauled to two hot godet rollers to obtain FDY yarn. The two tows are winded with a speed of 2800-3200m / min after being networked through a network device to obtain multi-strands of stranding composite yarn of fully drawn yarn / pre-oriented yarn. The device is to add two cold godet rollers on the filament device. The network device and a winding device are arranged to the back of the cold godet rollers and two hot godet rollers. The invention shortens the production process, reduces theequipment occupying space, lowers the consumption of the production cost, raw materials and energies and effectively solves the technical problem of finishing the spinning and the stranding in one step. The whole process is stable. The product quality is reliable. The quality defect that monofilament in yarn is easy to appear in a composite yarn product can be completely eliminated. The yield is three times of that of the prior art. And the production efficiency can be improved greatly.

Owner:WUJIANG FUDONG TEXTILE GROUP

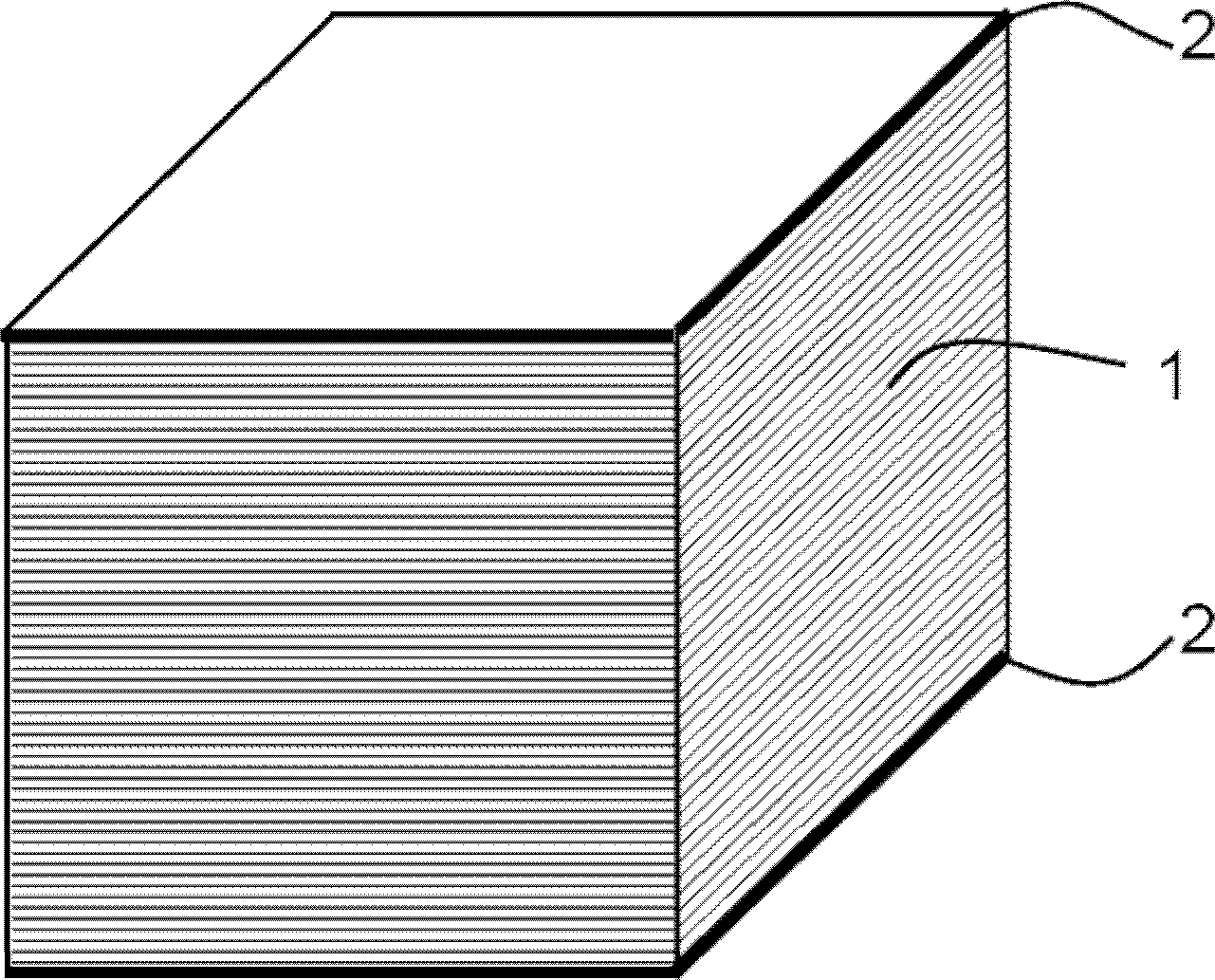

Method for manufacturing amorphous alloy stator iron core for motor

InactiveCN102738976AShort production processProduction energy saving and environmental protectionManufacturing stator/rotor bodiesApplying solid insulationStatorAlloy

The invention, which belongs to the magnetic circuit component field of the motor, more particularly relates to a method for preparing a high-performance stator iron of an amorphous alloy, wherein the stator iron is used for a motor. The method comprises the following steps: carrying out lateral shearing on an amorphous strip to obtain a plurality of amorphous slices with the same shape; carrying out stacking, compaction and clamping on the amorphous slices, carrying out cutting wholly, and then carrying out mechanical fastening along a stator shaft; and carrying out whole annealing processing on a complete amorphous alloy iron core. According to the method, the mechanical fastening is used to replace adhesion fixing among the amorphous slices to solve problems that interlaminar fracture occurs frequently with utilization of the interlaminar adhesion method and the iron core performance is reduced due to the existence of the adhesion stress, thereby further substantially improving the performance of the stator iron core of the amorphous alloy.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

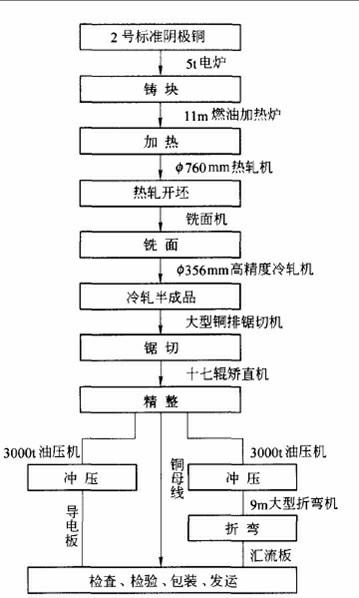

Process for specially-shaped electrolytic conductive material

InactiveCN102543310AReduce consumptionShort production processCable/conductor manufactureElectrolysisConductive materials

The invention discloses a process for a specially-shaped electrolytic conductive material. The process comprises the following steps of: 1) by taking highly-pure cathode copper as a raw material, performing centrifugal vacuum up-drawing continuous-casting on an oxygen-free copper rod by using a traction unit; 2) processing the oxygen-free copper rod in the step 1) by using a continuous extrusion unit to form a blank of the specially-shaped electrolytic conductive material; 3) drawing and finishing the blank of the specially-shaped electrolytic conductive material by using a fully-automatic hydraulic drawing machine to form the specially-shaped electrolytic conductive material, wherein the blank is formed in the step 2); and 4) checking and packaging the specially-shaped electrolytic conductive material which is formed in the step 3). The invention provides the specially-shaped electrolytic conductive material which is high in production efficiency, high in yield, high in product quality and free from environmental pollution and can overcome the defects of the conventional production process.

Owner:徐高磊

High-toughness casting aluminum alloy and preparation method thereof

Owner:宁波旭润铝业有限公司 +1

Method for preparing Chinese medicament dreg needling non-woven composite material

The invention relates to a method for preparing a Chinese medicament dreg needling non-woven composite material, which is characterized by comprising the following steps of: firstly, preparing two same single-layer fiber webs namely an upper single-layer fiber web and a lower single-layer fiber web, and spreading a Chinese medicament dreg layer between the upper single-layer fiber web and the lower single-layer fiber web to ensure the upper single-layer fiber web, the lower single-layer fiber web and the Chinese medicament dreg layer are combined into a 'sandwich' composite material blank of which the middle part is filled with the Chinese medicament dreg layer; secondly, according to product requirements, combining a five-layer composite material blank consisting of three layers of fiber webs and two layers of Chinese medicament dregs filled in the three layers of the fiber webs, or combining a seven-layer composite material blank consisting of four layers of the fiber webs and three layers of the Chinese medicament dregs filled in the four layers of the fiber webs; and finally, selecting any one of three reinforcement modes of needling reinforcement, needling hot rolling reinforcement and needling hot air reinforcement to perform reinforcement so as to prepare the Chinese medicament dreg needling non-woven composite material. The material prepared by the method has better sound-absorbing and heat-shielding performance, and can be widely applied in the fields of house decorative materials, automotive interior decoration materials and the like. The method has the advantages of simple process, short flow, more selectivity, low requirement on raw materials, low cost and good product performance.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com