Method and device for gasifying multi-segment staged converted fluidized bed

A fluidized bed and coal gasification technology, applied in the field of coal gasification, can solve the problems of low volume utilization rate of the gasifier, insufficient scale of the gasifier, and high amount of fine powder entrained by the gas, so as to reduce the power consumption and structure of coal grinding. Simple, wide range of coal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

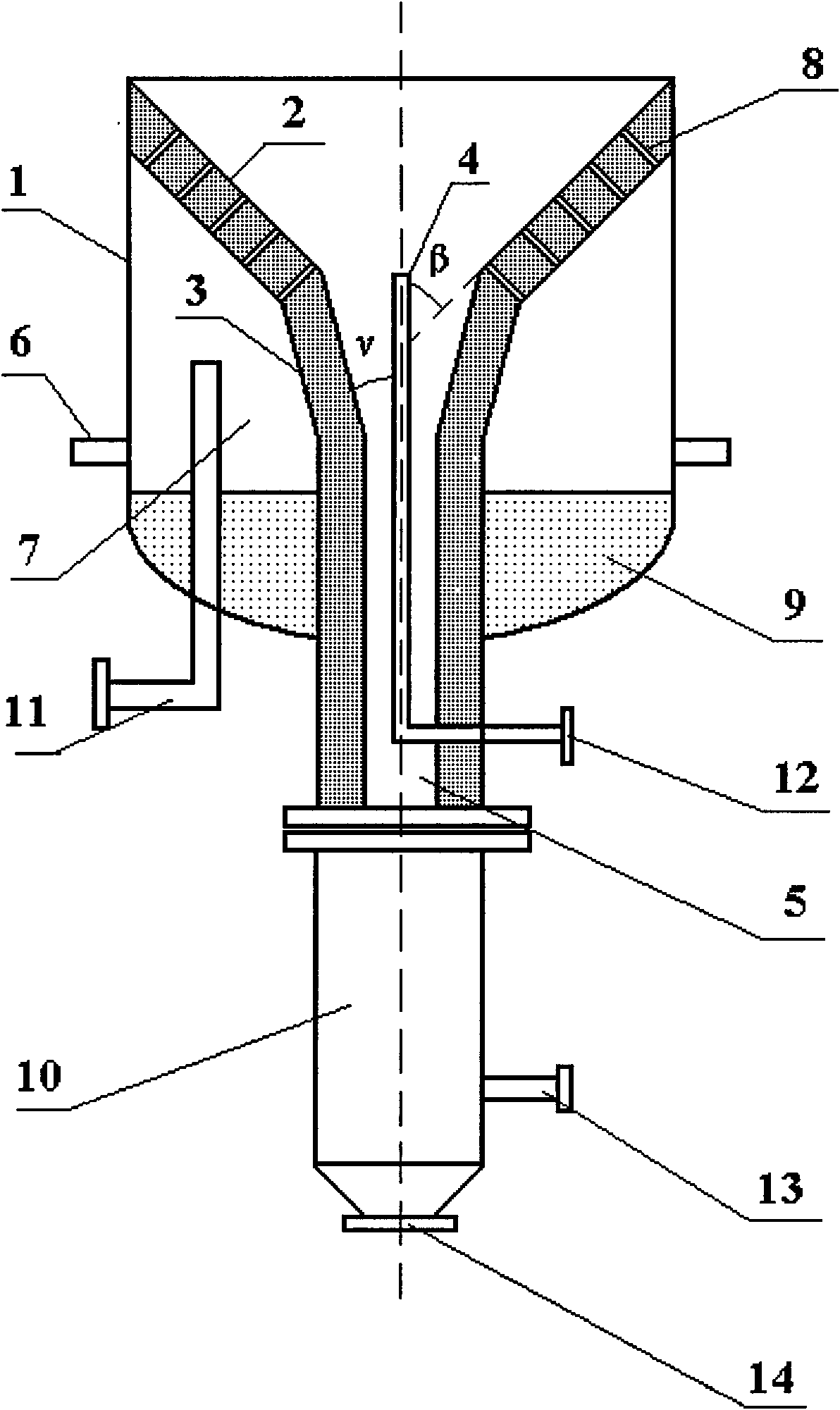

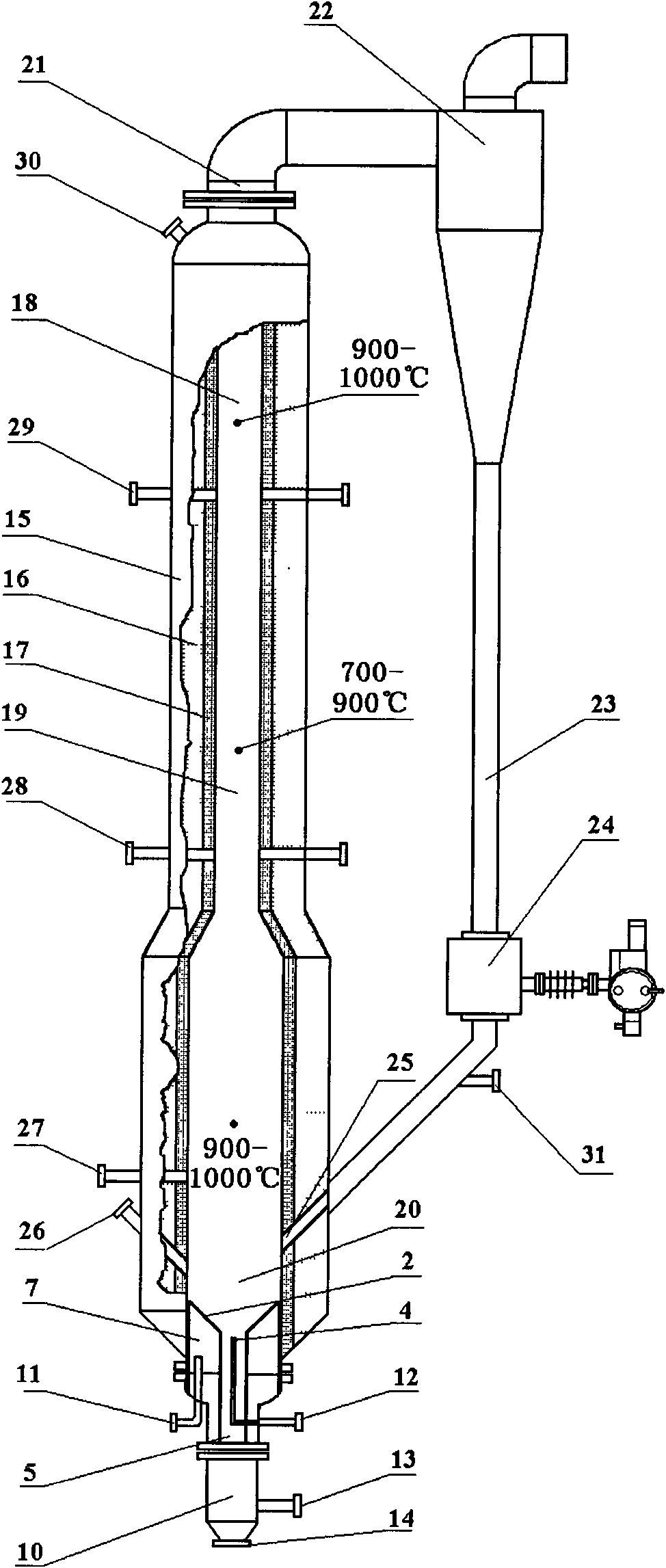

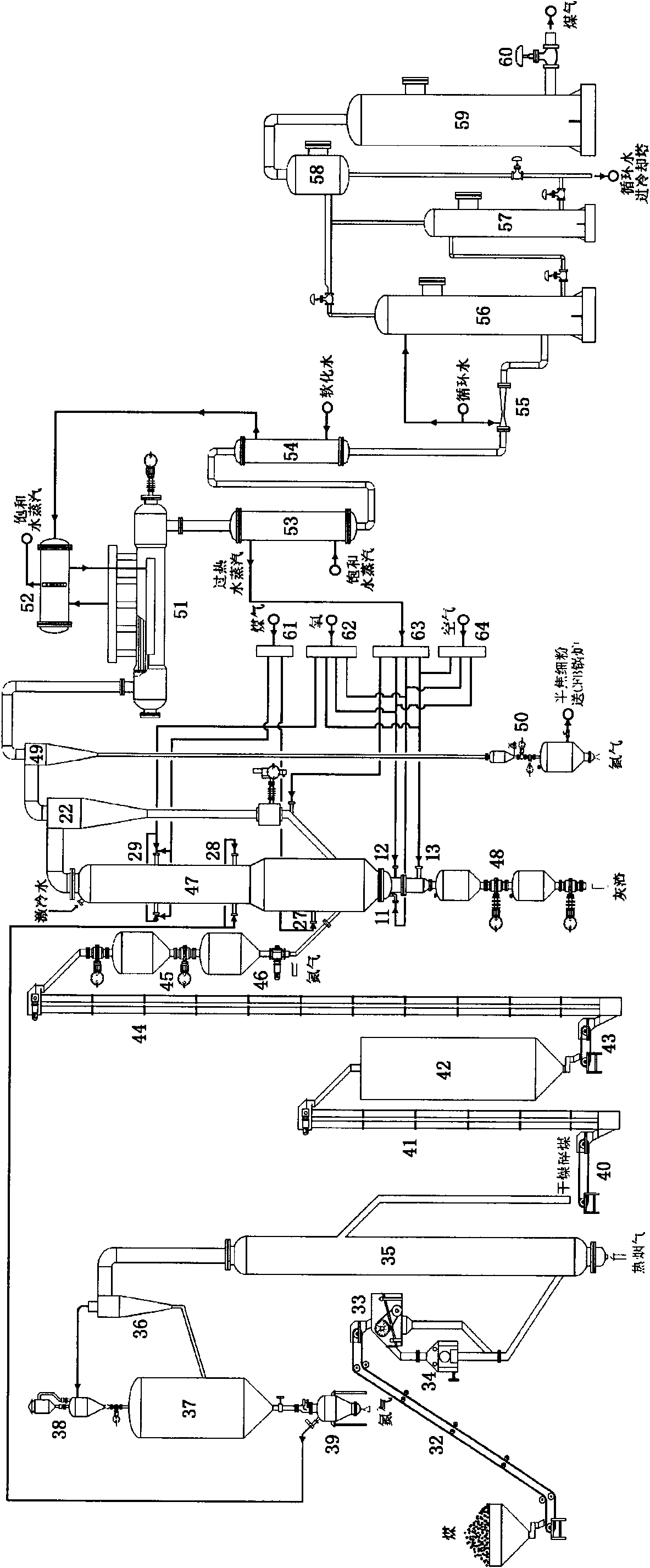

[0044] It consists of a fused ash separation unit, a pyrolysis gasification reactor, and a semi-coke fine powder circulation conveying unit. The fused ash separation unit consists of a cylindrical air chamber shell 1, a conical distribution plate 2, and a reducer 3. Central jet pipe 4, annular separation pipe 5, distributor connecting flange 6, heat insulation material 9, which is ash fall pipe 10, distribution plate gasification agent inlet pipe 11, central pipe gasification agent inlet pipe 12, annular separation pipe gas Chemical inlet pipe 13, slag outlet 14 constitutes. The conical distribution plate 2 is located on the upper part of the cylindrical air chamber shell 1, and is in the shape of an inverted cone. There are evenly distributed gas outlets 8 on the conical distribution plate 2; the lower part of the conical distribution plate 2 is connected with the reducer 3, and the lower part of the reducer 3 Connected with the annular separation pipe 5, there is a heat insu...

Embodiment 2

[0055] The opening ratio of the conical distribution plate is 1.5%, the aperture is Φ4mm, and the angle β between the conical generatrix and the central axis is 30°. The angle γ between the conical generatrix of the reducer and the central axis is 7°.

[0056] The crushed coal feed rate in the lower part of the fluidized bed is 2000kg / h, and the oxygen feed rate is 1000Nm 3 / h, the water vapor volume is 2000kg / h, the fine coal feed volume in the middle of the gasifier is 550kg / h, the gasifier pressure is controlled at 1.0MPa, and the circulating gas volume of the upper combustion nozzle is 180Nm 3 / h, oxygen content 90Nm 3 / h, steam rate 55kg / h, all the other are with embodiment 1.

Embodiment 3

[0057] Embodiment 3: The opening ratio of the conical distribution plate is 1.0%, the aperture is Φ4mm, and the angle β between the conical generatrix and the central axis is 40°. The angle γ between the conical generatrix of the reducer and the central axis is 7°.

[0058]The crushed coal intake in the lower part of the fluidized bed is 2500kg / h, and the oxygen intake is 1250Nm 3 / h, the water vapor volume is 2500kg / h, the fine coal feed volume in the middle of the gasifier is 650kg / h, the gasifier pressure is controlled at 1.5MPa, and the circulating gas volume of the upper combustion nozzle is 230Nm 3 / h, oxygen content 115Nm 3 / h, steam rate 70kg / h, all the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com