Patents

Literature

6083results about How to "No smell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waterborne ultra-thin steel structure fire retardant coating and preparation method thereof

ActiveCN102838907AGood foaming effectThe pores are small and uniformFireproof paintsCarbonizationMaterials science

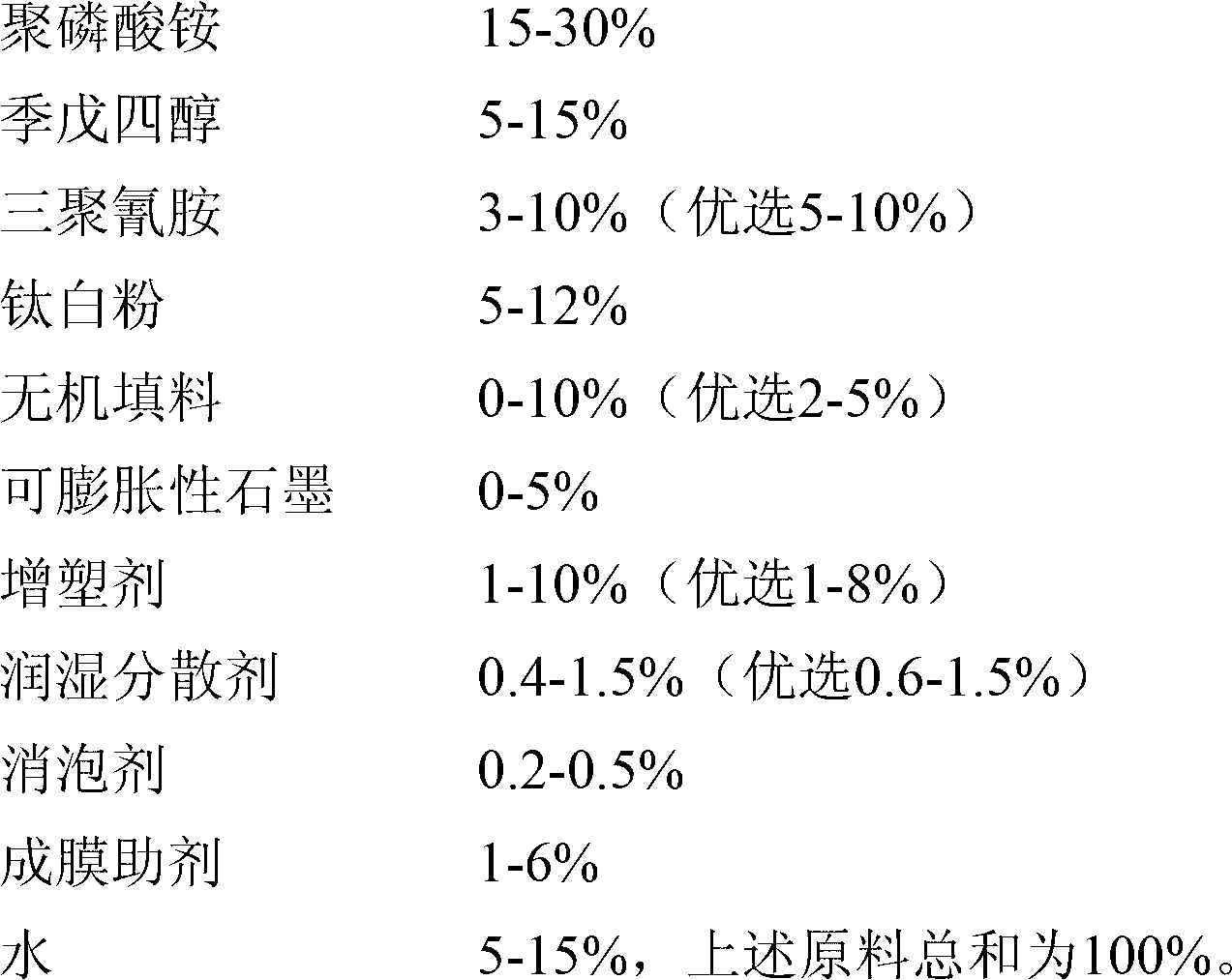

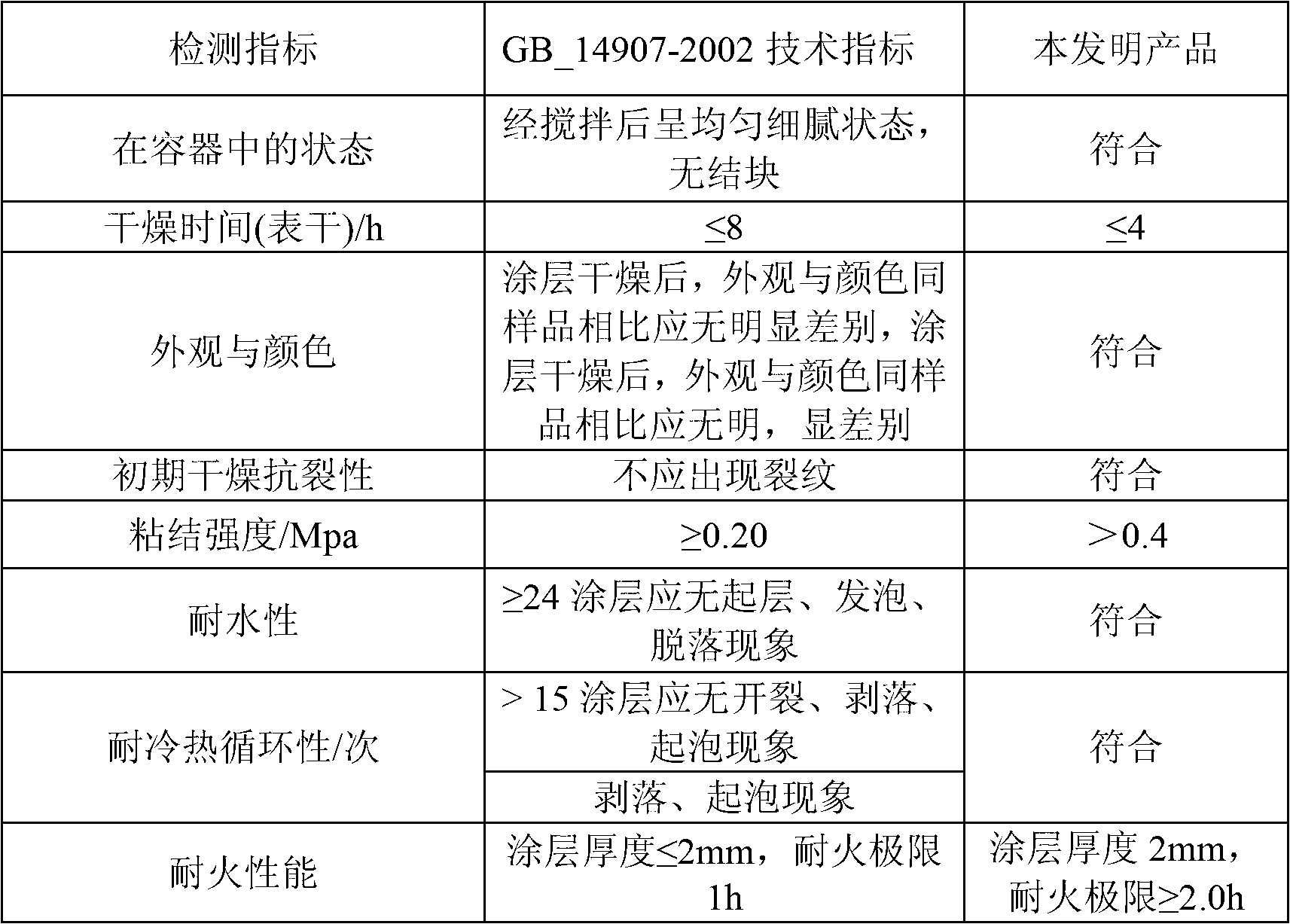

Provided is a waterborne ultra-thin steel structure fire retardant coating and a preparation method thereof. The raw material ratio of the coating includes 15-50% by weight of polymer latex, 15-30% by weight of ammonium polyphosphate, 5-15% by weight of pentaerythritol, 3-10% by weight of cyanurtriamide, 5-12% by weight of titanium dioxide, 2-13% inorganic filler, 0-5% by weight of expansiveness graphite, 1-10% by weight of plasticizer, 0.4-1.5% by weight of wetting dispersant, 0.2-0.5% by weight of defoamer, 1-6% by weight of coalescing agents and 5-15% by weight of water, and total raw material ratio is 100%. A high-speed dispersion method or a grinding dispersion method is adopted in preparation of the coating. A coating layer of the fire retardant coating can form a carbonization layer which is good in foaming effect, small and uniform in air holes and high in expansion times when in heating. The final fire retardant performance of the coating is far higher than technical requirements of a national standard. The waterborne ultra-thin steel structure fire retardant coating is a waterborne coating product, is non-poisonous and odorless and environment-friendly, and can be coated in a mode of brushing or spraying or roller coating.

Owner:SOUTH CHINA UNIV OF TECH +1

Anaerobic digestion handling method for restaurant garbage

ActiveCN101224999AHarmlessRealize resource processingBio-organic fraction processingClimate change adaptationSlurryOxygen

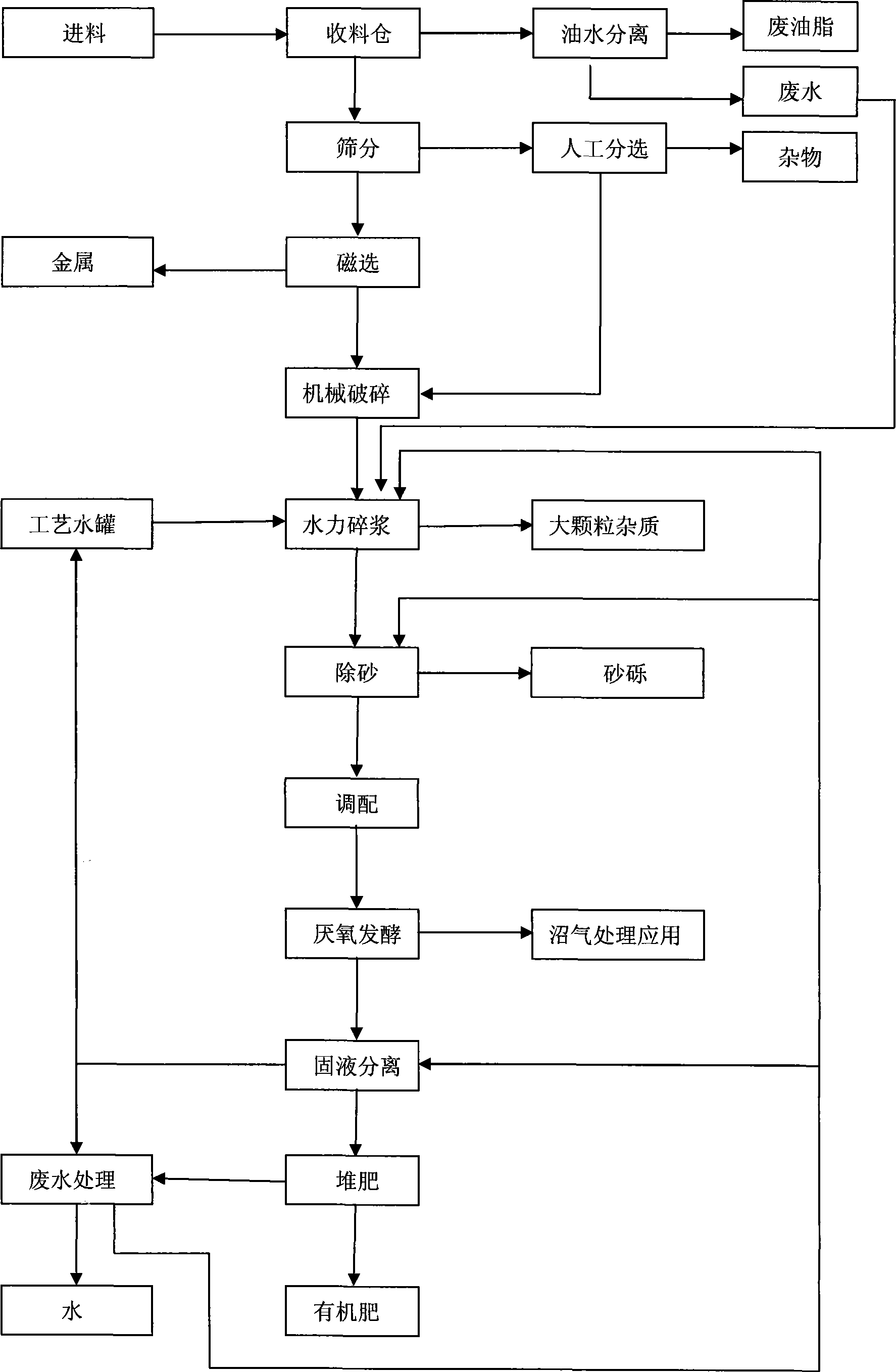

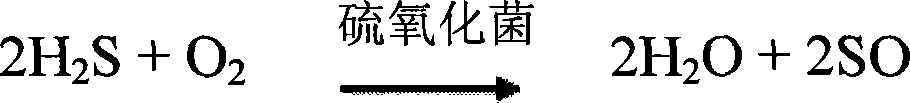

The invention provides a method for resourceful treatment of restaurant garbage, which is characterized in that the restaurant garbage is completely degraded after treatment with the working procedures of oil separating, preliminary selecting, mechanical crushing, hydraulic pulping, slurry blending, anaerobic fermentation and oxygen-control composting, finally the marsh gas is decomposed via anaerobic digestion and is utilized as energy after desulfurization treatment; the high-quality organic manure is produced from the biogas residues via oxygen-control composting; the separated oil can be recycled as the regenerated industrial raw oil; the wastewater generated in the treatment process can be recycled, and finally the redundant wastewater reaching the standard is discharged after biochemical treatment; and the odor generated by the garbage in the treatment process is directly discharged after reaching the standard via biofiltration treatment, thus the restaurant garbage can be transformed into the clean regenerated energy of electric power and the pollution-free organic manure to completely realize resourceful treatment of restaurant garbage. The resourceful treatment of restaurant garbage has the advantages of innocuity, no peculiar smell, no secondary pollution during the treatment process and realization of harmless and resourceful treatment of restaurant garbage.

Owner:宝林

Complex foam extinguishing agent for coal mine

InactiveCN102614615AHigh bonding strengthReduce the drainage rateFire extinguisherSodium bicarbonateMass ratio

The invention discloses a complex foam extinguishing agent for a coal mine and belongs to the technical field of fire prevention and extinguishing. The extinguishing agent is prepared from the following raw materials: main materials are 40 to 60 percent aqueous solution of ammonium bicarbonate or sodium bicarbonate and concentrated sulfuric acid in a solute mass ratio of 2:1-3:1, and auxiliary materials are a stabilizer and a foamer, wherein the auxiliary materials are 0.1 to 2 percent of the total weight of the main materials. Through a test, the extinguishing agent has the foaming coefficient of 20-200 and the foam stabilizing time of more than or equal to 2.5 hours. According to the foam extinguishing agent, the foam of inert gas carbon dioxide is applied to fire prevention and extinguishing of the coal mine, and the foam is diffused in a fire area and fills a fire space, so that the oxygen concentration in the fire area is rapidly reduced, fire is extinguished due to oxygen deficiency in the fire area, temperature is reduced and a fire extinguishing effect is good. The technology also can be applied to coal bed transformation, CO2 foam is easily absorbed by coal to displace partial methane, the recovery ratio of coal seam gas is improved, and CO2 is acid to reduce the generation of secondary precipitates, so that a gas drainage effect is improved. The complex foam extinguishing agent is simple and feasible, and low in cost.

Owner:抚顺正工矿业科技发展有限公司

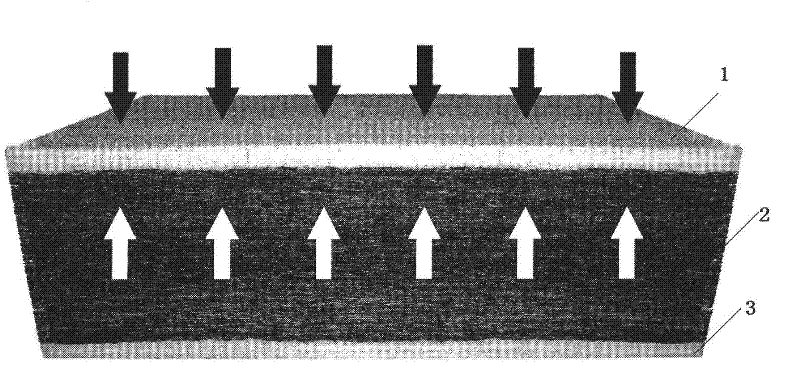

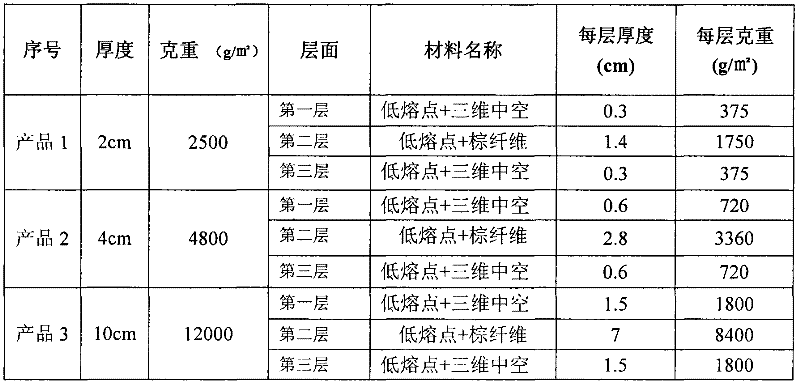

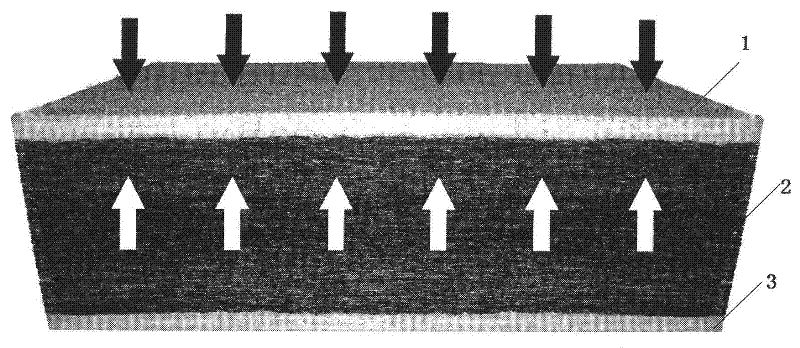

Polyester fiber coconut fiber plate and preparation method thereof

The invention discloses a polyester fiber coconut fiber plate and a preparation method thereof. The polyester fiber coconut fiber plate is characterized by including three layers, wherein the upper and lower layers are made from same materials which are low melting point double-component sheath core fiber and three-dimensionally coiled round hollow fiber, the middle layer is made from low melting point double-component sheath core fiber and coconut fiber, and the three layers are molded integrally through a process. The coconut fiber plate is formed by heat-melting hot-air penetration, melting, bonding and cooling technologies. The polyester fiber coconut fiber plate is environmental-friendly, formaldehyde-free, odorless, temperature-difference-resistant, deformation-free, elastic, strong in tension, impact-resistant, uniform in thickness, and good in sound insulation effect; three layers are molded integrally through the process, the upper and lower layers made from polyester fiber cotton have strong tension, the lining is formed by combining the low melting point polyester fiber with the coconut fiber; and under stress, each layer orderly buffers pressure so as to avoid deformation.

Owner:昆山吉美川纤维科技有限公司

Production method for liner gloves aqueous polyurethane coating connection material

InactiveCN101328383ABreathableGood moisture permeabilityPolyurea/polyurethane coatingsWater basedPropanoic acid

The invention discloses a production method for insert gloves water-based polyurethane coating bonding materials. The method comprises the following steps of: under the protection of dry nitrogen, adding polyether glycols (including polyether diatomic alcohol and / or polyether triatomic alcohol) having undergone vacuum dewatering and isocyanate into a reaction vessel; heating the mixture up to between 80 and 100 DEG C for reaction after even mixing; then adding a hydrophilic chain extender such as dihydromethyl propionic acid (DMPA) and a catalyst for reaction at a temperature of between 80 and 100 DEG C; finally adding the chain extender and a solvent into the mixture for reaction at a temperature of between 55 and 65 DEG C until the NCO content of the isocyanate group does not change; discharging the reactant after temperature reduction to obtain an ionomer; neutralizing a preformed polymer with triethylamine or diethanolamine or triethanolamine and then adding water the mixed solution for emulsification to obtain water-based polyurethane latex; and carrying out reduced pressure distillation to remove the solvent and obtain the product. The synthesized water-based polyurethane resin which serves as a gloves coating has the advantages of good air and moisture permeability, excellent mechanical performance, solvent resistance, ageing resistance, resistance to corrosion caused by chemical mediators, oil resistance, resistance to hooking, cutting and piercing, excellent abrasion resistance, odorlessness, innocuous and nondestructive for contacting with skin, etc.

Owner:ANHUI UNIVERSITY +1

Conditioning deodorization antibiotic mildew-proof wallpaper

The present invention relates to a humidity-regulating, odor-removing, antibacterial and mould-proof wallpaper, which can effectively regulate the air humidity, absorb the polluting gases in the air and inhibit the reproduction of bacteria and mould. The wallpaper is produced by the drying, cooling and embossing of a basal paper and pasty material coated on the basal paper. According to weight percentages, the pasty material is made from 20 percent to 60 percent of PVC, 25 percent to 50 percent of filling, 5 percent to 15 percent of titanium pigment, 3 percent to 5 percent of the mixture of nano-ZnO and nano-TiO2, 1.5 percent to 3.5 percent of mould inhibitor, 1.5 percent to 3.5 percent of plasticiser, 0.5 percent to 2.5 percent of viscosity depressant, 1.5 percent to 2.5 percent of stabilizer and 0.5 percent to 1.0 percent of bisphenol A. Firstly, the PVC is made into paste and then uniformly mixed with the bisphenol A and the plasticiser; secondly, after being uniformly mixed with the filling, the paste is uniformly mixed with the titanium pigment, the nano-ZnO, the nano-TiO2 and the mould inhibitor and then the stabilizer; and finally, the viscosity depressant is added to regulate the viscosity of the paste in order to obtain the pasty material, which is then coated on the basal paper. The wallpaper has the advantages of no toxicity, no offensive odor, environment-friendliness, long service life, waterproofness and no deformation.

Owner:HONGQIJU CONSTR GRP CO LTD

Method for extracting industrial hemp oil rich in cannabidiol

InactiveCN105505565ASimple processReduce energy consumptionFatty-oils/fats productionSolventChemistry

The invention discloses a method for extracting industrial hemp oil rich in cannabidiol. The method includes the steps that supercritical carbon dioxide fluid is adopted for extracting industrial hemp oil from industrial hemp, during extraction, cooled industrial hemp powder is placed in a material barrel of an extraction kettle, CO2 gas is injected into the extraction kettle, the temperature and pressure in the extraction kettle are kept, the CO2 gas makes contact with raw materials in a supercritical state, the industrial hemp oil and other ingredients in the industrial hemp powder are dissolved in the supercritical fluid, the fluid containing cannabidiol and other ingredients throttles and expands in the extraction kettle and enters a separation kettle to be analyzed, and the industrial hemp oil is obtained and collected. The CO2 fluid in the supercritical state is used as an extraction solvent, reuse is achieved in the same system, the process is simple, energy consumption is low, the extraction period is short, is only 1-2 h and is 1 / 4 of the production period in the prior art, and the extracted industrial hemp oil has the advantages of being good in quality, high in purity, free of abnormal smells, solvent residues and environmental pollution and the like.

Owner:GUIZHOU AEROSPACE WUJIANG MACHINERY & ELECTRICITYEQUIP +1

Ferment making black garlic method

InactiveCN101120783ASolve the smellSolve the discomfortFood preparationSocial benefitsNutritive values

The present invention relates to a black garlic manufacturing method through fermentation, which can effectively solve the problem of peculiar smell or discomfort of garlic. The technical proposal is as following. Firstly, far infrared heating device is used to produce anion. Secondly, garlic is marinated in the garlic fermentation inducing medium. Thirdly, after the garlic is fished out, the garlic is put into the far infrared heating device. Fourthly, the garlic is heated and fermented step by step. And lastly, the black garlic is made. The garlic fermentation inducing medium is made by the following components based on weight-volume percent: salt 8.6 percent, ethanol 4.1 percent, amino acids 3.1 percent, protein 0.6 percent, sugar 12.4 percent, ash content 7.9 percent, lipid 0.02 percent and water for the rest. The present invention has simple method, good garlic processing effect. After procession, the garlic has no peculiar smell, is convenient to eat, has high nutritive value, is used widely, and has great economic and social benefits.

Owner:北村清彦 +1

Anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and preparation method thereof

ActiveCN101597410AGood oil resistanceReach high temperaturePlastic/resin/waxes insulatorsClimate change adaptationPolymer scienceUltra fine

The invention relates to an anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and a preparation method thereof. The sheath material uses chlorinated polyethylene rubber as main raw material and adds chlorosulfonated polyethylene rubber, triallyl isocyanurate, 1,3-bis (tert-butyl peroxide isopropyl) benzene, trioctyl trimellitate, carbon black, antioxidant 1010, ultra-fine talc powder, antimony trioxide, and high-activity magnesium oxide R-150 according to ratios; the preparation method is as follows: at first, mixing part of the auxiliary agents, then mediating, internal mixing, open mixing, granulating and extruding are carried out on the mixture to form cables, thus the cables are obtained. In the formula, high temperature resistant plasticizer is utilized, various auxiliary agents with appropriate proportions are added into the formula, so that chlorinated polyethylene rubber cable material can reach a high temperature of 105 DEG C, and can be used at the lowest temperature of minus 50 DEG C. The sheath material has the advantages of good anti-aging property, excellent electrical insulation and mechanical property, environmental protection and high flame resistance, thereby being suitable for cold and oil-contaminated severe environment and transmission and distribution circuits of which the current-carrying capacities are large and the rated voltages are at or below 450 / 750V. Meanwhile, compared with traditional chloroprene rubber cable material, the sheath material has the characteristics of low cost, fast extruding speed and high output benefit.

Owner:NINGBO WELL ELECTRIC APPLANCE CO LTD

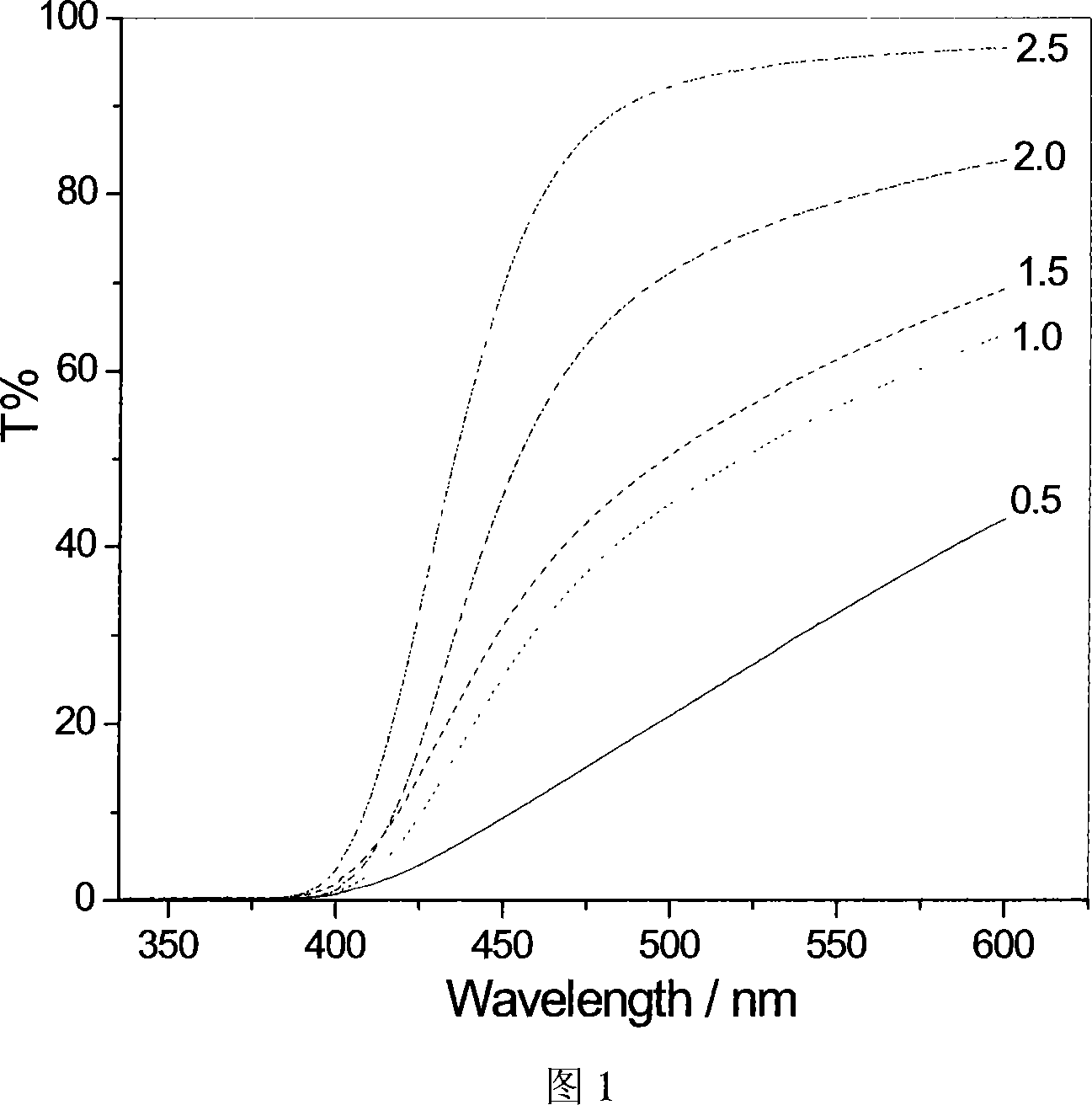

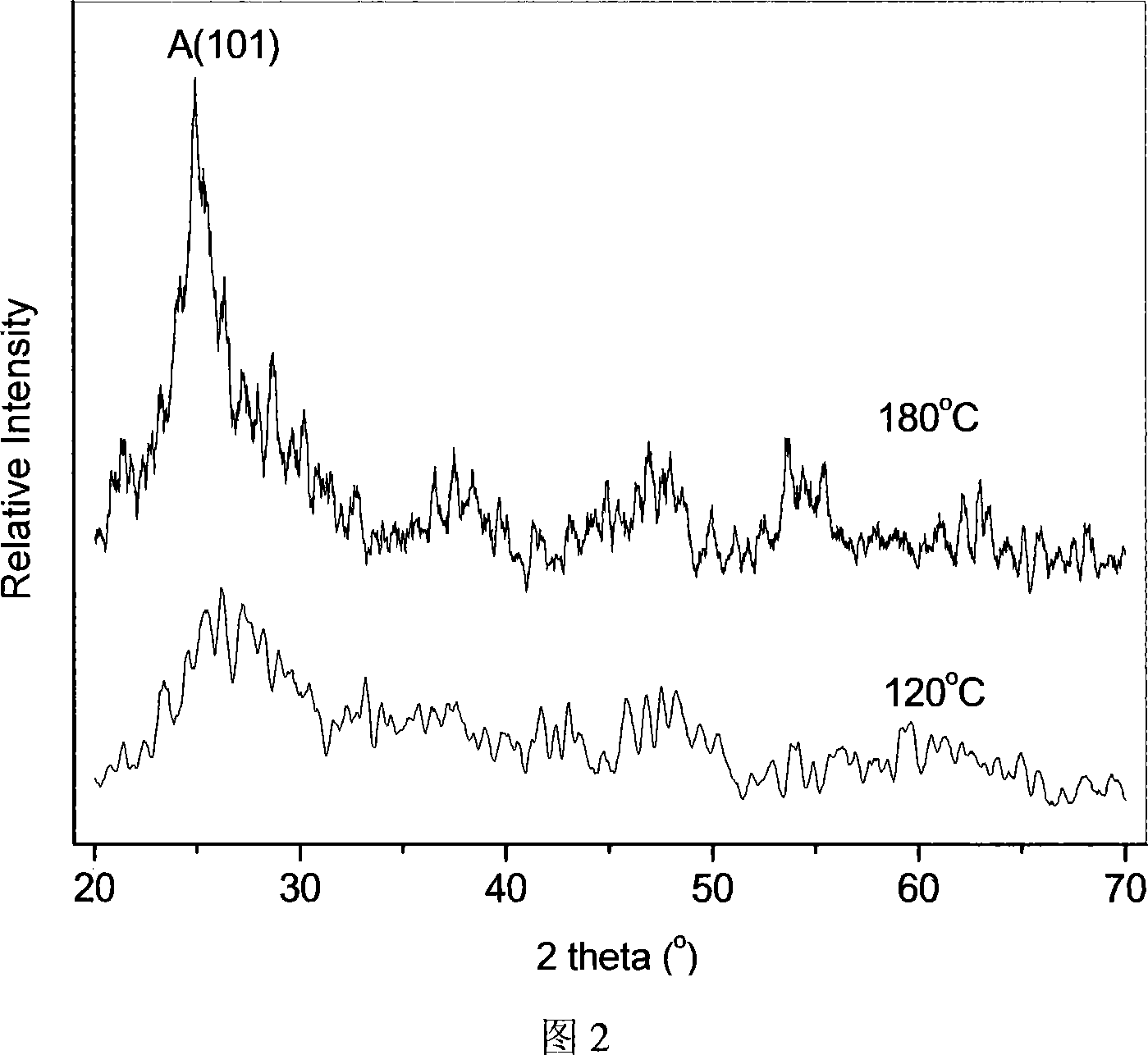

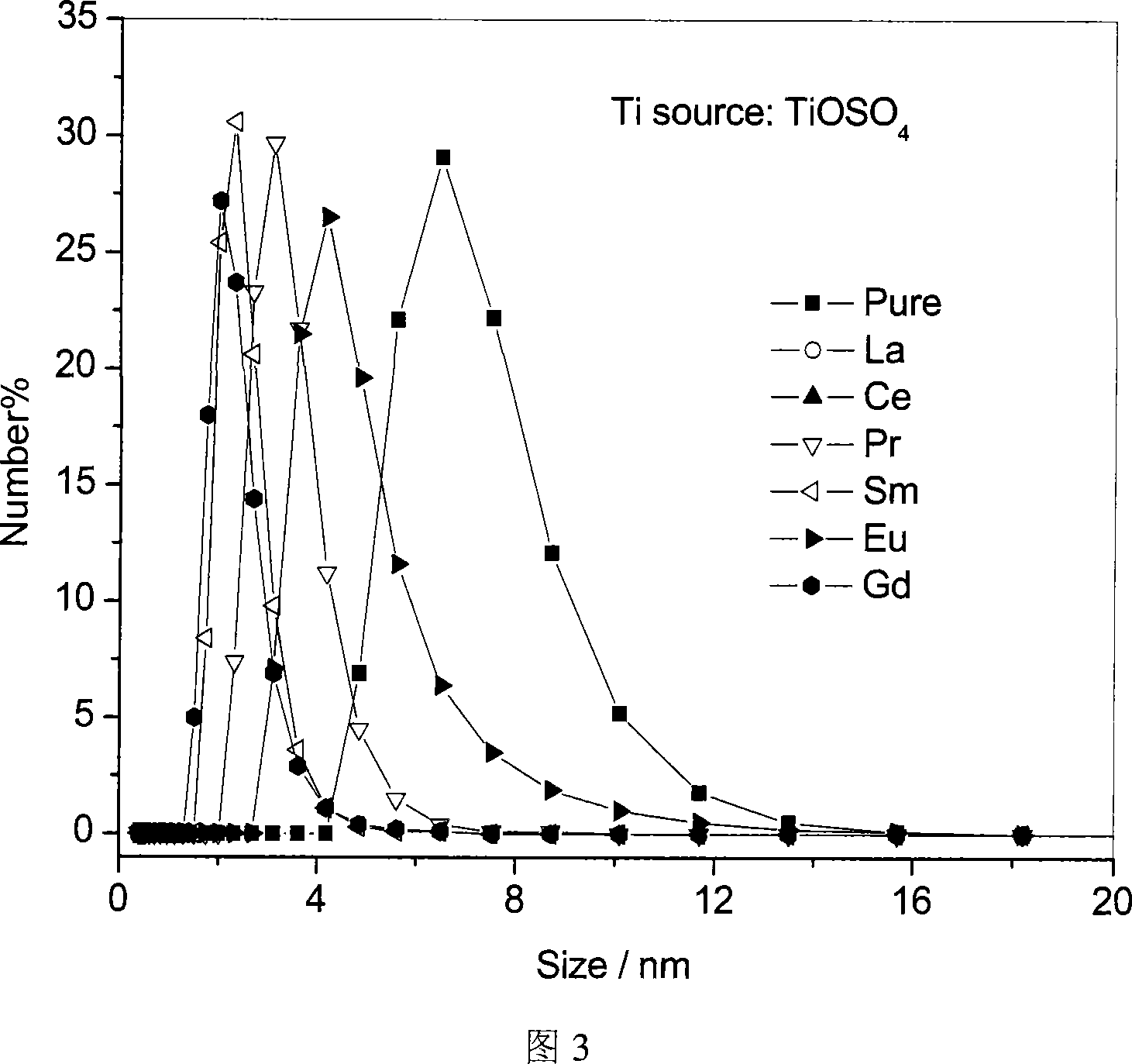

Method for preparing sol of neutral Nano titanium dioxide

This invention discloses a method for preparing neutral titanium dioxide nanosol. The method comprises: (1) preparing amorphous titanium dioxide; (2) dispersing and dissolving amorphous titanium dioxide; (3) performing hydrothermal treatment to obtain neutral titanium dioxide nanosol. The obtained neutral titanium dioxide nanosol (below 10 nm) is transparent and golden, and does not have any odor. Besides, the neutral titanium dioxide nanosol has such advantages as high stability, certain crystallinity, high specific surface area, high adhesiveness, reduced particle sizes after doped with transition metal, and high utility of visible light. The method has such advantages as wide raw materials and easy operation, and is suitable for large-scale production.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

Stevioside glycoside refining process

InactiveCN1349997AHigh yieldNo smellSugar derivativesSugar derivatives preparationAlcoholGlycoside formation

The present invention adopts ethyl alcohol as reinfing solvent, and adopts the following steps: mixing stevioside and ethyl alcohol according to a certain proportion, stirring in dissolving process, solid-liquid separation of dissolved mixture, respectively decolouring obtained solid and liquid, drying to obtain refined stevoiside, in which the refined solid content is up to 88%, and its total recorery rate is high, and the refined stevioside is colourless, and has no abrormal taste.

Owner:青岛创升生物科技有限公司

Bio-organic fertilizer

InactiveCN104774054ALow costQuick costBio-organic fraction processingOrganic fertiliser preparationSnow moldMicrobial agent

The invention discloses bio-organic fertilizer, and belongs to the technical field of organic fertilizer. The proportion by weight of all raw materials of the bio-organic fertilizer is dried chicken manure : edible mushroom : compound microbial agent : corn flour or rice bran : functional strain = 110-140 : 390-360 : 0.1-0.5 ; 0.1. The compound microbial agent comprises mould, bacillus, lactic acid bacteria, actinomycetes and saccharomycetes. The strains are efficient viable bacteria. Each gram of the compound microbial agent comprises the number of the mould ranges from 5 hundred million to 8 hundred million, the number of the efficient viable bacteria of bacillus ranges from 12 hundred million to 15 hundred million, and the number of the actinomycetes ranges from 10 hundred million to 12 hundred million and the saccharomycetes of 15 hundred million to 18 million. According to the bio-organic fertilizer, the chicken manure and mushroom dregs serve as main materials, and the high-quality organic fertilizer can be fermented quickly by adding the compound microbial agent and the functional strain.

Owner:YONGZHOU WANXIDENG AGRI DEV

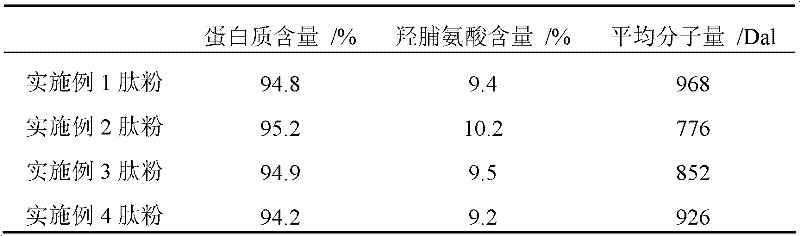

High-purity fishy smell and foreign odor-free fish collagen protein peptide and preparation method thereof

The invention discloses a high-purity fishy smell and foreign odor-free fish collagen protein peptide and a preparation method thereof. The preparation method comprises the following steps: cleaning fish skins, and then cutting into blocks and mincing; performing stirring treatment with NaCl solution; centrifugally degreasing to remove paraprotein; adding water to regulate the pH value of initial slurry to be 8.0-8.5; performing combined gradient enzymolysis on alkali protease and neutral protease; deactivating enzyme after the enzymolysis is ended; performing adsorption bleaching by activated carbon; and then performing rough filtration, fine filtration, evaporation concentration and spray drying to prepare the high-purity fishy smell and foreign odor-free fish collagen protein peptide. The high-purity fishy smell and foreign odor-free fish collagen protein peptide disclosed by the invention has a simple process and is easy to industrial production; fishy smell, foreign odor and non-collagen proteins are fully removed in production; the low-temperature biological enzymolysis technology is adopted, and other substances are not added, thereby, the product quality is improved; an obtained fish collagen protein peptide powder has the characteristics the content of amino acid hydroxyproline is not less than 9 percent, and the average molecular weight is lower than 1000Dal; no fishy smell or foreign odor cannot generated, and obvious fishy smell or foreign odor also cannot be generated through heating treatment under the acid conditions. The high-purity fishy smell and foreign odor-free fish collagen protein peptide can be widely applied to processing of various foods and cosmetics as a green functional ingredient.

Owner:广州合诚实业有限公司

Method of preparing walnut polypeptide powder

InactiveCN101228918ALess impuritiesAnti-fatigueMetabolism disorderProtein composition from vegetable seedsEnzymatic hydrolysisCentrifugation

The invention relates to a preparation method of a walnut peptide powder, which effectively embodies a plurality of biological functional properties of the walnut peptide powder, reserves a plurality of nutritional components of walnuts. The polypeptide content in the walnut peptide powder is 60-80 percent, while the walnut peptide powder is light yellow or yellow-white color and has functions of anti-fatigue and antioxidation, etc. The invention comprises the following operation steps: crushing the walnut cakes before extracting the walnut protein, then carrying out enzymatic hydrolysis and centrifugation to the crude walnut protein to acquire the supernatant, dialyzing the supernatant and removing impurities and macromolecular compounds, and then concentrating the acquired dialysate, and at last vacuum drying to prepare the walnut peptide powder and packing into finished products.

Owner:NORTHWEST A & F UNIV +1

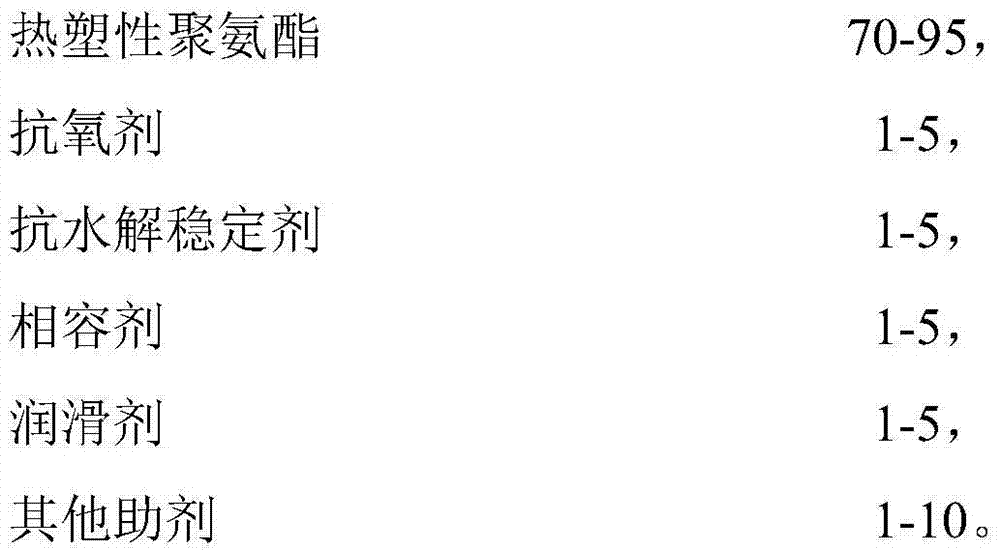

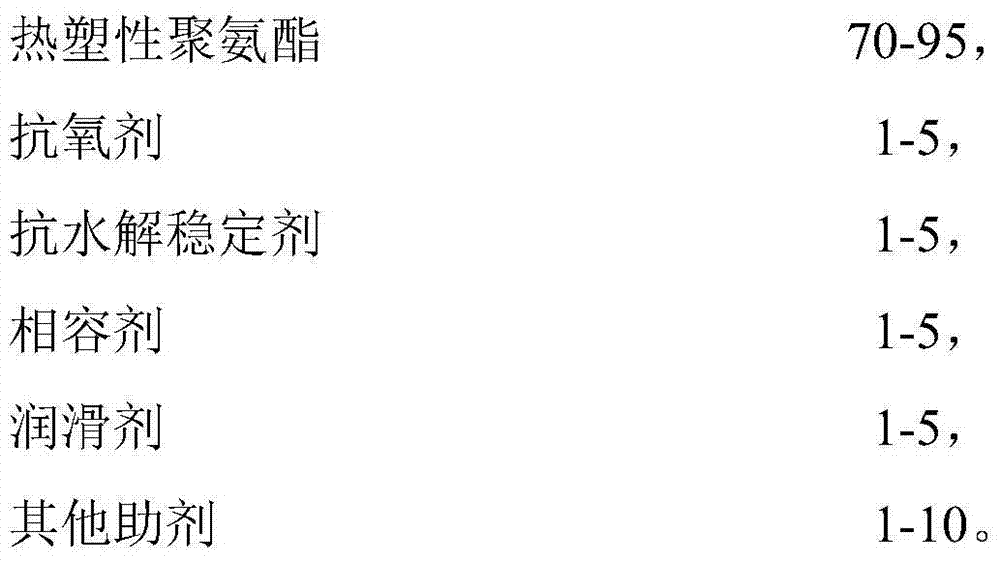

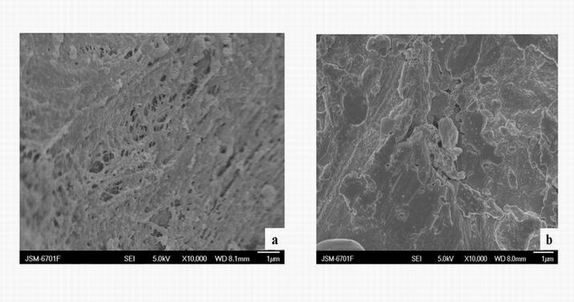

Thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and preparation method thereof

The invention relates to a thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and a preparation method thereof. The composite material is prepared from the following components in parts by weight: 70-95 parts of thermoplastic polyurethane, 1-5 parts of antioxidant, 1-5 parts of hydrolysis-resistant stabilizer, 1-5 parts of compatilizer, 1-5 parts of lubricant and 1-10 parts of other assistant. Compared with the prior art, the antioxidant, hydrolysis-resistant stabilizer, lubricant and other assistants are added, so that the modified composite material has the advantages of favorable mechanical properties, high elasticity, favorable wear resistance, higher heat stability, hydrolysis resistance, higher oxidation resistance and higher processability. When being used for FDM 3D printing, the thermoplastic polyurethane modified composite material has the characteristics of smooth printing process, no odor, smooth printing product surface, beautiful appearance, stable size, low tendency to shrinkage, favorable mechanical properties, high flexibility, high heat stability, high hydrolysis resistance, high oxidation resistance and high processability.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

Camellia oil preparation method for cosmetics

ActiveCN101305974AImprove quality requirementsCrystal clear appearanceCosmetic preparationsToilet preparationsCamellia oleiferaFiltration

The invention relates to a preparation method of cosmetics camellia oil. High-quality camellia seeds are selected to be used as the raw material; the camellia seeds are roasted under the negative pressure and at the lower temperature, and are husked after natural cooling and are squeezed at the room temperature to obtain high-quality crude oil with low acid value and pale yellow color; impurities are removed through filtration under the heating condition, alkali refining and ethanolic extracting two-stage process is utilized for acid stripping and de-coating; then the mixture composed of active carbon and floridin is used as de-coloring agent for de-pigmentation; peroxide and unclean flavor are removed through deodorization; then the drying winterization is acted; finally, the cosmetics camellia oil is obtained, wherein, the acid value is less than 0.1 mgKOH / g, the peroxide value is less than 0.5 mmol / kg, the appearance is colourless approximately as well as clear and translucent, and no unclean flavor exists. The cosmetics camellia oil reaches or exceeds the requirement of the national standard GB11765-2003 on first level expressed tea-seed oil, and can be directly used for manufacturing the cosmetic such as skin care oil for babies; in addition, an edible camellia oil fabrication plant can be improved for production, thereby lowering the investment cost greatly.

Owner:广东新大地生物科技股份有限公司

Wet rheumatalgia-relieving plaster for traumatic injury and method of producing the same

The invention relates to a rheumatalgia-relieving plaster for treating trauma and process for preparation, wherein the plaster is prepared from 108 kinds of Chinese herbs including Sichuan aconite root, Kusnezoff monkshood root, jack-in-the-pulpit tuber, pinellia tuber, seed of nuxvomica, momordica seed, chaulmoogra seed, stinkweed root, pricklyash peel, pangolin scales, sargentgloryvine, root bark of chinese wolf berry, zedoary, shiny pricklyash, achyranthes and cyathula root, spicebush root and burred tuber.

Owner:吴兴保

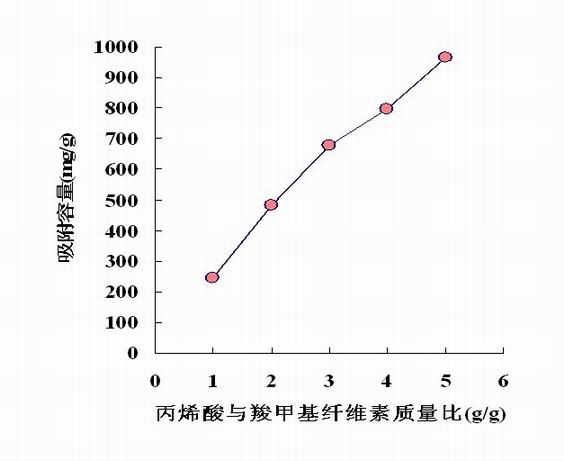

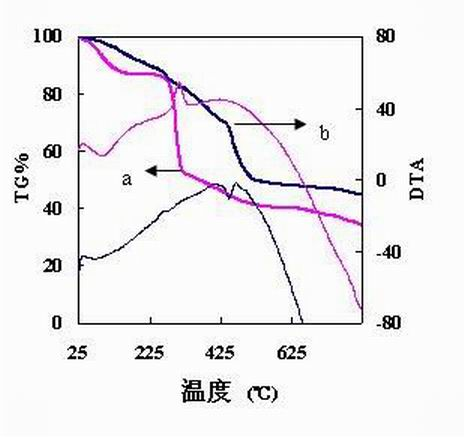

Preparation and application of carboxymethyl cellulose of wheat straw

InactiveCN101985479AReduce dosageImprove stabilityOther chemical processesWater contaminantsChloroacetic acidsChloroacetic acid

The invention discloses carboxymethyl cellulose of wheat straw. The wheat straw is crushed and subjected to pretreatment with dilute alkali, bleaching and alkalization, and then reacts with chloroacetic acid before being etherified so as to obtain the carboxymethyl cellulose of the wheat straw; and the carboxymethyl cellulose of the wheat straw is subjected to graft copolymerization together with acrylic acid to obtain a carboxymethyl cellulose-based polymer adsorbent. The adsorbent is applied to the treatment of wastewater containing heavy metal ions, has high adsorbability and large adsorption capacity and ensures high metal ion removal rate. After treatment, the adsorbent has high stability and can completely meet the requirements of heavy-metal wastewater treatment; and the treated wastewater is clear and transparent without odor and can meet the national emission standard. The invention has the advantage that the resources of raw materials are wide, the cost is low, the use of waste is realized, and secondary pollution caused by burning of the wheat straw is avoided, thus being conducive to environmental protection.

Owner:GANSU TIPTOP PLANT TECH CORP

Preparation method for edible fungus flavor food

The invention discloses a preparation method for an edible fungus flavor food. The edible fungus can be any one from edible agaricus bisporus, straw mushrooms, oyster mushrooms, shii-take, needle mushrooms, pleurotus nebrodensis, pleurotus eryngii, agrocybe aegerita, hypsizigus marmoreus, agaricus pratensis schaeff, spring mushrooms, stropharia rugoso-annulata, sparassis crispa, macrolepiota procera, tremellodon gelatinosum, black trumpet mushrooms, hericium erinaceus, pholiota nameko, lepista personata, mitake mushrooms, lactarius hatsudake, golden oyster mushrooms, pholiota adiposa, cantharellus cibarius, termitomyces albuminosus, tricholoma giganteum, pleurotus citrinopileatus, calocybe gambosa, truffle, amillariella mellea, fungus suillus, beef-steak fungus, lactarius deliciosus, tricholoma matsutake, agaricus bitorquis, pleurotus pulmonarius, toadstool and russula vinosa, and after treatment, the edible fungus is steeped into a steeping liquor prepared from red wine vinasse, high quality dry red wine and a flavouring agent in a vacuum and normal temperature and normal pressure combined condition, so as to obtain the flavor food; the edible fungus flavor food for leisure is prepared through oil-bath dewatering; a flavor food flavor puffed food is obtained through a swelling process, so as to meet consumers' hobbies and requirements.

Owner:徐州绿之野生物食品有限公司

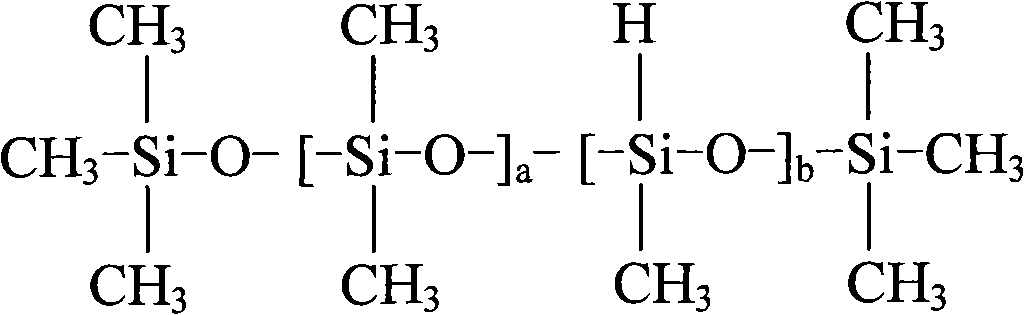

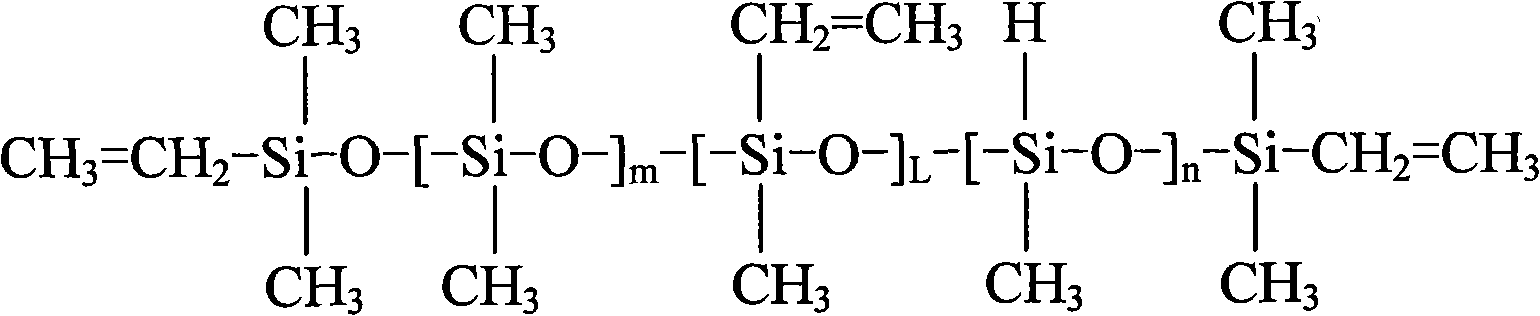

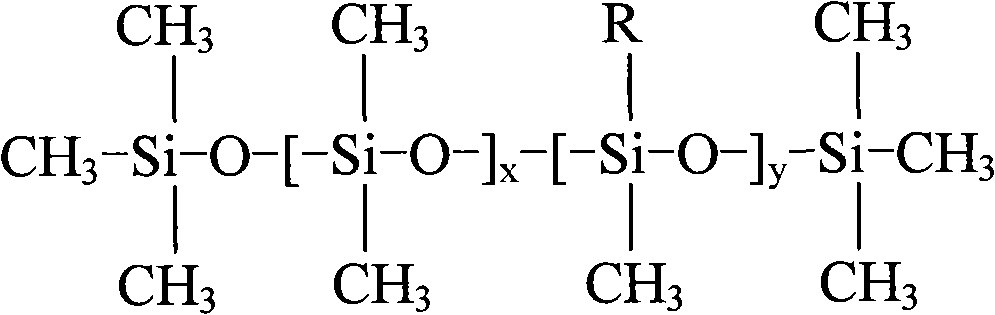

Silastic composition and preparation method thereof

The invention relates to a silastic composition and a manufacturing method thereof. The silastic composition comprises a component A and a component B, the component A is composed of mixing base adhesive and platinum coordination complex, whereas the component B is composed of the mixing base adhesive, hydrogen-containing silicone oil, a thickening agent and a depressor; the mixing mass ratio is: component A: component B is 0.5-99:1-99.5. The silastic composition of the invention is a solid-state mixing silastic containing platinum curing ingredient, so no curing ingredient is needed in the process of molding, besides, the vulcanization effect is good, the vulcanization moulding temperature is low, thus saving electricity, reducing exhaust emission and improving productivity; moreover, the silastic product is odorless and has fine physical and mechanical properties.

Owner:东莞市贝特利新材料有限公司

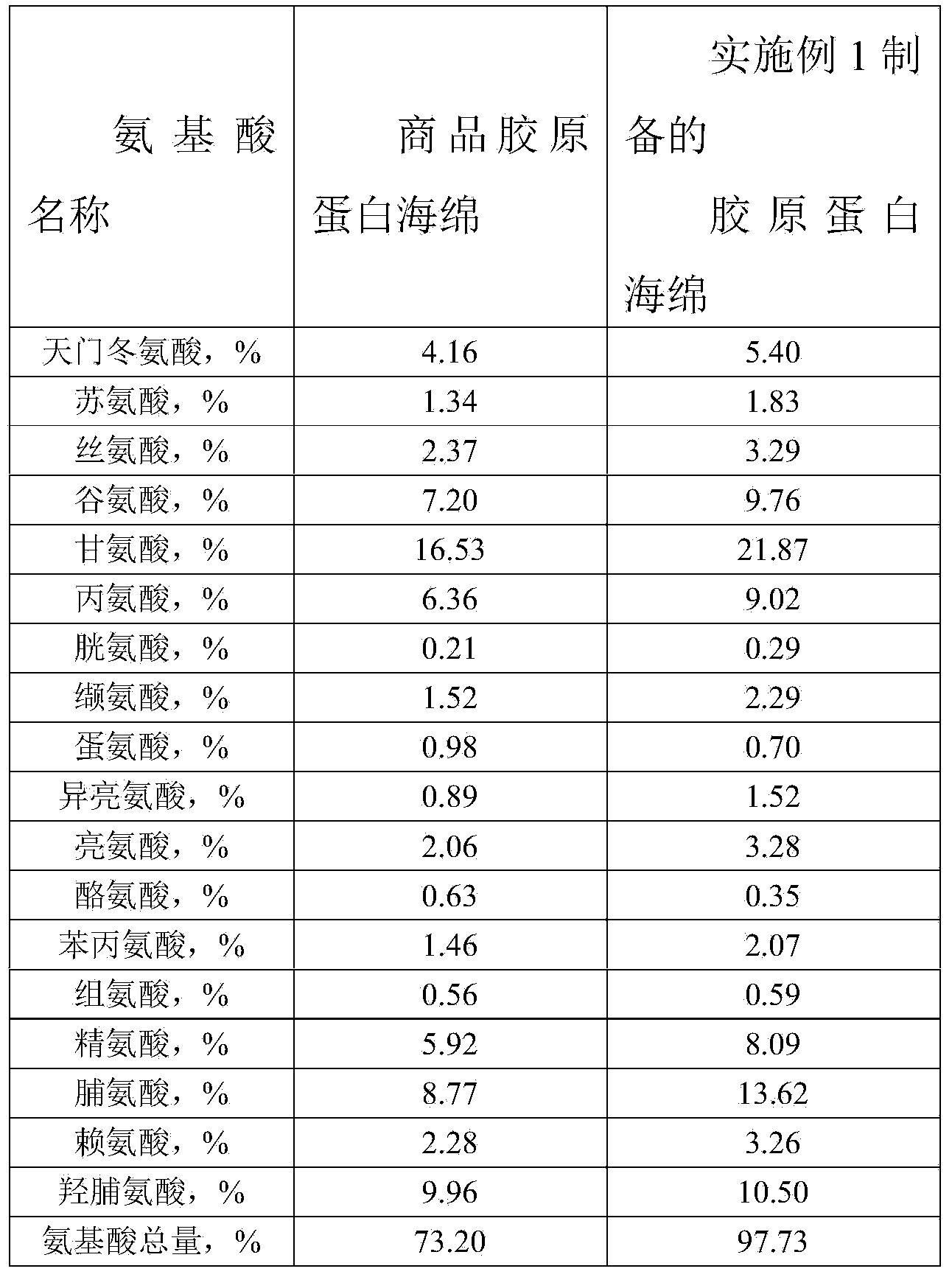

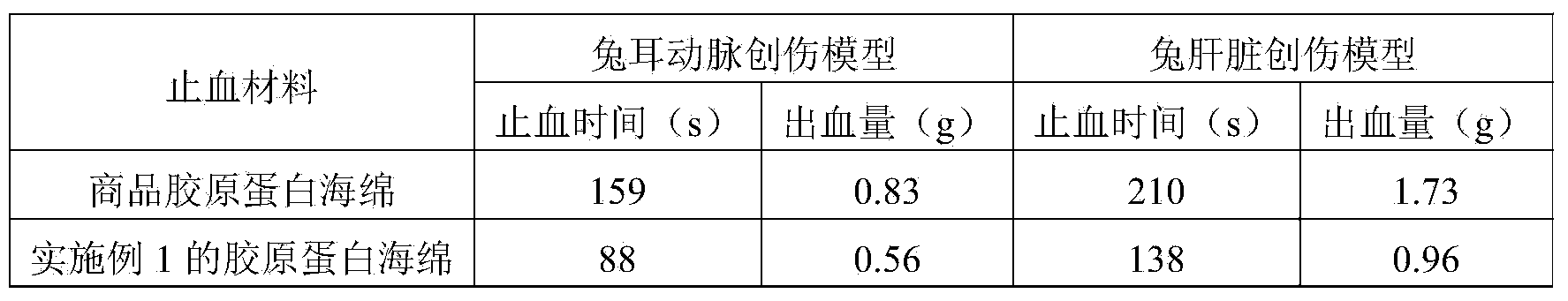

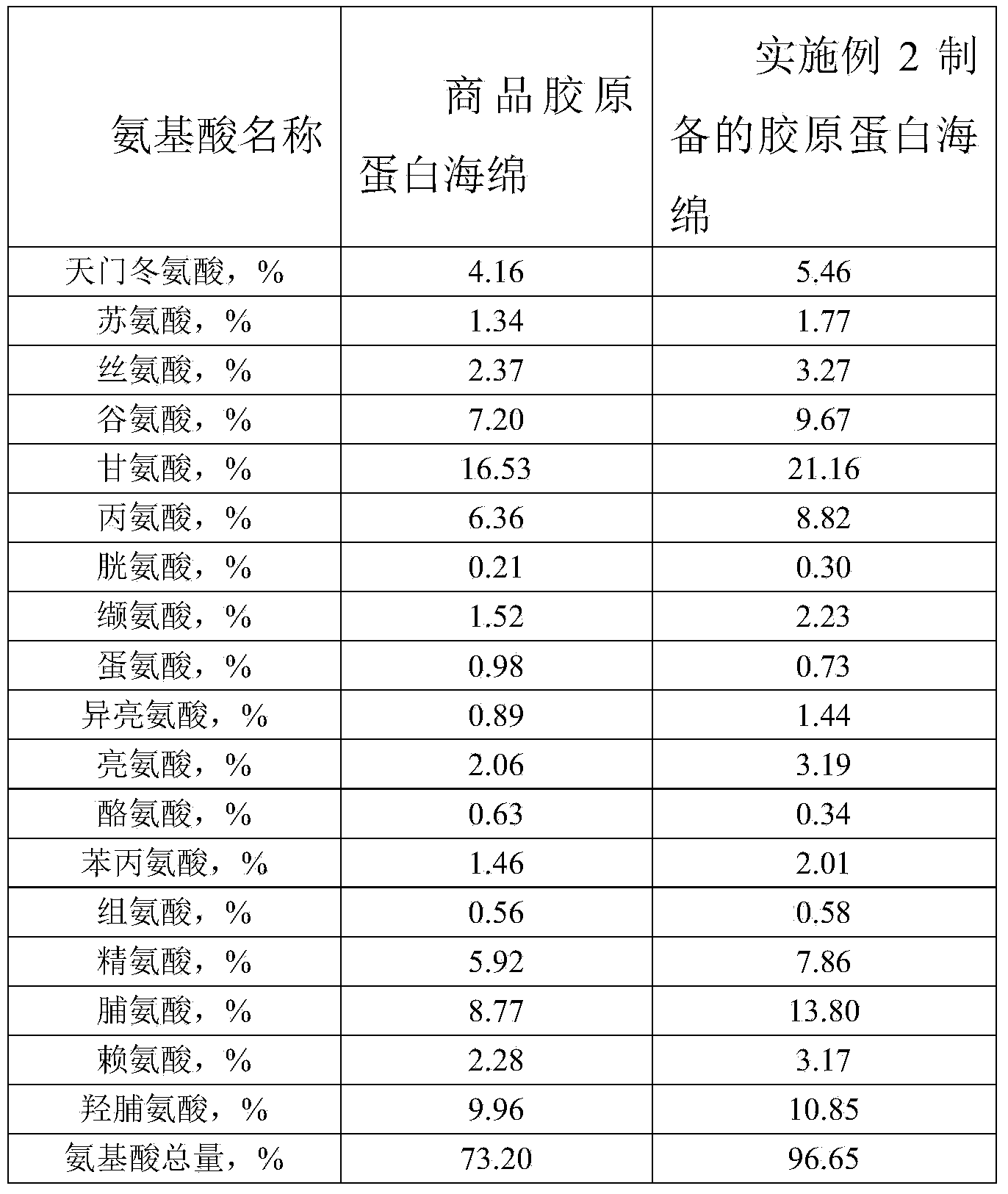

Preparation method of high-purity collagen protein sponge

InactiveCN103772734AGood removal effectHigh purityConnective tissue peptidesPeptide preparation methodsFreeze-dryingCollagen sponge

The invention provides a preparation method of high-purity collagen protein sponge, and relates to a preparation method of collagen protein sponge. The preparation method of the high-purity collagen protein sponge is used for solving the problems that the collagen protein sponge prepared by using a conventional method is long in production cycle and low in yield and purity and has poor hemostasis performance. The preparation method of the high-purity collagen protein sponge comprises the following steps: step one. pretreating fresh bovine heel tendons; step two. extracting collagen protein; step three. centrifuging; step four. salting out; step five. dissolving; step six. carrying out gradient dialysis; step seven. pre-freezing; step eight. carrying out freeze drying; and step nine. sterilizing. The final product prepared by using the method has a smooth and flat surface and relatively good hemostatic performance and is uniform in pore size distribution. The product has relatively high purity (the total amount of amino acids reaches 97.73%), an obvious hemostatic effect and no abnormal taste, is safe, non-toxic, high in yield and short in time; liquid is clear without impurities; the production cycle is shortened; the whole preparation process is carried out at a room temperature; the biological activity of the collagen protein is maintained; and the application of the high-purity collagen protein sponge in clinical is improved.

Owner:HARBIN INST OF TECH

Solid energy saving screw cleaning agent

The invention provides a solid energy saving screw cleaning agent which can prepare non-corrosive and non-abrasive energy saving screw cleaning material. The raw material formula of the cleaning agent is as follows by weight percentage: 40-60% of matrix resin, 30%-40% of modified powder and 10-20% of auxiliary agent, and the sum of the weight percentage of all the components is 100%; the auxiliary agent is a cleaning surface, a surface active agent, a lubricating agent, a forming agent and a blowing activator; the raw material formula of the modified powder is as follows by weight percentage: 83-97% of inorganic powder, 2.0-8.0% of dispersing agent and 1.0-5.0% of coupling agent. According to the proportion of the formula, the matrix resin, the prepared modified powder, the cleaning agent, the surface active agent, the lubricating agent, the forming agent and the blowing activator are added into a high-speed mixer, and then are extruded and formed by an extruder to obtain the solid screen cleaning agent.

Owner:彭超

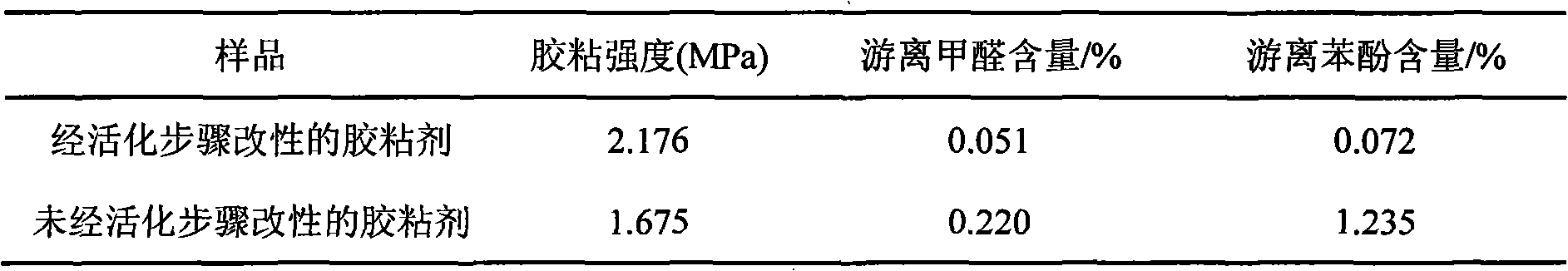

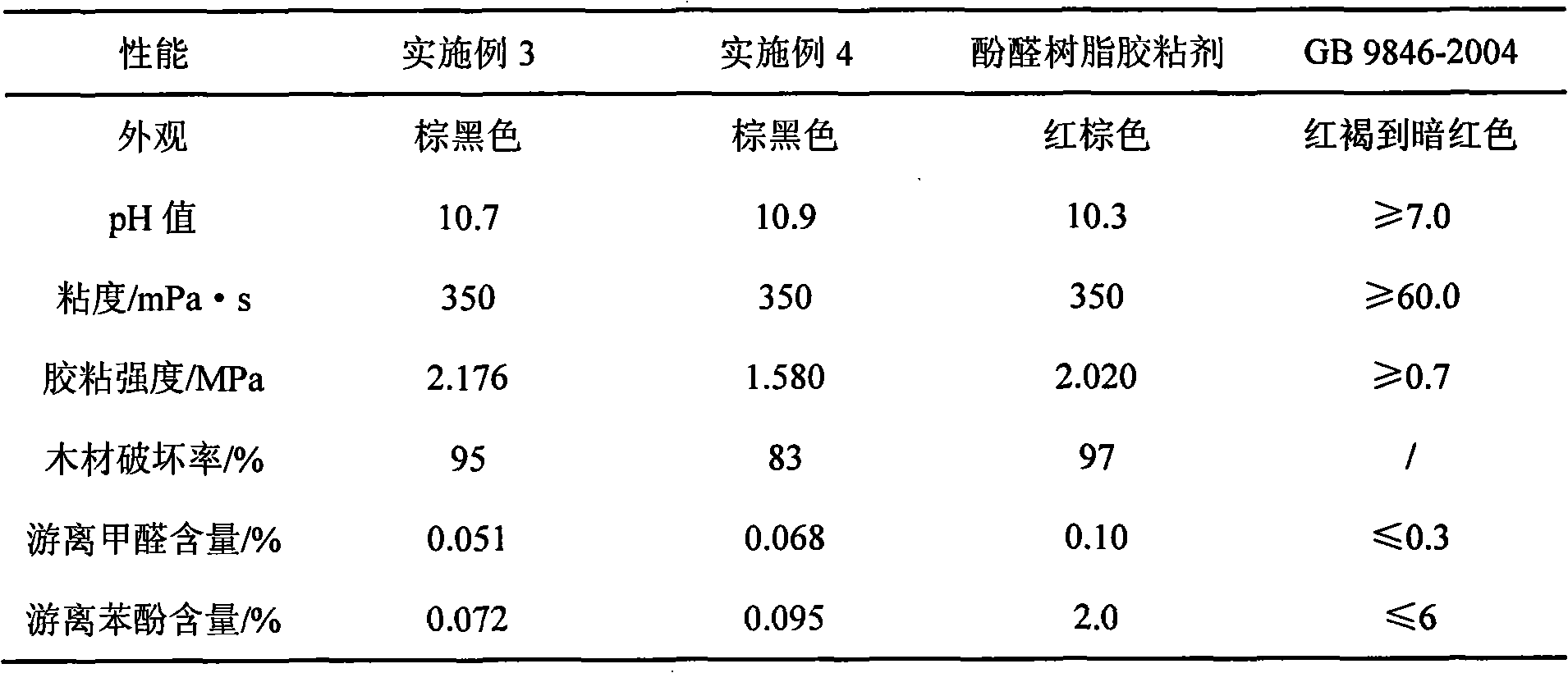

Environment-friendly type alkali lignin modified phenolic resin adhesive and preparation method thereof

InactiveCN101358120AGood water resistanceLess phenolAldehyde/ketone condensation polymer adhesivesProduct propertyPhenols

The present invention relates to an environment-friendly alkali-lignin-modified phenolic resin adhesive and a preparation method thereof. The method includes the following steps: water is added into alkali lignin powder, acid is then added, and under a temperature between 100 DEG C and 120 DEG C, acidolysis lasts for one to three hours; desugarized alkali lignin is obtained; the desugarized alkali lignin powder, sodium hydroxide and water are uniformly mixed, oxidant and 2-naphthol are added for reaction, the temperature is reduced to 45 DEG C to 50 DEG C, formaldehyde and phenol are added so that polycondensation reaction occurs, and the environment-friendly alkali-lignin-modified phenolic resin adhesive is prepared. The method adopts acidolysis desugarization to reduce a great deal of alcoholic hydroxyl content in the alkali lignin and modifies the alkali lignin by alkaline hydrolysis, degradation and nucleophilic addition reaction, thus greatly increasing the chemical reaction activity of the alkali lignin, the amount of toxic phenol required in the technique of preparing modified phenolic resin is little, and the residual phenol and formaldehyde are less, so the environment-friendly alkali-lignin-modified phenolic resin adhesive has the advantages of green production technique and product properties.

Owner:SOUTH CHINA UNIV OF TECH

Glass cleaning agent composite for electronic industry

InactiveCN1482223AEasy to cleanRaw materials are easy to getInorganic non-surface-active detergent compositionsSodium bicarbonateSodium metasilicate

The electronic industrial glass cleaning agent composition belongs to the field of electronic industrial cleaning technology. The cleaning agent consists of sodium metasilicate, sodium hydroxide, sodium carbonate, sodium bicarbonate, Pluronic polyol, CMC, fluoric surfactant, complexing agent, defoaming agent and deionized water. It is used to clean substrate glass and coated conducting glass. During the cleaning, the cleaning agent in 1-5 % is compounded with deionized water in 95-99 % to compound the cleaning liquid for showering or ultrasonic cleaning to eliminate pollutant on glass fastcompletely. It is used to replace strong acid and strong alkali cleaning agent and has no damage to glass surface and no corrosion to ITO film. The cleaning agent has no bad smell, no toxicity and no corrosion, and is safe, reliable, environment friendly and low in cost.

Owner:SHANDONG UNIV

Method for producing acerbity-removing persimmon wine

ActiveCN101215498AReduce astringencyTypical styleAlcoholic beverage preparationMicroorganism based processesYeastAlcohol

The invention discloses a production method for persimmon wine to remove acerbity, which comprises the following procedures: (1) selecting fruits, cleaning and beating; (2) protecting the color; (3) enzymolysising; (4) removing acerbity and clarifying; (5) adjusting ingredient; (6) fermenting; (7) ageing; (8) filtering, filling in bottles and sterilizing; (9) stocking, wherein removing acerbity and clarifying is completed via charging 0.3-0.6g gelatin into one kilogram persimmon juice, standing for 30-40 minutes, clarifying and filtering. The invention protects the color of persimmon juice and reduces oxidation by adding ascorbic acid and citrate, applies gelatin to remove acerbity and clarify, which can effectively remove acerbity and suspended granules in persimmon juice and enable persimmon wine without acerbity and to be easily clarified,) and employs brewing dry yeast to ferment at higher temperature, which has short ferment period. The persimmon wine is clear, transparent, lucidus and free of sediment, which has typical style, good taste, pure flavour, coordinated alcohol and acerbity, full wine body, tasty, good aftertaste, no objectionable odour, fresh persimmon flavour and wine flavour.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Health table salt

The invented healthy edible salt is prepared by mixing with sodium chloride, various amino acid, peptide substance, vitamin B family, polysaccharide, or chitin, antioxidant, nucleic acid seasoning, potassium chloride, calcium salt, magnesium salt, selenium salt, and potassium iodide. It can effectively prevent various diseases, also can prevent osteoporosis, cancer, diabetes, dysinsulinosis, lithiasis, coronary heart disease, senile dementia, bark farus etc. it also possesses the functions of antisenility, antifatigue, antidepression, improving immune power, promoting growth etc.

Owner:岳静 +1

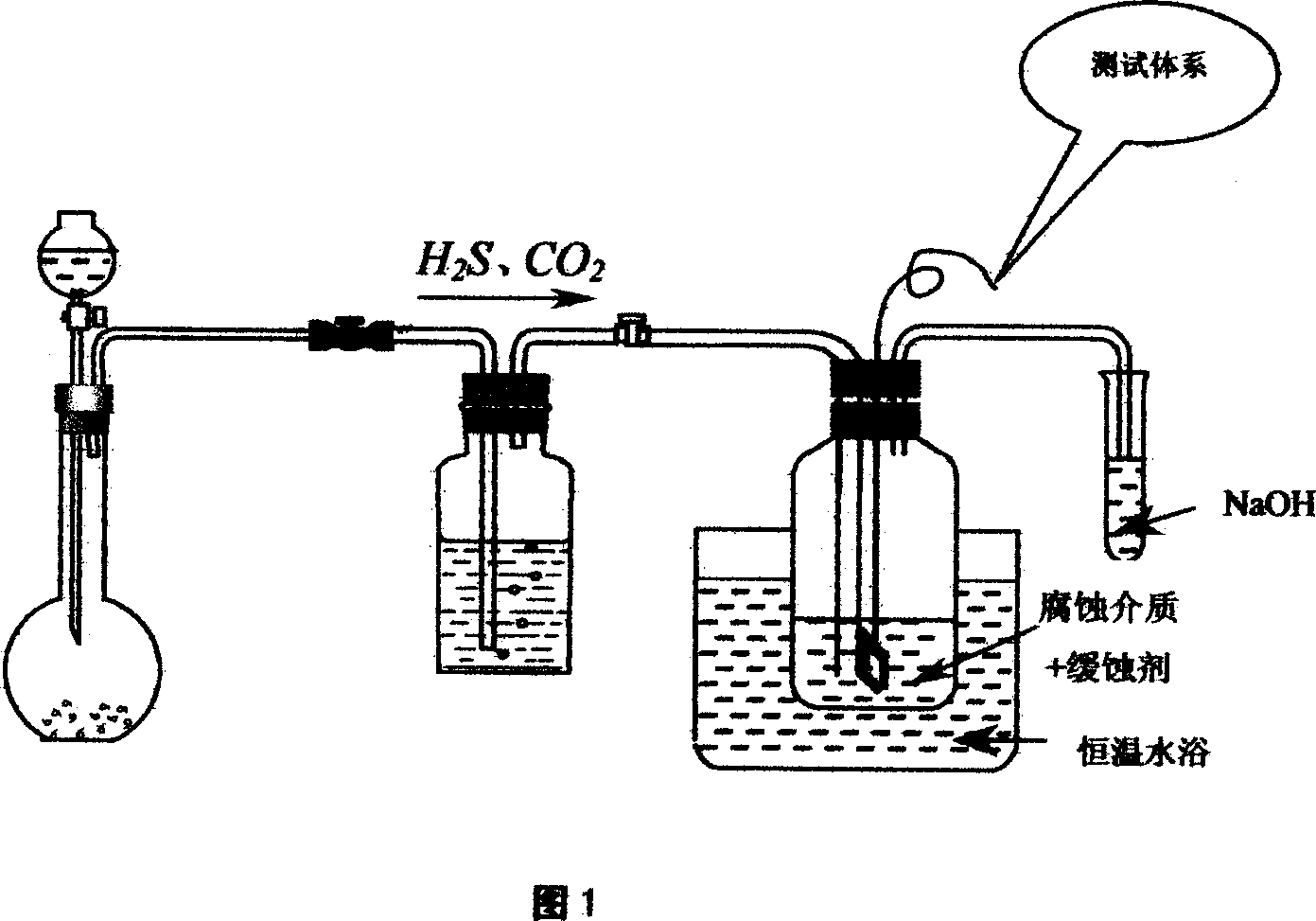

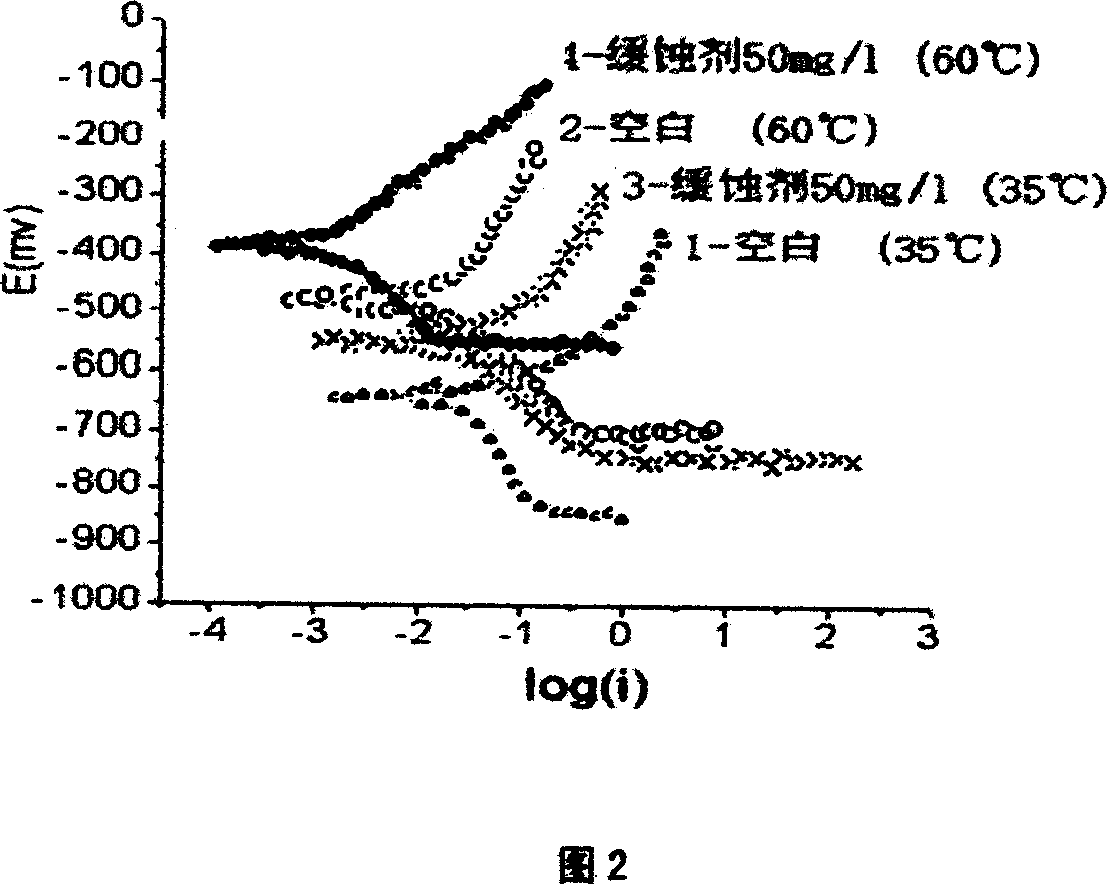

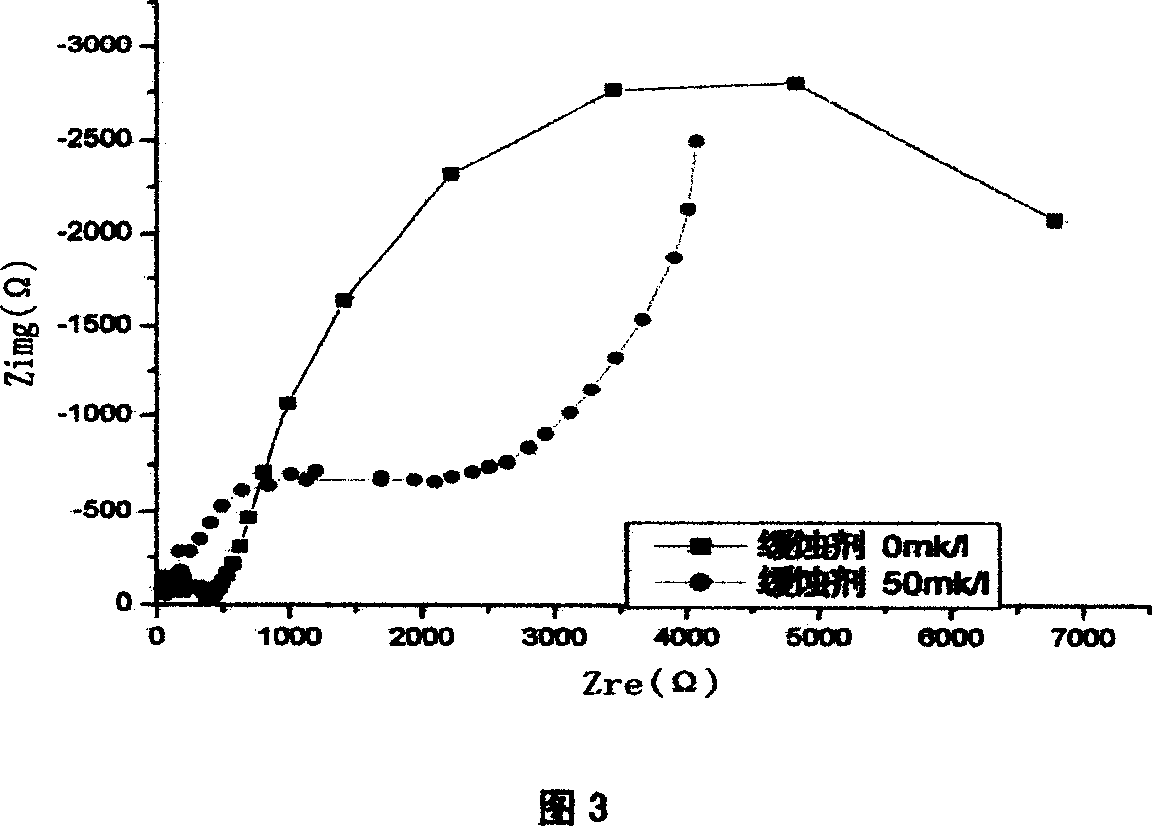

Corrosion inhibitor resistant to H2S and CO2

InactiveCN1966774ADoes not affect separation efficiencyGood corrosion inhibition effectBorehole/well accessoriesIsopropyl alcoholFatty alcohol

The invention relates the chemical engineering field, especially a H2 and CO2 inhibiter. H2 and CO2 are produced accompany to oil-gas field exploitation and transfusion process, and can corrode exploitation equipment. The inhibiter contains at least (by wt. %): isopropyl alcohol 10-30, fatty alcohol polyoxyethylene ether .1-0.5, and litol polyoxyethylene ether 0.1- 1.0. The inhibiter can be used in oil / water well with high temperature and pressure, and has the advantages of good corrosion resistance, low consumption, low cost and high efficiency.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

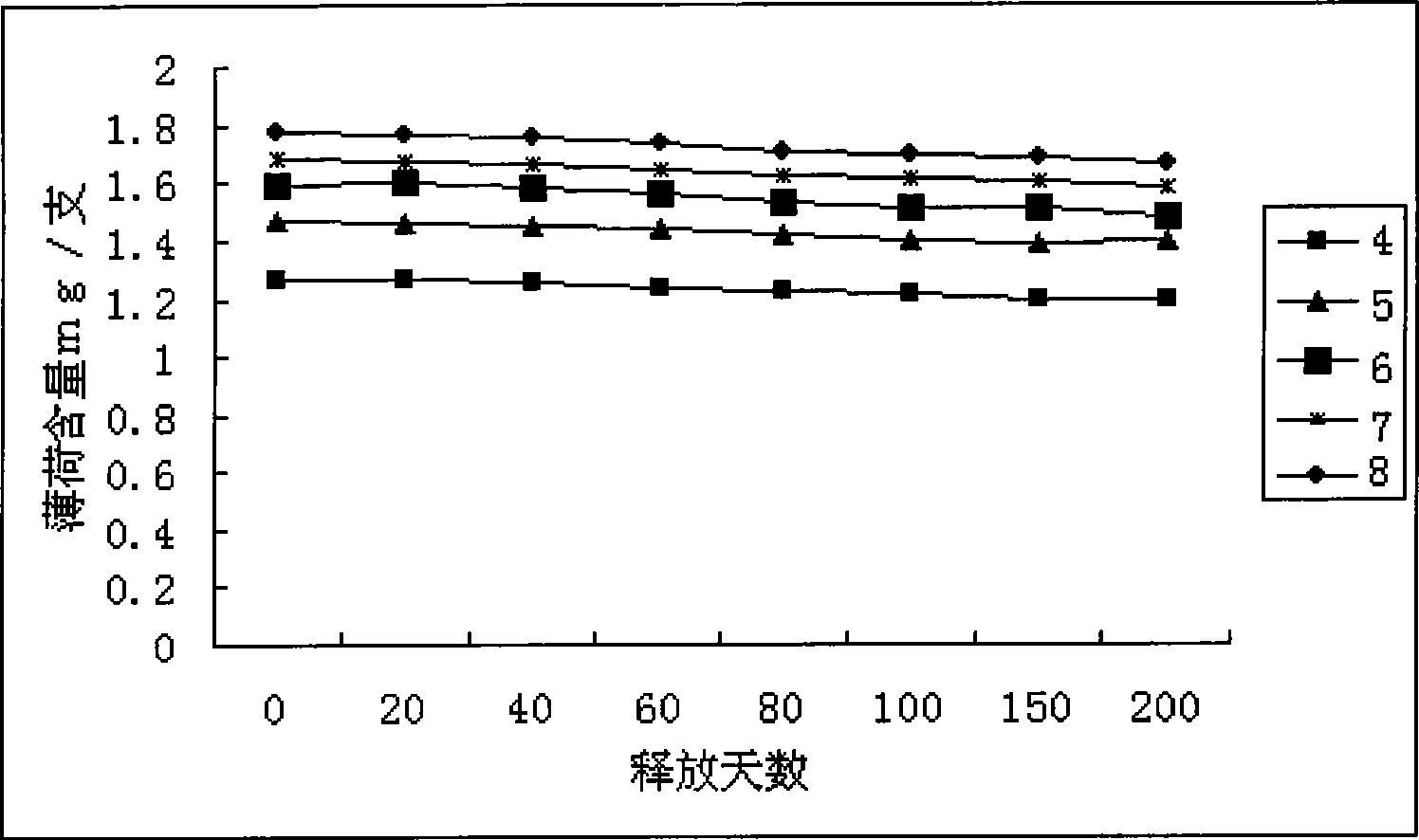

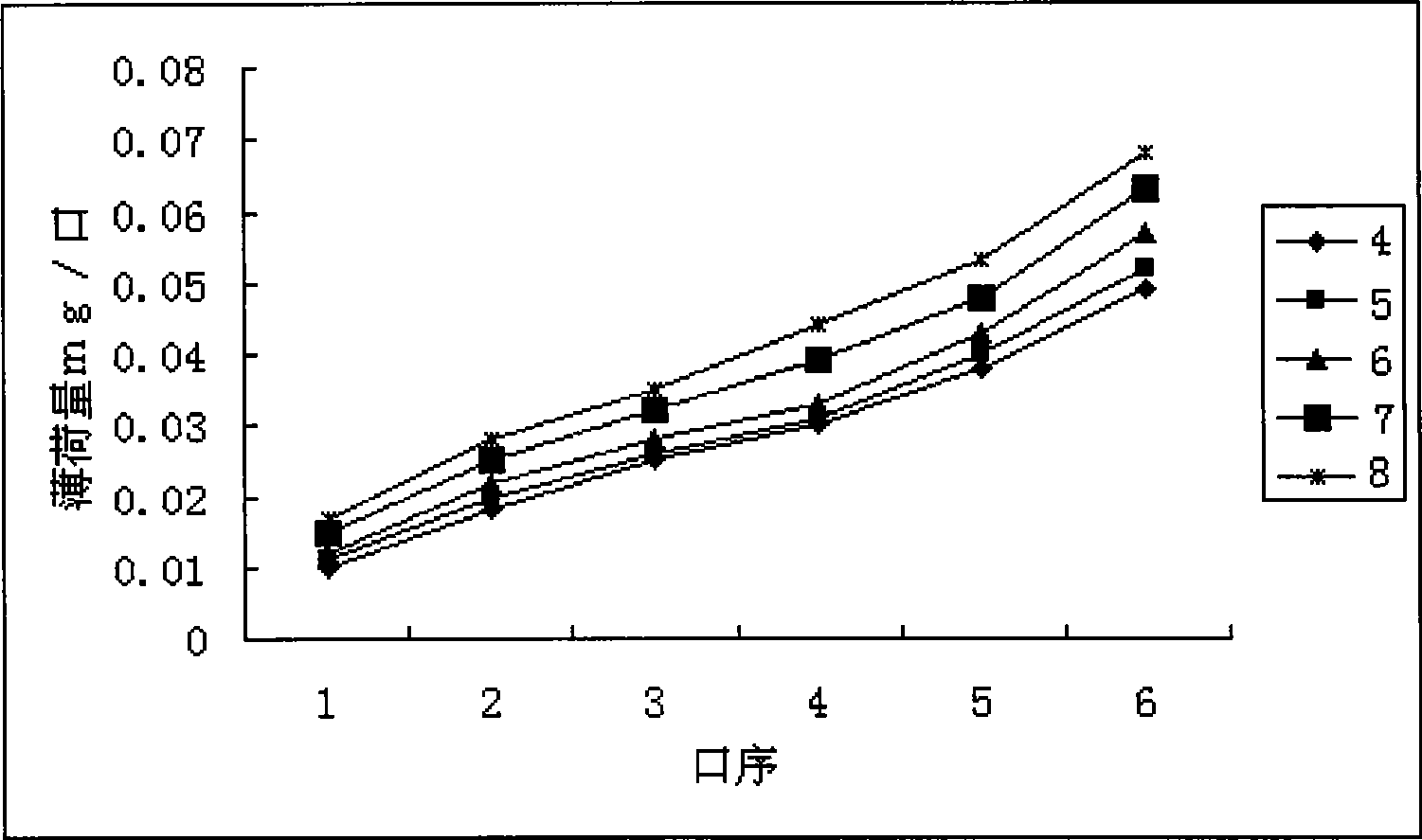

Cigarette filter tip rod capable of sustained releasing mint and production technique thereof

ActiveCN101390657AReduce volatilitySimple processTobacco smoke filtersMembrane technologyRoom temperature

The invention discloses a mint-releasing cigarette filter tip and a production technique thereof, relating to a cigarette filter tip and the production technique thereof. The mint-releasing cigarette filter tip contains tow material in which cotton thread infused with mint essence solution is wrapped; film-forming material solution is adsorbed at the outer layer of the cotton thread infused with mint essence solution; mint essence is added in the film-forming material solution; and the film-forming material includes natural macromolecular material and synthetic macromolecular material. The mint-releasing cigarette filter tip has the advantages that: 1, adopting membrane technology, mint is low in volatility at room temperature, so the mint can be effectively released when taking the cigarette;2, the production technique is simple; 3, the mint-releasing cigarette filter tip is not changed in performance; 4, the mint-releasing cigarette filter tip can be preserved for more than one year at room temperature; 5, the mint-releasing cigarette filter tip is low in cost.

Owner:HUBEI CHINA TOBACCO IND

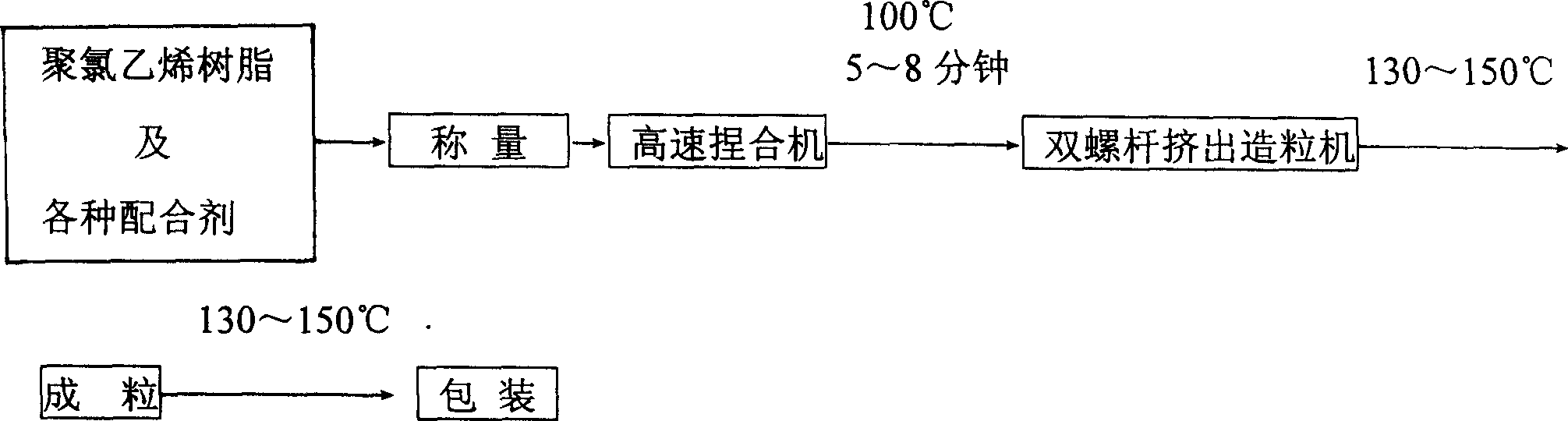

Flexible vinyl dedicated to wire and cable

ActiveCN1760258AGood heat resistanceLow volatilityPlastic/resin/waxes insulatorsTransmission linePlasticizer

A soft polyviny chloride plastic for electric transmission line or cable is proportionally prepared from PVC resin, refractory plasticizer, stabilizer, antioxidizing agent, filler and lubricant. Its advantages are high refractory class (120deg.C), long high-temp stabilizing duration (300 min), and low high-temp volatilization.

Owner:CHANGSHU ZHONGLIAN PHOTOELECTRICITY NEW STUFF +1

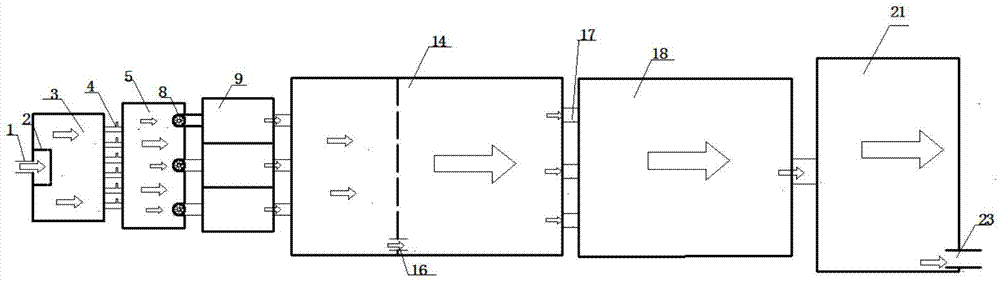

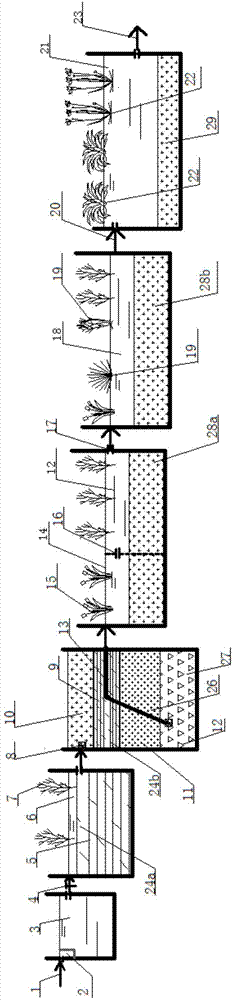

Ecological combined treatment method and device for rural distributed sewage

InactiveCN103880257AEfficient purificationImprove processing efficiencyMultistage water/sewage treatmentConstructed wetlandBiological filter

The invention discloses an ecological combined treatment method and device for rural distributed sewage. The method comprises the steps of A) rural sewage collection and pretreatment; B) treatment by a biological filter; C) treatment by an artificial wetland and a stabilization pond; D) ecological landscape configuration. The device is characterized in that a main water inlet pipeline is respectively connected with a lattice pool and a regulation pool, the regulation pool is connected with a horizontal flow biological filter through a water distribution pipe, the horizontal flow biological filter is connected with a vertical flow biological filter through a filter screen-water distribution pipe, the vertical flow biological filter is connected with a first-level artificial wetland via a perforated water collection pipe which is horizontally arranged, the first-level artificial wetland is connected with a second-level artificial wetland through an overflow weir, the second-level artificial wetland is connected with the stabilization pond through a straight flow water drain pipe, and a main water drain pipe is arranged at the tail end of the stabilization pond. According to the method, energy consumption is not required, the operation and the maintenance are simple and convenient, and the method further has the advantages of landscape effect, economic benefits, simple structure and low investment; high-efficient purification of rural distributed domestic and farming sewage is realized, and the removal rate of nitrogen, phosphorus, COD and the like in sewage is above 80% after treatment.

Owner:大长江环境工程技术有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com