A food baking device

The technology of a food baking device and a fire exhaust pipe is applied in the directions of baking bread devices, household appliances, applications, etc., which can solve the problems of moisture loss and poor taste of bread, and achieve the effects of improving taste, improving efficiency and reducing baking time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

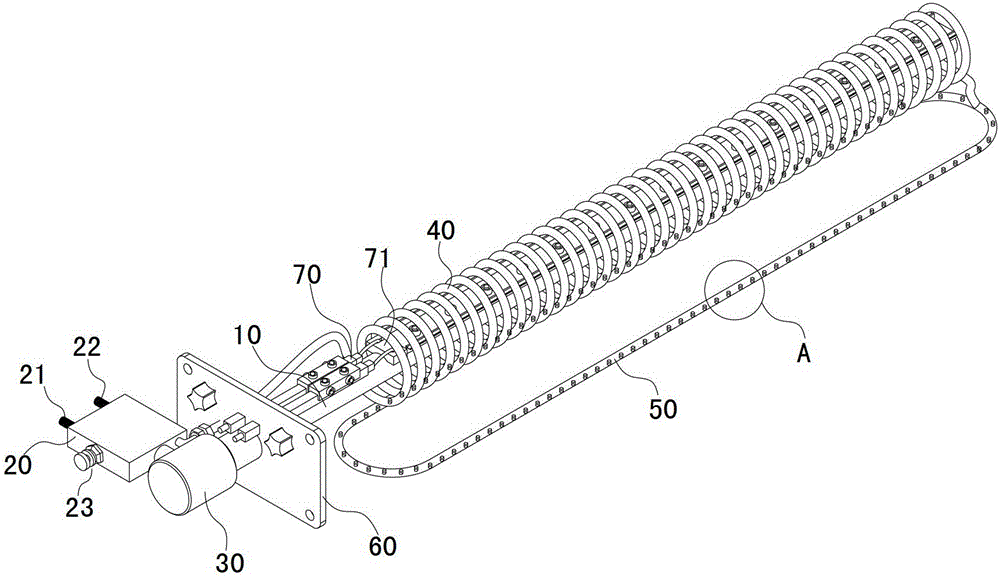

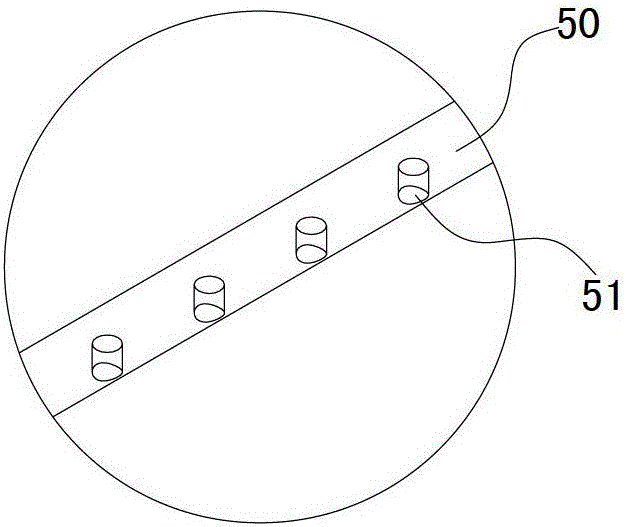

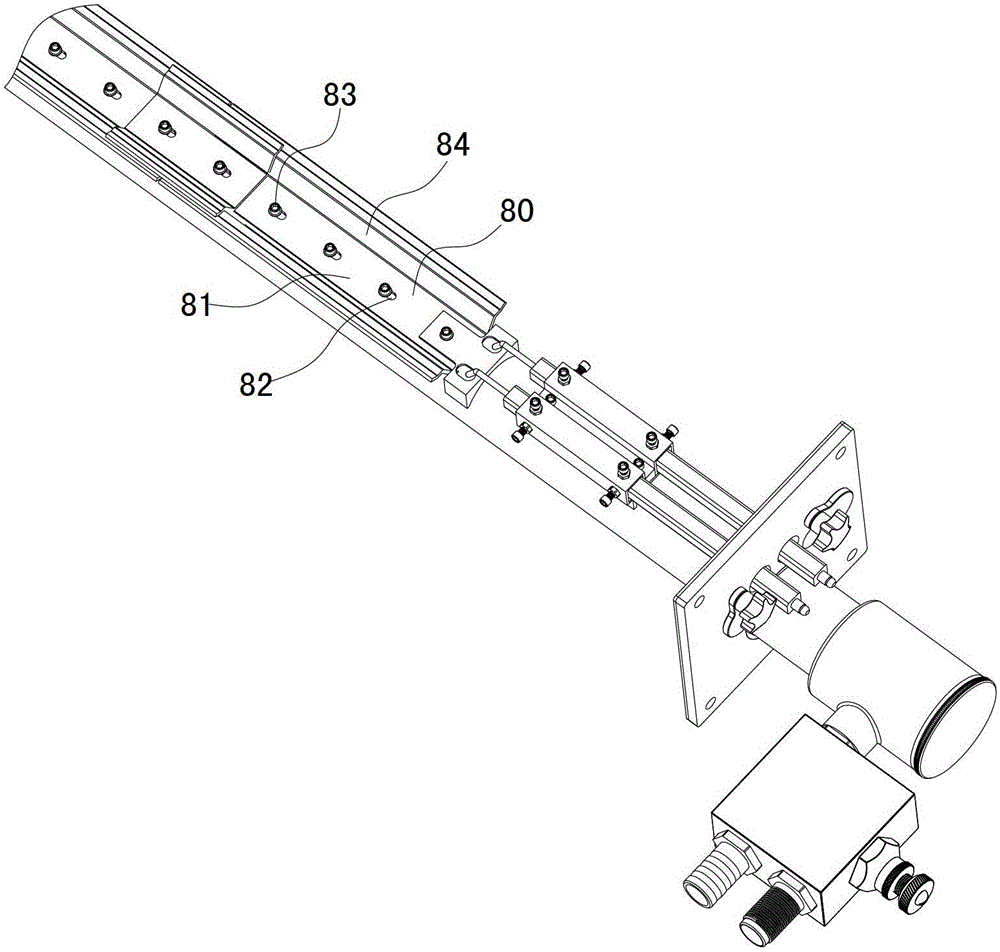

[0023] see figure 1 , 2 3. The food baking device of the present invention comprises a fire pipe 10, a steam pipe 40, and a baking pipe 50, wherein the fire pipe 10 is a pipeline with a larger diameter, one end of which is open, and the other end is a blind end. The open end of the fire exhaust pipe 10 is used to input gas and air into the lumen of the fire exhaust pipe 10, and the inside of the lumen of the fire exhaust pipe 10 forms a combustion chamber for accommodating a mixture of gas and air. The gas and air entering the opening of the fire exhaust pipe 10 are fully mixed in the combustion chamber, and a plurality of flame injection holes (not shown) are opened on the wall of the fire exhaust pipe 10. 10 are arranged in the lengthwise direction. The steam pipe 40 is in a spiral shape, and it is wound around the periphery of the fire pipe 10 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com