Patents

Literature

10737results about How to "Easy to eat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

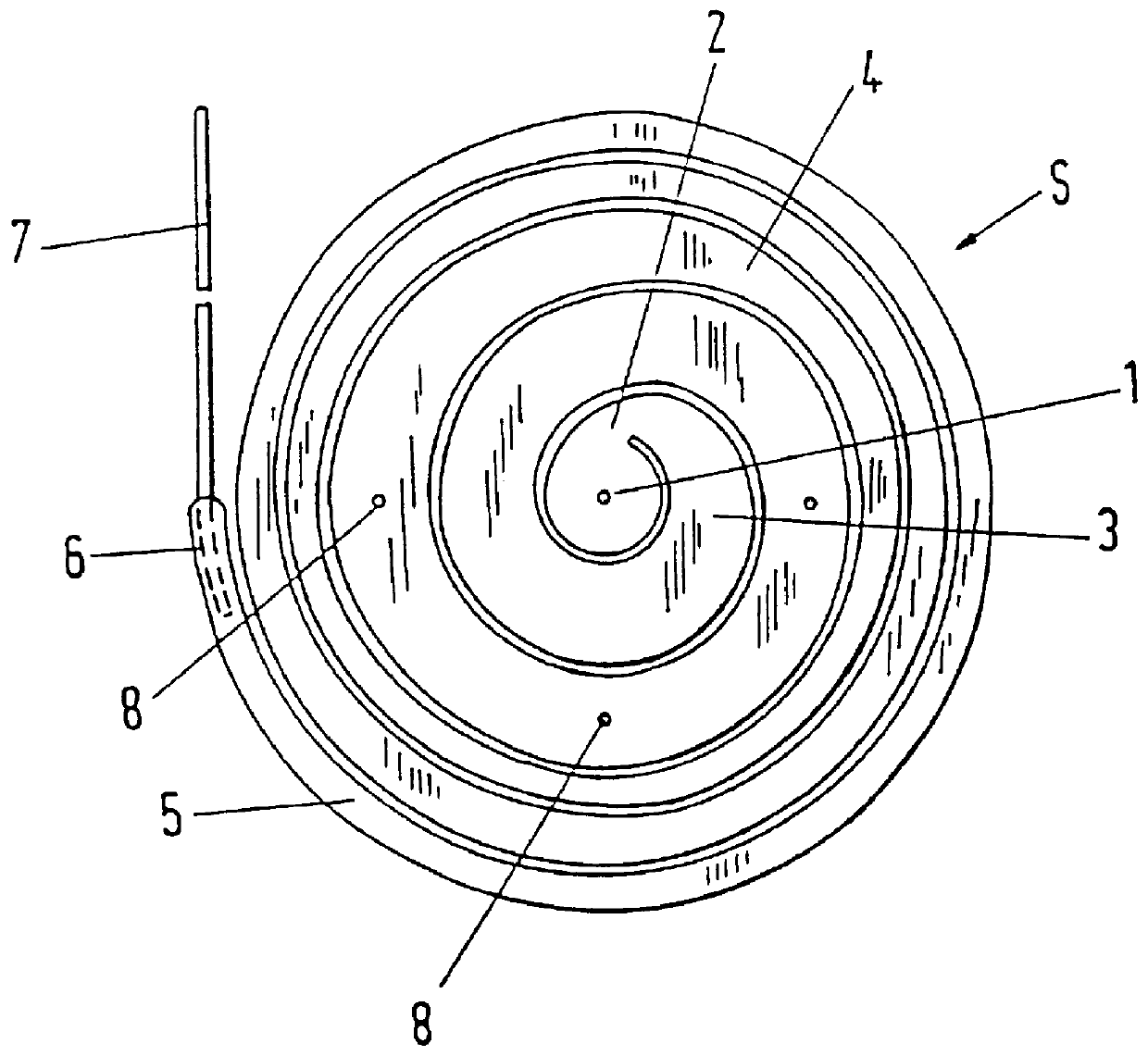

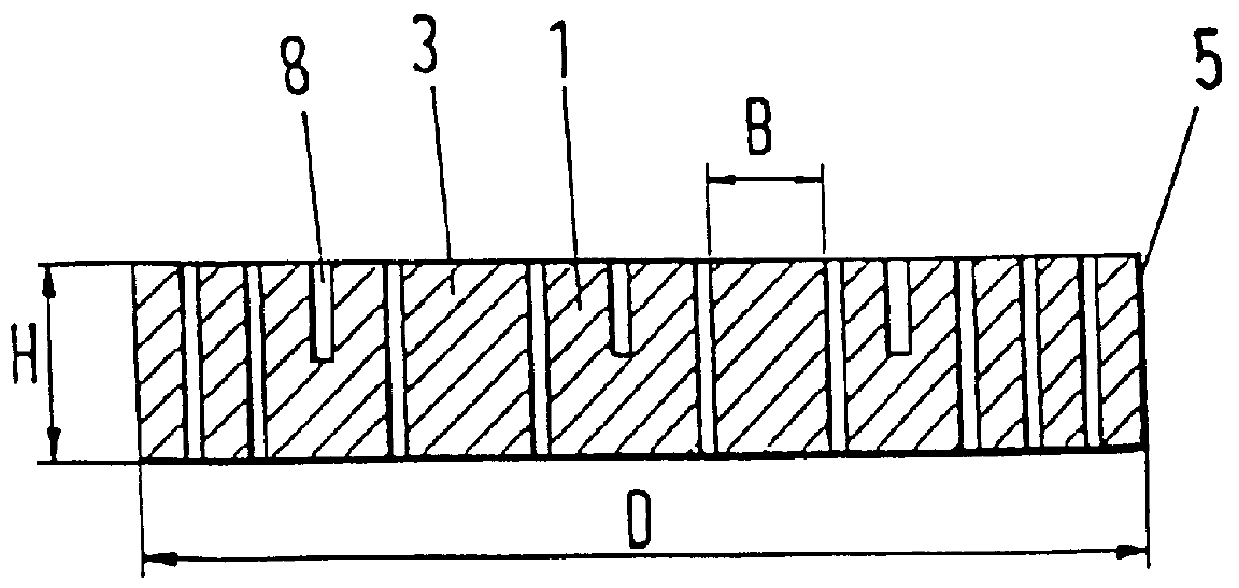

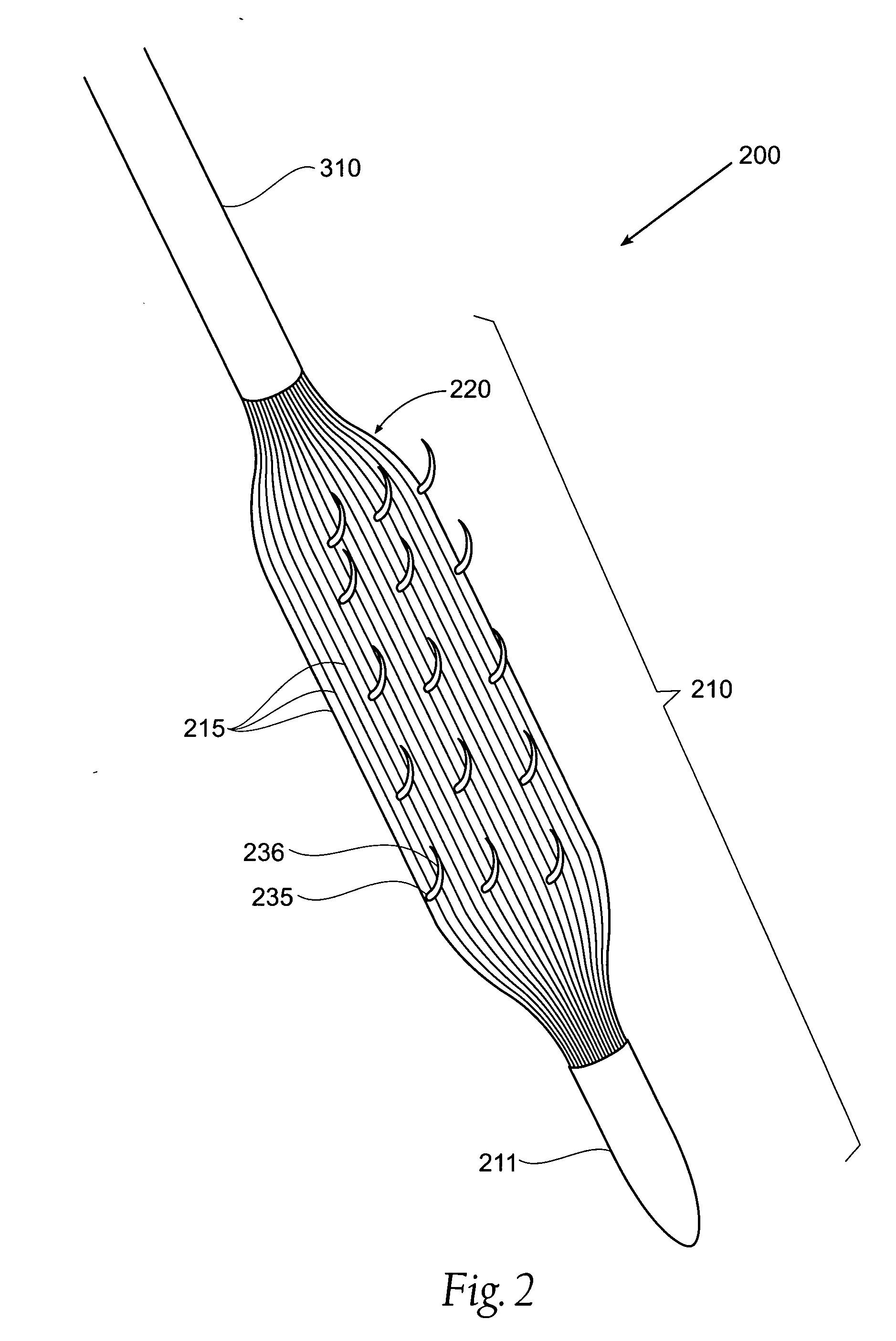

Intervertebral prosthesis

InactiveUS6165218AEvenly distributedCanting of the elastic body is preventedSurgical scissorsJoint implantsInterior spaceIntervertebral disc

An implant, in particular an intervertebral prosthesis, which consists of an elongated elastic body which is form-elastic and takes on the form of a spiral S in the force free state. The spiral can be drawn by a reverse winding up into an insertion instrument which is only insubstantially larger in the insertion region than the cross-section of the elongated elastic body in order to reach the inner space of an intervertebral disc through a small opening in the annulus fibrosus and to push in and sever off the self winding spiral when the interior is filled. This has the advantage that inner spaces of differing sizes can be filled with the same spiral.

Owner:ZIMMER GMBH

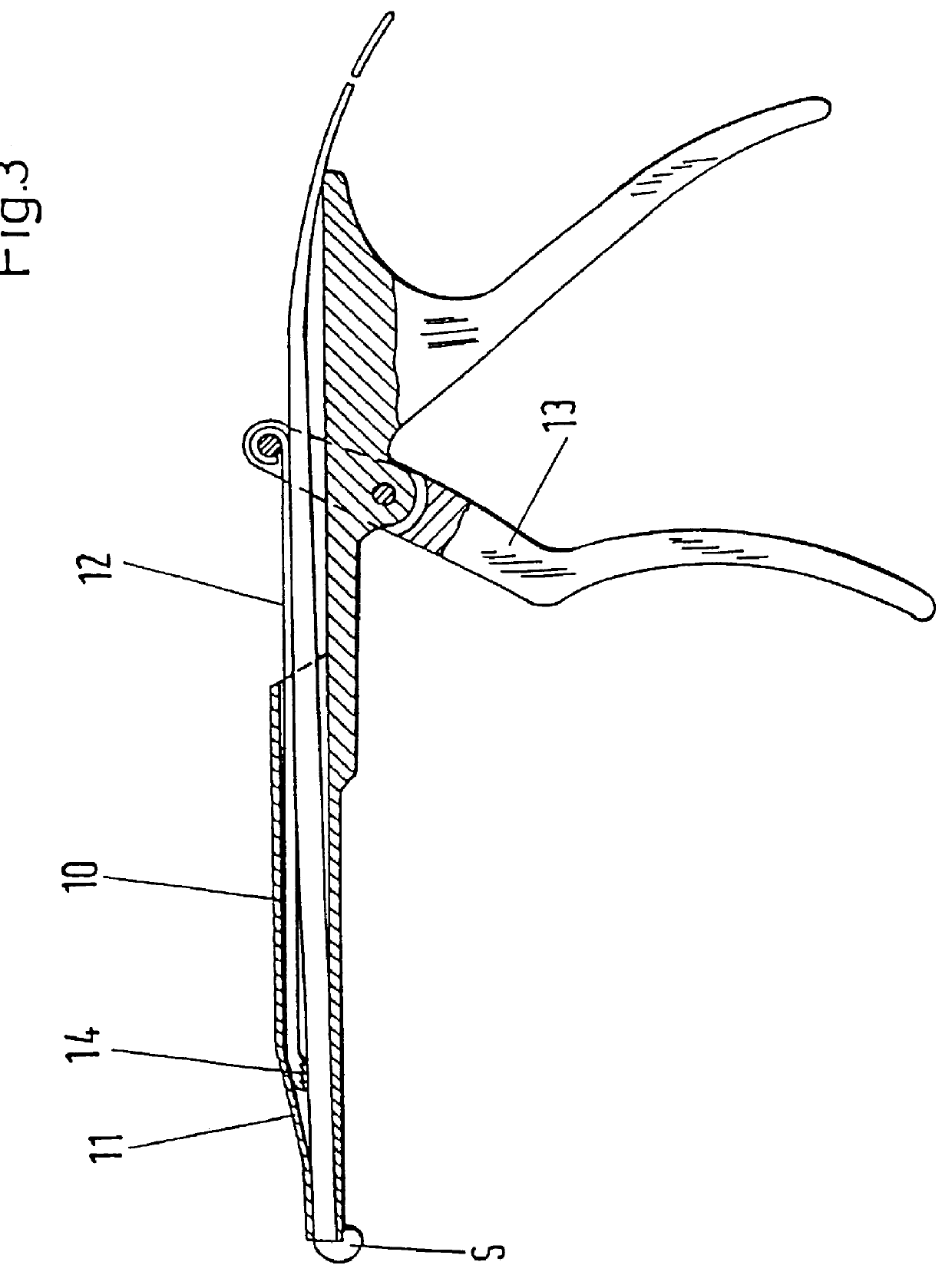

Surgical weight control device

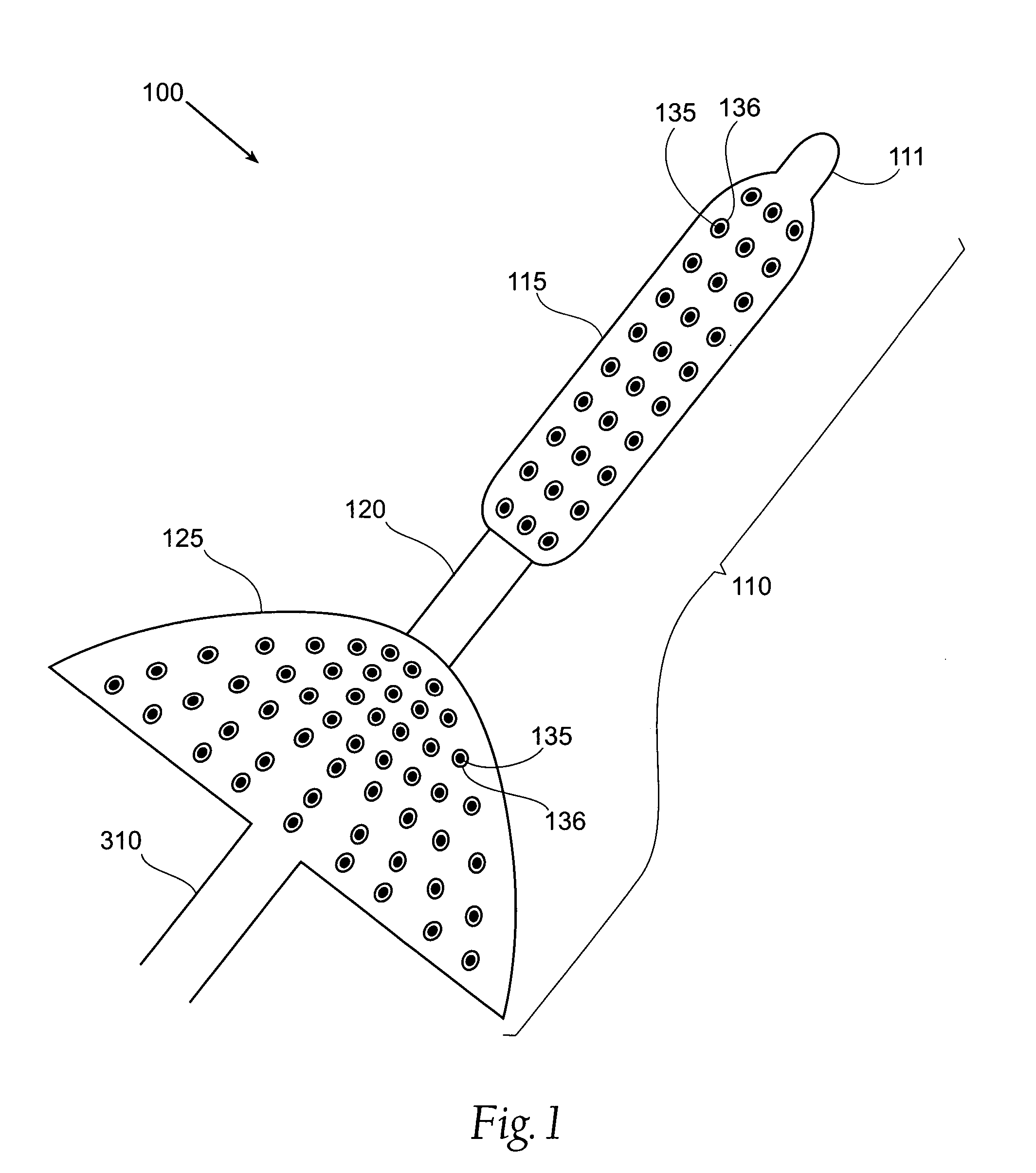

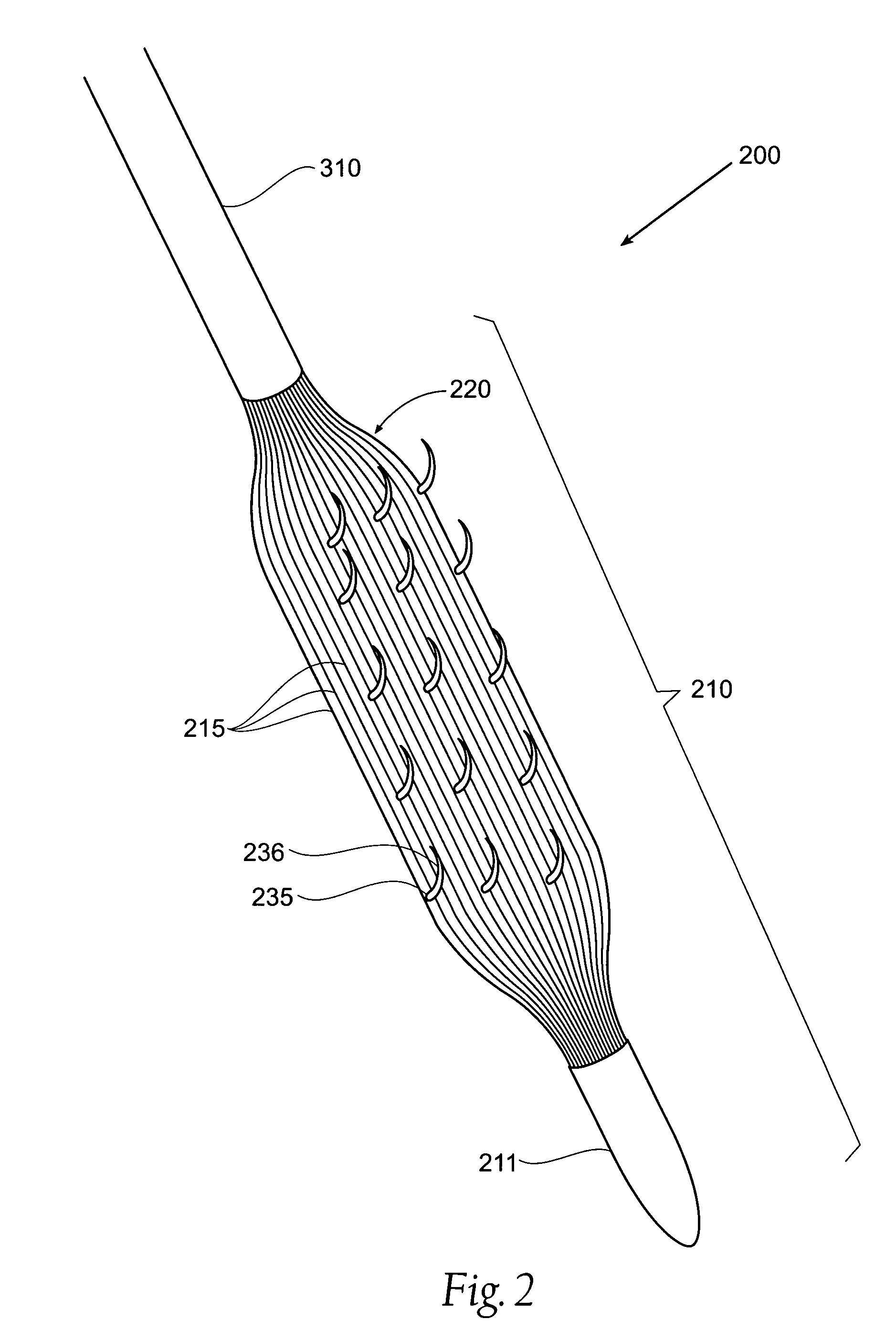

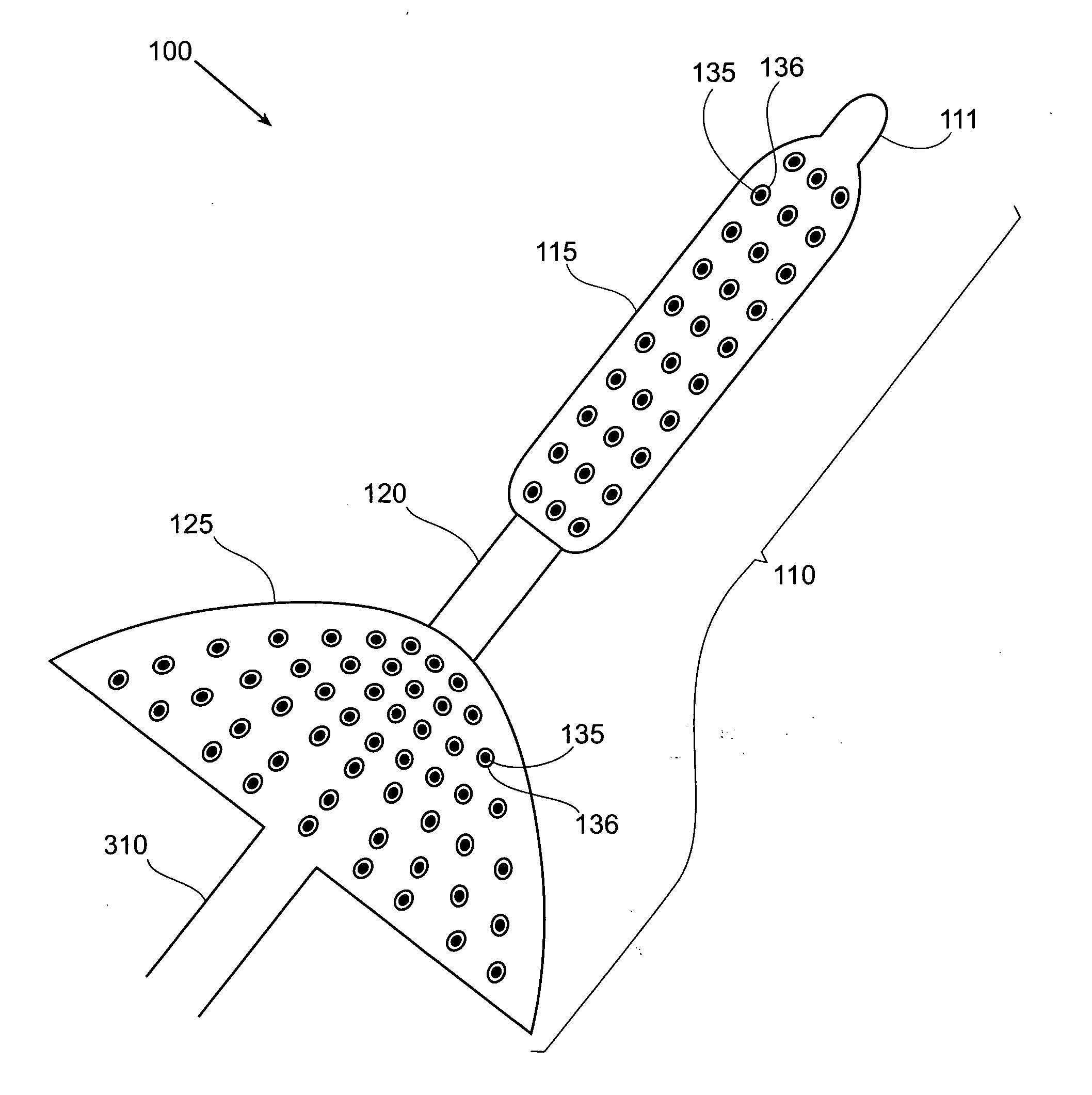

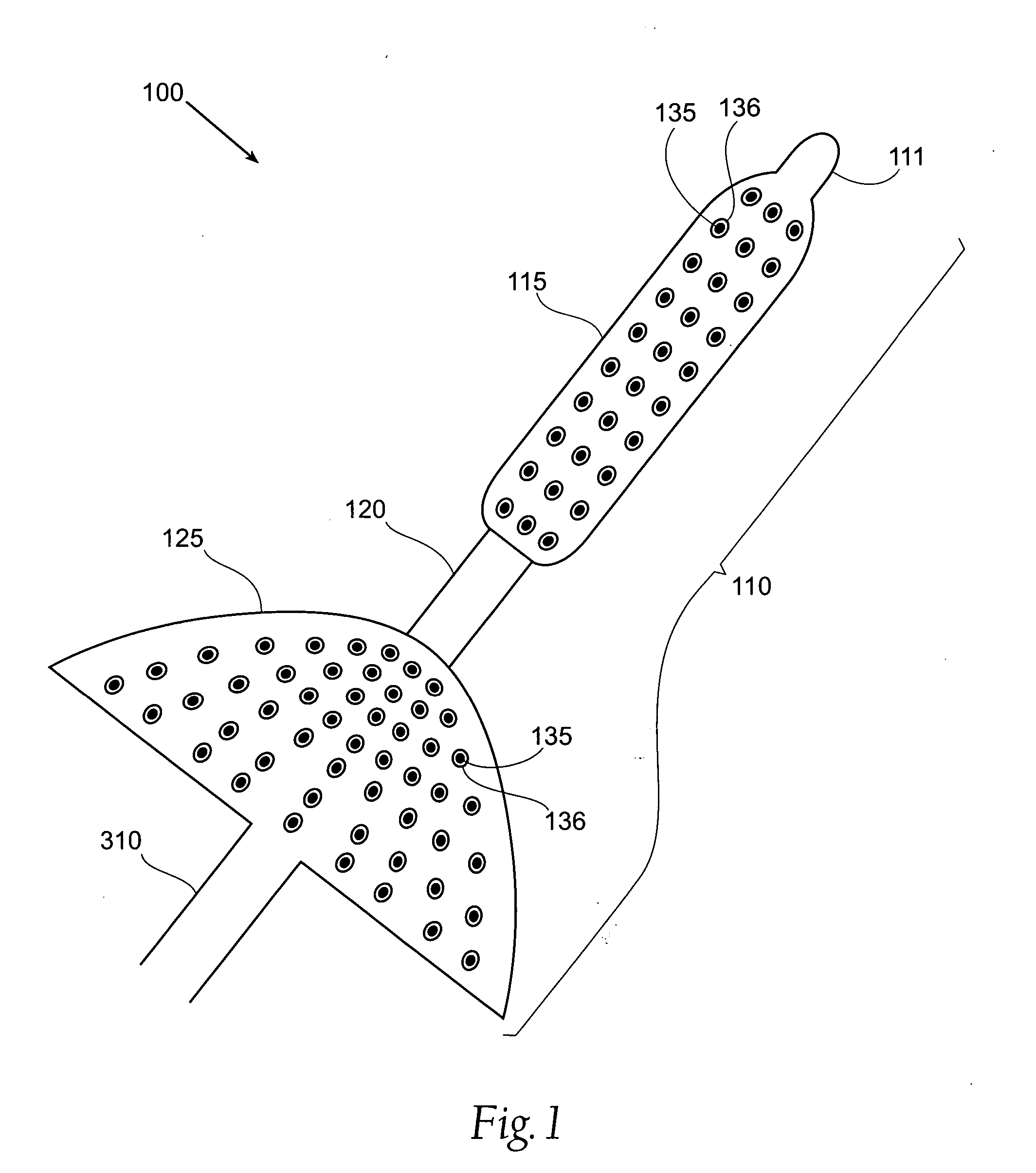

InactiveUS7326207B2Optimize quantityEasy to eatStentsBalloon catheterCurative treatmentPhysical therapy

This invention provides a method and system for the curative treatment of obesity. A first aspect of this invention is that it enables identification of the nerves responsible for the relaxation of the stomach muscles that occurs prior to and during eating. A second aspect of the invention is that it allows the physician to identify focal nerve sites in the stomach and upper duodenum that are associated with producing sensations of hunger and satiety. Nervous transmission from these sites can be modulated or blocked all together so as to minimize the sensation of hunger. A third aspect of this invention is that allows a physician to shrink selected portions of the innermost oblique muscle and middle circular muscle layers of the stomach. This can be performed in a physician's office using local anesthesia. Shrinkage of these muscles produces a feeling of satiety that enhances the patient's efforts to restrict his caloric intake.

Owner:MEDERI RF LLC

Surgical weight control device

InactiveUS20050183732A1Great quantityFacilitate feeding processStentsBalloon catheterCurative treatmentInferior oblique muscle

This invention provides a method and system for the curative treatment of obesity. A first aspect of this invention is that it enables identification of the nerves responsible for the relaxation of the stomach muscles that occurs prior to and during eating. A second aspect of the invention is that it allows the physician to identify focal nerve sites in the stomach and upper duodenum that are associated with producing sensations of hunger and satiety. Nervous transmission from these sites can be modulated or blocked all together so as to minimize the sensation of hunger. A third aspect of this invention is that allows a physician to shrink selected portions of the innermost oblique muscle and middle circular muscle layers of the stomach. This can be performed in a physician's office using local anesthesia. Shrinkage of these muscles produces a feeling of satiety that enhances the patient's efforts to restrict his caloric intake.

Owner:MEDERI RF LLC

Food material mixed with rhizopus oligosporus and preparation method of food material

InactiveCN104719780AEliminate cumbersomenessEasy to manufactureFood preparationRhizopus oligosporusFood material

The invention relates to a food material mixed with rhizopus oligosporus and a preparation method of the food material. The food material comprises the following components in parts by weight: 80 to 99.999 parts of food materials, 0.001 to 20 parts of rhizopus oligosporus and 0 to 150 parts of water. By adopting the food material and the preparation method, the prepared food material mixed with the rhizopus oligosporus can be provided for consumers and can be directly insulated and fermented to obtain a rhizopus oligosporus product by the consumers, so that not only is the production process simplified, but also convenience in eating is realized, meanwhile, the fresh rhizopus oligosporus product can be provided for the consumer, and the rhythm of modern life and the development direction can be satisfied.

Owner:王晓东

Application of bacteroides fragilis in preparation of composition for treating inflammatory bowel diseases

InactiveCN103156888AEnhance pharmacological effectsGood treatment effectMilk preparationBacteria material medical ingredientsPharmacologic actionBowels diseases

The invention relates to the technical field of application of bacteroides fragilis, and in particular relates to application of bacteroides fragilis in preparation of a composition for treating inflammatory bowel diseases. The experiments show that bacteroides fragilis is safe and nontoxic and strong in pharmacologic action, and has good treating effect of treating inflammatory bowel diseases, thereby indicating that the bacteroides fragilis has good edible and medicinal prospects. According to the invention, a novel use of bacteroides fragilis is explored and a novel application field is developed. Bacteroides fragilis as a probiotic can be used for preparing foods or medical compositions for treating inflammatory bowel diseases so as to provide health-cared foods or treating medicines suitable for human body to take.

Owner:广东知光生物科技有限公司

Pressure lowering and lipid lowering sweet corn soup and preparation method thereof

InactiveCN104799176AEasy to storeEasy to eatNatural extract food ingredientsFood ingredient functionsGinkgo bilobaLipid lowering

The invention discloses pressure lowering and lipid lowering sweet corn soup and a preparation method thereof. The pressure lowering and lipid lowering sweet corn soup consists of the following raw materials in parts by weight: 40-50 parts of corn, 10-15 parts of oat, 5-10 parts of leek, 5-10 parts of pawpaw, 5-8 parts of cucumber, 4-6 parts of celery, 5-8 parts of chicken meal, 3-5 parts of coix seed, 3-4 parts of tangerine peel, 2-4 parts of mulberry leaf, 1-3 parts of cochinchinese asparagus root, 2-3 parts of ginkgo leaf, 1-3 parts of gynostemma pentaphyllum, 2-4 parts of medlar, 1-3 parts of egg, 2-3 parts of lactic acid bacteria tablet, 5-6 parts of grape juice and 5-7 parts of nutritional additive. The pressure lowering and lipid lowering sweet corn soup prepared by the invention is convenient to store, carry and eat, can be eaten after a can is opened, contains various nutrient substances, is rich in nutrition, has good mouthfeel, can also lower the lipid and can be eaten by various kinds of people; the formula contains natural plant compositions such as the tangerine peel, the mulberry leaf, the cochinchinese asparagus root and ginkgo leaf; the sweet corn soup has the effects of lowering lipid, lowering pressure, tonifying lung, strengthening spleen, protecting liver and nourishing kidney, can be eaten for a long time, can nourish the five internal organs, improves the immunity and has a health care effect of strengthening the body.

Owner:HEFEI YUEJIE ECOLOGICAL AGRI TECH

High-dietary-fiber nutritional meal replacement powder and processing method thereof

InactiveCN104757545ARich in vitaminsComprehensive Mineral NutrientsFood preparationFiberMeal replacement

The invention discloses high-dietary-fiber nutritional meal replacement powder and a processing method thereof, relates to a meal replacement powder food, and particularly relates to the high-dietary-fiber nutritional meal replacement powder which contains polyunsaturated fatty acids, is rich in nutrition, diversified in mouthfeel, and easy to process, store and eat as well as a processing method thereof. The high-dietary-fiber nutritional meal replacement powder comprises the following raw materials in parts by weight: 3-30 parts of flaxseed powder, 20-60 parts of cereal powder, 10-35 parts of soybean powder, 3-16 parts of dietary fiber powder and 1-15 parts of fruit and vegetable powder. The processing method of the high-dietary-fiber nutritional meal replacement powder comprises the following steps: carrying out hot air drying curing or expansion curing on cereals and soybeans respectively, and crushing at a low temperature to 80-100 meshes for later use; drying flaxseed powder, dietary fiber powder, cereal powder, soybean powder and fruit and vegetable powder, blending in proportion, and mixing evenly; and packaging quantitatively so as to obtain the nutritional meal replacement powder.

Owner:XIAMEN BAIQUAN LIKANG BIOLOGICAL SCI & TECH CO LTD

Various grains composite rice with steady quality and preparation method thereof

InactiveCN101366475AGreat tasteAdjustable structureFood preparationAdditive ingredientThermal stability

The invention relates to food, in particular to minor cereal composite rice with steady quality and a production method thereof. The minor cereal composite rice is characterized in that the minor cereal composite rice is produced through the following steps: five cereals are taken as main raw materials, cucurbits, vegetables and potatoes are added (or are not added), and processes such as raw material pretreatment, mixing and stirring, pelletized molding by adopting a process of 'secondary extrusion, moderate cooking, intermediate supplement, and temperature reduction pelletization', drying, polishing and so on, are performed. The minor cereal composite rice takes the five cereals as the main raw materials, has the appearance and characteristics of rice except that the nutrient component is different from that of the rice, has the advantages of good palatability, smooth surface, compact structure, steady quality, good eating performance, balanced nutrition, strong health care function, washing-free convenience, long storage period, and good thermal stability during the cooking, and can be eaten as staple food like ordinary rice.

Owner:奥生平 +1

Method for fabricating mango potato chips

InactiveCN103976312ANovel tasteNutrition and healthFood preparationMonosodium glutamateBiotechnology

The invention discloses a method for fabricating mango potato chips. The mango potato chips are prepared by the following steps: raw material selection, raw material pre-treatment, slicing, color-protecting, seasoning, frying, packaging and the like. A seasoner is prepared from the following raw materials by weight percent: 15-20% of mango powder, 2-4% of salt, 6-10% of white sugar, 1-2% of aginomoto, 1-3% of yeast extract, 3-5% of mint powder and 2-4% of yam flour. The potato chips prepared by the method are novel in taste, nutrient and healthy, and convenient to eat. The flavor contains Chinese herbal medicinal ingredients, can help digestion, and is good for health. The method is simple in process, the technique is easy to master, therefore, popularization is easy, and industrialized production is also easy.

Owner:ANHUI QUANLI ELECTRONICS TECH

Production technology of barley seedling powder and product thereof

The invention relates to a production process of chewable tablets of barley shoot powder and a product thereof and belongs to the deep processing technology field of agricultural products. The production process is characterized in that the barley shoot powder is main base material, and the chewable tablets of the barley shoot powder with smooth appearance, green color and crispness and freshness is made after the processes of composite stabilizer, making soft material, granulation, drying, tabletting, sterilization and packing. The method has the advantages of simple process, higher industrialization degree, low production cost, realizing the full utilization of the barley shoot and promoting the added value of the barley shoot. The chewable tablets of the barley shoot powder produced by the invention which is leisure-base health care food can fully enhance physique and body immune, simultaneously has the function of catharsis, reducing blood lipid and preventing cerebral thrombosis and coronary heart disease.

Owner:NANJING AGRICULTURAL UNIVERSITY

Method for making dumplings and buns and eating method

The invention discloses a method for making dumplings and buns and an eating method. The process comprises the following steps of: primarily processing raw materials to cut the raw materials into small pieces or not cut the raw materials as required; mixing the primarily processed raw materials and corresponding flavorings and processing the mixture into cooked food or food by conventional cooking technology or food processing technology; picking up foreign matters from the processed cooked food or food, wherein the foreign matters are inedible ingredients or bones; juicing and dicing the food; adding dipping sauce into the food and uniformly mixing the dipping sauce and the food to make stuffing; rolling dough or leaven dough into wrappers; and adding the stuffing into the wrappers to make the dumplings and buns. By using the conventional cooking technology or food processing technology, vegetables and meats are cooked, picked, juiced and chopped to make the stuffing, the stuffing is filled in the wrappers to make the dumplings or buns, and the dumplings or buns are eaten by dipping the special dipping sauce. The method overcomes various disadvantages of the prior art and has the advantages of convenient preparation, convenient eating, unique flavor and capability of meeting the tastes of different groups of people.

Owner:肖卫

Ferment making black garlic method

InactiveCN101120783ASolve the smellSolve the discomfortFood preparationSocial benefitsNutritive values

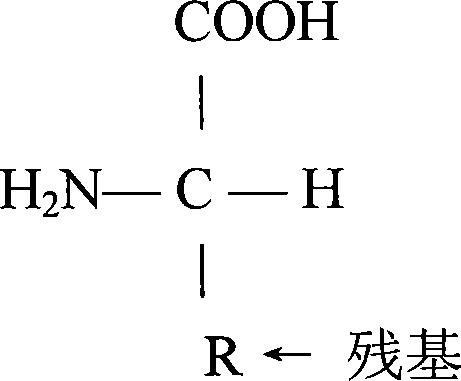

The present invention relates to a black garlic manufacturing method through fermentation, which can effectively solve the problem of peculiar smell or discomfort of garlic. The technical proposal is as following. Firstly, far infrared heating device is used to produce anion. Secondly, garlic is marinated in the garlic fermentation inducing medium. Thirdly, after the garlic is fished out, the garlic is put into the far infrared heating device. Fourthly, the garlic is heated and fermented step by step. And lastly, the black garlic is made. The garlic fermentation inducing medium is made by the following components based on weight-volume percent: salt 8.6 percent, ethanol 4.1 percent, amino acids 3.1 percent, protein 0.6 percent, sugar 12.4 percent, ash content 7.9 percent, lipid 0.02 percent and water for the rest. The present invention has simple method, good garlic processing effect. After procession, the garlic has no peculiar smell, is convenient to eat, has high nutritive value, is used widely, and has great economic and social benefits.

Owner:北村清彦 +1

Application of bacteroides fragilis in preparing composition for preventing and treating colon cancer

InactiveCN103142656AInhibit tumor growthPromote apoptosisMilk preparationBacteria material medical ingredientsBacillus fragilisTumor growth

The invention relates to the technical field of application of bacteroides fragilis, and in particular relates to application of bacteroides fragilis in preparing a composition for preventing and treating colon cancer. Experiments show that bacteroides fragilis induces an organism to generate the anti-tumor effect in vivo, inhibit the tumor growth, accelerate tumor cell apoptosis and prolong the lifetime, so that bacteroides fragilis has a good effect in preventing and treating colon cancer. The invention explores novel use of bacteroides fragilis and develops a novel application field, thereby indicating that the bacteroides fragilis has good edible and officinal prospect. Bacteroides fragilis serving as probiotic can be used for preparing foods or medical compositions for preventing and treating colon cancer so as to provide a clinically health-care and preventing and treating food suitable for human to take.

Owner:广州知光生物科技有限公司

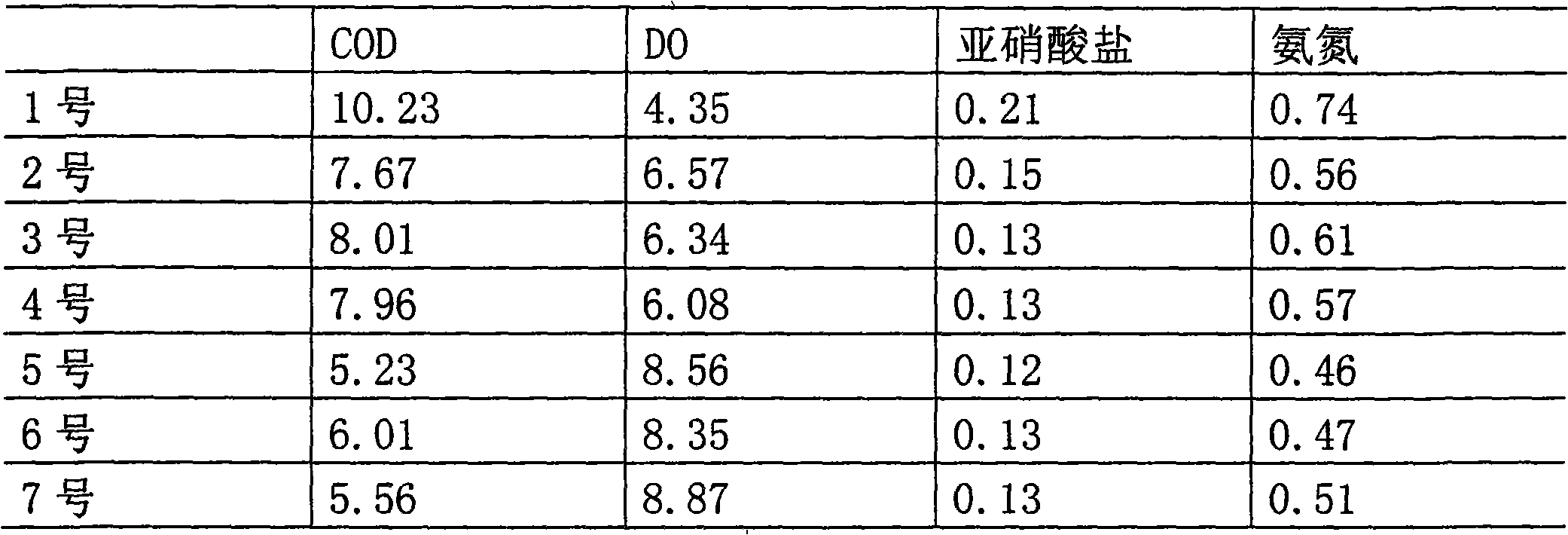

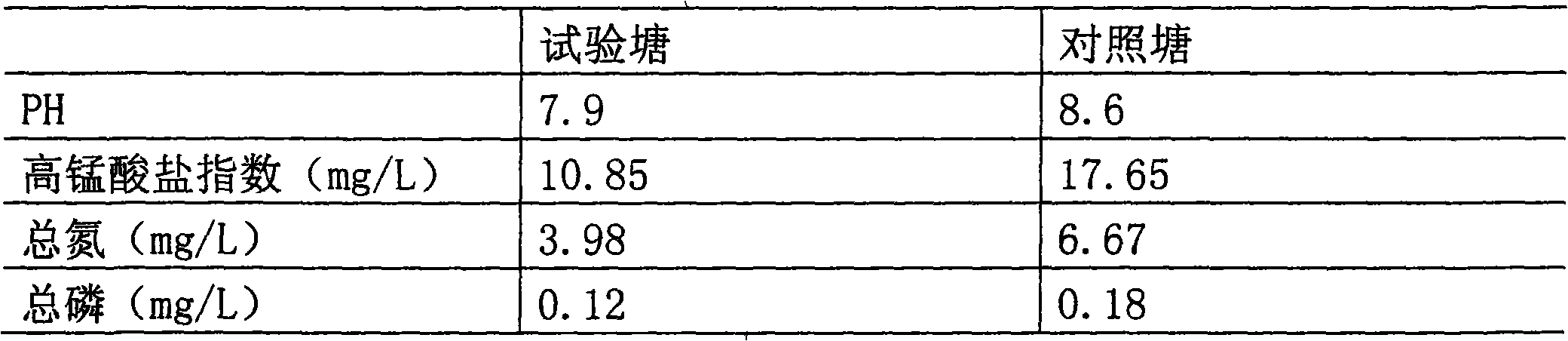

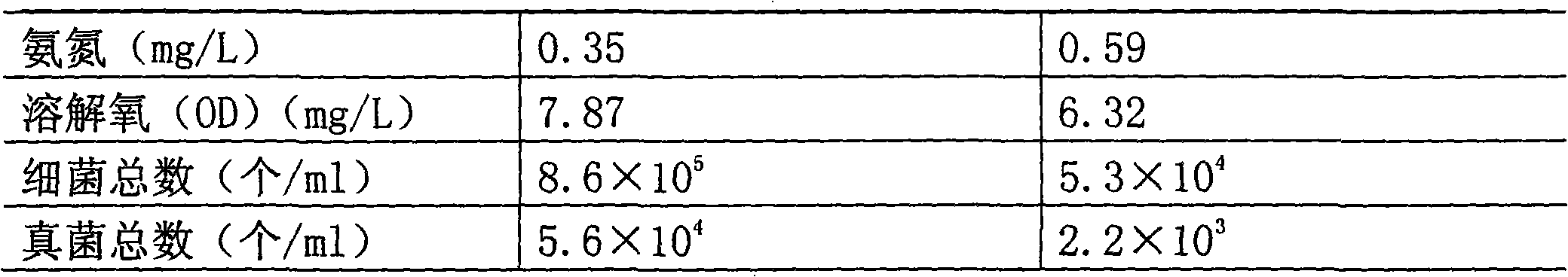

Compound microecologics for purifying water quality

InactiveCN101629157AImprove the environmentImprove water qualityFungiBacteriaBiotechnologyWater quality

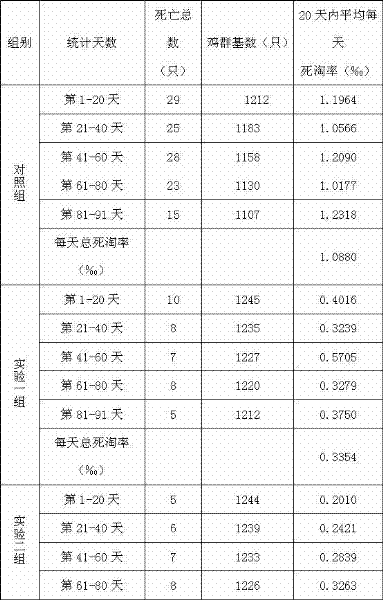

The invention relates to compound microecologics for purifying water quality and a preparation method thereof, belonging to the technical field of applied biotechnology. The method is characterized by conforming to the principle of diversified development of microecologics, utilizing various kinds of beneficial bacteria with different functions, carrying out scientific combination according to the proportion occupied by each kind of bacteria determined by orthogonal experiment, and forming efficient the multifunctional compound microecologics with the functions of intestine environment improvement, eating promotion, harmful bacteria restriction, water quality improvement, and the like. The invention is more characterized in that beneficial bacteria in the invention can be obtained easily at various parent strain markets, liquid fermentation technology is adopted for enlarging culture, and viable breeding accelerator, protective agent, viable absorbent, and the like are added to ensure the stability and the high efficiency of the compound microecologics. The invention solves the problems of unstable product characteristics, unsatisfactory using effect, low viable bacteria survival rate, and the like of microecologics at the current market.

Owner:江苏省江大绿康生物工程技术研究有限公司

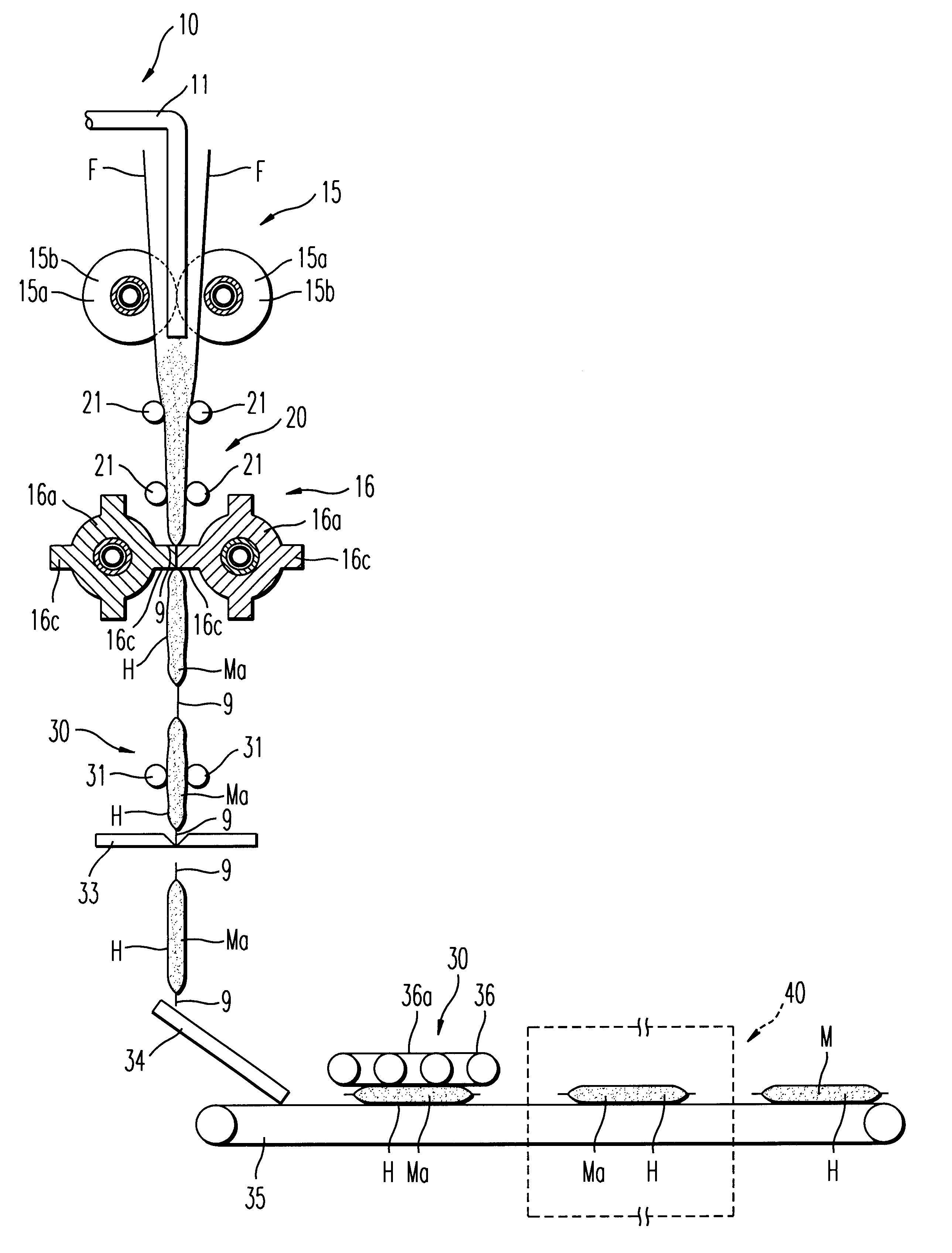

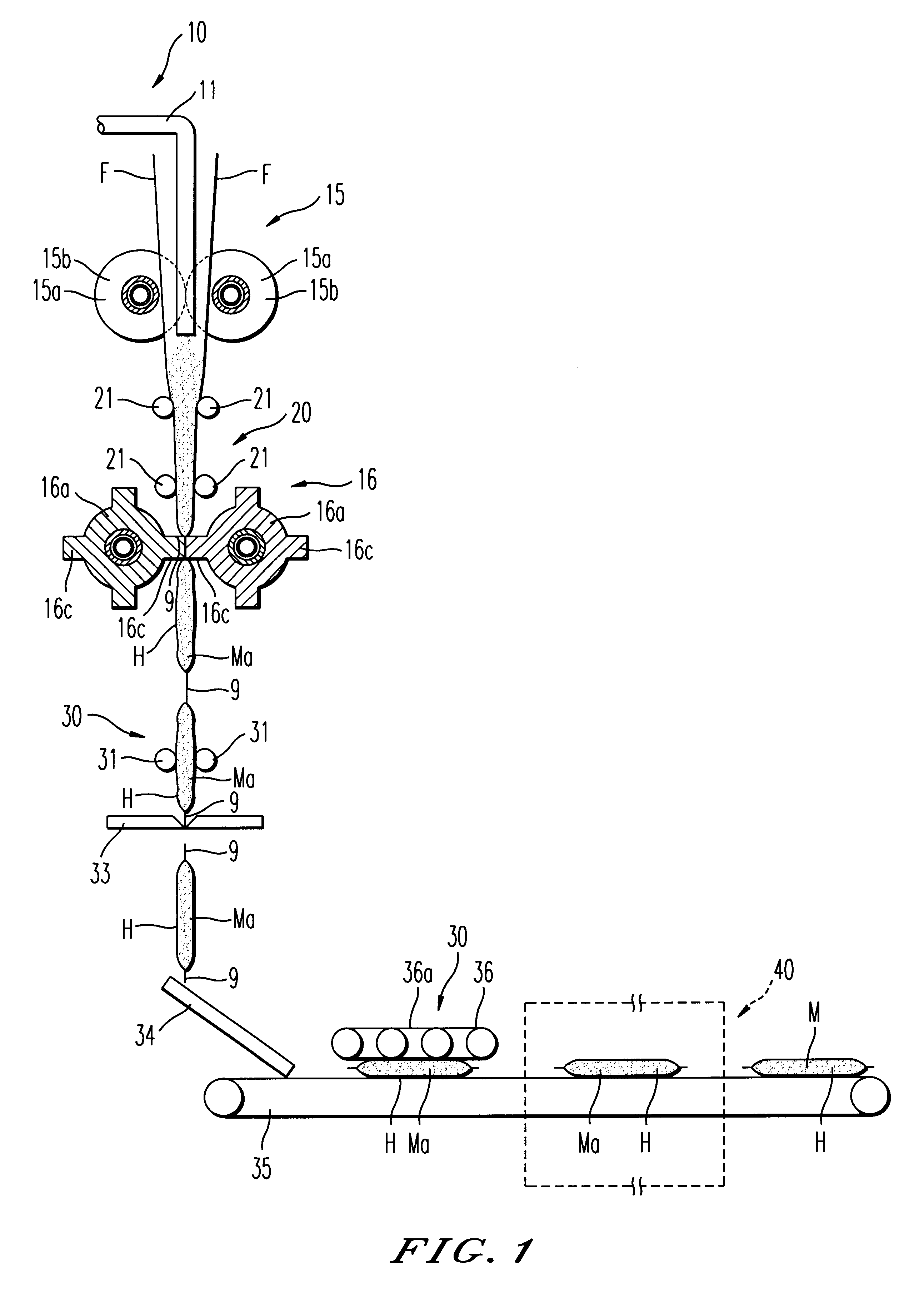

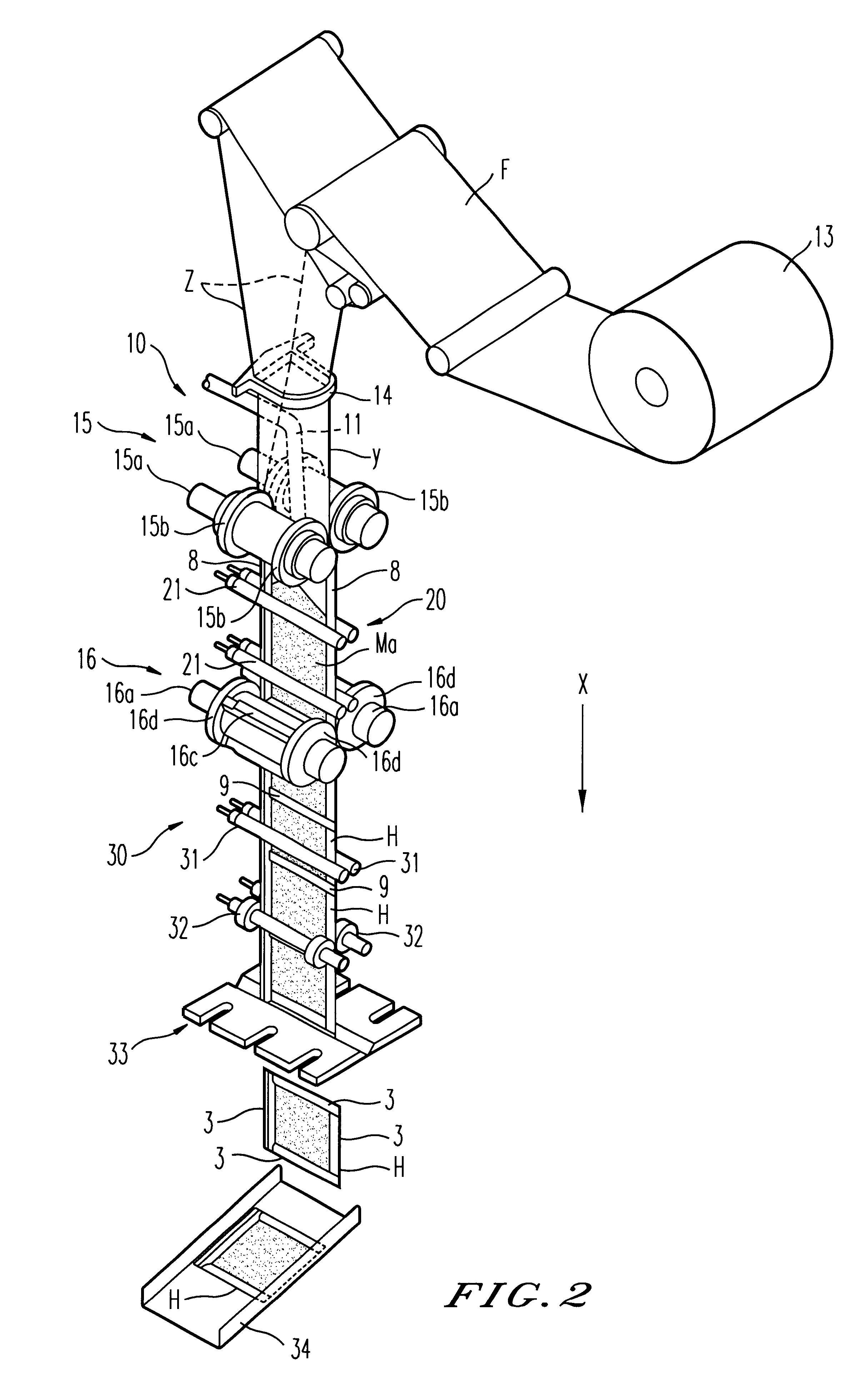

Method of making plate-like frozen raw hamburger-like matter packaged by film

InactiveUS6254911B1Avoid quality changesGive durabilityWrappersConfectioneryMeat burgerMechanical engineering

A method of making a plate-like frozen raw hamburger-like matter includes: a filling step for filling a constitutional material of the raw hamburger-like matter between a first thermal seal a second thermal seal, provided in a direction perpendicular to the conveying direction; a deaerating step of pressing the film so that the filled constitutional material is extended until the second thermal seal is provided; a forming step for forming the plate-like raw hamburger-like matter by equalizing the constitutional matter, therein; and a freezing step for maintaining its shape by rapidly freezing the package bag enclosing the raw hamburger-like matter.

Owner:TERU

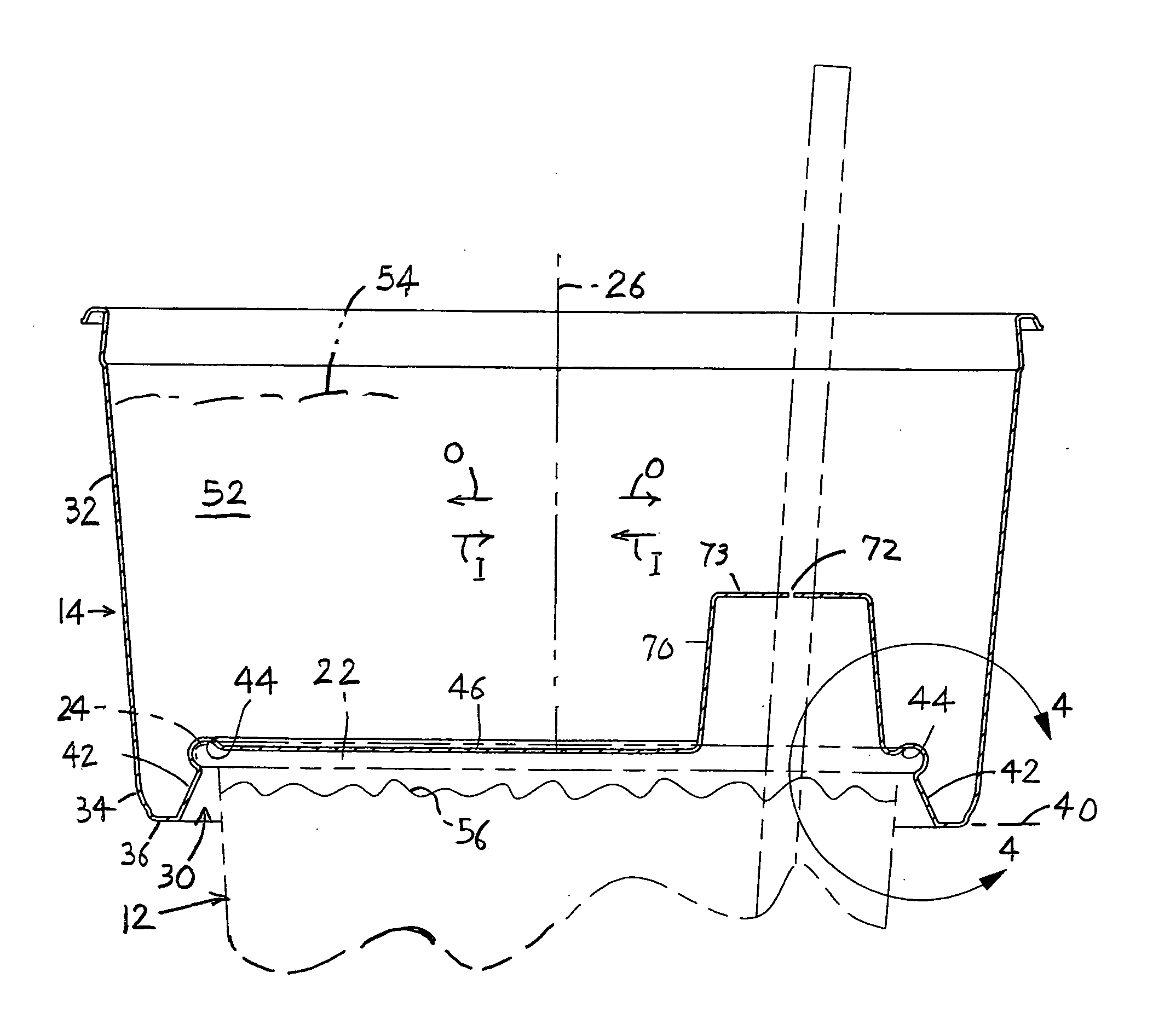

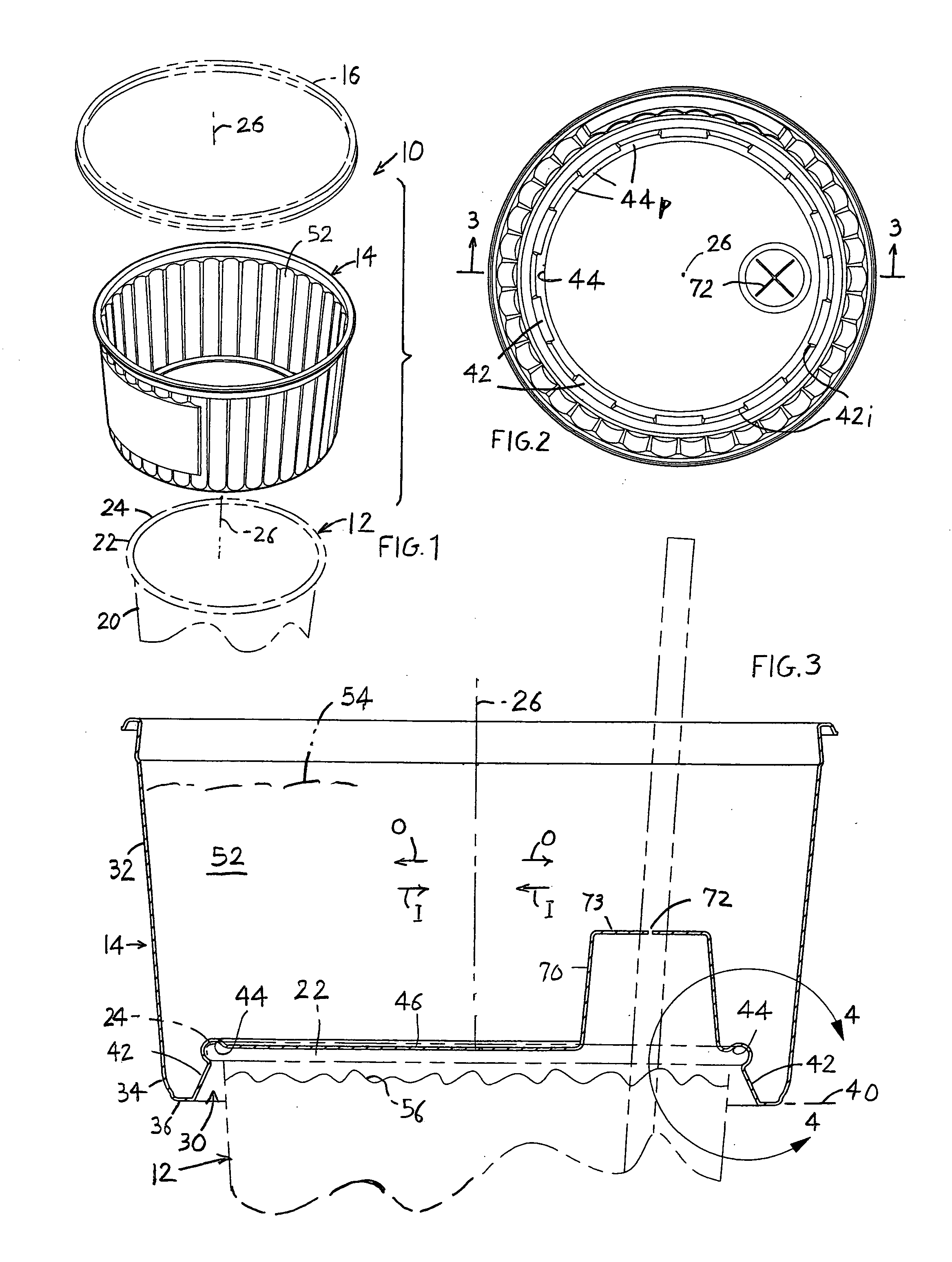

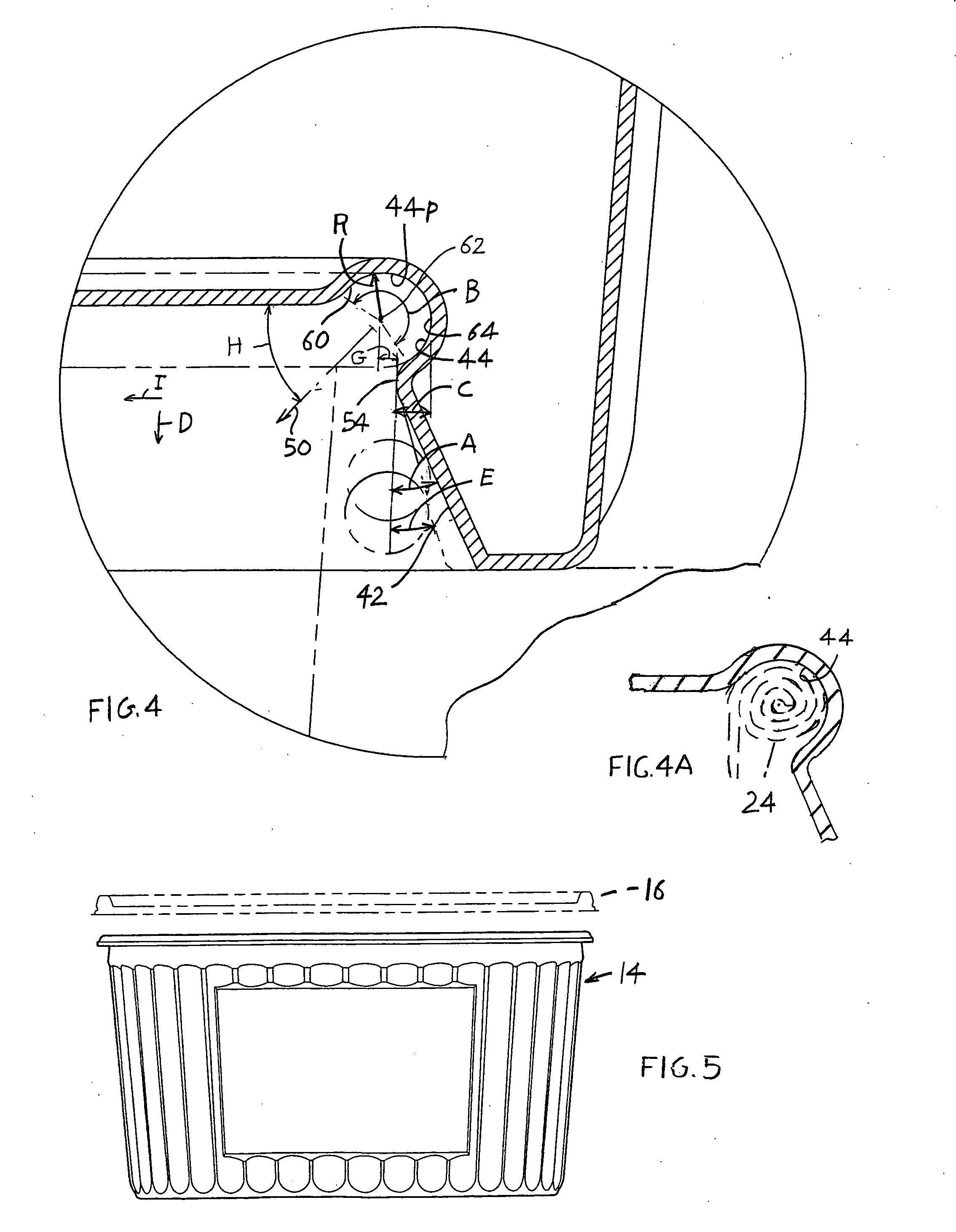

Food container attachable to cup

Owner:VOVAN TERRY

Fermented feed additive, preparation method and application

ActiveCN102550815ASlow down digestionPromote digestion and decompositionFood processingAnimal feeding stuffMonosodium glutamateBacillus licheniformis

The invention discloses a fermented feed additive, a preparation method and application thereof. The fermented feed additive is prepared by fermenting mixed strains and mixed auxiliary materials consisting of monosodium glutamate protein, bean pulp, bran, cottonseed meal, corn fibers, rice bran and powdered rice hulls, wherein the mixed strains are obtained by mixing activated strains of lactobacillus acidophilus, lactobacillus planetarium, lactobacillus casei, saccharomyces cerevisiae, bacillus subtilis and bacillus licheniformis in a proportion of (1-5): (1-5): (1-5): (1-5): (1-5): (1-5); and the dosage of the fermented feed additive is 5 to 100 percent of the weight of the animal feed when used for the animal feed. According to the fermented feed additive, the bean pulp, the bran, the cottonseed meal and other raw auxiliary materials are sufficiently utilized, so that the food consumption in the animal feeding process is reduced; the fermented feed additive can be used to partiallyor completely replace the animal feed, and antibiotic medicaments can be reduced or prevented from being used; and no medicament is left, so that the feeding cost of farmers is reduced.

Owner:WEIFANG ZHONGKEJIAYI BIO FODDER TECH

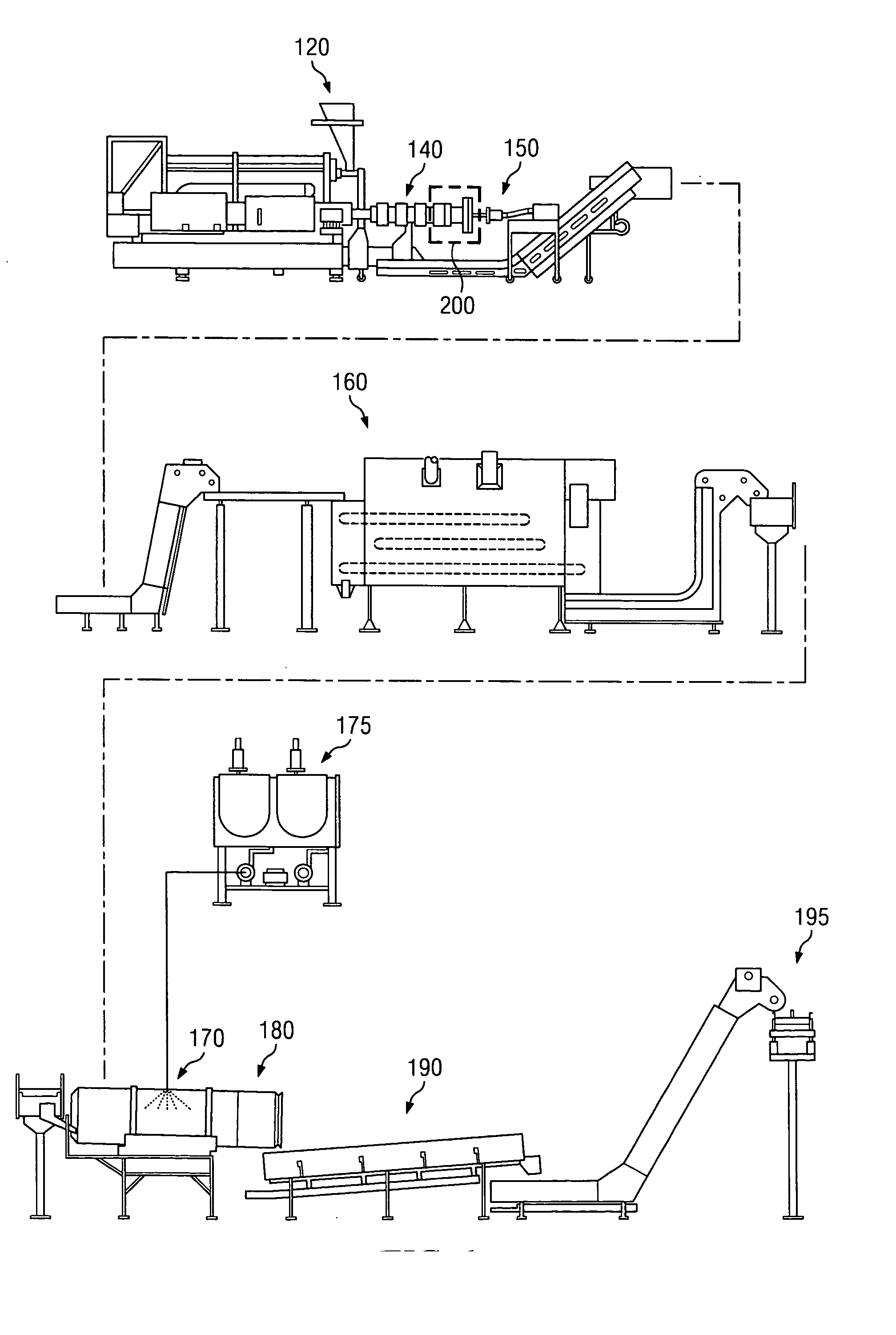

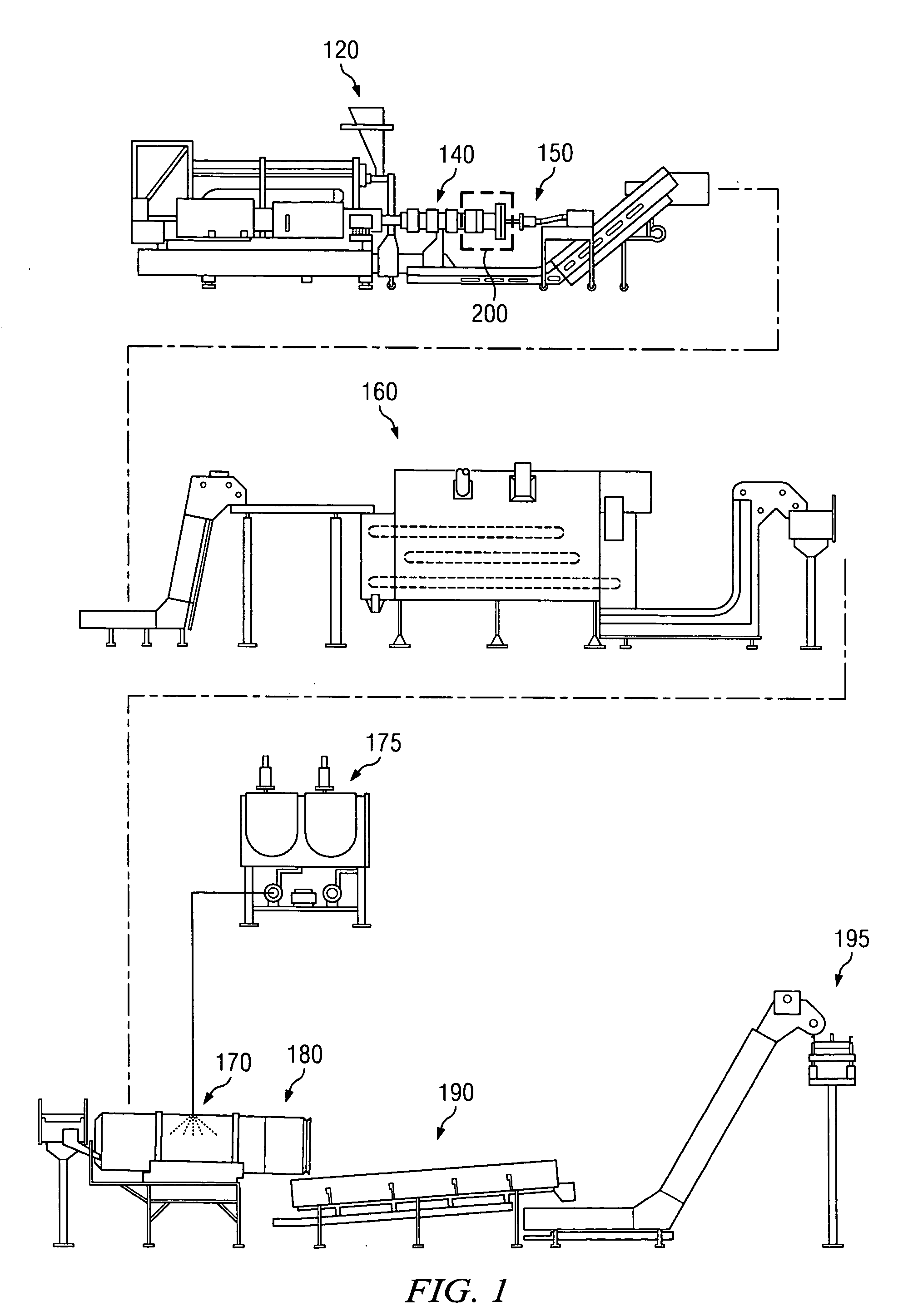

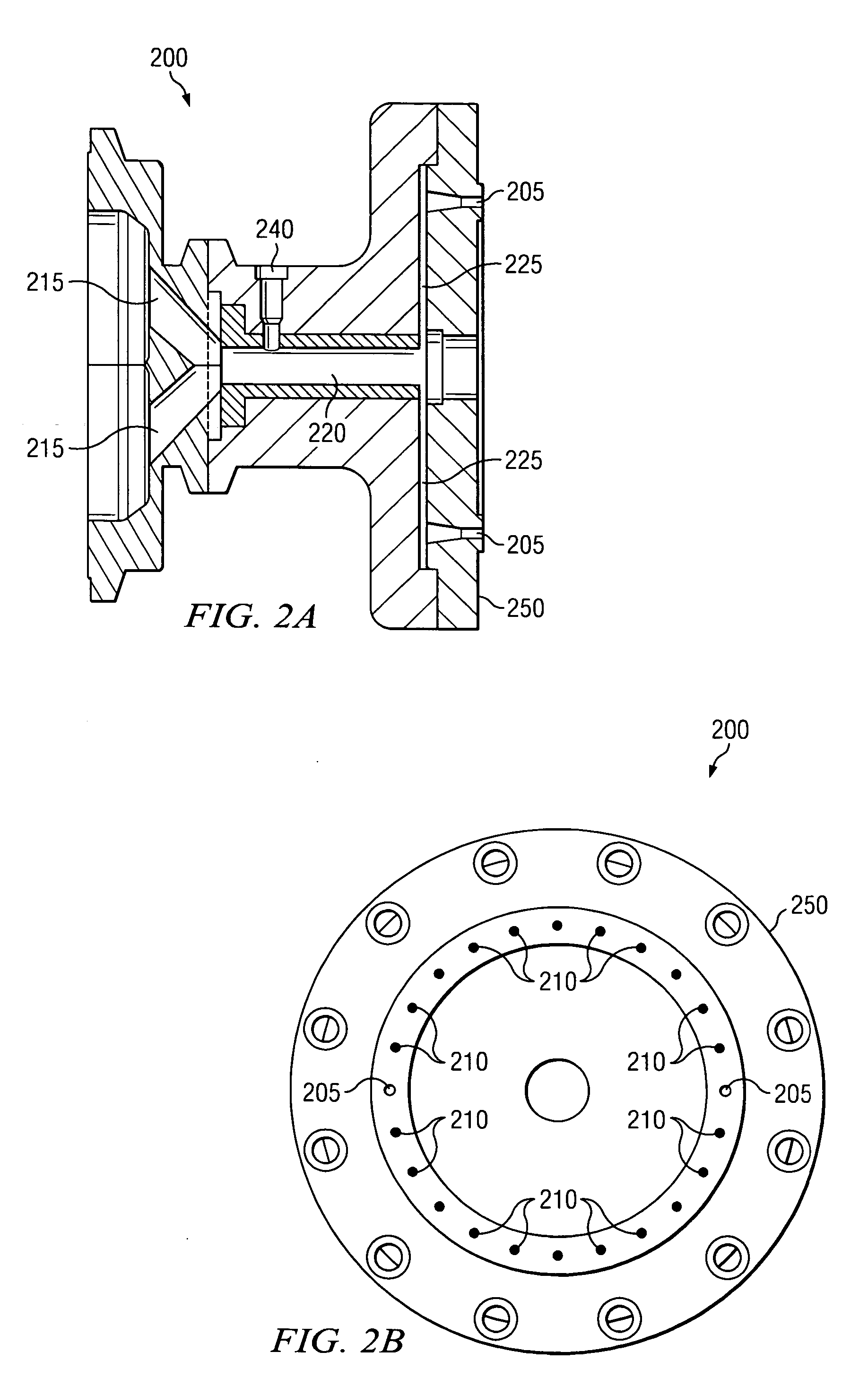

Low carbohydrate direct expanded snack and method for making

A method for making a low carbohydrate high protein puffed snack food product. Ingredients comprising soy isolate, soy concentrate, corn meal, and water are introduced into an extrudate. The ingredients are extruded through a die orifice at a high specific mechanical energy. The ingredient formula ranges have been determined that maximize volumetric expansion and the set operating conditions and keep texture, color, and flavor acceptable. The puffed snack is then dried and seasoned. There are minimal off-flavors in the product.

Owner:FRITO LAY NORTH AMERICA INC

Method for producing cordyceps militaris fermentation rice by utilizing solid state fermentation of rice

The invention provides a method for producing cordyceps militaris fermentation rice (cordyceps rice for short) by utilizing solid state fermentation of rice, and the method is characterized in that the rice is taken as a main fermentation substrate; and the cordyceps mycelia grows in the rice through a solid state fermentation manner so as to obtain the rice rich in the cordyceps mycelia. The method comprises the following steps: 1. preparing a cordyceps militaris liquid strain; 2. preparing a rice solid state fermentation culture medium; and 3. inoculating and fermenting. In the method, the medical effect of the cordyceps militaris is organically combined with the nutrition of the rice, thus the product contains various nutritive components and mineral elements, especially cordycepin andcordycepic acid, wherein, the content of the cordycepin is more than or equal to 600mg / 100g, and the content of the cordycepic acid is more than or equal to 3g / 100g, thereby improving the immunity ofthe organism, inhibiting tumours, preventing ageing, and satisfying the requirements of healthy eating of people.

Owner:王永显

Production method of whole-grain fast-food nutritional porridge

InactiveCN103815299AIncrease productionProduct quality is stableFood preparationPre treatmentBrewing

The invention discloses a production method of whole-grain fast-food nutritional porridge. Whole grains are taken as raw materials; the purpose of balanced nutrition is achieved through preprocessing and grinding the raw materials and proportioning nutritional ingredients well; the whole-grain fast-food nutritional porridge is prepared by the processes of extruding for curing by a double-screw extruder, accurately controlling the gelatinization degree of starch in the raw materials, granulating for forming, pre-drying, roasting, and cooling. High viscosity of a porridge body during brewing is ensured by accurately controlling the gelatinization degree of the starch in the raw materials in the preparation process, so that any thickener or auxiliary material does not need to be added, the manually cooked porridge can be brewed with hot water without adding cured powdery materials, good granule shape can be kept after the porridge is brewed for 20 minutes, and the appearance and the mouth feel of the fast-food nutritional porridge can be equivalent to those of porridge cooked at home.

Owner:谷伊家食品科技有限责任公司

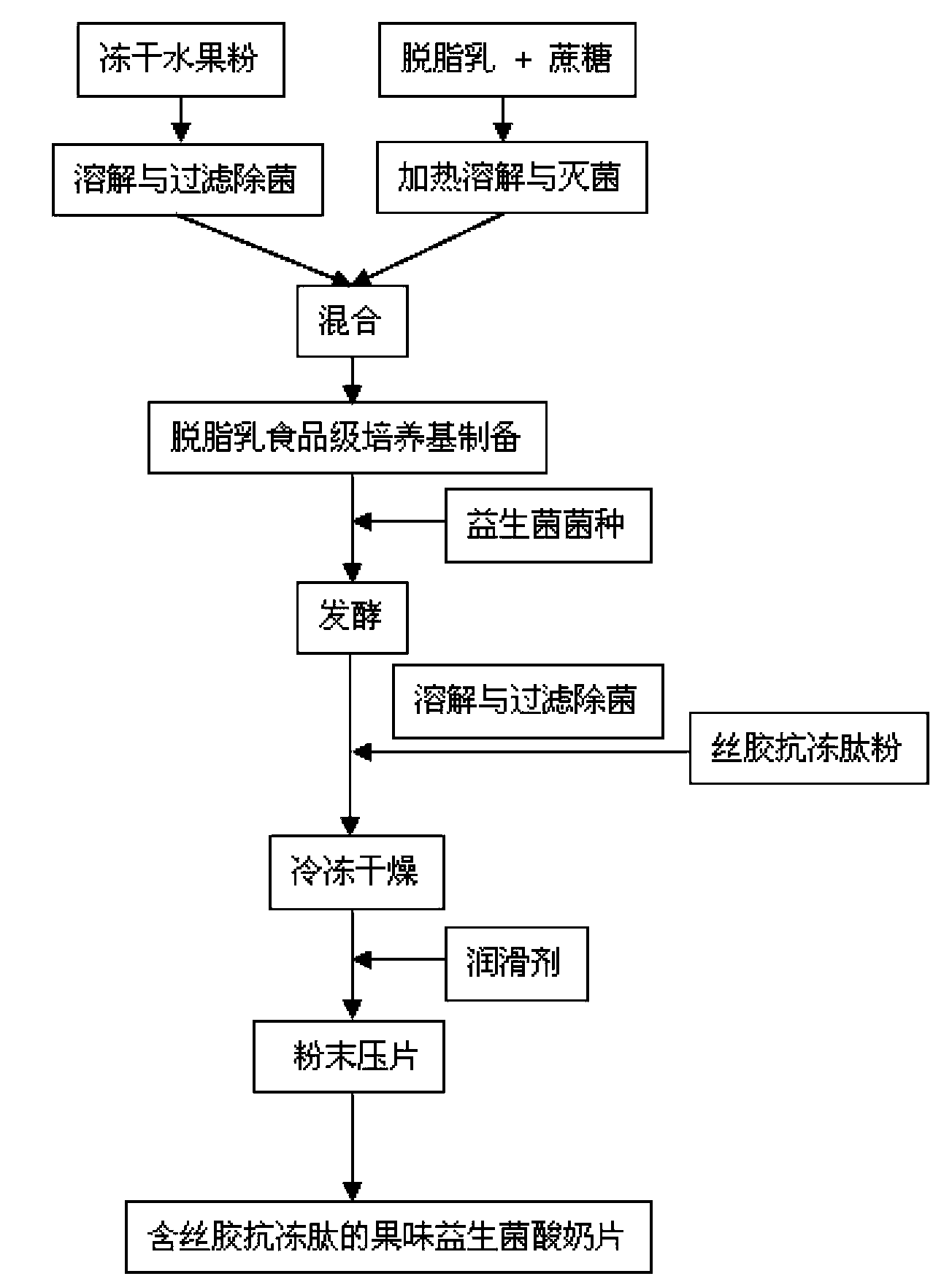

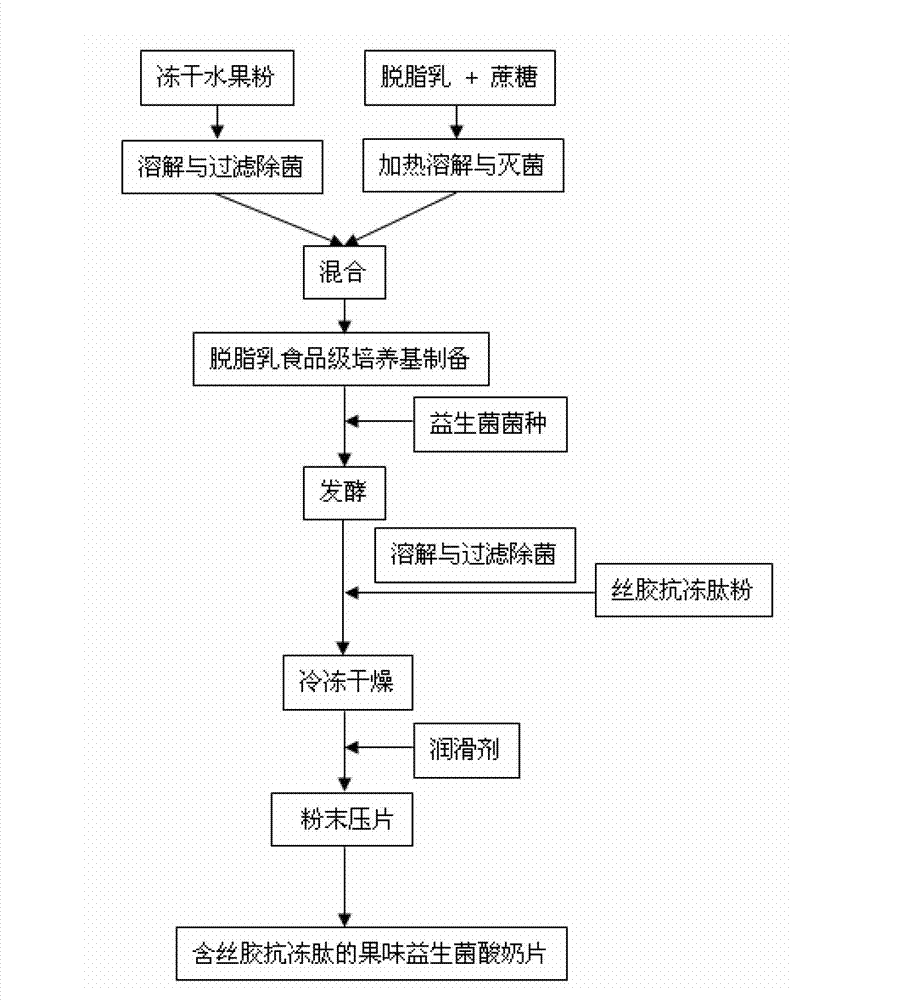

Fruity probiotic yogurt slice containing antifreeze sericin peptide and method for preparing same

ActiveCN103109930BRich in physiological functionsRich in antioxidantMilk preparationProbiotic yogurtBiotechnology

The invention discloses a fruity probiotic yogurt slice containing antifreeze sericin peptide. The raw materials for preparing the fruity probiotic yogurt slice comprise 10-14 parts of skimmed milk powder, 2-5 parts of sucrose, 1-3 parts of sericin peptide, 1-4 parts of fruit material, 0.1-0.6 part of lyophilized active probiotics and 0.1-0.4 part of magnesium stearate. The invention further discloses a method for preparing the product which is the fruity probiotic yogurt slice. The method mainly comprises the following steps of: preparing a skimmed-milk food-grade culture medium, fermenting the probiotics, adding the antifreeze sericin peptide, freezing and drying fermented milk in vacuum, and pressing powder into slices. As the fruity probiotic yogurt slice contains the antifreeze sericin peptide and the lyophilized fruit powder which is rich in the vitamin B group, the number of the probiotics in the fruity probiotic yogurt slice can be increased, the retention time of the activity of the probiotics can be prolonged, and the taste, flavor and nutritional and healthcare values of the fruity probiotic yogurt slice can be improved. The fruity probiotic yogurt slice can serve as a functional food for supplementing the vitamin B group, improving the immunity and promoting the intestinal health.

Owner:SHANGHAI JIAOTONG UNIV

High-dietary fiber five-cereal puffing powder and preparation process thereof

The invention relates to high-dietary fiber five-cereal puffing powder and a preparation method, and belongs to the field of food processing. The five-cereal puffing powder comprises the following raw materials: coarse rice powder, wheat meal, oatmeal, millet meal, glutinous corn meal, soybean meal, wheat bran meal, calcium lactate, ferrous gluconate, zinc gluconate, vitamin B1, vitamin B2 and vitamin B6. A method for processing the five-cereal puffing powder comprises the following steps of: screening coarse cereals, grinding, milling, sieving with an 80-mesh sieve, mixing uniformly in a ratio, adjusting the moisture of materials, balancing the moisture, extruding and puffing by using double screws, drying, crushing, and sieving with a 100-mesh sieve, enhancing mineral elements and the vitamins. The high-dietary fiber five-cereal puffing powder has the characteristics that the puffing powder is prepared from natural grain coarse cereals, emulsifying agents and sweeteners are not added, the mineral elements and the vitamins are enhanced, the content of dietary fibers reaches the specified standard of national high-dietary fiber foods, and the puffing powder can be eaten only by being infused by boiling water, so that the high-dietary fiber five-cereal puffing powder is an ideal nutritional and convenient food which is suitable to be eaten by middle and old-aged people.

Owner:HEFEI UNIV OF TECH

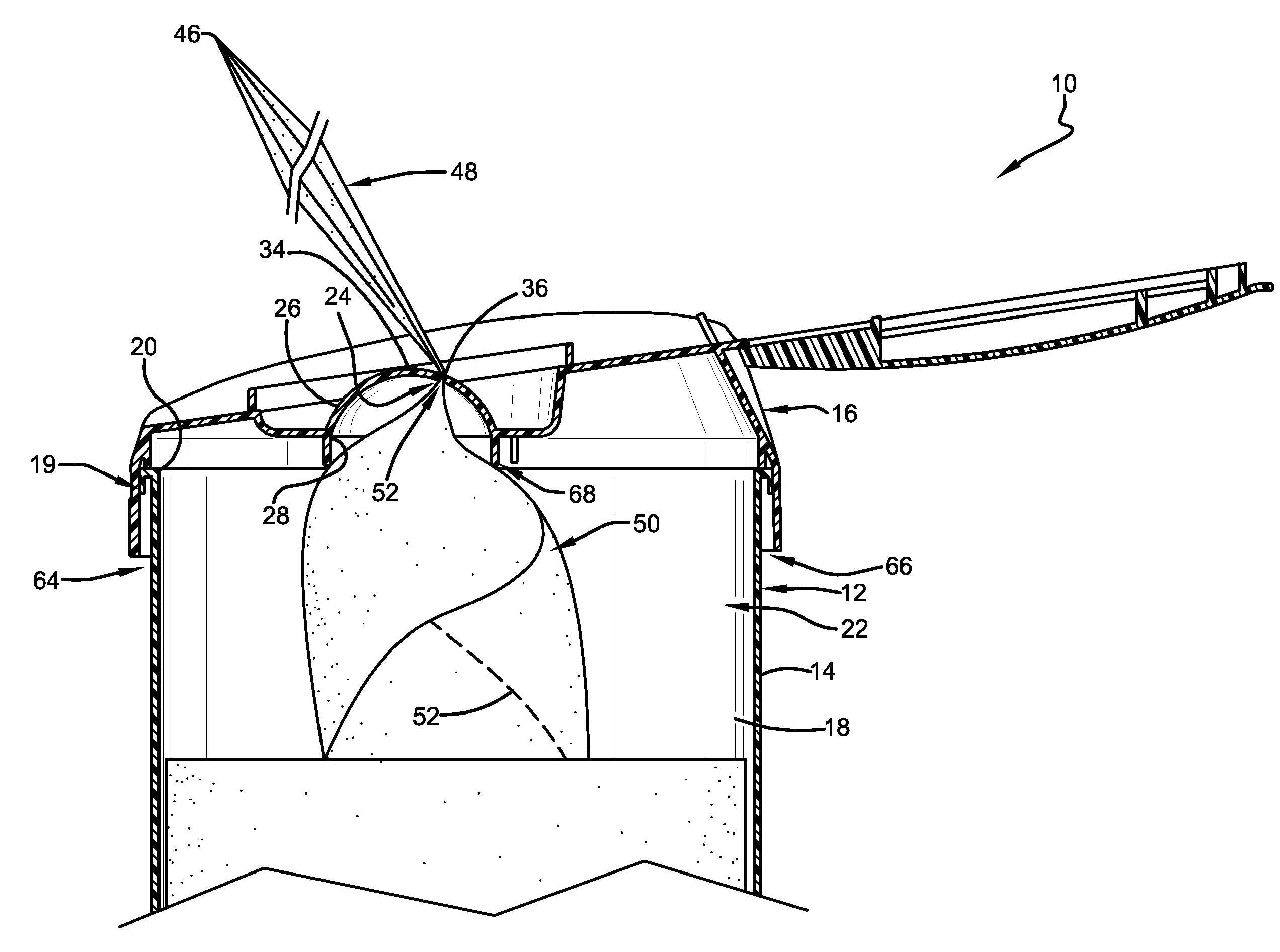

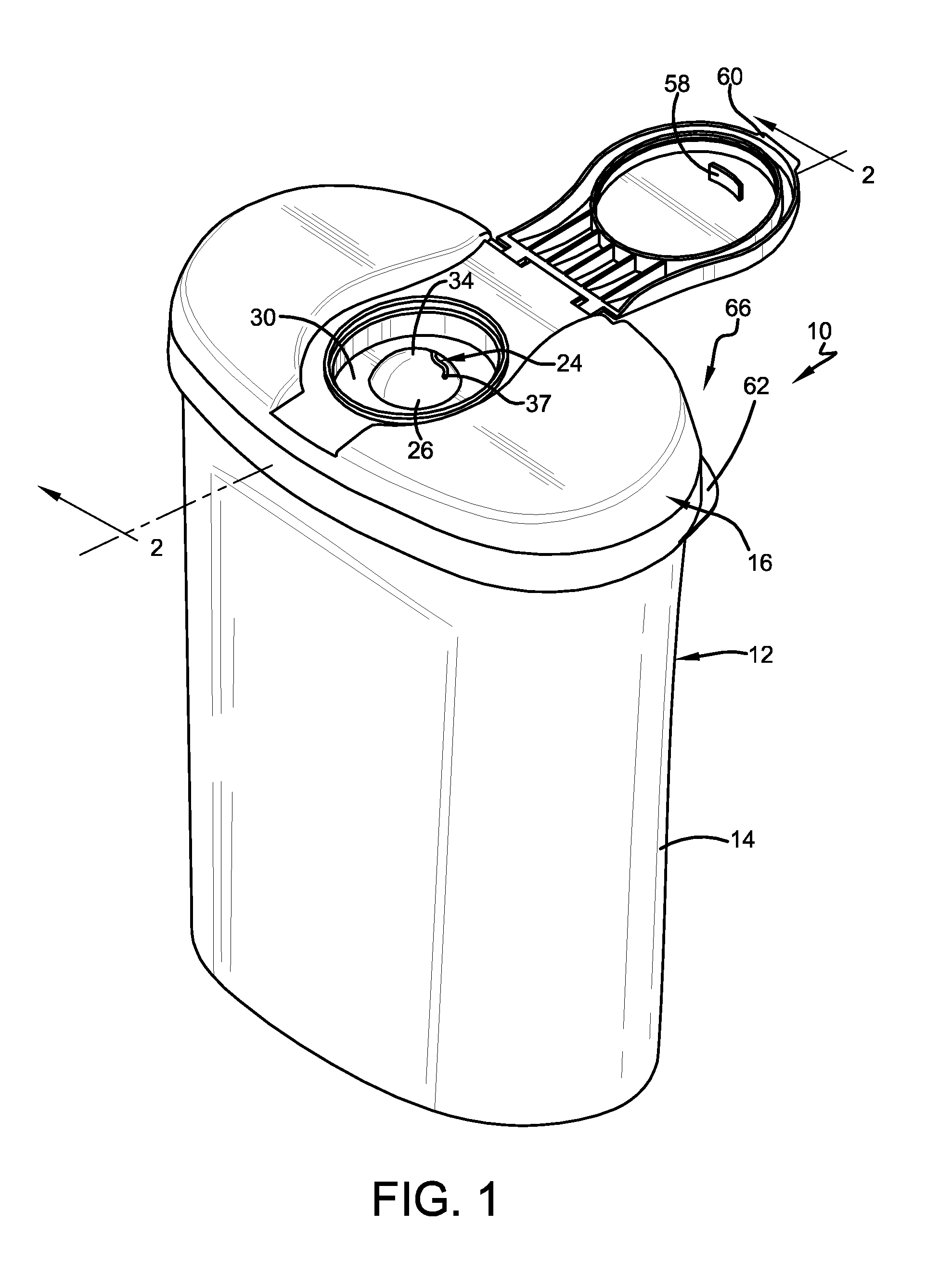

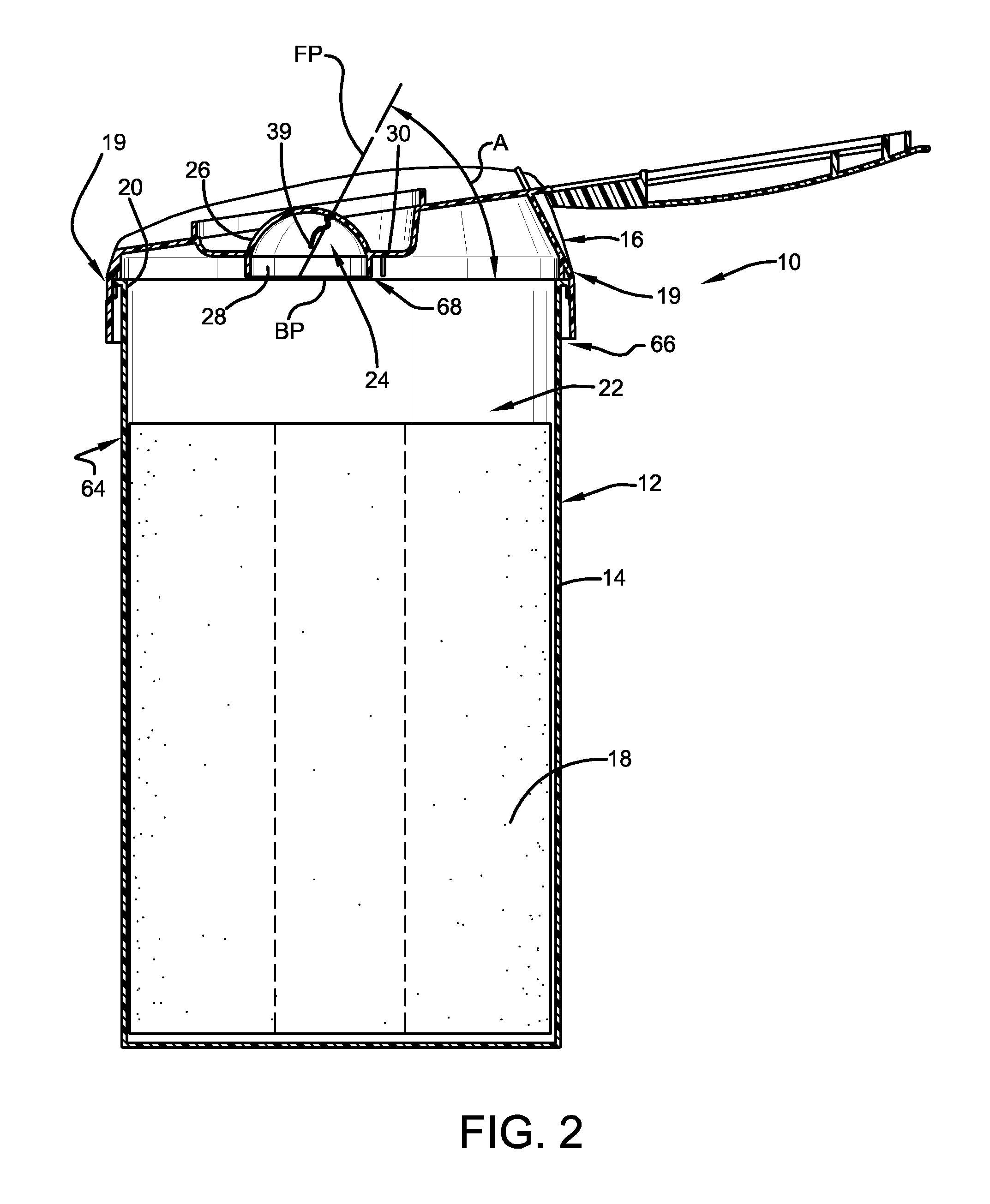

Wipes dispenser

ActiveUS20120145737A1Reduce taperAvoid problemsFlat article dispensingDomestic applicationsEngineeringMechanical engineering

Owner:GOJO IND INC

All-round price wheat germ flour and method of preparing

InactiveCN101176537AExtended shelf lifeAchieve full utilizationFood preparationBiotechnologyAnimal science

The invention relates to wholesome wheat embryo powder and the production method, belonging to the technical field of food, which resolves the problems of wheat embryo powder of watery taste, short guarantee period and large loss of nutritional ingredients. The invention adopts the technical proposal that the invention makes the wheat embryo into 40 to 60 mesh grains with microcapsule technology and the whole nutritional ingredients of the wheat embryo are retained in the grains. A xanthan layer and a lecithin layer are coated outside the grain orderly. The invention comprises the following steps: synthetically sterilizing and enzyme killing, super micron crushing, matching, homogeneously emulsifying, sterilizing and enzyme killing, sponging drying, boiling prilling, spray finishing and packing via vacuum charging. The invention can utilize the wheat embryo completely without any industrial waste, therefore can protect environment and achieve industrialized mass production. The invention has the advantages of long guarantee period, convention edible method, mild taste, full-bodied wheat perfume, high content of nutritional ingredient and easy commercialization.

Owner:HUALONG RIQING FOOD

Meal replacement powder with balanced nutrients and preparation method of meal replacement powder

InactiveCN105285952AConvenience for daily dietBalanced nutritionFood ingredient functionsLarge intestinePerilla seed oil

The invention discloses meal replacement powder with balanced nutrients. The meal replacement powder comprises the following components: millet, lotus roots, buckwheat, coix seeds, oat, black kerneled rice, Chinese yam, lotus seeds, yellow corn, potatoes, Chinese chestnuts, black sesame seeds, konjak, fermented black beans, Chinese wolfberry fruits, walnuts, mulberries, red jujubes, radix puerariae, olive oil, perilla seed oil, maltodextrin, whey protein concentrate, L-malic acid, L-carnitine and milk calcium. The invention further discloses a preparation method of the meal replacement powder with balanced nutrients. After the meal replacement powder is eaten for a long term, the effects of controlling postprandial blood sugar, nourishing the liver, nourishing the kidney, protecting heart and cerebral vessels, and recuperating the spleen, the stomach and large intestines can be obtained, and the nutrient and health status of people can be effectively improved and promoted.

Owner:华海正元(福建)生物科技有限公司 +1

Round-shaped glutinous rice cake and its preparation method

InactiveCN101011121AOvercome the disadvantage of easy aging and hardeningEasy to eatDough treatmentBakery productsIcing sugarDischarge pressure

The invention relates to a method for producing glutinous rice cake, which comprises that immerging the glutinous rice in 100 deals in normal-temperature pure water, filtering and breaking the glutinous rice into powder to be put into the boiler; adding 0.5-10% pure water, 0.5-2.5% emulsifier and 0.3-2.5% common slat at the mass ratio of glutinous rice, boiling via 0.1-0.2MP pressure in steam, aging at slow-discharge pressure; adding 5-40% white sugar and 5-60% dense sugar at mass ration of glutinous rice to be mixed; mixing the 0.5-5% flour, 0.01-0.2% sodium citrate and 0.5-5% pure water at mass ratio of glutinous rice into pulp, to be put into the boiler; taking off and cooling. The inventive glutinous rice cake will not solidify for long time, with better taste and abundant nourishments.

Owner:金钟振

Fruity probiotic yogurt slice containing antifreeze sericin peptide and method for preparing same

ActiveCN103109930ARich in physiological functionsRich in antioxidantMilk preparationProbiotic yogurtBiotechnology

The invention discloses a fruity probiotic yogurt slice containing antifreeze sericin peptide. The raw materials for preparing the fruity probiotic yogurt slice comprise 10-14 parts of skimmed milk powder, 2-5 parts of sucrose, 1-3 parts of sericin peptide, 1-4 parts of fruit material, 0.1-0.6 part of lyophilized active probiotics and 0.1-0.4 part of magnesium stearate. The invention further discloses a method for preparing the product which is the fruity probiotic yogurt slice. The method mainly comprises the following steps of: preparing a skimmed-milk food-grade culture medium, fermenting the probiotics, adding the antifreeze sericin peptide, freezing and drying fermented milk in vacuum, and pressing powder into slices. As the fruity probiotic yogurt slice contains the antifreeze sericin peptide and the lyophilized fruit powder which is rich in the vitamin B group, the number of the probiotics in the fruity probiotic yogurt slice can be increased, the retention time of the activity of the probiotics can be prolonged, and the taste, flavor and nutritional and healthcare values of the fruity probiotic yogurt slice can be improved. The fruity probiotic yogurt slice can serve as a functional food for supplementing the vitamin B group, improving the immunity and promoting the intestinal health.

Owner:SHANGHAI JIAO TONG UNIV

Frozen instant noodles and processing method thereof

InactiveCN102178171AStrong fresh-keeping abilityNot subject to storage conditionsFood preparationMixed materialsInstant noodle

The invention relates to frozen instant noodles and a processing method thereof. The frozen instant noodles comprise raw materials of flour, starch, wheat gluten, albumen powder, vegetable jelly, alkali, common salt, food dye and water. During processing, the mixed materials are synchronously placed in dough kneading equipment, vacuum stirred and then are let stand; the dough is subjected to rolling and pulling type composite calendaring for multiple times, is cured and is subjected to rolling and pulling type continuous calendaring and is chopped into short noodles; and finally, the noodles are boiled, washed and sub-packaged into boxes and refrigerated at a temperature of -18DEG C.

Owner:牛选欣

Method for making stewed duck with bean sauce

InactiveCN101715974ASolve processabilitySolve for uniformityFood preparationBiotechnologyAdditive ingredient

The invention relates to the field of food processing and discloses a method for making a stewed duck with bean sauce. In the invention, injection seasoning technology, vacuum massaging technology and compression marinating technology are integrated into a novel processing technique. The stewed duck with bean sauce made by the invention has the advantages of rich sauce fragrance, tender meat quality, proper elasticity and unique taste. The method overcomes the defects that the traditional stewed ducks with bean sauce cannot be pickled uniformly and the making period is too long, can effectively keep nutrient components in the duck, and can prolong the shelf life of the finished product. The raw materials and making parameters of the method are quantified, so the method can ensure the stable quality of products, facilitates the quality control, and has a prospect for large-scale industrialized production.

Owner:夏威夷

Vacuum freeze-drying processing method of dendrobium officinale

InactiveCN102178847AKeep the original stateKeep the tasteMetabolism disorderDigestive systemFreeze-dryingAdditive ingredient

The invention discloses a vacuum freeze-drying processing method of dendrobium officinale, comprising the following steps of: (1) washing and draining fresh steam sections of dendrobium officinale and cutting into segments; (2) arranging the drained dendrobium officinale in a freeze-drying device for pre-freezing and constant-temperature freezing at 30 DEG C below zero to 35 DEG C below zero; (3)carrying out sublimation drying on the dendrobium officinale processed in the step (2); (4) heating the dendrobium officinale after the sublimation drying in the step for (3) for evaporating residualwater; and (5) packing the condensed dendrobium officinale products with water content of 6-9% dried in the step (4) into clean and sanitary food-grade aluminum-foil bags, sealing to the dendrobium officinale products. The dendrobium officinale products processed by the method disclosed by the invention are rich in dendrobium officinale polysaccharide, and can be directly eaten or taken as ingredients for stewing soup to eat or making tea to drink. The dendrobium officinale products keep original state, taste and pharmacological effects of the dendrobium officinale, can be stored and transported at normal temperature, and has more than five years of shelf life.

Owner:湖南龙石山铁皮石斛基地有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com