Patents

Literature

270results about How to "Reduce tar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

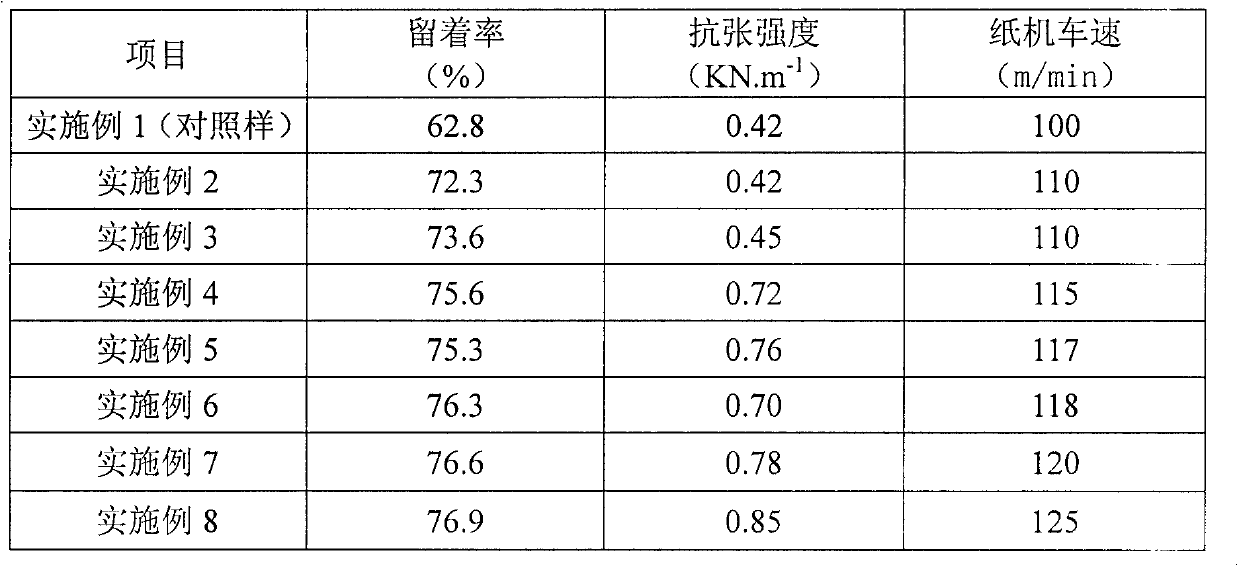

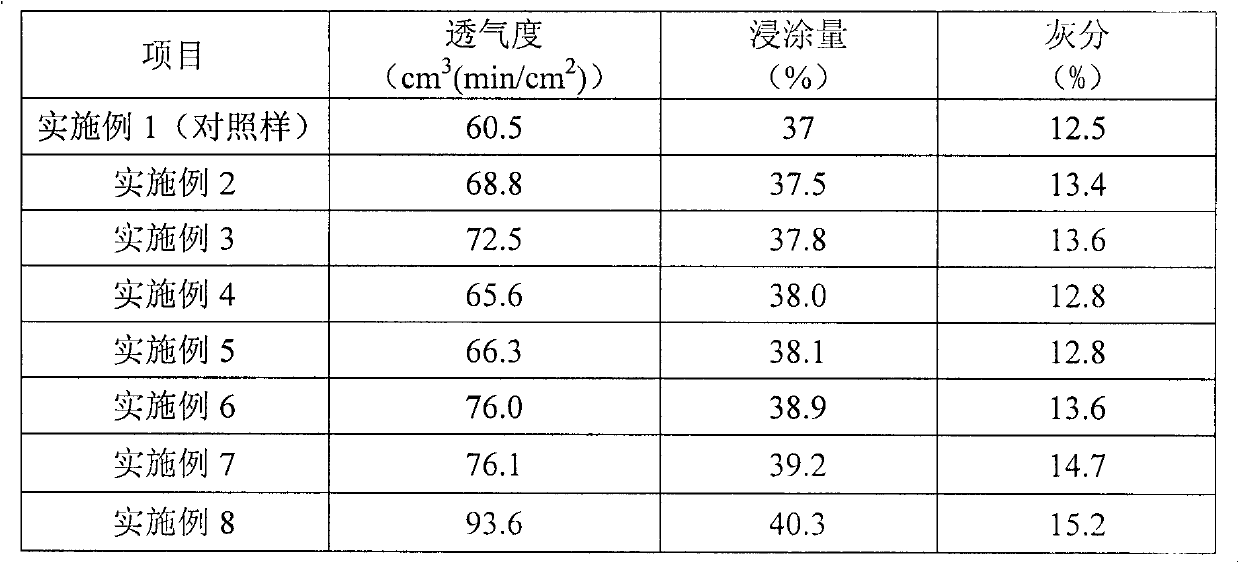

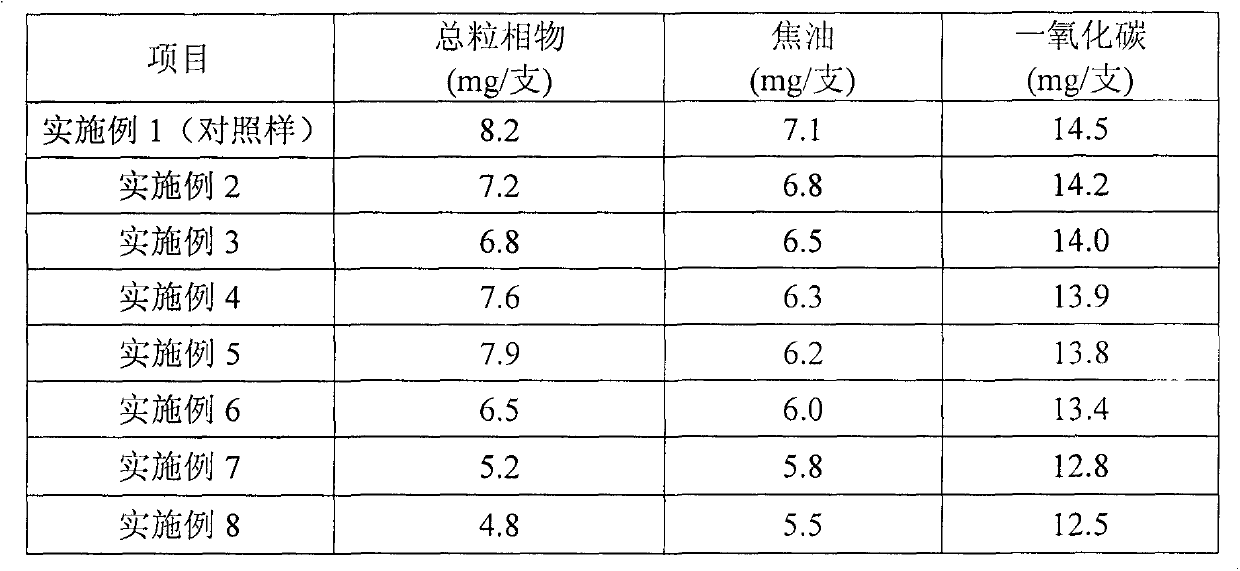

Preparation method for paper-making process tobacco sheet and finished product of paper-making process tobacco sheet

ActiveCN103141928AImprove single layer retentionImprove breathabilityTobacco preparationPlant fibrePaper based

The invention belongs to the field of tobacco industry and relates to a preparation method for a functional harm-reduction and tar-reduction paper-making process tobacco sheet and a finished product of the paper-making process tobacco sheet. The preparation method for the paper-making process tobacco sheet comprises the following steps of extracting and concentrating effective components of tobacco; mixing formulas; pulping and blending fibers; manufacturing paper with pulp; dipping, drying and tearing and shaping. The blending process comprises the following steps of: adding non-tobacco plant fiber pulp of which the beating concentration is 3-4 percent and the Schopper-Riegler (SR) beating degree is 18-28 to tobacco mixed fiber pulp, adding filling to a machine chest, regulating the pulping concentration to 2-3 percent by water, and evenly mixing. By the use or the combine use of the filling and the non-tobacco plant fiber pulp, the combustion state of the sheet can be improved while physical properties, such as the air permeability, the retention and the tensile strength of a paper base, are improved, i.e., harmful ingredients of smoke, such as tar and carbon monoxide of the paper-making process tobacco sheet, can be effectively reduced, and hazard indexes of cigarettes are reduced. Meanwhile, technical-economic indicators, such as the speed and the input- output efficiency of a paper machine, also can be improved.

Owner:杭州利群环保纸业有限公司

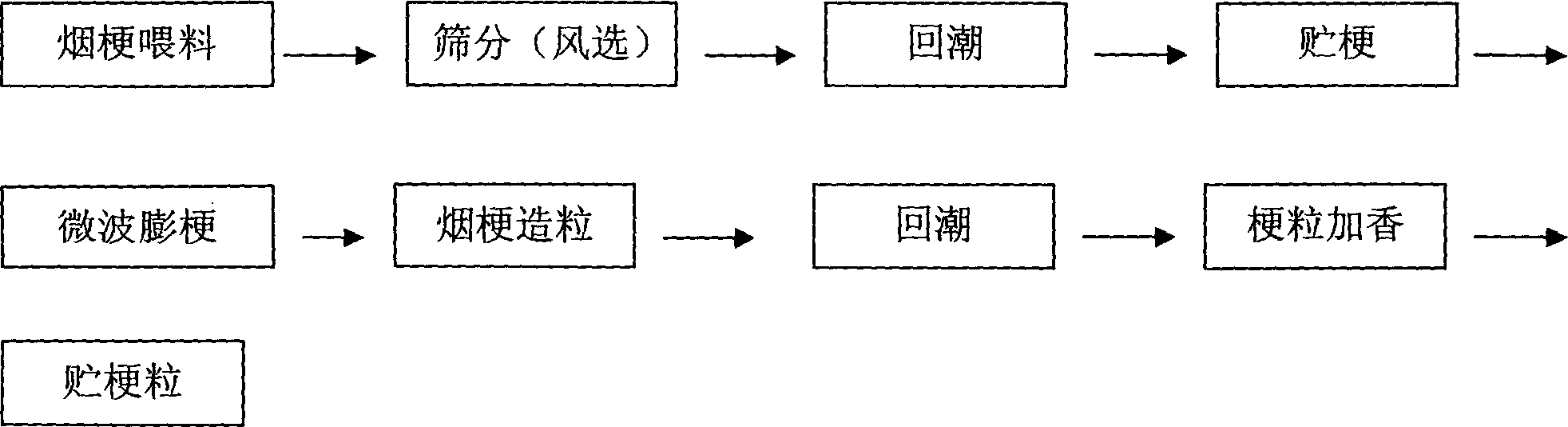

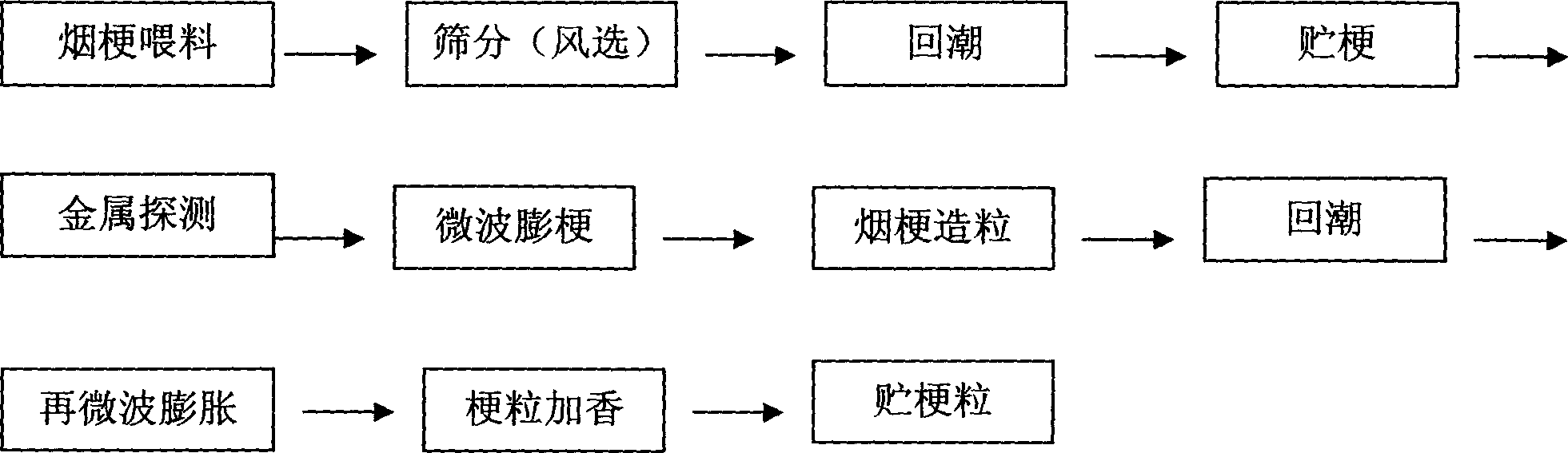

Tobacco peduncle granule production process

The invention relates to a process of preparing tobacco stalk granule, comprising following steps: (1) expanding and drying stalk with microwave drying machine to make the water content of stalk be between 4%-10%; (2) granulating stalk; (3) humidifying the granular stalk to make the water content be increased to 10-20%; (4) adding flavoring agents into granular stalk; (5) storing. The filling value of produced granular stalk is higher and the cut tobacco consummation can be greatly reduced, the wooden smell can also be reduced, and the coke tar and nicotine content can be considerably reduced. The invention is characterized by simple and successive process and low treating cost.

Owner:YUNNAN KUNCHUAN TOBACCO EQUIP CO LTD

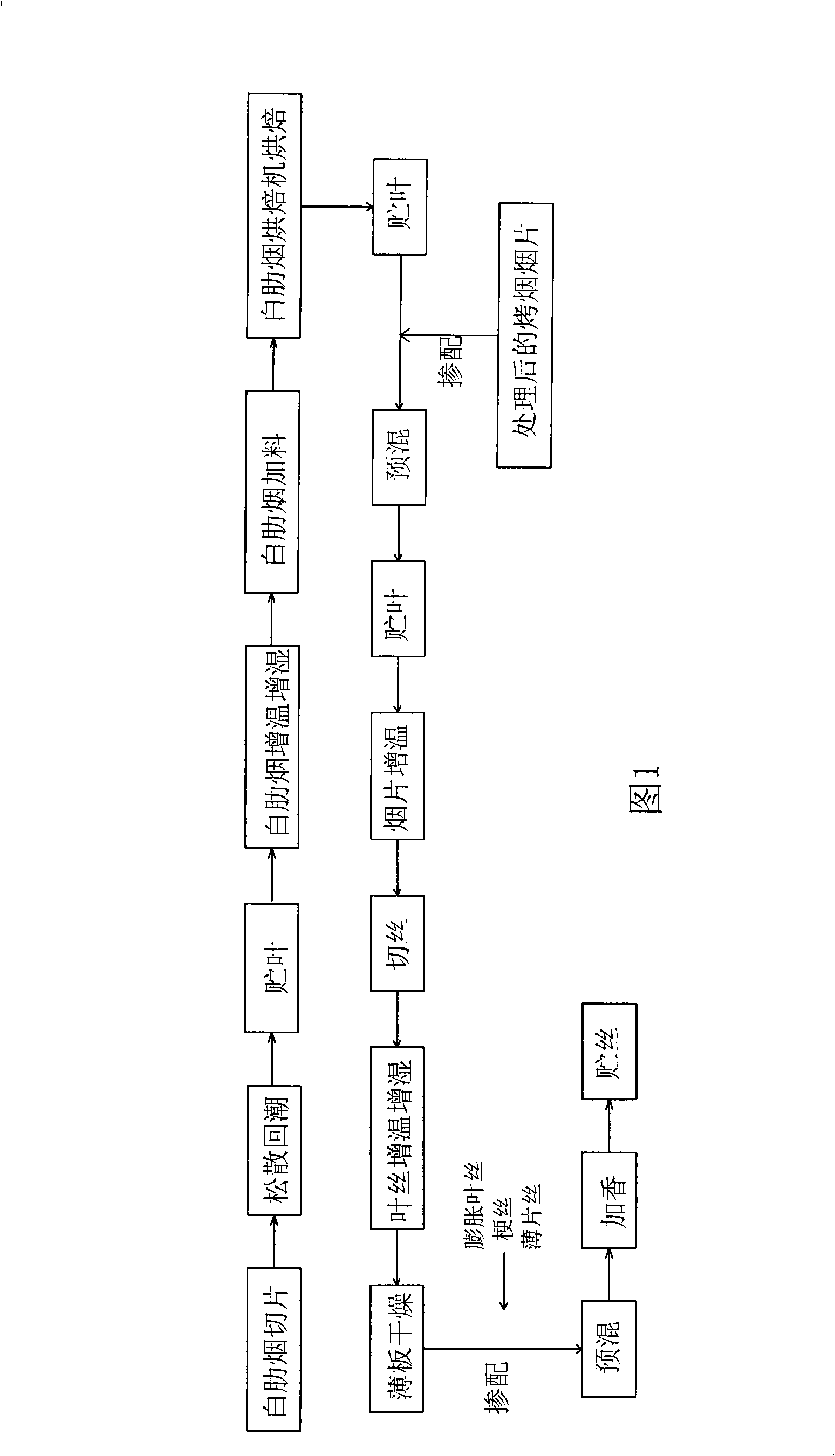

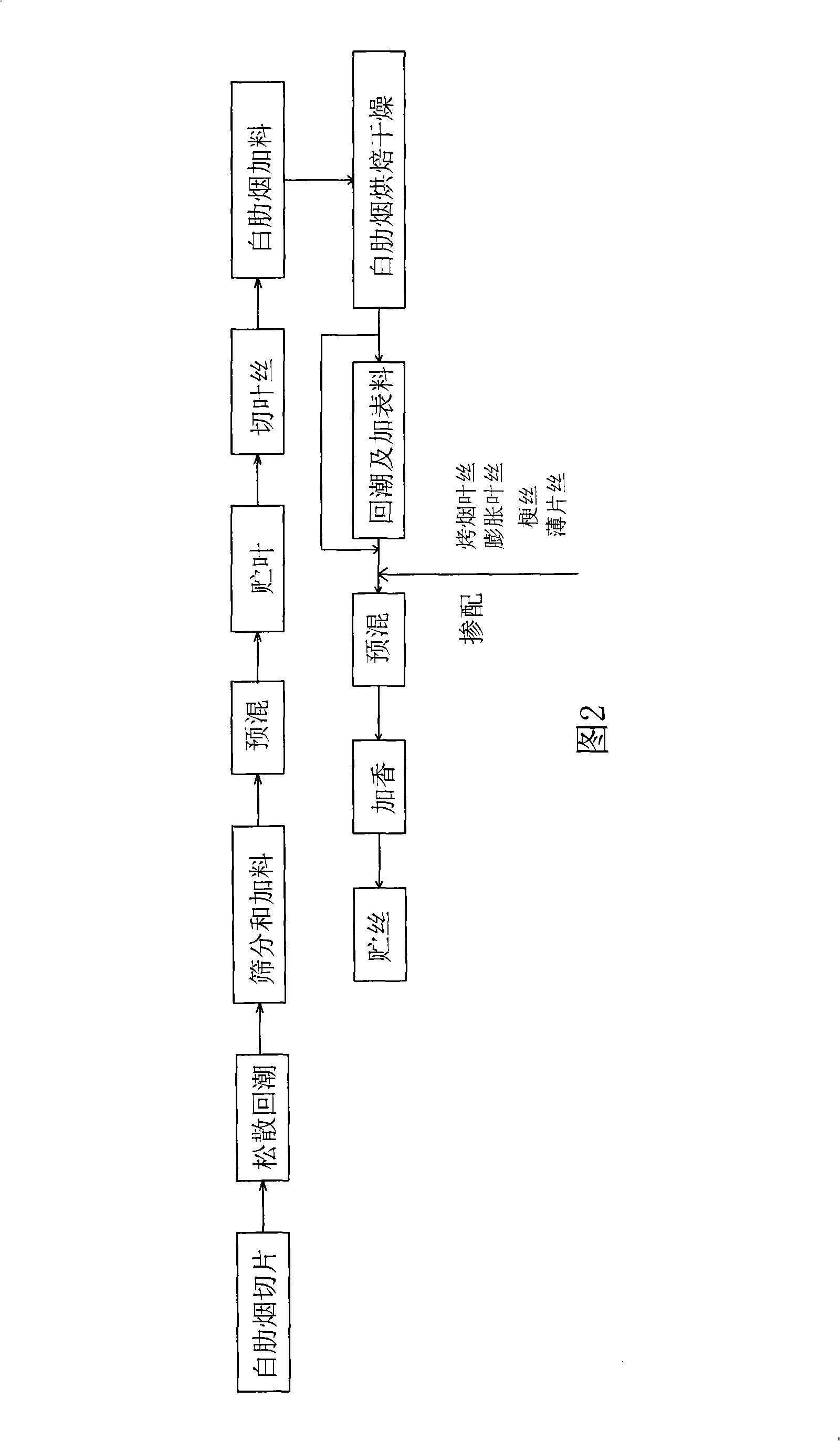

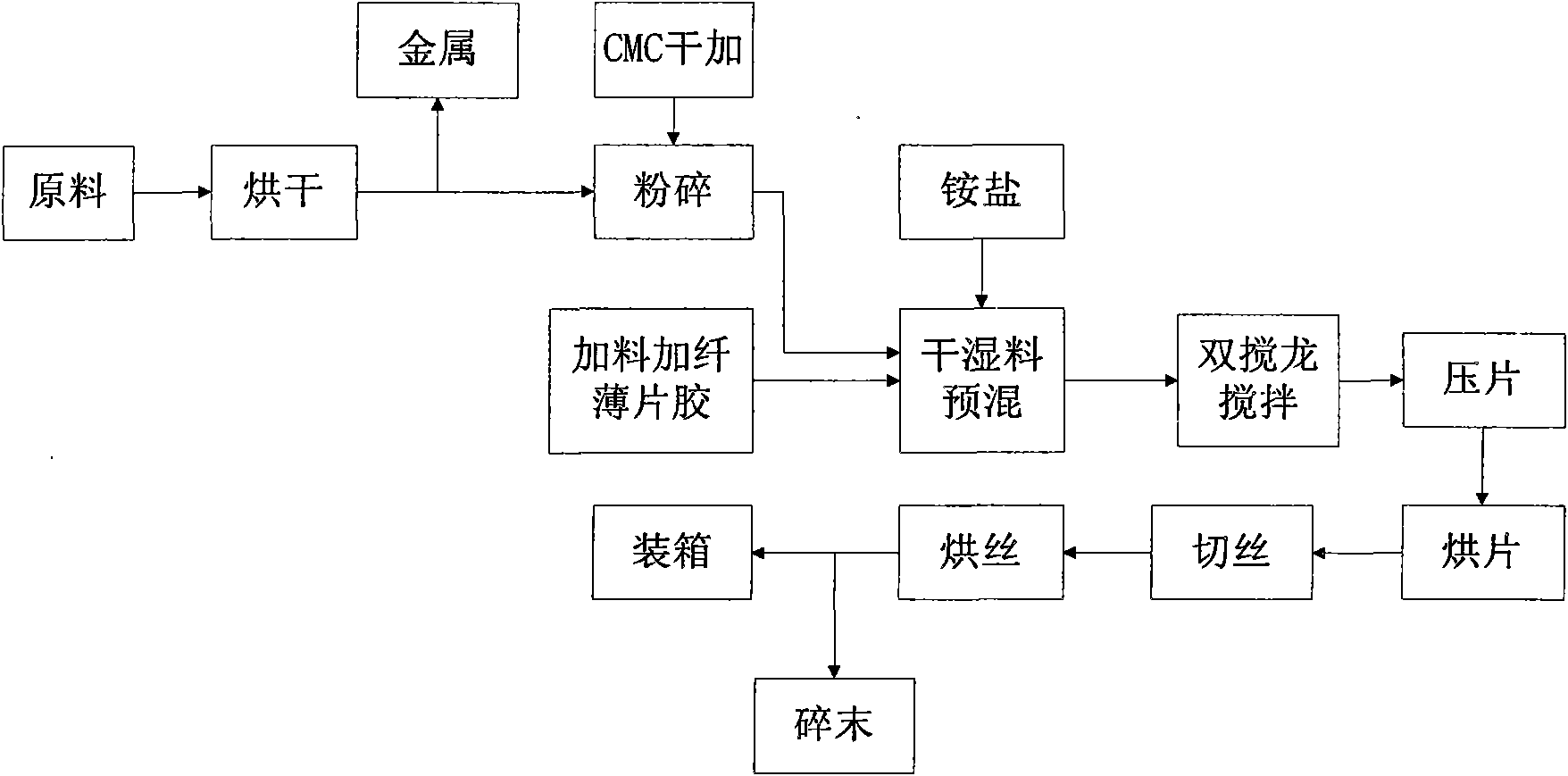

Process technique for burley tobacco in blend type cigarette

The invention discloses a burley tobacco processing and treating technic in a blended type cigarette. The technic performs a burley tobacco leaf blade making workshop section, a burley tobacco making leaf shred workshop section, and a leaf shred mixing workshop section. The burley tobacco processing and treating technic is used for processing and treating a burley tobacco which is used as an individual formula module in the blended type cigarette, and is impenetrated in the whole process from leaf blade making to leaf shred marking; aiming at the treatment of the material of the burley tobacco, for example, the feed liquid of the burley tobacco is applied by steps and proportion; the baking and the drying of the burley tobacco are performed after cutting shred; the existing burley tobacco baking mode is substituted, a burley tobacco leaf shred baking and drying process mode is adopted, the water ratio and the temperature of the exported leaf shred is fed back and controlled; the processing route of the existing burley tobacco processing technic is changed, a processing technic for shred mixing is adopted. The burley tobacco processing and treating technic can adopt different processing parameters and routes according to the needs of products and different qualities and characters of different burley tobacco raw materials, thus the aesthetic quality of the blended type cigarette is improved, the process flow is simpler, and the processing method is more flexible.

Owner:XIAMEN TOBACCO IND

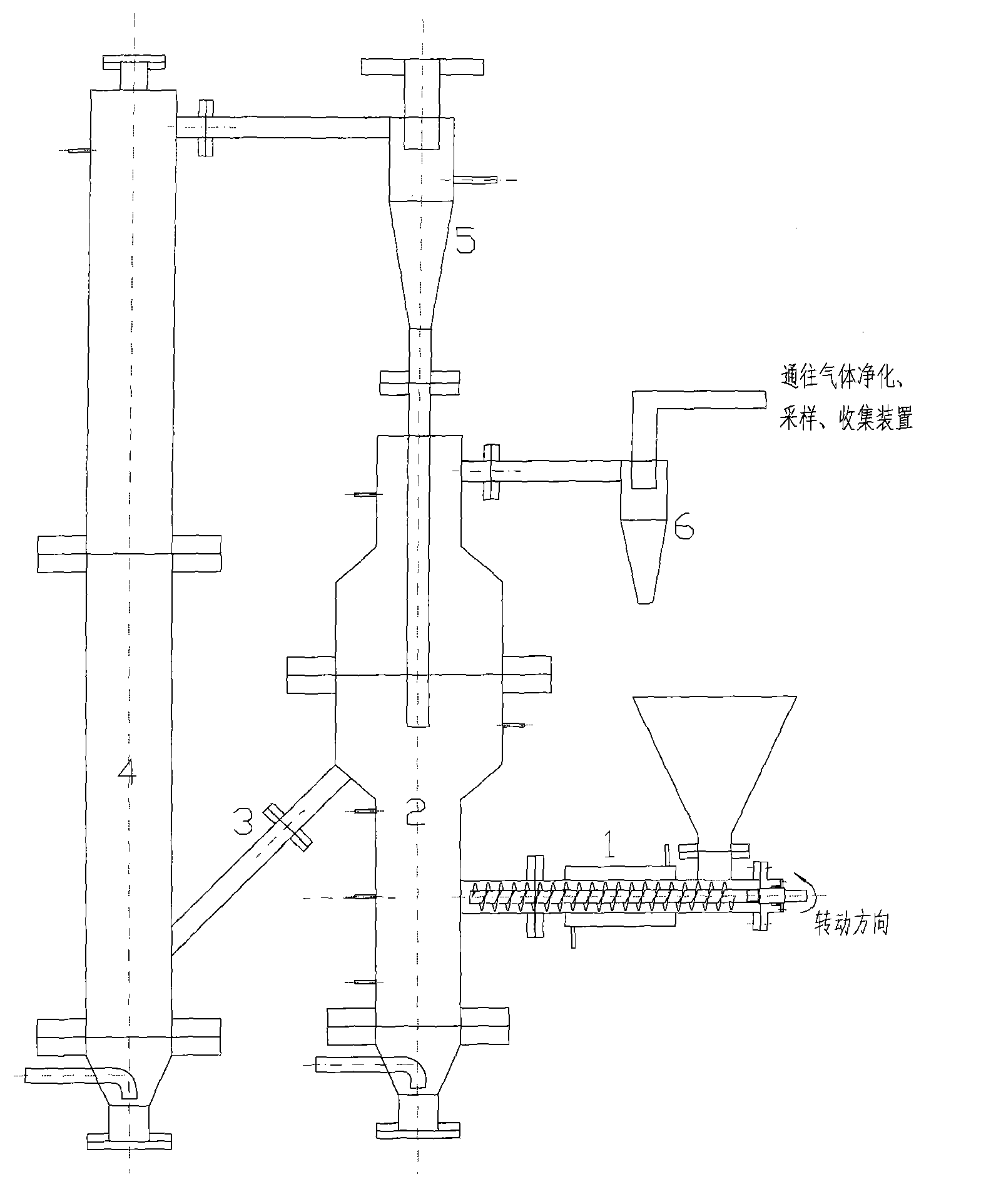

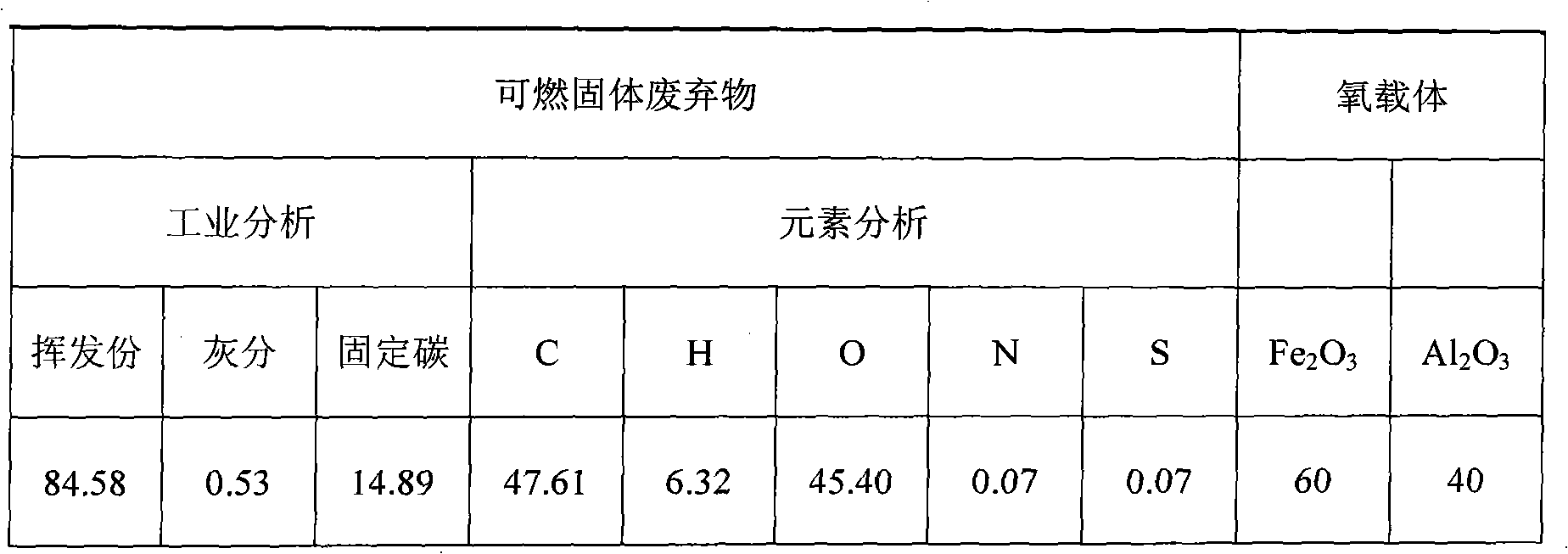

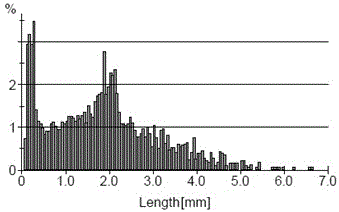

Method for producing synthesis gas by combustible solid waste chemical chain gasification and interconnected fluidized bed reactor

ActiveCN101638590ALower Gasification CostsHigh calorific valueCombined combustion mitigationChemical/physical processesFluidized bedLattice oxygen

The invention provides a method for producing synthesis gas by combustible solid waste chemical chain gasification and an interconnected fluidized bed reactor. The method is implemented in an interconnected fluidized bed reactor, and the interconnected fluidized bed reactor comprises a fuel reactor and an air reactor communicated with each other internally. The combustible solid waste produces gasification reaction with a carrier of oxygen to produce synthesis gas, and the oxygen element necessary for the gasification of combustible solid waste comes from the lattice oxygen in the carrier component of oxygen; the carrier of oxygen without lattice oxygen is transported to the air reactor, in the air reactor, the carrier of oxygen is re-oxidized by high-temperature air to recovery to latticeoxygen; the carrier of oxygen recovered with lattice oxygen is carried out the air reactor by high-speed air, returns back to the fuel reactor for cycle use and produces gasification reaction with the combustible solid waste again. The invention relates to a high-efficiency combustible solid waste gasification technique breaking the prior art, and the invention can produce high-quality synthesisgas and reduce the contents of tar and carbon deposite during the gasification process.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

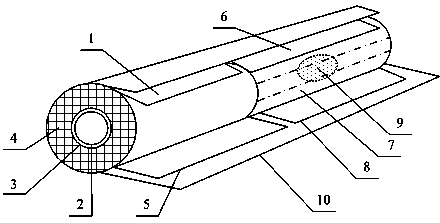

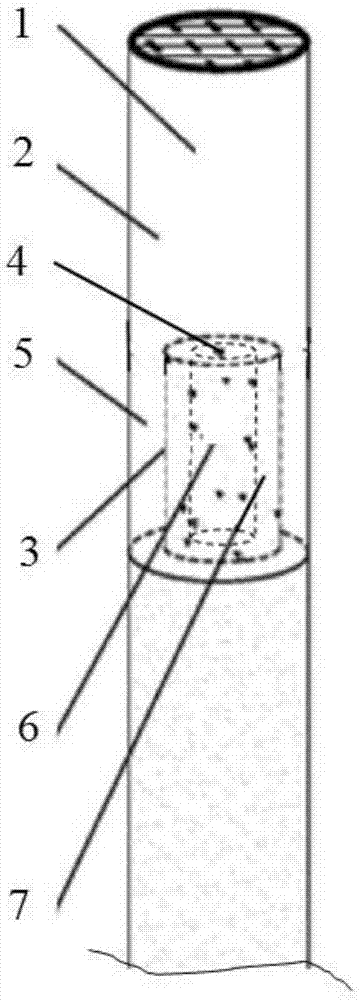

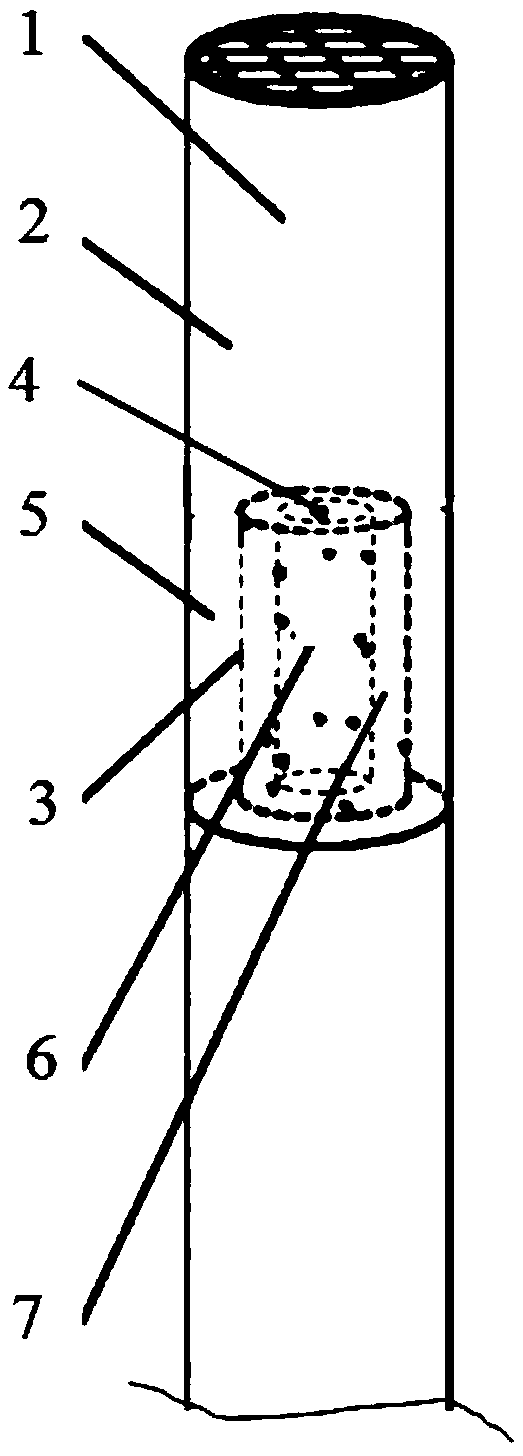

Novel solid-state cigarette core of electronic cigarette and preparation method for novel solid-state cigarette core

InactiveCN104223366AIncrease contact areaIncrease the heating areaTobacco devicesHeater RodEngineering

The invention relates to a novel solid-state cigarette core of an electronic cigarette and a preparation method for the novel solid-state cigarette core, belongs to the technical field of electronic cigarettes, and particularly relates to a solid-state cigarette core of the electronic cigarette and a preparation method thereof. The solid-state cigarette core of the electronic cigarette is prepared by heating an aroma carrier material and has a filtering effect. Through a design of a hollow cigarette core, a contact area between the cigarette core and a heating rod is increased, and a heating area and the heating efficiency of an atomizer are increased; a fibrous material is taken as a carrier to fully adsorb the aroma carrier material, and by indirectly heating the thermosensitive solid aroma carrier material, smoke which can be inhaled by a consumer is formed, and the consumer is endowed with the natural tobacco feel. Meanwhile, through reasonable combination of the paper hollow cigarette core and a filter element, the aroma carrier function and the filtration function of the material are perfectly combined, the smoke which has certain resistance to suction and which can be inhaled by the consumer is formed, the contents of tar and harmful granular matters in the smoke of the electronic cigarette are reduced, the smoking feel similar to the conventional cigarettes is endowed, and the electronic cigarette smoking pleasure is greatly improved.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

Microwave tobacco stem expansion method

ActiveCN102726826AGuarantee stabilityEliminate charring of tobacco stemsTobacco treatmentProcess engineeringManufacturing engineering

The invention belongs to the technical field of tobacco manufacturing and particularly relates to a microwave tobacco stem expansion technology. The method comprises the following steps of preparation of raw materials, quantitative feeding, temperature raising of tobacco stems, microwave expansion, microwave dehumidification, cooling shaping and production of cut stems. The method has the advantages that the production cost is low, the structure is stable, the cut stems do not retract when absorbing water and can be directly produced without ageing treatment, the seamless joining between specialized, large-scaled and continuous processing of microwave expansion tobacco stems and production of cut tobacco is realized, the cycle of producing, storing and preparing cut tobacco is unnecessary, the logistics and warehousing cost during the ageing period of expanded tobacco stems is unnecessary, and the economic benefits are quite obvious.

Owner:HONGTA TOBACCO GRP

Cigarette with dobble-layer of cigarette paper

The present invention discloses cigarette with tobacco encircled with two, one inner and one outer, layers of cigarette paper. The inner layer of cigarette paper contains inorganic stuffing 20-40 wt%, combustion assistant 6-10 wt% and essence 12-18 wt%; and the outer layer of cigarette paper contains inorganic stuffing 25-35 wt% and combustion assistant 5-10 wt%. The said inorganic stuffing is calcium carbonate, magnesium hydroxide, magnesia, trihydroxyl aluminum or their mixture; the combustion assistant is the mixture of potassium citrate and sodium citrate with weight ratio between potassium ion and sodium ion of 2-4; and the essence is one of menthyl palmitate, vanillin, menthyl carbonate and beta-carotene. The present invention can reduce the side flow fume of cigarette, lower tar and reduce fragrance loss.

Owner:YUNNAN RES INST OF TOBACCO SCI

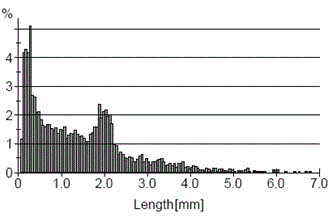

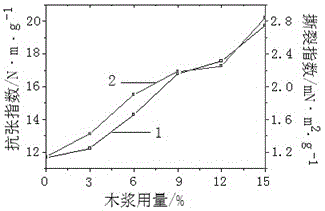

Reconstituted tobacco paper base and method for improving quality of reconstituted tobacco paper base by adding wood pulp fiber

The invention provides a reconstituted tobacco paper base and a method for improving quality of the reconstituted tobacco paper base by adding wood pulp fiber. The method for improving quality of the reconstituted tobacco paper base by adding wood pulp fiber includes steps of impregnating for extracting tobacco stem and tobacco powder, grinding, pulping, sheeting, pressing and drying. Wood pulp fiber accounting for 3-15% of tobacco material pulp by weight percent is added into the tobacco material pulp in the sheeting step. Researches show that tensile index, tear index and permeability of the reconstituted tobacco paper base with the added wood pulp fiber are improved evidently, overall absorbent property of the reconstituted tobacco paper base is improved, contents of tar, CO and total particulate matter in the sheeted paper base are lowered evidently, tar reduction and harm reduction for reconstituted tobacco are better played, sensory evaluation of cigarettes made by applying the sheeted paper base to cigarette production is improved comprehensively, and technical support for improving the quality of the reconstituted tobacco is provided.

Owner:CHINA TOBACCO GUANGDONG IND +1

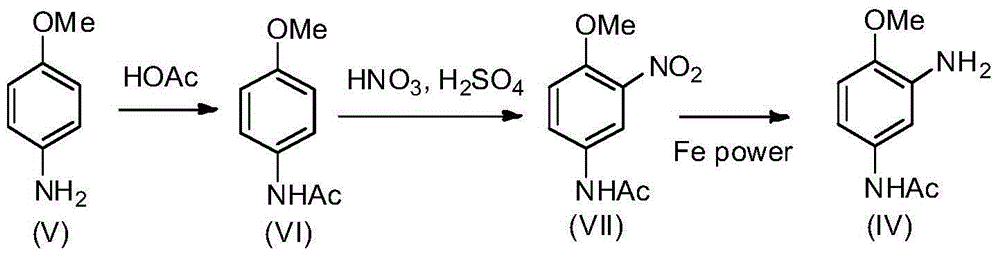

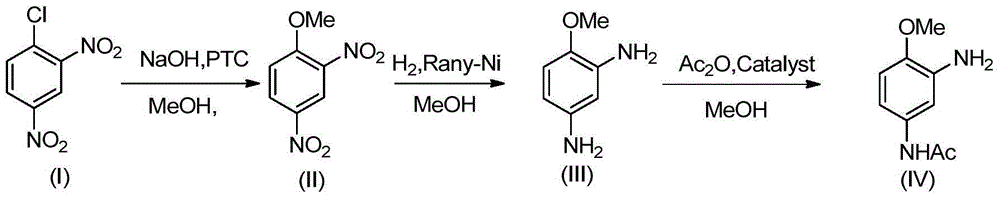

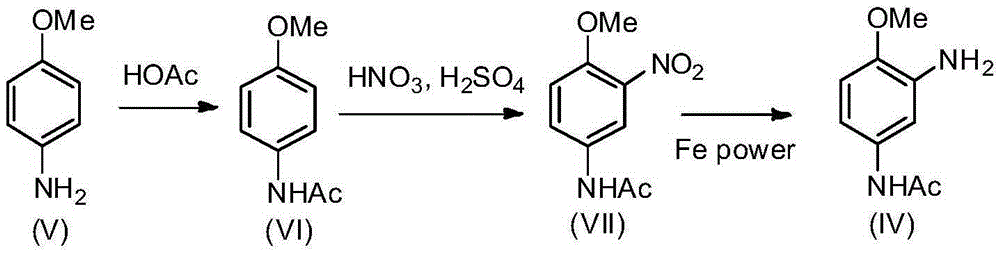

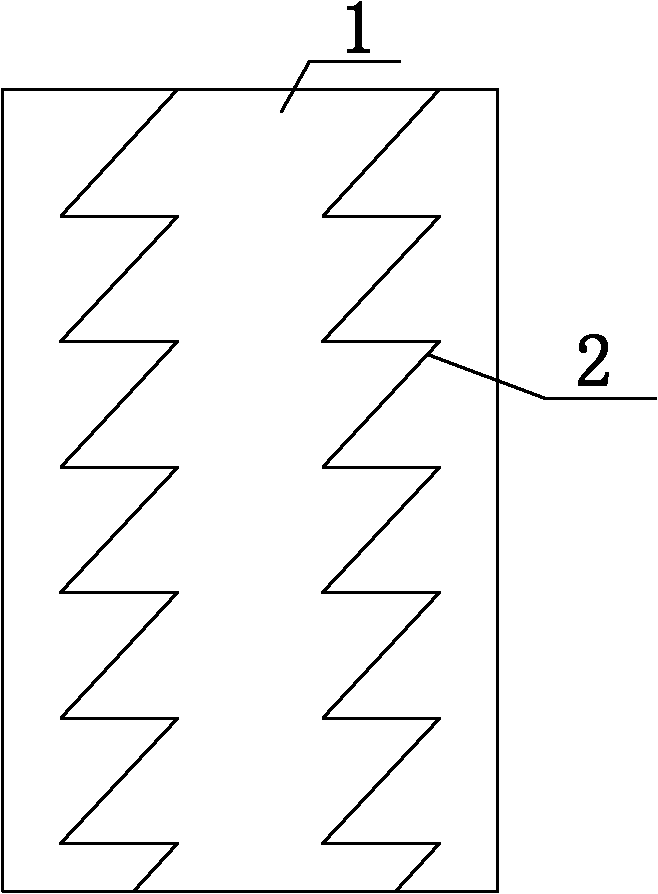

Synthesis process of 2-amino-4-acetamino anisole

InactiveCN104788334AReduce dosageReduce lossOrganic compound preparationCarboxylic acid amides preparationAcetic anhydrideEnergy consumption

The invention discloses a synthesis process of 2-amino-4-acetamino anisole. The synthesis process comprises the following steps: in methanol, under the action of an acid-binding agent, 2,4-diaminoanisole (III) and acetic anhydride are subject to acylation reaction shown in the description to obtain 2-amino-4-acetamino anisole (IV), wherein the molar ratio of the acid-binding agent to 2,4-diaminoanisole is (0.3 : 1)-(0.6 : 1). The synthesis process is low in energy consumption and cost, less in waste solids and waste liquid, environment-friendly, simple in operation, mild in reaction condition and high in industrial safety factor, the yield of the target compound is above 86% (counting according to original reaction raw materials), the HPLC purity is above 99.0%, the target compound is high in yield and good in quality, and the synthesis process is more suitable for industrial production.

Owner:SHANGHAI ZONGXING CHEM TECH CO LTD

Filter tip additional material capable of reducing harmful ingredients as well as preparation method and application thereof

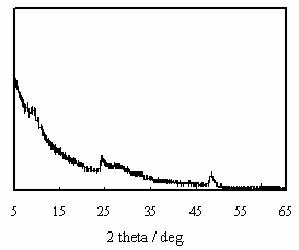

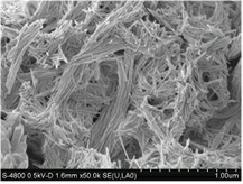

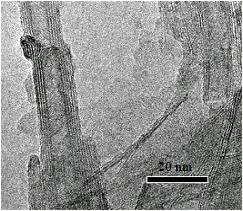

InactiveCN102178348AReduce tarEasy to prepareMaterial nanotechnologyAlkali titanatesAdditive ingredientEngineering

The invention relates to a filter tip additional material as well as a preparation method and an application thereof. The additional material is a titanate nano tube and is synthesized by adopting the conventional hydrothermal method. The additional material can be widely applied to the filter tip of a cigarette, and multiple harmful substances in main stream smoke of the cigarette can be reduced.

Owner:FUZHOU UNIV +1

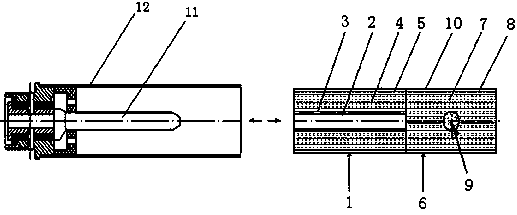

Tobacco fiber paper filter stick and preparation method thereof

InactiveCN103829374AConsistent colorRealize visualizationCigarette manufactureTobacco smoke filtersTarPapermaking

The invention relates to the field of tobacco filter sticks, and discloses a tobacco fiber paper filter stick and a preparation method of the tobacco fiber paper filter stick. The paper filter stick is composed of a filter element and forming paper, wherein the filter element is obtained by coiling paper fiber, the paper fiber is tobacco fiber pulp and long fiber pulp which are obtained by grinding tobacco raw materials and long fiber raw materials into liquid, then the tobacco fiber pulp and the long fiber pulp are subjected to pulp matching, sheet making, squeezing and drying to be manufactured into a fiber paper base, and the tobacco fiber paper filter stick can be obtained through smearing, drying and rolling. On the basis of wet process papermaking, tobacco fiber and long fiber are mixed according to a proper proportion in the pulp matching stage of papermaking, and the obtained paper filter stick not only has higher tar and nicotine removing capacity than a cellulose acetate filter stick, but also can successfully eliminate wooden offensive odor of the long fiber. Raw materials of the filter stick come from natural plants, and therefore the filter stick only has the scent of tobacco and does not have the scent of paper or chemical fiber, the color of the filter stick is consistent to that of cut tobacco of cigarettes, and the filter stick has the texture of natural material of tobacco and guides a new direction for the technical field of cigarettes.

Owner:CHINA TOBACCO GUANGDONG IND +1

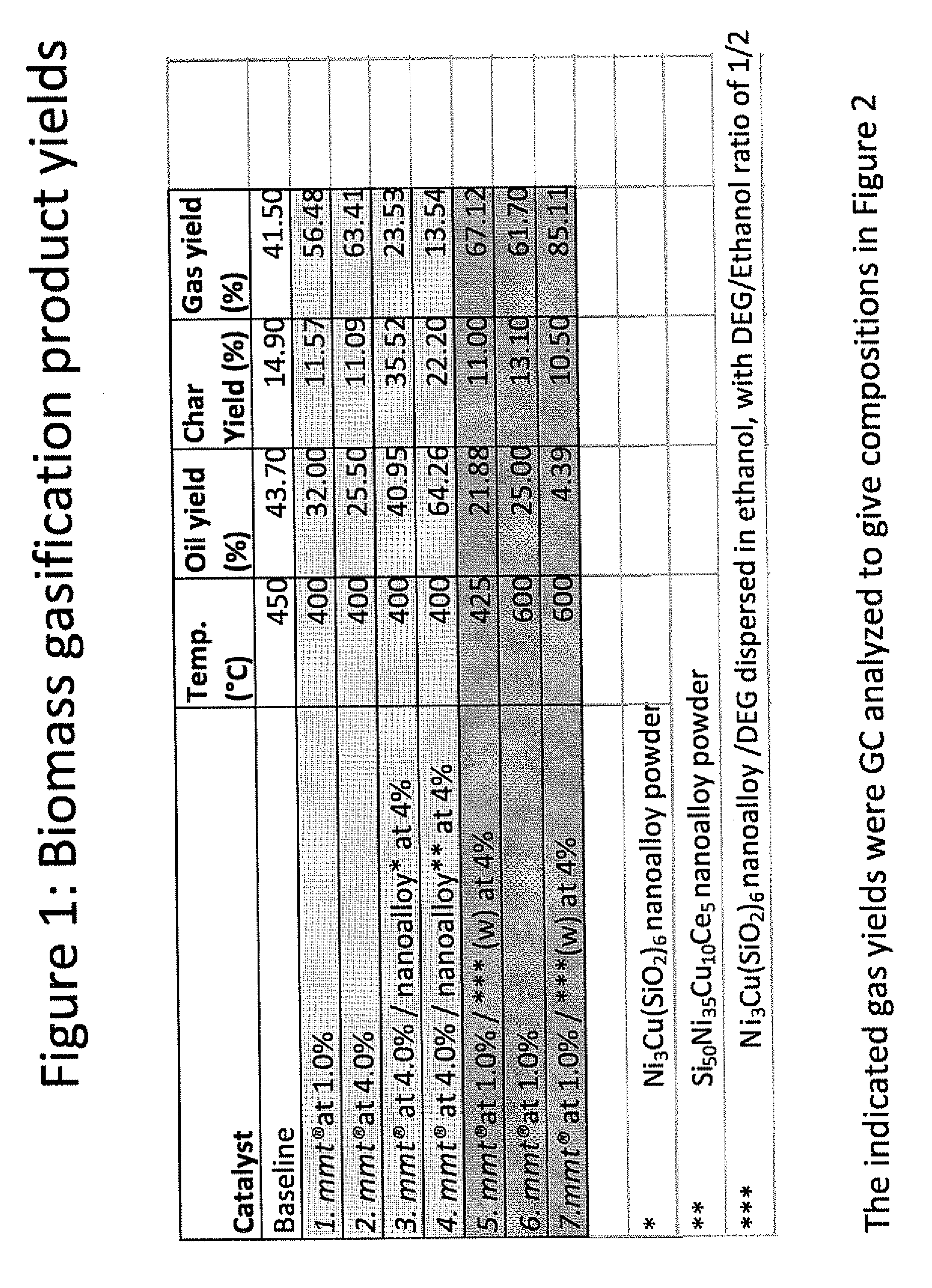

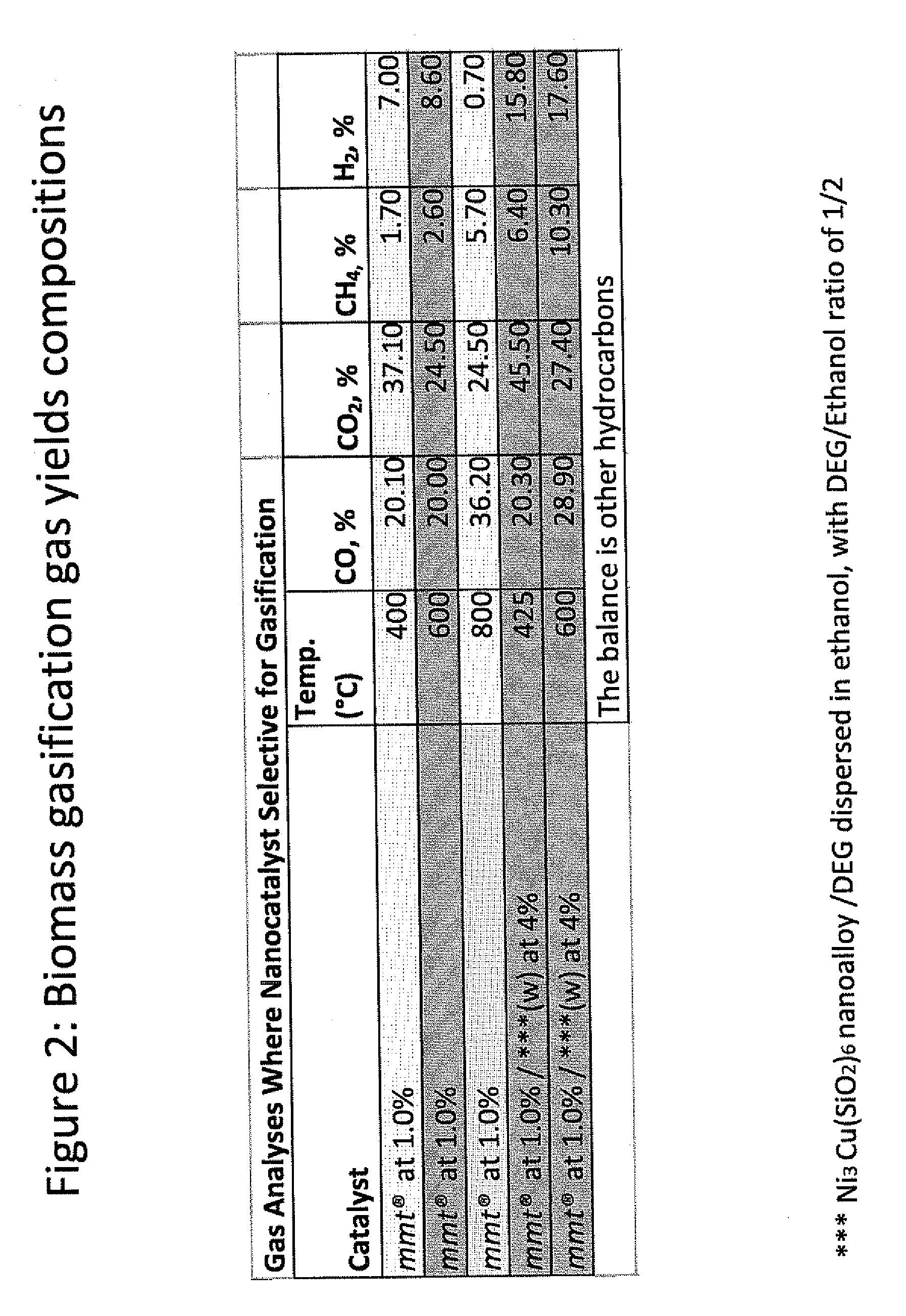

Nanoparticle Catalyst Compounds and/or Volatile Organometallic Compounds and Method of Using the Same for Biomass Gasification

InactiveUS20100299990A1Improve gasificationHigh gas yieldBiofuelsWaste based fuelNano catalystOil production

A nanocatalyst, dual catalyst and methods for improving the efficiency and output of a biomass gasification process are provided where the catalysts comprise a volatile organometallic compound(s) and / or a nanoalloy catalyst. By the catalyst and method, a very high biomass gasification conversion efficiency of over 85% can be achieved. The subject nanocatalyst cracks and gasifies lignin, which is generally inert in conventional gasification, at relatively low gasification temperatures. The subject disclosure also provides a means to increase gas yields and lower lignin content in the resulting product relative to conventional gasification. Alternatively, oil production may be increased, if desired. Moreover, the resulting gas may achieve a Fischer-Tropsch reactor favorable H2:CO ratio of about 9:1. The energy input to the gasification is correspondingly reduced to reduce costs and the environmental impact associated with the gasification process.

Owner:AFTON CHEMICAL

Ternary tobacco fiber paper filter stick of composite moistening plants and preparation method thereof

ActiveCN103054189AImprove adsorption capacityPromote absorptionCigarette manufactureTobacco smoke filtersFiberCellulose acetate

The invention relates to the technical field of tobacco filter sticks and discloses a ternary tobacco fiber paper filter stick of composite moistening plants. The ternary tobacco fiber paper filter stick is composed of a filter element and a molding paper wrapped on the filter element, the filter element comprises two sections of tobacco fiber paper filter elements and a moistening plant filter element arranged between the two sections of tobacco fiber paper filter elements, the tobacco fiber paper filter element is reeled by paper fibers, and the moistening plant filter element is pressed by throat moistening plant particle. The ternary tobacco fiber paper filter stick is based on wet-method papermaking and enables tobacco fiber slurry and long fiber slurry to be mixed according to appropriate proportion in a papermaking slurry mixing stage, and the prepared paper filter stick has stronger tar and nicotine removal capability than cellulose acetate fibers, does not bring in miscellaneous gas, wet whistles and returns sweet. Raw material resources are natural plants, the ternary tobacco fiber paper filter stick has no paper or chemical fiber taste, the color of the ternary tobacco fiber paper filter stick is same with that of cigarette scraps, the ternary tobacco fiber paper filter stick has strong natural material texture of tobaccos, and guides a new research direction for the technical field of cigarettes.

Owner:CHINA TOBACCO GUANGDONG IND

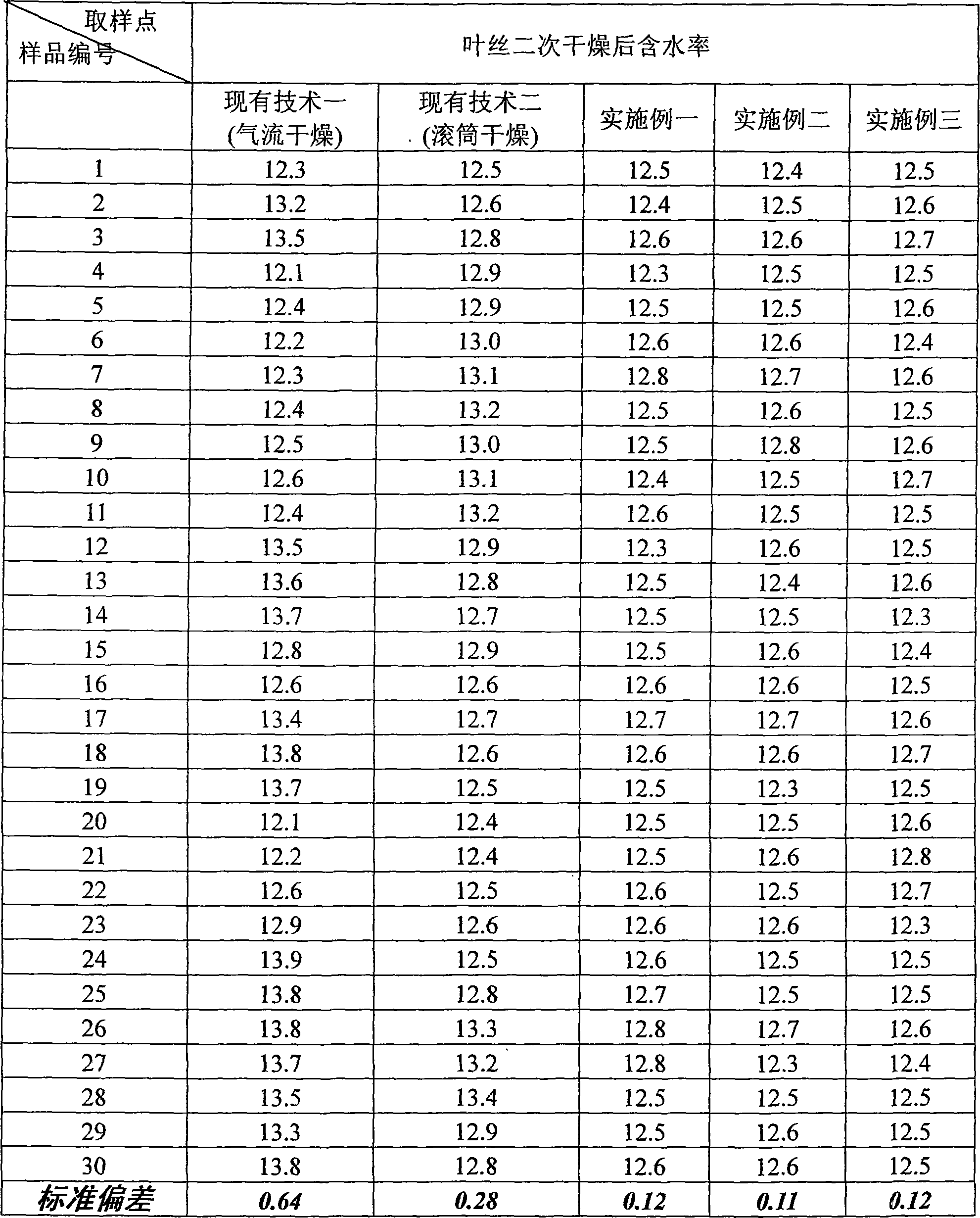

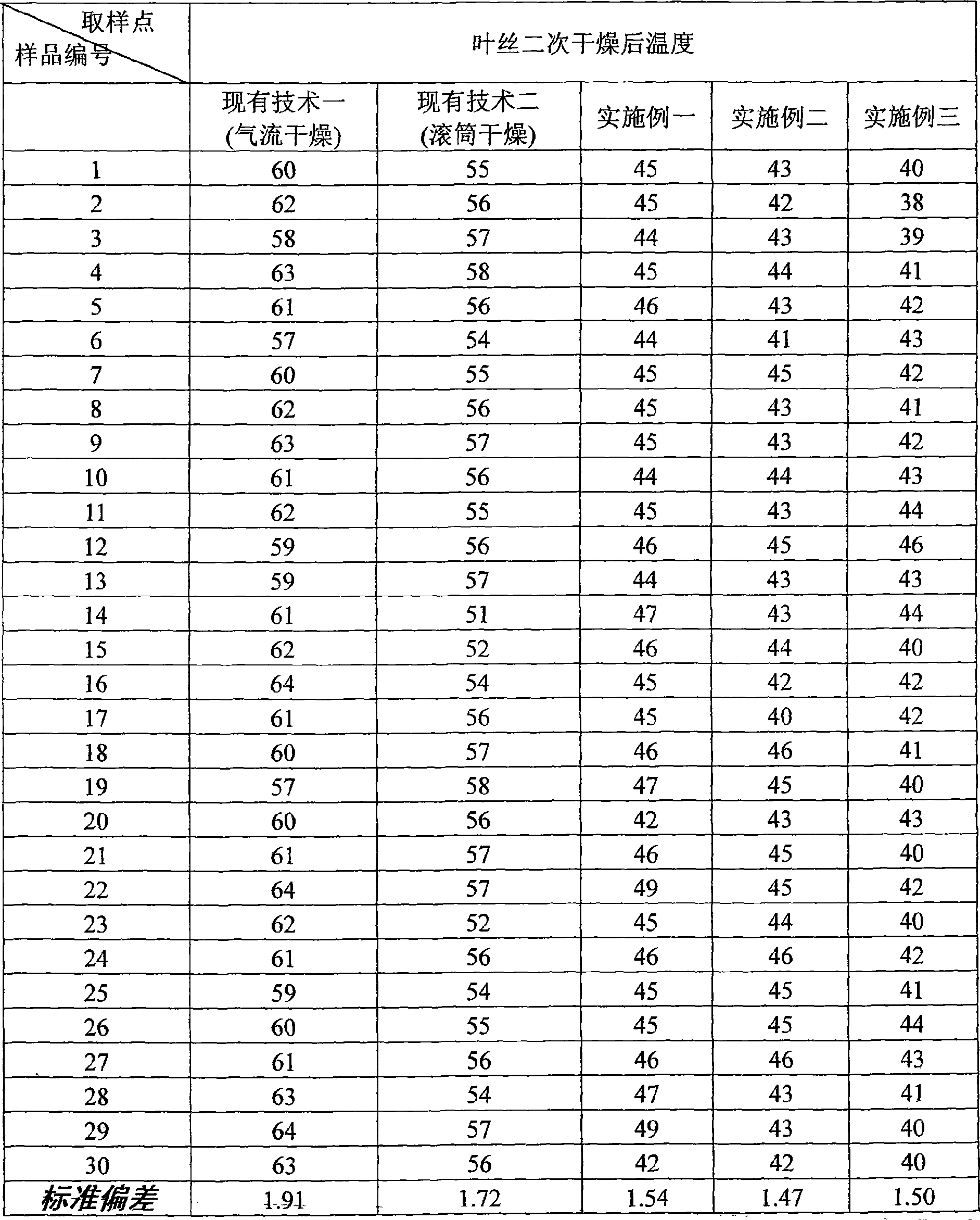

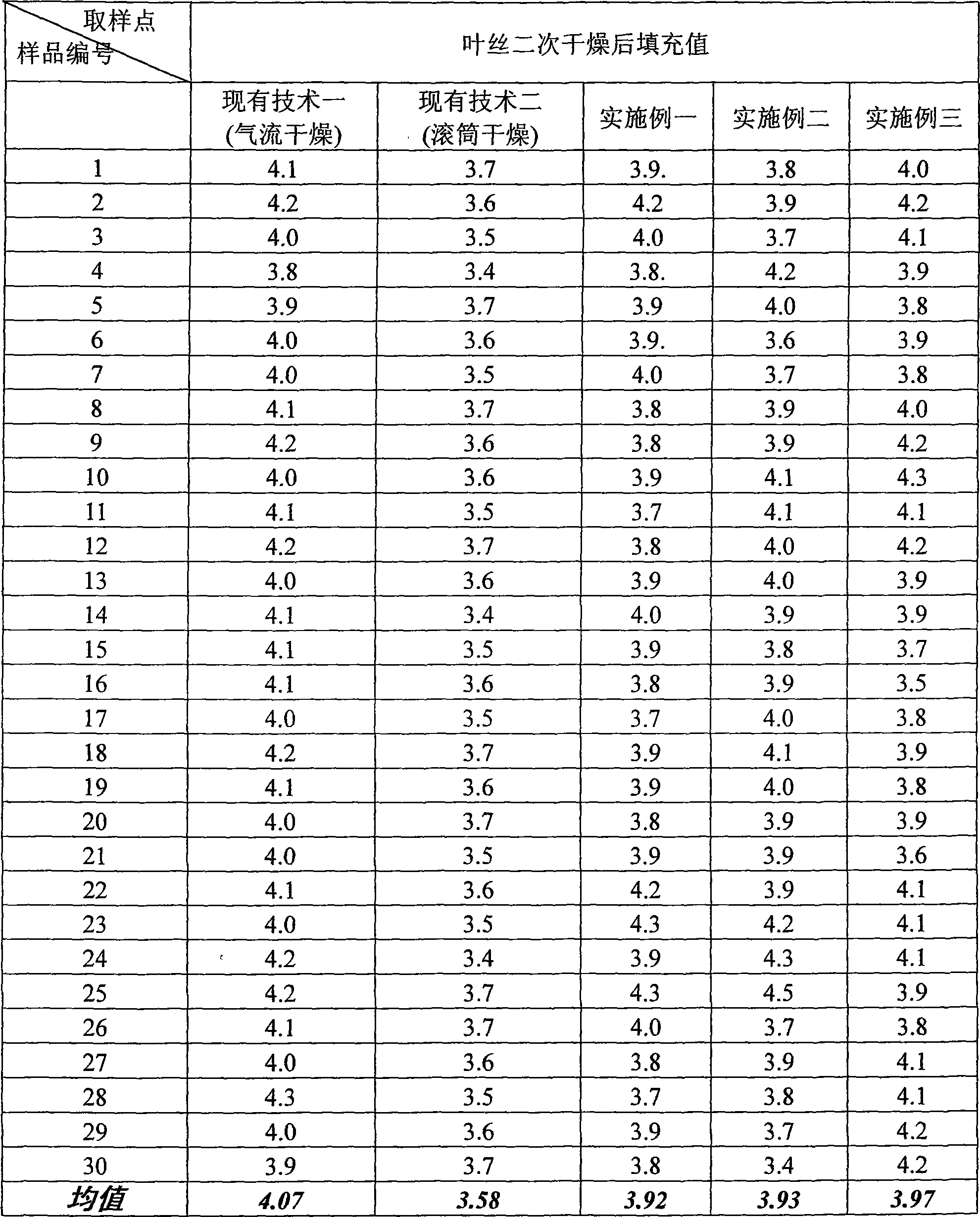

Drying method of tobacco fila in the cigarette processing course

ActiveCN101116527AGood filling effectImprove uniformityTobacco preparationTemperature controlAdditive ingredient

The present invention discloses a cut tobacco -drying technics during processing cigarette, which comprises two steps: the first step is to balance the water content of cut tobacco to 20 percent, and the cut tobacco is guided into a pneumatic drier, wherein the technics air temperature in the first section of pneumatic drier is controlled between 80 and 100 DEG C, and that in the second section is controlled between 70 and 90 DEG C, then the cut tobacco with 20 percent water content is dried and the water content is lowered to about 14 to 16 percent; and the second step is that the dried cut tobacco is guided into a roller dry machine for the secondary drying procedure, wherein the temperature of the wall of the roller is controlled between 70 and 80 DEG C, to control the water content of the dried cut tobacco between 12.0 percent and 13.0 percent. The present invention can not only improve both the uniformity of the water content and temperature stability of the processed tobacco with increased filling capability of the dried tobacco, but also reduce the loss of the fragrance of tobacco, to significantly decrease the content of injurious ingredients contained in cigarette such as tar, smoke and nicotine.

Owner:XIAMEN TOBACCO IND

Cigarette filter rod with zeolite fragrance beads and cigarette zeolite fragrance bead preparation method

The invention discloses a cigarette filter rod with zeolite fragrance beads and a cigarette zeolite fragrance bead preparation method. The cigarette filter rod comprises the zeolite fragrance beads, the zeolite fragrance beads take zeolite as a carrier, adsorb essence suitable for cigarette and are provided with open adsorption holes, and the adsorption holes adsorb the essence. According to the cigarette filter rod, the zeolite fragrance beads serve as solid fragrance beads and are used in cigarette filter rod, zeolite has open adsorption holes and high adsorption capacity, fragrant substances can be stably released when cigarettes are smoked after densely covered adsorption holes of the zeolite adsorb the essence, and stable fragrance can be acquired when the cigarettes are smoked.

Owner:SHANGHAI JUHUA TECH

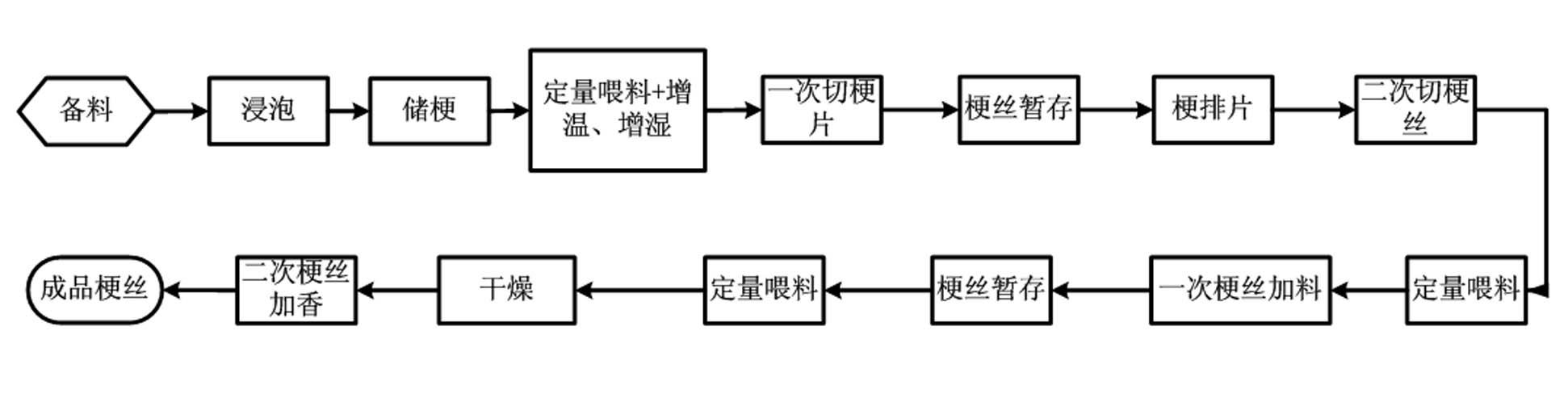

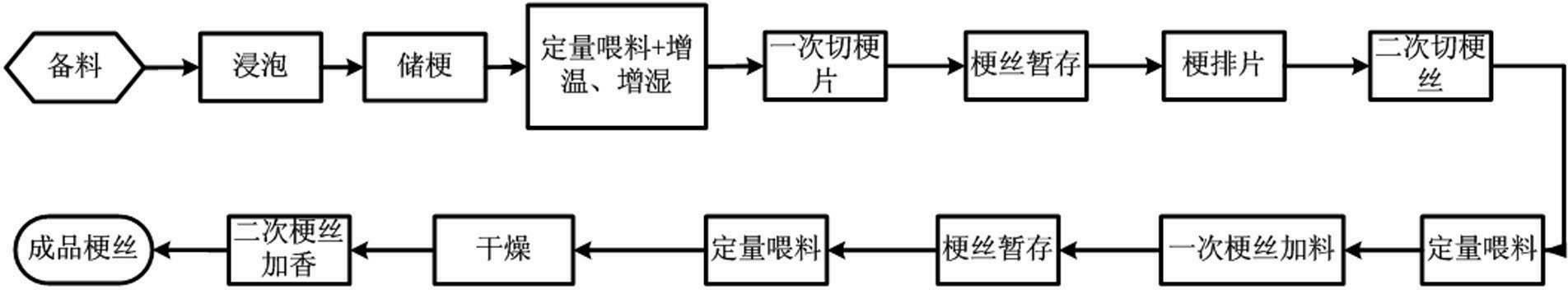

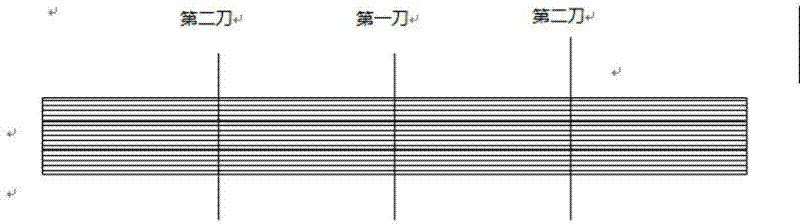

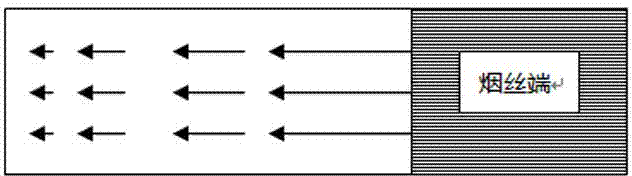

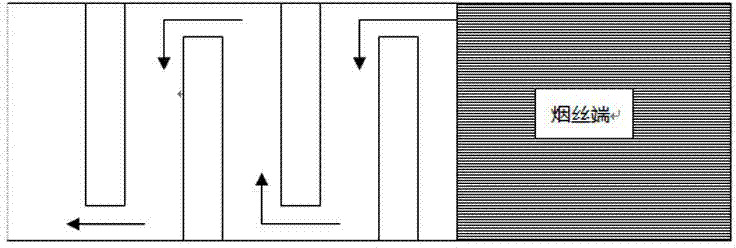

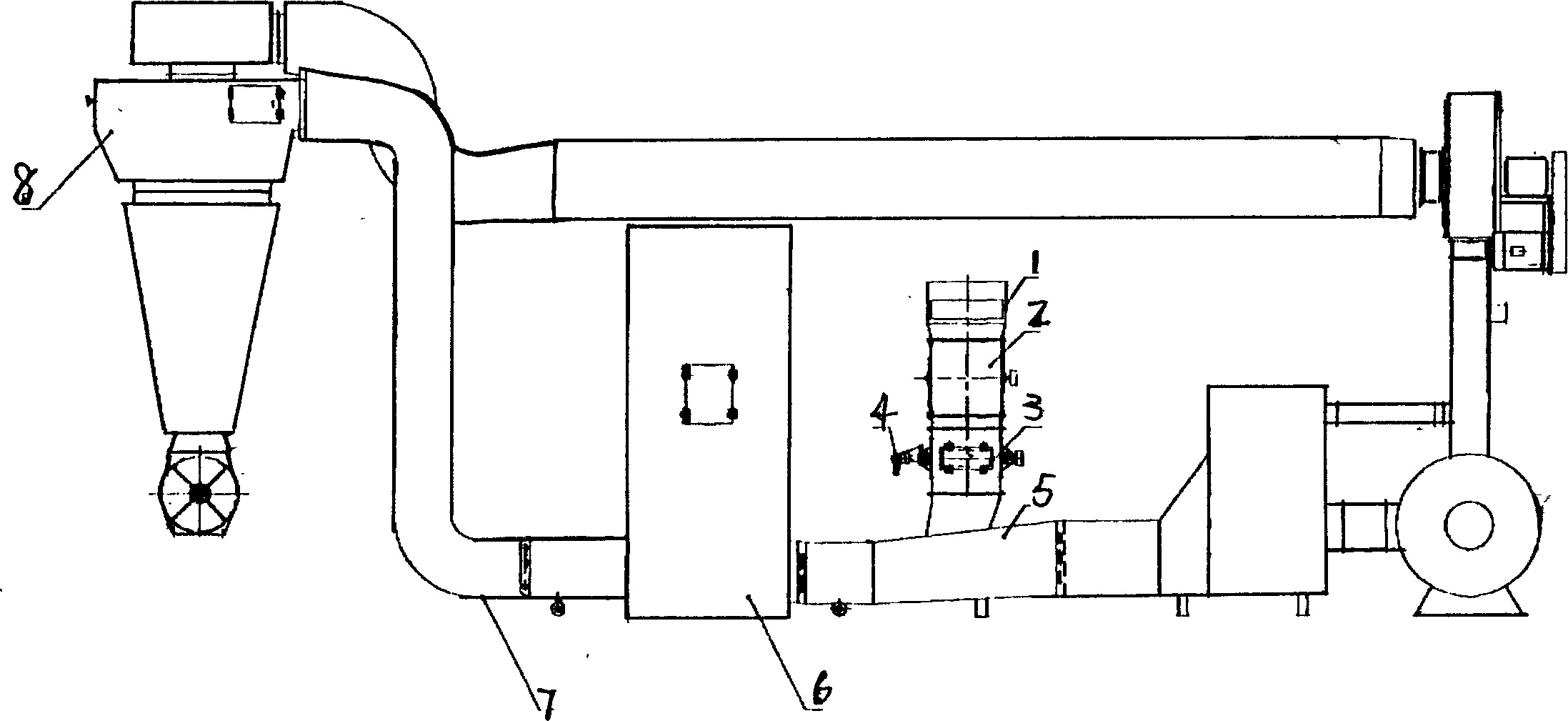

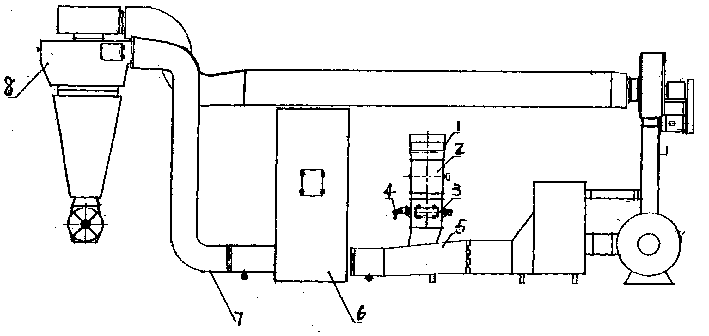

Technology for treating expanded stems

The invention discloses a technology for treating expanded stems, belongs to the technical field of shred making of tobacco, and in particular relates to the technical field of shred making with tobacco stems. The technology comprises the following steps of: soaking the tobacco stems, storing the stems, quantitatively feeding, heating and humidifying, slicing the stems for the first time, temporarily storing the stem slices, discharging the stem slices, cutting the stems into shreds for the second time, quantitatively feeding, adding the primary stem shreds, storing the stem shreds, quantitatively feeding, drying, and performing secondary flavoring, thus obtaining a stem shred finished product. The obtained product has the advantages of good bulkiness, low breaking rate, low production cost, pure aroma, high filling value, light wood mixed gas, comfortable mouthfeel, soft smoke, capability of reducing tar of cigarettes and good compatibility with the tobacco shreds.

Owner:HONGTA TOBACCO GRP

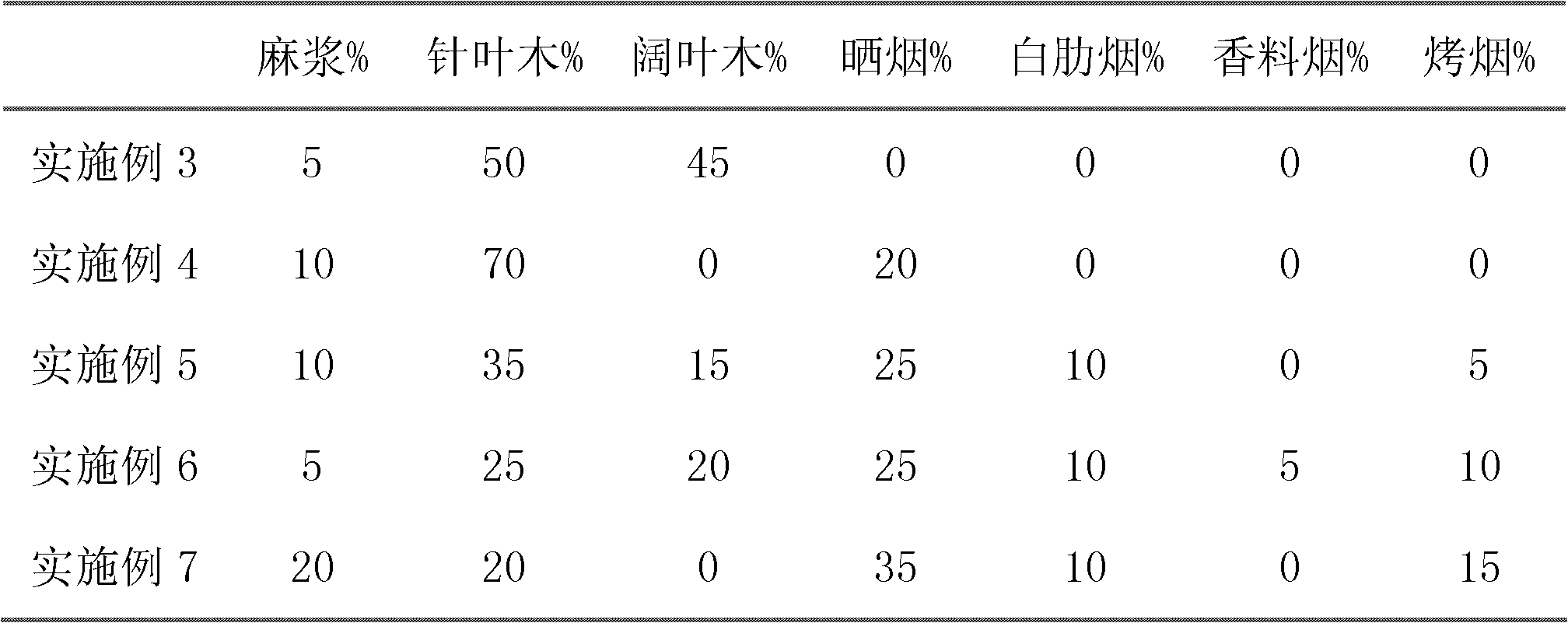

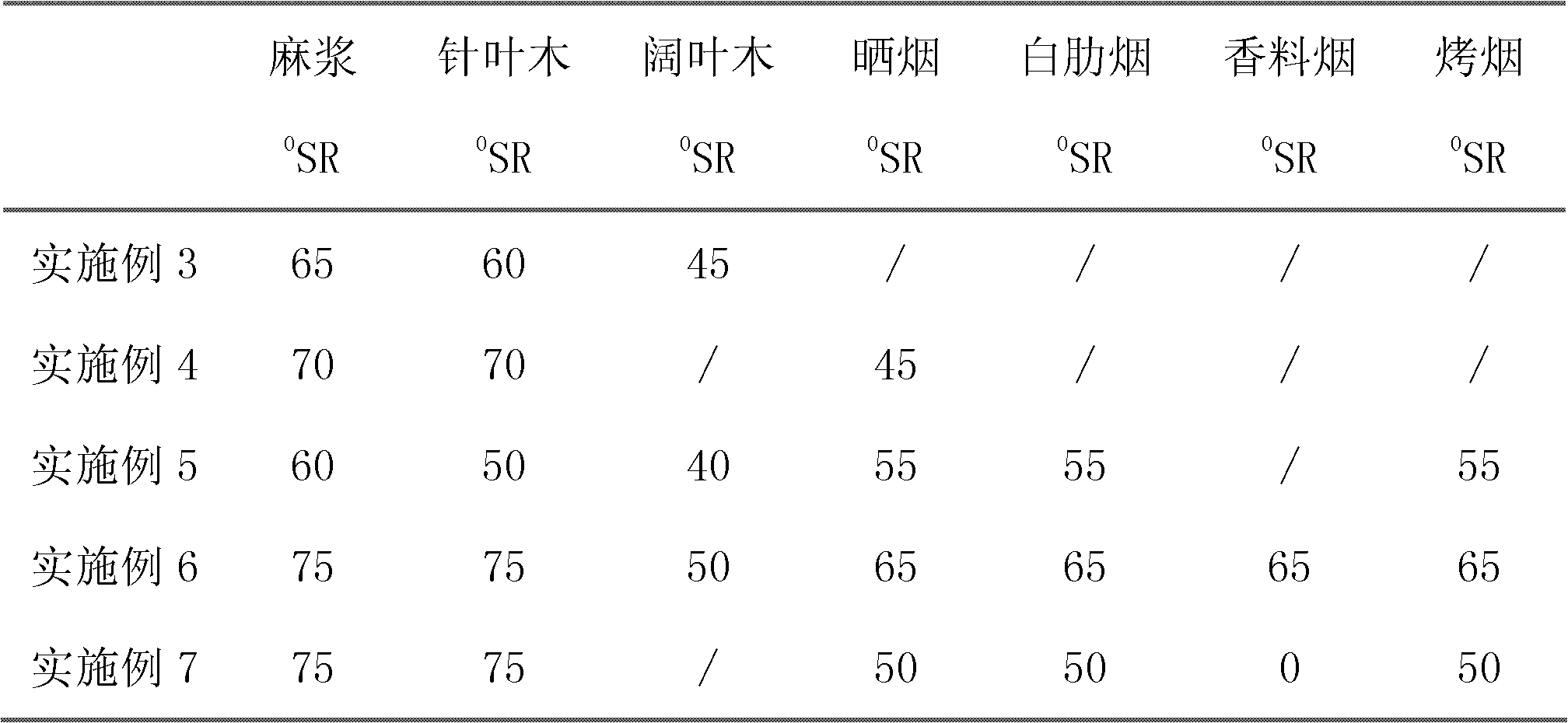

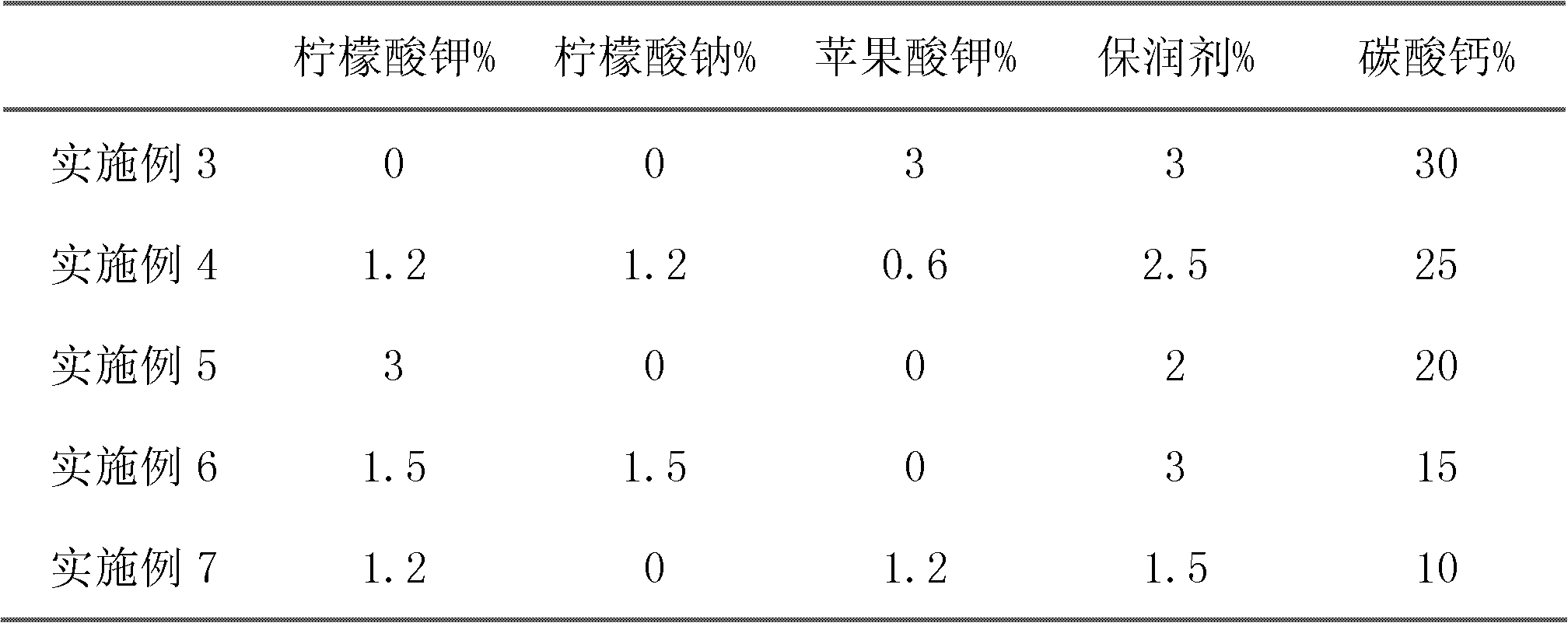

Preparation method of mechanically-wrapped tobacco-coated cigar wrapper

The invention relates to a preparation method of a tobacco-coated cigar wrapper which can reform the smoking flavor of cigar. The method comprises the following steps of: extracting tobacco raw materials (such as shreds or stems of burley tobacco, aromatic tobacco, sun-cured tobacco and flue-cured tobacco) alone or in combination; making a tobacco extract; adding combustion promoters and humectants to the tobacco extract; squeezing the tobacco raw materials and then blending and pulping with a paste mill to obtain tobacco slurry; blending additional wood pulp fibers commodity alone or in combination until reaching 40 degree SR to 75 degree SR to obtain additional fiber slurry; adding the tobacco slurry into the additional fiber slurry and then adding calcium carbonate to obtain mixed slurry; making a paper base with a fixed quantity of 28 g / m<2> to 40 g / m<2> from the mixed slurry by using a fourdrinier board machine; and coating the tobacco extract on the paper base to make a novel cigar wrapper, wherein the coating amount of the tobacco extract is 3 g / m<2> to 20 g / m<2>. The cigar wrapper produced by the invention can not only meet the requirements for sensory quality of cigars but also achieve conversion of manual wrapping to mechanical wrapping of cigar, and greatly increases cigar production efficiency.

Owner:HUBEI CHINA TOBACCO IND +1

Preparation method of cacao flavor, products obtained thereby and usage thereof

ActiveCN101445766AImprove tobacco qualityKeep the smellTobacco treatmentEssential-oils/perfumesMacromolecular SubstancesFlavor

The invention relates to the field of flavor preparation, in particular to a method for preparing cacao flavor, comprising the steps: composite liberation, zymohydrolysis, concentration, and the like, are carried on the cacao powder which is a raw material. The invention also relates to the cacao flavor prepared by the way and the usage of the flavor which is taken as cigarette additive. The preparation method can degrade giant molecule substances, such as starch, protein, pectine and the like, in cacao, improving the quality of the cacao flavor while maintaining the aroma of the cacao.

Owner:上海华宝孔雀香精有限公司

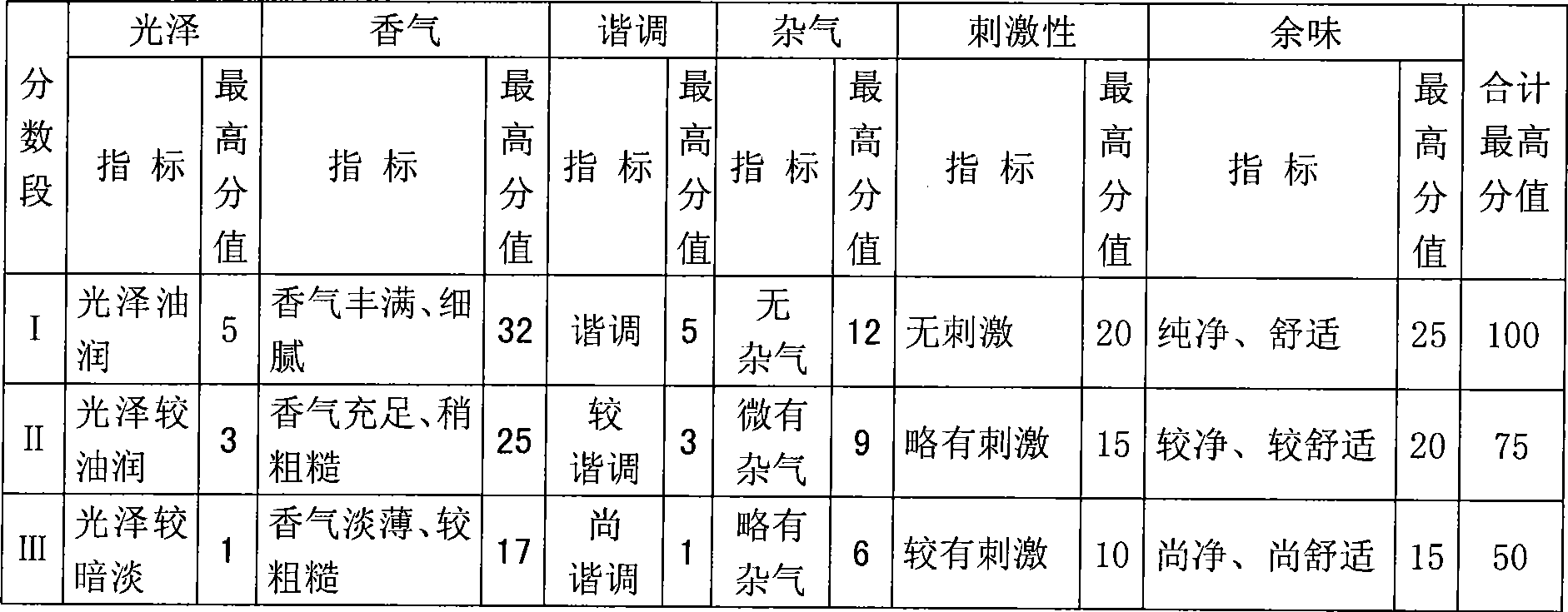

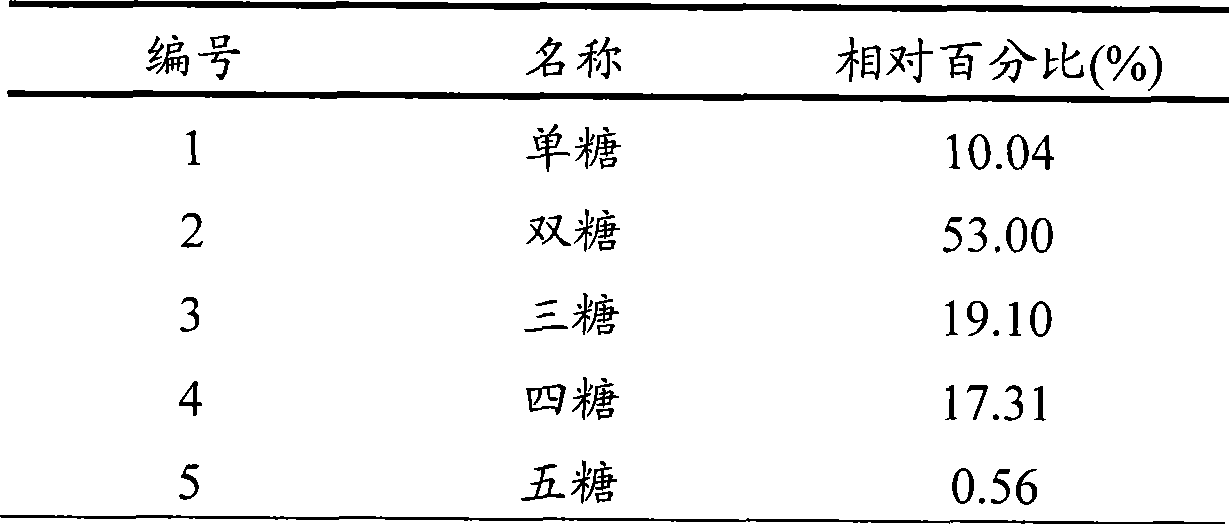

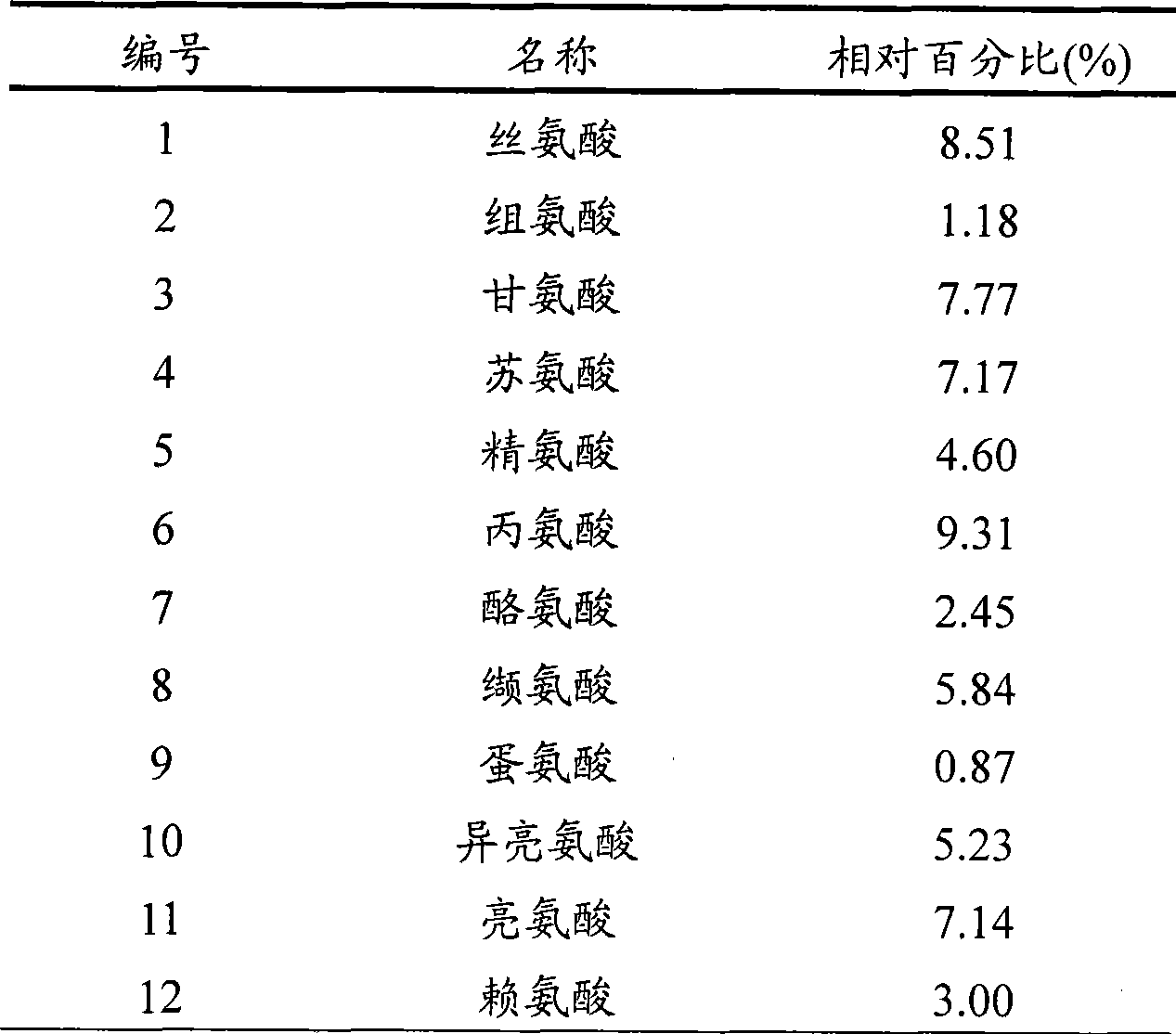

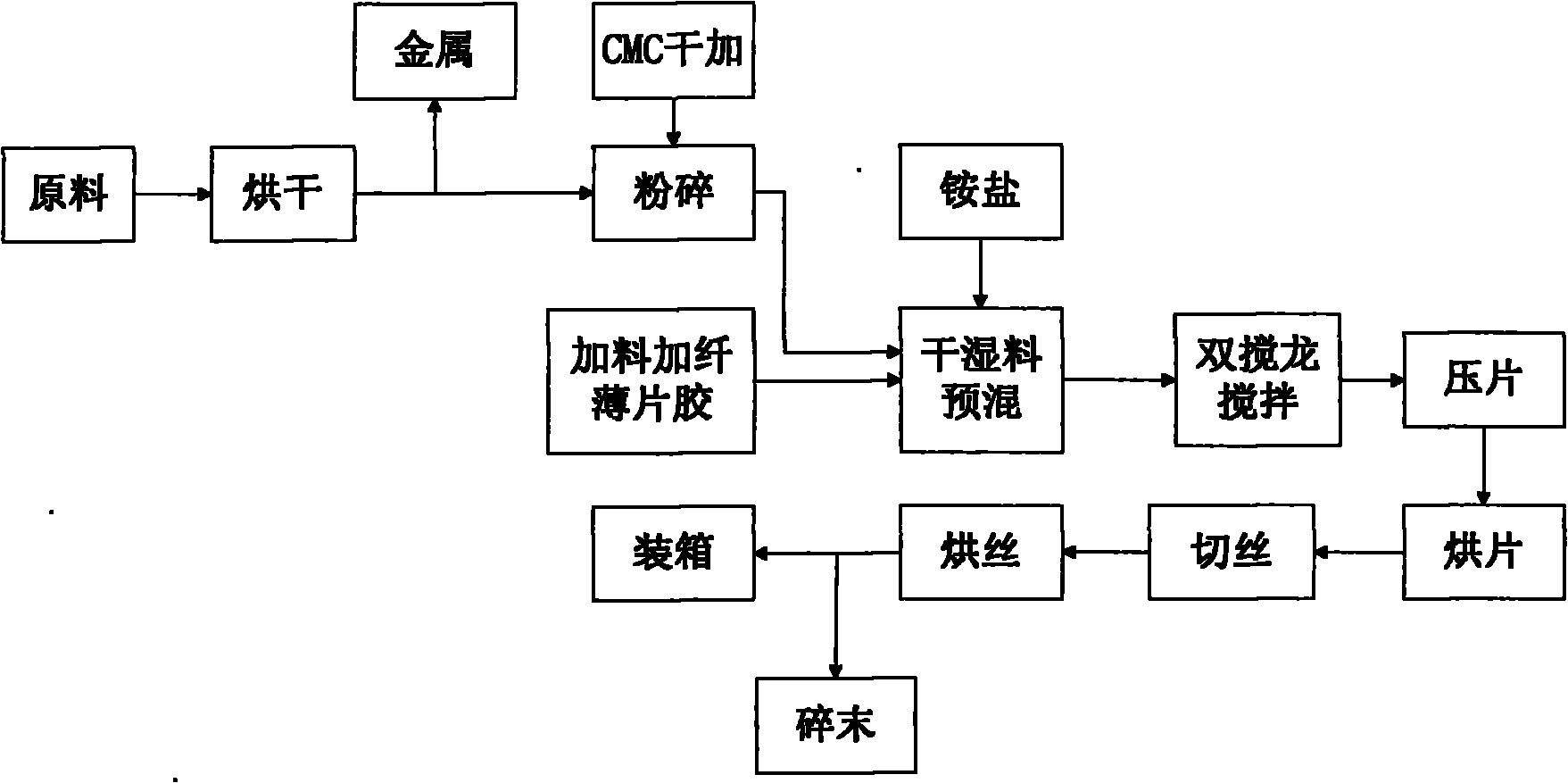

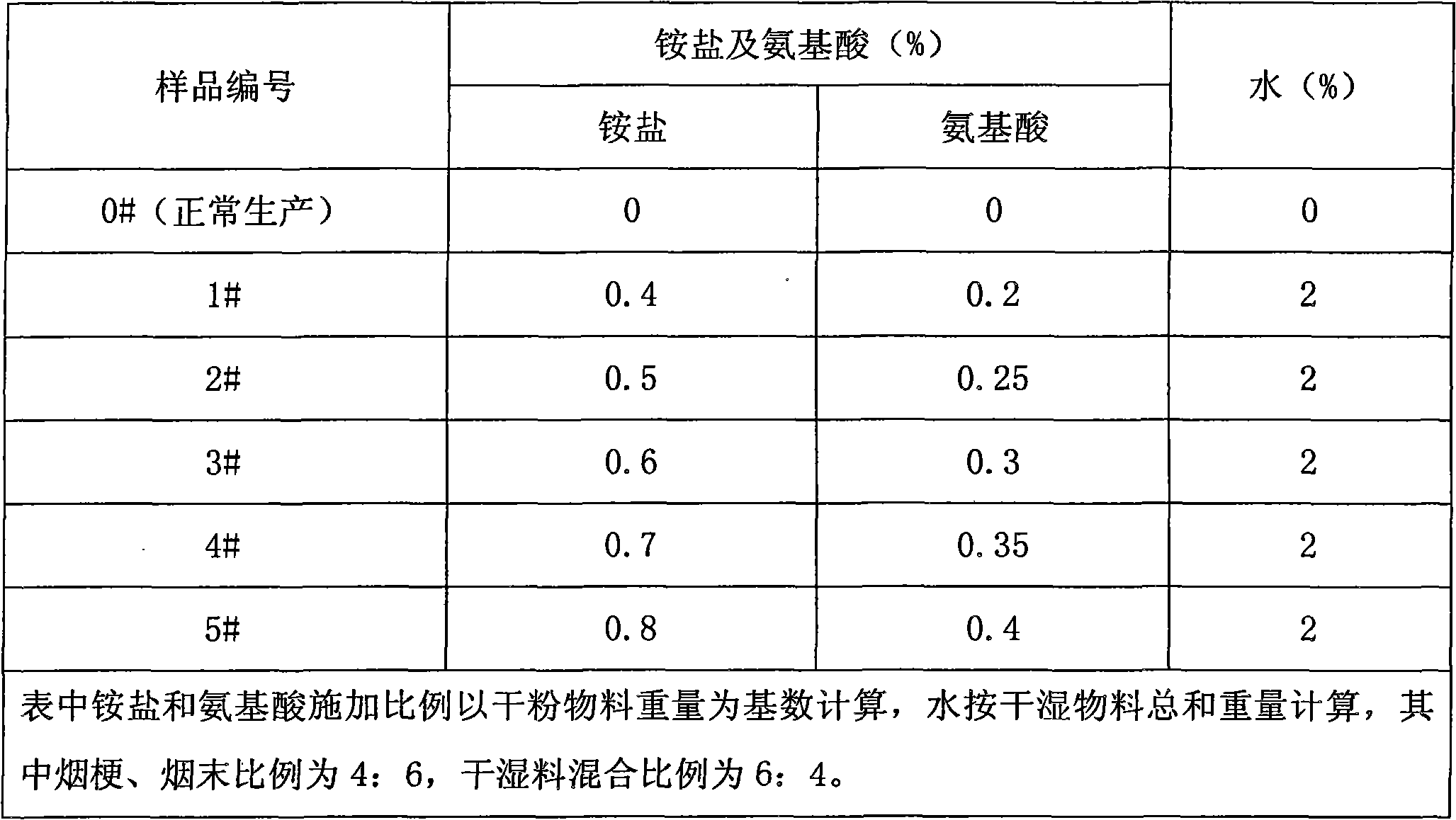

Ammonium salt-containing tobacco leaf reproduced by means of rolling

The invention relates to an ammonium salt-containing tobacco leaf reproduced by means of rolling. The tobacco leaf comprises the following components in parts by weight: 0.4-0.8 part of ammonium salt, 0.2-0.4 part of amino acid, 100 parts of dry material and 66-67 parts of wet material. Compared with the tobacco leaf reproduced by means of rolling, the ammonium salt and the amino acid are added into ammonium salt-containing tobacco leaf reproduced by means of rolling, thereby being capable of reducing the impure gas and the piquancy of the reproduced tobacco leaf, so that the ammonium salt-containing tobacco leaf has abundant fragrance; improves the remaining smell; leads the tobacco leaf with heavy impure gas, dirty oral cavity and piquancy feel to have natural tobacco fragrance; has unconspicuous impure gas and piquancy fell; leads the tobacco gas to have sweet and wet feel; can clean the oral cavity; and is smooth to a throat. The reproduced tobacco leaf not only improves the quality of sense organ, but also reduces the content of objectionable constituents such as phenol, CO and the like, and the content of tar, CO and the like in smoke indexes.

Owner:CHINA TOBACCO SHANDONG IND

Garbage cracking catalytic gasification furnace

InactiveCN102031149AReduce manufacturing costsSmall external areaChemical industryCombustible gas productionCatalytic reformingWater vapor

The invention discloses a garbage cracking catalytic gasification furnace. The cracking catalytic gasification furnace mainly comprises a preheating chamber, a cracking gasification chamber and a catalytic reforming chamber, wherein the preheating chamber is provided with an air inlet, an ash outlet, a fire grate and an electric heating tube; the air inlet is connected with an air inlet pipe; the air inlet pipe is provided with a magnetizer; strong-magnetic-field magnets are arranged around an air passage in the magnetizer and the magnets with the same polarity are arranged opposite to each other; the cracking gasification chamber is provided with a feed port and a vapor inlet; the catalytic reforming chamber is provided with a gas inlet, a product gas outlet and an electric heating tube; a magnetizer is arranged at the gas inlet; and a proper amount of catalyst is placed in the catalytic reforming chamber. Combustion heat of low-temperature part of garbage can maintain continuous cracking of the garbage under the action of a magnetic field, and catalytic reforming temperature of tar gas can be obviously reduced, and energy is saved. The equipment has a simple structure, low cost and higher product gas calorific value and can realize low-cost recycling of the garbage.

Owner:YANTAI UNIV

Cigarette filter rod containing aromatic silica gel beads and preparation method of aromatic silica gel beads for cigarettes

InactiveCN107836749AStrong adsorption performanceImprove stabilityTobacco smoke filtersCigarette filterSilica gel

Owner:SHANGHAI JUHUA TECH

Tobacco slice and cigarette

ActiveCN103211288AReduce the presence of hazardous substancesReduce tarTobacco preparationHazardous substanceTar

The invention provides a tobacco slice and a cigarette. The tobacco slice comprises a slice substrate, wherein the slice substrate is prepared by adopting a mixture comprising agricultural waste materials and tobacco waste materials as raw materials. The cigarette comprises cut tobacco, wherein 2 to 100 mass percent of cut tobacco slices are mixed in the cut tobacco, in addition, the tobacco slice comprises the slice substrate, and the slice substrate is prepared by adopting a mixture comprising agricultural waste materials and tobacco waste materials as raw materials. The tobacco slice prepared by adopting the mixture of the agricultural waste materials and the tobacco waste materials as the raw materials is added into the cigarette, harmful substances in the main flow smoke gas of the cigarette can be obviously reduced, the tar is reduced, and the smoke gas state is improved, so the main flow smoke gas is fluffy and soft, the mouth feeling comfort is improved, the oral cavity residue is reduced, the defect of smoke gas concentration reduction caused by too high content when only non-tobacco slices are adopted can be overcome, meanwhile, the goal of resource reutilization is also reached, and the problem of tobacco slice raw material shortage is solved.

Owner:ZHONGYAN SHIWEICE (YUNNAN) RECONSTITUTED TOBACCO CO LTD

Functional low-gram-weight cigarette paper and preparation method thereof

ActiveCN104790264AGood technical effectImprove sensory qualityFlexible coversCoatings with pigmentsFiberAdditive ingredient

The invention relates to functional low-gram-weight cigarette paper, wherein the body phase thereof contains cut tobacco fibres or a first tobacco powder, a second tobacco powder is attached to the outer surface of at least one side of the body phase, and the first tobacco powder is the same as or different from the second tobacco powder. The invention further relates to a preparation method of the functional low-gram-weight cigarette paper. The preparation method comprises the following steps: (1) preparing paper pulp; (2) preparing special suspension stabilizing fluid for cigarette paper coating; and (3) making paper by a paper machine. The functional low-gram-weight cigarette paper disclosed by the invention is uniform in colouring and capable of improving the non-transparency of the cigarette paper; moreover, the functional low-gram-weight cigarette paper is good in stiffness and beneficial to roll; meanwhile, the functional low-gram-weight cigarette paper is good in ash wrapping force and capable of improving the smoking feeling of cigarettes. The functional low-gram-weight cigarette paper disclosed by the invention is also capable of effectively improving the sensory quality of the rolled cigarette produced during a smoking process and reducing harmful ingredients in the smoke of the cigarettes. Therefore, the functional low-gram-weight cigarette paper disclosed by the invention has a wide application prospect.

Owner:CHINA TOBACCO YUNNAN IND

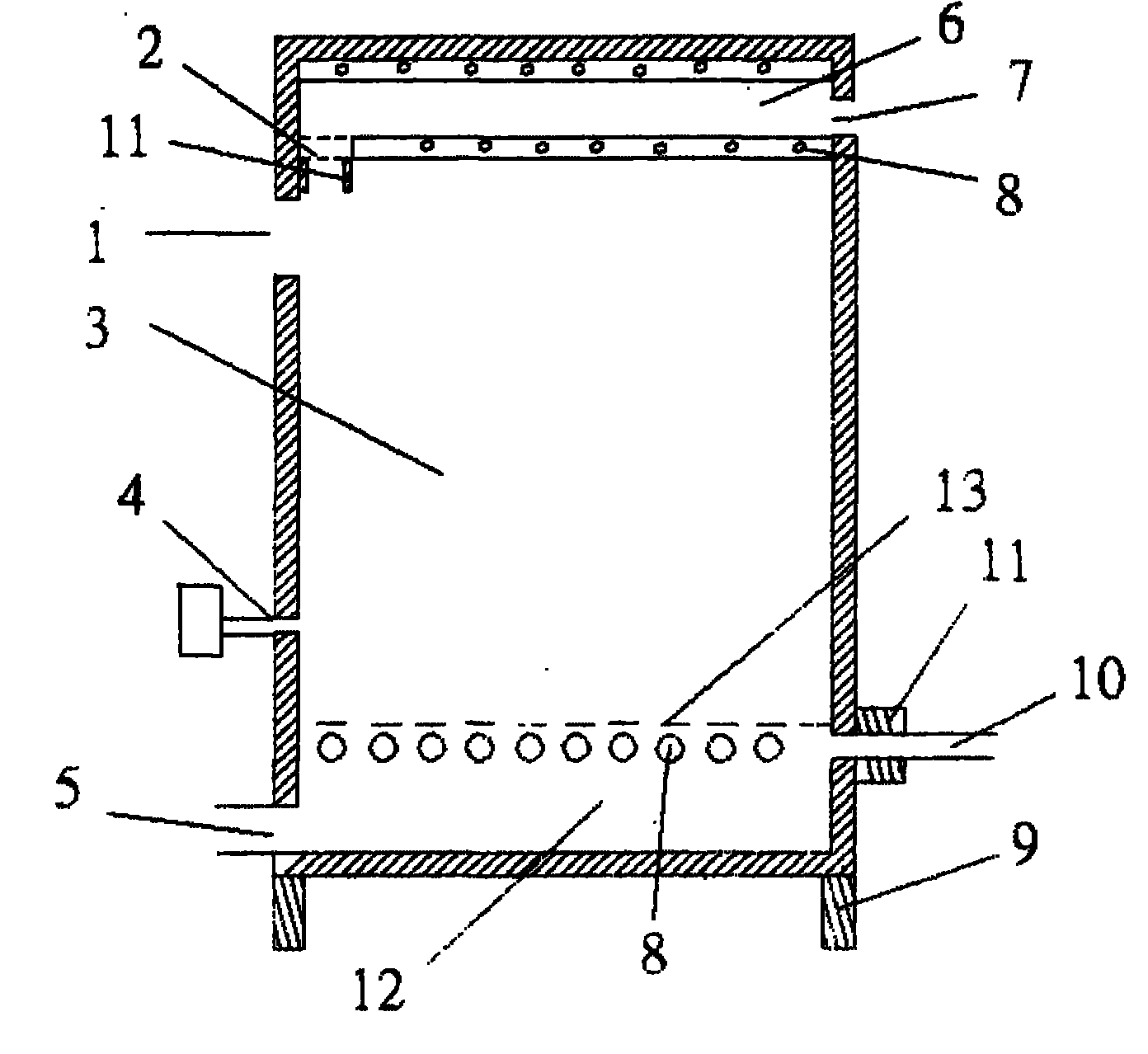

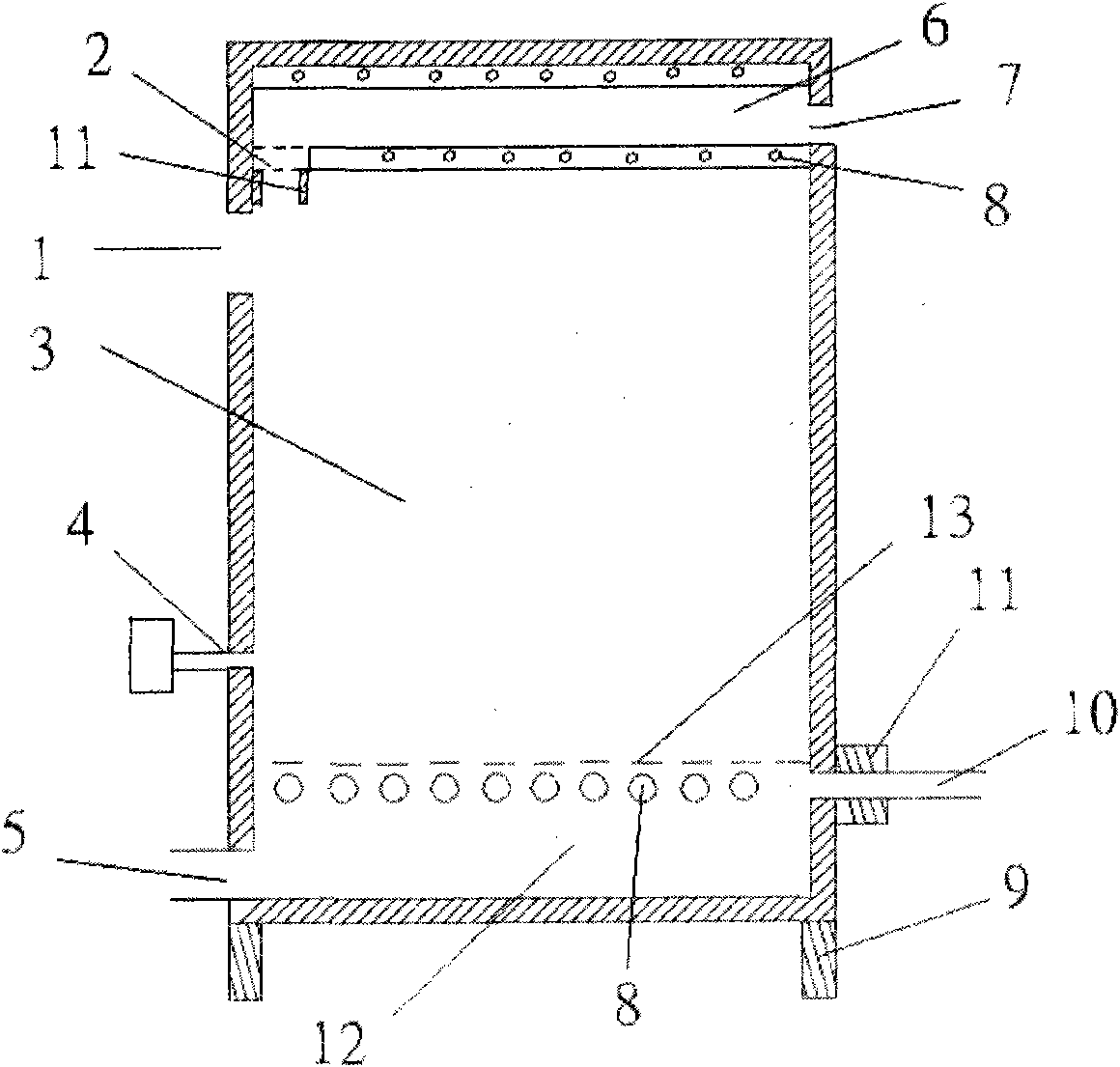

Additive for reducing the content of coke tar and whitedamp in the cigarette smoke and method of use thereof

An additive capable of reducing tar and carbon monoxide contained in cigarette is provided, as well as the application method of the additive, which contains inorfil loaded with metal-salt. The accretion provided by the present invention prepared and added conveniently with low cost is suitable for requirement of industrialized production, capable of well decreasing the tar and carbon monoxide contained in cigarette smoke and greatly reducing the harm to the smoker.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Tobacco flue-curing and amending agent

InactiveCN1370474AIncrease the amount of aromaIncrease aromaTobacco preparationPotassium nitratePhosphate

The present invention belongs to tobacco flue-curing and amending technology. The tobacco flue-curing and amending agent consists of licorice, potassium gluconate, potassium citrate, potassium nitrate, ammonium dibasic phosphate, fructose, sugar and water. It can raise the quality of treated tobacco in the process of tobacco flue-curing and amending. The said product can be formed into solid, liquid, aerosol or other forms.

Owner:吴昊

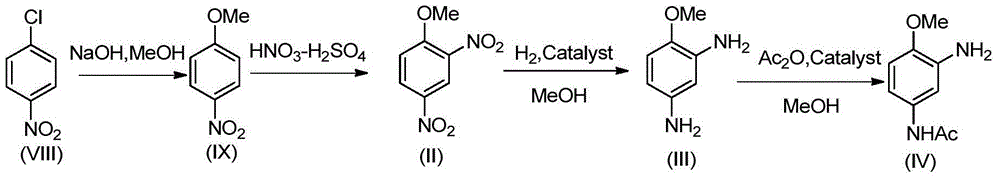

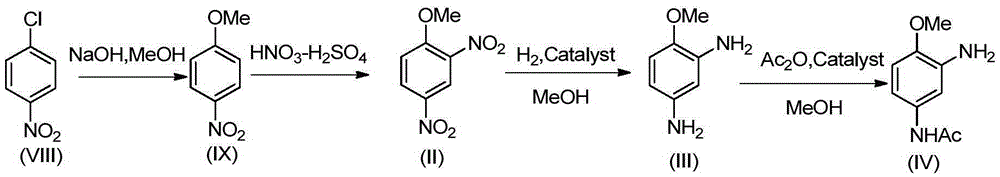

2-amino-4-acetamino anisole synthesis process

InactiveCN105348132AReduce process time and energy consumptionReduce dosageOrganic compound preparationCarboxylic acid amides preparationChemistryAcetic anhydride

The invention discloses a 2-amino-4-acetamino anisole synthesis process. The process comprises the following steps that in methyl alcohol, 2,4-diaminobenzene methyl ether (III) and acetic anhydride are subjected to an acylation reaction as follows under the effect of an acid-binding agent to obtain 2-amino-4-acetamino anisole (IV), wherein the mole ratio of the acid-binding agent to the 2,4-diaminobenzene methyl ether is 0.3:1-0.6:1. The synthesis process is low in energy consumption, low in cost, small in amount of solid waste and liquid waste, free of pollution, environmentally friendly, easy to operate, mild in reaction condition and high in industrial safety coefficient, the target compound yield is 86% or above (based on initial reaction raw materials), the HPLC purity is 99.0% or above, and the target compound is high in yield, good in quality, and more applicable to industrial production.

Owner:安徽奥瑞化工有限公司

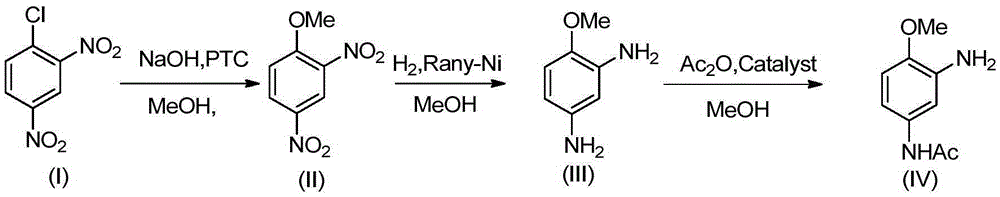

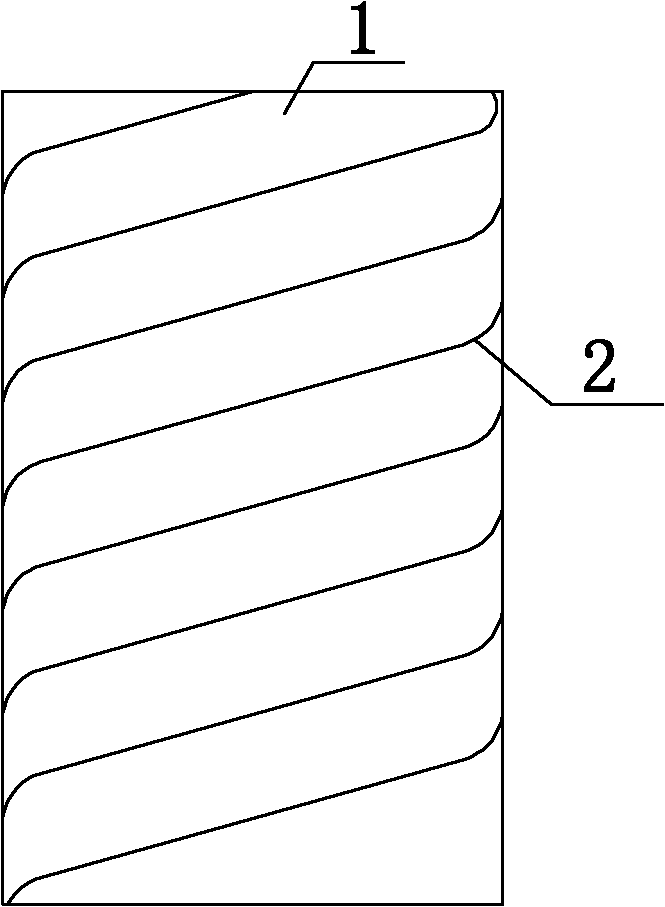

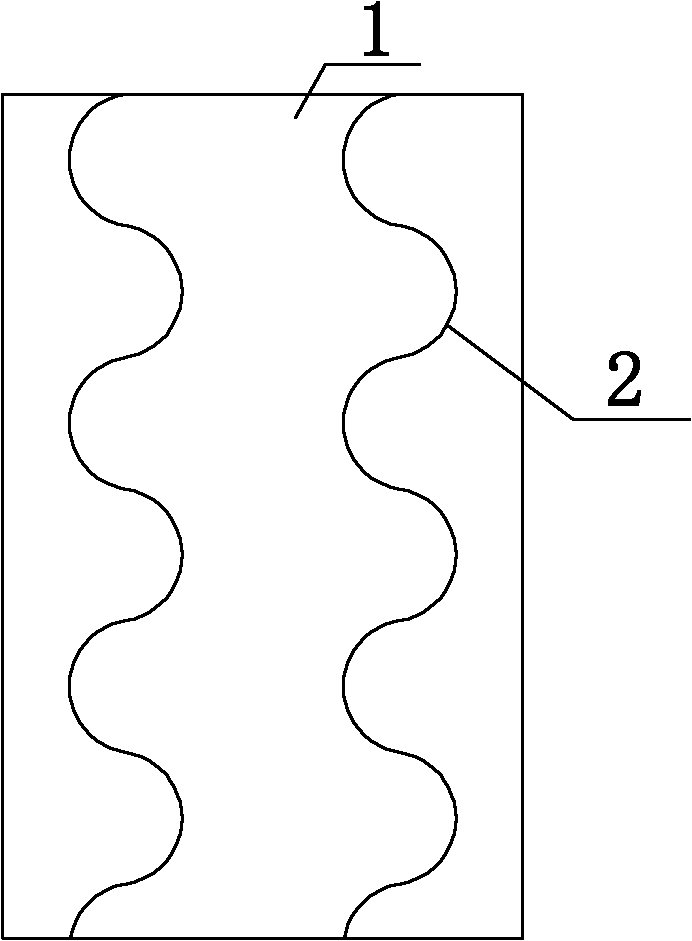

Cigarette filter tip

InactiveCN101822429AIncreased flow distanceReduce tarTobacco smoke filtersTobacco pipesEngineeringCigarette filter

The invention discloses a cigarette filter tip, which belongs to the field of filter tips. The cigarette filter tip comprises a filter tip bar, wherein the filter tip bar is a solid bar, and the surface of the solid bar is provided with continuous grooves or protrusions. The cigarette filter tip prolongs the flowing distance of cigarette smoke to make the smoke softer, and can properly reduce tar and harm.

Owner:郑敦森 +2

Composite solid filter rod and preparation method thereof

ActiveCN102499475ASimple processIncrease flow lengthTobacco smoke filtersPolymer sciencePolyvinyl chloride

The invention provides a composite solid type filter rod, belongs to the technical field of cigarette process, and particularly relates to a design and manufacturing method of a new material filter rod in a cigarette filter. The filter rod consists of one or a combination of more than one of medical grade PVC (polyvinyl chloride), medical grade PLA (poly lactic acid) and polycaprolactone serving as a raw material, and an auxiliary material glyceryl triacetate, wherein the weight ratio of the raw material to the auxiliary material is (1-9):1. According to the composite solid filter rod and the preparation method, the passing route of smoke in the filter can be effectively prolonged, and harmful ingredients in the smoke can be effectively filtered.

Owner:SHANGHAI HUABAO BIOLOGICAL TECH

Catalyst and aromatic amino compound preparation method

ActiveCN105080567AHigh yieldReduce contentOrganic compound preparationAmino compound preparationMischmetalNitro compound

The present invention provides a catalyst and an aromatic amino compound preparation method. The catalyst comprises a carrier, a main precious metal, a minor precious metal, a main non-precious metal and a minor non-precious metal, wherein the main precious metal, the minor precious metal, the main non-precious metal and the minor non-precious metal are loaded on the carrier, the main precious metal is Pd, the minor precious metal is Pt, the main non-precious metal is Fe, Ce or Mn, and the minor non-precious metal is at least one selected from Ni, Cu, Zn, Co, Mo, V, Sn and a rare earth metal. According to the present invention, the catalyst has high catalysis activity and high selectivity when the catalyst is used for catalyzing aromatic nitro compound hydrogenation to produce aromatic amino compounds, and the by-product content can be significantly reduced so as to obtain the high aromatic amino compound yield.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Cut tobacco fast puffing and drying process

InactiveCN1436495AReduce green miscellaneous gasHigh expansion rateTobacco preparationTarLower grade

The present invention relates to the tobacco processing process and is especially the puffing and drying process of cut tobacco. The tobacco process includes feeding material, heating cut tobacco, puffing and discharge. The beneficial effects of the present invention includes reserving tobacco fragrance in cut tobacco, reducing the green and sundry smell in cut tobacco, converting the color of low-grade cut tobacco, raising the puffing rate of cut tobacco, reducing cost of cigarette, raising filled tobacco amount, decreasing tar content in cigarette, making cut tobacco soft, loose elastic and no oxidation and browning, killing bacteria and other toxic microbes and producing no environmental pollution.

Owner:江苏智思机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com