Patents

Literature

508 results about "Baked goods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This is a list of baked goods.Baked goods are cooked by baking, a method of cooking food that uses prolonged dry heat, normally in an oven, but also in hot ashes, or on hot stones.The most common baked item is bread but many other types of foods are baked as well.

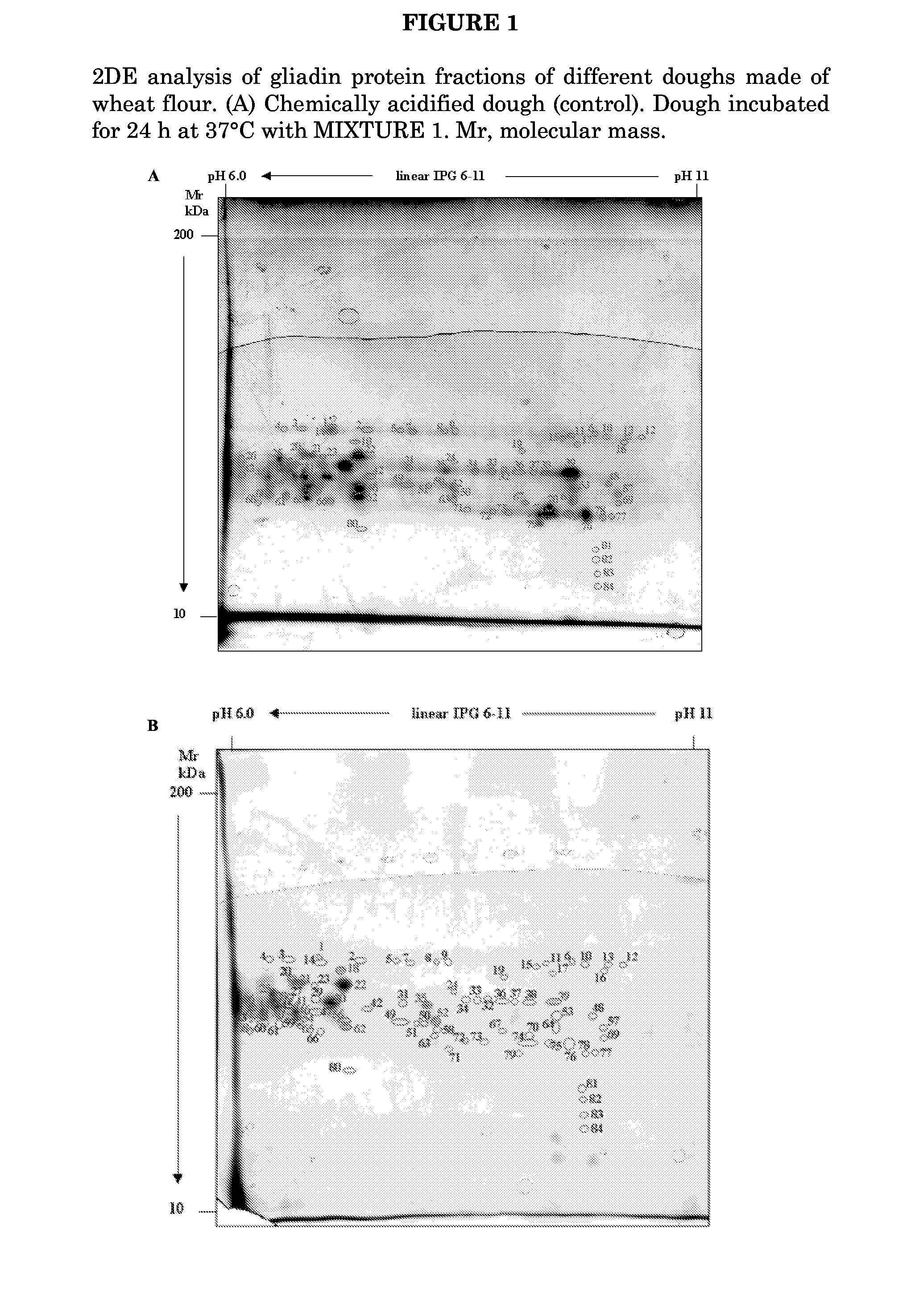

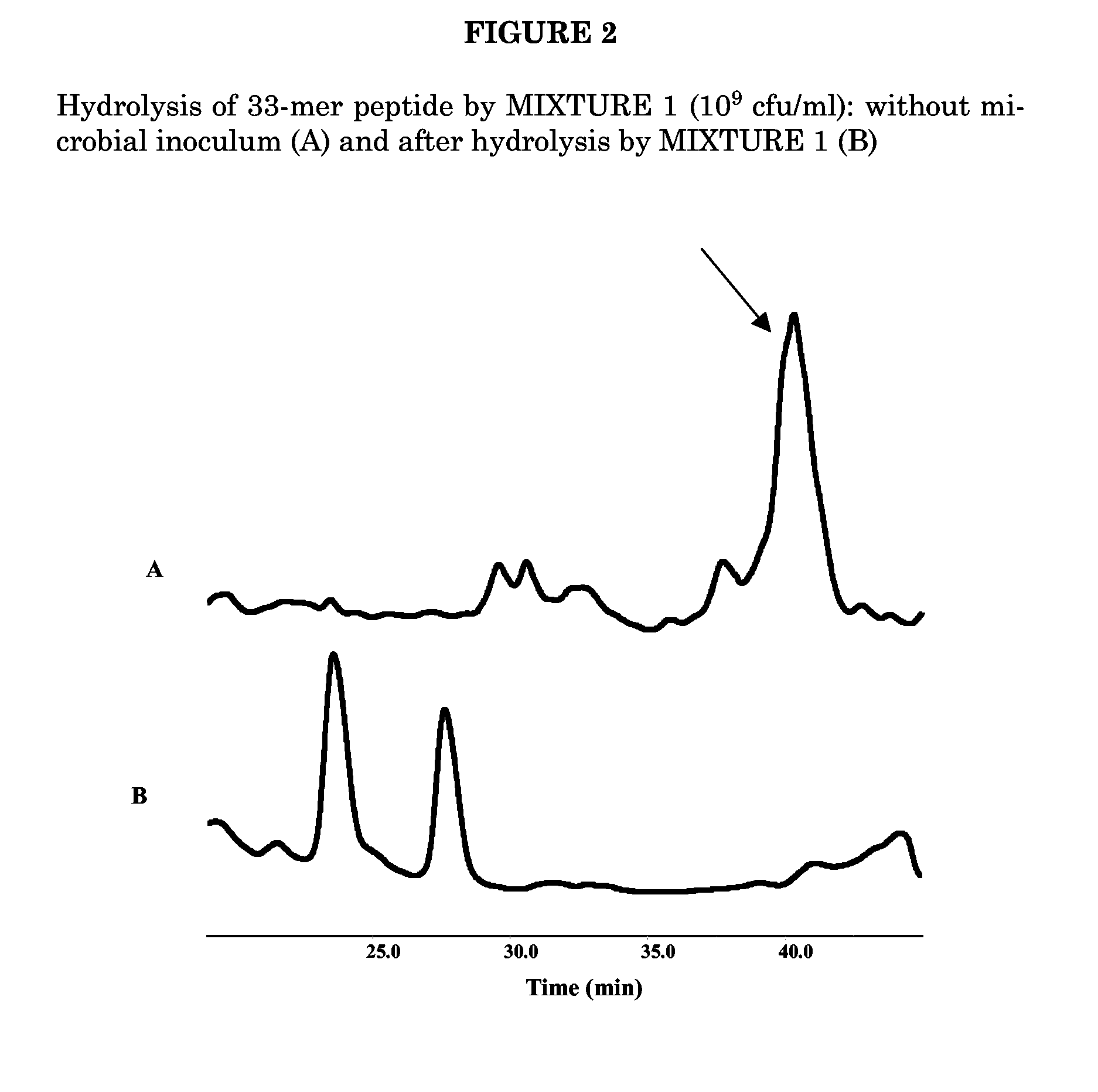

Mixture of at Least 6 Species of Lactic Acid Bacteria and/or Bifidobacteria in the Manufacture of Sourdough

A mixture of at least 6 species of lactic acid bacteria and / or Bifidobacteria is disclosed for use in bakery and medical field. The preferred mixture comprises Streptococcus thermophilus, Bifidobacterium infantis, Bifidobacterium longum, Bifidobacterium breve, Lactobacillus acidophilus, Lactobacillus plantarum, Lactobacillus casei, Lactobacillus delbrueckii subsp. bulgaricus. Said mixture is useful for a sourdough, a leavening composition. Baked goods and other food products obtained therefrom are disclosed. These goods have low or no gluten content and are suitable for the integration of the diet of a subject suffering from celiac disease, for decreasing the risk of allergies due to wheat flour albumins and globulins, for the treatment of schizophrenic symptoms, in the preparation of products for enteric diet.

Owner:VSL PHARMA INC

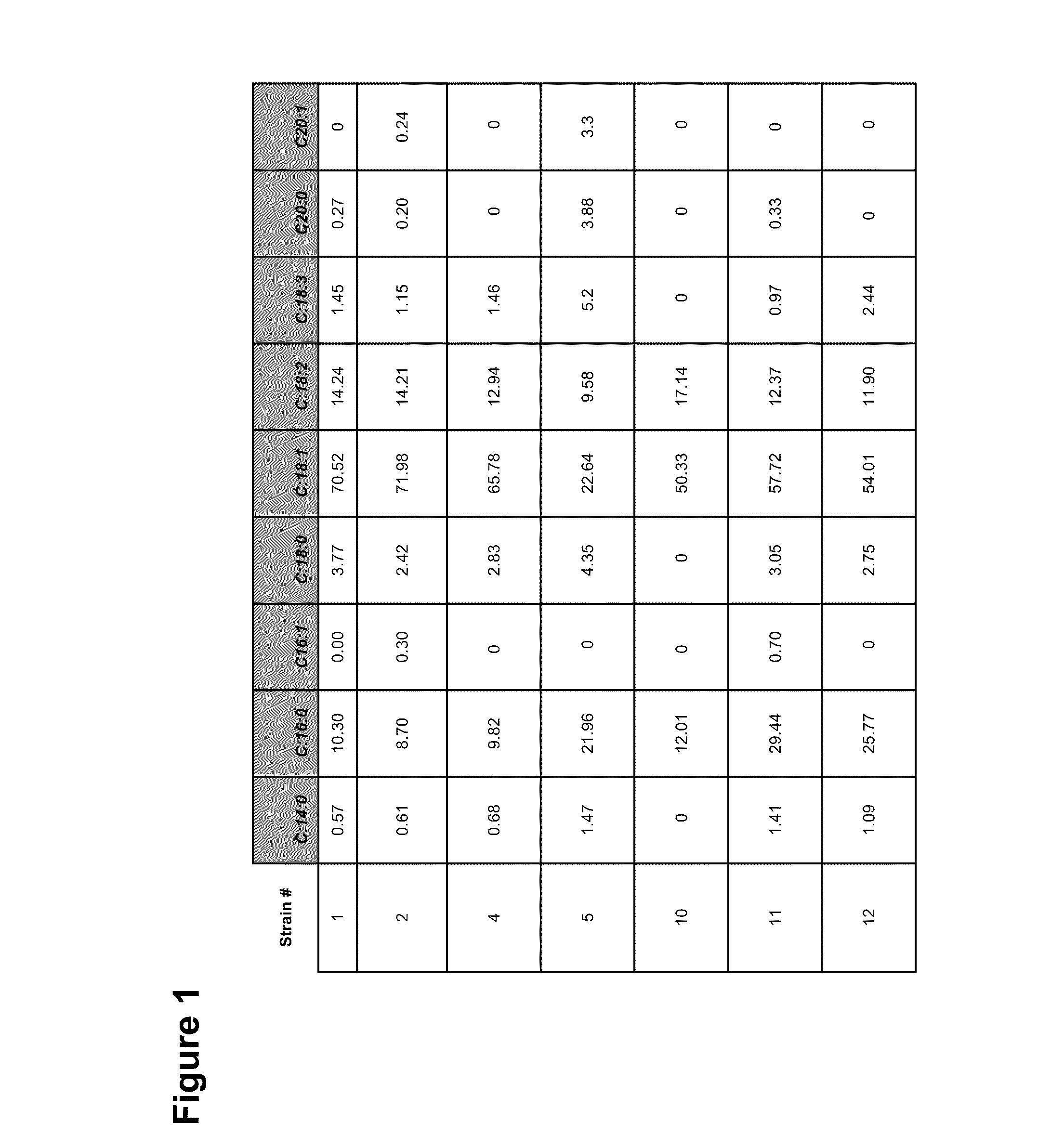

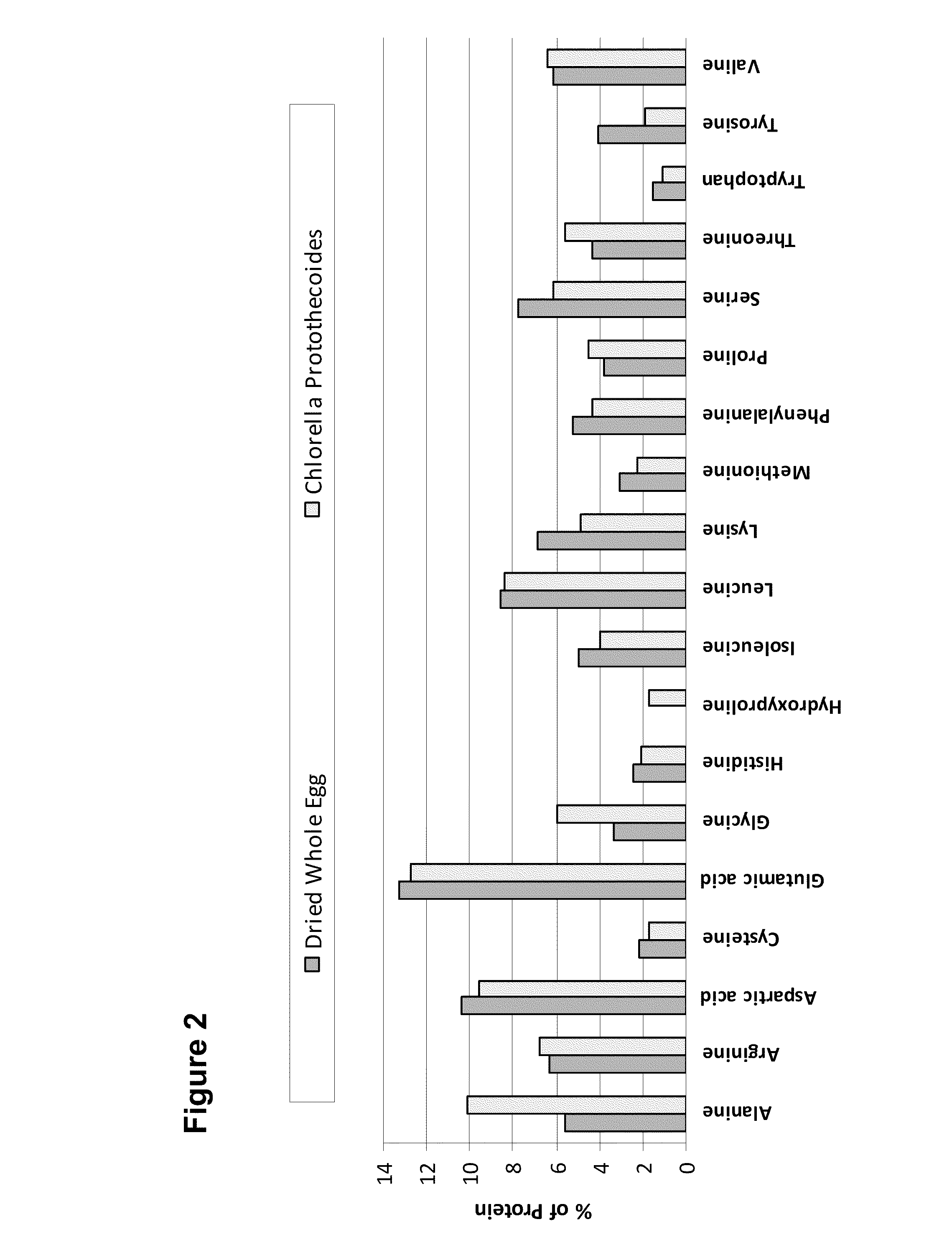

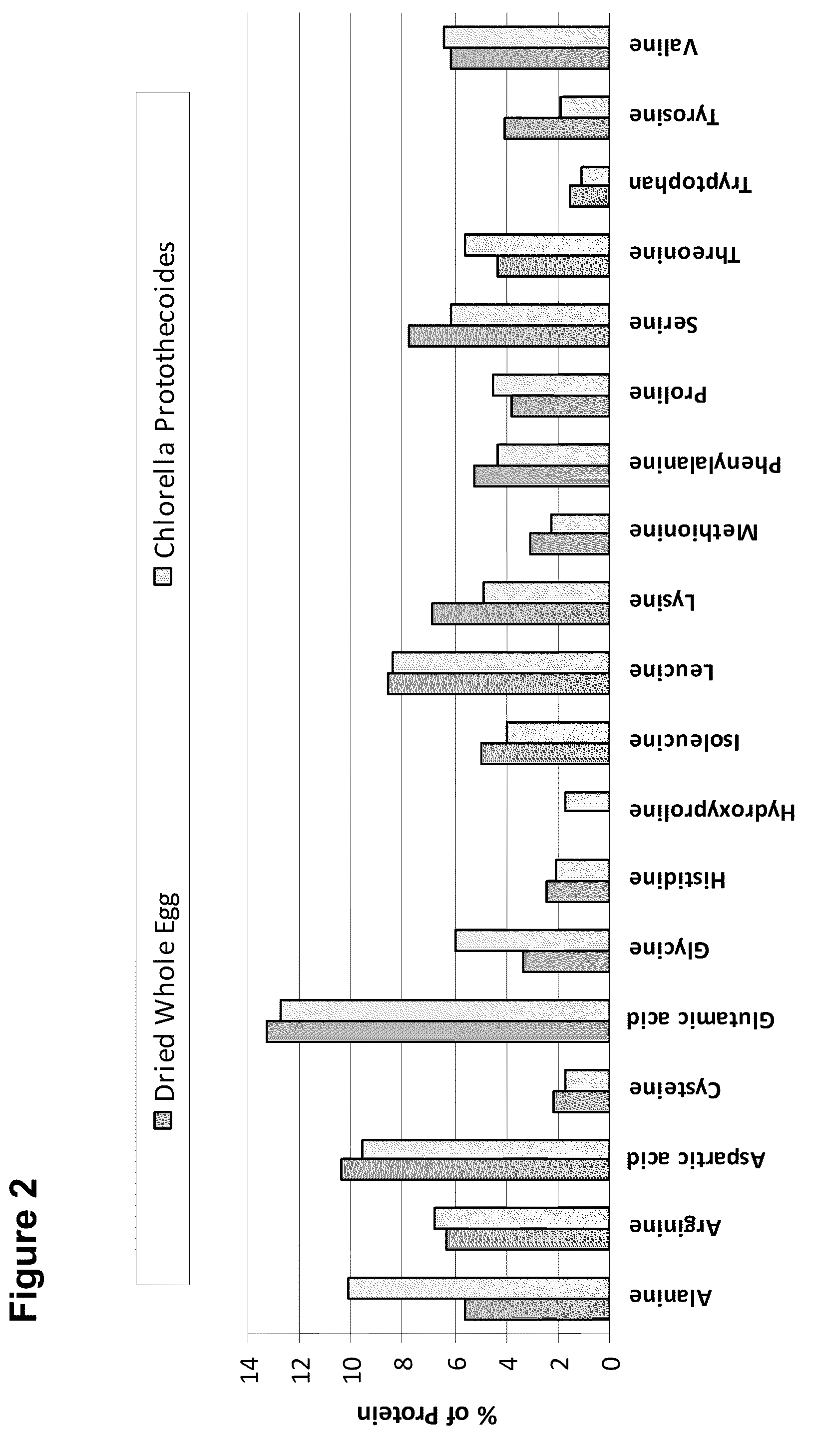

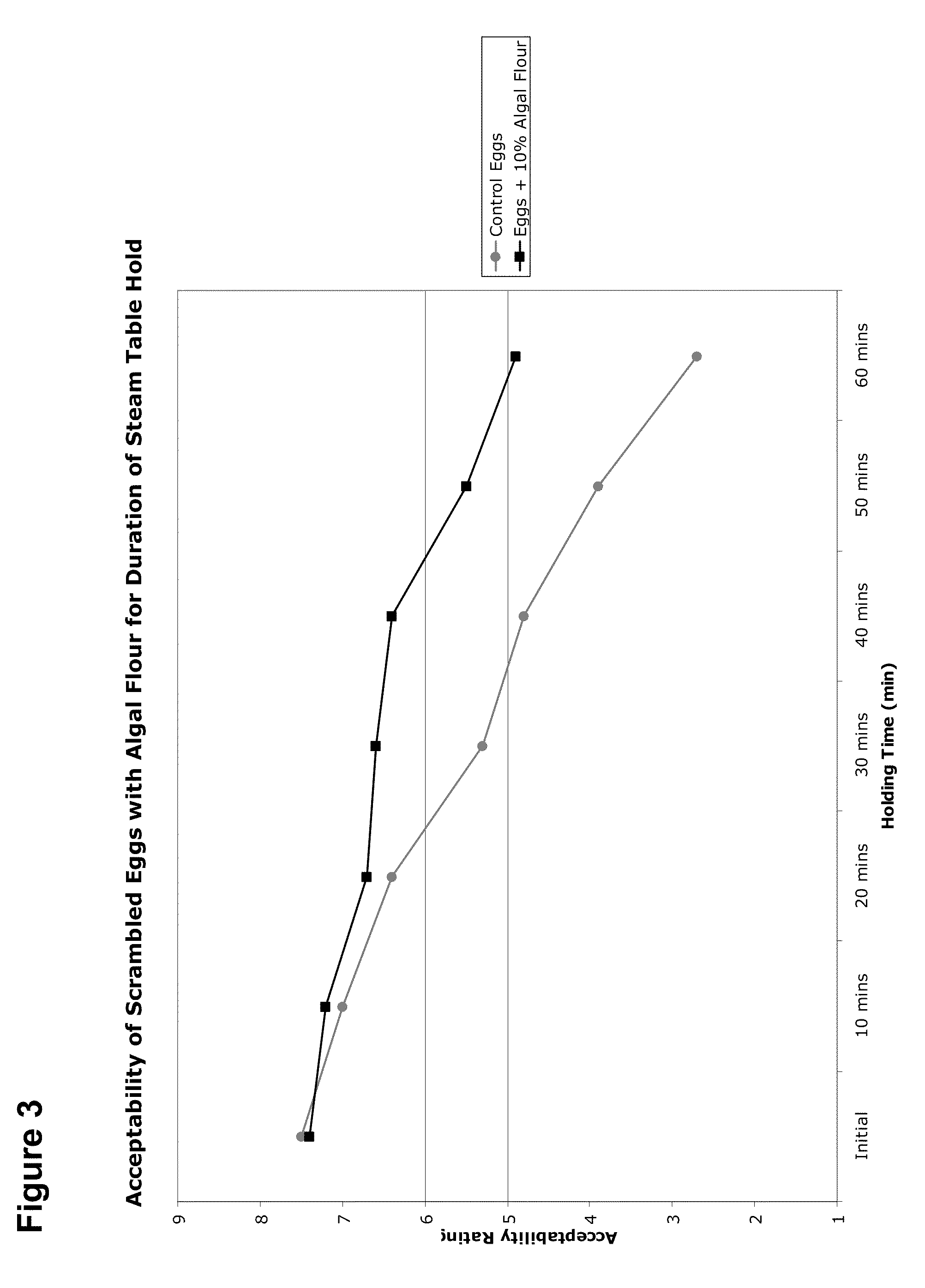

Healthier Baked Goods Containing Microalgae

Provided herein are microalgae-containing baked goods with novel properties compared to preexisting products of the same type. Methods of formulating and manufacturing these foods to deliver reduced fat, reduced cholesterol, and increased fiber content are disclosed herein. Various embodiments include elimination or reduction of eggs, butter, animal fat, and saturated oils in favor of healthy oil-containing microalgae biomass and oils, including the manufacture of foods with lower calories than preexisting products of the same type. Methods of producing raw materials for the manufacture of novel processed baked foods and intermediates such as cake and bead mixes are also provided.

Owner:TERRAVIA HLDG INC

Reduced Pigmentation Microalgae Strains and Products Therefrom

InactiveUS20100297292A1Reduced colorationIncrease rangeMilk preparationDough treatmentHypopigmentationCarotenoid

The invention provides unique and novel strains of microalgae that have been subjected to non-transgenic methods of mutation sufficient to reduce the coloration of biomass produced by the strains. Biomass produced from such strains can be used in the manufacture of baked goods, gluten free foods, beverages, high lipid algal flours, and other foods. Pigments such as carotenoids and chlorophyll can be undesirable for consumer acceptance when incorporated into foods such as mayonnaise, yogurt, and white sauces that are not traditionally associated with colors such as yellow, red, orange and green. Some pigments, such as chlorophyll, can also create undesirable taste profiles. Use of reduced pigment microalgal biomass expands the range of food products that can be manufactured with healthy lipid profiles. High protein containing biomass of the invention, also reduced in pigmentation, is also incorporated into products such as meat analogues, nutritional bars and meal replacement beverages. The reduced pigmentation microalgae also allow for incorporation of higher amounts of biomass into certain food products that could otherwise be achieved using highly pigmented microalgal biomass. Methods of generating novel reduced pigment microalgae are disclosed herein. The strains provided by the invention are also useful in the manufacture of healthy, neutral colored extracted triglyceride oils.

Owner:TERRAVIA HLDG INC

Baked Goods Comprising High-Potency Sweetener

ActiveUS20070224321A1Improve flavor profileImproving temporal profile profileDough treatmentBakery productsBaked goodsSweetness

The present invention relates generally to baked goods comprising non-caloric or low-caloric high-potency sweeteners and methods for making and using them. In particular, the present invention relates to different baked goods comprising at least one non-caloric or low-caloric natural and / or synthetic high potency sweetener and at least one sweet taste improving composition. The present invention also relates to baked goods and methods that can improve the tastes of non-caloric or low-caloric natural and / or synthetic high-potency sweeteners by imparting a more sugar-like taste or characteristic. In particular, the baked goods and methods provide a more sugar-like temporal profile, including sweetness onset and sweetness linger, and / or a more sugar-like flavor profile.

Owner:THE COCA-COLA CO

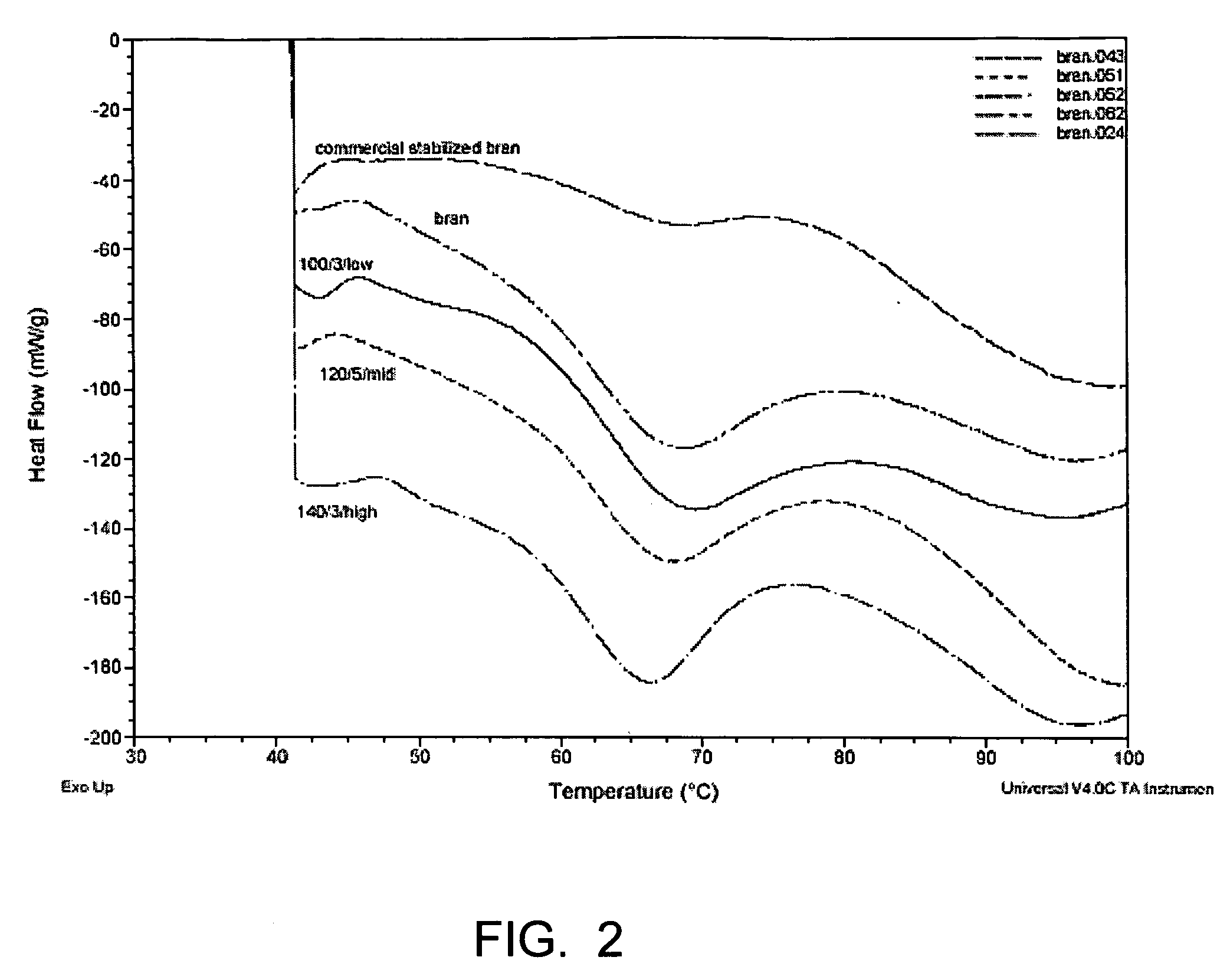

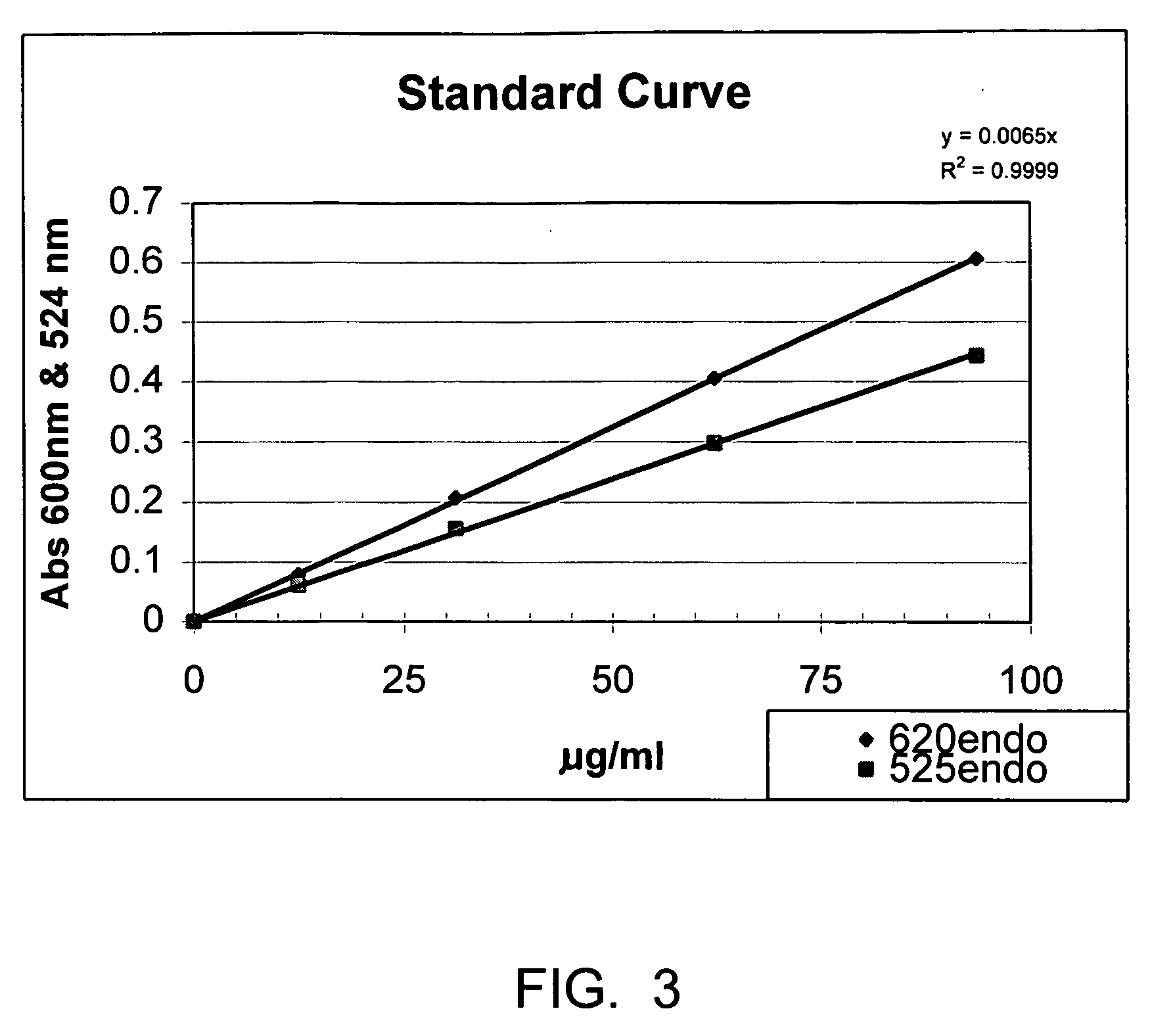

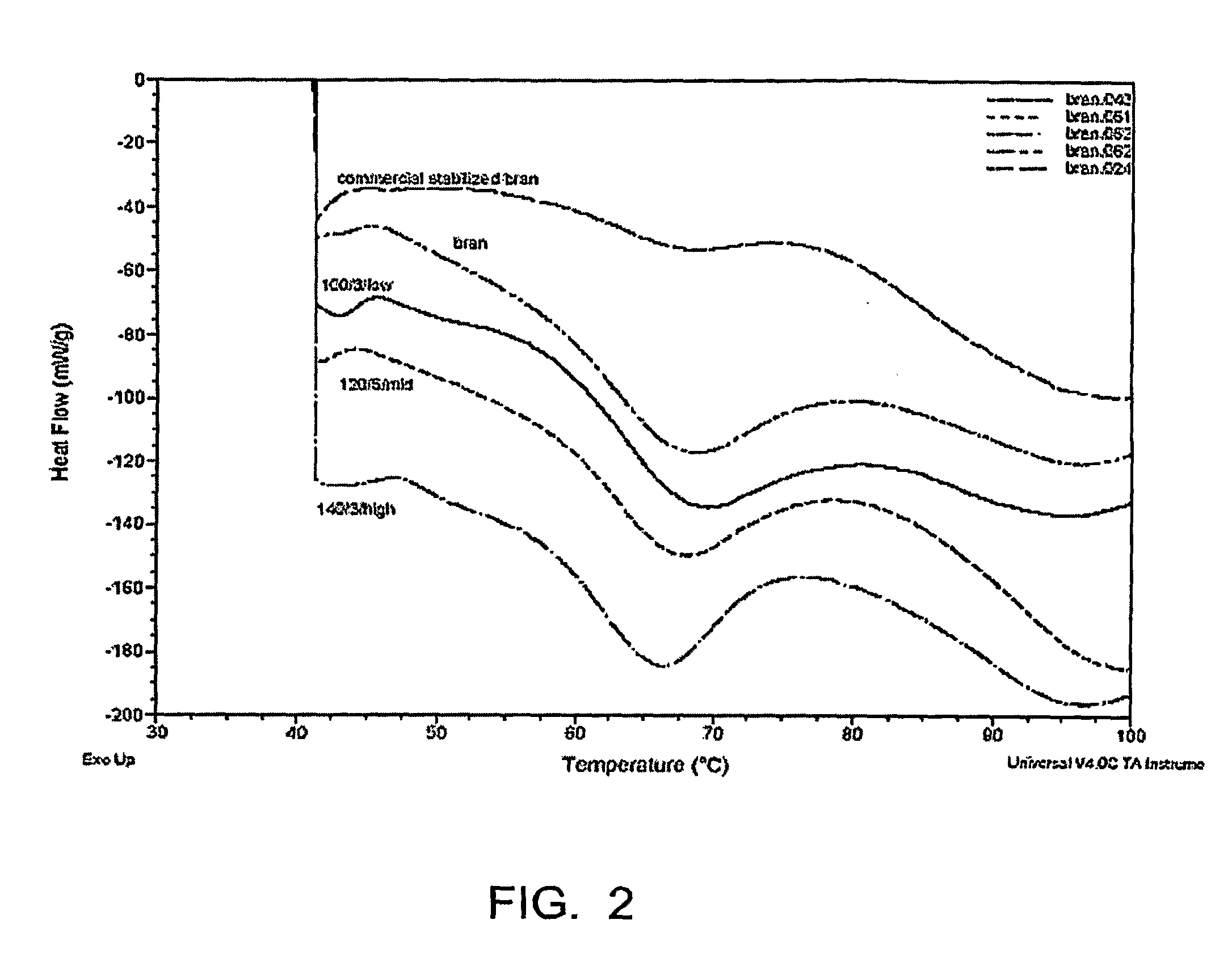

Production of stabilized whole grain wheat flour and products thereof

ActiveUS20070292583A1Superior oven spreadNice appearanceDough treatmentBaking mixturesAntioxidantLipoxygenase activity

A stabilized bran component and a stabilized whole grain wheat flour containing the component are produced by subjecting a bran-enriched coarse fraction which contains bran, germ and starch to grinding or milling to reduce grittiness of the coarse fraction without substantially damaging the starch due to abrasion. The coarse fraction may be stabilized by heating to substantially reduce the lipase and lipoxygenase activity of the coarse fraction without substantial gelatinization of the starch. High levels of natural antioxidants and vitamins are retained while avoiding substantial acrylamide formation during the stabilization. The stabilized coarse fraction or stabilized bran component may be combined with a fine fraction which contains predominantly endosperm to obtain a stabilized whole grain wheat flour. The stabilized whole grain wheat flours and the stabilized bran component exhibit extended shelf life and may be used for making baked goods, such as cookies, with desirable oven spread, and a non-gritty mouthfeel.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

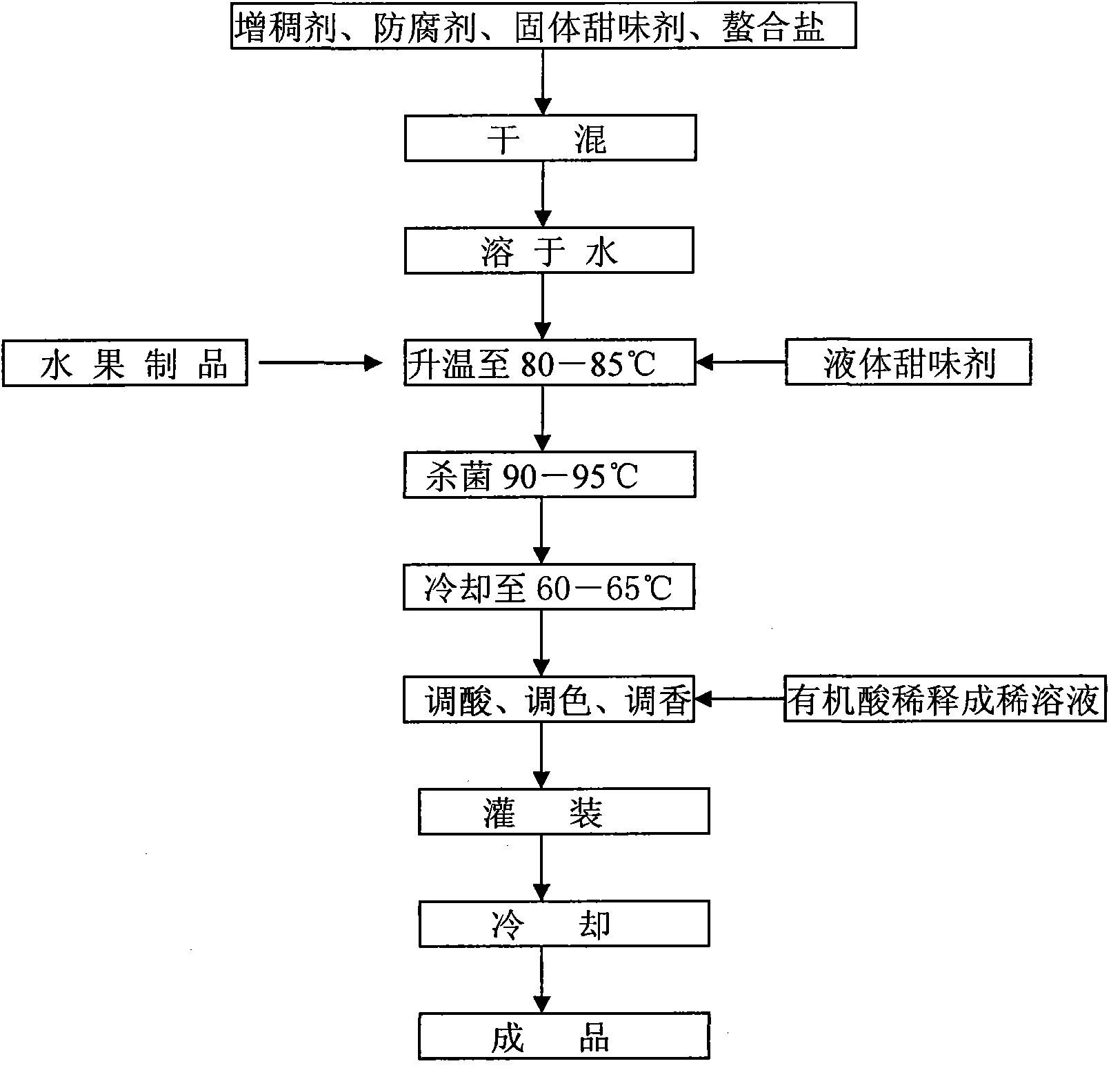

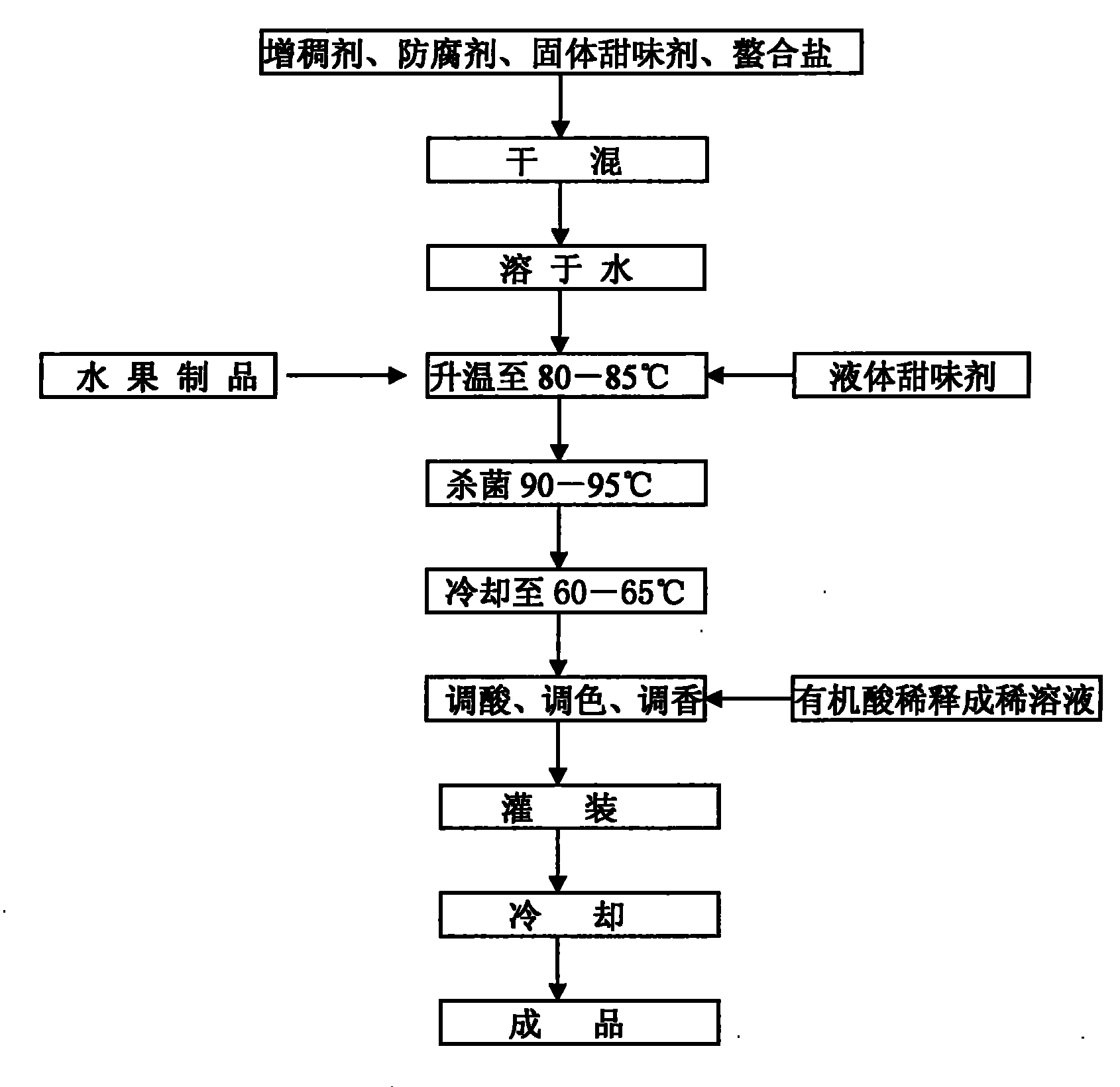

High-temperature baking resistant jam and preparation method and application thereof

ActiveCN101843306AImprove high temperature resistanceSolve prone to collapseBakery productsFood preparationOrganic acidFlavor

The invention discloses a high-temperature baking resistant jam and a preparation method and application thereof. The preparation method comprises the following steps of: uniformly mixing a thickening agent, a preservative, a solid sweetening agent and chelated salt, and dissolving the mixture in water; raising the temperature to a temperature of between 80 and 85 DEG C with continuous stirring, adding a liquid sweetening agent and fruit products, and sterilizing at the temperature of between 90 and 95 DEG C for 10 to 15 minutes; and cooling to the temperature of between 60 and 65 DEG C, and adding a food flavor, a food color and prepared organic acid solution to obtain the high-temperature baking resistant jam. The jam has good high temperature resistance, can be baked at a high temperature for more than 20 minutes without deformation, off-flavor and discoloration, has high transparency, and is suitable to be used as sandwich, stuffing, surface decoration and seasoning of baked goodssuch as cakes, bread and the like. The high-temperature baking resistant jam has the advantages of simpleness and wide sources of raw materials, simpleness and easy operation of the preparation method, and no need of complicated equipment, and can be produced by slightly adjusting the conventional production lines of manufacturers for fruit drinks and seasonings.

Owner:广州合诚实业有限公司

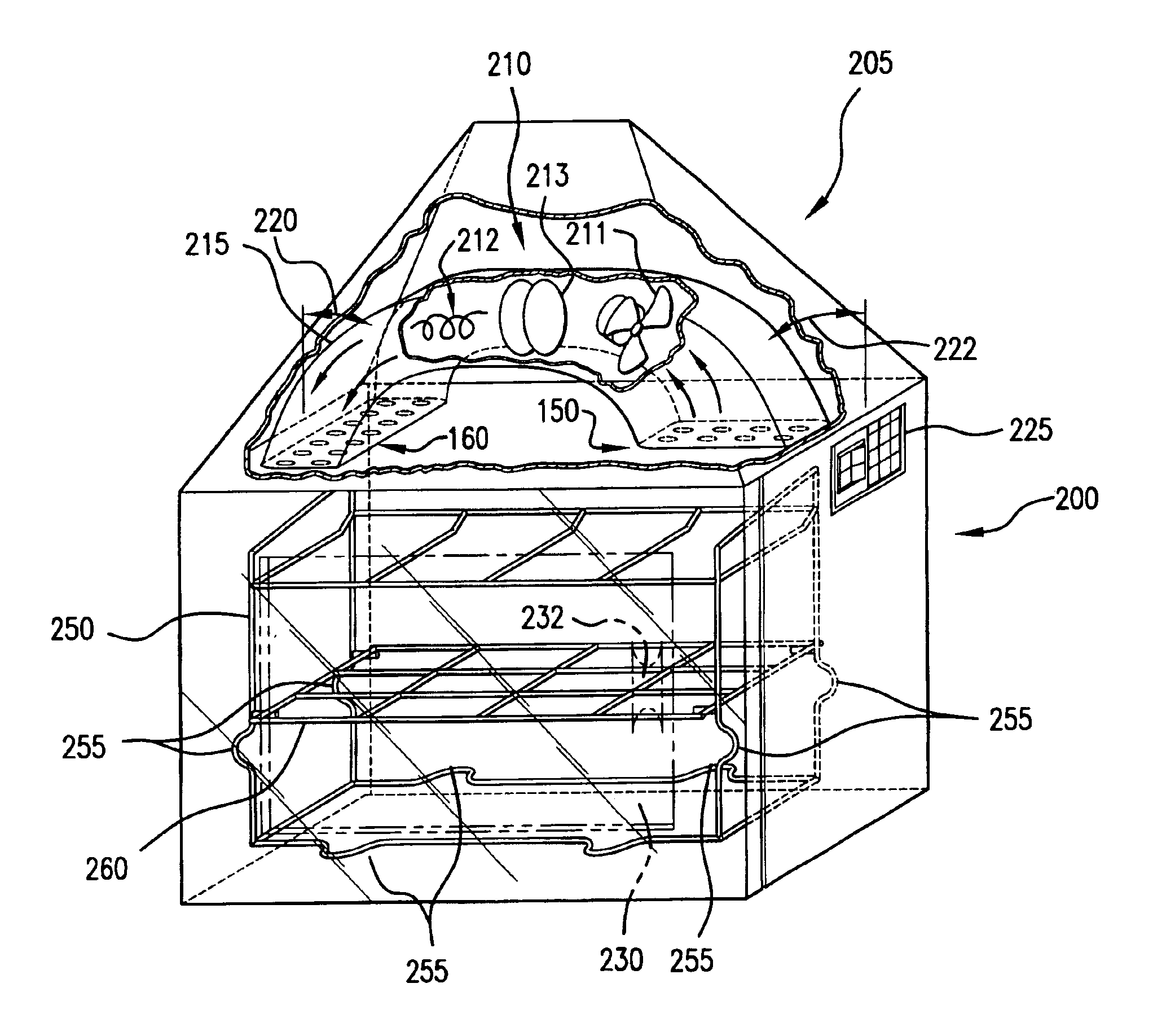

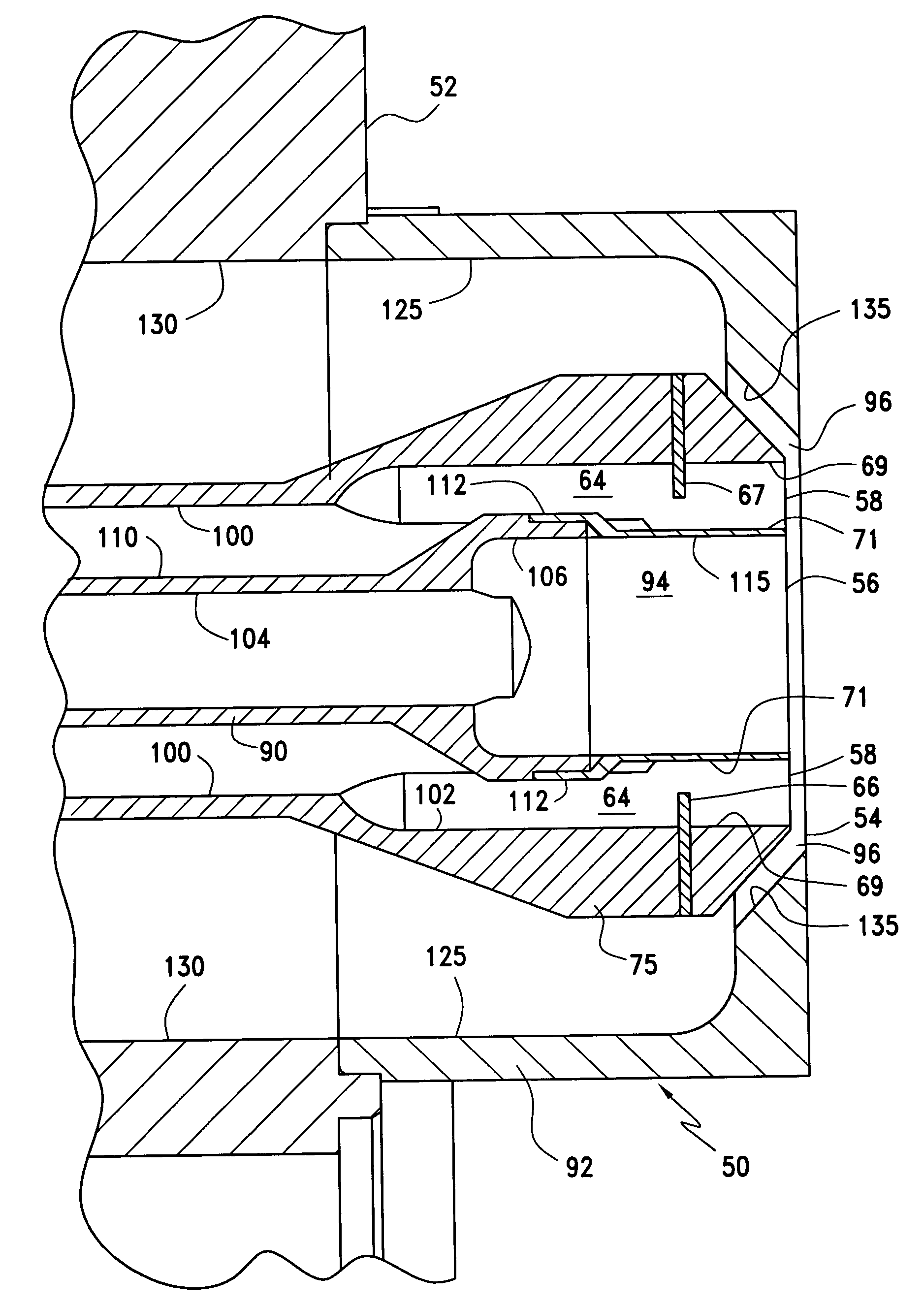

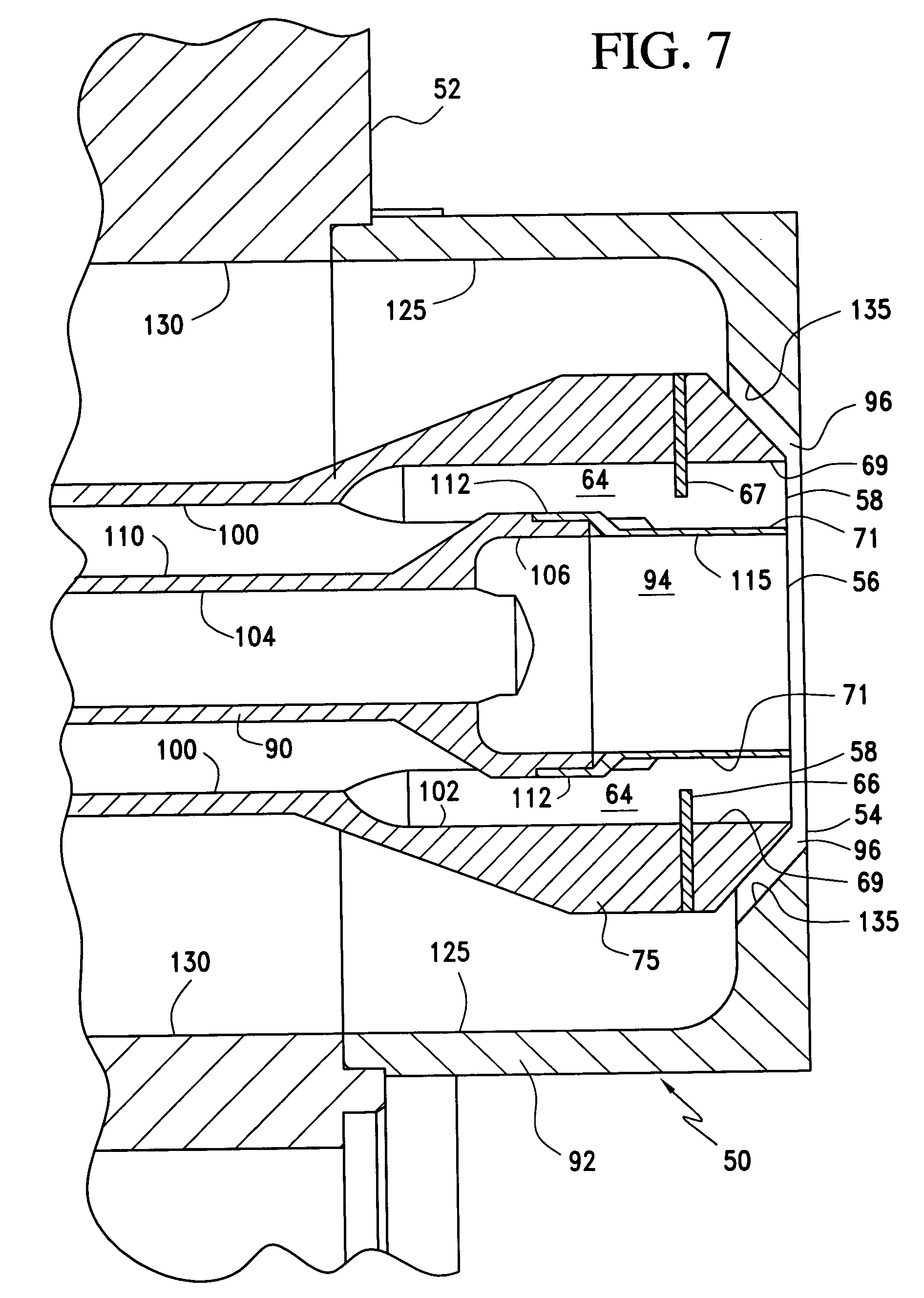

Apparatus for controlling the drying of previously baked goods

A merchandiser for displaying and warming previously baked dough products, such as a filled pastry shell or other baked dough product, under controlled drying conditions, including an enclosure having one or more wall members that define an interior space, with at least a portion of one of the wall members being transparent, an opening for access into the interior space, a removable support member within the enclosure that includes at least one support surface for previously baked dough products and a spacing arrangement configured and adapted to reproducibly position the support member within the interior space of the enclosure member to facilitate substantially uniform airflow around each support surface and throughout the enclosure, and a heating system for providing heated air in the enclosure, wherein the substantially uniform airflow provides controlled drying of the previously baked dough products in the enclosure. A merchandiser including an air-moving device, a heat source, and a reflective device disposed therebetween is also included.

Owner:NESTEC SA

Trans fat replacement system and method of making a baked good with a trans fat replacement system

The invention provides a trans fat replacement system that is a stable and shelf storable mixture of an edible oil and an expanded, low-density carbohydrate for use in preparing baked goods having a reduced trans fat content. Depending upon formulation and processing, the mixture can have a consistency ranging from generally granular to an almost paste-like consistency. The trans fat replacement system consists of at least one edible oil and an expanded, low-density carbohydrate having a bulk density less than about 0.4 g / cc. The trans fat replacement system can be used to reduce or eliminate the amounts of traditional fats used to make baked goods. In one representative formulation, the trans fat replacement system can take the form of a generally, paste-like mixture that is suitable for spreading and is especially useful for the preparation of laminated dough products such as biscuits and croissants.

Owner:GENERAL MILLS INC

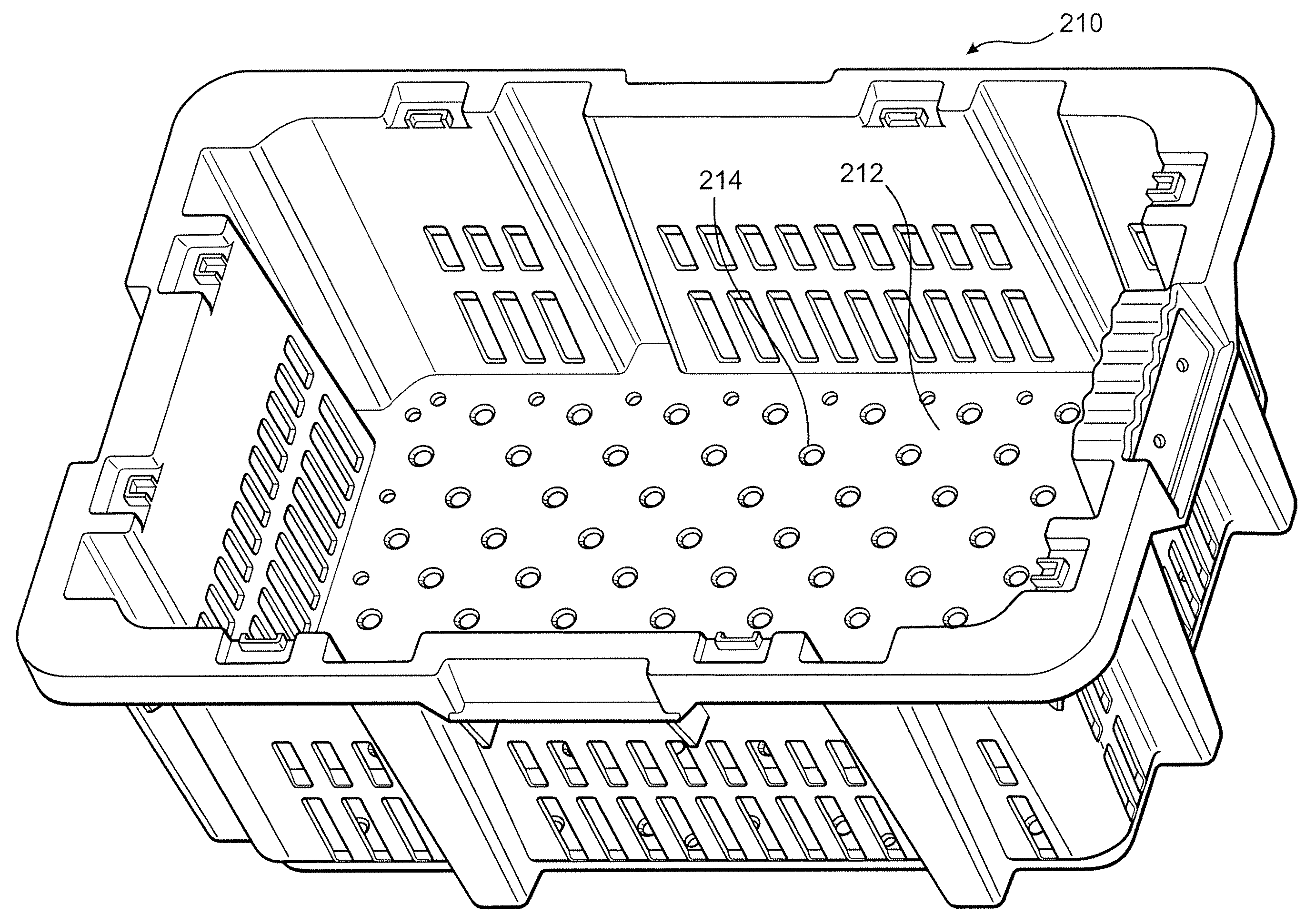

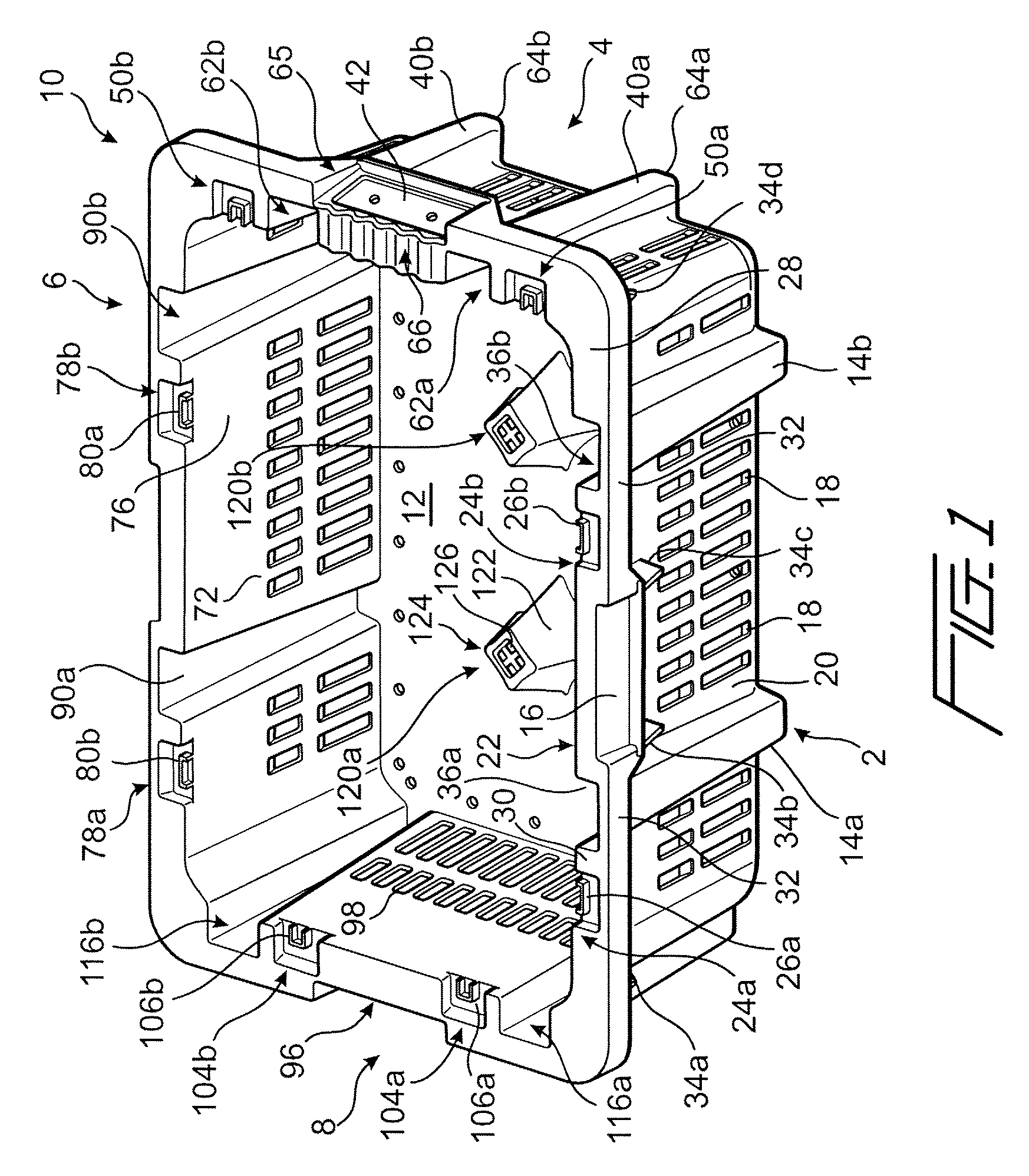

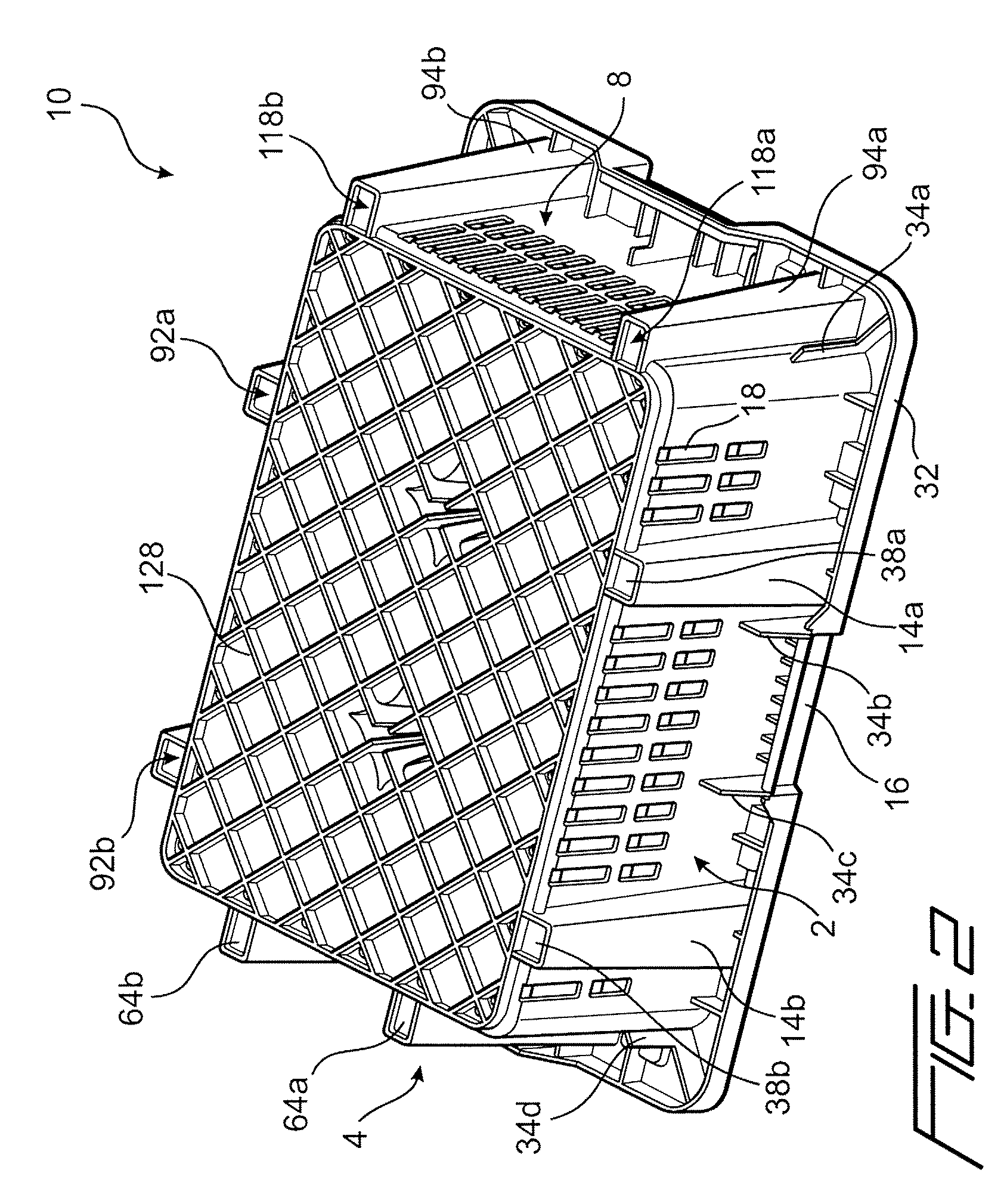

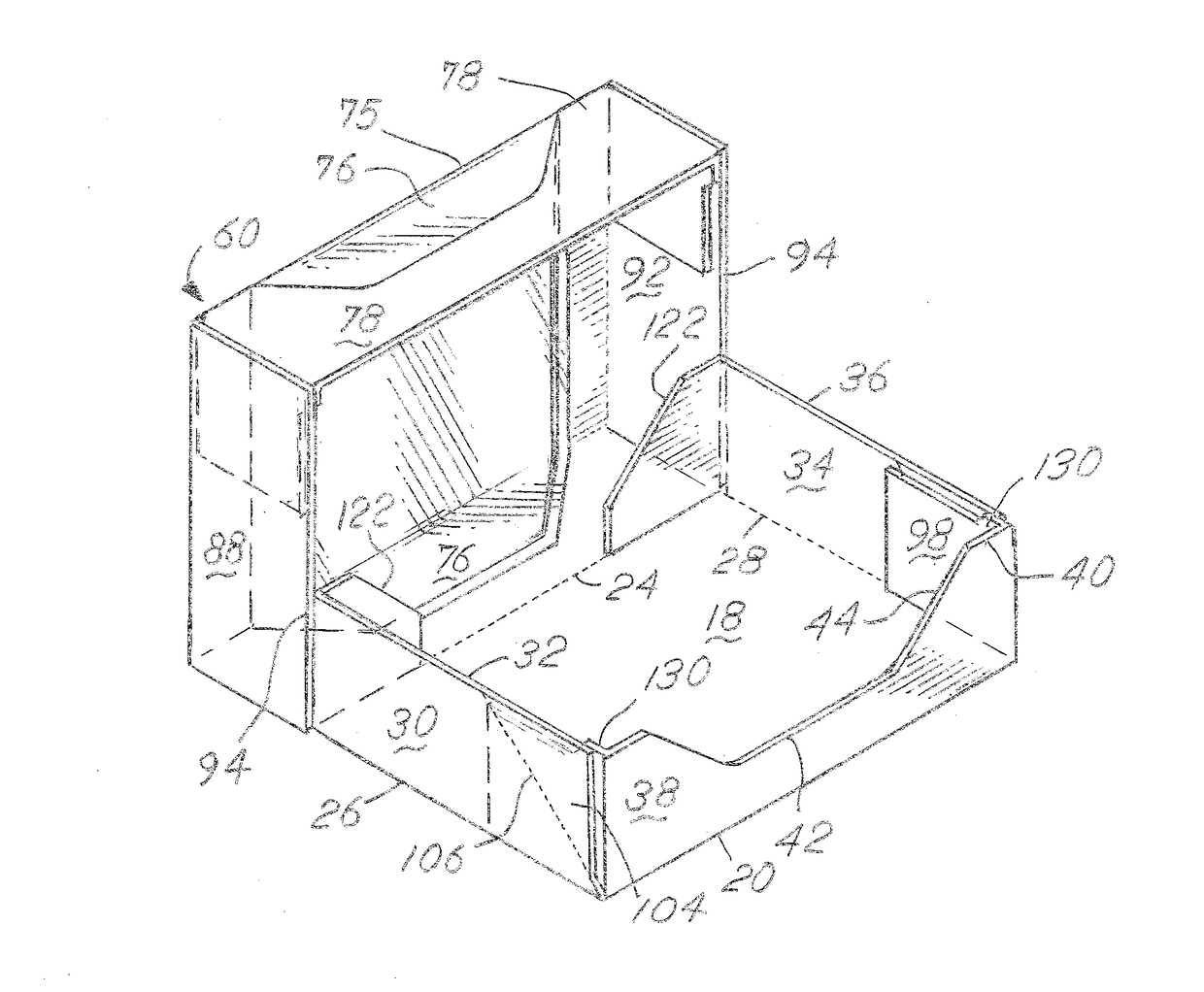

Nestable and stackable container for the transport of heavy baked items

A container for containing and transporting baked goods includes a front wall, left side wall, rear wall and a right side wall, wherein each of the walls is substantially orthogonal to a base. The base includes a substantially flat, smooth upper surface. Integrally formed as part of and rising from the base are a plurality of base projections, each with a plurality of sloped curved wall surfaces. There are at least two stacking feet per wall of the container. The container further includes 180° stacking recesses located on a rim that surrounds the container and that substantially prevent an upper container from shifting or sliding when stacked in a 180° stacking orientation, preferably for the transportation of baked goods. Each of the recesses further comprises a “U” or “[” shaped projection to interface and retain the stacking feet of an upper container when stacked in the 180° stacking orientation.

Owner:ORBIS CANADA

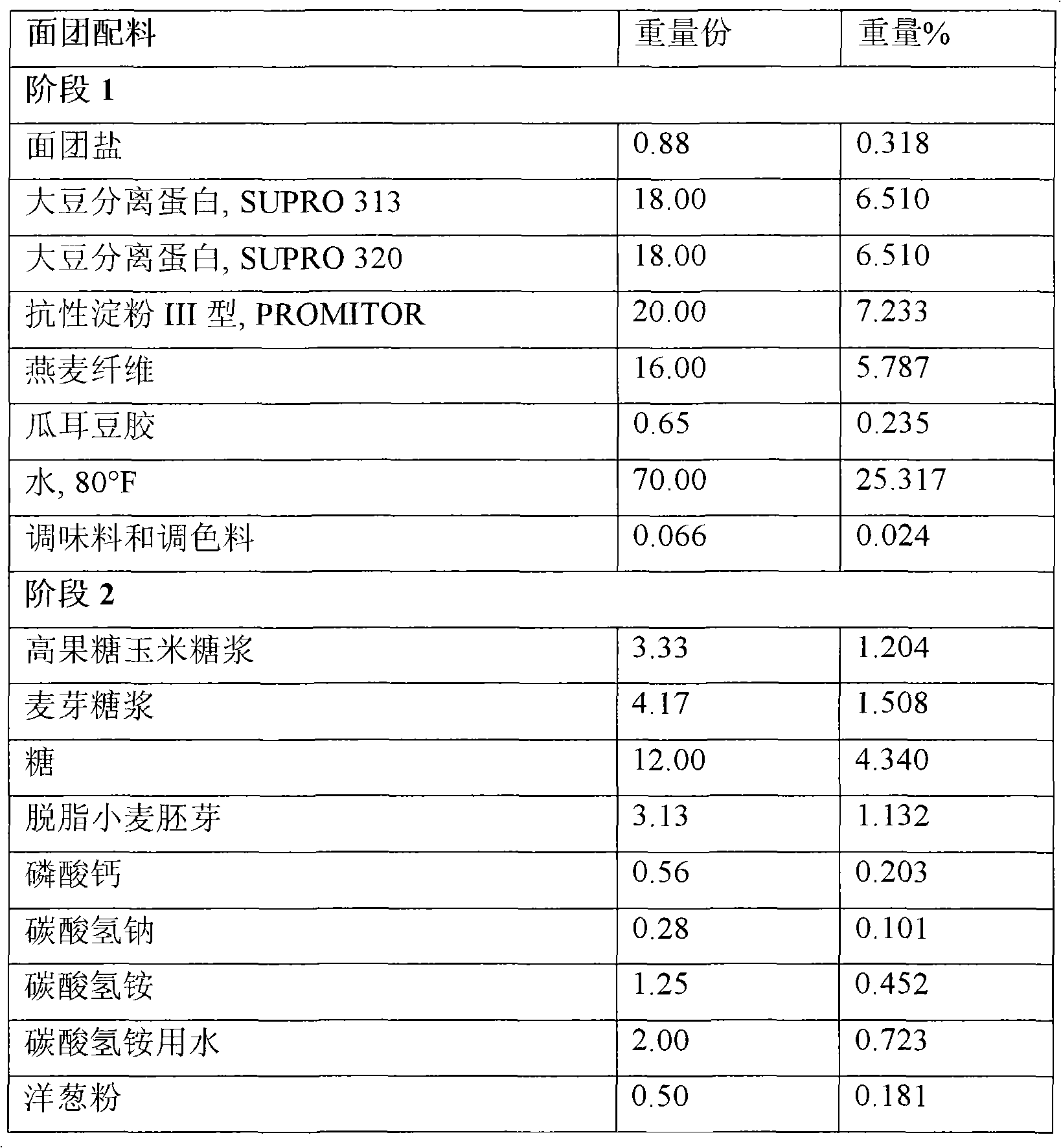

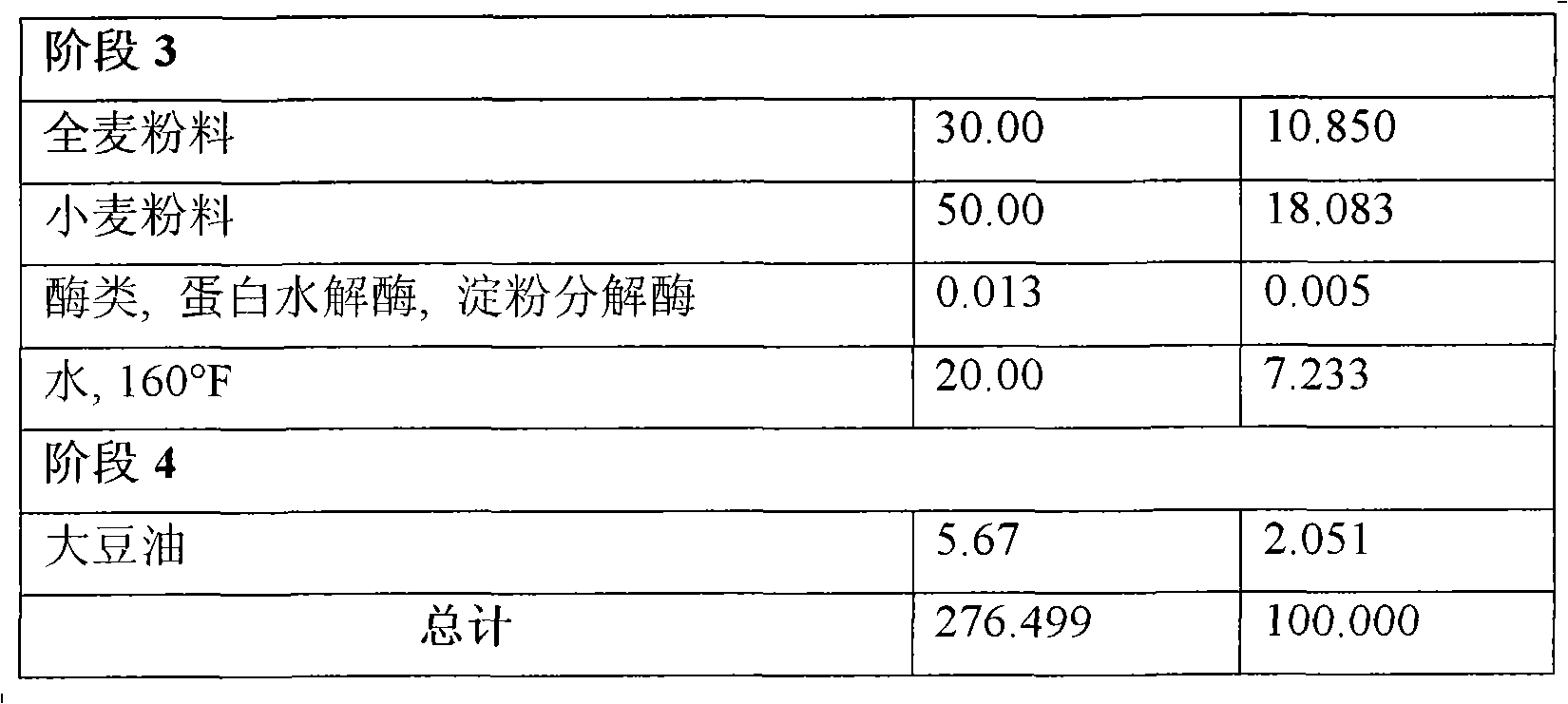

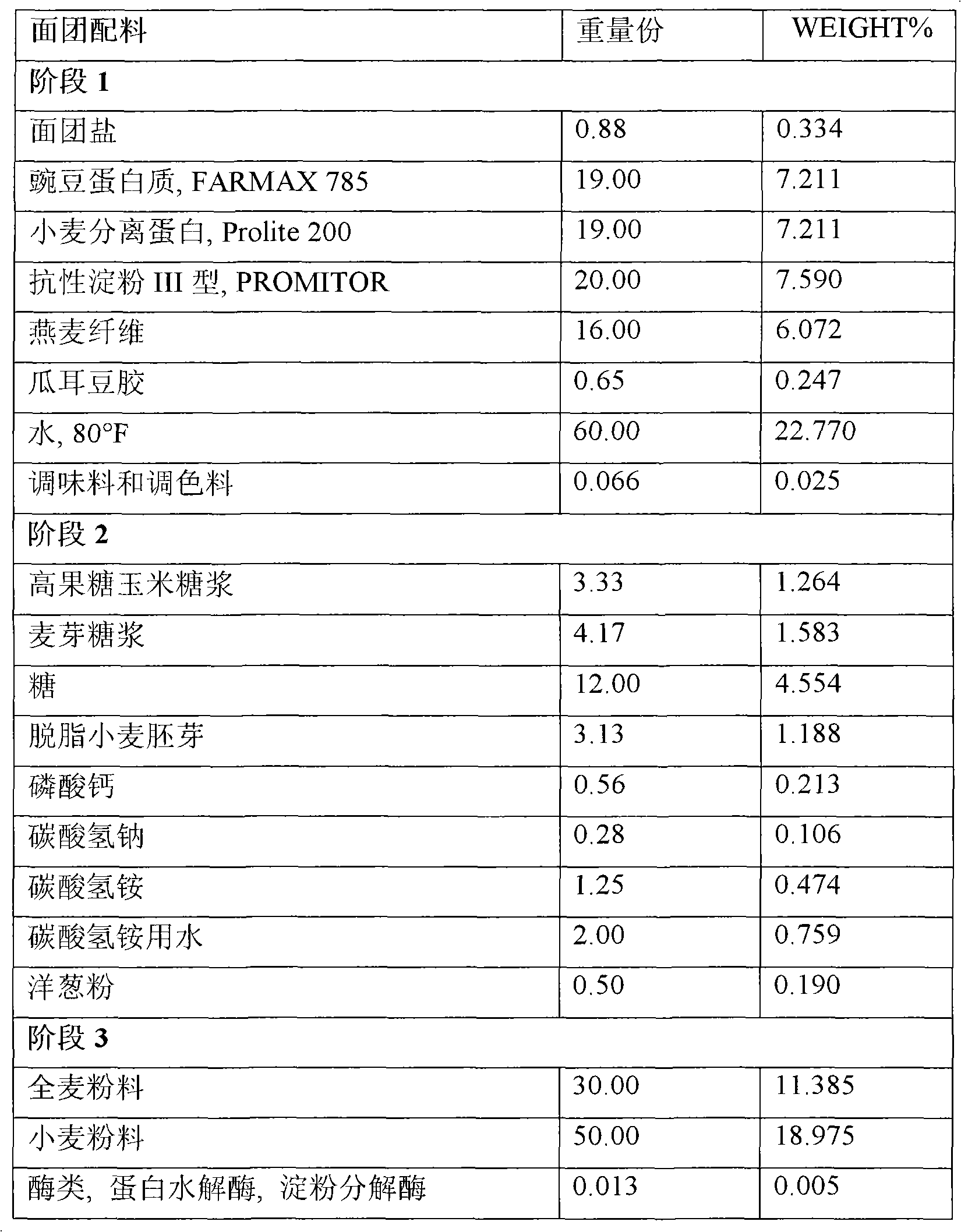

High fiber and high protein baked goods production

InactiveUS20100303991A1Pleasant tastePotential healthDough/pre-mixesConfectioneryStarch gelatinizationHigh protein food

Substantially uniform hydration and dispersion of high amounts of protein and fiber are achieved while avoiding lump formation, hard textures, and off-tastes in the continuous, mass production of high protein and high fiber content sheetable doughs, and baked goods such as crackers, snacks, and cookies made from the sheeted doughs, by hydrating the protein and fiber with water at a temperature below the denaturization temperature of the proteins, and steaming the hydrated mixture without substantial gelatinization of starch during dough production. The steamed, hydrated mass may be admixed with ingredients comprising at least one flour comprising starch to obtain a dough while avoiding substantial gelatinization of starch of the at least one flour during mixing. The baked goods may have a protein content of at least about 4 g, a fiber content of at least about 4 g, and a whole grain flour content of at least about 4 g per 30 g serving.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

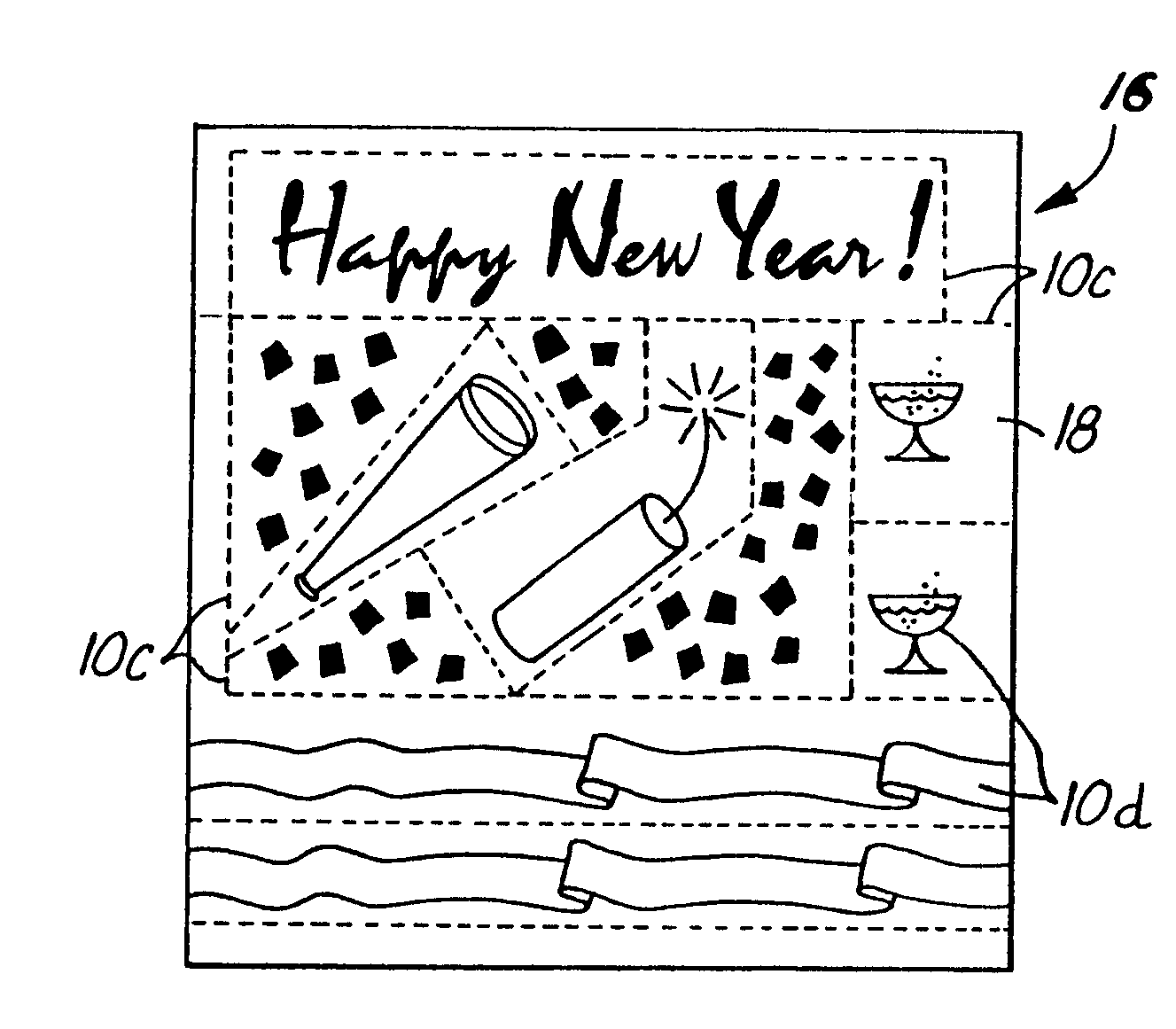

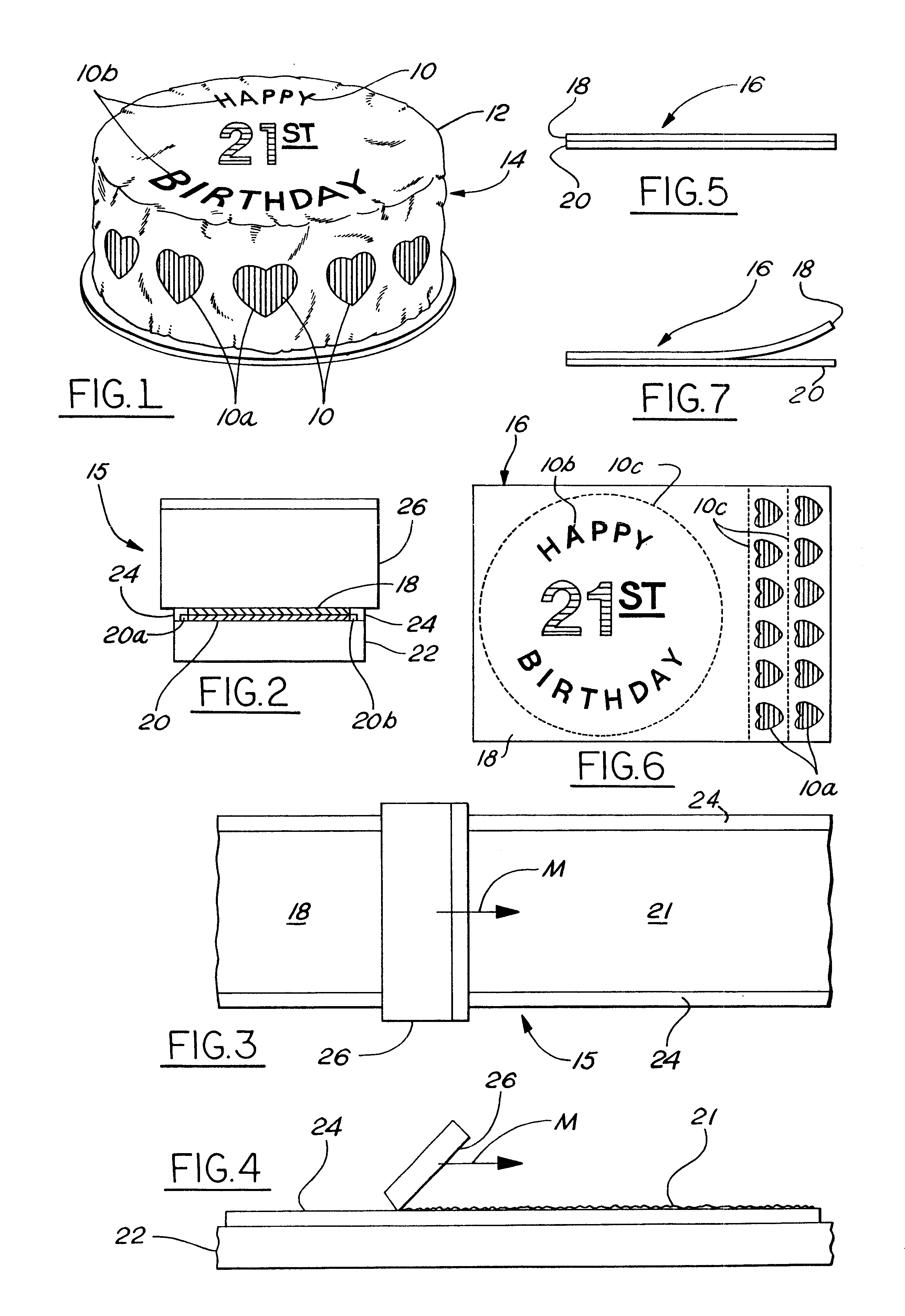

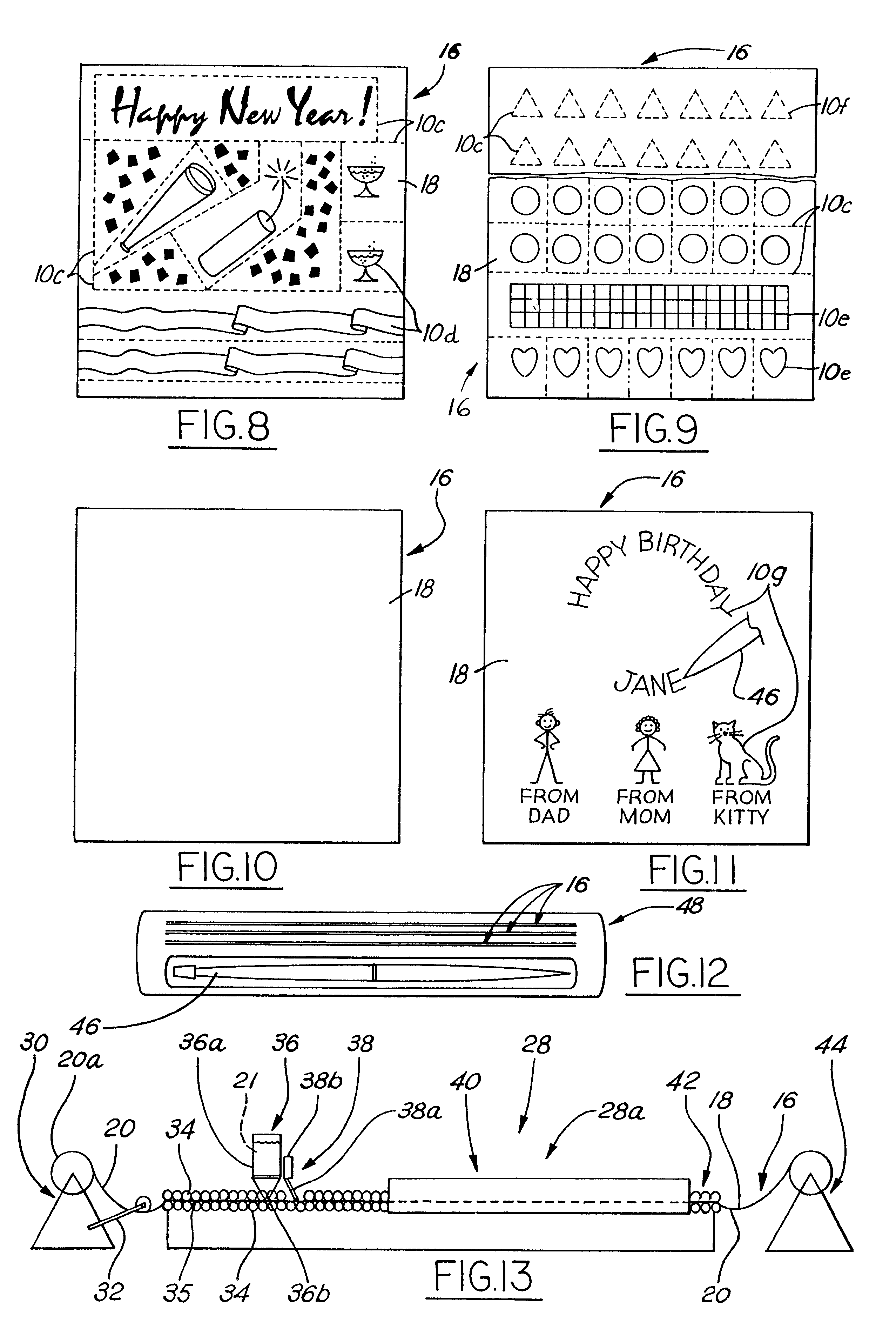

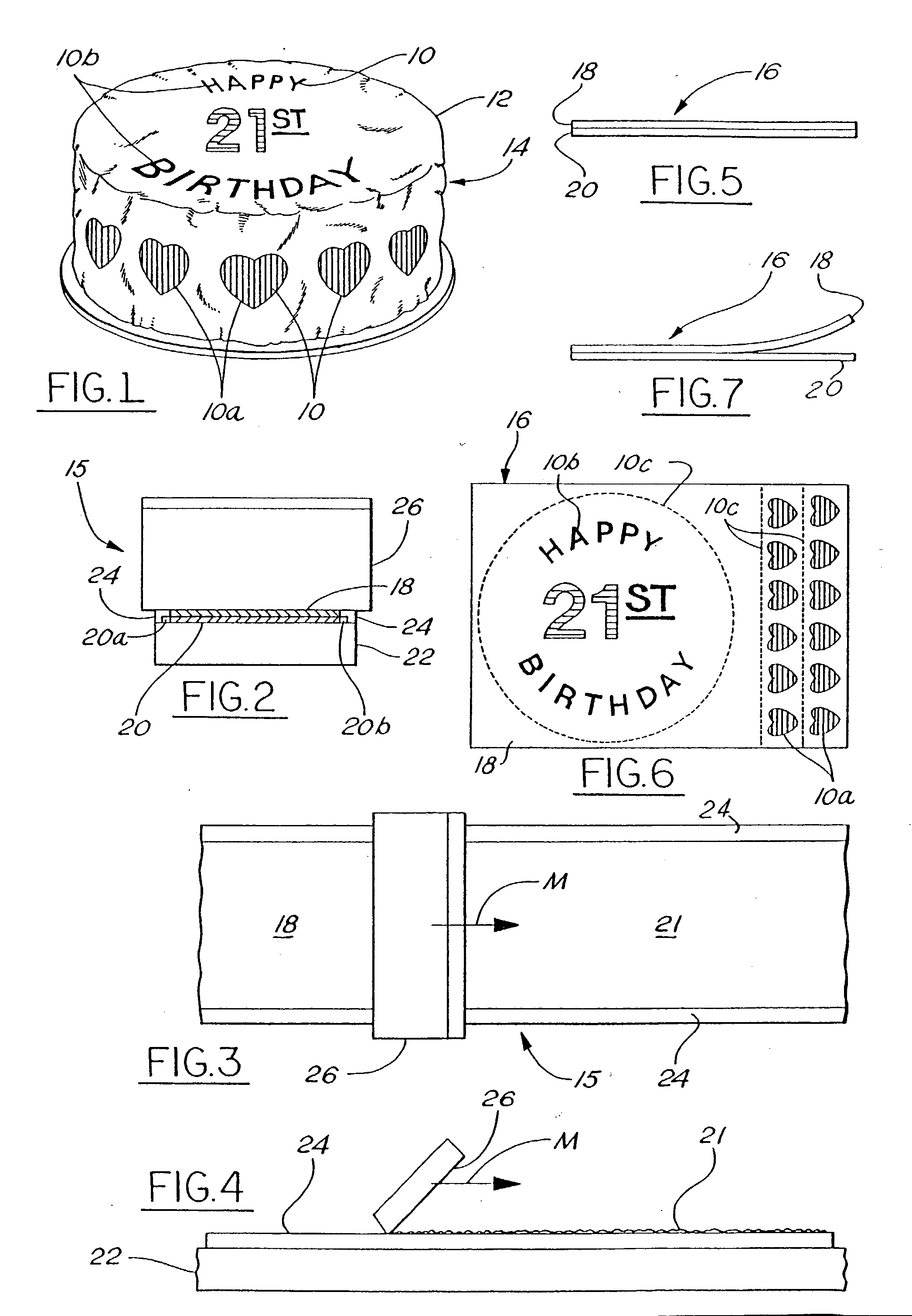

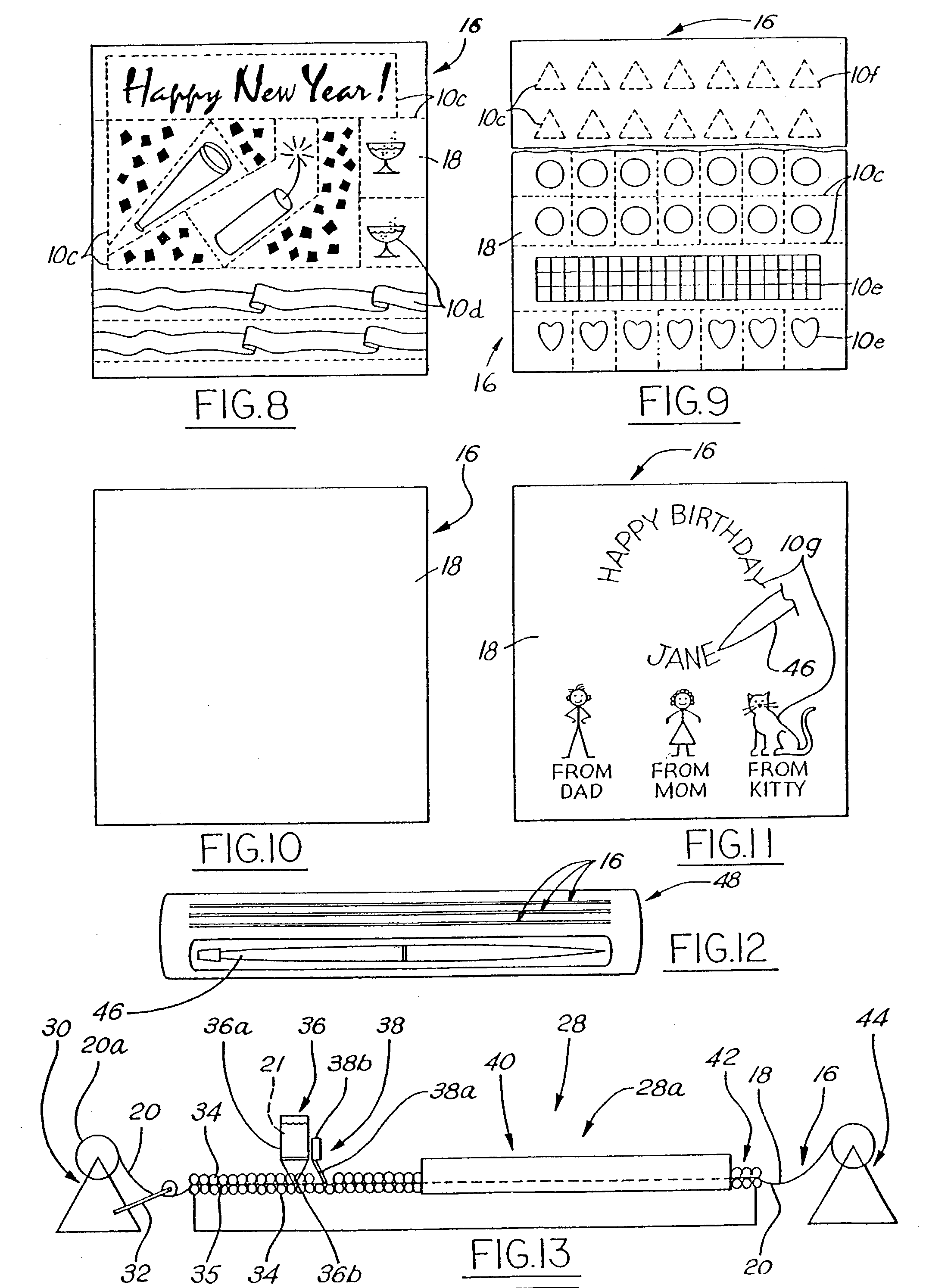

Method of making and using an edible film for decorating foodstuffs

An edible film and method of making and using same for decorating foodstuffs, in particular baked goods, wherein anyone can easily, inexpensively and artistically decorate foodstuffs. The edible film according to the present invention is composed of an edible polymer film which is preferably releasably mounted upon a flexible substrate to provide a reinforced edible film. The edible film is peelably released from the substrate to provide decorations for the foodstuff. The edible film may be decoratively prepared into predetermined decorations prior to distribution, which may include being pre-printed, pre-cut, colored, or being of pre-selected opacity and sheen. Alternatively, the edible film may be distributed in a not yet finalized decoration form, wherein finalization is left up to the user.

Owner:DECOPAC INC

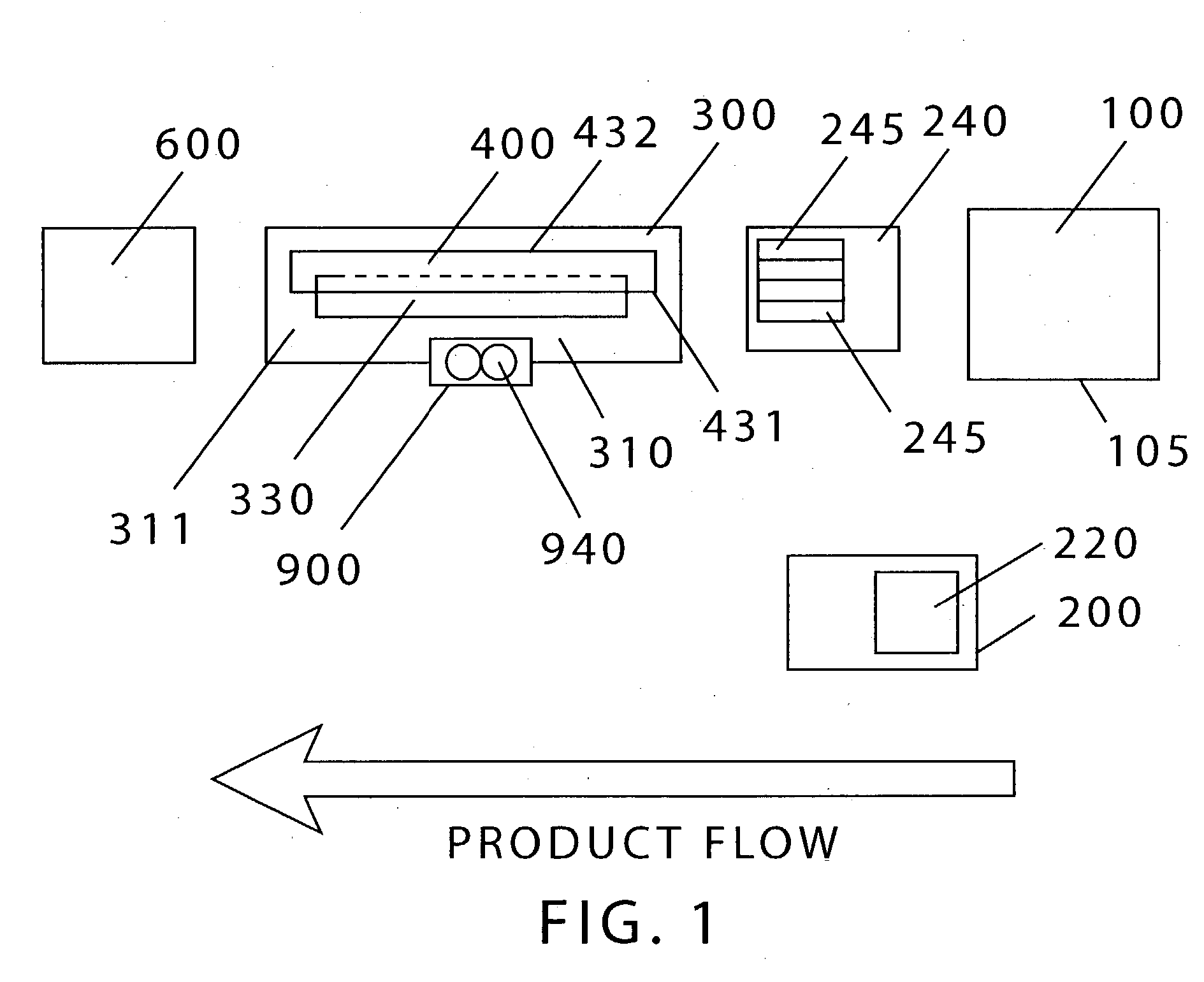

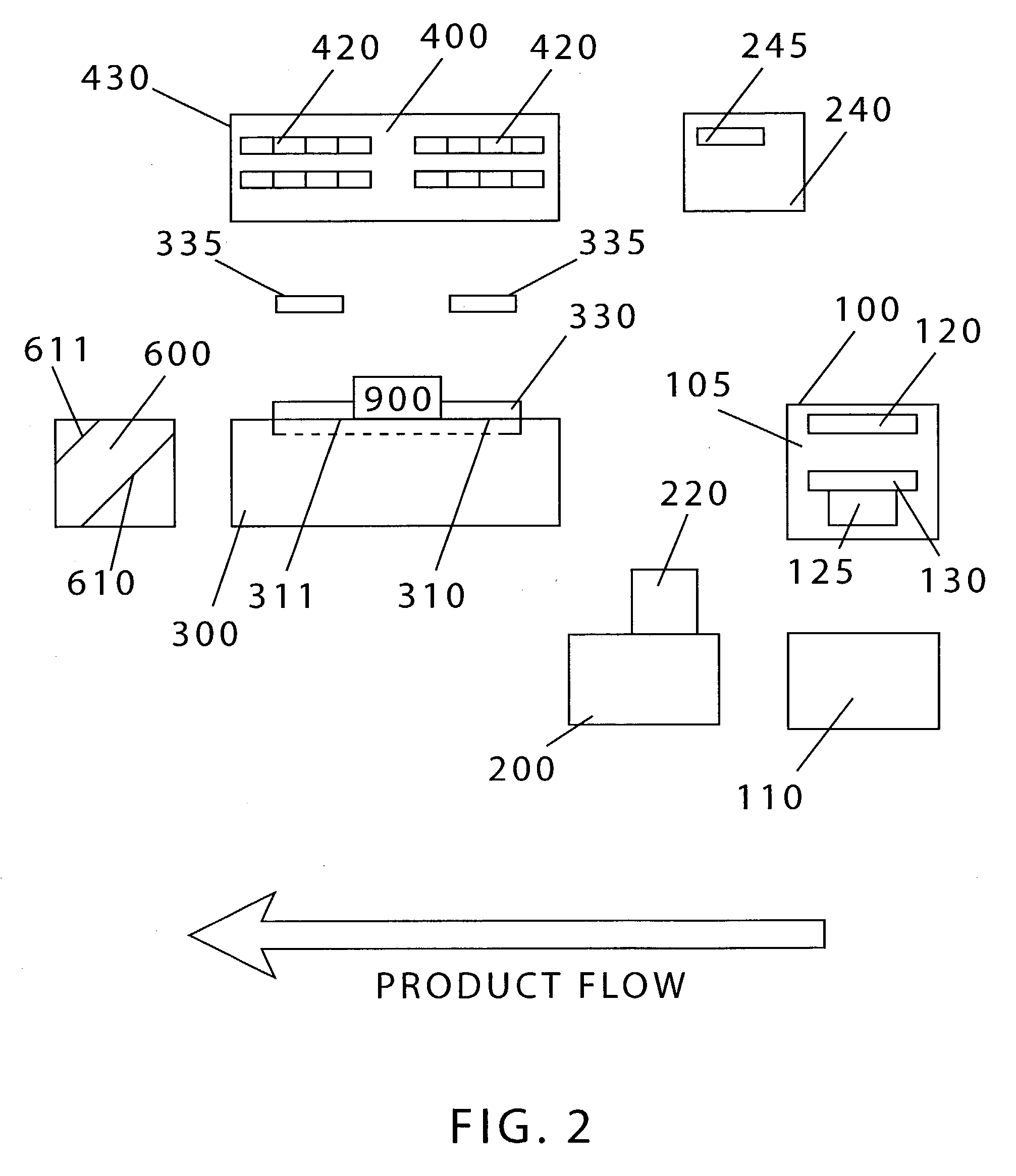

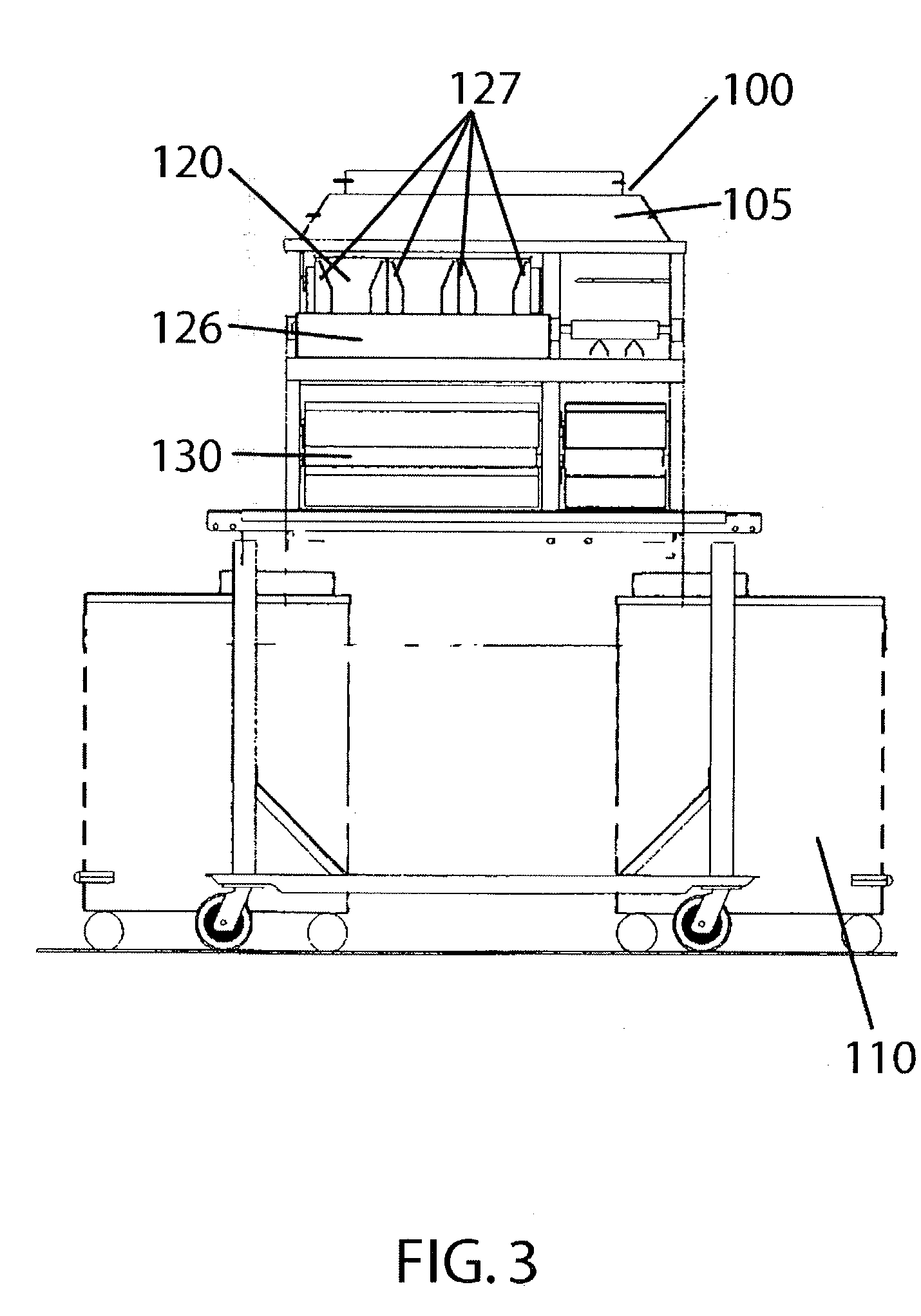

Fast-food sandwich preparation kitchen arrangement

The food preparation kitchen of the present invention provides an arrangement and method of use of kitchen equipment to facilitate a combination of batch preparation and made-to-order assembly of fast-food sandwiches. This food preparation kitchen includes a broiling member for broiling frozen sandwich products; a first product holding member for holding sandwich products from the broiling means; a receiving container for holding sandwich products wherein the receiving container is operationally compatible with the broiling member and the first product holding member; a toasting member for toasting baked goods such as sandwich buns; a second product holding member for holding toasted baked goods from the toasting member; an assembly board for assembling fast-food sandwiches from products taken from the first and second holding members; a steam generating assembly for increasing the temperature of products removed from the first or second holding members; and a heat staging member for maintaining sandwiches assembled at the assembly board at elevated temperatures. In the method of use of the invention, batch preparation of the sandwich products is utilized in the broiling, toasting, and first and second holding steps. Made-to-order preparation is utilized at the assembly board by taking the necessary ingredients from the first and second holding members.

Owner:BURGER KING CO LLC

Omega-3 Fatty Acids Encapsulated In Zein Coatings and Food Products Incorporating the Same

Disclosed are processes for stabilizing omega-3 fatty acids for use in food products. The processes permit creation of a variety of food forms and food ingredients that contain omega-3 fatty acids like docosahexaenoic acid and eicosapentaenoic acid wherein these foods and food forms are stable for months without developing fishy aromas or tastes. This stability enables the incorporation of omega-3 fatty acids into food forms such as ready to eat cereals, trail mixes, chips, granola bars, toaster pastries, baked goods, cookies, crackers, fruit pieces and fruit leathers. The processes utilize a zein coating to protect and stabilize the omega-3 fatty acids.

Owner:KELLOGG CO

Non-flour containing baked and related food compositions

Non-flour containing baked and related food compositions are made with egg protein and soy protein isolate stabilized with a hydrocolloid component. Fats and oils may be added without collapsing the matrix of egg protein and soy protein isolate. The food compositions may be used by cellacs and are sufficiently low in net carbohydrates as to be useful in diet programs requiring a low level of carbohydrates for weight loss.

Owner:BELLAR WILLIS F

Composition and method for making high-protein and low-carbohydrate food products

InactiveUS20050129823A1Effectively reducing the net carbohydrate total of the traditional productIncrease nutritionDough treatmentBaking mixturesAdditive ingredientProtein isolate

Conventional food compositions for use in making baked goods and extruded food products are improved by reducing the carbohydrate content. This is done by substituting the conventional flour in whole or in part by a combination of starch that is resistant to amylase digestion and / or from about 1-150 baker's percent of a first proteinaceous ingredient comprising at least about 70% by weight protein, and a second proteinaceous ingredient selected from the group consisting of (i) between about 0.5-100 baker's percent of a wheat protein isolate product; (ii), between about 0.5-100 baker's percent of a wheat protein concentrate product; (iii) between about 0.5-100 baker's percent of a devitalized wheat gluten product; (iv) between about 0.5-20 baker's percent of a fractionated wheat protein product; (v) between about 0.5-20 baker's percent of a deamidated wheat gluten product; (vi) between about 0.5-30 baker's percent of a hydrolyzed wheat protein product; and (vii) any combination of ingredients (i) to (vi).

Owner:MGP INGREDIENTS

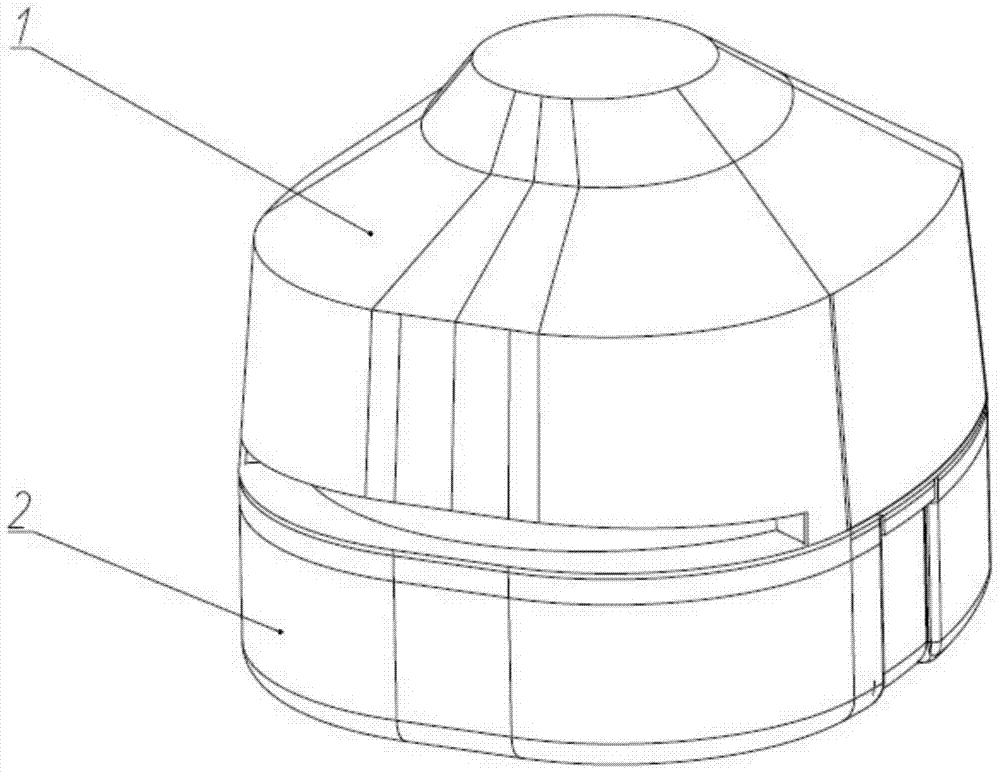

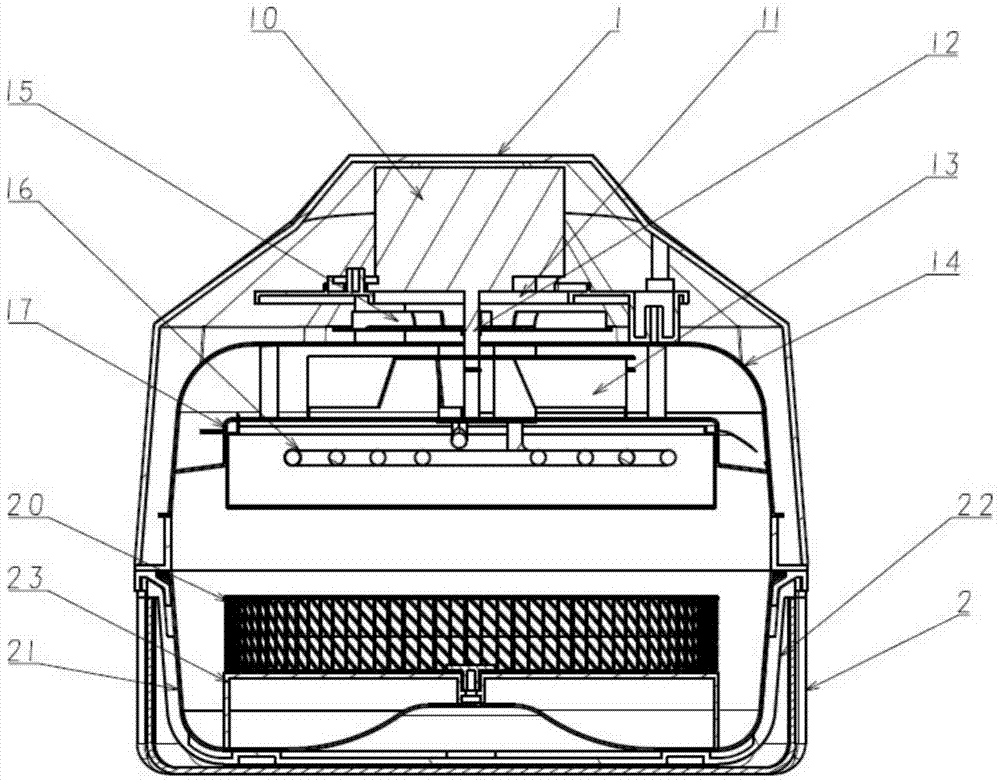

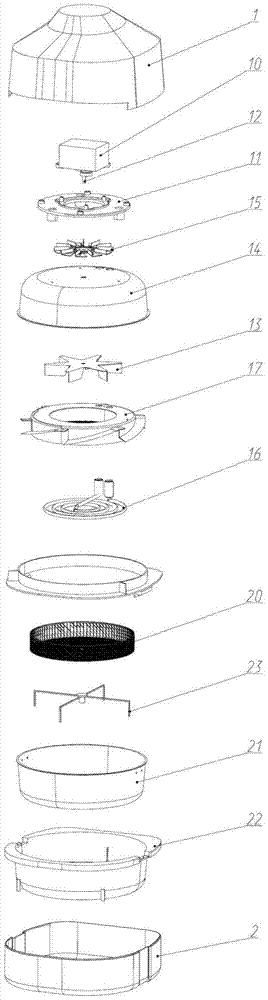

Air fryer heated by cyclone heat circulation

The invention discloses an air fryer heated by a heat cycle formed by a cyclone, which comprises: a windshield, the windshield is open at the lower part, and has a small hole in the center of the upper part; a motor assembly, the motor assembly is installed on the The upper part of the windshield, and includes a motor transmission shaft, the motor transmission shaft passes through the small hole in the upper center of the windshield; an exhaust fan, the exhaust fan is installed in the windshield, and is connected to the windshield The motor transmission shafts are connected; the rotating air duct unit is installed in the windshield, and is located below the exhaust fan, and is connected and fixed with the windshield through a connecting column. The upper part of the channel unit is provided with a ventilation opening, and the lower part is open, wherein the rotating air channel unit can make the wind going vertically downward through the joint action of the exhaust fan and the windshield rotate and go downward at a certain angle, forming whirlwind. The air fryer heats through the cyclone to form a heat cycle so that the hot air can bake the food more evenly.

Owner:KINGCLEAN ELECTRIC GREEN TECH SUZHOU

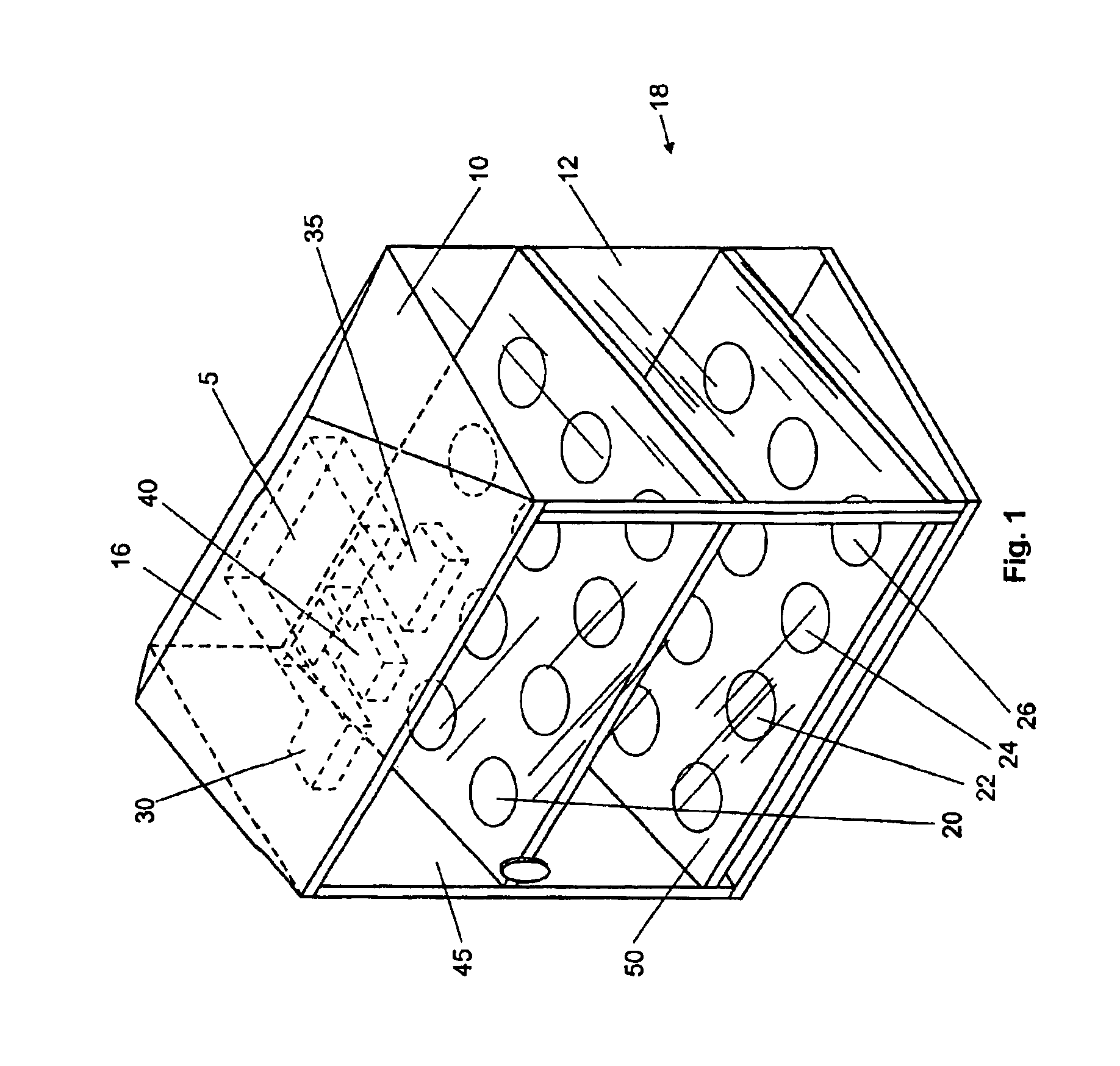

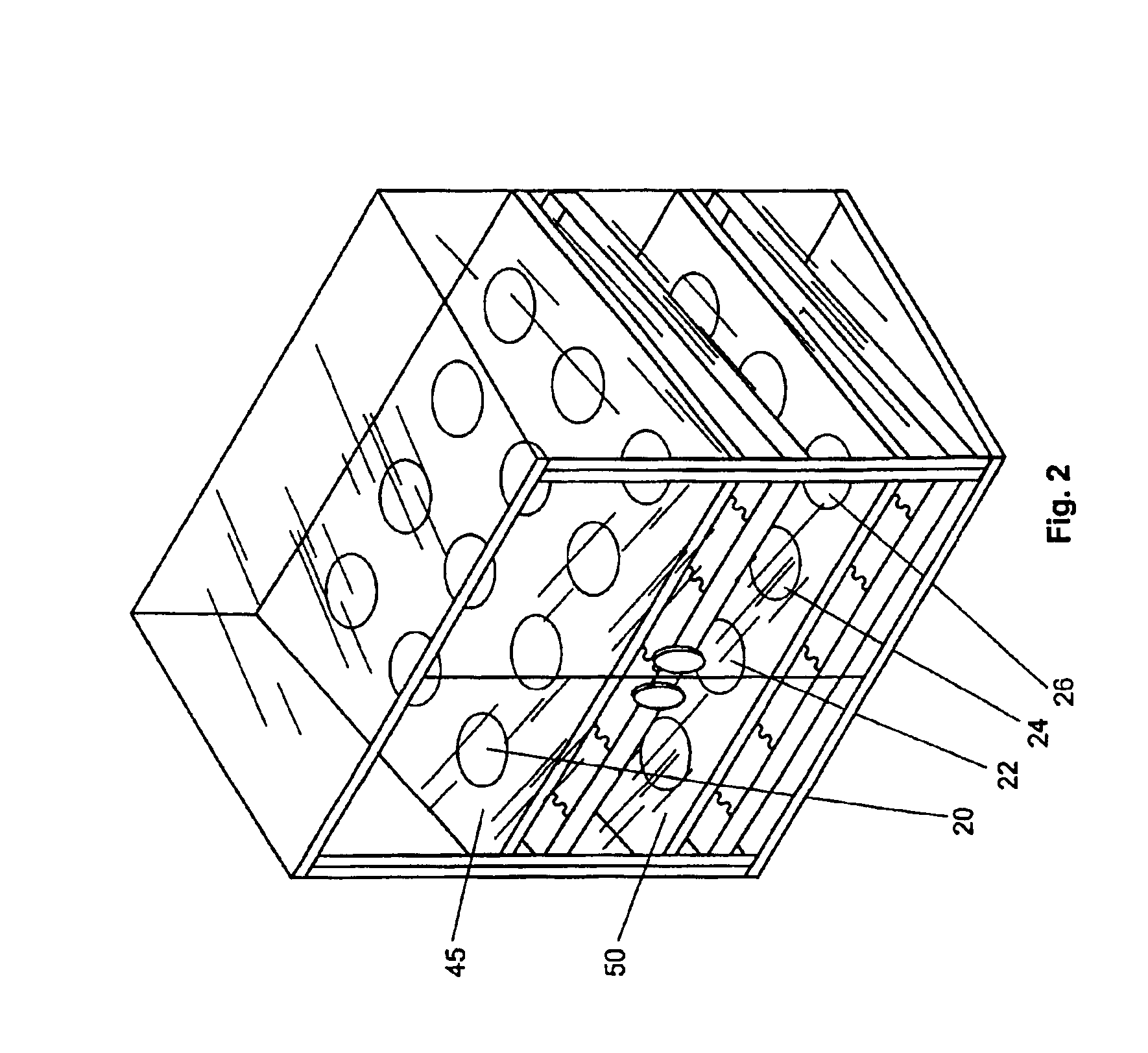

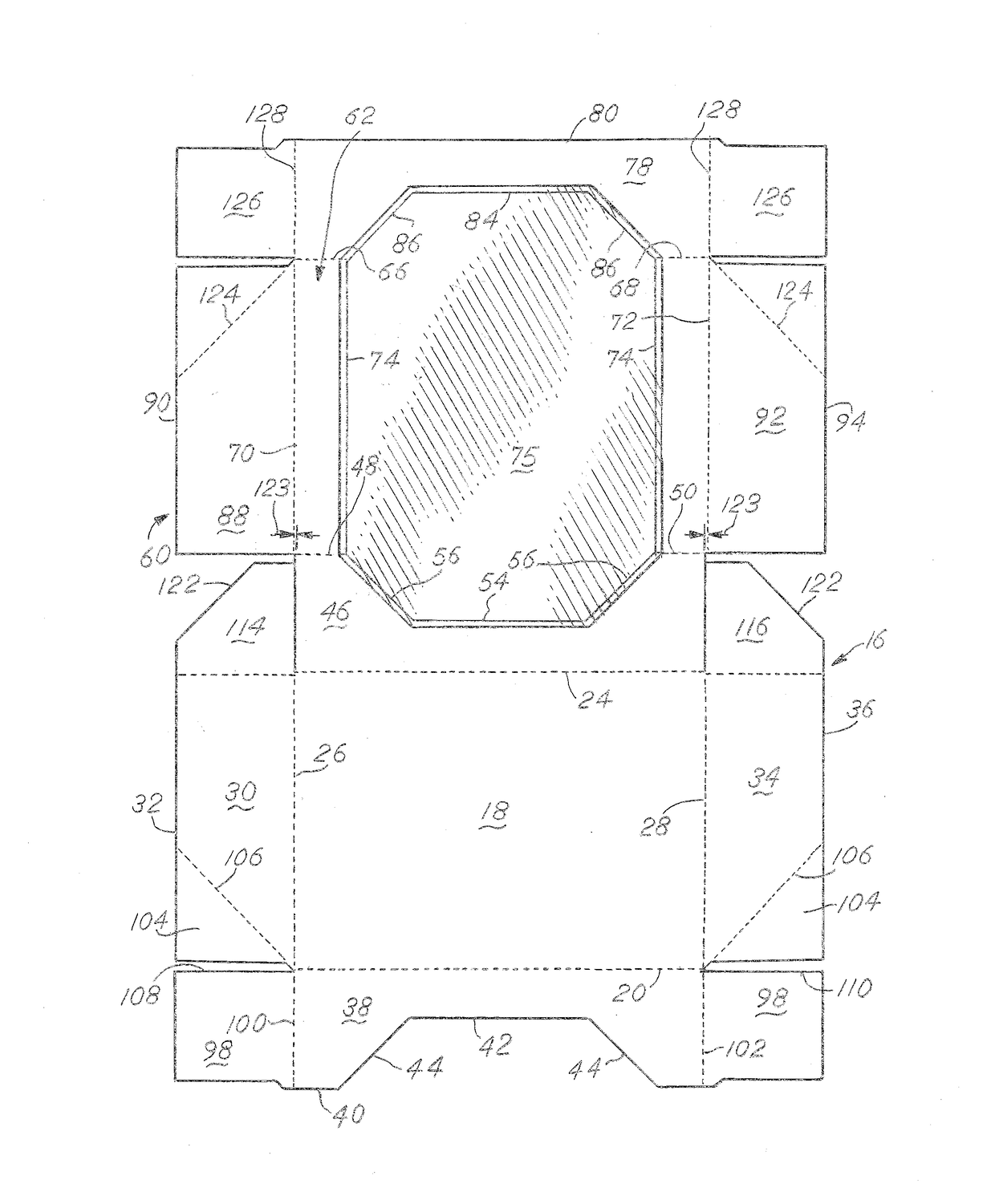

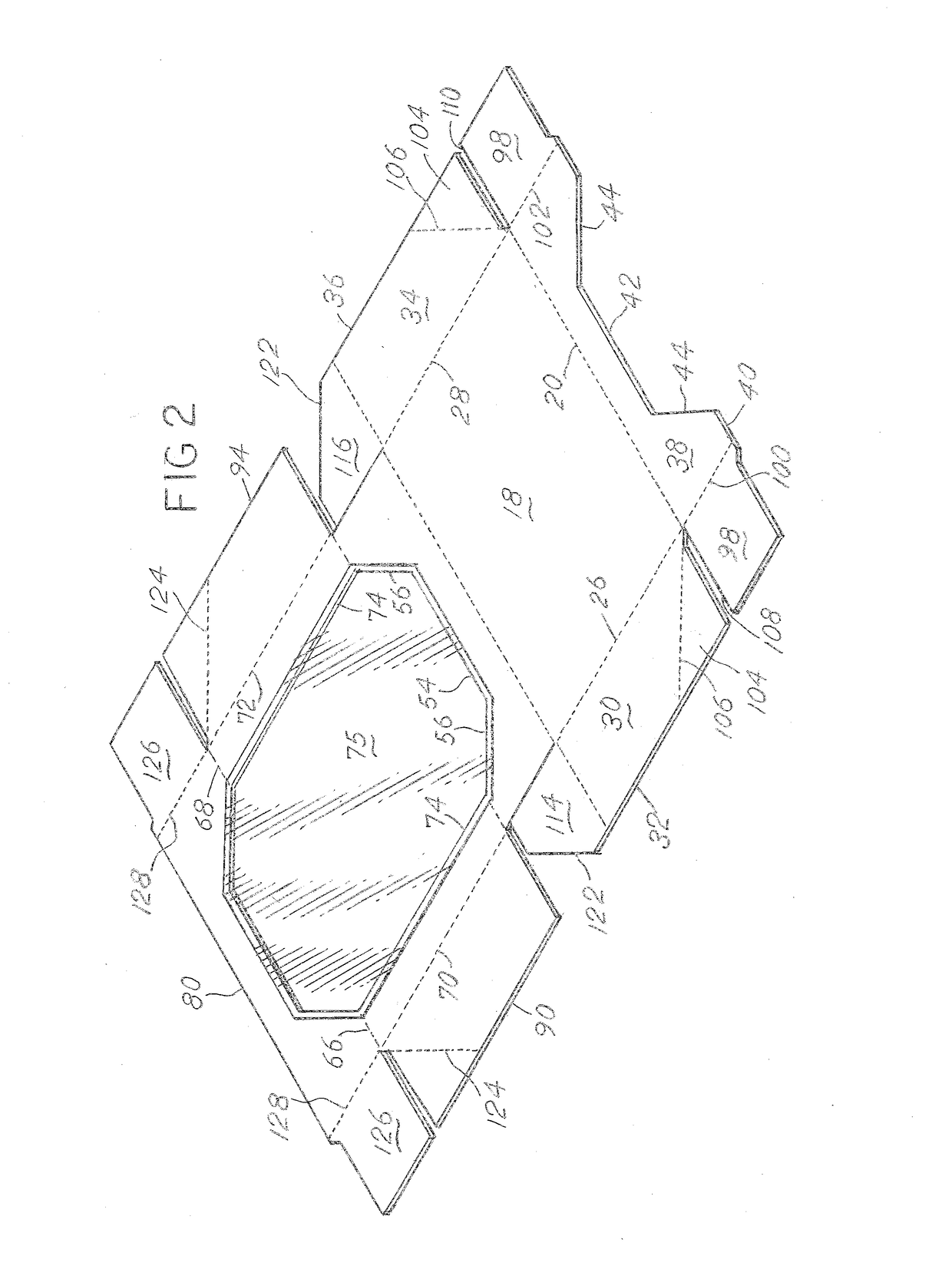

Baked goods box

A folding baked goods box that has a lower box portion having upstanding walls including a back wall that has a lower window edge. A lid portion of the box is hingedly attached to the lower box at the back wall. The top includes oppositely located lateral window edges that define lateral sides of a window. The lid portion includes a lid front that extends downwardly from the top and has a lower window edge is located within the front. The window in the baked goods box extends continuously from the lower window edge of the back wall across the top of the lid portion, between lateral window edges to the lower window edge of the front of the lid portion. The lid portion is adapted for being fitted over the lower box portion.

Owner:INDIANA CARTON

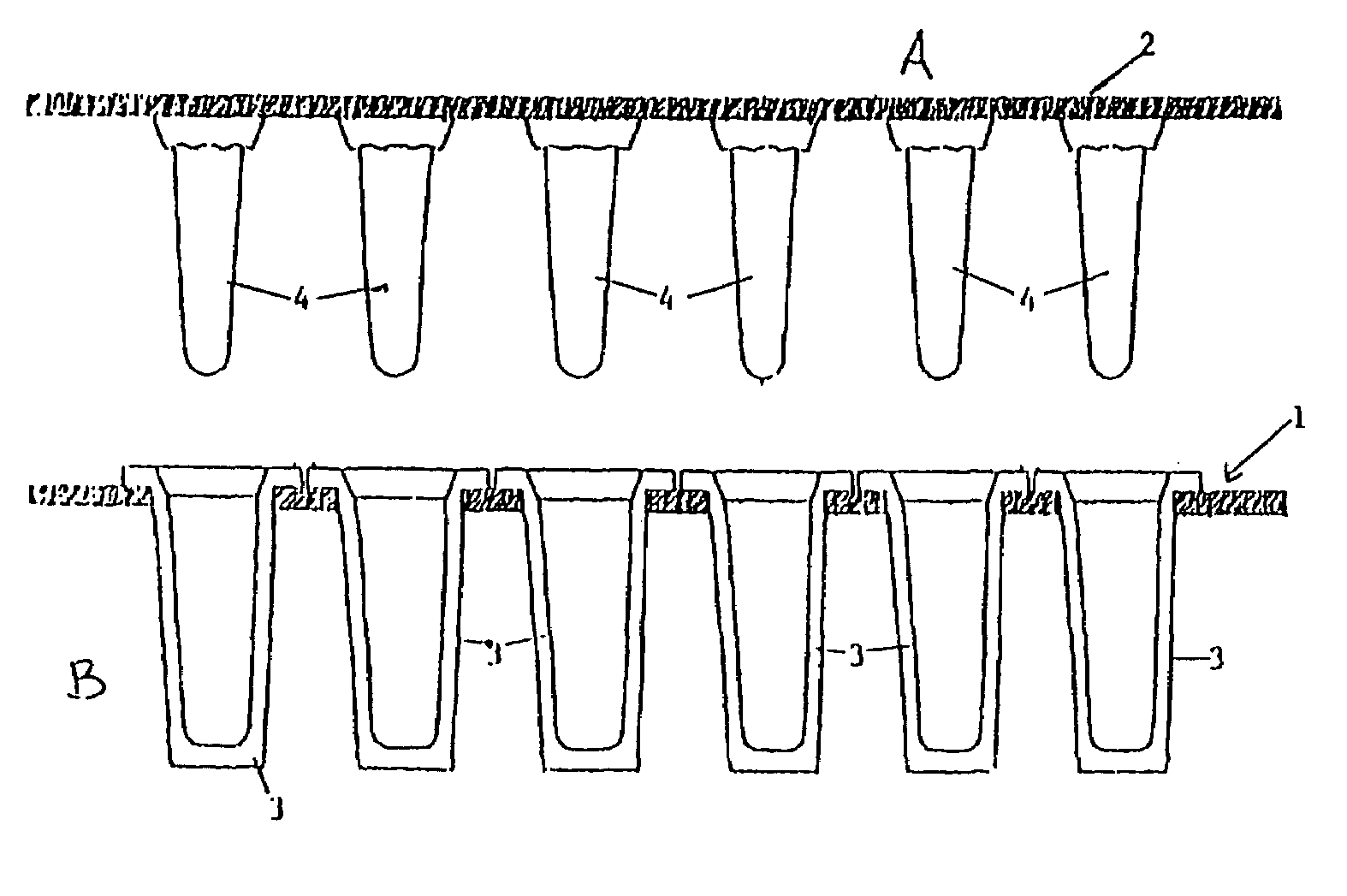

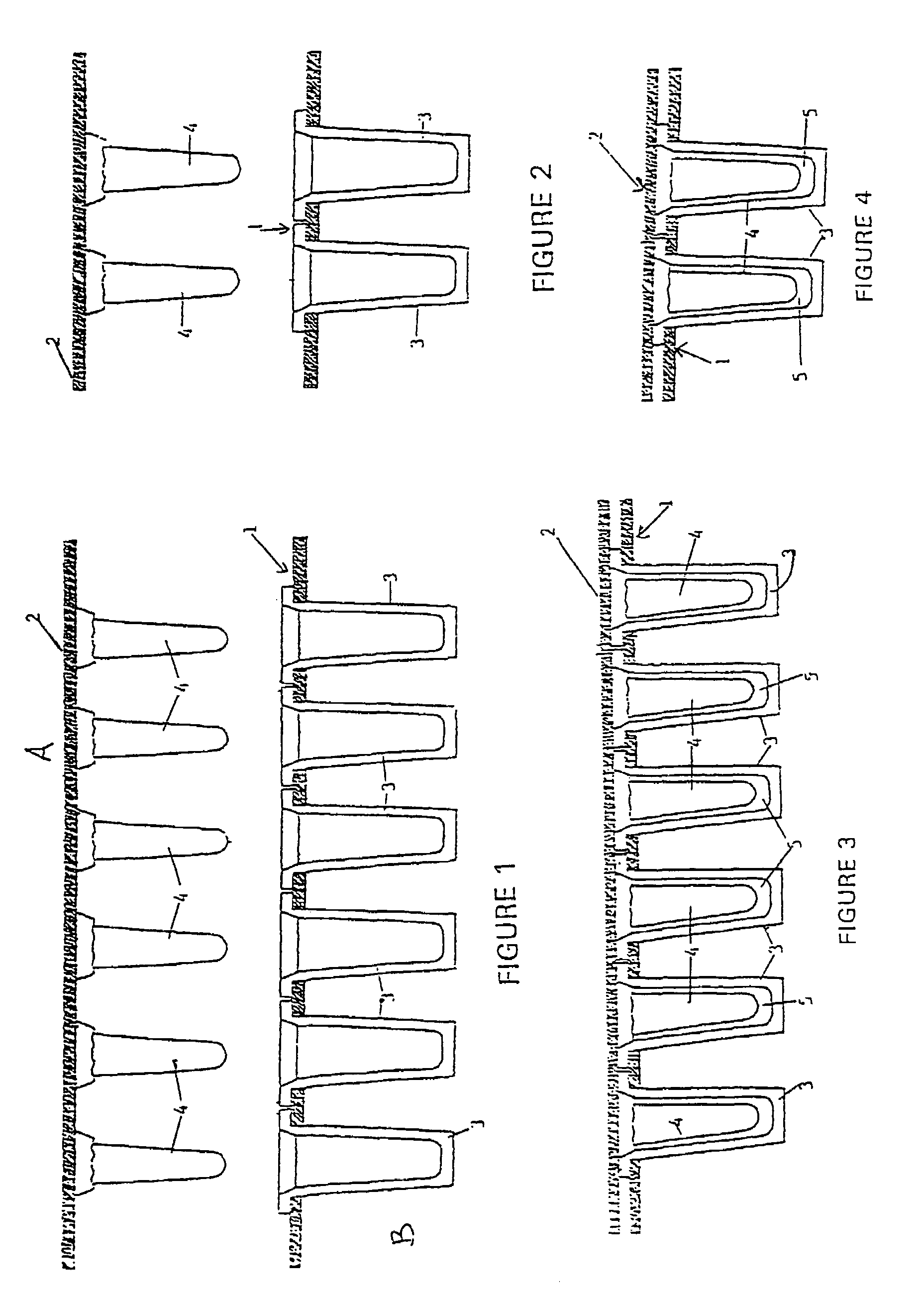

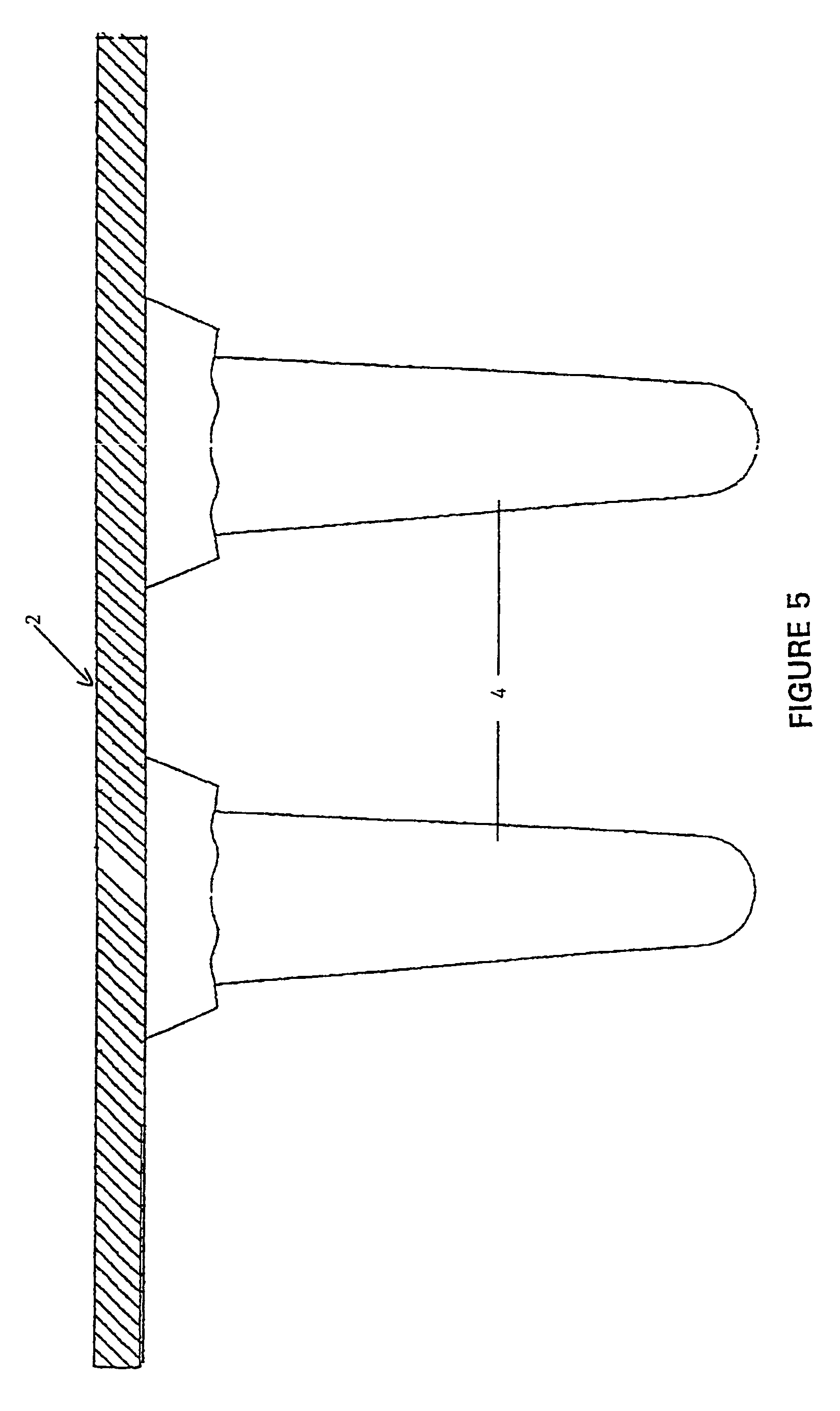

Production of triple coextruded baked bar goods

InactiveUS7264836B2Increase pressurePreventing unevenness discontinuityDough treatmentMilk preservationBaked goodsEngineering

A triple coextruded baked good having a bar shape with a desired substantially smaller height than width, is continuously produced with distinct, at least substantially uniform concentric fillings which are visually apparent at opposing cut ends of the baked piece. The bar-shaped products are preferably cookies with dissimilar fillings, such as a fruit filling and a cheese-cake filling. Undesirable excessive flow of a middle filling or layer towards the cross-sectional ends or sides rather than the top and bottom of the coextrudate is substantially reduced by obstructing and diverting the flow of the middle filling through the middle die orifice so that it flows towards the top and bottom elongated portions of the middle annulus. A baked product having a substantially even middle concentric layer which is desirably uniformly thick and continuous at least across the top and bottom is obtained. Post-extrusion shaping or mechanical flattening of the dough with a roller is not needed to obtain a desired cross sectional shape having a substantially rectangular middle portion and curved or rounded shoulders, thereby avoiding sticking and tearing of the dough. Ultrasonic cutting of the baked product is employed to avoid substantial visual smearing of one layer of filling into another.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Means for replacing common sugars if foods for enhanced nutrition

InactiveUS20080260925A1Great tasteSuperior digestive toleranceFood ingredient functionsFood preparationLow glucoseSide effect

A means for replacing common sugars (particularly sucrose) in a range of foods that maximizes sugar-like taste, texture and other key properties of sugar while minimizing the undesirable traits such as blood sugar response, digestive side effects, high caloric content and aftertastes. Various differing ratios and combinations of high intensity sweetening agents, high molecular weight bulking agent(s), substantially non-digestible sugar(s), and low molecular weight sugar alcohol(s) are used for various applications such as tabletop sugar substitute, frozen deserts, condiments, baked goods, chocolate and confectionaries have different formulations. These sugar replacement approaches are highly relevant to the production of diabetic-friendly foods, diet and / or reduced calorie foods, non-cariogenic (tooth-friendly) foods and other sweet, low-glycemic foods.

Owner:ZINK GALEN PAUL

Process for making a baked cup shaped food product

A process for manufacturing a food product, a food product produced thereby and a plant for production of the food product. The food product may have a generally truncated cone shape which allows the product to be stood on its base. The baking mixture is inserted into mould cavities of a tray and fitting a second tray with male formers corresponding to the mould cavities into the first tray prior to baking. The trays may pass through the oven on an endless conveyor as part of a plant which includes a filling station, for filling the baked product with sweet or savoury fillings, and a freezing station. The food product is baked with a high liquid content to allow for the formation of a thin, tough impervious layer of gelatinised starch skin to form on the product surfaces.

Owner:ARTOS INT

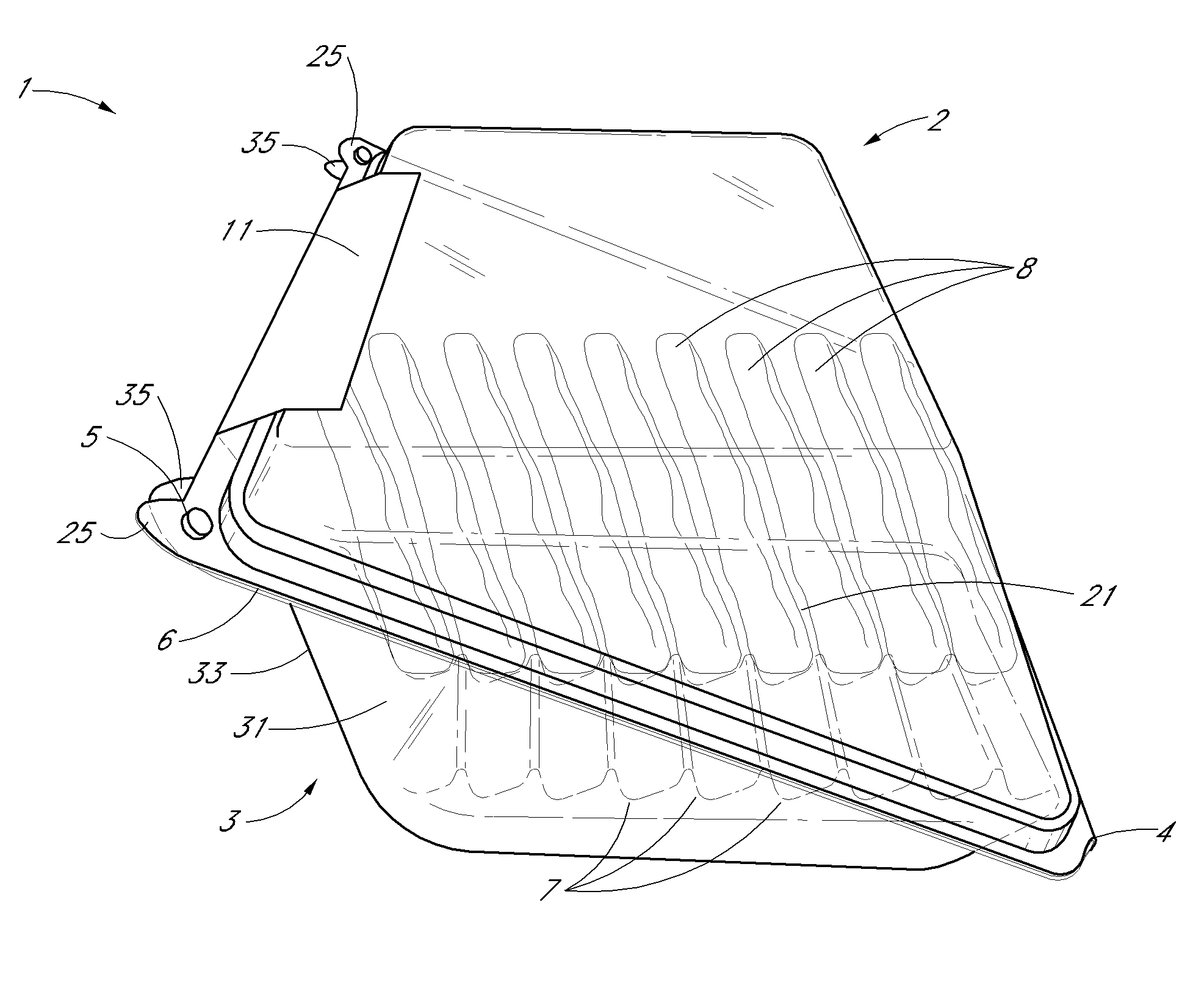

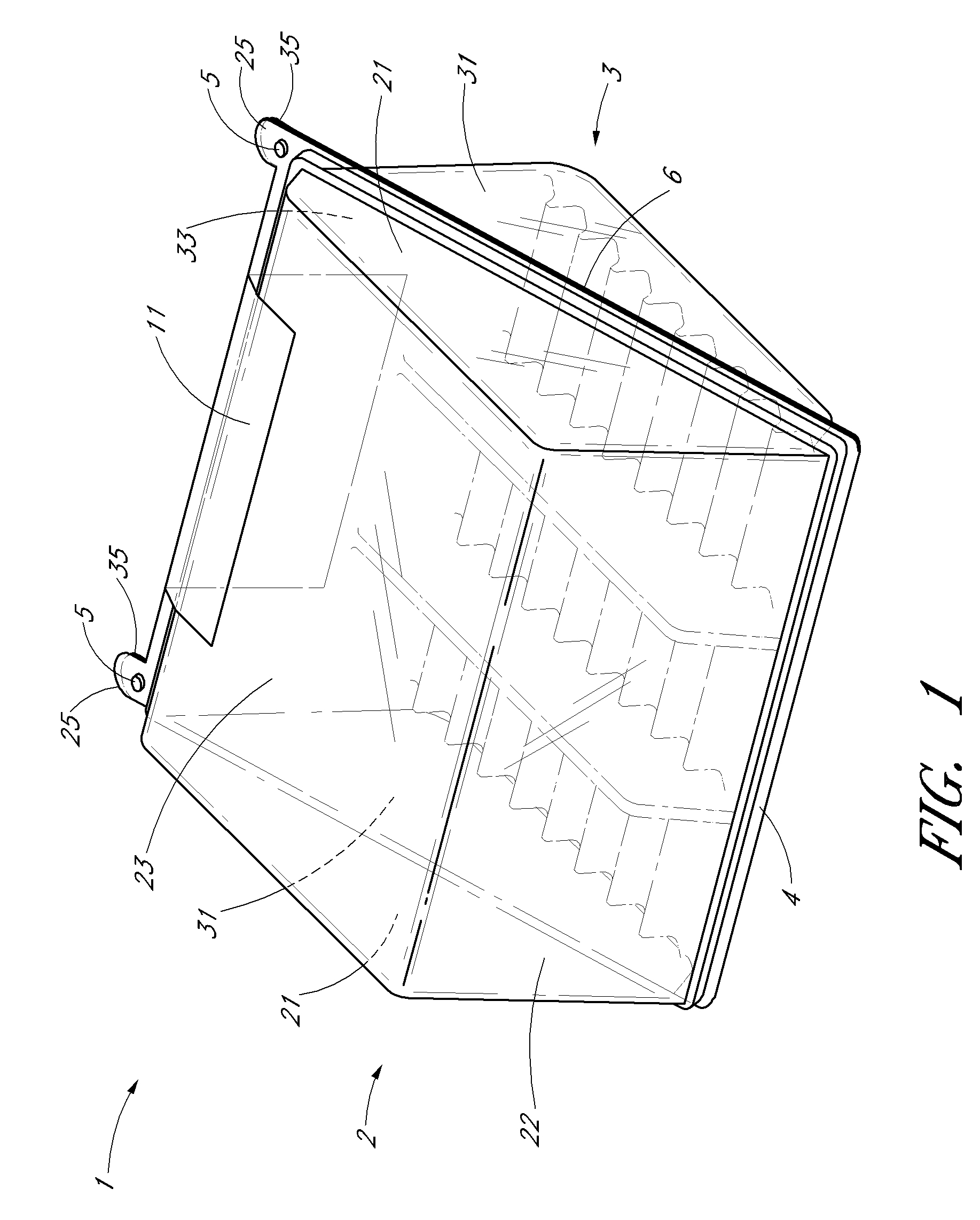

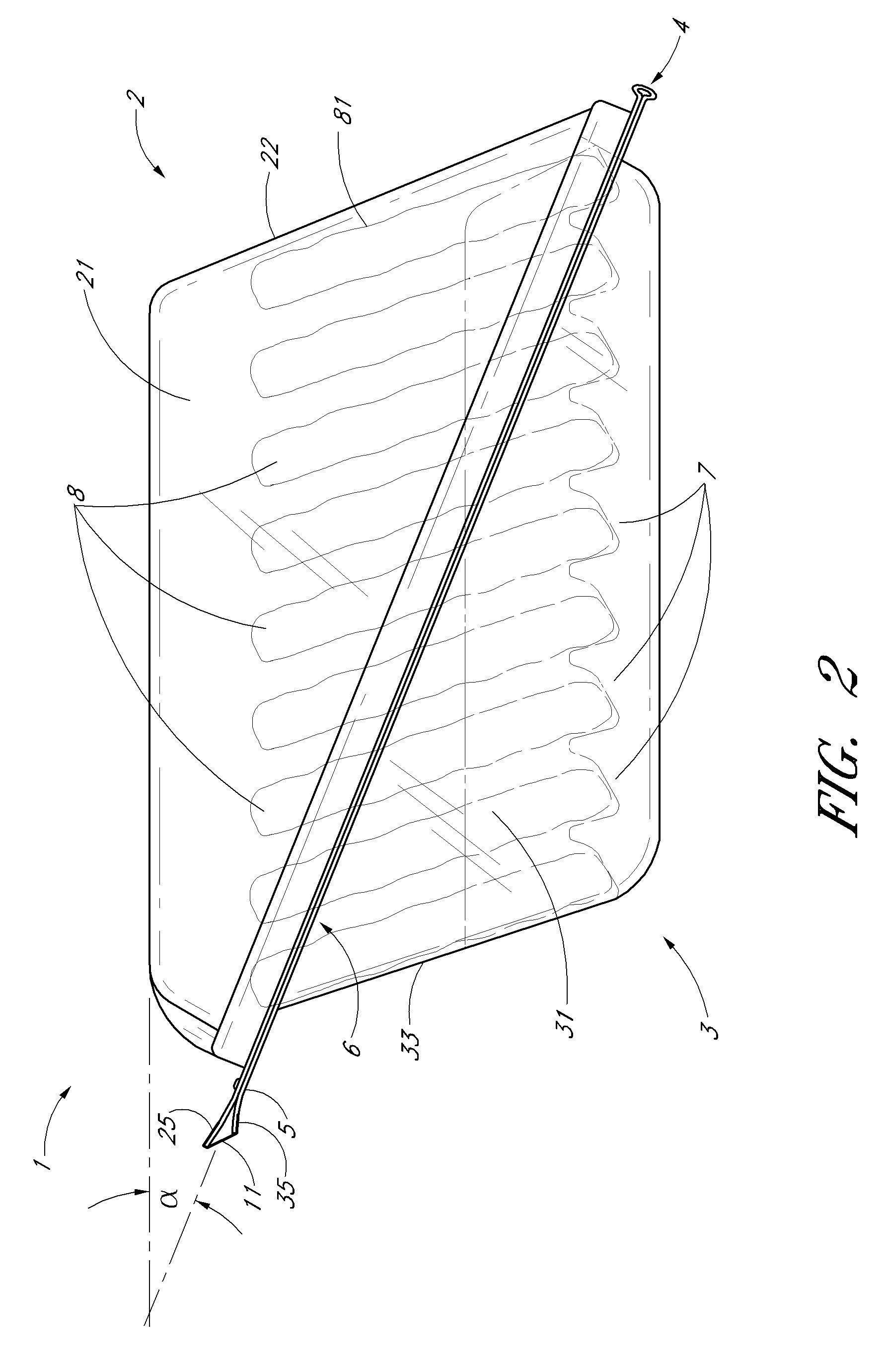

Display and storage container

A container comprises a clamshell-like shape. The container includes a hinge positioned low on a viewing face and opens high on the rear end. The interior of the container is shaped so as to present its contents at a desirable viewing angle, the container intended to provide an unobstructed view through the viewing face. The container may comprise a closing mechanism at the rear end to hold the container closed. The container can contain products for sale, including cookies, slices of pound cake, other baked goods, and other products.

Owner:PACTIV PACKAGING

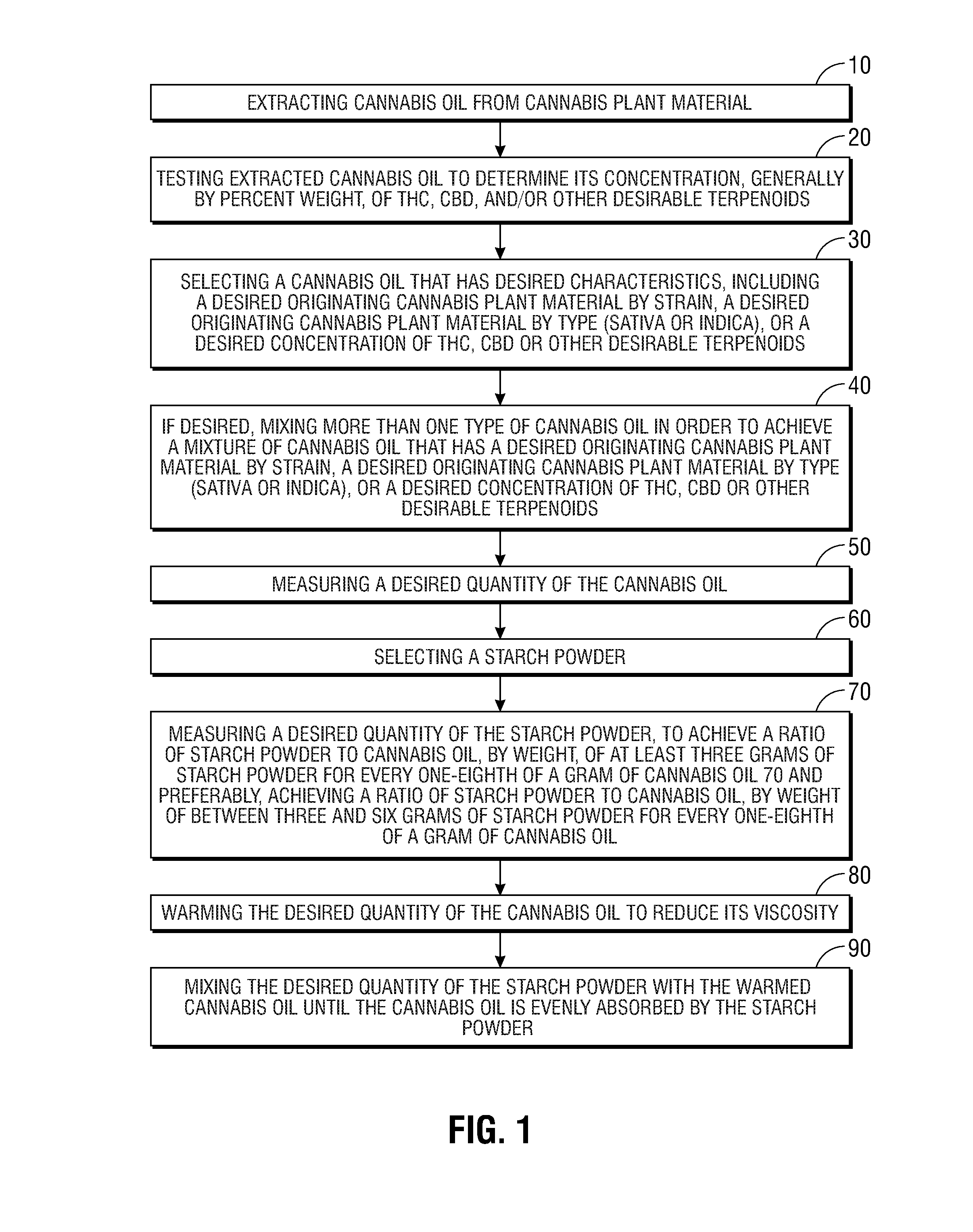

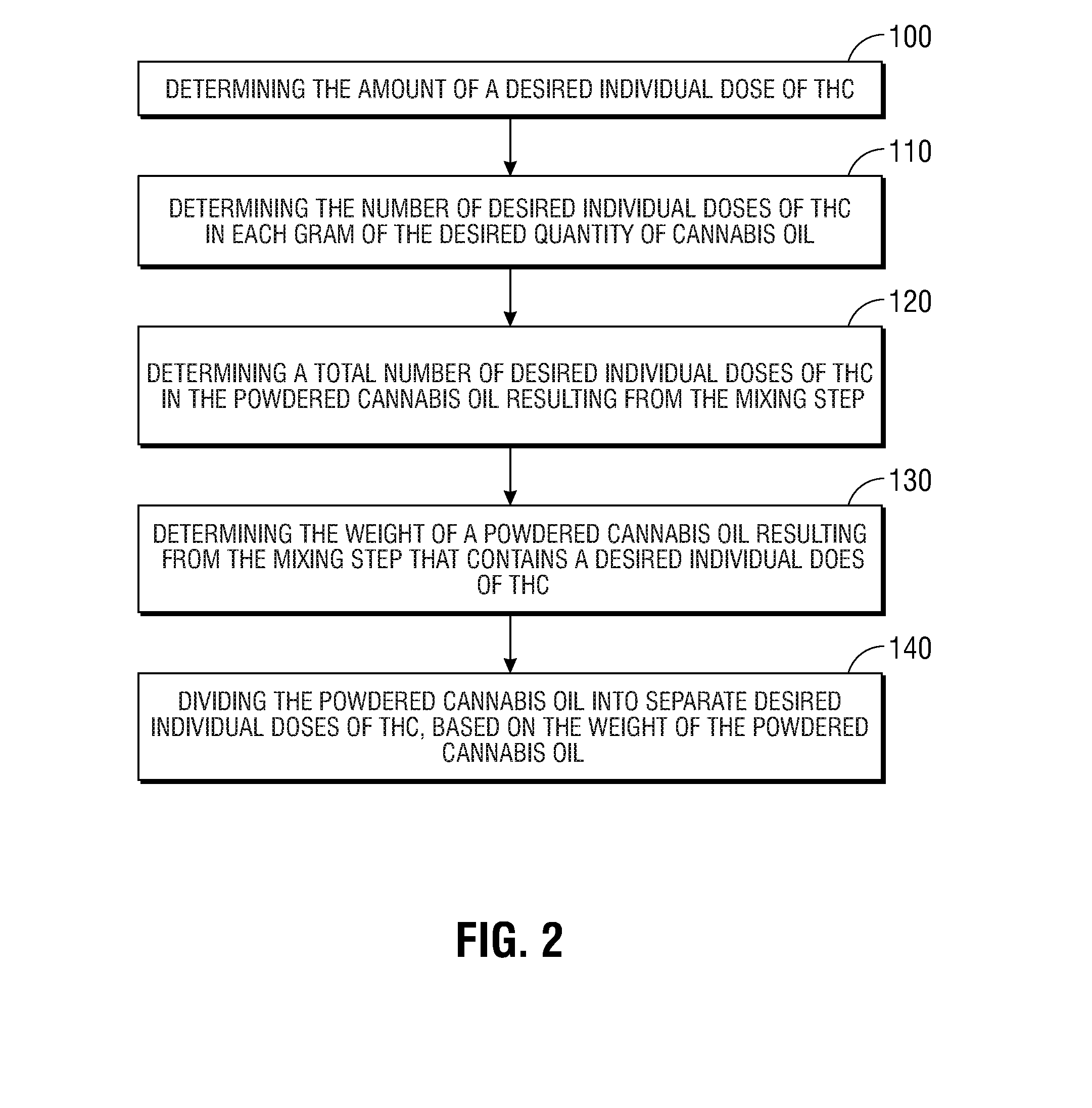

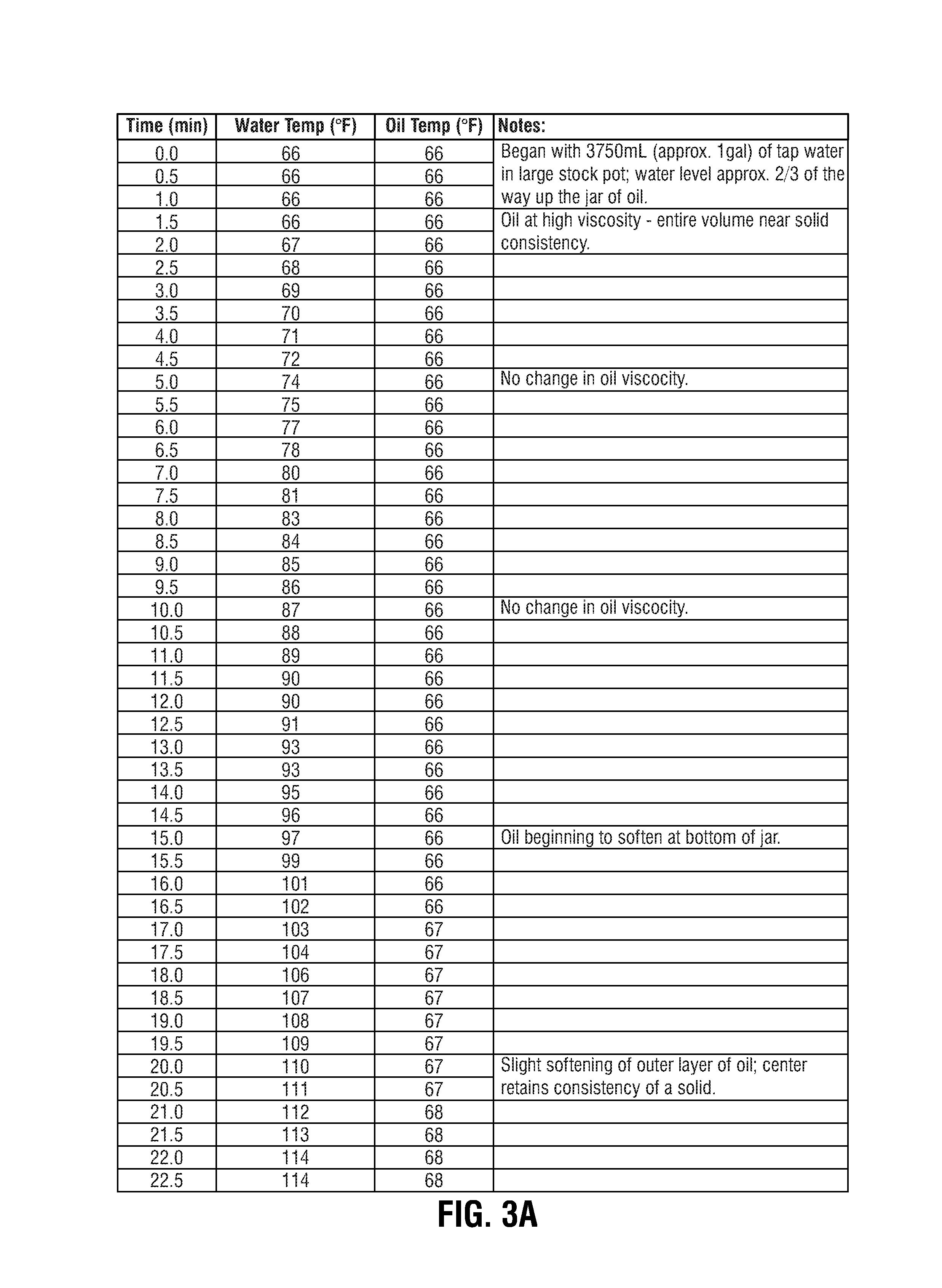

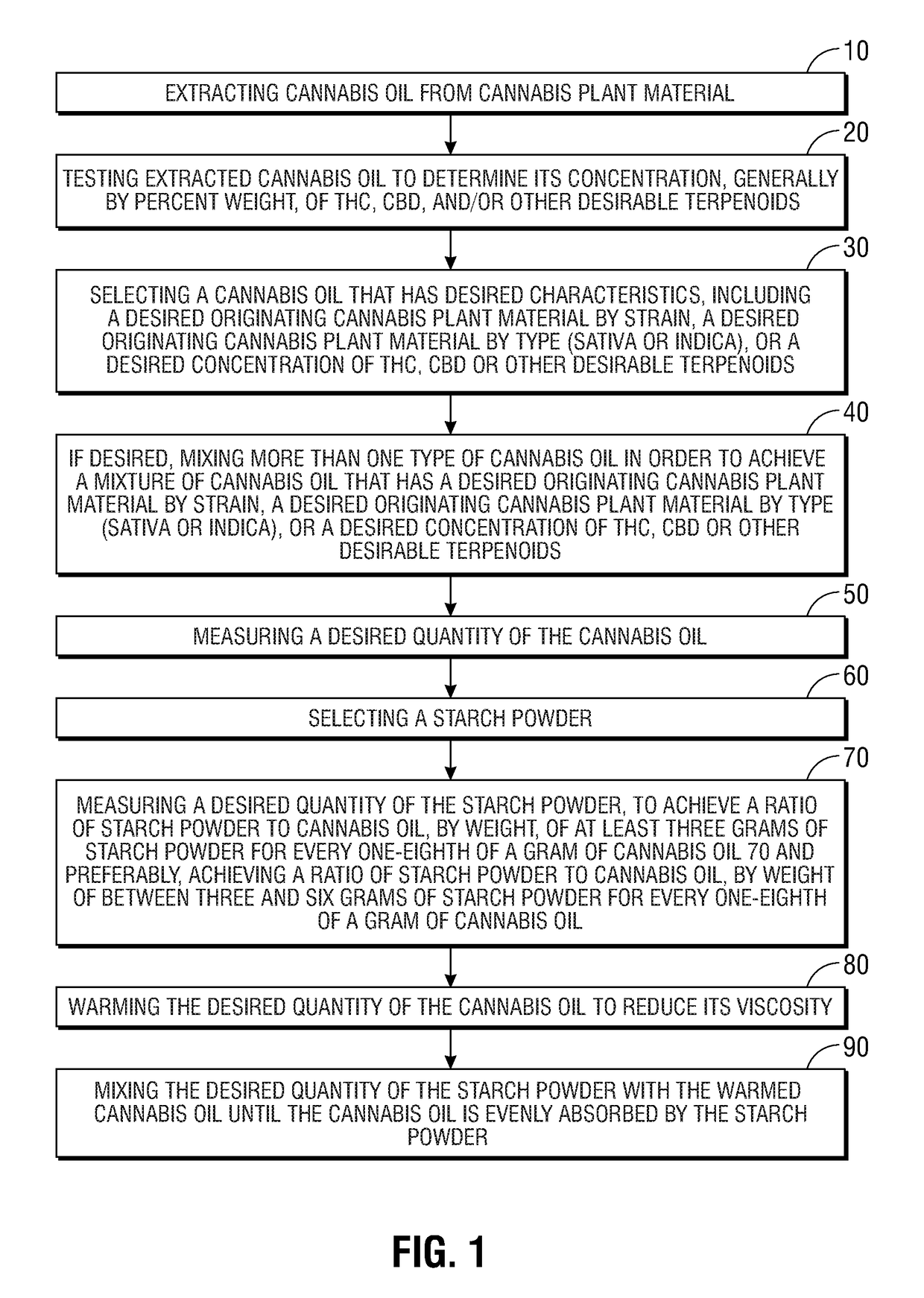

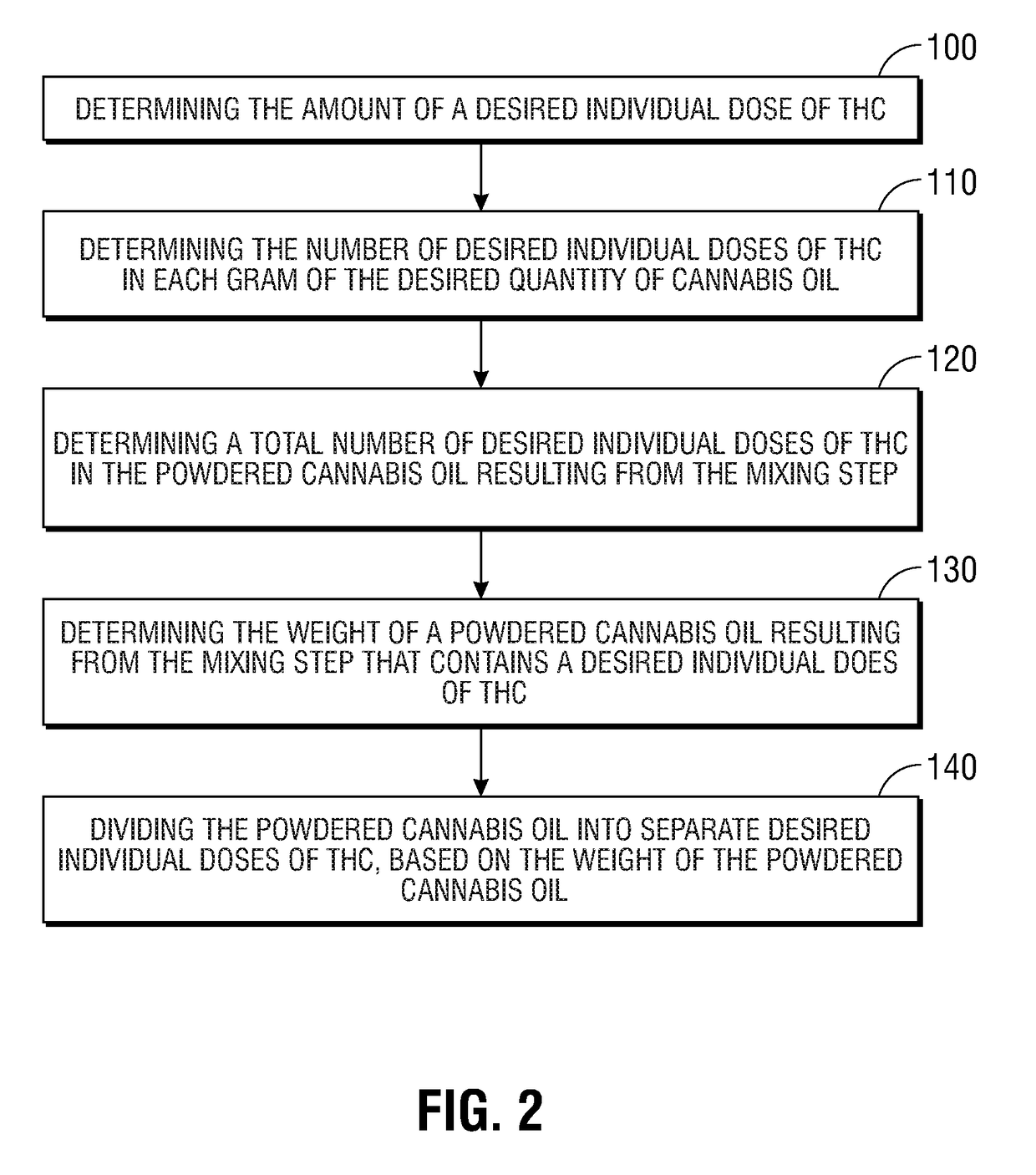

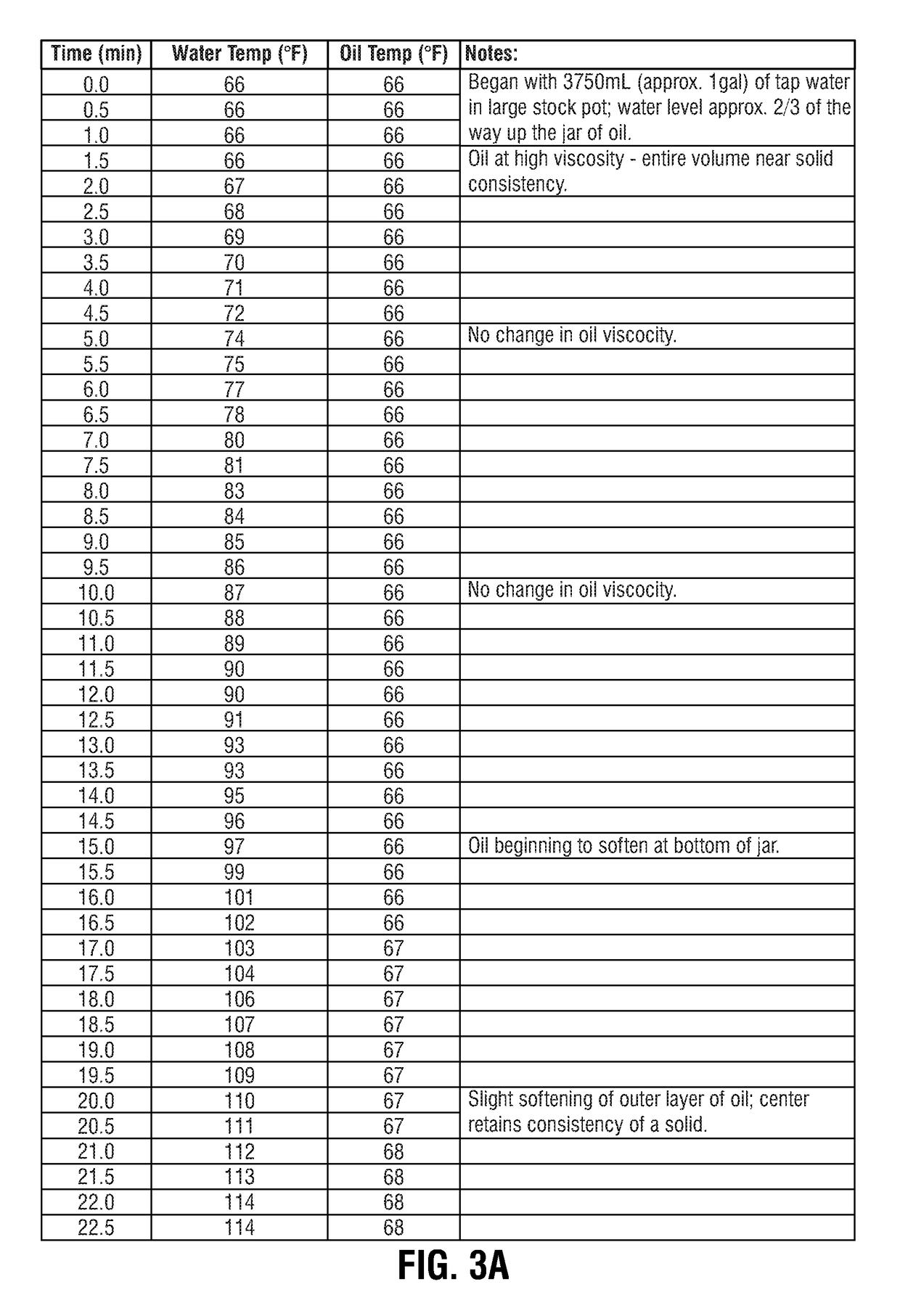

Method For Conducing Concentrated Cannabis Oil To Be Stable, Emulsifiable And Flavorless For Use In Hot Beverages and Resulting Powderized Cannabis Oil

ActiveUS20160243177A1Accurately repeatably deliverSocially acceptableOrganic active ingredientsPowder deliveryCannabisGram

A method for producing powderized cannabis oil, and the resulting powderized cannabis oil, in which concentrated cannabis oil is mixed with and absorbed by a modified starch powder, preferably maltodextrin, in a ratio of at least three grams of starch powder for every one-eighth of a gram of cannabis oil is disclosed. Further disclosed are beverages, baked goods and single-serve beverage brewing cartridges utilizing or incorporating the powderized cannabis oil to create human-consumable products that contain an emulsified, tasteless, and odorless dose of cannabis oil.

Owner:BETTERLIFE PHARMA US INC

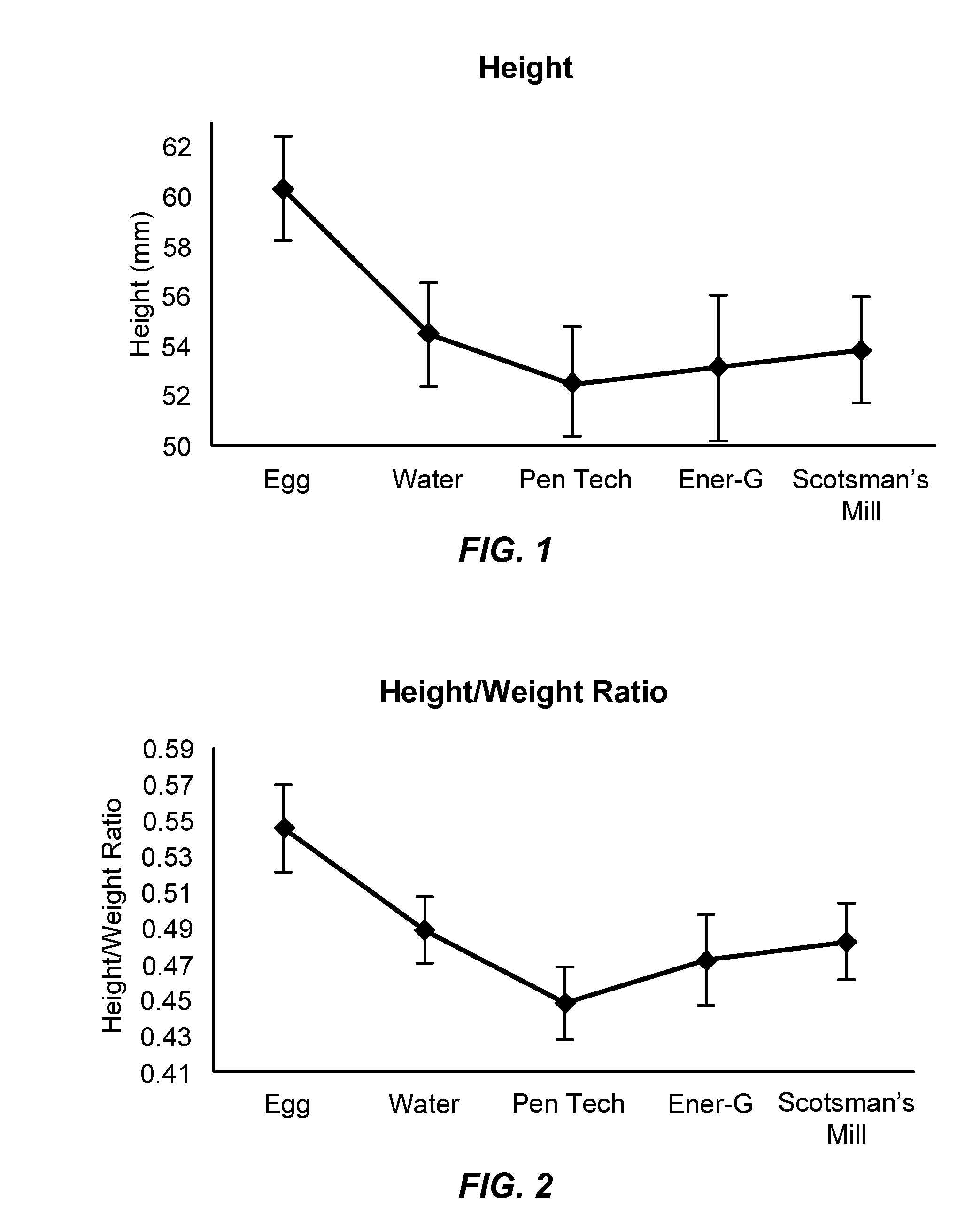

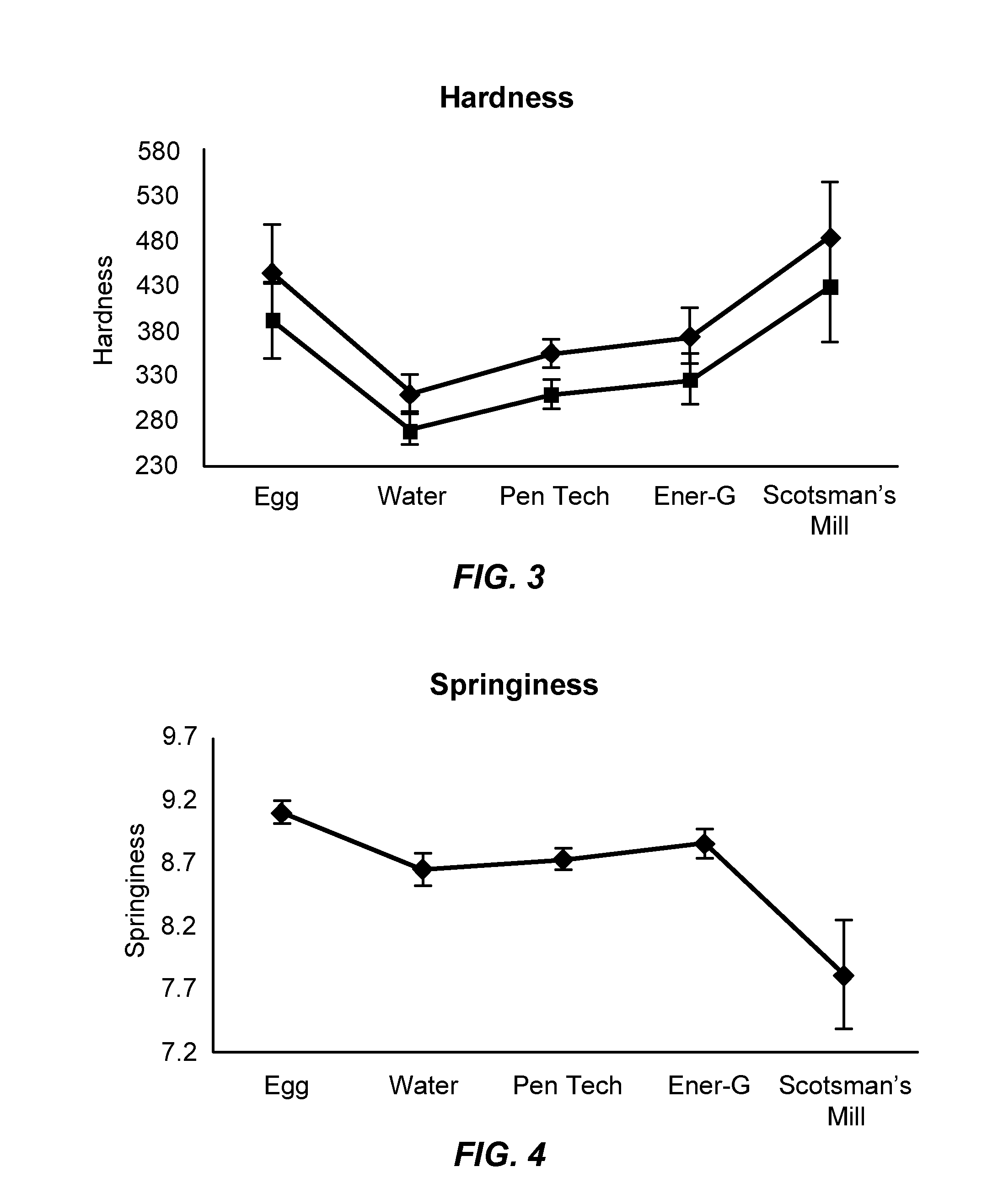

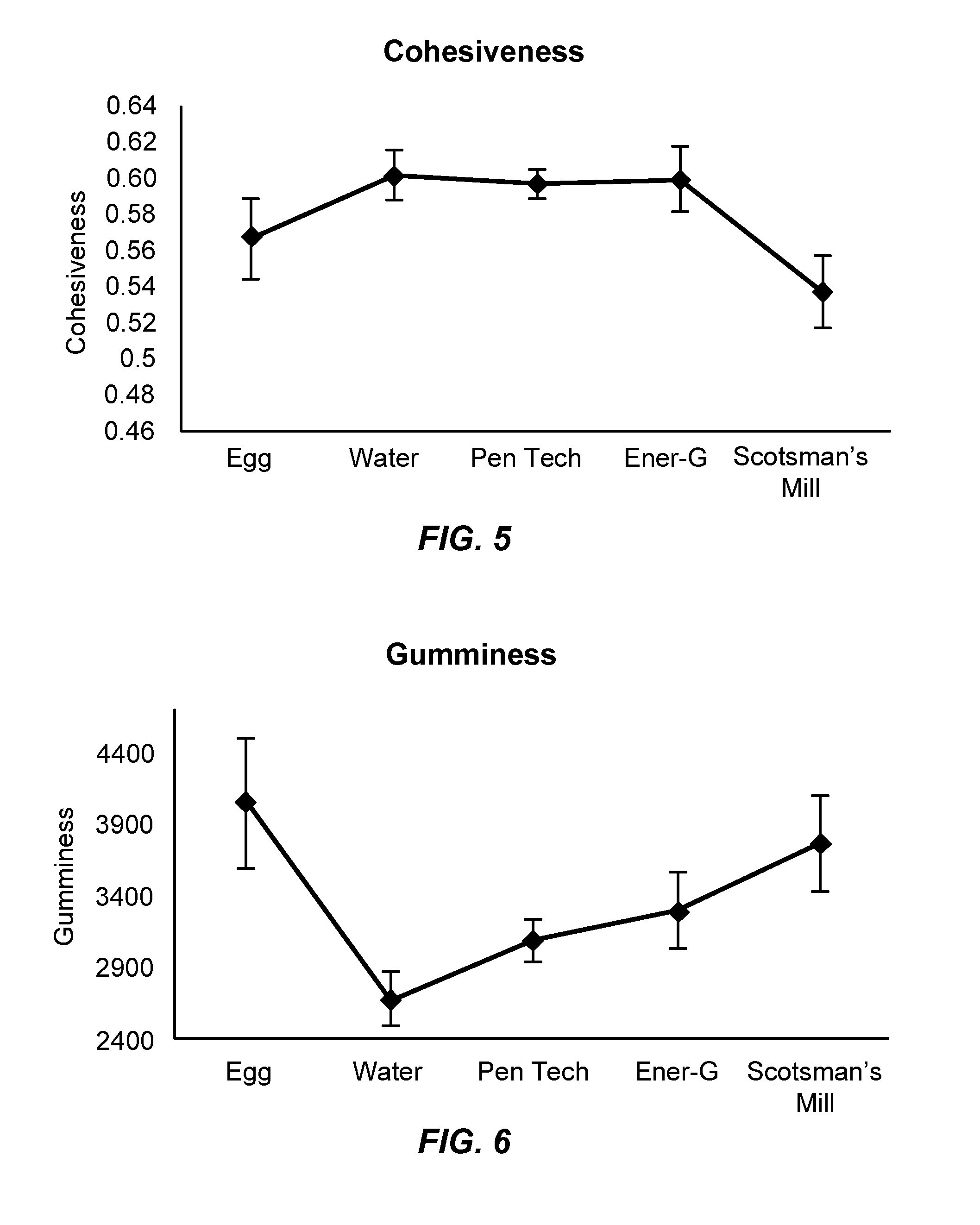

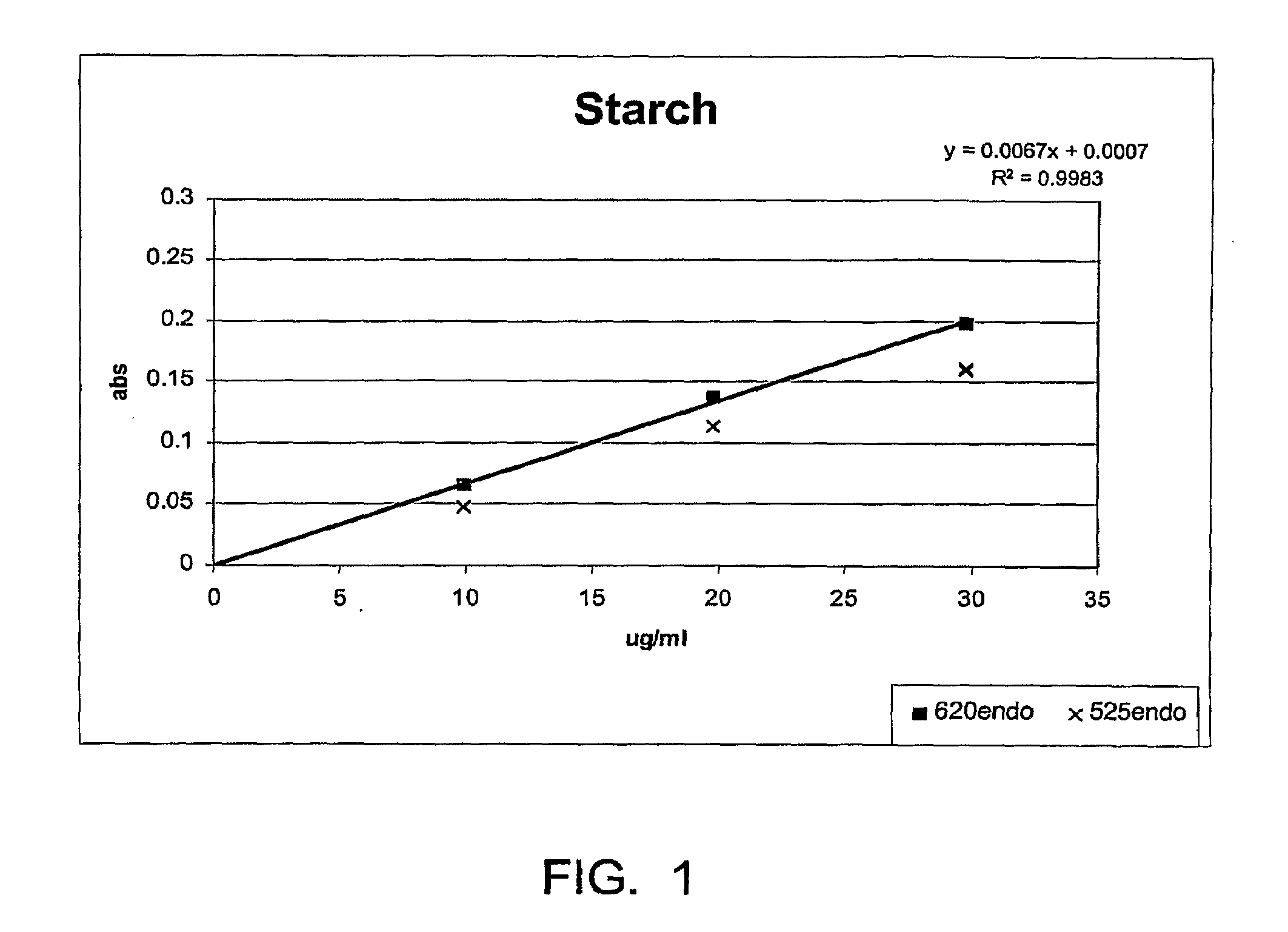

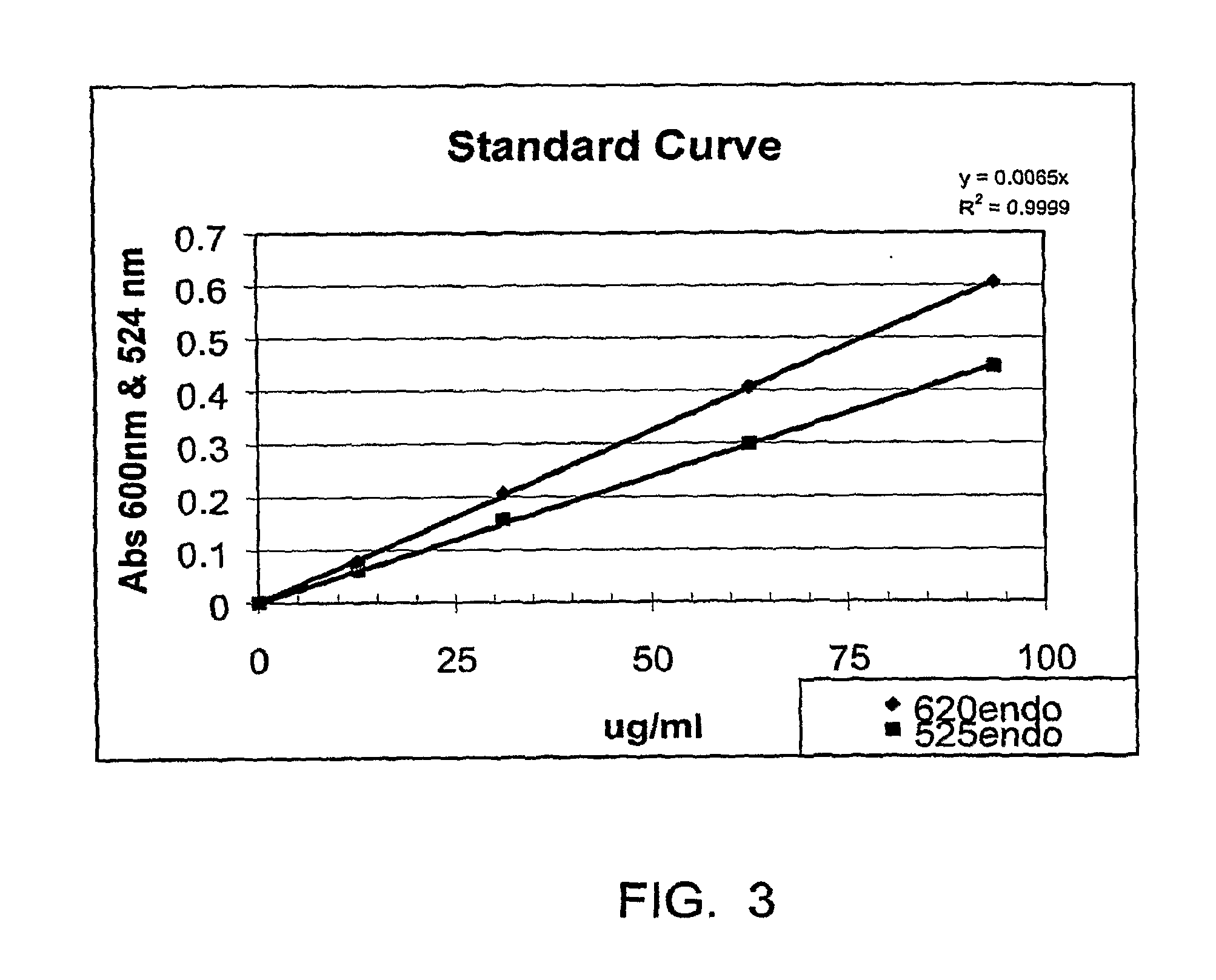

Plant-based egg substitute and method of manufacture

Disclosed herein are non-egg compositions that can be used as egg substitutes. The disclosure is directed to egg substitutes and methods of manufacturing the same, and compositions comprising the egg substitutes, including edible compositions such as baked goods and edible emulsions.

Owner:HAMPTON CREEK INC

Quality improver for flour and minor cereal flour and using method thereof

ActiveCN102232399AImprove liquidityImprove mixing processing effectDough treatmentPre-baking dough treatmentFrost crackBaked goods

The invention discloses a quality improver for flour and minor cereal flour and a using method thereof. The improver is mainly prepared by compounding transglutaminase, an enzyme preparation commonly used in flour products, other auxiliary materials and the like according to a certain proportion. The invention relates to the manufacturing of raw wet flour products, baked foods and minor cereal foods by using the quality improver containing the transglutaminase. Specifically, the method comprises the following steps of: 1) adding into the minor cereal flour or the flour according to a certain proportion and mixing; 2) kneading a dough; 3) preserving heat for certain time; and 4) obtaining a finished product. The improver can improve the processability of the minor cereal flour and the flour and the network structure of gluten, noodles are difficult to rupture during the cooking, dissolved matter is reduced, and the frost crack is prevented during the refrigeration; and the improver has the functions of improving the volumes of bread and minor cereal bread, reinforcing side walls of the bread and the minor cereal bread, improving slicing performance, shortening fermentation time, increasing moisture absorption and the like.

Owner:TAIXING YIMING BIOLOGICAL PRODS

Myceliated vegetable protein and food compositions comprising same

ActiveUS20200060310A1Reduce flavorReduced aromaProtein composition from vegetable seedsProteins working-up by texturisingBiotechnologyHigh protein food

Provided is a food composition which include a myceliated high-protein food product and methods to make such compositions, which are mixtures of myceliated high-protein food products and other edible materials. A food composition includes dairy alternative products, ready to mix beverages and beverage bases; extruded and extruded / puffed products; sheeted baked goods; meat analogs and extenders; baked goods and baking mixes; granola; and soups / soup bases. Food compositions also include texturized plant protein which can be used for making meat-structured plant protein meat analog or meat extender products. The food compositions have reduced undesirable flavors and reduced undesirable aromas due to use of myceliated high-protein food products as compared to use of similar high-protein material that is not myceliated.

Owner:MYCOTECH

Production of stabilized whole grain flour and products thereof

ActiveUS20090238935A1Reduces lipase and lipoxygenase activityLow levelDough treatmentMilk preservationAntioxidantLipoxygenase activity

A stabilized bran component and a stabilized whole grain flour containing the component are produced by subjecting a bran-enriched coarse fraction which contains bran, germ and starch to grinding or milling to reduce grittiness of the coarse fraction without substantially damaging the starch due to abrasion. The coarse fraction may be stabilized by heating to substantially reduce the lipase and lipoxygenase activity of the coarse fraction without substantial gelatinization of the starch. High levels of natural antioxidants and vitamins are retained while avoiding substantial acrylamide formation during the stabilization. The stabilized coarse fraction or stabilized bran component may be combined with a fine fraction which contains predominantly endosperm to obtain a stabilized whole grain flour. The stabilized whole grain flours and the stabilized bran component exhibit extended shelf life and may be used for making baked goods, such as cookies, with desirable oven spread, and a non-gritty mouthfeel.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Method for conducing concentrated cannabis oil to be stable, emulsifiable and flavorless for use in hot beverages and resulting powderized cannabis oil

ActiveUS9629886B2Socially acceptableEliminating and minimizing effectOrganic active ingredientsBiocideCannabisGram

A method for producing powderized cannabis oil, and the resulting powderized cannabis oil, in which concentrated cannabis oil is mixed with and absorbed by a modified starch powder, preferably maltodextrin, in a ratio of at least three grams of starch powder for every one-eighth of a gram of cannabis oil is disclosed. Further disclosed are beverages, baked goods and single-serve beverage brewing cartridges utilizing or incorporating the powderized cannabis oil to create human-consumable products that contain an emulsified, tasteless, and odorless dose of cannabis oil.

Owner:BETTERLIFE PHARMA US INC

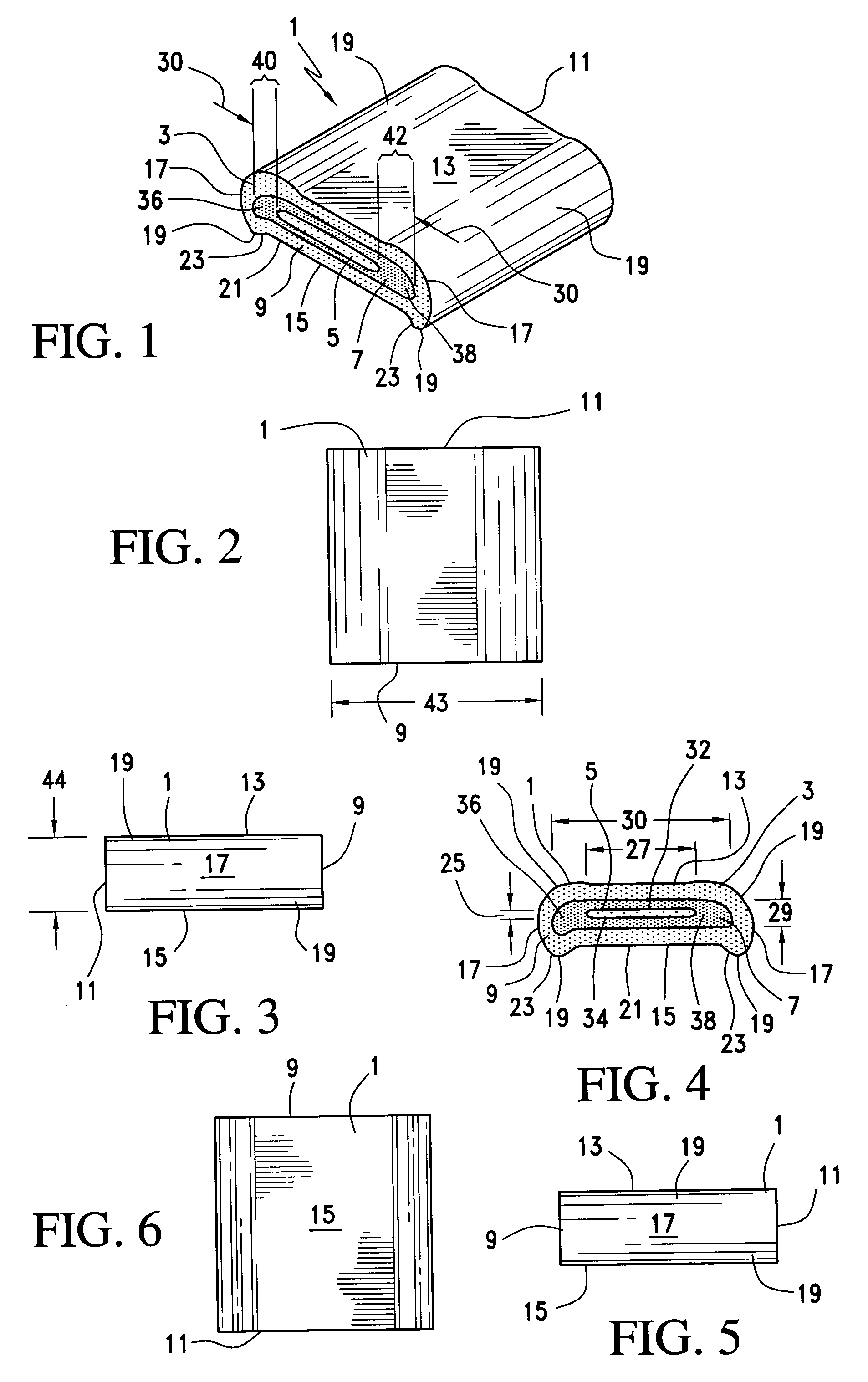

Edible film and method of using same for decorating foodstuffs

An edible film and method of using same for decorating foodstuffs, in particular and baked goods, wherein anyone can easily, inexpensively and artistically decorate foodstuffs. The edible film according to the present invention is composed of an edible polymer film which is preferably releasably mounted upon a flexible substrate to provide a reinforced edible film. The edible film is peelably released from the substrate to provide decorations for the foodstuff. The edible film may be decoratively prepared into predetermined decorations prior to distribution, which may include being pre-printed, pre-cut, colored, or being of pre-selected opacity and sheen. Pre-printing may be accomplished by any suitable printing process utilizing edible inks. Alternatively, the edible film may be distributed in a not yet finalized decoration form, wherein finalization is left up to the user. For example, the reinforced edible film may be distributed without being pre-printed or only partially pre-printed, wherein the user controls subsequent printing, writing, drawing or otherwise marking upon the edible film, such as by use of edible ink writing instruments. Further, the user may purchase sheets of the reinforced edible film and thereafter cut the reinforced edible film sheets into shapes defined by the user.

Owner:JACK GUTTMAN

High fiber and high protein baked goods production

ActiveCN101897353APleasant tasteNo smellDough/pre-mixesConfectioneryHigh protein foodAdditive ingredient

Substantially uniform hydration and dispersion of high amounts of protein and fiber are achieved while avoiding lump formation, hard textures, and off-tastes in the continuous, mass production of high protein and high fiber content sheetable doughs, and baked goods such as crackers, snacks, and cookies made from the sheeted doughs, by hydrating the protein and fiber with water at a temperature below the denaturization temperature of the proteins, and steaming the hydrated mixture without substantial gelatinization of starch during dough production. The steamed, hydrated mass may be admixed with ingredients comprising at least one flour comprising starch to obtain a dough while avoiding substantial gelatinization of starch of the at least one flour during mixing. The baked goods may have a protein content of at least about 4 g, a fiber content of at least about 4 g, and a whole grain flour content of at least about 4 g per 30 g serving.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Calcium fortification of bread dough

ActiveUS20050170049A1Highly manageableEasy transferDough treatmentBaking mixturesBaked goodsAqueous solution

Calcium additives useful for fortifying baked goods, such as bread products, with calcium are disclosed. The calcium additives are particularly useful for fortifying leavened baked goods with calcium. Methods for preparing the calcium additives and using the calcium additives to fortify baked goods are also disclosed. Generally, the calcium additives comprise suspensions of calcium carbonate in acidic aqueous solutions such as citric acid solutions.

Owner:LESAFFRE YEAST CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com