Micron-nano-sized aerator

A micro-nano aeration and micro-porous technology, which can be used in flotation water/sewage treatment, sustainable biological treatment, oxidized water/sewage treatment, etc., can solve the problems of low power efficiency, long repair time, and high maintenance cost. The effect of large mass transfer rate coefficient, long residence time and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

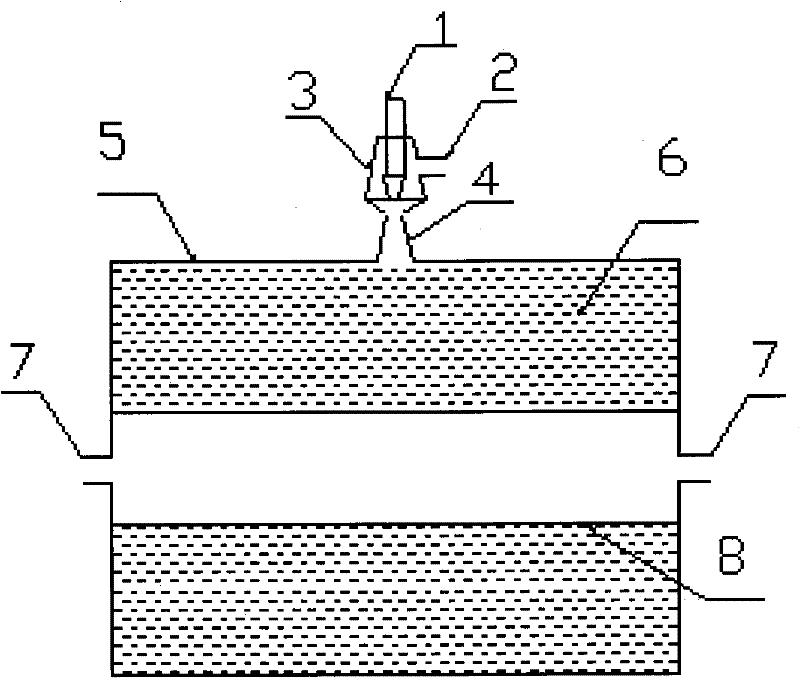

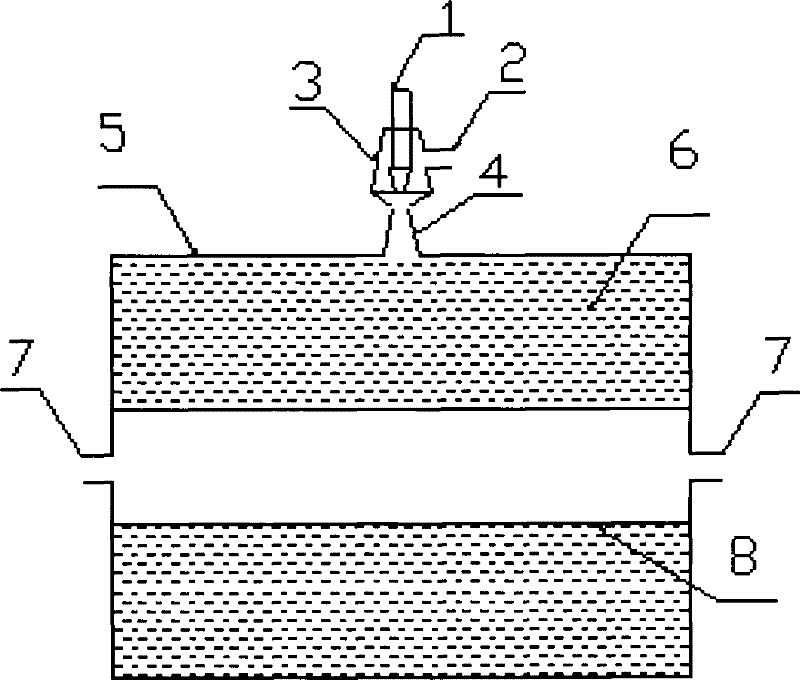

[0011] like figure 1 , The present invention consists of gas-water nozzle 1, compressed air inlet 2, gas-water mixing chamber 3, diffusion pipe 4, metal jacket 5, PTFE plastic sheet 6, jet outlet 7, microporous plastic round tube 8. The shape of the metal jacket 5 is a cylinder, and the microporous plastic circular tube 8 is a hollow plastic tube. A gas-water mixing chamber 3 is arranged on the middle side wall of the metal jacket 5 , a diffusion pipe 4 is communicated between the gas-water mixing chamber 3 and the metal jacket 5 , and the diffusion pipe 4 is communicated with the metal jacket 5 . An air-water nozzle 1 is installed at the inlet end of the air-water mixing chamber 3, and the air-water nozzle 1 is connected to an external air-water mixing pump. A compressed air inlet 2 is opened on the side of the air-water mixing chamber 3 . A microporous plastic circular tube 8 with jet outlets 7 at both ends is coaxially arranged in the center of the metal jacket 5 , and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com