Patents

Literature

119results about How to "Increase ash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for paper-making process tobacco sheet and finished product of paper-making process tobacco sheet

ActiveCN103141928AImprove single layer retentionImprove breathabilityTobacco preparationPlant fibrePaper based

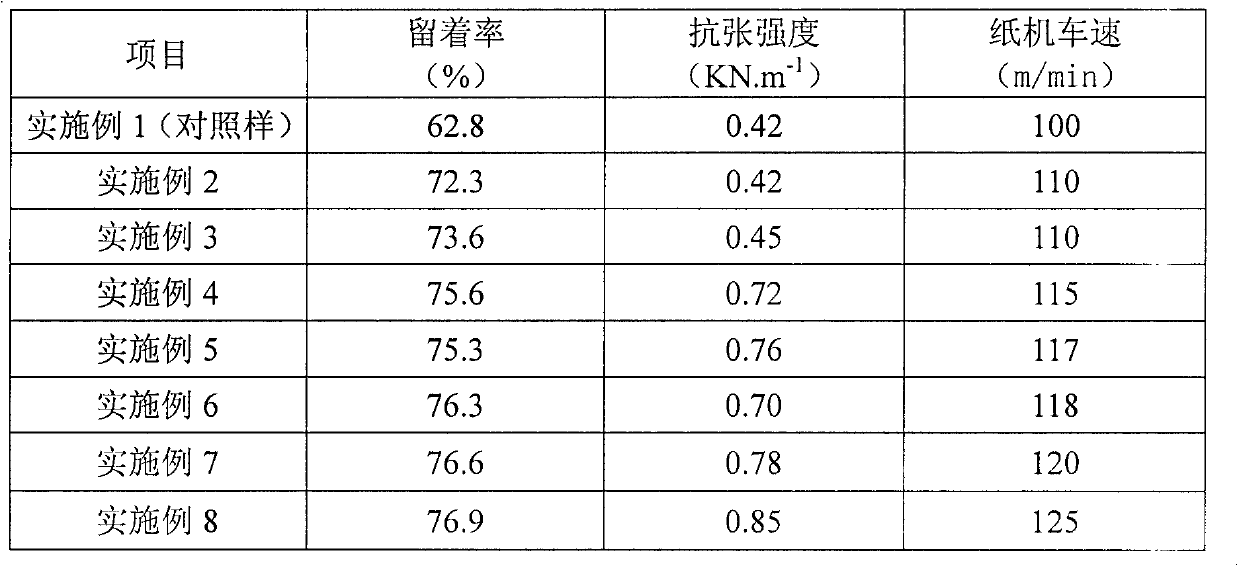

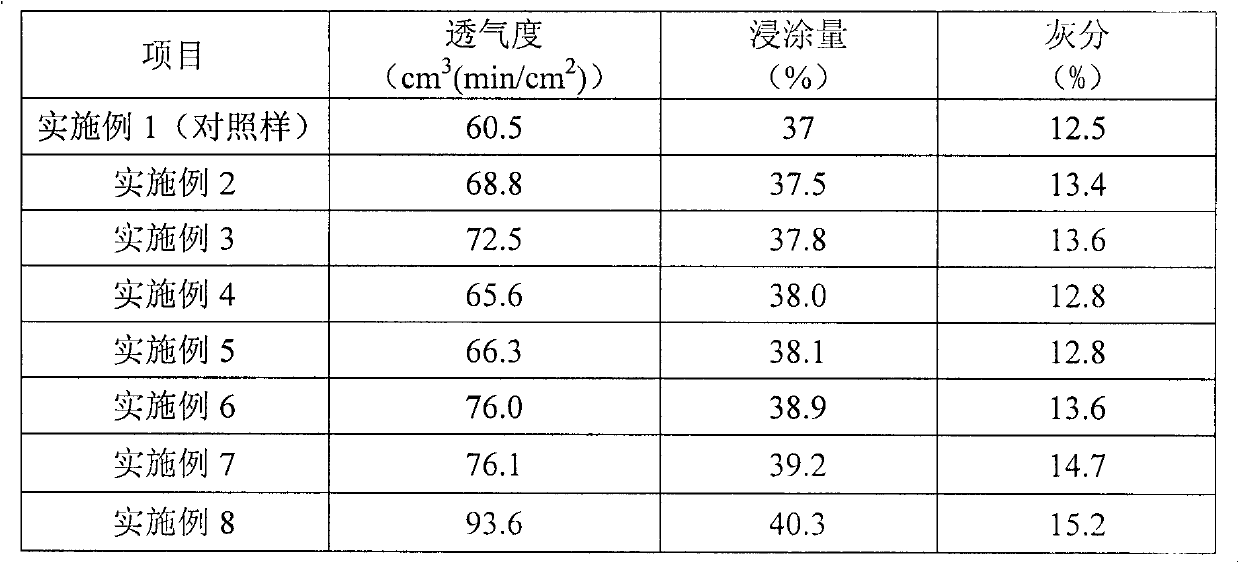

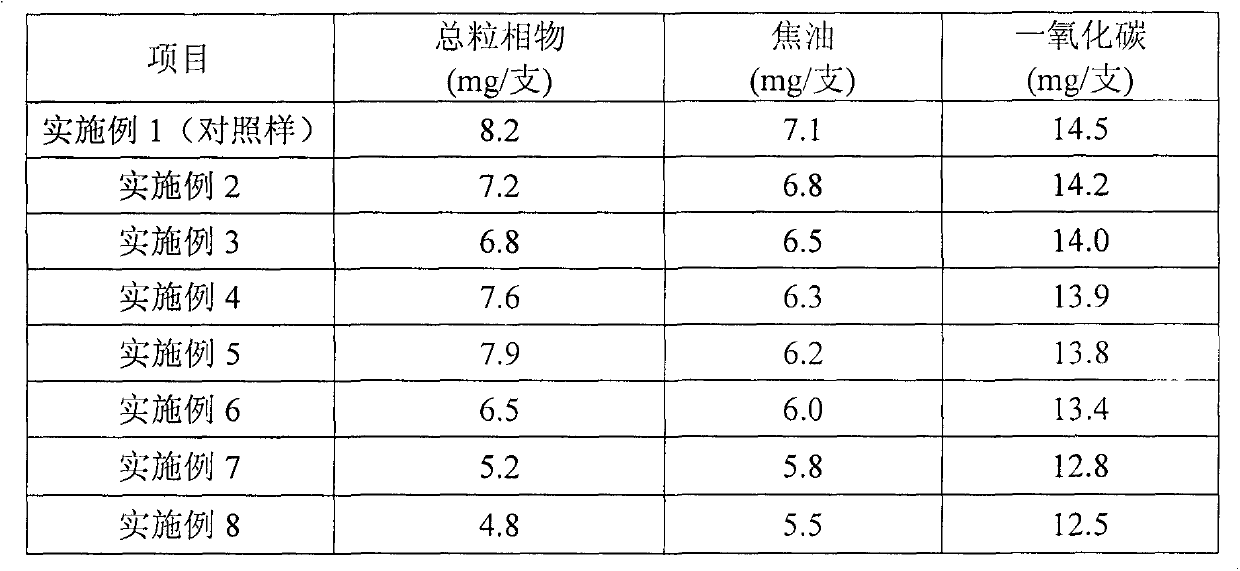

The invention belongs to the field of tobacco industry and relates to a preparation method for a functional harm-reduction and tar-reduction paper-making process tobacco sheet and a finished product of the paper-making process tobacco sheet. The preparation method for the paper-making process tobacco sheet comprises the following steps of extracting and concentrating effective components of tobacco; mixing formulas; pulping and blending fibers; manufacturing paper with pulp; dipping, drying and tearing and shaping. The blending process comprises the following steps of: adding non-tobacco plant fiber pulp of which the beating concentration is 3-4 percent and the Schopper-Riegler (SR) beating degree is 18-28 to tobacco mixed fiber pulp, adding filling to a machine chest, regulating the pulping concentration to 2-3 percent by water, and evenly mixing. By the use or the combine use of the filling and the non-tobacco plant fiber pulp, the combustion state of the sheet can be improved while physical properties, such as the air permeability, the retention and the tensile strength of a paper base, are improved, i.e., harmful ingredients of smoke, such as tar and carbon monoxide of the paper-making process tobacco sheet, can be effectively reduced, and hazard indexes of cigarettes are reduced. Meanwhile, technical-economic indicators, such as the speed and the input- output efficiency of a paper machine, also can be improved.

Owner:杭州利群环保纸业有限公司

Preparation and application for paper-making process reconstituted tobacco sizing agent coated with calcium carbonate

InactiveCN104705775AImprove performanceRealize the function of reducing focus and harmTobacco preparationFiberProcess engineering

The invention relates to a method and application for a paper-making process reconstituted tobacco sizing agent coated with calcium carbonate. The method comprises the steps that wood pulp fibers, tobacco stem fibers and fragment fibers are used for preparing a sizing agent, then, the sizing agent is soaked into a soluble carbonate solution for 0.5 h to 3 h, and then water is removed through centrifuge dripping; the sizing agent fiber with no water is added into a soluble calcium salt with the calcium ion concentration ranging from 1 mol / L to 3 mol / L, the concentration of the sizing agent is controlled to range from 3% to 10%, and a reaction is performed at room temperature for 3 min to 5 min; in the sizing agent solution, citric acid with the mass concentration ranging from 0.01% to 0.03% is added as a crystal form control agent, and CO2 is led into the solution at the temperature ranging from 20 DEG C to 35 DEG C for a reaction for 0.5 h to 1 h until the pH value of the solution ranges from 7.0 to 7.5, so that a certain amount of nano calcium carbonate coats the surface of paper-making process reconstituted tobacco, and centrifuge dripping is carried out to obtain the paper-making process reconstituted tobacco sizing agent coated with calcium carbonate. The method has the advantages of being easy to implement, high in efficiency and high in application value.

Owner:CHINA TOBACCO YUNNAN IND

Method of preparing quaternary ammonium type cationic starch

InactiveCN101033260AReasonable production processReduce the temperatureQuaternary ammonium cationSynthesis methods

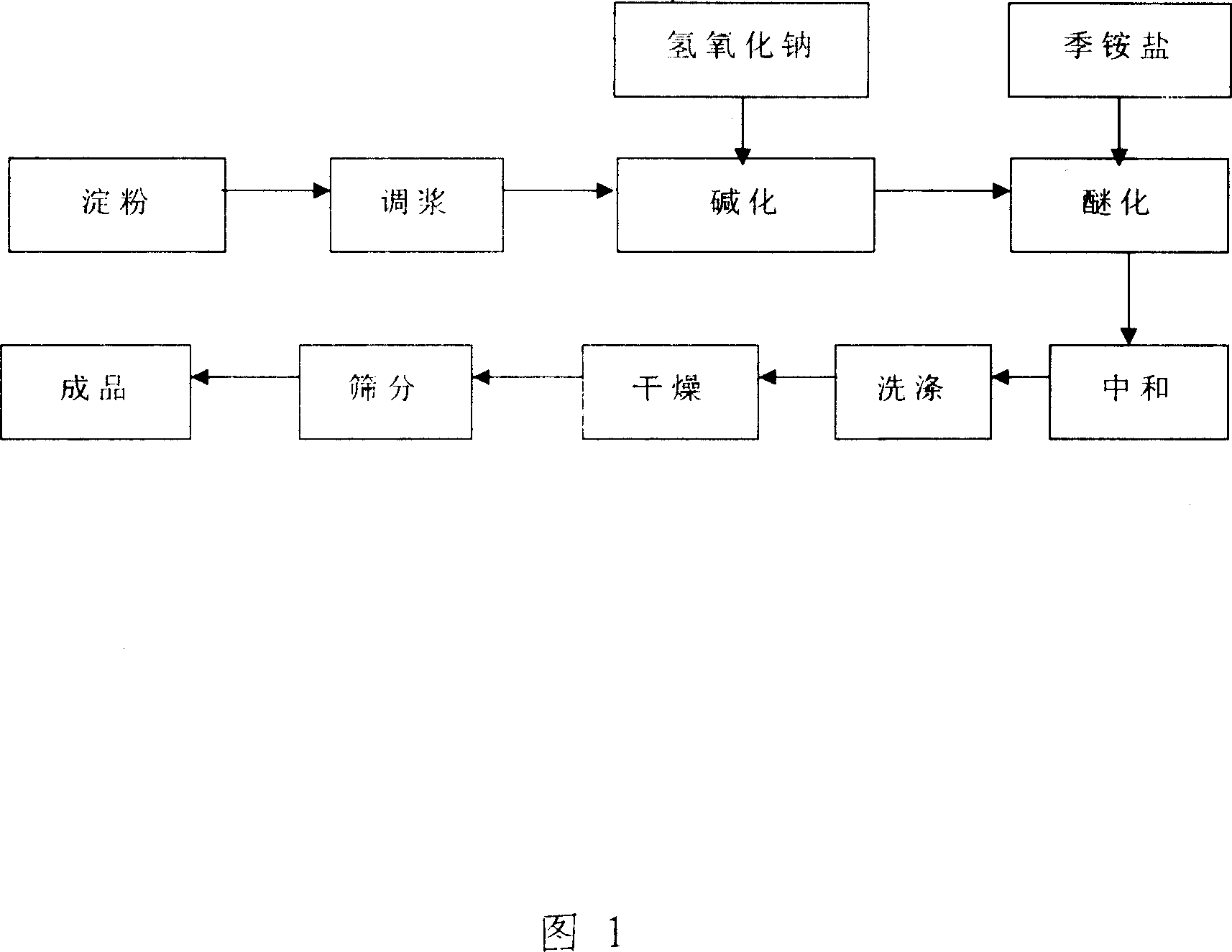

This invention relates to a synthesis method of quaternary ammonium cationic starch, which takes starch, quaternary ammonium, and sodium hydroxide as raw materials in water medium, and conducts eight steps of conditioning, alkalization, etherification, neutralization, washing, drying, screening, and packaging. The product is white powder, and gels to be the thick translucent gel heated to 50~66deg.C in water with DS values of 0.01 to 0.05. This invention is reasonable, makes the general starch has cationic performance and higher substitution, lowers the gelatinization temperature and freezing, so its effect can completely achieve the requirement of paper industry.

Owner:四平帝达变性淀粉有限公司

Process for the production of low ash fuel

The present invention describes a process for the production of low ash fuel using calcined petroleum coke by crushing and screening of calcined petroleum coke below 3 mm size, mixing the crushed and screened materials to achieve a bulk density in the range of 760 to 800 kg / m3, mixing 10-100% of the resultant calcined petroleum coke with 0 to 50% coke breeze, pre-soaking the mix so obtained with 5-10% water, mixing with hinder followed by kneading in presence of live stream, then briquetting and curing of the raw briquettes in a furnace in a controlled oxidising atmoshpere to obtain the low ash fuel.

Owner:COUNCIL OF SCI & IND RES

High-permeability super black decorated base paper and preparation method thereof

ActiveCN103614949AImprove permeabilityImprove breathabilitySpecial paperPaper/cardboardTitaniumWet strength

The invention relates to high-permeability super black decorated base paper and a preparation method of the high-permeability super black decorated base paper, and belongs to the technical field of decoration base paper. The preparation method is characterized by comprising the following steps: taking pulp mixed from bleached softwood pulp and bleached hardwood pulp according to the mass ratio of 1:(3.6-4.4) as a main raw material; reducing the beating degree of bleached wood pulp to 32 SR, enabling the mass concentration to reach 4%, and then pumping into a repulping pond for later use; directly adding a black pigment to the repulping pond, wholly substituting kaoline for titanium dioxide to prepare the decorated base paper with a black and shiny color, the fluorescent whiteness of 6%-8%, the basis weight of 70-90g / m<2>, the ash content of 10%-15%, the wet strength of 6.5-9N, the dry strength of 35-50N, the water absorption of 20-35mm / 10 minutes and the air permeability of 15-20s / 100ml. The high-permeability super black decorated base paper disclosed by the invention has the advantages of uniformity in coloring, good covering power, high air permeability, low basis weight and high paper output ratio; a processed decorating plate is high in stereoscopic impression, pure and bright in color and luster, green and environmental-friendly without white patterns.

Owner:ZIBO OU MU SPECIAL PAPER

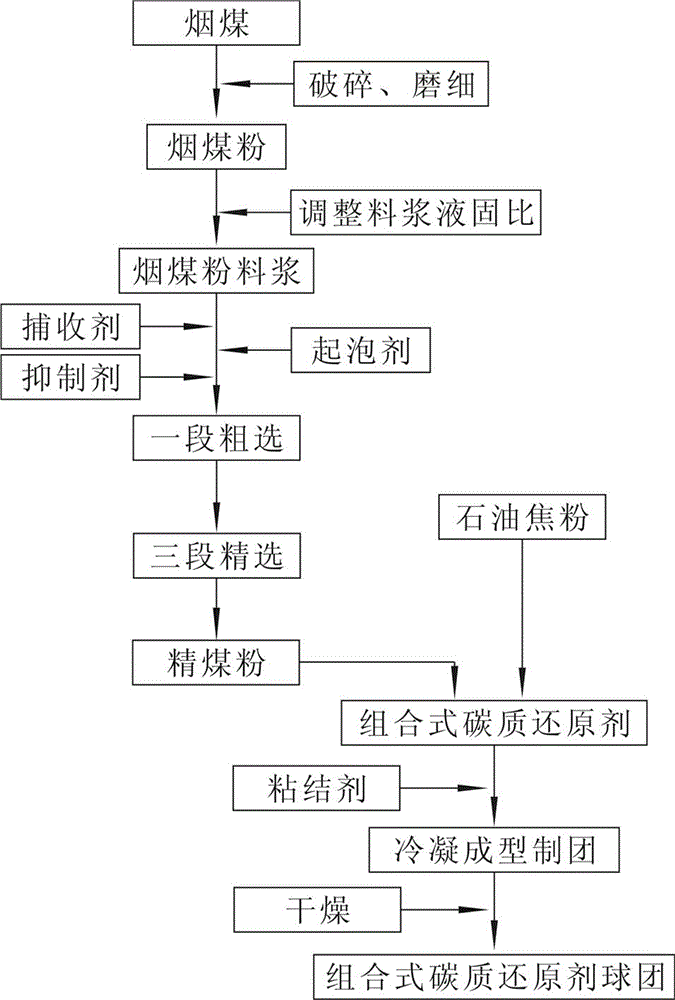

Combined carbonaceous reducing agent for smelting metal silicon and preparation method thereof

ActiveCN102976330AMeet physical and chemical performance requirementsPoor improvementSilicon compoundsPetroleumPetroleum coke

The invention discloses a combined carbonaceous reducing agent for smelting metal silicon and a preparation method thereof. The combined carbonaceous reducing agent comprises refined pulverized coal and petroleum coke powder, wherein the refined pulverized coal accounts for 70-80% of the total weight; the refined pulverized coal is prepared from the raw material soft coal by oil agglomeration selective flocculation de-ashing treatment; the refined pulverized coal contains 75-80% of fixed carbon, 3.5-4.5% of ash content and 16-21% of volatile content by weight; and 2-3% of binder is added into the mixture of the refined pulverized coal and the petroleum coke powder, and then a combined carbonaceous reducing agent pellet is prepared by cold press molding briquetting and drying treatment. According to the invention, the ash content and impurities in the soft coal are removed by a flotation method, the petroleum coke powder serves as supplement of the fixed carbon, and the two are combined to obtain a combined carbonaceous reducing agent with high content of fixed carbon, low ash content and low content of impurities. Through the invention, the problem that the reducing effect is unsatisfactory by using the soft coal only is solved, the smelting efficiency and the product quality are improved, and the added value of the soft coal is increased.

Owner:KUNMING METALLURGY INST

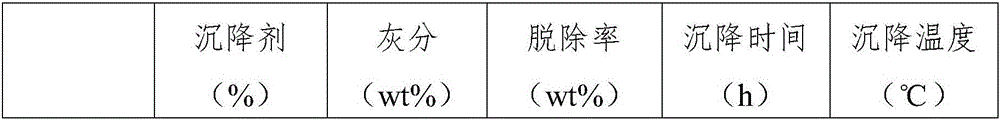

Catalyzing and cracking slurry oil settling agent and preparation method and application thereof

ActiveCN106318440ALess attractiveIncrease settling velocitySedimentation separationHydrocarbon oils refiningPolyethylene oxideEthylene Homopolymers

The invention discloses a catalyzing and cracking slurry oil settling agent. The catalyzing and cracking slurry oil settling agent is prepared from raw materials including, by weight, 10.0-12.0% of polyoxyethylene and allyl polyethylene oxide block polymers, 7.0-8.0% of PPG (poly propylene glycol) 8000, 5.0-7.0% of dimethyl diallyl ammonium chloride homopolymers, 4.0-6.0% of polyoxyethylene sorbitan laurate and the balance of aromatic hydrocarbon oil. The invention further discloses preparation method and application of the catalyzing and cracking slurry oil settling agent. Attraction between the catalyzing and cracking slurry oil and solid catalyst powder can be lowered by the aid of the formulated settling agent, settling velocity and remove rate of the catalyst powder are increased, ash content is effectively reduced, and quality is further guaranteed for the catalyzing and cracking slurry oil settling agent.

Owner:JIANGSU CHUANGXIN PETROCHEM

A kind of manufacturing method of micro-coating elegant pure paper

InactiveCN102277776AReduce loadReduce processing costsDefoamers additionWater-repelling agents additionFiberWhite water

The invention discloses a method for making slightly-coated elegant pure paper. The method comprises the following key steps of: making poplar APMP (alkaline peroxide mechanical pulp), CTMP (chemithermomechanical pulp), bleached chemical needlebush pulp and bleached chemical reed pulp; blending; adding auxiliary materials; making wet paper sheets; squeezing for dehydrating; primarily drying; slightly coating; secondarily drying; calendering; and finishing. The method can greatly lower the production cost, improve the looseness and thickness of paper sheets and ensure high strength of elegant pure paper, solves the problems that glues applied to AKD (alkyl ketene dimer) pulp have a low retention rate and are easy to be hydrolyzed, overcomes the defects of low fine fiber retention rate, high filler loss and the like in the highly-proportional chemimechanical pulp blending process, reduces the pulp consumption and lowers the white water load and subsequent waste water treatment cost, solves the problems of low whiteness, high surface roughness, low surface strength and the like due to the highly-proportional chemimechanical pulp, and can greatly increase the ash content and lower theproduction cost.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Manufacturing method of novel environment-friendly kraft board paper

The invention discloses a manufacturing method of novel environment-friendly kraft board paper. According to the manufacturing method, starch in pulp is recycled, COD (chemical oxygen demand) of wastewater is reduced, retention and drainage agents, aluminum sulfate and macromolecular dry strength agents are added into a flowing system in order to solve the problems of short fibers and low pulp retention, the pulp retention and the strength of subsequent finished paper are improved, starch and small fibers are adsorbed on long fibers, high retention of the starch is achieved, a PH (potential of hydrogen) valve of the pulp is adjusted to neutral by the aluminum sulfate, anionic trash in the pulp is removed by the aid of aluminum ions, mutual combination between fibers is improved by the aidof the dry strength agents, combining capacity of the fibers is enhanced, the combining capacity of the fibers and the physical strength of the finished paper are improved by the aid of chemical fiber modified technique, sizing agents are added into the pulp, so that the strength of the finished paper is improved, high ash content is kept, the utilization rate of waste paper is increased, the strength of the finished paper is enhanced, and the manufacturing method is applicable to production lines of most kraft board paper and has a quite wide market prospect.

Owner:JIANGSU LEE & MAN PAPER MFG

Preprocessing method of raw materials for ferrosilicon smelting

InactiveCN101280356AReduce the degree of deteriorationGood volatileSocial benefitsPretreatment method

The invention relates to the smelting technology, in particular to silicon iron smelting raw material and a preprocessing method. The preprocessing method comprises the following steps: firstly, silicon contained raw material is mixed with the carbonaceous reducing agent according to a certain ratio; secondly, a 40 to 80 mm oval or oblate pellet is pressed into form through a mechanical way; thirdly, after drying, the percentage of moisture is controlled for less than two percent, and then the raw material can be used as silicon iron smelting raw material. The silicon iron smelting raw material and the preprocessing method have the advantages that the raw material resource is rich, the price is inexpensive, and the energy saving effect is obvious, simultaneously, because a great amount of , the silicon fine powder and siliceous colliery waste are adopted by the technology, the social benefit and the environmental benefit are quite good.

Owner:樊玉山

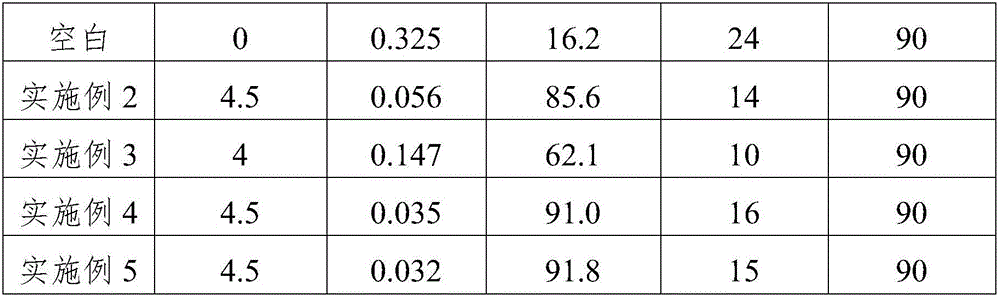

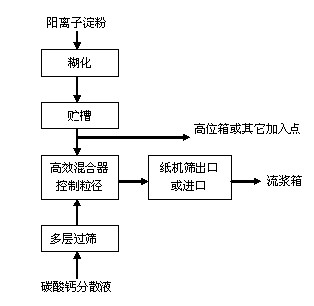

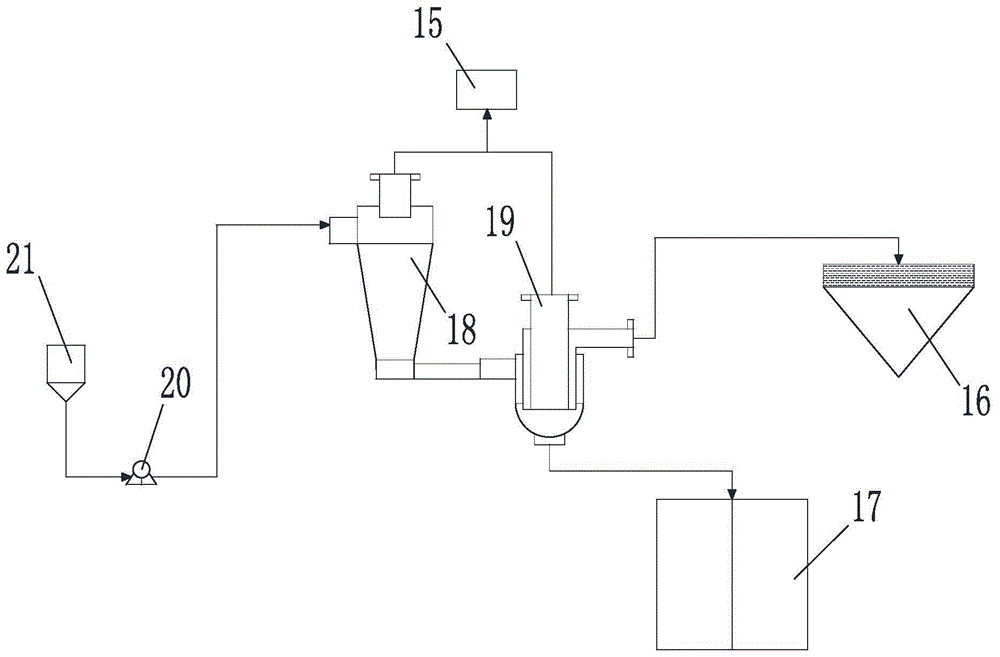

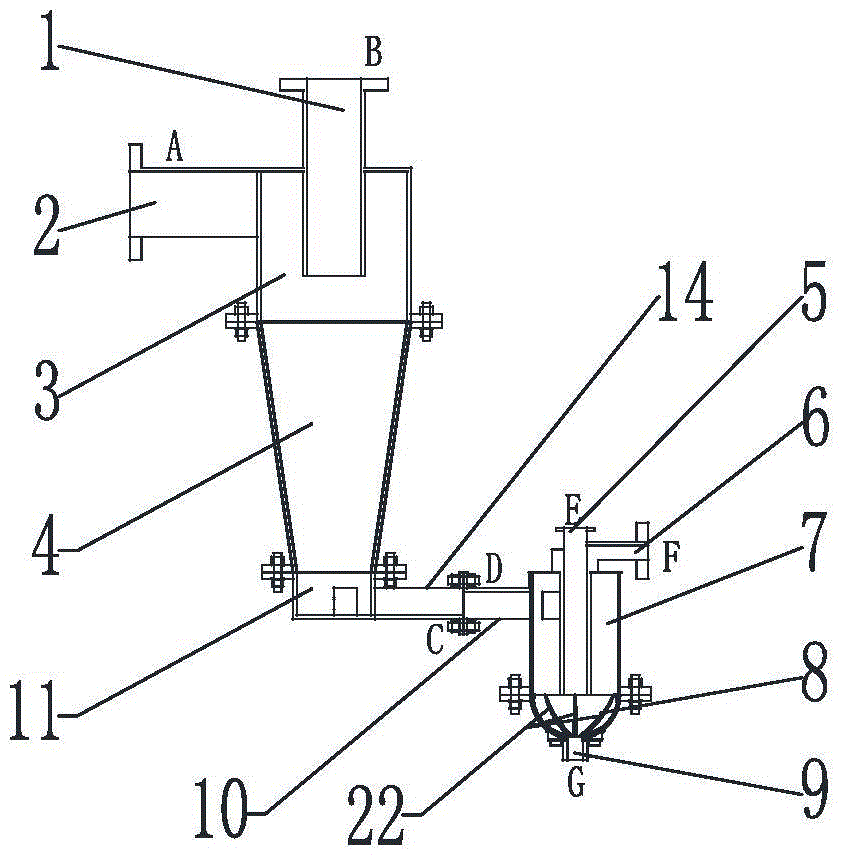

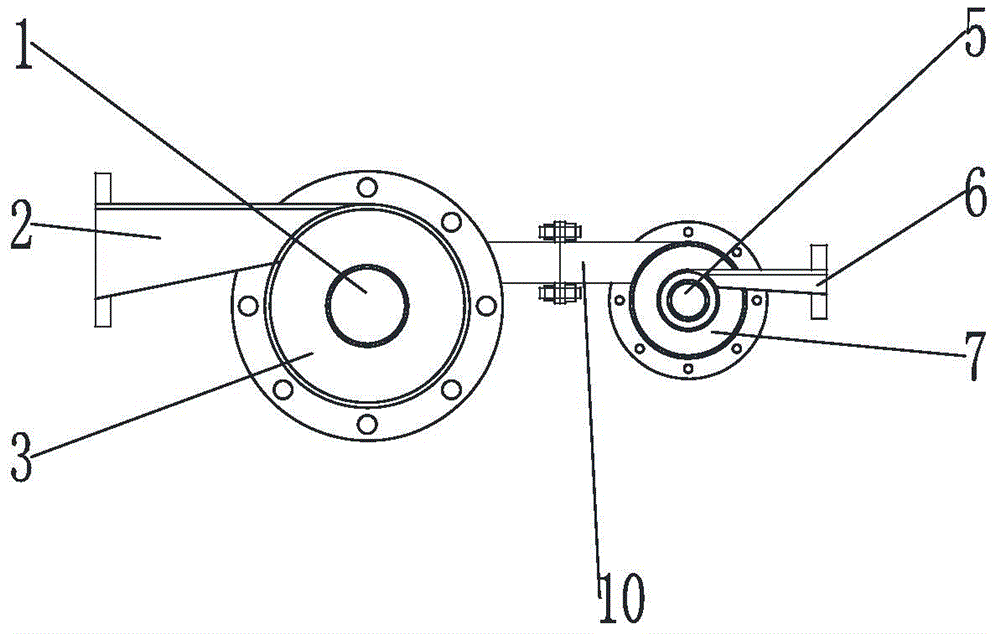

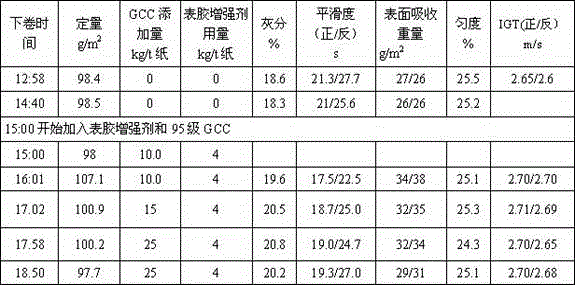

Method for fill feeding in papermaking

ActiveCN102677543AImprove stabilityFine granularityPulp material addition processesFiberFlocculation

The invention discloses a method for fill feeding in papermaking, which is characterized by comprising the following steps of: (1) firstly gelatinizing quaternary ammonium type cation starch, diluting to 1-3 percent concentration, conveying to a high-efficient mixer by a piston pump; conveying calcium carbonate with 10-30 percent concentration to the high-efficient mixer by a centrifugal pump; and (2) completing pre-flocculation of the quaternary ammonium type cation starch and the calcium carbonate in the high-efficient mixer, conducting multilayer filtering on the pre-flocculation bodies in the mixer, thus obtaining the pre-flocculation bodies with proper granules. With the adoption of the method, on the premise that the strength property of paper is guaranteed, the ash content can be effectively improved, the ash content of facial gummed paper can be improved from 25% to 35%, and the dry steam consumption can be reduced by 10%, moreover, the fiber materials can be greatly reduced, thus the method has wide application prospects.

Owner:YUEYANG FOREST & PAPER CO LTD +1

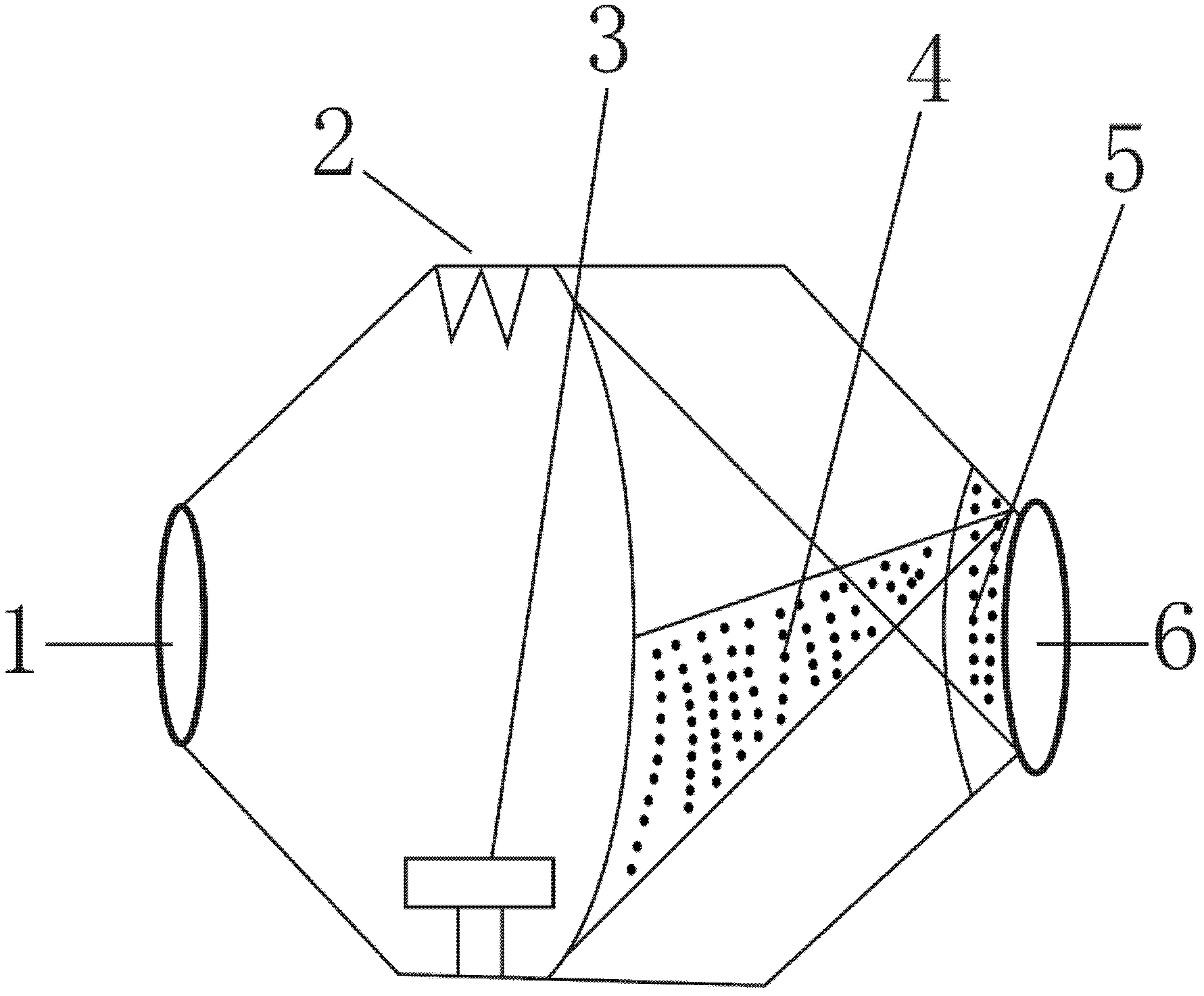

Coal slime recovery device and process

ActiveCN104307624AIncrease ashFine particleReversed direction vortexWet separationCycloneHigh density

The invention discloses a coal slime recovery device and process. The coal slime recovery device comprises a two-stage cyclone separation device, a flotation device, a high-frequency vibrating screen and a spiral separator; the two-stage cyclone separation device comprises a pre-stage cyclone and a post-stage cyclone; a first overflow port and a first underflow port are formed in the pre-stage cyclone, and a second overflow port, a third overflow port and a second underflow port are formed in the post-stage cyclone; a first granular material is obtained at the first overflow port, a second granular material is obtained at the second overflow port, a third granular material is obtained at the third overflow port, and a second underflow product is obtained at the second underflow port. The coal slime recovery device and process have the benefits that a small quantity of fine coal is obtained after the first granular material and the second granular material are floated, the third granular material has the characteristics of fine particle and high ash content and also has good ash reduction effect and large fine coal recovery rate after being further treated by the high-frequency vibrating screen, the second underflow product has the characteristics of high density and low ash content, and a small quantity of fine coal can be recovered after the second underflow product is further treated by the spiral sorter.

Owner:SHANDONG UNIV OF SCI & TECH

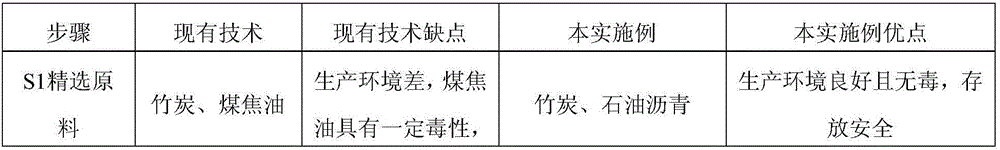

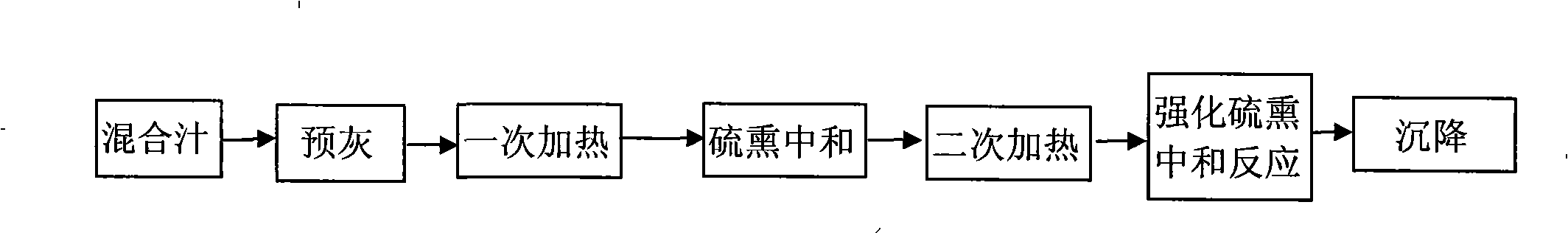

Preparation technology of bamboo columnar carbon with ultrahigh performance

InactiveCN106512938AHigh strengthImprove adsorption capacityGas treatmentCarbon compoundsActivated carbonDesorption

The invention discloses a preparation technology of a bamboo columnar carbon with ultrahigh performance. The preparation technology comprises steps as follows: S1), selection of a raw material: the raw material is a bamboo carbonized material; S2), grinding and sieving: the raw material is sieved with a 325-mesh sieve, and the bamboo carbonized material of 325 meshes or fewer than 325 meshes is taken as one raw material; S3), powder grinding and material mixing: a small amount of petroleum asphalt is added to the bamboo carbonized material powder of 325 meshes or fewer than 325 meshes for powder grinding and mixing treatment, and a first mixture is obtained; S4), stirring: water is added to the first mixture for stirring; S5), pre-extrusion; S6), pressing and extrusion molding; S7), segmented drying; S8), carbonizing; S9), gradient type activation: the carbonized material is put in an activating furnace to be activated for 1-2 h at the temperature of 750-850 DEG C and then is activated for 1-3 h after the temperature is increased to 850-950 DEG C, and the bamboo columnar activated carbon is obtained. The bamboo columnar activated carbon prepared with the technology has the characteristics that strength, adsorbability and adsorption capacity are high, the ash content is low, adsorption speed and desorption speed are high, obvious cracks on the outer surface are avoided, the yield of follow-up carbonized and activated products is high and the like.

Owner:JIANGSU PURESTAR EP TECH CO LTD

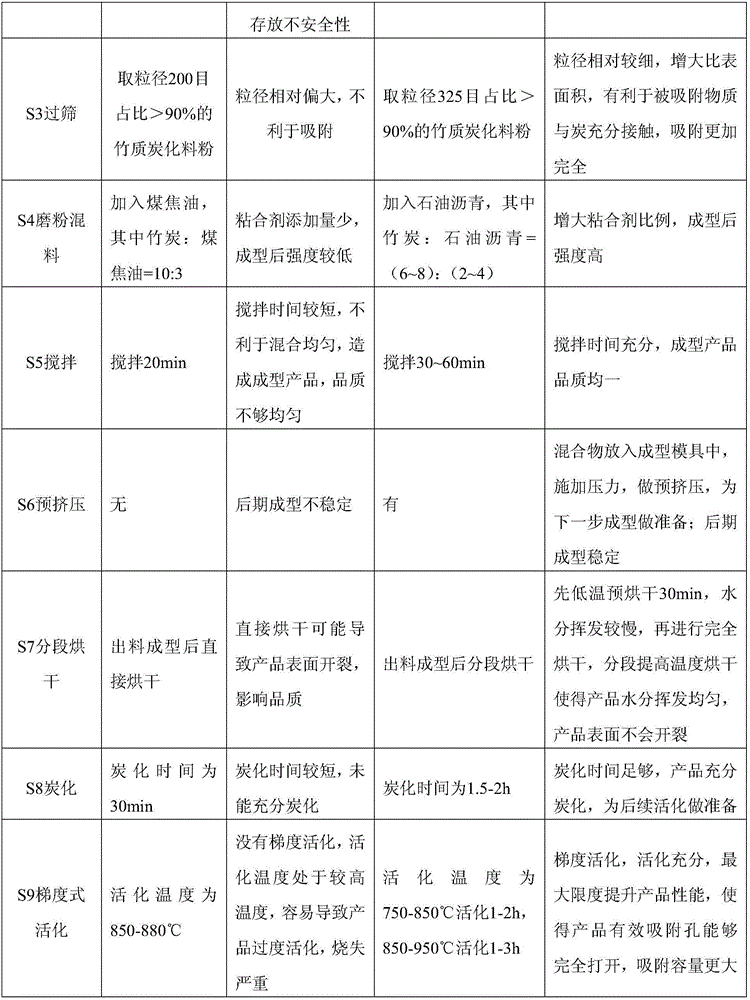

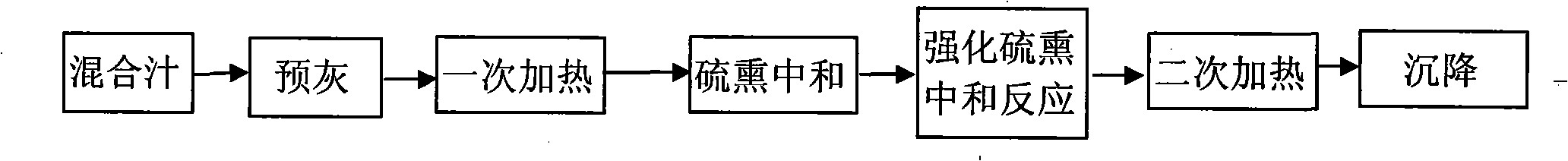

Sugar clarification technique method for intensifying stoving neutralization reaction

A sugar-manufacturing clarification technique for intensifying sulfitation neutralization reaction adopts a sulfurous clarification technique, comprising preliming, first heating, sulfitation neutralization, second heating, sedimentation and a working procedure of intensifying sulfitation neutralization reaction; the working procedure of intensifying sulfitation neutralization reaction is the procedure that sulfitation-neutralized cane juice goes through ultrasonic intensified treatment, namely, the sulfitation-neutralized cane juice passes through an ultrasonic processor, and ultrasonic field energy is applied to the running cane juice; the working procedure of intensifying sulfitation neutralization reaction is carried out after the working procedure of sulfitaion neutralization and before the second heating or is carried out after the second heating and before the working procedure of sedimentation; the intensity of the ultrasonic intensified treatment for intensifying the sulfitation-neutralized cane juice is within 0.5W / cm<2> and 10W / cm<2>; the time of the ultrasonic intensified treatment is within 1s to 300s. The method can improve the speed and the degree of the cane juiceneutralization reaction, improve the decolorization effect, and reduce the residual sulfur content.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY +1

Production method for making high-grade cardboard using brush wood sheet hot grinding pulp to replace OCC (obsolescence corrugated cardboard) pulp

ActiveCN106223091AIncreasing the thicknessImprove grade and performancePaper recyclingCellulose treatment using microorganisms/enzymesLaboratory cultureObsolescence

The invention relates to a production method for making a high-grade cardboard using brush wood sheet hot grinding pulp to replace OCC (obsolescence corrugated cardboard) pulp. The production method comprises the following steps of pulp preparation: using waste box cardboards to prepare OCC pulp; using ONP (old news paper) to prepare ONP pulp; using brush wood sheets to prepare wood chip pulp, mixing the wood chip pulp, saccharomyces chevalieri and a binder, and culturing; pulp blending: using the ONP pulp as a grey board topcoat layer; mixing the OCC pulp and the wood chip pulp to form a grey board liner layer; mixing the OCC pulp and the wood chip pulp to form a grey board core layer; mixing the OCC pulp and the wood chip pulp to form a grey board bottom layer; paper making: using the approaching pulp to make the paper. Compared with the prior art, the production method has the advantages that the wood chip pulp is cultured by microorganisms, so that the thickness, compactness and stiffness of grey board are improved; the raw material structure of the grey board is optimized, the usage amount of OCC waste paper is reduced, the problem of raw material cost of the grey board is reduced, and the economic benefit is obviously improved.

Owner:LIANSHENG PAPER IND LONGHAI

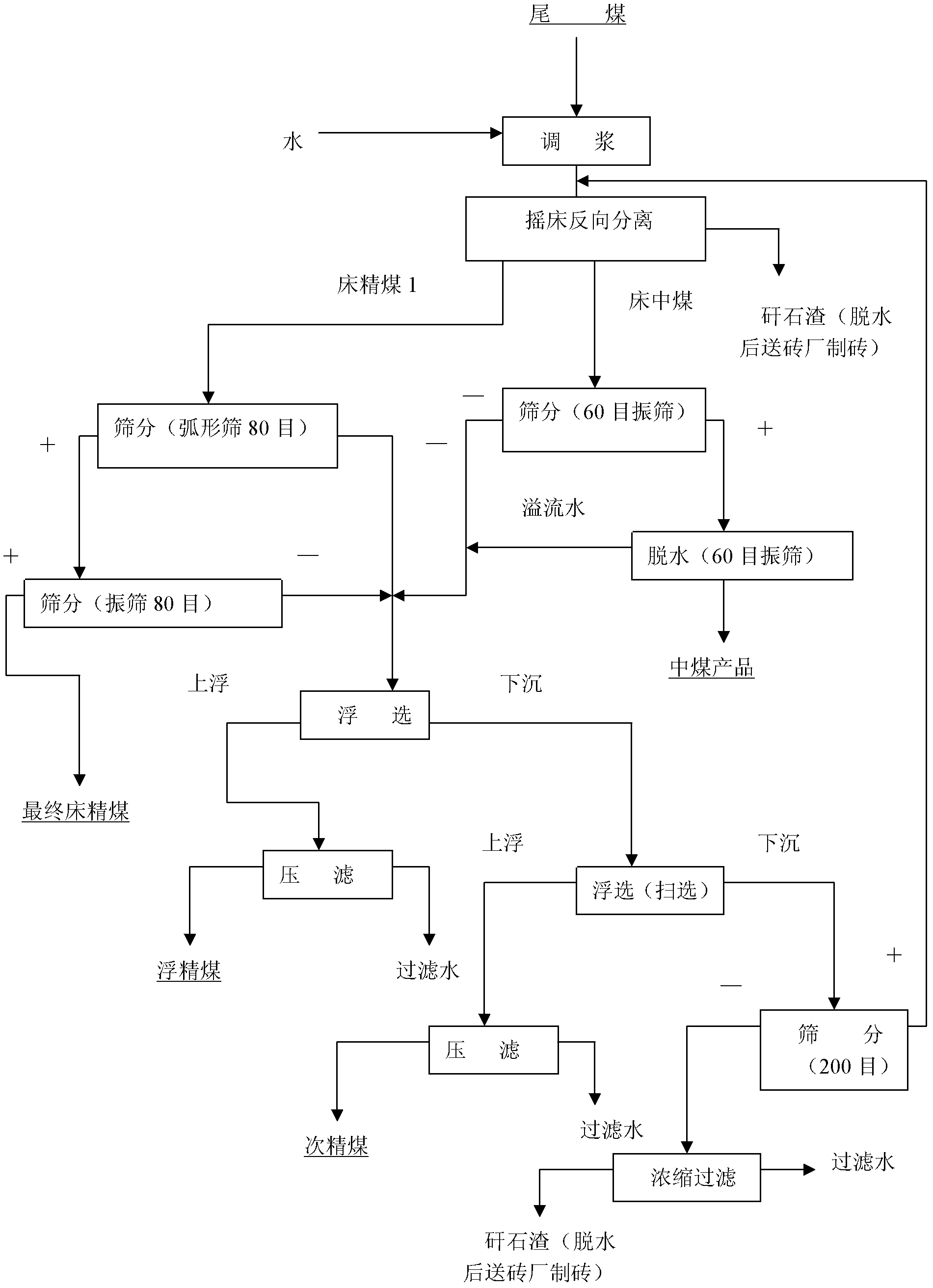

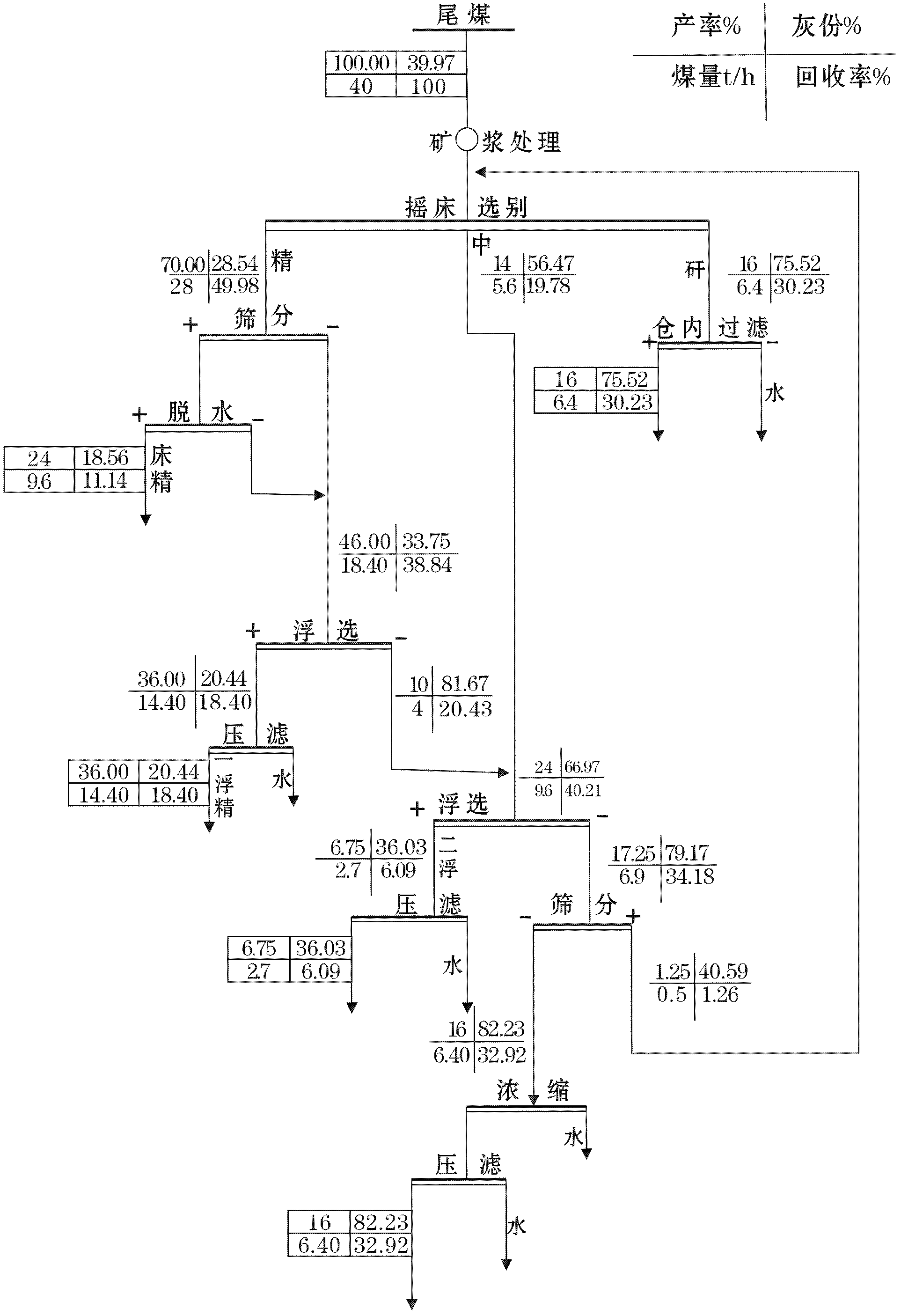

Technique for recycling cleaned coal from low-value gangue or tail coal of coal washery

The invention relates to a technique for recycling cleaned coal from low-value gangue or tail coal of a coal washery. The technique comprises the following steps of: crushing the gangue into powder with the grain size of 2mm, and dissociating coal from gangue mineral monomers; adding water into the powder or the tail coal of the coal washery to obtain ore pulp, carrying out reverse separation by virtue of a table concentrator, wherein light coal enters into a tailing slot to be prepared into a bed cleaned coal product, heavy gangue mineral enters into a concentrate slot to be prepared into gangue slag which can be used for making bricks, and an accretion body between the light coal and the heavy gangue mineral and a part of gangue mineral enter into a middling slot to be prepared into a bed midding coal product; screening the bed cleaned coal product to remove fine gangue component, dehydrating oversize products to obtain a final bed cleaned coal product; carrying out flotation separation on the bed middle coal product by adopting a flotation machine, and carrying out filter pressing on floating products to obtain a floating cleaned coal product, wherein a sink product is the gangue slag used for making bricks. By applying the technique provided by the invention, cleaned coal in the tail coal or gangue can be economically and reasonably recycled in a large scale, the reverse separation by using table concentrator is organically combined with certain flotation and the like, thus technological adaptability is high and technical index is good; coal gangue with ash content up to 62-72% can be processed into cleaned coal or secondary cleaned coal with the ash content of 27-40% only, technological process is simple and compact, operation cost is low, net profit created by each ton of the coal gangue is 50-80 yuan, no 'three wastes' pollution is produced, and the technique provided by the invention is safe and environmentally friendly.

Owner:高华

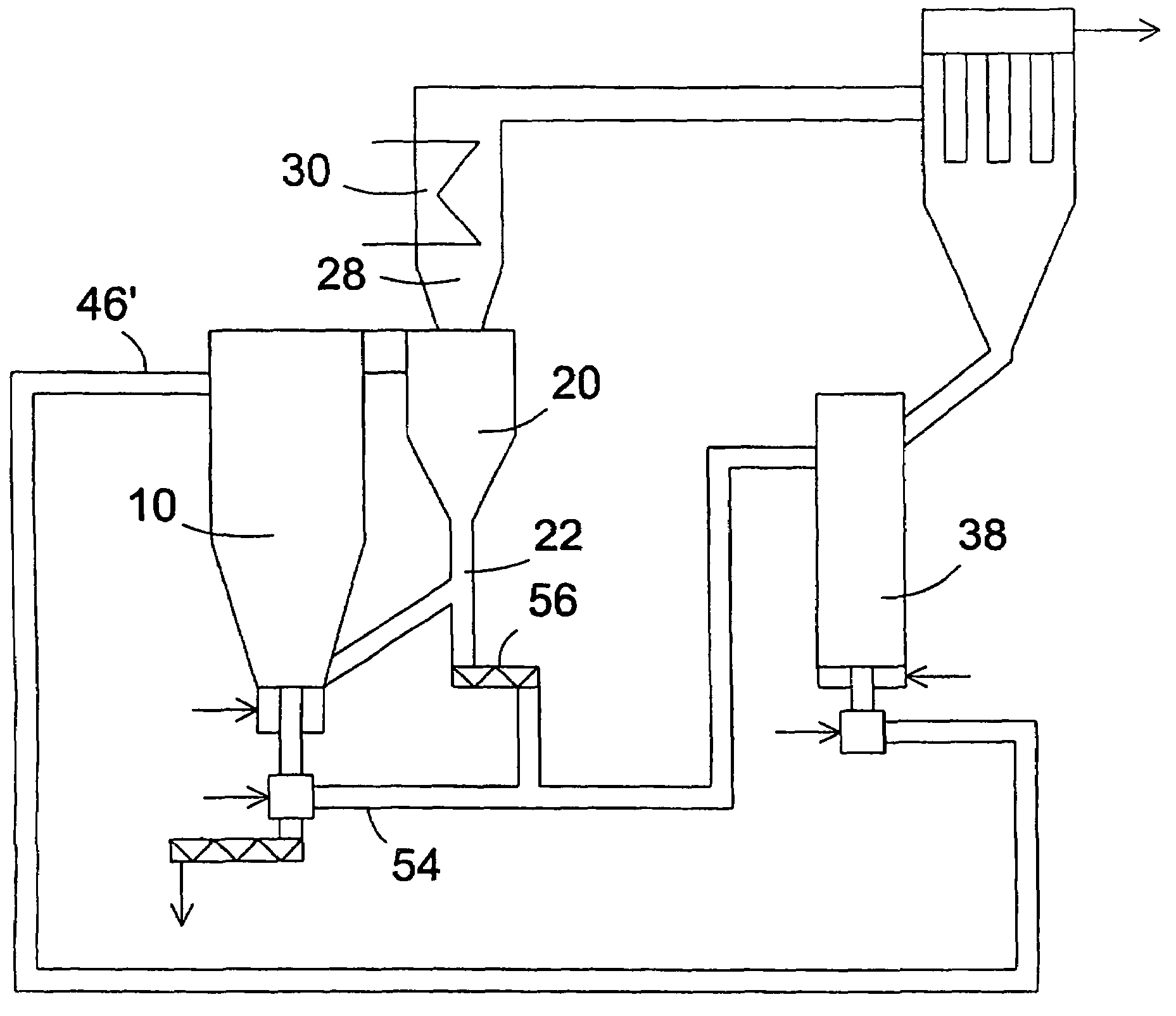

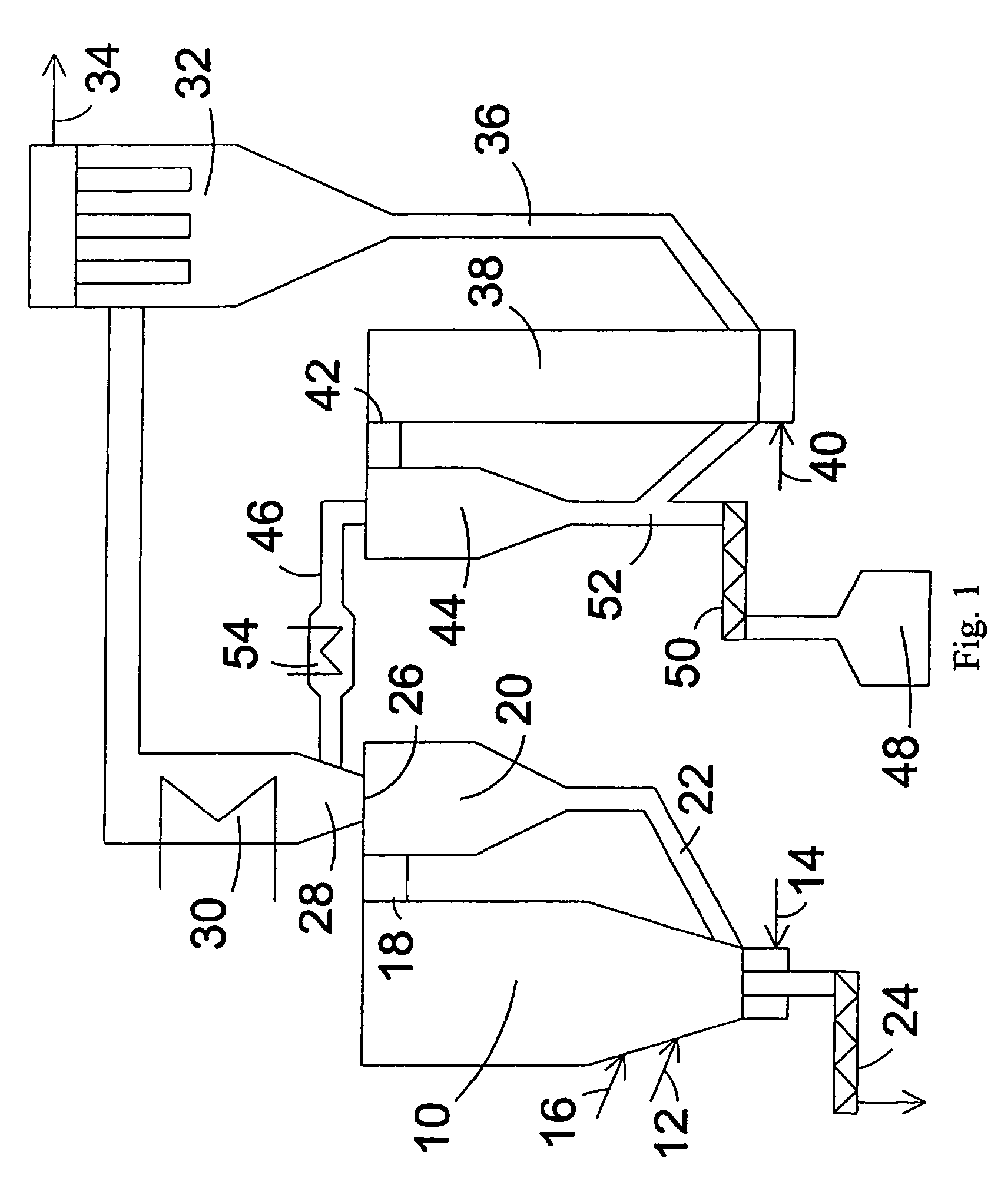

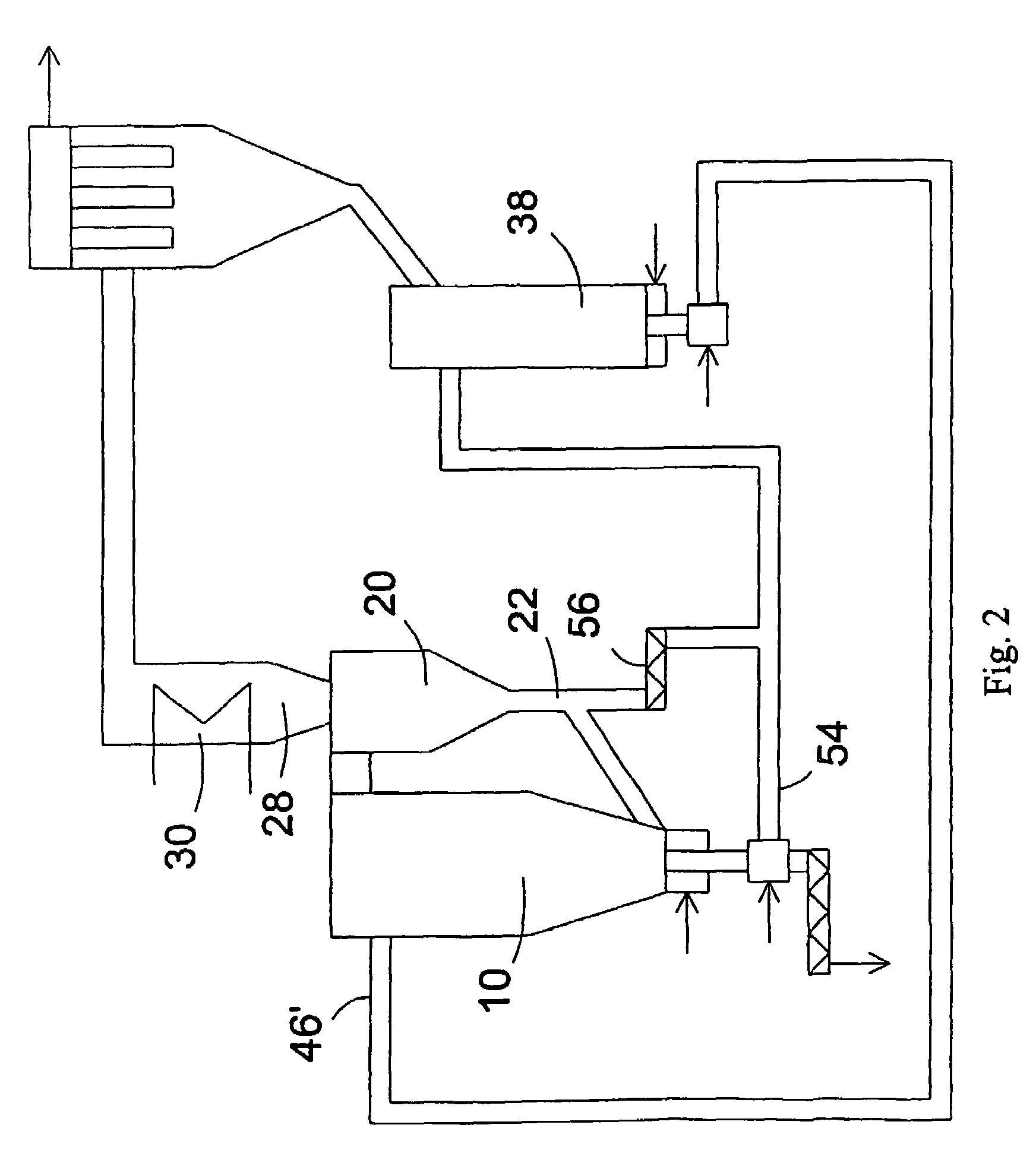

Method and apparatus for gasifying carbonaceous material

InactiveUS7503945B2Avoid problemsReduce compoundingHydrogenGas modification by gas mixingTarResidual carbon

A method and an apparatus for gasifying carbonaceous material, in which (a) gasifying carbonaceous material is gasified in a gasification reactor of a gasification system to produce a product gas, (b) the product gas, ash particles entrained with the product gas, residual carbon, and gasified tar compounds are discharged from the gasification reactor to a product gas channel, (c) the product gas discharged from the gasification reactor is cooled using a gas cooler disposed along the product gas channel, so that the tar compounds are condensed to a liquid from that tends to stick to heat exchange surfaces of the gas cooler, (d) solid material including the ash particles and the residual carbon is separated from the gasification system, (e) the solid material separated from the gasification system is guided to an ash reactor, and oxygen-containing gas is supplied to the ash reactor, whereby the residual carbon in the solid material reacts with oxygen, and additional ash particles and exhaust gas are generated, and (f) ash particles from the ash reactor are guided along a conveying duct to the gas cooler or to a location upstream of the gas cooler, thereby increasing the ash content of the product gas and decreasing the tendency of the condensed tar compounds to stick to the heat exchange surfaces of the gas cooler.

Owner:FOSTER WHEELER ENERGIA OY

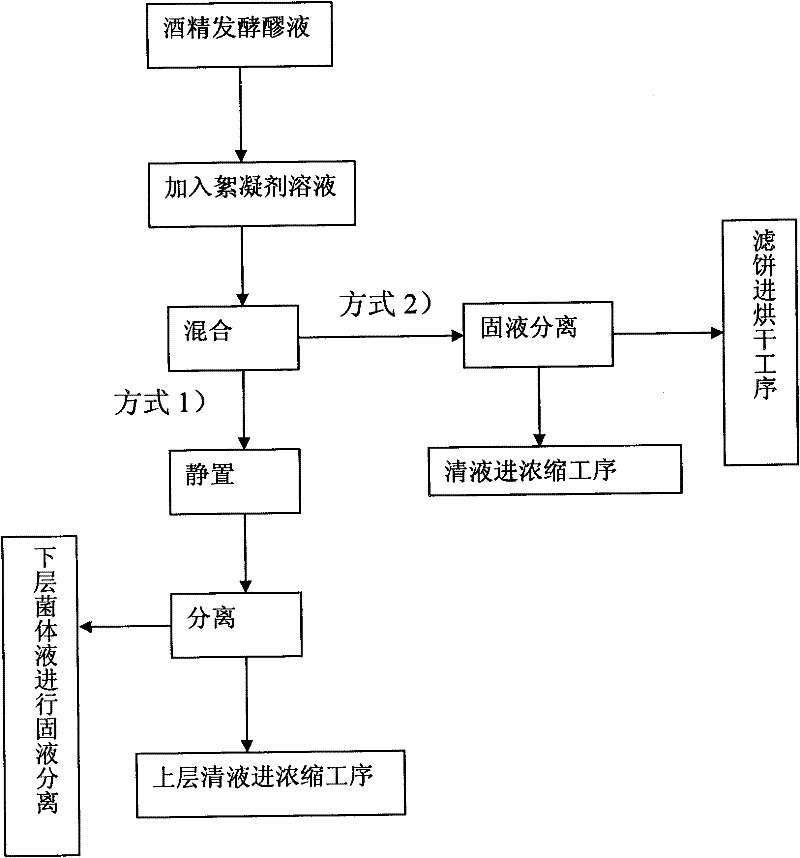

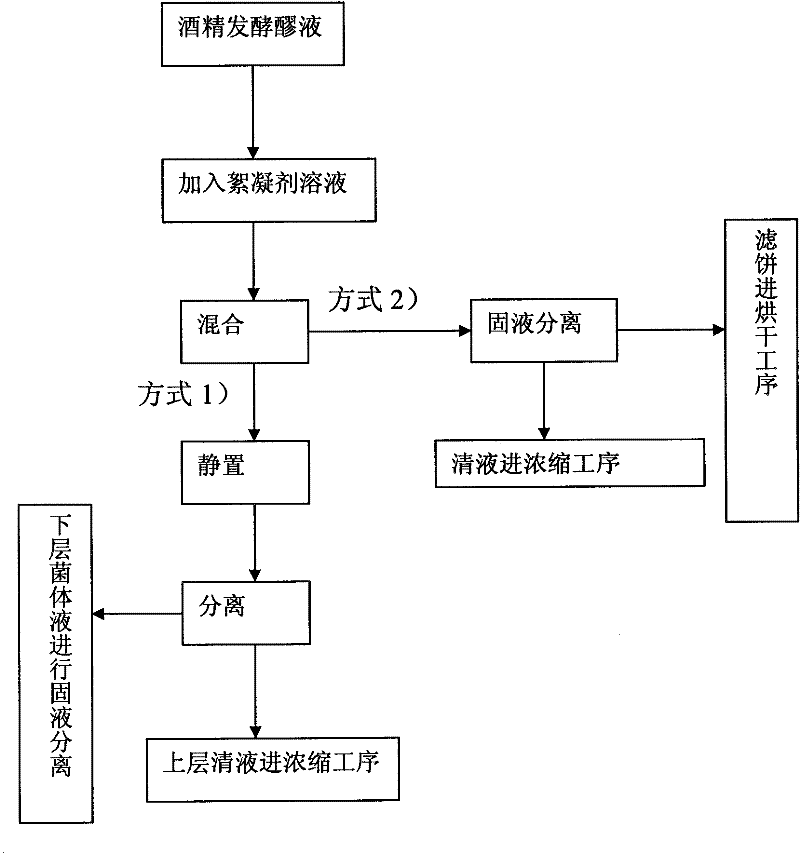

A kind of separation method of alcohol fermentation mash

ActiveCN102260139AIncrease ashLight in massFood processingAnimal feeding stuffBody fluidSodium hydroxide

The invention discloses a separation method of an alcoholic fermented liquor, comprising the steps of mixing the alcoholic fermented liquor with a flocculating agent solution and processing the mixture according to any one of the following ways: way 1) standing the mixture for layering to obtain supernatant liquor and subnatant bacterial body fluid, discharging the supernatant liquor and carrying out condensation, and carrying out solid-liquid separation on the subnatant bacterial body fluid; and way 2) directly carrying out solid-liquid separation on the mixture. The flocculating agent is a substance that can flocculate and or precipitate thalline in the alcoholic fermented liquor. Compared with the present common separation methods, the method overcomes that normal production can not be satisfied due to difficult direct filtering, increasement of ash content and deepending of color in the subsequent forage, reduction of the quality of the forage and extremely high cost when using sodium hydroxide to raise PH value existing in the prior art, and is simple and practical and has low investment of device. Compared with the prior art, the method can reduce cost by about 70%.

Owner:安徽中粮生化燃料酒精有限公司 +1

Heavy metal polluted soil composite repair agent and soil repair method thereof

InactiveCN109575929AImplement resourcesAchieve recyclingContaminated soil reclamationOrganic fertilisersSorbentSludge

The invention discloses a heavy metal polluted soil composite repair agent and a soil repair method thereof, and belongs to the technical field of soil repairing. The invention provides the heavy metal polluted soil composite repair agent. The heavy metal polluted soil composite repair agent is prepared by the following method: heating sludge in high-temperature vacuum, and washing and drying thesludge to obtain sludge biochar; heating forestry and agricultural residues in high-temperature vacuum, and washing and drying the forestry and agricultural residues to obtain forestry and agricultural residue biochar; mixing the sludge biochar with the forestry and agricultural residue biochar; and mixing the mixed biochar with a sodium citrate solution, performing oscillating reaction, and washing and drying the solution at the end of the reaction to obtain the heavy metal polluted soil composite repair agent. According to the heavy metal polluted soil composite repair agent and the soil repair method thereof, the sludge and the forestry and agricultural residues are used as the raw materials; the two biochars are mixed in different proportions, so that the ash content and the carbon content of the composite adsorbent are increased; and by use of the sodium citrate solution for modification, the activity of the biochar is improved, so that the content of heavy metal elements in a biological use state in the soil is effectively reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

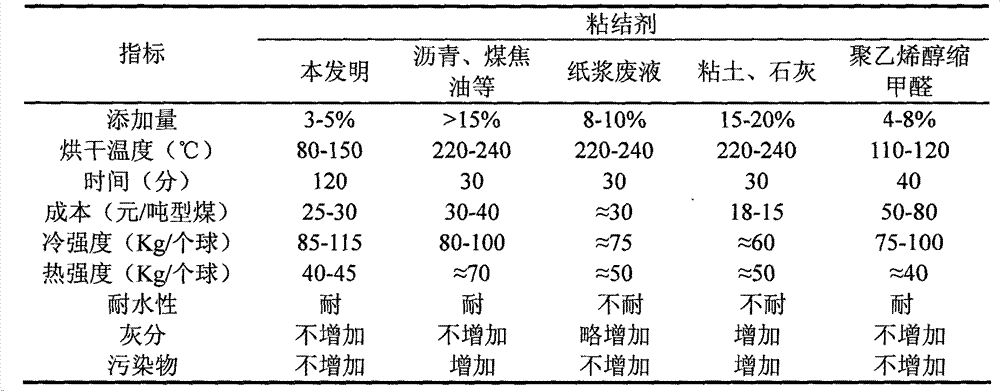

Novel waterproof compound coal binder

InactiveCN103710065AImprove adhesionConvenient and cheap sourceSolid fuelsSodium BentoniteEconomic benefits

The invention discloses a novel waterproof compound coal binder mainly used for the molding production of industrial gasification briquette from pulverized anthracite. The binder comprises bentonite, starch, extraordinary resin, cement and an organic polymer material. The binder has the advantages of low consumption, simple preparation technology, low cost, no secondary pollution, and suitableness for various coals. Molded gasification briquette processed in the invention has high cold and hot strengths (a cold compression strength of 85-115kg / ball and a hot compression strength of 40-45kg / ball, has a strong binding power and a good waterproof property, so the binder has a good economic benefit and application prospect.

Owner:ZHENGZHOU UNIV

Process for preparing activated carbon for air-raid shelters

ActiveCN107934960AImprove adsorption capacityLarge adsorption capacityCarbon compoundsRAIDActivated carbon

The invention discloses a process for preparing activated carbon for air-raid shelters. The process comprises the following steps: finely selecting raw materials, preparing a first mixed liquid, preparing a second mixed liquid, preparing a third mixed liquid, soaking, calcining, preparing a fourth mixed liquid, performing secondary soaking, and performing secondary calcining. The process has the advantages that the produced activated carbon for air-raid shelters has the advantages of being high in strength, good in adsorption property, large in adsorption capacity, small in ash content, rapidin adsorption velocity, long in protection time, good in protection effect, and the like, has very good effects in industrial waste gas treatment, prevention of toxic and harmful gases, and the like,and particularly has excellent adsorption properties which are comparable by common granular carbon for benzene, hydrocyanic acid and chloroethane in waste gases; meanwhile, due to the product, defects of conventional coal columnar carbon are solved, the field of activated carbon is further widened, defects of the coal columnar carbon are further alleviated, and a relatively excellent product is provided for waste gas treatment, toxic and harmful gas prevention, and the like.

Owner:宁夏浦士达环保科技有限公司

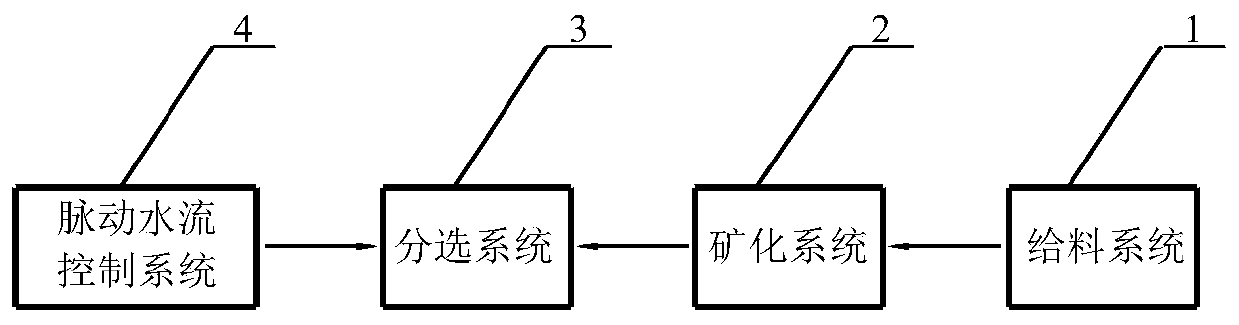

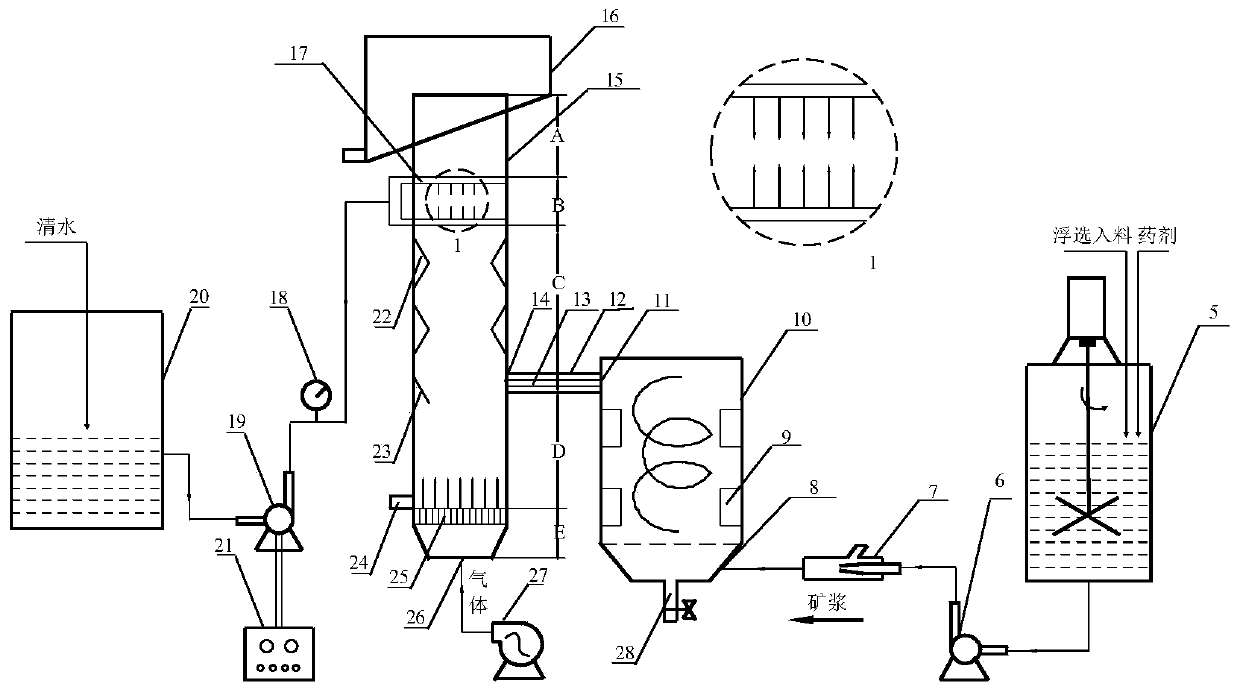

High ash fine grain coal slurry separation equipment and method

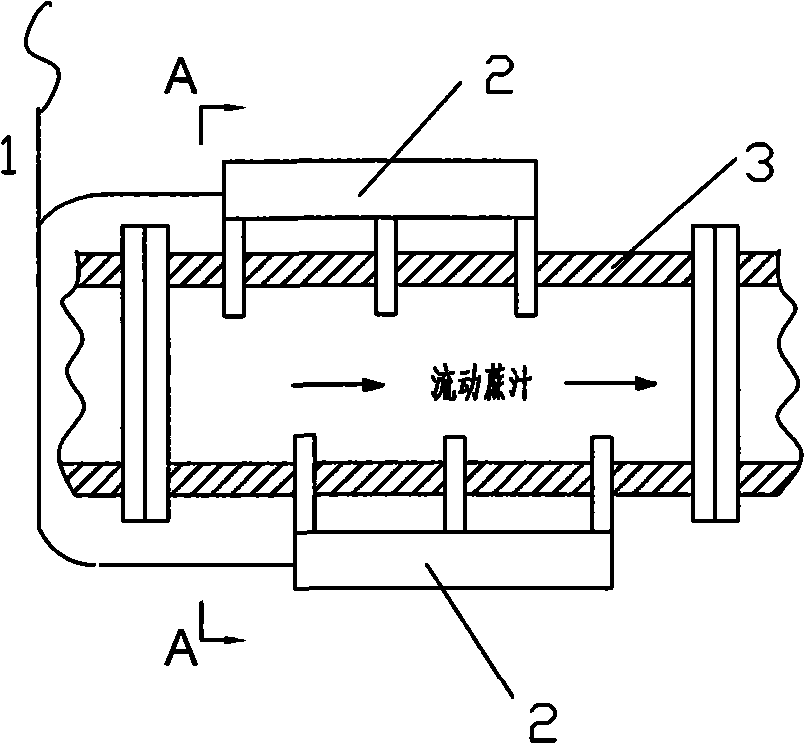

ActiveCN109759242AImprove recycling effectIncrease the probability of collisionSeparation devicesFlotationControl systemWater flow

The invention provides a high ash fine grain coal slurry separation equipment and method which areapplicable to the field of coal washing. The separation equipment comprises four parts, specifically afeeding system, a mineralization system, a separation system and a pulse water flow control system. The equipment is characterized in that a coal slurry mineralization area is separated from a separation area, and the ore separation system is internally provided with a damping block and a pulse water flow device. Flotation materials are fed into the feeding system, the size mixing operation is completed, coal slurry subjected to size mixing enters the mineralization system to be subjected to turbulent collision, mineralized bubbles are formed, the mineralized bubbles enter the separation system after passing through a disorder eliminating pipe, meanwhile the pulse water flow control system supplies the separation system with pulse water flows with certain frequency and waveform, the finecoal ash content is lowered, and the coal slurry separation selectivity is improved. Recycling of low ash coarse particles is effectively improved, high ash thin slurry carried by water flow and the thin slurry covering the surface of the particles are beneficially reduced by means of the damping block and the pulse water flow effect, and the separation selectivity is improved. The equipment has high coal slurry adaptability on different coal qualities, the separation effect is good, the separation efficiency is high, the production operation cost is low, and the economical benefit is outstanding.

Owner:CHINA UNIV OF MINING & TECH +1

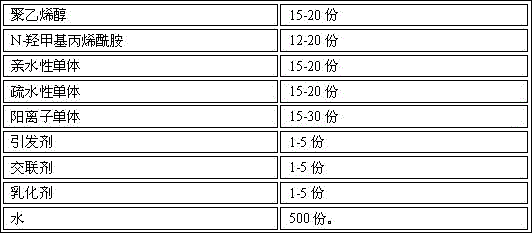

Surface glue reinforcing agent and preparation method thereof

InactiveCN106283867APromote migrationImprove function and effectWater-repelling agents additionHydrophilic monomerFiber

The invention belongs to the field of papermaking additives, and particularly relates to a surface glue reinforcing agent and a preparation method thereof. The surface glue reinforcing agent is prepared from polyvinyl alcohol, N-methylol acrylamide, hydrophilic monomers, hydrophobic monomers, cationic monomers, an initiating agent, a crosslinking agent, an emulsifying agent and water. The molecules of the surface glue reinforcing agent contain a large quantity of functional groups such as hydroxyl and carboxyl, the surface glue reinforcing agent can strongly adhere to fibers, and the bonding strength among fibers can be improved; meanwhile, the surface glue reinforcing agent has the function of forming a net structure through self-crosslinking, the acting force between the reinforcing agent and other reinforcing agents and between the reinforcing agent and fibers and filler is increased, and the acting effect of the reinforcing agent is improved; due to the good film forming property of the surface glue reinforcing agent, migration of surface glue to the interior of paper can be reduced, the surface strength of paper can be improved, and the linting and dusting phenomenon can be avoided. By means of the preparation method, the defect that the strength of body paper is reduced in a body paper highly-filling technology or a method of adopting a staple fiber raw material (like secondary fibers) in a high proportion can be overcome, the ash content of paper can be improved, and cost can be reduced.

Owner:SHANDONG YUANGEN CHEM TECH RES & DEV CO LTD

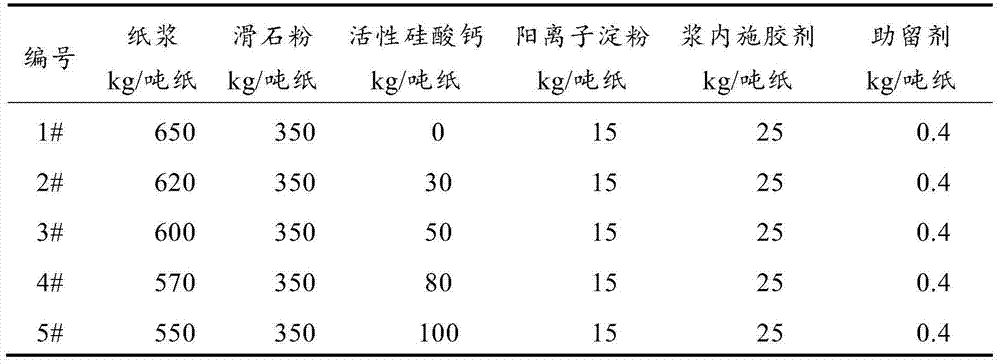

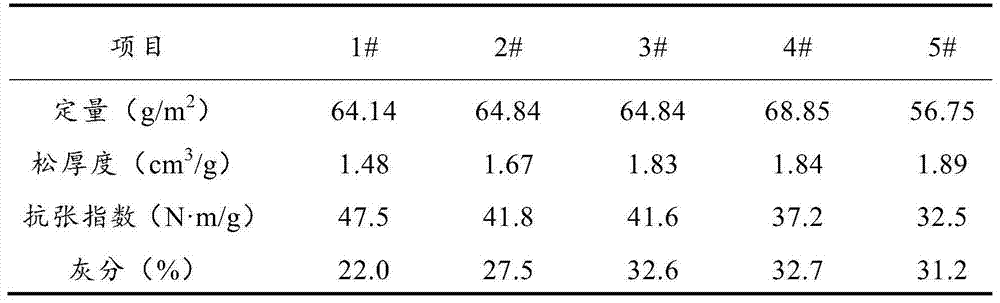

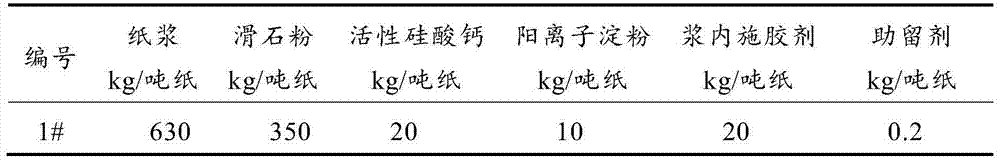

Application of calcium silicate as retention aiding intensifier in papermaking

InactiveCN104120621AGood strength performanceImprove paper ashInorganic compound additionRetention agents additionPapermakingIntensifier

The invention discloses application of calcium silicate as a retention aiding intensifier in papermaking and belongs to the technical field of applications of calcium silicate in papermaking. According to the invention, calcium silicate is adopted to serve as the retention aiding intensifier for the papermaking to be applied to the papermaking, wherein calcium silicate is preferably active calcium silicate. An application method comprises the following steps: (1) mixing calcium silicate with water to obtain a dispersion liquid; sieving the dispersion liquid by a screen and taking the slurry for later use; (2) adding papermaking filler into paper pulp and adding the slurry obtained in the step (1); or simultaneously adding the slurry obtained in the step (1) and the papermaking filler into the paper pulp; and (3) adding other papermaking additives and carrying out papermaking according to conventional papermaking processes. Calcium silicate is adopted to serve as the retention aiding intensifier to be applied to the papermaking and the operation is simple; the paper ash content and bulk are obviously increased; the plant fiber using amount is saved and the production cost is reduced.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

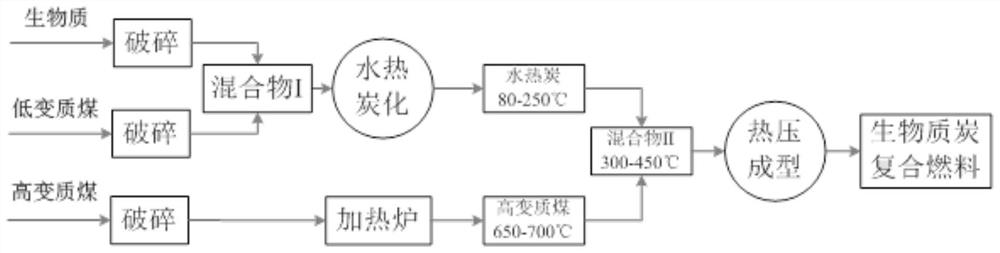

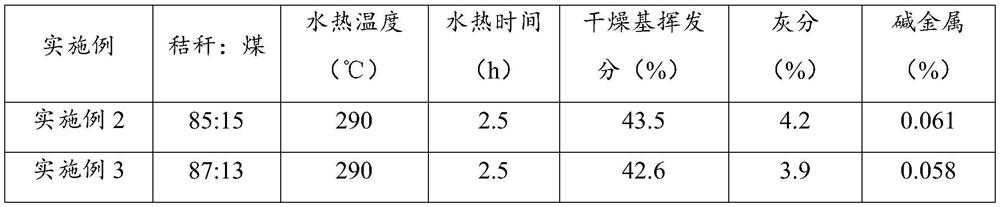

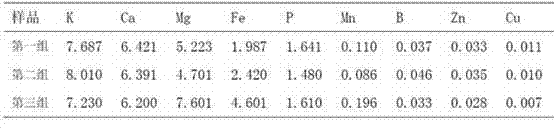

Preparation method of biomass charcoal composite fuel for blast furnace injection

The invention provides a preparation method of a biomass charcoal composite fuel for blast furnace injection, which comprises the following steps: mixing crushed biomass raw materials and low metamorphic coal, carrying out hydrothermal carbonization treatment, then mixing with preheated high metamorphic coal, carrying out heat preservation, and finally carrying out hot pressing treatment. According to the method, the yield of biomass hydrothermal carbonization is increased by utilizing mineral substances in the low-rank coal, and meanwhile, ash, volatile components and water in the low-rank coal can be partially removed, so that the caking property is improved. And then the mixture is mixed with the preheated high-metamorphic coal, so that the ignition point of the mixture can be improved, the explosiveness of the mixture is reduced, and the ash fusion point of the composite fuel can be further improved by utilizing the characteristic of high ash fusion point of the high-metamorphic coal. The biomass charcoal composite fuel can completely replace fossil fuel to be used for blast furnace injection, the emission amount of carbon dioxide and pollutants in the ironmaking production process is reduced, and in addition, the fuel formed through hot pressing has the advantages of being large in volume density and high in compressive strength and is suitable for long-distance transportation and long-term storage.

Owner:BAOSHAN IRON & STEEL CO LTD +1

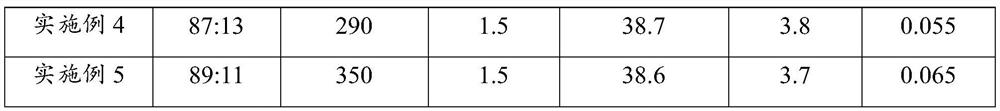

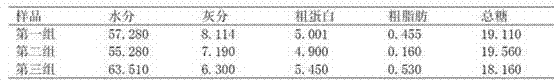

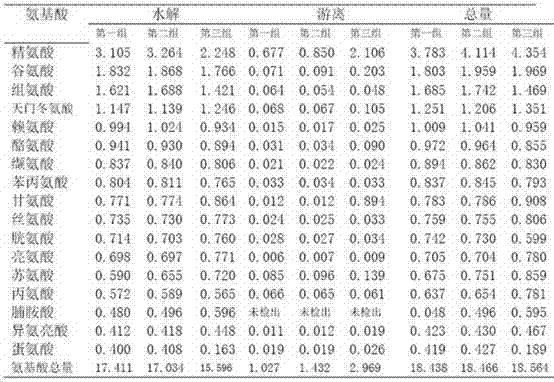

Low-altitude cultivation method for polygonum viviparum

InactiveCN102187779ASolve the problem that cannot be cultivated in low altitude conditionsHigh ash contentCultivating equipmentsHorticultureTemperature controlArginine

The invention provides a low-altitude cultivation method for polygonum viviparum. The problem that the polygonum viviparum cannot be cultivated under low-altitude condition is solved by adopting the means of formulated fat ball and shed house temperature control. Meanwhile, the polygonum viviparum cultivated by the method has the characteristics of high glucose, high ash content and high K, and also has the characteristics that arginine serves as a main component and glutamic acid, histidine and aspartic acid serve as auxiliary components on the basis of multiple amino acids.

Owner:CHONGQING ACAD OF CHINESE MATERIA MEDICA

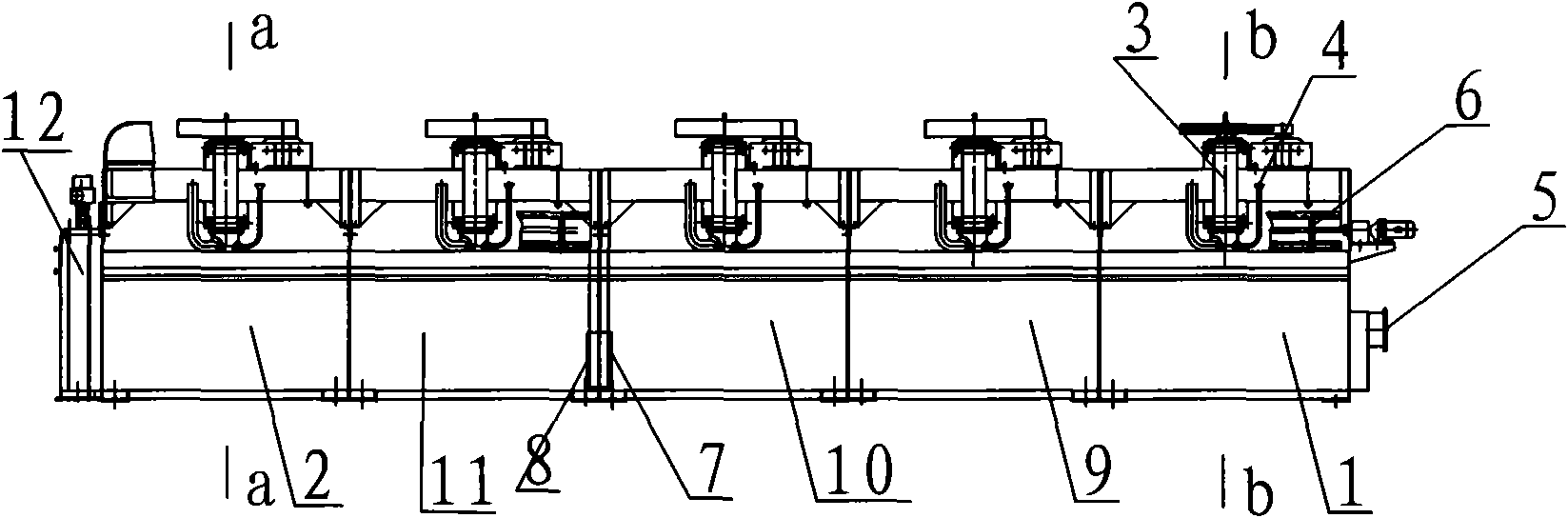

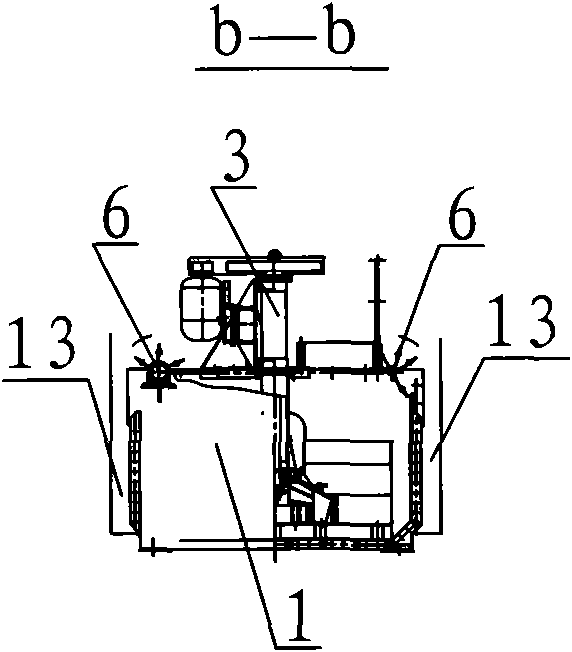

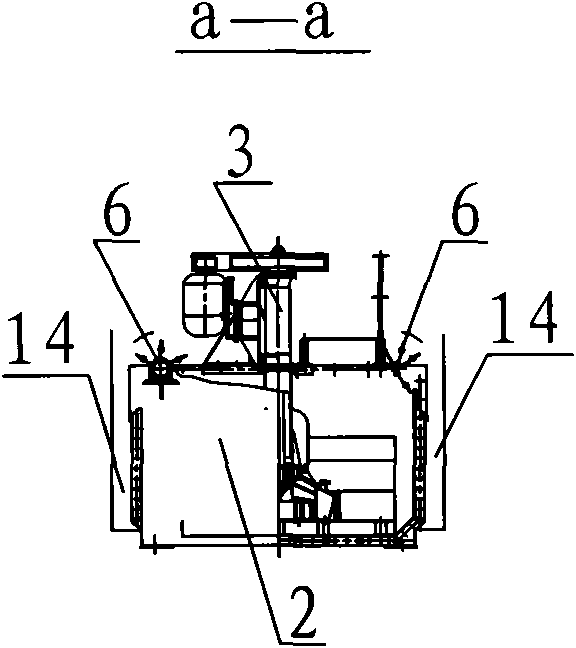

Three-product coal slurry flotation machine and system

The invention discloses a three-product coal slurry flotation machine and a three-product coal slurry flotation system. The three-product coal slurry flotation machine is characterized in that raw coal slurry is divided into three products, i.e. flotation clean coal, flotation middling coal and waste coal slurry through arranging a primary concentration device and a secondary middle flotation device. During work, the ash content of the flotation clean coal can be adjusted at any time according to needs, and the ash content of the waste coal slurry is adjusted at any time according to needs through adjusting the ash content of the flotation middling coal in the secondary middle flotation device. After the three-product coal slurry flotation machine and the three-product coal slurry flotation system are applied to the flotation of the coal slurry, the ash content of flotation waste coal is improved to be higher while the ash content of the flotation clean coal is reduced to be lower. The three-product coal slurry flotation machine and the three-product coal slurry flotation system have the advantages of high recovery rate, less total investment, simpler system and lower operating cost, and the improvement of the resource utilization is greatly facilitated.

Owner:JINYITONG SCI ANDTECH BEIJING CO LTD

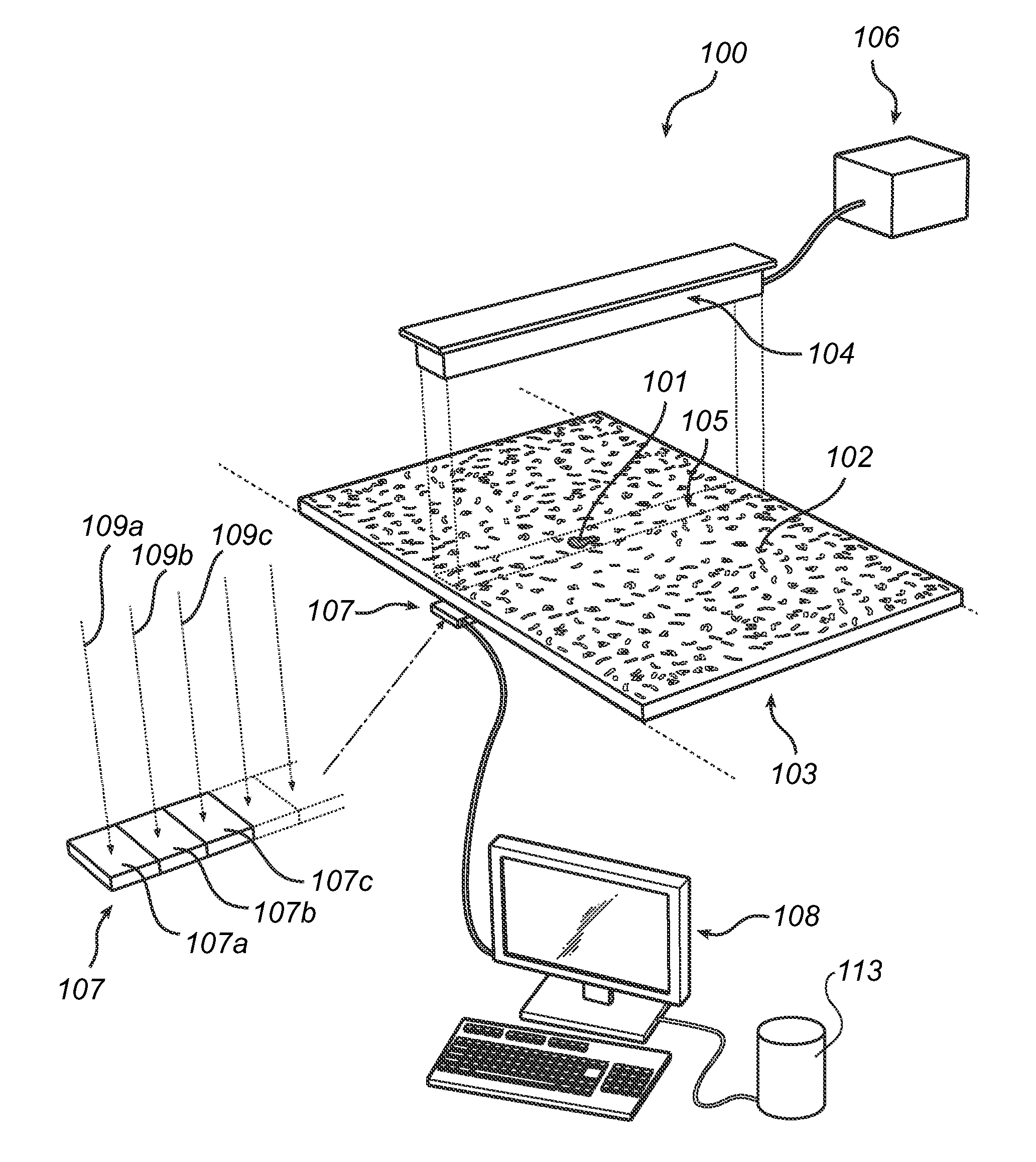

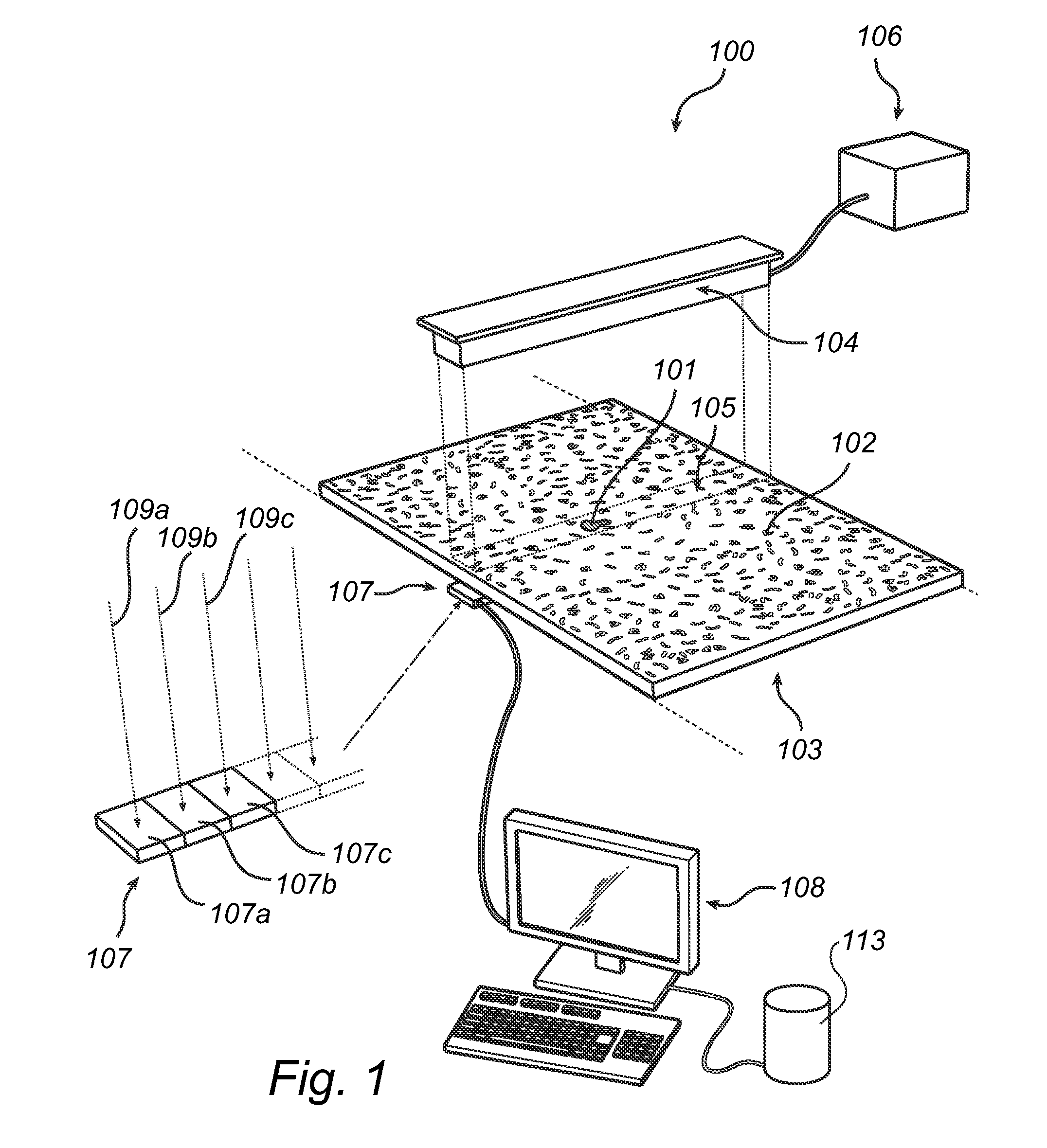

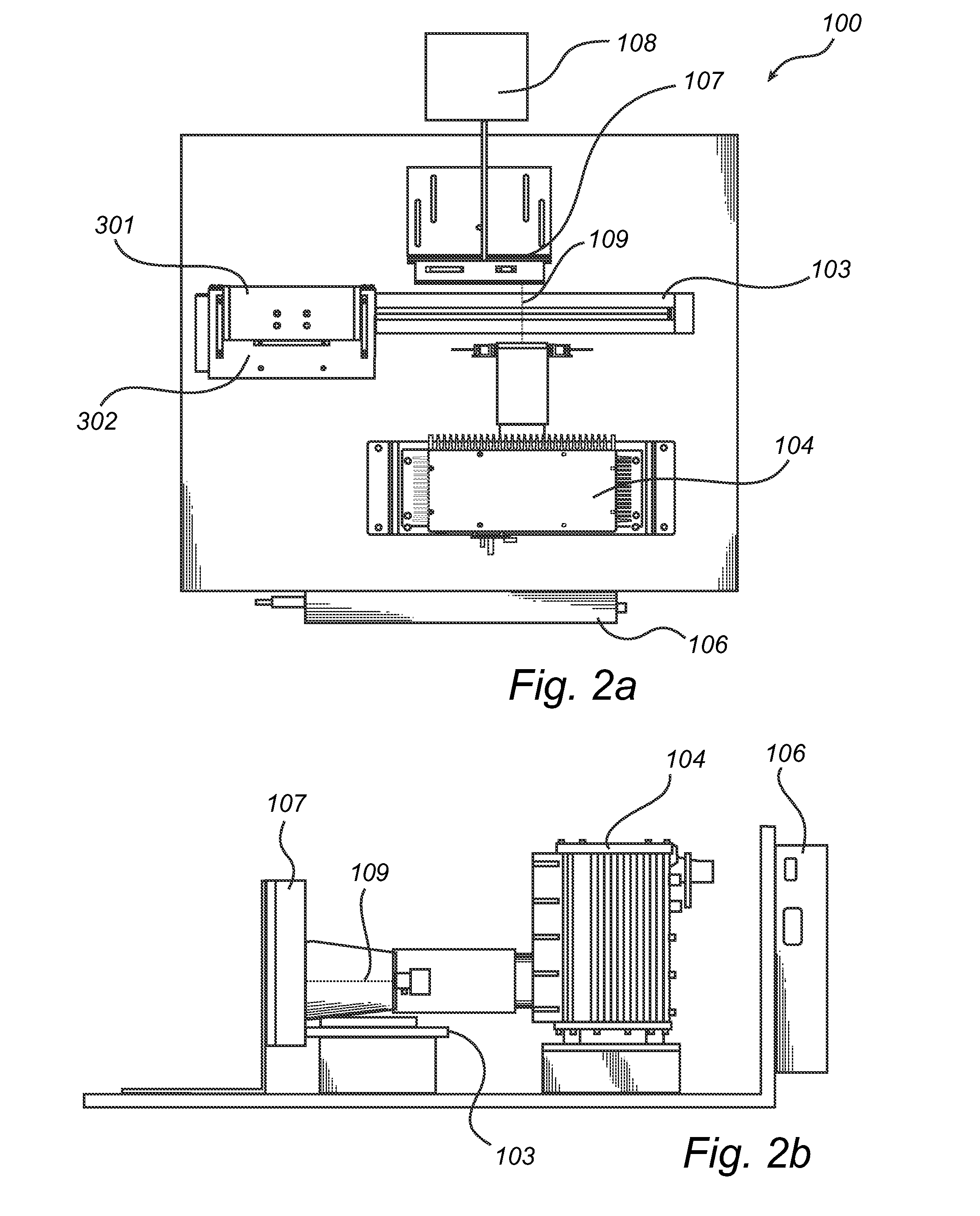

Method and apparatus for estimating the ash content of a biological material

ActiveUS20130195243A1Efficiently useIncrease ashMaterial analysis by transmitting radiationPhysicsAttenuation coefficient

A method for measuring ash content in a biological material in an automated or semi-automated procedure is disclosed. The method includes the steps of scanning the biological material with electromagnetic radiation of at least two different energy levels, determining the amount of radiation transmitted through the sample of the biological material at the energy levels and estimating the moisture content in the biological material based on a relationship between the determined amount of radiation transmitted through the biological material. Thereafter, the ash content in the biological material is estimated, based on the estimated moisture content in the biological material, and average attenuation coefficients for the biological material without moisture, attenuation coefficients for a combustible part of the biological material and attenuation coefficients for ash of the biological material at the energy levels. A corresponding apparatus is also disclosed.

Owner:MANTEX IP AB

Process for extracting salicin from populus euphratica fallen leaves

ActiveCN104262421AReduce pollutionReduce manufacturing costSugar derivativesSugar derivatives preparationSolventChemistry

The invention discloses a process for extracting salicin from populus euphratica fallen leaves. The process is characterized by comprising the following steps: adding calcium oxide into populus euphratica fallen leaf shreds, and adding water for decomposing; extracting the solution twice at the temperature of 30 DEG C, collecting filtrate, and combining the filtrate; adjusting the pH value to 10.0-12.5, allowing the solution to stand, and collecting the filtrate; concentrating the filtrate, adding a clarifying agent or an adsorbent for decolorizing while stirring at the temperature of 70 DEG C, and colleting the filtrate; adjusting the pH value to 3.0-5.0 at a normal temperature, allowing the solution to stand, and collecting the filtrate; adding ammonium water or ammonia gas into the filtrate for adjusting the pH value to 7.0-9.0, concentrating the filtrate till the specific weight is 1.2, and crystalizing the filtrate at the normal temperature in a static manner for 72 hours; and separating a crystal, drying the separated crystal at 80 DEG C, and smashing the dried crystal. The process has the beneficial effects that water with low environmental pollution is taken as an extraction solvent, so that the production cost and the workshop requirement are lowered; ash is removed by adopting sulfuric acid or sulfate, and the crystal is obtained through the crystallizing step, so that the purity of a final product is increased, and can be over 65 percent in general; and natural fallen leaves of populus euphratica in autumn are taken as raw materials, so that damage to vegetation is prevented.

Owner:TUMU SHUKER KUNSHEN PLANT EXTRACTION CO LTD

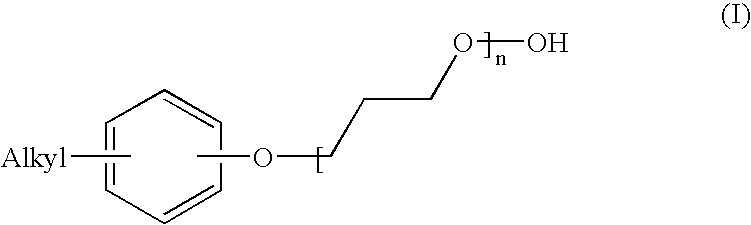

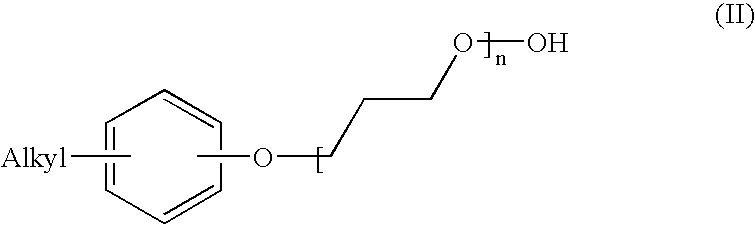

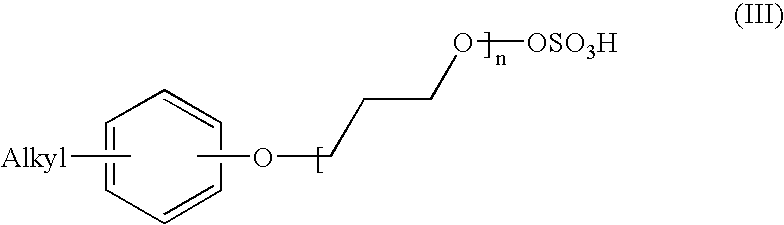

Alkylaryl-o-ethoxylate blends with their respective sulfates

InactiveUS20040092422A1Efficiently and inexpensively carry-outImprove stabilityOrganic detergent compounding agentsNon-ionic surface-active compoundsSulfateEthoxylation

A process for the preparation of mixed ethoxylated alkyl phenol / alkyl phenol ethoxy sulfate surfactants, such surfactants, and detergent formulations incorporating the same. The mixed surfactants are more tolerant of sodium carbonate, allowing greater amounts of sodium carbonate to be used so that the amount of surfactant can be reduced resulting in overall cost savings in the resultant laundry product.

Owner:CHURCH & DWIGHT CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com