Egg body baking and producing device

A production device and egg body technology, applied in baking, special commodity baking, food science and other directions, can solve the problems of labor-intensive, large floor space, low efficiency, etc., to improve baking efficiency and reduce land occupation Area, baking uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

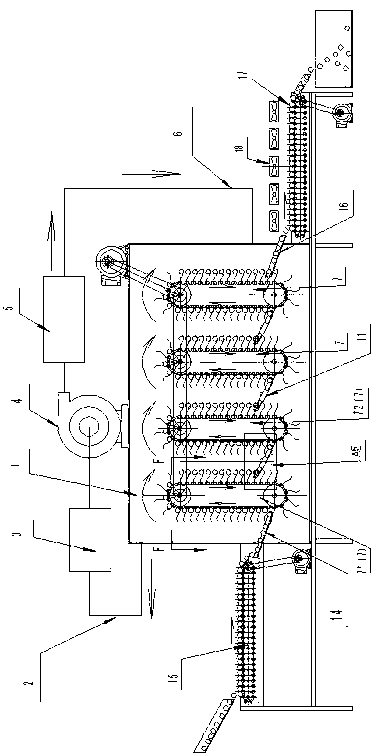

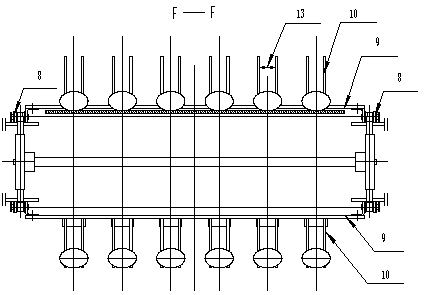

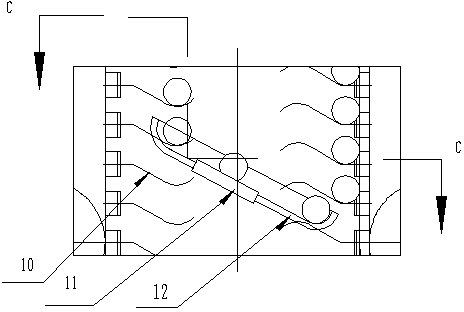

[0017] refer to figure 1 , figure 2 , image 3 and Figure 4 , a kind of egg body baking production device, comprises a baking box 1, and described baking box 1 is provided with egg body input and output delivery device one by one, and described baking box is provided with hot gas discharge pipeline 2, and the hot gas discharged After the water is removed by the water eliminator 3, it is output by the blower 4, and after the heat is absorbed by the air heat exchanger 5, it is sent to the bottom of the oven through the hot air inlet pipe 6, so as to realize air circulation heating and bake the egg body.

[0018] In order to facilitate the transmission of egg bodies in space, the one-by-one input and output tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com