Patents

Literature

368 results about "Diffusion tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

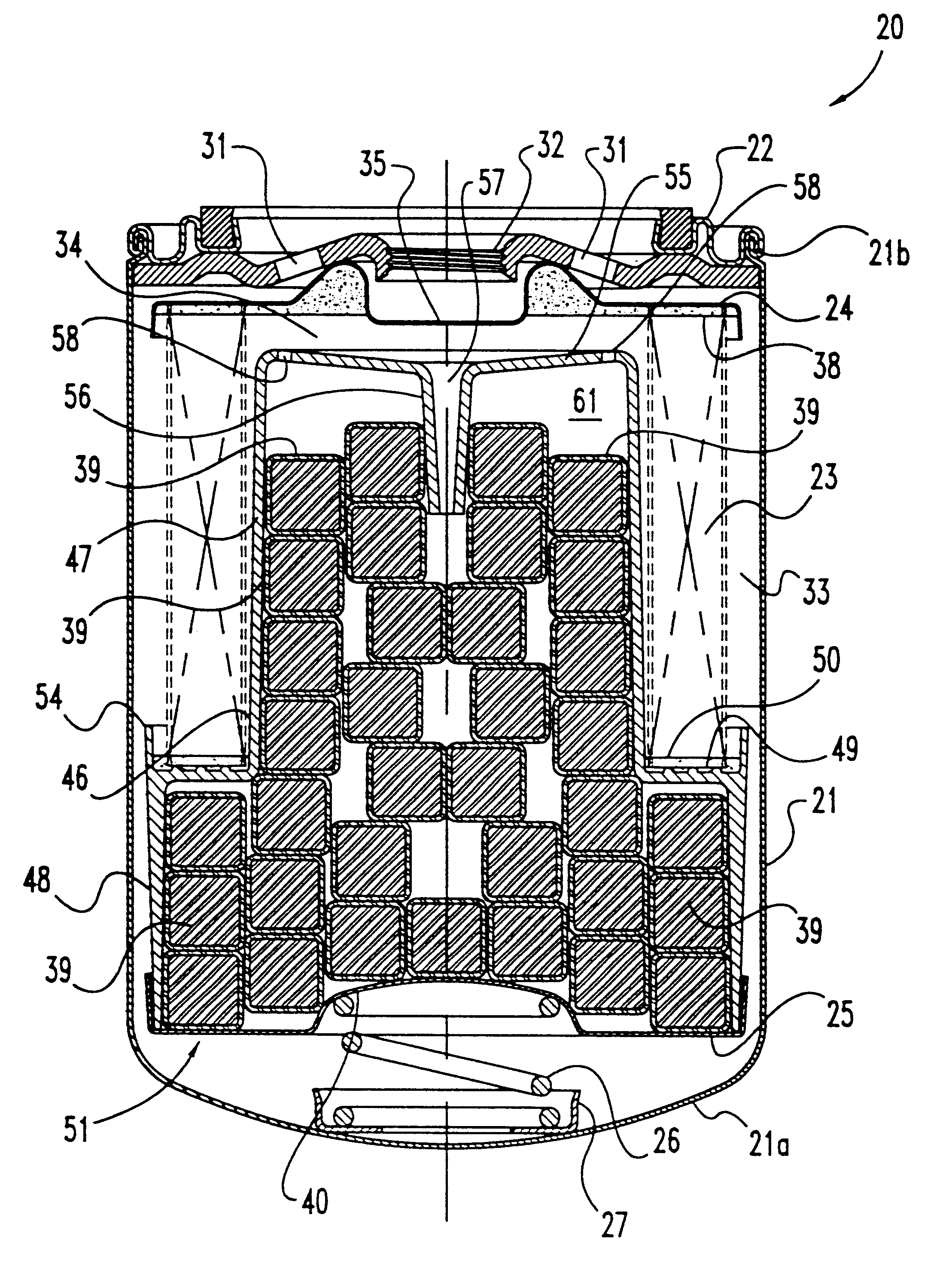

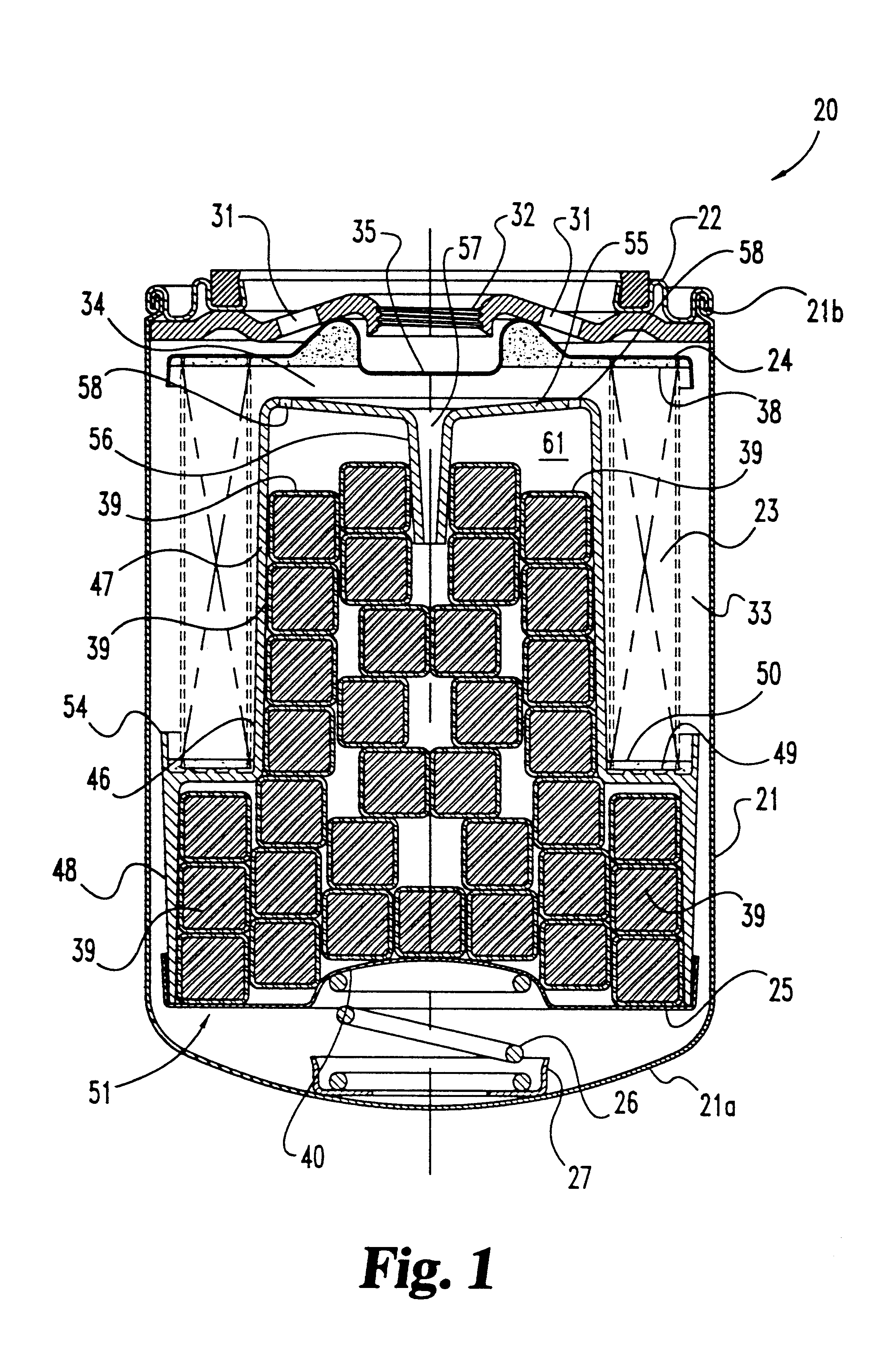

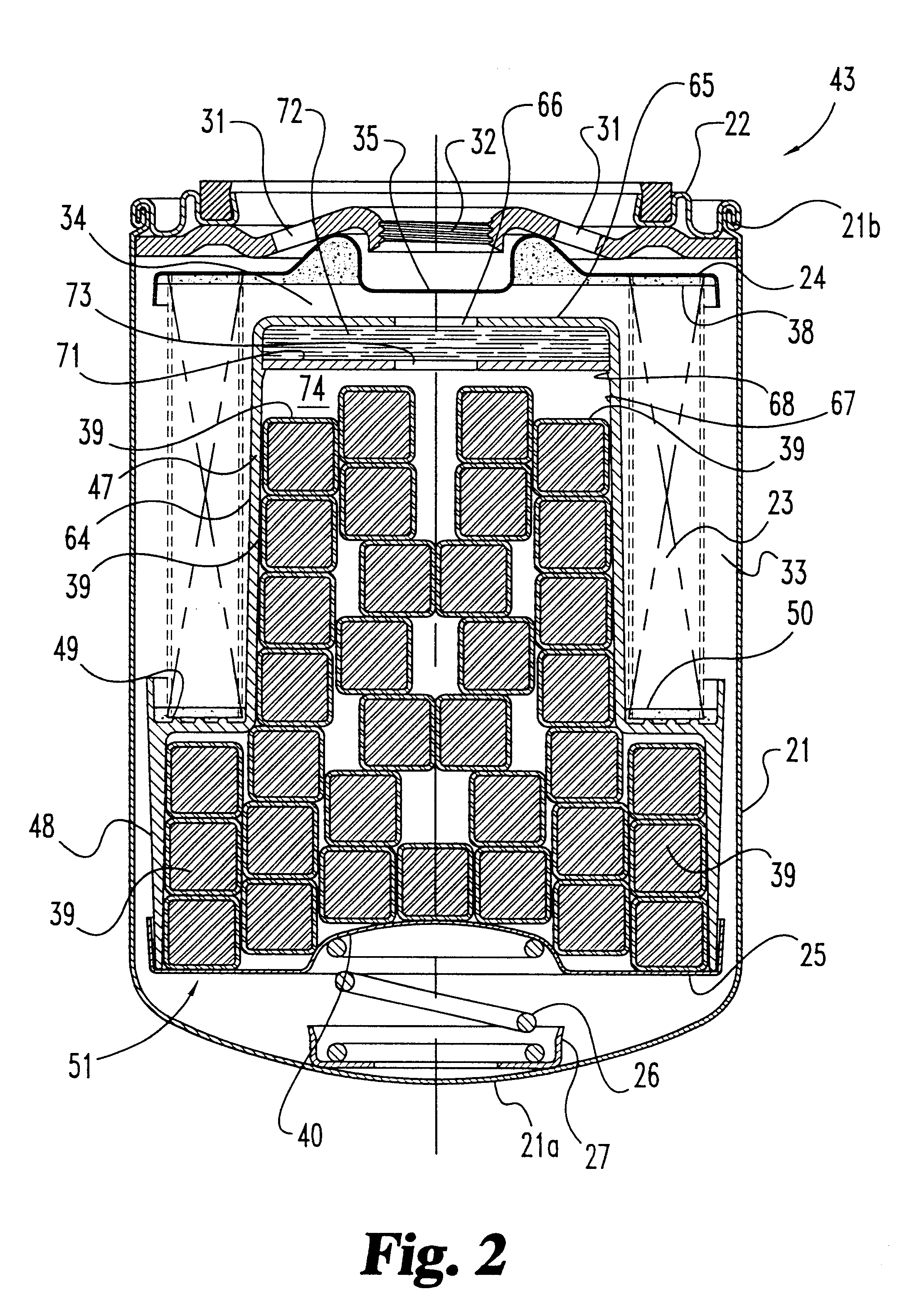

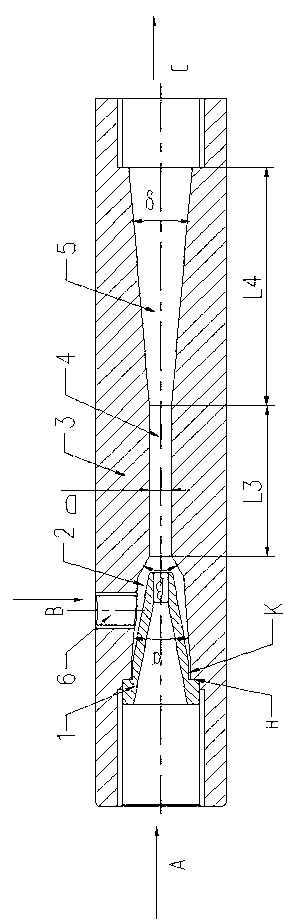

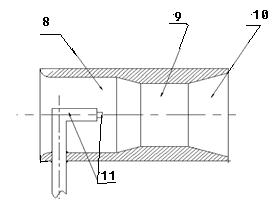

Slow release coolant filter

InactiveUSRE37369E1Transportation and packagingSolid sorbent liquid separationEngineeringCooling fluid

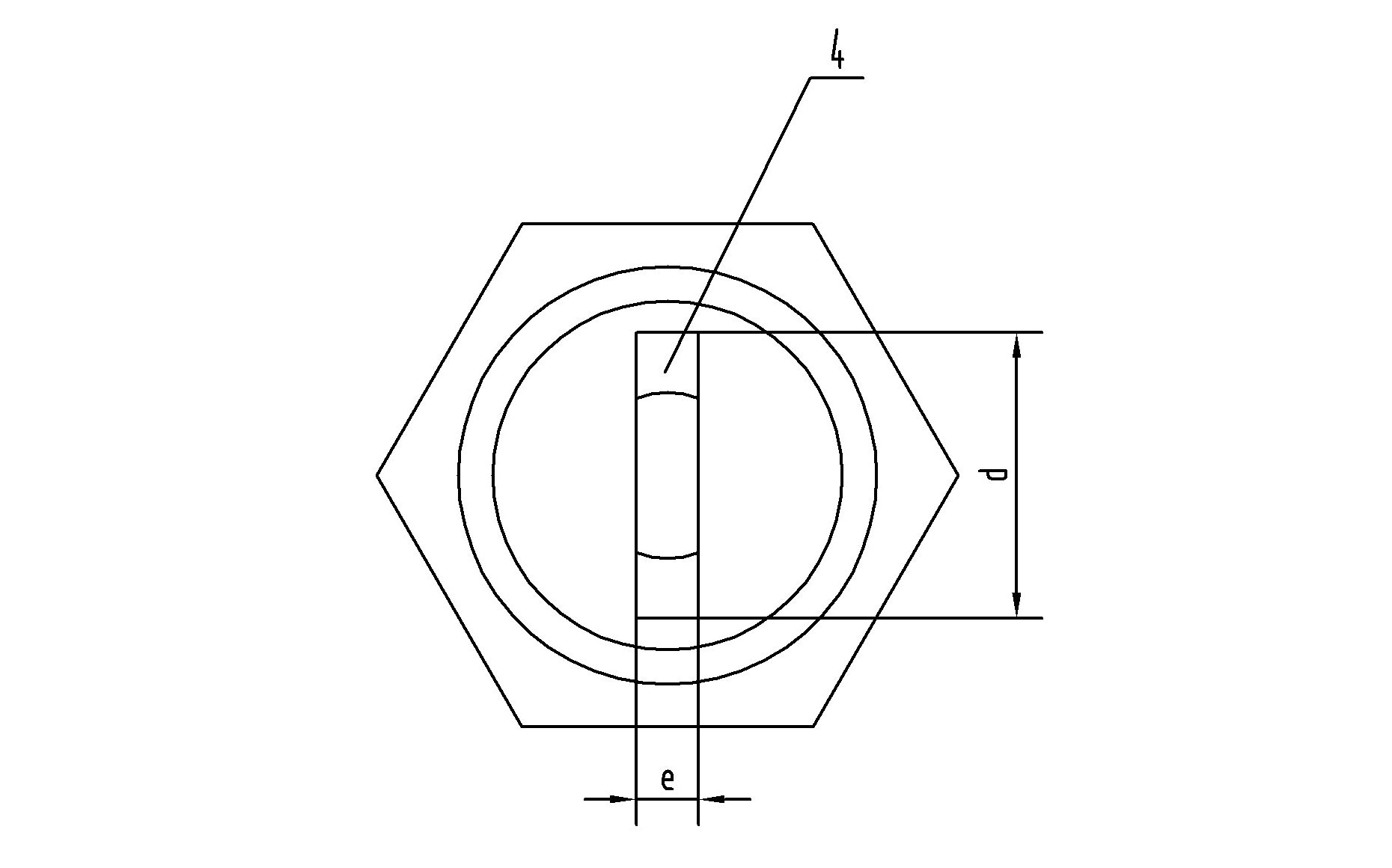

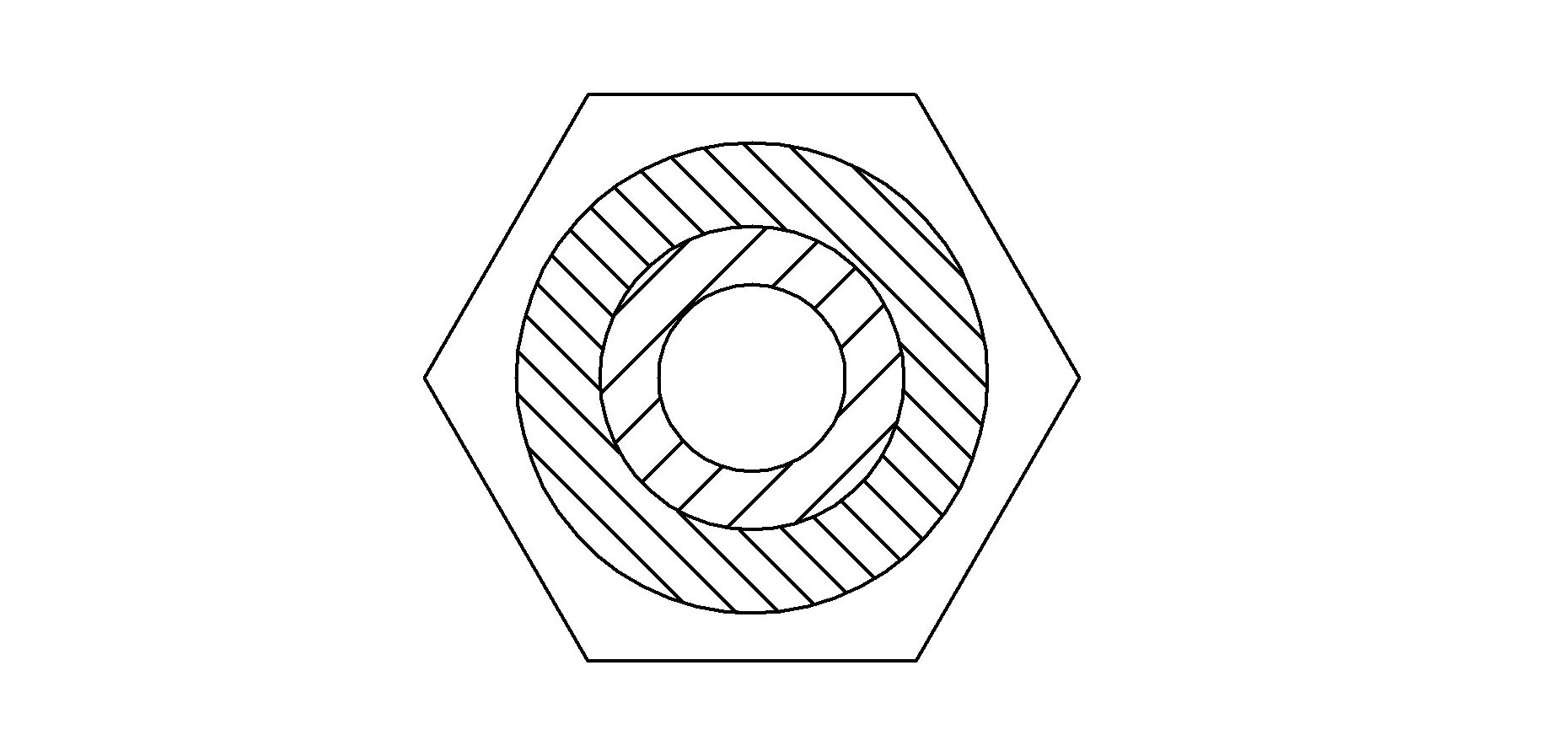

A coolant filter for use in filtering a coolant solution which flows through the coolant filter includes a filter housing assembly which is made up of an outer housing which is crimped to a nutplate which defines an internally threaded flow outlet. A generally cylindrical filter element is positioned inside of the filter housing assembly and a first endplate is bonded to the end of the filter element which is adjacent to the nutplate. An endplate member is provided for attachment to the opposite end of the filter element and is configured in such a way so as to define an interior chamber where supplemental coolant additive pellets are stored. A closing plate is applied across the open end of the interior chamber so as to create an enclosed chamber for the supplemental coolant additive pellets. A slow release mechanism is provided for controlling the rate of release of the supplemental coolant additive from the enclosed chamber into the coolant solution. In one embodiment of the present invention, the slow release mechanism includes a diffusion tube which defines a diffusion orifice. In another embodiment of the present invention, the slow release mechanism includes a semipermeable (or osmotic) membrane wafer. In both instances, the slow release mechanism is positioned between the source of supplemental coolant additive and the flow outlet in the nutplate.

Owner:FLEETGUARD INC

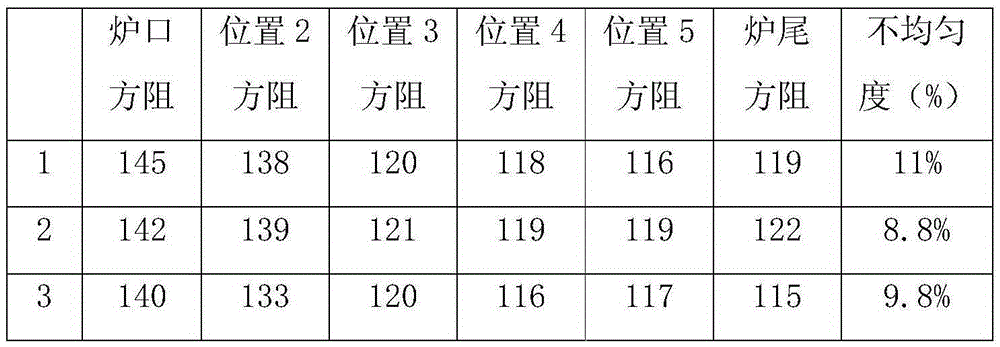

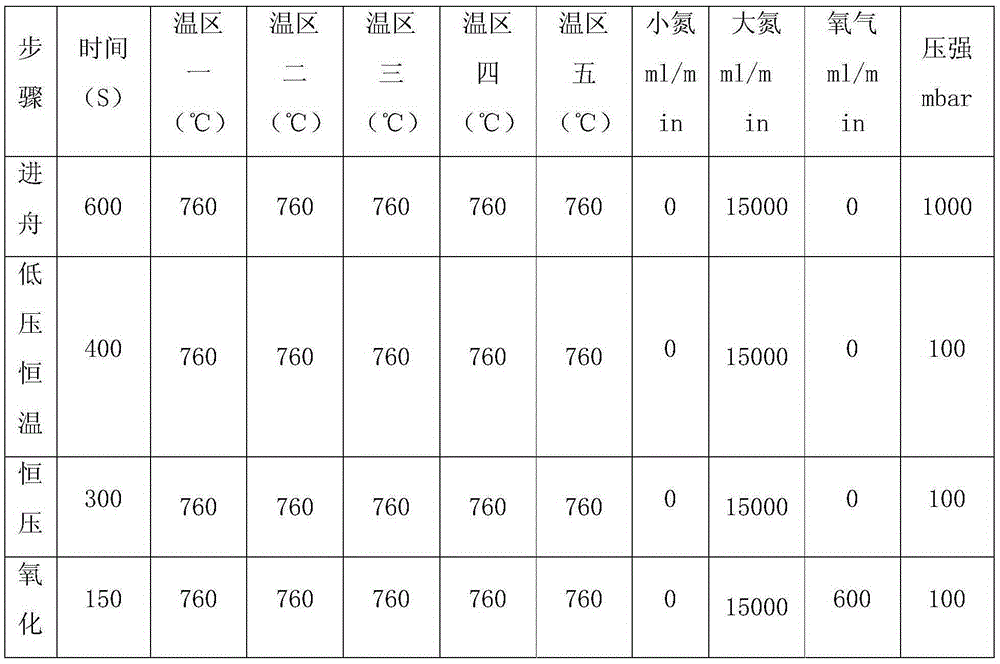

Low-pressure diffusion technology for crystalline silicon cell

ActiveCN105261670AIncrease chance of contactImprove uniformityFinal product manufactureSemiconductor/solid-state device manufacturingDiffusion methodsInternal pressure

The invention discloses a low-pressure diffusion technology for a crystalline silicon cell. The technology comprises the following steps: (1) a high-temperature oxidation before diffusion; (2) a low-pressure diffusion, namely preparing a PN knot by a sub-step diffusion method; and (3) annealing, namely changing internal pressure to remove impurities. According to the low-pressure diffusion technology, the uniformity between diffusion sheets can be improved; the temperature of a temperature zone in a fire hole is lowered, namely the temperature uniformity of various temperature zones of a diffusion tube is improved; the problem of a great fluctuation of sheet resistance of the fire hole of a diffusion furnace is solved; the service lifetime of a vacuum pump is prolonged; and the production cost of a diffusion procedure is reduced.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

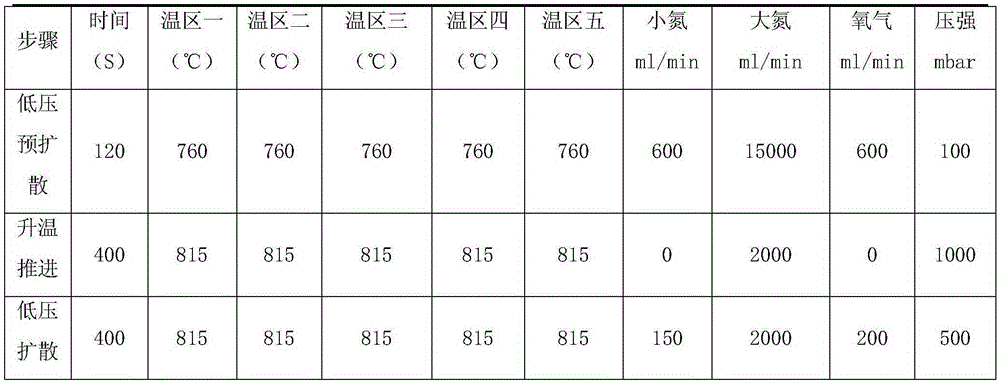

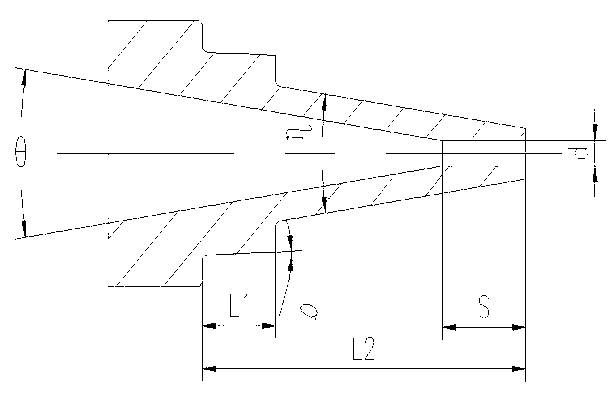

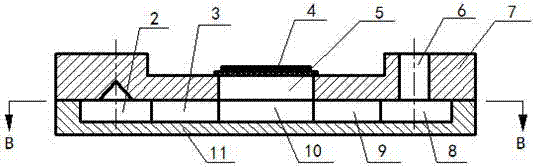

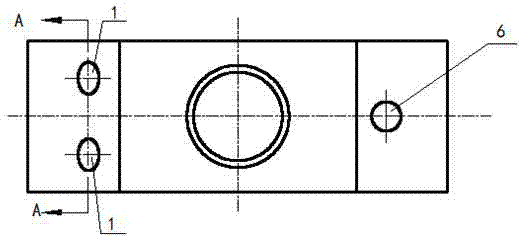

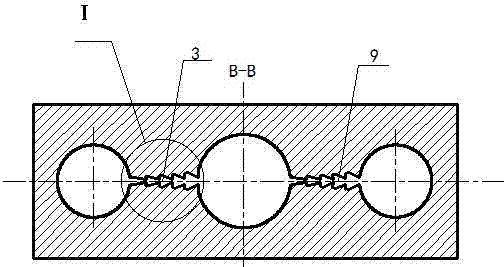

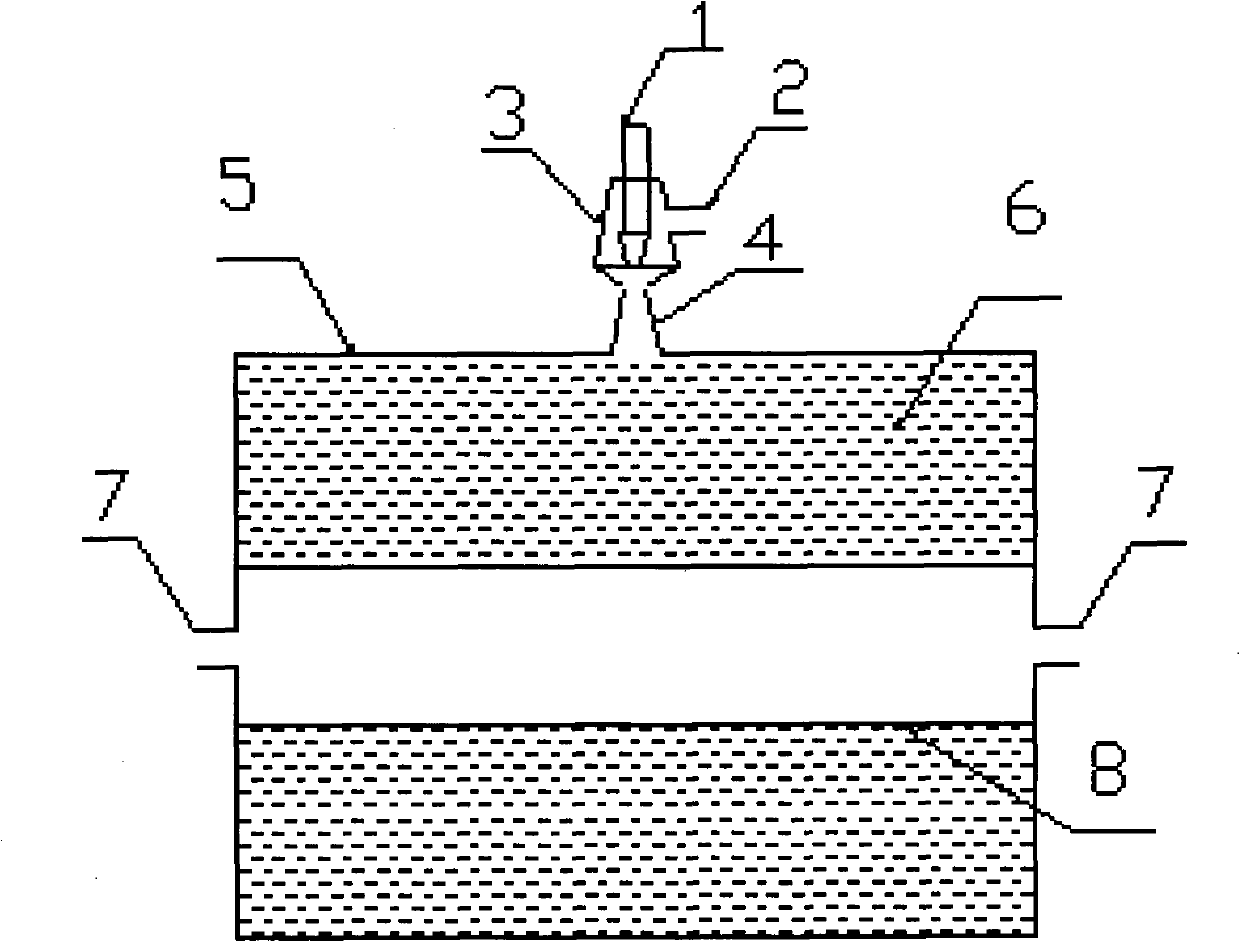

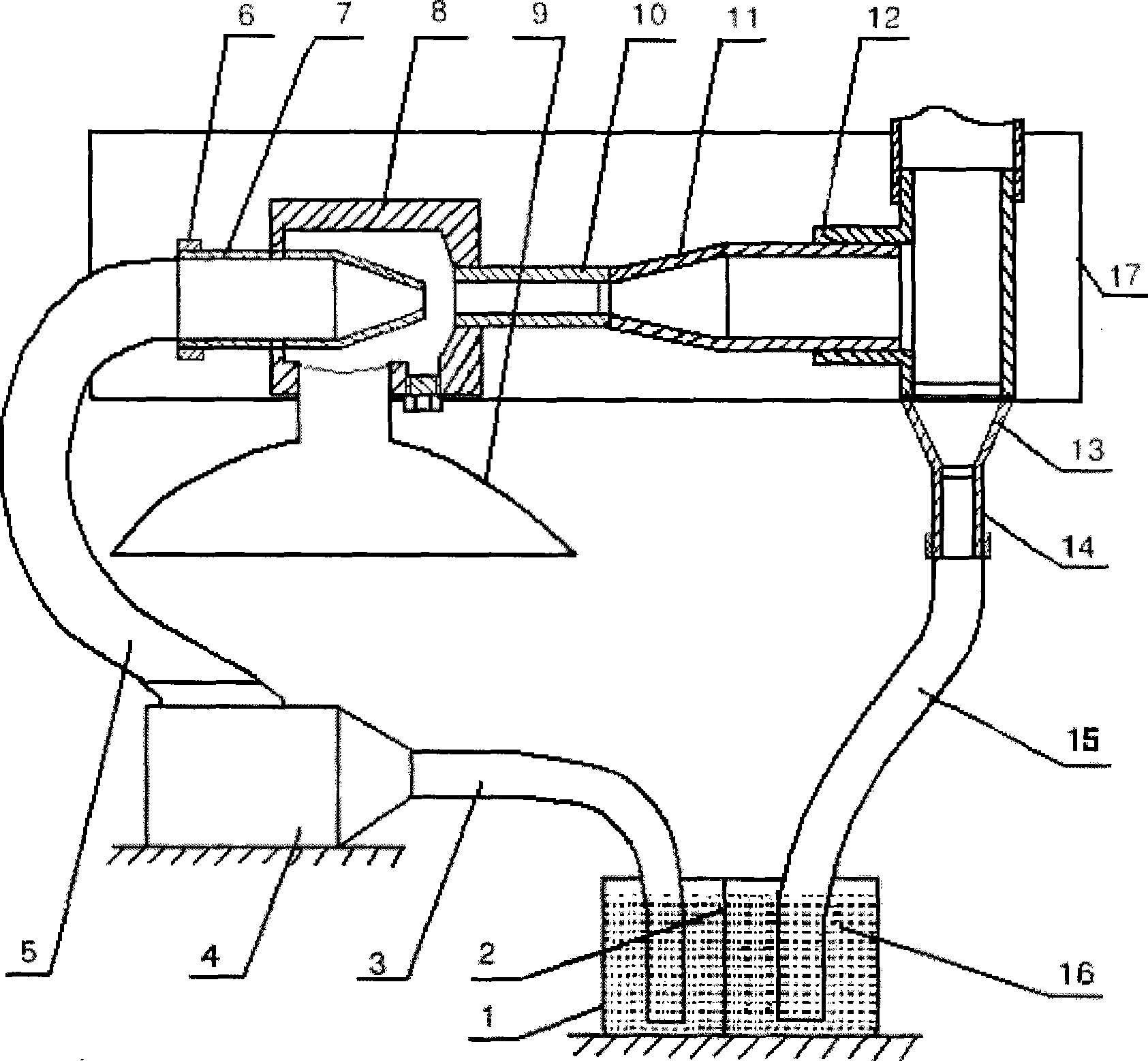

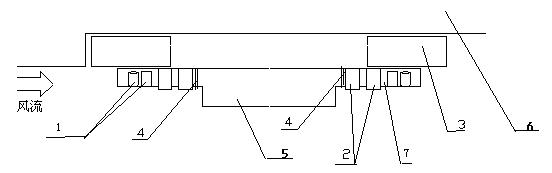

Automatic pesticide mixing device

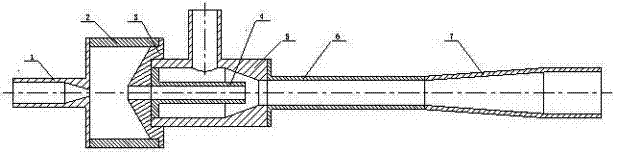

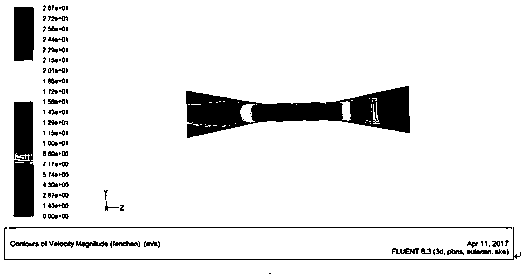

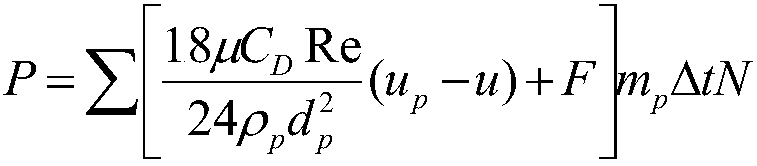

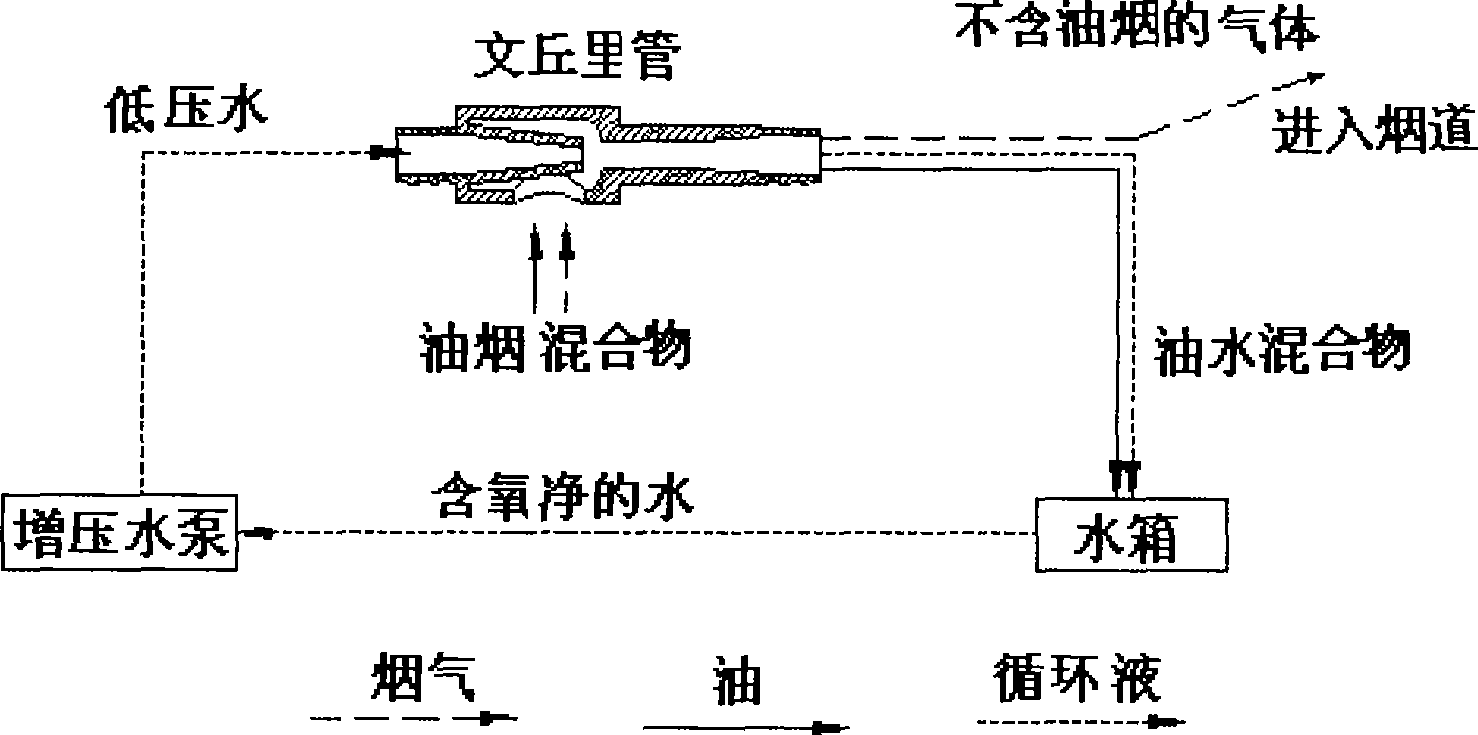

ActiveCN101816989ASmall structure sizeSave power sourceLiquid spraying apparatusInsect catchers and killersJet flowDiffusion tube

The invention relates to an automatic pesticide mixing device, in particular to a novel pesticide mixing device, which can separately store pesticide stock solution and water and rapidly and automatically uniformly mix the pesticide stock solution and the water and is applied to different pesticide-mixing working conditions. The automatic pesticide mixing device mainly comprises a jet flow part and a spiral part, wherein the jet flow part mainly comprises an adjusting gasket 1, a jet flow nozzle 2, a suction chamber 3, a suction inlet joint 4, a jet flow pesticide-mixing device main body 5, a mixing tube 6 and a diffusion tube 7; and the spiral part mainly comprises a spiral unit 8 and a spiral shell 9. In order to adapt to different working conditions, the jet flow nozzle 2, the suction inlet joint 4 and the spiral unit 8 are designed into a detachable and replaceable form. The automatic pesticide mixing device separately stores the pesticide stock solution and the water, rapidly and automatically uniformly mixes the pesticide stock solution and the water, and is suitable for various pesticide-mixing working conditions.

Owner:JIANGSU UNIV

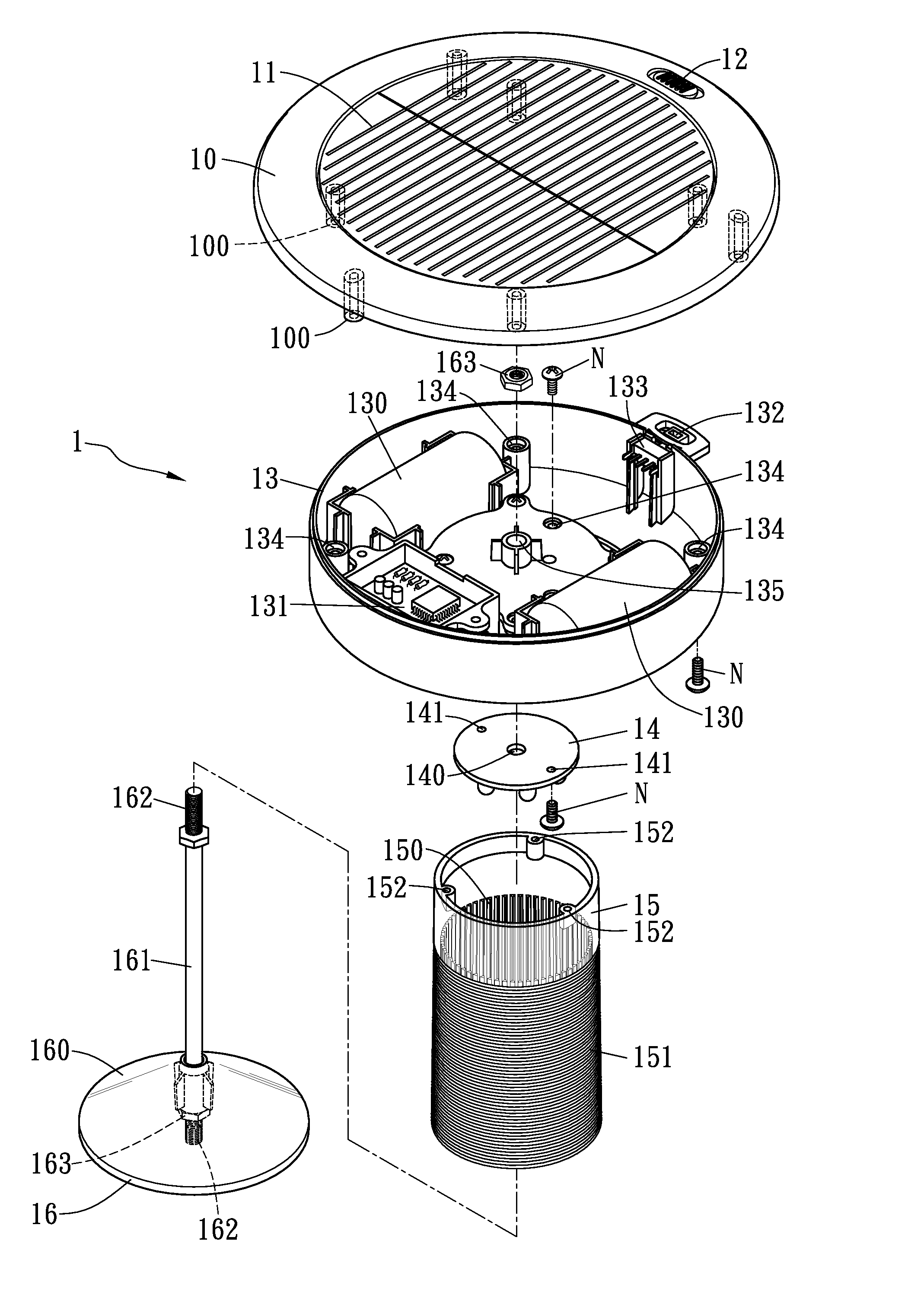

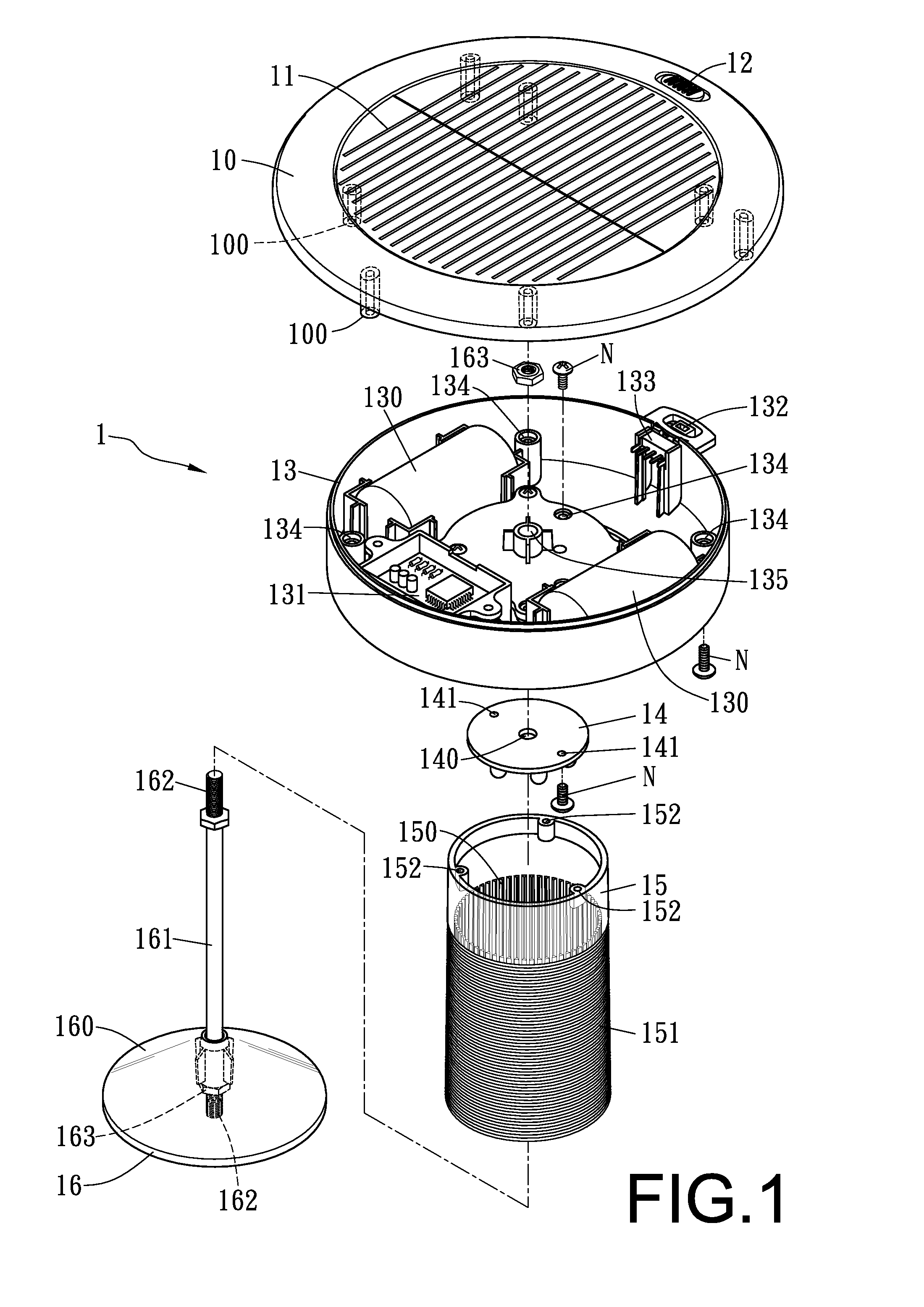

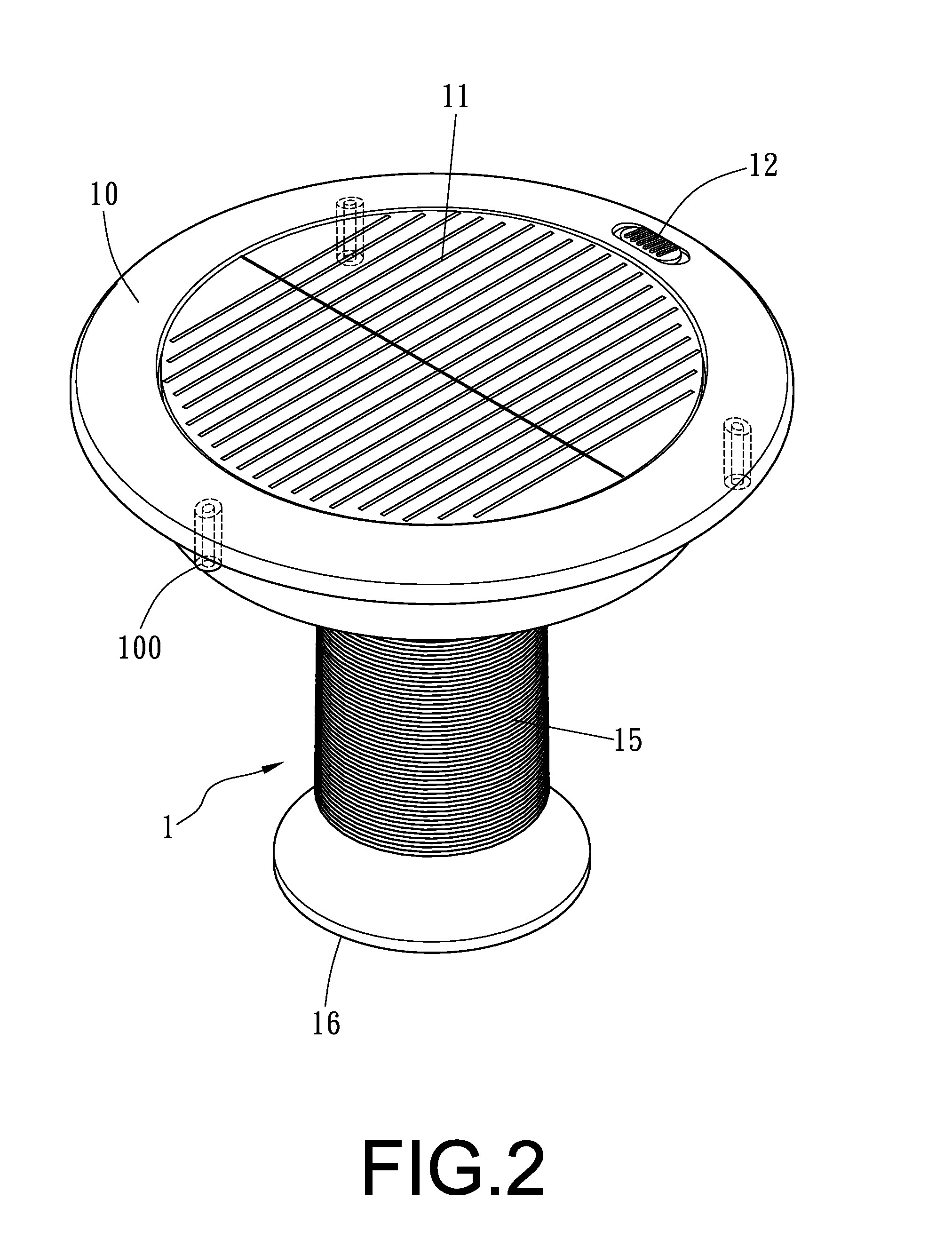

Solar lamp

A solar lamp includes a supporting board for being loaded with a solar panel, a lower shell, an LED board, a light diffusion tube and a reflecting base. The lower shell is fixed under the supporting board, having a battery and a circuit board. The LED board and the reflecting base are threadably engaged the lower shell. The light diffusion tube possesses refracting grooves on its wall. The reflecting base is positioned under the light diffusion tube by means of an adjustment rod. The solar lamp, able to convert sunlight into power energy without any wiring connection, can be easily assembled in any lamp base to create a great light diffusion via the alternate refraction of the refracting grooves and reflecting surfaces of the lower shell and the reflecting base.

Owner:WANG CHING HSIANG

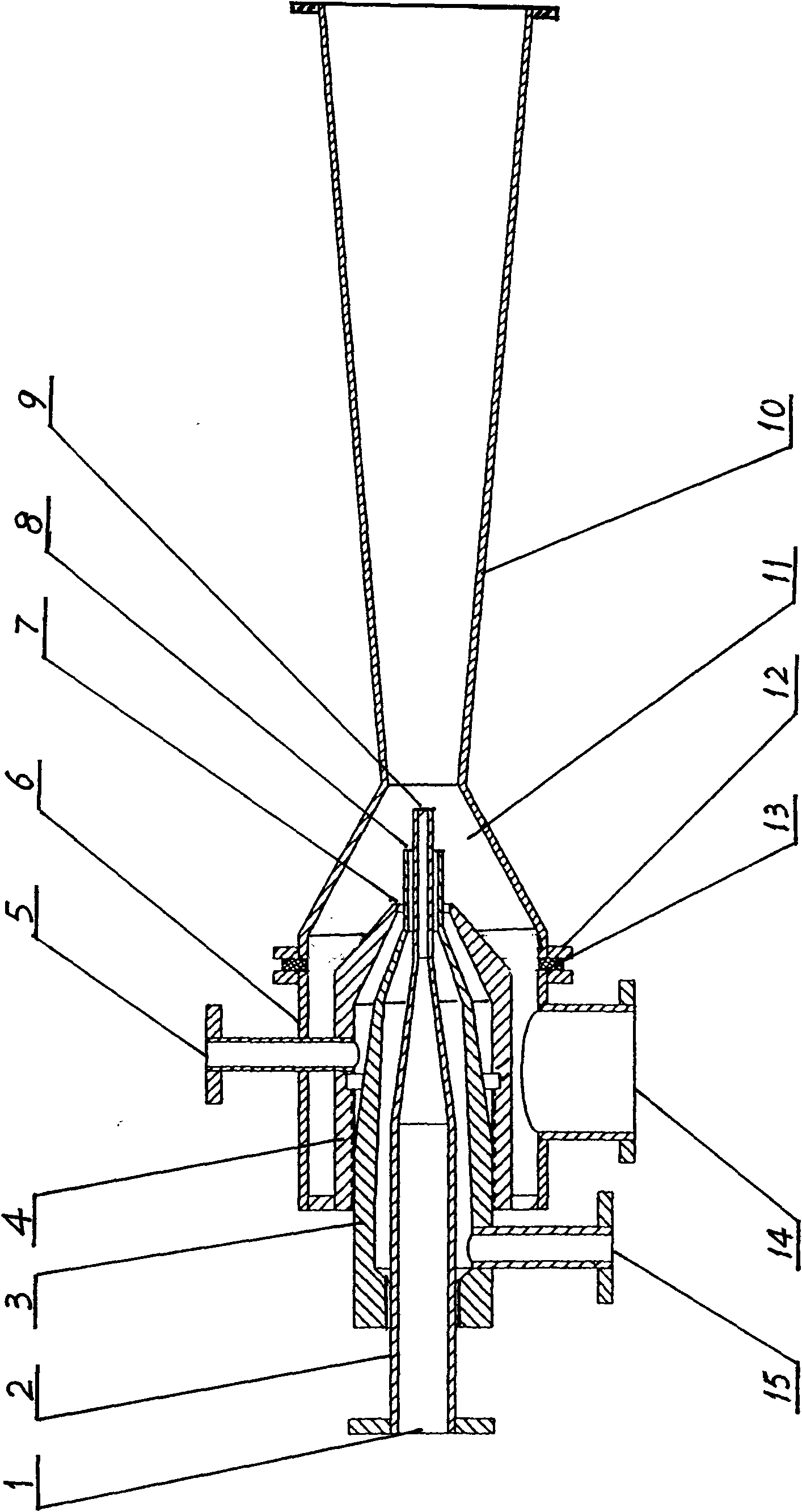

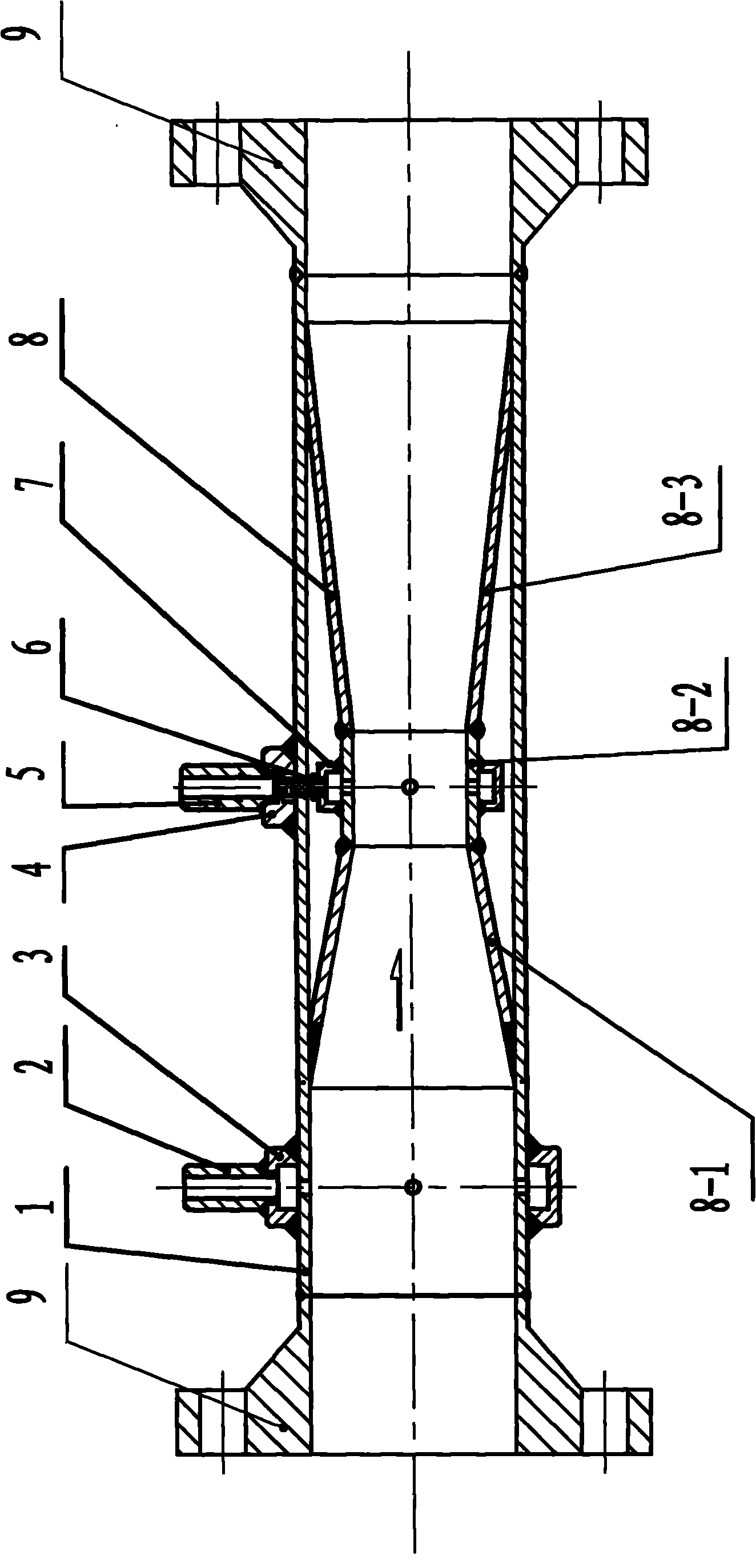

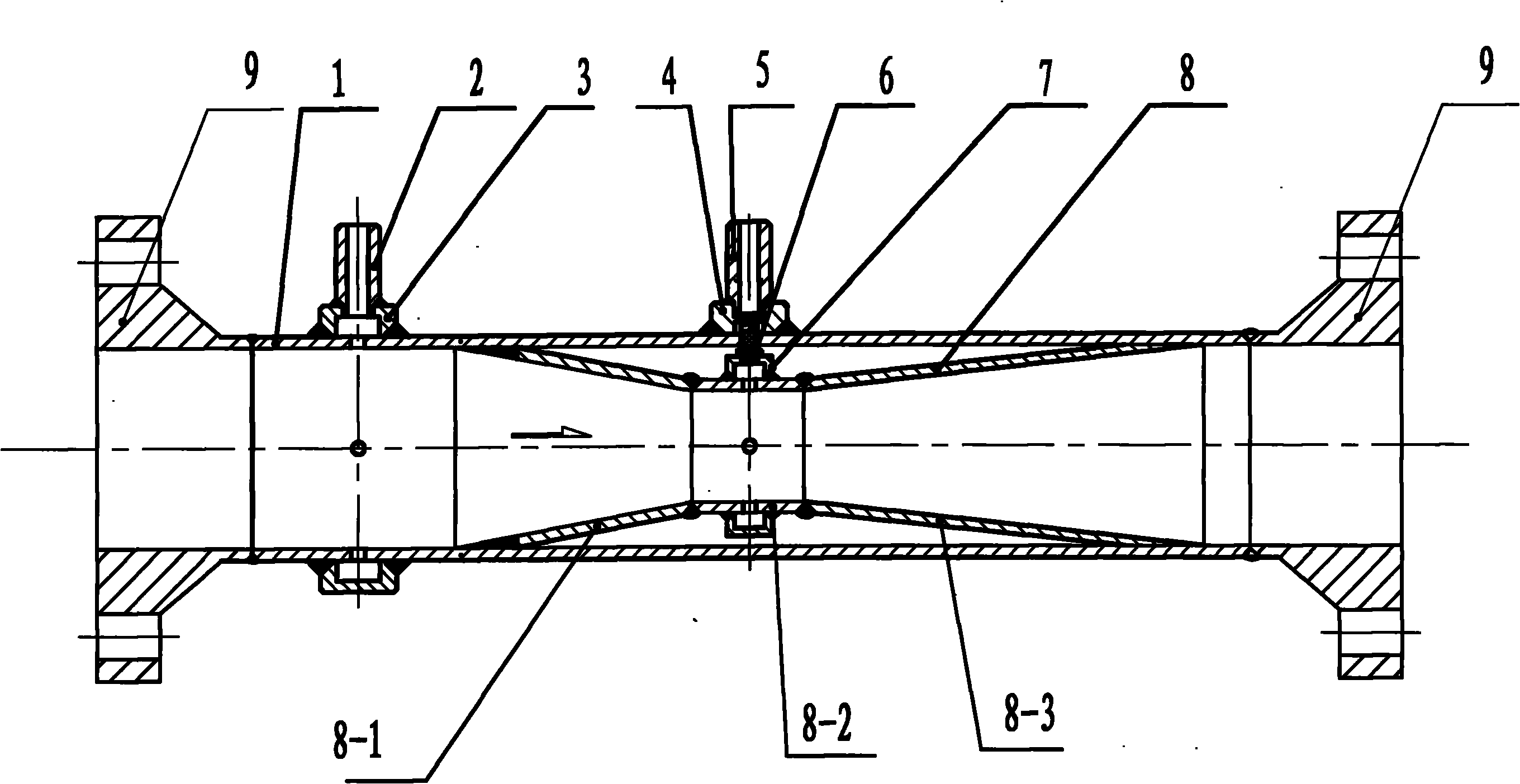

Self-oscillation pulsed liquid-gas jet pump

InactiveCN102865256AImprove Jet Pump EfficiencyWell mixedJet pumpsMachines/enginesSelf-oscillationSpray nozzle

The invention relates to a self-oscillation pulsed liquid-gas jet pump. The jet pump comprises an upper nozzle, a self-oscillation cavity, a collision body, a lower nozzle, a suction chamber, a throat pipe and a diffusion tube, wherein the upper nozzle, the self-oscillation cavity, the collision body and the lower nozzle are connected sequentially to form a self-oscillation pulsed jet nozzle; after passing through the self-oscillation pulsed jet nozzle, a main jet flow of high-pressure liquid is modulated into a pulsed jet flow and enters the suction chamber of a liquid-gas jet pump; and gas is introduced under the action of jet turbulent diffusion, and boosted and exhausted through the diffusion tube after mixing and energy exchange in the throat pipe. The self-oscillation pulsed liquid-gas jet pump has the advantages that the self-oscillation pulsed jet nozzle and the liquid-gas jet pump are combined, and the main jet flow is changed into pulsed jet flow through the self-oscillation pulsed jet nozzle, so that the mass transfer capability of the main jet flow is improved, and the efficiency of the liquid-gas jet pump is improved. The device is not provided with a motion part, simple in structure and reliable in operation, and is suitable for waste gas absorption and treatment, oil and gas exploitation, vacuumization, aeration and other application situations.

Owner:SHANGHAI UNIV

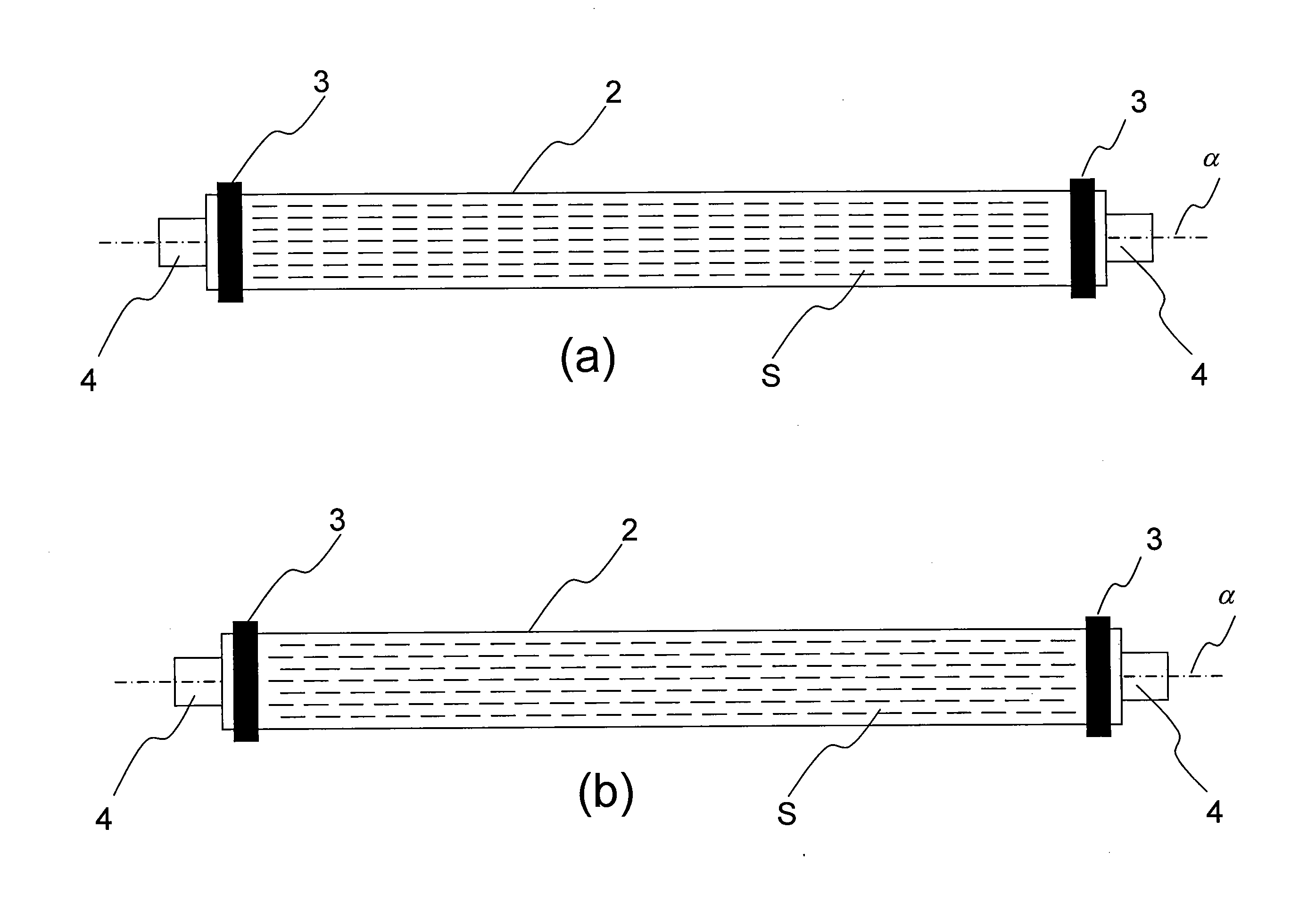

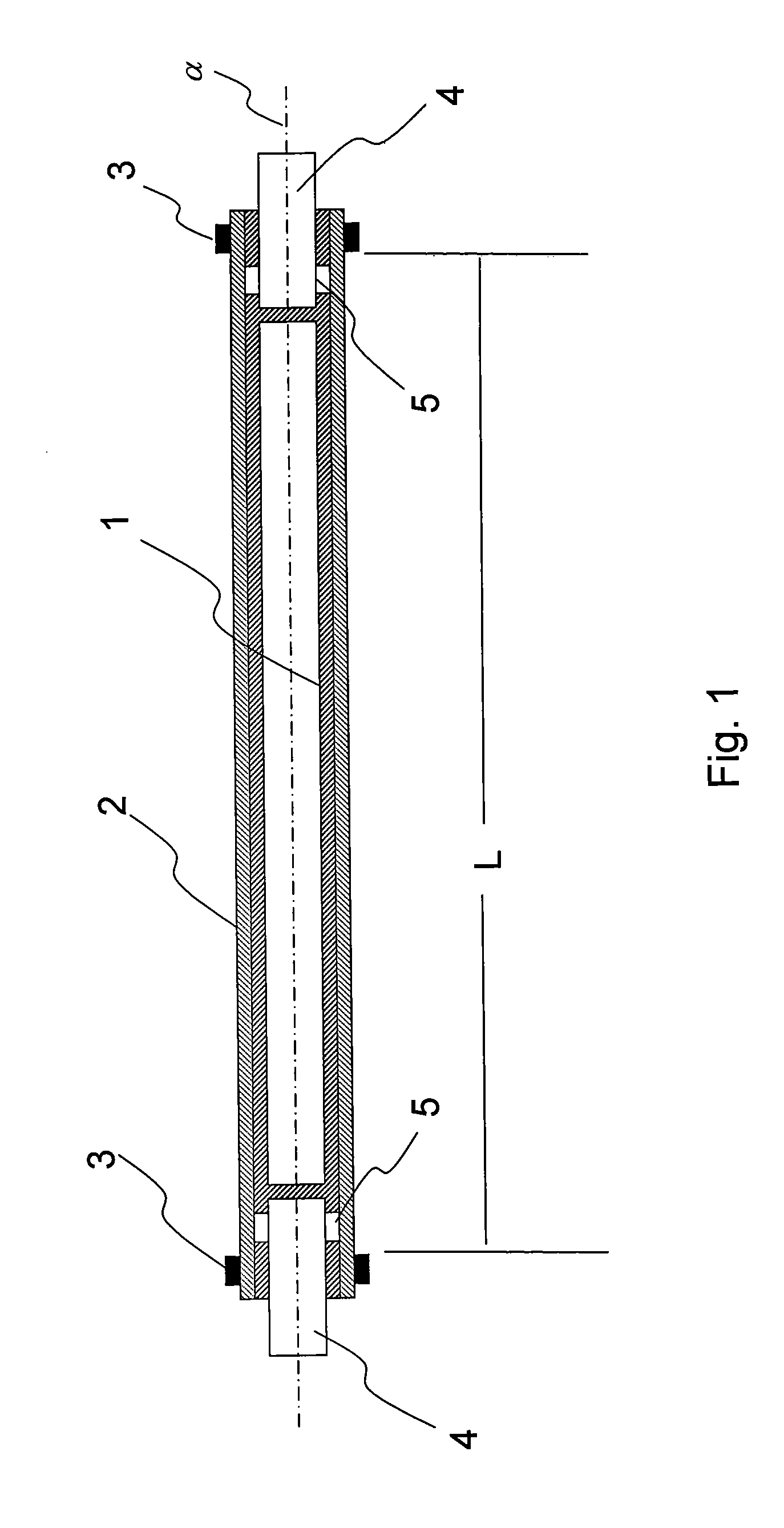

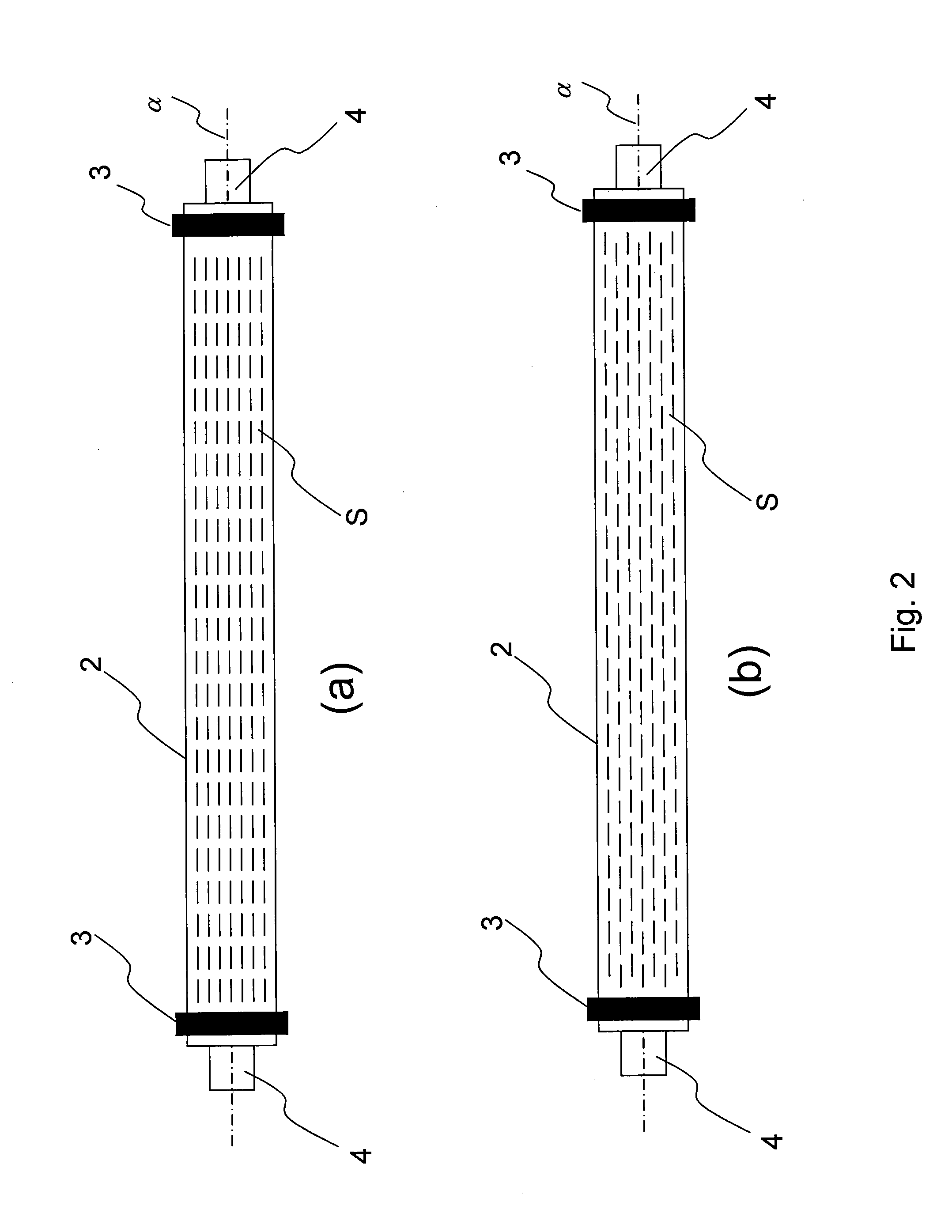

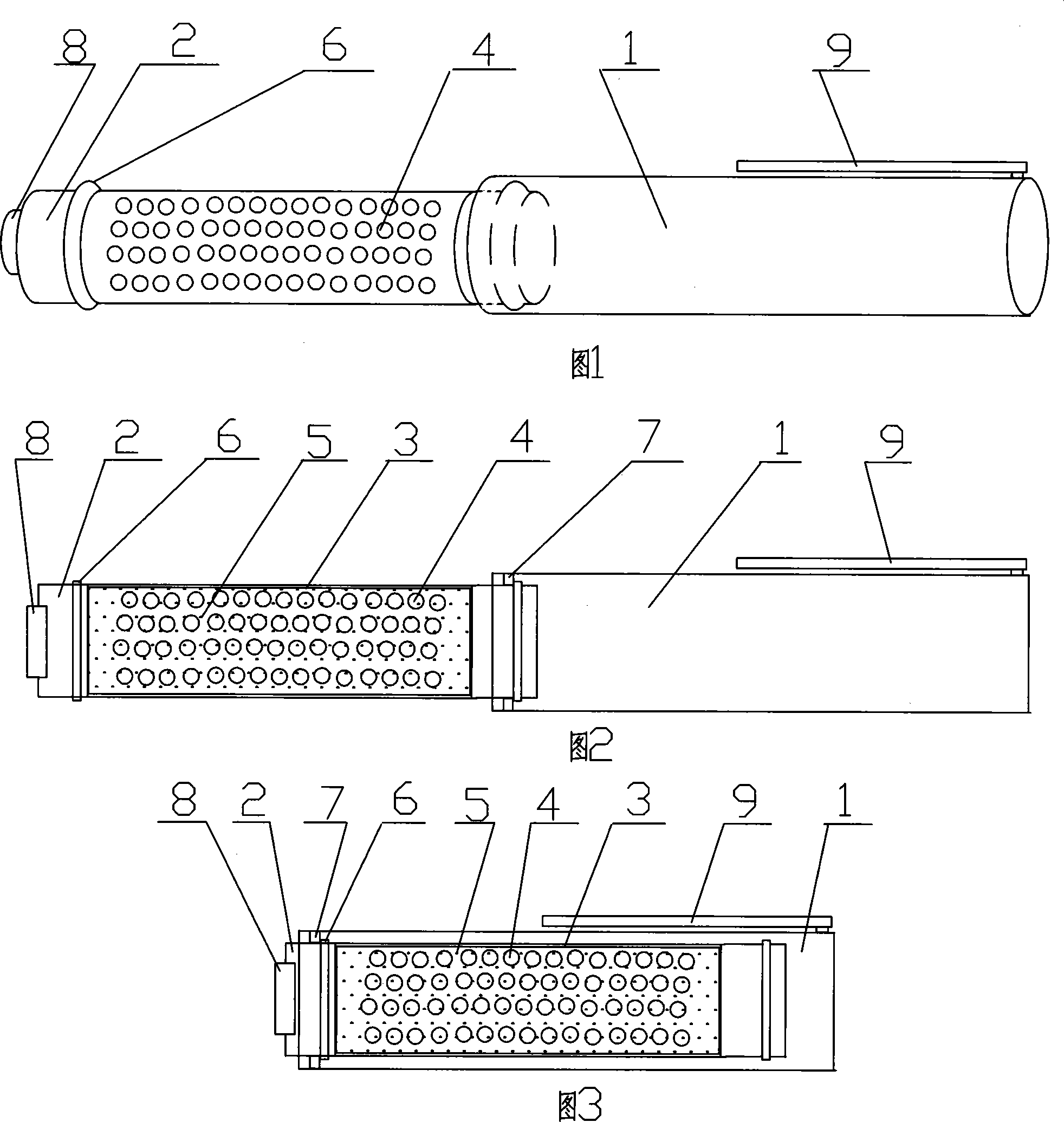

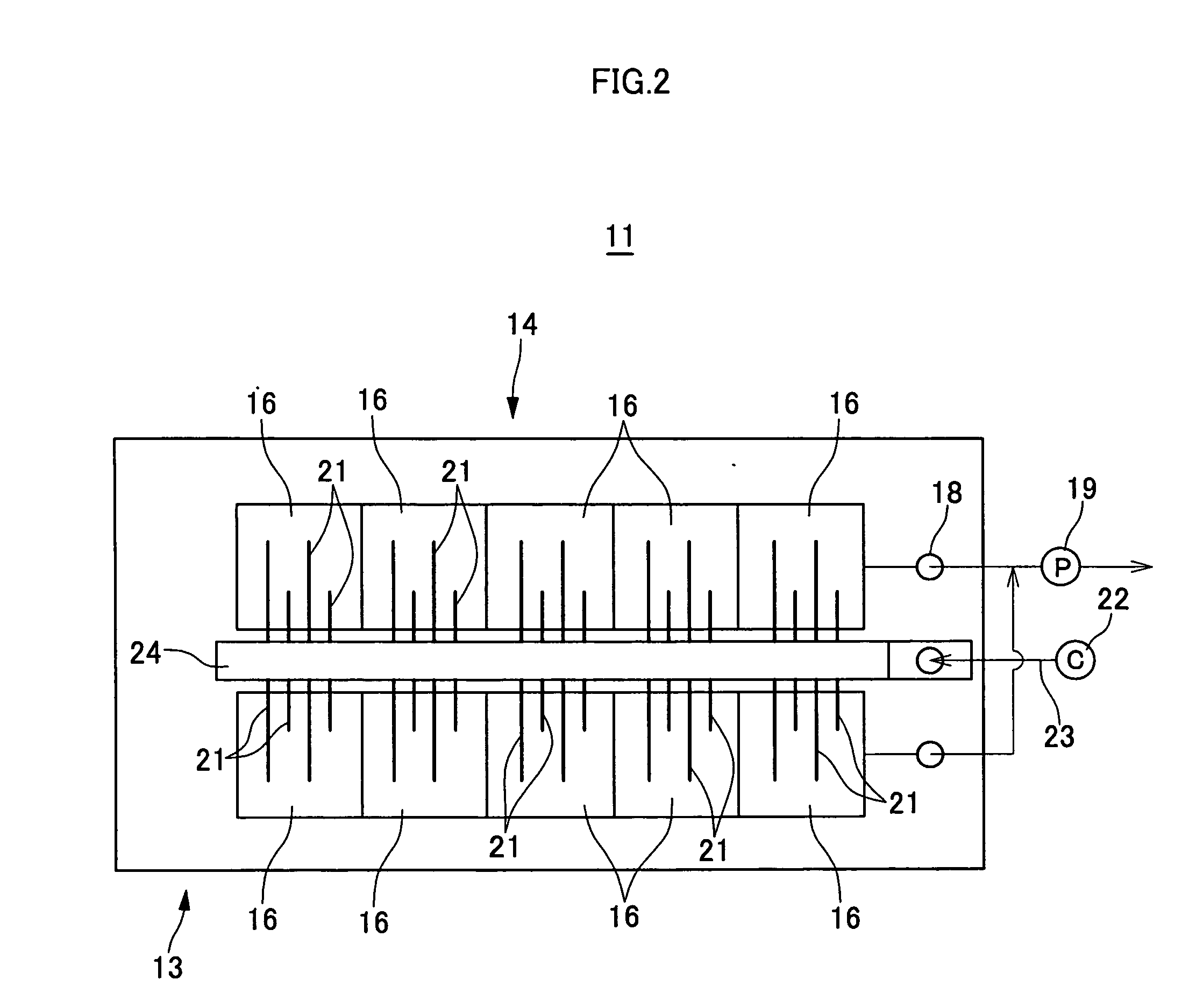

Fine bubble diffusing pipe, fine bubble diffusing apparatus, and submerged membrane separation apparatus

InactiveUS20100224541A1Even amountStable membrane filtrating operationLighting and heating apparatusTransportation and packagingEngineeringGas supply

A fine bubble diffusing tube that can generate fine bubbles evenly and uniformly even when the diffusing tube has a long length, a fine bubble diffusing device using such a tube and a submerged membrane separation apparatus are produced. The fine bubble diffusing tube is provided with a cylindrical supporting tube 1, and an elastic sheet 2 with fine slits formed therein, with the elastic sheet 2 being placed to cover the outer circumference of the supporting tube 1, so that, upon supplying a gas to a space between the elastic sheet 2 and the supporting tube 1, the fine slits of the elastic sheet 2 are opened to generate fine bubbles, and the supporting tube 1 has a length L of 1000 mm or more in the longitudinal direction, with gas supply units 4 serving as gas flow inlets being attached to the two ends of the supporting tube.

Owner:TORAY IND INC

Adjustable multi-streaming type steam jet heat pump

InactiveCN101625000AImprove energy utilizationReduce flow impact lossJet pumpsMachines/enginesFront edgeDiffusion tube

The invention discloses an adjustable multi-streaming type steam jet heat pump. One or more than one conical-cylindrical surrounding nozzle with annular nozzle mouths are coaxially sleeved at the outer side of a conical-cylindrical central nozzle positioned in the center of a pump body, a nozzle mouth of the central nozzle is positioned at the topmost end and is in stepped arrangement with the annular nozzle mouths of the surrounding nozzles, the surrounding nozzles are respectively provided with a working steam inlet, a jet steam inlet is arranged on the lateral wall of the pump body, a cavity body at the front part of the pump body and the outer side of the nozzle mouth is of a steam mixed chamber, and the outer end of the steam mixed chamber is connected with the small mouth end of a diffusion tube. Working steam is jetted from the central nozzle in high speed, other strands of working steams are jetted from the nozzle mouths of the surrounding nozzles, a plurality of strands of steams form a certain-speed distribution field and act together so as to ensure that the pressure intensity at the nozzle mouths is reduced, and the jet steam is sucked in, and the steams are mixed through the steam mixed chamber, and slowed down and pressurized by the diffusion tube to generate jet stream with adjustable speed gradient, thereby the flow impact loss at the front edges of the nozzle mouths is effectively reduced, the energy loss is decreased, and the mechanical efficiency is improved.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Tube type pump-free type samplers

InactiveCN101126686AImprove stabilityGood sample rateWithdrawing sample devicesActivated carbonAbsorption capacity

The utility model relates to a sampler, in particular to a tube non-pump sampler, aiming at providing a tube non-pump sampler with compact size, simple and convenient operation, safety and reliability. The utility model adopts the technical proposal of comprising a sleeve, an diffusion tube, a copper net and an activate carbon; wherein, the copper net is lined internally inside the diffusion tube; the activated carbon is filled inside the copper net; the diffusion tube is closed at one end and an diffusion tube cover is arranged at the other end; the diffusion tube is sleeved inside the sleeve which is closed at one end; a locating convex ring is arranged at both ends of the diffusion tube; a locating convex ring cooperated with the locating convex ring of the diffusion tube is arranged at unclosed end of the sleeve; expansion holes are evenly arranged on the diffusion tube. The utility model has the advantages of meeting good result in sampling ratio, absorption capacity and sample stability and other performances and providing wide prospect for application fields such as environment monitoring, occupational health and sanitation and anti-epidemic station for giant potential in miniaturization, economization and portability.

Owner:山东省职业卫生与职业病防治研究院

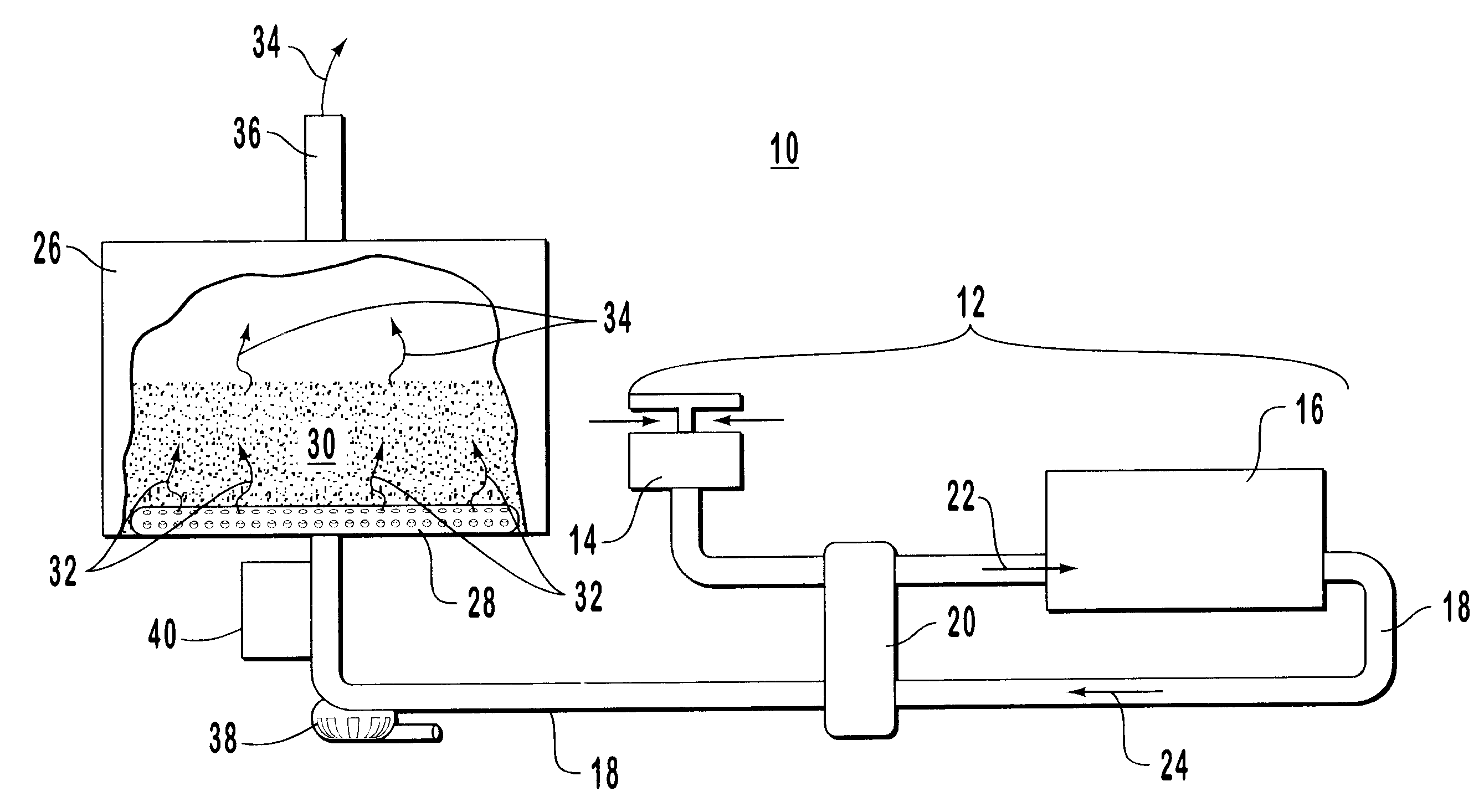

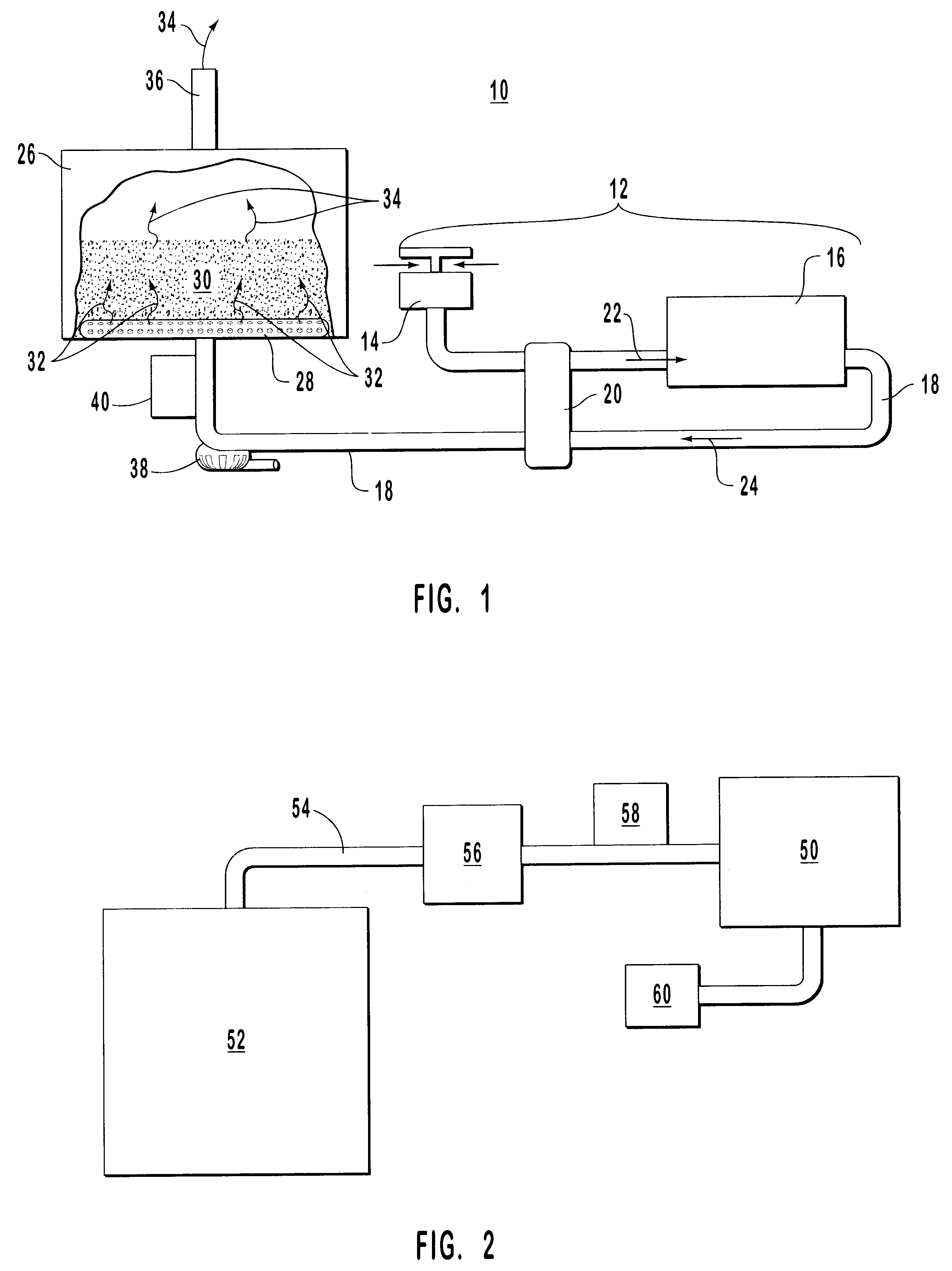

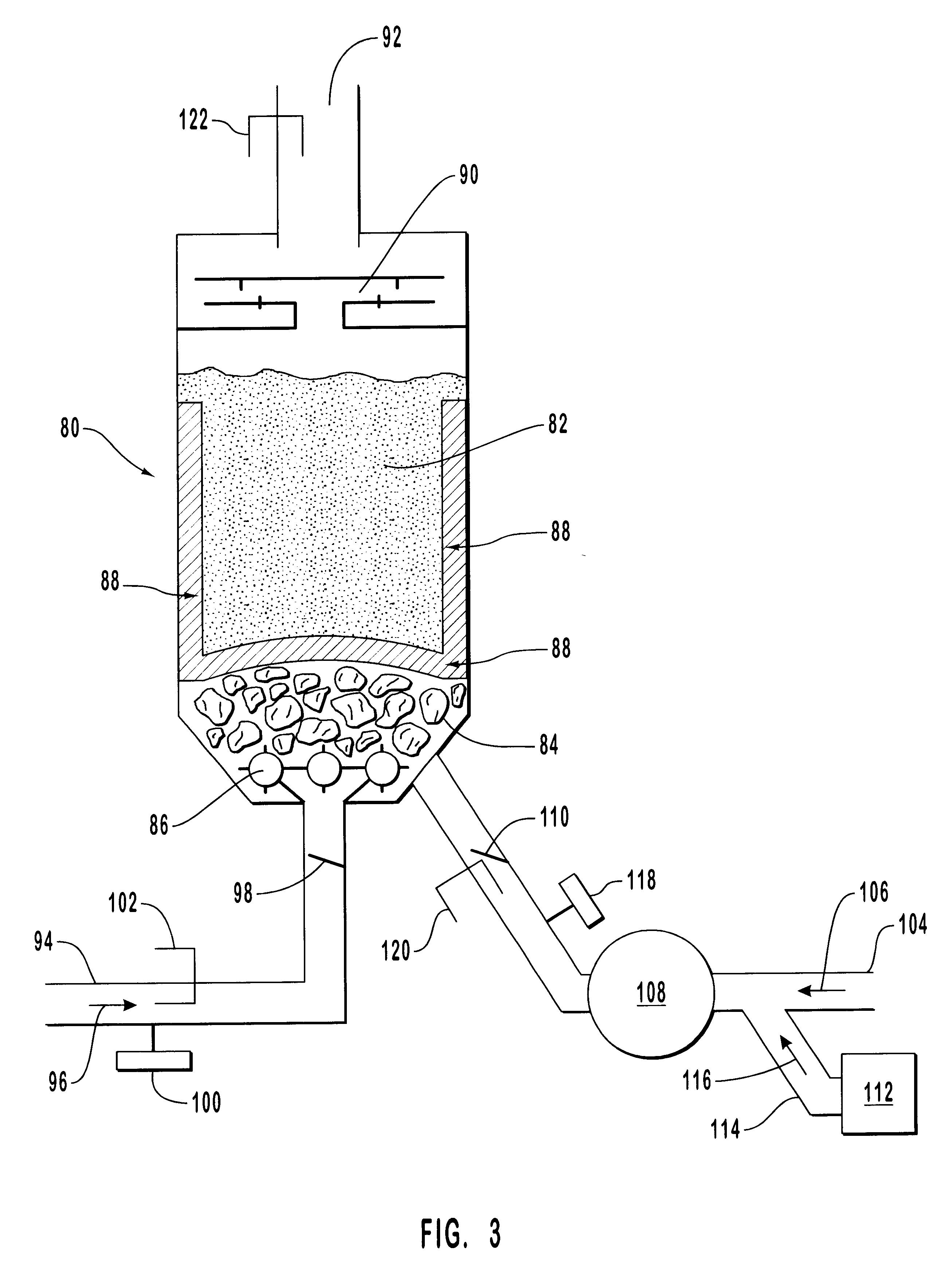

Methods and apparatus for low back pressure muffling of internal combustion engines

InactiveUS6457552B2Improve efficiencyIncrease powerExhaust apparatusSilencing apparatusExternal combustion engineEngineering

Systems and apparatus for muffling sounds produced by an internal combustion engine, and optionally catalytically degrading pollutants within waste exhaust gases. The systems and apparatus utilize a bed of particles within a muffling chamber. The gases are introduced using a diffusion tube with holes therethrough. The muffling particles preferably include silica or alumina, which can also catalytically degrade pollutants. Typically, the muffling / reaction chamber is maintained at a temperature in a range from about 50° C. to about 500° C., which is much lower than temperatures within conventional muffling systems for diesel engines. The muffling systems operate as substantially lower back pressure compared to conventional muffling systems. The systems and apparatus can be adapted to be used in combination with diesel engines or other internal combustion engines and industrial burners.

Owner:THOMAS C MAGANAS & STELLA MAGANAS 1988 FAMILY TRUST +1

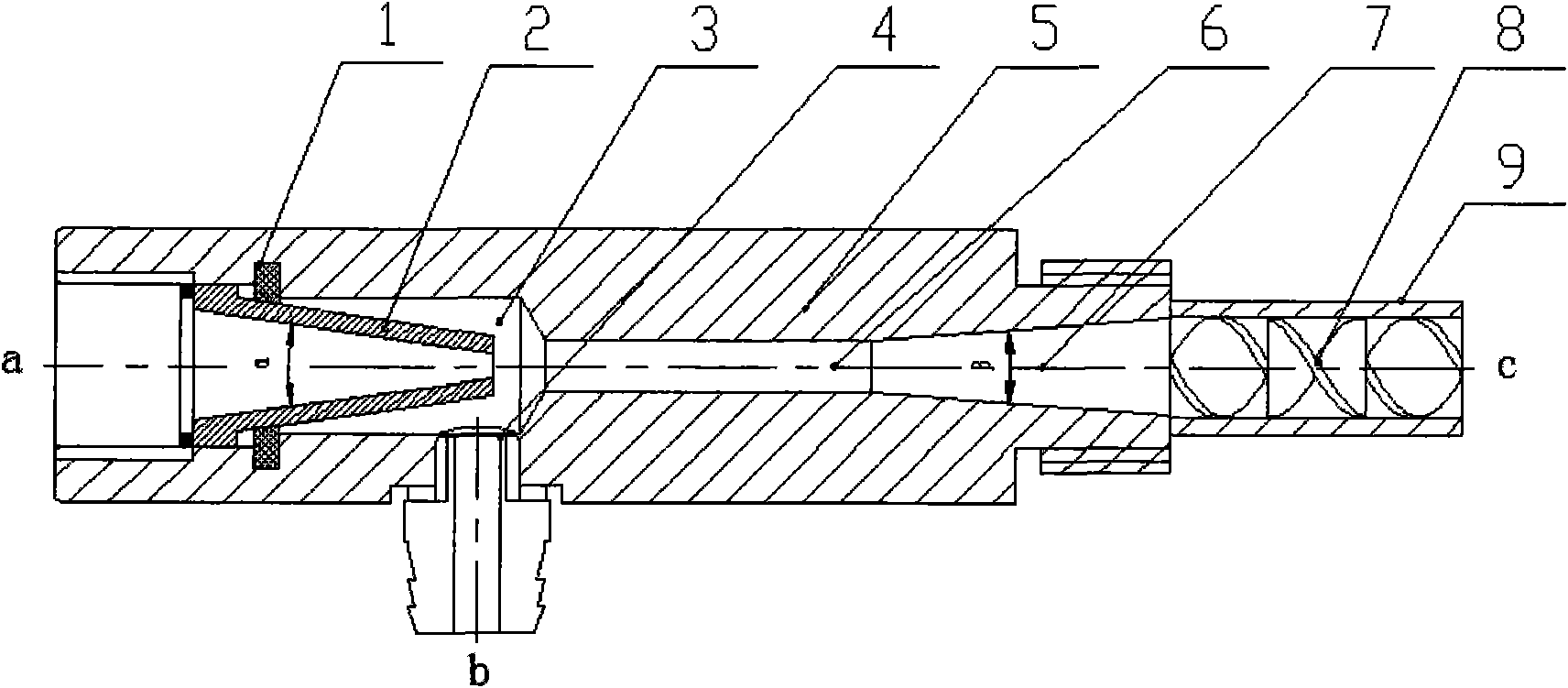

Vehicle-mounted pesticide mixing device

The invention relates to a vehicle-mounted pesticide mixing device, in particular to an online pesticide mixing device for a large and medium sprayer with a large spray volume. The device can automatically suck pesticide liquid and uniformly mix the pesticide liquid and water online. The vehicle-mounted pesticide mixing device comprises a jet nozzle 1 and a pesticide mixing device shell 3, wherein the pesticide mixing device shell comprises a suction chamber, a tube, a diffusion tube and a pesticide suction port. The requirements of spraying of pesticide liquids of different concentrations are met, the structure is simple, and the nozzle and the shell are convenient to change. According to the vehicle-mounted pesticide mixing device, pesticide and water in the large and medium sprayer are stored separately, and the operations of mixing and spraying are conducted online, so that the degree of automation is high, and environment friendliness and high efficiency are achieved.

Owner:JIANGSU UNIV

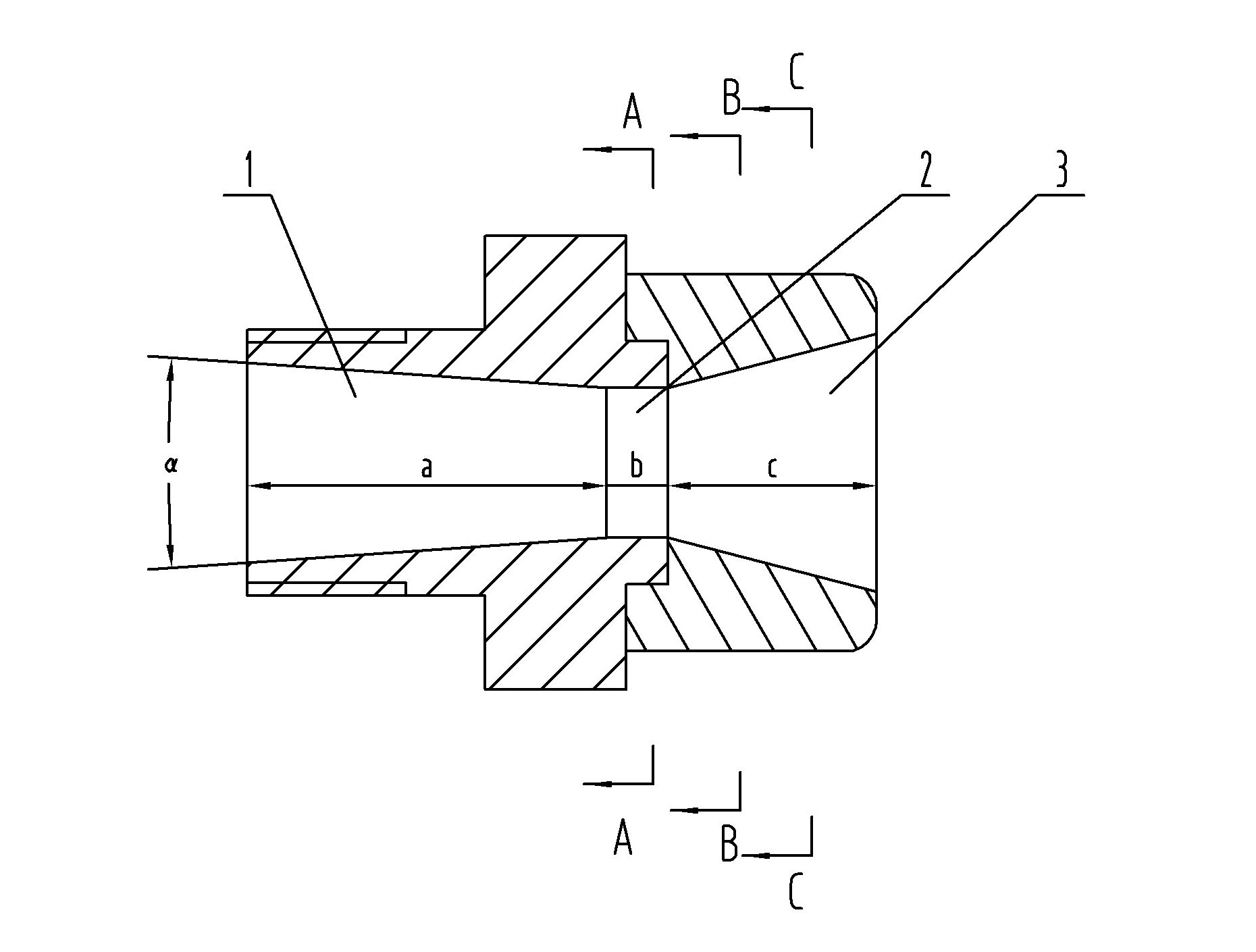

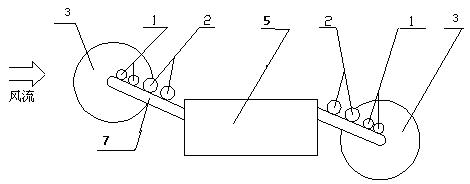

Flat jet flow nozzle and special coating machine

ActiveCN102535823AIncrease output resistanceImprove compactnessSpray nozzlesBuilding constructionsEconomic benefitsPipe

The invention belongs to the technical field of building machinery, and particularly relates to a flat jet flow nozzle and a special coating machine which are used for coating various materials on surfaces of the inner wall and the outer wall of a building. The flat jet flow nozzle comprises a shrinkage pipe section, a throat pipe section and a diffuse pipe section from left to right in sequence, the shrinkage pipe section is in a hollow cone shape, the cone angle alpha is in a range being greater than or equal to 30 degrees and less than or equal to 120 degrees, the length of the shrinkage pipe section a is in a range being greater than or equal to 8mm and less than or equal to 30mm, the throat pipe section is in a hollow cylinder shape, the length of the throat pipe section b is in a range being greater than or equal to 1mm and less than or equal to 4mm, an inner cavity of the diffuse pipe section is a flat hole which is formed in a way that the tail of an inner cavity of the throat pipe section gradually transits to the end surface of the tail end of the nozzle, the length of the diffuse pipe section c is in a range being greater than or equal to 3mm and less than or equal to 12mm, the height of the flat hole d is in a range being greater than or equal to 3mm and less than or equal to 12mm, and the width of the flat hole e is in a range being greater than or equal to 1.5mm and less than or equal to 6mm. In the nozzle and the coating machine which are provided by the invention, the coating effect is uniform and smooth, the bonding degree of the materials and a wall body is high, the compactness of the materials is high, the coating efficiency is high, the coating quality is ensured, and further the special coating machine is wide in application range, obvious in economic benefit, and is beneficial to popularization and application.

Owner:河南恒睿机械制造有限公司

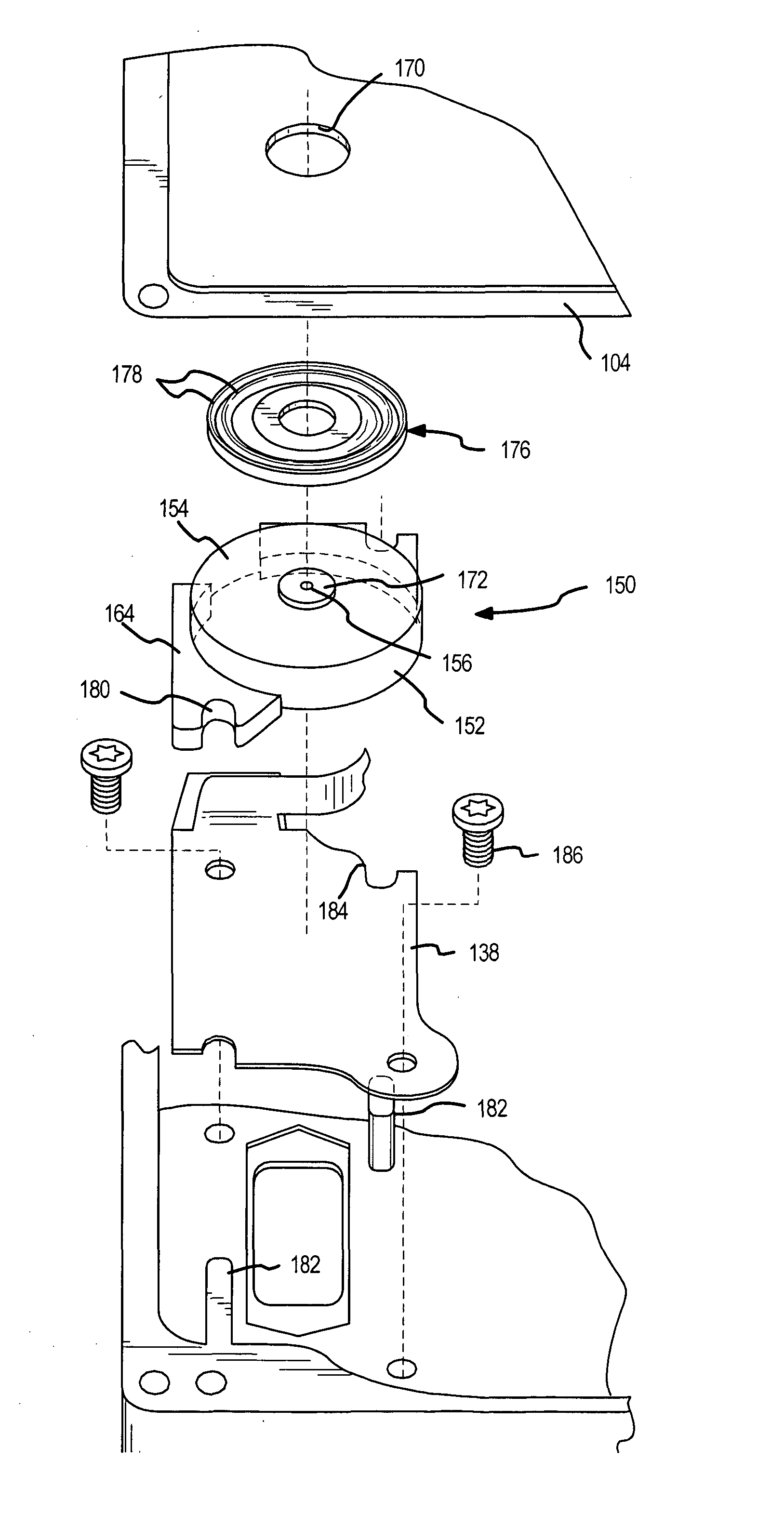

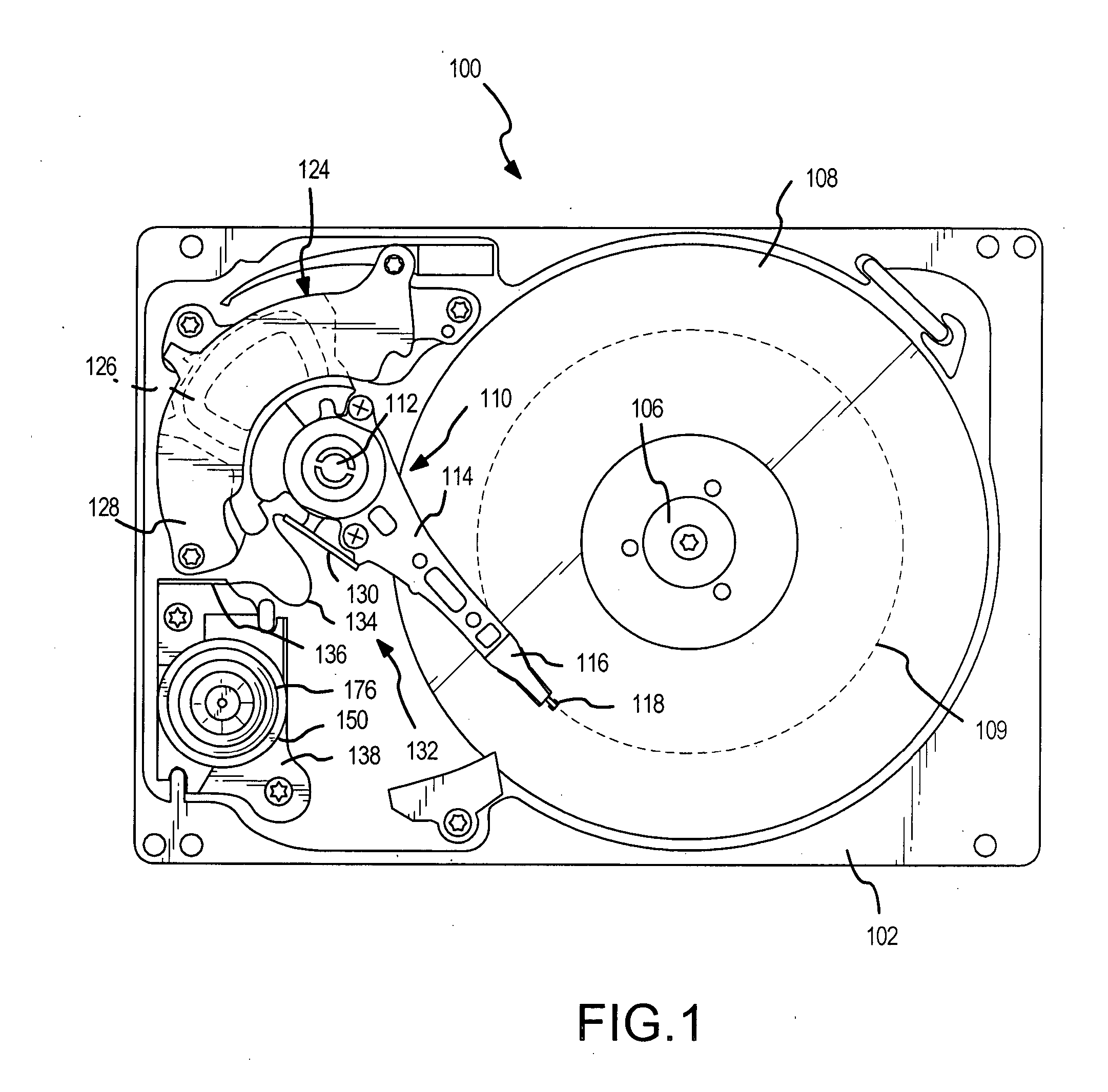

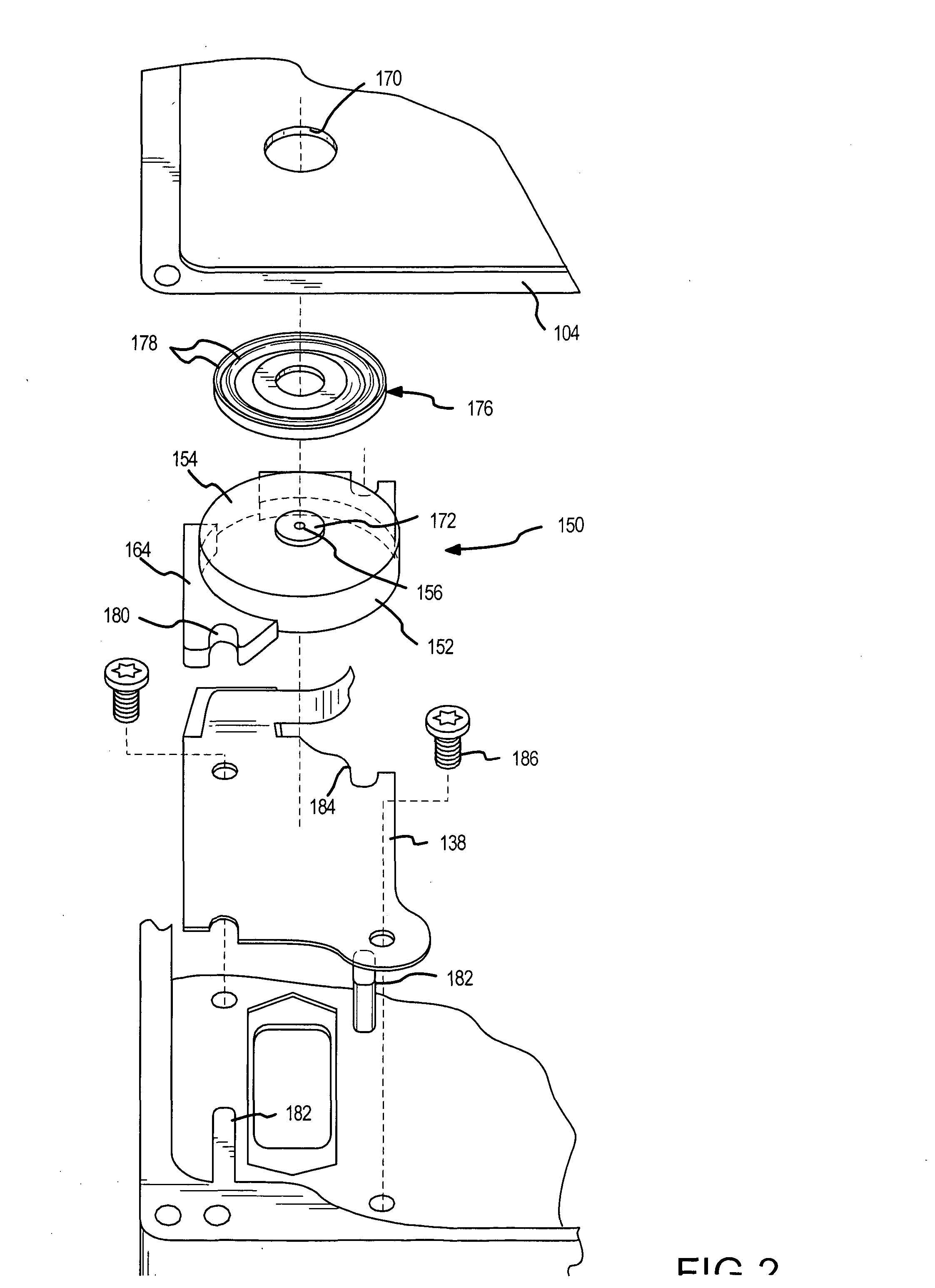

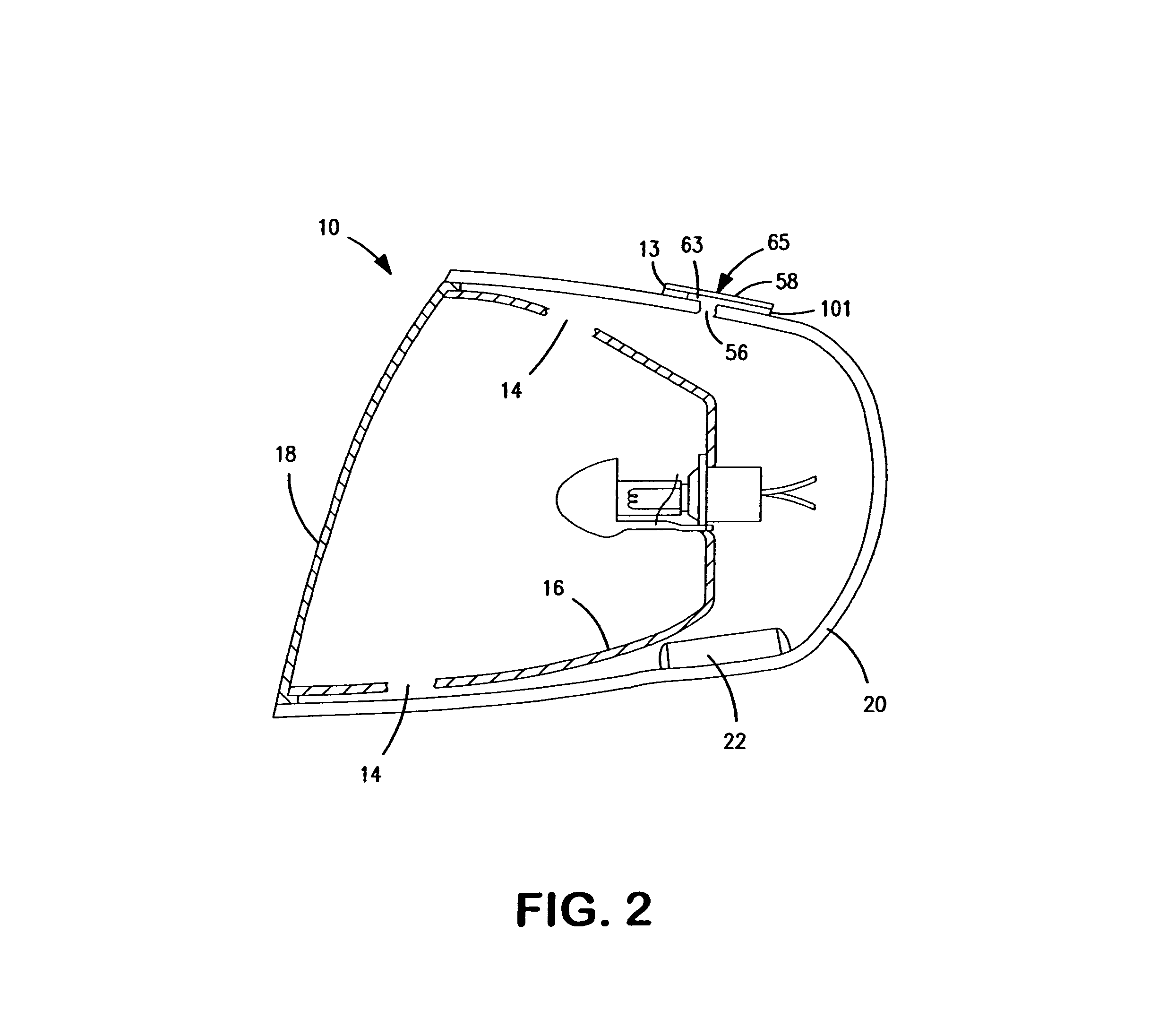

Disc drive breather filter mount

ActiveUS20050036232A1Prevent leakageEasy to fixDisposition/mounting of recording headsApparatus for flat record carriersBreatherAdhesive

A breather filter is assembled within a disc drive without the use of adhesives by positioning the filter atop a flex circuit bracket on a base plate of the drive. In one embodiment, a breather port is formed through a top cover of the disc drive, and an inlet of the breather filter is sealed against the top cover of the drive. Compressing the top cover against the top of the breather filter helps to retain the filter in position between the flex circuit bracket and the top cover without an adhesive connection to the top cover. In a second embodiment, the breather port is formed in the flex circuit bracket, and the filter is securely attached to the flex circuit bracket so that no connection is required between the filter and the top cover. A diffusion tube may be formed integrally with the breather filter itself or within the body of the flex circuit bracket when the breather port is located in the flex circuit bracket. The connection of the breather filter to the flex circuit bracket allows a top-down assembly of the disc drive so that an adhesive connection between the filter and the top cover of the drive is not required.

Owner:SEAGATE TECH LLC

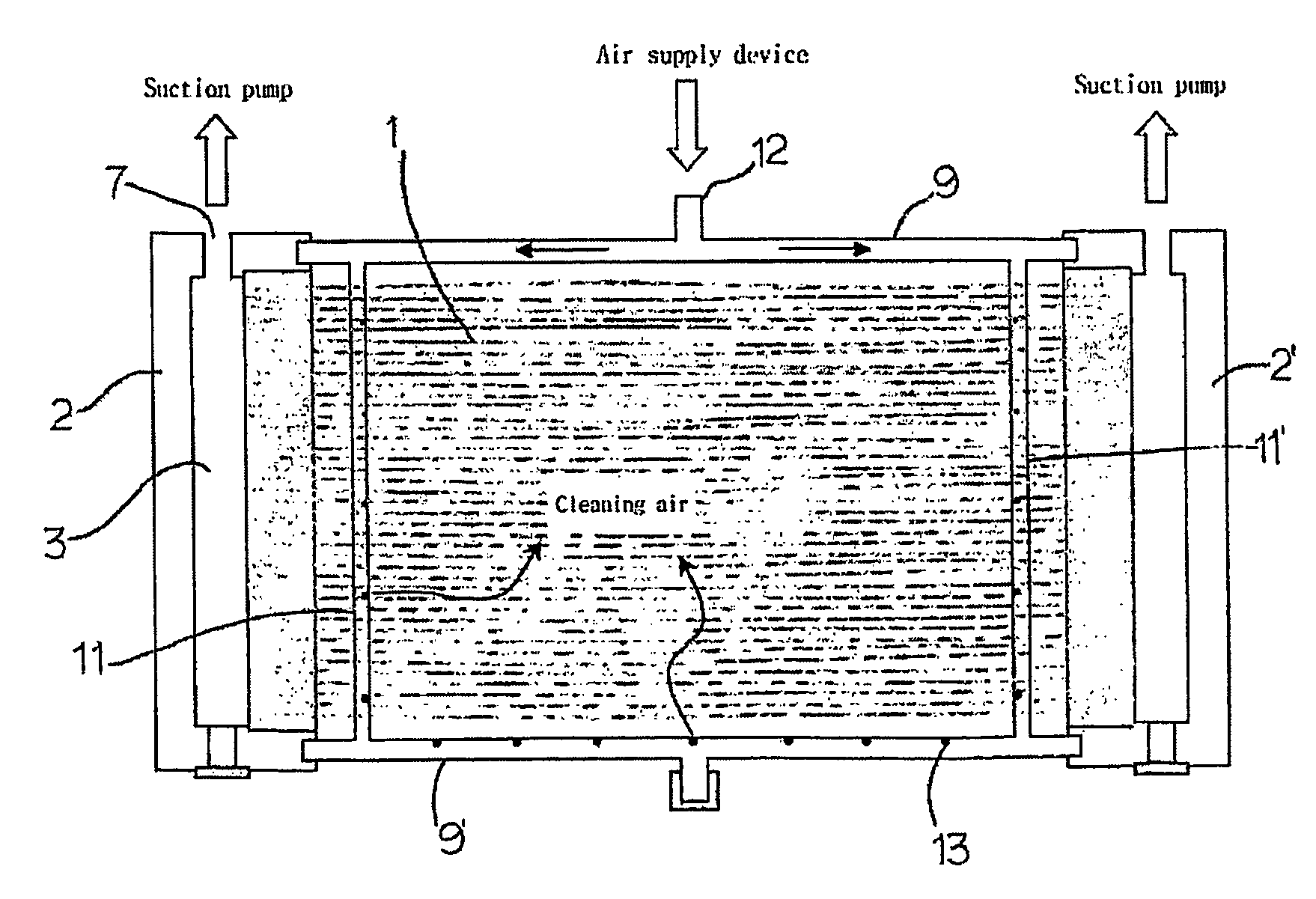

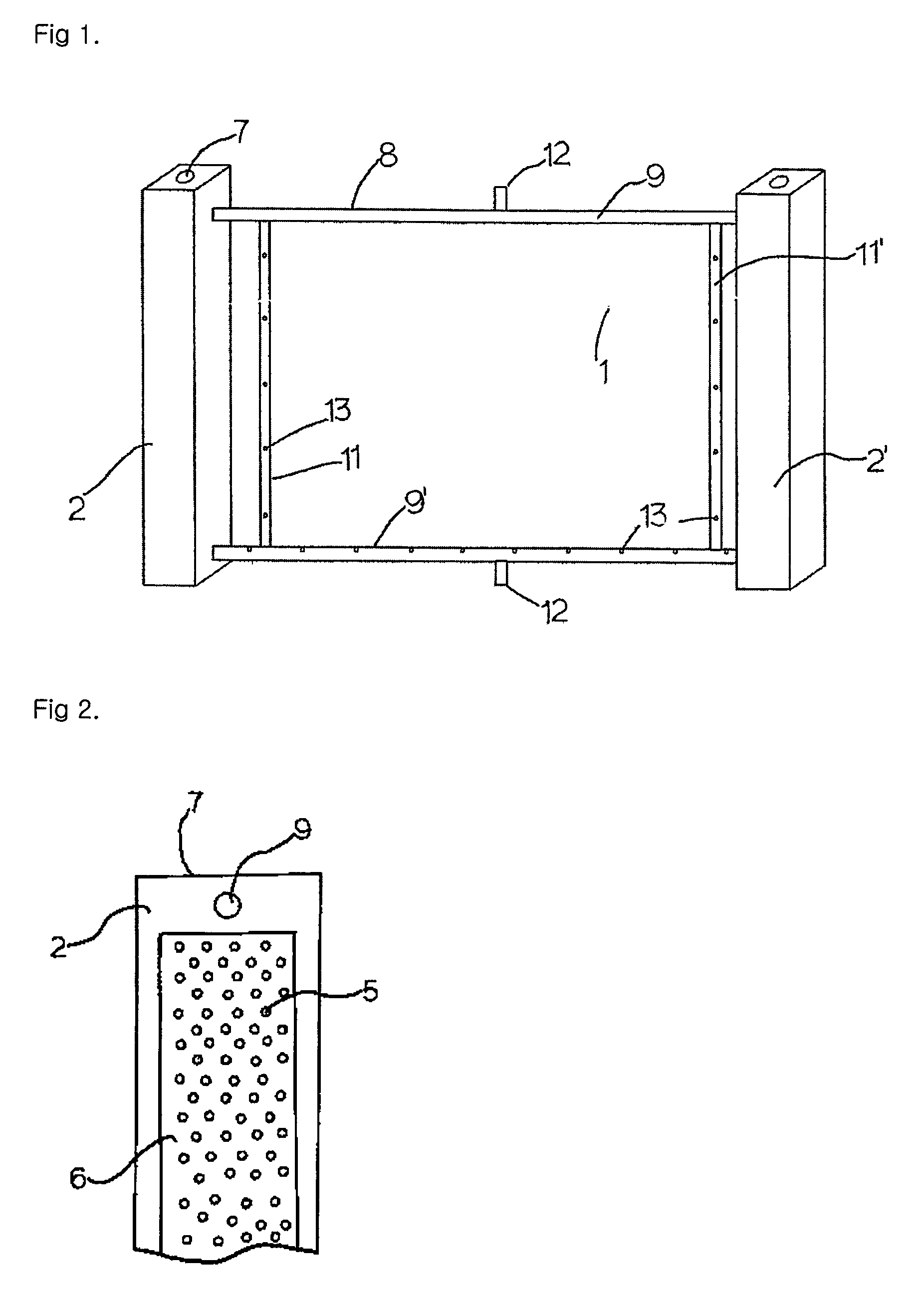

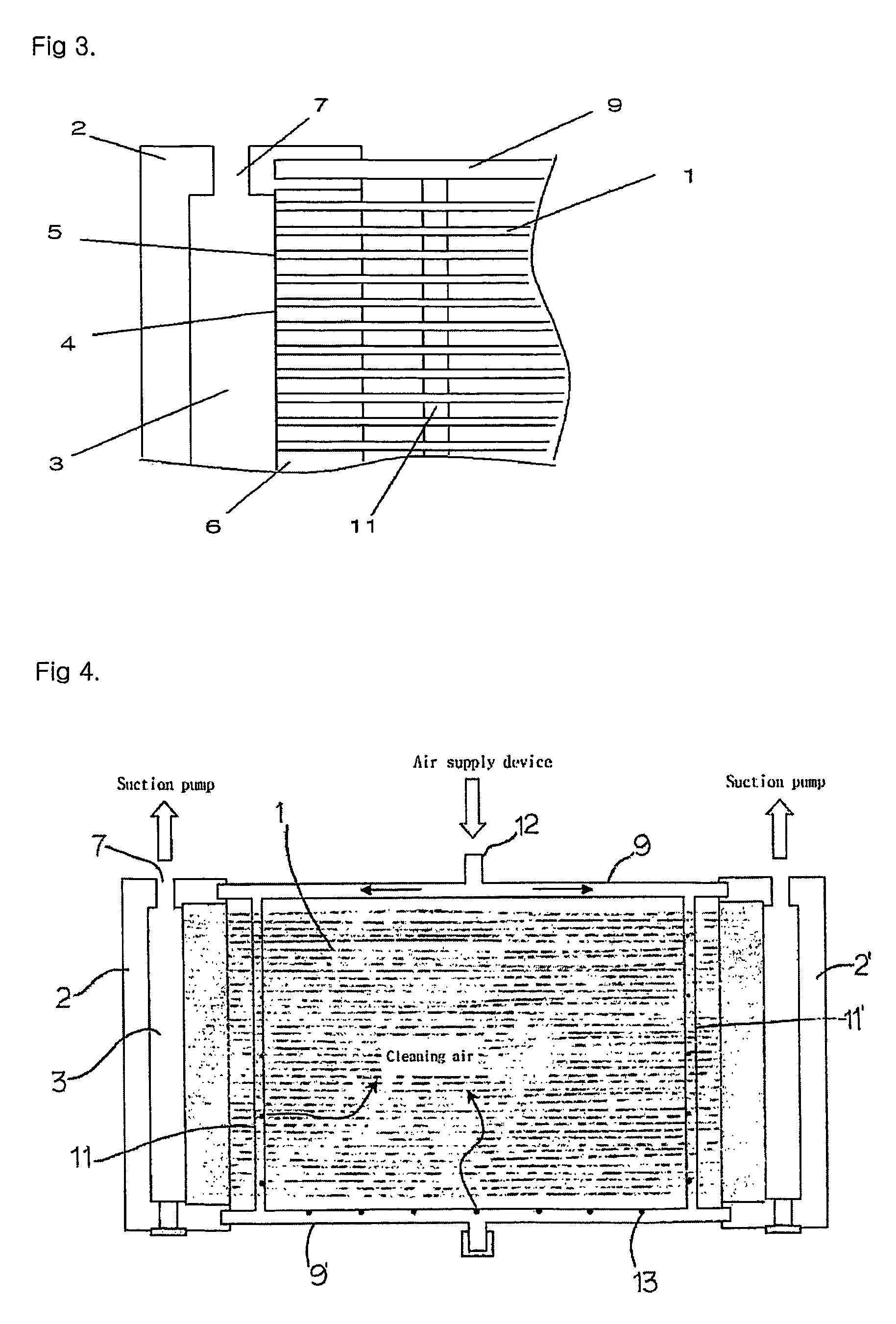

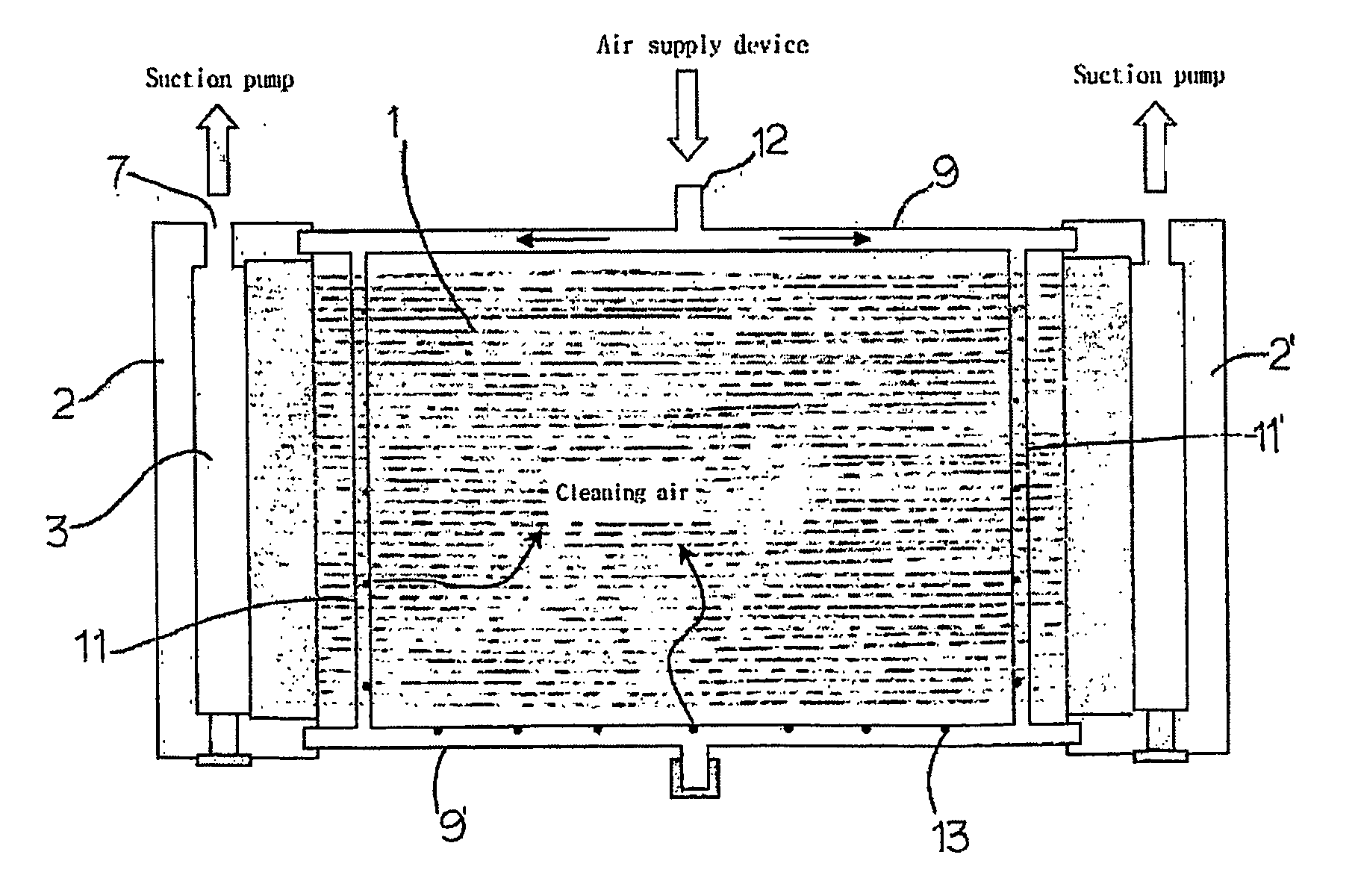

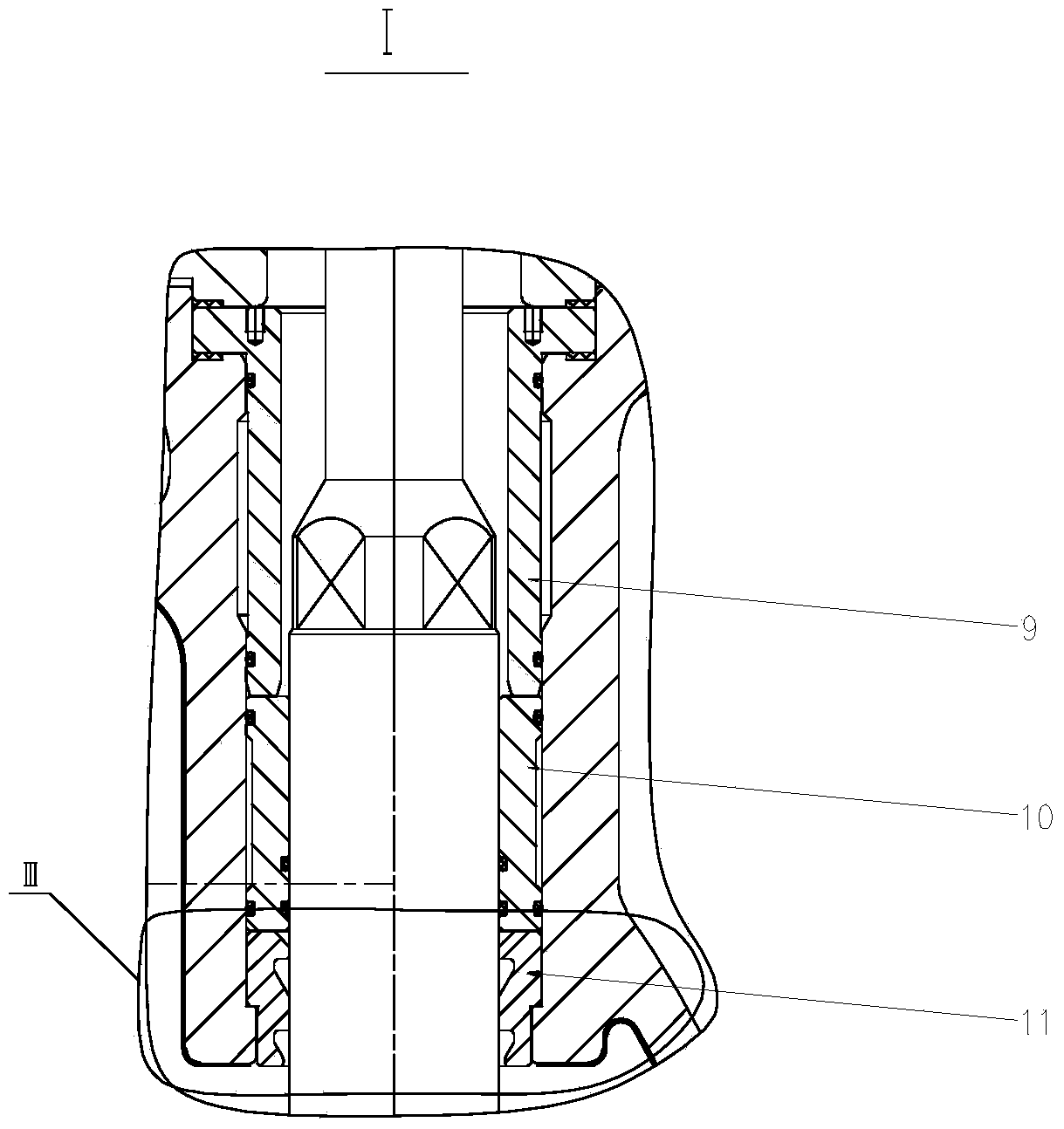

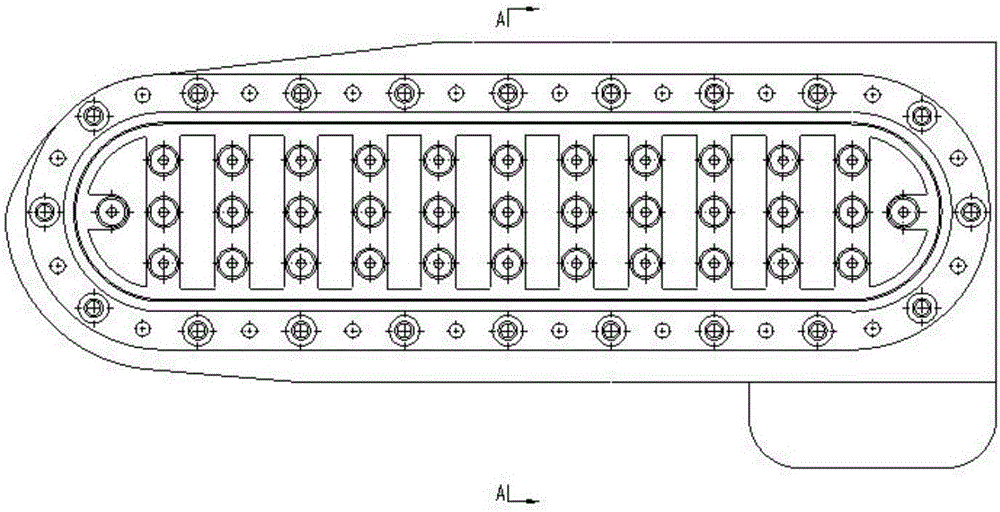

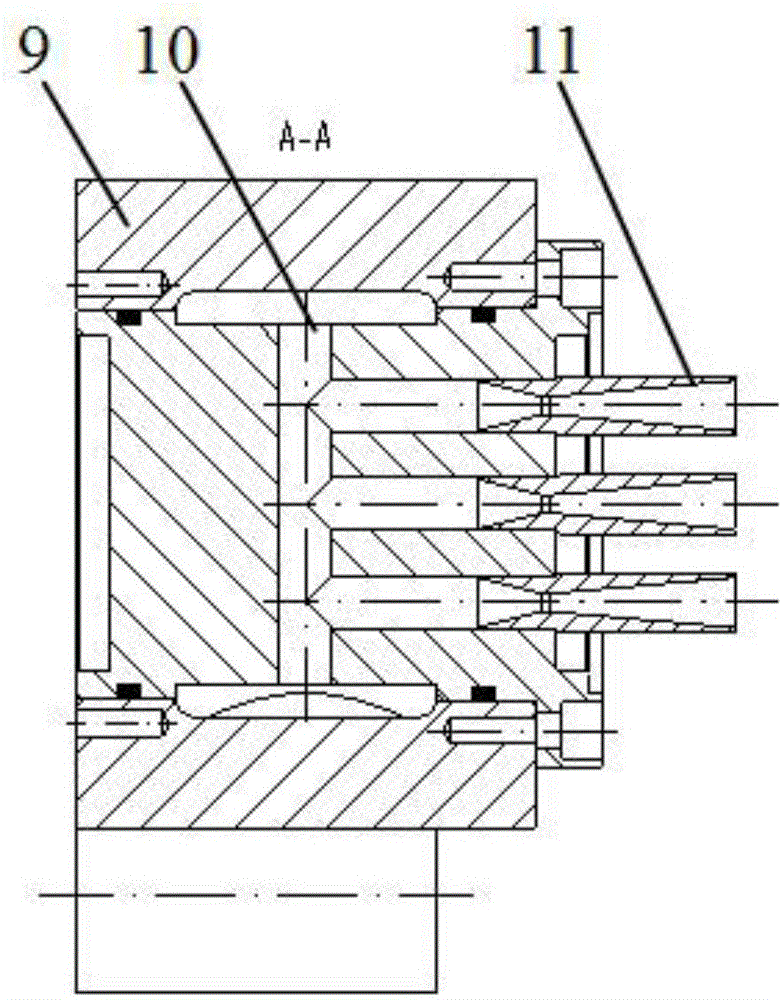

Submerged hollow fiber membrane module

InactiveUS7686955B2Improve scalabilityPrevent water leakageSemi-permeable membranesMembranesHollow fibreWater leakage

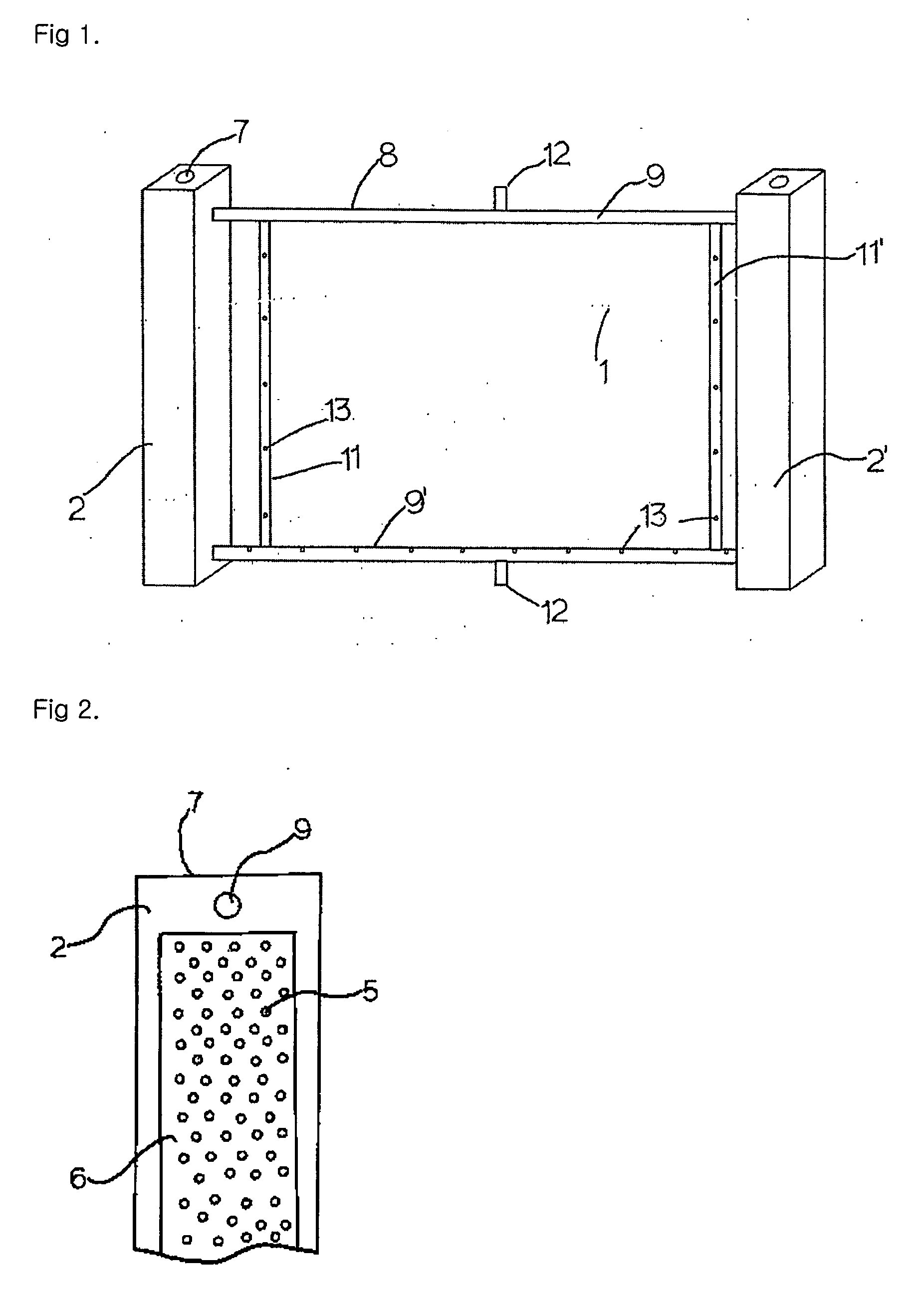

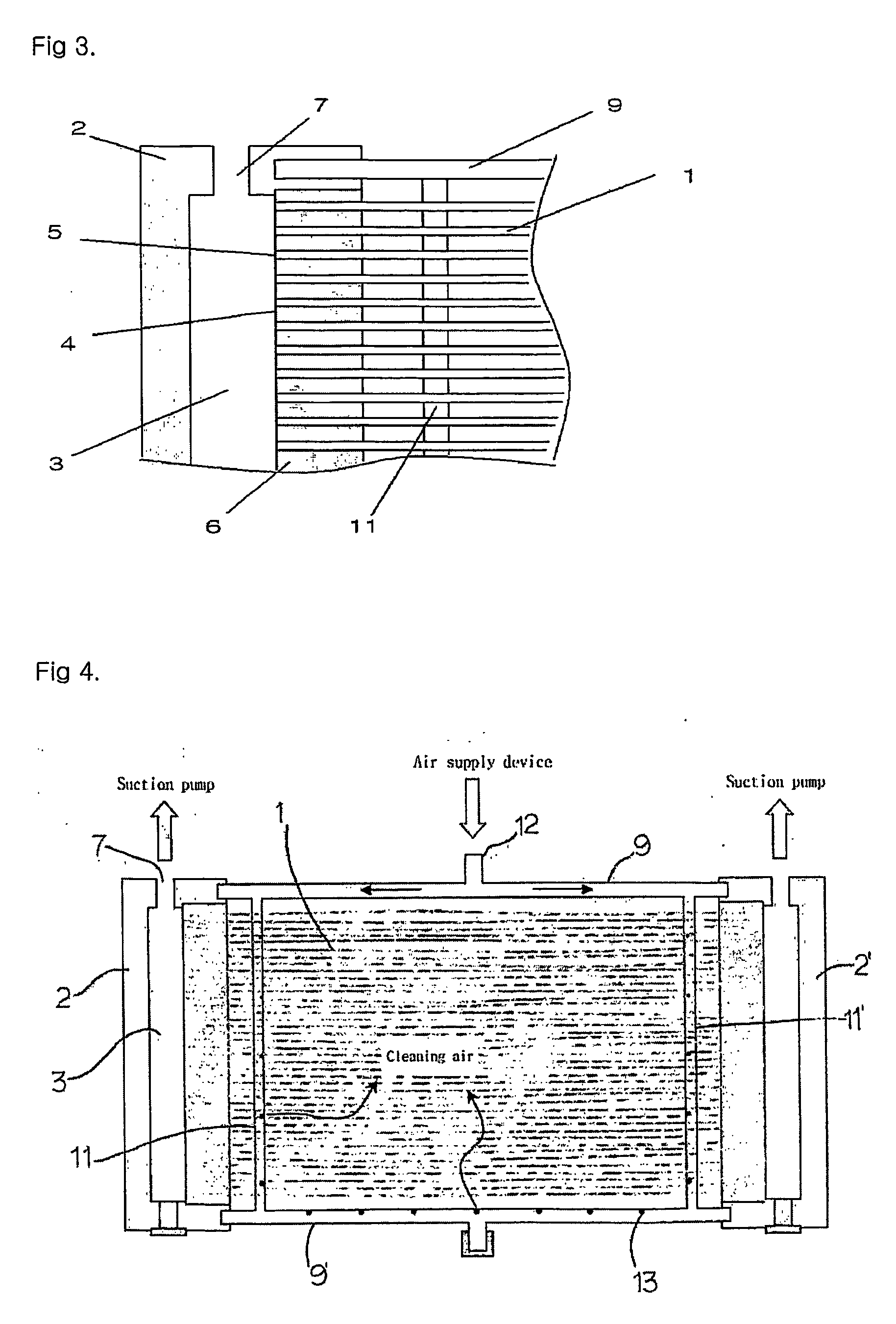

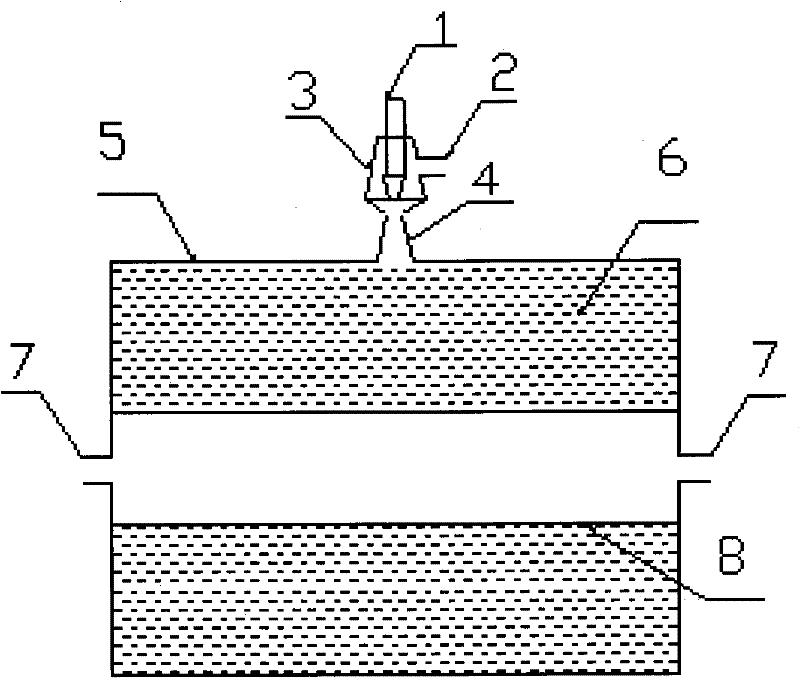

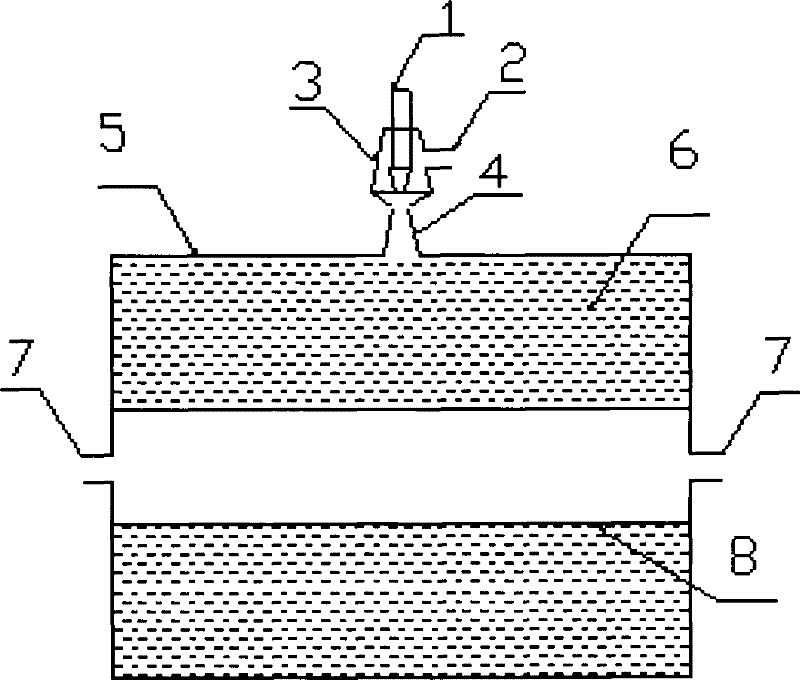

The present invention discloses a submerged hollow fiber membrane module which is of such a structure that it is easy to expand a module processing capability according to a treatment capacity, provides convenient module coupling properties and module manufacturing properties, maintains a stable flux under an efficient air diffusion condition and prevents the damage of membranes and water leakage caused by the loosening of module connecting regions. The submerged hollow fiber membrane module comprises [I] two module headers (2 and 2′) having a filtrate water collecting portion (3) for collecting filtrate water filtered through hollow fiber membranes and a filtrate water outlet (7), [II] an air diffusion unit 8 consisting of support tubes (9 and 9′) fixing the two module headers (2 and 2′) while keeping them spaced a predetermined distance and air diffusion tubes (11 and 11′) having air diffusion holes (13), and [III] a bundle of hollow fiber membranes (1) having both opposite ends fixed to the insides of the module headers (2 and 2′) by an adhesive (6) so as to form a water collecting space within the module headers (2 and 2′), the ends (5) of the hollow portions of the hollow fiber (20) membranes being opened and disposed in parallel to a filtrate water discharge surface (4).

Owner:KOLON IND INC

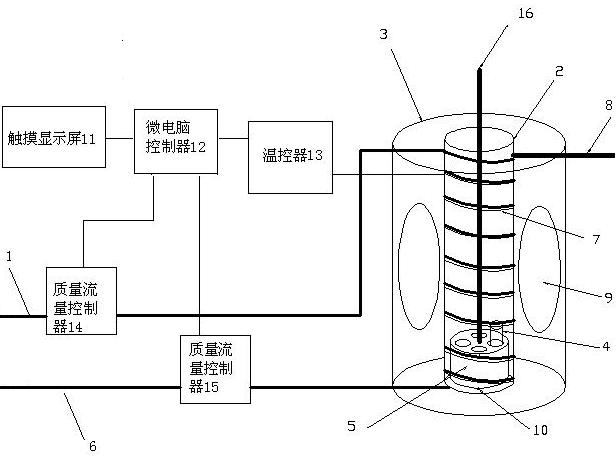

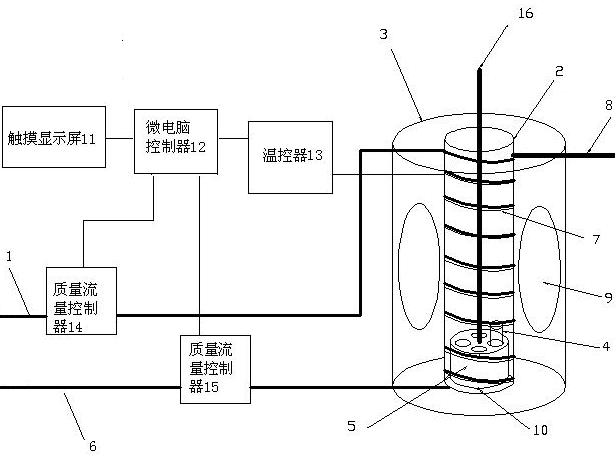

Dynamic gas distribution instrument

InactiveCN102580606AImprove stabilityImprove accuracyMixer accessoriesMixing gases with gases/vapoursMicrocomputerAutomatic control

The invention discloses a dynamic gas distribution instrument, which is used for distributing standard gas with a certain concentration, and is used for calibrating measuring instruments and measuring processes in the physical, chemical and other measuring fields. The dynamic gas distribution instrument comprises a diluent gas inlet copper tube, a feed gas inlet tube, a gas outlet tube, a control system, a thermostatic chamber, a gas mixing chamber, a glass diffusion tube and a diffusion tube bracket. According to the dynamic gas distribution instrument, an embedded microcomputer is applied for automatic control, thus the dynamic gas distribution instrument not only has higher stability and accuracy, but also combines hydraulic distribution and gaseous distribution together; and moreover, the dynamic gas distribution instrument has a wider applicable scope, is simple to operate at the same time, can continuously distributing for a long time, and is suitable for being popularized and used in basic level environments, hygiene monitoring, metering and other mechanisms.

Owner:广东省职业病防治院

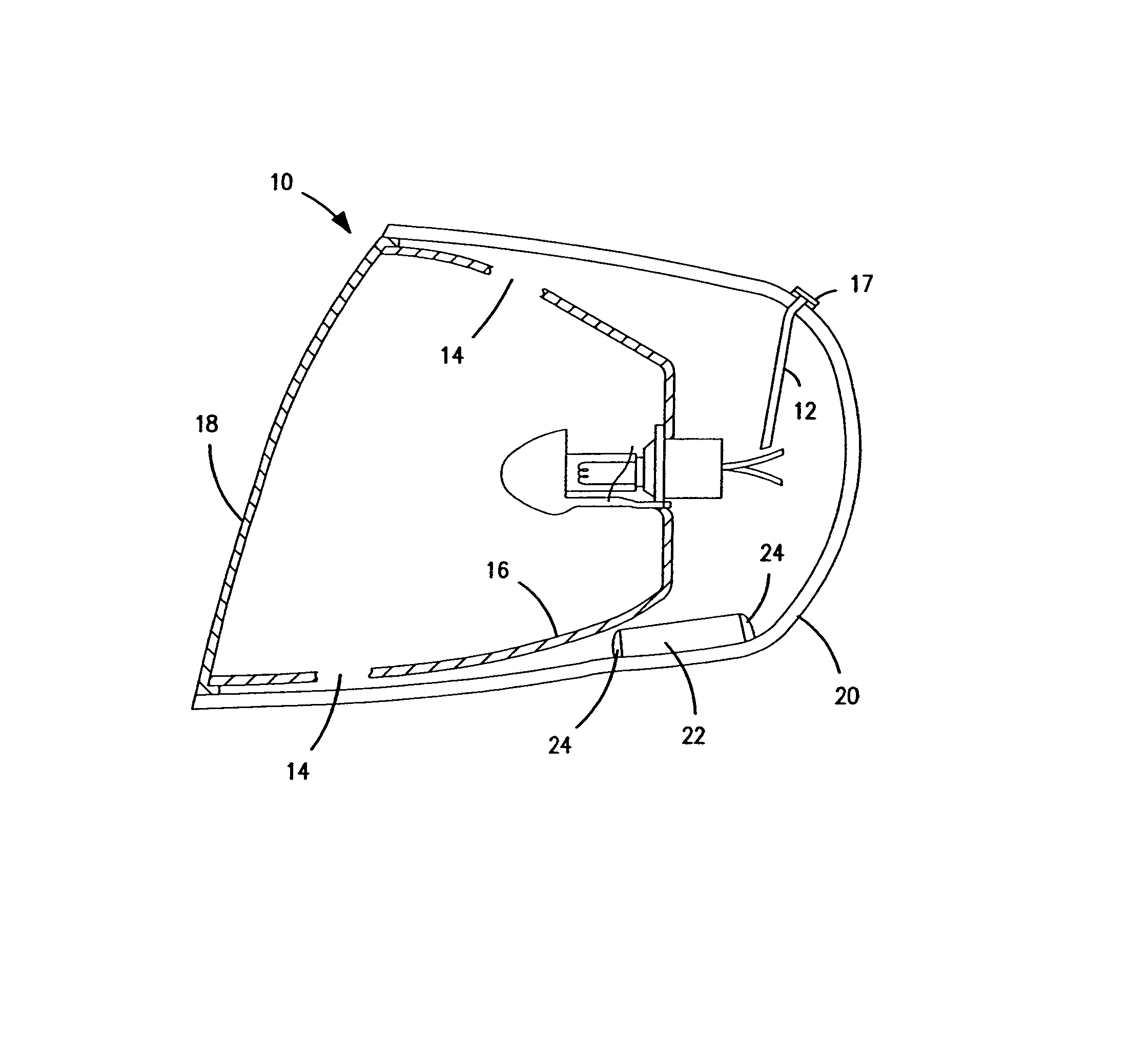

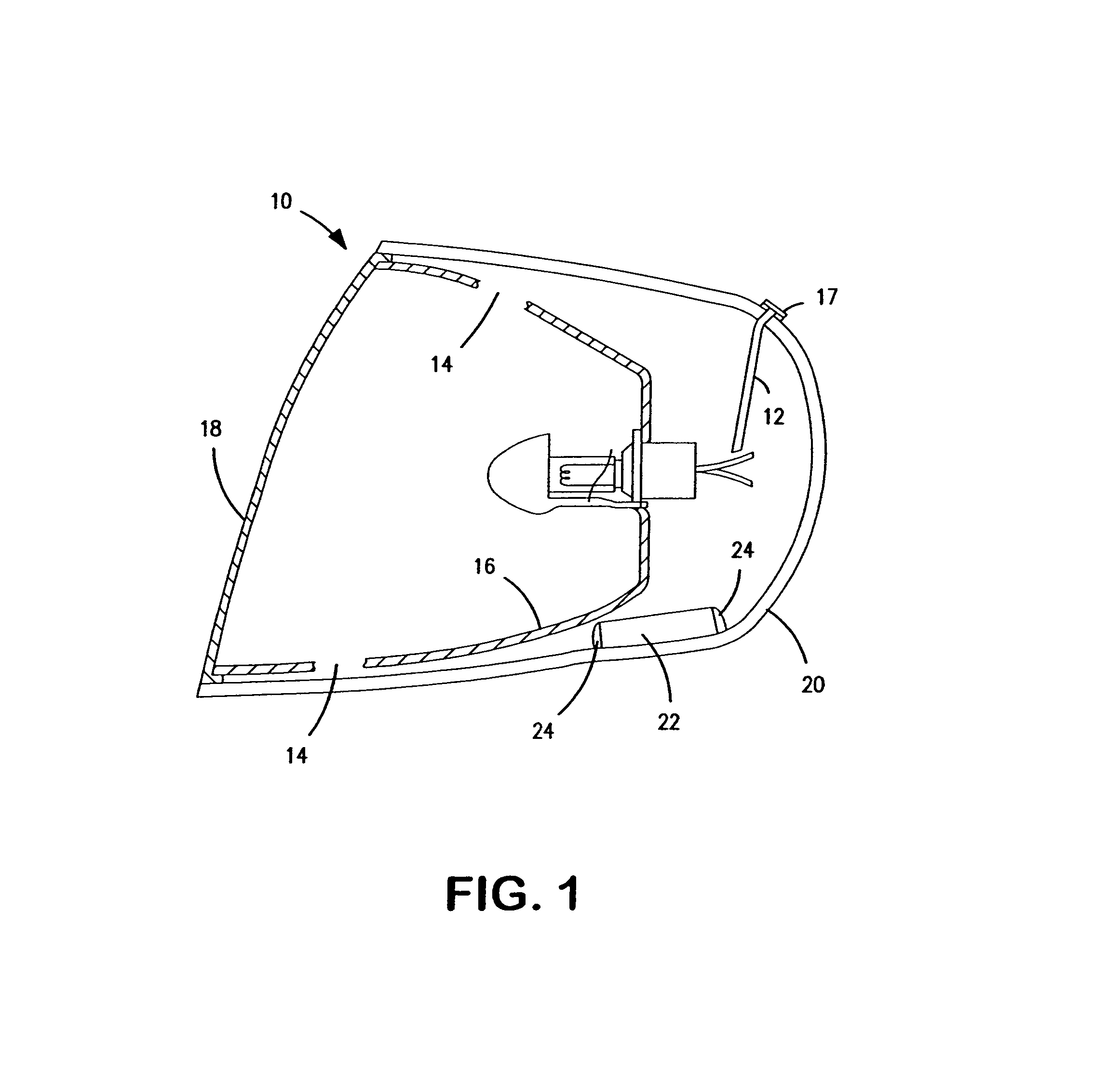

Venting system for minimizing condensation in a lighting assembly

ActiveUS7217314B2Lighting heating/cooling arrangementsIsotope separationInterior spaceCelsius Degree

In one aspect, the invention is a lighting assembly comprising a housing defining an internal space within the housing, and an ambient space surrounding the housing, a light source within the internal space; a high capacity desiccant within the internal space, the high capacity desiccant being nonregenerating at temperatures of up to about 50 degrees Celsius and about 11.0% relative humidity; and a diffusion tube having a first opening proximate to the internal space and a second opening proximate to the ambient space, the diffusion tube providing gaseous communication between the internal space and the ambient space.

Owner:WL GORE & ASSOC INC

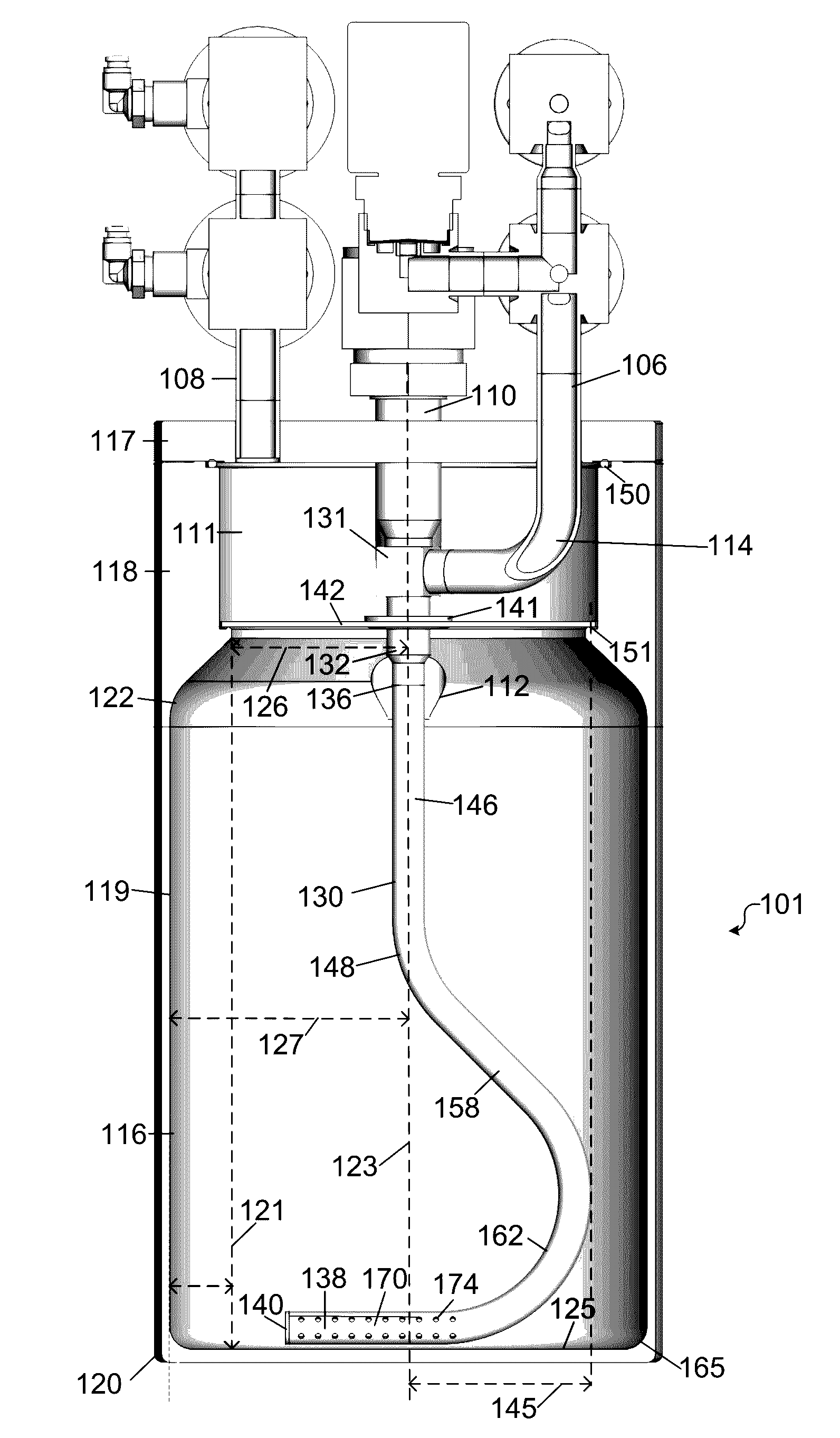

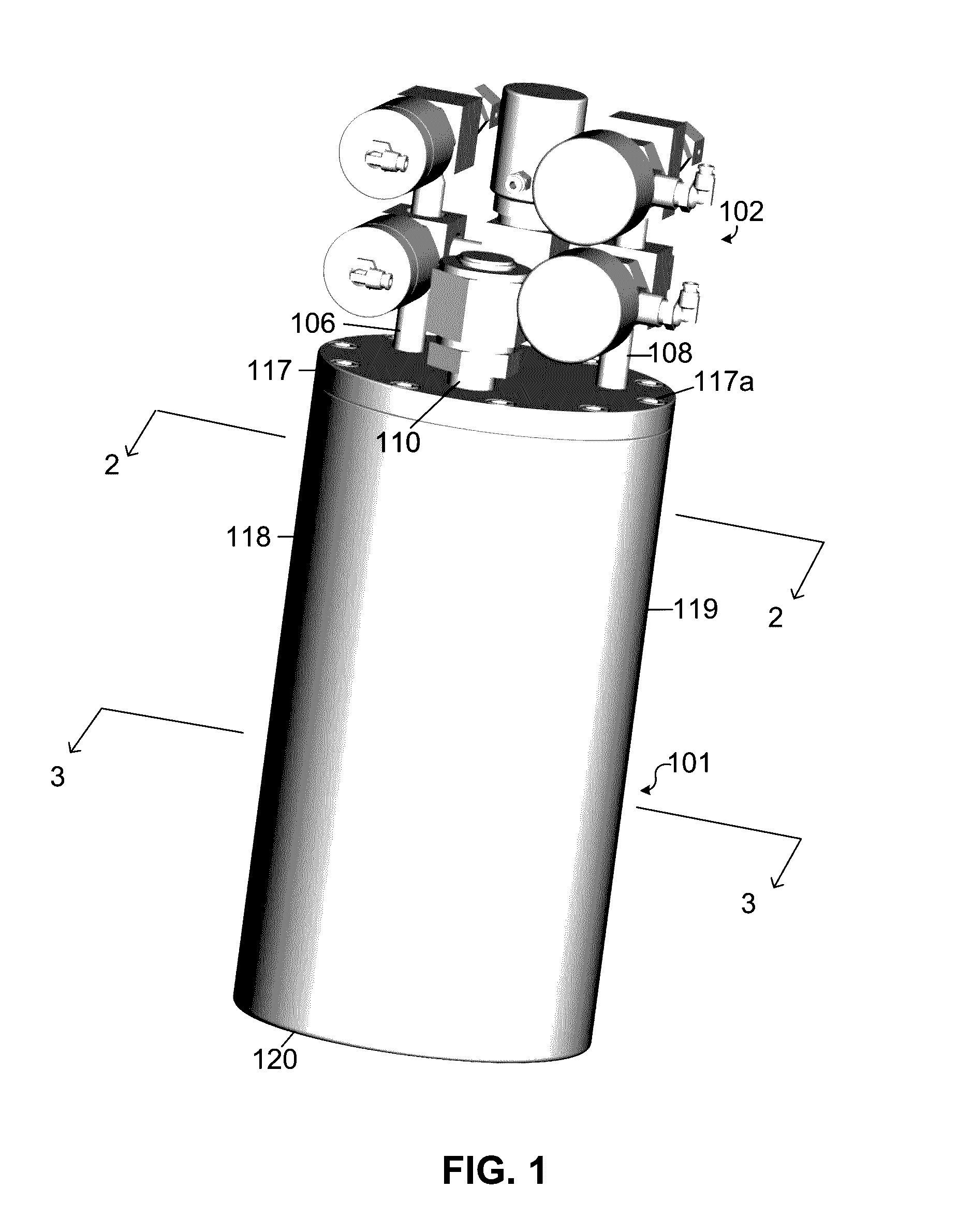

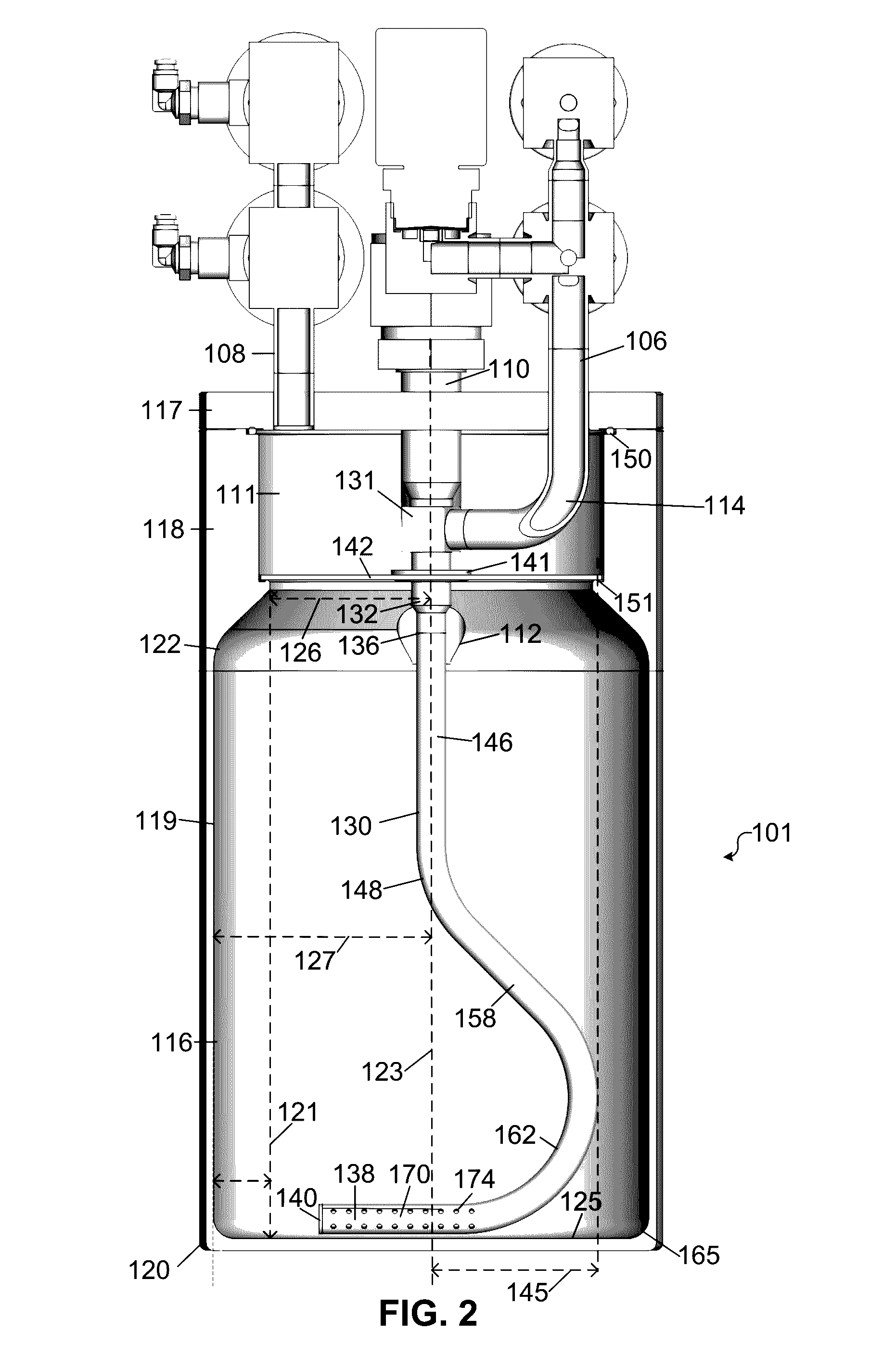

Vessel and method for delivery of precursor materials

ActiveUS20160305019A1Prevent flow communicationImprovement to precursor utilizationChemical vapor deposition coatingLow volumeBiomedical engineering

A vessel for conveying a precursor-containing fluid stream from a precursor material contained within the vessel using a carrier gas. The vessel defines an interior volume segmented into an upper volume and a lower volume, the upper volume being in fluid communication with the lower volume, the lower volume containing substantially all of the precursor material and being separated from the upper volume by a separator. The vessel includes a diffuser tube that extends from an inlet port, through the separator and has a distal end having a plurality of openings formed therein and extends along the bottom interior wall of the vessel.

Owner:VERSUM MATERIALS US LLC

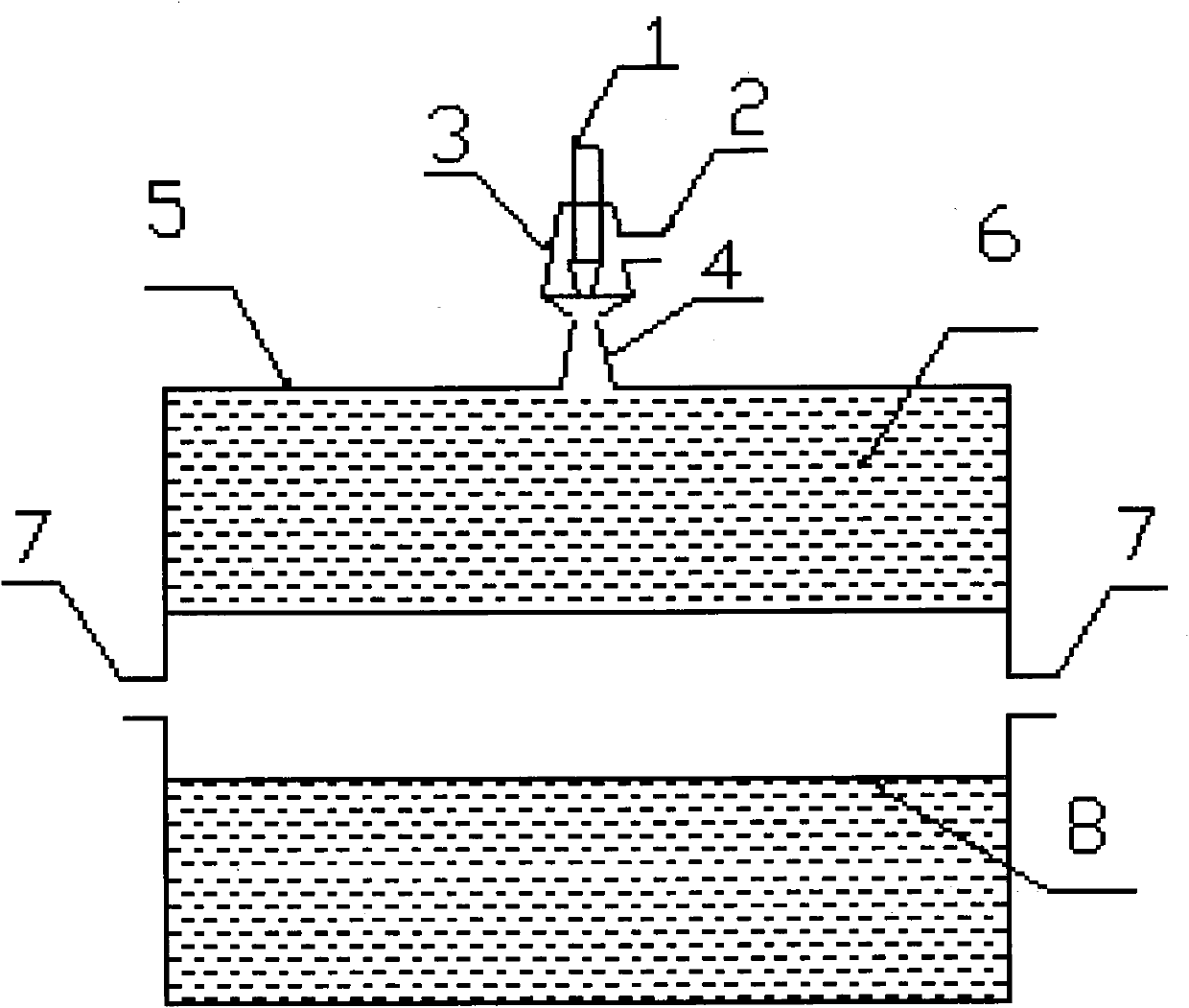

Piezoelectric micro-mixer

InactiveCN103170265AEfficient mixingFull and efficient mixingFlow mixersTransportation and packagingPump chamberEngineering

The invention relates to the field of micro-mechanics for microfluid pumping and mixing, and in particular relates to a piezoelectric valveless micro-mixer, which comprises two inlet channels, an inlet buffer chamber, an inlet vortex tube, pump chambers, a piezoelectric vibrator, an upper substrate, a pump body, an outlet vortex tube, an outlet buffer chamber and an outlet channel. The two inlet channels are intersected at the inlet buffer chamber, the included angle of central lines of the two inlet channels is less than or equal to 90 degrees, and the vortex tubes are produced by adding triangular bodies in diffusion tubes. The piezoelectric micro-mixer provided by the invention has the main advantages that the two inlet channels are intersected at the inlet buffer chamber, so that fluids to be mixed are firstly mixed in the inlet buffer chamber, and then are further mixed in the specially designed vortex tubes effectively, so that the required mixing time is greatly shortened, and the mixing efficiency is improved.

Owner:JIANGSU UNIV

Micron-nano-sized aerator

InactiveCN102001719AIncrease contact areaIncrease the mass transfer rate coefficientTreatment using aerobic processesSustainable biological treatmentEngineeringOxygen

The invention discloses a micron-nano-sized aerator for sewage treatment and air flotation and the like. An air-water mixing chamber is arranged on the central side wall of a metal outer sleeve, a diffusion tube is communicated between the air-water mixing chamber and the metal outer sleeve, an air-water nozzle is arranged at the inlet end of the air-water mixing chamber, and a compression air inlet is arranged on the side part of the air-water mixing chamber, a micropore plastic round tube of which two ends are provided with spraying outlets is coaxially arranged at the center of the metal outer sleeve, a polytetrafluoroethylene plastic sheet is tightly matched between the micropore plastic round tube and the metal outer sleeve, micro pores the aperture of which is 1-3mum are distributed on the side wall of the micropore plastic round tube, a multi-layer cellular porous polytetrafluoroethylene plastic sheet is coated on the outer wall of the micropore plastic round tube, and the micro pores on each cellular porous polytetrafluoroethylene plastic sheet are arranged in a staggering way. The liquid sprayed from the spraying outlets is vaporous, the diameter of the air bubble is in nano level, the vaporized moisture is ascended together in water body, the contact area of the vaporized moisture and the water body is large, the retention period is long, the mass transfer rate coefficient is high and the concentration of the dissolved oxygen is high.

Owner:CHANGZHOU UNIV

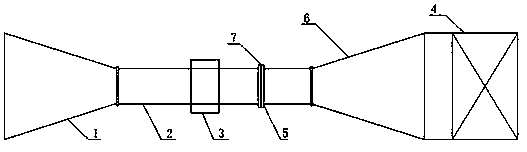

Extension-type Venturi tube and processing method and application method thereof

InactiveCN101893462AHigh compressive strengthImprove assembly accuracyVolume/mass flow by differential pressureWorking pressureEngineering

The invention discloses an extension-type Venturi tube and processing method and application method thereof, comprising a Venturi tube; wherein the Venturi tube is externally sheathed with a Venturi tube sleeve. The Venturi tube is composed of a front constricted tube, a middle tube and a rear diffusion tube, the inner diameter of the sleeve is equal to the maximum outer diameter of the front tube of the Venturi tube, and the two ends of the front constricted tube and the rear diffusion tube are fixed in the sleeve. The invention adds a sleeve to the original rolling plate type Venturi tube, thus greatly improving assembling accuracy. Fluid moves in a totally-enclosed sleeve, thus greatly improving compression strength of the invention and reducing possible leakage point, so that the Venturi tube can bear overhigh working pressure or can be used for flow measurement of danger medium. Meanwhile double insurance function is realized when bearing overhigh working pressure or being used for flow measurement of danger medium.

Owner:江阴市节流装置厂有限公司

Submerged hollow fiber membrane module

InactiveUS20070125697A1Improve scalabilityPrevent water leakageMembranesSemi-permeable membranesWater leakageAdhesive

The present invention discloses a submerged hollow fiber membrane module which is of such a structure that it is easy to expand a module processing capability according to a treatment capacity, provides convenient module coupling properties and module manufacturing properties, maintains a stable flux under an efficient air diffusion condition and prevents the damage of membranes and water leakage caused by the loosening of module connecting regions. The submerged hollow fiber membrane module comprises [I] two module headers (2 and 2′) having a filtrate water collecting portion (3) for collecting filtrate water filtered through hollow fiber membranes and a filtrate water outlet (7), [II] an air diffusion unit 8 consisting of support tubes (9 and 9′) fixing the two module headers (2 and 2′) while keeping them spaced a predetermined distance and air diffusion tubes (11 and 11′) having air diffusion holes (13), and [III] a bundle of hollow fiber membranes (1) having both opposite ends fixed to the insides of the module headers (2 and 2′) by an adhesive (6) so as to form a water collecting space within the module headers (2 and 2′), the ends (5) of the hollow portions of the hollow fiber (20) membranes being opened and disposed in parallel to a filtrate water discharge surface (4).

Owner:KOLON IND INC

Micron-nano-sized aerator

InactiveCN102001719BIncrease contact areaIncrease the mass transfer rate coefficientTreatment using aerobic processesSustainable biological treatmentEngineeringOxygen

The invention discloses a micron-nano-sized aerator for sewage treatment and air flotation and the like. An air-water mixing chamber is arranged on the central side wall of a metal outer sleeve, a diffusion tube is communicated between the air-water mixing chamber and the metal outer sleeve, an air-water nozzle is arranged at the inlet end of the air-water mixing chamber, and a compression air inlet is arranged on the side part of the air-water mixing chamber, a micropore plastic round tube of which two ends are provided with spraying outlets is coaxially arranged at the center of the metal outer sleeve, a polytetrafluoroethylene plastic sheet is tightly matched between the micropore plastic round tube and the metal outer sleeve, micro pores the aperture of which is 1-3mum are distributedon the side wall of the micropore plastic round tube, a multi-layer cellular porous polytetrafluoroethylene plastic sheet is coated on the outer wall of the micropore plastic round tube, and the micro pores on each cellular porous polytetrafluoroethylene plastic sheet are arranged in a staggering way. The liquid sprayed from the spraying outlets is vaporous, the diameter of the air bubble is in nano level, the vaporized moisture is ascended together in water body, the contact area of the vaporized moisture and the water body is large, the retention period is long, the mass transfer rate coefficient is high and the concentration of the dissolved oxygen is high.

Owner:CHANGZHOU UNIV

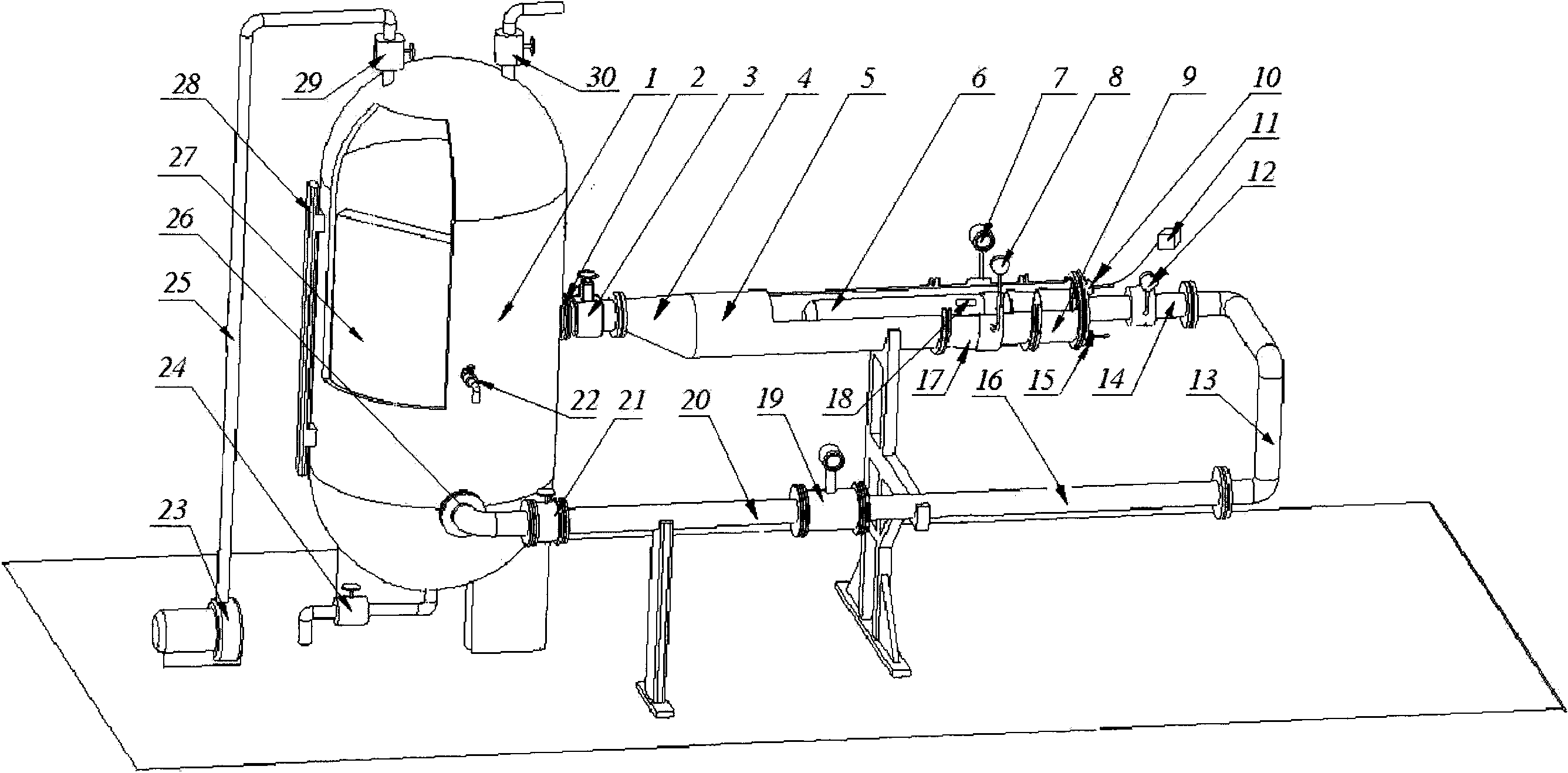

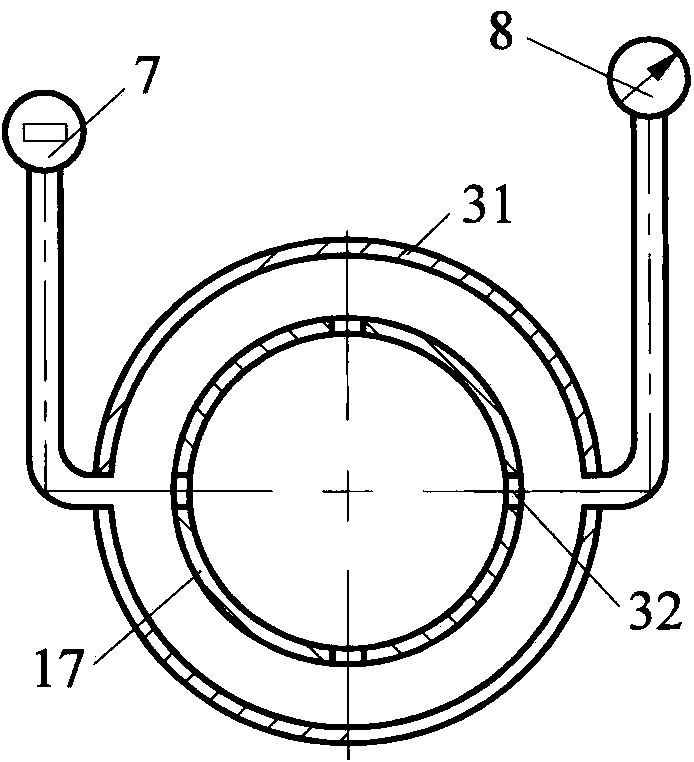

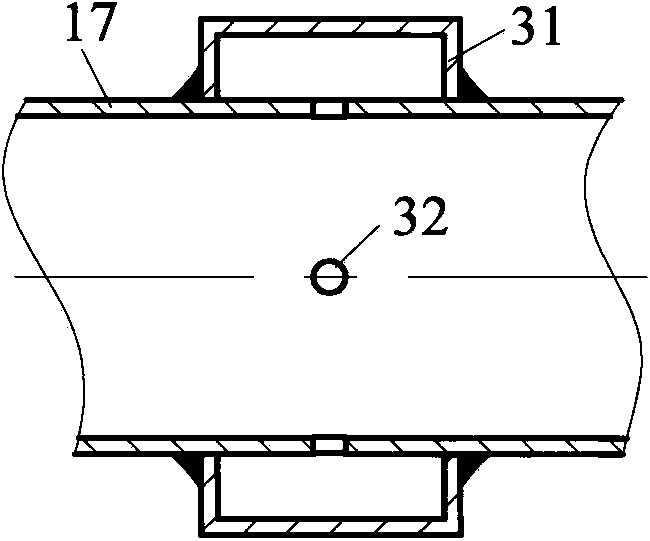

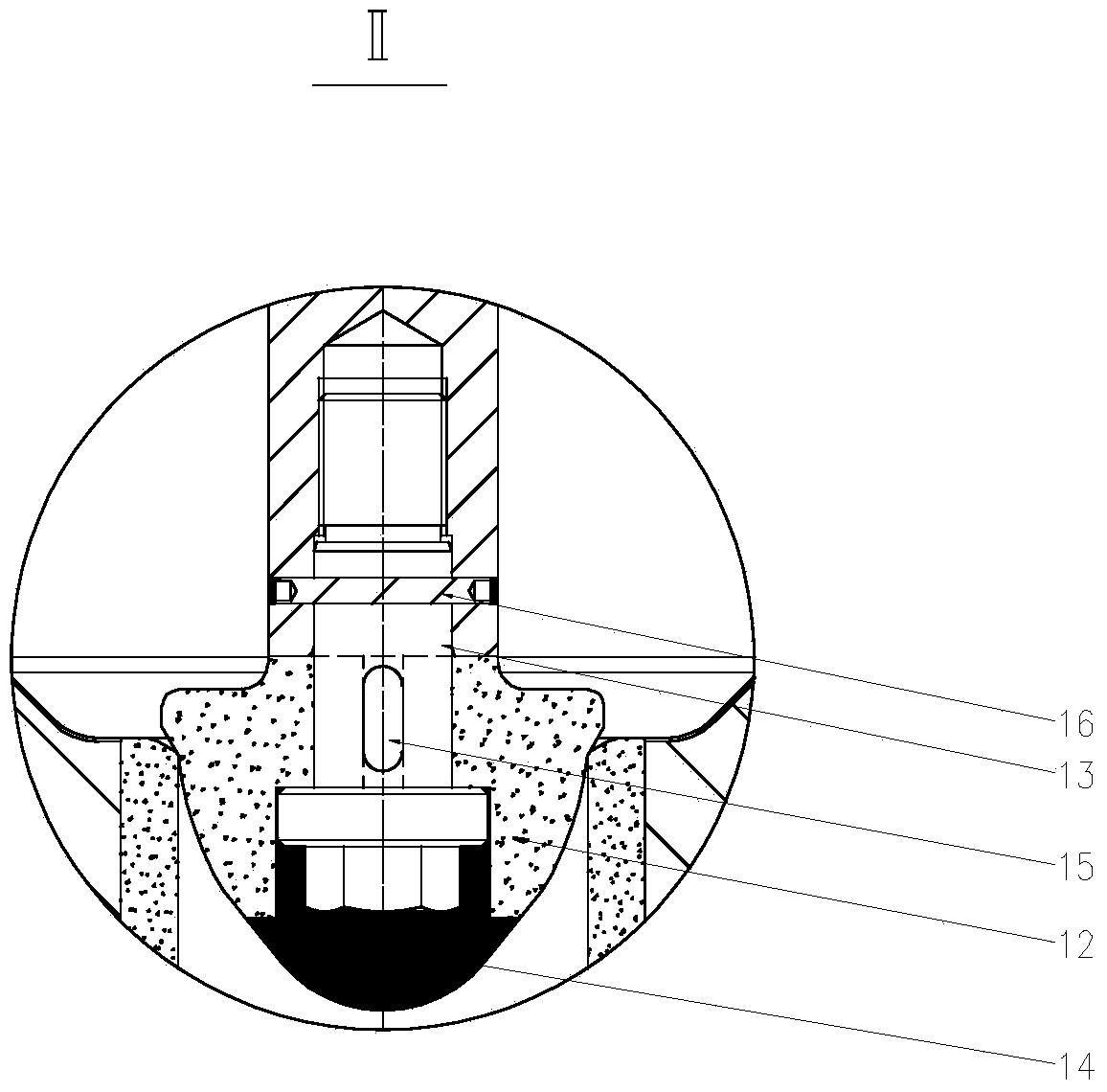

Closed test device for NPSH of submersible pump

ActiveCN103821710ASolve the problem that the cavitation performance test cannot be carried outPump testingPositive-displacement liquid enginesCavitationExhaust valve

The invention belongs to the technical field of fluid machinery, and particularly relates to a closed test device for the NPSH of a water-filling type submersible pump and a submersible pump for a well. The test device is composed of a cavitation tank, an inlet valve, a non-concentric diffusion tube, a suction tube, a submersible pump, a temperature meter, an inlet pressure gauge, a transition tube, a first seal joint, a revolution speed measurement instrument, an outlet pressure gauge, a water drainage tube, an outlet pressure measurement tube, a second seal joint, a flow meter upstream straight tube segment, an inlet pressure measurement tube, a revolution speed transducer, a flow meter, a flow meter downstream straight tube segment, a flow control valve, a water injection valve, a vacuum pump, a drainage valve, an exhaust tube, a partition plate, a liquid level meter, an extraction valve and a vent valve. The temperature meter, the inlet pressure gauge, the outlet pressure gauge, the revolution speed transducer, the revolution speed measurement instrument and the flow meter are used for measuring key parameters of the NPSH of the submersible pump. The test device has the advantages that the critical NPSH of the submersible pump under the conditions of different flows can be measured through the test device for the NPSH of the submersible pump, and the problem that a cavitation performance test of the submersible pump cannot be carried out is solved.

Owner:JIANGSU UNIV

Device and method for accurately measuring concentration of low-concentration dusts

InactiveCN107607447ASimple structureWide measurement rangeParticle suspension analysisTest channelDirect test

The invention provides a device and method for accurately measuring the concentration of low-concentration dusts, and belongs to the technical field of charge induction test. The structure of the device for accurately measuring the concentration of low-concentration dusts comprises a test channel, a charge induction assembly stretching into the test channel, and an airflow driver and a processingdisplay which are matched, the front end of the test channel is connected with a trumpet-shaped air inlet tube, the rear end of the test channel is connected with a trumpet-shaped diffusion tube and an airflow driver, and airflow sequentially goes through an air inlet tube, the test channel and the diffusion tube to form the Venturi effect. The detection device has the advantages of simple structure, wide measurement range, high precision of a measurement result especially when the concentration of the dusts is low, and small repetition error. The detection method can highly-efficiently and accurately test the concentration of low-concentration dust airflow, has a high precision, allows the concentration of the dusts to be directly tested through checking meters by establishing an experience database by means of a model, and is widely suitable for every measurement environment.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Injection-type reactor for preparing gas hydrates

The invention relates to an injection-type reactor, in particular an injection-type reactor for preparing gas hydrates, which comprises a nozzle, an entrainment chamber, a throat tube, a diffusion tube, a pin valve mounted at the nozzle and a flow controller mounted at the tail end of the throat tube. A visualized window is arranged at the diffusion tube, the reactor is provided with a reaction water inlet, a gas inlet, a gas valve, a valve, a gas-liquid outlet, a temperature sensor and a pressure sensor; the pin valve adjusts the area of the nozzle and further controls the intake amount of reaction water, and the flow controller can be replaced by another one with different apertures to change the drop size after injection. The injection-type reactor for preparing the gas hydrates enables the gas to contact and mix with the reaction water and then be injected and atomized at a high speed so as to increase the contact area between the gas and fogdrops, shorten the induction time of a hydration reaction, greatly improve the generation rate of the gas hydrates and realize the high-efficiency rapid generation of the gas hydrates, thereby being a novel high-efficiency reactor for preparing the gas hydrates.

Owner:SOUTH CHINA UNIV OF TECH

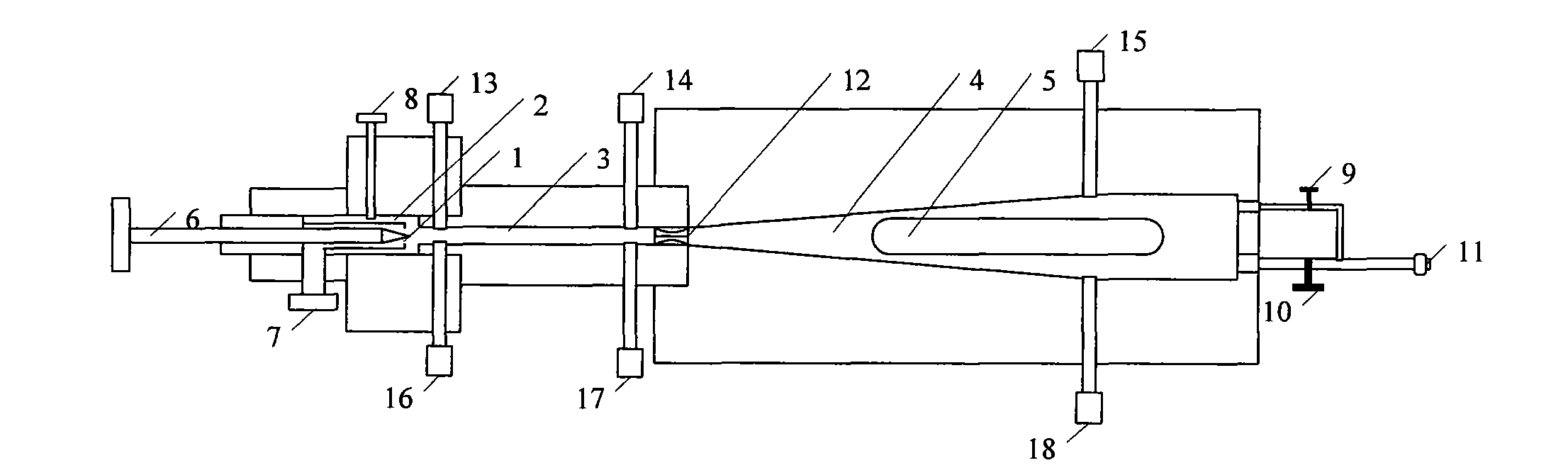

Circulation type dismounting and washing free cooking-fume exhauster

InactiveCN101430109AWill not polluteImprove performanceDomestic stoves or rangesLighting and heating apparatusLow noiseEngineering

The invention relates to an unpicking and washing-free recirculating range hood which comprises a lampblack absorbing part, a lampblack liquid dissolving circulating system and a case. A circulation loop comprises a grid plate and a water tank containing oxygen purification water solution, one end of an inlet tube is connected with the water tank, and the other end of the inlet tube is connected with a water pump, the water pump is sequentially connected with an outlet tube, a nozzle, a mixing chamber, a mixing tube, a diffusion tube, a tee pipe, a reducer, a straight tube and a return hose; one end of the return hose is arranged in the water tank, and a lampblack collecting hood is fixed on the mixing chamber. In the range hood, four components which are the nozzle, the mixing chamber, the mixing tube and the diffusion tube form a Venturi tube structure to generate a negative-pressure lampblack suction; which replaces the traditional suction methods in which a fan is driven by a motor; the oxygen purification water washing solution is employed to dissolve the lampblack which is circularly scoured in the tube, thus ensuring the tube wall to be free of oil stain, and realizing the free internal unpicking and washing of the range hood. The range hood does not need any mechanical rotating part when in operation, and has the advantages of no wear, low noise, reliable operation, safe use, low cost, simple maintenance and no environmental pollution, and no lampblack is directly discharged to the atmosphere.

Owner:WUHAN UNIV

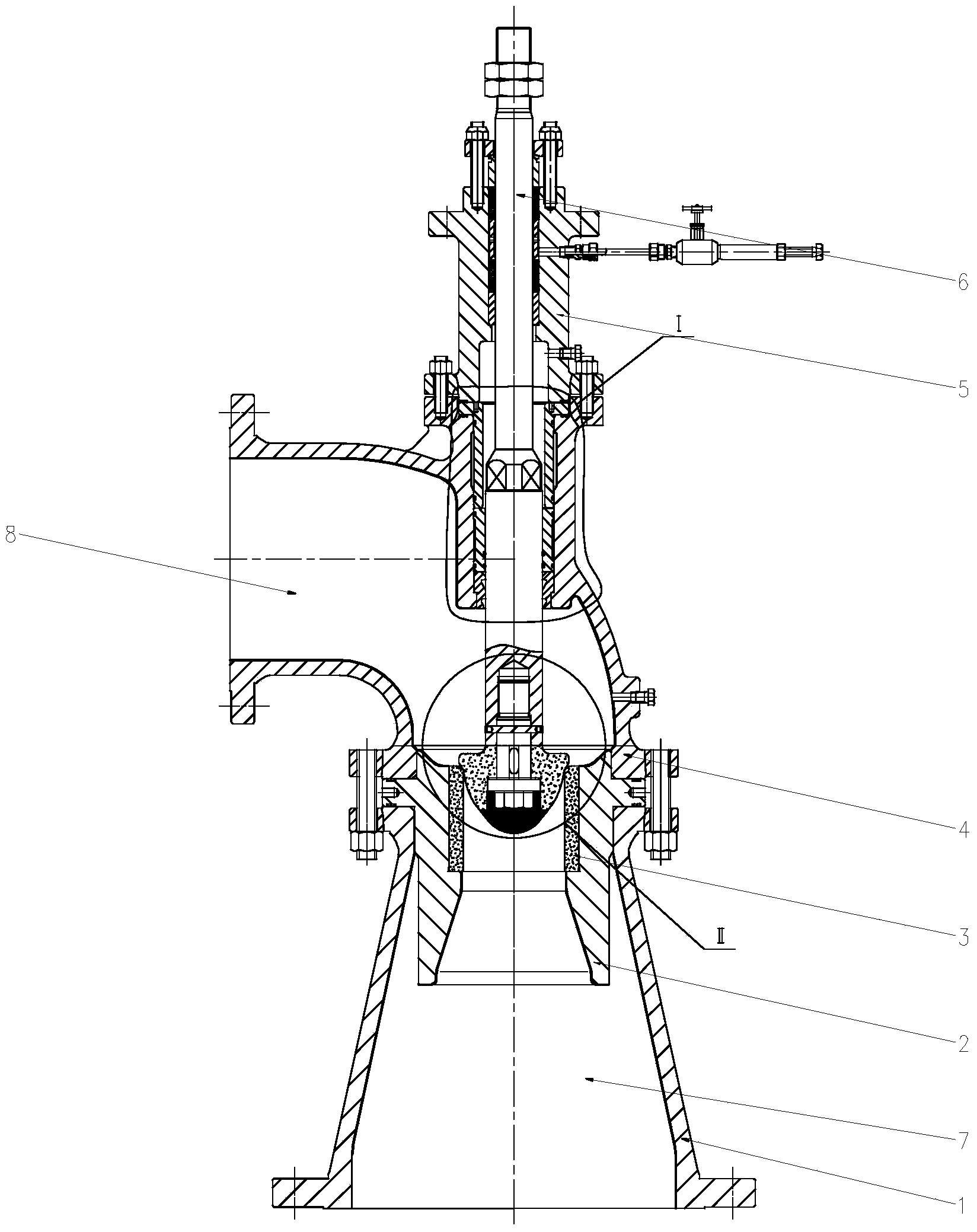

Black water coking-preventing impact-resistant shockproof regulating angle valve special for coal chemical industry

ActiveCN103591303AImprove anti-blocking performanceAvoid vortexLift valveValve housingsFluid controlControl valves

The invention relates to a regulating angle valve, in particular to a black water coking-preventing impact-resistant shockproof regulating angle valve special for the coal chemical industry, and belongs to the field of fluid control valves. The black water coking-preventing impact-resistant shockproof regulating angle valve comprises a diffusion tube and a valve body, wherein the lower end of the valve body is connected with the diffusion tube through a bolt. An inlet flowing channel is arranged in the valve body, an outlet flowing channel is arranged in the diffusion tube and is communicated with the inlet flowing channel, and the inlet flowing channel is perpendicular to the outlet flowing channel. A valve carrier base is arranged in the outlet flowing channel and is clamped through the diffusion tube and the valve body, and a valve carrier is arranged in the valve carrier base. The black water coking-preventing impact-resistant shockproof regulating angle valve is simple in structure and novel in design, can effectively solve the technical problems that a traditional black water regulating angle valve is easy to coke, poor in impact resistant performance, undesirable in shockproof effect and the like in a use process, is widely applied in sites of customers, and effectively lowers production operation cost of the customers.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

Micro-nano bubble generator

ActiveCN111298670AInflatable volumeSmall bubble diameterFlow mixersMixing methodsMicro nanoEngineering

The invention discloses a micro-nano bubble generator. The micro-nano bubble generator comprises a liquid inlet pipe, a swirl flow groove, a reducing pipe, an air inlet pipe, a shell, a throat pipe, adiffusion pipe, a mixing pipe, a breaker and release heads, wherein the reducing pipe, the throat pipe and the diffusion pipe are sequentially connected to form a Venturi-pipe-like water passing channel structure; a gap between the joints of the reducing pipe, the throat pipe and the diffusion pipe is a multi-stage air inlet; the inner walls of two ends of the shell are connected with the outer wall of the reducing pipe and the outer wall of the diffusion pipe respectively to form an air storage chamber which communicates with a throat flow channel through the multi-stage air inlet; and the breaker is arranged in the mixing pipe; and the outer side of the mixing pipe is connected with four release heads. According to the micro-nano bubble generator disclosed by the embodiments of the invention, large bubbles can be quickly broken; formed bubbles have the characteristics of small size and uniform dispersion; meanwhile, the diameters of the bubbles can be adjusted by replacement of therelease heads with different specifications.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

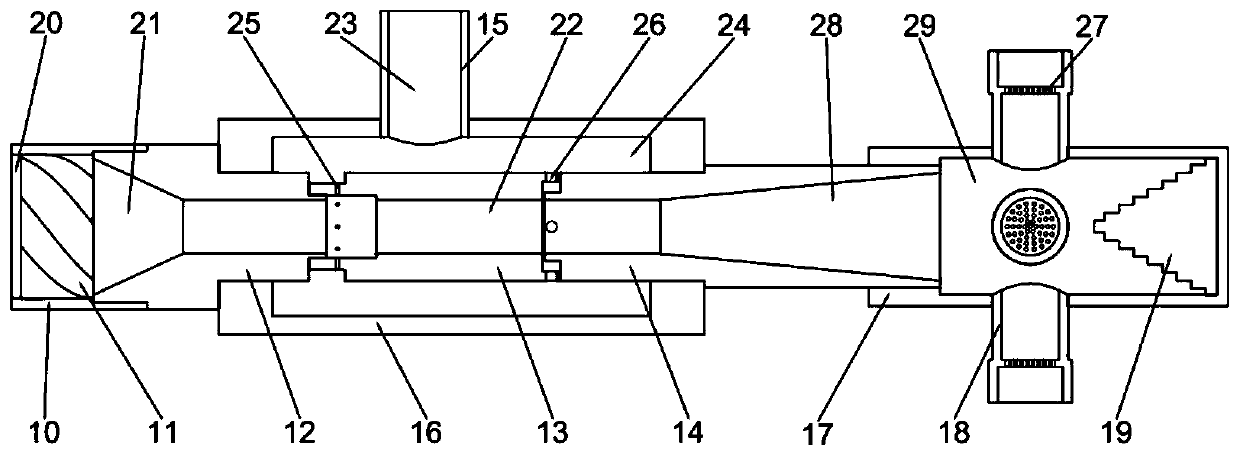

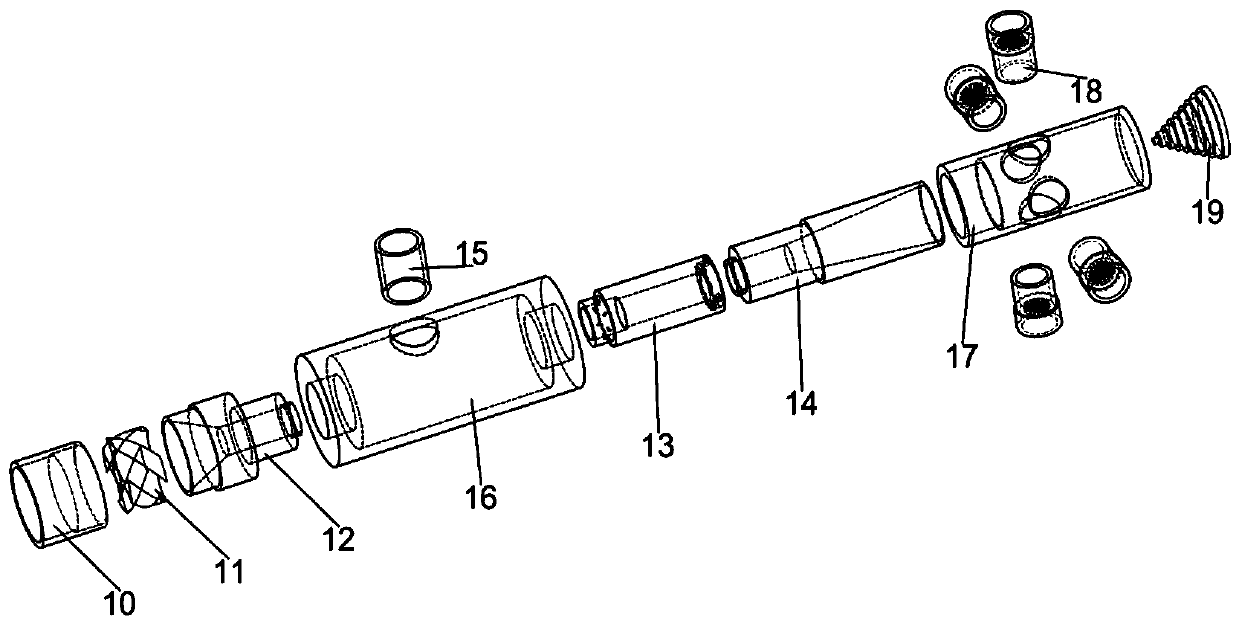

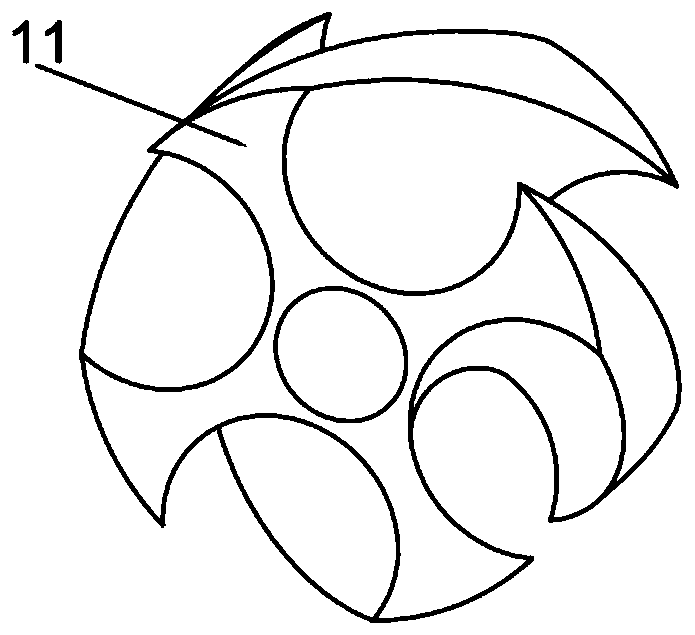

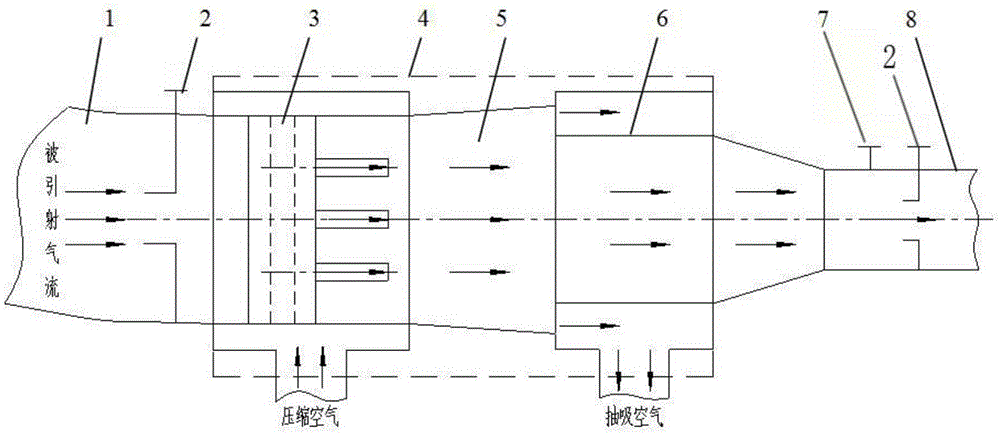

Unconventional layout form air intake and exhaust pipeline device

An unconventional layout form air intake and exhaust pipeline device can be applied to an airplane model with a complicated internal pipeline layout design to carry out an air intake and exhaust power simulation wind tunnel test. The unconventional layout form air intake and exhaust pipeline device includes an air intake duct, two pressure sensors, an injector, a diffuser pipe, a bypass suction pipeline, a temperature sensor and a jet pipe. The injector, the diffuser pipe and the bypass suction pipeline are arranged inside a core supporting member in a model. The air intake duct is connected with the injector. The injector is connected with the diffuser pipe. The diffuser pipe is connected with the bypass suction pipeline. The bypass suction pipeline is connected with the jet pipe. Injected air flow enters via the air intake duct, compressed air enters via the injector, and the bypass suction pipeline freely guides the flow by means of pressure differences inside and outside the pipeline. The air intake duct is provided with the first pressure sensor. The jet pipe is provided with the second pressure sensor and the temperature sensor. The bypass suction pipeline is provided with a flow regulating hole plate. The device of the invention is high in simulation and high in operability, exhibits good airtightness, and functions stably when being applied to an air intake and exhaust power simulation wind tunnel test.

Owner:中国航空工业集团公司哈尔滨空气动力研究所

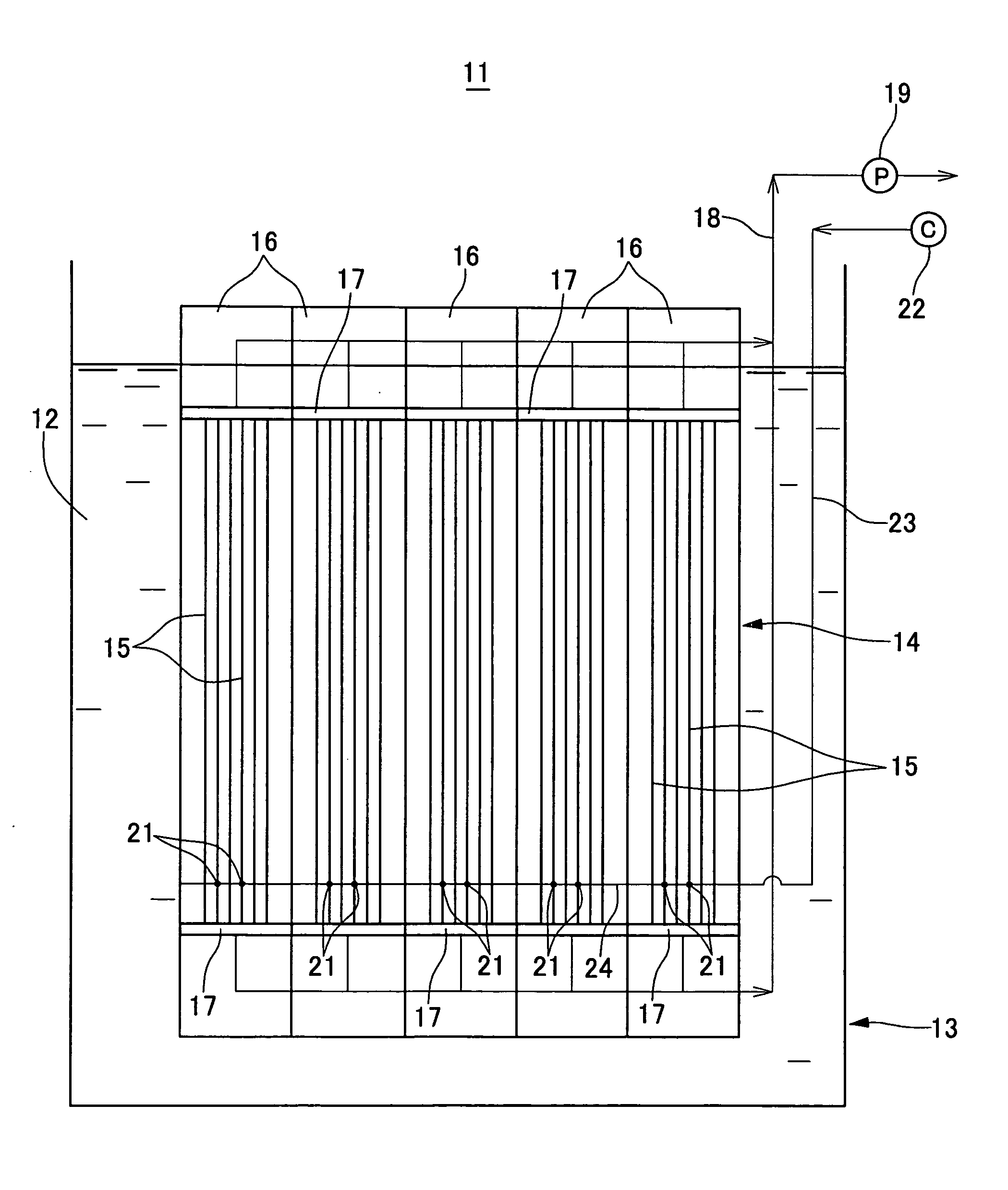

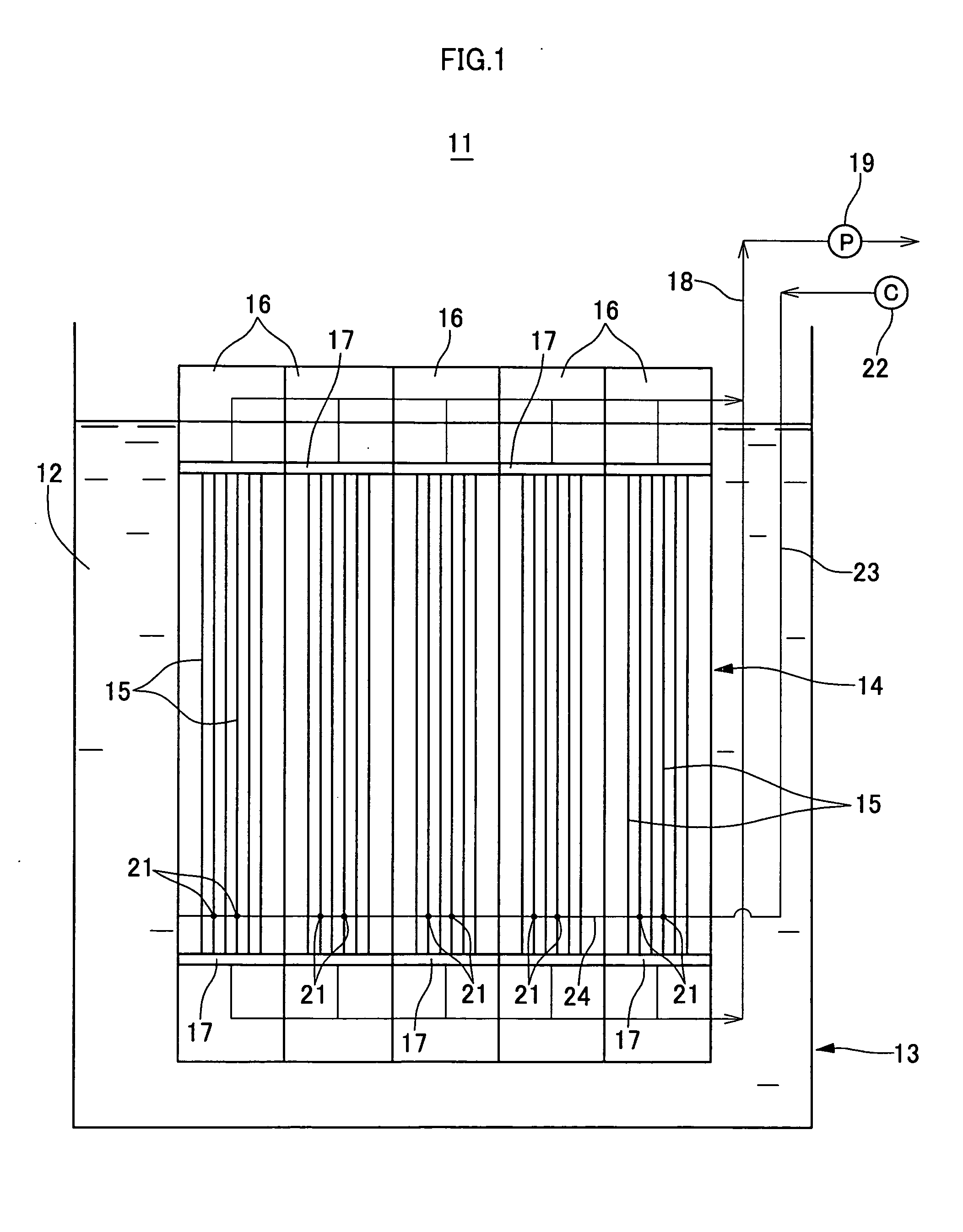

Filtration device

InactiveUS20060260998A1Efficiently separated and removedHigh densityMembranesTreatment using aerobic processesHollow fibre membraneFiber

There is provided a compact filtration device capable of efficiently separate and remove suspension components adhered to membrane surfaces or to between membranes by allowing bubbling action by means of bubbles from an air diffusion tube to effectively affect the entire hollow fiber membrane, and capable of disposing inside hollow fiber membranes in high density. In a filtration device 11 for performing solid-liquid separation by allowing a liquid to be treated 12 containing suspension components to permeate a membrane module 14 for immersion type suction filtration or external pressure filtration, said membrane module 14 is formed from bundled membranes 16 in which a multiplicity of hollow fiber membranes 15 with their axes being in the vertical direction are contacted closely with each other at the upper and lower ends thereof, and a diffuser tube 21 is threaded into between said multiplicity of hollow fiber membranes 15 for insertion at the lower part of the bundled membrane 16.

Owner:MAEZAWA IND +1

Induced draft water curtain dust removing device for intercepted coal mining machine

InactiveCN102182458AEliminate backflowIncreases chances of capturing dustDust removalFire preventionSprayerHigh pressure water

The invention discloses an induced draft water curtain dust removing device for an intercepted coal mining machine and belongs to the technical field of dust removing equipment of coal mining machines. On the basis of additionally arranging a special water supply pipeline on a high-pressure water pump, a water magnetizer and a work surface, the induced draft water curtain dust removing devices for the intercepted coal mining machine are arranged on two rocker arms of the coal mining machine for removing dust; and the induced draft water curtain dust removing device, which is arranged on each rocker arm, consists of two hydraulic dust and air absorbing devices adopting long diffusion tubes, two solid conical self-suction sprayers adopting short diffusion tubes and two adjustable sector self-suction sprayers, so that an intercepted long and narrow water curtain belt consisting of an air distribution diversion region, a dust removing regions and a purifying region is formed at the side wall of coal beside the coal mining machine within a wide clean mining range, thereby improving the dust removing effect.

Owner:HUAIBEI MINING IND +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com