Patents

Literature

1123results about How to "Reduce gravity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

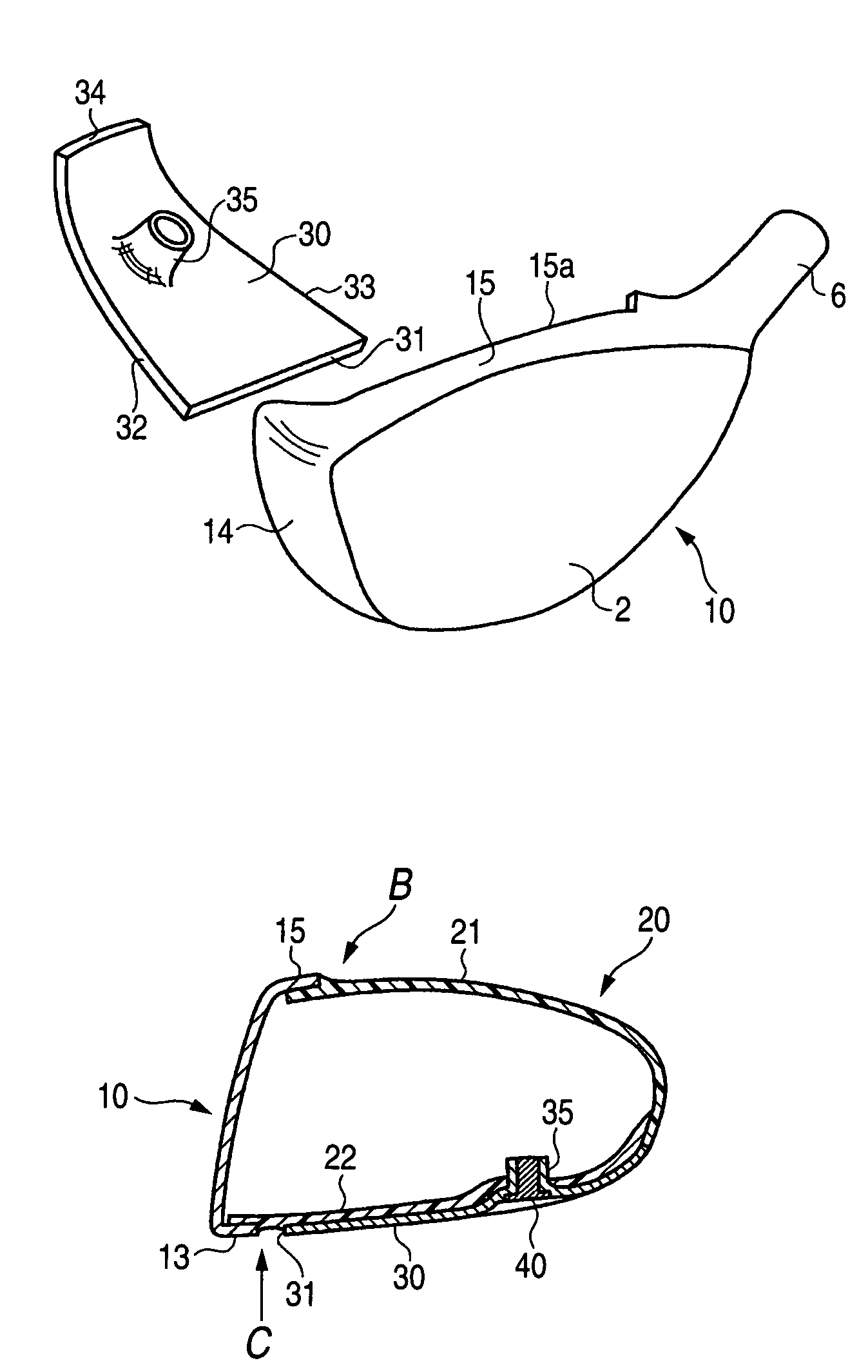

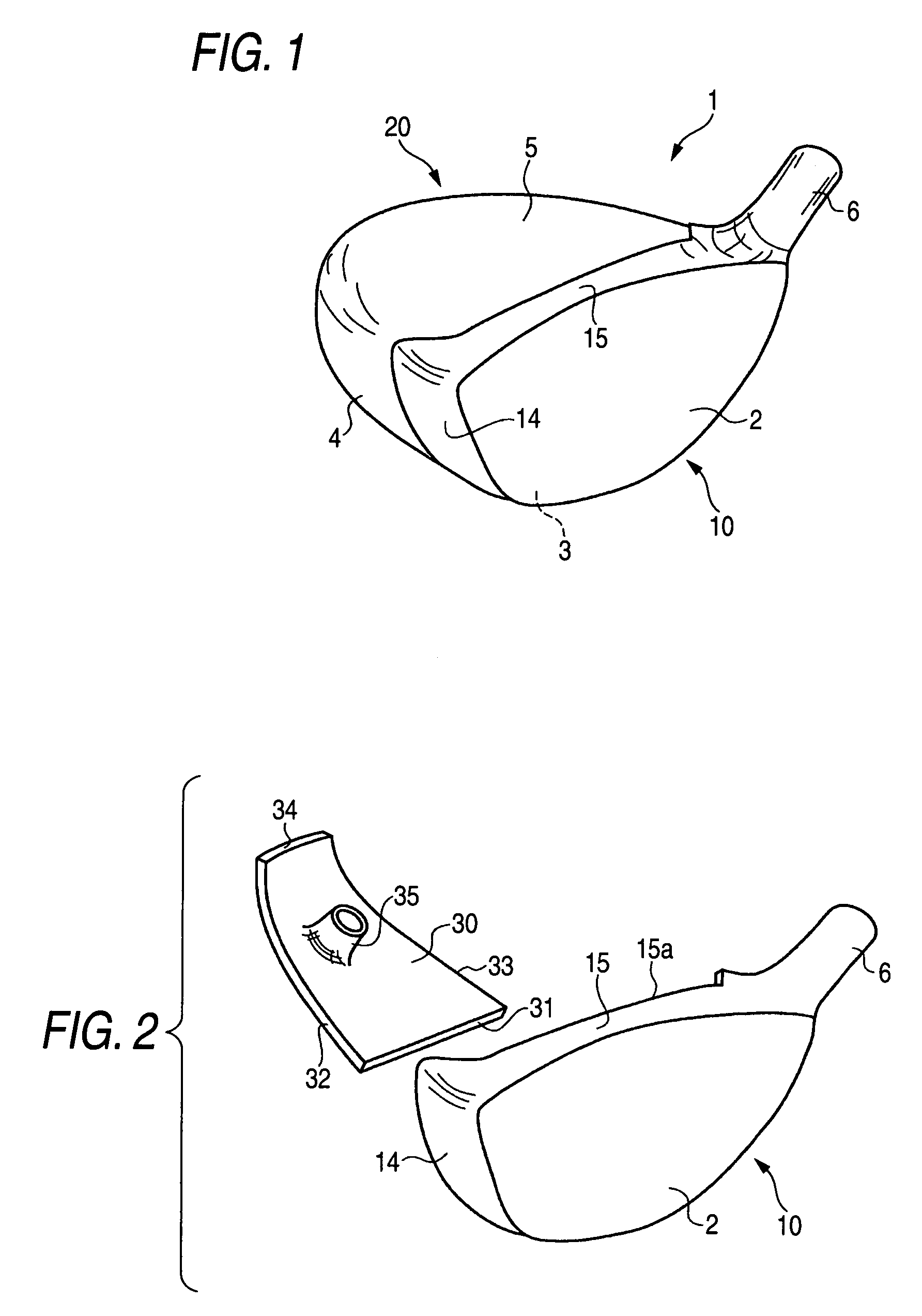

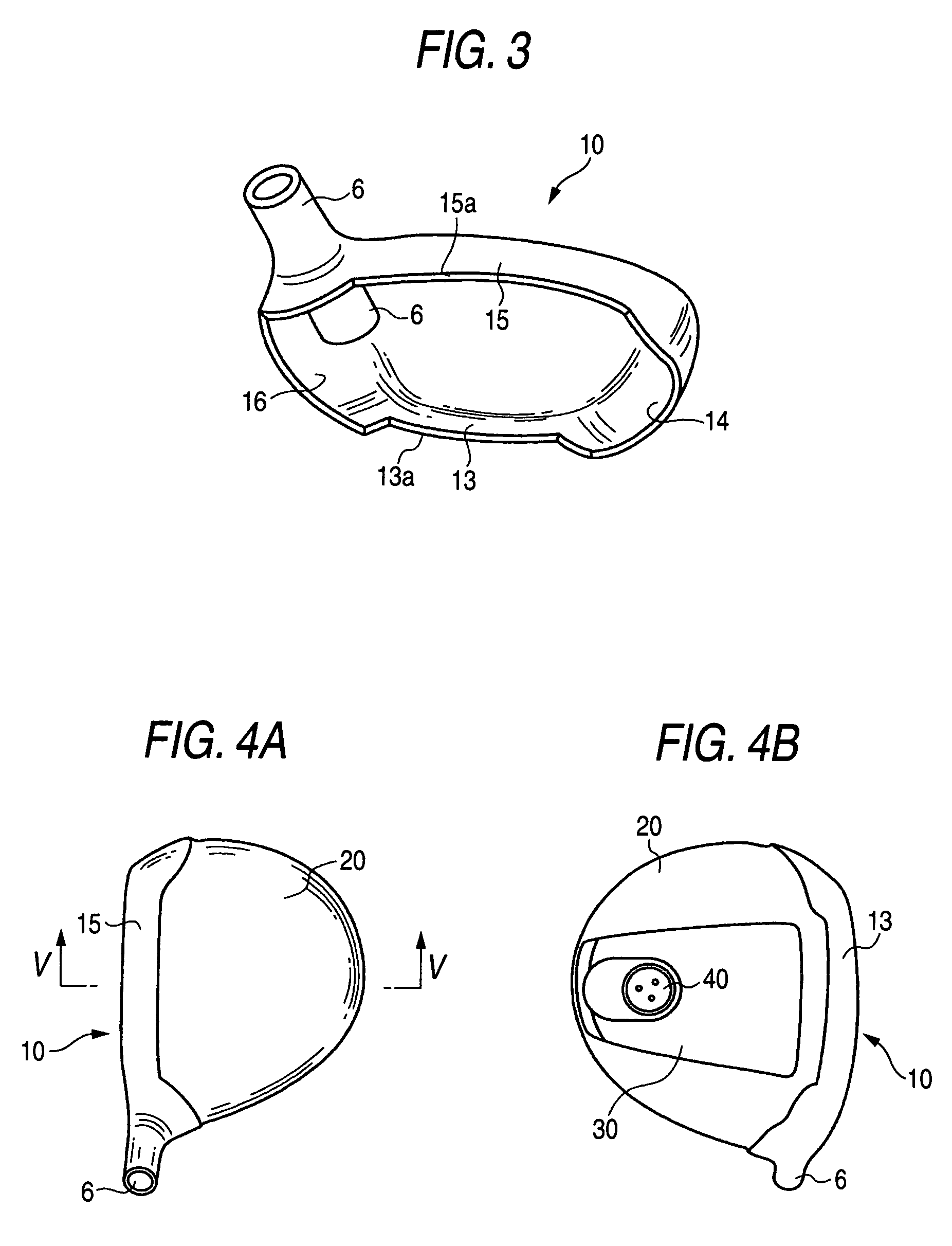

Golf club head

InactiveUS7344452B2Position of the center of gravity can be designed more easilySimple designGolf clubsRacket sportsMetallic materialsEngineering

A golf club head includes a front body formed of a titanium-based metal material, an FRP body, a metallic sole plate, and a weight member. The front body has a face portion, a metal sole portion, a metal side portion (toe), a metal crown portion, a metal side portion (heel), and a hosel portion. A slight gap is formed between a front side of the sole plate and the metal sole portion. Preferably, the front body is made of a titanium alloy, while the sole plate is made of stainless steel.

Owner:BRIDGESTONE SPORTS

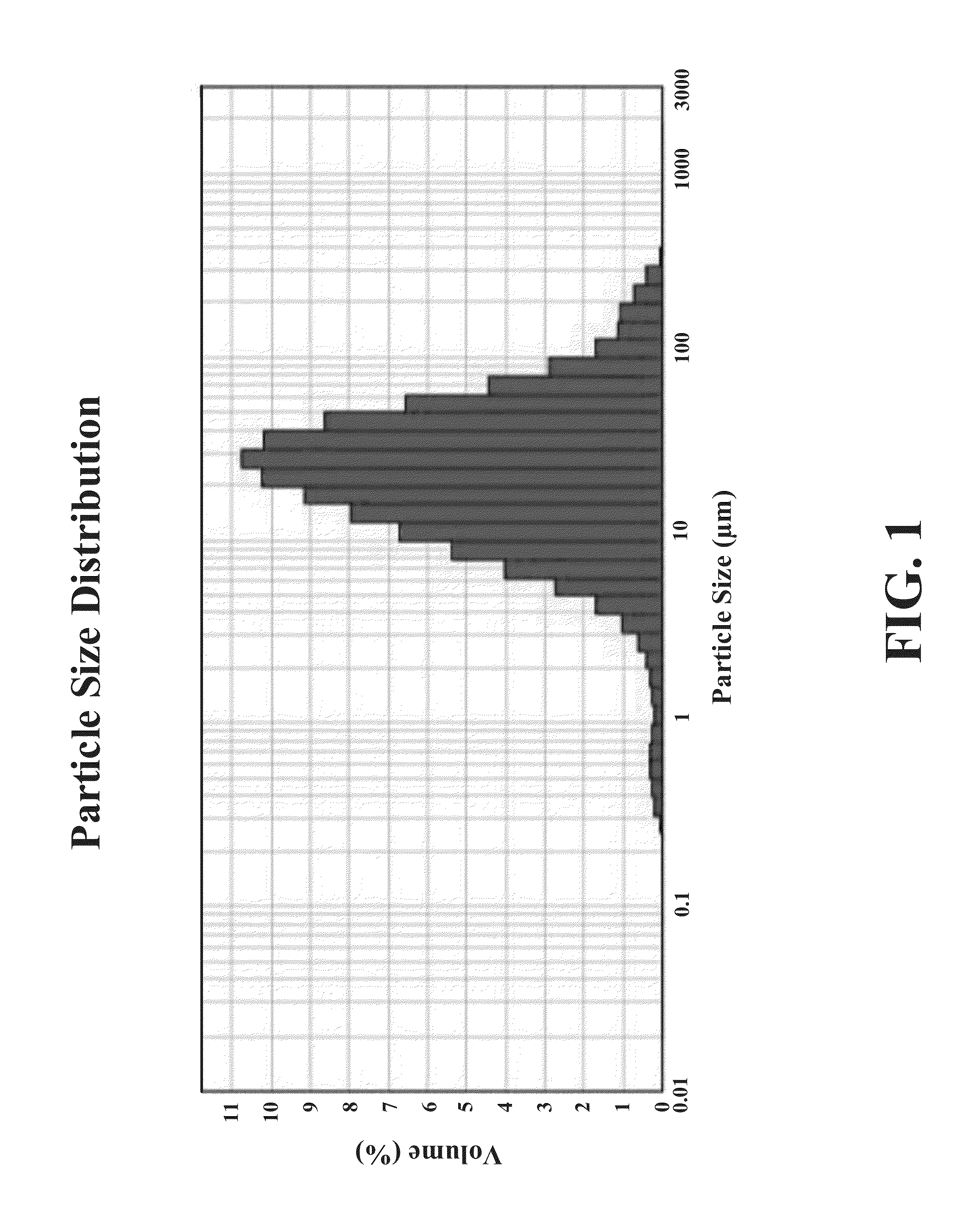

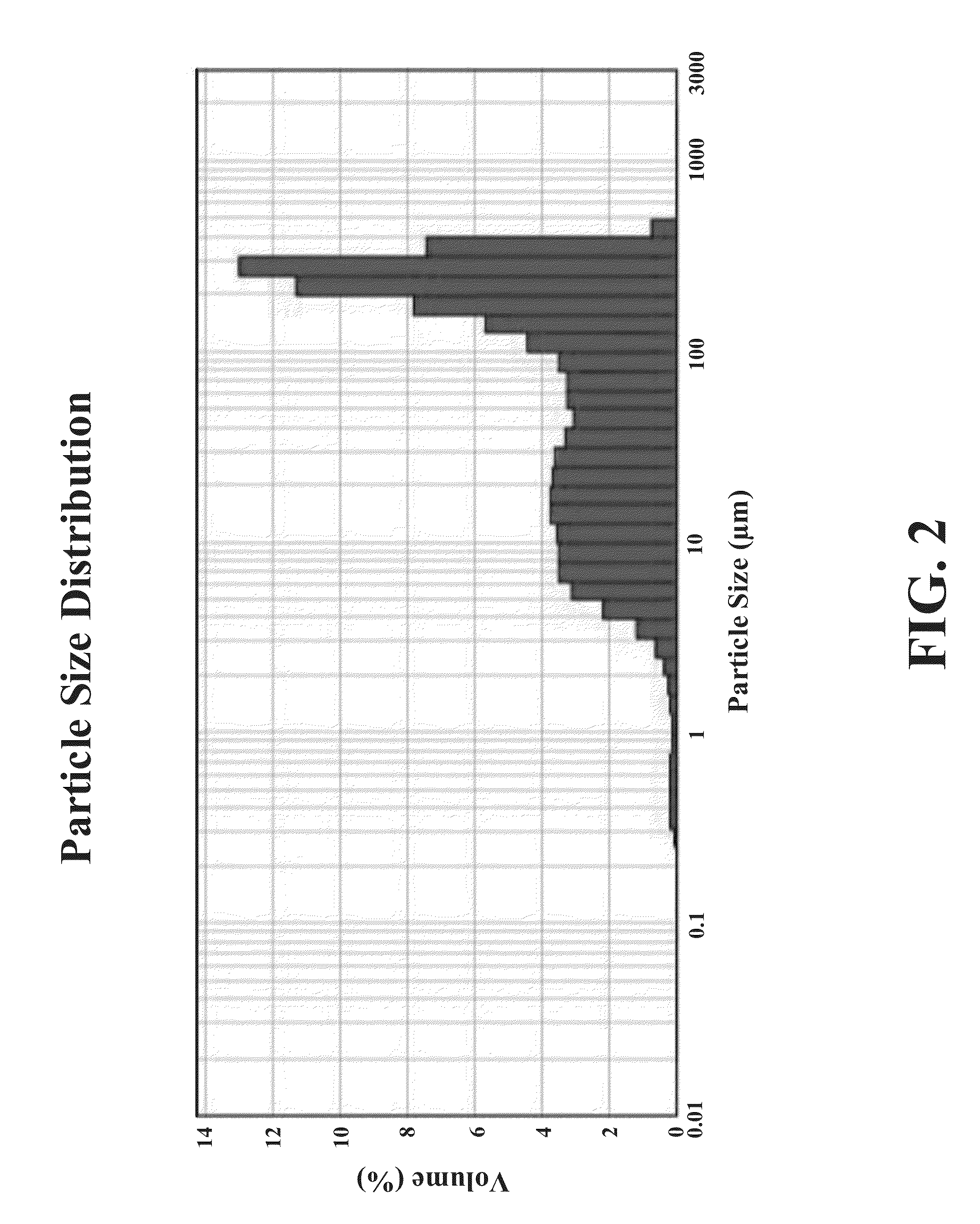

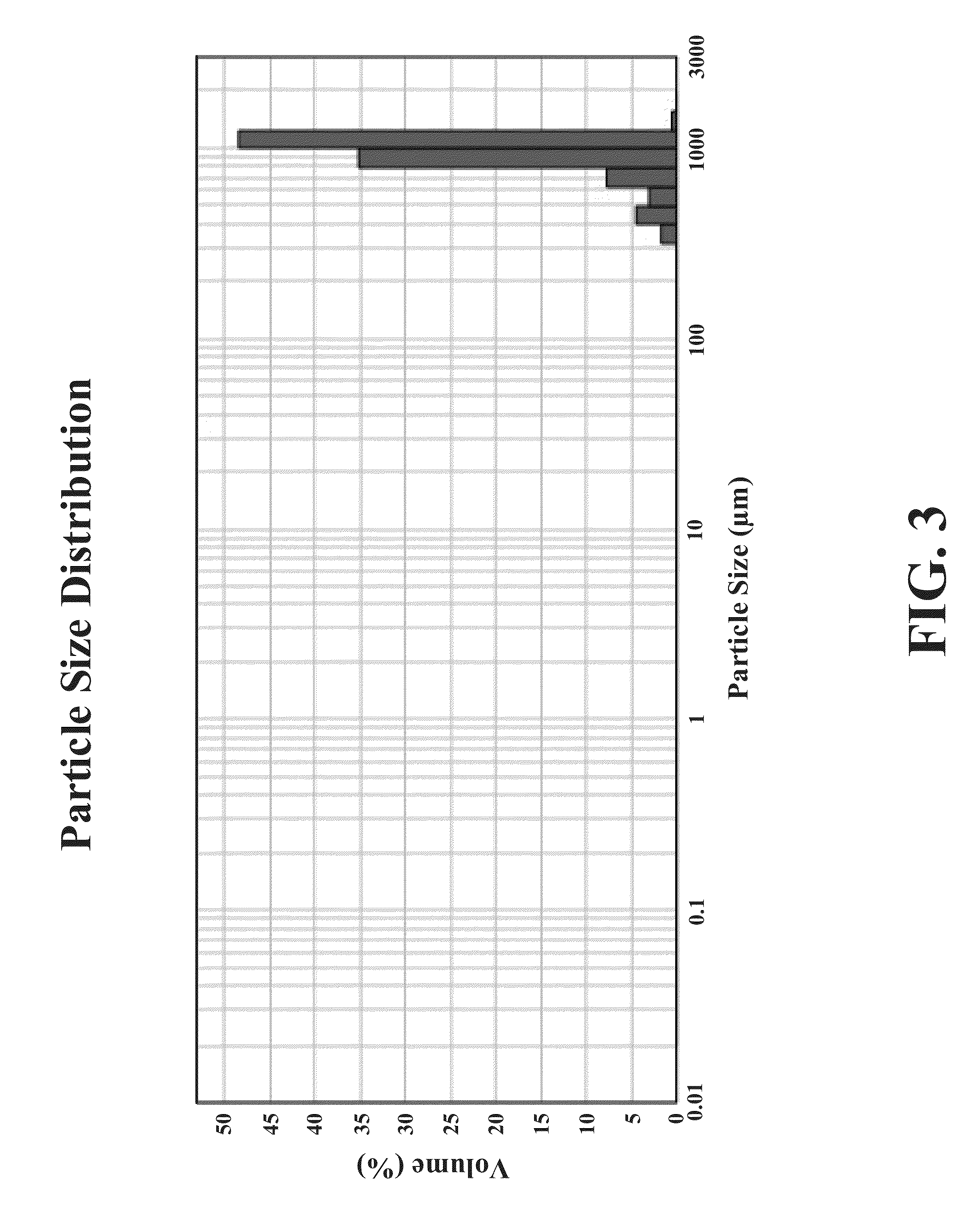

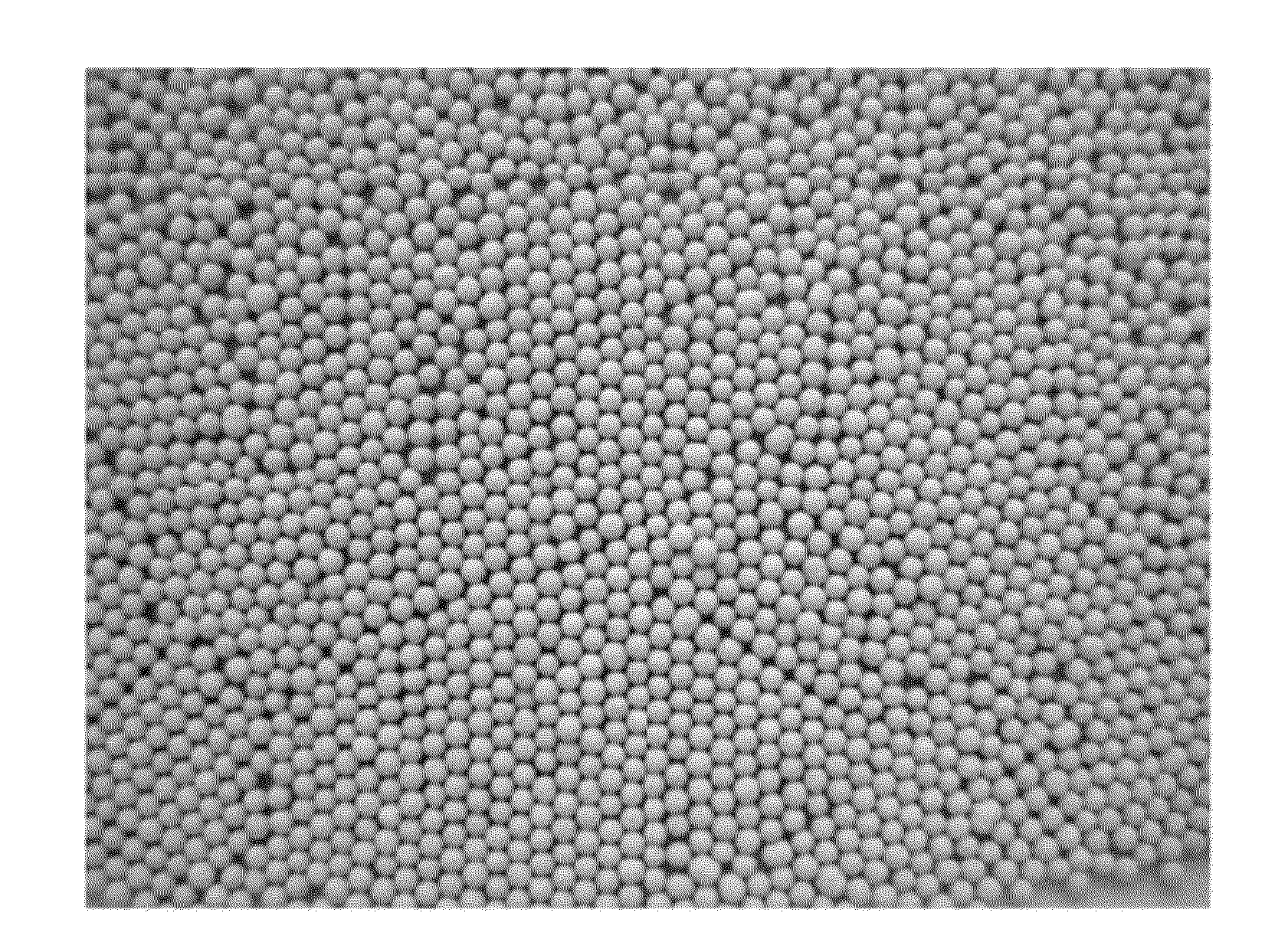

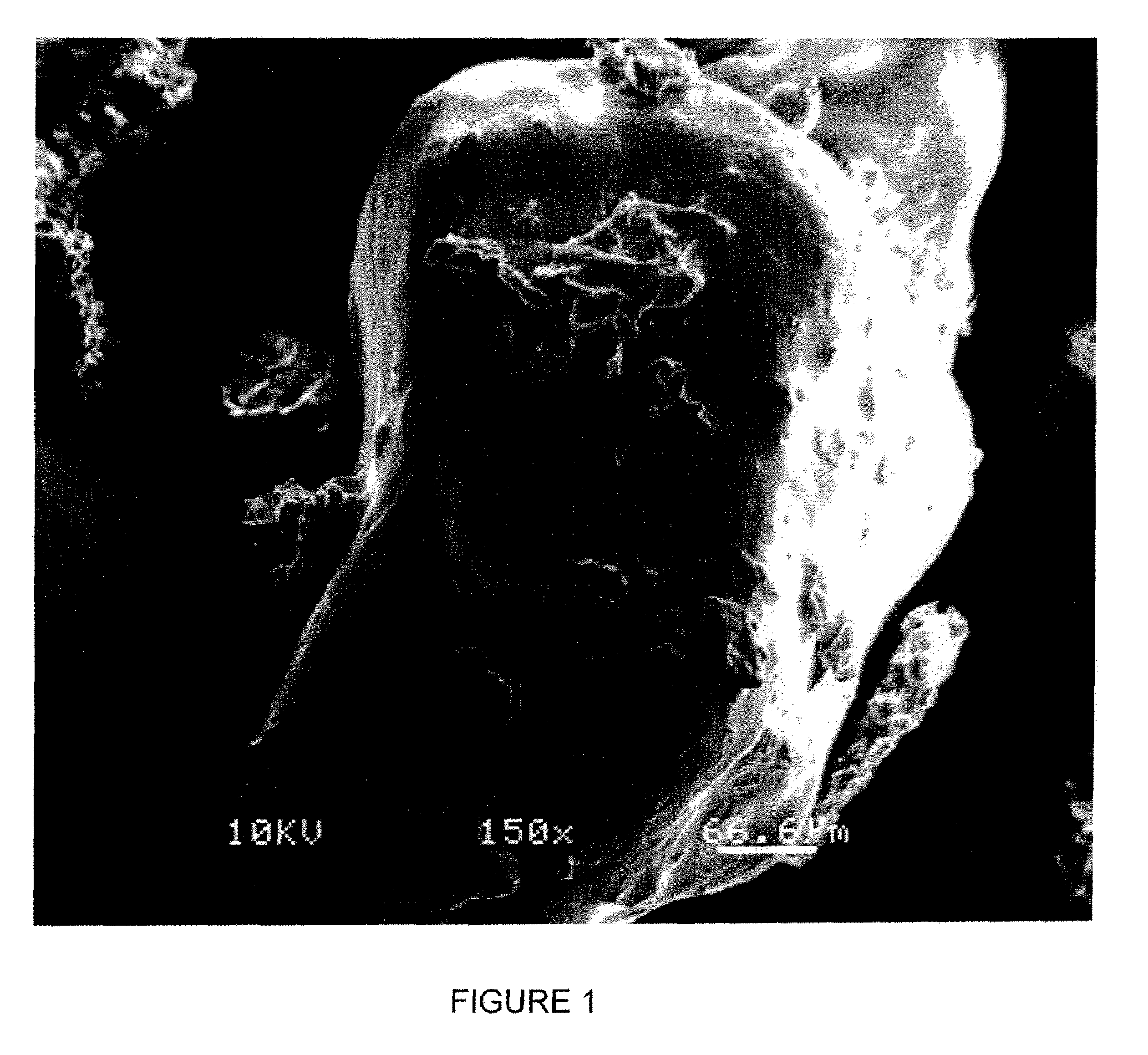

Lightweight proppant and method of making same

InactiveUS20060016598A1Manufactured usingSuitable viscosityFluid removalDrilling compositionPrillHigh intensity

A lightweight, high-strength proppant is disclosed, comprising the formation of finely dispersed ceramic precursors and sintering at low temperatures, causing the formation and retention of mesopores and micropores in pelletized ceramic. A method of manufacturing such a proppant is also disclosed, comprising the steps of manufacturing finely divided ceramic precursors and additives using grinding, milling, and preferably sol-gel processes, and dispersing the finely divided ceramic precursors and additives in a liquid, preferably water. The dispersion has a viscosity profile, which permits the shaping of spheres using conventional pelletizing techniques. Drying of the pellets and sintering at temperatures below 1,400.degrees. C. forms and retains mesopores and micropores in the ceramic. Preferred total pore volumes range from 0.05 to 0.7 cm.sup.3 / g. The pelletized and porous ceramic is useful as lightweight and high-strength proppants.

Owner:URBANEK THOMAS WILHELM

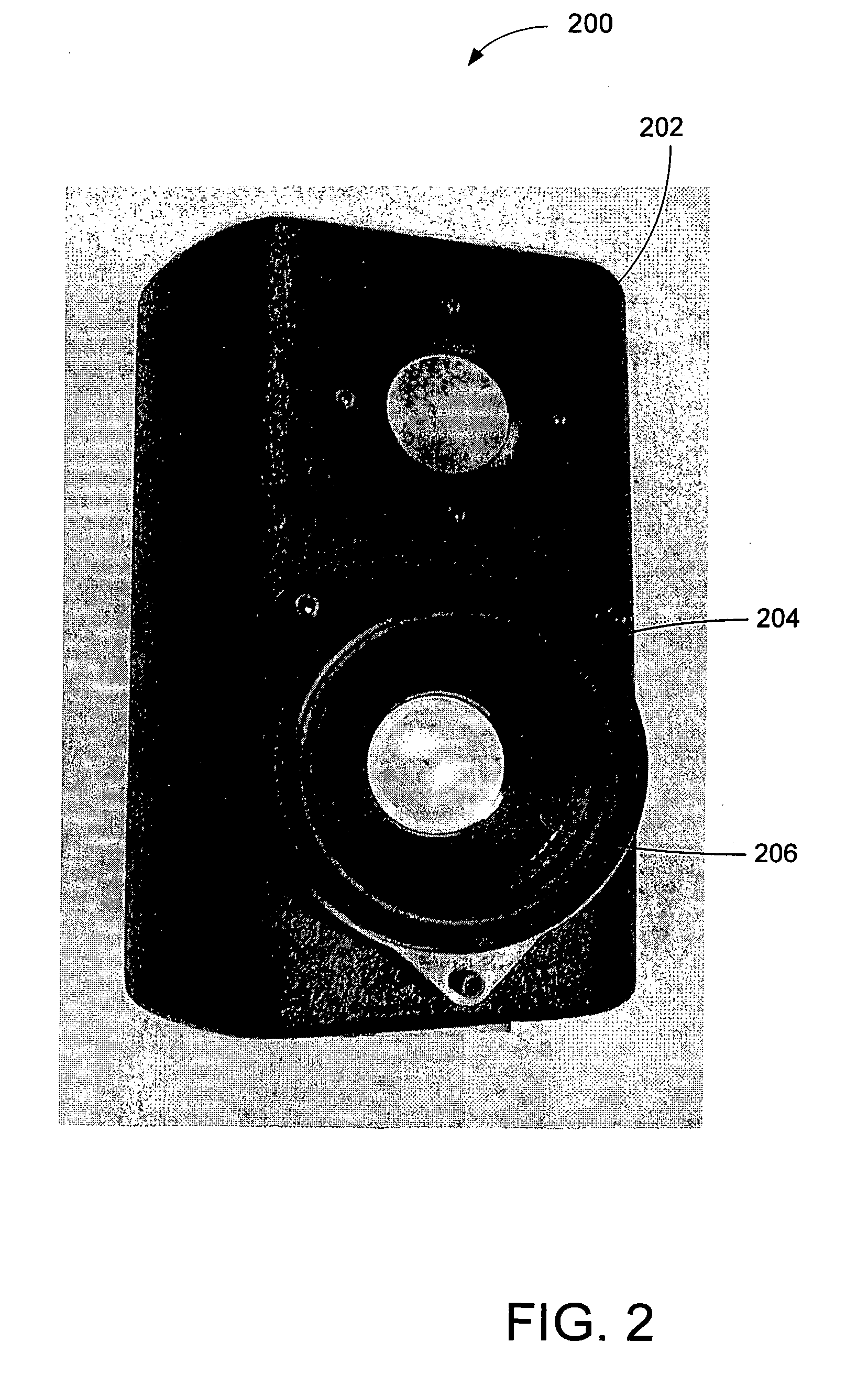

Loudspeaker plastic cone body

ActiveUS20060147081A1Easy to adjustImprove flow characteristicsFibre diaphragmsPolymeric diaphragmsFilling materialsEngineering

A loudspeaker cone body made of plastic includes a base carrier material and a filler material. The base carrier material is selected to optimize overall flow, weight and stiffness. The filler material may be a nanomaterial that provides for adjustment of process and acoustic related characteristics in the loudspeaker cone body that become relevant when the loudspeaker cone body is operated in a loudspeaker. Acoustic related characteristics that may be adjusted include a stiffness to weight ratio and an acoustic damping of the loudspeaker cone body. A predetermined weight percent of the filler material may be combined with the base carrier material to obtain repeatable desired acoustic related characteristics. The acoustic related characteristics may be adjusted by changing the predetermined weight percent of the filler material.

Owner:HARMAN INT IND INC

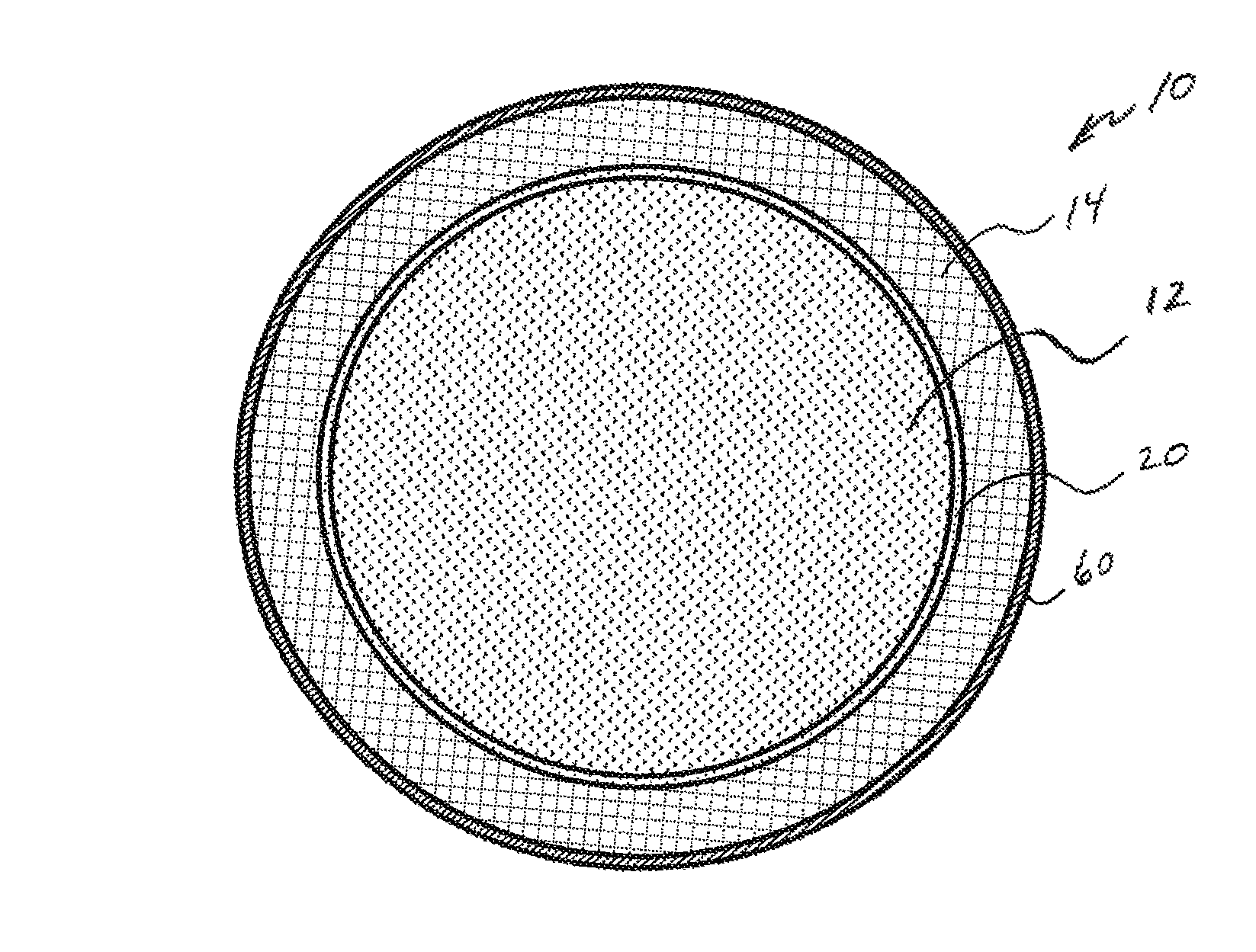

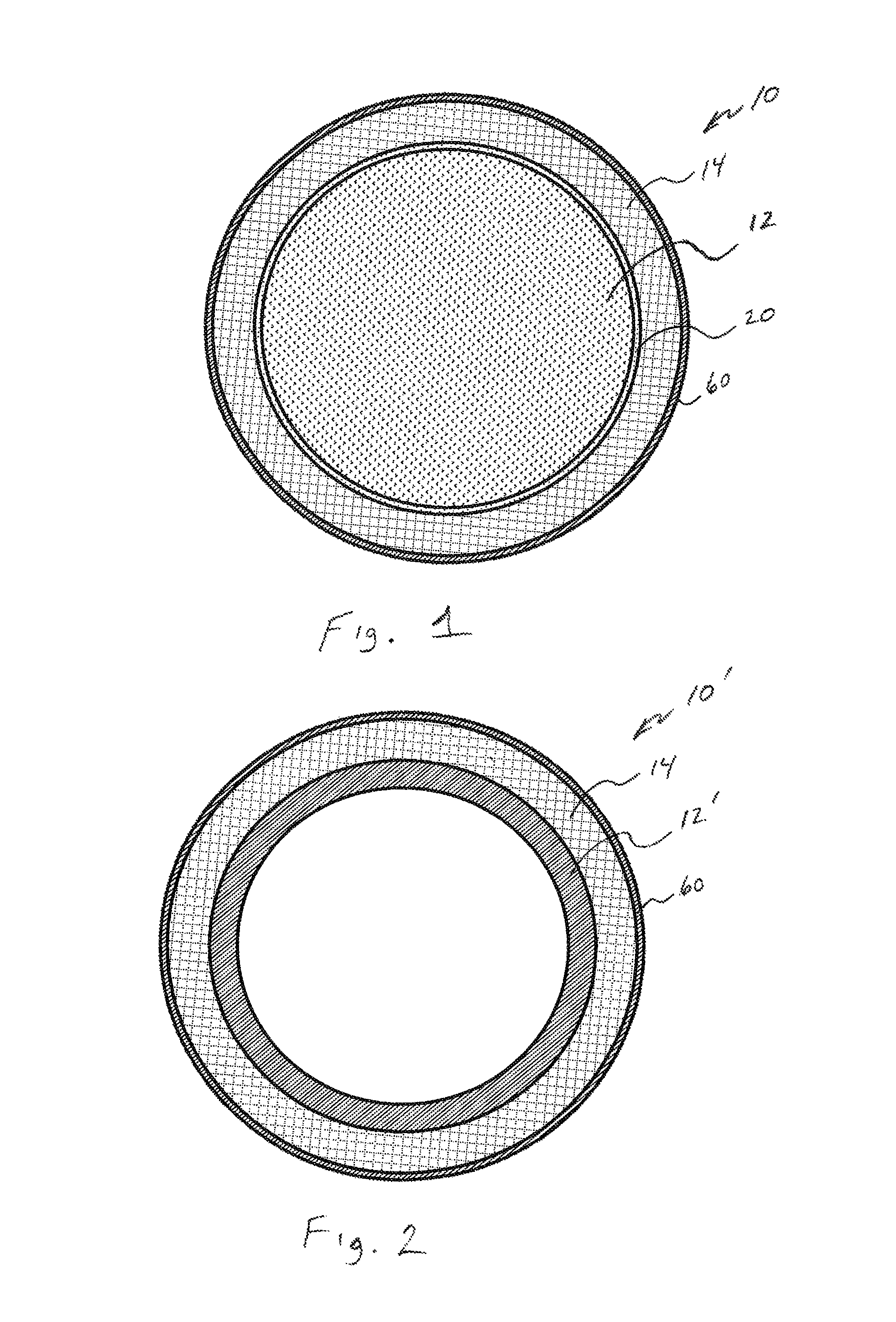

Foam-core golf balls

InactiveUS7452291B2Reduce decreaseIncrease in moment of inertiaGolf ballsSolid ballsEngineeringGolf Ball

A golf ball with a controlled moment of inertia and controlled spin rate is disclosed. The increase in moment of inertia is preferably accomplished by a reduction in the specific gravity or weight of the core, e.g., by foaming. Preferably, this reduction is less than about 15% in specific gravity or less than about 25% in weight to minimize the reduction in the coefficient of restitution of the core.

Owner:ACUSHNET CO

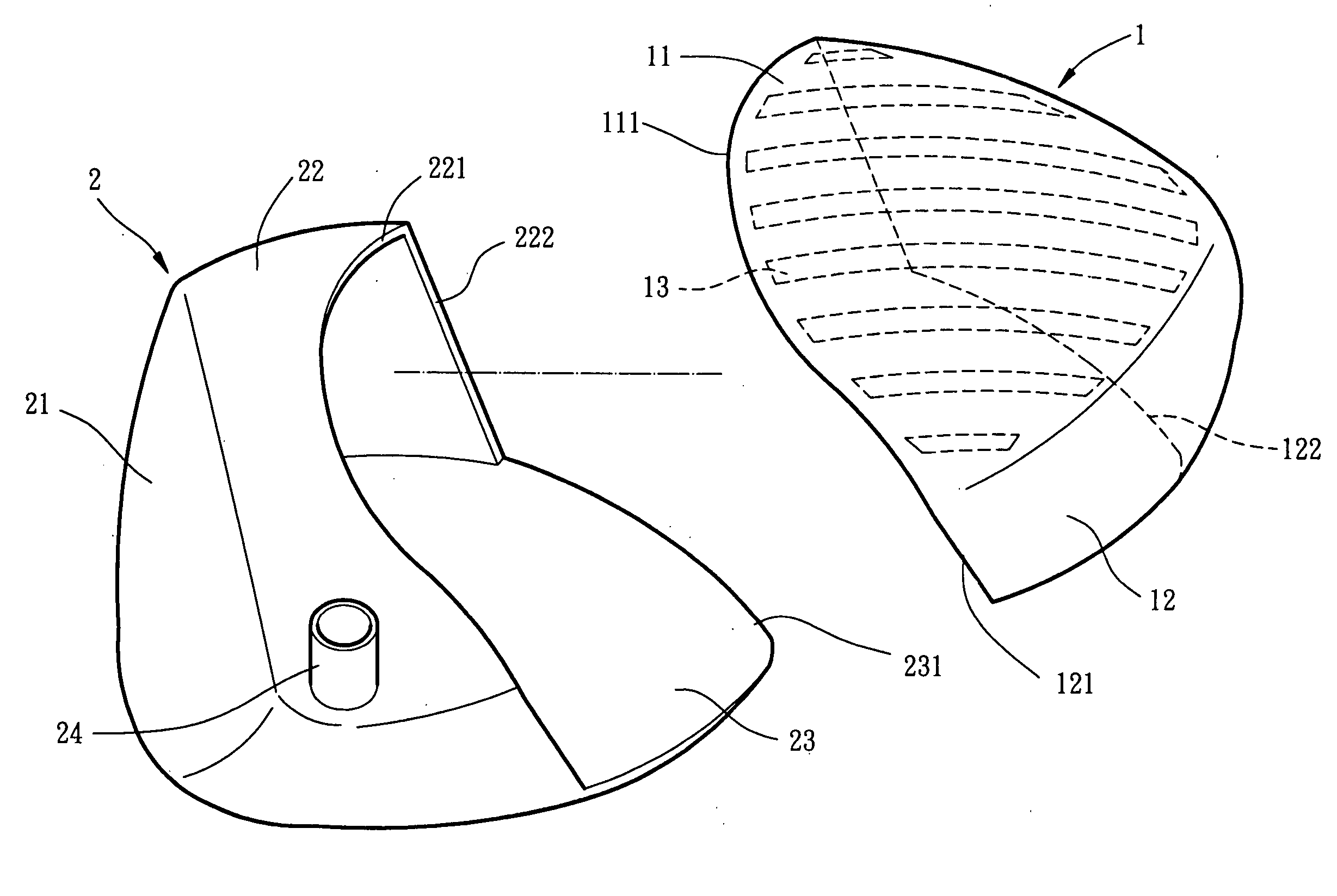

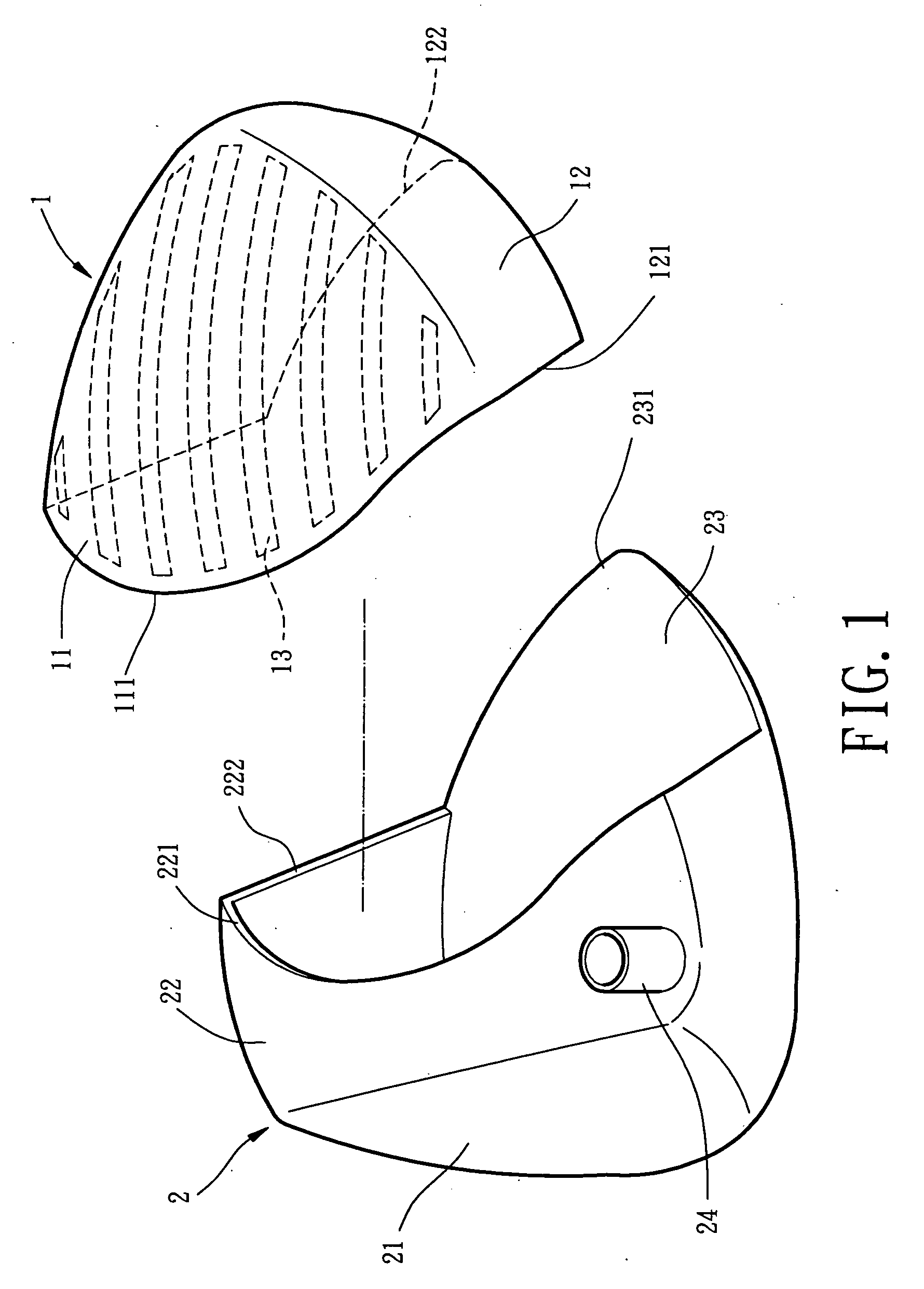

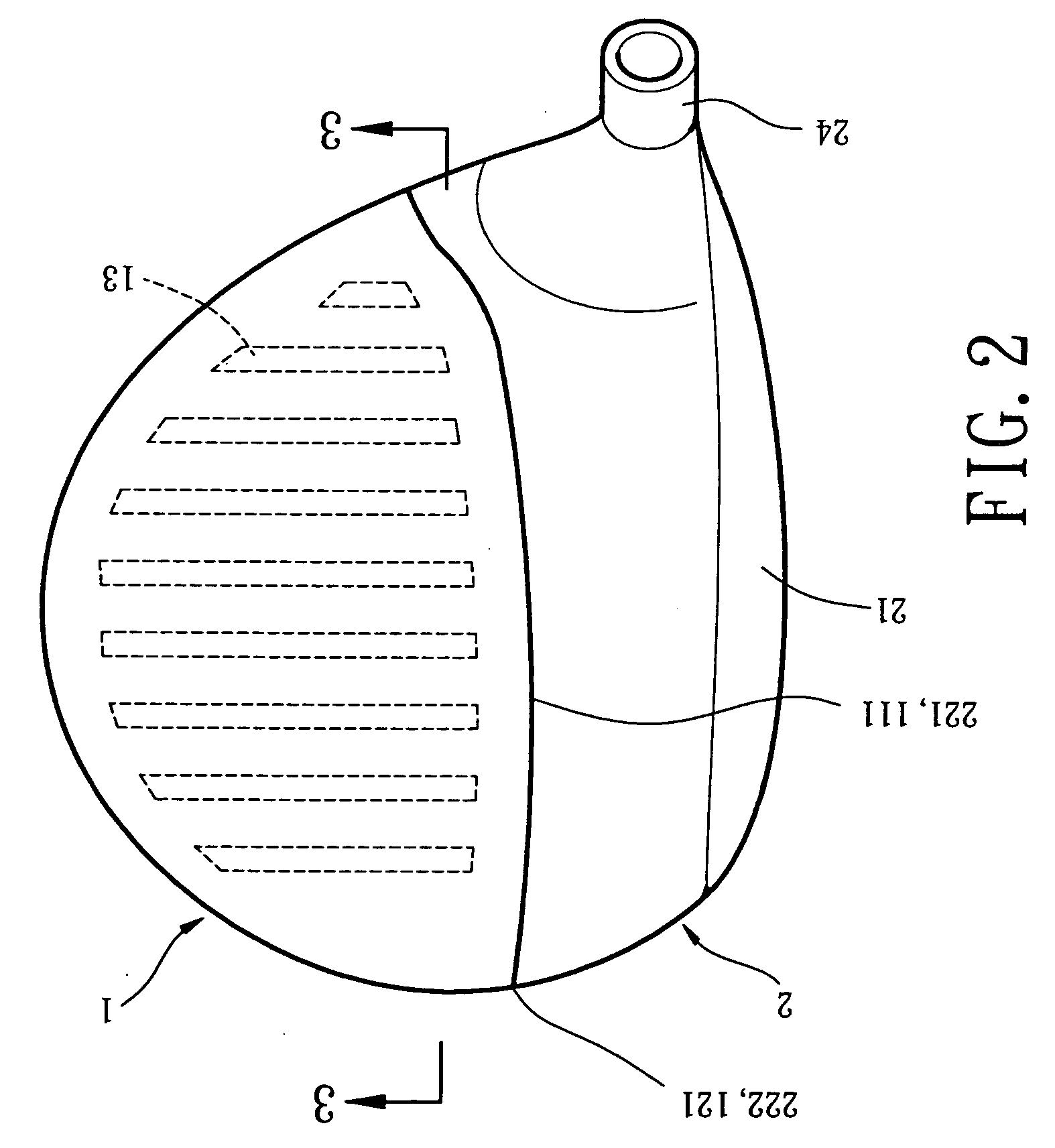

Weight-adjustable golf club head provided with rear lightweight covering

InactiveUS20080070721A1Thin thicknessLower center of gravityGolf clubsRacket sportsEngineeringGolf Ball

A weight-adjustable golf club head includes a rear lightweight covering and a golf club head body combined therewith. The rear lightweight covering has a rear crown portion and a rear wall portion extended therefrom. The golf club head body is combined with the rear lightweight covering which is designed to have a striking face, a front crown portion and a sole portion. The rear lightweight covering is made from a low specific gravity metal, and is designed to have a thickness less than 0.6 mm. The rear lightweight covering has an inner surface formed with a plurality of reinforcing ribs.

Owner:FUSHENG IND CO LTD

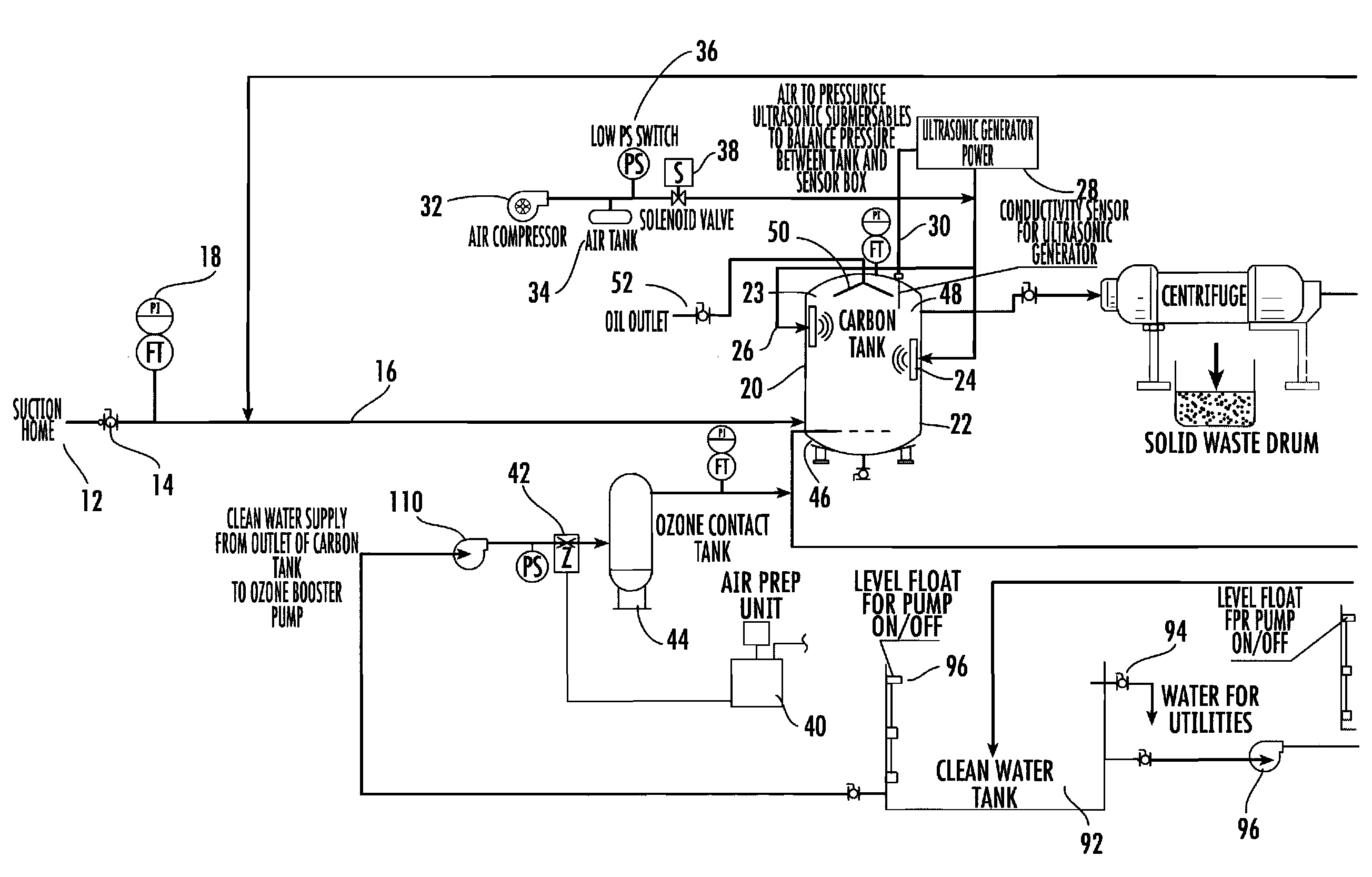

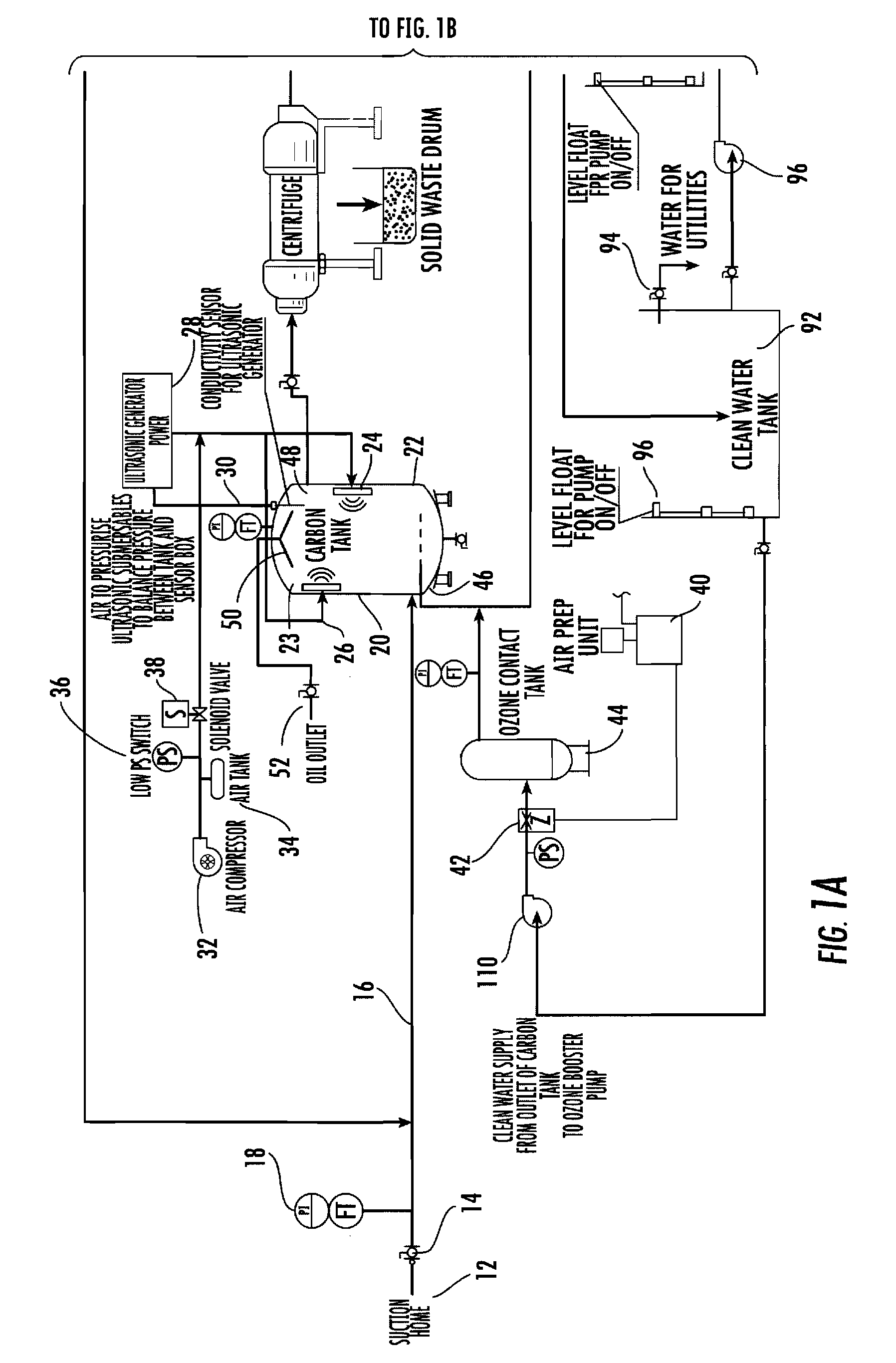

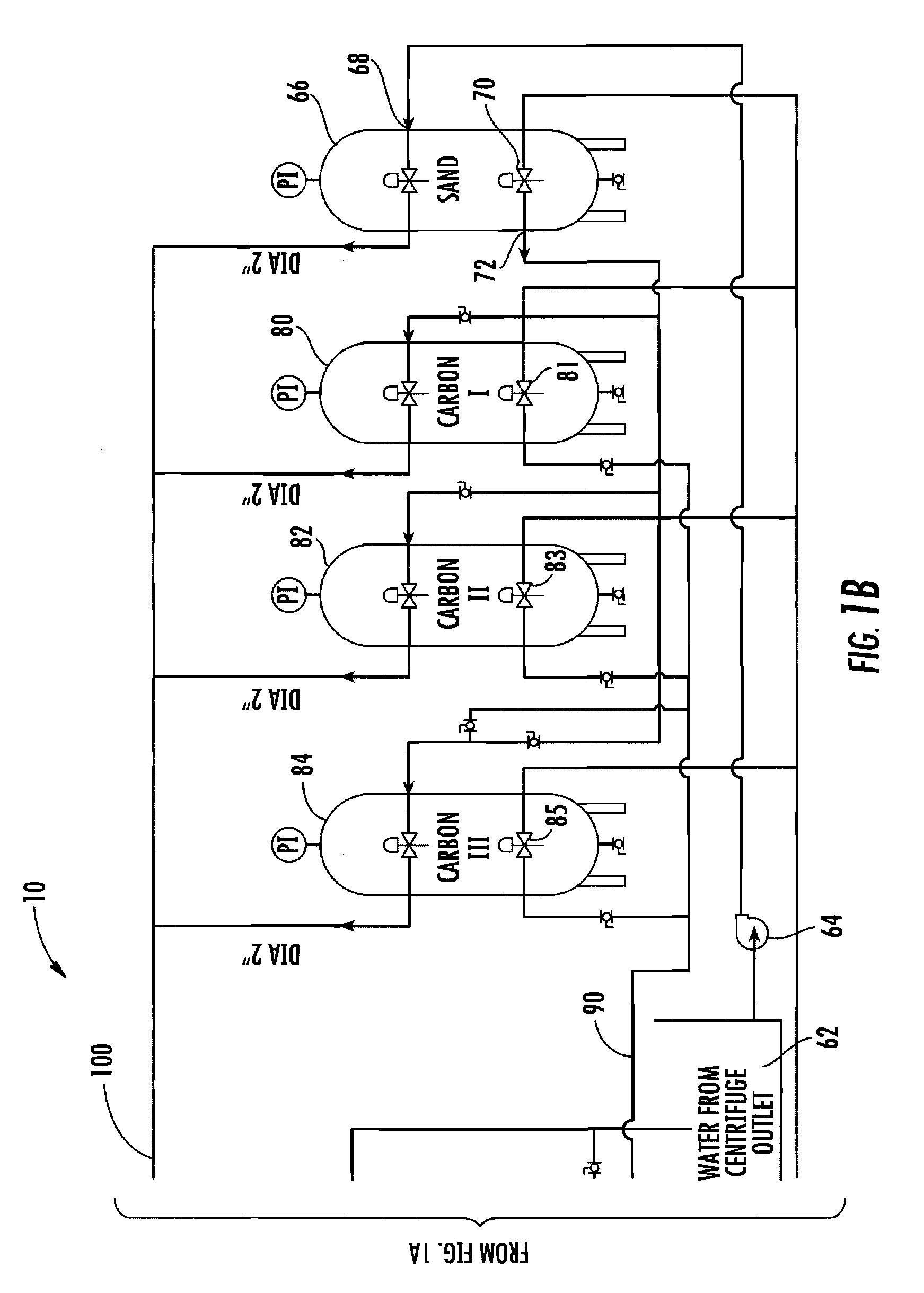

Enhanced water treatment for reclamation of waste fluids and increased efficiency treatment of potable waters

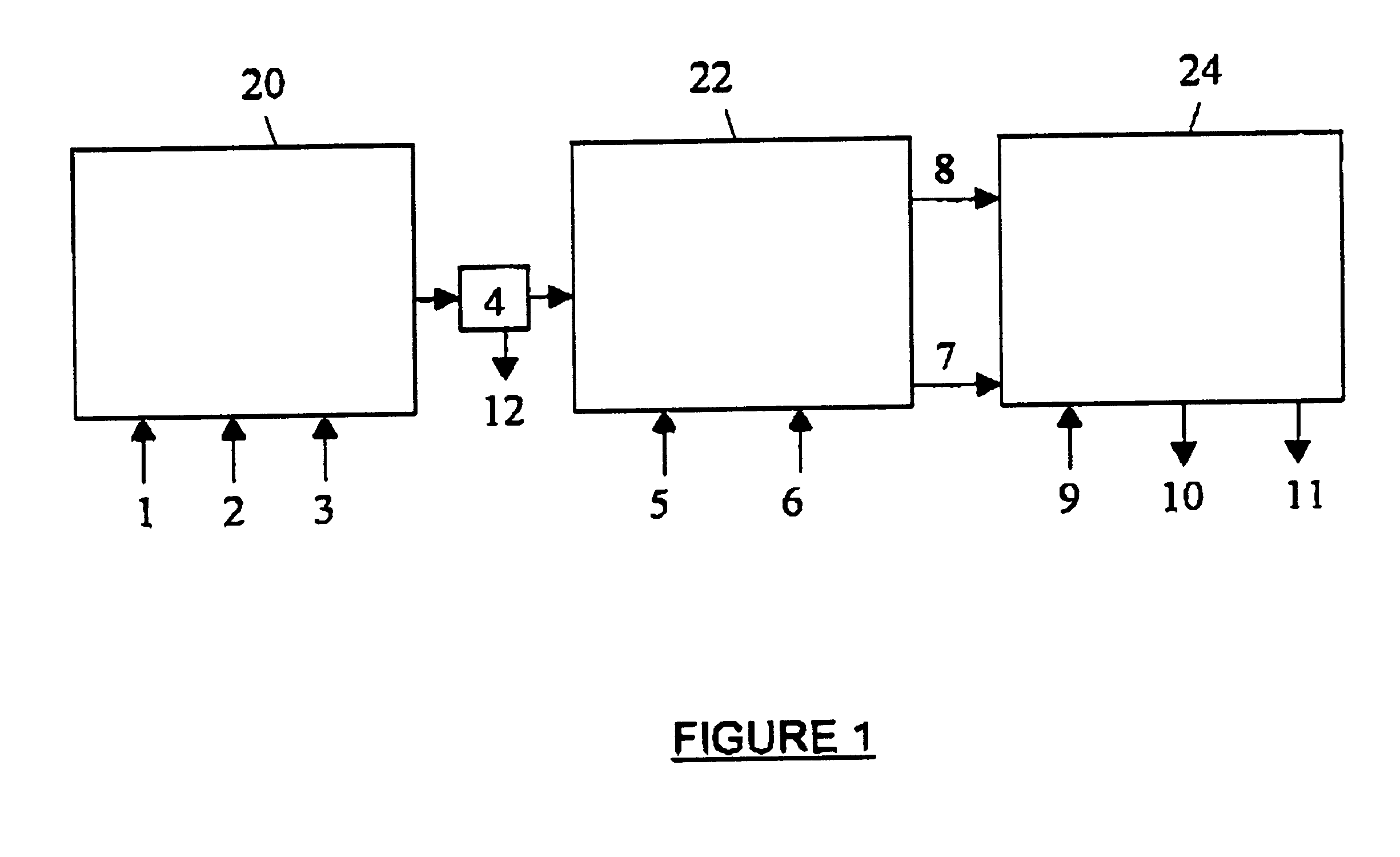

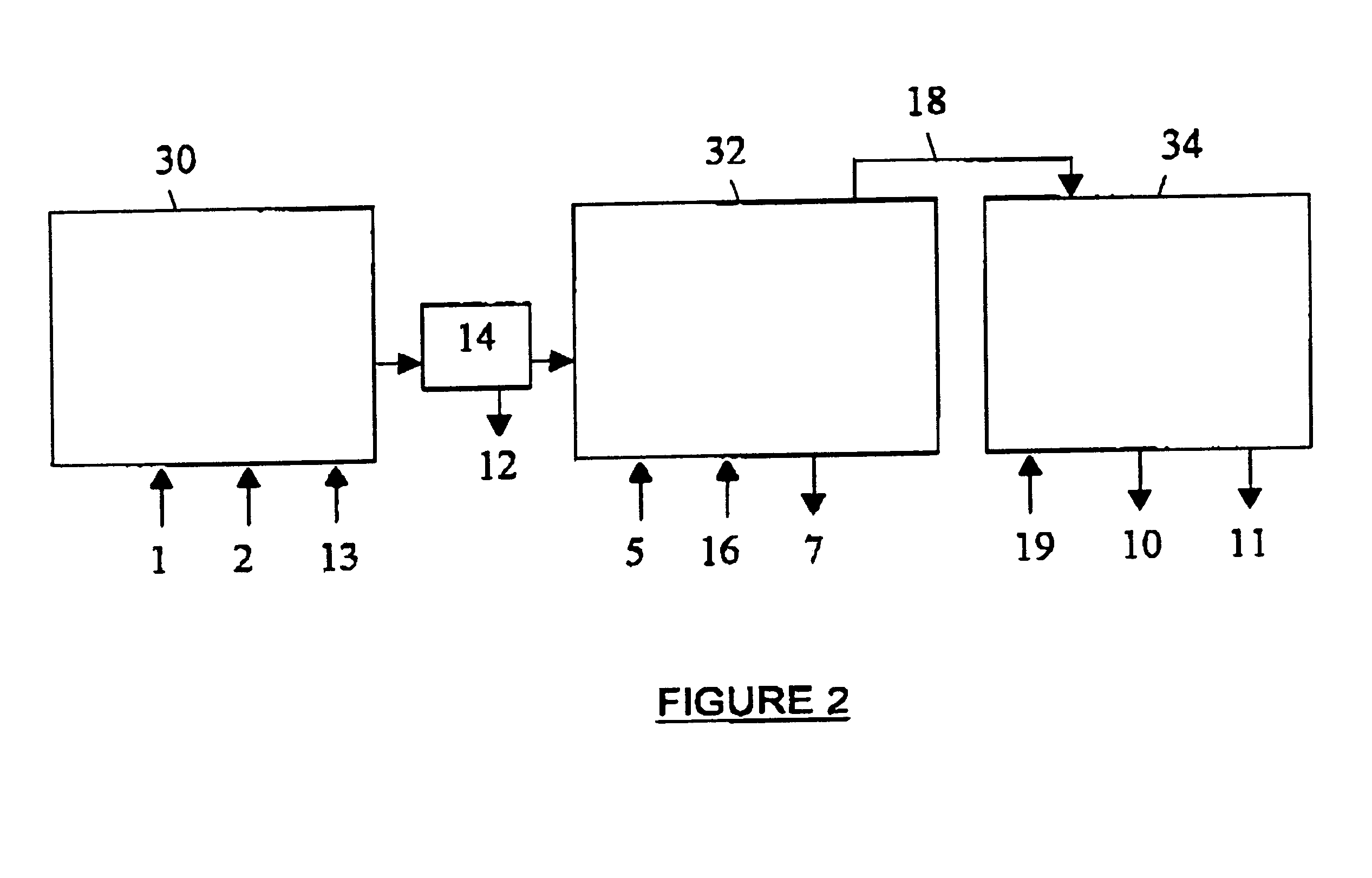

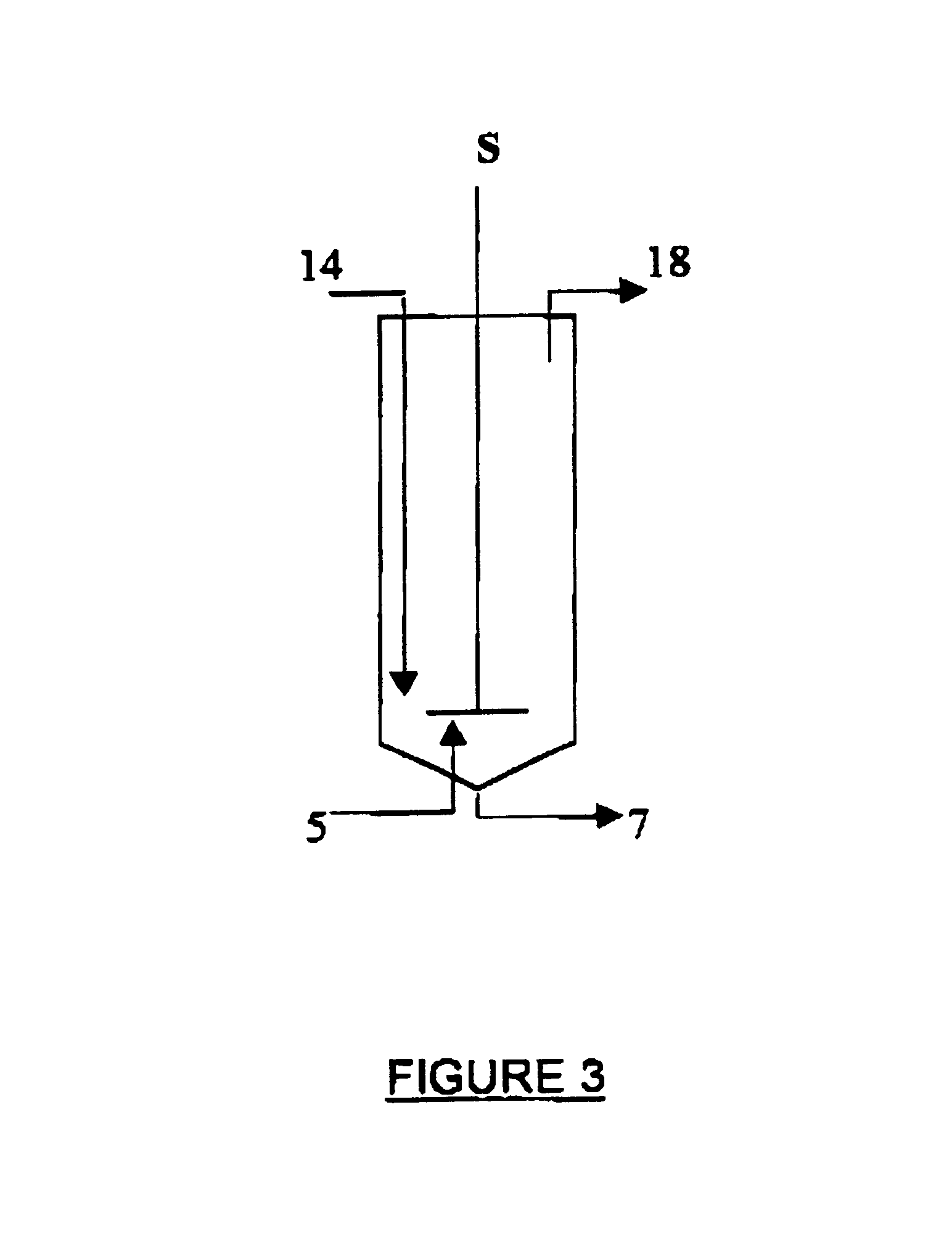

ActiveUS20090050572A1Low costCurrent expensiveWaste water treatment from quariesTreatment involving filtrationLiquid wastePotable water

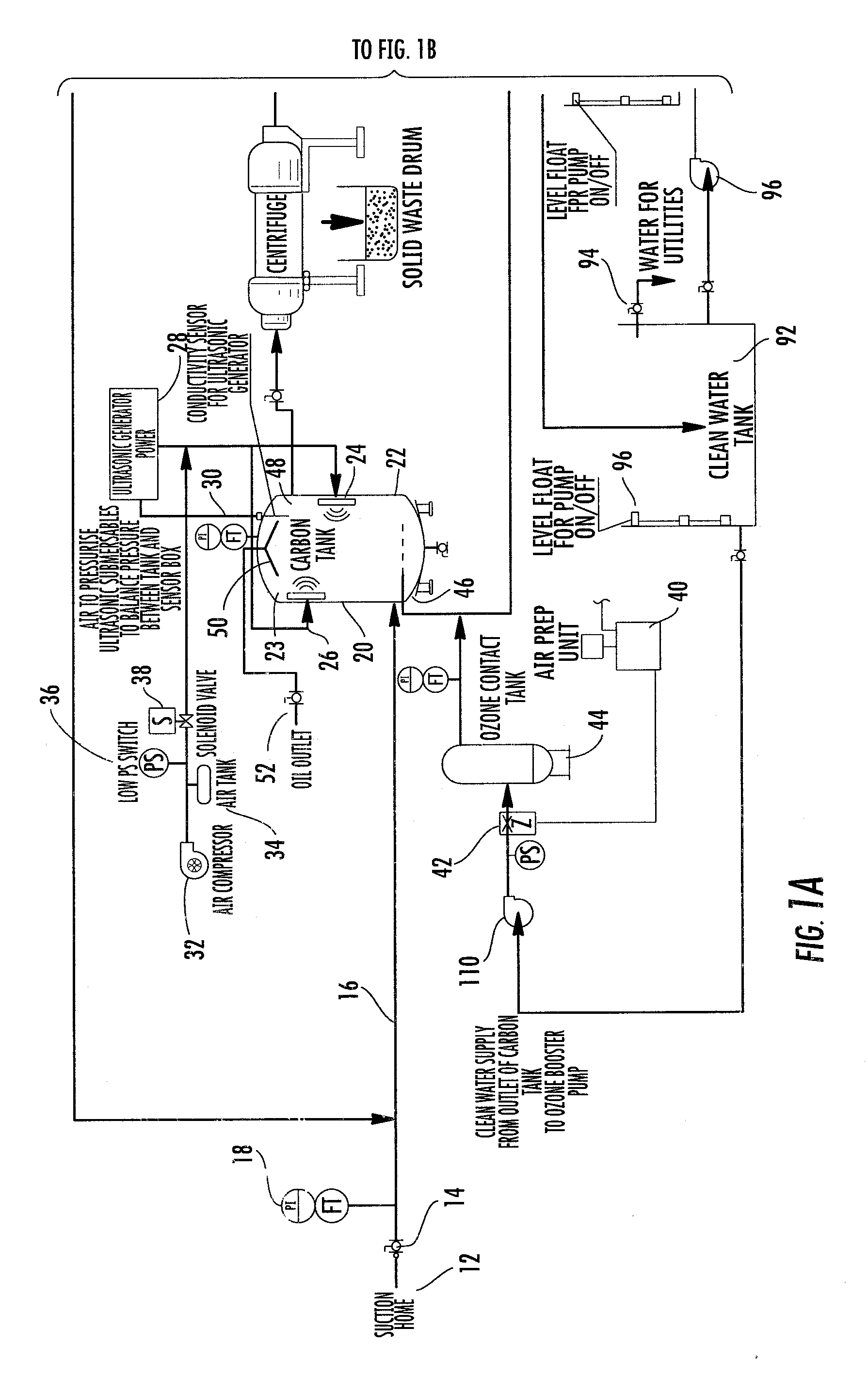

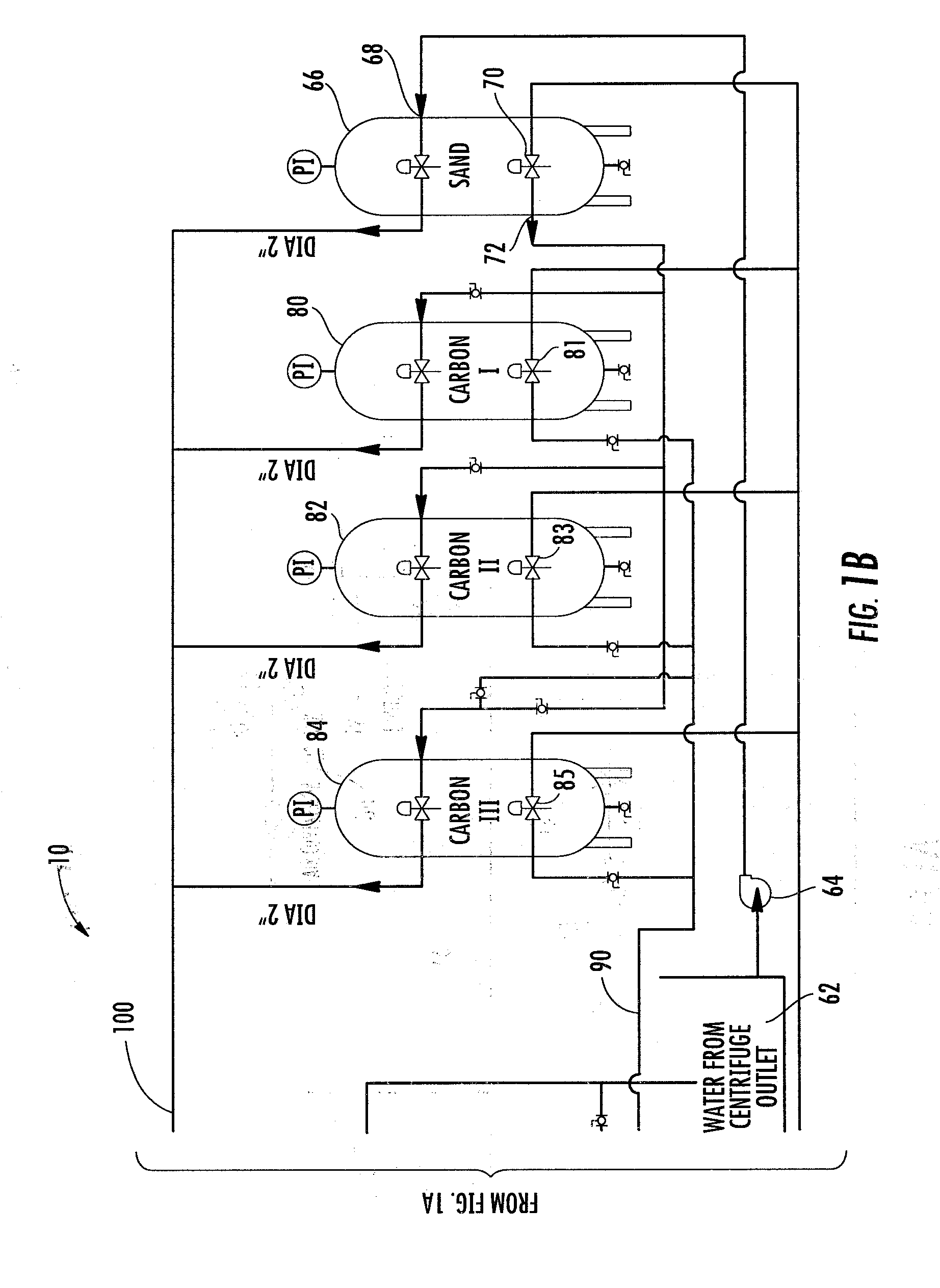

Disclosed is a process for reclamation of waste fluids. A conditioning container is employed for receipt of waste material on a continuous flow for treatment within the container by immersible transducers producing ultrasonic acoustic waves in combination with a high level of injected ozone. The treated material exhibits superior separation properties for delivery into a centrifuge for enhanced solid waste removal. The invention discloses a cost efficient and environmentally friendly process and apparatus for cleaning and recycling of flowback, or frac water, which has been used to stimulate gas production from shale formations. The apparatus is mobile and containerized and suitable for installation at the well site.

Owner:BRISBEN WATER SOLUTIONS

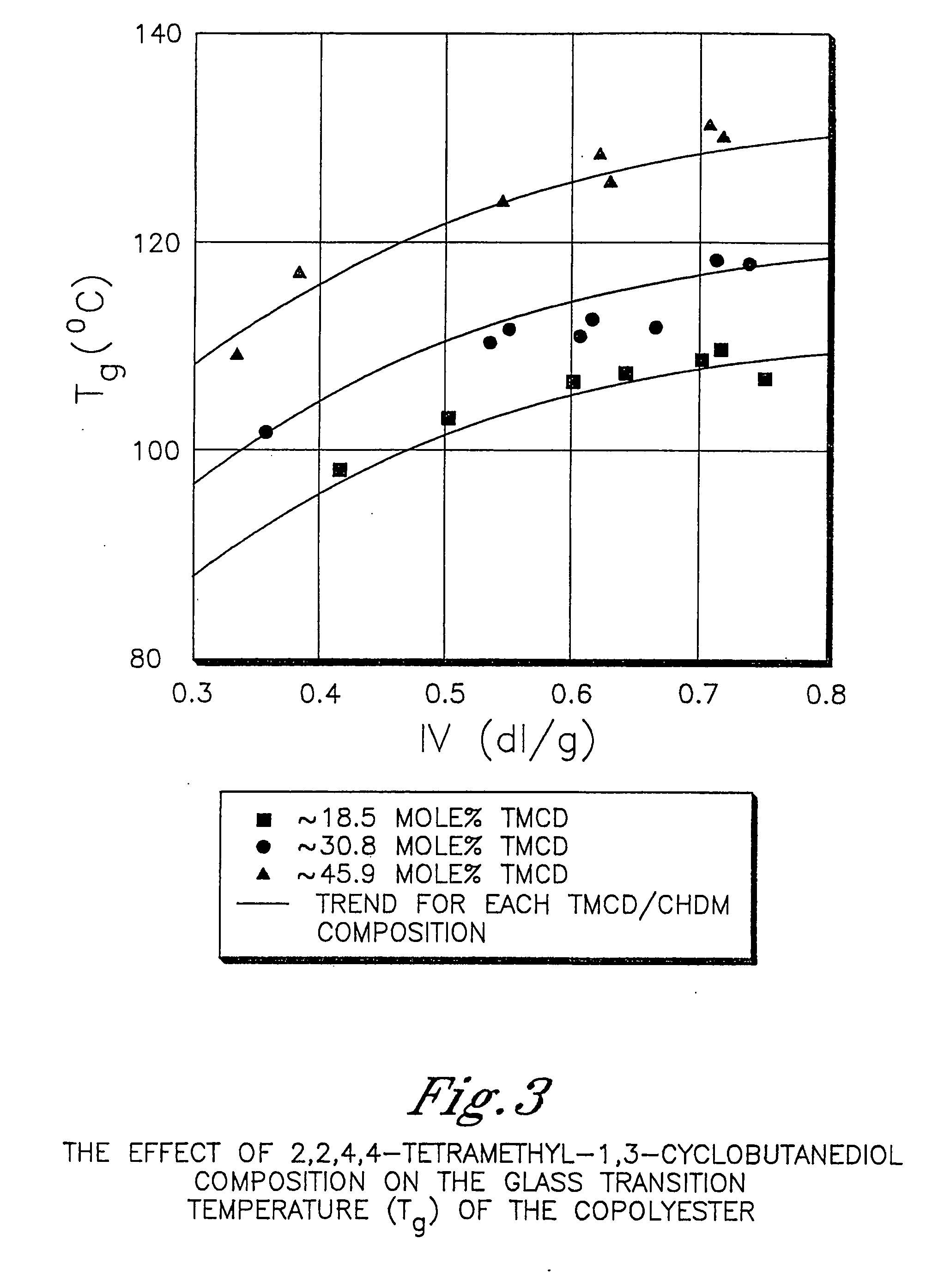

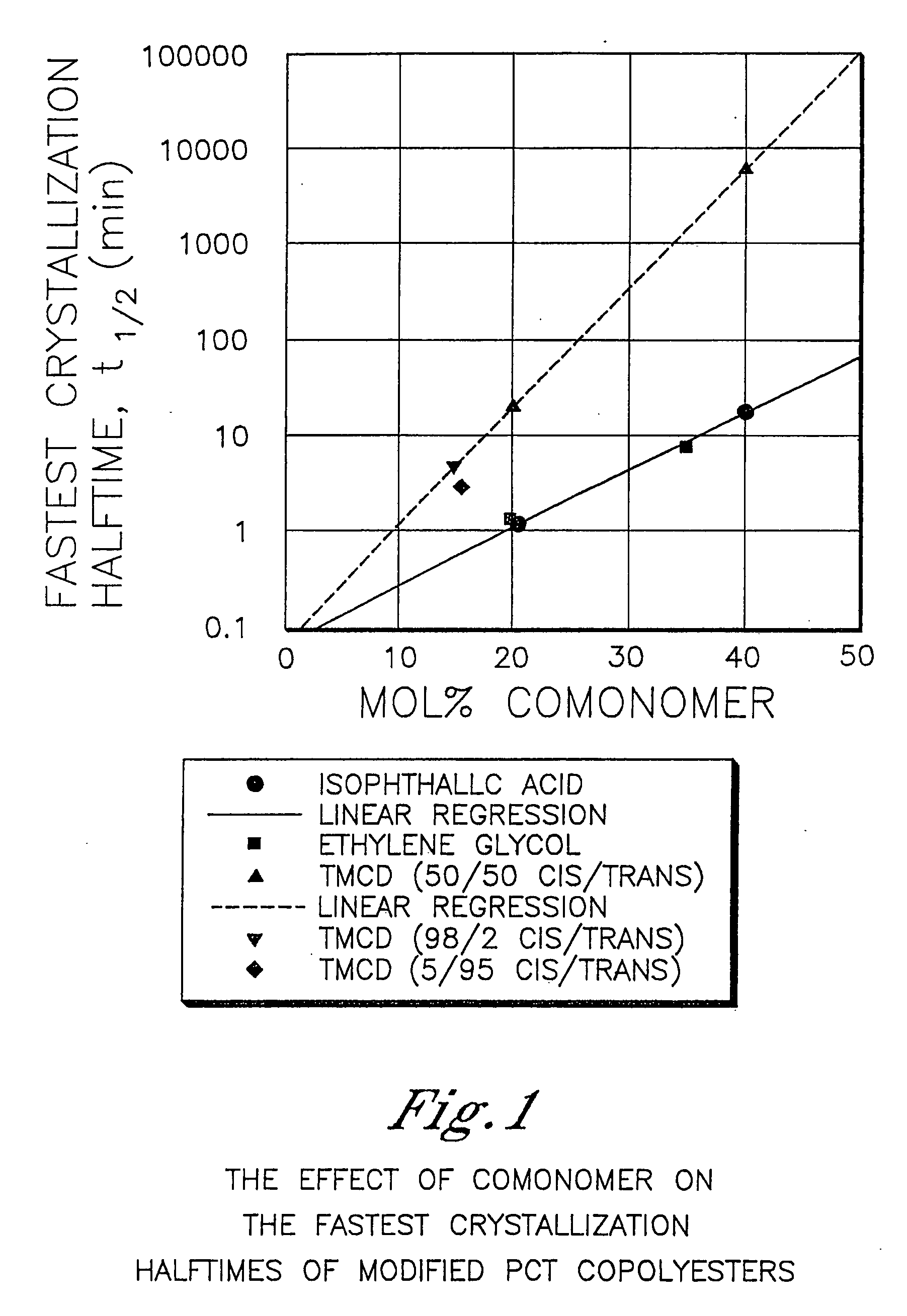

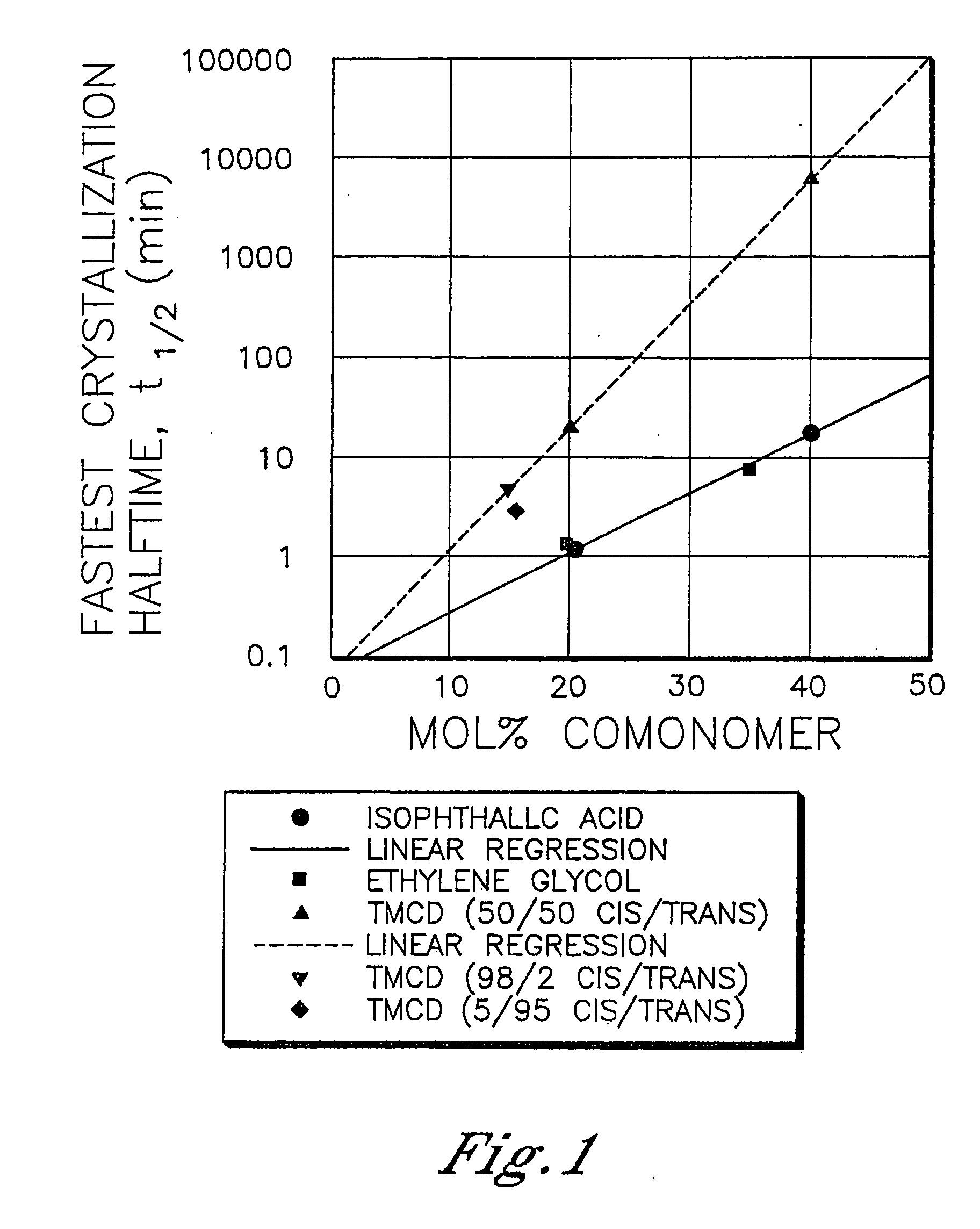

Polyester compositions containing cyclobutanediol having a certain combination of inherent viscosity and high glass transition temperature and articles made therefrom

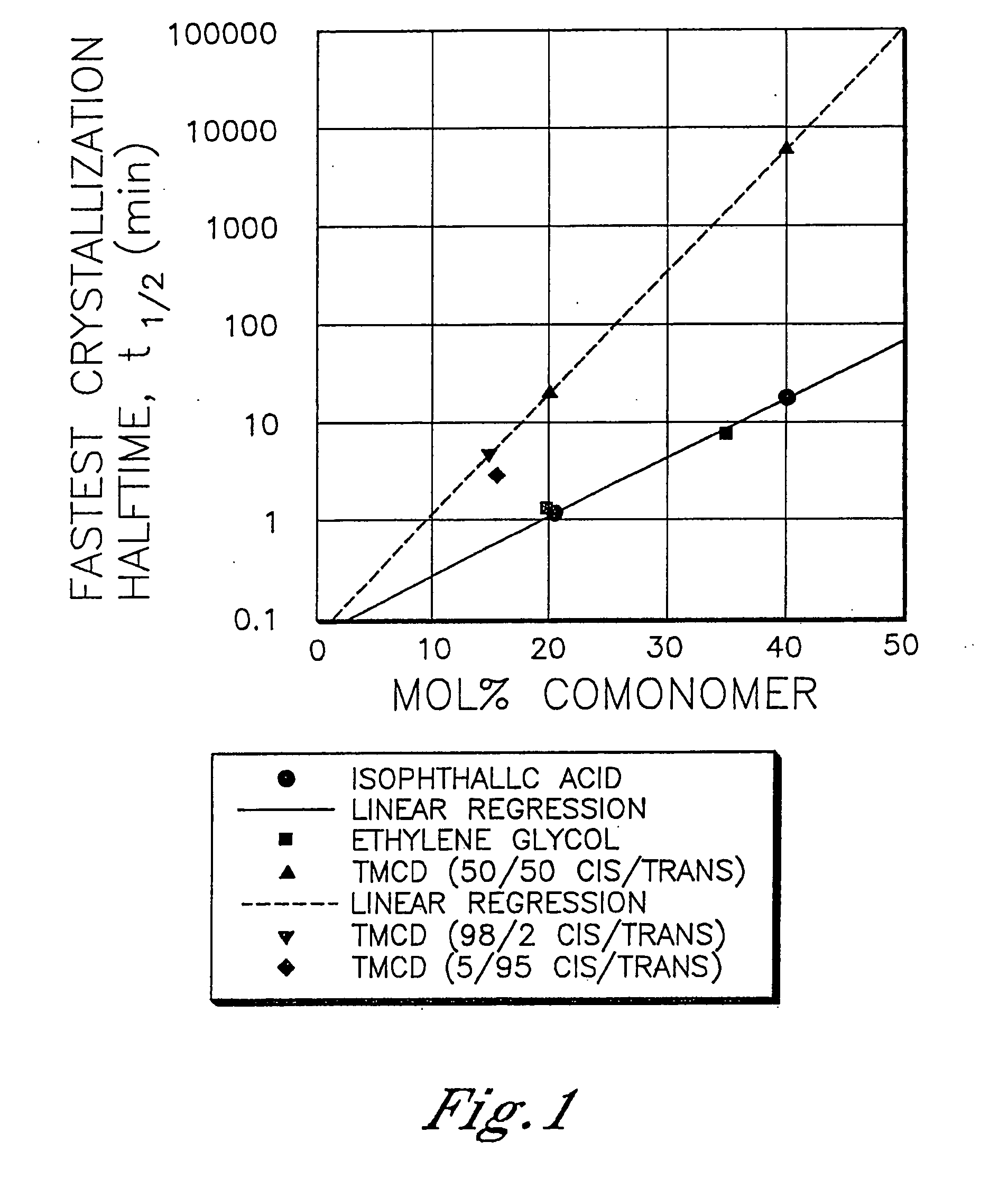

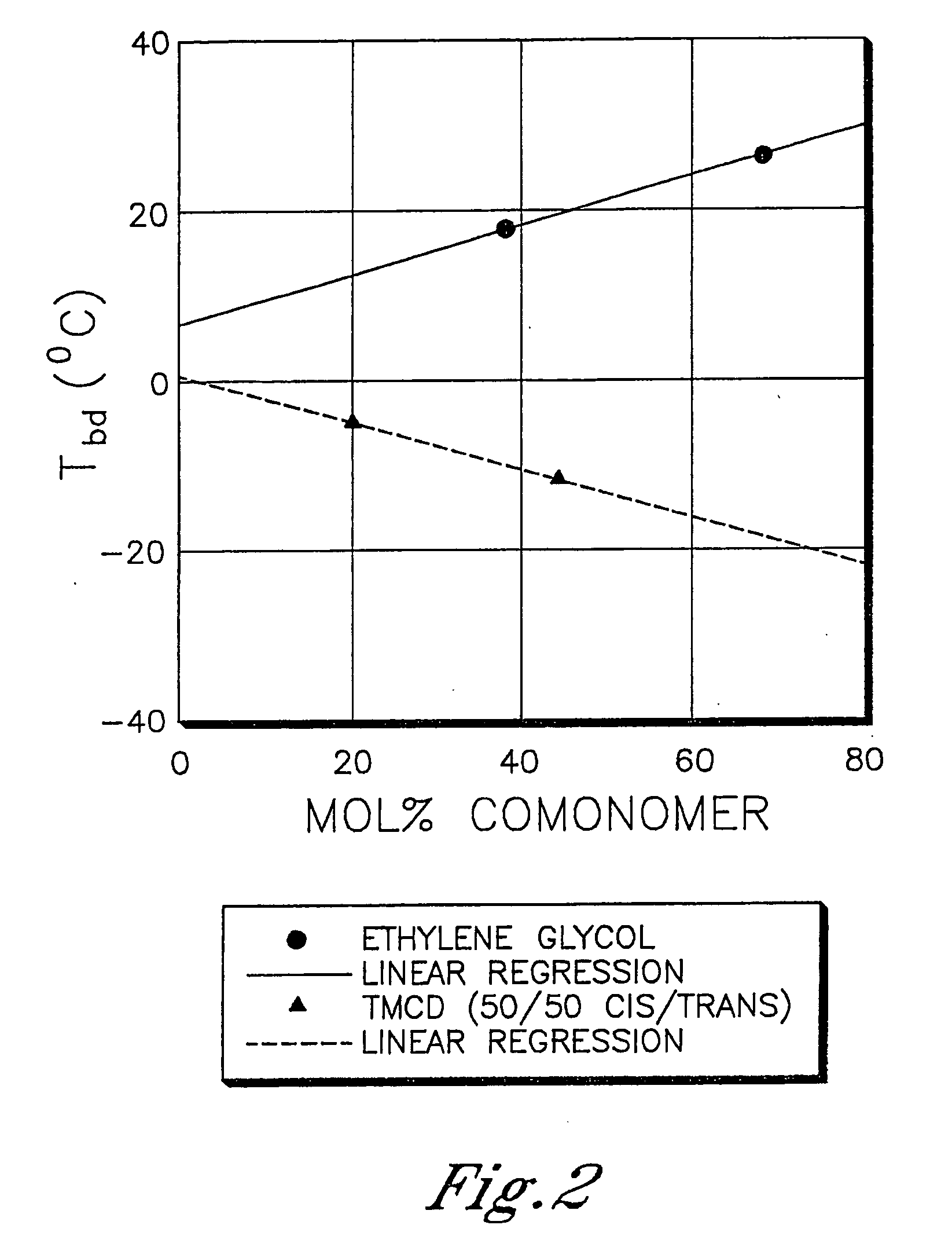

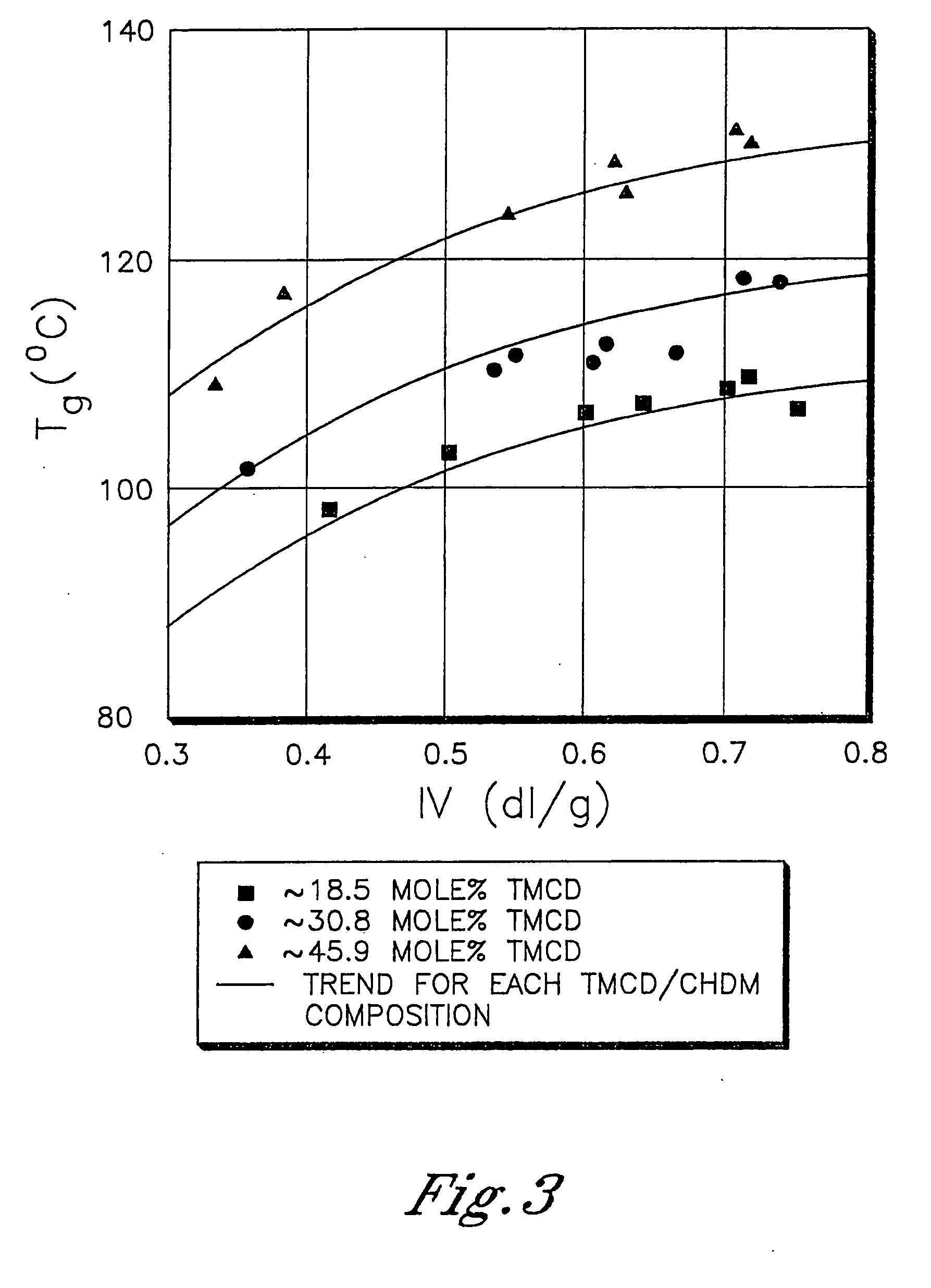

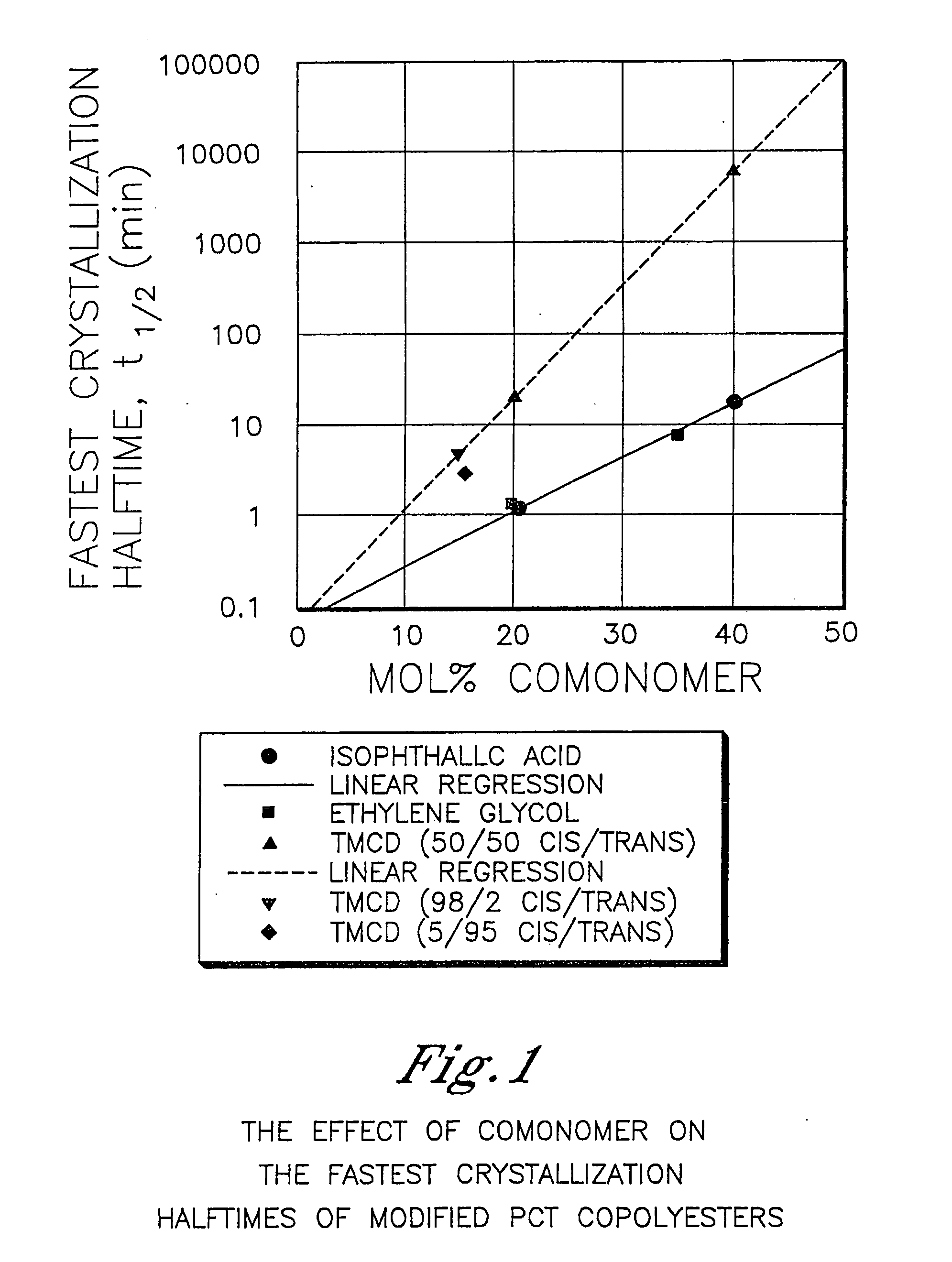

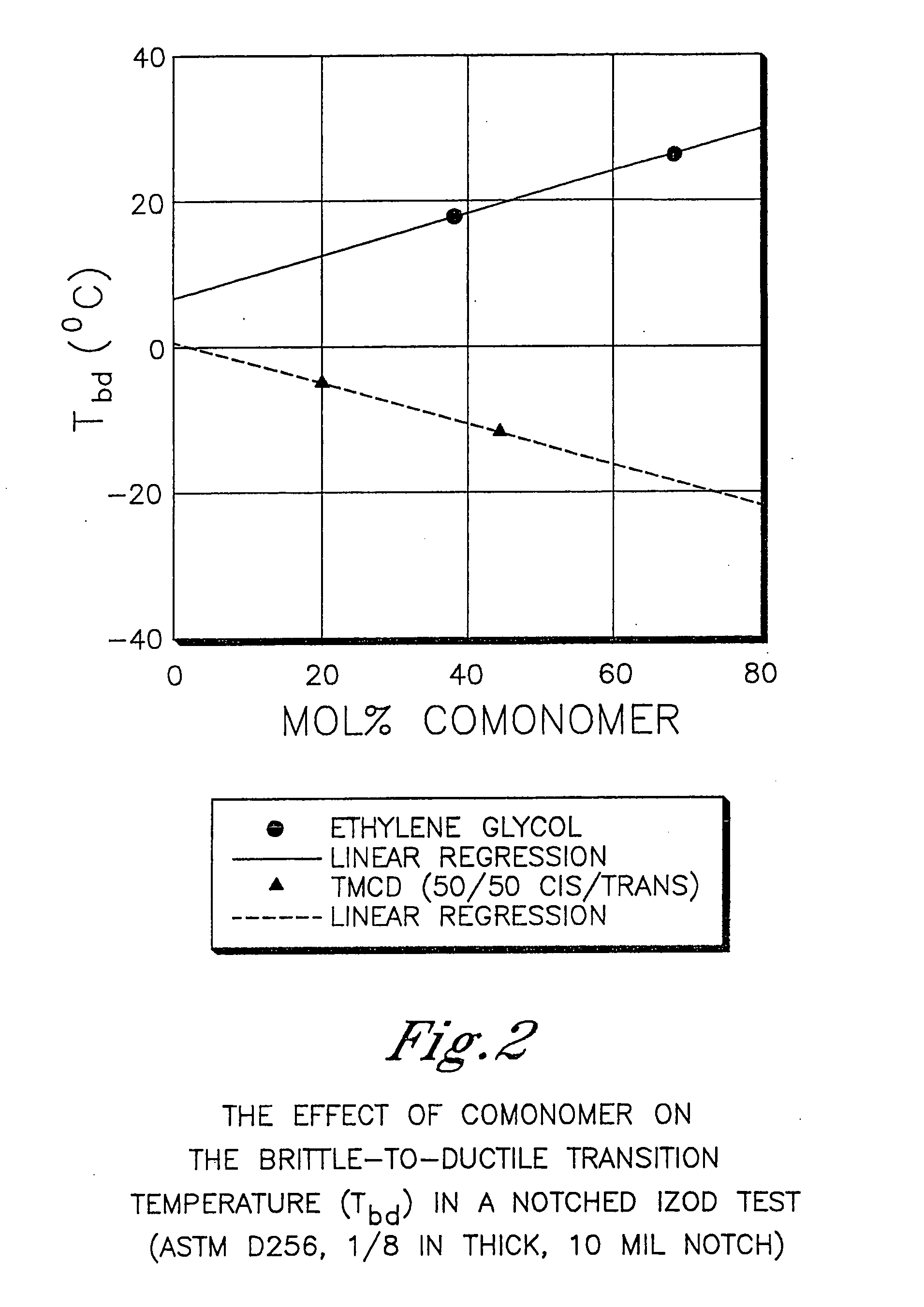

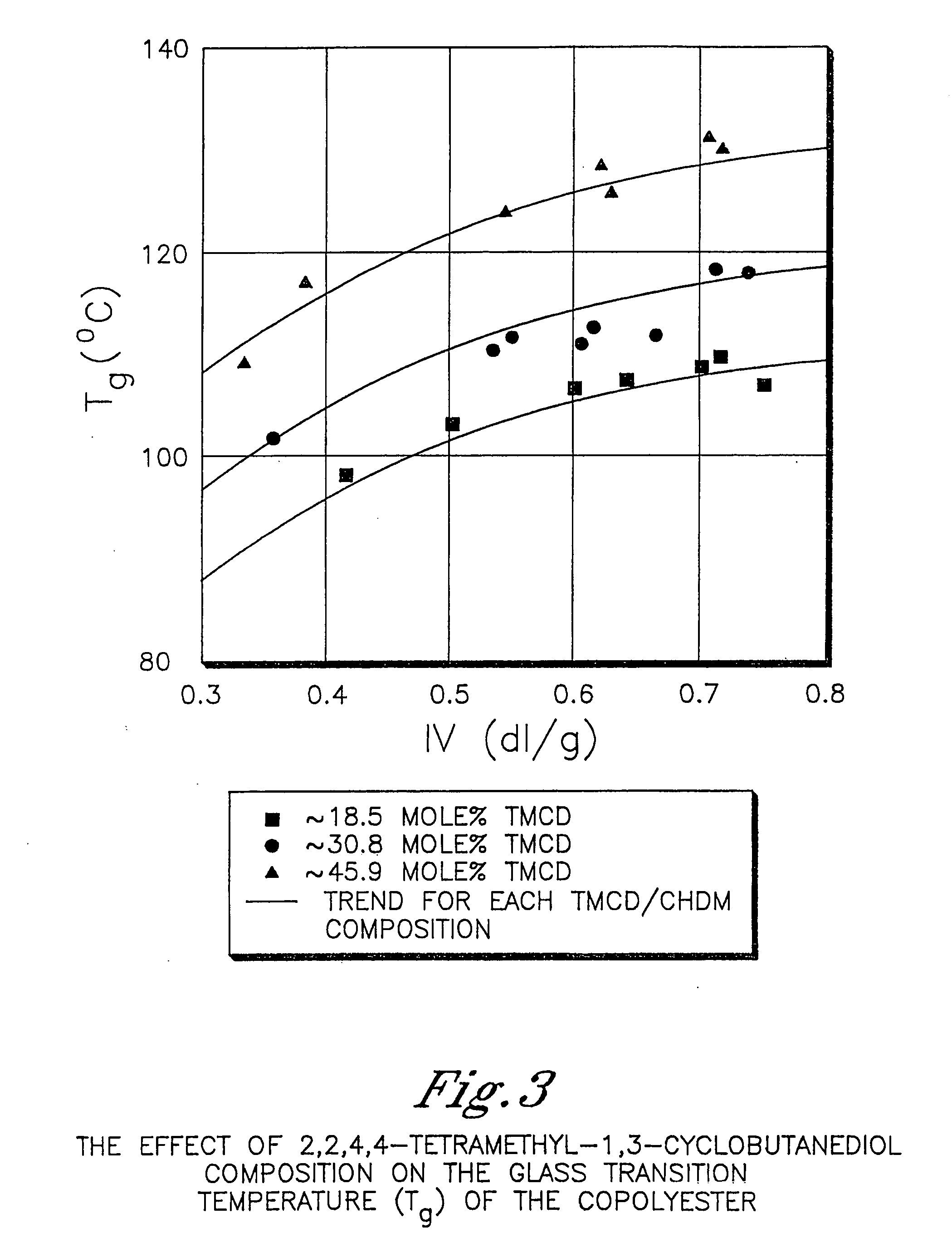

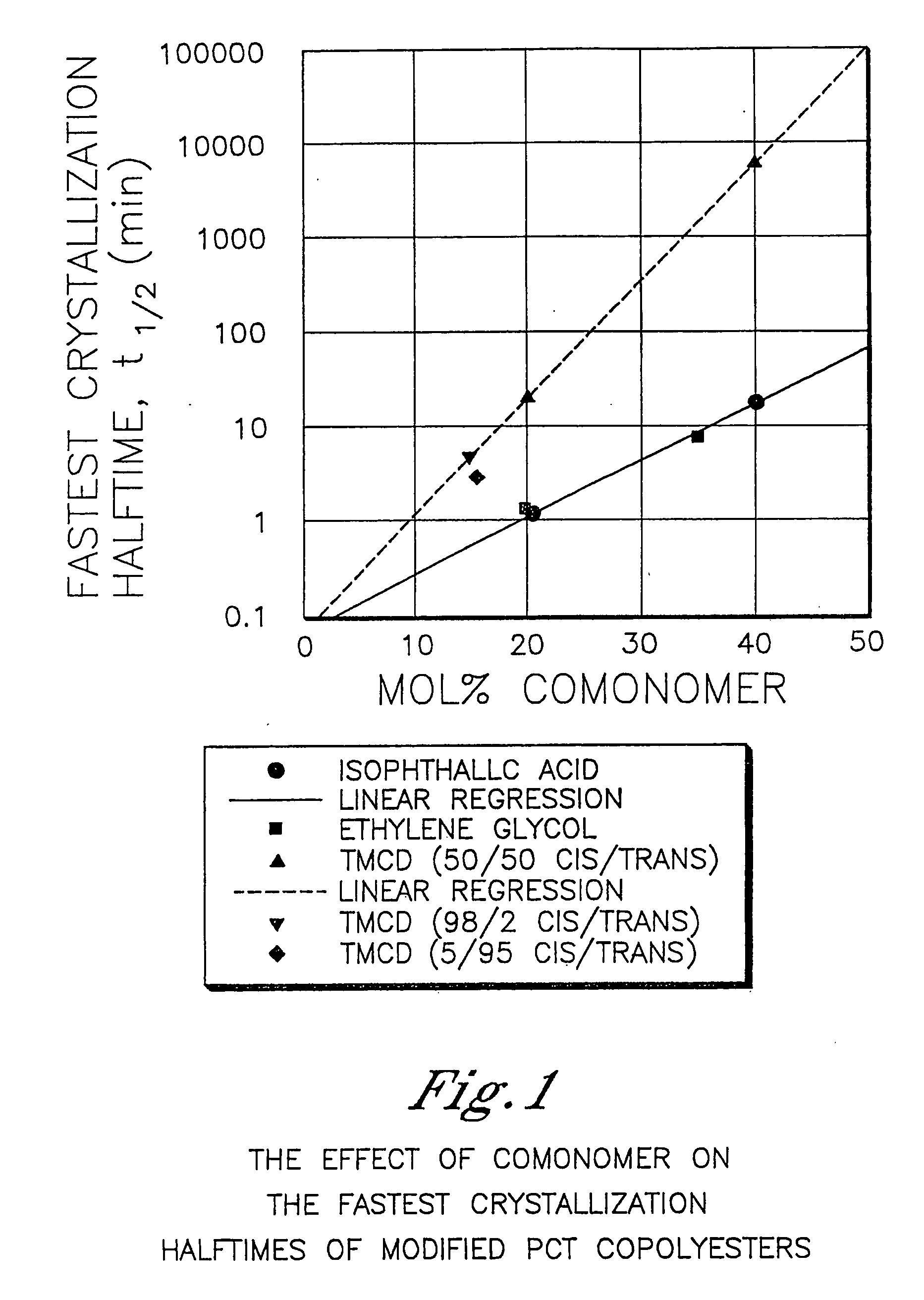

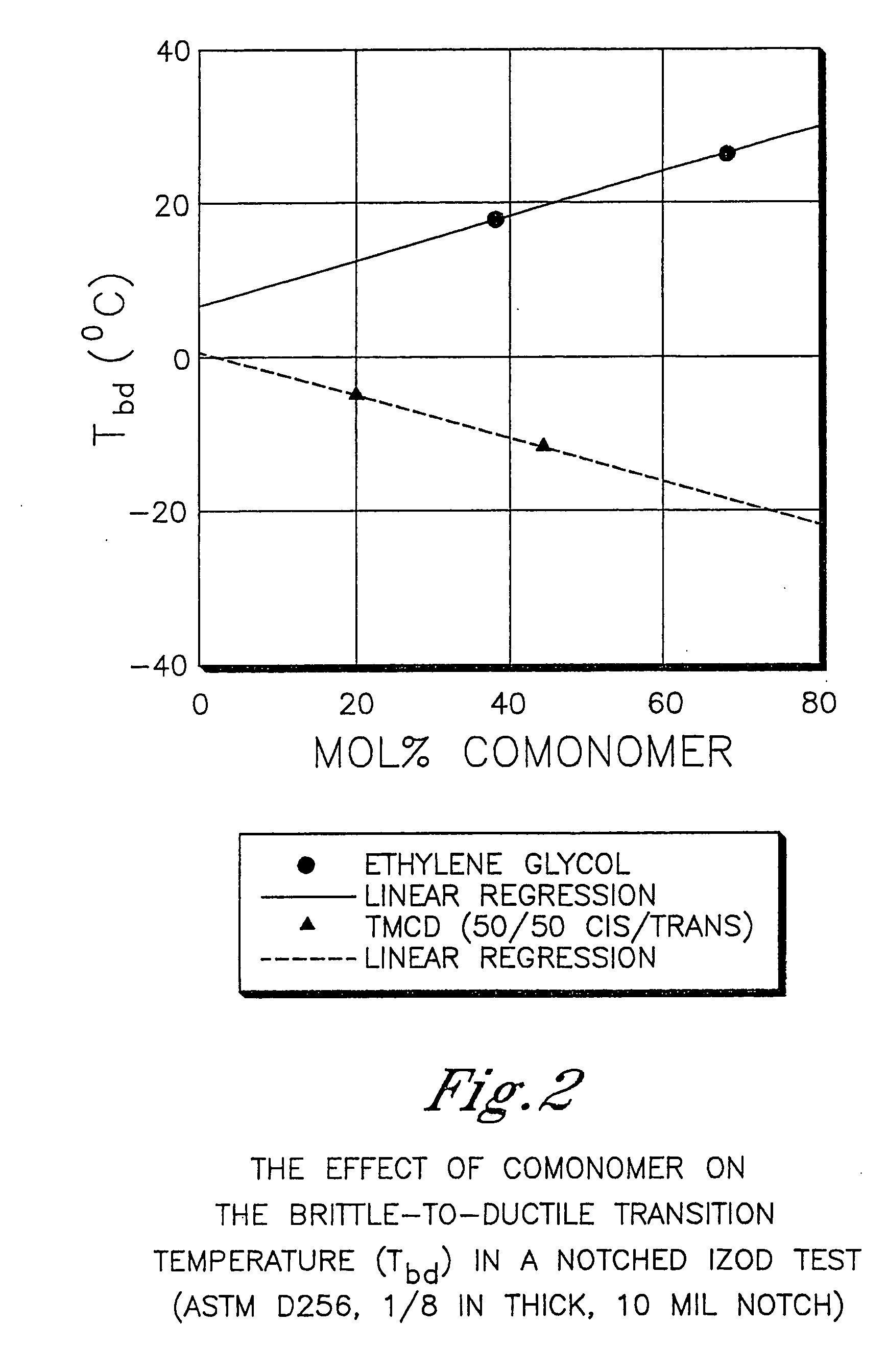

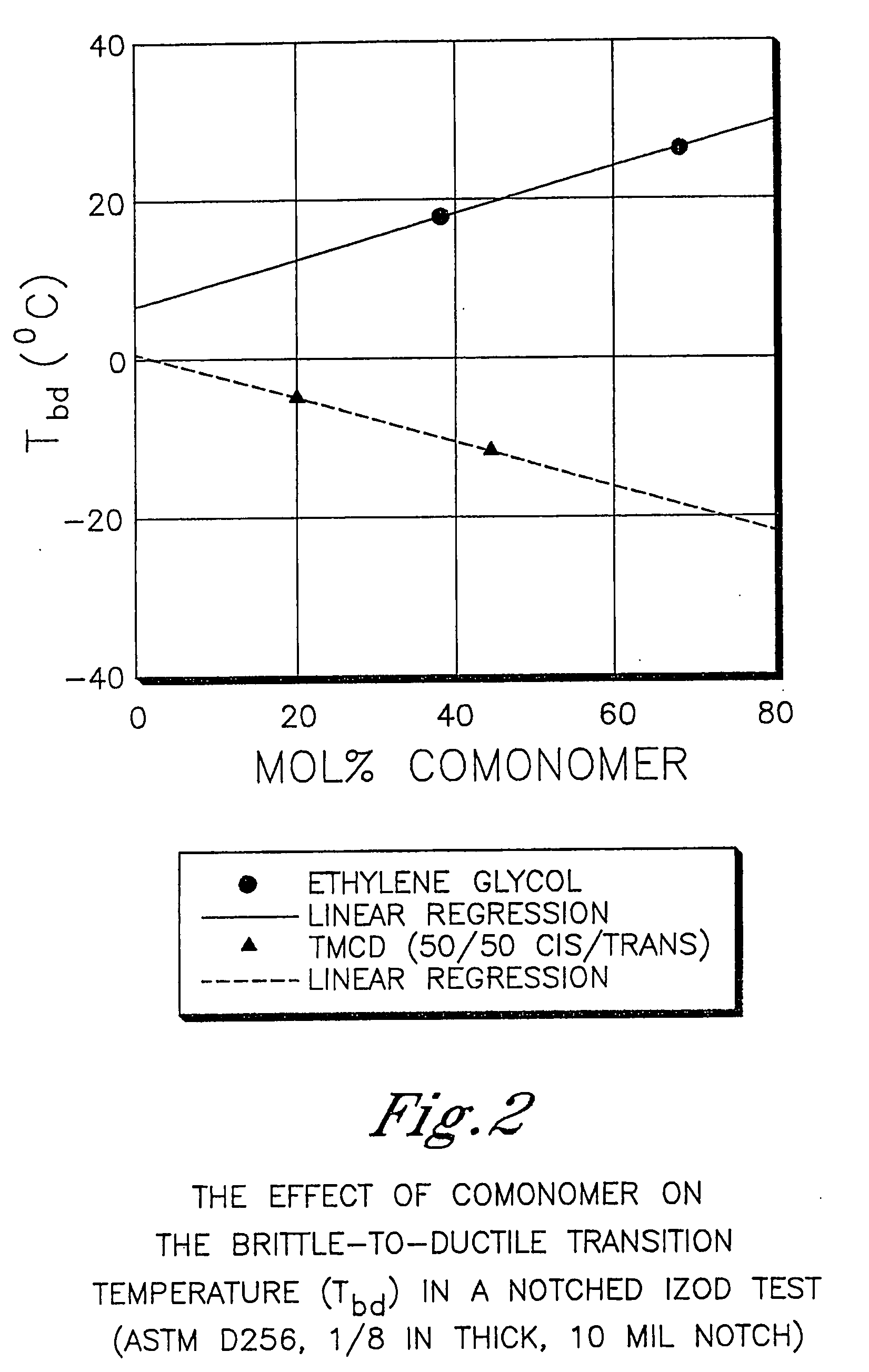

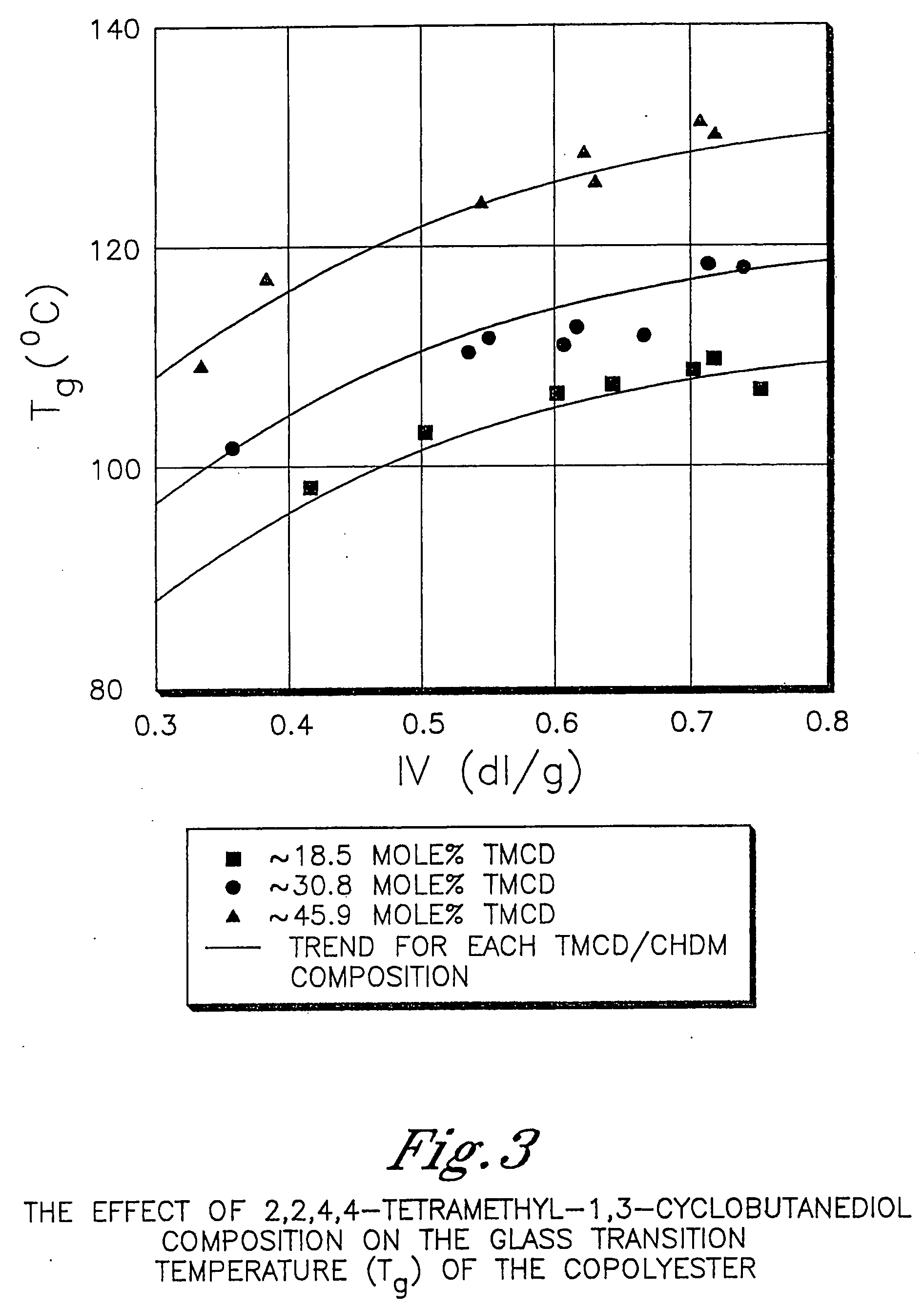

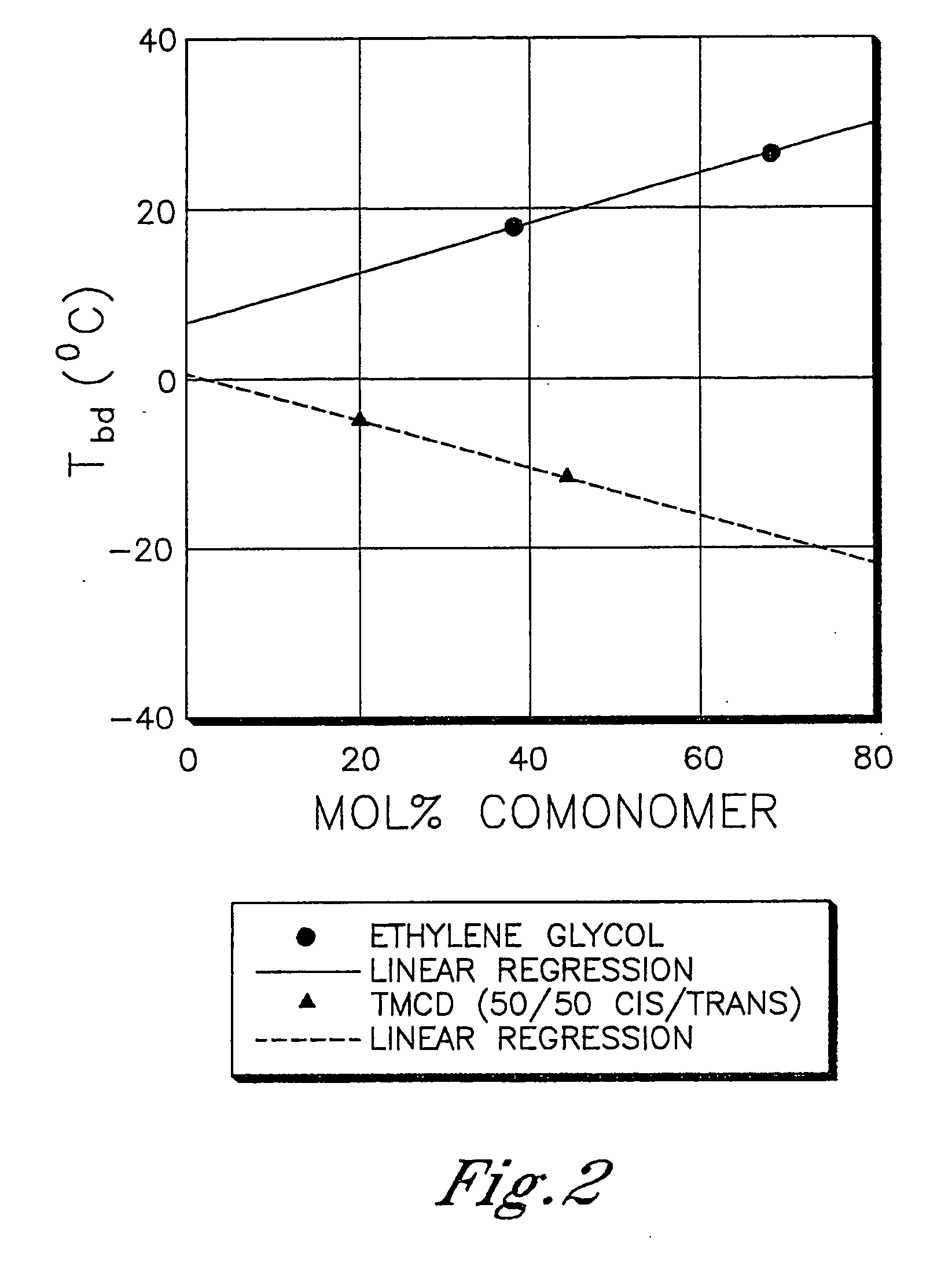

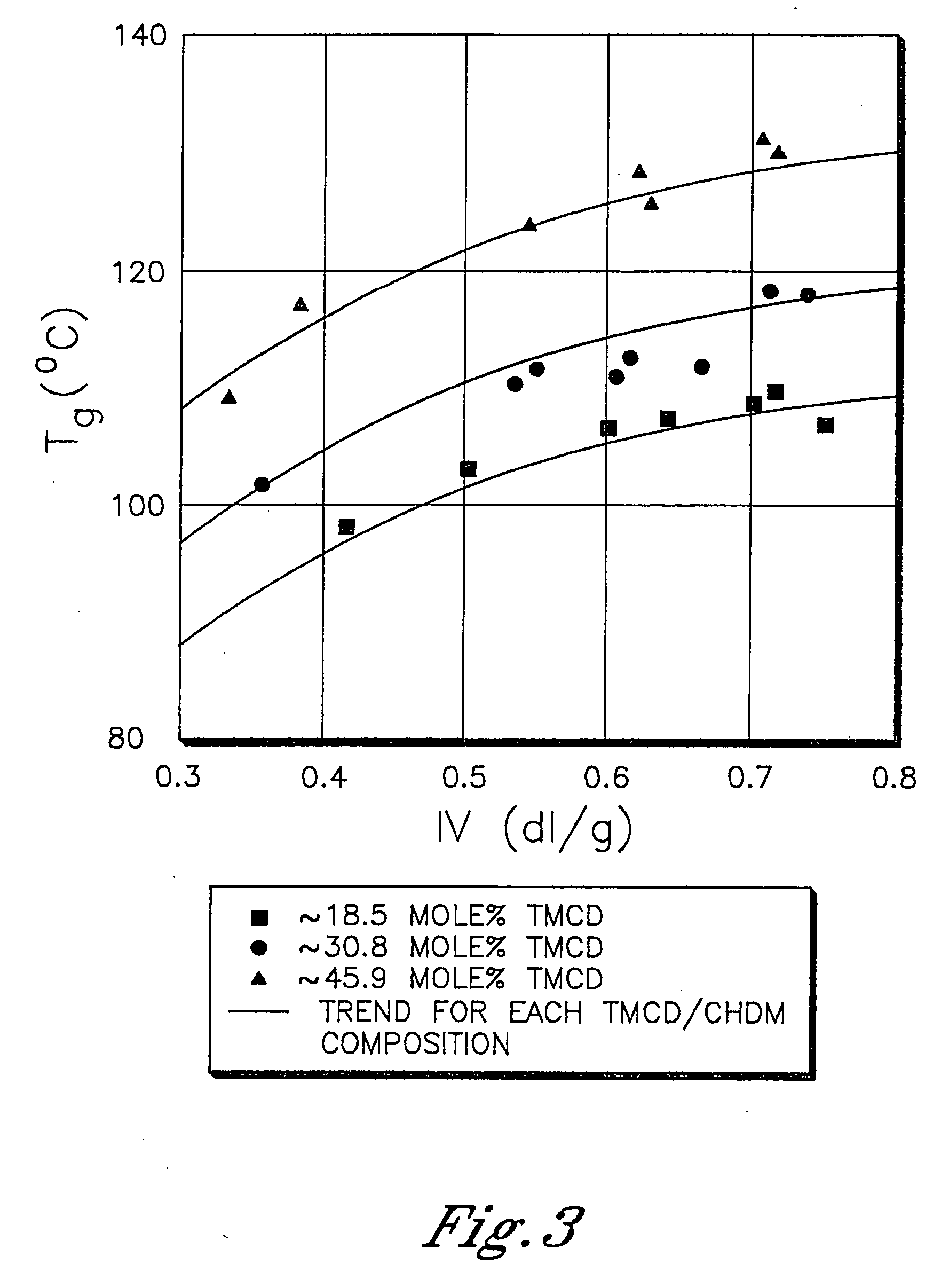

Described are polyester compositions comprising at least one polyester which comprises terephthalic acid residues, 2,2,4,4-tetramethyl-1,3-cyclobutanediol, and cyclohexanedimethanol, wherein the inherent viscosity and the Tg of the polyester provides for certain polyester properties. The polyesters may be manufactured into articles such as fibers, films, bottles or sheets.

Owner:EASTMAN CHEM CO

Polyester compositions containing cyclobutanediol having a certain combination of inherent viscosity and high glass transition temperature and articles made therefrom

ActiveUS20060287482A1Good chemical resistanceHigh impact strengthDialysis systemsDialysisFiberPolymer science

Described are polyester compositions comprising at least one polyester which comprises terephthalic acid residues, 2,2,4,4-tetramethyl-1,3-cyclobutanediol, and 1,4-cyclohexanedimethanol, wherein the inherent viscosity and the Tg of the polyester provides for certain polyester properties. The polyesters may be manufactured into articles such as fibers, films, bottles or sheets.

Owner:EASTMAN CHEM CO

Polyester compositions containing cyclobutanediol having a certain combination of inherent viscosity and moderate glass transition temperature and articles made therefrom

ActiveUS20060293495A1Easy to optimizeHigh impact strengthDialysis systemsDialysisFiberCyclohexanedimethanol

Described are polyesters comprising (a) a dicarboxylic acid component comprising terephthalic acid residues; optionally, aromatic dicarboxylic acid residues or aliphatic dicarboxylic acid residues; 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; and 1,4-cyclohexanedimethanol residues. The polyesters may be manufactured into articles such as fibers, films, bottles or sheets.

Owner:EASTMAN CHEM CO

Boron carbide composite bodies, and methods for making same

InactiveUS6862970B2Less expensivelyLow production costDoor/window protective devicesLayered productsReaction bonded silicon carbideHigh stiffness

A composite body produced by a reactive infiltration process that possesses high mechanical strength, high hardness and high stiffness has applications in such diverse industries as precision equipment and ballistic armor. Specifically, the composite material features a boron carbide filler or reinforcement phase, and a silicon carbide matrix produced by the reactive infiltration of an infiltrant having a silicon component with a porous mass having a carbonaceous component. Potential deleterious reaction of the boron carbide with silicon during infiltration is suppressed by alloying or dissolving boron into the silicon prior to contact of the silicon infiltrant with the boron carbide. In a preferred embodiment of the invention related specifically to armor, good ballistic performance can be advanced by loading the porous mass or preform to be infiltrated to a high degree with one or more hard fillers such as boron carbide, and by limiting the size of the largest particles making up the mass. The instant reaction-bonded silicon carbide (RBSC) composite bodies surpass previous RBSC's as armor materials, and in this capacity approach the ballistic performance of current carbide armor ceramics but with potentially lower cost manufacturing methods, e.g., infiltration techniques.

Owner:II VI DELAWARE INC +1

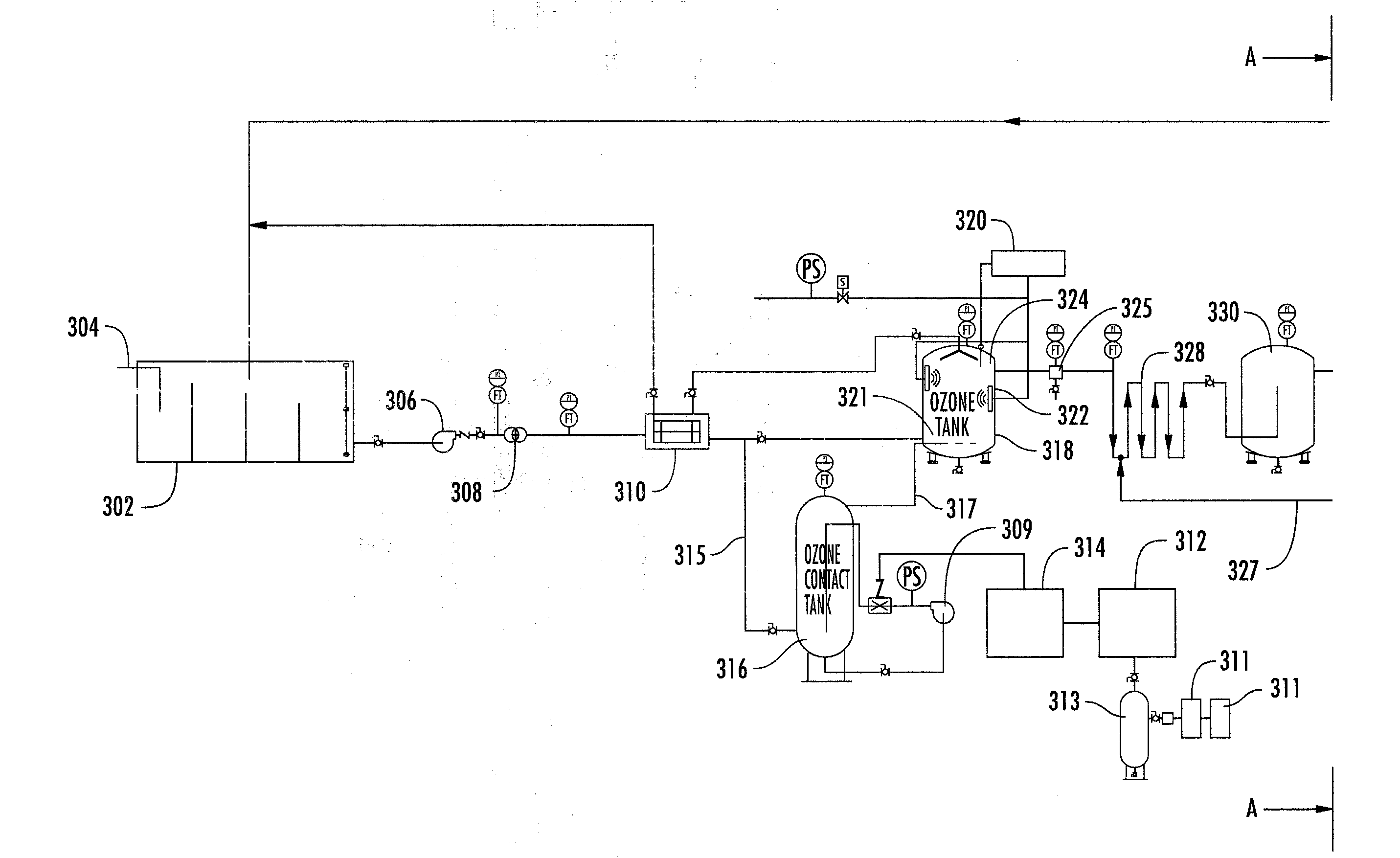

Enhanced water treatment for reclamation of waste fluids and increased efficiency treatment of potable waters

ActiveUS20090230059A1Low costCurrent expensiveSolid sorbent liquid separationSedimentation separationLiquid wastePotable water

Disclosed is a process for reclamation of waste fluids. A conditioning container is employed for receipt of waste material on a continuous flow for treatment within the container by immersible transducers producing ultrasonic acoustic waves in combination with a high level of injected ozone. The treated material exhibits superior separation properties for delivery into a centrifuge for enhanced solid waste removal. The invention discloses a cost efficient and environmentally friendly process and apparatus for cleaning and recycling of flowback, or frac water, which has been used to stimulate gas production from shale formations. The apparatus is mobile and containerized and suitable for installation at the well site.

Owner:BRISBEN WATER SOLUTIONS

Carbon fiber prepreg, and a production process thereof

InactiveUS6117551AImprove impact resistanceHigh tensile strengthDecorative surface effectsAdhesive processes with surface pretreatmentHigh concentrationFiber bundle

PCT No. PCT / JP97 / 04642 Sec. 371 Date Aug. 11, 1998 Sec. 102(e) Date Aug. 11, 1998 PCT Filed Dec. 16, 1997 PCT Pub. No. WO98 / 26912 PCT Pub. Date Jun. 25, 1998The present invention relates to a carbon fiber prepreg. The carbon fiber prepreg of the present invention is characterized in that a carbon fiber bundle comprising a plurality of continuous carbon filaments and having a hook drop value of 10 cm or more as the degree of fiber entanglement is impregnated with a base resin mainly composed of a thermosetting resin, and that particles of 150 mu m or less in particle size made of a thermoplastic resin account for 20 wt % or less based on the weight of the entire prepreg and distributed at a higher concentration in the surface zone than in the inside. The carbon fiber prepreg of the present invention is good in tackiness and less changing in tackiness with the lapse of time, and can form a composite with an excellent compression interlaminar shear strength (CILS) at high temperature after moisture absorption while maintaining good impact resistance. It also allows the production of a composite very higher than the conventional composite in the compressive strength (LCS) of a cross laminated panel. The carbon fiber prepreg of the present invention can be preferably used as a structural member in such areas as aerospace area, sporting area and civil engineering and architecture area.

Owner:TORAY IND INC

Film(s) and/or sheet(s) comprising polyester compositions which comprise cyclobutanediol and have a certain combination of inherent viscosity and moderate glass transition temperature

ActiveUS20060293494A1Improve bindingIncrease temperatureDialysis systemsDialysisCyclohexanedimethanolCarboxylic acid

Described are film(s) and / or sheet(s) comprising polyesters comprising (a) a dicarboxylic acid component having terephthalic acid residues; optionally, aromatic dicarboxylic acid residues or aliphatic dicarboxylic residues; 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; and 1,4-cyclohexanedimethanol residues.

Owner:EASTMAN CHEM CO

Silicone rubber compositions for producing cables or profiles with retention of function in the event of fire

InactiveUS6387518B1Improve the level ofPropertyFireproof paintsAntifouling/underwater paintsZinc boratePlatinum complex

A composition which is useful for producing profiles and cable insulation which retain their function in the event of fire, comprise peroxidically crosslinking or condensation-crosslinking silicone rubber, metal oxides selected from magnesium oxide, aluminum oxide, tin oxide, calcium oxide and barium oxide and metal compounds of this class which produce oxides on heating, boric acid, zinc borate, and a platinum complex having at least one unsaturated group.

Owner:WACKER CHEM GMBH

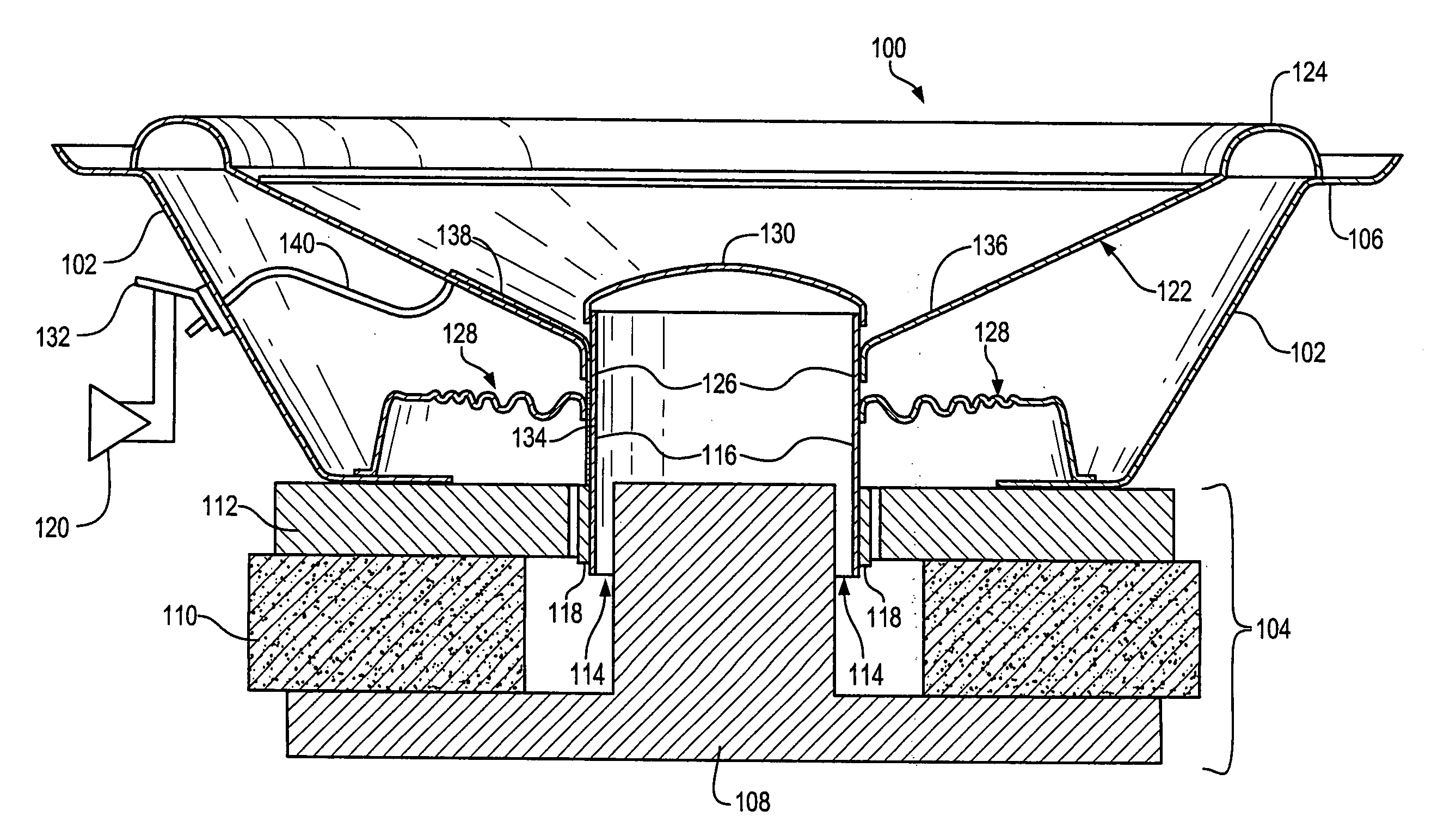

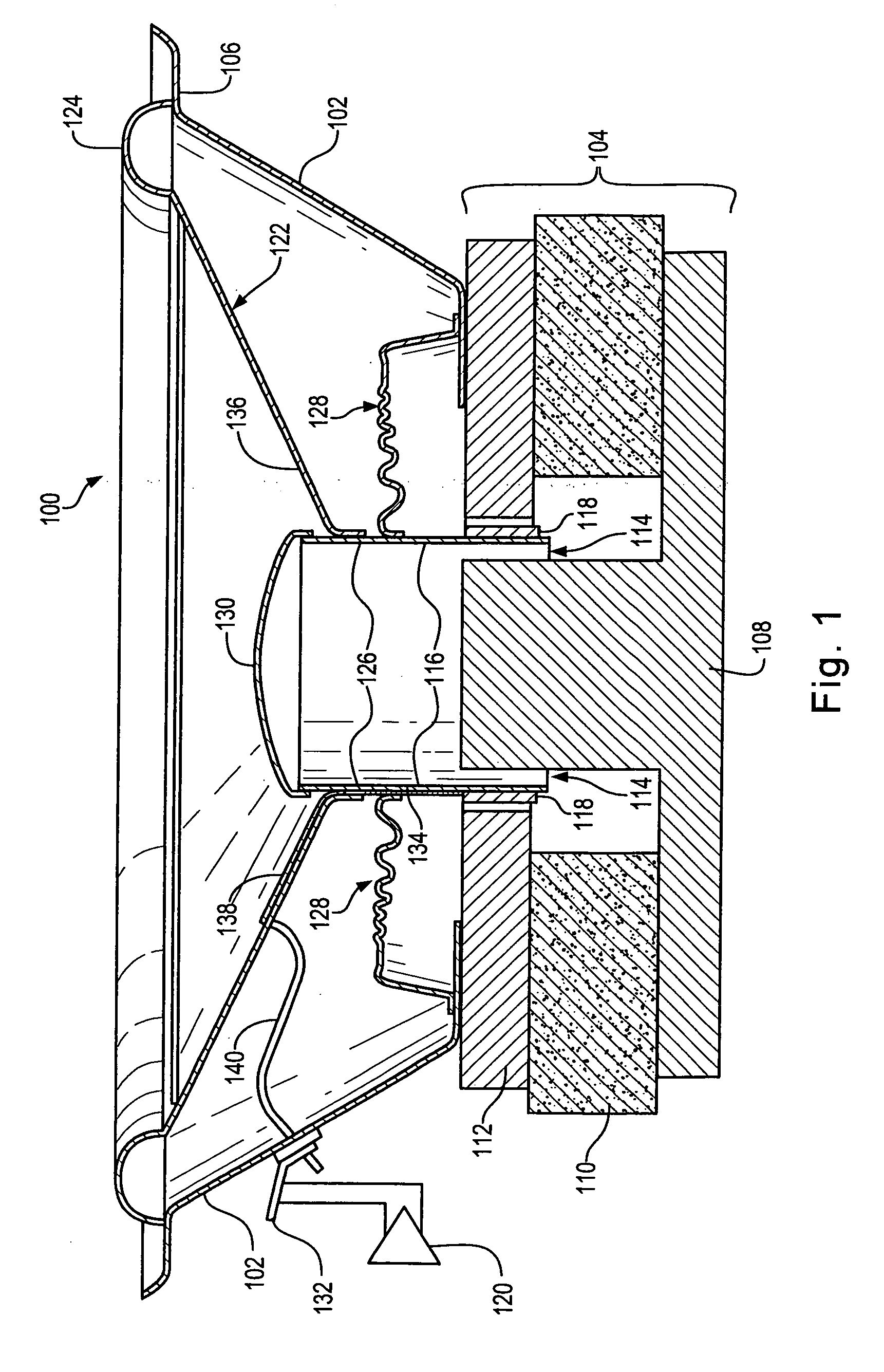

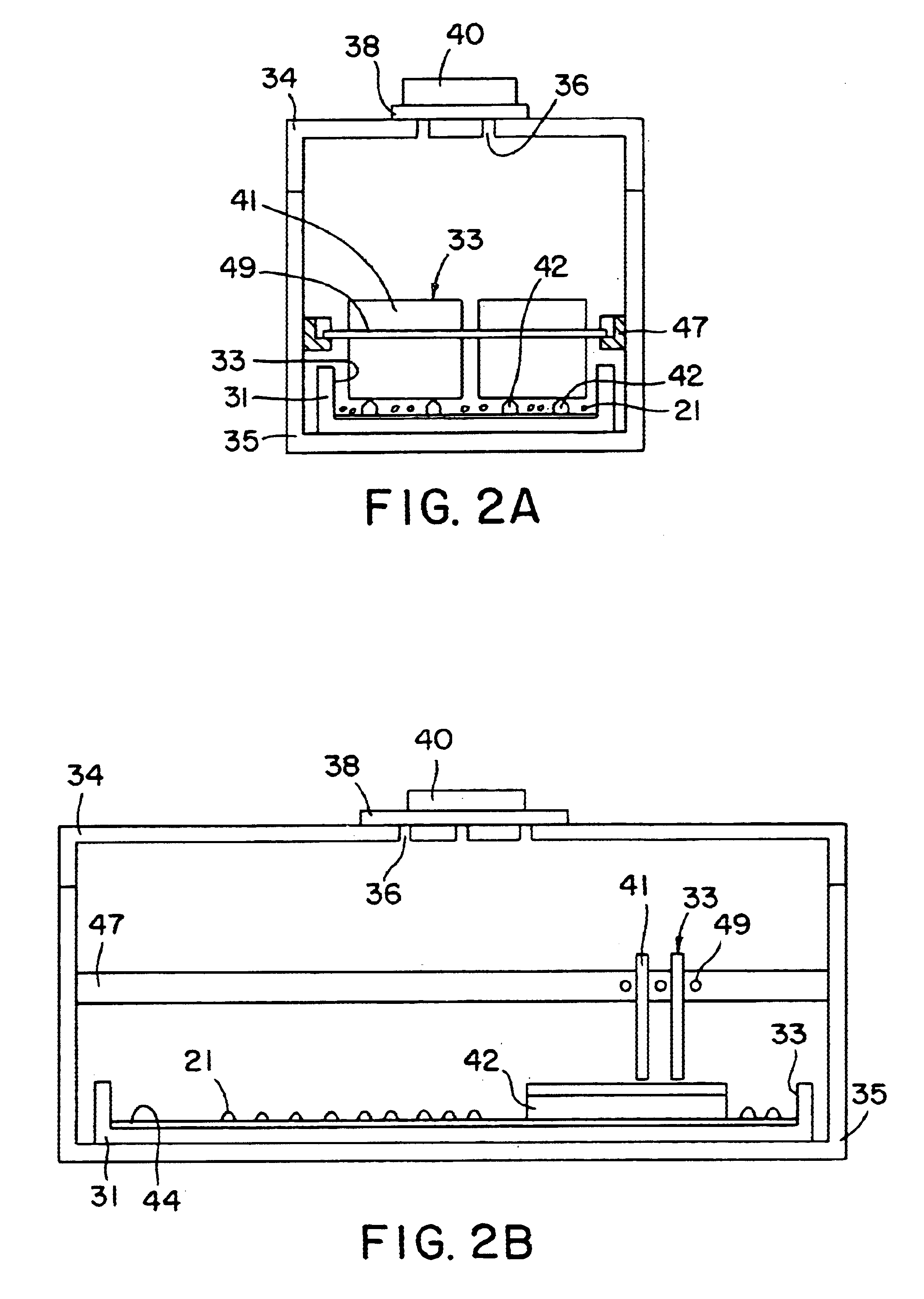

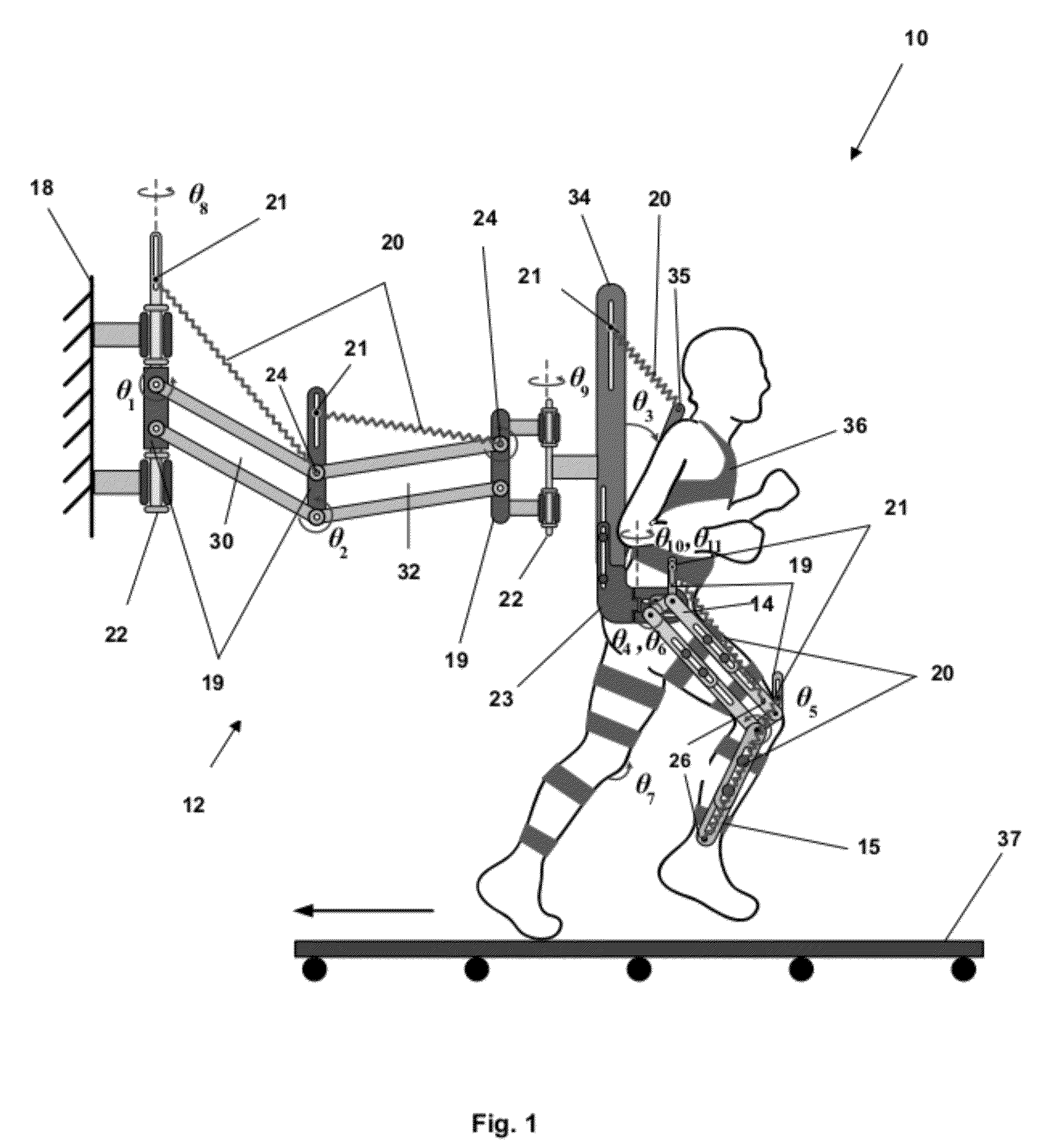

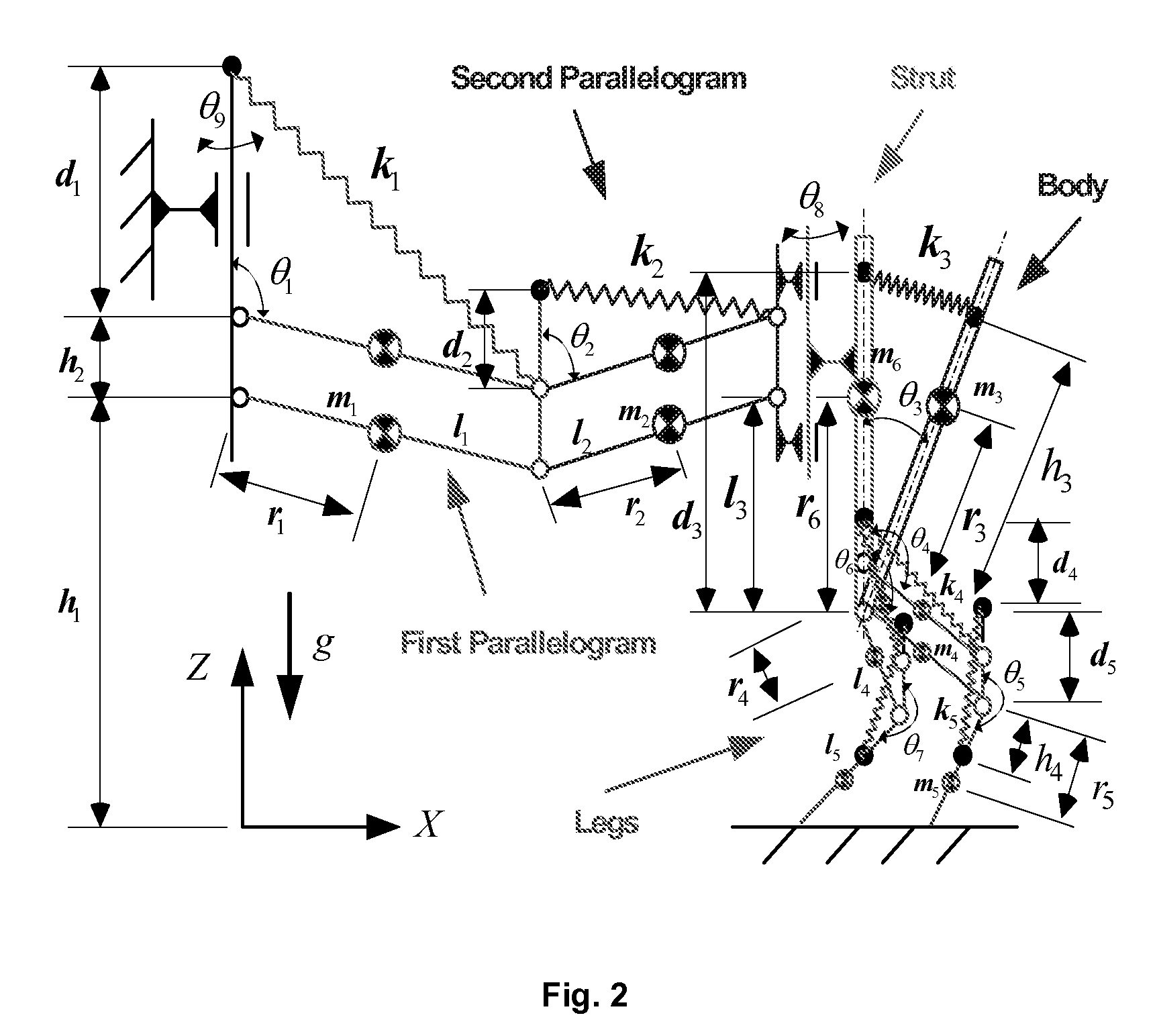

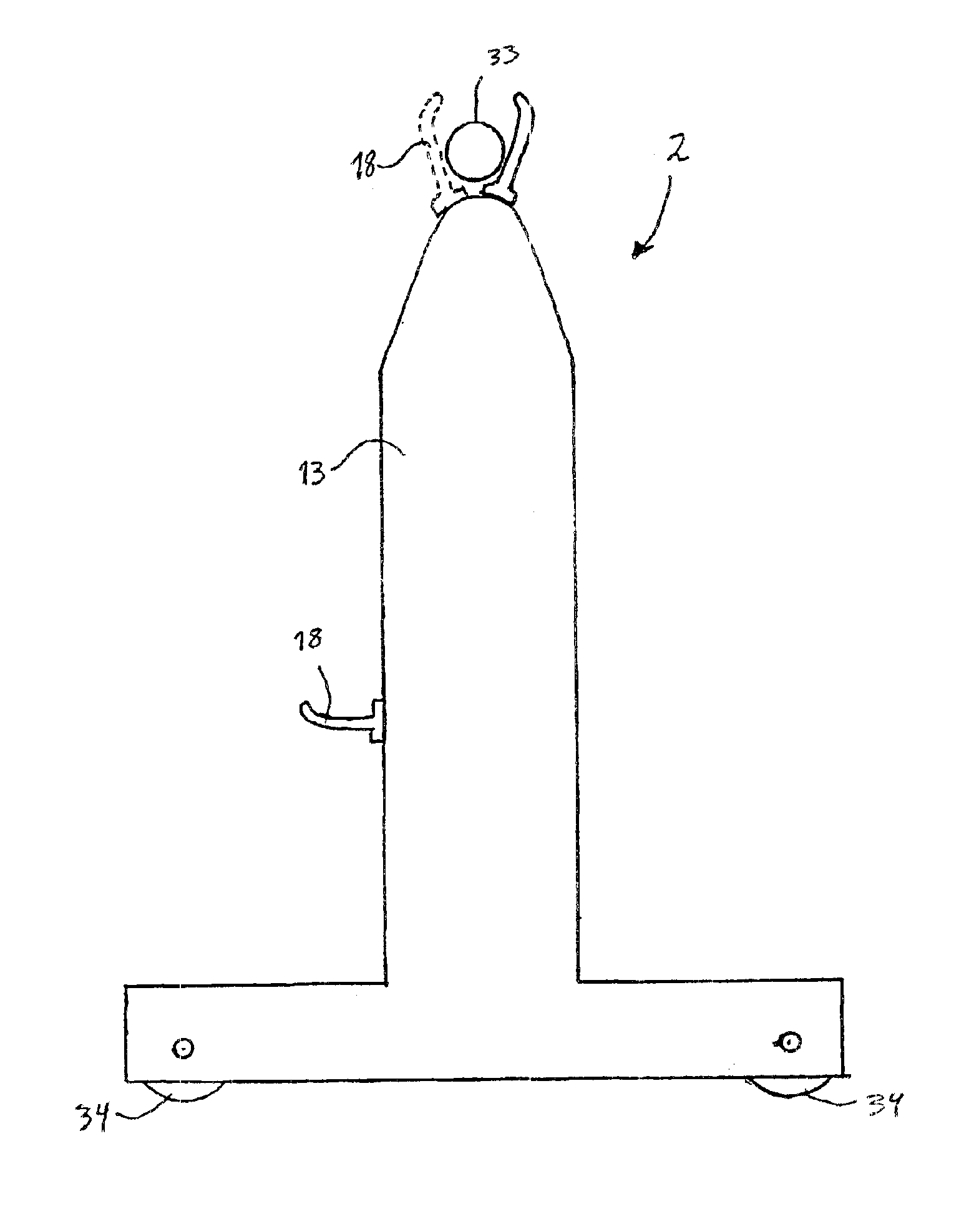

Apparatus and method for reduced-gravity simulation

The present invention comprises an apparatus and method for gravity-balanced apparatuses for training humans for space exploration and other applications. The embodiment of the simulation apparatus is less expensive to build and safe to operate and adaptable to numerous applications, including but not limited to theme parks, museums, training facilities, educational / research labs, and others, for people to experience walking and other perambulations in lower or zero gravity environments. The present invention is statically-balanced and comprises a spring apparatus that is easily adjusted. An embodiment of the present invention provides an apparatus and method for simulating walking in a zero-gravity or reduced-gravity environment.

Owner:ARROWHEAD CENT

Lost circulation and fluid loss materials containing guar chaff and methods for making and using same

InactiveUS20150072901A1Light weightReduce gravityFlushingDrilling compositionEngineeringLost circulation

A lost circulation additive including a guar chaff material. The method of forming a lost circulation fluid includes contacting the lost circulation additive with a base fluid. The method for treating a formation including injecting the loss circulation fluid into a wellbore.

Owner:LUBRIZOL OILFIELD SOLUTIONS

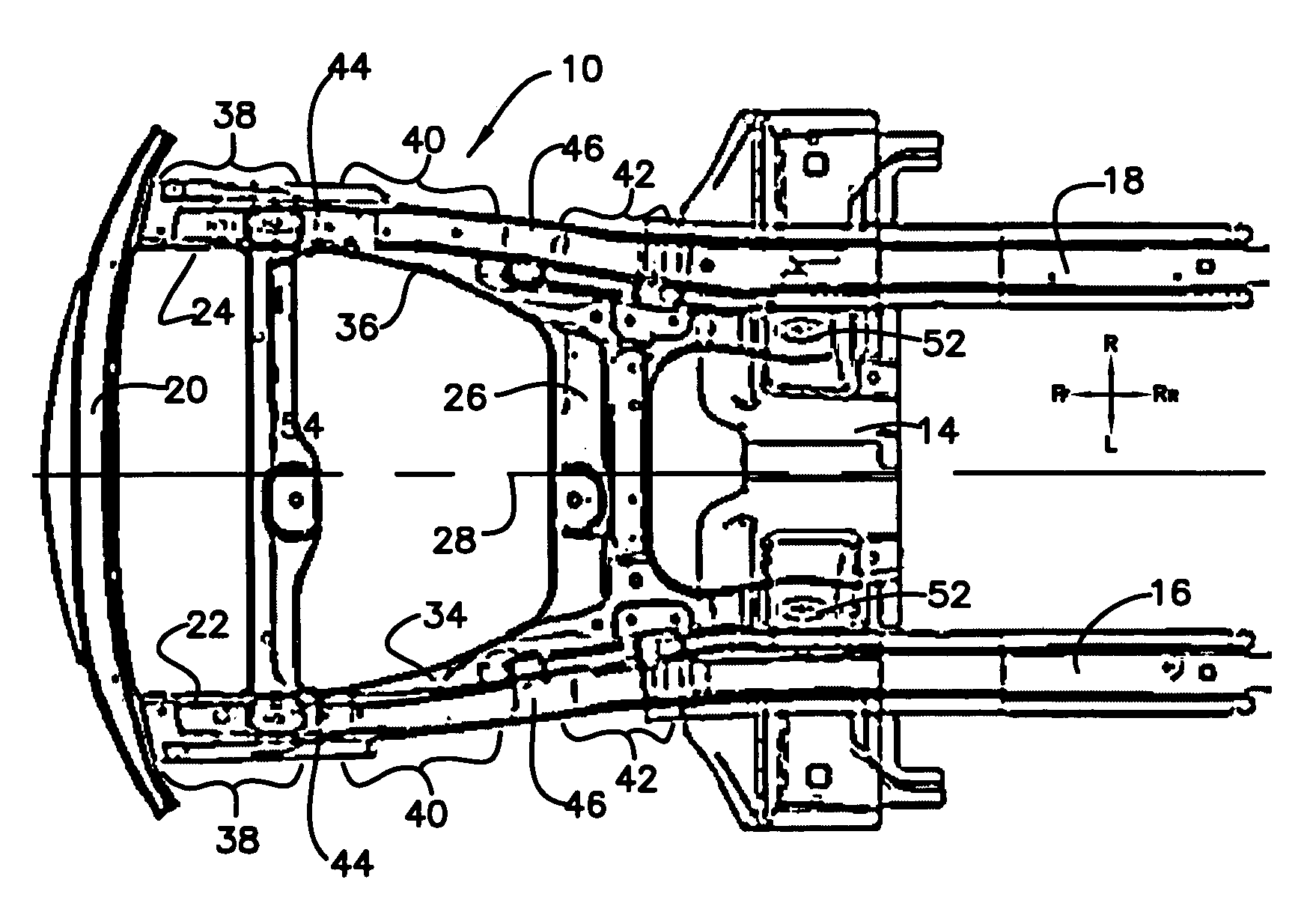

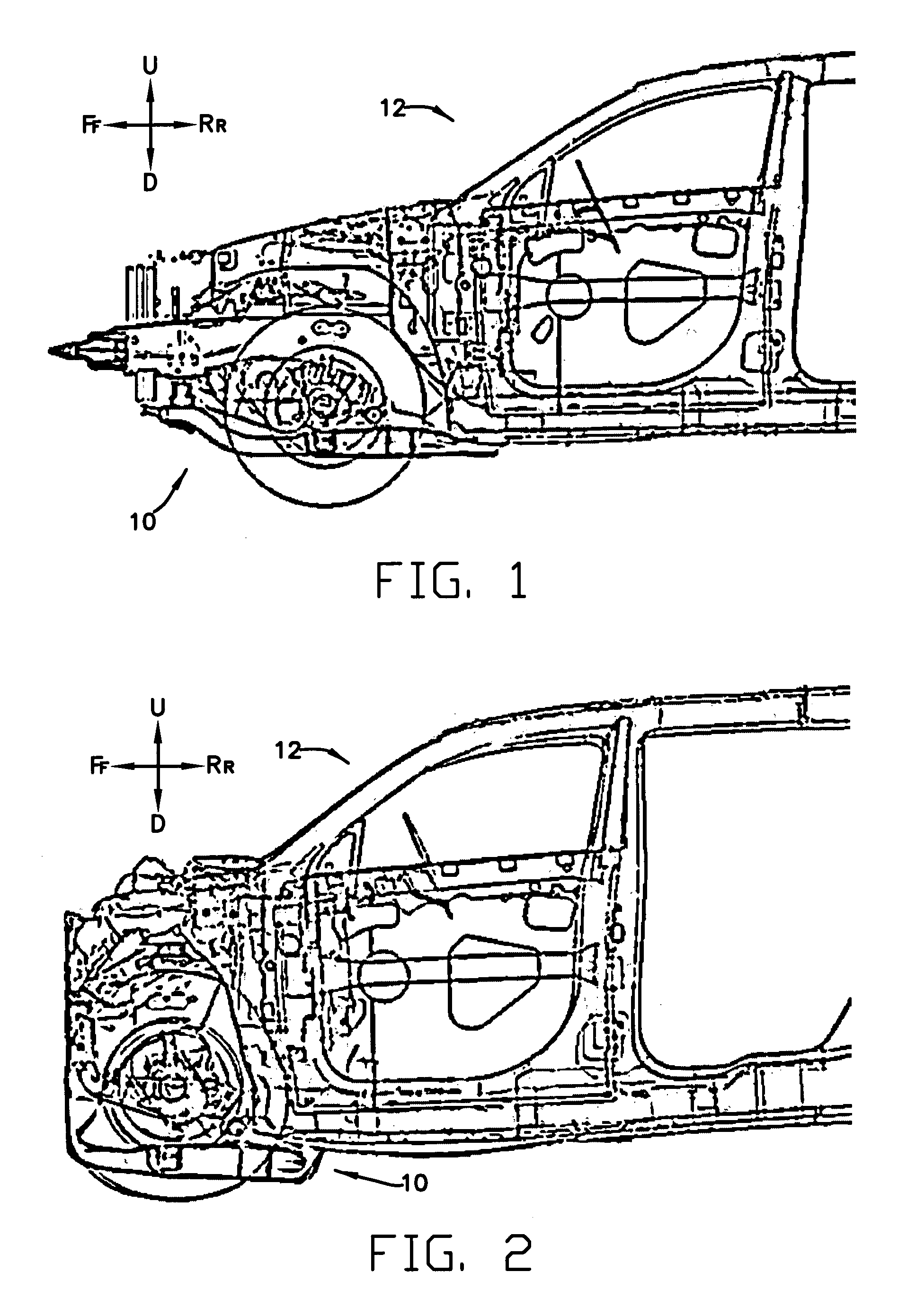

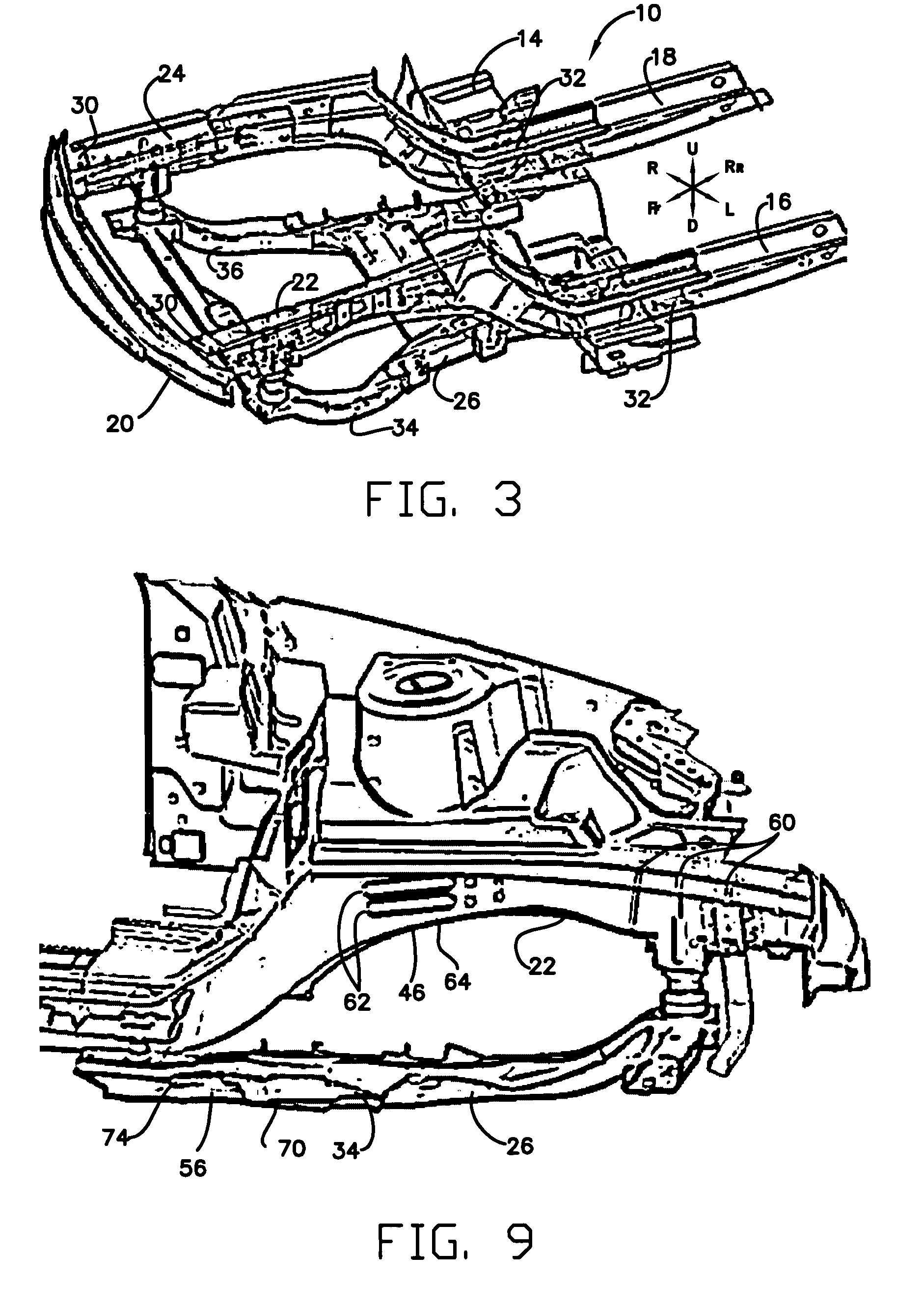

Energy absorbing front frame structure for a vehicle

ActiveUS6938948B1Many timesExtended durationVehicle seatsUnderstructuresEnergy absorptionEngineering

Owner:FCA US

Glass-ceramics and method for manufacturing the same

InactiveUS20090162608A1Suitability for press formingImprove productivityMagnetic materials for record carriersBase layers for recording layersGlass-ceramicAntimony

For providing glass-ceramics having properties suitable for use as a substrate of an information storage medium of next generation such as one for the perpendicular magnetic recording system without employing arsenic and antimony components which adversely affect human beings and the environment, there are provided glass-ceramics comprising SiO2, Li2O and Al2O3 on oxide basis, comprising lithium disilicate as a crystal phase, and comprising one or more elements selected from the group consisting of Sn, Ce, Mn, W, Ta, Bi, Nb, S, Cl and F.

Owner:OHARA

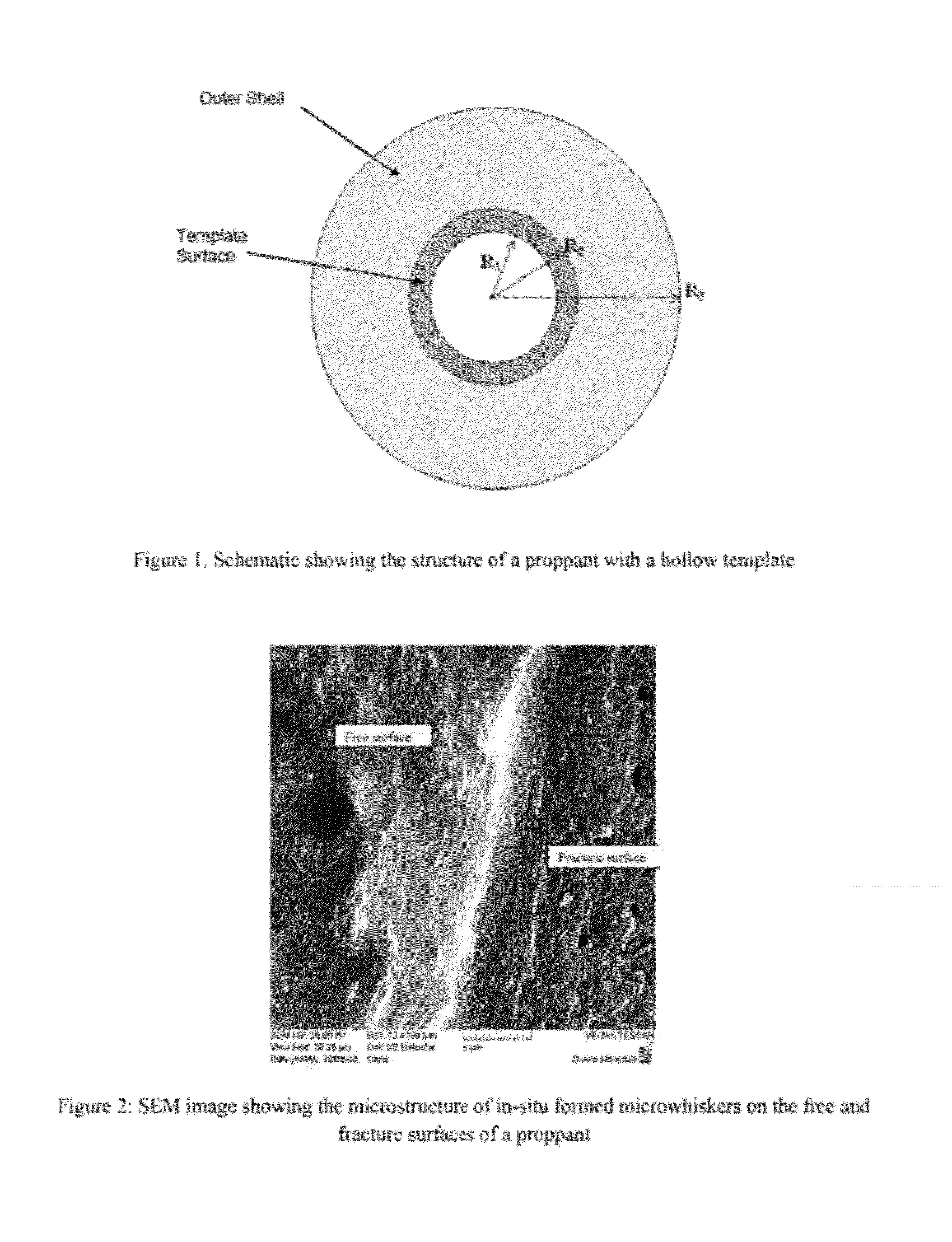

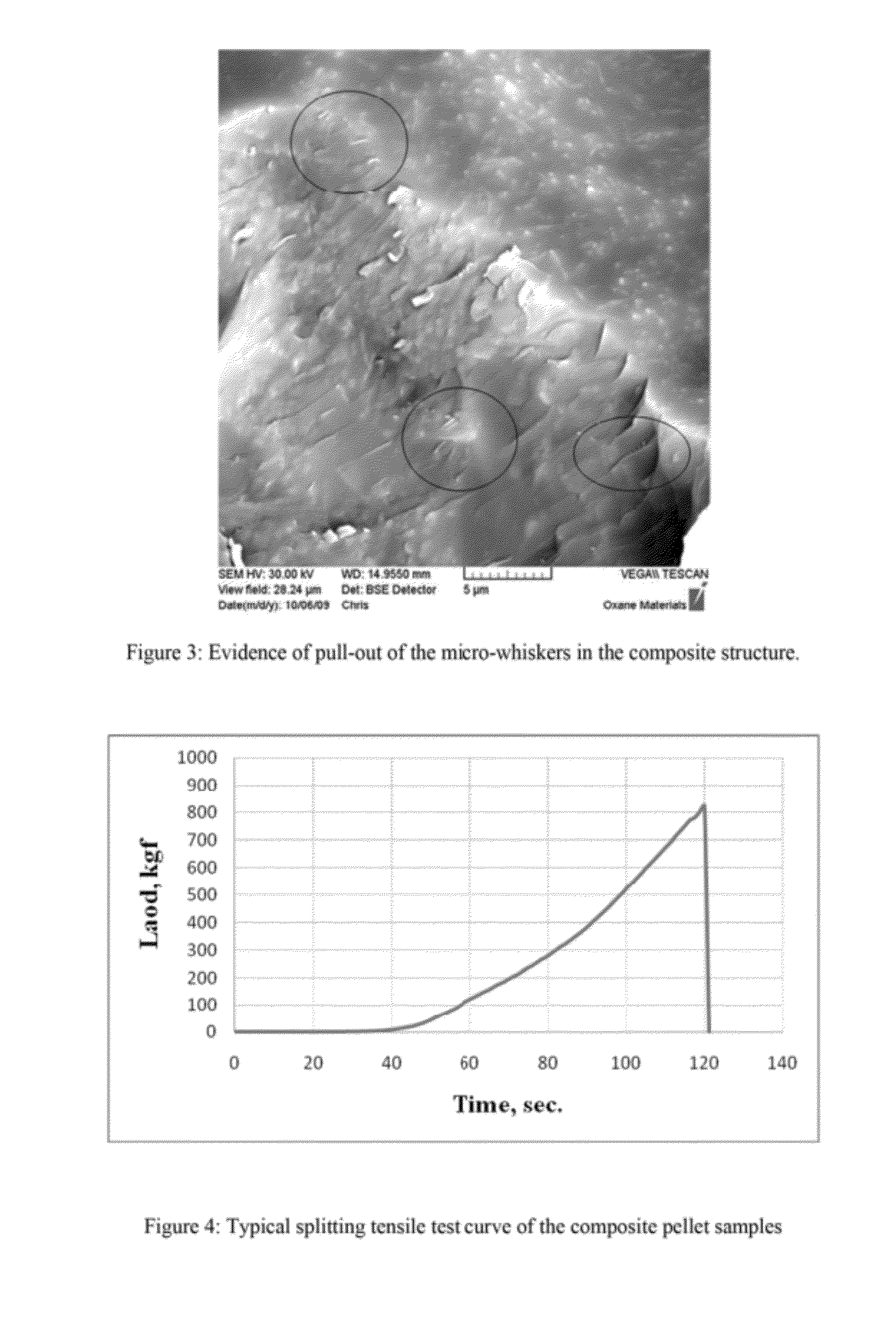

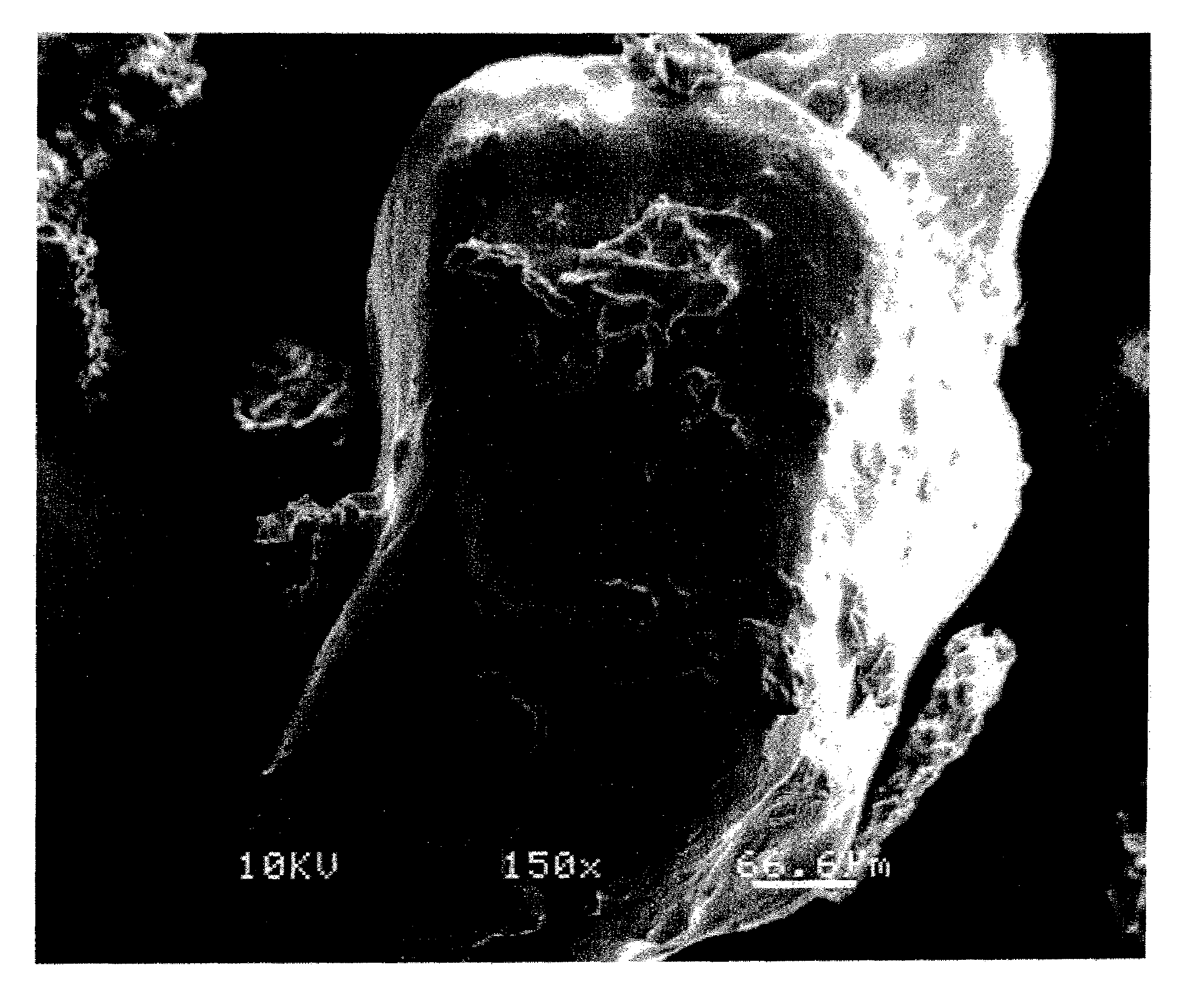

Self-Toughened High-Strength Proppant and Methods Of Making Same

Methods are described to make strong, tough, and lightweight whisker-reinforced glass-ceramic composites through a self-toughening structure generated by viscous reaction sintering of a complex mixture of oxides. The present invention further relates to strong, tough, and lightweight glass-ceramic composites that can be used as proppants and for other uses.

Owner:HALLIBURTON ENERGY SERVICES INC

Increasing buoyancy of well treating materials

ActiveUS20080277115A1Increase buoyancyHigh compressive strengthFluid removalFlushingApparent densityMetallurgy

A composite proppant having an increased buoyancy comprising a proppant substrate such as a porous ceramic or a silica sand coated with a material of a lesser actual density than the apparent density of the proppant substrate to increase the buoyancy of the composite proppant.

Owner:GEORGIA PACIFIC CHEM LLC

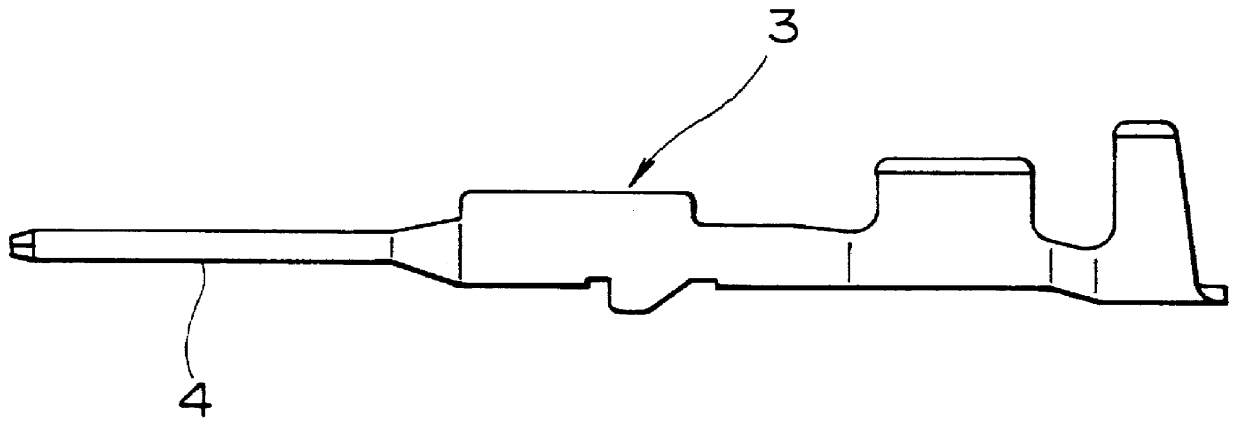

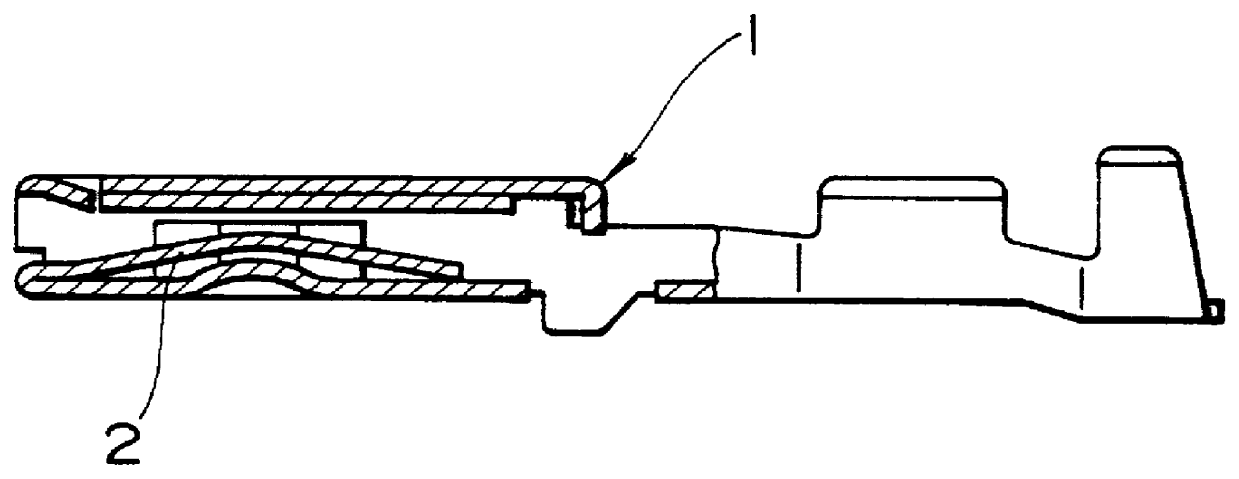

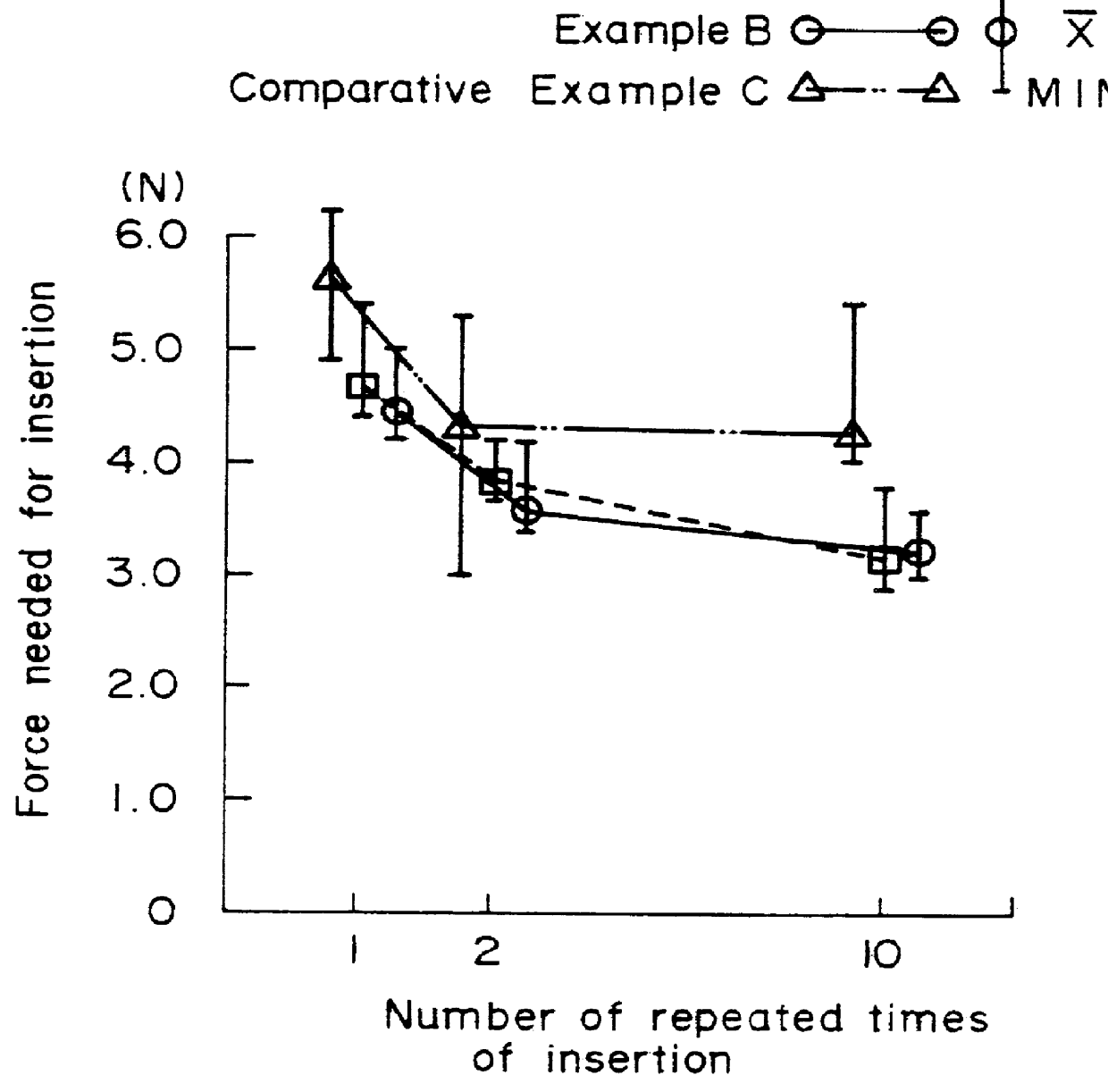

Hard coated copper alloys

InactiveUS6040067AHigh strengthImprove workabilityRecord information storageSolid state diffusion coatingCorrosionHigh resistance

The invention provides a coated Cu alloy and a process for producing the coated Cu alloy having a surface which has a low coefficient of friction and a high resistance to abrasion and is suitable for fabricating connectors, charging-sockets of electric automobiles etc. The coated Cu alloy is produced by coating the surface of a copper alloy with Sn and heat treating the coated Cu alloy at a temperature in the range of 100-450 DEG C. for 0.5-24 hours. The Cu alloy which is coated with Sn consists of 1-41 wt % Zn with the balance being Cu and incidental impurities. By using the coated Cu alloy, the force of insertion, resistance to abrasion and resistance to corrosion of connectors can be significantly improved.

Owner:DOWA METALS & MINING CO LTD +1

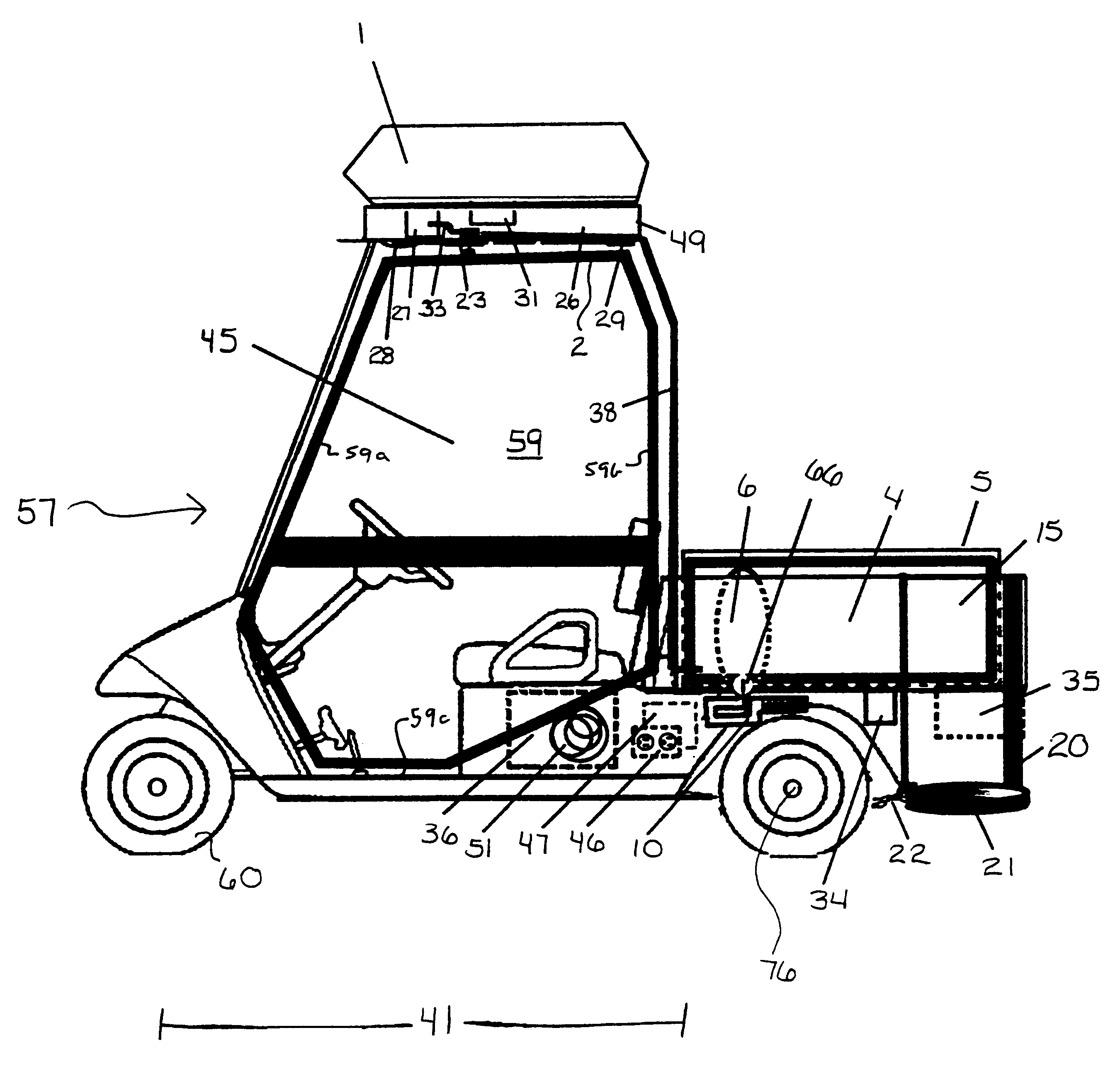

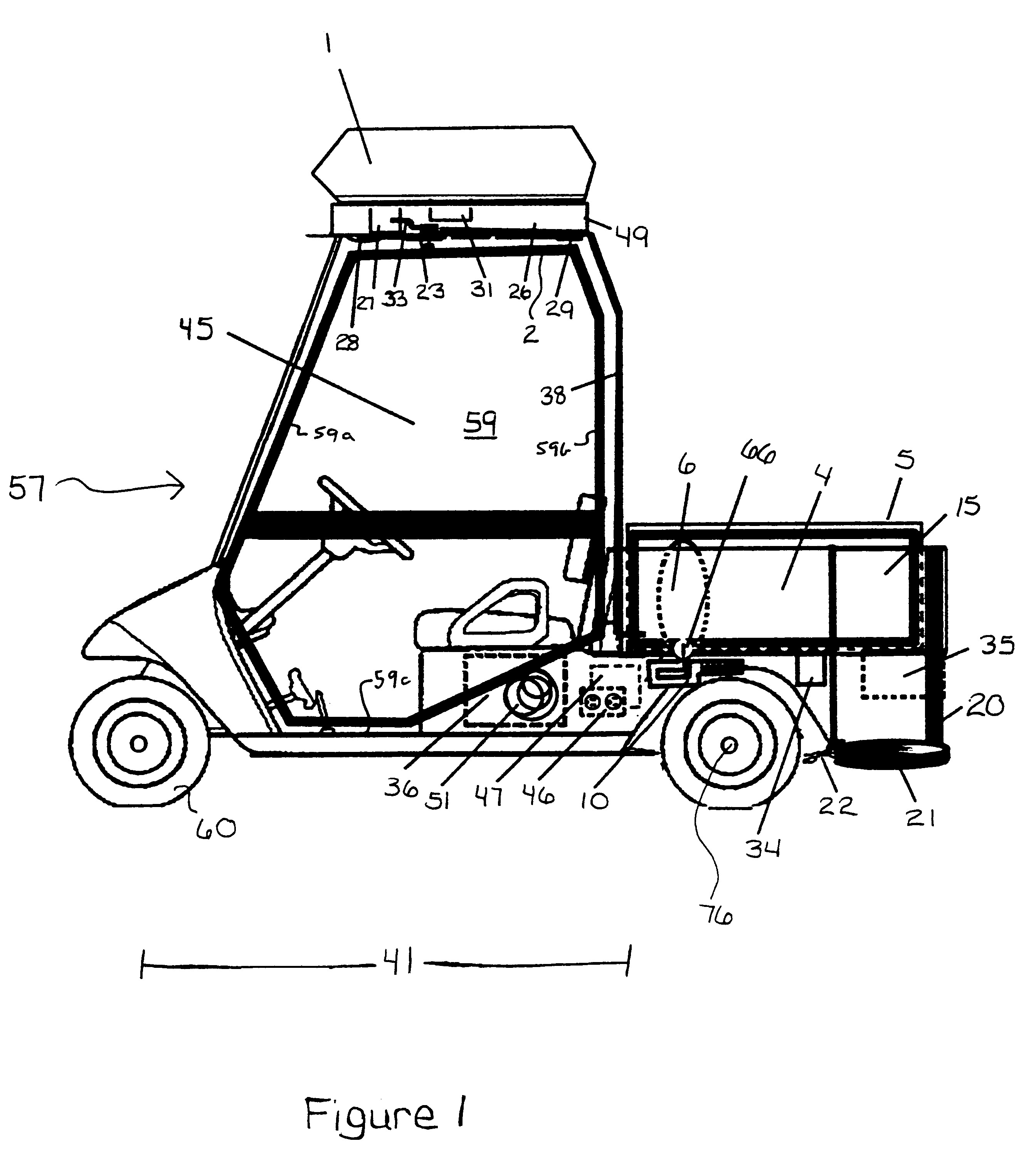

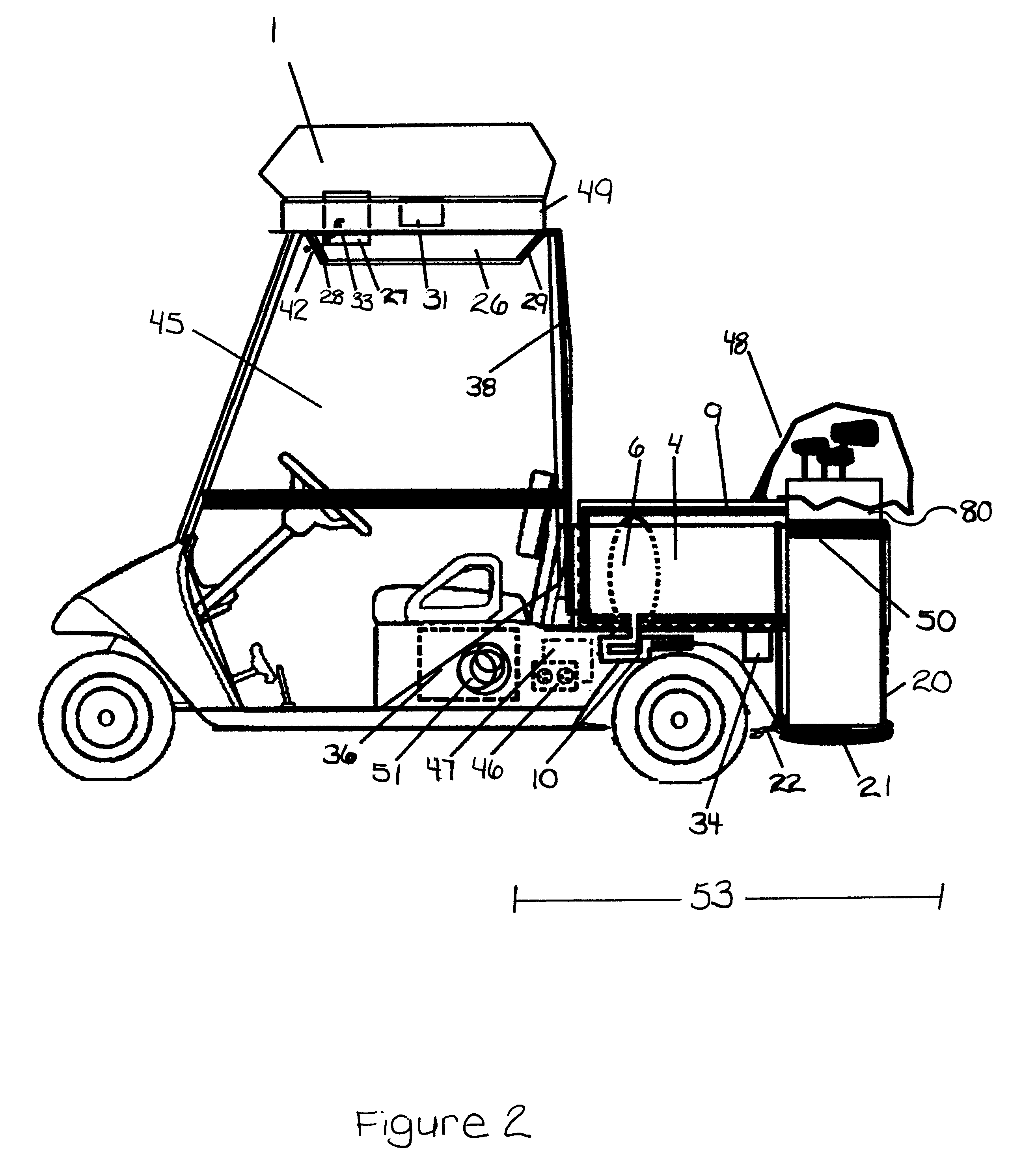

Air conditioned cart

InactiveUS6435293B1Sufficient powerMaximizes payload areaAir-treating devicesElectric propulsion mountingElectrical driveAir conditioning

A cart sealed for cooling having a battery powered electrical drive including an electrically powered mechanical air conditioner, a generator for powering the air conditioner, an outside power outlet powered by the generator, and a battery charger powered by the generator. The generator is wired to the charger to recharge the batteries for the cart when power requirements of the other units allow. There is an insulated case for the generator and a muffler-baffle system for quieting the exhaust from the generator through a series of baffles. A separate fuel supply for the generator is provided so the generator does not drain the motive drive fuel. A misting unit may be used to control the moisture level in the interior of the cart. A control panel in the interior of the compartment is used for controlling the generator, the air conditioner or both. A system of recirculating ducts insures that air within the interior of the cart is run through the air conditioning unit and then returned to the cart interior after it has been cooled so that recirculating air and not exterior air is cooled or heated depending on the setting of the air conditioning unit.

Owner:WILLIAMS ROBERT

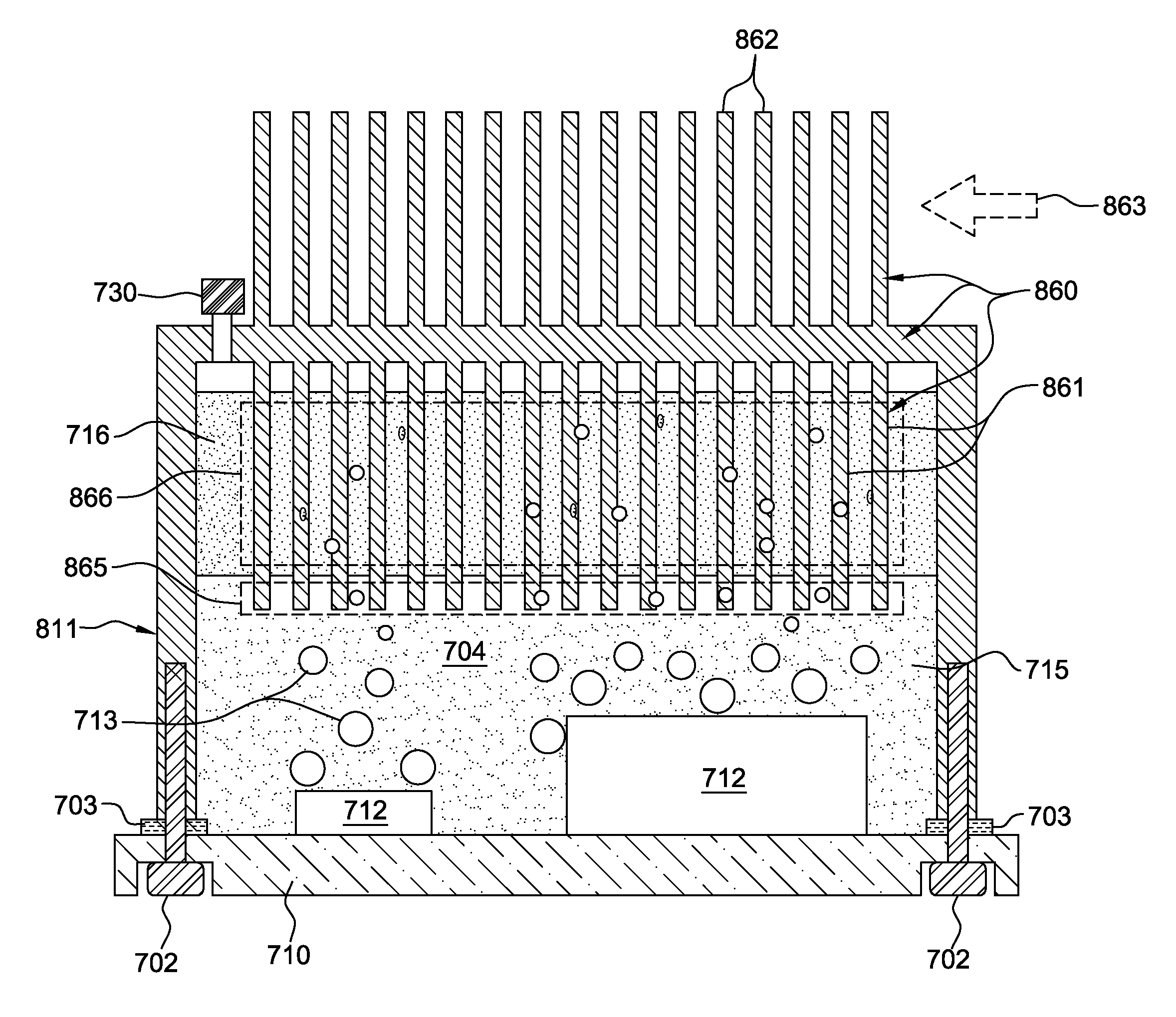

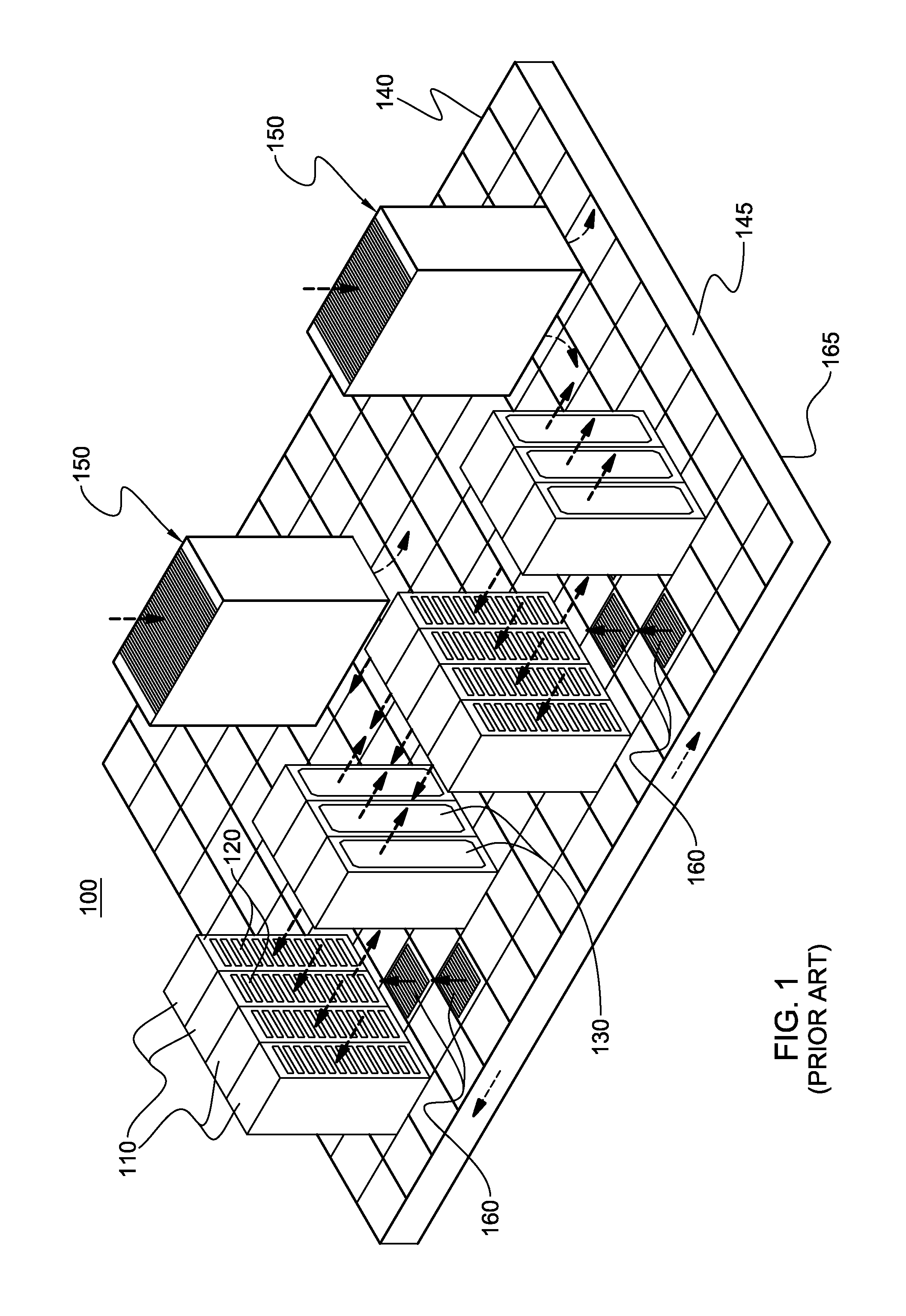

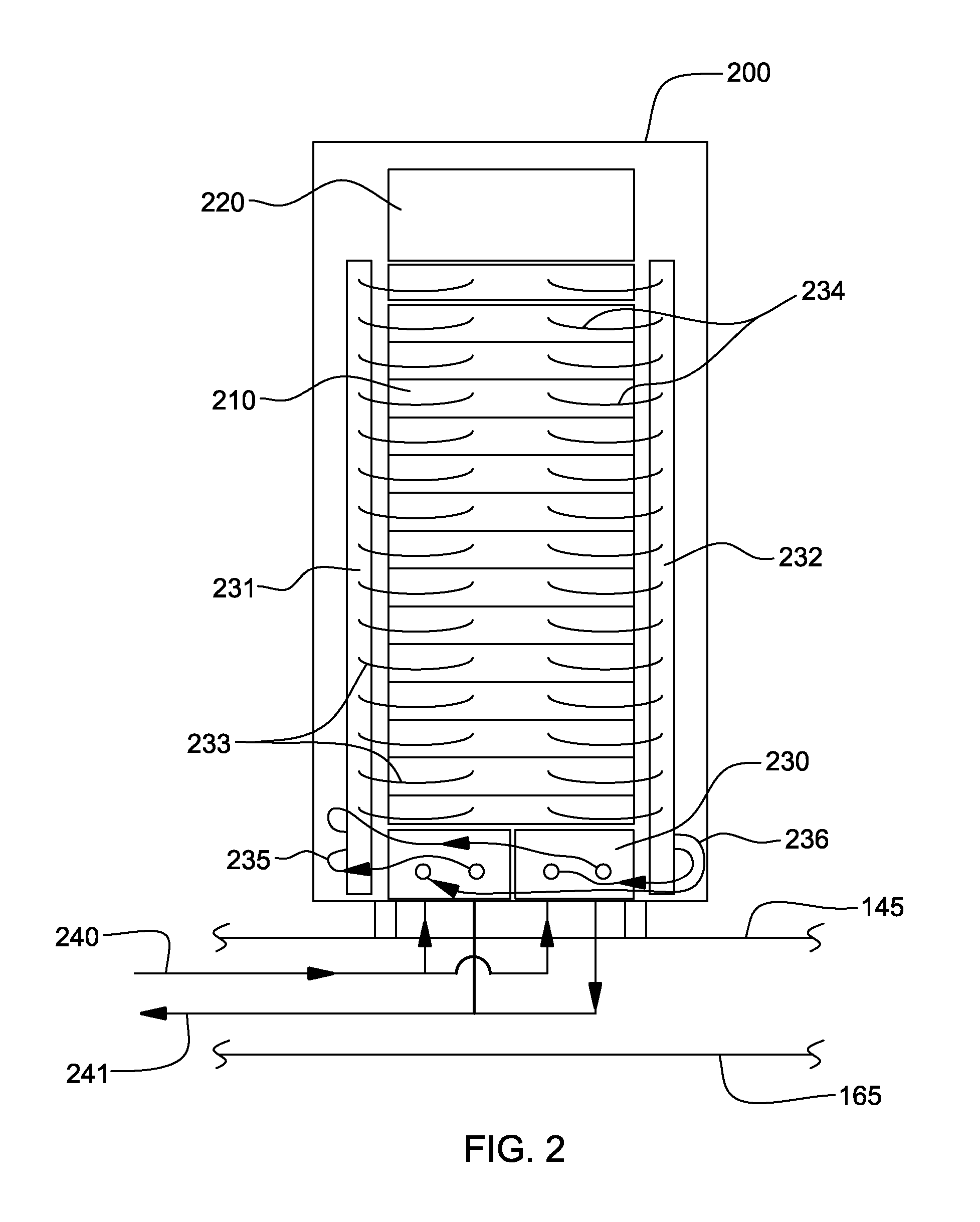

Multi-fluid, two-phase immersion-cooling of electronic component(s)

InactiveUS8619425B2Easy to condenseImprove cooling effectIndirect heat exchangersHeat exchange apparatusEngineeringElectronic component

Cooling apparatuses and methods are provided for immersion-cooling one or more electronic components. The cooling apparatus includes a housing at least partially surrounding and forming a fluid-tight compartment about the electronic component(s), and a boiling fluid mixture of first and second dielectric fluids within the fluid-tight compartment, with the electronic component(s) immersed within the mixture. A condensing fluid is also provided within the fluid-tight compartment, and is immiscible with the boiling fluid mixture. The condensing fluid has a lower specific gravity and a higher thermal conductivity than the boiling fluid mixture, and facilitates condensing of vaporized boiling fluid mixture. A cooling structure is provided within the compartment, and includes a condensing region and a sub-cooling region, with the condensing region being in contact with the condensing fluid, and the sub-cooling region being in contact with the boiling fluid mixture. The cooling structure facilitates heat removal from the fluid-tight compartment.

Owner:IBM CORP

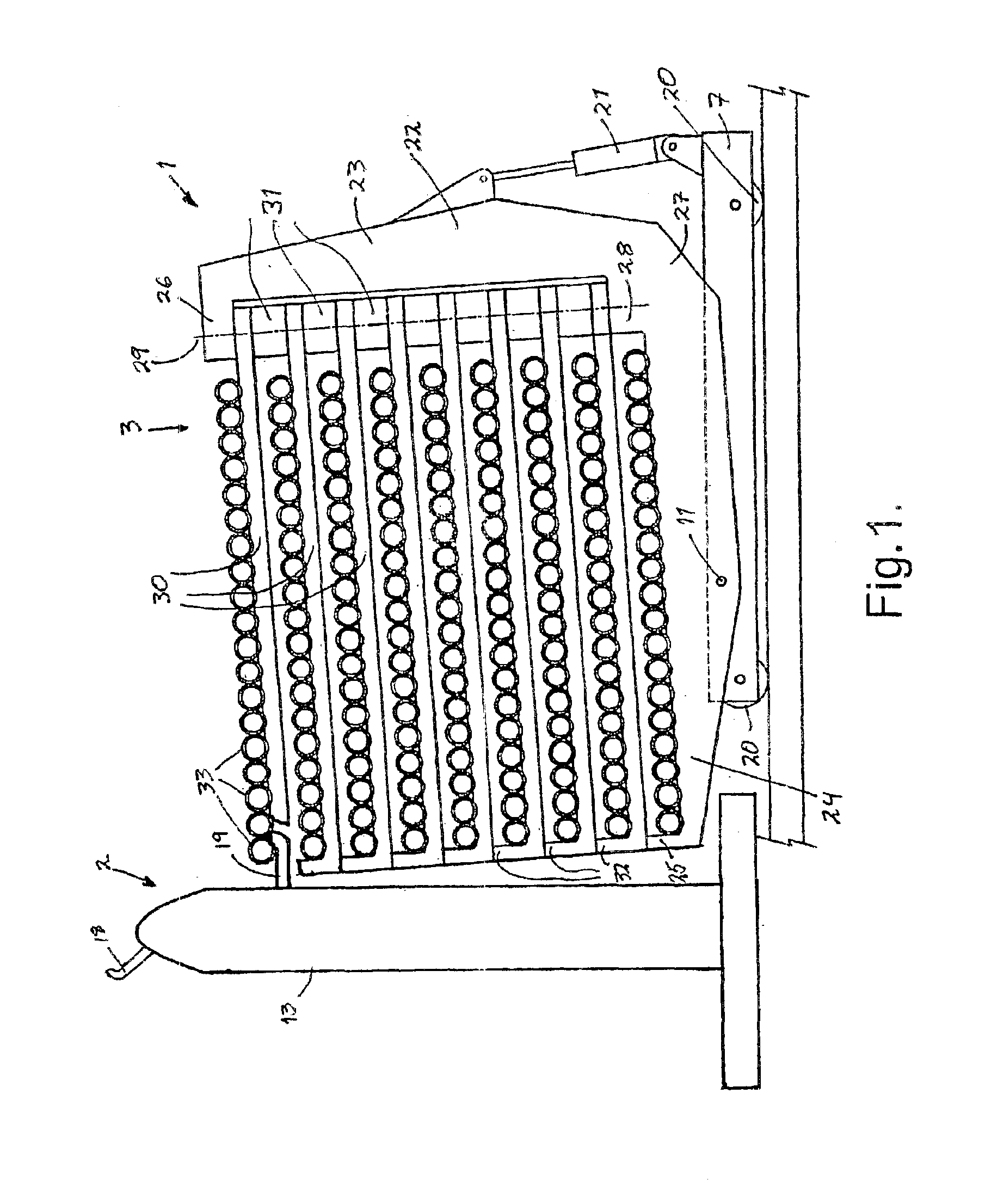

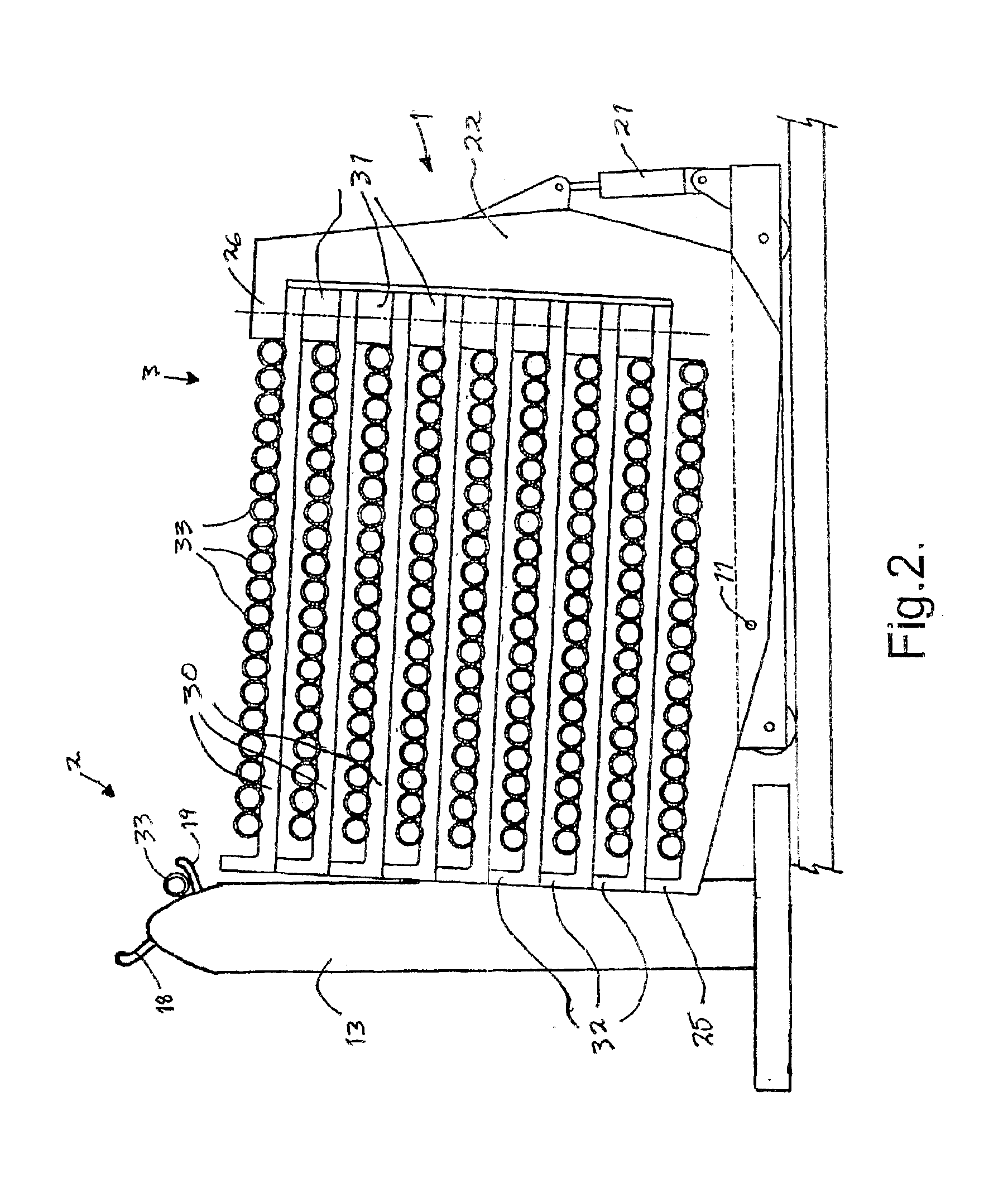

Horizontal pipe handling device

A device for handling pipes or stands including a transportation carriage for transport of pipes or stands between a pipe storage and a place for use. The carriage includes picking columns, each having a first picking arm arranged to move substantially vertically. The arms are capable of lifting at least one horizontal pipe or stand from the pipe storage. The picking columns are also equipped with a respective second picking arm, capable of motion substantially vertically on the opposite side of the picking column, to hold the pipe or stand between the first and second picking arms. Also described are a storage device and a pipe erecting device to be used together with the transportation carriage.

Owner:AKER KVAERNER MH

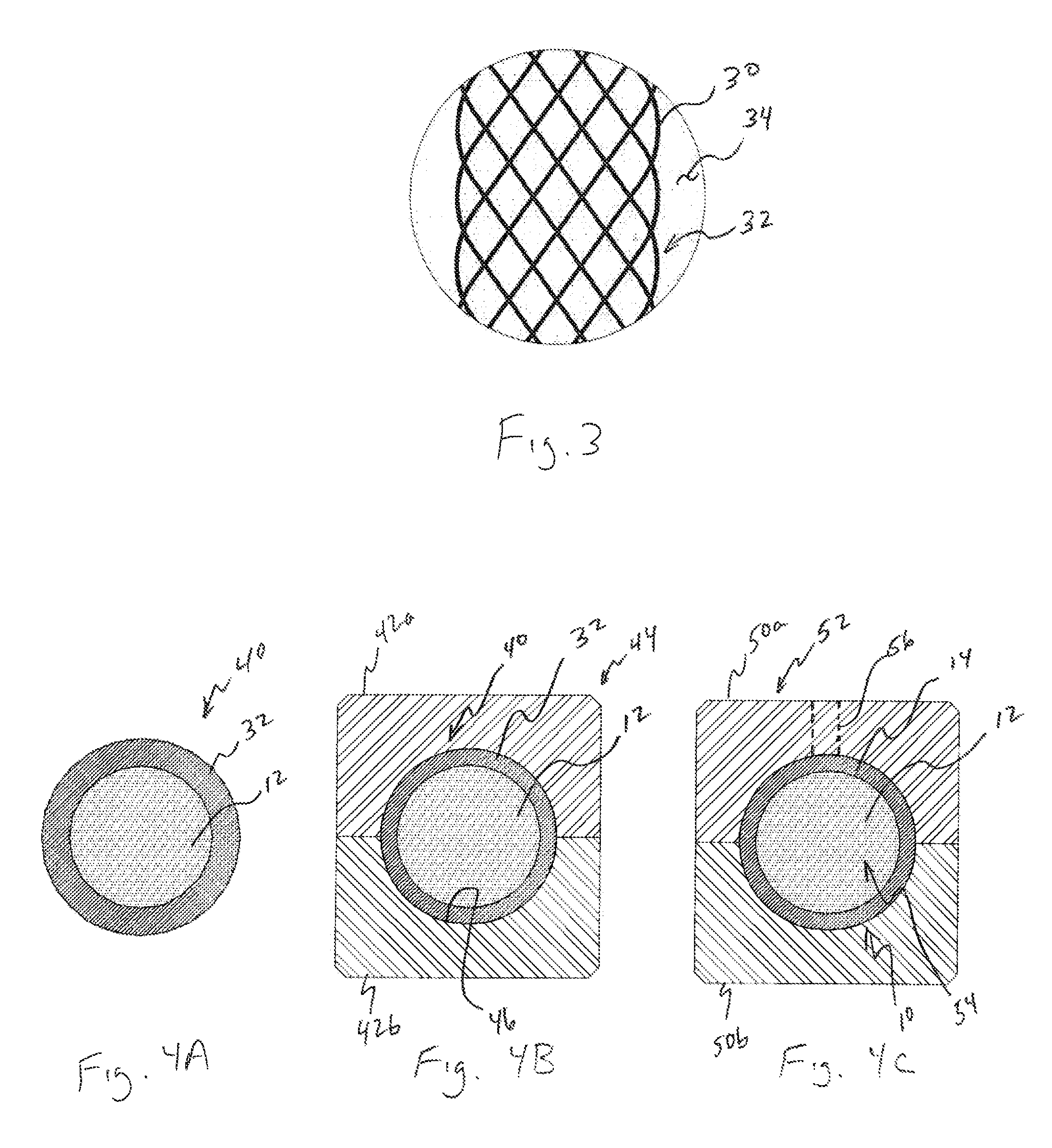

High strength, low density metal matrix composite ball sealer

High strength, low density ball sealer for sealing openings in oil or gas wells, such as perforations formed through the well casing or openings formed through slidable packers or sleeves received within a tubing string in the well, from the flow of a fluid injected into the well. The ball sealer is formed as having an inner core, and a metal matrix composite layer surrounding the core.

Owner:PARKER INTANGIBLES LLC

Precipitated aragonite and a process for producing it

InactiveUS6685908B1Less expensiveEfficient and less-expensiveInorganic/elemental detergent compounding agentsCalcium/strontium/barium carbonatesParticulatesAragonite

Owner:3P TECH

Polyester compositions containing cyclobutanediol and articles made therefrom

Described are polyesters containing (a) a dicarboxylic acid component having from 70 to 100 mole % of terephthalic acid residues, and up to 30 mole% of aromatic dicarboxylic acid residues or aliphatic dicarboxylic acid residues; and (b) a glycol component having from 40 to 65 mole % of 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues, and from 35 to 60 mole % of cyclohexanedimethanol residues; wherein the total mole % of the dicarboxylic acid component is 100 mole %, and the total mole % of the glycol component is 100 mole %. The polyesters may be manufactured into articles such as fibers, films, containers, bottles or sheets.

Owner:EASTMAN CHEM CO

Closed Cell Propylene-Ethylene Foam

ActiveUS20090247656A1Good anti-skid/traction propertyLight weightSolesSolid ballsFoaming agentAlpha-olefin

A closed cell foam material contains a propylene based polymer comprising from about 5% to about 32% by weight α-olefin units. The propylene based polymer has a heat of fusion, as determined by DSC, of less than 80 J / g. The material also contains 0.5 to 5 phr peroxide, 1.0 to 5.0 phr blowing agent, and 0.1 to 10 phr co-agent. The cells of closed cell foam material have a diameter in the range of 0.1 to 1.5 mm.

Owner:EXXONMOBIL CHEM PAT INC

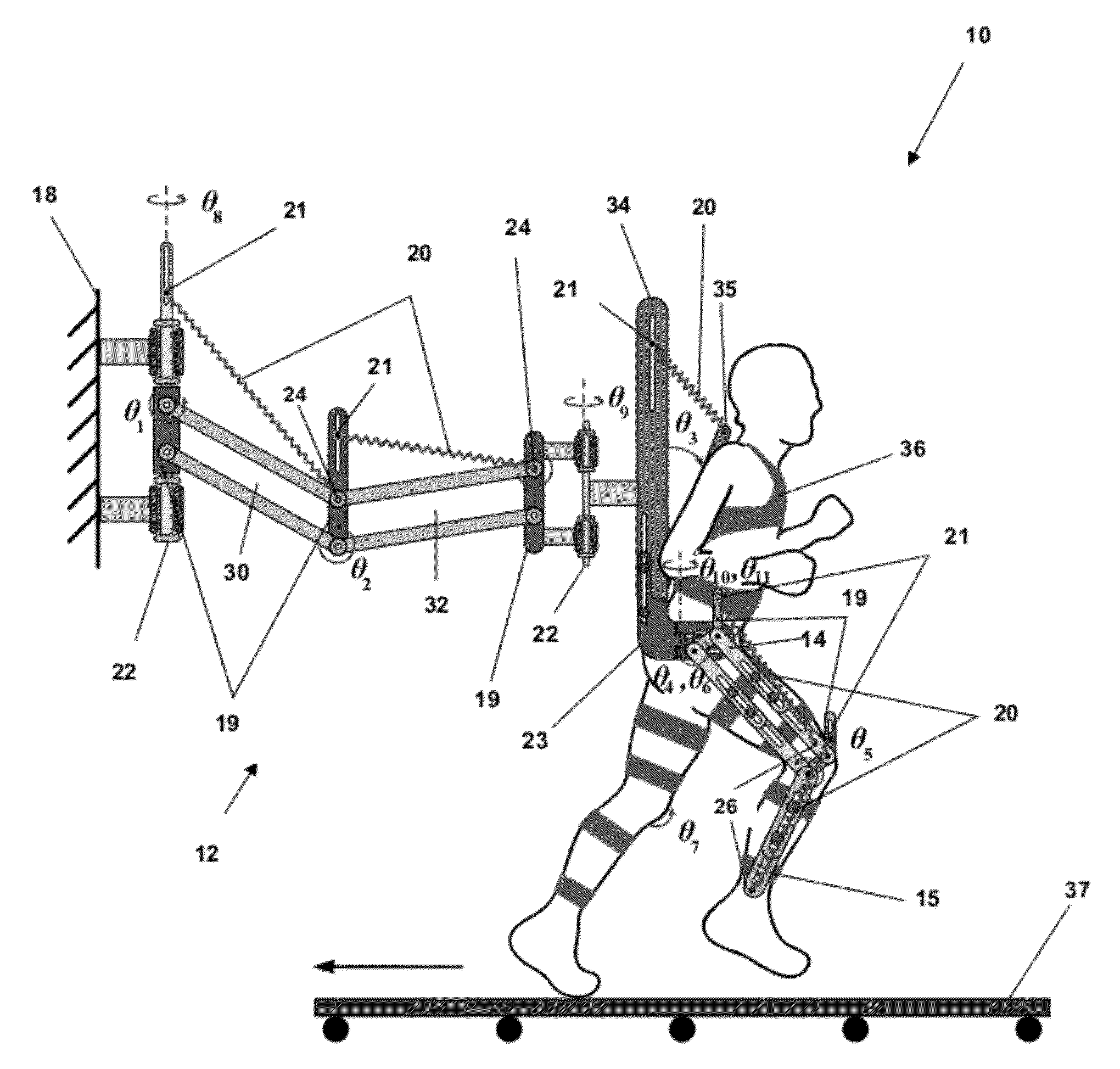

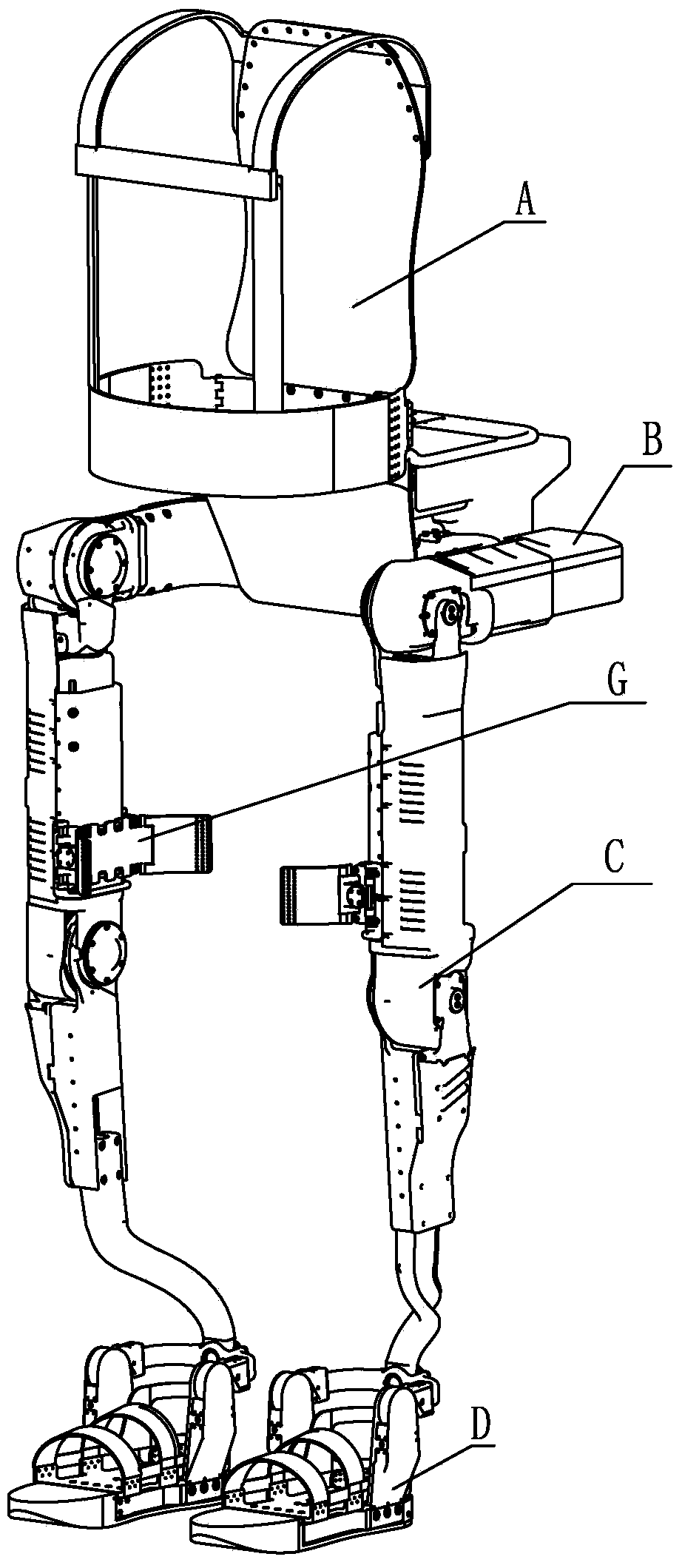

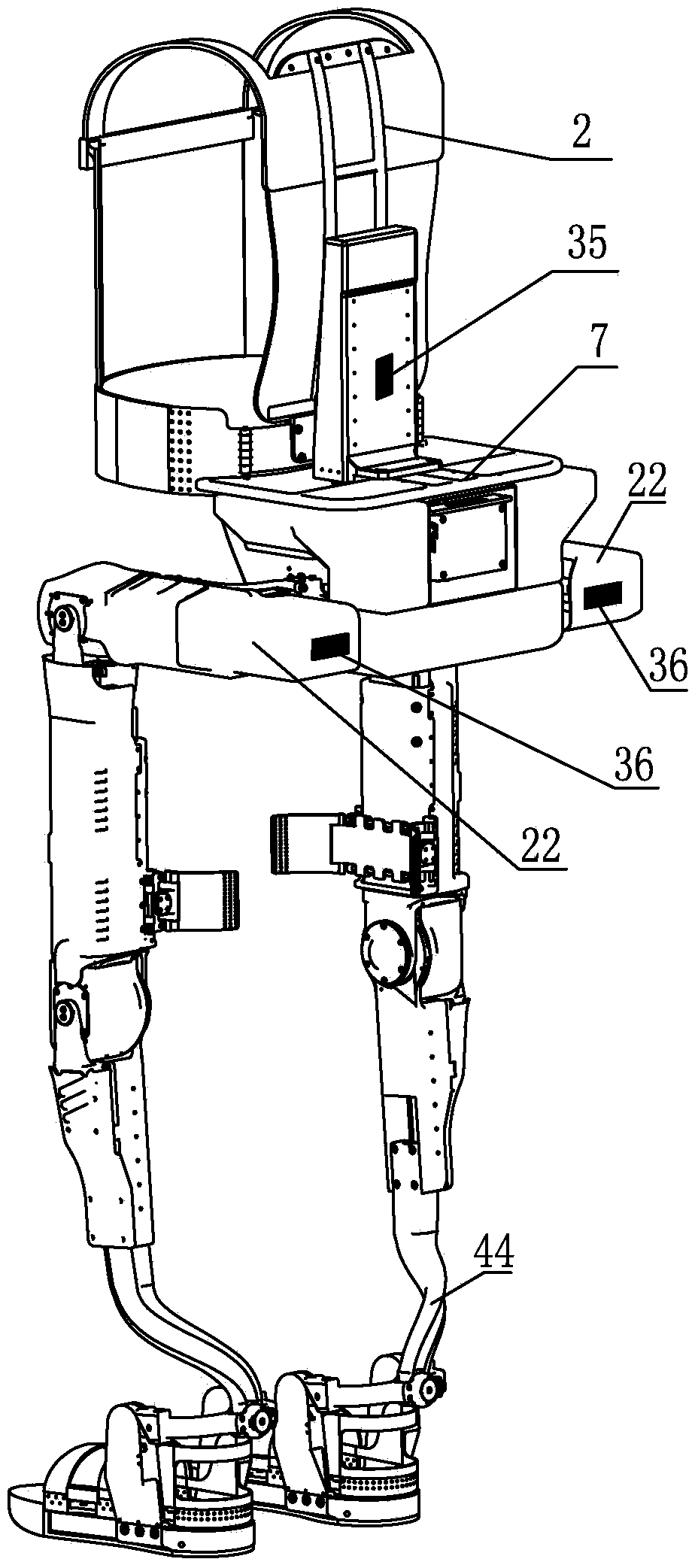

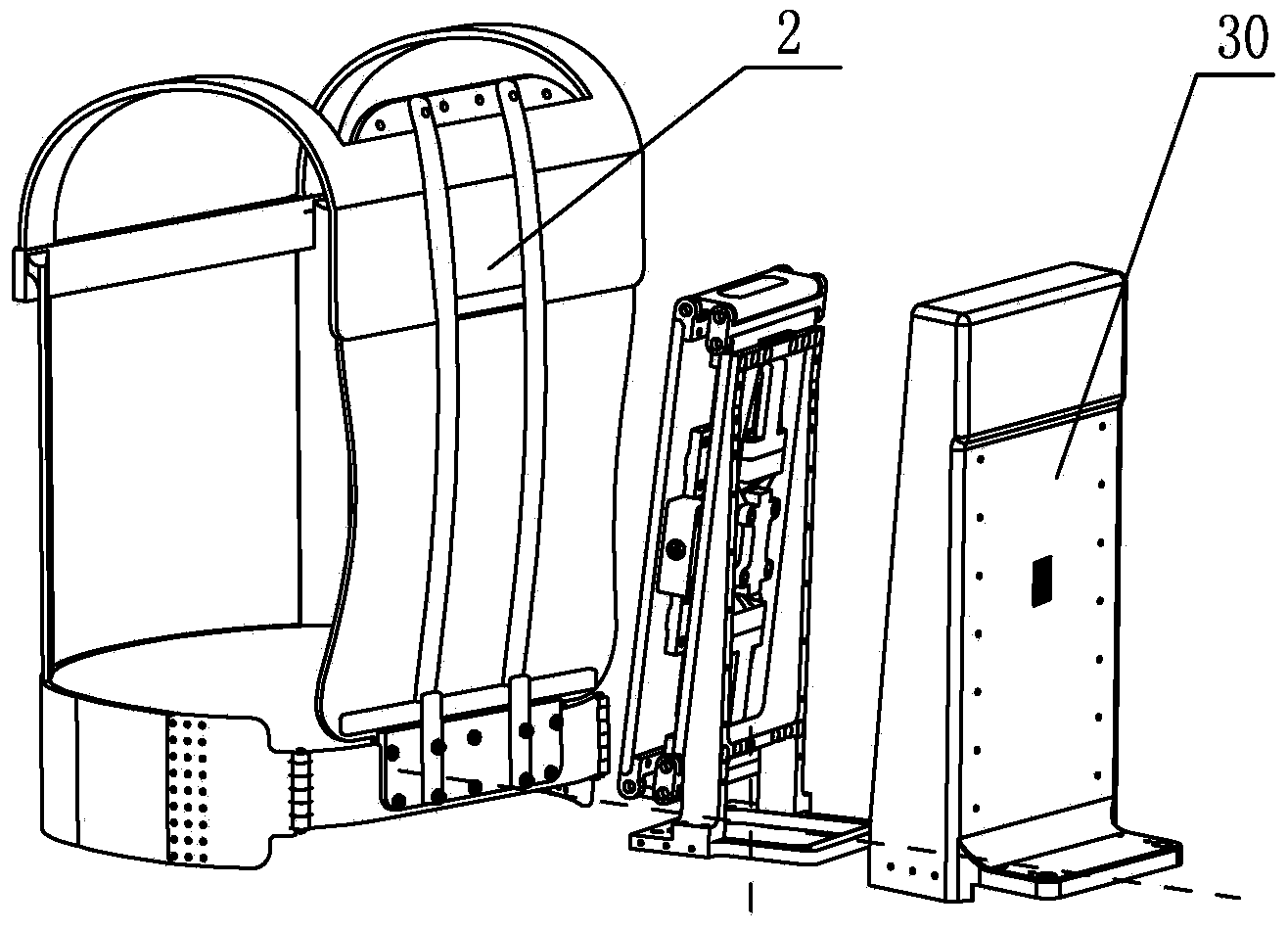

Exoskeleton robot system and kinematics extremity detection-based control method

The invention discloses an exoskeleton robot system and a kinematics extremity detection-based control method, and relates to an exoskeleton robot system and a control method to solve the problems that an accurate control effect cannot be achieved by the traditional electromyographic signal detection method for assisting in improving the walk of a human body, and man-machine interaction performance is low and an effective control method is lacked in the aspect of resisting self weight in the process of assisting in doing walk of the human body. The exoskeleton robot system comprises an upper body back, a left leg and a right leg; the left leg and the right leg respectively comprise a hip driving system, a knee driving system, a foot wearing system and a binding device; the exoskeleton robot system also comprises insole plates, a back detection shell, a nine-axis flight attitude measurement module, an industrial control computer, two thin film pressure sensors, two first angle sensors, two second angle sensors, two three-axis inclination sensors and three sets of three-dimensional contact force detection device. The exoskeleton robot system and the method are used for assisting in walking and performing detection and control of a moving posture of the human body.

Owner:HARBIN INST OF TECH

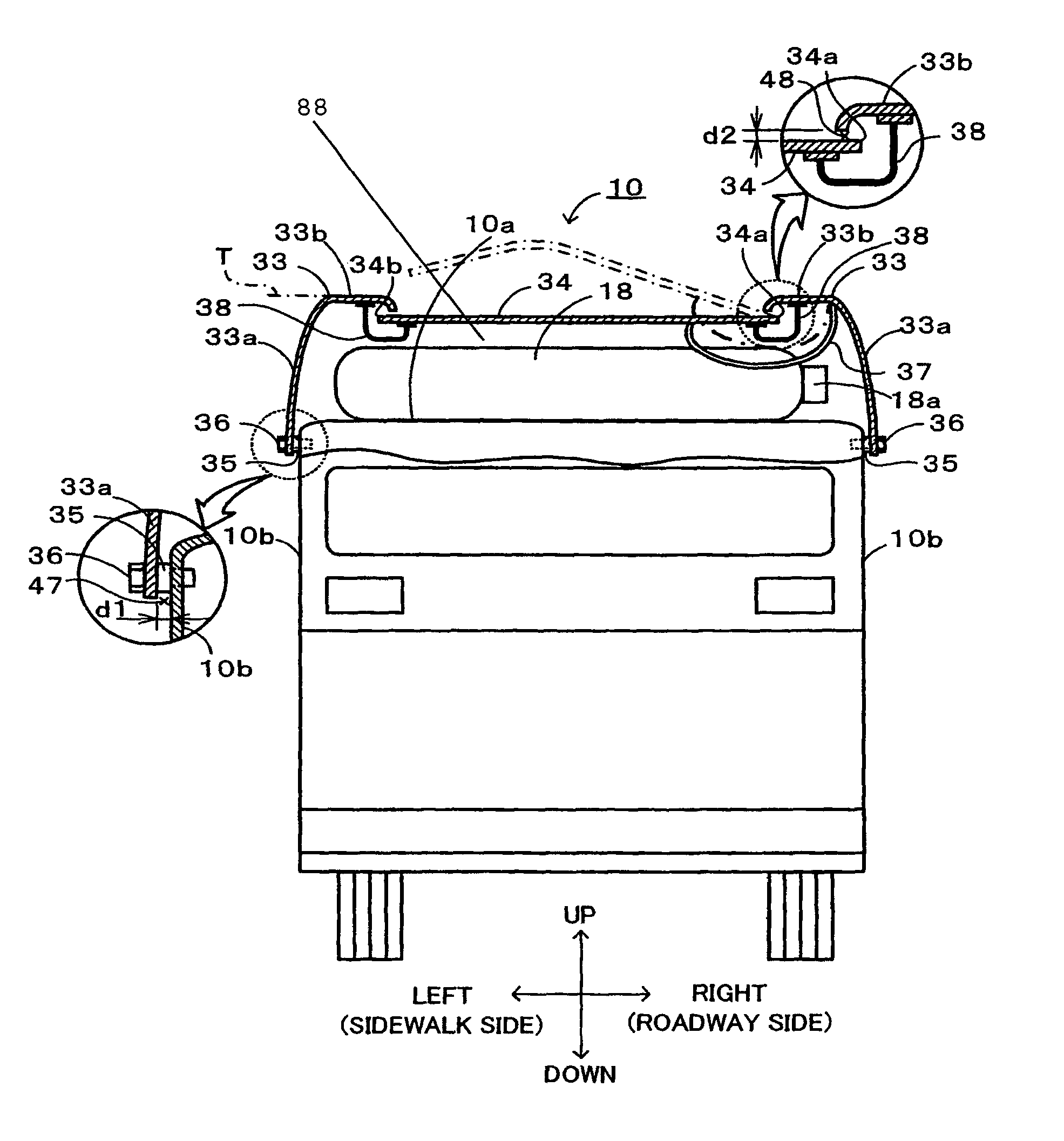

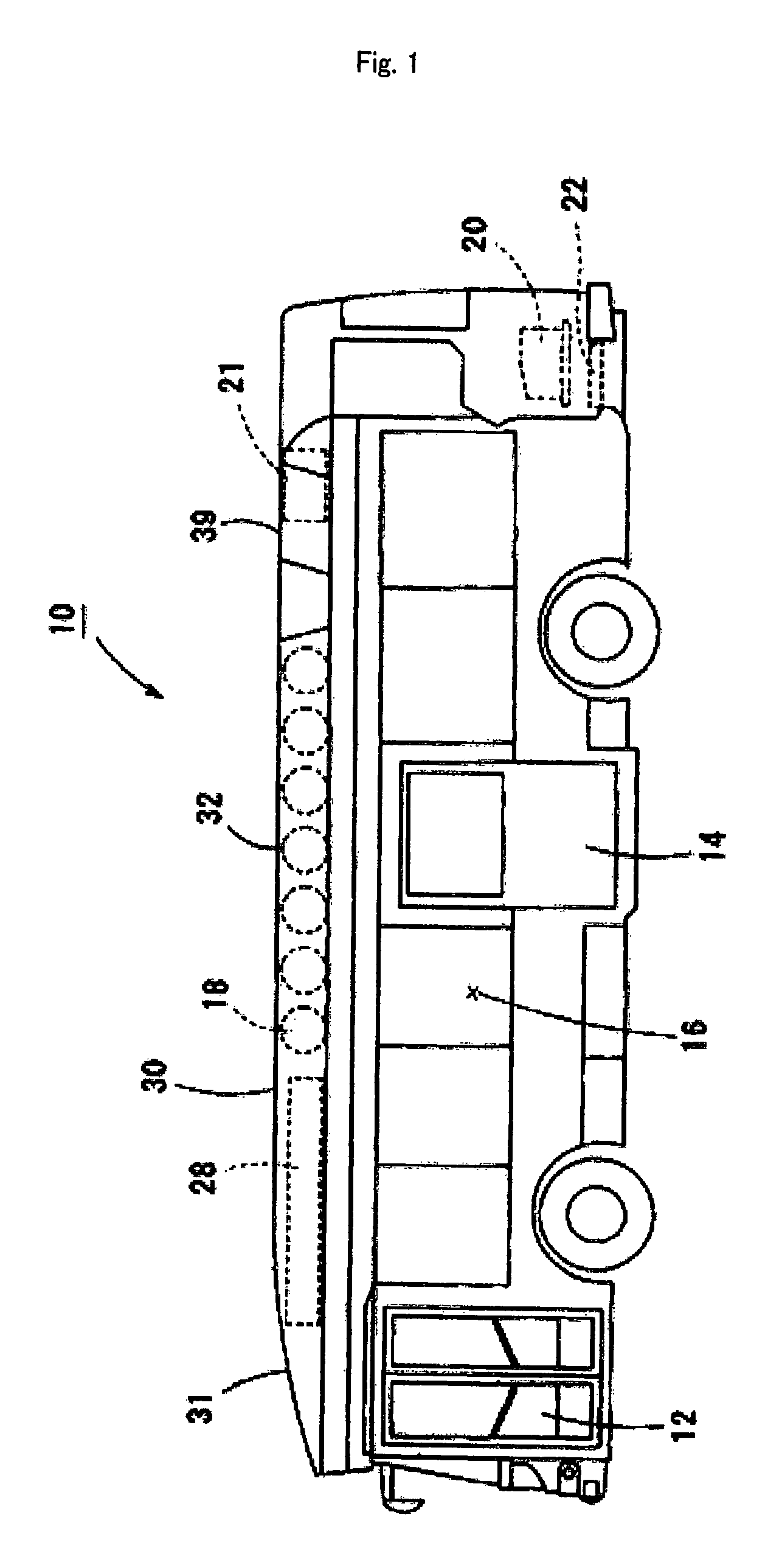

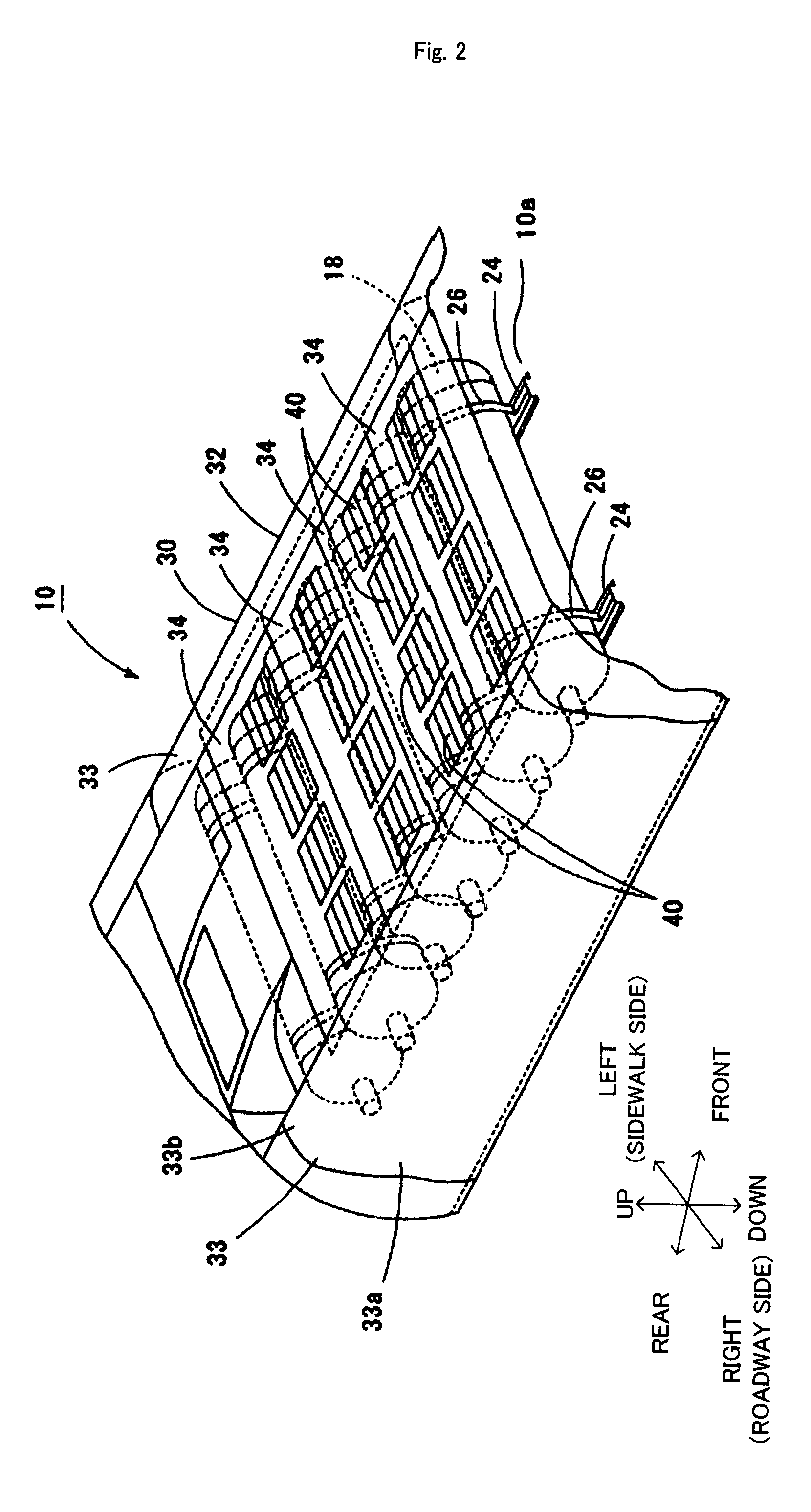

Gas fuel tank-equipped vehicle

ActiveUS7976067B2Reduce gravityEnsure efficient flowTank vehiclesUnderstructuresHydrogenShortest distance

Hydrogen leaking from a hydrogen cylinder has a lower specific gravity than air, thus rises in a cylinder housing space, and reaches a ventilating opening constituted by a group of slits formed in an upper surface of a roof cover. At this time, the ventilating opening is formed in a position above the hydrogen cylinder, and thus the leaking hydrogen can reach the ventilating opening in a short distance as compared with the case where the ventilating opening is formed in a position apart from the position above the hydrogen cylinder. The ventilating openings are provided in a plurality of locations, and thus the leaking hydrogen reaches the closest ventilating opening. The hydrogen gas reaches the ventilating opening, passes upward therethrough and flows outside.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com