Patents

Literature

7553results about How to "Extended stay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

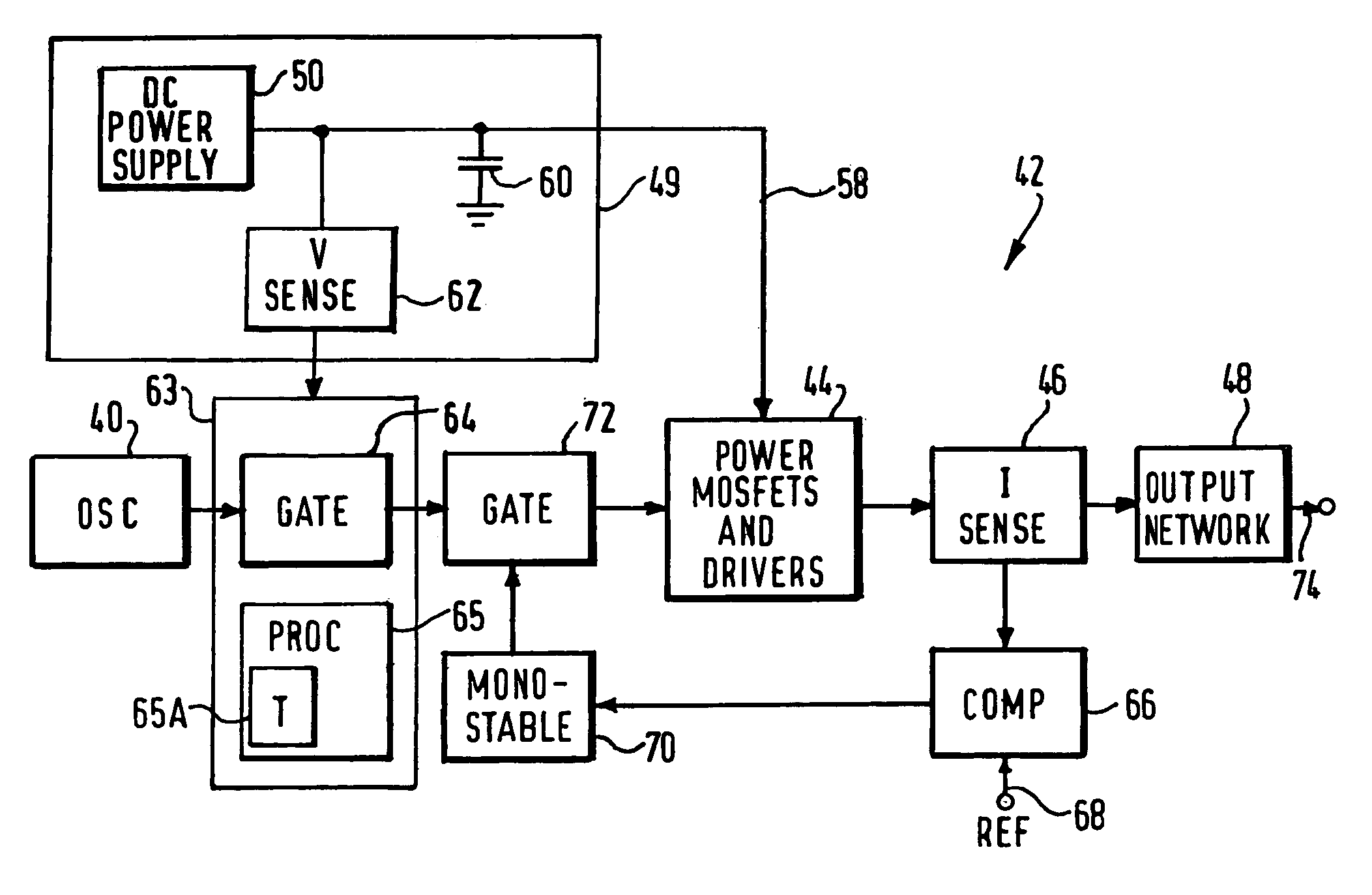

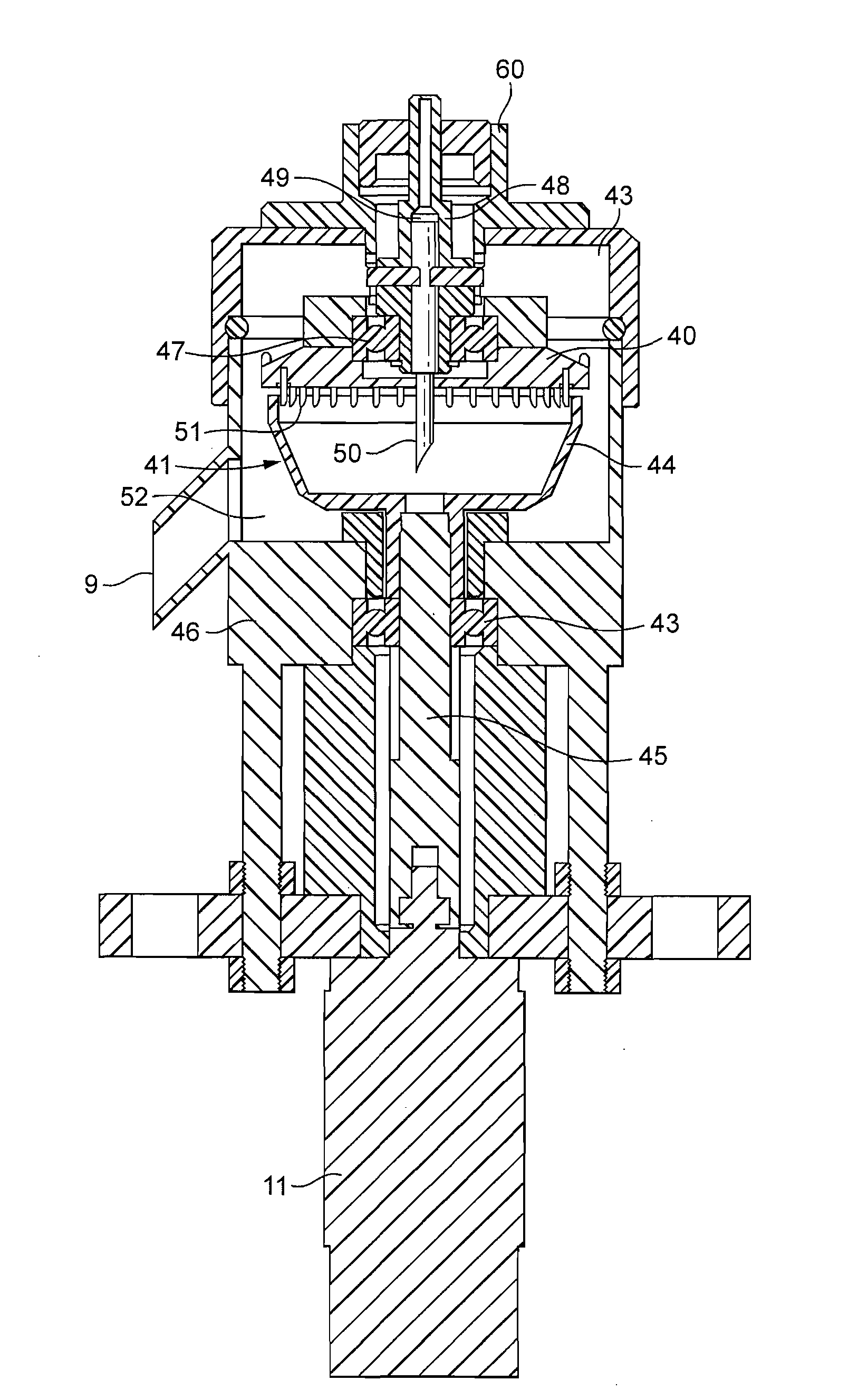

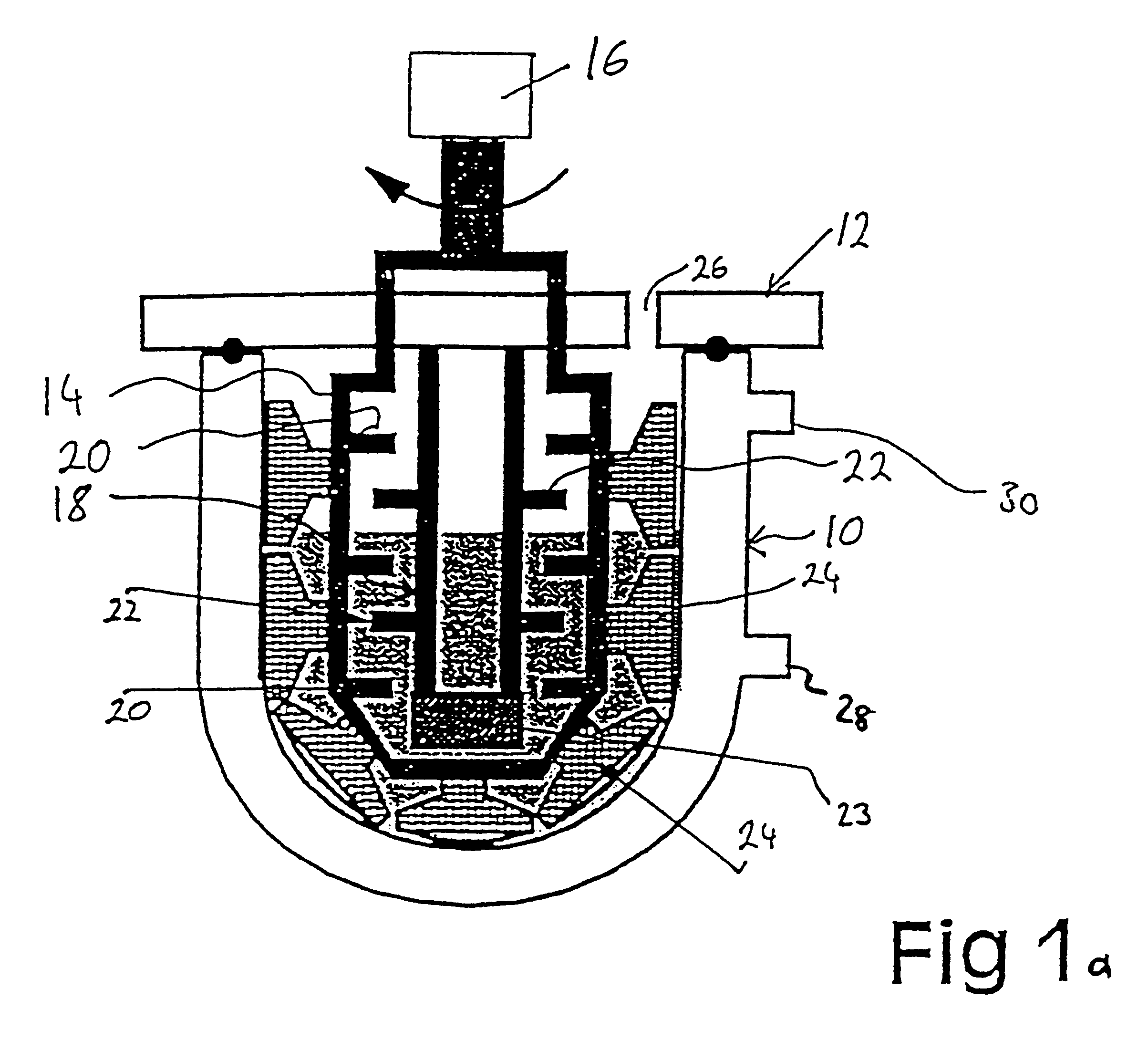

Electrosurgical generator

ActiveUS7195627B2High peak power capabilityReduces delay and unwanted coagulation effectSurgical instruments for heatingPeak valueContinuous wave

An electrosurgical generator for supplying RF power to an electrosurgical instrument for cutting or vaporising tissue has an RF output stage with RF output devices, a series-resonant output network and an RF output. The generator offers improved cutting and vaporising performance, especially in relation to the reliability with which an arc can be struck when presented with an initial load impedance load. This is achieved by virtue of the output stage being capable of maintaining output pulses of at least 1 kW peak by supplying the RF output devices from a large reservoir capacitor. An appropriate combination of cutting performance and haemostasis is provided by allowing for pulsed or continuous wave operation once an arc has been established, according to whether or not a surplus energy condition exists, as indicated by the voltage across the reservoir capacitor.

Owner:GYRUS MEDICAL LTD

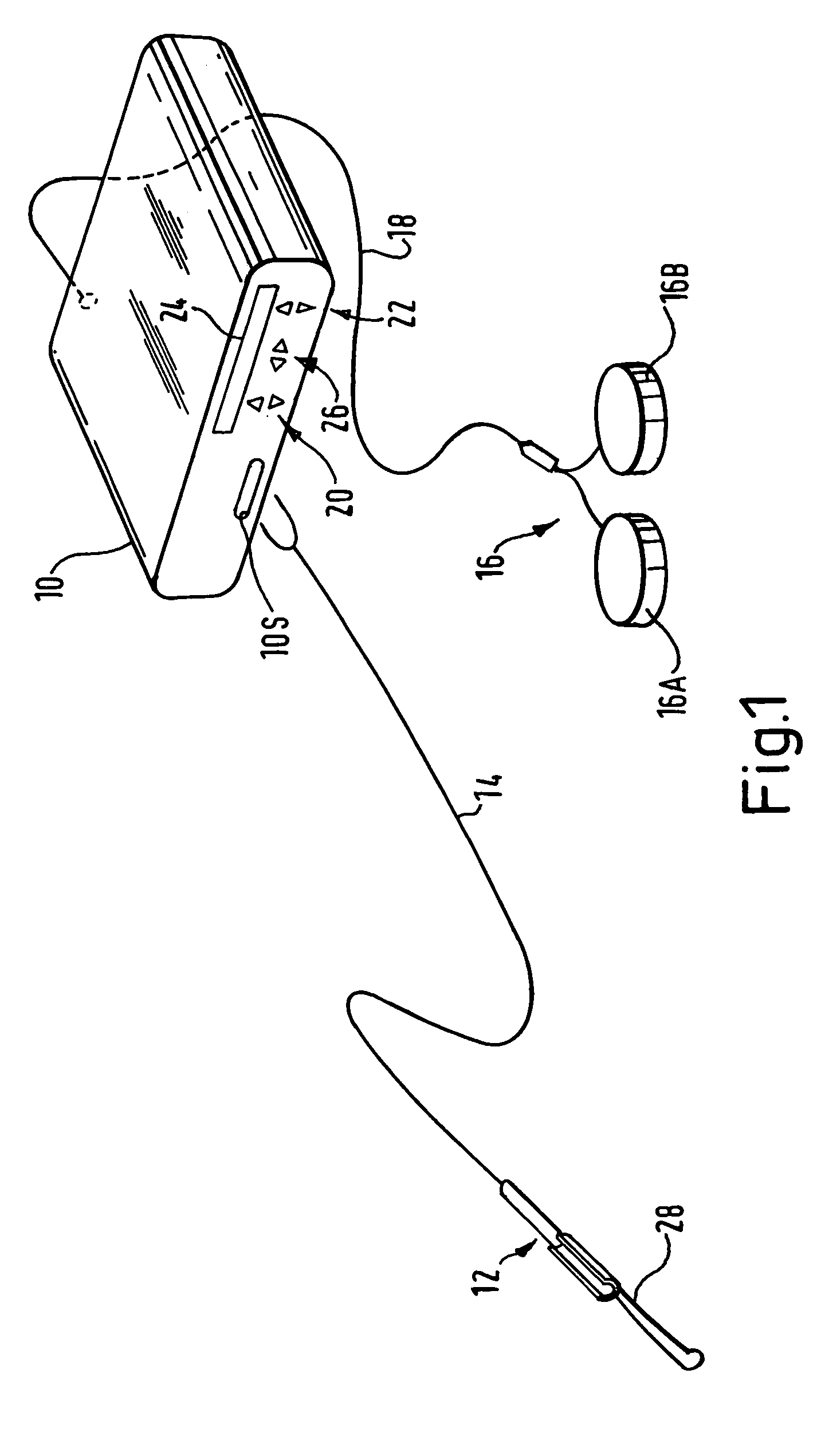

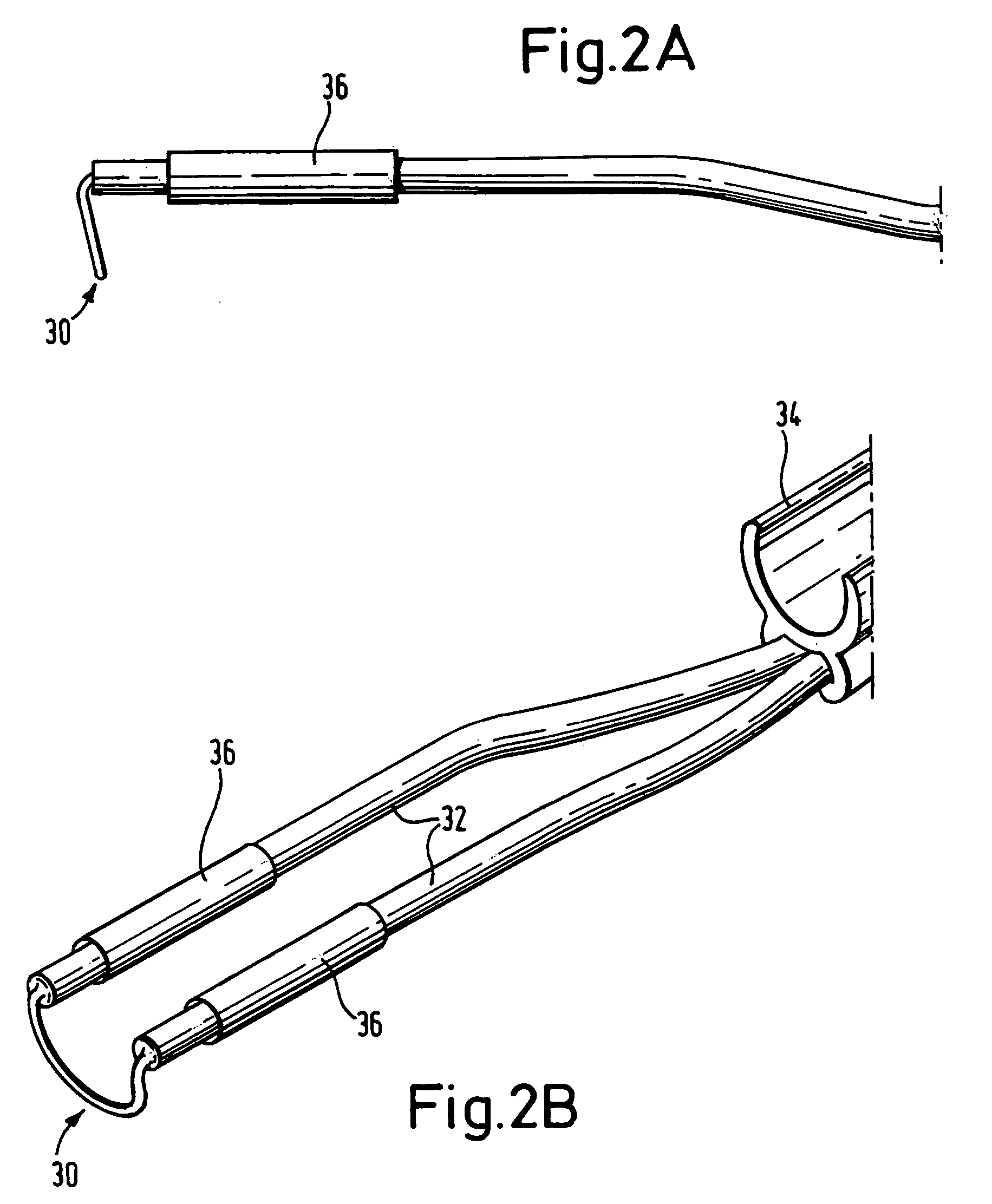

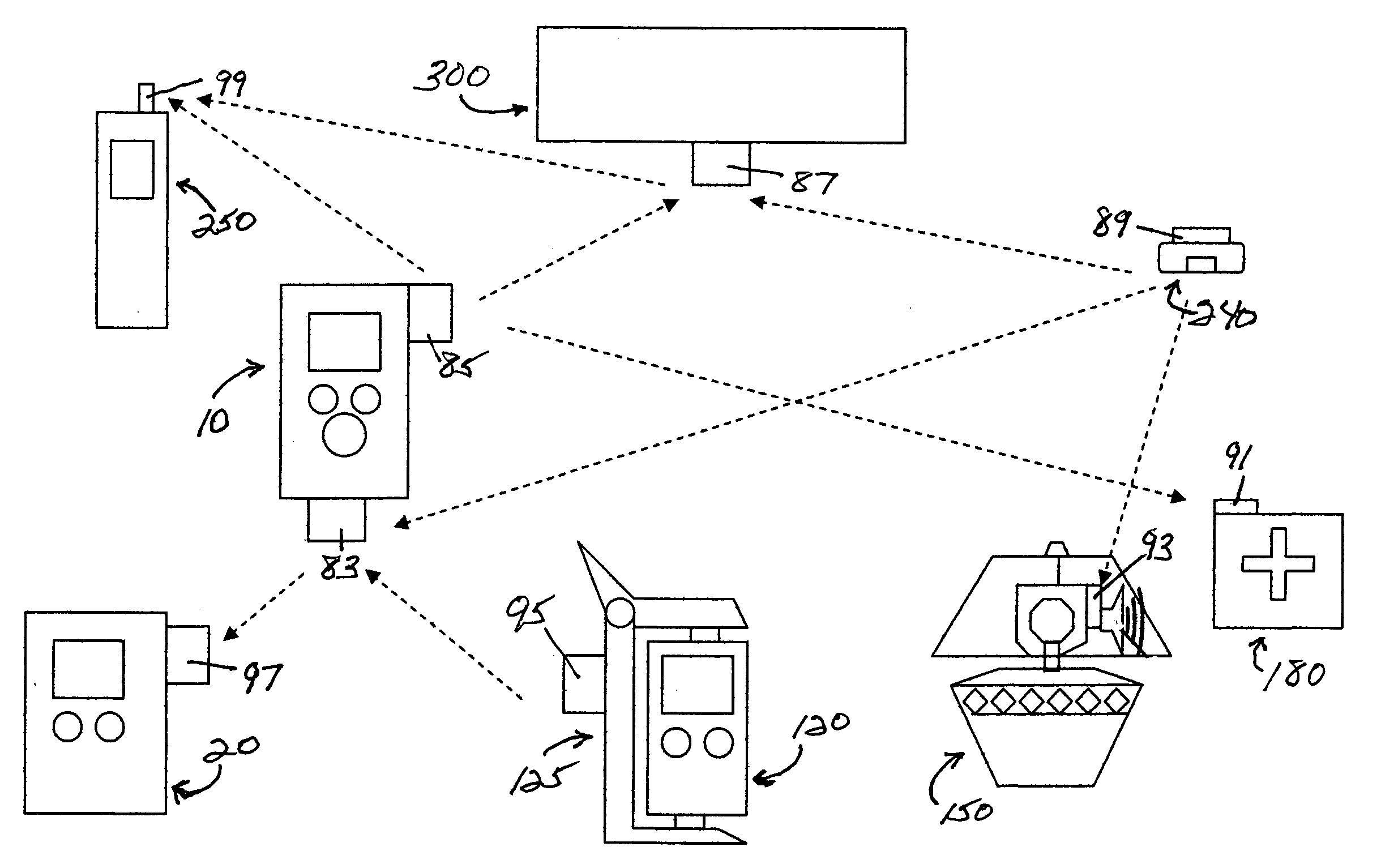

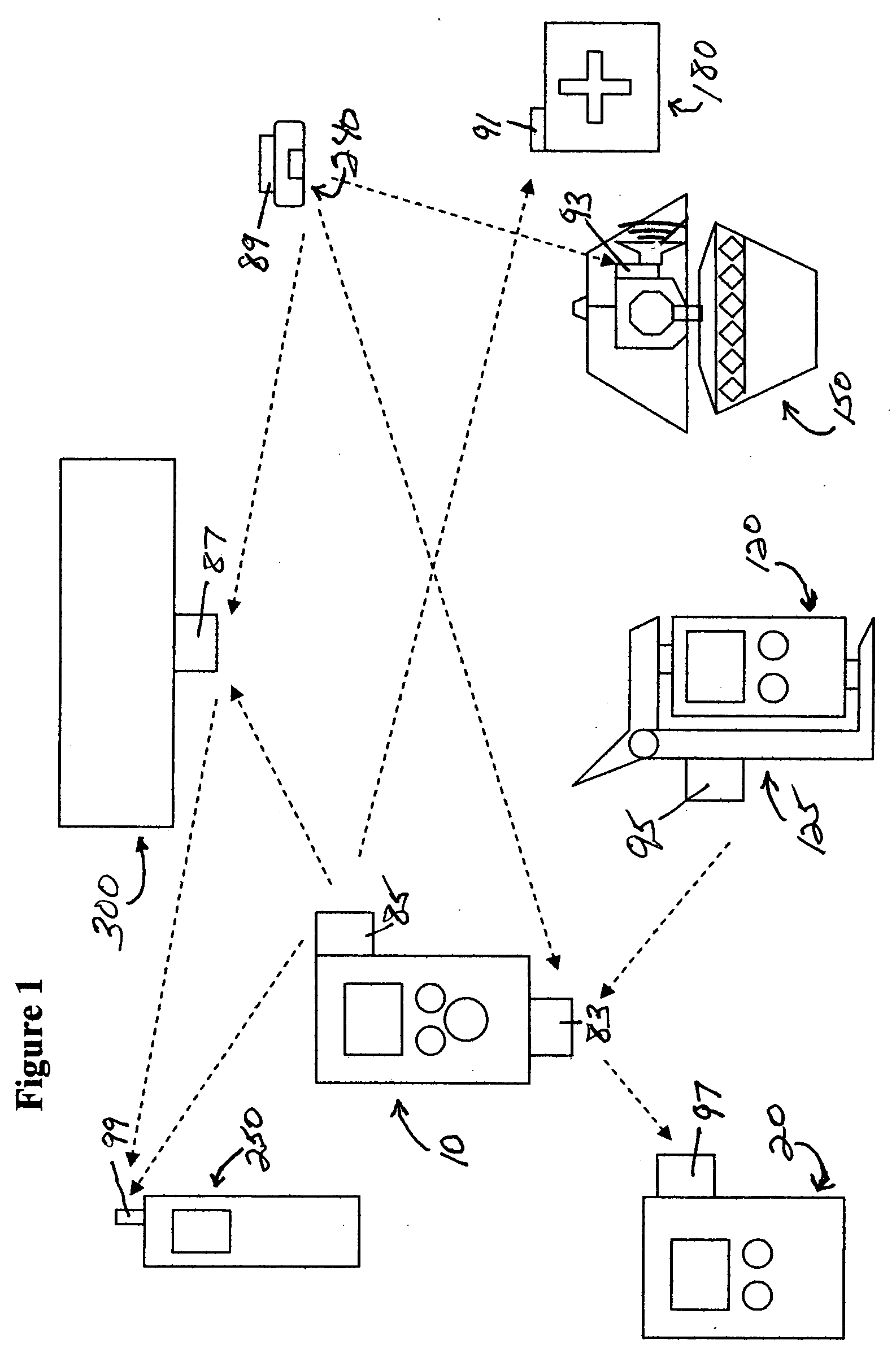

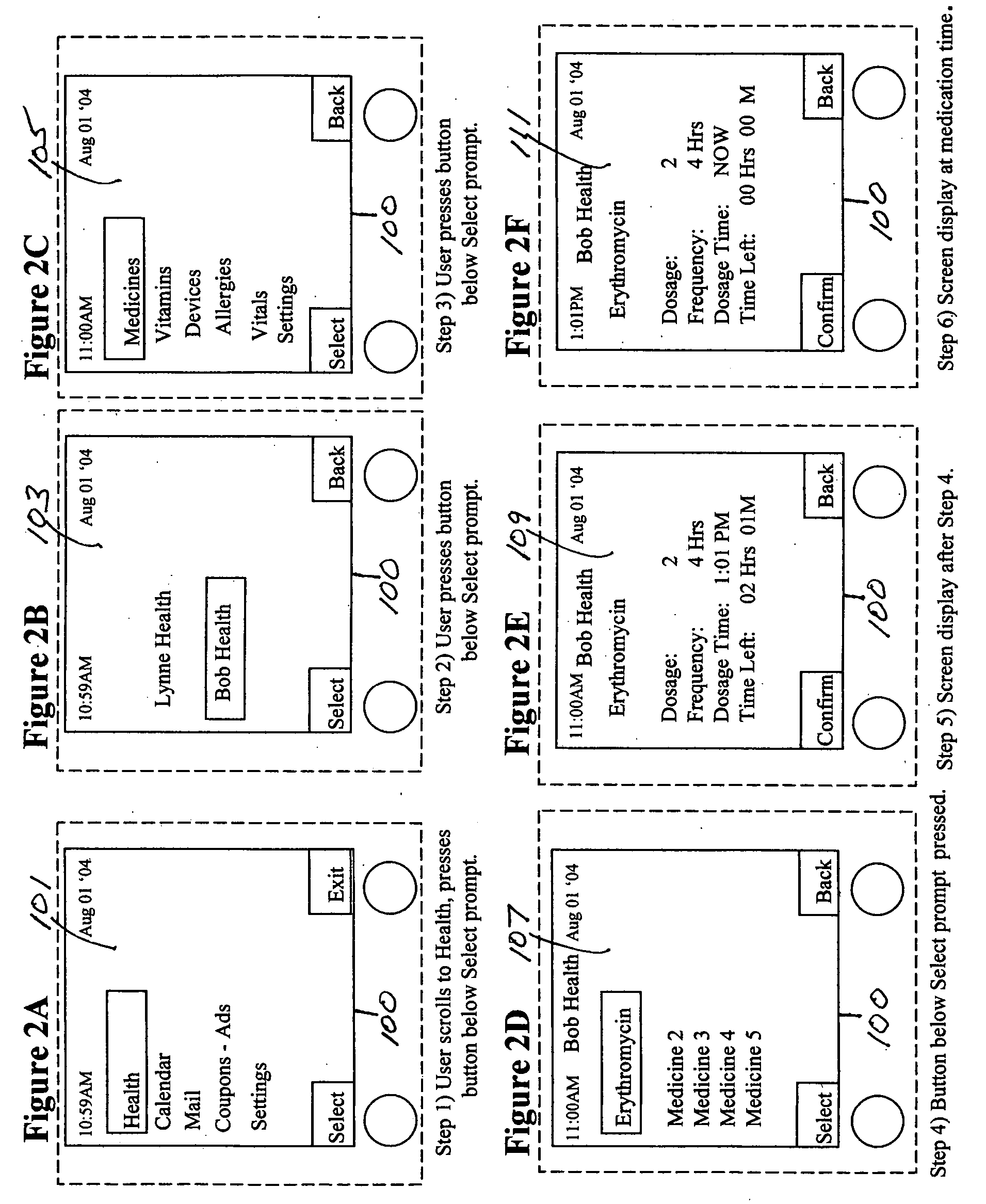

Medication & health, environmental, and security monitoring, alert, intervention, information and network system with associated and supporting apparatuses

InactiveUS20060154642A1Facilitate user and/or occupant well beingExtended stayDispersed particle filtrationDrug and medicationsNetworked systemHealth administration

Systems and apparatuses include devices, biosensors, environmental sensors, security related sensors, networked products, communications processors and components, alert and information components, processors, and software to support: 1) facilitating medication regimen and patient / user health administration, dosage control, tracking, compliance, information inquiry and presentation, reminder and notification; 2) providing monitoring, information, ordering, and intervention; 3) presenting the option of leveraging the preventative care, alert and notification components with other components to facilitate user or occupant well being, along with living, work area and dwelling environmental or security safety; and 4) enhancing the dwelling, living or work area with products that may be networked to support the widespread acceptance of these systems and apparatuses. The systems include a) processing, centralizing and communicating device commands and / or programs, e.g. a multifunctional device controller; b) device administration; c) patient / user information; d) dwelling environmental safety; e) security breach information; f) centralized and remote apparatus and system activations through primary component or at least one backup.

Owner:INSIGNIO TECH

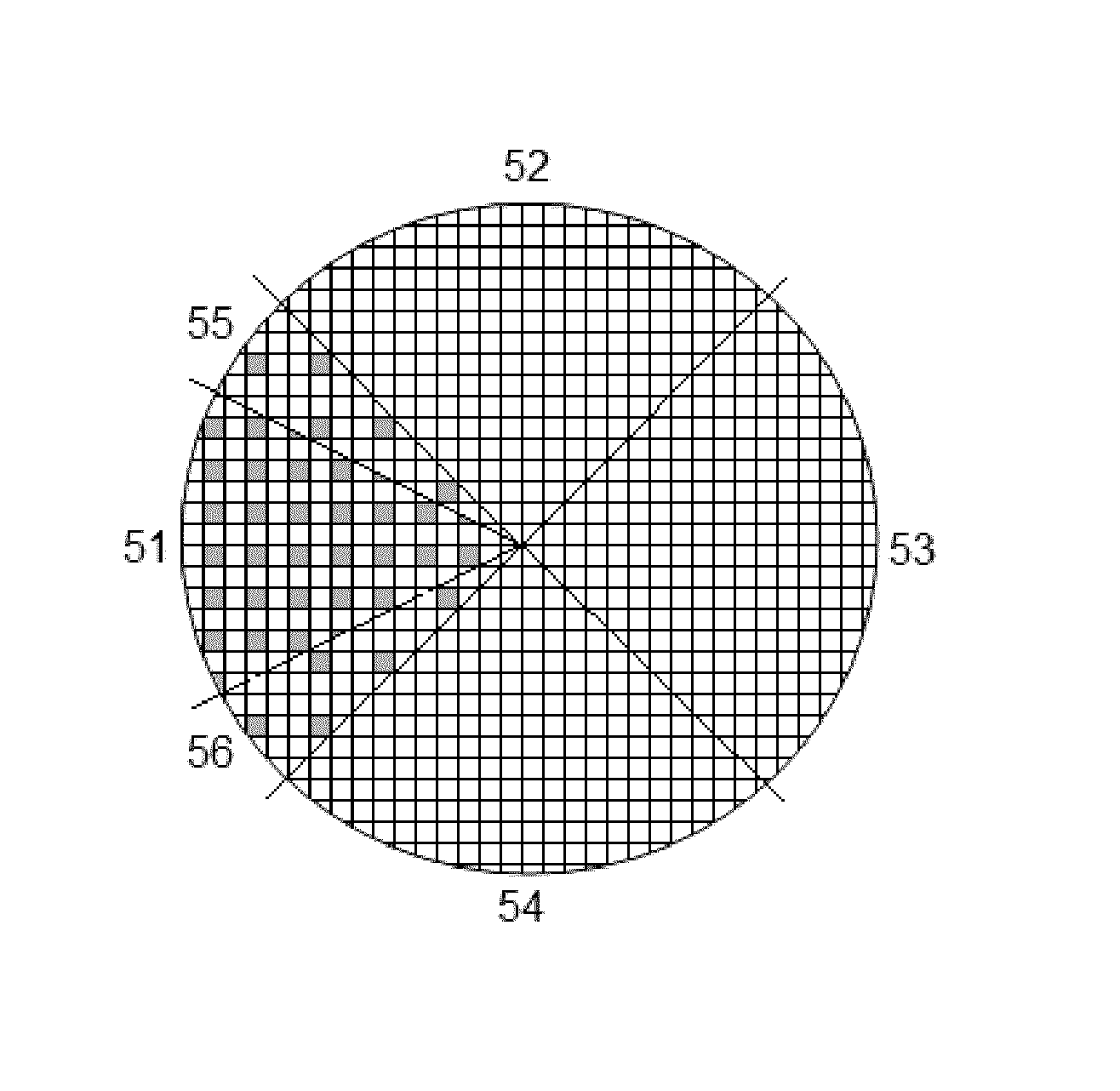

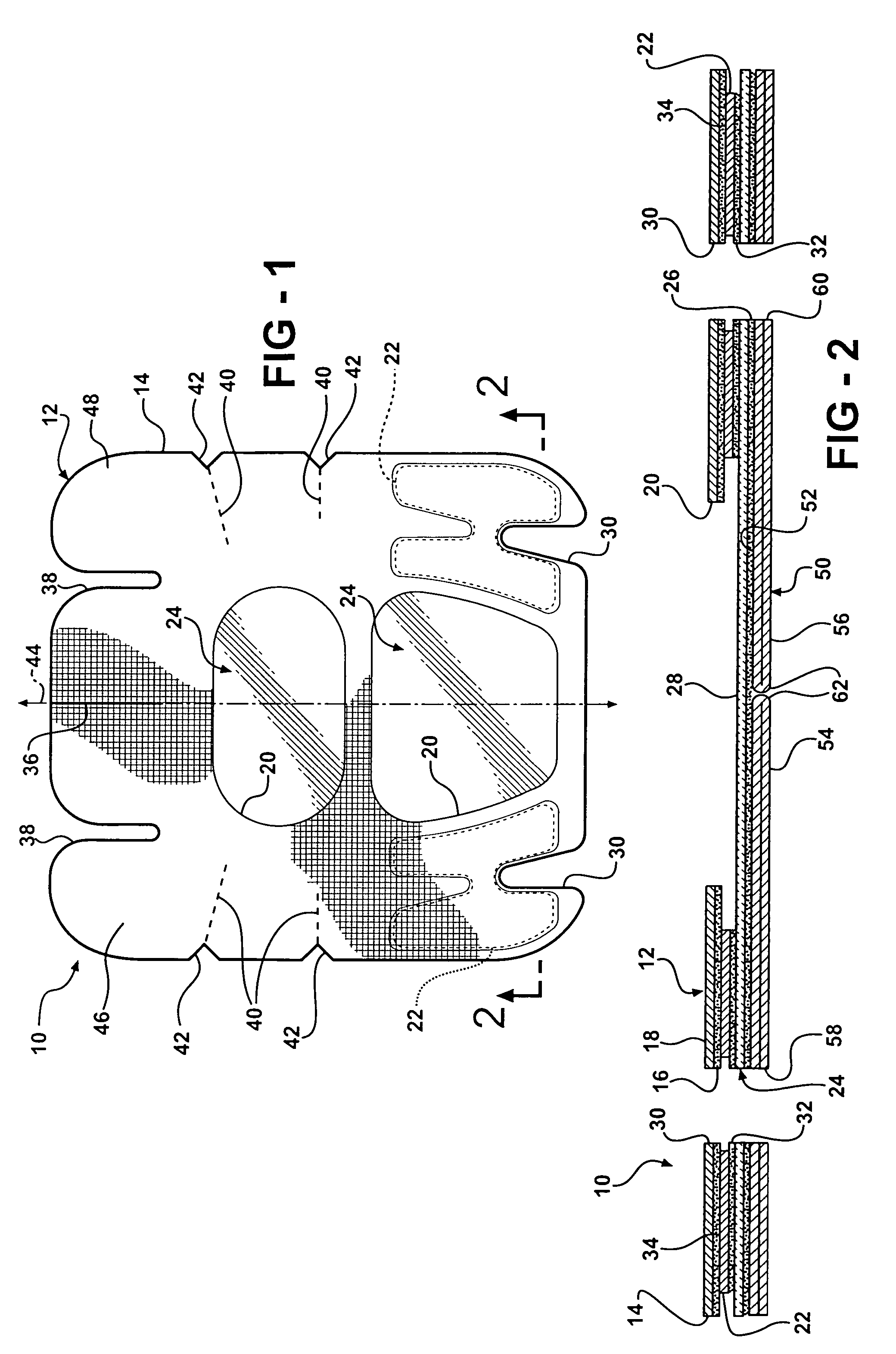

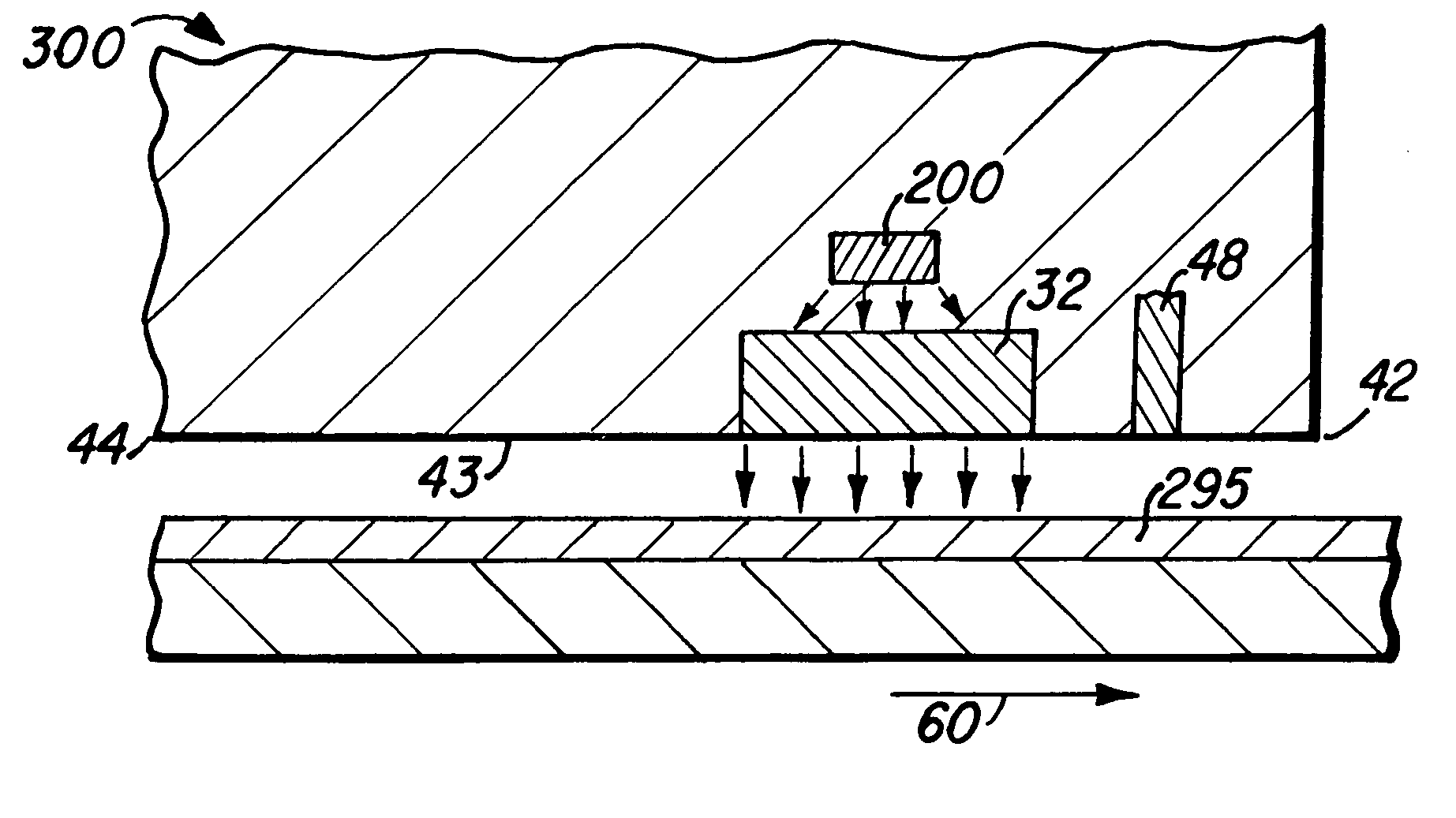

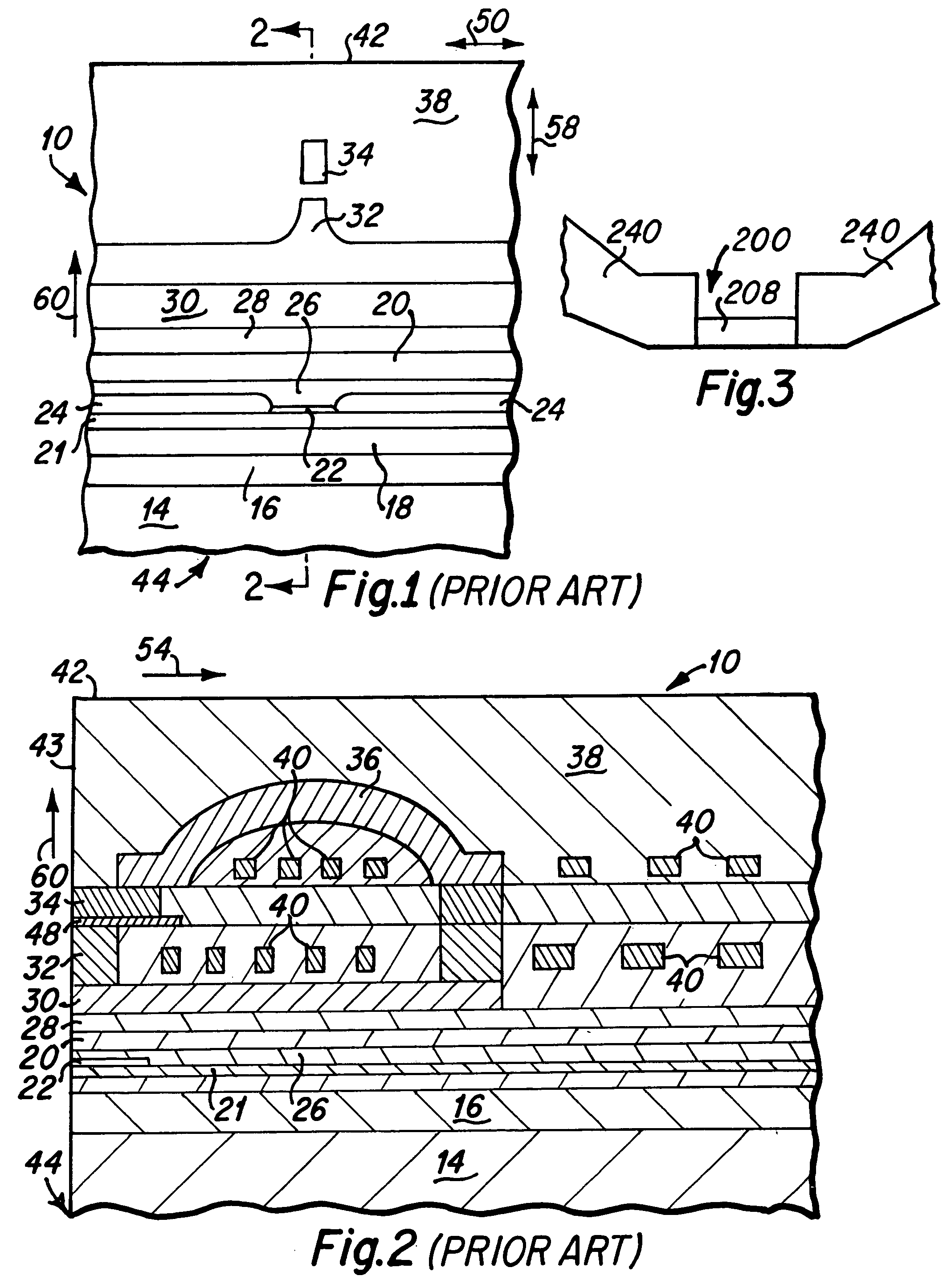

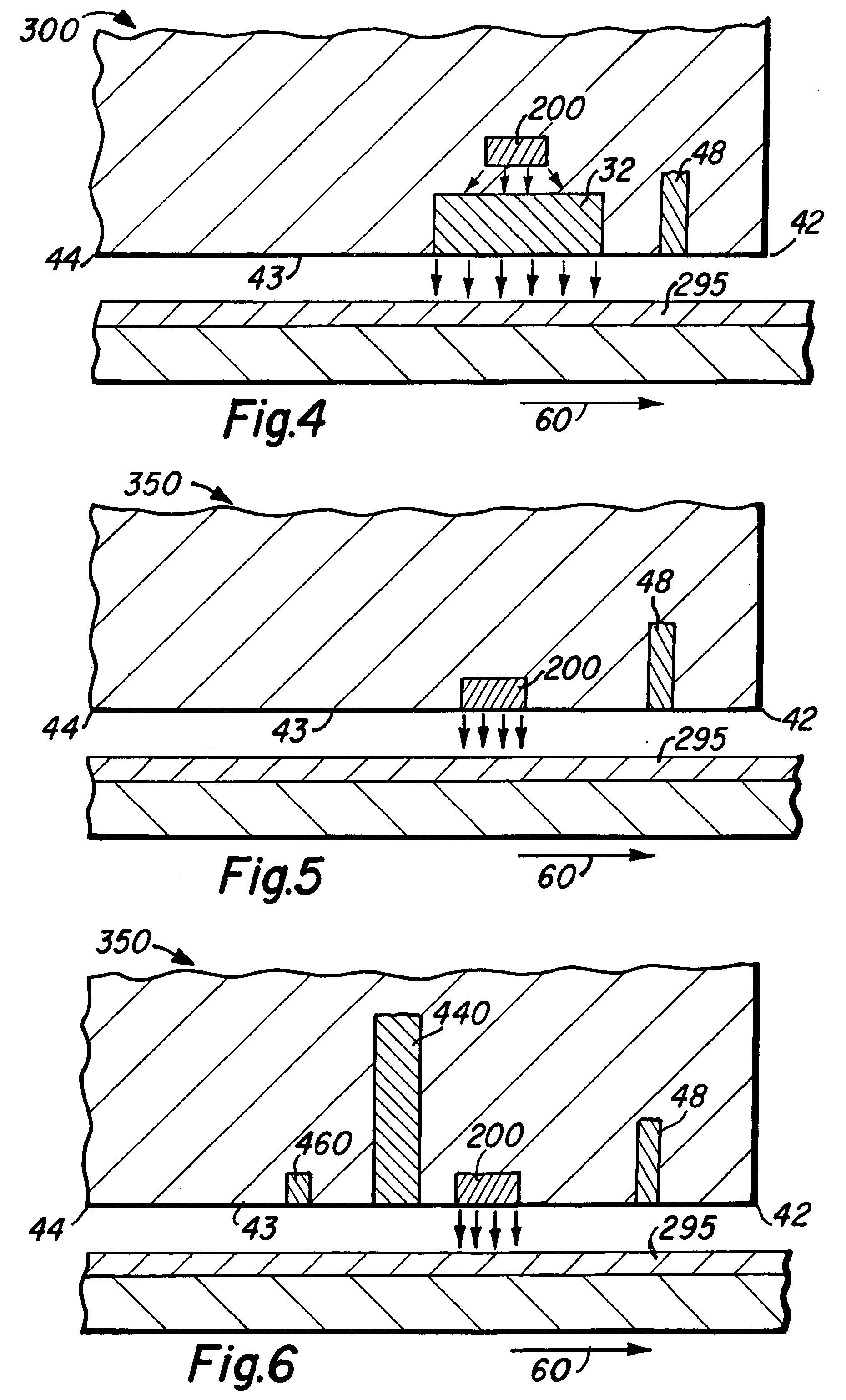

Shower plate having different aperture dimensions and/or distributions

ActiveUS8845806B2Improve uniformityUniform propertyElectric discharge tubesSemiconductor/solid-state device manufacturingSusceptorMechanical engineering

A shower plate is adapted to be attached to the showerhead and includes a front surface adapted to face the susceptor; and a rear surface opposite to the front surface. The shower plate has multiple apertures each extending from the rear surface to the front surface for passing gas therethrough in this direction, and the shower plate has at least one quadrant section defined by radii, wherein the one quadrant section has an opening ratio of a total volume of openings of all the apertures distributed in the section to a total volume of the one quadrant section, which opening ratio is substantially smaller than an opening ratio of another quadrant section of the shower plate.

Owner:ASM JAPAN

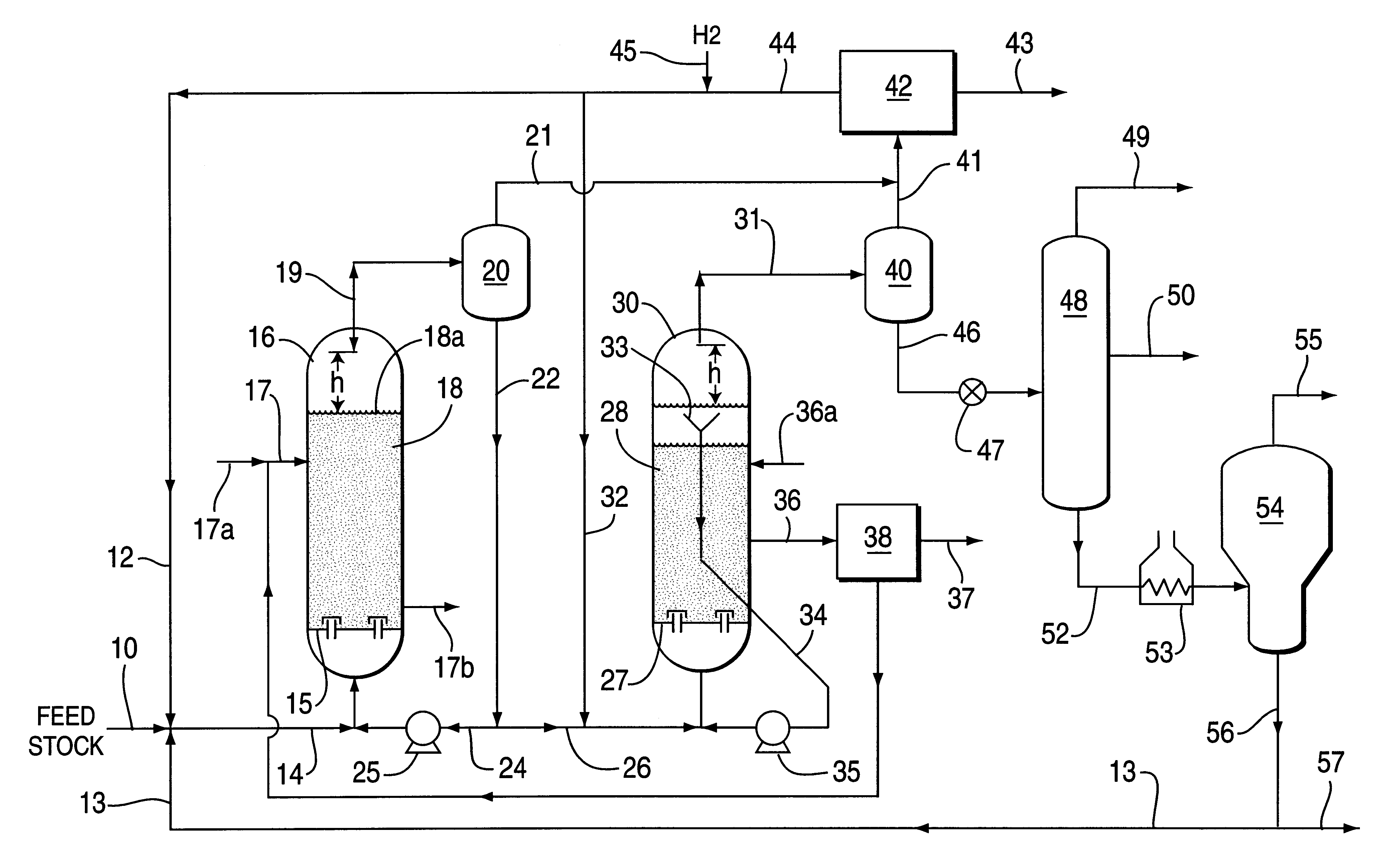

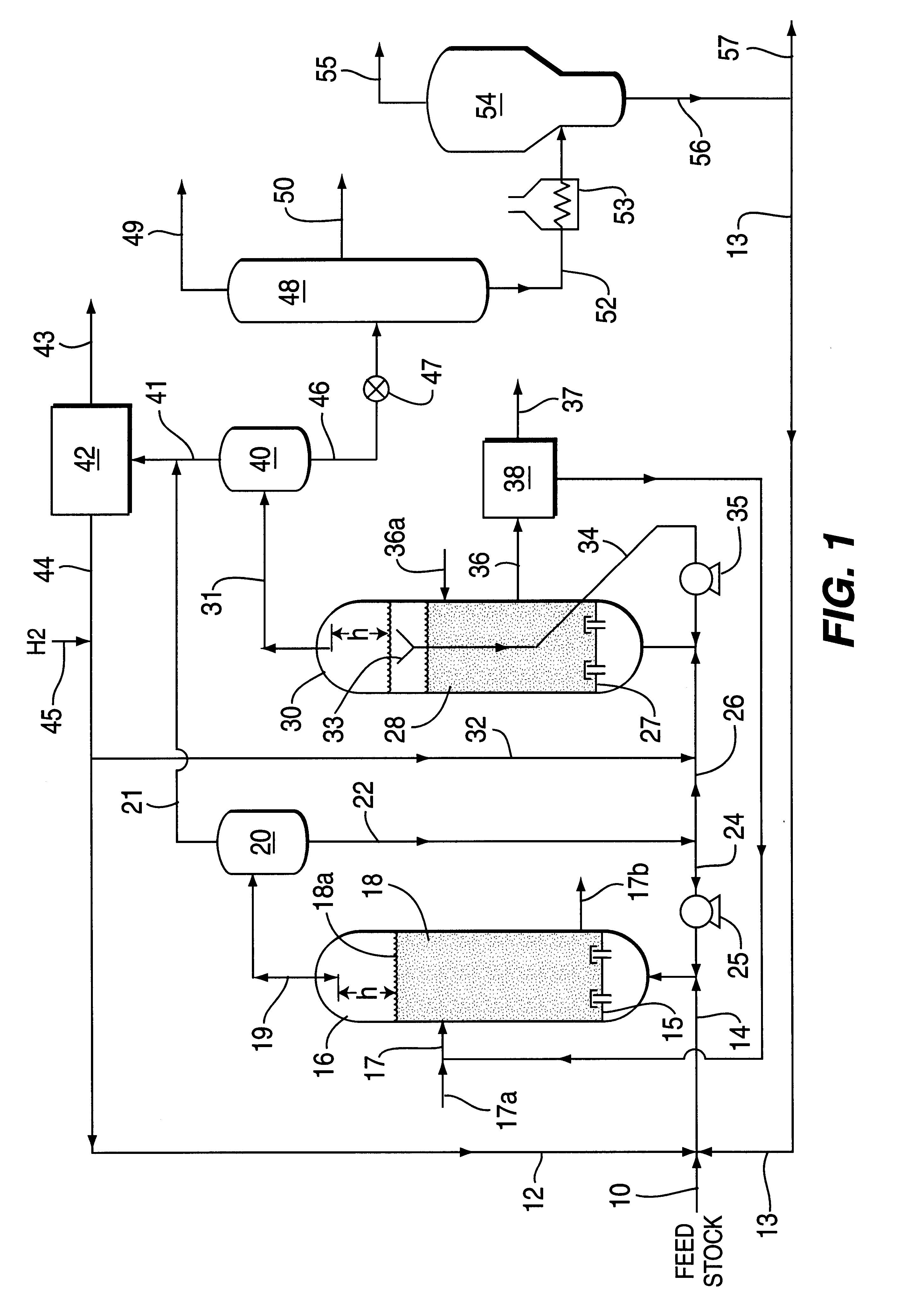

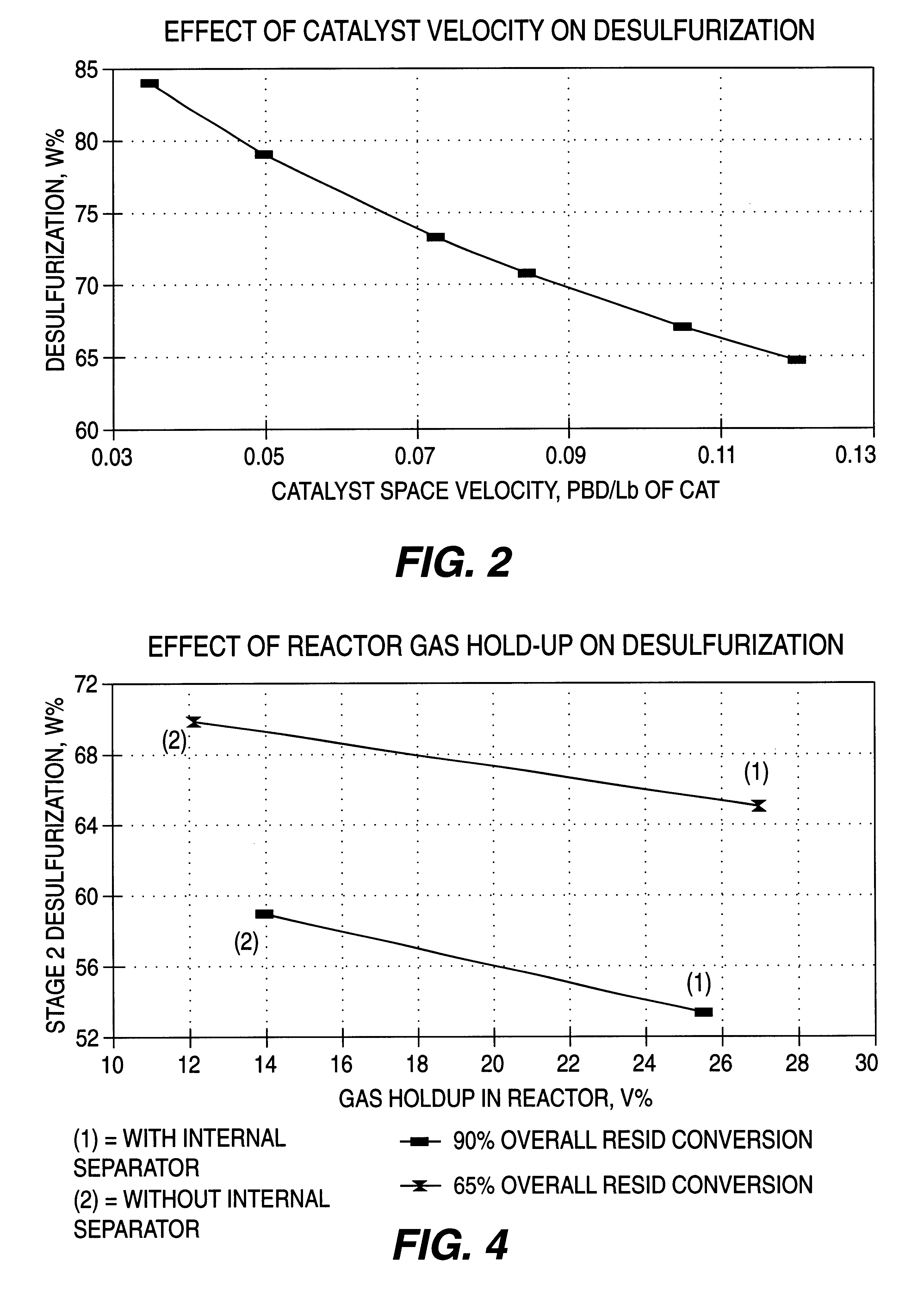

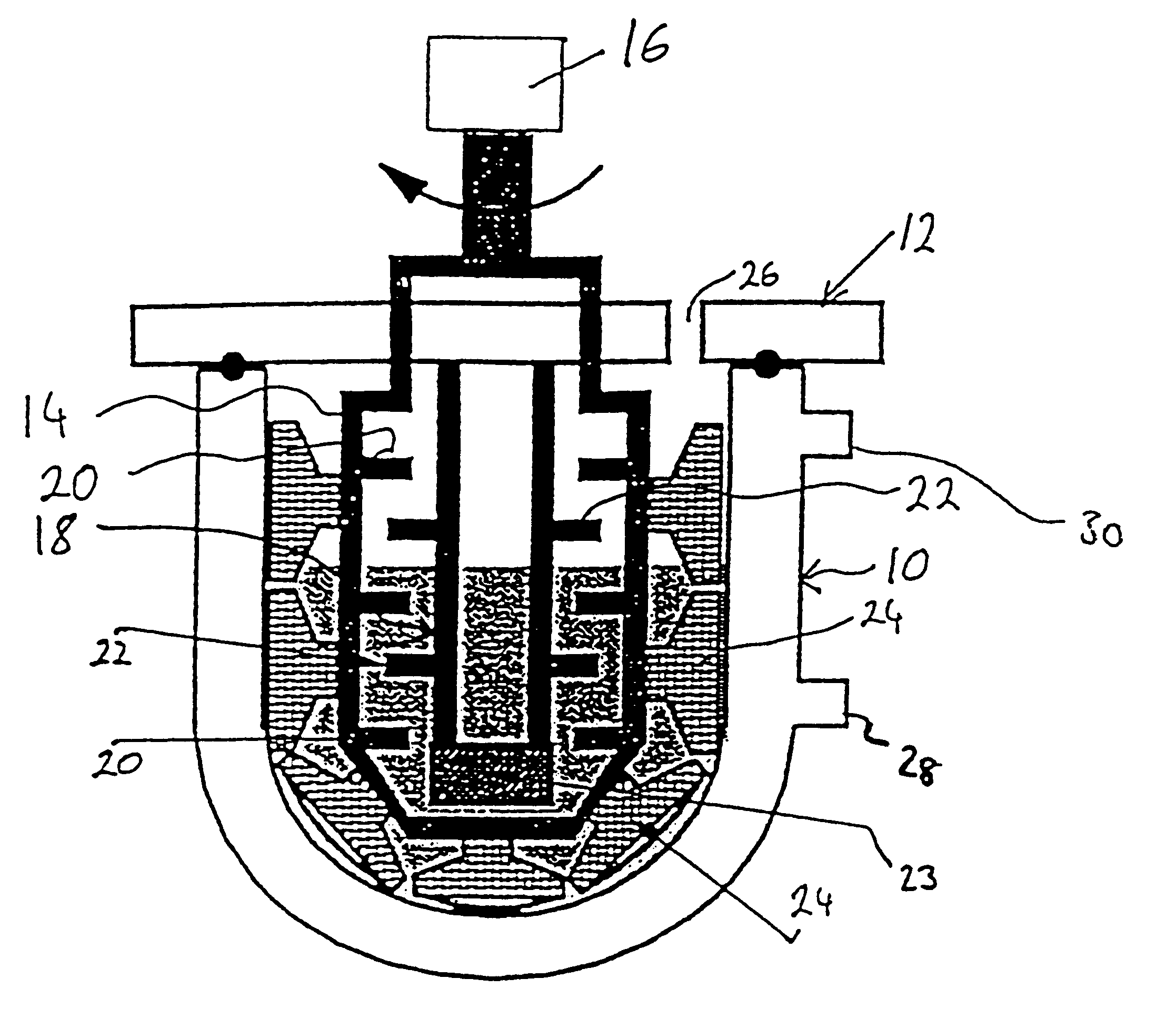

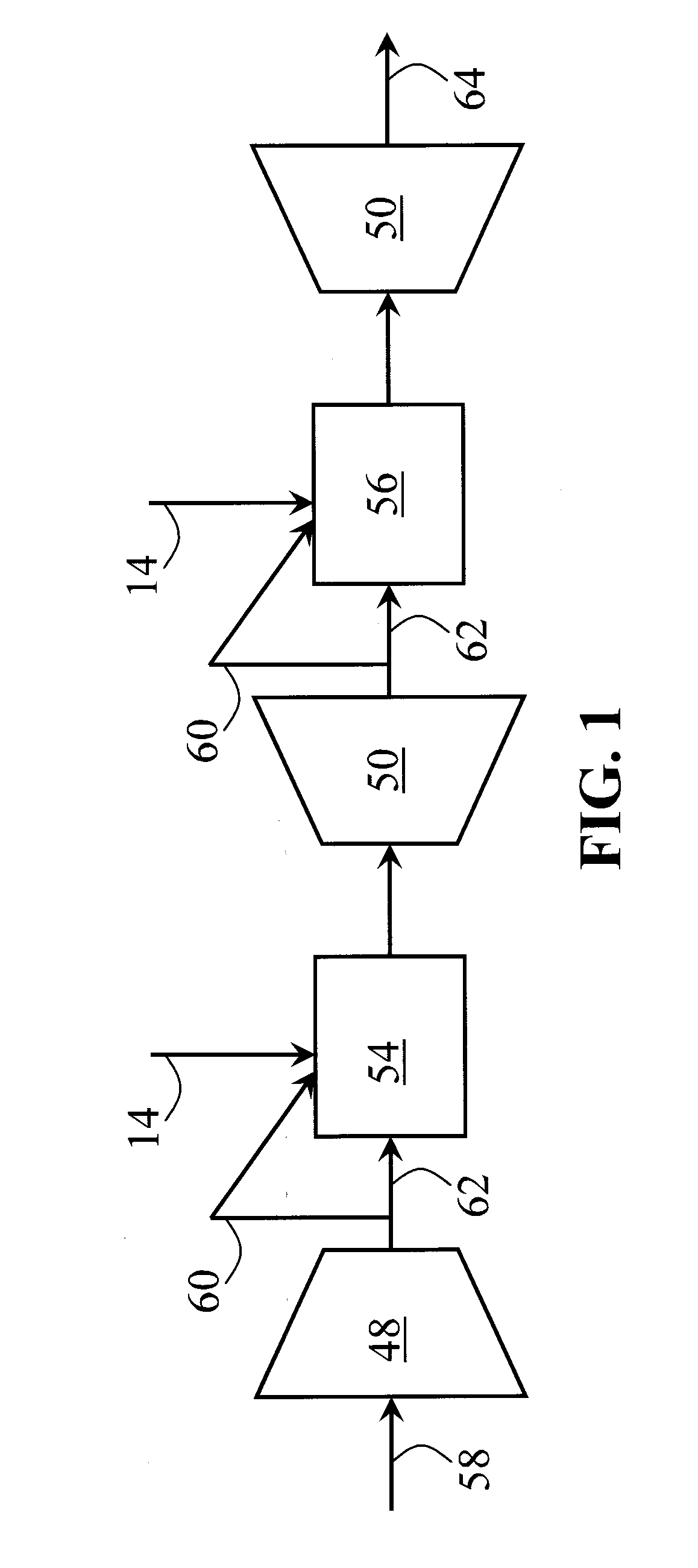

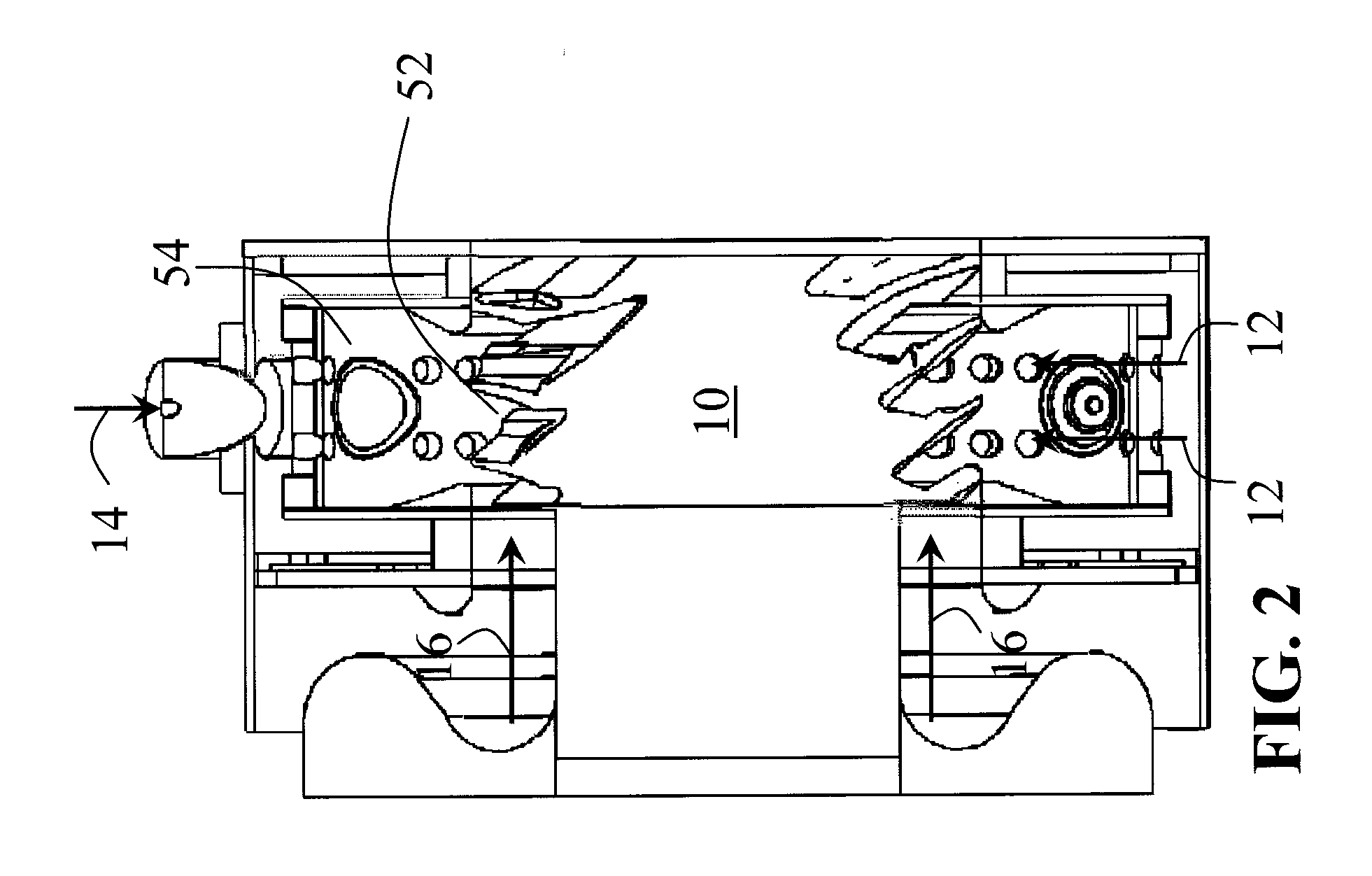

Catalytic hydrogenation process utilizing multi-stage ebullated bed reactors

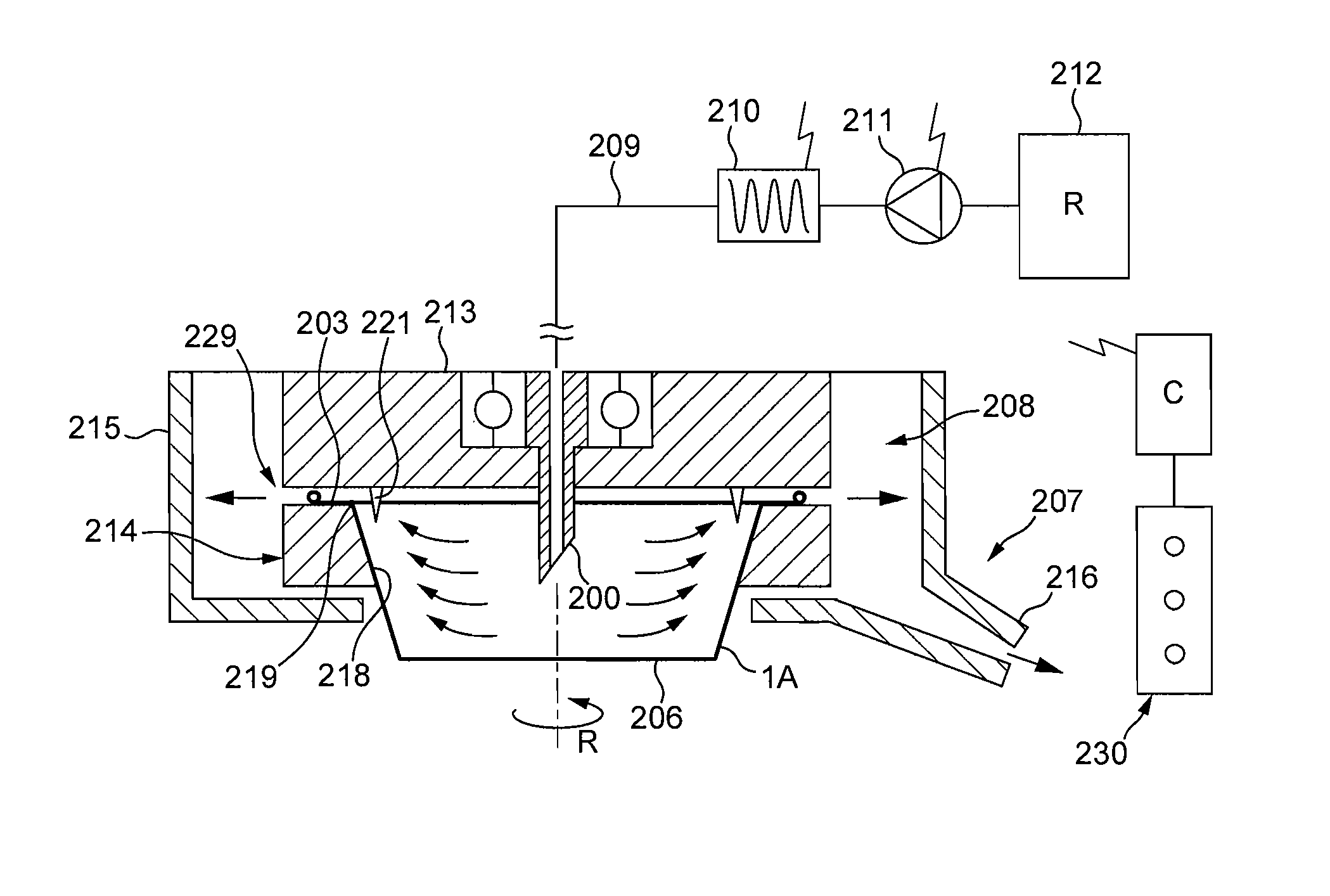

InactiveUS6270654B1Easy to processAvoid poor resultsCatalytic naphtha reformingHydrocarbon oil crackingChemistryBoiling point

A process for catalytic multi-stage hydrogenation of heavy carbonaceous feedstocks using catalytic ebullated bed reactors is operated at selected flow and operating conditions so as to provide improved reactor operations and produce increased yield of lower boiling hydrocarbon liquid and gas products. The disclosed process advantageously takes advantage of an external gas / liquid separation unit associated with the first stage reactor to allow for a more efficient and effective catalytic hydrocracking process. The more efficient process is primarily a result of the increased catalyst loading and lower gas hold-up in the ebullated reactors.

Owner:IFP NORTH AMERICA

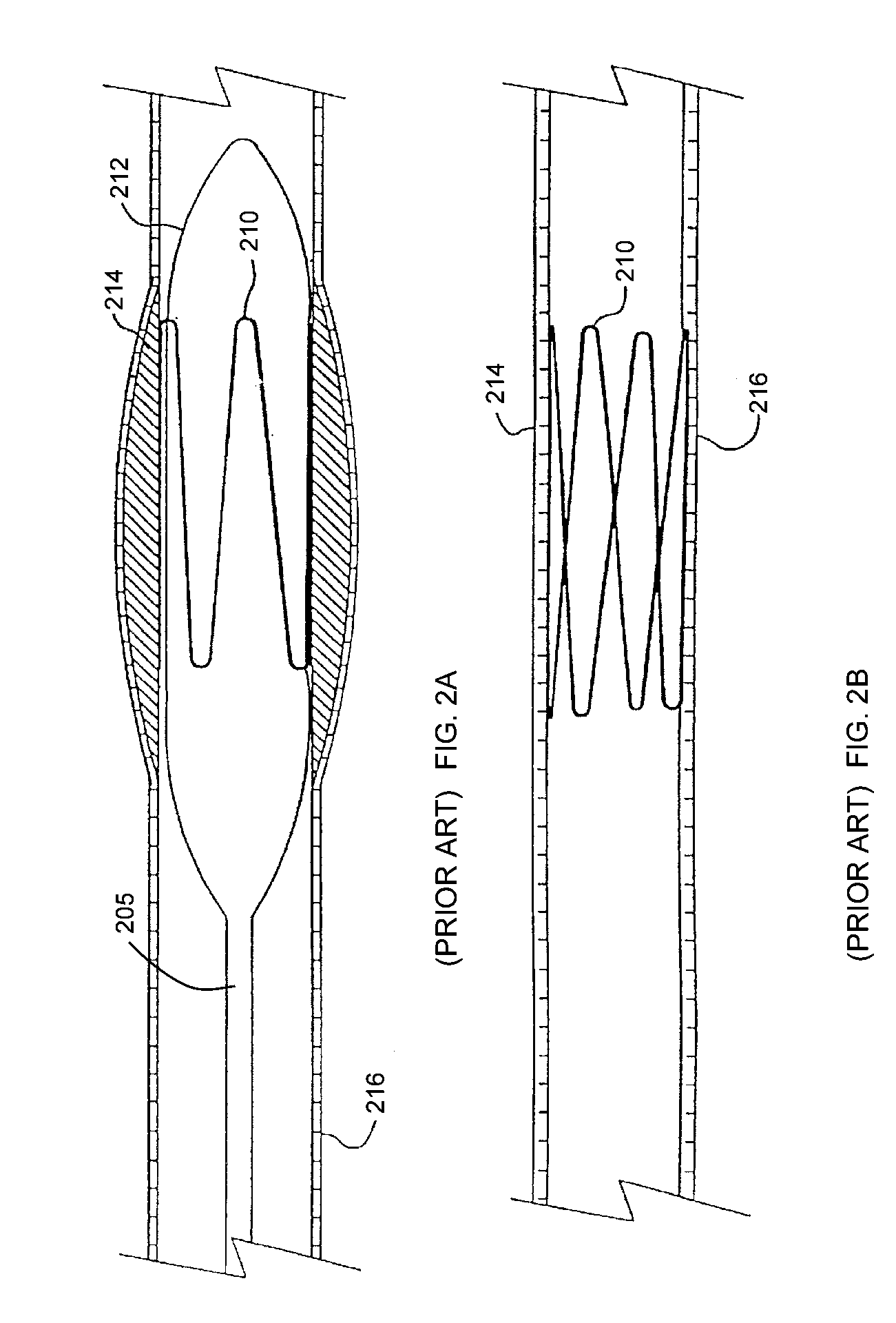

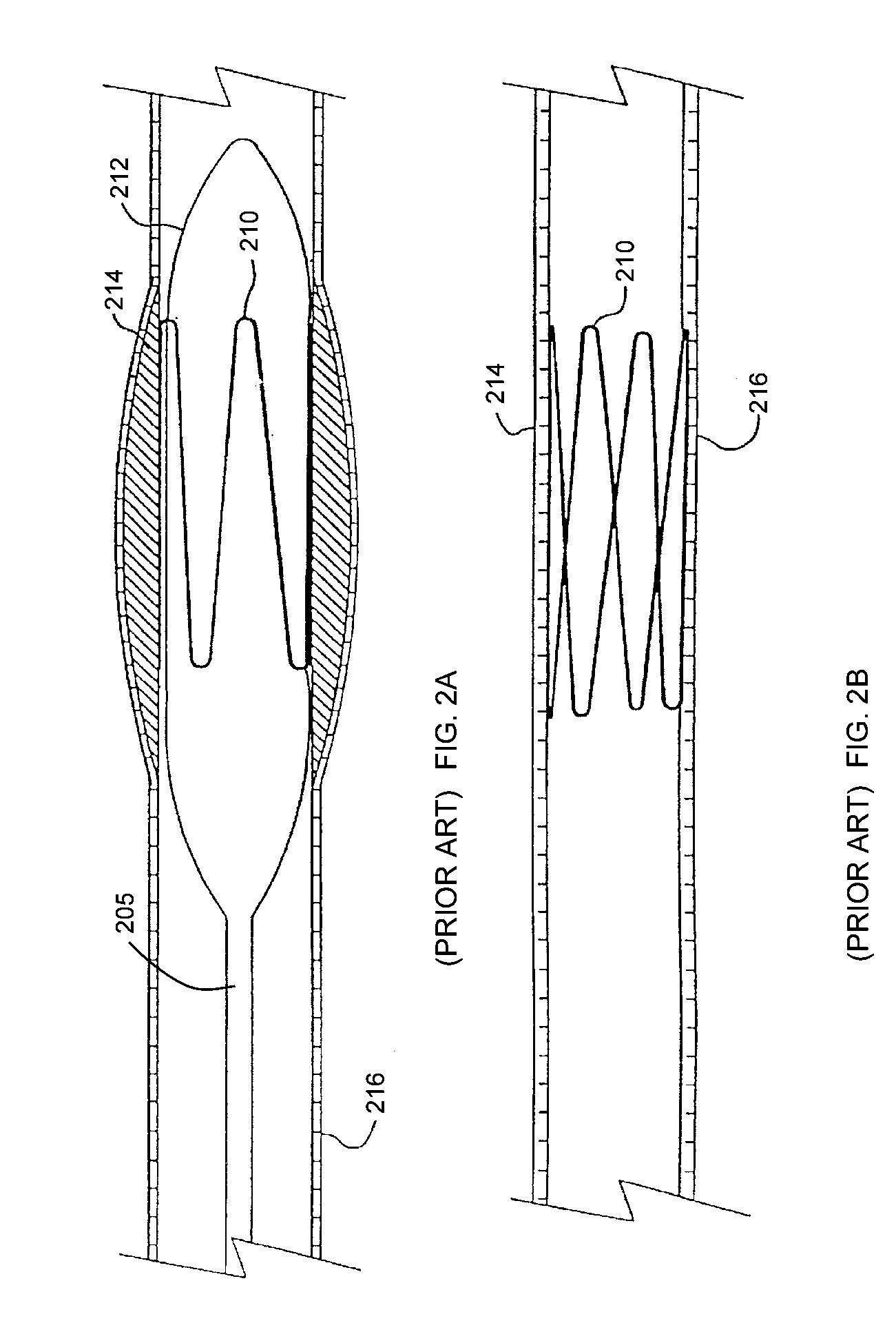

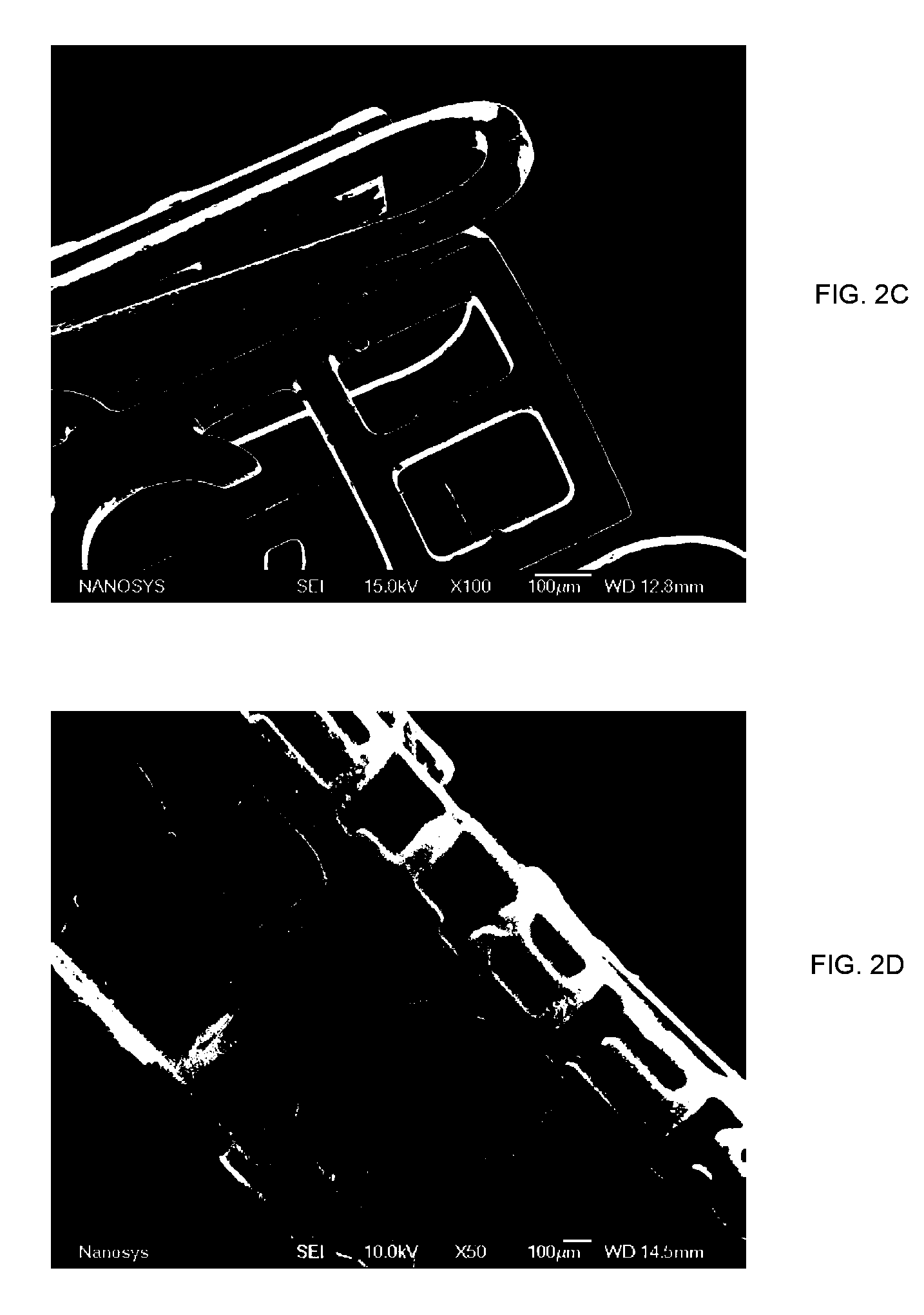

Medical Device Applications of Nanostructured Surfaces

ActiveUS20070282247A1Increase heightPrevent/reduce bio-foulingNanotechElectrotherapyMedicineNanofiber

This invention provides novel nanofiber enhanced surface area substrates and structures comprising such substrates for use in various medical devices, as well as methods and uses for such substrates and medical devices. In one particular embodiment, a method of administering a composition to a patient is disclosed which comprises providing a composition-eluting device, said composition-eluting device comprising at least a first surface and a plurality of nanostructures attached to the first surface, and introducing the composition-eluting device into the body of the patient.

Owner:RGT UNIV OF CALIFORNIA +1

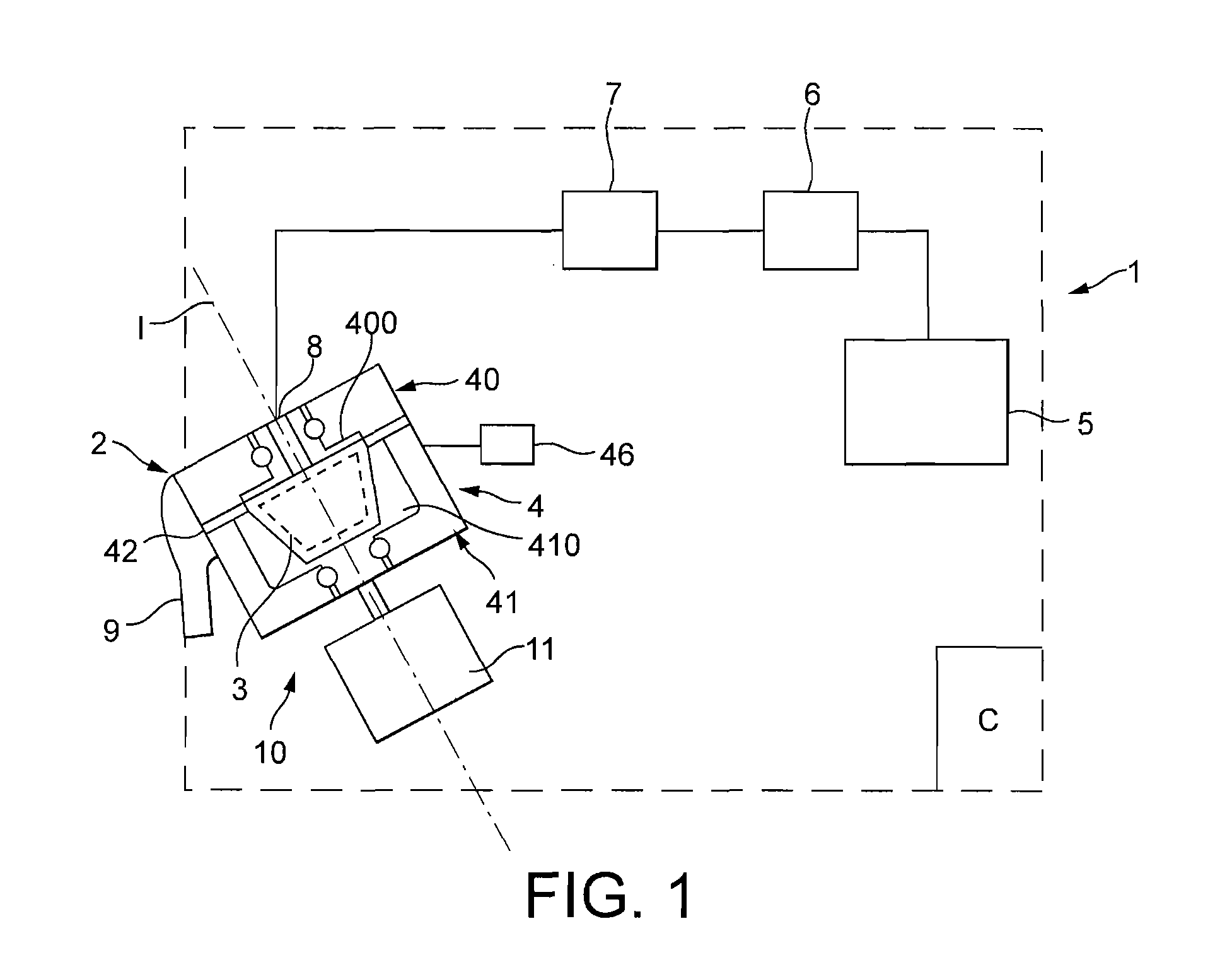

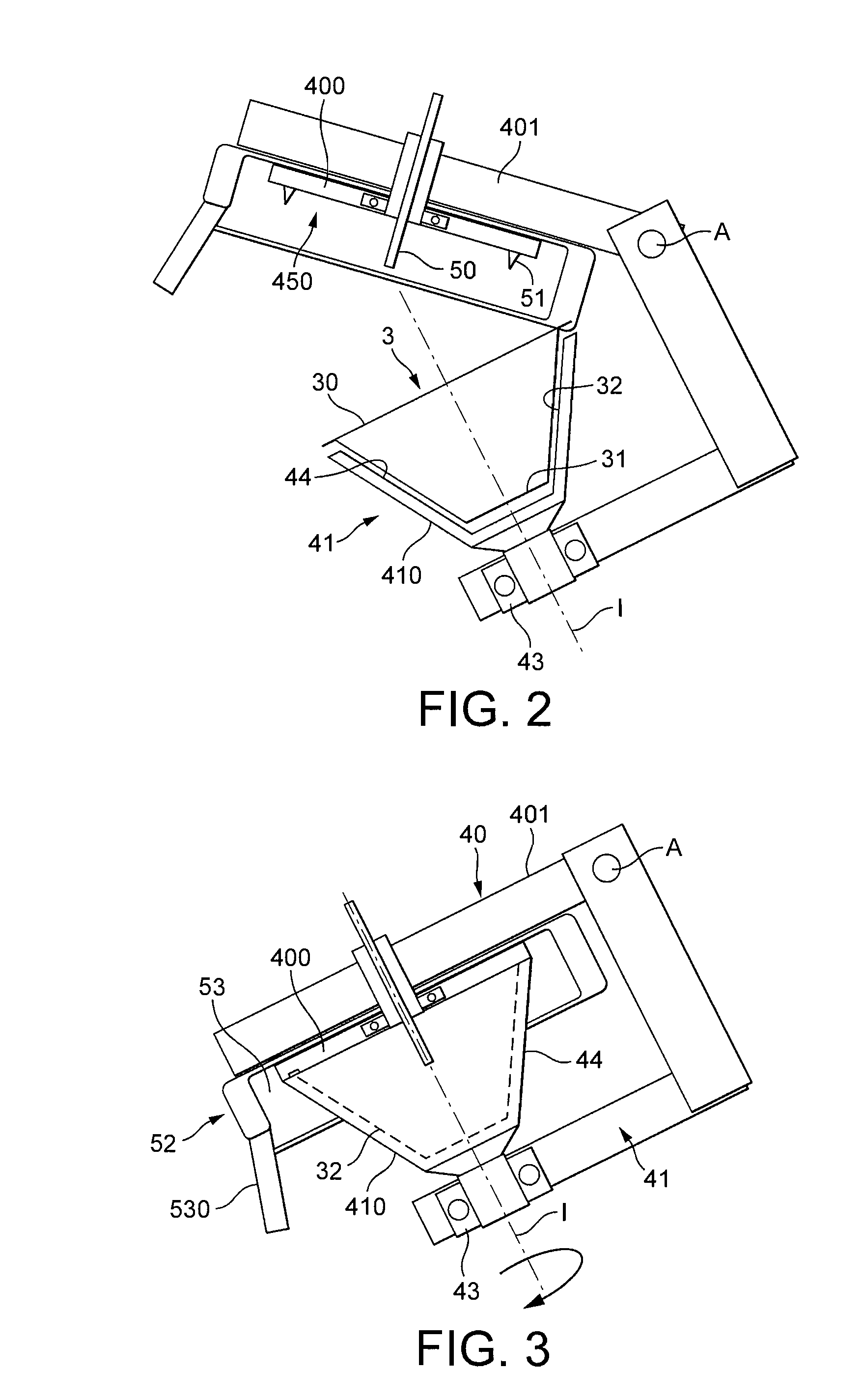

Method for preparing a beverage or food liquid and system using brewing centrifugal force

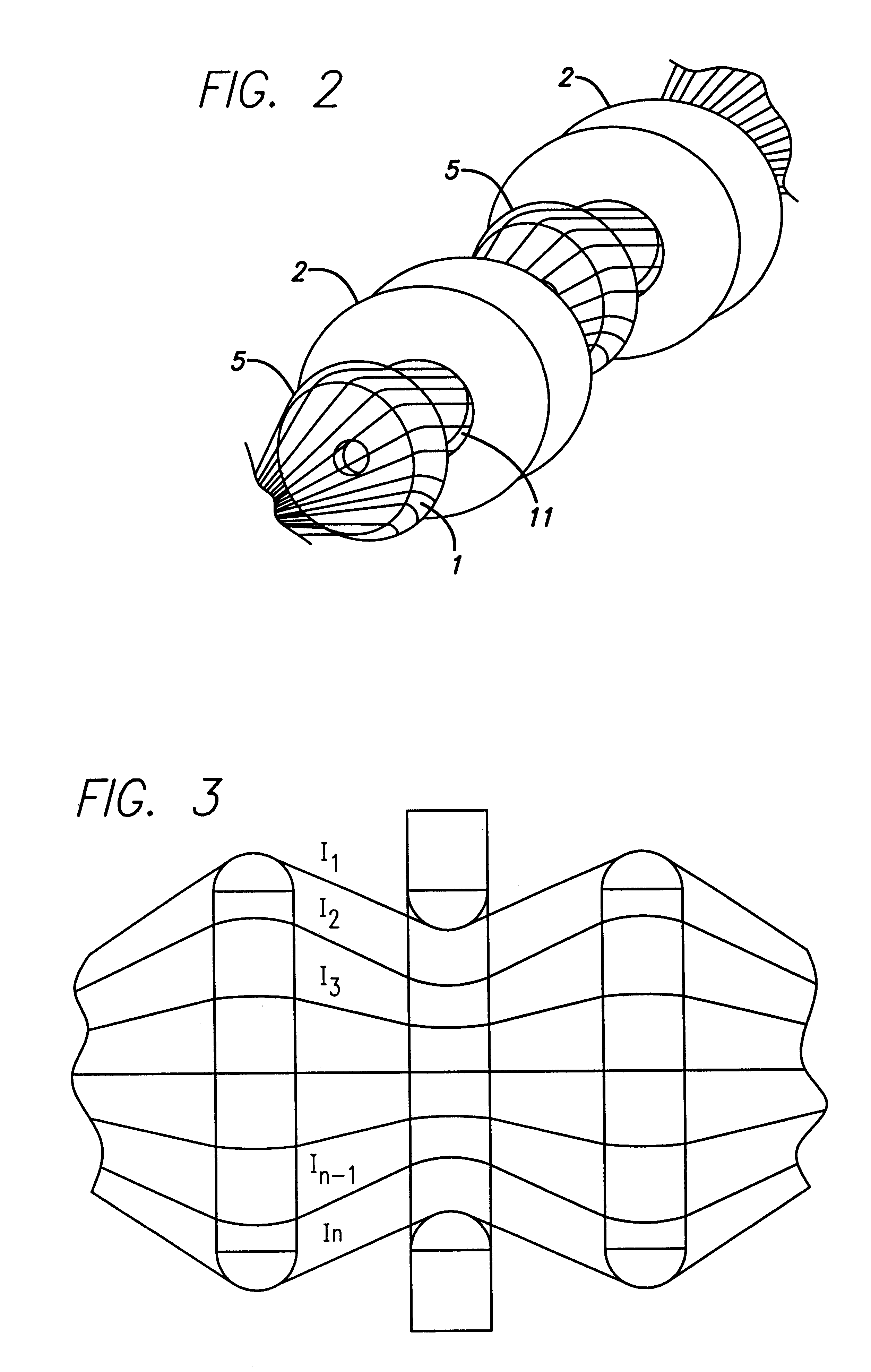

A capsule, device, system and method for preparing a liquid food or beverage. The capsule comprises an enclosure containing one or more extractable or infusible ingredients and configured and dimensioned to have a perimeter and be radially symmetrical about a central axis to facilitate rotation; and an opening arrangement that allows liquid food to leave the capsule after passing through the ingredient(s), wherein the opening arrangement is configured and positioned near or upon the perimeter of the enclosure to allow the liquid food to leave the capsule radially due to the application of the centrifugal forces. The method and device introduce liquid into the capsule to form the liquid food while applying centrifugal forces to the capsule to urge the liquid to pass through the ingredient(s).

Owner:SOC DES PROD NESTLE SA

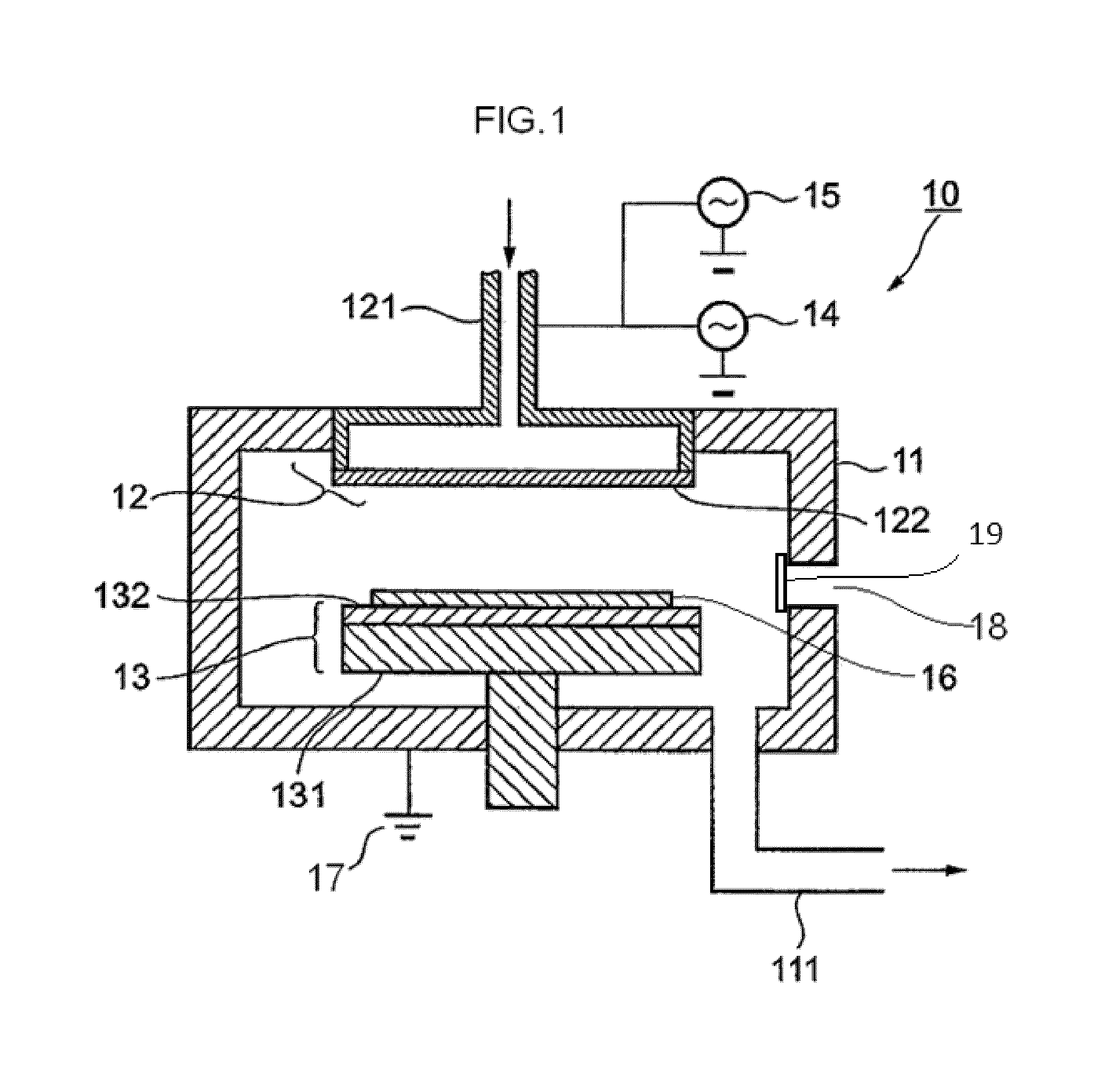

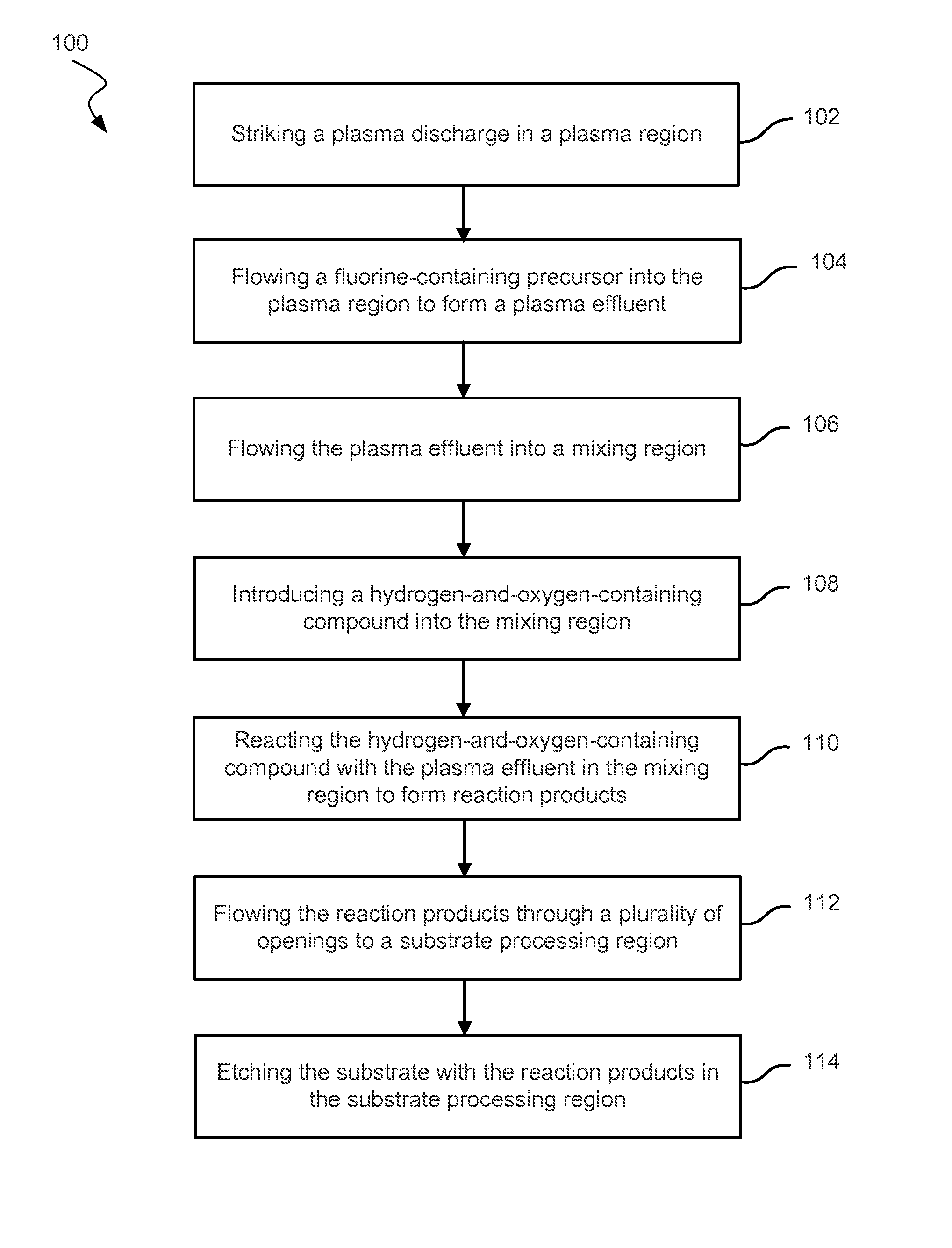

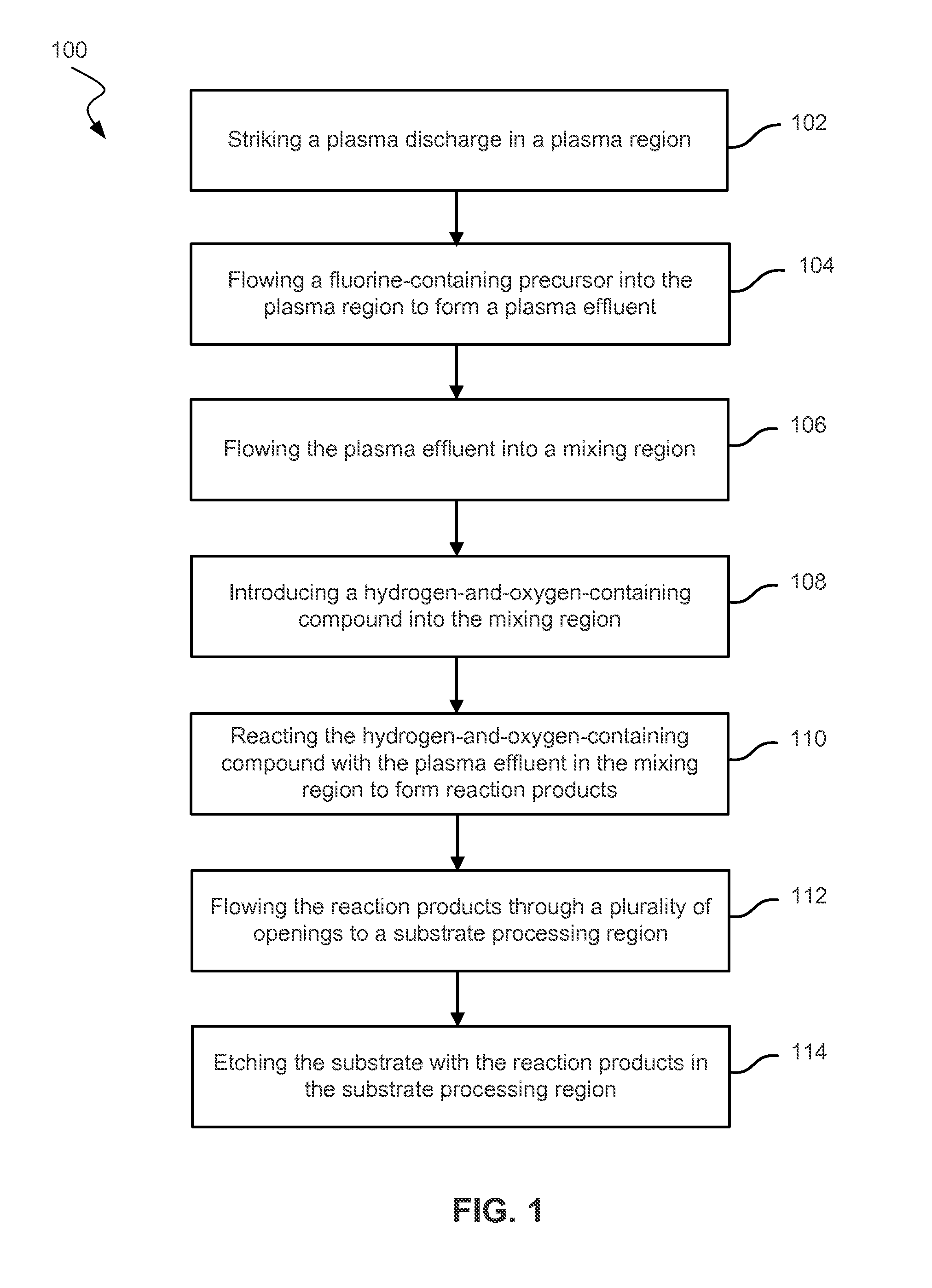

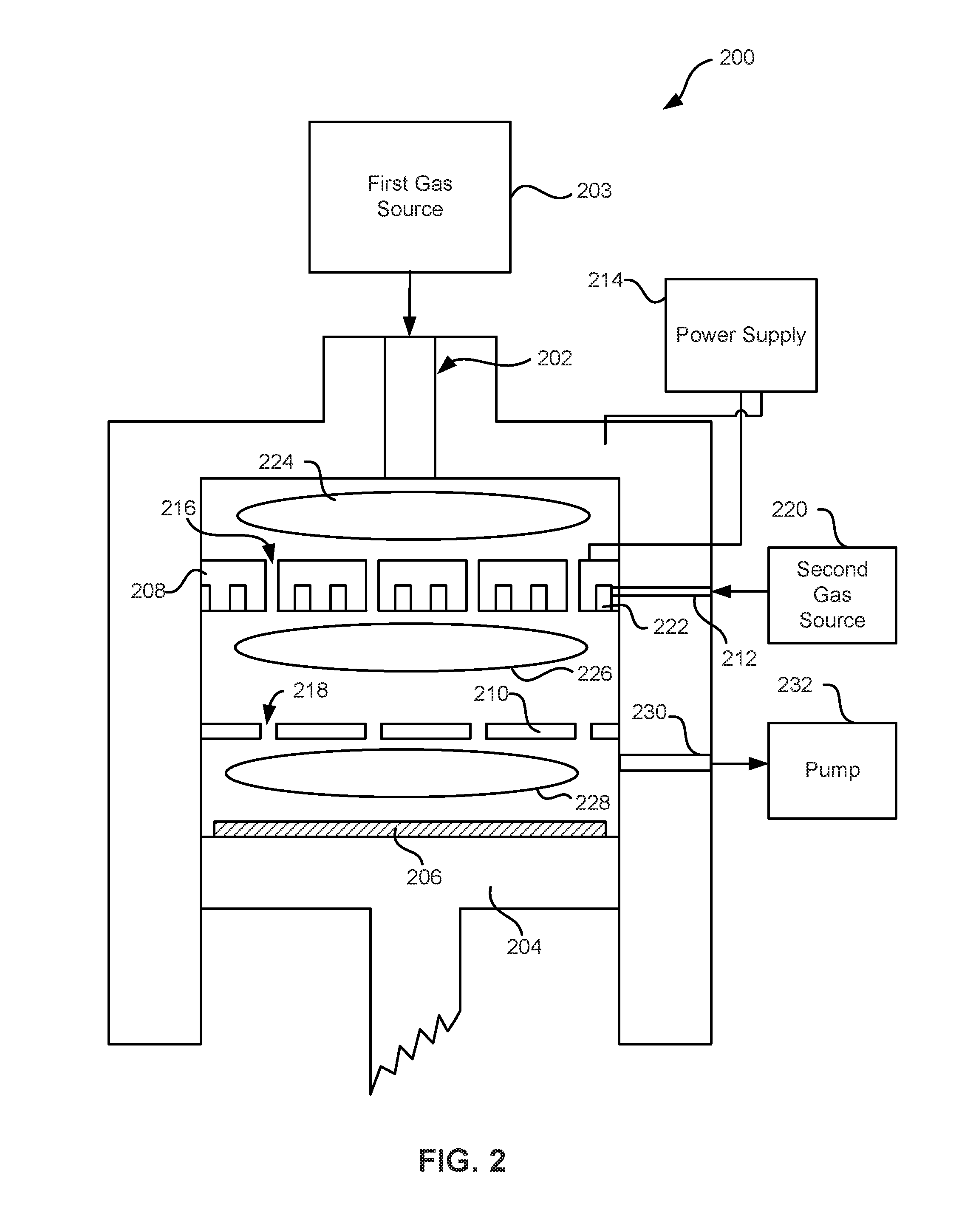

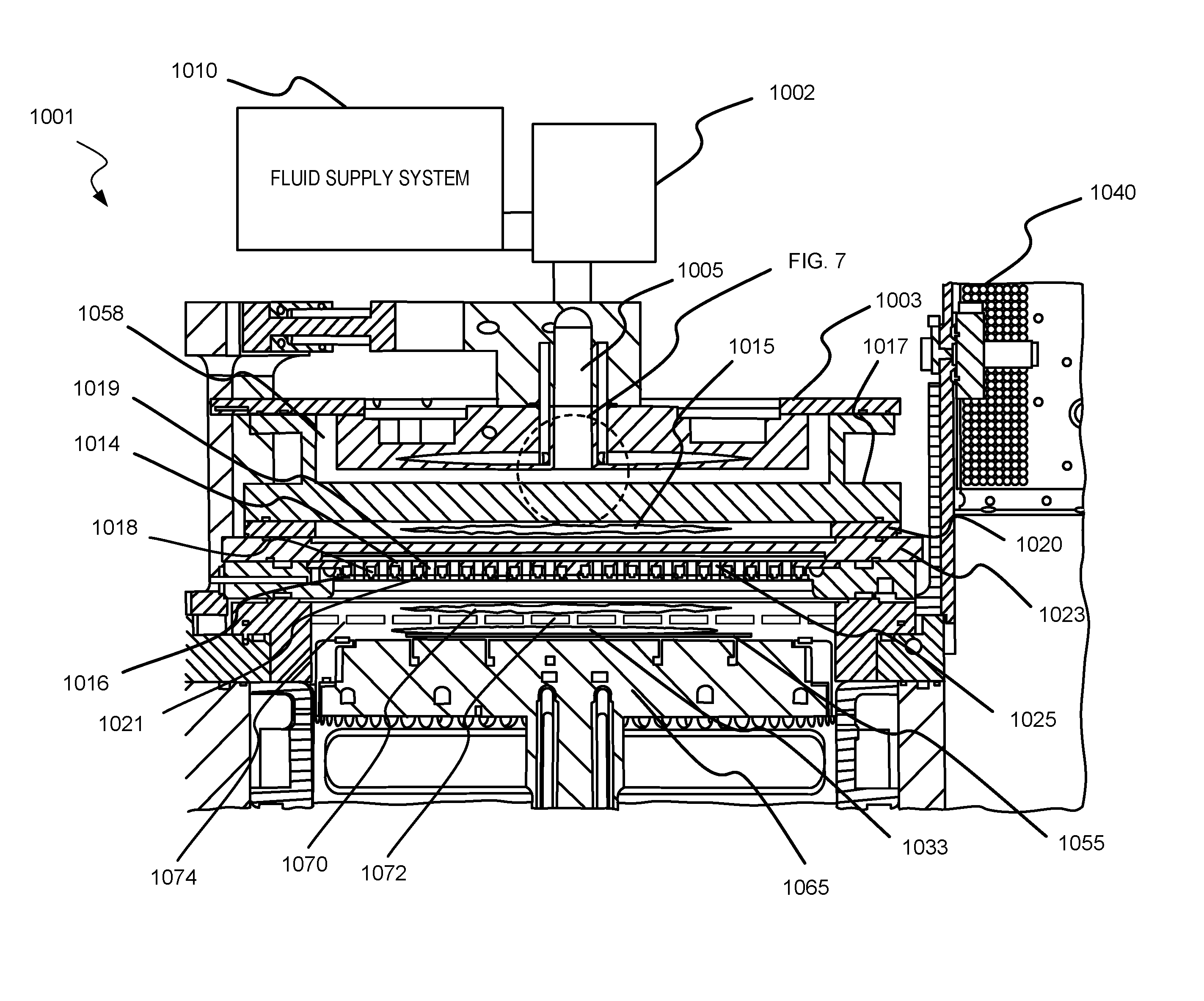

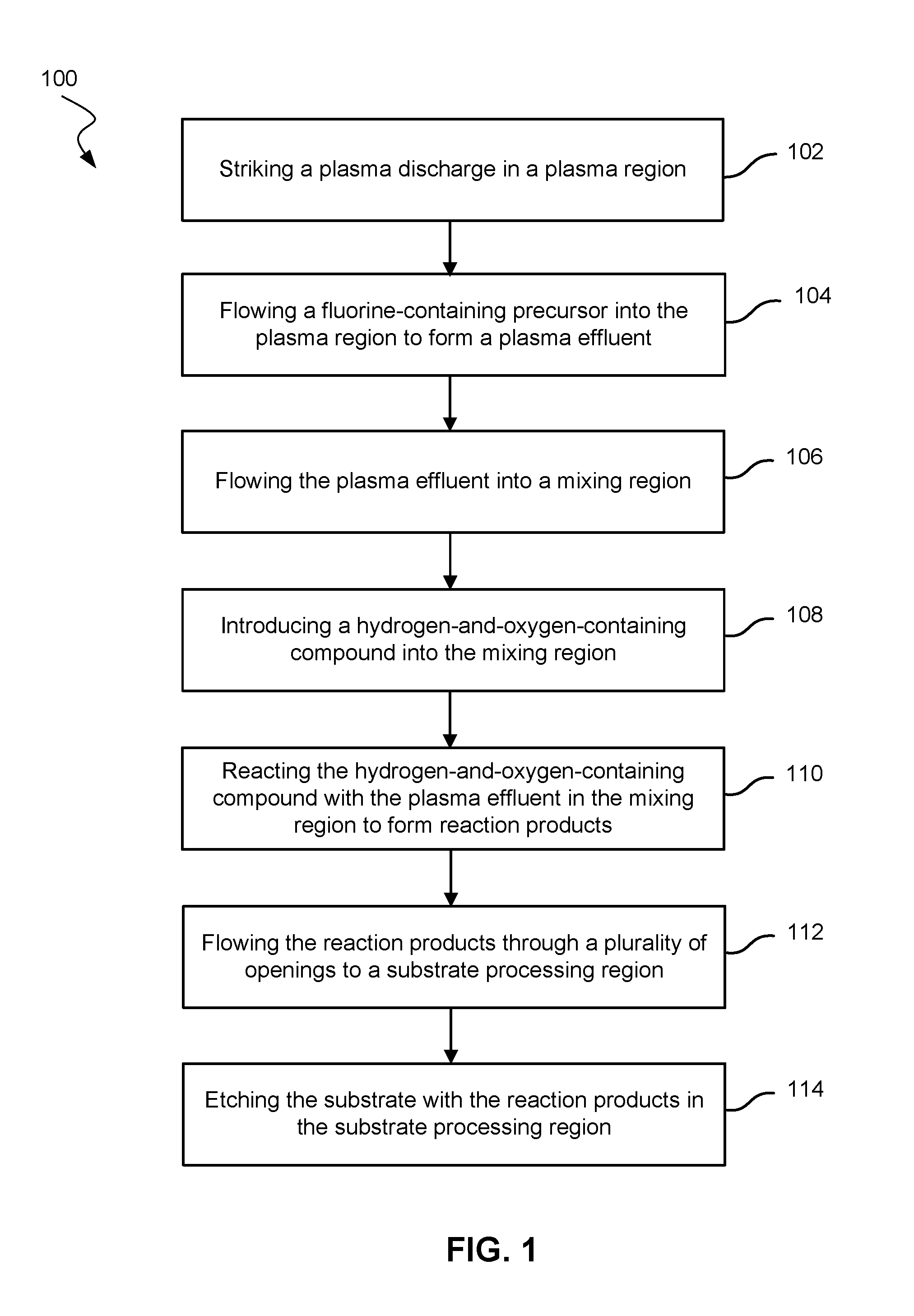

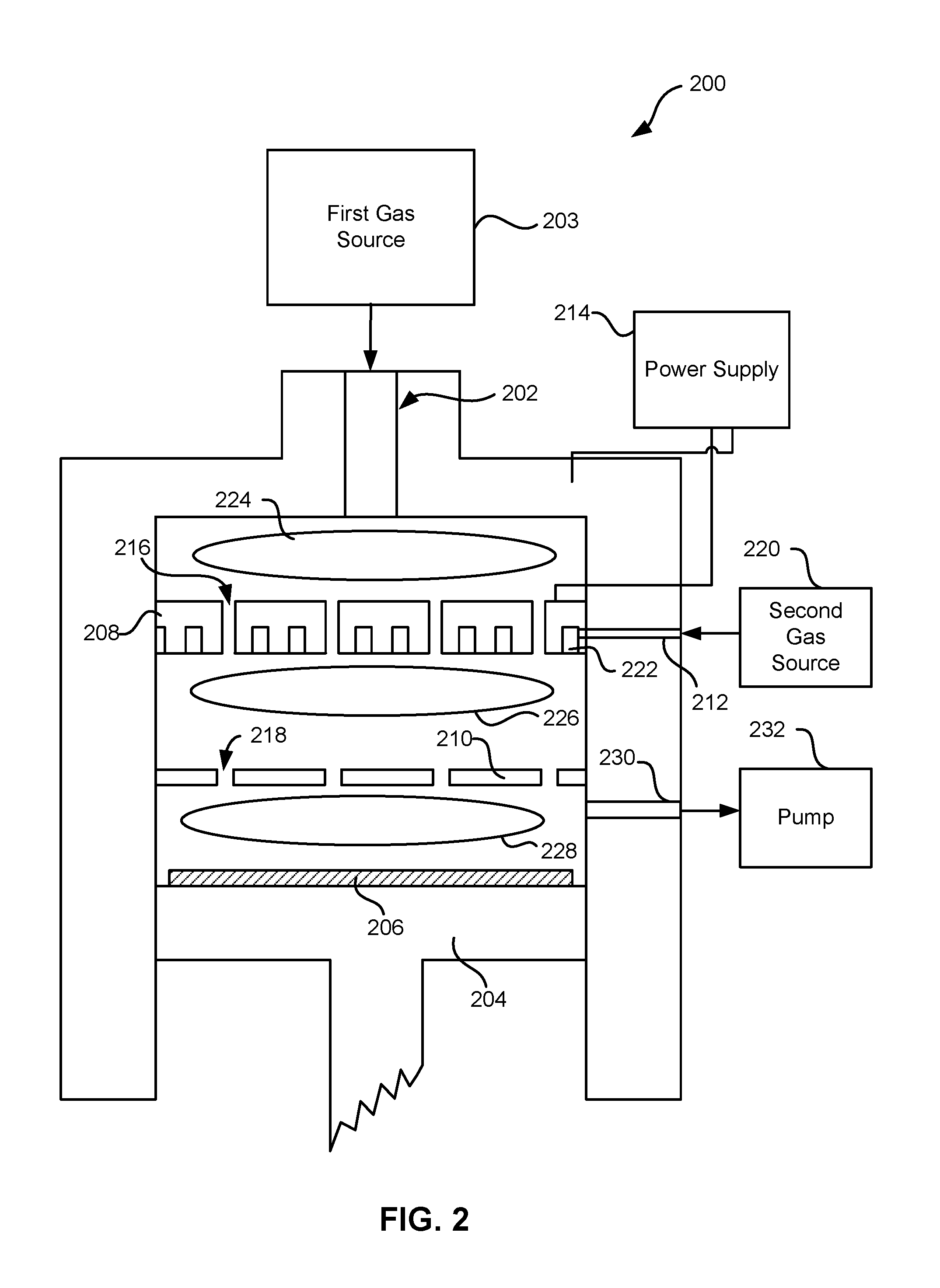

Oxide etch selectivity systems and methods

ActiveUS9349605B1Improve etch selectivityEnhance and suppress reactionElectric discharge tubesSemiconductor/solid-state device manufacturingHydrogenProcess region

Embodiments of the present technology may include a method of etching a substrate. The method may include striking a plasma discharge in a plasma region. The method may also include flowing a fluorine-containing precursor into the plasma region to form a plasma effluent. The plasma effluent may flow into a mixing region. The method may further include introducing a hydrogen-and-oxygen-containing compound into the mixing region without first passing the hydrogen-and-oxygen-containing compound into the plasma region. Additionally, the method may include reacting the hydrogen-and-oxygen-containing compound with the plasma effluent in the mixing region to form reaction products. The reaction products may flow through a plurality of openings in a partition to a substrate processing region. The method may also include etching the substrate with the reaction products in the substrate processing region.

Owner:APPLIED MATERIALS INC

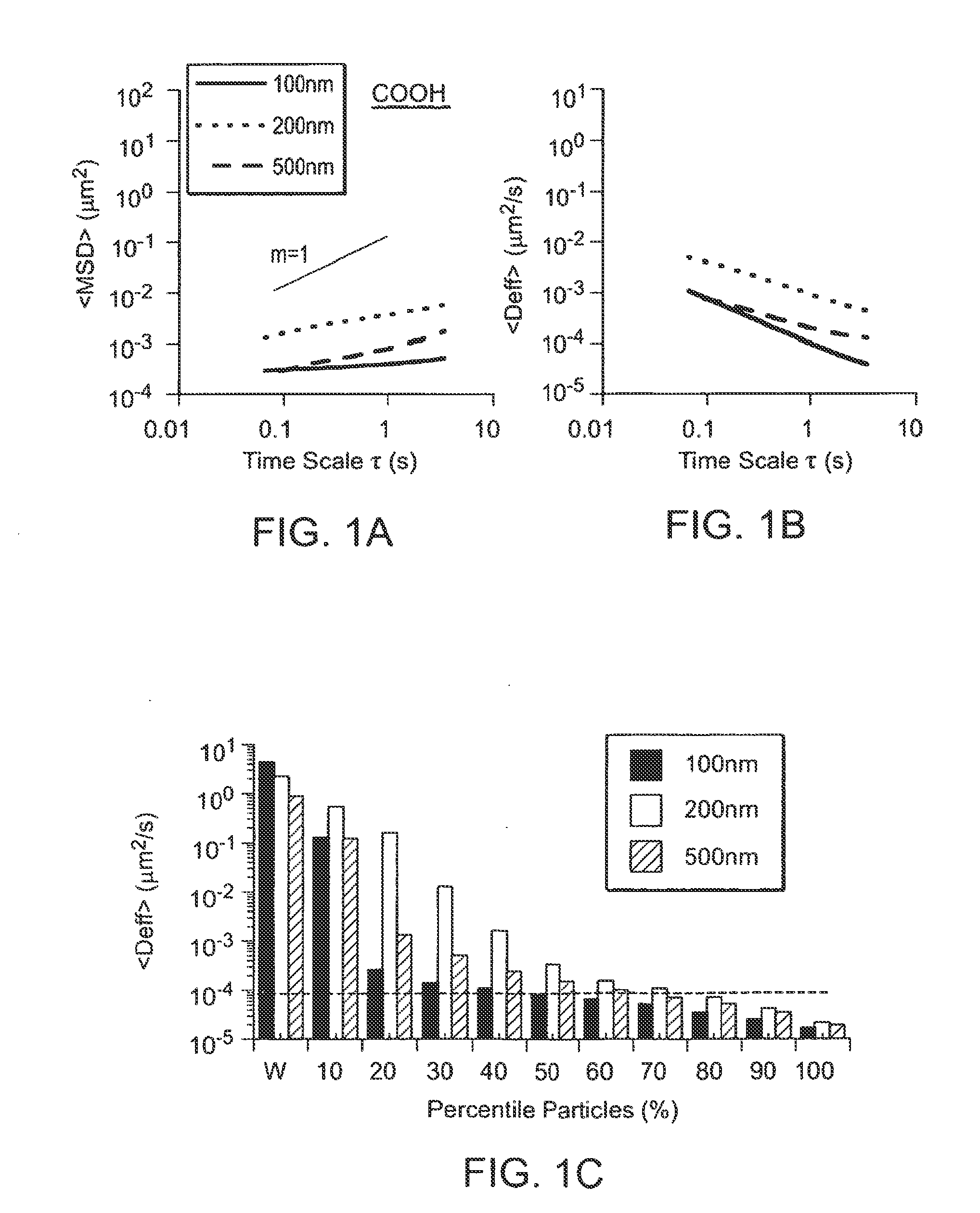

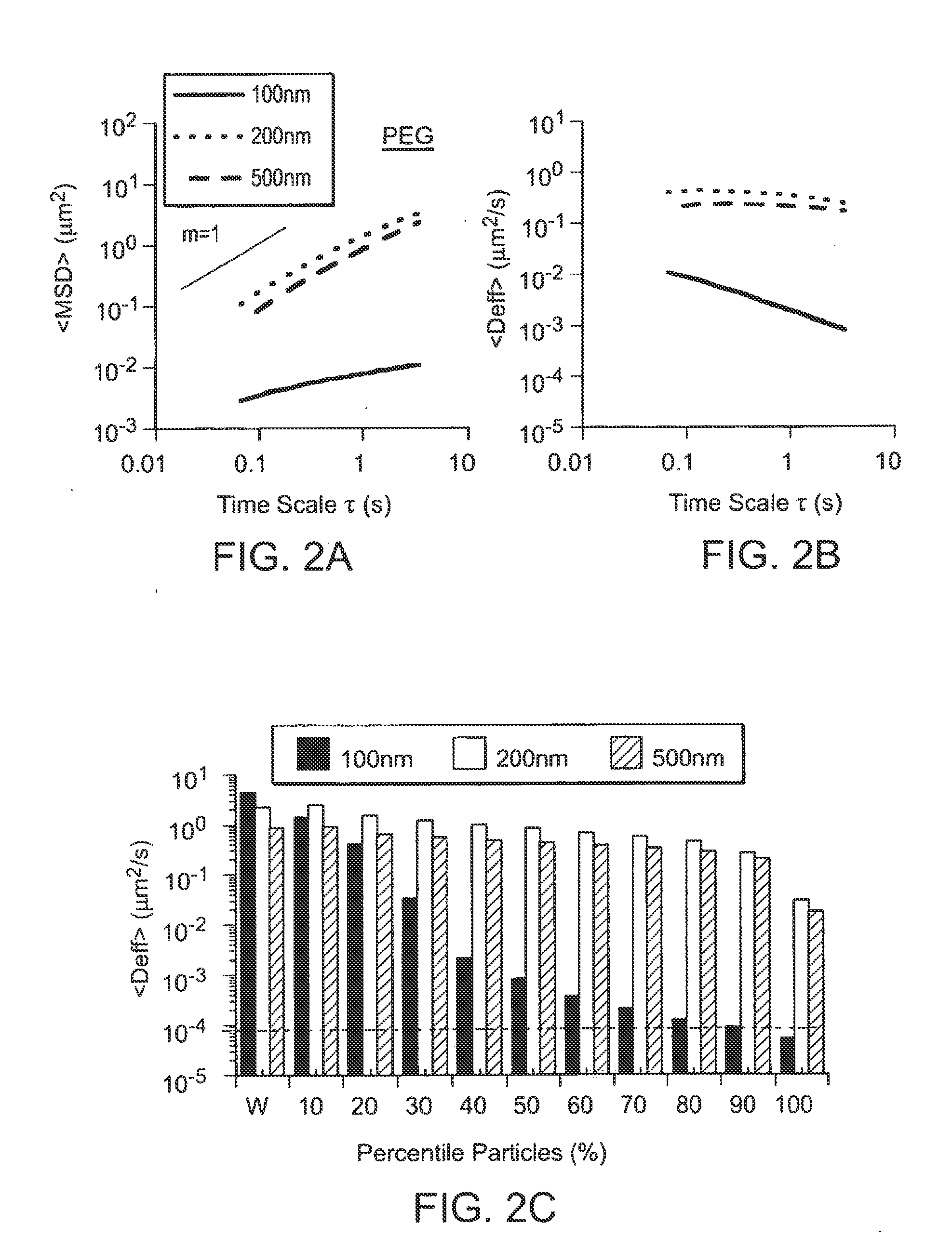

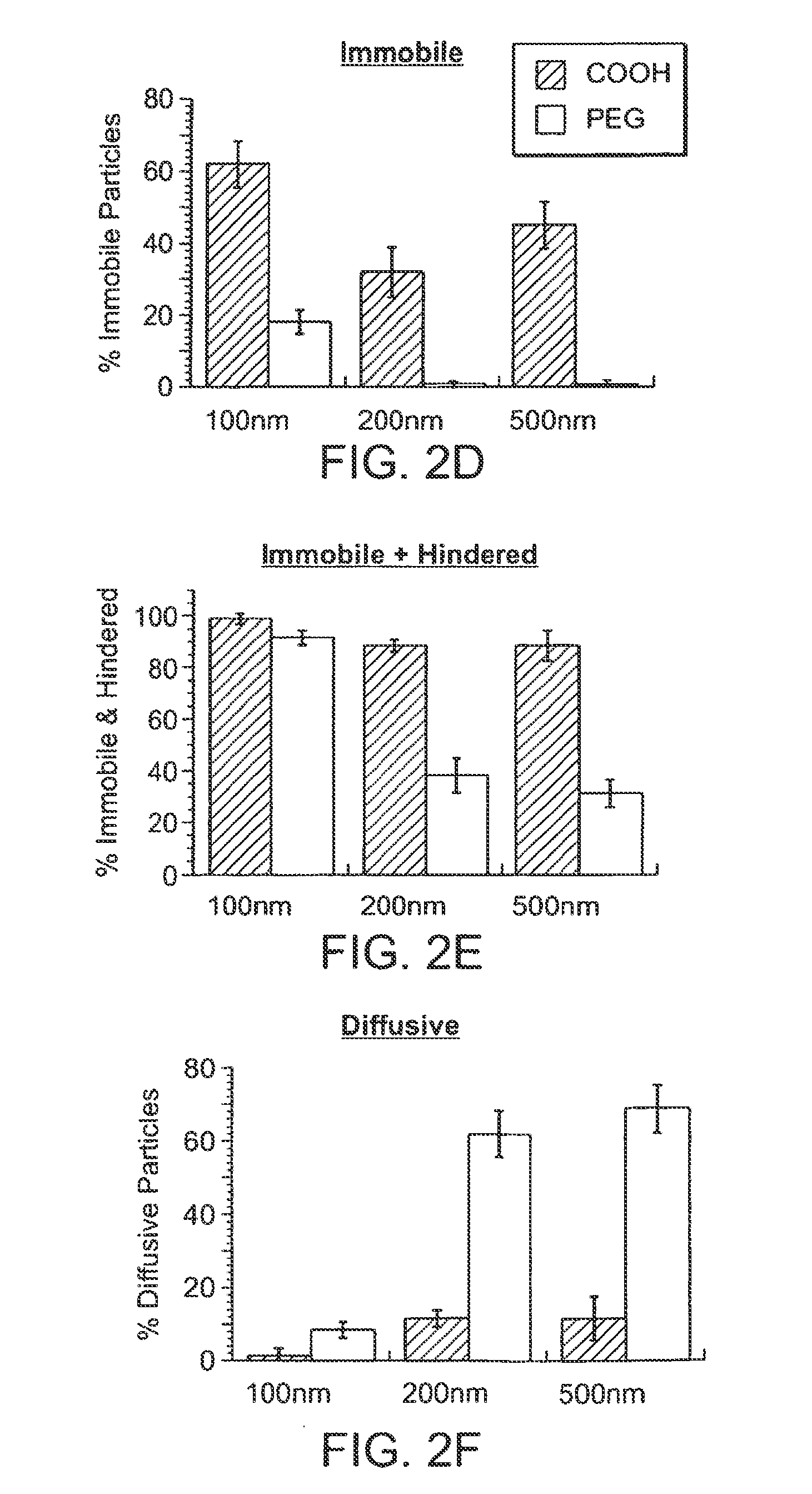

Compositions and methods for enhancing transport through mucus

InactiveUS20130164343A1Diffusion fastPromote adhesion and complexationPowder deliveryNanomedicineRespiratory mucusChemistry

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Oxide etch selectivity systems and methods

ActiveUS20170040175A1Improve etch selectivityEnhance and suppress reactionElectric discharge tubesSemiconductor/solid-state device manufacturingHydrogenProcess region

Embodiments of the present technology may include a method of etching a substrate. The method may include striking a plasma discharge in a plasma region. The method may also include flowing a fluorine-containing precursor into the plasma region to form a plasma effluent. The plasma effluent may flow into a mixing region. The method may further include introducing a hydrogen-and-oxygen-containing compound into the mixing region without first passing the hydrogen-and-oxygen-containing compound into the plasma region. Additionally, the method may include reacting the hydrogen-and-oxygen-containing compound with the plasma effluent in the mixing region to form reaction products. The reaction products may flow through a plurality of openings in a partition to a substrate processing region. The method may also include etching the substrate with the reaction products in the substrate processing region.

Owner:APPLIED MATERIALS INC

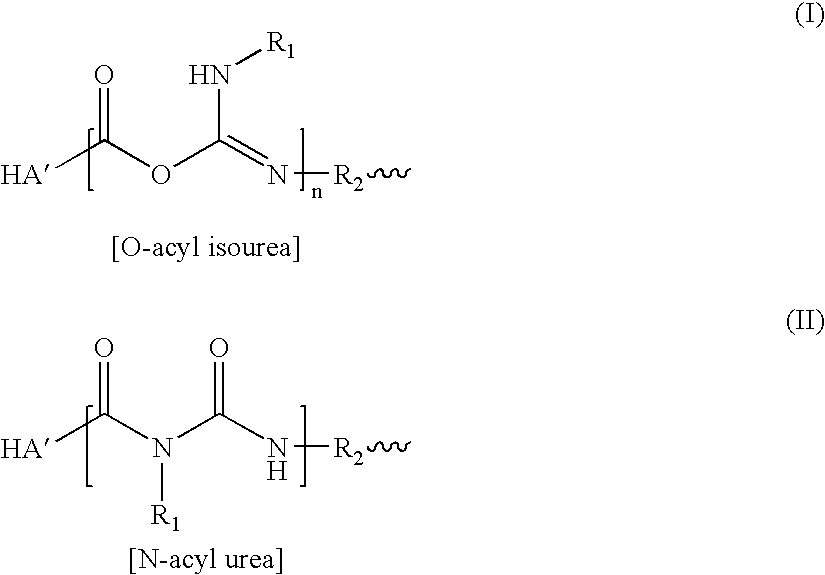

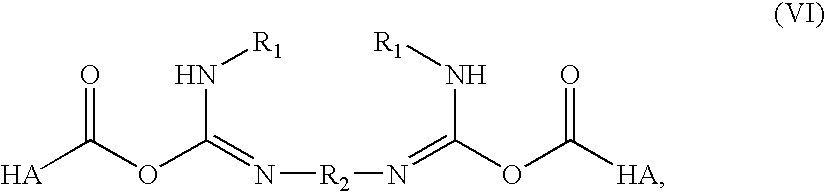

Treatment of arthritis and other musculoskeletal disorders with crosslinked hyaluronic acid

InactiveUS20070203095A1Reduce frequencyFast pain reliefBiocideOrganic active ingredientsDiseaseCarboxyl radical

A method of treating a subject having a musculoskeletal disorder includes administering to a subject's articular site in need thereof an effective amount of a hyaluronic acid (HA) composition. In one embodiment, the HA composition includes an HA derivative, wherein carboxyl functionalities of the hyaluronic acid derivative are each independently derivatized to include an N-acylurea or 0-acyl isourea, or both N-acylurea and 0-acyl isourea. In another embodiment, the HA composition includes a crosslinked HA gel that is prepared by reacting an uncrosslinked HA with a biscarbodiimide in the presence of pH buffer in a range of between about 4 and about 8. The composite can optionally include at least one second bioactive agent other than the HA derivative, such as a steroid.

Owner:ANIKA THERAPEUTICS INC

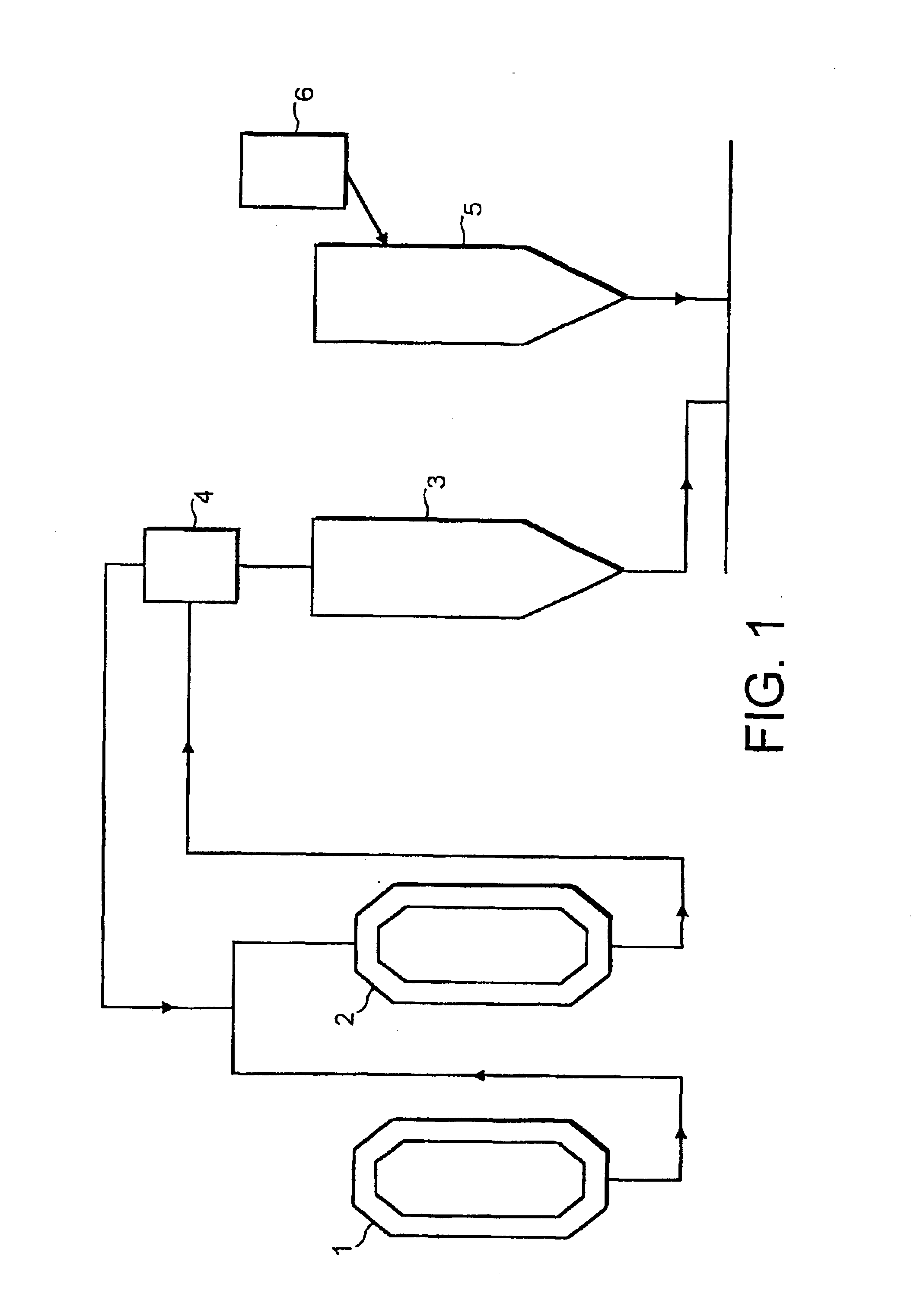

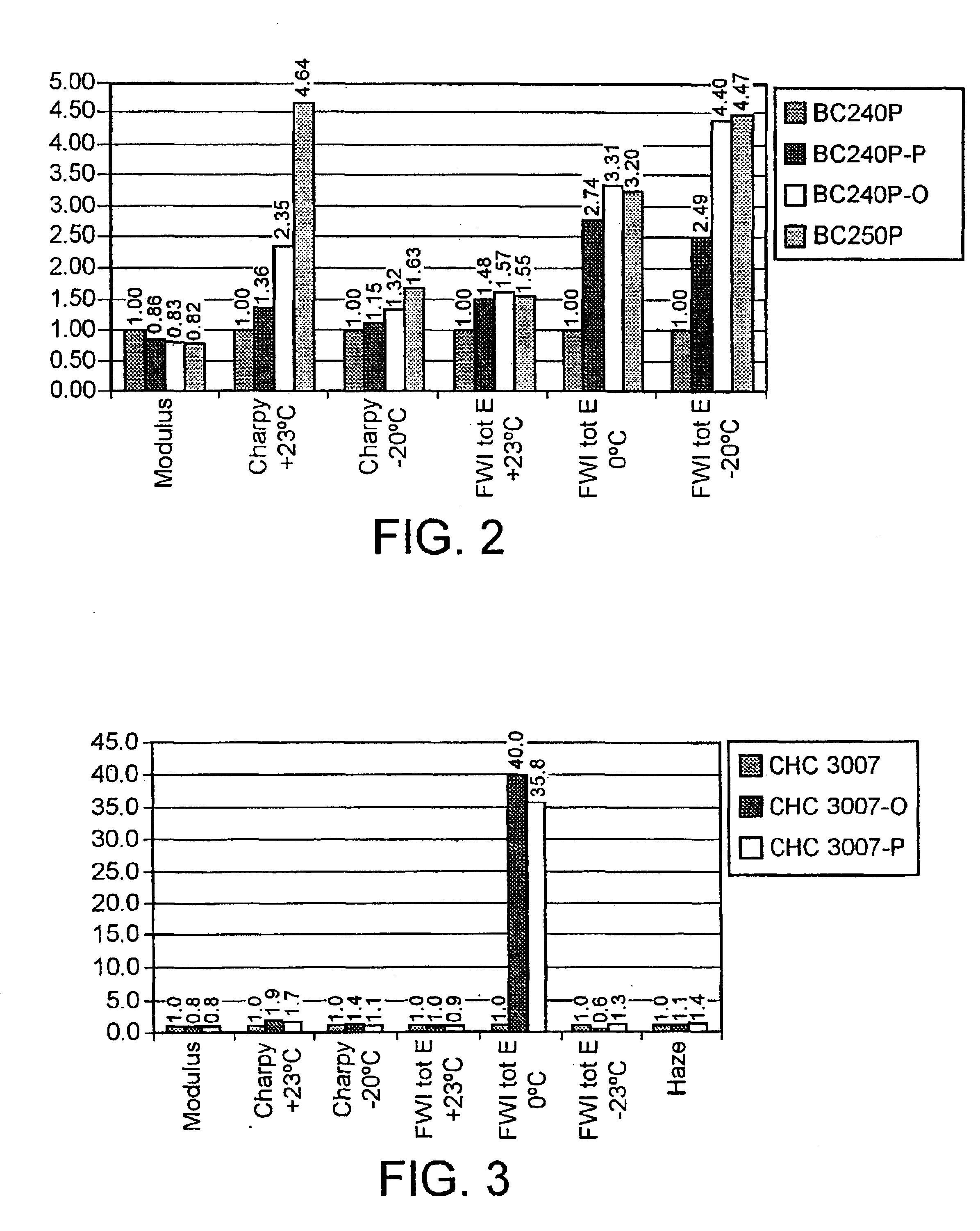

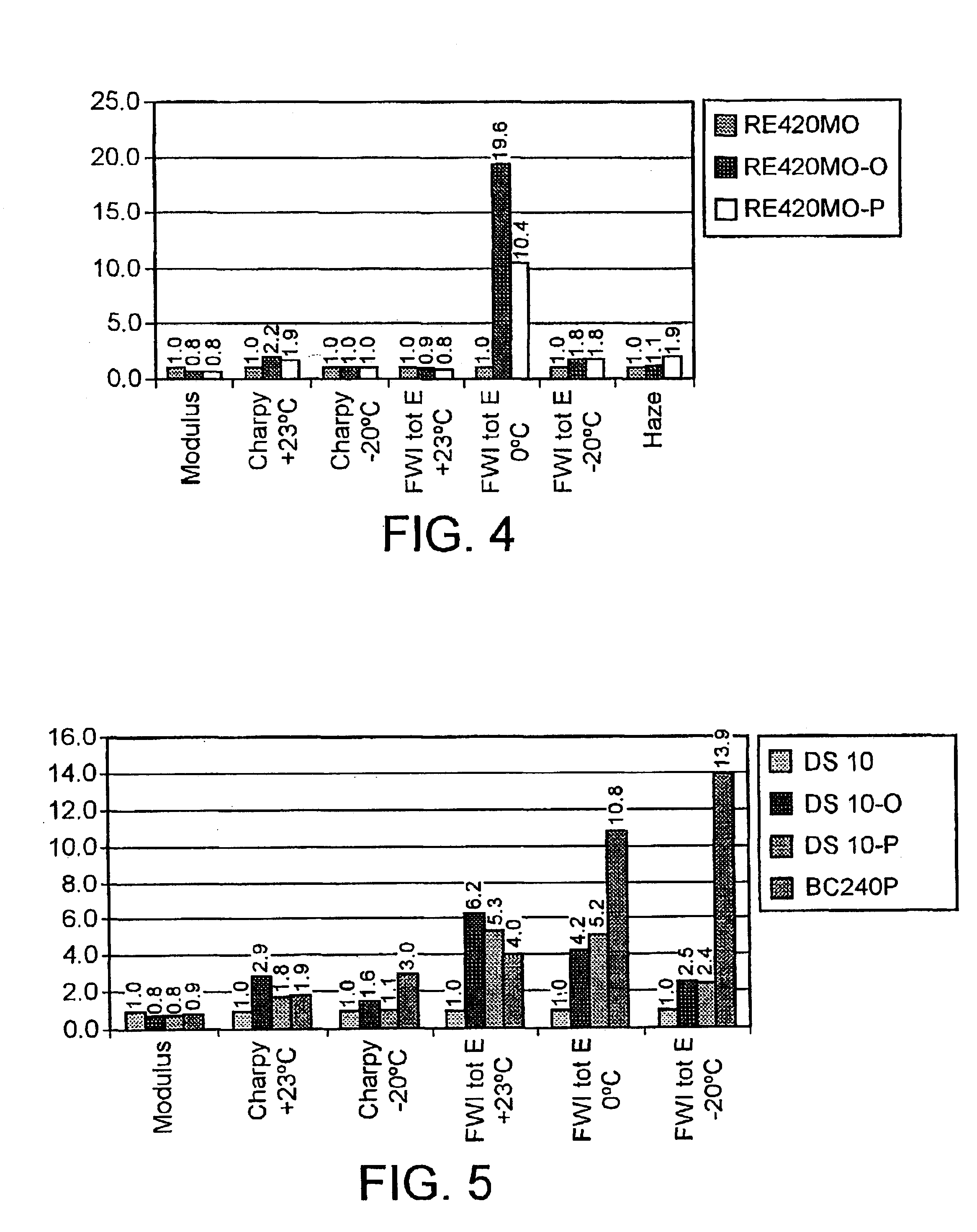

Process for producing propylene based polymer compositions

A process for the production of a propylene based polymer, the process comprising the following steps: (a) a first polymerization stage comprising homopolymerizing propylene or copolymerizing propylene and at least one alpha-olefin in the presence of an alpha-olefin polymerization catalyst whereby to produce a polypropylene component; (b) a second polymerization stage comprising copolymerizing ethylene and at least one alpha-olefin in the presence of an alpha-olefin polymerization catalyst whereby to produce an ethylene / alpha-olefin copolymer component; and (c) blending the polymer components produced in steps (a) and (b) whereby to produce a polymer blend, wherein the first and second polymerization stages are effected in separate polymerization reactors connected in parallel. Also provided are polymer compositions comprising: (i) 30 to 97% by weight, based on the total weight of the polymer composition, of a propylene based polymer; and (ii) 3 to 70% by weight, preferably 5 to 20% by weight, based on the total weight of the polymer composition, of an ethylene copolymer plastomer (e.g., an ethylene-propylene plastomer) containing at least 60% by weight ethylene.

Owner:BOREALIS TECH OY

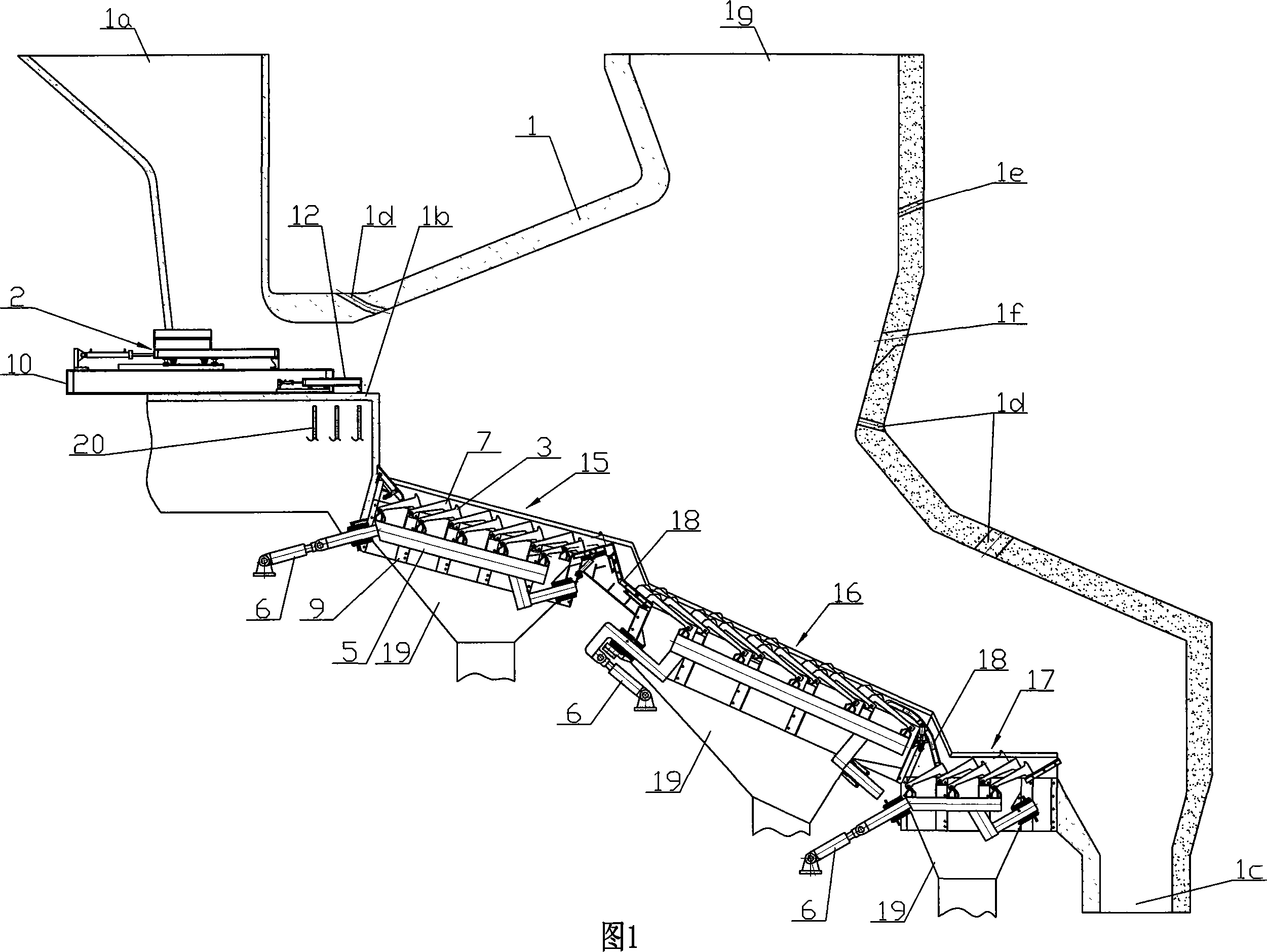

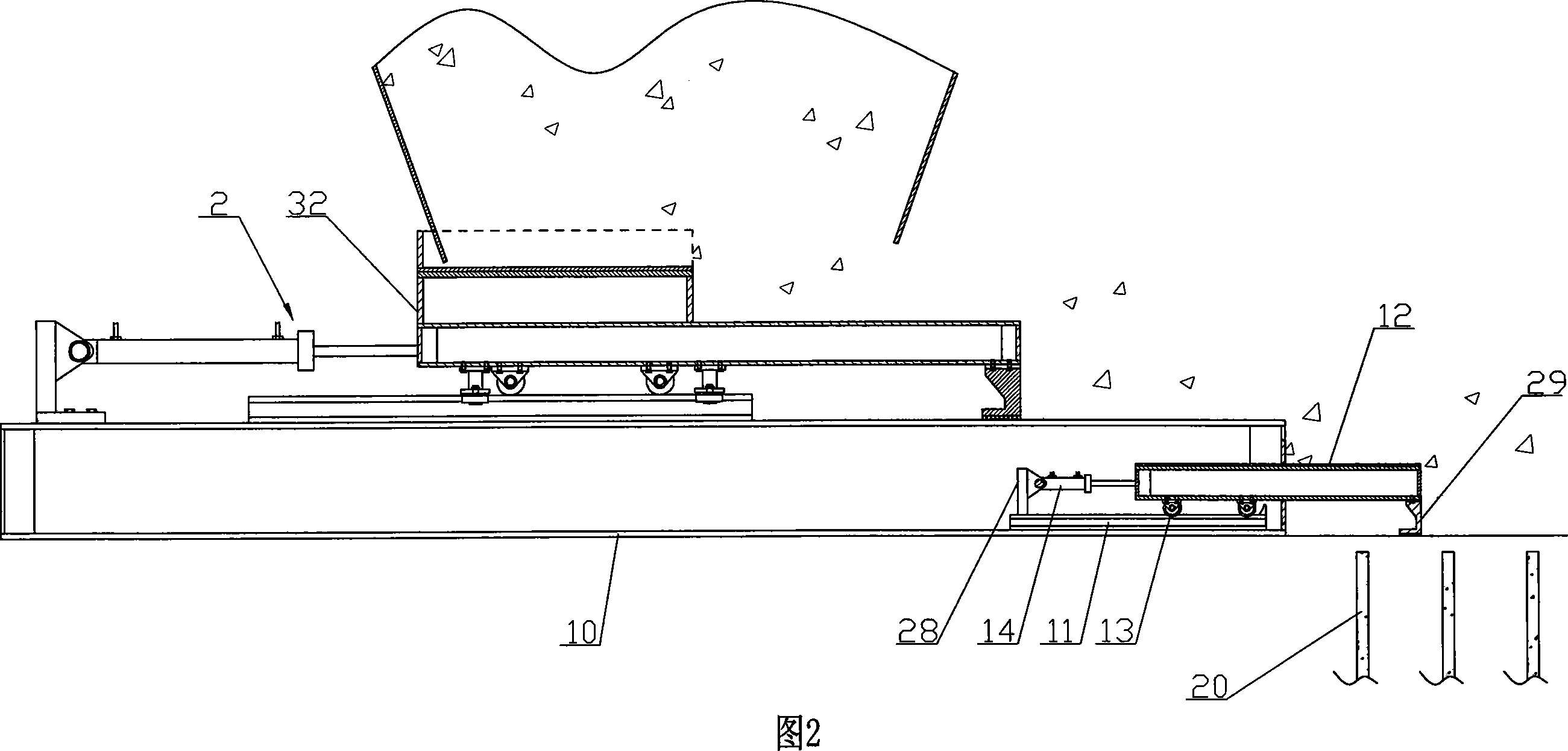

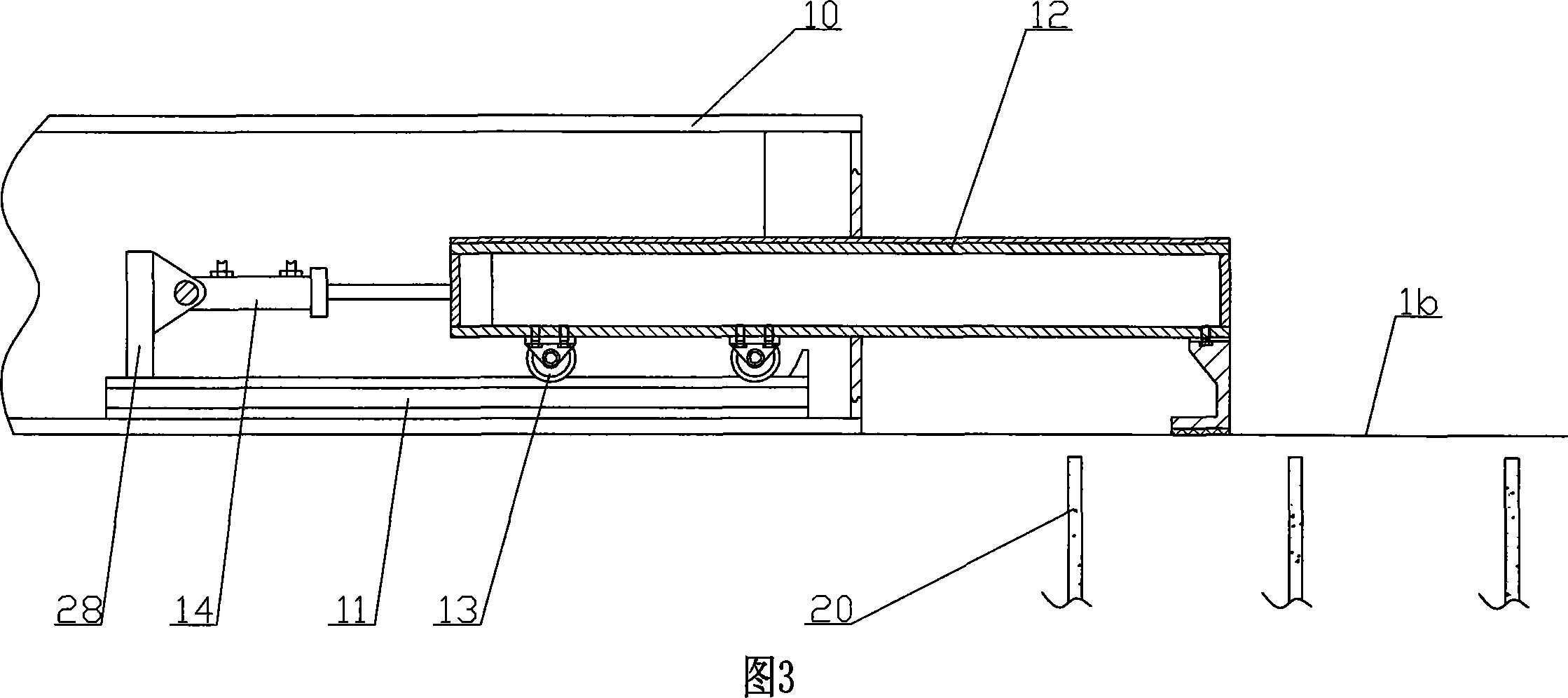

Multiple row sectional drive combined type domestic garbage incinerator

The invention relates to multi-column sectional drive combined type domestic incinerator. It is set three fire-grates that drying section, burning section, and firing section. The middle fire grate is connected between them. There is altitude fall between them that the drying section is the highest point; the firing one is the lowest point. The primary air chamber is respectively set under them. The incinerator fire grate system of the invention has independent drive mechanism, air supply system, and air chamber for each section which is convenient for controlling technical parameter that traveling speed, air quantity, air temperature, air pressure etc to realize full drying and burning for whole garbage layer.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

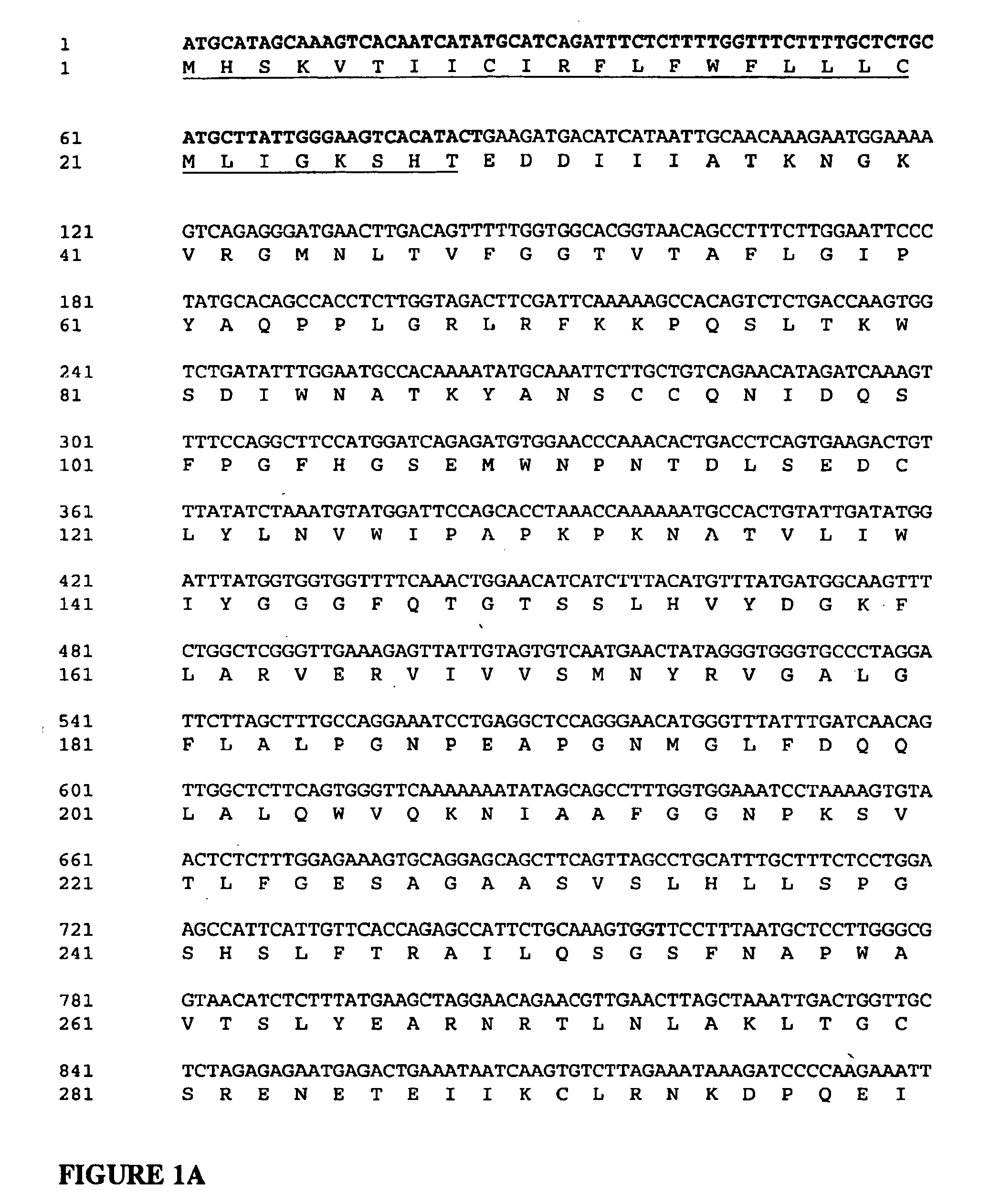

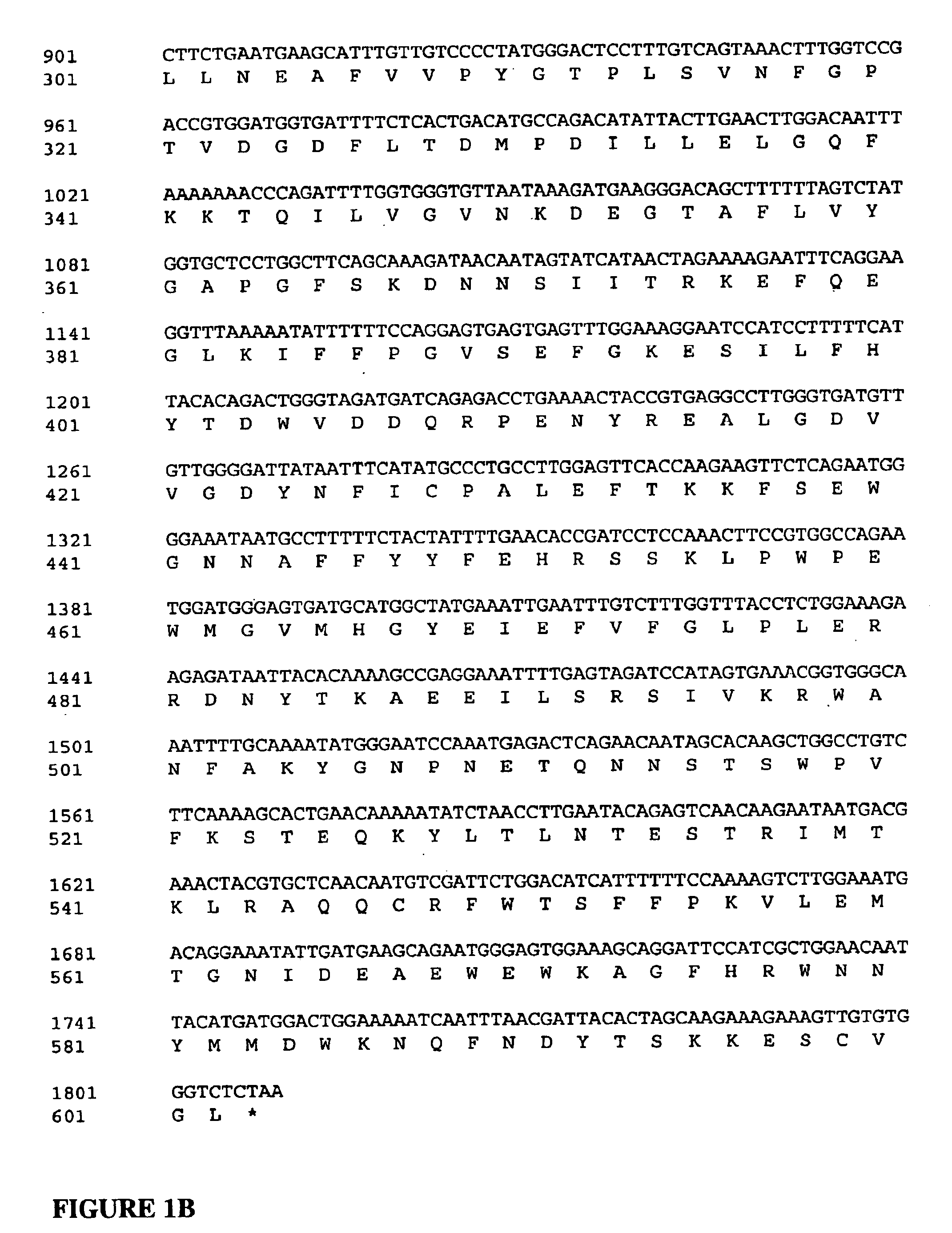

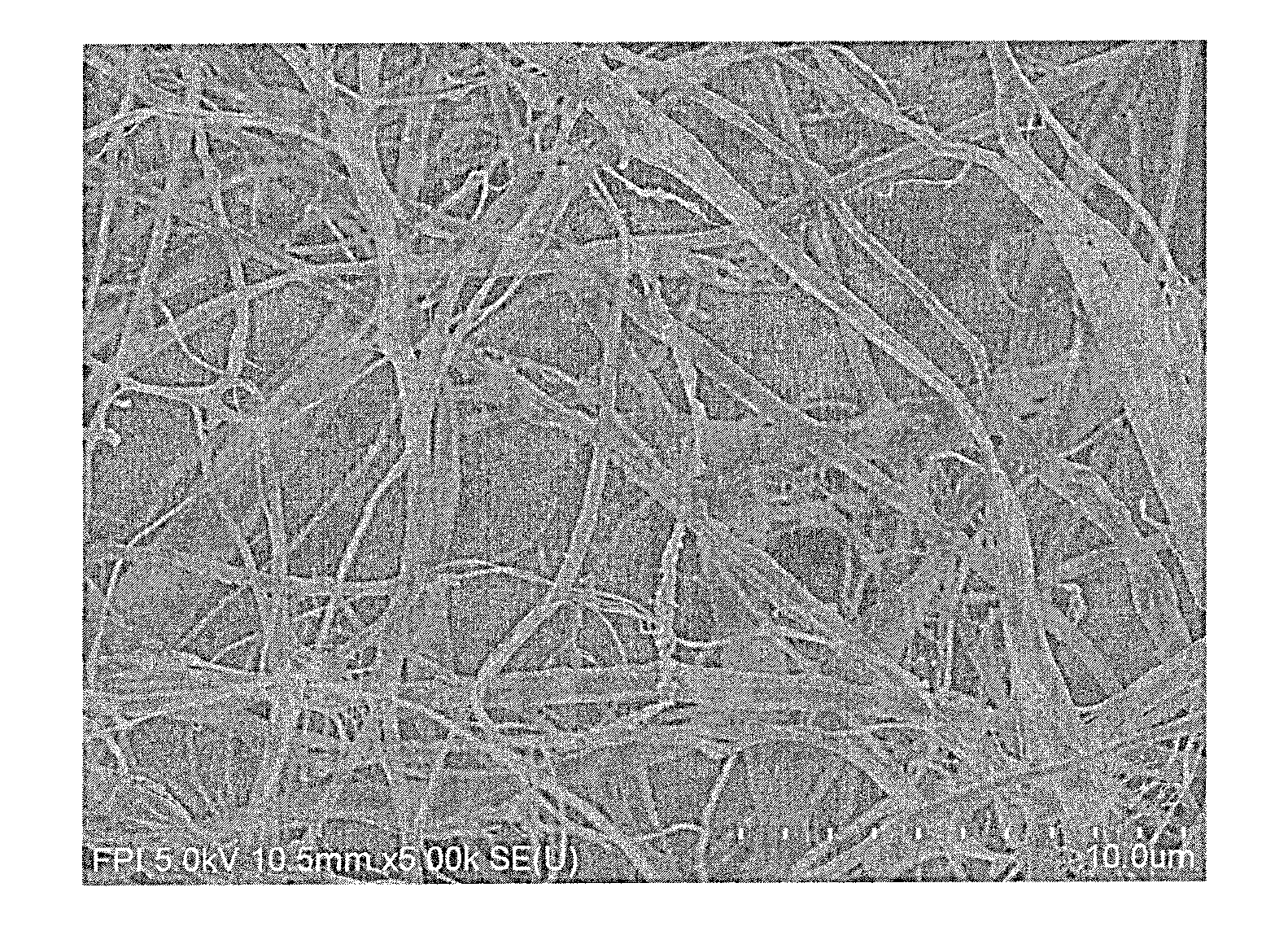

Production of hSA-linked butyrylcholinesterases in transgenic mammals

InactiveUS20060253913A1Promote formationImprove stabilityAnimal cellsVectorsMammalButyrylcholinesterase

The present invention provides methods for the large-scale production of recombinant butyrylcholinesterase fused to human serum albumin in cell culture, and in the milk and / or urine of transgenic mammals. The recombinant butyrylcholinesterase-albumin fusion protein of this invention can be used to treat and / or prevent organophosphate pesticide poisoning, nerve gas poisoning, cocaine intoxication, and succinylcholine-induced apnea.

Owner:PHARMATHENE

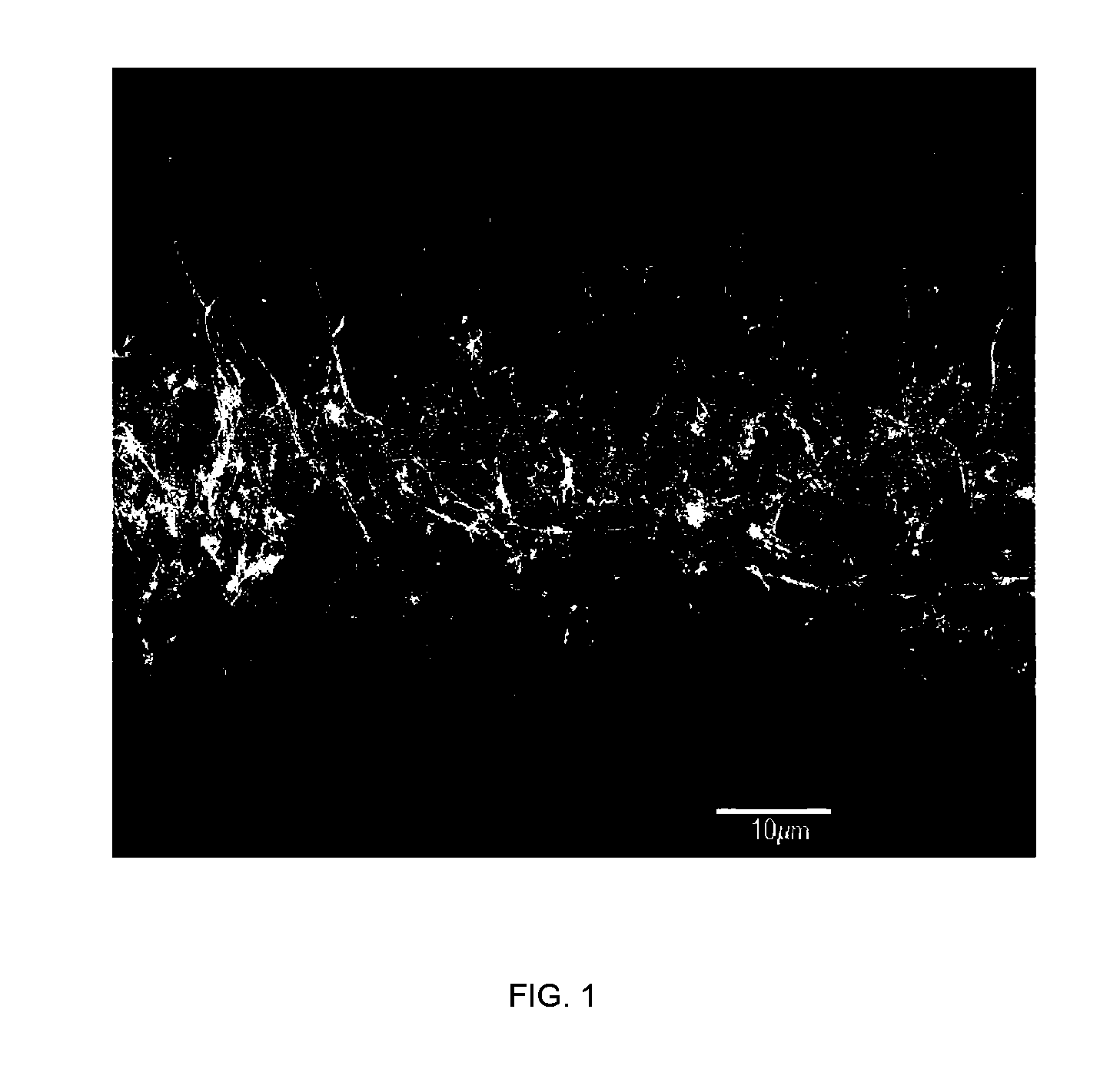

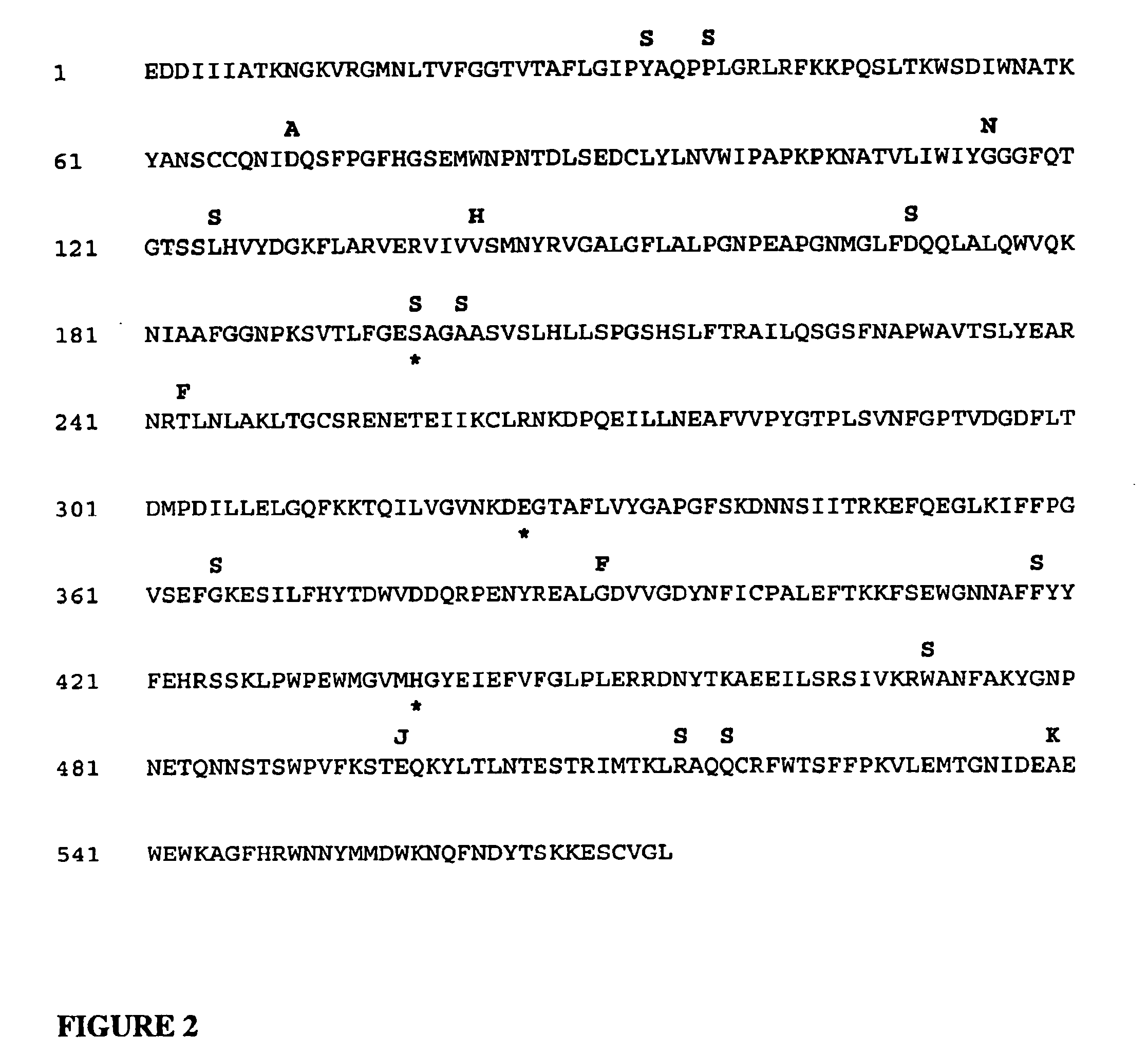

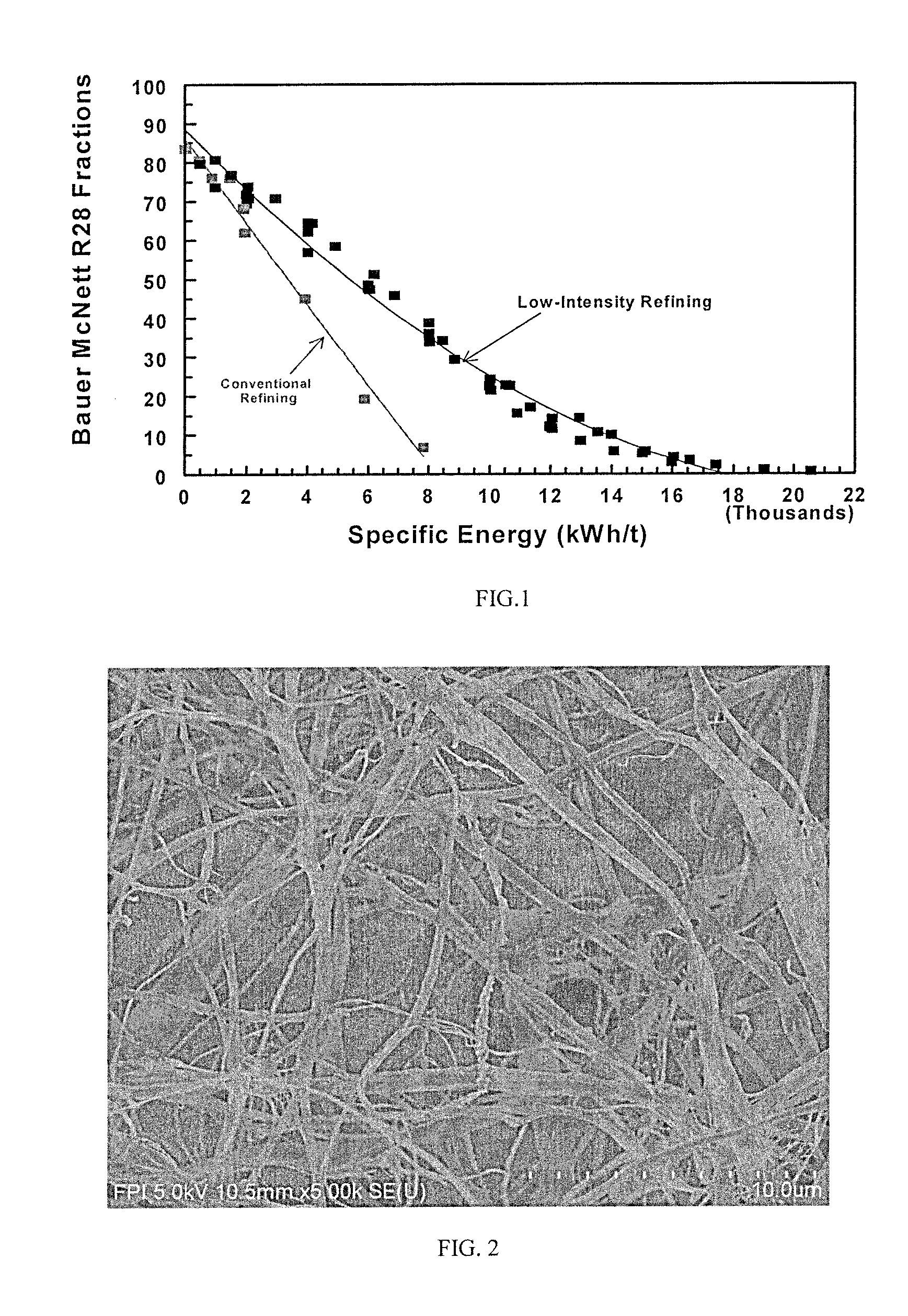

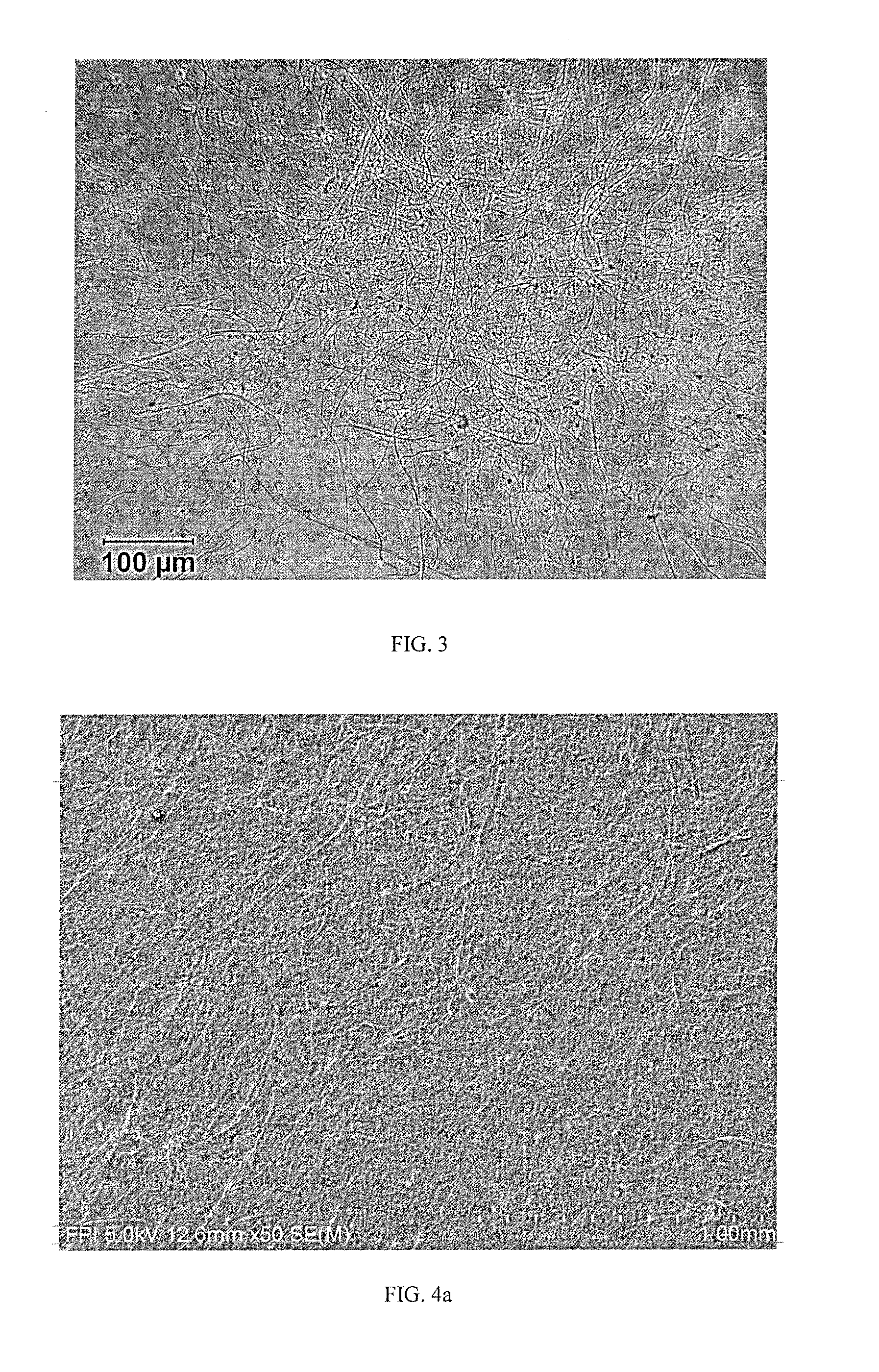

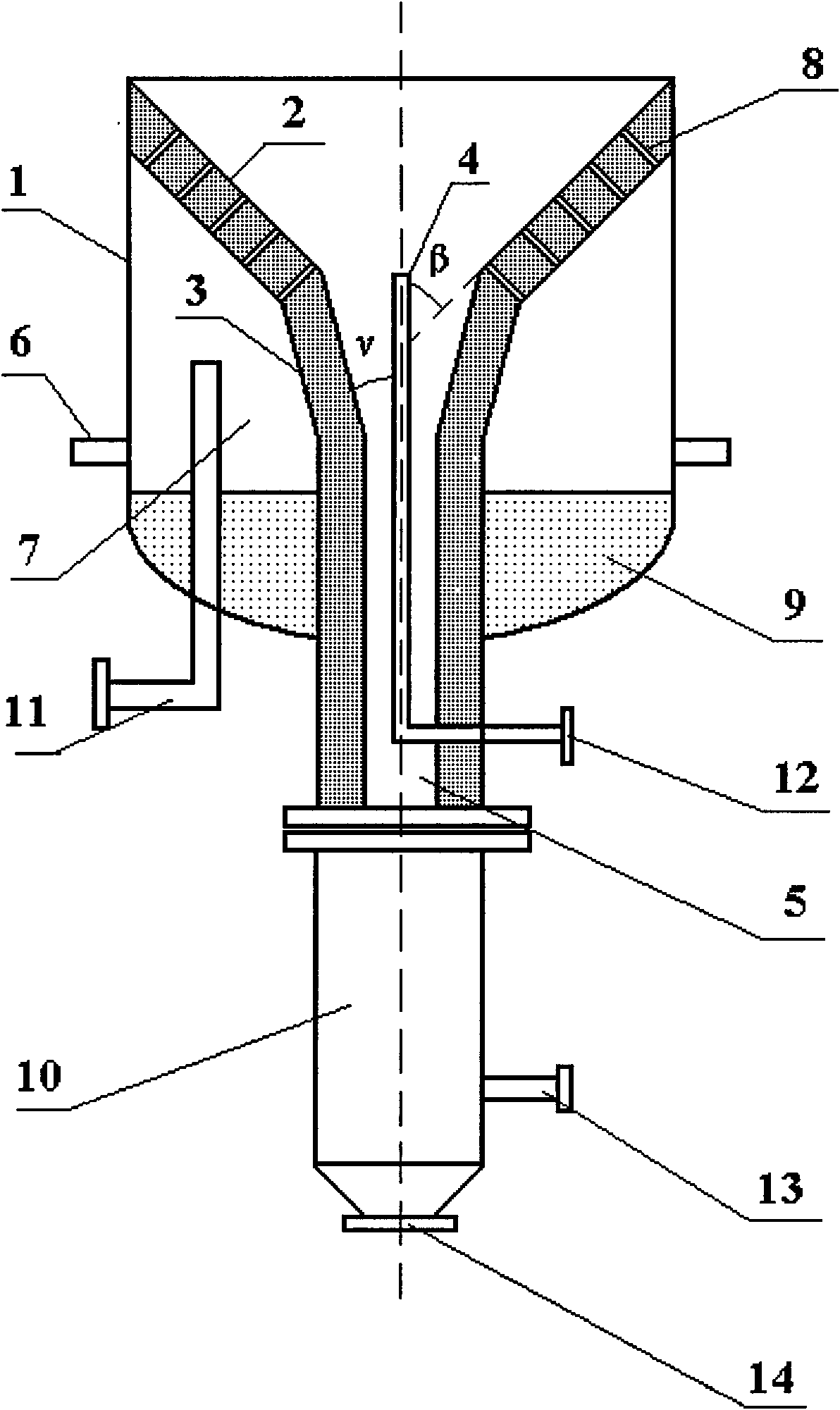

High aspect ratio cellulose nanofilaments and method for their production

ActiveUS20130017394A1High consistency refiningIncrease surface areaMaterial nanotechnologyFinely-divided cellulose conservationMicrometerPaperboard

A method to produce on a commercial scale, high aspect ratio cellulose nanofilaments (CNF) from natural lignocellulosic fibers comprises a multi-pass high consistency refining (HCR) of chemical or mechanical fibers using combinations of refining intensity and specific energy. The CNF produced represents a mixture of fine filaments with widths in the submicron and lengths from tens of micrometers to few millimeters. The product has a population of free filaments and filaments bound to the fiber core from which they were produced. The proportion of free and bound filaments is governed in large part by total specific energy applied to the pulp in the refiner, and differs from other cellulose fibrillar materials by their higher aspect ratio and the preserved degree of polymerization (DP) of cellulose, and are excellent additives for the reinforcement of paper, tissue, paperboard and the like. They display exceptional strengthening power for never-dried paper webs.

Owner:FPINNOVATIONS INC

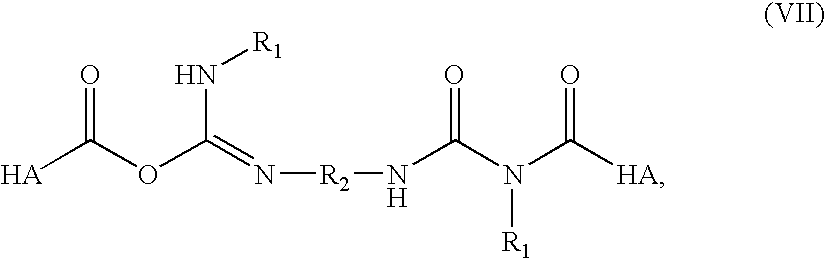

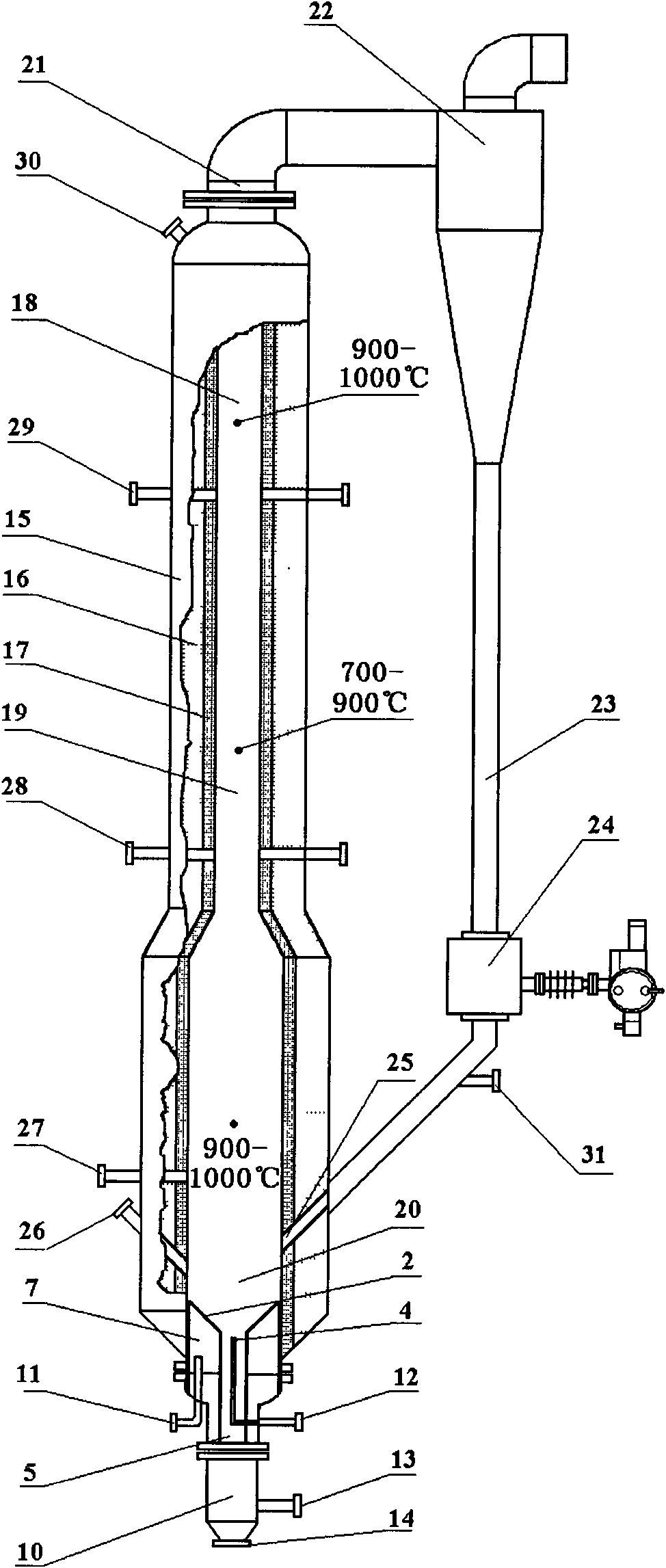

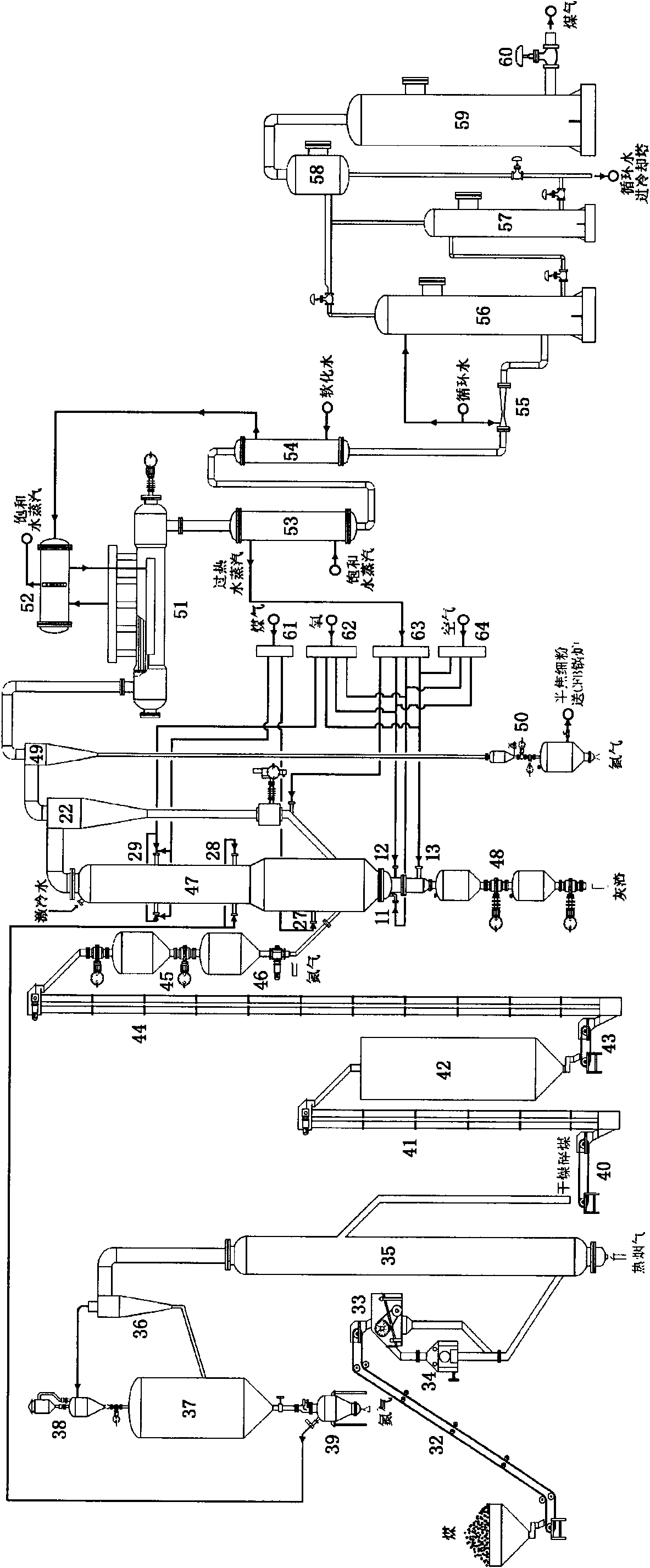

Method and device for gasifying multi-segment staged converted fluidized bed

ActiveCN101942344ALow ash carbon contentExtended stayEnergy inputCombined combustion mitigationFluidized bedProcess engineering

The invention relates to method and device for gasifying a multi-segment staged converted fluidized bed. The method comprises the following steps of: supplying coal; supplying gas; gasifying; slagging; and conveying fine powder. The device for gasifying the multi-grade staged converted fluidized bed comprises an agglomerating ash separating unit, a pyrolyzing and gasifying reactor of the multi-segment staged fluidized bed and a semicoke fine powder cyclic feeding unit. The invention has the advantages of high volume utilization rate of a gasifying oven, great handling capacity and high utilization rate of total carbon, is suitable for a coal staging and converting system and can be singly used for producing gas for mass coal-based methane synthesis and coal chemical industry.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

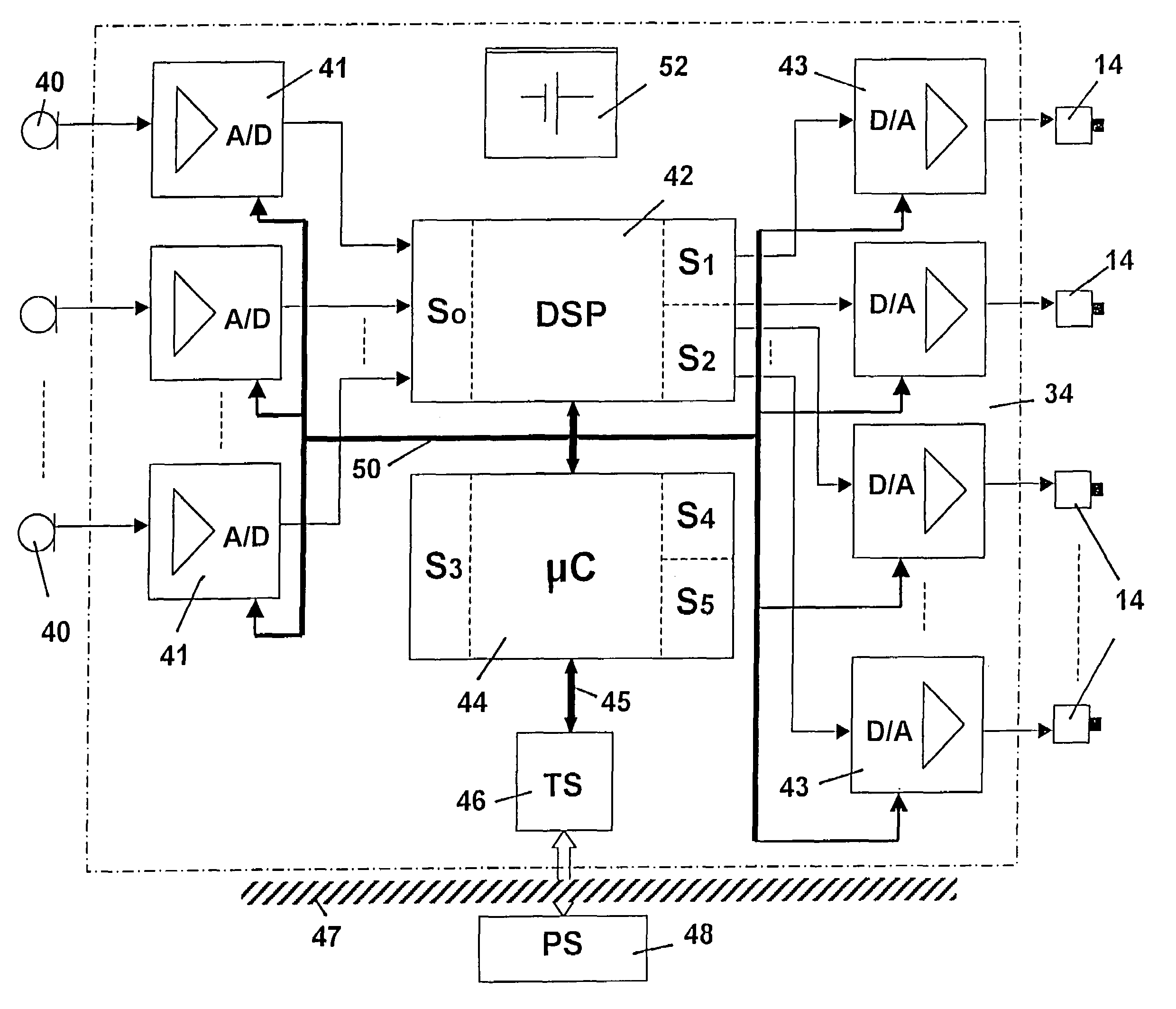

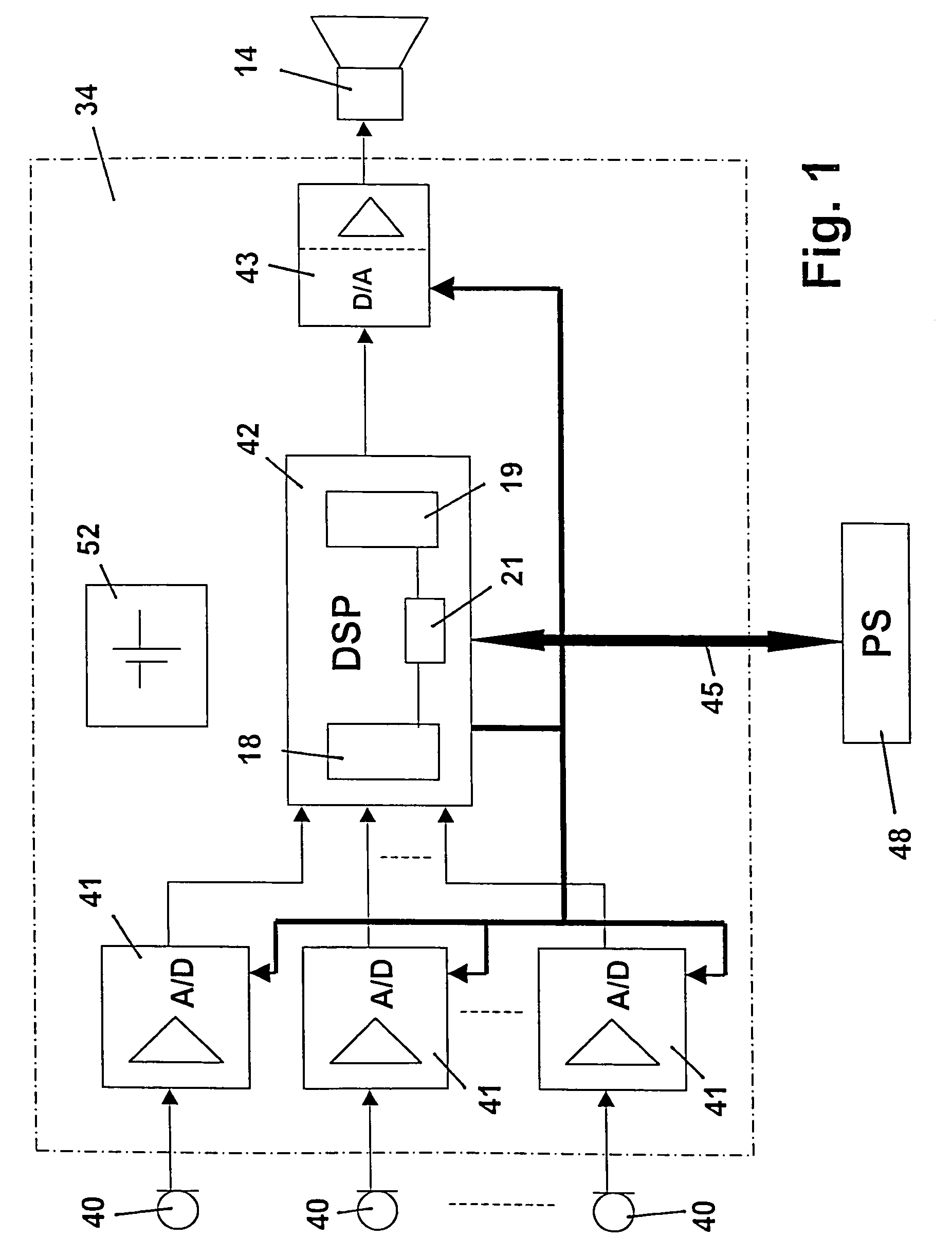

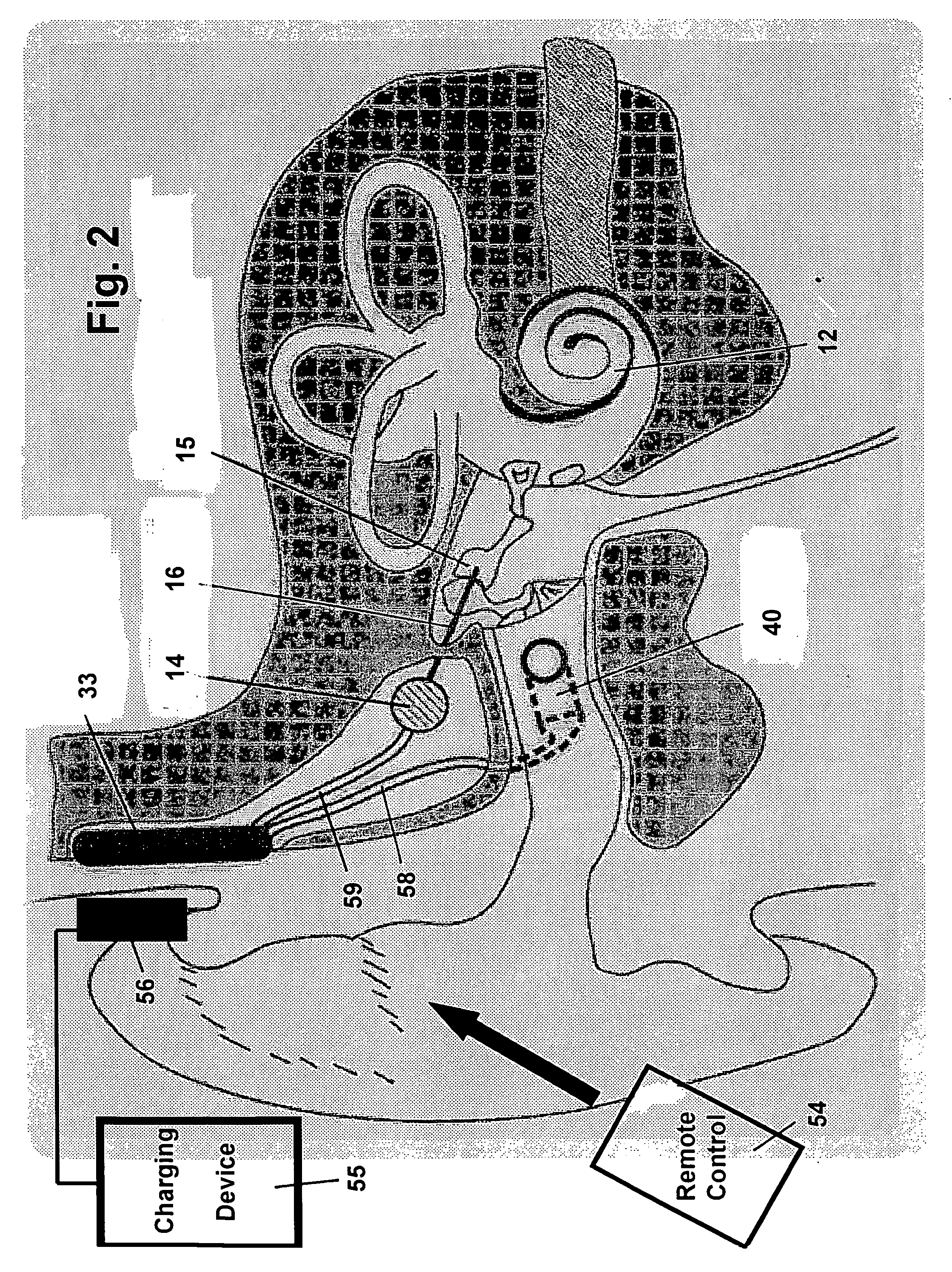

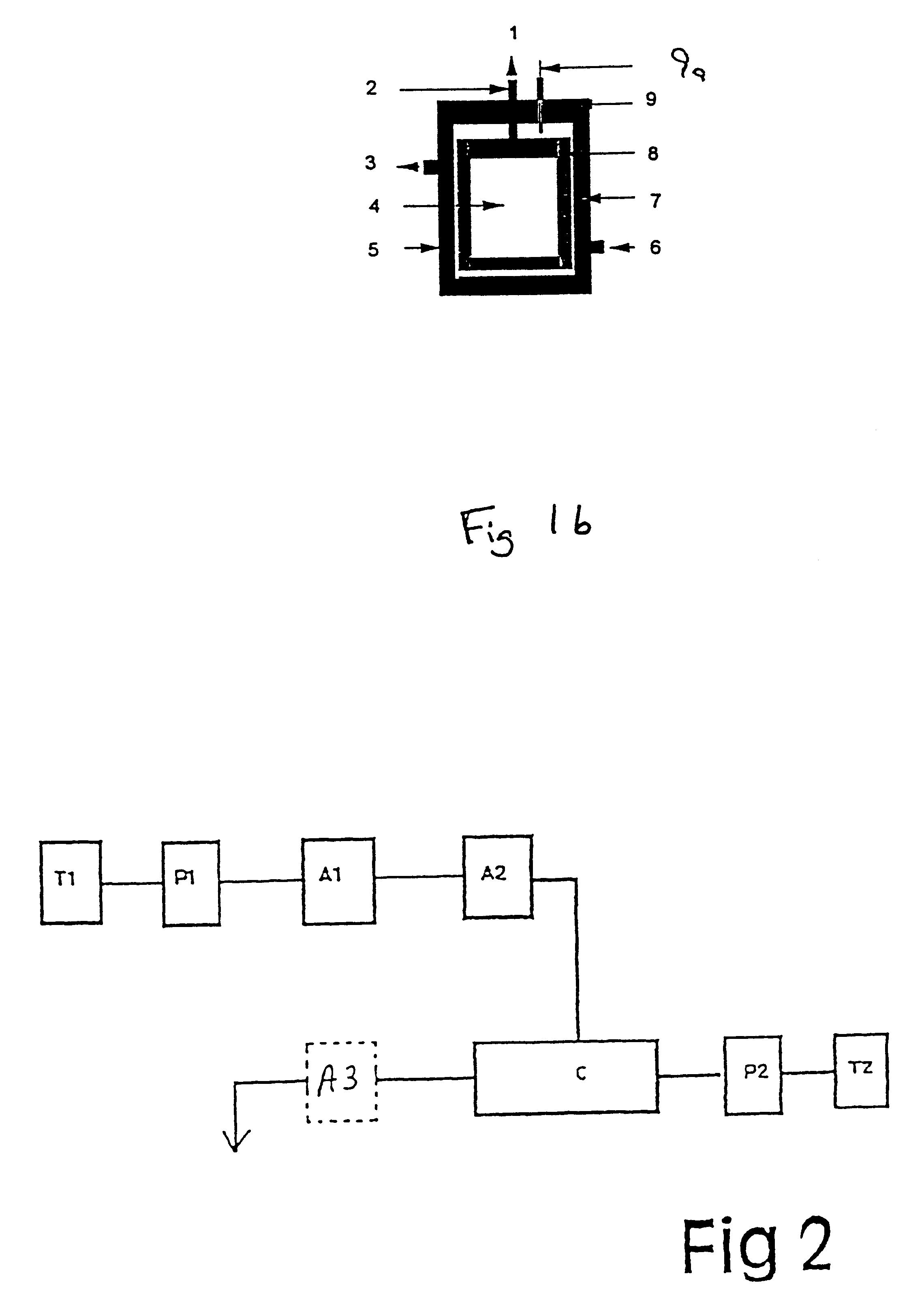

System for rehabilitation of a hearing disorder

InactiveUS7376563B2Improve understandingAdverse effectElectrotherapyElectric tinnitus maskersEngineeringHearing perception

A system for rehabilitation of a hearing disorder which comprises at least one acoustic sensor for picking up an acoustic signal and converting it into an electrical audio signal, an electronic signal processing unit for audio signal processing and amplification, an electrical power supply unit which supplies individual components of the system with current, and an actuator arrangement which is provided with one or more electroacoustic, electromechanical or purely electrical output-side actuators or any combination of these actuators for stimulation of damaged hearing, wherein the signal processing unit has a speech analysis and recognition module and a speech synthesis module.

Owner:COCHLEAR LIMITED

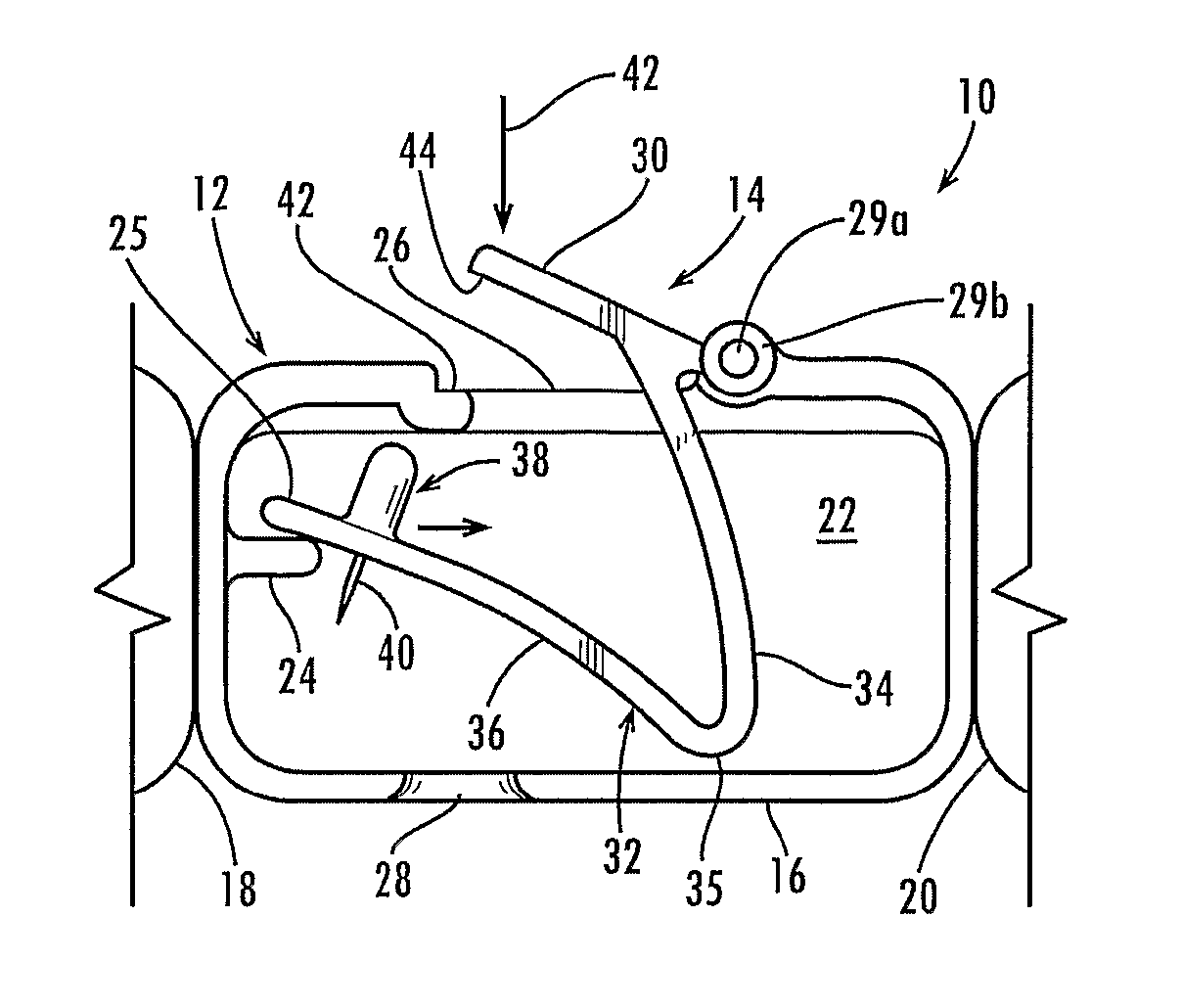

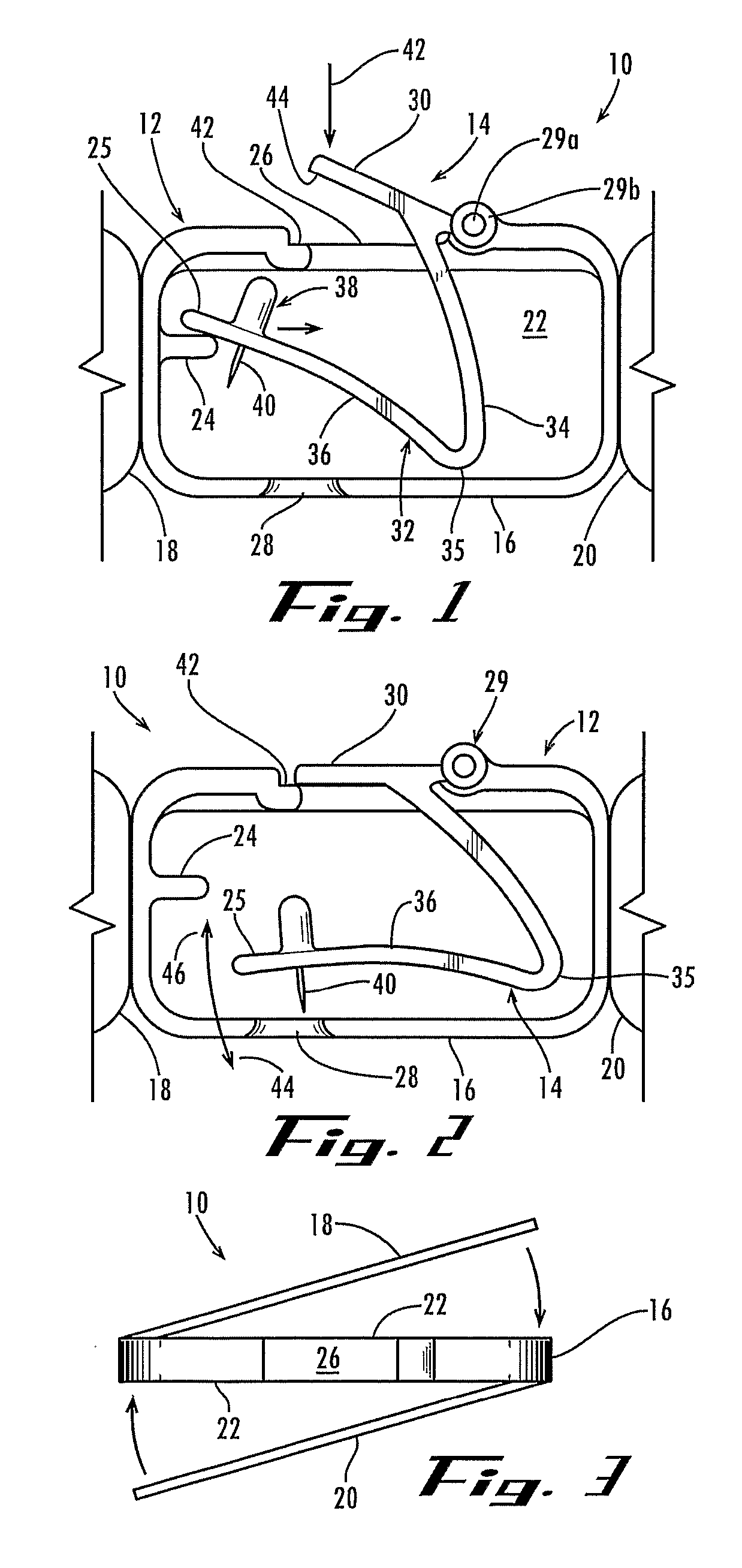

Low-Cost Lancing Device with Cantilevered Leaf Spring for Launch and Return

InactiveUS20070233166A1Inexpensive to manufactureLow costSensorsBlood sampling devicesActuatorLeaf spring

A lancing assembly is pivotally coupled to a housing and includes an actuator and a leaf spring carrying a lancet. When the actuator is in its set position, the leaf spring and lancet are in their set position with the leaf spring engaging a catch member of the housing. When the actuator is moved to its actuated position, the leaf spring pivots and deflects against the catch member, thereby storing a drive charge. The leaf spring then releases from the catch member as the stored charge launches the lancet to its lancing position. The leaf spring recharges towards the end of the lancing stroke, which return charge then retracts the lancet back into the housing.

Owner:FACET TECH LLC

Shear gel compositions

InactiveUS6673371B2Extended stayPowder deliveryCosmetic preparationsThickened fluidsPolymer chemistry

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

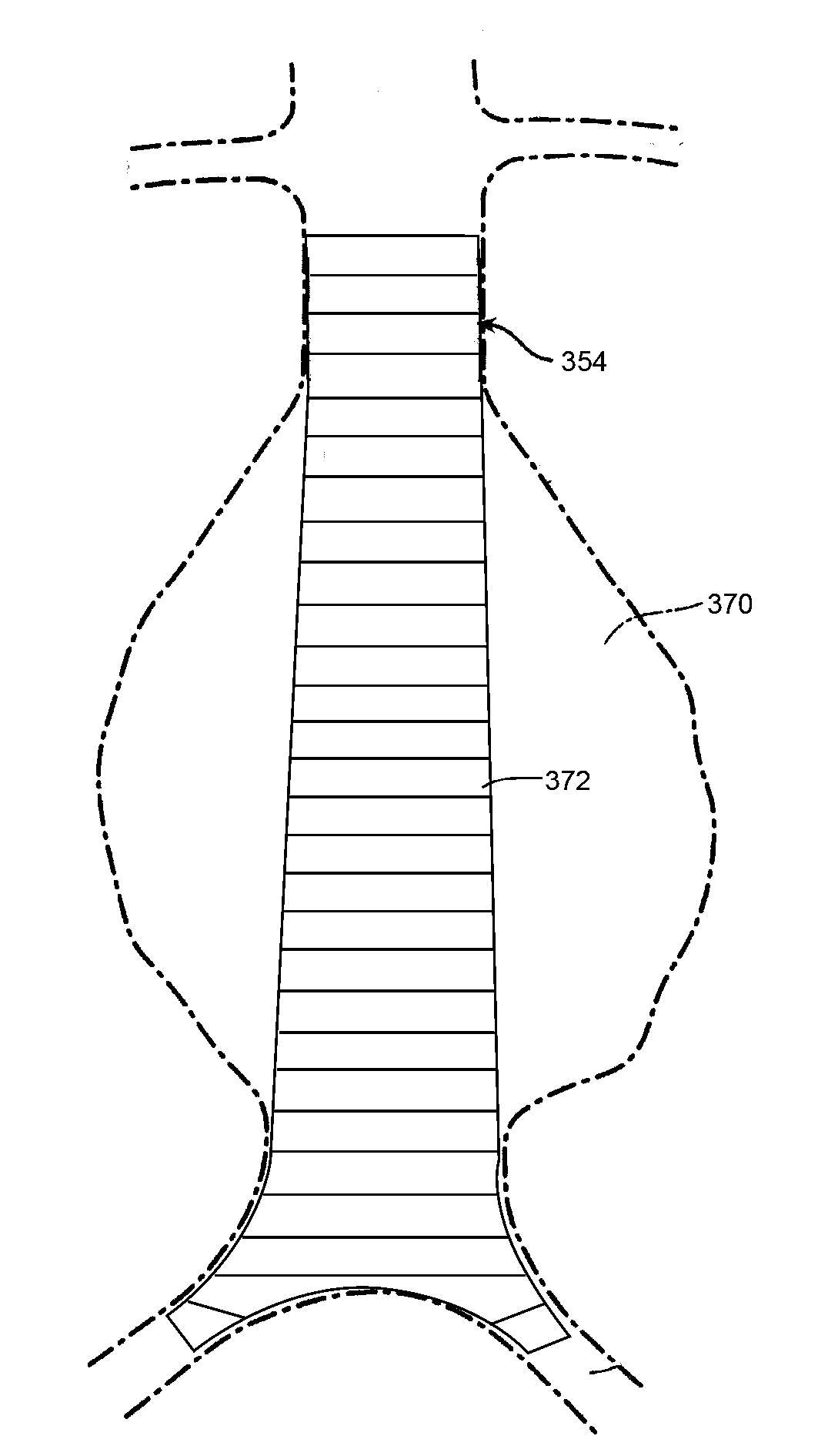

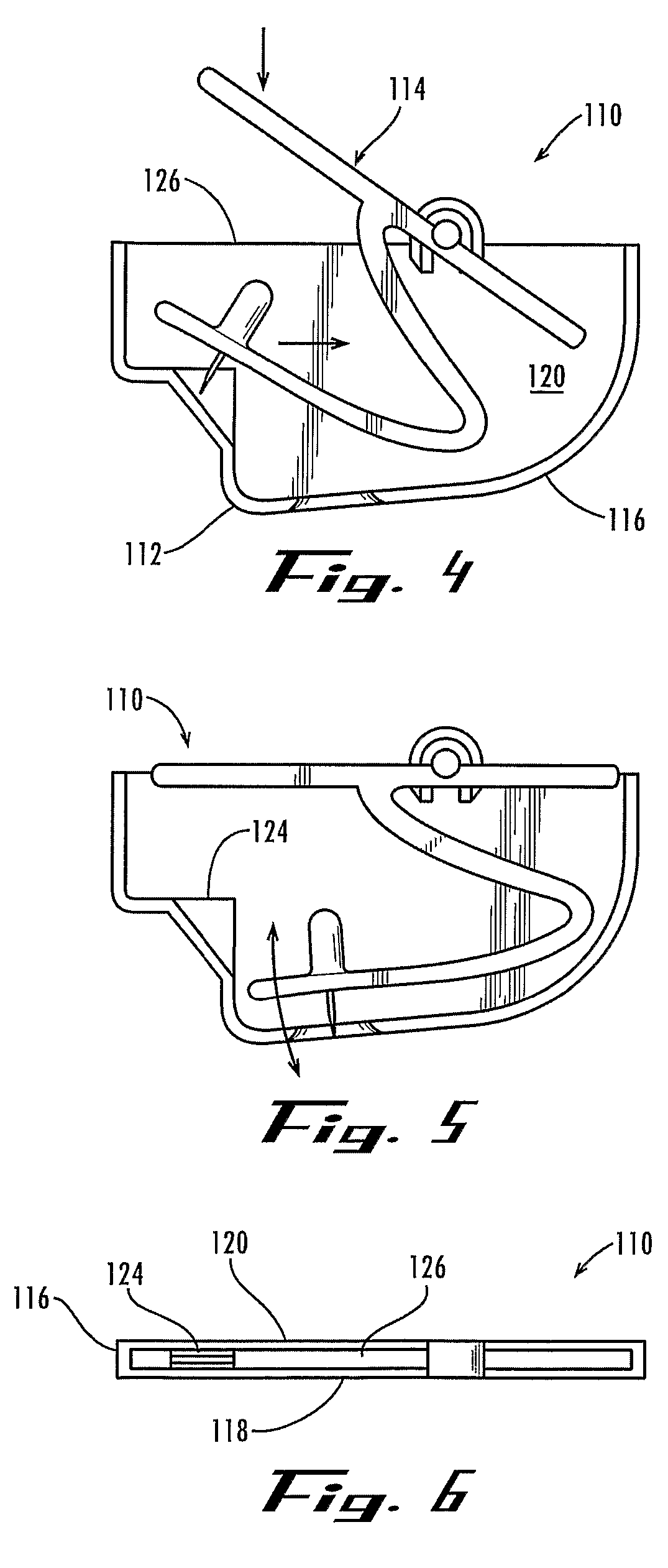

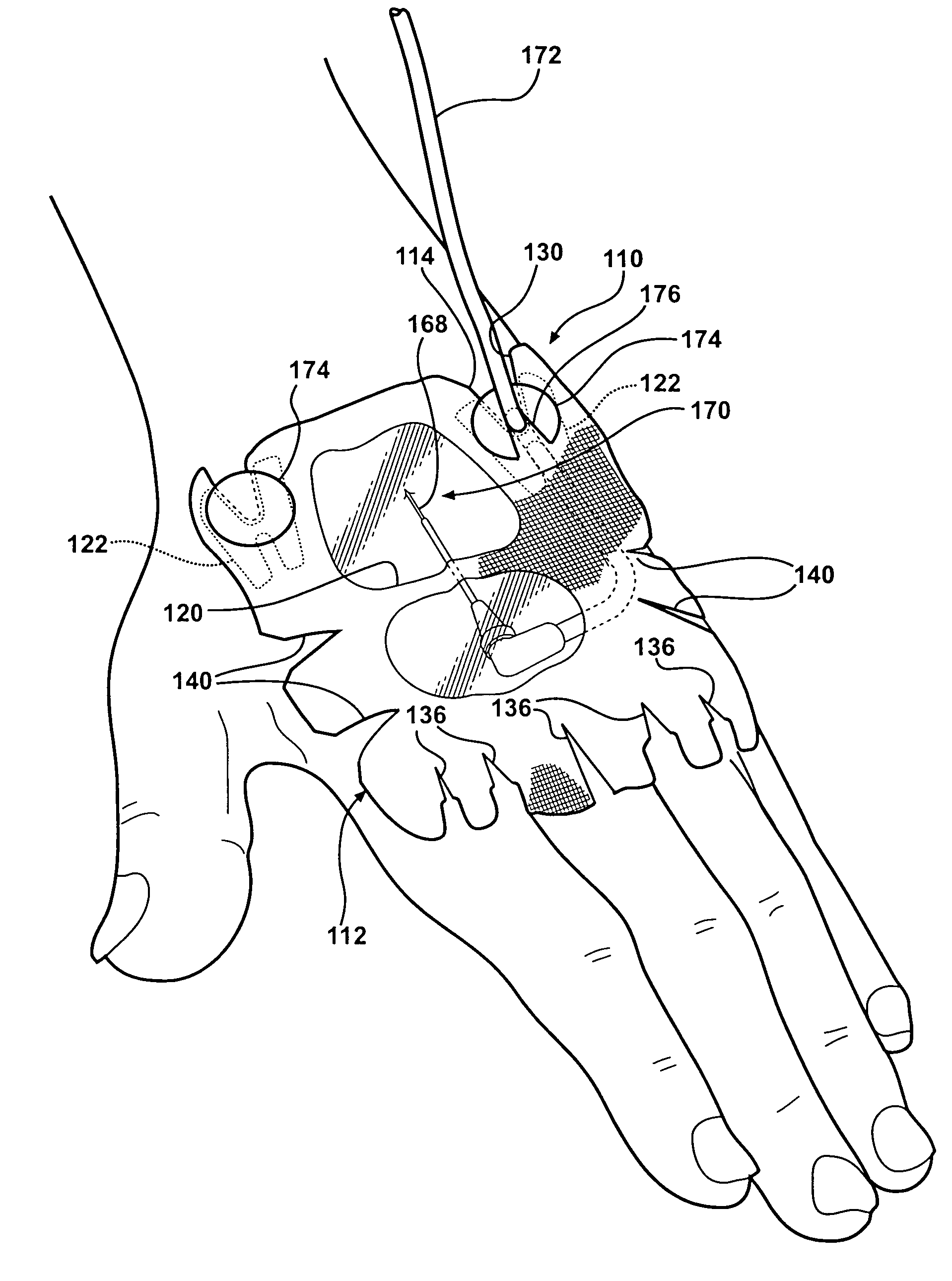

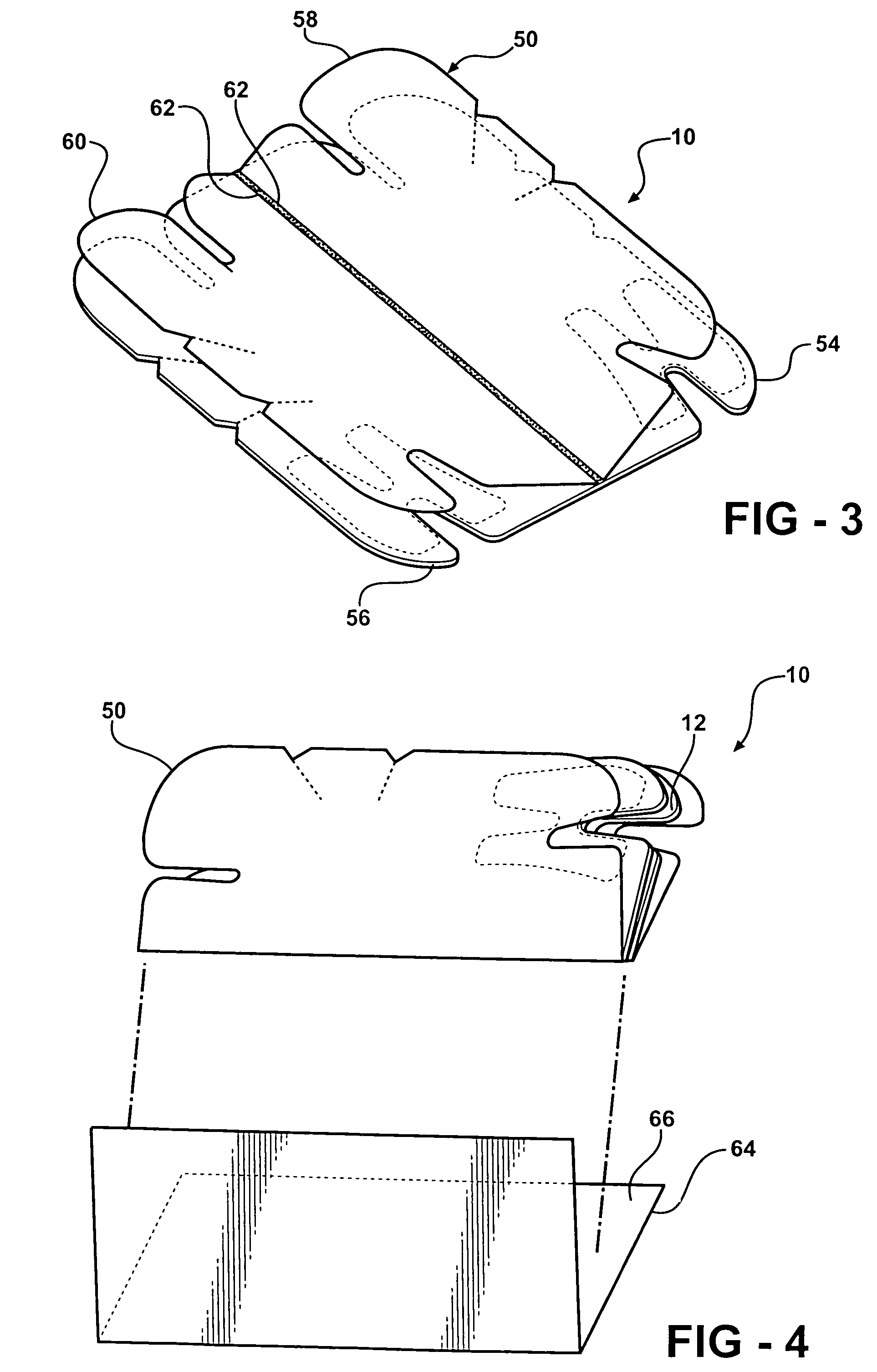

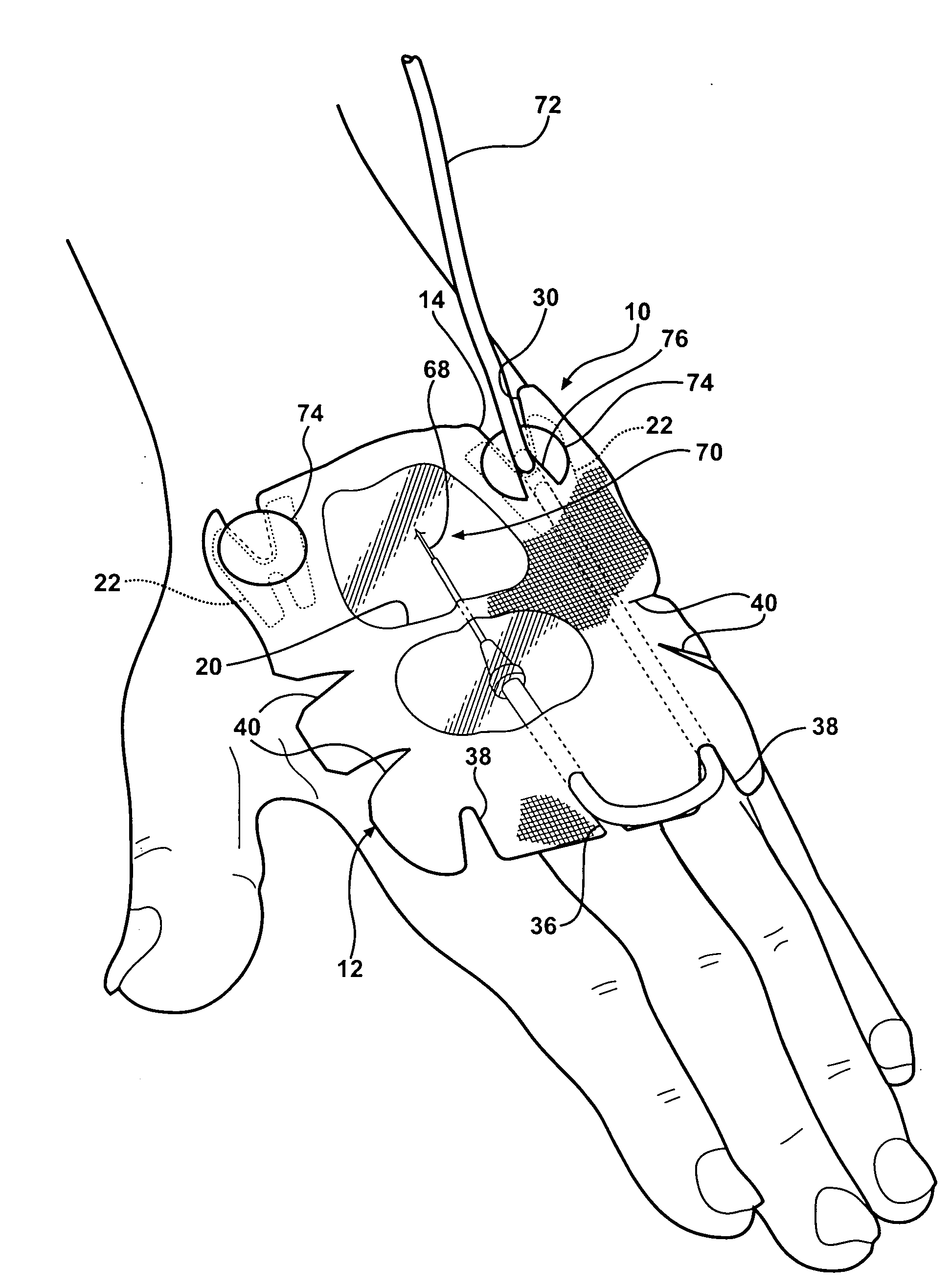

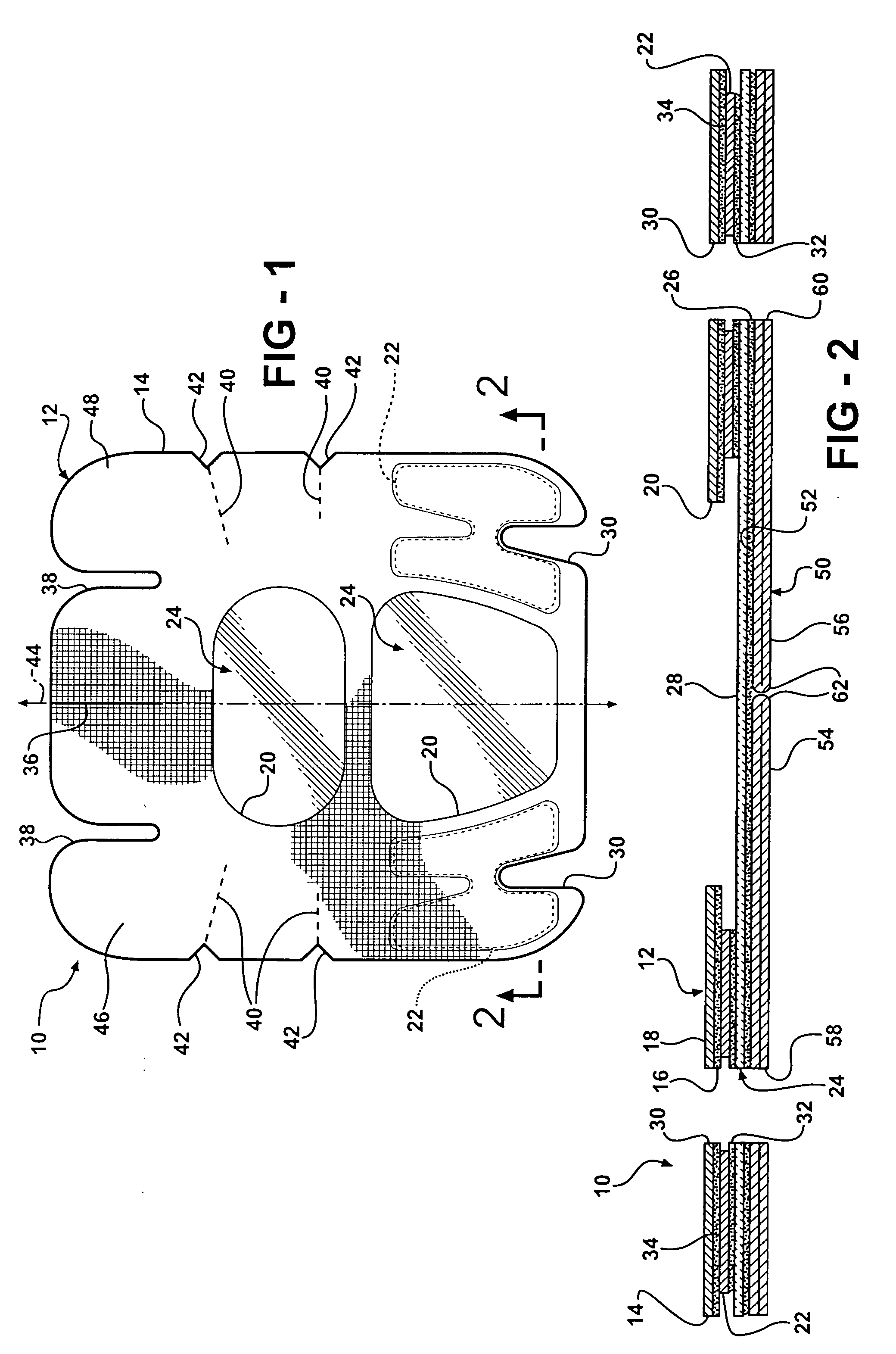

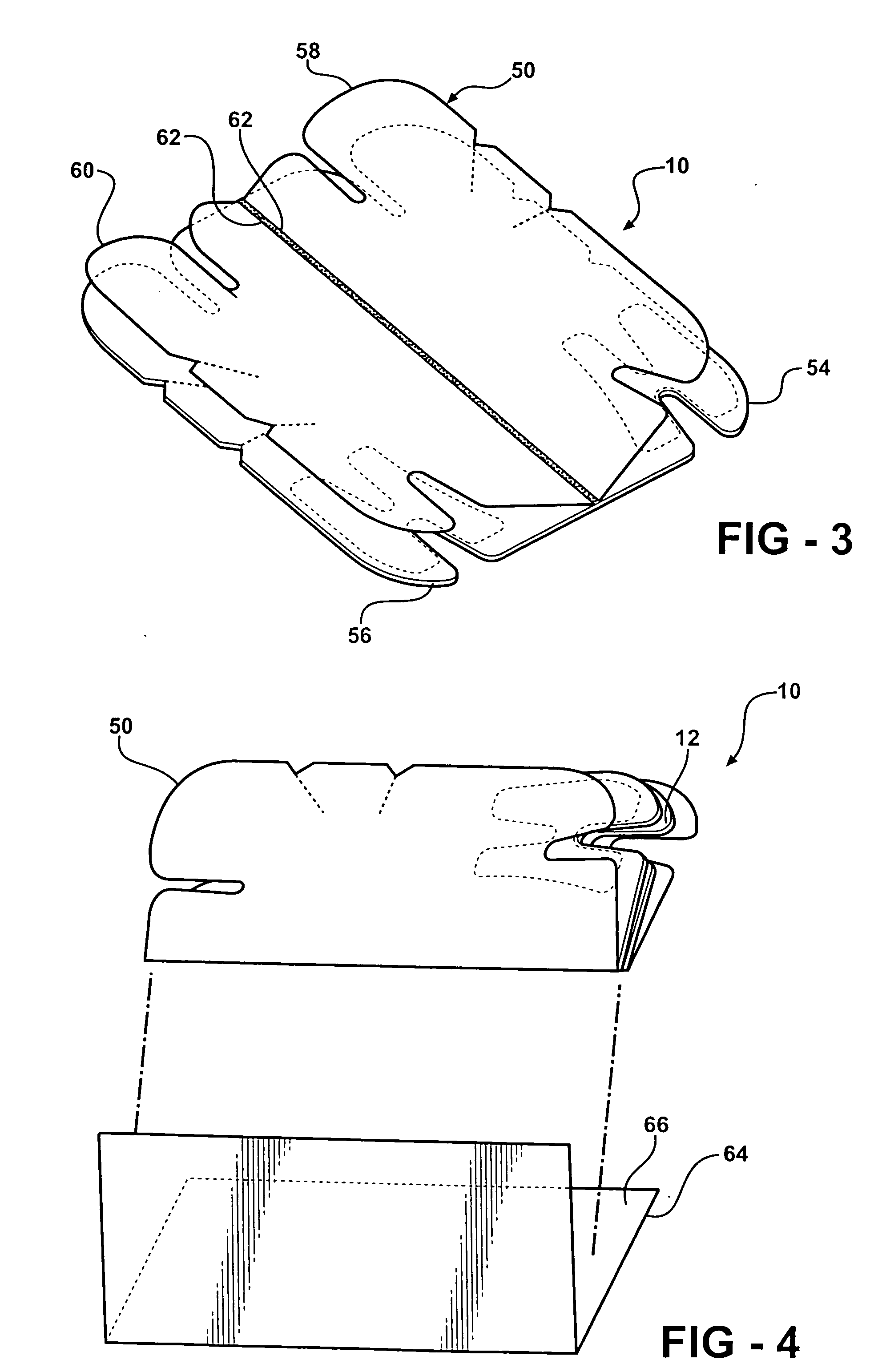

PIV dressing assembly

A PIV window dressing assembly with integral, built-in tubing anchors for the protection of a PIV catheter insertion site is disclosed that is interchangeably usable on both a right or left-hand side insertion site and that resists detachment from a patient's skin during use. The dressing assembly includes a fabric layer that is bounded by an edge. The fabric layer has an adhesive side, an opposite non-adhesive side, and at least one opening therein to allow for viewing therethrough. At least one reinforcement member is disposed between the fabric layer edge and the opening. The reinforcement member is adhered to the fabric layer adhesive side. A transparent film layer having an adhesive skin adhering side and an opposite non-adhesive side closes each of the openings in the fabric layer. The film layer non-adhesive side is adhered to the fabric layer adhesive side.

Owner:TRI STATE HOSPITAL SUPPLY

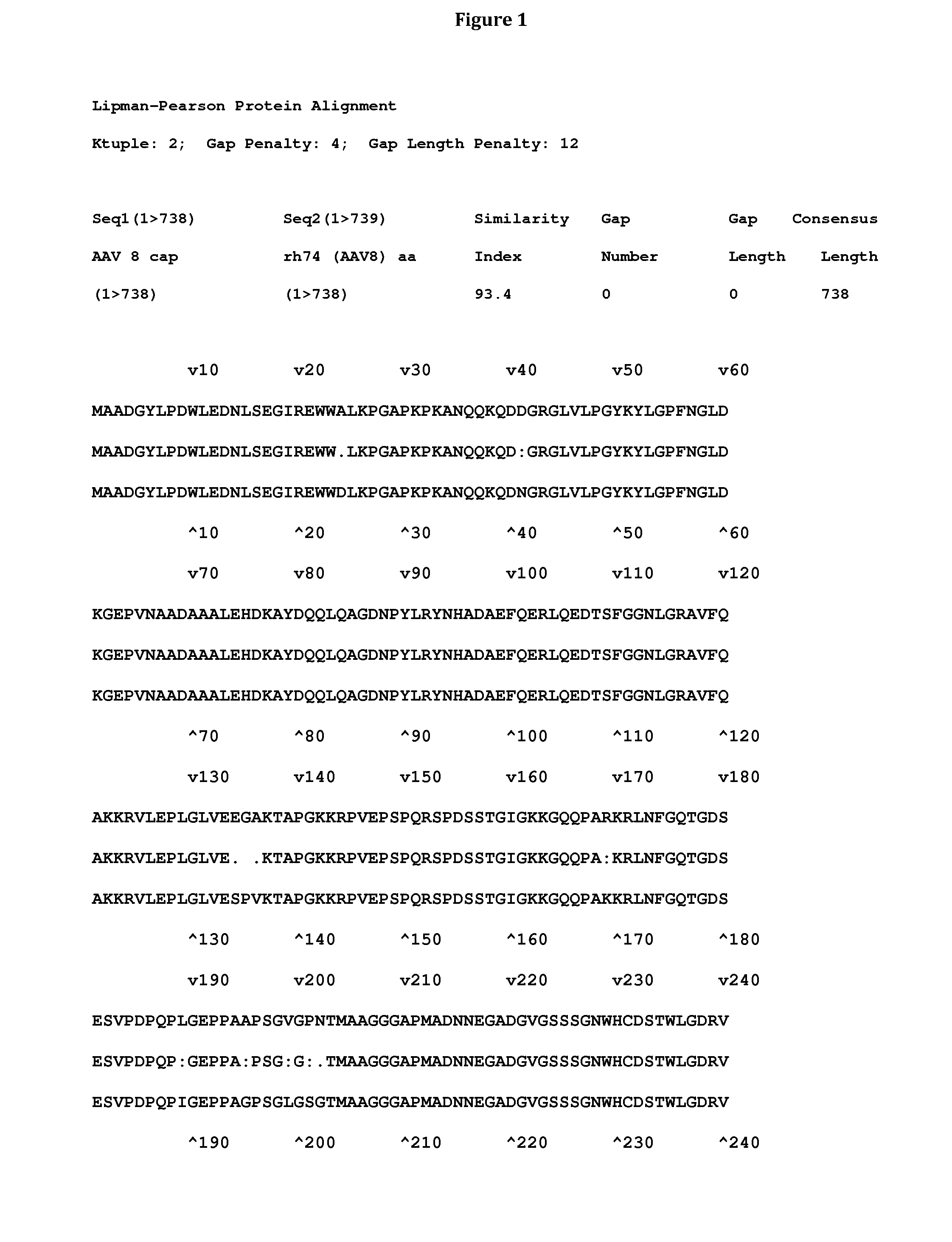

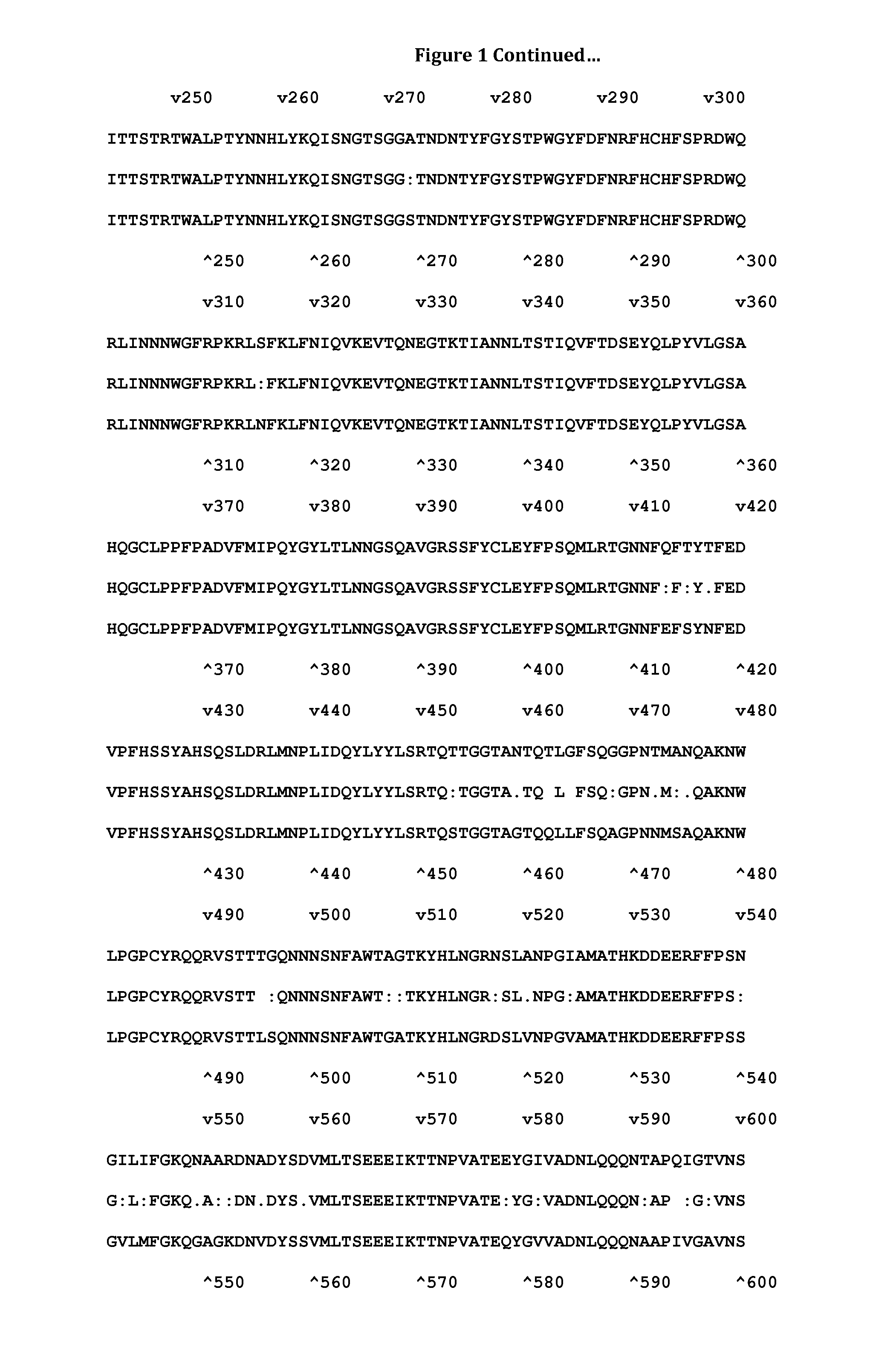

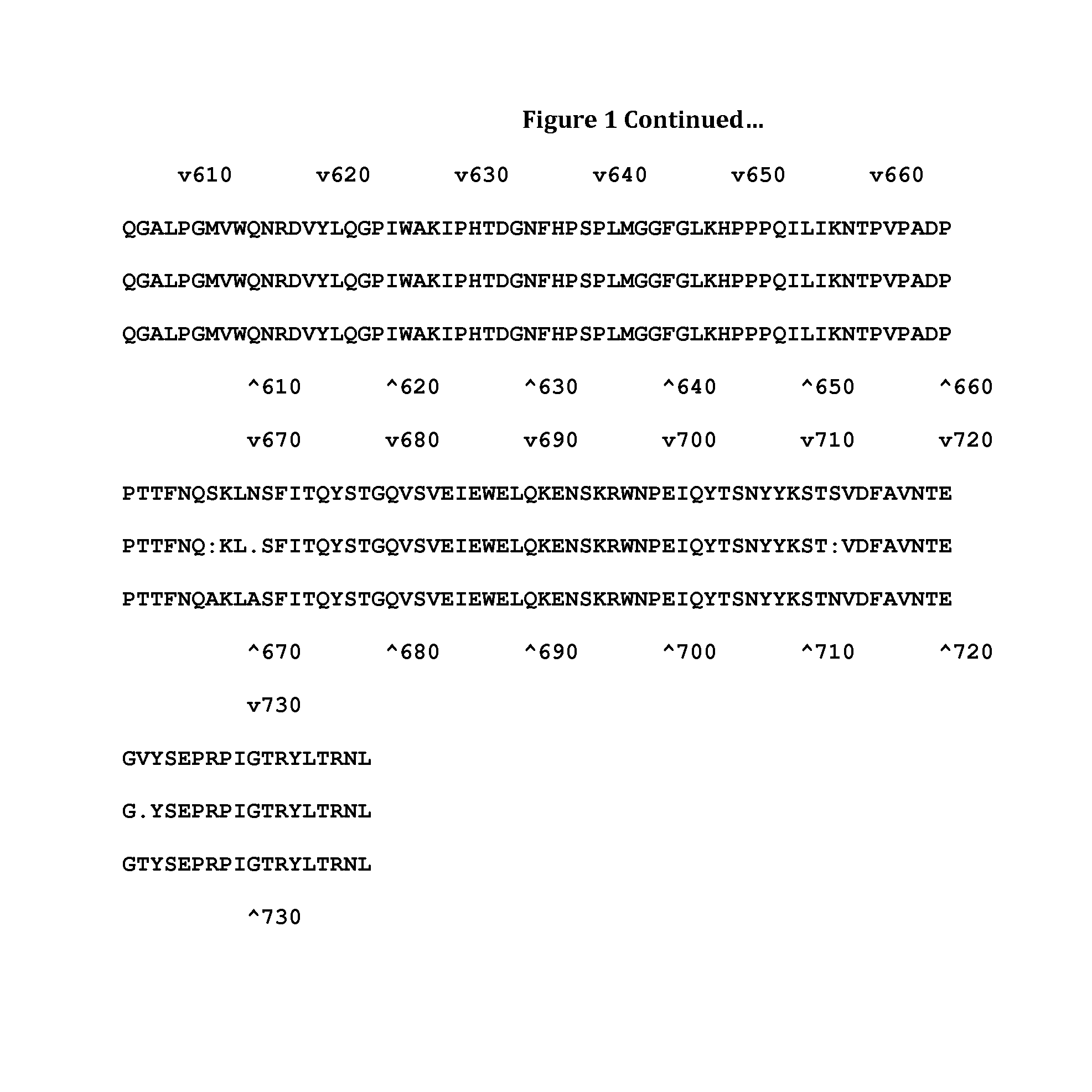

Recombinant adeno-associated virus delivery of alpha-sarcoglycan polynucleotides

ActiveUS9434928B2High transduction efficiencyIncrease volumePeptide/protein ingredientsOther blood circulation devicesFhit genePolynucleotide

Owner:NATIONWIDE CHILDRENS HOSPITAL

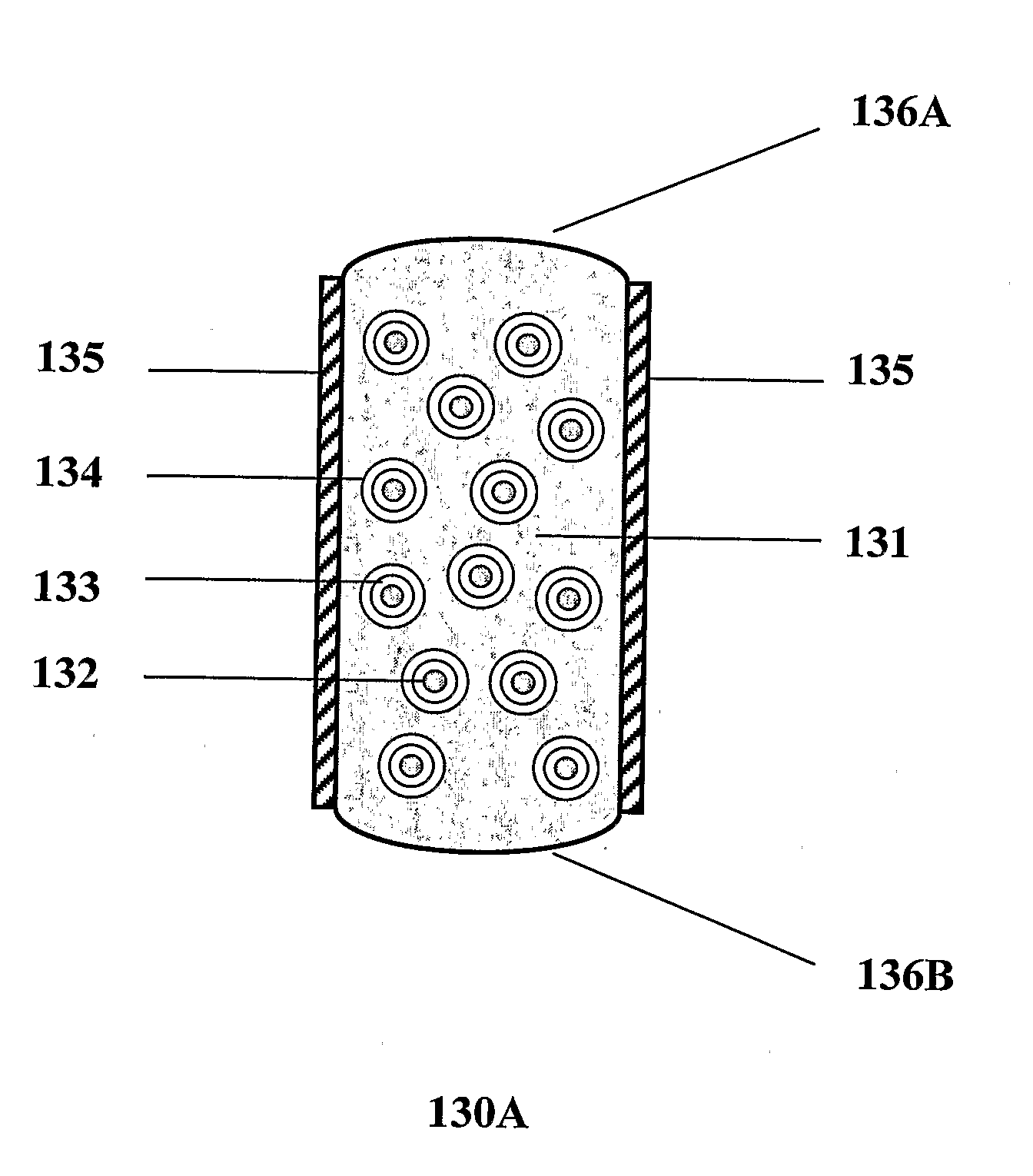

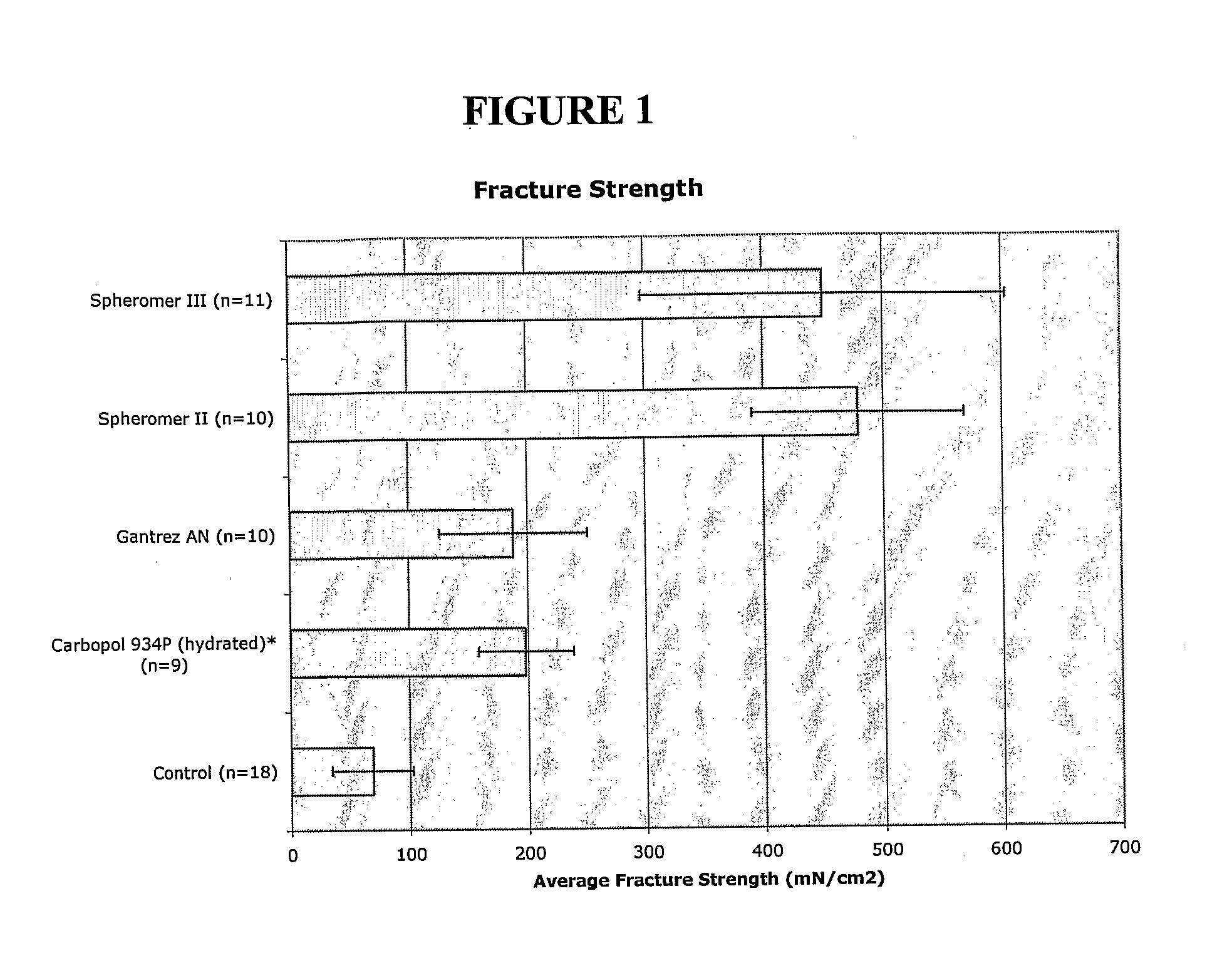

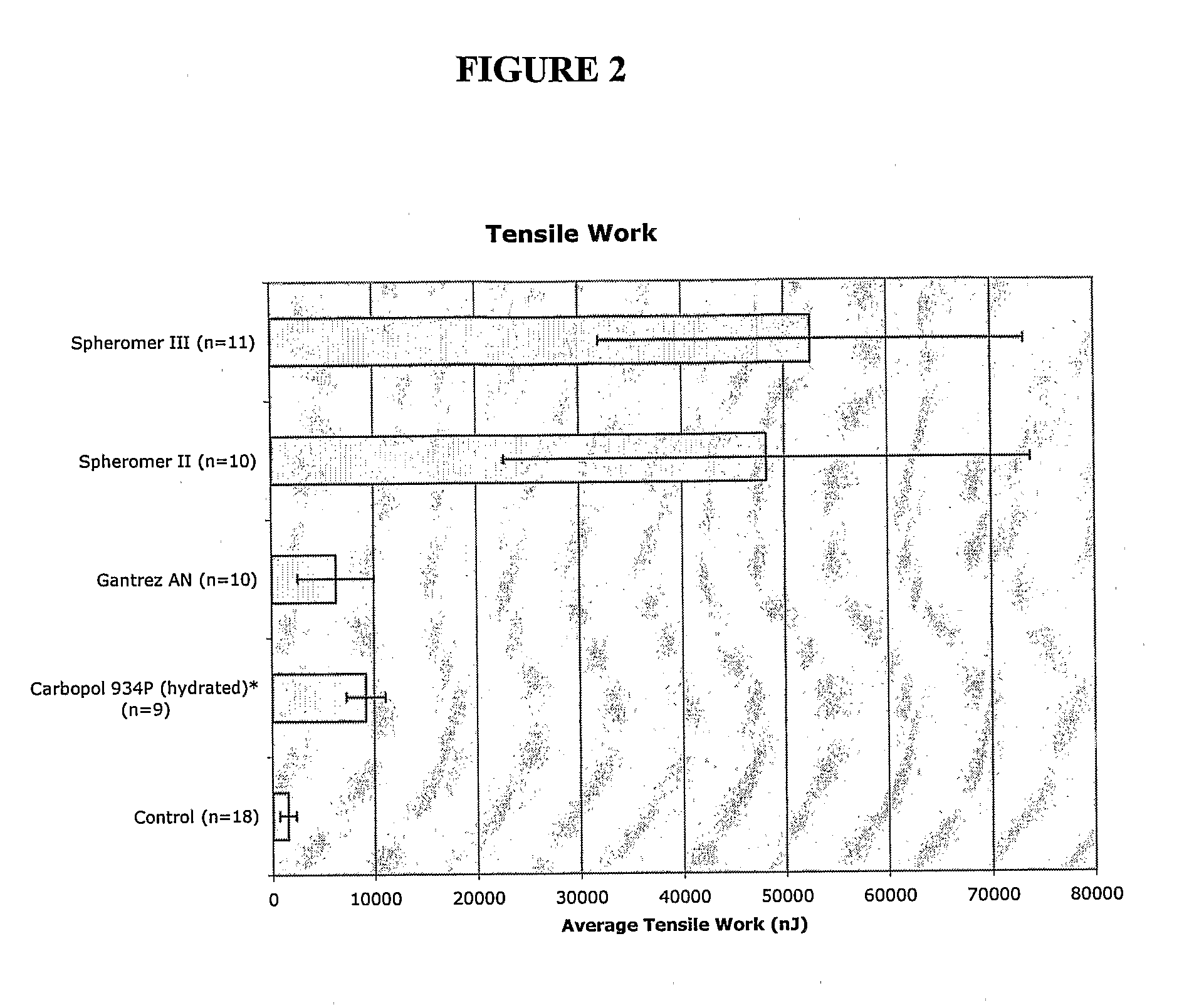

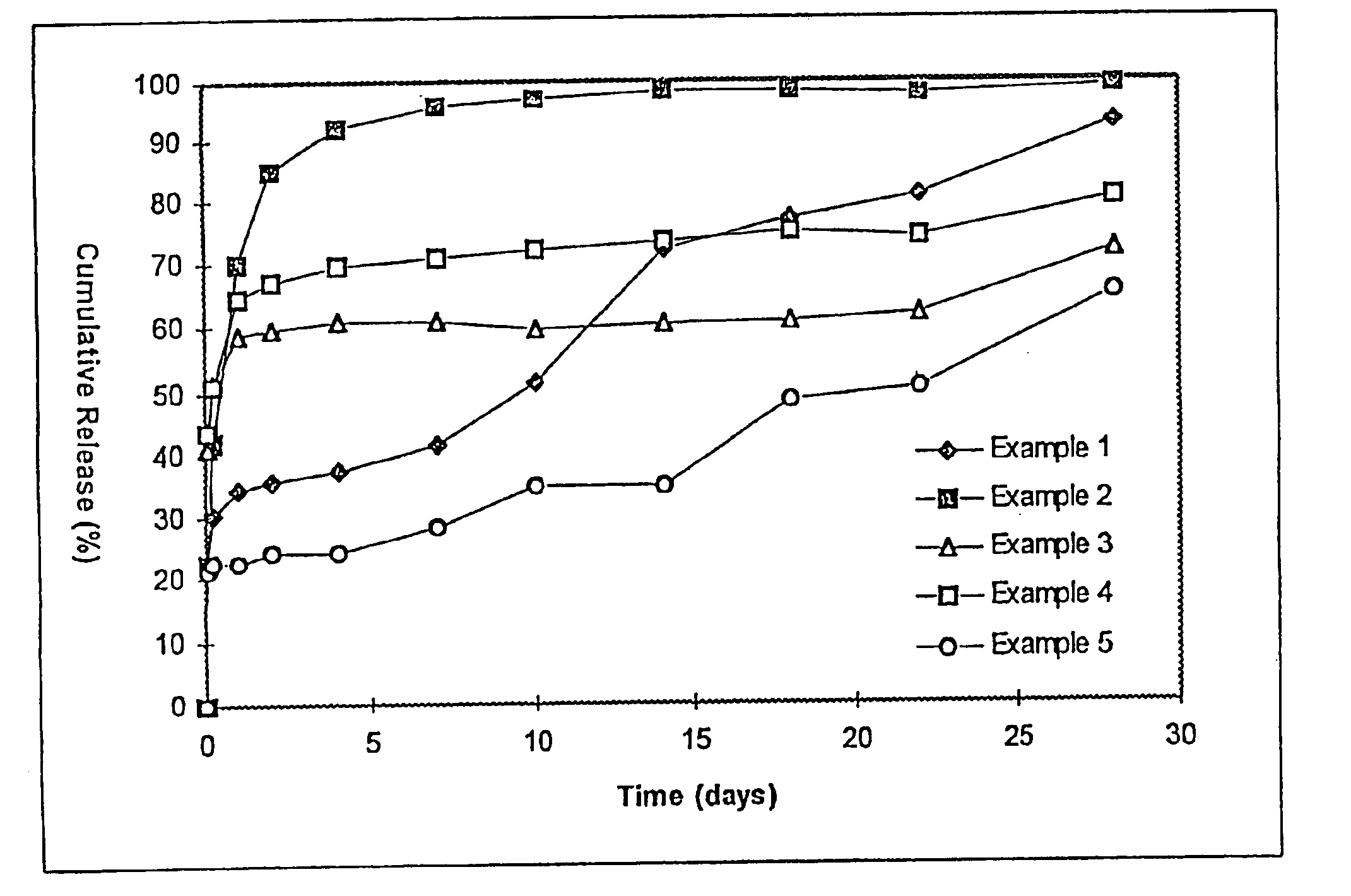

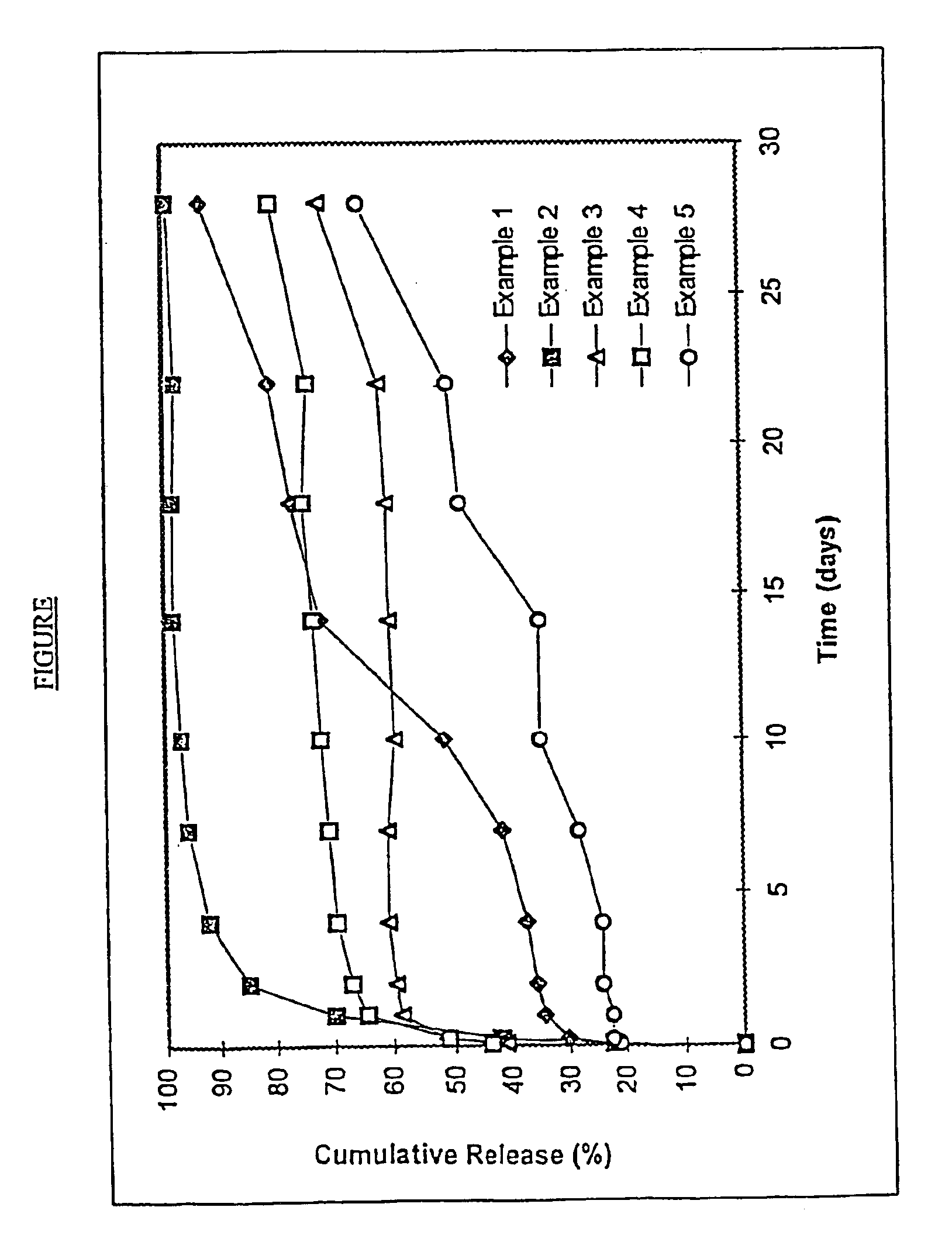

Bioadhesive Rate-Controlled Oral Dosage Formulations

InactiveUS20080260824A1Good bioadhesionImproving bioadhesion of polymersBiocidePowder deliveryDrug releasePolymer

The present invention relates to a bioadhesive drug delivery system (BIOadhesive Rate controlled Oral Dosage (BIOROD) formulation) in which a drug containing core either alone or coated with a rate controlling membrane system is enveloped on its circumference by a bioadhesive coating, thereby yielding a monolithic system that allows for drug release in a regulated manner. Also described herein are polymers with improved bioadhesive properties and methods for improving bioadhesion of polymers.

Owner:SPHERICS

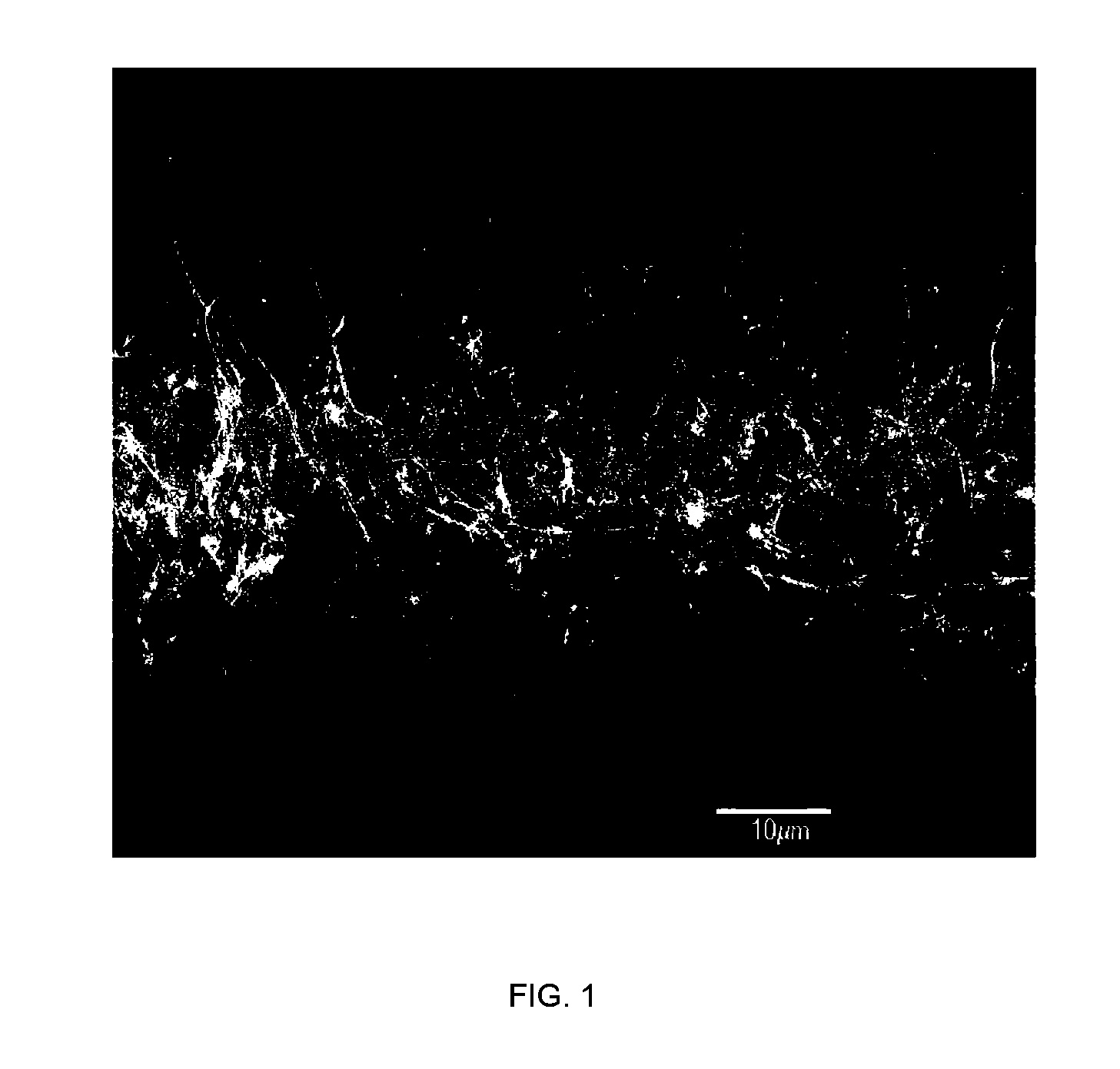

Medical device applications of nanostructured surfaces

ActiveUS7803574B2Improve adhesionIncrease frictionElectrotherapyNanostructure manufactureFiberNanofiber

This invention provides novel nanofiber enhanced surface area substrates and structures comprising such substrates for use in various medical devices, as well as methods and uses for such substrates and medical devices. In one particular embodiment, a method of administering a composition to a patient is disclosed which comprises providing a composition-eluting device, said composition-eluting device comprising at least a first surface and a plurality of nanostructures attached to the first surface, and introducing the composition-eluting device into the body of the patient.

Owner:RGT UNIV OF CALIFORNIA +1

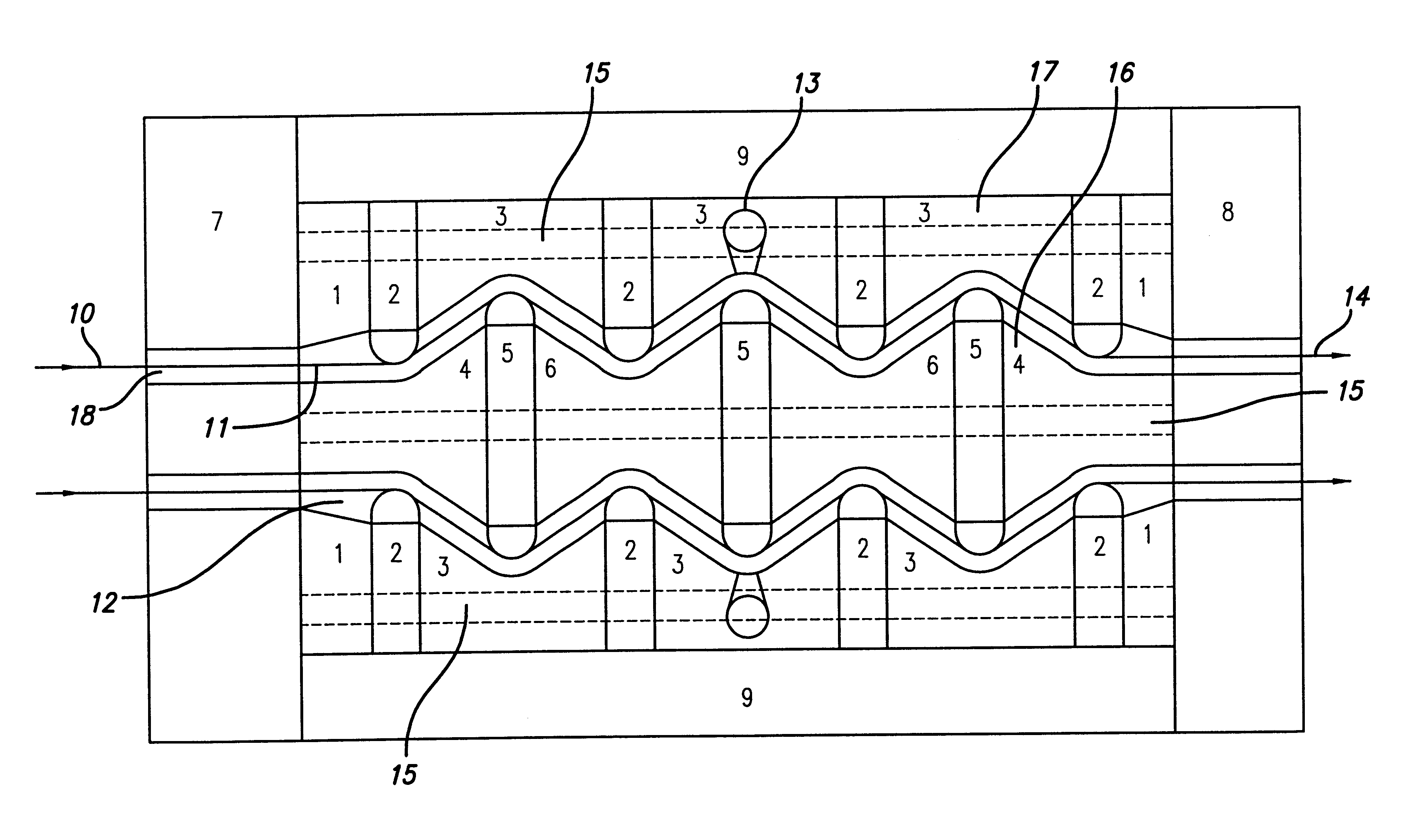

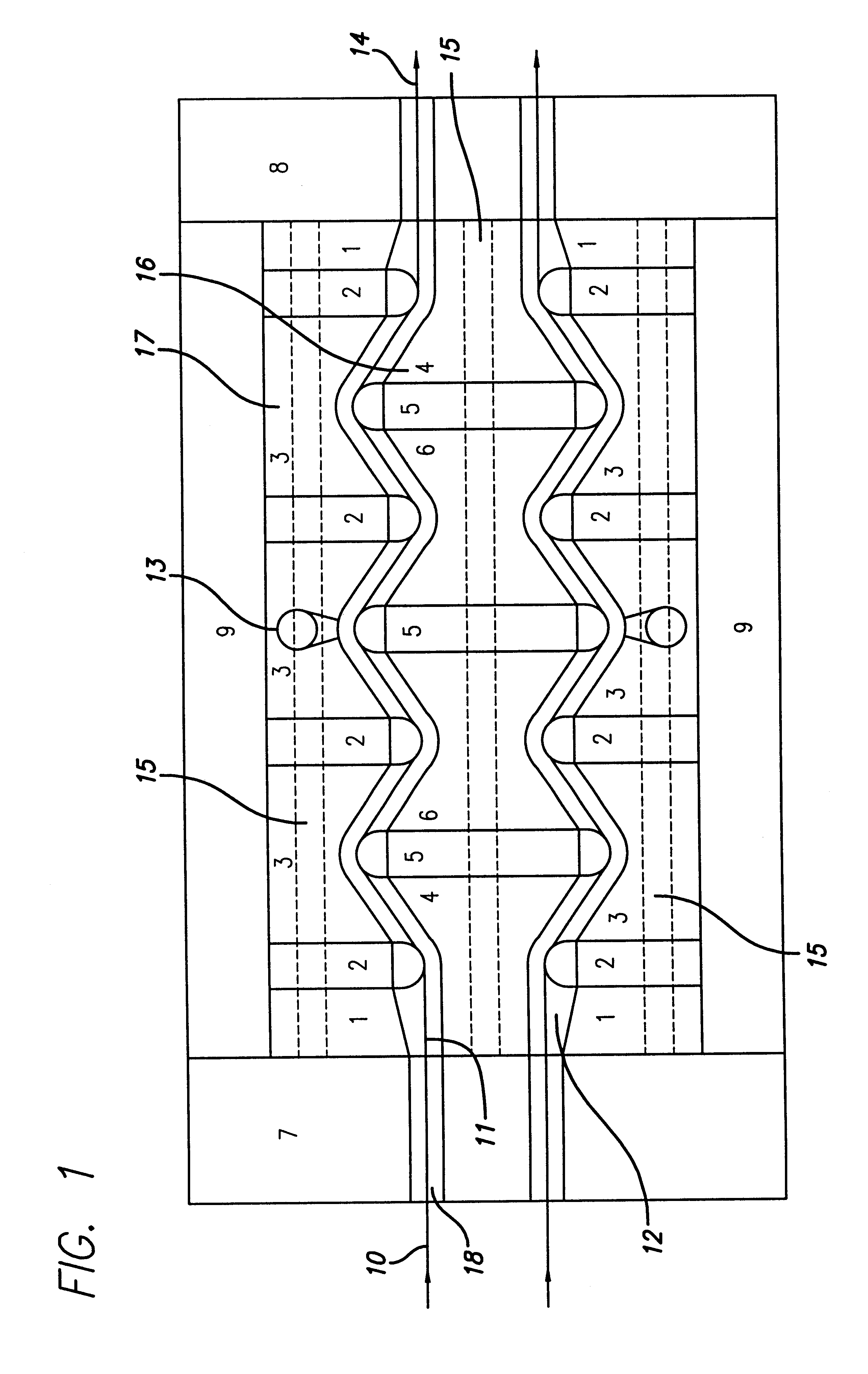

Process for manufacturing resin-coated fibers composite and an application thereof

InactiveUS6270851B1Prevent fracture of the fiber filamentsMaximize molten resin penetrating timeLiquid surface applicatorsCoatingsEngineeringFibrous composites

An apparatus for producing a resin coated fiber composite of a rod shape, tubular-shape or plate shape comprises a plurality of first members having an annular shape with a semi-circular ring shaped internal surface, second members having a disc shape with a semicircular ring shaped external surface, first connectors for assembling the first members, second connectors for assembling the second members, an outer die member semi-assembled with the first members and connectors, an inner die member semi-assembled with the second members and connectors, a heater, an inlet nozzle and an outlet nozzle, a zigzag shaped tunnel formed between the inner and outer die members for providing a narrow flow path of the fiber filaments, and resin inlet ports to fill the molten resin in the zigzag shaped tunnel and pressurize the flow path of the fiber filaments. A process for preparing a resin coated fiber composite of a rod-shape, tubular-shape or plate-shape comprises steps of spreading fiber filaments by passing the fiber filaments through a first member having a convex-concave portion to prevent fracture of the fiber filaments, and sequentially tensioning through a series of first and second members all along a narrow flow path to maximize molten resin penetrating surface area, impregnating pressurized molten resin into the fiber filaments continuously by passing the fiber filaments through a series of the first and second members all along the narrow flow path of a zigzag shaped tunnel to maximize molten resin penetrating time, and wherein pressurization of the molten resin maximizes penetration of molten resin into pores of the fiber filaments and minimizes possibility of resin degradation, stranding the resin-coated fiber filaments through a final set of the first members having the convex-concave portion for strengthening the fiber filaments, and integrating and pultruding the resin-coated fiber filaments continuously by passing the fiber filaments all along the narrow flow path of the zigzag shaped tunnel to form a desired diameter through the outlet nozzle.

Owner:SAMBARK LFT

PIV dressing assembly

ActiveUS20070060892A1Increasing catheter dwell timeExtended stayCatheterInfusion needlesMedicineBiomedical engineering

A PIV window dressing assembly with integral, built-in tubing anchors for the protection of a PIV catheter insertion site is disclosed that is interchangeably usable on both a right or left-hand side insertion site and that resists detachment from a patient's skin during use. The dressing assembly includes a fabric layer that is bounded by an edge. The fabric layer has an adhesive side, an opposite non-adhesive side, and at least one opening therein to allow for viewing therethrough. At least one reinforcement member is disposed between the fabric layer edge and the opening. The reinforcement member is adhered to the fabric layer adhesive side. A transparent film layer having an adhesive skin adhering side and an opposite non-adhesive side closes each of the openings in the fabric layer. The film layer non-adhesive side is adhered to the fabric layer adhesive side.

Owner:TRI STATE HOSPITAL SUPPLY

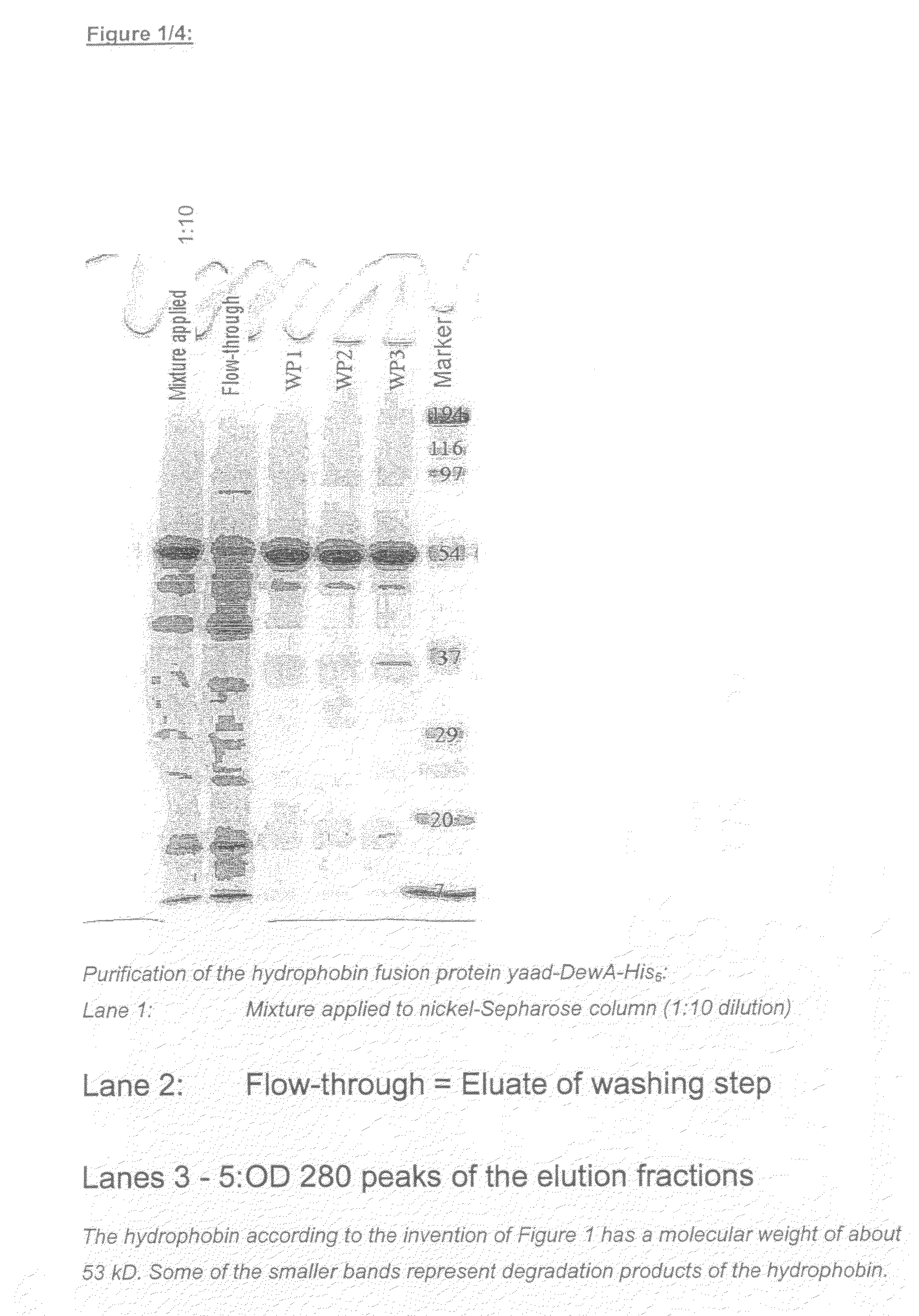

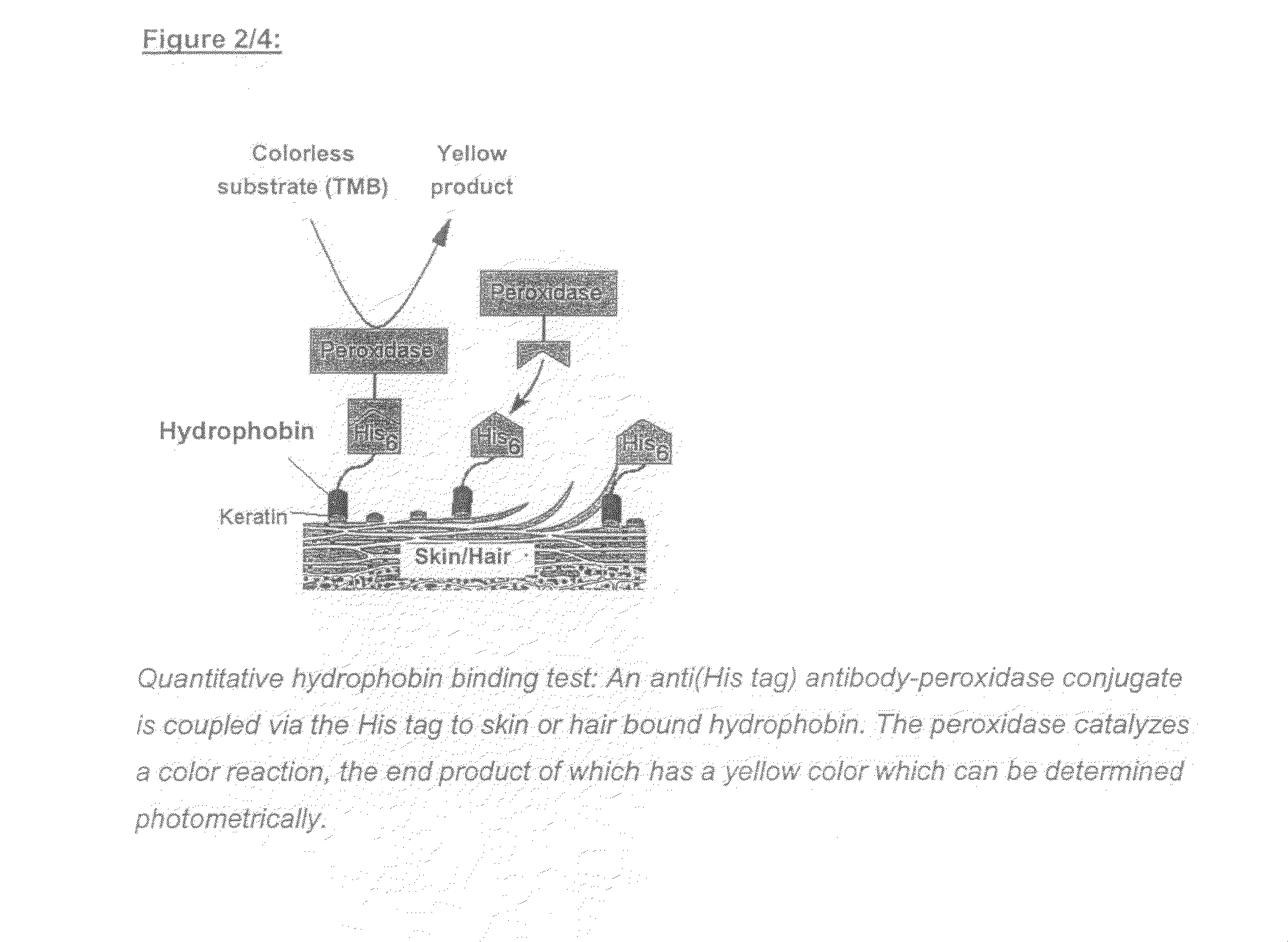

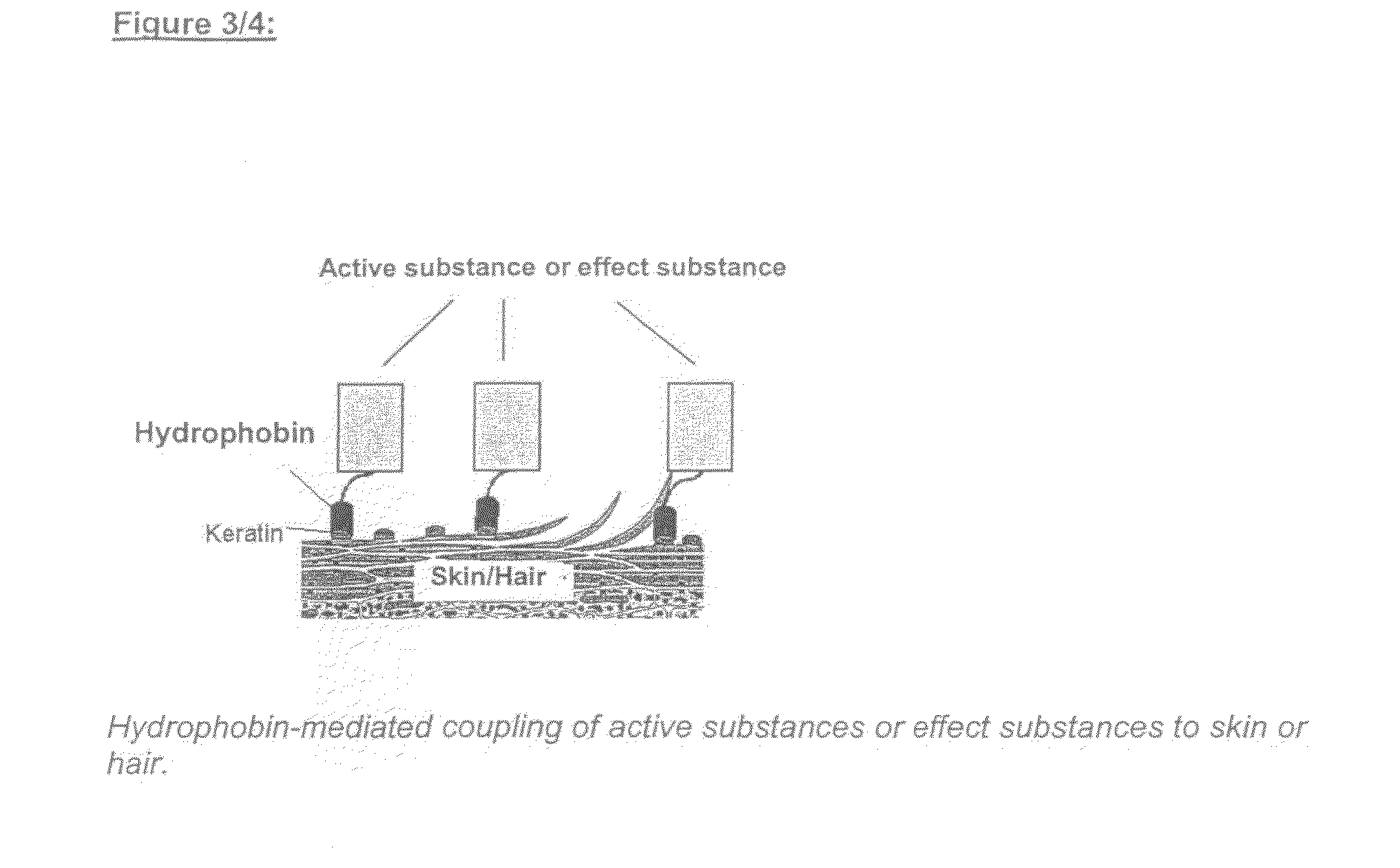

Use of Hydrophobin-Polypeptides and Conjugates From Hydrophobin-Polypeptides Having Active and Effect Agents and the Production Thereof and Use Thereof In the Cosmetic Industry

InactiveUS20090136433A1Feel goodGood skin compatibilityCosmetic preparationsBiocideMedicineCosmetic industry

Cosmetic composition for the treatment of keratin-containing materials, mucosa and teeth, comprising at least one hydrophobin polypeptide sequence (i)(I)Xn-C1-X1-50-C2-X0-5-C3-Xp-C4-X1-100-C5-X1-50-C6-X0-5-C7-X1-50-C8-Xm

Owner:BASF AG

Encapsulation method

InactiveUS6861064B1Easy to getImprove concentrationBiocideOrganic active ingredientsPolymer dissolutionEmulsion

A novel method of encapsulating an active substance in a biodegradable polymer, which comprises: a) dissolving said biodegradable polymer in an organic solvent therefor; b1) dispersing said active substance in the organic solution obtained in step a) to provide a dispersion with the active substance as the inner phase thereof; or alternatively b2) emulsifying said active substance, dissolved in water or other aqueous solvent therefor, in the organic solution obtained in step a) to provide an emulsion with the active substance as the inner aqueous phase thereof; and c) subjecting the dispersion obtained in step b1), or alternatively the emulsion obtained in step b2), to an encapsulation operation with an aqueous polyethylene glycol solution as a continuous phase to provide micro- or nanoparticles having the active substance encapsulated therein. Sustained release particles obtainable thereby.

Owner:PACIRA PHARMA INC

Heating device and magnetic recording head for thermally-assisted recording

InactiveUS7262936B2High densityEfficient heatingRecord information storageSpecial recording techniquesLeading edgeMagnetic media

A heating device for a magnetic recording head includes first and second separating layers, the first separating layer having preferably a higher or equal thermal resistance than the first separating layer, and a heater formed between the first and second separating layers. A magnetic recording head for recording on magnetic medium includes a heating device which generates a heat spot on the magnetic medium which is larger than a magnetic track width, and / or heats a portion of the magnetic recording head which is on a leading edge side of a write gap in the magnetic recording head.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Method for preparing a beverage or food liquid and system using brewing centrifugal force

Owner:SOC DES PROD NESTLE SA

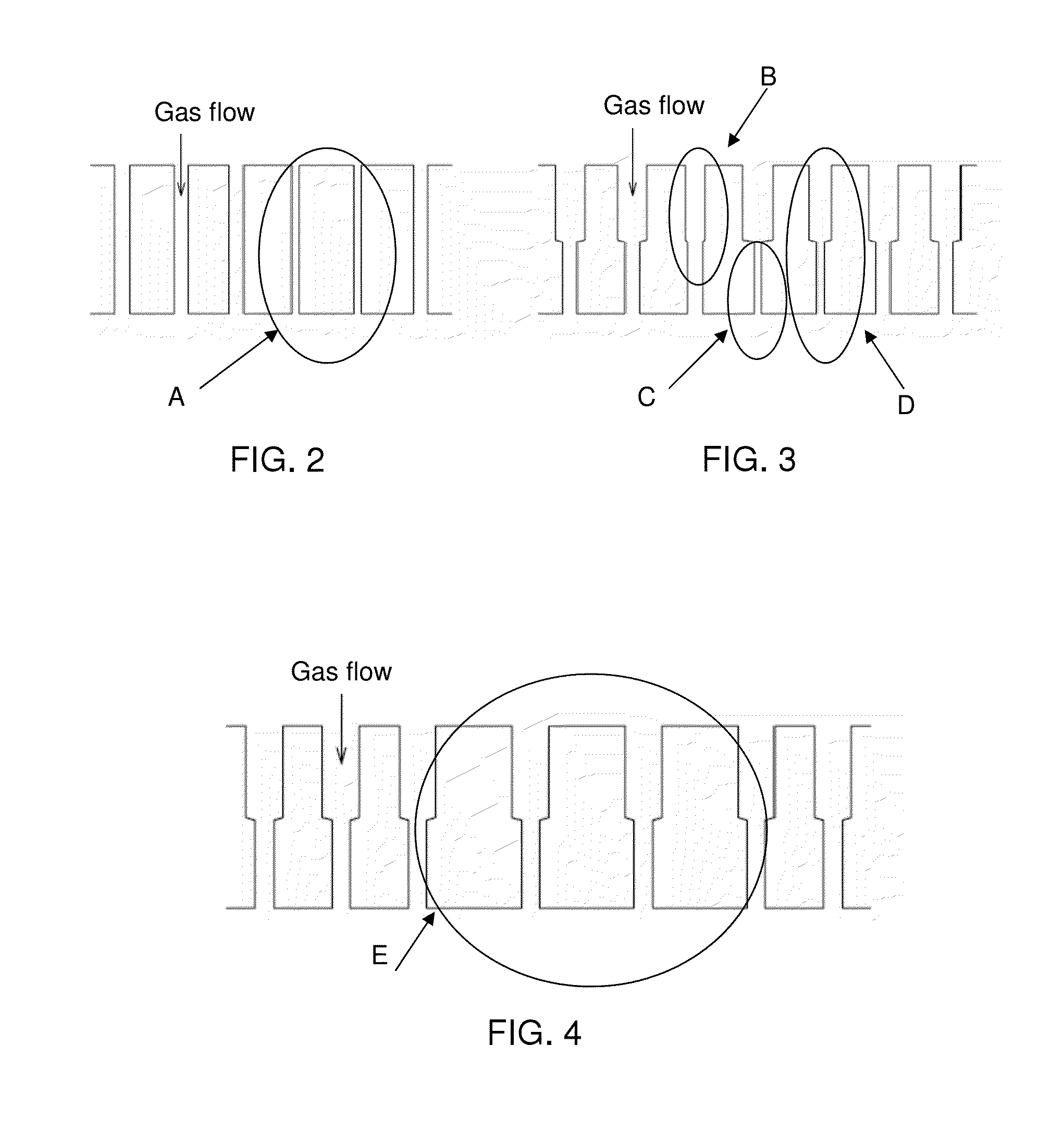

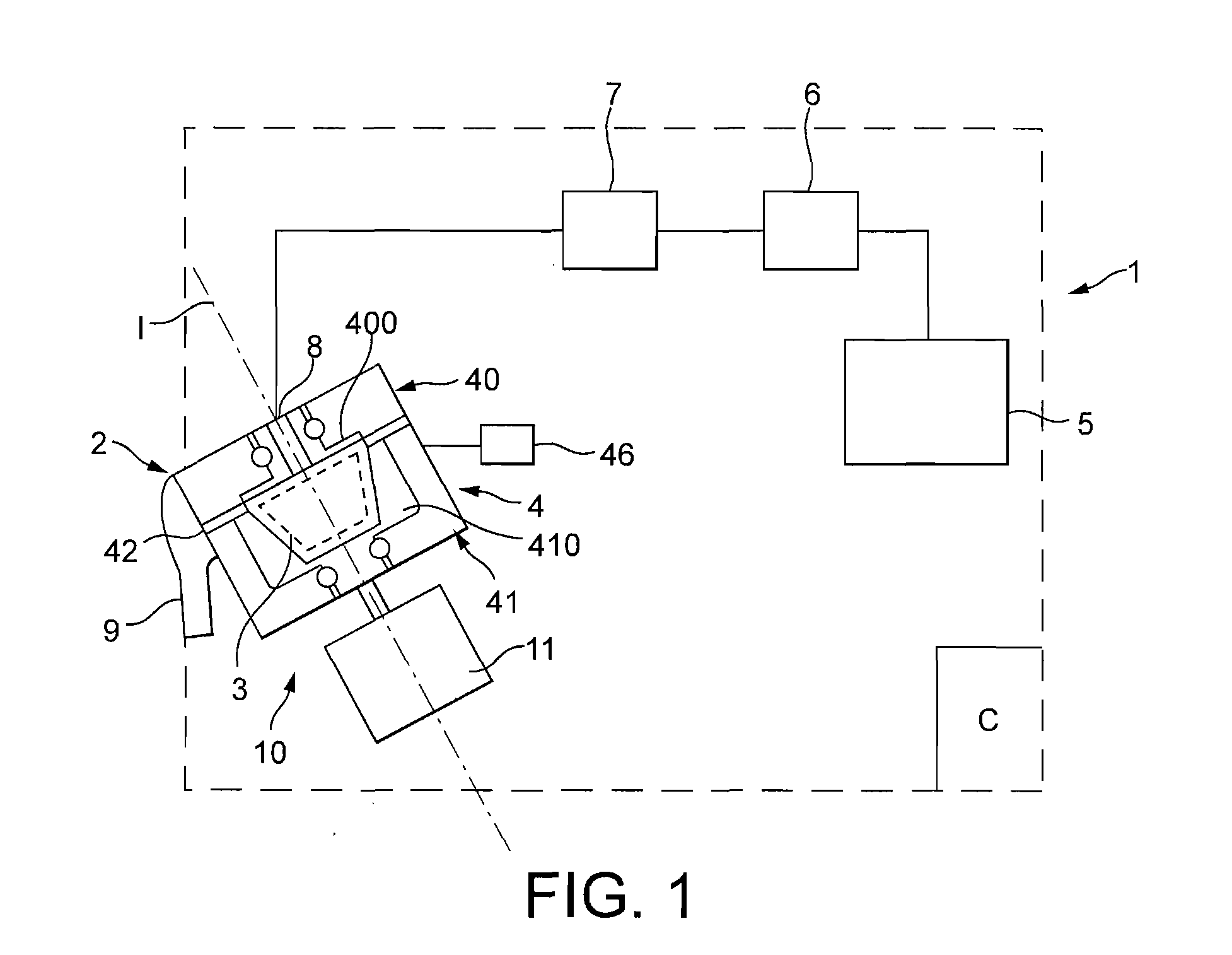

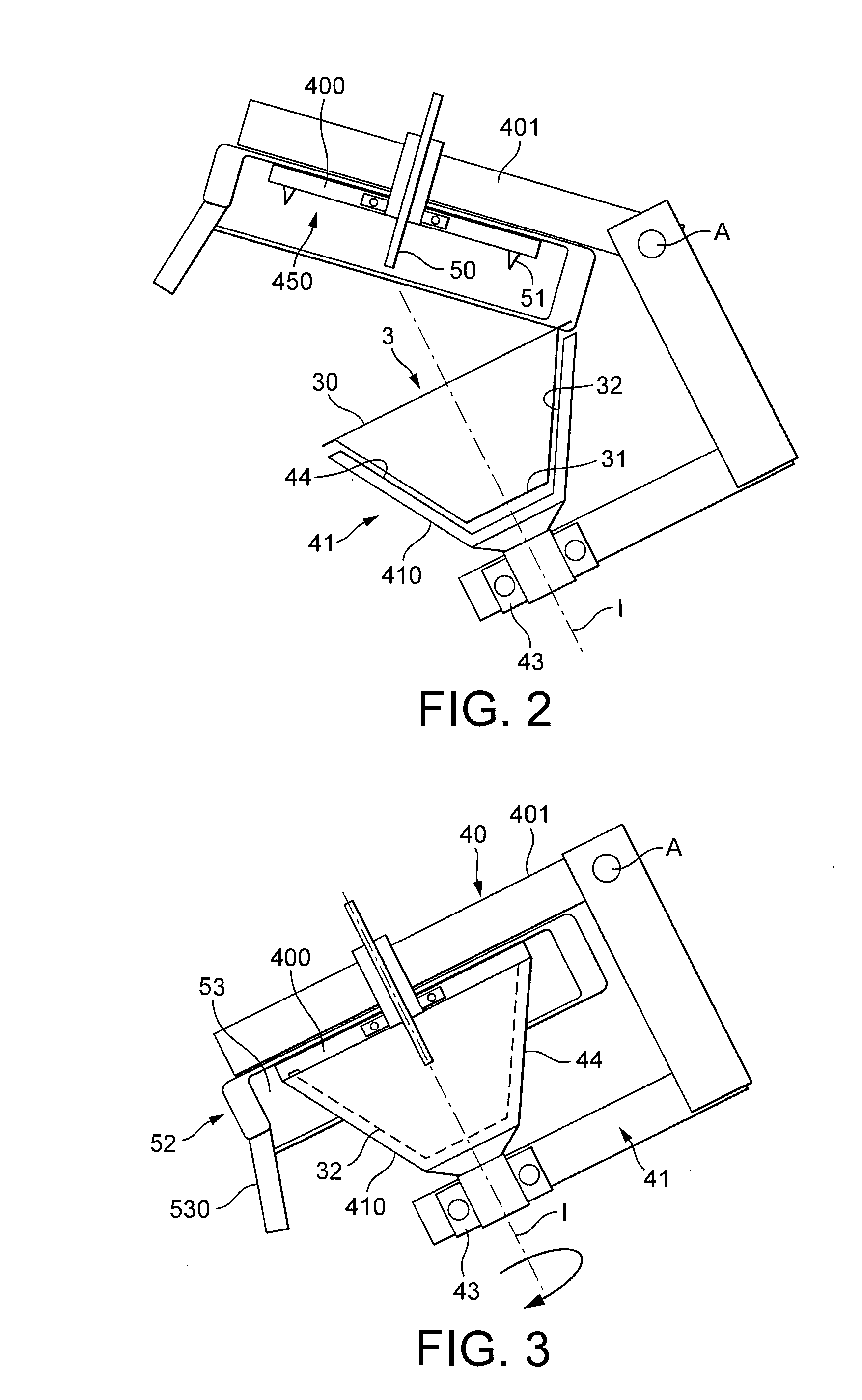

Apparatus and method for a gas turbine entrainment system

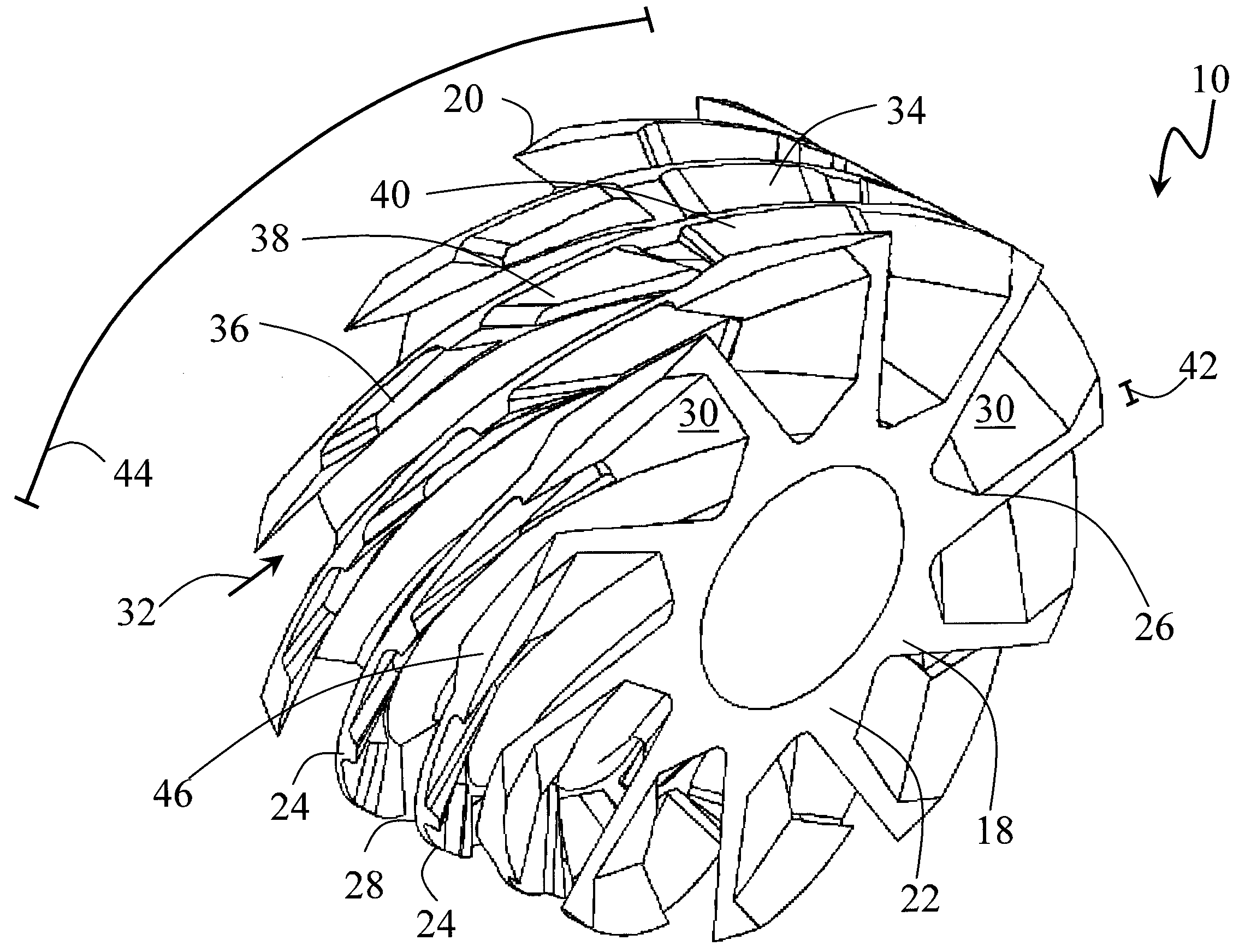

ActiveUS20090178412A1Reduce lossesFacilitate turbulenceContinuous combustion chamberEngine manufactureCombustion chamberCombustor

This invention relates to an apparatus for an entrainment system of a vortex burning combustion chamber or a vortex burning inter-turbine burner in a gas turbine. The entrainment system rapidly and thoroughly mixes hot combustion gases with non-combustion gases to reduce the gas temperature before entering a turbine. The entrainment system includes a plurality of helical vanes forming trenches and resulting in a highly helical flow path. The highly helical flow path provides an increased residence time for mixing of the combustion gases and non-combustion gases. Radial cavities in the helical vanes, canted vane angles and varying geometries further facilitate mixing while reducing losses. This invention also includes a method of mixing combustion and non-combustion gases in an entrainment system.

Owner:SPYTEK AEROSPACE CORP

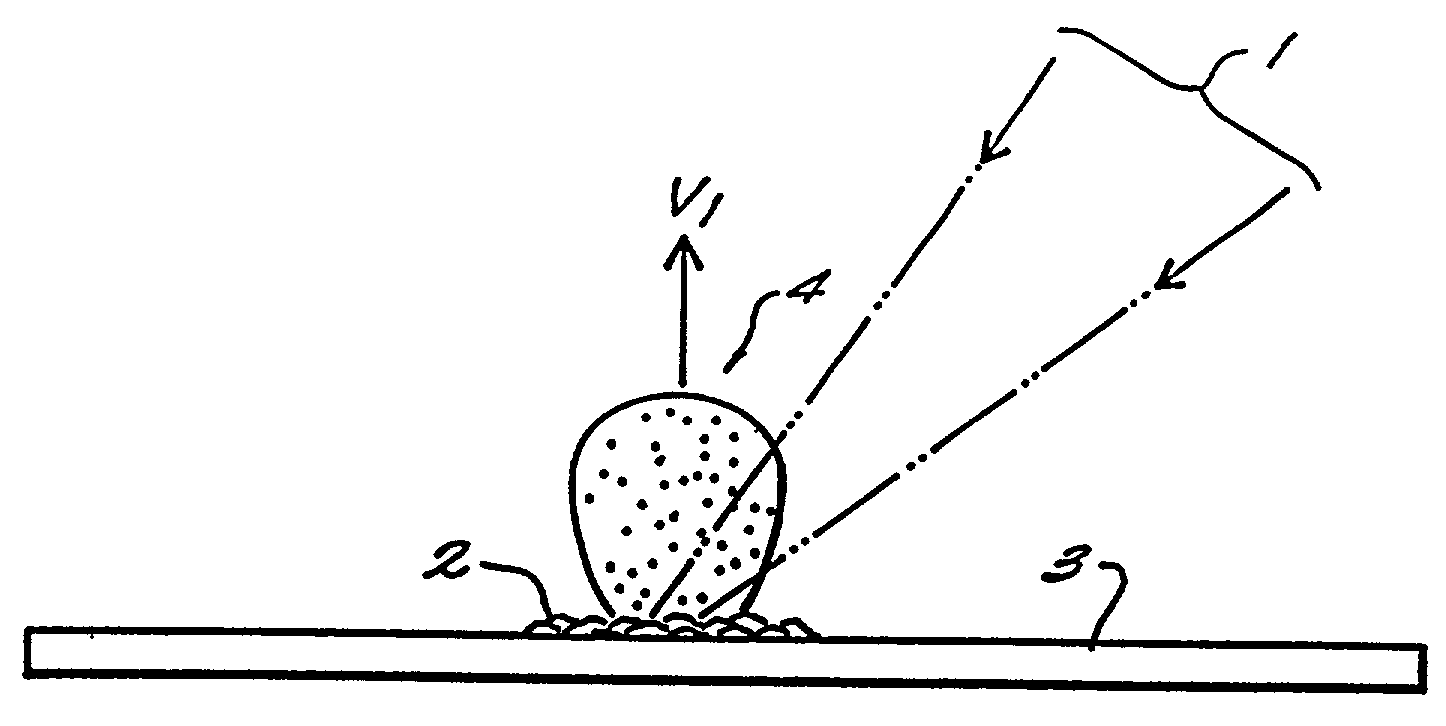

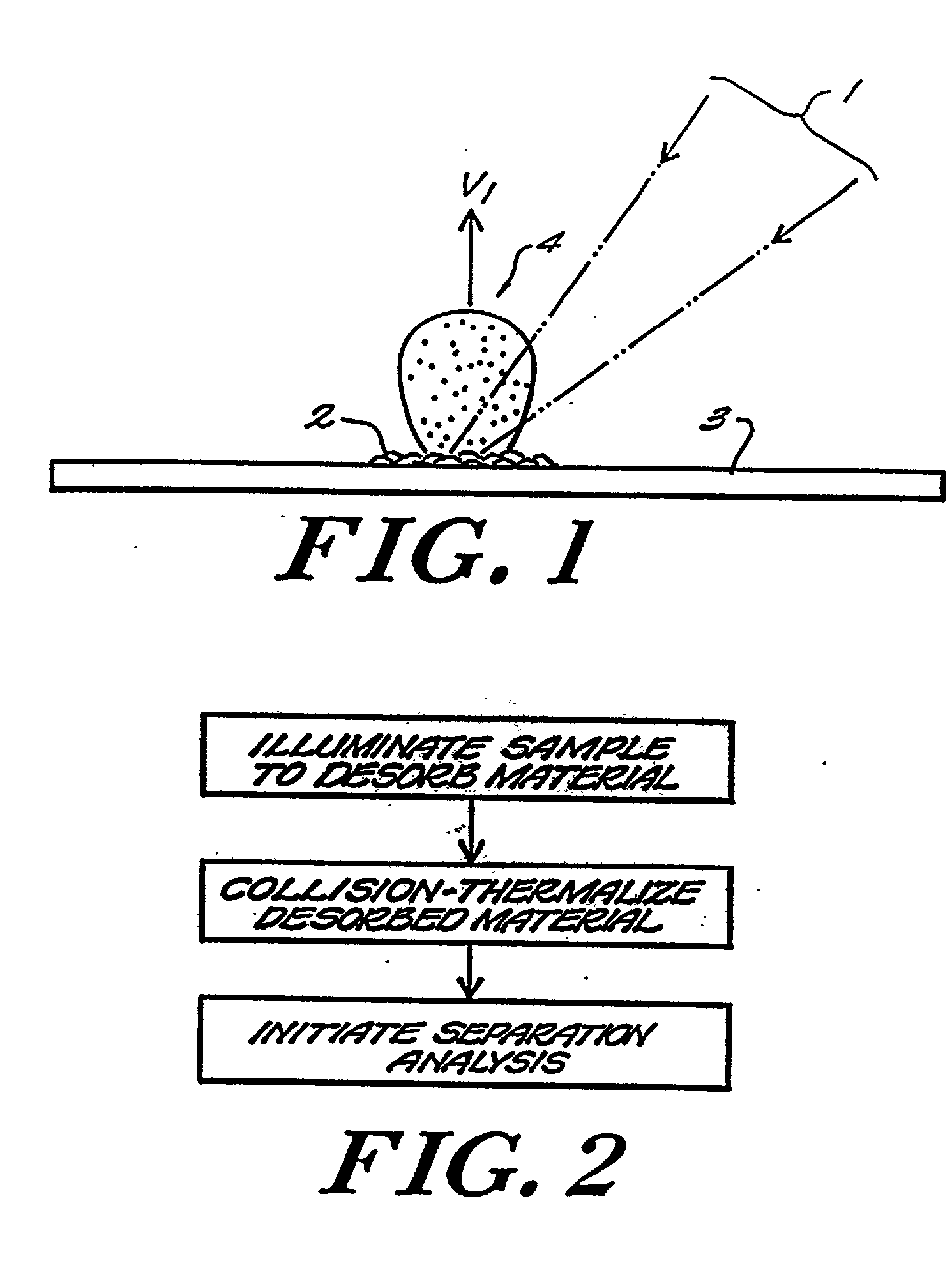

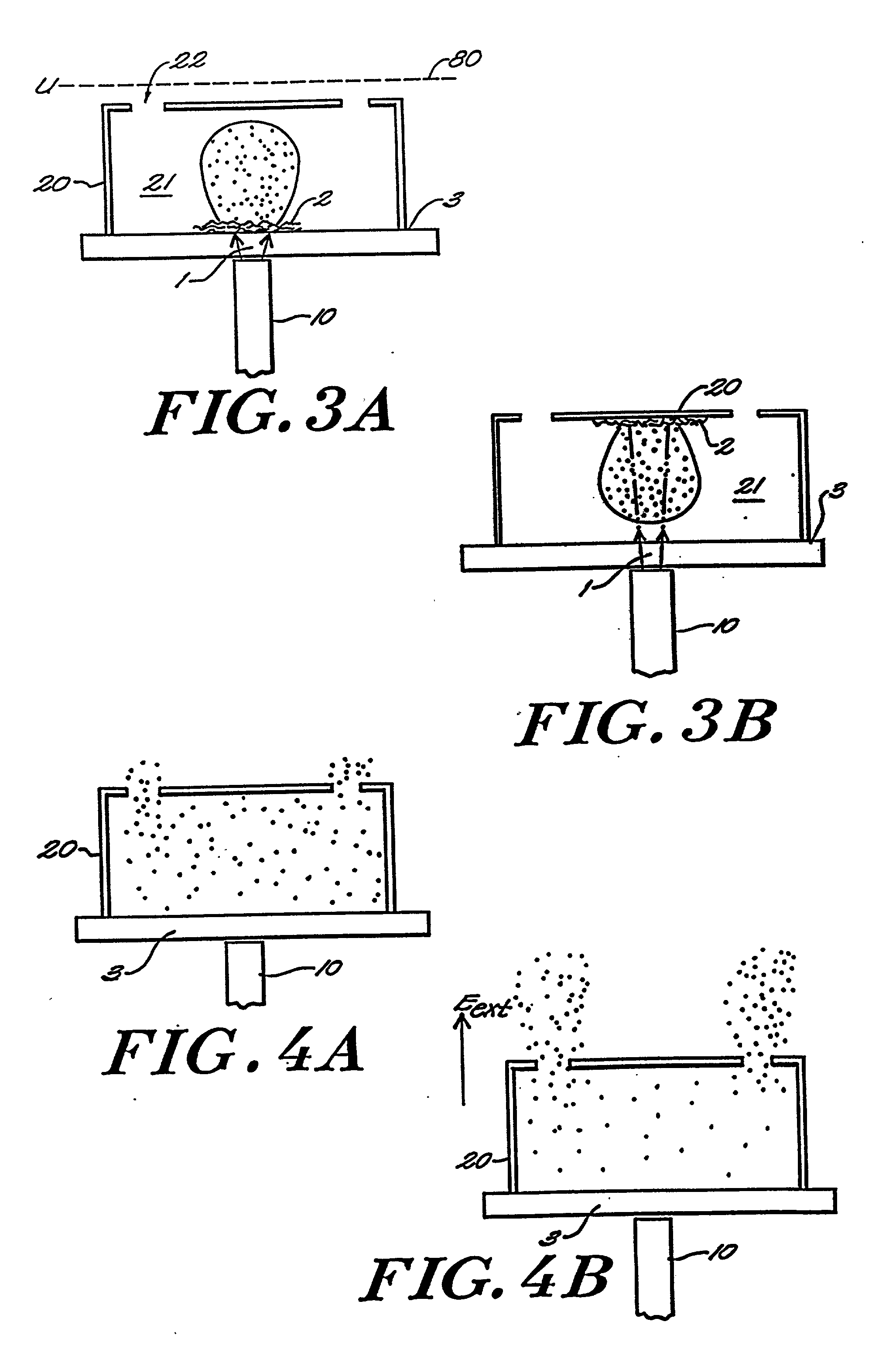

Method and apparatus for maldi analysis

InactiveUS20020005478A1Extended stayBroaden TOF peak widthSamples introduction/extractionMaterial analysis by electric/magnetic meansFiberPeak value

Matrix assisted laser desorption / ionization is performed in a manner to thermalize large analyte ions in a plume of desorbed material for spectroscopic analysis. The thermalized ions have a low or zero mean velocity and are presented at a well-defined instant in time, reducing artifacts and sharpening the spectral peaks. In one embodiment the light is delivered to a matrix or sample holder having a cover, baffle or compartment. The baffle or compartment impedes or contains a plume of desorbed material and the analyte undergoes collisions to lower its mean velocity and directionality. Thus "thermalized" the analyte ions are passed to a mass analysis instrument. In a preferred embodiment an optical fiber butts up against a thin transparent plate on which the specimen resides, with the matrix side in a vacuum acceleration chamber. A mechanical stage moves the specimen in both the x- and y- directions to select a point on the specimen which is to receive the radiation. The use of a fiber optic illuminator allows the entire stage assembly to be subsumed essentially within the dimensions of a conventional stage. In other embodiments, a thermalizing compartment is provided in a capillary tube about the end of the illumination fiber and the sample matrix is deposited along the inner cylindrical wall of the tube, so the capillary forms a migration path to the outlet for thermalization of the desorbed analyte. In other embodiments microstructures having the shape of a small lean-to, overhang or perforated cover plate, or providing a high aspect surface texture, provide the necessary containment to promote thermalization of the released analyte. A thin layer or cover of fibrous or permeable material may also be used to thermalize the analyte before mass analysis, and in other embodiment this material may also act as the substrate. An automated instrument may include a fixed array of illumination fibers which are illuminated at different times to eject samples from a corresponding array of points on the specimen.

Owner:AGENA BIOSCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com