Method for producing synthesis gas by combustible solid waste chemical chain gasification and interconnected fluidized bed reactor

A fluidized bed reactor, solid waste technology, applied in chemical instruments and methods, production of combustible gas, granular/powder fuel gasification, etc., can solve problems such as corrosion, increased gasification cost, and complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further described below in conjunction with embodiment, but does not constitute limitation to the present invention.

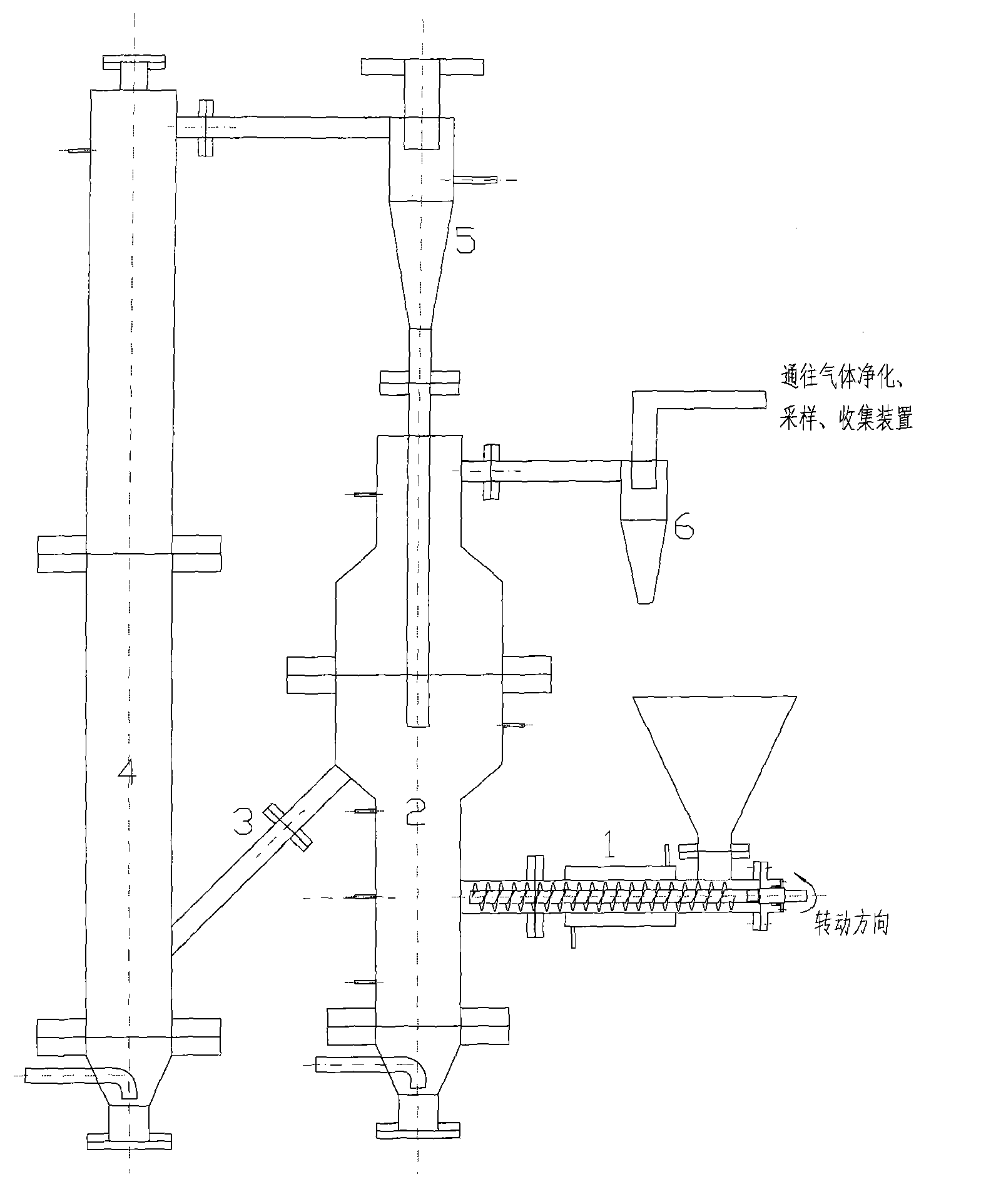

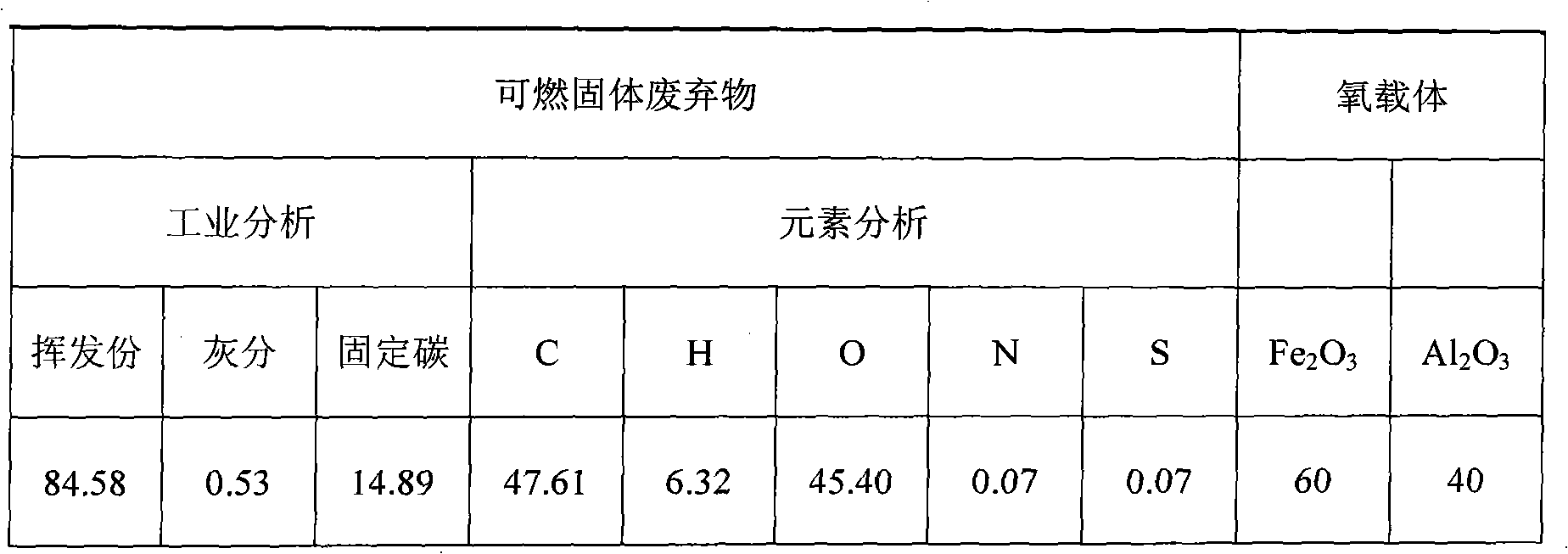

[0031] Select agricultural and forestry processing waste as biomass raw material, with an average particle size of 0.8mm; Fe 2 o 3 The ferric oxide particles with a mass percentage content of 60% are oxygen carriers, and the average particle diameter is 0.5 mm; the inner diameter of the bubbling fluidized bed 2 is 300 mm, and the height is 1200 mm; the diameter of the fluidized bed riser 4 is 100 mm, and the height is 2000 mm. The amount of oxygen carrier particles added is 30-40kg, and fresh oxygen carriers can be added to the bubbling fluidized bed 2 at any time according to the reaction process. The temperature of the bubbling fluidized bed 2 is stabilized within the range of 840-850°C, the temperature of the fluidized bed riser 4 is controlled within 900-950°C, and the synthesized gas is discharged and purified from the exh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com