Patents

Literature

5007 results about "Stock solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A stock solution is a concentrated solution that will be diluted to some lower concentration for actual use. Stock solutions are used to save preparation time, conserve materials, reduce storage space, and improve the accuracy with which working lower concentration solutions are prepared.

Preparation method of plant enzyme food

The invention discloses a preparation method of plant enzyme food, belonging to the field of food processing technology. The method comprises the following steps of: performing twice fermentation and compounding on the natural plant raw materials of fresh fruits, vegetables, mushrooms, medicines, grains and flowers to obtain the secondary-fermentation stock solution or raw sauce, and storing; filling and sealing the secondary-fermentation stock solution or raw sauce to obtain liquid or sauce-type plant enzyme food or compound plant enzyme food; or performing low-temperature concentration and freeze drying to obtain solid plant enzyme food or compound plant enzyme food. Due the adoption of the preparation method, the obtained natural plant enzyme food has the functions of improving the immunity of human body, activating cells, promoting metabolism and the like.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Head hair dyeing method

There is provided a head hair dyeing method using a two-part hair dye composition which contains: a first part containing a first part stock solution and a propellant, the first part stock solution containing an alkali agent and a surfactant; a second part containing a second part stock solution and a propellant, the second part stock solution containing hydrogen peroxide and a surfactant; and two aerosol containers for respectively discharging the first part and the second part as foam, the method including respectively discharging the first part and the second part as foam from the containers, applying the foam mixture to the head hair, and then re-foaming the mixture on the head hair.

Owner:KAO CORP

Plant enzyme and preparation method thereof

The invention provides a preparation method for plant enzymes. According to the method, a plurality of plants, vegetables and fruits, seeds, herbal medicines, mushrooms and alga are used as raw materials, natural extraction of plant enzymes is carried out to obtain liquid containing plant active components, and a liquid stock solution of plant enzymes is obtained after fermentation and maturation of the liquid containing plant active components; the obtained liquid stock solution of plant enzymes contains a multienzyme ferment, a protein decomposition enzyme, a fat decomposition enzyme, a starch decomposition enzyme, proanthocyanidin, a plurality of natural vitamins, mineral matters, amino acids, trace elements, etc. The obtained liquid stock solution of plant enzymes is prepared into plant enzyme oral liquid, plant enzyme solid powder or plant enzyme capsules. The preparation method provided in the invention has the following advantages: preparation conditions in the method are simulation of natural generation conditions of enzymes, so preparation theory is scientific; preparation equipment is simple, applicable to large scale production; obtained plant enzymes never contain artificial pigments, synthetic fragrances or antiseptics, and are pure natural. The plant enzymes can be extensively used in health products or cosmetic and make-up products.

Owner:JILIN AODONG OHTAKA ENZYME

Compositions and methods to prevent AAV vector aggregation

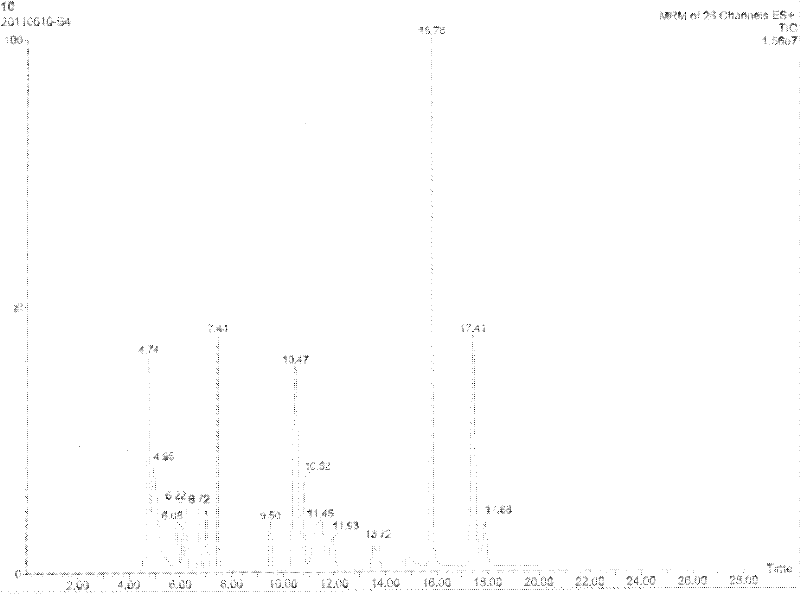

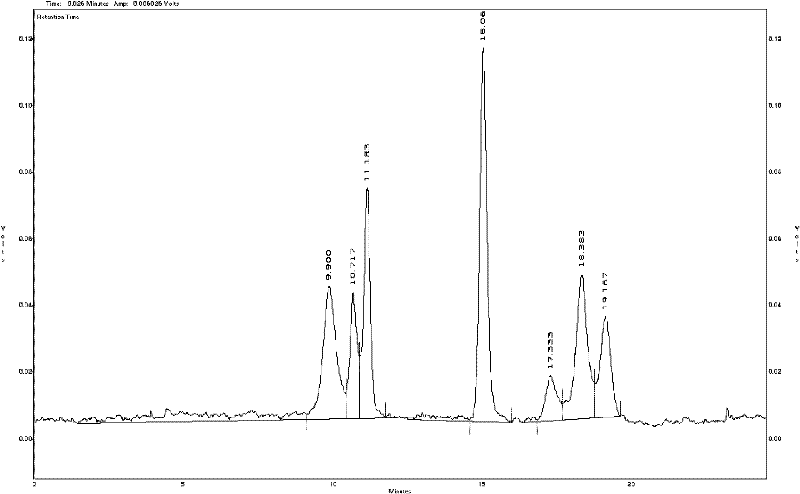

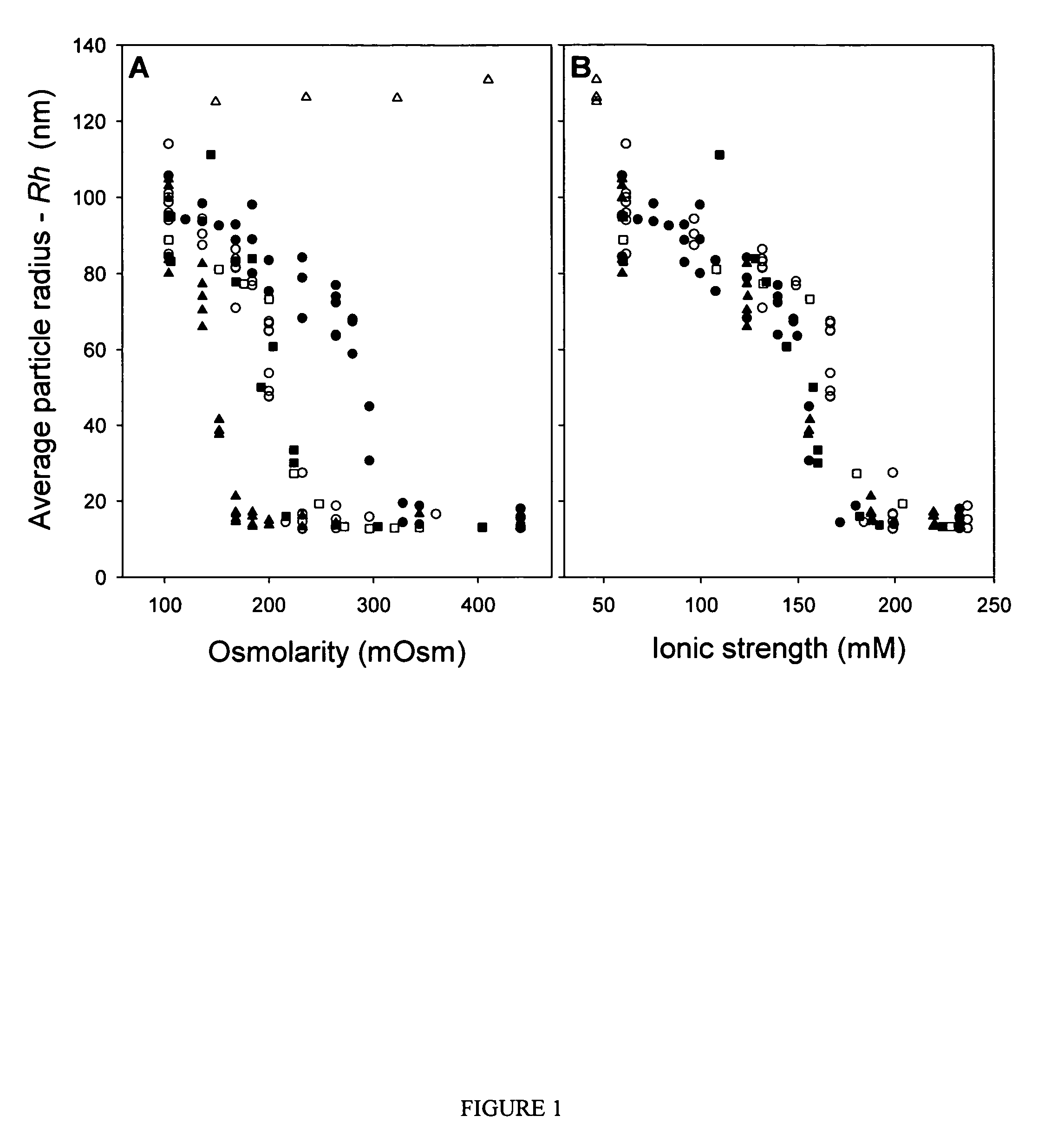

ActiveUS7704721B2Increase ionic strengthImprove efficiencyRecovery/purificationSsDNA virusesFreeze thawingIonic strength

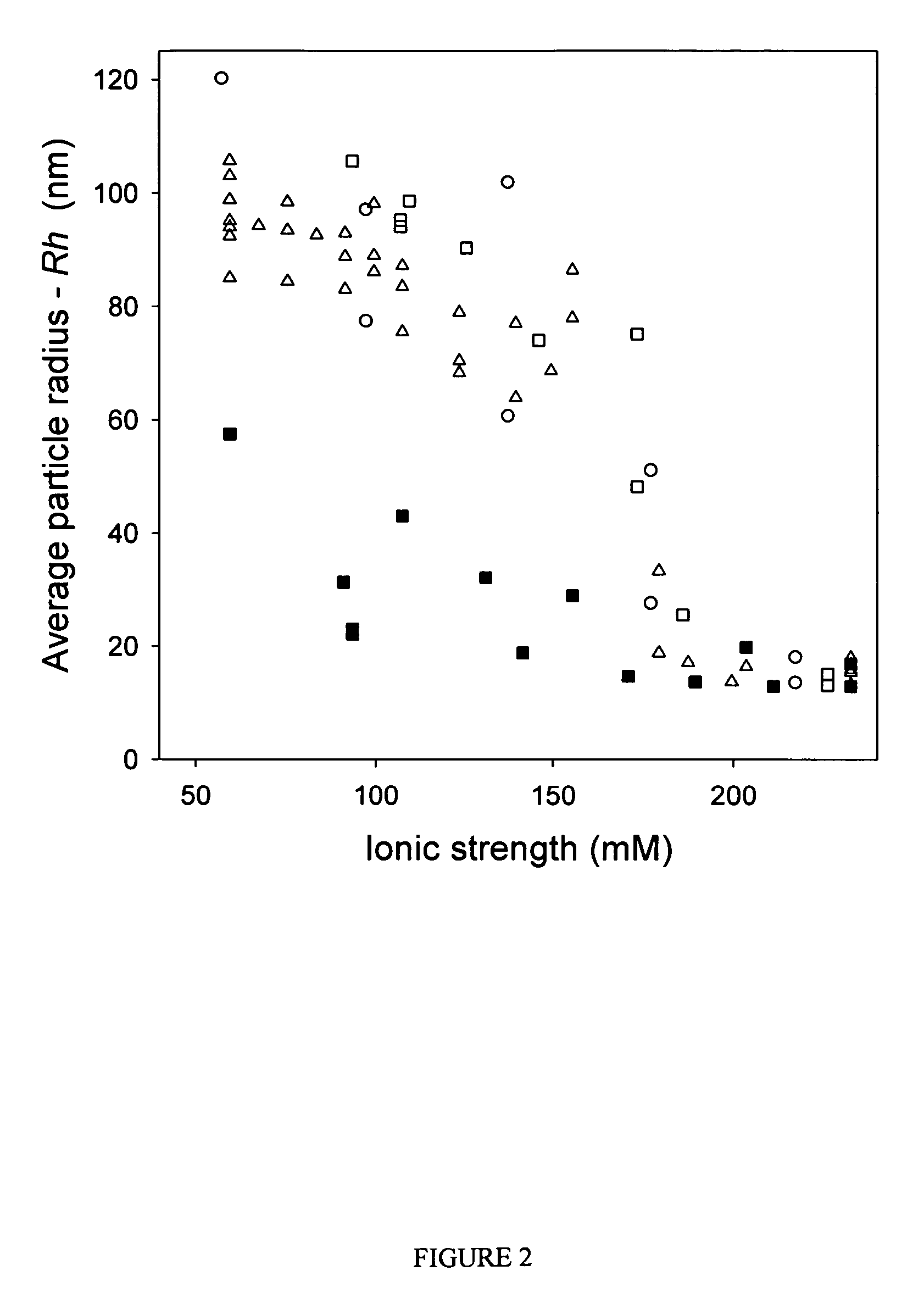

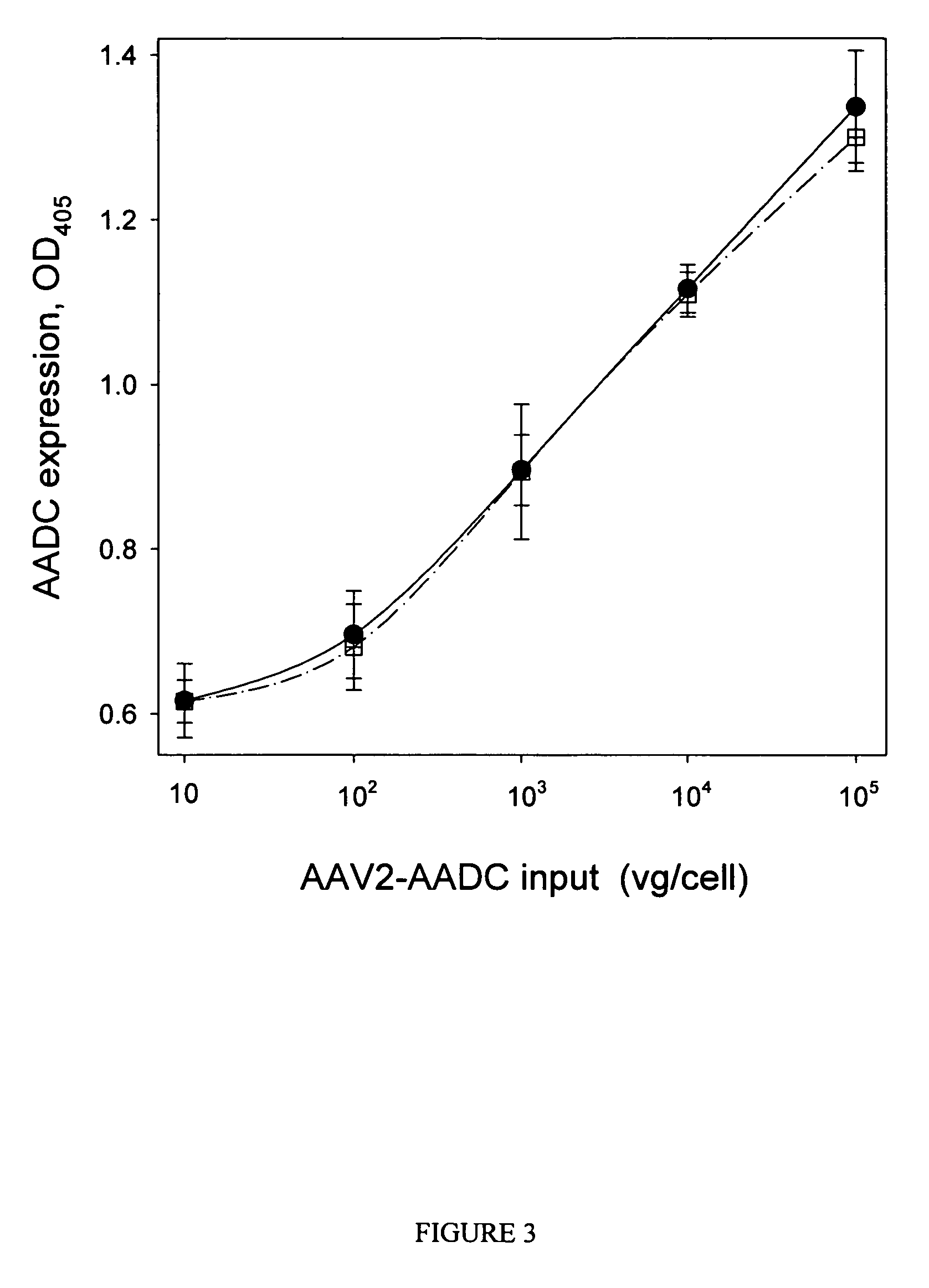

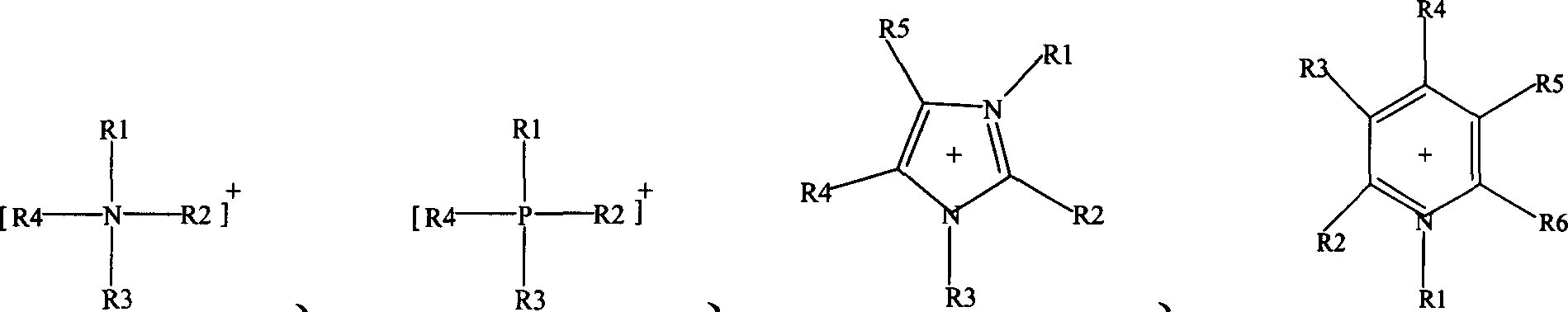

Compositions and methods are provided for preparation of concentrated stock solutions of AAV virions without aggregation. Formulations for AAV preparation and storage are high ionic strength solutions (e.g. μ˜500 mM) that are nonetheless isotonic with the intended target tissue. This combination of high ionic strength and modest osmolarity is achieved using salts of high valency, such as sodium citrate. AAV stock solutions up to 6.4×1013 vg / mL are possible using the formulations of the invention, with no aggregation being observed even after ten freeze-thaw cycles. The surfactant Pluronic® F68 may be added at 0.001% to prevent losses of virions to surfaces during handling. Virion preparations can also be treated with nucleases to eliminate small nucleic acid strands on virions surfaces that exacerbate aggregation.

Owner:GENZYME CORP

Method for preparing cellulose fiber using ion liquid as solvent

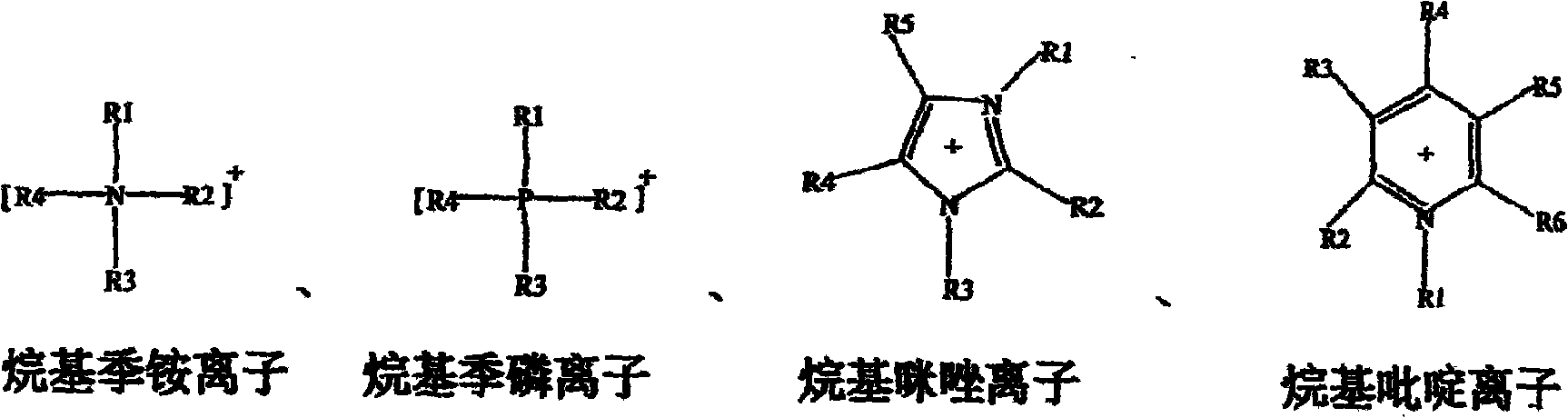

InactiveCN1851063ANon-volatileAvoid pollutionFilament/thread formingSpinning solutions preparationCellulose fiberSolvent

The invention discloses the method of producing the fibrin fiber by the ion liquid, the producing process includes the below steps: the crushed fibrin and the ion liquid are mixed evenly, the melting time keeps 1-100 hour under the temperature of 50-150 degree, the even steady filature original liquid is formed, the thickness of the filature original liquid is 5_35%; the filature original liquid is sifted and take off the doff to spin the silk, the freezing bath is composed of the water or the water and the ion, the thickness of the ion liquid in the freezing bath is 0-50%, the temperature is 0-90 degree. The conducing effect of the invention is showed below: the adopted solution is ion liquid which has the innocuity, volatility and the favor of protecting the condition and the health of the handling personnel; the melting point of the ion liquid has the wide range. so it is favor of controlling the temperature in the temperature range of the aggregation and the filature; the freezing reagent is composed of the water or the compound of the water and the ion liquid, it is the healthy solution and can protect the condition; the ion liquid has many merits such as the without volatility, the reclaiming easy, the falling of the cost, saving the resource and the energy and the improved producing efficiency.

Owner:DONGHUA UNIV

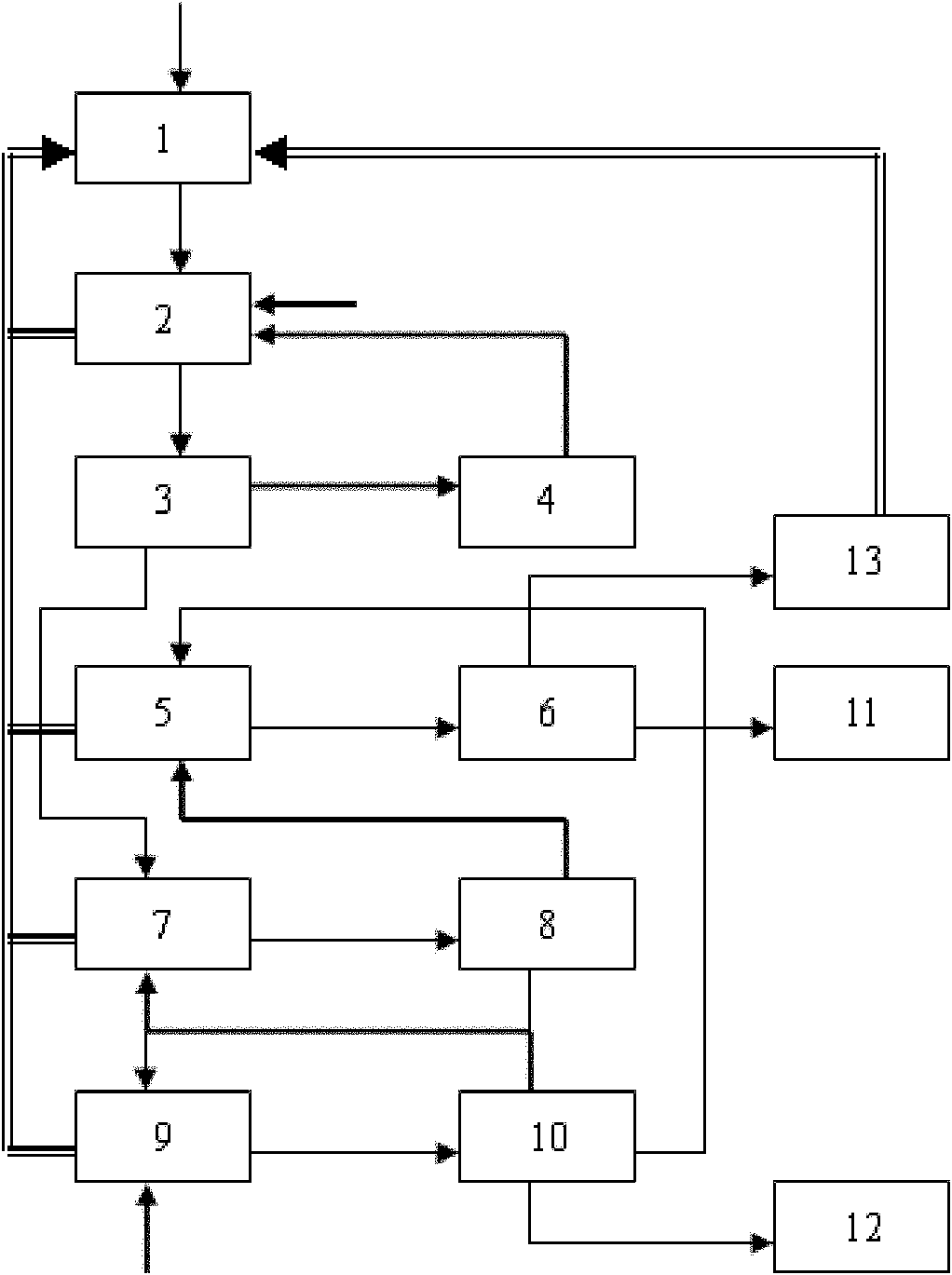

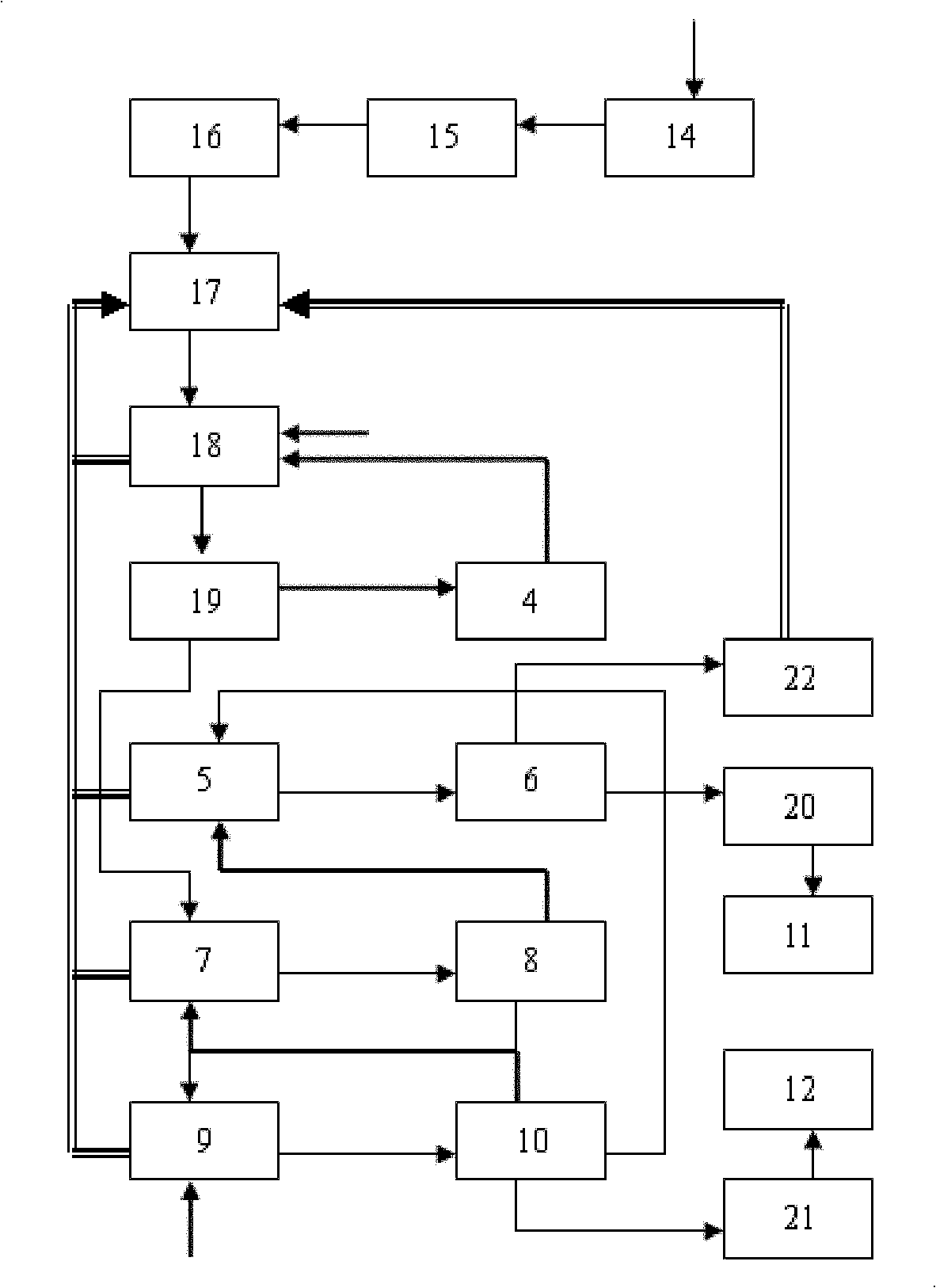

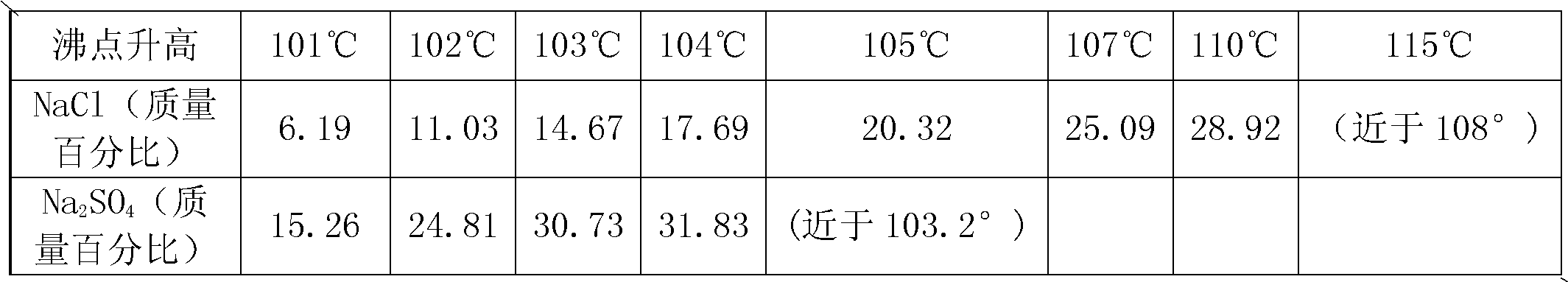

Wastewater evaporation concentration process and device system

InactiveCN102070272AAvoid easy cloggingGuaranteed uptimeMultistage water/sewage treatmentAlkali metal chloridesProcess systemsSludge

The invention discloses a wastewater evaporation concentration process and a wastewater evaporation concentration device system. The process comprises the following steps of: delivering softened wastewater to be treated to a mechanical vapor recompression (MVR) system to perform evaporation and concentration, compressing the generated secondary steam and then delivering the compressed steam to an evaporator to recycle, delivering the concentrate to a triple-effect mixed flow forced circulating evaporation crystallization system to perform evaporation and crystallization, performing solid-liquid centrifugal separation on the crystallized concentrate and crystal grains, returning the separated mother solution to a stock solution tank or continuously performing evaporation and crystallization, and reclaiming the separated crystal, wherein the secondary steam generated by evaporation and crystallization is recycled for the evaporation crystallization system. After the wastewater is evaporated and concentrated by adopting the process of mechanical vapor recompression circulating evaporation and triple-effect mixed flow forced circulating evaporation crystallization, the wastewater does not need to be discharged to the ground water area, and the wastewater is discharged in a form of steam or closed and embedded in a form of sludge or the like, so the purpose of zero discharge of the wastewater can be fulfilled; and the process system has high heat efficiency, low energy consumption, energy conservation, great reduction in running cost, low temperature difference, low corrosion, difficult scale formation and long equipment service life.

Owner:华电水务工程有限公司 +1

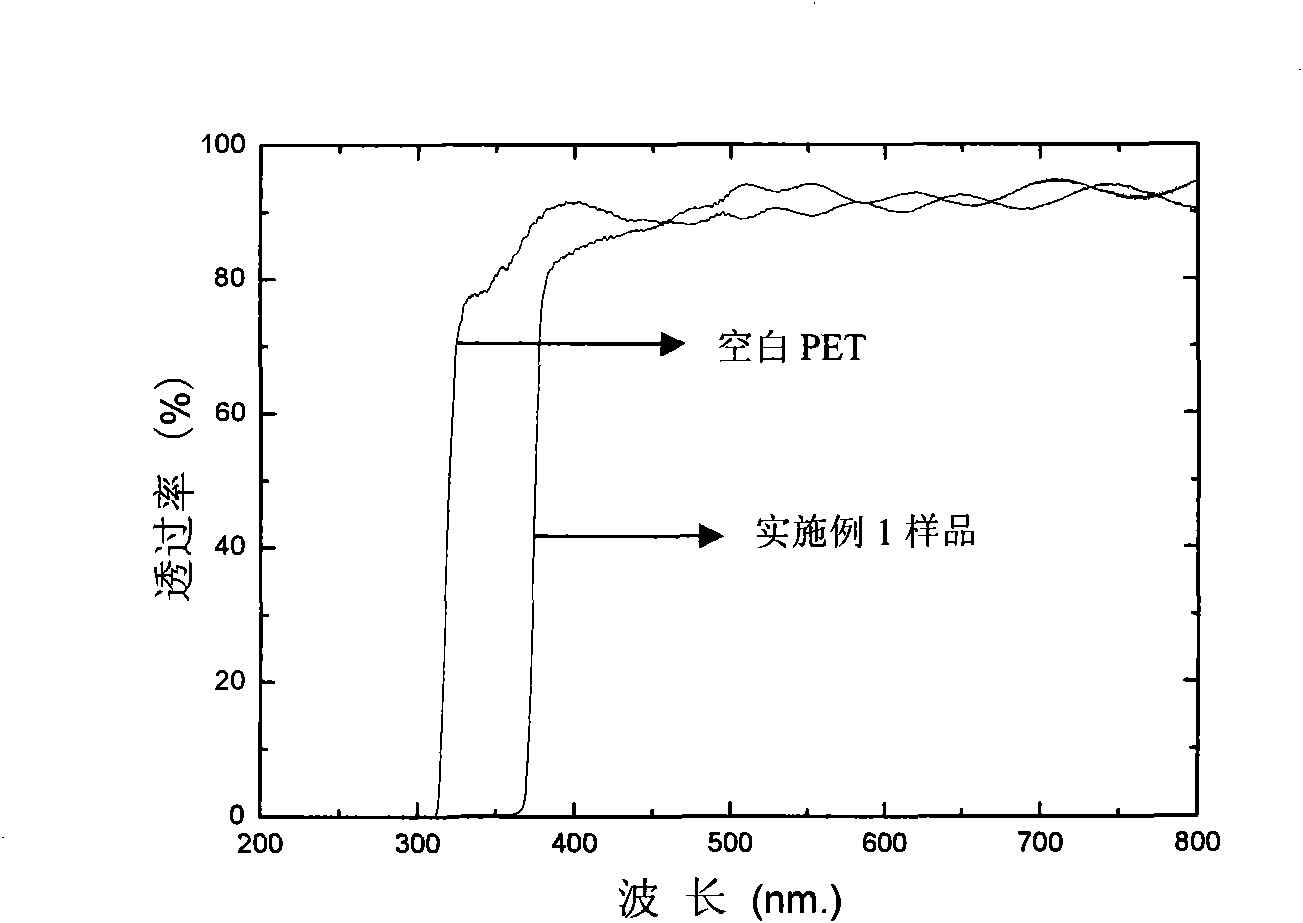

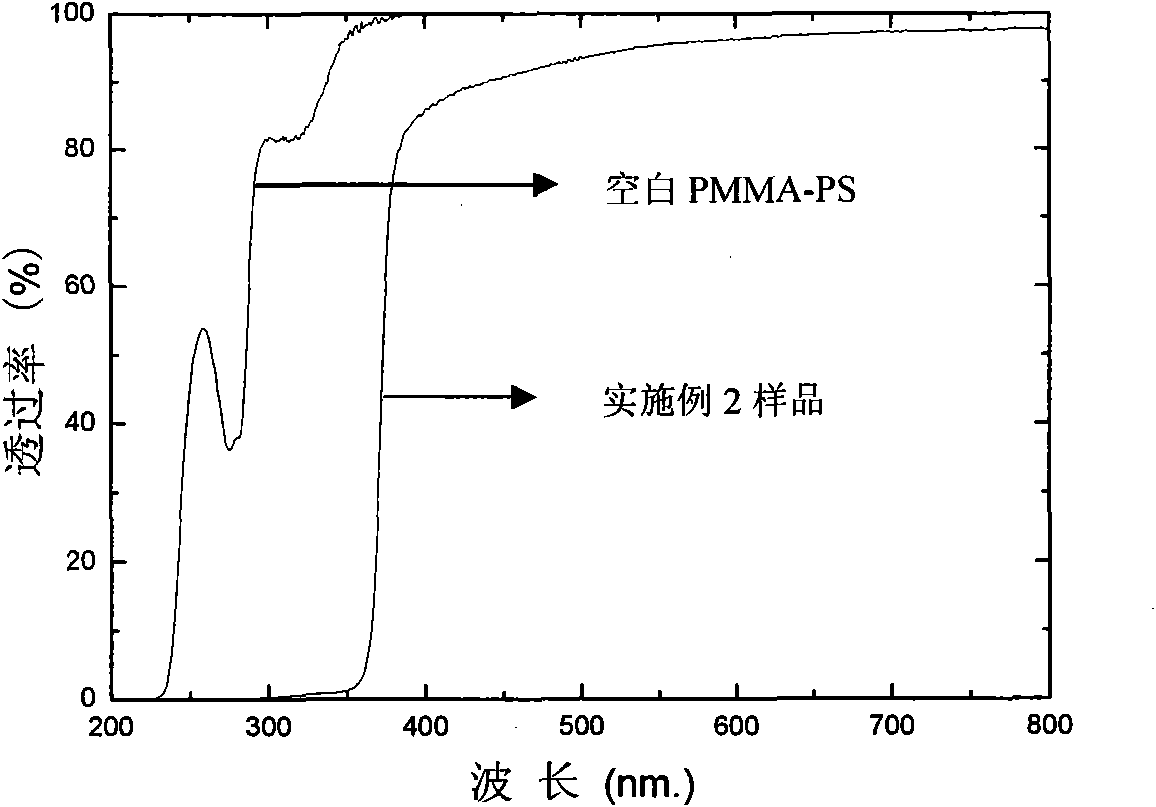

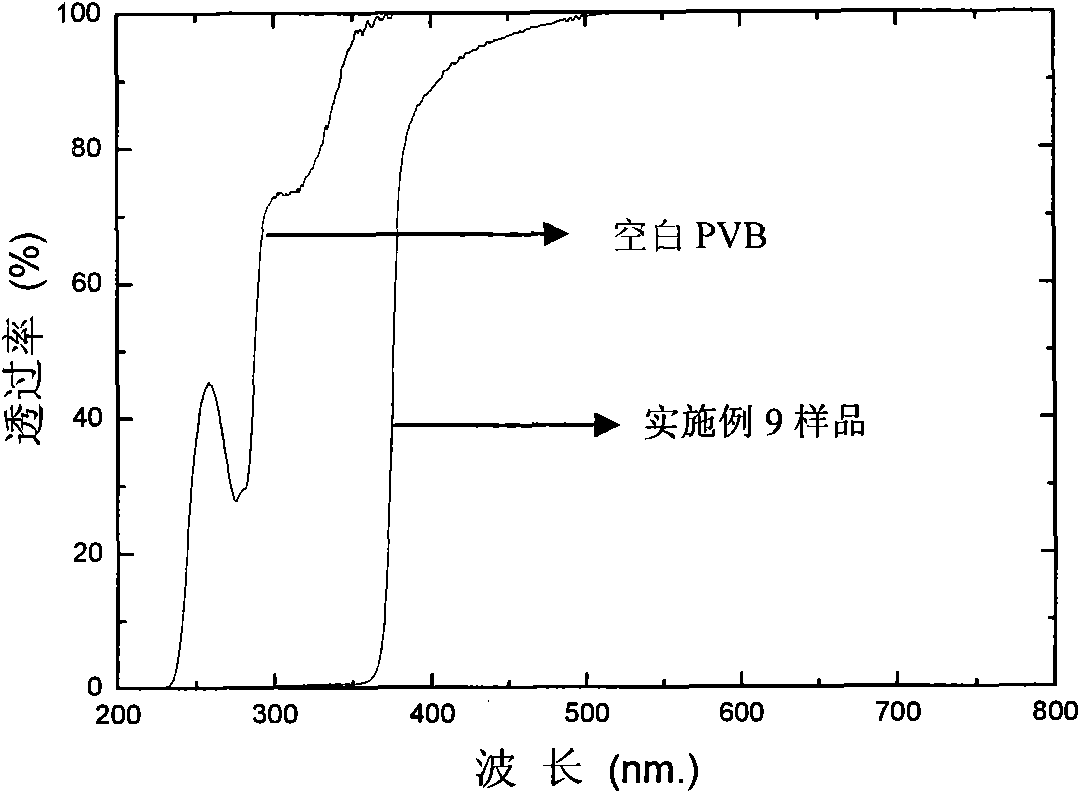

Highly-transparent ultraviolet-resistant energy-saving film and preparation method thereof

The invention relates to a highly-transparent ultraviolet-resistant energy-saving film and a preparation method thereof, belonging to the field of composite films synthesized by compounding polymer and inorganic nano-particles and aiming at overcoming the defects that the prior film has low visible light transmission and high production cost. The highly-transparent ultraviolet-resistant energy-saving film comprises the following components by the weight percent: 50-99.8 of organic polymer, 0.2-50 of metal-oxide nano-particles and 0-39.9 of polymer auxiliary agent. The highly-transparent ultraviolet-resistant energy-saving film is prepared by a solution mixing method or a solution-melting mixing method; with the solution mixing method, the organic polymer and the metal-oxide nano-particles are dispersed in dispersing medium to prepare film preparing stock solution, and the film preparing stock solution is used for preparing the energy-saving film on a substrate; with the solution-melting mixing method, the mixture of the organic polymer and the metal-oxide nano-particles is dried to prepare master batch, and the master bath is mixed with the organic polymer and the polymer auxiliary agent to prepare the energy-saving film. The highly-transparent ultraviolet-resistant energy-saving film has high visible light transmission, good ultraviolet resistance and energy-saving effect, simple preparation process and low cost, thereby being suitable for industrial production.

Owner:BEIJING UNIV OF CHEM TECH +1

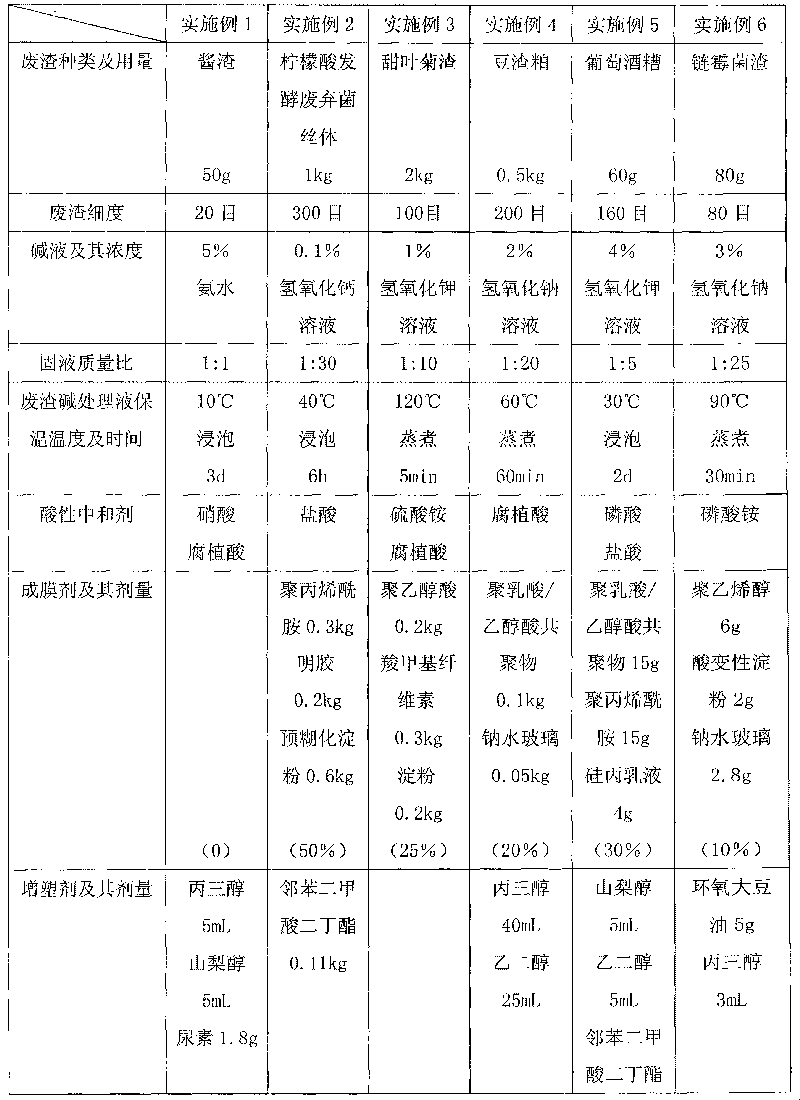

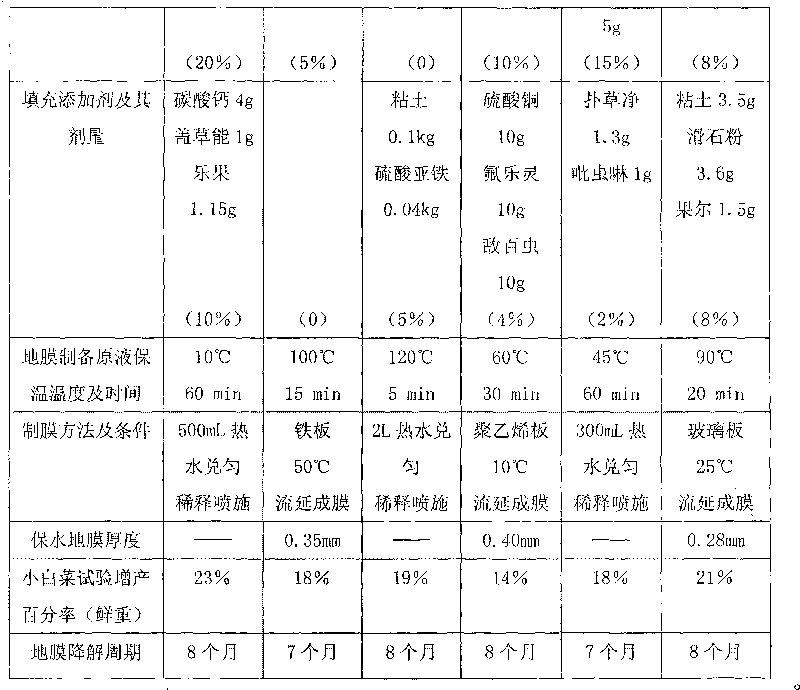

Method for preparing degradable mulch by reusing organic waste residues of biomass

InactiveCN101712805ASolve pollutionAchieve reuseClimate change adaptationOrganic fertilisersPlastic mulchMoisture

The invention discloses a method for preparing degradable agricultural mulches by reusing organic waste residues of biomass, which can be widely used for preparing biodegradable nutritional type water-retention mulches by recycling the by-product residues in the fermentation brewing industry and the sugar industry. In the process, low-concentration alkali liquor is mainly used for processing the waste residues, specified neutralizing agents are used for neutralizing the fertilizers such as N, P, K and the like required for growing the plants which are generated and auxiliary film-forming agents, plasticizers and the like are used for preparing mulch stock solution, or casting or diluting or spraying is carried out. The mulch is low in cost and convenient to operate, such substances as pesticides, weedicides, trace fertilizers and the like can be added to the mulch according to the requirements of different crops, and the mulch not only has the effects of heat preservation, moisture preservation and fertilizer betterment but also has moderate degradation period. The degradation rate of the ground mulch reaches 55-70% after 4 months and almost reaches 100% after about 8 months.

Owner:BEIJING UNIV OF CHEM TECH

Phase-change energy-storage fibre and method for making same

ActiveCN101041911AHigh phase change enthalpyFunction increaseConjugated cellulose/protein artificial filamentsMelt spinning methodsCelluloseWax

The invention discloses a phase-variable energy-storage fiber and relative production, which comprises that using cellulose slurry to prepare cellulose adhesive solution, to be mixed with phase-variable wax fused solution to prepare spinning dope to obtain the phase-variable energy-saving adhesive fiber. The functional fiber is mainly formed by cellulose and wax, while the wax content is 10-40% (relative to the cellulose content). And the inventive production has simple process, significantly reduced phase-variable material loss in the process, improve the phase-variable material content and improve the phase-variable energy-saving function and mechanical function.

Owner:潍坊欣龙生物材料有限公司

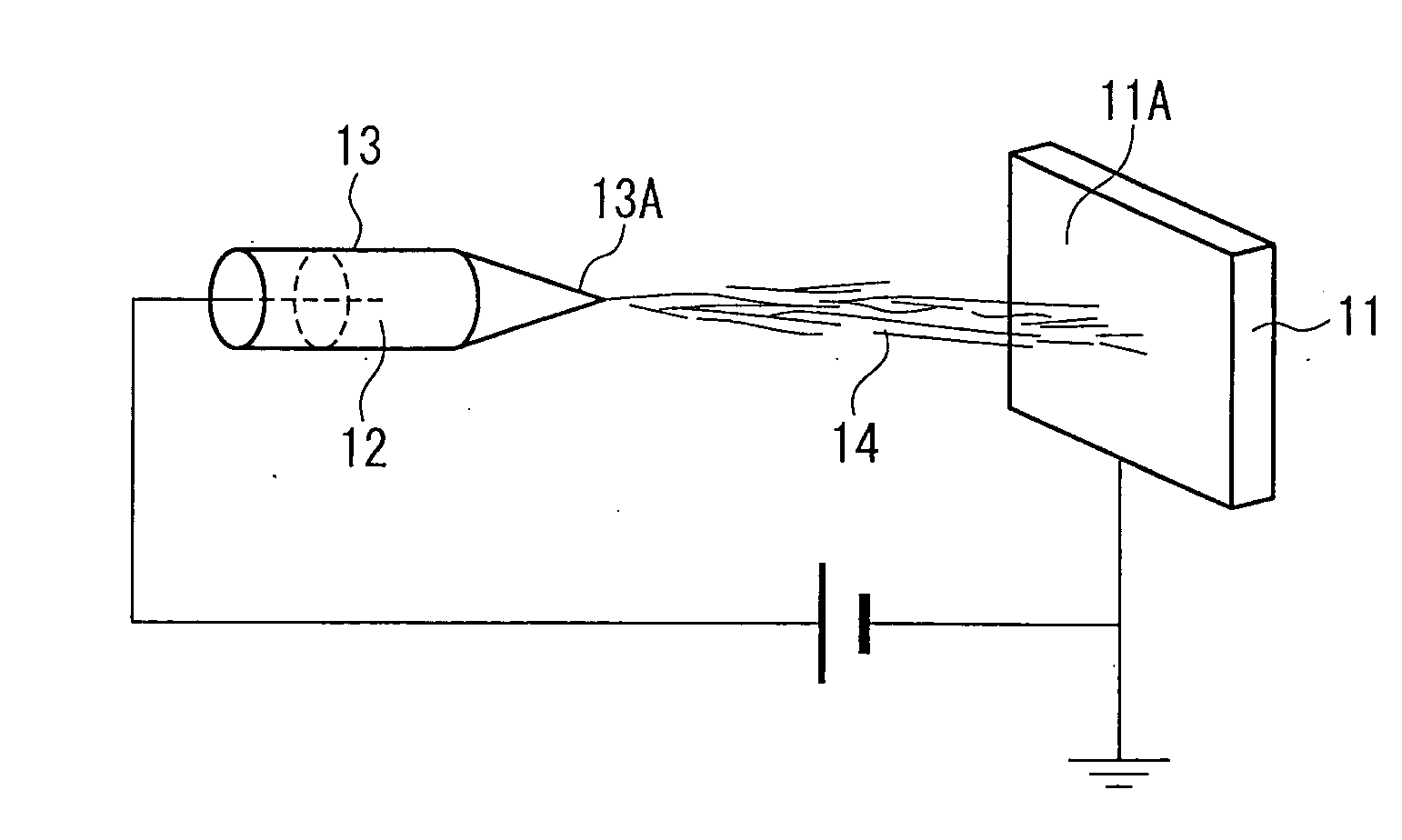

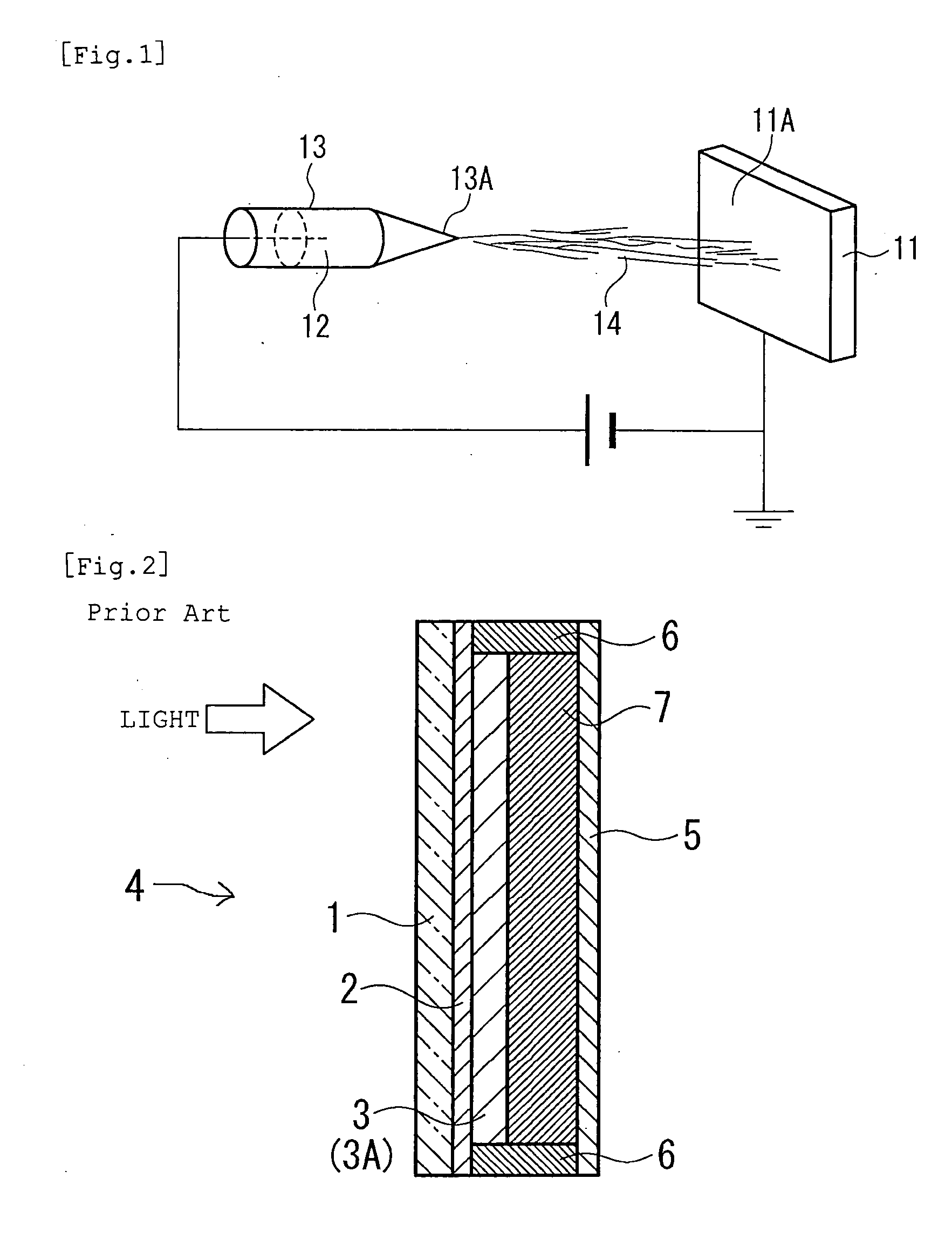

Dye sensitive metal oxide semiconductor electrode, method for manufacturing the same, and dye sensitized solar cell

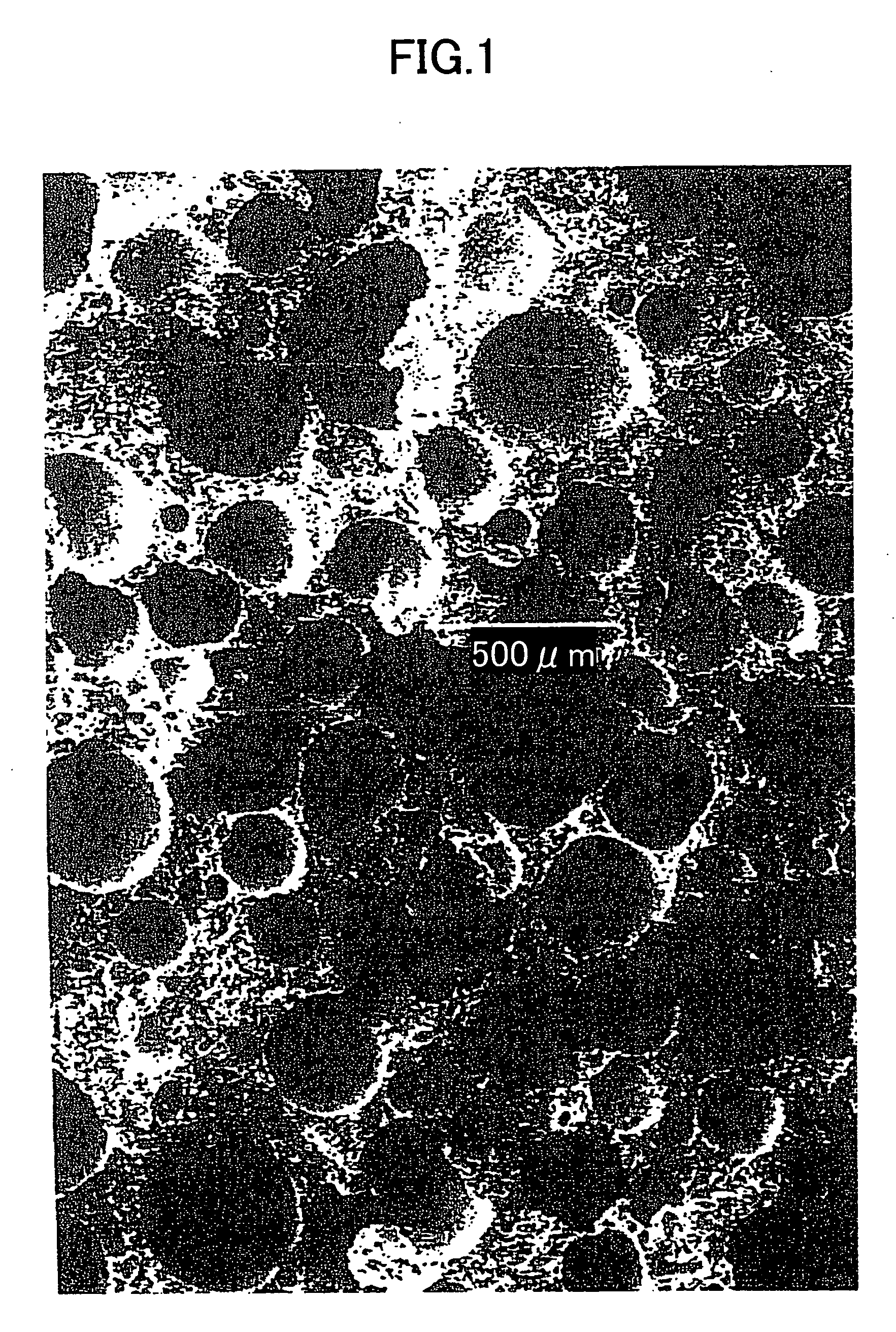

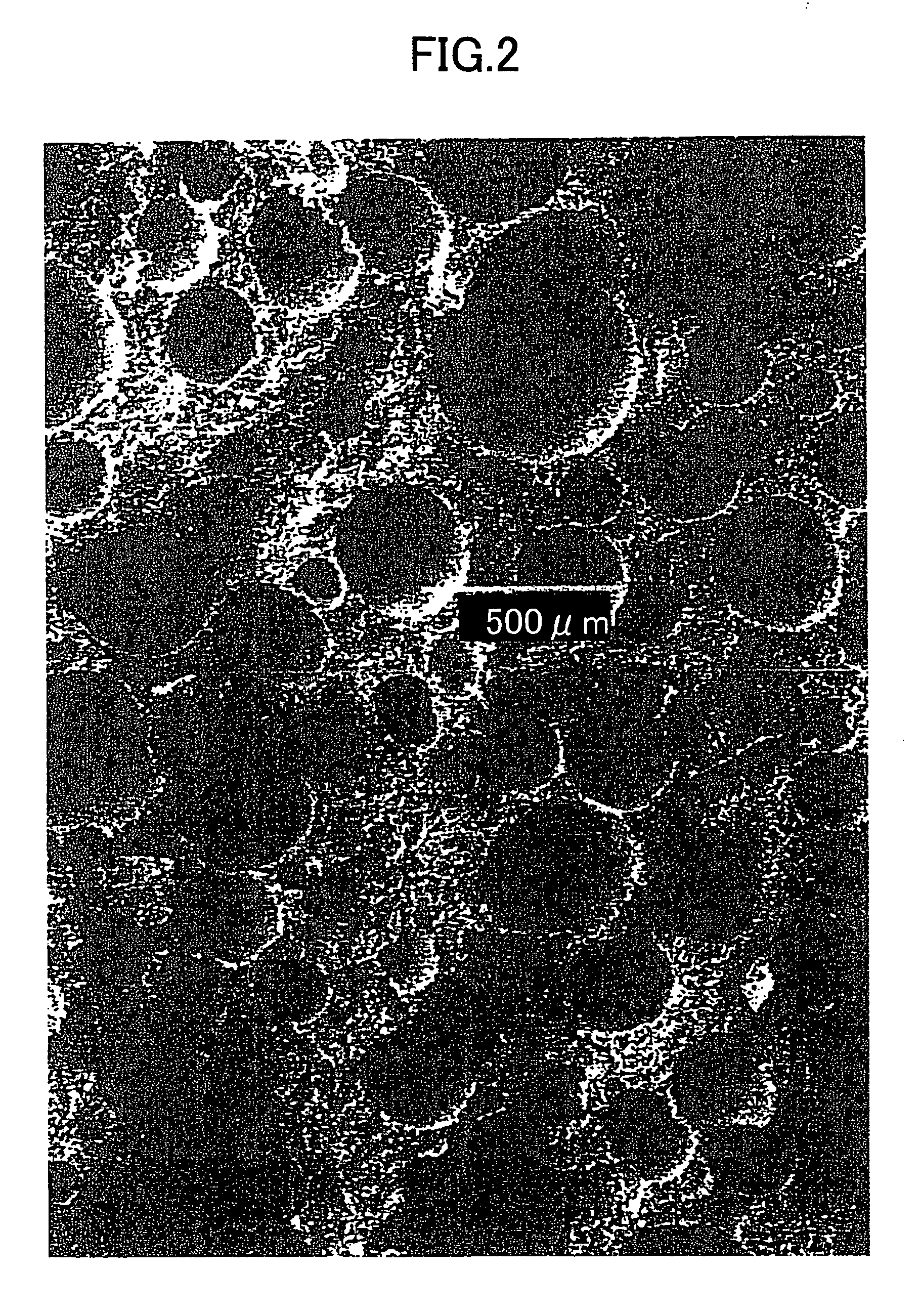

InactiveUS20070243718A1Improve conductivityImprove power generation efficiencyElectrolytic capacitorsFinal product manufactureFiberSemiconductor electrode

Provided are a dye sensitized metal oxide semiconductor electrode having a metal oxide semiconductor film that can adsorb a sufficient amount of dye due to a high specific surface area and exhibits high electrical conductivity due to tight contact of metal oxide particles, and a dye sensitized solar cell that exhibits high power generation efficiency by using this dye sensitized metal oxide semiconductor electrode. The dye sensitized metal oxide semiconductor electrode is produced by forming a metal oxide semiconductor film on a transparent conductive film formed on a substrate. A stock solution containing a metal oxide precursor is jetted onto the transparent conductive film by electrospinning. A nanofiber layer containing a metal oxide precursor is deposited on the transparent conductive film, and this deposited layer is fired.

Owner:BRIDGESTONE CORP +1

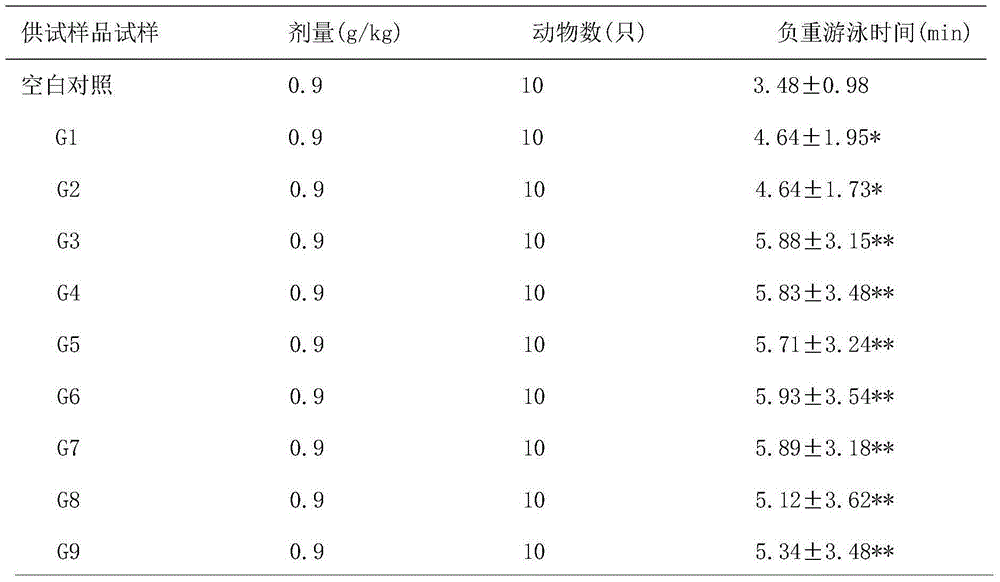

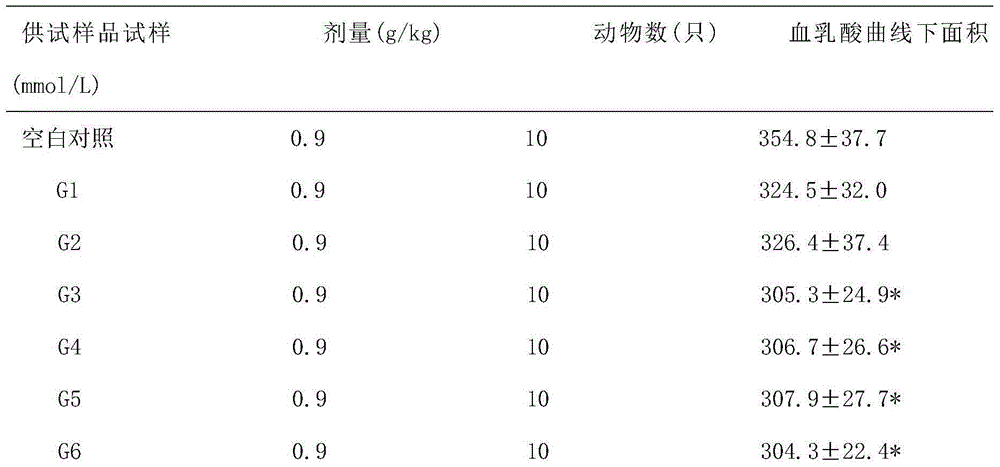

Preparation method of enzyme

InactiveCN105919846AEnhance cell viabilityIncrease vitalityCosmetic preparationsToilet preparationsHas active ingredientRoom temperature

The invention relates to an enzyme preparation method. The enzyme is prepared by mixing, fermenting and extracting the following raw materials in parts by weight: 100 to 200 parts of natural organic fruits and vegetables, 100 to 200 parts of traditional Chinese herbals, 5 to 10 parts of clean water, 1 to 30 parts of probiotics, 500 to 2500 parts of edible sugar, and 100 to 400 parts of salt. Specifically, the preparation method comprises the following steps: picking, weighing, and washing natural organic fruits and vegetables and traditional Chinese herbals, drying natural organic fruits and vegetables and traditional Chinese herbals in the air, putting natural organic fruits and vegetables and traditional Chinese herbals into an extraction tank; after all raw materials have been added into the extraction tank, adding clean water, white sugar, salt, and probiotics, evenly mixing; carrying out primary fermentation for 7 to 15 days, naturally extracting a liquid containing effective components, controlling the indoor temperature in a range of 10 to 25 DEG C; filtering to obtain an enzyme primary liquid; delivering the obtained enzyme primary liquid into a tank body in a fermentation aging chamber by a liquid pump through a pipeline, keeping a constant room temperature (25-37 DEG C) of the fermentation aging chamber; and carrying out fermentation aging for 240 to 480 days to obtain the liquid enzyme stock solution.

Owner:李健明

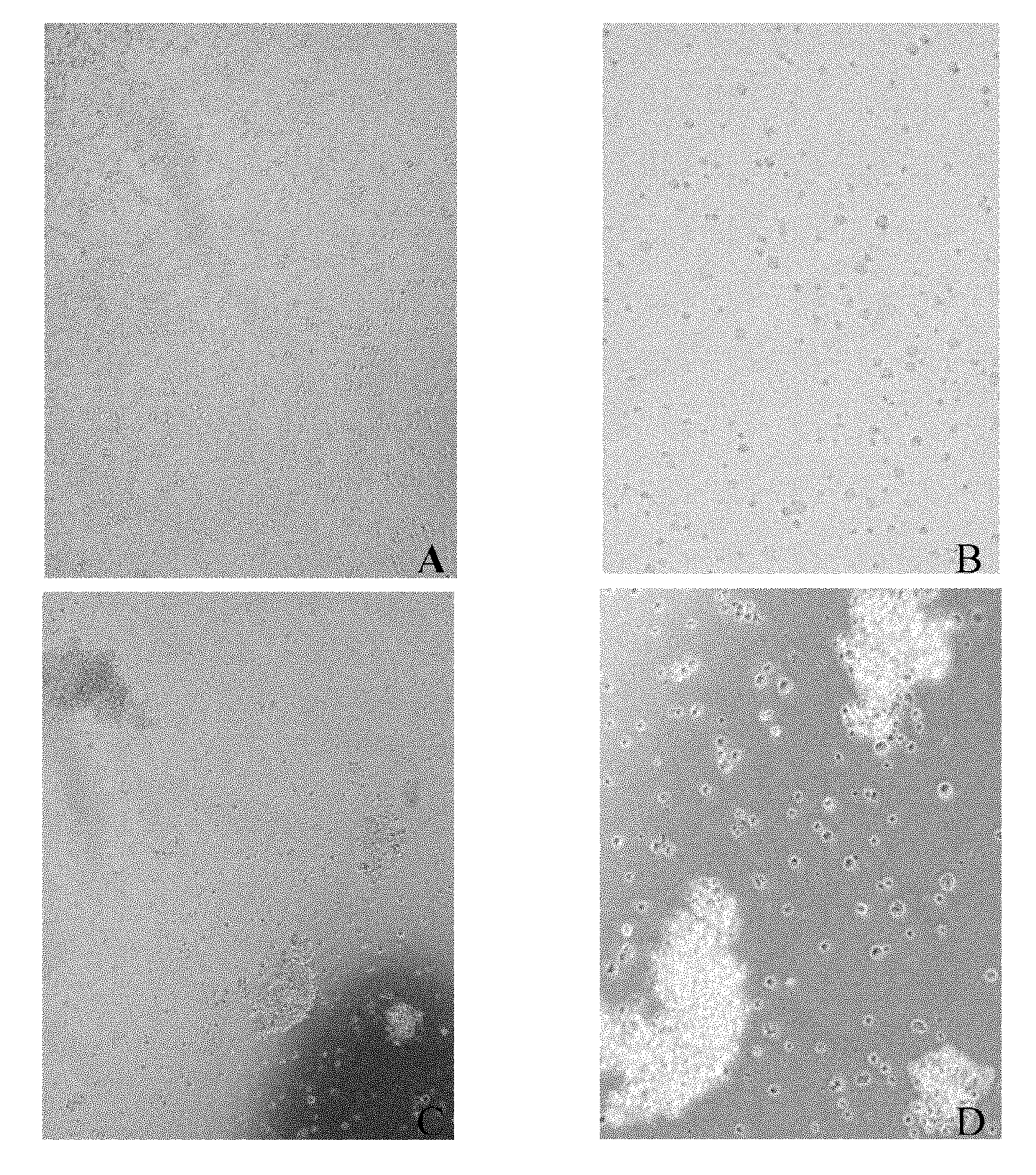

Preparation method of human umbilical cord mesenchymal stem cell factor freeze-dried powder

InactiveCN106367386AHigh purityHigh protein contentCosmetic preparationsToilet preparationsFreeze-dryingFiltration

The invention relates to a preparation method of human umbilical cord mesenchymal stem cell factor freeze-dried powder, and aims to solve the problems of low cell factor yield and poor activity in the prior art. Umbilical cord mesenchymal stem cells are sequentially separated and subjected to passage, culture supernatant fluid is collected, filtered and concentrated, freeze-dried excipients and 50 DEG C deionized water are added, protein concentration is adjusted, and the materials are blended, sub-packaged and then freeze-dried under the freeze-drying condition of 50-100Pa pressure intensity and temperature ranging from -30 DEG C to -35 DEG C to obtain the human umbilical cord mesenchymal stem cell freeze-dried powder. The collected culture supernatant fluid is firstly frozen and stored, filtering and concentrating processes of the culture supernatant fluid include unfreezing the culture supernatant fluid at room temperature and filtering the cells by 0.45 micrometer filter membranes, ultra-filtration and concentration of 3KD filter membranes include concentrating the supernatant fluid to be 1 / 10 of the original volume of the supernatant fluid, and 0.22 micrometer filter membranes perform filtration sterilization to obtain the human umbilical cord mesenchymal stem cell freeze-dried powder stock solution for preparing the human umbilical cord mesenchymal stem cell freeze-dried powder. The prepared freeze-dried powder can effectively store various cell factors secreted by the human umbilical cord mesenchymal stem cell and with biological activity, and the obtained cell factors are high in yield, good in activity and easy to store and transport.

Owner:中卫华医(北京)生物科技有限公司 +1

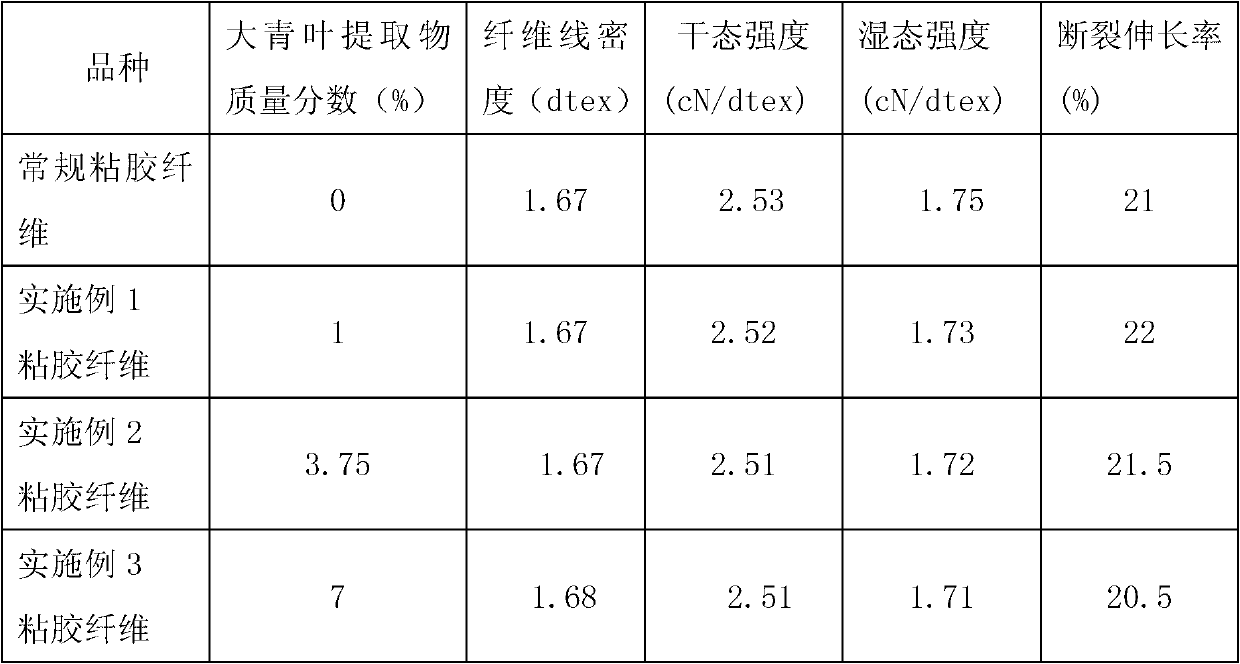

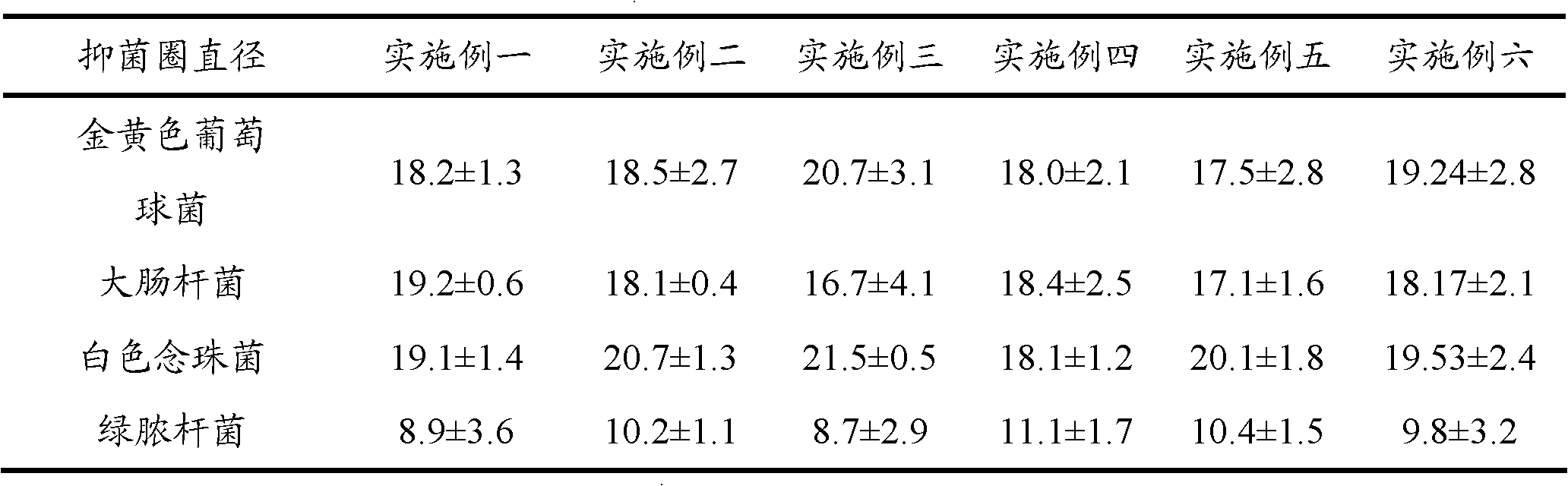

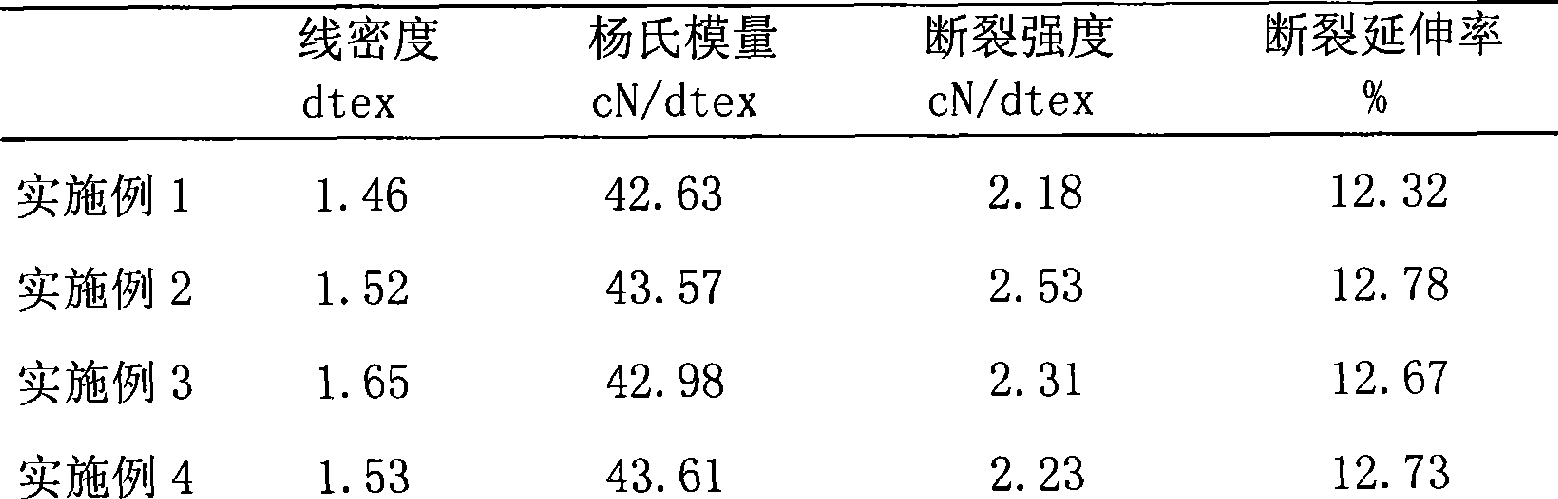

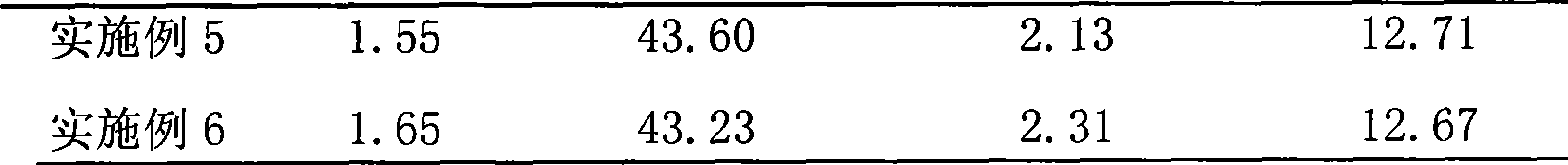

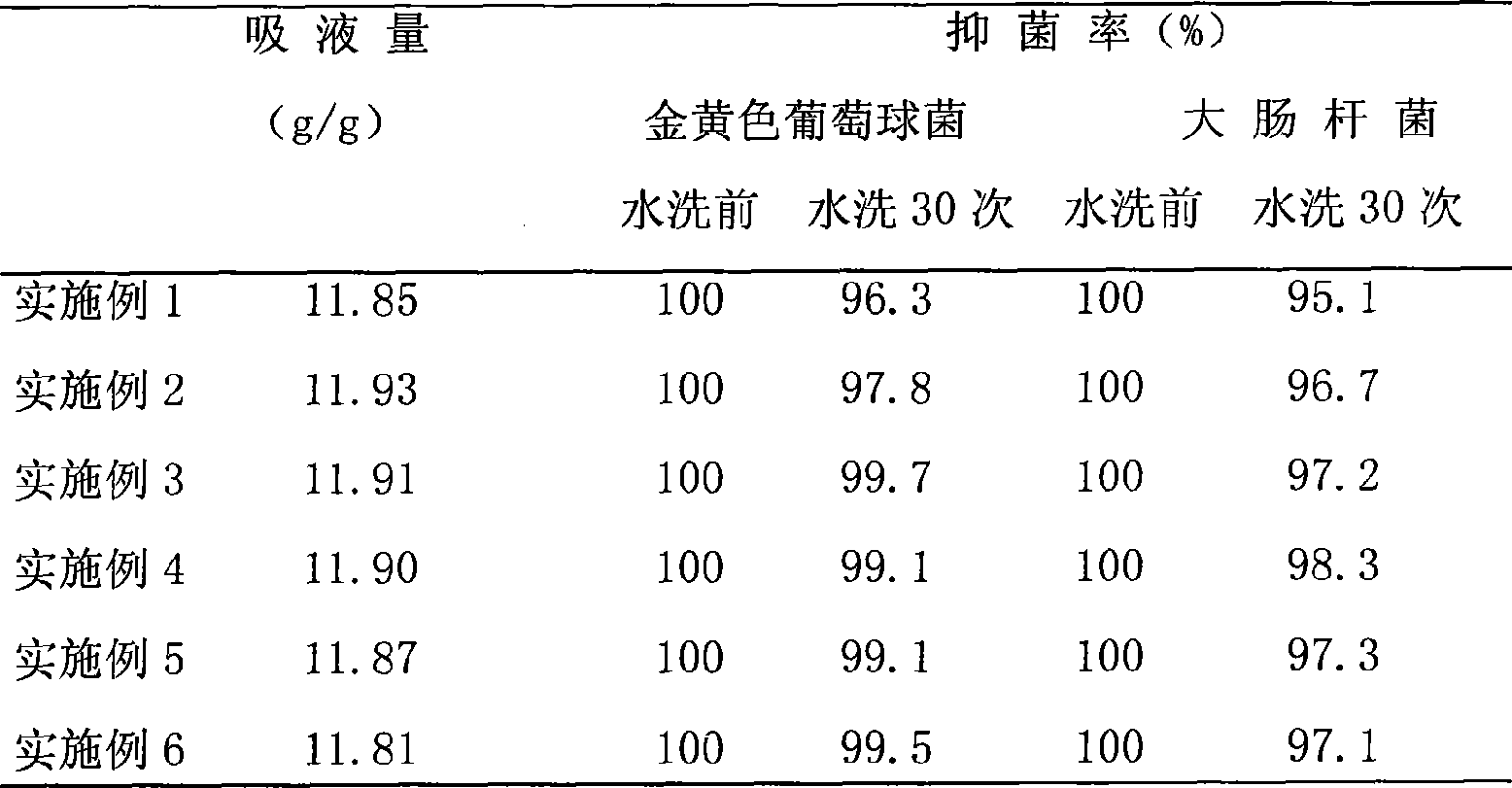

Viscose containing natural antimicrobials and preparation method thereof

InactiveCN102926013AImprove antibacterial functionNo side effectsArtificial filaments from viscoseCellulose/protein filament chemical after-treatmentViscose fiberStock solution

The invention provides viscose containing natural antimicrobials. The viscose containing the natural antimicrobials comprises the viscose and the antimicrobials contained in the viscose. The viscose containing the natural antimicrobials is characterized in that the antimicrobials is natural indigowoad leaf extract powder, a natural indigowoad leaf extract powder solution added with dispersing agent is added into a viscose filature stock solution, the additive amount of the natural indigowoad leaf extract powder is 1%-7% of the quality of the viscose filature stock solution, the additive amount of the dispersing agent in the natural indigowoad leaf extract powder solution is 0.1%-1.0% of the quality of water in the natural indigowoad leaf extract powder solution. The preparation method of the viscose comprises the steps of dissolving the indigowoad leaf extract powder into water and adding the dispersing agent to obtain the indigowoad leaf extract powder solution, adding the indigowoad leaf extract powder solution to the viscose filature stock solution according to a ratio of 10%-14% of the quality of the viscose filature stock solution, and then shaping a obtained solution according to conventional wet spinning jet process to obtain the viscose. The viscose has a durable antibacterial function and has no side effect on human bodies. The preparation method has reasonable and simple technology, and is suitable for industrialized production.

Owner:单修铎

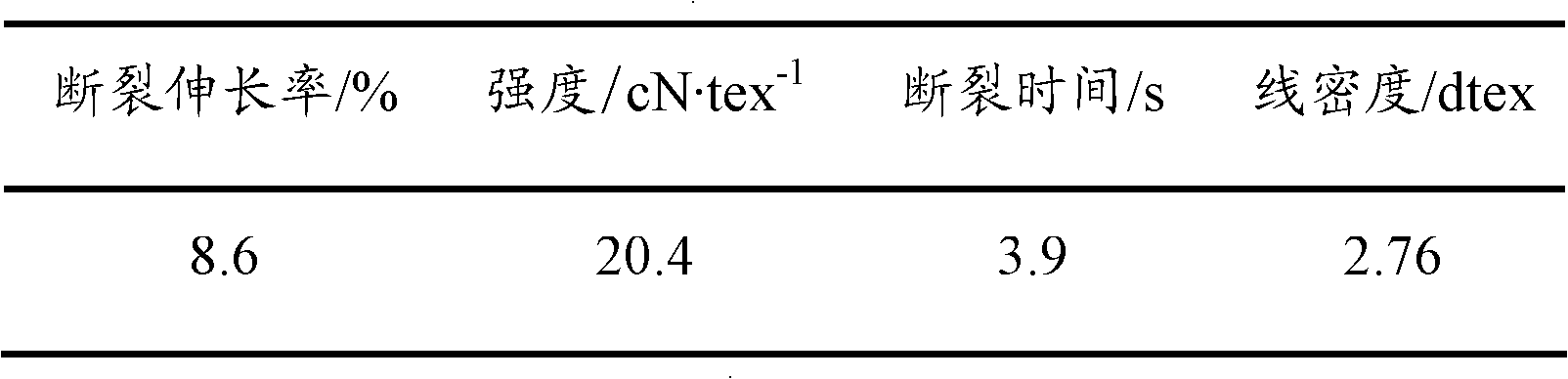

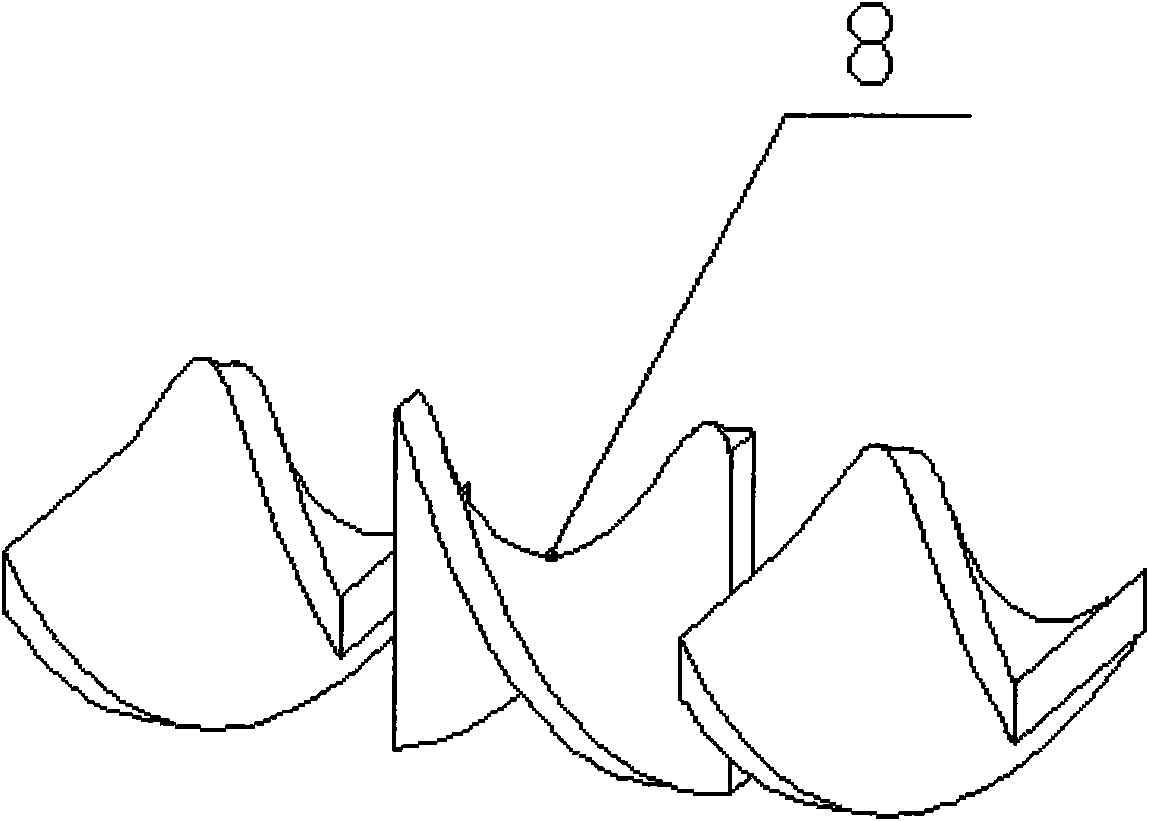

A method for preparing polyacrylonitrile carbon fiber precursors by dry jet wet spinning

ActiveCN102277629AFull and even contactInhibition formationArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentYarnGas liquid reaction

The invention relates to a method for preparing a polyacrylonitrile carbon fiber precursor. The method comprises the following steps of: copolymerizing acrylonitrile and copolymerization components in multicomponent solution so as to form polymer spinning stock solution which has a relatively uniform and controllable molecular structure, performing demonomerization on the spinning stock solution,defoaming, filtering, and preparing the polyacrylonitrile carbon fiber precursor by a dry-jet wet-spinning process. The key technology of the method is that: a gas storage box is arranged on a dry wet spinning pack, the gas storage box and the liquid level of coagulating bath fluid form a dry-jet wet-spinning air layer into a confined space, and ammonia is persistently aerated into the space to carry out gas-liquid reaction with spinning solution trickle in the air layer. The polyacrylonitrile precursor prepared by the method has regular sections and few defects, the density is not less than 1.187g / cm<3>, the density after carbonization is not less than 1.79g / cm<3>, the strength is not less than 5.1GPa, and the modulus of elasticity is 280 to 300GPa.

Owner:KINGFA SCI & TECH CO LTD +1

Universal adhesive and preparation technology thereof

InactiveCN102604588AExtended shelf lifeAvoid serious wasteMineral oil hydrocarbon copolymer adhesivesChemical industryHydrocarbon solventsProduction line

The invention relates o a universal adhesive and a preparation technology thereof. The universal adhesive is prepared by using the following raw materials in parts by weight: rubber, a tackifying resin, a hydrocarbon solvent, an ester solvent and a propellant; the preparation technology comprises the following steps of: firstly adding the barreled hydrocarbon solvent and the ester solvent to the stirred vessel through the compressed air of an air compressor, then successively adding the rubber, the tackifying resin and the other additives one by one to prepare a stock solution; and respectively charging the stock solution to iron tanks on an aerosol filling production line, sealing and then filling the propellant to obtain the product. When in use, the universal adhesive provided by the invention is rapid to operate and convenient to use; in addition, environment-friendly solvents such as methyl acetate and ethyl acetate are mainly adopted in the universal adhesive so that the universal adhesive is safer in use and environment-friendly; finally, the aerosol packaging form of the universal adhesive is firstly put forward; the universal adhesive has good packaging leak tightness and is long in the quality guarantee period; the rest of universal adhesive can be stored for long term after the universal adhesive is used, thereby the serious wasting of the universal adhesive is avoided; and the universal adhesive is in line with and abides by the standard requirements of energy saving, emission reduction and environmental protection.

Owner:FUJIAN NANAN DAYANG AEROSOL MFG

Process and device for the dose dispensing of a radioactive solution

An apparatus and method for automatically dispensing a radioactive dose by filling a container, such as a vial or disposable syringe, with a required radioactive dose in a sterile environment; the apparatus being stand alone and radioactive-shielded. The apparatus further includes a control device for accurately dispensing and diluting the required radioactive dose using an online radioactivity measurement, which does not require knowledge of the volumetric radioactivity of the stock solution.

Owner:TOCHON DANGUY HENRI JAQUES +1

Preparation method of cellulose membrane by using ion liquid as solvent

The invention provides a method for making a cellulose membrane taking ionic liquid as a solvent. The method comprises the following steps that: (1) floccosem or crushed cellulose is mixed with the ionic liquid and is dissolved for 0.5 to 120 hours at a temperature of between 50 and 160 DEG C to prepare a membrane making stock solution, the concentration is between 5 and 35 percent; (2) after the membrane making stock solution is filtered and deaerated, the membrane is made, wherein, a solidification solution is an ionic liquid aqueous solution with a temperature of between 0 and 95 DEG C and a concentration of between 0 and 90 percent. The method is convenient and simple as well as economic, protects the environment and satisfies the industry needs. The cellulose membrane made by the method can be taken as a packaging material, a decorating material and a printing material or a filter membrane and a reverse osmosis membrane.

Owner:高小山

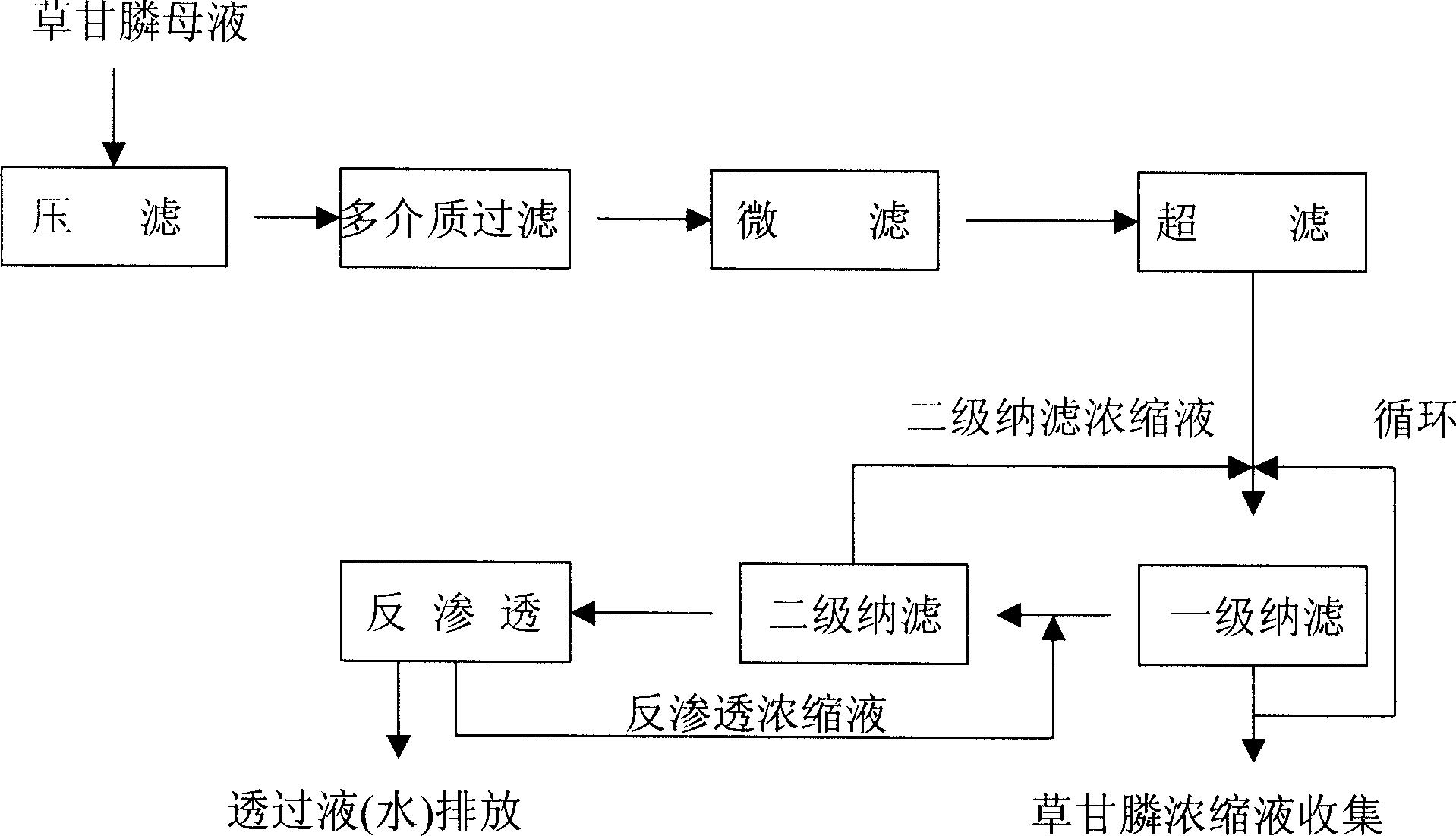

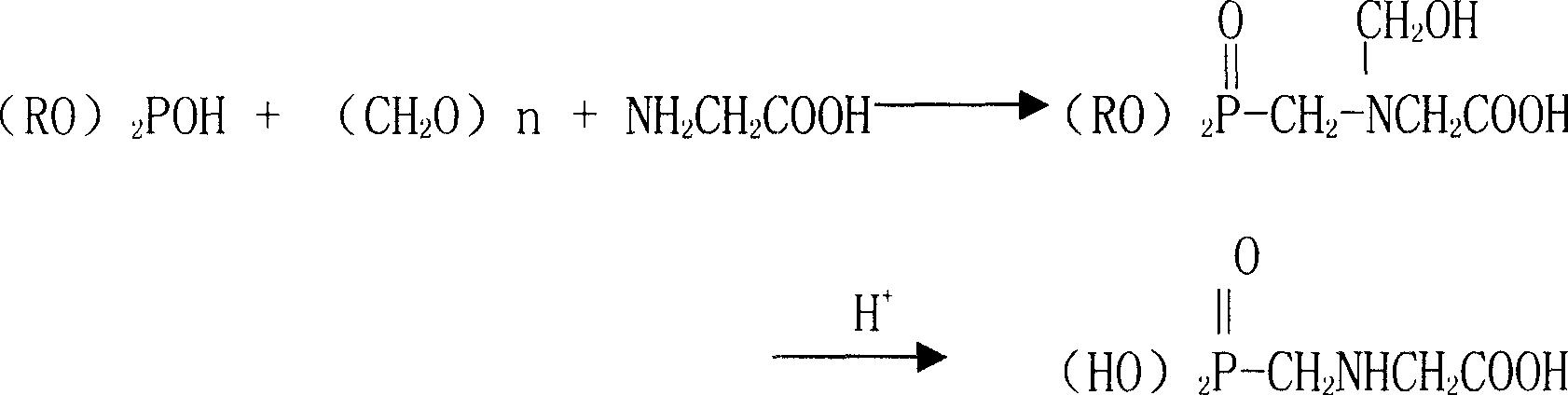

Process for separation and purification of glyphosate from glyphosate solution by membrane technology

InactiveCN1827626AAvoid decompositionQuality improvementBiocideGroup 5/15 element organic compoundsSolid componentDecomposition

The invention discloses a method for extracting glyphosate from heavy glyphosate stock solution by membrane separation technique. It consists of filtering the mother liquid, removing the solid component of the system, then according to the molecular structure, molecular mass, particle size and electric charge, from the big one to the small one, separating step by step by selecting appropriate hyperfiltration membrane, nanofiltration membrane and reverse osmosis membrane to obtain the effective composition of glyphosate. The invention unitizes the separation, concentration and the purification, and is performed at normal temperature. The barrier separation process is excellent in that it is of no change of phase, avoids the decomposition of glyphosate caused by high enrichment and concentration, effectively improves the product quality and yield rate, greatly reduces the energy consumption, is of consecutive operation, low operation cost, and it is energy-saving, highly effective, environment-friendly, furthermore, it can be operated by combining with routine thickening operating unit or be operated individually and is suitable for industrial continuous production.

Owner:捷马化工股份有限公司

Method for producing light gypsum board

ActiveUS20060162839A1High strengthImprove adhesionConstruction materialLaminationFoaming agentMetallurgy

Owner:YOSHINO GYPSUM CO LTD

Production method of functional Chinese wolfberry fruit enzyme and product thereof

ActiveCN105167072APromote absorptionGood eyesightFood ingredient functionsFood preparationEffervescent tabletEnzymatic hydrolysis

The present invention discloses a production method of functional Chinese wolfberry fruit enzyme and product thereof. The production method includes pulping Chinese wolfberry fruits, conducting enzymatic hydrolysis, adjusting the solid content and pH value, sterilizing, inoculating probiotics and fermenting, conducting centrifugal separation, drying the thick slurry to obtain the Chinese wolfberry fruit enzyme powder, continuously inoculating the clear juice with probiotics and fermenting to obtain the Chinese wolfberry fruit enzyme stock solution, and after-ripening to obtain the Chinese wolfberry fruit enzymes. And the enzymes obtained can be used to produce other Chinese wolfberry fruit enzyme products including Chinese wolfberry fruit enzyme beverage, Chinese wolfberry fruit enzyme powder, effervescent tablets, chewable tablets, buccal tablets, granules, capsules, etc. The products have efficacies of clearing heat and toxins, replenishing blood, improving eyesight, lowering blood lipids and losing weight, improving body oxidation resistance, regulating balance of intestinal floras, enhancing immunity, promoting beauty, facilitating sleep, and preventing aging.

Owner:宁夏全通枸杞供应链管理股份有限公司

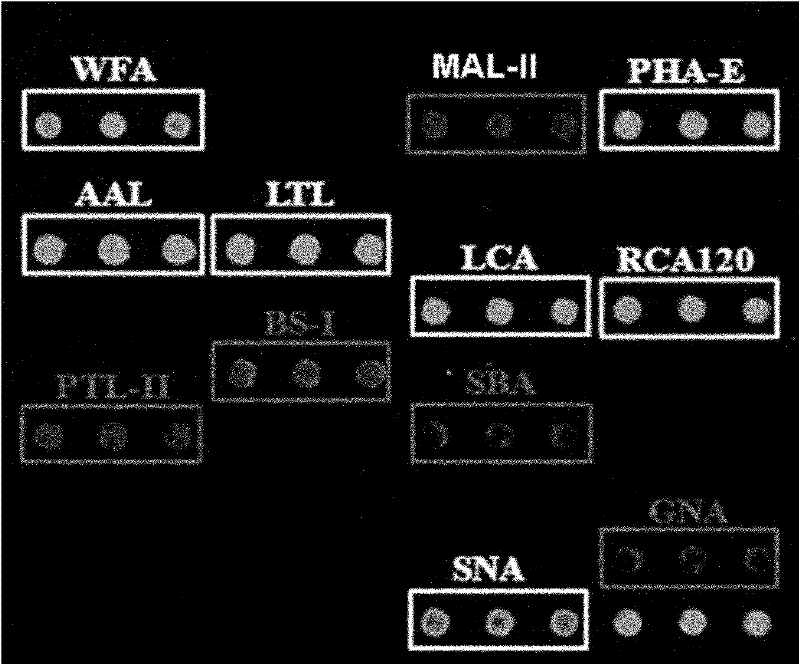

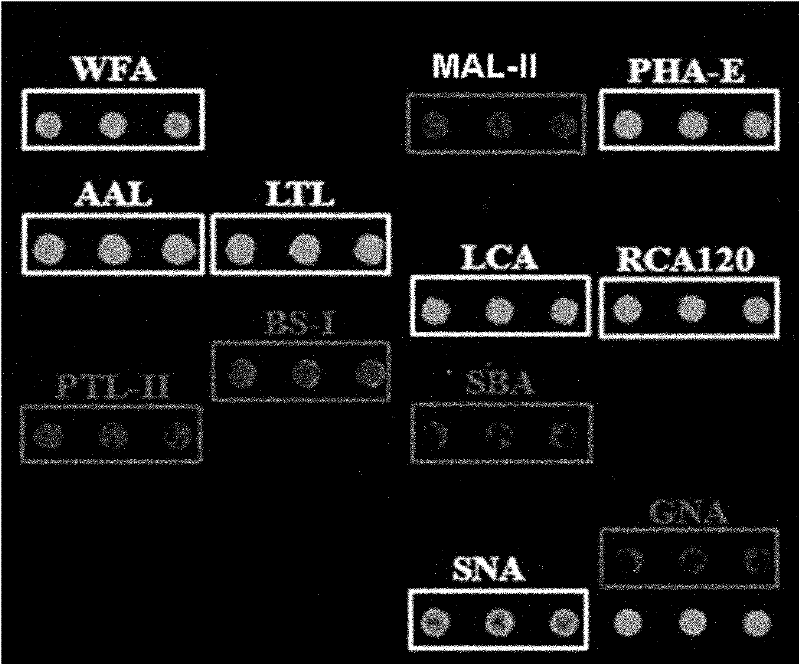

Method for detecting alternative biological markers of liver neoplasms in saliva, serum and urine

The invention provides a method for detecting alternative biological markers of liver neoplasms in saliva, serum and urine so as to detect expression information of alternative biological markers of liver neoplasms in a rapid, convenient and accurate manner. The method mainly comprises the following steps of: 1) preparing agglutinin chips corresponding to detection of saliva, serum and urine samples respectively; 2) pretreating stock solutions of saliva, serum and urine samples, removing impurities and purifying proteins, labeling by using a fluorescent reagent and removing redundant fluorescence by using G-25 columns to obtain corresponding samples to be detected; and 3) respectively loading three samples to be detected onto corresponding agglutinin chips to obtain respective glycoprotein sugar chain spectrum in each sample to be detected, and obtain information of the alternative biological markers according to reaction results of any sample to be detected. By the method, the sensibility during detection is high and detection results are accurate; moreover, the method has the advantages of safety, no damage, convenience for sample collection, simplicity in storage and the like.

Owner:NORTHWEST UNIV

Alginate antibacterial dressing and its preparation method

ActiveCN102552966AAbundant resourcesGood biocompatibilityAbsorbent padsConjugated artificial filamentsFiberWound healing

The invention relates to an alginate antibacterial dressing and its preparation method. The preparation method comprises the following steps of: preparing a spinning stock solution from soluble alginate, a water-soluble chitosan derivative or water-soluble chitin derivative and simultaneously adding a silver-based antibacterial agent into a coagulation bath, carrying out wet spinning to obtain a blend fiber product and further obtain the alginate antibacterial dressing, which can be used as a wound dressing, a hemostatic material and the like. The antibacterial dressing obtained in the invention has good biocompatibility, permeability and water absorption, can be used to rapidly stop bleeding, ease pain and promote wound healing, continuously acts on regenerative bacteria, and has a lasting and high-efficient sterilizing characteristic.

Owner:青岛高新区尚达医药研究所

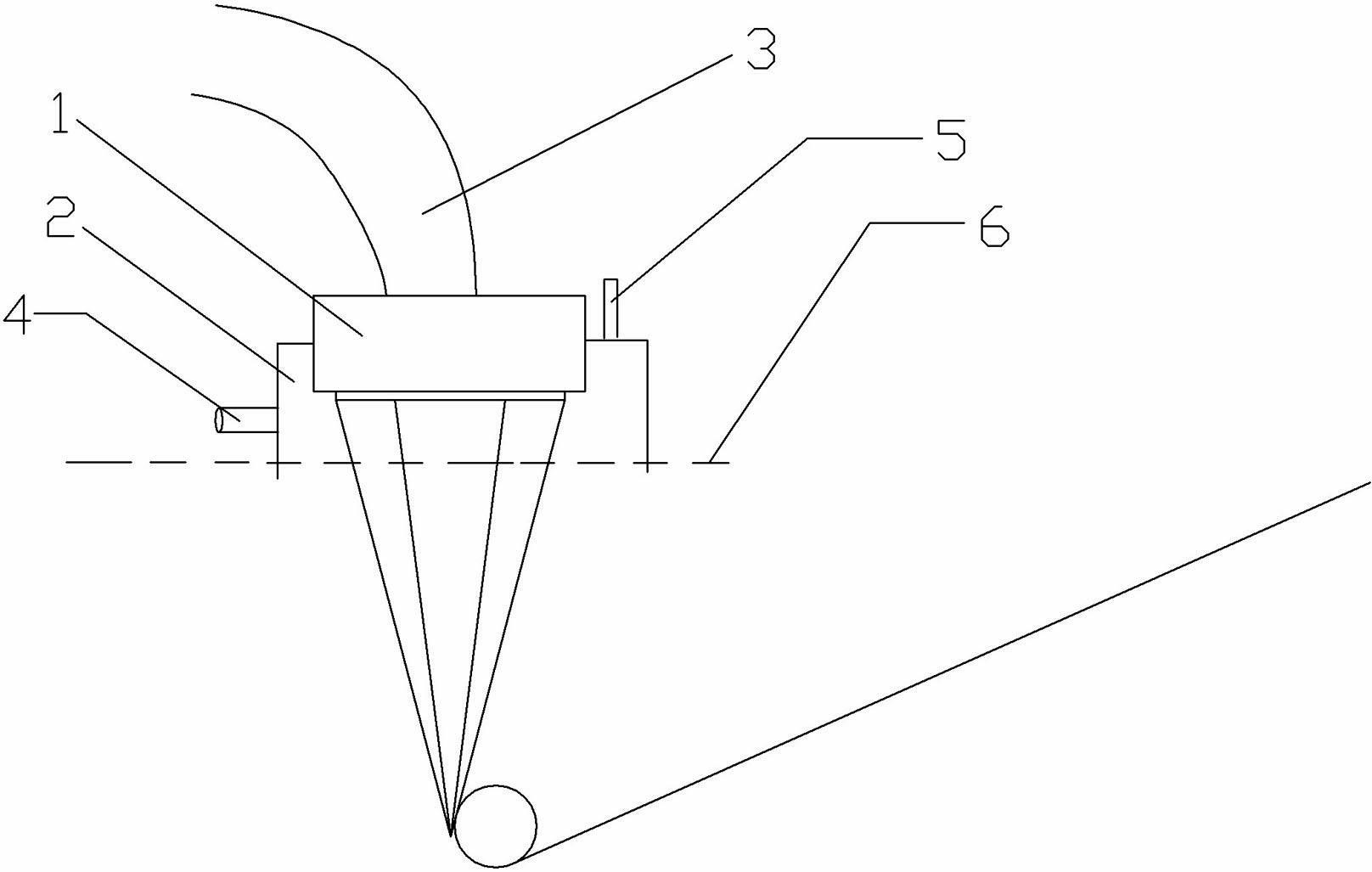

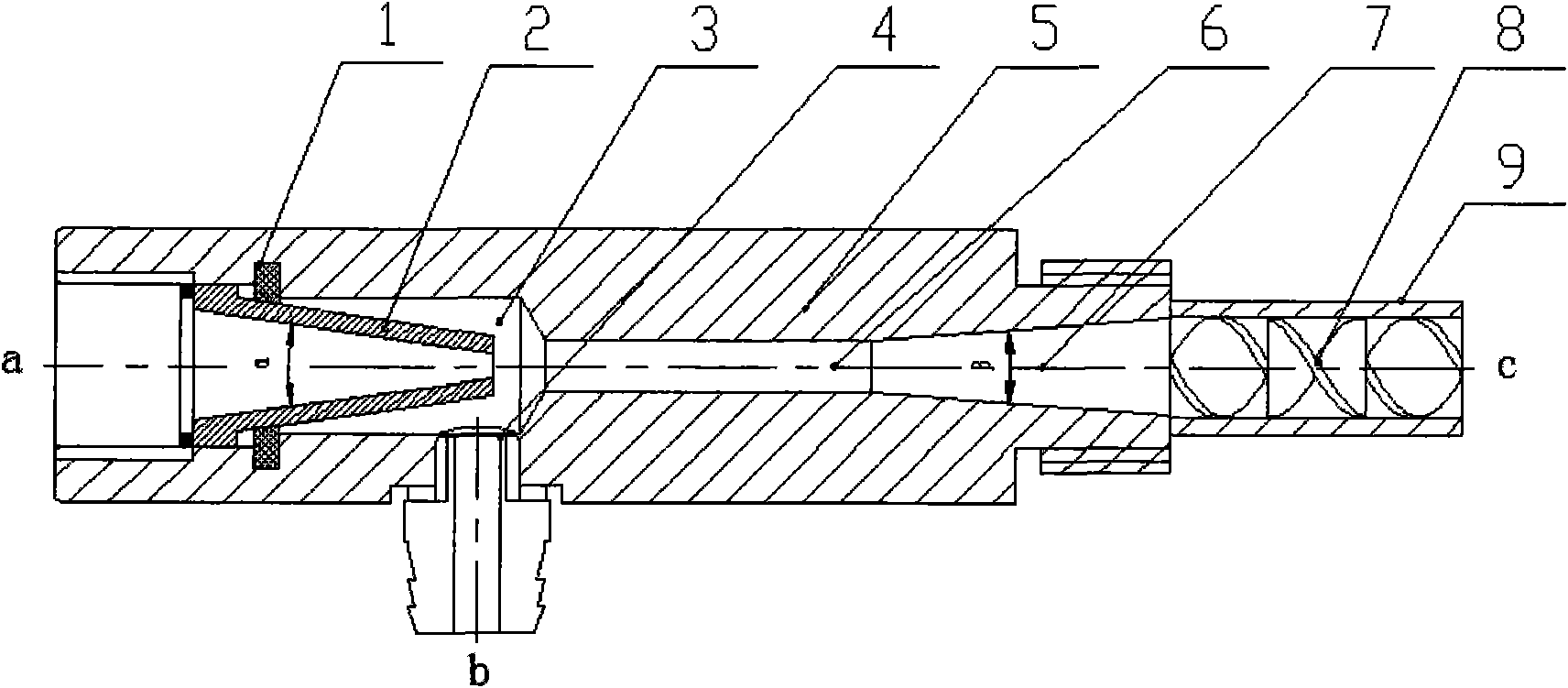

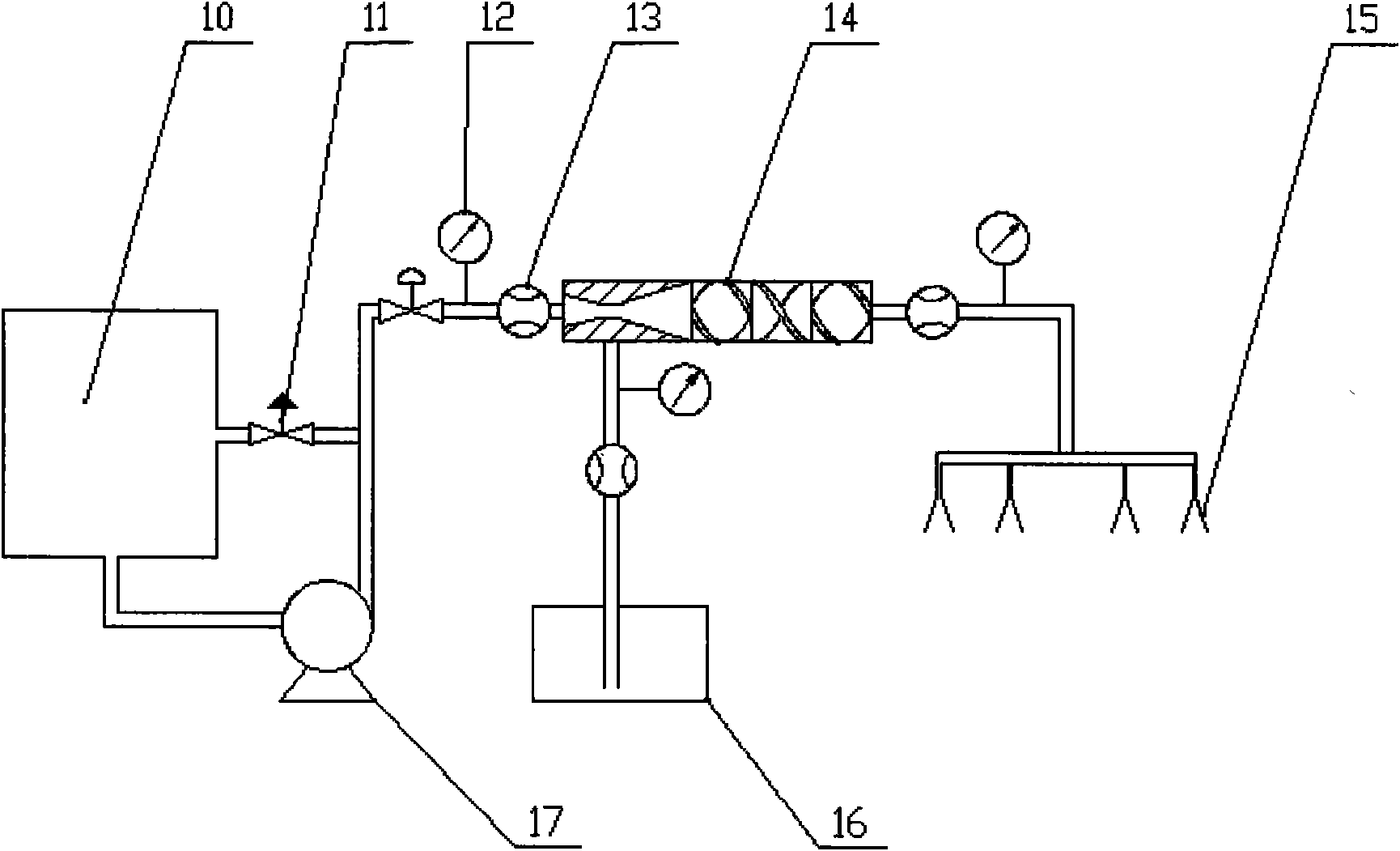

Automatic pesticide mixing device

ActiveCN101816989ASmall structure sizeSave power sourceLiquid spraying apparatusInsect catchers and killersJet flowDiffusion tube

The invention relates to an automatic pesticide mixing device, in particular to a novel pesticide mixing device, which can separately store pesticide stock solution and water and rapidly and automatically uniformly mix the pesticide stock solution and the water and is applied to different pesticide-mixing working conditions. The automatic pesticide mixing device mainly comprises a jet flow part and a spiral part, wherein the jet flow part mainly comprises an adjusting gasket 1, a jet flow nozzle 2, a suction chamber 3, a suction inlet joint 4, a jet flow pesticide-mixing device main body 5, a mixing tube 6 and a diffusion tube 7; and the spiral part mainly comprises a spiral unit 8 and a spiral shell 9. In order to adapt to different working conditions, the jet flow nozzle 2, the suction inlet joint 4 and the spiral unit 8 are designed into a detachable and replaceable form. The automatic pesticide mixing device separately stores the pesticide stock solution and the water, rapidly and automatically uniformly mixes the pesticide stock solution and the water, and is suitable for various pesticide-mixing working conditions.

Owner:JIANGSU UNIV

Method for producing inocula for livestock and poultry by multi-thalli mixed liquid

InactiveCN101386827AReduction factorReduce ammonia nitrogenFungiBacteriaDiseaseBacillus licheniformis

The invention relates to a method for fermentation production of a poultry bacterial agent by multi-bacteria miscible liquid, wherein aerobic bacteria, namely Bacillus subtilis, Bacillus licheniformis, bacillus natto, beer yeast, Aspergillus niger and Aspergillus oryzae are cultured in a shaking table according to different culture mediums, so as to culture a mother seed solution; simultaneously Lactobacillus acidophilus, bifidobacteria and enterococcus faecalis are subjected to anaerobic culture by utilization of Kille flasks, and a mother bacterial solution of photosynthetic bacteria is cultured by a Kille flask under the condition of illumination; the prior stock solution is inoculated into a seed tank for anaerobic culture and fermentation according to 4 percent of the inoculum concentration, and the fermentation time is between 48 and 60 hours; and the cultured seed liquid is inoculated into a productive tank for anaerobic culture and fermentation according to 10 percent of the inoculum concentration, the fermentation time is between 60 and 72 hours, and the fermentation end point is reached when the pH value is reduced to 4.0. The method has the advantages that the microscopic examination viable count of the bacterial agent is more than 5 billion per milliliter, so that the bacterial agent is safe and nontoxic, thereby not only improving the disease resistance of poultry but also promoting the quick growth of the poultry, reducing the feed-meat ratio and improving the quality of meat, eggs and milk.

Owner:张培举

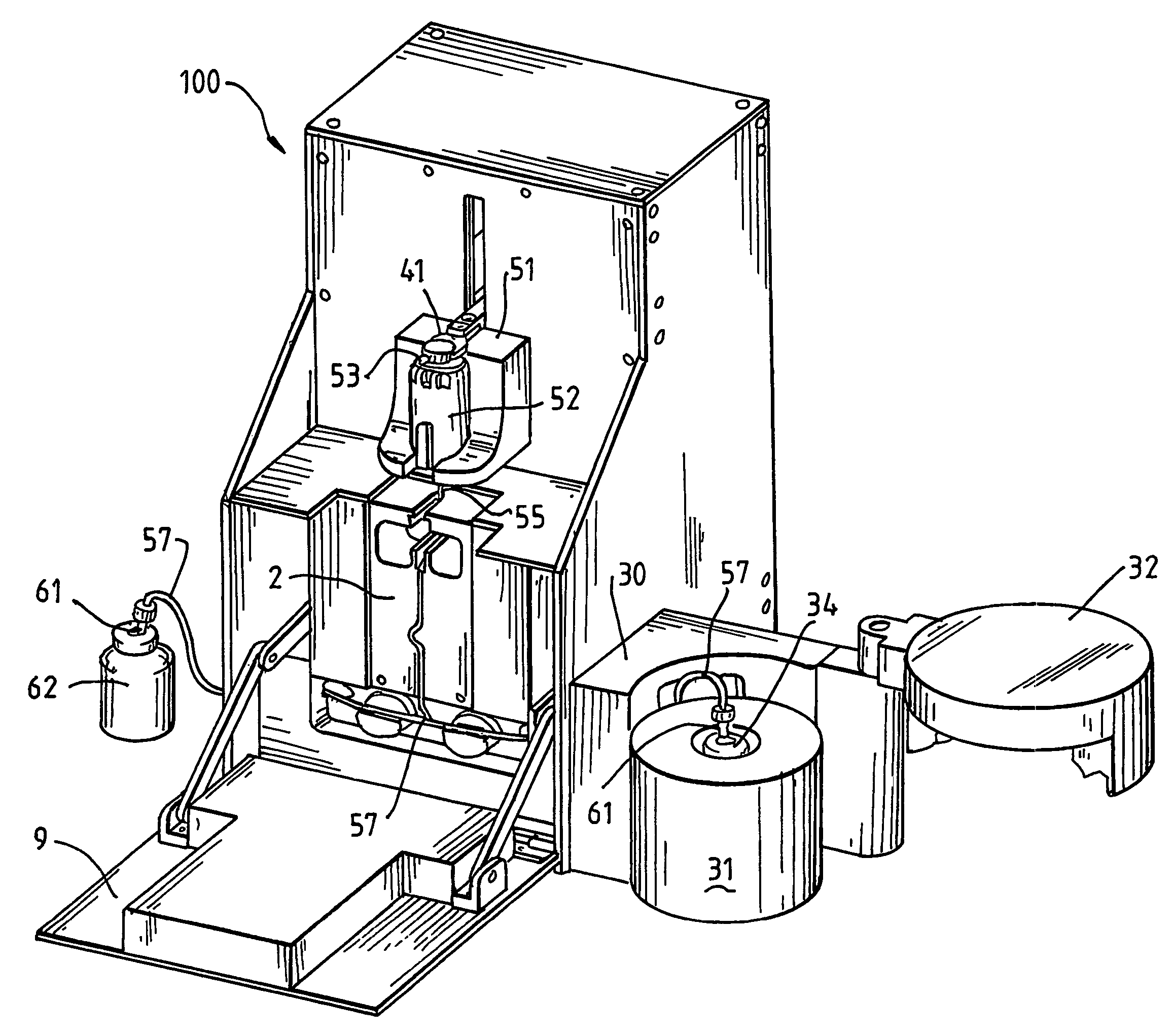

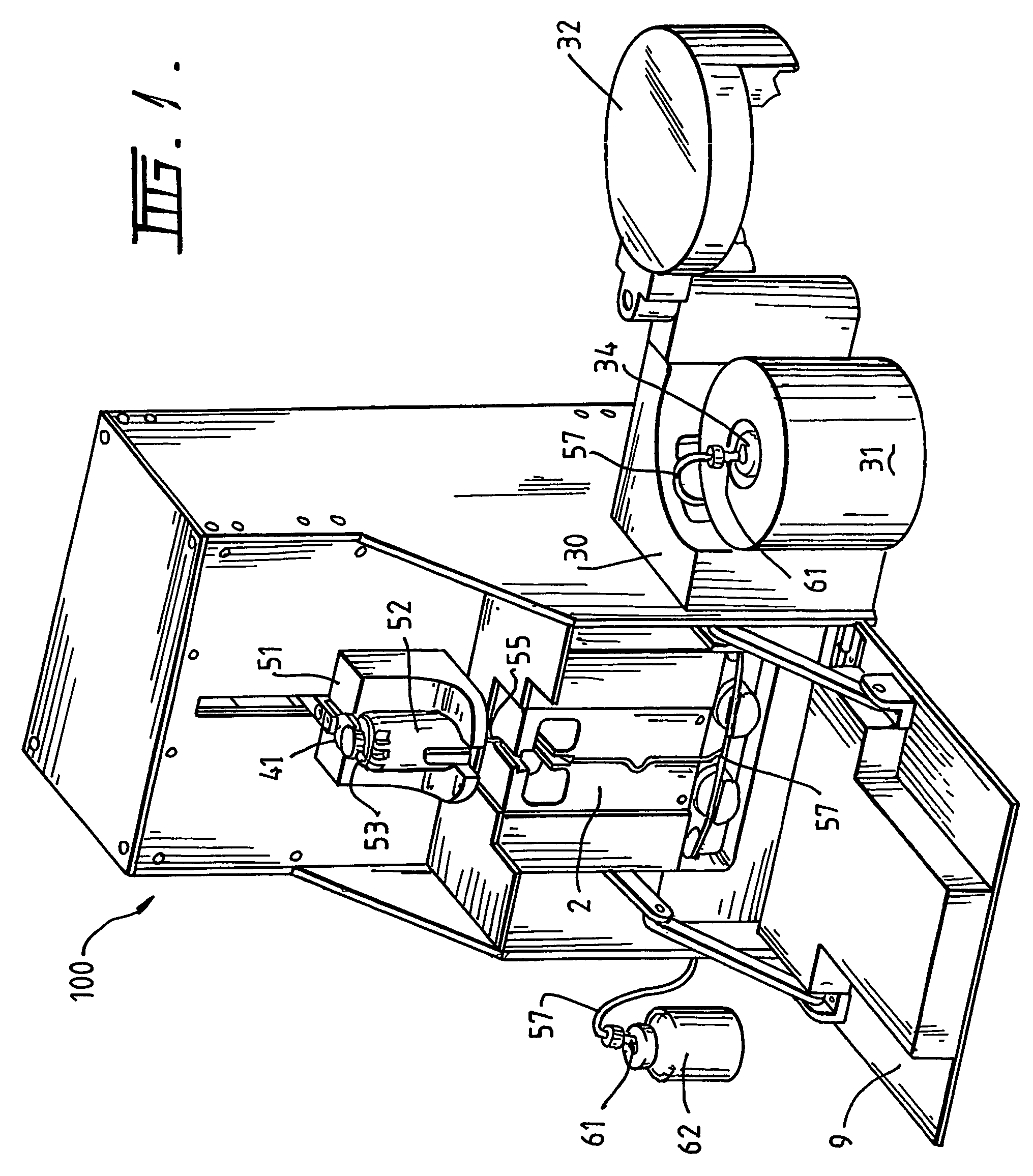

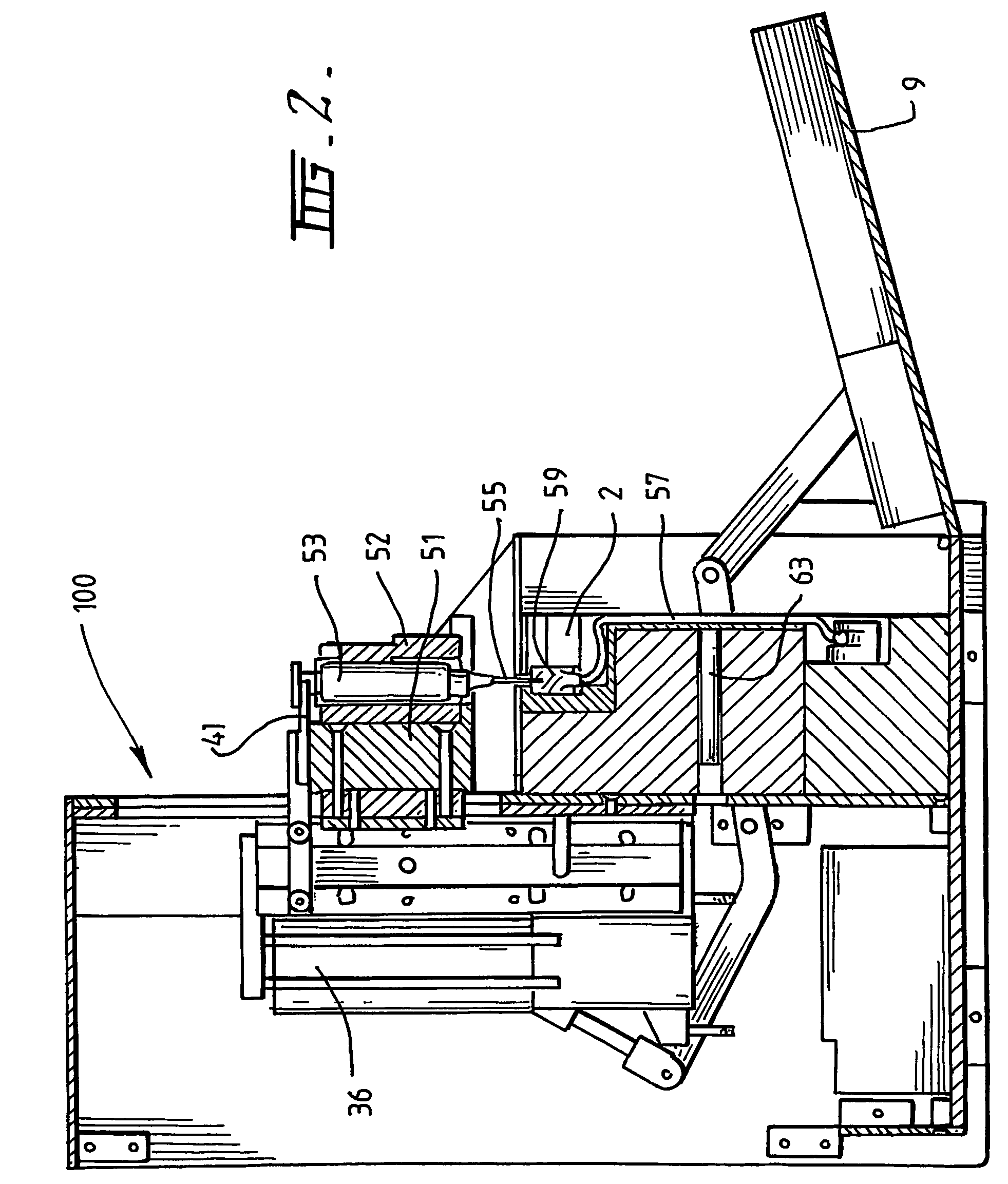

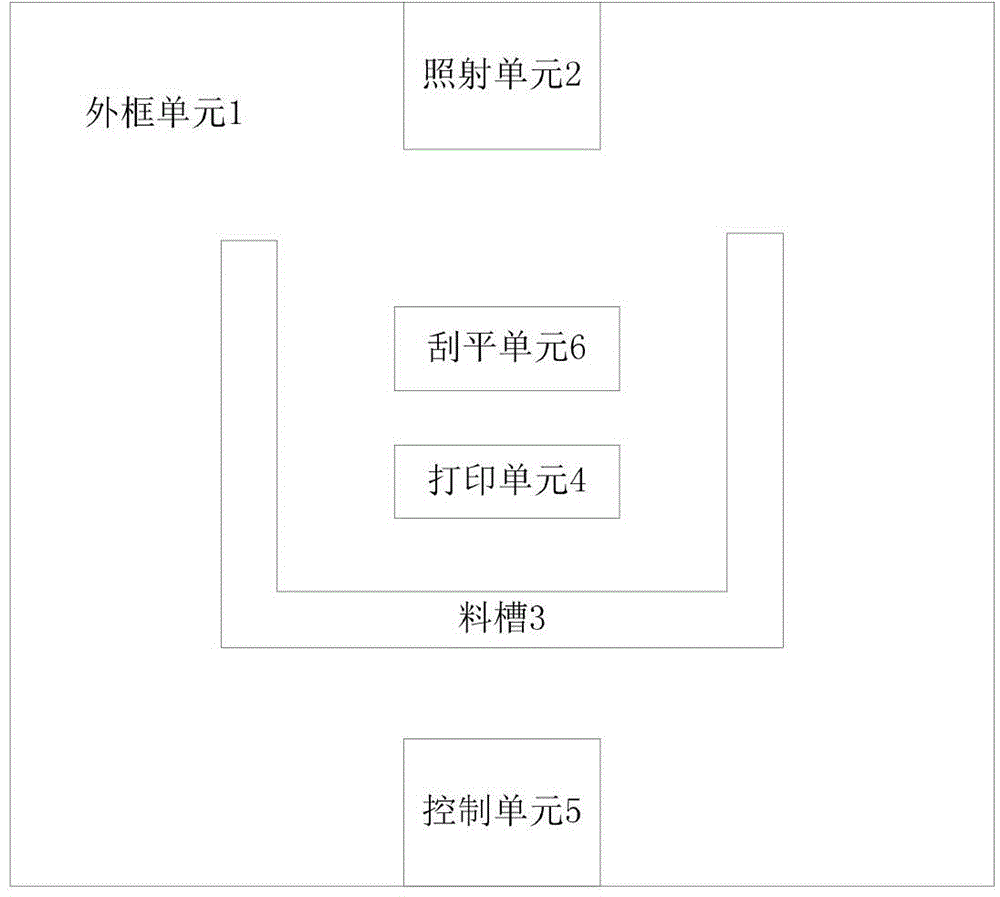

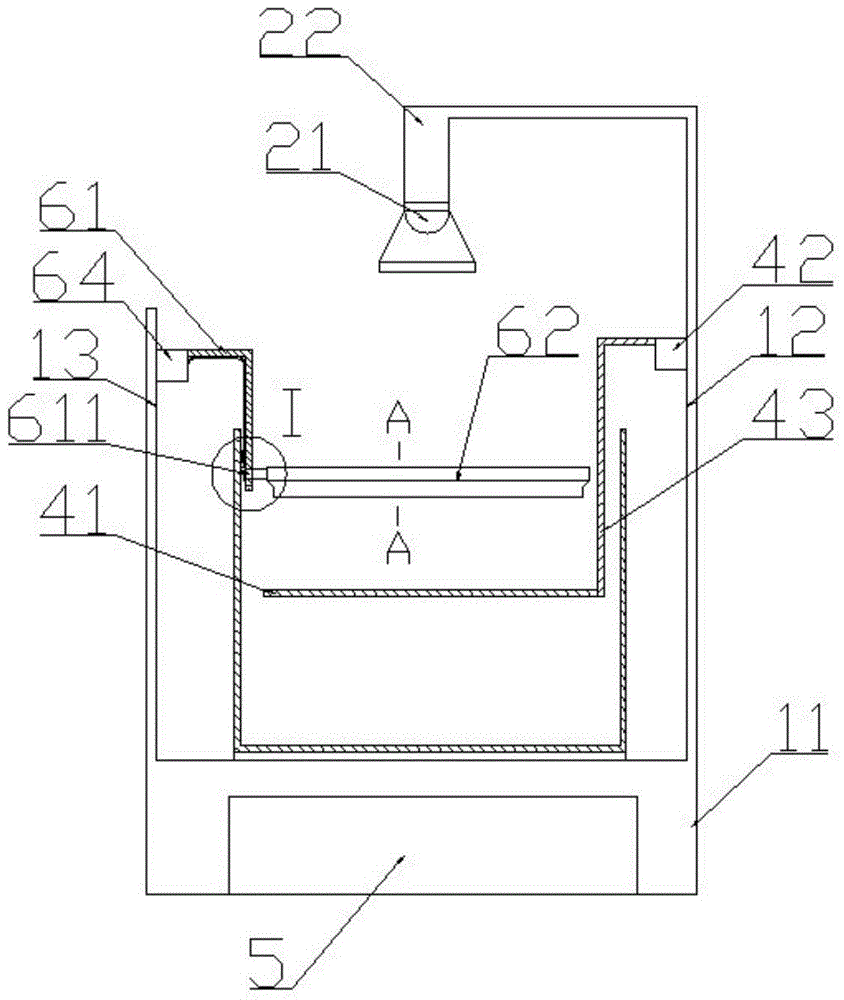

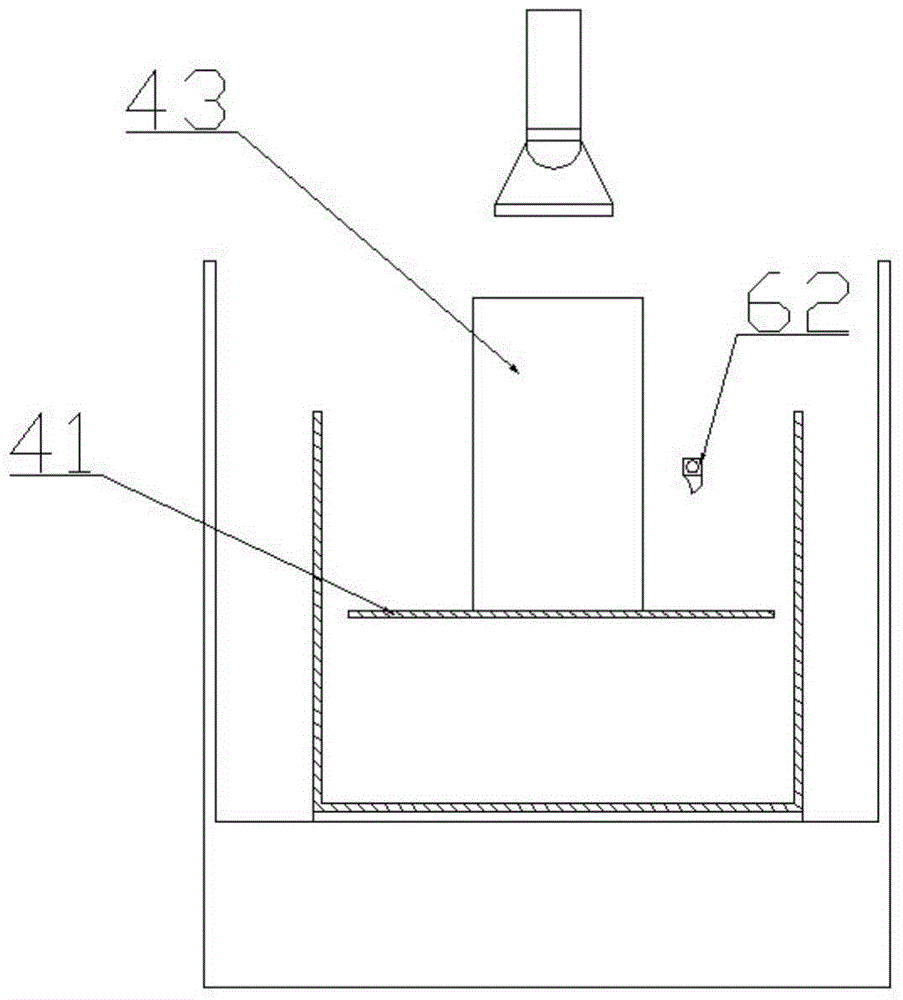

3D laser printer with leveling function and light-curing printing method thereof

InactiveCN104527065AAvoid influenceExcellent printing surfaceAdditive manufacturing apparatusScraping - actionReciprocating motion

The invention discloses a 3D laser printer with a leveling function. The printer comprises an outer frame unit, a trough, a printing unit, an irradiation unit, a leveling unit and a control unit, wherein the outer frame unit is used for forming a low-cost framework; the trough is used for containing a printing stock solution; the printing unit can longitudinally move relative to the outer frame unit and is positioned at an operation station in the trough; the irradiation unit is used for providing a light-curing laser light source; the leveling unit is positioned between the printing unit and the irradiation unit and is used for leveling the printing surface; the control unit is used for controlling the operating state of each unit; and the leveling unit can longitudinally move, a leveling plate arranged on the leveling unit can horizontally and transversely move in the trough, and the scraping action and leveling action can be simultaneously finished in a reciprocating motion. The invention also discloses a light curing printing method suitable for the 3D printer. The printer disclosed by the invention is stable in printing and high in precision, the levelness of each section is well controlled, and the overall printing deformation rate is low.

Owner:NINGBO HI TECH ZONE TAIBO TECH CO LTD

Improved preparation of cellulose spinning solution with ion liquid as solvent

InactiveCN101476166AImprove solubilityReduced gel particle contentArtificial filaments from cellulose solutionsSpinning solutions preparationApparent viscosityDistillation

The invention provides a method for preparing an improved fibrino spinning original solution that ion liquid is used as solvent, which includes: two phases of swelling and dissolution, namely, placing dried fibrino dissolving pulp and 1-butyl-3-methyl imidazole villaumite with 1%-20% water ratio into a dissolution device for uniform mixing, firstly, leaving and swelling in 70-100 DEG. C, then stronger stirring for swelling to plasm shape without dissolution; secondly, raising temperature to 80-125 DEG. C slowly in stirring state, stirring and reducing pressure distillation for removing water component, fibrino can be dissolved completely after 2-8h; finally, reducing stirring speed, and reducing temperature of plasm to 90-100 DEG. C and keeping 30-60 min for obtaining straw yellow spinning original solution. The method provided by the invention has advantages that the spinning original solution is more uniform, dissolution is more fully, gelatin particle in the spinning original solution is reduced, the spinning original solution quality is increased; apparent viscosity of the spinning original solution is reduced, accordingly, solid content in the spinning original solution is increased further.

Owner:DONGHUA UNIV

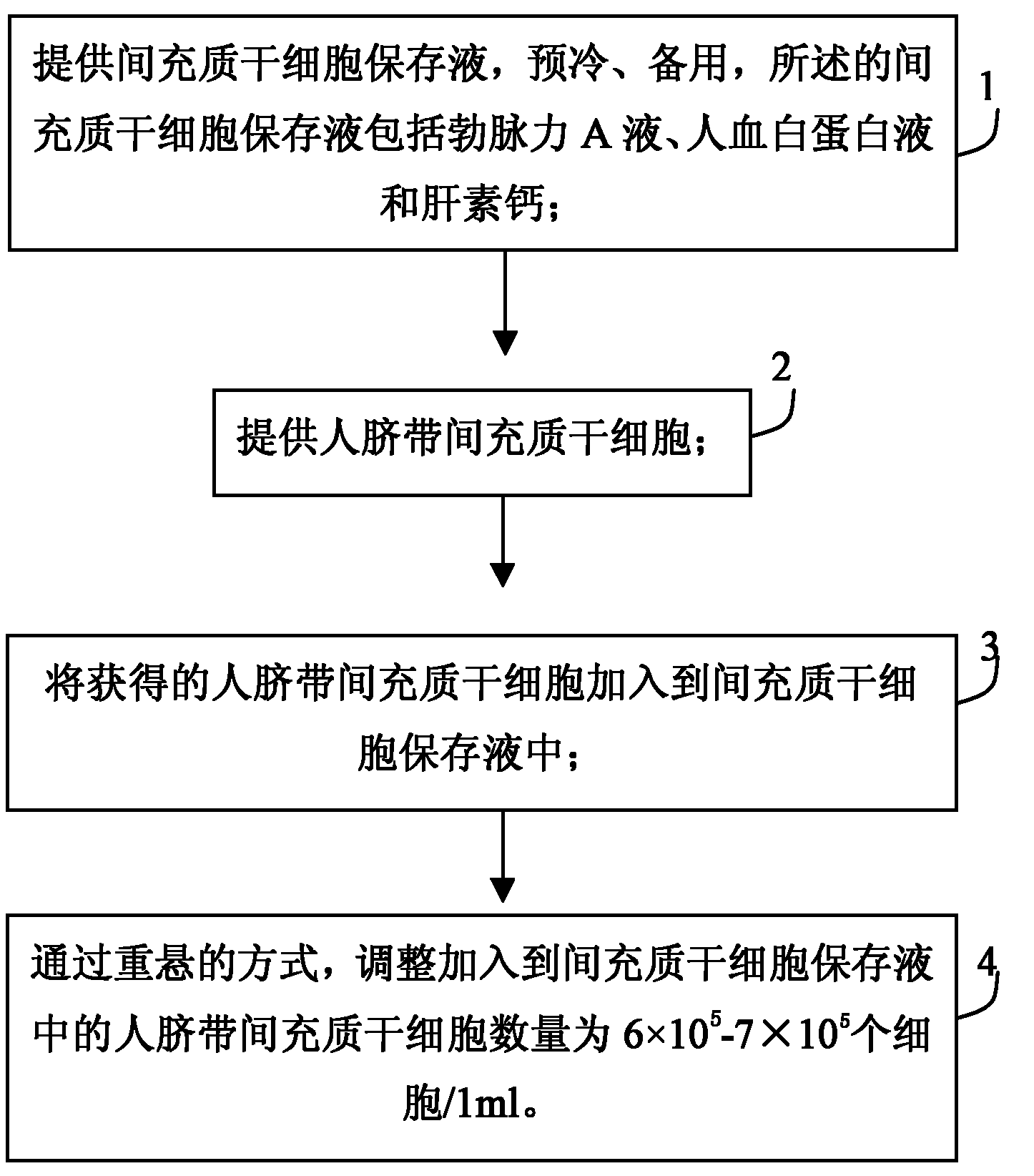

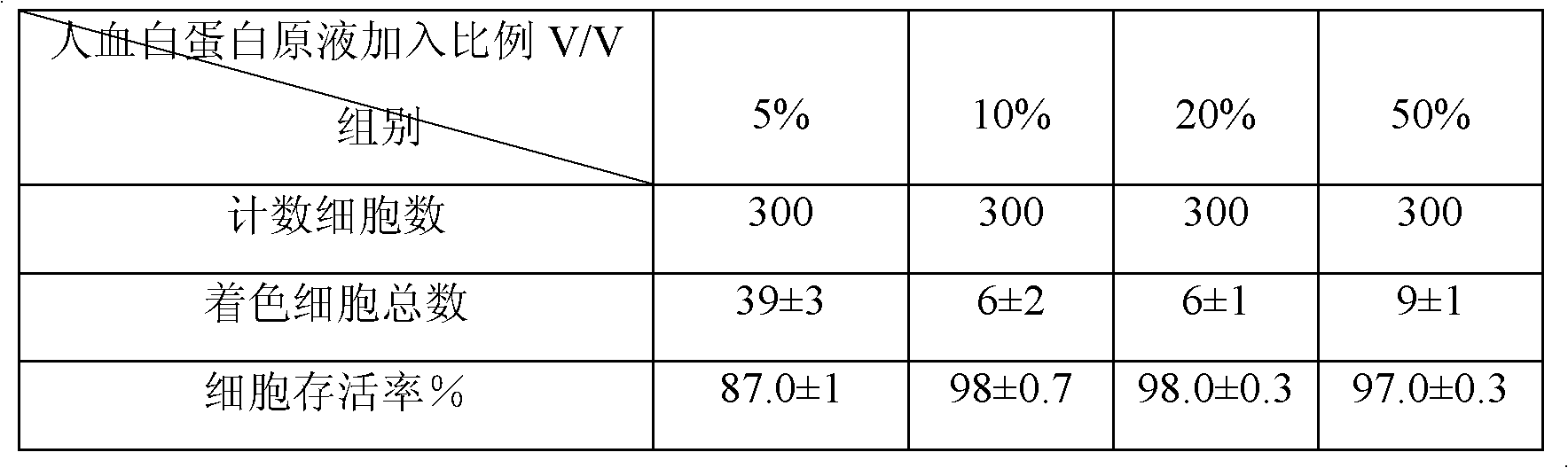

Human umbilical cord mesenchymal stem cell (HUMSC) anti-hepatic fibrosis injection and preparation method thereof

ActiveCN102008507ALong shelf lifeRepair damageDigestive systemUnknown materialsRingers solutionMedicine

The invention discloses a human umbilical cord mesenchymal stem cell (HUMSC) anti-hepatic fibrosis injection and a preparation method thereof. The injection is composed of 10%-50% of human albumin stock solution, 49.5%-89.5% of acetated Ringer's solution and 0.5% of heparin calcium, wherein, the concentration of the human albumin stock solution is 10%, and 1ml of the injection contains 6*10<5>-7*10<5> HUMSCs. The preparation method comprises the following steps: providing an MSC preserving fluid and pre-cooling the MSC preserving fluid for later use, wherein, the MSC preserving fluid comprises the human albumin stock solution, the Acetated Ringer's solution and the heparin calcium; providing the HUMSCs and adding the HUMSCs to the MSC preserving fluid; and adjusting the number of the HUMSCs added to the MSC preserving fluid to be 6*10<5>-7*10<5> HUMSCs / ml by means of re-suspending. The injection provided by the invention has the advantages of obvious curative effect and high stability, and is convenient in storage and transport and safe in use, thus being capable of bringing gospel to patients with hepatic fibrosis.

Owner:中源协和生物细胞存储服务(天津)有限公司

Green tea-sorghum crispy rice

InactiveCN103583997AStrong tea aromaUnique tasteNatural extract food ingredientsFood ingredient functionsGreen teasSorghum

The invention relates to the technical field of foods, in particular to a green tea-sorghum crispy rice which is prepared by the following raw materials in percentage by weight: 30 to 50 percent of sorghum, 20 to 40 percent of wheat, 3 to 5 percent of green tea leaves, 1 to 5 percent of green tea powder, 1 to 5 percent of dairy salt, 1 to 5 percent of chicken powder, 0.05 to 0.1 percent of sorbic acid, and 5 to 10 percent of water; the green tea-sorghum crispy rice is prepared by the following steps: (1), soaking for 15 to 30 minutes after green tea leaves are added into water and boiled, cooling, and filtering for removing the leaves and keeping a stock solution; (2), grinding the 30 to 50 percent of sorghum and 20 to 30 percent of wheat into powder, then blending by using the stock solution obtained in the step (1), adding the dairy salt, the chicken powder and the sorbic acid during the blending process, and finally preparing for obtaining a dough; (3), pressing into thin sheets by using a die, spreading the green tea powder onto the thin sheets, finally baking inside a baking oven at the temperature ranging from 210 GEG C to 230 DEG C for 5 to 10 minutes, and adopting a vacuum plastic bag for packaging. The green tea-sorghum crispy rice produced by the method in the invention, has a strong tea perfume, is unique in taste and is full-flavoured.

Owner:SICHUAN LANYI TECH

Method for producing antimicrobial calcium alginate fiber

ActiveCN101381907AEvenly distributedImprove antibacterial propertiesAlginate artificial filamentsAbsorbent padsCalcium alginateMechanical property

The invention discloses a method for manufacturing an antimicrobial calcium alginate fibre. A sodium alginate is used as spinning stock solution; in a solidification bath containing an antimicrobial agent, the antimicrobial calcium alginate fibre is obtained by a wet-method spinning process; and the antimicrobial agent is a cationic compound which is combined with large molecules of the calcium alginate fibre through ionic bonds. The antimicrobial calcium alginate fibre obtained by the method has no toxicity and no side effect on human body; the antimicrobial agent and the large molecules of the fibre are combined by the ionic bonds in order that the antimicrobial agent has long-lasting antimicrobial function; in addition, the fibre retains the excellent quality of the calcium alginate fibre, has excellent hygroscopic property and good mechanical property, can be used for manufacturing medical dressings, has the advantages of convenient use, comfortable application and good ventilation, the acceleration of the healing of wound, the relieving of the pains of patients and the like, can be also used for manufacturing clothing and industrial textiles by pure spinning or blended spinning with cotton, mucilage glue, bamboo pulp, fur, ramie, soybean protein fibre and the like.

Owner:山东康康新材料科技有限公司

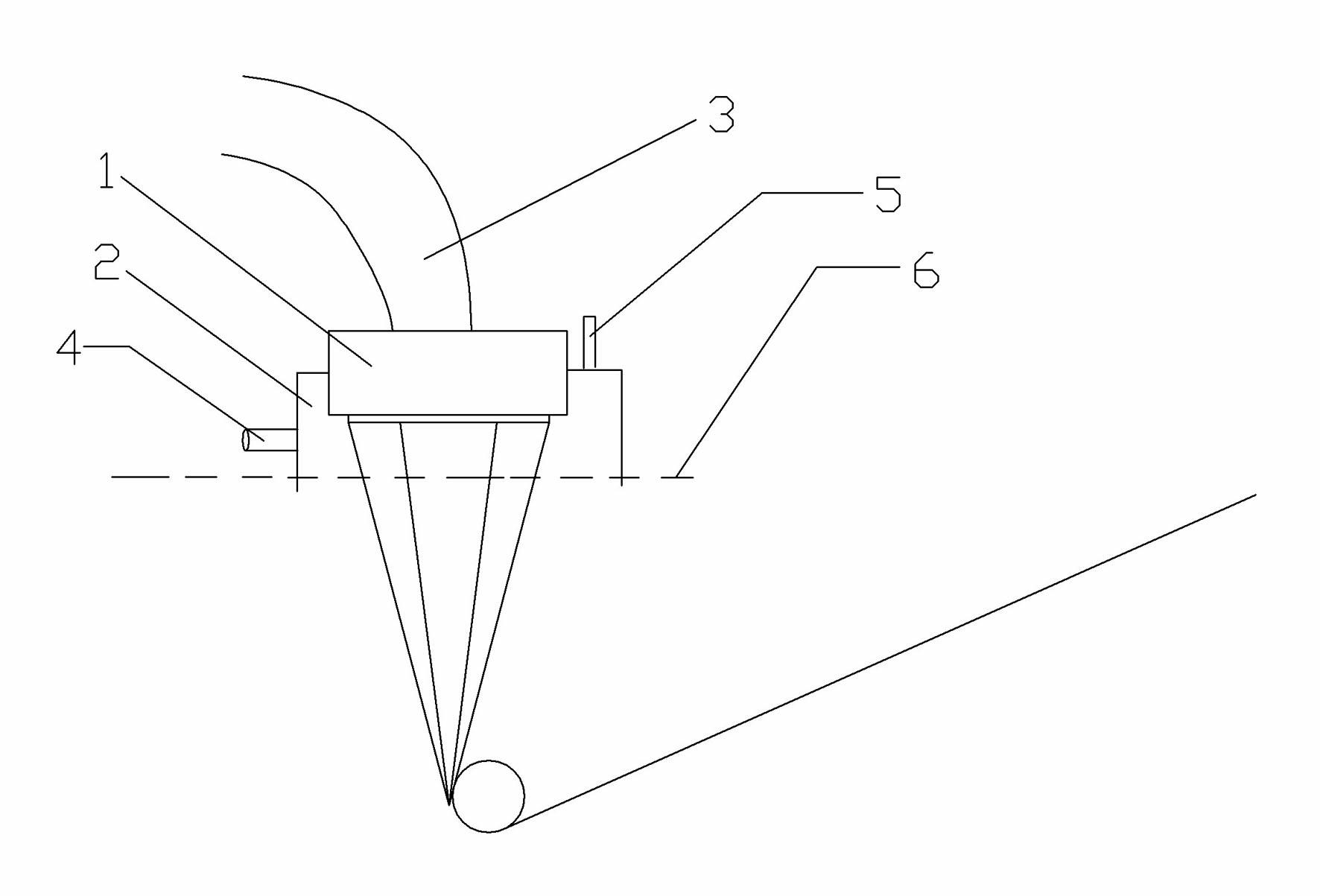

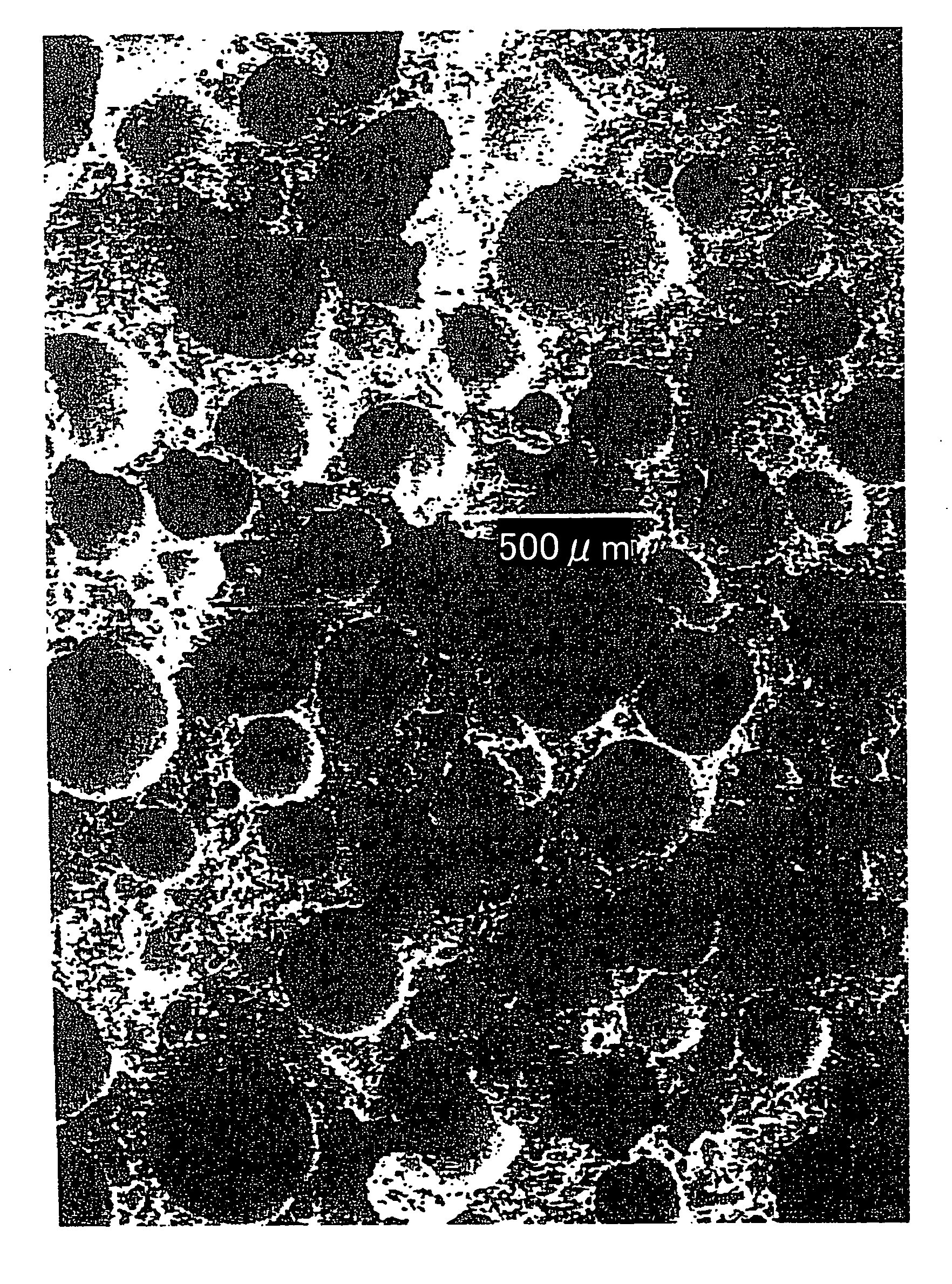

Biodegradable nerve conduit with bilayer structure and preparation method thereof

InactiveCN102085393APorosity can be adjustedAdjustable intensityFilament/thread formingTubular organ implantsFiberLactide

The invention relates to a biodegradable nerve conduit with a bilayer structure and a preparation method thereof. The biodegradable nerve conduit comprises a reticular monofilament liner which is made of polyglycollide-lactide (PLGA) and used as a framework structure and a nano fiber felt which is made of a biodegradable material and used as an outer layer structure. The preparation method comprises the following steps of: (1) preparing PLGA monofilaments by adopting a fused spinning method, stretching for orientating, and then weaving into a reticular liner conduit; (2) dissolving the biodegradable material into an organic solvent to prepare a spinning stock solution with a mass fraction of 3-20 percent; and (3) carrying out electrostatic spinning by using the spinning stock solution on the surface of the reticular liner conduit by taking the reticular liner conduit as a receiving device to obtain the biodegradable nerve conduit. The biodegradable nerve conduit has good biocompatibility, proper degradation time and higher mechanical strength and can promote the regeneration and the restoration of damaged nerves. The preparation method has the advantages of simpleness of operation, low cost, environmental protection, high economic benefit and good application prospect.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com