Patents

Literature

148results about How to "Novel taste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for fabricating mango potato chips

InactiveCN103976312ANovel tasteNutrition and healthFood preparationMonosodium glutamateBiotechnology

The invention discloses a method for fabricating mango potato chips. The mango potato chips are prepared by the following steps: raw material selection, raw material pre-treatment, slicing, color-protecting, seasoning, frying, packaging and the like. A seasoner is prepared from the following raw materials by weight percent: 15-20% of mango powder, 2-4% of salt, 6-10% of white sugar, 1-2% of aginomoto, 1-3% of yeast extract, 3-5% of mint powder and 2-4% of yam flour. The potato chips prepared by the method are novel in taste, nutrient and healthy, and convenient to eat. The flavor contains Chinese herbal medicinal ingredients, can help digestion, and is good for health. The method is simple in process, the technique is easy to master, therefore, popularization is easy, and industrialized production is also easy.

Owner:ANHUI QUANLI ELECTRONICS TECH

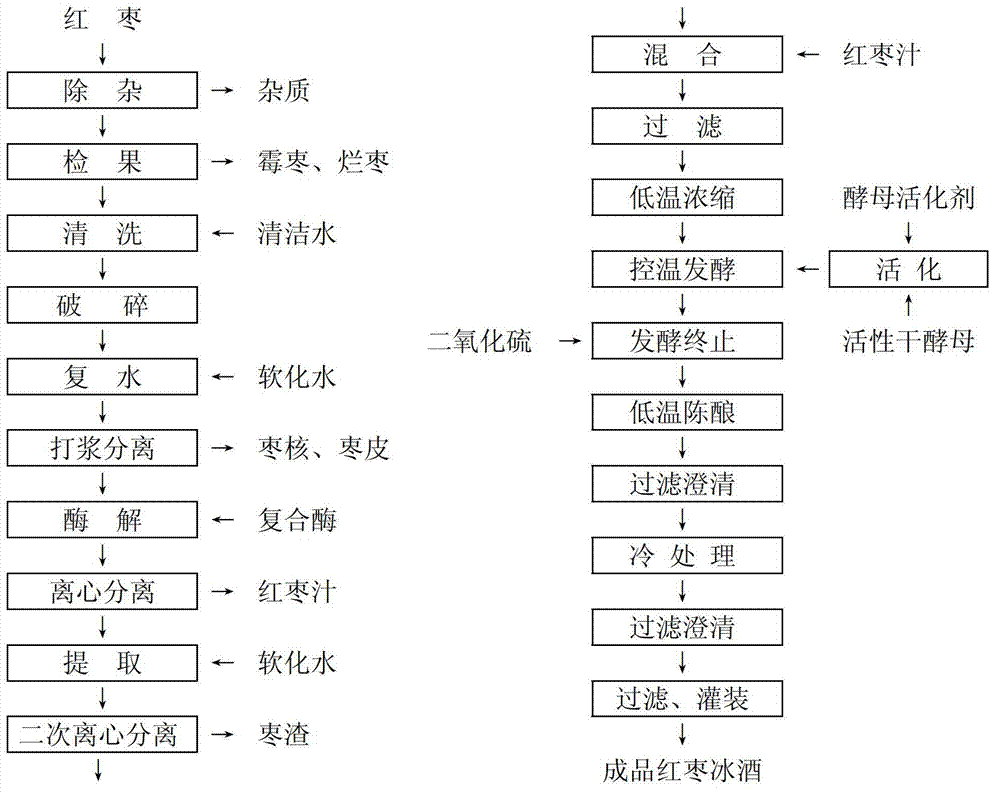

Production process of red date ice wine

ActiveCN102851172ARetain nutritional valueMeet the needs of tastingAlcoholic beverage preparationFruit wineYeast

The invention relates to a production process of a red date ice wine. The process comprises the steps of impurity removing, fruit selecting, washing, crushing, rehydrating, beating, separating, enzymolysis, centrifugal separating, extracting, secondary centrifugal separating, filtering, low-temperature concentrating, yeast activating, controlled-temperature fermenting, fermentation stopping, low-temperature aging, filtering and clarifying, cold treating, sterilizing and filtering, and filling. The process provided by the invention has the advantages that: red date is adopted as a raw material, and a low-temperature rehydration and high-temperature extraction two-stage process is adopted, such that red date juice color, flavor and various rich nutrient contents are ensured, and physiologically active substances in red dates are extracted to a maximal extent; with a two-step method red date ice wine production process that red date juice is produced first and biological fermentation is then carried out, the produced product has a date red color, clarified wine body, rich fragrance, and delicate and mellow mouthfeel. The ice wine has typical characteristics of iced fruit wines, and assists in filling the vacancy in domestic market.

Owner:CHINA LIGHT IND INT ENG CO LTD

Method for processing cured fish

The invention discloses a method for processing cured fish, which comprises the following steps: removing internal organ and fish gills of the fresh fish, cleaning the fish and immersing the fish in the Chinese herbal medicine concentrate, brining, preparing ingredient, preserving, air drying, airing and other steps. Compared with the cured fish processed by traditional method, the cured fish has the advantages of unique local flavor, novel mouthfeel, abundant abundant nutrition, health safety and Chinese herbal medicine component-rich, and is suitable to people of all ages.

Owner:ANHUI WANGJIABA ECOLOGICAL AGRI

Mung bean chip and making method thereof

The invention discloses a mung bean chip which is made from the following raw materials in percent by weight: 70-80 percent of mashed potatoes, 15-20 percent of mung bean flour, 4-5 percent of mung bean paste, 4-5 percent of glutinous rice flour, 2-3 percent of red wine, 2-3 percent of cabbage mustard freeze-drying particles, 1-2 percent of kale borecole freeze-drying particles, 1-2 percent of agaricus blazei murill, 0.5-1 percent of five spice powder, 1-2 percent of green onion, 1-2 percent of ginger, 1.0-2 percent of bicarbonate soda, 2-3 percent of salt, 5-10 percent of white sugar, 0.5-1 percent of monosodium glutamate and a proper amount of water. The mung bean chip is made by adopting the steps of: selecting raw materials, preprocessing the raw materials, steaming and boiling, smashing, blending, gelatinizing, twisting, cooling, slicing, drying, frying and packaging. The mung bean chip has the characteristics of novel taste, health and nutrition, convenience for eating and no additive, and also has the advantages of simple process, easiness in mastering of a technology, less investment, high effect taking speed, convenience for generalization, and easiness in realization of standardized, normalized and industrialized production.

Owner:WUHU XIANGRONG FOOD

Drinking liquid and preparation method thereof

InactiveCN103637316ANovel tasteAlcoholic beverage preparationFood ingredient functionsLemon juiceFood science

The invention discloses a drinking liquid and a preparation method thereof, wherein the drinking liquid comprises the following components in parts by weight: 5-15 parts of garlic juice, 5-15 parts of ginger juice, 5-15 parts of lemon juice and 8-20 parts of vinegar. By adopting the scheme, the drinking liquid disclosed by the invention has novel and unique taste and higher market application value due to the combination of the garlic juice, the ginger juice, the lemon juice and the vinegar.

Owner:SHENZHEN RUGUO TECH

Production method of health care moon cake containing purple potato and oat and stuffing

The invention relates to a production method of a health care moon cake containing purple potato and oat and stuffing. The method includes washing and peeling purple potatoes, mashing the purple potatoes into muddy potatoes after cooking and curing, washing oat grains clean, cooking and curing the oat grains after soaking, and mixing the oat grains into the mashed purple potatoes with even stirring to obtain the purple potato and oat stuffing which can be used independently or mixed with other moon cake stuffing with even stirring. The mixed moon cake stuffing comprises, by weight, 30-90 parts of the purple potato and oat stuffing, 10-80 parts of the other moon cake stuffing and 0-10 parts of white sugar, wherein the purple potato and oat stuffing comprises, by weight, 60-90 parts of purple potato jam and 10-40 parts of oat grains. The other steps are the same with producing processes for the conventional moon cake to obtain the health care moon cake containing the purple potato and the oat. The moon cake is rich in nutrition, anthocyanidin and dietary fibers, and has good health care function.

Owner:TIANJIN GUOZHIYUAN BIOLOGICAL TECH

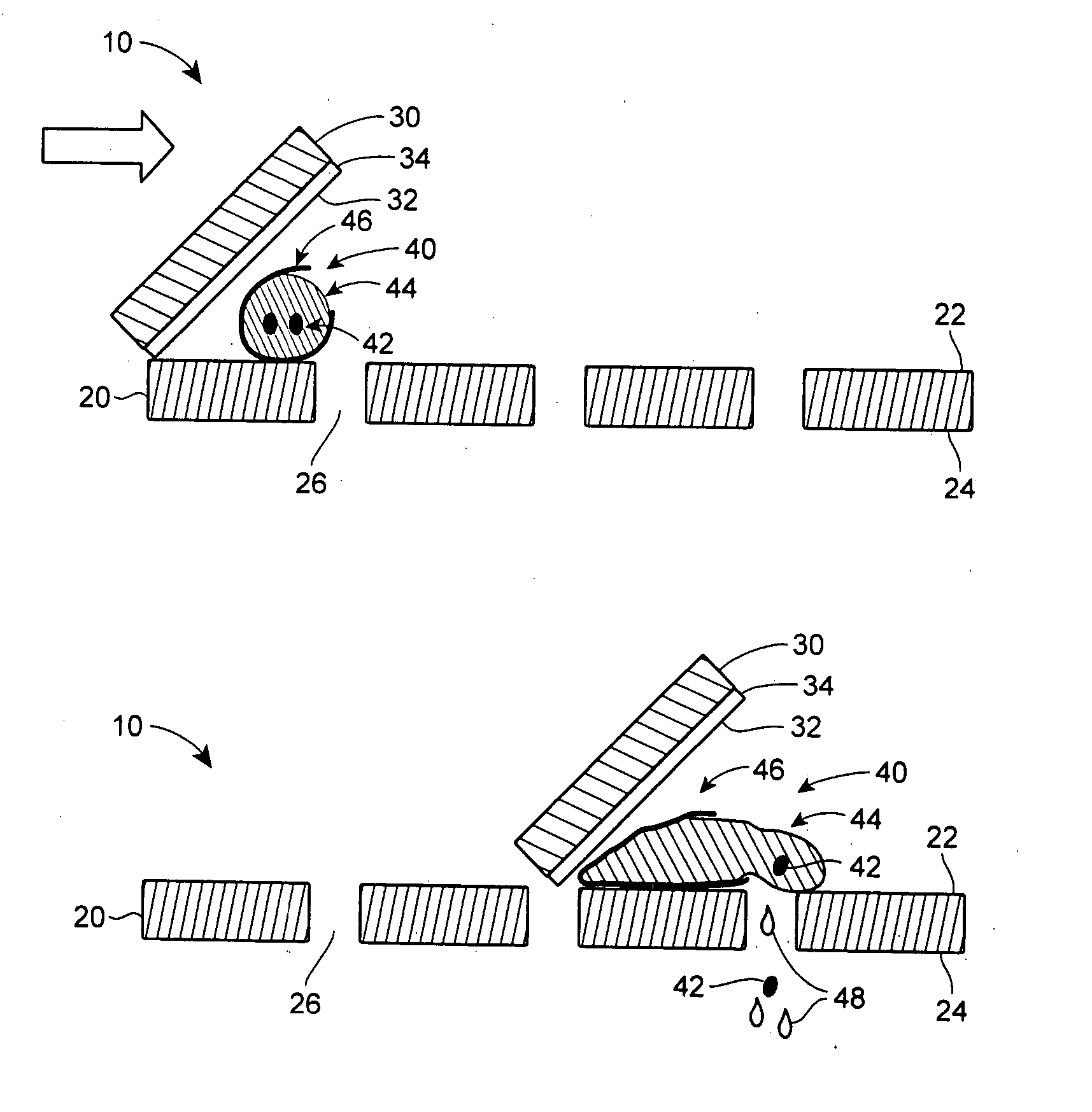

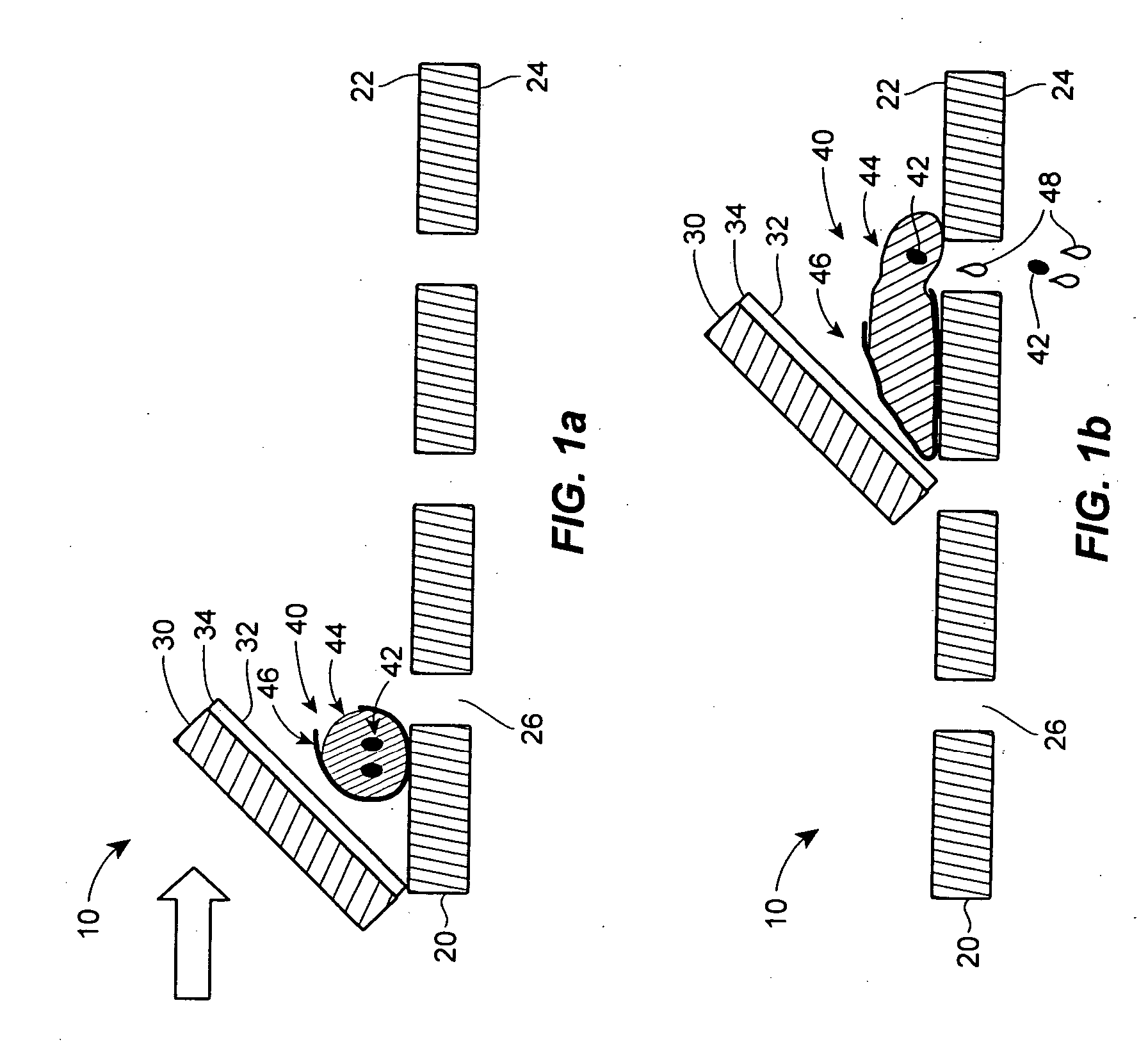

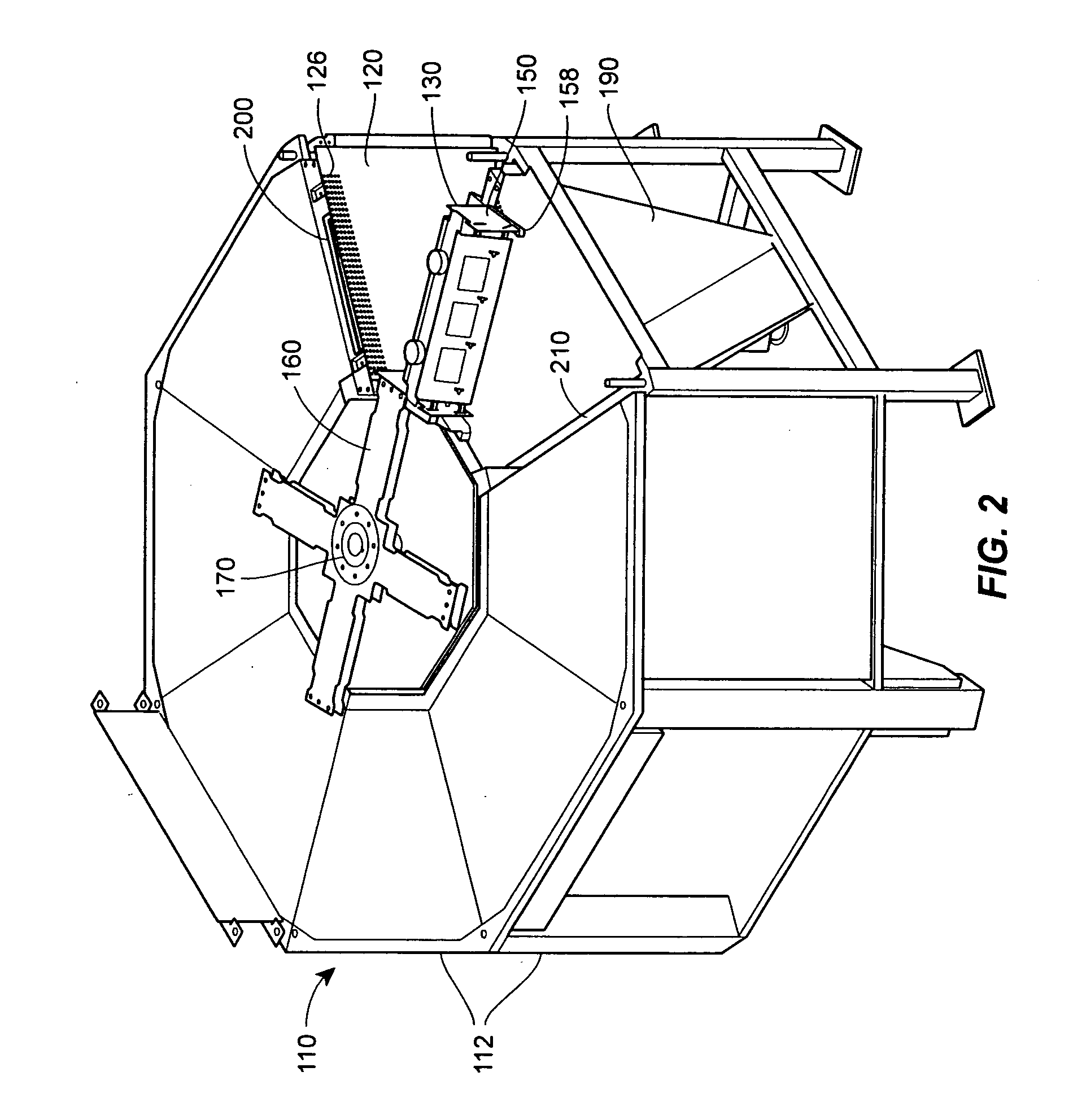

Method and apparatus for removal of grape seeds from grape skin

InactiveUS20070104842A1Increase the juice yieldAvoid disadvantagesFruit stoningWine preparationGrape seedEngineering

The invention provides a method and apparatus for separating grape seeds from the pulp and skin of a grape comprising depositing grapes on a plate having apertures there-through and driving the grapes across the plate by means of a blade such that the grape seeds and juice will pass through the apertures of the plate while retaining grape skin. The grape juice may then be separated from the seeds and recombined with the pulp and skin for fermentation to produce a wine having an improved flavor profiles as a result of the different tannin contents of skin and seeds. Also provided is a method and apparatus for opening grape berries without fracturing their grape seeds.

Owner:E & J GALLO WINERY

Manufacture method of spicy chips

The invention discloses picy chips, which are prepared through the following steps: sorting, raw material pretreatment, slicing, color protection and dehydration, frying, seasoning, packaging and the like; the seasoning formula is prepared through the following raw materials according to weight percentage: 50 to 60 percent of pepper powder, 3 to 5 percent of salt, 10 to 20 percent of white sugar,3 to 5 percent of gourmet powder, 3 to 5 percent of yeast extractive, 1 to 3 percent of disodium ribonucleotides, 10 to 15 percent of maltodextrin, 0.5 to 0.8 percent of chrysanthemum powder, 5 to 10percent of xylitol, 0.2 to 0.4 percent of orange peel powder, 1 to 2 percent of turmeric yellow powder, 2 to 3 percent of atractylis ovata powder, 2 to 4 percent of hawthorn powder, 1 to 2 percent ofsalvia miltiorrhiza powder, 0.5 to 1 percent of cortex moutan powder and 1 to 2 percent of agaricus blazei murrill powder; the chips prepared by the invention have novel taste, are healthy and nutrient and are convenient to eat; the technology of the invention is simple and easy to master, requires less invest, has high efficiency, and is convenient for generalization and easy for realizing standardization, normalization and industrial production.

Owner:阜阳知识源互联网科技服务有限公司

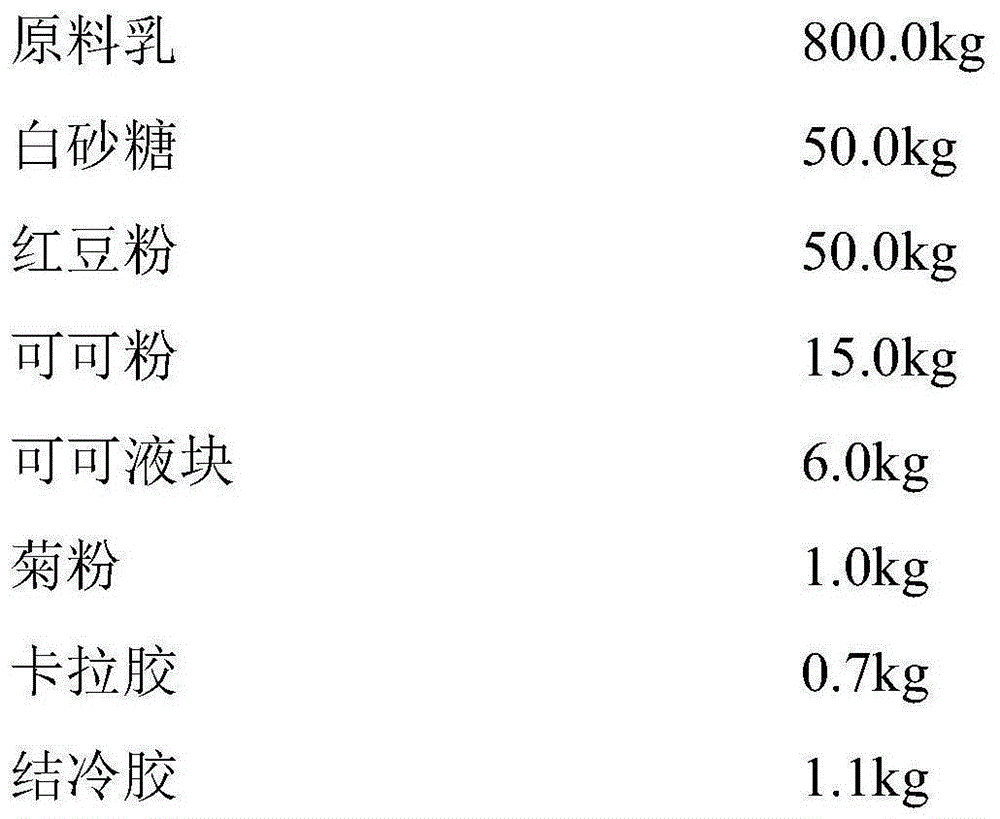

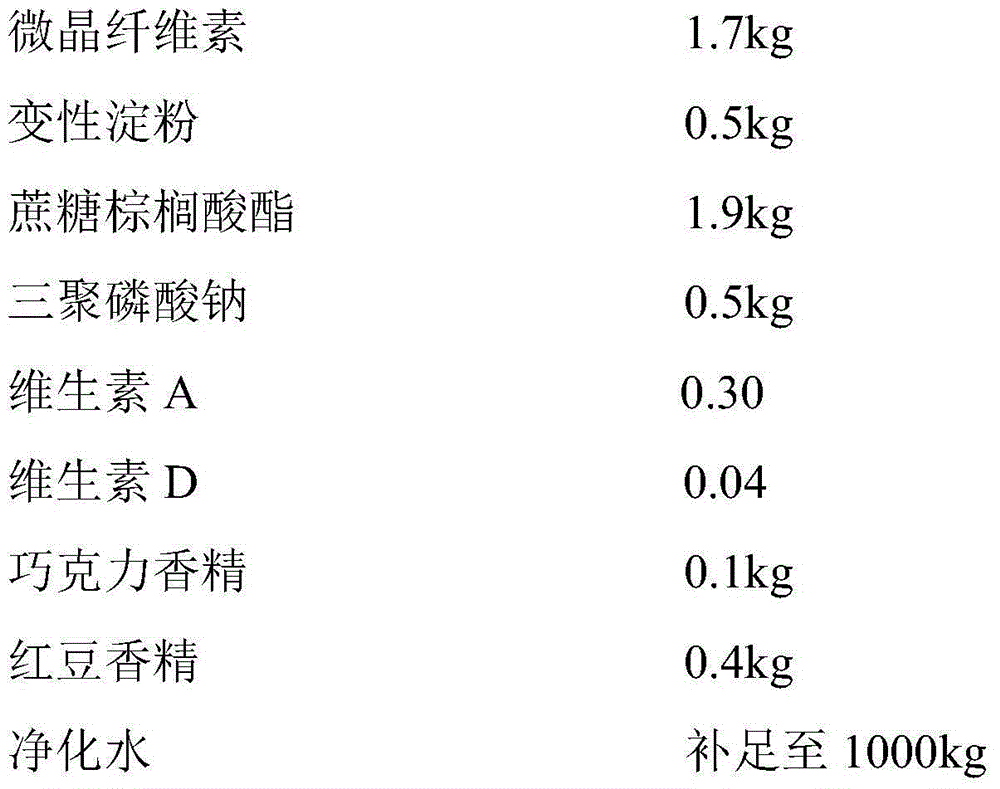

Red bean and chocolate liquid milk product and preparation method thereof

InactiveCN104430897ARandom combinationSolve stability problems such as precipitationMilk preparationCocoa PowdersFlavor

The invention discloses a red bean and chocolate liquid milk product and a preparation method thereof. The red bean and chocolate liquid milk product includes the following materials of: 28-98% of raw milk, 0.001-6% of sweet substance, 0.1-0.35% of thickening agent, 0.01-0.21% of emulgator, 0.5-5% of red bean puree and / or red bean powder, 0.3-2% of cocoa powder, 0.1-1% of cocoa liquor, 0.01-1% of dietary fiber, 0.01-0.17% of composite salt, 0.02-0.1% of edible essence and the balance of water. The preparation method includes the steps of: 1, adding the cocoa powder and the cocoa liquor, and mixing to obtain cocoa solution; 2, preheating the raw milk, adding the sweet substance, the thickening agent, modified starch and the emulgator, and then mixing to obtain solution A; 3, mixing the cocoa solution with the solution A, homogenizing, sterilizing and cooling, and thereby obtaining the product. The red bean and chocolate liquid milk product is particular in flavor, rich in nutrition, and good in stability.

Owner:BRIGHT DAIRY & FOOD CO LTD

Crude chocolate sample composition, manufacturing method thereof and dessert using the same

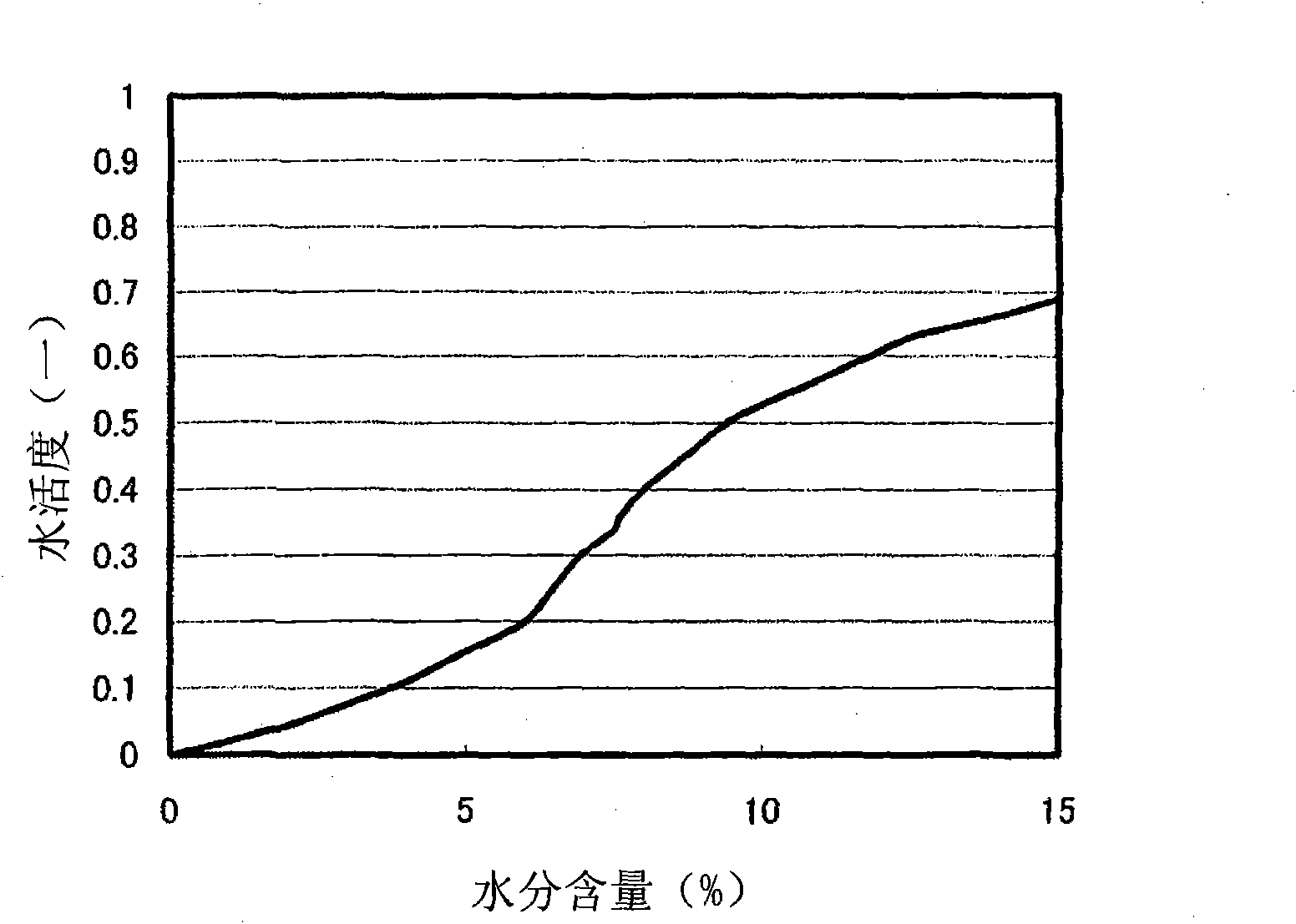

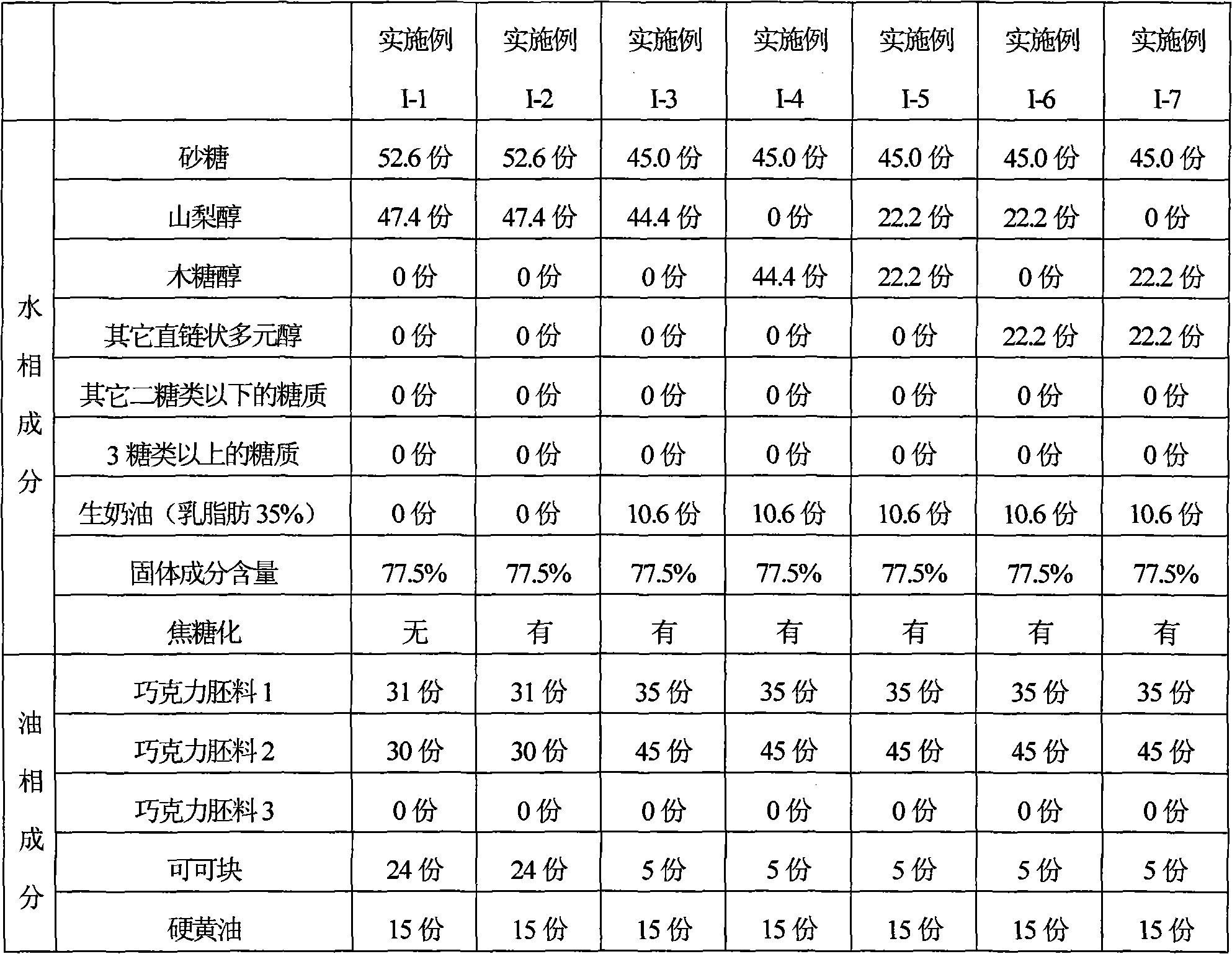

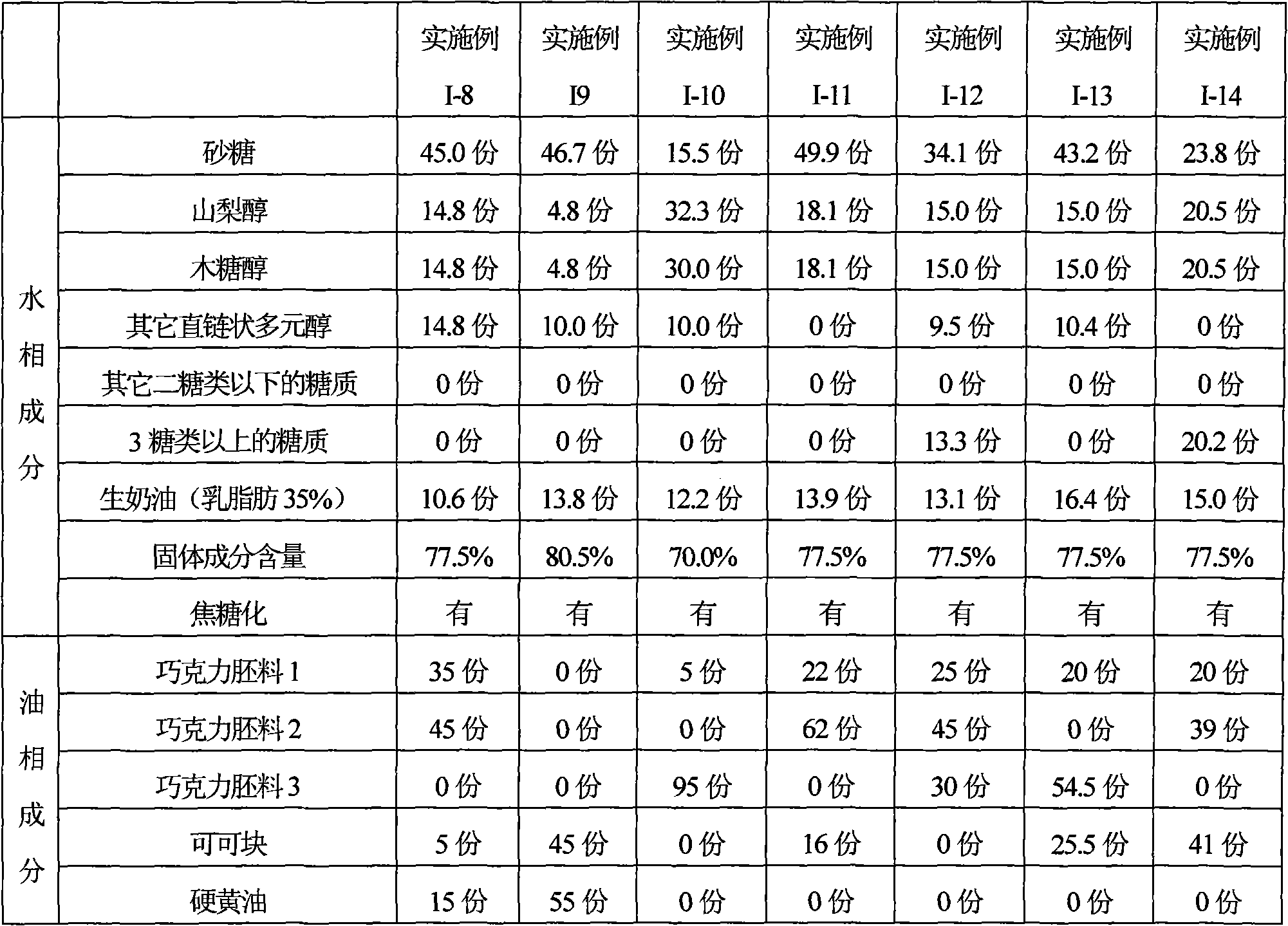

The invention provides a crude chocolate sample composition, a method for manufacturing the crude chocolate sample composition effectively and a novel dessert for using the crude chocolate sample composition with above advantages. The crude chocolate sample composition has the flavor and taste of the crude chocolate sample; and the crude chocolate sample composition can maintain the better flavor and taste when circulated for around one year. The above problem is solved by a crude chocolate sample composition, wherein the crude chocolate sample composition comprises the following components in percentage by weight: 40-70% of sugar comprising disaccharide or below, 5-25% of hard butter and 8-18% of moisture; the water activity is lower than 0.600; and the content of the straight chain polyatomic alcohol in the disaccharide is 5-25% by weight.

Owner:UHA MIKAKUTO CO LTD

Instant konjak vermicelli and its prodn. technique

An instant long-thread konjak vermicelli as an instant food is prepared proportionally from long-thread konjak vermicelli, edible salt, citric acid, sodium citrate, isovitamin C, flavouring and vegetables through preparing long-thread konjak vermicelli, rinsing, thermal desulfurizing, acidifying, mixing with others and packing.

Owner:重庆市鱼泉榨菜(集团)有限公司

Coffee corn flour

InactiveCN101366432APromote peristalsisPromote detoxificationFood preparationCoffeeAnimal scienceCorn flour

The invention relates to coffee corn flour. At present, a coffee type beverage which has additional heal-care function besides the function of coffee is not developed in the field of coffee beverage; coffee represents taste and groups with special requirements; and the mouthfeel of the coffee corn flour is superior to the common beverage. The coffee corn flour comprises the following compositions: corn flour and coffee powder; the corn flour and the coffee powder are mixed by a stirrer; the stirring time is between 5 and 20 minutes; the weight portions of the corn flour are between 30 and 70; and the weight portions of the coffee powder are between 30 and 70. The coffee corn flour is applied to the field of a functional beverage.

Owner:林红

Special barbecue sauce for roast meat

InactiveCN106387847ANovel tasteImprove health benefitsFood ingredient as taste affecting agentNatural extract food ingredientsHuman bodyFruit juice

The present invention discloses a special barbecue sauce for roast meat. The special barbecue sauce for the roast meat comprises the following components in parts by mass: 35 parts of plain boiled water, 5-8 parts of fresh gingers, 2-5 parts of tomatoes, 2-5 parts of fennel, 1-2 parts of mints, 1-2 parts of honey, 1-2 parts of vinegar, 1-2 parts of edible salt, 1-2 parts of soy sauce and 2-5 parts of fruit juice. The barbecue sauce breaks the traditional way of barbecue sauce preparing and is novel and unique in tastes, and meat quality is burnt outside but tender inside. By brushing the barbecue sauce in the barbecue, the barbecue sauce can effectively promote the nutrient release of the roast meat, ensure the moisture content of the meat, and prevent toxic substance accumulations. At the same time, by adding Chinese herbal medicines, the health-care effects of the barbecue sauce are increased and the special barbecue sauce can resist invasion of toxic substances to the human body and prevent internal heat.

Owner:防城港市港口区思达电子科技有限公司

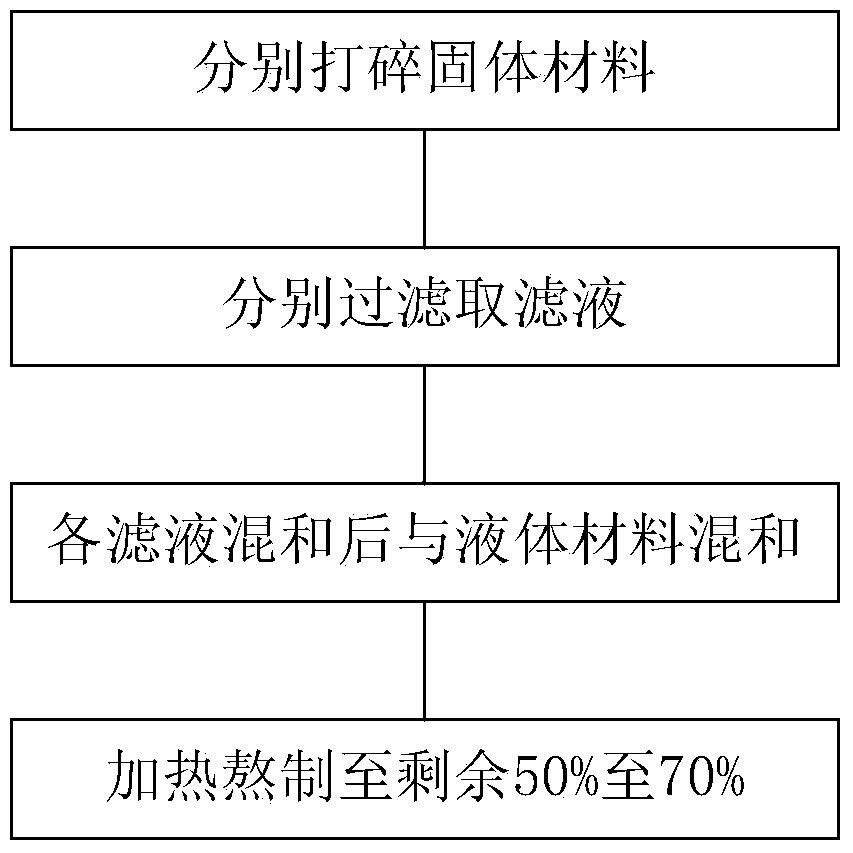

Dendrobium officinale healthcare green juice

The invention discloses dendrobium officinale healthcare green juice, comprising the following raw materials in parts by weight: 200-250 parts of fresh dendrobium officinale strips, 100-150 parts of aloe, 50-150 parts of carambola, 50-100 parts of kiwi fruit, 50-150 parts of green apples, 30-60 parts of acacia honey, 5-10 parts of a stabilizer, 1-2 parts of citric acid, and the balance of water. A preparation method of the dendrobium officinale healthcare green juice comprises the following steps: washing main raw materials, i.e., fresh dendrobium officinale strips, aloe and carambola, then putting the main raw materials into a full-automatic crushing juicer, respectively, mixing all the juice after juicing, adding acacia honey, citric acid and the stabilizer, and blending the concentrated juice with water to obtain the dendrobium officinale healthcare green juice provided by the invention; and finally performing degasification, sterilization and filling. By studying taste, nutrition and health care effect of the juice through the adding proportion of each ingredient into drink, the juice with novel flavor and good taste is obtained. The problem in the prior art that various beverages have unbalanced nutrition and non-obvious healthcare functions is solved.

Owner:GUANGXI JIANBAO SHIHU

Highland barley instant noodles

The invention relates to instant noodles, in particular to highland barley instant noodles, and belongs to the field of food. The noodle cake of the instant noodles comprises wheat flour, vegetable oil, starch, edible salt, wheat gluten and food additive. The instant noodles are characterized in that: the noodle cake also comprises highland barley powder, wherein the noodle cake comprises 70 weight percent of wheat flour and 30 weight percent highland barley powder; the water for kneading dough during manufacturing the noodle cake is replaced by using cattle bone soup; the cattle bone soup is manufactured by the following steps of: 1) flushing cattle bones and breaking big bone sticks, 2) peeling onion and removing roots and cutting the onion into sections, 3) mixing water, cattle bone and onion in a mass ratio of 10: 1: 0.5, 4) cooking the mixture by using a pressure cooker under the air pressure of 1.2 atmospheric pressure and cooling the soup to normal temperature after cooling for 2 hours, and 5) removing bone residue and onion residue from the cattle bone soup for kneading dough; and the noodle cake of the instant noodles has novel taste and more complete nutrition. Process flow and equipment for the highland barley instant noodles are not changed except the noodle cake compared with the common instant noodles; and the operation is easy.

Owner:西安美立方产品设计开发有限公司

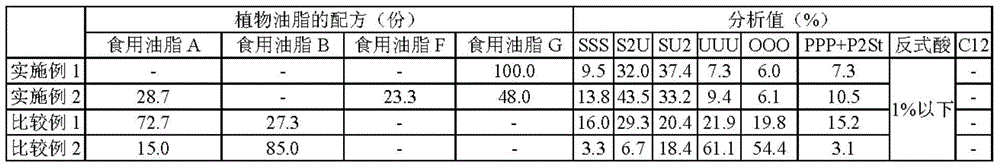

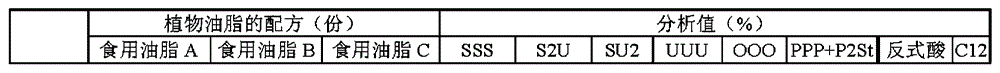

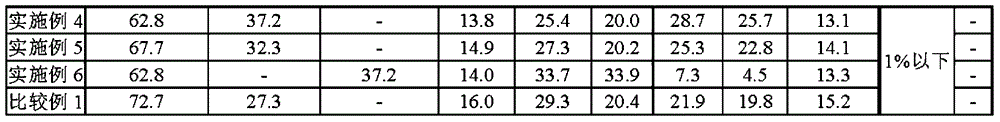

Non-lauric non-trans fat composition for chocolate coating

Owner:FUJI OIL CO LTD

Low sugar black tea flavor tea oil mooncake and preparation method thereof

InactiveCN106417496AHigh nutritional valueFull shapeDough treatmentModified nutritive productsNutritive valuesCooking & baking

The invention provides a low sugar black tea flavor tea oil mooncake and a preparation method thereof, and belongs to the food processing field. The preparation method of the low sugar black tea flavor tea oil mooncake includes the specific process steps of raw auxiliary material weighing, preprocessing, cake crust preparation, crust dividing, stuffing filling, shaping, baking, cooling and packaging. The low sugar black tea flavor tea oil mooncake is high in nutritive value, and rich in multiple amino acids, and contains multiple functional factors of tea polyphenol and the like. By adopting a low sugar formula, the low sugar black tea flavor tea oil mooncake overcomes the defects that traditional mooncakes are high in sugar content, soil content and heat, agreeable in sweetness, and nutrient and healthy. Fructo-oligosaccharide is added as prebiotics, can promote propagation of in-vivo Bifidobacterium, and further has multiple healthcare effects of preventing caries and the like. Tea oil is added, rich in unsaturated fatty acid, and difficult to oxidize in high temperature baking, and has multiple healthcare functions.

Owner:ZHANGZHOU COLLEGE OF SCI & TECH

Room-temperature-drinkingtype red date and cerealyoghourt and preparation method thereof

InactiveCN107307077AMeet the needs of healthy nutritionNovel tasteMilk preparationMilk preservationWhole milkHydrolysis

The invention discloses a normal-temperature drinking jujube cereal yoghurt and a preparation method thereof, which relate to yoghurt processing. The raw materials are composed of grain enzymatic hydrolysis powder, whole milk powder, white granulated sugar, lactic acid bacteria strains, concentrated jujube juice, compound stabilizer, and the balance is water. Add milk powder into hot water, dissolve and let it stand for hydration to obtain milk powder liquid A; preheat and homogenize milk powder liquid A, sterilize, cool, and ferment to obtain fermented milk base B; put enzymatically hydrolyzed grain powder into hot water to dissolve , after dissolving, carry out colloid mill treatment, after refining, make the grain enzymatic hydrolyzed powder gelatinize, and then obtain the material liquid C after homogenizing under pressure; mix the compound stabilizer and sugar, add it to hot water, and stir to obtain the compound Stabilizer feed liquid D; add red date concentrated juice to water, stir and dissolve to obtain feed liquid E; pour fermented milk base B, feed liquid C and compound stabilizer feed liquid D into the blending tank, stir, then inject feed liquid E, and then Stir and mix, chill, and prepare the liquid after constant volume; filter the constant volume liquid, preheat, degas, homogenize, sterilize, and aseptically fill.

Owner:XIAMEN HUIERKANG FOOD

Manufacturing method of shrimp-flavored potato chips

InactiveCN103960626ANovel tasteNutrition and healthFood ingredient as taste affecting agentFood preparationFlavorMonosodium glutamate

The invention discloses a manufacturing method of shrimp-flavored potato chips, which comprises the following steps: raw material selection, raw material pretreatment, slicing, color protection, seasoning, deep-frying, packaging and the like. The seasoning is prepared from the following raw materials in percentage by weight: 15-20% of fine shrimp flesh powder, 5-10% of minced shrimp flesh, 2-4% of salt, 6-10% of white sugar, 1-2% of monosodium glutamate, 1-3% of yeast extract, 0.2-0.4% of orange peel powder, 2-4% of malt flour and 2-4% of wolfberry fruit powder. The potato chips prepared by the method have novel flavor, are nutritional and healthy, and are convenient to eat; and the traditional Chinese medicine components in the seasoning can promote digestion and are beneficial to good health. The method is simple in technique, easy to master and convenient for wide popularization, and can easily implement industrial production.

Owner:ANHUI QUANLI ELECTRONICS TECH

Red bean chip and making method thereof

The invention discloses a red bean chip which is made from the following raw materials in percent by weight: 70-80 percent of mashed potatoes, 15-20 percent of red bean flour, 4-5 percent of red bean paste, 4-5 percent of glutinous rice flour, 2-3 percent of red wine, 2-3 percent of crowndaisy chrysanthemum freeze-drying particles, 1-2 percent of spinach freeze-drying particles, 1-2 percent of mushroom freeze-frying particles, 1-2 percent of chilli powder, 1-2 percent of curcuma powder, 1-2 percent of green onion, 1-2 percent of ginger, 1-2 percent of bicarbonate soda, 2-3 percent of salt, 5-10 percent of white sugar, 0.5-1 percent of monosodium glutamate and a proper amount of water. The red bean chip is made by adopting the steps of: selecting raw materials, preprocessing the raw materials, steaming and boiling, smashing, blending, gelatinizing, twisting, cooling, slicing, drying, frying and packaging. The red bean chip has the characteristics of novel taste, health and nutrition, convenience for eating and no additive, and also has the advantages of simple process, easiness in mastering of a technology, less investment, high effect taking speed, convenience for generalization, and easiness in realization of standardized, normalized and industrialized production.

Owner:WUHU XIANGRONG FOOD

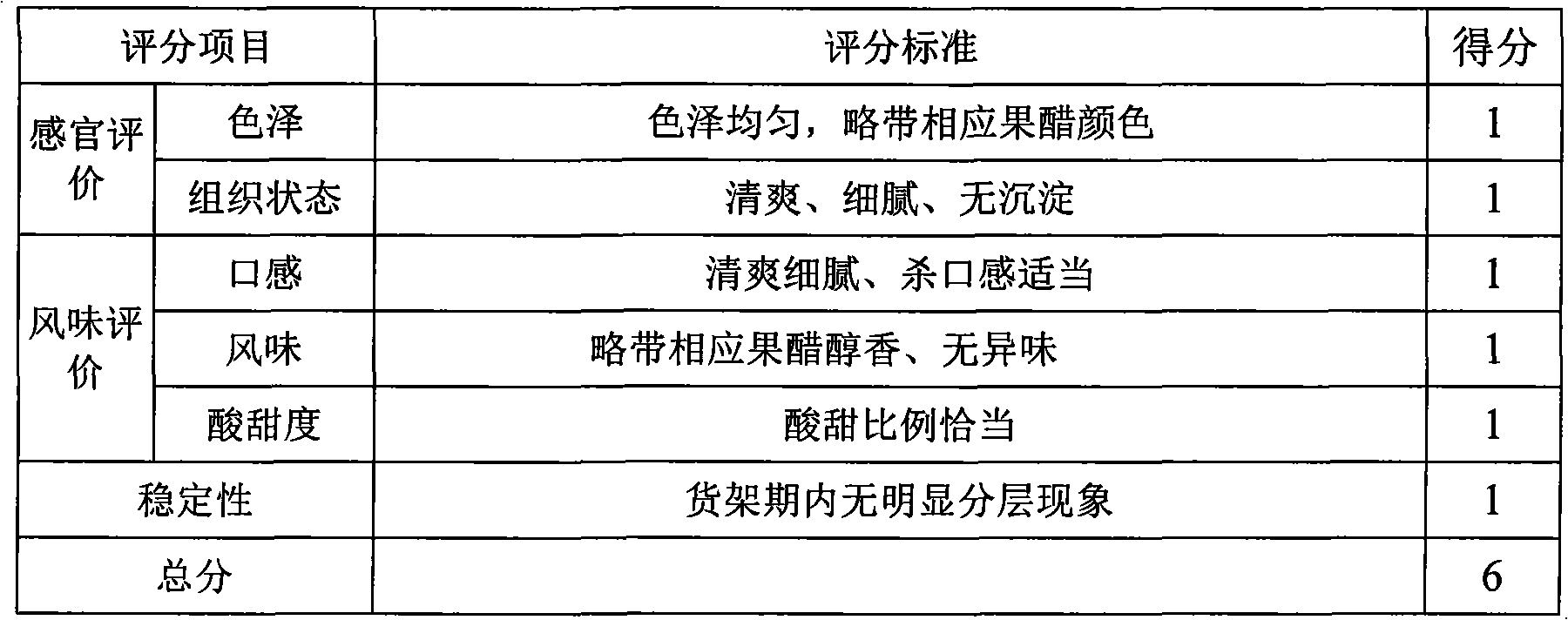

Fruit vinegar-containing milk beverage and preparation method thereof

The invention relates to the field of liquid milk processing, in particular to fruit vinegar-containing milk beverage and a preparation method thereof. Based on the total amount of 100 weight parts, the fruit vinegar-containing milk beverage comprises the following raw materials in part by weight: 30 to 50 parts of milk, 2 to 4 parts of fruit vinegar, 0.008 to 0.01 part of lactic acid bacteria starter, and a thickener comprising two or all of 0.08 to 0.3 weight parts of pectin, 0.3 to 0.6 weight parts of carboxymethyl cellulose and 0.05 to 0.2 weight part of propylene glycol alginate, whereinthe pectin is a purchased product, and has the sugar content of 12 to 16 percent and the acid content of 3.5 to 6 percent. The fruit vinegar-containing milk beverage realizes the combination of the milk and the fruit vinegar, is not remarkably demixed and of normal flavor in shelf life, and has a long quality guarantee period.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Healthy snow chrysanthemum tea wine with blood pressure and blood fat reducing effects and preparation method of healthy snow chrysanthemum tea wine

ActiveCN103992929AEasy to prepareEasy to operateMetabolism disorderAlcoholic beverage preparationSaccharumSucrose

The invention discloses a healthy snow chrysanthemum tea wine with blood pressure and blood fat reducing effects and a preparation method of the healthy snow chrysanthemum tea wine. Every 500mL of healthy snow chrysanthemum tea wine is prepared from the following raw materials: 30-40g of snow chrysanthemum, 8-15g of semen cassiae, 8-15g of hawthorn, 5-10g of ginkgo leaves, 50-60g of white spirit, 15-25g of cane sugar, 10-20g of malt sugar, 5-10g of xylitol, 5-10g of lemon juice and the balance of water. The healthy snow chrysanthemum tea wine disclosed by the invention has the healthcare functions of reducing blood pressure and blood fat.

Owner:润天(重庆)医学技术研究院有限公司

Fermented blank bean pickled vegetables and processing method thereof

The invention discloses fermented blank bean pickled vegetables. The fermented blank bean pickled vegetables are characterized in that fermented blank beans and vegetables are taken as major materials; the vegetables are soaked in salt and prepared into the major materials of the pickled vegetables; the fermented blank beans are prepared into the major materials and a finished product is stirred. The invention further discloses a processing method of the fermented blank bean pickled vegetables. The novel pickled vegetable product provided by the invention has nutritional value and is unique in flavor, delicious and tasty. Compared with traditional pickled vegetables, the fermented blank bean pickled vegetables have affluent protein, amino-acid, mineral and vitamins and brand-new pickled vegetables eating experience is brought forth; the taste and flavor are innovative, the demand for food diversity of people is satisfied and the species of the pickled vegetables in the pickled vegetable food market are enriched; the process specification of the fermented blank bean pickled vegetables is simple and suitable for popularization and application.

Owner:SICHUAN CAIHUAXIANG FOOD

Savoury and crisp chicken processing method

The invention relates to a method for producing fried crisp chicken, which comprises that 1, pretreating the chicken that killing, washing, cleaning and shaping the chicken, dewatering and frying at 160-200Deg. C in oil until the skin is yellow; 2, preparing 1000 deals of chicken, 1-2 deals of amomum fruit, 4-6 deals of meat top, 3-5 deals of grass top, 4-6 deals of fruit, 2-3 deals of alpinin, 1-2 deals of Cinnamomum cassia, 1-2 deals of dahurian angelica root and 2-3 deals of clove; 3, putting the materials into boiler, adding common salt, honey, sugar, peppertree, star anise, ginger and water, when the water is boiled, adding the fried chicken, boiling for 15-20min. The invention has better taste.

Owner:刘忠军

Tea wine and method for preparing same

ActiveCN107057927ARich and elegant tea fragranceNovel tasteAlcoholic beverage preparationMicroorganism based processesChemistryDistillation

The invention relates to the field of food processing and agricultural byproduct processing, in particular to tea wine and a method for preparing the same. The tea wine comprises 15-30 parts of tea leaves, 60-100 parts of wort, 0.001-0.004 part of lactobacilli, 10-20 parts of baijiu and the balance water. The method includes tea making, dealkalization, pre-fermentation, post-fermentation, distillation and ageing to ultimately obtain finished tea wine products. The tea wine and the method have the advantages that the tea wine prepared by the aid of the method has strong and elegant tea aroma and novel taste and is icy, mellow and fresh, the mouths of drinkers are full of the tea aroma and wine flavor, and the tea wine has tea flavor in wine aroma and accordingly has aftertaste which lingers.

Owner:贵溪市堆金酒业有限公司

Manufacturing method of hawthorn-flavored potato chips

InactiveCN103960625ANovel tasteNutrition and healthFood ingredient functionsFood preparationMonosodium glutamateChipped potatoes

The invention discloses a manufacturing method of hawthorn-flavored potato chips, which comprises the following steps: raw material selection, raw material pretreatment, slicing, color protection, seasoning, deep-frying, packaging and the like. The seasoning is prepared from the following raw materials in percentage by weight: 15-20% of hawthorn powder, 2-4% of salt, 6-10% of white sugar, 1-2% of monosodium glutamate, 1-3% of yeast extract, 0.2-0.4% of orange peel powder, 0.5-1% of cortex moutan powder and 2-4% of rhizoma atractylodis macrocephalae powder. The potato chips prepared by the method have novel flavor, are nutritional and healthy, and are convenient to eat; and the traditional Chinese medicine components in the seasoning can promote digestion and are beneficial to good health. The method is simple in technique, easy to master and convenient for wide popularization, and can easily implement industrial production.

Owner:ANHUI QUANLI ELECTRONICS TECH

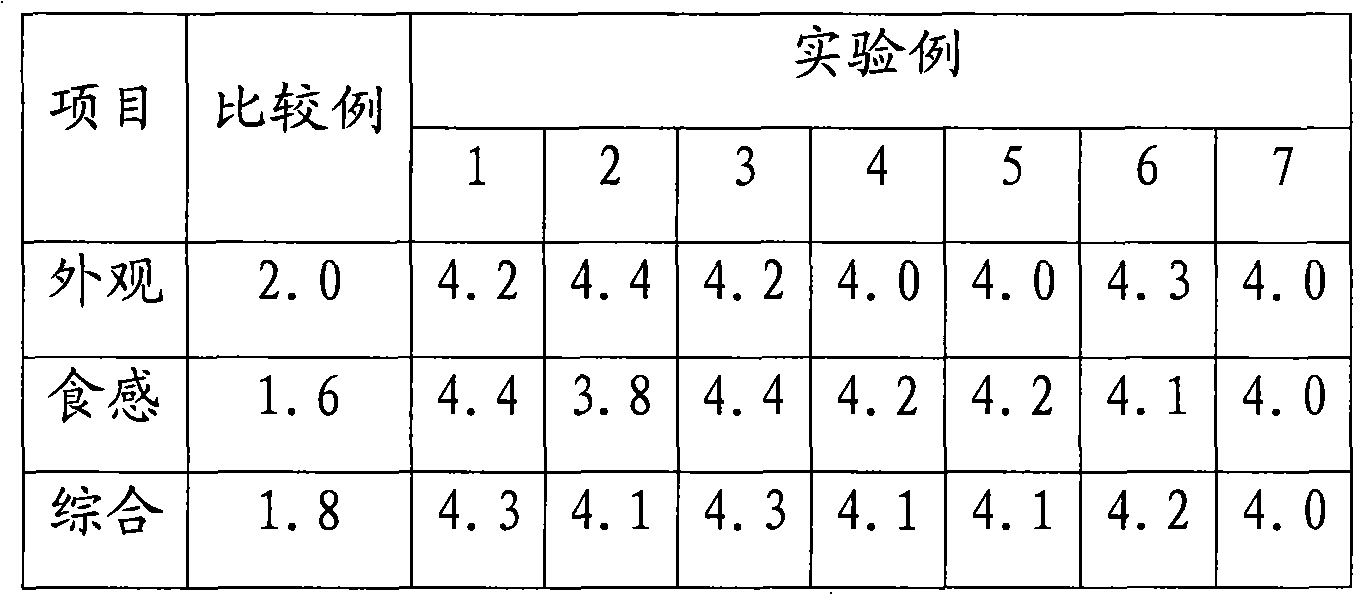

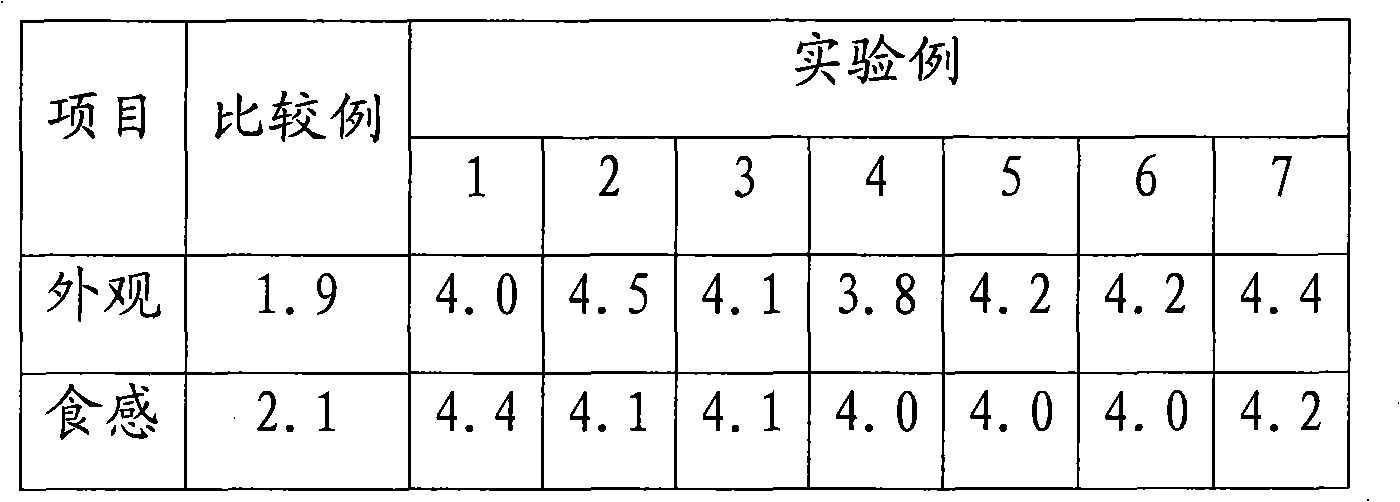

Coating composition for bakery food and bakery food using the same

ActiveCN101797006AGood moisturizing effectGreat tasteConfectioneryPreservation by coatingFlavorBaked goods

The purpose of the present invention is to provide a coating composition for bakery food products, which coating composition is capable of offering a variety of flavors, has superior moisture-retaining property, the coating composition being pleasantly mild, smooth and flexible and in the form of gel; as well as a bakery food product coated with the coating composition. The above problem is solved by the coating composition for bakery food products of the present invention, said coating composition comprising agar, a saccharide, a modified starch and water, which coating composition is in the form of gel.

Owner:MATSUTANI CHEM INDS CO LTD

Preparation method of canned sardines

The invention provides a preparation method of canned sardines. The method comprises the steps as follows: 1) performing pretreatment; 2) salting prepared sardine blocks; 3) placing drained sardine blocks in a mixed liquid of acetic acid and tea polyphenol; 4) performing frying; 5) preparing soup; 6) performing boiling in a pressure cooker; 7) performing cold storage; 8) putting cold-stored sardine blocks in a frying pan for frying at the oil temperature of 150-180 DEG C for 5-8 min; 9) putting wormwood and brown sugar at the bottom of the pan, placing the sardine blocks on a shelf in the pan,sealing the pan with a lid, stopping heating after heating the sardine blocks for 20-25 min, and taking out and cooling the sardine blocks; 10) preparing soup; 11) placing the sardine blocks treatedin step 9 in the soup prepared in step 10 for cooking; 12) placing drained sardine blocks in iron cans; and 13) placing sealed cans in a high-pressure water spray type sterilization kettle for sterilization again. Prepared sardine has no fishy smell, long shelf life, delicious taste, good taste, proper softness and is fresh, nutrient, convenient and safe.

Owner:李韵婷

Colored bean jelly

The invention provides a colored bean jelly, which belongs to a food. The colored bean jelly is prepared by using starch, water, and one or more than one of cooked diced pork, fruit pulp dices and vegetable dices as raw materials. The colored bean jelly is bright in color, good in aesthetics, rich in nutriments, novel in taste, cool in the mouth and beneficial to human health, and has the functions of maintaining beauty, keeping young, and nourishing and preserving the health, and the like.

Owner:王永水

Manufacture method of beef flavor potato chips

The invention discloses a beef flavor potato chip. The beef flavor potato chip is prepared through the steps of material selection, raw material pretreatment, slicing, color protection, dewatering, oil frying, seasoning, package and the like. Spices of the beef flavor potato chip are prepared from the following ingredients in percentage by weight: 15 to 20 percent of fine beef powder, 5 to 10 percent of minced beef, 5 to 10 percent of fine pork powder, 5 to 9 percent of salt, 5 to 10 percent of white sugar, 5 to 8 percent of monosodium glutamate, 5 to 10 percent of chilli powder, 5 to 10 percent of black pepper powder, 1 to 3 percent of yeast extracts, 0.5 to 0.8 percent of chrysanthemum powder, 5 to 10 percent of xylitol, 0.2 to 0.4 percent of orange peel powder, 1 to 2 percent of turmeric powder, 2 to 3 percent of bighead atractylodes rhizome powder, 2 to 4 percent of hawthorn fruit powder, 1 to 2 percent of salvia miltiorrhiza powder, 0.5 to 1 percent of cortex moutan powder and 1 to 2 percent of agaricus blazei murrill powder. The beef flavor potato chip manufactured according to the invention has the advantages that the flavor is novel, the beef flavor potato chip is healthy and nutritive, the eating is convenient, the process is simple, the technology can be easily mastered, the investment is low, the effect taking speed is high, the general popularization is convenient,and the standardized, normalized and factory production can be easily realized.

Owner:阜阳知识源互联网科技服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com