Patents

Literature

683results about How to "Improve gasification efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

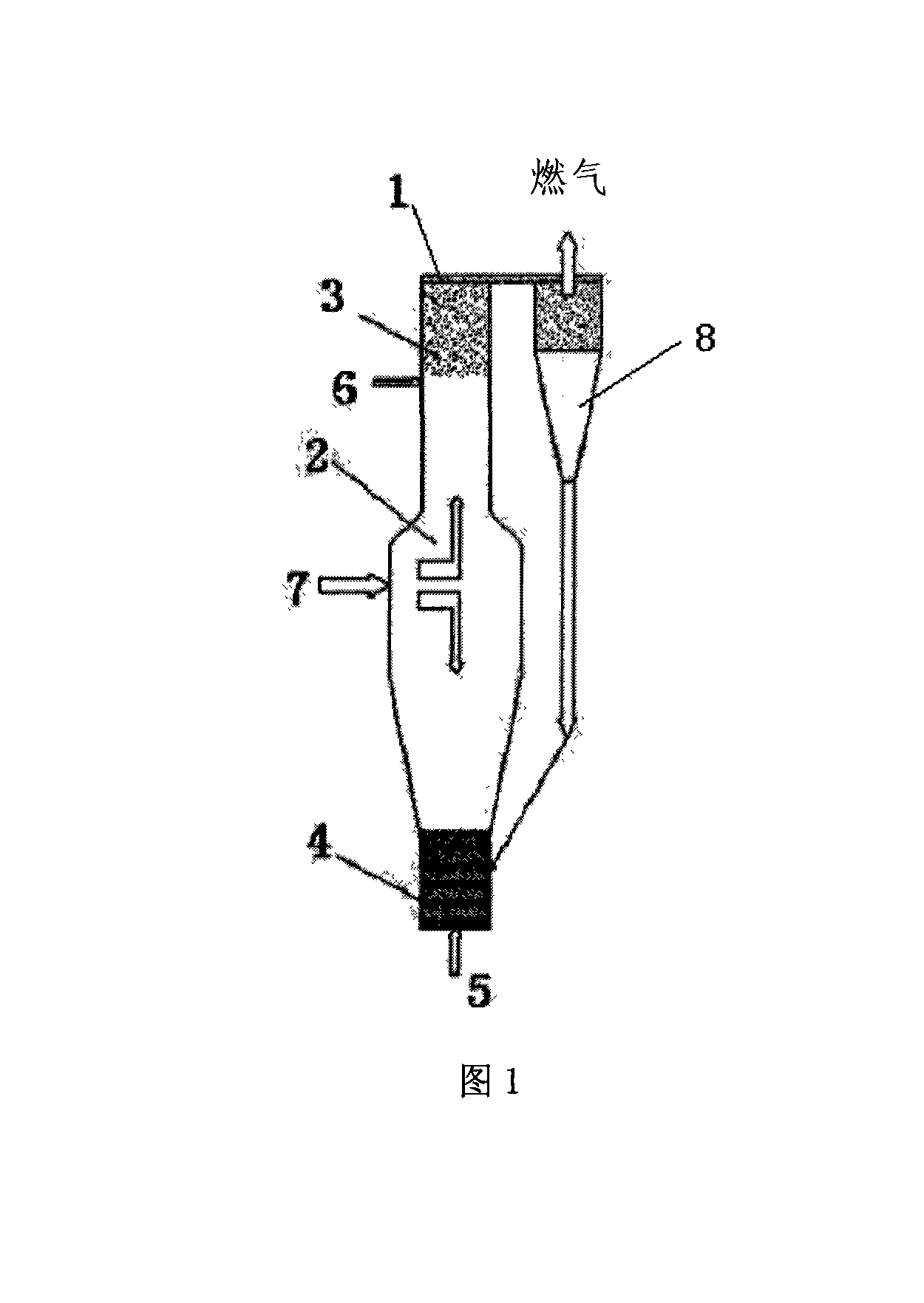

Method for combination processing heavy oil by pyrolysis and gasification

ActiveCN101451073AReasonable useImprove gasification efficiencyThermal non-catalytic crackingCoke ovensOil processingThermal energy

The invention relates to a heavy oil processing method by combining thermal cracking and gasification. A raw material is conducted to a reactor from the bottom of a gas-solid separation region, is dispersed into oil drops through an atomizer; a lightweight component of the oil drop is volatilized to form oil gas in the falling process of the oil drops in a thermal cracking region; a heavy component is condensed to form coke, wherein the oil gas carries out thermal cracking reaction; coke particles drop into a gasification region and carry out gasification reaction at a temperature of between 800 and 1,600 DEG C to generate synthetic gas; one part of residual fine coke particles drop into an ash hopper to form clinker; the other part of the residual fine coke particles and the generated gas flow upwards together, are contacted with the descending liquid drops and carry out heat exchange; gas phase and coke in the gas-solid separation region of the upper part of the rector are separated; the separated fine coke particles re-drop into the thermal cracking region and the gasification region and continuously react; and the separated gas phase flows out of the rector, enters a subsequent separation system and is separated into synthetic gas, dry gas, liquid gas, gasoline, diesel, oil slurry and other products. The method has high gasification efficiency and reasonable utilization of heat energy and reduces energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

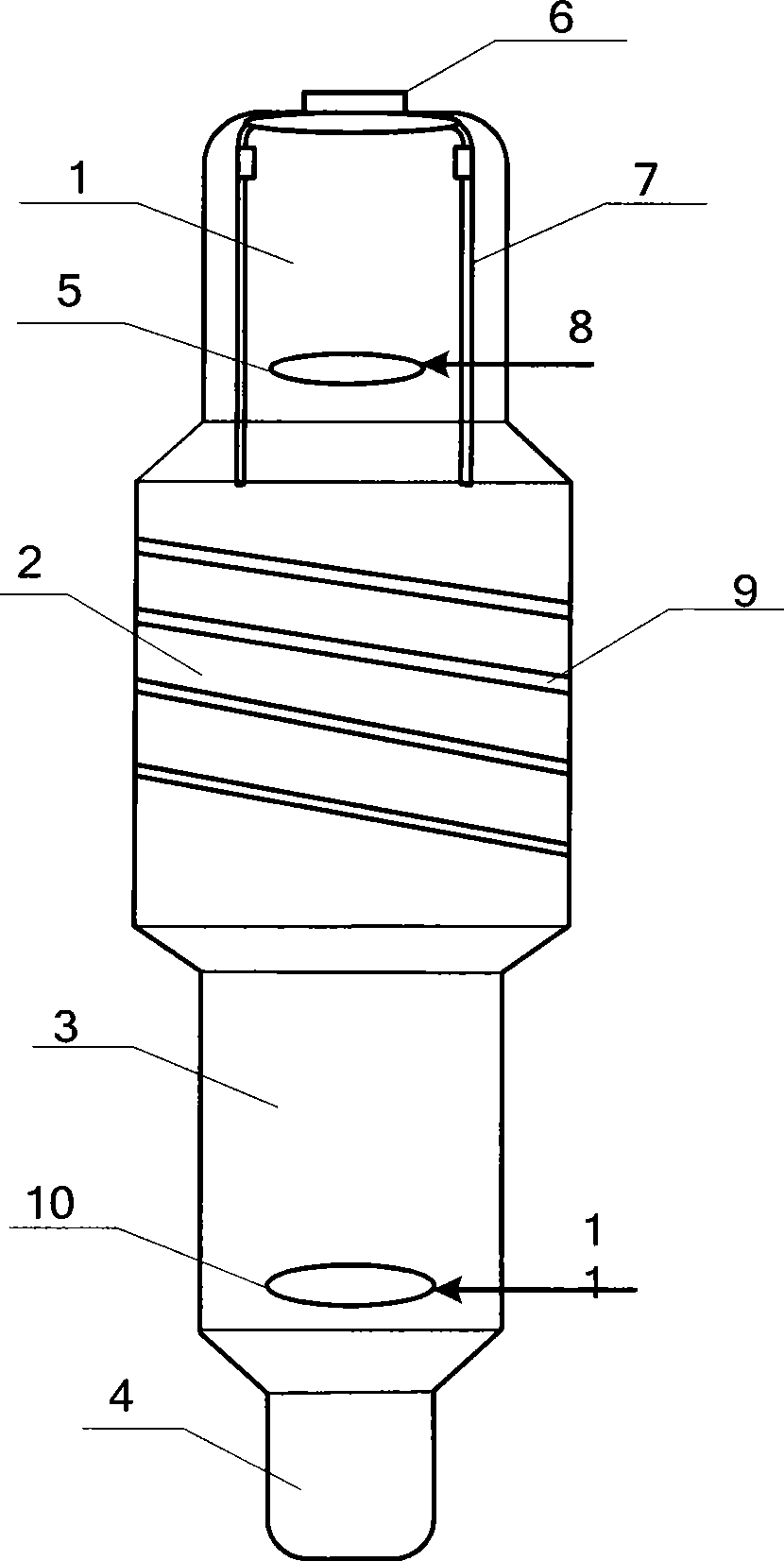

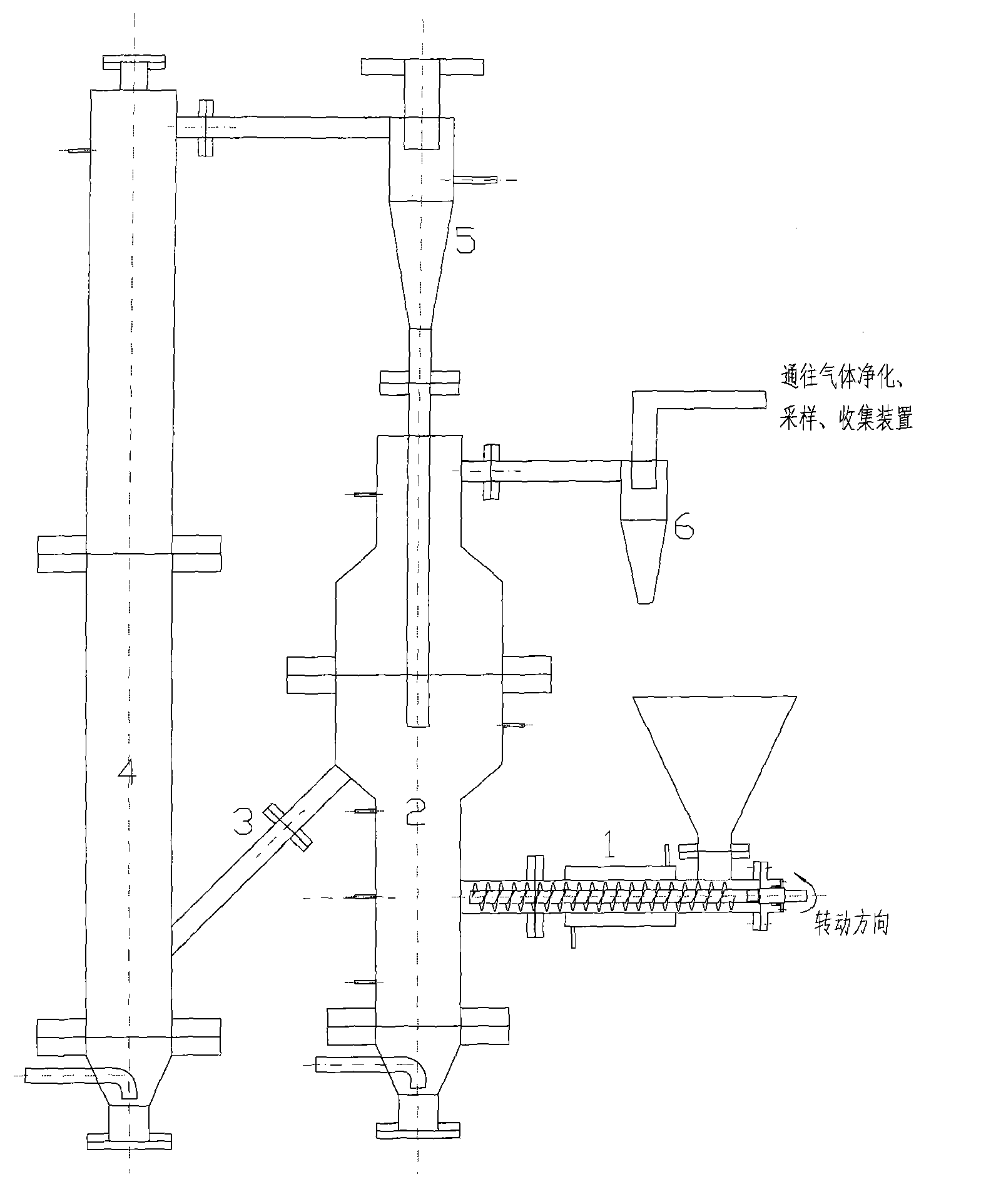

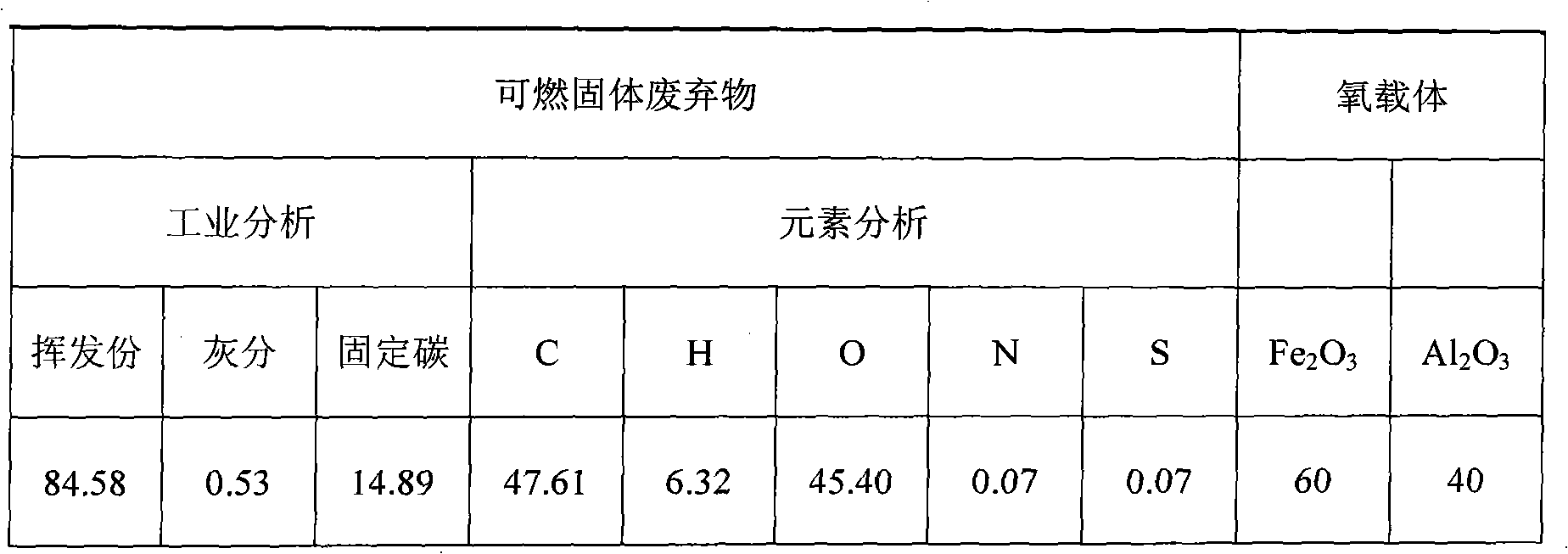

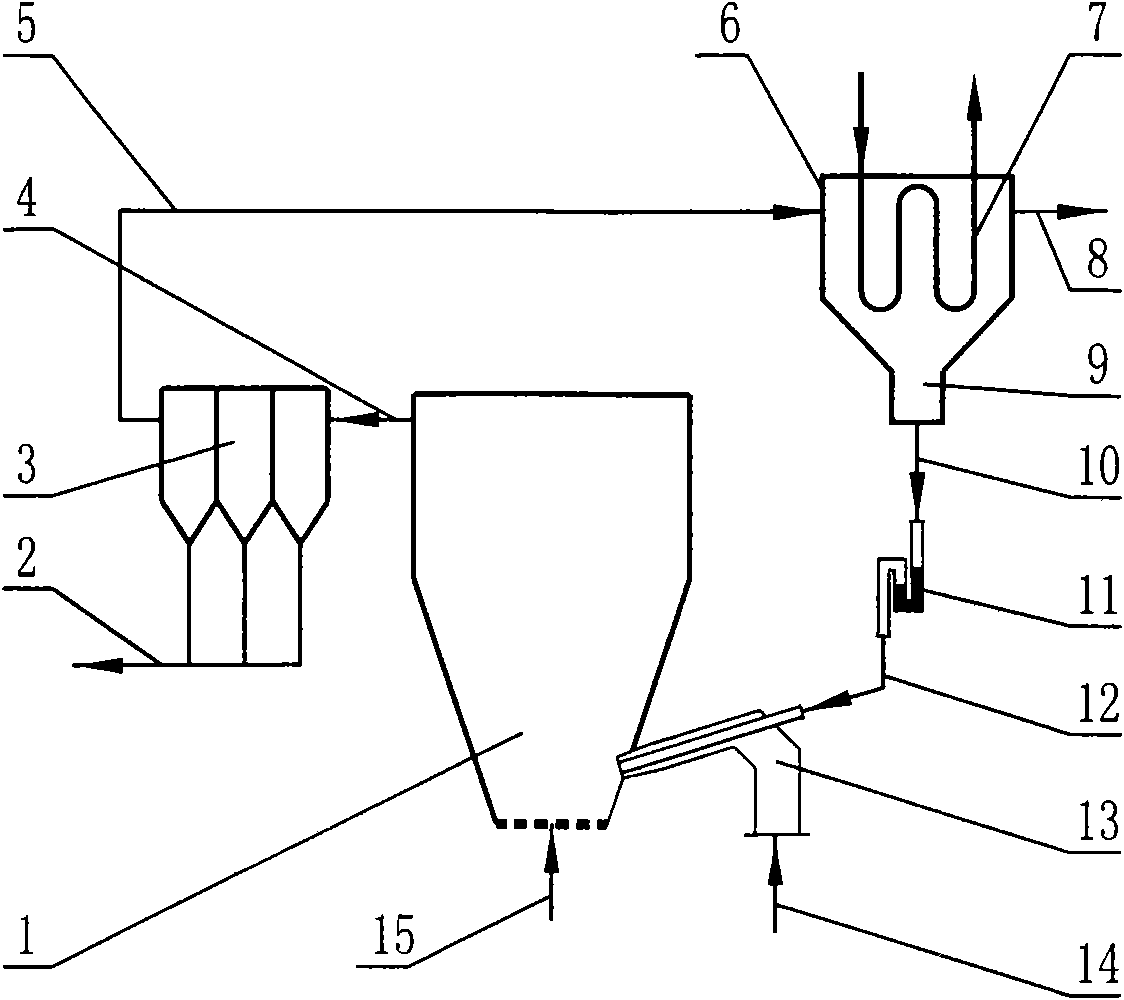

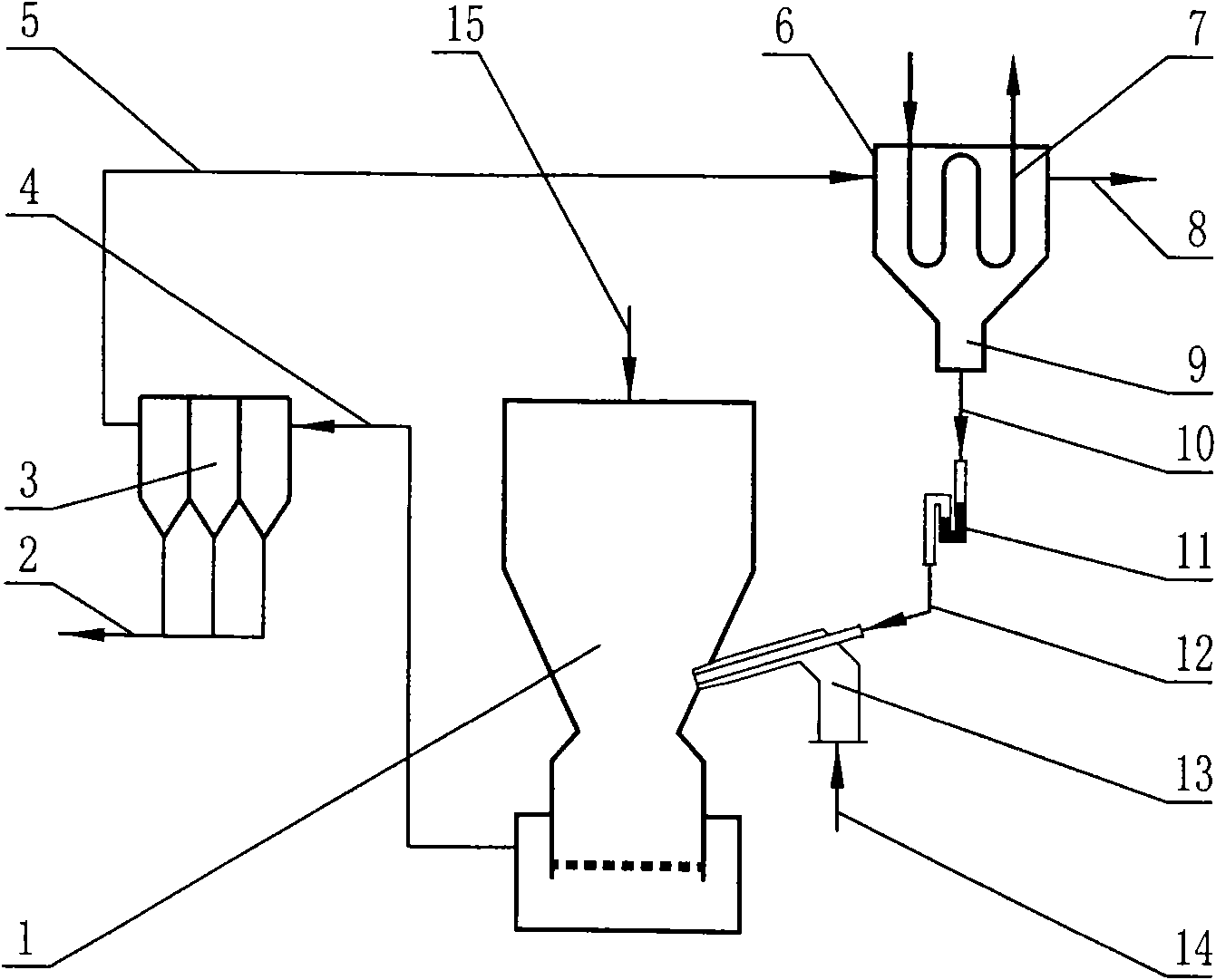

Method for producing synthesis gas by combustible solid waste chemical chain gasification and interconnected fluidized bed reactor

ActiveCN101638590ALower Gasification CostsHigh calorific valueCombined combustion mitigationChemical/physical processesFluidized bedLattice oxygen

The invention provides a method for producing synthesis gas by combustible solid waste chemical chain gasification and an interconnected fluidized bed reactor. The method is implemented in an interconnected fluidized bed reactor, and the interconnected fluidized bed reactor comprises a fuel reactor and an air reactor communicated with each other internally. The combustible solid waste produces gasification reaction with a carrier of oxygen to produce synthesis gas, and the oxygen element necessary for the gasification of combustible solid waste comes from the lattice oxygen in the carrier component of oxygen; the carrier of oxygen without lattice oxygen is transported to the air reactor, in the air reactor, the carrier of oxygen is re-oxidized by high-temperature air to recovery to latticeoxygen; the carrier of oxygen recovered with lattice oxygen is carried out the air reactor by high-speed air, returns back to the fuel reactor for cycle use and produces gasification reaction with the combustible solid waste again. The invention relates to a high-efficiency combustible solid waste gasification technique breaking the prior art, and the invention can produce high-quality synthesisgas and reduce the contents of tar and carbon deposite during the gasification process.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

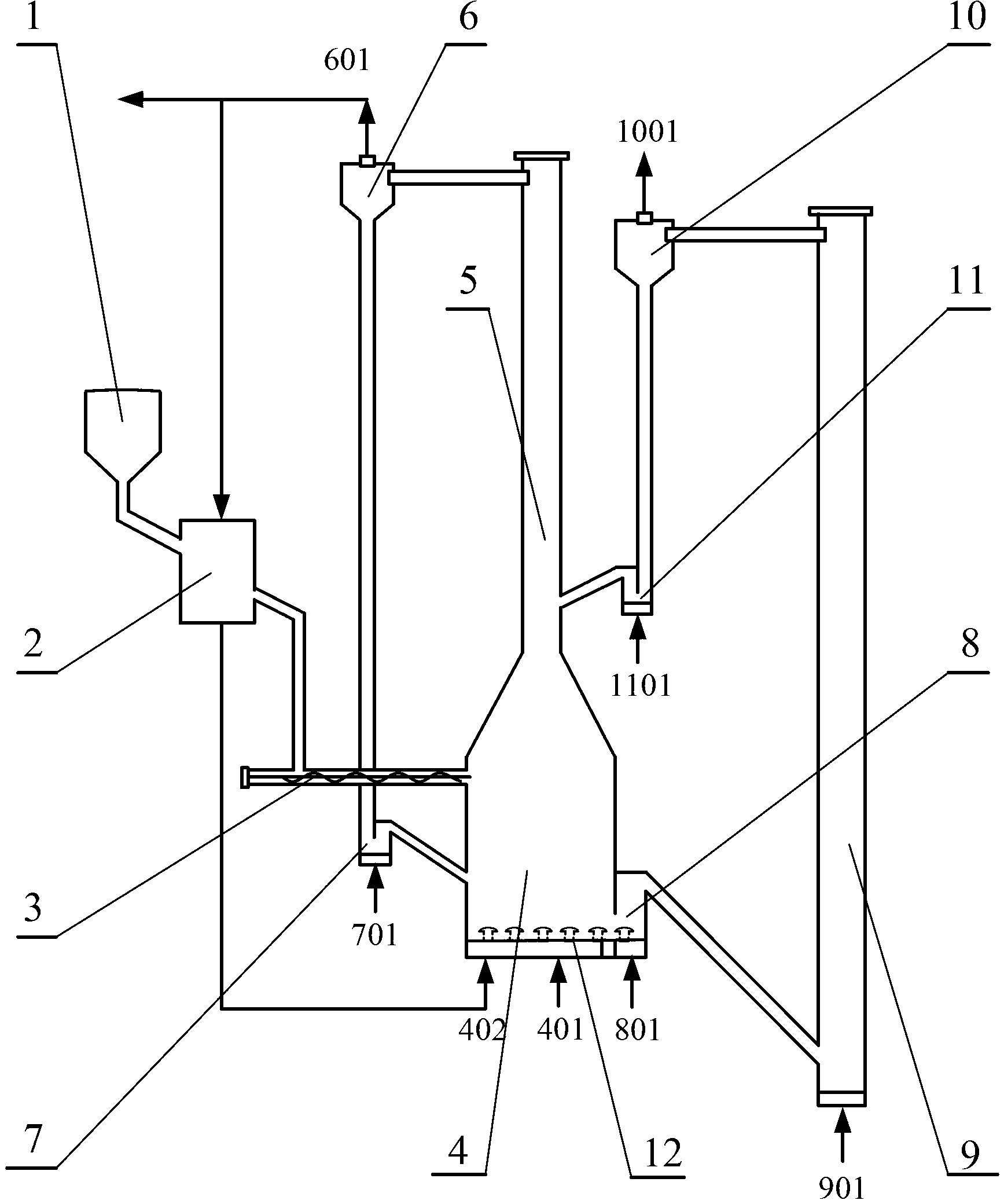

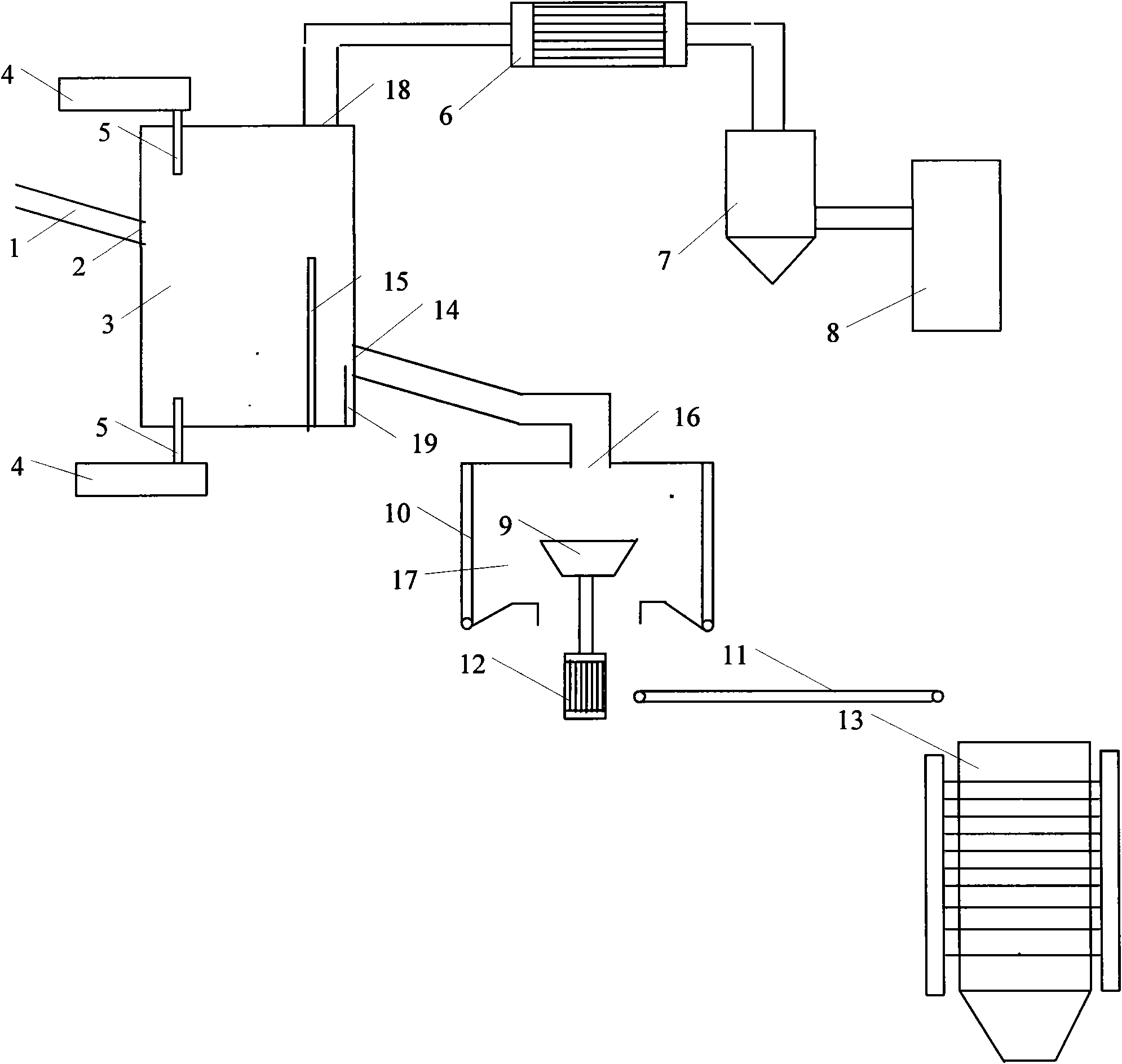

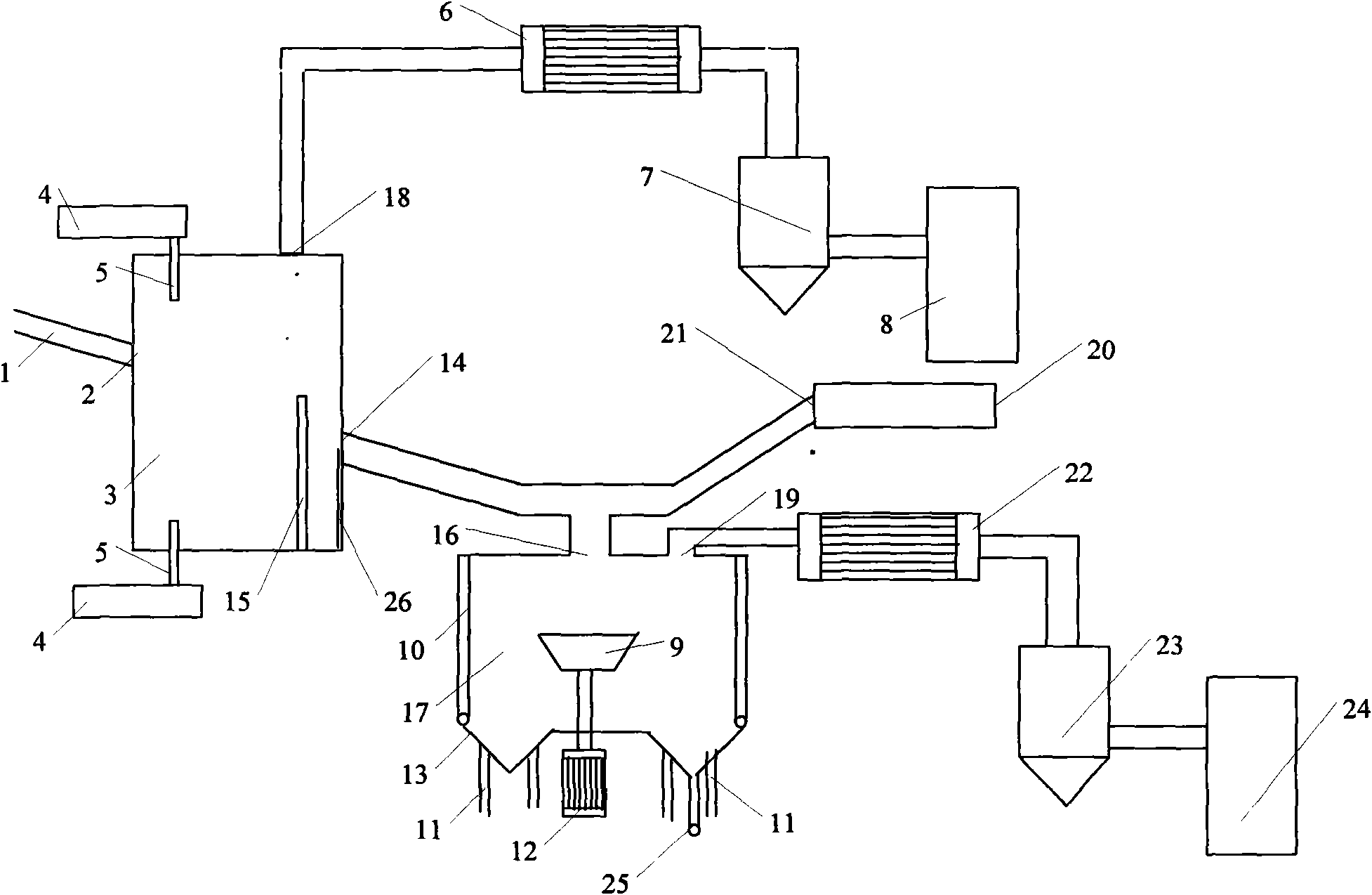

Coal gasification device for circulating fluidized bed and manufacturing method thereof

InactiveCN101054536AImprove gasification efficiencyReduce outputEnergy inputGranular/pulverulent flues gasificationCycloneHearth

A circulating fluidized bed coal gasification apparatus includes coal blending system, generator, cyclone dust collector, exhaust-heat boiler, water-cooling tower and Venturi scrubber, wherein the generator has up-and-down two rows of gasifying agent nozzles, helix dust collector and storage groove. The gas pipe which communicates to the cyclone dust collector is set on the top. A feed back pipe which communicates to the generator is set at the bottom of the cyclone dust collector. The cyclone dust collector communicates to the exhaust-heat boiler by gas pipe. The exhaust-heat boiler communicates to the water-cooling tower by gas pipe and communicates to the Venturi scrubber by gas pipe. The characteristics are: the feed back pipe facing to the generator hearth of the cyclone dust collector is a feed back machine with small-sized fluid bed; the cyclone dust collector is composed of at least two tandem dust collector; coal blending system has wind feeding and dust coal drier. The invention achieves the transition of the boiling bed to the circulating fluidized bed and increases the system gasification efficiency.

Owner:宋建元

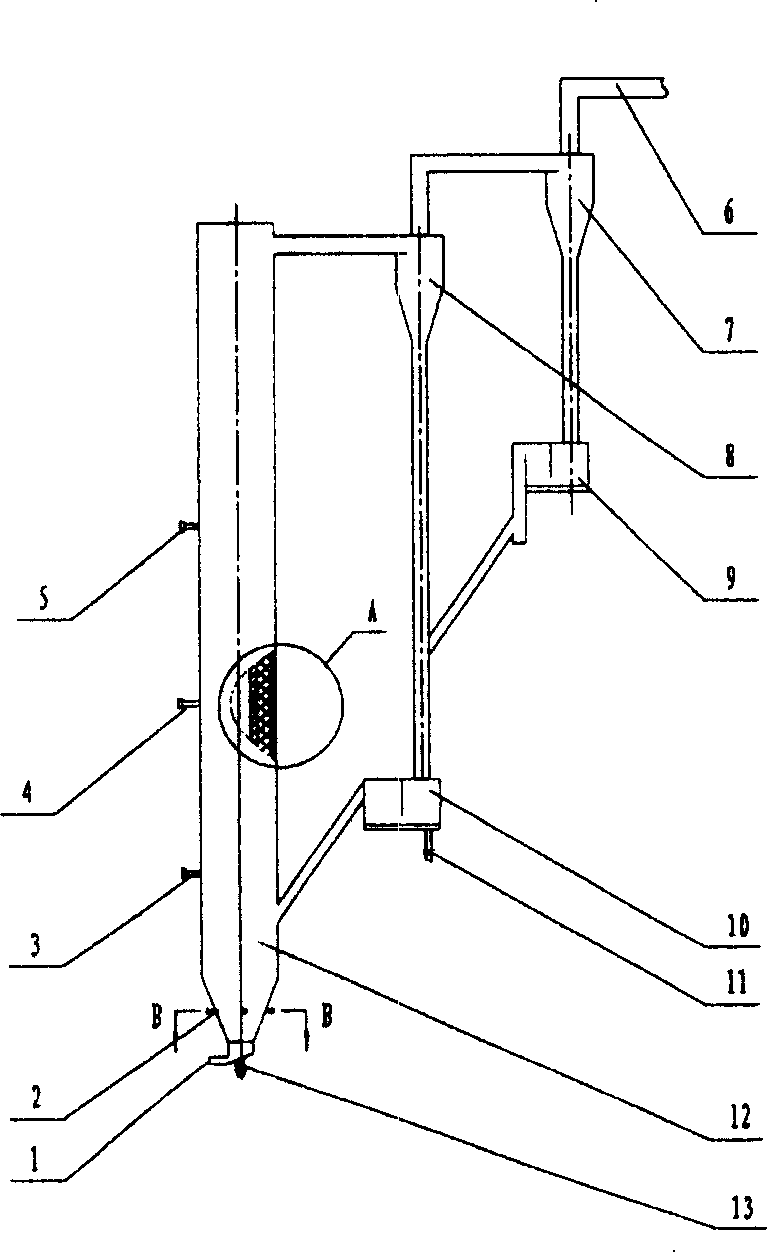

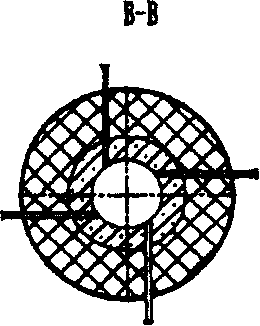

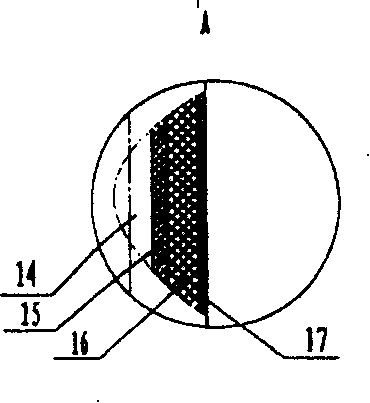

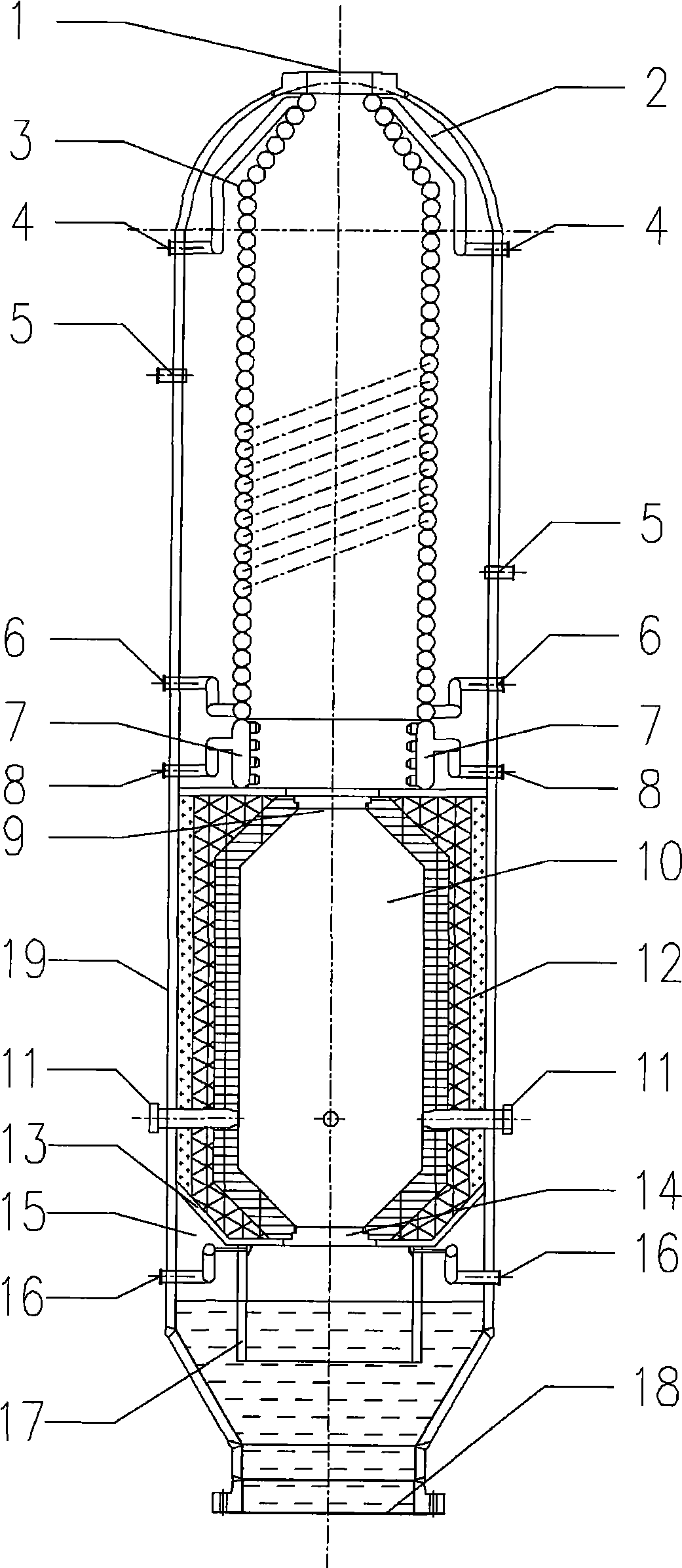

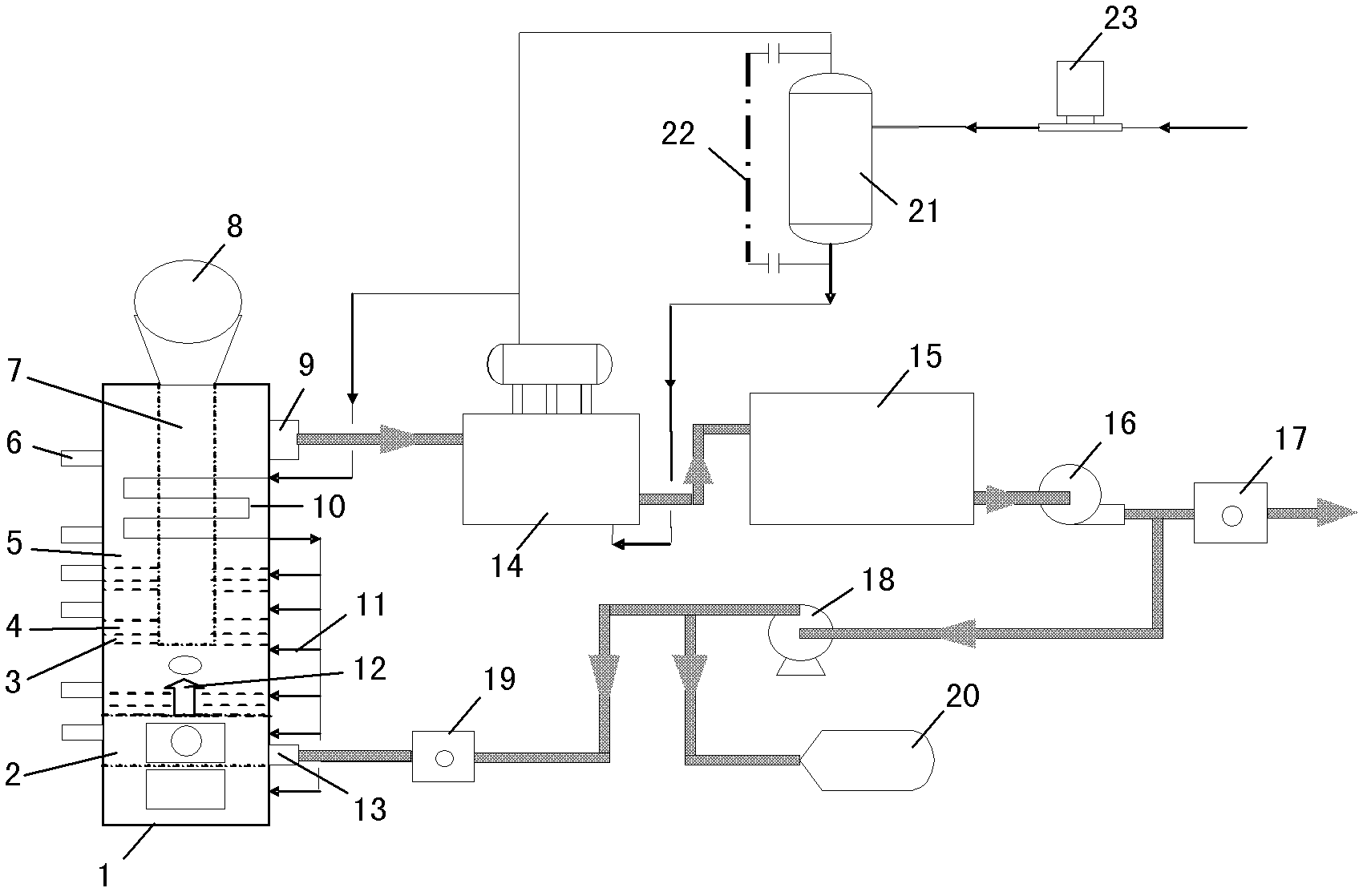

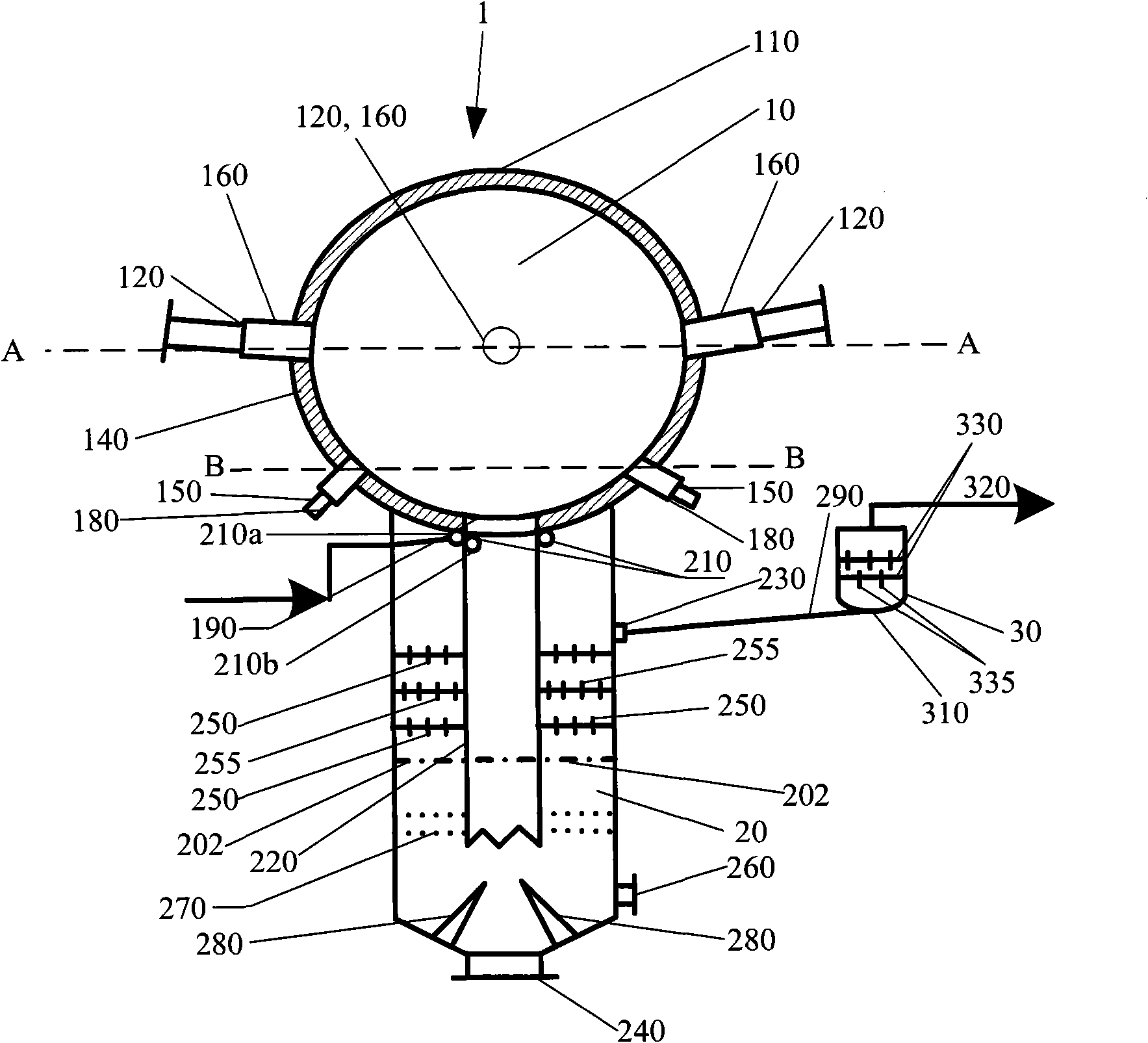

Fine coal pressurization dense phase transporting bed gasification method and device

ActiveCN101240196AIncrease speedGuaranteed to loop multiple timesCombined combustion mitigationGranular/pulverulent flues gasificationHigh rateHigh flux

A pulverized coal pressure dense transport bed gasification method and installation of the invention relates to gasification technology and employs in-furnace desulfurization craft. Pulverized coal and desulfurizer are sent into gasification furnace through the middle and lower part of gasification furnace by a feeder, and then react with a gasifying agent. Reaction mass flow upward from the bottom of the gasification furnace, and enter into a multistage gas-solid separator from an export on the top of the gasification furnace. Most solids are separated in the gas-solid separator and enter into the low part of the gasification furnace by a high flux return feeder to continue to participate in reaction. Gas products with a small amount of solid enter into a gas cooler which can recover gas manifested heat to generate steam. The enter modes of the gasifying agent are bottom once wind and cyclone twice wind, otherwise, the reactor can also be use to burn. Because of the high-rate cycle, high solid content and high gas-solid mixing in the gasification furnace of the invention, the gasification strength and gasification rate of the gasification furnace can be improved and higher gasification efficiency and carbon conversion rate can be obtained.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

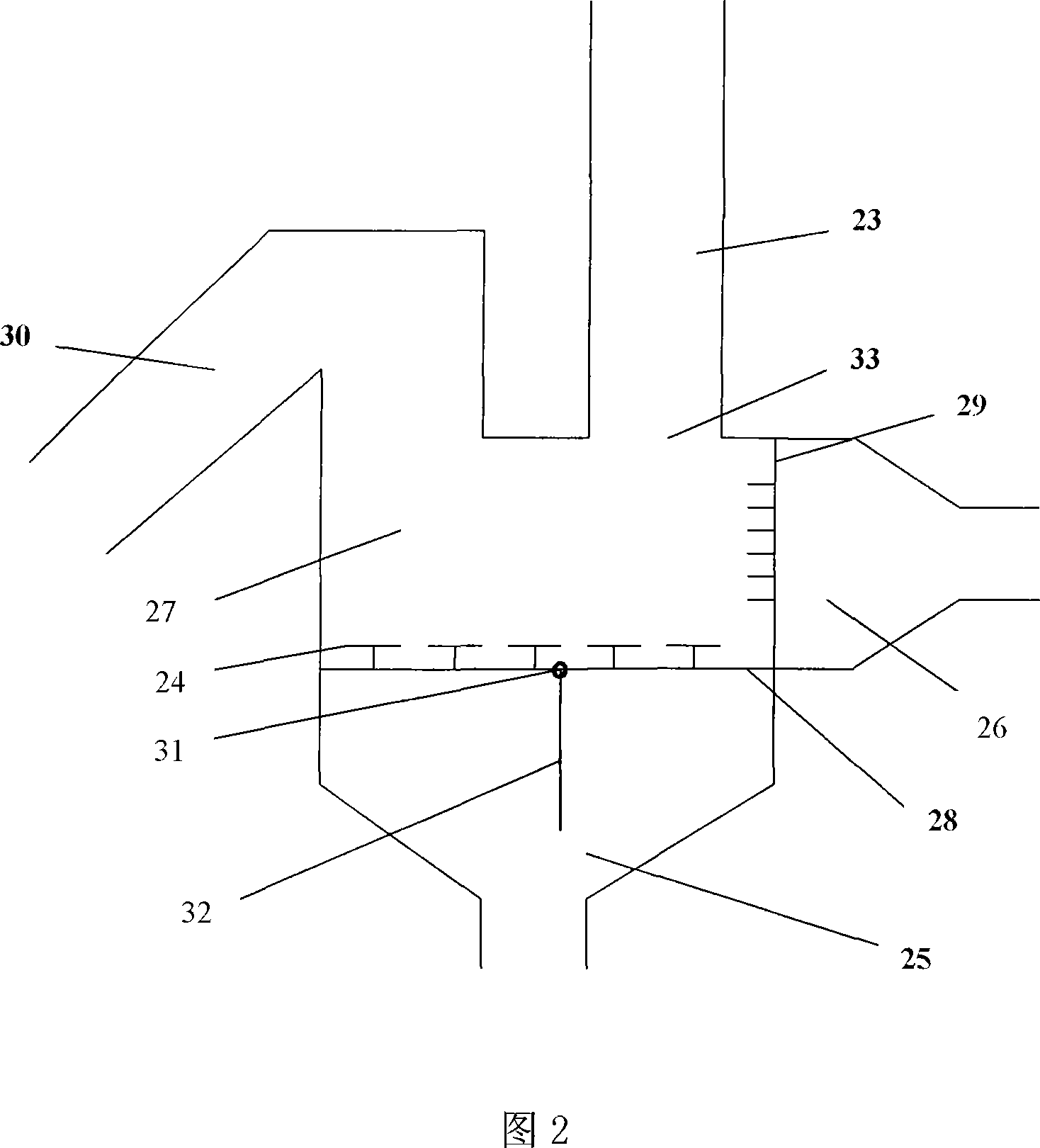

Two-stage gasification method and gasification device for fuels with wide size distribution

ActiveCN102703131AExtensive sources of raw materialsWide particle size distributionCombined combustion mitigationGranular/pulverulent flues gasificationTarProcess engineering

The invention relates to a two-stage gasification method and a gasification device for a fuel with wide size distribution. The two-stage gasification method for the fuel with wide size distribution comprises the steps of 1) adding the fuel to a fluidized bed pyrolyzer by a feeding device; adding a gasifying agent to the fluidized bed pyrolyzer; drying / pyrolyzing or partly gasifying the fuel under semicoking of the pyrolyzer and heating of the gasifying agent; and 2) sending the solid and gas generated in the step 1) to a fluidized bed gasification furnace, adding the gasifying agent to the fluidized bed gasification furnace, finishing complete gasification of semicoke; removing tar by high-temperature pyrolysis, part oxidization and semicoke catalytic reforming in the fluidized bed so as to produce clean gas. With the adoption of the method, the traditional fuel gasification process is divided into a material pyrolysis stage and a semicoke gasification stage, which are performed in an upper fluidized bed pyrolyzer and a lower fluidized bed gasification furnace.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

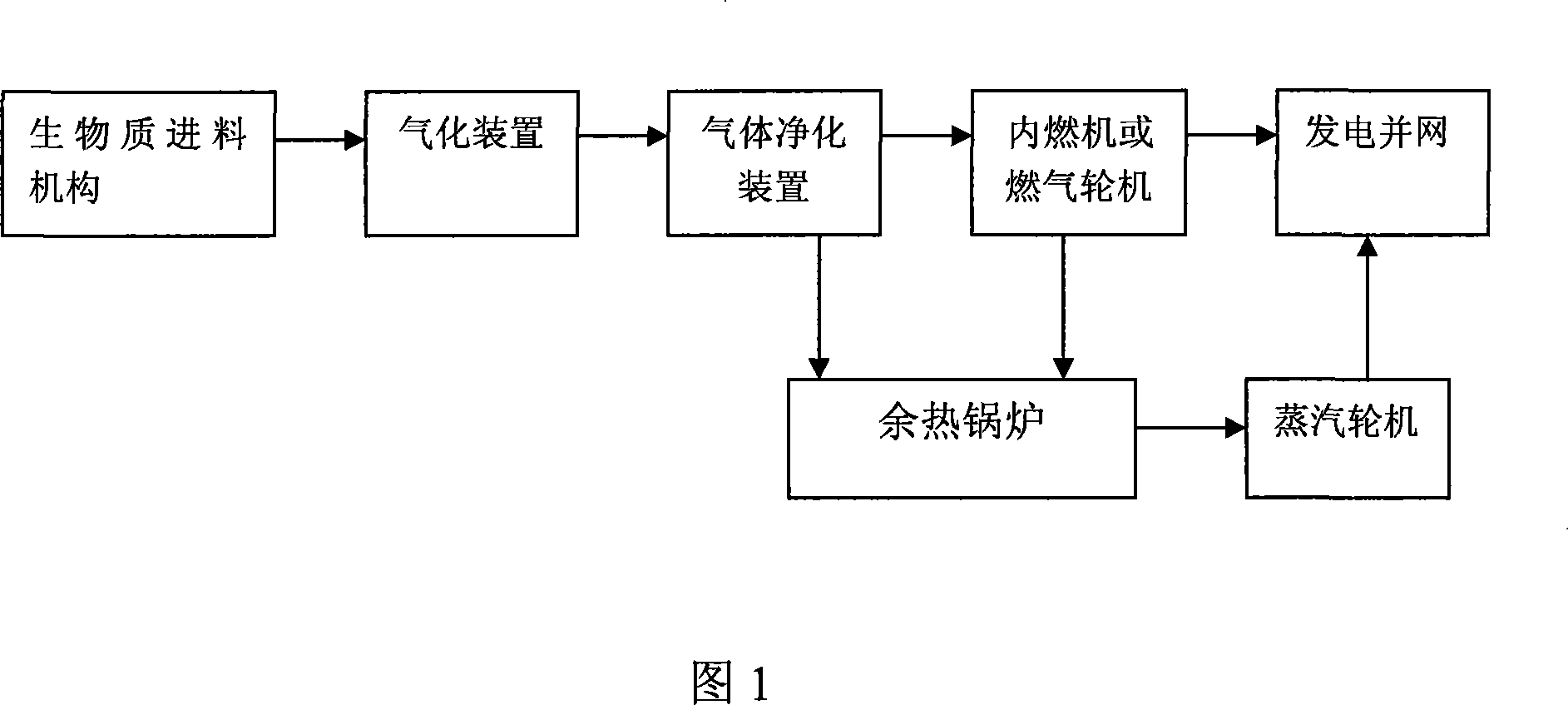

Power generation method using biomass

InactiveCN101158312AAdaptableStrong production intensityProductsInternal combustion piston enginesAgricultural residueInternal combustion engine

The invention relates to a method for generation by a biomass. The method utilizes the gasification technology, which converts the forestry and agricultural residues comprising wasted straws, sawdust, haulms, rice husks, bagasse, etc. into the flammable gas approaching the coal gas; after the dust and the tar of the flammable gas is removed by a purifier, the flammable gas is conveyed in a gas internal combustion engine or a gas turbine for generation. The invention has strong raw material adaptability, can dispose the biomass raw material of different types, and has the advantages of large production intensity, high gas heat value, little tar content, high gasification efficiency, strong load adaptability, easy start and stop, large adjustable range, stable operation, extremely high flexibility in scale. Furthermore, the generation scale depends on the quantity of the raw material and the requirement of the power, and can be designed and matched according to the requirement of the user.

Owner:WUHAN LIREN INVESTMENT

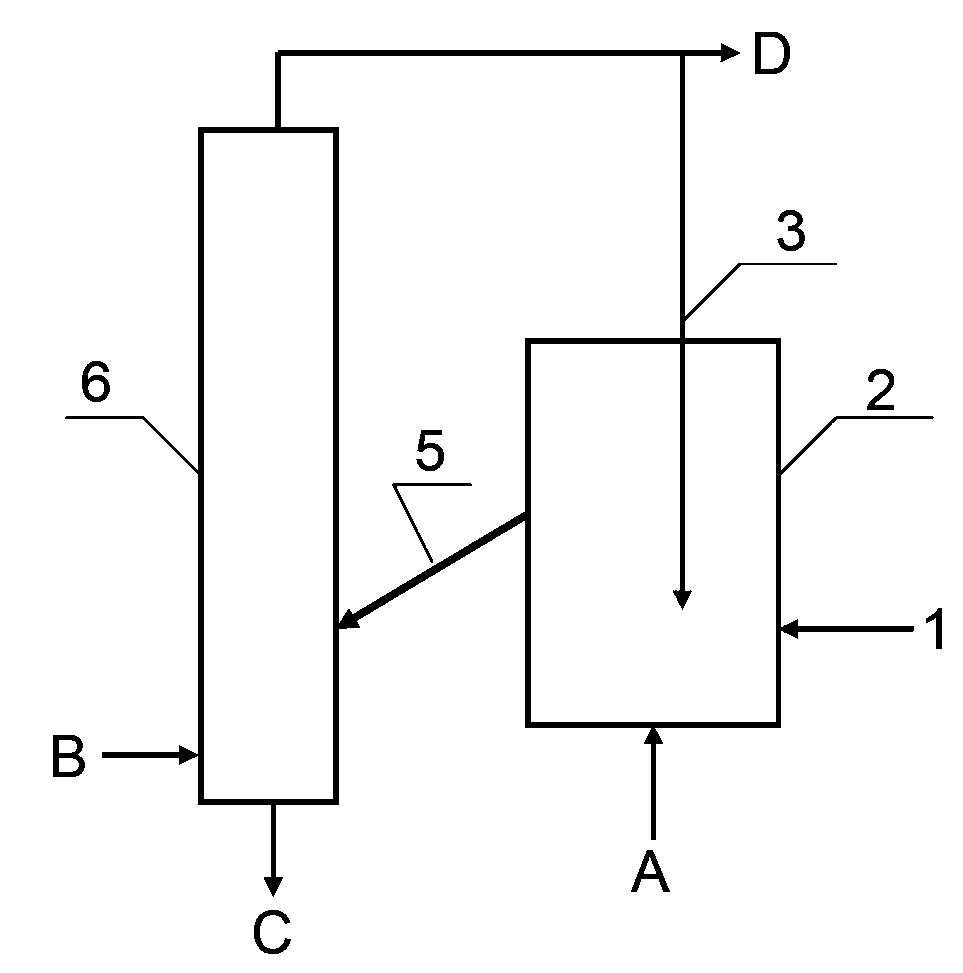

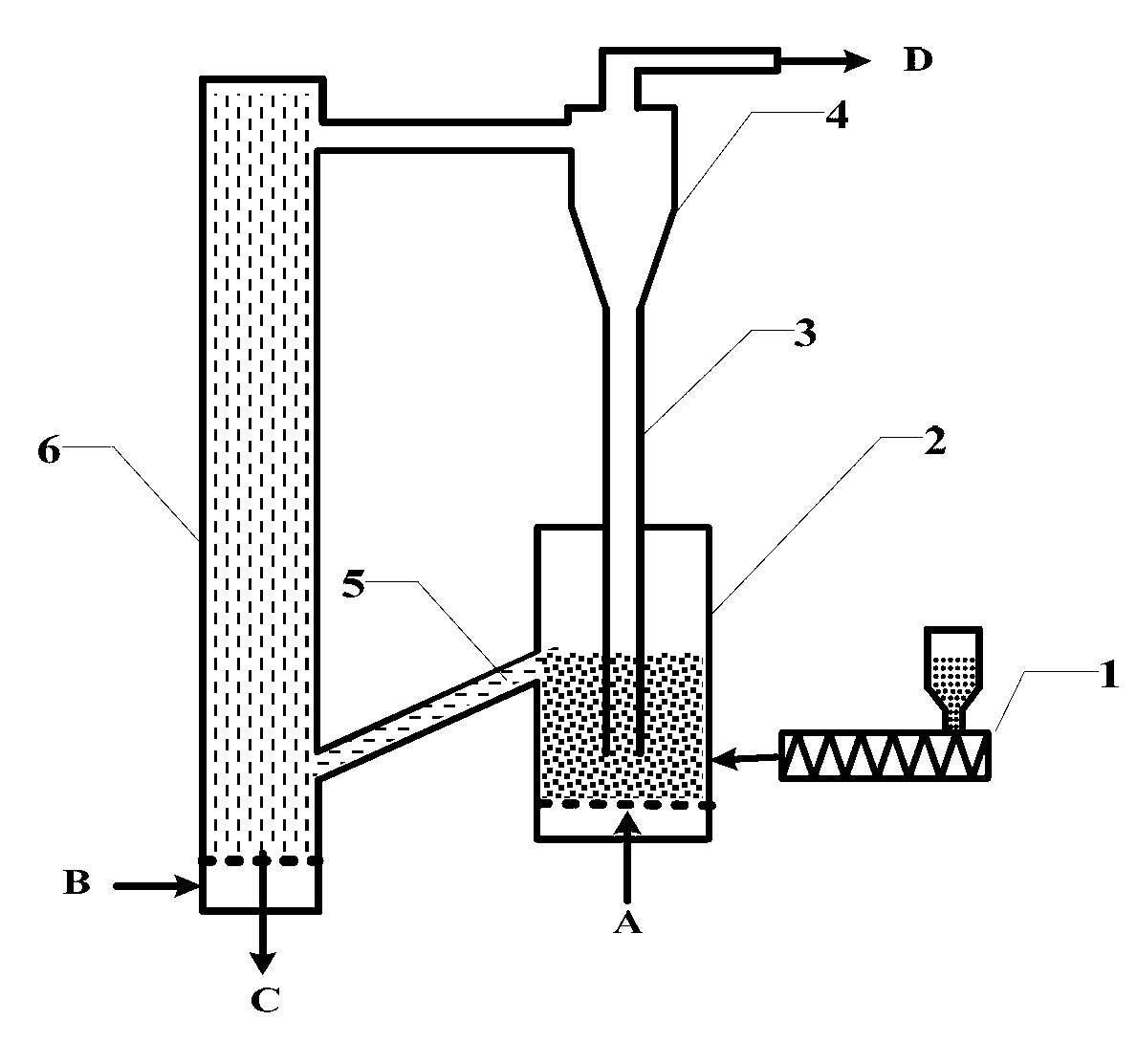

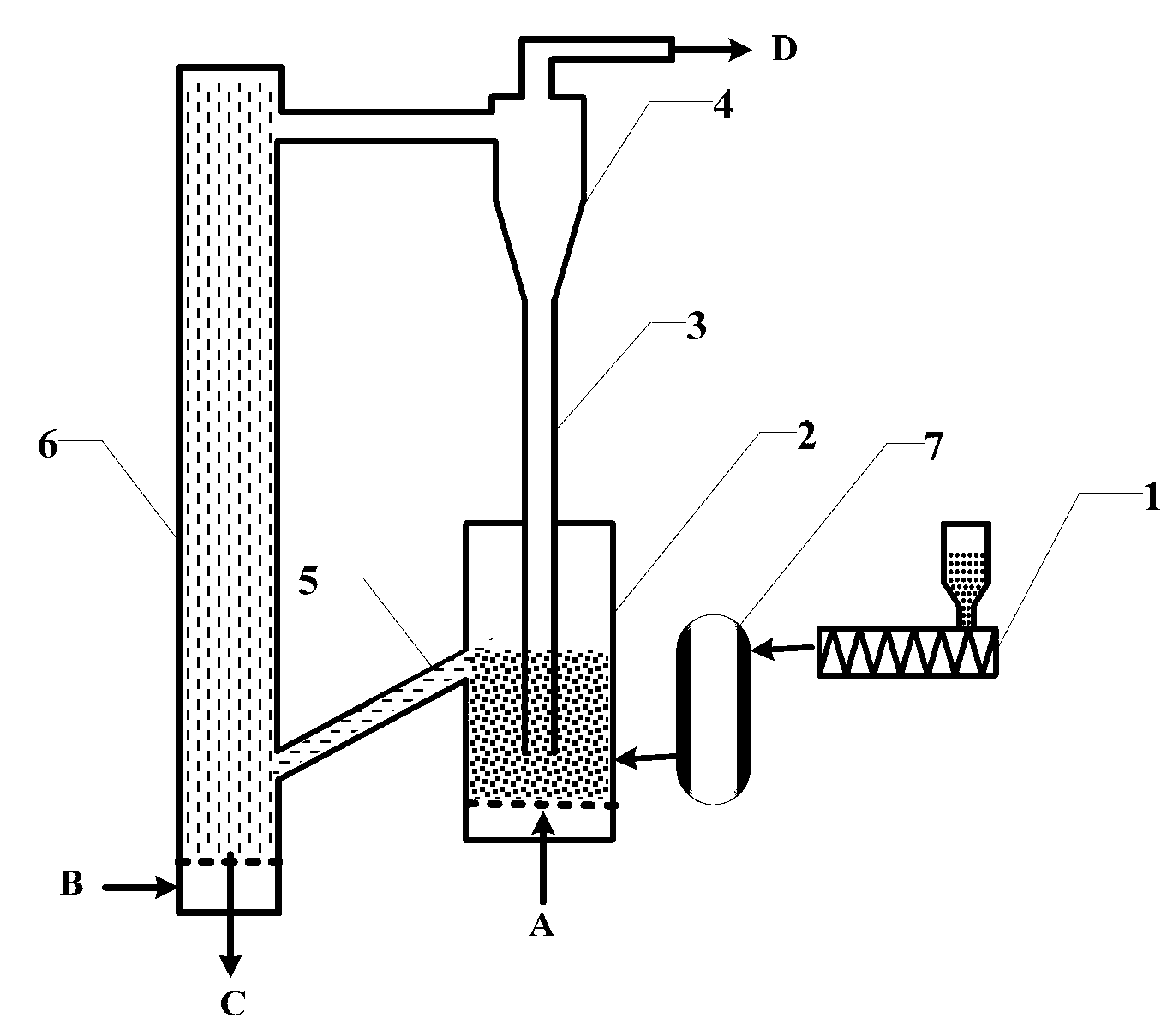

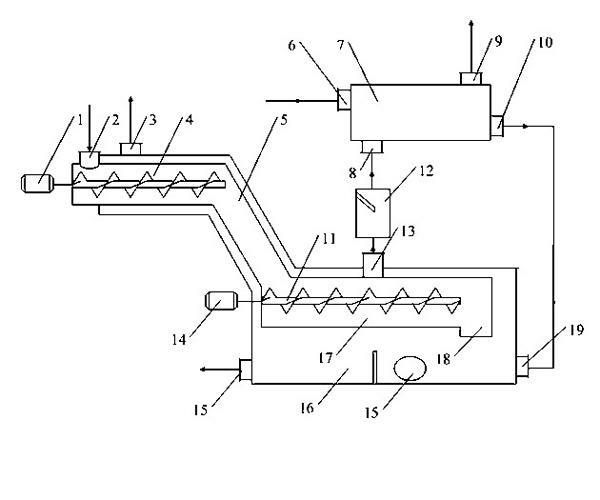

Method and device for biomass compound gasification

InactiveCN101225315AImprove gasification efficiencyReduce tar contentBiofuelsSpecial form destructive distillationTarBiomass

The invention discloses a biomass complex gasification method and a device of the gasification. The thermal decomposition, the gasification, part of the oxidation process are combined in one reactor by the integrating the fluidized bed and the airflow bed. Firstly, the biomass is decomposed at 500 to 600 degrees C and generates hard coke; secondly, the hard coke with large grain sizes are partly oxidized and gasified in the hard coke gasifying section, which provides heat and generates combustible gas for the thermal decomposition section; thirdly, the reaction gases with small hard coke grains discharged from the thermal decomposition section and the catalyst fast flows upwards through the macromolecular gasifying section, and the reaction gas are partly oxidized because of the function of the secondary gasifying agent, the heavy tar component is forced simultaneously through thermal cracking reaction and catalytic cracking reaction with the catalyst at the temperature over 1000 degrees C and transformed to lightweight combustible gas; at last, the unreacted hard coke is sent back to the furnace through the gas-solid separation device and the solid recycling device. The biomass complex gasification method has the advantages of high gasification efficiency, low tar content, high control ability of the gas component, stable operation and easy enlargement.

Owner:江苏中科龙城能源系统有限公司

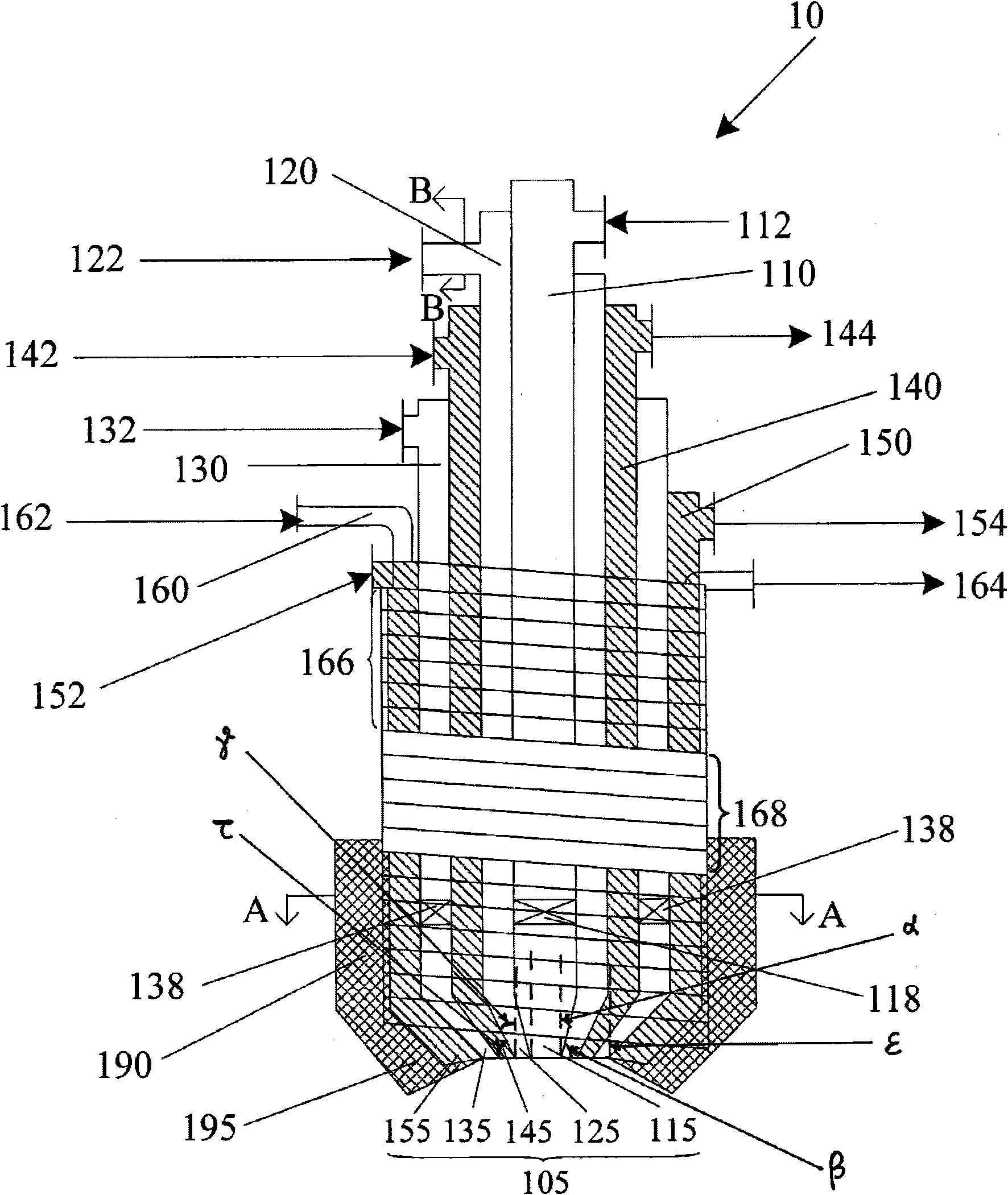

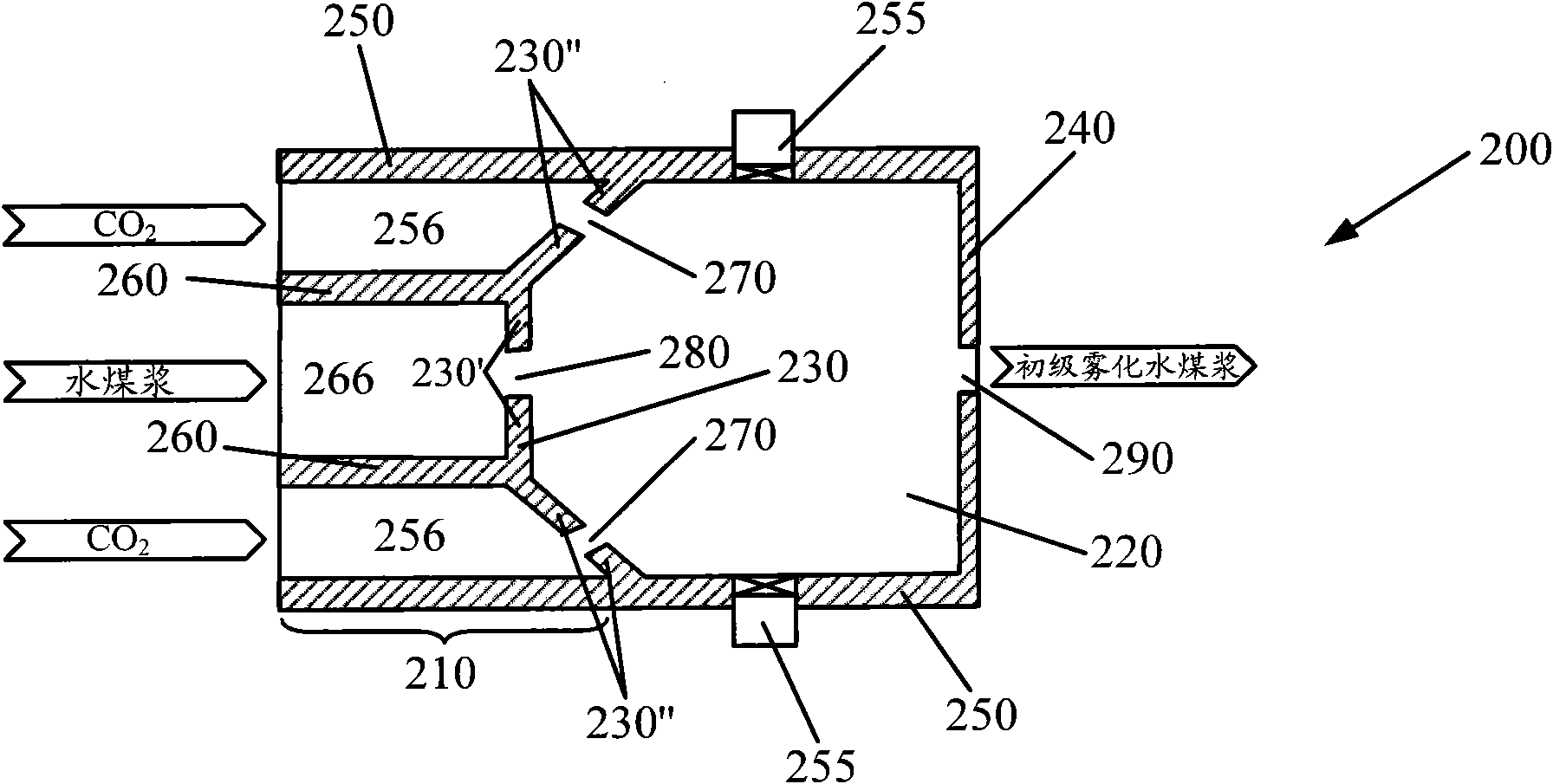

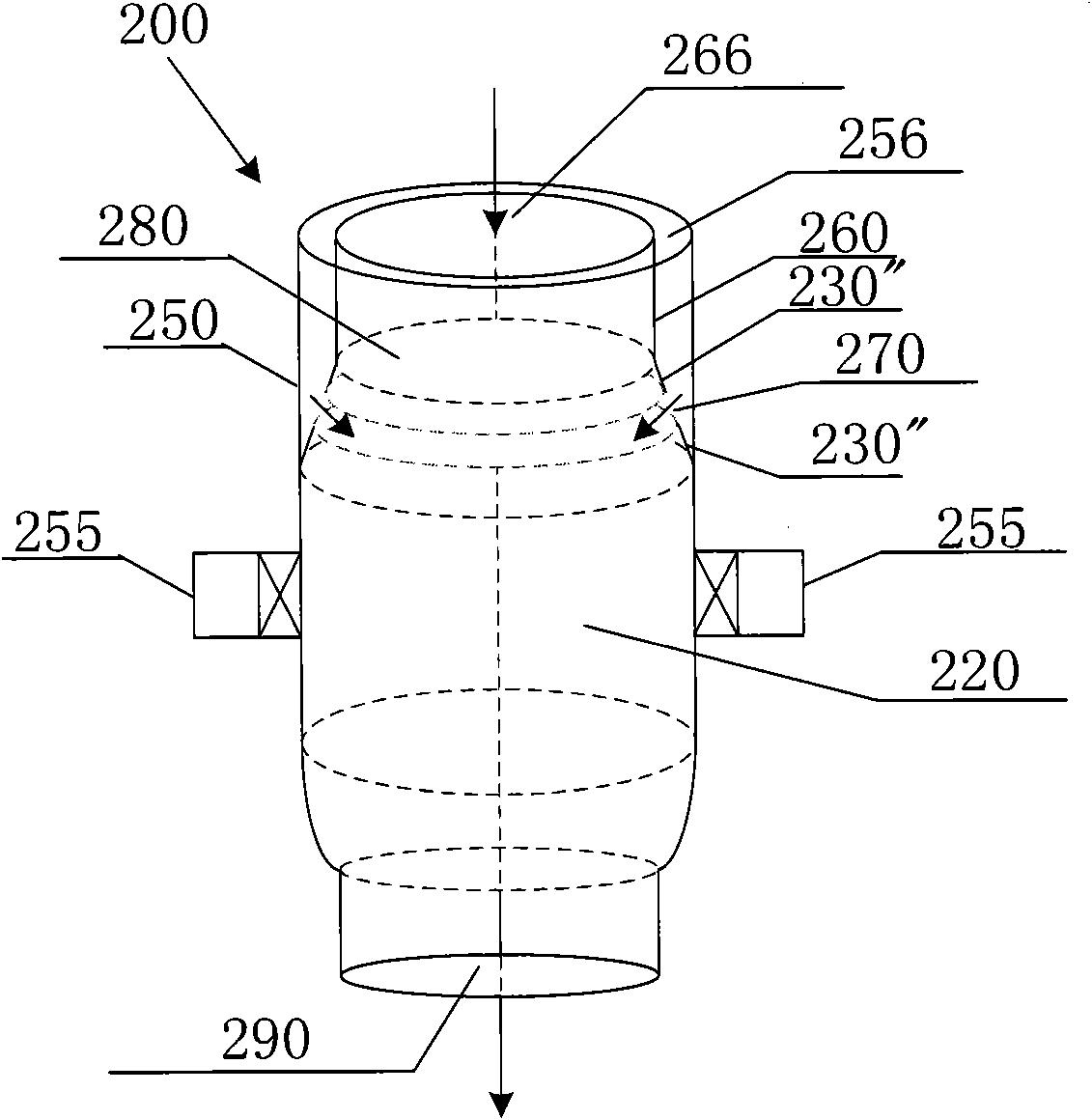

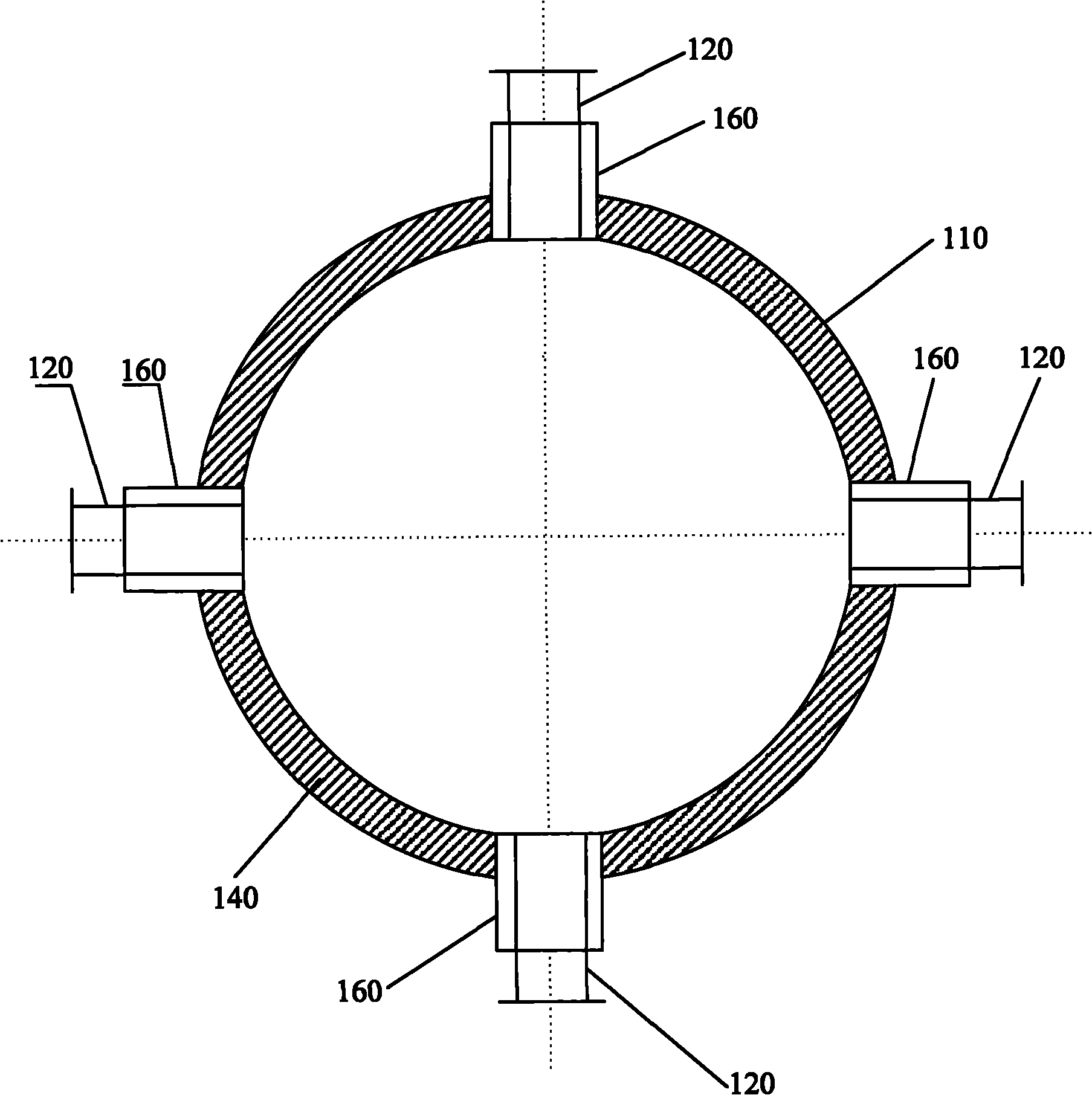

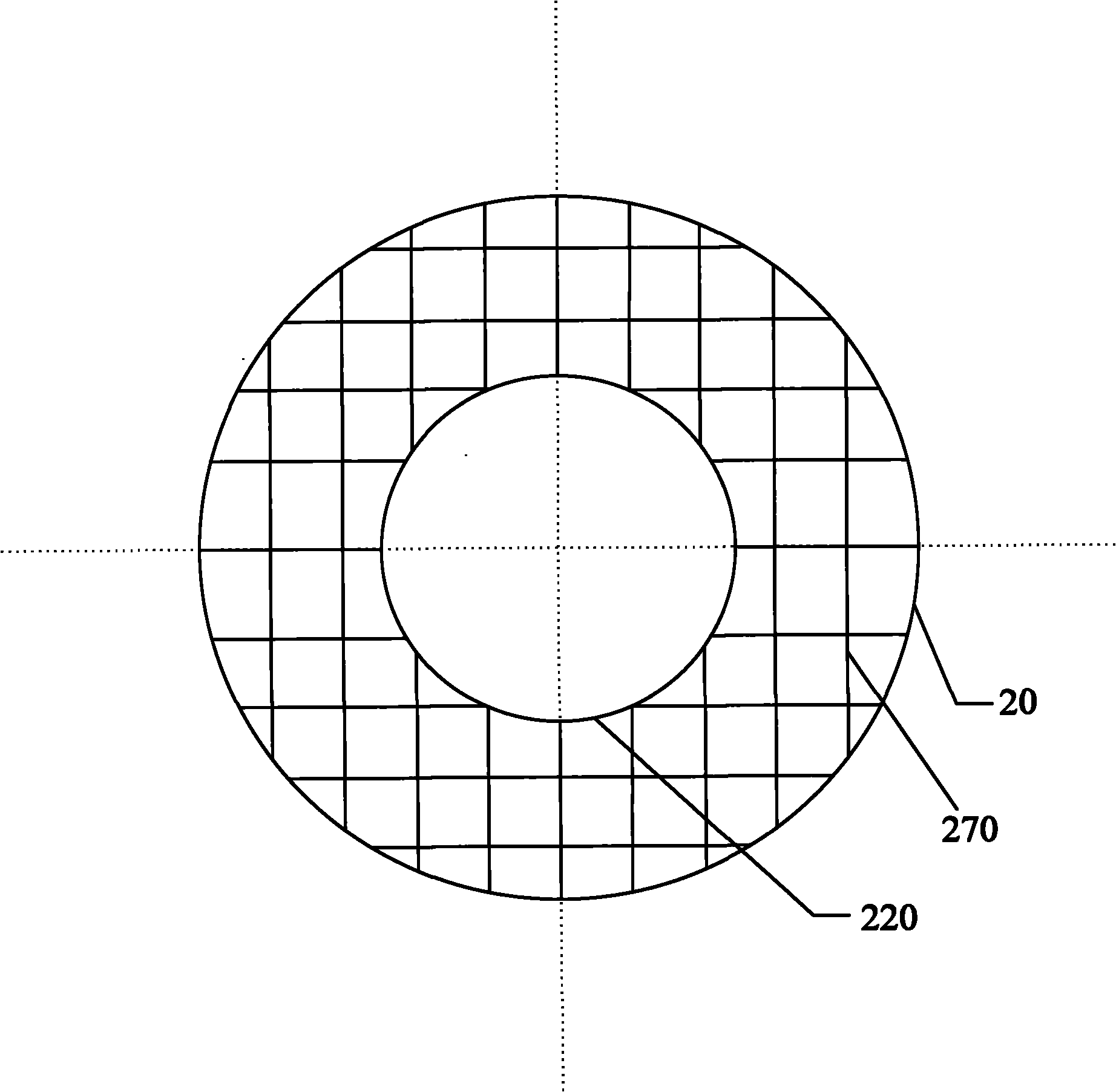

Process nozzle and system for gasifying water coal slurry and application thereof

ActiveCN102031152AEffective protectionImprove cooling effectLiquid spraying apparatusGranular/pulverulent flues gasificationCoal slurryWater jacket

The invention provides a process nozzle and a system for gasifying water coal slurry. The process nozzle comprises a first oxygen channel, a water coal slurry channel, a second oxygen channel, a first cooling water jacket and a cooling water coil, wherein the first oxygen channel comprises a first oxygen channel inlet and a first oxygen channel outlet; the water coal slurry channel comprises at least one water coal slurry channel inlet and a water coal slurry channel outlet; the second oxygen channel comprises a second oxygen channel inlet and a second oxygen channel outlet; the first cooling water jacket comprises a first cooling water jacket inlet and a first cooling water jacket outlet; and the cooling water coil comprises a cooling water coil inlet and a cooling water coil outlet. The process nozzle is characterized in that: the first oxygen channel is positioned at the central position of the process nozzle; the water coal slurry channel is positioned between the first oxygen channel and the second oxygen channel and surrounds the periphery of the first oxygen channel; and the second oxygen channel surrounds the periphery of the water coal slurry channel. The process nozzle reduces the length of combustion flame more effectively, reduces the ablation of flame on a refractory brick, promotes the mixing and atomization of water coal slurry and oxygen and improves gasification efficiency.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

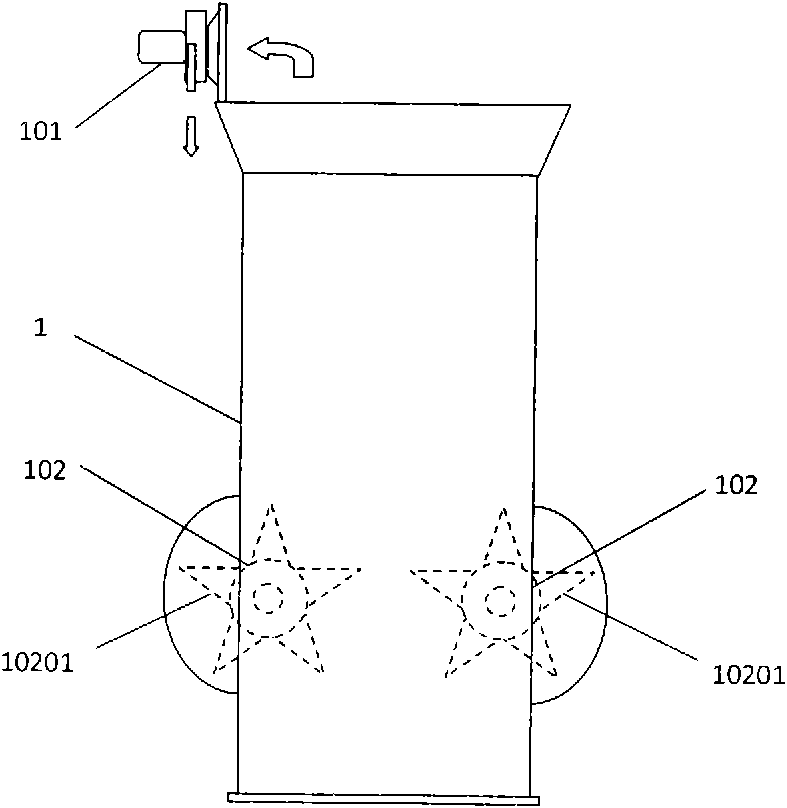

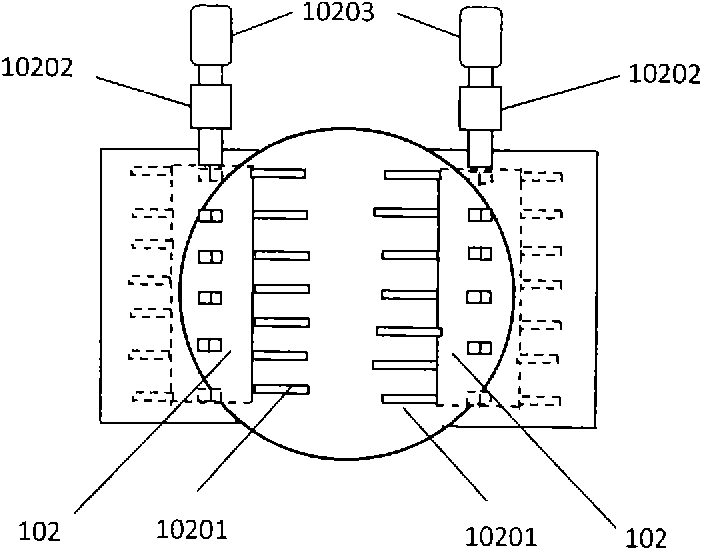

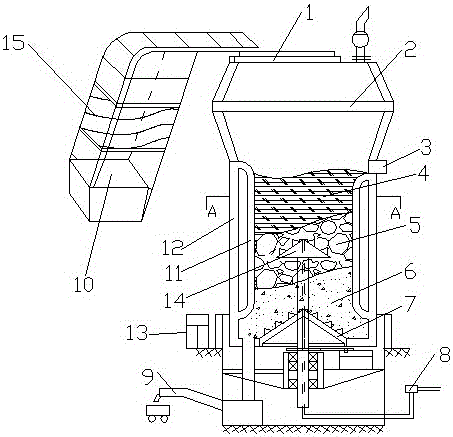

Internal-combustion heating type biomass gasification furnace

ActiveCN101021334AImprove biomass gasification rate and gas calorific valueImprove gasification efficiencyDomestic stoves or rangesLighting and heating apparatusNitrogen gasEngineering

The present invention relates to an internal combustion heated biomass gasification furnace. Its structure is characterized by that it adopts a cylindrical furnace body, in the furnace body interior a coiled internal combustion pipe is set, the internal combustion pipe inlet is positioned in the lower portion of said cylindrical furnace body, and its outlet is extended to the exterior of furnace body from the top portion of cylindrical furnace body, its igniter is positioned in the internal combustion pipe inlet; over the cylindrical furnace body a helical feeding mechanism is set, its helical feeding hole is positioned on the eccentric position of cylindrical furnace body top portion, on the centre axis position of said cylindrical furnace body a stirring shaft with stirring blades is set, on the inside wall of cylindrical furnace body several layers of baffle plates are set, the combustion-supporting air inlet is set in the top portion of said cylindrical furnace body, and the gas outlet in the furnace body is positioned in the lower portion of said furnace body.

Owner:ANHUI WEIDA ENVIRONMENTAL PROTECTION TECH

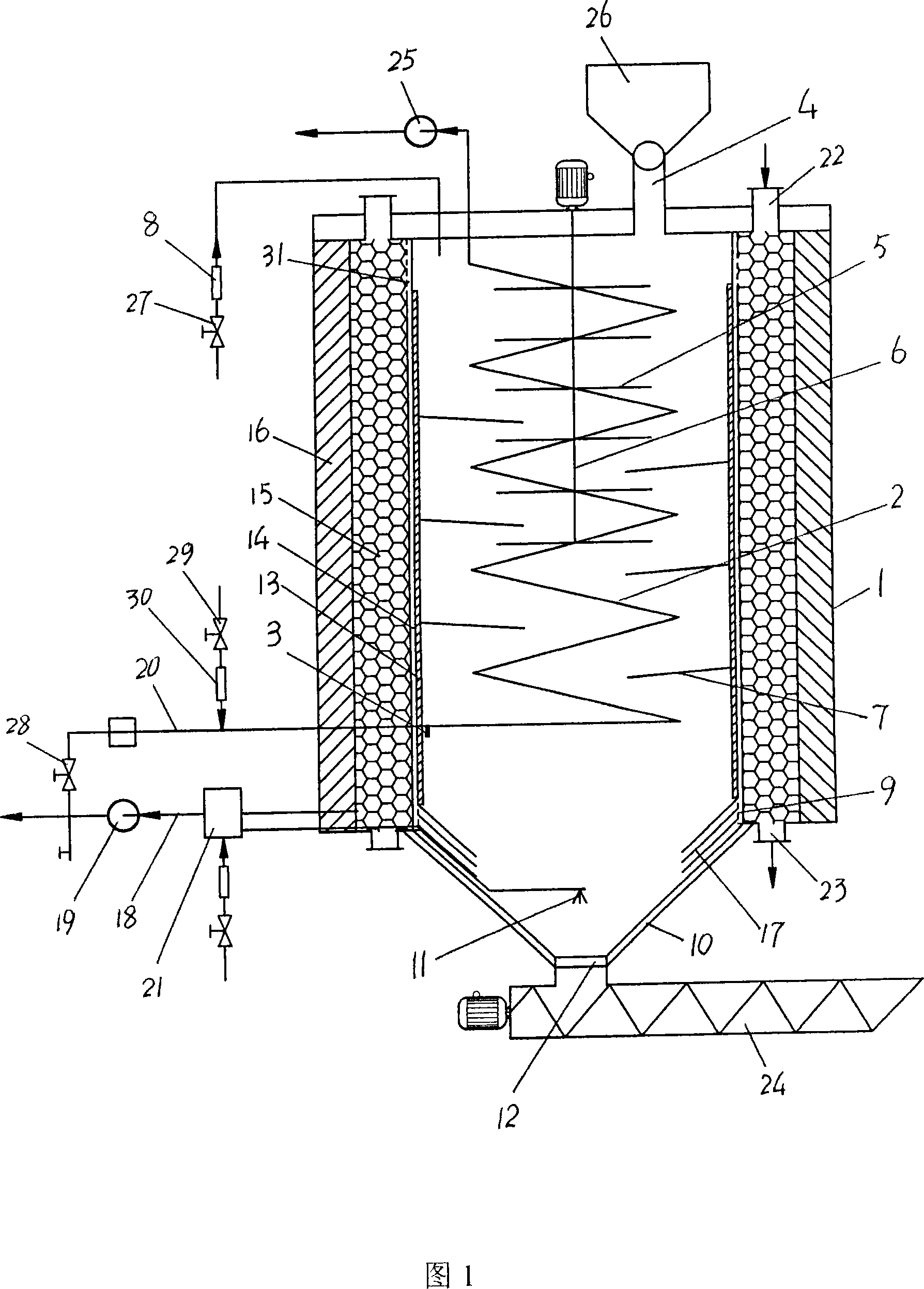

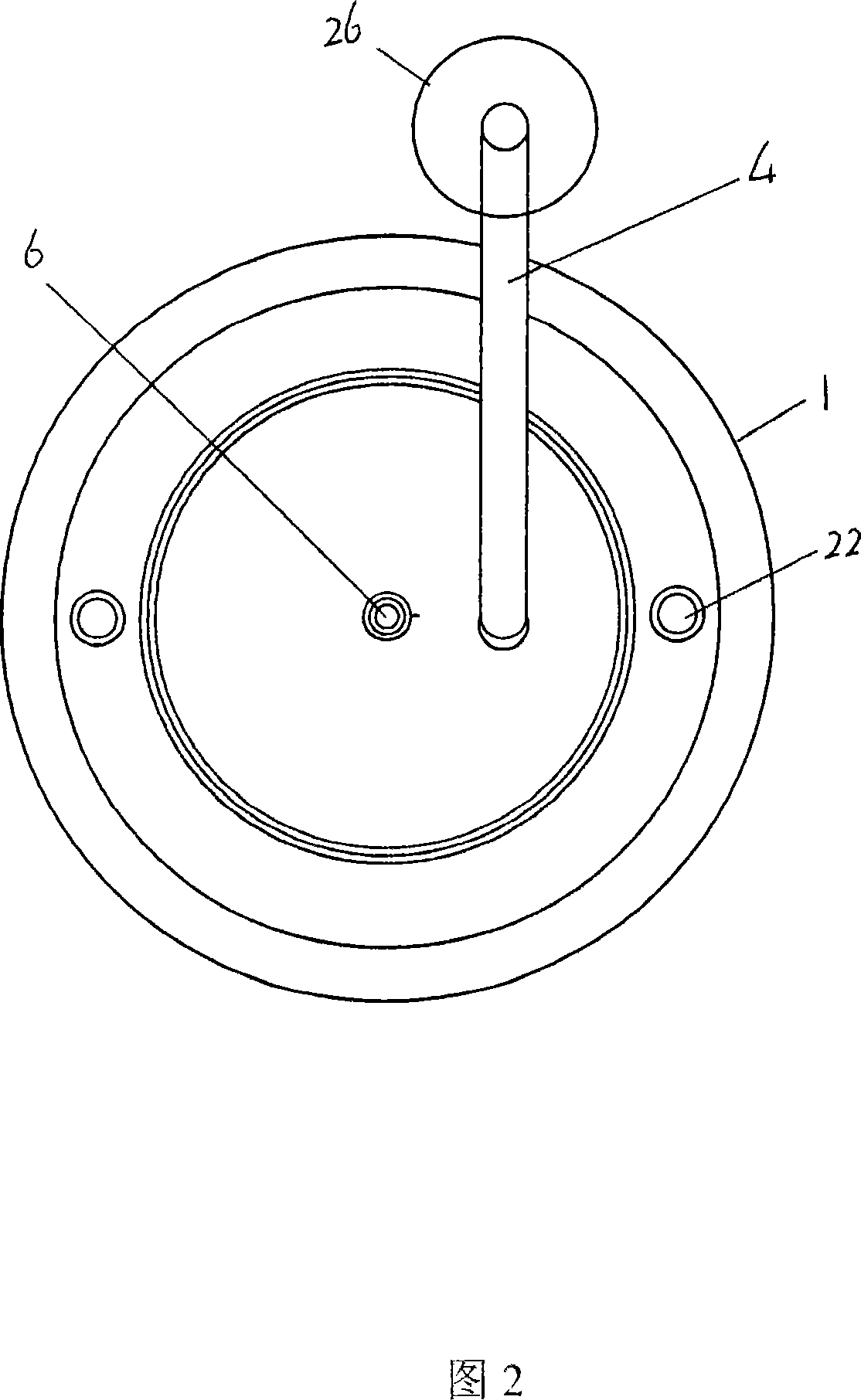

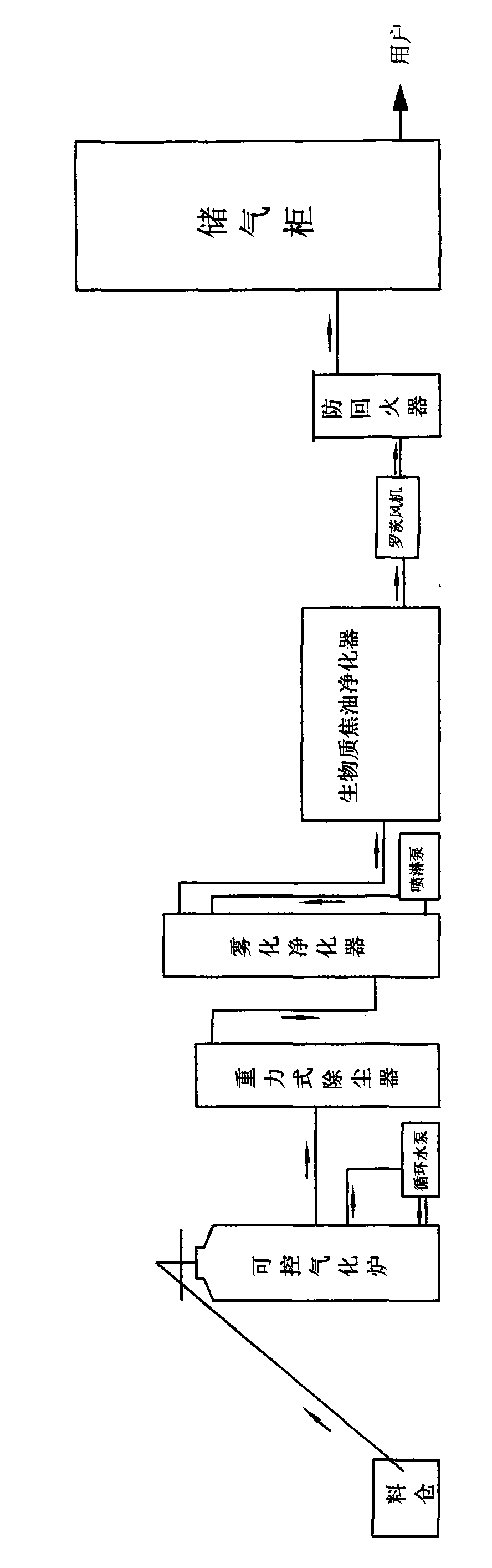

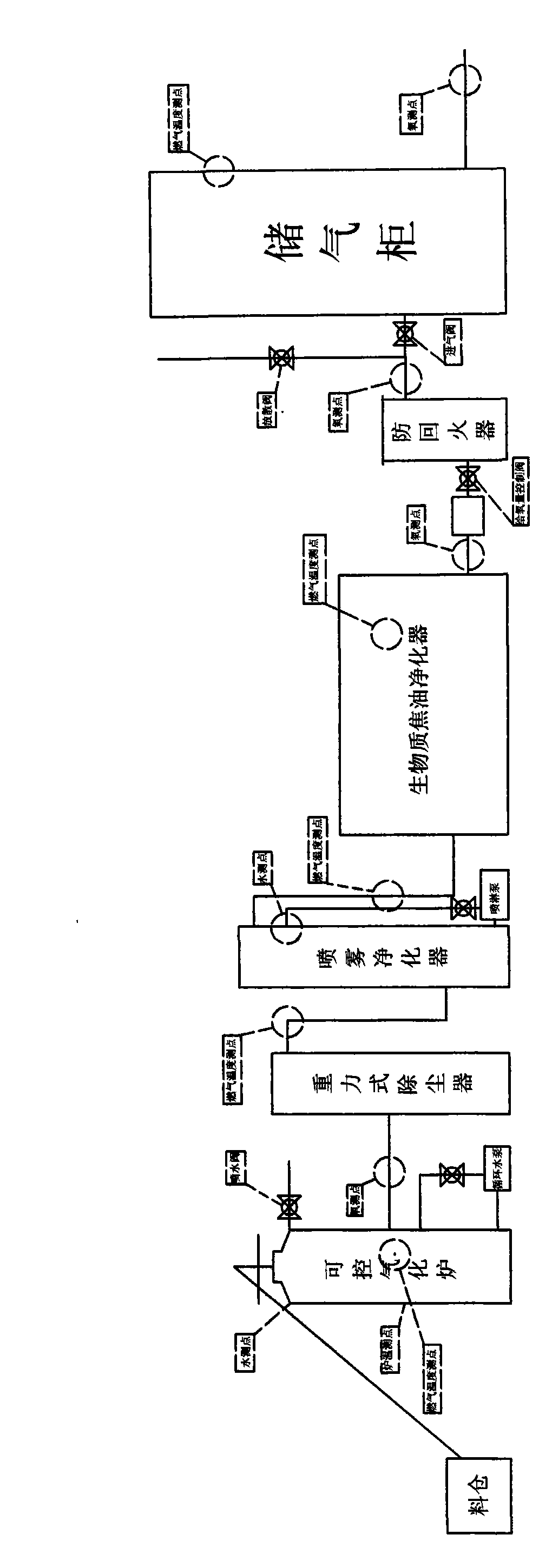

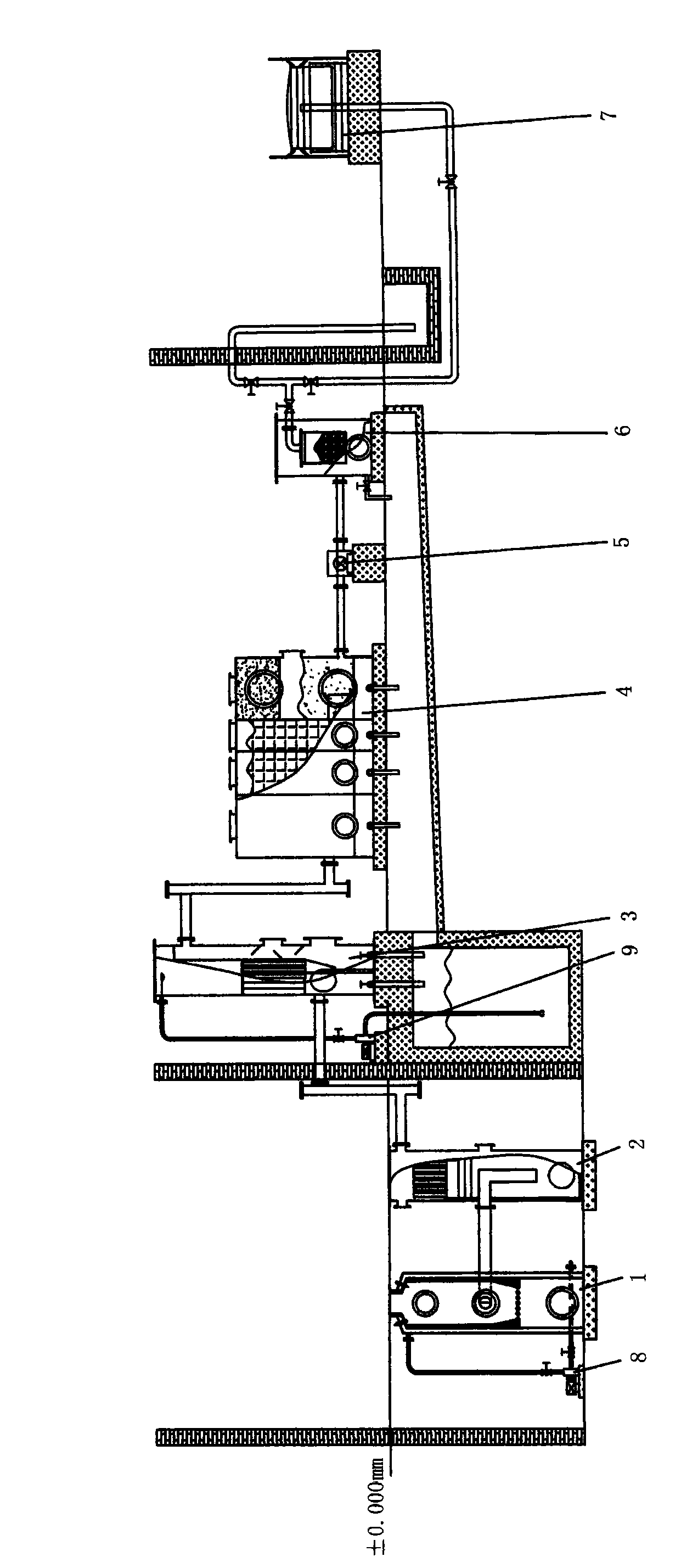

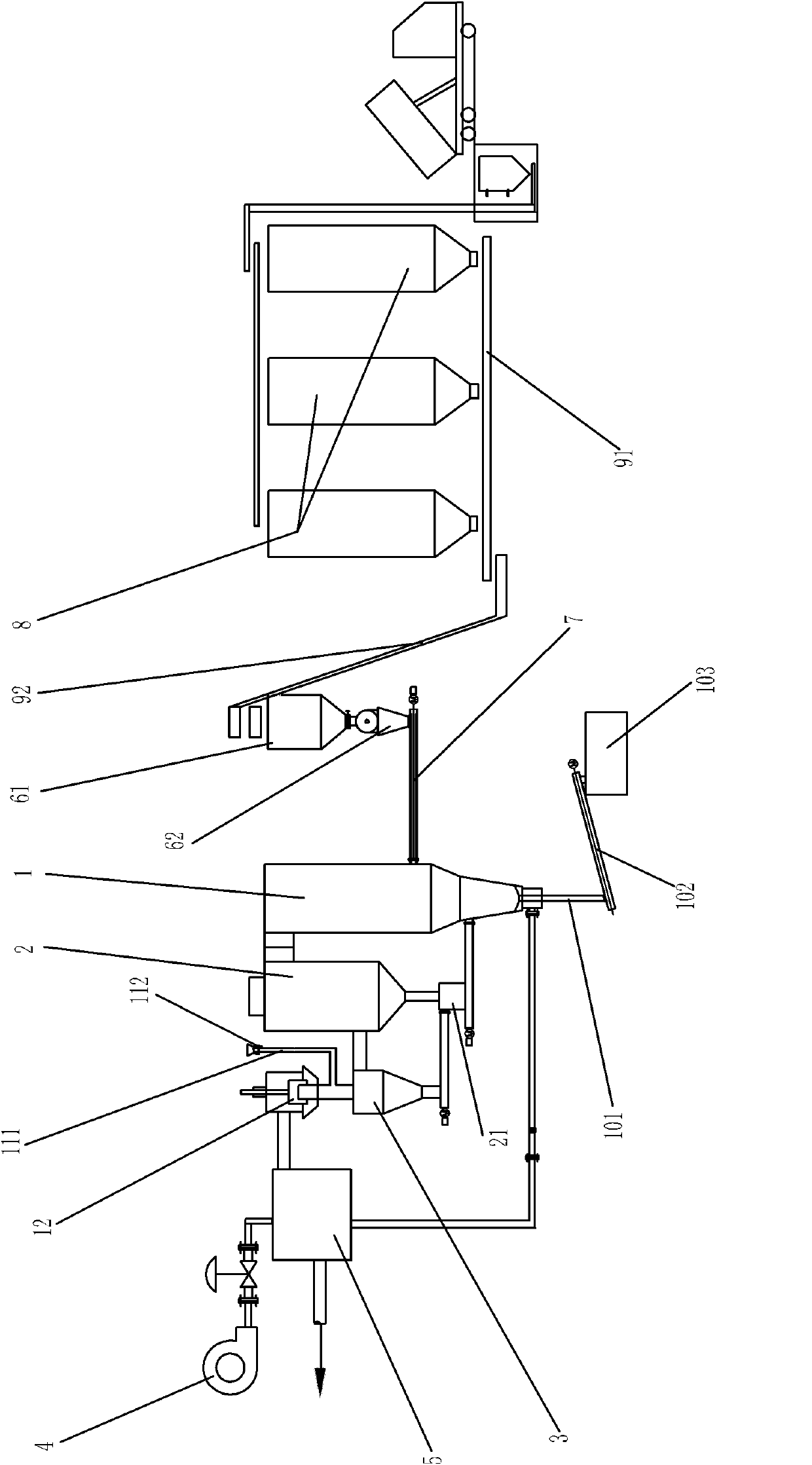

Method for preparing fuel gas by gasifying biomass materials and device thereof

InactiveCN101649226AReduce cloggingSolve the blockageCombined combustion mitigationCombustible gas productionTarProcess engineering

The invention relates to a method for preparing fuel gas by gasifying biomass materials and a device thereof, belonging to the technical fields of methods for preparing fuel gas by solid biomass materials in a gasifying process and the devices thereof. The method comprises the following steps: feeding, gasifying, dedusting, spraying and purifying, detarring, pumping front-end gases and conveying rear-end fuel gas by a Roots blower, and conveying the fuel gas to a fuel gas storage cabinet through a tempering preventing device. The device realizing the method comprises a feeding mechanism, a controllable gasifying furnace and a circulation water pump, a gravity deduster, a spraying purifier and a spraying pump, a biomass tar purifier, the Roots blower, the tempering preventing device and thefuel gas storage cabinet. The device is used for transforming the solid biomass materials of straws and the like into the fuel gas with less impurities and high heat value and supplying the fuel gasfor users centrally.

Owner:ZHENYU COMPLETE SET ELECTRIC EQUIP GROUP BEIJING

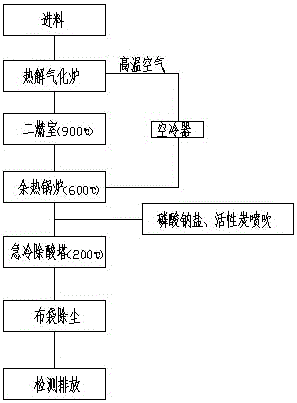

Two-stage plasma gasifying, melting and cracking method and device of waste containing organic matters

ActiveCN102000691ANo emissionsComplete gasificationSolid waste disposalGlass furnace apparatusGeneration rateHigh energy

The invention relates to a treatment method of waste containing organic matters, in particular to two-stage plasma gasifying, melting and cracking method and device of the waste containing organic matters, belonging to the field of gasifying, melting and cracking techniques. In the invention, the serious defects of high energy consumption of the waste containing organic matters and more flying ash during the plasma arc melting and cracking are solved, thereby thoroughly utilizing the energy of the organic matters and maximizing the treating efficiency, thoroughly cracking the tar, reducing the generation rate of Dioxin, obtaining synthesis gas with high quality and high heat value as much as possible, providing guarantee for the subsequent gasification power generation, the hydrogen energy recovery or the production of green liquid fuel, simultaneously finishing one-step recovery of noble metals and direct utilization of glass bodies in the field of building materials, laying foundation for the large-scale commercial development and application of the energy of the waste containing organic matters, and thoroughly solving the possible pollutant discharging problem in the gasifying process of the organic matters, particularly the dangerous waste.

Owner:HOOTECH

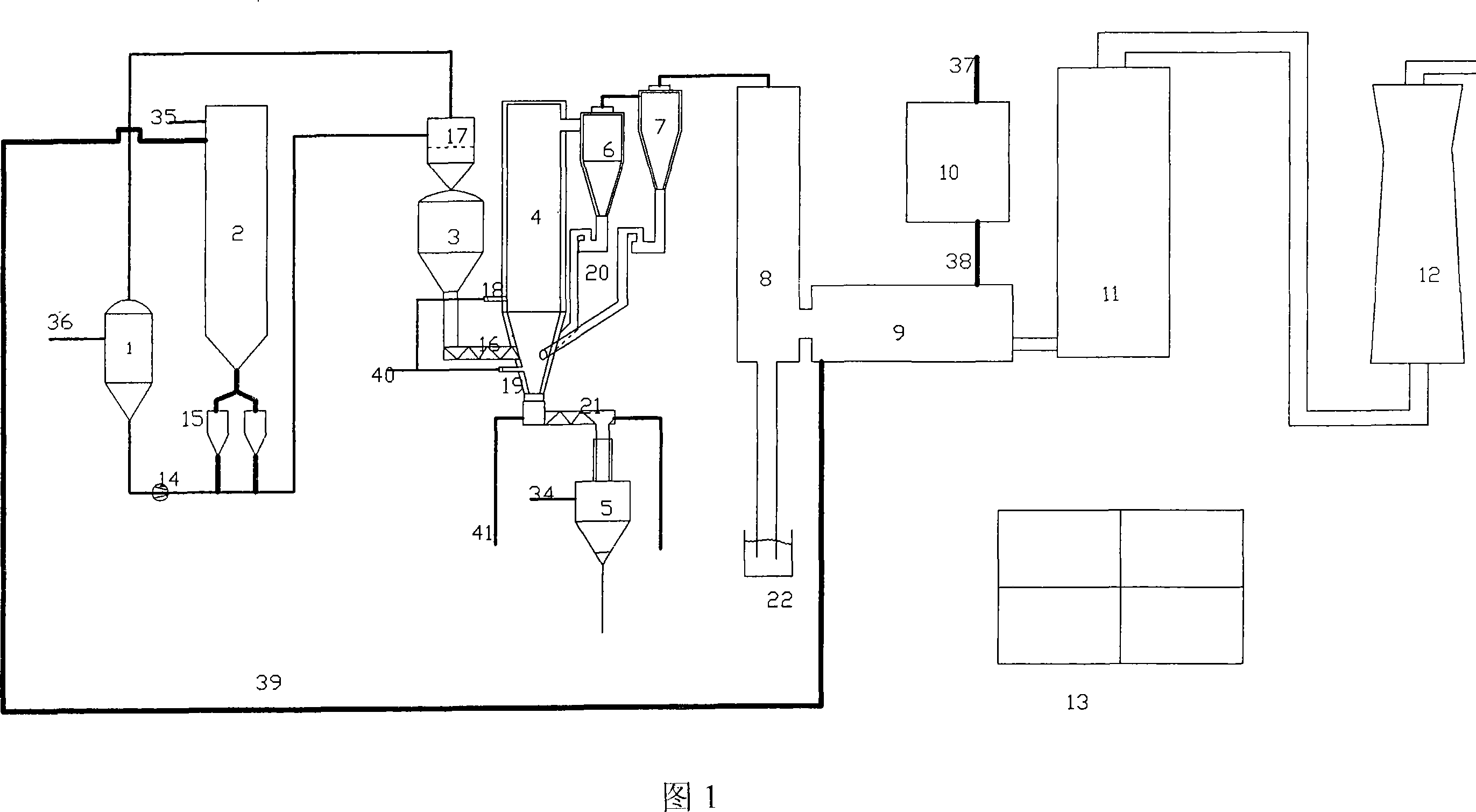

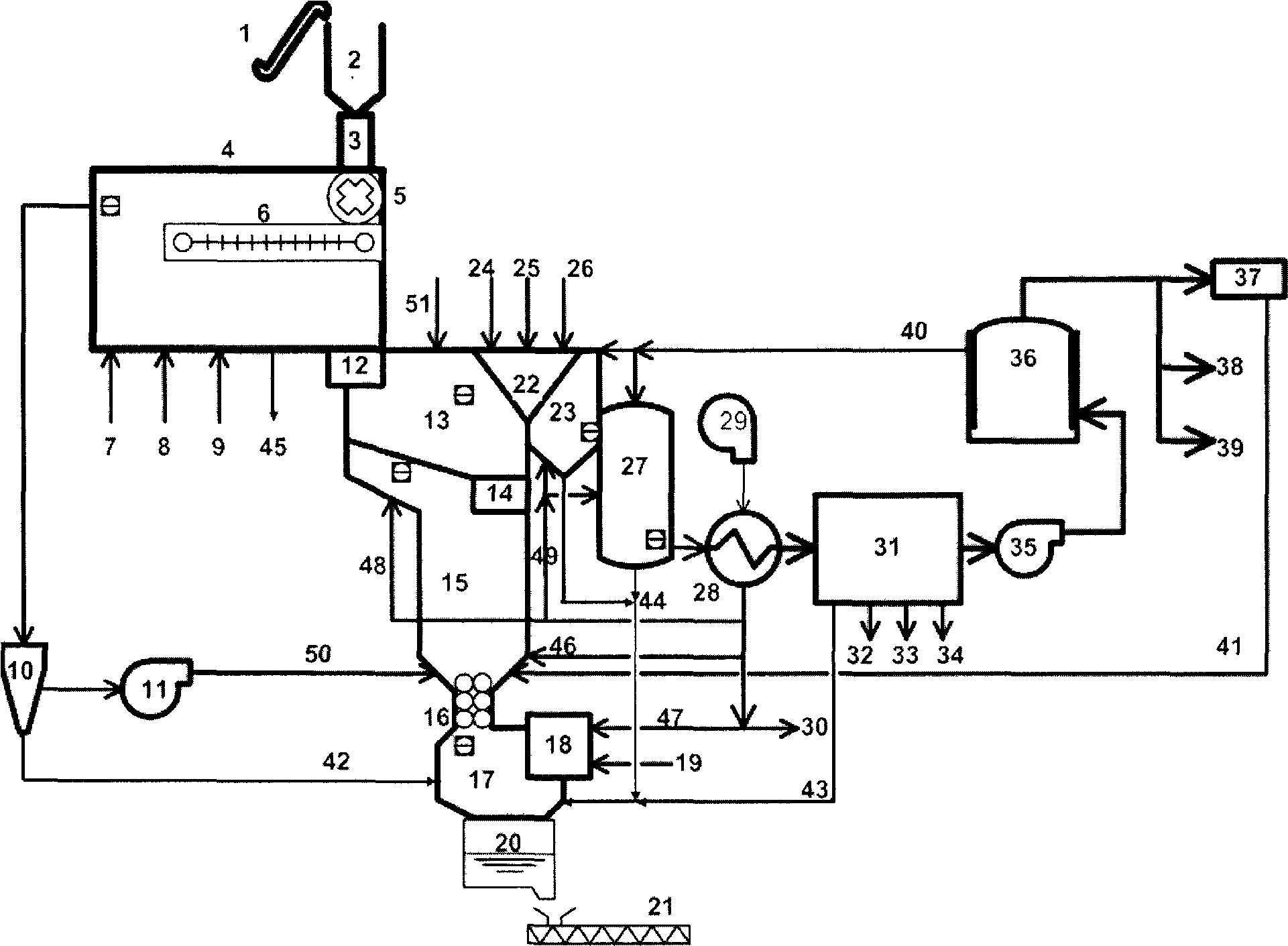

Apparatus for preparing synthesis gas based on dual fluidized bed biomass gasification and preparation method thereof

InactiveCN102977927AReduce outputHigh calorific valueBulk chemical productionGranular/pulverulent flues gasificationCycloneGas phase

The present invention discloses an apparatus for preparing synthesis gas based on dual fluidized bed biomass gasification, including a hopper, a dryer, a screw feeder, a pyrolysis fluidized bed, a reforming fluidized bed, a reforming cyclone separator, a calcination fluidized bed, a calcination cyclone separator, a first U-shaped refeeder, a second U-shaped refeeder and a third U-shaped refeeder. The method of the apparatus for preparing synthesis gas includes: feeding biomass into the hopper, feeding the dried biomass to the pyrolysis fluidized bed, pyrolyzing and gasifying, and feeding carbon residue into the calcination fluidized bed. In the calcination fluidized bed, the coke in solid residue is combusted with oxygen to decompose calcium carbonate. The products of gas phase and solid phase are separated by the calcination cyclone separator. The heat-carrying agent calcium oxide is fed into the reforming fluidized bed. The pyrolysis gas carries calcium oxide to increase to promote catalytic cracking of tar. The reformed gas is obtained by reforming the pyrolysis gas. The synthesis gas is obtained from a synthesis gas outlet. The apparatus for preparing synthesis gas can reduce the tar yield, and improve the synthesis gas heat value ?and gasification efficiency.

Owner:SOUTHEAST UNIV

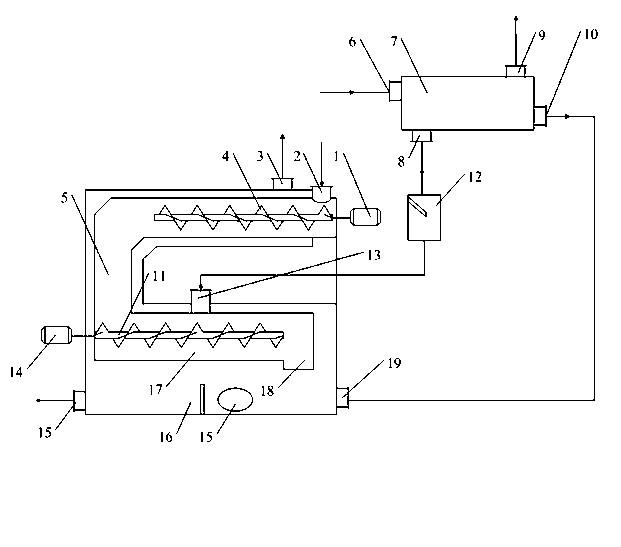

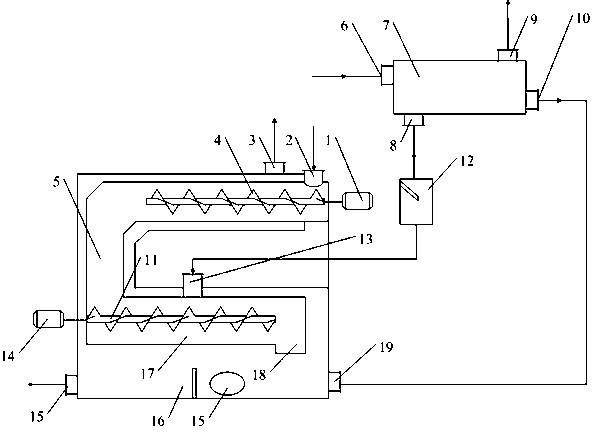

Multilevel-control polyradical biomass-gasification energy regeneration system

ActiveCN101519604AImprove gasification efficiencyHigh reforming efficiencyBiofuelsEnergy inputOxygenMoisture

The invention provides a multilevel-control free-polyradical biomass-gasification energy regeneration system, which can transform extensive biomass and carbon-containing raw materials, including energy crops, agriculture-forestry byproducts, organic waste, industrial and dangerous waste and the like, into high-grade energy. The system is designed for continuous operation. Gasification comprises the following steps of performing pretreatment, performing pyrolysis, transforming carbon, fusing ash, cracking tar, reforming syngas and utilizing waste heat, wherein the steps are precisely controlled one by one and integrated so as to achieve optimum; moisture from the pretreatment of the materials is led into a carbon-transforming unit so as to realize oxygen-free pyrolysis; gasification gas is in contact with a large number of free polyradicals in a free-polyradical reaction-accelerating unit; and the obtained product is purified and then enters downstream application, such as power generation, hydrogen production and biomass methanol / ethanol production. The system has the advantages of needing no auxiliary fuel, maximizing gasification efficiency and thoroughly cracking tar and clearing pollutants, and is an upstream technique for the application of biomass renewable energy. As energy utilization meets all strict environmental protection standards, the system is also an energy-saving environment-friendly technique for non-incineration harmless treatment.

Owner:浙江瑞拓展泰再生能源有限公司

Indirect gasification device and method for solid fuel

InactiveCN101235321AReduce qualityExtended stayGranular/pulverulent flues gasificationHeat carrierFluidized bed

The invention relates to an indirect gasification unit solid fuel and method for separating gasification and combustion processes of solid fuel, gasification products with high quality can be got through gasifying solid fuel by the method, a circulating fluidized bed and a spout-fluid bed are kept communicated through an external separator and a refeed line, bed materials in the circulating fluidized bed, the spout-fluid bed and the external separator are high-temperature inert heat carrier particles, solid fuel, gasification medium and high-temperature inert heat carrier particle are mixed in the spout-fluid bed, solid fuel is pyrolized and gasified, residual coke particles and inert heat carrier particle of gasification reaction flow into a circulating fluidized bed through the external separator and the refeed line, coke particles and air / oxygen are combusted in the circulating fluidized bed, inert heat carrier particle is heated up, high-temperature inert heat carrier particle which is heated up returns to the spout-fluid bed after separating by a whirlwind separator, which provides heating source for pyrolysis and gasification of solid fuel.

Owner:SOUTHEAST UNIV

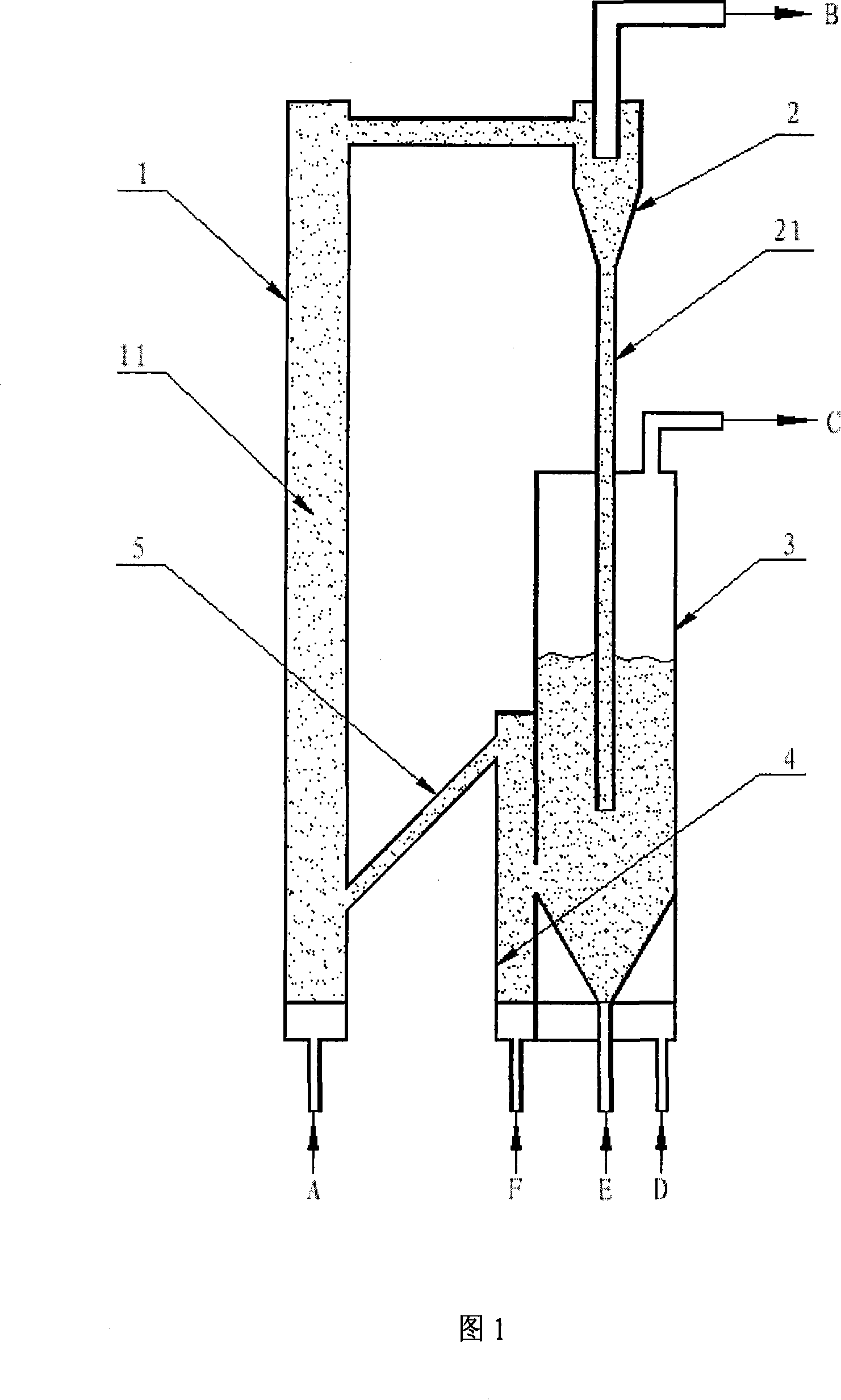

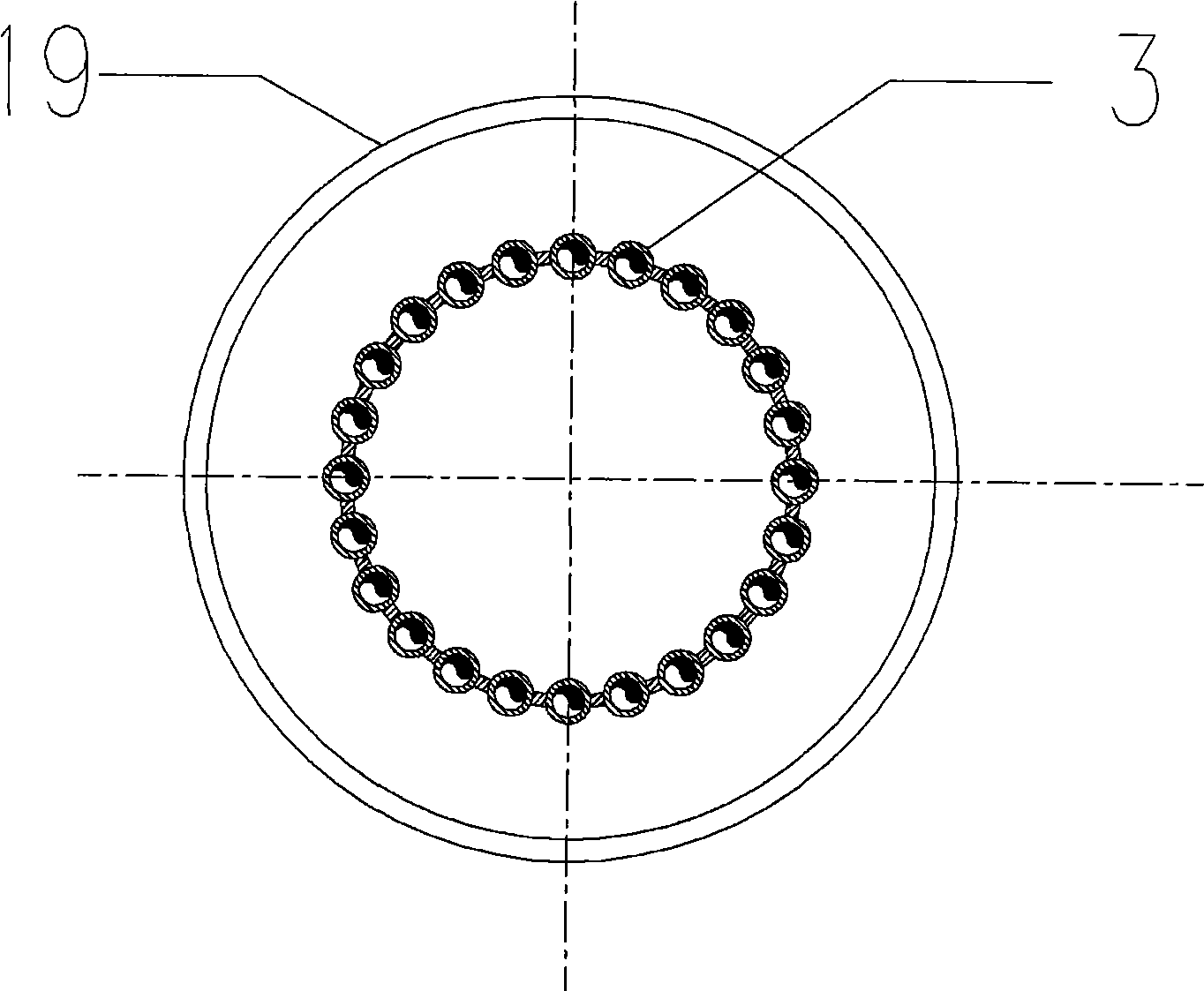

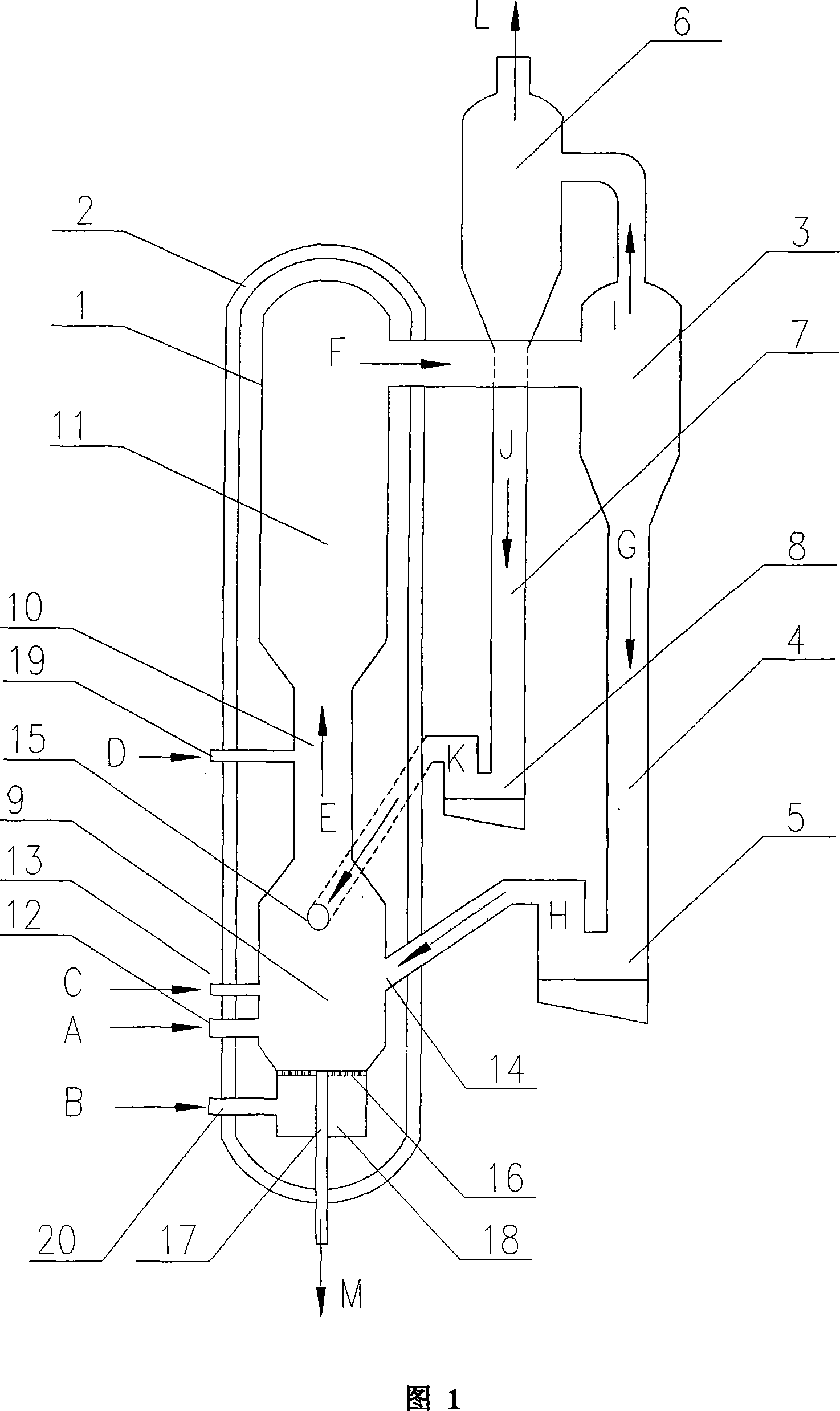

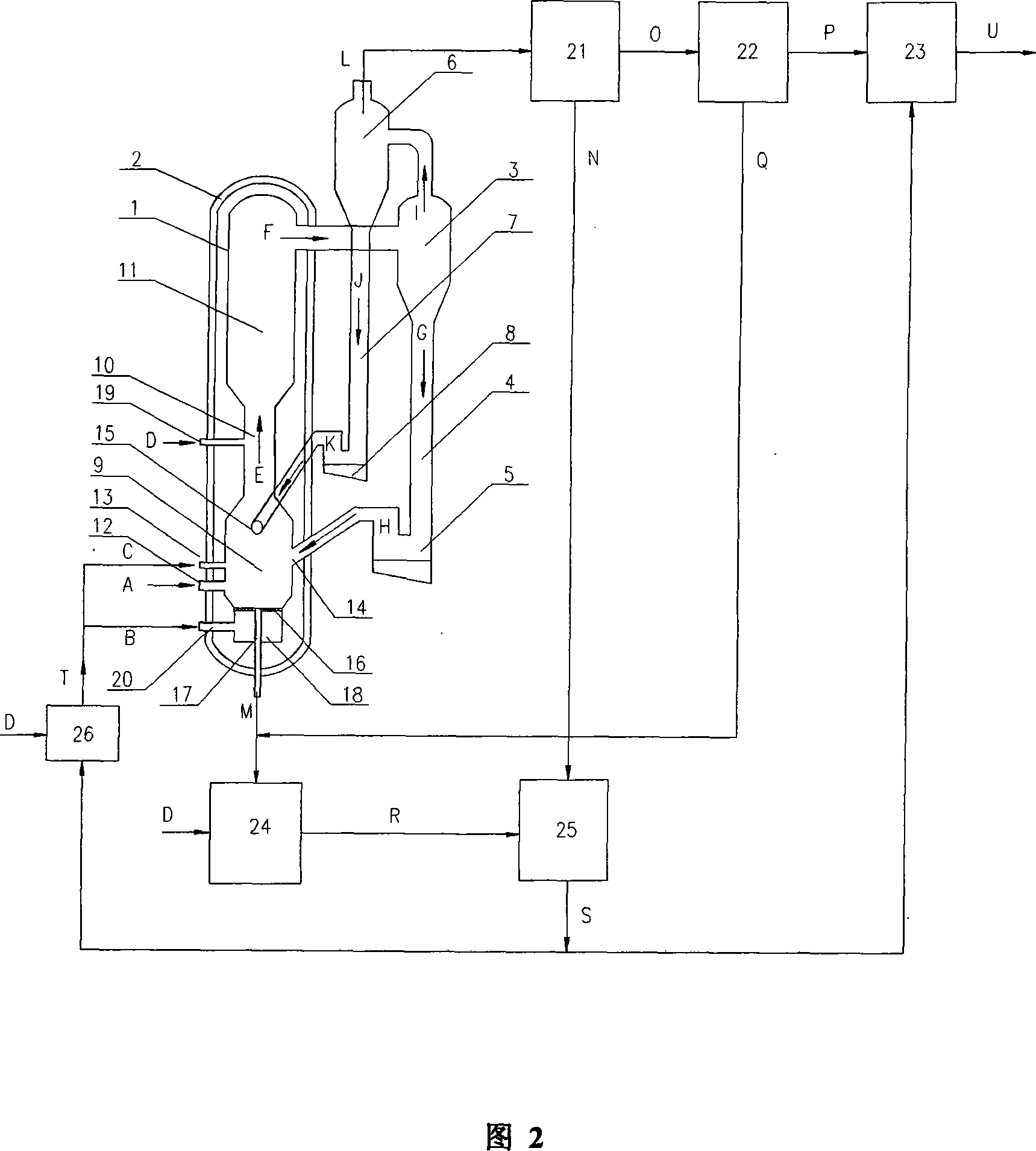

Gasifying device for liquid fuel or solid fuel aqueous slurry

ActiveCN101508915AImprove sensible heat utilization efficiencyEasy to processCombined combustion mitigationGranular/pulverulent flues gasificationCooling chamberSolid fuel

The invention relates to a gasifying device of liquid fuel or solid fuel water slurry. The gasifying device comprises a gasification furnace housing (19) that is a right cylinder, and the internal structure is divided into three segments that are respectively a gas cooling chamber (2), a vaporizing chamber (10) and a cinder collection chamber (15) from top to bottom; the three chambers are vertically and axially connected in the gasification furnace housing (19); the top of the gasification furnace housing (19) is provided with a gas outlet (1), and the bottom is provided with a cinder equipment interface (18). Compared with the prior art, the gasifying device has the advantages of simple structure, easy manufacture, low investment cost, etc.

Owner:WISON ENG +1

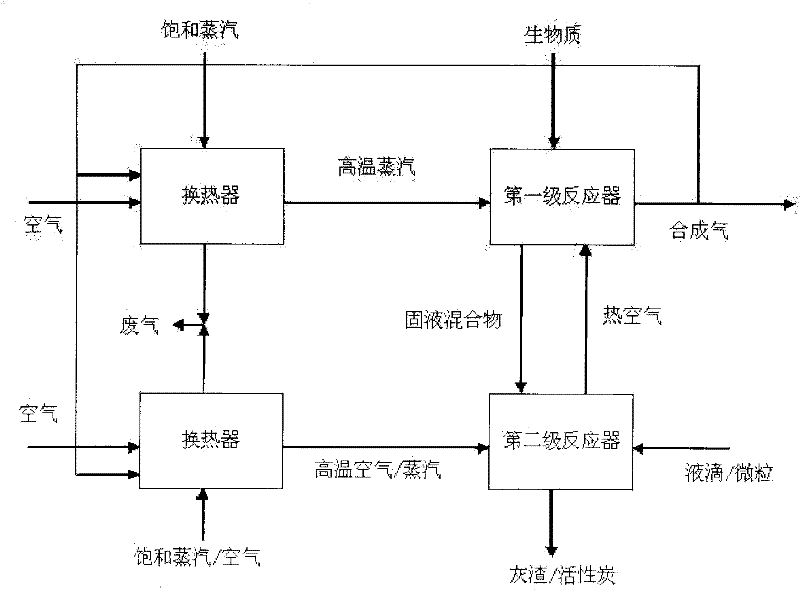

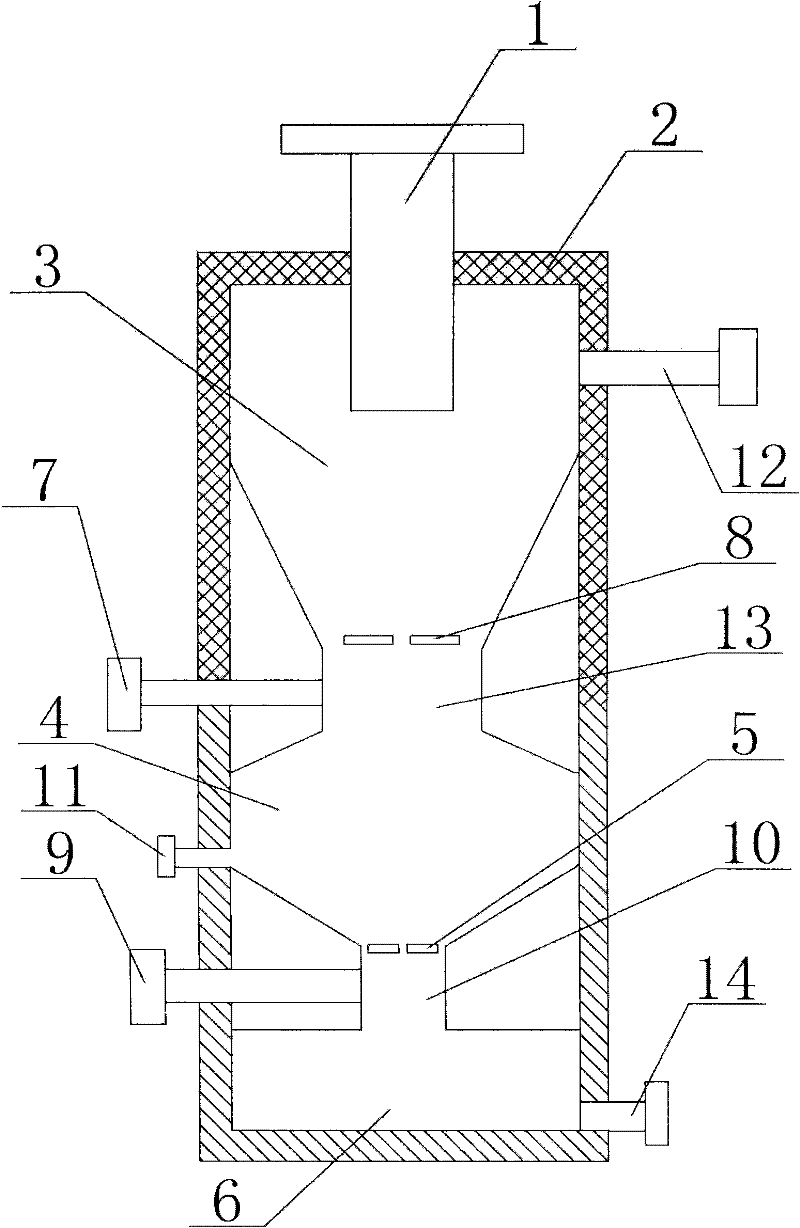

Two-stage high-temperature preheated steam biomass gasification furnace

The invention discloses a two-stage high-temperature preheated steam biomass gasification furnace. According to the invention, steam with a high temperature is used as a gasification agent. Fuel gas with high quality and high heat value is obtained through the gasification of the biomass. Meanwhile, active carbon, which is a byproduct, is produced. The gasification furnace is composed by a first reactor and a second reactor. The first reactor is a fixed bed gasification section, where volatile matters in feedings are removed. During the process, only high-temperature preheated pure steam provided by a high-temperature air generator is used. The second reactor is a spouted bed gasification section, where a high-temperature preheated mixture of air and steam is used for a complete cracking reaction and a tar breaking reaction. The biomass gasification furnace provided by the present invention has advantages of high gasification efficiency, high gasification speed, complete reaction, high utilance of raw materials, and is energy saving and environment protecting. The fuel gas produced by the gasification furnace has advantages of good quality and high heat value.

Owner:万贤法

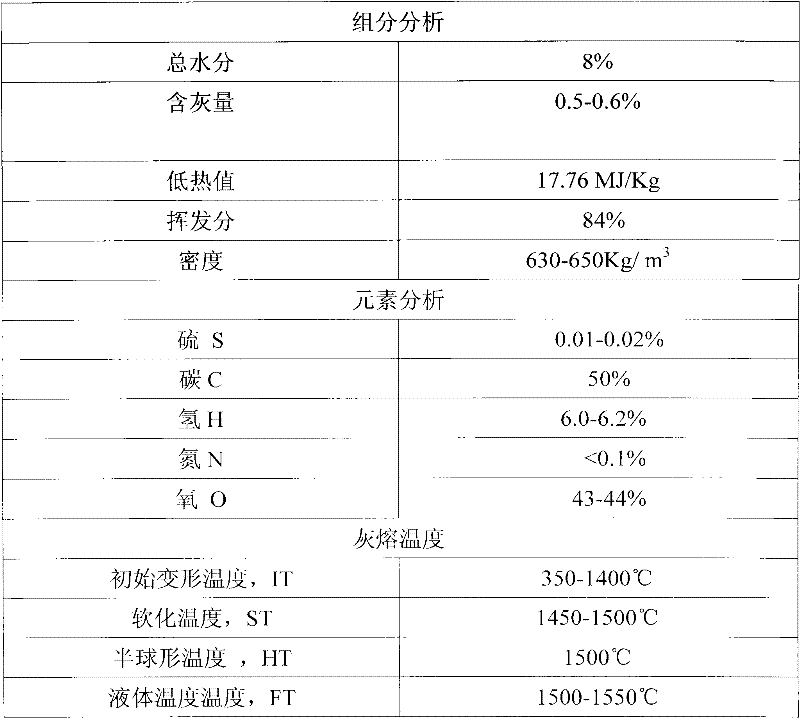

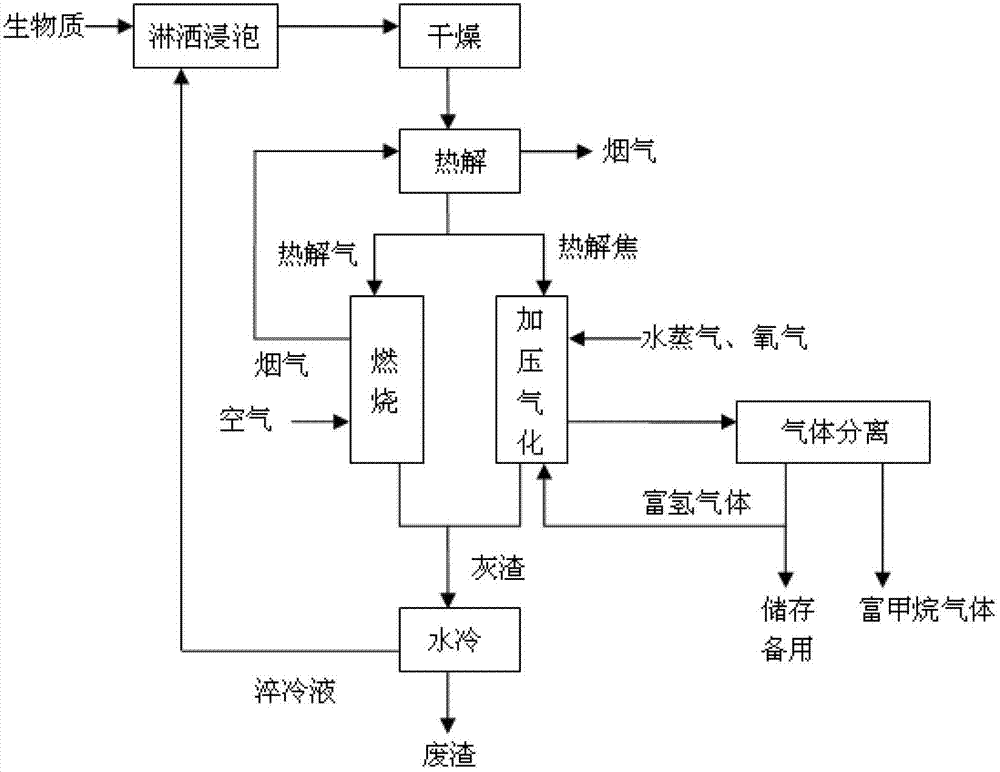

Method for preparing methane-rich gas through autocatalytic gasification of biomass

ActiveCN102786994AEasy to synthesizeImprove gasification efficiencyGaseous fuelsBiofuelsParticulatesAlkaline earth metal

The invention aims to provide a method for preparing methane-rich gas through cyclic utilization of alkali / alkaline earth metals contained in biomass for autocatalytic pyrolysis and autocatalytic pressurized gasification of the biomass. According to the method, water quenching is carried out on biomass ash so as to cyclically extract alkali / alkaline earth metals in the biomass ash, and the alkali / alkaline earth metals are sprinkled on and dipped in biomass; the biomass containing the alkali / alkaline earth metals undergoes autocatalytic pyrolysis at a low temperature of 280 to 320 DEG C at first, then a pyrolysis gas product enters into a combustion reactor and burns together with solid particles separated from a gasification reactor so as to supply heat for the process of pyrolysis, a pyrolysis solid product enters into the gasification reactor and undergoes autocatalytic pressurized gasification in a steam / oxygen atmosphere, hydrogen-rich gas is separated from crude synthetic gas produced in gasification and is returned to the pressurized gasification reactor, and the pyrolysis solid product is subjected to hydrogasification at the same time. With the method provide by the invention, biomass can be used for preparing methane-rich gas with low tar content, and high gasification efficiency is obtained. The method has the advantages of simple operation, less water consumption, strong technological adaptability and easy operation.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Coal gasification system and method of blast furnace slags

ActiveCN101597658AWide adaptabilityImprove gasification efficiencyEnergy inputRecycling and recovery technologiesSlagEnergy conservation

A coal gasification system and a method of blast furnace slags relate to the blast furnace slag utilization technology. The system comprises a slag gasifier, a coal injection system, a gas collecting device and a slag collecting device; wherein, the slag gasifier is provided with a slag inlet, a slag outlet, a gas outlet and a partition; the gas outlet is connected with the gas collecting device; a damper is arranged at the slag outlet which is connected with the slag collecting device. The method comprises the following steps: the blast furnace slags are placed into the slag gasifier from the slag inlet through a slag runner; pulverized coal and gasifying agents are injected into the slag gasifier by a spray gun, and the outflow velocity of the slags out of the slag outlet is controlled by regulating the height of the damper. The method of the invention has enormous environmental benefits and is of significance to realize the national goal of energy conservation and emission reduction.

Owner:NORTHEASTERN UNIV

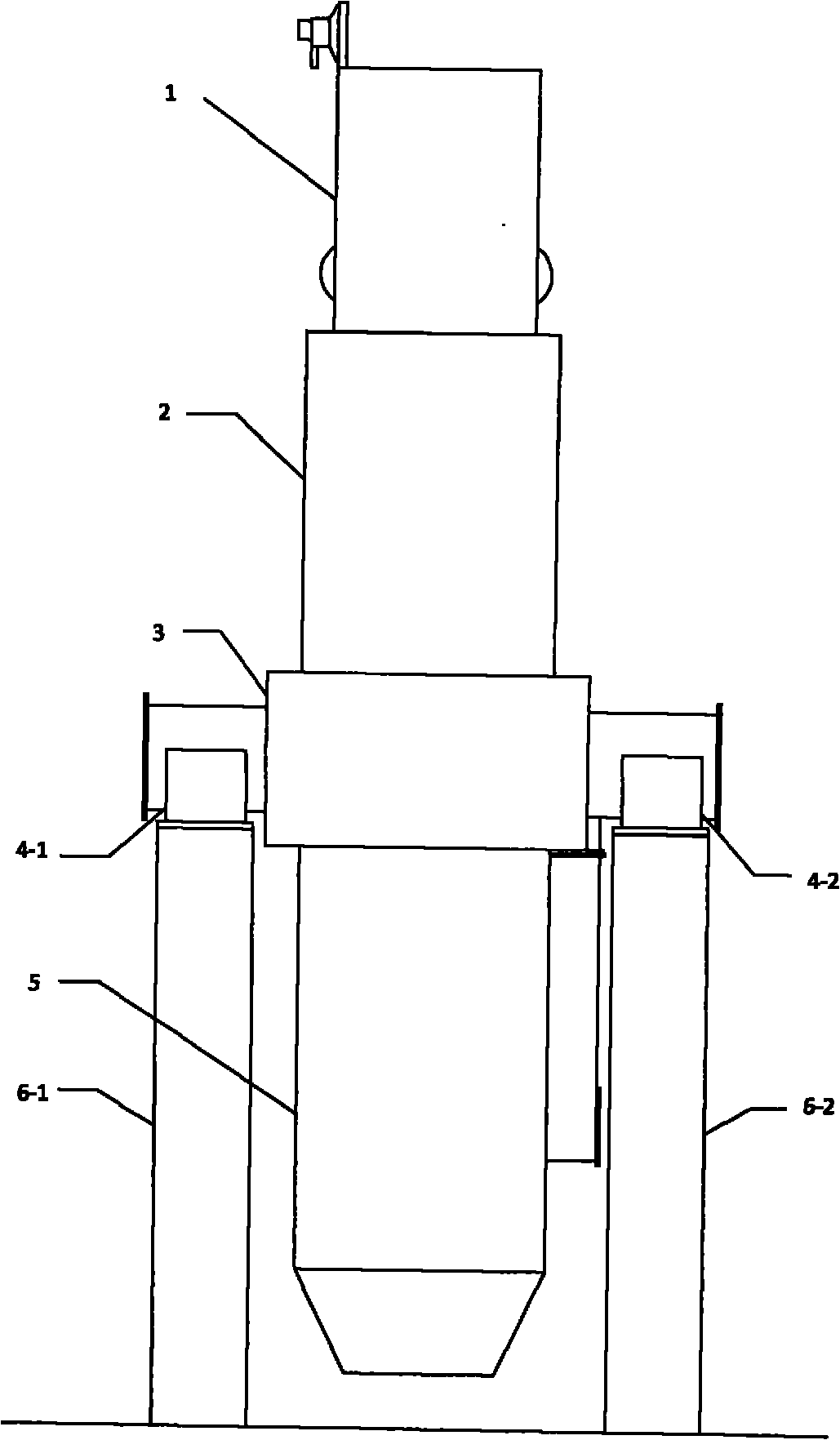

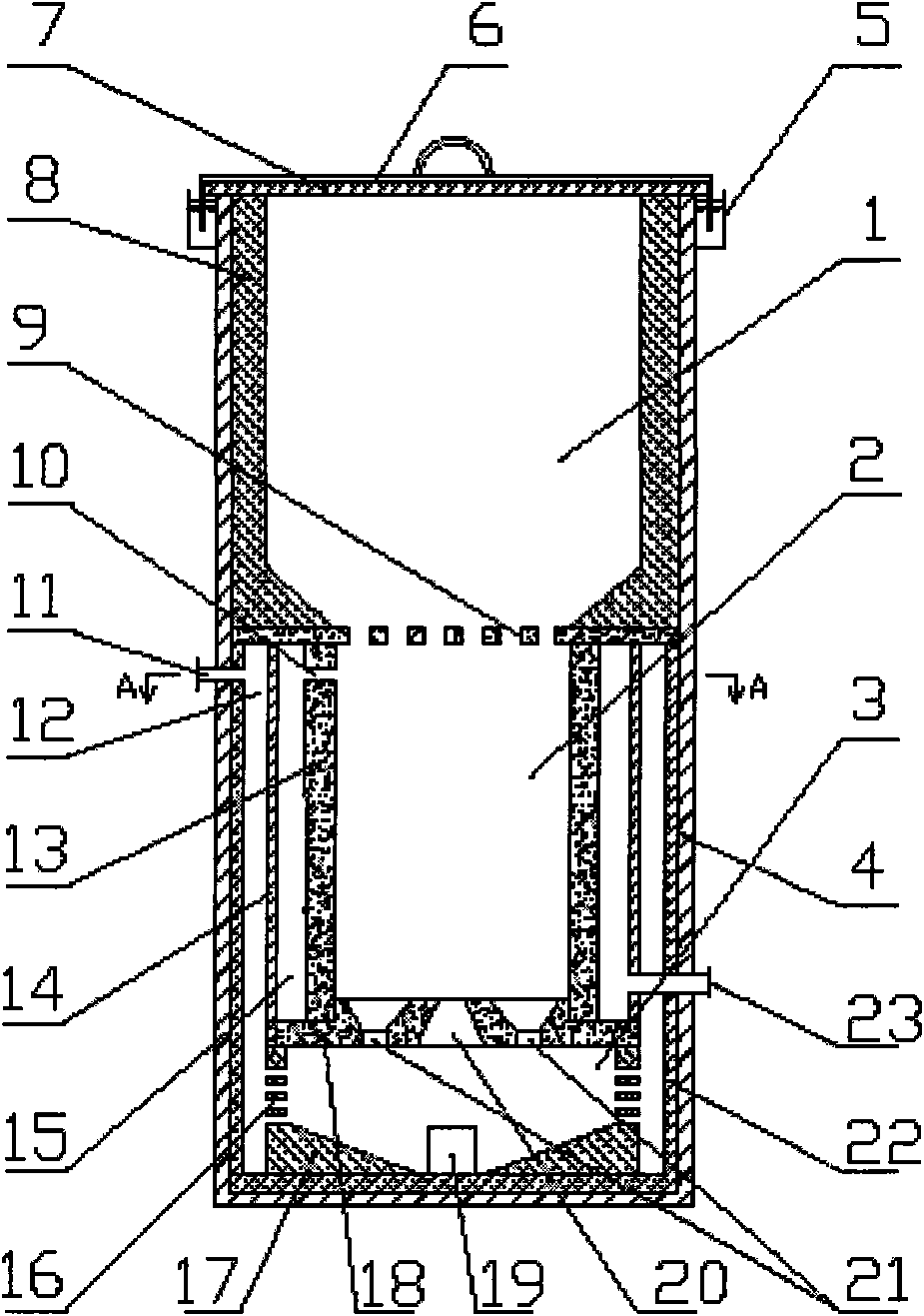

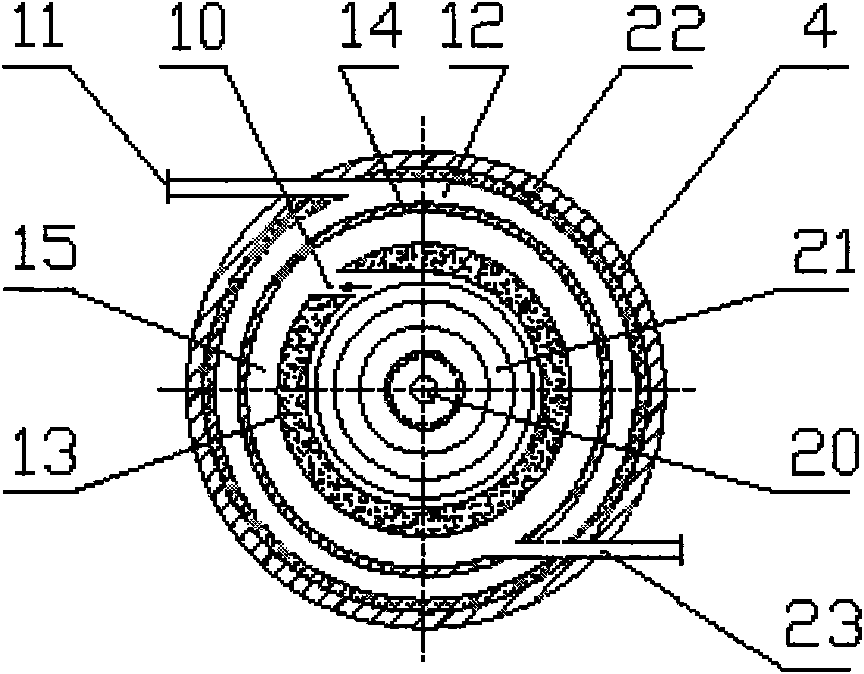

Vertical pyrolysis gasifier

ActiveCN105674284AIncrease profitImprove gasification efficiencyIndirect carbon-dioxide mitigationIncinerator apparatusSlagEngineering

A vertical pyrolysis gasifier comprises a feeding mechanism, a flow guiding tube of a slag extractor, a sealing mechanism, a working region and a stirring mechanism, wherein the flow guiding tube communicates with a water jacket to form backflow; the sealing mechanism comprises a first sealing door and a second sealing door; the second sealing door is arranged at a V-shaped projection of the upper end of a gasifier body; the first sealing door and the second sealing door cannot be opened simultaneously; the working region comprises a drying region, a pyrolysis gasification region and a burning region; a smoke outlet is formed in the gasifier body and positioned in the upper end of the drying region; the stirring mechanism comprises a slag discharging plate and a stirring plate; the slag discharging plate and the stirring plate are arranged on the same rotating shaft; and a hollow structure which communicates with the outside is arranged in the rotating shaft. The vertical pyrolysis gasifier not only is good in sealing performance and high in work efficiency, but also improves a security environment of operators of a workshop, and avoids hidden danger of gasifier explosion caused by blockage of pyrolysis gas flow.

Owner:江苏联兴成套设备制造有限公司

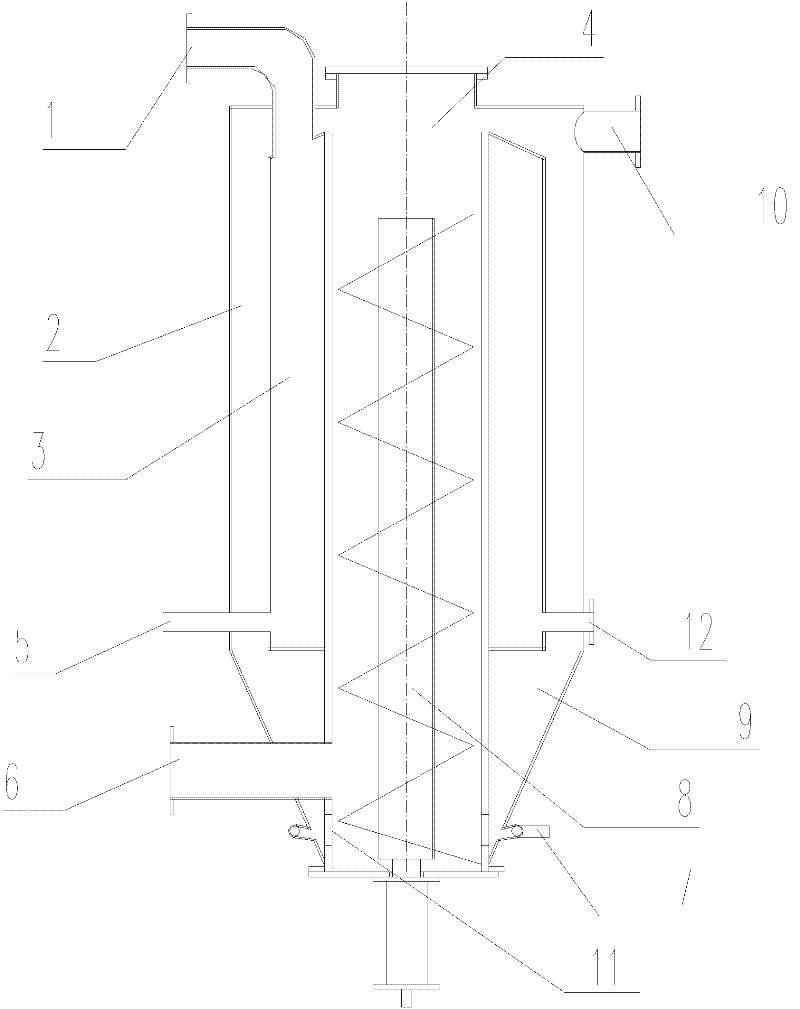

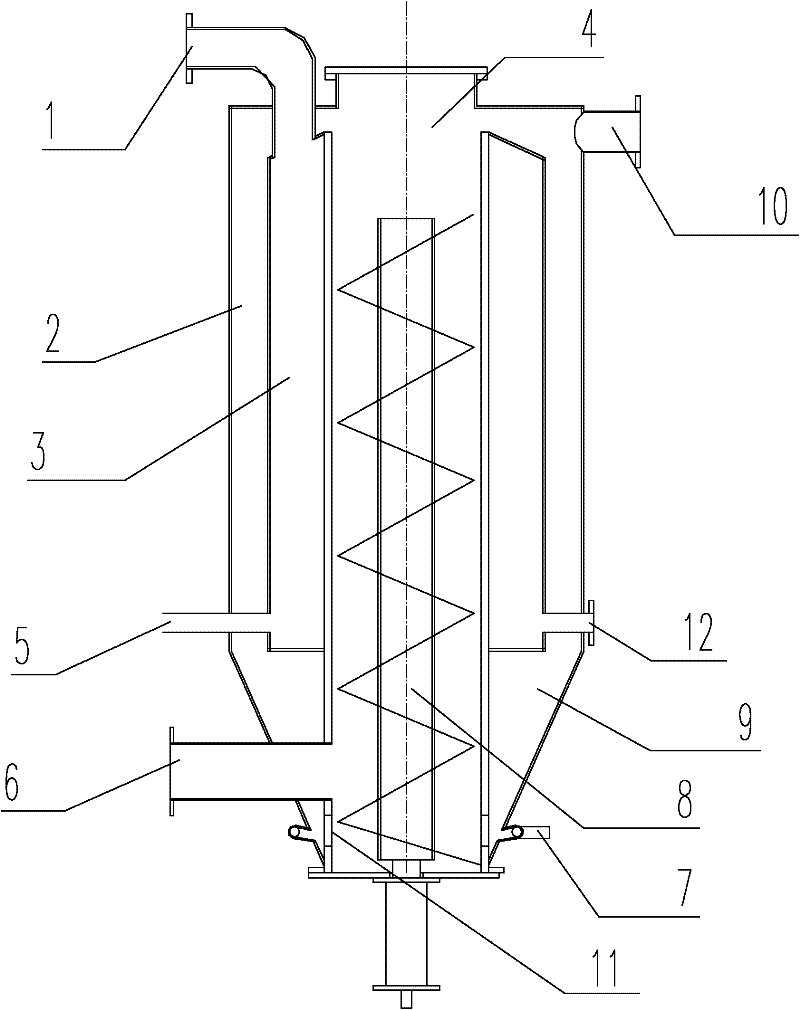

Internal circulation external heating type gasification device

ActiveCN102260536AReduce heat lossExtended stayGranular/pulverulent flues gasificationWater vaporResidual carbon

The invention discloses an internal circulation external heating type gasification device. The device comprises a central gasification chamber, an annular heating chamber, a peripheral gasification chamber, a residual carbon reflux chamber and the like. Biomass micron fuel enters the annular heating chamber and is efficiently burned, so that the required heat is provided for the central gasification chamber, the peripheral gasification chamber and the residual carbon reflux chamber. Cracking and gasification raw materials absorb the heat in the down-up movement process of the central gasification chamber to be cracked and gasified, and an initial cracking product then enters the peripheral gasification chamber and is further gasified; and residual carbon refluxes through the residual carbon reflux chamber and enters the central gasification chamber to carry out a water gas reaction with water vapor, so that medium-calorific-value gas of which the content of CO and the content of H2 are equal and CO and H2 account for about 80 percent of the total amount is obtained. In the device, an internal circulation external heating mode is used for gasification; and the device has the advantages of high heat utilization rate, heat transfer efficiency and gasification efficiency and the like, and the calorific value of gas is high. The internal circulation external heating type gasification device can be widely applied to the preparation of the gas by cracking and gasifying municipal organic refuse, agricultural and forest residues and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Compound coal gasification system and method of blast furnace slags

ActiveCN101597657AWide adaptabilityImprove gasification efficiencyRecycling and recovery technologiesCombined combustion mitigationSlagEnergy conservation

A compound coal gasification system and a method of blast furnace slags relate to the blast furnace slag utilization technology. The system comprises a slag gasifier, a heat exchanger, a gas deduster, a gas storage tank, a coal feeding device, a spray gun, a secondary coal feeding device and a particle gasifier. The method comprises the following steps: the blast furnace slags are placed into the slag gasifier from a slag inlet through a slag runner; pulverized coal and gasifying agents are injected into the slag gasifier, the generated gas enters the heat exchanger, undergoes cooling and dedusting and then enters the gas storage tank; when flowing out of the slag outlet, the slags are mixed with the pulverized coal in a pipeline and react with the gasifying agents to generate gas which enters the heat exchanger, undergoes cooling and dedusting and then enters the gas storage tank. The method of the invention has enormous environmental benefits and is of significance to realize the national goal of energy conservation and emission reduction.

Owner:NORTHEASTERN UNIV

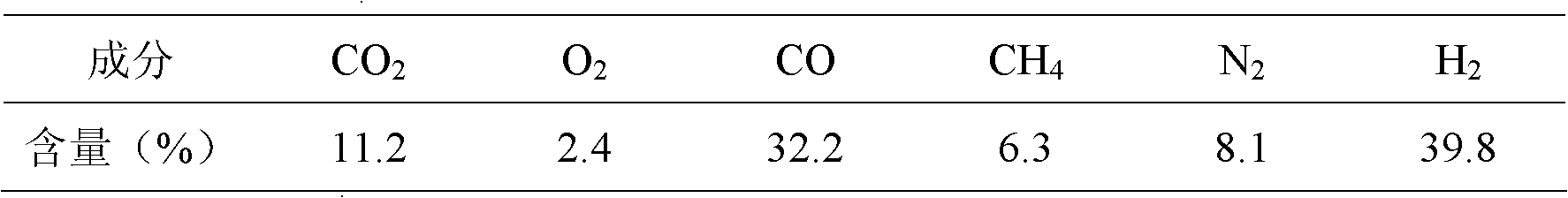

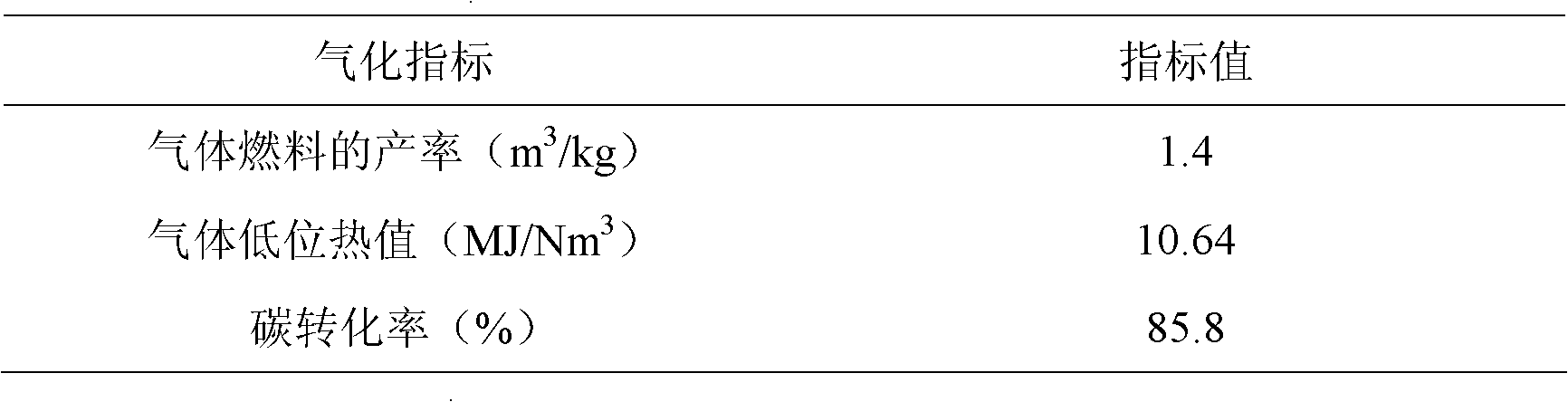

Method for self-heating pyrolysis gasification of biomass by gas backflow combustion

InactiveCN102643676AKeep warmImprove gasification efficiencyEnergy inputCombustible gas productionWater vaporSelf heating

A method for self-heating pyrolysis gasification of biomass by gas backflow combustion includes using air and steam as gasifying agent for pyrolysis gasification of the biomass in a pyrolysis gasifier, making the steam generated by a vaporizer into super-heated steam to compensate heat for the interior of the gasifier by waste heat of produced gas, allowing part of the produced gas to flow back into the gasifier to be combusted for supplying heat for gasification, removing tar by high-temperature pyrolysis, ensuring the whole gasifier to be under high temperature, and allowing gasification of biological pyrolytic carbon and cracking of the tar to tend to be through. By the method using the waste heat of combustible gas, part of the gas flows back to supply heat required by the biomass for pyrolysis gasification, interior high temperature of the gasifier is guaranteed, reaction is accelerated, and gasifying efficiency is improved. The produced combustible gas is low-tar gas with caloric value reaching 10MJ / Nm<3>, combustion is isolated from other reactions, and accordingly operation control is facilitated.

Owner:GUANGXI UNIV

Household up-draft biomass gasification device

InactiveCN101560411ASettlement requires ignition,Resolution timeCombined combustion mitigationGasification with fuel pre-distillationRadiation lossTar

The invention discloses a household up-draft biomass gasification device, which has an upright cylinder structure and is characterized in that the household up-draft biomass gasification device comprises a destructive distillation chamber arranged at the upper section thereof, a main gasification chamber arranged at the middle section thereof and an ash chamber arranged at the lower section thereof; all the sections are respectively separated by a heat storage grille and a heat storage grate; and the main gasification chamber is enclosed by a radiation cylinder on the periphery. The household up-draft biomass gasification device has no need of an external firing heat source, fast firing speed and high temperature of the gasification center, remarkably reduces tar content, reduces radiation loss of a furnace body, and has high gasification efficiency, long fire banking time of the gasification furnace, simple and compact structure, convenient operation and low operating cost.

Owner:安徽喜阳阳新能源科技有限公司

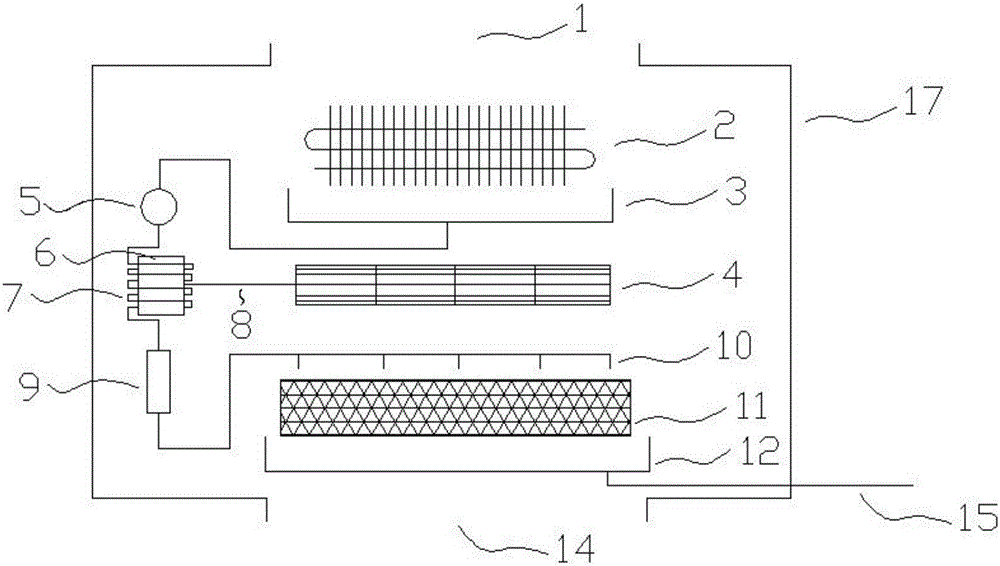

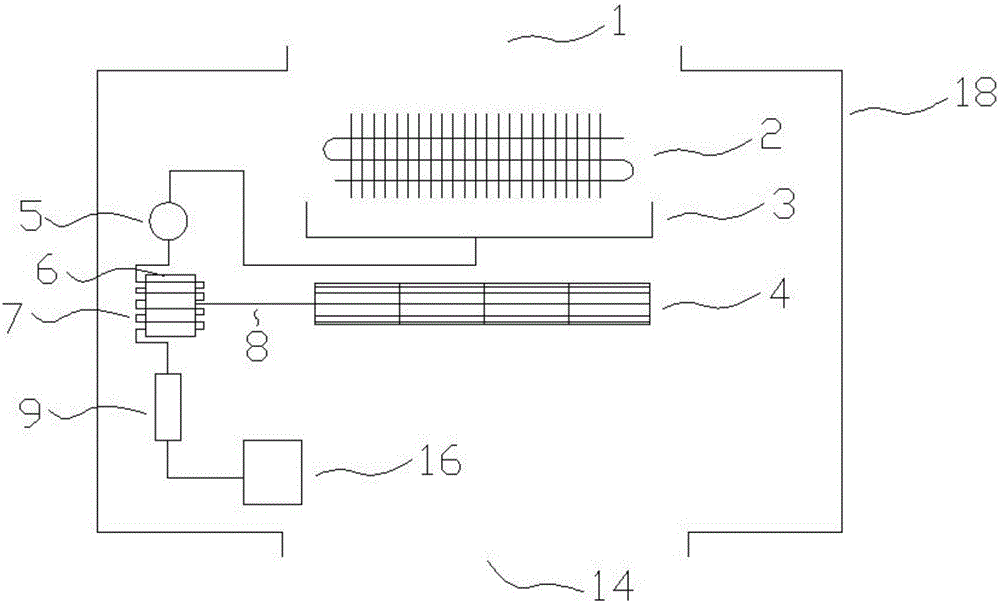

Air conditioner provided with condensate water preheating humidification device

InactiveCN106287967AImprove gasification efficiencyImprove cooling effectCondensate preventionLighting and heating apparatusEngineeringWater collection

The invention relates to an air conditioner provided with a condensate water preheating humidification device. The condensate water preheating humidification device comprises a water pump, a heat exchange device, a disinfection and sterilization device and a gasification and atomization device, wherein the upper stream of the water pump communicates with the bottom of a condensate water collection box through a water pipe; the lower stream of the water pump communicates with the heat exchange device through a water pipe; the heat exchange device surrounds a motor, so that heat generated by the motor is fully utilized to preheat condensate water; the lower stream of the heat exchange device is provided with the disinfection and sterilization device; and the condensate water passes through the disinfection and sterilization device and then enters the gasification and atomization device near an air outlet. The condensate water is preheated, so that subsequent condensate gasification efficiency is improved, and the humidification effect is enhanced; and besides, heat generated during work of the motor is fully utilized, and heat dissipation of the motor is improved, so that the working efficiency of the motor is improved.

Owner:李一鸣

Dense-phase conveying-bed coal pressurizing gasifying apparatus and method

ActiveCN101024782AExtended stayEfficient mixingCombined combustion mitigationGranular/pulverulent flues gasificationCycloneProcess engineering

The invention relates to a dense phase conveying bed coal preesurized gasification device and a gasification method. The gasification reactor includes pressure case, mixing section, lifting section, and conveying section. The mixing section adopts low flow speed, and has inlet for coal limestone, assistant gasification agent, and has grid plate, scum pipe, air chamber and main gasification agent inlet. The lifting section has assistant air or oxygen inlet and adopts high flow velocity mode. The convey section adopts middle velocity mode, and the outlet of convey section has two high efficiency cyclone separator. The material return mouth of material return section is inserting into gasification reactor.

Owner:SOUTHEAST UNIV

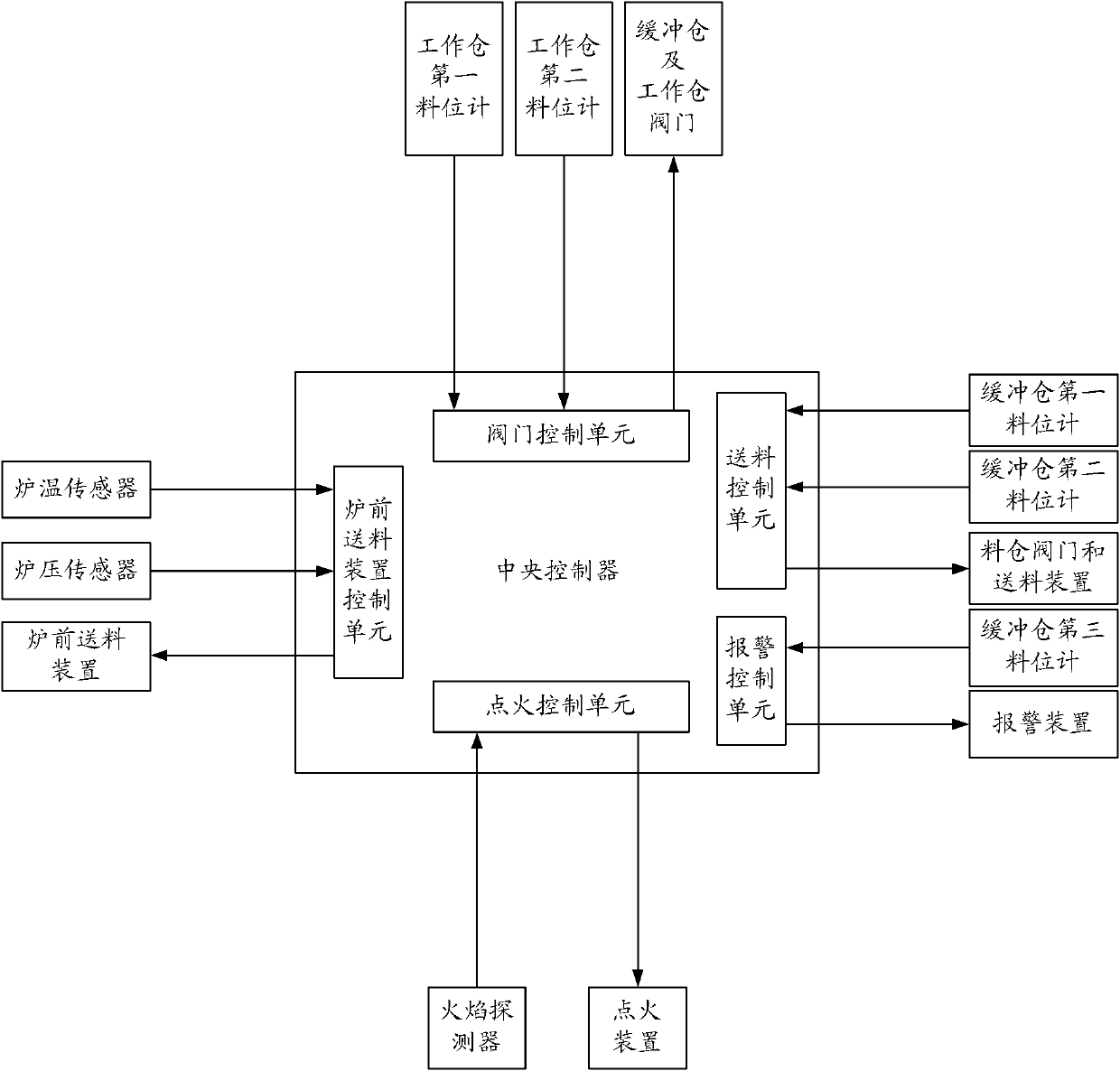

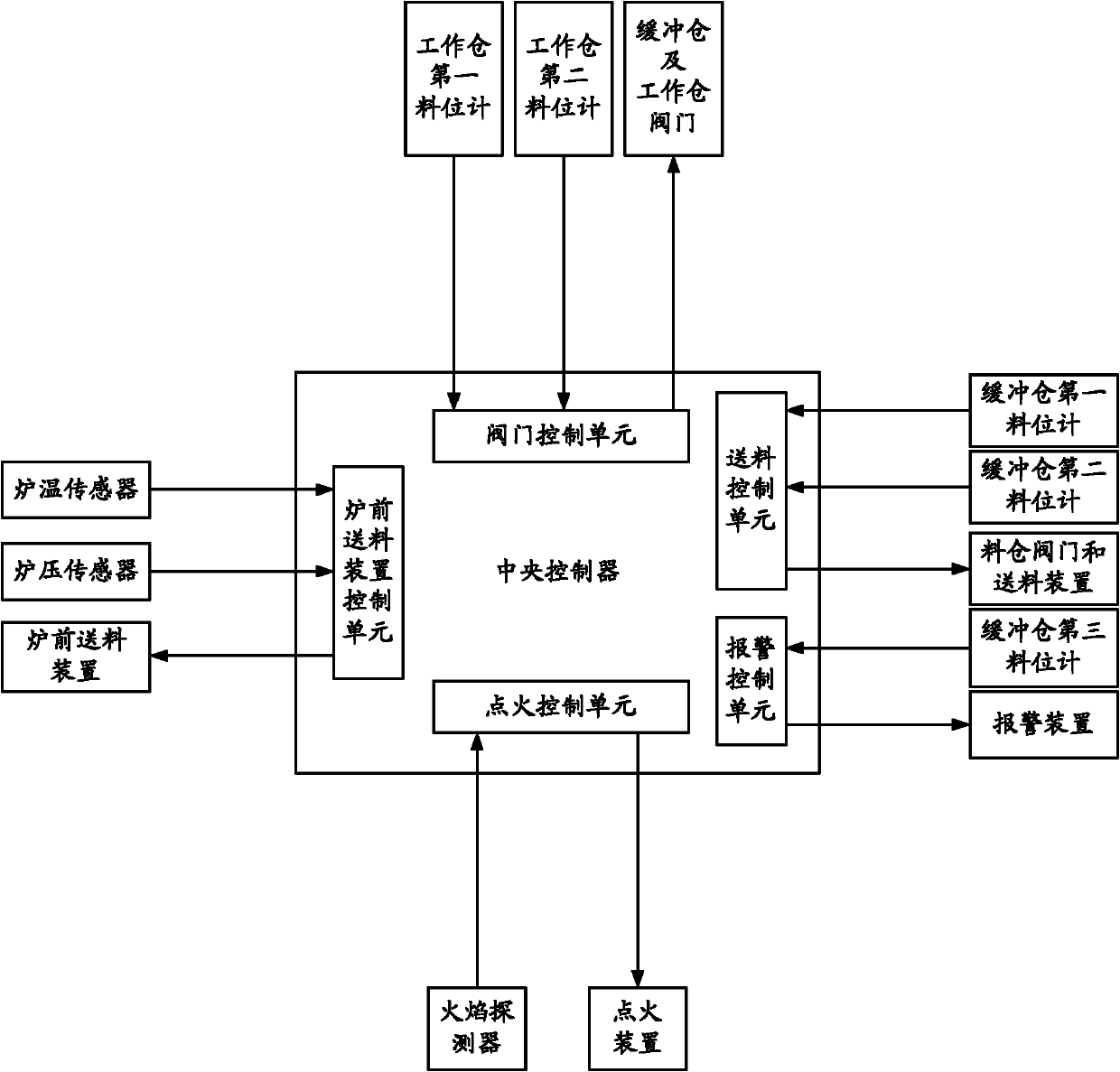

Automatic biomass gas feeding and diffusing control system and biomass gasification reaction system

ActiveCN101995836ARealize automatic controlHigh calorific valueProductsReagentsFurnace temperatureFluidized bed

The invention discloses an automatic biomass gas feeding and diffusing control system. The system comprises a first level gage of a work bin, a second level gage of the work bin, a valve control unit, a furnace temperature sensor, a furnace pressure sensor, a furnace front feeding device control unit, a flame detector and an ignition control unit, wherein the first level gage is used for sensing low material level in the work bin and transmitting a low material level signal to the valve control unit; the second level gage is used for sensing high material level in the work bin and transmitting a high material level signal to the valve control unit; the valve control unit is used for controlling the opening and closing of valves of a buffer bin and the work bin according to the received signals; the furnace temperature sensor is used for sensing temperature in a fluidized bed gasification reactor and transmitting a temperature signal to the furnace front feeding device control unit; the furnace pressure sensor is used for sensing pressure in the fluidized bed gasification reactor and transmitting a pressure signal to the furnace front feeding device control unit; the furnace front feeding device control unit is used for controlling the feeding frequency of a furnace front feeding device according to the received signals; the flame detector is used for sensing the flame of a diffusing device and transmitting a signal indicating whether the diffusing device has the flame or not to the ignition control unit; and the ignition control unit is used for controlling the opening of an ignition device according to the received signal.

Owner:GUANGZHOU DEVOTION THERMAL TECH

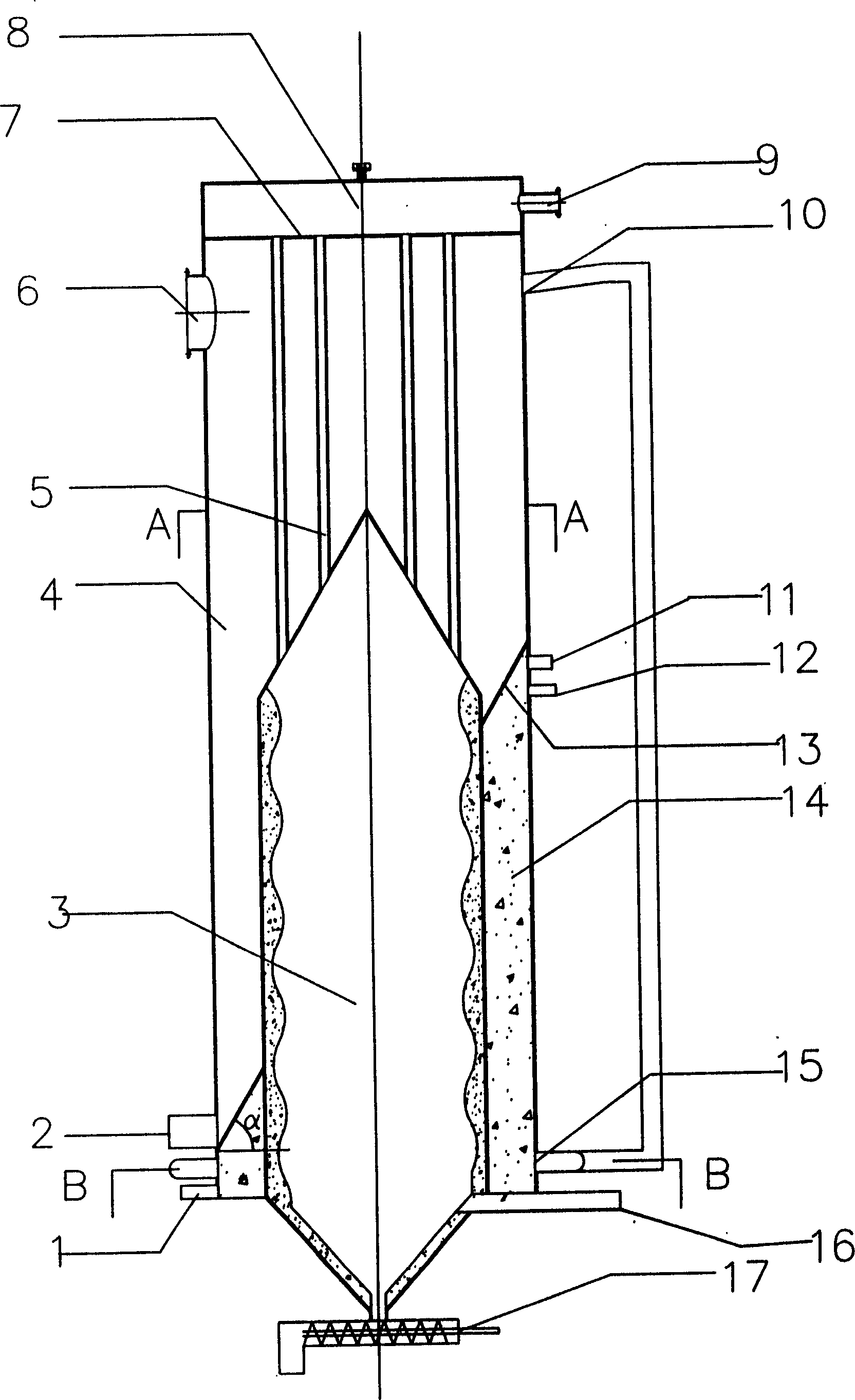

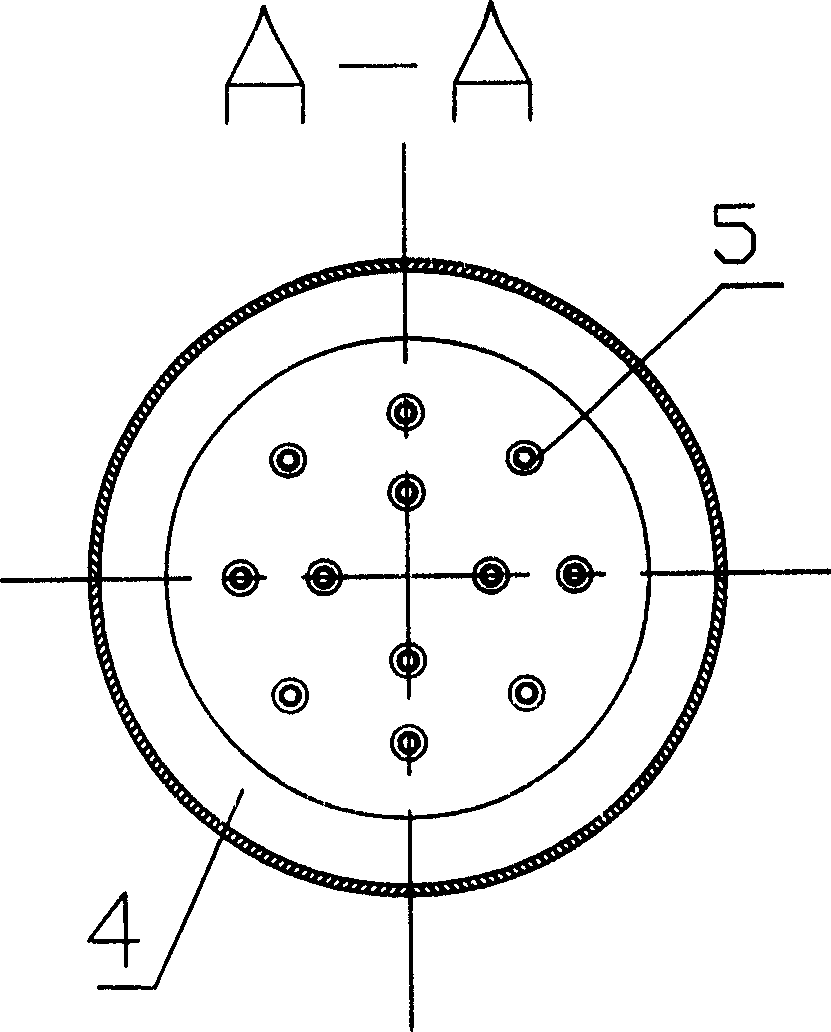

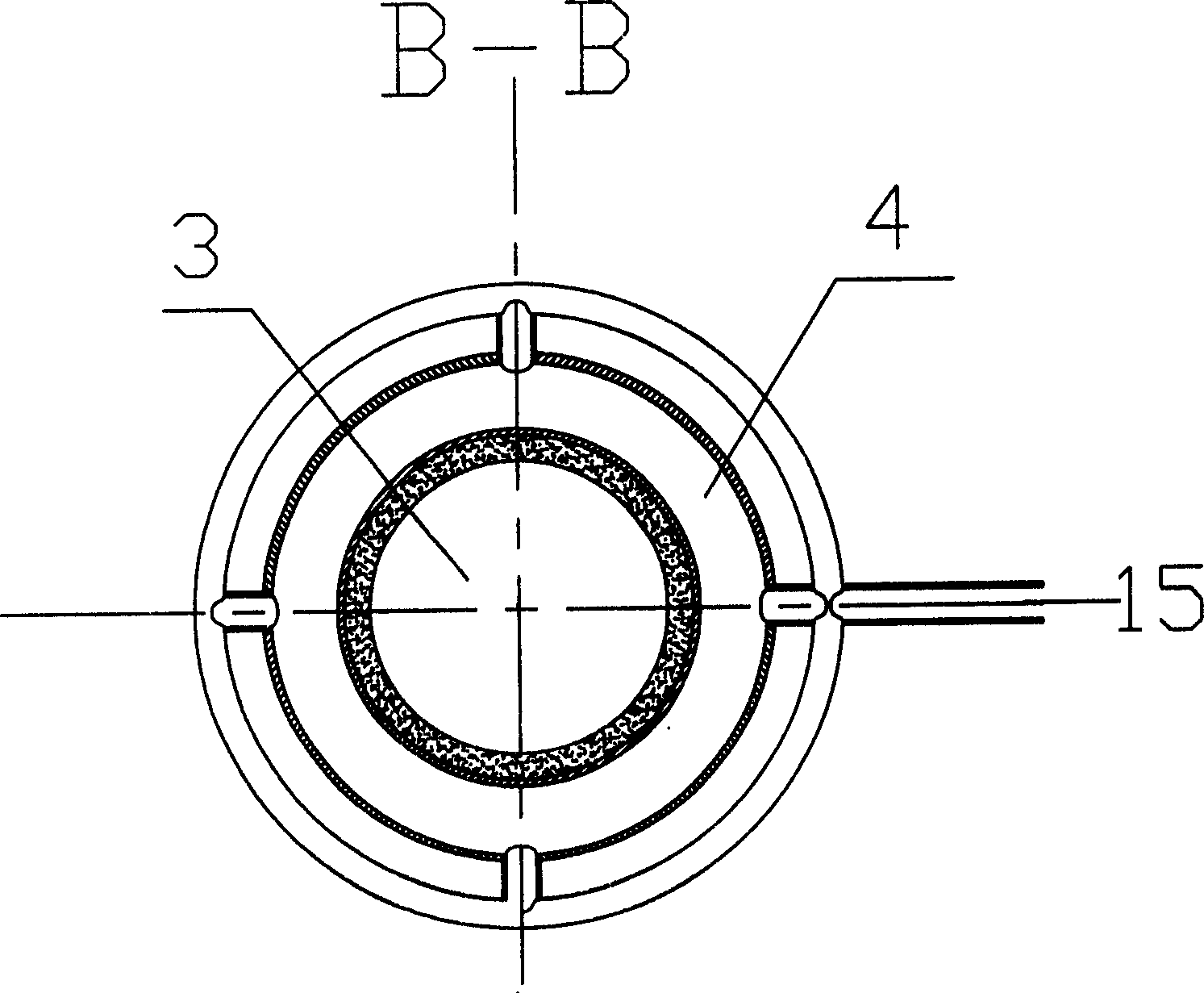

Cracking and gasifying reforming furnace

InactiveCN1888017ACompact structureLow costSpecial form destructive distillationCombined combustion mitigationCatalytic reformingCombustor

The present invention discloses one kind of cracking and gasifying reforming furnace, which includes one dust cloud combustor, one cracking and gasifying chamber and one catalytic reforming chamber. Micron level fuel is burnt in the dust cloud combustor to provide heat for cracking and gasifying and catalytic reforming, the material to be cracked and gasified absorbs heat in the cracking and gasifying chamber to crack and gasify, and the cracked and gasified product is pressurized into the catalytic reforming chamber and reformed to obtain medium heat value fuel gas containing CO and H2 in about 80 %. The cracking and gasifying reforming furnace adopts crop stalks and solid forest waste crushed to micron level as outer heat source, has less investment in apparatus, high heat efficiency, low cost, high gas yield and high heat value of fuel gas product, and may be used in utilizing organic garbage to produce fuel gas.

Owner:HUAZHONG UNIV OF SCI & TECH

Method and device for three-stage separating biomass gasification

InactiveCN102676236AReduce oxygen consumptionHigh calorific valueEnergy inputCombustible gas productionAir preheaterGeneration rate

The invention discloses a method and a device for three-stage separating biomass gasification. The device mainly comprises a reacting furnace, a pyrolysis chamber which is a biomass pyrolytic reaction chamber is arranged on the upper portion of the reacting furnace, a gasification chamber and a combustion chamber are positioned in the reacting furnace, the gasification chamber is positioned inside the combustion chamber, the pyrolysis chamber and the gasification chamber are connected with a feeding pipe, a flue gas channel is arranged outside the pyrolysis chamber and the feeding pipe, a feeding device is arranged on the upper pyrolysis chamber, the lower gasification chamber is communicated with the combustion chamber, a high-temperature gas extraction outlet is arranged in the middle of the gasification chamber, flue gas rises up along the flue gas channel from the combustion chamber to the periphery of the pyrolysis chamber and then is exhausted via a flue gas outlet, and the exhausted high-temperature gas is separated and purified by a separator prior to entering an air pre-heater. Three processes of a biomass gasification generating system are completely separated, the length of a reduction area is increased, and time and temperature required by tar pyrolysis are guaranteed, so that content of tar in the gas is reduced, gas generation rate of the gasification furnace is increased, and quality of the biomass gas is improved. The device has the advantages of convenience for temperature control, energy saving, environmental protection, operating continuity and the like.

Owner:JINAN BAOHUA NEW ENERGY TECH

Coal water slurry gasification furnace for gasifying coal water slurry

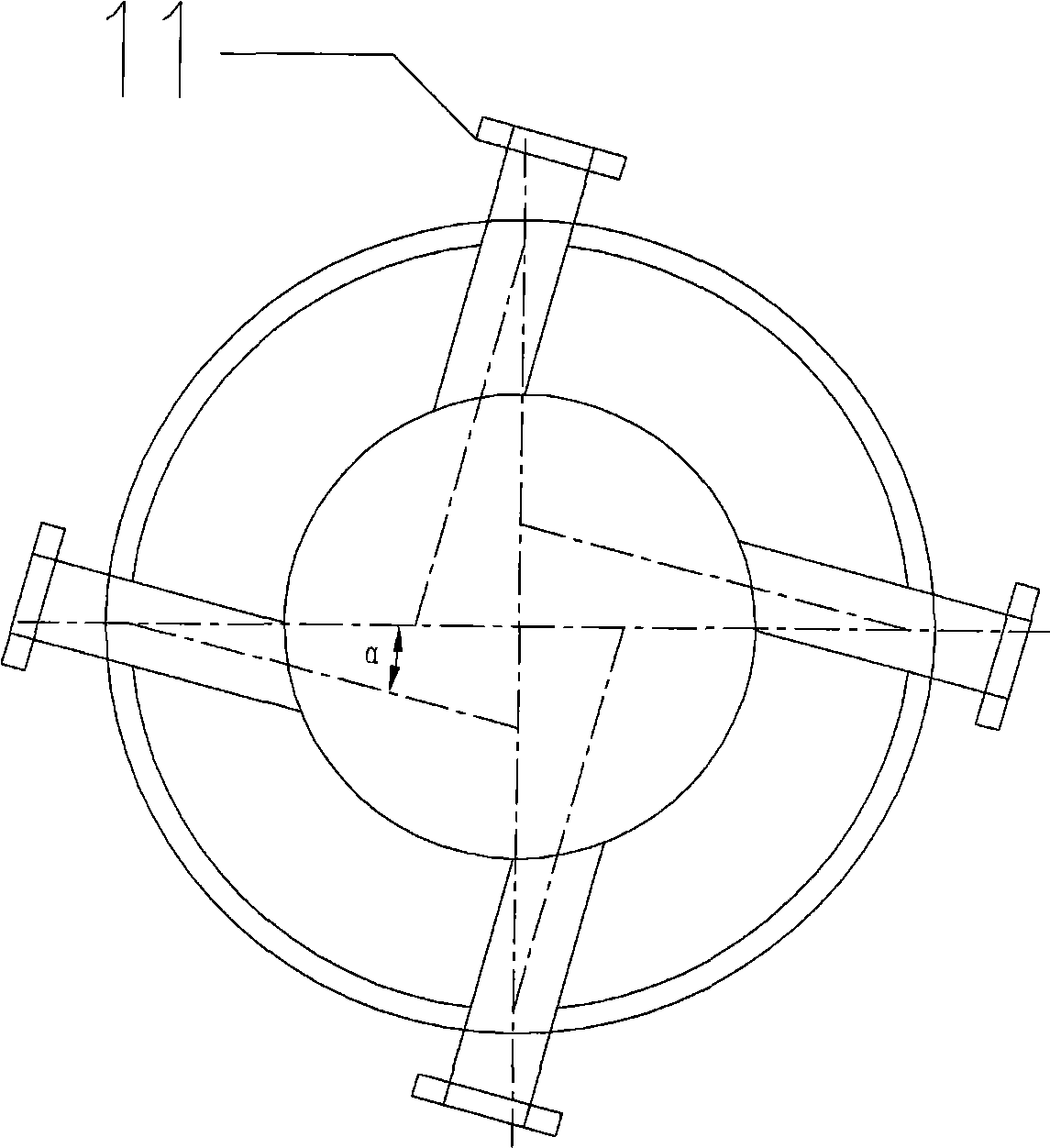

ActiveCN101892086AFully atomizedImprove gasification efficiencyCombined combustion mitigationGranular/pulverulent flues gasificationCoal waterCombustion chamber

The invention provides a coal water slurry gasification furnace for gasifying coal water slurry, which comprises a combustion chamber and a chilling chamber, and is characterized in that: the combustion chamber further comprises a quasi-elliptic large-diameter combustion chamber shell, at least two coal water slurry and oxygen three-channel process nozzle chambers which are symmetrically arrangedat the large diameter of the combustion chamber shell and slightly incline downwards, at least two coal water slurry and oxygen three-channel nozzles which slightly incline downwards and are detachably arranged in each coal water slurry and oxygen three-channel process nozzle chamber and of which the openings face the inside of the combustion chamber, a fireproof brick which is lined in the combustion shell, at least two oxygen nozzle chambers which are positioned at the periphery below each coal water slurry and oxygen three-channel process nozzle chamber and incline upwards, at least two oxygen nozzles which incline upwards and are detachably arranged in each oxygen nozzle chamber and of which the openings face the inside of the combustion chamber, and a combustion chamber slag hole which is formed at the bottom of the combustion chamber, wherein the chilling chamber is arranged on the lower part of the combustion chamber and below the combustion chamber slag hole.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Fixed bed straw gasification process with tar backflash

ActiveCN101580739ARealize automatic burnbackAvoid secondary pollutionCombined combustion mitigationFixed-bed gasificationThermal insulationFixed bed

The invention provides a fixed bed stalk gasification process with tar backflash. The process comprises the following steps of: under the condition of thermal insulation, removing dust in high-temperature combustible gas generated by a gasification furnace; collecting tar in the combustible gas by a method combining inertia and cooling; and automatically refluxing the collected tar to a high-temperature oxygen enriched combustion zone of the gasification furnace for combustion and cracking under actions of gas injection and self gravity. The process has the advantages of greatly lowering the content of the tar in the combustible gas, realizing the automatic backflash of the tar, improving the overall gasification efficiency, calorific value of the combustible gas and the quality of the combustible gas, and solving the secondary pollution problem of the tar.

Owner:XUZHOU KERONG ENVIRONMENTAL RESOURCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com