Patents

Literature

1129results about How to "Reduce cooking time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stir-frying Apparatus with Overhead Heating Device

InactiveUS20050223906A1Free handsEnvironmentally friendlyRoasters/grillsBaking plantsFresh airKnife blades

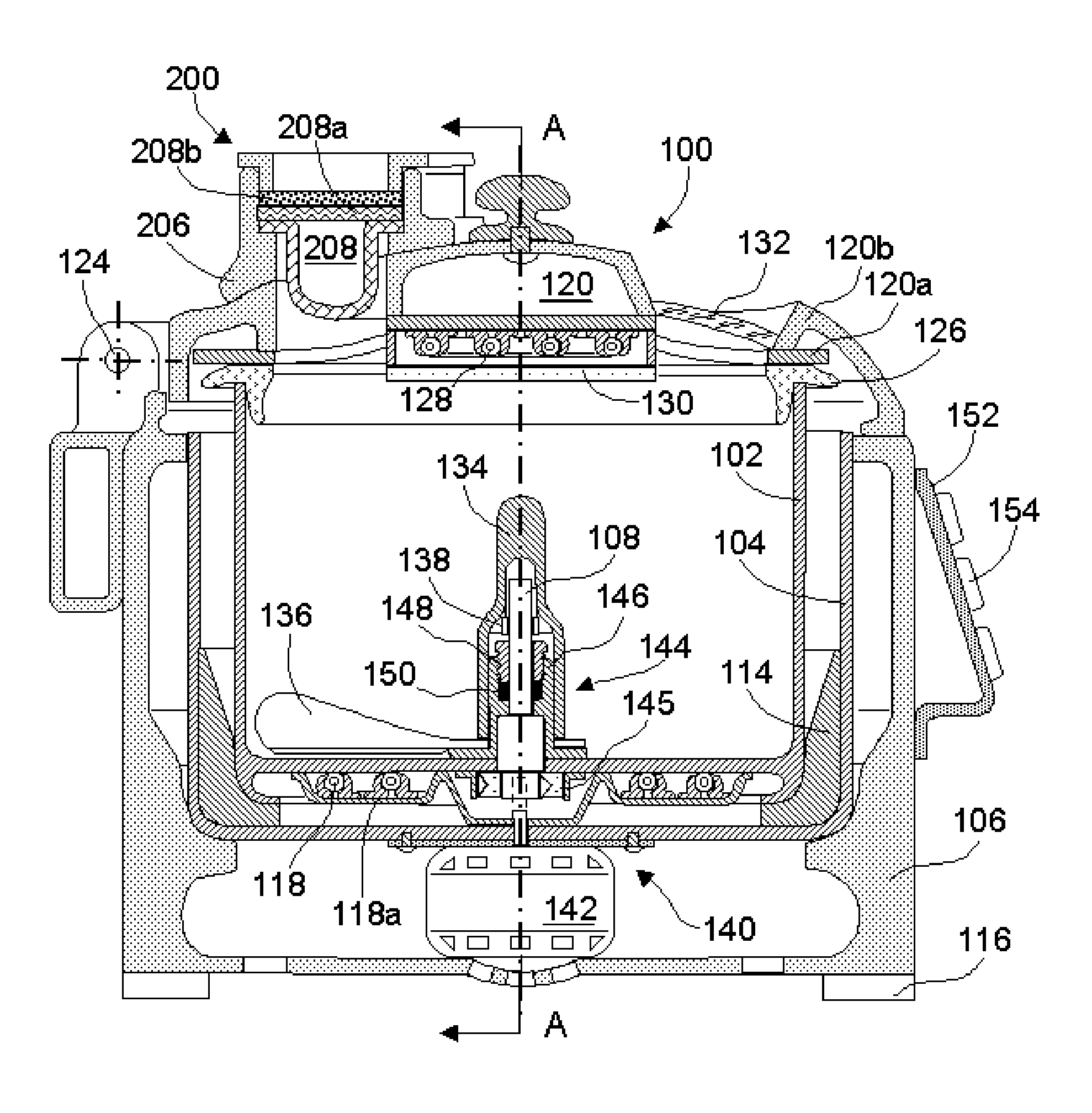

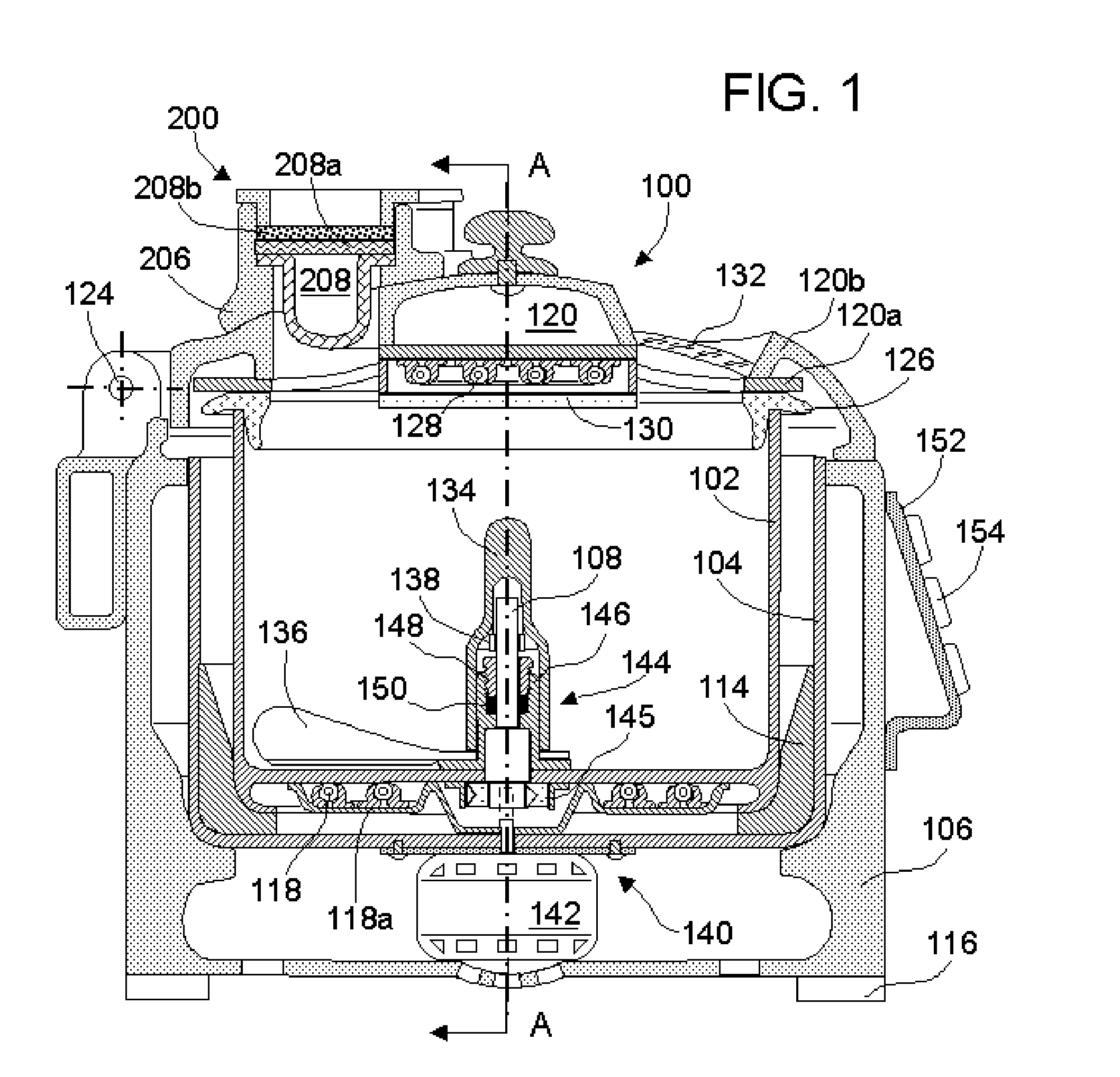

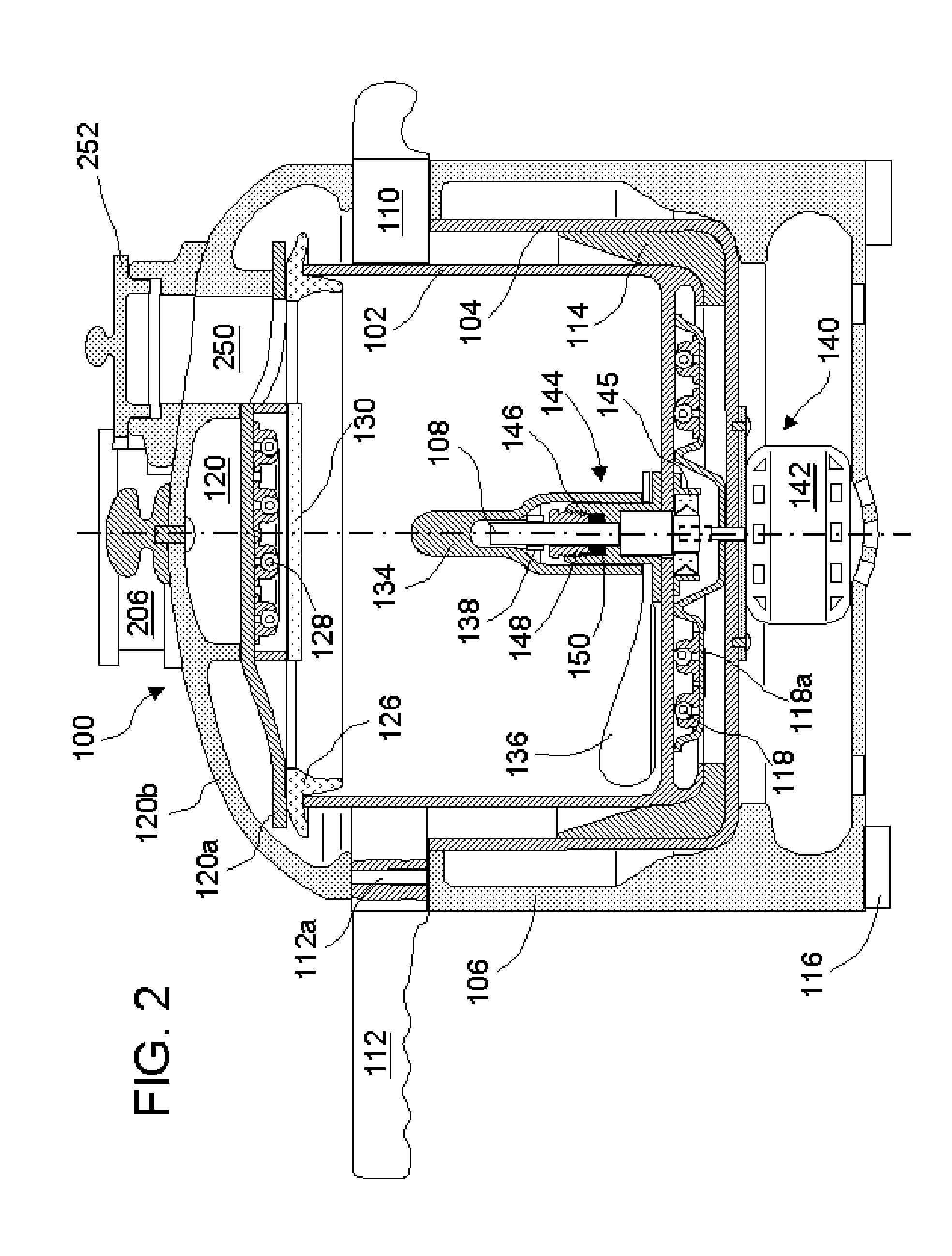

A stir-frying apparatus (100) with an overhead-heating device (128). Apparatus (100) comprises a container (102) for holding foods, a lid (120) covering on top of container (102), a bottom heating device (118) installed underneath container (102) and an overhead heating device installed on lid (120), a stirring blade (136) rotatably and removably installed inside container (102) for stirring foods, a power-drive assembly (140) operationally coupled with blade (136) for driving blade (136) through repeating stirring cycles, a coupling device (134) for coupling assembly (140) and blade (136), a venting device (200) for filtering and deodorizing cooking fumes, a blowing device (202) for forcing fresh air into apparatus (100) for the removal of moisture from therein-side, and an ingredient adding conduit (250) for use of adding ingredients during a frying process.

Owner:XU ZHAOXIA +1

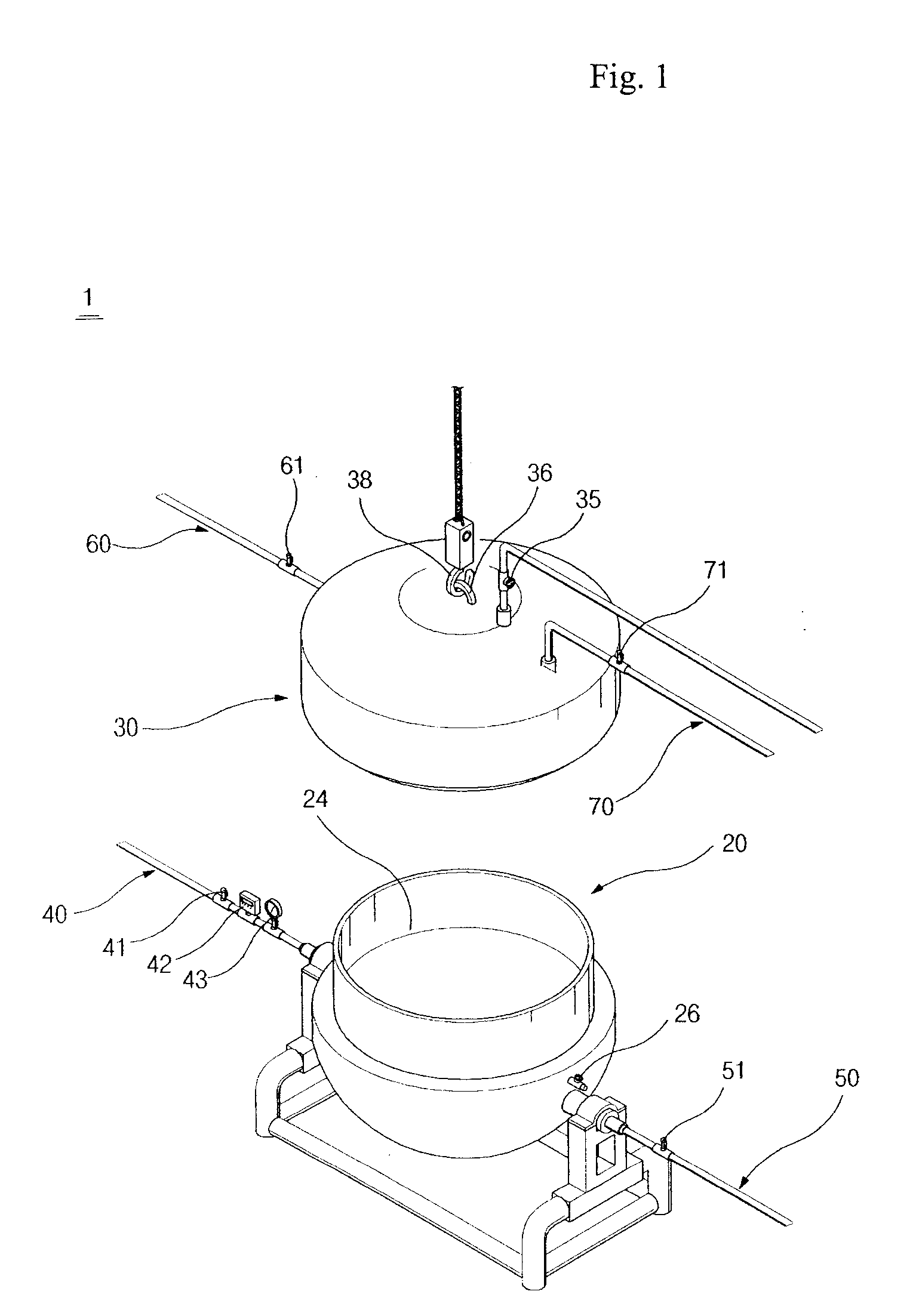

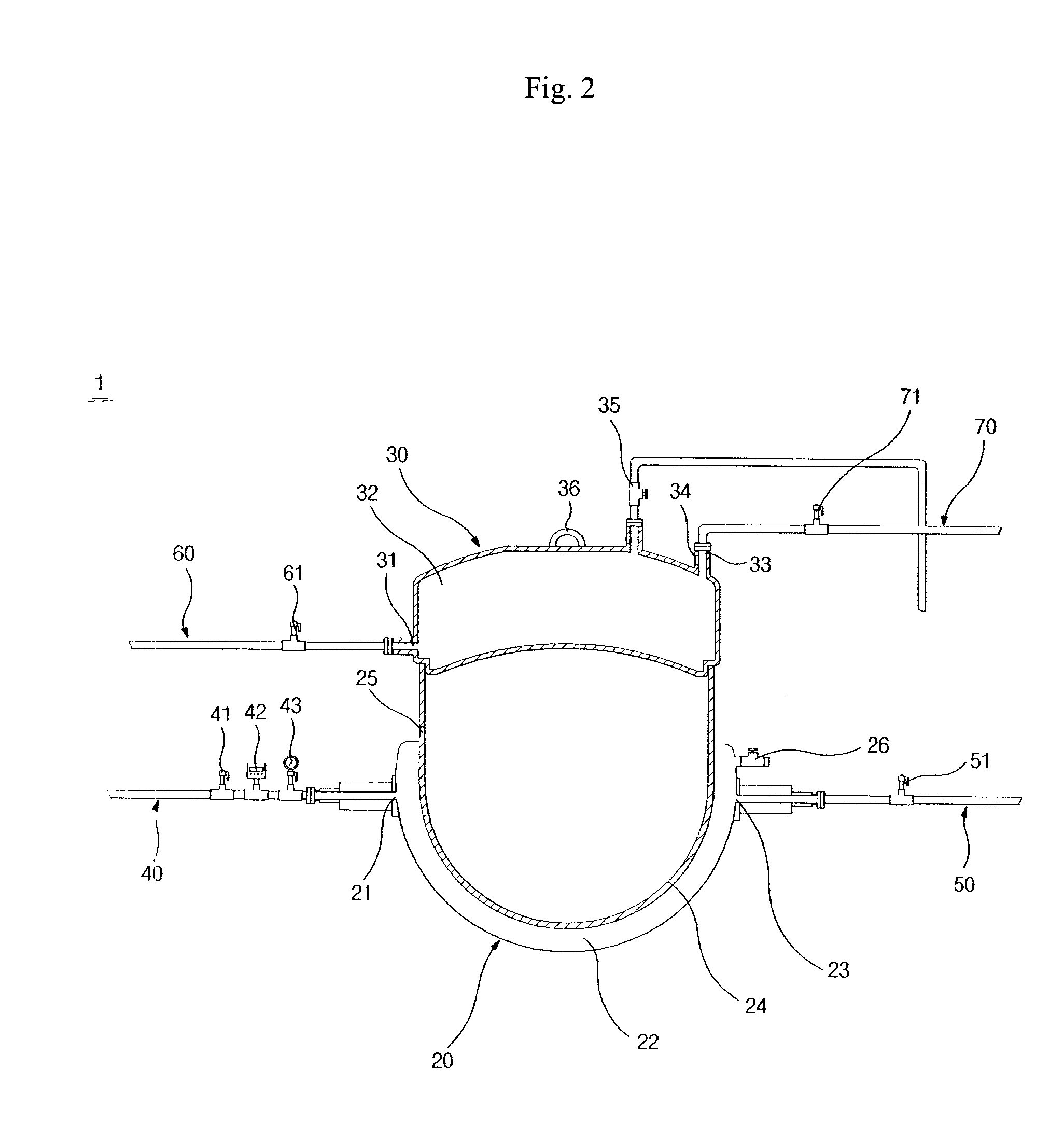

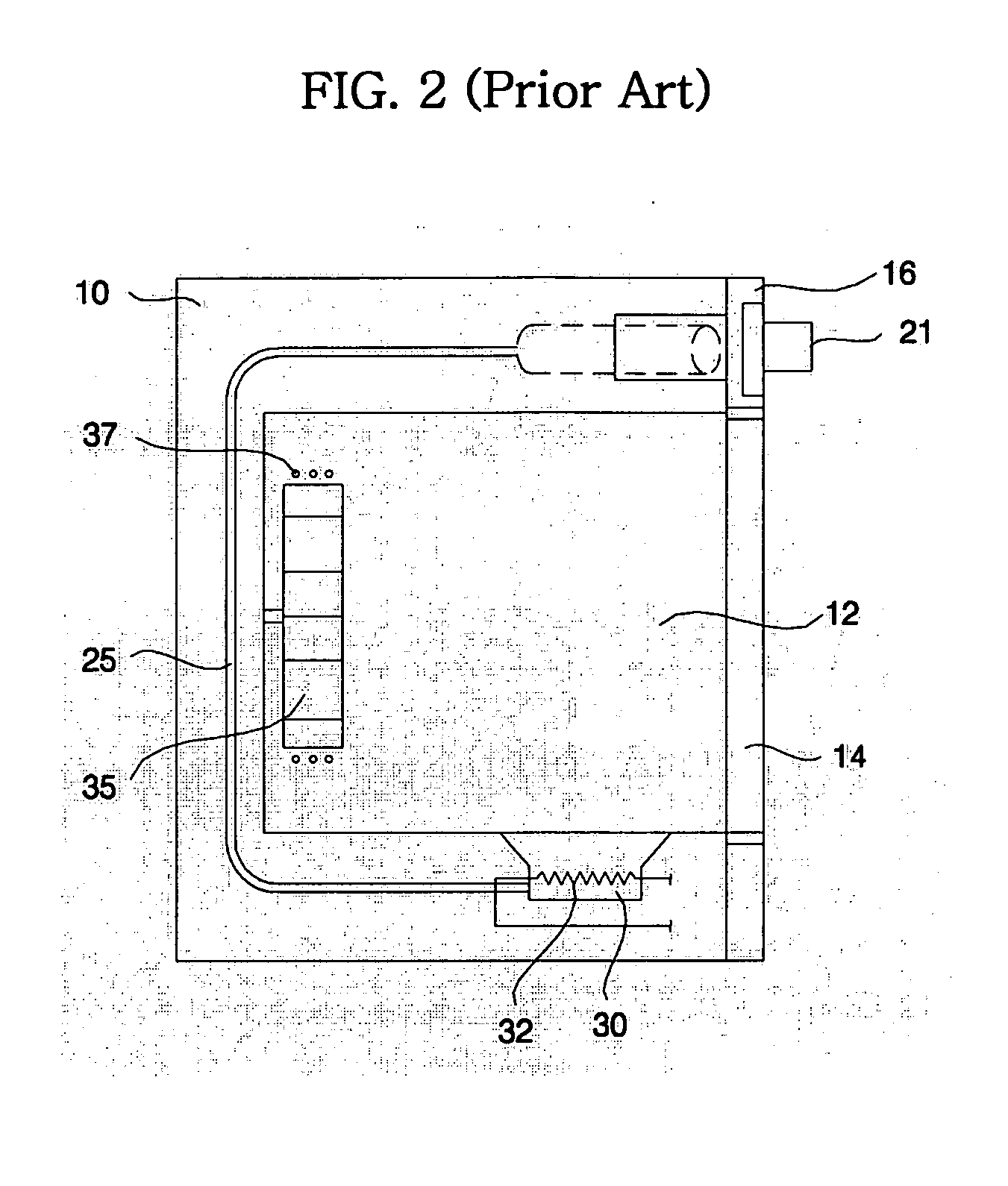

Vapor Heating Type Cooking Apparatus

InactiveUS20070209656A1Avoid stickingImprove the inconvenienceLighting and heating apparatusCooking-vessel lids/coversInterior spaceWater discharge

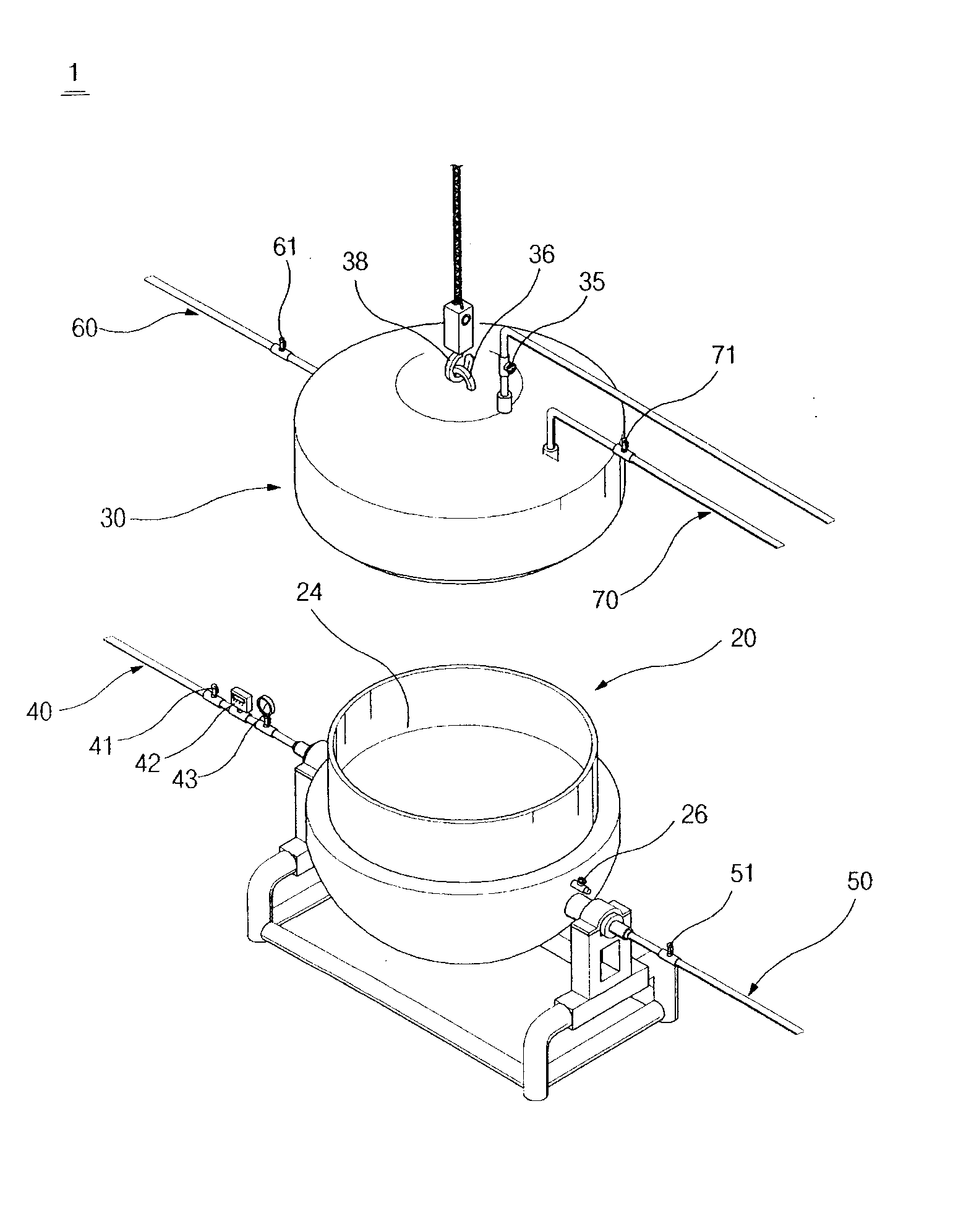

The present invention relates to a vapor heating type cooking apparatus cooking food materials using high pressure vapor as a heat source. A vapor heating type cooking apparatus includes: a vapor supply section generating the high pressure vapor; a vapor supply pipe and a vapor discharge pipe for introducing and discharging the high pressure vapor; a body section including a vapor introduction opening connected to the vapor supply pipe, an interior space having a dual structure so as to circulate the high pressure vapor in the caldron in which food materials are accommodated, a vapor discharge opening provided between the interior space and the vapor discharge pipe; a cooling water supply pipe and a hot water discharge pipe; a lid section including a cooling water introduction opening connected to the cooling water supply pipe, a storage space having a dual structure, in which the cooling water is temporarily stored, and a hot water discharge opening provided between the storage space and the hot water discharge pipe; and a control section for controlling introduction and discharge of the high pressure vapor, the cooling water, and the hot water.

Owner:LEE WON KI

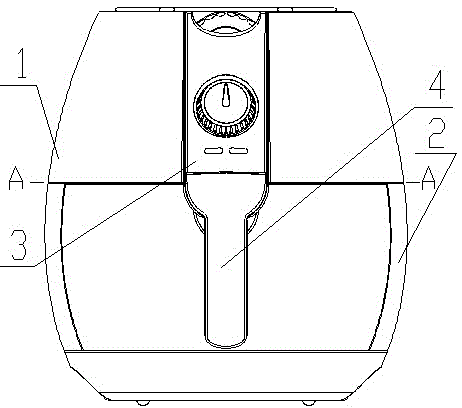

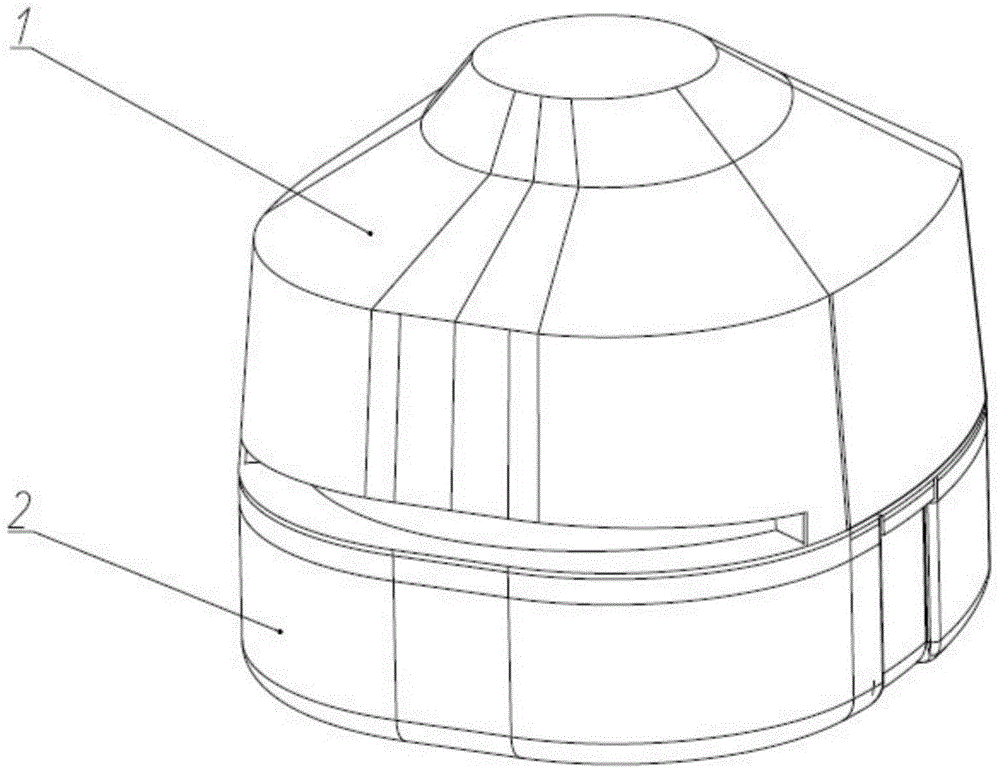

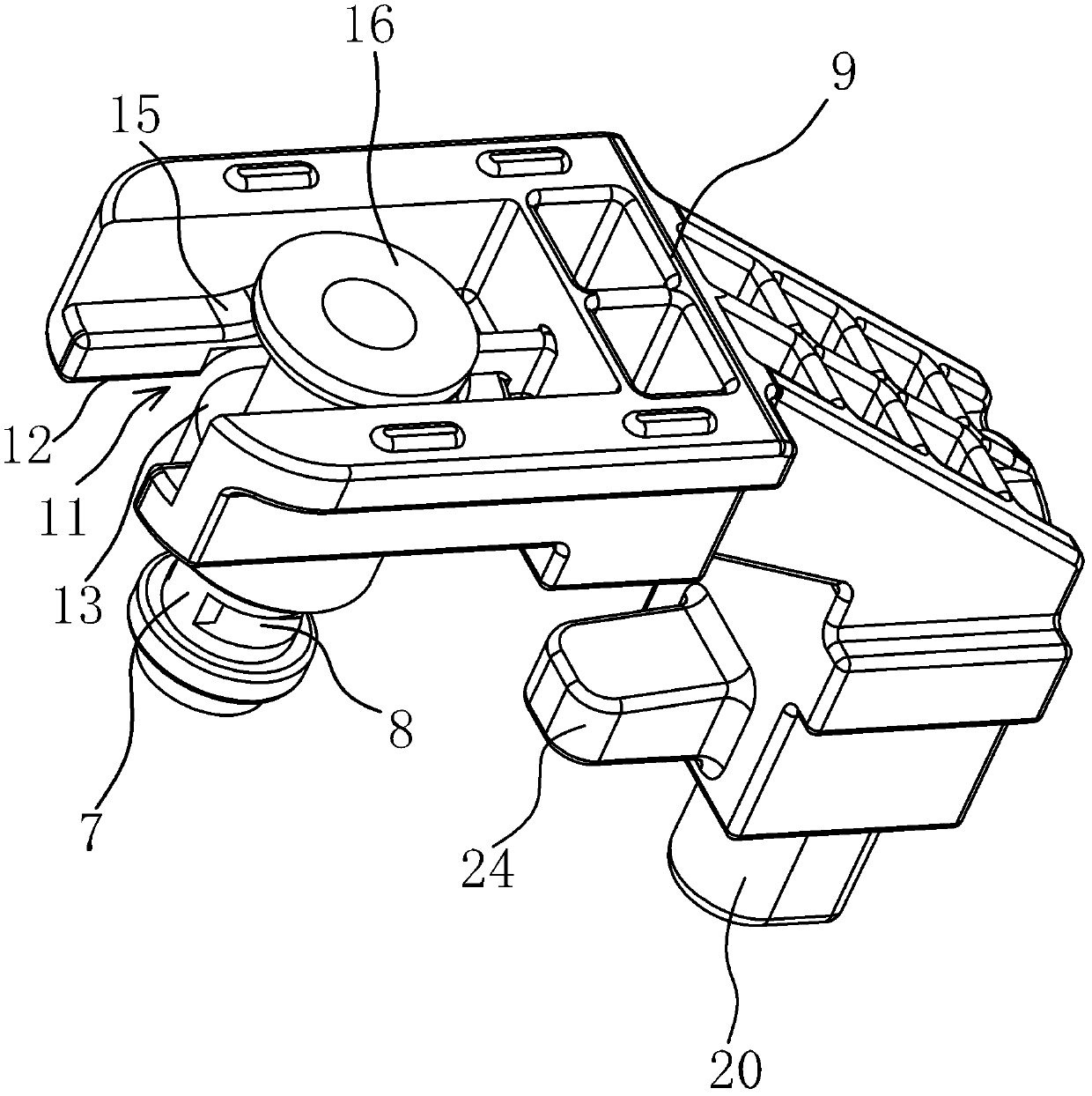

Smokeless air fryer

The invention relates to a smokeless air fryer which finishes the cooking of foods and does not exhaust smoke by utilizing the high-speed hot air circulation technology. The smokeless air fryer comprises an air fryer fixed body and an air fryer movable body, wherein a top-driven power supply switch is arranged on one side of the lower end surface of a boss part at the front part of the air fryer fixed body, and a timer is arranged at the boss part; a top-driven boss is arranged on one side of the upper end surface of a handle of the air fryer movable body, and the handle is in locking and opening matching with an object containing mesh basket; the top-driven boss is in top-driven opening and closing matching with the top-driven power supply switch on one side of the lower end surface of the boss part of the air fryer fixed body; a planer screw type electric heating tube is arranged below hot air blades of the air fryer fixed body, a power supply joint of the planer screw type electric heating tube is connected with the inner wall of the air fryer fixed body through a connection assembly, and a tube body of the planer screw type electric heating tube is elastically connected with the inner wall of the air fryer fixed body through a tension spring; and the center of the bottom of an oil collecting backflow pot of the air fryer movable body is in an arc bulge shape, and the wall circumference and the bottom of the oil collecting backflow pot are in an arc shape.

Owner:NINGBO CARELINE ELECTRIC APPLIANCE CO LTD

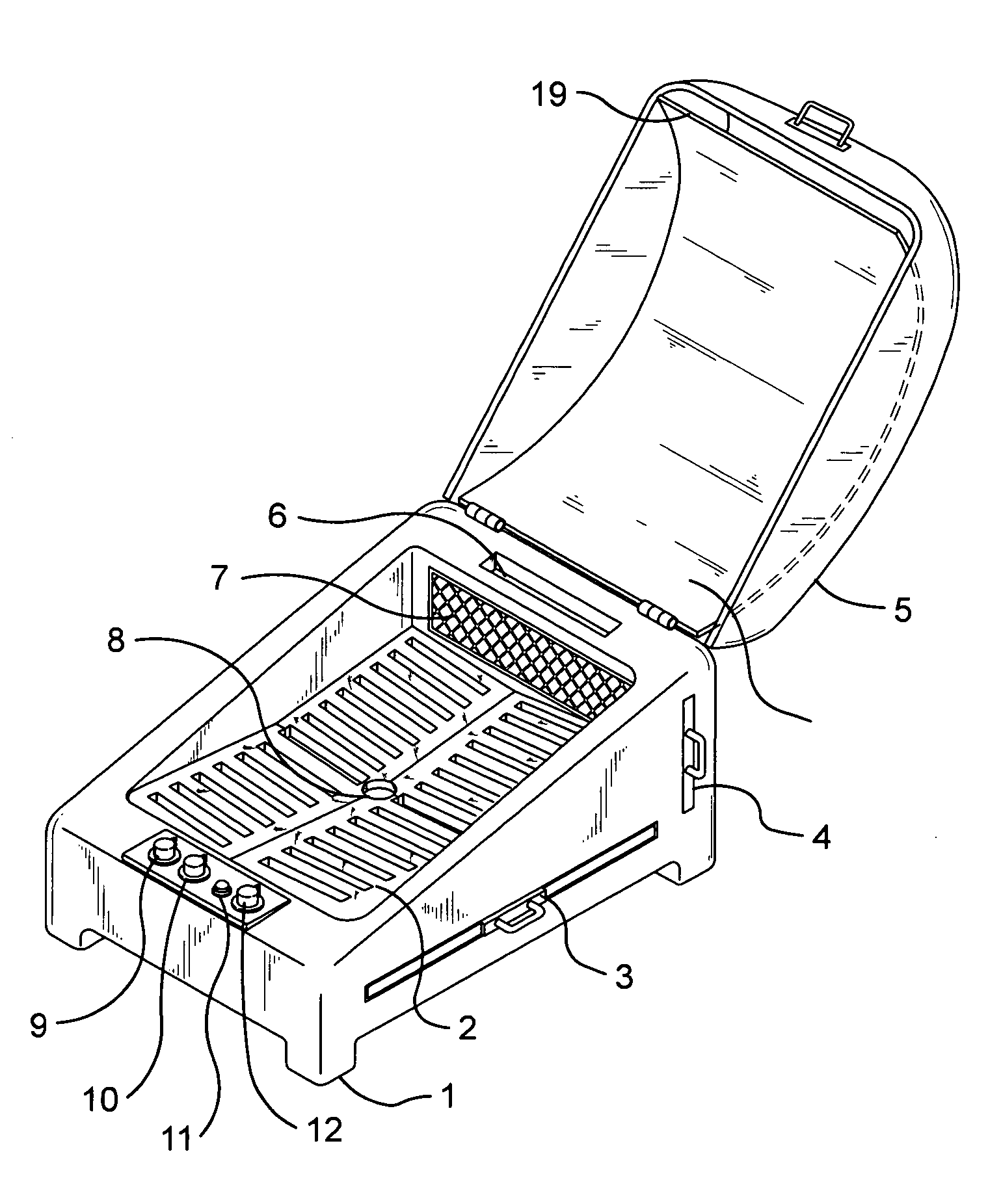

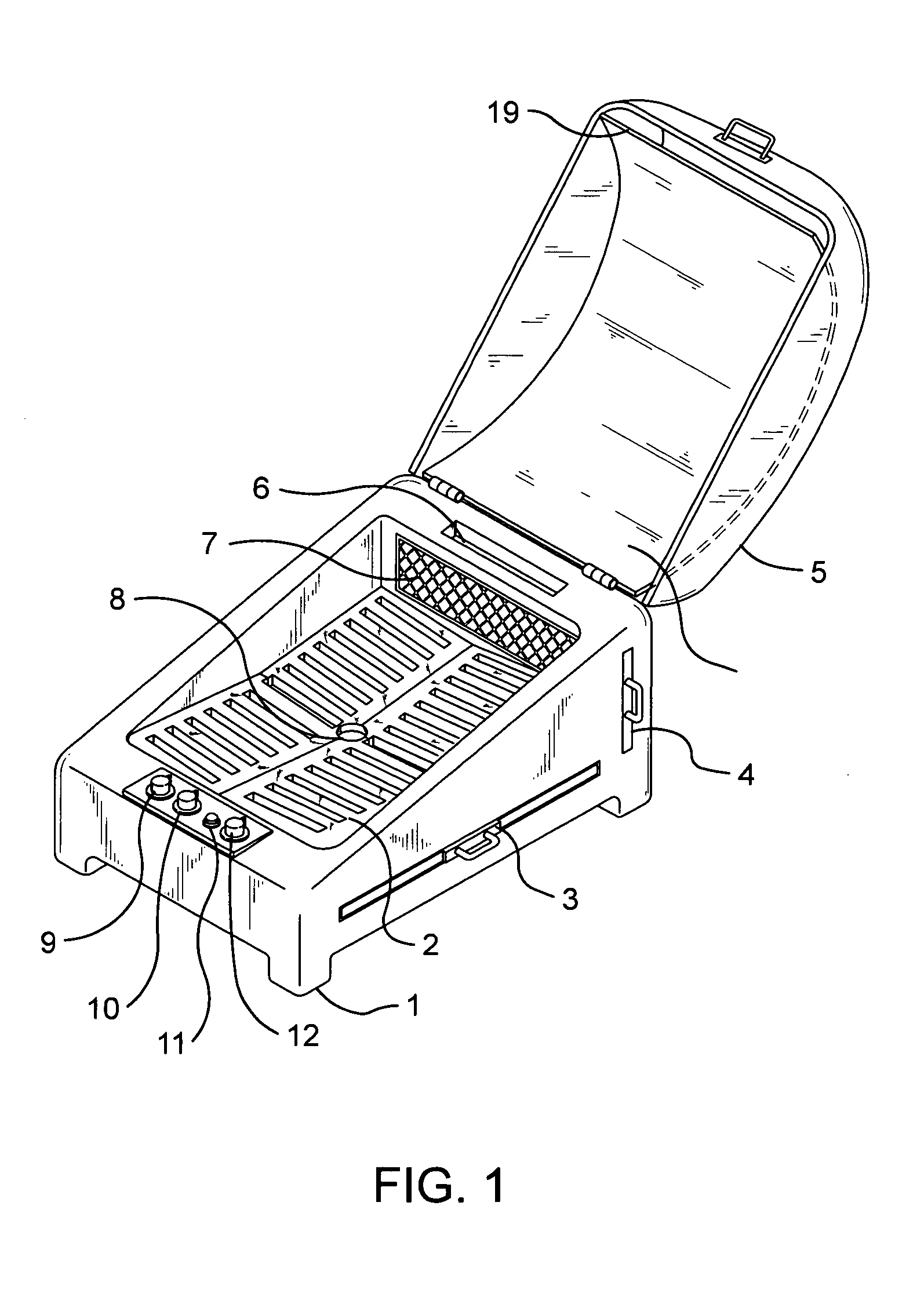

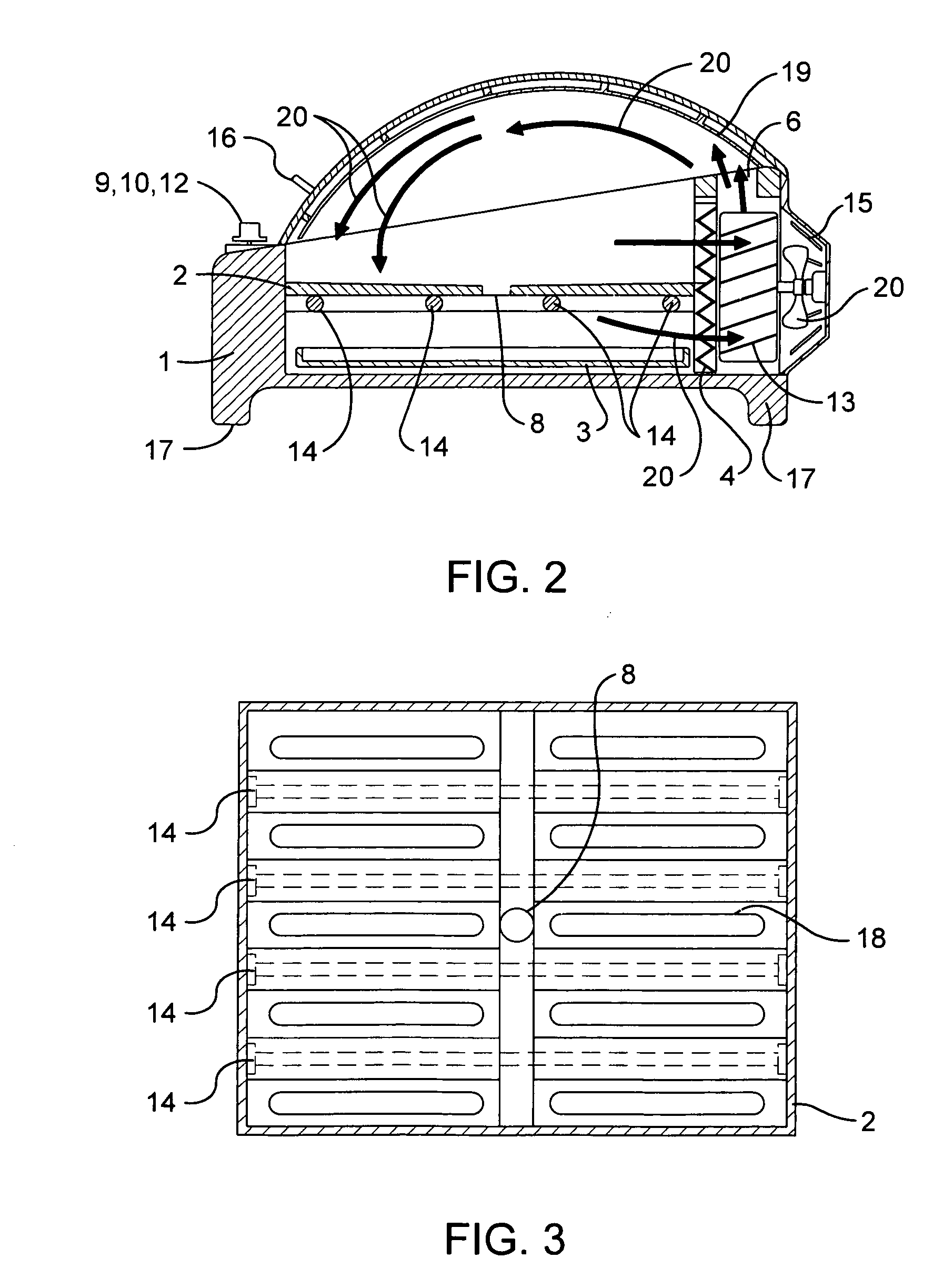

Convection grill

A portable electric grill for that has utilizes an electric fan to draw smoke and cooking odors through a filter then redirects and circulates the cleaner hot air around food to create convection heating thereby improve and making faster the cooking process. The grill can be used for indoor or outdoor use. It has a removable lid that when in the down position it provides the circulation of the hot air throughout the grill. It has a removable grill plate that either sits on top of heating elements or has heating elements imbedded in the grill plate. The grill plate is used for searing various foods and then allowing the convection air to cook the foods throughout. It has controls for regulating temperature, cooking time and fan speed. It has a pull-out grease tray to catch and dispose of drippings from cooking food. The filter is removable for cleaning.

Owner:JONES EDWARD MICHAEL

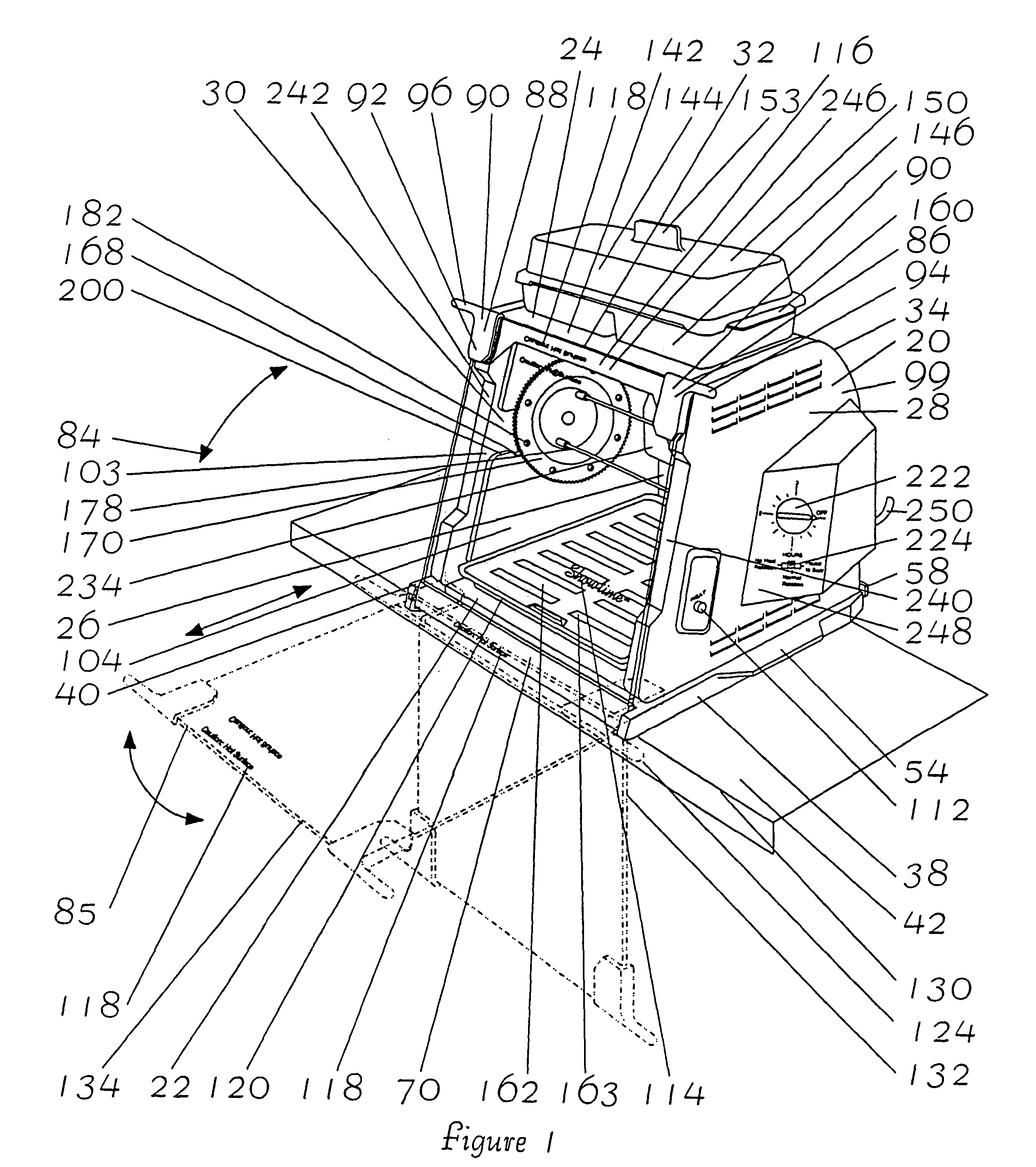

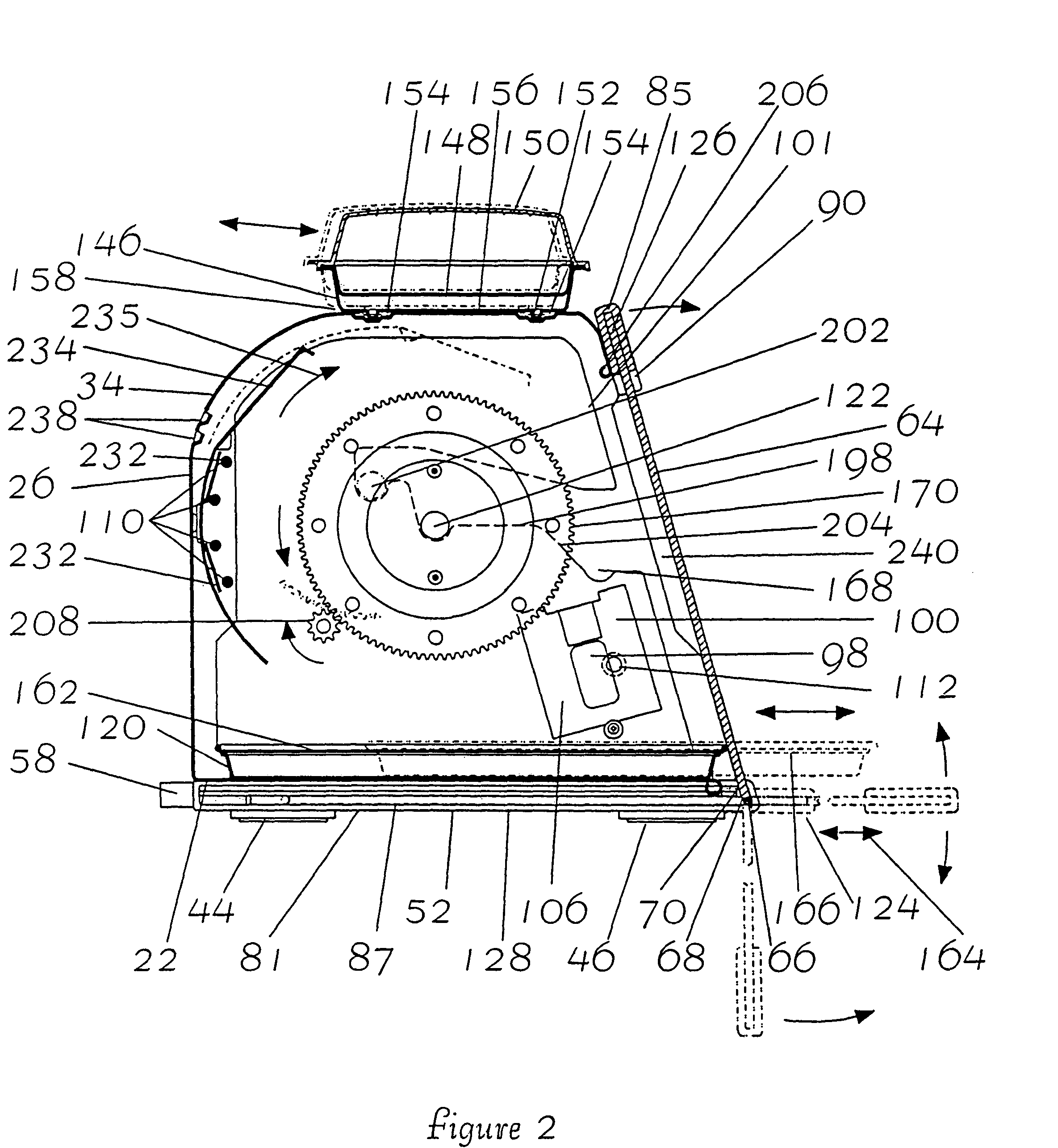

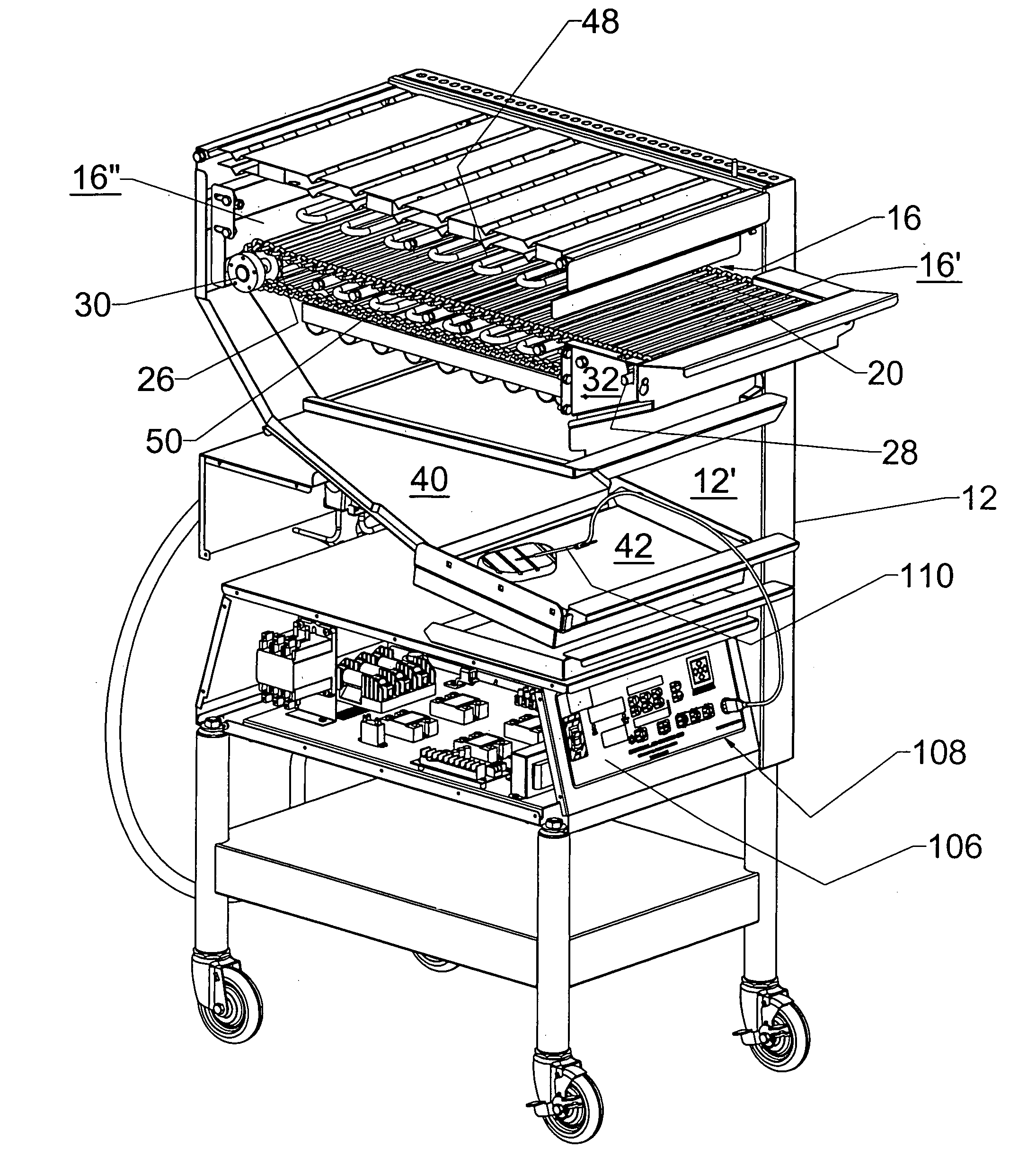

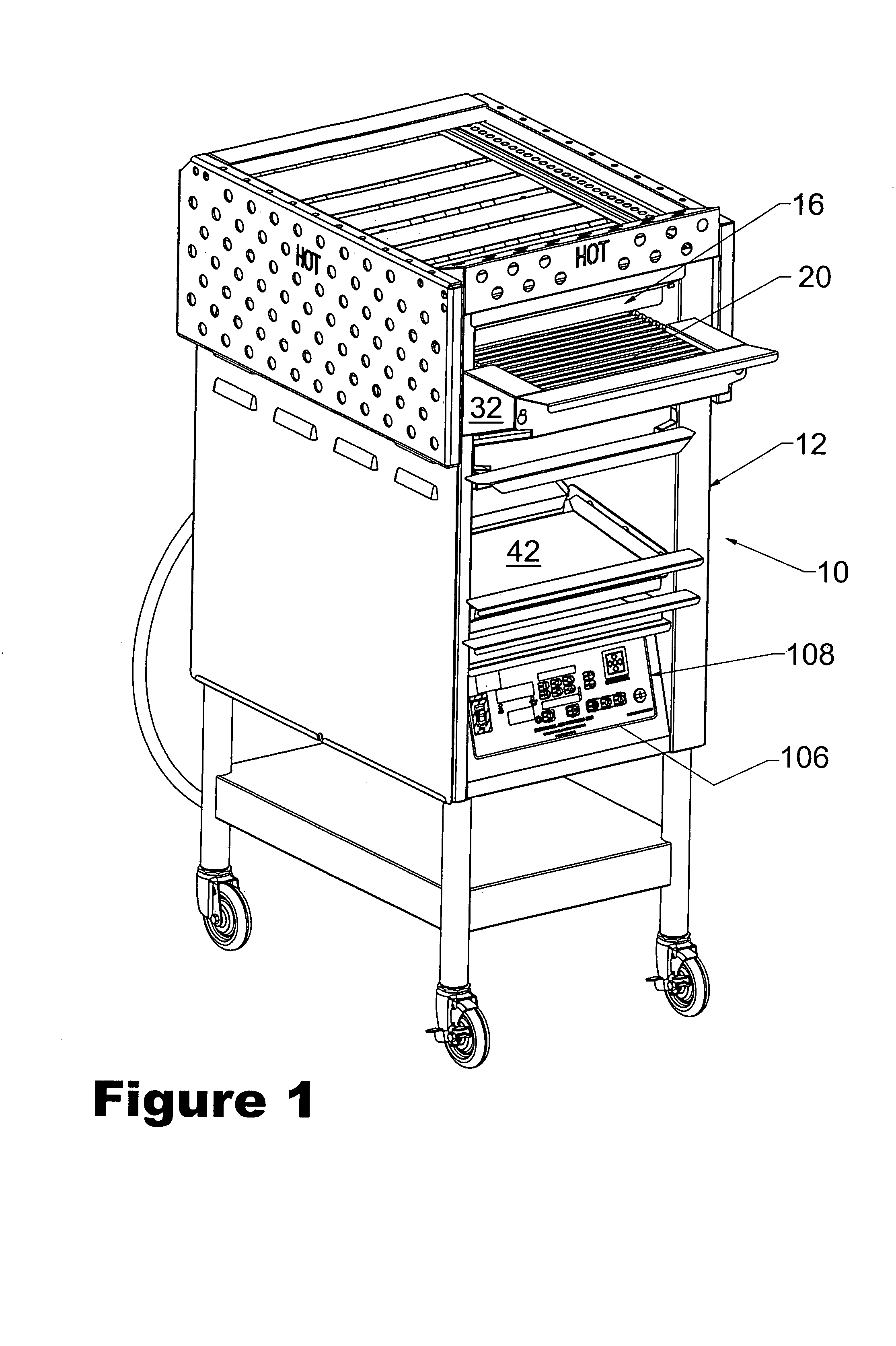

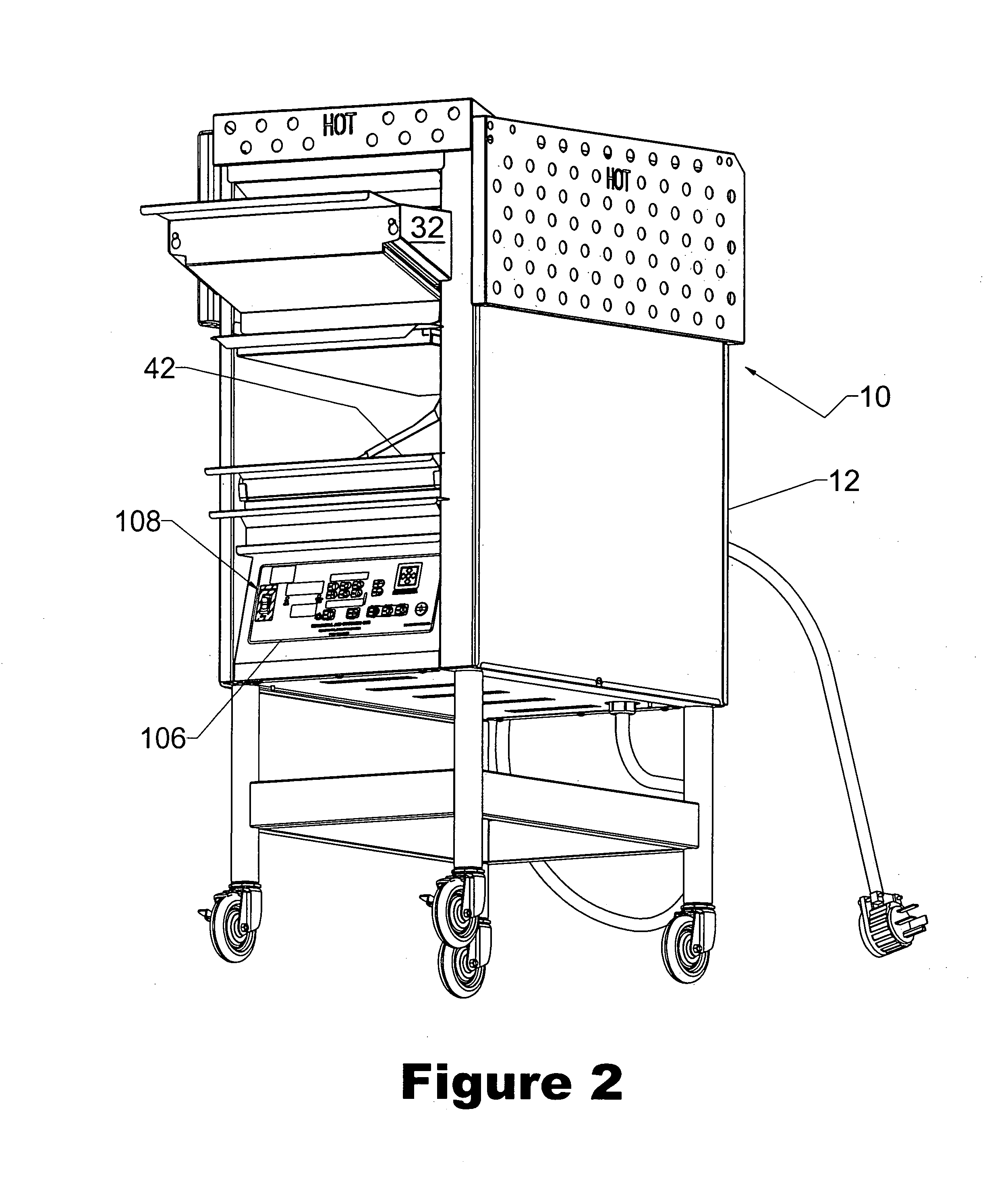

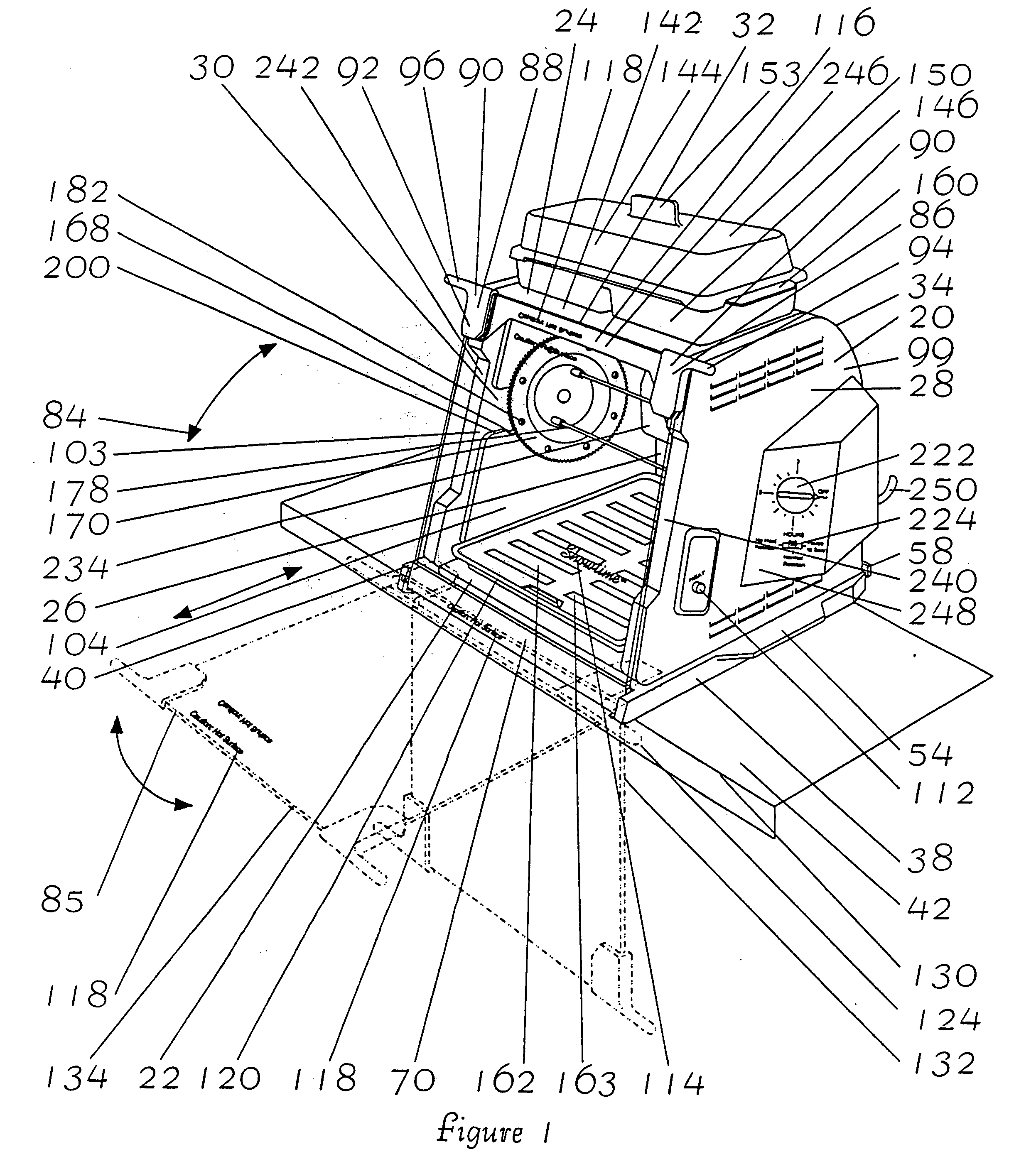

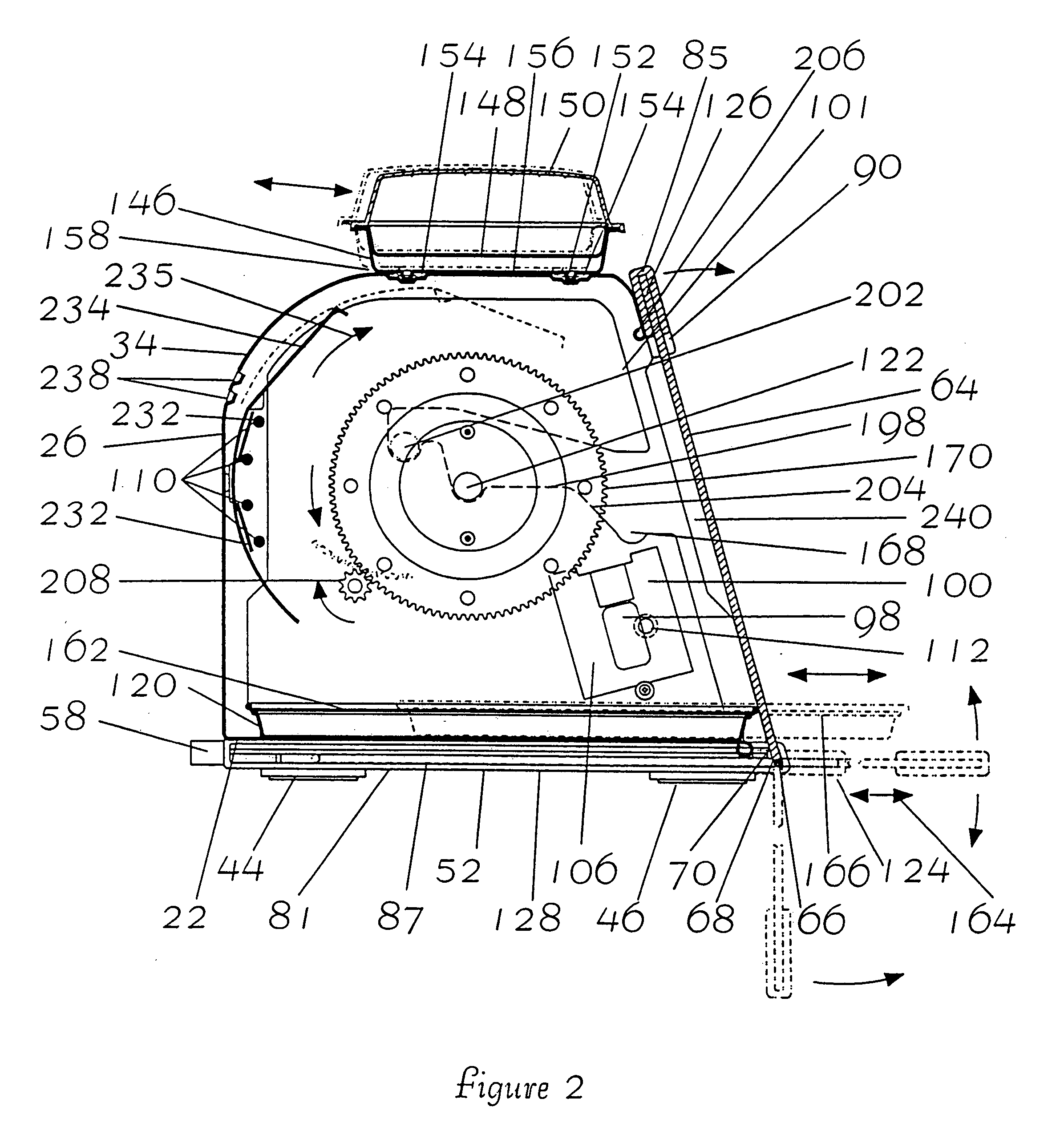

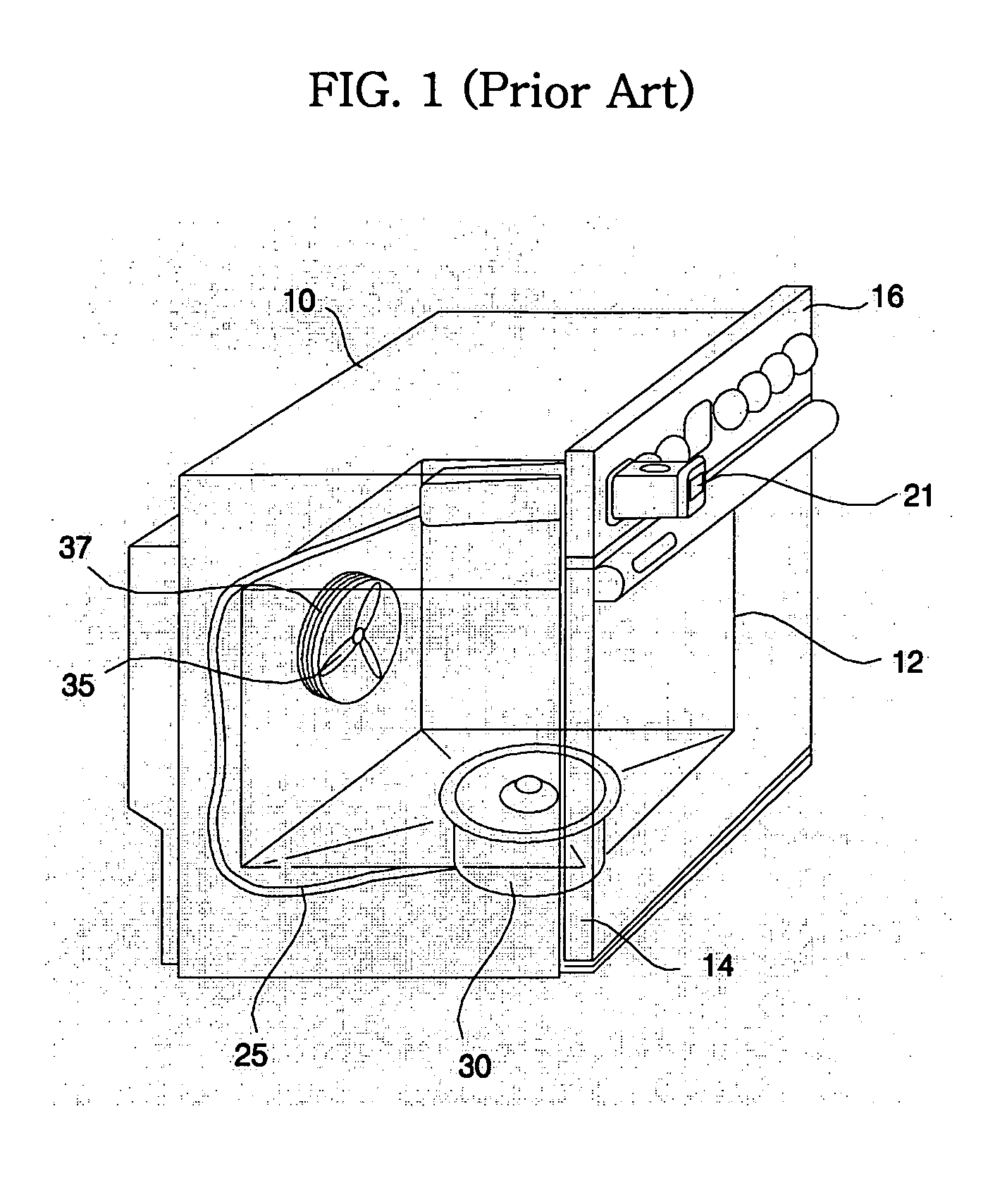

Enclosed rotisserie with detachable electronic components

InactiveUS7021204B2Easy to insertEasy to removeRoasting apparatusRoasters/grillsEngineeringElectronic component

The present invention is directed toward an improved rotisserie oven, having the following features: a removable side mounted control box; single wall oven cabinet construction; single wall oven cabinet construction with tabs protruding from the lower side edges of the oven cabinet which mount feet to support the cabinet; a rigid heat coil structurally connected to the removable control box; a heat coil, supported by a bracket within the oven cabinet which both allows the heat coil to be slid in and out of the oven cabinet and allows for expansion of the heat coil when the coil is energized; a light bulb integrated with the removable control box so that the bulb's globe protrudes into the interior of the oven cabinet when the control box is mounted on the oven cabinet; a drive mechanism integrated into the removable control box which allows the control box to be easily removed from the oven cabinet; a drip pan located below the spit, which has its liquid catching reservoir recessed in from the pan's perimeter; a drip pan cover with an array of small holes recessed into its surface; a spit assembly, whose axis of rotation is located closer to a glass view port located on the oven cabinet's exterior than to the heater located within the oven cabinet; and a spit assembly, whose axis of rotation is located closer to the oven cabinet's loading door than to the top, bottom, back and heat coil within the oven cabinet, using the rotisserie in combination with specific foods and eating schedule, to help people lose weight.

Owner:RONCO HLDG

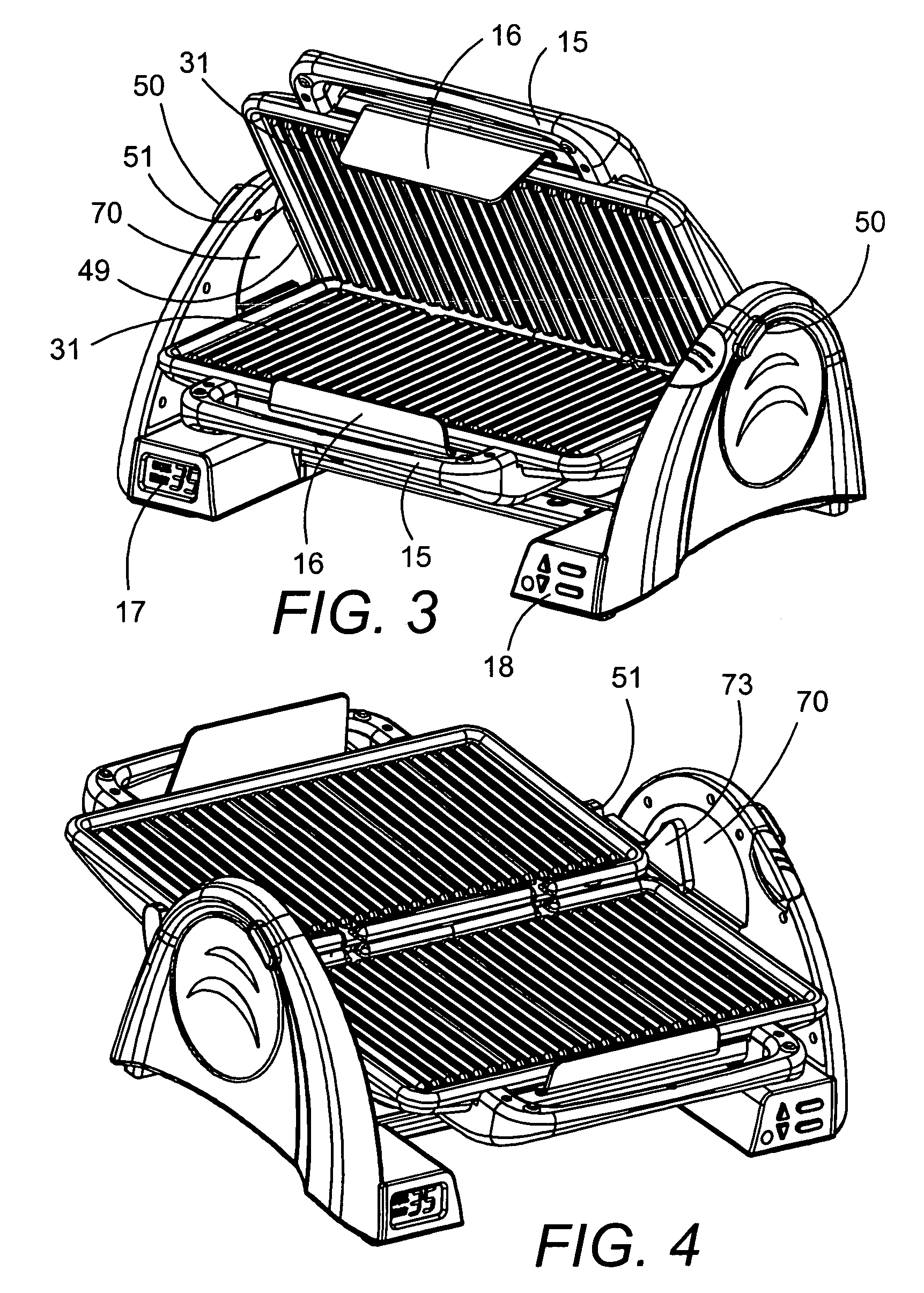

Griddle

ActiveUS20080105136A1Reduce cooking timeAir-treating devicesMilk preservationProcess engineeringInternal heating

A high-speed griddle for cooking food products has a griddle platen having a cook surface for receiving food products thereon, and heating means are provided for heating the platen. A clamshell cover is configured for sealing contact with the cook surface of the platen, the cook surface and cover cooperating to enclose a cook volume. An electromagnetic energy source is configured for emitting energy into the cook volume, the energy source emitting energy of a frequency selected to cause internal heating of food products within the cook volume. In addition, a convection air system is configured to provide a flow of heated air into the cook volume. The heated platen, electromagnetic energy source, and convection air system cooperate to rapidly cook food products within the cook volume.

Owner:TURBOCHEF TECH INC

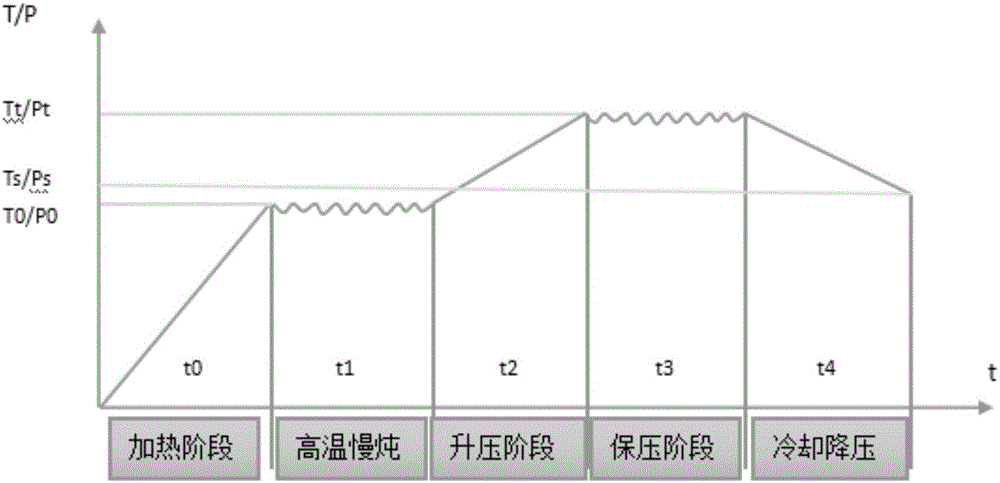

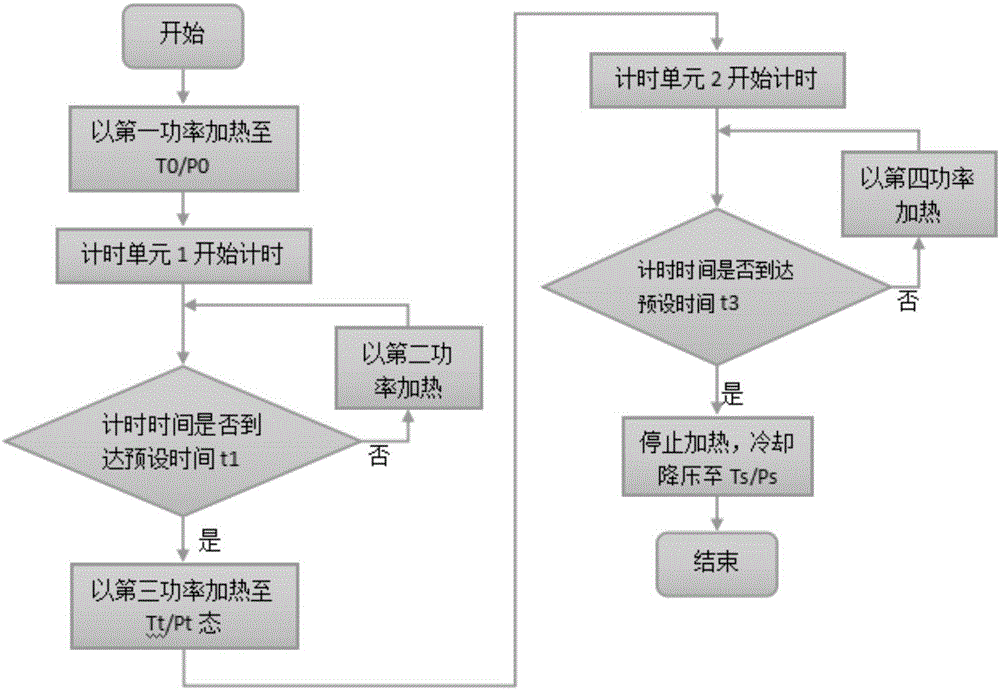

Pressure cooker and soup cooking method thereof

The present invention provides a soup cooking method for a pressure cooker. The soup cooking method at least includes the following steps. In the heating stage, the control element controls the heating element to heat the inner pot with the first power to the first state, and the cooking cavity reaches the first set temperature T0; In the stage of high temperature and slow stewing, the control element controls the heating element to heat the inner pot with the second power, so that the temperature of the cooking cavity is maintained within the range of T0±2°C; in the step-up stage, the control element controls the heating element to heat the inner pot with the third power, When the float floats up, the cooking cavity reaches the first set pressure Pt; in the pressure maintaining stage, the control element controls the heating element to heat the inner pot with the fourth power, so that the pressure of the cooking cavity is maintained within the range of Pt±20Kpa. The pressure cooker soup cooking method provided by the invention can improve cooking quality. The invention also provides a pressure cooker using the soup cooking method.

Owner:JOYOUNG CO LTD

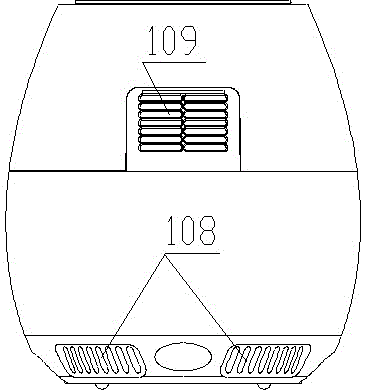

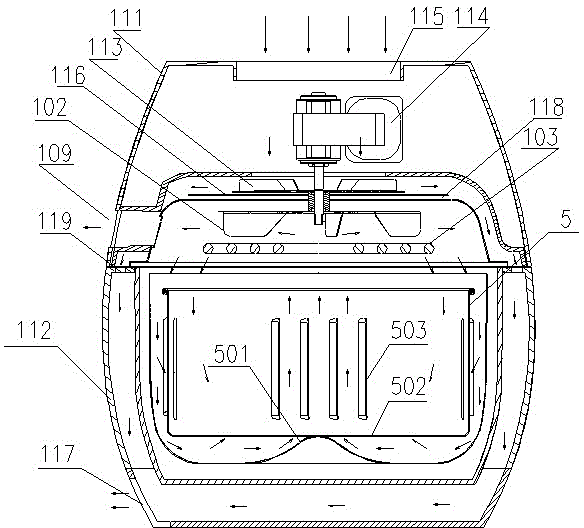

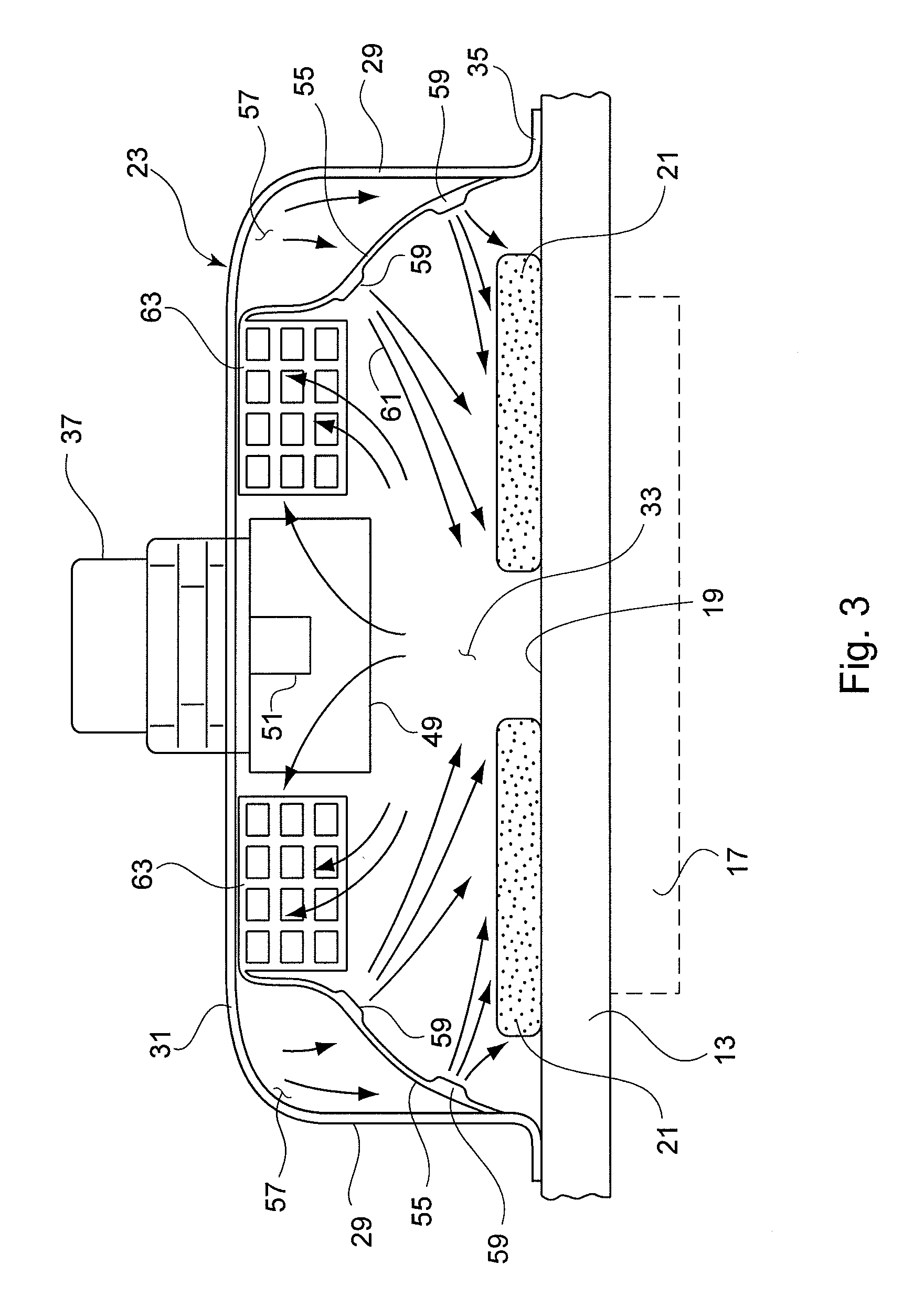

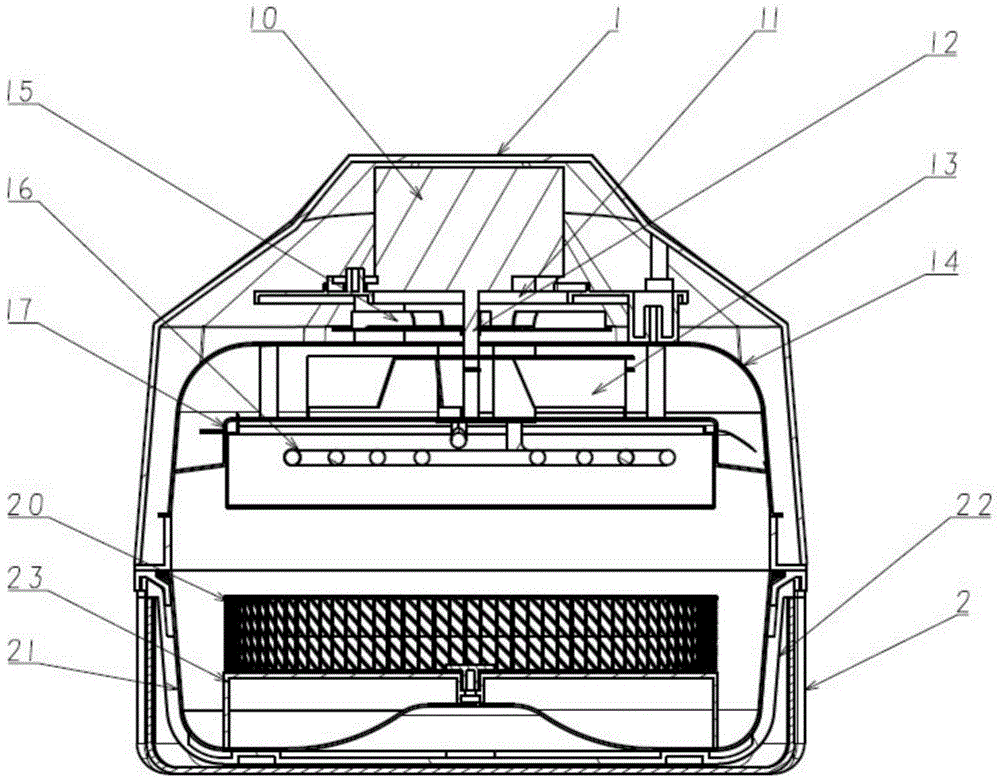

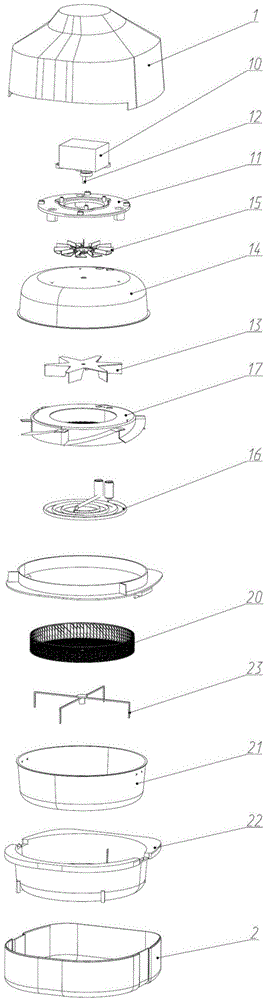

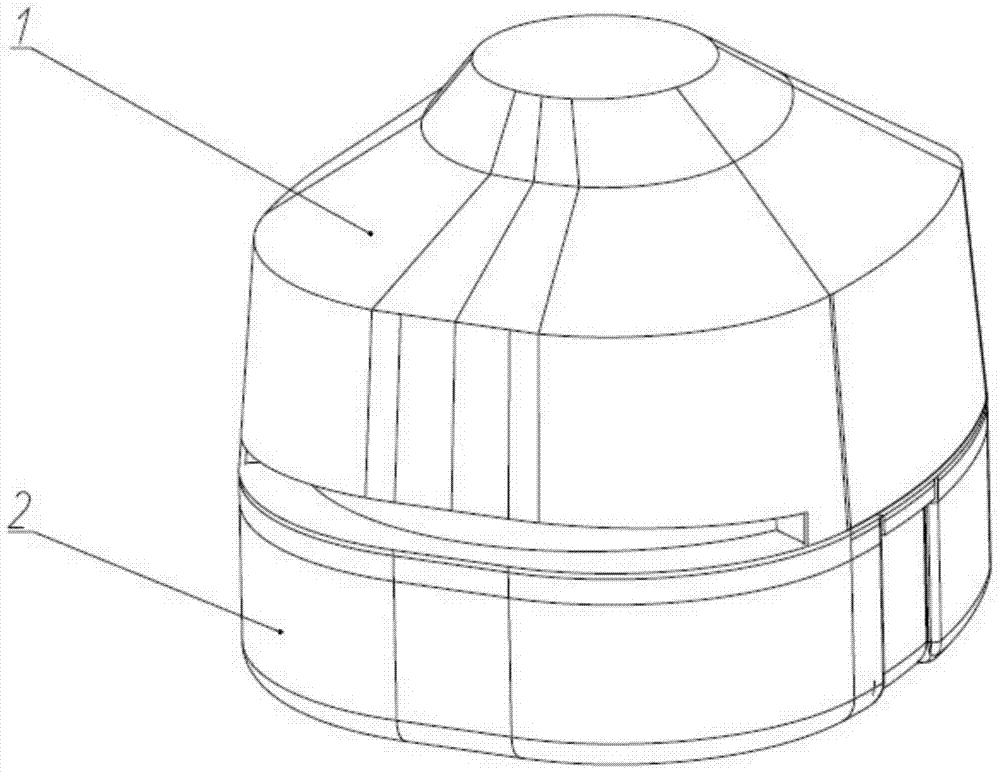

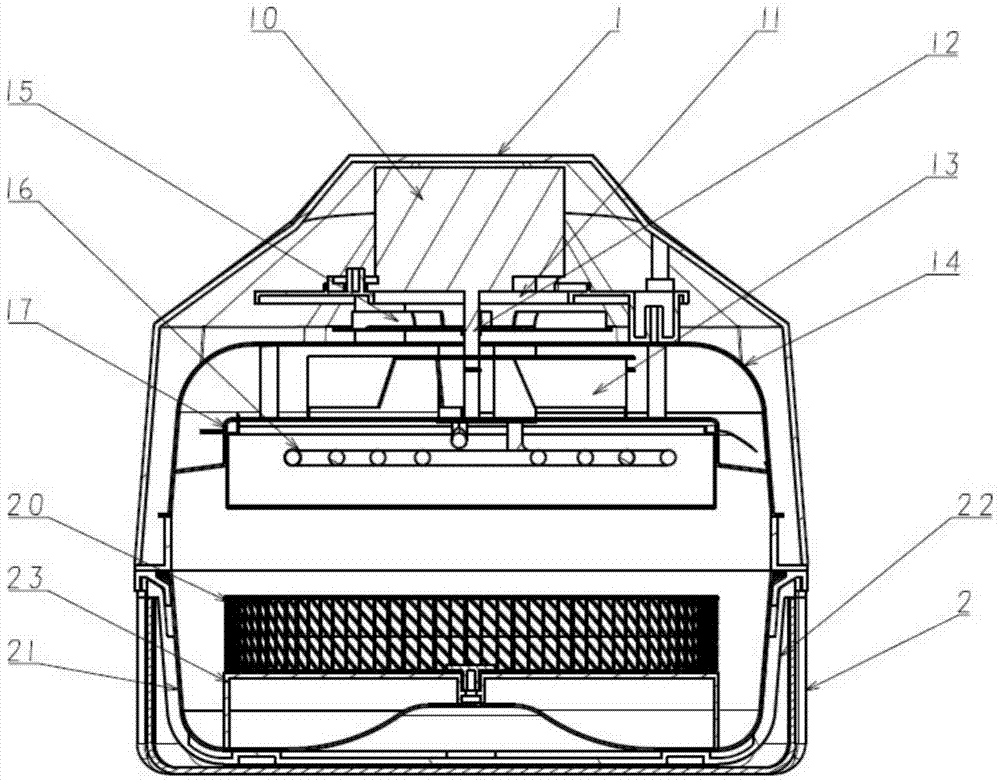

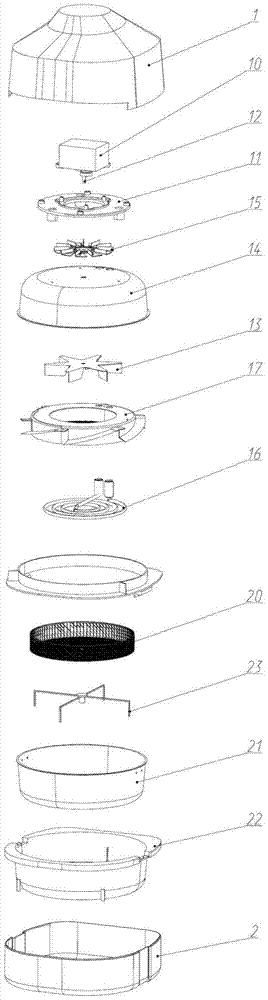

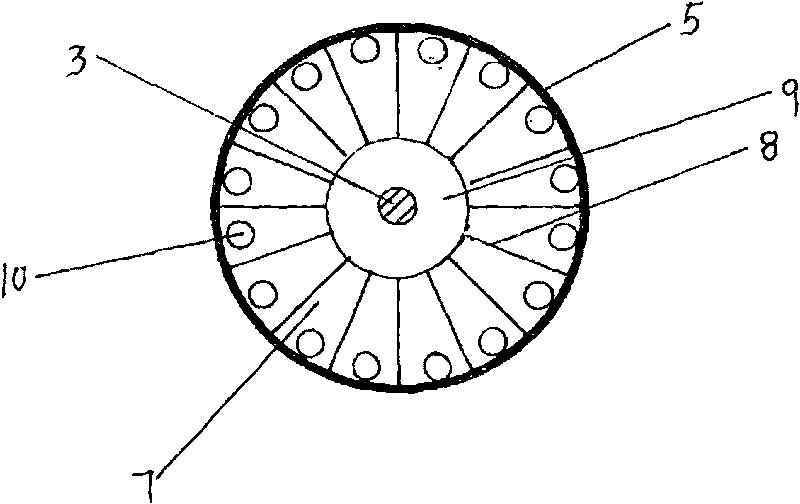

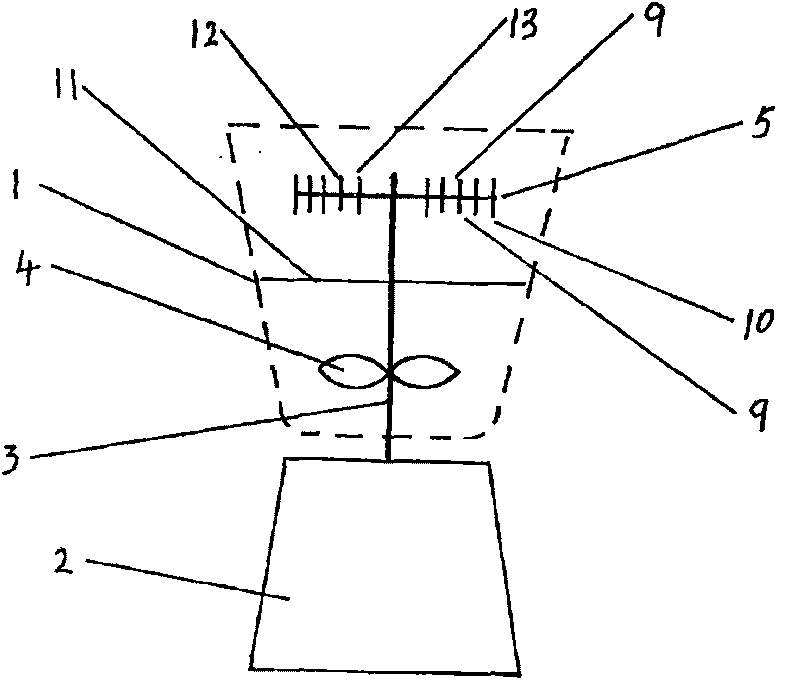

Air fryer capable of forming thermal cycle heating through cyclone

The invention discloses an air fryer capable of forming thermal cycle heating through cyclone. The air fryer comprises a windshield cover, a motor assembly, an extractor fan and a rotating air duct unit, wherein the lower part of the windshield cover is opened, and a small hole is formed in the center of the upper part of the windshield cover; the motor assembly is arranged at the upper part of the windshield cover and comprises a motor transmission shaft, and the motor transmission shaft penetrates through the small hole in the center of the upper part of the windshield cover; the extractor fan is arranged in the windshield cover and is connected with the motor transmission shaft; the rotating air duct unit is arranged in the windshield cover, is positioned under the extractor fan and is fixedly connected with the windshield cover through a connecting post, a ventilating opening is formed in the upper part of the rotating air duct unit, and the lower part of the rotating air duct unit is opened; the rotating air duct unit can enable air flowing downwards under the combined action of the extractor fan and the windshield cover to flow downwards rotationally along a certain angle to form the cyclone. According to the air fryer disclosed by the invention, the thermal cycle heating is formed through the cyclone, and thus food can be more uniformly baked by hot air.

Owner:KINGCLEAN ELECTRIC GREEN TECH SUZHOU

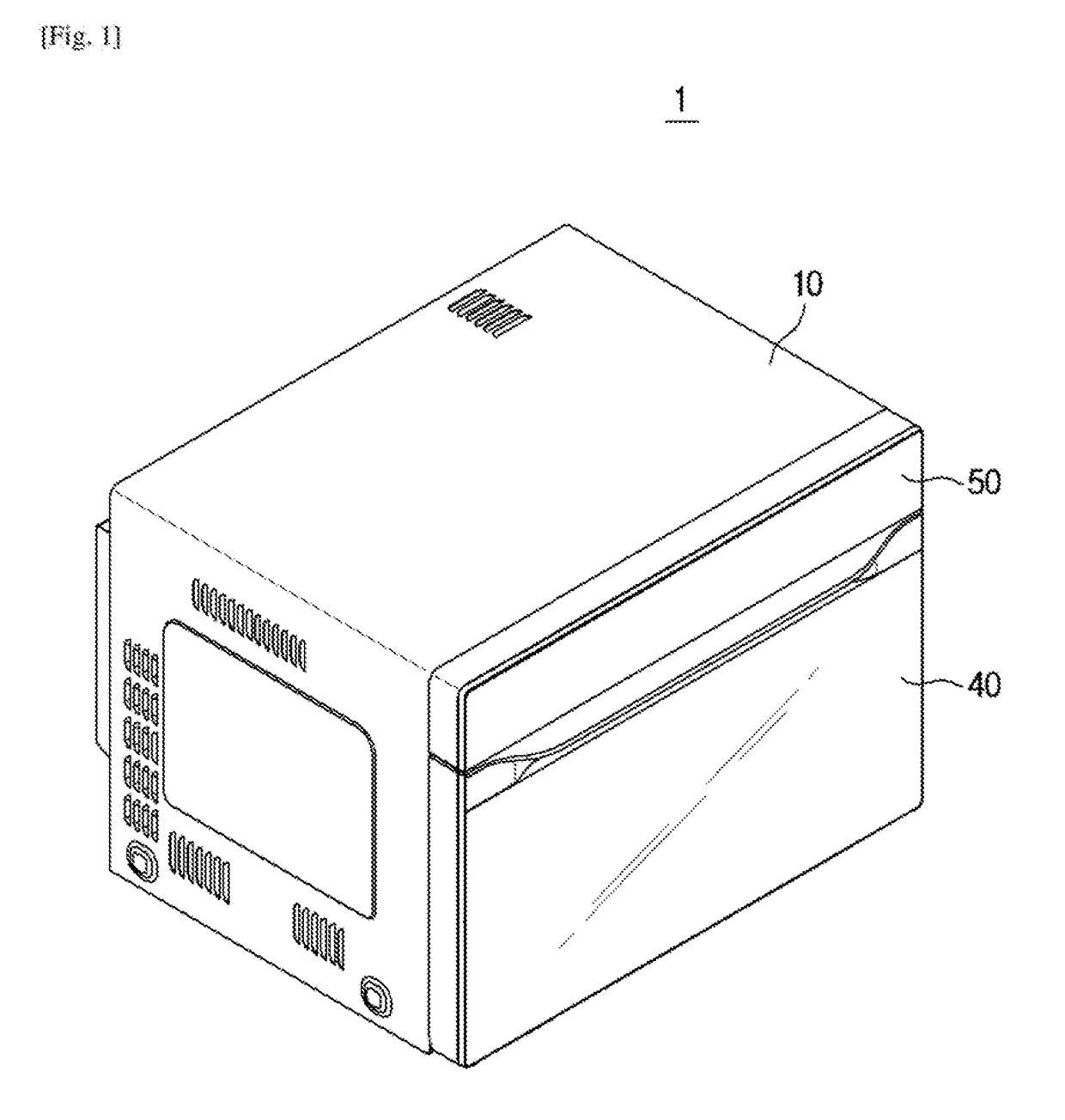

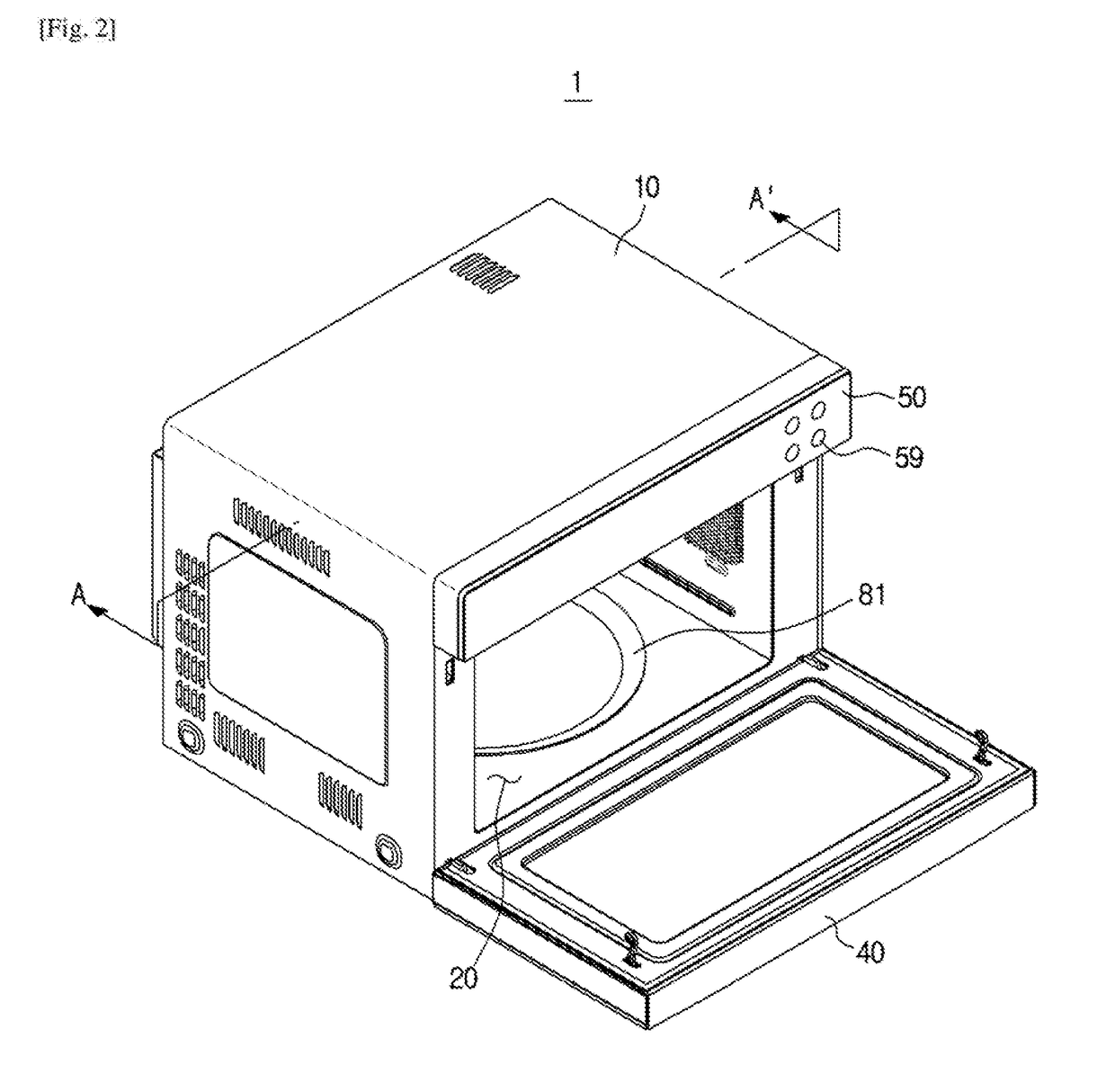

Cooking apparatus

ActiveUS20180220498A1Reduce cooking timeCook evenlyDomestic stoves or rangesStoves/ranges shelves or racksIngested foodWaste management

In accordance with an embodiment of the present disclosure, a cooking apparatus includes a casing, a cooking chamber provided inside the casing and including a discharge plate at which a plurality of outlet holes are formed, a tray provided at a bottom surface of the cooking chamber to support food, and a hot air discharging unit configured to discharge high-temperature air into the cooking chamber through the outlet holes, wherein the plurality of outlet holes are formed at a first area facing the tray.

Owner:SAMSUNG ELECTRONICS CO LTD

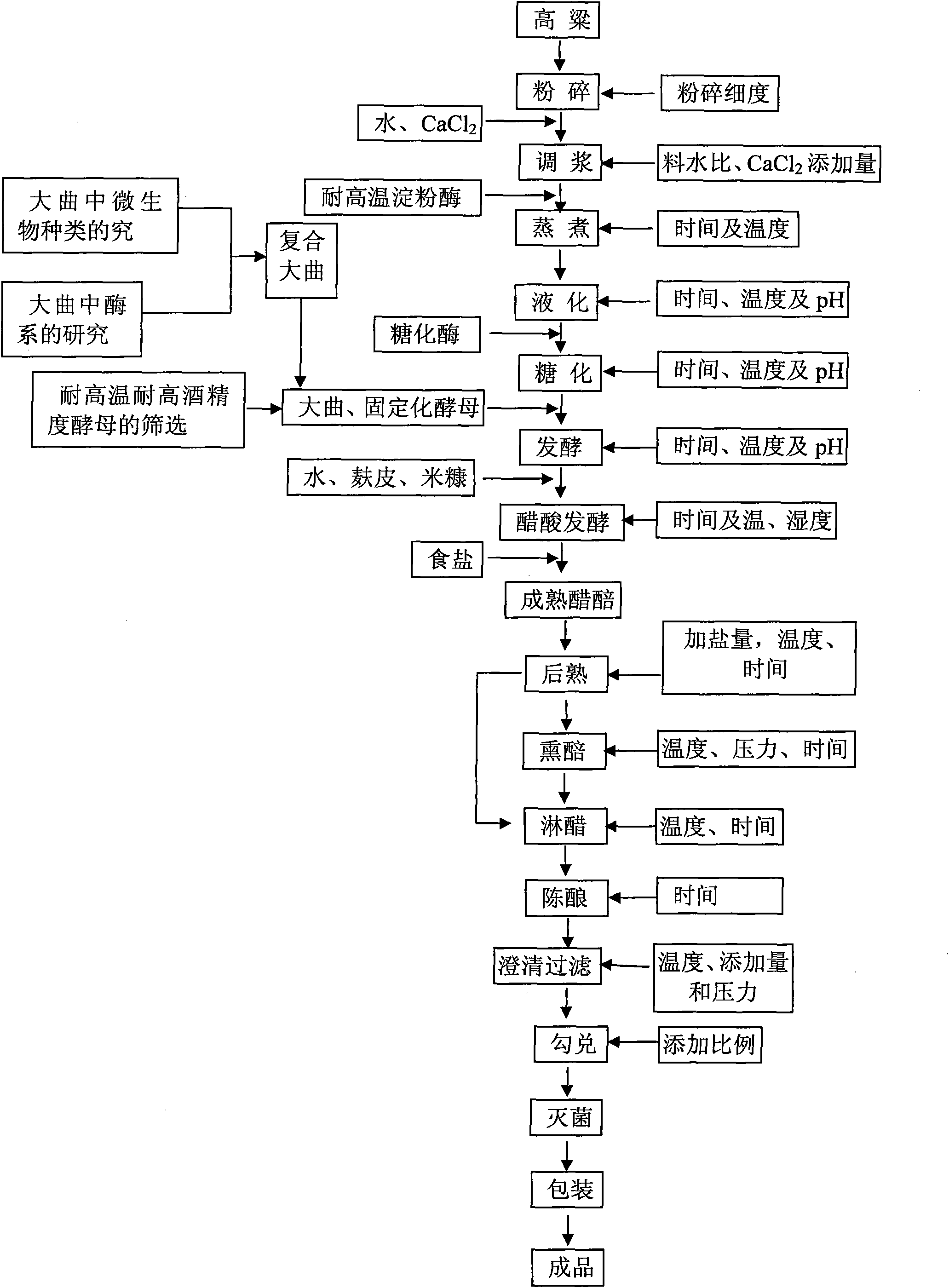

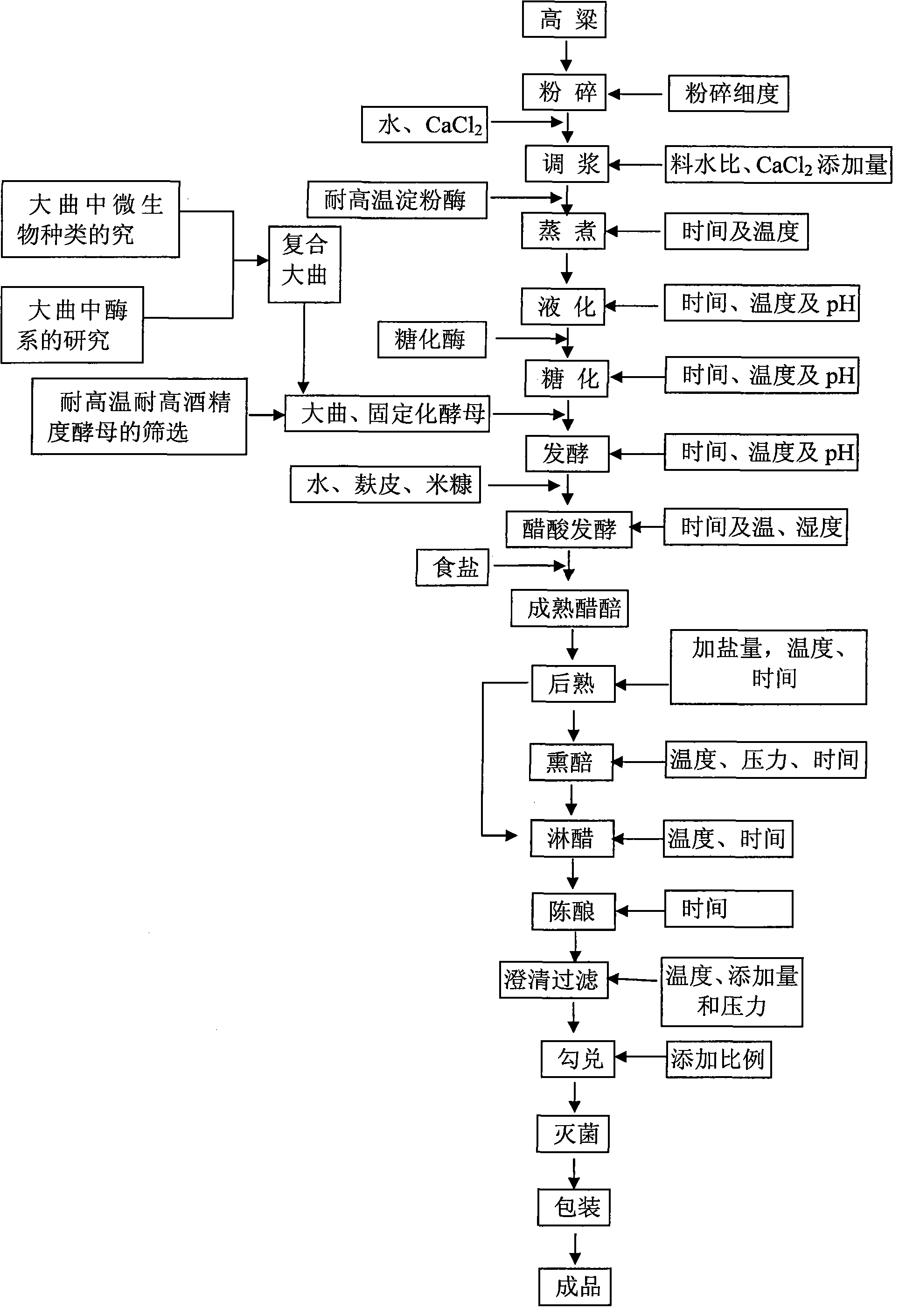

Standardized and industrialized production process for Shanxi mature vinegar

ActiveCN101857833ASystematization of processHigh technology contentMicroorganism based processesVinegar preparationMaterials processingSaccharomyces

The invention relates to a production process for vinegar, in particular to the standardized and industrialized production process for Shanxi mature vinegar, which solves the problems of long production process period, complex process, unstable product quality, low raw material utilization rate and the like, of the prior production process. The production process comprises the following steps of: performing material processing before alcoholic fermentation, crushing, mixing, liquefaction and saccharification; selecting high-temperature resistant and high-alcoholic strength resistant saccharomyces, and adding a composite yeast to perform alcoholic fermentation; adding the composite acetic bacteria into vinegar residue, stirring with a vinegar residue stirrer, fermenting the vinegar residue in an acetyl hydrate fermenting tank, and turning the vinegar residue with a vinegar residue turning machine; tamping the vinegar residue in the acetyl hydrate fermenting tank, covering a layer of table salt on the tamped vinegar residue, and standing the vinegar residue; fuming the vinegar residue by the combination of a vinegar residue fuming furnace and a steam vinegar residue fuming jar; pouring vinegar; ageing the vinegar; clarifying the vinegar with a crude acidic protease, and filtering the vinegar with kieselguhr; blending the vinegar and the traditional Shanxi mature vinegar; sterilizing the vinegar; and packing the vinegar. The process of the invention has the advantages of systematized flow, standardized technological parameters, scale production procedure, normalized product quality and optimized production process.

Owner:山西金龙鱼梁汾醋业有限公司

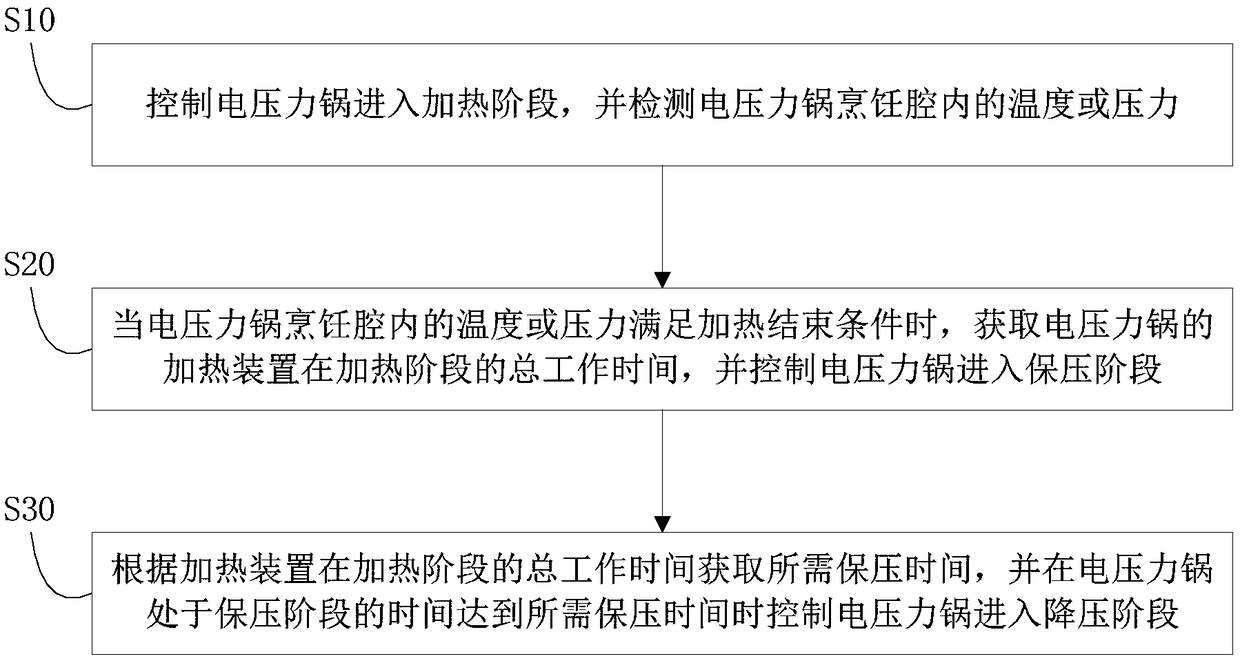

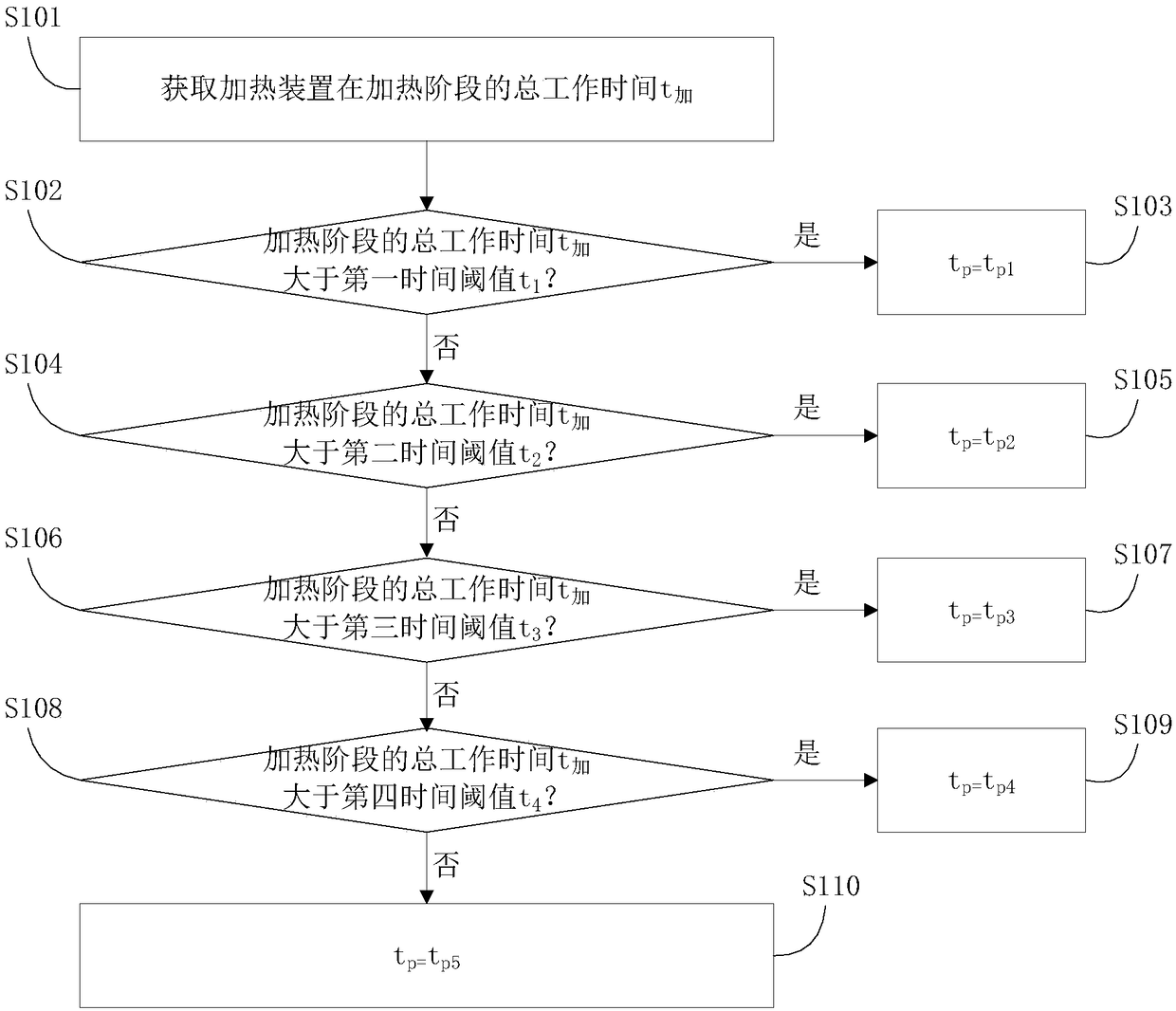

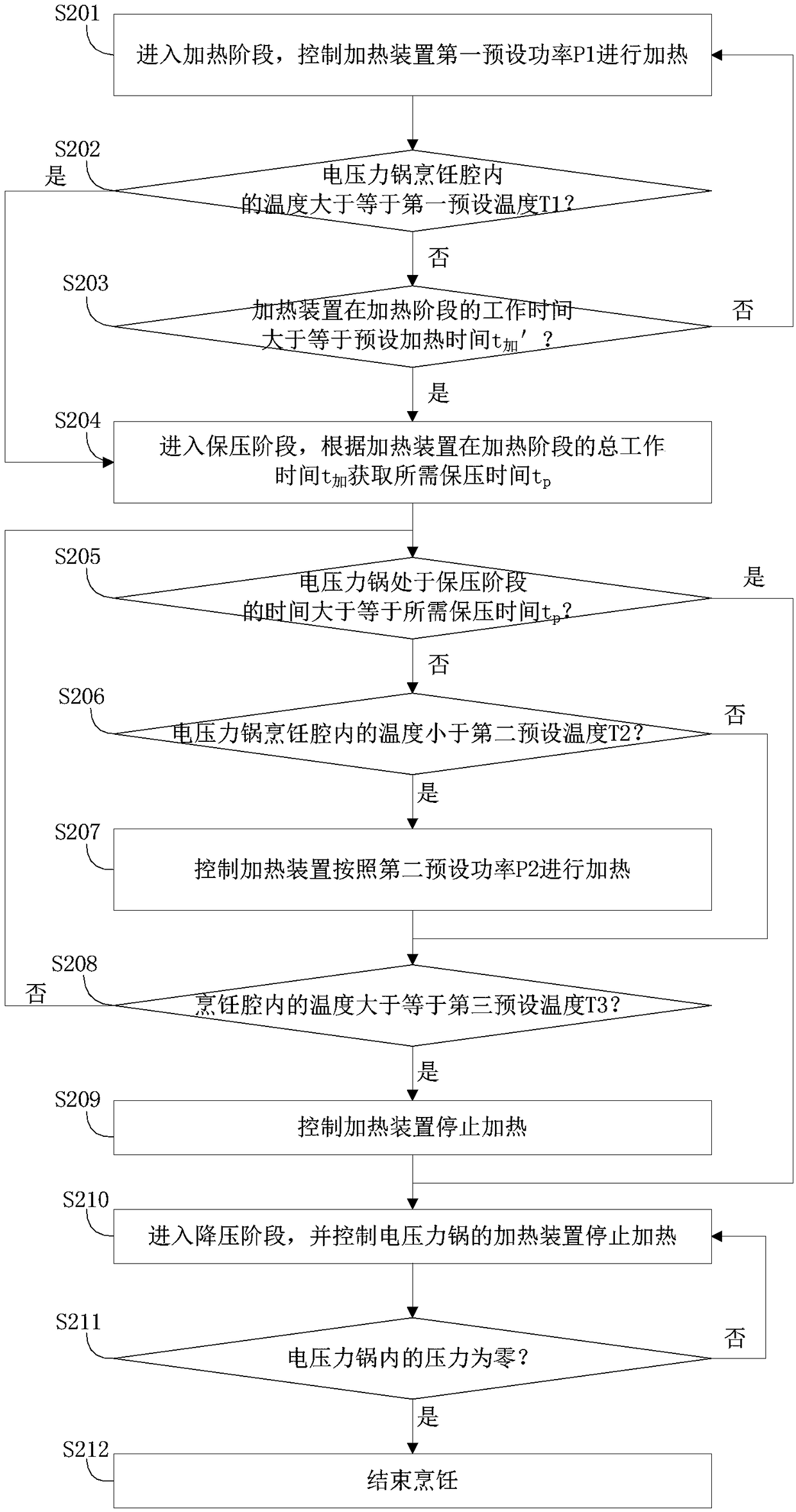

Electric pressure cooker and cooking control method thereof

The invention discloses an electric pressure cooker and a cooking control method of the electric pressure cooker. The method comprises the following steps: controlling the electric pressure cooker toenter the heating stage, and detecting the temperature or pressure inside a cooking cavity of the electric pressure cooker; when the temperature or pressure inside the cooking cavity of the electric pressure cooker satisfies the heating finishing condition, acquiring the total work time of a heating device of the electric pressure cooker at the heating stage, and controlling the electric pressurecooker to enter the pressure maintaining stage; acquiring the needed pressure maintaining time according to the total work time of the heating device at the heating stage, and controlling the electricpressure cooker to enter the pressure reduction stage when the time during the pressure maintaining stage of the electric pressure cooker reaches the needed pressure maintaining time, thus the pressure maintaining time of the pressure maintaining stage can be adjusted according to the total work time of the heating stage, the total cooking time of the electric pressure cooker is shortened, the user experience is promoted, and the competitiveness of the product is promoted.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

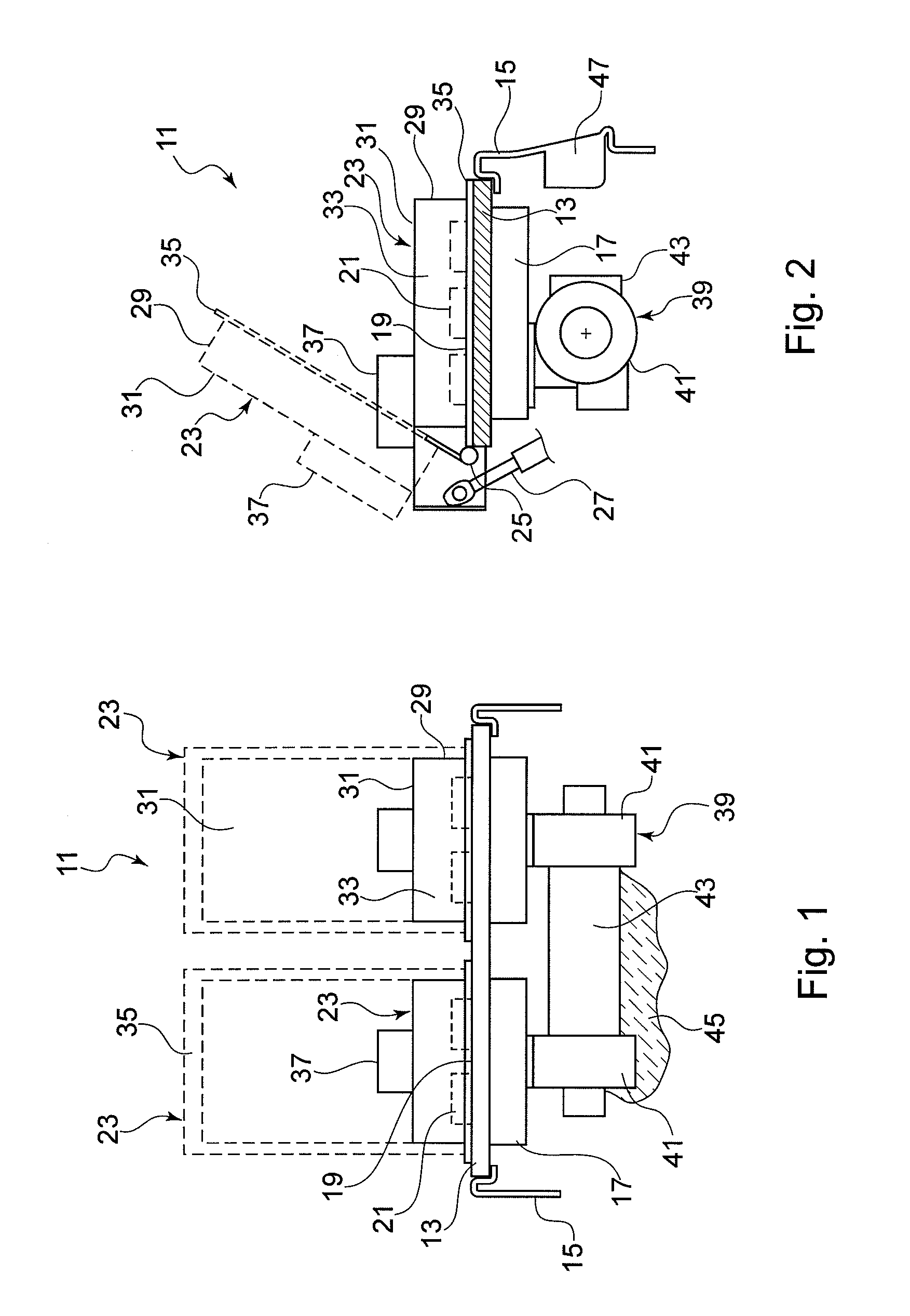

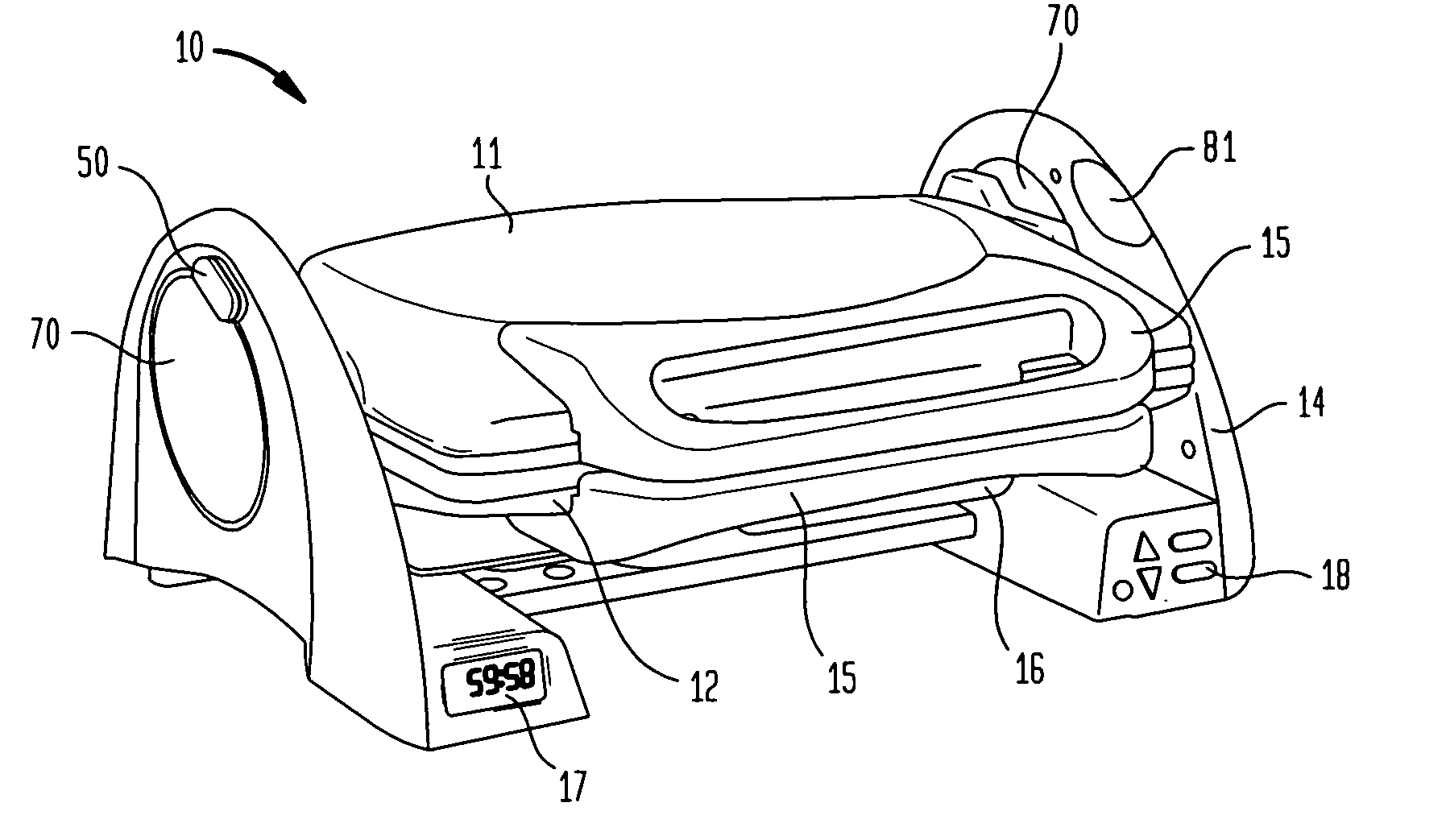

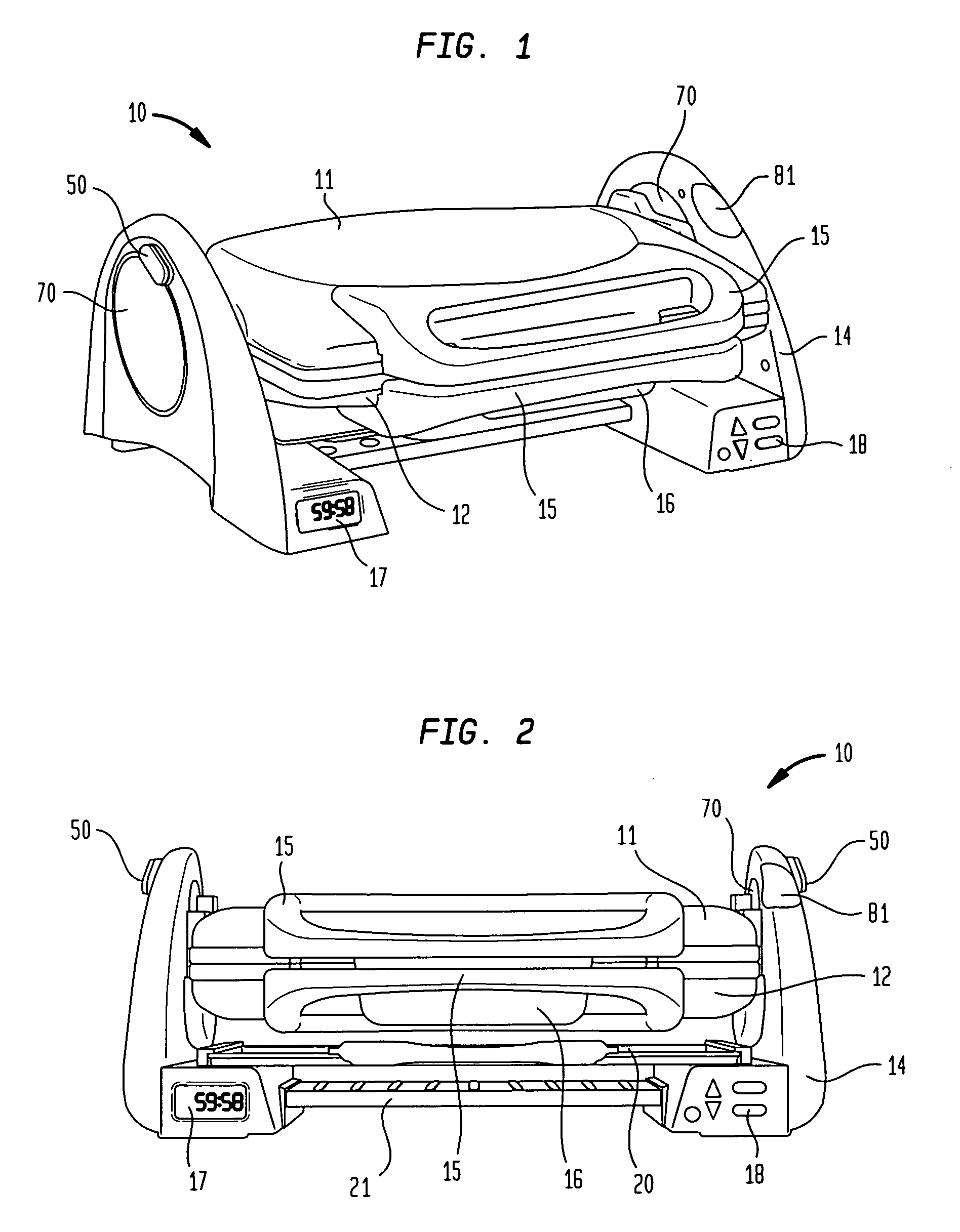

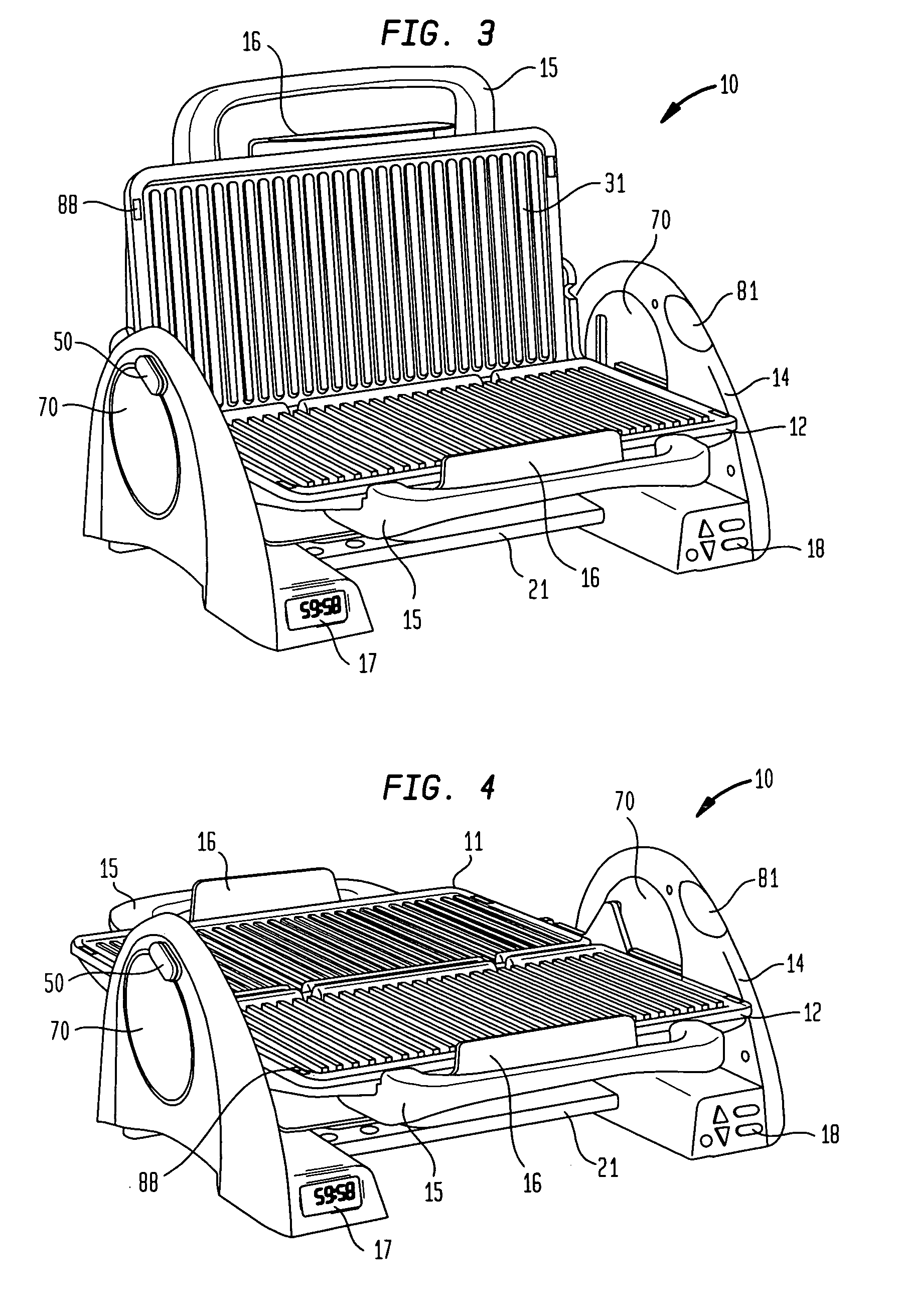

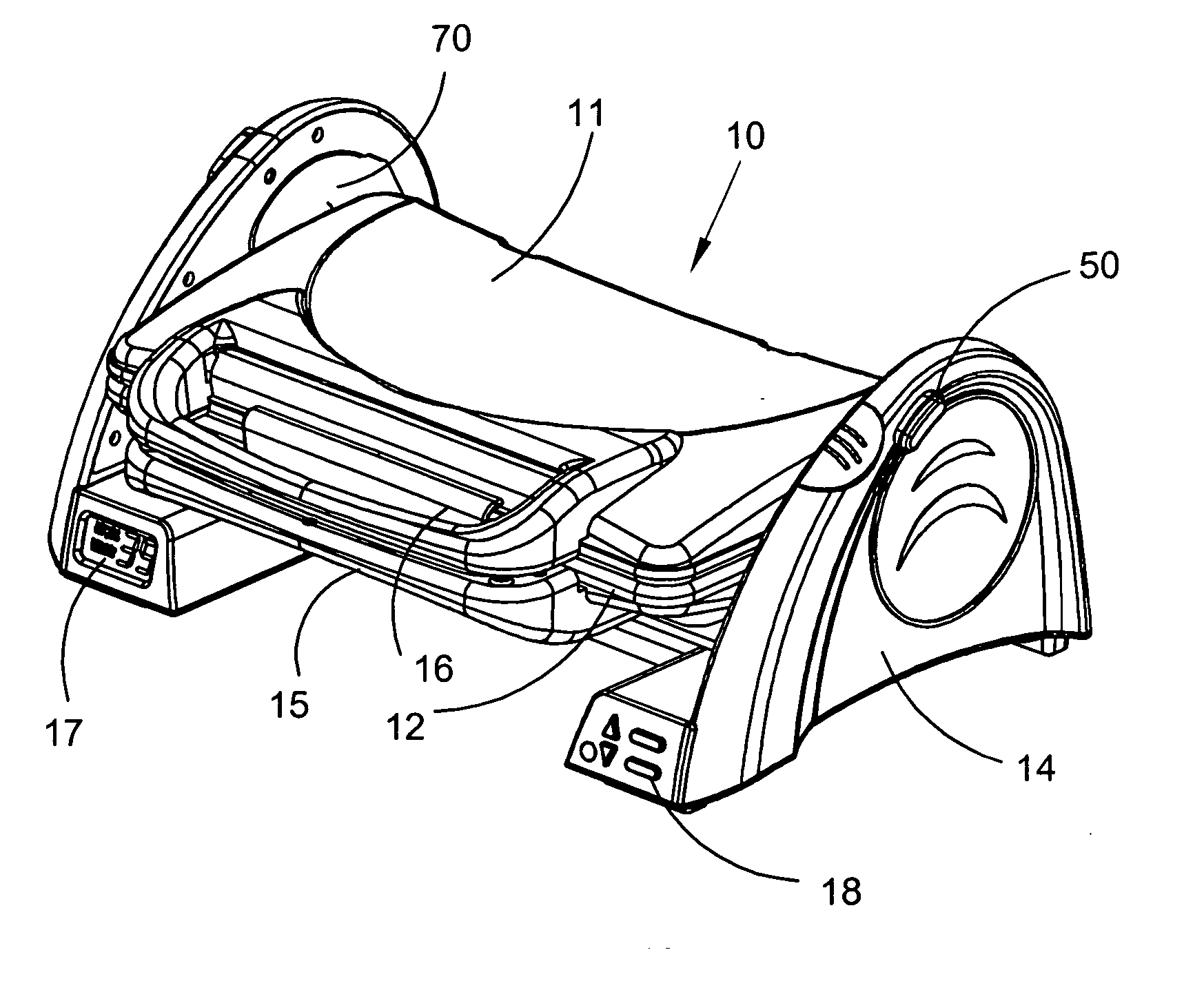

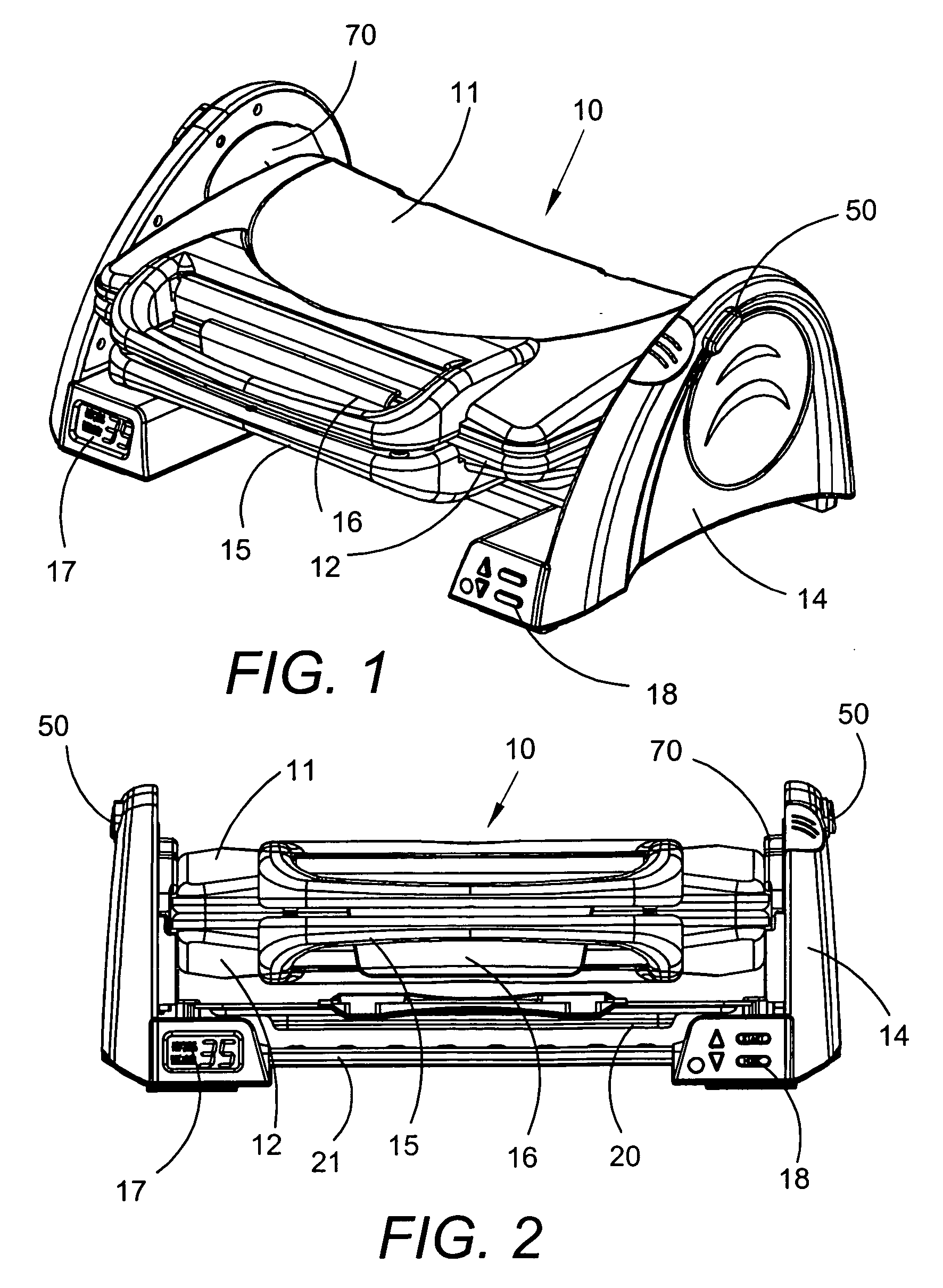

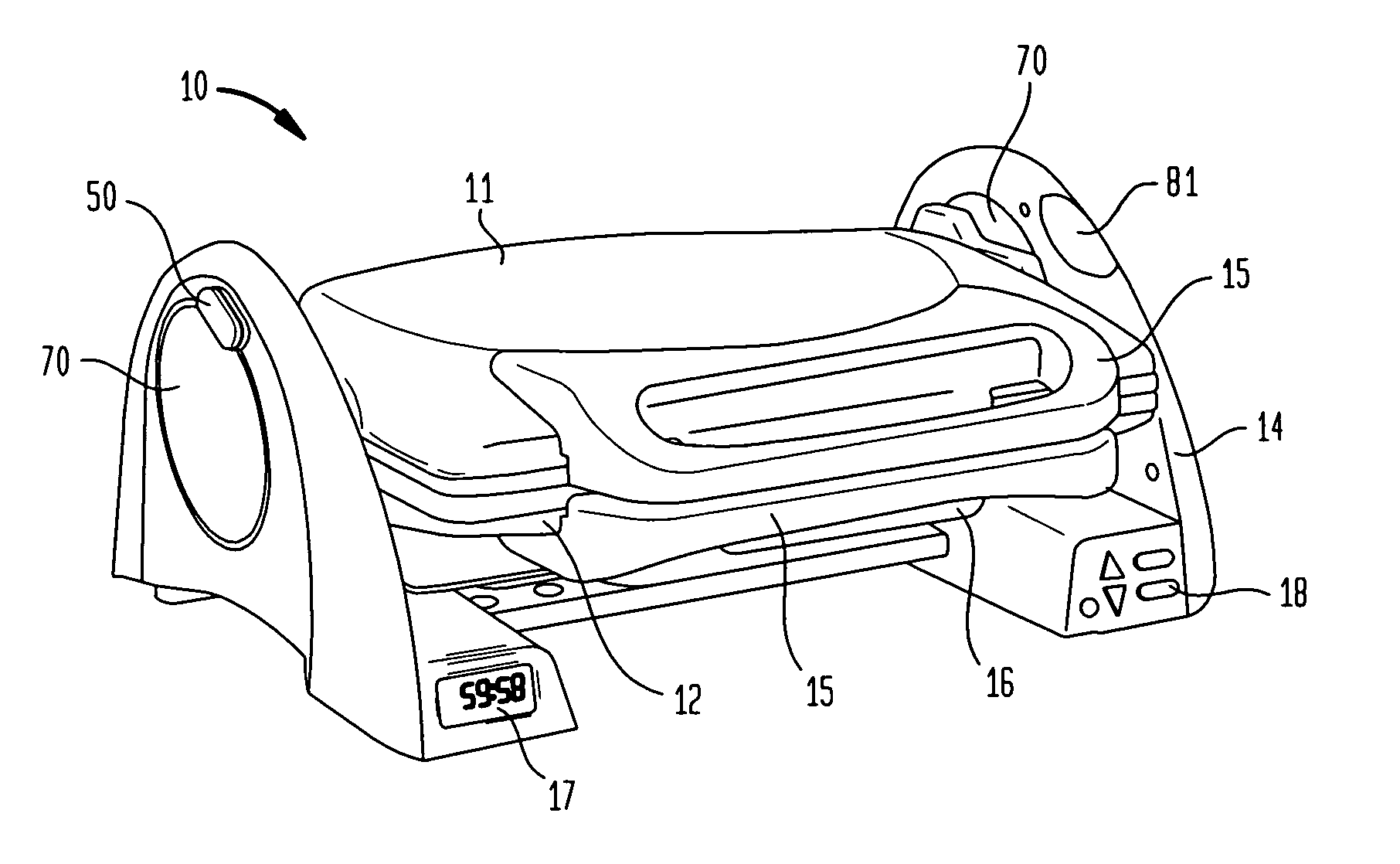

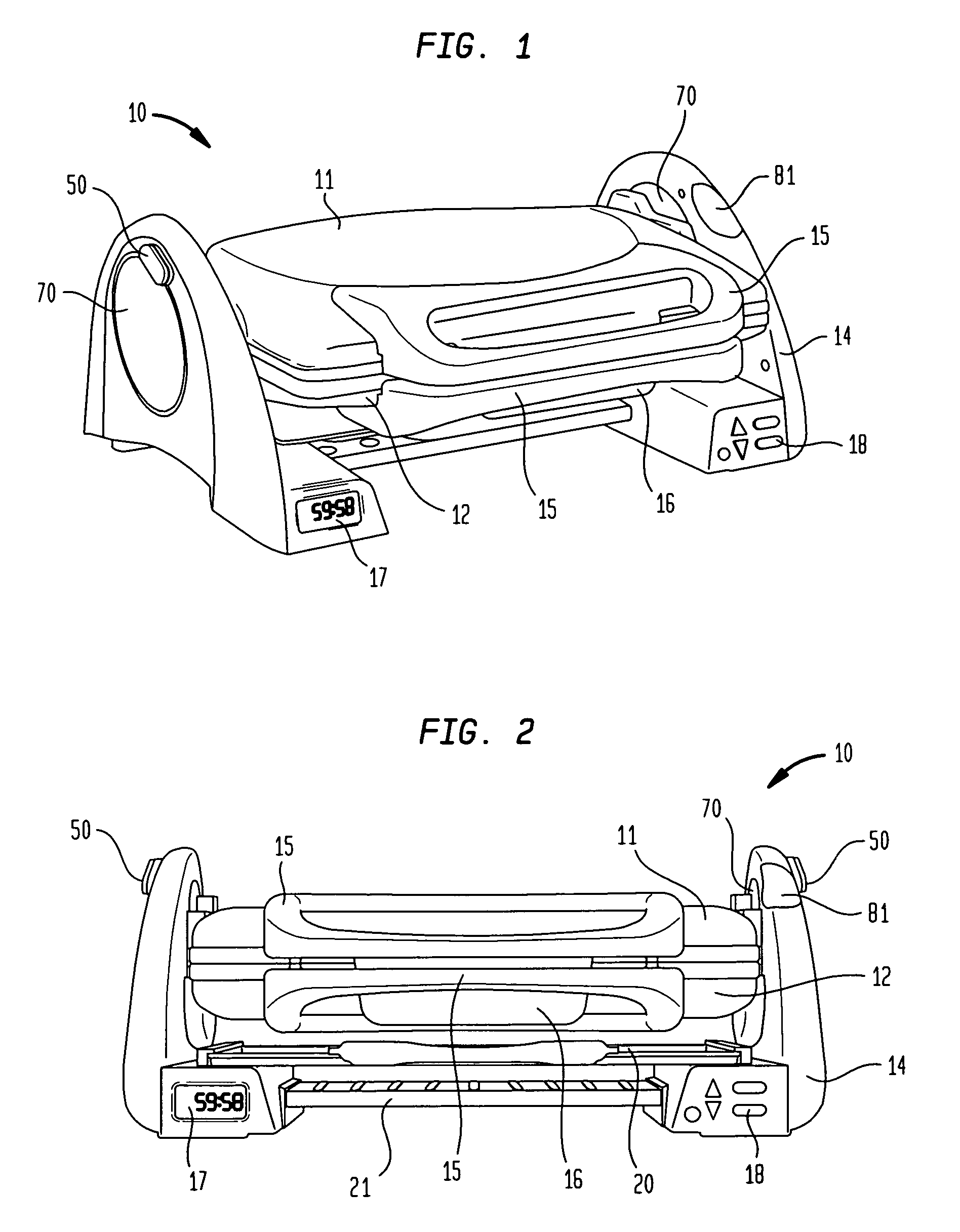

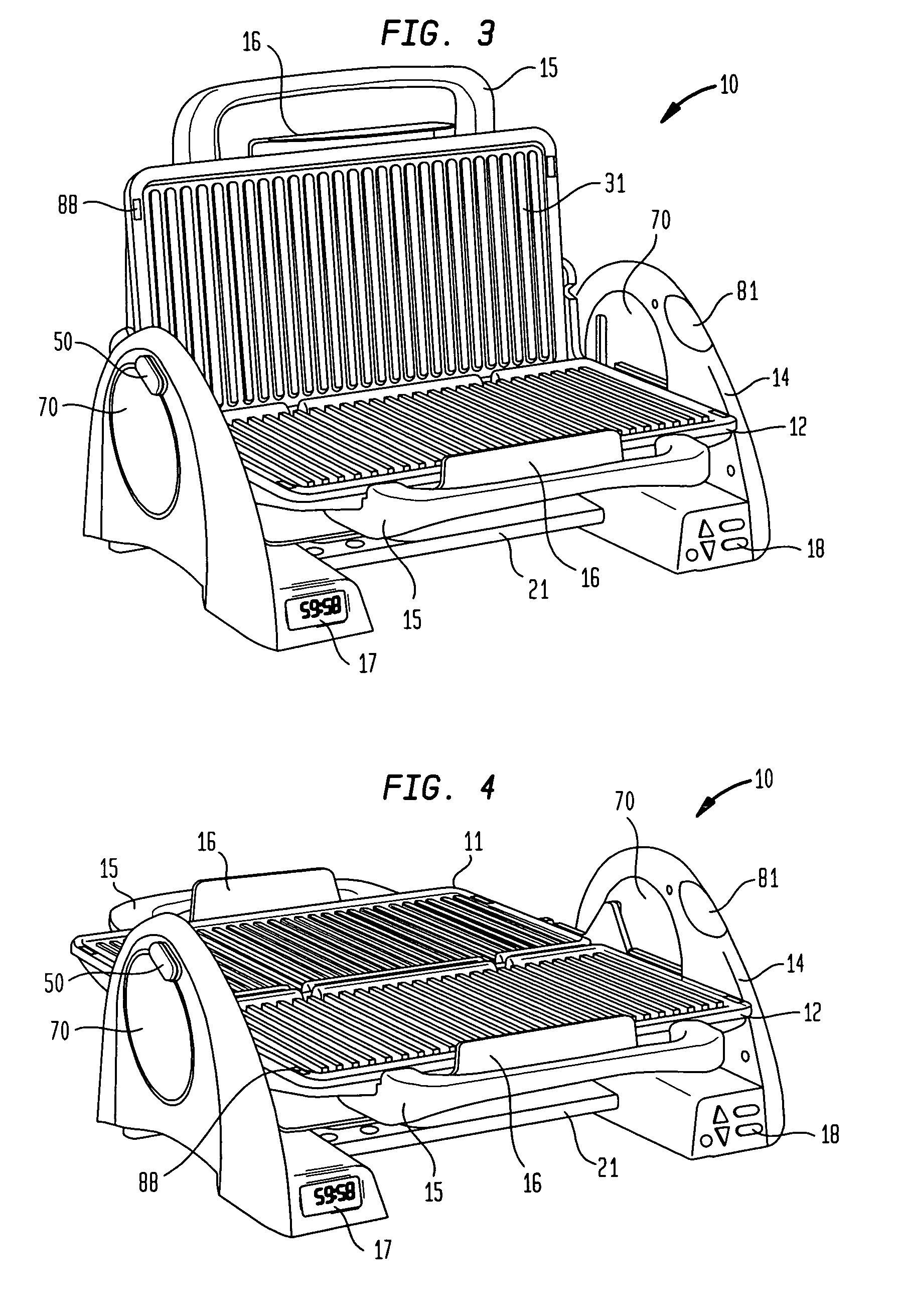

Tiltable pannini grill

InactiveUS20060213373A1Reduce cooking timeEasy to placeDomestic stoves or rangesElectrical heating fuelUser inputDisplay device

An electric grill for use to create healthier meals is disclosed. The electric grill comprises a support structure which holds a top heating section and a bottom heating section connected by a hinge. The hinge allows for a wide range of movement whereby the top heating section may be face to face with the bottom heating section, may be perpendicular, or may be at a 180 degree angle. Moreover, the top and bottom heating sections may be tilted such that excess grease, oils and juices may be separated from the food being cooked. The electric grill disclosed herein also may include a digital read-out display and a user input keypad.

Owner:SOUTH ASIA INT H K +1

Conveyorized food broiling apparatus

InactiveUS7038172B1Shorten speedExtended cooking timeThermometer detailsElectric heatingControl systemEngineering

A programmable control system for a cooking apparatus having a housing defining a cooking chamber with one or more food transport conveyors traveling there-through between opposing cooking elements. A food probe is provided for insertion into cooked food items to ascertain the internal cooked temperature and a control program to automatically call for the probing of temperature readings of food items on a predefined schedule, and to record the temperature readings. The control program also compensates for temperature degradation when the apparatus is under significant cooking loads. The control program also compensates for the malfunction in the cooking elements, wherein if one cooking element on one side of the conveyor path malfunctions, a corresponding heating element on the opposite side of the conveyor is deactivated and simultaneously the conveyor speed is slowed to compensate for the reduction in heating to maintain balanced cooking of the food.

Owner:MARSHALL AIR SYST

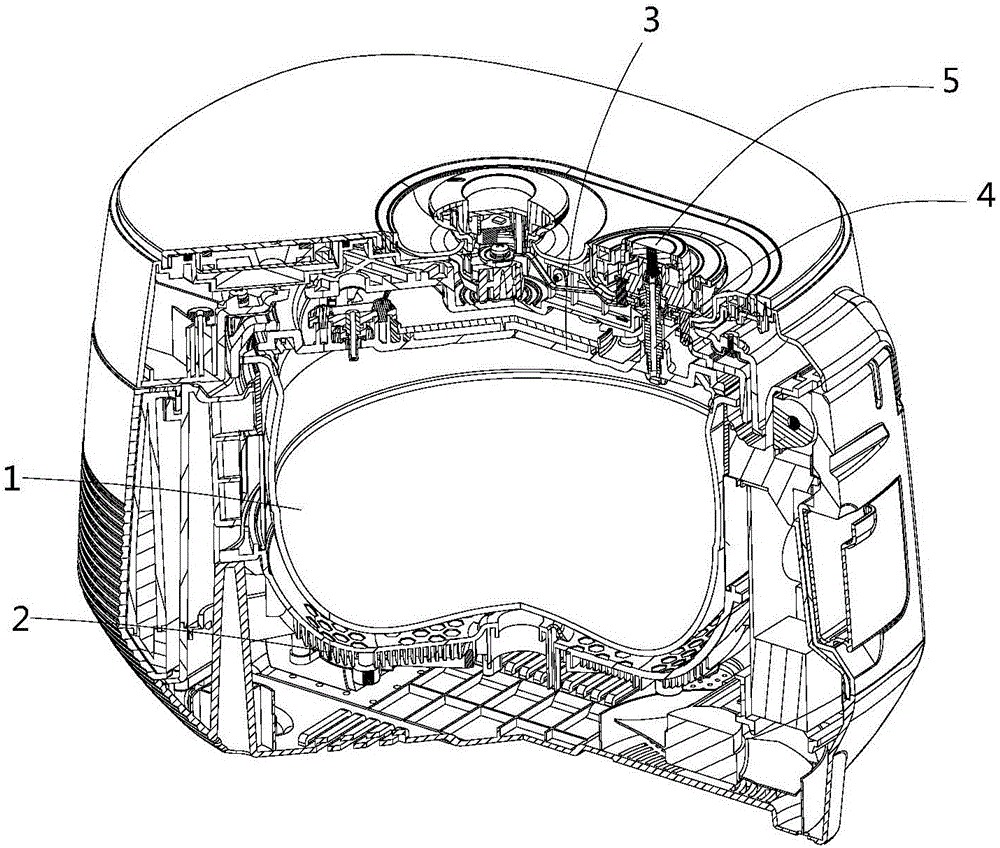

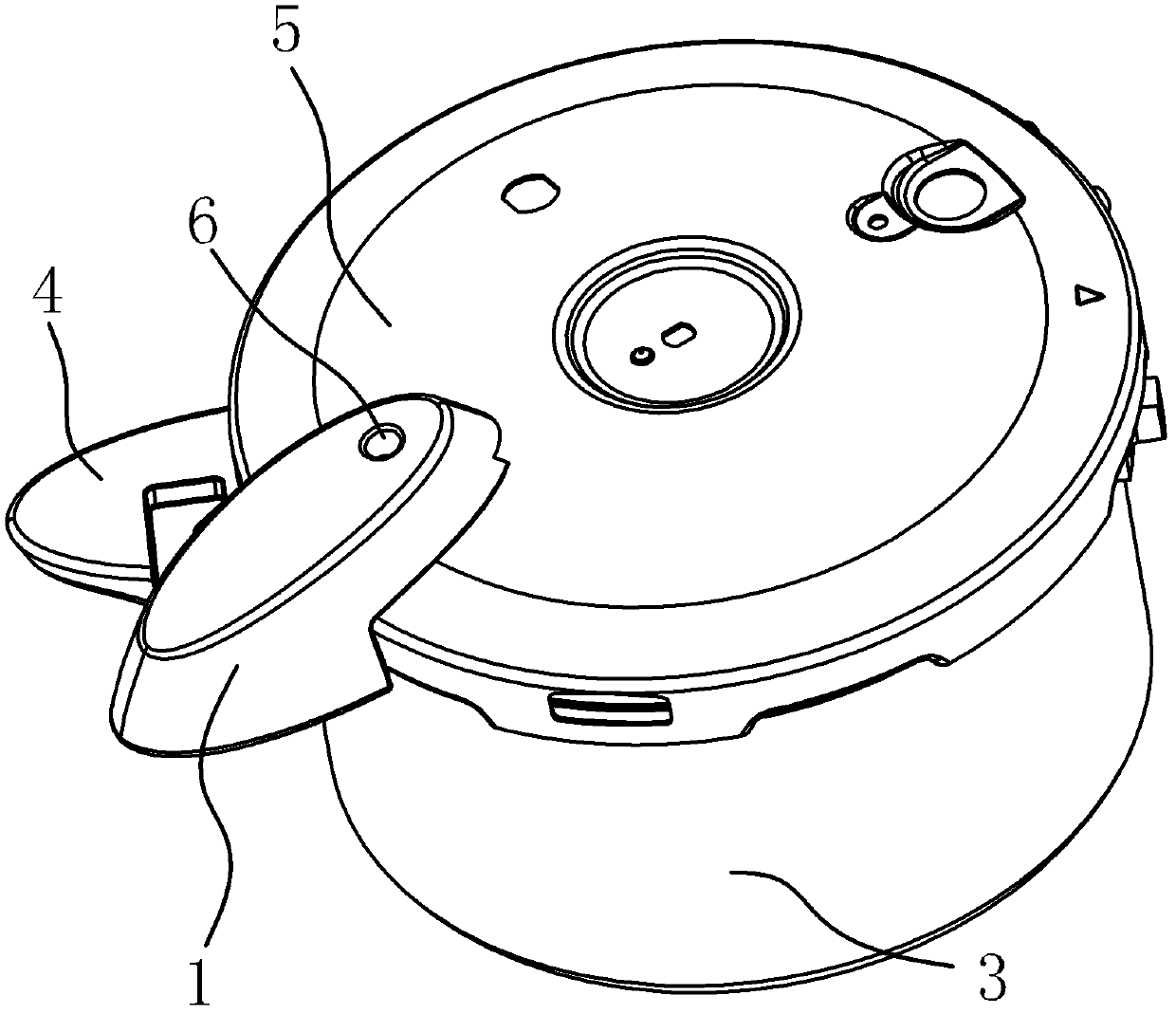

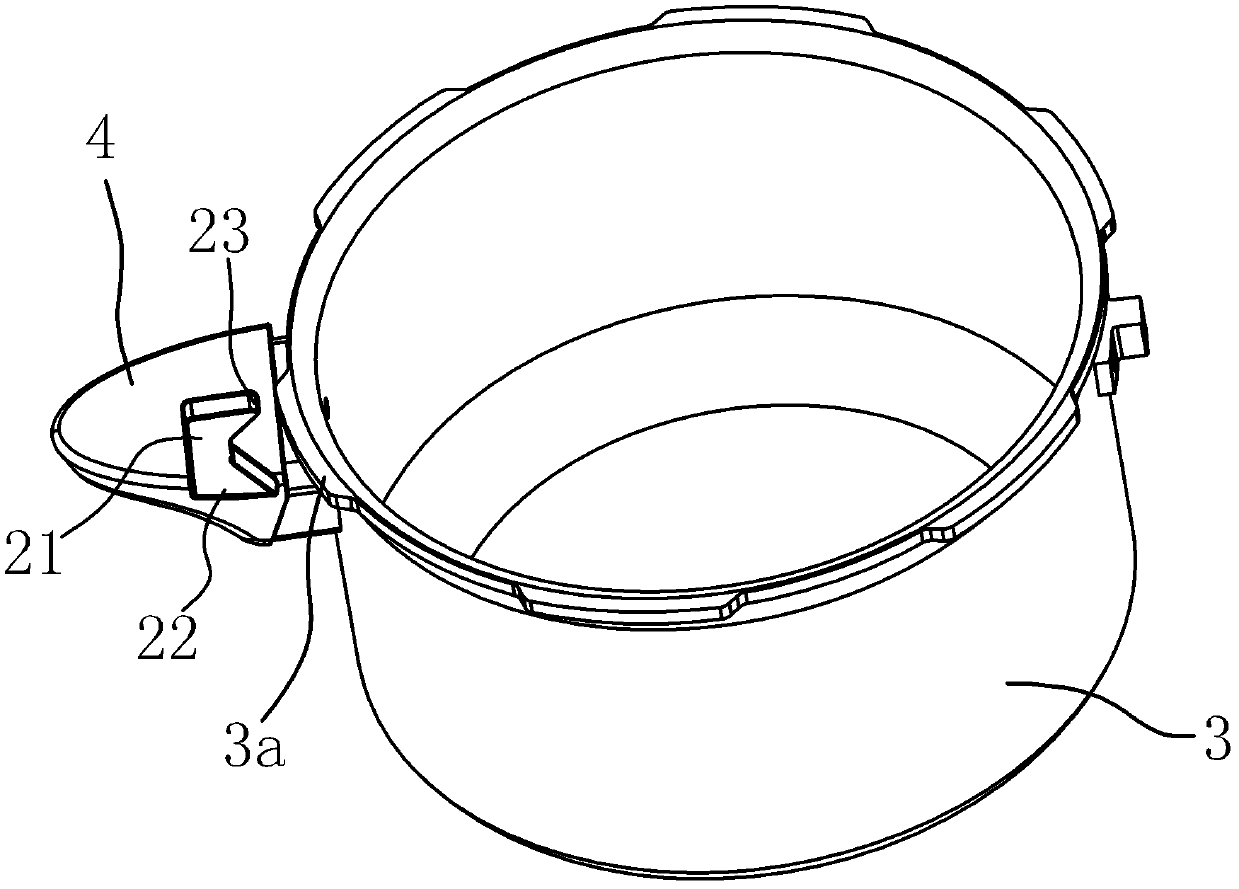

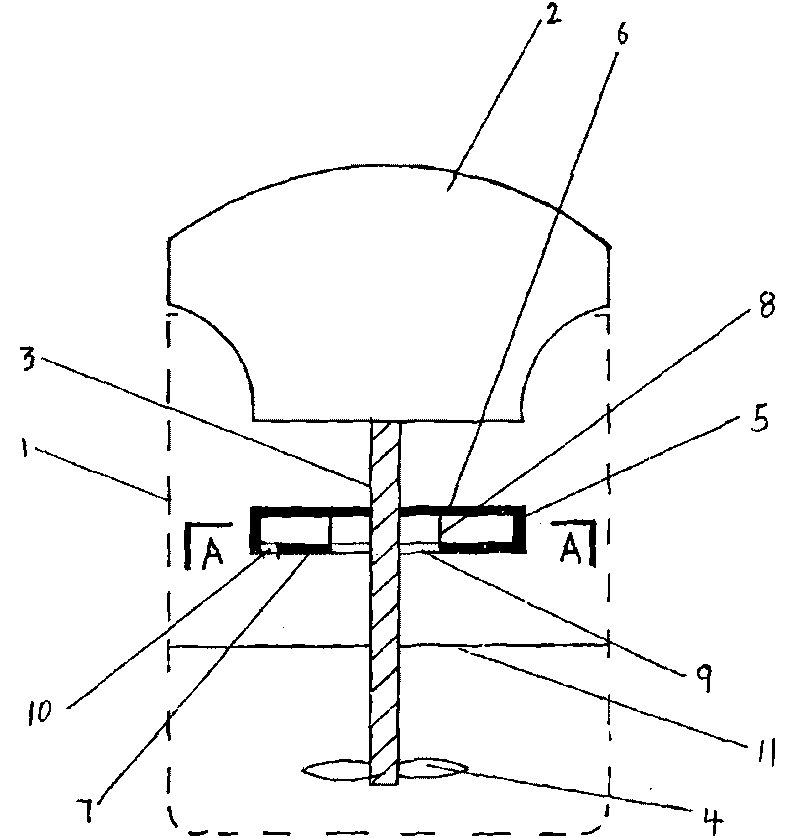

Cover opening and closing safety device of pressure cooker

ActiveCN102319018BEnsure safetyShorten the ascent strokePressure-cookersEngineeringMechanical engineering

The invention relates to a pressure cooking device comprising: - a vessel and a lid to form a cooking chamber, - a first port, - an opening safety means movable between a release position and a locking position, said opening safety means being designed to be in the locking position when the pressure inside the chamber is greater than or equal to a pre-determined value referred to as the rising pressure, characterised in that said opening safety means is designed to pass through a first intermediate position in which it releases said first port when it moves in either direction between said release and locking positions, , said device comprising an actuating means (13) for actuating the opening safety means, designed to allow the opening safety means to be moved into its first intermediate position. Pressure cooking devices.

Owner:ZHEJIANG SUPOR CO LTD

Air fryer heated by cyclone heat circulation

The invention discloses an air fryer heated by a heat cycle formed by a cyclone, which comprises: a windshield, the windshield is open at the lower part, and has a small hole in the center of the upper part; a motor assembly, the motor assembly is installed on the The upper part of the windshield, and includes a motor transmission shaft, the motor transmission shaft passes through the small hole in the upper center of the windshield; an exhaust fan, the exhaust fan is installed in the windshield, and is connected to the windshield The motor transmission shafts are connected; the rotating air duct unit is installed in the windshield, and is located below the exhaust fan, and is connected and fixed with the windshield through a connecting column. The upper part of the channel unit is provided with a ventilation opening, and the lower part is open, wherein the rotating air channel unit can make the wind going vertically downward through the joint action of the exhaust fan and the windshield rotate and go downward at a certain angle, forming whirlwind. The air fryer heats through the cyclone to form a heat cycle so that the hot air can bake the food more evenly.

Owner:KINGCLEAN ELECTRIC GREEN TECH SUZHOU

Prepared high hardness pulp using grass kind plant as raw material and preparation method thereof

ActiveCN101089290AReduce dosageReduce manufacturing costDigestersPulping with acid salts/anhydridesKappa numberHardness

The present invention discloses a method for preparing high-hardness pulp by using graminoid plant as raw material and its cooking process. The hardness of said high-hardness pulp is equal to Kappa number 24-50. The described cooking method includes the following steps: preparing graminoid plant raw material, soaking said raw material, feeding said raw material into a cooker, adding cooking liquor into said cooker, introducing steam to make heating operation to attain the requird pressure, then heat-insulating to the required time.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

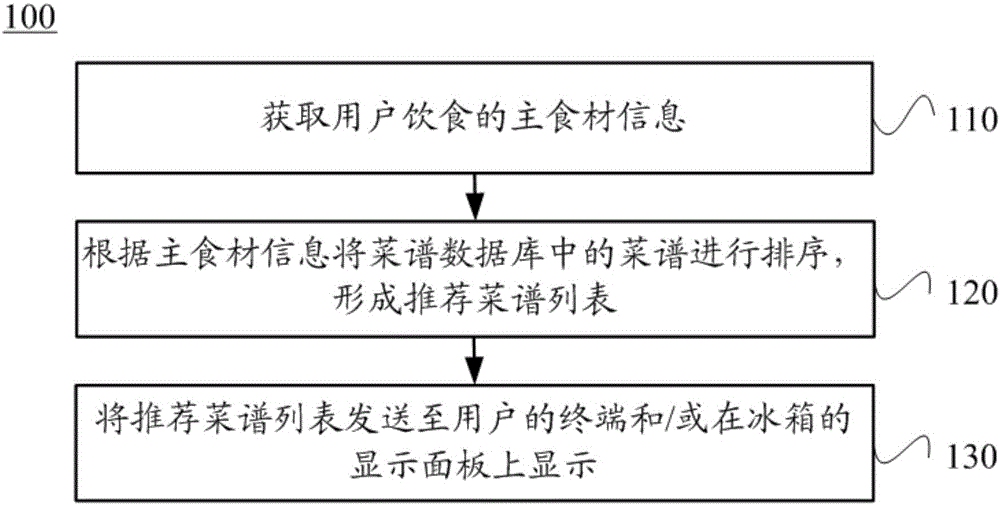

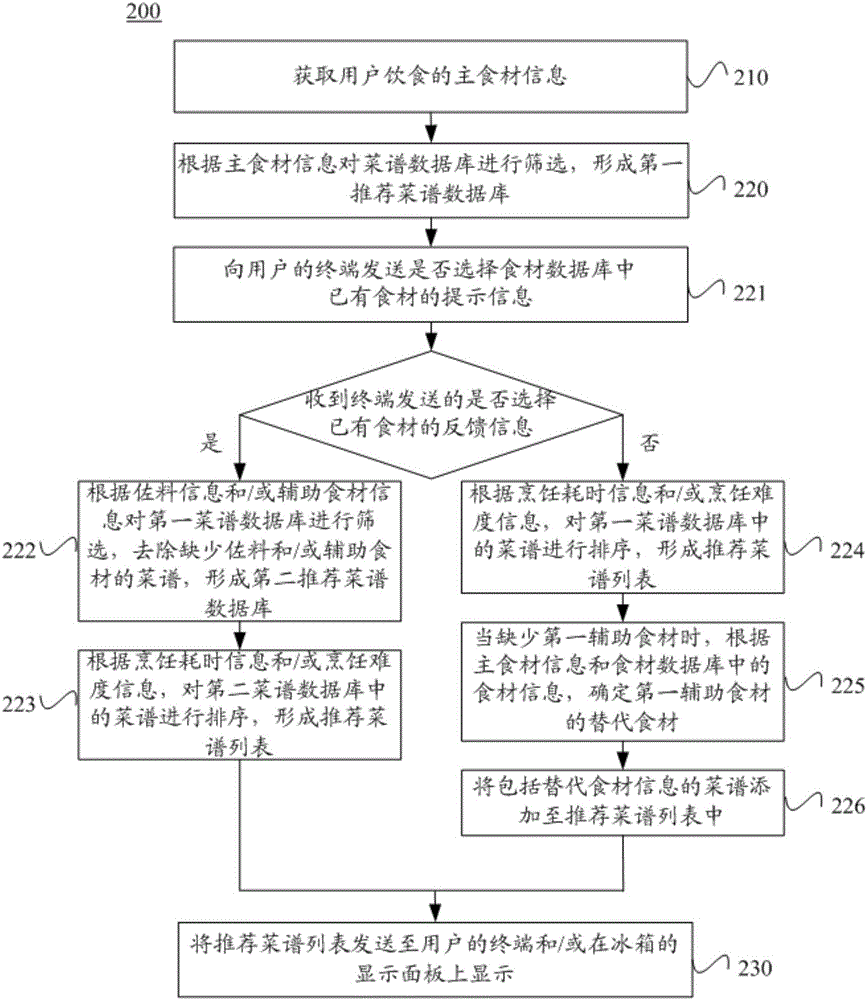

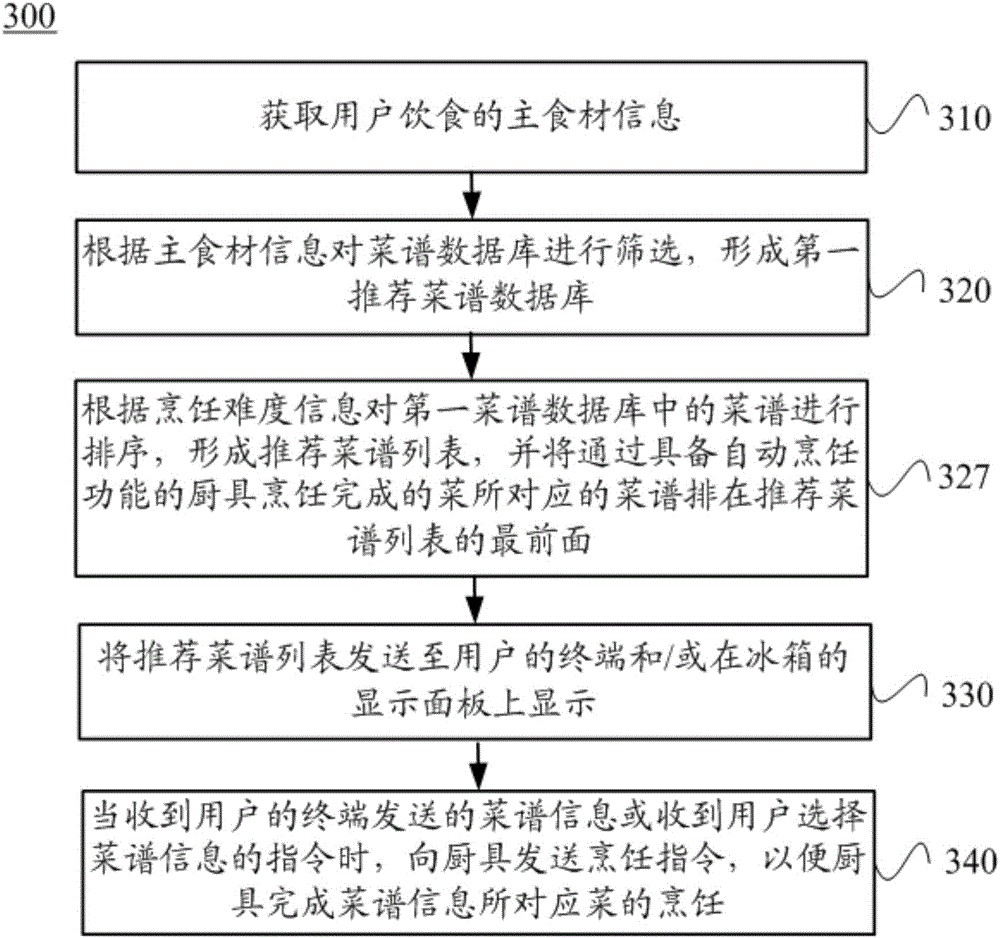

Menu recommendation method and device

InactiveCN106096234ARealize private customizationAvoid Situations That Cannot Be Actually OperatedComputer-assisted diets prescription/deliverySpecial data processing applicationsComputer terminalHuman–computer interaction

The invention relates to a menu recommendation method and device. The method comprises the following steps of: obtaining staple food material information of user diet; ranking menus in a menu database according to the staple food material information so as to form a recommended menu list; and sending the recommended menu list to terminals of users and / or displaying on display panels of refrigerators. According to the menu recommendation method and device, the recommended menu list which is formed according to the obtained staple food material information of the user diet is sent to the terminals of the users and / or directly displayed on the display panels of the refrigerators, so that private menu customization can be carried out for each user.

Owner:MIDEA GRP CO LTD

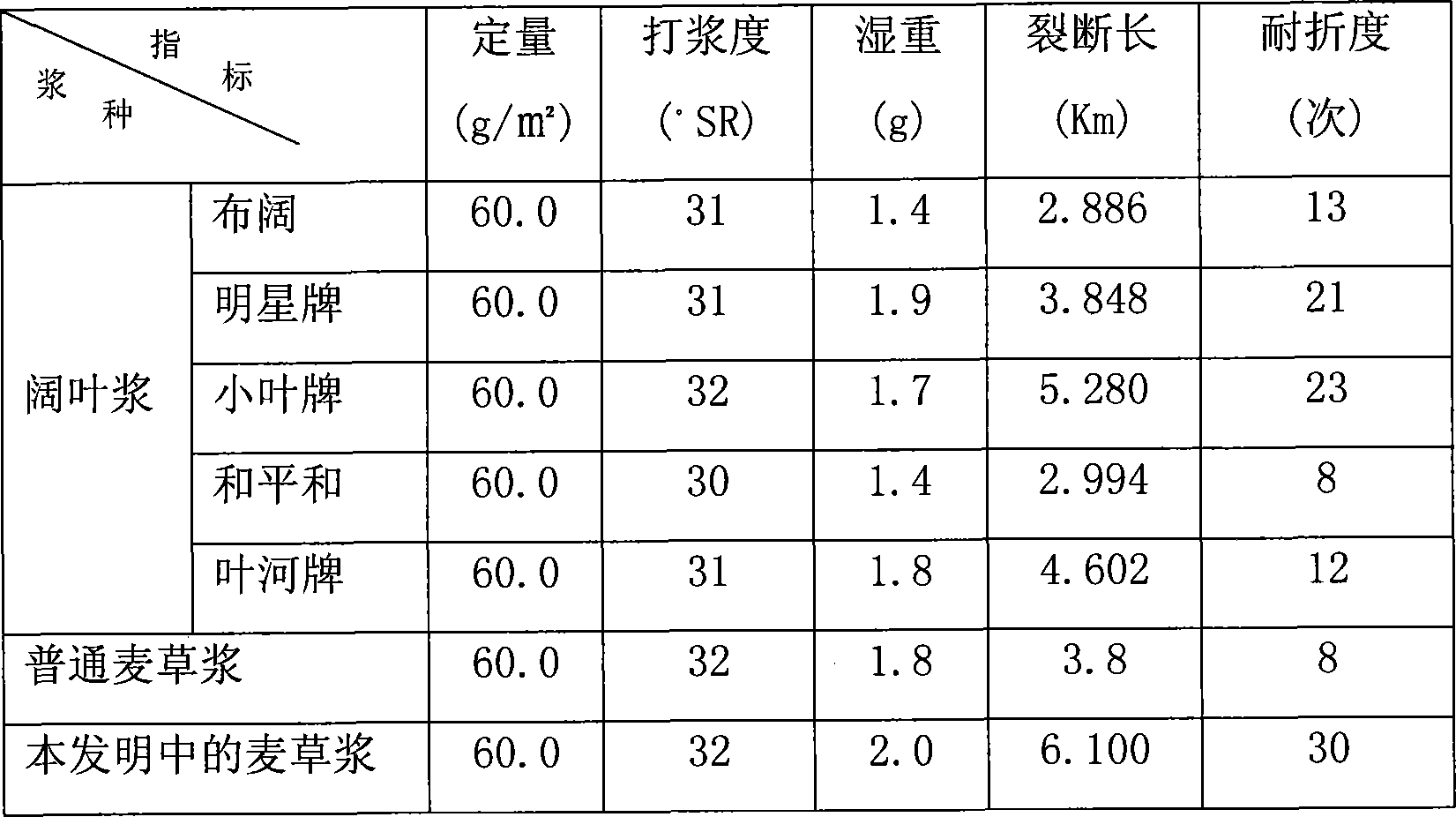

Prepared bleach chemical pulp using grass kind plant as raw material and preparation method thereof

ActiveCN101089291AReduce manufacturing costQuality improvementDigestersPulp de-wateringKappa numberFolding endurance

The present invention discloses a bleached chemical pulp prepared by using graminoid plant as raw material and its preparation method. Said invention is characterized by that it utilizes a high-hardness pulp which is obtained by using cooking process and whose permanganate number is 16-28 and equal to Kappa number 26-50 and makes said high-hardness pulp undergo the processes of pulp-washing and bleaching treatment so as to obtain the invented bleached chemical pulp whose breaking length is 4500-8000 m and folding endurance is 20-70 times.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Electric grill

An electric grill for use to create healthier meals is disclosed. The electric grill comprises a support structure which holds a top heating section and a bottom heating section connected by a hinge. The hinge allows for a wide range of movement whereby the top heating section may be face to face with the bottom heating section, may be perpendicular, or may be at a 180 degree angle. Moreover, the top and bottom heating sections may be tilted such that excess grease, oils and juices may be separated from the food being cooked. The electric grill disclosed herein also may include a digital read-out display and a user input keypad.

Owner:SOUTH ASIA INT H K

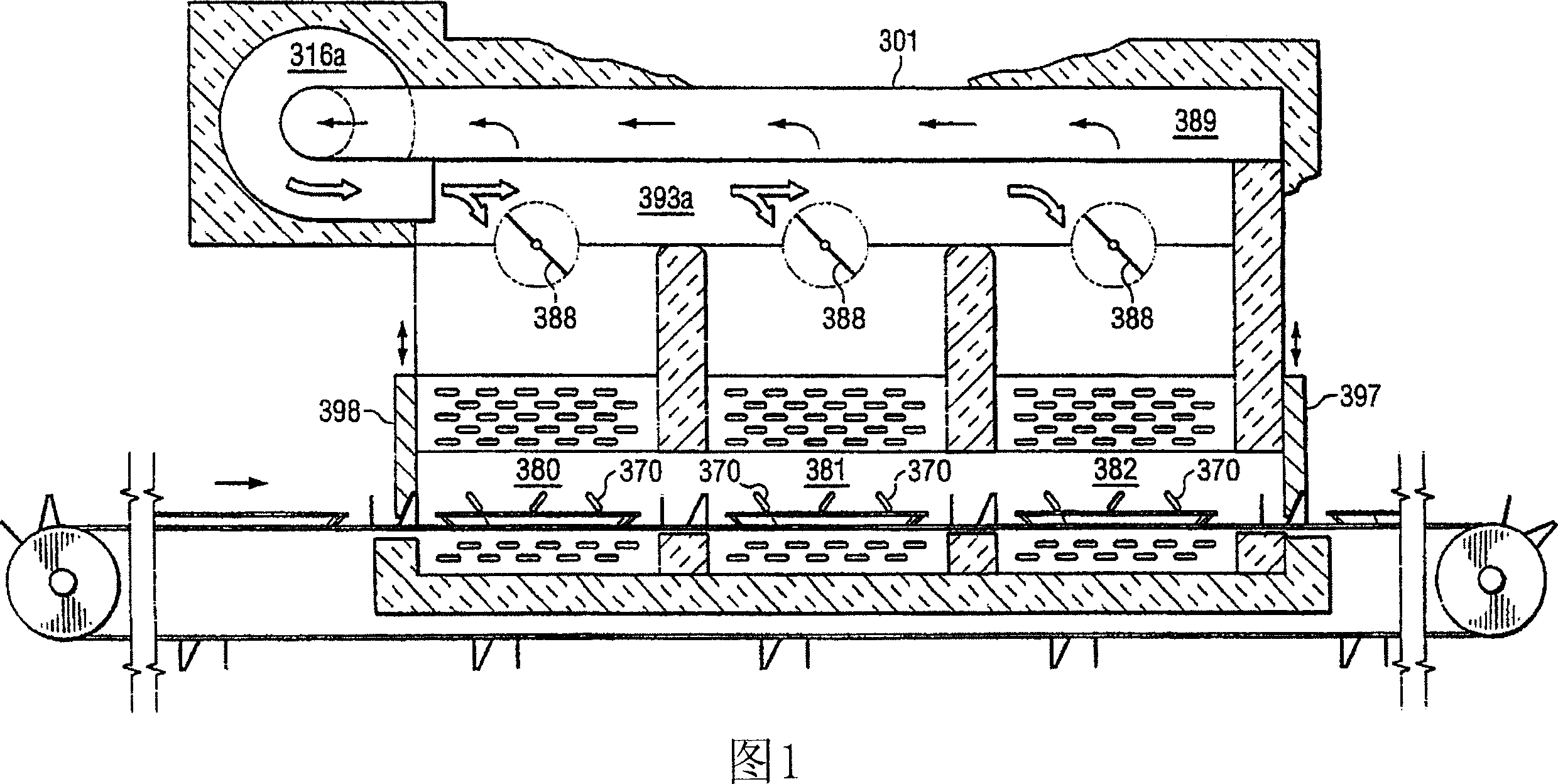

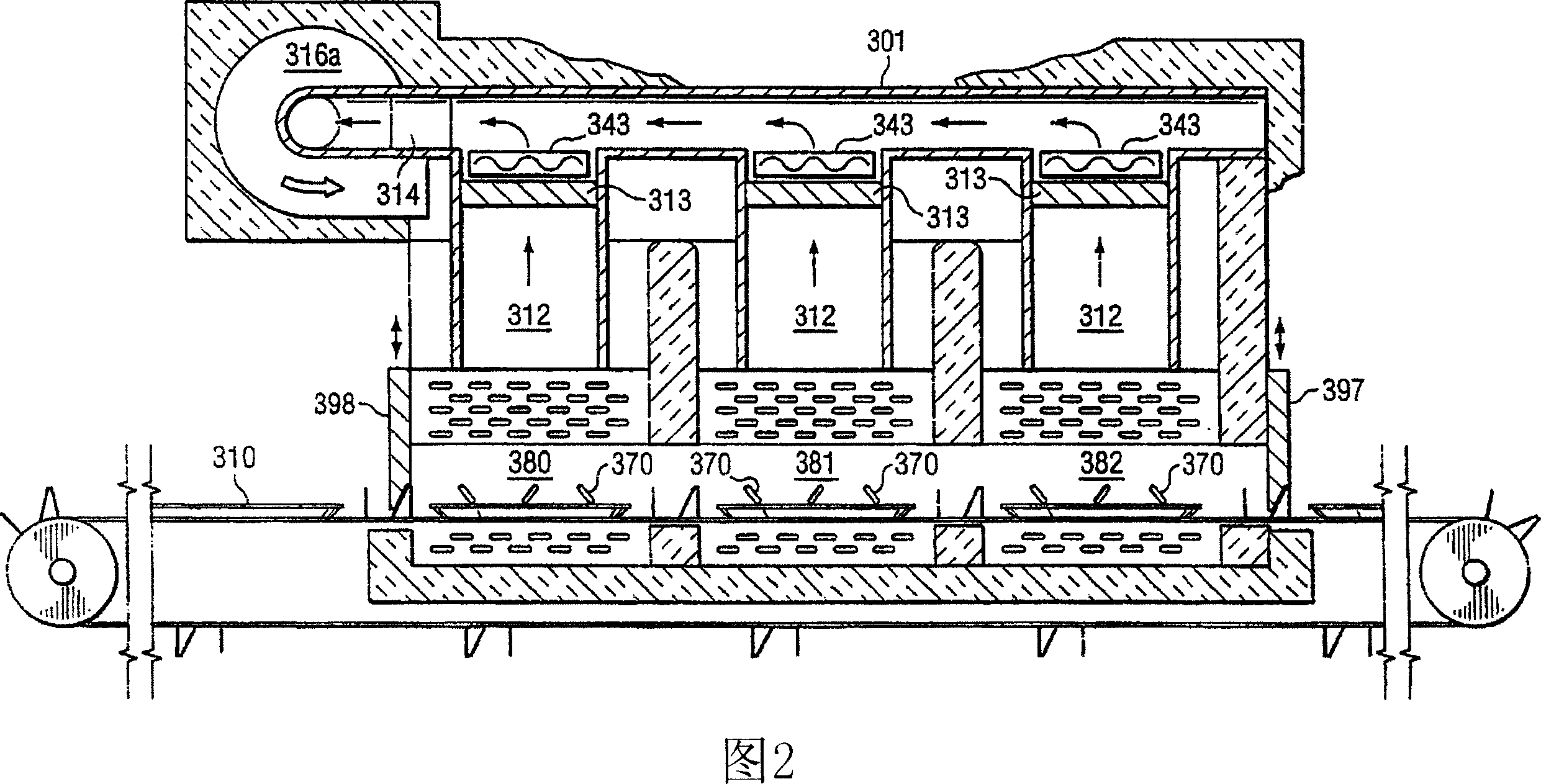

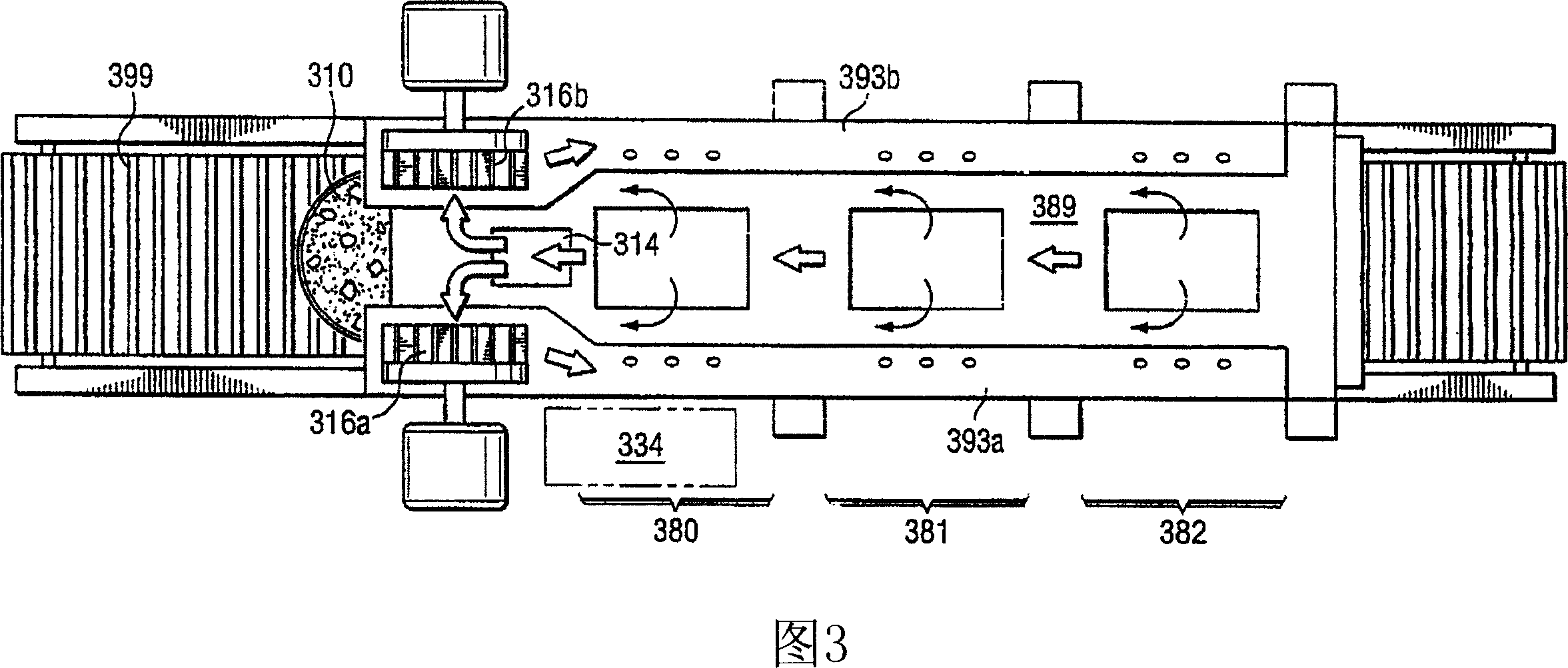

Conveyor oven

InactiveCN1968609AIncrease the number ofIncrease turn rateDomestic stoves or rangesLighting and heating apparatusProcess engineeringFood products

Owner:特博切夫技术有限公司

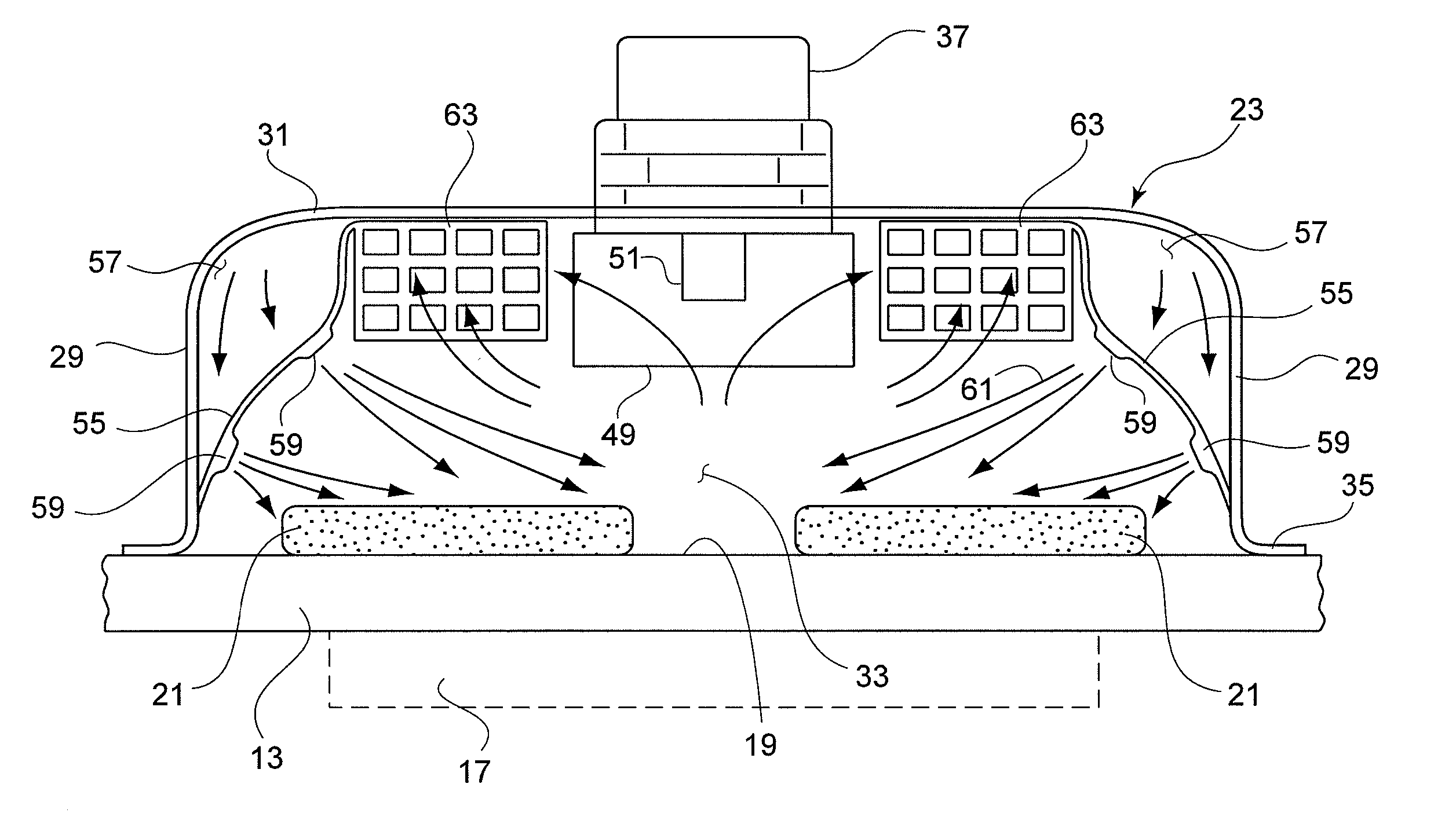

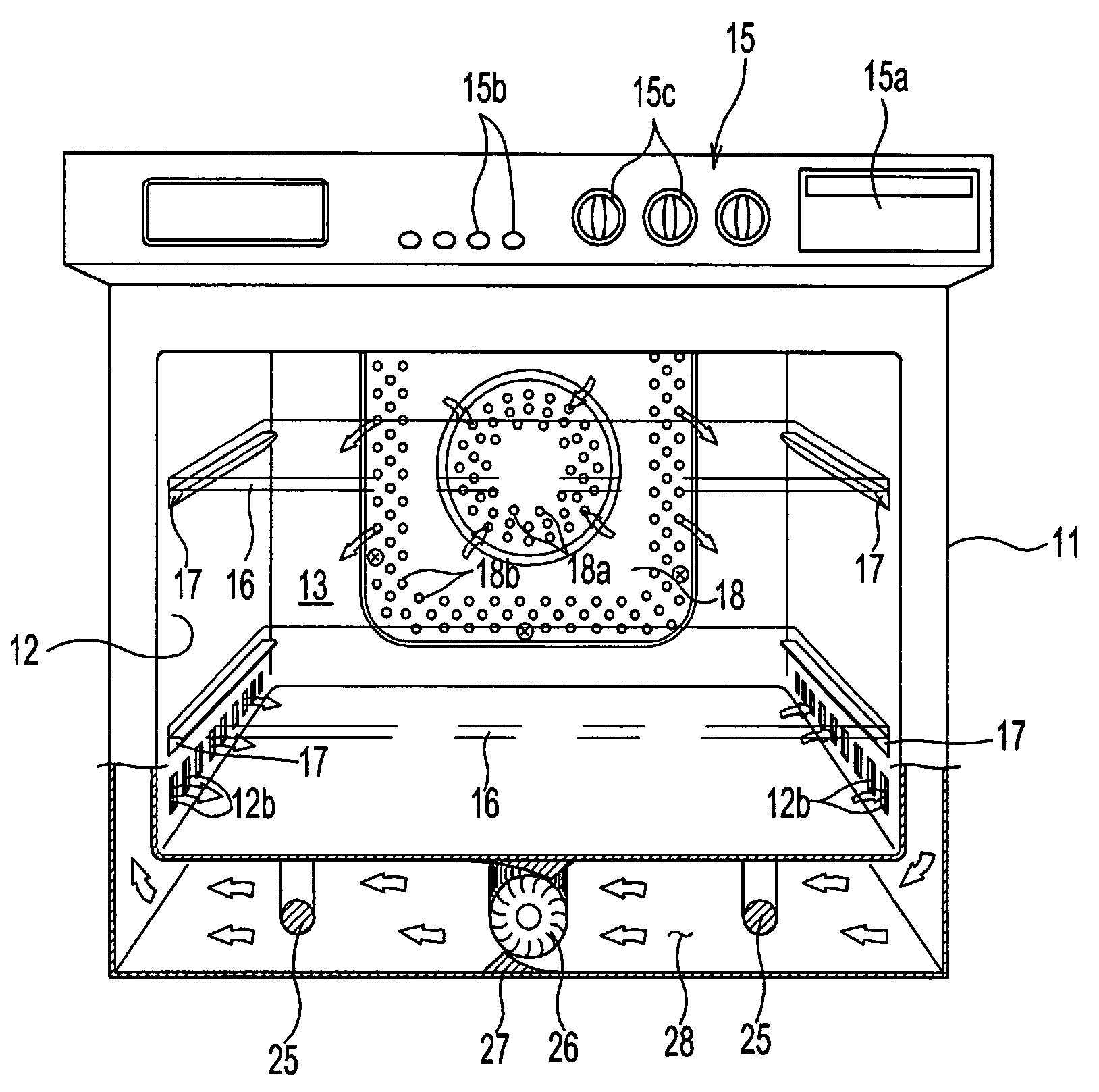

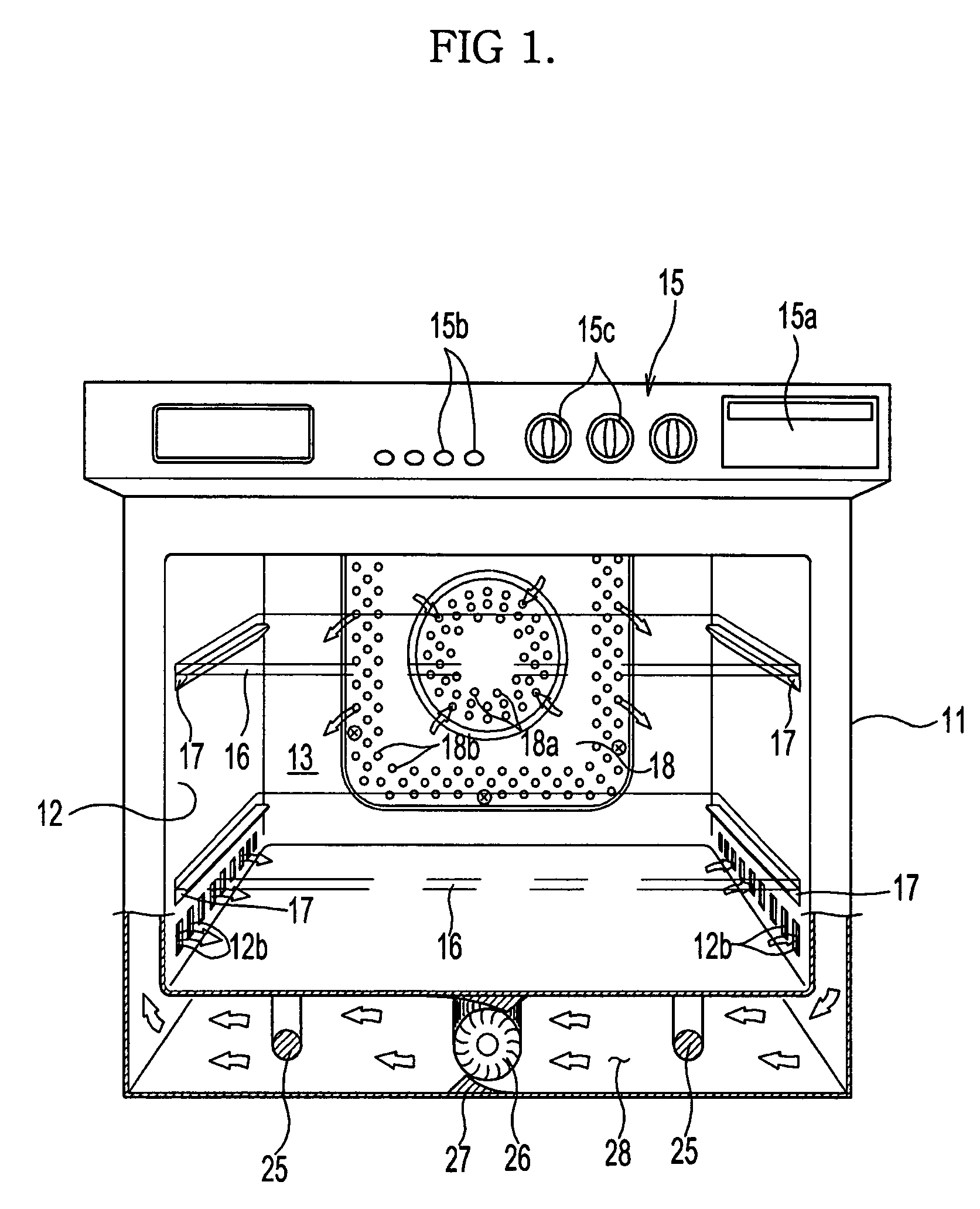

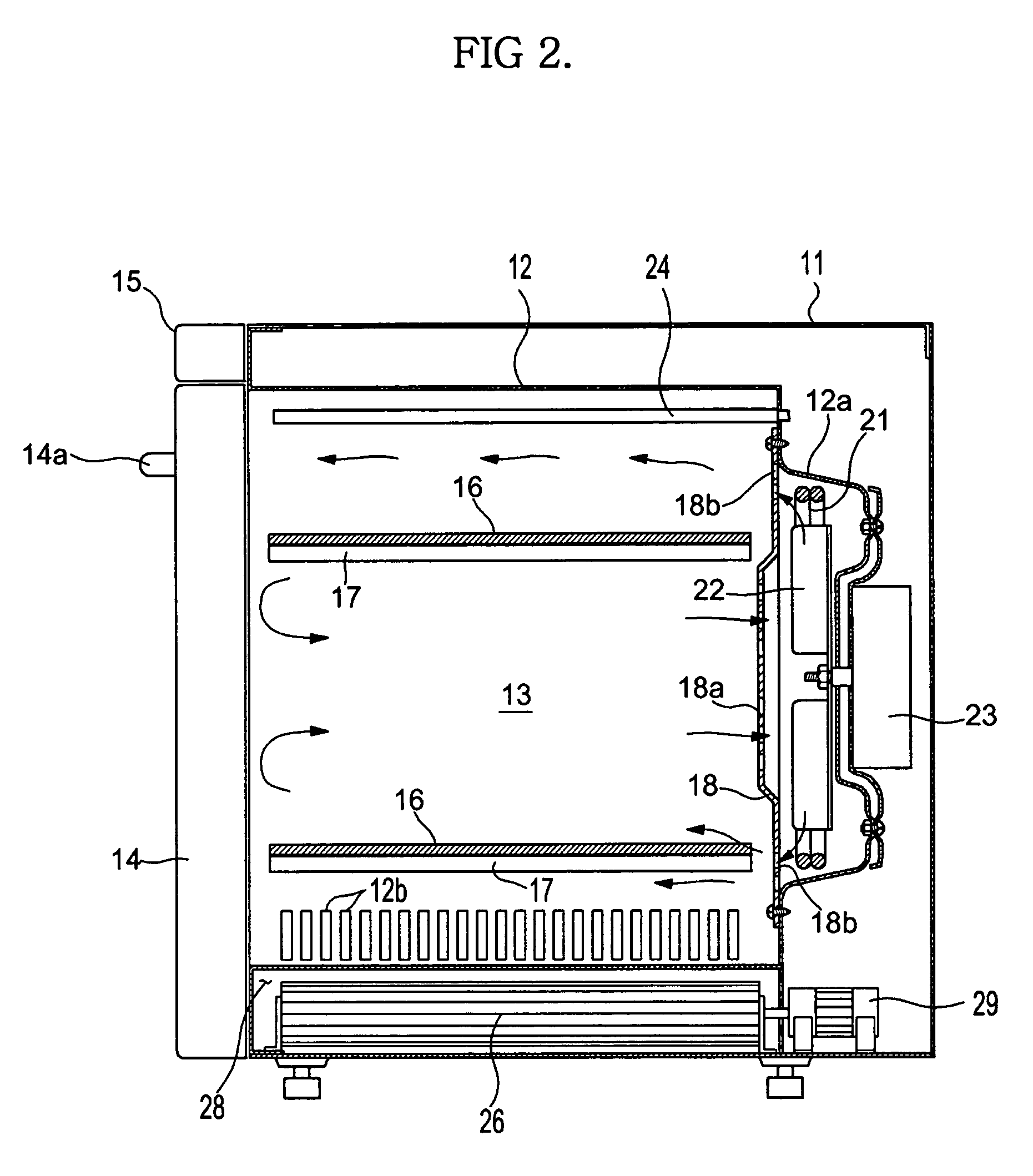

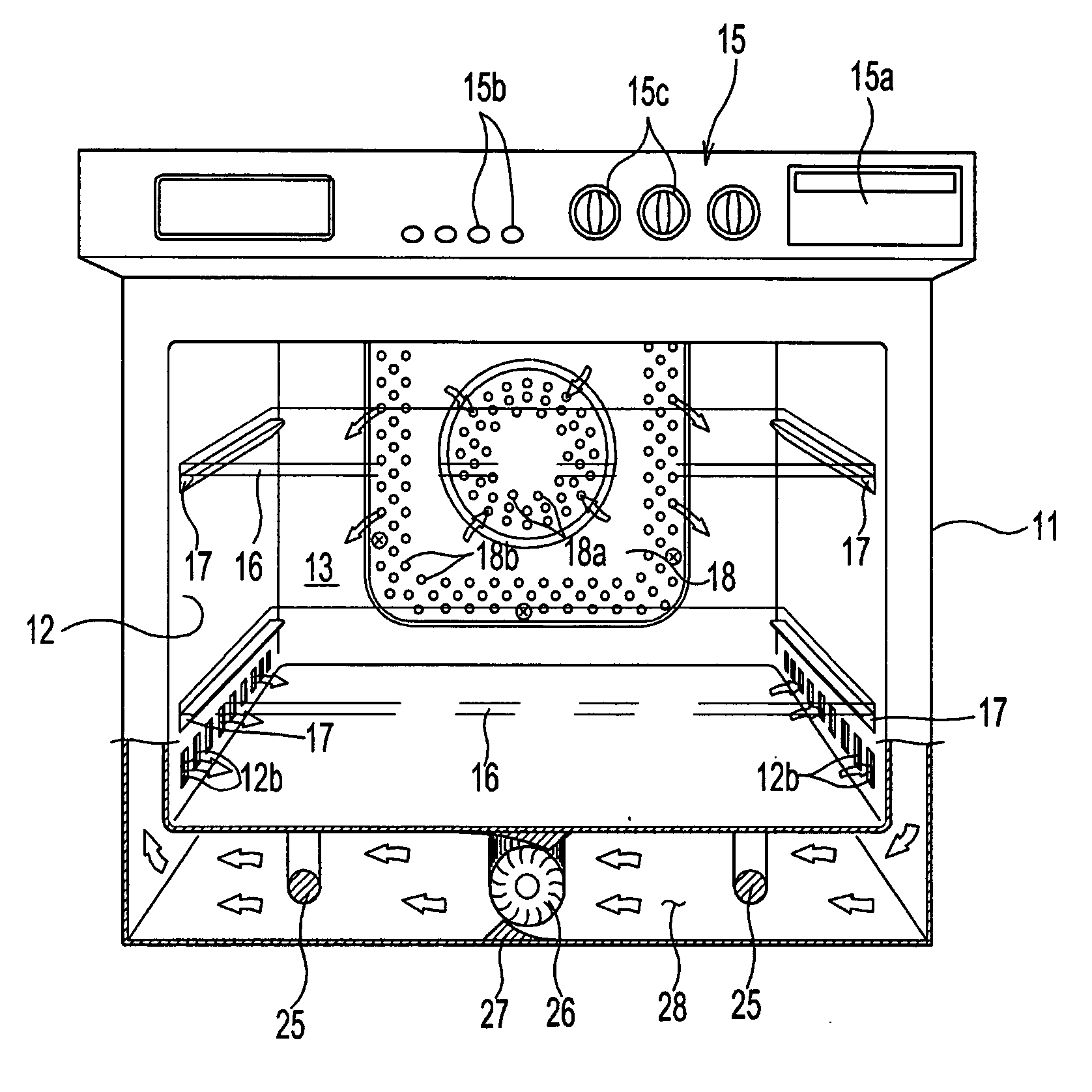

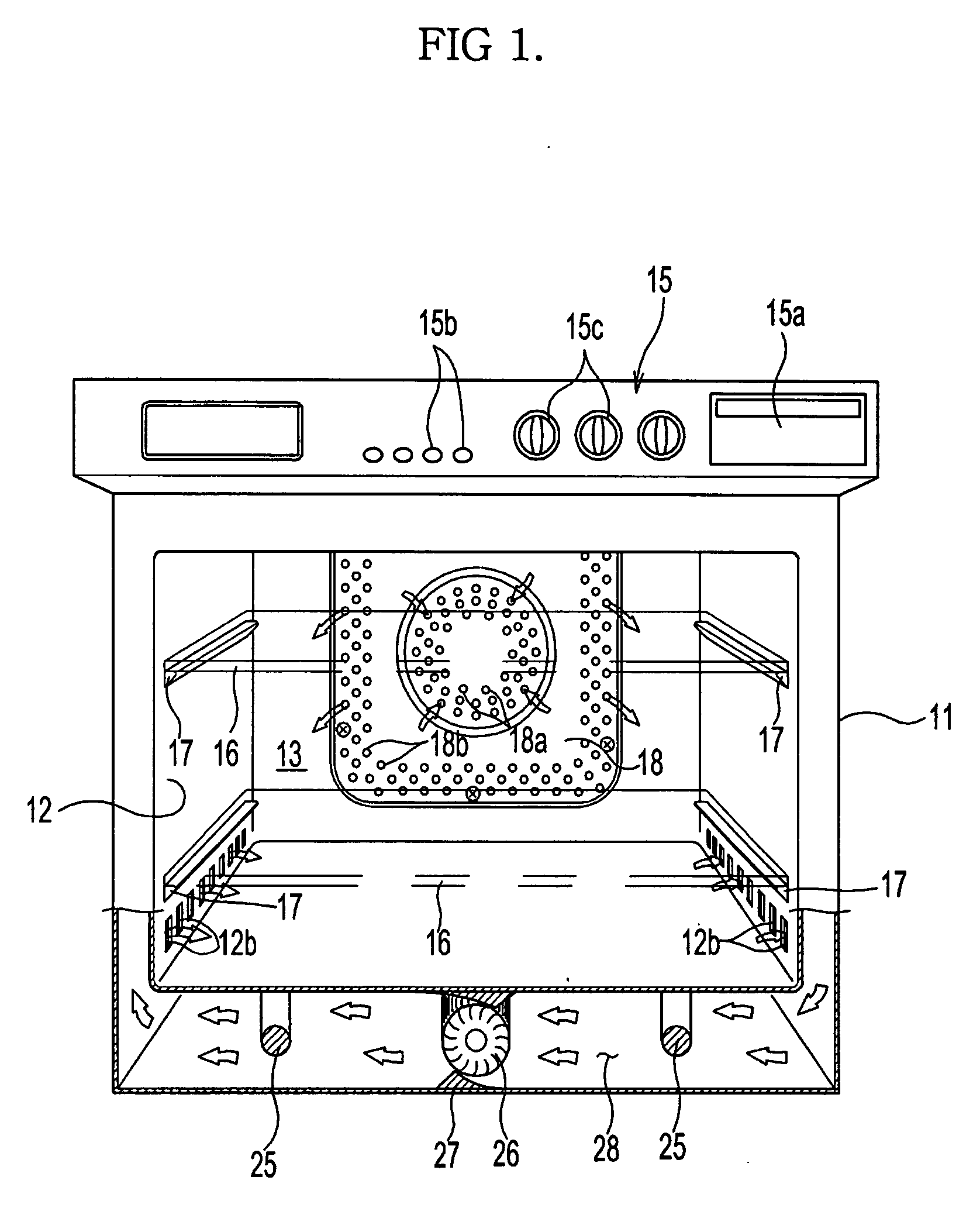

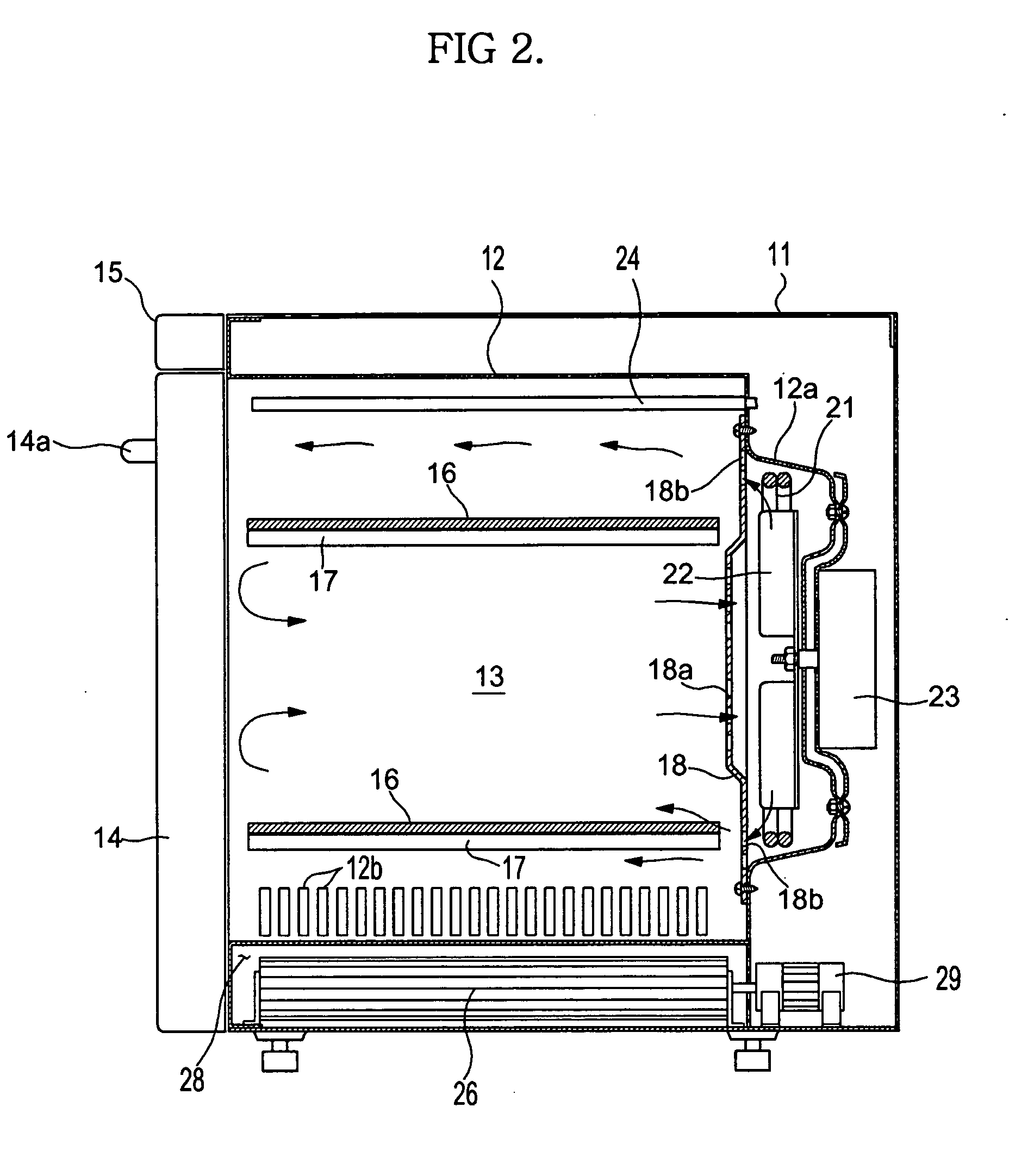

Electric oven

InactiveUS7102105B2Improve heating efficiencyImprove heat transfer efficiencyAir-treating devicesDomestic stoves or rangesEngineeringHeat transfer

An electric oven including lower heaters arranged under a cooking chamber thereof. The electric oven includes an outer case defining the appearance of the electric oven, an inner case inwardly spaced apart from the outer case by a predetermined distance, and lower heaters arranged between bottom walls of the outer and inner cases. The inner case internally defines a cooking chamber, and a blowing fan is installed near the lower heaters to circulate air existing in the cooking chamber toward the lower heaters. With the electric oven configured as stated above, heat generated by the lower heaters is transferred to the cooking chamber in the form of conductive heat and convective heat, resulting in fast and efficient heat transfer and even cooking of food.

Owner:SAMSUNG ELECTRONICS CO LTD

Electric oven

InactiveUS20060131298A1Improve heat transfer efficiencyImprove heating efficiencyAir-treating devicesDomestic stoves or rangesEngineeringIngested food

An electric oven including lower heaters arranged under a cooking chamber thereof. The electric oven includes an outer case defining the appearance of the electric oven, an inner case inwardly spaced apart from the outer case by a predetermined distance, and lower heaters arranged between bottom walls of the outer and inner cases. The inner case internally defines a cooking chamber, and a blowing fan is installed near the lower heaters to circulate air existing in the cooking chamber toward the lower heaters. With the electric oven configured as stated above, heat generated by the lower heaters is transferred to the cooking chamber in the form of conductive heat and convective heat, resulting in fast and efficient heat transfer and even cooking of food.

Owner:SAMSUNG ELECTRONICS CO LTD

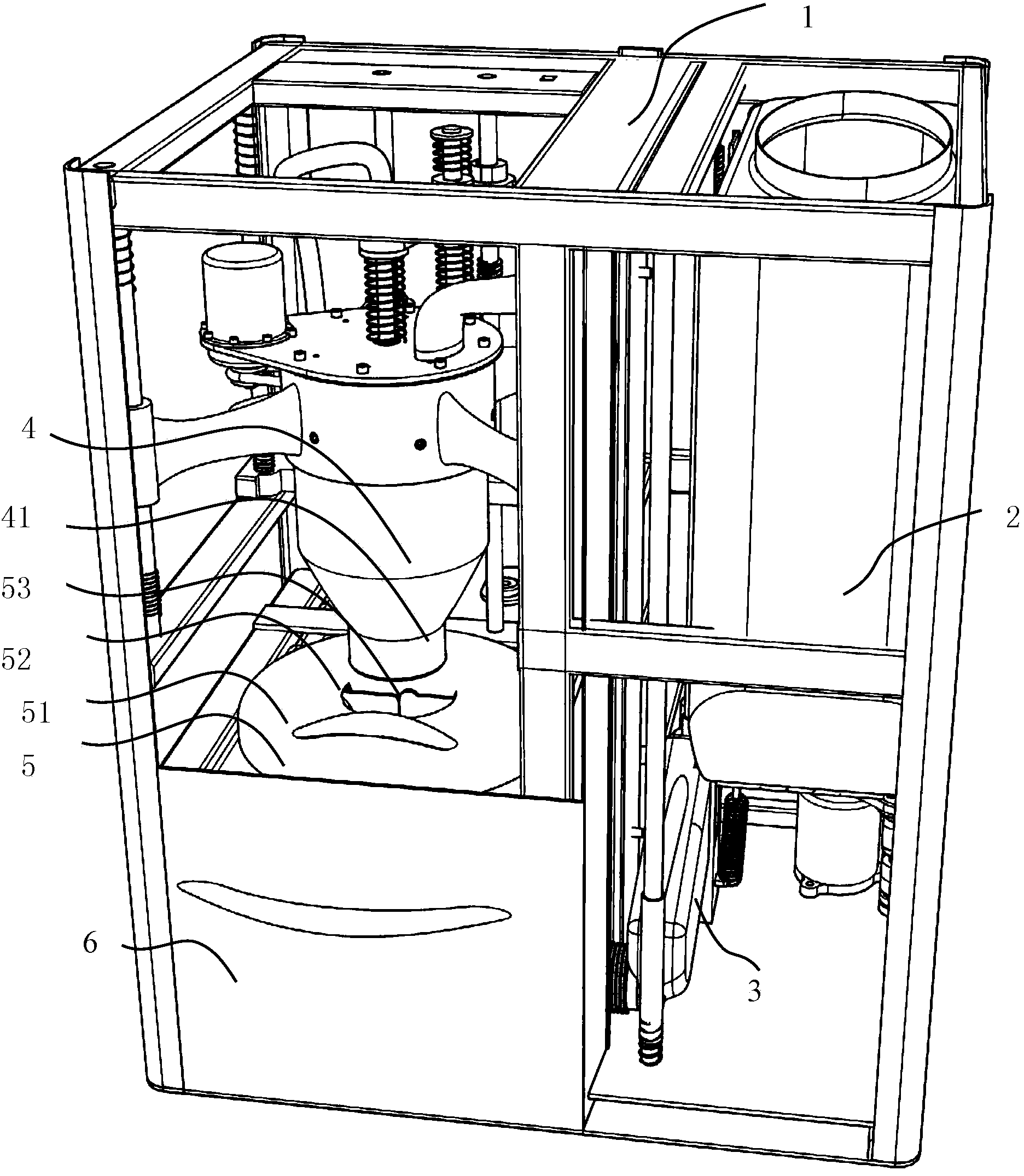

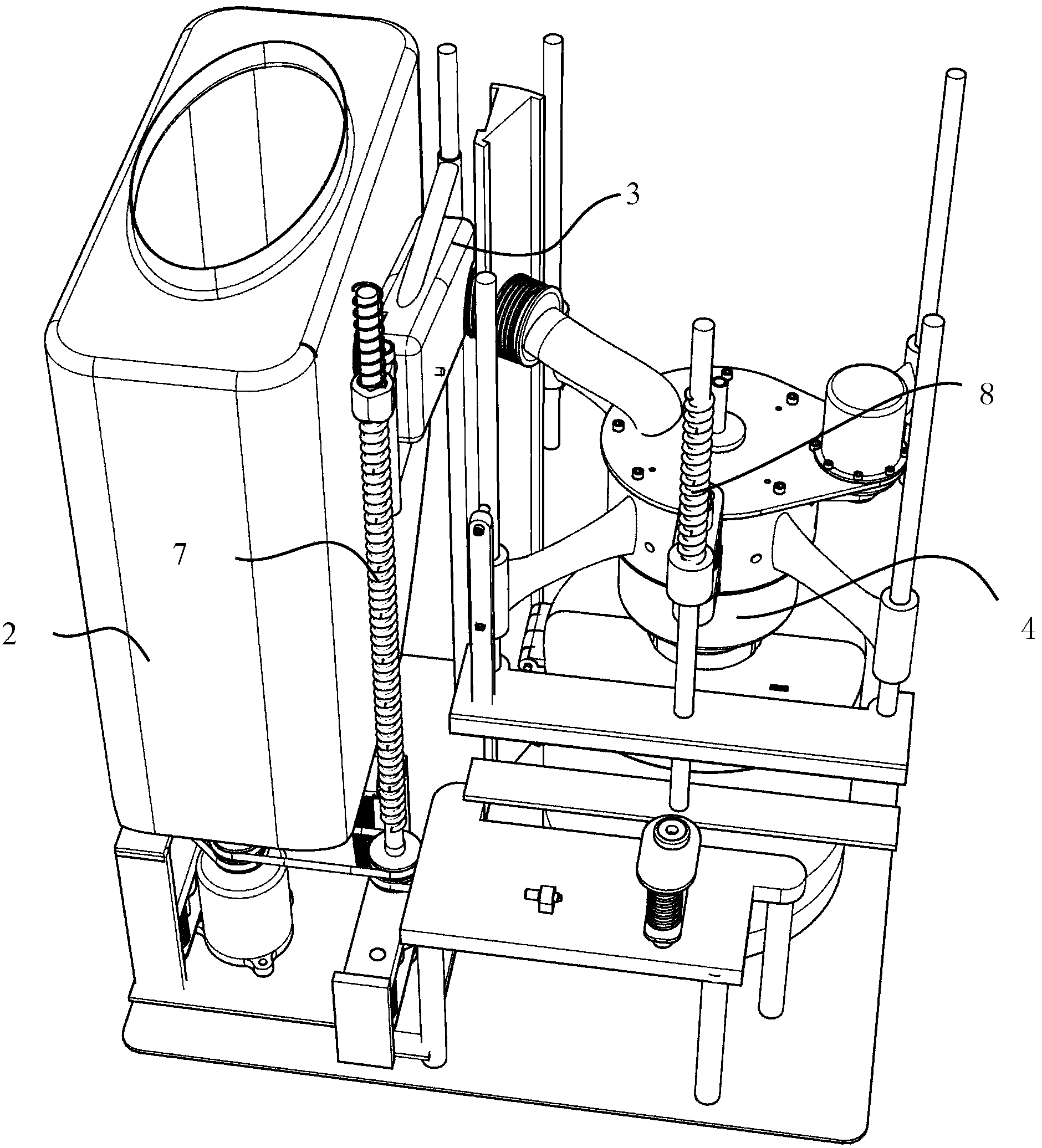

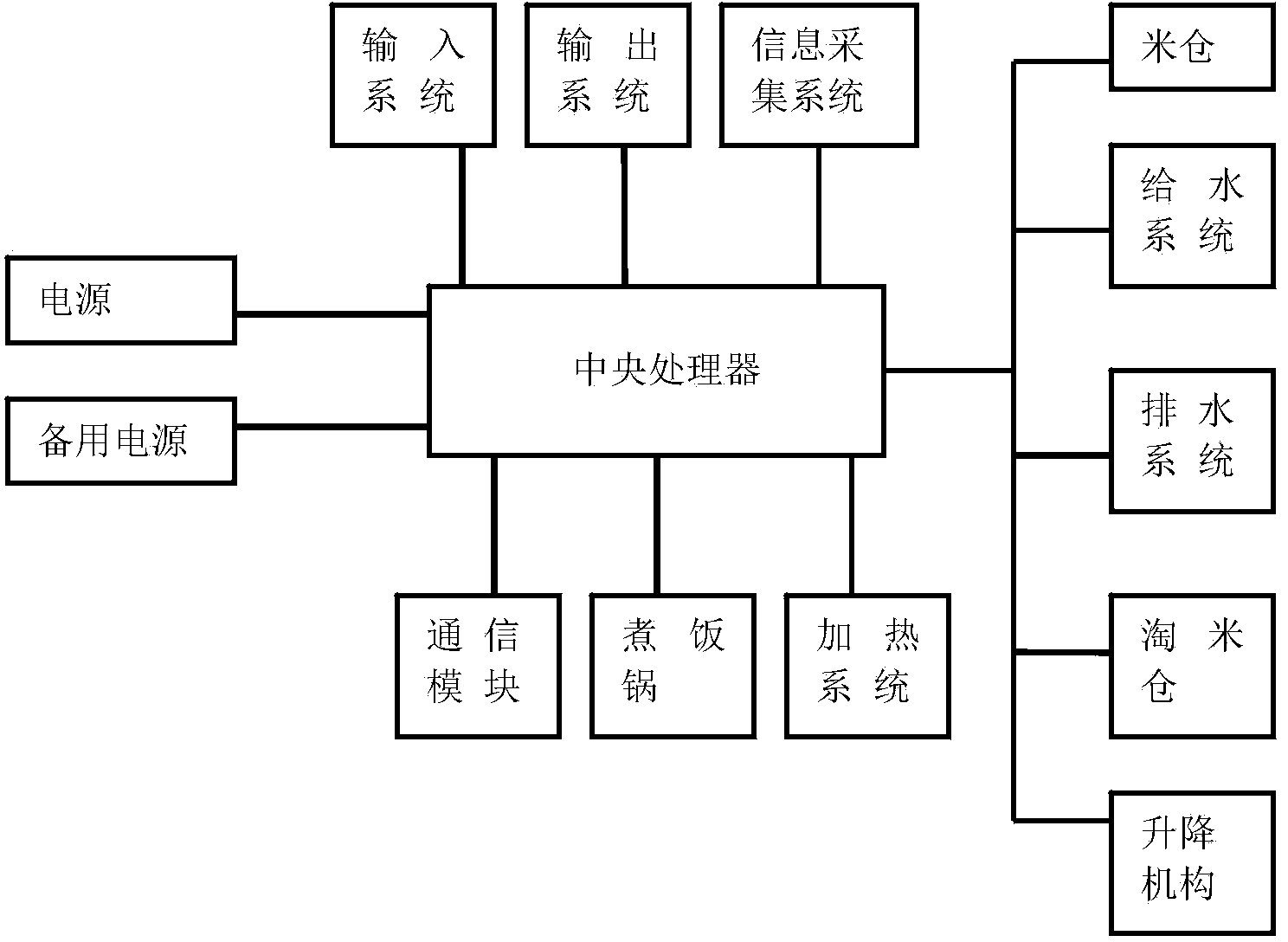

Electric cooker remote control method

ActiveCN103838160ALow costShorten control timeCooking vesselsProgramme control in sequence/logic controllersEmbedded systemSelf checking

The invention discloses an electric cooker remote control method, and relates to the technical field of electric appliance remote control. The method includes the steps that a user remotely sends cooking information to an electric cooker through a mobile terminal or a computer, the electric cooker carries out system self-checking after receiving the cooking information and feeds back a self-checking result to the user, and the electric cooker starts to cook after the self-checking result is detected to be normal. A central processor of the electric cooker controls the processes of automatic rice measuring, rice adding, water feeding, rice washing and cooking. The electric cooker remote control method has the advantages that people can send the cooking information to the electric cooker at home at any place, the electric cooker automatic executes all procedures of rice cooking, rice is precisely measured, water is added, the rice does not need to be soaked, and quality and taste of cooked rice are not influenced. The user can know whether water supplies and power supplies at home are cut off in real time, whether rice in a rice barn is insufficient and other information. Binding of the electric cooker and the mobile terminal or the computer achieves the fact that multiple mobile terminals or computers control one electric cooker, and any person at home can remotely control the electric cooker for cooking.

Owner:广西北部湾粮油技术研究有限公司

Food processor with rotary type defoaming device

InactiveCN101703365AEliminate generationContinuous heatingBeverage vesselsStrainersSocial benefitsEconomic benefits

The invention relates to a food processor with a rotary type defoaming device. A main body of the food processor comprises a pulverization cutter, a motor, a pulverization knife shaft and a barrel body; a rotary type defoaming device is arranged on the food processor; the rotary type defoaming device comprises a defoamer main body, wherein the rotation center position of the defoamer main body is provided with a shaft center installation hole, or the defoamer main body is provided with a rotating shaft; and the defoamer main body is connected with a power shaft, and the power shaft is the self pulverization knife shaft or other power shafts of the food processor. The invention can actively eliminate foam generated when foods are pulverized, heated and cooked in time, enables the pulverization operation or the heating and cooking operation to be continuously and quickly carried out without intermittent stop, shortens the pulverization or cooking time greatly, enhances the working efficiency, can meet the rhythm of the modern family life and the requirement of quick rhythm of the modern commercial management, enhances the quality of the modern family life and the efficiency of the commercial management obviously and has great economic benefit and social benefit.

Owner:王晓东

Tiltable pannini grill

InactiveUS7514655B2Easy to placeReduce cooking timeDomestic stoves or rangesElectrical heating fuelUser inputDisplay device

Owner:SOUTH ASIA INT H K +1

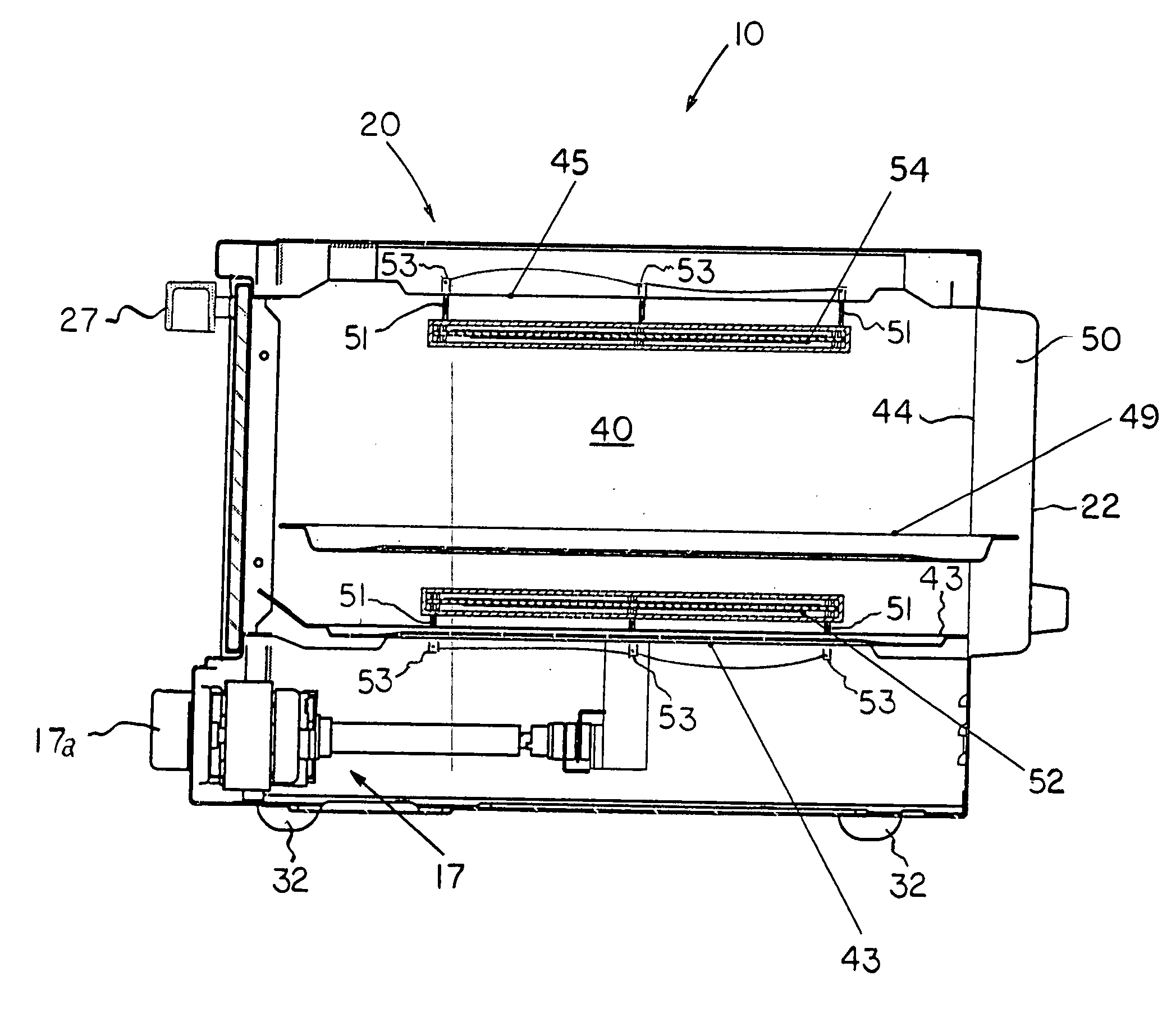

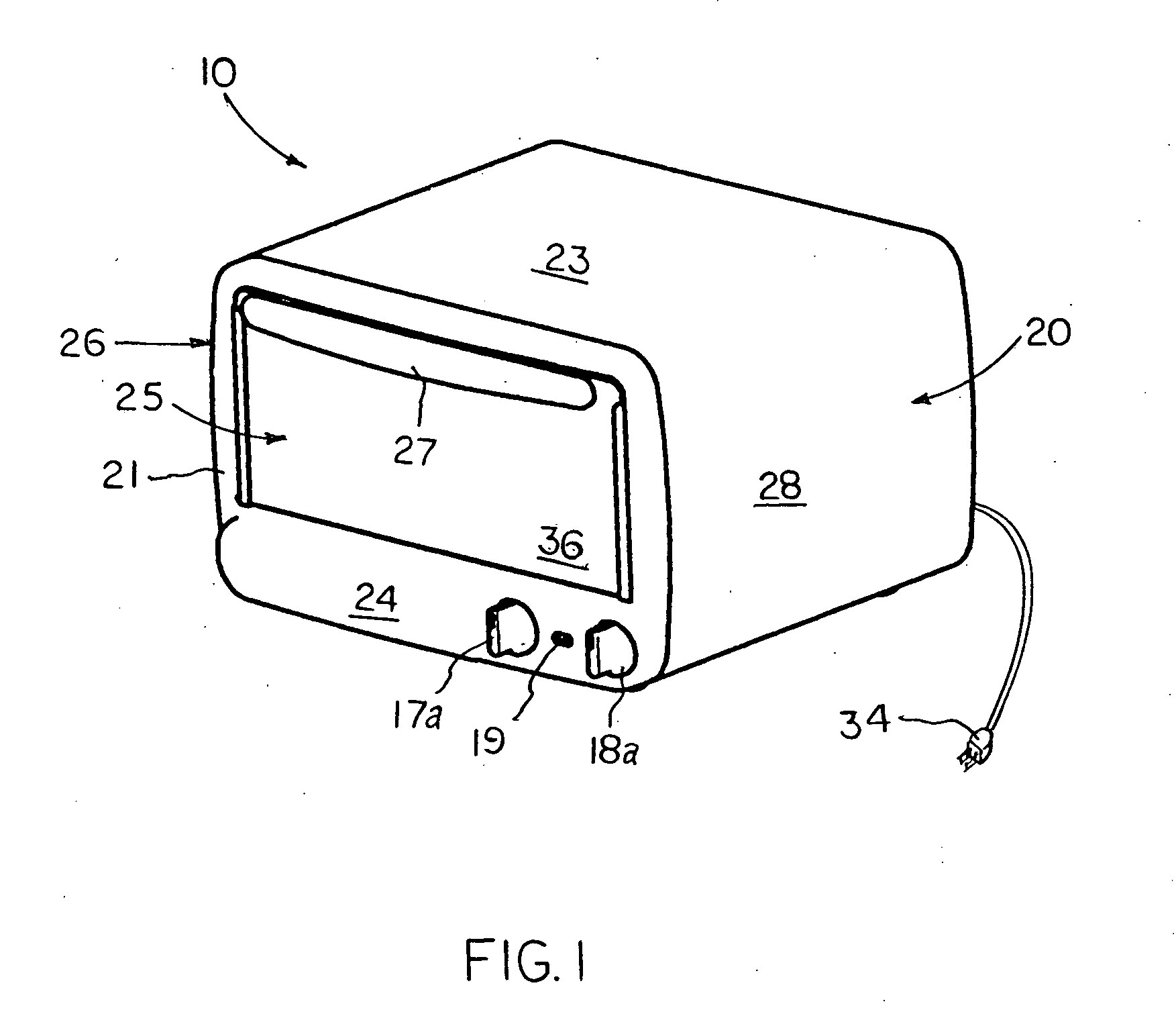

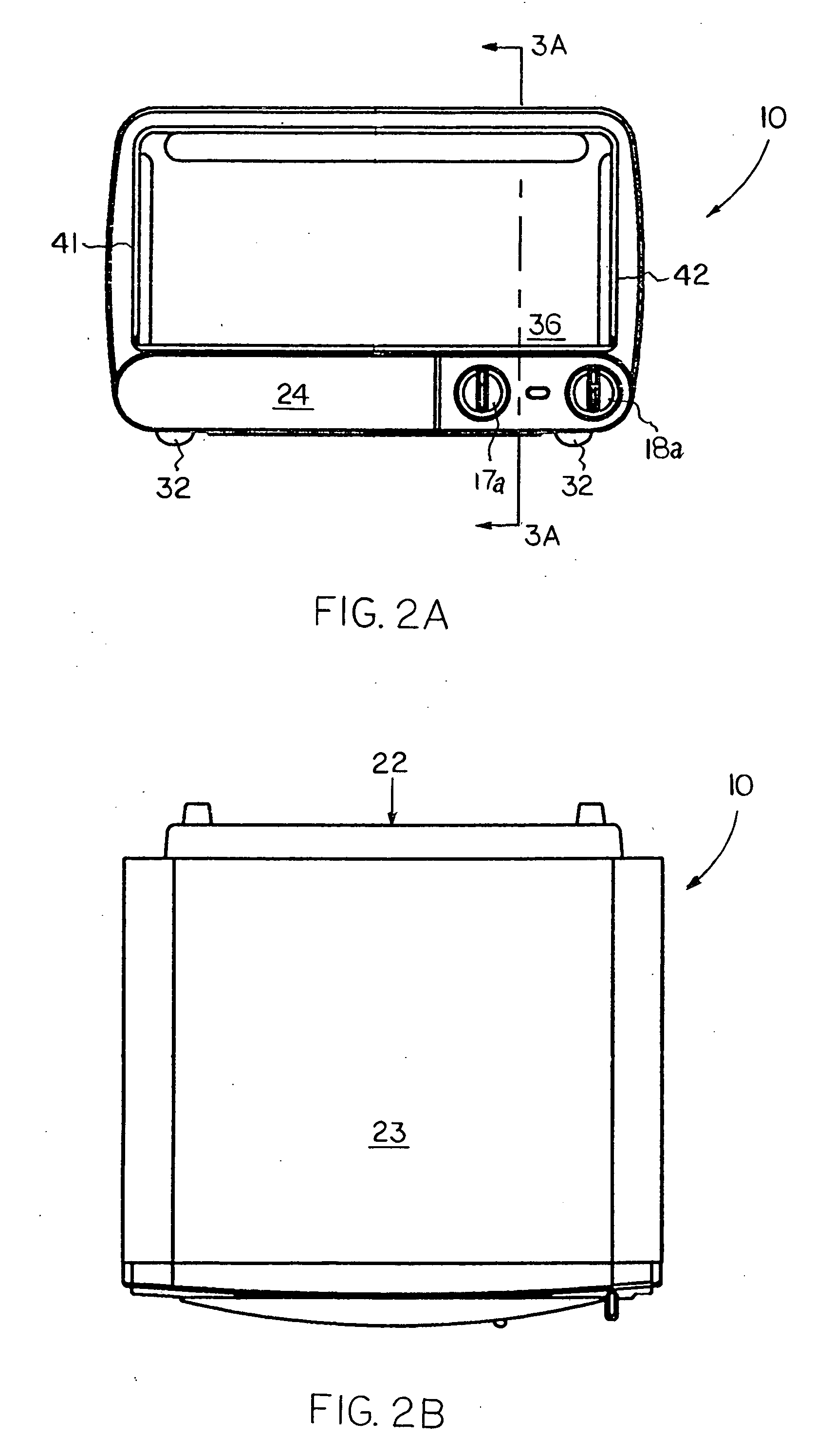

Toaster oven with low-profile heating elements

InactiveUS20080099461A1Increase usable capacityReduce cooking timeDomestic stoves or rangesElectrical heating fuelComputer moduleProcess engineering

A toaster oven appliance including low-profile heating elements having a predetermined single-sided surface area calculated to provide uniform heating within the cooking chamber, facilitate cleaning and to increase its usable capacity is disclosed. Various alternative configurations of top, bottom, and side-mounted heating elements in combination with both fixed and vertically movable heating element embodiments are provided for use with standard and digital controls. The heating elements are positioned both internally and externally of the cooking chamber and are provided in unsheathed, plain-sheathed, and metallic-sheathed types for a given application of the present oven. In one embodiment the heating elements are constructed as removable plug-in modules for convenient cleaning and replacement. The present toaster oven further includes an optional forced convection fan to reduce cooking temperature and shorten cooking cycles. An optional rotisserie mechanism is also provided in conjunction with the aforementioned combinations of heating elements and heating controls.

Owner:ACORNE ENTERPRISES

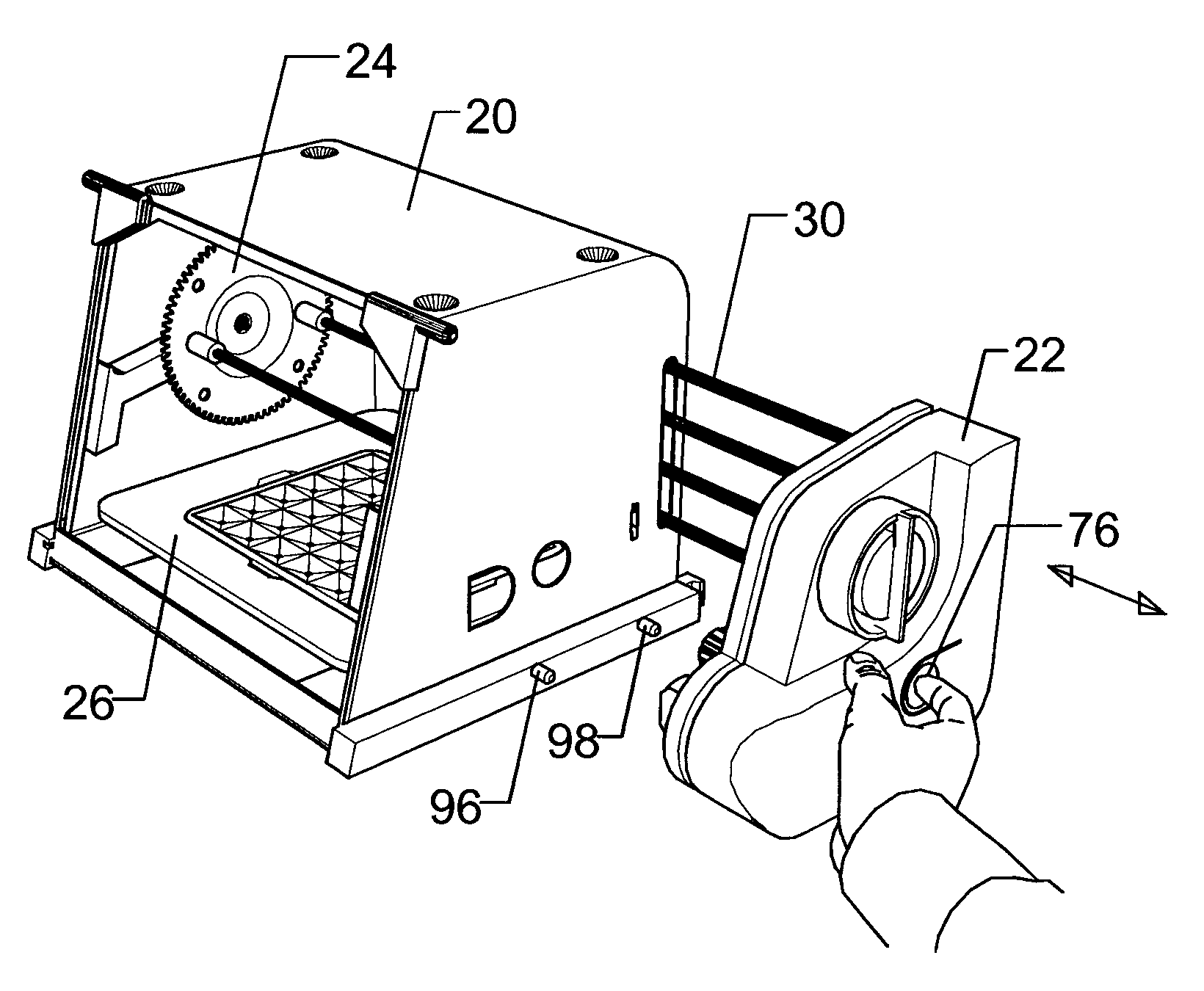

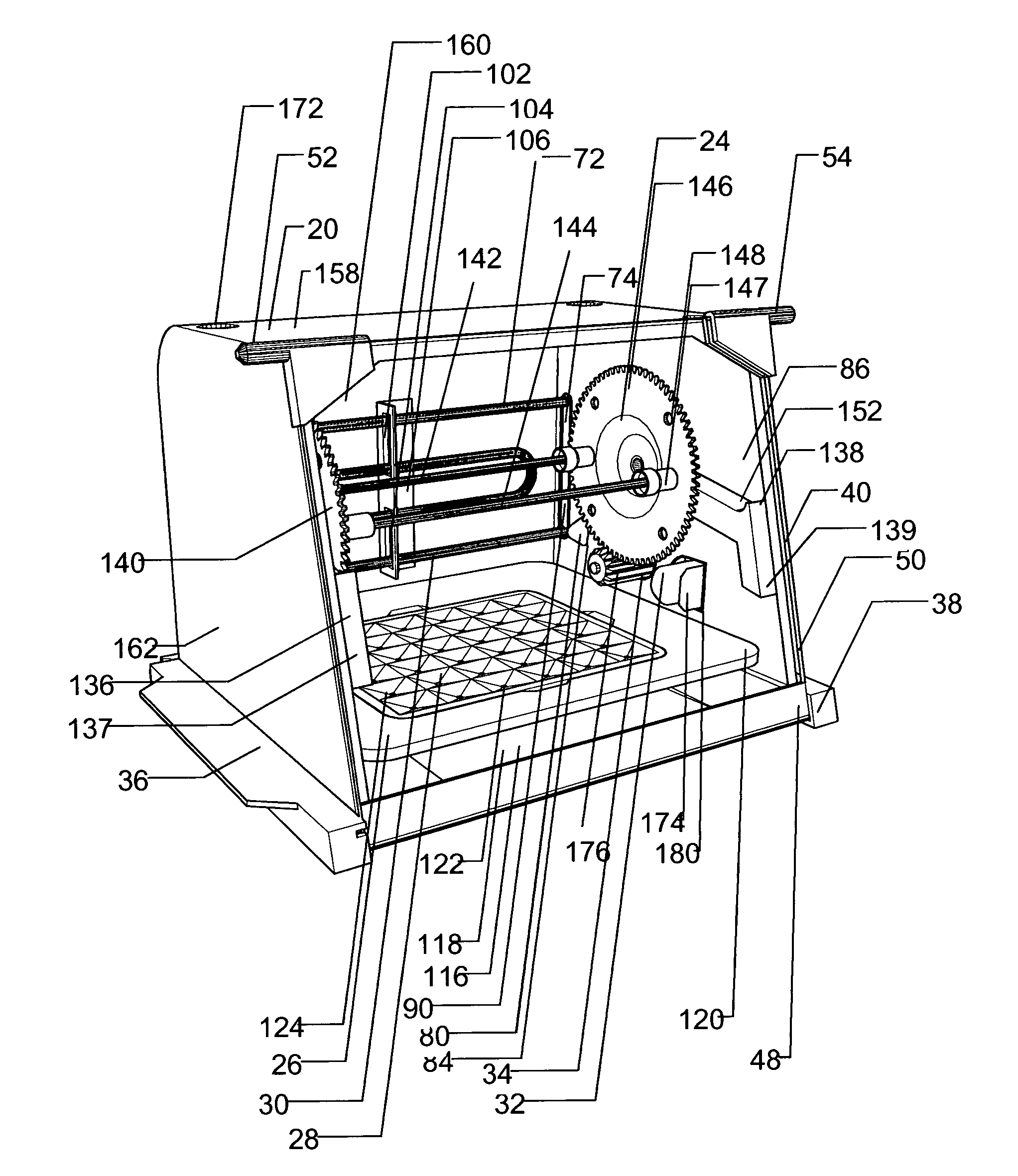

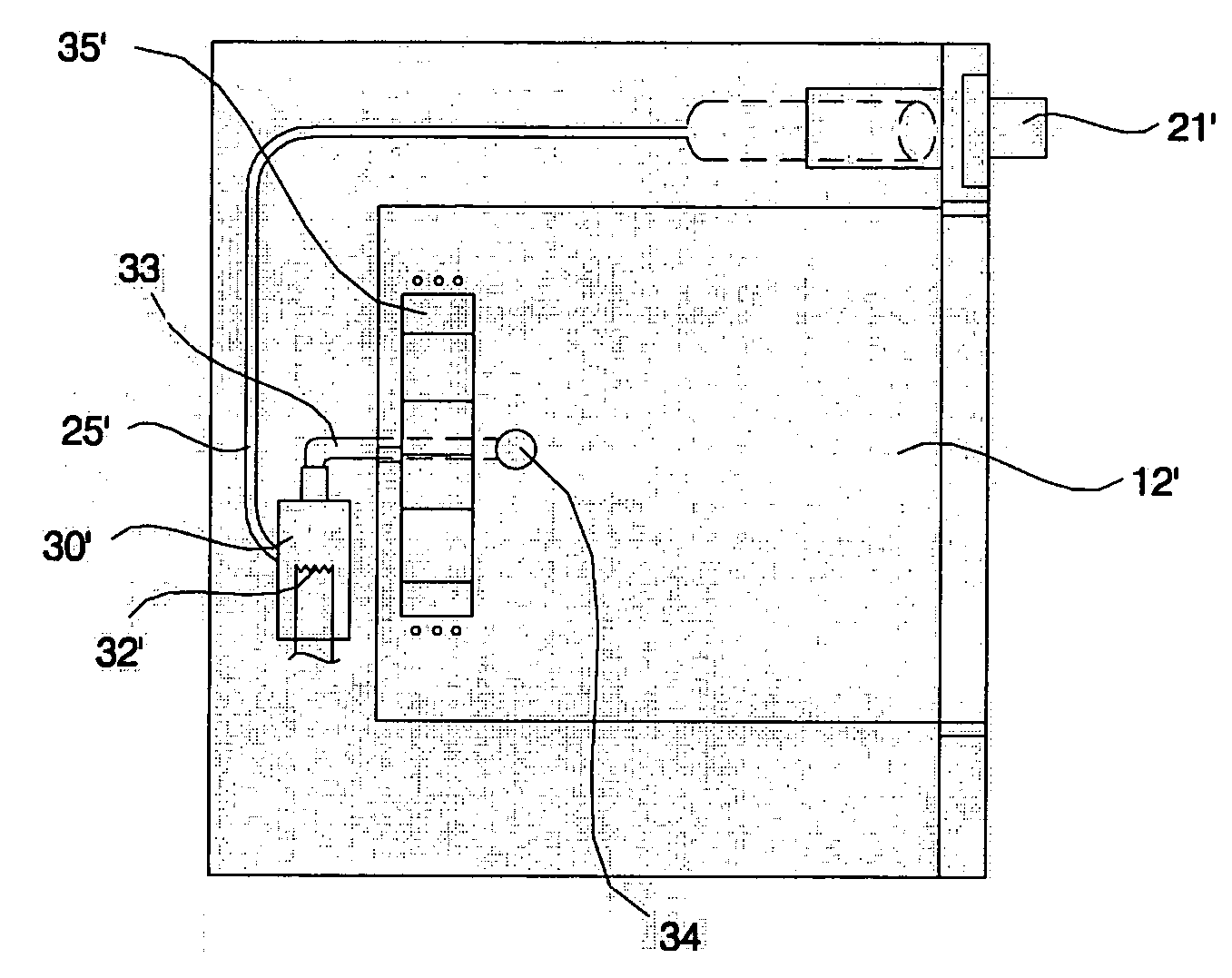

Food cooking apparatus with detachable electronic components

InactiveUS20050056633A1Easy to insertEasy to removeCharge supportsBaking ovenEngineeringElectronic component

The present invention is directed toward a food cooking apparatus, particularly a toaster oven, having the following features: a removable side mounted control box; single wall oven cabinet construction; single wall oven cabinet construction with tabs protruding from the lower side edges of the oven cabinet which mount feet to support the cabinet; a rigid heat coil structurally connected to the removable control box; a heat coil, supported by a bracket within the oven cabinet which both allows the heat coil to be slid in and out of the oven cabinet and allows for expansion of the heat coil when the coil is energized; a light bulb integrated with the removable control box so that the bulb's globe protrudes into the interior of the oven cabinet when the control box is mounted on the oven cabinet; and a drive mechanism integrated into the removable control box which allows the control box to be easily removed from the oven cabinet.

Owner:RONCO ACQUISITION

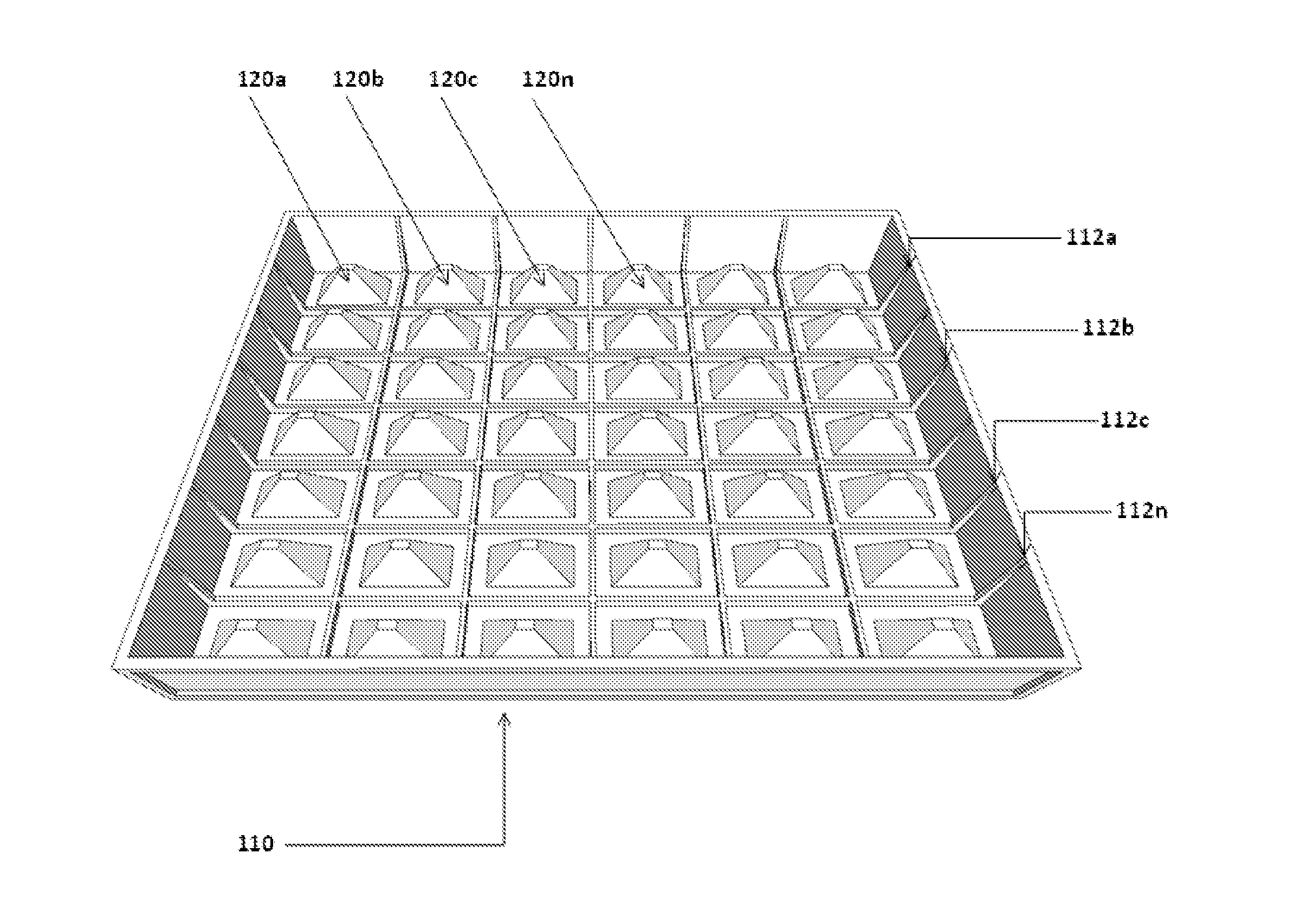

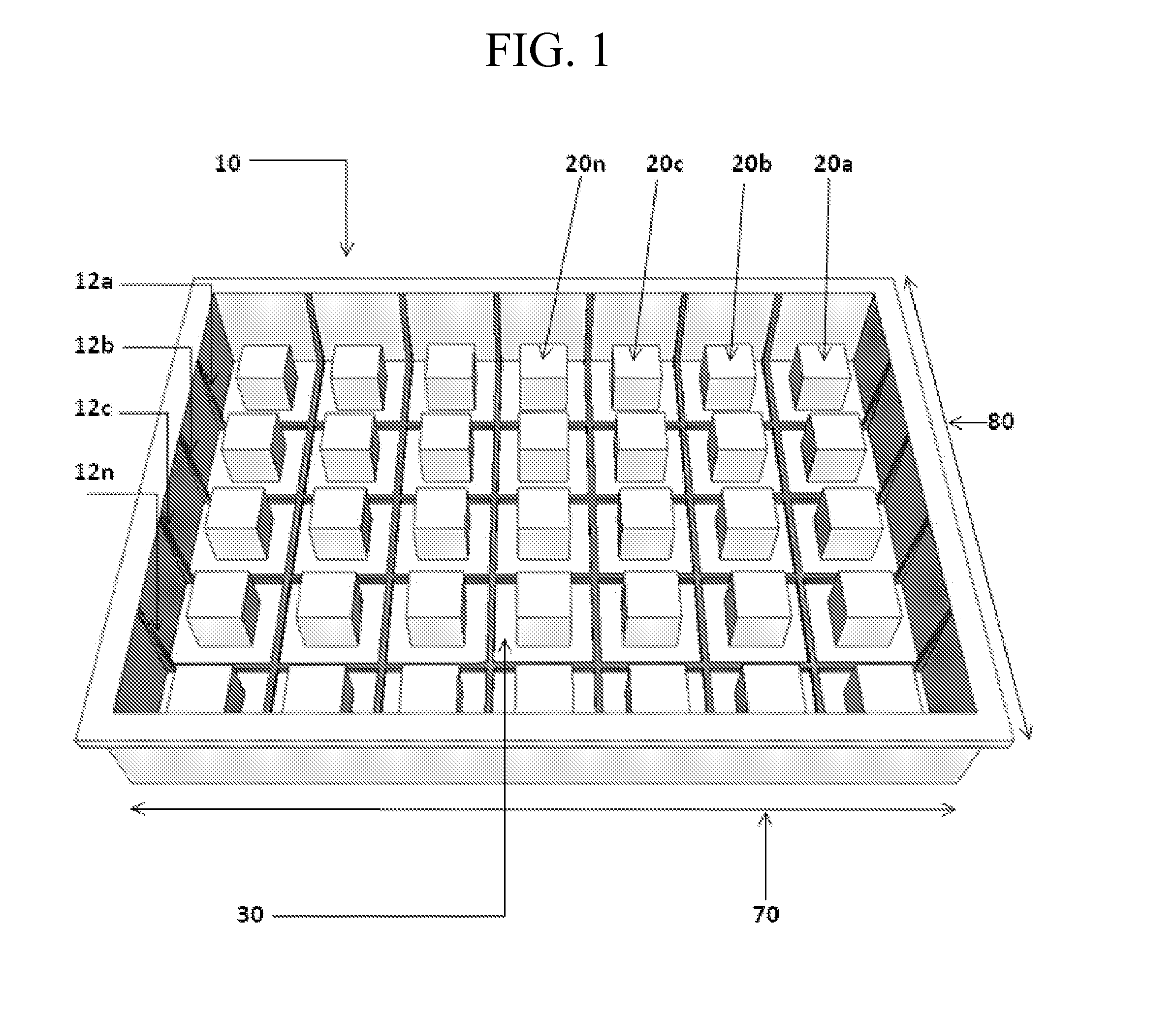

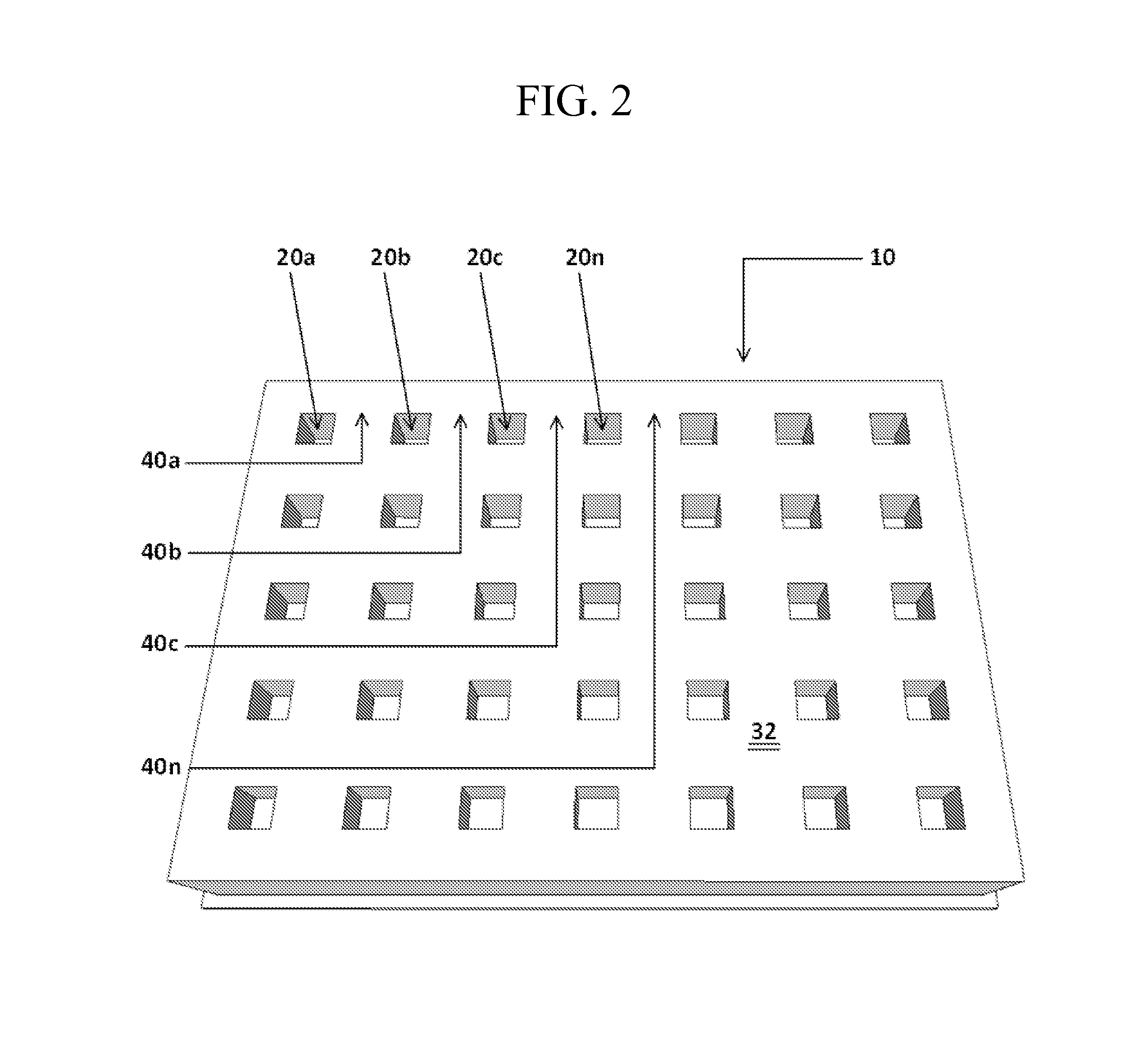

Food pans with thermal conveyance depressions

InactiveUS20130129890A1Excellent mean of portion controlImproves transfer of heating and cooling propertyDough treatmentMilk preservationEngineering

Various types of food preparation pans such as but not limited to food preparation pans used for baking, steaming, chilling, freezing and molding various foods and food combinations intended for consumption are disclosed. The pan includes a plurality of thermal conveyance depressions protruding in a vertically oriented disposition relative to a horizontal inner pan bottom surface; and upwardly projected depressions in an outer pan bottom surface of the thermal conveyance depressions to form hollow depressions spaced in between by bridging portions.

Owner:COX MONTE WILLIAM

Steam generator for steam oven

InactiveUS20060096970A1Small sizeIncrease in sizeDomestic stoves or rangesOven air-treatment devicesEngineeringWater supply

A steam generator for a steam oven. The steam generator includes a water injection unit for supplying water from the outside to the steam generator therethrough; a water tank installed outside a cooking chamber for storing the water supplied through the water injection unit; a flow adjusting unit installed at an outlet of the water tank for adjusting the quantity of the supplied water; a steam pipe connected between the flow adjusting unit and the cooking chamber for changing the water therein into steam and supplying the steam to the inside of the cooking chamber; and a heater installed in the steam pipe for heating the water supplied to the inside of the steam pipe, thereby reducing the overall size of the oven to relatively increase the size of the cooking chamber, and rapidly generating the steam without increasing the capacity of the heater to shorten the overall cooking time.

Owner:LG ELECTRONICS INC

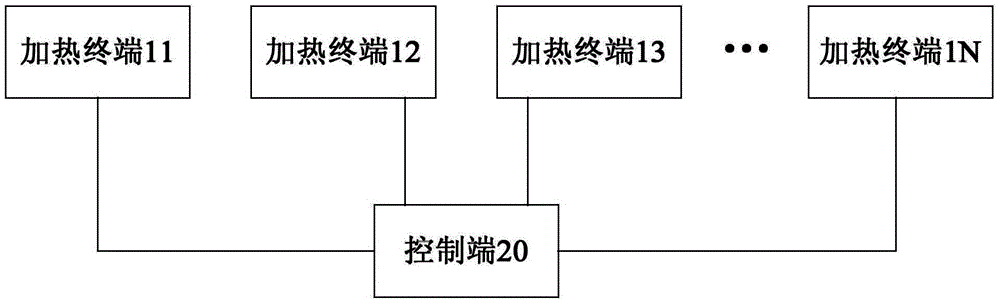

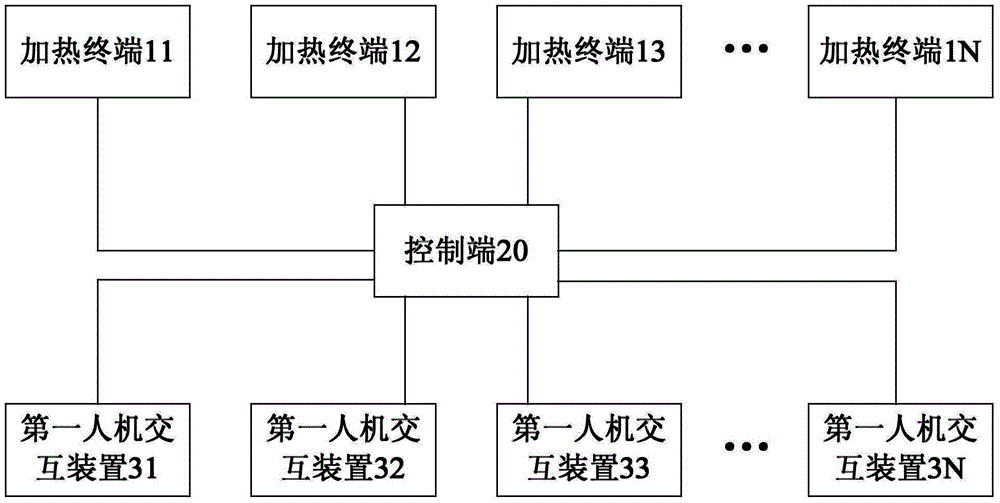

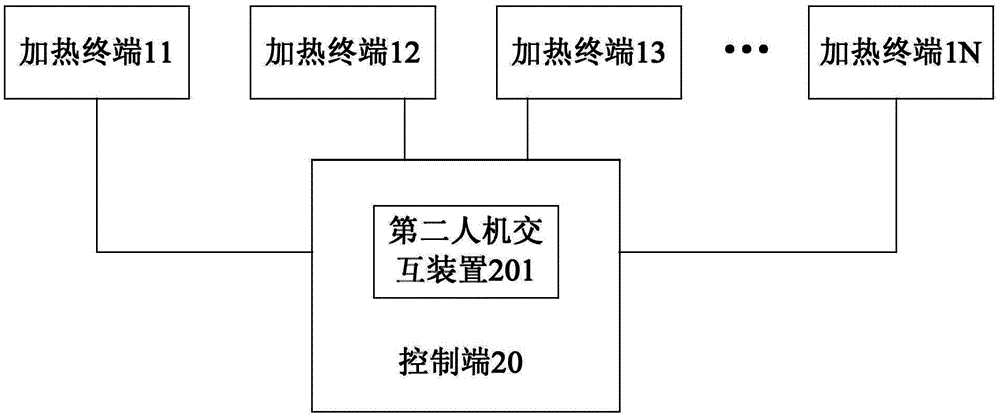

Automatic cooking system and control method thereof

ActiveCN105204451AConsistent cooking timeSame end timeCooking vesselsProgramme total factory controlLife qualityStart time

The invention discloses an automatic cooking system comprising multiple heating terminals and a control terminal for controlling the multiple heating terminals. The control terminal acquires the cooling time of a dish to be cooked by each of the heating terminals about to work in the multiple heating terminals, generates corresponding start time according to the cooking time of each heating terminal about to work, and controls the starting of the corresponding heating terminals about to work according to the start time of the heating terminals about to work so as to enable the end time of the dishes cooked by the heating terminals about to work to be consistent. According to the automatic cooking system, the multiple terminals for cooking different dishes can complete cooking at the same time, the cooking time is greatly reduced, and convenience is brought to users. Moreover, multiple different dishes are completed at the same time, users do not need to wait, users can feel that all the multiple different dishes are just taken out of the pot, and the living quality of people is improved. The invention further discloses a control method of the automatic cooking system.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com