Method for preparing column shaped horniness phase composite wear-resistant jaw plate

A hard phase, columnar technology, applied in the direction of grain processing, etc., can solve the problems of inability to directly improve the toughness of the wear-resistant working surface, brittle cracks of the wear-resistant layer, poor toughness, etc., and achieve the organic unity of wear resistance and toughness, high resistance Effects of compressive strength and material structure compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Embodiment: preparation high chromium alloy is the hard phase, and A3 steel is the columnar cemented carbide phase composite jaw plate of matrix

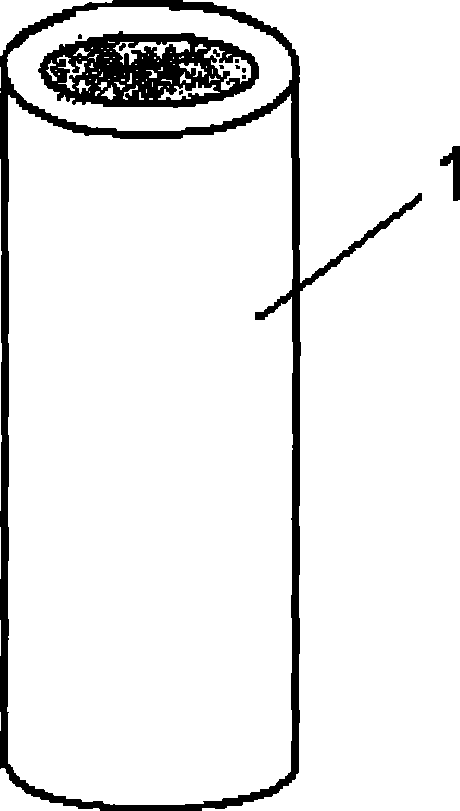

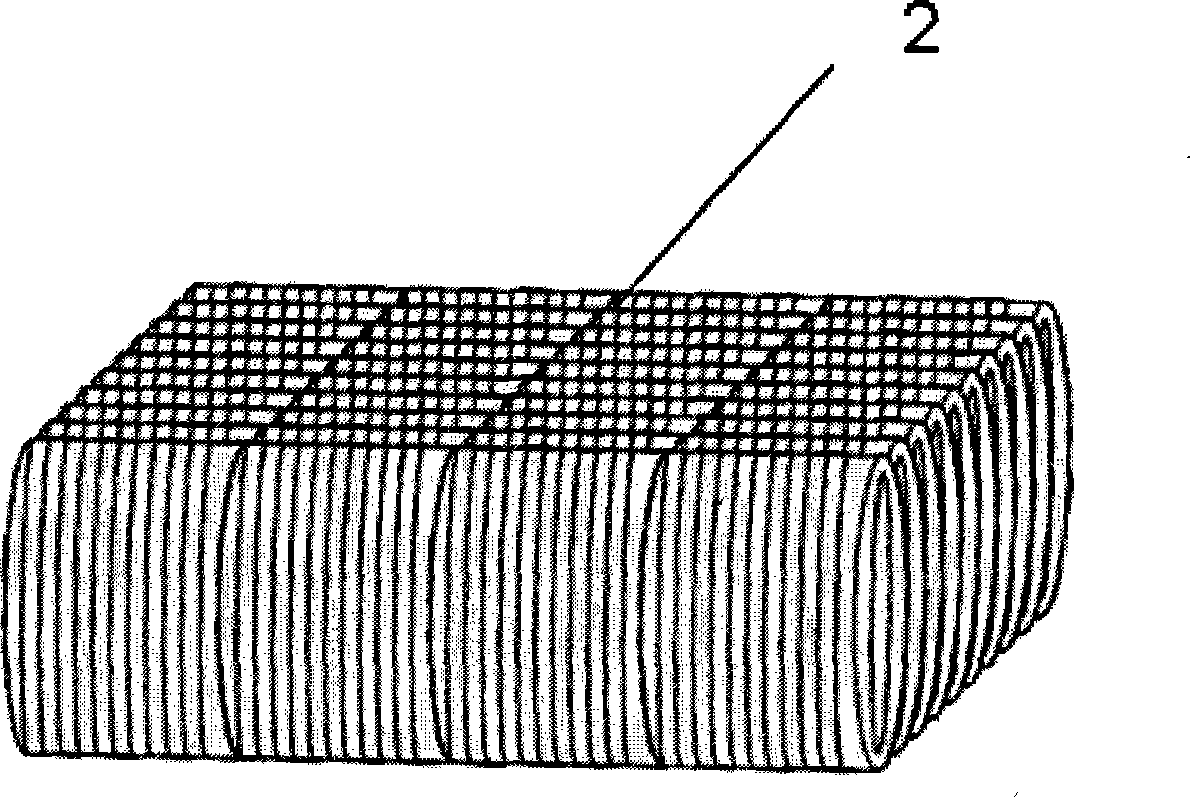

[0034] 1. Wrap the alloy powder in low-carbon steel pipe skin to form alloy powder core wire 1 with a diameter of 3mm; the alloy powder is high-carbon ferrochrome powder with a particle size of 100-150 mesh; The shape of the rack on the top is woven into a three-dimensional alloy wire skeleton 2 with a certain thickness; the three-dimensional alloy wire skeleton 2 is fixed by binding and welding, and the actual volume of the alloy powder core wire skeleton accounts for the total volume of the rack composite material. 20% to 80% of the volume;

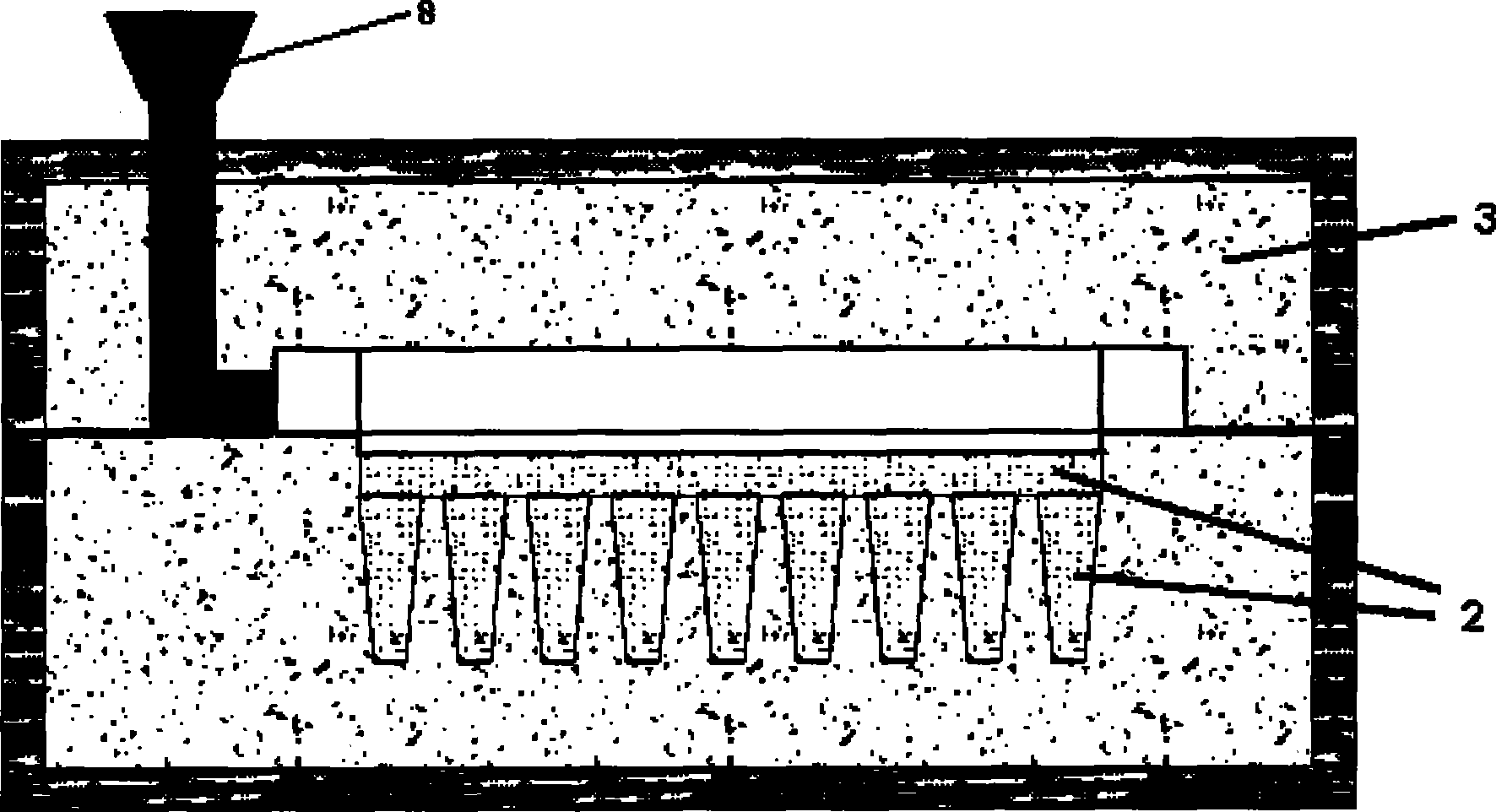

[0035] 2. Make jaw plate sand mold 3 according to casting process requirements, and put alloy wire skeleton 2 with three-dimensional structure into sand mold 3 to be cast;

[0036] 3. A3 steel is used as the base metal 4, smelted and melted by an intermediate frequency furnace, and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com