Patents

Literature

391 results about "Interlaminar shear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

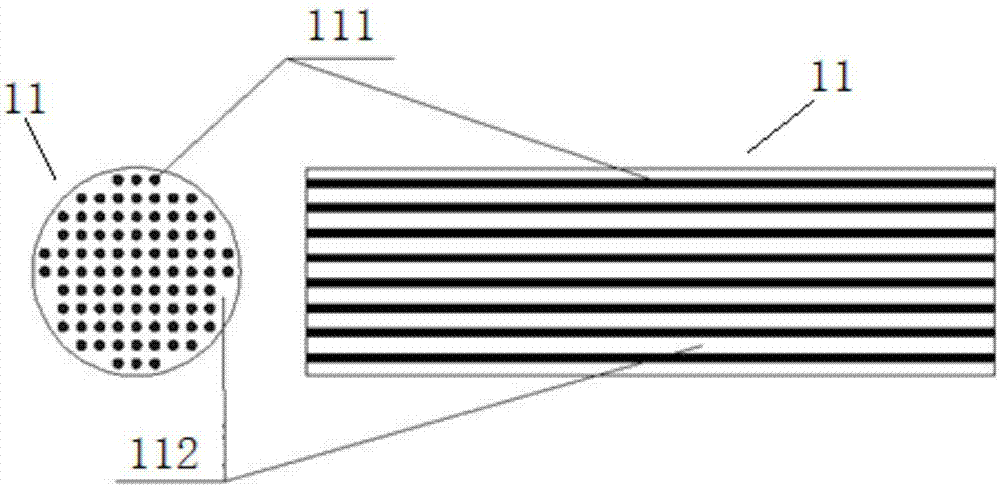

Two-dimensional fiber cloth reinforced composite material and preparation method thereof

InactiveCN101224989AImprove fracture toughnessImprove use reliabilityMetal powderStructural stability

The invention discloses a two-dimensional fiber cloth reinforced ceramics based composite material and the preparation technique, which adopts the two-dimensional fiber cloth as the reinforcing phase and the ceramic powder or the refractory metal powder as the stuffing, and the carbon and the carborundum as the base. The process steps are following: first the sizing agent with different ceramic powder and metal powder is coated on the two-dimensional fiber cloth, and then overlapping, puncturing and repeated densification are carried out. The preparation method has the advantages of lowering preparation cost and shortening preparation cycle, and the two-dimensional fiber cloth reinforced ceramics based composite material has the advantages of high shear strength between layers, structural stability and high reliability. The types of fiber cloth and the base can be adjusted and optimized in a wider range according to the applications, so as to be applicable for different fields.

Owner:NAT UNIV OF DEFENSE TECH

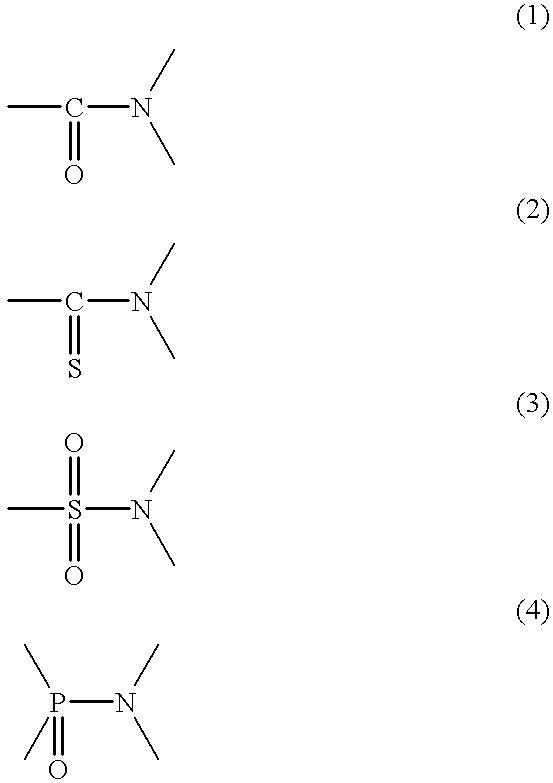

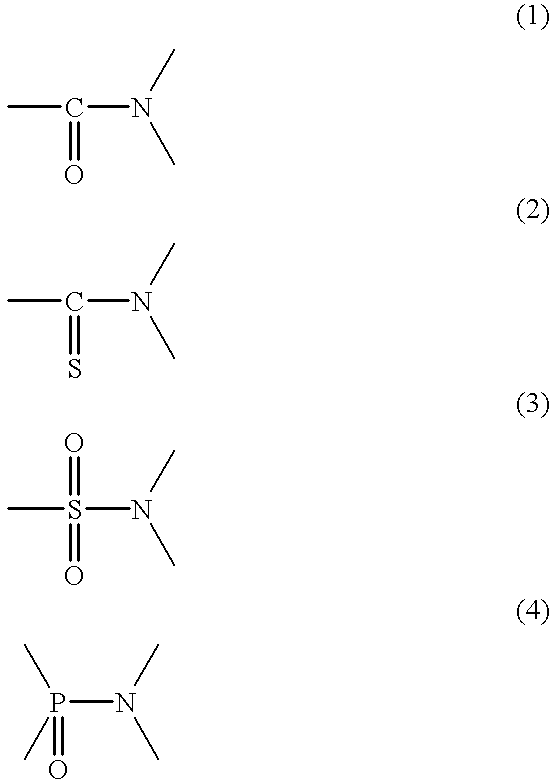

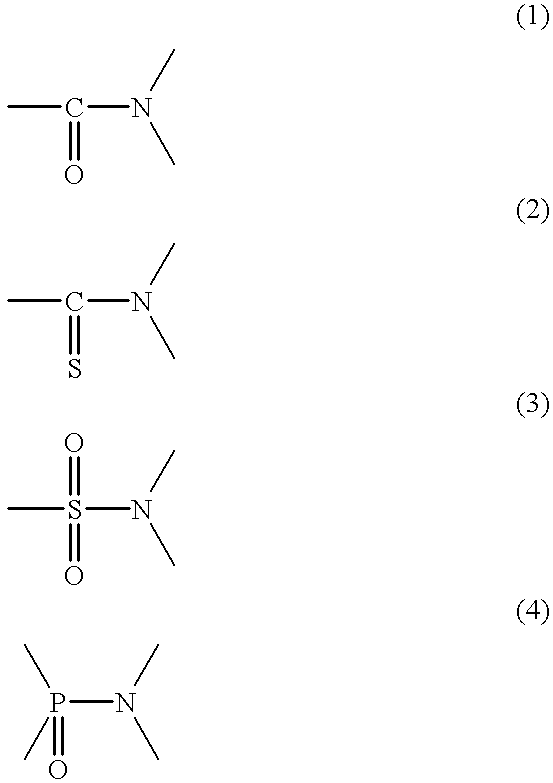

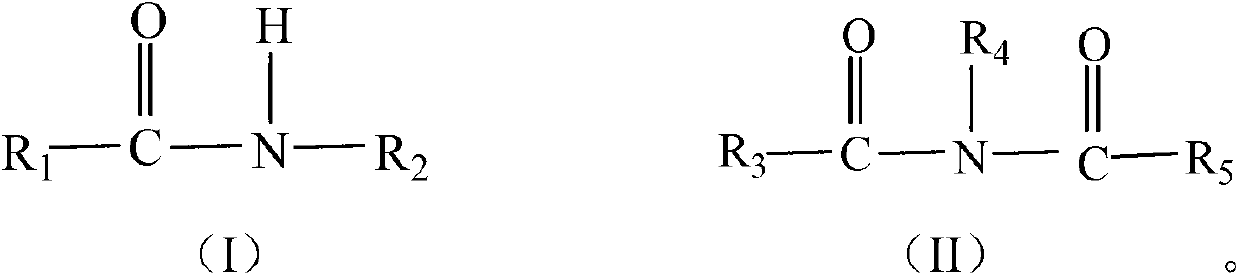

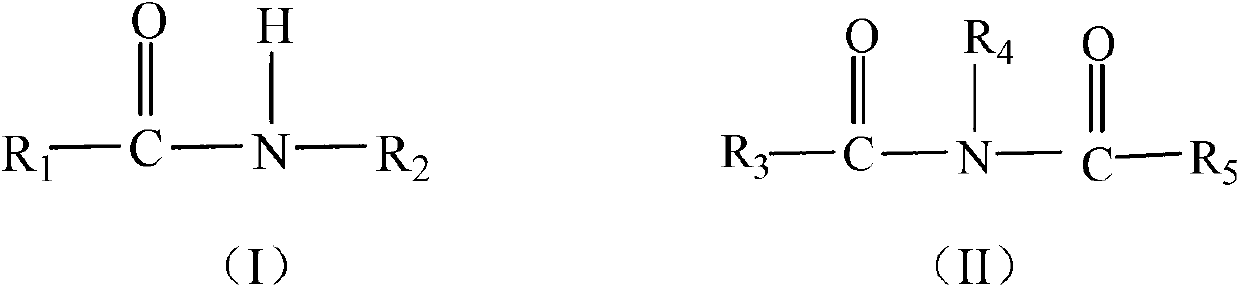

Epoxy resin composition for fiber-reinforced composite material, prepreg, and fiber-reinforced composite material

InactiveUS20020007022A1Synthetic resin layered productsThin material handlingInterlaminar shearFiber-reinforced composite

In order to realize the objectives stated above, the thermosetting resin composition for carbon fiber reinforced composite materials of the present invention chiefly comprises the following components. (A) Thermosetting resin (B) Compound containing one functional group which can react with thermosetting resin (A) or its curing agent, and a moiety selected from the following formulae (1) to (4) Furthermore, the present invention also relates to a prepreg formed by impregnating reinforcing fiber with the aforesaid resin composition and to carbon fiber reinforced composite materials comprising reinforcing fiber and a cured aforesaid thermosetting resin composition. In accordance with the present invention, there can be obtained a thermosetting resin composition where the adhesion to reinforcing fiber by the cured material and the elastic modulus of the cured material are excellent, and by using this resin composition there can be obtained carbon fiber reinforced composite materials which are excellent in their 0° compressive strength, 90° tensile strength and interlaminar shear strength, and which also have outstanding impact resistance.

Owner:TORAY IND INC

Carbon fiber prepreg, and a production process thereof

InactiveUS6117551AImprove impact resistanceHigh tensile strengthDecorative surface effectsAdhesive processes with surface pretreatmentHigh concentrationFiber bundle

PCT No. PCT / JP97 / 04642 Sec. 371 Date Aug. 11, 1998 Sec. 102(e) Date Aug. 11, 1998 PCT Filed Dec. 16, 1997 PCT Pub. No. WO98 / 26912 PCT Pub. Date Jun. 25, 1998The present invention relates to a carbon fiber prepreg. The carbon fiber prepreg of the present invention is characterized in that a carbon fiber bundle comprising a plurality of continuous carbon filaments and having a hook drop value of 10 cm or more as the degree of fiber entanglement is impregnated with a base resin mainly composed of a thermosetting resin, and that particles of 150 mu m or less in particle size made of a thermoplastic resin account for 20 wt % or less based on the weight of the entire prepreg and distributed at a higher concentration in the surface zone than in the inside. The carbon fiber prepreg of the present invention is good in tackiness and less changing in tackiness with the lapse of time, and can form a composite with an excellent compression interlaminar shear strength (CILS) at high temperature after moisture absorption while maintaining good impact resistance. It also allows the production of a composite very higher than the conventional composite in the compressive strength (LCS) of a cross laminated panel. The carbon fiber prepreg of the present invention can be preferably used as a structural member in such areas as aerospace area, sporting area and civil engineering and architecture area.

Owner:TORAY IND INC

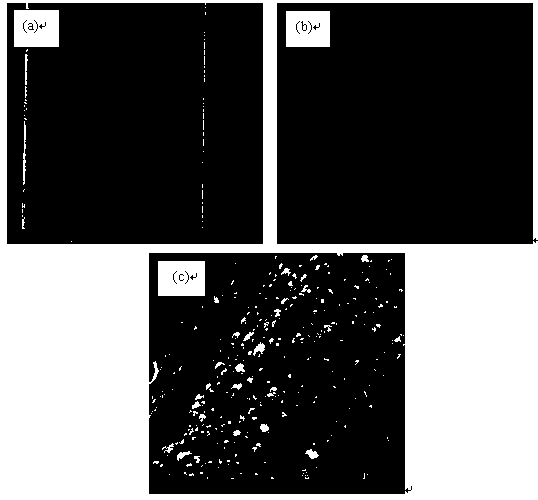

Method for preparing graphene oxide grafting surface modification carbon fiber

ActiveCN102787488AIncrease roughnessImprove interface performanceCarbon compoundsCarbon fibresCarbon compositesResin matrix

A method for preparing a graphene oxide grafting surface modification carbon fiber relates to a carbon fiber modification method, and is used for solving the technical problems that the existing carbon fiber has low surface activity, reduced surface tension and poor wettability with a resin matrix, and the interlaminar shear strength of a composite material is caused to reduce. The method comprises the steps as follows: 1, graphite oxidization; 2, separation of graphite oxide mother liquor; 3, functionalization of graphite oxide; 4, carbon fiber surface functionalization; and 5, carbon fiber surface graphite oxide treatment. The graphite oxide uniformly covers the carbon fiber surface, the roughness of the carbon fiber surface can be greatly improved, and accordingly, the interfacial properties of a carbon fiber reinforced composite material can be improved by an anchoring action. The interfacial shear strength of the surface grafting graphene oxide carbon fiber / carbon composite material which is prepared through graphene oxide grafting modification can be improved by 25% in comparison with that of the untreated surface grafting graphene oxide carbon fiber / carbon composite material.

Owner:HARBIN INST OF TECH

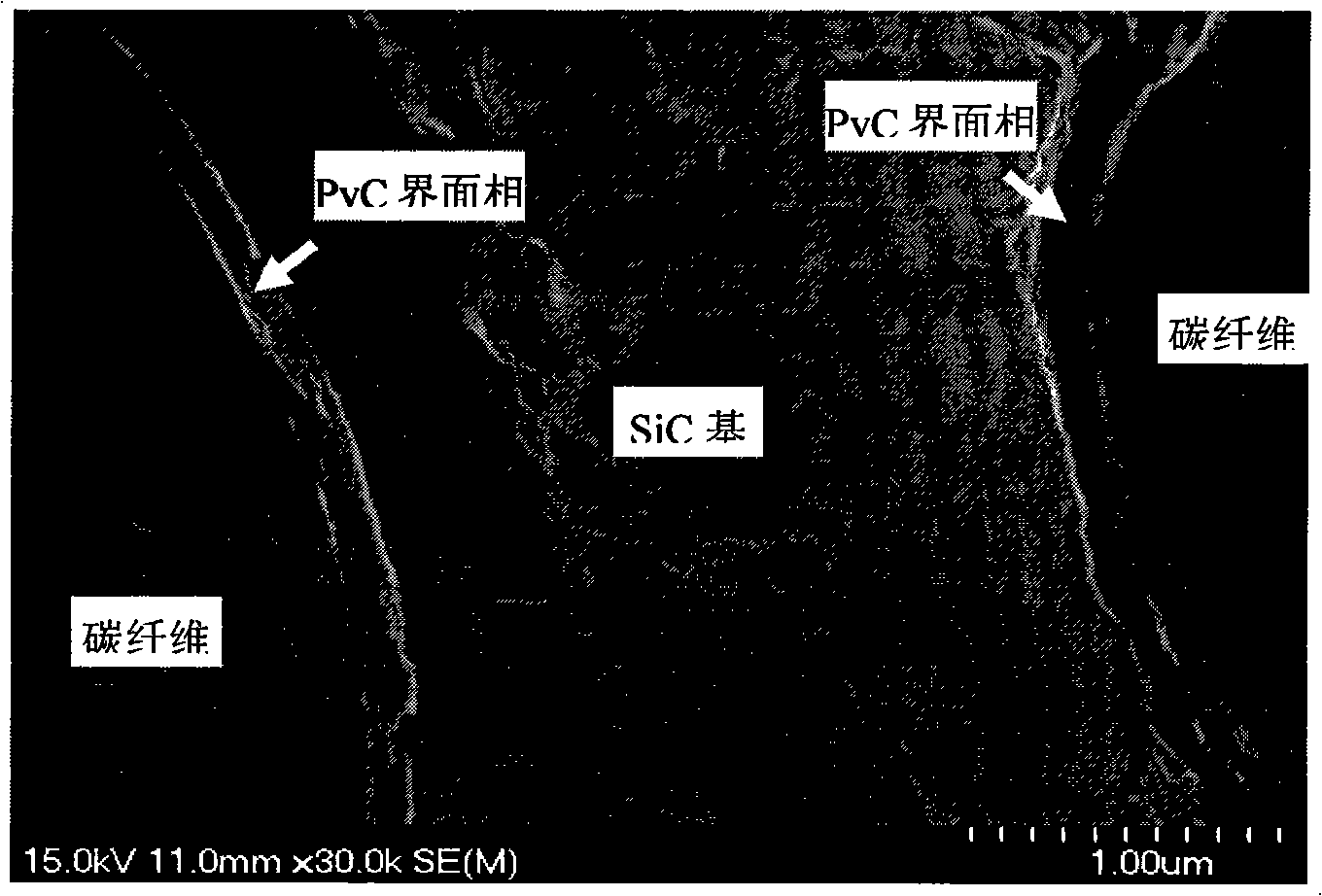

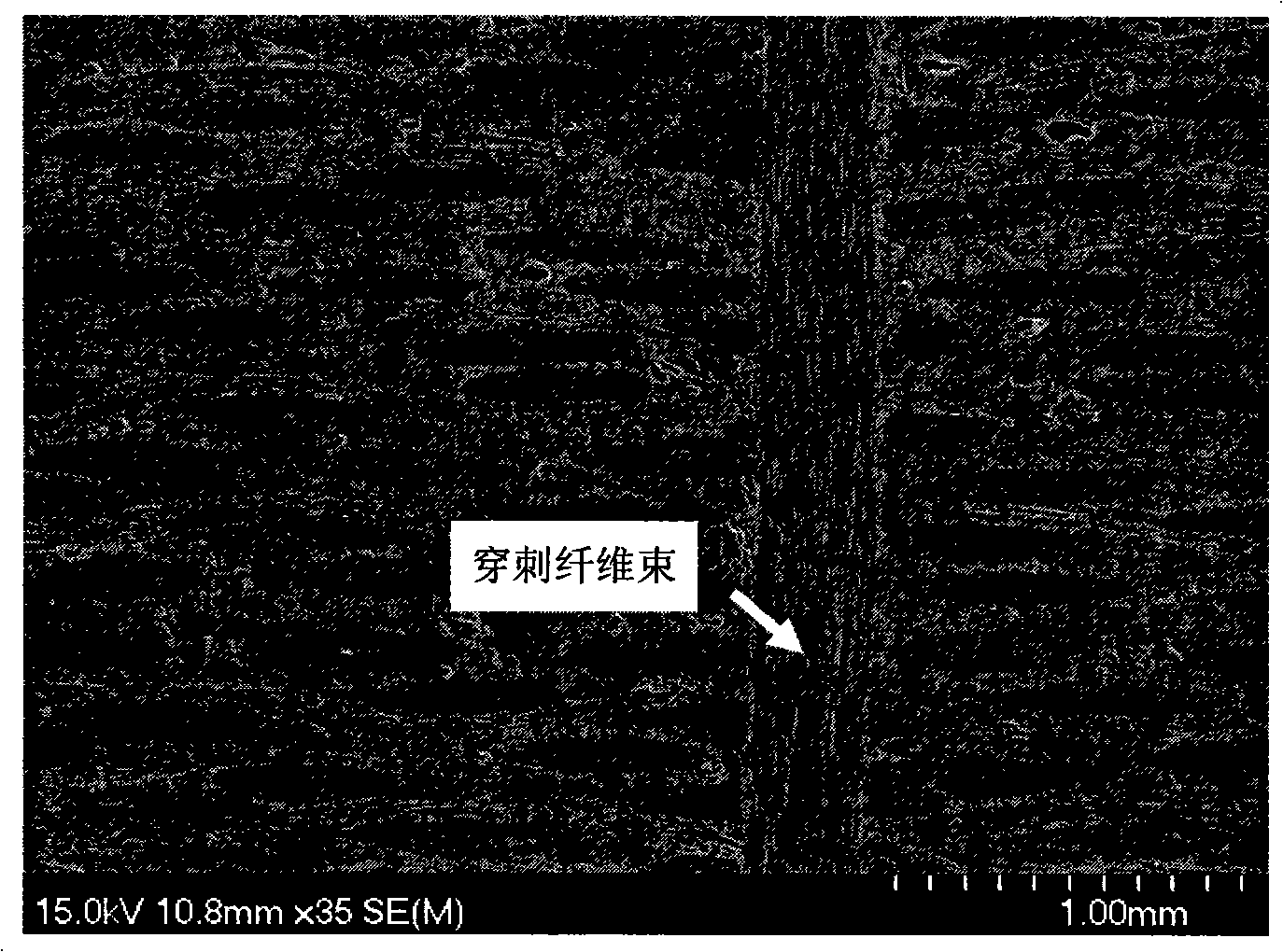

Process for preparing carbon/silicon carbide composite material

ActiveCN101337825AIncreased interlaminar shear strengthHigh tensile strengthInterlaminar shearPyrolytic carbon

The invention discloses a preparation method for a carbon / carborundum composite material. Firstly, carbon fibre is woven into single-layer plain cloth; a plurality of layers of the plain cloth are superposed, and are punctured and stitched with carbon fiber, thus forming a prefabricated carbon fiber body. The prefabricated carbon fiber body is arranged in a vacuum furnace and boiled off as well as pretreated; subsequently, pyrolytic carbon deposits, thus getting the C / C composite material; the multihole C / C composite material is heated; a SiC basal body is impregnated in the treated C / C composite material by adopting the CVI method, thus getting the C / SiC composite material. As the C / SiC composite material is prepared by puncturing and stitching the prefabricated carbon fiber body in combination of the CVI method. The interlaminar shear strength of the C-SiC composite material at 1200 DEG C is increased to 36 to 49MPa from 22 to 24MPa of the prior art; the tensile strength is increased to 275 to 345MPa from 220 to 300MPa of the prior art.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

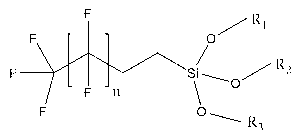

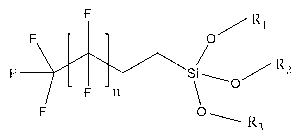

Aramid fiber surface modification method

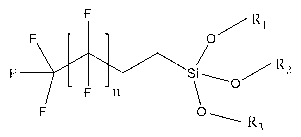

ActiveCN102797152AStable traits and qualityIncrease surface polarityFibre typesPolymer scienceOrganic solvent

Belonging to the field of chemical fiber production, the invention relates to an aramid fiber surface modification method. The method provided in the invention consists of: preparation of a surface modification treating agent, coating of the surface treatment agent, and drying treatment. For the surface modification treating agent in the surface modification treating agent preparation, a fluorocarbon silane coupling agent with the following molecular structure is adopted and dissolved in an organic solvent for direct use, or a fluorocarbon active agent is adopted and emulsified as well as dispersed in water for direct use. After being treated by the surface modification method provided in the invention, the aramid fiber is soft and dispersive, its characters and quality are stable. Also the fiber surface polarity is enhanced, and the interfacial properties of an aramid fiber and epoxy resin matrix are improved. The interlaminar shear strength of a modified aramid fiber / epoxy composite material can reach 50-58MPa.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

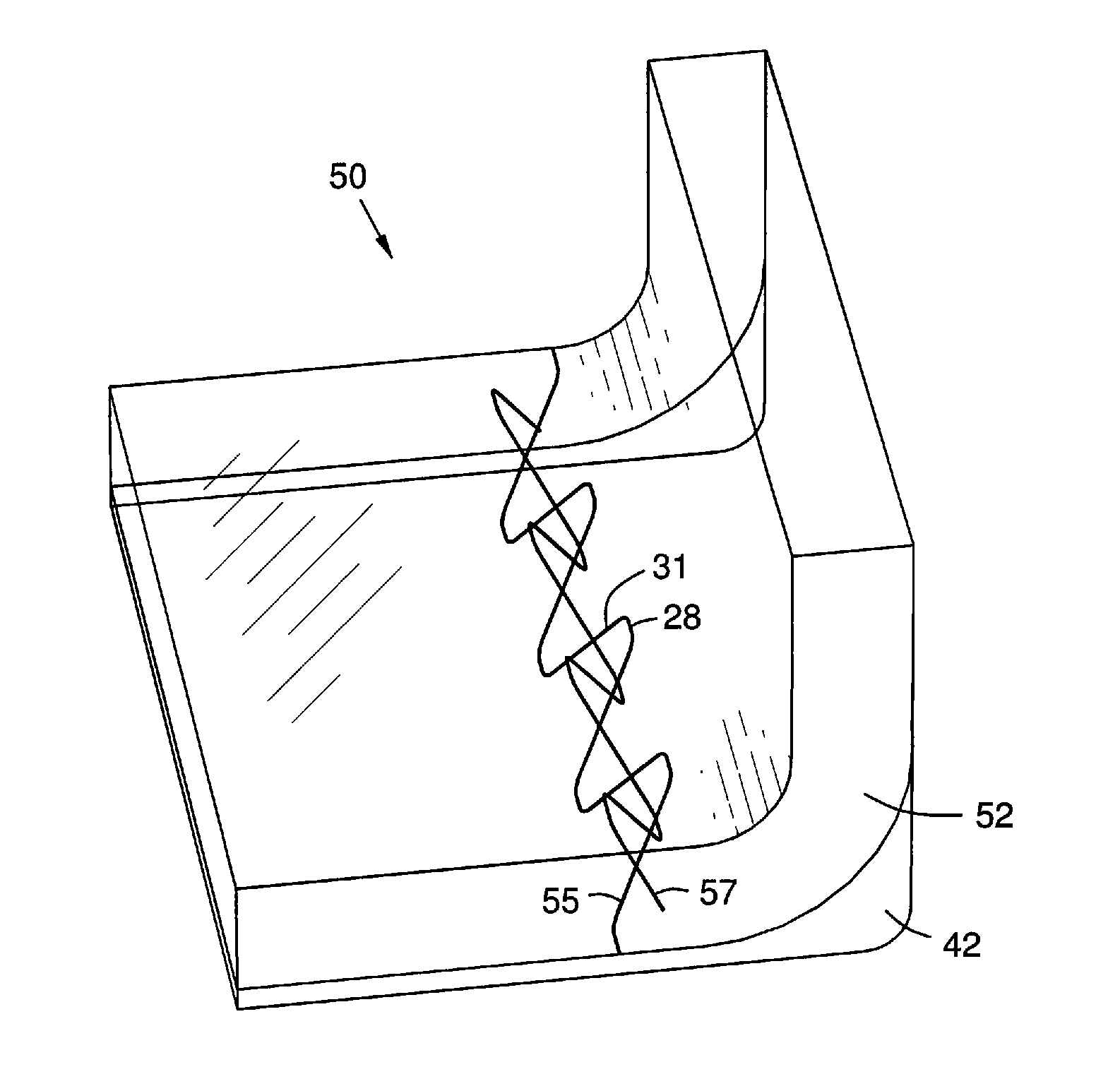

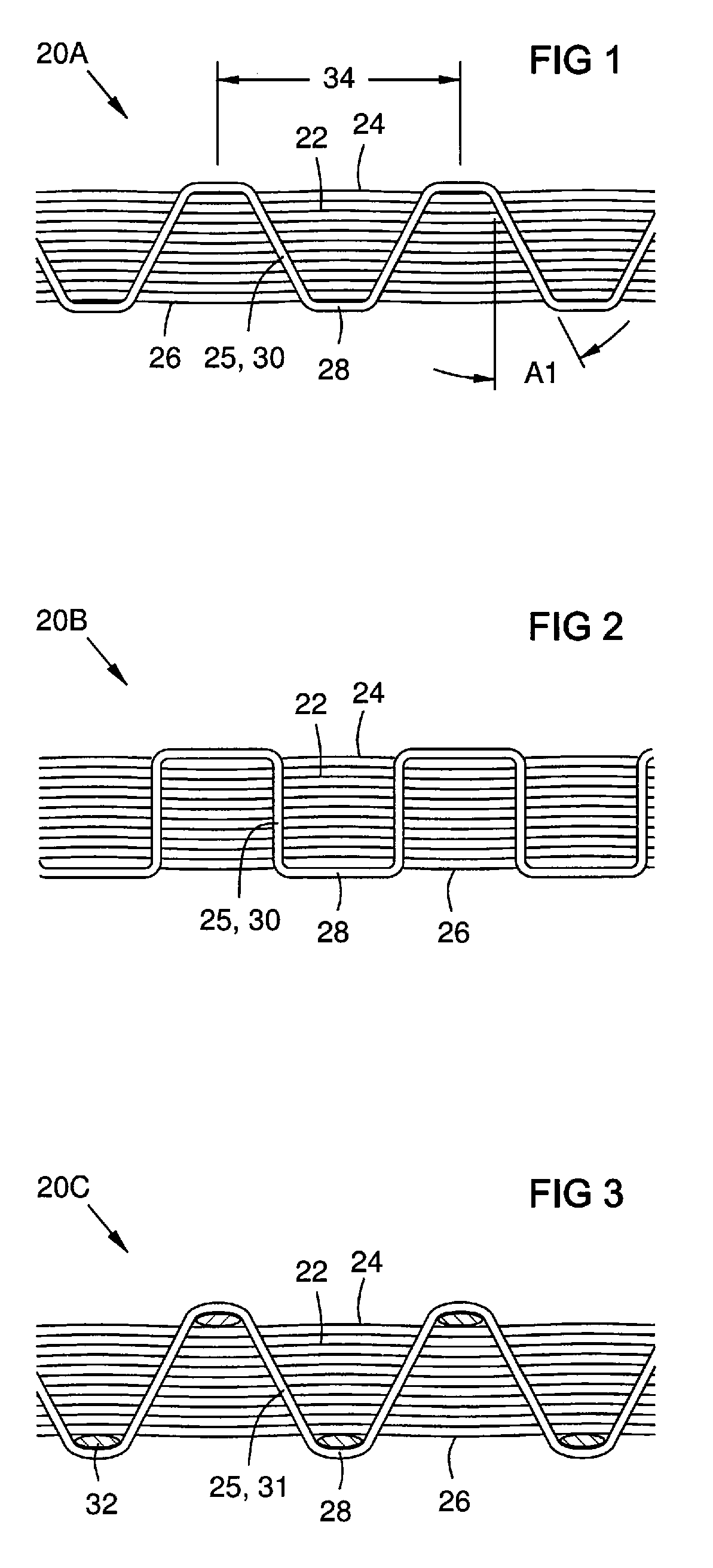

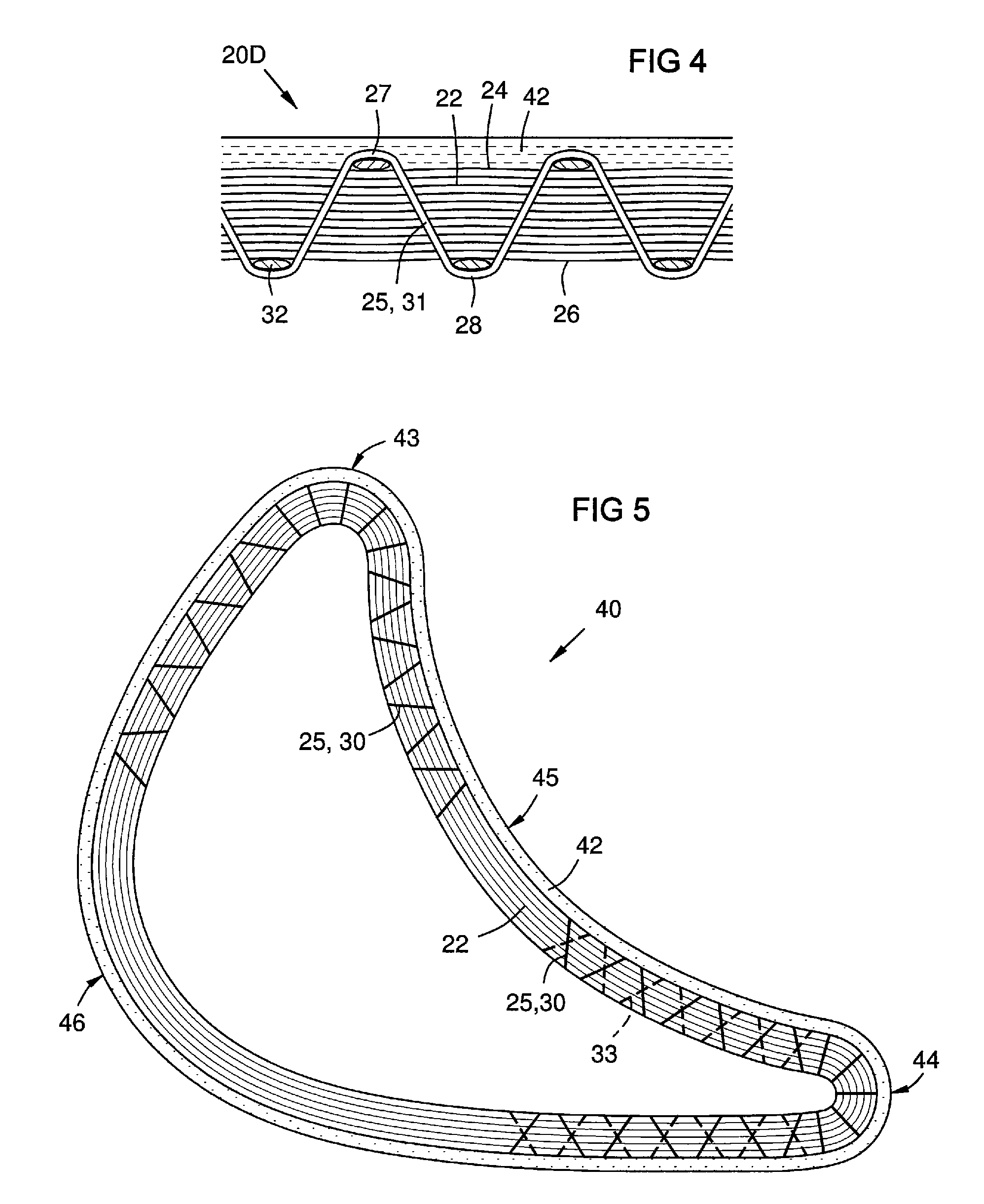

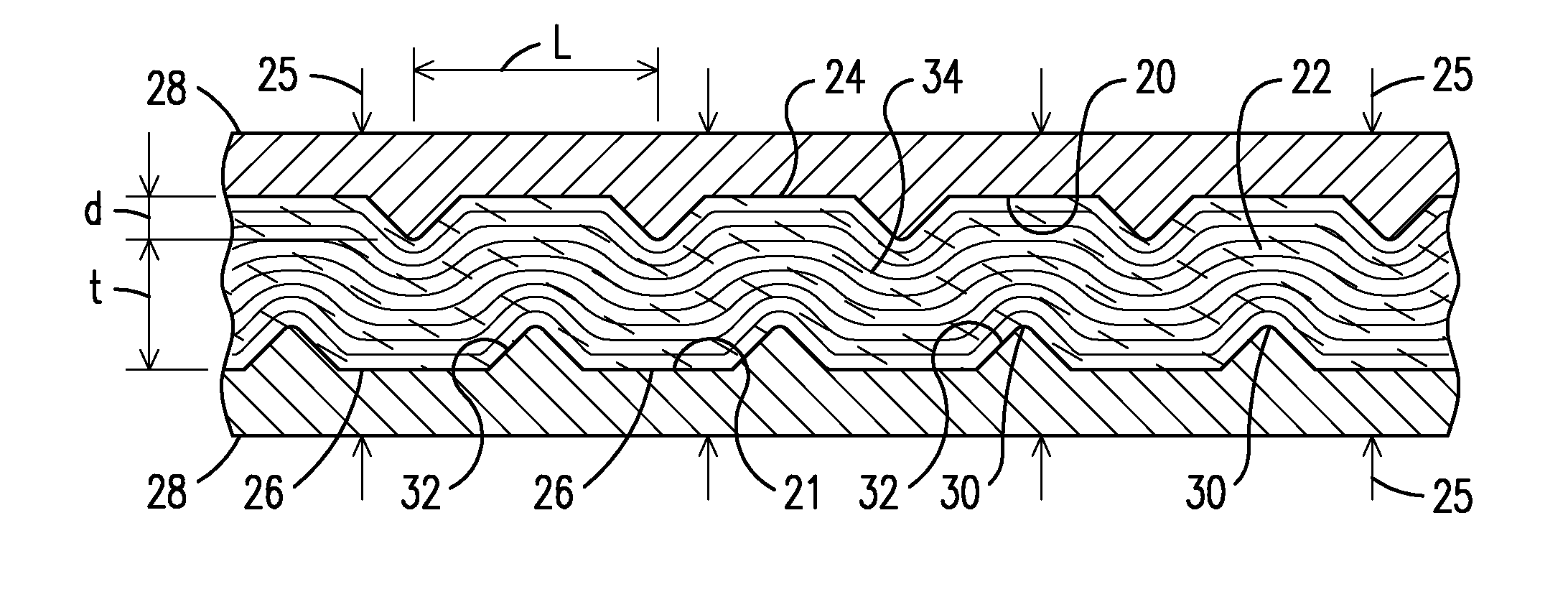

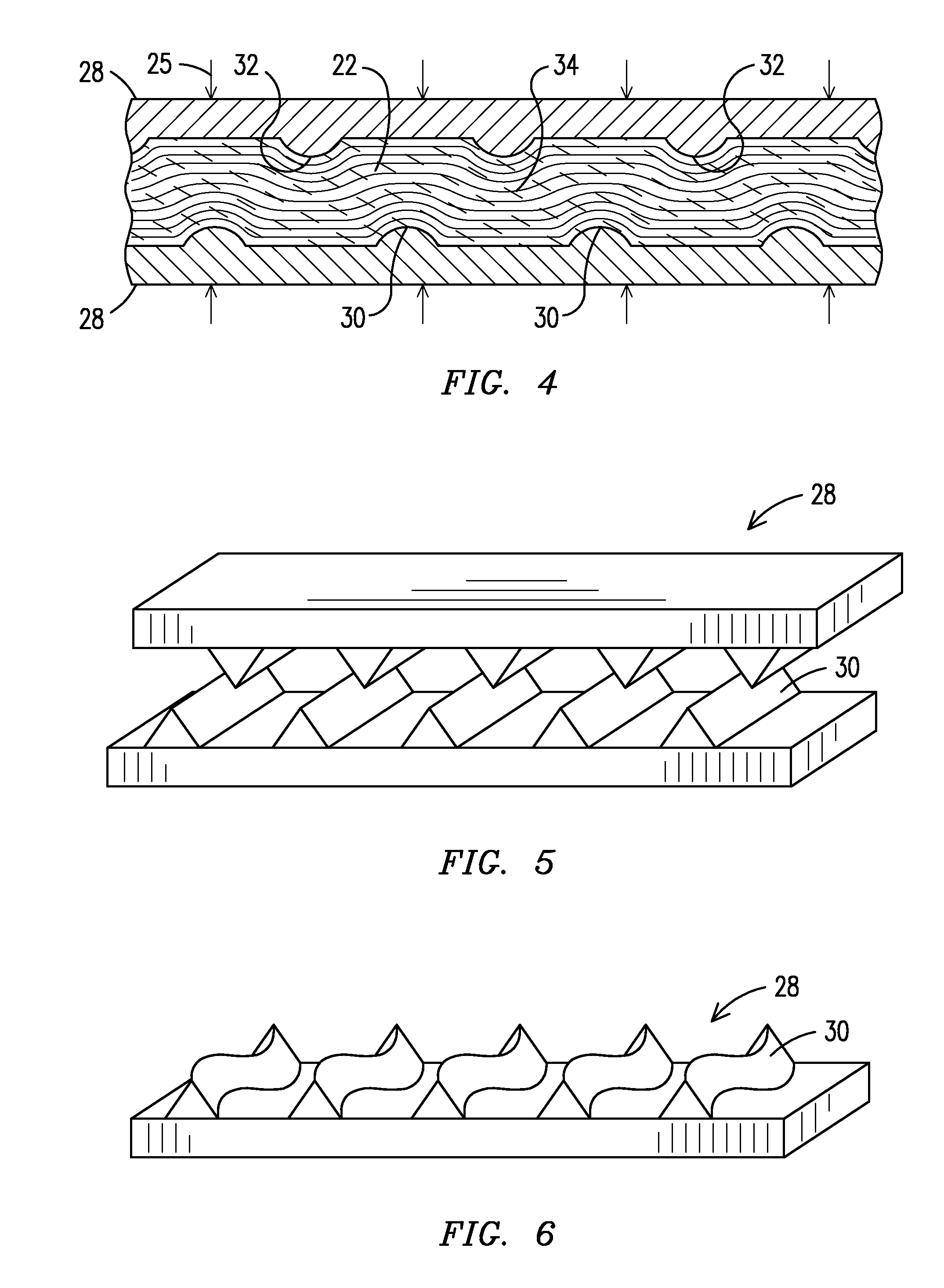

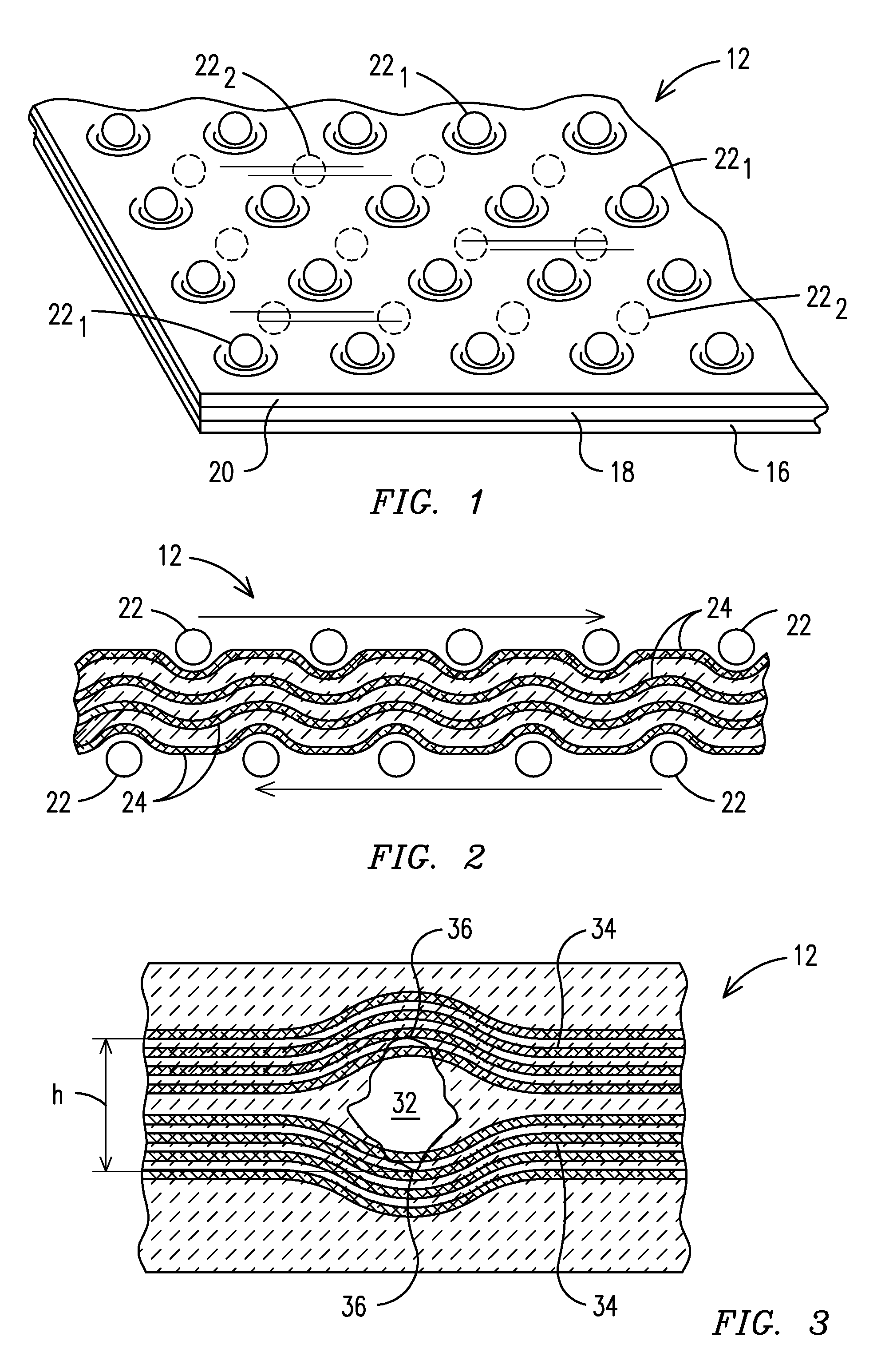

Ceramic matrix composite wall with post laminate stitching

A stitching geometry and method for selective interlaminar reinforcement of a CMC wall (20A). The CMC wall is formed of ceramic fiber layers (22) individually infused with a ceramic matrix, stacked, and at least partially cured. A row of holes is formed in the wall, and a ceramic fiber thread (25) is infused with a wet ceramic matrix and passed through the holes to form stitches (28, 30, 31). The stitches are then cured, causing them to shrink more than any remaining wall shrinkage, thus tensioning the stitches and compressing the wall laminae together. The stitches may have through-wall portions (30, 31) that are angled differently in different wall areas as a function of interlaminar shear over interlaminar tension, optimizing wall reinforcement locally depending on magnitude and direction of shear. Alternate rows of stitches (54, 56) may have offsets in a stitch direction (34) and / or different through-wall angles (A1, A2).

Owner:SIEMENS ENERGY INC

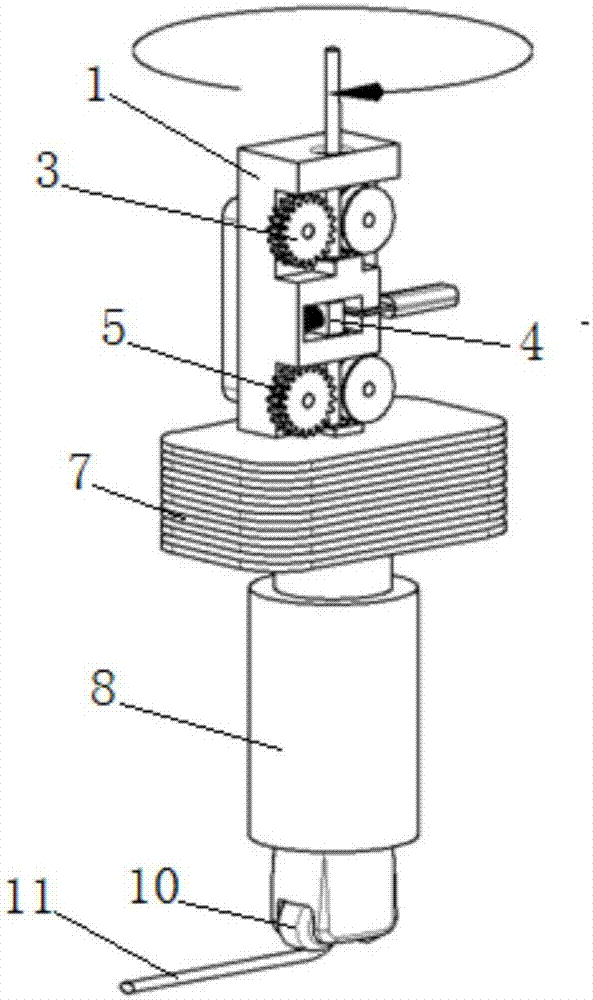

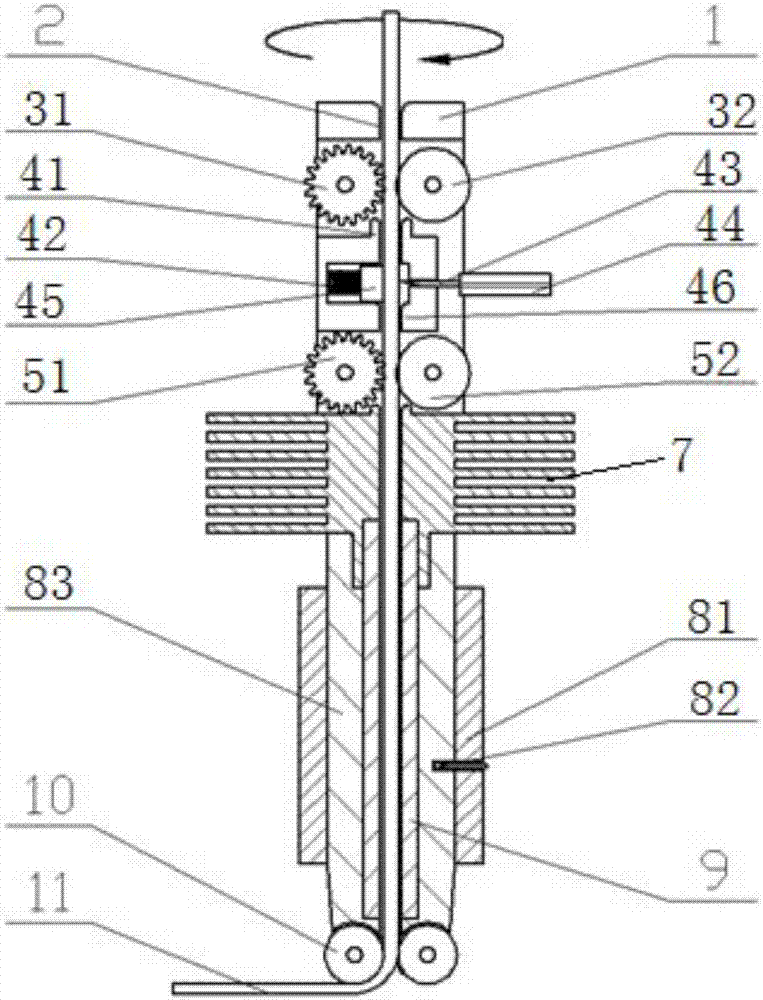

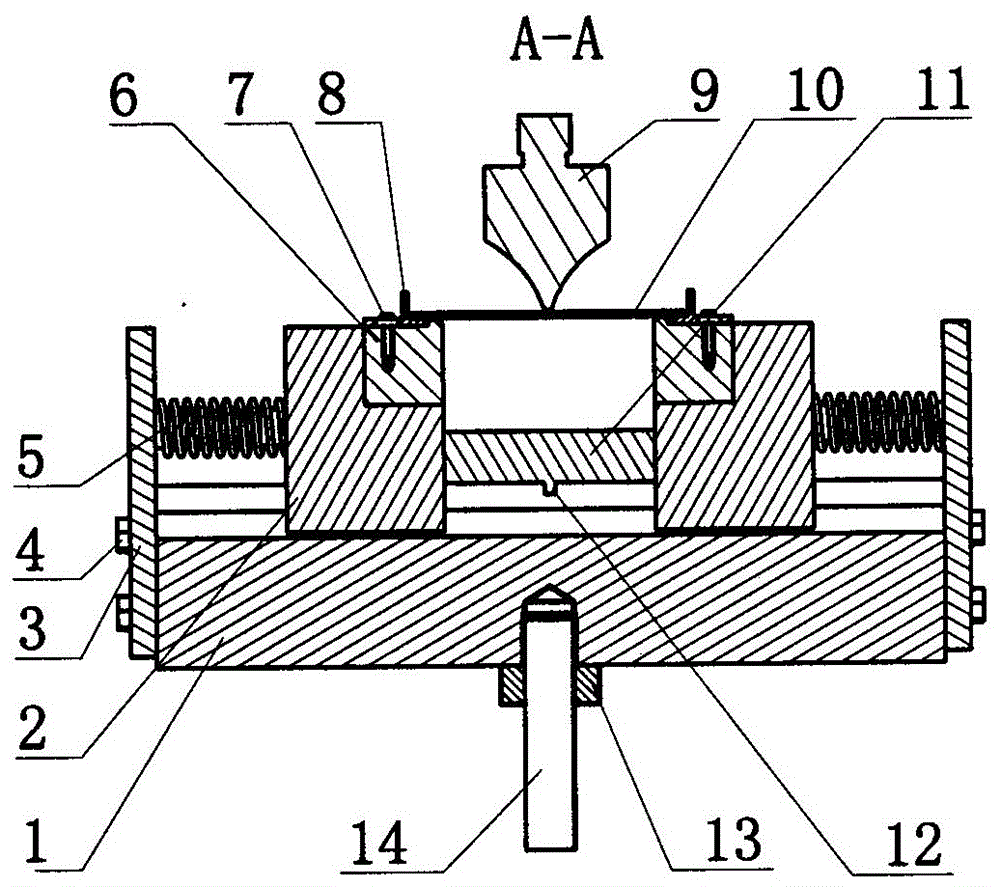

Continuous filament prepreg 3D printing spray head and 3D printer and printing method thereof

ActiveCN107379539APrecisely control the printing directionPrecise control of printing accuracy3D object support structuresApplying layer meansMolten stateInterlaminar shear

The invention discloses a continuous filament prepreg 3D printing spray head and a 3D printer and a printing method thereof. The continuous filament prepreg 3D printing spray head comprises a rotating mechanism, a fixed support, a heat dissipation device, a heating device, a guide channel and pressing wheels. The heat dissipation device is screwed to the lower end of the fixed support, the heating device is connected to the lower end of the heat dissipation device, the guide channel sequentially penetrates the fixed support, the heat dissipation device and the heating device and used for downwards supplying prepreg, and the pressing wheels are arranged at the lower end of the heating device, distributed on the two sides of the guide channel and used for compacting the continuous filament prepreg which is in a molten state. The fixed support is provided with a feeding device, a shearing mechanism and a shearing and re-feeding device, wherein the feeding device and the shearing and re-feeding device are used for providing power for downward feeding, and the shearing mechanism is used for shearing off the prepreg according to needs. By means of the continuous filament prepreg 3D printing spray head and the 3D printer and the printing method thereof, continuous filament prepreg 3D printing is achieved, the overall strength and the interlaminar shear strength of non-metal 3D printing are improved, and the technical difficulty of continuous filament prepreg structural component forming is lowered.

Owner:SHANGHAI AEROSPACE SYST ENG INST +1

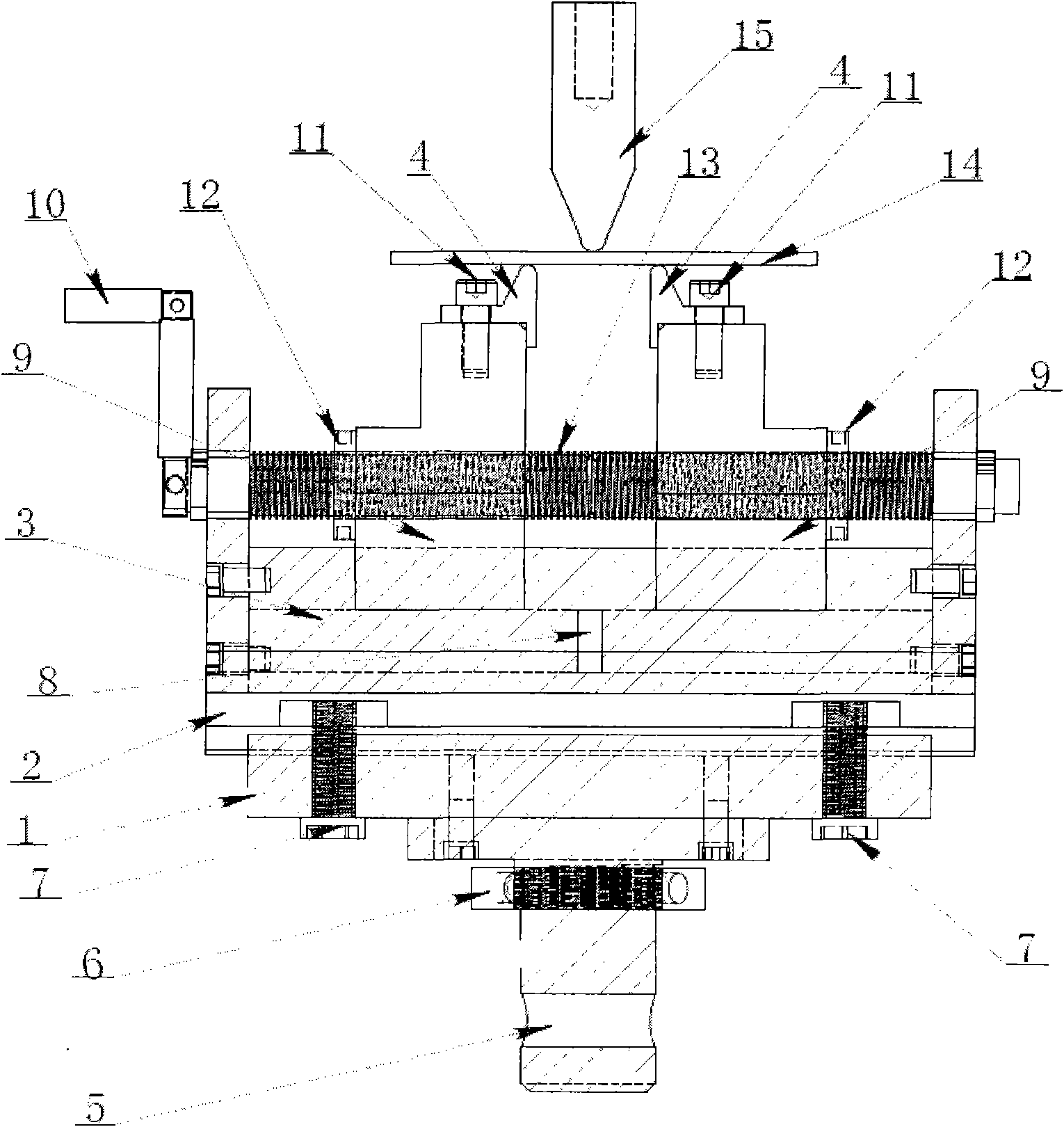

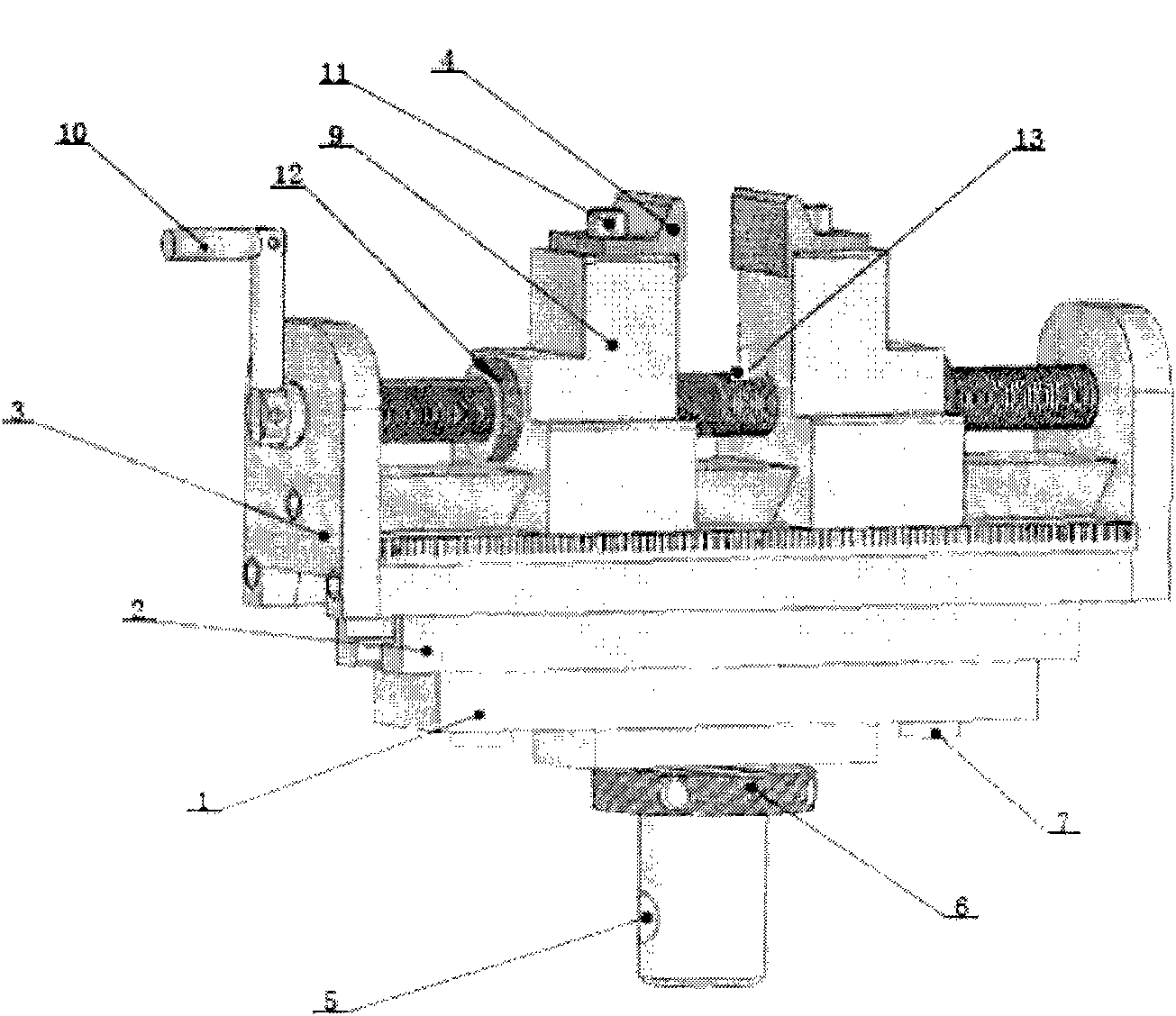

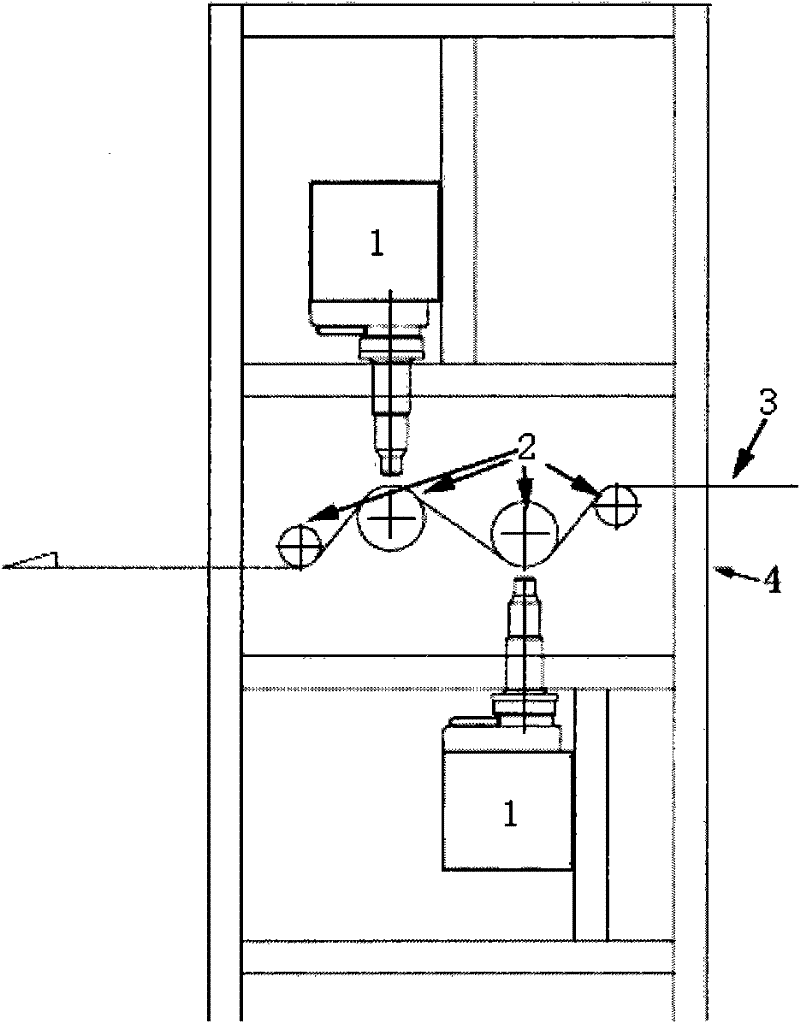

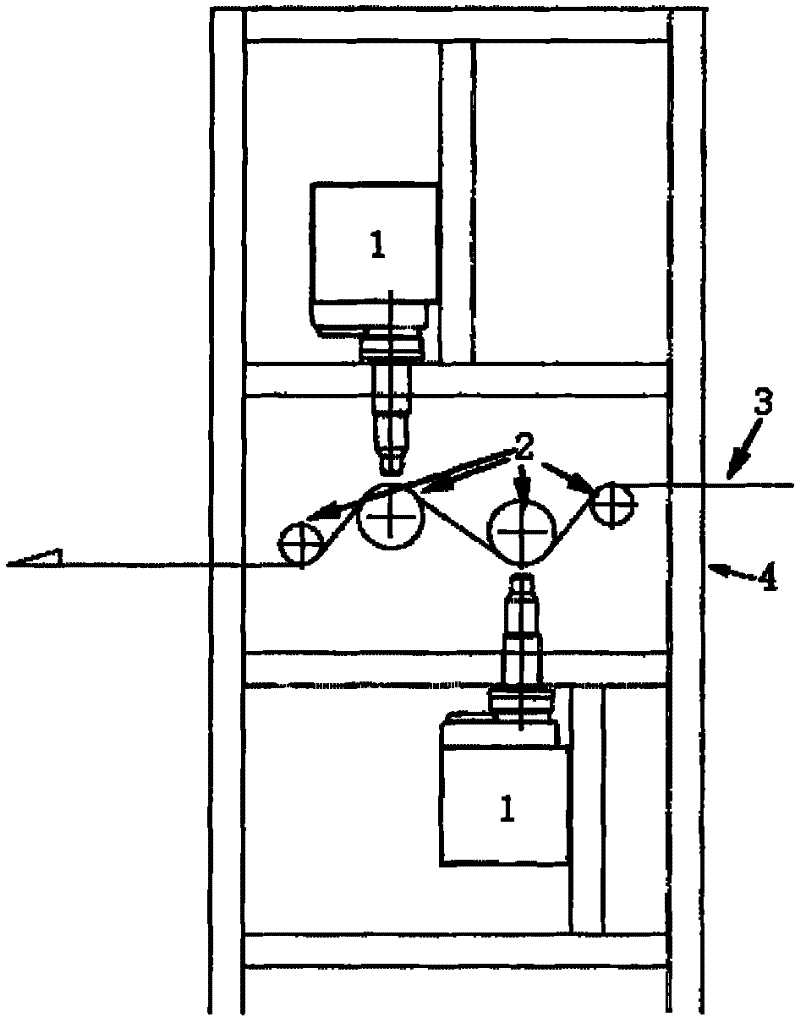

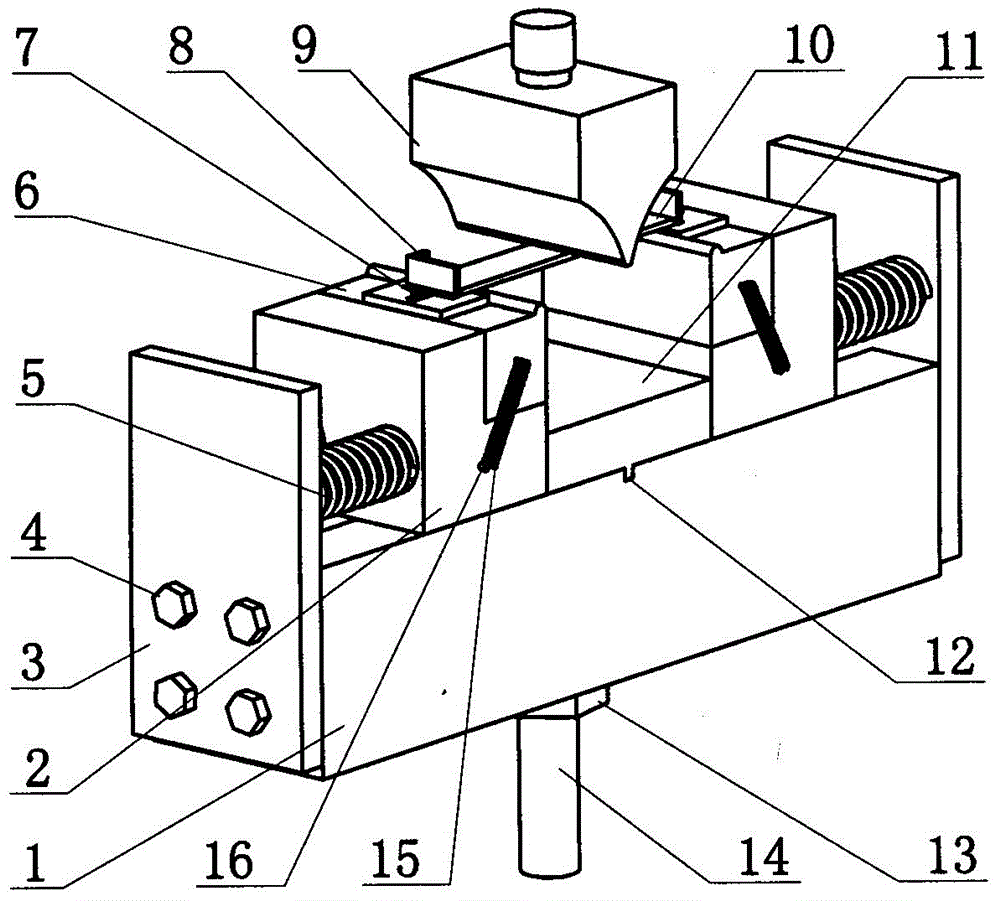

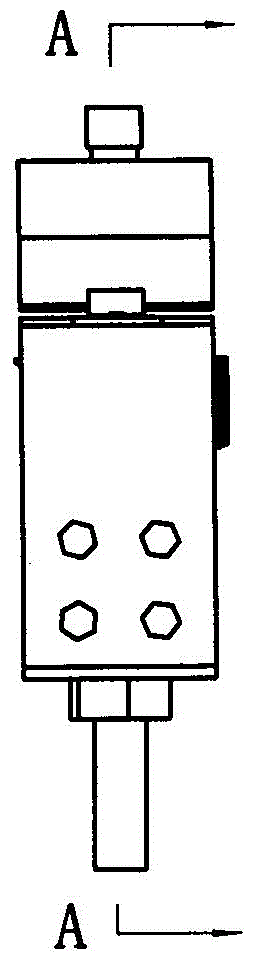

Clamp improving bending and interlaminar shearing test efficiency of composite material

ActiveCN102141489AAdapt to test requirementsUsing mechanical meansStrength propertiesTest efficiencyInterlaminar shear

The invention provides a clamp for improving bending and interlaminar shearing test efficiency of a composite material, which comprises a supporting device connected with a mechanical property test machine and a regulating platform arranged on the supporting device, and is characterized in that: (1) the regulating platform slides left and right along a slideway on the upper surface of the supporting device; (2) both sides of the bottom part of a span regulating mechanism have a boss, the bosses on the two sides are clamped on the two sides of the regulating platform, and a positioning pin hole is formed in the middle of the span regulating mechanism and is matched with a positioning pin on the regulating platform; and (3) two sliding blocks which can move towards each other are arranged on the span regulating mechanism, the symmetrical centerline of the two sliding blocks is centered with the centerline of the regulating platform, and supports are arranged on the two sliding blocks. The clamp has a unique structure, can ensure the centerline of the pressure head of the test machine is centered with the centerline of the supports and make the regulation and measurement of the span for test convenient and the replacement of supports of different specifications convenient, is high in precision and convenient for regulation and can improve test efficiency.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Super hybrid carbon nano material modified carbon fiber/epoxy matrix composite material and preparation method thereof

InactiveCN103552325AImproved interlaminar shear performanceThe interface is firmly bondedSynthetic resin layered productsModified carbonResin matrix

The invention relates to a super hybrid carbon nano material modified carbon fiber / epoxy matrix composite material and a preparation method thereof. The composite material an epoxy resin matrix material and an inorganic nano filler which is uniformly dispersed in the epoxy resin matrix material, wherein the composite nano inorganic filler is composed of graphene and carbon nanotubes. The excellent mechanical properties of the graphene and carbon nanotubes and the active functional groups on the surface are utilized to effectively enhance the mechanical properties of the epoxy resin matrix and the interface bonding strength between the matrix and the carbon fibers. The prepared composite material has excellent interlaminar shear property, and the interlaminar shear strength is enhanced from 50 MPa to 68 MPa.

Owner:JIAXING UNIV

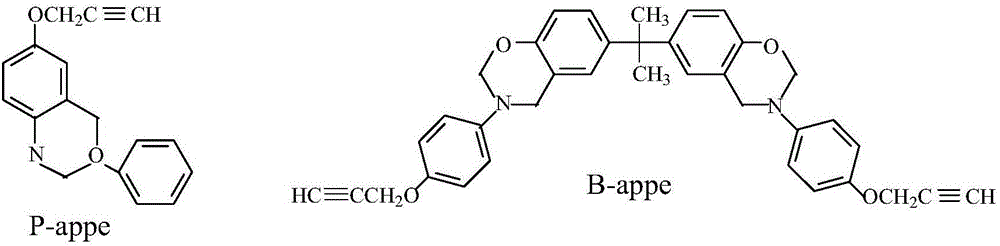

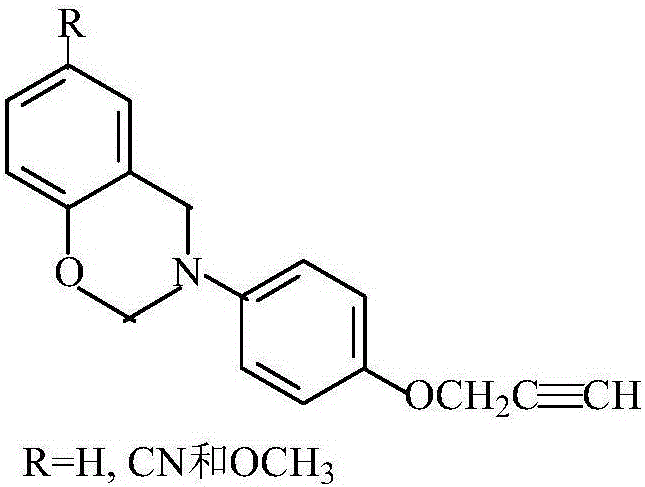

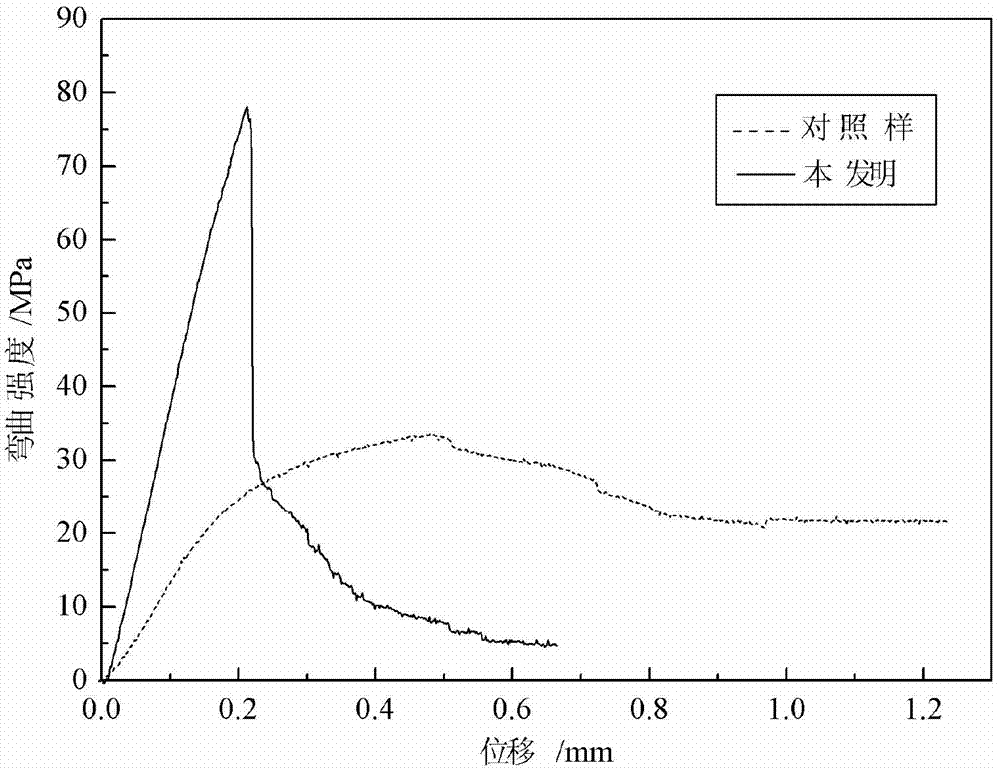

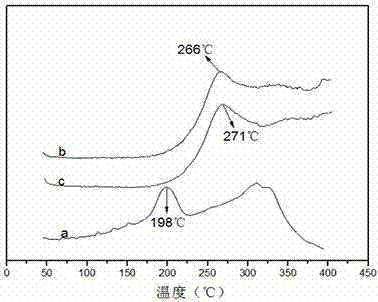

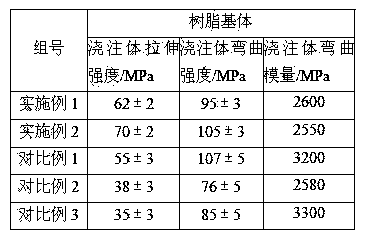

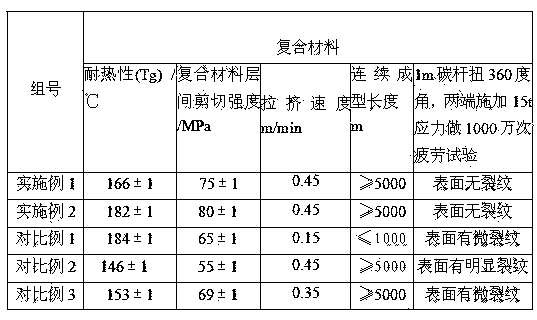

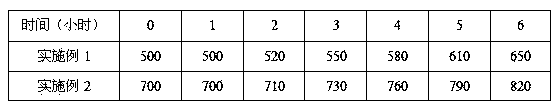

Method for improving mechanical property of silicon-containing arylacetylene resin based composite material

InactiveCN104962085AImprove bending strengthIncreased flexural modulusInterlaminar shearResin-Based Composite

The invention relates to a method for improving the mechanical property of a silicon-containing arylacetylene resin based composite material. The method specifically comprises the following steps of uniformly mixing benzoxazine containing propargyl ether and silicon-containing arylacetylene resin (PSA) in a solvent, and obtaining prepreg compounds of carbon fibers and modified silicon-containing arylacetylene resin PSA; after overlaying the prepreg compounds of the carbon fibers and the modified silicon-containing arylacetylene resin, obtaining a carbon fiber reinforced modified silicon-containing arylacetylene resin composite material through hot press molding. The propargyl ether type benzoxazine modified silicon-containing arylacetylene resin prepared by the method is wide in process window, can be cured and molded at the temperature of 120 to 260 DEG C, and cannot release small molecular substances during curing, the glass-transition temperature of the cured modified silicon-containing arylacetylene resin is still higher than 500 DEG C, the heat stability is not influenced greatly, the mechanical property of the PSA resin after modifying is improved. The interlaminar shear strength of the carbon fiber reinforced modified PSA based composite material is obviously improved, and is expected to be used as a high-temperature-resistant lightweight-structure material.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method of chopped carbon fiber reinforced phenolic resin base composite material

The invention provides a preparation method of a chopped carbon fiber reinforced phenolic resin base composite material, which comprises the following steps: dissolving chopped carbon fibers after dispersion, which are used as the reinforcing material, in anhydrous alcohol; meanwhile, adding phenolic resin, and evenly mixing; and carrying out die pressing to obtain the chopped carbon fiber reinforced phenolic resin base composite material. The chopped carbon fibers in the material have a three-dimensional network structure, the three-dimensional network structure converts the combination of fibers and resin matrix from two-dimensional connection to three-dimensional connection with spatial effect; when being subjected to shear action, work needs to be applied to overcome the binding force between the matrix and the fibers, so that the expansion of the cracks consumes more energy, thereby enhancing the interlaminar shear strength, avoiding the generation of aggregation and requiring low cost.

Owner:SHAANXI UNIV OF SCI & TECH

Composite material, method for the production and use thereof

ActiveUS7867612B2Increase apparent interlaminar shear strength and bending strengthLayered productsSpecial tyresInterlaminar shearUltimate tensile strength

A composite material is described that contains a reinforcing resin and reinforcing fibers, wherein the reinforcing fibers have a coating containing polyphenylene sulfide and the proportion of polyphenylene sulfide relative to the uncoated fibers is 0.001 to <0.01 wt. %. The composite material shows higher apparent interlaminar shear strength and bending strength as compared with similar composite materials having no PPS coating in the above concentration range.

Owner:TOHO TENAX EURO

Three-dimensional alumina fiber fabric reinforced oxide ceramic and preparation method thereof

The invention discloses three-dimensional alumina fiber fabric reinforced oxide ceramic. Al2O3, SiO2 and SiOC ceramics are used as a substrate, a three-dimensional alumina fiber fabric is used as a reinforcing body, alumina and silicon dioxide in the substrate are introduced by a sol-gel process, and the SiOC ceramic is obtained by high-temperature cracking of polysiloxane. The preparation method of the three-dimensional alumina fiber fabric reinforced oxide ceramic comprises the following steps: performing vacuum soaking, gelating and high-temperature ceramic treatment on oxide sol serving as a precursor, and repeating for multiple times to obtain an alumina fiber reinforced oxide blank body; soaking the blank body in vacuum by using a polysiloxane-ethanol solution as a precursor, and performing crosslinking and high-temperature ceramic treatment to complete a densifying process; and repeating the steps for multiple times to obtain the oxide ceramic blank body, and oxidizing to prepare the three-dimensional alumina fiber fabric reinforced oxide ceramic. The three-dimensional alumina fiber fabric reinforced oxide ceramic has the advantages of high bending strength, high modulus, good interlaminar shear strength and the like.

Owner:NAT UNIV OF DEFENSE TECH

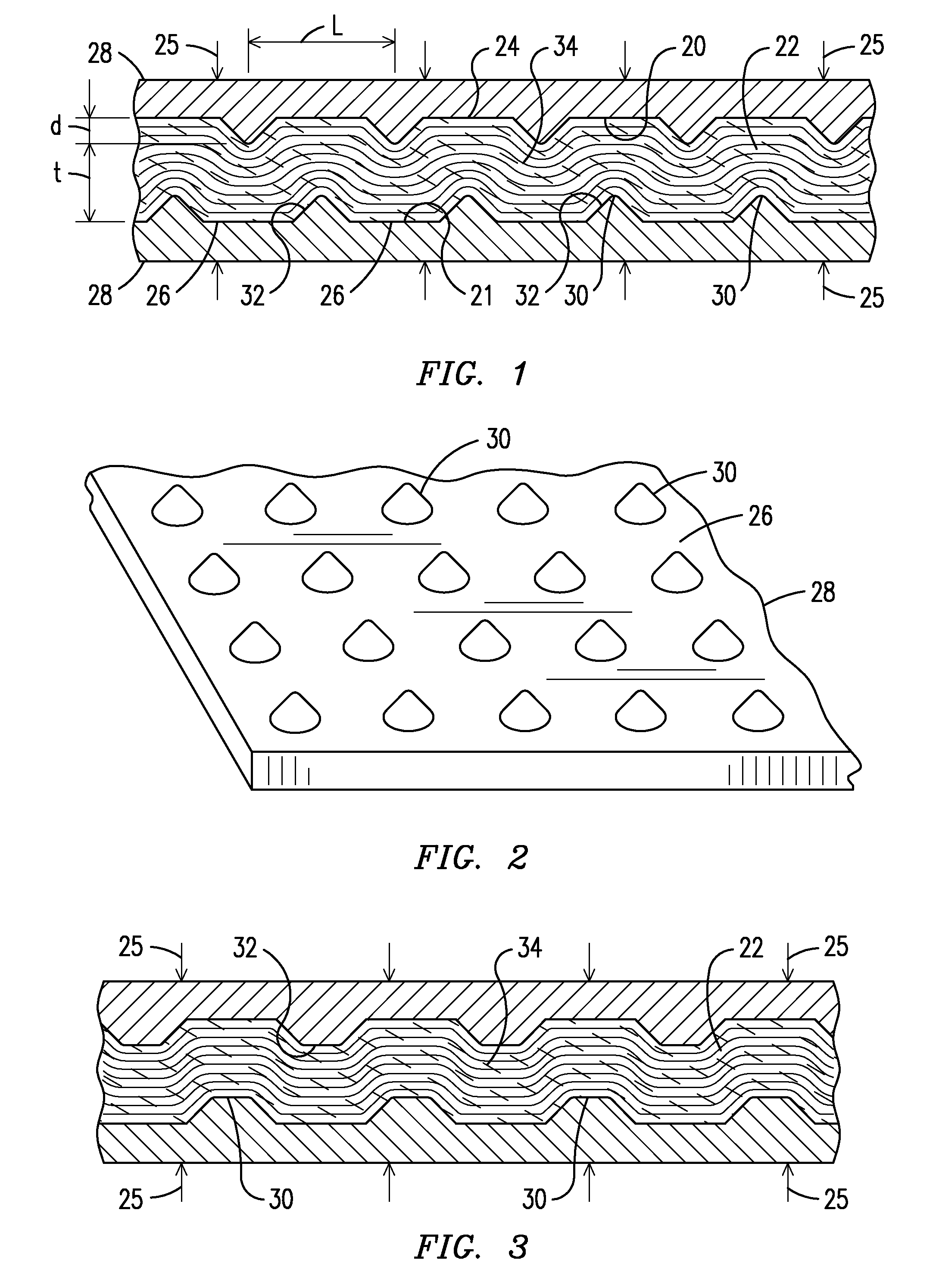

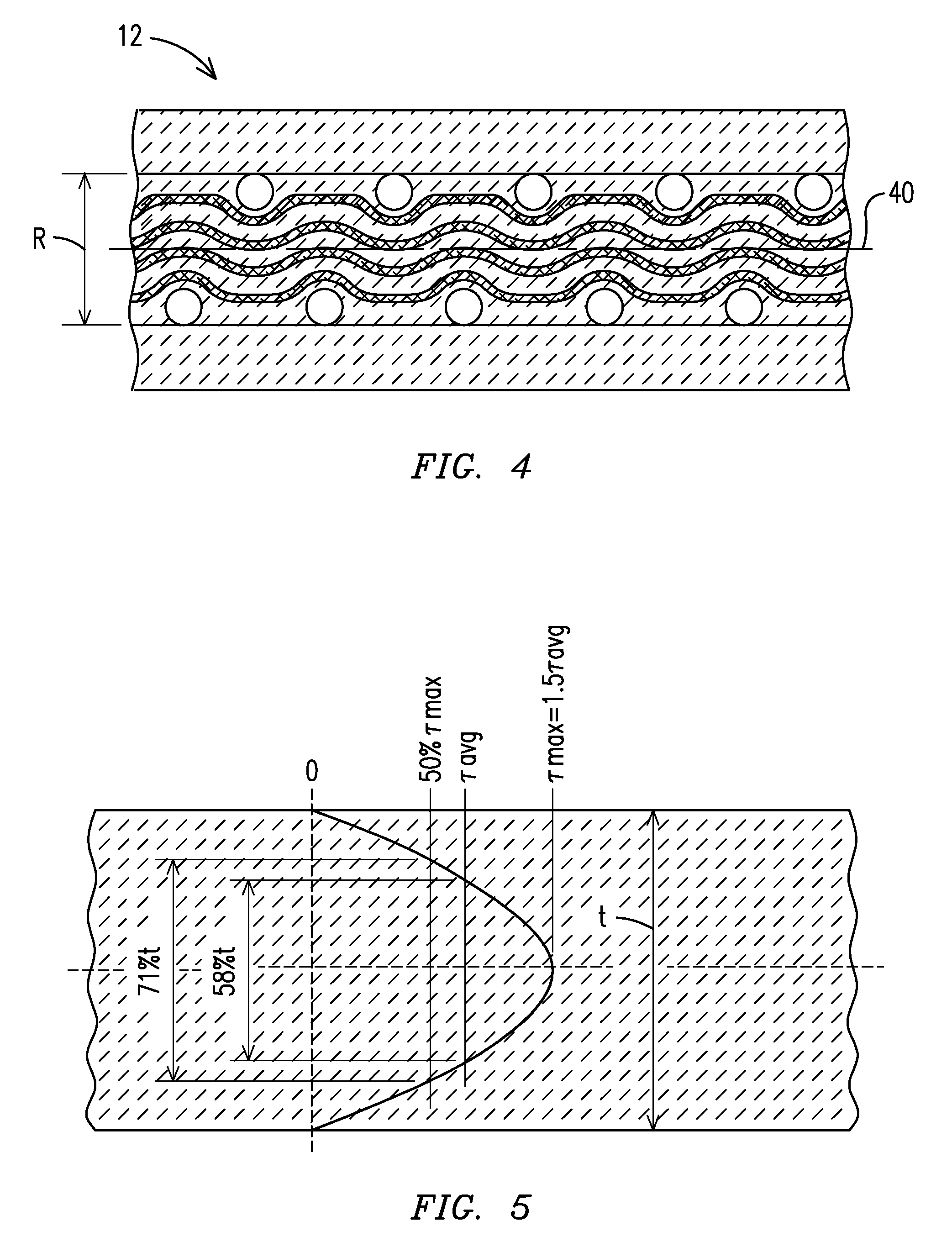

Methodology and tooling arrangements for increasing interlaminar shear strength in a ceramic matrix composite structure

Methodology and tooling arrangements for increasing interlaminar shear strength in a ceramic matrix composite (CMC) structure are provided. The CMC structure may be formed by a plurality of layers of ceramic fibers disposed between a top surface and a bottom surface of the composite structure. A plurality of surface recesses are formed on the surfaces of the structure. For example, each of the surfaces of the composite structure may be urged against corresponding top and bottom surfaces of a tool having a plurality of asperities. The plurality of surface recesses causes an out-of-plane sub-surface fiber displacement along an entire thickness of the structure, and the sub-surface fiber displacement is arranged to increase an interlaminar shear strength of the structure.

Owner:SIEMENS ENERGY INC

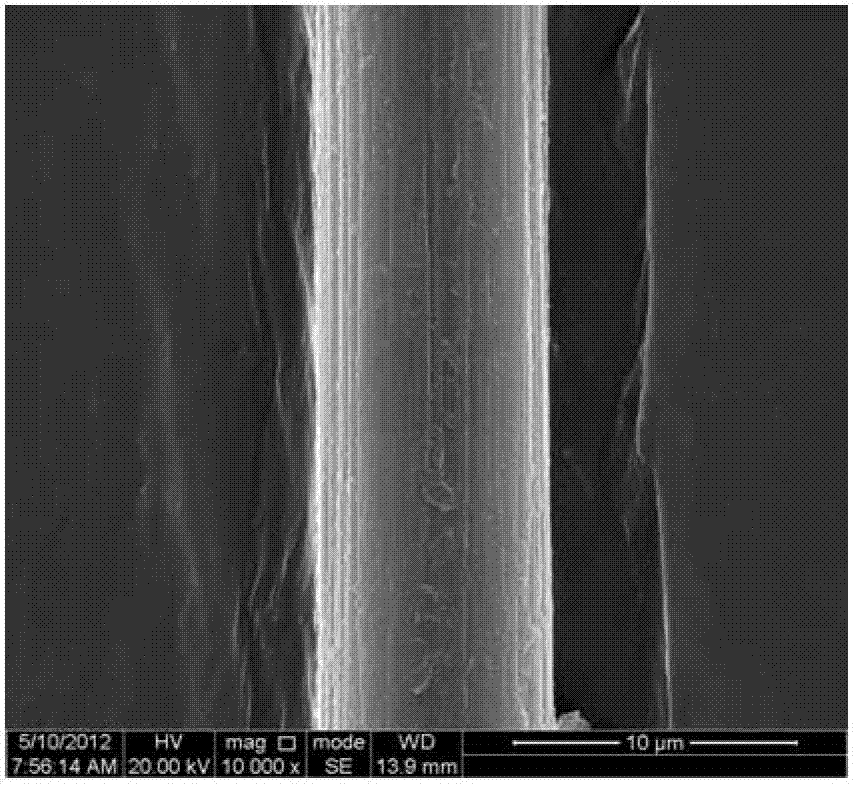

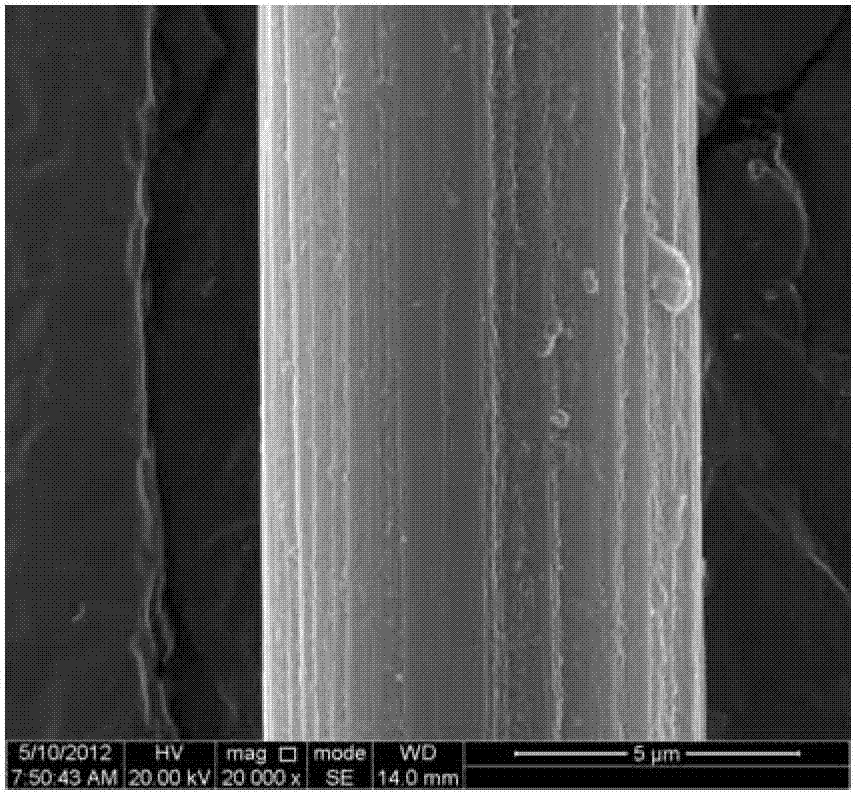

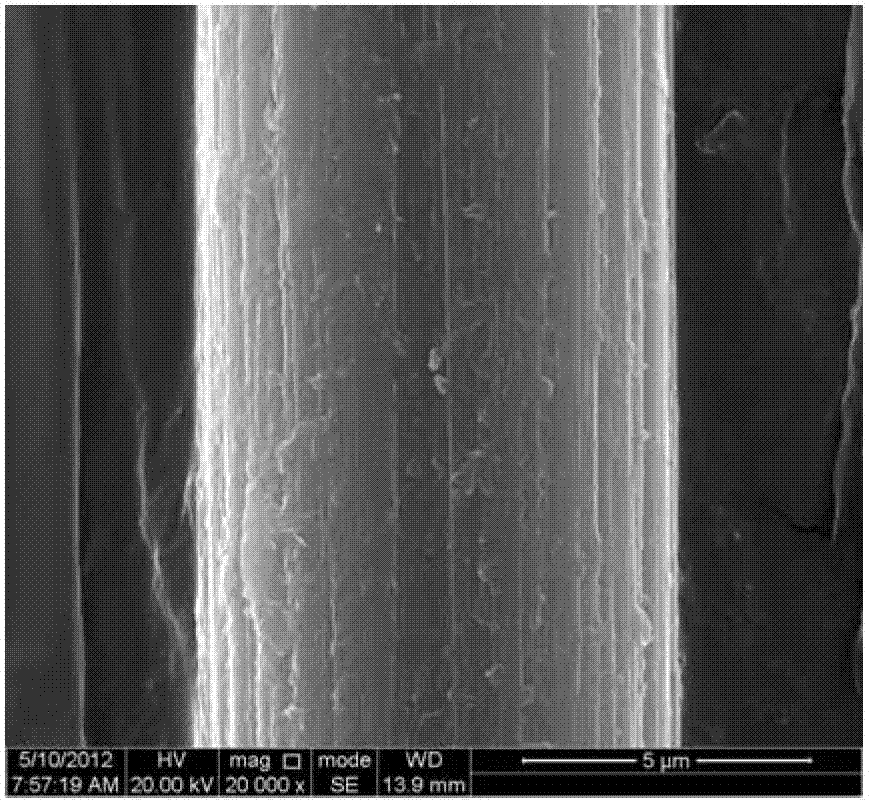

Carbon fiber surface treatment method

ActiveCN102345228AIncreased content of active polar functional groupsGroove deepeningPhysical treatmentAmbient humidityInterlaminar shear

The invention relates to a carbon fiber surface treatment method. The method comprises that under an atmosphere environment, air is adopted as a carbon fiber surface treatment medium, electroneutral low temperature plasma is emitted by a plasma emitting device for low temperature plasma bombardment to the surface of a moving carbon fiber tow at a speed of 60-150m / h; the ambient temperature of carbon fiber treatment ranges from -10DEG C to 50DEG C; the gap between the carbon fiber and the plasma emitting device is 5-30mm; the ambient humidity of carbon fiber surface treatment is 30-90%; the power of carbon fiber surface treatment ranges from 500 to 800W / tow; and the temperature of carbon fiber surface treatment by low temperature plasma is 30DEG C-100DEG C. The method of the invention can enhance the content of active and polar functional groups on the carbon fiber surface, deepen grooves on the carbon fiber surface, increase the specific surface area, improve the interlaminar shear strength of carbon fiber composite materials, save energy and reduce energy consumption, and is clean and free of pollution.

Owner:PETROCHINA CO LTD

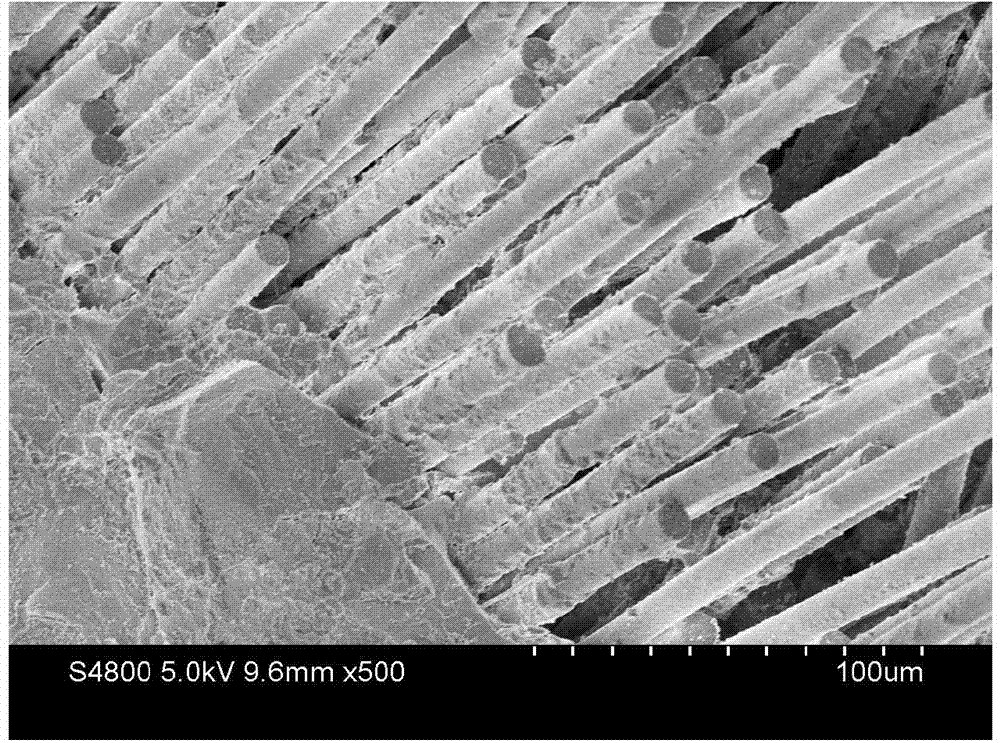

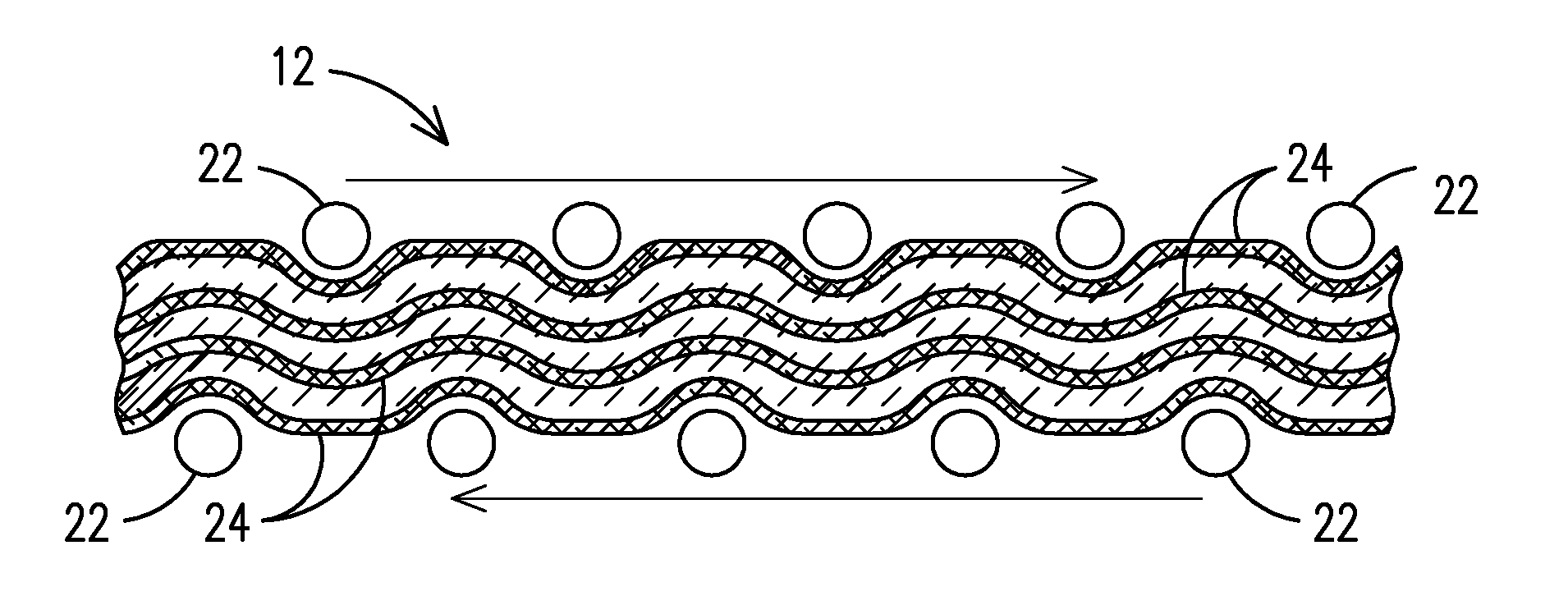

Subsurface inclusions of objects for increasing interlaminar shear strength of a ceramic matrix composite structure

InactiveUS8293356B2Ceramic layered productsGlass/slag layered productsInterlaminar shearUltimate tensile strength

A ceramic matrix composite (CMC) structure 12 includes a plurality of layers (e.g., 16, 18, 20) of ceramic fibers. The CMC structure 12 further includes a plurality of spaced apart objects 22 on at least some of the plurality of layers along a thickness of the composite structure. The inclusion of the objects introduces an out-of-plane fiber displacement arranged to increase an interlaminar shear strength of the structure.

Owner:SIEMENS ENERGY INC

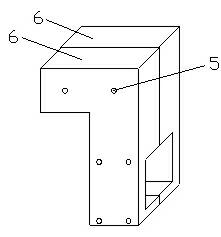

Clamp and method for testing pavement interlayer shear fatigue test piece

InactiveCN102095680ASimple test methodUsing mechanical meansMaterial analysisShear stressInterlaminar shear

The invention relates to a clamp and a method for testing a pavement interlayer shear fatigue test piece. At present, no one does research on interlayer shear fatigue of a pavement structure at home and abroad. The invention provides the clamp for testing the pavement interlayer shear fatigue test piece, which comprises an upper clamp component and a lower clamp component; the upper clamp component and the lower clamp component are abnormally-shaped blocks of which the longitudinal sections are L-shaped; each abnormally-shaped block is formed by splicing two same parts; the upper clamp component and the lower clamp component are buckled; and through slots are formed on the middle parts of transverse buckling parts. By using the structure, left and right ends of the test piece are fixed by the upper clamp and the lower clamp; a bonding layer in the middle of the test piece is positioned at the combined part of the through slots of the two clamps; and a vertical waveform load parallel to the bonding layer in the middle of the test piece is exerted to obtain a relation between a shear stress (strain) and an experimental loading frequency, so a fatigue shear characteristic parameter of the test piece can be obtained.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

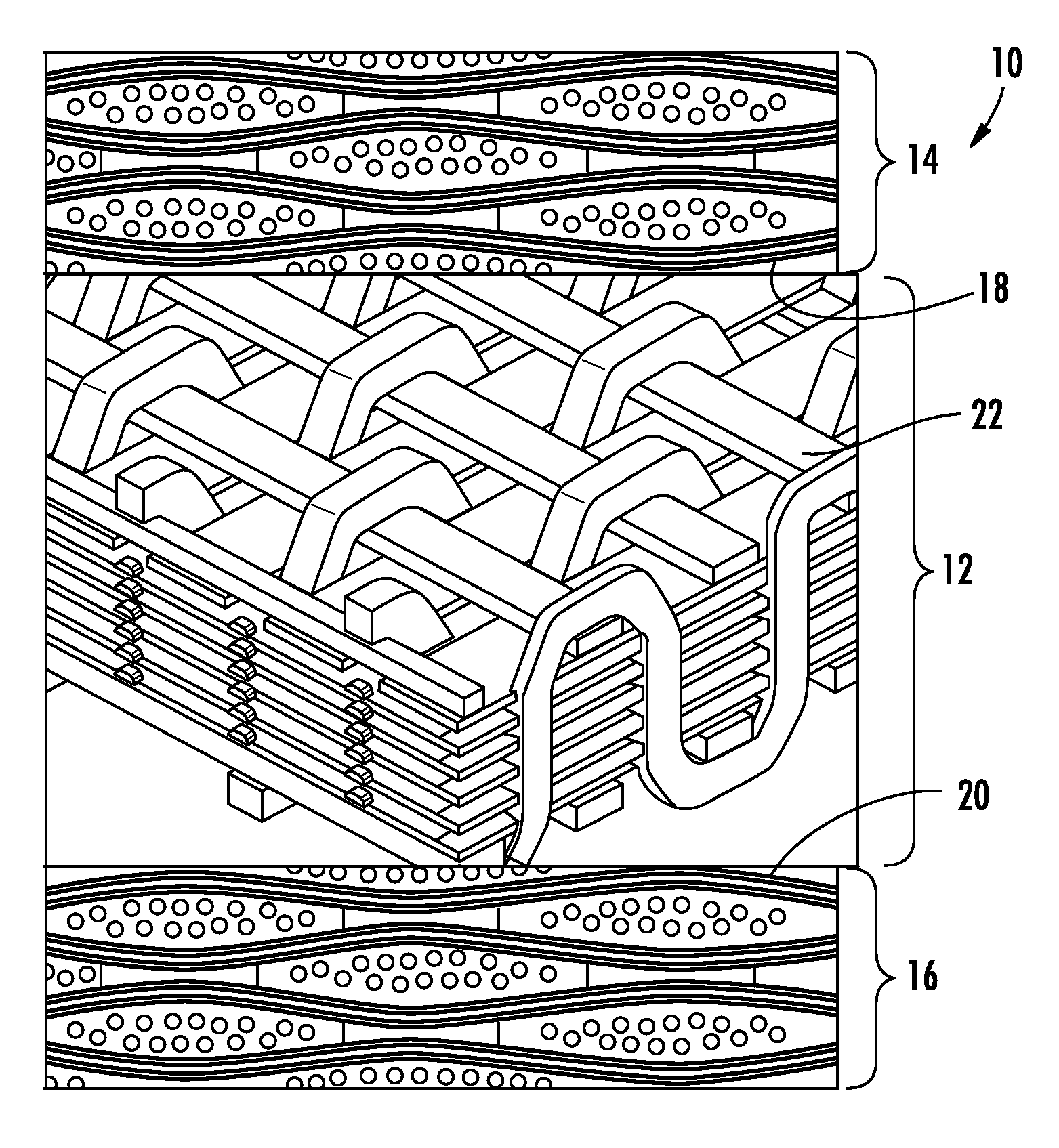

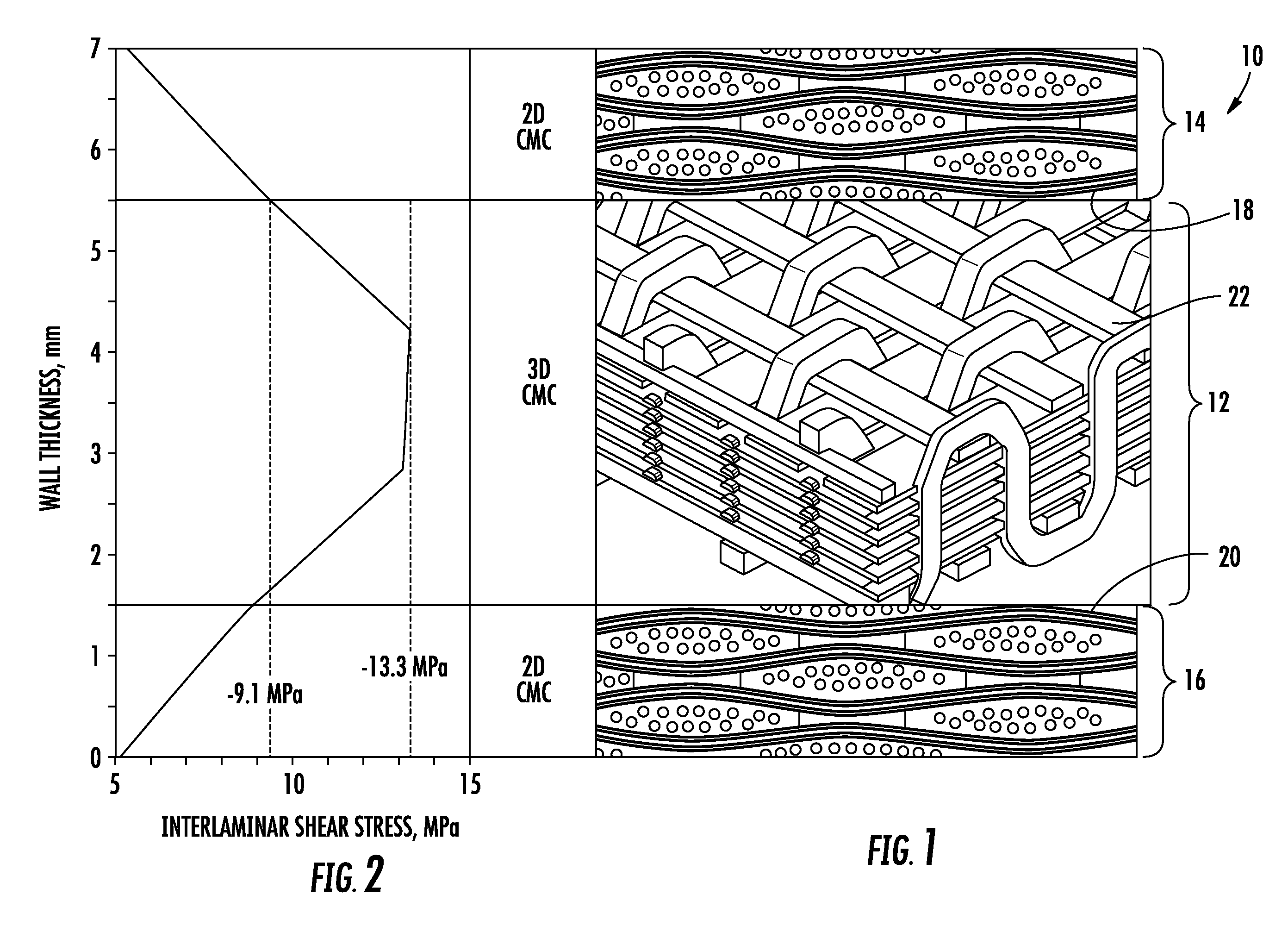

Multilayered ceramic matrix composite structure having increased structural strength

ActiveUS20100056006A1Improve strength propertiesImprove bending strengthSynthetic resin layered productsLaminationMetallurgyInterlaminar shear

A multilayer ceramic matrix composite structure is disclosed. The ceramic matrix composite structure may include a three-dimensional weave fabric forming a core layer. The ceramic matrix composite structure may also include a two-dimensional weave fabric attached to an outer top surface of the three-dimensional weave fabric such that the two-dimensional weave fabric forms a top layer, and a two-dimensional weave fabric attached to an outer bottom surface of the three-dimensional weave fabric generally opposite to the outer top surface such that the two-dimensional weave fabric forms a bottom layer. The structure may include increased interlaminar shear strength.

Owner:SIEMENS ENERGY INC

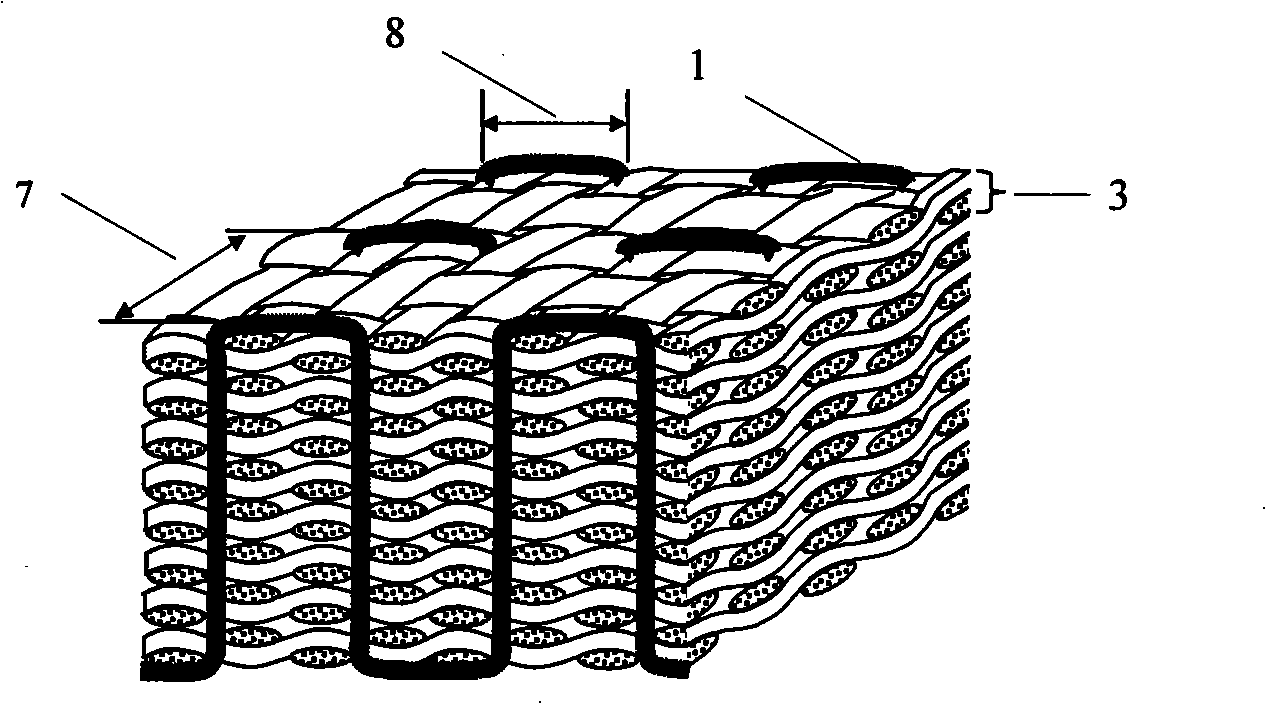

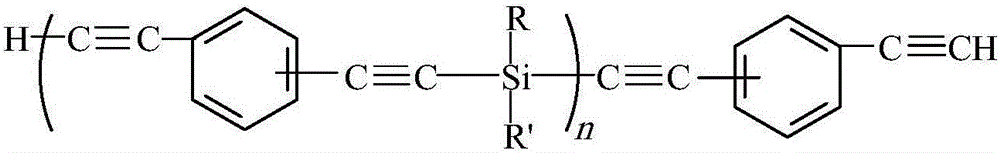

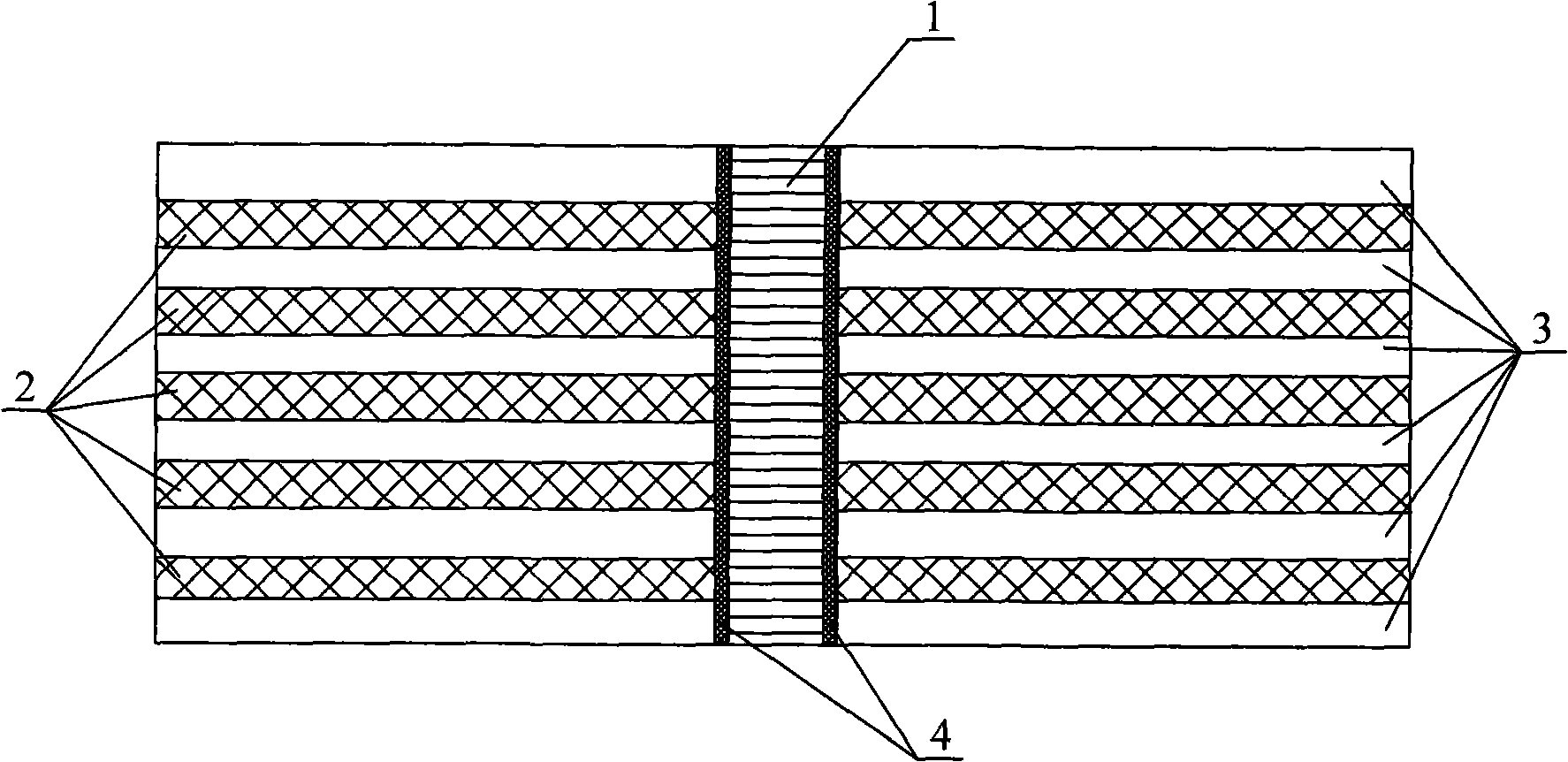

Reinforcement method for continuous filament reinforced metallic matrix composite

The invention discloses a reinforcement method of a continuous fiber-reinforced metal matrix composite, relates to the fiber-reinforced metal matrix composite, and aims at solving the problems that the rigidity and the strength character of a structural piece of the fiber-reinforced metal matrix composite are low along the thickness direction, the strength of in-plane shear and interlaminar shear is low, the impact ductility is low, and delamination is easy to occur. The reinforcement method is realized according to the steps as follows: after a fiber prefabricated part (2) is prepared, a wire (1) is added in the fiber prefabricated part (2), the fiber prefabricated part (2) and a composite material matrix (3) are processed through molten metal infiltration by heating, and the reinforcement to the continuous fiber-reinforced metal matrix composite is completed after cooling. Because the wire originally has high strength and high toughness and has stronger binding capacity with the matrix, the existence of the wire effectively strengthens the strength between fibrous composite layers or the strength along the weak direction such as thickness, etc., increases the interlaminar strength, the impact ductility and the damage tolerance of fibrous composite, and avoids the demixion.

Owner:HARBIN INST OF TECH

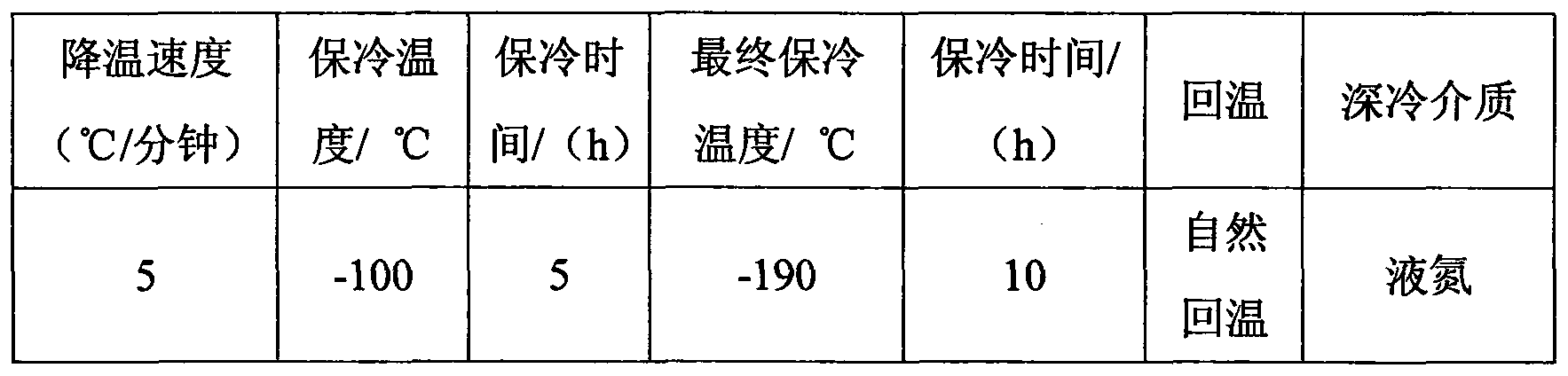

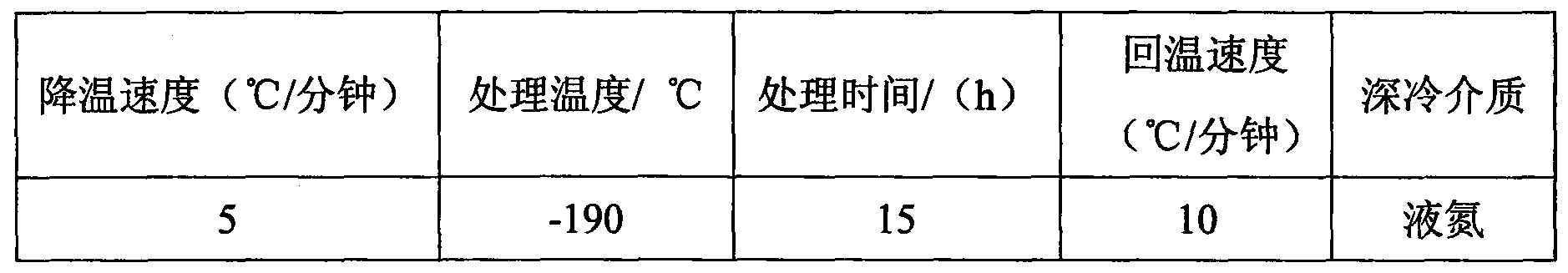

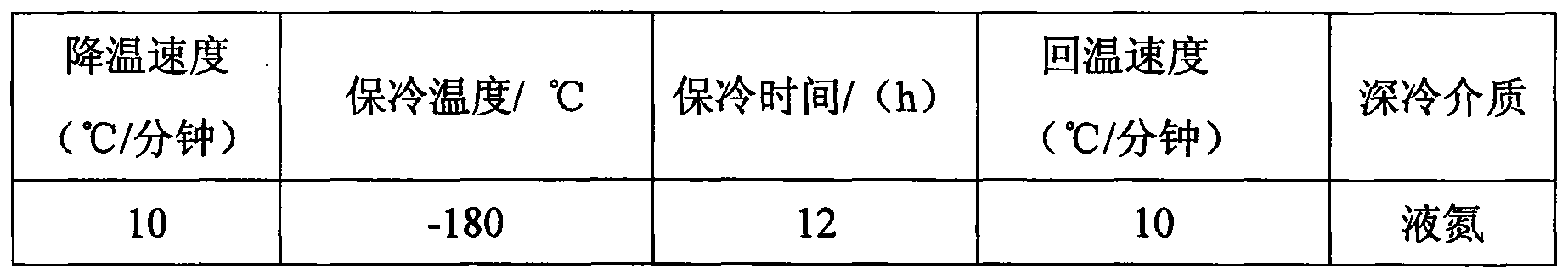

Method for modification of glass fiber composite material by ultralow temperature treatment

Owner:DONGHUA UNIV

Preparation of carbon fiber/epoxy resin prepreg sprayed with aminated carbon nanotubes

InactiveCN104558659AHigh compressive strengthHigh modulusSynthetic resin layered productsCoatingsInterlaminar shearCarbon fiber composite

The invention belongs to the field of preparation of composite materials, and particularly relates to a preparing method of a carbon fiber prepreg sprayed with carbon nanotubes in an electrostatic manner. The method is characterized in that: the surface of a carbon fiber / epoxy resin prepreg is rapidly sprayed with the amino-grafted carbon nanotubes by adoption of an electrostatic spraying technology, thus obviously improving compression strength and modulus and interlaminar shear strength of a carbon fiber composite material. The method comprises following technical steps of: I) grinding the amino-grafted carbon nanotubes and a preferred electrostatic spraying agent in a ball mill according to a certain ratio to obtain a uniform and stable suspension; II) putting the suspension obtained in the step I) into an electrostatic spraying device, and uniformly spraying the surface of the carbon fiber / epoxy resin prepreg with the carbon nanotubes; and III) controlling the thickness of a carbon nanotube coating on the surface of the carbon fiber prepreg to be 10-80 [mu]m. The interlaminar content of the carbon nanotubes in the composite material is controllable. A processing process of the composite material is not influenced. The method is simple and convenient in operation and prone to popularization and application in practical production.

Owner:BEIJING UNIV OF CHEM TECH

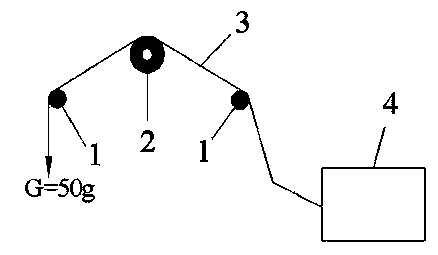

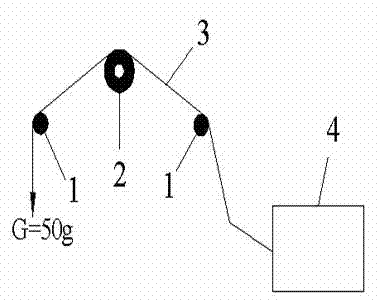

Testing method for interlaminar shearing stress state

ActiveCN101995357AAvoiding Defects in Shear StrengthExquisite structureMaterial strength using steady shearing forcesPositive pressureInterlaminar shear

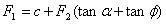

The invention relates to a testing method for the interlaminar shearing stress state, which is a method for evaluating the shearing strength between a cement concrete deck and an asphalt pavement layer. The method can simultaneously acquire the cohesive force C and the friction angle between interfaces by testing once, and is a reasonable testing method for the shearing strength between the cement concrete deck and the asphalt pavement layer. The testing method comprises the following steps: (a) an inclined plane with an inclined angle of 5 degrees-30 degrees, namely a rigid triangular block (8), is arranged in a direction vertical to load application (4); a horizontal force-measuring device (5) is positioned behind the rigid triangular block (8); a loading specimen (1) and a fixed specimen (3) are positioned in a clamp (10); the load vertically applied to the loading specimen (1) is converted into a horizontally applied force to realize application of positive pressure on a shearing interface (2); (b) bearing balls (9) are arranged on the inclined plane to eliminate the effect of the frictional force on the inclined plane to the test result; and (c) based on the testing method, the cohesive force and the friction angle between the interfaces are acquired by calculating with a calculation formula as shown in the specification.

Owner:SOUTHEAST UNIV

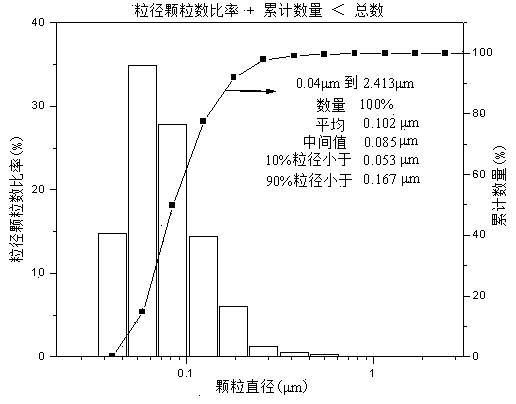

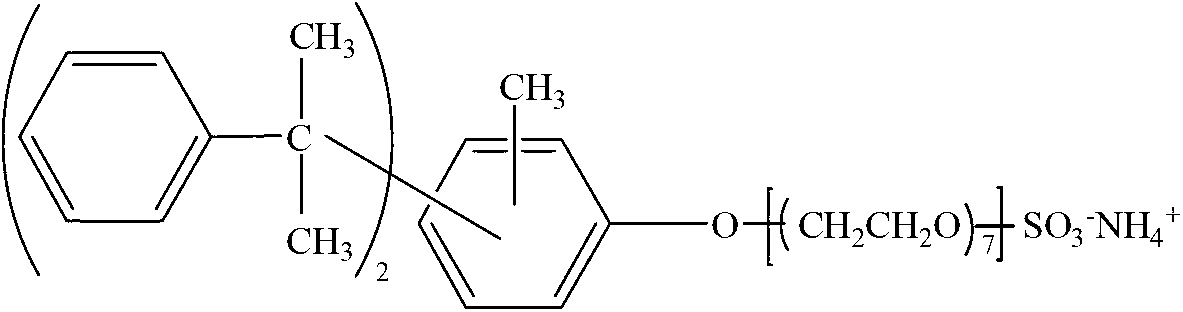

Preparation method and use of nano-SiO2-modified glass fiber film-forming agent emulsion

The invention discloses a preparation method and use of a nano-SiO2-modified glass fiber film-forming agent emulsion. The nano-SiO2-modified glass fiber film-forming agent emulsion comprises main slurry, an emulsifier, modified nano-SiO2 particles, a diluent and deionized water. Based on the mass of the main slurry, emulsifier mass content is in a range of 4-8%, diluent mass content is in a range of 10-50%, nano-SiO2 particle mass content is in a range of 0.5-3% and a mass ratio of the deionized water to the main slurry is 60-90: 10-40. The nano-SiO2-modified glass fiber film-forming agent emulsion obtained by the preparation method has the advantages of less emulsifier use amount, uniform particle size distribution, good temperature resistance, acid and alkali resistance and storage stability. After an impregnating agent prepared from the nano-SiO2-modified glass fiber film-forming agent emulsion coats glass fibers, uniformly-distributed nano-SiO2 particle layers are formed on surfaces of the glass fibers so that glass fiber wear resistance and breaking strength are obviously improved. The highest glass fiber-reinforced composite material interface interlaminar shearing strength is 31.74MPa.

Owner:UNIV OF JINAN

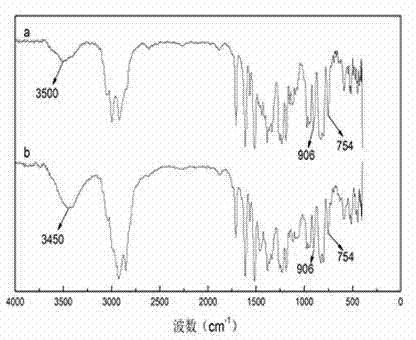

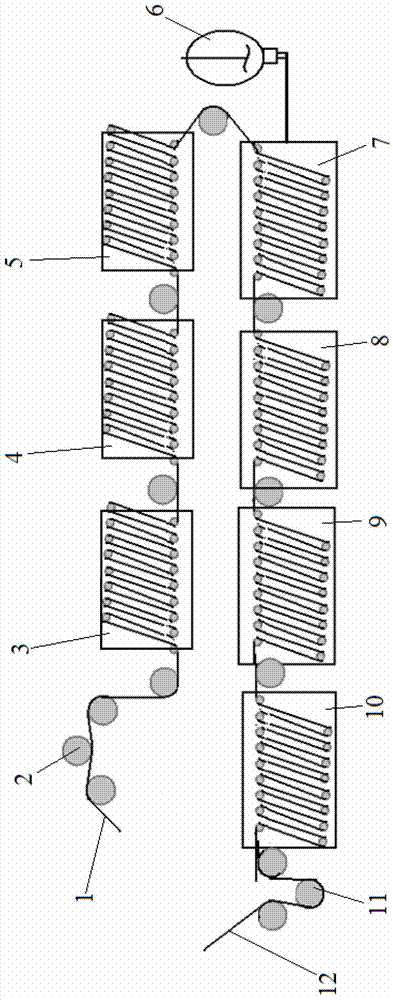

Temperature-resistant type emulsion sizing agent for carbon fiber, as well as preparation method and application of sizing agent

InactiveCN104294602AHigh glass transition temperatureImprove temperature resistanceCarbon fibresEmulsionMass ratio

The invention discloses a temperature-resistant type emulsion sizing agent for a carbon fiber. The temperature-resistant type emulsion sizing agent comprises the following materials: main size, an emulsifying agent, an additive and deionized water, wherein the main size is glycidyl amine type epoxy resin modified by dodecanamine, and in modification, the mass ratio of dodecanamine to the epoxy resin is (10-40) to (60-90); the mass of the emulsifying agent is 5-15% of the mass of the main size; the additive comprises a diluting agent and a penetrating agent, the mass of the diluting agent is 0-100% of the mass of the main size, and the mass of the penetrating agent is 1-5% of the mass of the main size; the mass ratio of the deionized water to the main size is (50-90) to (10-50). The invention also discloses a preparation method and application of the sizing agent. The sizing agent disclosed by the invention is high in stability and does not cause pollution to the environment, and the preparation method is simple; in the presence of a flexible molecule, namely dodecanamine, the carbon fiber has relatively high operability; proved by experiments, after the carbon fiber is treated by the sizing agent, the post processability is obviously improved; and the interface temperature resistance and the interlaminar shear strength (ILSS) of the carbon-fiber-enhanced epoxy resin composite material are also obviously improved.

Owner:UNIV OF JINAN

Preparation method for carbon fiber surface composite coating

ActiveCN103031724AImprove surface roughnessHigh surface energyPhysical treatmentCarbon fibresInterlaminar shearResin matrix

The invention provides a preparation method for a carbon fiber surface composite coating and relates to a preparation method for a composite coating. The invention aims to solve the problem that in the carbon fiber composite material prepared by the conventional method, a weak interface exists between a carbon fiber and a resin matrix. The preparation method comprises the following steps: I, preprocessing the carbon fiber; II, coating; III, solidifying; IV, carbonizing; and V, functionalizing the coating to obtain the carbon fiber surface composite coating. The preparation method has the advantages as follows: I, the interlaminar shear strength of the composite material is increased by 16 to 62 percent respectively; II, the composite materials is tightly linked with the carbon fiber, difficult to strip and high in stability; III, different functions are given to the carbon fiber by adjusting the chemical constitution and the component proportioning of phenolic resin slurry or the preparation method can be applied to different types of resin matrix composite materials; and IV, the preparation method is a continuous method, simple, high in efficiency, good in effect and easy in industrialized production. The preparation method is mainly applied to preparation of the carbon fiber surface composite coating.

Owner:HARBIN INST OF TECH

Preparation method of acrylic polymer grafted carbon fiber multi-scale reinforcement

InactiveCN103275282AThe surface is inertSmall specific surface areaPhysical treatmentInterlaminar shearResin matrix

The invention discloses a preparation method of an acrylic polymer grafted carbon fiber multi-scale reinforcement, relating to a carbon fiber reinforcement and a preparation method thereof. The preparation method comprises the following steps of: 1) performing oxidation treatment on a carbon fiber surface; 2) grafting a silane coupling agent to the carbon fiber surface after the oxidation treatment; 3) obtaining chain transfer agent grafted carbon fiber through a reaction between the carbon fiber surface grafted silane coupling agent and a chain transfer agent; and 4) initiating acrylic monomer grafting polymerization on the surface of the chain transfer agent grafted carbon fiber to finally obtain an acrylic polymer grafted carbon fiber multi-scale reinforcement. The method disclosed by the invention has the advantages that the roughness of the carbon fiber surface can be greatly improved, a great quantity of active functional groups can be introduced, the reaction activity of the carbon fiber surface is improved, the wettability and cohesiveness between the carbon fiber and a resin matrix are improved, and the interlaminar shear strength of an epoxy composite material is enhanced by 40-50%.

Owner:NANCHANG HANGKONG UNIVERSITY

Carbon nano dual-cured resin matrix for pultrusion process and composite of carbon nano dual-cured resin matrix

The invention relates to a carbon nano dual-cured resin matrix for a pultrusion process and a composite of the carbon nano dual-cured resin matrix. The resin matrix is made from the following raw materials in parts by weight: 50-90 parts of epoxy resin and a curing agent thereof, 10-50 parts of vinyl ester resin and an initiator thereof, 1-2 parts of carbon nanotubes, and an appropriate amount of optional additives; the resin matrix is a dual-cured homogeneous system formed by the epoxy resin and the curing agent thereof, the vinyl ester resin and the initiator thereof, and the carbon nanotubes uniformly dispersed in the resin matrix. The resin system has the characteristics of low viscosity, high invasion with fibers, high curing speed and uniform heat and mass transfer; the resin matrix is high in stability and continuity in the pultrusion process. The composite prepared through pultrusion is high in flexibility, higher in interlaminar shear strength, high in heat resistance, and excellent in surface smoothness and rigidity.

Owner:SHANDONG YANGXIN FENGYUAN SCI & TECH

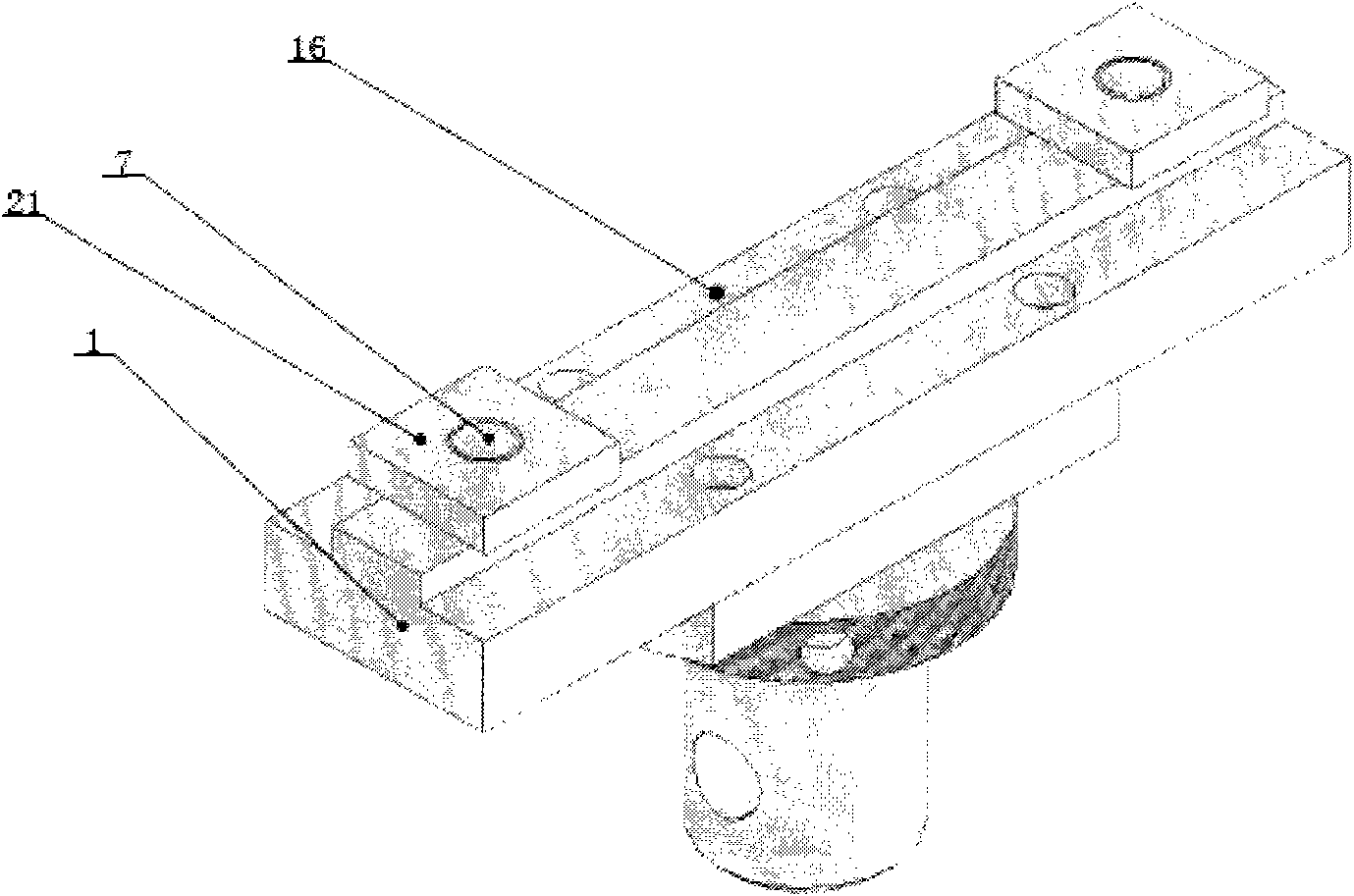

Composite material bending and interlaminar shear sample fast assembly fixture

PendingCN106769433AAvoid adjustment inconvenienceQuick switchStrength propertiesTest efficiencyInterlaminar shear

The invention discloses a composite material bending and interlaminar shear sample fast assembly fixture. The problems that the samples are inconvenient to adjust in the testing process, position centering cannot be guaranteed and the like are solved. The fast assembly fixture comprises a positioning and adjusting assembly for assembling samples on a testing machine, and a supporting seat. The technical key points are that the positioning and adjusting assembly is composed of a limiting stopper, a supporting block, an adjusting pad and a slide block; the limiting stopper is fixed on the supporting block; the supporting block is connected with the slide block through a tension spring; a T-shaped boss of the slide block is matched with a T-shaped slideway of the supporting seat; the slide blocks are assembled between baffles at two ends of the supporting seat by utilizing the adjusting pad and a thrust spring; the adjusting pad arranged between the two slide blocks is matched with the positioning groove of the supporting seat for inserting and limiting by virtue of a positioning table; and the bottom of the supporting seat is fixedly connected with a lower platform through a positioning guide rod. The fixture is reasonable in structural design, the sample position centering operation is easy, the supporting span is convenient and rapid to adjust, and the bending test and interlaminar shear test are rapidly switched, so that the test efficiency is improved, and the experimental result accuracy is ensured.

Owner:SHENYANG SHENGYUAN INSPECTION TECH

Sizing agent for emulsion type carbon filter and preparation method and application thereof

The invention discloses a sizing agent for emulsion type carbon filter and a preparation method and application thereof. The sizing agent is prepared by 2-40% of epoxy resin, 1-20% of modifiers, 0-96.5% of water and 0.5-15% of surfactant. After the carbon fiber sized by the sizing agent is prepared into a polyamide, polyimide or polyetherimide resin-based carbon fiber composite material, as the sizing agent comprises the modifiers which have similar or same structural units with matrix resin in the carbon fiber composite material, stronger interface bonding forces exist between the carbon fiber and a sizing agent layer and between the sizing agent layer and the thermoplastic matrix resin; the carbon fiber is effectively combined with the thermoplastic matrix resin through a sizing agent transitional connecting layer so as to form an organic whole; and compared with current carbon fiber composite material, the interlaminar shear strength is improved by over 20%, so that the carbon fiber composite material is higher in integral performance.

Owner:KINGFA SCI & TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com