Patents

Literature

109results about How to "Lower vulcanization temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

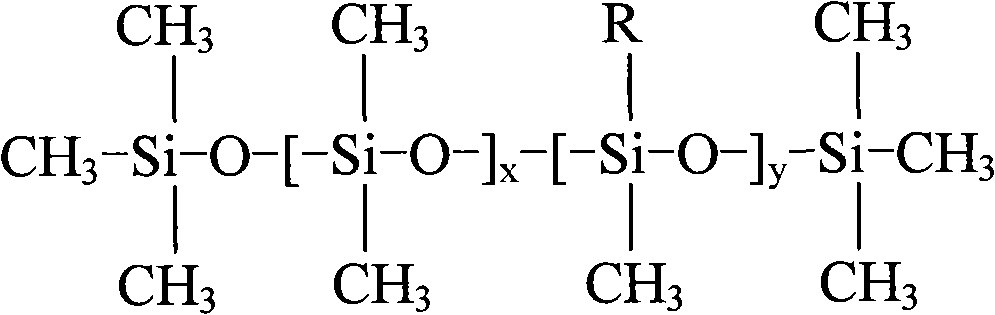

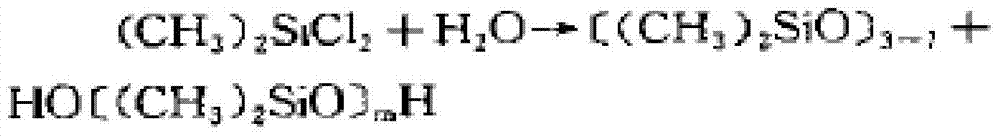

Silastic composition and preparation method thereof

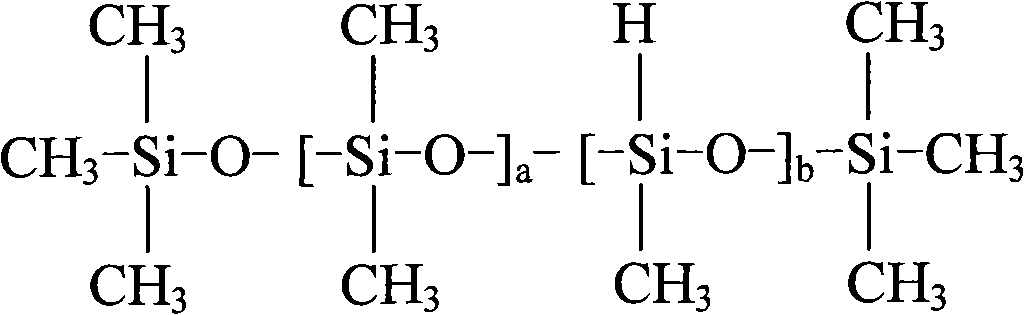

The invention relates to a silastic composition and a manufacturing method thereof. The silastic composition comprises a component A and a component B, the component A is composed of mixing base adhesive and platinum coordination complex, whereas the component B is composed of the mixing base adhesive, hydrogen-containing silicone oil, a thickening agent and a depressor; the mixing mass ratio is: component A: component B is 0.5-99:1-99.5. The silastic composition of the invention is a solid-state mixing silastic containing platinum curing ingredient, so no curing ingredient is needed in the process of molding, besides, the vulcanization effect is good, the vulcanization moulding temperature is low, thus saving electricity, reducing exhaust emission and improving productivity; moreover, the silastic product is odorless and has fine physical and mechanical properties.

Owner:东莞市贝特利新材料有限公司

High temperature resistance non halogen flame retardant cable sheath material and preparation method thereof

ActiveCN101613506AImprove temperature resistanceOvercome the problem of not being able to prepare high temperature resistant halogen-free flame retardant cable sheathing materialsRubber insulatorsPolymer scienceVulcanization

The invention discloses a high temperature resistance non halogen flame retardant cable sheath material and a preparation method thereof. The high temperature resistance non halogen flame retardant cable sheath material comprises the following components with the following parts by weight: 100 parts of ethylene-propylene-diene monomer (EPDM), 1.5-6 parts of vulcanizing agent, 1.5-6 parts of co-vulcanization agent, 0.5-5 parts of coupling agent, 4-20 parts of antiager, 4-30 parts of softener and 80-250 parts of inflaming retarding filling agent. In the invention, the halogen-free material is adopted, thick smoke, corrosive halogenide gas and other harmful substances are not generated in the process of burning; the cable sheath of the invention features excellent elasticity and tenacity, not only has obvious inflaming retarding effect, but also improves heat-resisting and anti-aging properties, can resist high temperature, and has high mechanical strength and wide application range; in addition, the production process is easy and is convenient for rubber-producing enterprises to achieve self-sufficiency.

Owner:SICHUAN MINGXING CABLE

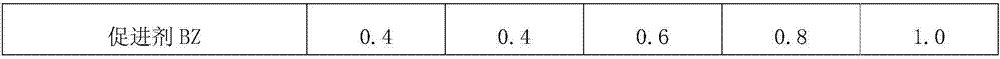

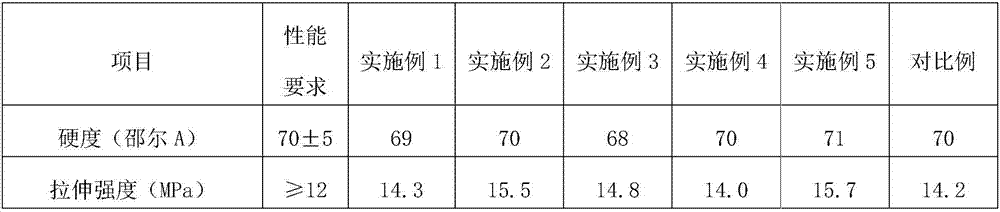

Wear-resisting sole material and preparation method thereof

The invention relates to a formula of a rubber sole material and an improvement of the preparation method of the rubber sole material. The wear-resisting sole material comprises the following components by weight percent: 50-60% of natural rubber 3L, 3-5% of accelerator, 40-45% of filler, 1-1.5% of hardener and 1.5-2% of vulcanizing agent, wherein the hardener is high styrene; and the acceleratoris the mixture of inorganic accelerator, polyethylene glycol, stearic acid, antioxidant and tackifier and the accelerator also contains organic accelerator which is perferably selected from accelerator D, accelerator M and accelerator DM. The sole material of the invention is prepared from good natural rubber by adding the accelerator with various functions; and the sole prepared from the material has light weight, good wear resistance, water resistance and good heat retention property and is suitable to be used as the sole of the shoe with high wear strength such as tennis shoe and outdoor sneaker.

Owner:CHINADIVE WATERSPORTS INC

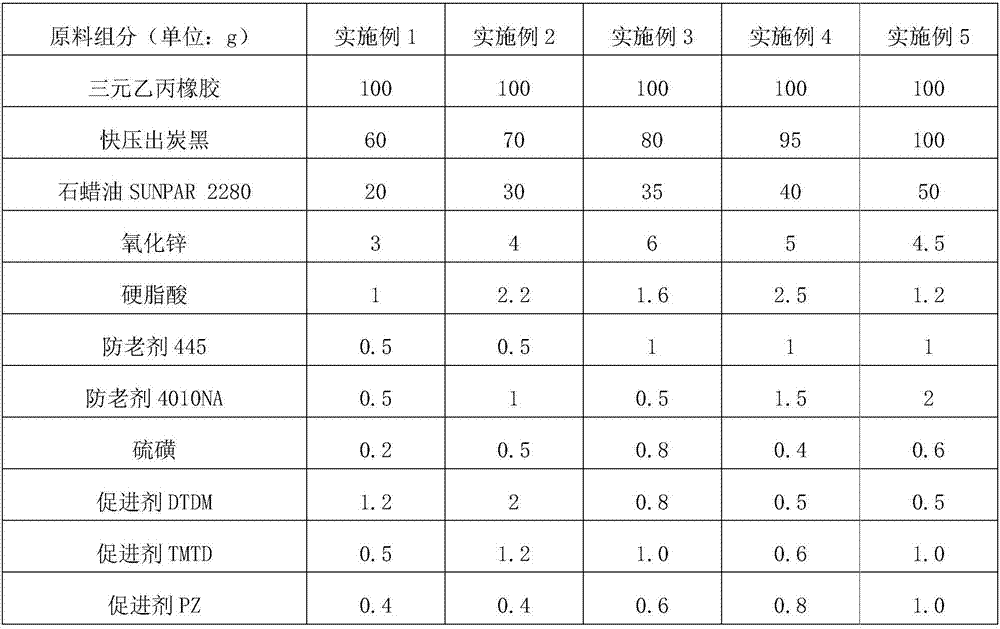

Heat aging-resisting and low-pressure change sulfur vulcanized EPDM (Ethylene-Propylene-Diene Monomer) rubber composition, preparation method, application and application product thereof

ActiveCN107189236AImprove heat aging resistanceGood physical and mechanical propertiesVulcanizationPolymer science

The invention discloses a heat aging-resisting and low-pressure change sulfur vulcanized EPDM (Ethylene-Propylene-Diene Monomer) rubber composition, a preparation method, application and an application product thereof. The composition is prepared from 100 parts of EPDM rubber, 50 to 130 parts of carbon black, 10 to 60 parts of paroline, 2 to 8 parts of zinc oxide, 0.5 to 3 parts of stearic acid, 1 to 6 parts of an anti-aging agent, 0.2 to 1 part of sulfur and 1 to 6 parts of an accelerator. Compared with a sulfur vulcanized EPDM rubber composition prepared in the prior art, the composition has the advantages that heat aging resistance and low compression set are remarkably increased, and the composition is applied to rubber products having the requirements on heat aging resistance and low pressure change, and is particularly applied to an outer adhesive layer of a rubber hose which adopts a poly-4-methyl-1-pentene (TPX) coating and vulcanizing technology; meanwhile, the preparation method of the composition is simple, the vulcanization temperature is lower, and the purpose of saving energy is achieved.

Owner:NANJING ORIENTLEADER TECH CO LTD

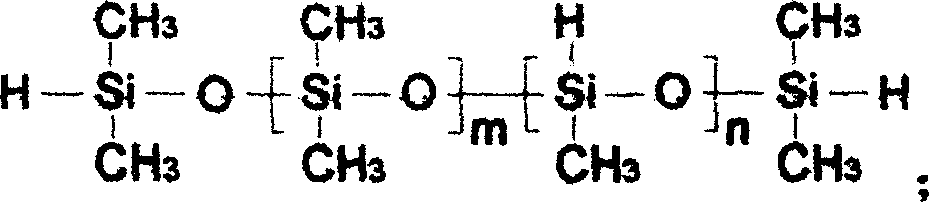

Bicomponent platinum catalyst vulcanizer and its preparation method

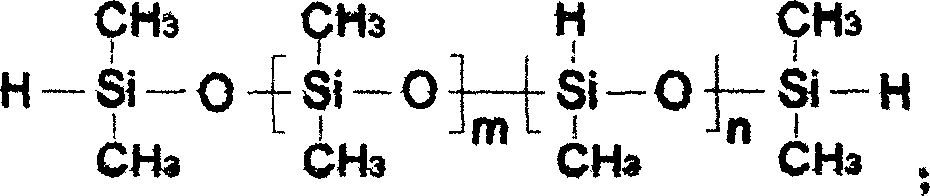

The present invention relates to a double-component platinum catalyst curing agent. It includes agent A and agent B which can be uniformly mixed when they are used, in which the agent A is mixture of vinyl raw rubber, gas phase white carbon black and platinum complex, and the agent B is mixture of vinyl raw rubber, gas phase white carbon black, silicon oil whose end contains hydrogen and inhibitor. When the agent A and agent B are mixed, their mass ratio is agent A: agent B = (0.8-1.0)(1.0-1.5). Said invention also provides the preparation method of said double-component platinum catalyst curing agent.

Owner:SHENZHEN ANPIN SILICONE MATERIAL

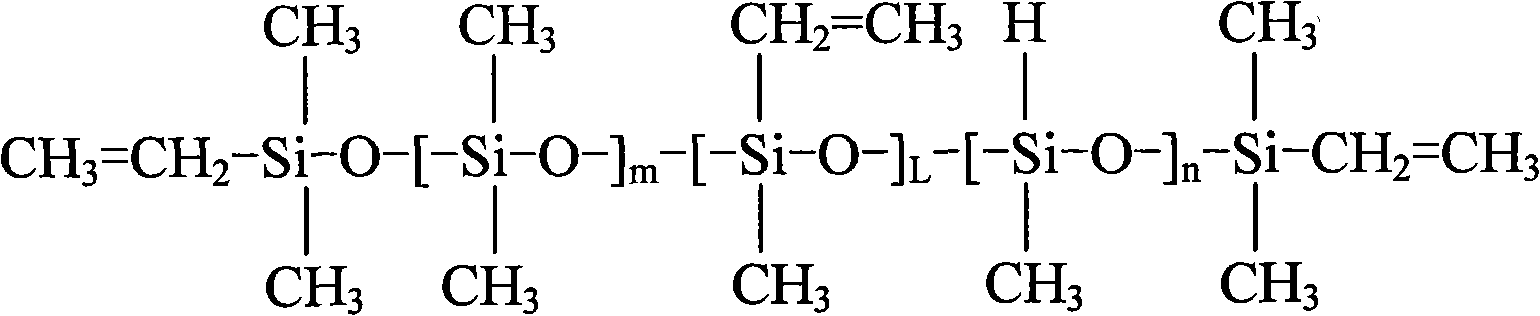

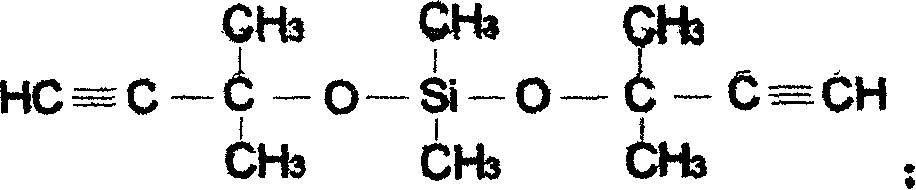

Novel platinum vulcanizing agent and preparation technology thereof

InactiveCN104927363ATo achieve the purpose of cross-linking vulcanizationFast vulcanizationEnvironmental resistancePolymer science

The invention relates to the technical fields of a vulcanizing agent and a preparation technology of the vulcanizing agent, particularly to a novel platinum vulcanizing agent and a preparation technology thereof. The novel platinum vulcanizing agent comprises a component A and a component B which are respectively added while in use, wherein the component A is the mixture of methyl vinylsiloxane rubber and a 1,3-divinyltetramethyldisiloxane platinum complex compound; the component B is the mixture of methyl hydrogen polysiloxane, gas phase silicon dioxide and an inhibitor. Compared with the prior art, the novel platinum vulcanizing agent disclosed by the invention uses the methyl vinylsiloxane rubber as a carrier, and under the existence of a platinum catalyst, vinyl double bonds and the methyl hydrogen polysiloxane are liable to generate a silicon hydrogen addition reaction, so that the purpose of cross-linking vulcanization is realized; the gas phase silicon dioxide is added for adjusting the hardness of vulcanization products, the vulcanization speed is high and is 1 / 3-1 / 2 higher than the vulcanization speed of the conventional platinum vulcanizing agent, and the production efficiency is improved; the vulcanization temperature is 10%-30% lower than that of the conventional platinum vulcanizing agent, and the purposes of energy conversation and environmental protection are achieved; the addition proportion is 30%-50% lower than that of the conventional platinum vulcanizing agent, and the production cost is reduced; the inhibitor is used, the storage time is greatly prolonged, and the storage time can reach 20-48h; in addition, the hygiene grade and the environmental protection grade are high, and the preparation technology is simple.

Owner:东莞市圣力堡有机硅科技有限公司

Mico-crosslinking thermoplastic elastomer and preparation method thereof

ActiveCN104356582AKeep for recyclingLower vulcanization temperatureFoaming agentThermoplastic elastomer

The invention relates to the technical field of high-molecular materials, and provides a mico-crosslinking thermoplastic elastomer and a preparation method thereof. The mico-crosslinking thermoplastic elastomer comprises the following components: a styrene type thermoplastic elastomer, synthetic rubber, white mineral oil, a foaming agent, a crosslinking agent, an antioxidant, a light stabilizer, zinc oxide, zinc stearate, abrasion-resistant agent and nano calcium carbonate. The preparation method comprises the following steps: placing the component materials into an internal mixer, and carrying out internal mixing for 10-15 minutes; controlling discharge temperature at 130-135 DEG C; then pressing into a uniform flaky shape by virtue of a double-roller open mill for discharge; finally cutting a material into a specified dimension, placing into a large-flake vulcanizing machine, carrying out vulcanizing forming, and controlling vulcanizing temperature at 170-175 DEG C and vulcanizing time at 180-350 seconds so as to obtain the mico-crosslinking thermoplastic elastomer. The mico-crosslinking thermoplastic elastomer disclosed by the invention has the characteristics of low density, high abrasion resistance, uniformity in froth, good low temperature flexibility, dimensional stability and the like.

Owner:MAOTAI FUJIAN SOLES CO LTD

Non-conducting rubber applied to power cable accessories and preparation method of non-conducting rubber

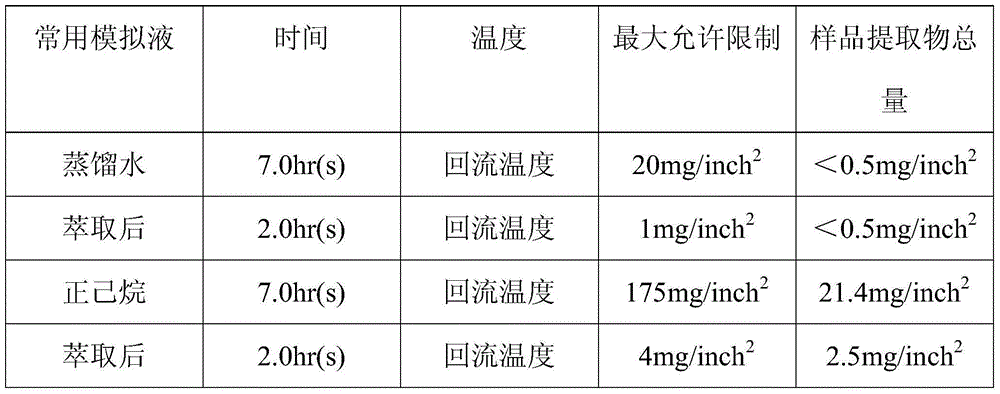

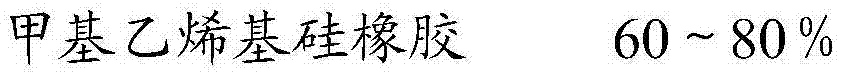

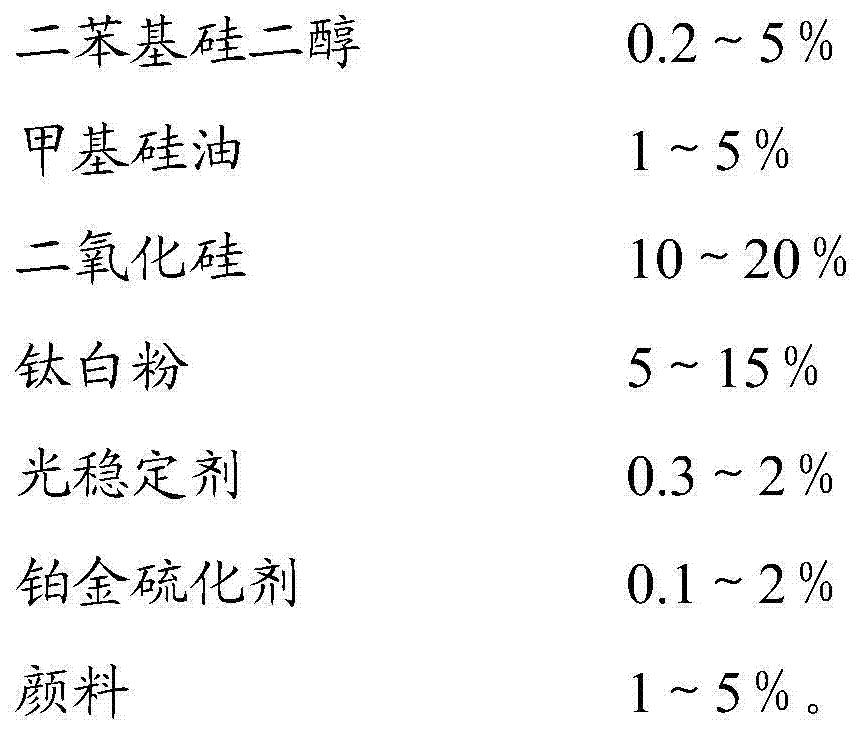

ActiveCN103756329ALower vulcanization temperatureHigh hygiene levelRubber insulatorsInsulation resistanceMethyl silicone

The invention relates to the technical field of polymer materials, and particularly relates to non-conducting rubber applied to power cable accessories and a preparation method of the non-conducting rubber. The non-conducting rubber comprises the following raw materials by mass percent: 60-80% of methyl vinyl silicone rubber, 0.2-5% of diphenyl silanediol, 1-5% of methyl silicone oil, 10-20% of silicon dioxide, 5-15% of titanium dioxide, 0.3-2% of light stabilizer, 0.1-2% of platinum vulcanizing agent, and 1-5% of pigment. The non-conducting rubber is mainly applied to 10-35kV of separable shielding cable accessories, not only has high insulation resistance and excellent electrical property, but also does not lose the elasticity when being continuously used at -100 DEG C to 180 DEG C, displays excellent deformation property, and simultaneously has good thermal conductivity and hydrophobicity and excellent mechanical property.

Owner:SHENZHEN SHENBO NEW MATERIALS

Degradable highly-elastic sponge and preparation technology thereof

The invention relates to degradable highly-elastic sponge and a preparation technology thereof. The degradable highly-elastic sponge and the preparation technology thereof have the advantages that thedegradable highly-elastic sponge is made of green, natural and healthy materials according to the environment-friendly preparation technology, harmless to human bodies and capable of avoiding resource waste and environment pollution, and its mechanical properties including rebound resilience and compression set value are in compliance with the international standards; through adoption of recyclable pineapple fibers, resource waste is reduced and physical properties of low-density sponge with natural latex matrixes are improved to comply with the international standards; sodium alcohol ether sulphate and sodium lauryl sulfate which serve as foaming agents substitute for traditional pollutional ones to further avoid pollution; the high-performance low-density sponge with the excellent mechanical properties can be produced at a low preparation cost; the preparation technology is safe, simple and environment friendly.

Owner:德清舒华泡沫座椅有限公司

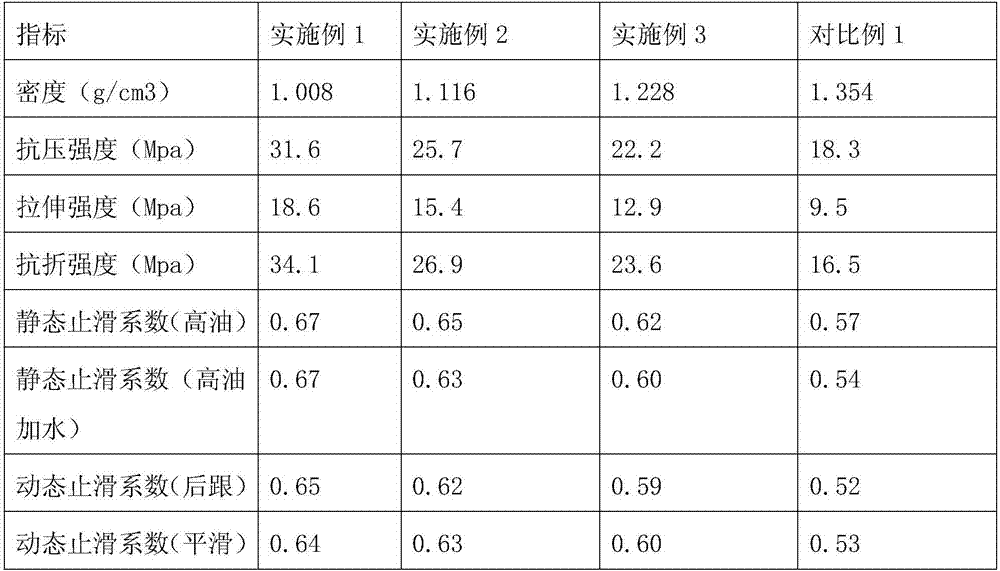

Antiskid wear-resistant sole material and preparation method thereof

The invention discloses an antiskid wear-resistant sole material which comprises 15-20% of natural 3L rubber, 10-20% of butyl rubber, 10-15% of styrene butadiene rubber, 5-10% of short fiber, 10-15% of carbon black, 10-15% of white carbon black (SiO2), 1-2% of stearic acid (SA), 2-3% of paraffin oil, 2-3% of bis-silane tetrasulfide (Si-69), 3-6% of sulfur (S), 1-2% of an active agent, 0.5-0.7% of an antioxidant, 3-5% of zinc oxide (ZnO), 0.3-0.5% of magnesium oxide, 1-2% of an accelerant and 1-3% of a filler. According to the antiskid wear-resistant sole material disclosed by the invention, the antiskid coefficient of the sole is improved, the loss index of the obtained material is low, and the abrasion property and tear resistance are strong. The antiskid wear-resistant sole material has relatively good wear resistance and puncture resistance, improves the comfort and safety of the mountain climbing fitness exercise, prolongs the service life of shoes to a certain degree, and has a broad market application prospect.

Owner:朱伟萍

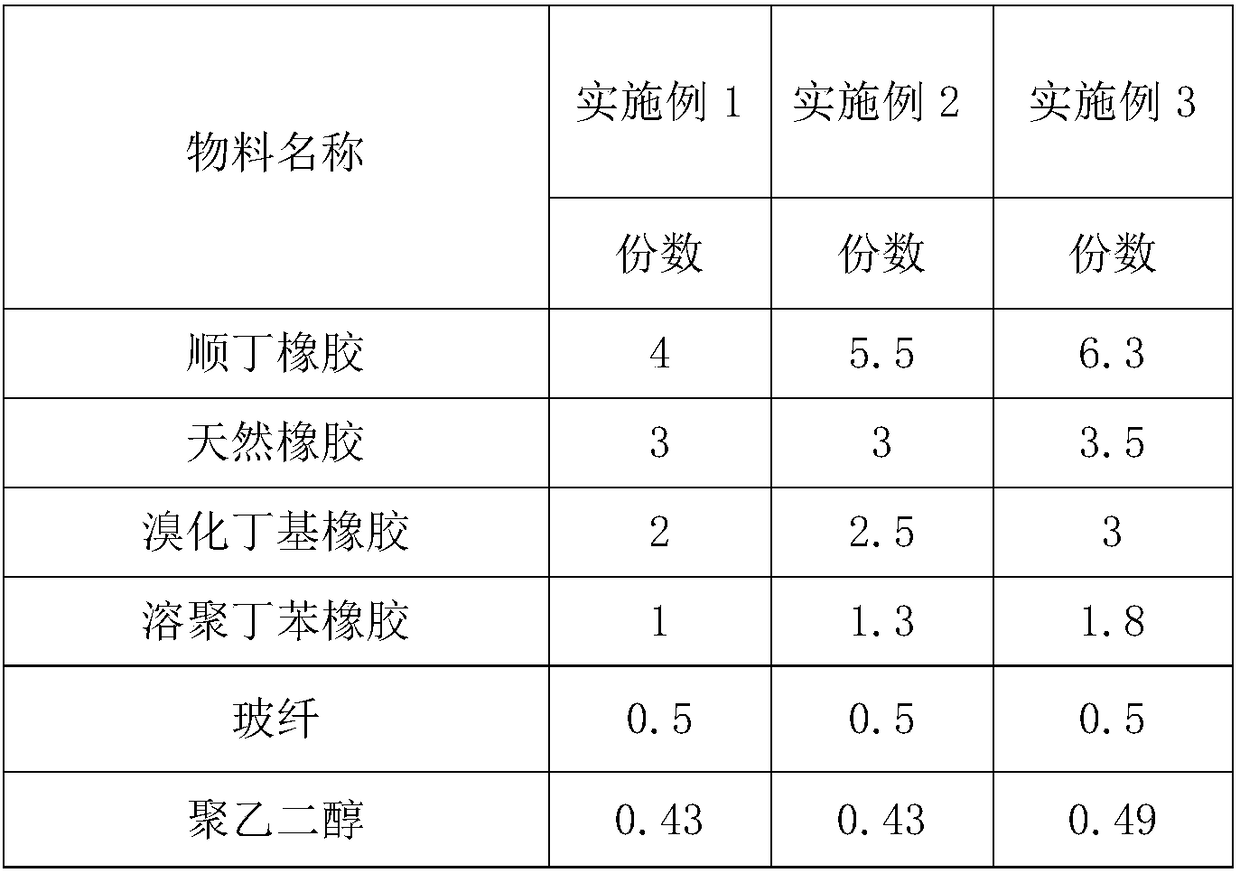

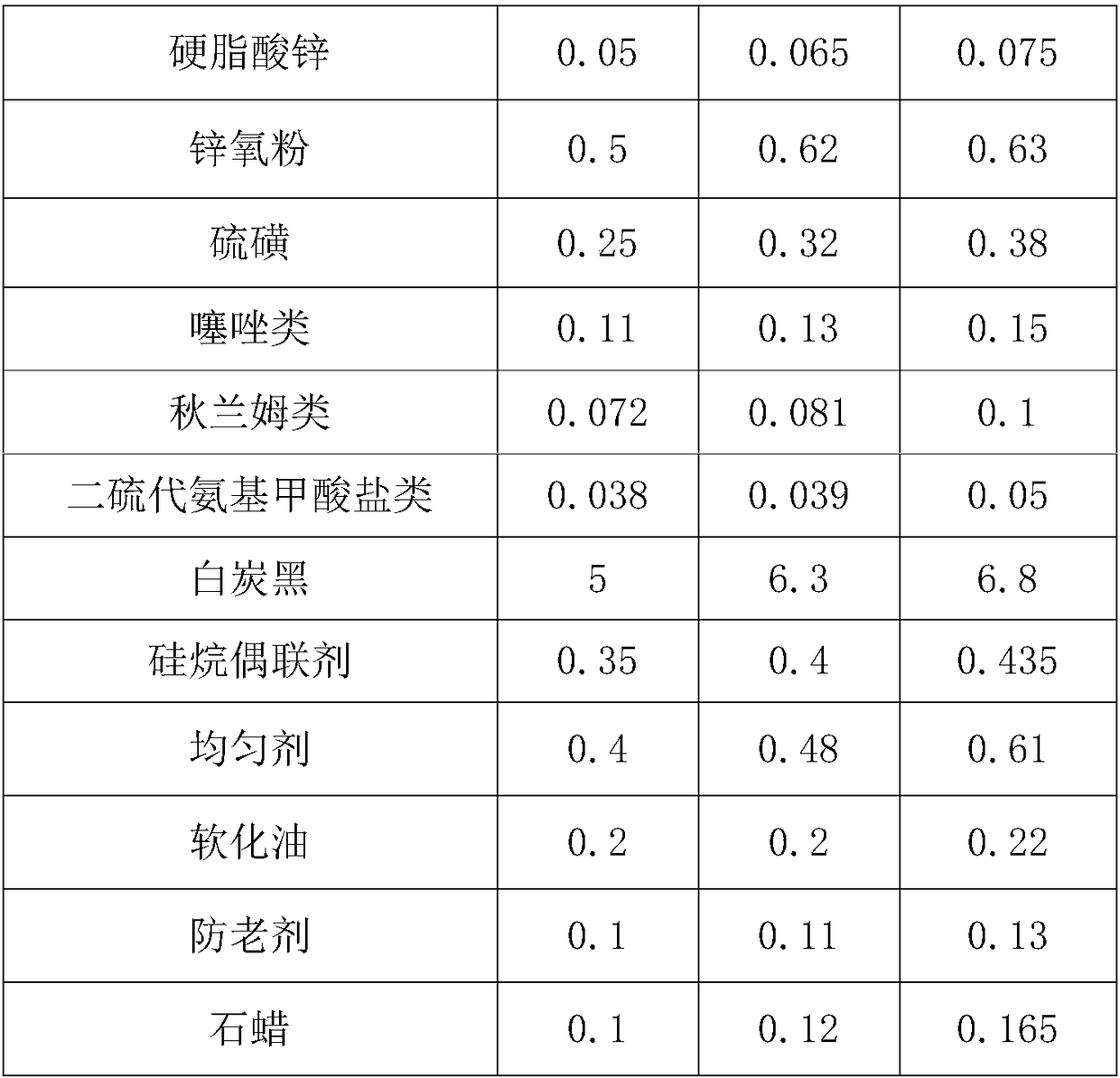

Rubber for sports shoe soles and preparation method thereof

InactiveCN108192163AImprove physical strengthGood vibration damping performanceSolesChemistryButadiene-styrene rubber

The invention discloses rubber for sports shoe soles. The rubber for the sports shoe soles comprises the following components in parts by mass: 30-70 parts of butadiene rubber, 20-40 parts of naturalrubber, 15-30 parts of brominated butyl rubber, 10-20 parts of solution-polymerized styrene-butadiene rubber, 5-10 parts of glass fiber, 2-5 parts of polyethylene glycol, 0.5-2 parts of zinc stearate,2-5 parts of zinc oxide powder, 2.5-4 parts of a vulcanizing agent, 1.5-2.5 parts of an accelerator, 30-50 parts of white carbon black, 3-4.5 parts of a silane coupling agent, 4-7 parts of a homogenizing agent, 2-5 parts of softening oil, 1-3 parts of an anti-aging agent and 0.5-1 part of paraffin. The invention further provides a preparation method of the rubber for the sports shoe soles. Rubbershoe soles for sports shoes, prepared according to the technical scheme adopted by the invention, have many properties such as super wear resistance, good folding resistance and anti-slip performance; the preparation method is simple in production process and is suitable for wide application.

Owner:ANTA CHINA

Heat-conducting composite material, rubber composition, pipe material for cooling media and preparation method for pipe material

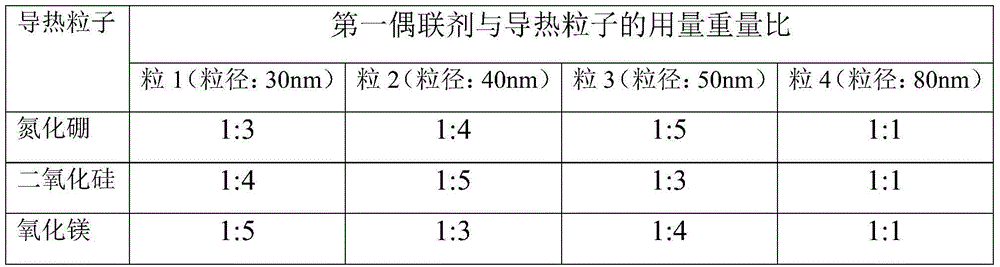

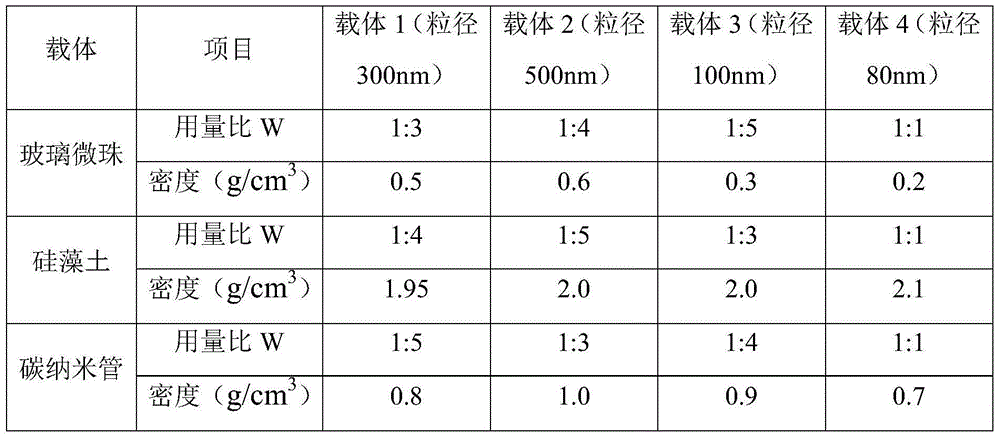

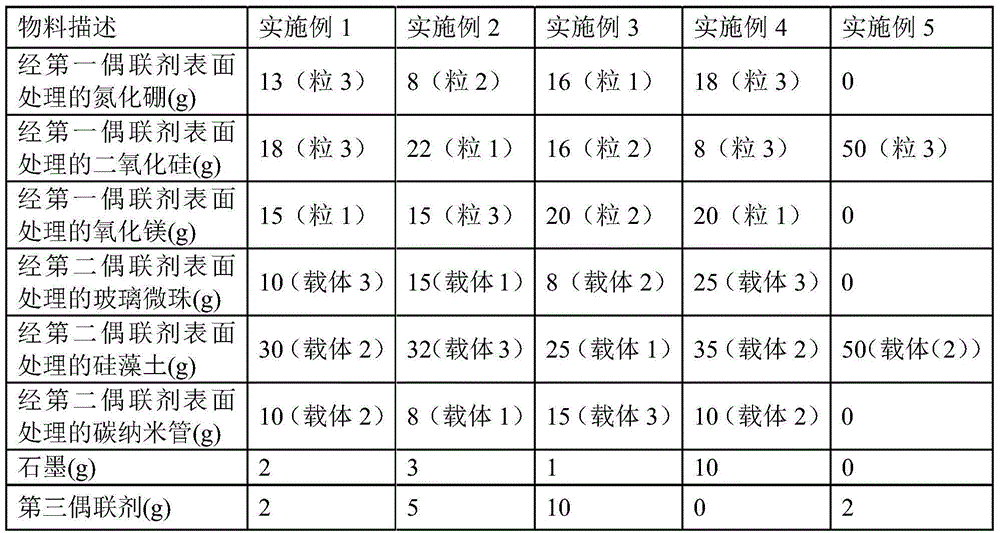

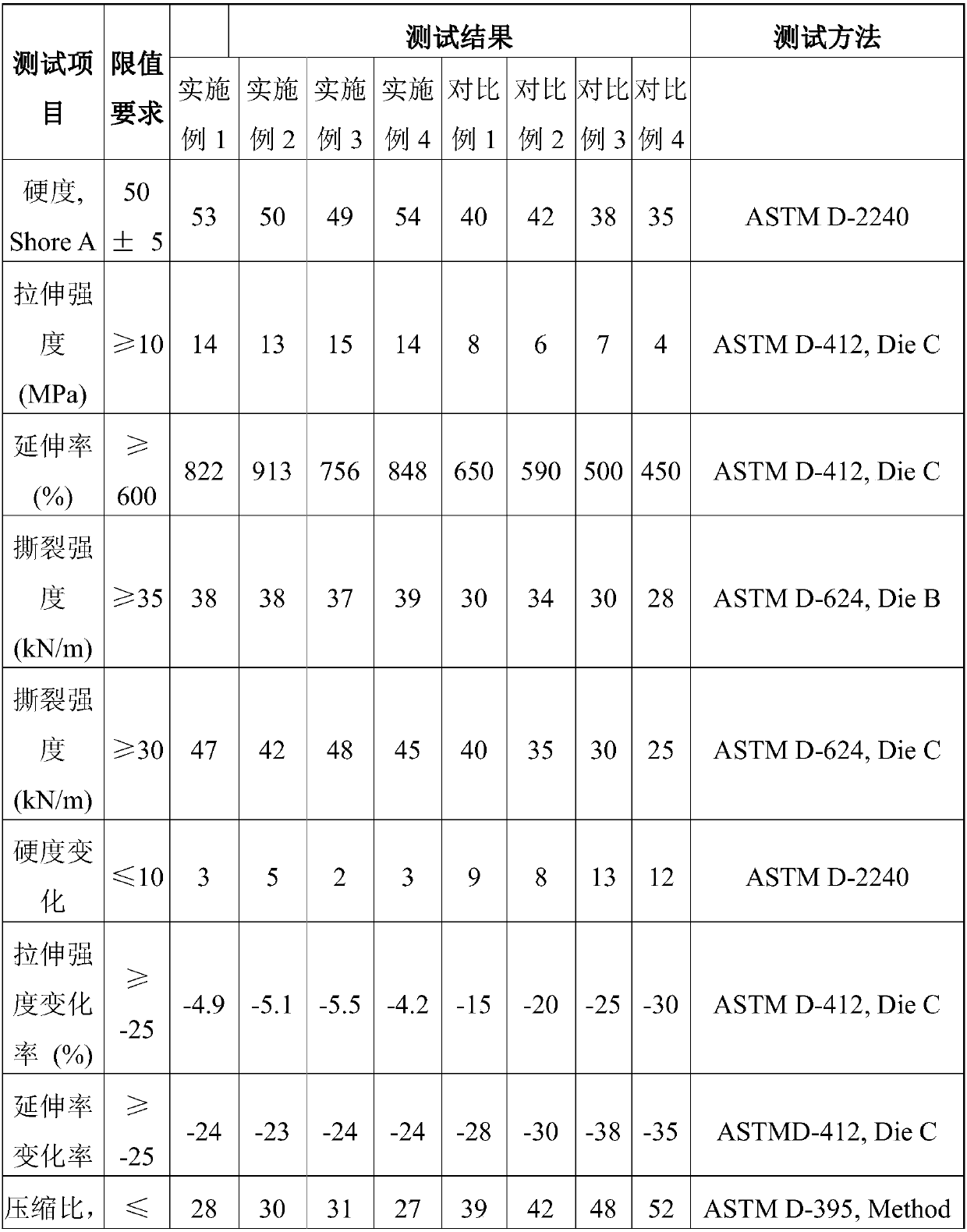

The invention discloses a heat-conducting composite material, a rubber composition, a pipe material for cooling media and a preparation method for the pipe material. The heat-conducting composite material contains heat-conducting particles and a carrier, wherein the heat-conducting particles are subjected to surface treatment by a first coupling agent, and the carrier is subjected to surface treatment by a second coupling agent; and the heat-conducting particles which are subjected to surface treatment by the first coupling agent are at least partially filled in the carrier which is subjected to surface treatment by the second coupling agent, and the carrier is a porous, void or hollow granular matter. According to the heat-conducting composite material, the heat-conducting particles which are subjected to surface treatment by the first coupling agent and the carrier which is subjected to surface treatment by the second coupling agent are adopted, and the heat-conducting particles which are subjected to surface treatment by the first coupling agent are at least partially filled in pores of the carrier which is subjected to surface treatment by the second coupling agent, so that the compatibility of the heat-conducting composite material, containing the heat-conducting particles and the carrier, with base rubber is improved; and the heat-conducting composite material is added in the rubber composition, heat conducting channels are formed in milled rubber which is prepared through mixing the rubber composition containing the heat-conducting composite material, and then, the thermal sensitivity of the milled rubber is improved.

Owner:BYD CO LTD

Low smell EPDM for automobile wire harness and preparation method thereof

The invention relates to a low smell EPDM (ethylene propylene diene monomer) for an automobile wire harness and a preparation method thereof. The EPDM is prepared by the method of: (1) firstly addingEPDM into an open mill, then adding zinc oxide, stearic acid and an antioxidant RD in order, mixing the substances evenly, then further adding carbon black and paraffin oil, mixing the substances evenly, finally adding an environment-friendly accelerator and sulfur, and conducting mixing to obtain mixed compound; (2) placing the mixed compound in a die and conducting primary vulcanization to obtain a section of vulcanized EPDM; and (3) taking out the section of vulcanized EPDM for secondary vulcanization, thus obtaining the target product EPDM. Compared with the prior art, the low smell EPDM provided by the invention meets the characteristics of rubber itself in the aspects of strength, compression set and the like, at the same time also can meet the requirements of low emission and low smell, also takes into account the low pollution characteristic, and is especially suitable for making automobile parts and the like.

Owner:DELPHI PACKARD ELECTRIC SYST

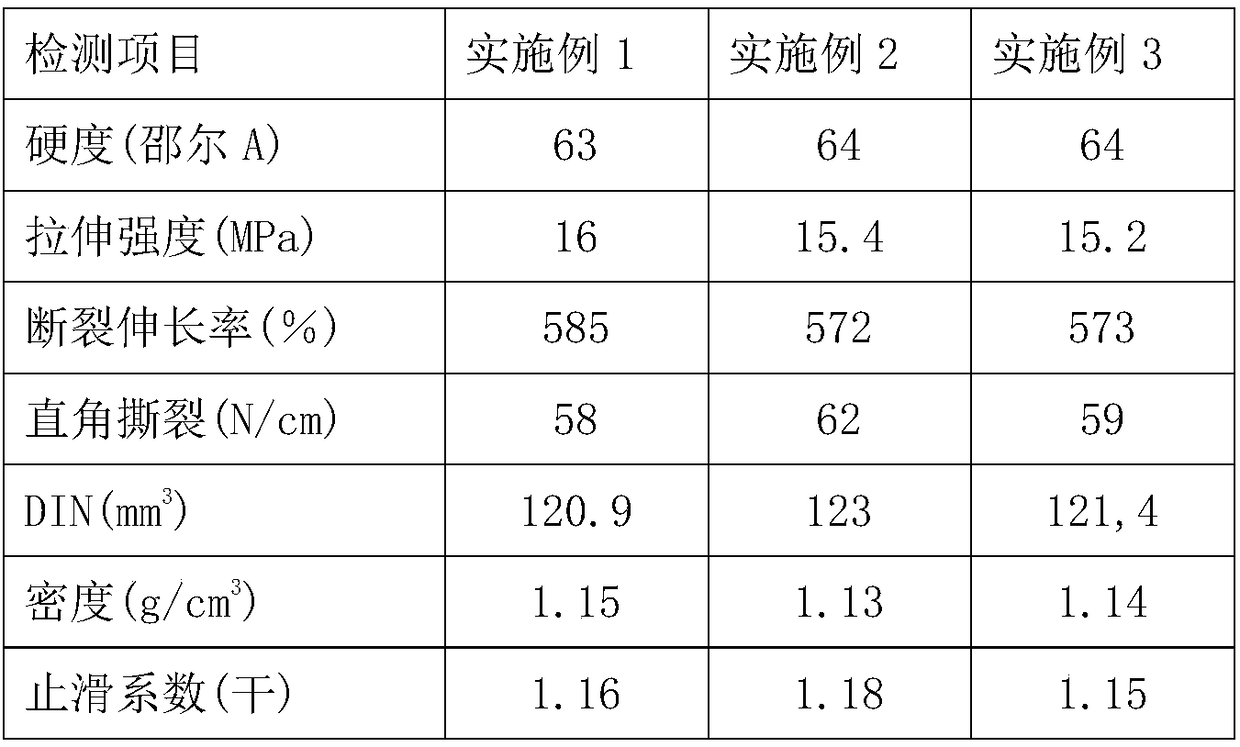

Wear-resistant rubber for sports shoe soles and preparation method thereof

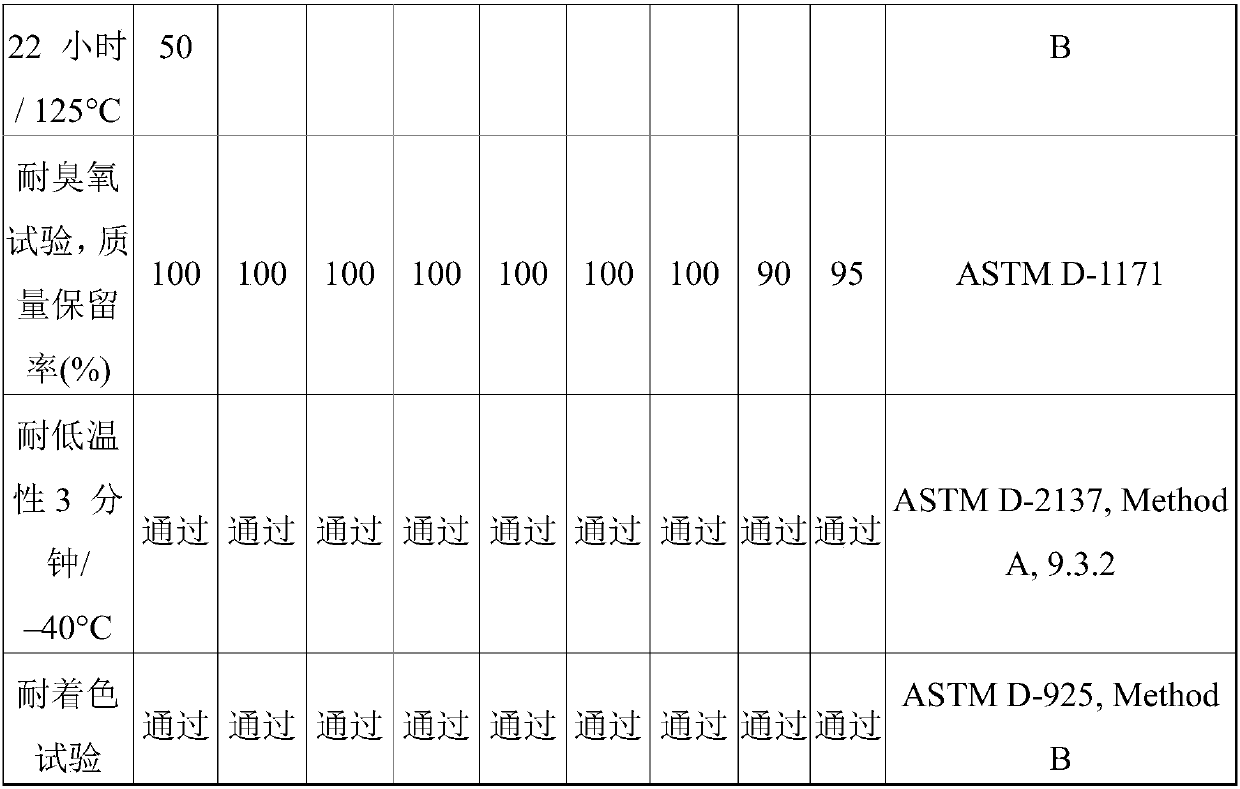

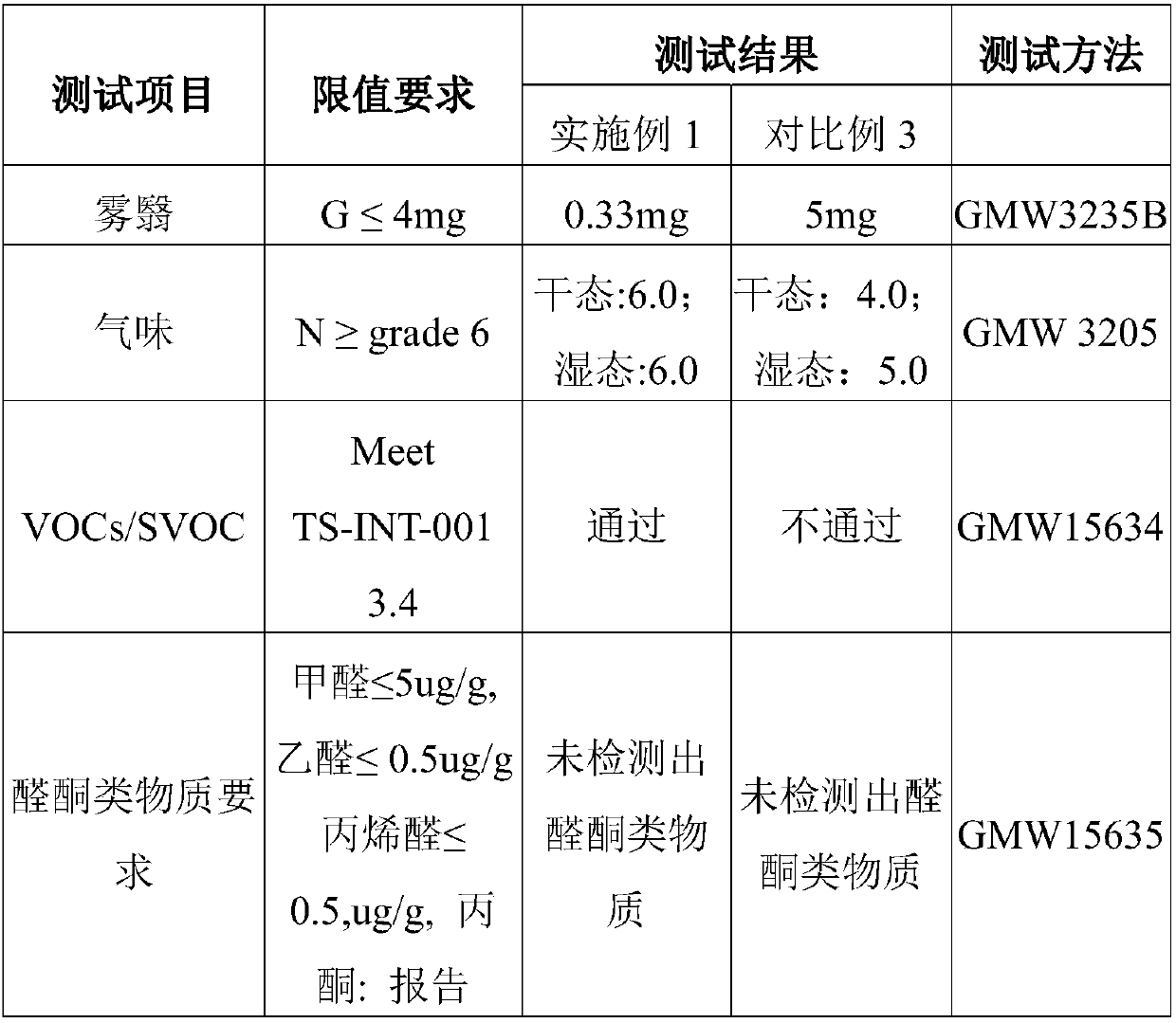

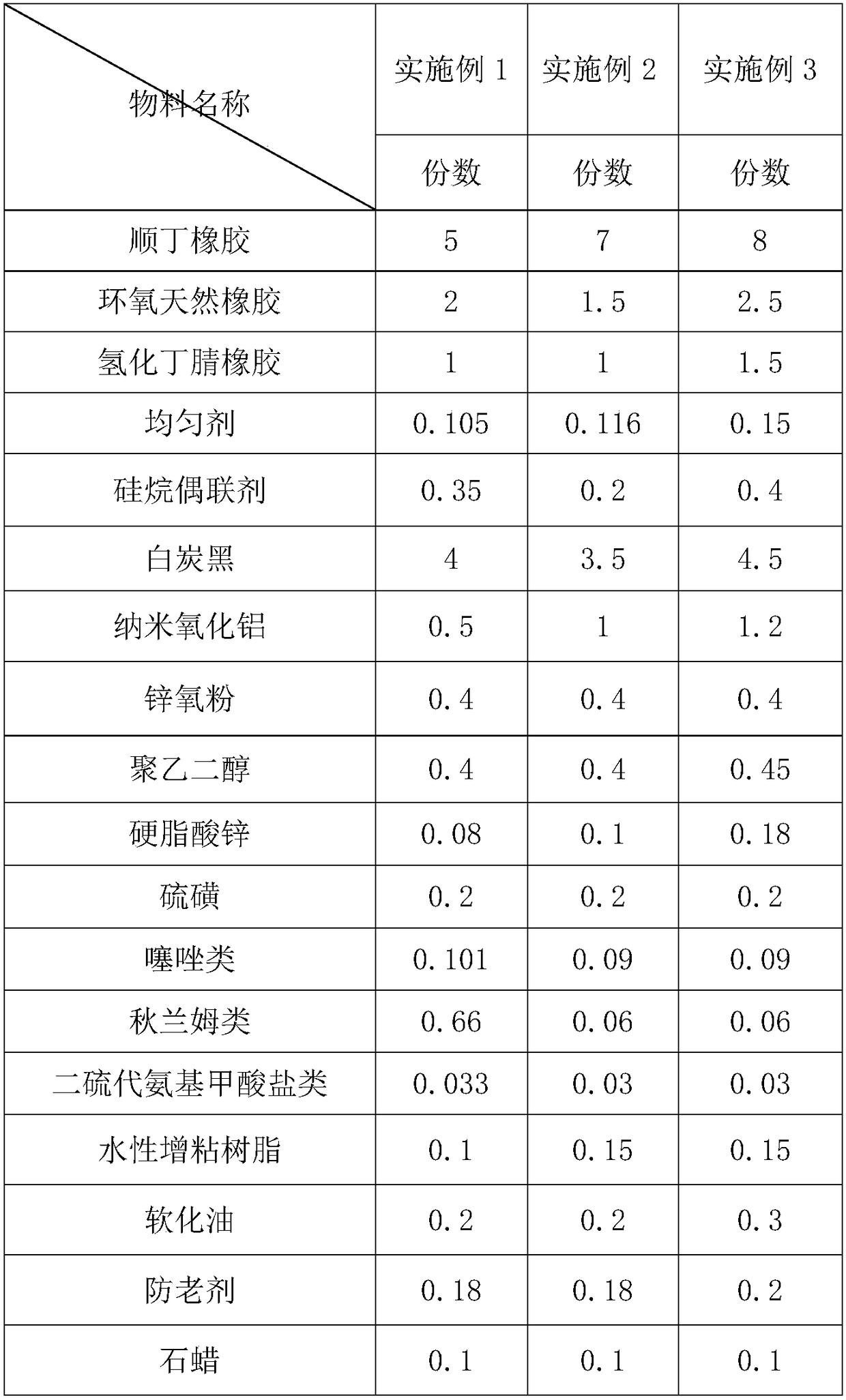

The invention discloses wear-resistant rubber for sports shoe soles. The wear-resistant rubber for the sports shoe soles comprises the following components in parts by mass: 50-80 parts of butadiene rubber, 10-30 parts of epoxy natural rubber, 5-20 parts of hydrogenated butadiene-acrylonitrile rubber, 1-2 parts of a homogenizing agent, 2-5 parts of a silane coupling agent, 25-65 parts of a reinforcing agent, 2-5 parts of zinc oxide powder, 2-5 parts of polyethylene glycol, 0.5-2 parts of zinc stearate, 1.5-2 parts of a vulcanizing agent, 1.6-2.1 parts of an accelerator, 0.5-2 parts of a tackifier, 2-5 parts of a softening oil, 1-3 parts of an anti-aging agent and 0.5-1 part of paraffin. The invention further provides a preparation method of the wear-resistant rubber for the sports shoe soles. Wear-resistant rubber shoe soles for the sports shoe soles, prepared according to the technical scheme adopted by the invention, have super wear resistance which is incomparable with that of ordinary rubber soles, and have many properties such as good weather resistance and folding resistance; the preparation method is simple in production process and is suitable for wide application.

Owner:ANTA CHINA

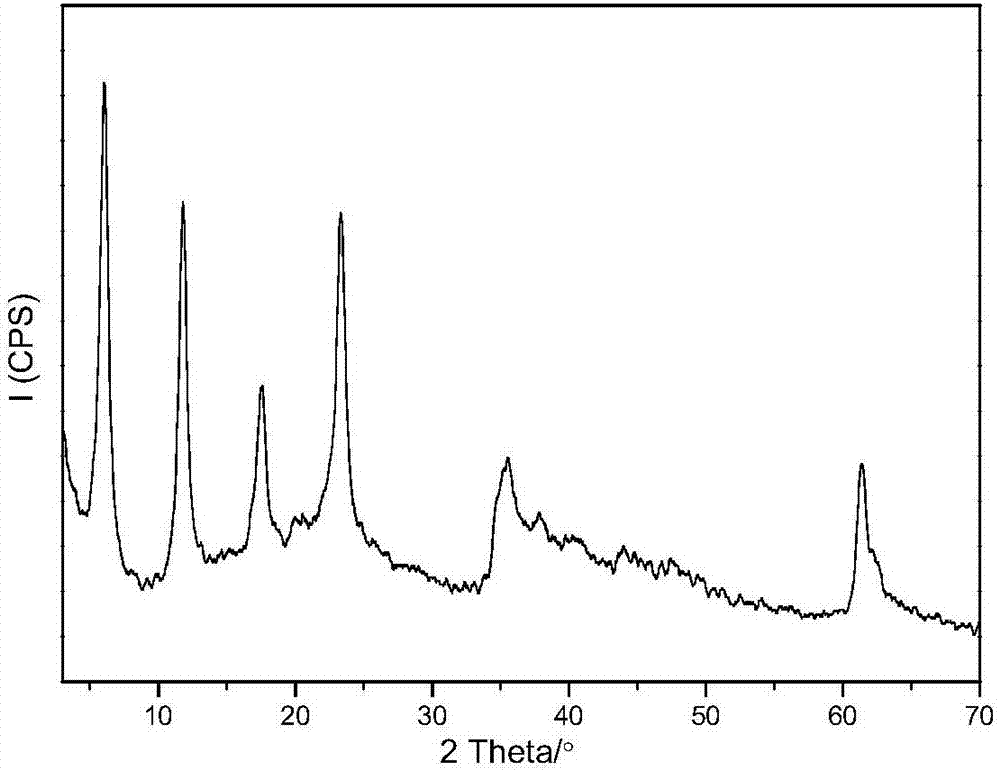

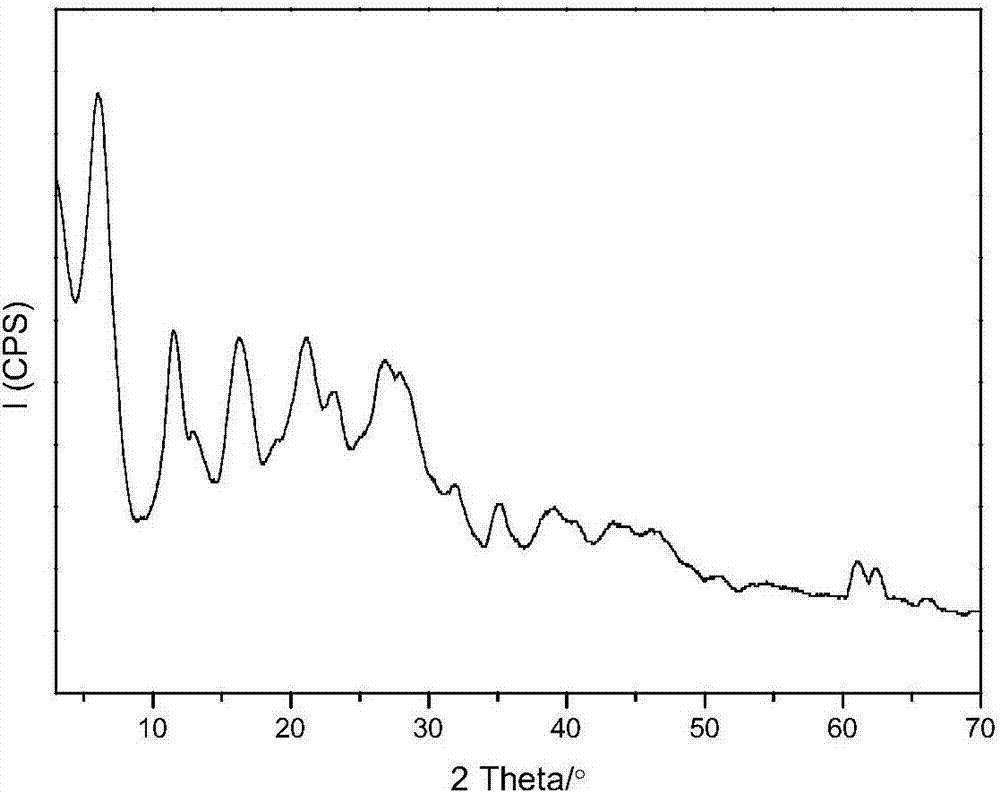

Intercalated hydrotalcite anti-ultraviolet aging agent for rubber as well as preparation method and usage method thereof

The invention discloses an intercalated hydrotalcite anti-ultraviolet aging agent for rubber as well as a preparation method and a usage method thereof, and belongs to the technical field of inorganic functional materials. According to intercalated hydrotalcite provided by the invention, a cross-linking agent is introduced into an interlayer of hydrotalcite by utilizing the characteristic that a guest molecule of the interlayer can be exchanged, and is enabled to generate a chain reaction with a molecular chain of the rubber to produce a cross bond; the anti-ultraviolet aging performance of vulcanized rubber is enhanced; the hydrotalcite which is small and further uniform in particle size and is spherical in morphology is obtained through a template agent, and owns a larger specific surface area; the ultraviolet shielding effect of the hydrotalcite is enhanced. The intercalated hydrotalcite can be also modified by using a modifying agent and etched; the interfacial action between the hydrotalcite and the rubber is ameliorated; the dispersity and the uniformity in the rubber are promoted and the physical and mechanical properties of the rubber are improved; the hysteresis loss and the heat generation under dynamic deformation are decreased.

Owner:BEIJING UNIV OF CHEM TECH

Oil-resistant conveying belt covering rubber

InactiveCN104292537AHigh bonding strengthInhibit or delay oxidative degradationRubber materialVulcanization

The invention relates to oil-resistant conveying belt covering rubber prepared from the following raw materials in parts by weight: 100 parts of butadiene-acrylonitrile rubber, 1-2 parts of a promoter, 1-2 parts of a vulcanizing agent, 4-6 parts of a vulcanization activator, 5-8 parts of a plasticizer, 8-12 parts of a softening agent, 20-60 parts of reinforcing filler, 12-18 parts of a filling agent and 2-4 parts of an anti-aging agent. The preparation method comprises the following steps: (1) plasticating the 100 parts of butadiene-acrylonitrile rubber in an open mill; (2) putting a plasticated rubber material into an internal mixer, sequentially adding the reinforcing filler, the vulcanization activator, the plasticizer and the anti-aging agent with the weight parts, stirring for a period of time, then adding the softening agent and the filling agent, continuously stirring, finally adding the vulcanizing agent and the promoter, and uniformly stirring to obtain mixed rubber; and (3) performing rubber sheet extrusion on the mixed rubber material by virtue of the open mill to obtain the oil-resistant conveying belt covering rubber. The oil-resistant conveying belt covering rubber disclosed by the invention adopts the butadiene-acrylonitrile rubber as a main raw material; and by adding reasonable compounding agents into the butadiene-acrylonitrile rubber, the oil resistance of the covering rubber can be effectively improved, and the service life of a conveying belt can be prolonged.

Owner:SHANXI DEBANG RUBBER PROD

Butadiene-acrylonitrile rubber used in low-temperature vulcanized high-performance screw pump stator and preparation method thereof

InactiveCN105086024ALower vulcanization temperatureSave energy and costChemical industryCarbon blackStator

The invention discloses butadiene-acrylonitrile rubber used in a low-temperature vulcanized high-performance screw pump stator and a preparation method thereof. The rubber is prepared from, by mass, 100 parts of butadiene-acrylonitrile rubber bodies, 60 parts of N330 high-abrasion-resistance carbon black, 5 parts of nano-zinc oxide, 2 parts of gamma-amine propyle triethoxysilane (KH550), 1 part of stearic acid, 1 part of 4010 anti-aging agents, 1.5 parts of sulphur, 2.5 parts of accelerant-DM, 0.25 part of accelerant-TMTD, 0.15 part of accelerant-MgO and 2 parts of phthalic acid dioctylterephthalate (DOP). The butadiene-acrylonitrile rubber bodies, the sulphur, the stearic acid, the nano-zinc oxide, the gamma-amine propyle triethoxysilane, the 4010 anti-aging agents, the N330 high-abrasion-resistance carbon black, the phthalic acid dioctylterephthalate (DOP) and a mixture of the DM, the TMTD and the MgO are added in sequence, and slab vulcanization is conducted on a rubber compound according to the set vulcanizing temperature and the measured vulcanizing time. The preparation method is simple in process, high in production efficiency and capable of saving energy and reducing consumption, and the obtained vulcanized rubber is excellent in swelling resistance and abrasion resistance.

Owner:SHENYANG POLYTECHNIC UNIV

Vulcanization method of addition silicone rubber

ActiveCN109929127AImprove vulcanization characteristicsIncrease vulcanization rateCross-linkVulcanization

The invention discloses a vulcanization method of addition silicone rubber. Ammonia is a common well-supplied and low-cost inorganic compound, and ammonia gas is introduced into water to obtain ammonia water. Some carbon dioxide is introduced into the ammonia water to obtain carbonized ammonia water. The addition type silicone rubber is synthetic rubber which is vulcanized by hydrosilylation reaction to form a cross-linked network. According to the method, the ammonia, the ammonia water, the carbonized ammonia water or liquid ammonia is added into the addition silicone rubber to change the vulcanization characteristic of the addition silicone rubber, the vulcanization rate of the addition silicone rubber is increased by the method, the vulcanization temperature is reduced, the vulcanization time is shortened, the production efficiency is improved, and meanwhile, the method facilitates hot vulcanization compound molding of silicon rubber and low softening point materials (such as thermoplastic ABS, PMMA, PC / ABS and PC).

Owner:NANTONG MEMTECH TECH +1

Anti-aging conductive rubber and preparation method thereof

The invention discloses anti-aging conductive rubber and a preparation method thereof, and relates to the field of conducting materials. The conductive rubber is prepared from the following raw materials including silicon rubber, isoprene-butadiene rubber, modified carbon nanometer tubes, carbon black N220, silver-plated glass fiber, simethicone, zinc oxide, vulcanizing agents, anti-aging agents, accelerants and ultraviolet ray light stabilizing agents. According to the preparation method, the raw materials are subjected to staged compounding and two-stage vulcanization treatment to prepare the anti-aging conductive rubber. The preparation of the conductive rubber is simple and convenient; in the production process, the thin conduction times and the vulcanization time are properly reduced; the vulcanization temperature is lowered; the production cost output is reduced; the conductive filling materials of a finished product have the characteristics of good anti-aging performance, high tensile intensity and good conductive performance; the service life is long; the anti-aging conductive rubber is suitable for being popularized and used.

Owner:HEFEI DONGHENGRUI ELECTRONICS TECH CO LTD

Sports footwear sole material, and preparation method thereof

InactiveCN107266735ASolve the qualitySolving Elasticity ProblemsSolesPolymer scienceButadiene-styrene rubber

The invention provides a sports shoe sole material and a preparation method thereof, and relates to the field of shoe materials. The sports shoe sole material includes the following raw materials in parts by weight: butadiene rubber, natural rubber, brominated butyl rubber, styrene-butadiene rubber, and isoprene rubber , silicone rubber, polyurethane rubber, silica, paraffin oil, activator, sulfur, accelerator, tackifier, zinc stearate, light stabilizer, plasticizer and anti-aging agent. The preparation method comprises the following steps: (1) weighing raw materials, (2) masticating, kneading, mixing, cutting into pieces, and molding. The invention solves the problems of heavy weight, low elasticity, poor adhesiveness and poor aging resistance of existing sports shoe sole materials.

Owner:HEFEI KANGZHIHENG MACHINERY TECH CO LTD

Rubber crawler belt for excavator and preparation method thereof

The invention discloses a rubber crawler belt for an excavator, belonging to the technical field of rubber crawler belts. The rubber crawler belt comprises the following raw materials by weight: 50 to 60 parts of isoprene rubber, 20 to 25 parts of butadiene-acrylonitrile rubber, 15 to 18 parts of butadiene rubber, 10 to 15 parts of silicone rubber, 1 to 2 parts of paraffin, 5 to 8 parts of zinc oxide, 2 to 4 parts of stearic acid, 32 to 35 parts of silica-alumina carbon black, 1 to 2 parts of sulfur, 13 to 16 parts of plant oil, 1 to 2 parts of an anti-scorching agent, 1 to 3 parts of a promoter, 0.2 to 0.6 part of an anti-oxidant and 0.5 to 1 part of a plasticizer. The invention also discloses a preparation method for the rubber crawler belt. The rubber crawler belt provided by the invention has good physical properties and can meet demands on usage in severe environments.

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

Oil-resistant rubber material without free-state sulfur

The invention discloses an oil-resistant rubber material without free-state sulfur, and relates to a rubber material. Adopted matrix rubber is mixed rubber of nitrile rubber (N41) and rubber alloy (N7030), an adopted sulfuration system is sulfur-carrier thiuram (TMTD or TRA) sulfuration agents without elemental sulfur, adopted sulfuration accelerators are sulfenamide (CZ) or thiazoles (DM), adopted anti-aging agents are amine (RD and 4010NA) anti-aging agents, adopted fillers are one or two kinds of CaCO3, talcum powder and spraying carbon black, adopted reinforcing agents are a mixture of N330, N550 and N774, adopted plasticizers are ester plasticizers (DOS), and a binding system is a mixture of novel binding agents (AS-88) and white carbon black (WCB). According to the oil-resistant rubber material, as sulfur carriers are used as the sulfuration agents, the prepared rubber material is good in oil resistance, does not contain the free-state sulfur, and is more environmentally friendly accordingly, and various properties can meet the national oil resistant rubber pipe standard.

Owner:NANTONG ZHANPENG PLASTIC

Rubber plastic material for elevator and preparation method thereof

The invention discloses a rubber plastic material for an elevator and a preparation method thereof. The rubber plastic material for the elevator is prepared from the following raw materials in parts by weight: 40-50 parts of natural rubber, 60-75 parts of butadiene styrene rubber, 5-15 parts of high styrene resin, 10-15 parts of dioctyl sebacate, 6-12 parts of phenolic resin, 5-13 parts of argil, 8-15 parts of medical stone, 10-14 parts of carbon black, 15-20 parts of zinc oxide, 10-15 parts of sulfur, 10-14 parts of a vulcanization accelerator, 12-15 parts of stearic acid, 13-16 parts of boric acid, 15-18 parts of a crosslinking agent and 15-21 parts of a surfactant. The rubber plastic material for the elevator has excellent abrasion resistance, comprehensive mechanical properties and good low temperature performance.

Owner:NANTONG HONGTU RUBBER & PLASTIC

Preparation method of antibacterial and wear-proof medical rubber gloves

The invention discloses a preparation method of antibacterial and wear-proof medical rubber gloves and belongs to the technical field of rubber preparation. The method comprises steps as follows: firstly, nitrile rubber, fluorinated silicone rubber and sulfur are mixed at a certain temperature, homemade sulfurized mixed glue is formed, the dispersity of superfine particles in a matrix is advantageously improved, and improvement of uniform dispersity and hardness of wear-proof substances in the rubber gloves is promoted, and the wear resistance of the rubber gloves is advantageously improved; then, the insides of the rubber gloves are effectively filled with quartz sand powder. Superfine aluminum oxide powder is soaked in a silver nitrate solution, a silver-supporting structure layer is formed, bacteria are accordingly killed, and the antibacterial property of the rubber gloves is improved. A homemade antibacterial emulsion is prepared from nano zinc oxide and isothiazolinone through mixing, rubber glove bodies are soaked in the homemade antibacterial emulsion, and bacteria are killed; besides, metal ions are released slowly when nano zinc oxide and bacteria make contact, the wear resistance of the rubber gloves is further improved and the antibacterial and wear-proof medical rubber gloves have broad application prospects.

Owner:CHANGZHOU DINGRI ENVIRONMENTAL PROTECTION TECH

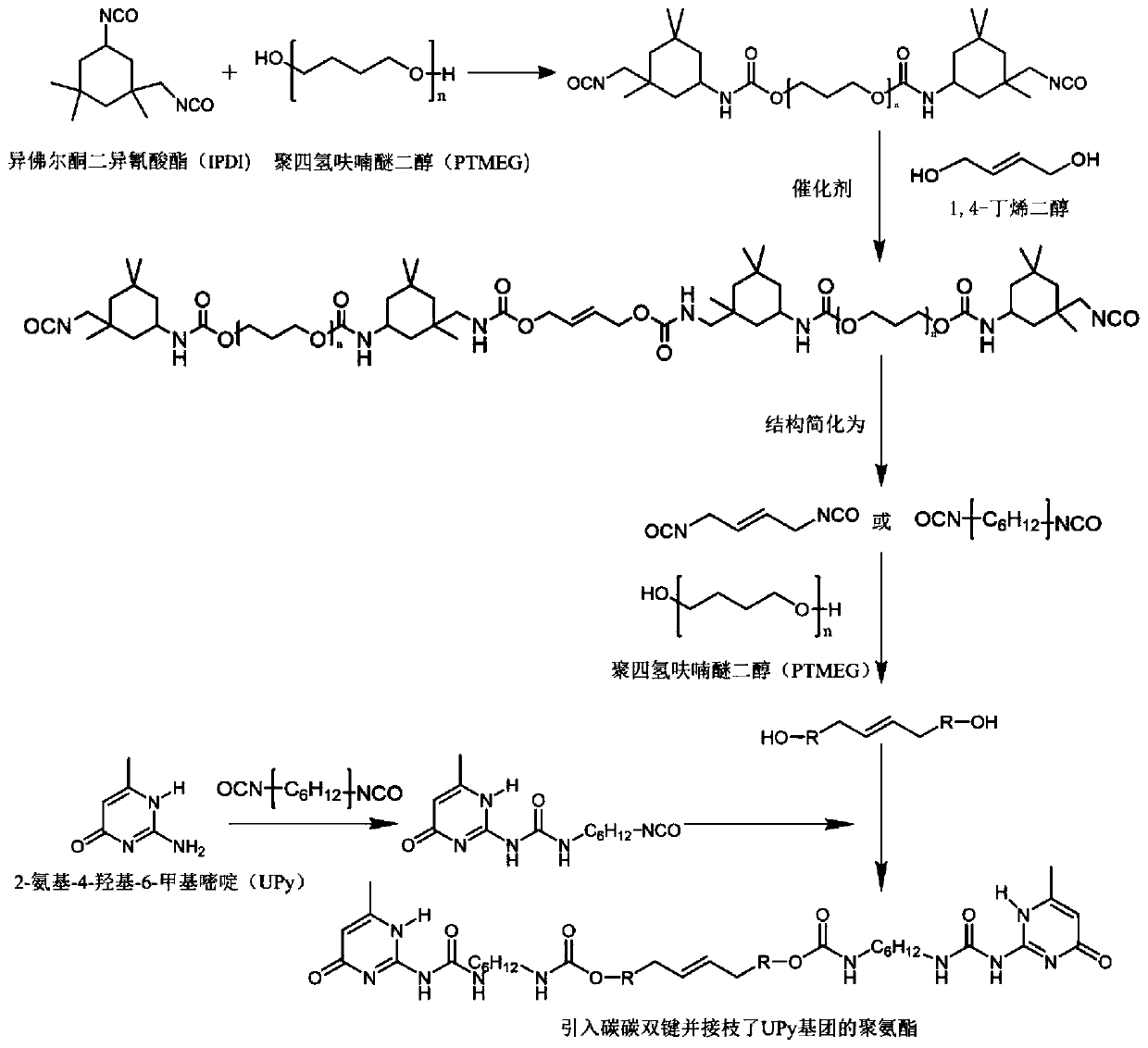

Epoxidized natural rubber composite material with self-repairing function and preparation method thereof

The invention provides an epoxidized natural rubber composite material with a self-repairing function and a preparation method thereof, which belong to the technical field of composite materials. Theepoxidized natural rubber composite material comprises the following components in parts by mass: 100 parts of an epoxidized natural rubber matrix, 1-3 parts of dicumyl peroxide, 1-40 parts of polyurethane, 1-2 parts of an anti-aging agent and 0.5-1 part of an ultraviolet light absorber. According to the preparation method, UPy grafted polyurethane is synthesized firstly, then the UPy grafted polyurethane is reacted with a rubber molecular chain to prepare the composite material with the self-repairing function, the prepared composite material can achieve self-repairing under the condition that the complete end is broken, meanwhile, good strength and stability are achieved, and the preparation method is simple and low in cost.

Owner:JIANGSU UNIV

Shoe sole suitable for running, and making method thereof

The invention provides a shoe sole suitable for running and a preparation method thereof, and relates to the technical field of shoe soles. The shoe sole suitable for running includes the following raw materials by weight: nitrile rubber, brominated butyl rubber, nano silicon dioxide, chlorinated polyethylene , polyethylene wax, magnesium oxide, nano zinc oxide, sulfur, quartz glass fiber, polyvinyl formal fiber, boron fiber, polyamide fiber, vulcanization accelerator, plasticizer, antioxidant, white smoke activator, coupling agent, softener, light stabilizer and heat stabilizer. The preparation method comprises the following steps: (1) weighing raw materials, (2) adding into an internal mixer, (3) adding into a double-roller open mill, and (4) vulcanizing and forming. The invention solves the problem that the existing soles do not have the properties of anti-skid, high compressive strength, flexural strength, good toughness and light weight.

Owner:合肥梵清电子商务有限公司

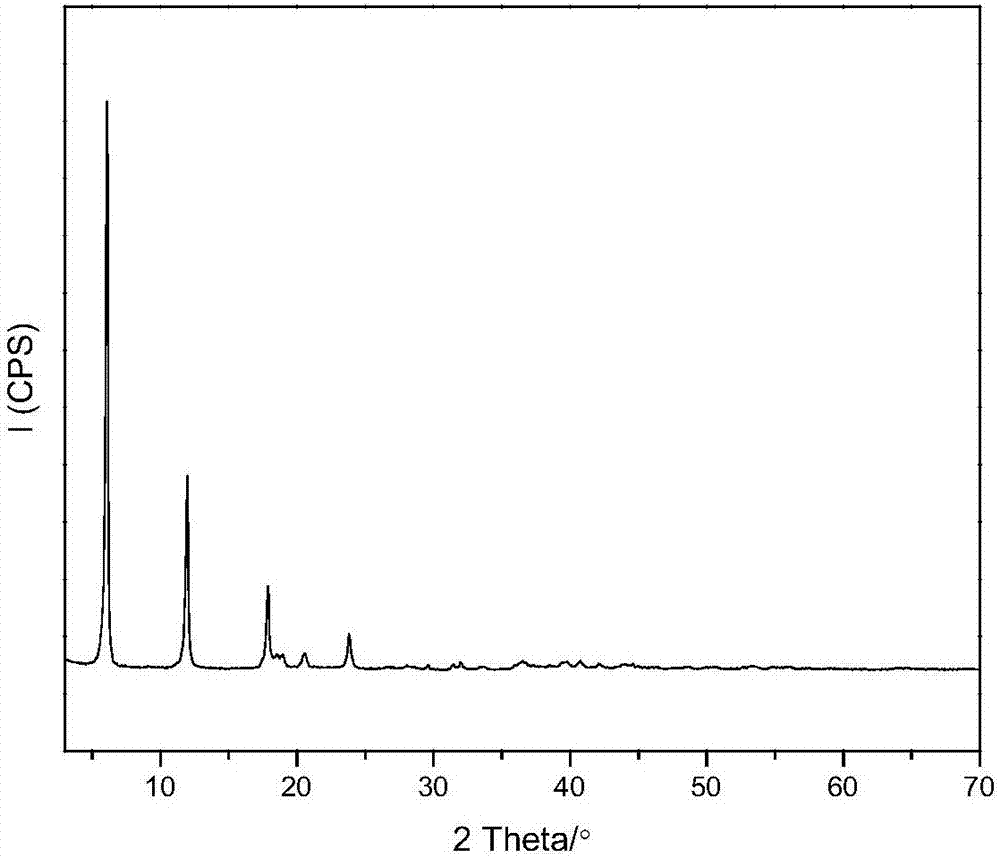

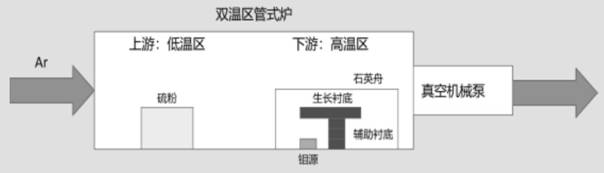

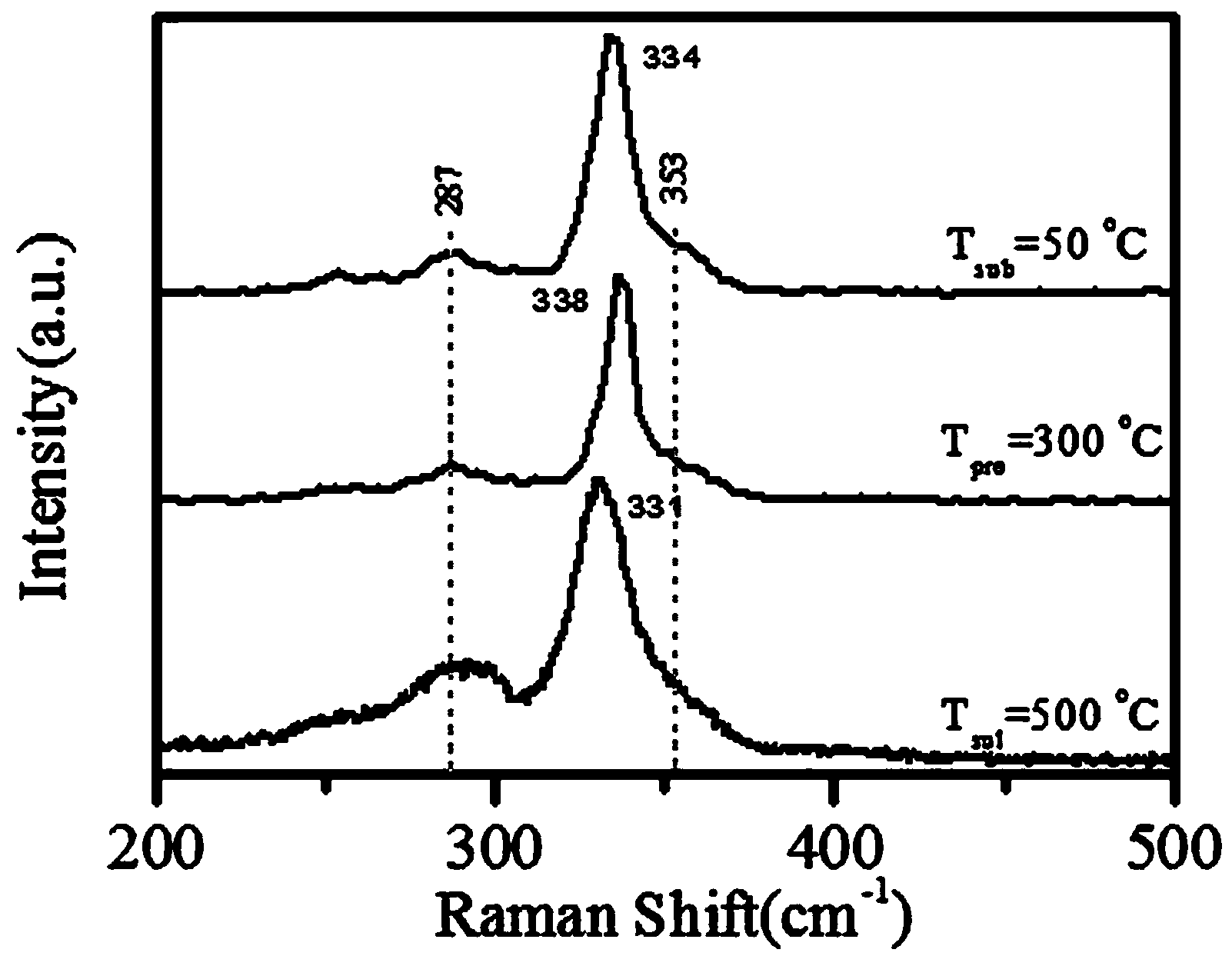

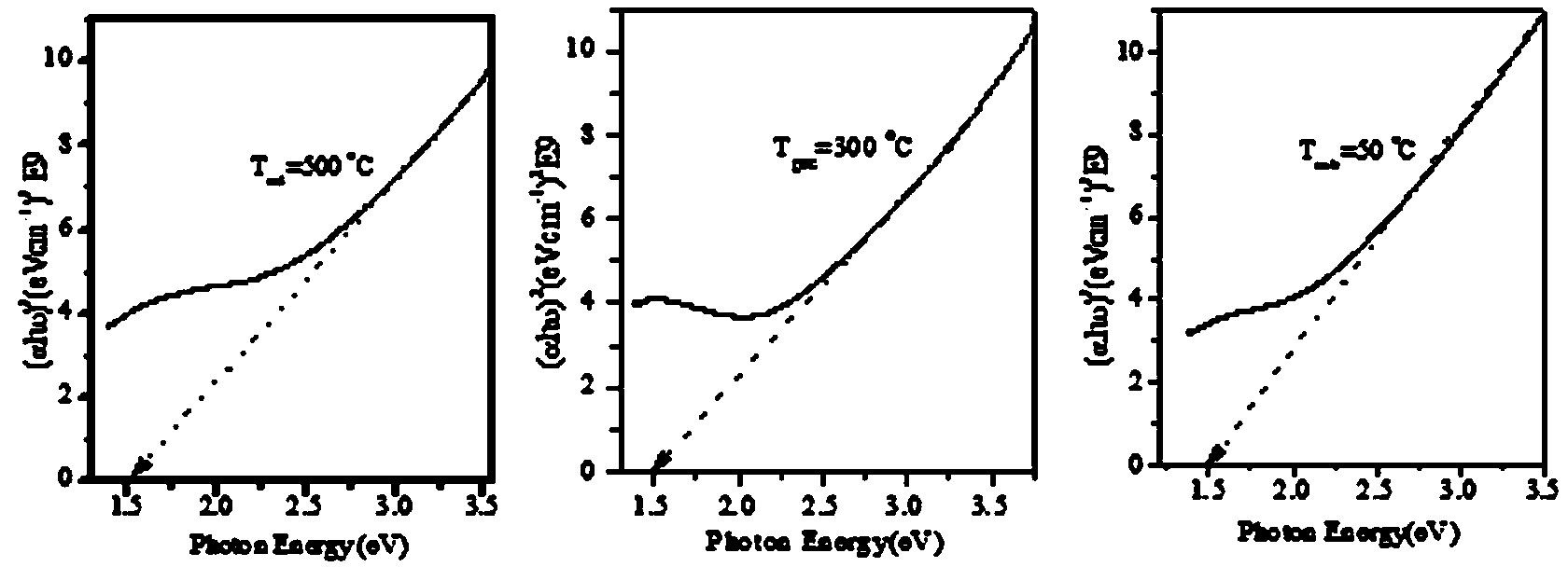

Preparation method of large-area molybdenum disulfide film

ActiveCN112853290AUniform layersIncrease the areaPolycrystalline material growthVacuum evaporation coatingPhysical chemistryThin membrane

The invention belongs to the field of material preparation, and particularly relates to a preparation method of a large-area molybdenum disulfide film. According to the method, a confinement space method is adopted, a magnetron sputtering method and a chemical vapor deposition method are combined, and reaction parameters are optimized to obtain a large-area MoS2 film material. The film obtained on the basis of a two-step method has the characteristics of large area, good uniformity, strong controllability, good crystallinity and the like, and the method is simple to operate, short in time consumption and capable of being produced and applied on a large scale.

Owner:NANCHANG UNIV

Adhesive for hot water-cured lining hard rubber and preparation method thereof

ActiveCN102127378ALower vulcanization temperatureFully vulcanizedNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceVulcanization

The invention relates to an adhesive for lining hard rubber, in particular to an adhesive for hot water-cured lining hard rubber, which is a mixture of components A and B in a weight part ratio of 4:1. The component A comprises 100 parts of natural rubber, 1 to 3 parts of pigment, 20 to 40 parts of sulfur, 50 to 150 parts of zinc oxide, 15 to 40 parts of tackifying resin, 1 to 3 parts of accelerator DM1, 2 to 5 parts of mixed oil 933 and 400 to 700 parts of mixed solvent, wherein the mixed solvent is 2 or 3 of toluene, dimethylbenzene and gasoline. The component B comprises solution of polyisocyanate. Before use, the component B is added into the component A, the components are mixed uniformly (for at least 1 minute), and the adhesive for brushing can be obtained. The adhesive is applicable to hot water-cured lining hard rubber and has big adhesion force.

Owner:SHANGHAI SHUANGPU ANTICORROSION RUBBER LINING

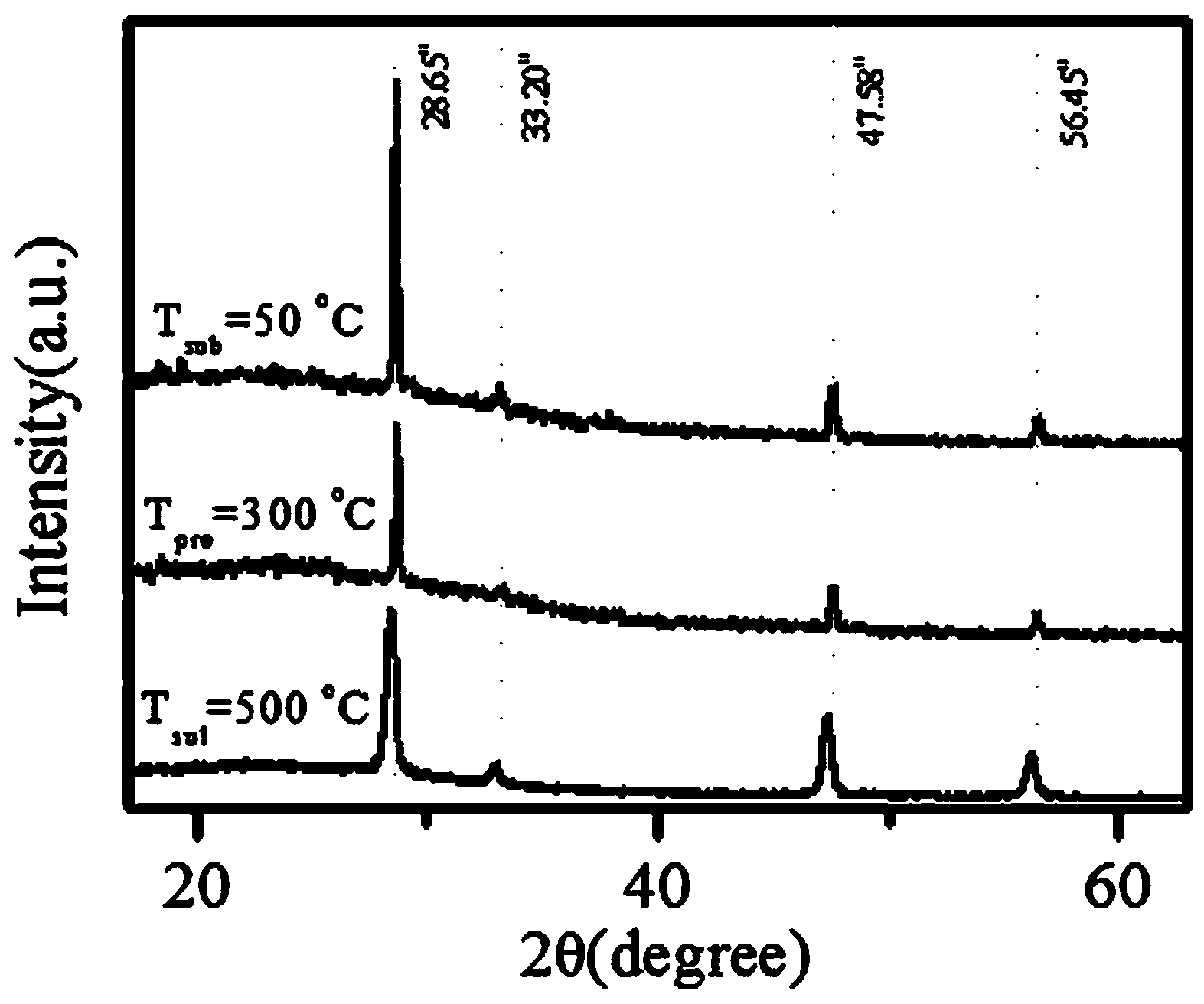

Preparation method of high-quality copper-zinc-tin sulphur semiconductor film

InactiveCN104278238AQuality improvementHigh purityFinal product manufactureVacuum evaporation coatingVulcanizationEvaporation

The invention discloses a preparation method of a high-quality copper-zinc-tin sulphur semiconductor film. The method comprises the following steps: through a vacuum heating evaporation mode, sequentially placing high-purity copper, zinc and tin, which are respectively put in different tungsten boats or molybdenum boats on a substrate which is heated to 20-200 DEG C, so as to obtain a metal film precursor; and then obtaining a high-quality copper-zinc-tin sulphur film by vulcanizing the metal film precursor. Adhesion of a precursor metal layer on the substrate and chemical combination among three elements are affected by changing the temperature of the substrate, so that the vulcanization efficiency is increased, and preparation of the high-quality copper-zinc-tin sulphur semiconductor film is achieved. The equipment disclosed by the invention is relatively simple, and easy to operate; the prepared film is high in purity, good in quality, high in film-forming rate, and high in efficiency; and the problems that impurities are formed at the vulcanization stage in the prior art to cause influence on film quality, long vulcanization time and high vulcanization temperature are solved.

Owner:WUYI UNIV

Modified attapulgite reinforced cable sheath material

InactiveCN105542262AGood high and low temperature resistanceGood oil resistanceRubber insulatorsInsulated cablesEmulsionAcrylonitrile

The invention discloses a modified attapulgite reinforced cable sheath material. The modified attapulgite reinforced cable sheath material is prepared from, by weight, 30-50 parts of NBR-2707 type butadiene-acrylonitrile rubber, 50-70 parts of SBR-1502 type emulsion polymerized butadiene styrene rubber, 1-2 parts of stearic acid, 2-4 parts of N, N-meta phenylene bismaleimide, 0.5-2 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 1-2 parts of zinc diethyldithiocarbamic acid, 2-6 parts of paraffin, 0.5-1.5 parts of antiager DPPD, 3-8 parts of nano-hydroxyapatite powder, 4-8 parts of enhancer DH-2, 15-25 parts of semi-reinforcement carbon black and 10-20 parts of modified attapulgite. The modified attapulgite reinforced cable sheath material has excellent processability and mechanical strength, and is simple in processing process, high in practicality and easy to popularize.

Owner:SUZHOU KEMAO ELECTRONICS MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com