Silastic composition and preparation method thereof

A silicone rubber composition and the technology of the composition, applied in the field of rubber, can solve the problems of high material cost, high cost of use, blooming, etc., and achieve the effects of low vulcanization temperature, stable size, energy saving and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

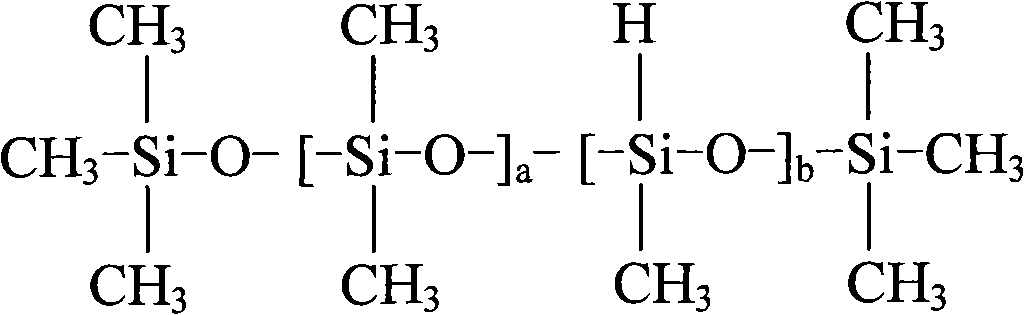

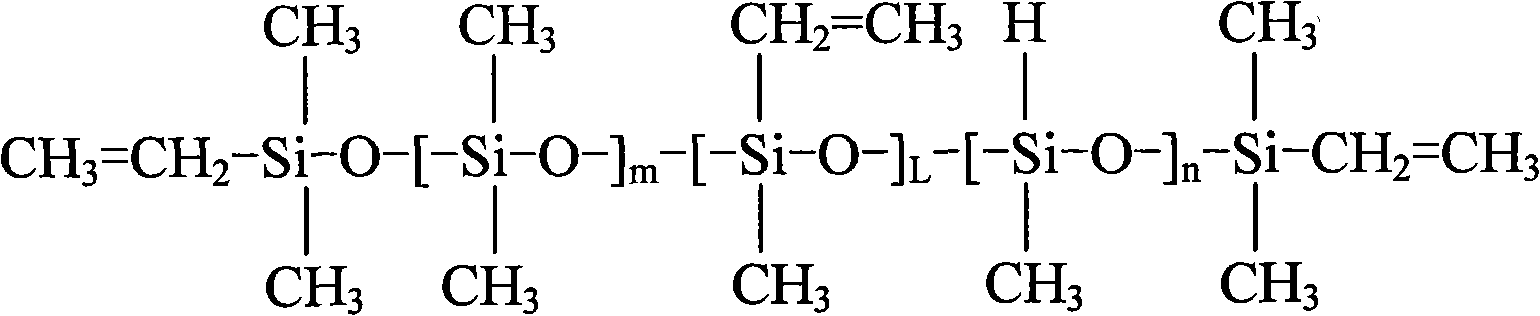

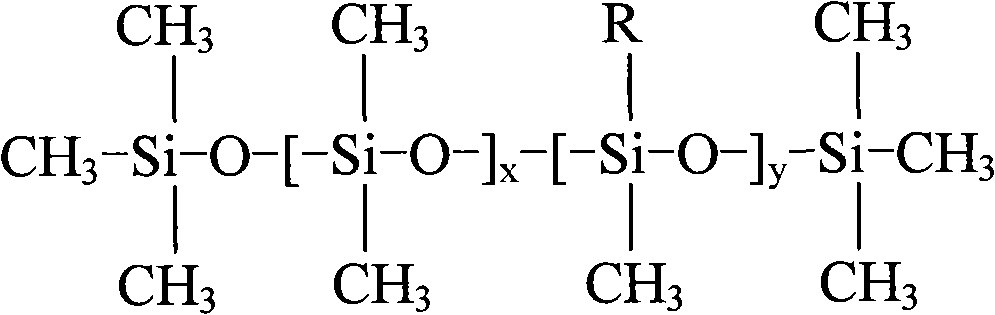

[0063] 1. Preparation of mixing base rubber: in parts by mass:

[0064] 30 parts of polymer I (molecular weight 600,000, vinyl mole percent content 0.05%), polymer II (molecular weight 600,000, vinyl mole percent content 0.25%) 40 parts, polymer III (molecular weight 600,000, ethylene 5 parts based molar percentage), 8 parts of polymer IV (viscosity 20000mpas) and 2 parts of hydroxyl silicone oil with a viscosity of 50mm2 / s at 25°C, put them into a vacuum kneader, mix well, and then precipitate 38 parts Method silicon dioxide zeosil-132 (produced by Rodia Korean company), added in several times, and finally added 0.3 parts of zinc stearate, after forming a large group, control the temperature at 170 ° C, vacuum degree of about 0.09Mpa, heat treatment for 3 hours, filter Let cool and set aside.

[0065] 2. Preparation of component A:

[0066] Put 150 parts by mass of the above-mentioned mixing base rubber into a kneader, and after forming a large group, dilute 0.3 parts by ma...

Embodiment 2

[0073] When preparing component A, the platinum complex is diluted with polymer II and then added to the mixing base rubber. When preparing component B, use 16 parts by mass of hydrogen-containing silicone oil (hydrogen-containing mass content: 0.6%), and the other procedures are the same example 1.

Embodiment 3

[0075] When preparing component A, the platinum complex is diluted with polymer III and then added to the mixing base rubber. When preparing component B, use 8 parts by mass of hydrogen-containing silicone oil (hydrogen-containing mass content: 1.6%), and the other procedures are the same example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com