Patents

Literature

135results about How to "The interface is firmly bonded" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

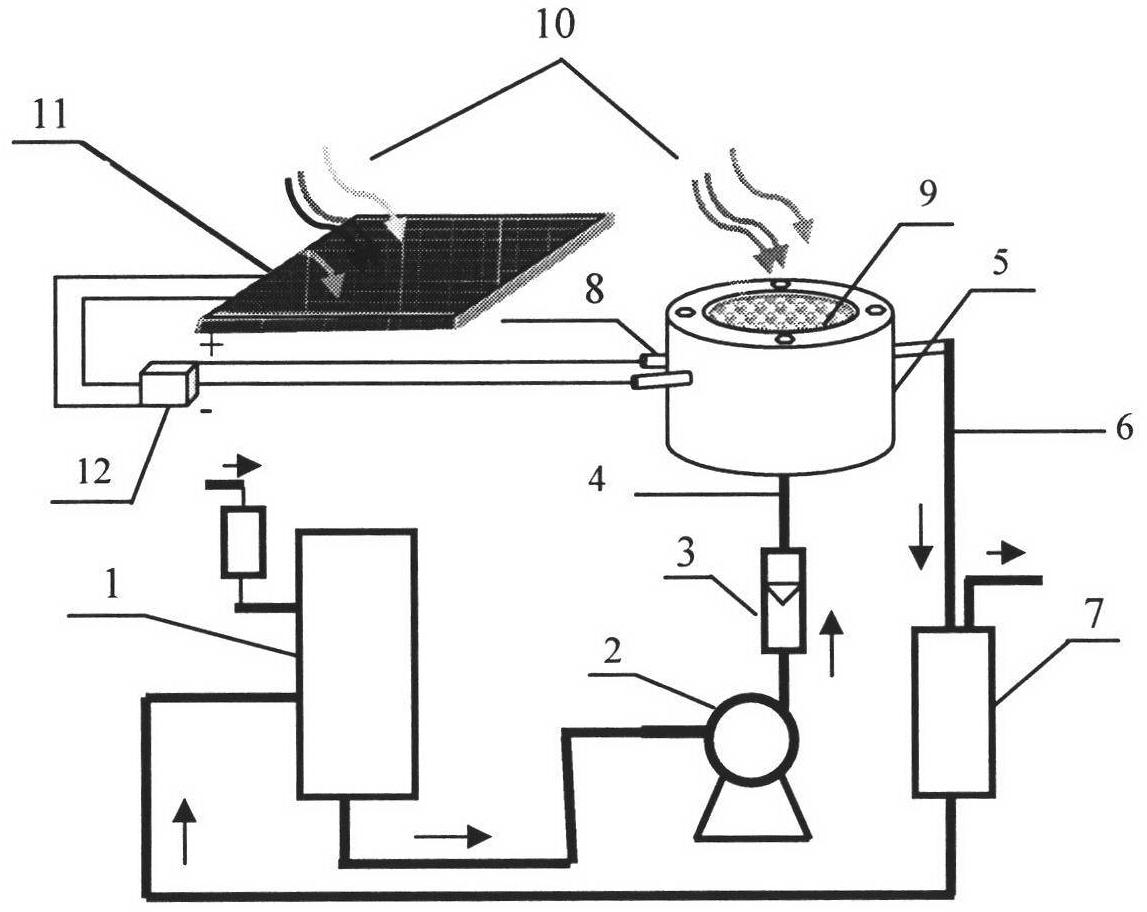

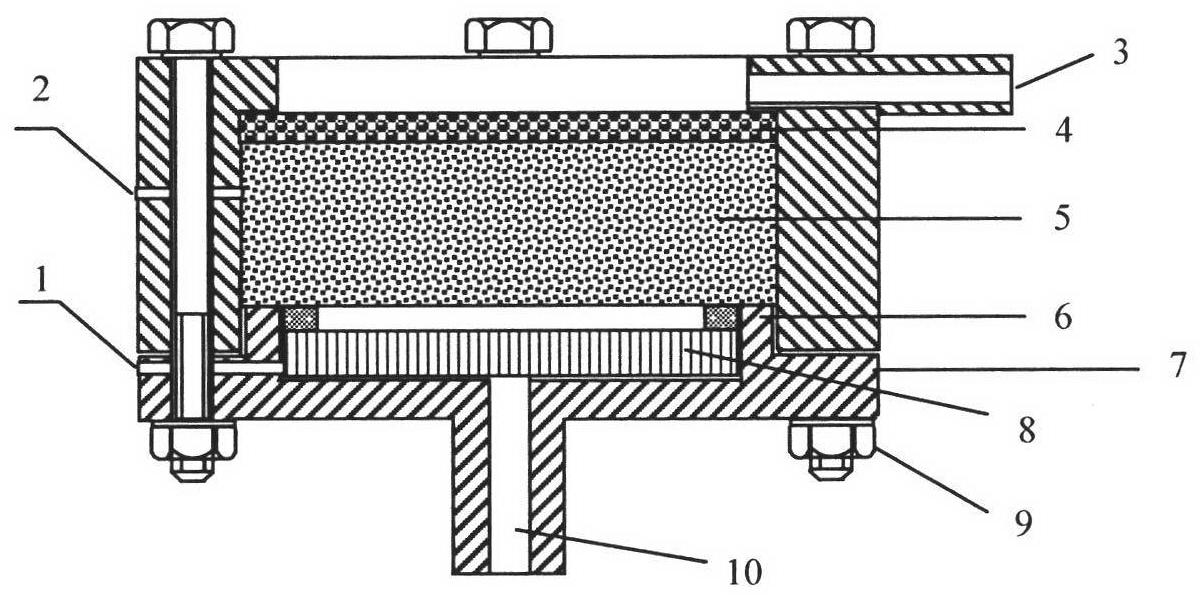

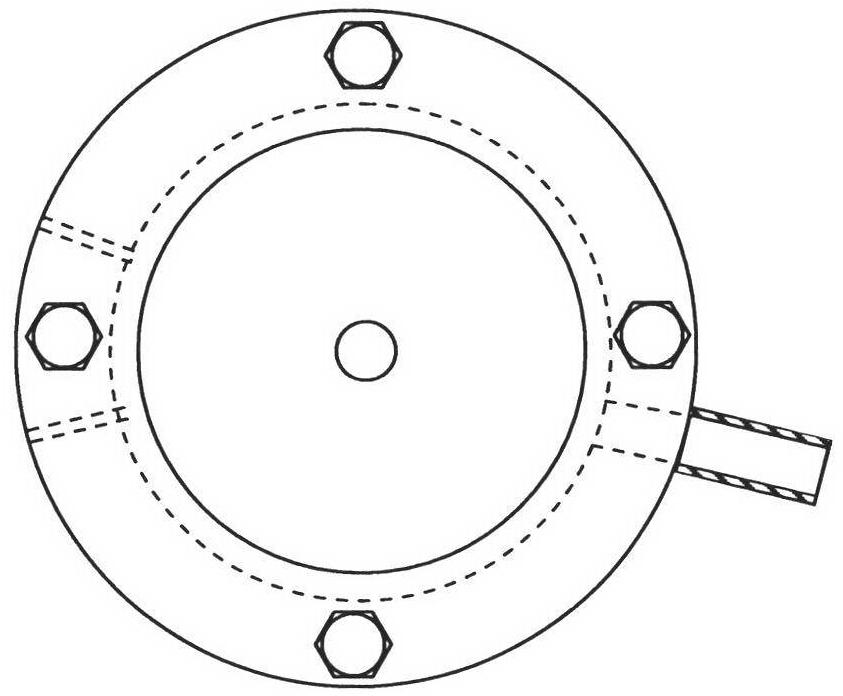

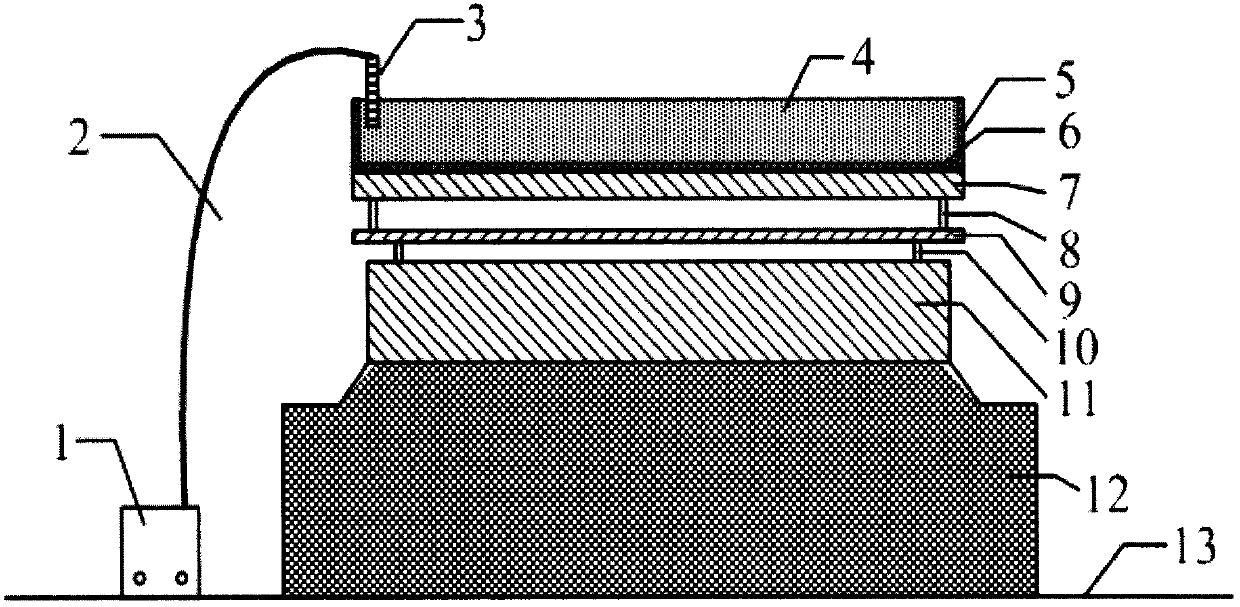

Organic wastewater treatment film reactor utilizing sunlight-assisted electro-catalysis

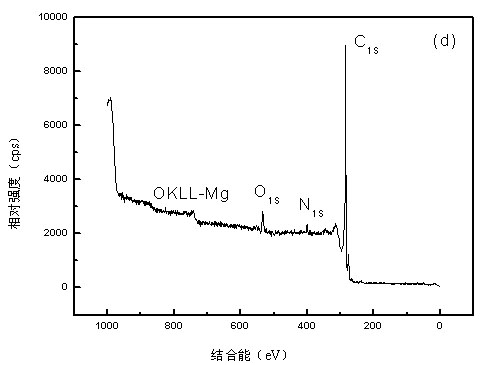

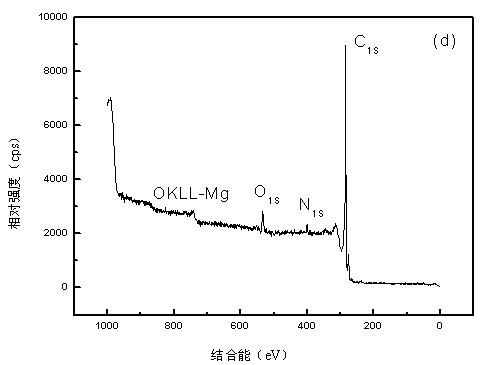

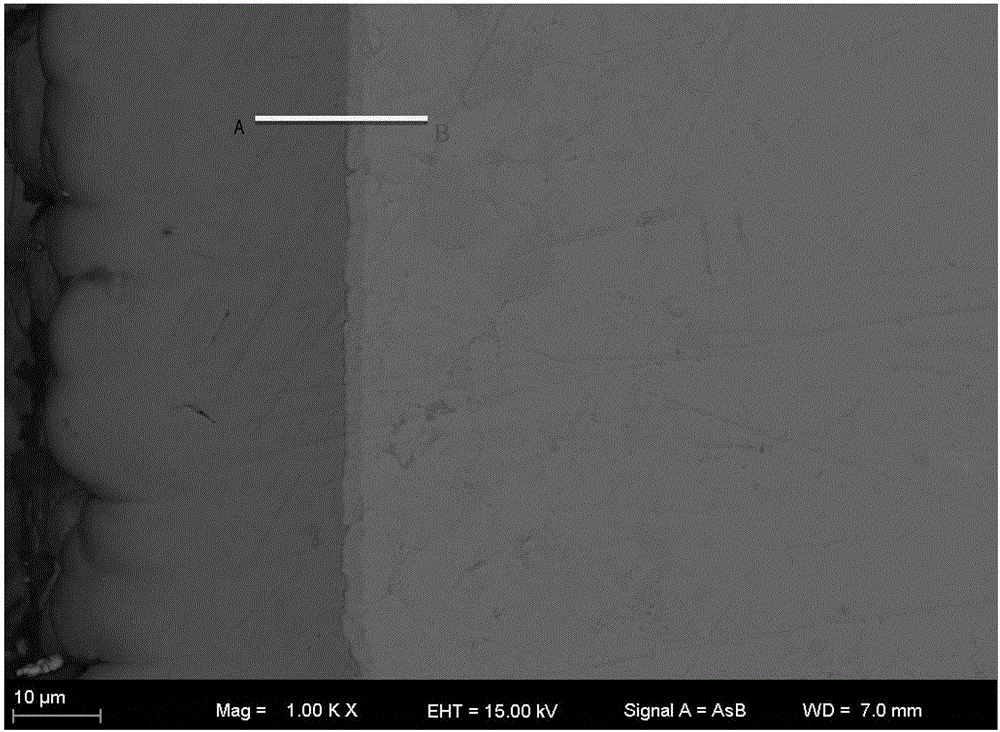

InactiveCN102603037AAccelerated adsorption/desorption rateThe actual user interface increasesWater/sewage treatment by irradiationEnergy based wastewater treatmentPhoto assistedPorous channel

The invention relates to an organic wastewater treatment film reactor utilizing solar energy photo-assisted electro-catalysis, which comprises a storage tank of water to be processed, a flow controllable constant flow pump, a photoelectric chemical reactor, a clear water storage tank and a solar battery component, wherein a photo anode and a cathode are correspondingly arranged in the reactor; the photo anode takes a porous metal membrane as a base body, and a TiO2 nano tube or a TiO2 mesoporous membrane is formed on the surface of a porous titanium membrane (net) by an electrochemical anisotropic etching technology; a porous channel film is used as the base body; a metal oxide coating electrode with high electrochemical catalytic activity and high electrical conductivity is prepared by a dipping film-forming method, simultaneously, by doping and modifying operations, the electrode material has photo catalytic activity and the reaction efficiency is improved. The reactor integrates electrochemistry, photocatalysis and film separation technologies; the three technologies are coupled to enhance a synergistic effect; the wastewater treatment efficiency can be improved; a solar component is adopted as a power supply; the clean solar energy is utilized to the maximal degree, and the organic wastewater treatment film reactor has social benefits of reducing environment load and economic benefits of reducing cost.

Owner:NANJING UNIV OF TECH

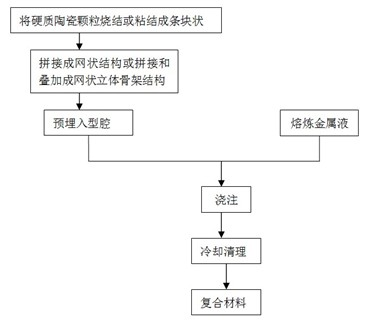

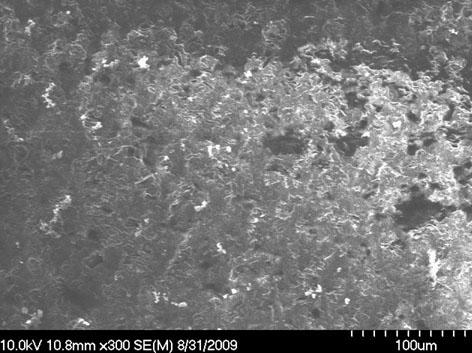

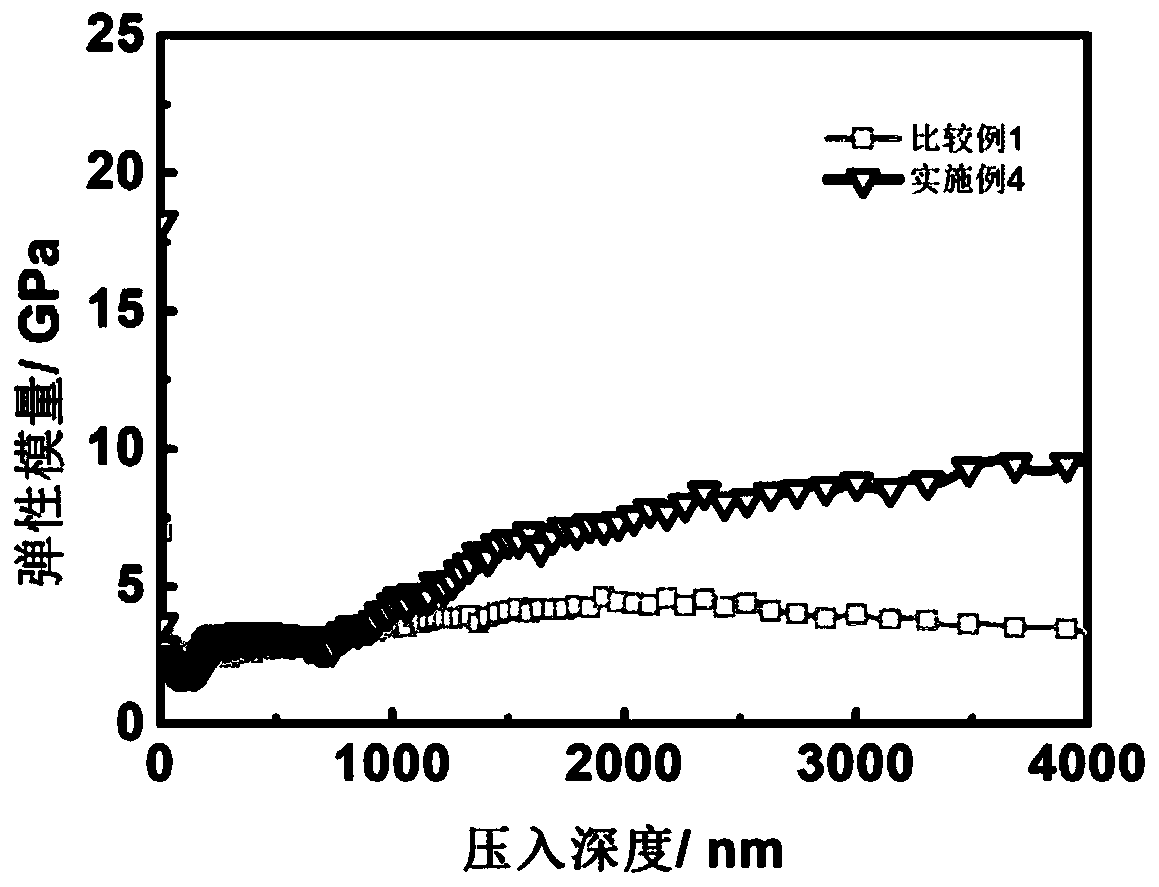

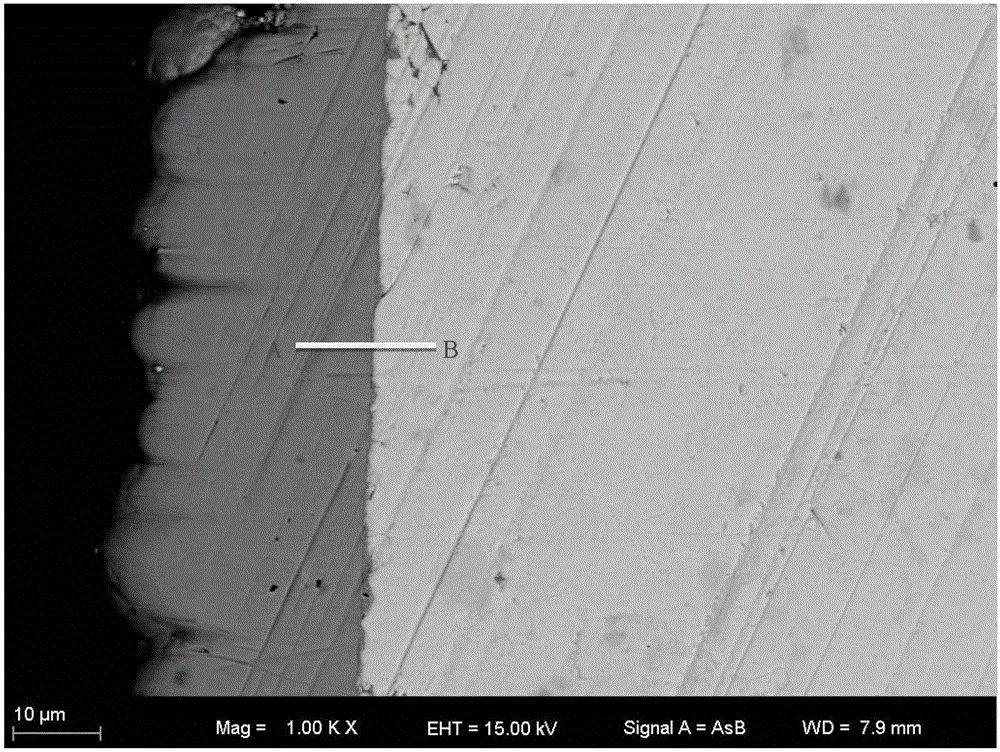

Super hybrid carbon nano material modified carbon fiber/epoxy matrix composite material and preparation method thereof

InactiveCN103552325AImproved interlaminar shear performanceThe interface is firmly bondedSynthetic resin layered productsModified carbonResin matrix

The invention relates to a super hybrid carbon nano material modified carbon fiber / epoxy matrix composite material and a preparation method thereof. The composite material an epoxy resin matrix material and an inorganic nano filler which is uniformly dispersed in the epoxy resin matrix material, wherein the composite nano inorganic filler is composed of graphene and carbon nanotubes. The excellent mechanical properties of the graphene and carbon nanotubes and the active functional groups on the surface are utilized to effectively enhance the mechanical properties of the epoxy resin matrix and the interface bonding strength between the matrix and the carbon fibers. The prepared composite material has excellent interlaminar shear property, and the interlaminar shear strength is enhanced from 50 MPa to 68 MPa.

Owner:JIAXING UNIV

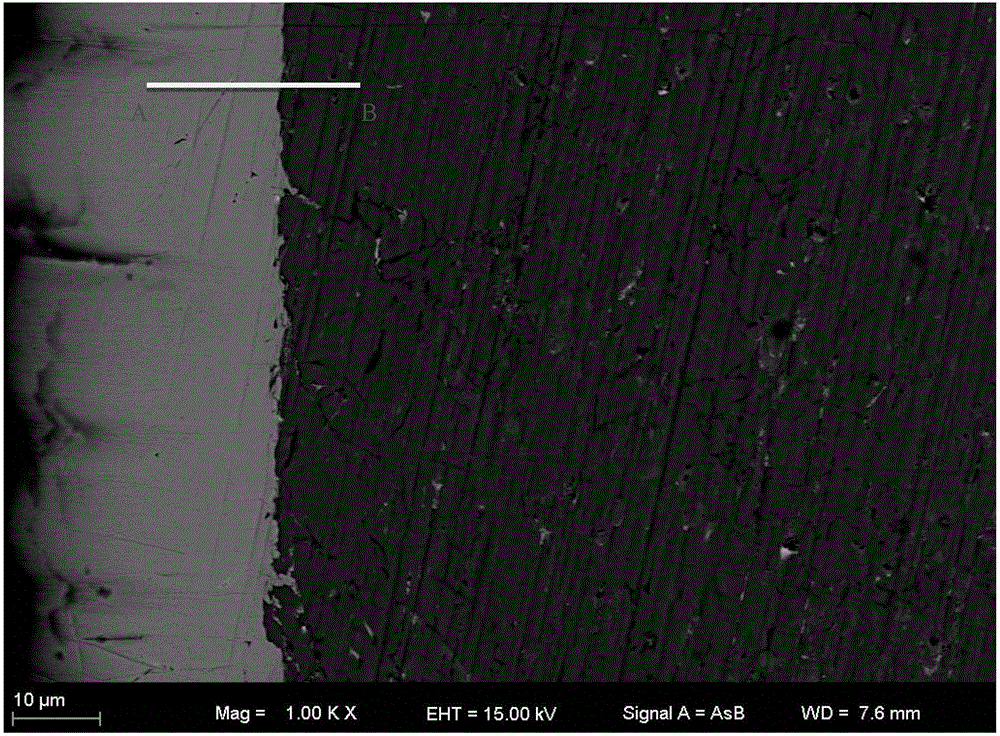

Graphene oxide/carbon nano-tube collaboration-modified glass fiber reinforced epoxy composite material and preparation method thereof

The invention relates to a graphene / carbon nano-tube collaboration-modified glass fiber reinforced epoxy composite material and a preparation method thereof. The composite material comprises an epoxy resin base material and inorganic nanometer filler which is uniformly dispersed in the epoxy resin base material, wherein the composite nanometer inorganic filler is composed of graphene oxide with thickness of 0.35nm-20nm and diameter of 5 microns-100microns and the carbon nano-tube with the diameter of 30nm-50nm and length of 10 microns-20 microns. The graphene / carbon nano-tube collaboration-modified glass fiber reinforced epoxy composite material can be used for effectively improving the mechanical performances of epoxy resin matrix and interface bonding strength between the matrix and the glass fiber by utilizing the excellent mechanical performances and the surface active functional groups of the graphene oxide and the carbon nano-tube, so that the interlayer shearing strength of the glass fiber composite material is effectively improved.

Owner:JIAXING UNIV

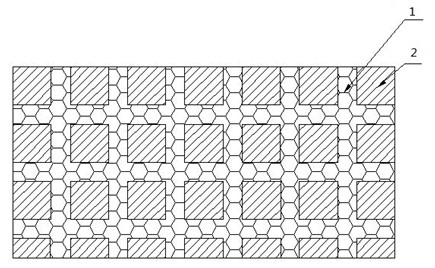

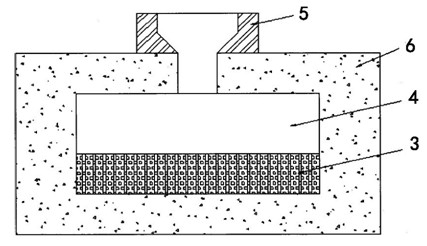

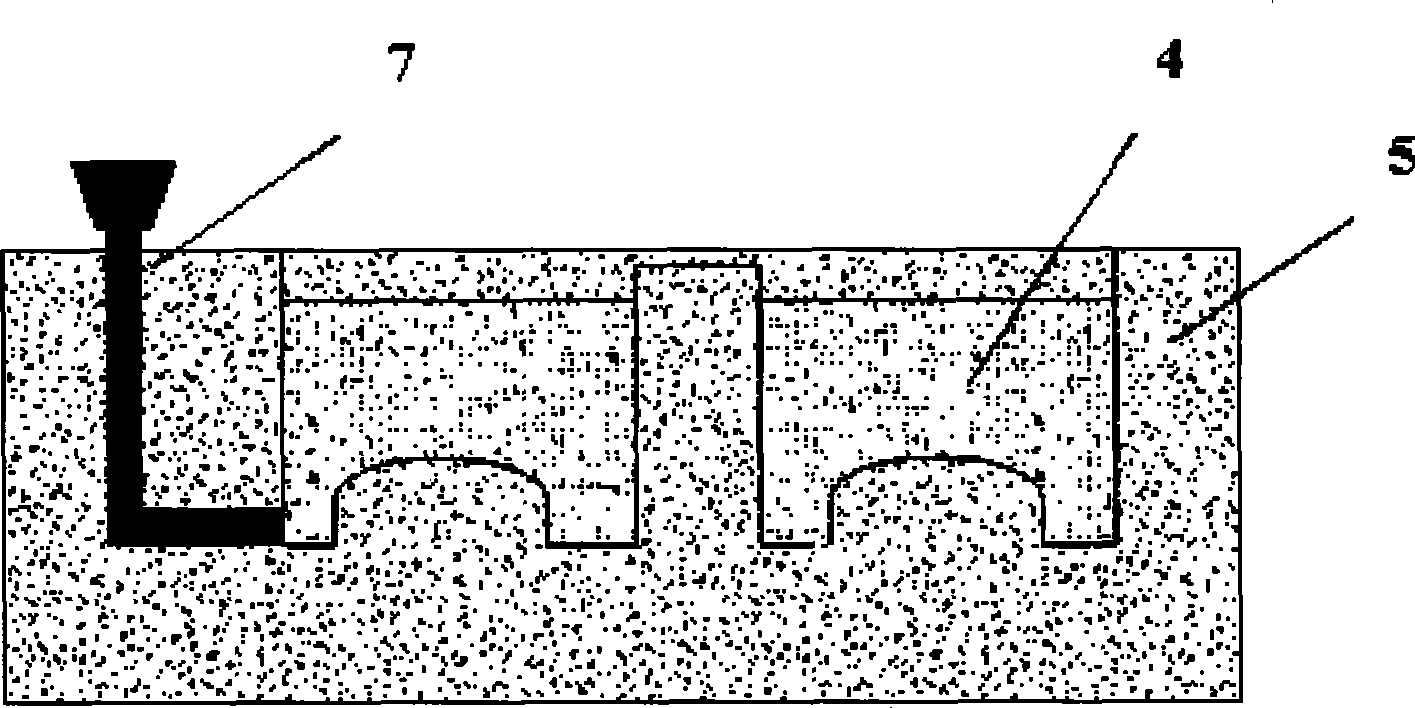

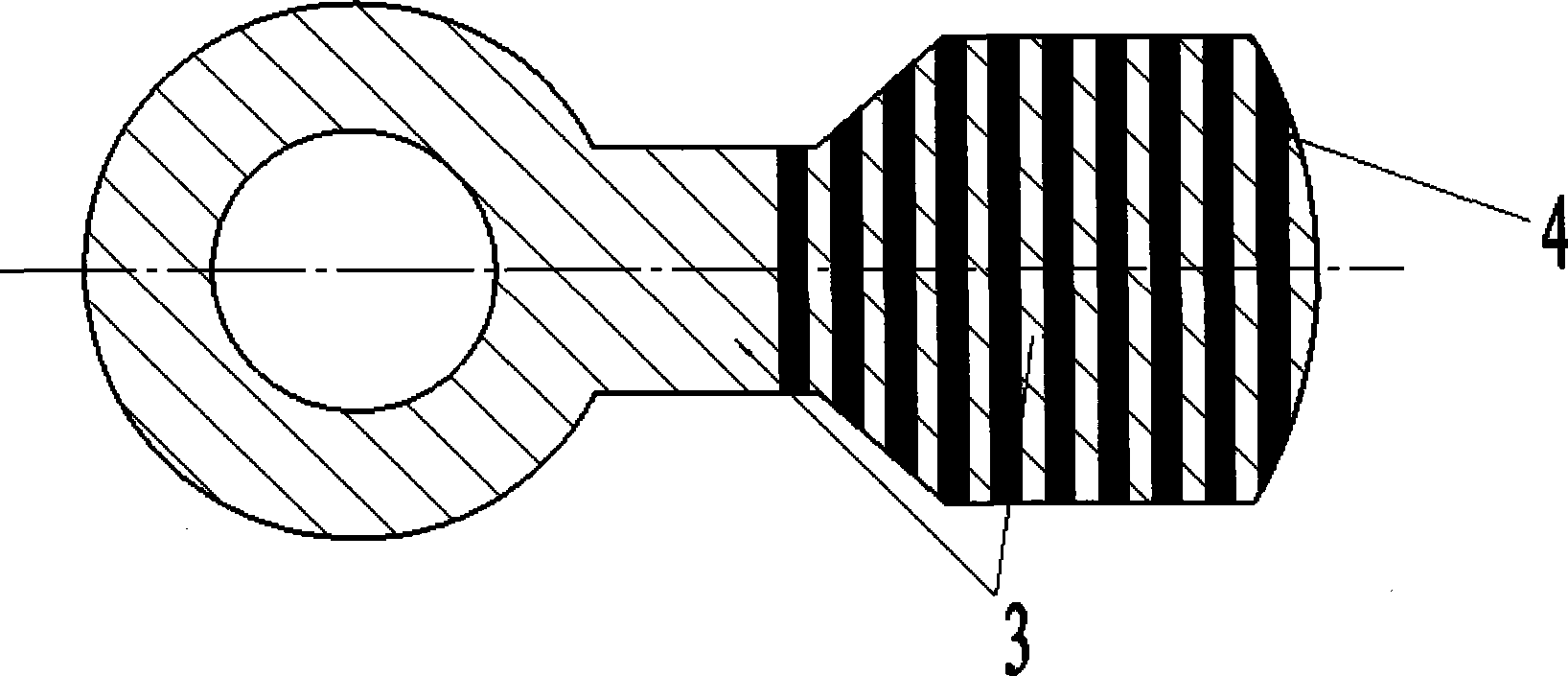

Method for preparing ceramic particle reinforced steel-based mesh material

The invention provides a method for preparing a ceramic particle reinforced steel-based mesh material, which comprises: forming a mixture of hard ceramic particles and alloy powder into strip blocks by powder sintering or by using and adhesive; joining the strip blocks into a corresponding mesh structure or joining and overlapping the strip blocks into mesh three-dimensional framework structure; and performing normal sand casting or lost foam casting, namely melting a substrate metal material, pouring the molten substrate metal material in a molding cavity, allowing the molten substrate metal material to cool and condense at room temperature, removing sand and obtaining the ceramic particle reinforced steel-based mesh material. The obtained ceramic particle reinforced steel-based mesh material gives full play to the high wear resistance of the ceramic particle hard phase and the toughness of the steel base; and the method with convenience for regulation and reliable process solves the problem of incomplete reaction of the composite material, nonuniform reinforcing phase particle distribution, pollution weakening on a reinforcing phase interface and the like and is used in wear resistance fields of mines, power, metallurgy, coal, building materials and the like.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing hybrid composite material of carbon fibers/carbon nanotubes/bismaleimide resin

InactiveCN101787128AIncreased interlaminar shear strengthImprove interface strengthFiberCarbon fibers

The invention belongs to the technical field of nano materials, and in particular relates to a method for preparing a hybrid composite material of carbon fibers / carbon nanotubes / bismaleimide resin. The method comprises the following steps: after carboxylating, acylating and chlorinating the surfaces of purified carbon nanotubes and dried carbon fibers, introducing diamine or polyamine with a feature structure thereon, wherein a large amount of the diamine or the polyamine are jointed on the surfaces of the carbon nanotubes and the carbon fibers; performing an addition reaction on the carbon nanotubes jointed with the amidogen and the bismaleimide resin to obtain a carbon nanotubes-containing bismaleimide resin linear block polymer serving as a substrate; and compositing the substrate and the carbon fibers in a certain mode to form a multi-dimensional hybrid composite material structure linked by covalent bonds finally. The method has the advantages of strengthening and toughening bismaleimide by using the strength and the toughness of the carbon nanotubes, improving the bonding strength between the bismaleimide and the carbon fiber substrate surface, improving overall performance of the multi-dimensional hybrid composite material of the carbon fibers / the carbon nanotubes / the bismaleimide resin, and widening the application of the carbon fibers, the carbon nanotubes and the bismaleimide resin.

Owner:TONGJI UNIV

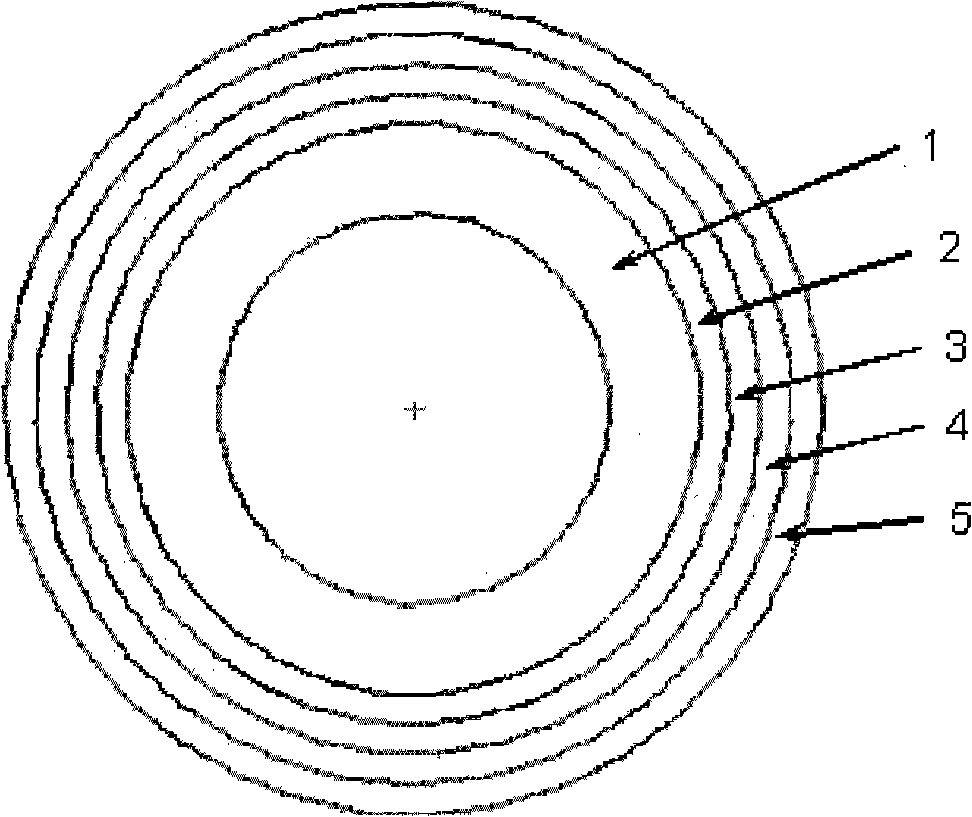

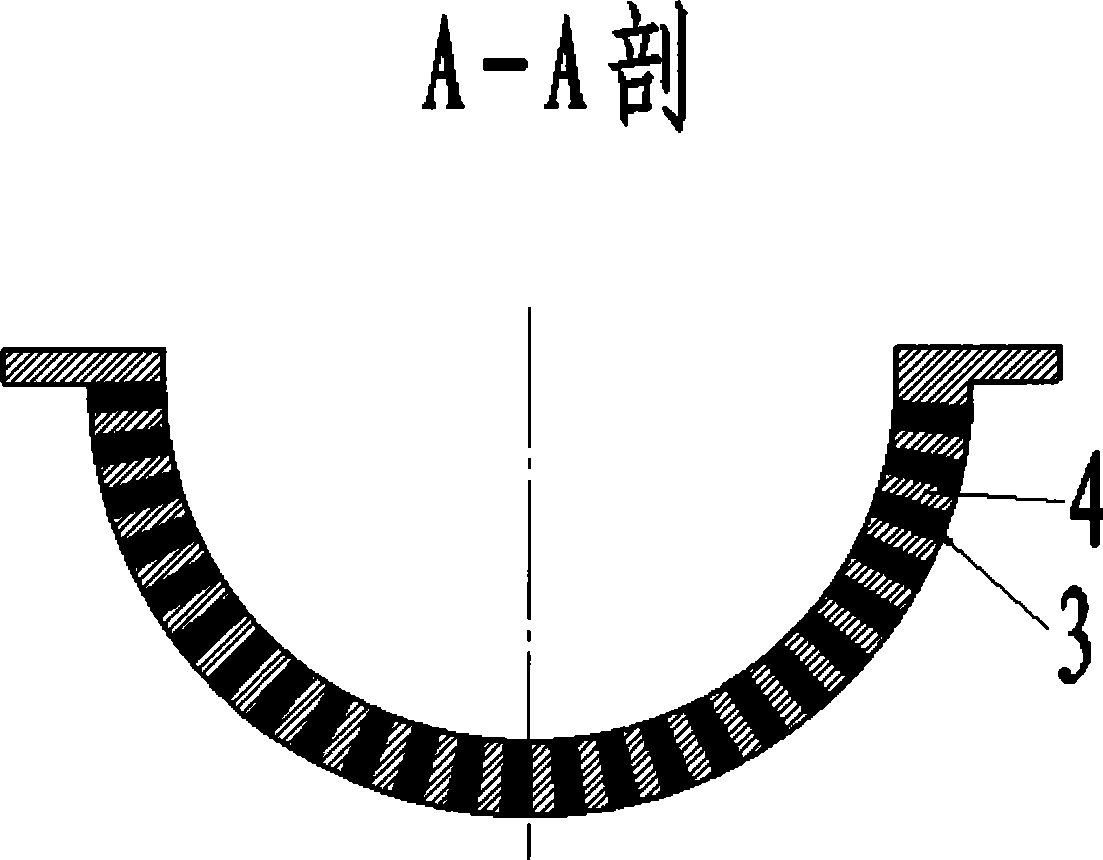

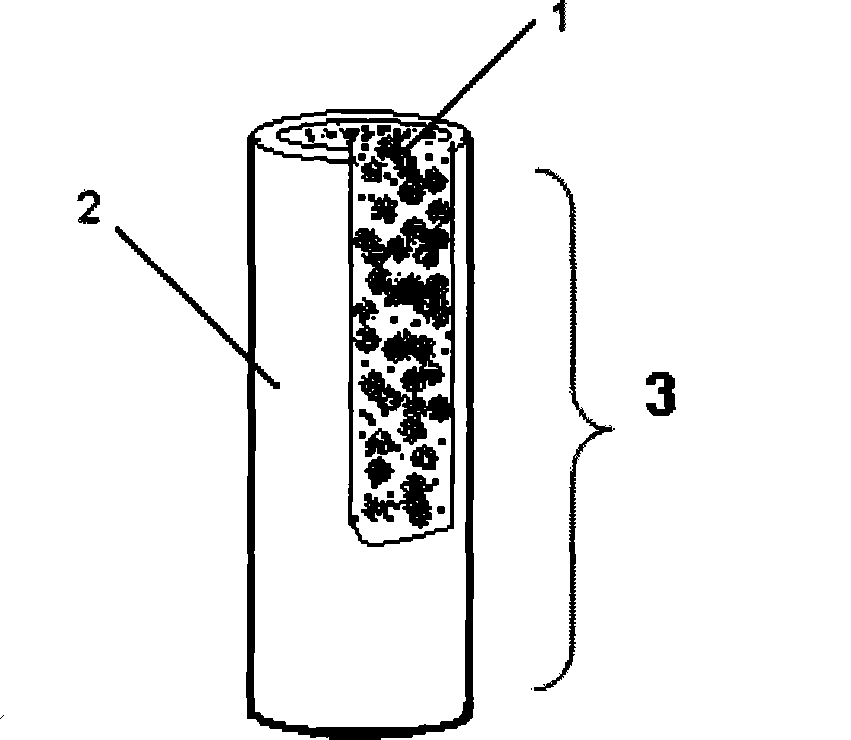

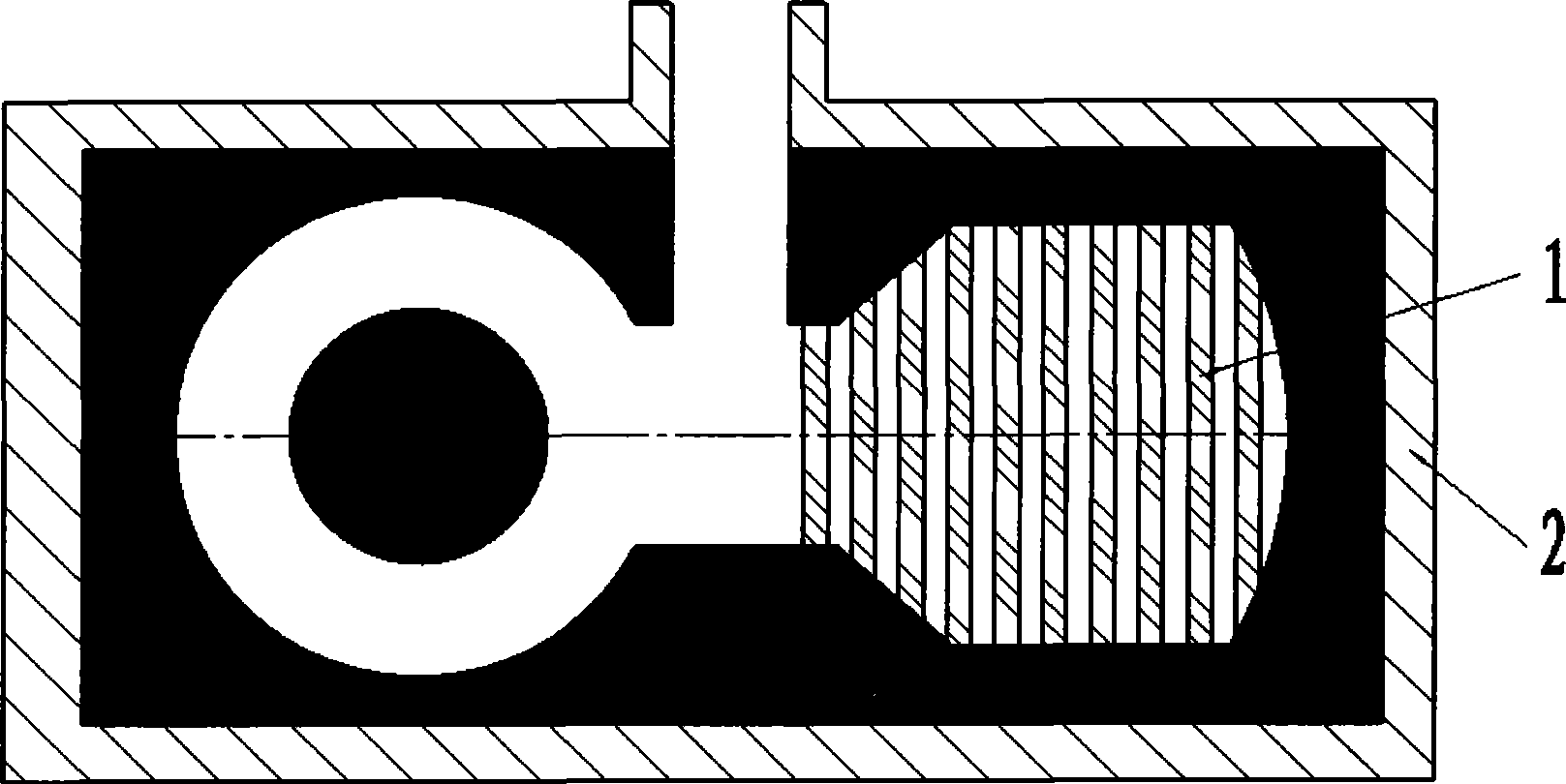

Large size tubular solid oxide fuel cell and preparation thereof

InactiveCN101359746AEasy to operateGood repeatabilityFinal product manufactureSolid electrolyte fuel cellsAdhesiveSlurry

The invention discloses a large-size tubular solid oxide fuel cell and a preparation method thereof, and the method comprises: powder material of each functional layer of a solid oxide fuel cell is respectively added with an organic solvent, a dispersant, an adhesive and a plasticizer, and fully ground to obtain a uniform support anode slurry, an active anode slurry, an electrolyte slurry, an active cathode slurry and an electricity-receiving cathode slurry. The outer surface of a mold is impregnated with the support anode layer by layer after the vacuum treatment; the support anode tube is filled with combustible organic matter after demoulding; the active anode and the electrolyte are impregnated to form a support anode / active anode / electrolyte composite membrane; then the external side of the electrolyte is impregnated with the active cathode and the electricity-receiving cathode after sub-temperature sintering, that is, after pre-burning and high-temperature sintering; and the large-size tubular solid oxide fuel cell is obtained after sintering. The invention has advantages of simple process, low manufacturing cost, achieving good-performance large-size tubular solid oxide fuel cell and good prospect of industrialization.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

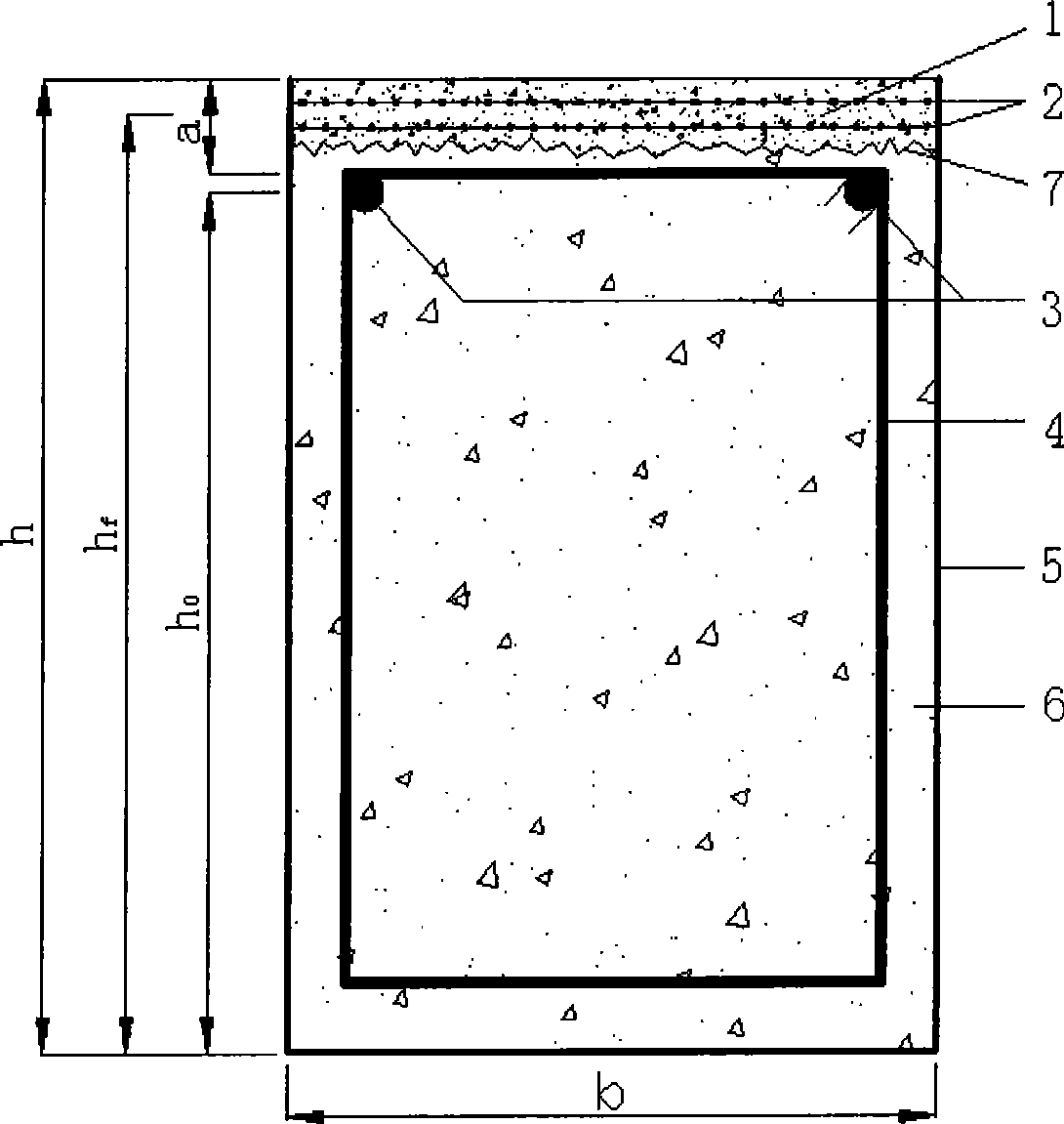

Construction structure for textile reinforced composite reinforced bar concrete and manufacturing method thereof

InactiveCN101481930AHigh strengthLimit or improve cracksSolid waste managementBuilding reinforcementsFiberRebar corrosion

The invention belongs to the technical field of concrete reinforcement, relating to utilizing fiber mesh grids to enhance the concrete strength. The arrangement of structural reinforcing steel, the thickness of concrete protective layers of main stress ribs and the grade of the concrete strength of the invention are designed according to the design criterion of a reinforced concrete structure. The invention is characterized in that before the initial setting of the concrete, fine concrete and the fiber mesh grids are cast on the outer side of the stretched and drawn area of the structure or the external surface of a large-scale integral structure, the total thickness of the fiber mesh grids and the fine concrete ranges from 10mm to 20mm, concrete with equal thickness of external surfaces are replaced, and the fiber mesh grids are evenly distributed in the fine concrete. The grid type or the plate type structure of the invention can adopt the structure of replacing partial reinforcing steel with the fiber mesh grids. The invention can effectively control cracks and solve the problems of concrete cracking and reinforcing steel corrosion, and has the advantages of firm bonding of the boundary surfaces of the fine concrete and the concrete, light self weight, low production cost, corrosion resistance, safe and durable usage, etc.

Owner:DALIAN UNIV OF TECH

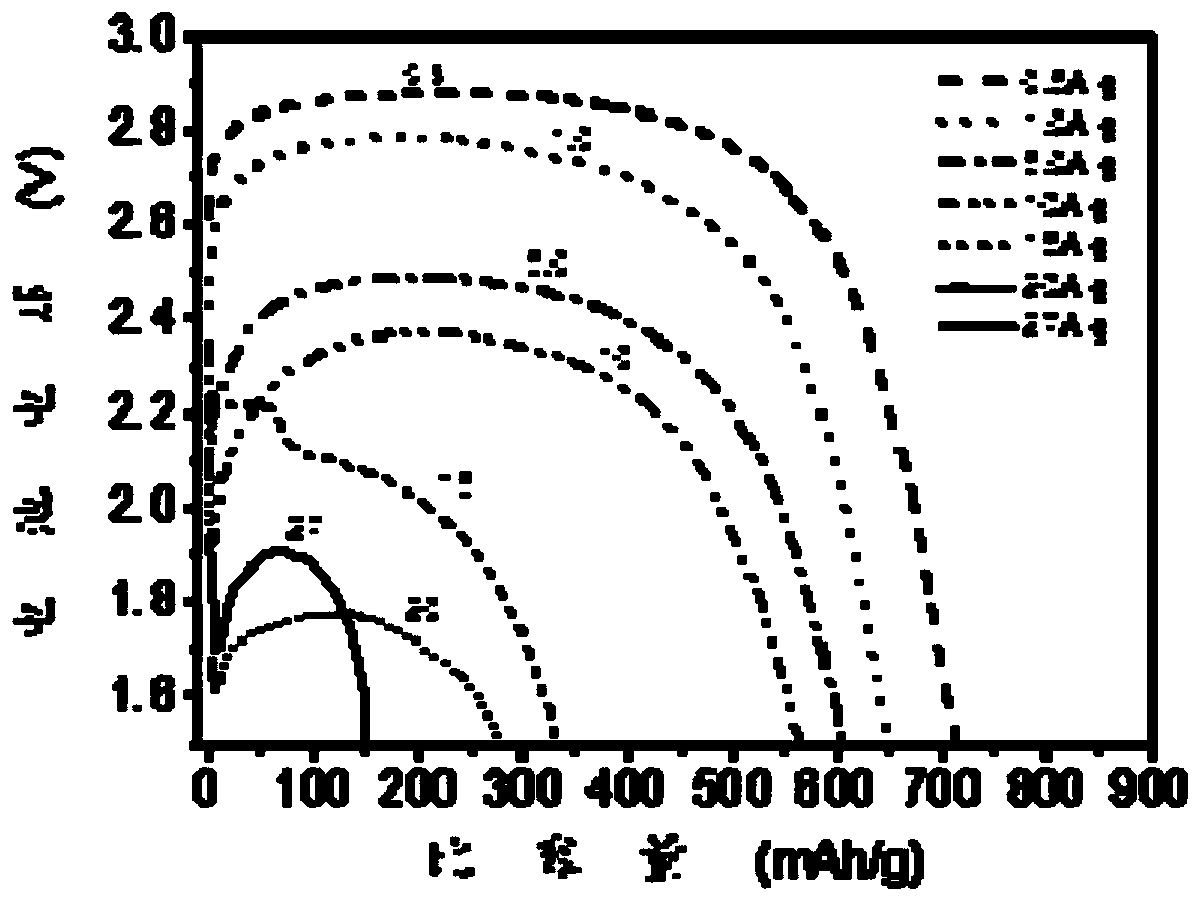

Method for preparing cathode material for high capacity lithium ion battery

InactiveCN101325253AImprove electrochemical performanceImprove wettabilityElectrode manufacturing processesCarbon compositesChemical reaction

The invention relates to the preparation technology of cathode materials for rechargeable secondary lithium-ion batteries and provides a method of preparing the cathode materials for high-capacity lithium-ion batteries. The lithium-ion battery utilizes the techniques of the in-situ carbothermic reduction reaction and the in-situ chemical reaction ball milling to prepare the uniformly-dispersed metal oxide / carbon composite cathode materials. The prepared composite cathode materials can remarkably increase the capacity of the lithium-ion batteries and have excellent cycle performance. The composite cathode materials prepared by the method make full use of high-capacity metal oxides, additionally, the metal oxides, in the form of small granules, are uniformly dispersed on the surface of the carbon-based matrix with high interface bonding strength, so that the volume change caused by the insertion and the extraction of lithium ions during the recharging process is well attenuated by the carbon-based matrix and the cycle performance is also kept excellent.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

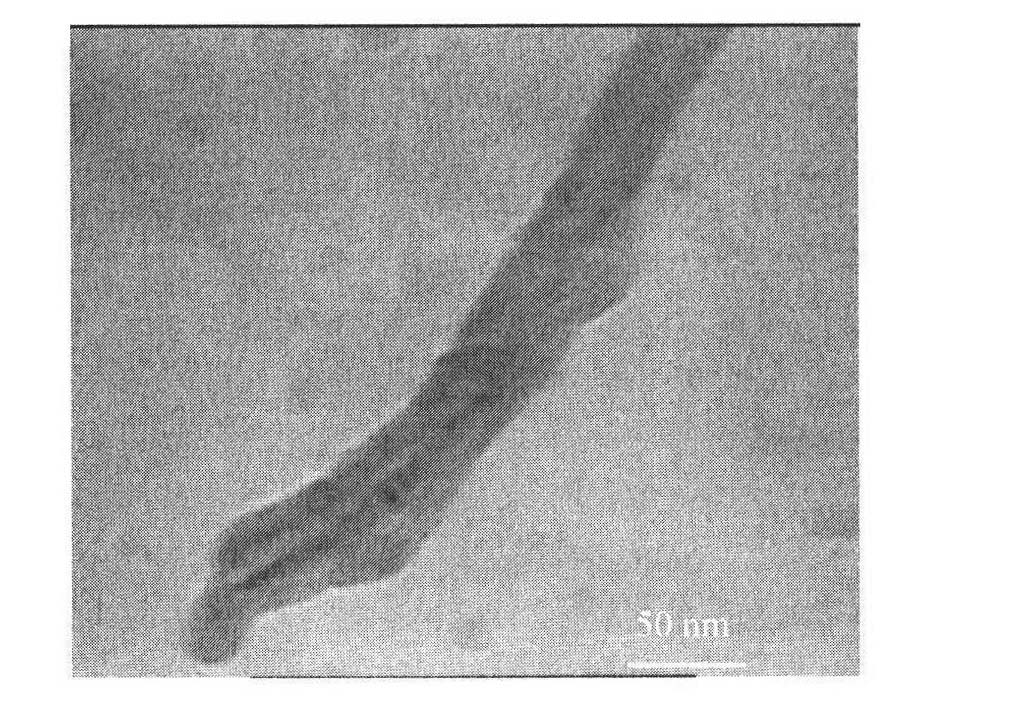

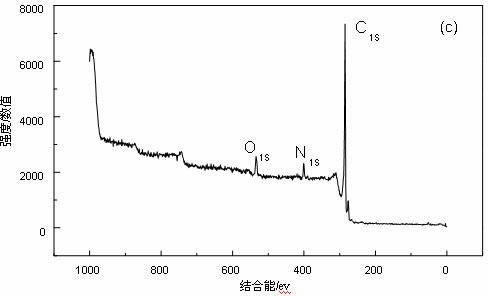

Preparation method of glass fiber/carbon nanotube/epoxy resin multi-dimensional hybrid composite material

InactiveCN102276795AIncreased interlaminar shear strengthImprove interface strengthResin matrixCarbon nanotube

The invention relates to a preparation method of a glass fiber / carbon nanotube / epoxy resin multi-dimensional hybrid composite material. The preparation method provided by the invention comprises the following steps of: treating glass fiber with a silane coupling agent; carrying out surface carboxylation and chlorination on carbon nanotubes, then introducing diamine or polyamine to the carbon nanotubes, and modifying the carbon nanotubes connected with an amino group by a polybasic anhydride compound to prepare the carbon nanotubes carrying an anhydride group; dispersing the treated carbon nanotubes in an epoxy resin matrix by ultrasonic oscillation and high-speed stirring, and curing with an organic anhydride curing agent; and compounding the obtained carbon-nanotube-containing epoxy resin polymer used as a matrix with the coupling-agent-treated glass fiber to form a multi-dimensional hybrid composite material structure linked through covalent bonds. The preparation method provided by the invention has the advantages that: the composite material is convenient to prepare, the dispersion of the carbon nanotubes in epoxy resin is improved, and the strength and toughness of the carbon nanotubes are utilized to toughen epoxy resin and to improve the bonding strength with the base surface of the glass fiber, thereby enhancing the overall performance of the glass fiber / carbon nanotube / epoxy resin multi-dimensional hybrid composite material and broadening the applications of the glass fiber, carbon nanotubes and epoxy resin.

Owner:TONGJI UNIV

Silk fiber reinforced high polymer composite material

InactiveCN1775855AAbundant resourcesGood biocompatibilityBiocompatibility TestingUltimate tensile strength

The invention relates to a silk fiber reinforced high polymer compounding material which is made up of 15-65% silk fiber and the rest is matrices. The matrices could be one or the mixture of poly-caprolactone and poly-lactic acid. It has simple technology, and broad application range. It keeps good biocompatibility and biodegradability.

Owner:SHANGHAI JIAO TONG UNIV

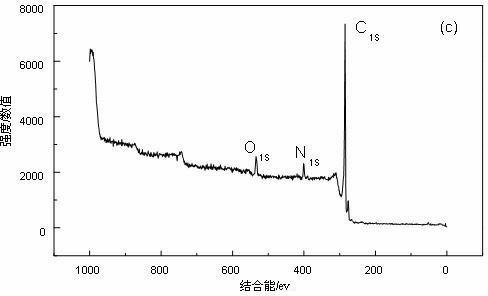

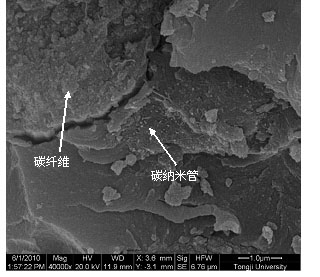

Method for preparing carbon nanofiber and carbon nanotube modified carbon fiber/epoxy resin multi-dimensional hybrid composite

InactiveCN101979436AImprove the shortcomings of insufficient interlaminar shear strength, etc.CurableFiberCarbon fibers

The invention belongs to the technical field of nano materials and particularly relates to a method for preparing a carbon nanofiber and carbon nanotube modified carbon fiber / epoxy resin multi-dimensional hybrid composite. The method comprises the following steps of: performing surface carboxylation and acylation treatment on carbon nanotubes, carbon nanofibers and carbob fibers; introducing diamine or polyamine to the obtained product; modifying amino carbon nanofibers and carbon nanotubes with an aromatic polyanhydride compound to prepare the carbon fibers, the carbon nanofibers and the carbon nanotubes carrying anhydride radicals; and ultrasonically oscillating the carbon nanofibers, the carbon nanotubes and the epoxy resin with the anhydride and stirring the mixed materials at a high speed to make the carbon nanofibers and the carbon nanotubes uniformly dispersed in the epoxy resin matrix and make the carbon nanofibers and the carbon nanotubes grafted with the anhydride and the epoxy resin fully undergo a chemical crosslinking reaction so as to obtain an epoxy resin linear block polymer, and combining the epoxy resin linear block polymer serving as a matrix and the carbon fibers to form multi-dimensional hybrid composite structures connected by covalent bonds. In the invention, by using the carbon nanotubes, the carbon nanofibers and the strength and toughness toughened epoxy resin, the bonding strength of carbon fiber interfaces is improved, so that the integral performance of the carbon fiber / epoxy resin multi-dimensional hybrid composite is improved, and the application range of the carbon fibers and the epoxy resin is widened.

Owner:TONGJI UNIV

Method for preparing composite wear-resistant foreplate

InactiveCN101412095AInhibited DiffusionReduce the temperatureGuiding/positioning/aligning arrangementsWear resistantHardness

The invention discloses a method for preparing a composite antiwear guide plate, which comprises the following steps: alloy dust core bars are bound into bundles and arranged in a guide plate casting mould cavity, and the volume of the alloy dust core bars accounts for 20 to 60 percent of the total volume of the guide plate; molten matrix metal is cast into the guide plate casting mould cavity, the alloy dust core bars are melted and dissolved under the heat effect of the matrix metal, a great number of alloy elements and the molten matrix metal generate metallurgical combination reaction so as to generate a highly dispersed alloy structure on the original position; and finally the alloy structure is cooled and solidified, and the bar-shaped hard phase is metallurgically and transitionally combined into a whole with the matrix metal, thereby preparing the composite guide plate which takes the high-strength and high-ductility metal as the matrix and contains a certain number of metallurgically combined bar-shaped hard points. The composite anti-wear guide plate has high strength and high ductility of the matrix metal and high hardness and high wear resistance of the hard phase, can simultaneously bear high pressure and strong wear, and has the characteristics of long service life, low price, simple preparation and so on.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

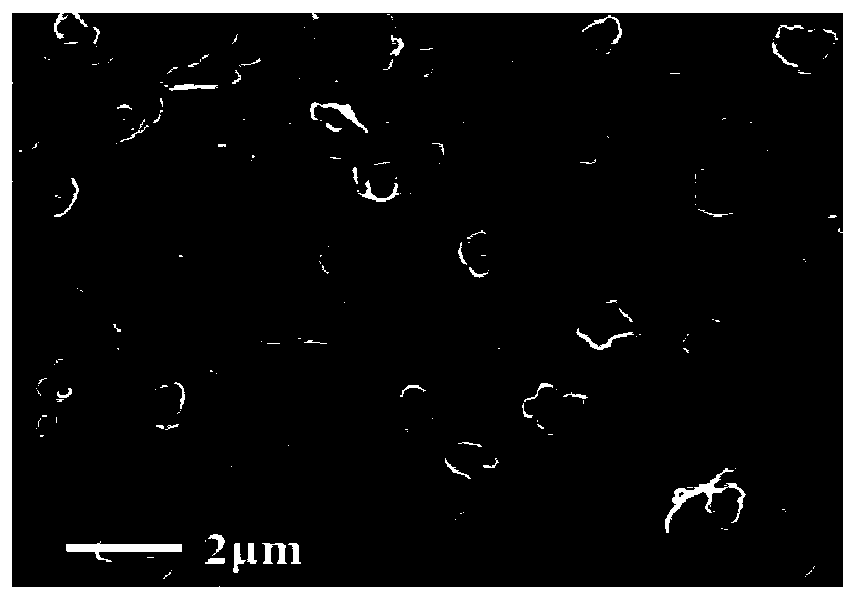

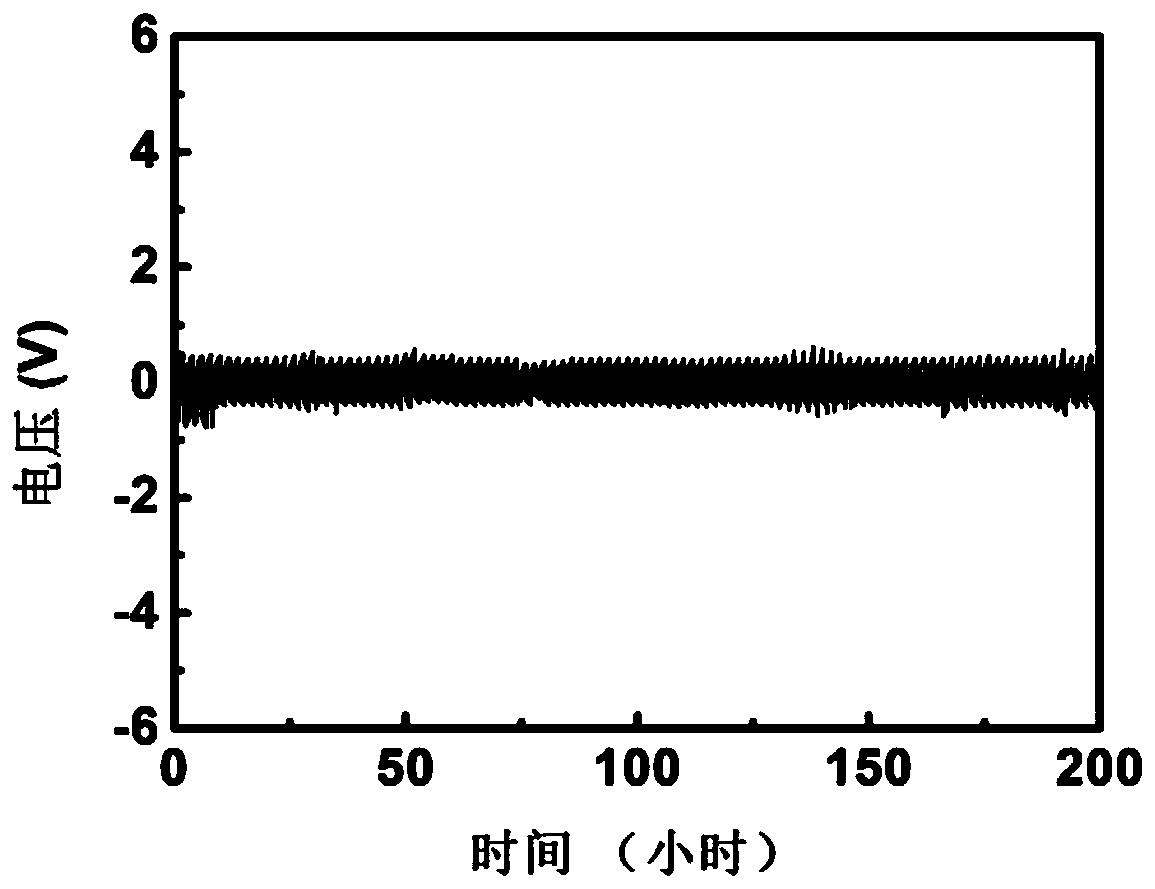

Organic-inorganic composite coating film on surface of metal lithium negative electrode, and preparation method

The invention provides an organic-inorganic composite coating film on the surface of a metal lithium negative electrode. The film comprises a siloxane organic phase formed by condensation of LiSixOy inorganic particles and silane; and the film uniformly coats the surface of metal lithium, and has the characteristics of relatively high ionic conductivity, high young modulus, small interface resistance, improved long-term working stability of the metal lithium, and the like. Meanwhile, the invention also provides a preparation method of the organic-inorganic composite coating film on the surface of the metal lithium negative electrode. The silane which is distributed on the surface of the metal lithium is subjected to adaptive phase splitting along with a first-time deposition process of the lithium to form an organic-inorganic composite double-phase structure, and the metal lithium is guided to be uniformly deposited and stripped in a charging process, so that the growth of lithium dendrites is inhibited. The cycle lives of the metal lithium negative electrode and a battery system are remarkably prolonged, and the safety of the metal lithium negative electrode and the battery system during use is guaranteed.

Owner:UNIV OF SCI & TECH BEIJING

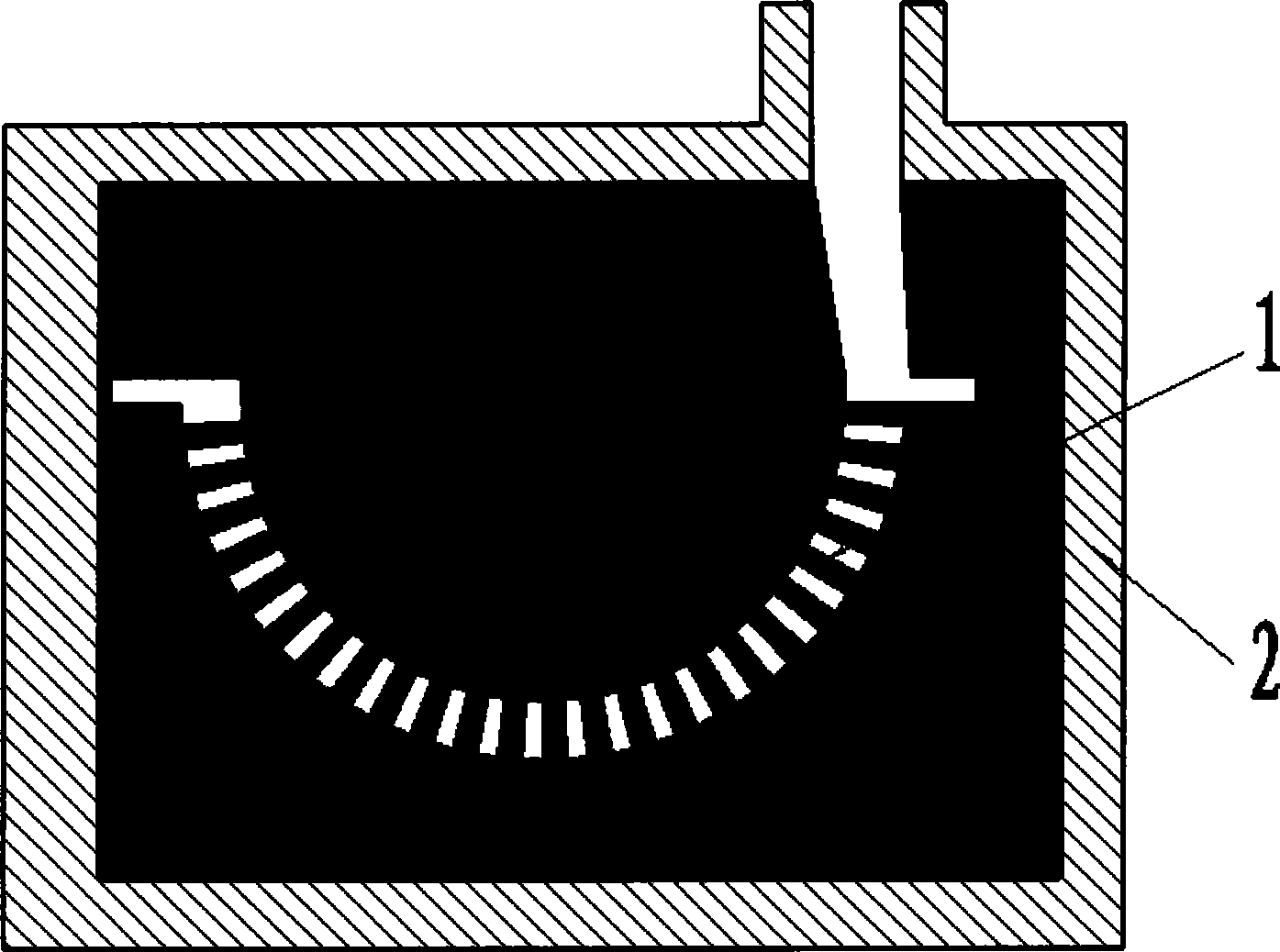

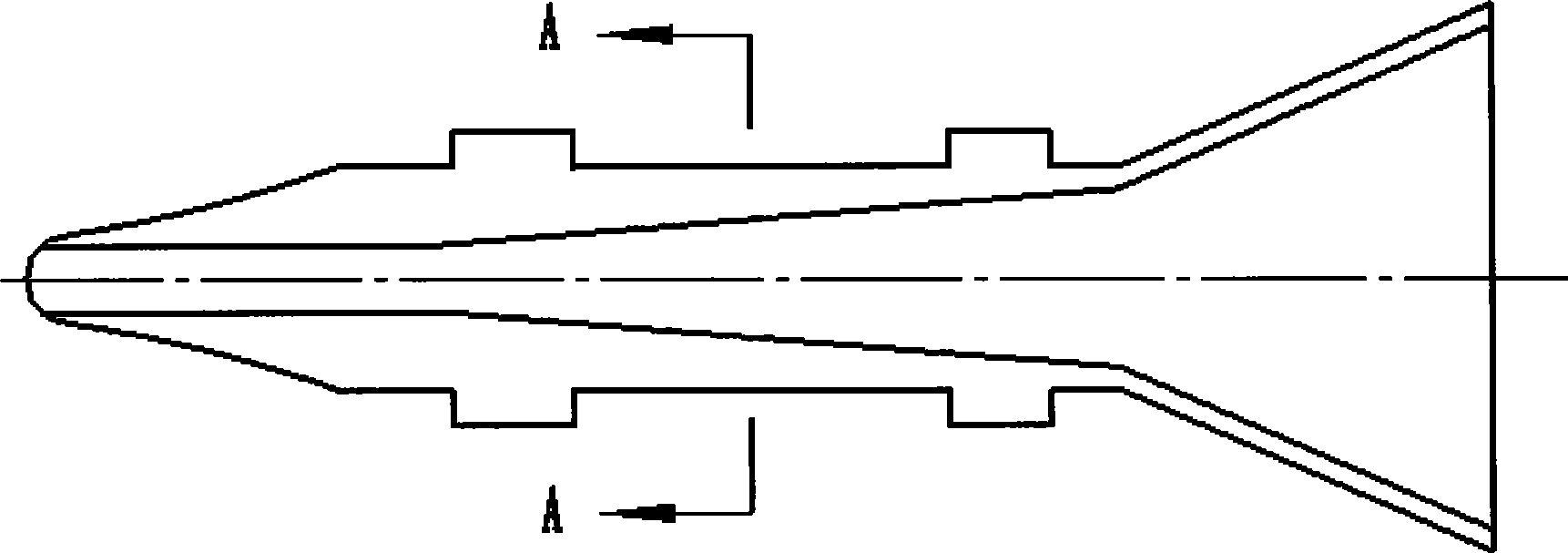

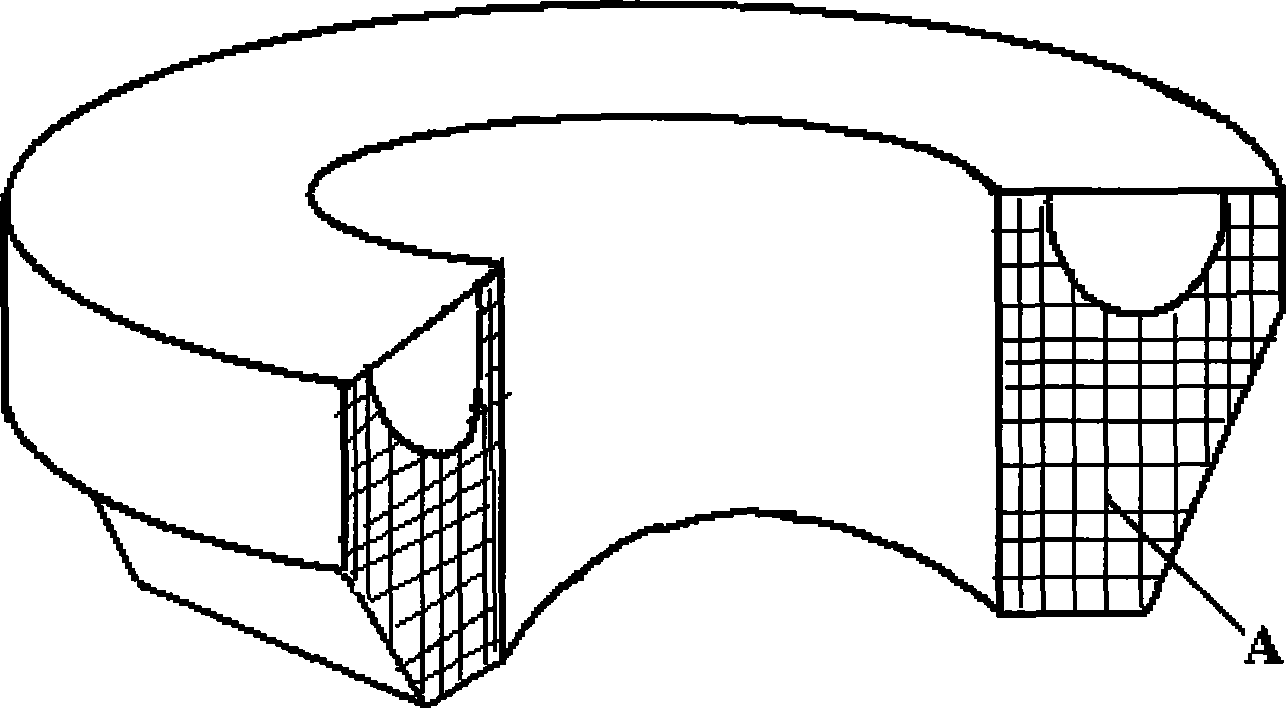

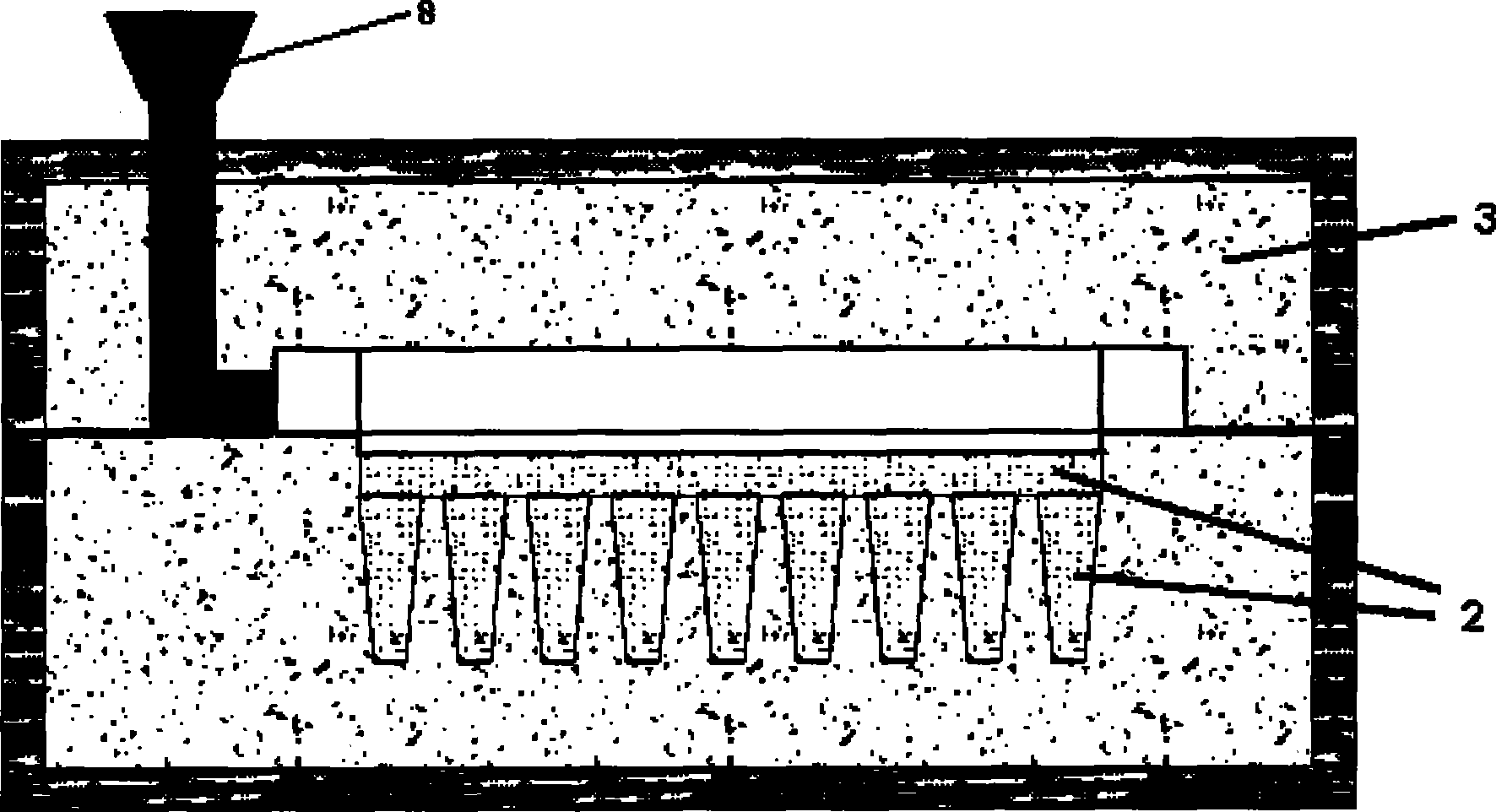

Method for preparing primary column shaped horniness phase composite wear-resistant grinder dish

The invention discloses a method for preparing a composite wear resistant abrasive disk with a protogenous columnar hard phase. The wear resistant abrasive disk prepared by the method is formed by pouring and compounding a high hardness columnar alloy hard phase and a high tenacity base metal. The method comprises the following steps: weaving an alloy powder core wire material into a framework similar to the shape of the abrasive disk, and pouring smelted high temperature base material molten steel into a die cavity of an abrasive disk casting mould; putting the woven framework similar to the shape of the abrasive disk into the casting die cavity filled with the high temperature base metal molten steel quickly, performing cast-infiltration, sintering or melting on the woven alloy powder core wire material framework by using the heat of the high temperature base metal molten steel so as to generate a highly-dispersed high hardness columnar alloy hard phase in situ; and cooling the phase at room temperature to produce the composite wear resistant abrasive disk using high-tenacity and high-strength metal as a base and containing the metallurgically-combined protogenous columnar hard phase. The composite wear resistant abrasive disk with the protogenous columnar hard phase has ultra wear resistance and good impact resistant toughness, and the service life of the abrasive disk is close to or exceeds the imported products of the same type.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Rapid welding method for steel and aluminum or aluminum alloy

InactiveCN103111743AThe interface is firmly bondedImprove bindingWelding/cutting media/materialsSoldering mediaLap jointAluminum can

The invention discloses a rapid welding method for steel and aluminum or aluminum alloy. The rapid welding method includes the following steps: (1), clearing away oil stain and oxide film on the surfaces of steel plates, aluminum plates and Al-Si brazing filler metal before welding; (2), placing sheet Al-Si brazing filler metal with an oxide-film-removed surface between to-be-welded faces of the steel plates and the aluminum plates; (3), adopting alternating-current resistance mash welder; and (4), naturally cooling joints of the steel and the aluminum after finishing welding. In the rapid welding method, dissimilar metals like the steel and the aluminum are adopted, the Al-Si brazing filler metal are added to realize overlap welding of the steel plates and the aluminum plates, so that formed overlap joint interfaces of the steel and the aluminum plates are bonded stably, and bonding quality is reliable. By adopting the Al-Si brazing filler metal, overlap joints of the steel and the aluminum with high interface bonding strength can be produced. Tests prove that shear strength of the overlap joints of the steel and the aluminum is greater than 80 MPa (million pascal), extension strength is greater than 140 MPa, and quality requirements of light-weight engineering structures on the overlap joints of the steel and the aluminum can be met.

Owner:SHANDONG UNIV

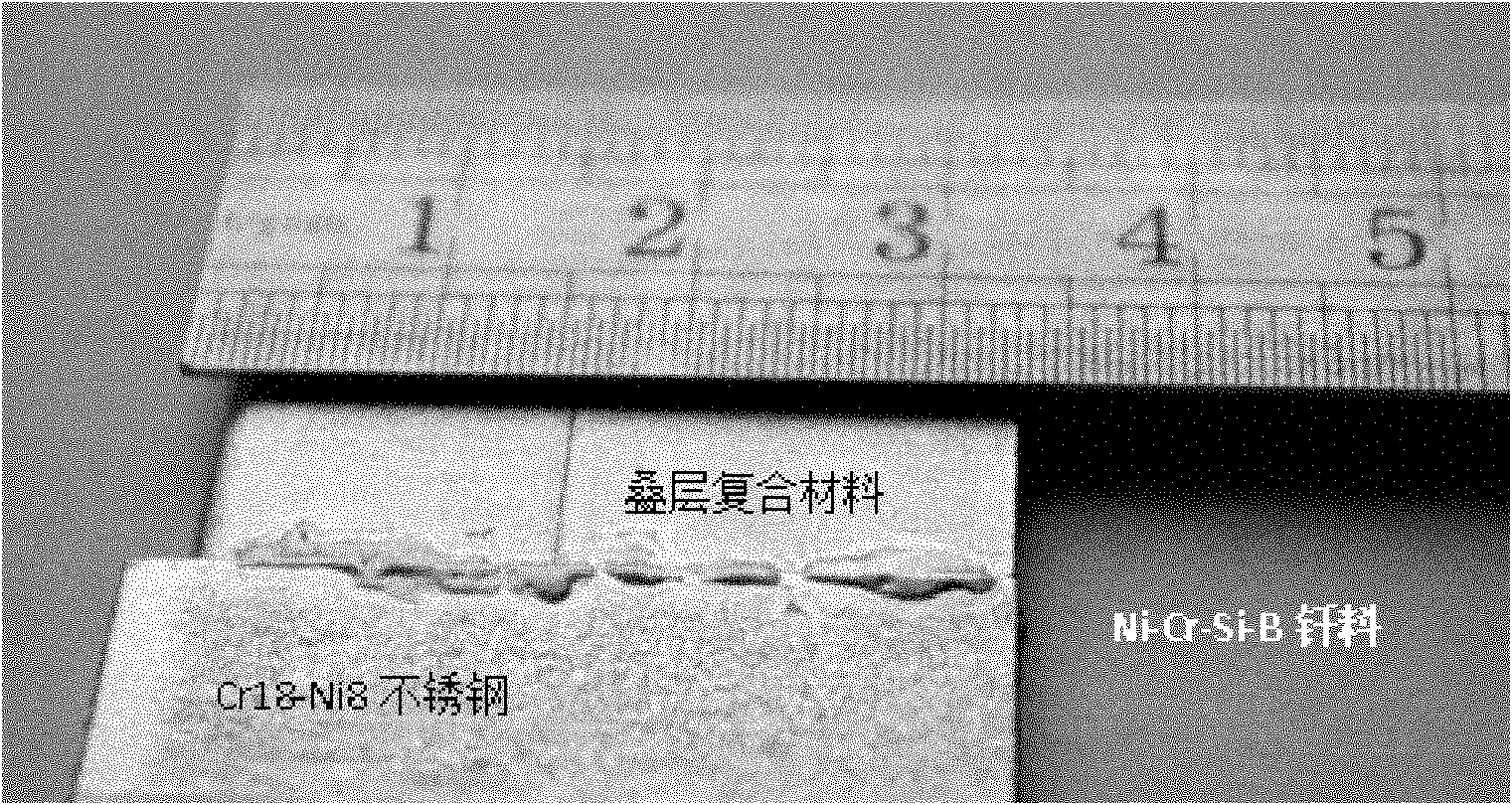

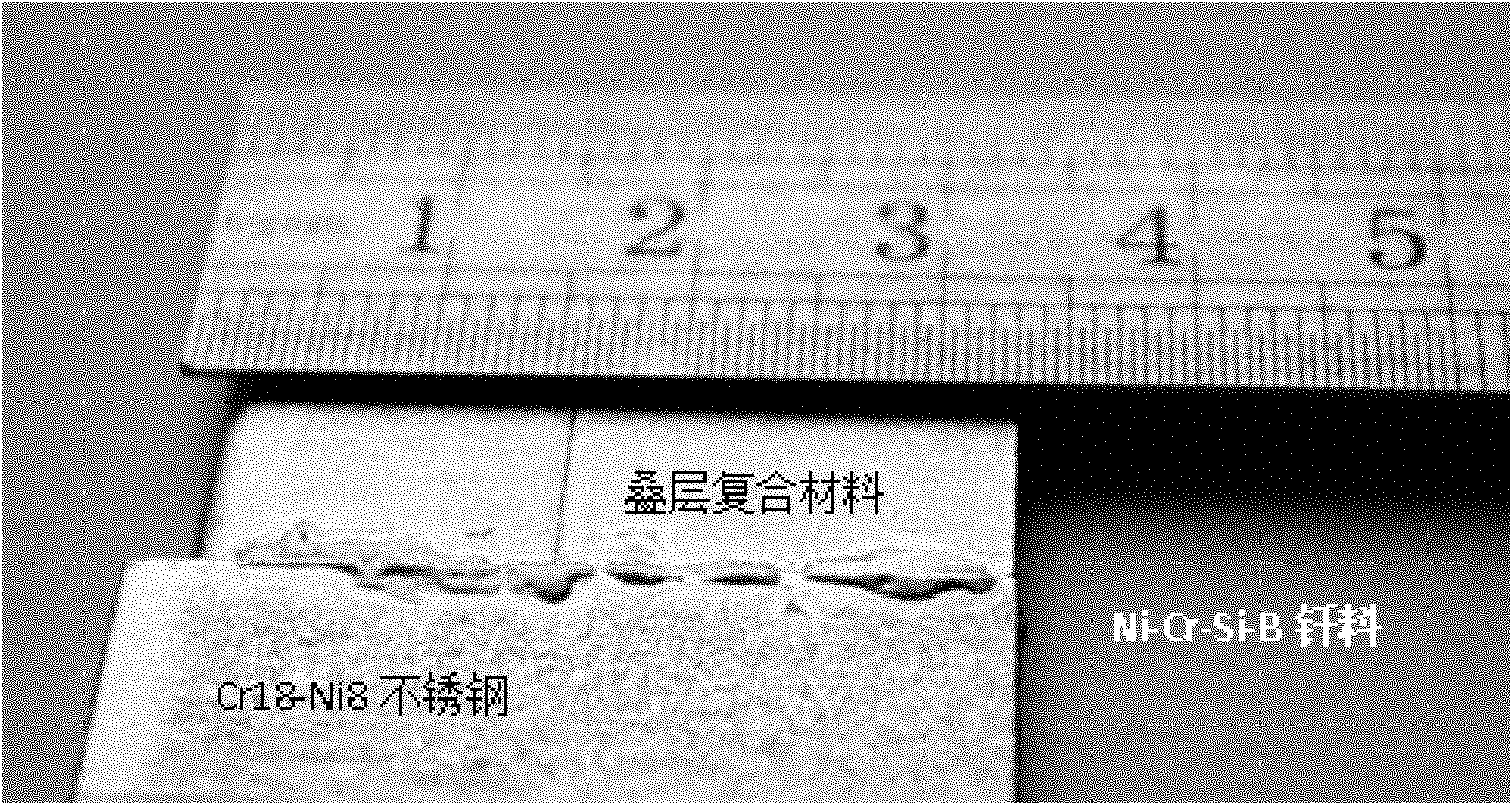

High temperature brazing process of super nickel laminated material and Cr18-Ni8 stainless steel

InactiveCN101941106AEffect of small welding operationsSmall temperature intervalSoldering apparatusHeating furnaceFiller metal

The invention discloses a high temperature brazing process of a super nickel laminated material and Cr18-Ni8 stainless steel. The high temperature brazing process comprises the following steps of: (1) cleaning the to-be-brazed surfaces of the super nickel laminated material and the Cr18-Ni8 stainless steel before brazing, removing oil stain and oxide film on the surfaces to be brazed, and drying; (2) filling Ni-Cr-Si-B series paste nickel-based high temperature filler metal between the super nickel laminated material and the Cr18-Ni8 stainless steel; (3) putting the assembled weldment in a vacuum heating furnace for vacuum brazing at a temperature of 1050-1230 DEG C; and (4) controlling the cooling rate, cooling the temperature of a vacuum chamber to be lower than 100 DEG C, and taking the weldment out. By using the vacuum brazing process, a joint with reliable connection, beautiful brazing seam and stable interface bonding can be obtained. The high temperature brazing process meets the requirements for high temperature structural materials in the fields of aerospace, chemical equipment, and the like.

Owner:SHANDONG UNIV

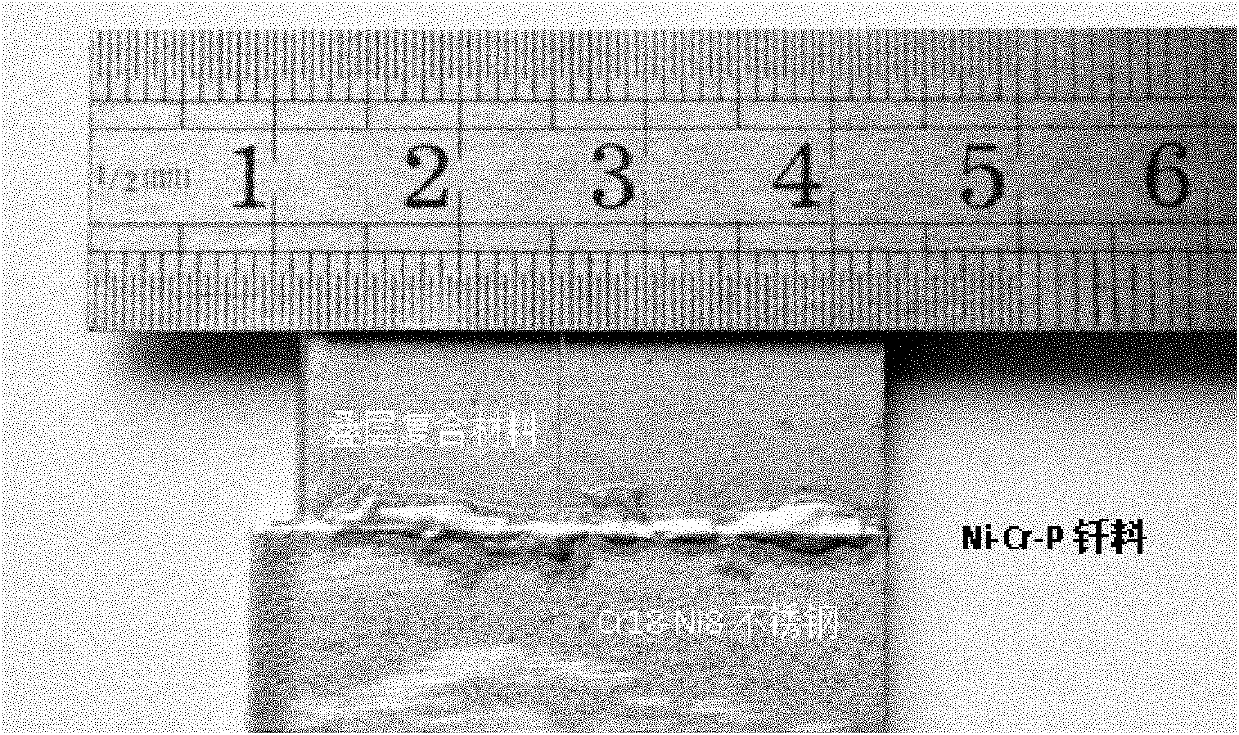

Vacuum brazing process for super-Ni laminated material and Cr18-Ni8 stainless steel

InactiveCN101992331AImprove performanceBeautiful brazing seamWelding/cutting media/materialsWelding/soldering/cutting articlesFiller metalMetallic Nickel

The invention discloses a vacuum brazing process for a super-Ni laminated material and Cr18-Ni8 stainless steel, which is characterized by comprising the following steps: (1) prior to brazing, cleaning the super-Ni laminated material and the Cr18-Ni8 stainless steel, and removing oil stains on the surfaces of parts and the oxidation film on the surfaces to be brazed; (2) carrying pick-up fitting and fixing on the parts to be brazed in a super-Ni laminated material-brazing filler metal-stainless steel mode, wherein the brazing filler metal is Ni-Cr-P nickel-based brazing filler metal; and (3) carrying out vacuum brazing on the fixed workpiece in a vacuum brazing furnace, wherein the vacuum degree of the vacuum brazing furnace is greater than 1.33*10<-3>Pa, the brazing heat temperature is 920-1100 DEG C, and the holding time is 5-25 min. By using the method, brazed joints having the advantages of no crack, fine interface combination and beautiful surface appearance can be obtained, and the reliable connection of laminated materials can be realized, thereby meeting the requirements of aerospace, power and other fields for high-performance materials.

Owner:SHANDONG UNIV

Method for preparing composite wear-resistant hammerhead

The invention discloses a method for preparing a high-ductility and high-abrasion composite hammerhead, which comprises the following steps: alloy dust core bars are bound into bundles and arranged in a hammerhead casting mould cavity, and the volume of the alloy dust core bars accounts for 20 to 60 percent of the total volume of the hammerhead; molten matrix metal is cast into the casting mould cavity, the alloy dust core bars are melted and dissolved under the heat effect of the matrix metal, a great number of alloy elements and the molten matrix metal generate metallurgical combination reaction so as to generate a highly dispersed alloy structure on the original position; and finally the alloy structure is cooled and solidified, and the bar-shaped hard phase is metallurgically and transitionally combined into a whole with the matrix metal, thereby preparing the composite hammerhead which takes the high-strength and high-ductility metal as the matrix and contains a certain number of metallurgically combined bar-shaped hard points. The composite hammerhead has high strength and high ductility of the matrix metal and high hardness and high wear resistance of the hard phase, can simultaneously bear high pressure and strong wear, and has the characteristics of long service life, low price and so on.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

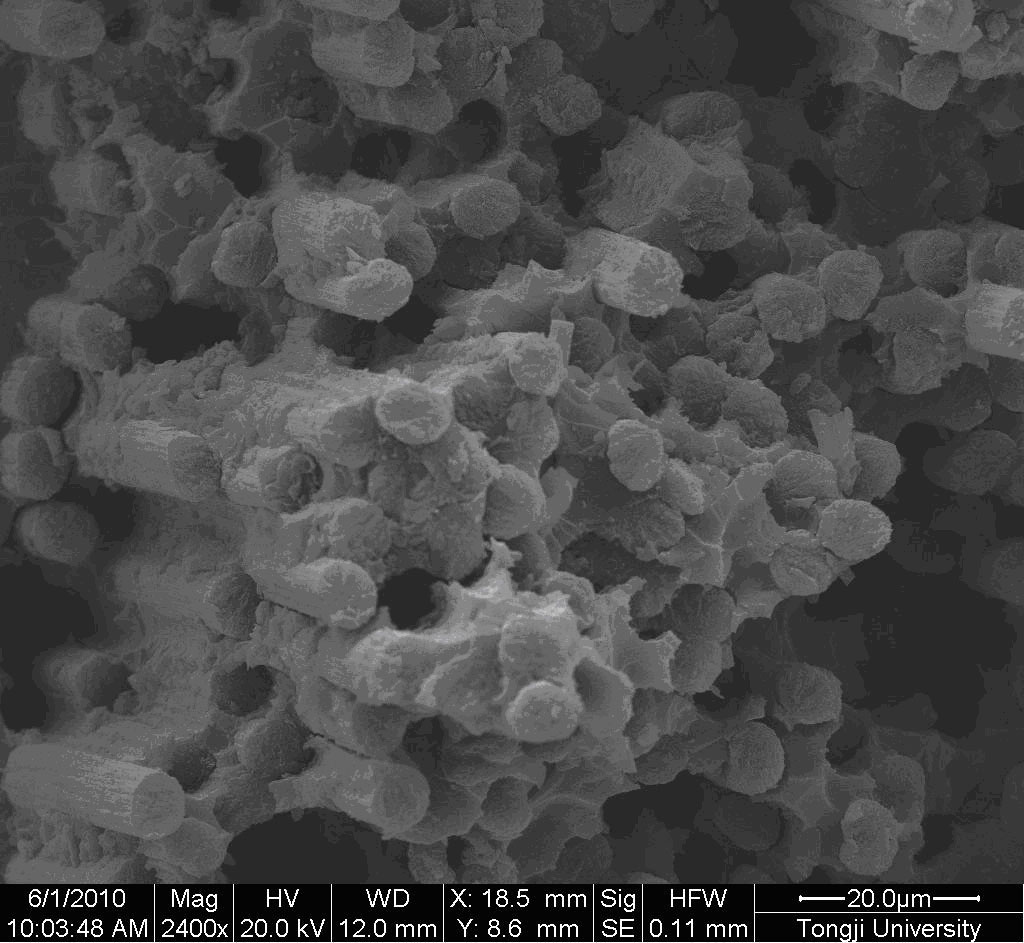

Method for preparing carbon nano fiber and carbon nano tube modified carbon fiber/bismaleimide resin multi-dimensional hybrid composite material

InactiveCN102010595AImprove the shortcomings of insufficient interlaminar shear strength, etc.CurableFiberCarbon fibers

The invention belongs to the technical field of nano materials, and particularly relates to a method for preparing a carbon nano fiber and carbon nano tube modified carbon fiber / bismaleimide resin multi-dimensional hybrid composite material. The method comprises the following steps of: performing surface carboxylation, acylation and chloration on carbon nano tubes, carbon nano fibers and carbon fibers, then introducing diamine or polyamine onto the carbon nano tubes, performing Michael addition reaction on the carbon nano tubes connected with the amine and bismaleimide resin to obtain a bismaleimide resin linear block polymer containing the carbon nano tubes and serving as a matrix, and compounding the matrix and the carbon fibers to form a covalent bond connected multi-dimensional hybrid composite material structure. The method toughens bismaleimide by using the strength and toughness of the carbon nano tubes and the carbon nano fibers to improve the bonding strength of the carbon fiber interface so as to improve the integral performance of the carbon nano fiber and carbon nano tube modified carbon fiber / bismaleimide resin multi-dimensional hybrid composite material and broaden the application range of the carbon fibers, the carbon nano fibers, the carbon nano tubes and the bismaleimide resin.

Owner:TONGJI UNIV

Iron-based alloy powder used for laser manufacturing of high-speed railway switch bedplates

InactiveCN106555127AWith wear and corrosion resistanceImprove performanceBallastwayMetallic material coating processesCrack resistanceLaser fabrication

The invention discloses an iron-based alloy powder used for laser manufacturing of high-speed railway switch bedplates. The iron-based alloy powder comprises, by mass, 1.0-1.2% of C, 12-15% of Cr, 3-4.8% of W, 1-2% of Ti, 4-6% of Ni, 2.1-4.1% of B, 0.2-0.3% of Si, 0.1-0.15% of Y2O3, 0.12-0.19% of Hf, and the balance of Fe. The proportions of all elements are adjusted to improve the crack resistance, the formability, the technologic stability and the component uniformity of the alloy powder in a laser cladding layer in order to meet the high-speed railway switch bedplates' requirements of the corrosion resistance, the wear resistance, the fatigue resistance and other comprehensive performances.

Owner:沈阳大陆激光工程技术有限公司

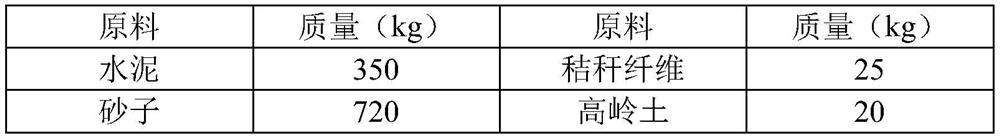

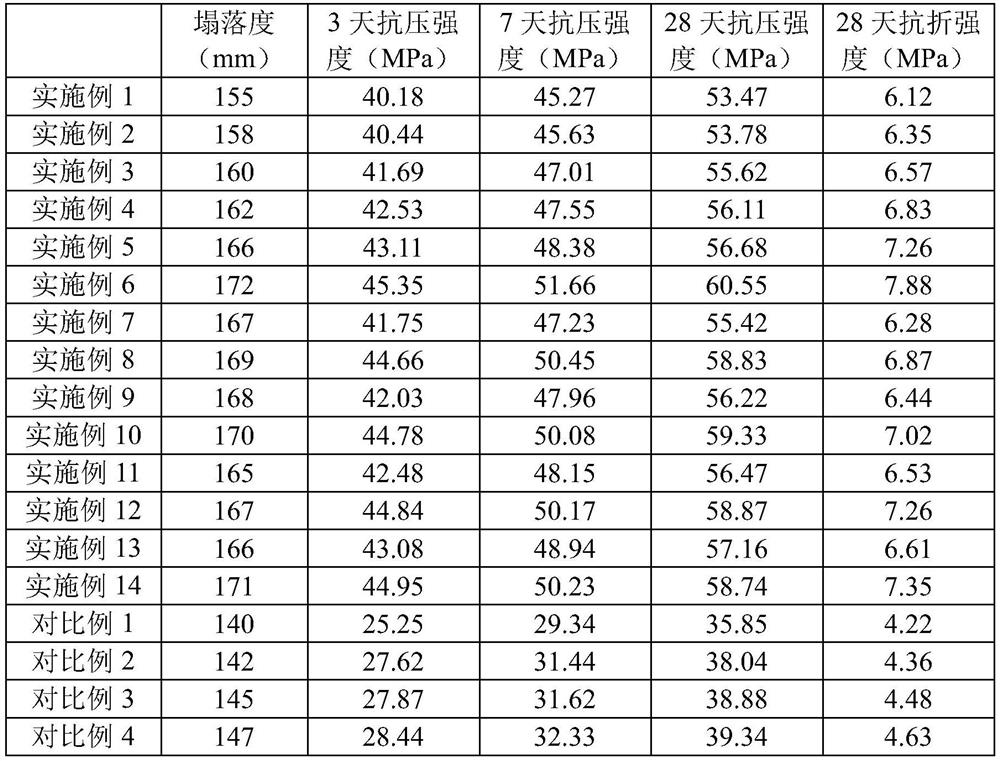

High-strength lightweight porous concrete and preparation method thereof

InactiveCN112299875AAvoid stress concentrationRelieve stress concentrationCeramicwareFiberFoaming agent

The invention relates to the technical field of concrete, and particularly discloses high-strength light porous concrete and a preparation method thereof. The high-strength lightweight porous concreteis prepared from the following raw materials in parts by weight: 350-400 parts of cement, 700-800 parts of sand, 1100-1200 parts of stones, 170-230 parts of a mineral admixture, 220-280 parts of water, 20-30 parts of coarse whiting, 25-40 parts of straw fibers, 15-30 parts of kaolin, 5=10 parts of a foaming agent, 12=18 parts of a tackifier, 4=8 parts of expanded perlite and 3=5 parts of a waterreducing agent. The mineral admixture is prepared from the following raw materials in parts by weight: 50-70 parts of steel slag, 30-50 parts of fly ash and 90-110 parts of slag; the preparation method comprises the following steps: fully foaming the foaming agent through a foaming machine, and uniformly mixing the foam with cement paste to prepare the high-strength light porous concrete. According to the concrete, closed foam holes are formed in the concrete so that the lightweight effect is achieved, and the added straw fibers and mineral admixtures can improve the mechanical strength of theconcrete.

Owner:北京城建九混凝土有限公司

Explosive welding forming method of titanium-pure aluminum-aluminum alloy composite plate

InactiveCN107627019AAdvancedApparent molding speedNon-electric welding apparatusAlloy compositeFuel oil

The invention provides an explosive welding forming method of a titanium-pure aluminum-aluminum alloy composite plate. The explosive welding forming method of the titanium-pure aluminum-aluminum alloycomposite plate performs explosive welding forming according to the performance requirements of a titanium plate, an aluminum plate and an aluminum alloy plate; and an ammonium nitrate fuel oil mixture is adopted, and remote instantaneous explosive welding forming is performed on a ground sand grain substrate. Compared with the related art, the explosive welding forming method of the titanium-pure aluminum-aluminum alloy composite plate is high in speed, firm in interface bonding, good in interface shearing strength and high in bonding rate, the shearing strength of the titanium-pure aluminum-aluminum alloy composite plate reaches 230 MPa, the explosive welding bonding rate is 99%, controllability is good, the welding process is safe and reliable, and the explosive welding forming methodof the titanium-pure aluminum-aluminum alloy composite plate is a reliable and effective method for preparing the titanium-pure aluminum-aluminum alloy composite plate.

Owner:XIAN AERONAUTICAL UNIV

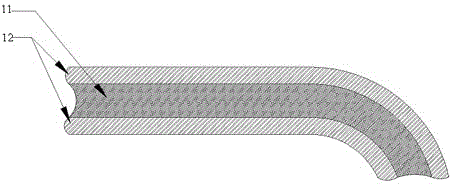

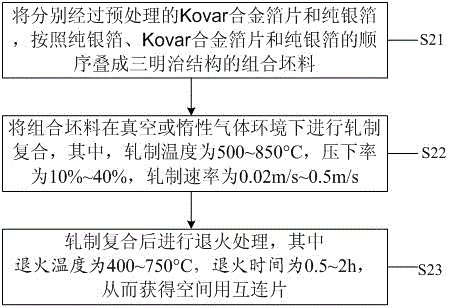

Spaceborne Kovar/silver metal laminated composite material and preparation method thereof

ActiveCN106711261AThe interface is firmly bondedGood space environment adaptabilityFinal product manufacturePhotovoltaic energy generationKovarInert gas

The invention relates to a spaceborne Kovar / silver metal laminated composite material and a preparation method thereof. The composite material comprises a Kovar alloy foil piece and two pure silver foils, and is characterized in that the pure silver foils acting as surface layers and the Kovar alloy foil piece acting as an interlayer form a laminated sandwich structure, and the top, middle and bottom layers form chemical bonds through rolling and bonding so as to be connected into an integral whole. The preparation method comprises the steps of laminating the pure silver foils and the Kovar alloy foil piece into a combined blank with a sandwich structure according to a sequence of the pure silver foil, the Kovar alloy foil piece and the pure silver foil; performing hot rolling and composite bonding on the combined blank; performing further annealing processing at the atmosphere of an inert gas after rolling and bonding, and acquiring a spaceborne Kovar / silver metal laminated composite material after annealing processing. The composite material has good space environment adaptability, thermal conductivity, electrical conductivity and weldability, and meets requirements of space electronic packaging applications; and the spaceborne Kovar / silver laminated composite material is simple in production process, sable and controllable in quality, convenient to operate and capable of realizing large-area automatic roll-to-roll batch production.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

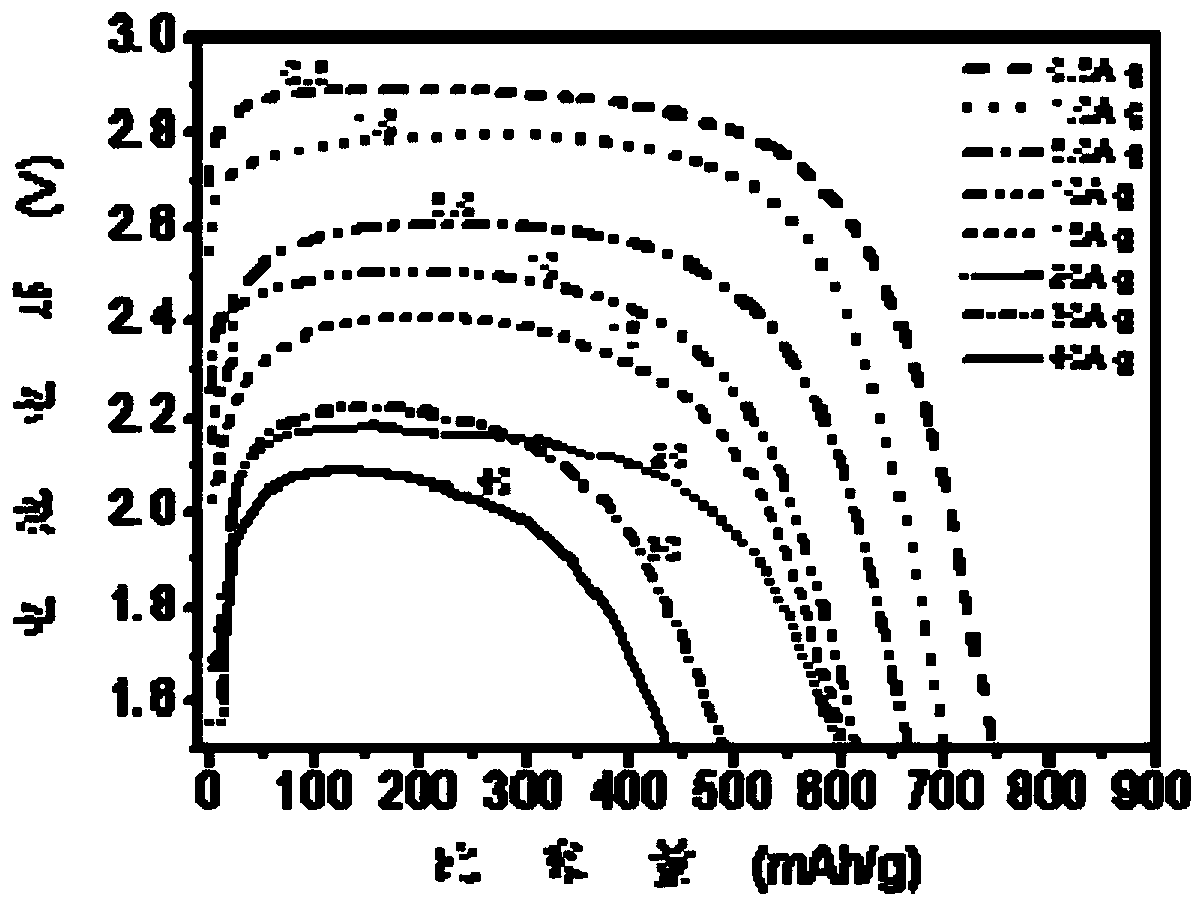

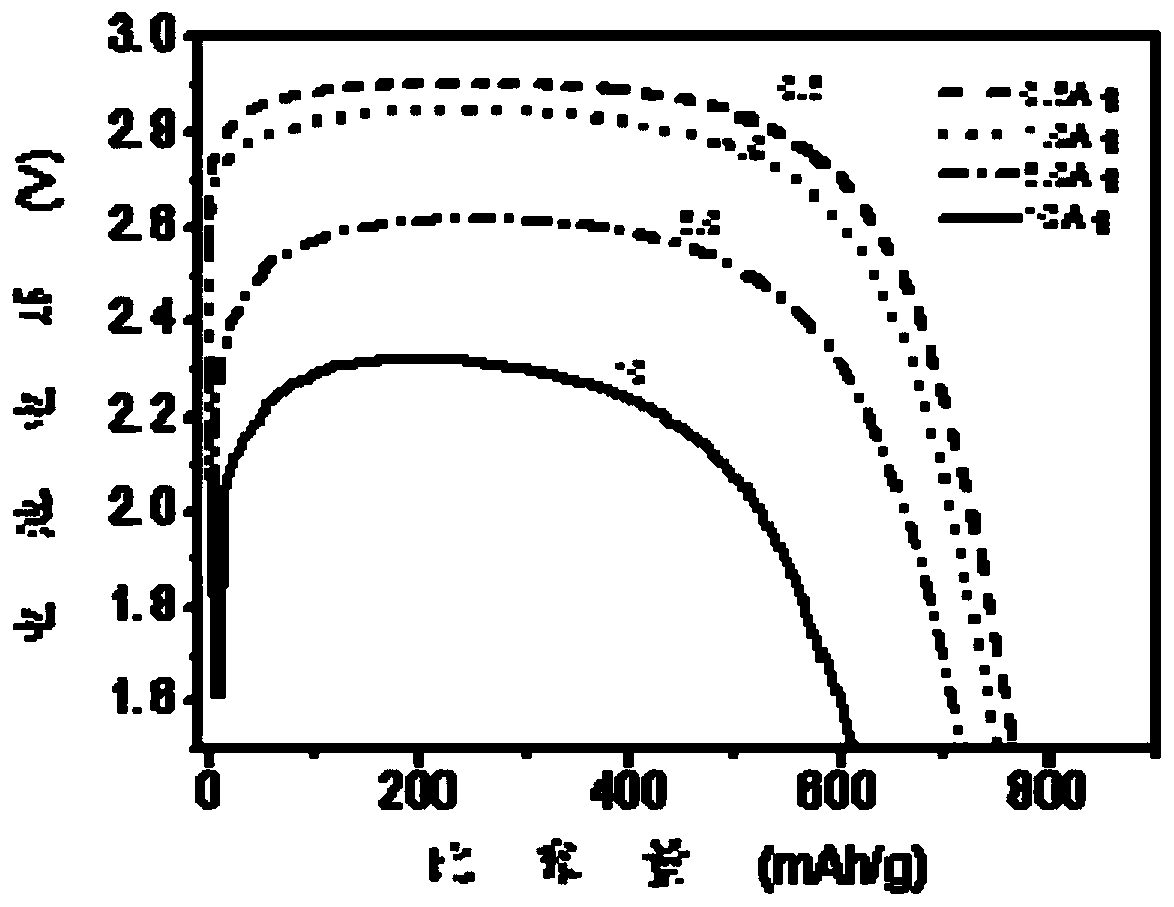

Positive electrode material for ultrahigh-power-density lithium carbon fluoride battery and preparation method and application of positive electrode material

InactiveCN110380013AIncrease the discharge current densityUltra High Power DensityMaterial nanotechnologyElectrode carriers/collectorsElectrolytic agentCarbon nanofiber

The invention relates to a positive electrode material for an ultrahigh-power-density lithium carbon fluoride battery and a preparation method and application of the positive electrode material. The positive electrode material is prepared by mixing the following raw materials in percentage by mass: 80% of a carbon fluoride active material; 8% of a super-conductive carbon black; 2% of carbon nanofibers; and 10% of polyvinylidene fluoride. According to the preparation method, the positive electrode material is improved through a two-step conductive agent mixing method, and carbon-coated aluminumfoil is adopted as a positive electrode current collector, so that the discharge current density of the prepared lithium carbon fluoride battery is improved to be greater than 40A / g, and the ultrahigh power density is realized. Specifically, a carbon fluoride active material with a high specific surface area is used as an active material, so that the liquid absorption and liquid retention capabilities of the positive electrode material on an electrolyte are remarkably improved, and the ion transmission resistance and reaction polarization are reduced. The positive electrode material is improved by adopting a method of mixing the conductive agent by a two-step method, so that the conductive agent and the carbon fluoride active material are in full contact, and the positive electrode material is uniformly mixed.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

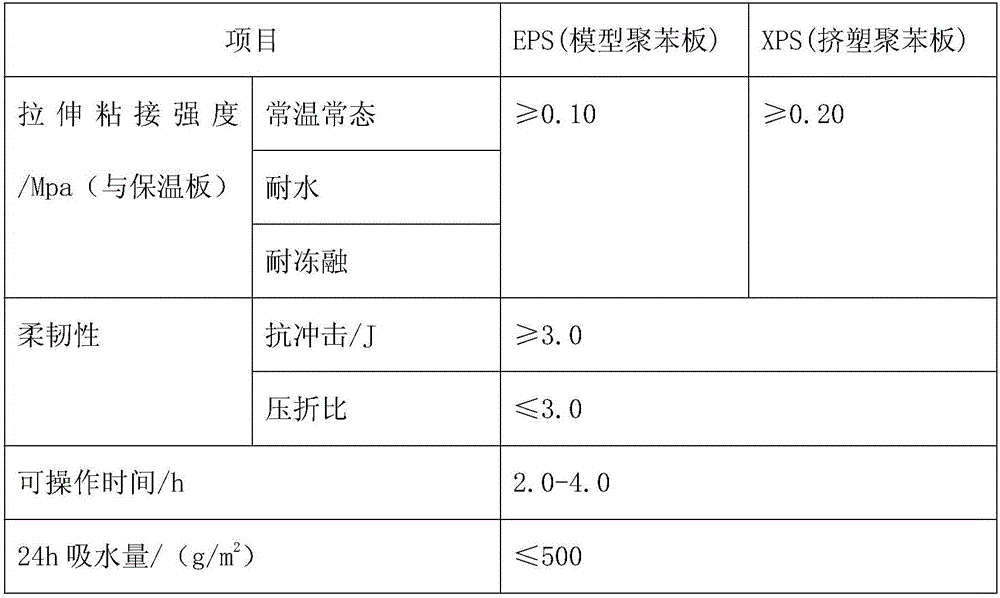

Dry-mixed thermal-insulation board finishing mortar and preparation method thereof

The invention discloses a dry-mixed thermal-insulation board finishing mortar which is prepared from the following raw materials in parts by weight: 80-100 parts of Portland cement, 10-20 parts of yellow sand, 5-8 parts of modified nano bamboo charcoal powder, 5-10 parts of talcum powder, 3-5 parts of desulfurized gypsum, 3-5 parts of limestone, 1-5 parts of cellulose ether, 5-15 parts of tree ash, 3-6 parts of wood fiber, 1-6 parts of naphthalene high efficiency water reducing agent salt, 6-10 parts of vinyl acetate-ethylene copolymer rubber powder and 2-4 parts of fumed silica. The dry-mixed thermal-insulation board finishing mortar has the advantages of favorable anti-crack durability, low fold ratio, low water absorptivity, small shrinkage, excellent bonding property with the thermal-insulation board, and high combination firmness with the interface; the formed finishing layer has the advantages of acid resistance, aging resistance, collision resistance, rain permeation resistance, crack resistance and the like; and the product has low density and low cost.

Owner:安庆市凯瑞建材有限公司

Alloy electrode for skutterudite thermoelectric element and preparation method thereof

ActiveCN106299099AImprove conductivityGood welding performanceThermoelectric device manufacture/treatmentThermoelectric device detailsChemical platingSkutterudite

The invention relates to an alloy electrode for a skutterudite thermoelectric element and a preparation method thereof. The alloy electrode provided by the invention is an alloy electrode deposited at two end parts of the skutterudite thermoelectric element. The alloy electrode is made of a Ni-Mo alloy or a Ni-W alloy, wherein the molar percentage content of Mo in the Ni-Mo alloy is 10%-40%, the molar percentage content of W in the Ni-W alloy is 5%-40%. In the invention, the selected electrode material is a Ni(Mo) or Ni(W) alloy electrode prepared through an electroplating or chemical plating method. The alloy electrode is good in conductivity and excellent in weldability, the coefficient of thermal expansion of a Ni-containing electrode can be adjusted through substances with a small coefficient of thermal expansion such as Mo and W, and the difference between the electrode material and a skutterudite thermoelectric material in coefficient of thermal expansion is reduced.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

Medical porous alumina based ceramic composite material

InactiveCN101757683AImprove mechanical propertiesFacilitate depositionProsthesisCeramic compositeNitrogen gas

The invention belongs to the field of biological ceramic materials, and relates to a medical porous alumina based ceramic composite material. Firstly, 1-8% of calcium fluoride, 90-98% of alumina and 1-5% of diopside are mixed according to the mass percentage, and then the calcium fluoride, the alumina and the diopside are milled by balls to prepare mixed powder; and then the mixed powder material is placed into a graphite mould to be molded and pressed, hot-pressed and sintered in the argon or nitrogen atmosphere, wherein the sintering temperature is 1400 DEG C, the pressuring temperature is 1320 DEG C, the sintering pressure is 30 MPa and the heat preservation and pressure maintaining are carried out for 30 minutes at the sintering temperature. The composite material not only has good mechanical property and bioactivity, but also is distributed with micropores on the surface and is more beneficial to the growth of bone tissues. Simultaneously, the composite material has low manufacture cost and better application prospect in terms of the restoration, replacement and the like of bones of the human body.

Owner:SHANDONG UNIV

Method for preparing column shaped horniness phase composite wear-resistant jaw plate

InactiveCN101412101AImprove wear resistanceHigh tensile strengthGrain treatmentsCompound aWear resistant

The invention discloses a method for preparing a composite crushing plate with a columnar hard phase. A gear rack of the composite crushing plate with the columnar hard phase prepared by the method is formed by compounding a high hardness columnar hard phase and a high tenacity base metal. The method comprises the following steps: weaving alloy powder core materials into an alloy powder core material framework according to the shape of the gear rack on the crushing plate; fixing the framework on the crushing plate through binding or welding; through a casting method, performing in situ reaction on the alloy powder core materials to generate the columnar hard phase by using the high temperature of melted base molten metal; and performing the metallurgical combination of the hard phase and a base metal interface to form a high wear resistant high tenacity composite material on the gear rack of the crushing plate. The composite crushing plate prepared by the method has the advantages of high wear resistance, high tenacity, high tensile strength, high compression strength and the like. The method has the characteristics of small equipment input, low cost, simple operation and the like, and can be widely applied to various jaw type crushers.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

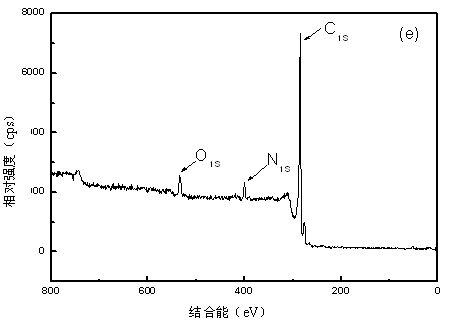

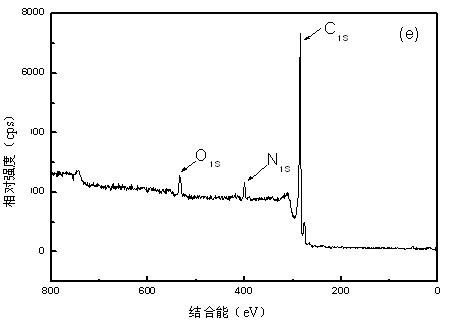

High-interface-bonding-firmness carbon fiber/carbon nanotube composite material and preparation technique thereof

InactiveCN103626997AGood dispersionThe interface is firmly bondedPigment physical treatmentPigment treatment with non-polymer organic compoundsFiberCarbon fibers

The invention belongs to the technical field of nano materials, and particularly relates to a high-interface-bonding-firmness carbon fiber / carbon nanotube composite material and a preparation technique thereof. The preparation technique comprises the following steps: carrying out carboxylation and acyl-chlorination on purified carbon nanotubes and dried carbon fibers, introducing diamines or polyamines with characteristic structure so as to connect abundant diamines or polyamines onto the surfaces of the carbon nanotubes and carbon fibers, carrying out addition reaction on the carbon nanotubes and a bismaleimide resin to obtain a carbon-nanotube-containing bismaleimide resin linear block polymer, and compounding the block polymer used as a base with the carbon fibers in a certain mode to finally form a multidimensional hybrid composite material structure connected by covalent bonds. The strength and toughness of the carbon nanotubes are utilized to strengthen the bismaleimide and enhance the bonding strength with the carbon fiber base surface, thereby enhancing the overall performance of the carbon fiber / carbon nanotube / bismaleimide resin multidimensional hybrid composite material.

Owner:DANYANG DANJIN AVIATION MATERIAL TECH

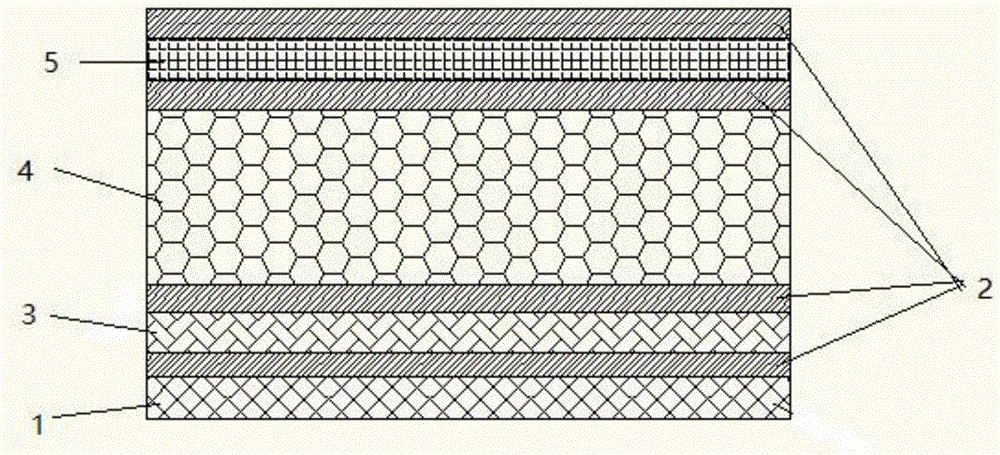

Waterproof and environment-friendly paper honeycomb composite board for automotive interior, and preparation method of composition board

The invention discloses a waterproof and environment-friendly paper honeycomb composite board for automotive interior, and a preparation method of the composition board. The waterproof and environment-friendly paper honeycomb composite board is formed by compounding a piece of non-woven fabric, a hot melt adhesive membrane, a bamboo fiber felt, another hot melt adhesive membrane, a paper honeycomb core, another hot melt adhesive membrane, a GMT felt and another hot melt adhesive membrane from bottom to top; each hot melt adhesive membrane is prepared from the following raw materials in parts by weight: 20-30 parts of ternary co-polypropylene, 10-20 parts of a vinyl-propylene copolymer, 5-10 parts of C5 / C9 copolymer resin, 2-4 parts of high molecular weight polypropylene (PP) wax and 1-2 parts of an antioxidant; the bamboo fiber felt is prepared from the following raw materials in parts by weight: 40-50 parts of bamboo fiber, 5-10 parts of brucite powder, 5-8 parts of sepiolite powder, 10-15 parts of a urea-formaldehyde resin adhesive, 7-12 parts of silicone acrylic emulsion, 1-2 parts of nano titanium dioxide and 4-6 parts of castor oil. The waterproof and environment-friendly paper honeycomb composite board has the characteristics of being less in odor and less in volatile organic compounds (VOC), resisting low temperature and heat aging, being permanent in moisture resistance, mould-proof and free from undesirable odor, and the like, and is non-toxic and environmentally-friendly.

Owner:合肥杰迈特汽车新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com