Patents

Literature

387results about How to "Evenly baked" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

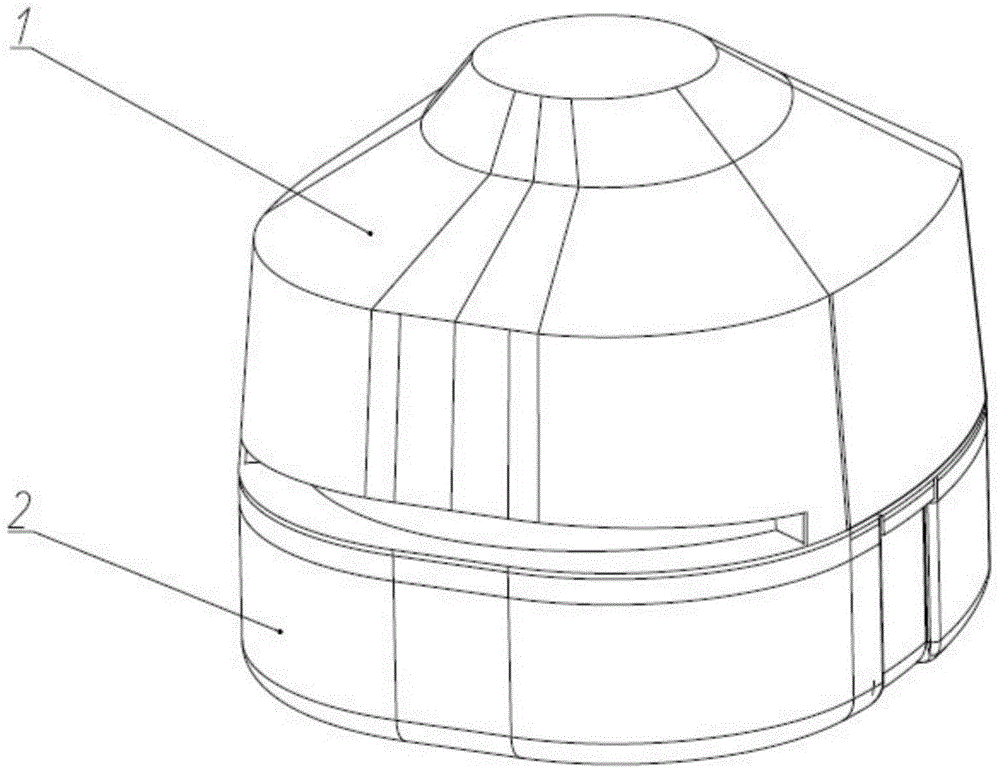

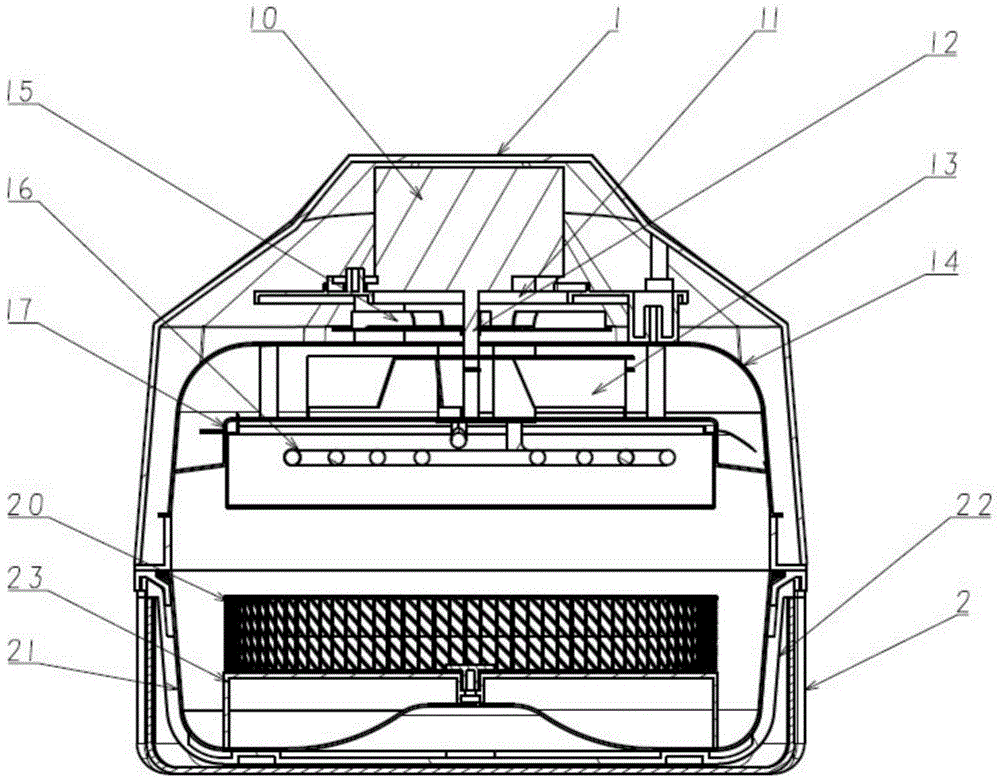

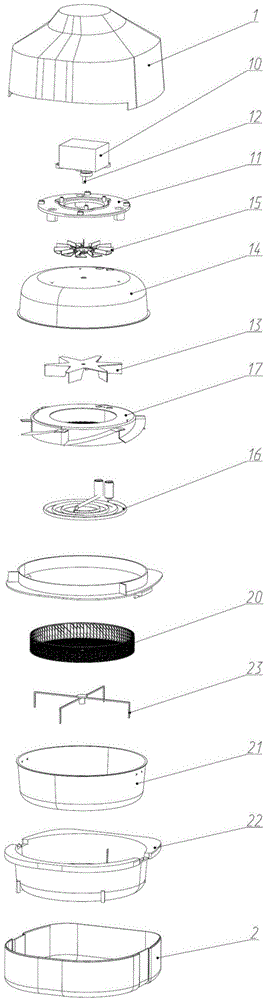

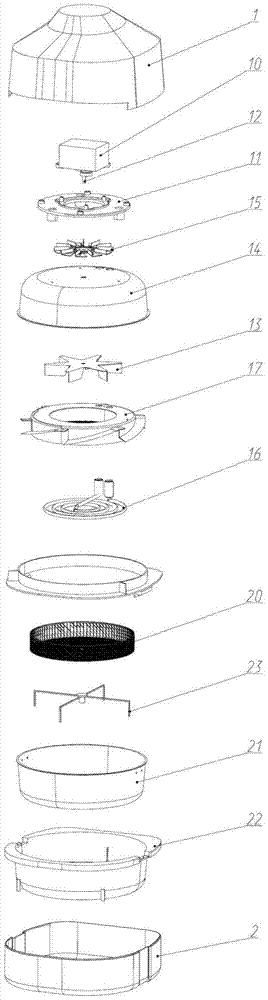

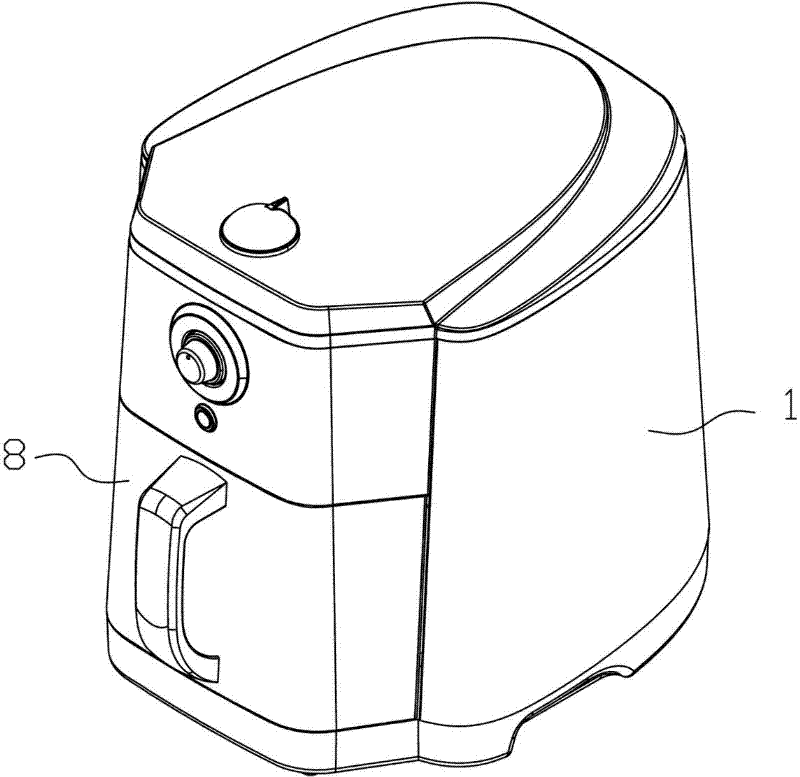

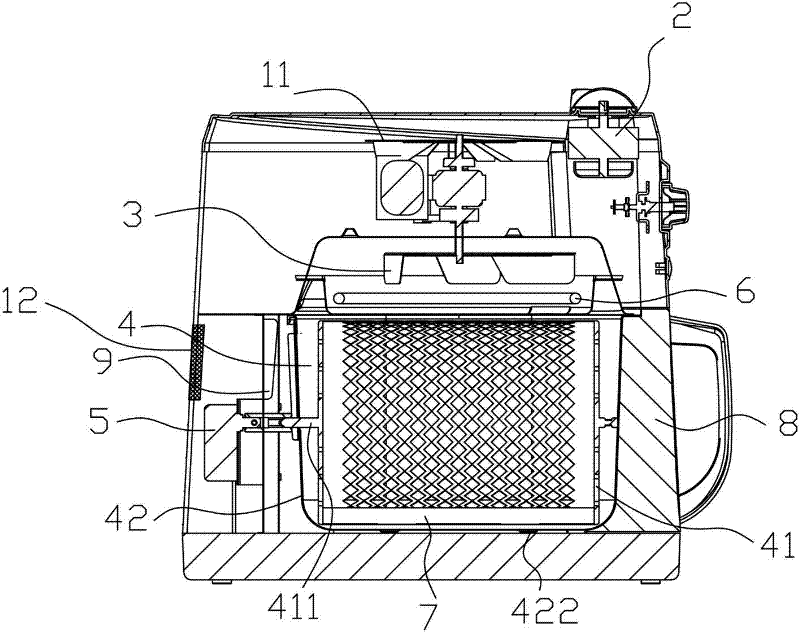

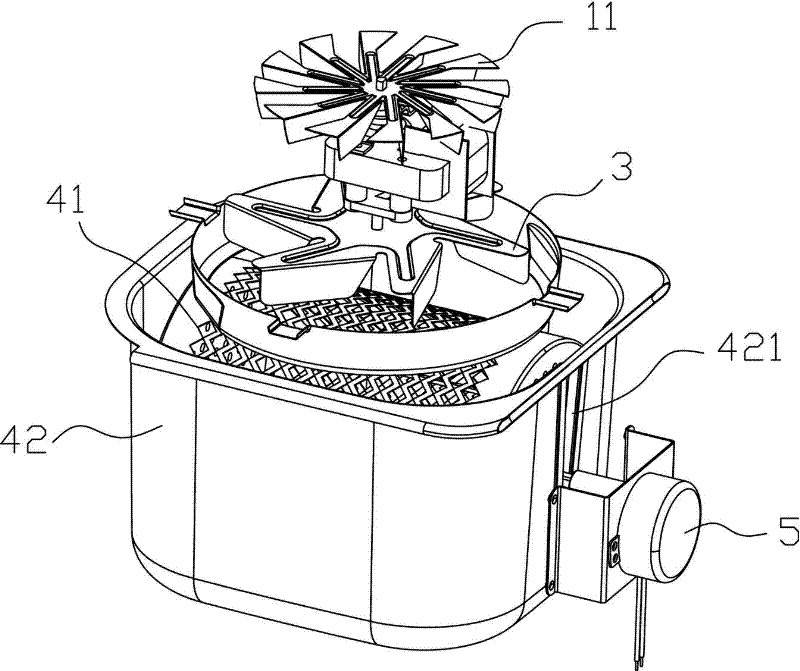

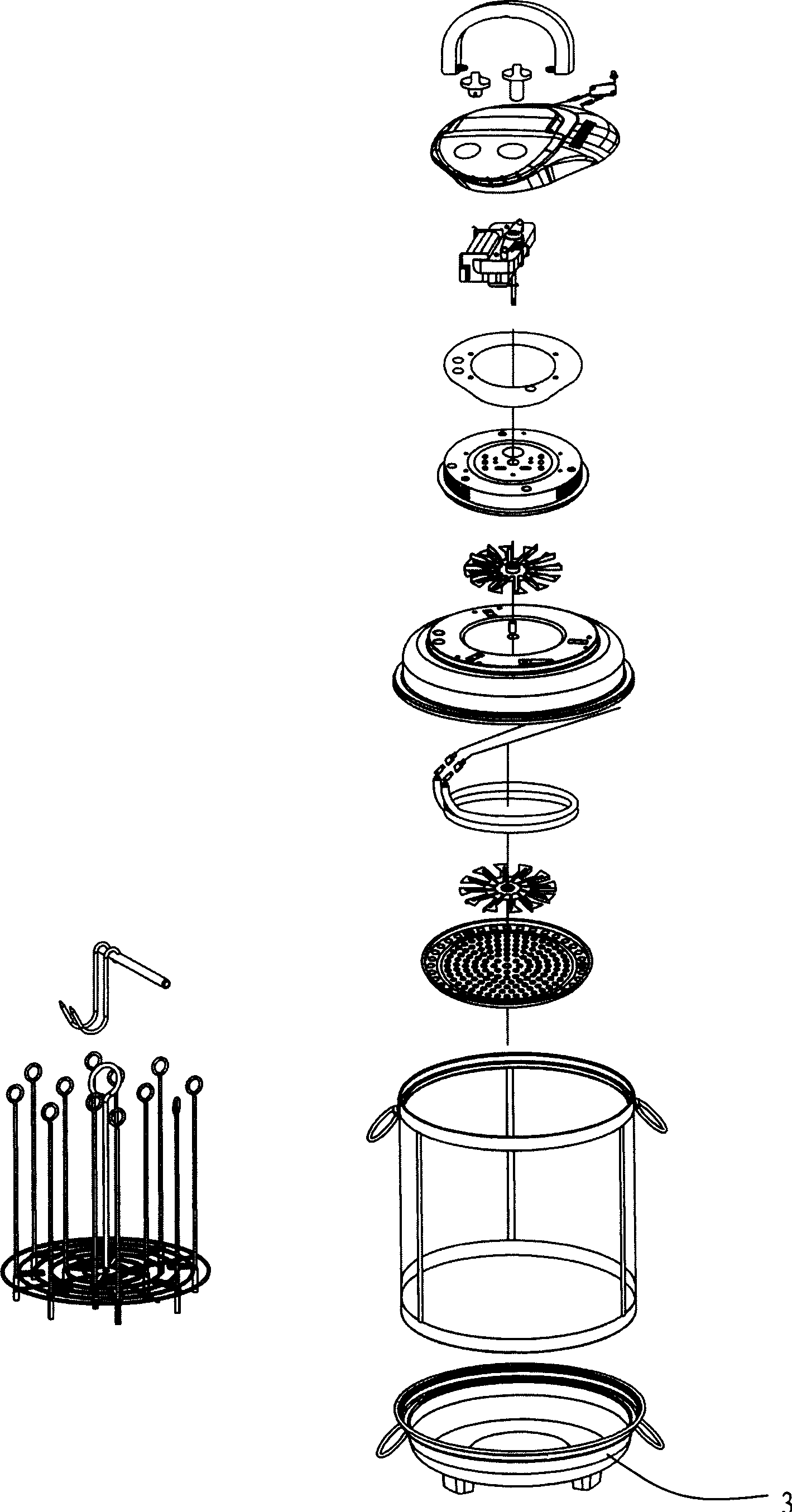

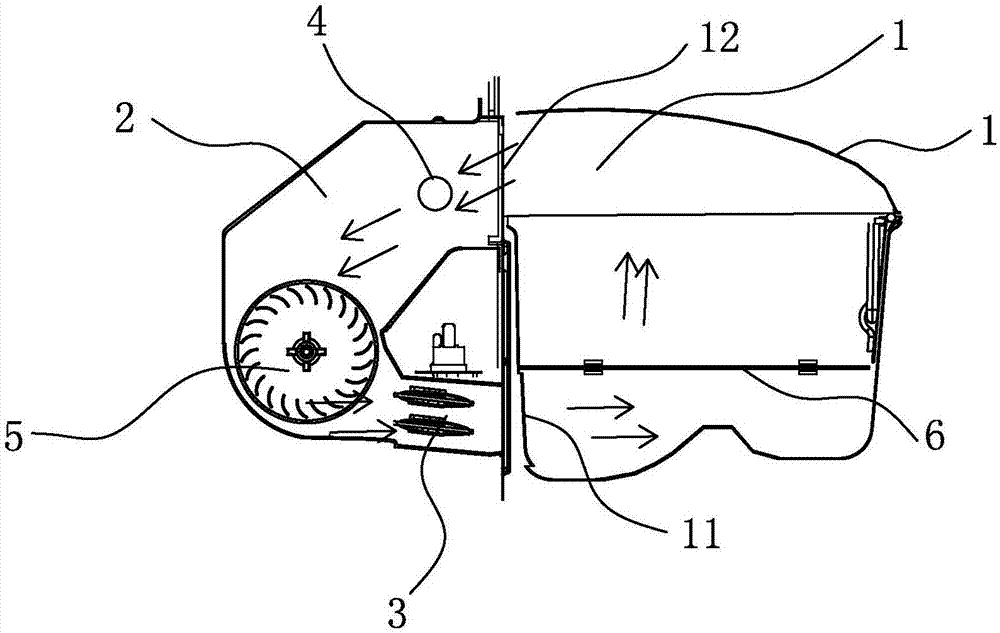

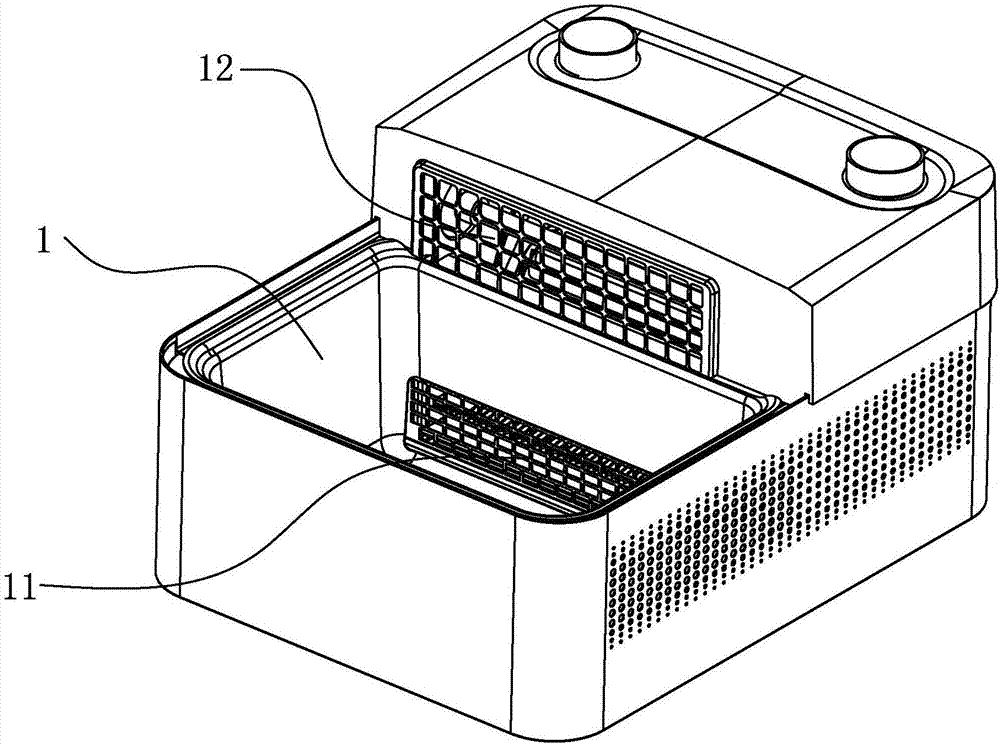

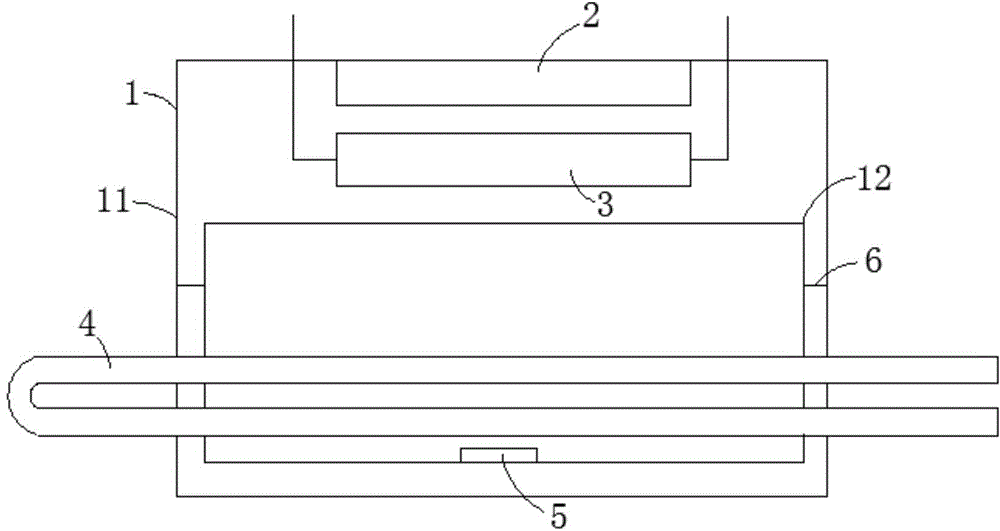

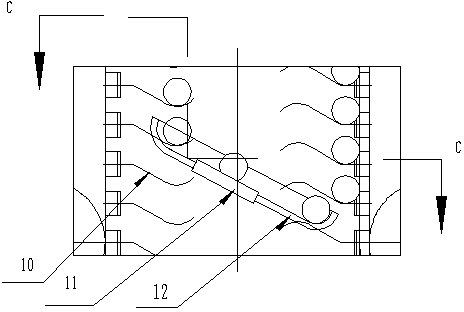

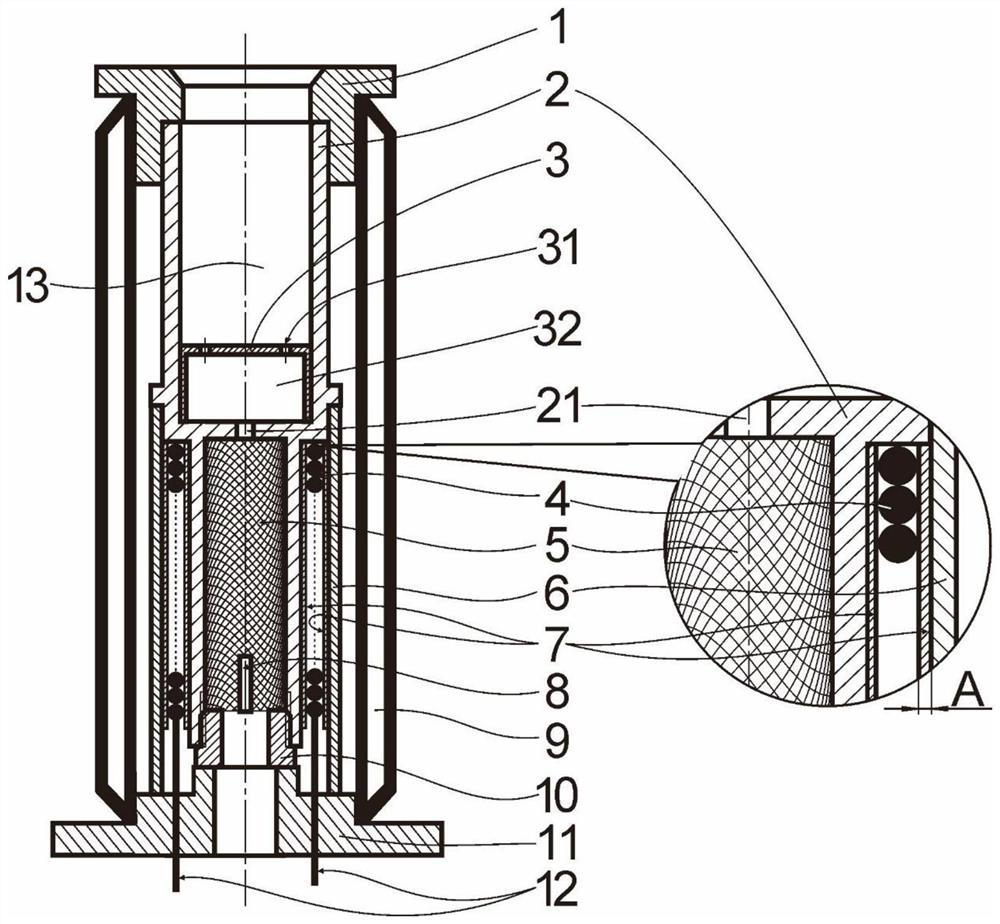

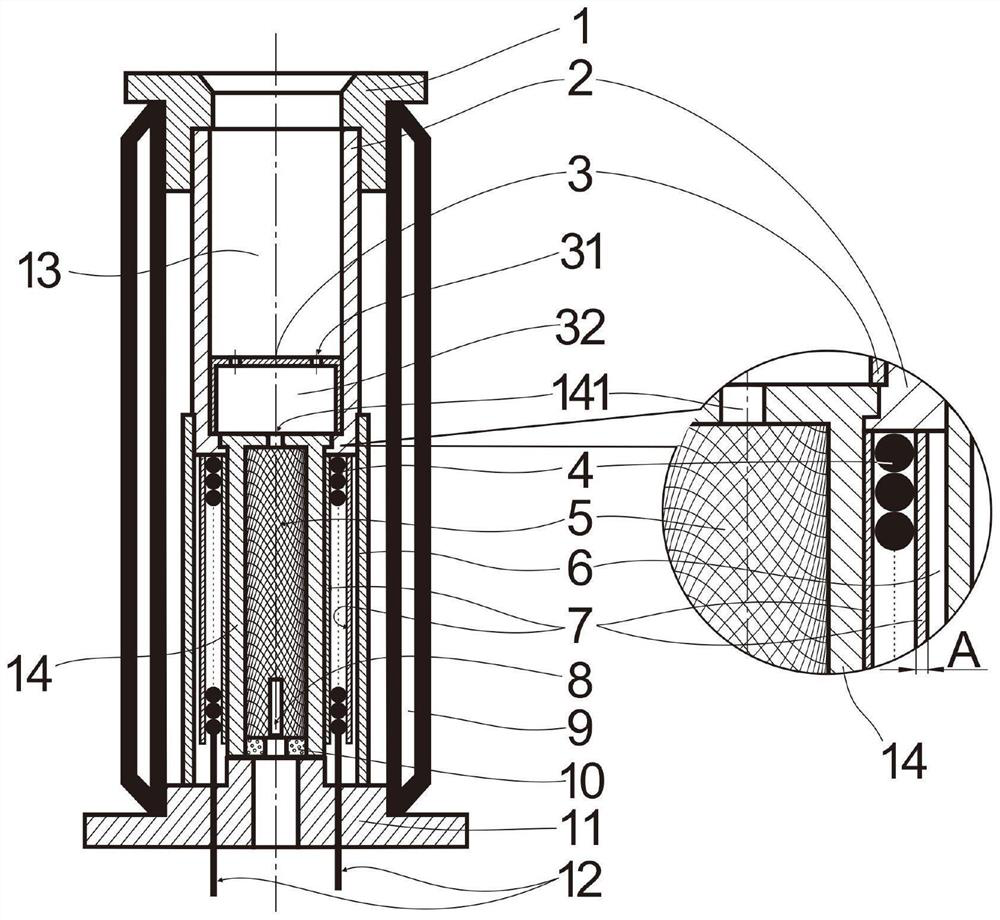

Air fryer capable of forming thermal cycle heating through cyclone

The invention discloses an air fryer capable of forming thermal cycle heating through cyclone. The air fryer comprises a windshield cover, a motor assembly, an extractor fan and a rotating air duct unit, wherein the lower part of the windshield cover is opened, and a small hole is formed in the center of the upper part of the windshield cover; the motor assembly is arranged at the upper part of the windshield cover and comprises a motor transmission shaft, and the motor transmission shaft penetrates through the small hole in the center of the upper part of the windshield cover; the extractor fan is arranged in the windshield cover and is connected with the motor transmission shaft; the rotating air duct unit is arranged in the windshield cover, is positioned under the extractor fan and is fixedly connected with the windshield cover through a connecting post, a ventilating opening is formed in the upper part of the rotating air duct unit, and the lower part of the rotating air duct unit is opened; the rotating air duct unit can enable air flowing downwards under the combined action of the extractor fan and the windshield cover to flow downwards rotationally along a certain angle to form the cyclone. According to the air fryer disclosed by the invention, the thermal cycle heating is formed through the cyclone, and thus food can be more uniformly baked by hot air.

Owner:KINGCLEAN ELECTRIC GREEN TECH SUZHOU

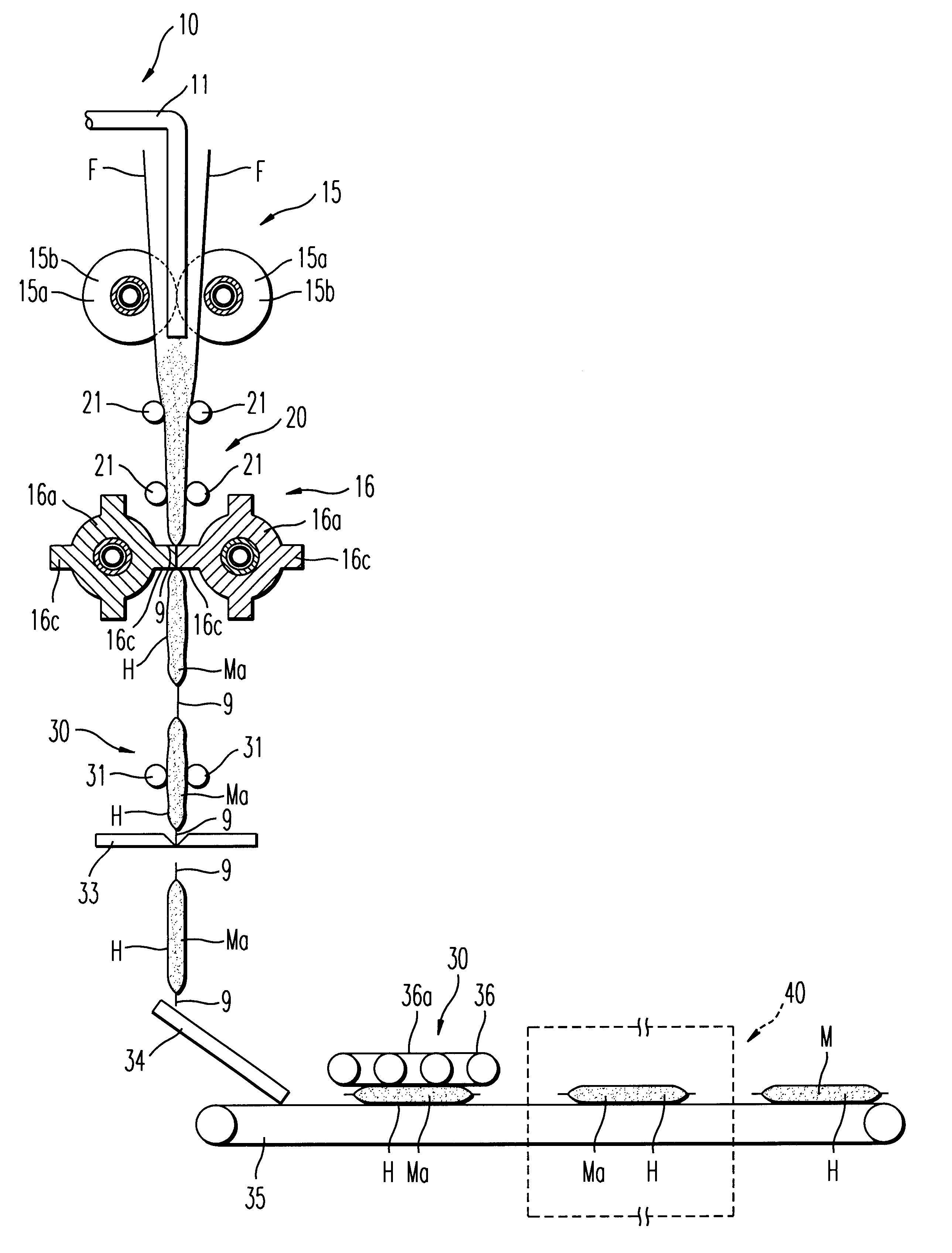

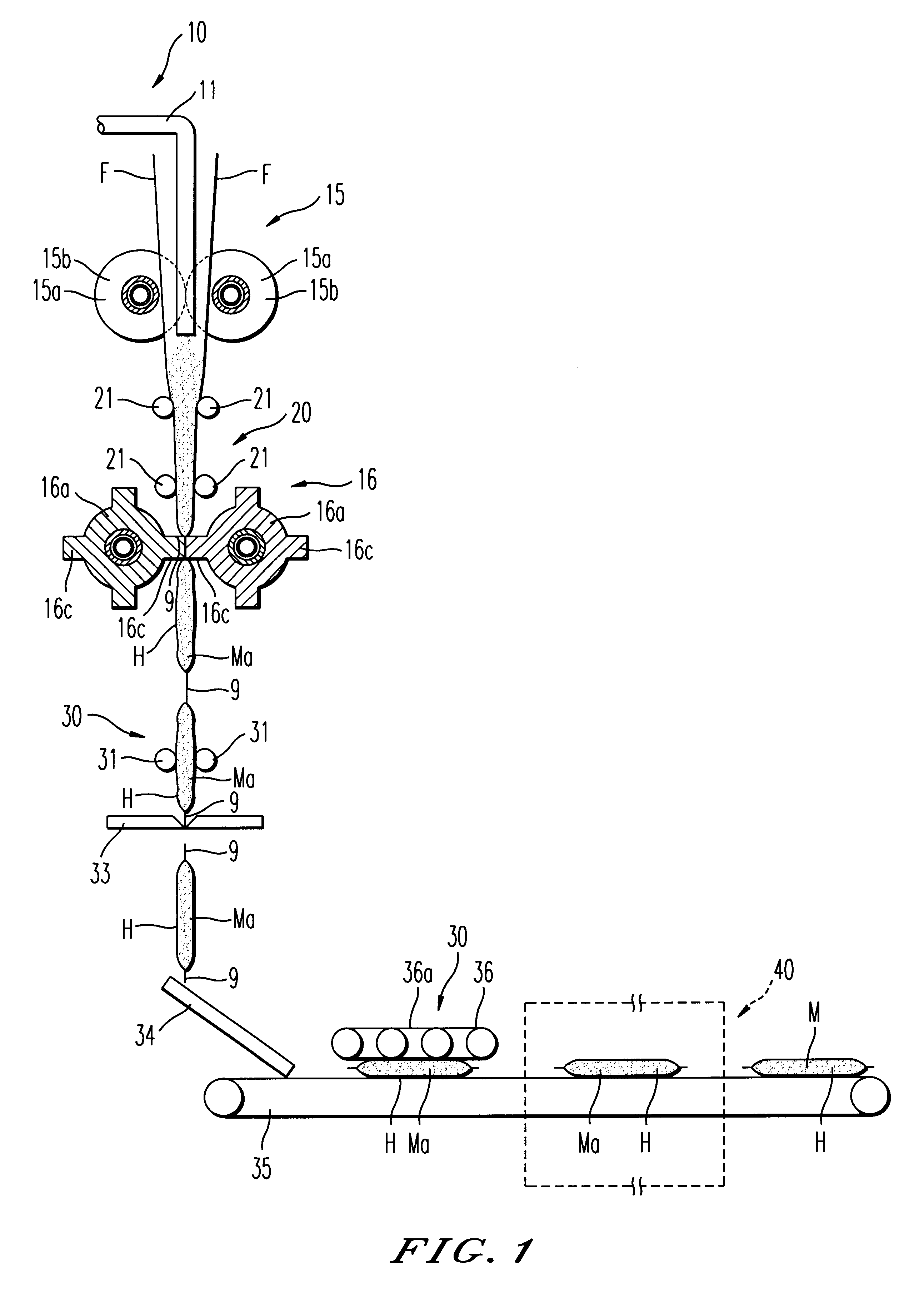

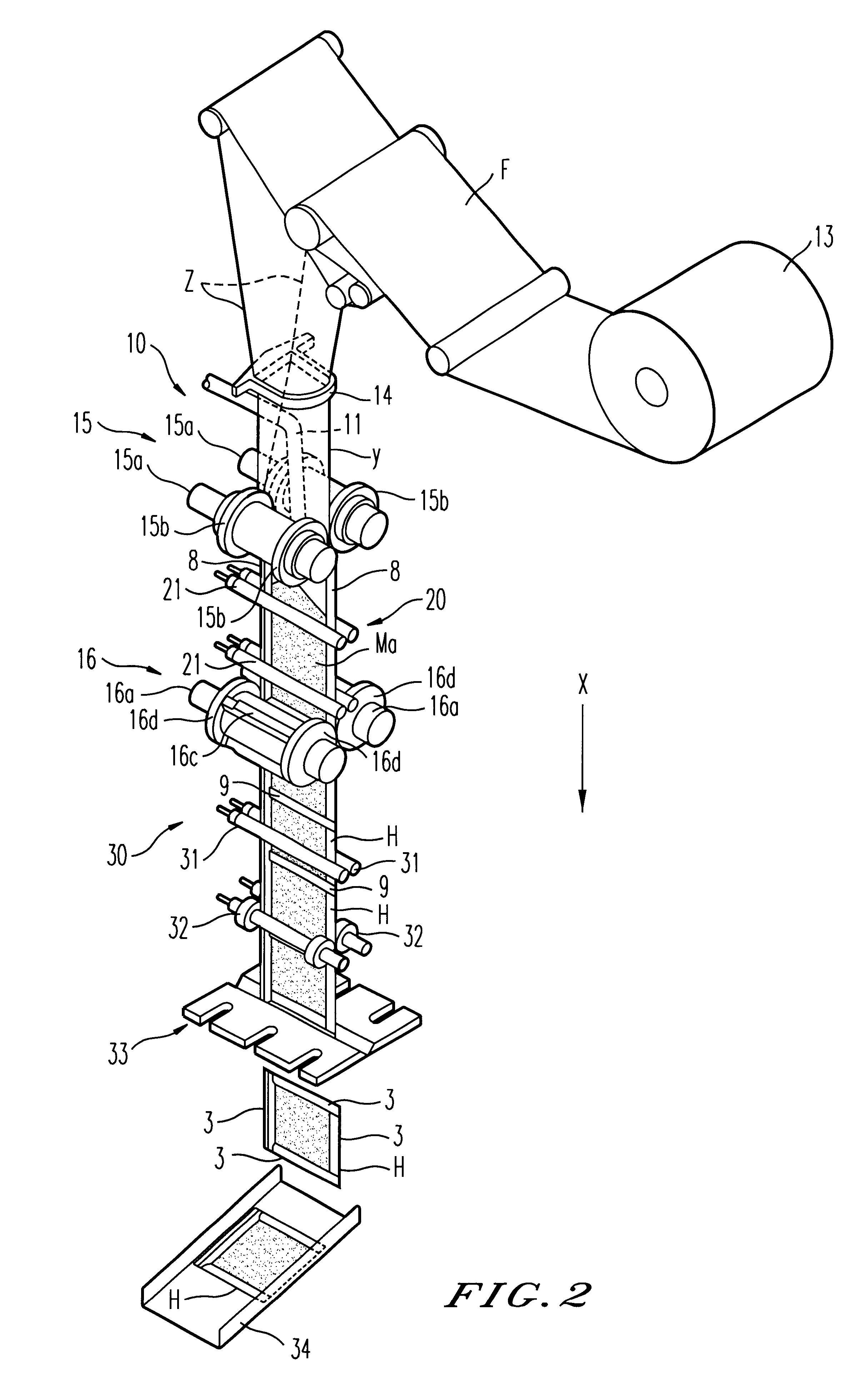

Method of making plate-like frozen raw hamburger-like matter packaged by film

InactiveUS6254911B1Avoid quality changesGive durabilityWrappersConfectioneryMeat burgerMechanical engineering

A method of making a plate-like frozen raw hamburger-like matter includes: a filling step for filling a constitutional material of the raw hamburger-like matter between a first thermal seal a second thermal seal, provided in a direction perpendicular to the conveying direction; a deaerating step of pressing the film so that the filled constitutional material is extended until the second thermal seal is provided; a forming step for forming the plate-like raw hamburger-like matter by equalizing the constitutional matter, therein; and a freezing step for maintaining its shape by rapidly freezing the package bag enclosing the raw hamburger-like matter.

Owner:TERU

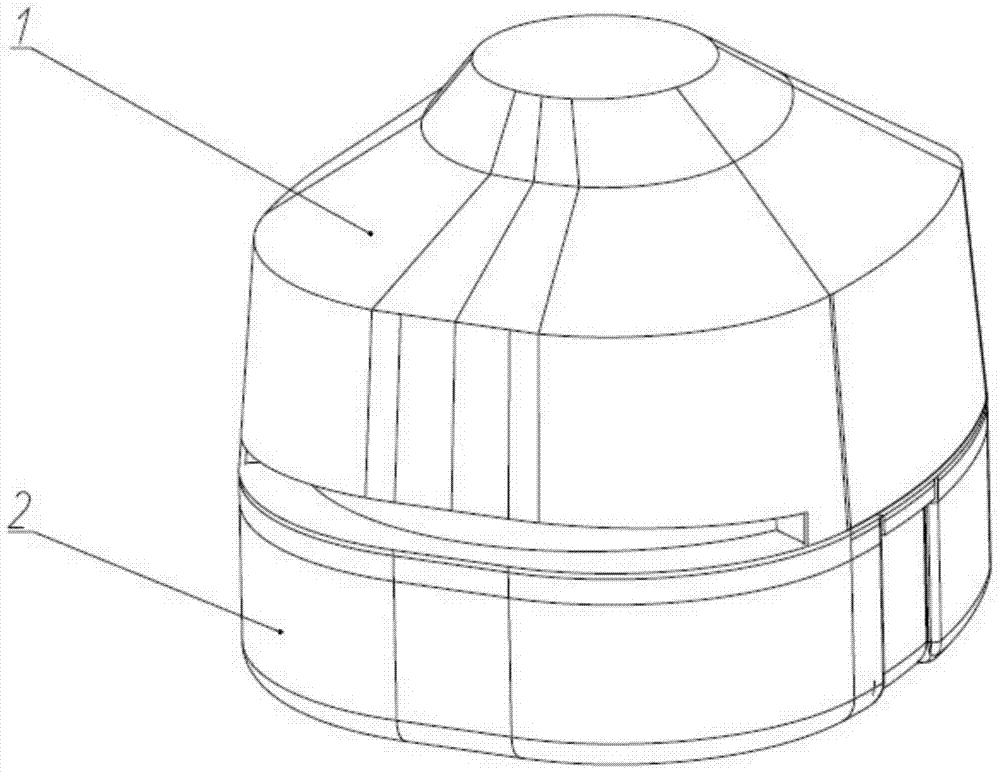

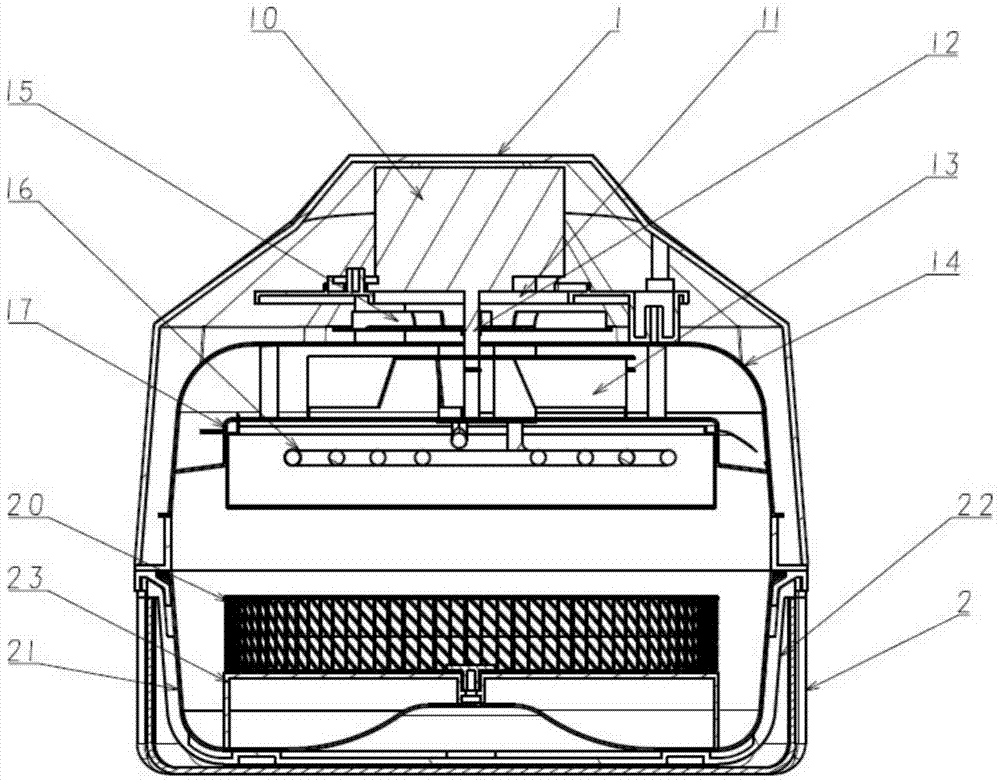

Air fryer heated by cyclone heat circulation

The invention discloses an air fryer heated by a heat cycle formed by a cyclone, which comprises: a windshield, the windshield is open at the lower part, and has a small hole in the center of the upper part; a motor assembly, the motor assembly is installed on the The upper part of the windshield, and includes a motor transmission shaft, the motor transmission shaft passes through the small hole in the upper center of the windshield; an exhaust fan, the exhaust fan is installed in the windshield, and is connected to the windshield The motor transmission shafts are connected; the rotating air duct unit is installed in the windshield, and is located below the exhaust fan, and is connected and fixed with the windshield through a connecting column. The upper part of the channel unit is provided with a ventilation opening, and the lower part is open, wherein the rotating air channel unit can make the wind going vertically downward through the joint action of the exhaust fan and the windshield rotate and go downward at a certain angle, forming whirlwind. The air fryer heats through the cyclone to form a heat cycle so that the hot air can bake the food more evenly.

Owner:KINGCLEAN ELECTRIC GREEN TECH SUZHOU

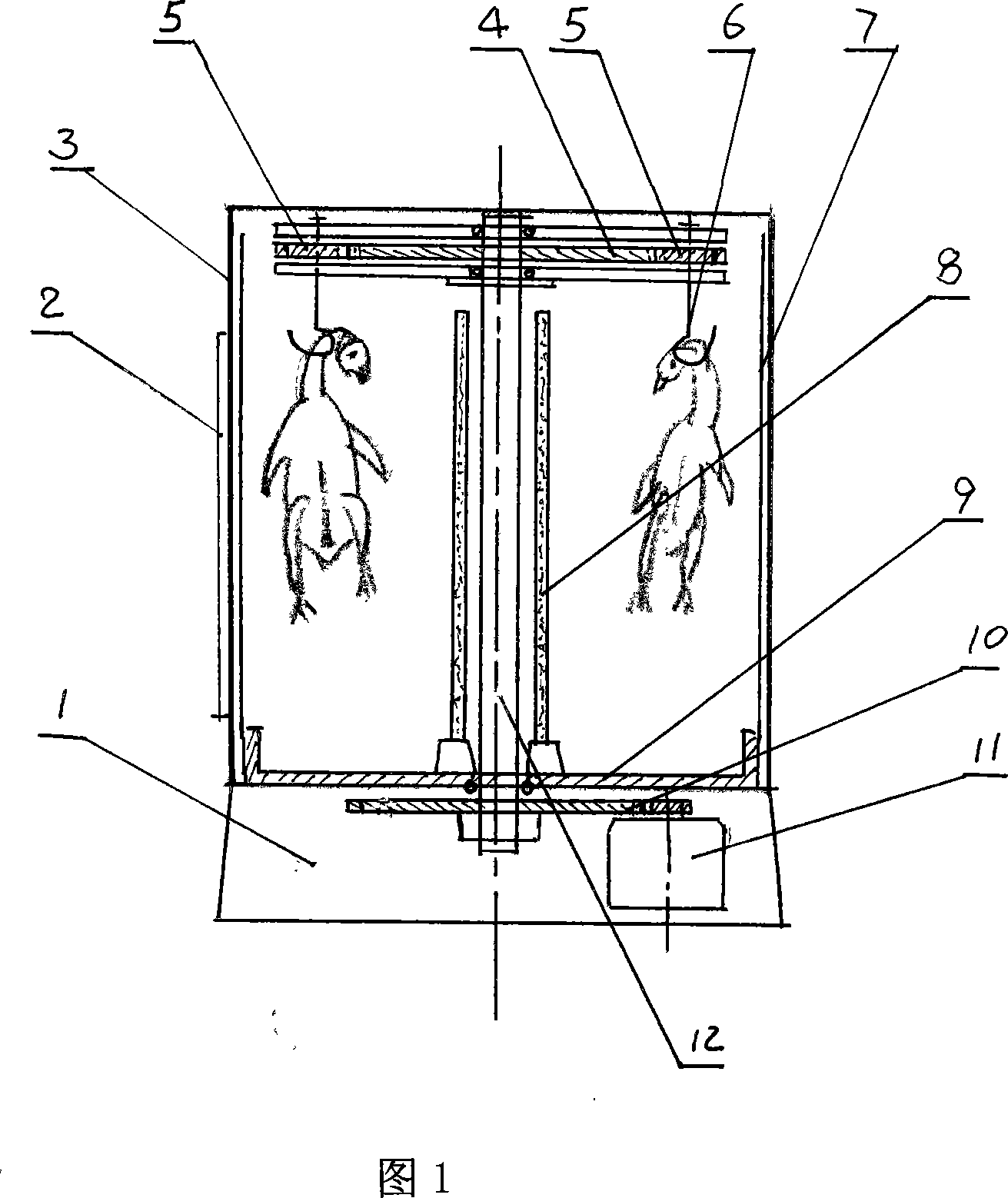

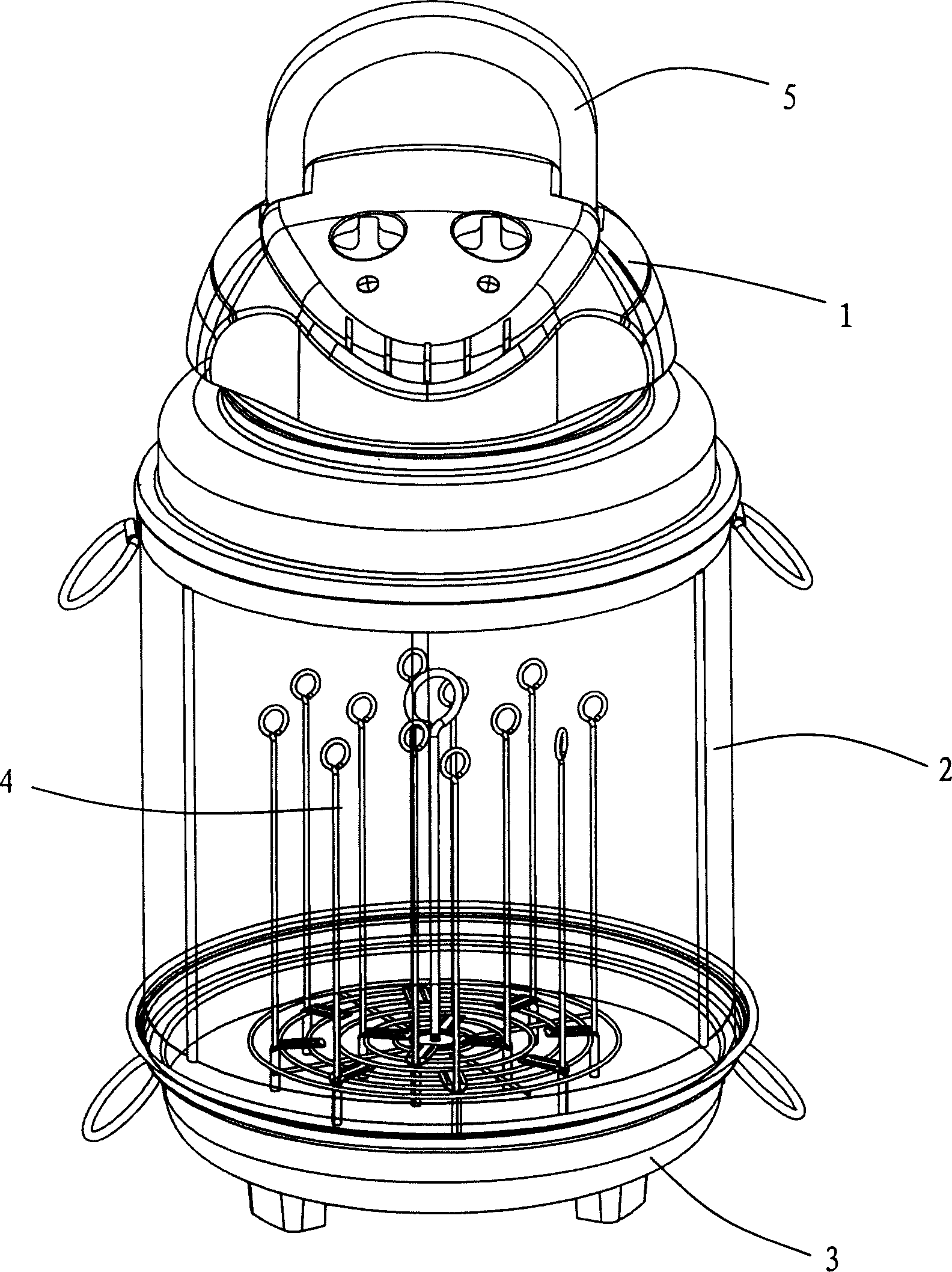

Hanging and rotating type baking oven

The invention discloses a hanging rotary oven, comprising a cylinder shell which is arranged vertically and is provided with a layer of reflector on the internal wall; a rotation axis which is positioned in the middle of the shell is driven by a motor in a base; a planetary gears element which is positioned on the top of the rotation axis consists of a central gear and planetary gears which are arranged around and joggle with the central gear; the central gear is fixedly connected with the rotation axis around which is vertically provided with infrared heat tubes and each pinion is connected with a food pothook at the bottom. The food is hung on the pothooks when being roasted; when the motor is on, the rotation of the rotation axis drives the central gear to rotate, resulting in the revolution of the roasted food; meanwhile, the planetary gears that joggle with the central gear drives the autorotation of the roasted food, thereby ensuring the roasting in each side and even roasting.

Owner:宗翠红

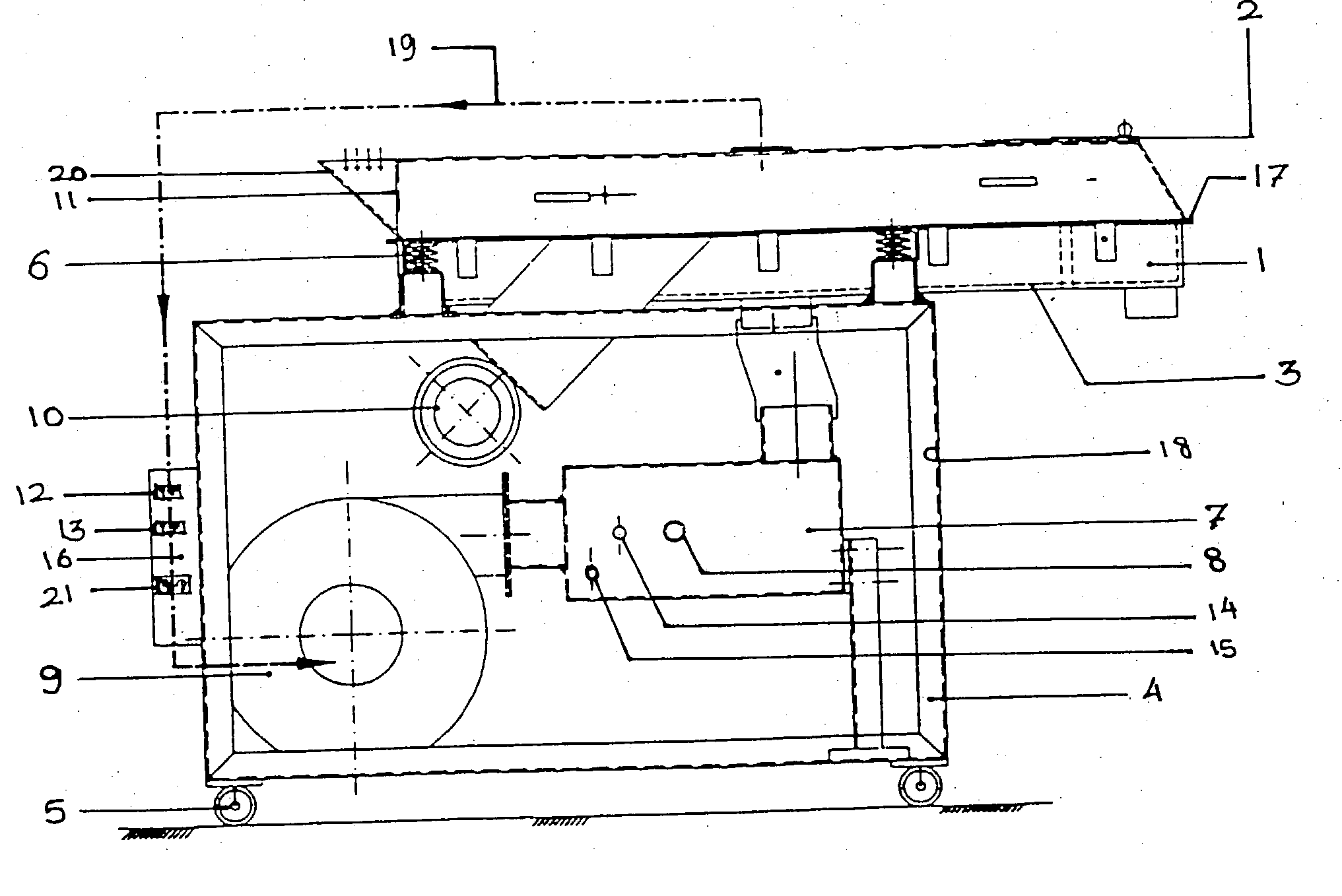

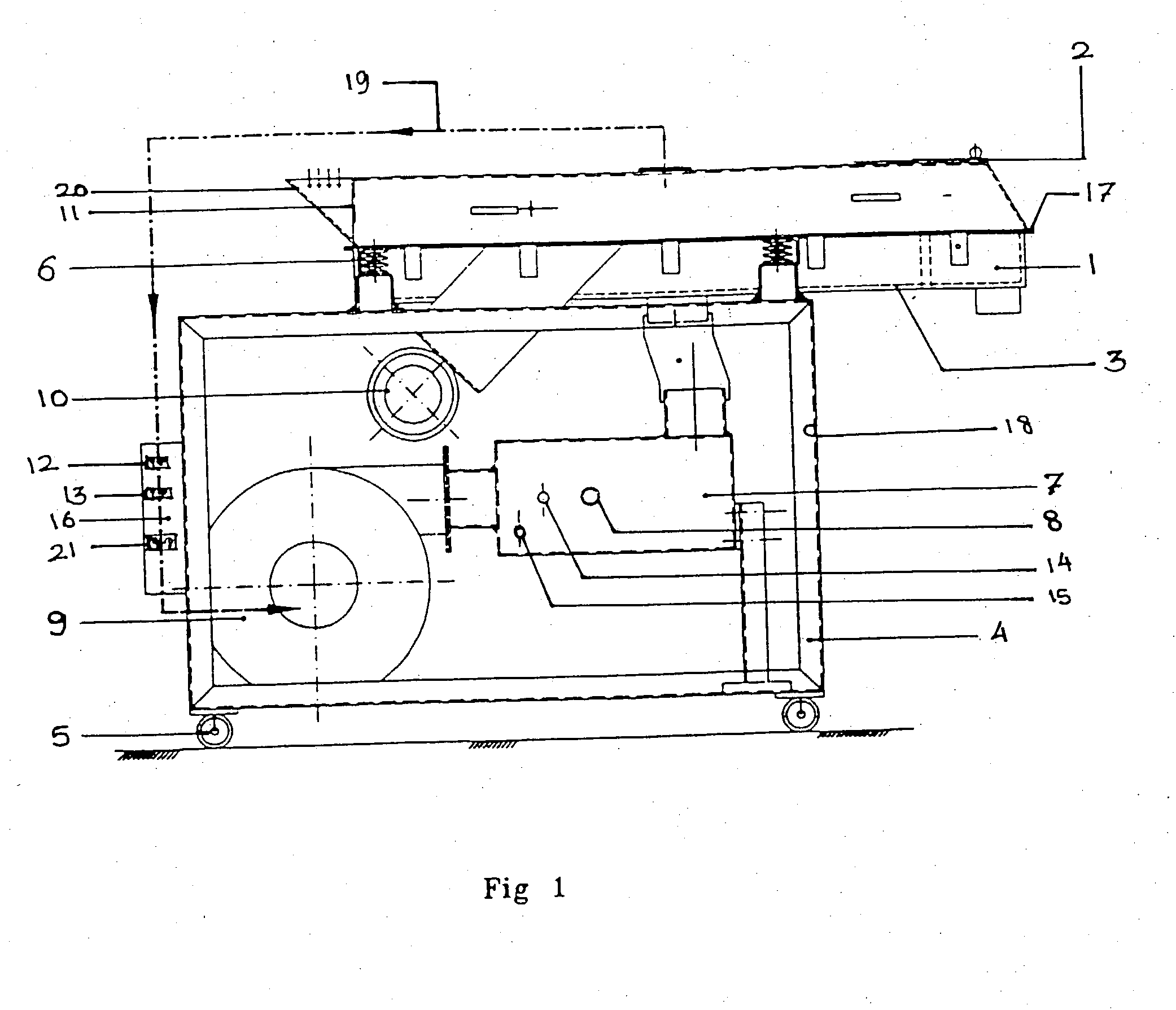

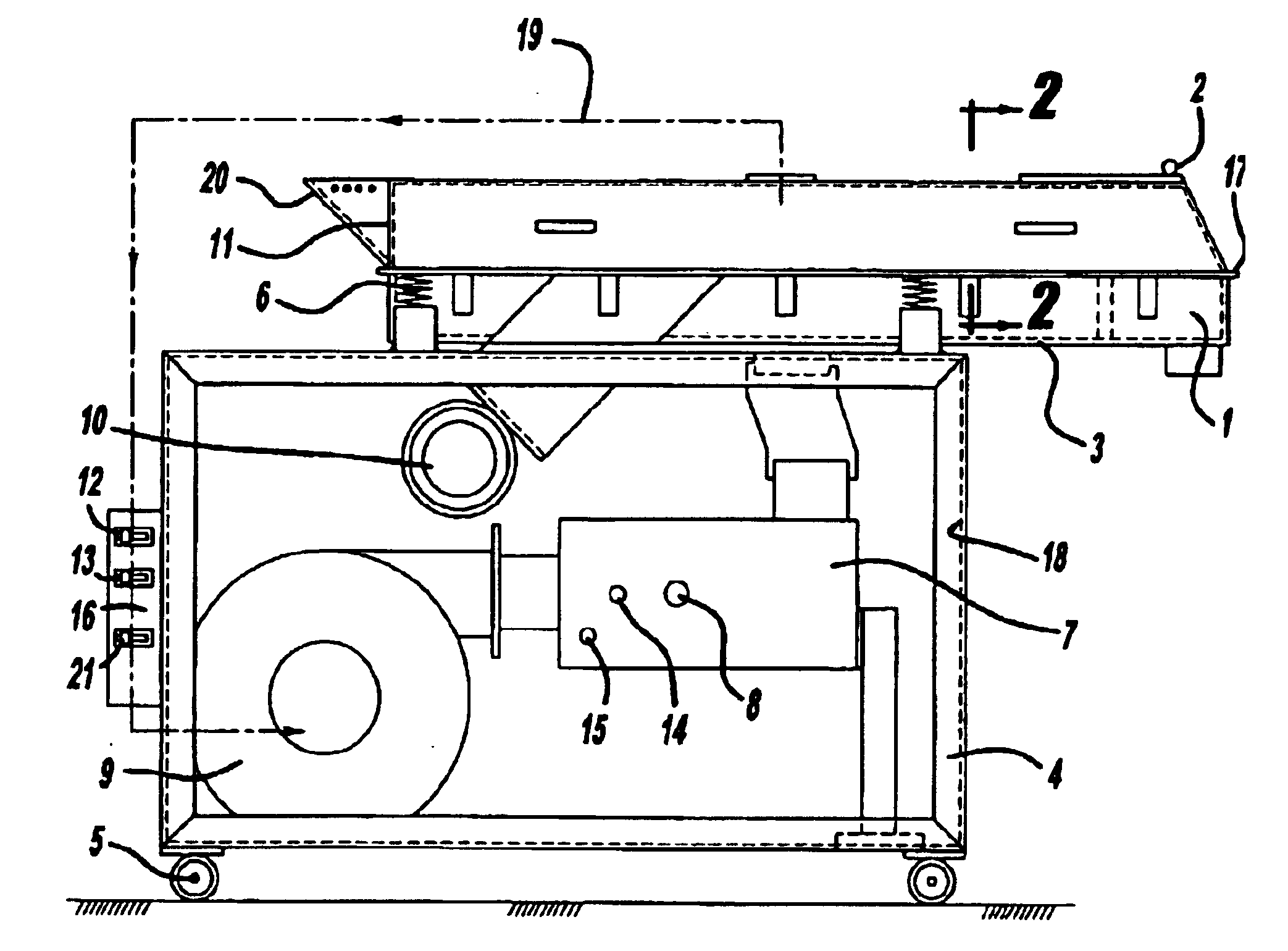

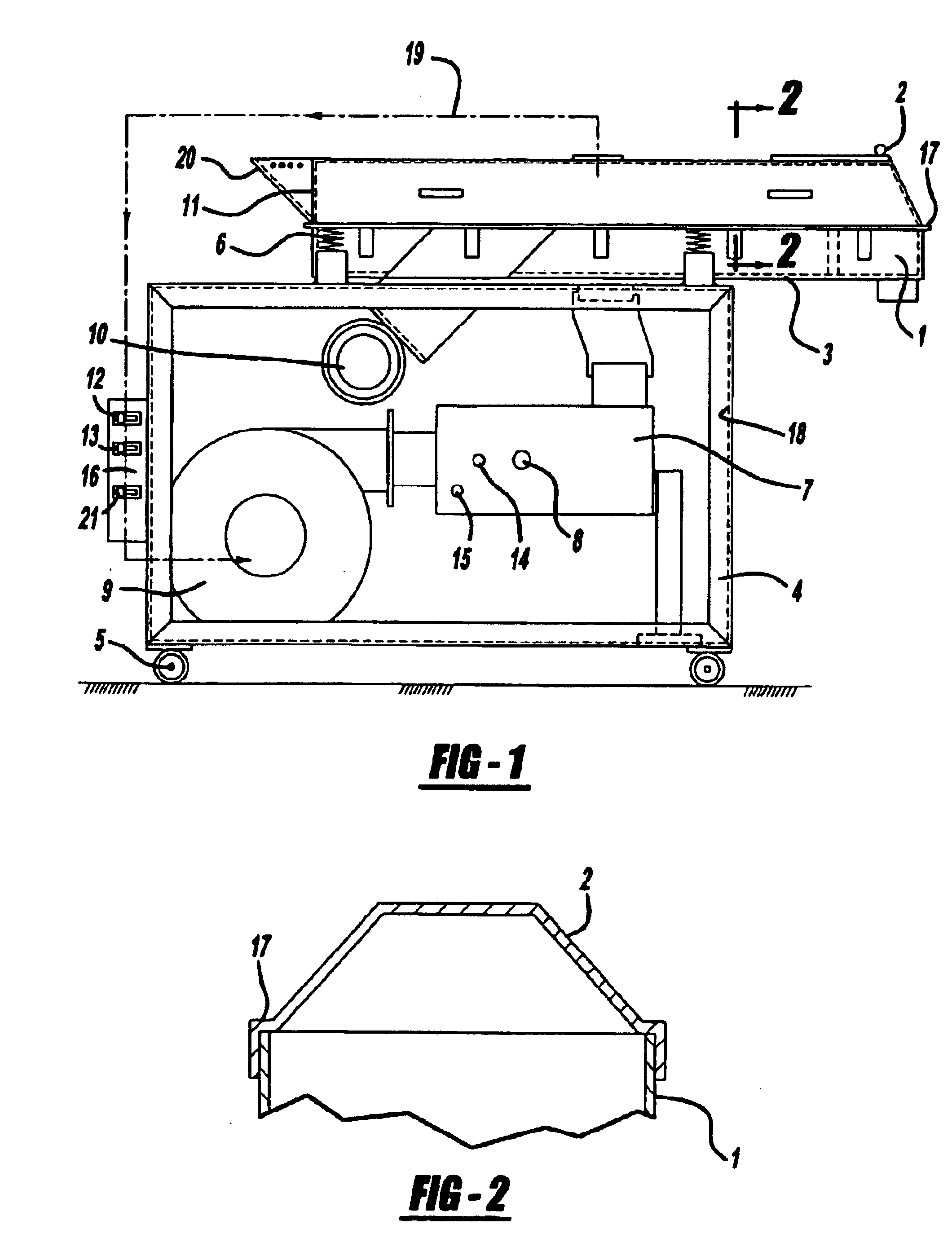

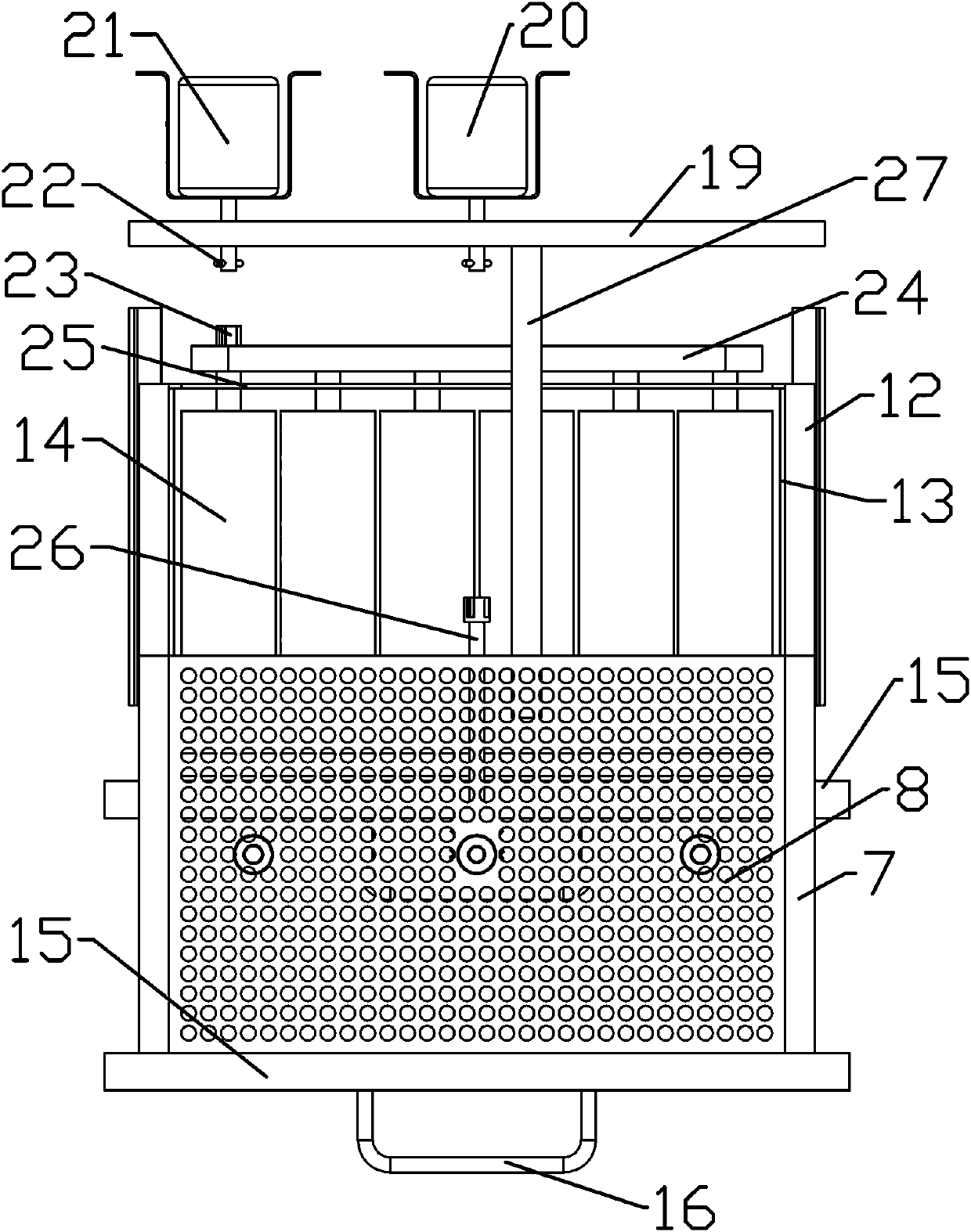

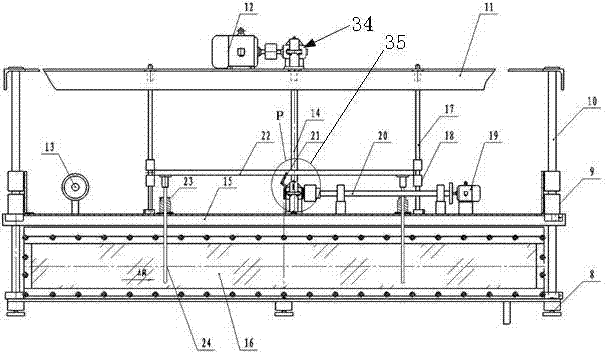

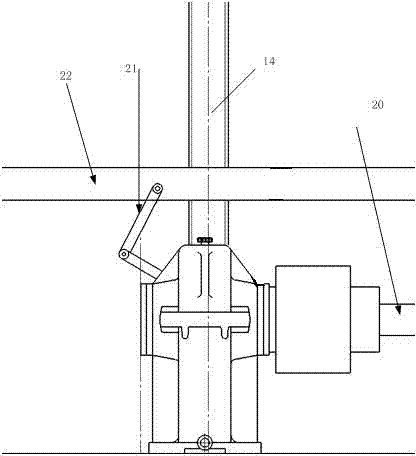

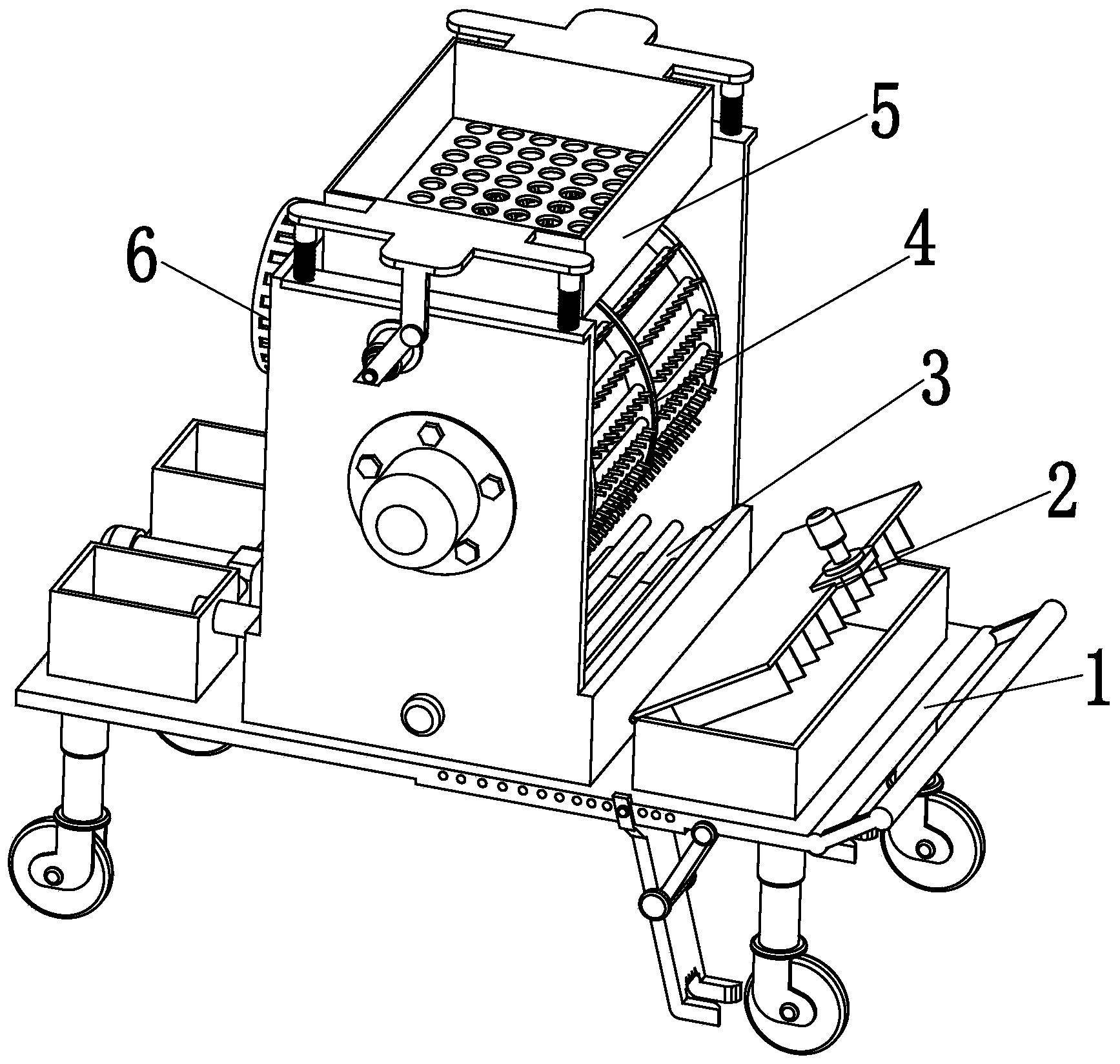

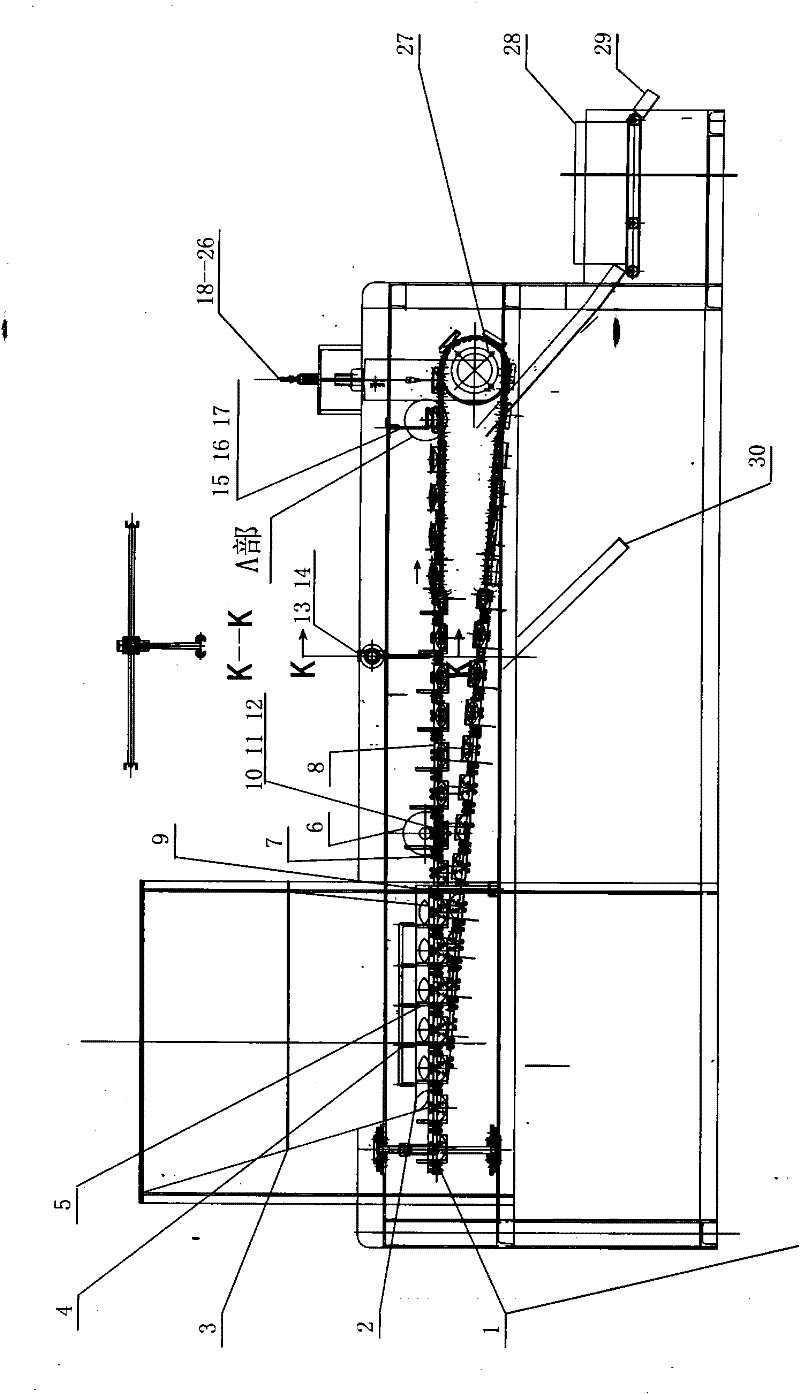

Continuous vibro fluidized bed roaster using flue gas

InactiveUS20040187709A1Reduction in human drudgeryClean and hygienic endGrain huskingGrain polishingCombustion chamberSolenoid valve

A continuous vibro fluidized bed roaster for roasting cereals, pulses, spices, oil seeds and ready-to-eat snack foods using flue gas, said roaster comprises of a main frame (4) which houses all the parts of the machine, the vibrating deck (1) is mounted on a set of coil springs (6) which is mounted on the main frame through screw fasteners, a perforated sieve (3) and a hood (2) are mounted on the vibrating deck (1) with rubber gasket (17) for sealing the hot air from leakage, a vibratory motor (10) is mounted on the feed end of the vibratory deck for imparting vibrations to the feed material, a vibratory feeder (11) is mounted on the feed side of the vibratory deck (1) for feeding the raw material in to the roaster through a hopper (20). A LPG burner (8) is fastened to the combustion chamber (7) using fasteners, a solenoid valve (14) mounted on the main frame (4) for regulating the LPG supply to the burner and also to close the LPG supply incase of electrical power failure with a signal for flame failure from the photo sensor (15), a blower (9) generates the air needed for the reducing the flue temperature is mounted at the end of the on the vibratory feeder (11) on to the main frame (4), a return duct (19) connects the hood (2) and the suction end of the blower (9), a temperature indicator is (21) is used for measuring the inlet temperature of the hot air admitted in to the roaster, an electrical panel (16) is mounted at the end of the main frame for housing all the required electrical controls and variable speed drive (13) for varying the residence time of travel of the raw material, a rheostat (12) for varying the feed rate of the raw material fed in to the vibrating deck, the roaster is covered by a set of covers (18) on all its sides, the complete machine is mounted on a set of castor wheels (5) for easy movement of the roaster to the required place, the materials of construction of the roaster are preferably of stainless steel but this shall not restrict the use of other materials as well.

Owner:COUNCIL OF SCI & IND RES

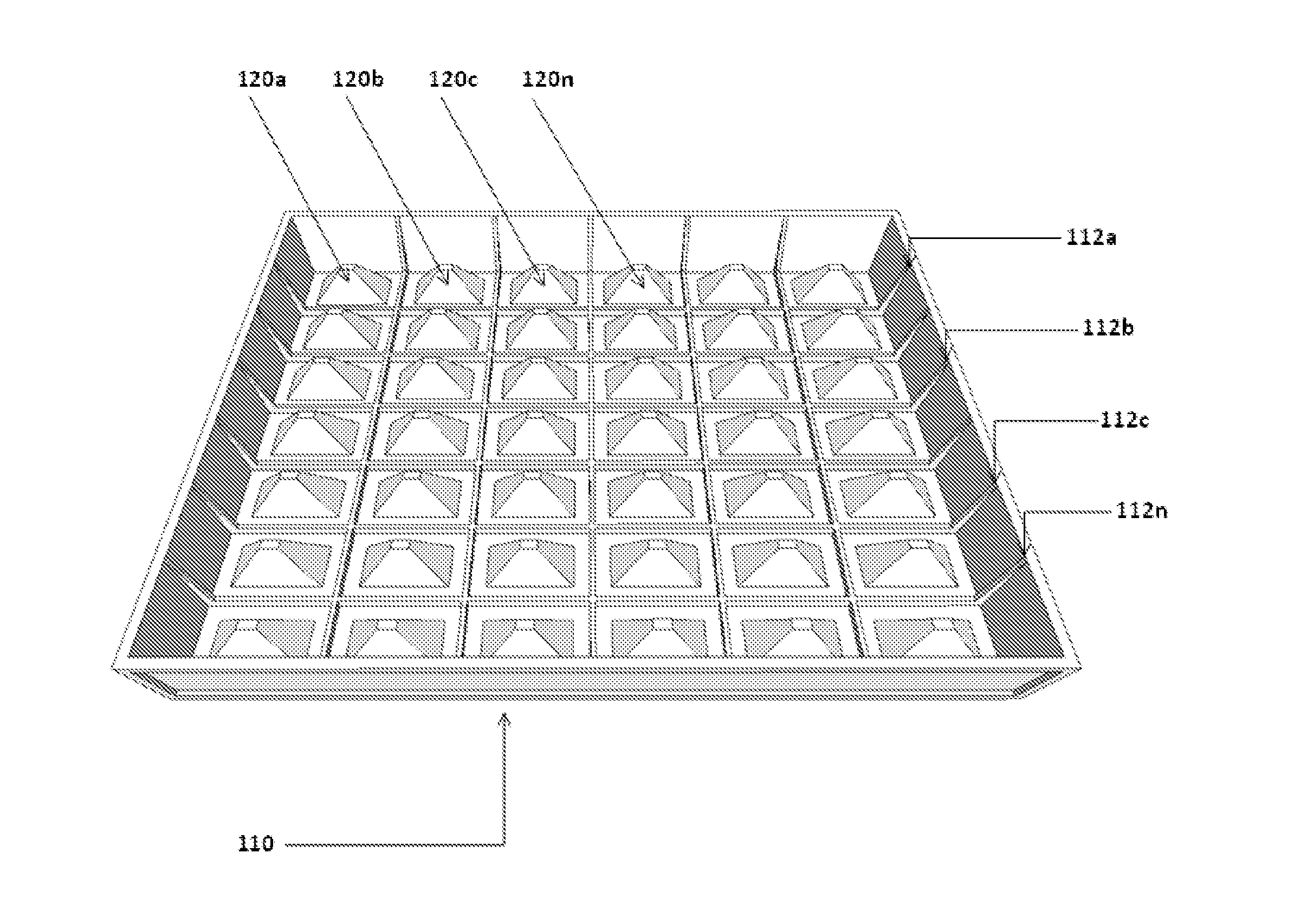

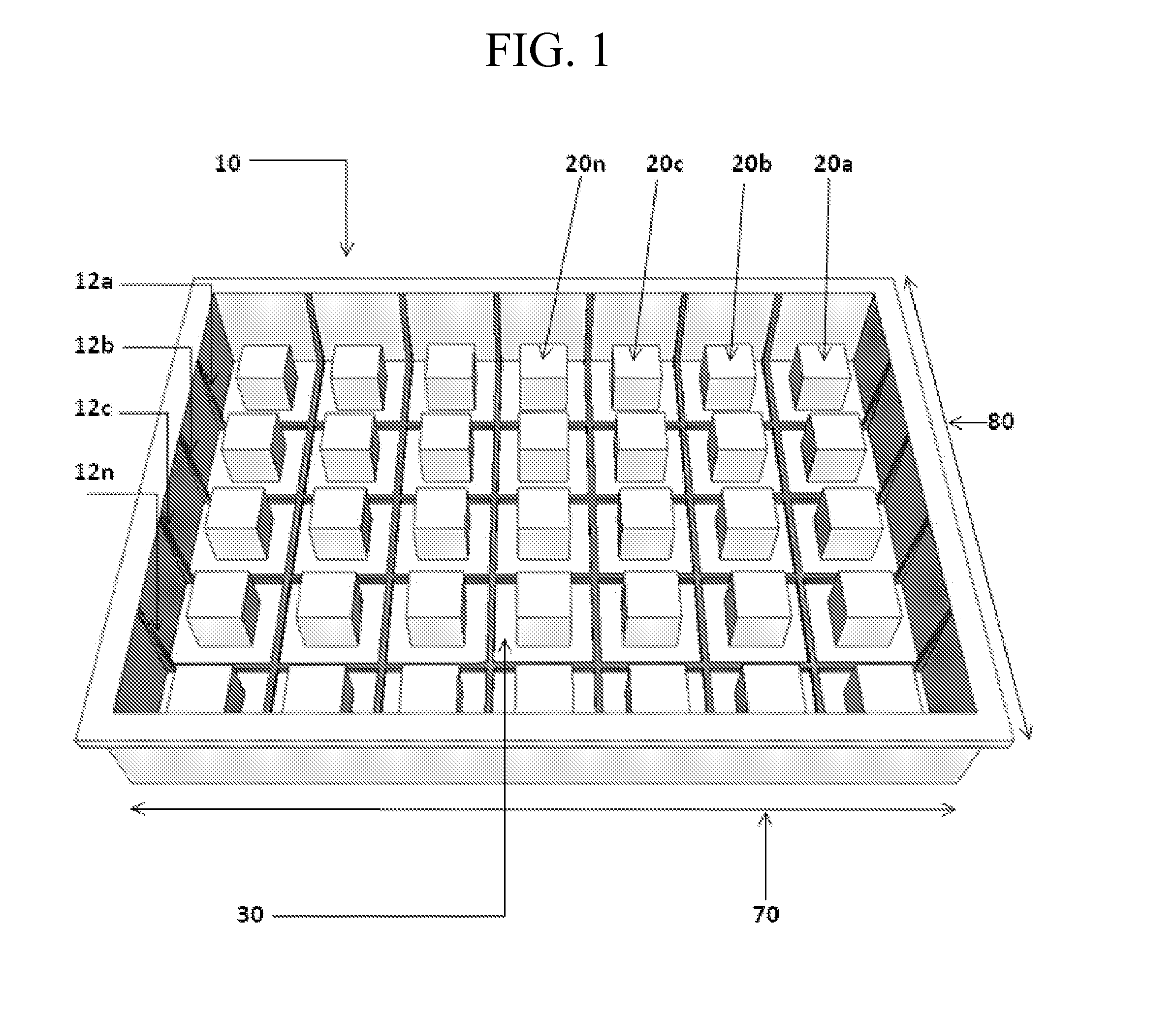

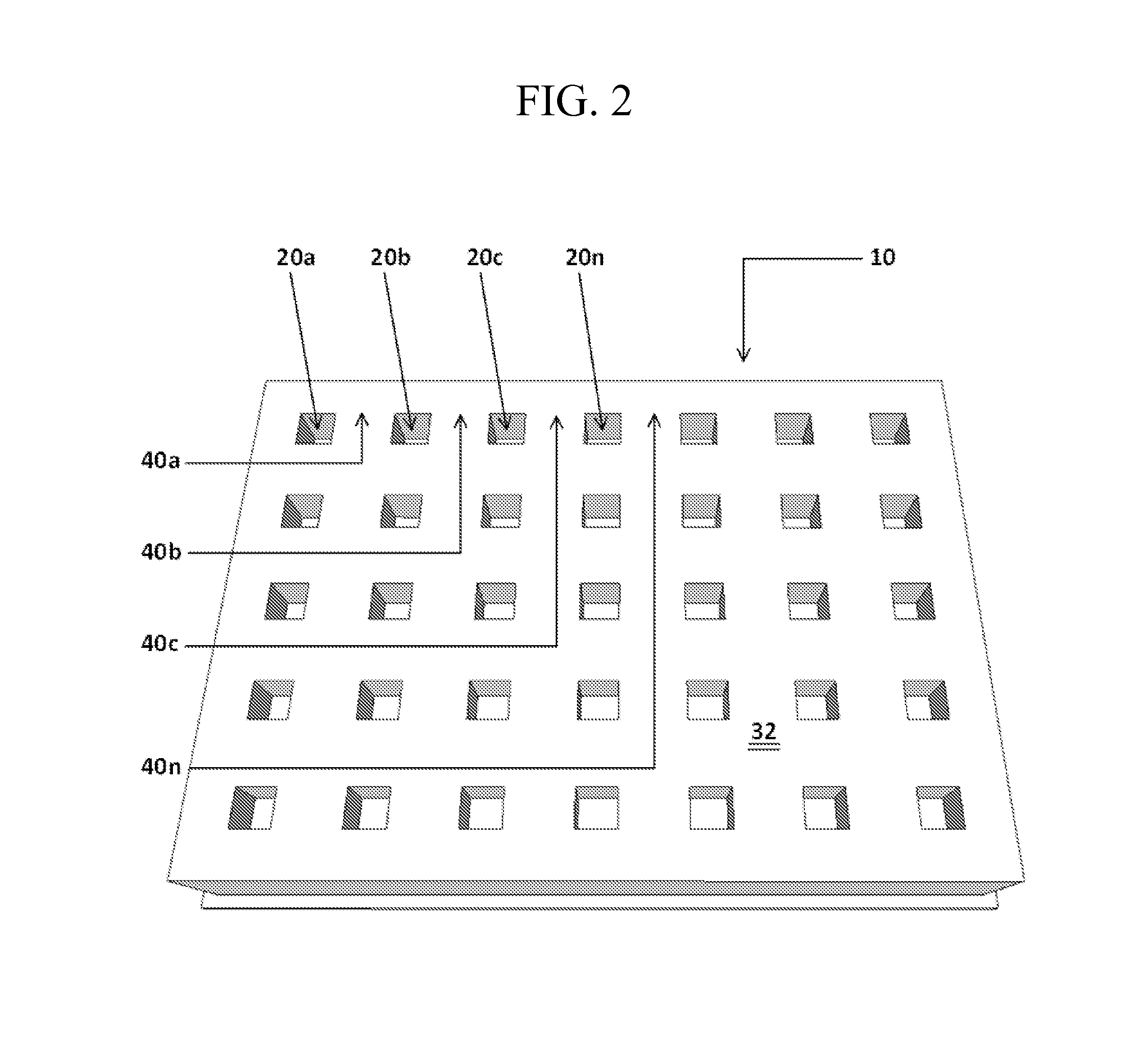

Food pans with thermal conveyance depressions

InactiveUS20130129890A1Excellent mean of portion controlImproves transfer of heating and cooling propertyDough treatmentMilk preservationEngineering

Various types of food preparation pans such as but not limited to food preparation pans used for baking, steaming, chilling, freezing and molding various foods and food combinations intended for consumption are disclosed. The pan includes a plurality of thermal conveyance depressions protruding in a vertically oriented disposition relative to a horizontal inner pan bottom surface; and upwardly projected depressions in an outer pan bottom surface of the thermal conveyance depressions to form hollow depressions spaced in between by bridging portions.

Owner:COX MONTE WILLIAM

Continuous vibro fluidized bed roaster using flue gas

InactiveUS6810794B2Reduction in human drudgeryClean and hygienic endGrain huskingGrain polishingFlue gasCoil spring

A continuous vibro fluidized bed roaster for roasting cereals, pulses, spices, oil seeds and ready-to-eat snack foods using flue gas, said roaster comprises of a main frame (4) which houses all the parts of the machine, the vibrating deck (1) is mounted on a set of coil springs (6) which is mounted on the main frame through screw fasteners, a perforated sieve (3) and a hood (2) are mounted on the vibrating deck (1) with rubber gasket (17) for sealing the hot air from leakage, a vibratory motor (10) is mounted on the feed end of the vibratory deck for imparting vibrations to the feed material, a vibratory feeder (11) is mounted on the feed side of the vibratory deck (1) for feeding the raw material in to the roaster through a hopper (20).

Owner:COUNCIL OF SCI & IND RES

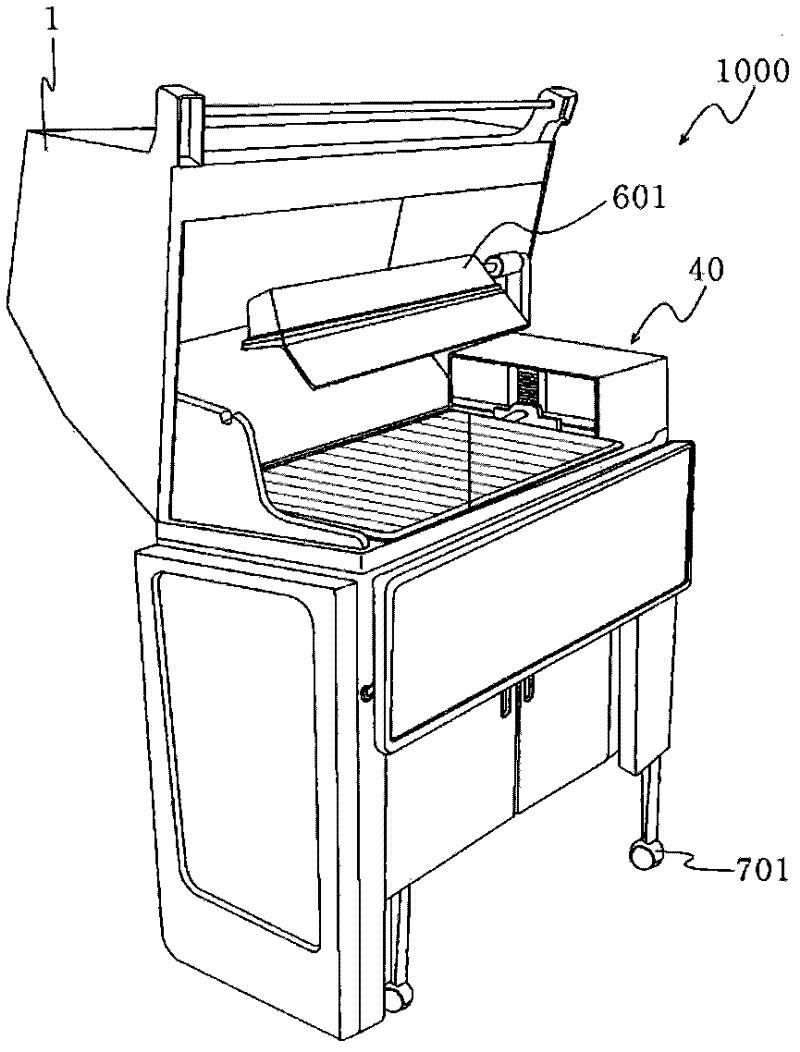

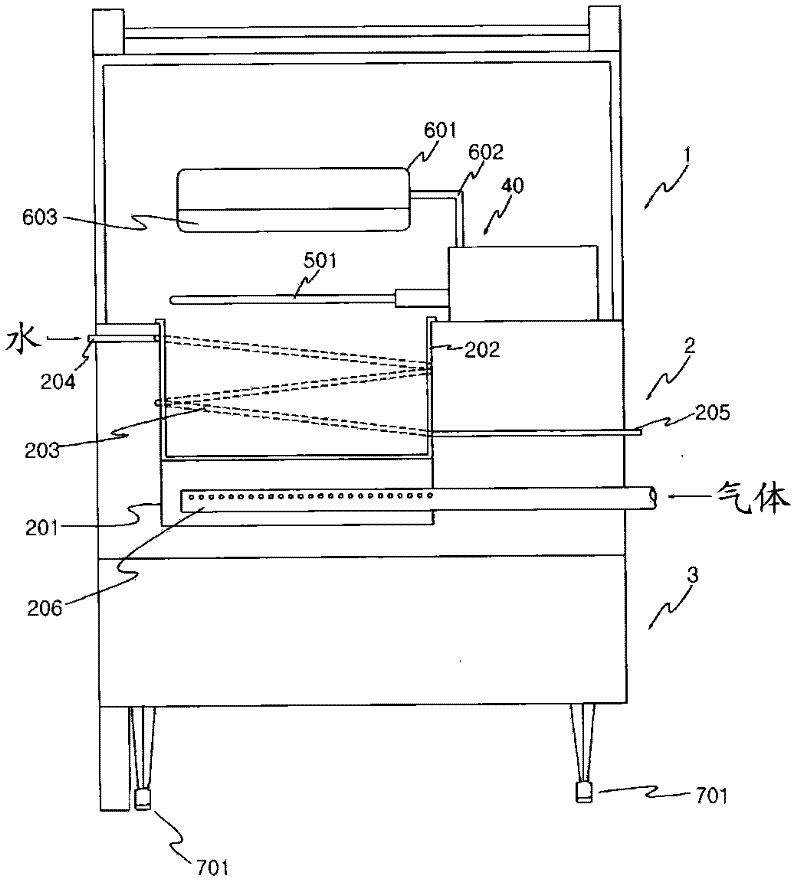

Mobile meat roaster

ActiveCN102378591AImprove work convenienceFree from inhalationRoasting apparatusEngineeringGrilled food

Owner:崔光镐

Hot whirlwind type multifunctional cooker

InactiveCN102342761AAvoid Process Safety IssuesImprove the heating effectRoasters/grillsDeep fat fryersBiochemical engineeringHeating effect

The invention discloses a hot whirlwind type multifunctional cooker. The hot whirlwind type multifunctional cooker comprises a main body, a control assembly, a heating assembly, an air blowing assembly and a containing assembly, wherein the containing assembly comprises a rotating type containing basket, a motor assembly is arranged on the main body, the air blowing assembly is arranged above the containing basket, and is used for blowing air towards the top of the containing basket, and the heating assembly comprises a plurality of heating pieces which are arranged between the air blowing assembly and the containing basket. In the invention, heat produced by the heating pieces can be driven by cyclonic eddy to flow into the whole heating space, so that a good and uniform heating effect can be achieved; and food to be processed can be overturned at the same time to achieve a good and uniform baking effect, so that the problem on the safety of food processing due to the excessive application and recycling of oil caused by immersing and frying the food in oil is solved. When an oil scoop is further provided to pour shoveled oil above the food, the oil can rotate together with the food, and can be uniformly mixed with the food, so that fried food is more uniform and healthy after being heated by high-temperature cyclonic eddy.

Owner:黄朝龙

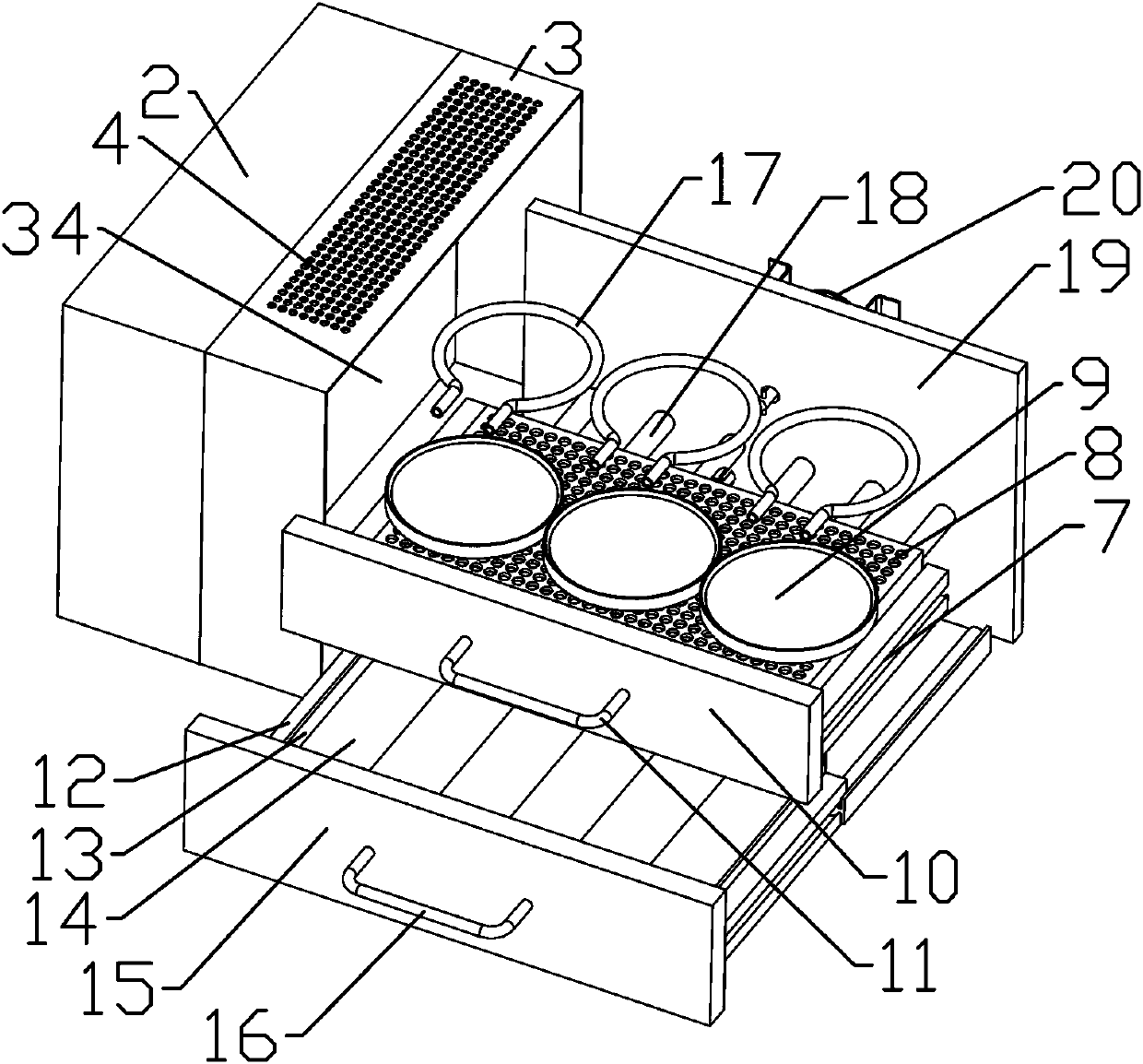

Multifunctional quick roasting oven

The invention relates to an oven, in particular to a multifunctional quick roasting oven. The multifunctional quick roasting oven comprises a box body. The front side of the box body is opened, a magnetron mounting box is arranged on the left side of the box body, a magnetron appointed to the box body is arranged in the magnetron mounting box, a heat isolating box is arranged between the magnetronmounting box and the box body, a columnar food bracket and a cake-shaped food bracket are arranged in the box body, the magnetron and a tubular electric heating component can be started at the same time, food is cooked quickly from inside to outside by means of microwaves generated by the magnetron, and food is roasted from outside to inside by means of heat radiated by the tubular electric heating component, and the magnetron and the tubular electric heating component improve the food processing efficiency. Meanwhile, the surface of the food forms hard scabs, so that heat of the food is prevented from being diffused, the food is crispy and sharp in taste, has certain hardness and is convenient to fetch and place. The oven is high in processing speed to quick-frozen food which needs not to be unfrozen. The processing step is simple. The multifunctional quick roasting oven can promote development of the quick-frozen food industry greatly and has relatively great promotion action to improve the living level of people.

Owner:郑州哆味哆客智能科技有限公司

Electricity oven

An electric oven for cooking food is composed of main body, roasting frame, heating tube, temp controller and timer. The said main body consists of oven core, oven body and tray. The said oven core comprises motor, thermal insulating plate, motor hood, cold air fan, cover for heating tube, heating tube, hot air fan, and guard. Its advantages are high heat efficiency and saving energy by 37%.

Owner:胡启康

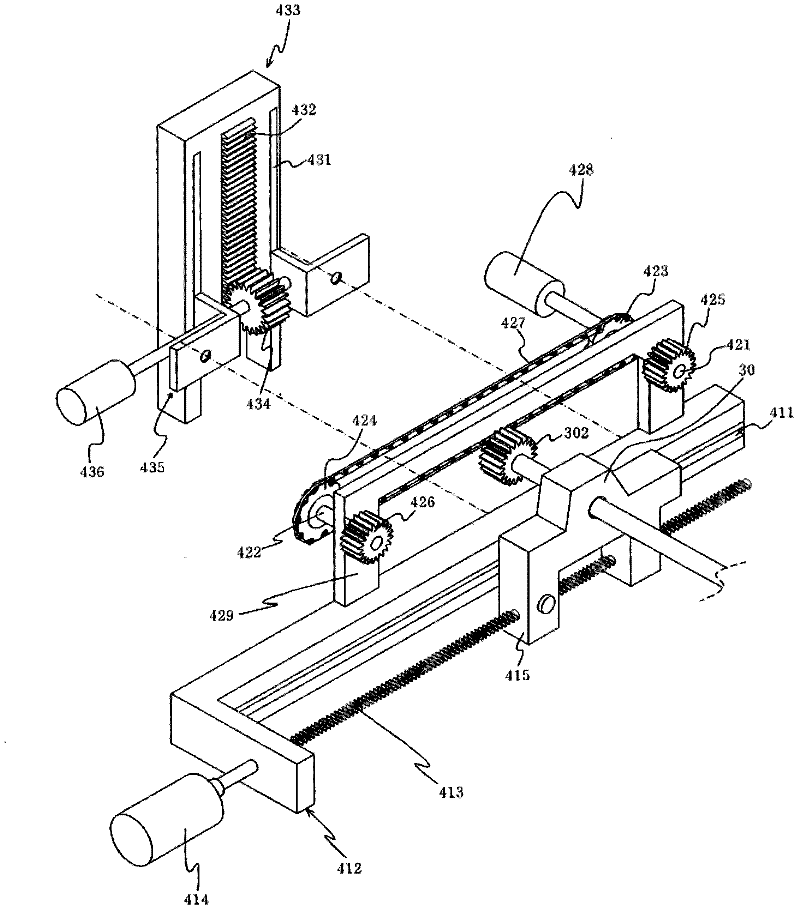

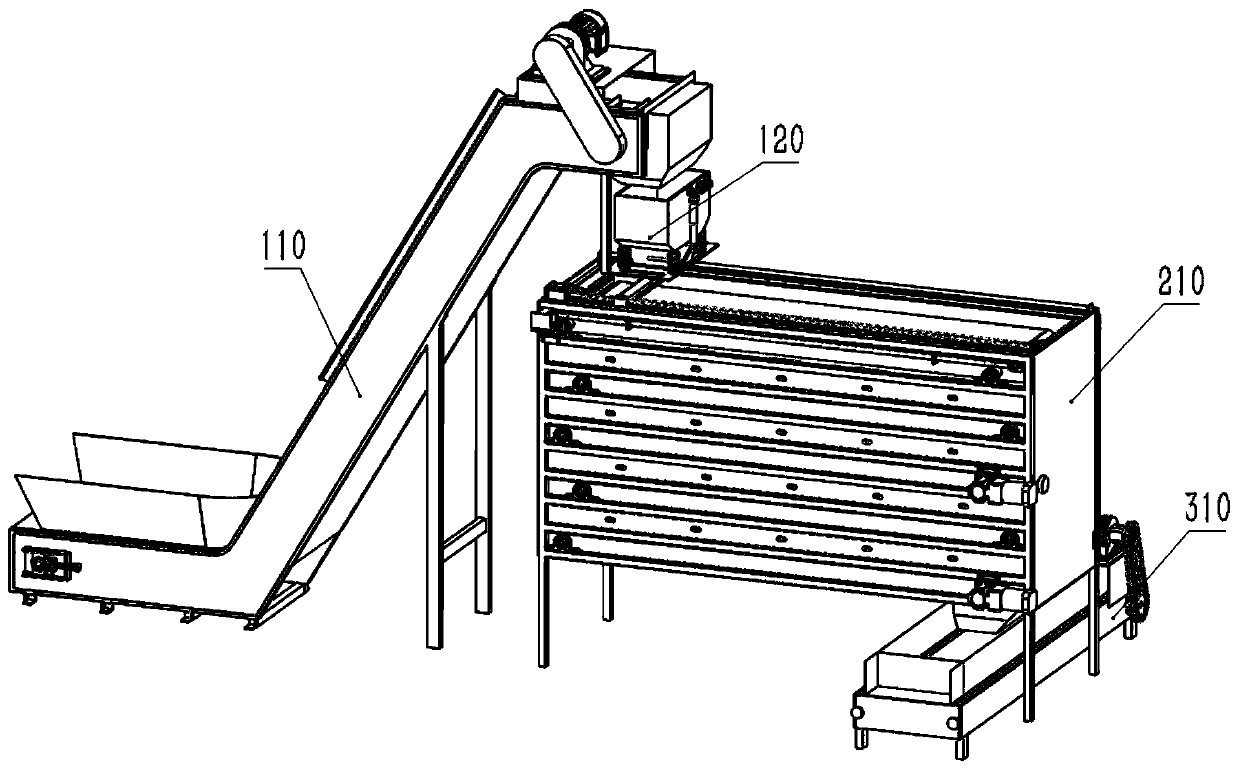

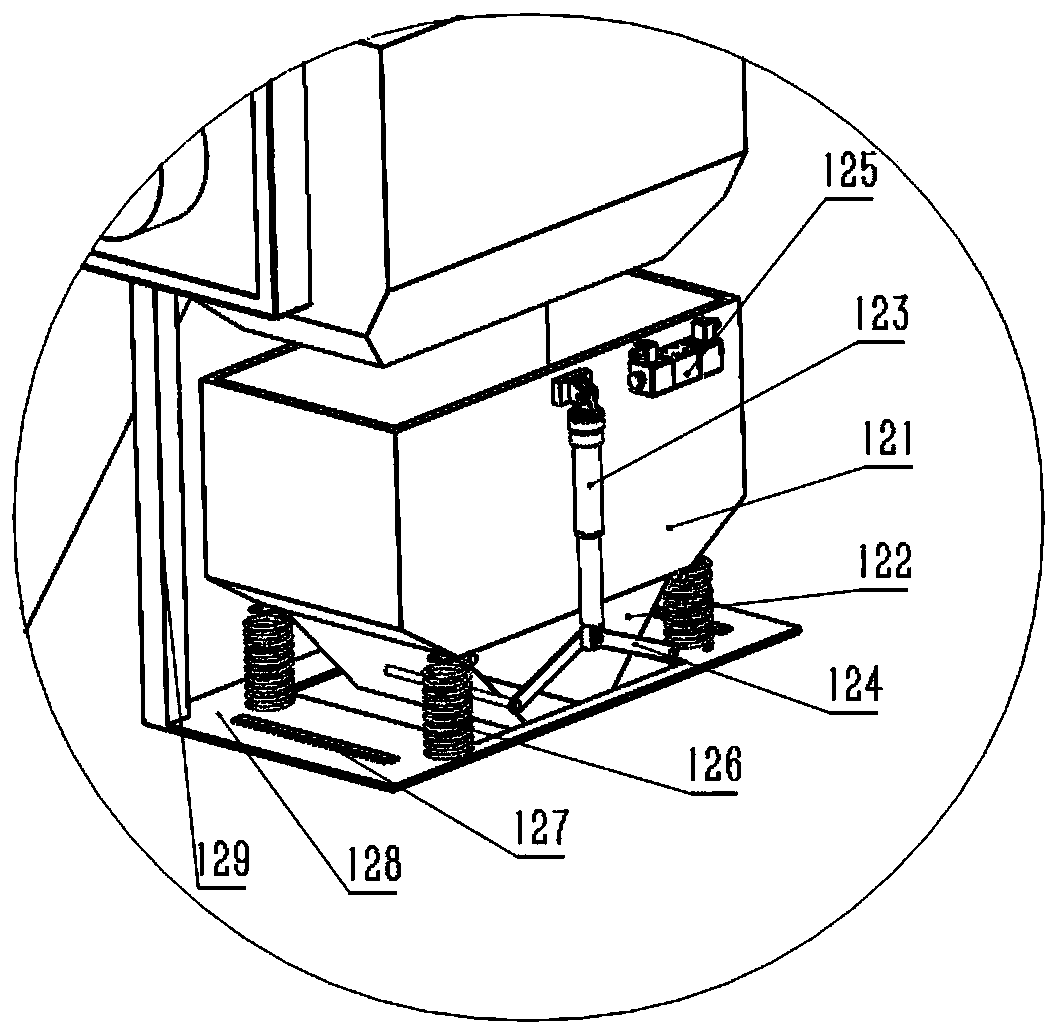

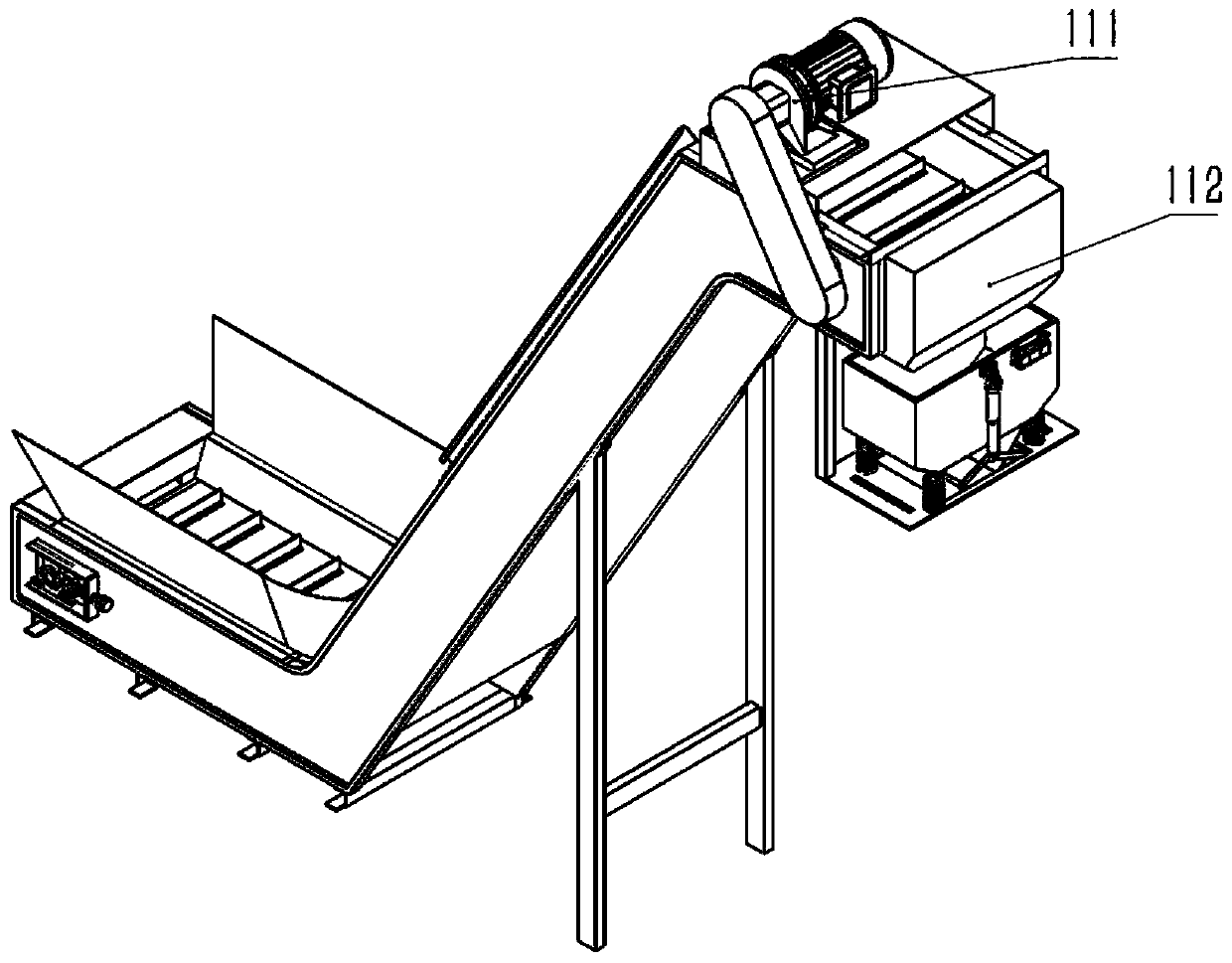

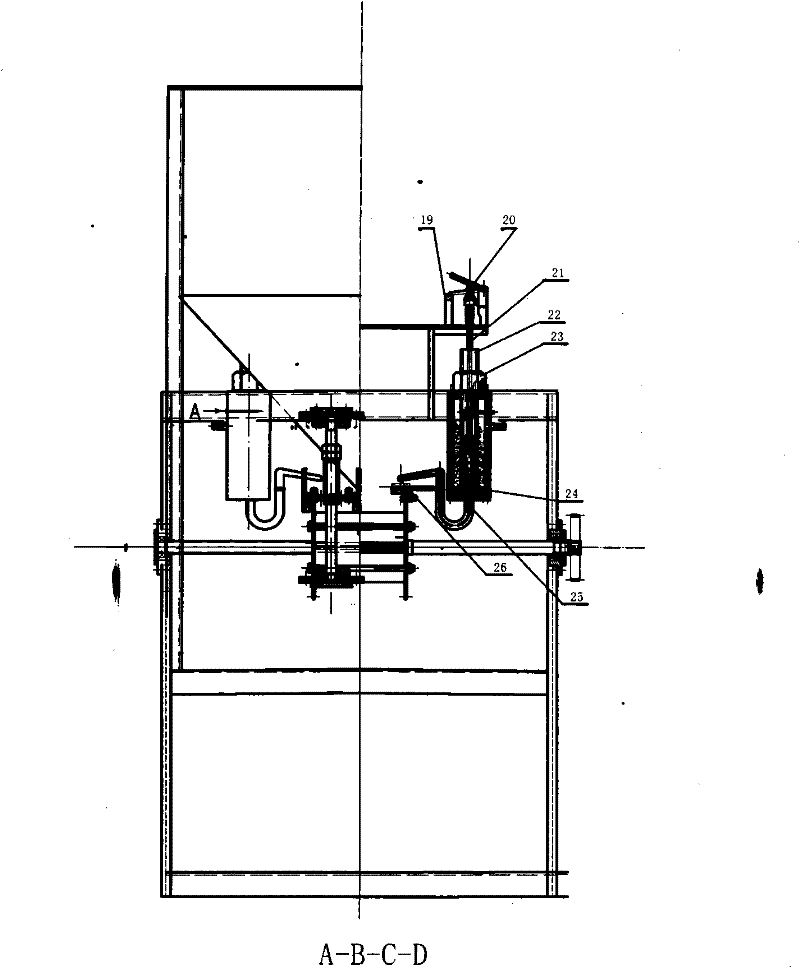

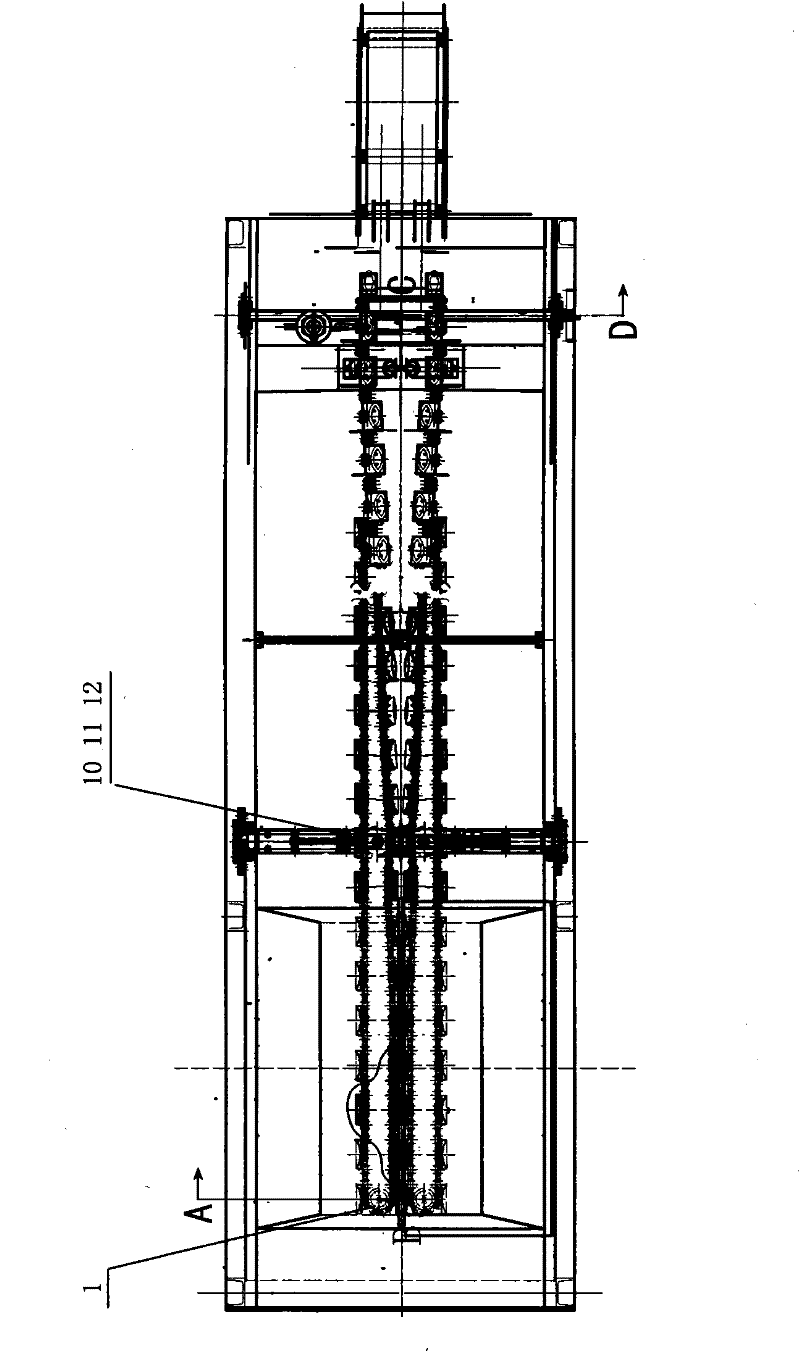

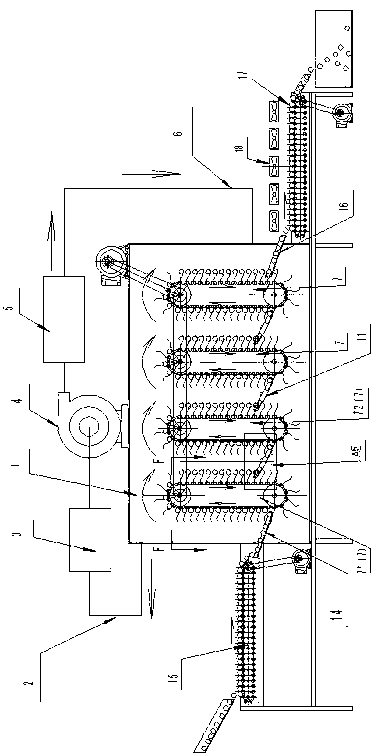

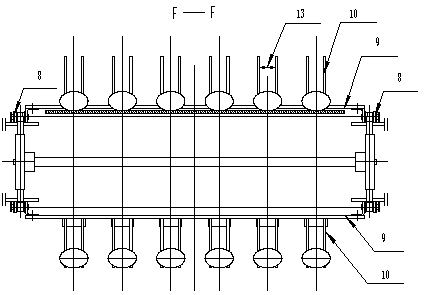

Multi-layer conveying belt tea leaf fragrance extraction machine and control method

PendingCN111217080AGuaranteed uniformityAchieve uniformitySievingConveyorsAgricultural engineeringTea leaf

The invention relates to a multi-layer conveying belt tea leaf fragrance extraction machine and a control method. The fragrance extraction machine comprises a PLC control unit, an automatic tea leaf feeding unit, a fragrance extraction and baking unit and an automatic tea leaf discharging unit, wherein the automatic tea leaf feeding unit comprises a vertical elevator and an automatic tea leaf weighing device, and the fragrance extraction and baking unit comprises a transferring conveying belt, a transverse leaf evening device, a longitudinal leaf evening device and a multi-layer conveying beltbaking unit; and the transferring conveying belt is arranged below a discharge port of the automatic tea leaf weighing device and conveys tea leaves to the multi-layer conveying belt baking unit, thetransverse leaf evening device moves in the length direction of the transferring conveying belt to evenly scrape the tea leaves on the transferring conveying belt, the longitudinal leaf evening device moves in the width direction of the transferring conveying belt to evenly scrape the tea leaves on the transferring conveying belt, and the multi-layer conveying belt baking unit comprises a plurality of layers of conveying belts for conveying the tea leaves from top to bottom and heating baking units arranged on the two sides of the conveying belts. The multi-layer conveying belt tea leaf fragrance extraction machine and the control method solve the problem that the tea leaves are stacked on the conveying belts, and guarantees the tea leaf baking uniformity.

Owner:ANHUI AGRICULTURAL UNIVERSITY

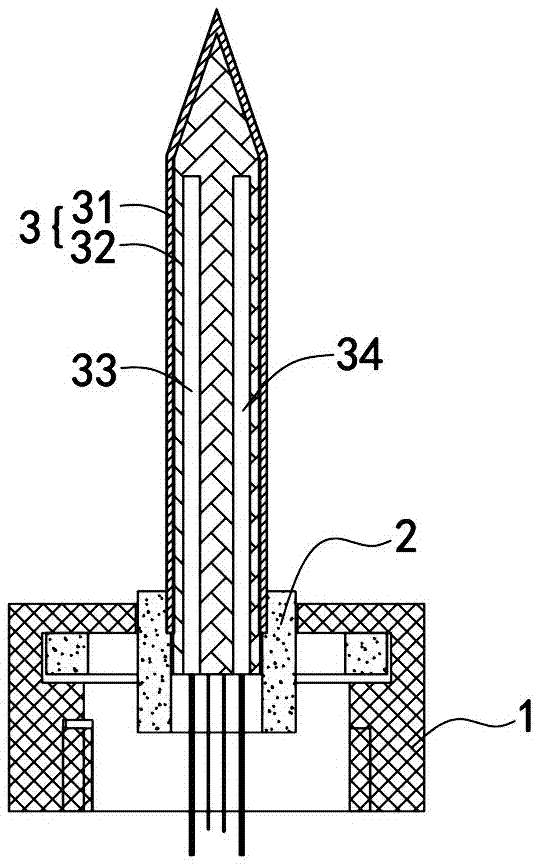

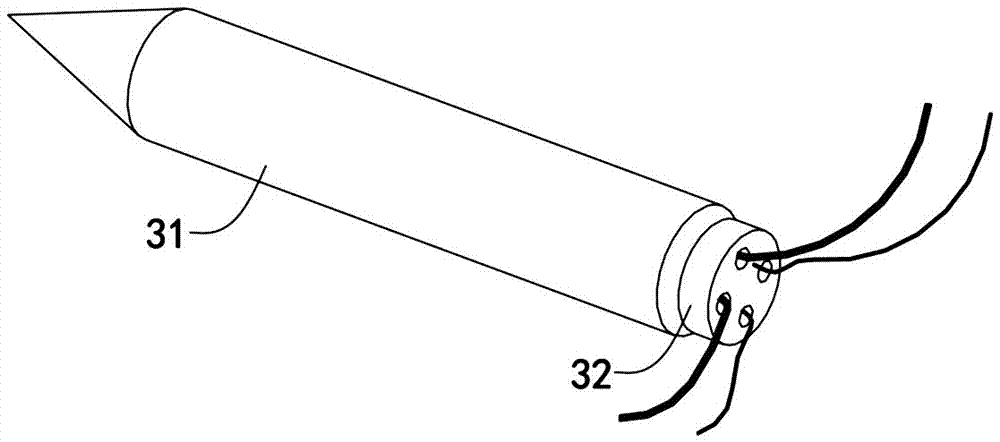

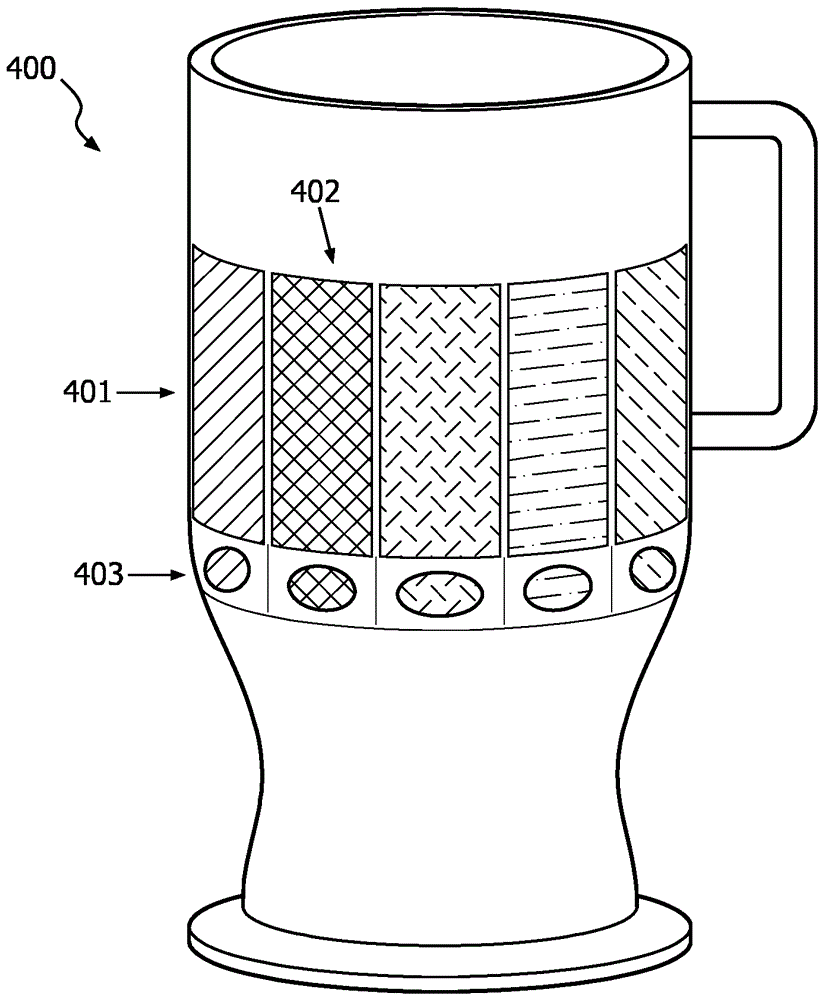

Circumferential heating type baking needle used for electronic cigarette and electronic cigarette

InactiveCN107252139AEvenly bakedQuick installationHeater elementsTobacco devicesEngineeringElectronic cigarette

The invention discloses a circumferential heating type baking needle used for an electronic cigarette and the electronic cigarette. The circumferential heating type baking needle used for the electronic cigarette comprises a baking needle head internally provided with an heating element, the exterior of the baking needle head is plated with a non-stick coating, the non-stick coating is a teflon non-stick coating or a teflon non-stick nano coating, a fixed support and a ceramic base are arranged on the baking needle head, the ceramic base is fixed in the fixed support, and the braking needle head is fixedly inserted into the ceramic base; the circumferential heating type baking needle used for the electronic cigarette is arranged in the electronic cigarette. The circumferential heating type baking needle used for the electronic cigarette and the electronic cigarette have the advantages that baking heating is uniform, installation is easy and rapid, the cigarette flavor is more mellow, tar and nicotine in the cigarette are reduced, health and hygiene are achieved, carbon deposition does not exit in use, and energy conservation and environmental protection are achieved.

Owner:SHENZHEN BUDDY TECH DEV CO LTD

Sheet food processing device

ActiveCN108955174AAvoid accumulationEvenly bakedDrying using combination processesDrying gas arrangementsMagnetEngineering

The invention relates to the technical field of food processing equipment, and particularly discloses a sheet food processing device. The sheet food processing device comprises a drying cylinder, wherein the outer periphery of the drying cylinder is rotationally connected with a sleeve, a first cavity is formed between the sleeve and the drying cylinder, a plurality of hot air holes are formed inthe side wall of the drying cylinder, one end of the drying cylinder is provided with a feeding valve and a pressure release valve, and the sheet food processing device further comprises a hot fan; across shaft is rotationally connected in the drying cylinder, a second cavity is arranged in the cross shaft, and the other end of the cross shaft is connected with a heat conduction tube; and a plurality of cylindrical air bags are fixed on the cross shaft, first magnets are fixed on the circumferential inner walls of the air bags, springs are fixed between the first magnets and the cross shaft,second magnets are fixedly arranged on the sleeves below each air bag, and when the first magnets and the second magnets are close to each other, the first magnets and the second magnets attract eachother, air inlet one-way valves communicating with the second cavity and the air bags are arranged on the cross shaft, a plurality of exhaust holes are formed in the air bags, and an air outlet one-way valve is arranged in the exhaust holes. According to the sheet food processing device, hard bean curd is subjected to centrifugal, heating type and extrusion type dehydration, so that the hard beancurd is good in drying effect and high in efficiency.

Owner:潍坊达美食品有限公司

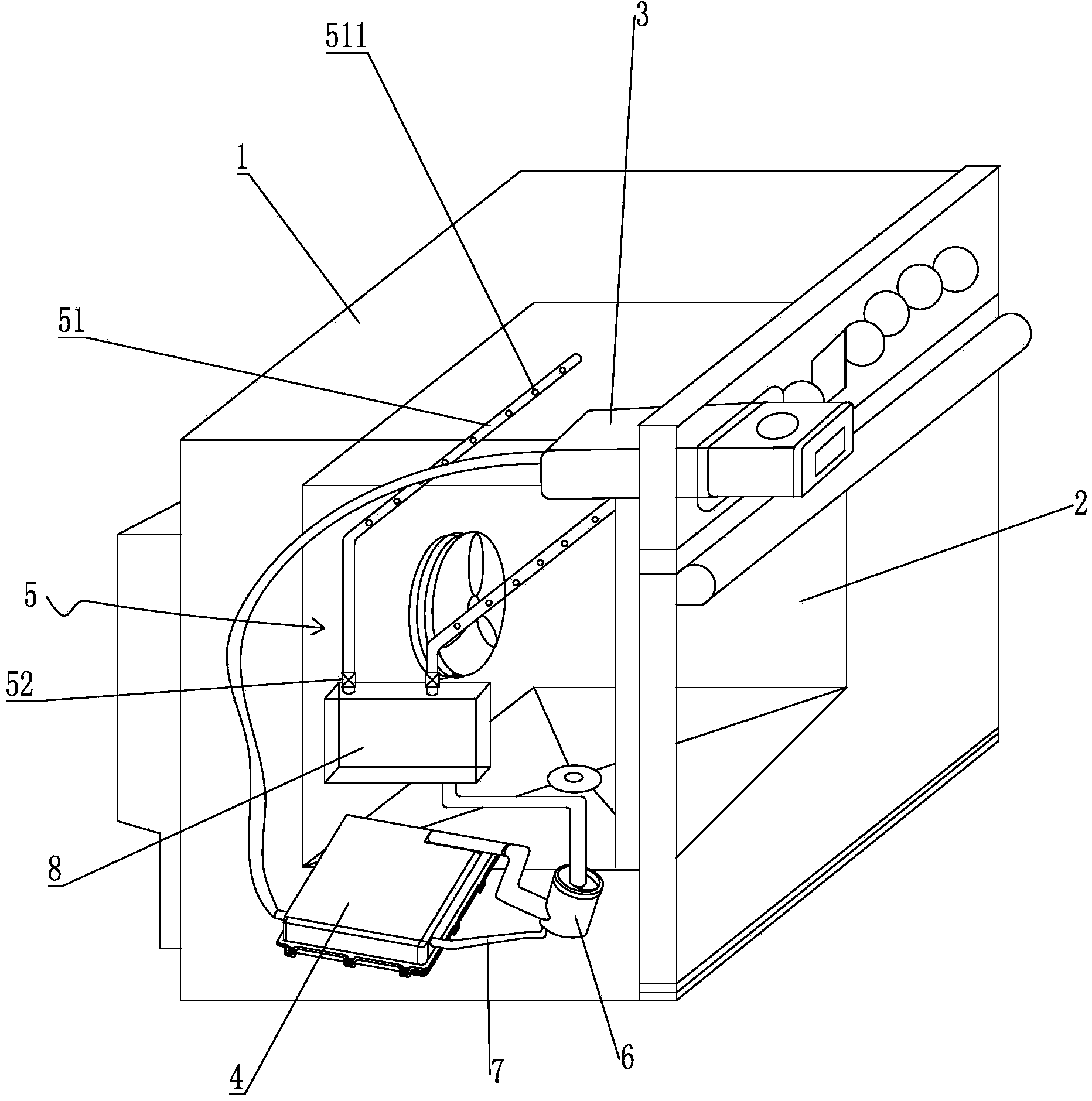

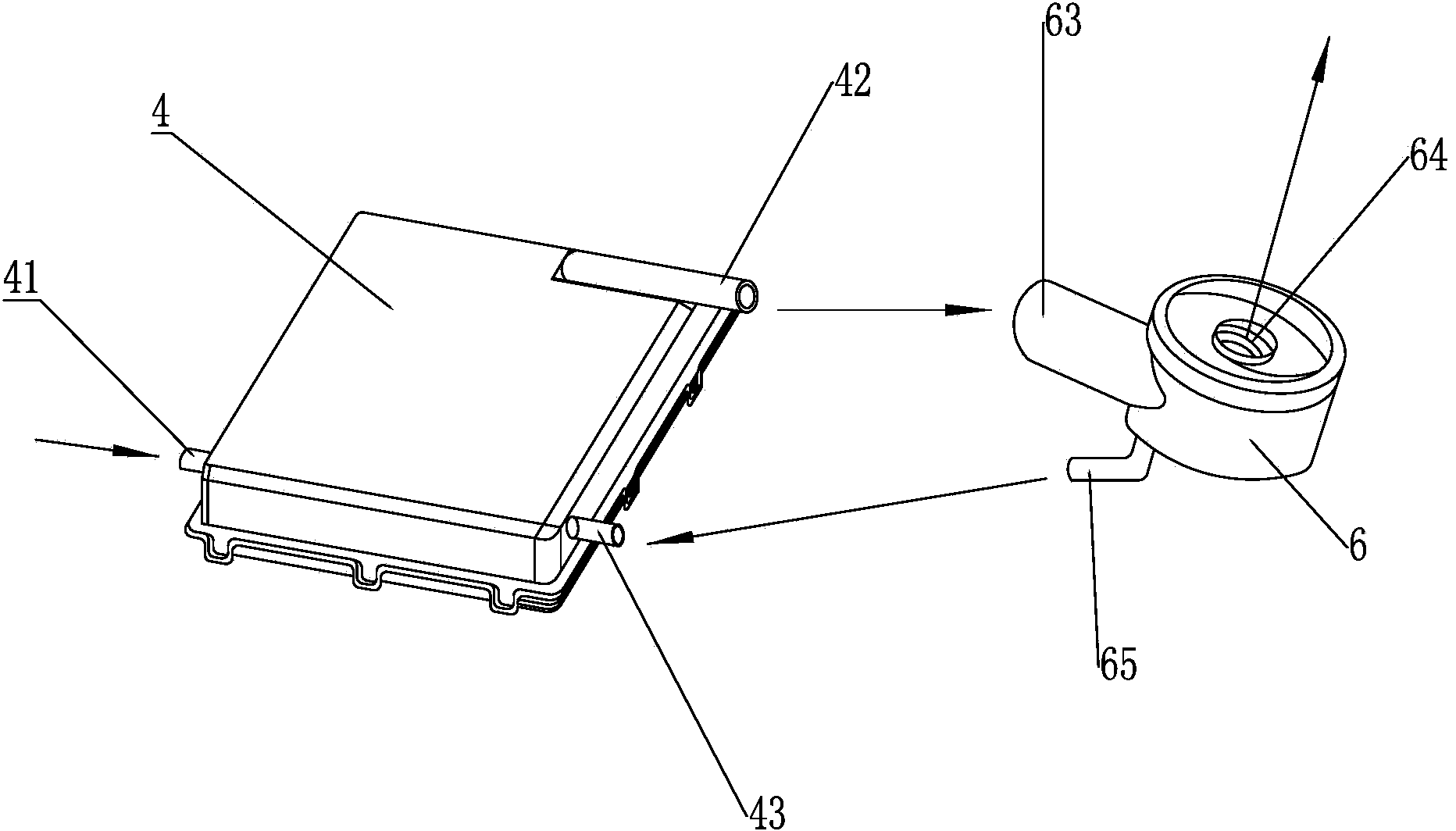

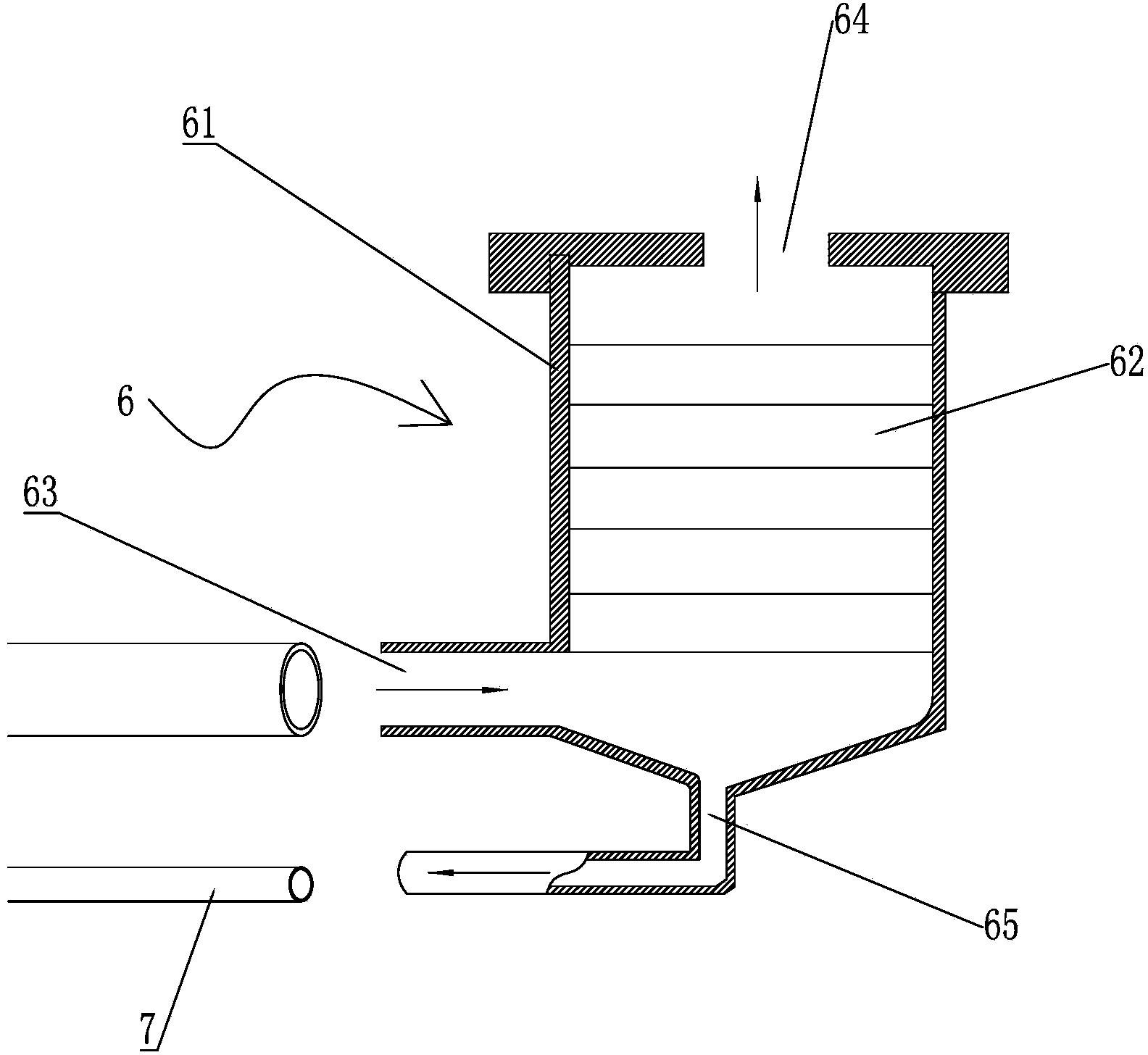

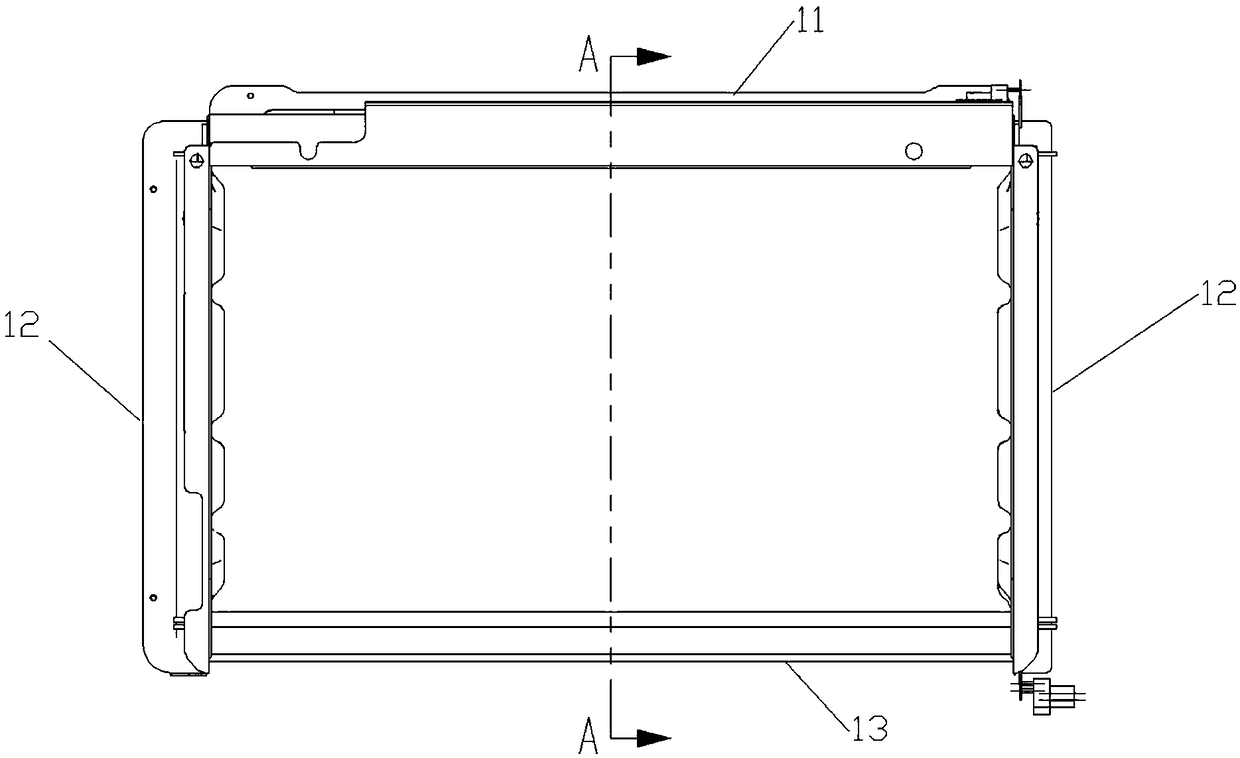

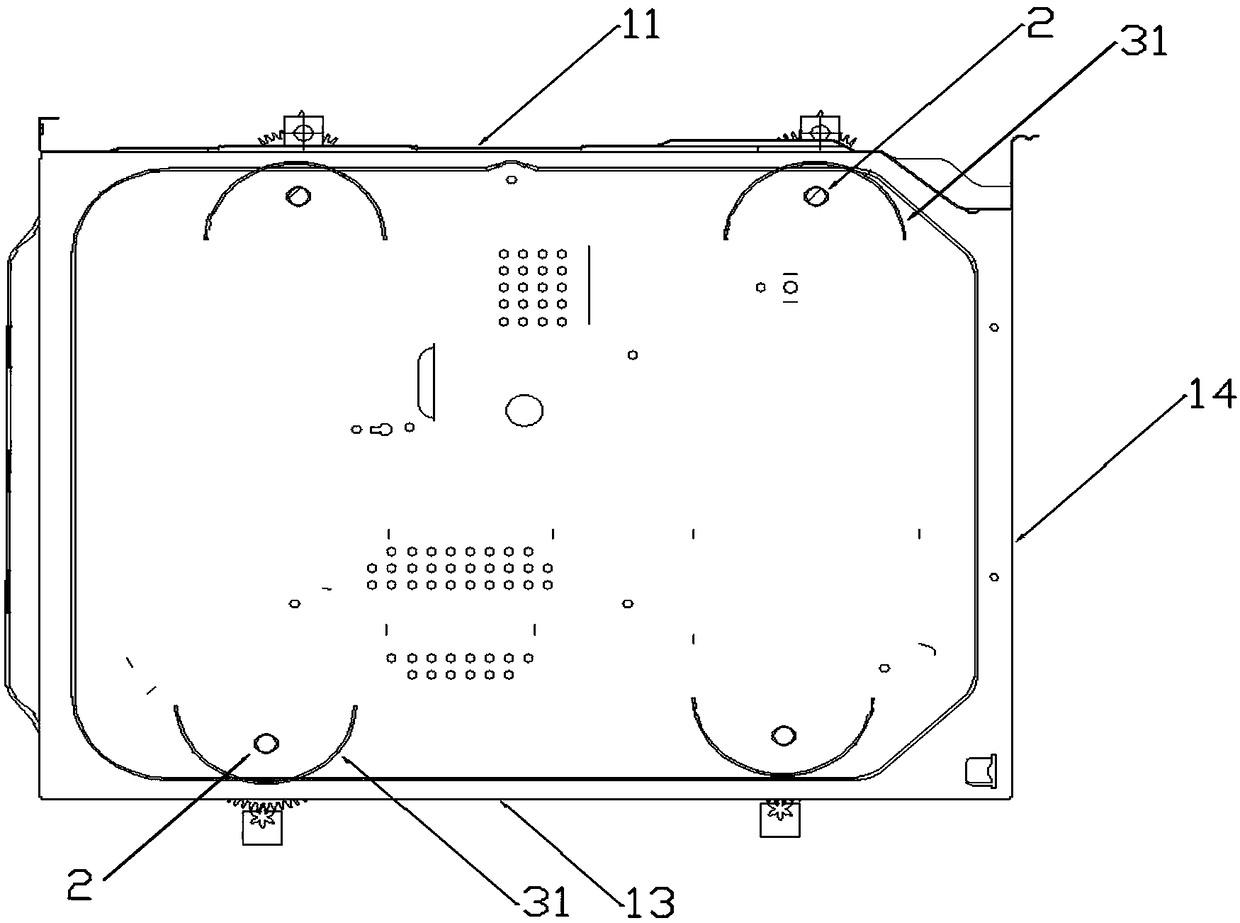

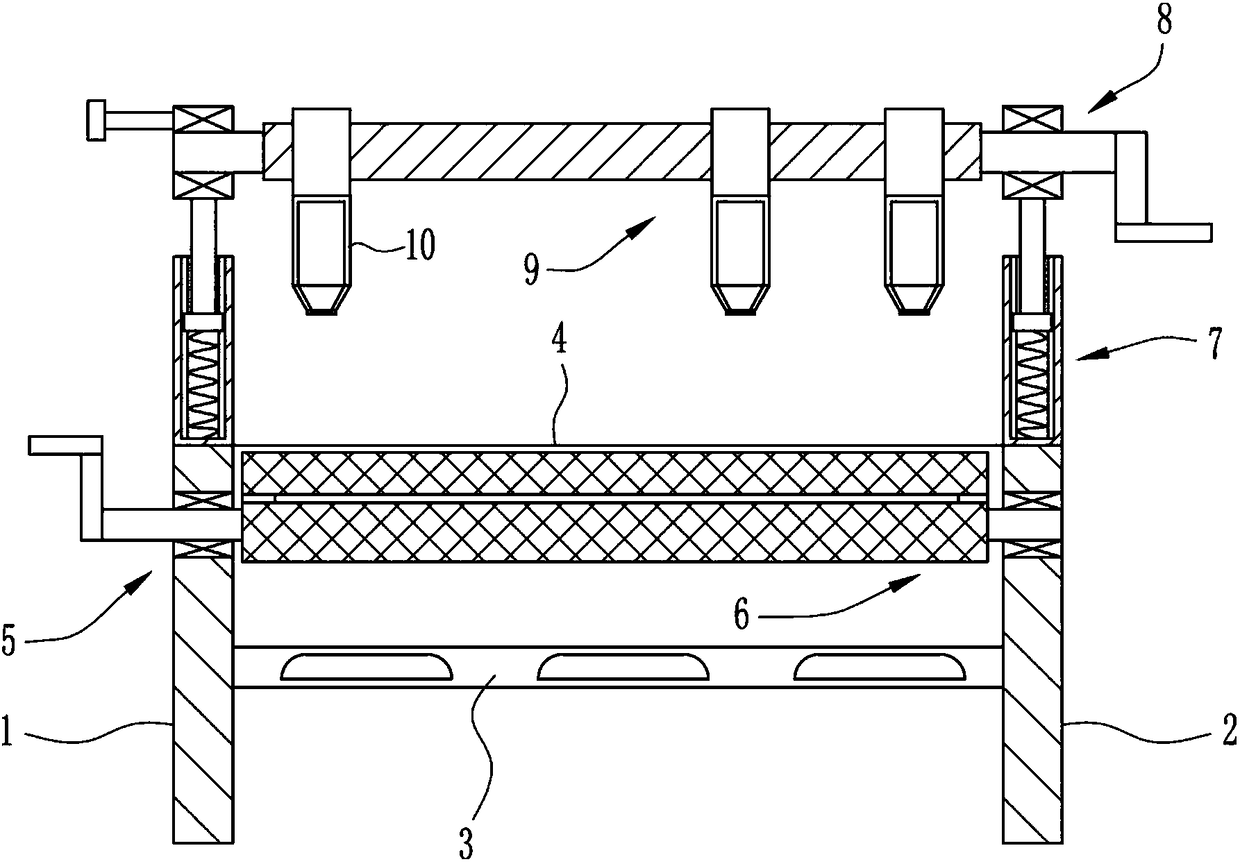

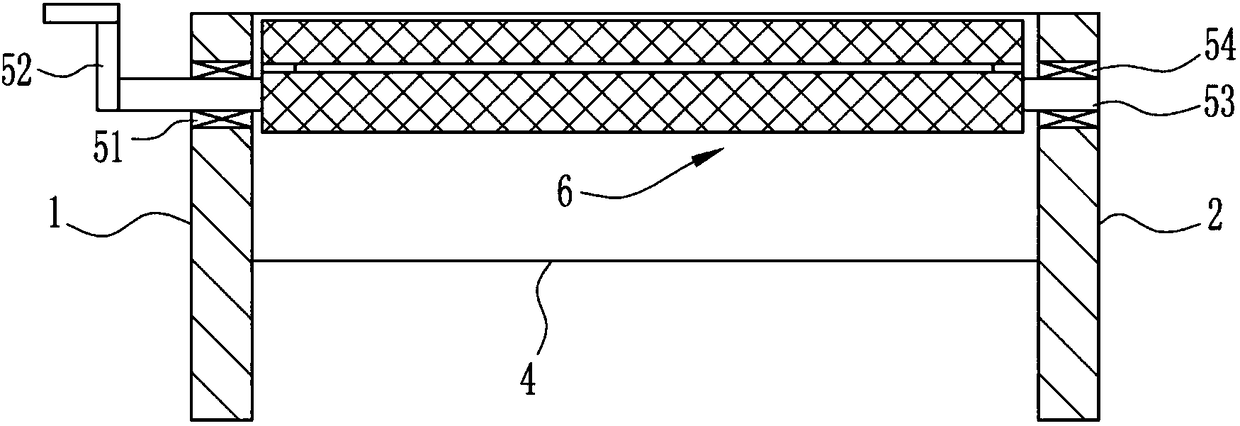

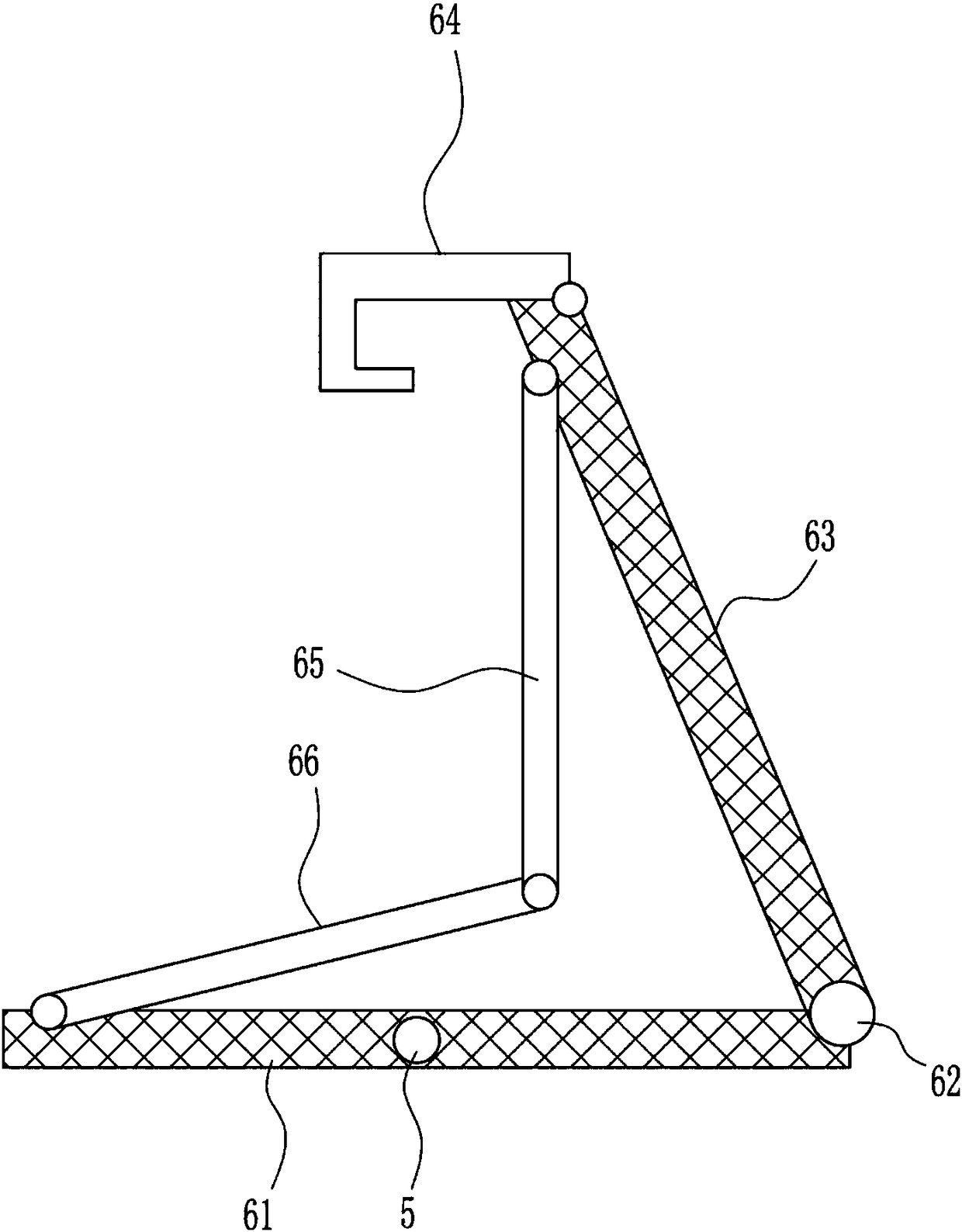

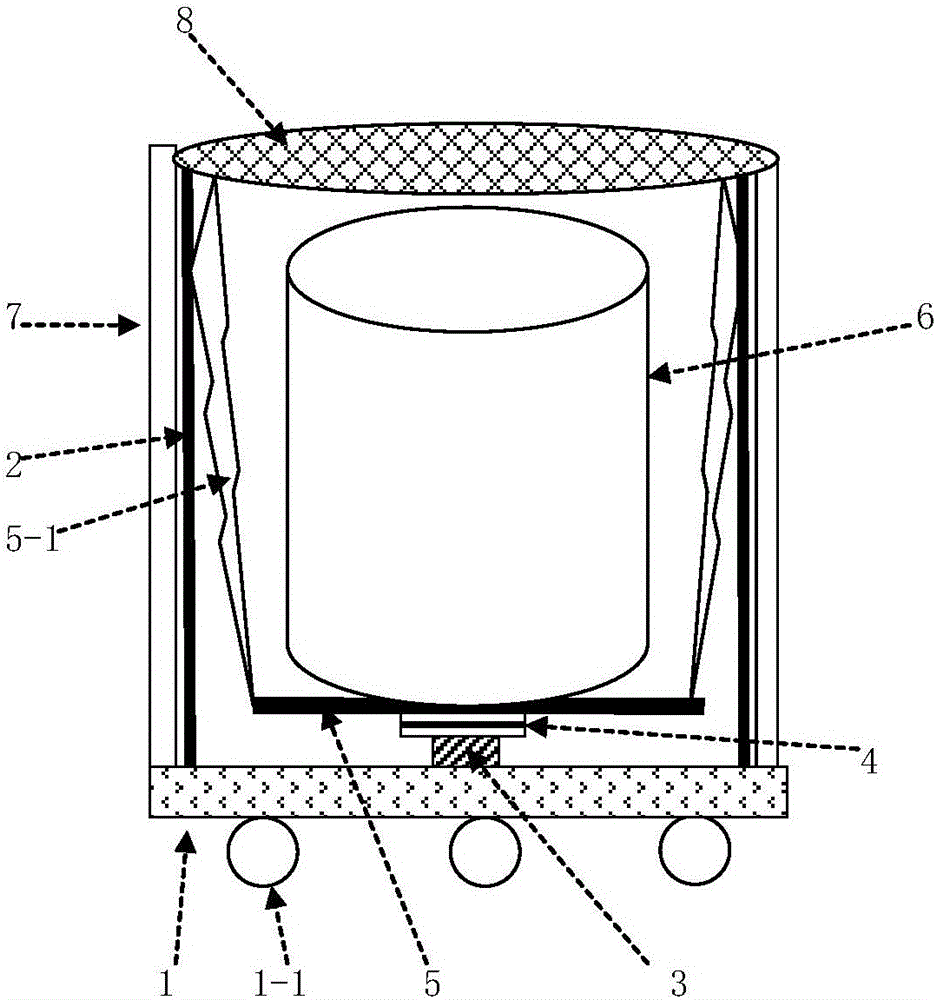

Steaming oven

The invention relates to a steaming oven. The steaming oven is characterized by comprising a tank body (1) and a steaming oven chamber (2), wherein a water filling device (3) is arranged on the tank body (1); a steam generator (4) is connected to the water filling device (3); a steam spraying device (5) is connected to the steam generator (4); a drying device (6) for reducing moisture in steam is arranged between the steam generator (4) and the steam spraying device (5). The drying device for reducing the moisture in the steam is arranged between the steam generator and the steam spraying device so as to greatly reduce the moisture in the steam, so that food cooked by the steaming oven is better in mouth feel and more delicious.

Owner:VATTI CORP LTD

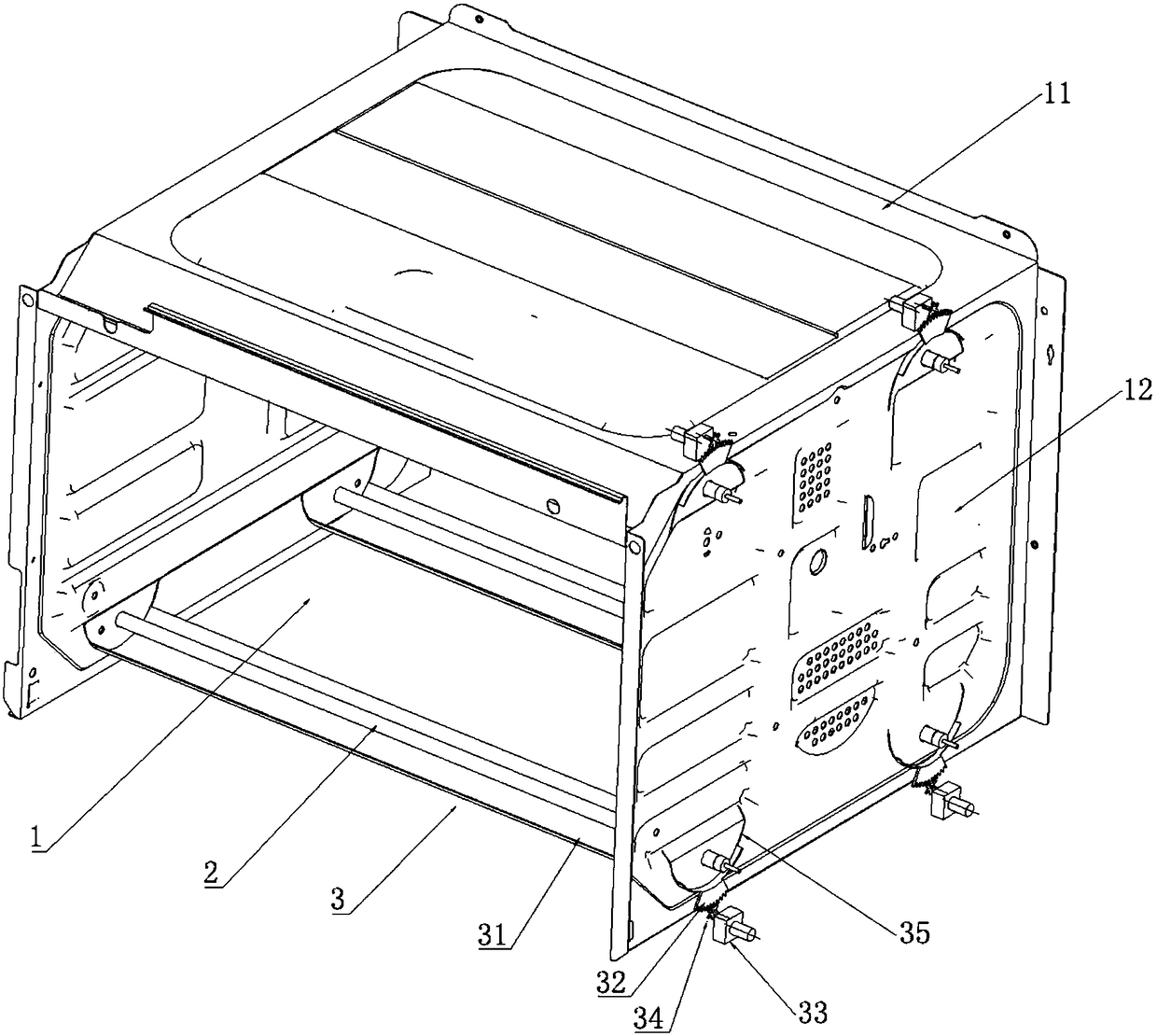

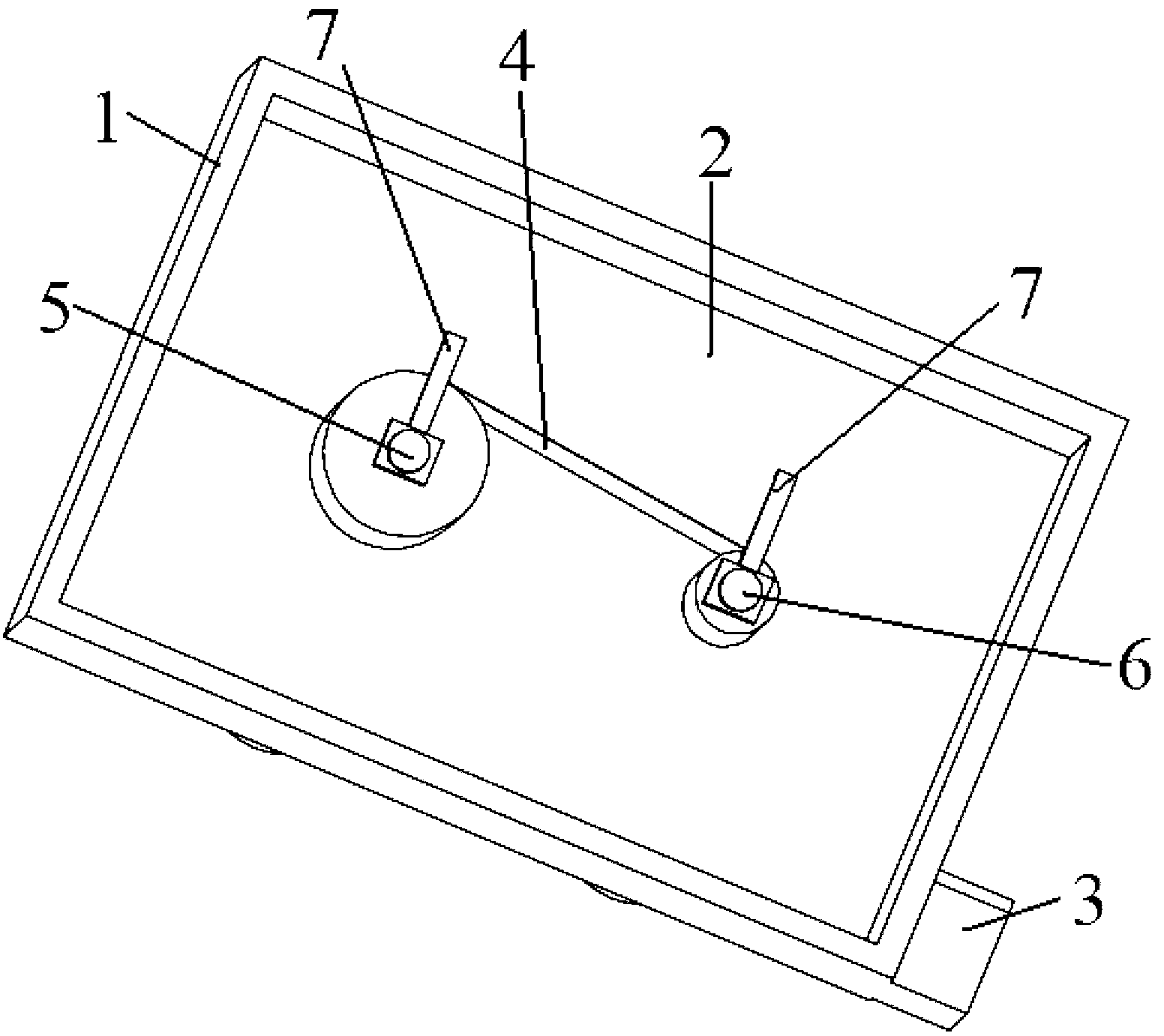

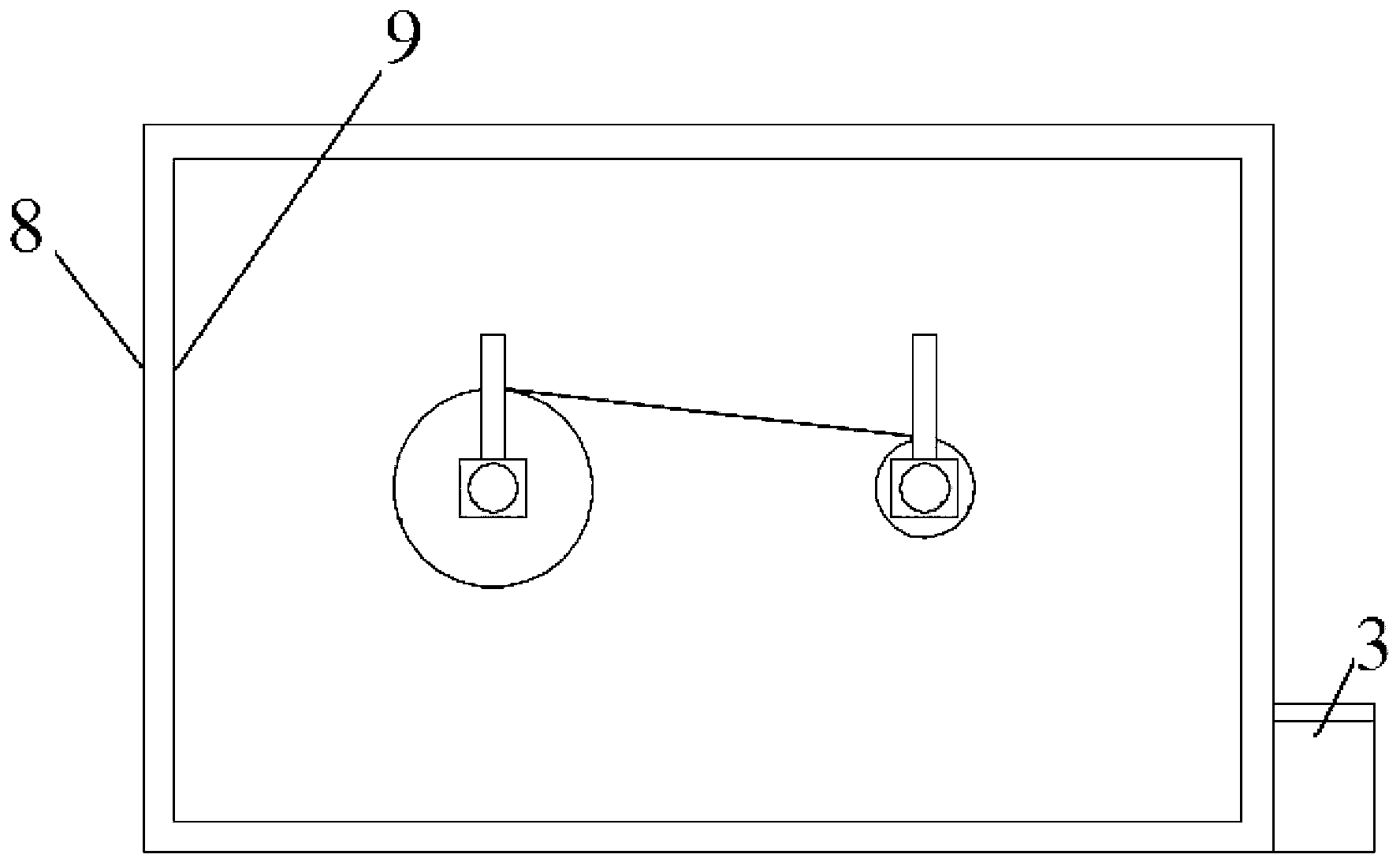

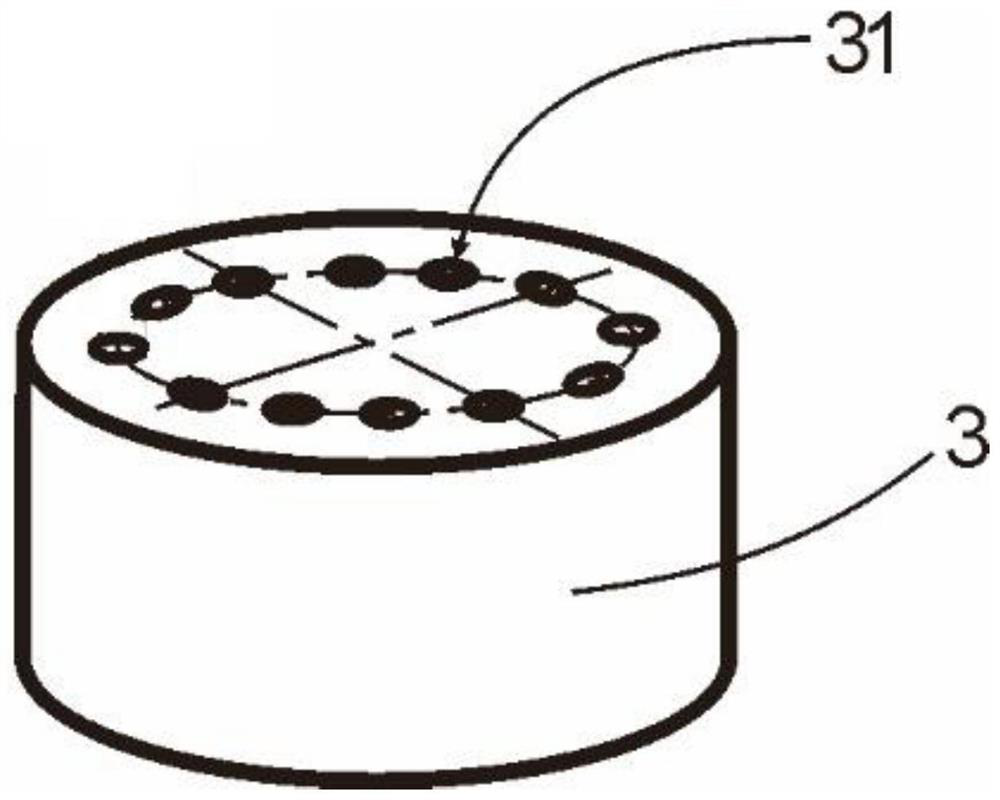

Oven with rotatable reflection cover and control method thereof

PendingCN108392094AEvenly bakedThere will be no problem of partial burntRoasters/grillsHeating timeFood material

The invention relates to the field of kitchen electrical appliances and discloses an oven with a rotatable reflection cover. The oven comprises a cavity (1), heating tubes (2) and rotatable reflectioncover assemblies (3). The heating tubes (2) correspond to the rotatable reflection cover assemblies (3) one to one to form a heating roasting assembly for reflecting heat to different angles, and theheating roasting assembly is arranged in the cavity (1). The invention further discloses a control method of the oven with the rotatable reflection cover. Roasting parameters such as heating time ofthe heating tubes (2) and rotation angles of the reflection cover (31) are determined according to the area and weight of food materials, and the food materials placed in the cavity (1) are roasted. According to the oven with the rotatable reflection cover, the rotation angle of the reflection cover (31) can be adjusted according to the difference of the area and weight of the food materials, thetemperature uniformity of the food materials is improved, and the cooking efficiency and quality are improved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Meat baking grill for food processing

The invention relates to a grill, in particular to a meat baking grill for food processing. The meat baking grill for food processing can bake meat conveniently and adjust taste of the meat conveniently. In order to solve the technical problem, the meat baking grill for food processing comprises a first support, a second support, a baking plate, a mounting box, an overturning component, a clampingcomponent, a lifting component, a swinging component, a seasoning spreading component and a condiment; and the mounting box is fixedly connected to the first support and the second support, the baking plate is fixedly connected to the inner bottom surface of the mounting box, the overturning component is fixedly connected to the first support and the second support, and the clamping component isin transmission connection with an outputting end of the overturning component. Effects of baking meat conveniently and conveniently adjusting the taste of the meat are achieved.

Owner:杨馨蕊

Vacuum oven and drying method of power lithium ion cell pole piece

ActiveCN103256792AEvenly bakedImprove drying uniformityDrying machines with progressive movementsHeating arrangementVacuum pumpingLithium

The invention discloses a vacuum oven and a drying method of a power lithium ion cell pole piece. The vacuum oven comprises an oven body, a heating device and a vacuum pumping device. A drying chamber is arranged in the oven body. Two parallel rotatable rotation shafts are arranged in the drying chamber. Two ends of a pole piece roll material are wound on the two rotation shafts respectively. Compared with the prior art, the two rotation shafts are arranged and rotate in two directions to drive the pole piece roll material to be wound back and forth. In the process of rolling the pole piece roll material, the heating device can dry the pole piece roll material at the same time. The pole piece roll material can be wound back and forth to ensure that pole pieces of all parts can be evenly dried. Thus, drying uniformity of the cell pole piece is improved.

Owner:奇瑞新能源汽车股份有限公司

Charcoal barbequing device

ActiveCN105747893ASimple structureEasy to operateRoasting apparatusRoasters/grillsElectricityFresh air

The invention discloses a charcoal barbequing device which comprises a base, an outer support, a bottom bearing, a rotary motor, a temperature difference electric semiconductor refrigerating sheet, an inner crossed support, a charcoal fire bucket, a side barbequing plate, an upper barbequing plate, an upper barbequing net and a hand-cranking air blower. One surface of the temperature difference electric semiconductor refrigerating sheet faces upwardly to receive heat from the upper portion of the charcoal barbecuing device, so that the temperature can be increased; the other surface of the temperature difference electric semiconductor refrigerating sheet faces downwardly to be in contact with fresh air, electric energy can be generated by the temperature difference electric semiconductor refrigerating sheet owing to temperature difference, a rotary shaft of the rotary motor can be driven by the electric energy to rotate, the inner crossed support and the charcoal fire bucket can be driven to rotate, shifters, on the inner crossed support, with sawteeth, can rotate with the inner crossed support, food skewers can be shifted by the shifters with the sawteeth to rotate, foods on the food skewers can be uniformly baked, and clamp nails on the side barbequing plate can be pushed aside when the foods on the food skewers are completely cooked by means of baking, so that the side barbequing plate can be separated from the outer support, and the food skewers can be taken out of the charcoal barbequing device.

Owner:CHANGZHOU UNIV

Environmentally friendly barbecue oven

ActiveCN107080470AIngenious structural designReduce baking timeClimate change adaptationRoasters/grillsProcess engineeringMechanical engineering

The invention relates to an environmentally friendly barbecue oven, and relates to the technical field of barbecue equipment structures. The barbecue oven comprises a barbecue oven body, and a plurality of carbon boxes at intervals are perpendicularly installed in the barbecue oven body; a skewer conveying device which can convey skewers and drive the skewers to rotate at 360 degree is arranged in the barbecue oven body, the skewer conveying device starts from one end of the barbecue oven body, winds the outer surfaces of the carbon boxes and extends to the other end of the barbecue oven body, and the skewer conveying device is driven by a driving mechanism in a connected mode; a plurality of seasoning adding devices which can rotate at 360 degree are arranged above the barbecue oven body, and an automatic skewer discharging device is arranged in the tail portion of the barbecue oven body. By means of the environmentally friendly barbecue oven, even roasting of skewers and even seasoning adding can be achieved, and the barbecue oven is energy-saving, environmentally friendly and healthy.

Owner:烟台陈工环保设备有限公司

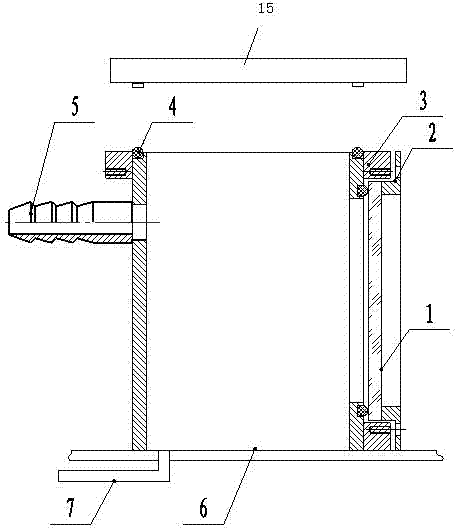

Postirradiation fuel rod vacuum bubble method leak detection box and leak detection system and leak detection method thereof

ActiveCN104505132AImprove radiation resistanceAccelerated corrosionNuclear energy generationNuclear monitoringRobot handMechanical engineering

The invention discloses a postirradiation fuel rod vacuum bubble method leak detection box and a leak detection system and a leak detection method thereof. A postirradiation fuel rod is dried through a baking device and then placed in an L-shaped lifting frame and then descends into water inside the leak detection box, the leak detection box is internally vacuumized, the fuel rod generates internal and external differential pressure; if the fuel rod is damaged, bubbles are formed around a damaged opening, the generation positions of the bubbles are determined through image collection, and accordingly the leak detection of the postirradiation fuel rod is finished. The postirradiation fuel rod vacuum bubble method leak detection box has the advantages of quick leak detection speed, simplicity in hot chamber operation and good economy, is simple in structure and low in cost, can be operated through a remote mechanical hand and is safe in structure; no excessive structure is in contact with the fuel rod, the damaged opening appears as far as possible, and the leak detection rate of the fuel rod is improved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

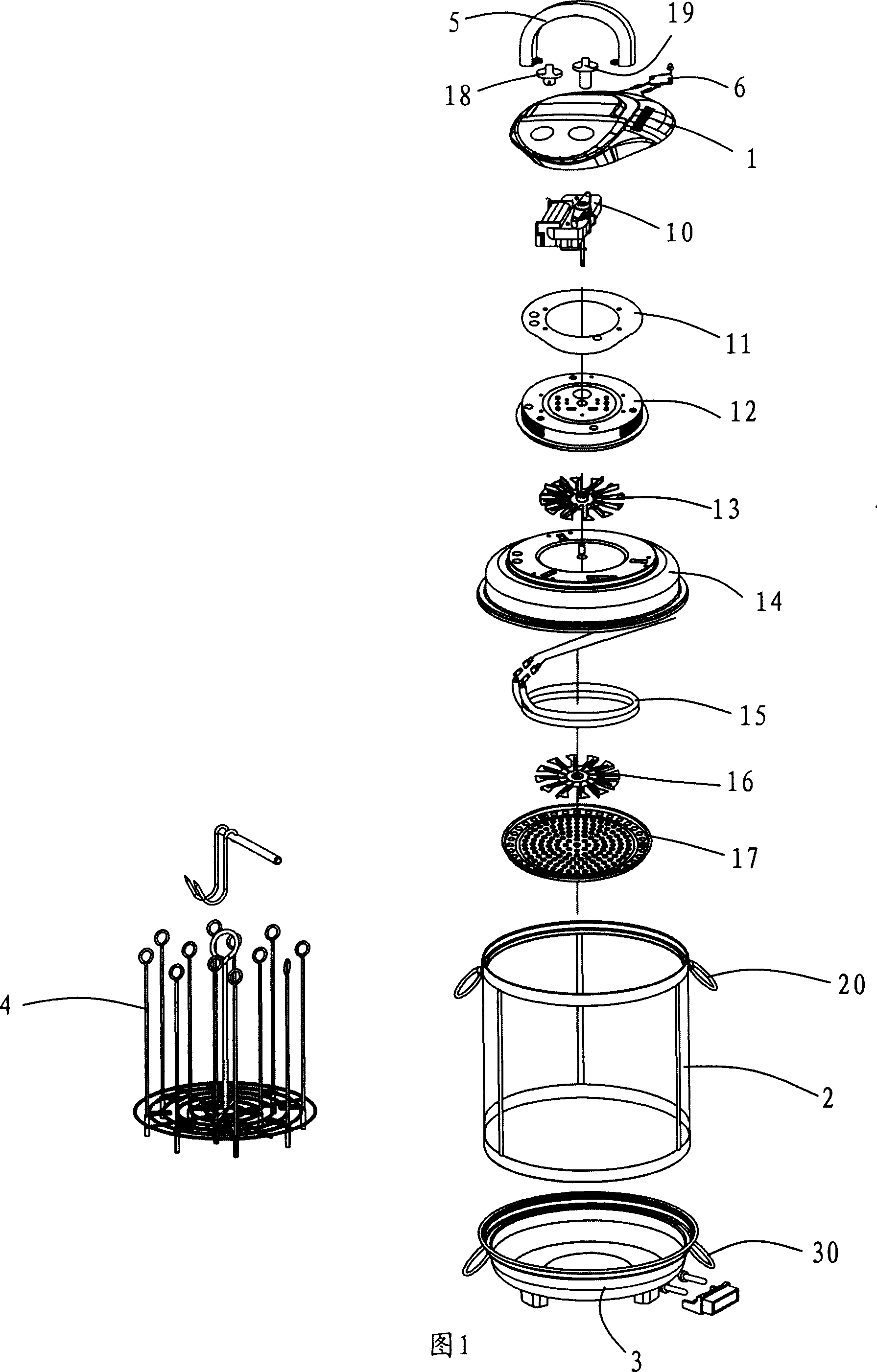

Air fryer

PendingCN106901617AEfficient cycleLarge air duct areaCooking-vessel lids/coversRoasting apparatusImpellerEngineering

The invention discloses an air fryer which comprises a shell, a heating device and a cross-flow fan, wherein the shell comprises a first chamber and a second chamber; the first chamber communicates with the second chamber; an air outlet is formed in the bottom of the first chamber; an air inlet is formed in the top of the second chamber; the heating device is arranged in the second chamber; the cross-flow fan is arranged in the second chamber and comprises an impeller and the axis of the impeller is horizontal; after the cross-flow fan is started, the air inlet is used for carrying out horizontal air inlet and the air outlet is used for carrying out horizontal air outlet. According to the air fryer, the thermal cycle efficiency can be effectively improved and the food can be uniform in baking color, crisp in surface and better in taste.

Owner:FOSHAN SHUNDE KUFU ELECTRIC APPLIANCES CO LTD

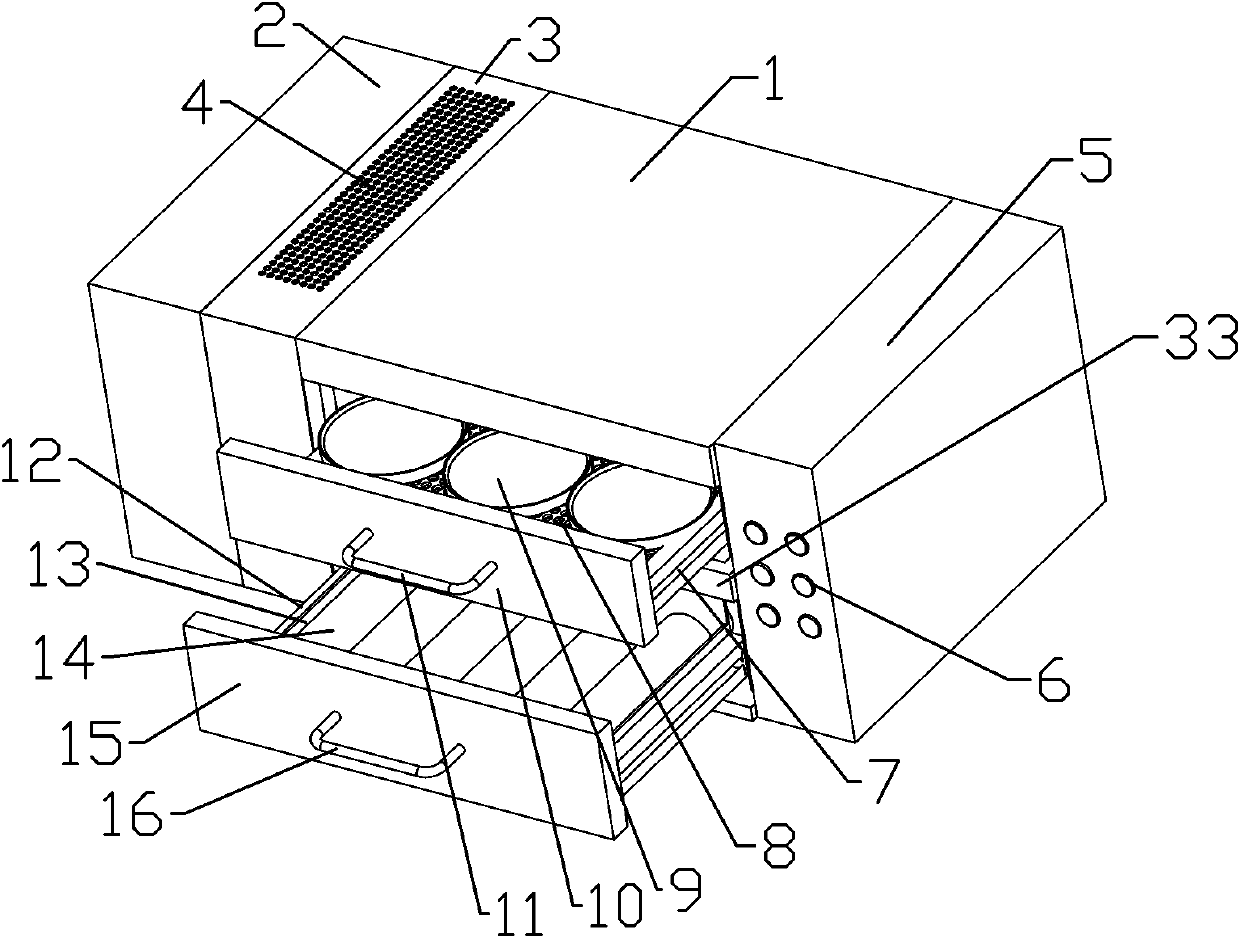

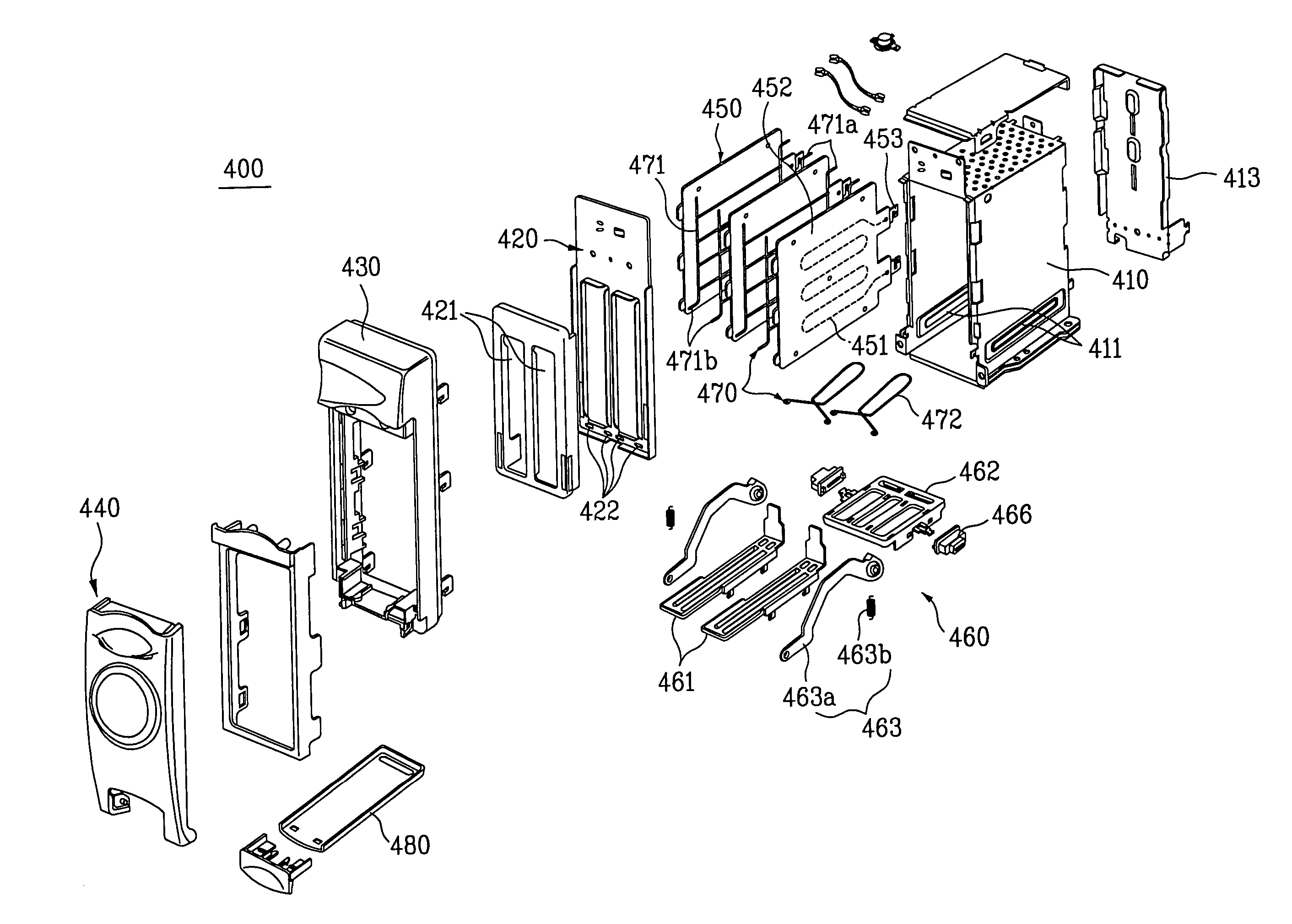

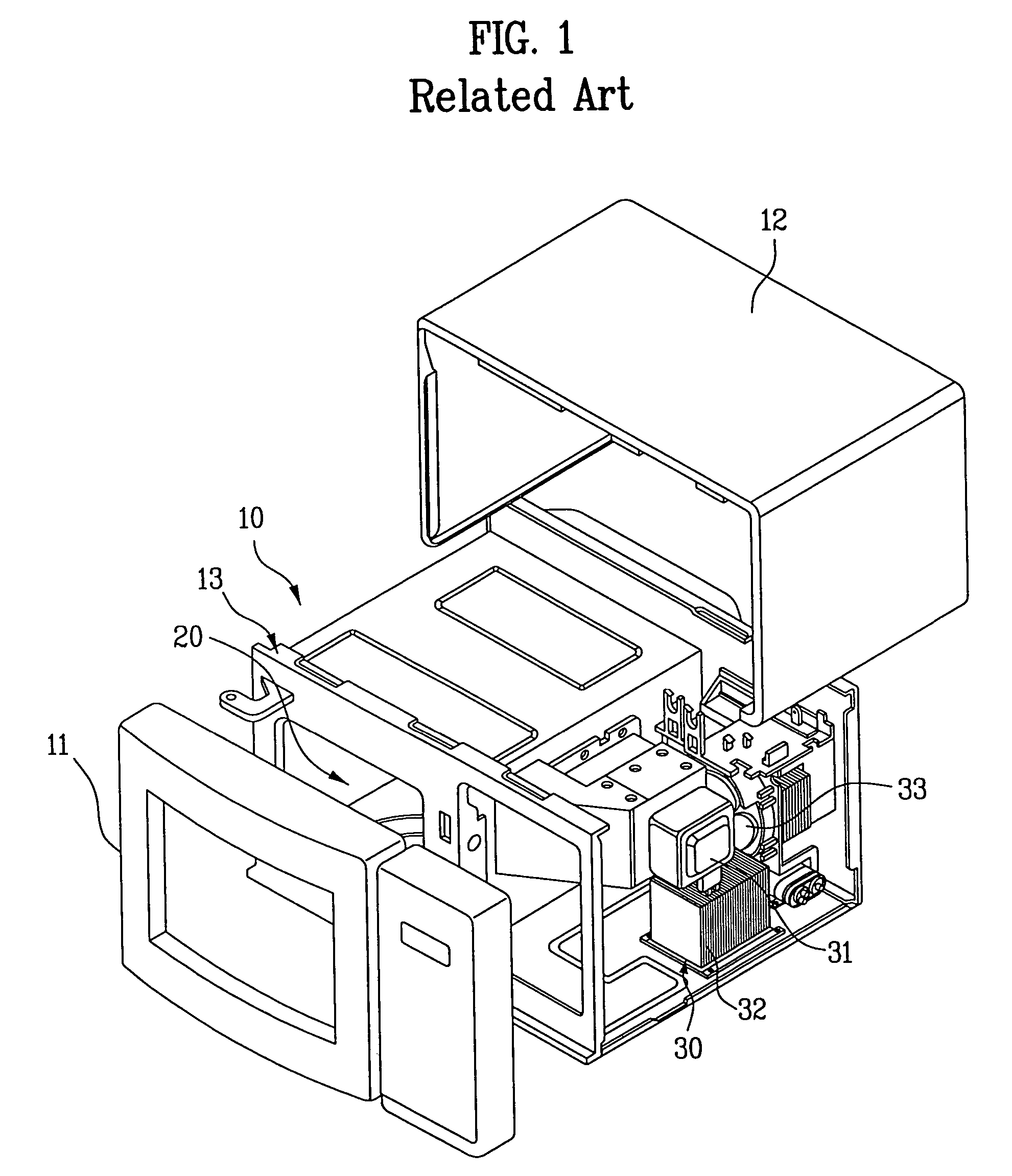

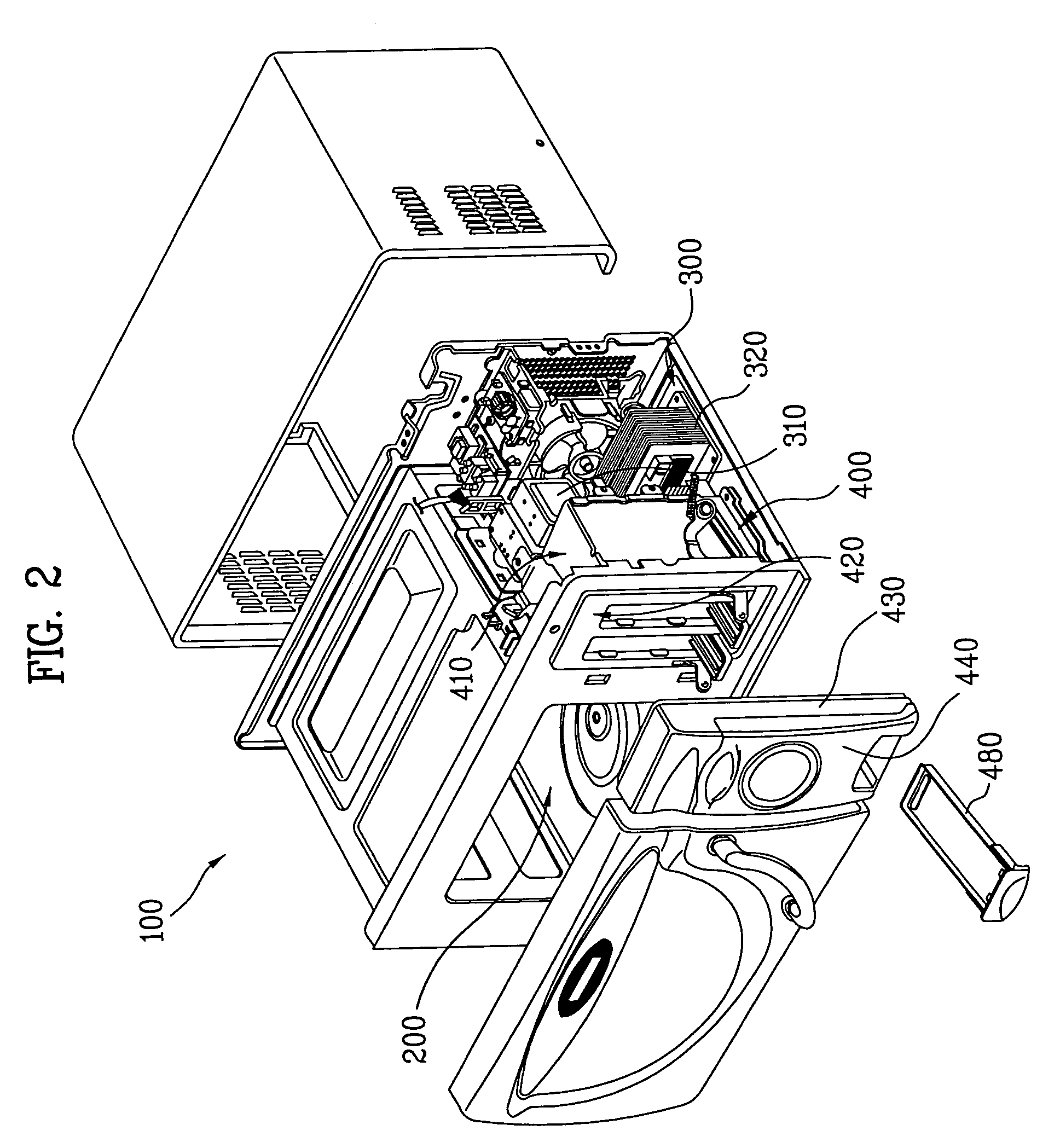

Combined toaster and microwave oven

InactiveUS7170039B2Avoid leaningEvenly bakedDomestic stoves or rangesMilk preservationMicrowave ovenMechanical engineering

The present invention relates to a combined toaster and microwave oven having a function to cook food by using microwave and a function to bake bread. Accordingly, the present invention provides a combined toaster and microwave oven comprising: a body forming an appearance thereof; a cavity formed in the body, for accommodating objects to be cooked by using microwave; an electronic chamber provided at a portion inside the body and in which electronic parts for applying microwave into the cavity are installed; and a toaster. The toaster comprises: a toaster case provided in the front of the electronic chamber and having slits on both sides thereof; at least one tray assembly having means for receiving and ejecting bread and preventing the bread from slanting; and a heater assembly installed inside the toaster case, for heating the bread.

Owner:LG ELECTRONICS INC

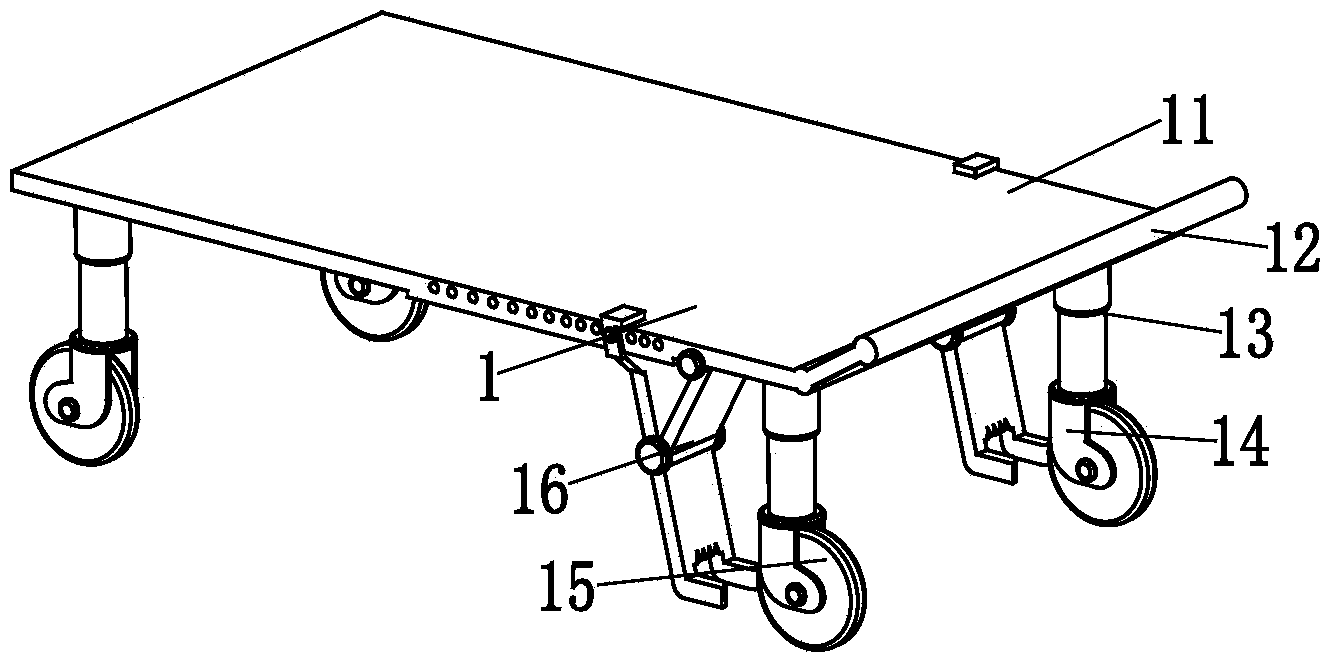

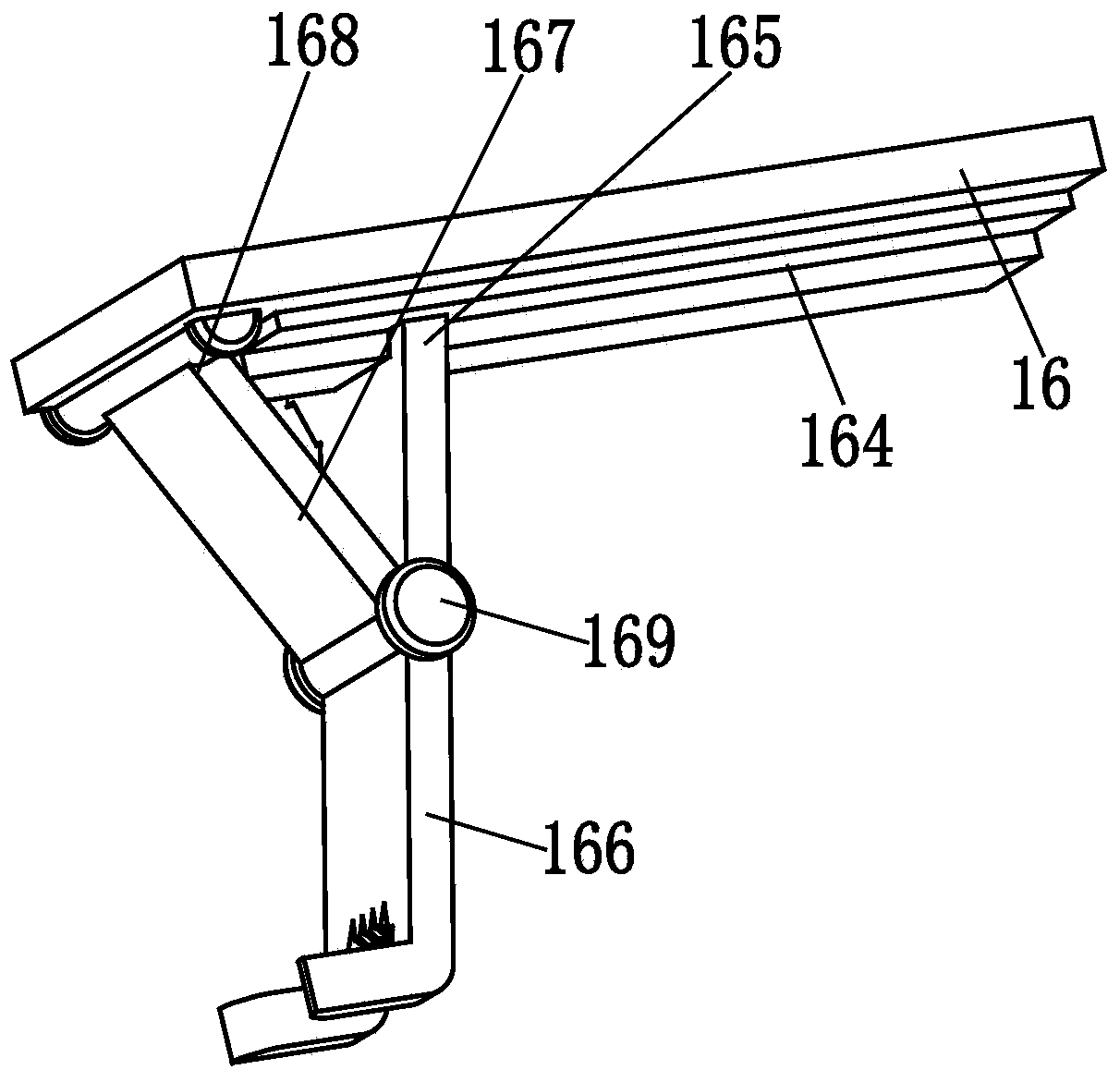

Baking equipment

ActiveCN104223967ASimple structureEasy to operateRoasters/grillsBread-toastersProcess engineeringAutomation

The invention relates to baking equipment. The baking equipment comprises a movable trolley, a slicing device, a baking oven, a grill, a material spreading device and a smoke exhaust device, wherein the slicing device is located on the rear side of the movable trolley, the baking oven is located right ahead the slicing device and the baking oven is fixedly connected with the movable trolley; the grill is installed above the baking oven and the material spreading device is located right above the grill; the smoke exhaust device is located on the front side of the baking oven and the smoke exhaust device is fixedly connected with the baking oven. The baking equipment has the advantages of simple structure, convenience in operation, low manufacturing cost and the like; the baking equipment can realize a function of rotatably baking sliced bread, the baking uniformity is good and the baking efficiency is high; the baking device can also realize a function of automatically spreading materials, and the automation level is improved; heat produced during baking is fully utilized and energy waste is reduced.

Owner:徐州市铜山区汉王镇农业服务发展有限公司

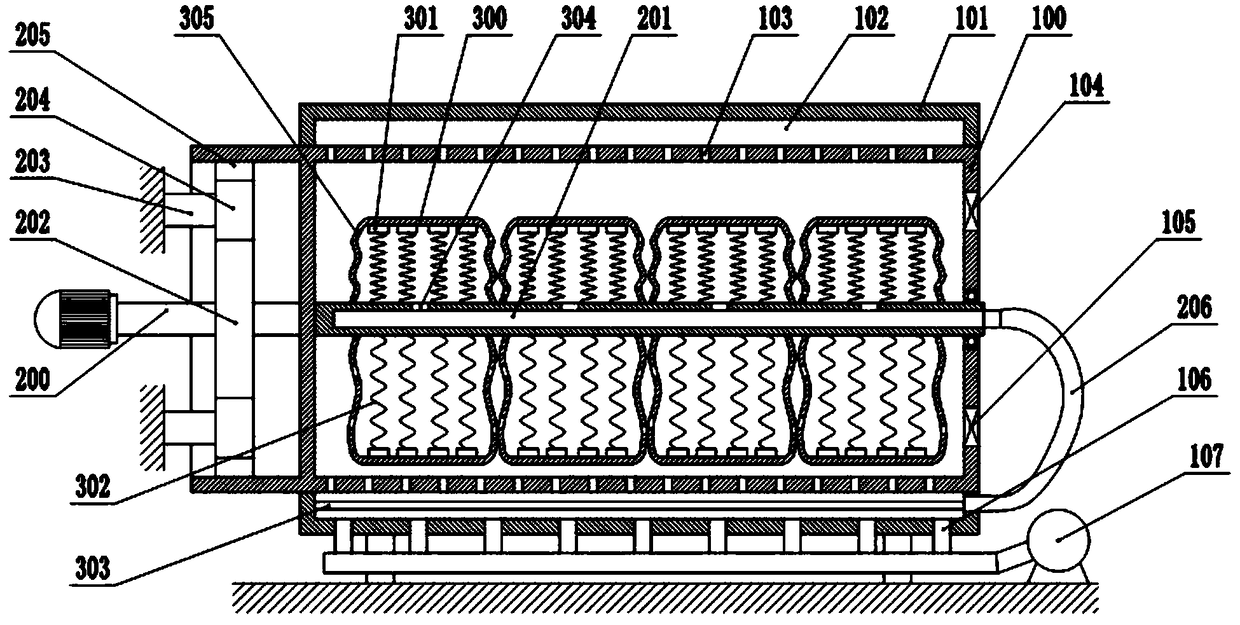

Automobile part baking chamber

InactiveCN104406385AEvenly bakedImprove roast qualityDrying gas arrangementsDrying machines with progressive movementsDisplay deviceEngineering

The invention relates to an automobile part baking chamber. The automobile part baking chamber comprises a chamber body, a fan, a heating device, a conveyor belt and a temperature sensor; the chamber body comprises an outer chamber and an inner chamber arranged in the outer chamber; a cavity surrounding the inner chamber is arranged between the outer chamber and the inner chamber; the fan is arranged on the inner wall of the upper part of the outer chamber; the heating device is arranged in the cavity and located under the fan; the conveyor belt penetrates through the outer chamber and the inner chamber; the temperature sensor is arranged at the bottom of the inner chamber and connected with an external display; a plurality of air holes are formed in the upper part of the inner chamber and the upper parts of the two sidewalls of the inner chamber. Compared with the prior art, the automobile part baking chamber is capable of controlling the baking temperature, and is uniform in baking and high in baking quality.

Owner:LIUZHOU JINTE NEW WEAR RESISTANT MATERIAL CO LTD

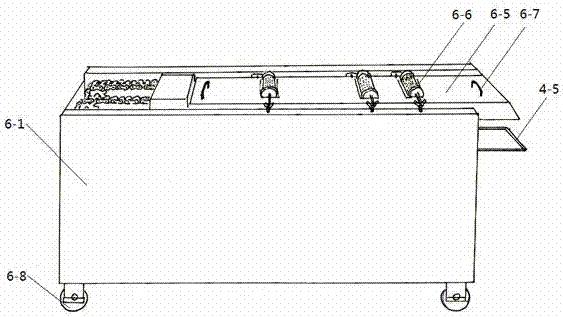

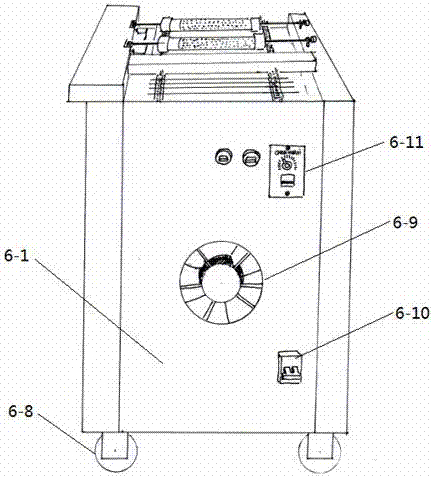

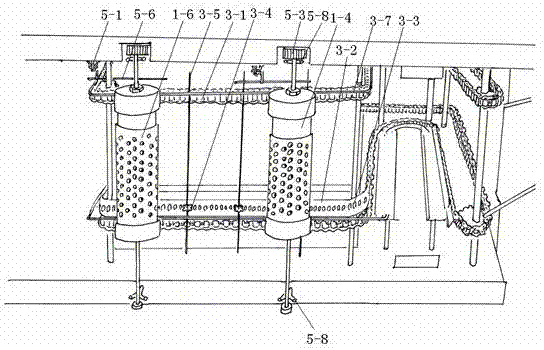

Chain belt type areca nut processing machine

The invention discloses a chain belt type areca nut processing machine. The machine is obtained by improving five former patents of the designer, and comprises a horizontal receiving chain wheel, a chute, a feeding device, a stop lever, material poking rods, a round blade, a chain belt, an areca nut claw nest, a belt-dividing bolt, a coring device, a marinating switch, a marinating gun, a vertical driving chain wheel, a baking tunnel, a discharge chute, an areca nut extrusion fixation device and the like. Areca nuts are placed on the chute in the feeding device, are queued by the material poking rods, fall into the areca nut claw nest on the chain belt from the mouth of the chute one by one, are centered by the extrusion fixation device, enter the round blade and are cut open, and then are cored by the coring device. The chain belt is transited from the horizontal chain wheel to the vertical chain wheel, so knife edges of two half areca nuts which are cut open in the claw nest on the belt face toward the sky along with the torsion of the chain belt, are marinated by the marinating switch and the marinating gun, and then slip out of the baking tunnel. The complete machine is full automatic, has high work efficiency which greatly exceeds that of the manual work, and can marinate cleanly, accurately and quantificationally; the product is uniform, is uniformly baked, and has guaranteed quality; the complete machine has a compact and simple structure and can be maintained easily; and the yield can be increased by increasing the quantity of the blade.

Owner:吴瑛

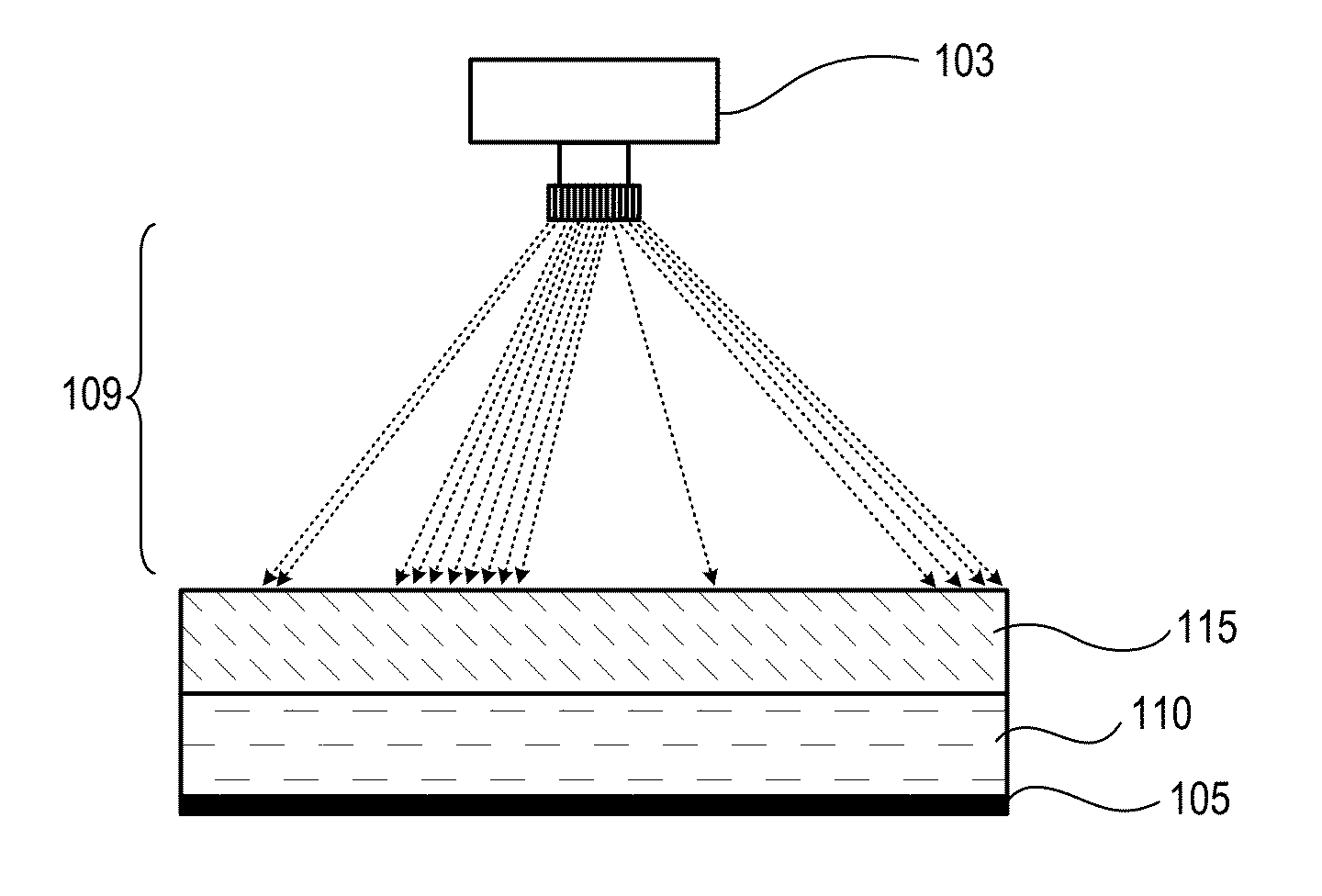

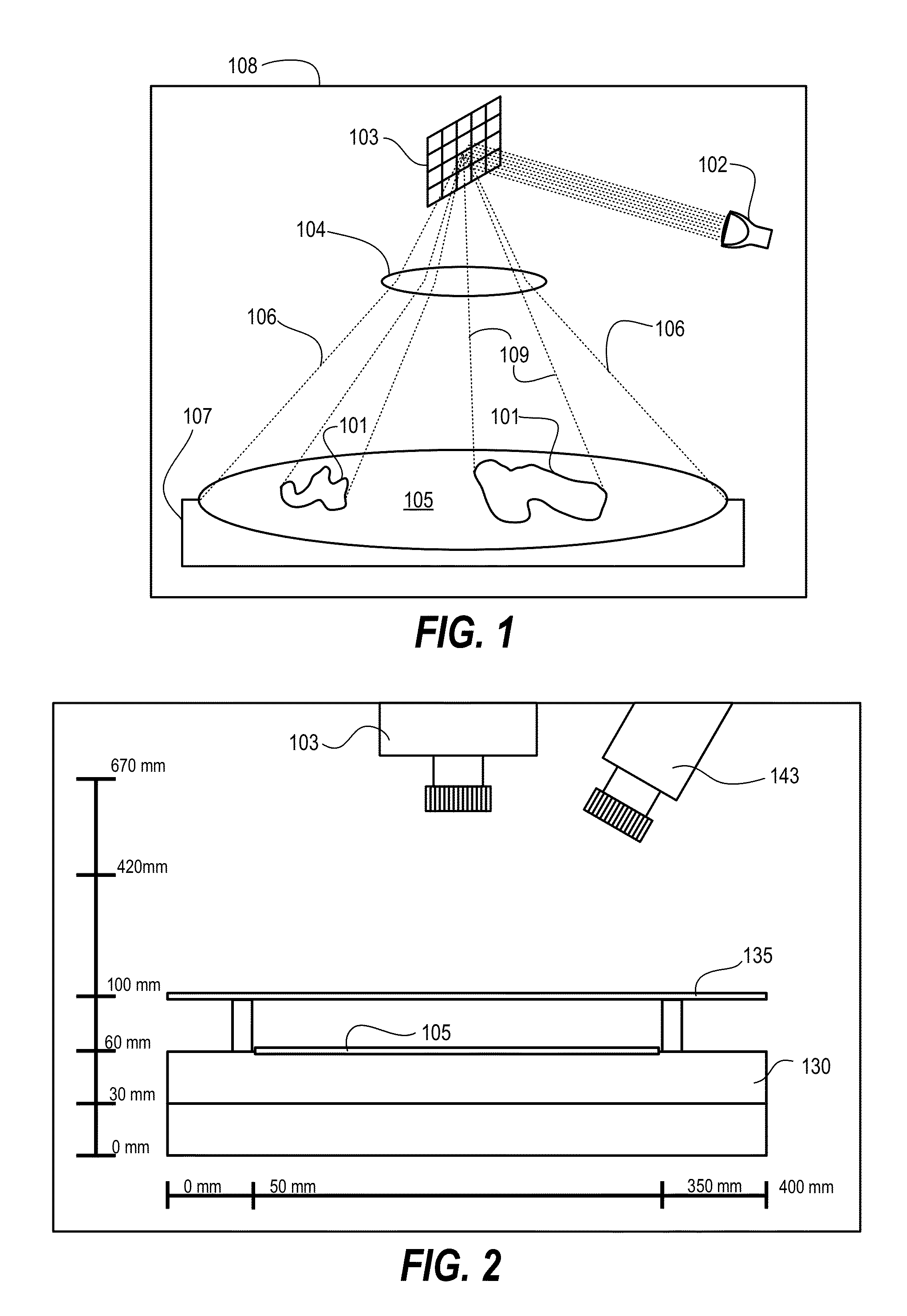

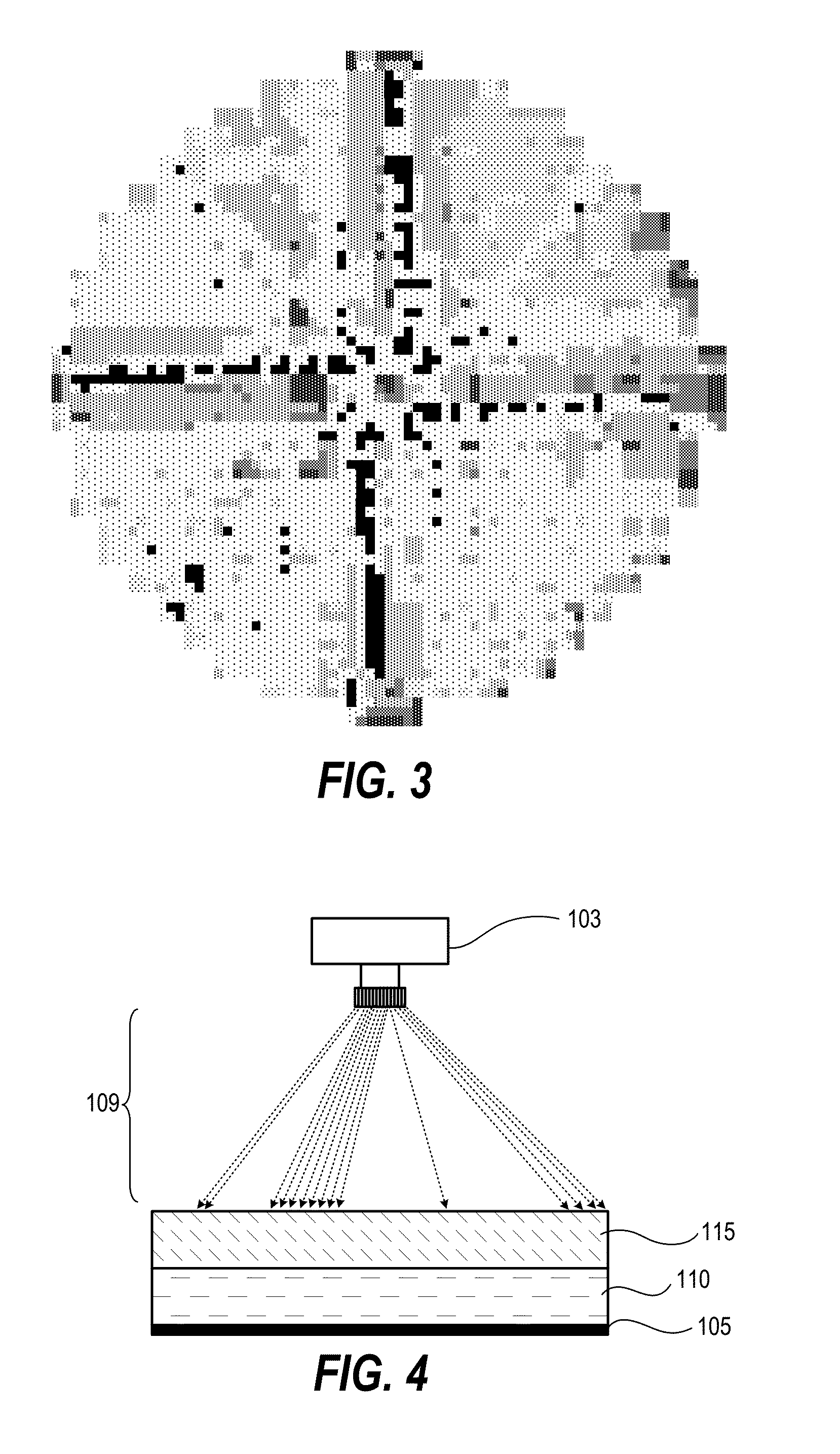

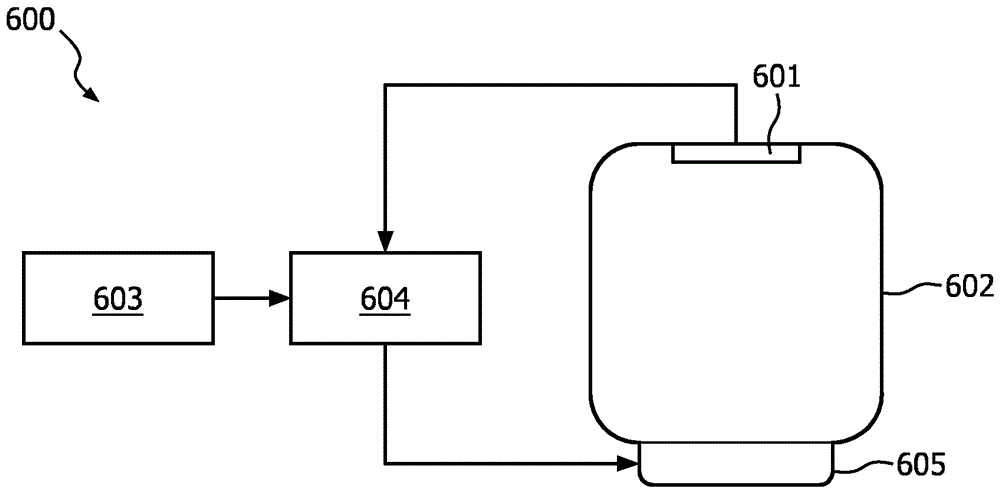

Substrate Tuning System and Method Using Optical Projection

ActiveUS20150147827A1Improve temperature uniformityScaling continuesSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingGrid basedOptoelectronics

Techniques herein include systems and methods that provide a spatially-controlled or pixel-based projection of light onto a substrate to tune various substrate properties. A given pixel-based image projected on to a substrate surface can be based on a substrate signature. The substrate signature can spatially represent non-uniformities across the surface of the substrate. Such non-uniformities can include energy, heat, critical dimensions, photolithographic exposure dosages, etc. Such pixel-based light projection can be used to tune various properties of substrates, including tuning of critical dimensions, heating uniformity, evaporative cooling, and generation of photo-sensitive agents. Combining such pixel-based light projection with photolithographic patterning processes and / or heating processes improves processing uniformity and decreases defectivity. Embodiments can include using a digital light processing (DLP) chip, grating light valve (GLV), or other grid-based micro projection technology.

Owner:TOKYO ELECTRON LTD

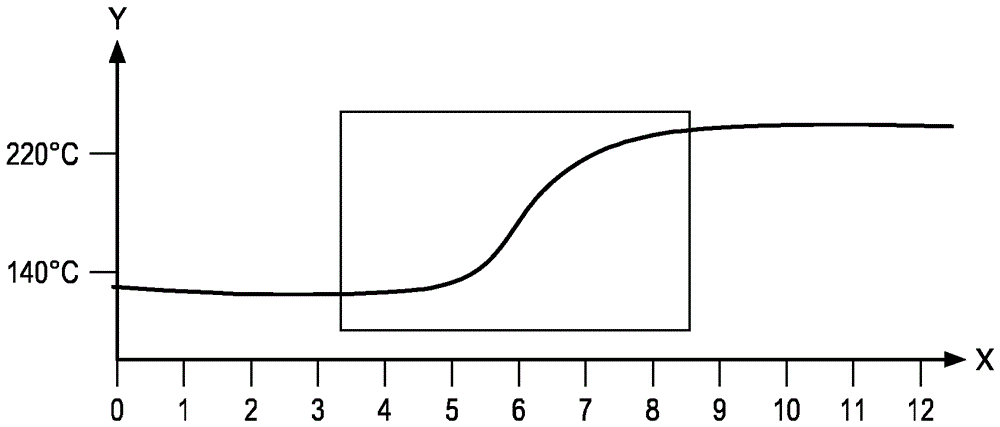

Method and device for roasting partially roasted coffee beans

ActiveCN105939643AEasy to storeEvenly bakedBeverage vesselsCoffee roasting methodsEngineeringCoffee bean

The present invention relates to a roasting method of roasting partially roasted coffee beans; the roasting method comprises the steps of: obtaining a roast level of the partially roasted coffee beans; determining a roasting profile for roasting based on at least the roast level of the partially roasted coffee beans prior to roasting; and roasting the partially roasted coffee beans according to the determined roasting profile. The present invention also proposes a method of making coffee, a roasting device and a coffee machine providing a segmented roasting solution.

Owner:FANSONE HLDG LTD

Egg body baking and producing device

ActiveCN103210965AShorten the lengthEvenly bakedSpecial goods bakingCooking & bakingProcess engineering

The invention provides an egg body baking and producing device which comprises a baking chamber, wherein the baking chamber is internally provided with a transporter for inputting and outputting egg bodies one by one, a hot gas discharging pipeline is arranged on the baking chamber, and discharged hot gas is output through a fan after being dewatered by a dewatering device, and enters the bottom of the baking chamber through a hot gas inlet pipe after heat of hot gas is absorbed by an air heat exchanger, so that the circulating heating of air can be realized, and egg bodies can be baked. The device not only can be used for evenly heating the egg bodies, but also is small in volume and high in baking efficiency.

Owner:福州闽台机械有限公司

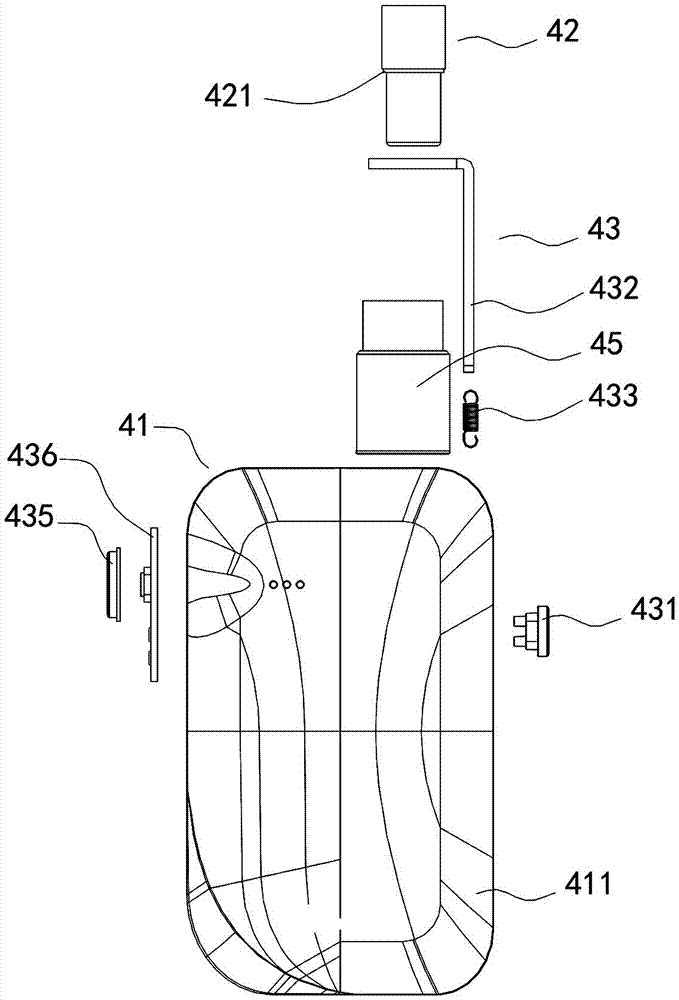

Smoke generating device for induction heating at front end of cigarette

The invention belongs to the field of novel cigarette smoking sets, and particularly relates to a smoke generating device for induction heating at the front end of a cigarette. The smoke generating device comprises a hollow heating cup (2), a heating body (5) and an induction coil (4), A hollow heating cup (2) comprises an upper hollow structure, a lower hollow structure and a baffle between the upper hollow structure and the lower hollow structure; a heating body (5) is arranged in the lower hollow structure, and an induction coil (4) is arranged on the periphery of the heating body (5); andthe heating body (5) is made of ferromagnetic metal and has a structure through which air can pass. According to the invention, the smoke generating device for induction heating at the front end of the cigarette is designed for the first time, and a plurality of airflow channels are formed inside and / or on the surface of the heating body, so that air flowing through the surface of the heating bodycan be quickly and fully heated; the problems that an existing electric heating cigarette is uneven in heating, a carbon heating cigarette is easy to roast and burn and not easy to control, aroma components are insufficient, and smoking feeling is poor are effectively solved.

Owner:CHINA TOBACCO YUNNAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com