Preparation method of biomass charcoal composite fuel for blast furnace injection

A biomass charcoal and composite fuel technology, which is applied to biofuels, waste fuels, fuels, etc., can solve the problem of high ash and alkali metal content, and achieve the effects of low alkali metal content, improved quality, and high fixed carbon content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

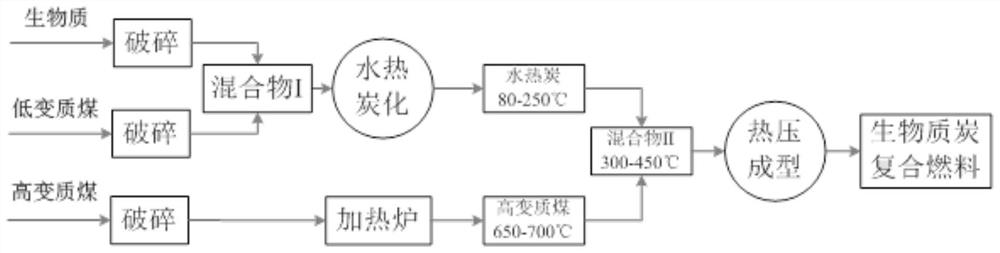

Method used

Image

Examples

Embodiment 1

[0045] A biochar composite fuel for blast furnace injection, which uses soybean straw from agricultural production as a biomass raw material, and is prepared through the following steps:

[0046] (1) The collected soybean stalks are removed by a vibrating sieve and a strong magnetic iron remover to remove impurities such as small stones and iron wires, and are crushed into straw chips with a particle size of less than 3mm by a shearing mill.

[0047] The low-rank coal in this embodiment is lean coal (volatile content 16.7%, ash content 9.5%, G value 18), and a pulverizer is used to crush large pieces of lean coal into particles with a particle size of less than 3 mm.

[0048] The crushed soybean stalks and lean coal were weighed separately, and the mixture I was composed according to the mass ratio of 85:15, and the mixture I and the ironmaking wastewater were mixed according to an appropriate ratio, and then put into a high-pressure reactor for hydrothermal carbonization react...

Embodiment 2~5

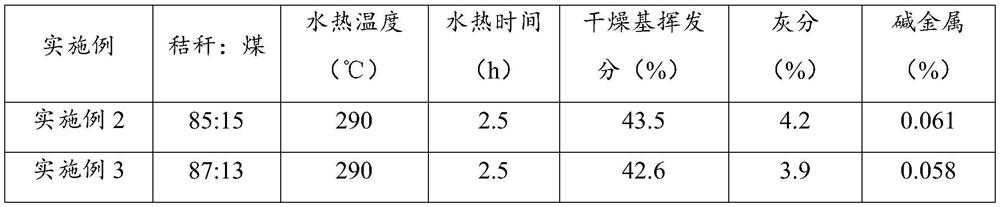

[0054] Embodiments 2 to 5 provide a biomass charcoal composite fuel for injection into a biomass blast furnace. Compared with Embodiment 1, the difference in preparation lies in the mass ratio of soybean straw to lean coal, hydrothermal carbonization temperature, water The thermal carbonization time is shown in Table 1. Other preparation methods are roughly the same as in Example 1, and will not be repeated here. Table 2 shows the performance of the biochar composite fuel prepared in Examples 2-5.

[0055] The preparation conditions of table 1 embodiment 2~5 and the technical index of the hydrothermal charcoal of preparation

[0056]

[0057]

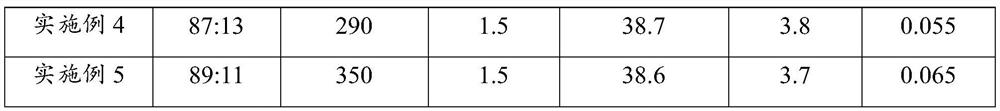

[0058] The performance of the biochar composite fuel prepared by table 2 embodiment 2~5

[0059] Example Example 2 Example 3 Example 4 Example 5 Bulk density (g / cm 3 )

2.39 2.43 2.48 2.49 Molding rate (%) 95 96 94 94 Compressive strength (MPa) 0.23 0.24 0.22 0.23 Moisture (%)...

Embodiment 6~10

[0063] Embodiments 6-10 provide a kind of biomass charcoal composite fuel for biomass blast furnace injection. Compared with Example 3, the difference is that the heat preservation temperature of hydrothermal charcoal, the preheating temperature of anthracite, and the temperature of hydrothermal charcoal anthracite The matching ratio is shown in Table 3. Other preparation methods are substantially the same as in Example 3, and will not be repeated here. Table 4 shows the properties of the biochar composite fuel prepared in Examples 6-10.

[0064] The preparation parameter of table 3 embodiment 6~10

[0065] Example Composite hydrothermal carbon insulation temperature (℃) Anthracite preheating temperature (℃) Composite hydrothermal charcoal: anthracite Example 6 140 650 30:70 Example 7 140 700 40:60 Example 8 140 700 50:50 Example 9 200 650 50:50 Example 10 250 650 50:50

[0066] Table 4 Example 6~10 prepares biochar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com