Patents

Literature

524results about How to "Improve baking efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

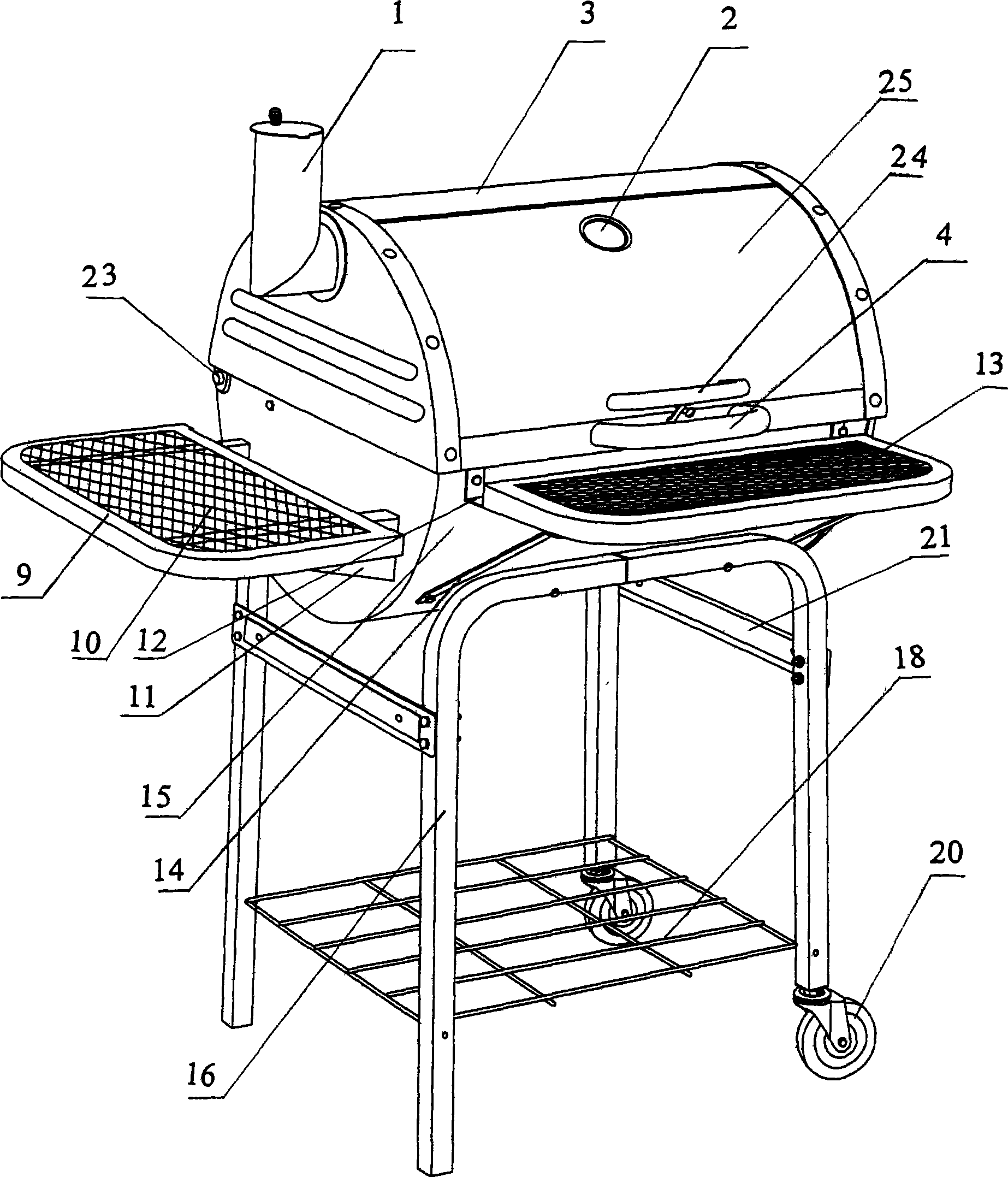

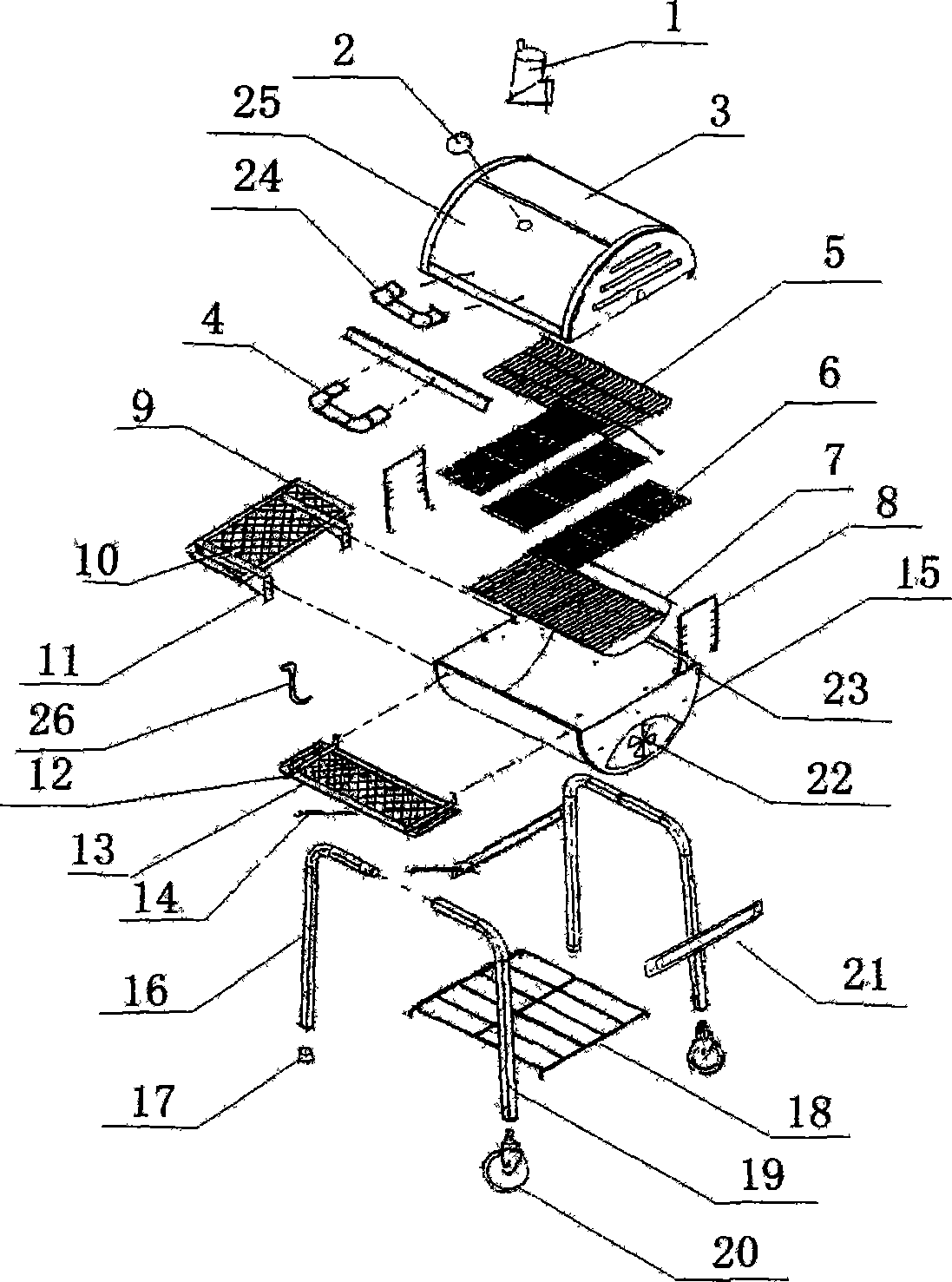

Barbecue furnace with cover

The invention relates to an oven with a cover cap, and belongs to the technical field of food processing and domestic instant food processing. The oven is characterized in that an oven hearth consists of a lower semicircular cylinder which is arranged transversely and has an upward opening and two ends connected to a fixed semicircular wall, and an upper semicircular cylinder connected with a cylinder edge by a shaft; two ends of the oven hearth fixed at the edges inside the upper semicircular cylinder on the circumferential wall are provided with calking grooves along a semicircle, the calking grooves are embedded into the edges of an arc moving door at one-quarter opening of an upper semicircular cover, and the middle of the upper semicircular cylinder is provided with a dial thermometer for measuring temperature of the oven hearth; three racks are arranged in the oven hearth, namely, a bottom layer, an upper rack and a middle rack; a cylindrical oven body is arranged on a bracket; and the oven is provided with a chimney, an air door and a shelf. The oven has the advantages as follows: because barbecue is roasted closely, heat is not easy to diffuse, roasting strength can be adjusted, the oven not only improves roasting efficiency and does not pollute environment, but also heat food evenly, shortens roasting time, and can supply enough smudging roasted food.

Owner:SHANGHAI YUQIANG OUTDOOR PROD CO LTD

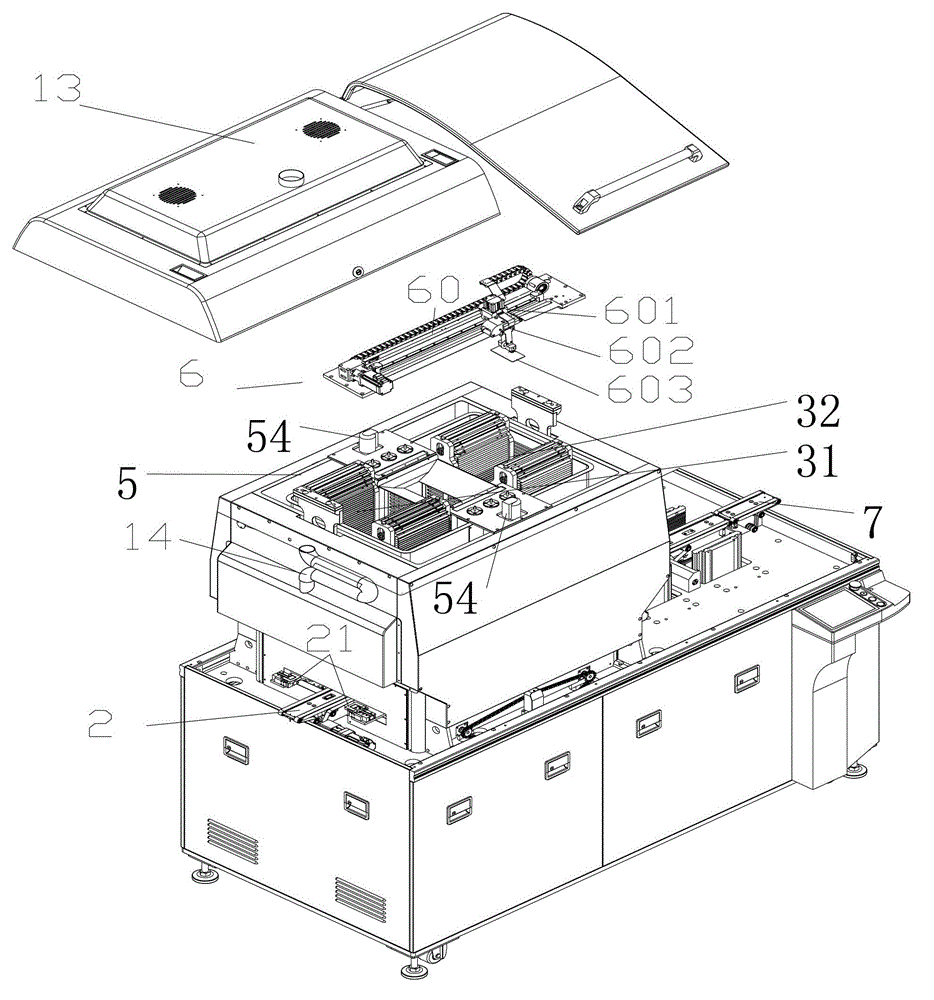

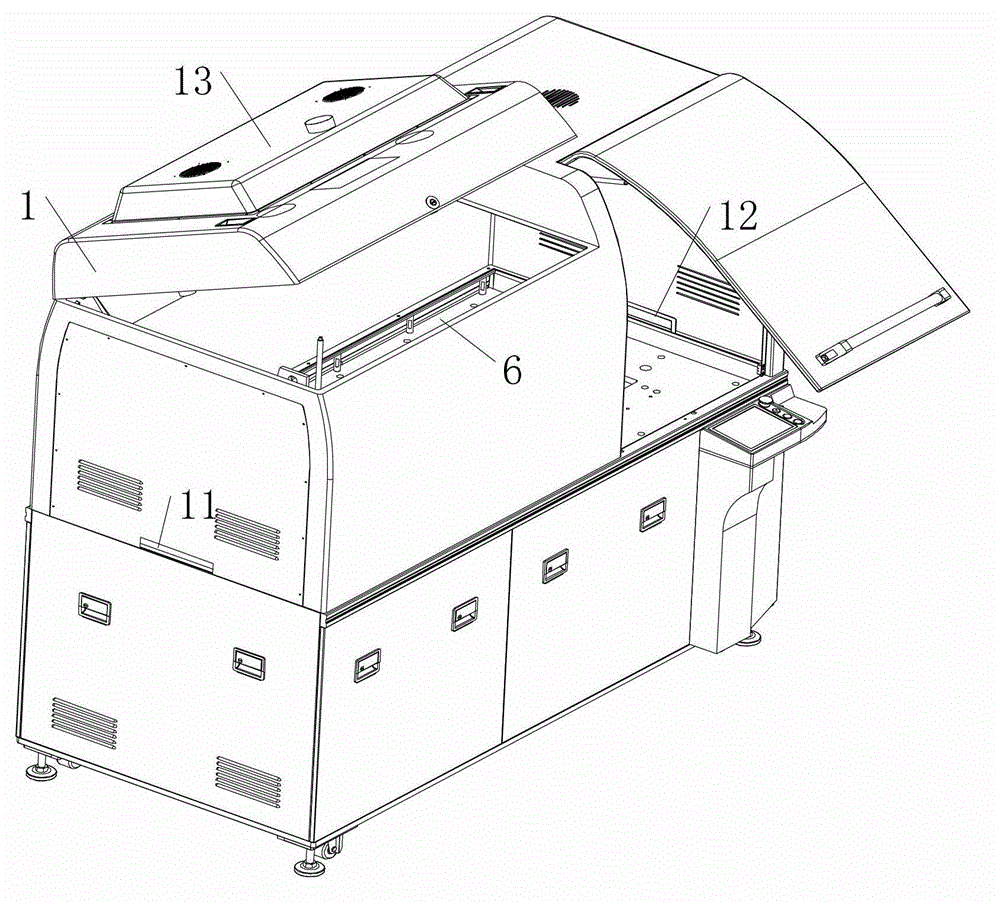

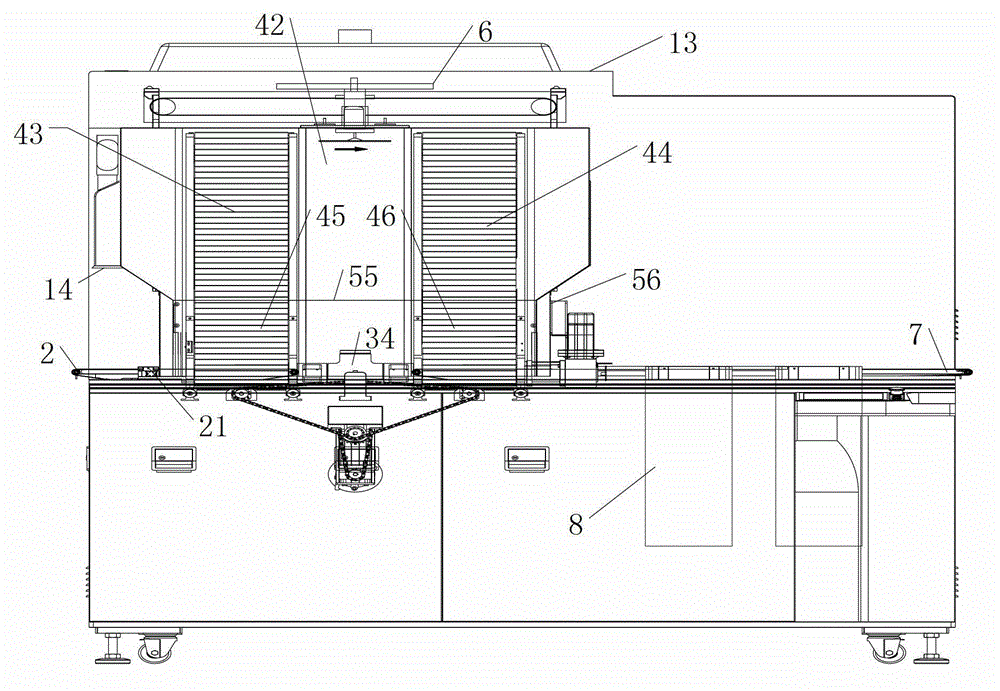

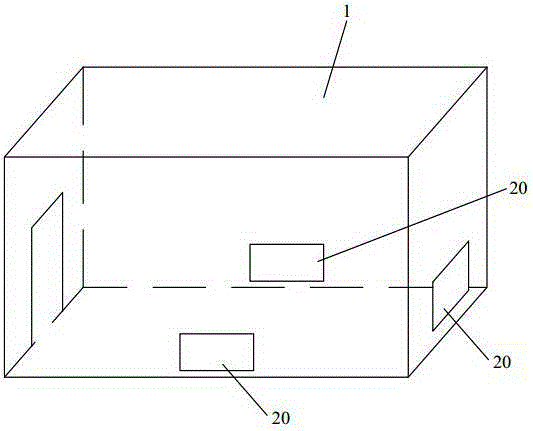

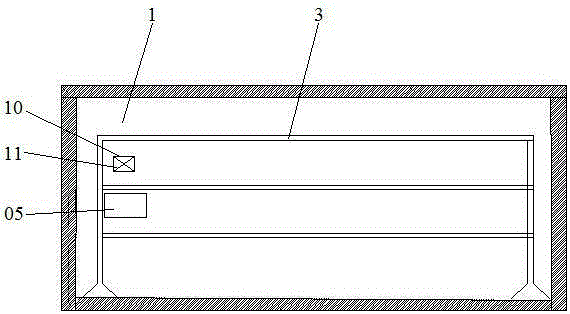

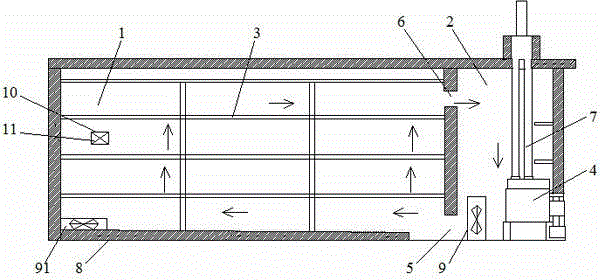

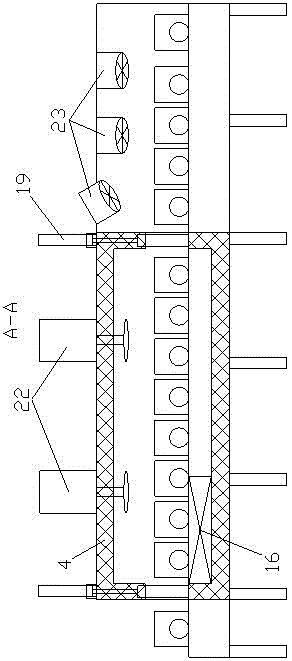

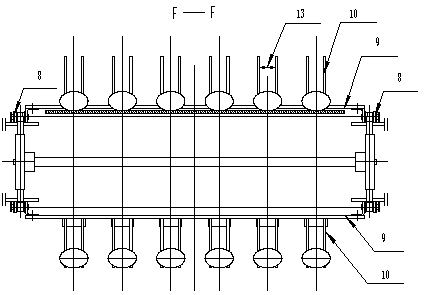

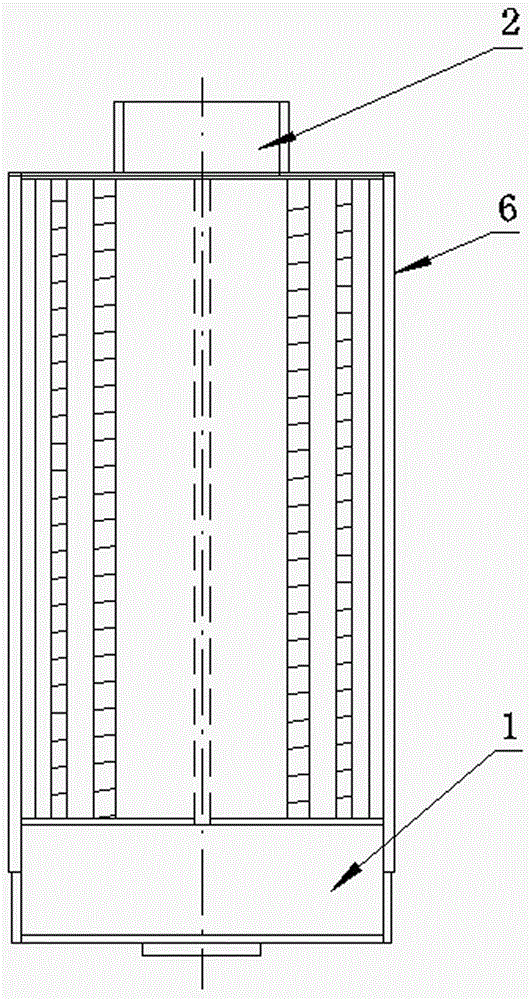

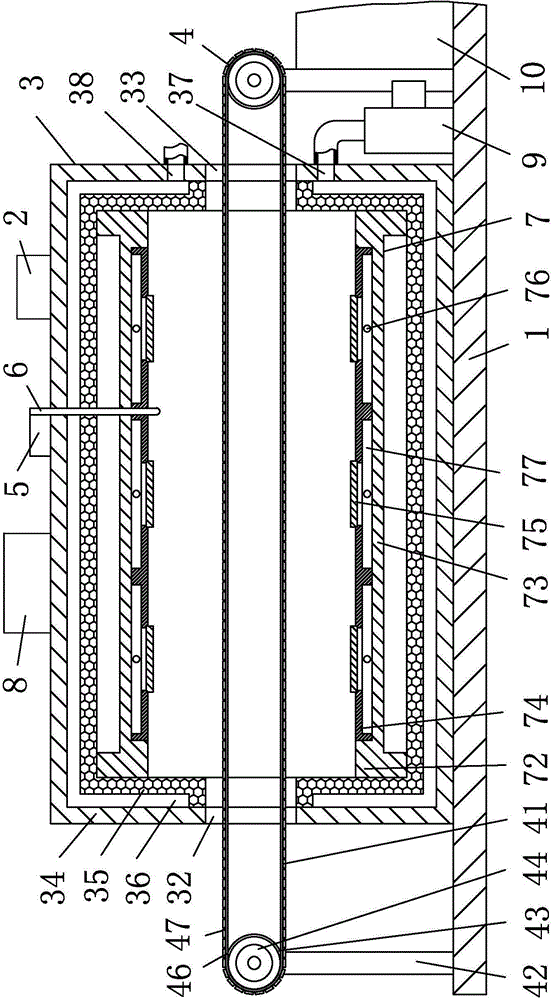

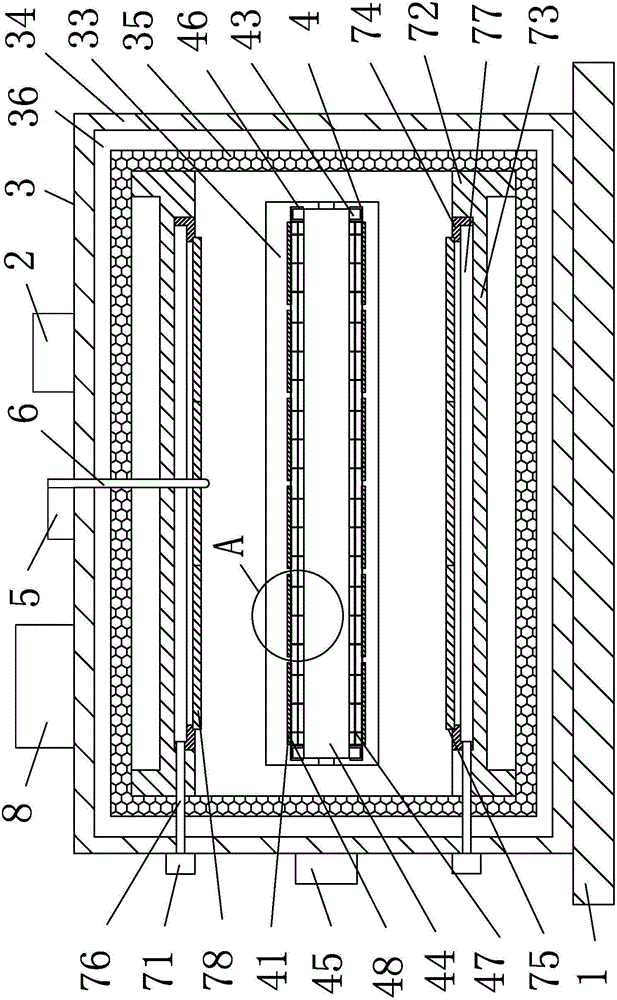

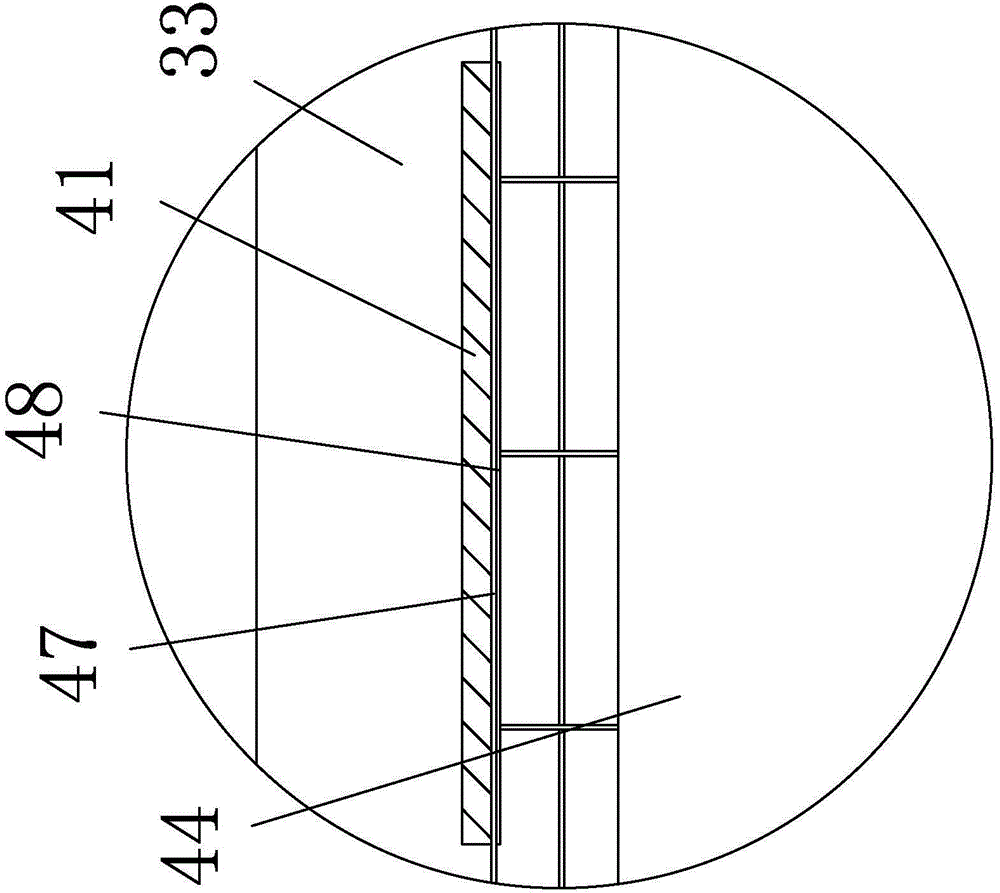

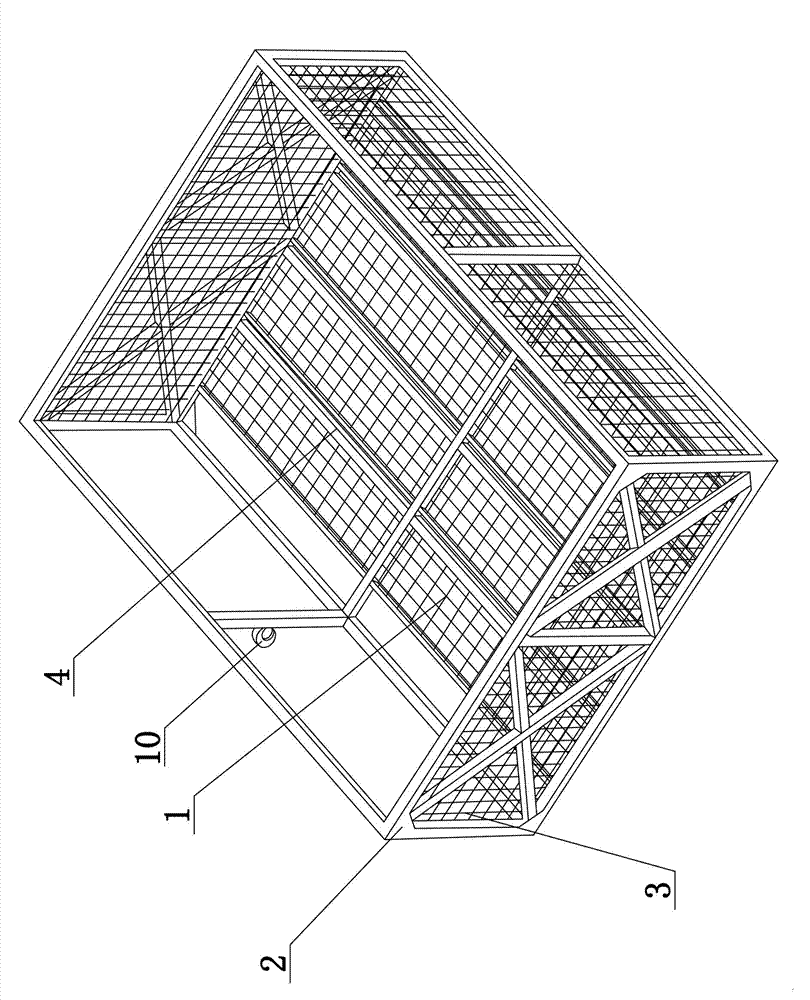

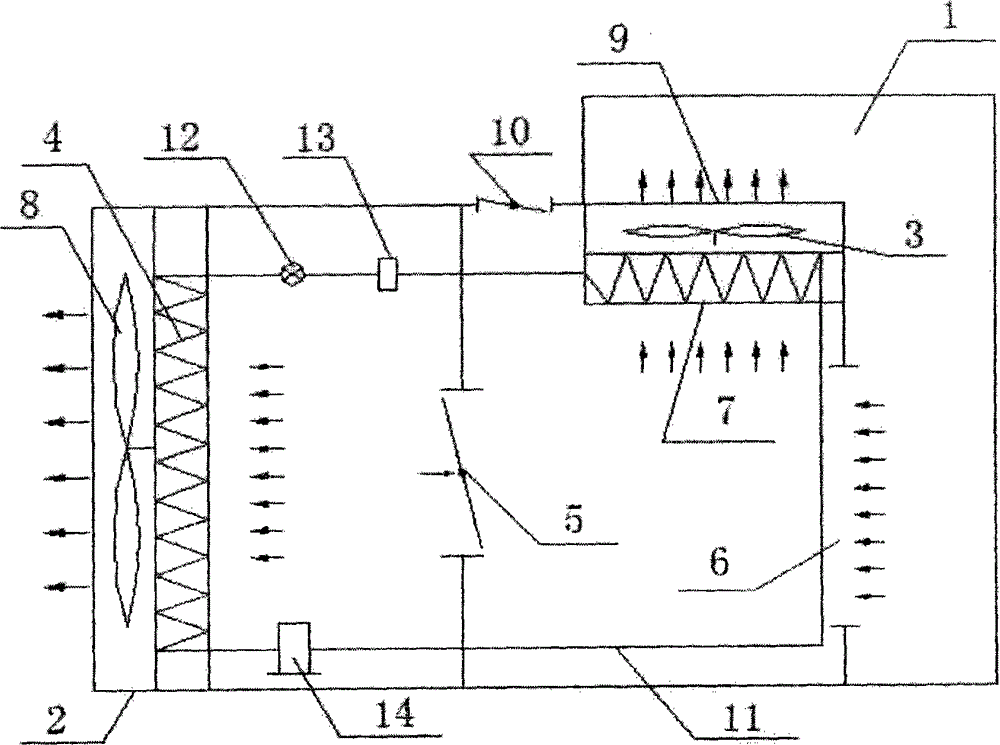

Automatic-circulation baking oven for sheet type printing material

ActiveCN102909949ASave spaceHigh degree of automationPrinting press partsProcess engineeringMaterial transfer

The invention discloses an automatic-circulation baking oven for a sheet type printing material and belongs to the technical field of sheet printing equipment. The baking oven comprises a shell, a feeding device, a material frame, a hot air duct, a heating device, a material transferring device and a discharging device, wherein the material frame comprises a feeding frame and a discharging frame; oppositely-arranged material clamping devices are adopted; each material clamping device comprises a crawler belt and a crawler belt frame; material supporting plates are arranged on the crawler belts to form material supporting clips for circular material supply; the hot air duct and the heating device form a circular heating and baking system; and materials are completely and uniformly baked. The embodiment of the invention breaks through the structure of the existing tunnel type baking oven, and replaces the existing tunnel type baking oven with the vertically-circulating material frame, and meanwhile, the circular hot air duct system is matched to bake, therefore, the space occupied by the baking oven of the embodiment of the invention is greatly reduced, and the degree of automation of the baking furnace is obviously improved; and moreover, the shell of the baking oven is positioned in a nearly-sealed state, so that the loss of heat is prevented, and the baking efficiency is greatly improved.

Owner:湖南三兴精密工业股份有限公司

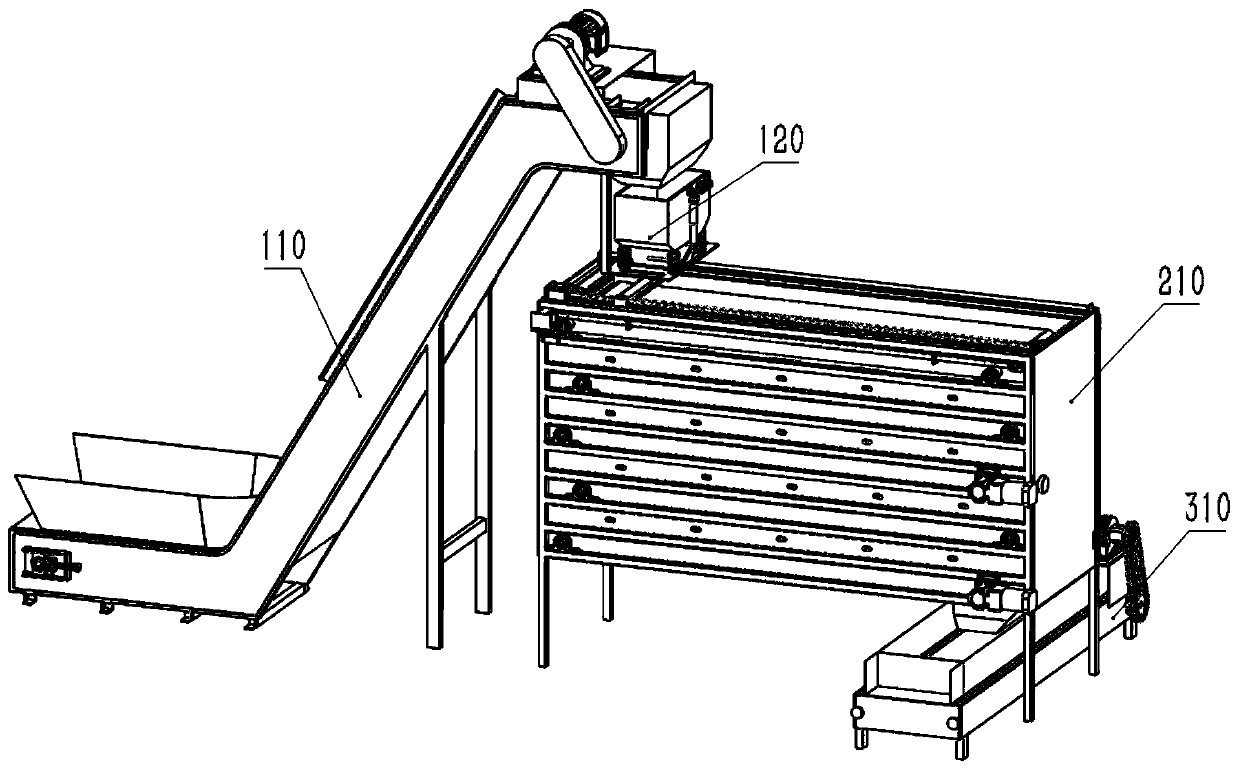

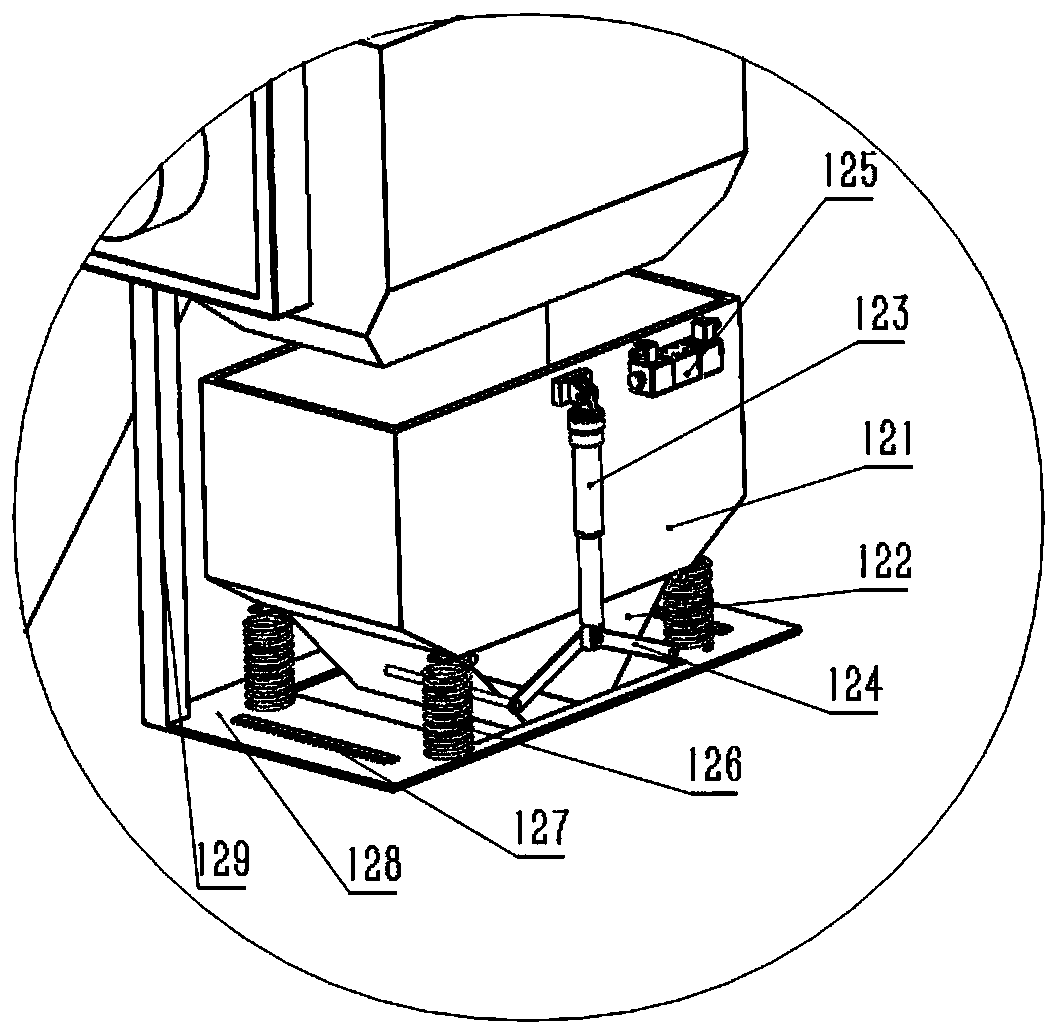

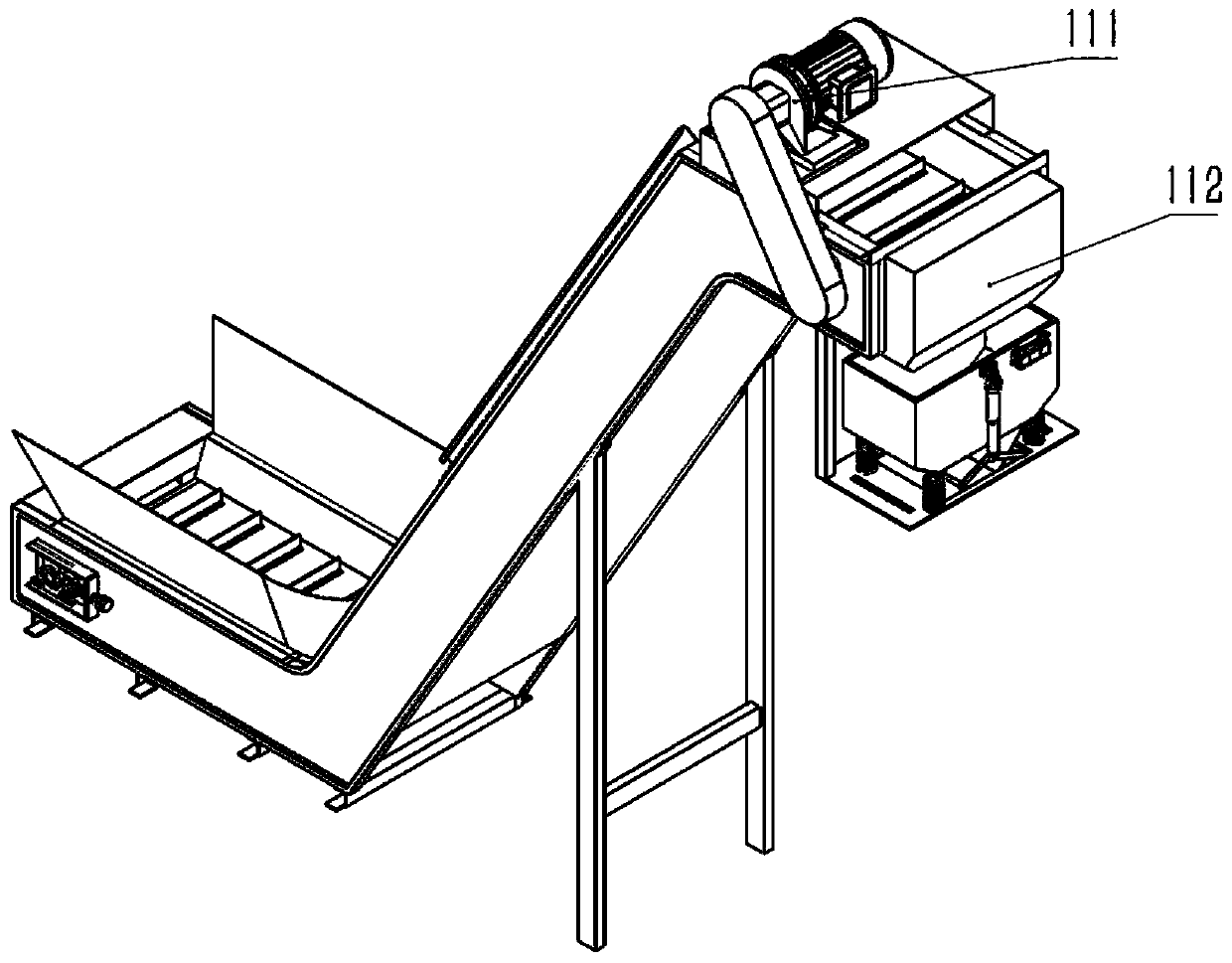

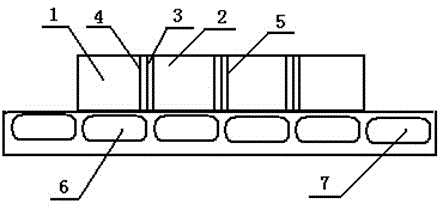

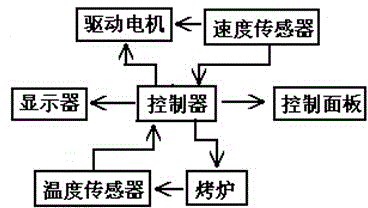

Multi-layer conveying belt tea leaf fragrance extraction machine and control method

PendingCN111217080AGuaranteed uniformityAchieve uniformitySievingConveyorsAgricultural engineeringTea leaf

The invention relates to a multi-layer conveying belt tea leaf fragrance extraction machine and a control method. The fragrance extraction machine comprises a PLC control unit, an automatic tea leaf feeding unit, a fragrance extraction and baking unit and an automatic tea leaf discharging unit, wherein the automatic tea leaf feeding unit comprises a vertical elevator and an automatic tea leaf weighing device, and the fragrance extraction and baking unit comprises a transferring conveying belt, a transverse leaf evening device, a longitudinal leaf evening device and a multi-layer conveying beltbaking unit; and the transferring conveying belt is arranged below a discharge port of the automatic tea leaf weighing device and conveys tea leaves to the multi-layer conveying belt baking unit, thetransverse leaf evening device moves in the length direction of the transferring conveying belt to evenly scrape the tea leaves on the transferring conveying belt, the longitudinal leaf evening device moves in the width direction of the transferring conveying belt to evenly scrape the tea leaves on the transferring conveying belt, and the multi-layer conveying belt baking unit comprises a plurality of layers of conveying belts for conveying the tea leaves from top to bottom and heating baking units arranged on the two sides of the conveying belts. The multi-layer conveying belt tea leaf fragrance extraction machine and the control method solve the problem that the tea leaves are stacked on the conveying belts, and guarantees the tea leaf baking uniformity.

Owner:ANHUI AGRICULTURAL UNIVERSITY

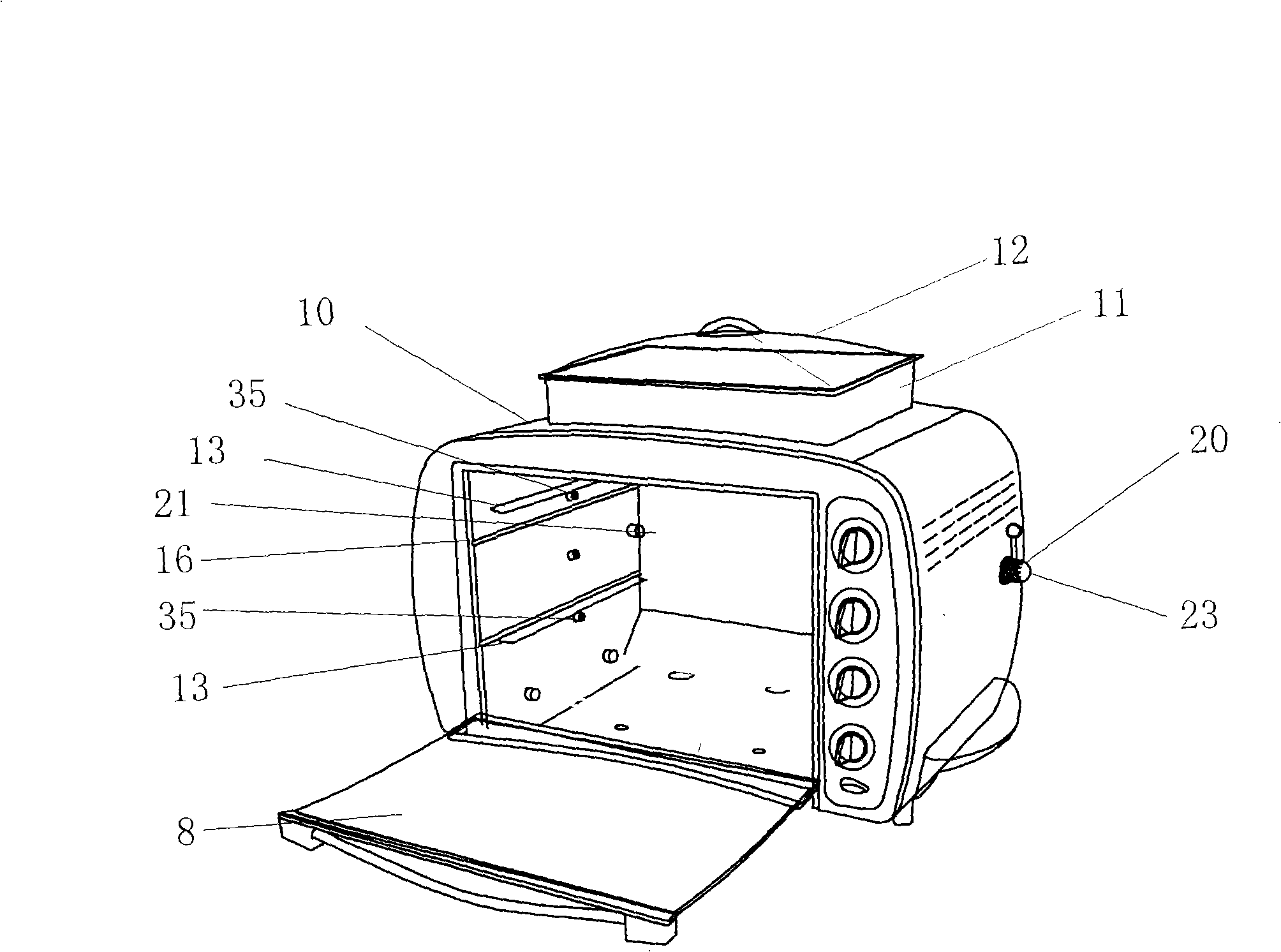

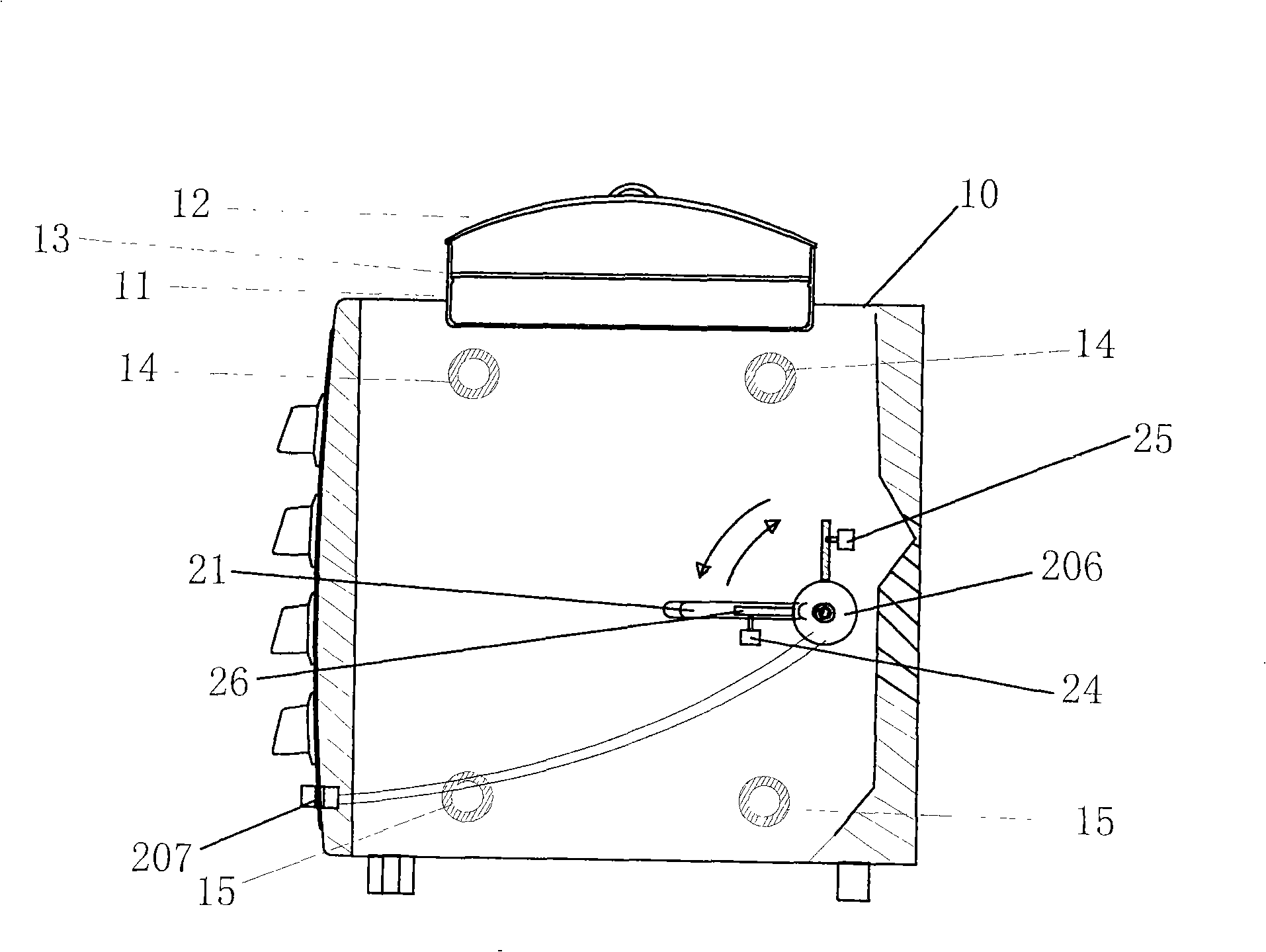

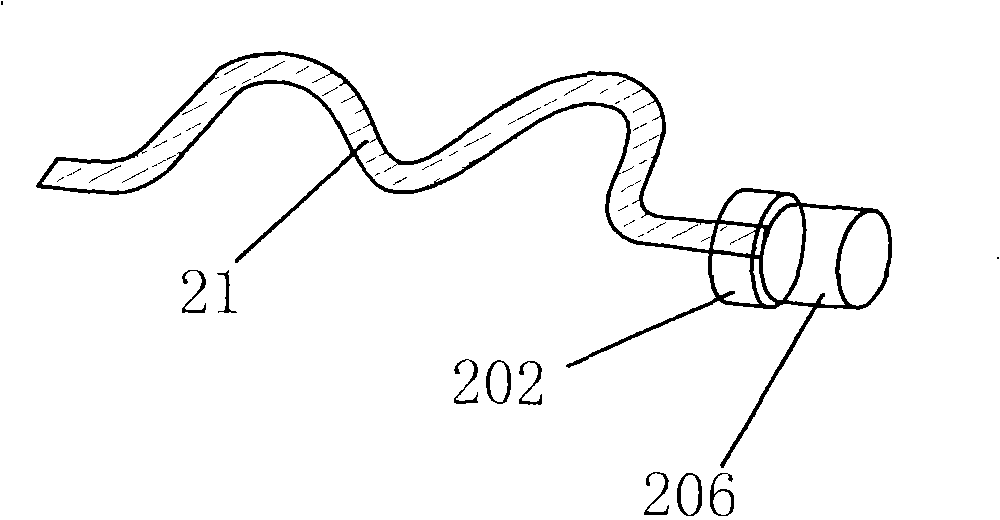

High-efficient energy-saving electric roaster

The present invention relates to a high-efficiency and energy-saving baking oven, which comprises an electric baking oven body, a baking oven gate, a control panel, an upper electrothermal pipe, a lower electrothermal pipe and a rotary electrothermal pipe module. The electrothermal pipe module comprises a rotary electrothermal pipe which can change a frame structure in the position through rotating around the two ends and a synchronous motor; the two ends of the rotary electrothermal pipe horizontally extend out of a left lateral plate and a right lateral plate in the cavity of the electric baking oven body; one end is connected with the synchronous motor through a rotary wheel; a lever is connected with the rotary electrothermal pipe or the rotary wheel; two micro switches are arranged on the two sides of the internal wall of the cavity of the electric baking oven body when the rotary electrothermal pipe rotates at two limit angles; when the lever contacts with the micro switch below, the synchronous motor is off to stop rotating and the rotary electrothermal pipe is on for heating; when the lever contacts the micro switch above, the synchronous motor is off to stop rotating and the spiral electrothermal pipe is off. Due to the structure, the present invention has the characteristics of high baking efficiency and automatic operation of the middle part of the electrothermal pipe.

Owner:李文庆

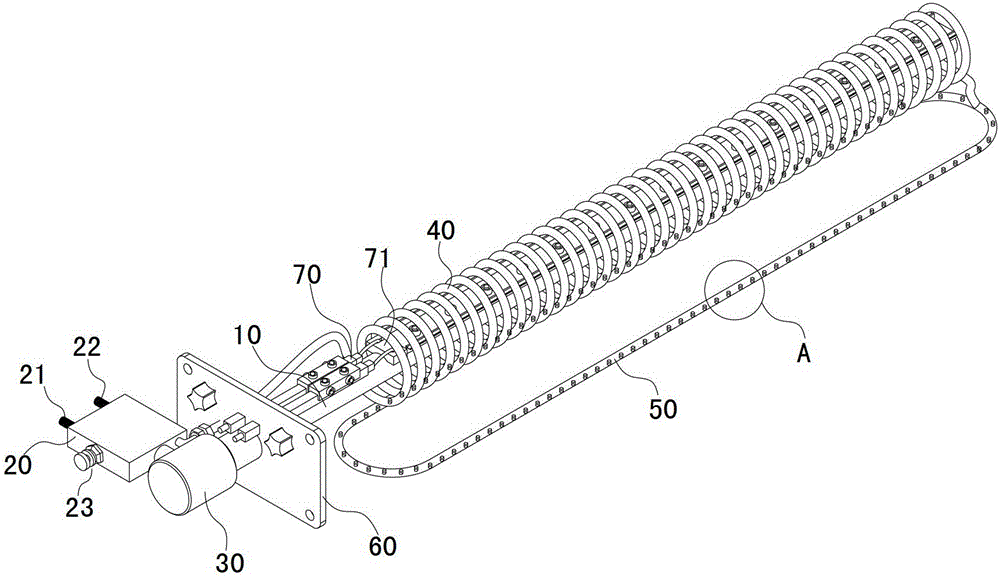

A food baking device

The invention relates to a food baking device which comprises a fire tube, a steam tube, a baking tube and an ignition mechanism, wherein one end of the fire tube is opened while the other end is a blind end, wherein the opened end of the fire tube is used for inputting natural gas and air to a tube cavity of the fire tube; a combustion chamber for accommodating the mixed gas composed of the natural gas and air is formed in the fire tube; a plurality of fire ejecting holes are formed in a tube wall of the fire tube; the steam tube is in a spiral form and is wound on the periphery of the fire tube; the inlet end of the steam tube is used for inputting steam to the tube cavity of the steam tube; the tube cavity of the baking tube is communicated with the outlet end of the steam tube; a plurality of gas outlets are arranged on the baking tube: the ignition mechanism is used for igniting the mixed gas in the fire tube. The food baking device utilizes the superheated steam to bake food, so that the water content in food can be kept, the mouth feeling of food is promoted, and under the same temperature, the superheated steam is used for baking food so as to reduce the baking time, increase the baking efficiency and save energy source.

Owner:广州浩胜食品机械有限公司

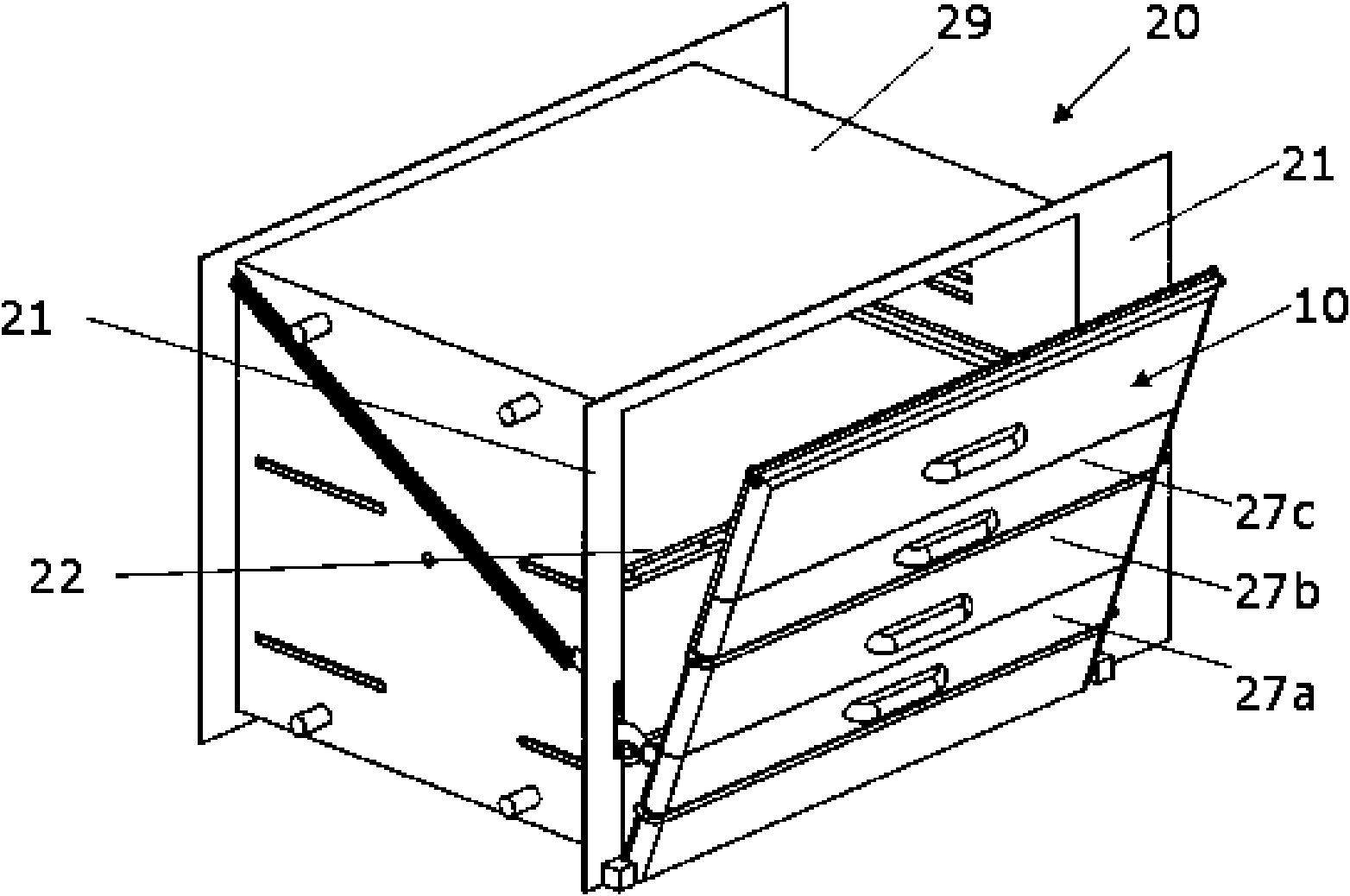

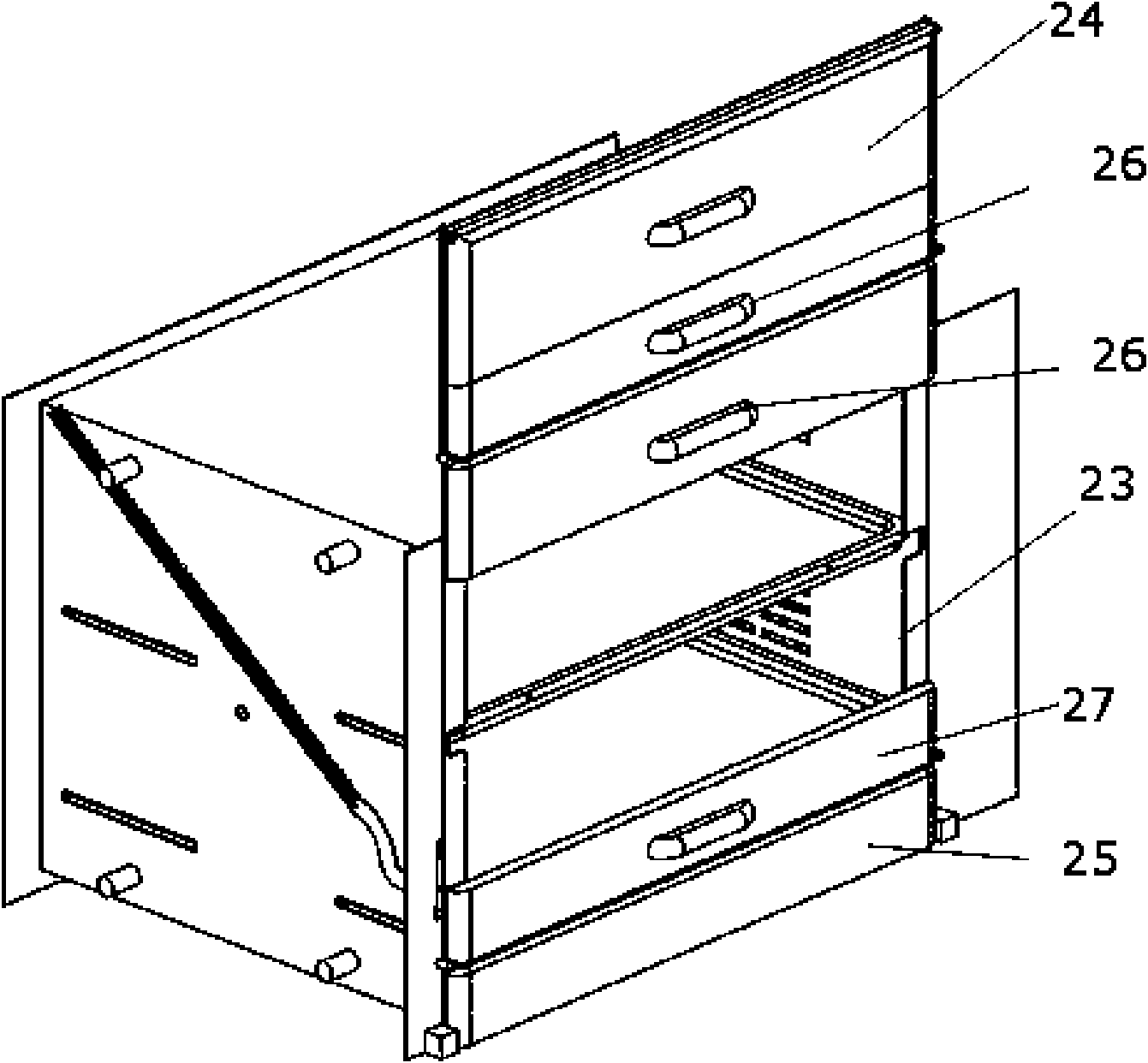

Oven door

The invention provides an oven door. The lower part of the oven door is hinged to a frame on two sides of a front opening of an oven part. The oven door comprises a U-shaped door frame, a slidable door frame, an upper door plate, a lower door plate and a plurality of openable doors, wherein the lower part of the U-shaped door frame is hinged to the frame on the two sides of the oven part; the slidable door frame is slidably sleeved on the U-shaped door frame; the upper door plate is arranged at the upper end of the slidable door frame; the lower door plate is fixedly arranged at the lower end of the U-shaped door frame; the plurality of openable doors are selectively opened or closed and are arranged between the upper door plate and the lower door plate; and a door handle is arranged on the upper door plate and each openable door respectively. The corresponding openable door can be opened as required and the whole door does not need to be opened, so that the heat loss of an oven provided with the oven door can be effectively reduced, and the baking efficiency of the oven is improved; in addition, only the corresponding openable door needs to be opened when food is taken out, and hands can be prevented from touching the high-temperature inner wall and baking pipe of the oven, so that the safety is improved.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

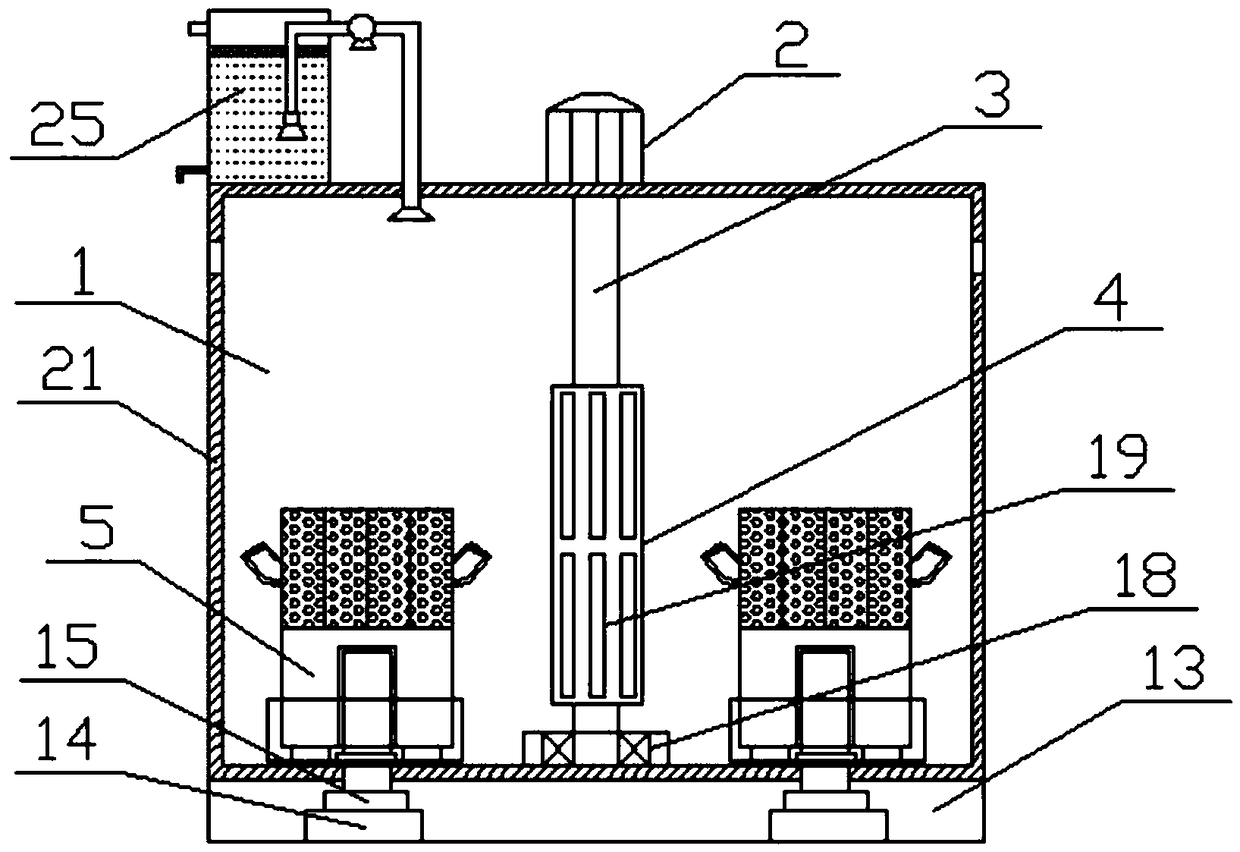

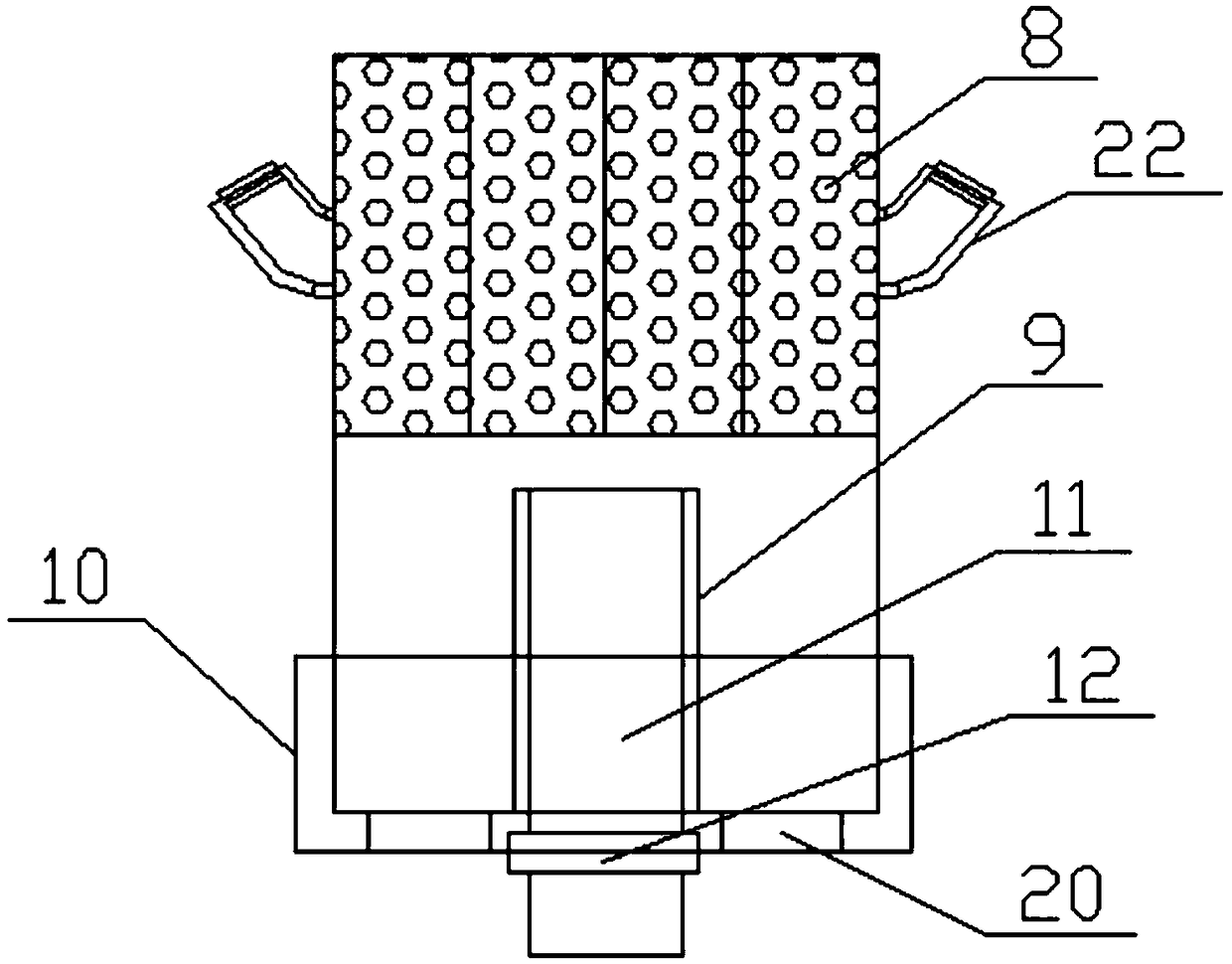

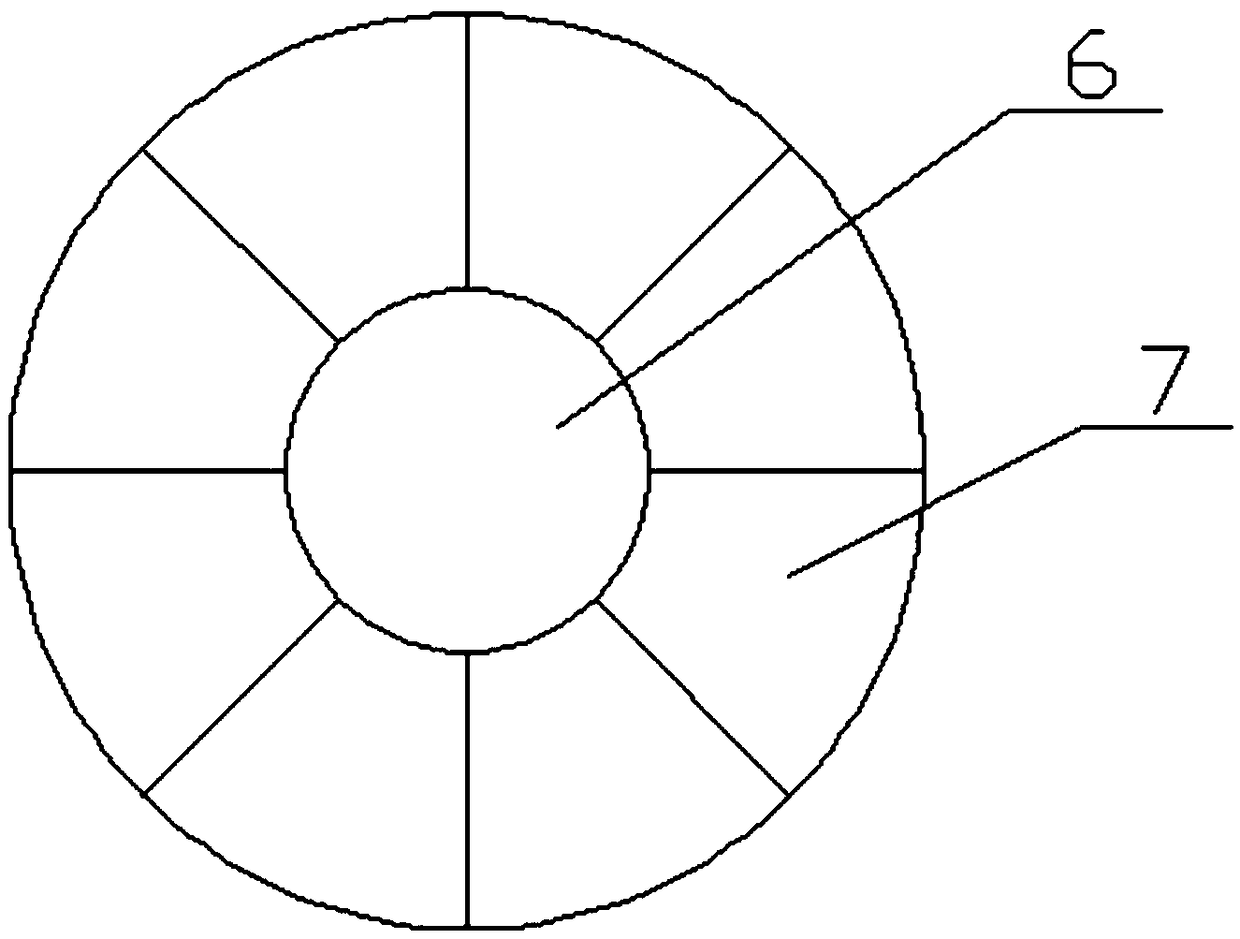

Heating piece tobacco baking chamber for waste heat recycling

InactiveCN105286072AHigh performance ratioIncrease heating capacityTobacco preparationFinal product manufactureCooking & bakingProcess engineering

The invention relates to the technical field of tobacco-baking equipment, in particular to a heating piece tobacco baking chamber for waste heat recycling. The heating piece tobacco baking chamber for waste heat recycling comprises a tobacco baking room provided with two tobacco hanging racks, each tobacco hanging rack comprises vertically arranged vertical rods and transversely arranged transverse rods, and the lower portions of the vertical rods are provided with supporting feet; the transverse rods are provided with tobacco clamps; the two tobacco hanging racks are arranged side by side; the tobacco baking room further comprises heating piece devices arranged on walls. One side of the tobacco baking room is further provided with waste heat recycling equipment. By means of the heating piece tobacco baking chamber, tobacco baking efficiency and quality are remarkably improved; hot air emitted by the heating piece devices is utilized to conduct baking, the heating piece devices are utilized, no additional heating device is needed, and the cost of the additional heating device is omitted; besides, the heating piece devices are small in size, space is saved, and the tobacco leaves can be baked effectively.

Owner:GUANGDONG BRANCH OF CHINA TOBACCO GENERAL +1

Liquefied petroleum gas tobacco curing house

InactiveCN104957745AImprove heating efficiencyEasy to useTobacco preparationDrying gas arrangementsFlueCuring of tobacco

The invention relates to the technical field of tobacco curing equipment, in particular to a liquefied petroleum gas tobacco curing house. The liquefied petroleum gas tobacco curing house comprises a hot air chamber provided with a heating device, and a tobacco curing chamber provided with a tobacco hanging rack, a circulation flue is formed between the tobacco curing chamber and the hot air chamber through an air inlet and an air return opening, and the heating device is connected with a heat exchange pipe. A first draught fan is arranged at the part, close to the air inlet, of the lower portion of the hot air chamber, and a second draught fan blowing upwards is arranged on the part, opposite to the first draught fan, of the lower portion of the tobacco curing chamber. The tobacco hanging rack comprises vertical rods arranged vertically and transverse rods arranged transversely, and a plurality of clamping parts used for being connected with the transverse rods in a clamping mode are arranged on the vertical rods. The novel tobacco curing house further comprises motors arranged on the lower portions of the vertical rods respectively and transmission rods connected with the motors, and the upper portions of the transmission rods are connected with the bottoms of the vertical rods. The heating device is a liquefied petroleum gas fuel heating device. Liquefied petroleum gas serves as fuel of the liquefied petroleum gas fuel heating device, environmental friendliness and cleanness are achieved, and the liquefied petroleum gas tobacco curing house has the advantages of being clean, sanitary, safe, cheap, high in heating efficiency, convenient to use and the like.

Owner:GUANGDONG BRANCH OF CHINA TOBACCO GENERAL

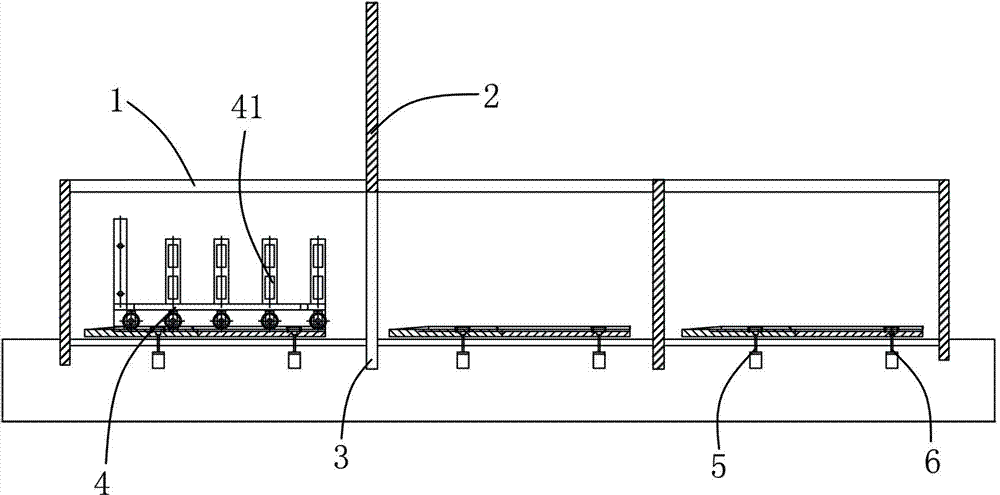

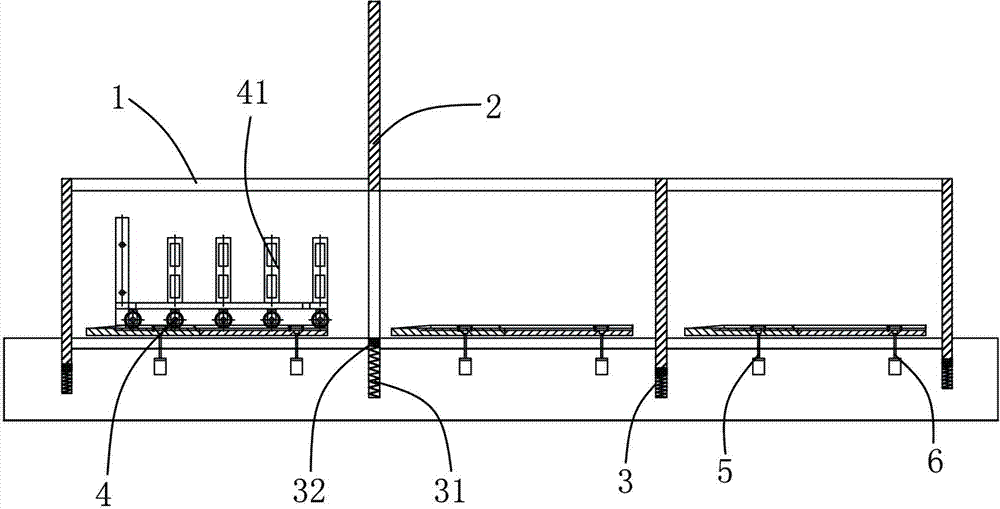

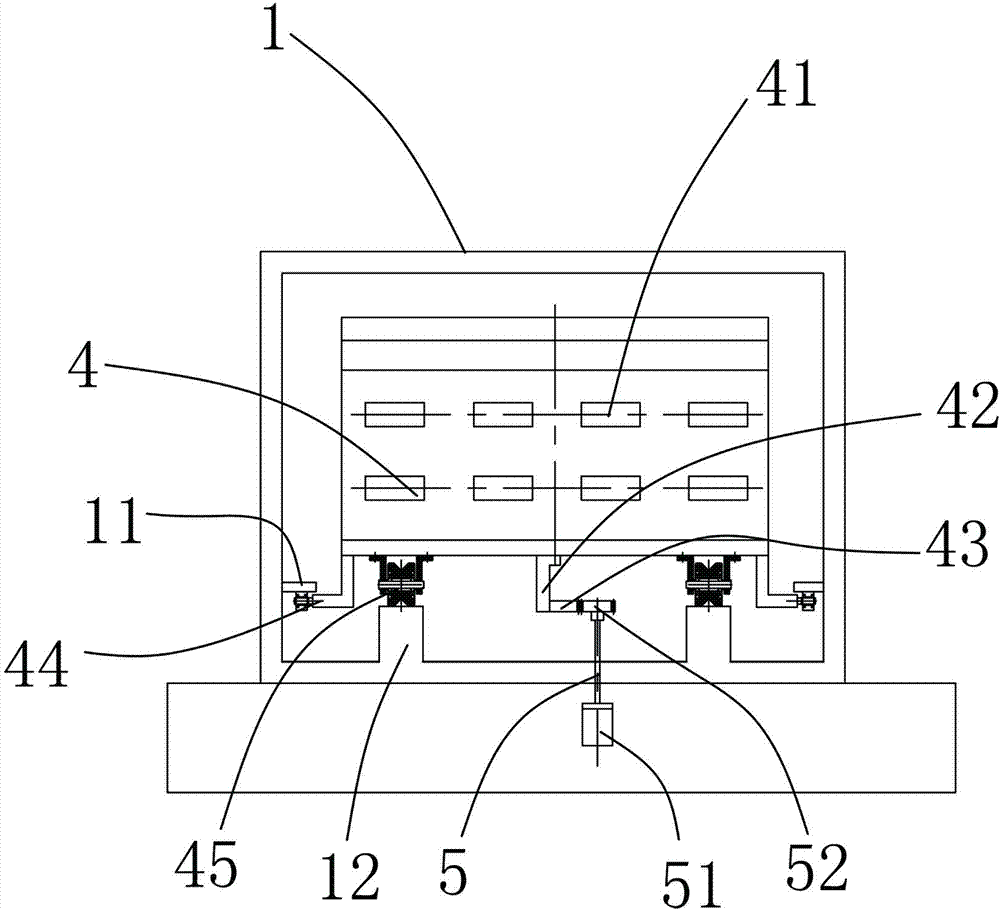

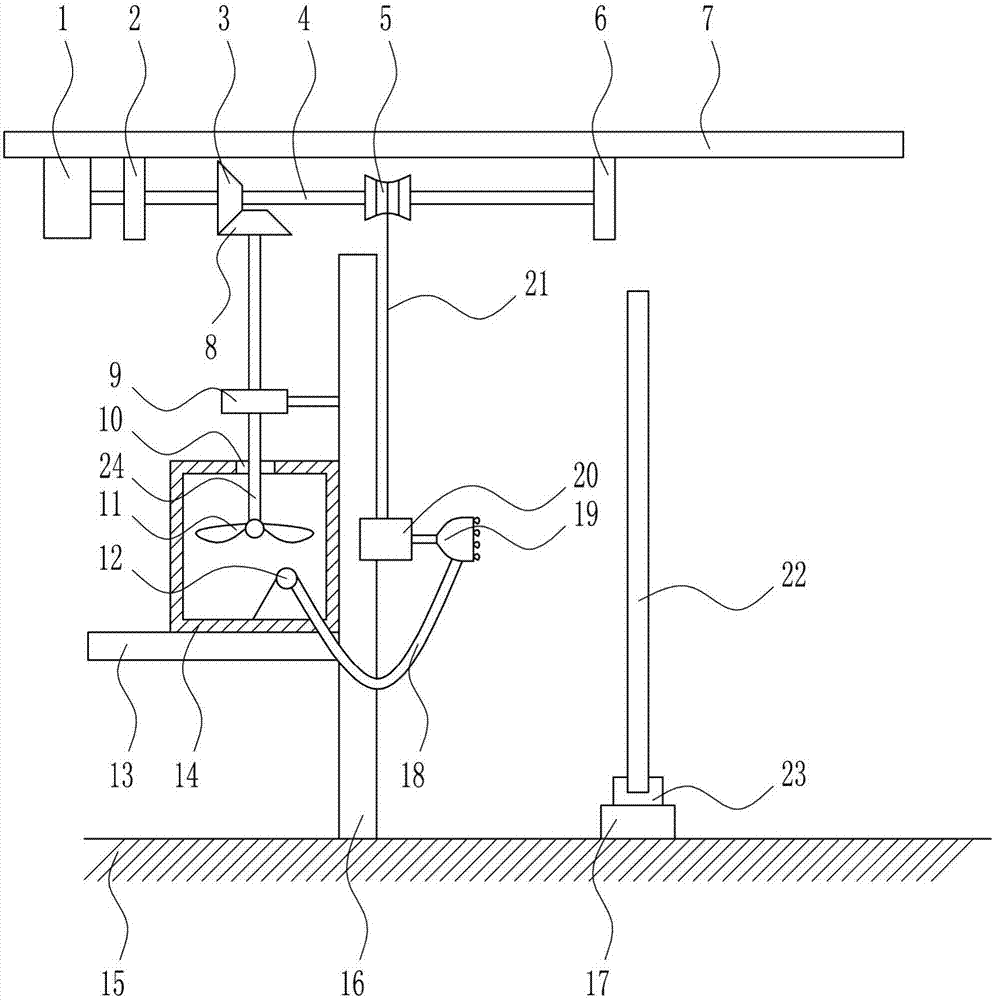

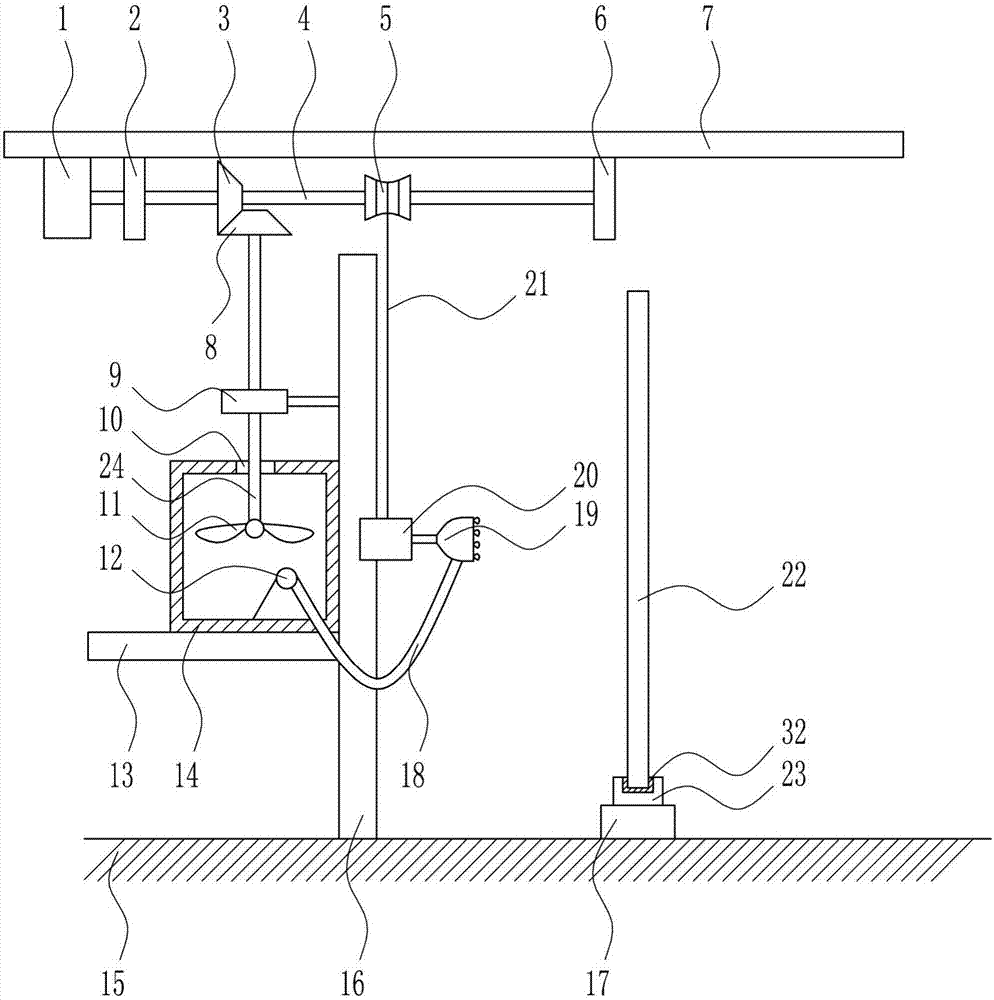

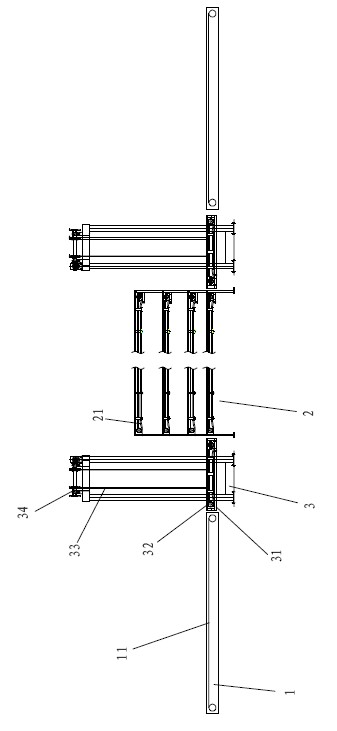

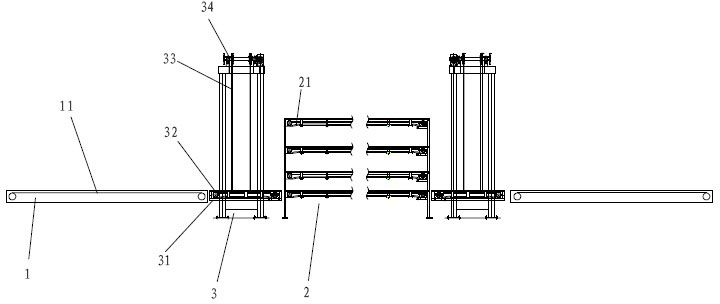

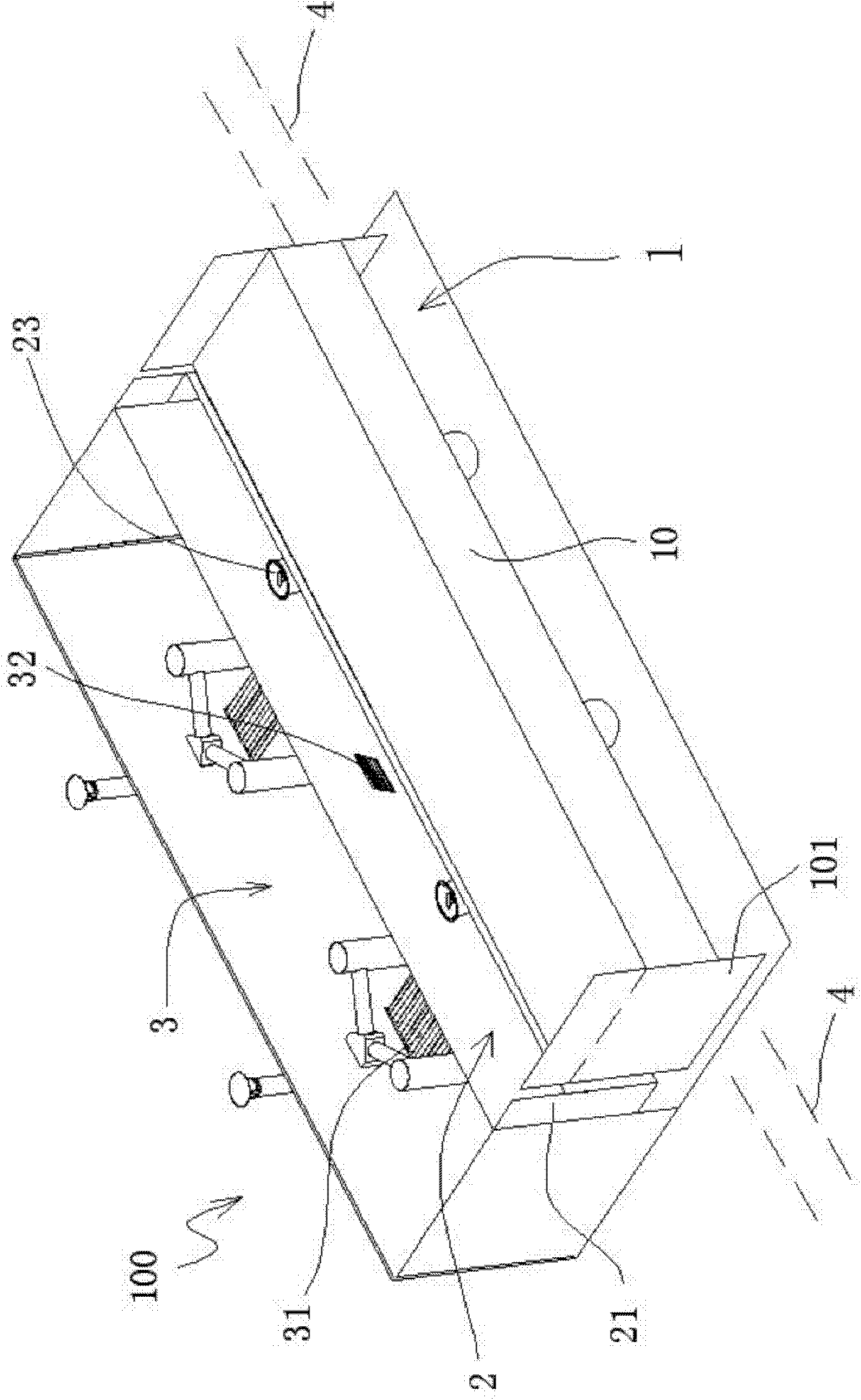

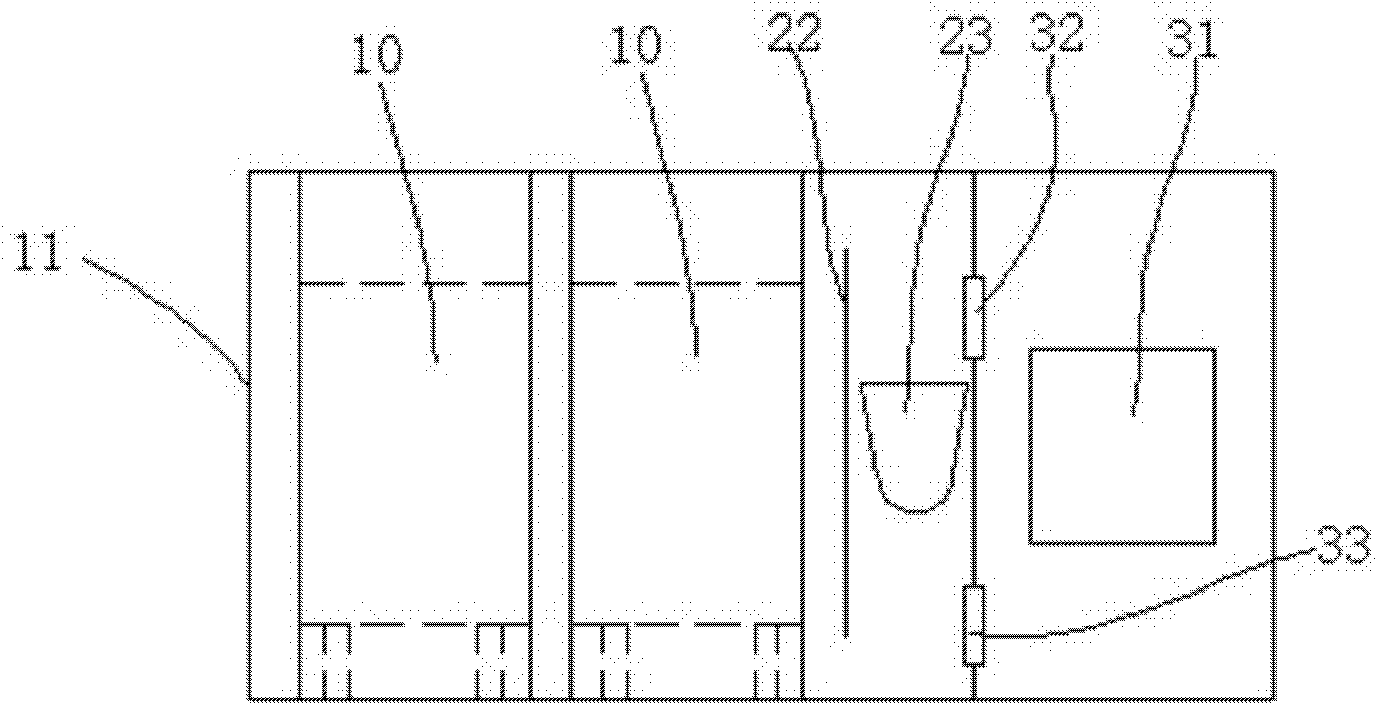

Automatic displacement feeding, baking and cooling device and method

ActiveCN104482741AImprove baking efficiencyImprove cooling efficiencyDrying machines with progressive movementsDrying solid materialsButt jointCooling time

The invention relates to an automatic displacement feeding, baking and cooling device and method. The device comprises a frame, wherein a feeding platform for conveying workpiece cages is arranged transversely on the front part of the frame; a drying box for baking workpieces in the workpiece cages is arranged longitudinally on one side of the frame; an inlet in the front end of the drying box is in butt joint with the outlet of the feeding platform; a precooling region for precooling the workpieces in the workpiece cages is arranged on the frame behind the drying box; a discharging platform is arranged longitudinally on the other side of the frame; a cooling region for forcibly cooling the workpieces in the workpiece cages is arranged on the back part of the discharging platform; an outlet in the front part of the discharging platform is in butt joint with the inlet of the feeding platform in order to send empty workpiece cages back; a line change platform for conveying the workpiece cages from the precooling region to the cooling region is arranged transversely on the back part of the frame. The workpiece cages are adopted for conveying workpieces of various shapes, so that feeding, drying and cooling functions are integrated, the baking and cooling time is short, and the production efficiency is greatly increased.

Owner:GUANGLONG PRECISION IND FUZHOU

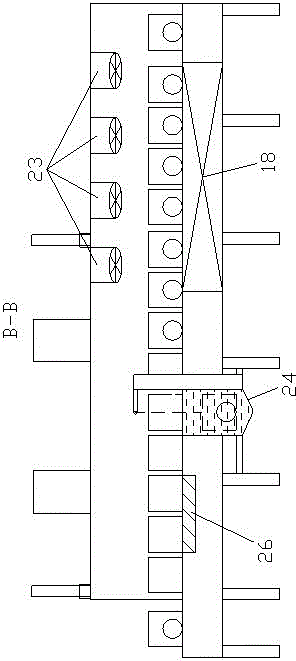

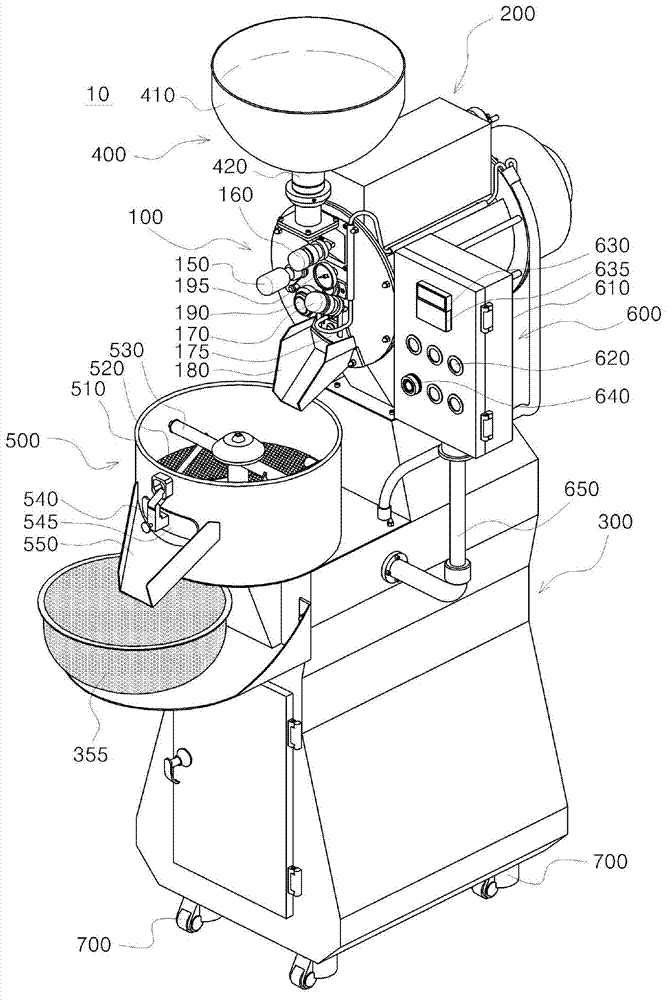

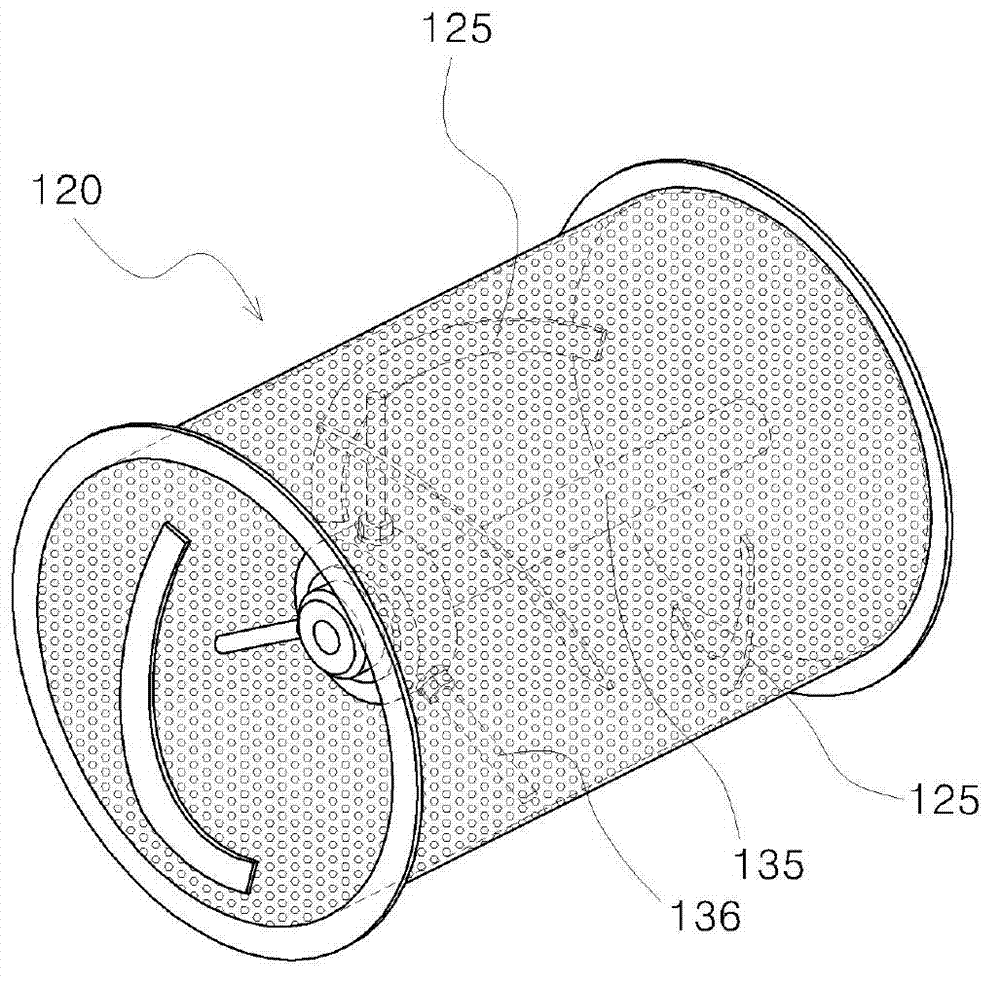

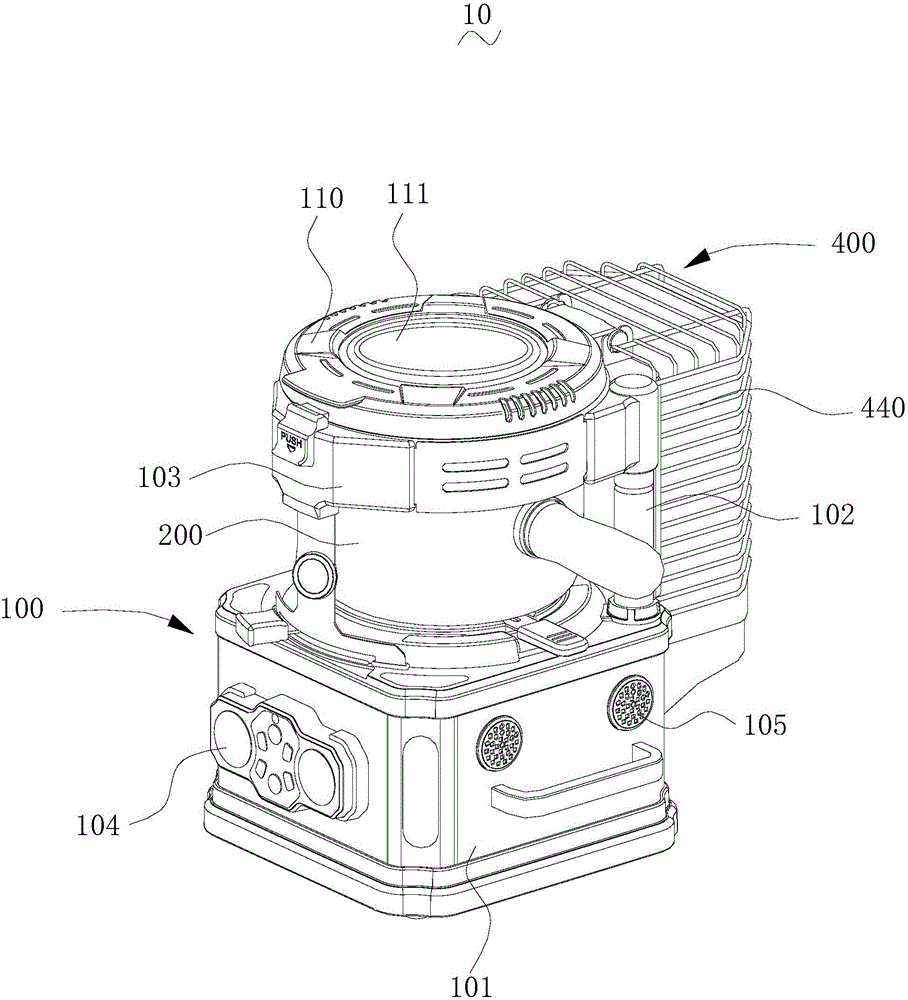

Roaster

InactiveCN103156266AQuality improvementImprove baking efficiency and productivityRoasters/grillsFood treatmentEngineering

The invention relates to a roaster. The roaster comprises: a roasting part which comprises a casing with a net-shaped drum in the interior; a heating part which is configured on the roasting part and has an air suction port for sucking external air; and a body part which is configured under the roasting part, and has a first blower in interior of the body part for sucking air. The interiors of the roasting part, the heating part and the body part are communicated with each other, to make the air flow. The roaster can uniformly roast articles to be roasted, thereby raising quality thereof.

Owner:郑淳哲

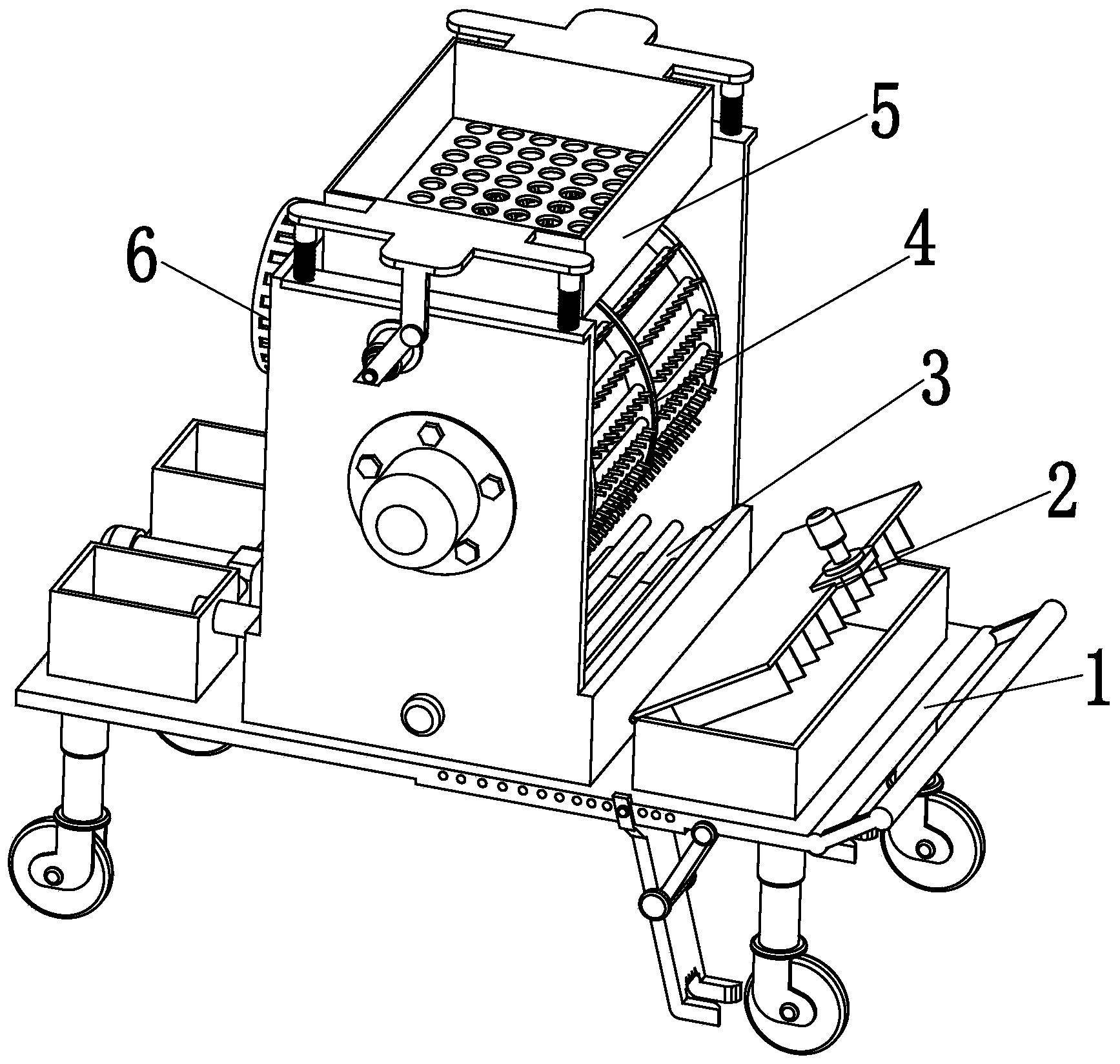

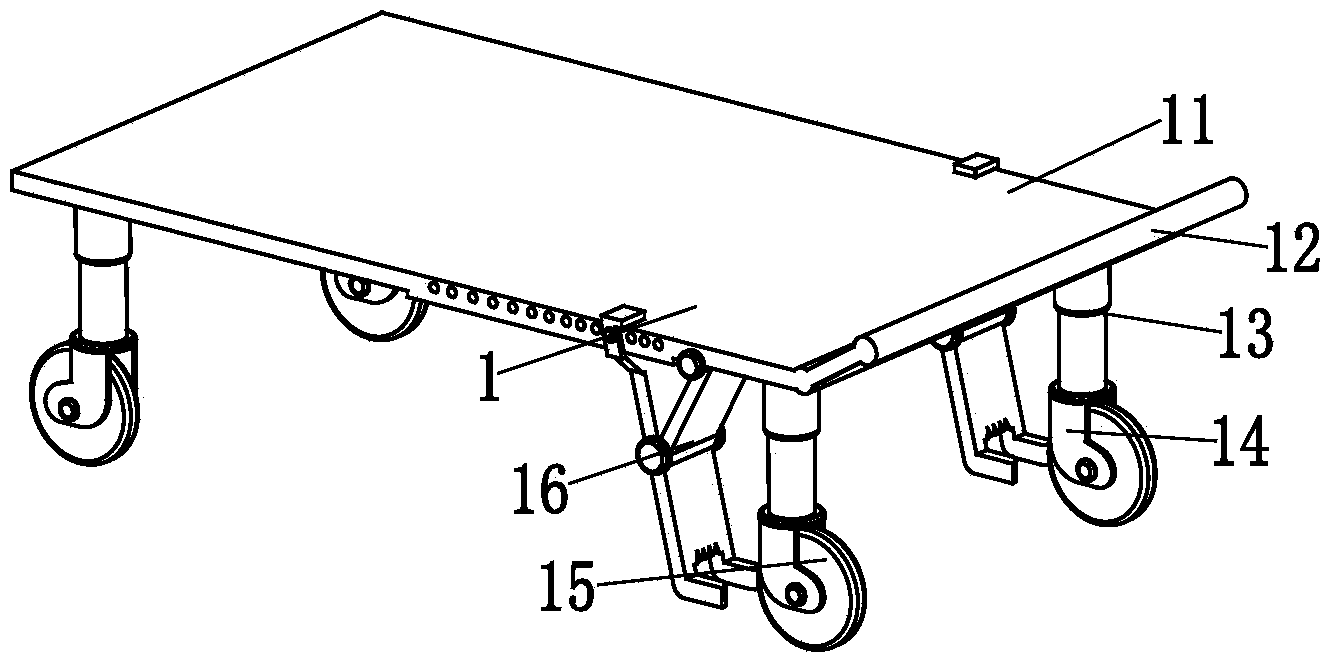

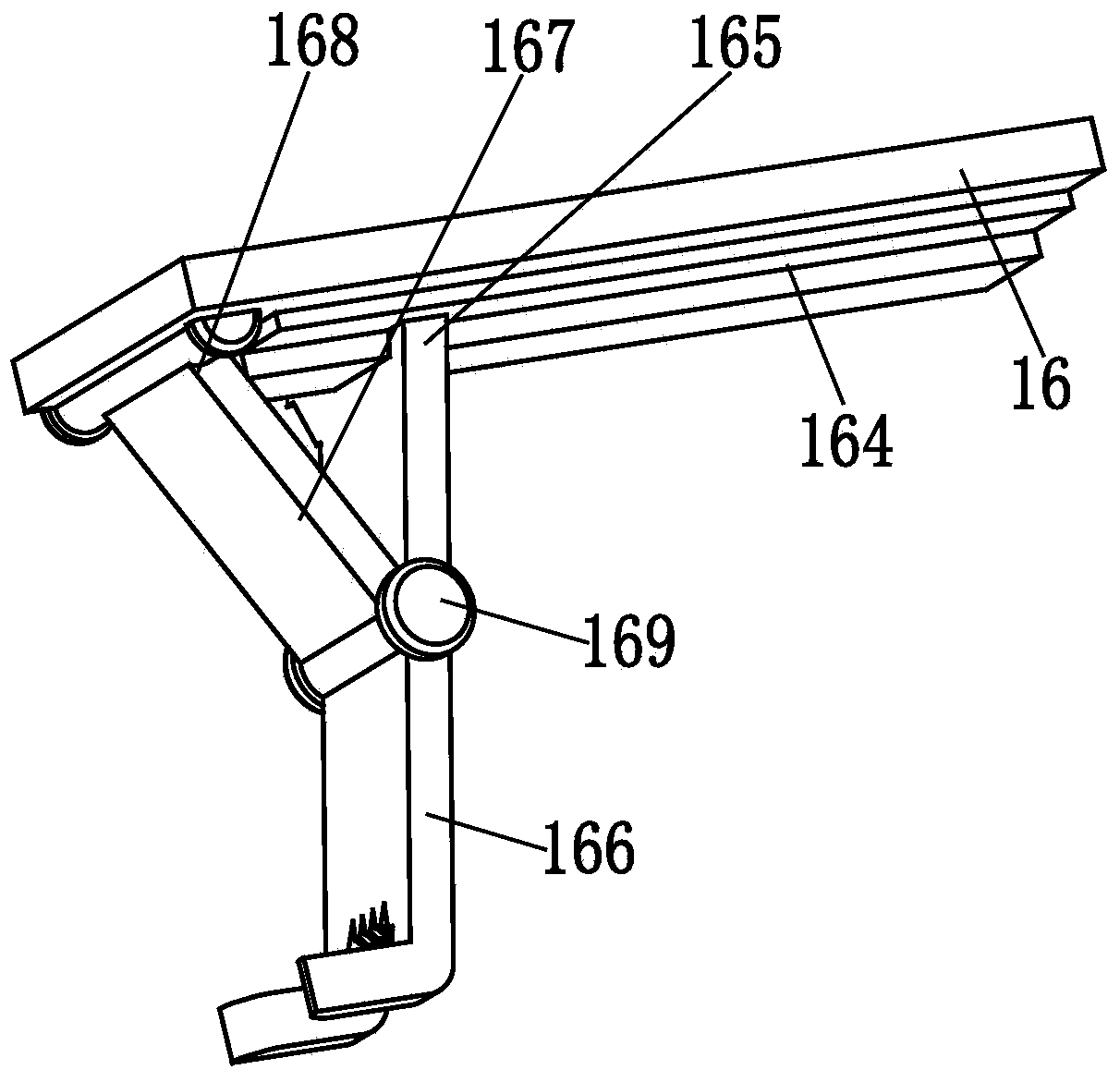

Baking equipment

ActiveCN104223967ASimple structureEasy to operateRoasters/grillsBread-toastersProcess engineeringAutomation

The invention relates to baking equipment. The baking equipment comprises a movable trolley, a slicing device, a baking oven, a grill, a material spreading device and a smoke exhaust device, wherein the slicing device is located on the rear side of the movable trolley, the baking oven is located right ahead the slicing device and the baking oven is fixedly connected with the movable trolley; the grill is installed above the baking oven and the material spreading device is located right above the grill; the smoke exhaust device is located on the front side of the baking oven and the smoke exhaust device is fixedly connected with the baking oven. The baking equipment has the advantages of simple structure, convenience in operation, low manufacturing cost and the like; the baking equipment can realize a function of rotatably baking sliced bread, the baking uniformity is good and the baking efficiency is high; the baking device can also realize a function of automatically spreading materials, and the automation level is improved; heat produced during baking is fully utilized and energy waste is reduced.

Owner:徐州市铜山区汉王镇农业服务发展有限公司

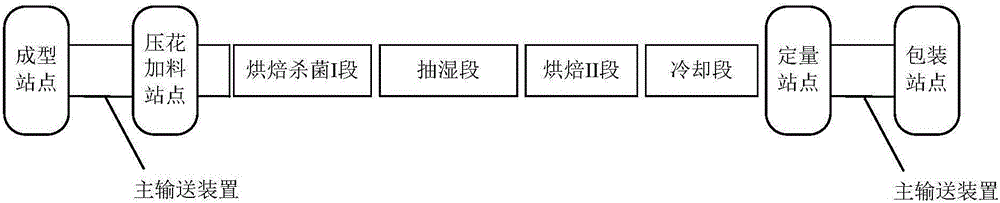

Biscuit production line

ActiveCN105145751AIncreased crunchinessHighly integratedDough treatmentBakery productsProduction lineManufacturing engineering

A biscuit production line sequentially comprises a biscuit forming site, an embossing feeding site, a baking sterilization I section, a dehumidification section, a baking II section, a cooling section, a quantification section, a packaging site, a main conveying device for transfer between the sites and a control device. The biscuit production line can produce biscuits of various types. Biscuit blank undergoes double-section baking, the baking efficiency and quality are improved, and the automatic production of biscuits is achieved.

Owner:瑞邦良品(广东)食品科技有限公司

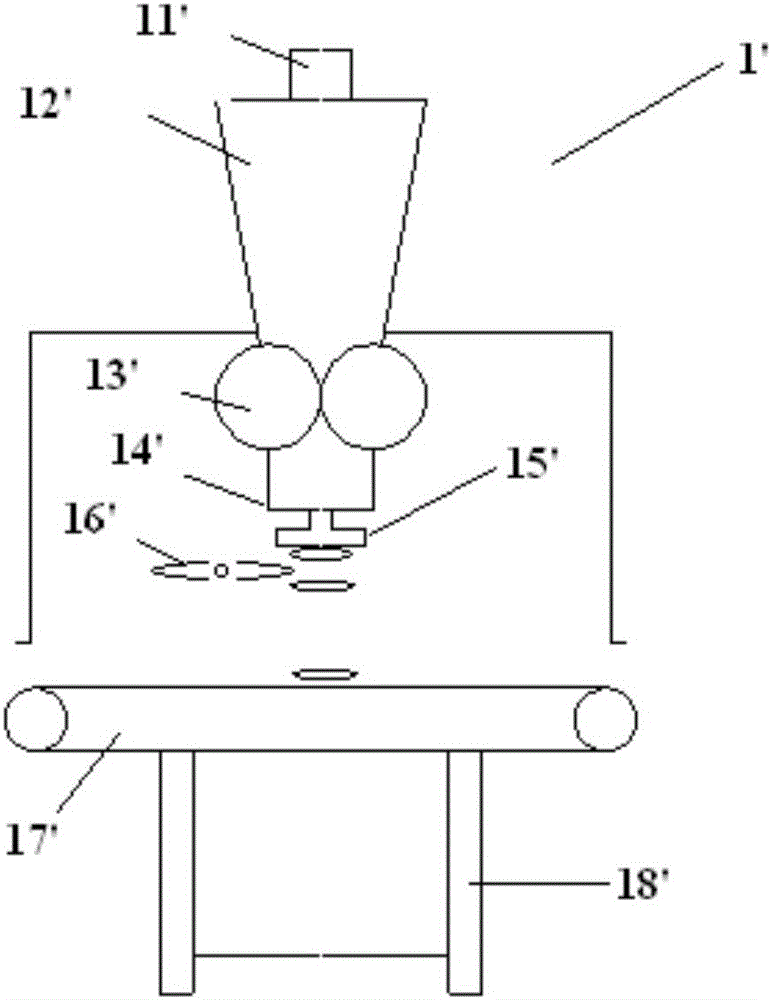

Egg body baking and producing device

ActiveCN103210965AShorten the lengthEvenly bakedSpecial goods bakingCooking & bakingProcess engineering

The invention provides an egg body baking and producing device which comprises a baking chamber, wherein the baking chamber is internally provided with a transporter for inputting and outputting egg bodies one by one, a hot gas discharging pipeline is arranged on the baking chamber, and discharged hot gas is output through a fan after being dewatered by a dewatering device, and enters the bottom of the baking chamber through a hot gas inlet pipe after heat of hot gas is absorbed by an air heat exchanger, so that the circulating heating of air can be realized, and egg bodies can be baked. The device not only can be used for evenly heating the egg bodies, but also is small in volume and high in baking efficiency.

Owner:福州闽台机械有限公司

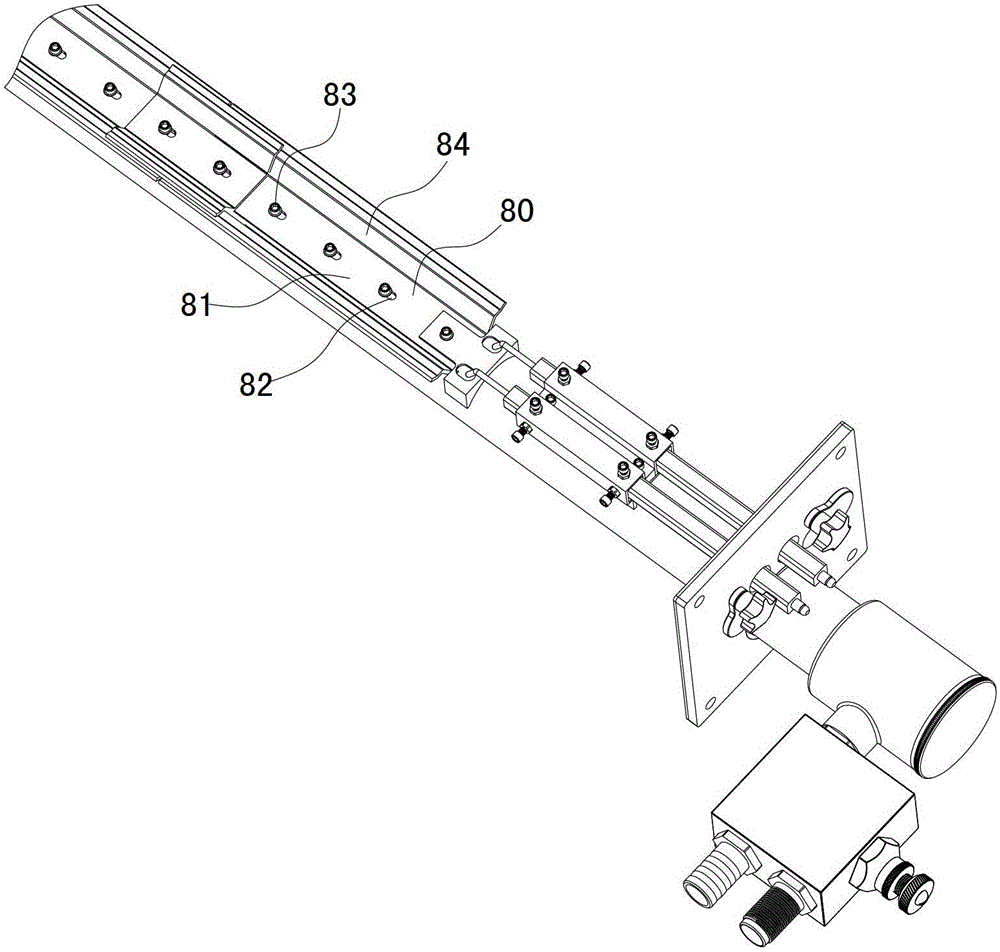

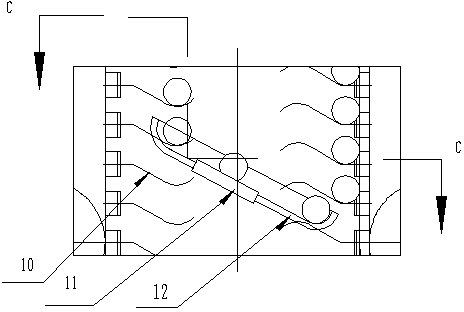

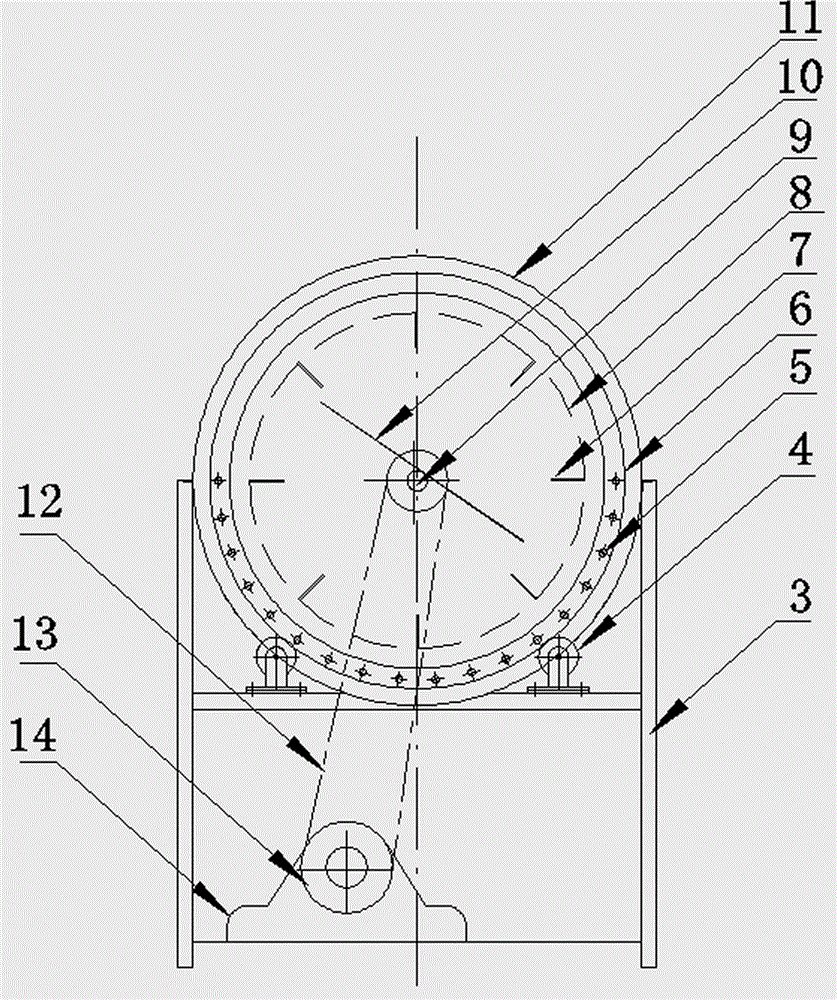

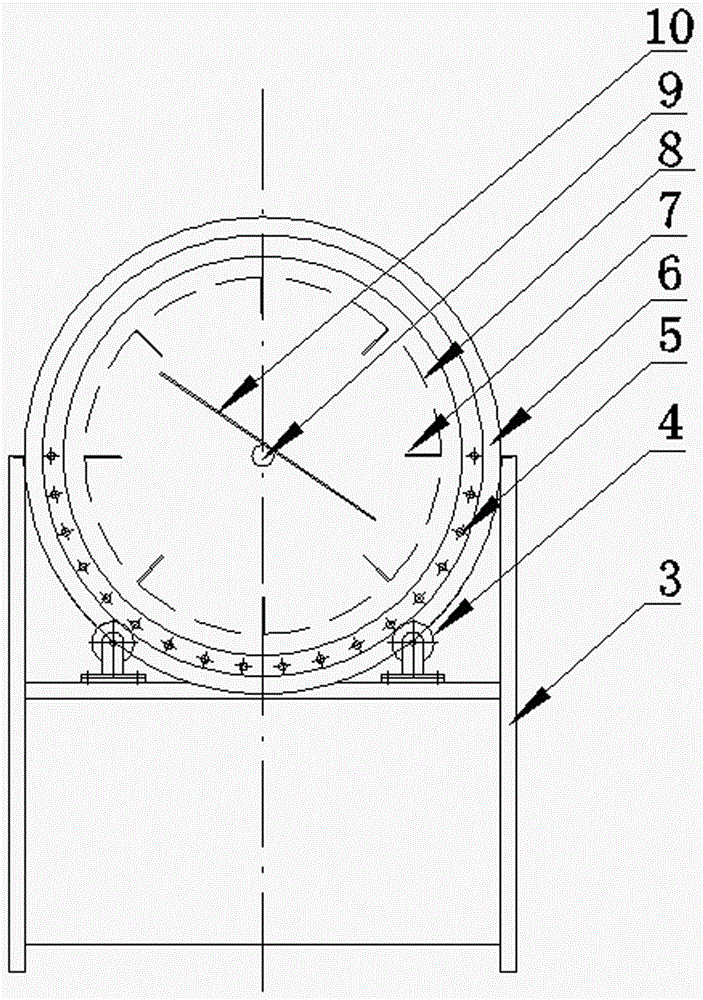

Baking apparatus and baking process for oolong tea

InactiveCN106035782AImprove baking efficiencyReduce the transfer linkPre-extraction tea treatmentThermodynamicsHeater Rod

The invention discloses a baking apparatus and baking process for oolong tea. The baking apparatus is prepared at first and is provided with a rotary drum, a rotary drum support, an electric heating rod, a motor transmission device, a plurality of stir-frying blades, a stir-frying guide plate, a helical groove, a discharge outlet, a feed inlet and a transmission mechanism driving rotation of the rotary drum. Controlling principles for baking in the invention are that a continuous baking mode of simultaneous feeding and discharging is employed and cooperated with three parameters consisting of set blanking speed, electric furnace temperature and rotating speed of the rotary drum, so rapid drying of the oolong tea is controlled, the water content of the oolong tea and optimal fire meet process requirements, the oolong tea can maintain a certain degree of dryness, and the fragrance and taste of the oolong tea are improved; so the product quality of the oolong tea is improved to a greatest extent.

Owner:福建茶叶进出口有限责任公司

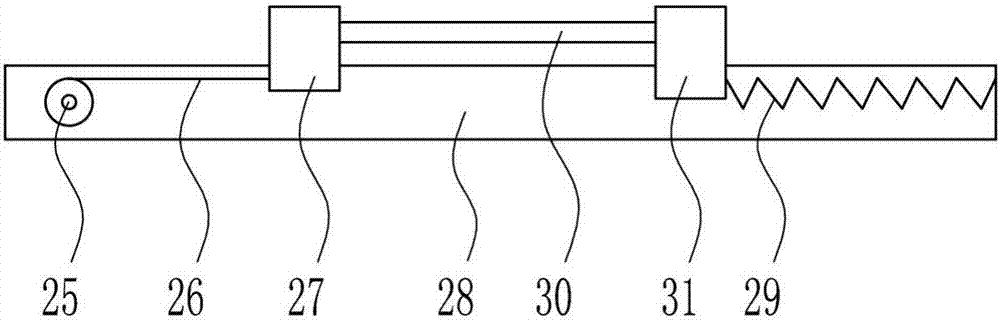

Tunnel baking line material conveying method and device

ActiveCN104729258AGuaranteed tightnessAchieve continuous bakingDrying machines with progressive movementsDrying solid materialsCooking & bakingFailure rate

The invention discloses a tunnel baking line material conveying method and device. The tunnel baking line material conveying device comprises a material bearing device, a main driving device and at least one standby driving device. The main driving device and the standby driving devices comprise a main driving structure and standby driving structures respectively. The material bearing device is provided with a driven driving structure matched with the main driving structure and the standby driving structures. The main driving structure or the standby driving structures drive the material bearing device to move in a sealable functional box through the driven driving structure. Due to the fact that each sealable functional box is internally provided with at least one independent tunnel baking line material conveying device which comprises the main driving device and the standby driving devices, during material conveying, the main driving device or the standby driving devices work, mechanical failures can be effectively reduced, tooth jumping or tooth clamping is prevented, and the tunnel baking line material conveying method and device have the advantages that the failure rate is low, the structure is simple, the production efficiency is improved, and the product percent of pass is increased.

Owner:SHENZHEN XINYUREN TECH

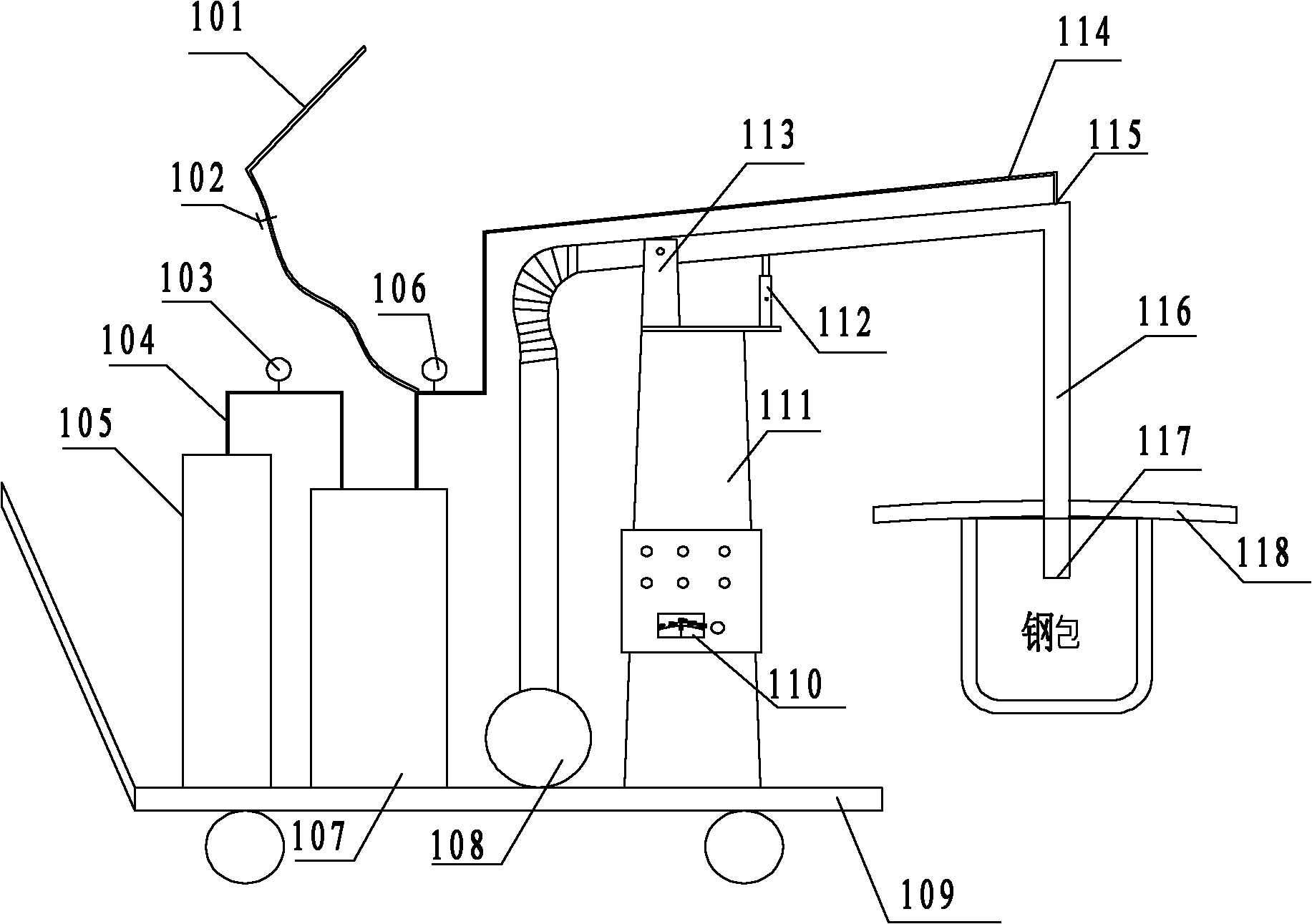

Steel ladle baking device

InactiveCN102211181AUniform temperatureImprove baking efficiencyMelt-holding vesselsThermal energyCooking & baking

The invention discloses a steel ladle baking device which comprises a fuel gas supply device, a heating and boosting device and an air outlet pipeline, wherein the inlet of the heating and boosting device is connected with the fuel gas supply device, the middle part of the air outlet pipeline is provided with a fuel port, the fuel port is connected with the outlet of the heating and boosting device by virtue of a fuel gas pipeline, the inlet of the air outlet pipeline is connected with a blast blower, and the outlet of the air outlet pipeline is connected with a nozzle. Compared with the prior art, the steel ladle baking device disclosed by the invention has the advantages that: the air outlet pipeline connected with the blast blower is arranged, fuel gas passes through the heating and boosting device and then enters into the air outlet pipeline by virtue of the fuel gas pipeline and flows in the air outlet pipeline, in the flowing process, and the fuel gas can be fully mixed with the air in the air outlet pipeline, thus a combustion flame after the fuel gas is sprayed out from the nozzle is longer, thermal energy can reach the bottom of a steel ladle tank, the temperature of the steel ladle tank is ensured to be uniform, and the baking efficiency of the steel ladle is improved.

Owner:SUFA HENGDIAN MACHINERY CNNC

Efficient aluminum alloy window varnish stoving device for hardware manufacturing

InactiveCN107321532AAvoid direct contactSpeed up dryingSpraying apparatusPretreated surfacesGear wheelBevel gear

The invention relates to a varnish stoving device, in particular to an efficient aluminum alloy window varnish stoving device for hardware manufacturing. The technical effect that the provided efficient aluminum alloy window varnish stoving device for hardware manufacturing is high in varnish stoving efficiency is achieved. In order to achieve the technical effect, the provided efficient aluminum alloy window varnish stoving device for hardware manufacturing comprises a first rotary motor, a left bearing seat, a first bevel gear, a first rotary shaft, a first reel, a right bearing seat, a top plate, a second bevel gear, a first bearing seat and the like. A first sliding rail is located on the left side of a moving device. A first sliding block is arranged on the first sliding rail. A nozzle is connected with the right side of the first sliding block. A holding plate is arranged on the left side of the first sliding rail. A varnish tank is arranged on the holding plate. The efficient aluminum alloy window varnish stoving device achieves the effects of high varnish stoving speed and varnish stoving efficiency, simple device structure, low device manufacturing cost and long device service life, and the working efficiency is higher due to the fact that rotary blades can rotate and the nozzle can move up and down when the first rotary motor rotates.

Owner:赵晓琴

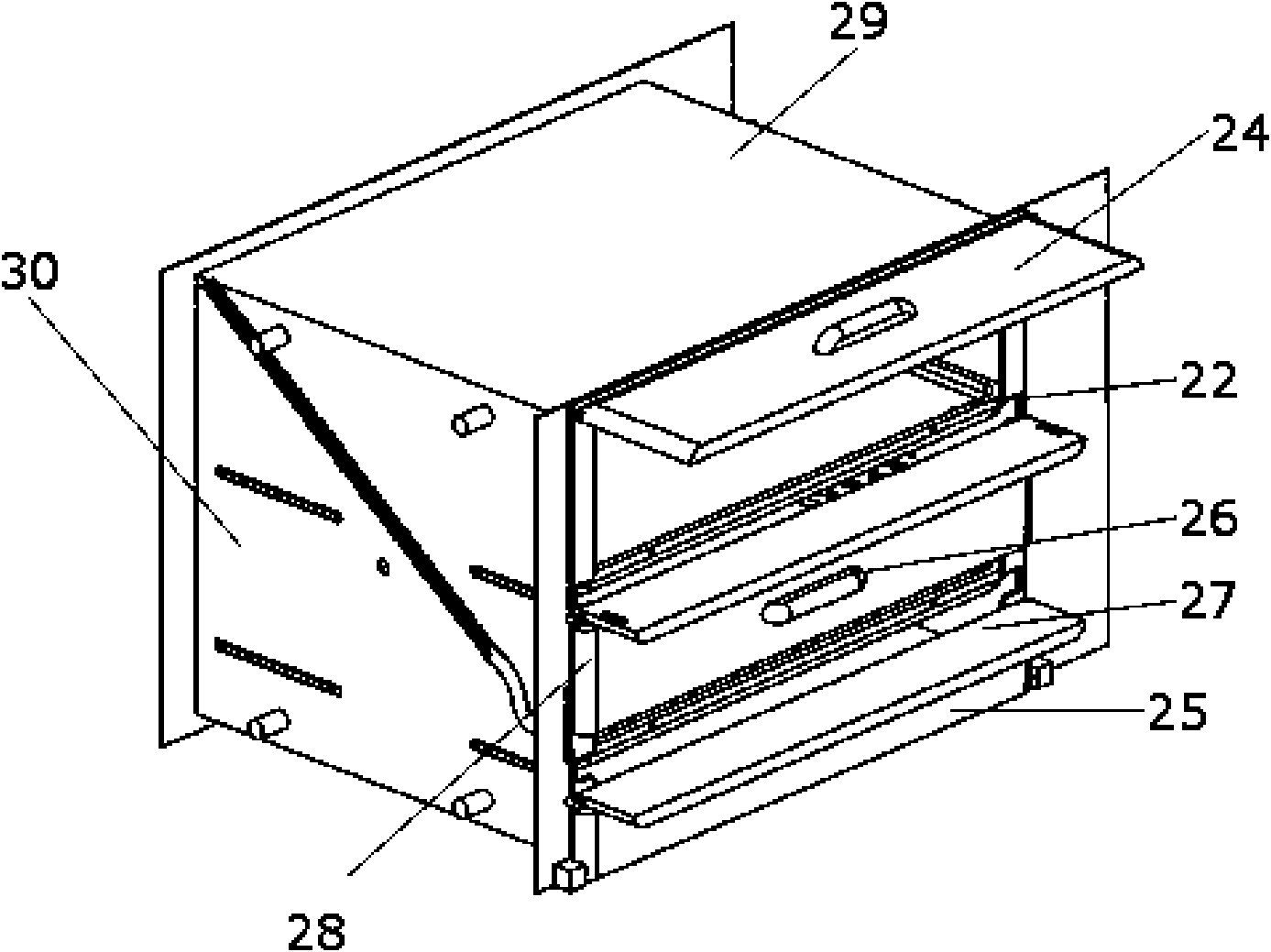

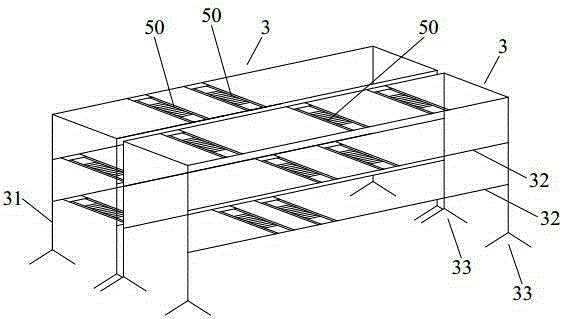

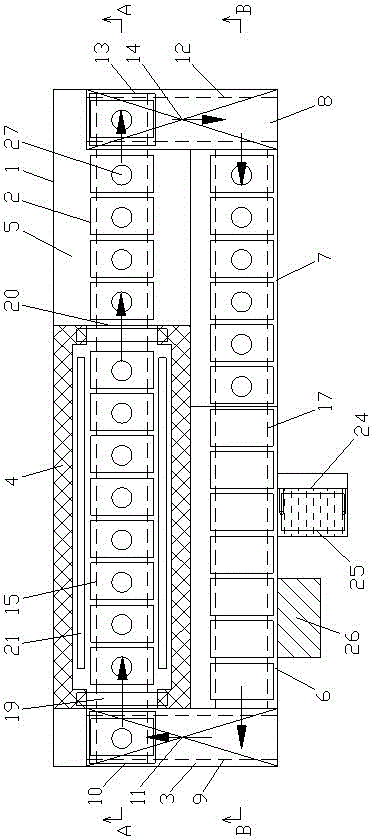

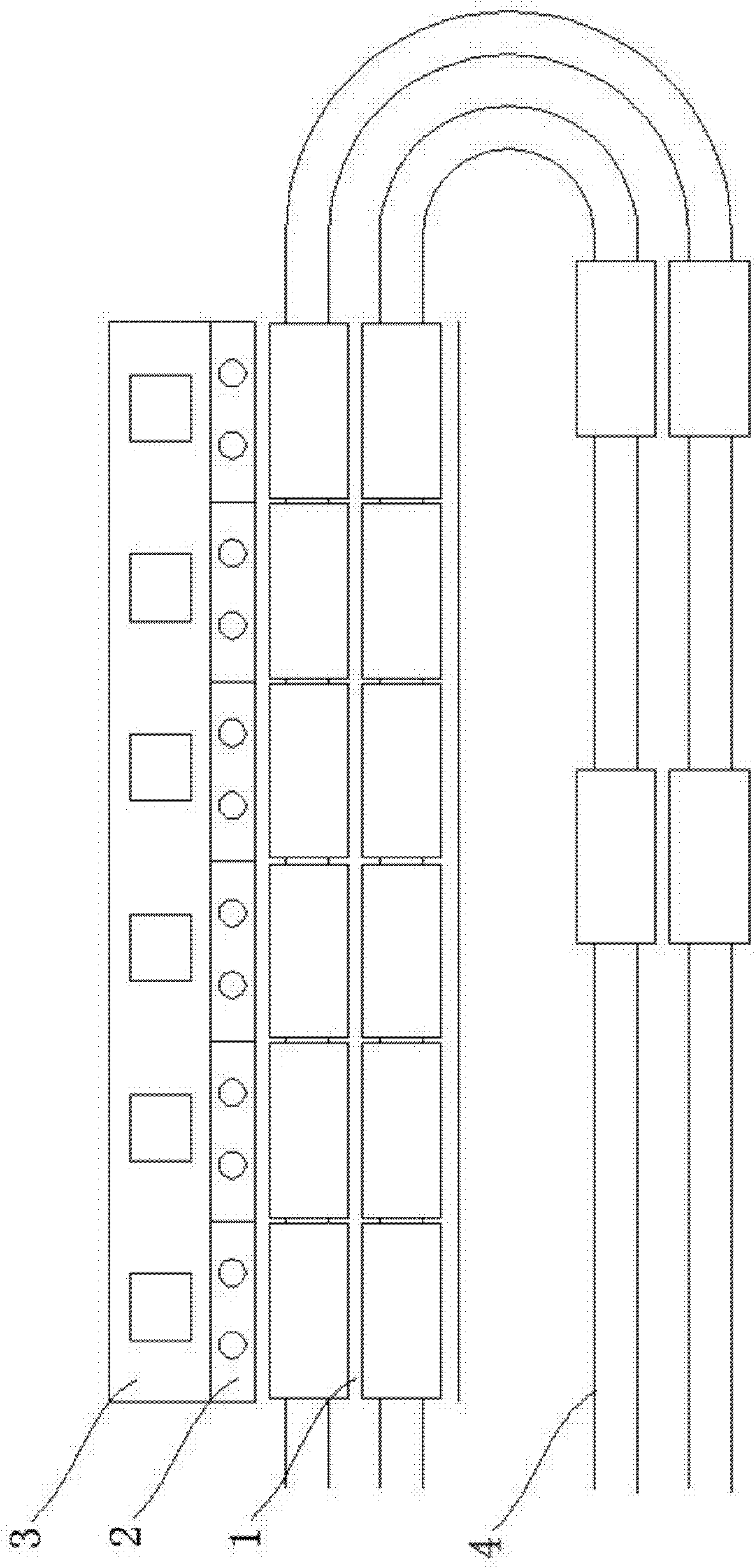

Multilayered baking oven system

ActiveCN102589264AImprove baking efficiencyImprove feeding efficiencyDrying chambers/containersDrying machines with progressive movementsProcess engineeringEngineering

A multilayered baking oven system comprises a conveying portion and a baking oven communicated with the conveying portion. At least two layers are arranged inside the baking oven from top to bottom, and the conveying portion is connected with the baking oven by a lifting system. The multiple layers of the baking oven can run simultaneously, a plurality of workpieces are baked at the same time, and baking efficiency of the baking oven is effectively improved; the conveying portion conveys the workpieces into the baking oven, manual intervention of operators is omitted, conveying efficiency is improved, and labor cost is also lowered; and heating temperature inside the baking oven is uniform, and a baking effect is good.

Owner:ZHEJIANG HUALI INTELLIGENT EQUIP CO LTD

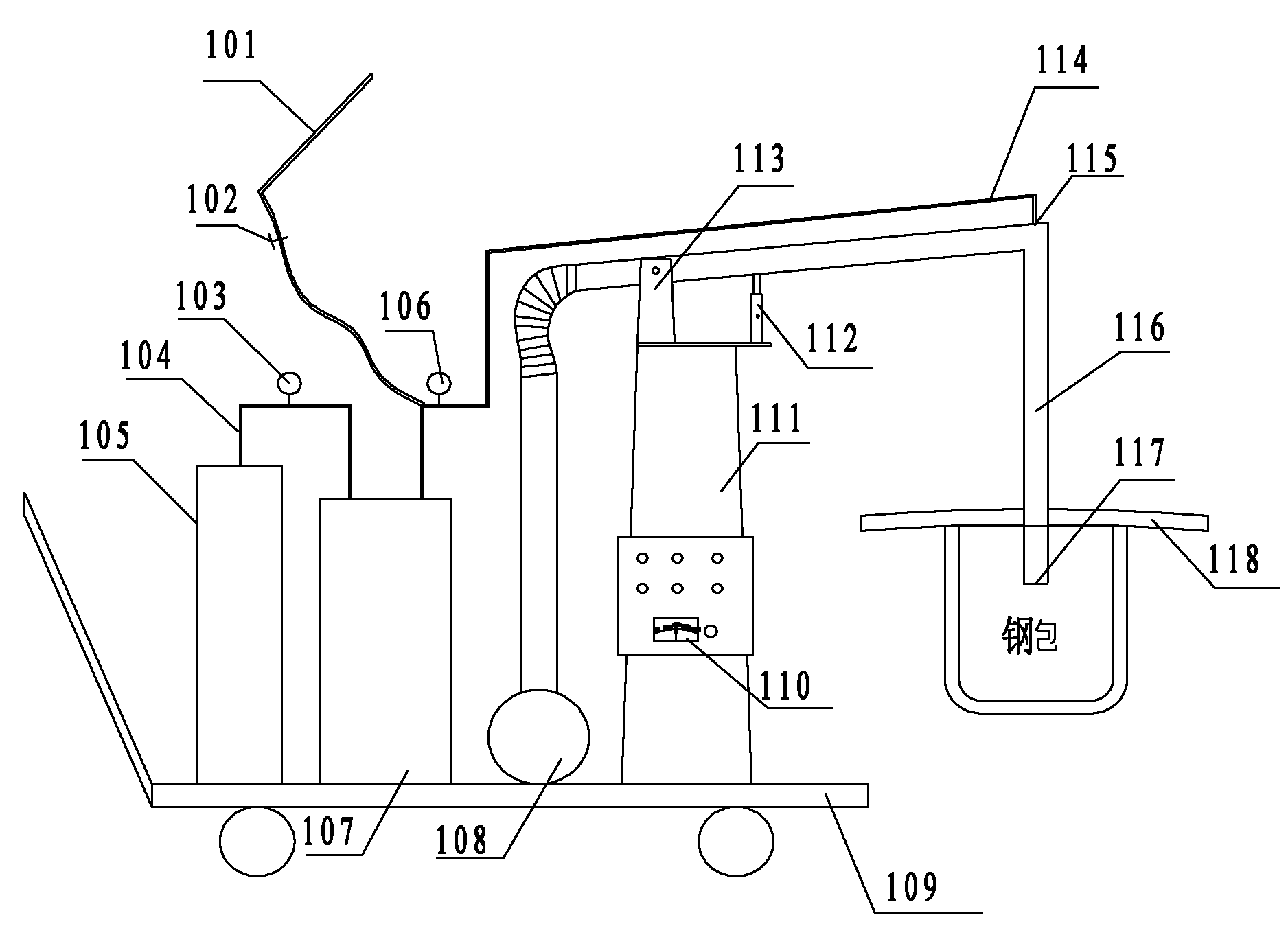

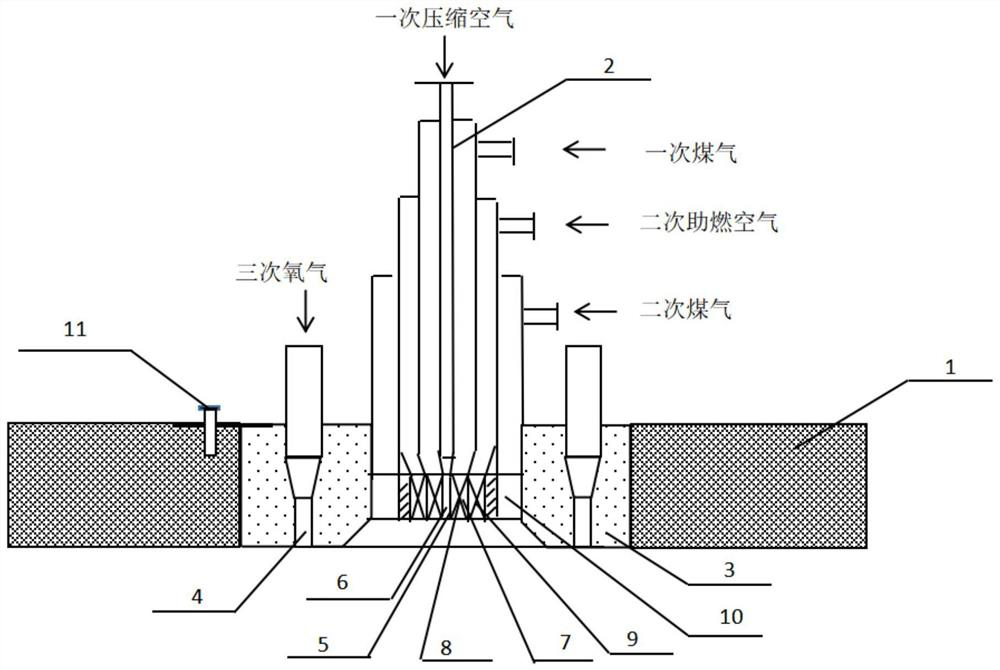

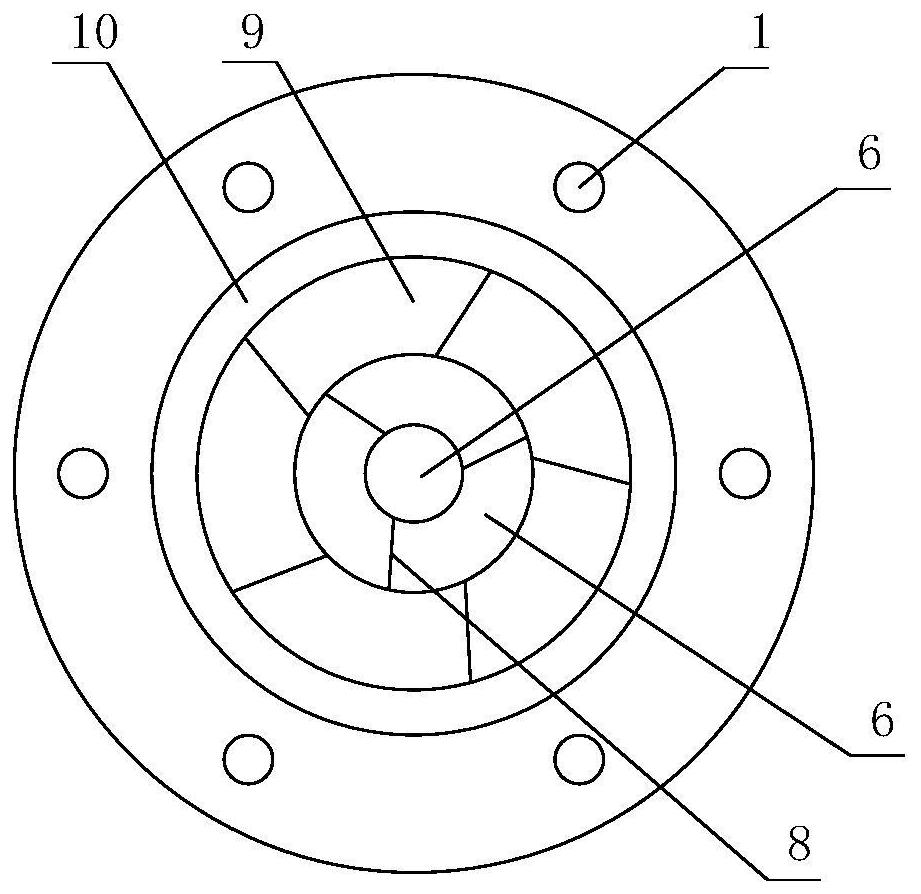

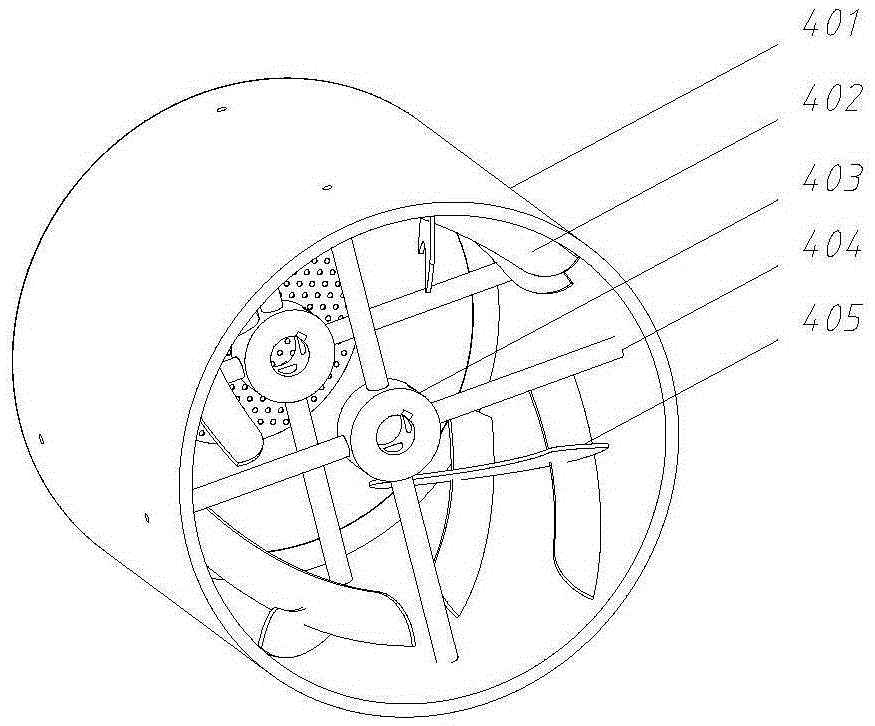

Oxygen jet multi-stage dispersion combustion roaster

PendingCN112944344AReduce the temperature difference between upper and lowerReduce productionMelt-holding vesselsIndirect carbon-dioxide mitigationThermodynamicsCombustion

The invention relates to an oxygen jet multi-stage dispersion combustion roaster which comprises a metal structure burner and a refractory burner brick; the metal structure burner is arranged in the center of a ladle cover; the metal structure burner is of a four-layer sleeve structure; a first-stage compressed air channel is arranged in the center; a first-stage gas channel, a second-stage combustion-supporting air channel and a second-stage gas channel are sequentially arranged outside the first-stage compressed air channel; a compressed air nozzle is of a contracted conical structure and is arranged at the bottom of the first-stage compressed air channel; a first-stage gas circular seam is arranged at the bottom of the first-stage gas channel; a second-stage air circular seam is arranged at the bottom of the second-stage combustion-supporting air channel; a second-stage gas circular seam is arranged at the bottom of the second-stage gas channel; an oxygen jet orifice is fixed outside the metal structure burner; and a whole burner nozzle is fixed in the burner brick. The oxygen jet multi-stage dispersion combustion roaster has the advantages that oxygen high-speed jet is utilized to strengthen steel ladle bottom heating, upper and lower temperature difference of a steel ladle is reduced, and a local high-temperature area formed by high oxygen concentration is avoided.

Owner:ANGANG STEEL CO LTD

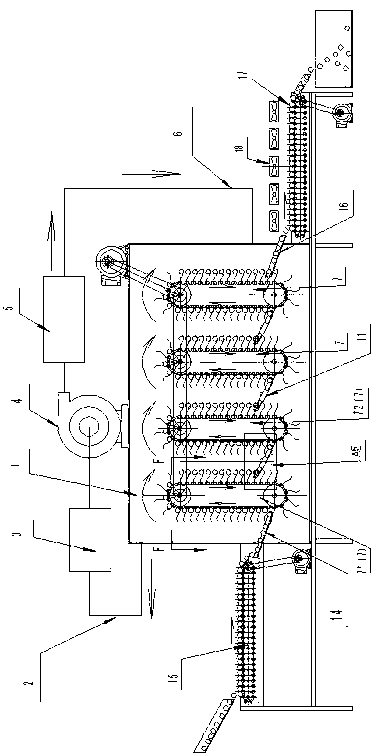

Tunnel curing barn adopting humiture subdivision control of alternate wind direction

ActiveCN102735035AEvenly heatedDrain evenlyDrying gas arrangementsDrying machines with progressive movementsAir cellOne-hot

Disclosed is a tunnel curing barn adopting humiture subdivision control of alternate wind direction, and the tunnel curing barn is formed by a plurality of work cells, which are penetrated through and connected by a track. Each work cell comprises a baking cell, an air-mixing layer and a hot air cell. Each work cell is provided with one hot air cell or the plurality of work cells share at least one hot air cell. The air-mixing layer is located between the baking cell and the hot air cell. Material trolleys which pass through the baking cells respectively move a distance of one baking cell every time, and the material trolleys are used for being filled with materials to be baked. A circulating fan is installed in the air-mixing layer to produce an ascending airflow or a descending airflow. A heating or heat exchanging device is disposed in the hot air cell. The whole tunnel curing barn is separated into a plurality of independent work cells by separating plates which are provided at the front end and the rear end of the material trolleys in the baking cells, and each work cell forms an independent hot air self-circulating system. The material trolleys on the track move forward at intervals and are capable of moving at fixed time and fixed quantity and staying in different work cells for drying according to temperature and humidity required by materials at different times.

Owner:北京华珍烘烤系统设备工程有限公司

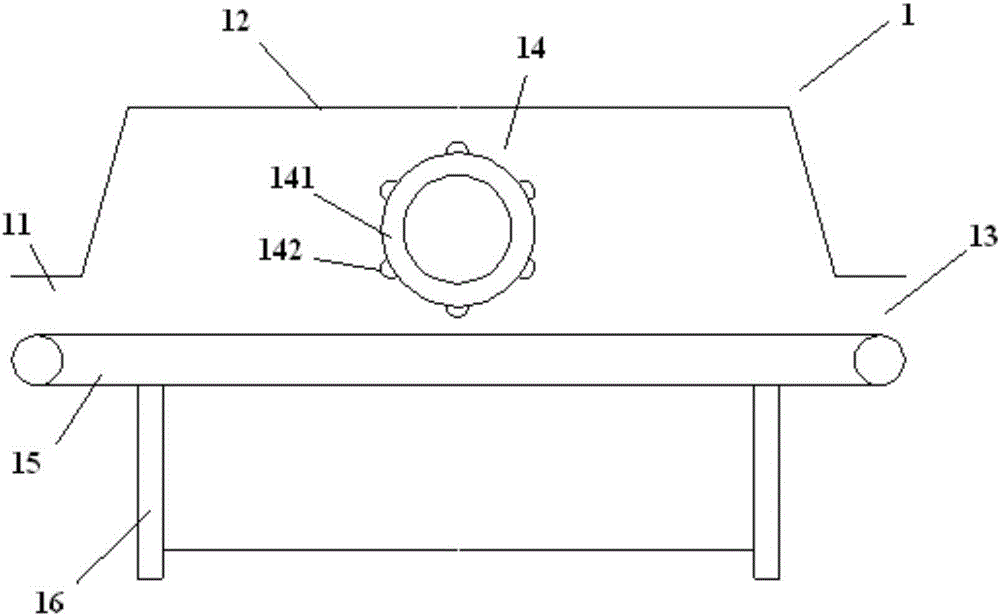

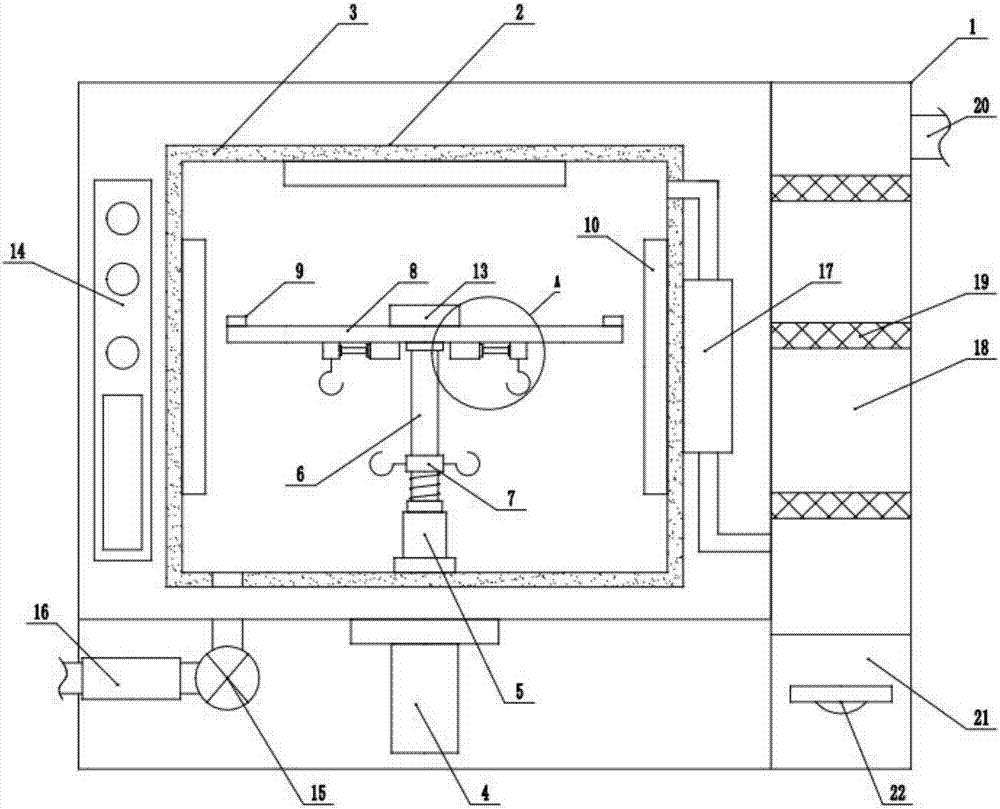

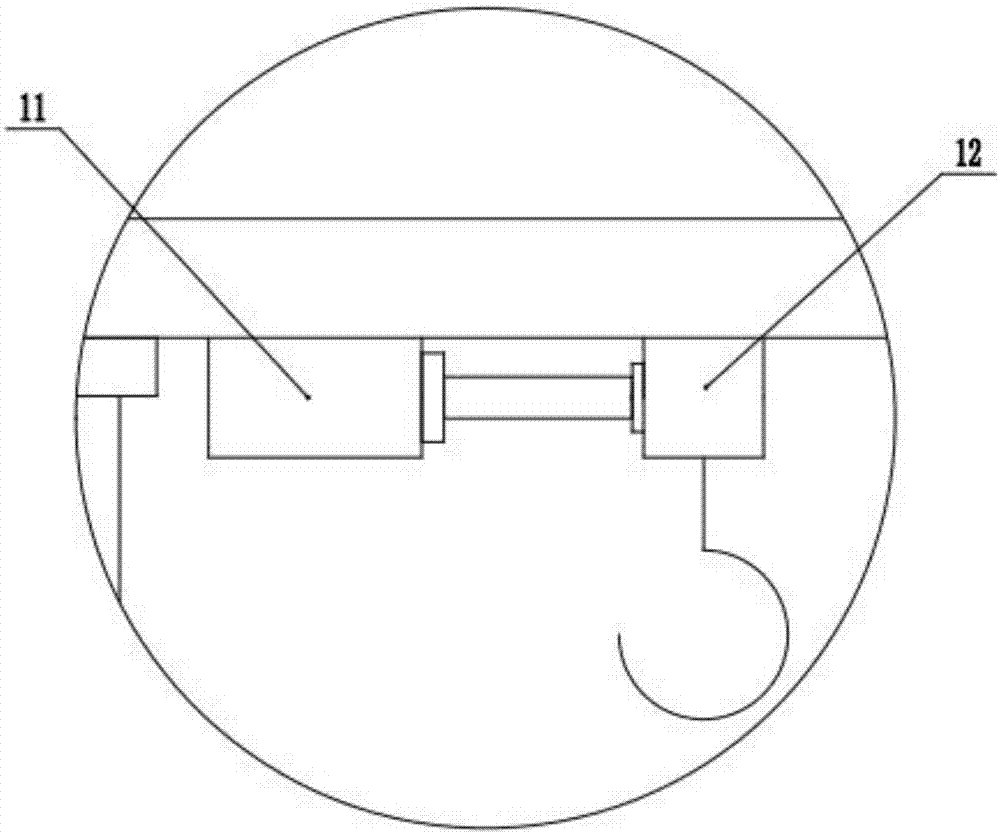

Clay oven roll baking machine

InactiveCN104430667ABaking quality is stableImprove baking efficiencyHigh-frequency/infra-red heating bakingOil/fat bakingThermometerEngineering

The invention relates to the field of food baking and provides a clay oven roll baking machine. The oven roll baking machine comprises a tank with a front inlet and a rear outlet, a conveying device, a thermometer, two gas type infrared heaters, a timer controller and a controller, wherein the conveying device is provided with a conveyer belt penetrating through the front inlet and the rear outlet, the surface of the conveyer belt is provided with pottery fragments, one end of the thermometer extends into the tank, the other end of the thermometer is provided with a temperature control switch, the gas type infrared heaters are provided with gas solenoid valves and are located in the tank and arranged on the upper side and the lower side of the conveyer belt respectively, and the temperature control switch, the gas solenoid valves and the time controller are electrically connected with the controller. The clay oven roll baking machine is stable in baking quality and high in baking efficiency; the pottery fragments on the surface of the conveyer belt enable baked clay oven rolls to have the taste of traditional clay oven rolls.

Owner:LISHUI LUMAISHAO RESTAURANT MANAGEMENT

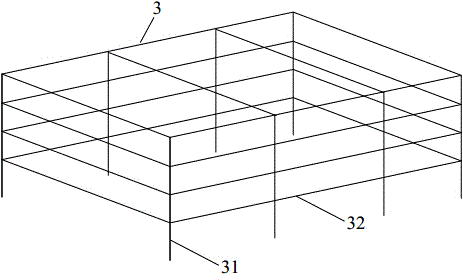

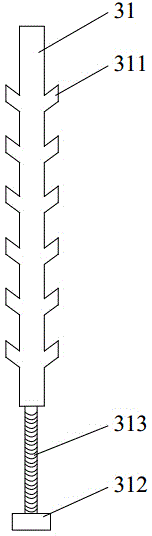

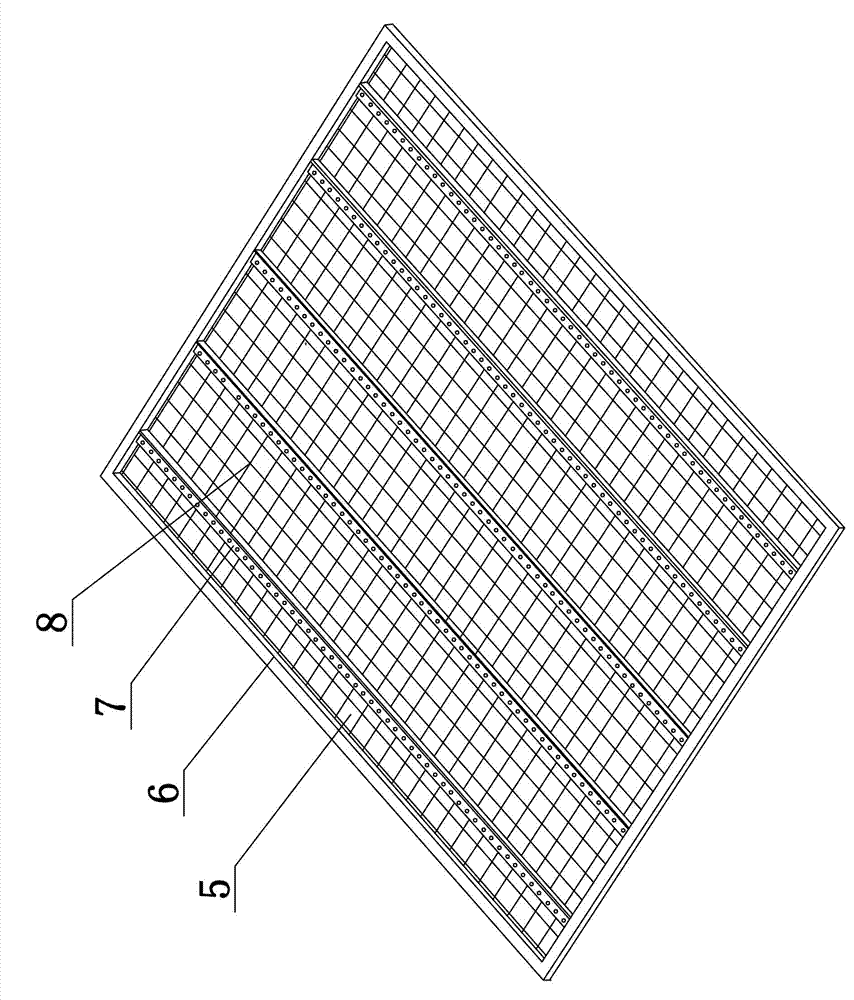

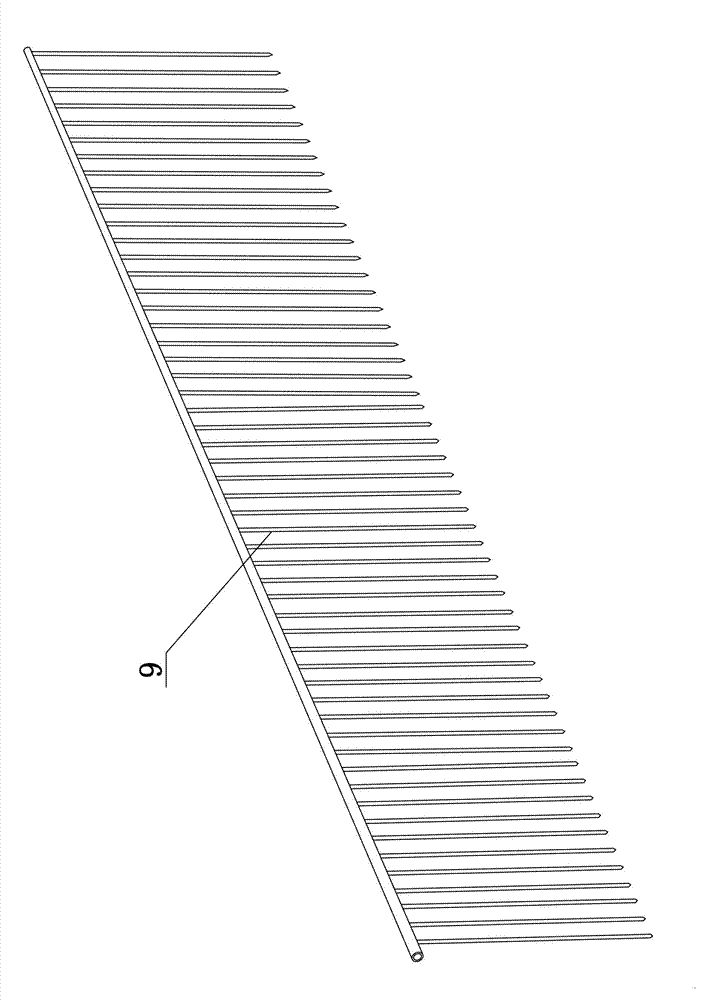

Laminated pin type oven for flue-cured tobaccos

InactiveCN102885393AEvenly heatedEvenly bakedTobacco preparationAgricultural engineeringStructural engineering

The invention relates to a laminated pin type oven for flue-cured tobaccos. The laminated pin type oven comprises a frame body, a frame cover plate and pins, wherein the frame body has a ventilated quadrangle structure, and the side surface of the frame body is opened; the frame cover plate is positioned on one opened side of the frame body; corresponding pin holes are formed on the surface, which is opposite to the frame cover plate, of the frame body and the frame cover body; and tobacco leaves are stacked in the frame body in a staggered and laminated manner, and the pins penetrate through the pin holes and the tobacco leaves in the frame body. The oven can change the condition that the tobacco leaves are stacked in disorder in the conventional large box for packaging the tobaccos, and ensures that gaps among the tobacco leaves can be uniformly reduced during a whole curing process and air passes through the gaps among the leaves at an equal speed, thus, the tobacco leaves can be uniformly heated, the air flows smoothly, the quality of the flue-cured tobaccos can be ensured, and the curing efficiency is improved.

Owner:HENAN AGRICULTURAL UNIVERSITY +1

Energy-efficient meat electric oven

ActiveCN107157339AAvoid reduction in baking efficiencyImprove baking efficiencyRoasting apparatusElectric machineryObject storage

The invention discloses an energy-efficient meat electric oven which comprises an oven body, wherein the right side of the oven body is fixedly connected with an object storage box; an inner oven is arranged in the oven body; a driving motor is arranged at the bottom of the oven body; the inner bottom of the inner oven is fixedly connected with an electric lifting device; the top of the electric lifting device is connected with a telescopic rod; the top of the telescopic rod is fixedly connected with a turntable; a sleeving connection piece is arranged on the telescopic rod in a sleeving manner; the sleeving connection piece is connected with the telescopic rod in a sleeving manner; the lower surface of the turntable is fixedly connected with an electric push rod; a sliding chute is formed in the lower surface of the turntable; the sliding chute is internally connected with a sliding block in a sliding manner; and the electric push rod is connected with the sliding block. According to the energy-efficient meat electric oven, reduction of the baking efficiency due to piling of meat is avoided; furthermore, the electric oven has a heat preservation function, and the meat baking efficiency is improved; before being baked, the meat is preheated, so that the heat and the time for baking of the meat are reduced, and the energy-efficient meat electric oven is convenient to use; and the electric oven can treat and then discharge lampblack gas and is favorable for environmental protection.

Owner:宁波品夏电器有限公司

Waste heat recovery dryer of high temperature heat pump

InactiveCN104807315AImprove recycling ratesIncrease heating capacityDrying gas arrangementsEvaporatorEngineering

The invention discloses a waste heat recovery dryer of a high temperature heat pump. The waste heat recovery dryer comprises a curing barn and a high temperature heat pump connected with the curing barn; the waste heat recovery dryer further comprises a first fan, an evaporator, a first electric adjusting valve, an air return port, a condenser, a second fan, an air delivery port and a second electric adjusting valve, wherein the first fan is arranged in the left end of the high temperature heat pump, the evaporator is arranged at the right side of the first fan, and the first electric adjusting valve is arranged at the right side of the evaporator; the air return port is formed in the right end of the high temperature heat pump and is communicated with the curing barn, the condenser is arranged at the right upper corner in the high temperature heat pump, the air delivery port is formed in the second fan and the second electric adjusting valve is arranged at the left side of the air delivery port. The waste heat recovery dryer and the curing bar can be arranged in an embedded way so as to realize close distance between waste heat recovery and waste heat heating; furthermore, the waste heat recovery dryer is fast in heating speed, simple in structure, convenient to use, and the labor intensity of installation can be reduced; in addition, the production cost can be reduced, the waste heat exhaust can be recovered and can be absorbed by the evaporator, the heat of the evaporator can be improved, the energy-saving effect can be realized, the high waste heat recovery rate can be realized, the rotating time of tobaccos can be greatly shortened, and a dehumidification function can be realized.

Owner:HUBEI KEYANG ENERGY SAVING EQUIP

Baking system in LED (Light Emitting Diode) packaging

InactiveCN104393149AUniform temperatureEasy to control speedSemiconductor devicesCooking & bakingThermal insulation

The invention discloses a baking system in LED (Light Emitting Diode) packaging. The baking system in the LED packaging comprises a controller, an oven, a transmission device and a plurality of temperature sensors; the oven comprises a plurality of sections of temperature zones; every temperature zone is provided with the temperature sensor; the controller is respectively connected with the oven, the transmission device and the plurality of temperature sensors; a thermal insulation device is arranged between the adjacent two temperature zones of the oven; bilateral sides of the thermal insulation device are provided with heating plates being identical to the temperature zone. According to the baking system in the LED packaging, the thermal insulation device is arranged between every two adjacent temperature zones, the difference between the actual temperature and the set temperature of every temperature zone is small, and the temperature in every temperature zone is uniform.

Owner:WUXI WISEN INNOVATION TECH

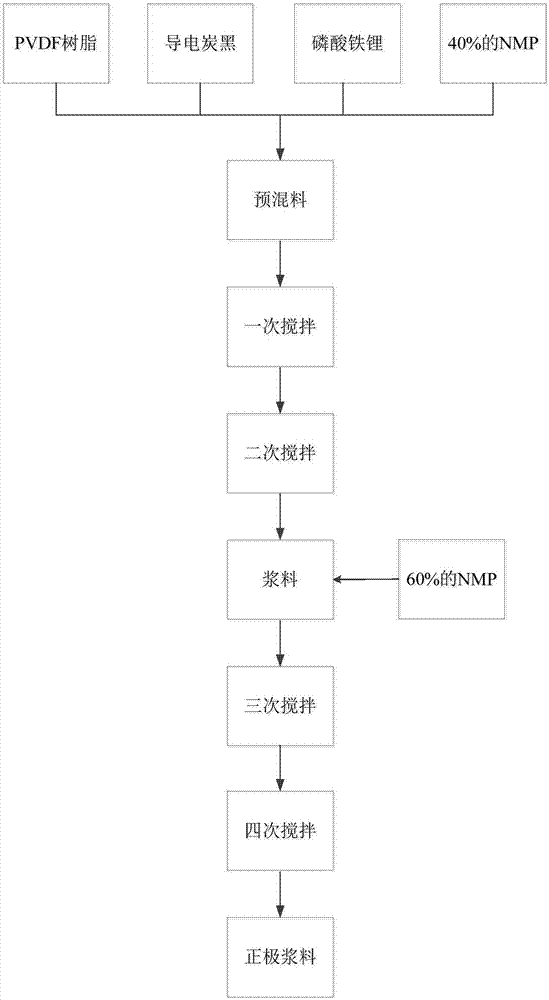

Positive pole sizing and preparation method and application thereof

ActiveCN106935853AStirring and pulping time compressionReduce dosageCell electrodesSecondary cellsAdhesiveSolid content

The invention discloses a positive pole sizing and a preparation method and application thereof. The method includes the following steps that firstly, an adhesive, a conductive agent, a positive pole active substance and a part of N-methyl-pyrrolidone (NMP) are mixed to obtain a premix; secondly, the premix obtained in the first step is kneaded and stirred; thirdly, the remaining NMP is added and stirred to obtain the positive pole sizing. By means of the method, the overall stirring and pulping time can be shortened to 165-195 min, the solid content of the obtained positive pole sizing is as high as 56+ / -1%, and the cost can be remarkably reduced. When the positive pole sizing is used for preparing negative poles, and the coating production efficiency is increased by 25% and reaches 25-30 m / min.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

Paint baking device for automobile metal part production

ActiveCN108940659AAvoid drippingReduce laborGas treatmentUsing liquid separation agentEngineeringMetal

The invention discloses a paint baking device for automobile metal part production. The paint baking device comprises a box body. A first rotating shaft is arranged in the middle of an inner cavity ofthe box body, a paint baking rotating cylinder is arranged on the outer wall of the lower end of the first rotating shaft in a sleeved mode, paint baking frames are symmetrically arranged on the leftside and the right side of the paint baking rotating cylinder, a first part placement area is formed in the circle center of the upper end of each paint baking frame, the second part placement areasare uniformly arranged on the outer side of the first part placement area and in the radius direction, air holes are formed in the outer walls of the second part placement area and the first part placement area, a rotary groove is formed in the outer side of the lower end of each paint baking frame, the second rotating shaft is arranged in the middle of each rotary groove in a sleeved mode, and the second rotating shaft is fixedly connected with the rotary groove through a flange plate. The invention relates to the technical field of the paint baking for the automobile metal part. The paint baking device for the automobile metal part production has the advantages of being convenient to access, uniform in heating, good in paint baking effect, and paint baking efficiency of the automobile part is improved.

Owner:ANHUI TIANYU AUTO PARTS MFG

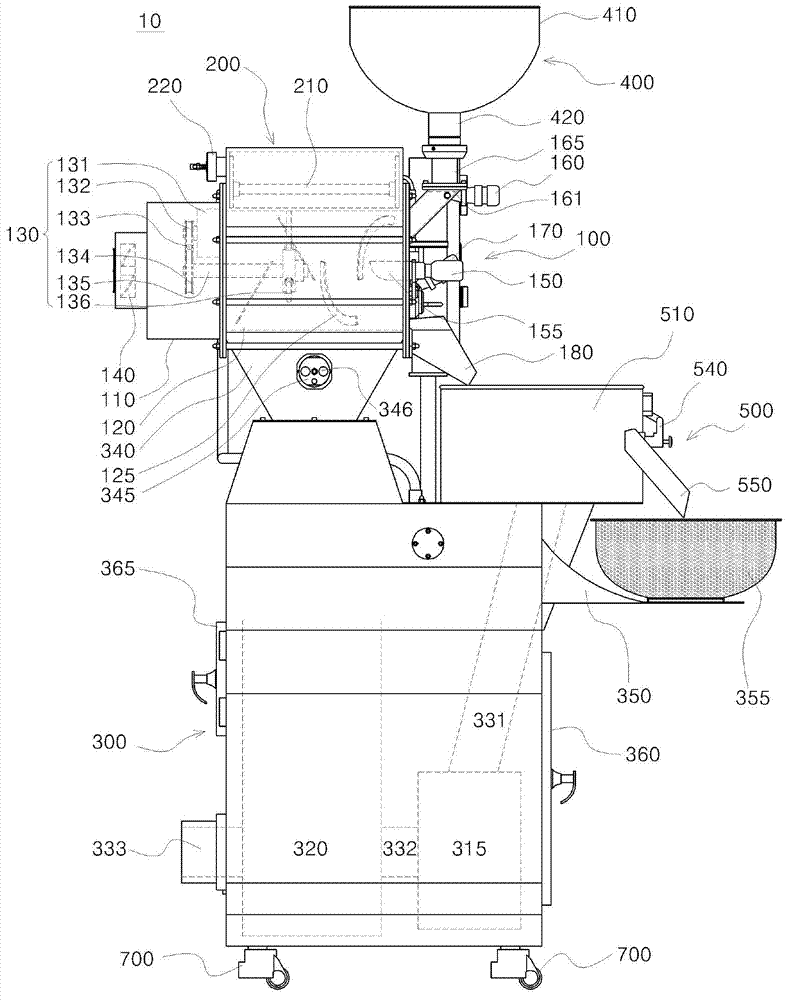

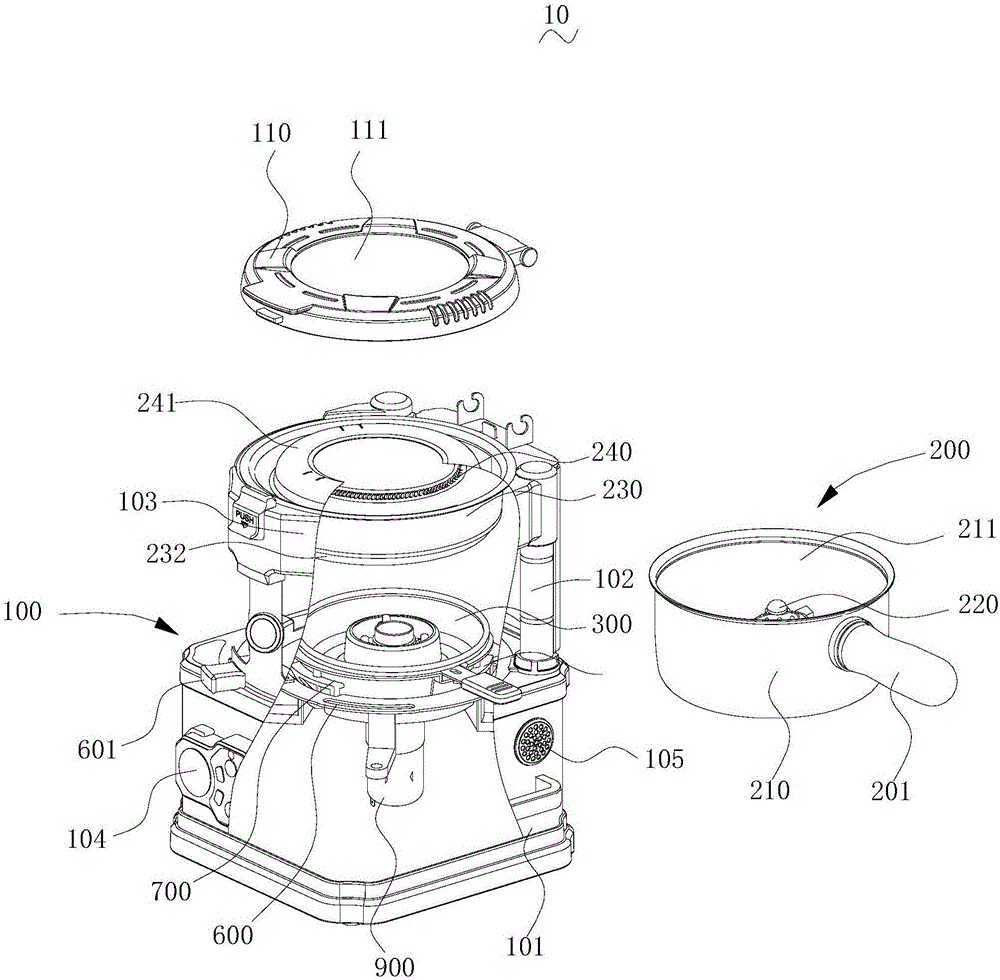

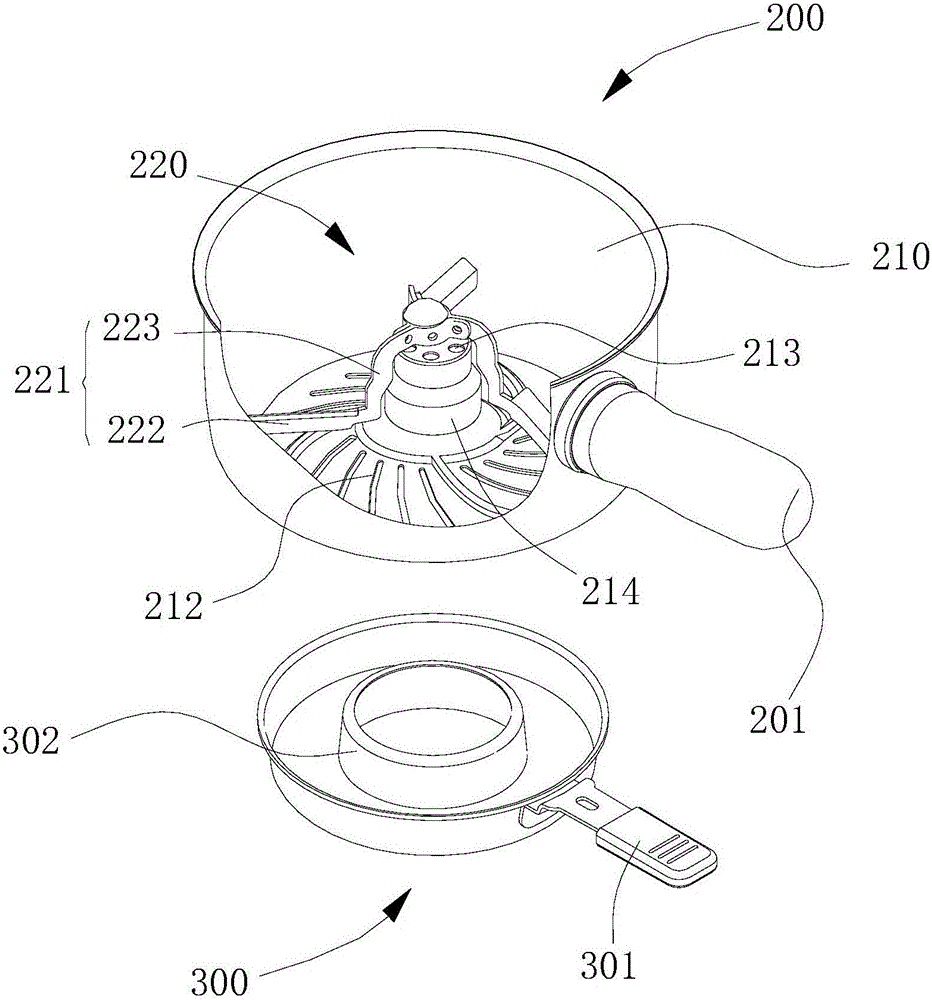

Coffee roasting machine

InactiveCN105935249AImplement automatic cleanupRealize the collectionBeverage vesselsFood treatmentDrive motorEngineering

The invention relates to a coffee roasting machine which comprises a head cover, a rack, a roasting heater, a roasting container and a bean shell storing container. The roasting container and the bean shell storing container are detachably arranged on the rack, the roasting container comprises a container body and a stirring component, the roasting heater is connected with the container body, the stirring component is used for being connected with a drive motor and rotatably arranged in the container body, the container body is provided with an opening, the head cover movably covers the opening of the container body, the end, far away from the opening, of the container body is provided with multiple material discharging channels, and the bean shell storing container is arranged at the end, provided with the material discharging channels, of the container body. When the roasting heater conducts heating to roast coffee beans in the roasting container, the coffee beans are rotated by means of the stirring component, bean shells and coffee beans are separated, the separated bean shells drop into the bean shell storing container though the material discharging channels, automatic cleaning and collecting of the bean shells in the roasting process are achieved, and therefore the roasting efficiency is improved.

Owner:洪英玉

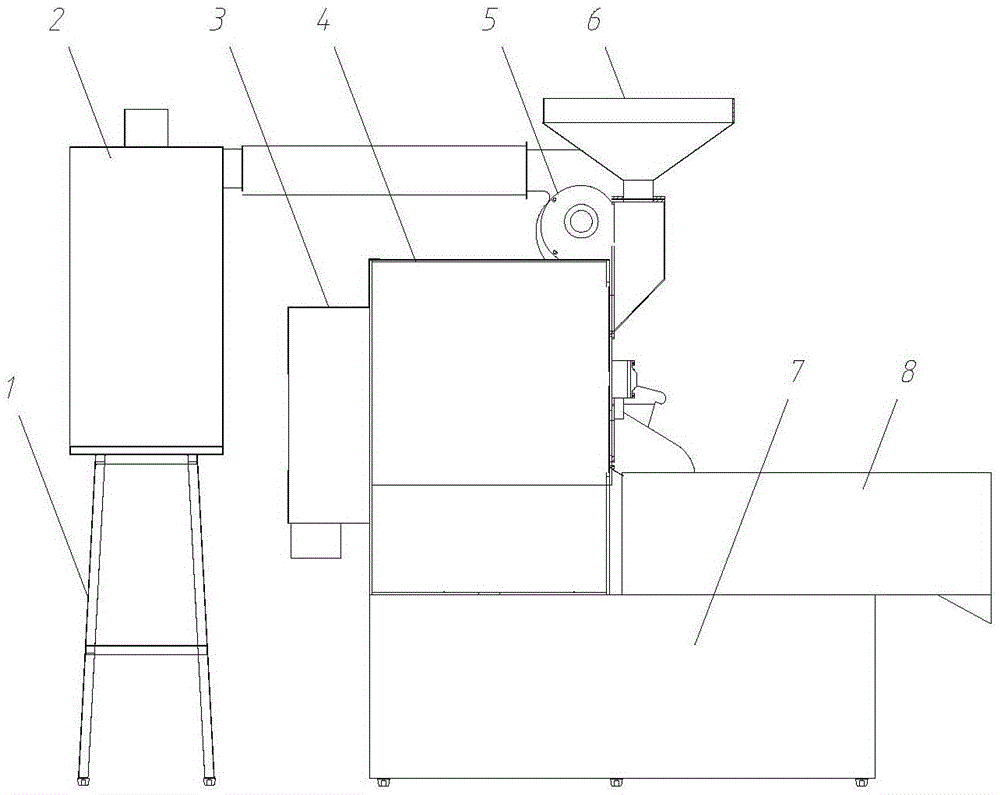

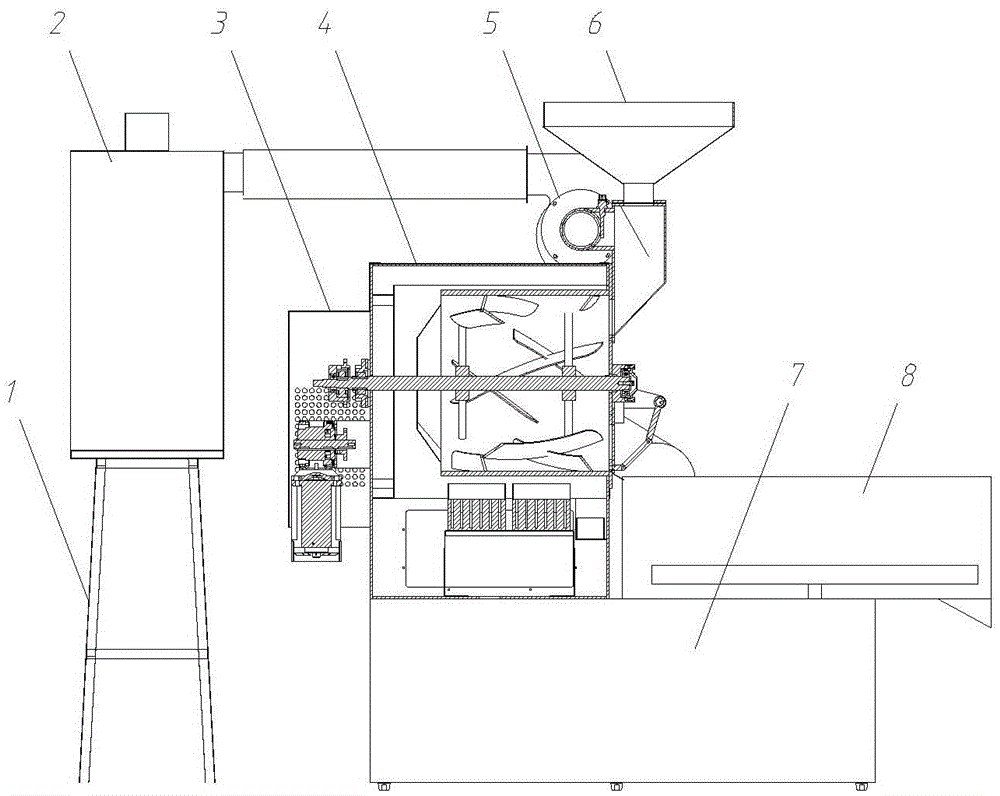

Half-direct-fire and half-hot-wind coffee bean baker and baking method thereof

The invention discloses a half-direct-fire and half-hot-wind coffee bean baker and a baking method thereof and relates to the technical field of production equipment. The coffee bean baker comprises a bottom support, a silver-skin collector, a gap regulating valve, a hopper, a roller, a driving device, a fire grate, a base and a cooling device. Through a half-direct-fire and half-hot-wind baking mode of the coffee bean baker, heat can be better circulated internally and utilized fully, and coffee beans with good taste can be baked in short time; the defects of heat loss and gradually increasing temperature on the outer wall of a baking oven are overcome; the running mode of heat in a baking environment of the coffee bean baker is changed, coffee beans with better taste are baked in short time, processing time is shortened for customers, and baking efficiency is improved.

Owner:ZHENGZHOU HAORAN MACHINERY EQUIP CO LTD

Operation method for baking scrap steel in converter

InactiveCN112280927AReduce harmShort baking timeManufacturing convertersProcess efficiency improvementProcess engineeringIndustrial engineering

The invention discloses an operation method for baking scrap steel in a converter. The method includes the following processing steps that preparation work is performed, specifically, the converter, scrap steel and a coal oxygen lance are prepared; Step 1, the coal oxygen lance is moved to a working position, igniting is performed in an ever-burning fire position of an oxygen lance opening, and then descending to a waiting position is performed; Step 2, two troughs of the scrap steel are added to the converter, the converter is shaken back and forth for 3-5 times to uniformly distribute the scrap steel, and then the furnace is shaken right, the opening degrees of coal gas and oxygen are adjusted to specified parameters, and it is judged that flames are normal. According to the method, thescrap steel is used in the converter special steel workshop, the specially-made coal oxygen lance is used, the purposes of short baking time, much scrap steel ratio increase, furnace lining damage reduction, baking efficiency improvement, consumption reduction and the like can be achieved, the opening degree change parameters, process lance position change and the like of a process adjusting valveare defined, through the baking method, the scrap steel ratio can be increased to 30% or above, the scrap steel baking time can be controlled within 10 min, efficient baking is achieved, and the process production rhythm is basically not affected.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com