Method for producing color composite polyester yarn through one step

A polyester yarn and color technology, which is applied in the field of melt spinning, can solve the problems of not realizing the process integration of color composite polyester yarn, not realizing the one-step method of the same spinning box, etc., and achieves short production process flow, high production efficiency, and energy efficiency. Low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

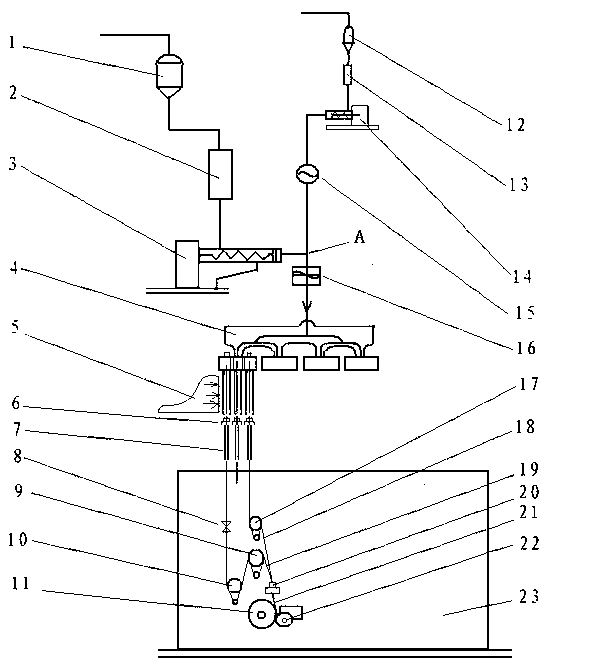

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] Such as figure 1 The production process flow diagram of the one-step method shown in the production of colored composite polyester yarn, the specific described method comprises the following steps:

[0020] a. The polyester chips in the chip silo 1 are transported to the chip dryer 2 for drying, and then transported to the screw extruder 3 to be heated and melted into a melt.

[0021] The polyester used in the present invention is polyethylene terephthalate (PET for short), and the PET raw material is vibrated and screened to remove powder and particles with inconsistent particle sizes, and the sliced raw material that meets the requirements is transported to the sliced bin 1 for standby. Before melting, the slices are also sent to the dryer 2 for drying to remove moisture in the slices. The dried chips enter the screw extruder 3 for heating and melting....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com