Patents

Literature

2301 results about "Biomass feedstock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biomass Feedstocks A feedstock is defined as any renewable, biological material that can be used directly as a fuel, or converted to another form of fuel or energy product.

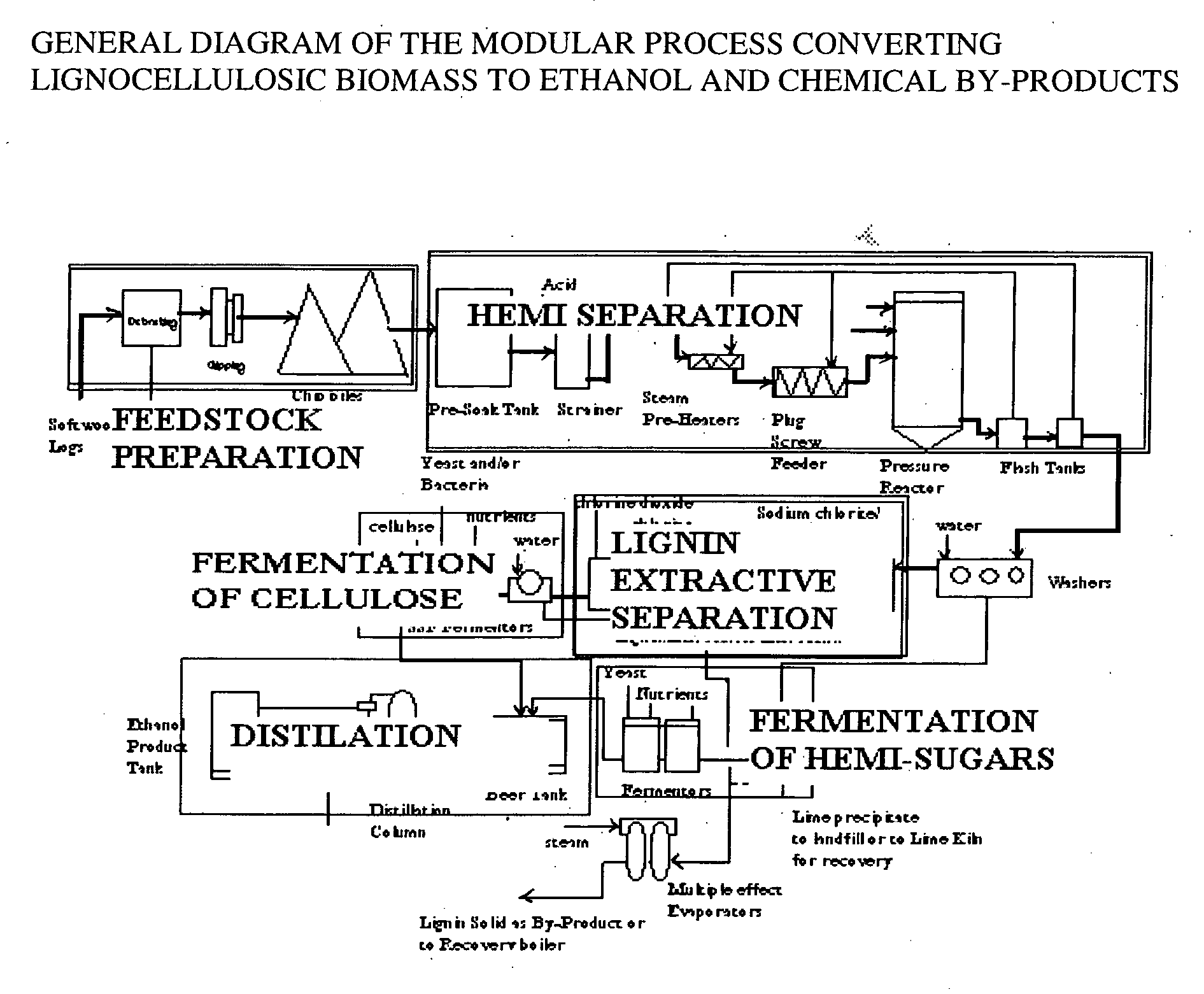

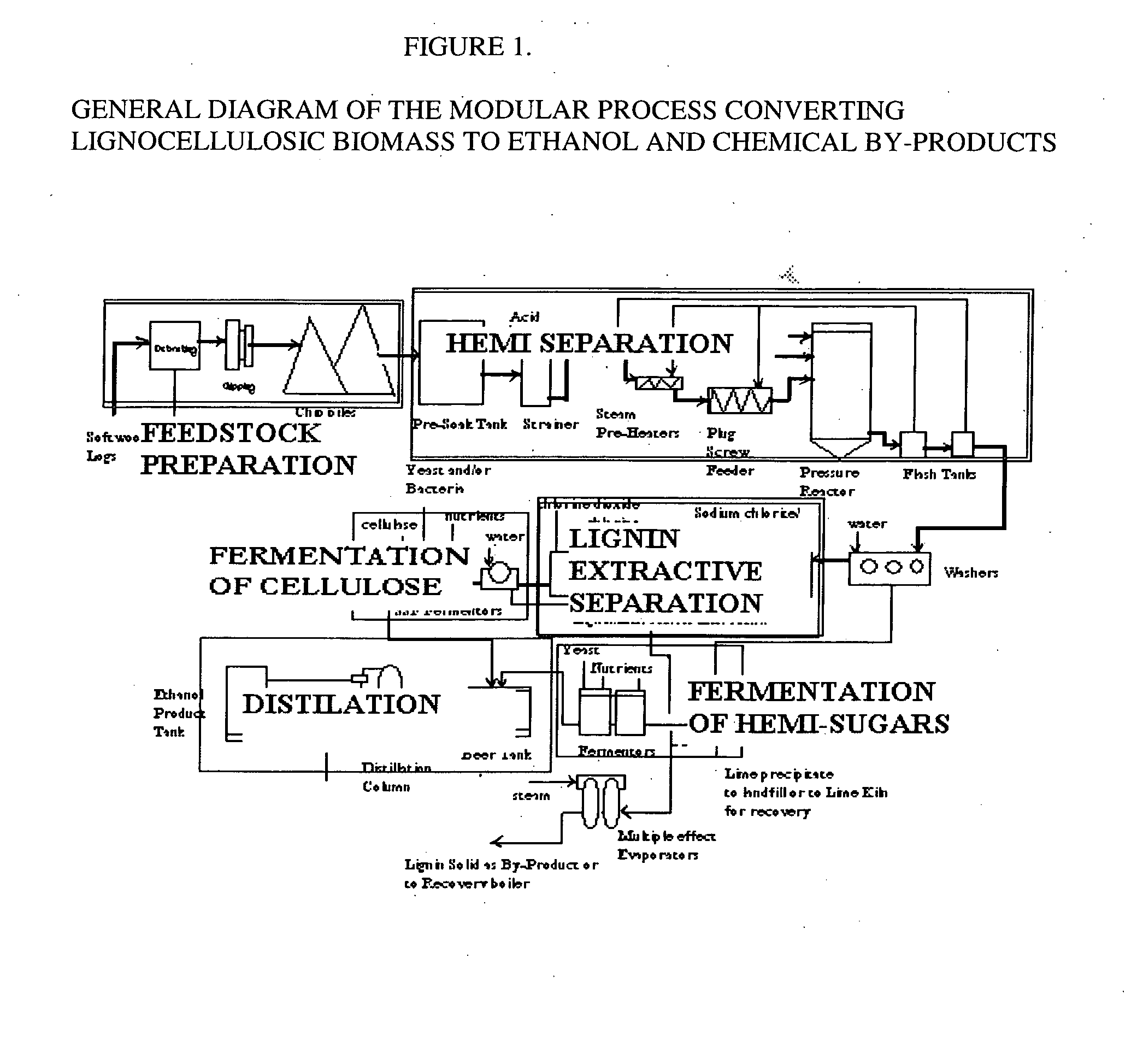

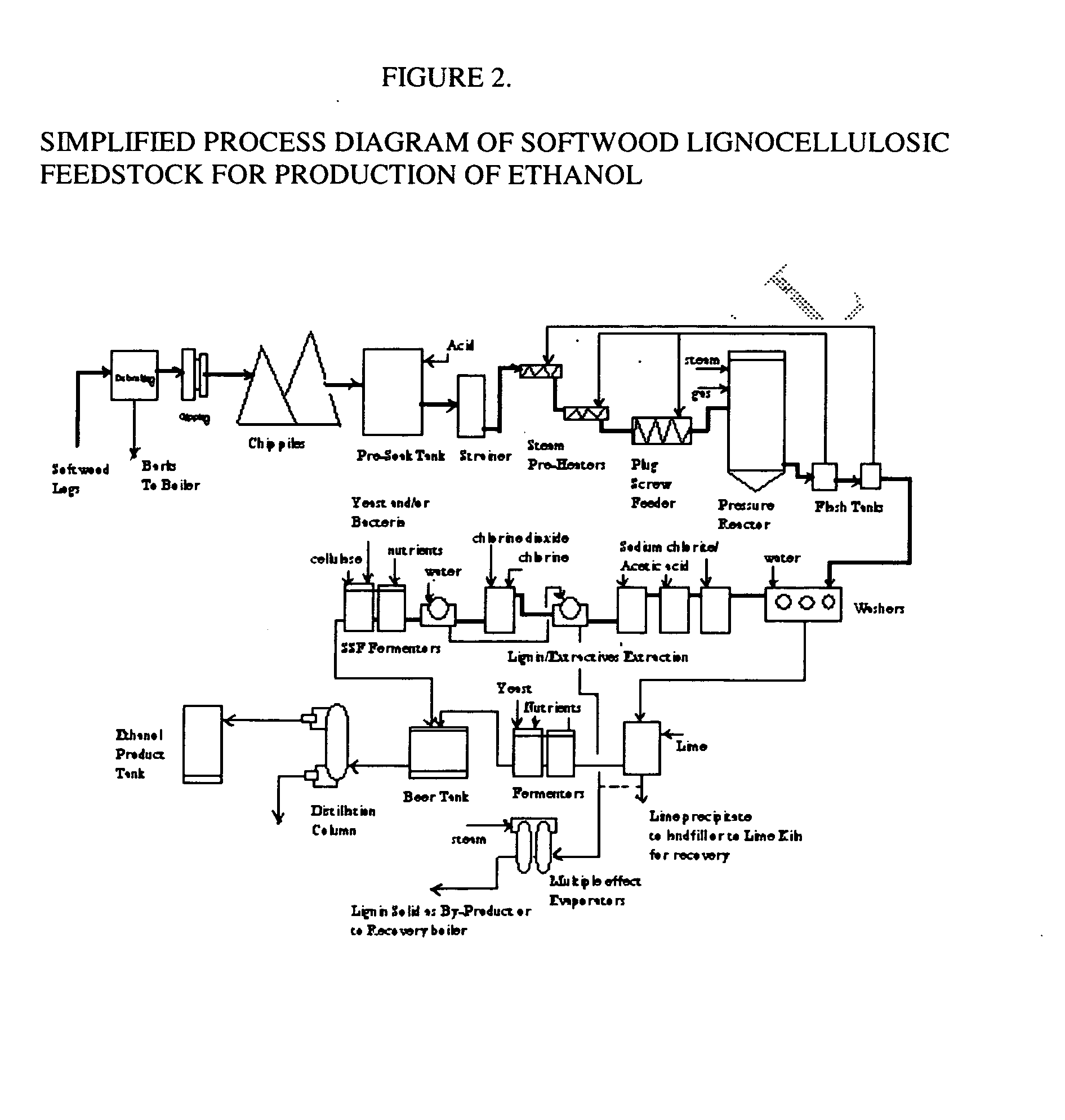

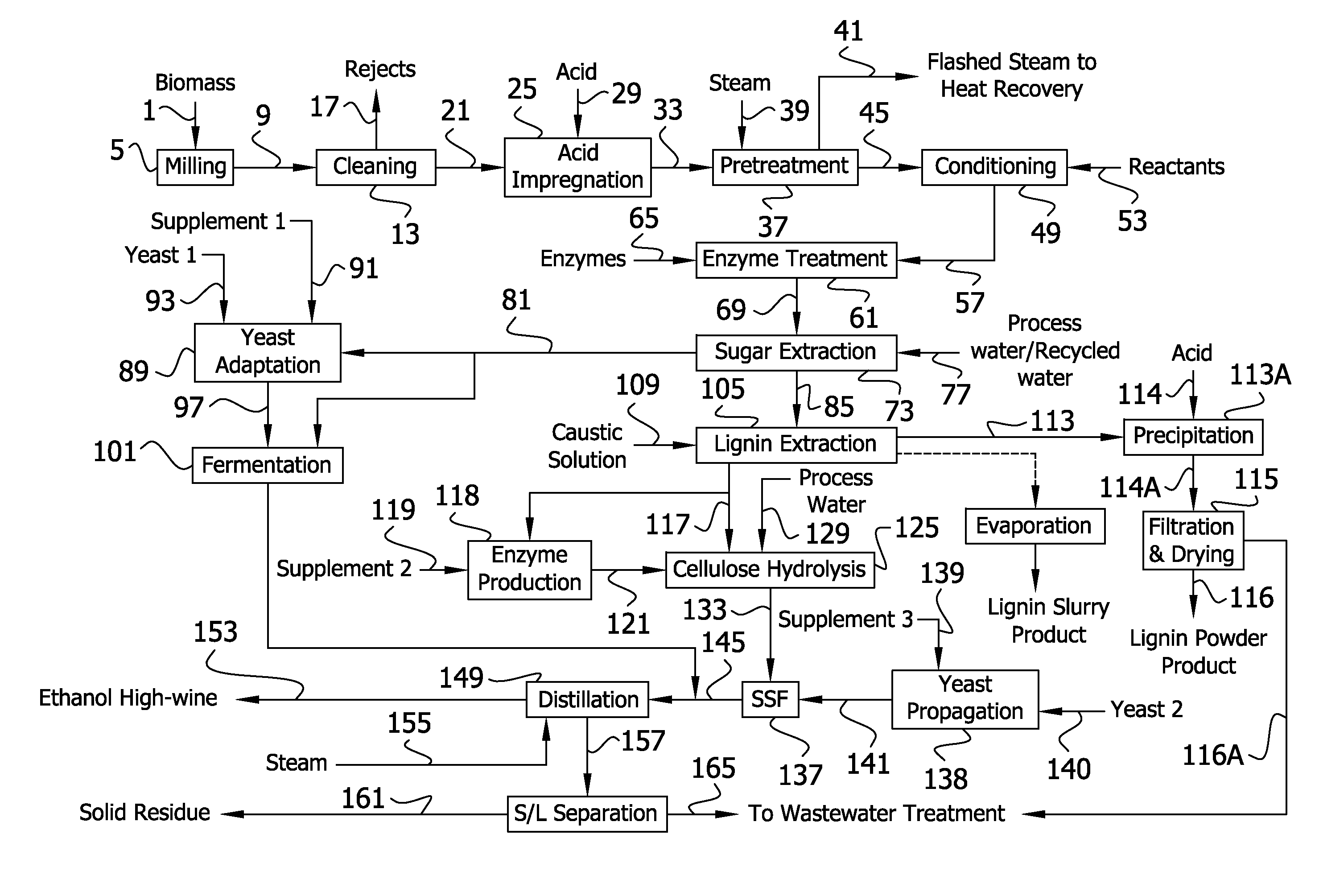

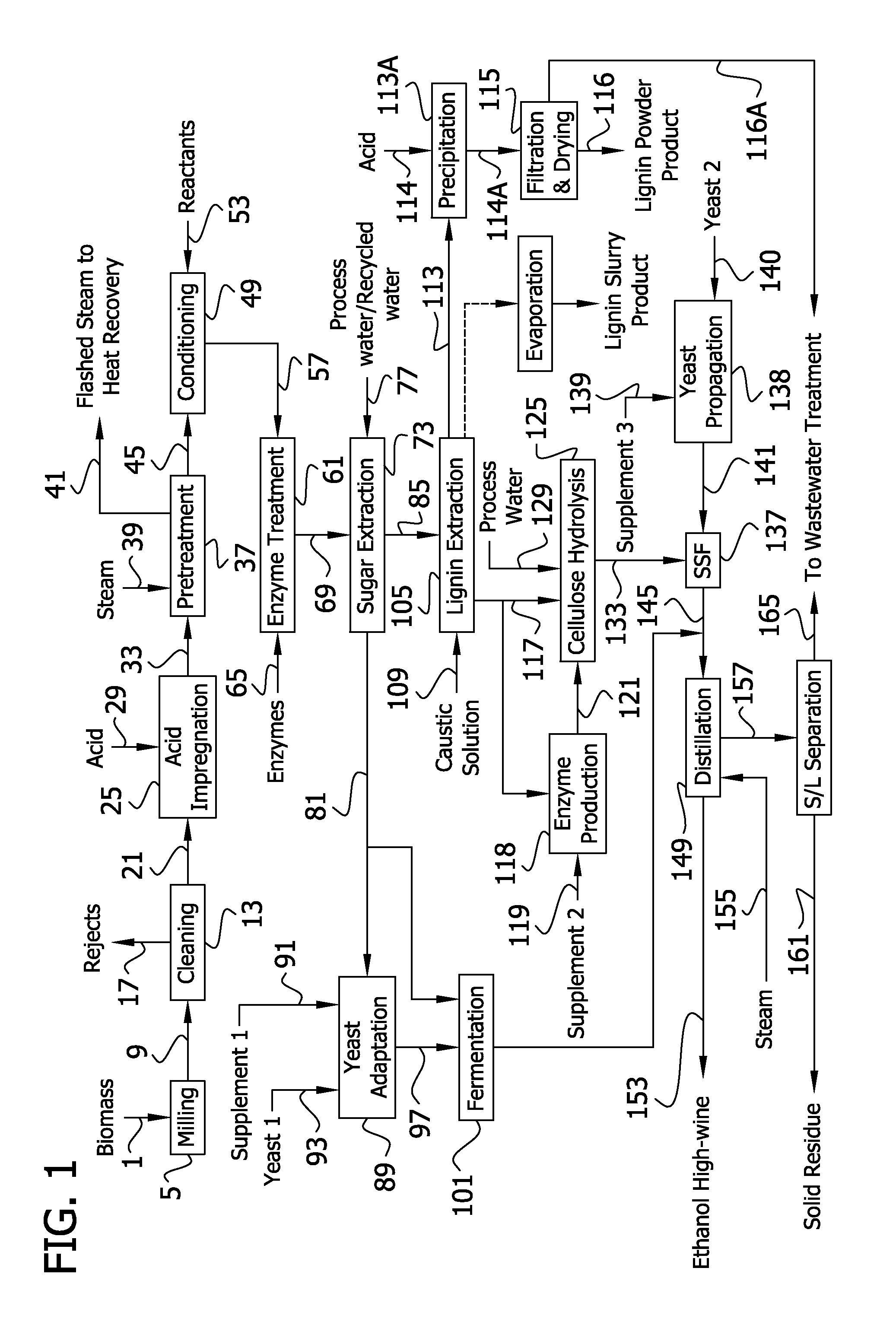

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

InactiveUS20080057555A1Robust and cost-effectiveImprove responseChemical industryBiofuelsChemical treatmentButanediol

A continuous and modular process converts lignocellulosic materials for the production of ethanol principally and / or chemicals such as methanol, butanediol, propanediol, hydrocarbon fuel, etc. Renewable lignocellulosic biomass such as but not all inclusive hardwoods (gum, beech, oak, sweet gum, poplar, eucalyptus, etc.), soft woods (pines, firs, spruce, etc.), corn stovers, straws, grasses, recycled papers, waste products from pulp and paper mills, etc can be used as feedstock. The process is designed to be modular and the feed entry point can be selected to adapt to different biomass feedstock. Lignocellulosic biomass such as hardwood and softwood are subjected to chemical / pressure treatment stages using potent and selective chemicals such as sodium chlorite / acetic acid (anhydrous) and chlorine / chlorine dioxide to separate the main components—lignin, cellulose (glucose) and hemicelluloses (xylose, arabinose, galactose)—into three process streams. The separated carbohydrates are further subjected to washing, cleaning, neutralization, and / or mild hydrolysis and subsequently fermented to produce ethanol. Residual lignin and extractives remained with the cellulose are removed by chemical treatment steps to enhance the fermentations of cellulose. Pre-hydrolysate after neutralization to neutralize and remove toxic components such as acetic acid, furfural, phenolics, etc. containing (xylose, arabinose, galactose) and hexoses (glucose) can be either separately or together with the purified cellulosic fraction fermented to produce ethanol. Approximately 100 gallons of ethanol, suitable to be used as a fuel, can be produced from one dried ton of wood. Significant amount of lignin are separated as a by-product and can be converted to hydrocarbon fuel, surfactant, drilling aid, or can be incinerated for generation of power and steam.

Owner:NGUYEN XUAN NGHINH

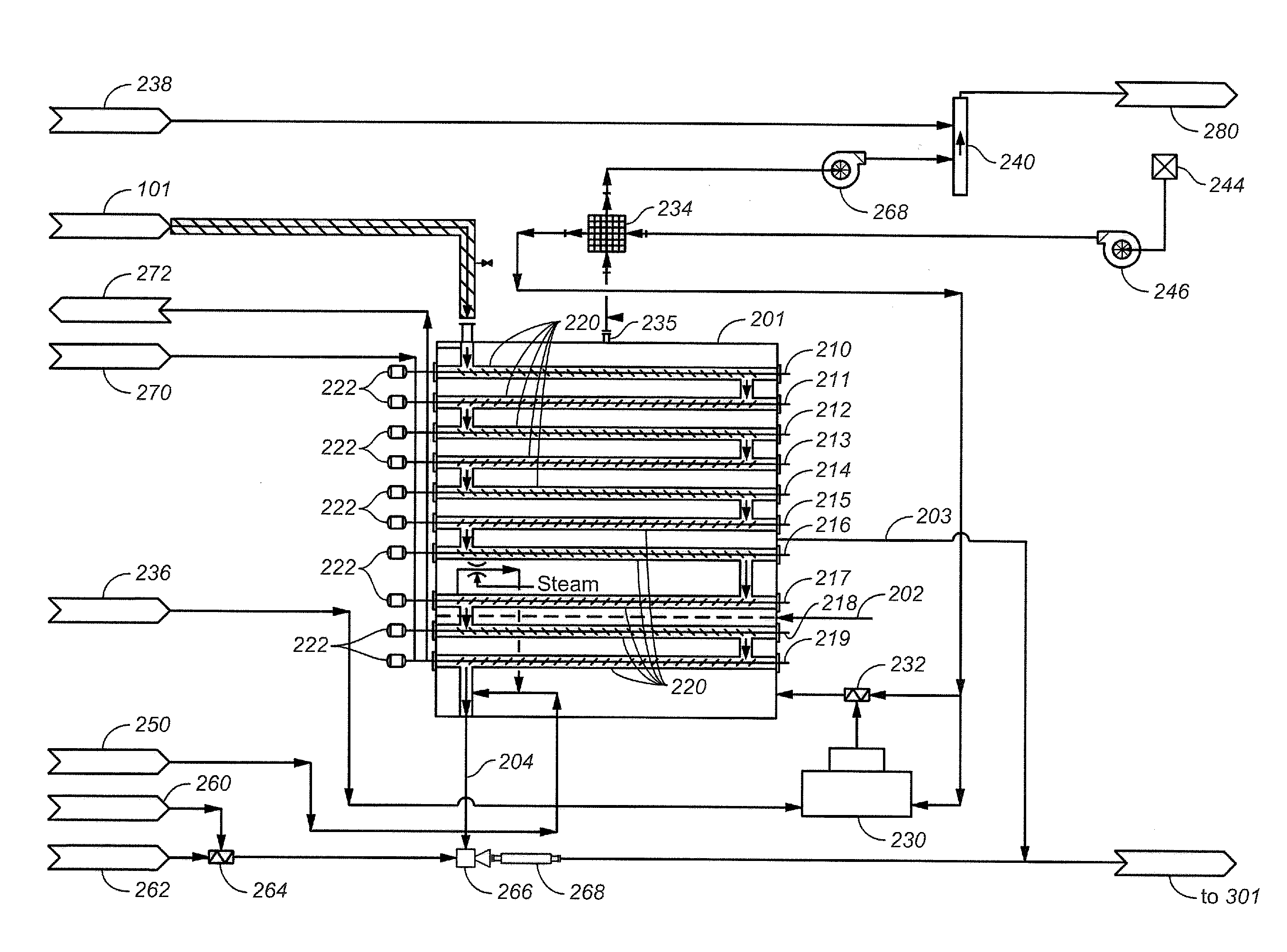

Steam Generation Processes Utilizing Biomass Feedstocks

Integrated catalytic gasification processes are provided involving generating steam for converting carbonaceous materials to combustible gases, such as methane. Generally, steam generated from the combustion of a biomass is provided to a catalytic gasifier, wherein under appropriate temperature and pressure conditions, a carbonaceous feedstock is converted into a plurality of product gases, including, but not limited to, methane, carbon monoxide, hydrogen, and carbon dioxide.

Owner:SURE CHAMPION INVESTMENT LTD

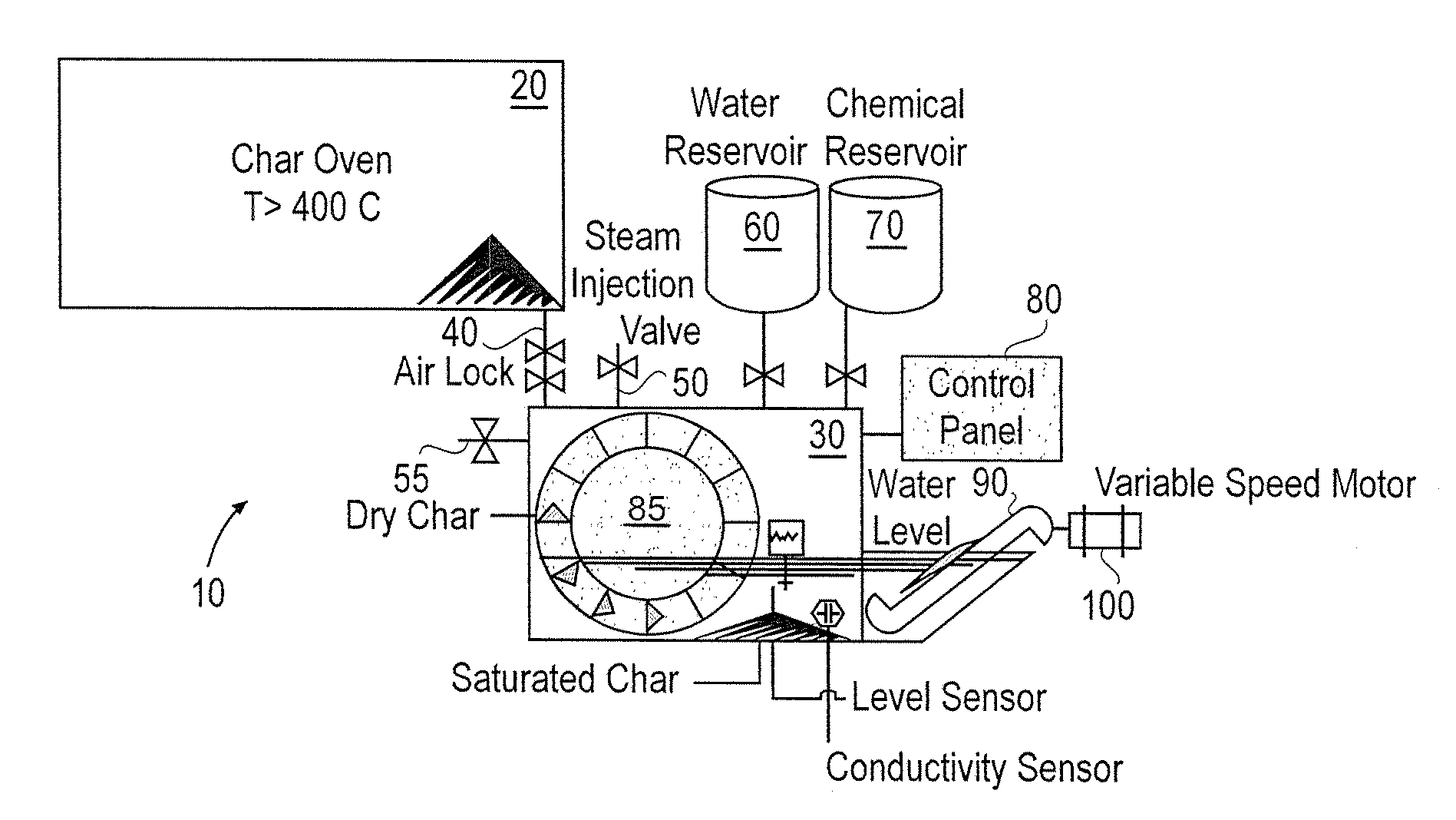

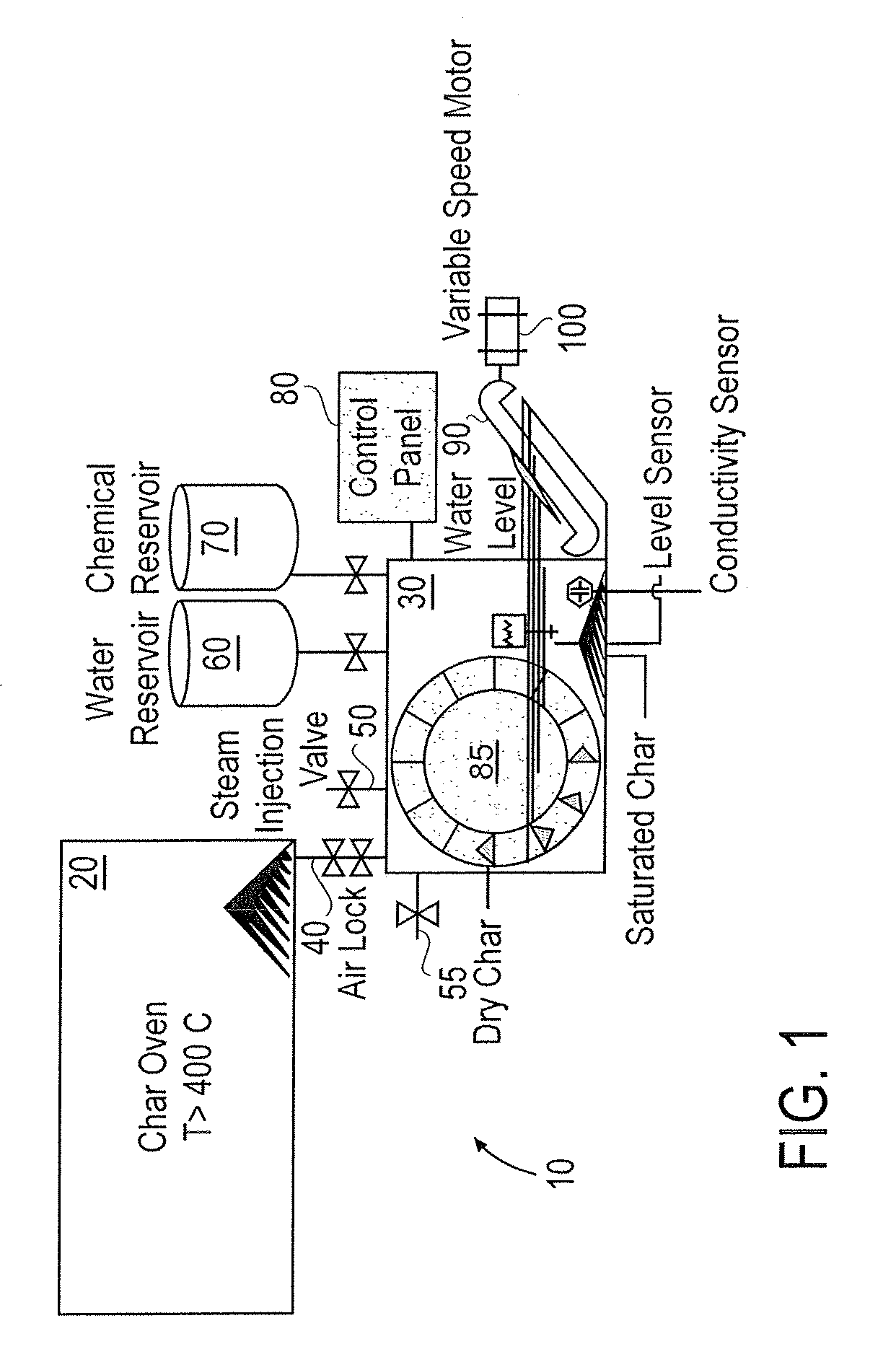

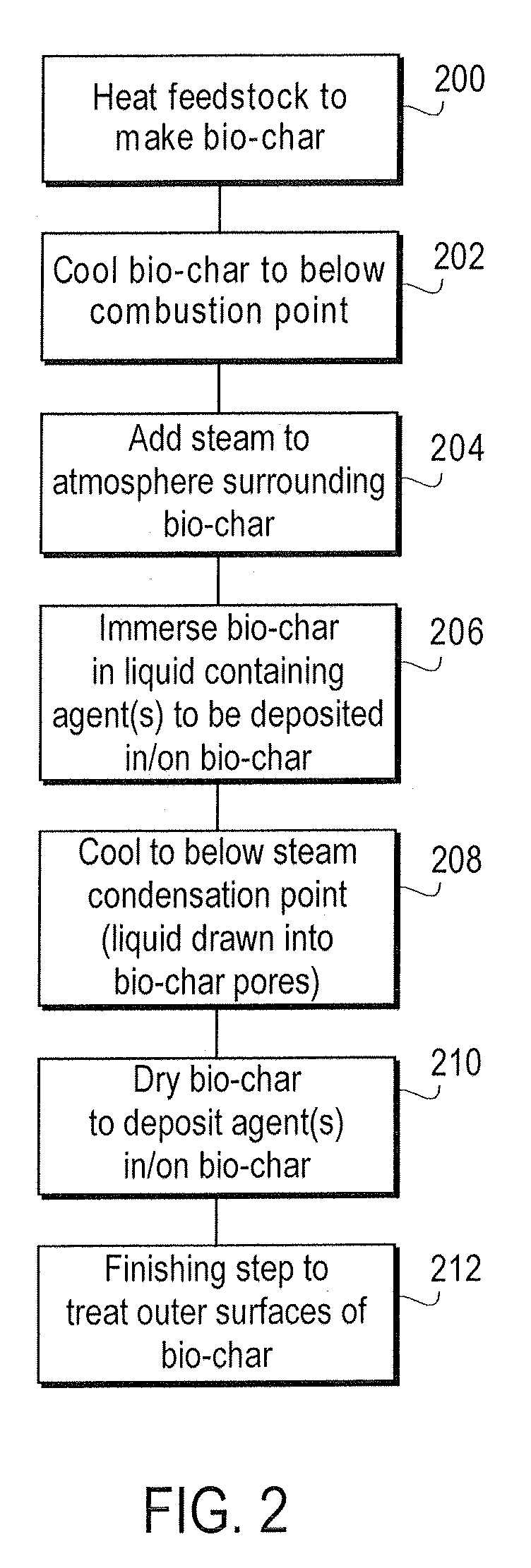

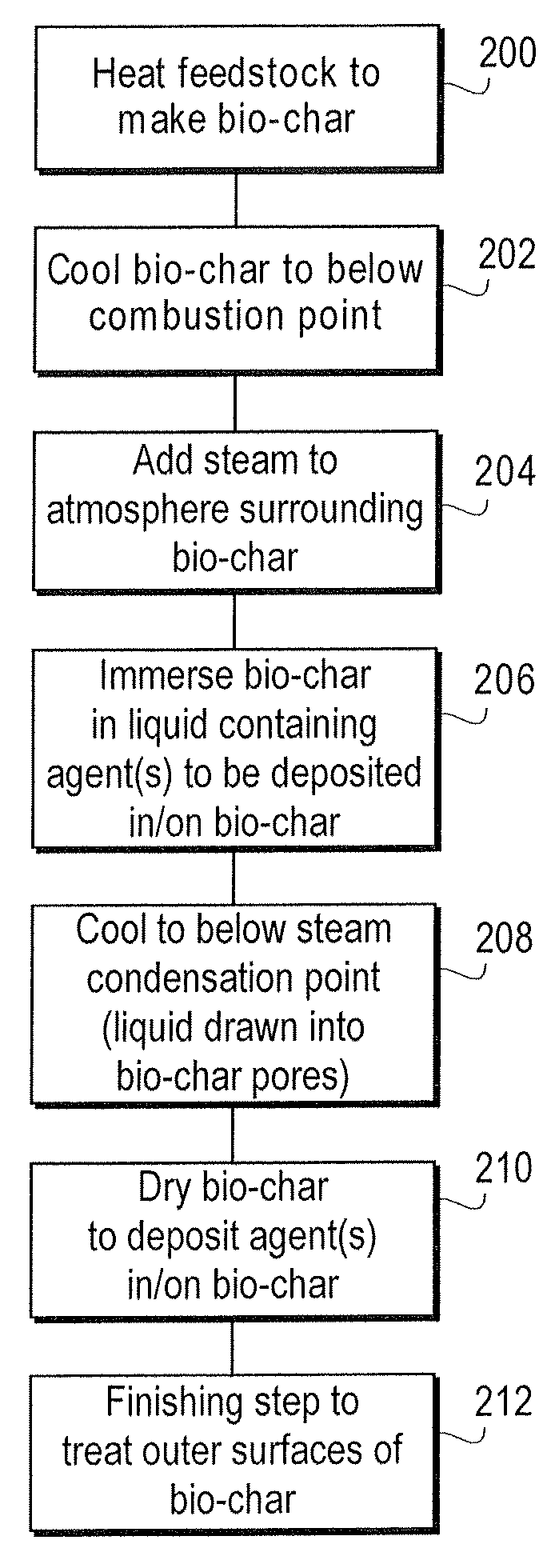

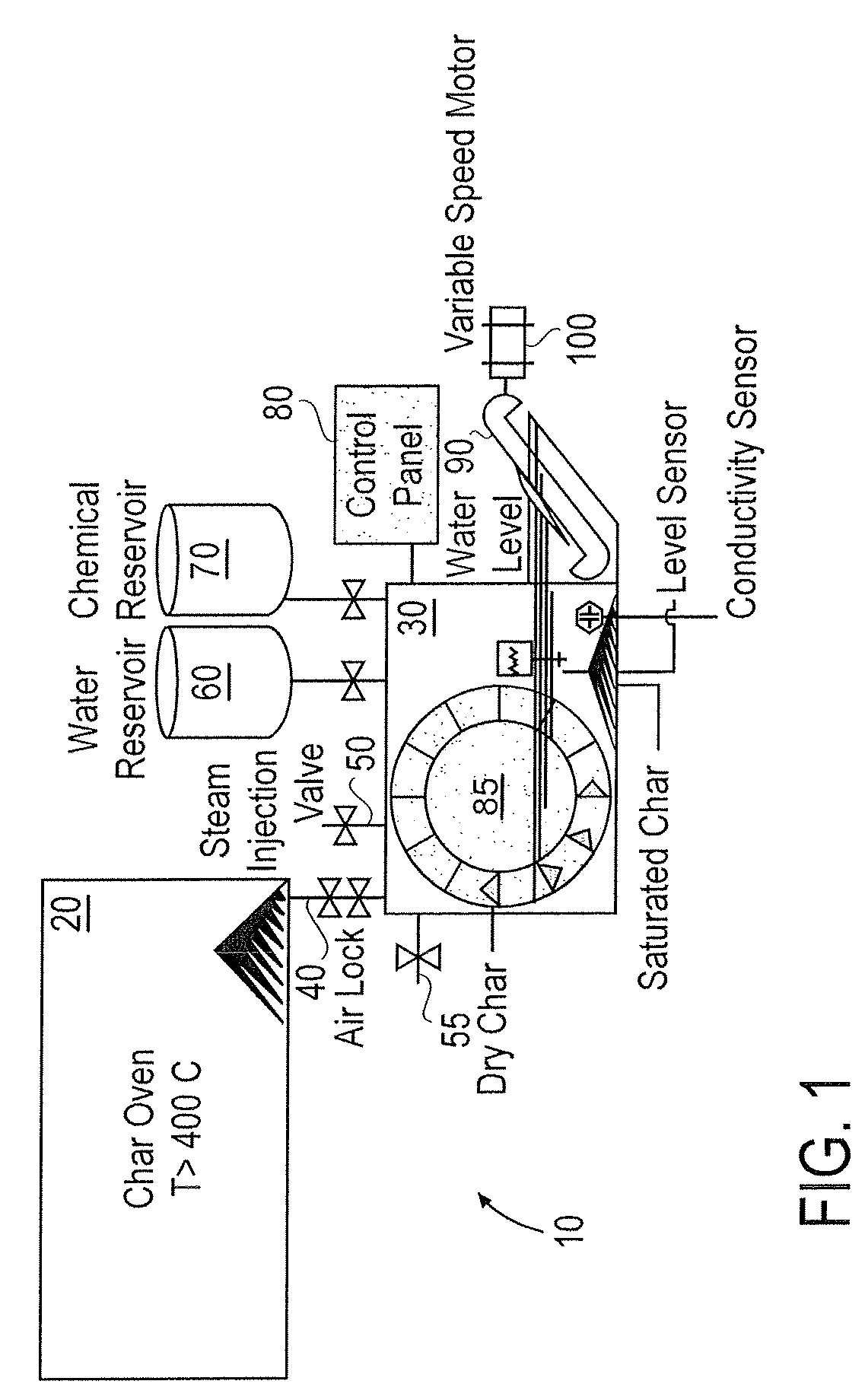

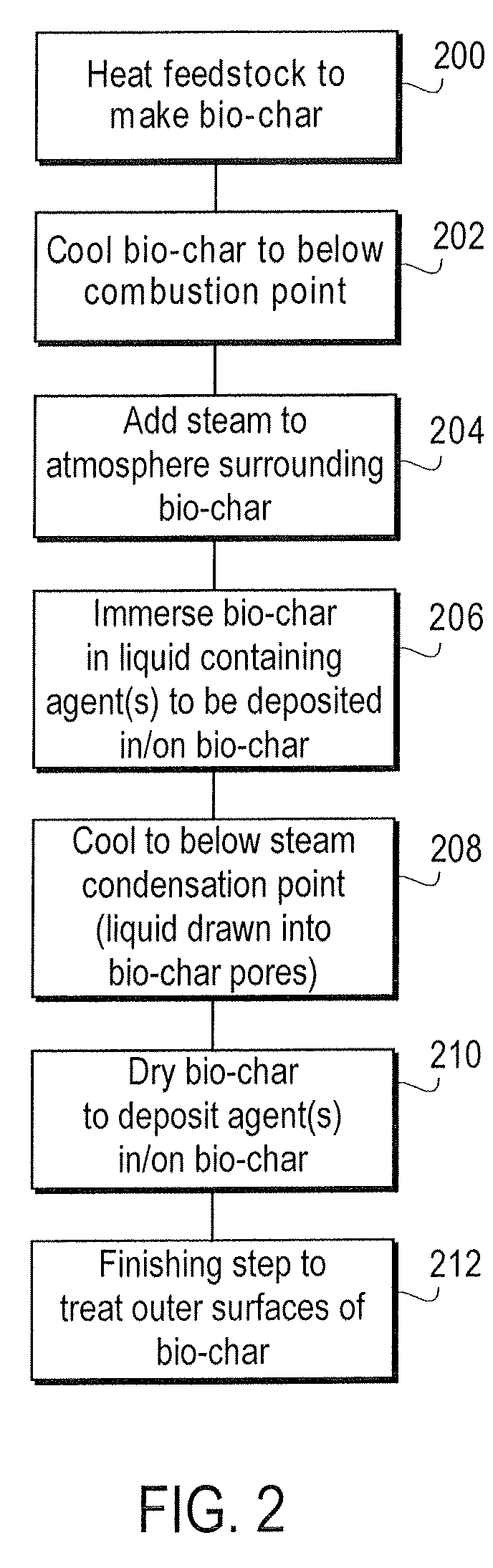

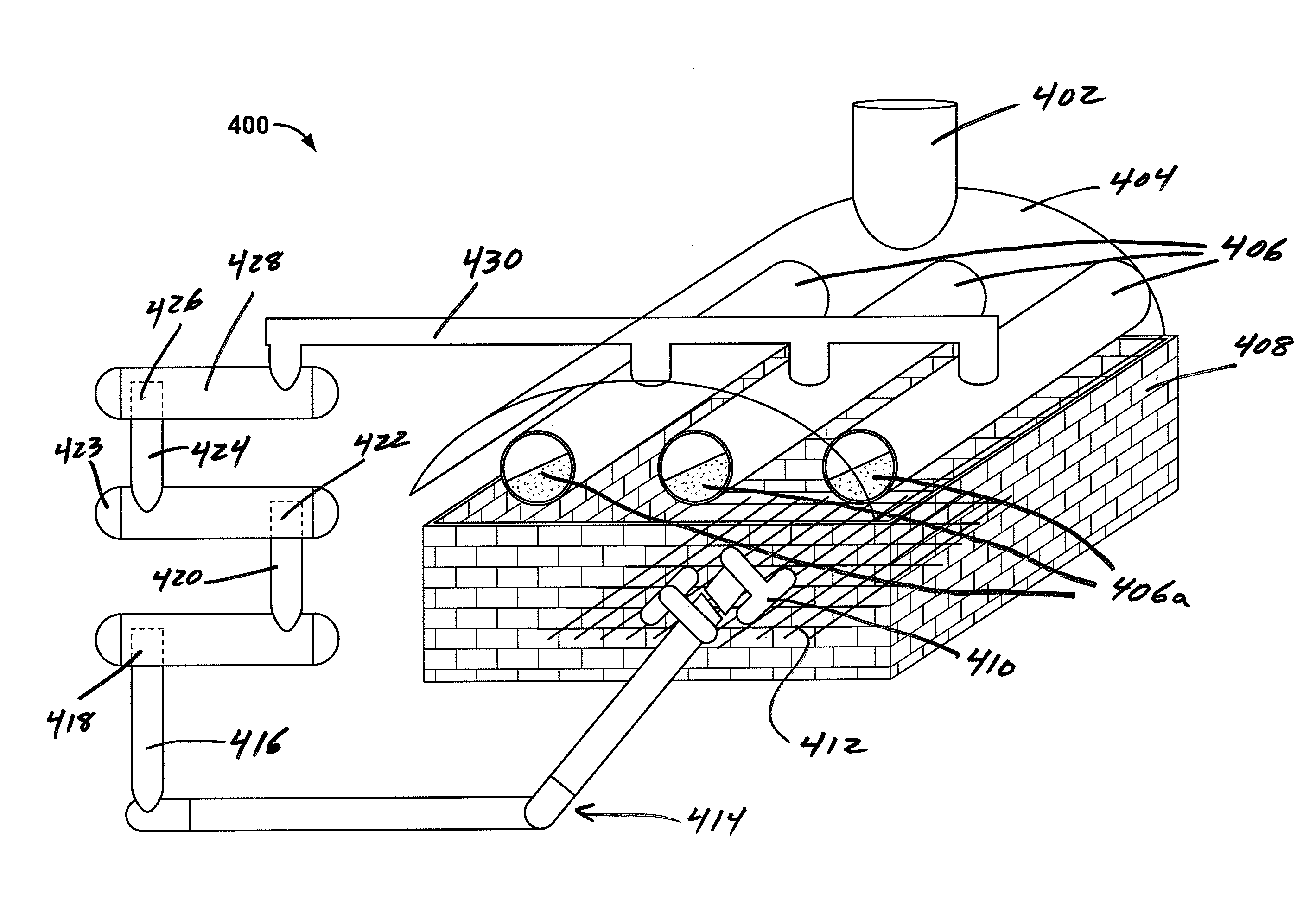

Method and apparatus for depositing agents upon and within bio-char

Methods and apparatuses for depositing agents relatively deep within pores of bio-char. Bio-char is first produced in an airtight oven by heating biomass feedstock. The bio-char is then cooled and steam is diffused into the pores of the bio-char. The steam-laden bio-char is immersed in a liquid bath containing soluble agents that are to be deposited in the pores of the bio-char. The liquid bath cools the char to below the condensation temperature of the steam, whereupon the condensing steam generates a partial vacuum within the pores, drawing the liquid into the pores. The bio-char is then removed from the liquid bath and dried so that the liquid within the pores evaporates, leaving behind the soluble agent. Accordingly, the invention yields bio-char that has soluble agent embedded relatively deep within its pores.

Owner:CARBON TECH HLDG LLC

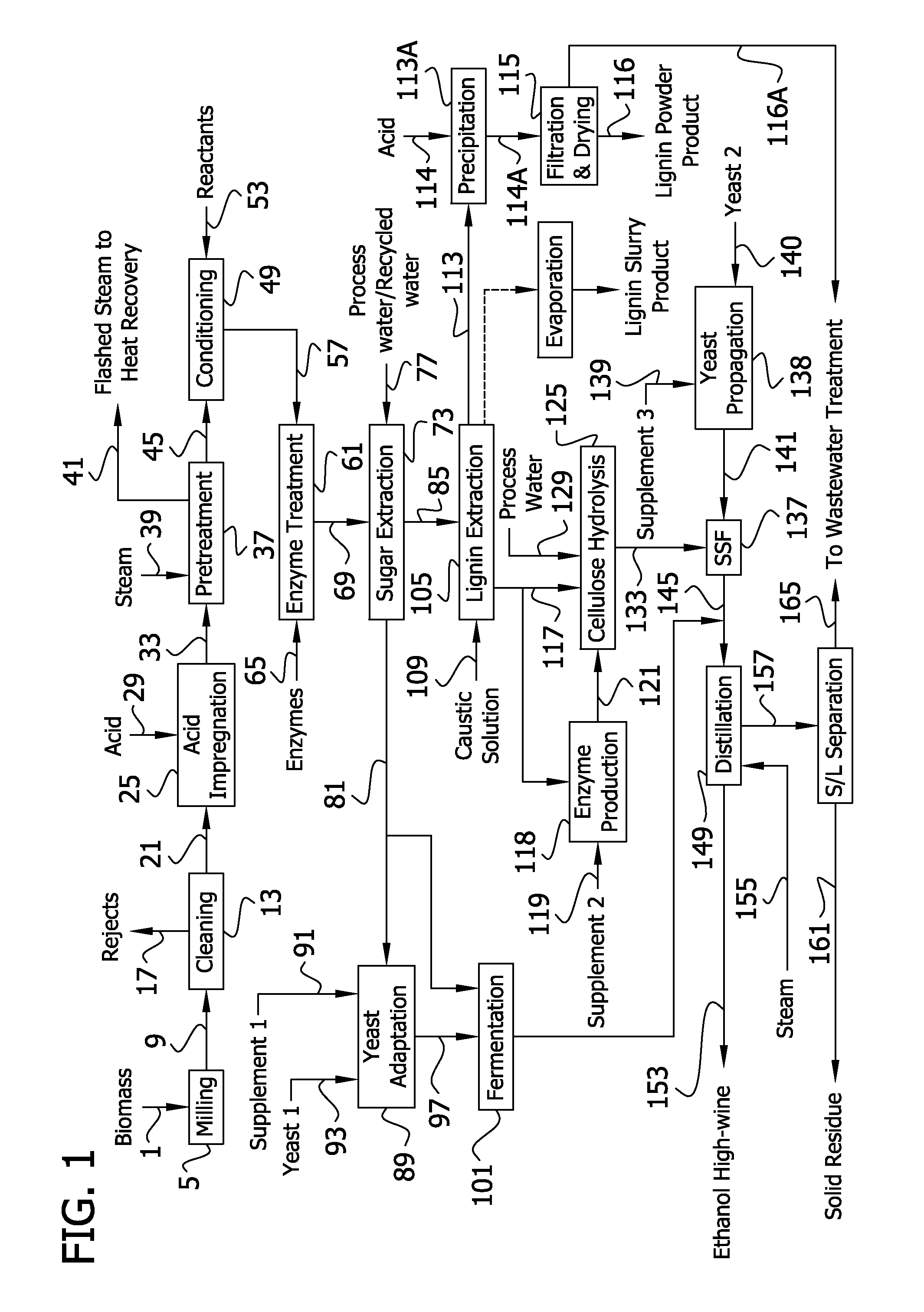

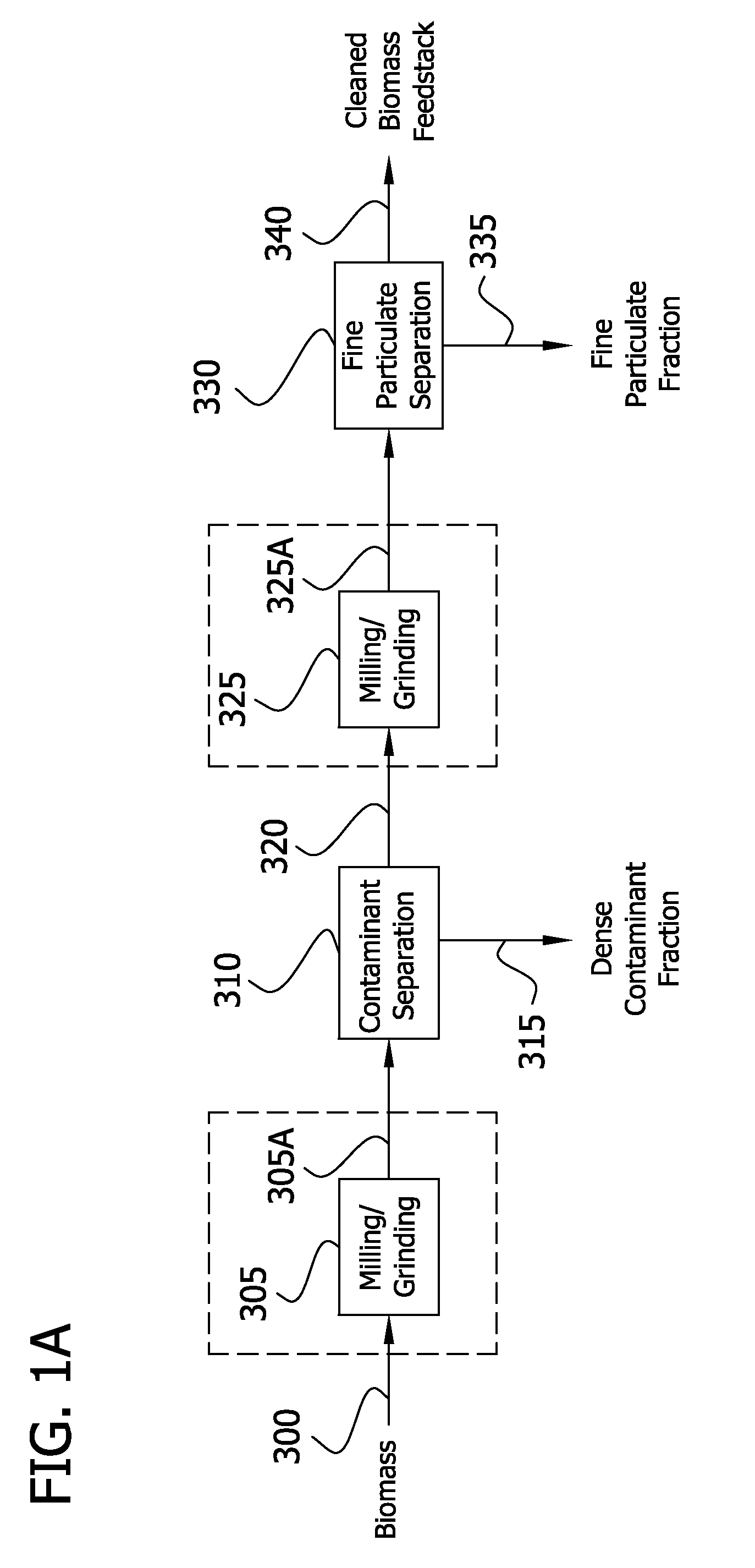

Method for producing ethanol and co-products from cellulosic biomass

InactiveUS20120006320A1Increased ethanol productionImproved co-productsFuel supply regulationPretreatment with acid reacting compoundsCelluloseLignocellulosic biomass

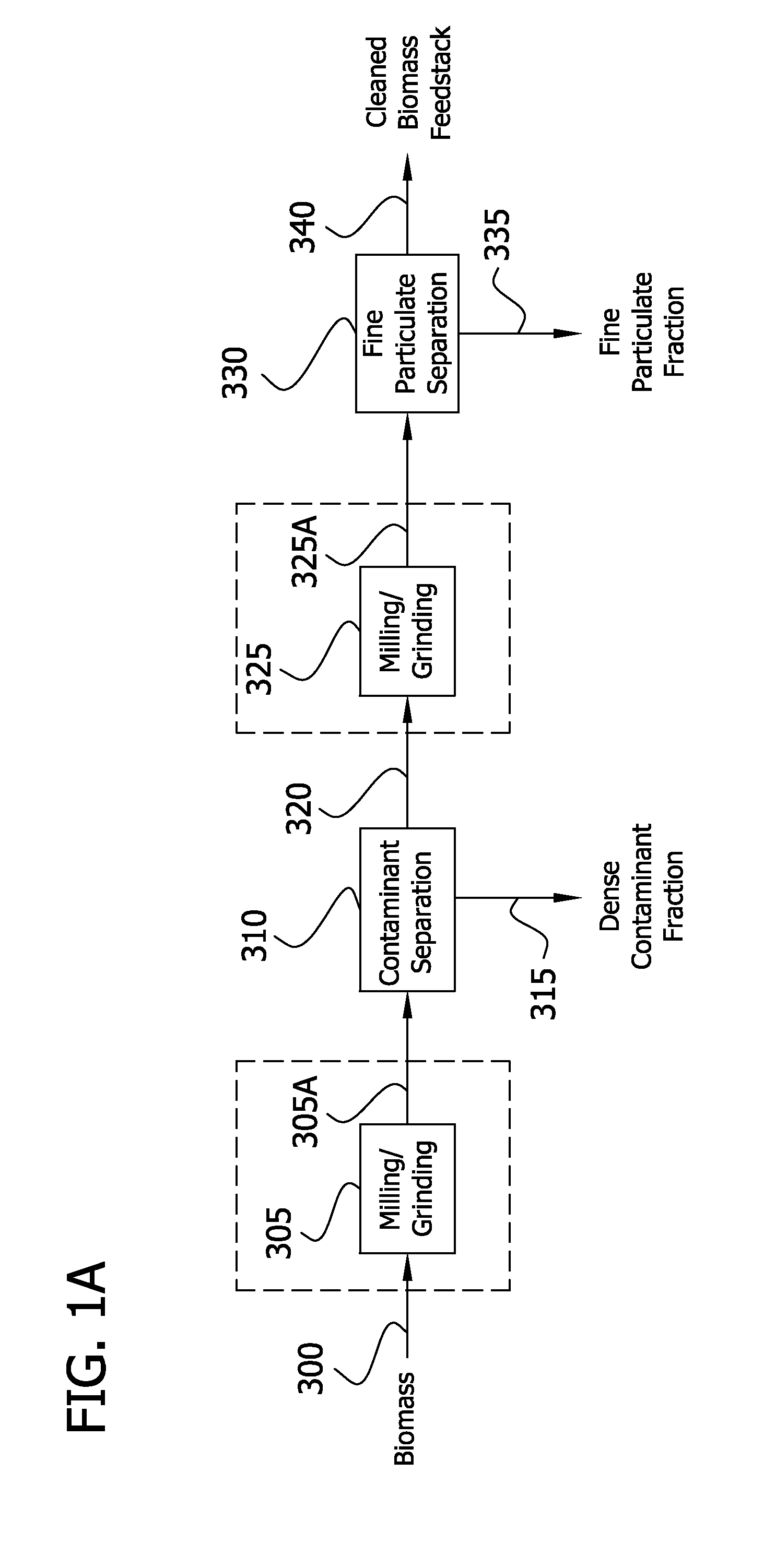

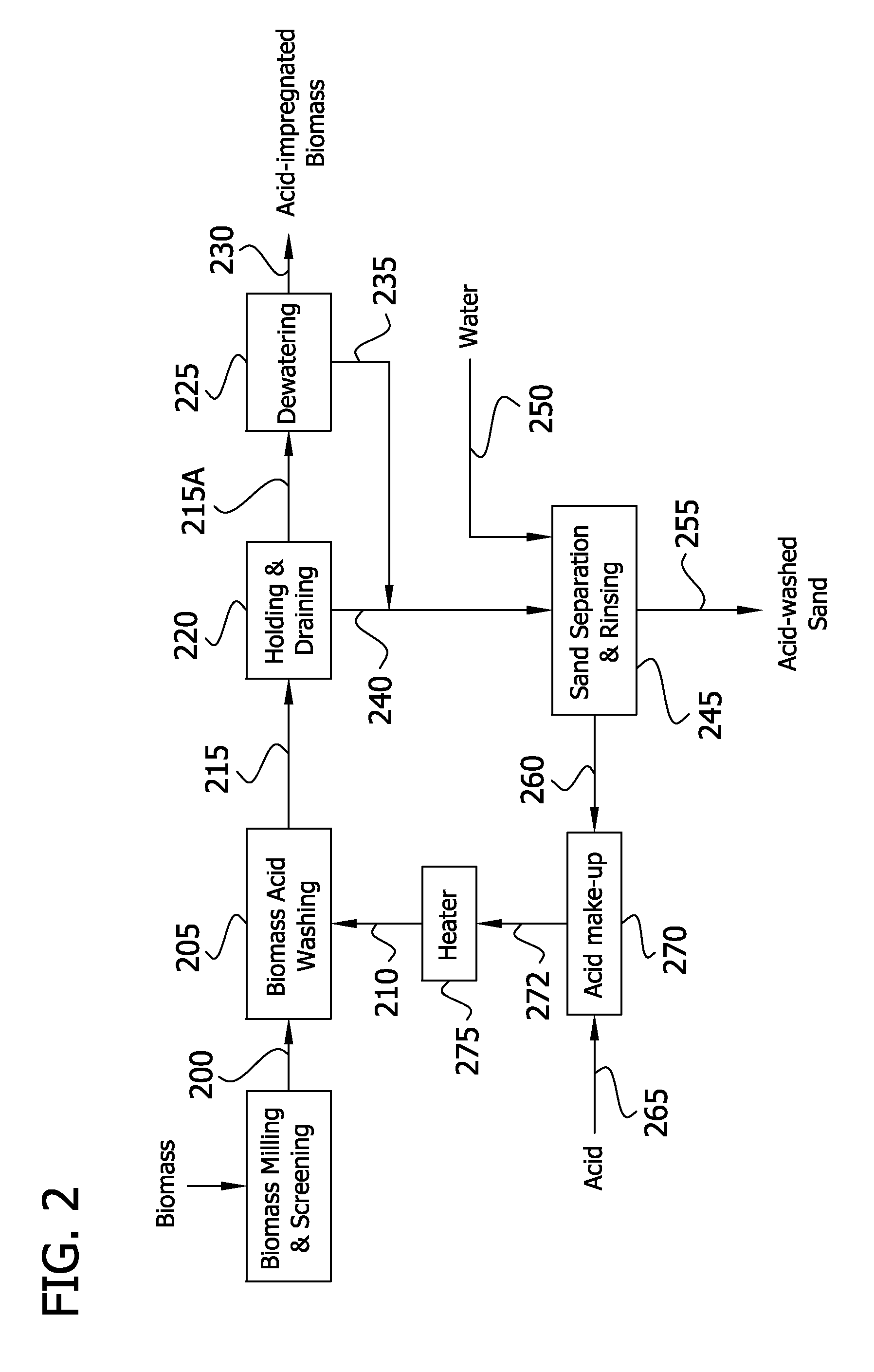

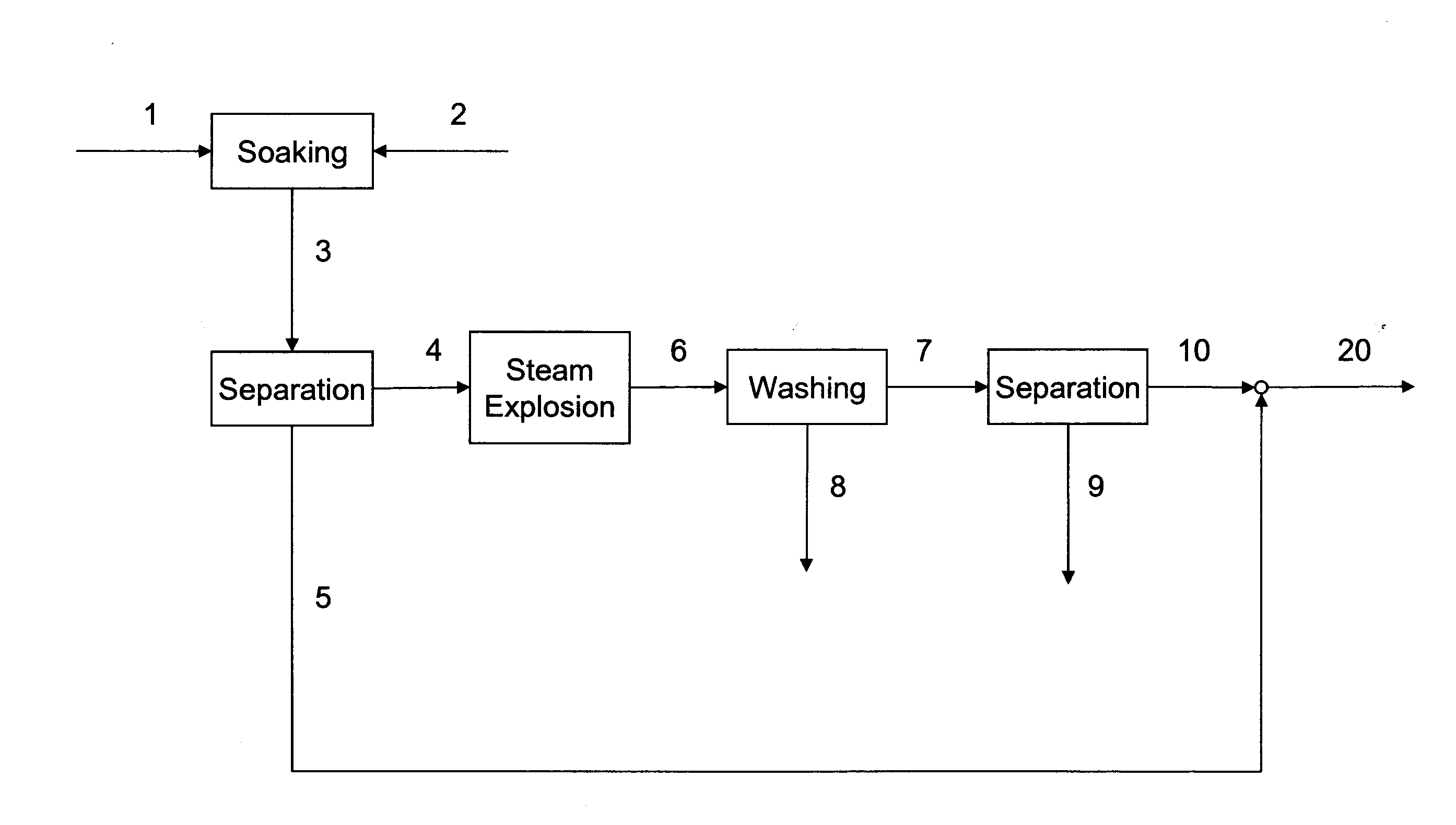

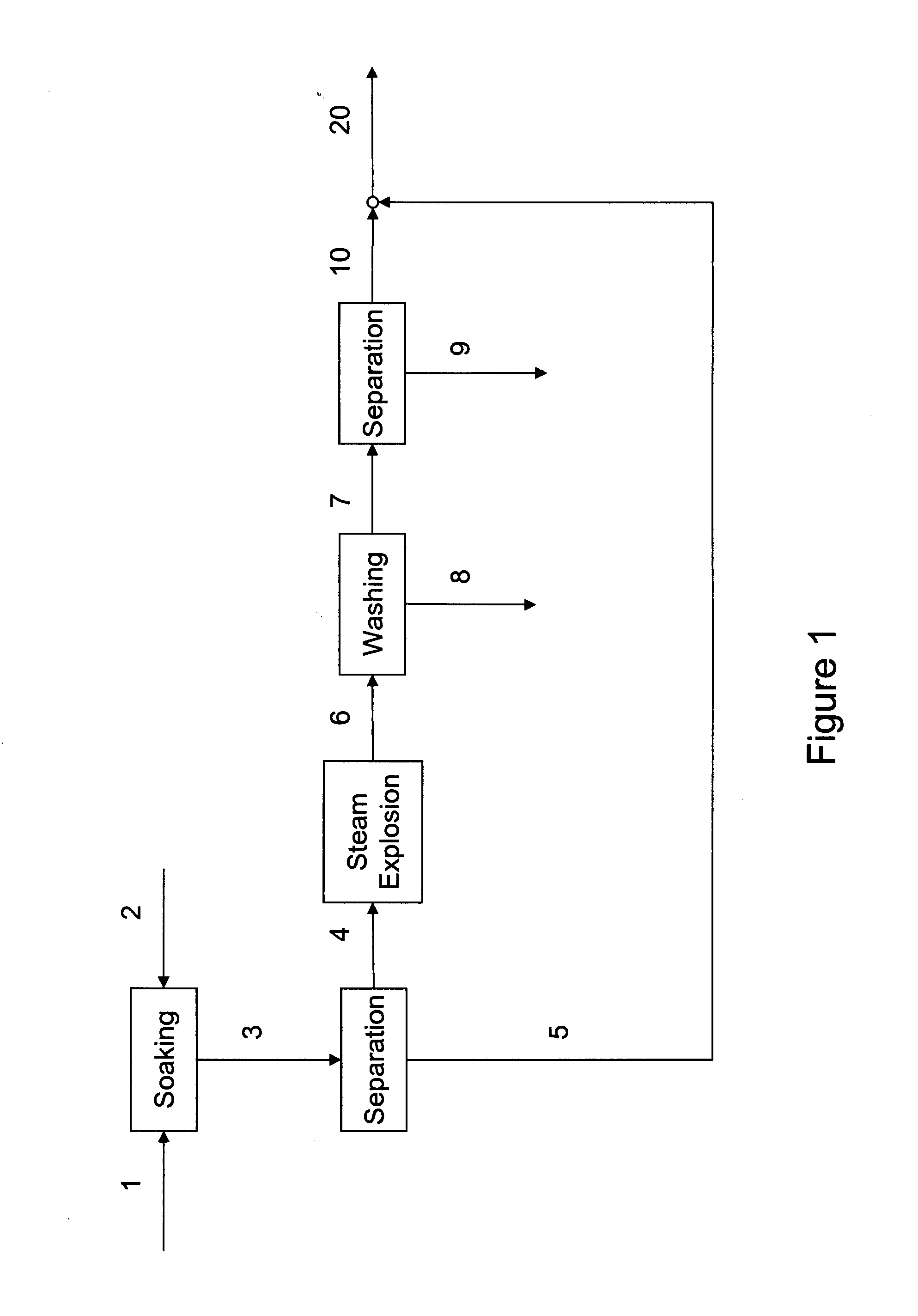

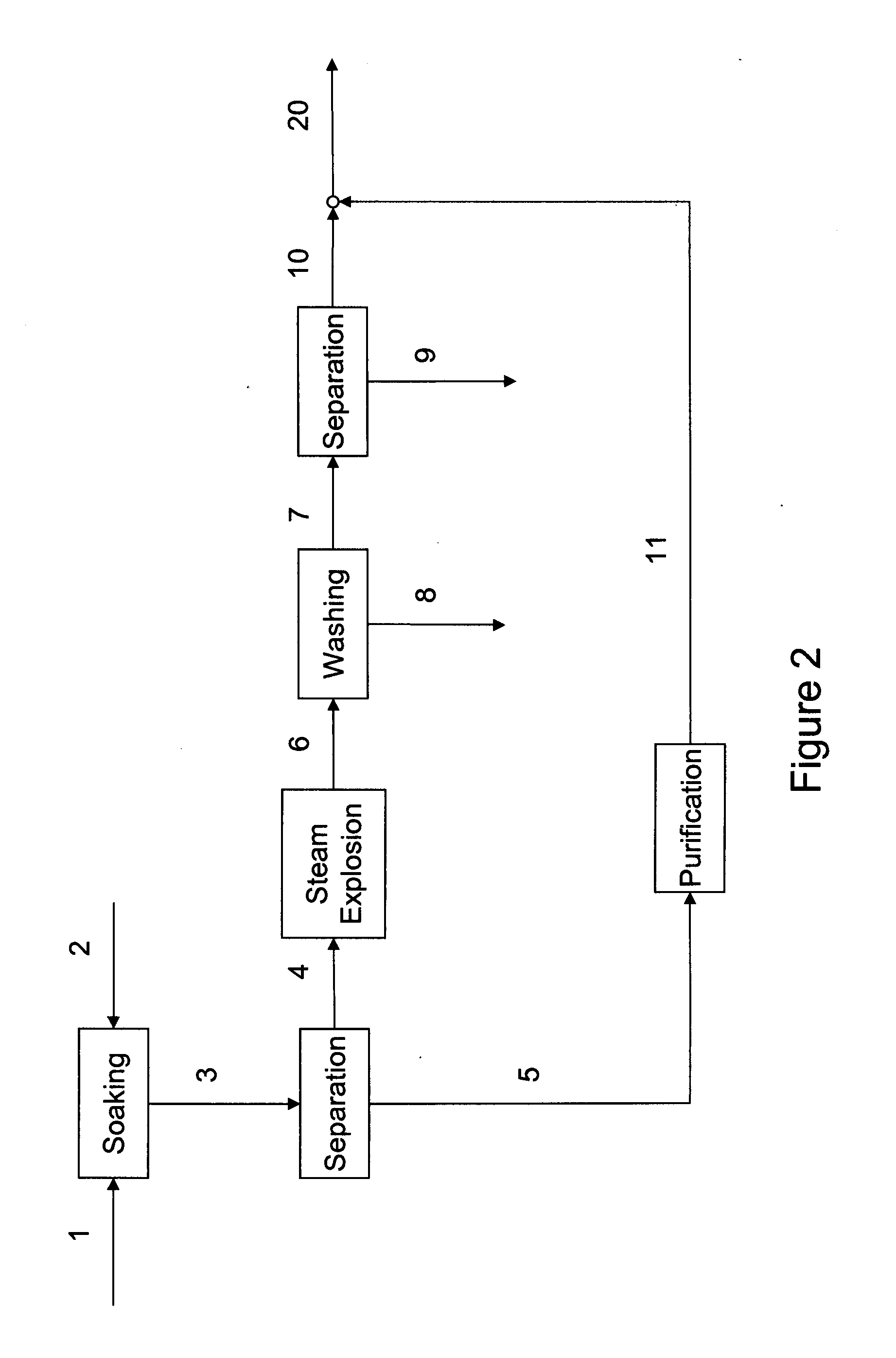

The present invention generally relates to processes for production of ethanol from cellulosic biomass. The present invention also relates to production of various co-products of preparation of ethanol from cellulosic biomass. The present invention further relates to improvements in one or more aspects of preparation of ethanol from cellulosic biomass including, for example, improved methods for cleaning biomass feedstocks, improved acid impregnation, and improved steam treatment, or “steam explosion.”

Owner:ABENGOA BIOENERGY NEW TECH

Method for producing fuel oil by biomass hydrothermal liquefaction

InactiveCN101805629AImprove conversion ratePotential for industrial applicationsLiquid hydrocarbon mixture productionMass ratioReaction temperature

The invention discloses a method for producing fuel oil by biomass hydrothermal liquefaction. The method is characterized by comprising the following steps: fully mixing a biomass raw material and solvent water (or adding catalyst water solution) to prepare seriflux, wherein a mass ratio of a catalyst to the raw material is 1:10 to 1:50, and the mass ratio of the raw material to water is 1:2 to 1:8; performing a reaction in a slurry bed reactor under a reducing atmosphere; controlling a liquefaction reaction temperature between 300 and 450 DEG C, a reaction pressure between 5 and 30 MPa and reaction time between 5 and 40 minutes; after the reaction, separating a product to obtain the fuel oil, solid residue, water, gas and the like. The method has the advantages of achieving complete biomass conversion, high oil product productivity, obtaining an oil product with a heat value equal to that of standard oil, relieving dependence on fossil energy, contributing to environment protection, lowering production cost and achieving good social and economic benefits.

Owner:EAST CHINA UNIV OF SCI & TECH

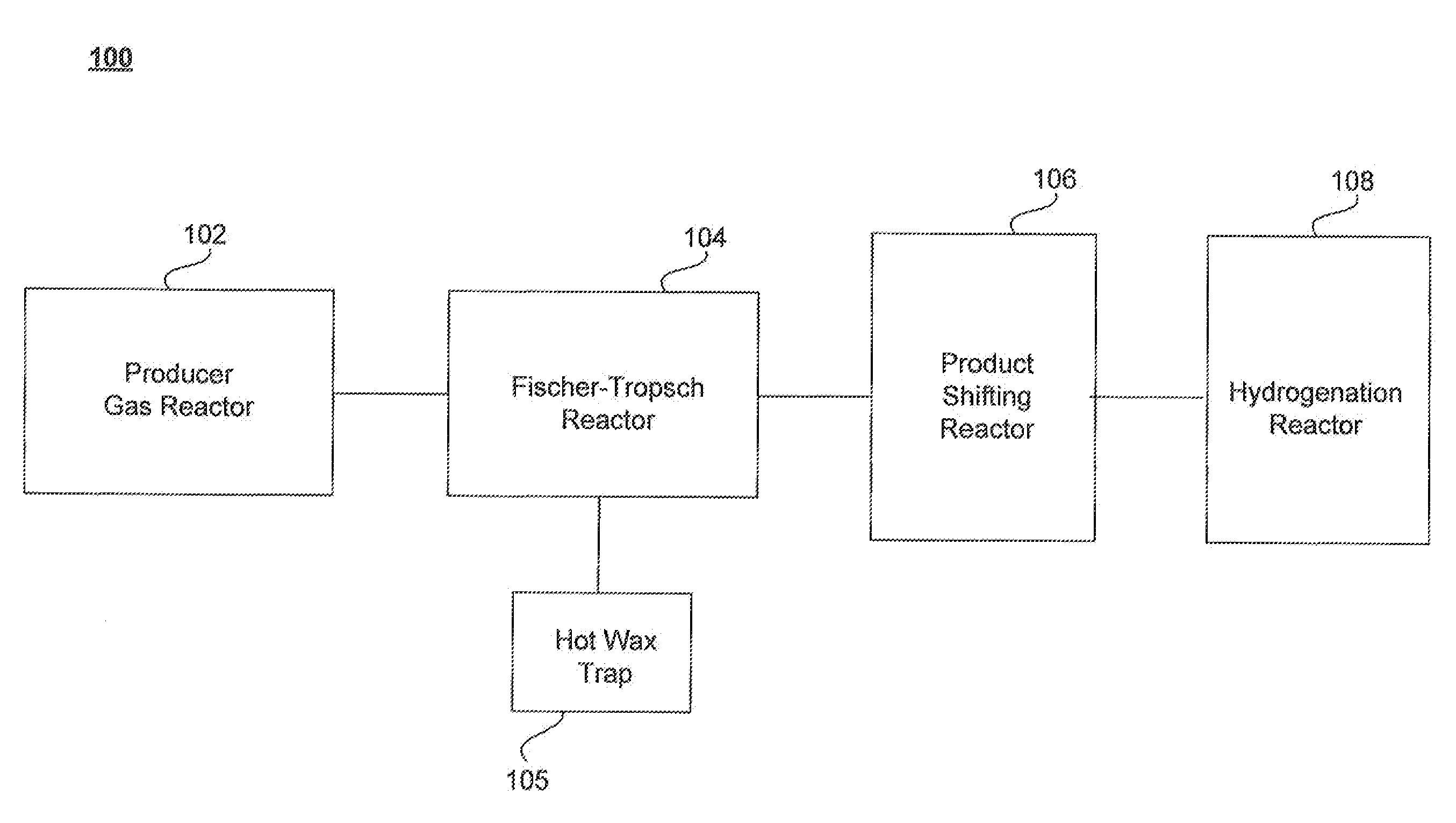

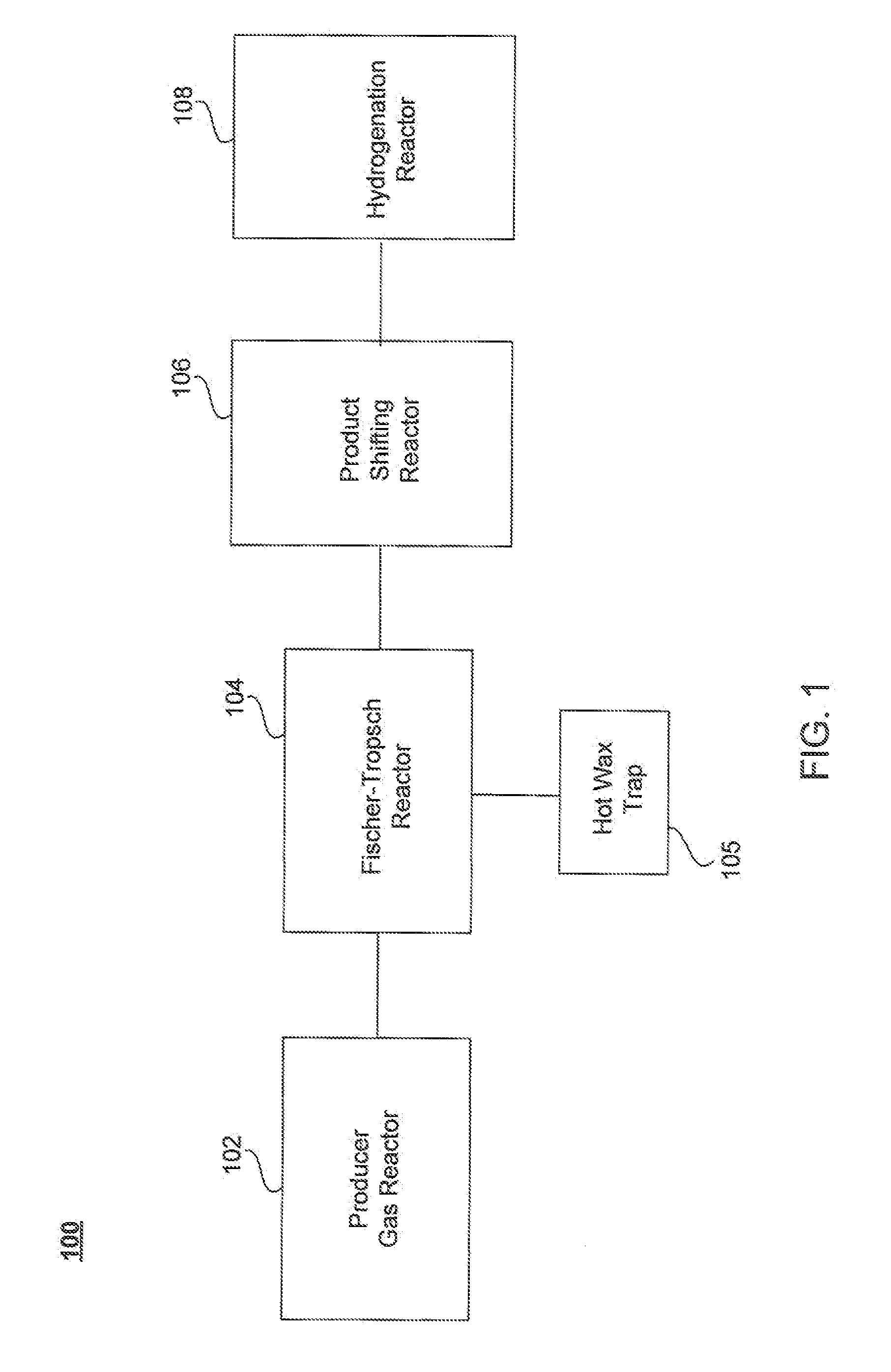

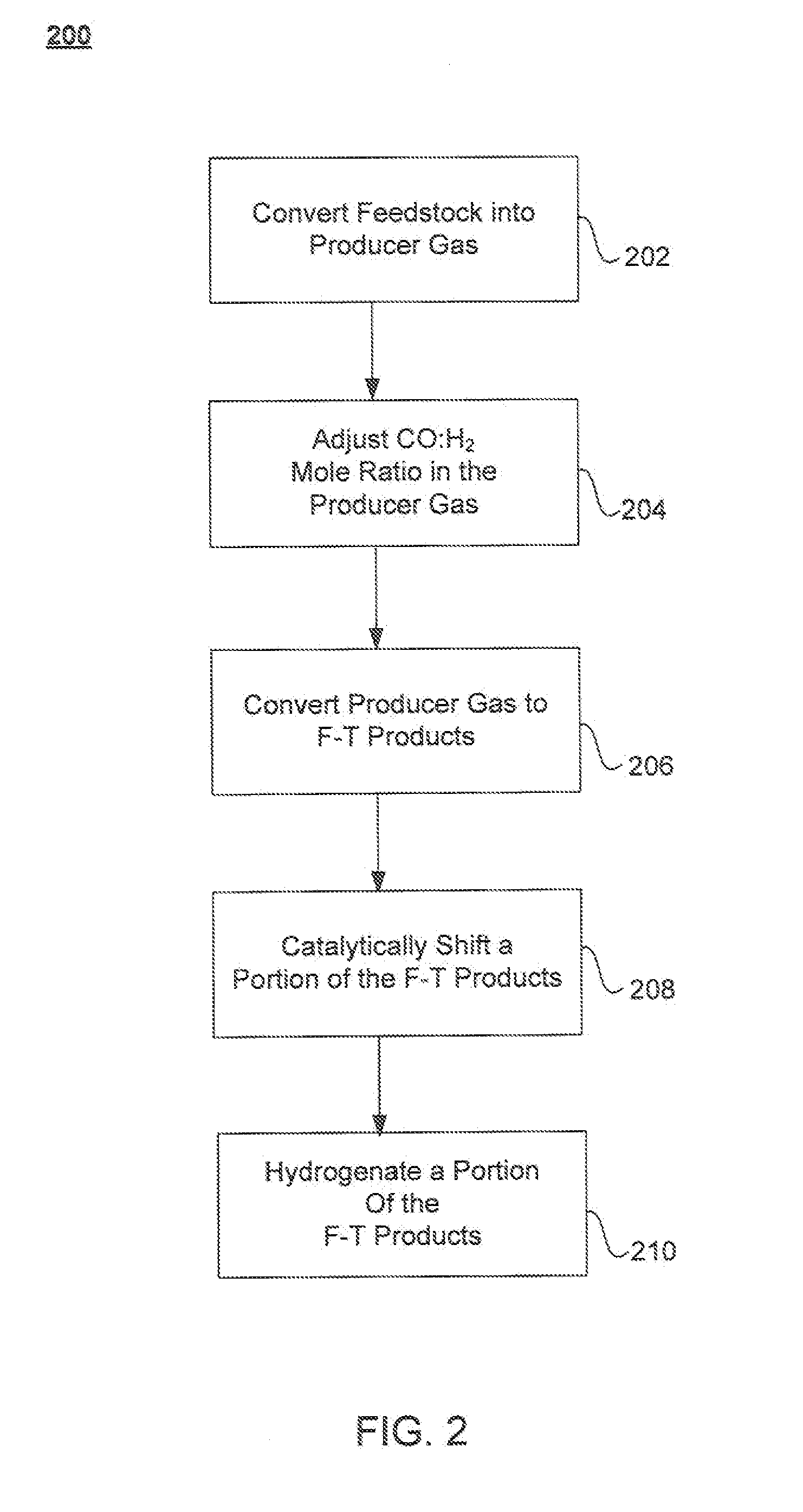

Conversion of biomass feedstocks into hydrocarbon liquid transportation fuels

InactiveUS20100036181A1Reducing and even eliminating transportationReducing and even eliminating and distribution costLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesProduct gasHydrocarbon

Methods for converting a carbon-containing feedstock into a fluid transportation fuel are described. The methods may include converting the carbon-containing feedstock into a producer gas comprising H2, CO, CO2, and N2, and reacting the producer gas with a substrate catalyst to produce a combination of Fischer-Tropsch (F-T) products, the F-T products including the fluid transportation fuel. A portion of the F-T products may be catalytically cracked to produce additional amounts of the fluid transportation fuel. A portion of the F-T products may also be hydrogenated to produce additional amounts of the fluid transportation fuel. Apparatuses are also described or converting a carbon-containing feedstock into a fluid transportation fuel. The apparatuses may include a producer gas reactor, a Fischer-Tropsch reactor, a cracking reactor, and a hydrogenation reactor.

Owner:COMMUNITY POWER CORP

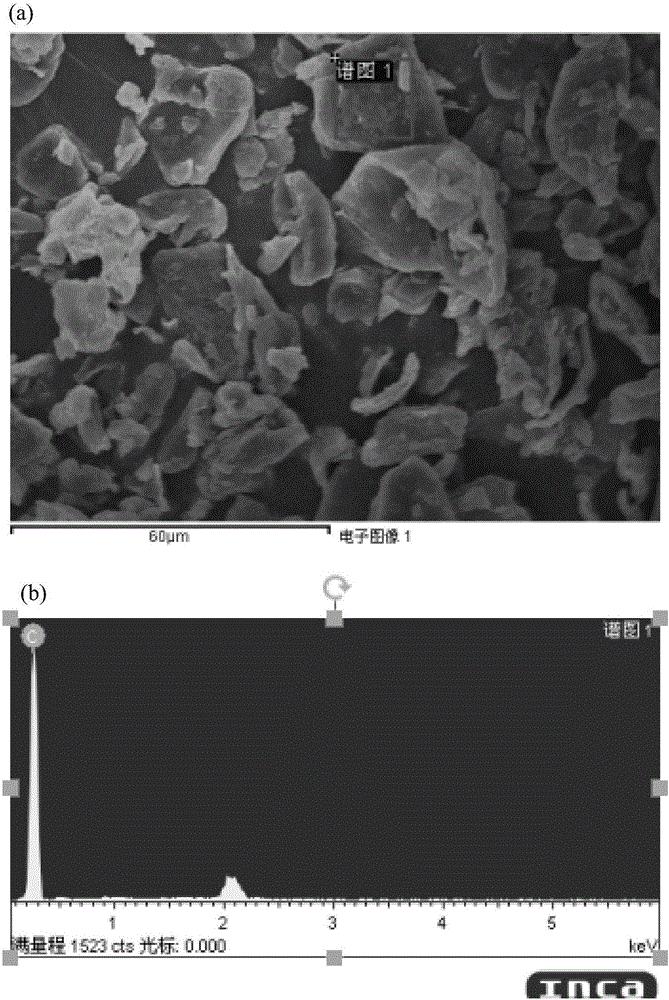

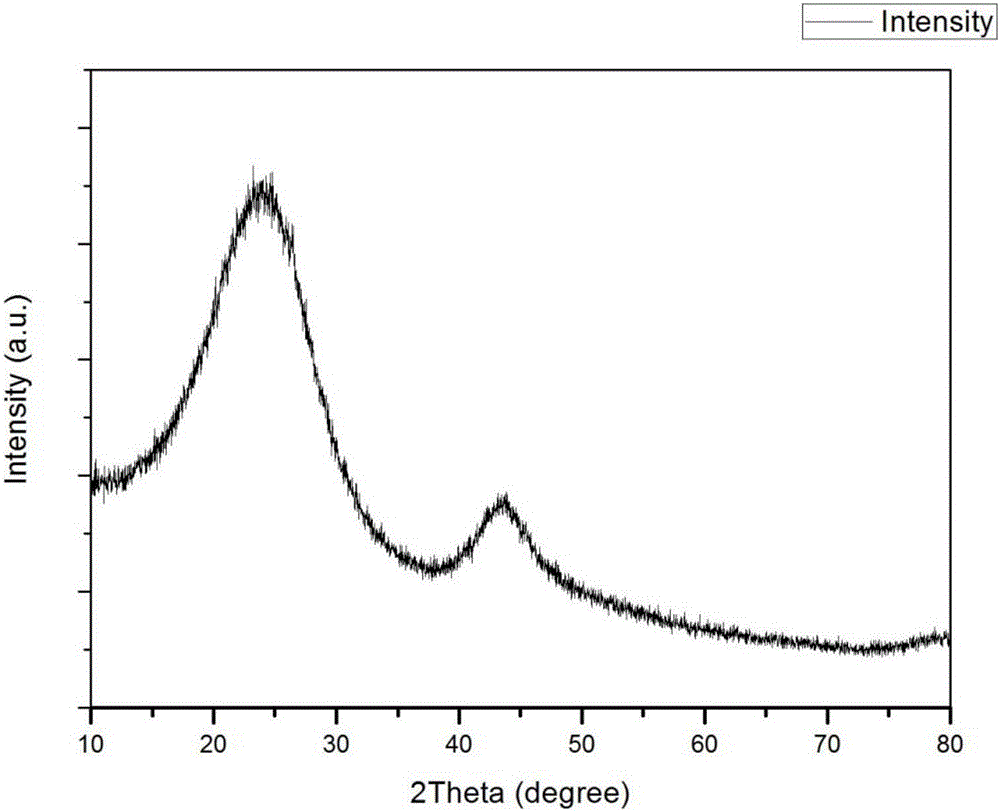

Biomass hard carbon negative electrode material for sodium ion battery, preparing method and sodium ion battery

ActiveCN106299365AImprove the first charge and discharge efficiencyImprove electrochemical performanceNon-aqueous electrolyte accumulatorsCell electrodesSodium-ion batteryLithium-ion battery

The invention relates to a biomass hard carbon negative electrode material for a sodium ion battery, a preparing method and the sodium ion battery and belongs to the technical field of sodium ion energy storage equipment. The biomass hard carbon negative electrode material is prepared through the method including the following steps that firstly, a biomass raw material is smashed, and precursor particles are obtained; secondly, in a protection atmosphere, the precursor particles are heated to 400-600 DEG C to be pre-sintered for 1.5-2.5 h, then cooled to the room temperature along with a furnace, then heated to 800-1600 DEG C to be sintered for 2-5 h and cooled, and an intermediate is obtained; thirdly, the intermediate is put into an alkali solution to be soaked, taken out, then put into an acid solution to be soaked, then washed with water to be neutral and dried, and a purified product is obtained; fourthly, the purified product is subjected to microwave vacuum activation for 3-15 s at the power of 1000-2000 W, and then the biomass hard carbon negative electrode material is obtained. The first-time charging and discharging efficiency of the obtained biomass hard carbon negative electrode material reaches up to 90% or above, the circulation stability is good, the reversible specific capacity is 300 mAh / g or above, and the biomass hard carbon negative electrode material has a good electrochemical property.

Owner:浙江瓦司特钠科技有限公司

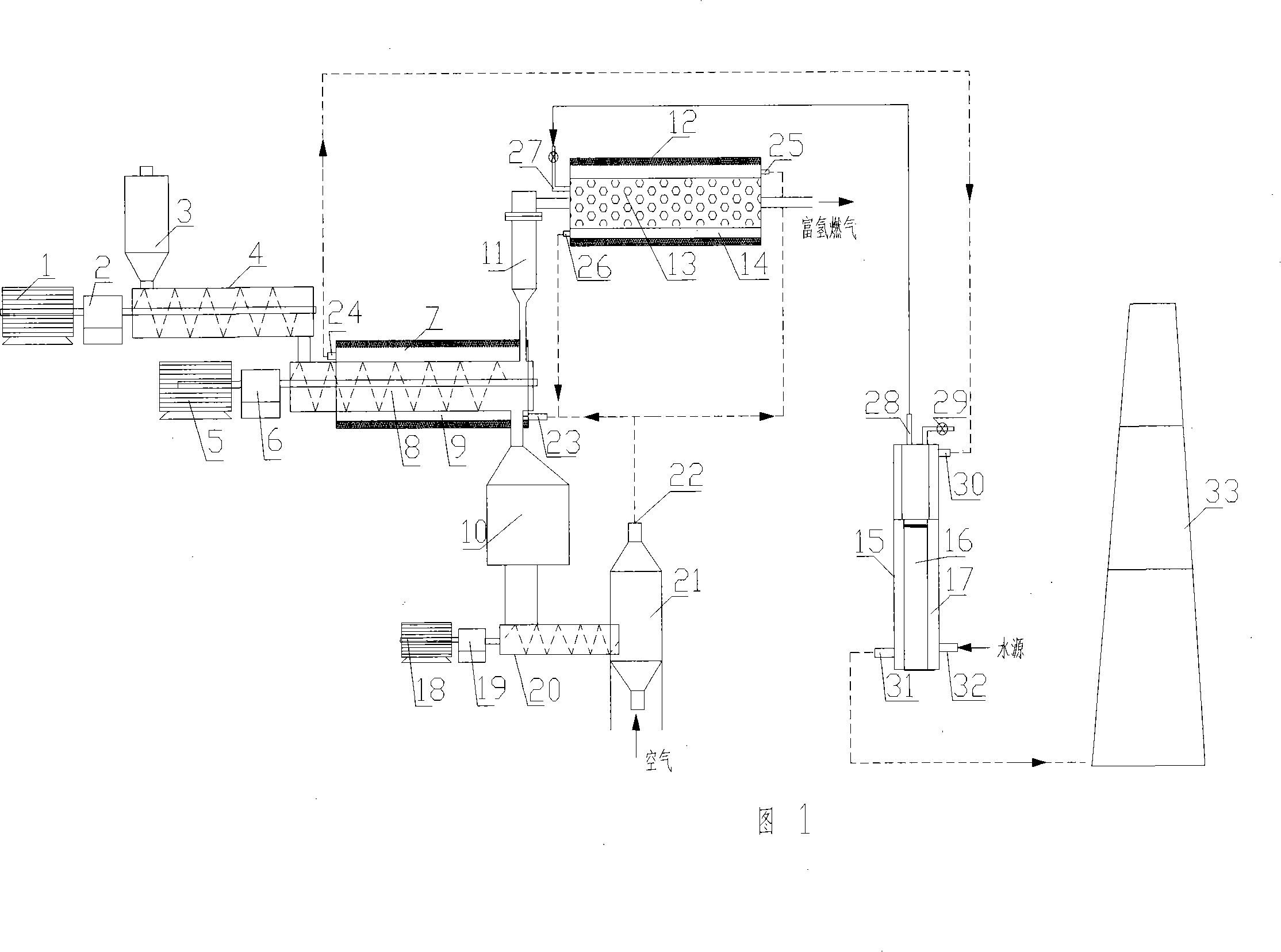

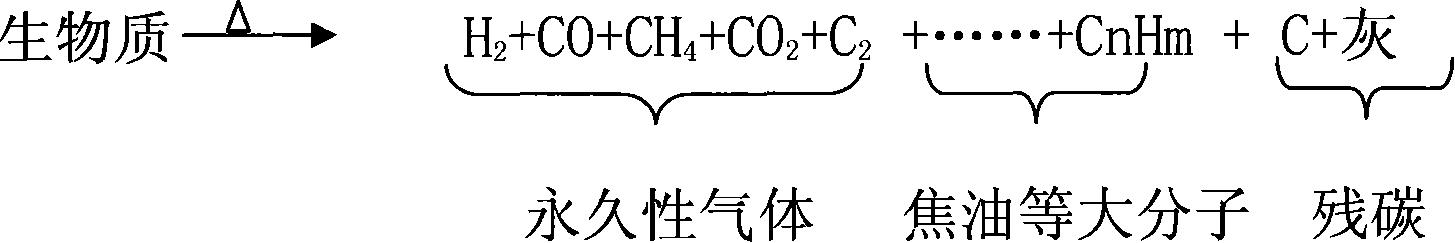

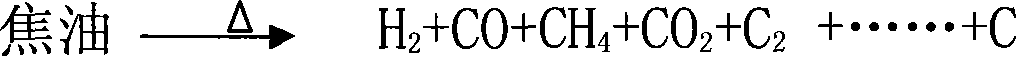

Method and device for preparing biomass hydrogen-rich combustion gas

InactiveCN101100621AReduce material requirementsReduce control requirementsHydrogenGaseous fuelsWater vaporGas phase

Production of biomass hydrogen-enriching fuel gas is carried out by thermal cracking for biomass raw materials at 550-650 deg. C under isolated air, converting it into gas-phase product and residual carbon, separating residual carbon from gas-phase product, transferring out of reacting system, burning to obtain heat energy, cracking at 800-950 deg. C and reforming into hydrogen, methane and other light hydrocarbons. It combines bitter spar catalyst and steam; it can eliminate tar, decrease methane content and increase hydrogen content. Hydrogen content reaches to 30%-55 wt%.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

Producing Liquid Fuel from Organic Material such as Biomass and Waste Residues

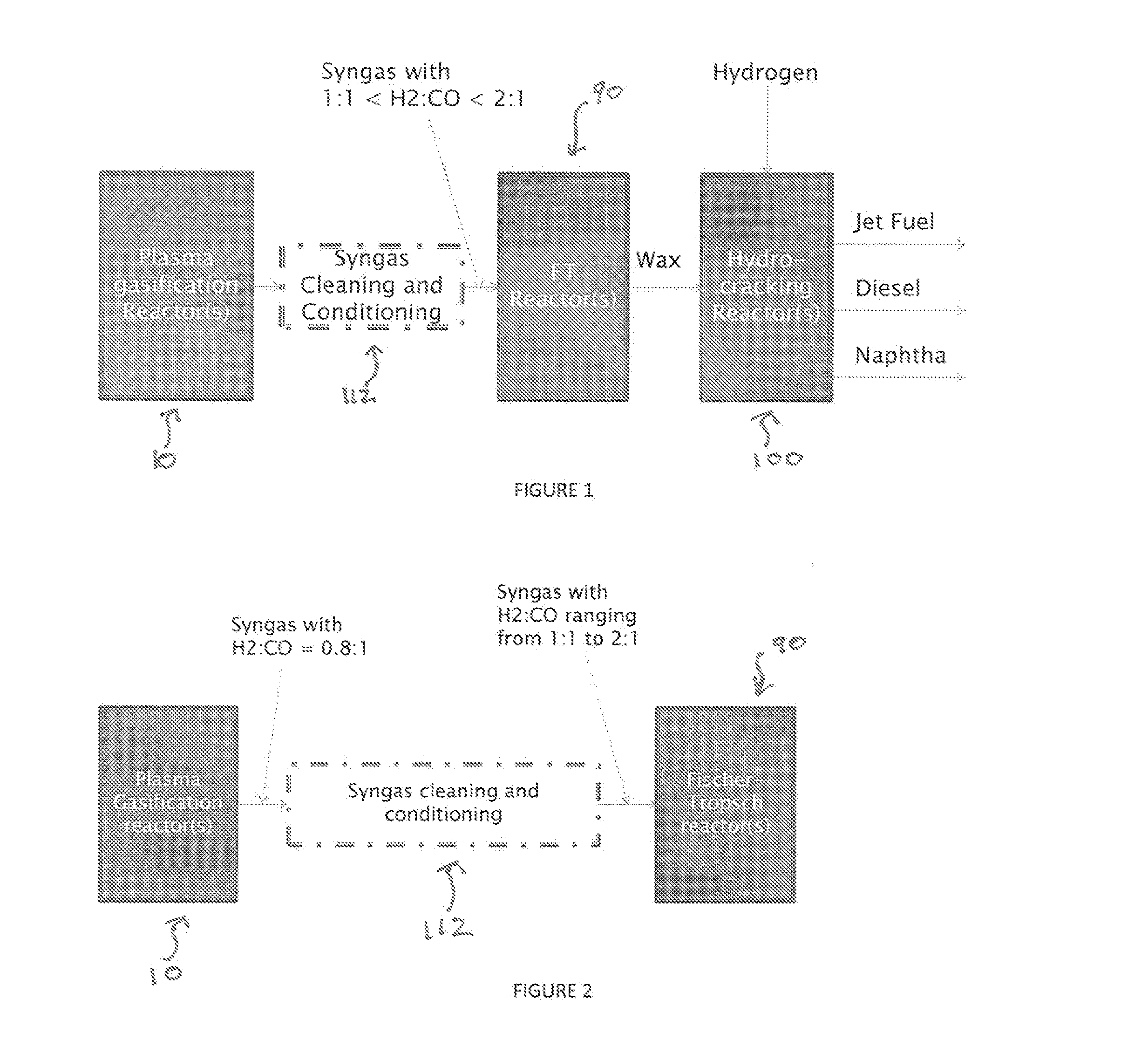

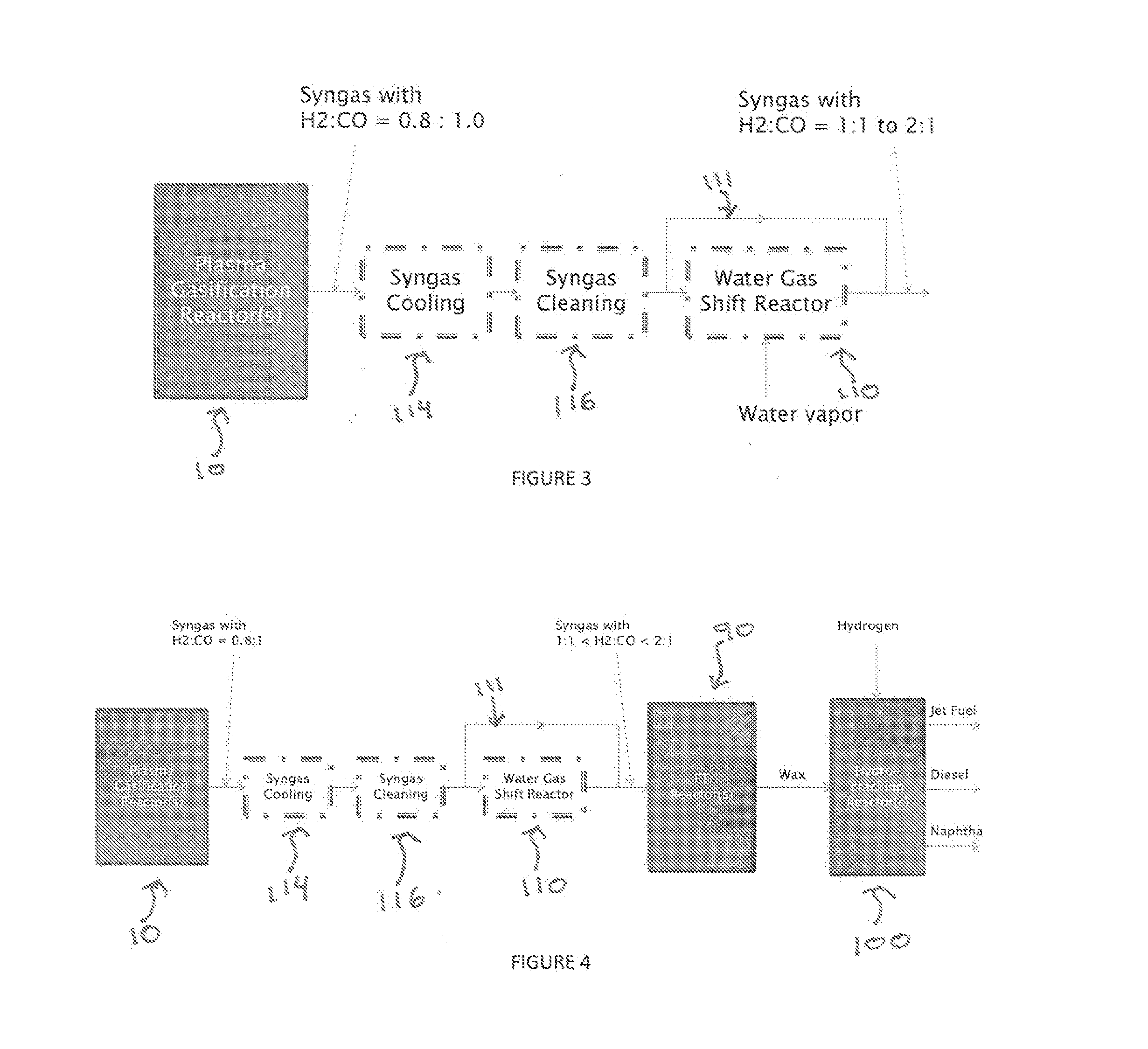

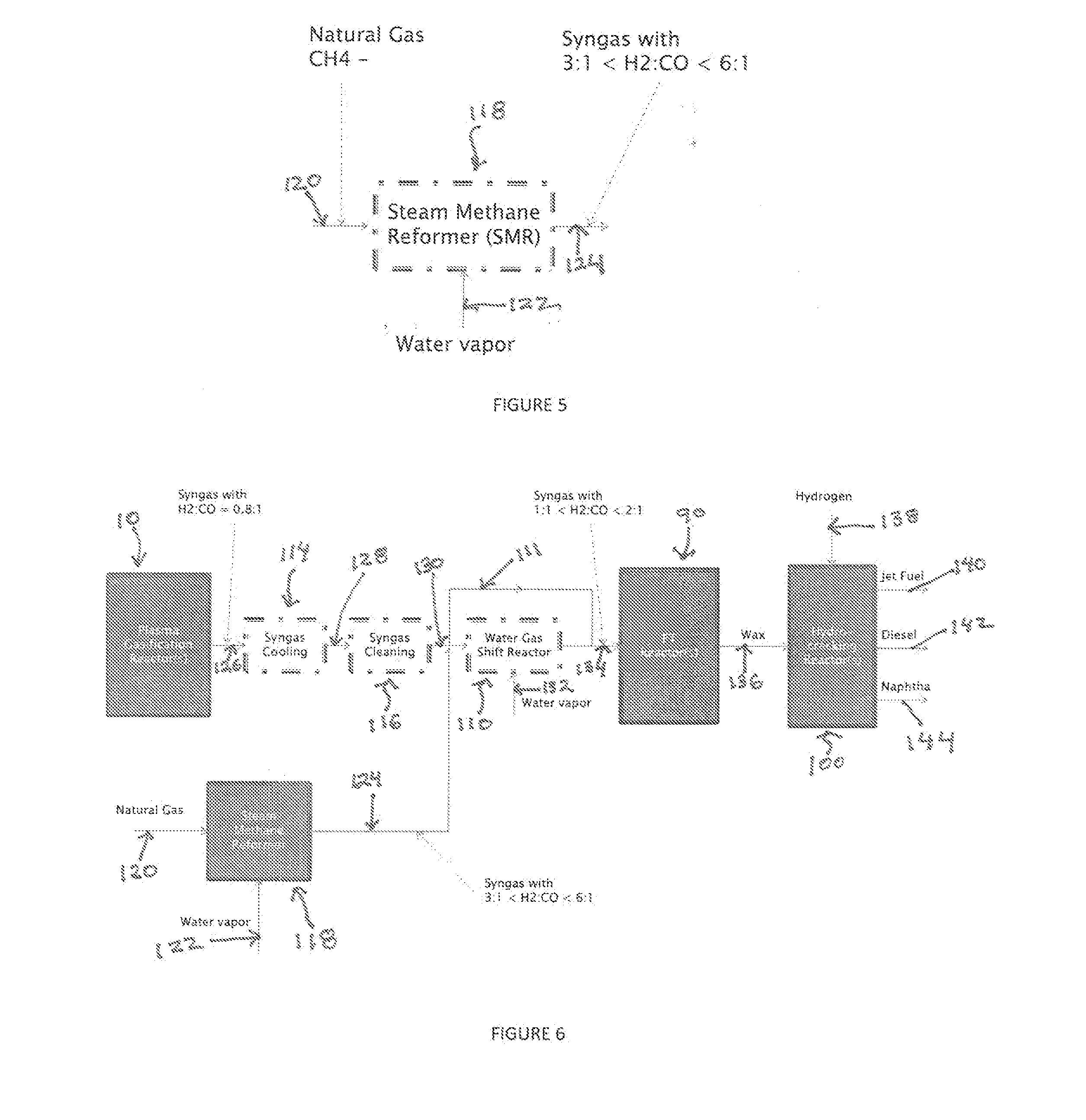

InactiveUS20140224706A1Combustible gas catalytic treatmentGas modification by gas mixingWaxForming gas

A process for producing liquid fuel from biomass feed stock comprising feeding a biomass feedstock into a one stage atmospheric pressure thermo-catalytic plasma gasifier, contacting the feedstock with oxygen or steam or both to obtain a syngas stream; splitting the syngas stream into first and second streams; conveying the first stream to a water gas shift reactor for producing a modified syngas stream containing CO and hydrogen; the second stream bypassing the water gas shift reactor and being added to the modified syngas steam; optionally reforming natural gas by steam methane reforming to produce a synthetic gas and optionally adding the synthetic gas to the water gas shift reactor; thereby obtaining a syngas having a H2:CO ratio of about 1:1 to about 2:1; subjecting the syngas to a Fischer Tropsch reaction thereby producing a wax product; and subjecting the product to a hydrogen cracking process to produce liquid fuel; and apparatus therefore.

Owner:SOLENA FUELS CORP

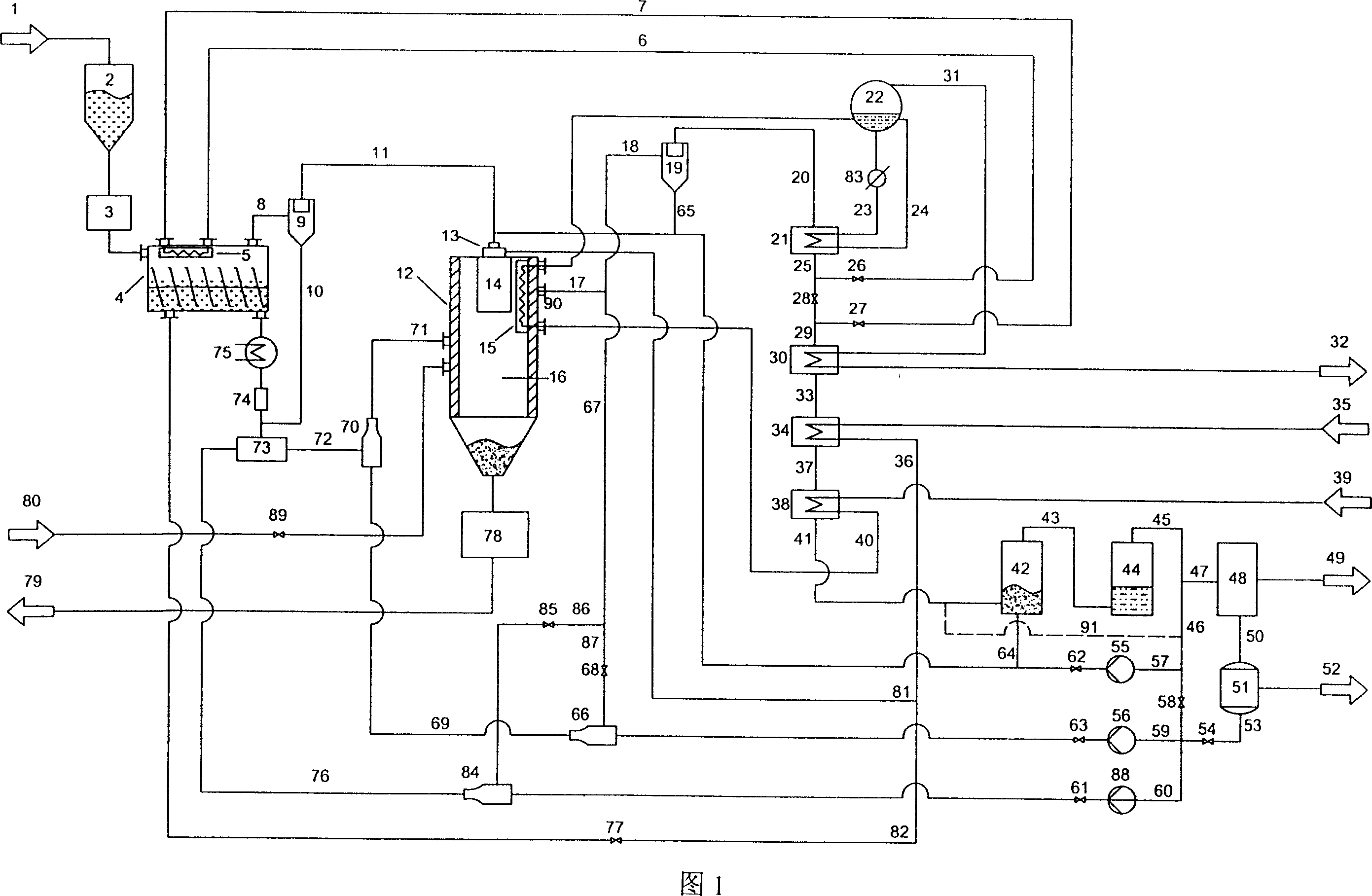

Compositely circulating high temperature gasifying process for making synthetic gas with biomass

ActiveCN1931959AImprove grindabilityAvoid burnsBiofuelsSpecial form destructive distillationSyngasTar

The compositely circulating high temperature gasifying process for making synthetic gas with biomass includes the steps of low temperature charring, powdering, high temperature gasifying, separating carbon containing clinker, purifying synthetic gas, and circulating utilization of synthetic gas. Biomass material is first pyrolyzed into pyrolyzed gas and charcoal and the pyrolyzed gas is burnt incompletely in the high temperature gasifying furnace to produce gasifying agent and heat; the charcoal is powdered and fed to the reducing area in the high temperature gasifying furnace to produce reduction reaction with the gasifying agent; and the fly ash and residual carbon produced in the purification are returned to the burning area in the high temperature gasifying furnace. The present invention can produce synthetic gas with CO and H2 content up to 72 %, and has gasifying efficiency of 80-84 % and carbon converting rate over 99 %.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

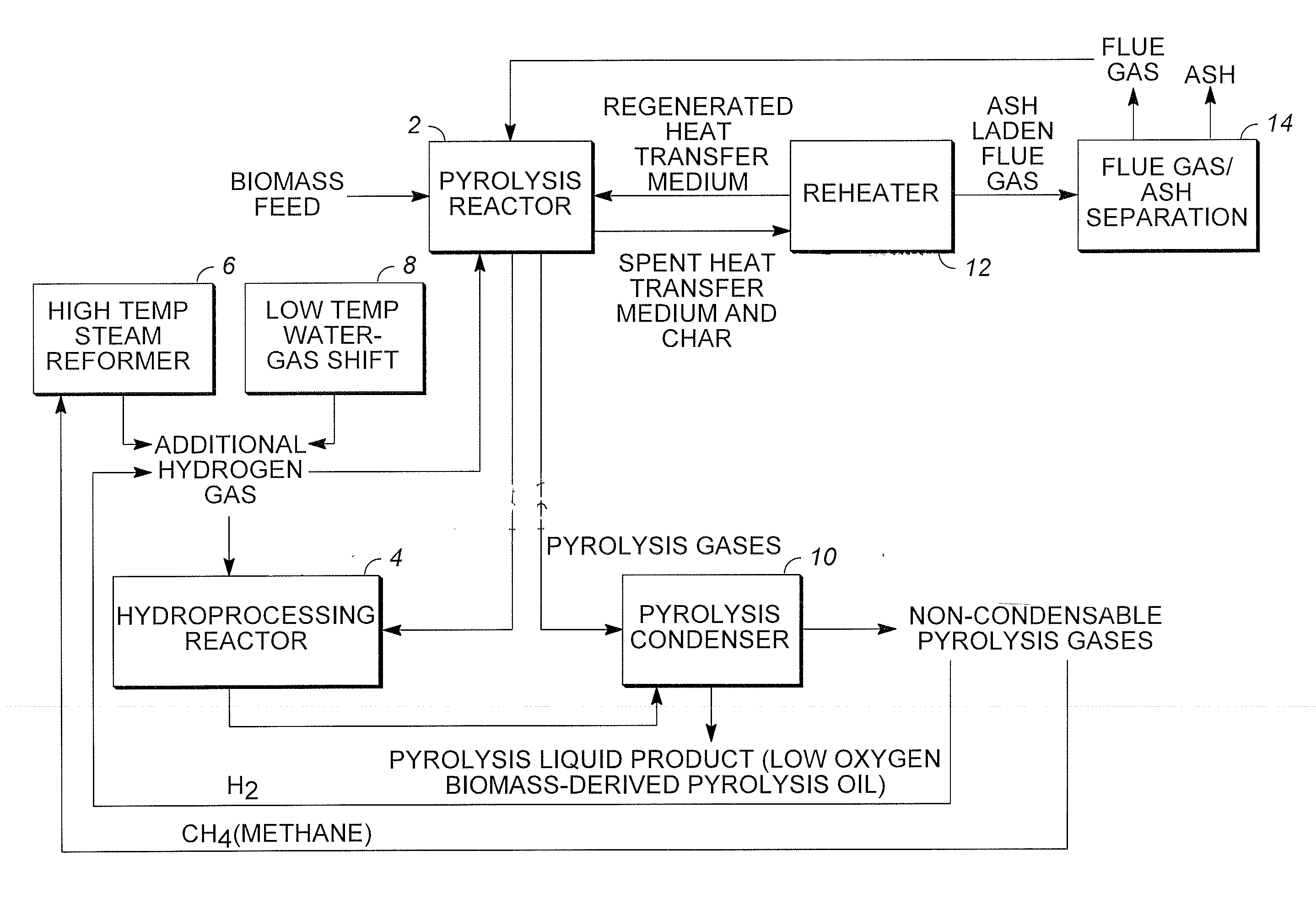

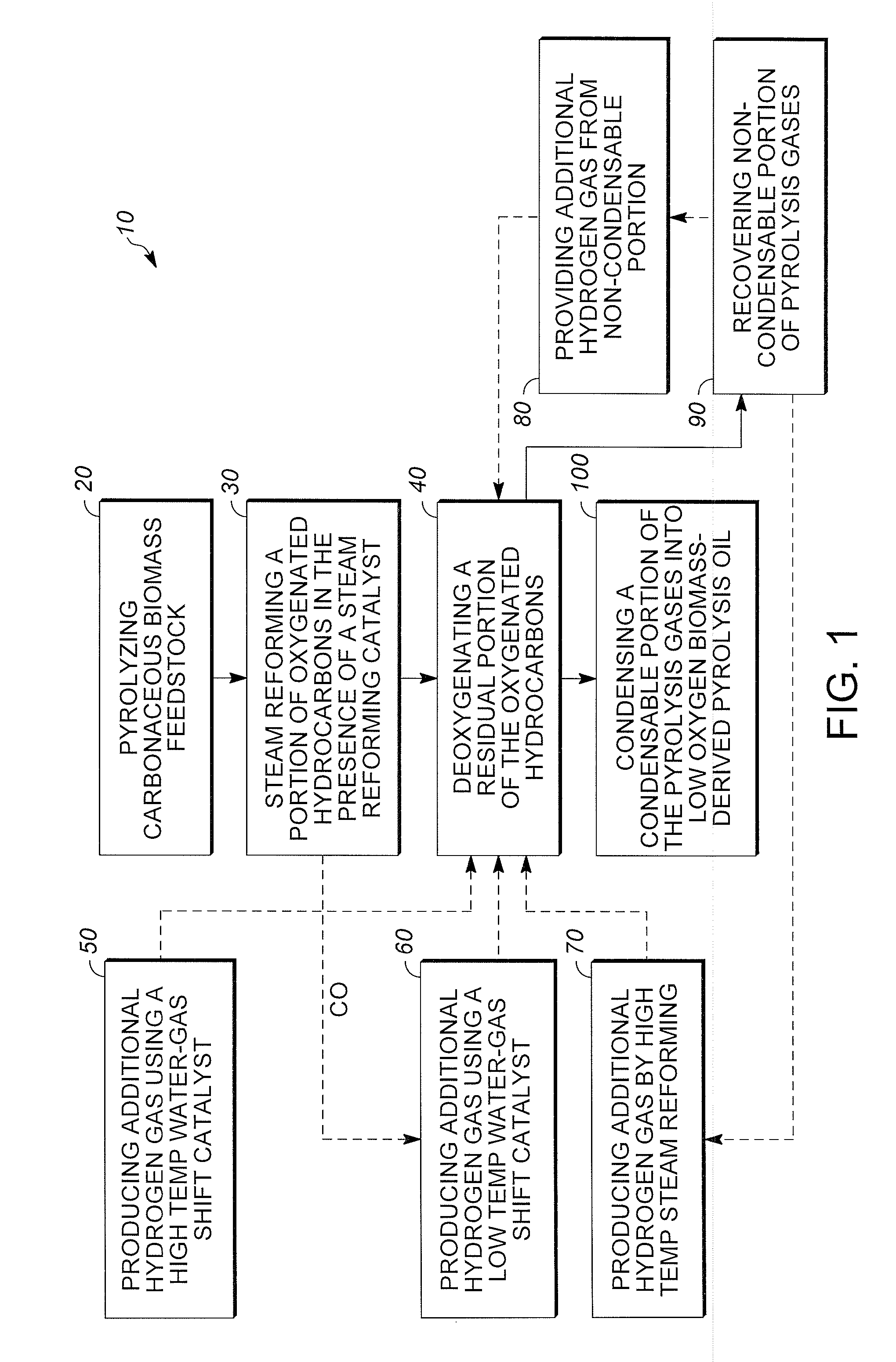

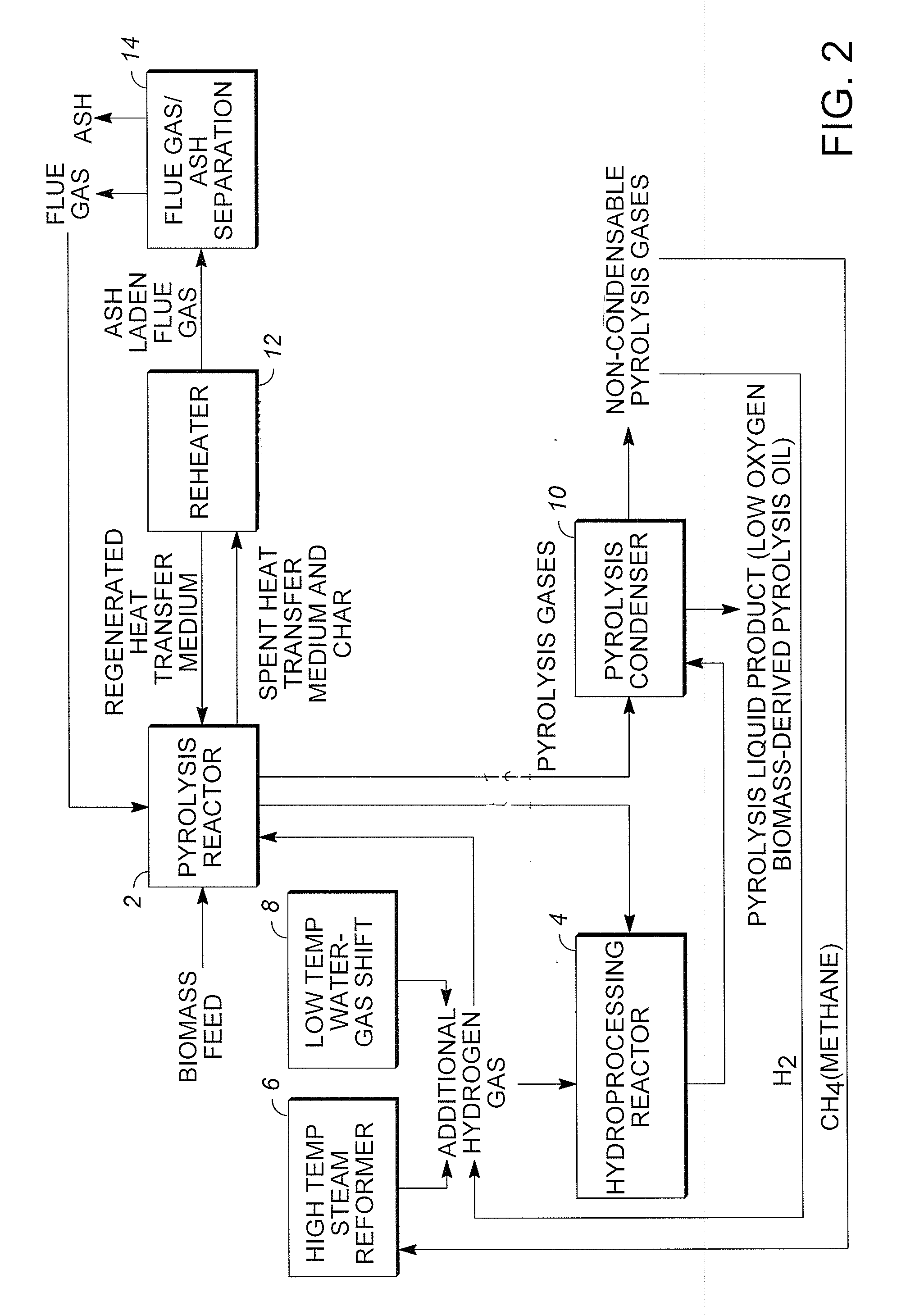

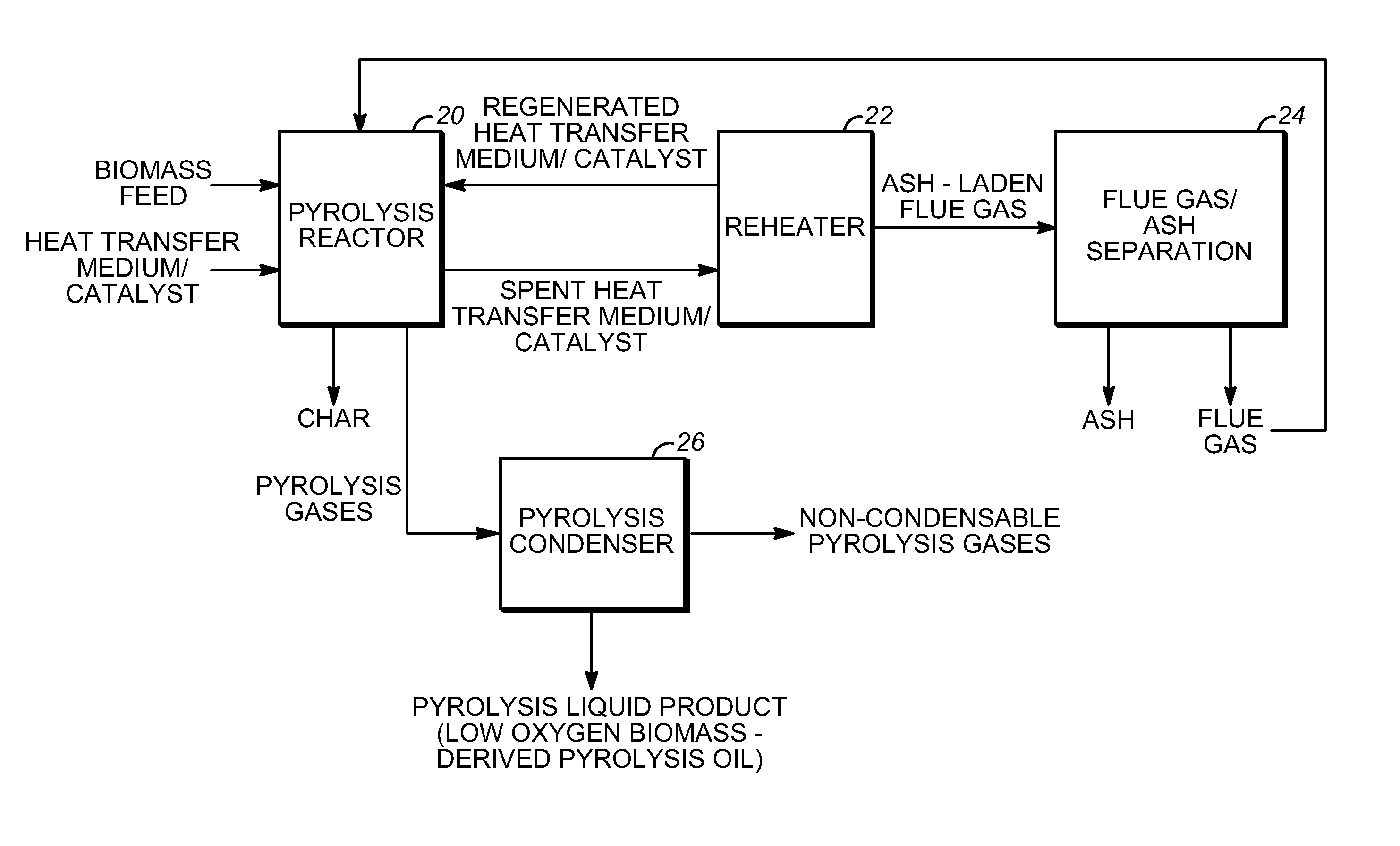

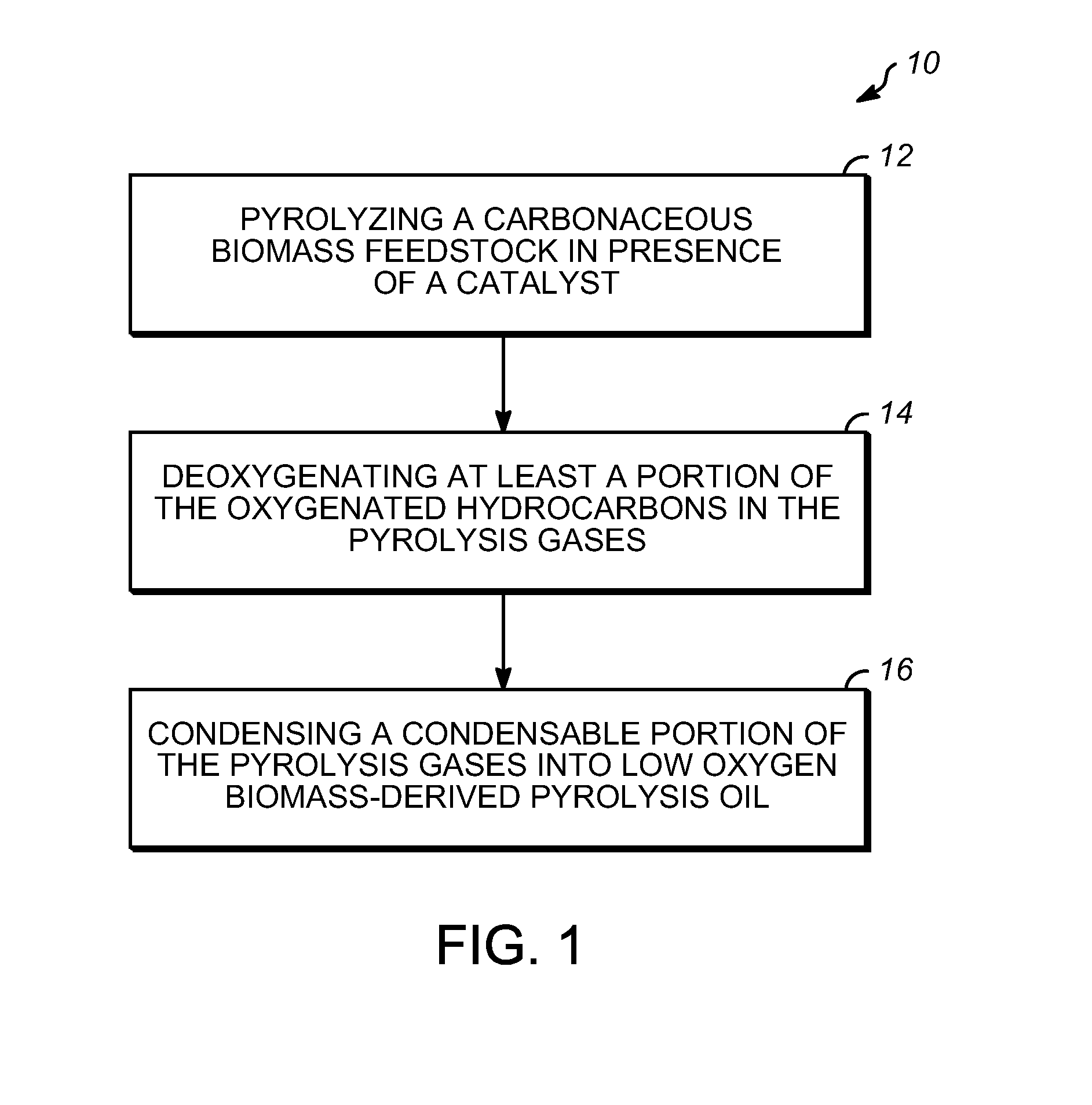

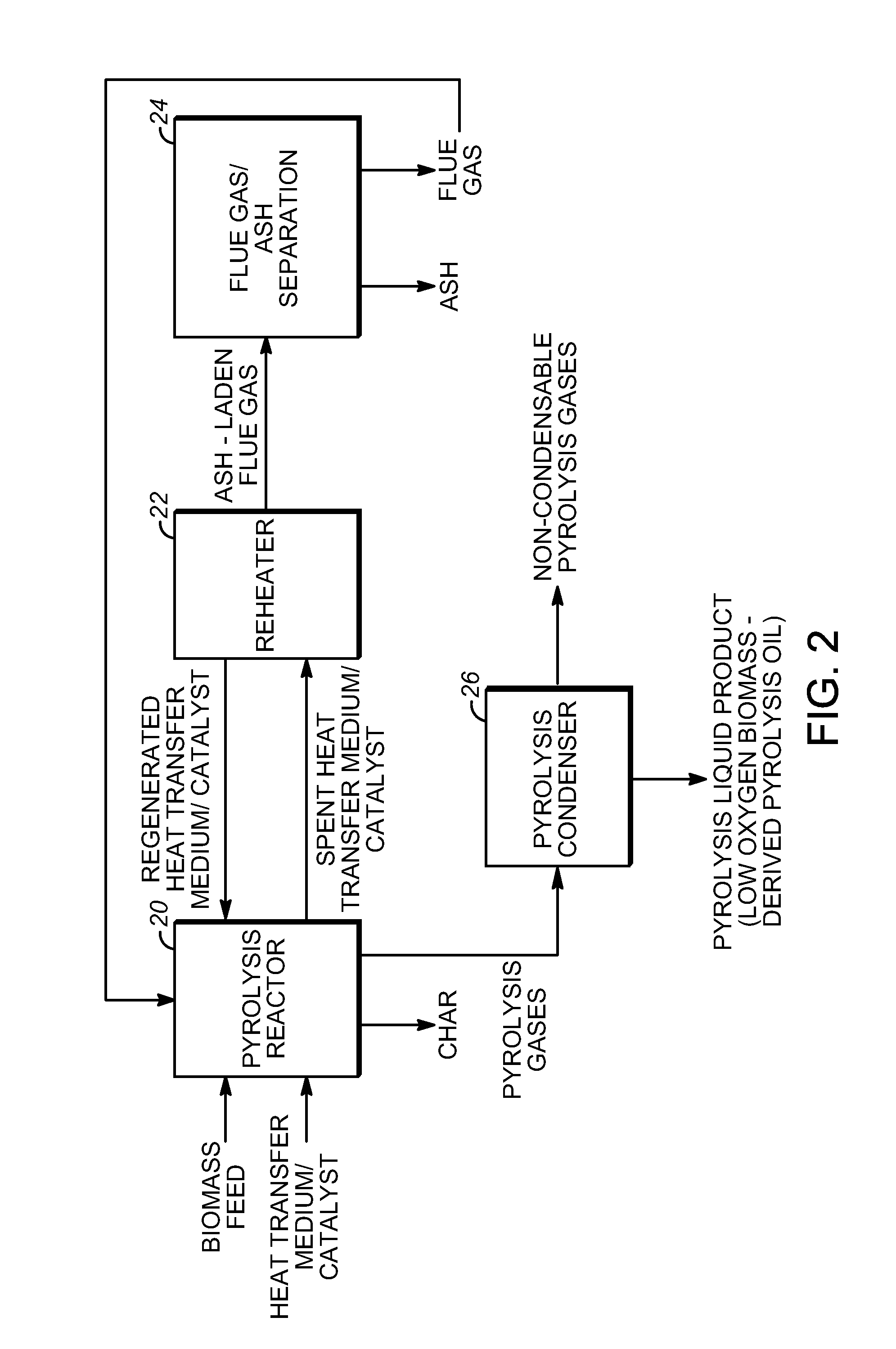

Low oxygen biomass-derived pyrolysis oils and methods for producing the same

InactiveUS20110201854A1Direct heating destructive distillationBiofuelsSteam reformingPartial oxidation

Methods are provided for producing low oxygen biomass-derived pyrolysis oil from carbonaceous biomass feedstock. The carbonaceous biomass feedstock is pyrolyzed in the presence of a steam reforming catalyst to produce char and pyrolysis gases. During pyrolysis, a portion of the oxygenated hydrocarbons in the pyrolysis gases is converted into hydrocarbons by steam reforming also yielding carbon oxides and hydrogen gas. The hydrogen gas at least partially deoxygenates a residual portion of the oxygenated hydrocarbons. Additional hydrogen gas may also be produced by water-gas shift reactions to deoxygenate the residual portion of the oxygenated hydrocarbons in the pyrolysis gases. Deoxygenation may occur in the presence of a hydroprocessing catalyst. A condensable portion of the pyrolysis gases is condensed to form low oxygen biomass-derived pyrolysis oil.

Owner:UOP LLC

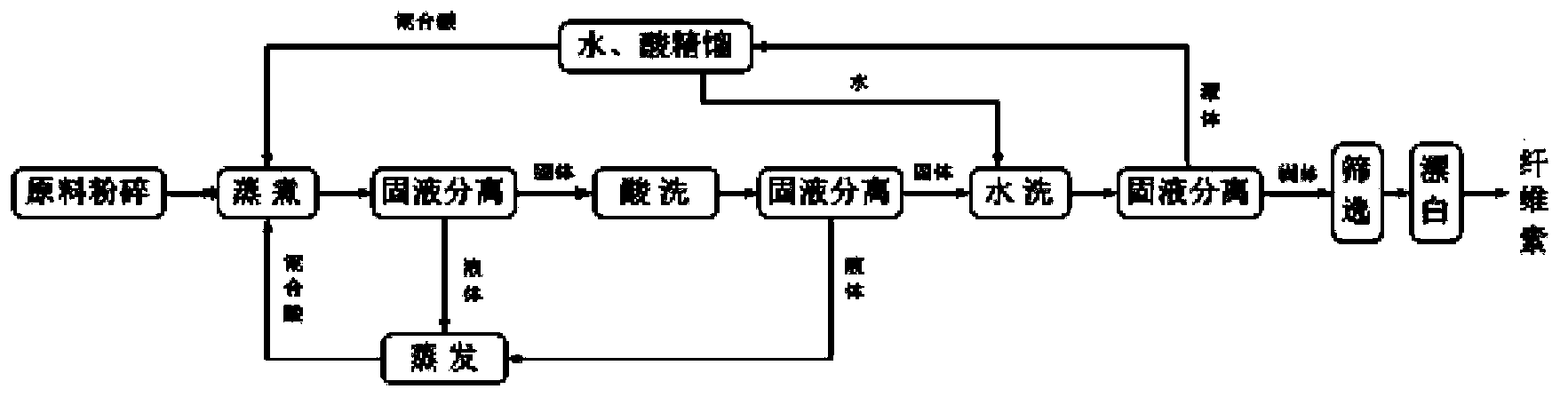

Technology for extracting cellulose from biomass raw materials

ActiveCN103898782AHigh purityReduce cooking timePulp bleachingPulping with acid salts/anhydridesAcetic acidOrganic acid

The invention relates to a cellulose extracting technology, and specifically relates to a technology that utilizes organic acids to extract cellulose from biomass raw materials in the presence of a hydrogen peroxide catalyst. The technology comprises the following steps: in the presence of a hydrogen peroxide catalyst, utilizing an organic acid to cook biomass raw materials, wherein the organic acid is composed of formic acid with a concentration of 70 to 95 wt% and acetic acid with a concentration of 70 to 95 wt%; extracting and screening so as to obtain screened cellulose pulp; and further bleaching the screened pulp so as to obtain the target cellulose; wherein the cellulose is dissolving pulp or industrial cellulose. The alpha-cellulose content of the cellulose obtained by the method provided by the invention is more than 90 wt%. The technology has the advantages of simple route and low energy consumption.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Method for producing a homogeneous biomass fuel for gasification applications

InactiveUS20070220805A1Smooth changeEasy to useBiofuelsSolid fuelsProcess engineeringVolumetric Mass Density

A method for producing a gasifier feedstock with uniform gasification characteristics from a number of biomass sources which each exhibit differences in their drying, pyrolysis, devolatization or gasification characteristics. The method allows biomass from a wide range and sources and with a wide range of gasification characteristics to be utilized within a gasifier without modification of the gasifier unit. The method produces a fuel pellet with controllable size, density and moisture content. The method smoothes any changes in calorific value which may exist between different feedstocks. It has been found that the gasification characteristics of a pellet formed in this way is strongly dependant upon the shape, moisture content and density of the pellet formed and less sensitive to the origin of the biomass feedstock.

Owner:ZEROPOINT CLEAN TECH

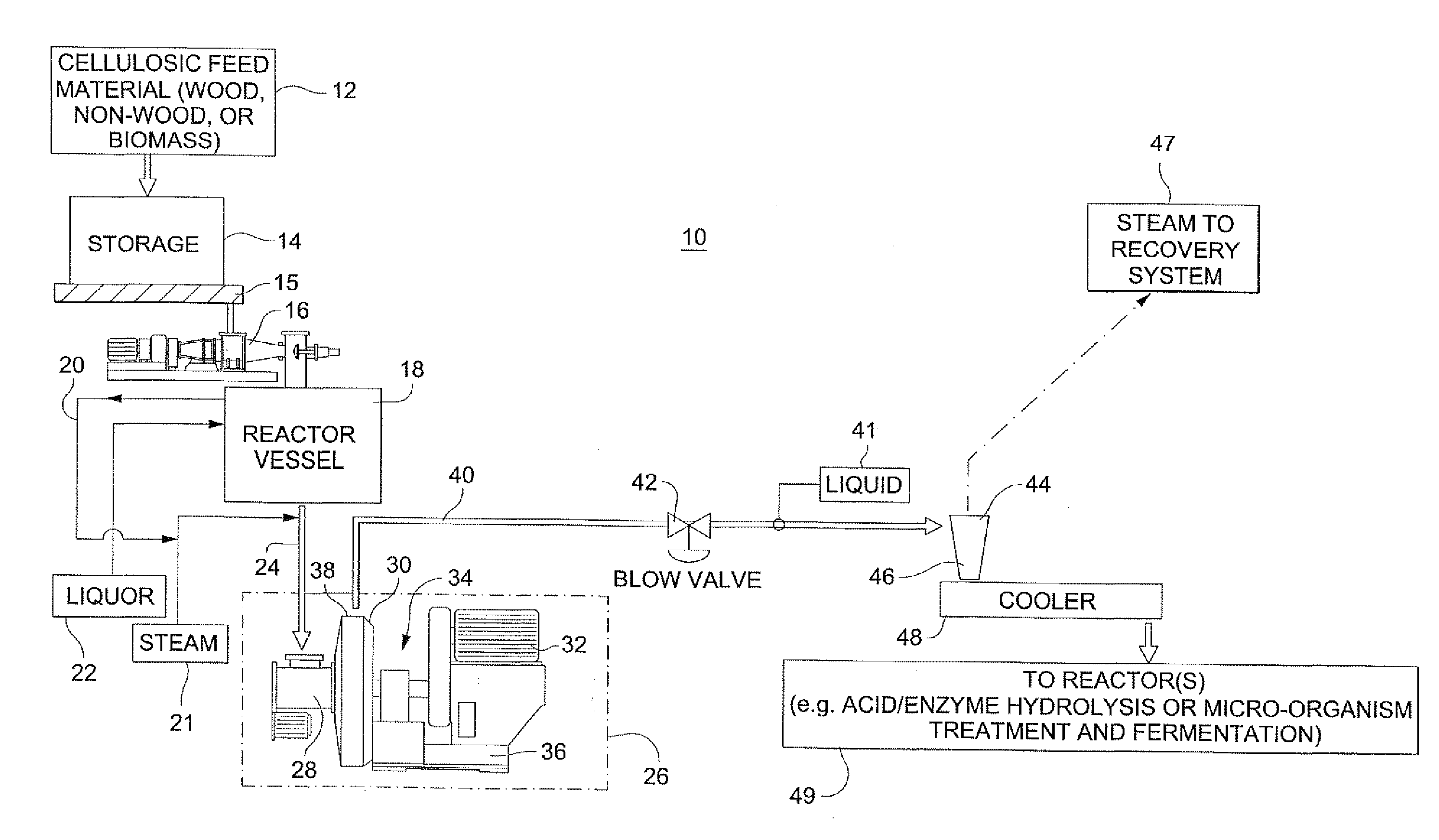

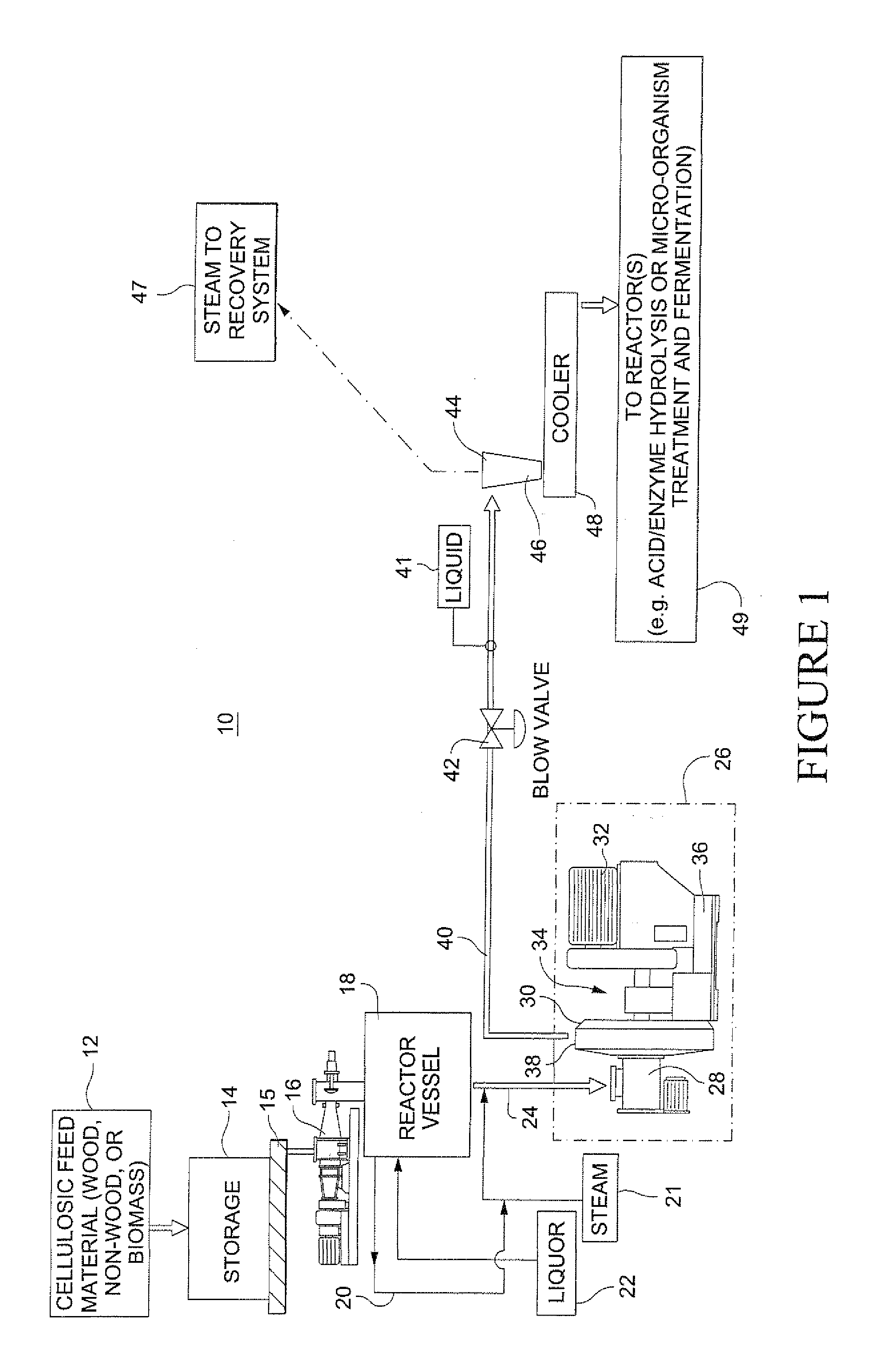

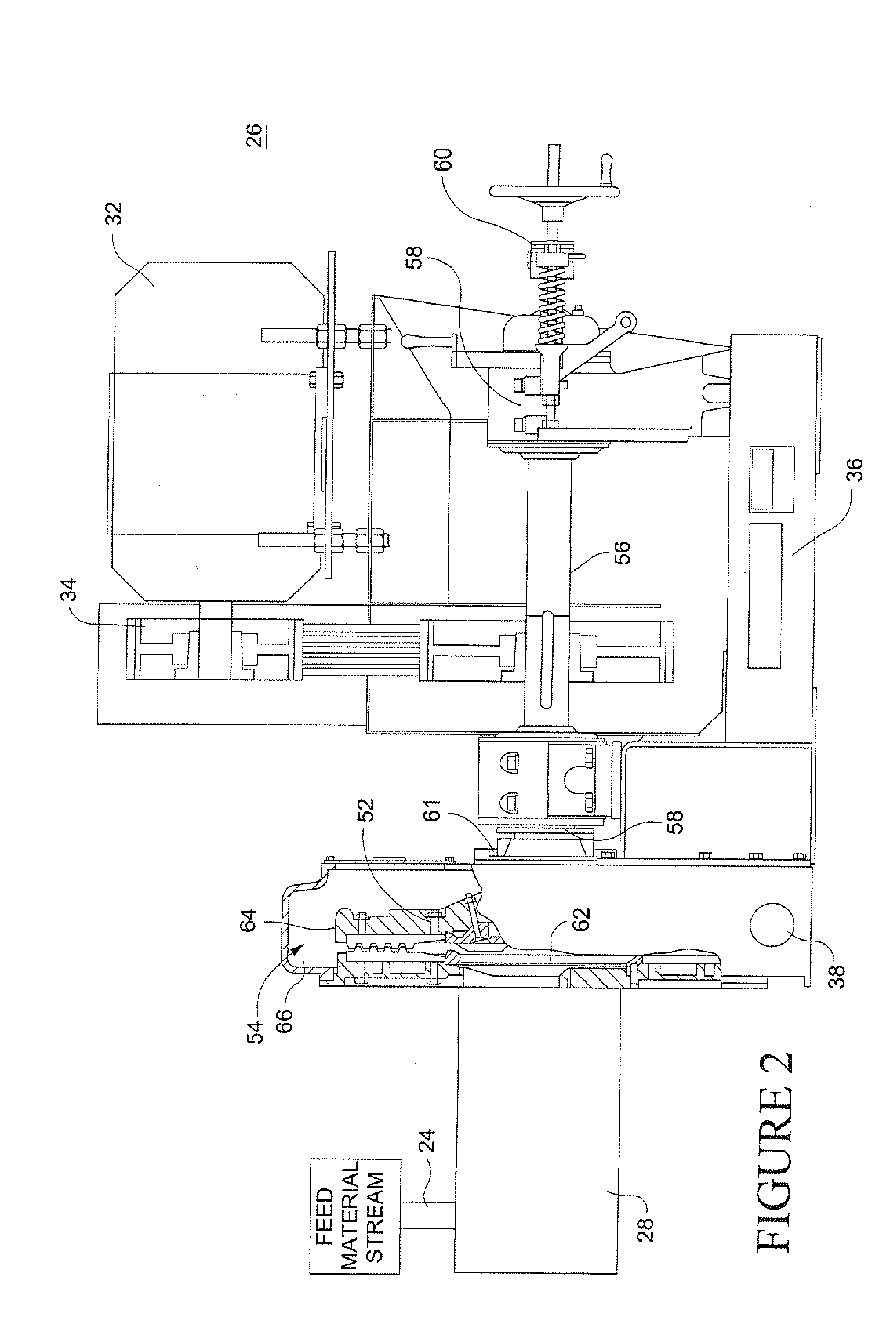

High pressure compressor and steam explosion pulping method

InactiveUS20080277082A1Reduce pressureRapid pressurePretreatment with water/steamPulp beating/refining methodsProcess engineeringHigh pressure

A steam explosion pulping method including: impregnating a cellulosic biomass feed material in a pressurized reactor vessel; discharging the impregnated feed material from the vessel to a high pressure compressor; elevating a pressure of the feed material in the compressor; discharging the pressurized feed material from the compressor to a conduit coupled to a blow valve; rapidly reducing pressure of the pressurized feed material as the feed material passes through the blow valve, and pulping the feed material by expansion of fluid in the feed material during the rapid pressure reduction.

Owner:ANDRITZ INC

Method for preparing biomass carbon by utilizing agricultural and forestry waste

InactiveCN102583311AImprove protectionRaw materials are easy to getSolid waste disposalCarbon preparation/purificationBiomass carbonSorbent

The invention relates to a method for preparing biomass carbon by utilizing agricultural and forestry waste, belonging to the technical fields of preparation of carbon materials and utilization of biomass resources. The method comprises the following steps of: adopting agricultural and forestry waste as raw materials; under the condition of subcritical water, fully mixing dried biomass materials and deionized water according to the proportion of 1:(10-30); under the protection of inert atmosphere, carbonizing for 2-6 hours at the temperature of 220-250 DEG C; and then carrying out vacuum filtration and hot-water cleaning, and drying to obtain the biomass carbon. The biomass carbon prepared by the invention is coaly carbon material with an aromatic-ring structure, is high in carbon content and calorific value and large in specific surface area, and can be used as a soil conditioner or an absorbent. The method has the advantages that the materials are low in cost and easy to obtain, the process is simple, the operation is convenient, the manufacturing cost is low, the industrial promotion is convenient, and the application range and the application value of biomass resources are further expanded in the aspect of carbon materials.

Owner:BEIJING FORESTRY UNIVERSITY

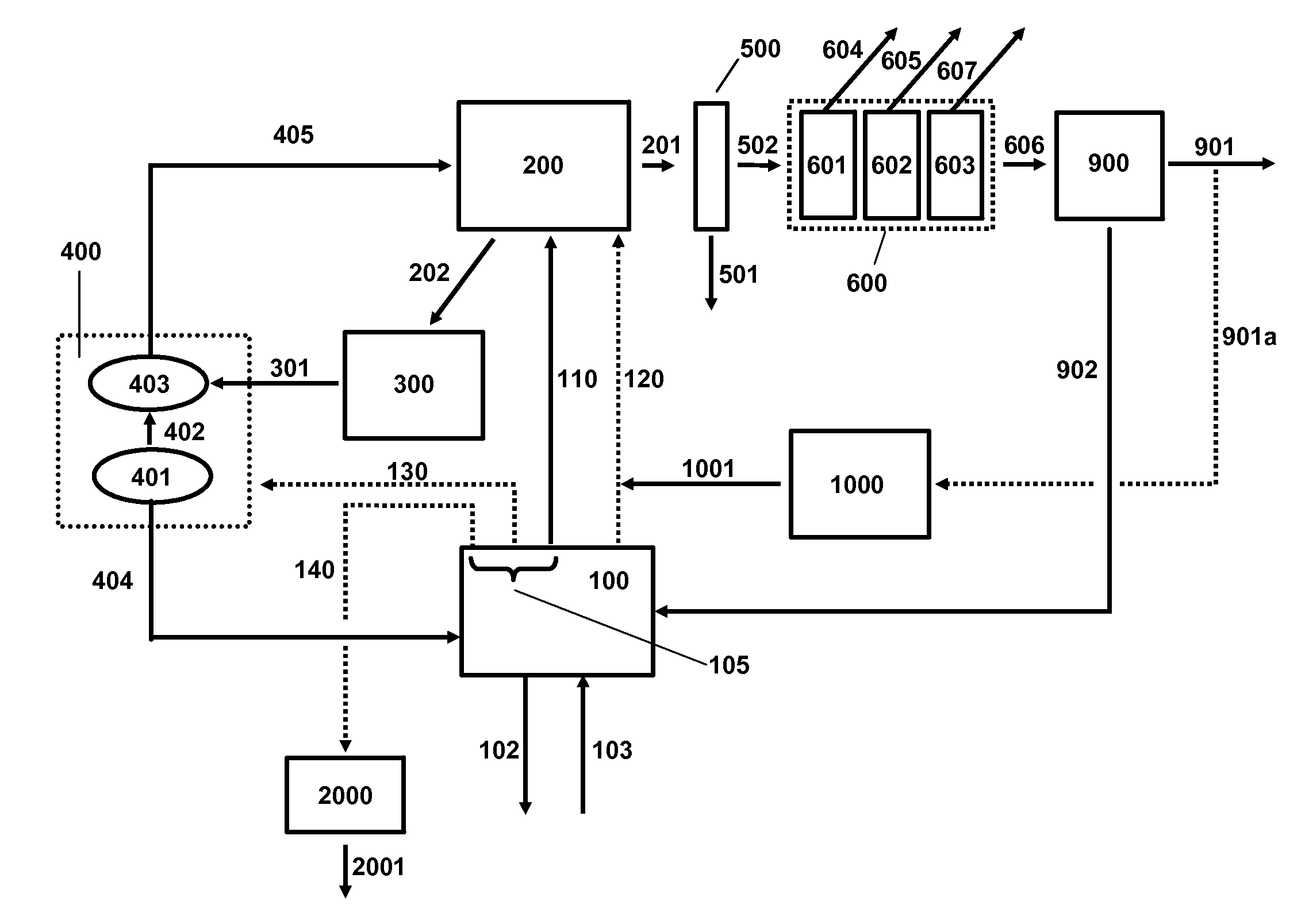

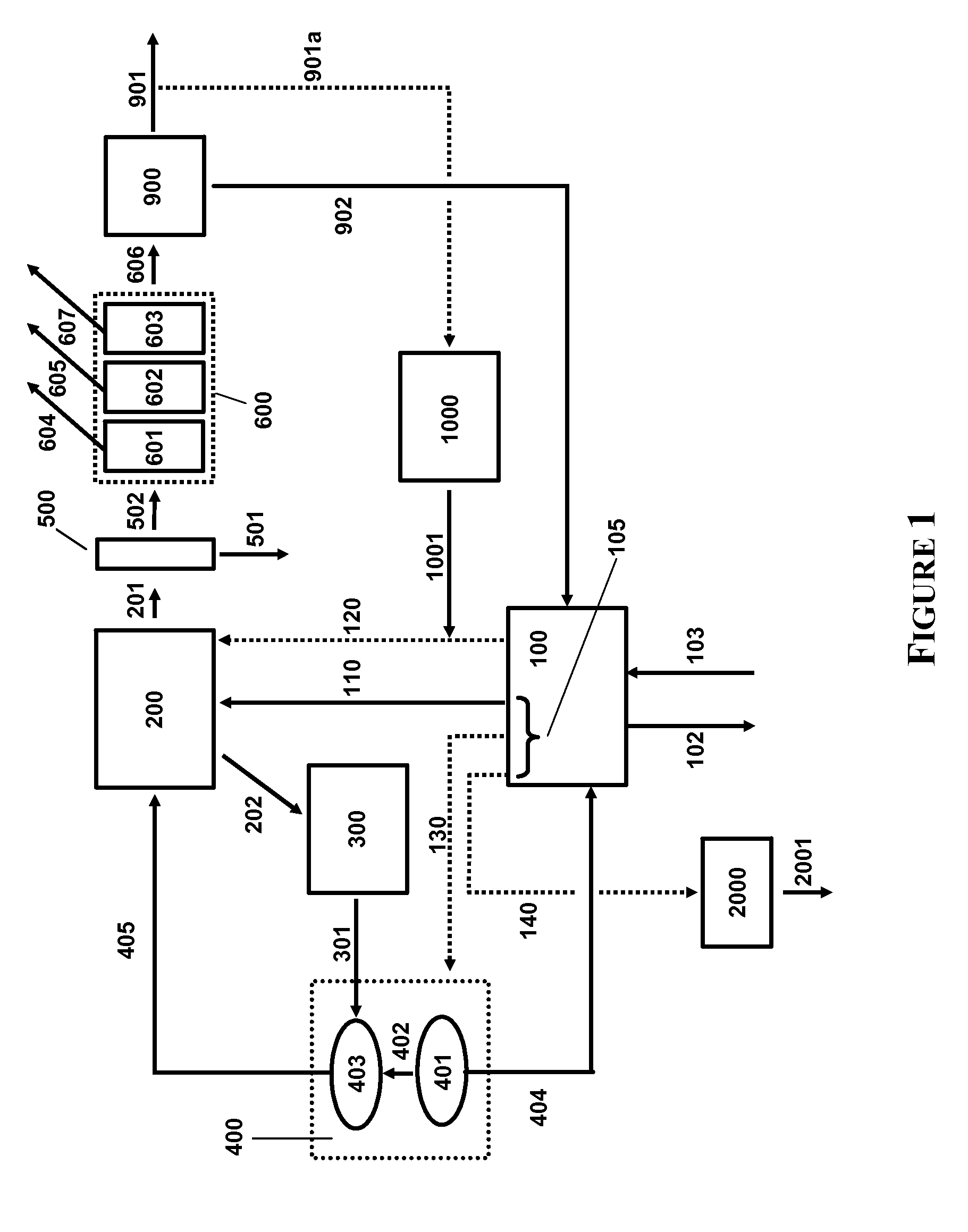

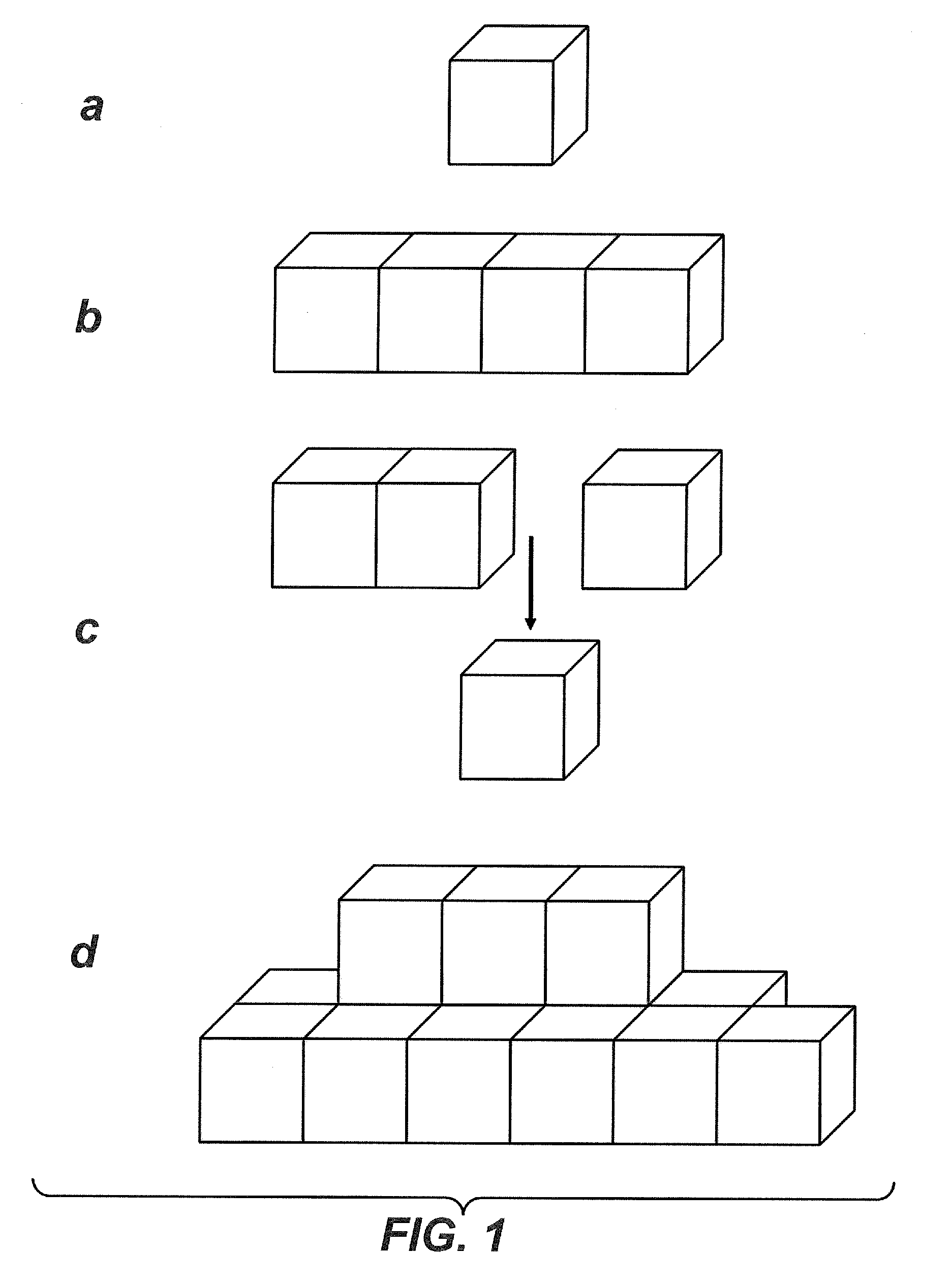

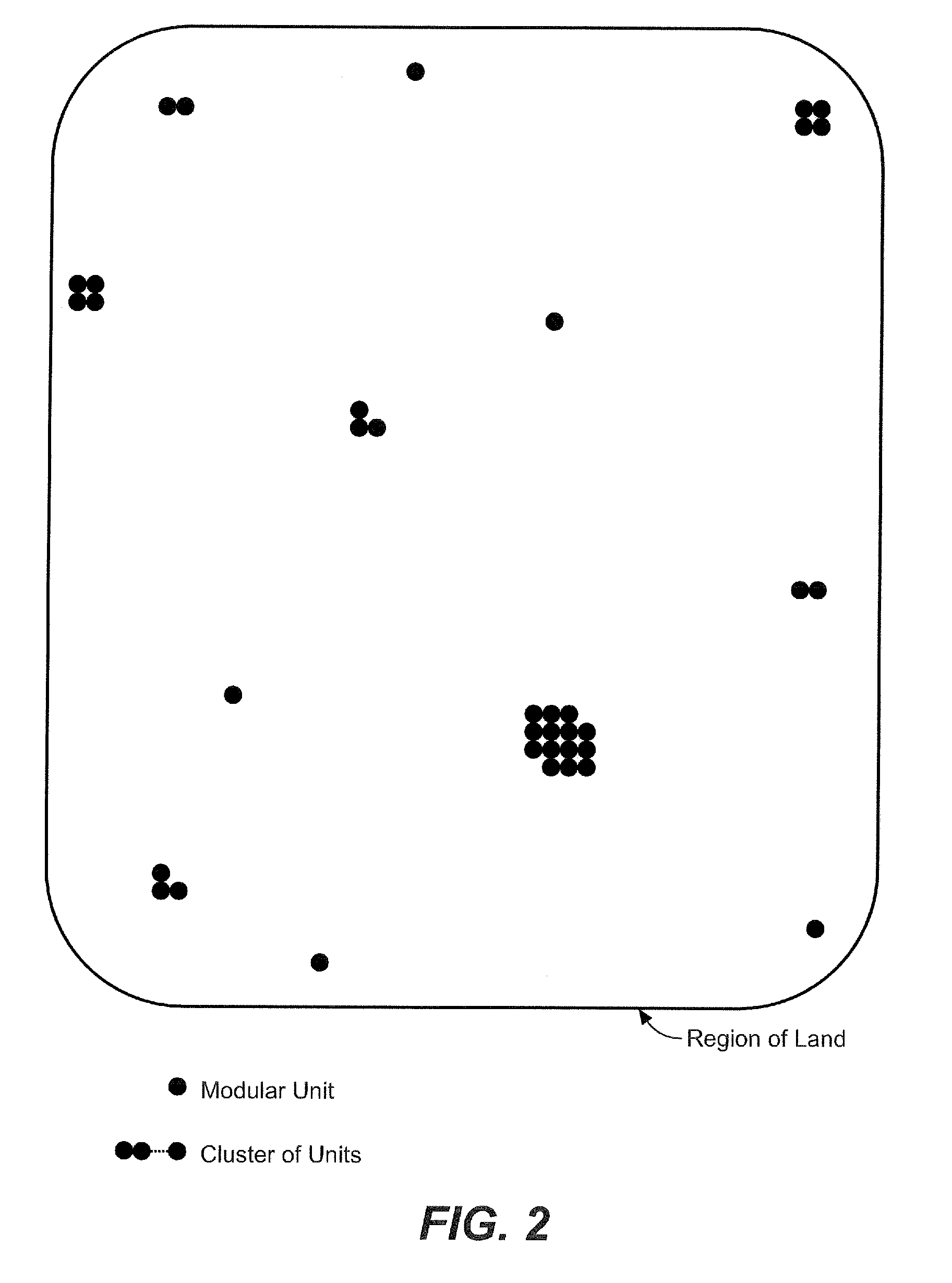

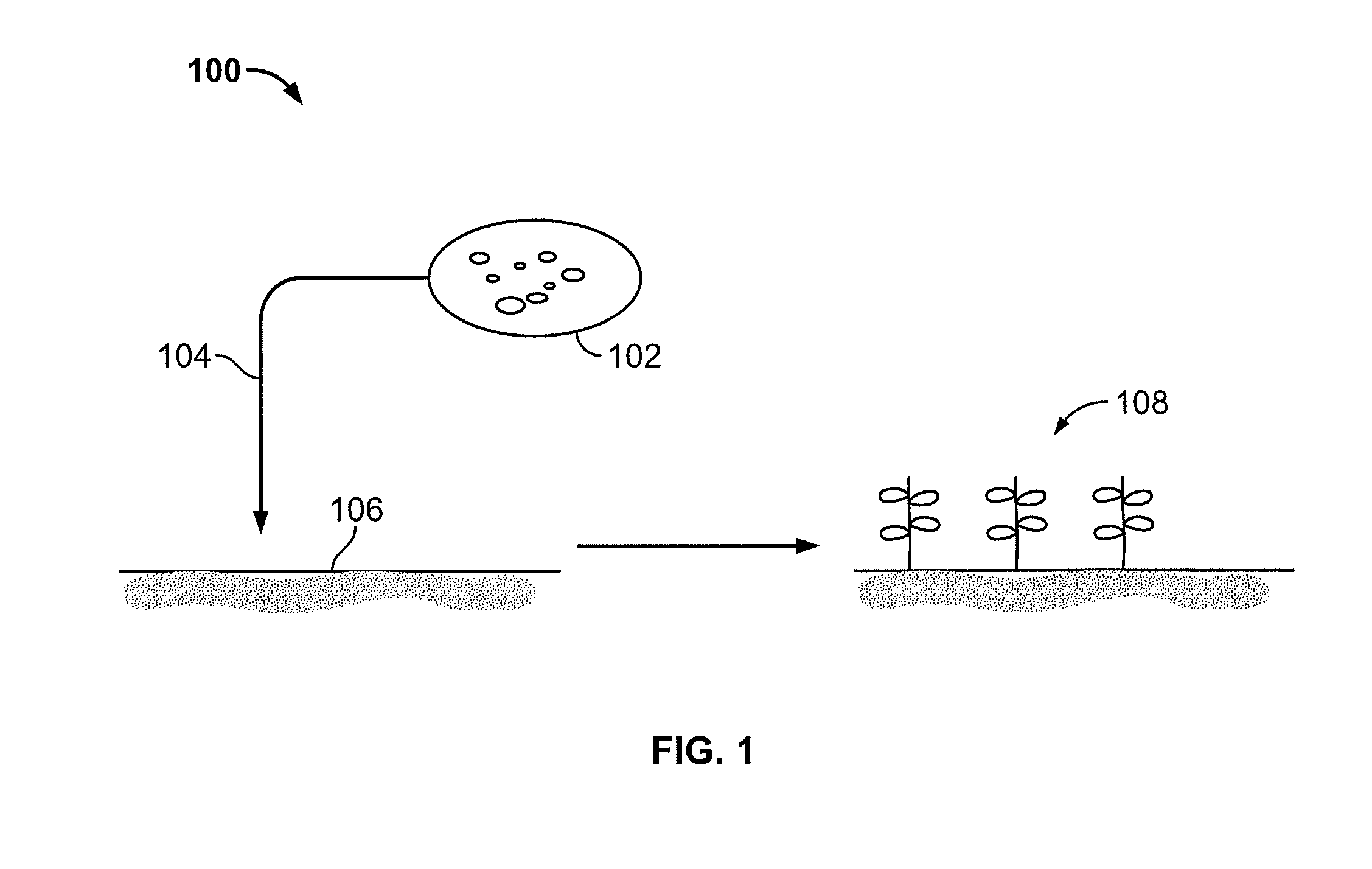

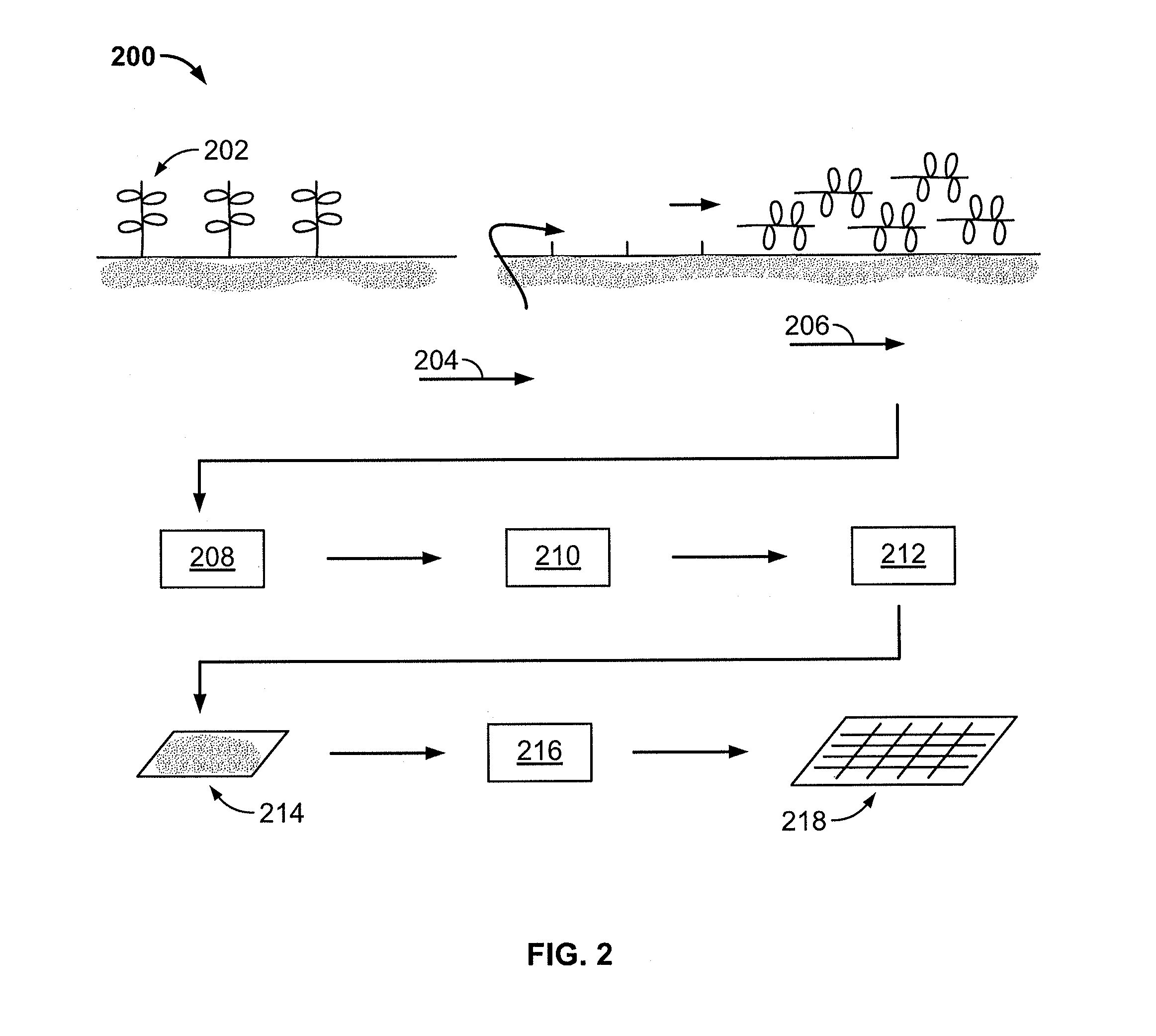

Modular and distributed methods and systems to convert biomass to syngas

The present invention provides modular and distributed methods and systems to convert biomass feedstocks into synthesis gas (syngas). The syngas can then be turned into liquid chemicals and fuels such as ethanol. The modular units of the invention bring the conversion process to the biomass source, thereby minimizing feedstock transportation costs. The modules are capable of being connected to, and / or disconnected from, each other to easily adjust the overall feedstock capacity. The present invention also provides methods and systems to determine an optimal number and distribution of modular conversion units spatially located within a region of land. The disclosed methods and systems are flexible, efficient, scalable, and are capable of being cost-effective at any commercial scale of operation.

Owner:HAAKON LLC

Methods for preparing ethylene glycol from polyhydroxy compounds

ActiveUS20120172633A1High yieldHigh selectivityOxygen-containing compound preparationOrganic compound preparationHydrogen pressureHeteropoly acid

This invention provides methods for producing ethylene glycol from polyhydroxy compounds such as cellulose, starch, hemicellulose, glucose, sucrose, fructose, fructan, xylose and soluble xylooligosaccharides. The methods uses polyhydroxy compounds as the reactant, a composite catalyst having active components comprising one or more transition metals of Groups 8, 9, or 10, including iron, cobalt, nickel, ruthenium, rhodium, palladium, iridium, and platinum, as well as tungsten oxide, tungsten sulfide, tungsten hydroxide, tungsten chloride, tungsten bronze oxide, tungsten acid, tungstate, metatungstate acid, metatungstate, paratungstate acid, paratungstate, peroxotungstic acid, pertungstate, heteropoly acid containing tungsten. Reacting at a temperature of 120-300° C. and a hydrogen pressure of 1-13 MPa under hydrothermal conditions to accomplish one-step catalytic conversion. It realizes efficient, highly selective, high yield preparation of ethylene glycol and propylene glycol from polyhydroxy compounds. The advantage of processes disclosed in this invention include renewable raw material and high atom economy. At the same time, compared with other technologies that converts biomass raw materials into polyols, methods disclosed herein enjoy advantages including simple reaction process, high yield of targeted products, as well as easy preparation and low cost for the catalysts.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

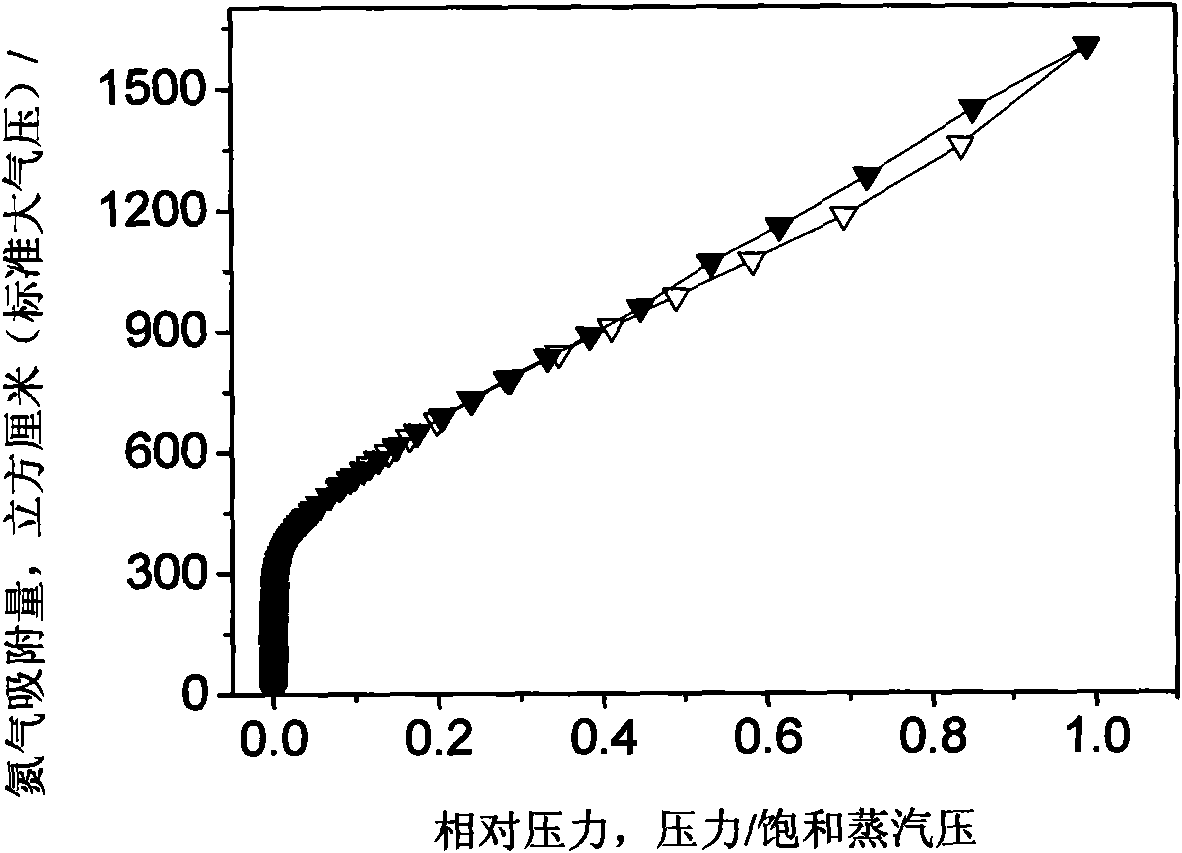

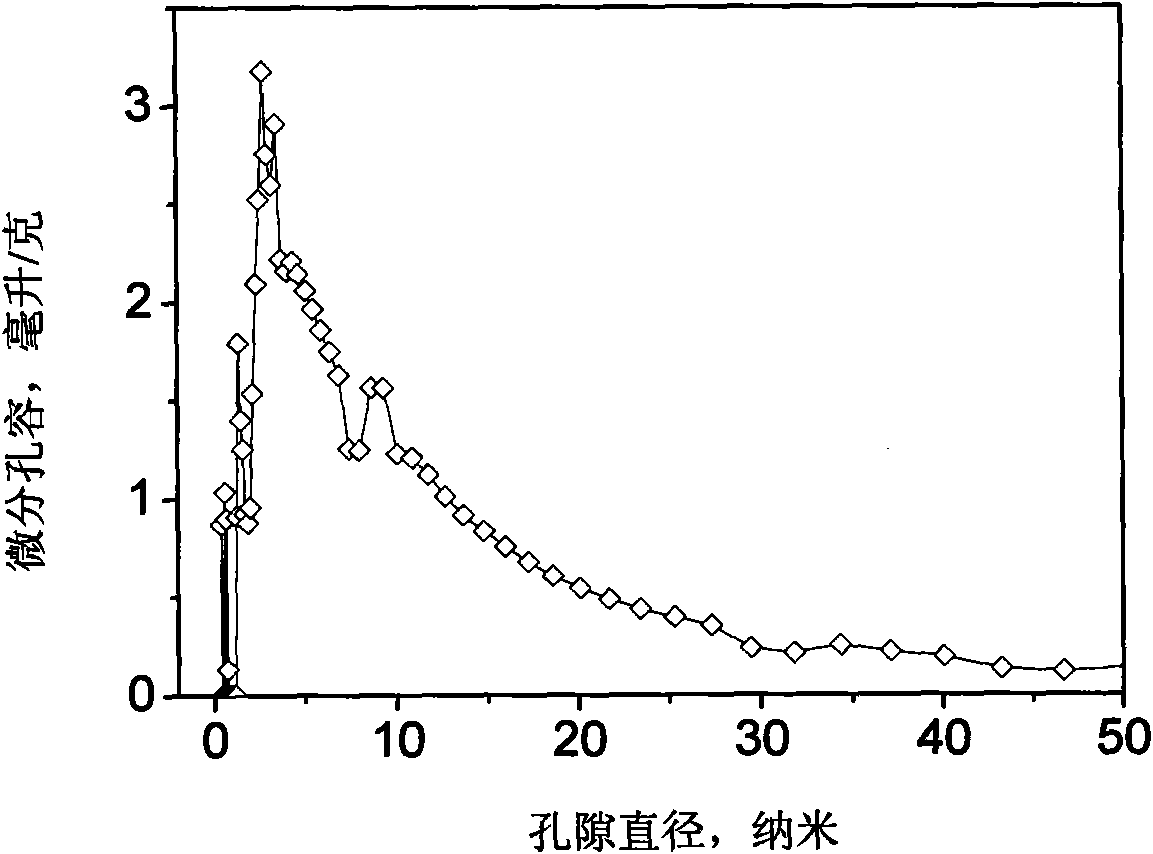

Preparation method of activated carbon with high pore volume

The invention discloses a preparation method of activated carbon with high pore volume, which comprises the following steps: after phosphoric acid and an activating auxiliary agent are prepared into asolution, mixing the biomass material, the activating agent phosphoric acid and the activating auxiliary agent according to the weight ratio of 1:1-5:0-0.05; dipping the mixture for 2-16h at 50-100 DEG C, raising the temperature to 400-600 DEG C at the temperature raising rate of 1-5 DEG C / min, and then, activating the mixture for 1-2h; and taking out the mixture and washing with water until thepH value of the filtered solution reaches 6-7, drying the mixture to the balance weight at 100-120 DEG C, thus, obtaining an activated carbon product. The preparation method of activated carbon with high pore volume successfully uses the phosphoric acid activating biomass material for preparing the activated carbon with high pore volume which reaches 2.6cm<3> / g by solving the difficult problem that in the traditional phosphoric acid activating process, the phosphoric acid solution is difficult to fully permeate into biomass material particles. The method has the characteristics of easy control, little pollution, easy industrial production and the like.

Owner:浙江瑞能炭材料科技有限公司

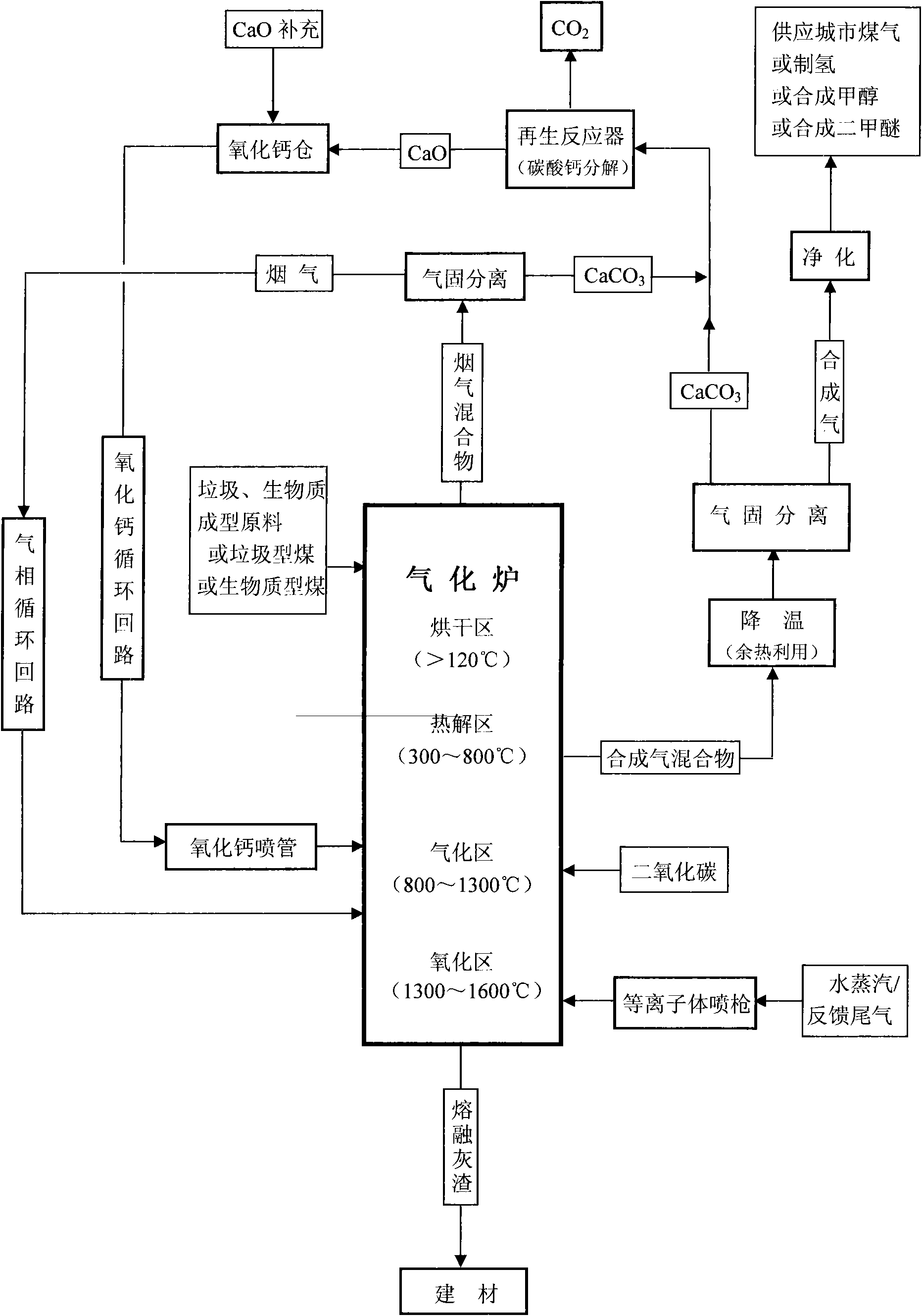

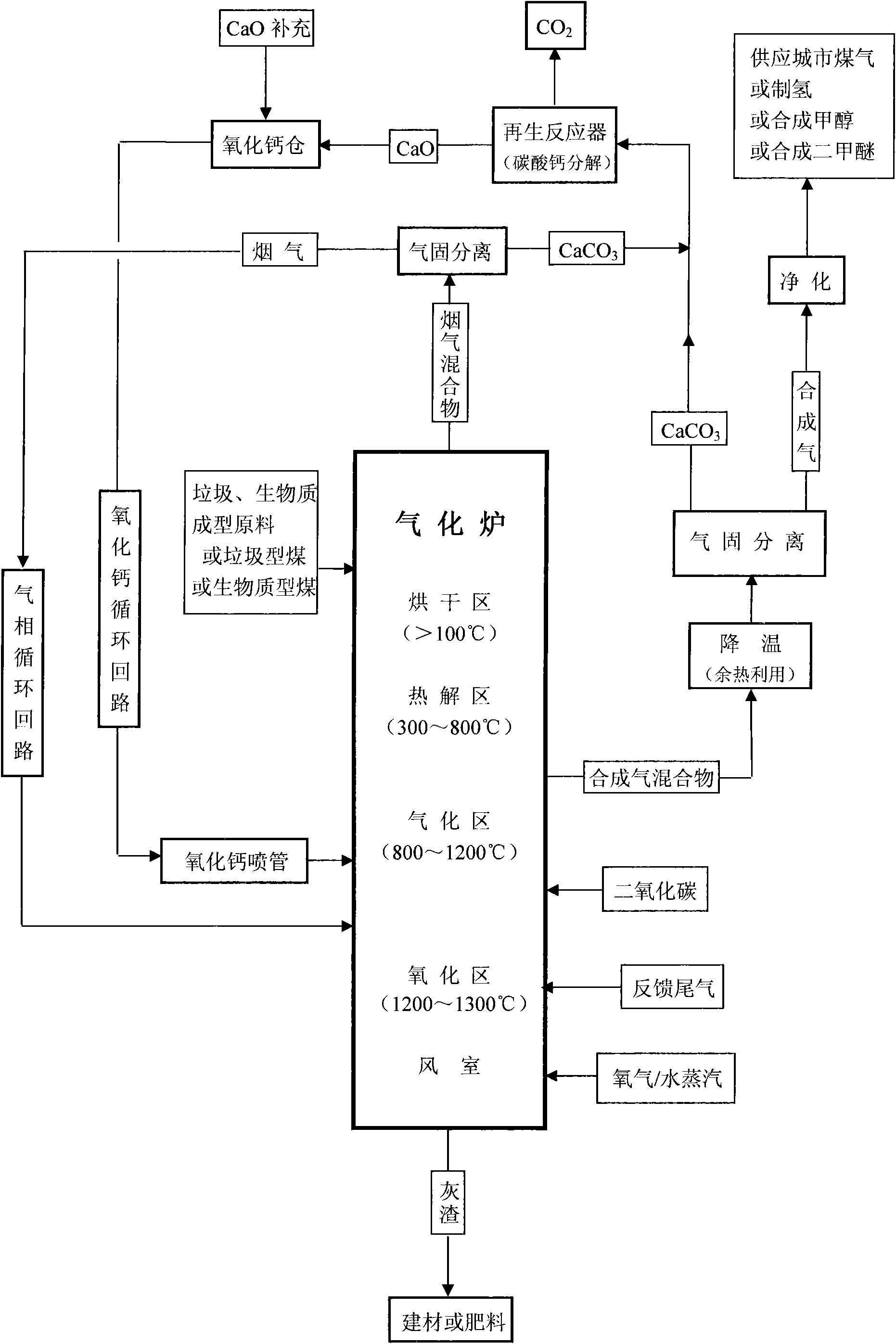

Gasification process for producing synthesis gas from garbage and biomass raw materials

InactiveCN101525118AEliminate pollutionHarmlessHydrogen productionSpecial form destructive distillationGas phaseWater vapor

The invention provides a gasification process for producing synthesis gas from garbage and biomass raw materials, which relates to a gasification processing technique of garbage and biomasses. The gasification process is characterized in that the technological process mainly comprises a raw material solid matter process, a gas phase circulation loop, a calcium oxide circulation loop and a synthesis gas drawing process; one or a mixture of more garbage, the biomasses and coal is sent into a gasification furnace to perform gasification so as to generate the synthesis gas; and simultaneously, calcium oxide is sent into the gasification furnace, an exothermic reaction of absorbing carbon dioxide by the calcium oxide provides the heat required by the gasification reaction in the furnace, and water vapor is sent into a plasma spraying gun and is heated to more than 3,100 DEG C to generate H2, O, O2 and H2O<*> which are sprayed into the gasification furnace to perform reactions with the garbage and the biomasses and supply heat into the furnace. The gasification process adopts a measure to spray the calcium oxide into the furnace to not only greatly reduce the electric energy consumption of the plasma spraying gun, but also improve the quality and the yield of the synthesis gas, thus the aim of transforming the garbage and the biomasses into clean energy can be achieved easily.

Owner:周开根

Method and apparatus for depositing agents upon and within bio-char

Methods and apparatuses for depositing agents relatively deep within pores of bio-char. Bio-char is first produced in an airtight oven by heating biomass feedstock. The bio-char is then cooled and steam is diffused into the pores of the bio-char. The steam-laden bio-char is immersed in a liquid bath containing soluble agents that are to be deposited in the pores of the bio-char. The liquid bath cools the char to below the condensation temperature of the steam, whereupon the condensing steam generates a partial vacuum within the pores, drawing the liquid into the pores. The bio-char is then removed from the liquid bath and dried so that the liquid within the pores evaporates, leaving behind the soluble agent. Accordingly, the invention yields bio-char that has soluble agent embedded relatively deep within its pores.

Owner:CARBON TECH HLDG LLC

Preparation method of high-yield biochar

ActiveCN104371748AHigh specific surface areaImprove pore structureProductsReagentsPorosityCarbonization

The invention discloses a preparation method of high-yield biochar, which mainly comprises the following steps: (1) putting a collected biomass raw material into a catalyst solution, stirring and impregnating at normal temperature, and filtering to obtain the biomass raw material containing moisture and catalyst, the moisture weight percentage is 50-150%, and the catalyst weight content is 0.5-5%; and (2) heating the biomass raw material containing moisture and catalyst in an oxygen-free or limited-oxygen atmosphere to 100-180 DEG C at the rate of 0.5-2 DEG C / minute, keeping the temperature for 1-2 hours, heating to 240-300 DEG C at the rate of 0.5-3 DEG C / minute, keeping the temperature for 1-3 hours, heating to 500-900 DEG C at the rate of 10-50 DEG C / minute, keeping the temperature for 1-4 hours, and cooling to obtain the biochar, wherein the yield of the biochar is greater than 40 wt% of the biomass raw material. The method does not need drying in the biochar preparation process; the biomass raw material containing moisture and catalyst and the multi-step carbonization technique are utilized to achieve the goal of enhancing the biochar yield; and the biochar has the characteristics of energy saving, large specific area and high porosity, and can be widely used in the fields of water treatment, functional textiles and the like.

Owner:DONGHUA UNIV

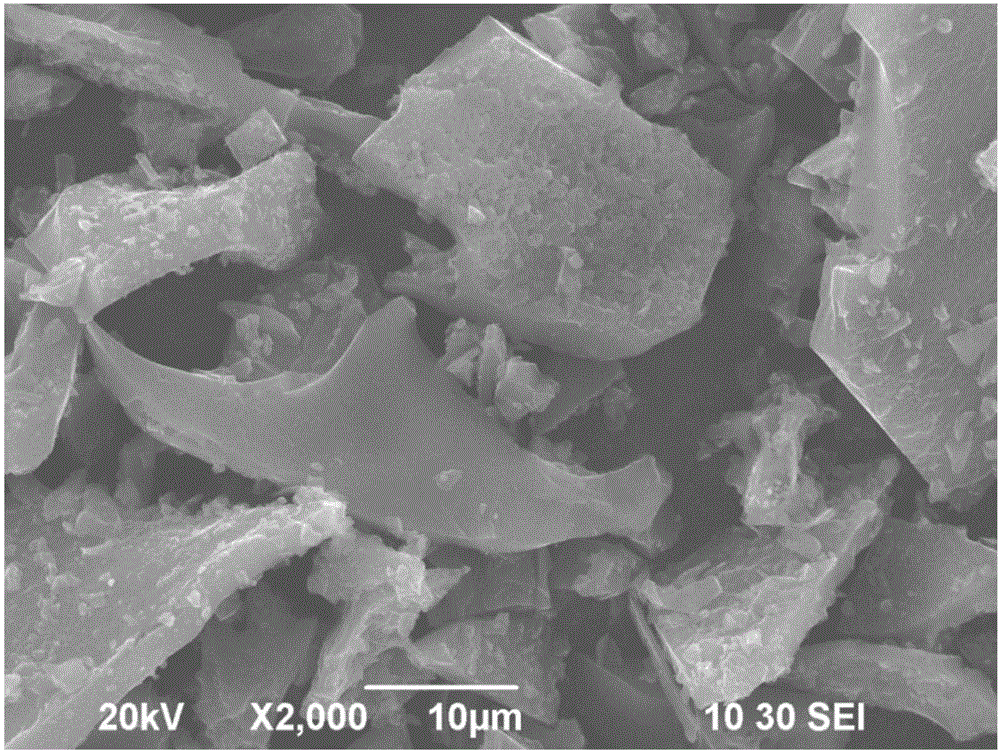

Preparation method of sulfur-active carbon/graphene composite material

ActiveCN106602013AWide variety of sourcesEasy to prepareCell electrodesLi-accumulatorsActivated carbonSulfur

The invention discloses a preparation method of a sulfur-active carbon / graphene composite material. The preparation method comprises the following steps of (1) pre-processing a biomass raw material; (2) mixing the pre-processed biomass raw material, graphene and an activating agent to form a solid mixed material; (3) performing activation, washing, solid-liquid separation and drying on the solid mixed material to obtain an active carbon / graphene composite material; and (4) combining the active carbon / graphene composite material with sulfur to obtain the sulfur-active carbon / graphene composite material. The composite material provided by the invention has the advantages of simple preparation process step, high efficiency and low energy consumption, and production on a large scale can be achieved.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Systems and methods for producing biochar-based products

An end-to-end system / process for producing advantageous end products from a raw biomass feedstock is provided. The process includes steps for enhancing biomaterial feedstock, biochar generation and end-product fabrication. The method steps may be employed in selecting, treating and handling biomass materials and their additive inputs to tailor their end performance. Each operative step in the process may be employed to enhance the overall effectiveness of biochar generation and use. Charring furnace design and operational parameters are provided that generate desirable biochar material for various applications, including specifically fabrication of ultra-capacitor electrodes and electric battery components.

Owner:CARBONCHARGE TECH LLC

Method for producing ethanol and co-products from cellulosic biomass

InactiveUS20110262984A1Increased ethanol productionImproved co-productsPretreatment with acid reacting compoundsBiofuelsCelluloseCo product

The present invention generally relates to processes for production of ethanol from cellulosic biomass. The present invention also relates to production of various co-products of preparation of ethanol from cellulosic biomass. The present invention further relates to improvements in one or more aspects of preparation of ethanol from cellulosic biomass including, for example, improved methods for cleaning biomass feedstocks, improved acid impregnation, and improved steam treatment, or “steam explosion.”

Owner:ABENGOA BIOENERGY NEW TECH

Low oxygen biomass-derived pyrolysis oils and methods for producing the same

Low oxygen biomass-derived pyrolysis oils and methods for producing them from carbonaceous biomass feedstock are provided. The carbonaceous biomass feedstock is pyrolyzed in the presence of a catalyst comprising base metal-based catalysts, noble metal-based catalysts, treated zeolitic catalysts, or combinations thereof to produce pyrolysis gases. During pyrolysis, the catalyst catalyzes a deoxygenation reaction whereby at least a portion of the oxygenated hydrocarbons in the pyrolysis gases are converted into hydrocarbons. The oxygen is removed as carbon oxides and water. A condensable portion (the vapors) of the pyrolysis gases is condensed to low oxygen biomass-derived pyrolysis oil.

Owner:UOP LLC

Saline-alkali soil paddy rice special-purpose carbon-based organic fertilizer and use thereof

InactiveCN105384579AGood water permeabilityImprove breathabilityExcrement fertilisersBioloigcal waste fertilisersAlkali soilPotassium

The invention relates to saline-alkali soil paddy rice special-purpose carbon-based organic fertilizer. The saline-alkali soil paddy rice special-purpose carbon-based organic fertilizer has a low cost and high fertilizer efficiency, is economic and environmentally friendly, improves a soil water binding capacity and permeability, and has functions of keeping fertility, slowly releasing fertilizer and reducing paddy rice salinization. The saline-alkali soil paddy rice special-purpose carbon-based organic fertilizer comprises biomass charcoal, chicken manure, pyroligneous liquor, fermented soybean meal and potassium humate. The biomass charcoal is prepared by thermal cracking charring of biomass raw materials under anoxic conditions. The saline-alkali soil paddy rice special-purpose carbon-based organic fertilizer can be used for paddy rice plantation, can improve a saline-alkali soil environment and can improve an organic paddy rice yield.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

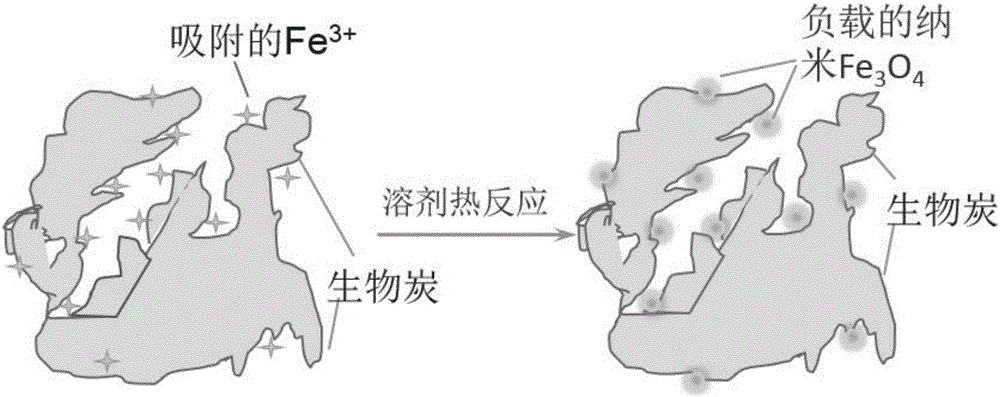

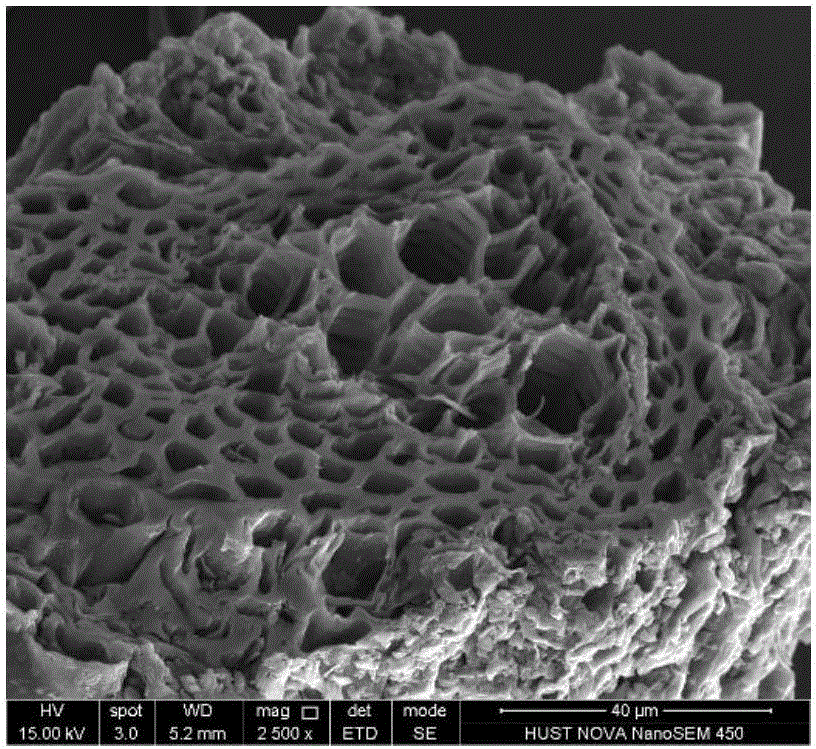

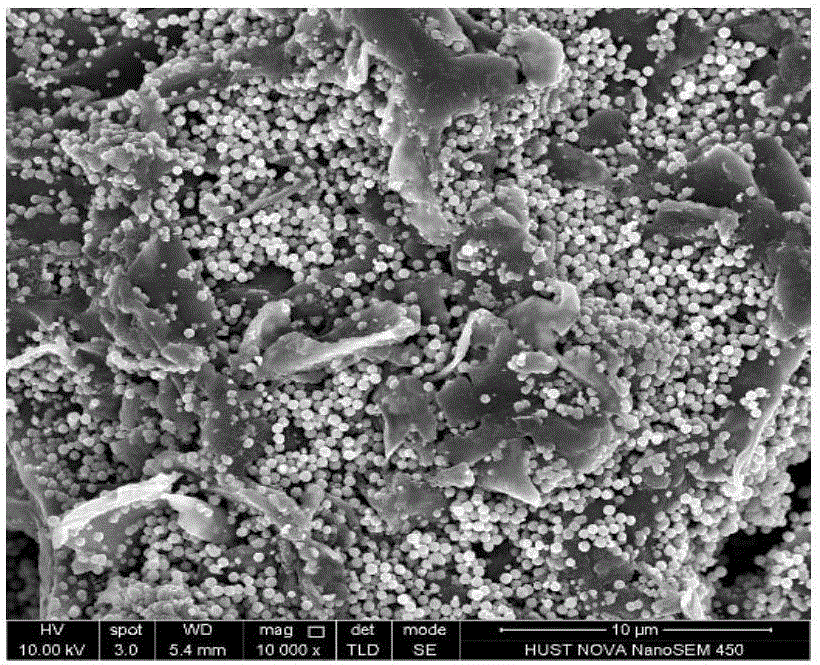

Magnetic biochar adsorbing material and preparation method thereof

InactiveCN106362690AGood lookingSimple structureOther chemical processesWater contaminantsSodium acetateSodium acetrizoate

The invention discloses a magnetic biochar adsorbing material and a preparation method thereof. The preparation method comprises the following steps: (1) preparation of biochar: by using powder obtained by treating plant biomass as a raw material, roasting under oxygen-free conditions to obtain porous biochar; (2) preparation of ferric iron precursor liquid: by using ethanediol as a dispersing agent, adding a solid-state ferric iron salt, continuing adding sodium acetate and a surfactant into the ethanediol, and stirring to form a disperse system which is the ferric iron precursor liquid; and (3) solvothermal reaction: uniformly mixing the biochar and ferric iron precursor solution to obtain a mixture, putting the mixture into a teflon hydrothermal reaction kettle, and carrying out solvothermal reaction to obtain the magnetic biochar adsorbing material. The pretreatment technique of the key biomass raw material and the specific conditions of solvothermal reaction in the preparation method are improved, thereby effectively solving the problem of poor connection stability between the magnetic biochar material magnetic particles and biomass.

Owner:HUAZHONG UNIV OF SCI & TECH

Biomass pretreatment process

Owner:CHEMTEX ITAL +1

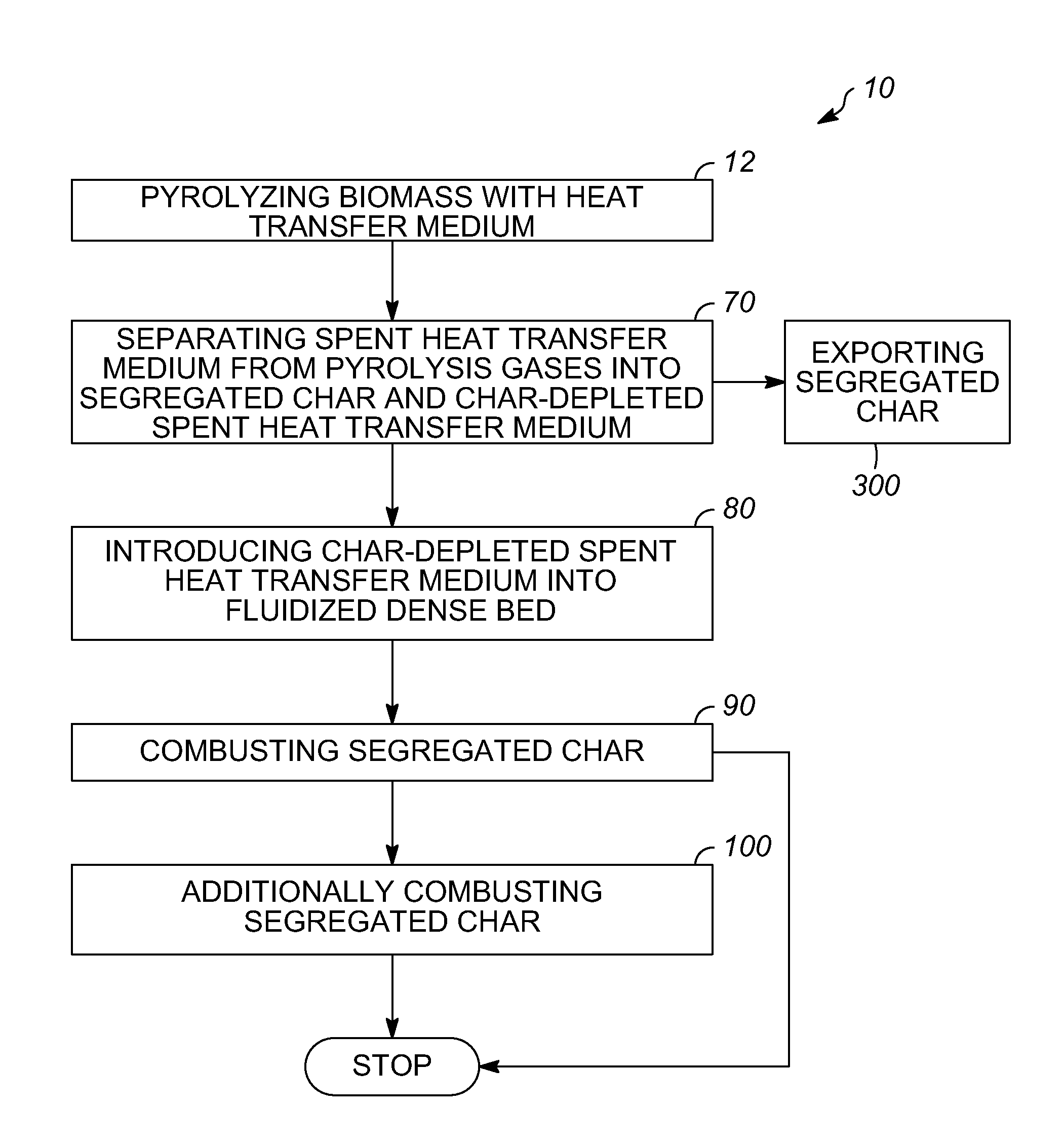

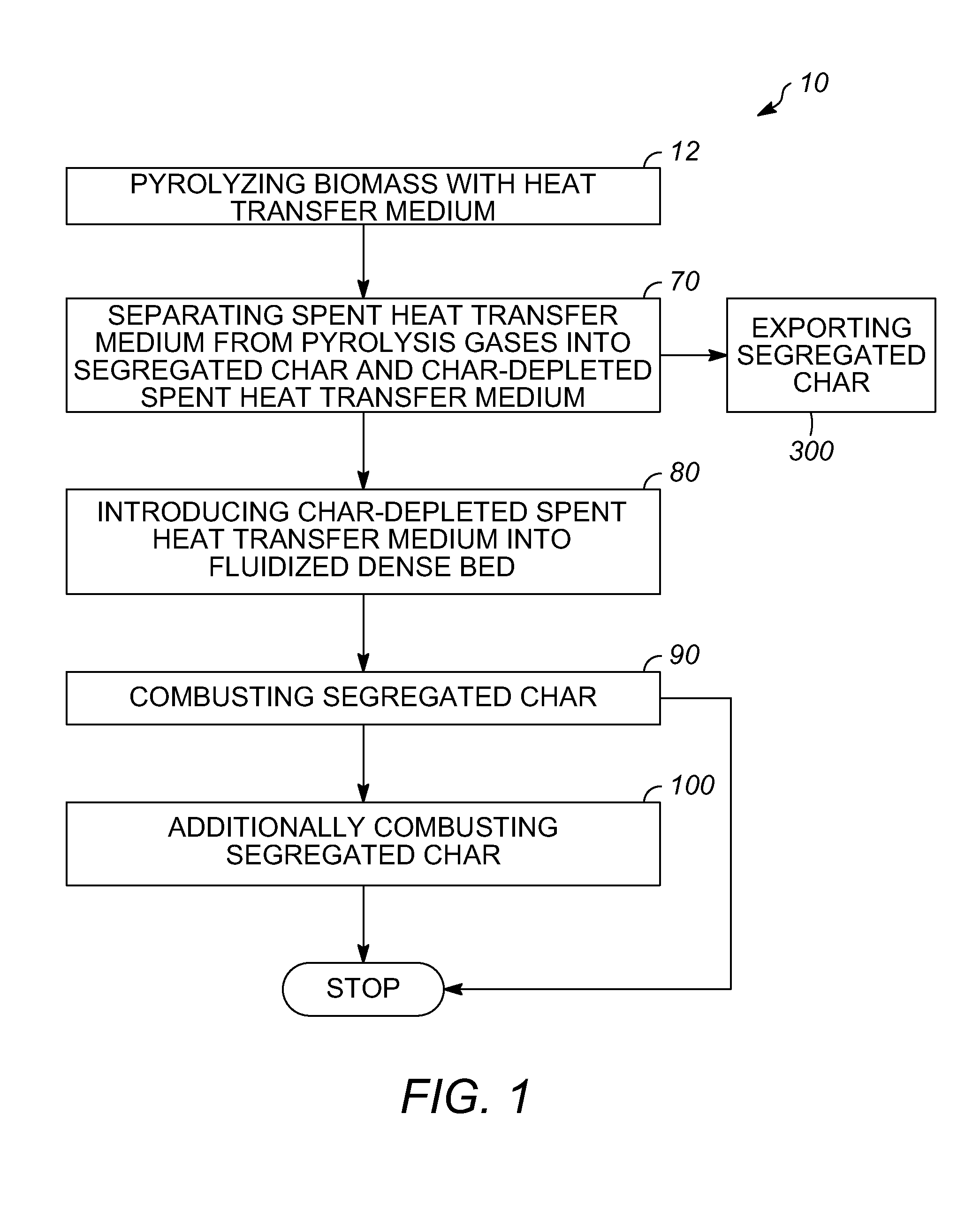

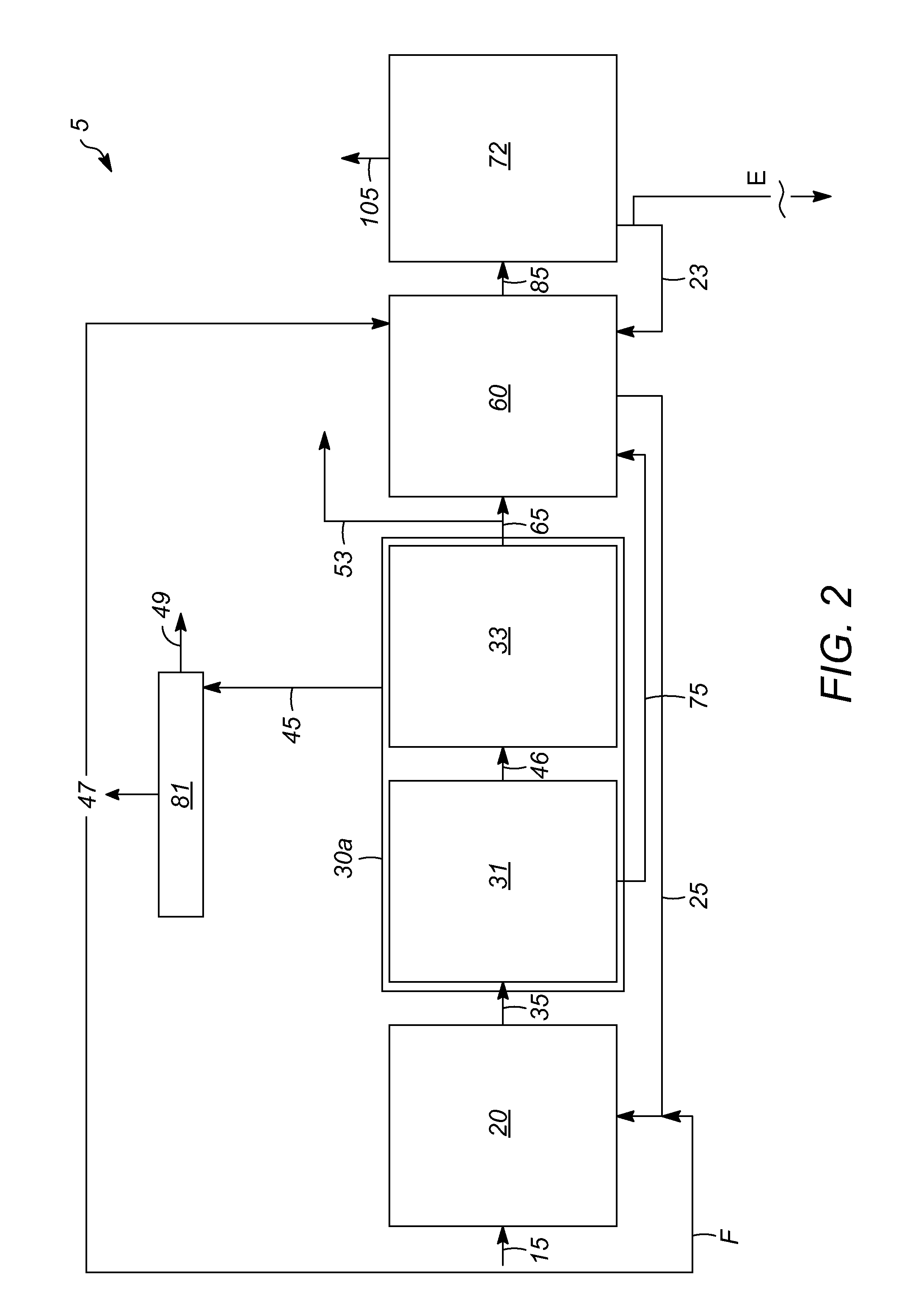

Char-handling processes in a pyrolysis system

Owner:ENSYN RENEWABLES

Biomass molding fuels

InactiveCN101899345AEmission reductionImprove effective utilizationBiofuelsSolid fuelsSulfurDirect combustion

The invention discloses biomass molding fuels. The fuels are granulated and molded after biomass material particles and a fuel additive are mixed, wherein, based on the weight of the biomass material particles, the fuel additive comprises the following components in percentages by weight: 0.1-5% of grease, 0.1-2% of sulfur fixation agent and 0.1-0.5% of combustion improver. The biomass molding fuel obtained in the invention is a high grade clean fuel suitable for use in industrial boilers and can be directly burned in various BMF (Biomass molding fuel) boilers.

Owner:GUANGZHOU DEVOTION THERMAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com