Patents

Literature

1062 results about "In situ reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In Situ Polymerase Chain Reaction ( In situ PCR) is a powerful method that detects minute quantities of rare or single-copy number nucleic acid sequences in frozen or paraffin-embedded cells or tissue sections for the localization of those sequences within the cells. The principle of this method involves tissue fixing...

Micro-region in-situ reaction preparation method for high strength fiber-reinforced ceramic matrix composite material

ActiveCN103086731AImprove mechanical propertiesEquivalent mechanical propertiesMaterial nanotechnologyMetallurgyInterface layer

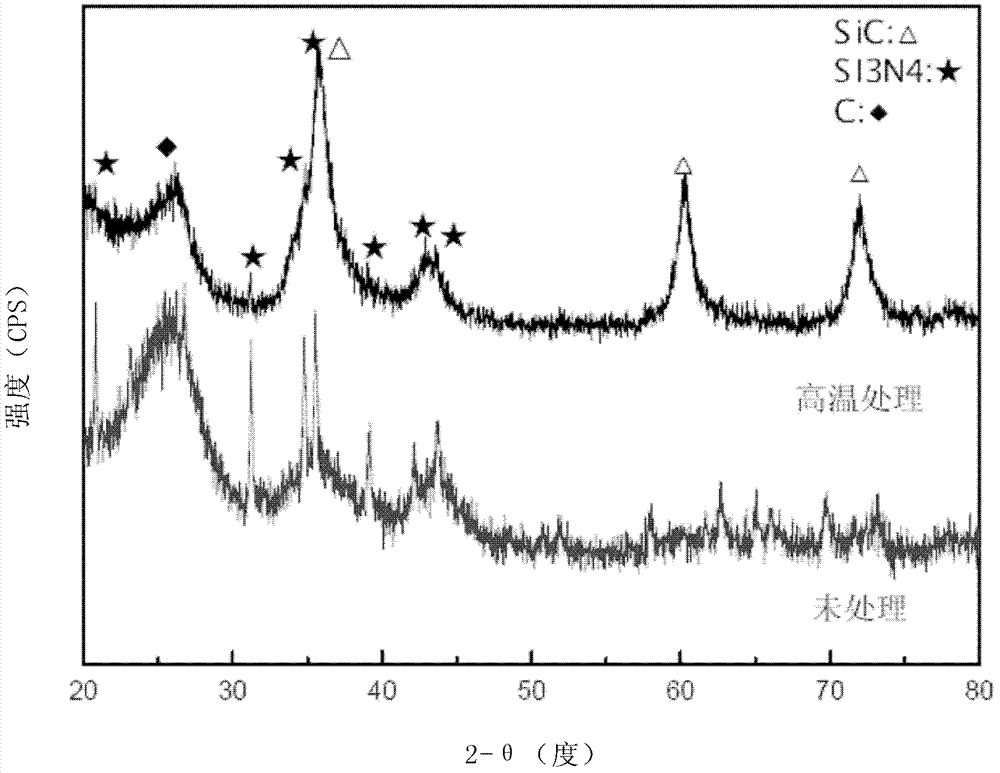

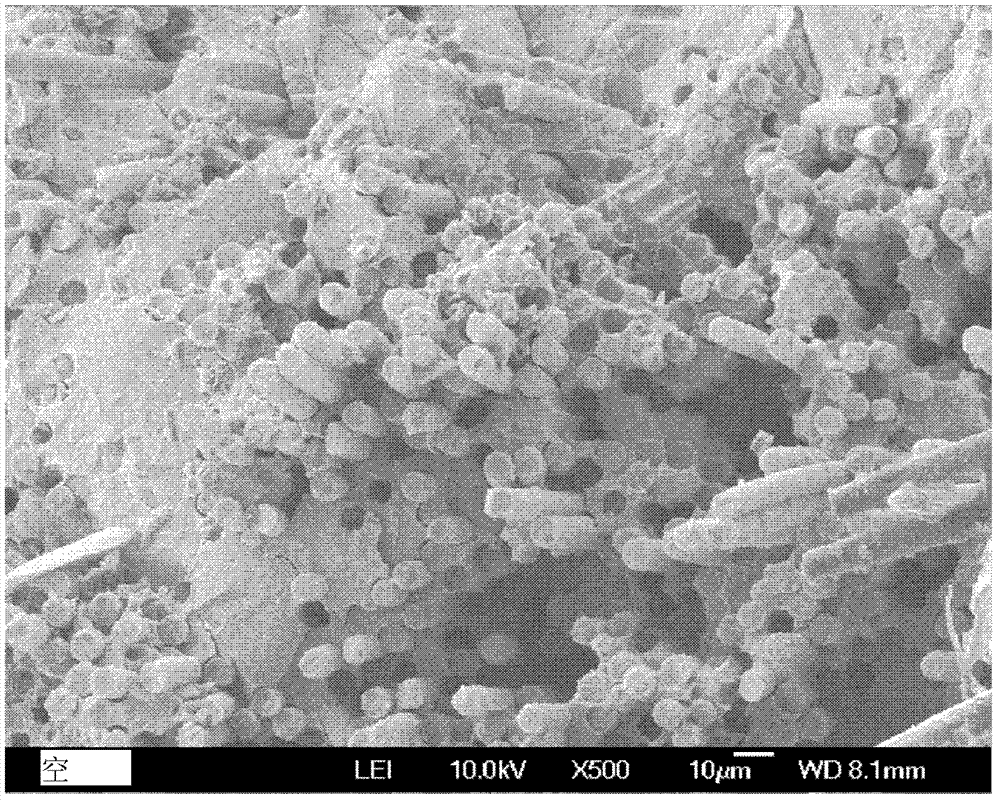

The invention relates to a micro-region in-situ reaction preparation method for a high strength fiber-reinforced ceramic matrix composite material. The method comprises the following steps: (1) depositing an interface layer on the surface of a composite material fiber preform so as to protect fiber reinforcement body, wherein the interface layer comprises a PyC interface, a BN interface, a SiC interface, and a composite interface of the PyC interface, the BN interface and the SiC interface, and a thickness of the interface layer is 10-2000 nm; (2) introducing a Si3N4 ceramic phase to pores of the composite material fiber preform to obtain a composite material pre-molding body; and (3) carrying out a densification treatment on the composite material pre-molding body to obtain the high strength fiber-reinforced ceramic matrix composite material, wherein the densification treatment comprises a high temperature treatment with a temperature of 1200-2300 DEG C, such that the Si3N4 and a carbon-containing phase in the composite material are subjected to a micro-region in-situ reaction through mutual diffusion so as to form the SiC phase.

Owner:嘉兴睿创新材料有限公司

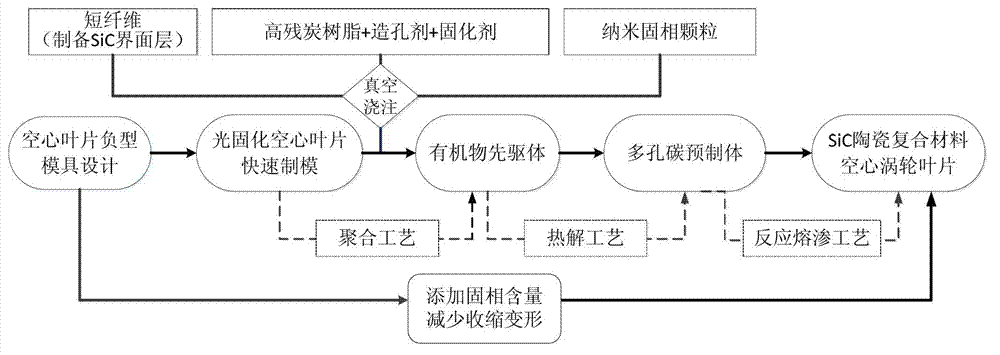

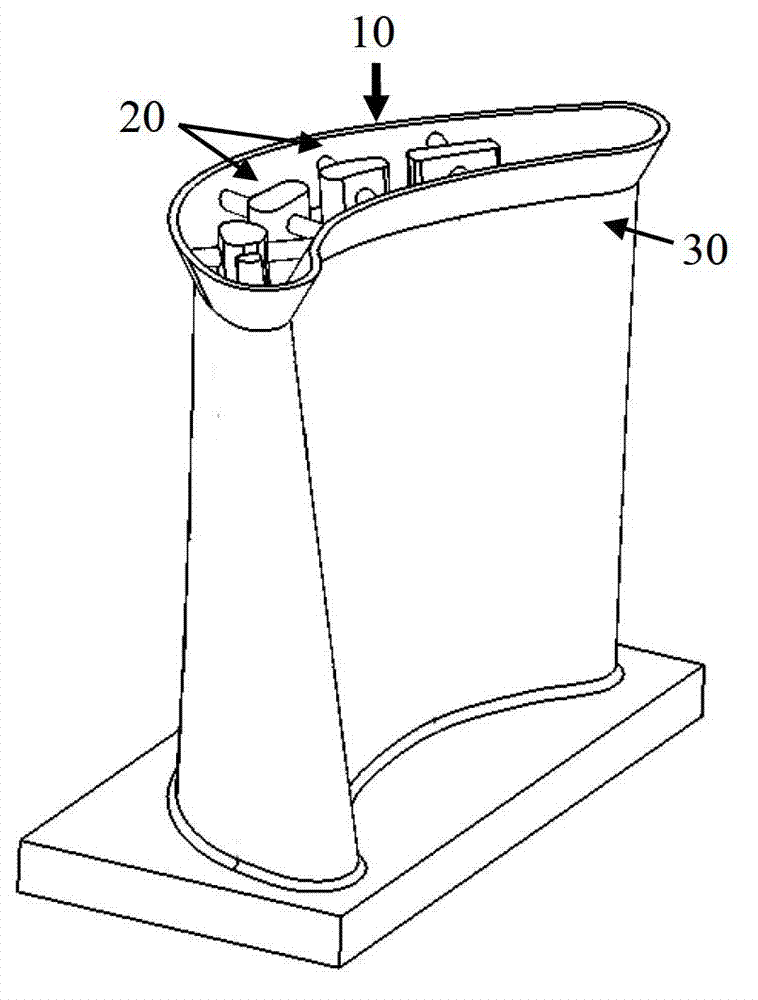

Method for manufacturing SiC ceramic-based turbine blade based on photocurable 3D printing

The invention discloses a method for manufacturing a SiC ceramic-based turbine blade based on photocurable 3D printing. The method comprises the following steps of firstly manufacturing a turbine blade resin mold based on the photocurable 3D printing technology, casting the blade resin mold by using a non-water-based gel-casting ceramic slurry, curing and carrying out pyrolysis carbonization process to obtain a porous carbon preform; by an in-situ reaction sintering technology, at 1420-1700 DEG C, carrying out siliconizing and silicon discharge processes on the carbon perform to obtain the porous SiC ceramic-based composites material turbine blade; and finally obtaining the dense SiC ceramic-based composites material turbine blade by a chemical vapor deposition / infiltration method. The method has the characteristics of near-net molding, free molding and complex molding and the purpose that ceramic parts are densified can be achieved at a lower temperature.

Owner:XI AN JIAOTONG UNIV

Method for acquiring highly-adaptive abrasion-proof titanium-based composite material on titanium alloy surface

InactiveCN101139709AReduce stressReduced tendency to crackMetallic material coating processesLaser beam welding apparatusIn situ reactionHigh power lasers

The invention discloses a method for preparing a Ti-based composite with high adaptability on a Ti-alloy surface, which pertains to the field of surface modification of metallic materials. The method comprises such procedures as: weighing by certain proportion spherical Ti alloy powder particles in proper particle sizes (45-150 micro meter) and TiB2, Cr3C2, TiC or B4C powder particles (3.4-30vol%, particle size 38-106 micrometer); mixing the powder evenly by a mechanical way; sending at the set powder-feeding rate the mixed powder by a powder feeder and coaxial powder-feeding nozzles into a molten bath formed by a high-power laser at the surface of a Ti-alloy substrate; the mixed powder carrying out in-situ reaction by the high temperature from the molten bath, and forming such steady and dispersion reinforced phases as in-situ self-grown TiC or TiB. The reinforced phases are featured by small particle size, steady thermal and mechanical properties, free pollution in interfaces, and high bond strength with the substrate. The method can substantially improve the hardness and wear resistance of Ti alloy surfaces, guarantees the high adaptability between the surface modified layer and the substrate, can be used for repairing and surface reinforcing treatment of Ti alloy parts bearing impact vibration load and thermal fatigue, etc.

Owner:有研科技集团有限公司

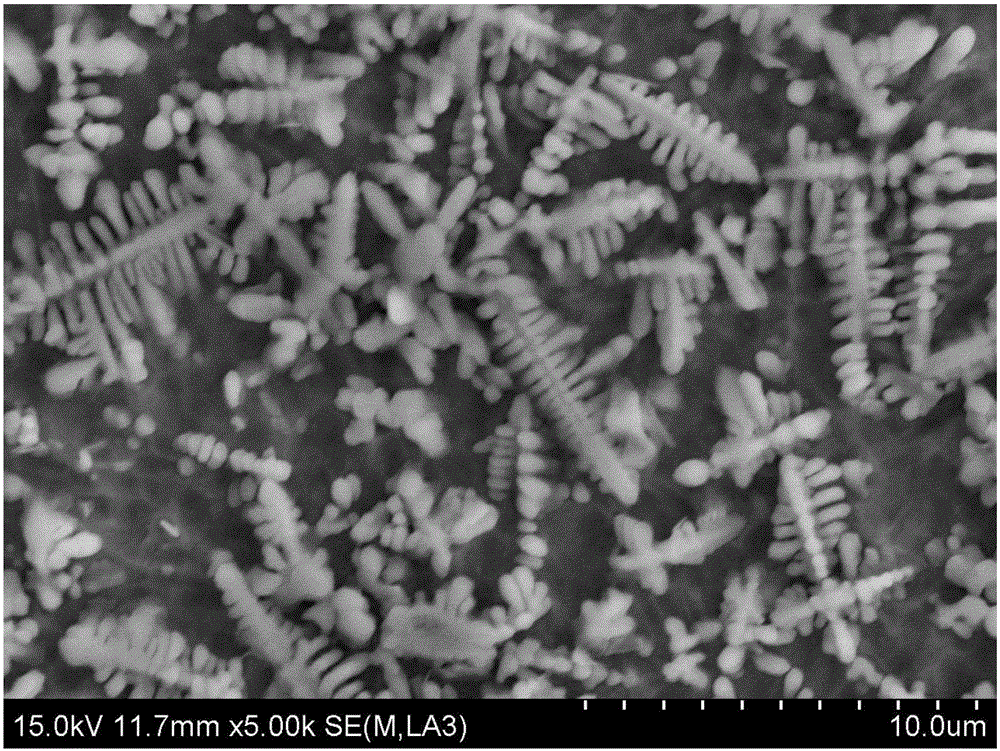

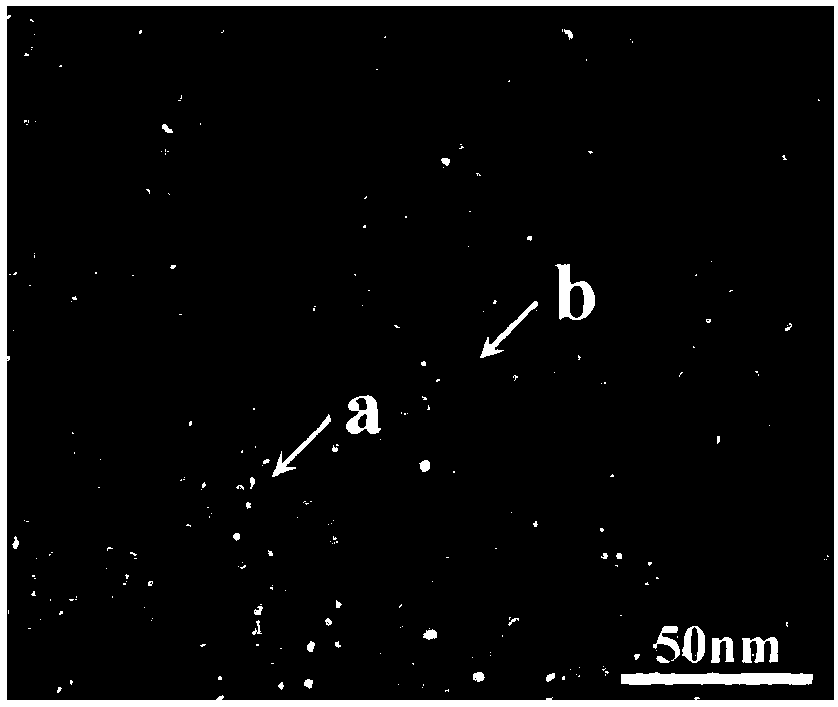

Vapour deposition in situ reaction method for preparing carbon nanotube reinforced aluminium matrix composite material

InactiveCN1730688AGood dispersionAvoid distractionChemical vapor deposition coatingMetal/metal-oxides/metal-hydroxide catalystsGas phaseCarbon nanotube

The invention provides a process for preparing carbon nano tube reinforced aluminum base composite material through gaseous phase in-situ reaction, which comprises using aluminum-base powder as carrying agent, preparing Ni catalyst with chemical deposition precipitation process, obtaining Al-Ni composite powder, preparing carbon nano tube on composite powder in-situ through chemical deposition precipitation process.

Owner:TIANJIN UNIV

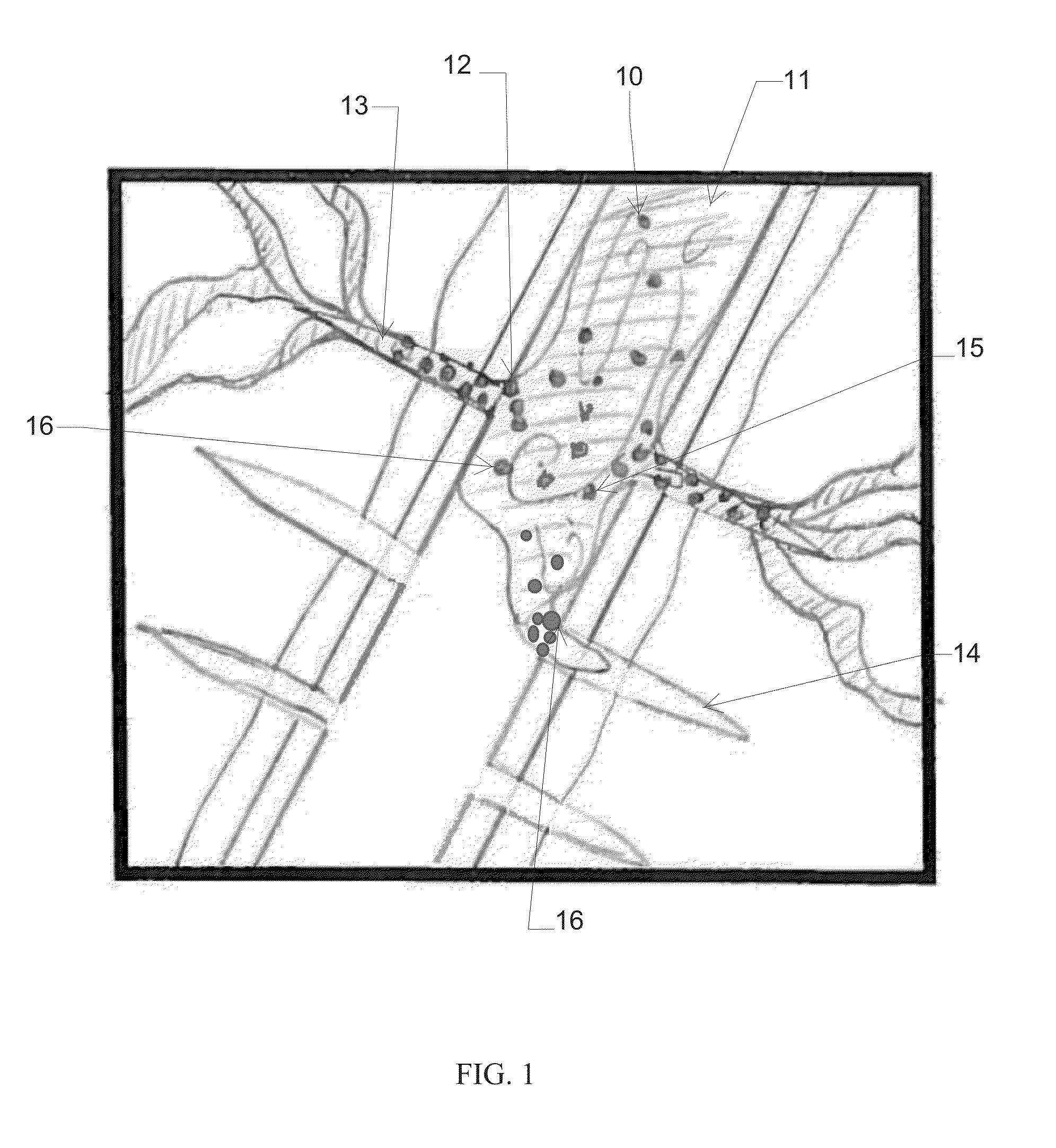

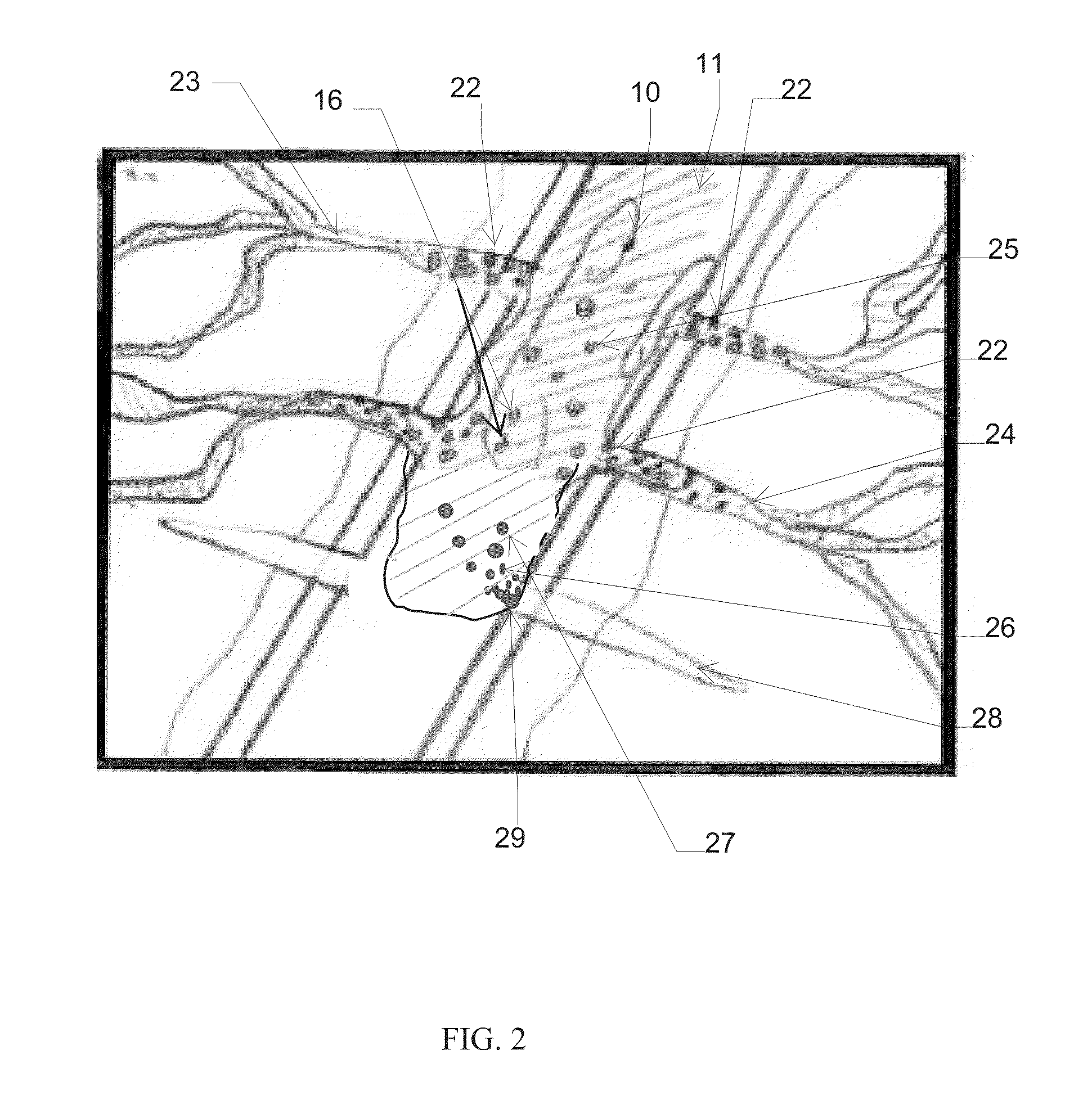

Method for improving isolation of flow to completed perforated intervals

A method for building a plug in a horizontal wellbore using a fluid pill containing a suspended well treatment composite. The well treatment composite contains a core comprising at least one deformable particulate and at least one dissolvable diverter. At least a portion of the surface of the core is coated with at least one viscosifying polymer and at least one crosslinking agent. The fluid pill is pumped into the wellbore at the end of a fracturing treatment and the fluid pill may be displaced by a displacement fluid. The fluid pill may be diverted to an area of lower permeability by disassociating the dissolvable diverter from the core. The disassociated diverter blocks an area of higher permeability. The sized particle distribution of the diverter is sufficient to at least partially block the penetration of fluid into the high permeability zone. In the lower permeability zone, a thickened gel is formed by the in-situ reaction of the viscosifying polymer and crosslinking. Deformable particulates in the gelled fluid form a bridge plug.

Owner:BAKER HUGHES INC

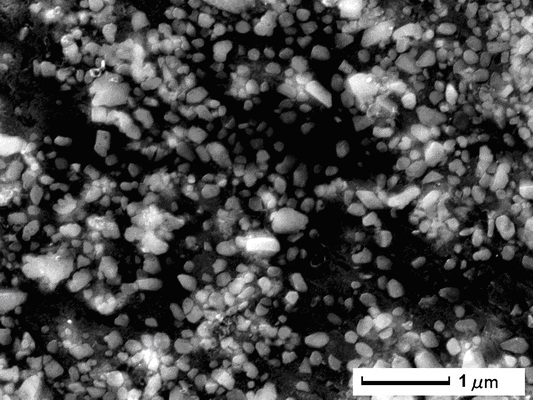

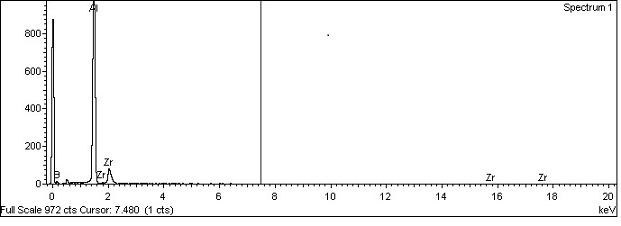

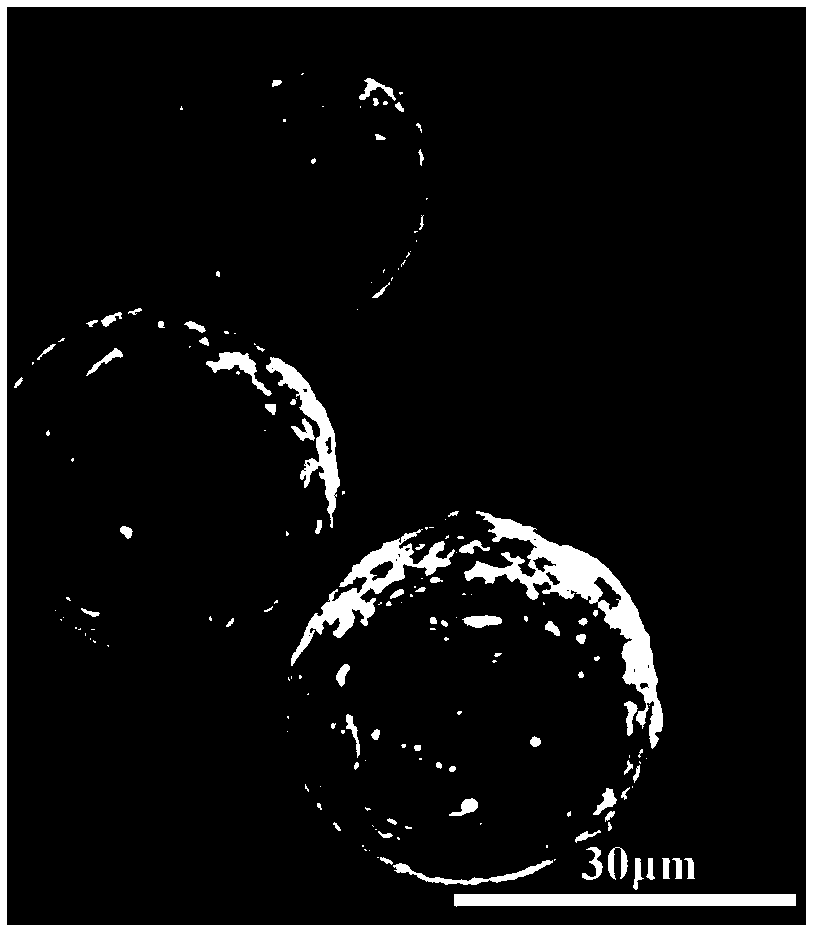

Novel nanometer phase dispersion strengthening cuprum as well as preparation method and product producing technique thereof

The invention relates to a dispersion-strengthened copper, the process for preparation thereof and the productive technology of products. The content of dispersion strengthening phase in dispersion-strengthened copper is 0.5-1.25wt%, the size of dispersion strengthening phase particle is 0.01-0.05um, and the distance is 0.1-0.5um. The process for preparing the nano-phase dispersion-strengthened copper comprises the following steps: firstly, mixing aluminium, ytterbium, lanthanum, cerium or zirconium powder with cuprous oxide powder in indoor temperature or inactive gas, and forming copper alloy powder with nanometer reinforcing phase in a copper base body through an in situ reaction synthesis method and through mechanical alloy, secondly, annealing under inactive gas, thirdly, milling compound powder and electrolytic copper powder in a second step with high energy to get nano-phase dispersion-strengthened copper alloy. Section bars which are needed are prepared through utilizing dispersion-strengthened copper which is got to anneal and do isostatic cool pressing, sintering densification and cold working. The process for preparing dispersion-strengthened copper has the advantages of low production cost, high yield and simple technique, and relative products which are prepared have excellent combination properties such as heat conductivity and electric conductivity.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

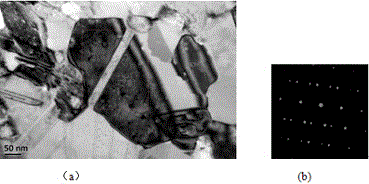

Endogenous nano ceramic reinforcement high-entropy alloy composite material and preparing method

The invention discloses an endogenous nano ceramic reinforcement high-entropy alloy composite material and a preparing method. High-entropy alloy particles serve as a base body phase, and meanwhile, in the high-energy ball milling process, mechanical alloying energy promotes the in-situ reaction to generate nano ceramic TiC, and an endogenous nano ceramic phase is segregated on the solid solution grain boundary, and ceramic phase reinforcement is generated; meanwhile, a flexible face-centered cubic solid solution is extruded to form a deformation twin, and therefore strength and plasticity combination of the high-entropy alloy composite material is achieved; and the high-strength high-toughness high-entropy alloy composite material is prepared, the excellent strength and the excellent strength are kept, and meanwhile, the plasticity of the composite material is improved.

Owner:NANJING INST OF TECH

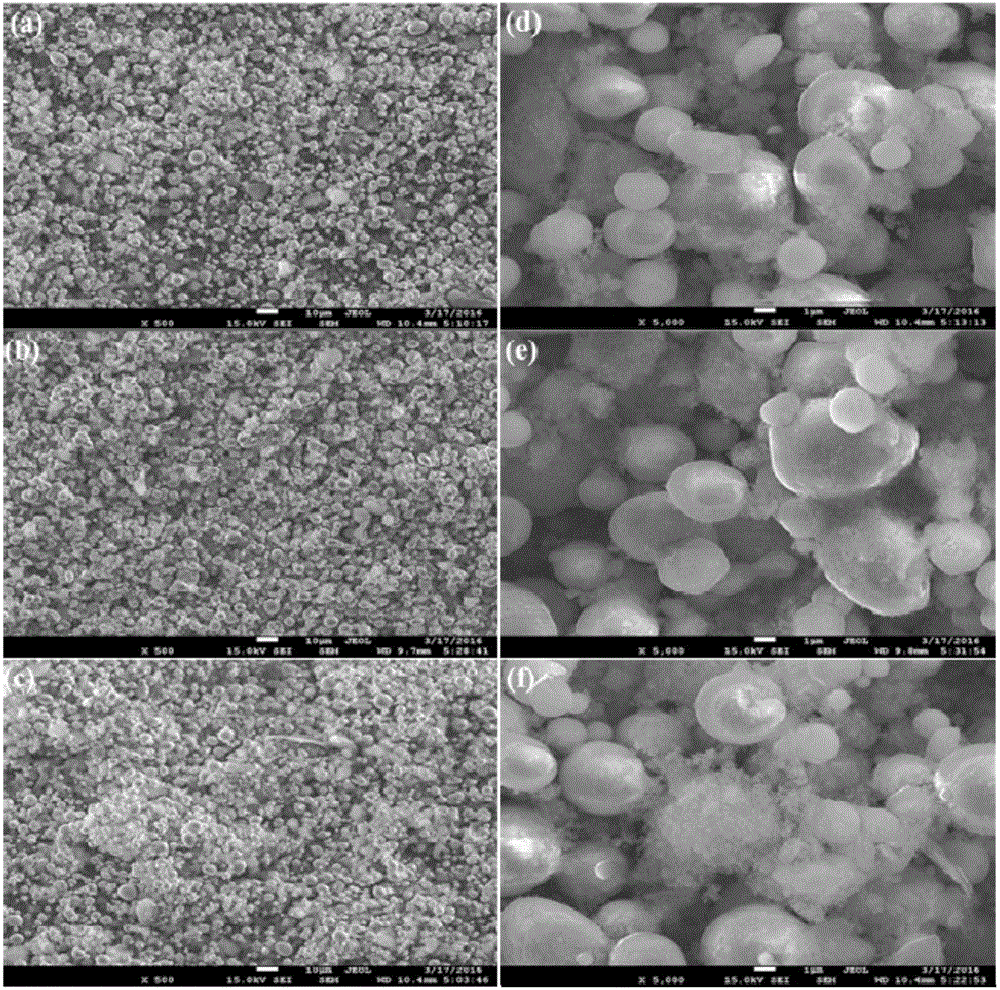

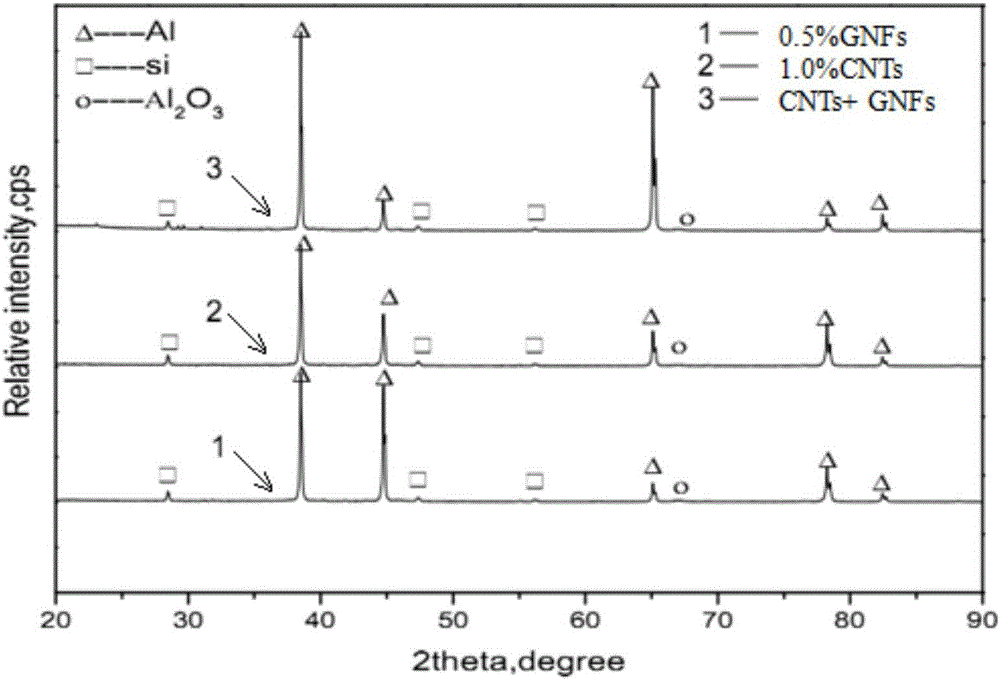

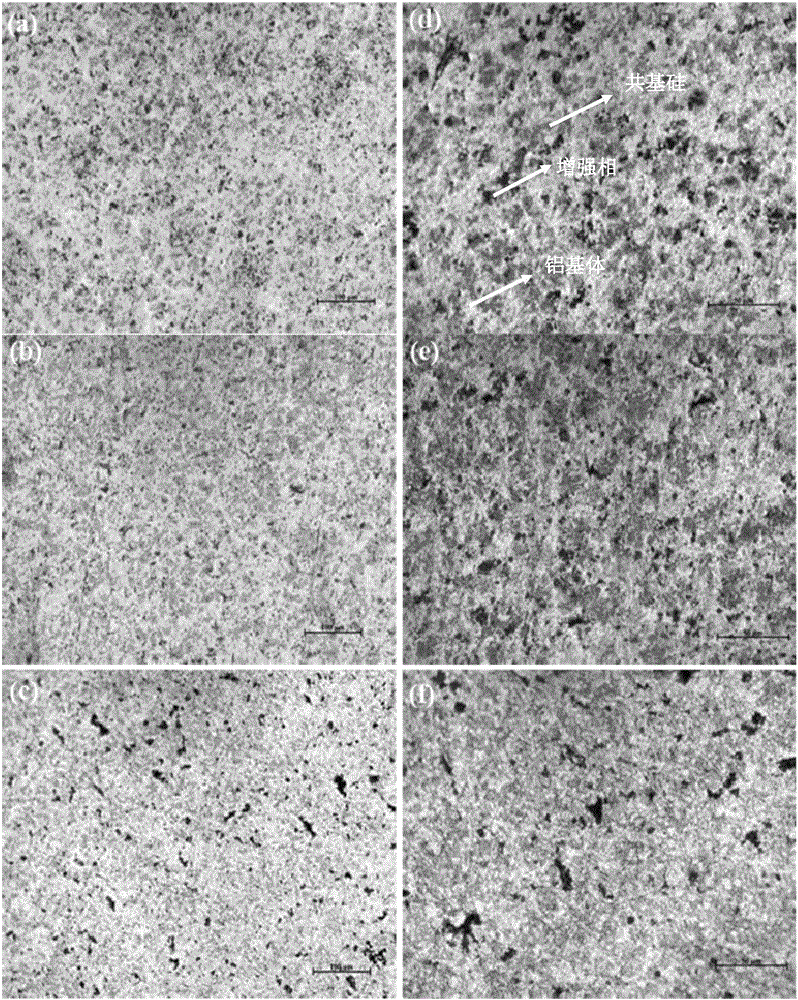

Carbon nano tubes (CNTs) and graphene nano flakes (GNFs) synergetic enhanced aluminum-based composite and preparation method

The invention discloses a GNFs / CNTs synergetic enhanced Al / Si / Al2O3 composite. The aluminum-based composite sample is mainly prepared from one or more of Al, SiO2, CNTs and GNFs. The CNTs and the GNFs are subjected to surface modification through gallic acid and rutin, and through combination with an in-situ reaction and a powder metallurgy technology, a CNTs independently enhanced aluminum-based composite, a GNFs independently enhanced aluminum-based composite and the CNTs and GNFs mixing enhanced aluminum-based composite with an Al / Si alloy as a matrix are prepared. The results show that 1, among the three composites, the 1% CNTs enhanced composite has the most excellent mechanical properties as well as the highest compactness, hardness and tensile strength; and 2, strengthening mechanisms of the CNTs enhanced aluminum-based composite mainly include the thermal expansion coefficient mismatch enhancement, Orowan enhancement and load transfer enhancement. The invention further discloses a preparation method of the aluminum-based composite. According to the method, the process is simple, production is easy, and broad application prospects are achieved.

Owner:SOUTHWEST JIAOTONG UNIV

In-Situ Kerogen Conversion and Oxidant Regeneration

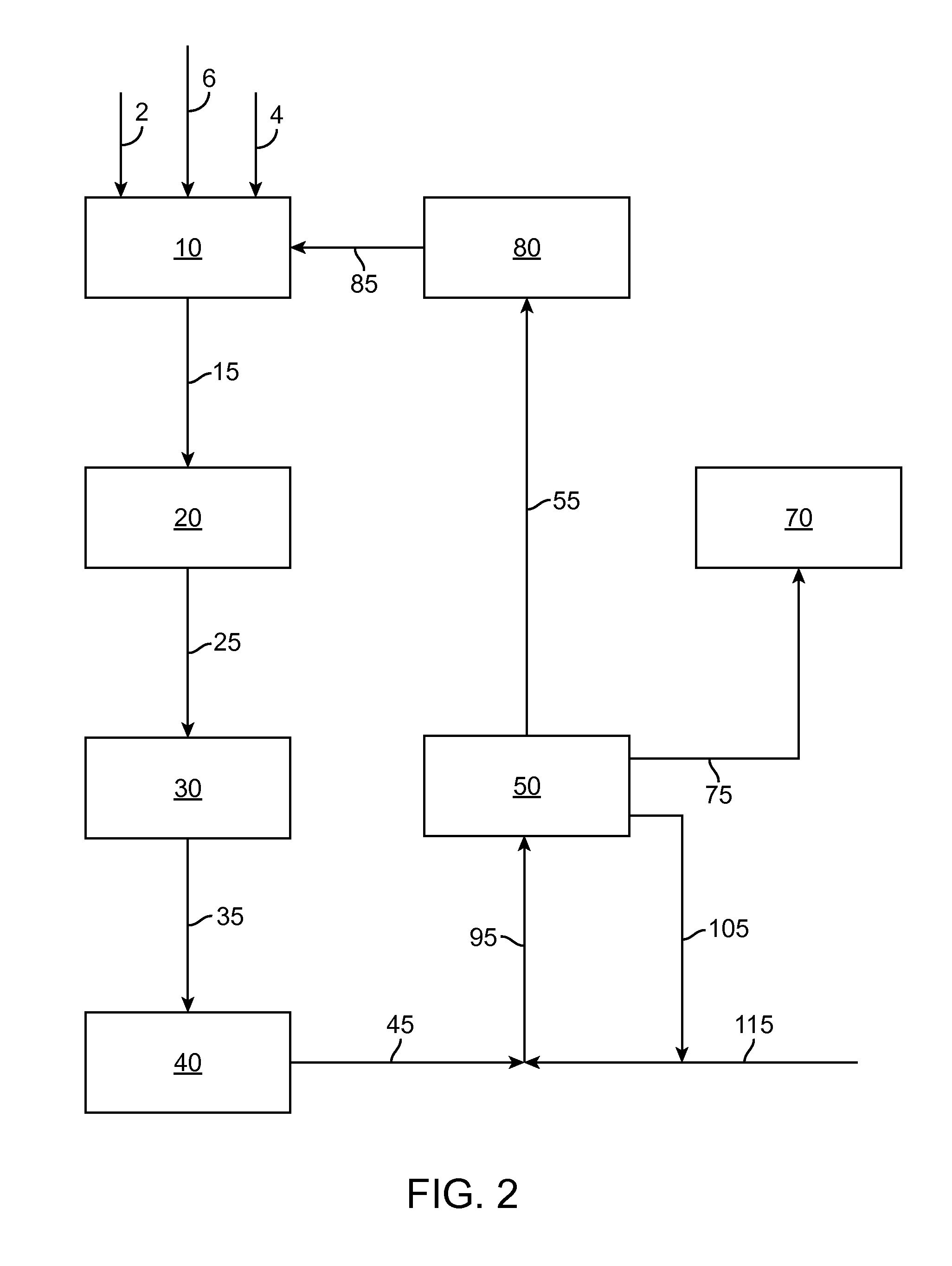

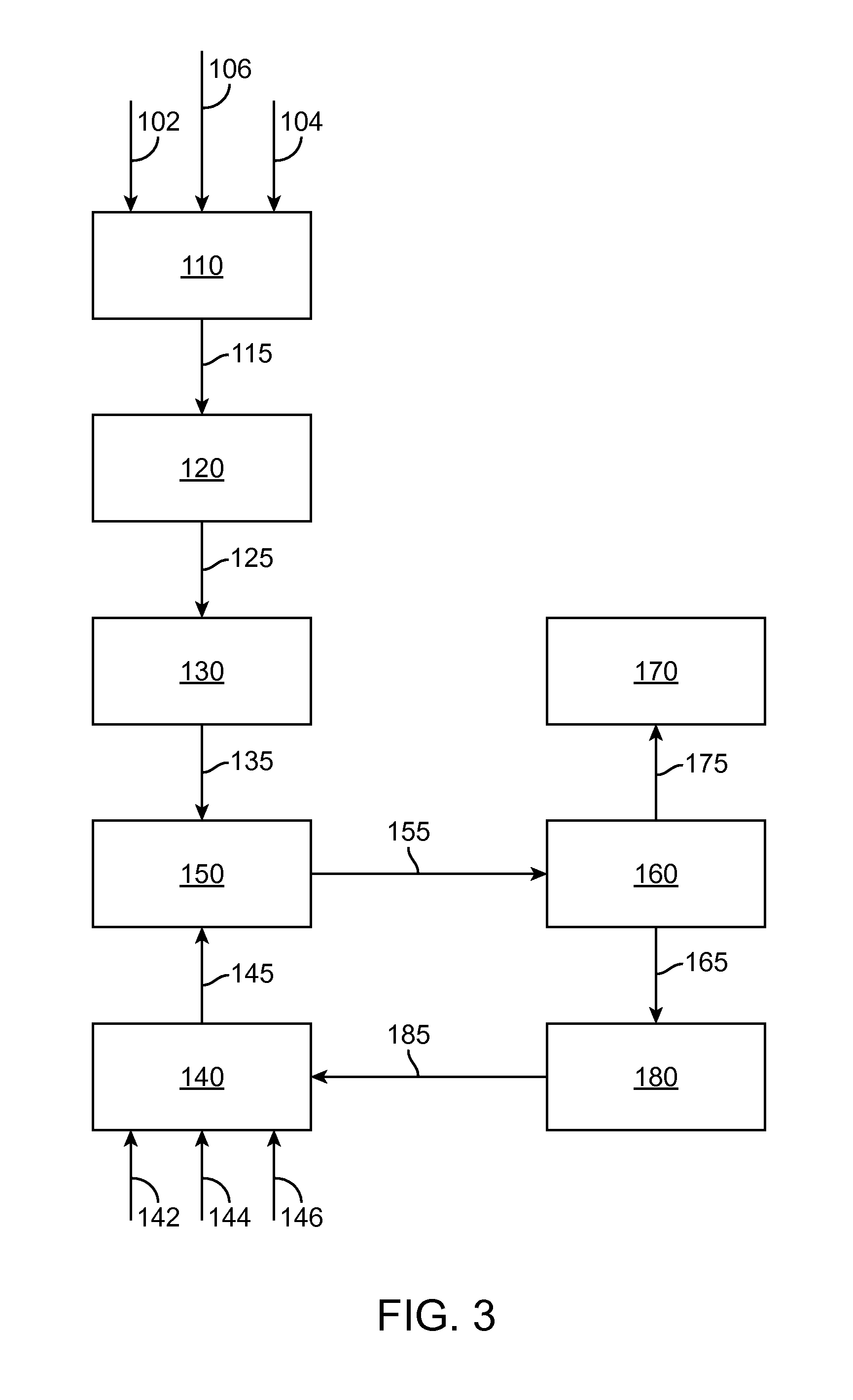

InactiveUS20130161002A1Process economyEfficient productionFluid removalDrilling compositionOrganic acidKerogen

Disclosed herein are methods for extracting a kerogen-based product from subsurface shale formations. The methods utilize in-situ reactions of kerogen involving liquid phase chemistry at formation temperatures and pressures. These methods rely on chemically modifying the shale-bound kerogen to render it mobile, using chemical oxidants. In the methods disclosed herein an oxidant is provided to the subsurface shale formation comprising kerogen in an inorganic matrix, the oxidant converting the kerogen to form organic acids, and forming a mobile kerogen-based product. The spent oxidant is regenerated in-situ to restore at least some of the original oxidation activity. At least a portion of the mobile kerogen-based product is recovered. The kerogen-derived product can be upgraded to provide commercial products.

Owner:CHEVROU USA INC

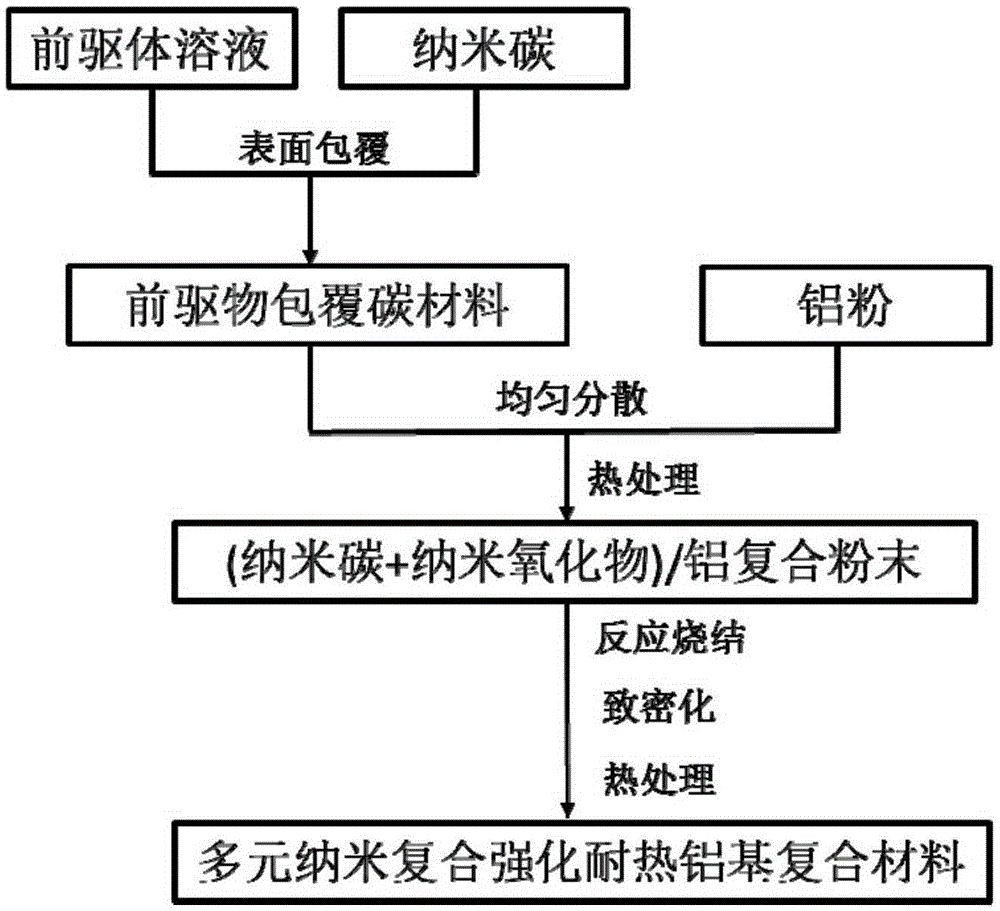

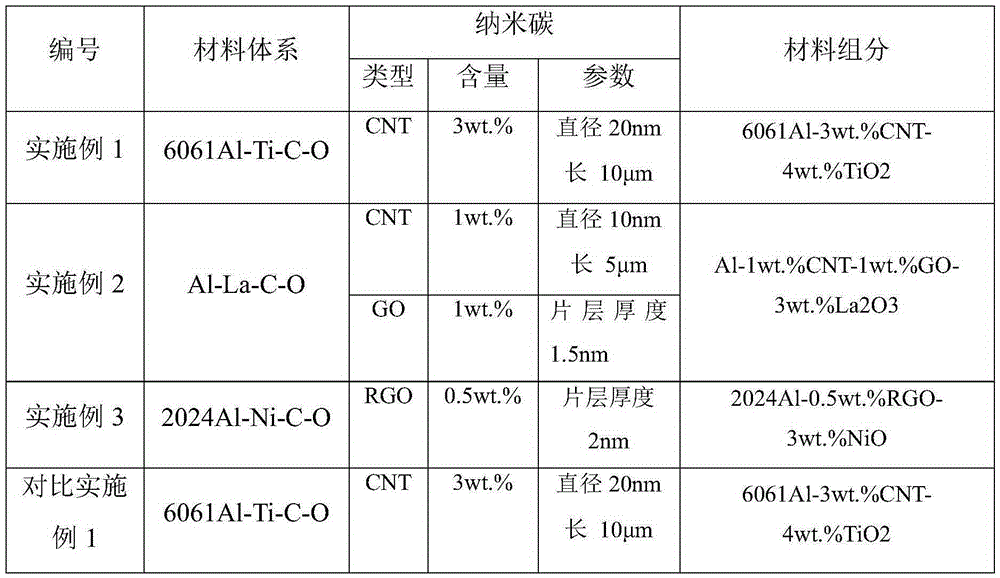

Preparing method of multielement nanometer composite strengthening thermal-resisting aluminum matrix composite

The invention provides a preparing method of a multielement nanometer composite strengthening thermal-resisting aluminum matrix composite. The surface of nanocarbon is coated with a metal ion precursor in advance, the nanocarbon is evenly scattered in aluminum powder, the precursor is converted into oxide through thermal treatment, reactive sintering and densifying treatment are carried out on the obtained composite powder, and the multielement nanometer strengthening aluminum matrix composite is obtained. The nanocarbon has the high specific surface area, the feature size of the nanocarbon is far larger than that of the nanometer oxide, and therefore a proper amount of nanometer oxide can be loaded and evenly led into the aluminum powder, metallic oxide, carbide, an intermetallic compound and other multielement nanometer strengthening phases are generated through the in-situ reaction, and the tissue stability and the thermal resistance of the aluminum matrix composite are improved coordinately. The method achieves the purposes of even leading of high-volume-content multielement nanometer strengthening phases and the space occupation control, and the conventional powder metallurgy technology can be adopted for preparing the multielement nanometer composite strengthening thermal-resisting aluminum matrix composite.

Owner:SHANGHAI JIAO TONG UNIV

In-situ kerogen conversion and oxidant regeneration

InactiveUS8851177B2More environmentally benignProcess economyFluid removalDrilling compositionKerogenOrganic acid

The invention relates to methods for extracting a kerogen-based product from subsurface shale formations. The methods utilize in-situ reactions of kerogen involving liquid phase chemistry at formation temperatures and pressures. These methods rely on chemically modifying the shale-bound kerogen to render it mobile, using chemical oxidants. In one embodiment, an oxidant is provided to the subsurface shale formation comprising kerogen in an inorganic matrix, the oxidant converting the kerogen to form organic acids, and forming a mobile kerogen-based product. The spent oxidant is regenerated in-situ to restore at least some of the original oxidation activity. At least a portion of the mobile kerogen-based product is recovered. The kerogen-derived product can be upgraded to provide commercial products.

Owner:CHEVROU USA INC

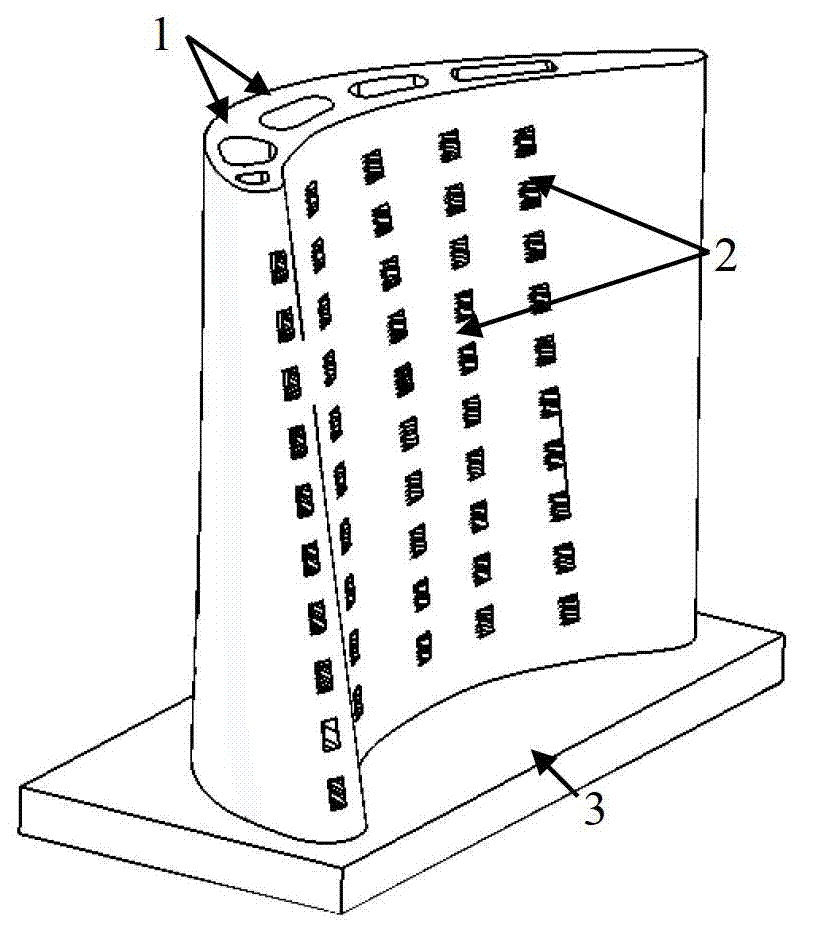

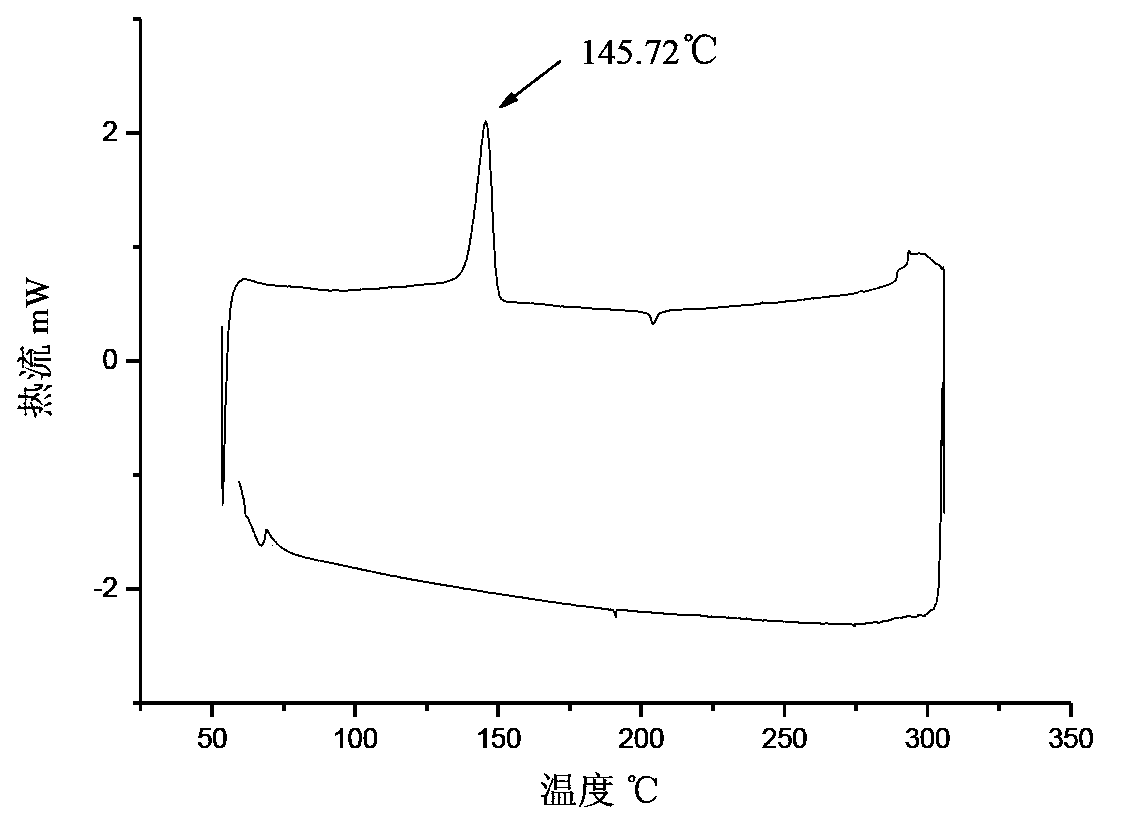

Preparation method of fiber-toughened SiC ceramic-based composite material three-dimensional member

The invention discloses a preparation method of a fiber-toughened SiC ceramic-based composite material three-dimensional member. The method comprises the following steps: adding fiber to liquid-state high char yield resin, pouring to a photo-curing mold, performing polymerization and curing on the resin, then manufacturing a controllable porous carbon preform through a thermolysis method, then performing high-temperature siliconizing, and preparing a SiC ceramic matrix by in-situ reaction of silicon on a carbon support to realize the manufacturing of the SiC ceramic-based composite material three-dimensional member. The method has the characteristics of near net shape formed variable cross-section complex structure, no crack defects, short production period, low cost and the like, and can be applied to development and manufacturing of blades of engines and other aerospace high-temperature-resistant complex structure parts.

Owner:XI AN JIAOTONG UNIV

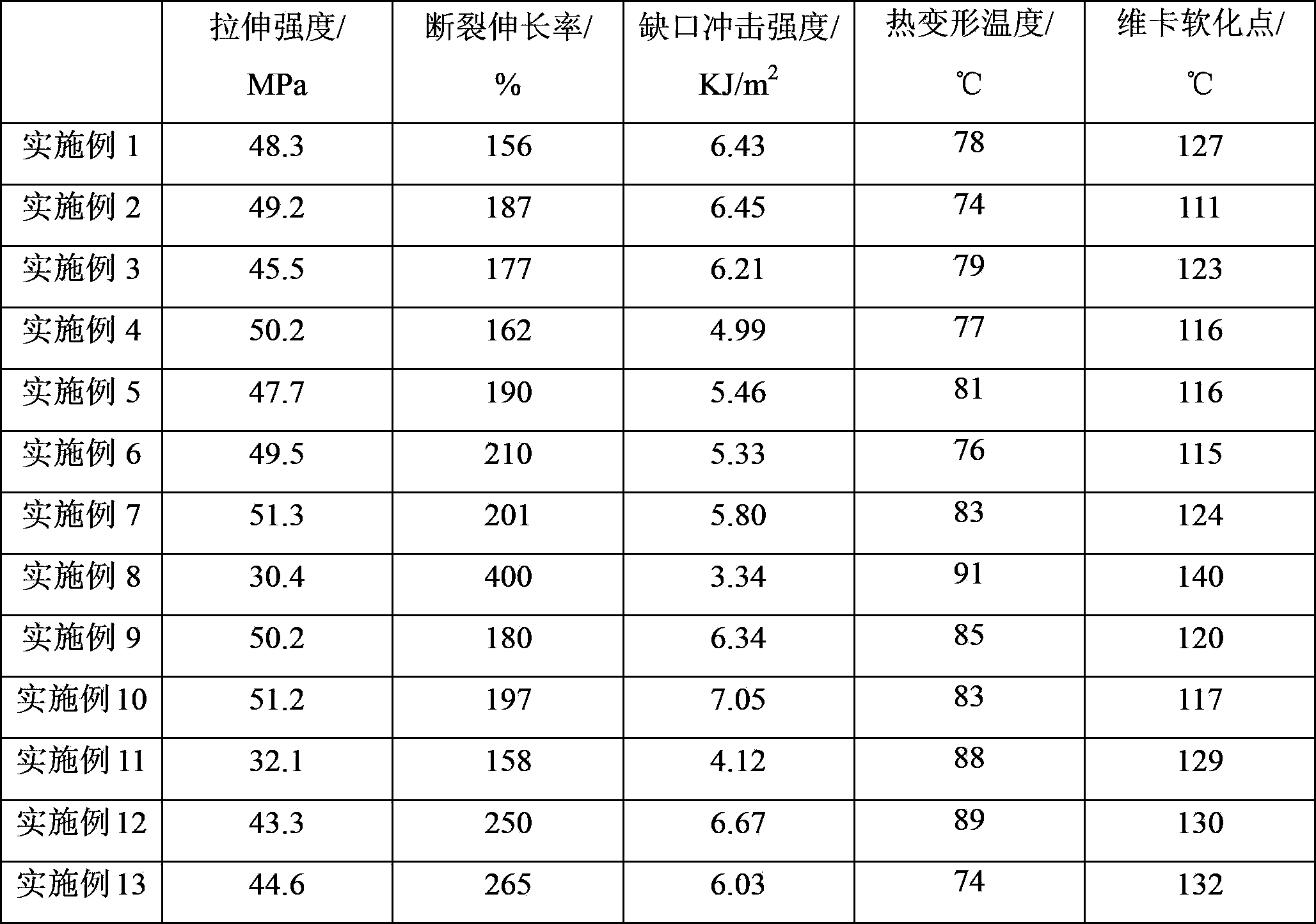

Novel heat-resistant high-toughness polylactic acid composite material and preparation method thereof

InactiveCN103819884AGuaranteed biodegradabilityExcellent mechanical properties and heat resistanceBiodegradable polyesterToughness

The invention belongs to the technical field of composite materials, and relates to a polylactic acid composite material and a preparation method thereof. The polylactic acid composite material is prepared from the following components in percentage by weight: 5 to 90 percent of polylactic acid, 5 to 80 percent of biodegradable polyester and 5 to 80 percent of heat-resistant master batch. The heat-resistant high-toughness polylactic acid composite material is obtained by continuous in-situ reaction extrusion. The composite material simultaneously has the characteristics of high toughness, high temperature resistance, low production cost, full biodegadability and the like.

Owner:SHANGHAI ZAIHE IND INVESTMENT CO LTD

Method for preparing UHTC (Ultra-High Temperature Ceramic) matrix composite material through modification of UHTC powder basal body

InactiveCN103058711AImprove mechanical propertiesGuaranteed mechanical propertiesFiberVacuum pressure

The invention discloses a method for preparing an UHTC (Ultra-High Temperature Ceramic) matrix composite material through modification of a UHTC powder basal body. The method comprises the steps of: introducing UHTC powder and a carbon organic precursor into C / SiC with a gas hole ratio of 30 vol% to 40 vol% by adopting a vacuum pressure impregnation way; and performing in-situ reaction on melting silicon and splitting carbon in the basal body, and compacting the material through the combination of RMI (Reactive Melt Infiltration) so as to prepare a C / SiC-UHTC composite material. For one aspect, the SiC basal body protects fibers from being eroded by the melting silicon so as to improve mechanical properties of the material as the C / SiC with the gas hole ratio of 30 vol% to 40 vol% is adopted as a prefabricated body; and for the other aspect, a certain amount of the UHTC powder is introduced into the prefabricated body to improve anti-ablation performances.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Sintering preparation method of boron carbide ceramic

The invention discloses a sintering preparation method of boron carbide ceramic, which comprises the following steps: 1. sintering: carrying out mixing and ball milling on boron carbide powder, carbon powder, metal powder, a dispersant, an adhesive and deionized water to make a slurry, carrying out spray granulation, pressing into a biscuit, presintering for debonding, and carrying out thermal-insulation sintering at lower sintering temperature (slightly higher than the melting point of metal), thereby implementing primary shrinkage sintering of the product by utilizing the surface tension of the molten metal in the system; and 2. sintering: continuing enhancing the sintering temperature, carrying out in-situ reaction to generate metal carbide, metal boride or metal boro-carbide and nano B4C which have higher sintering activity, and forming a solid solution with boron carbide granules by using the metal carbide, metal boride or metal boro-carbide and nano B4C as sintering assistants to promote the further shrinkage sintering of the system, thereby obtaining the high-performance boron carbide ceramic. The method has the advantages of both the normal-pressure sintering technique and the reactive sintering technique.

Owner:NINGBO VULCAN TECH CO LTD

High-strength cast magnesium alloy and preparation method thereof

ActiveCN102534330AReduce burning lossReduce the difficulty of protectionRare-earth elementCooking & baking

The invention discloses high-strength cast magnesium alloy and a preparation method thereof. The high-strength cast magnesium alloy comprises the following ingredients by mass percentage: 8 to 14 weight percent of Gd, 1 to 5 weight percent of Y, 0.6 to 2 weight percent of Al, less than 0.02 weight percent of impurity elements of Si, Fe, Cu and Ni and the balance of Mg. The preparation method of magnesium alloy comprises two process work procedures: smelting and subsequent heat treatment, wherein the smelting process work procedure is carried out under the protection condition of SF6 and CO2 mixed gas and comprises the steps of material baking, magnesium melting, Gd and Y addition, Al addition and casting, and the heat treatment process work procedure comprises solid solution treatment andaging treatment. Through the method of adding rare earth elements such as Al, Gd and Y into the alloy to generate Al-RE intermetallic compounds through in-situ reaction, the goal of refining crystalline grains is reached, the crystalline grain stability of the obtained high-strength cast magnesium alloy is excellent, the recession resistance performance of the refining effect is high, and higher tensile strength and elongation are realized.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of semisolid slurry of rare earth magnesium alloy

The invention discloses a preparation method of a semisolid slurry of a rare earth magnesium alloy. According to the guiding principle of promoting grain nucleation and inhibiting grain growth, pure aluminium is added into rare earth magnesium alloy melt, and a lot of fine dispersed Al2RE intermetallic compound particles which are generated by an in-situ reaction provide nuclei of heterogeneous nucleation for primary alpha-Mg so as to promote grain nucleation; and after the melt is transferred to a tundish, considering stability of a solid-liquid interface during the solidification process, the growth of a primary phase is delayed by reasonable control of cooling conditions in different stages of solidification so as to realize the effect of inhibiting grain growth. The invention provides a low-cost agitation-free green semisolid slurry preparation method. In comparison with a traditional semisolid slurry preparation technology, efficiency of the preparation method is improved greatly and cost is reduced remarkably. By the preparation method, a high-quality rheological slurry is provided for follow-up rheoforming of rare earth magnesium alloy, such as rheo-die casting, rheological squeeze casting and the like. The preparation method has a wide application prospect in rheoforming of a magnesium alloy.

Owner:SHANGHAI JIAO TONG UNIV

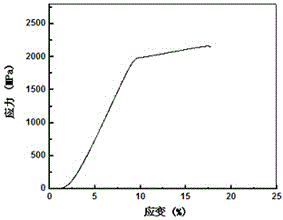

Manufacturing method of metal matrix nanocomposites with high toughness

The invention relates to the composite technical field, in particular to a manufacturing method of metal matrix nanocomposites with high toughness. According to the manufacturing method, the size, distribution, interface structure of reinforcement bodies and the metal matrix micro-structure are effectively controlled by the combined composite process of twice ball-milling, discharging plasma in situ reaction sintering and the large strain plastic deformation technology, so that ultra-fine grain metal matrix composites with evenly distributed in situ authigenic nanoparticles and good interface combination are manufactured, and good matching of intensity and toughness is obtained.

Owner:泰州赛龙电子有限公司

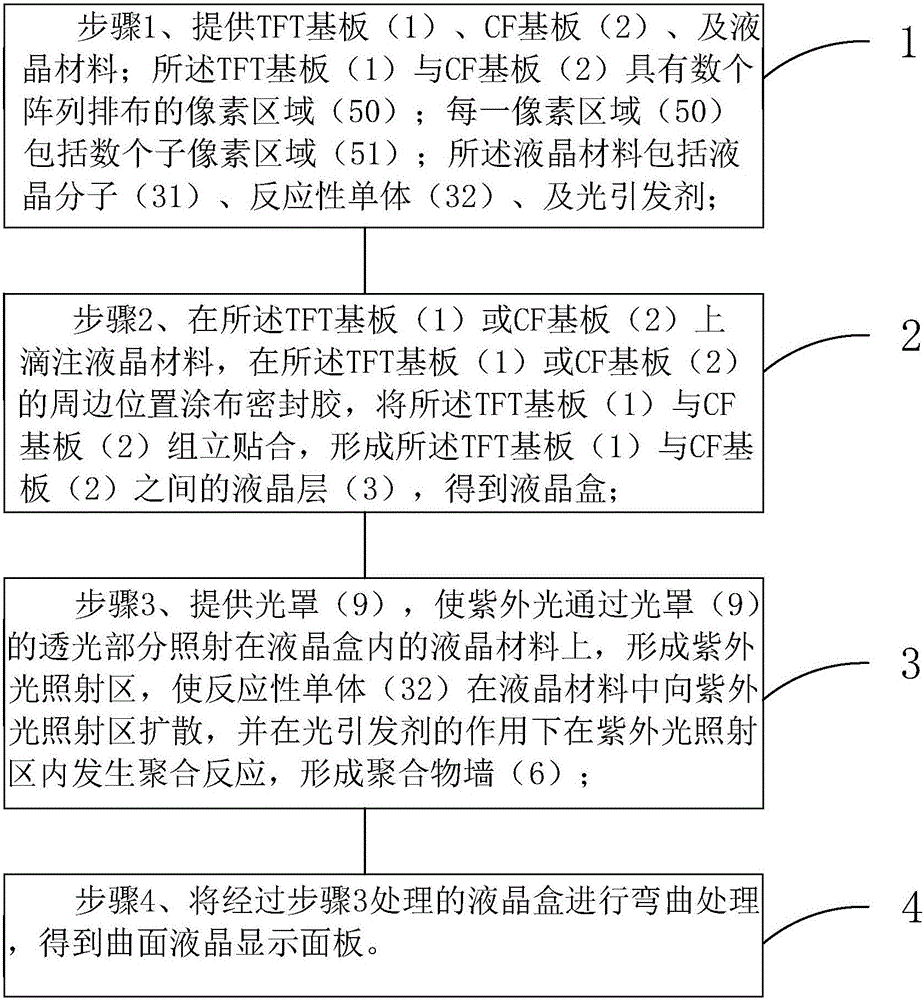

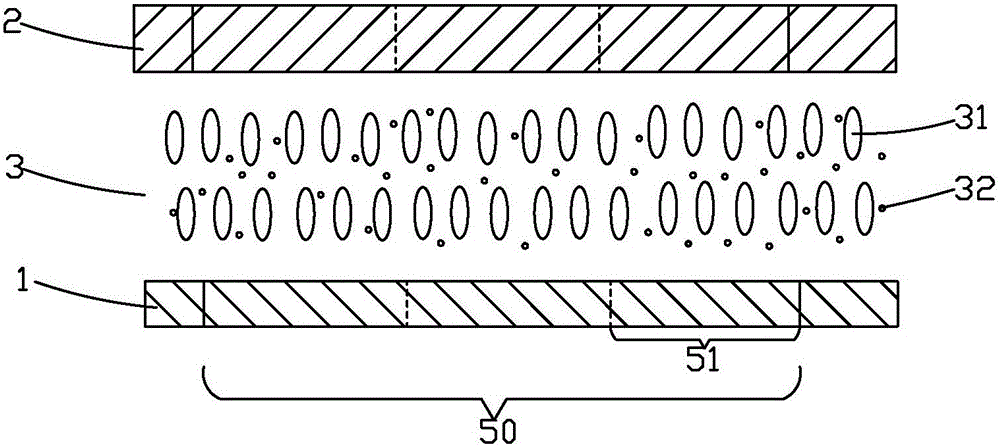

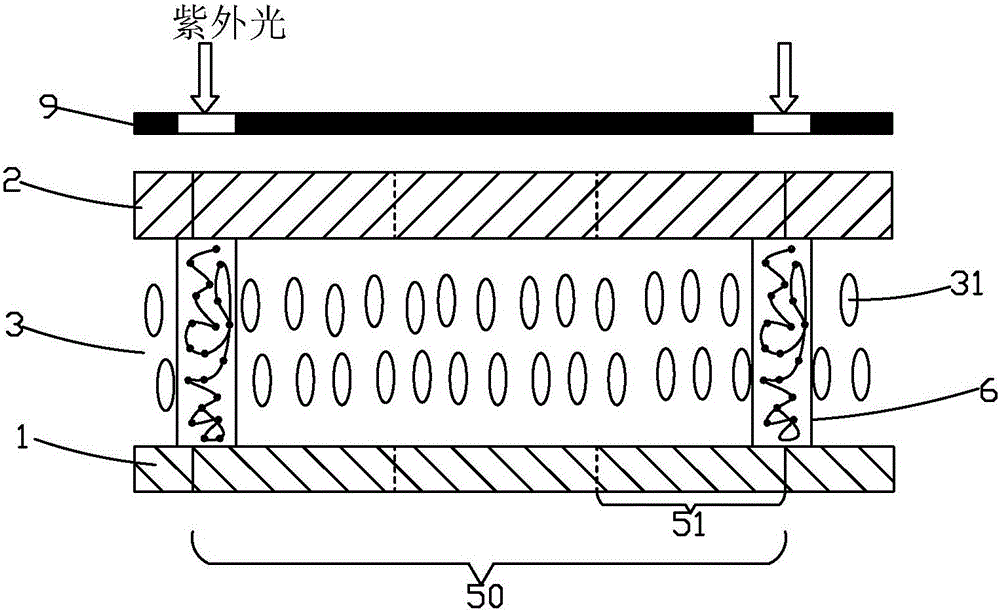

Curved-surface liquid crystal display panel and production method thereof

The invention provides a curved-surface liquid crystal display panel and a production method thereof. According to the production method, reaction monomers mixed in a liquid crystal material form a polymer wall at the edge of each corresponding pixel region between a TFT substrate and a CF substrate or the edge of each subpixel region by virtue of a photomask under the irradiation of ultraviolet light; compared with traditional partitions, the polymer walls are uniformly distributed on each pixel, so that the relatively uniform box thickness of a panel can be guaranteed during bending; meanwhile, the shearing stress between the TFT substrate and the CF substrate is effectively dispersed by virtue of the uniformly distributed polymer walls, so that a frame sealant can be protected from being damaged; and besides, compared with a method for forming the partitions by virtue of photoresistance photoetching, the production method has the advantages that the polymer walls are generated by virtue of in-situ reaction in a liquid crystal box, so that the problem that the box thickness is not uniform due to alignment deviation or terrain deviation is avoided.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

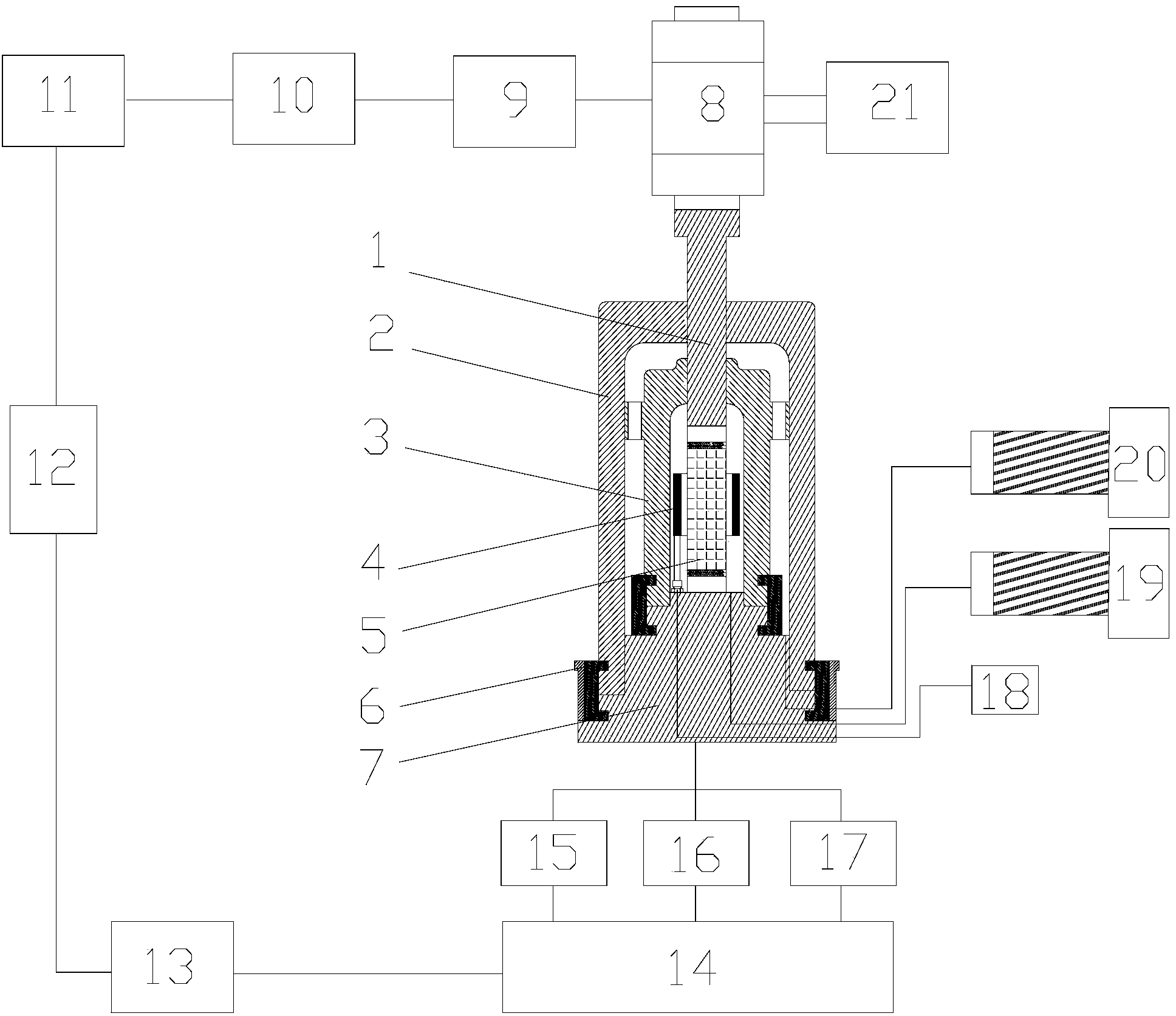

Dynamic loading system for measuring dynamic characteristics of natural gas hydrate sediments

InactiveCN103616290AQuick and accurate controlMeet the requirements of in situ generation experimentsMaterial strength using tensile/compressive forcesData acquisitionActuator

The invention discloses a dynamic loading system for measuring dynamic characteristics of natural gas hydrate sediments and belongs to the technical field of measurement of mechanical characteristics of natural gas hydrate sediments. The dynamic loading system is characterized in that the system is formed by connecting a three-axis pressure chamber, a heat exchanger, an axial loading piston, a hydraulic oil source, a hydraulic actuator, a servo valve, a servo driver, a servo controller, a digital / analog (D / A) interface, a data acquisition module, an industrial personal computer, a load sensor, a displacement sensor, a strain sensor, a low-temperature control system, an internal confining pressure loading system and an external confining pressure loading system, wherein the internal confining pressure loading system, the external confining pressure loading system and the low-temperature control system can rapidly and accurately control the pressure and temperature, so that the experimental requirement of performing in-situ reaction on submarine hydrates in a lab is met. The system has the effects that the dynamic characteristics of the natural gas hydrate sediments can be tested according to the system, important kinetic parameters are provided for safety mining of the submarine natural gas hydrates, and the system is relatively low in construction cost.

Owner:DALIAN UNIV OF TECH

Process for preparing polyolefine/montmorillonite nano non-halogen flame-resisting material

The present invention relates to the preparation process of nanometer flame retarding non-halogen polyolefin / montmorillonite material. Un-modified montmorillonite and ethylene monomer containing polar radical are made to produce in-situ reaction to form the nanometer flame retarding non-halogen polyolefin / montmorillonite material with intercalation structure. Owing to the blocking effect and nanometer effect of the intercalation structure of montmorillonite, the flame retarding non-halogen material has strengthened flame retarding performance, compensated mechanism and machining performance, and improved compatibility between montmorillonite and polyolefin.

Owner:SOUTH CHINA UNIV OF TECH

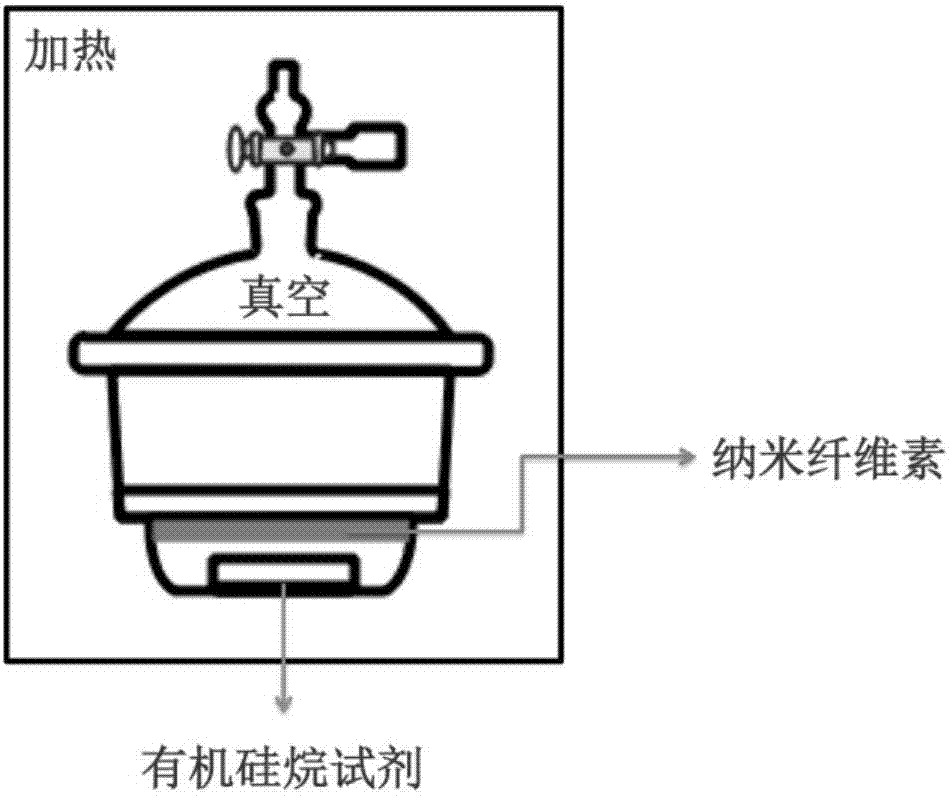

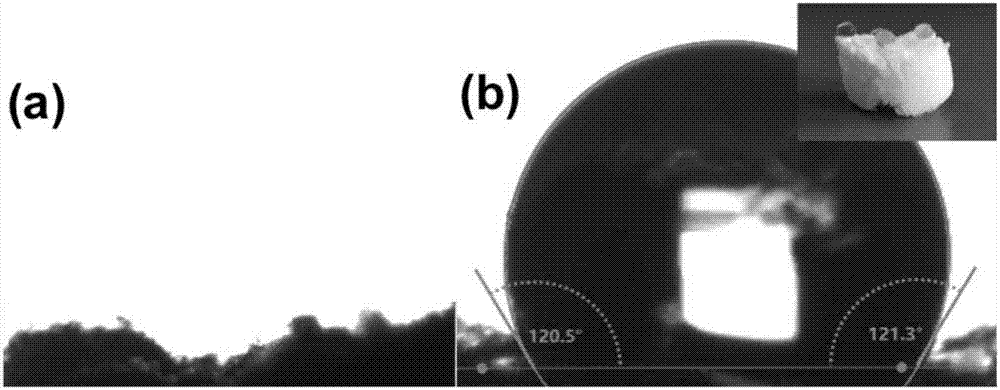

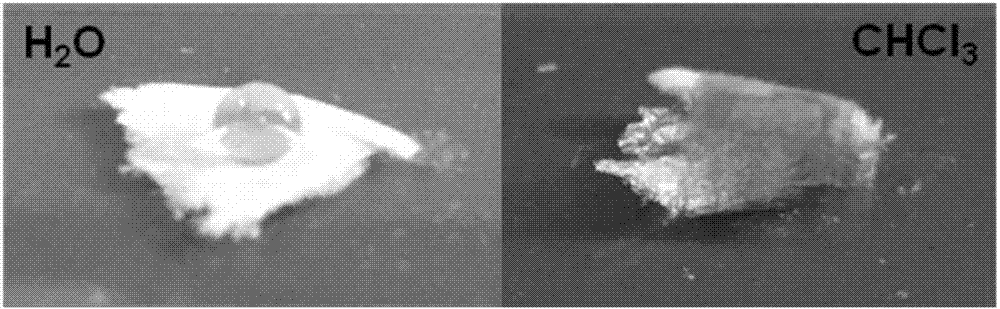

Hydrophobic modification method of nanocellulose

The invention discloses a hydrophobic modification method of nanocellulose. The method comprises the steps of putting the nanocellulose into a dryer, placing a small-sized open container at the bottom of the dryer, adding 5-10mL of a silanization agent, vacuating the dryer, putting the dryer into a drying oven and heating for a period of time so as to obtain a hydrophobic modified nanocellulose material. The hydrophobic modification method fully utilizes a chemical vapor deposition method, and the hydrophobic modified nanocellulose is directly prepared by using an in-situ reaction one-step method; the types of silanization agents which can be selected for use are wide, the solvent pollution is avoided, a complicated aftertreatment process is omitted, and the original good properties of the material can be maintained. The hydrophobic modification method provided by the invention is simple in preparation technology, free from environmental pollution and low in cost; the prepared hydrophobic modified nanocellulose is safe and biodegradable, thus being capable of being used in the fields such as chemical industry, food, environmental protection, textile and separation.

Owner:WUHAN UNIV

Vapor depositing in-situ reaction process for preparing carbon nanotube reinforced copper-base composite material

InactiveCN1888103ASolve the problem of fragmentationExcellent electrical performanceChemical vapor deposition coatingGas phaseCarbon nanotube

The present invention is preparation process of carbon nanotube reinforced copper-base composite material with high strength and high conductivity, and belongs to the field of copper-base composite material preparing technology. The preparation process includes the following steps: adding nickel nitrate hexahydrate, yttrium nitrate hexahydrate and ethanol soaked copper powder in certain weight proportion into distilled water to obtain nickel nitrate solution; dropping sodium hydroxide solution to the nickel nitrate solution to produce neutralizing reaction obtaining ternary Ni(OH)2 / Y(OH)3 / Cu colloid; washing, filtering, drying, grinding and calcining to obtain Ni / Y / Cu catalyst precursor; setting the precursor into reaction furnace, introducing H2 to reduce, and introducing N2 and reaction gas for catalytic cracking reaction to obtain composite carbon nanotube / Cu powder; initially pressing the composite powder, sintering and re-pressing to obtain carbon nanotube in-situ reinforced copper-base composite material.

Owner:TIANJIN UNIV

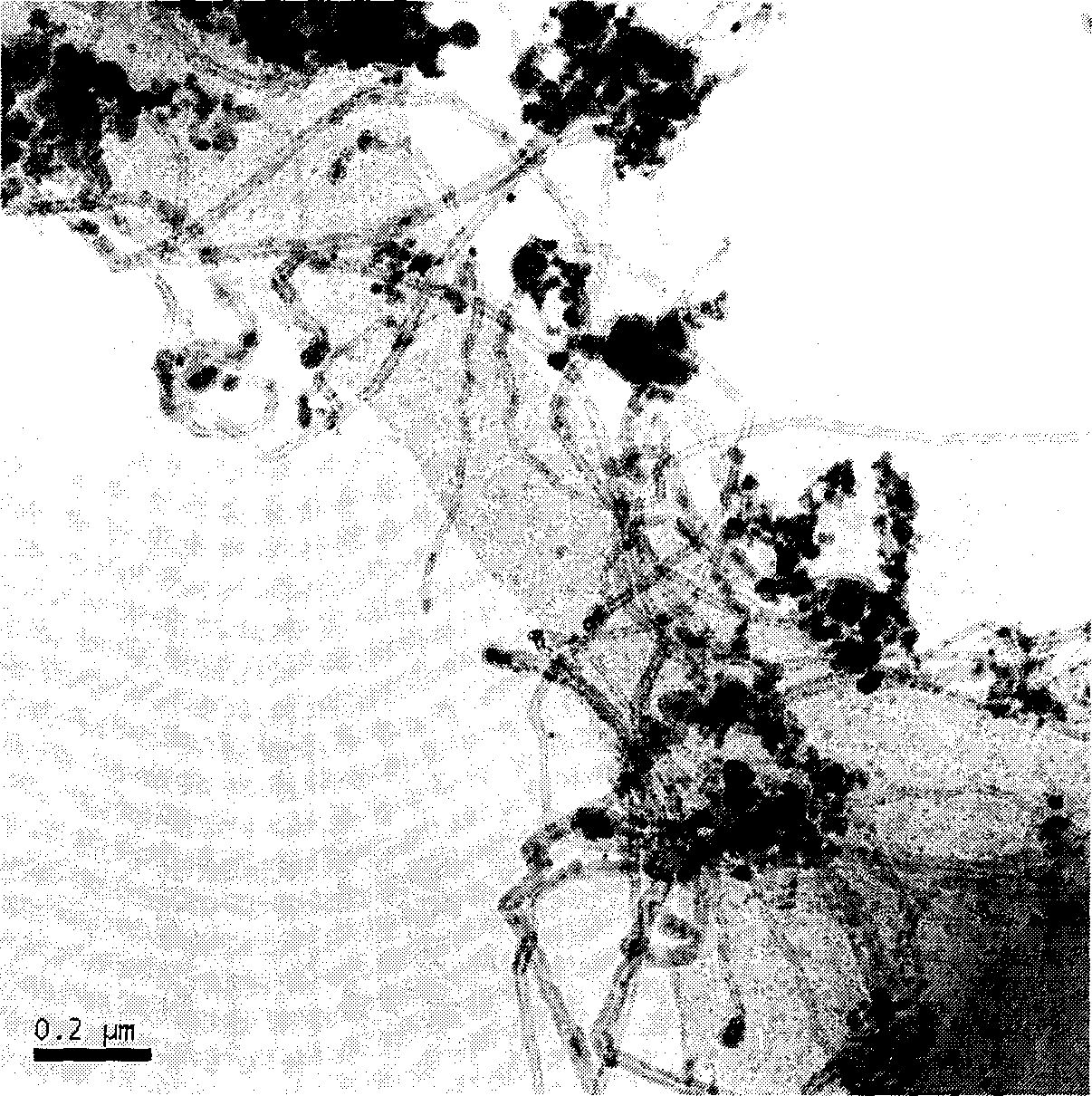

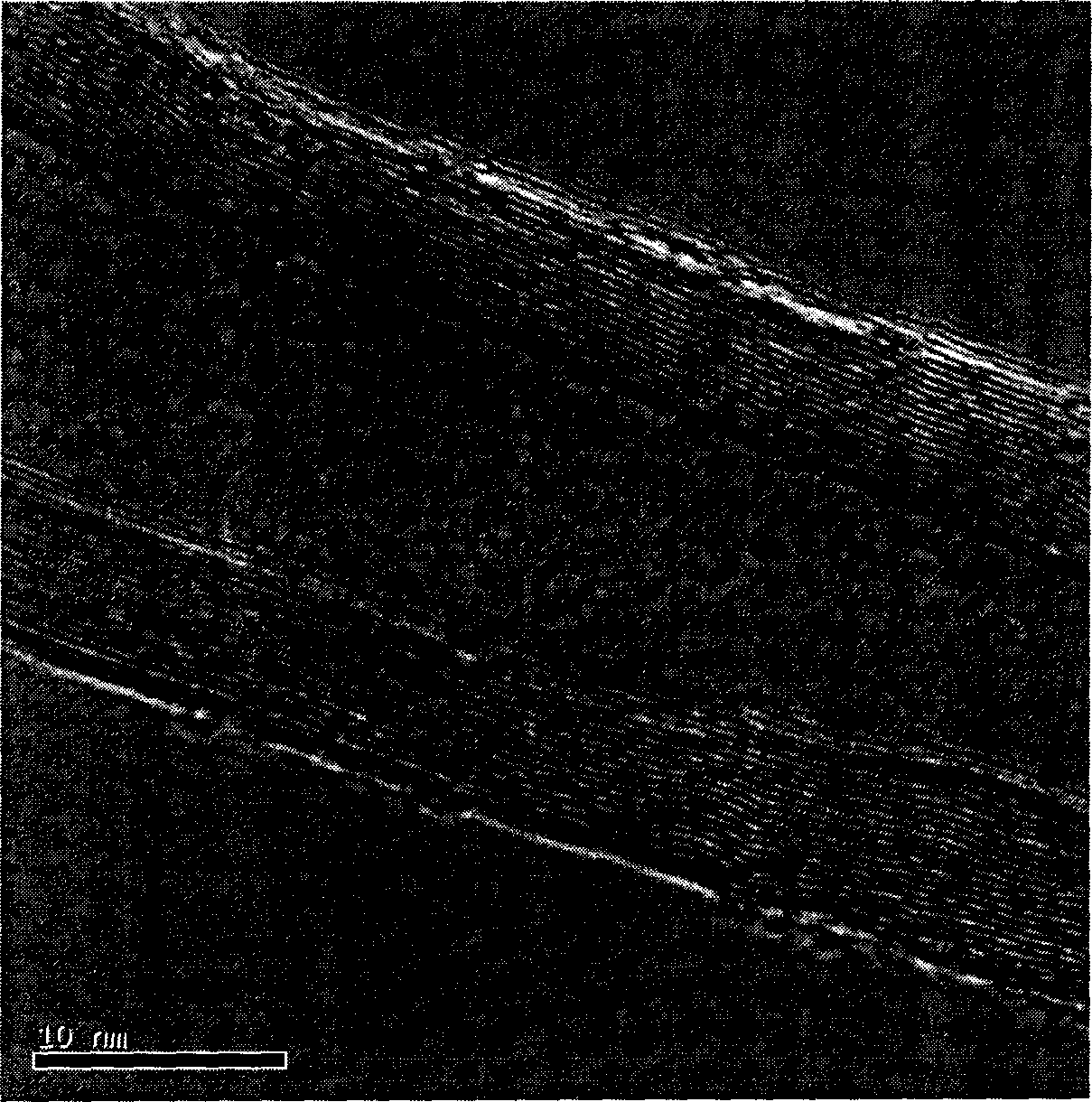

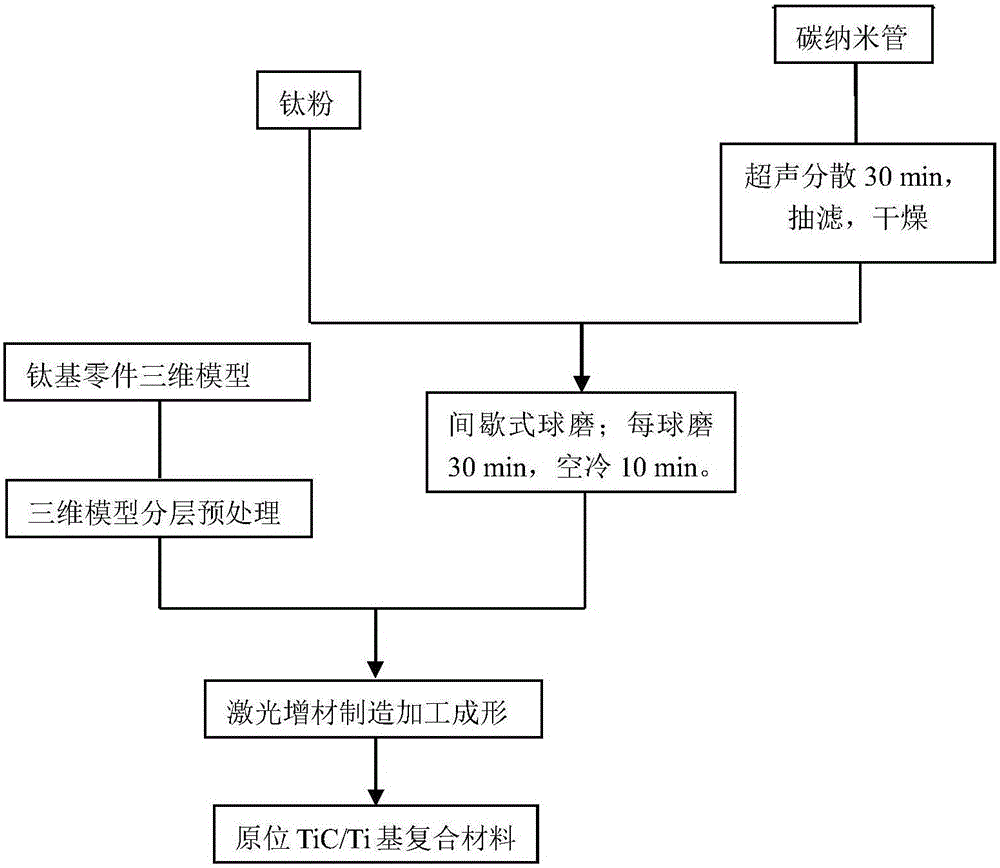

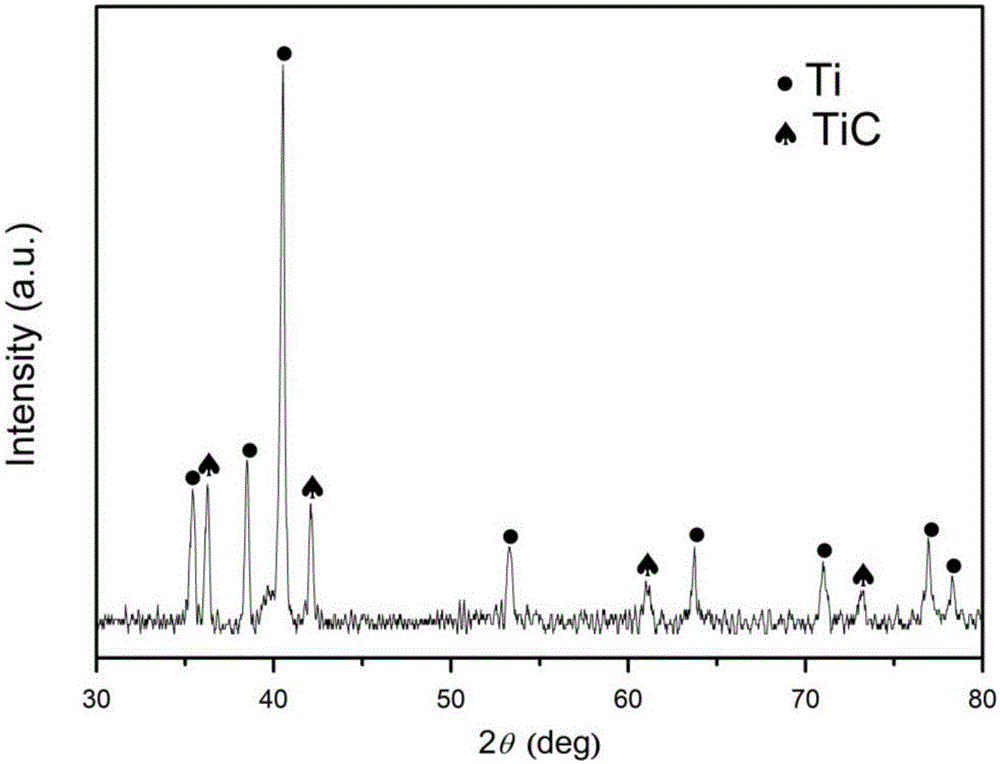

Method for manufacturing high-performance in-situ TiC reinforced titanium-based composite workpiece on basis of CNTs and laser additive manufacturing and processing technology

ActiveCN105033254AGood interface wettabilityTightly boundAdditive manufacturing apparatusIncreasing energy efficiencyTitanium matrix compositesCarbon nanotube

The invention discloses a method for manufacturing a high-performance in-situ TiC reinforced titanium-based composite workpiece on the basis of CNTs and a laser additive manufacturing and processing technology. The method includes the following steps that (1) the carbon nano tubes are subjected to preliminary ultrasonic dispersion treatment; (2) pure titanium powder with the average particle size of 45-75 microns is mixed with the carbon nano tubes to obtain a mixture, and CNTs / Ti mixed powder is obtained by ball-milling the mixture through a ball mill under the protection of argon; and (3) the ball-milled CNTs / Ti mixed powder is shaped through a laser additive manufacturing and processing method so as to obtain a high-performance in-situ TiC reinforced titanium-based composite body. The method has the advantages that in-situ TiC reinforcement phases are formed on the basis of a CNTs in-situ reaction and evenly distributed in a titanium substrate, and the interface bonding strength is high; grains of a composite are refined remarkably; net forming or near-net forming of a test piece can be achieved; any complex heterogeneous part can be formed.

Owner:南京瑞德增域三维技术发展有限公司

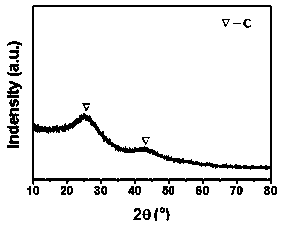

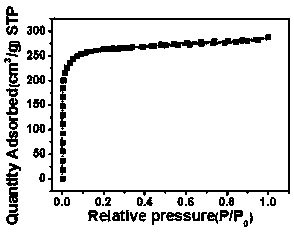

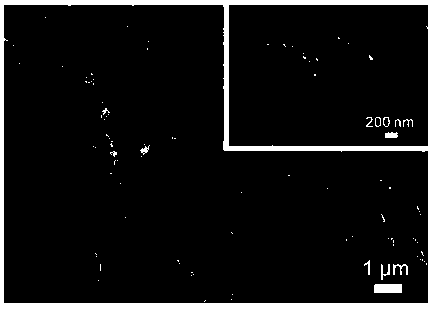

Porous nitrogen-doped carbon/carbon nanotube composite material, preparation method thereof and application

ActiveCN108063056ALow costSimple processHybrid capacitor electrodesHybrid/EDL manufacturePolypyrroleNitrogen gas

The invention discloses a porous nitrogen-doped carbon / carbon nanotube composite material, a preparation method thereof and the application in a super capacitor. The method comprises steps: (1) methylorange, ferric chloride and pyrrole are used to prepare polypyrrole nanotubes as a substrate, and in-situ reaction is carried out on the surface of the polypyrrole nanotubes to form a layer of metalorganic framework material (zeolite imidazole framework material 8, and ZIF-8 in short); (2) precursor powder is carbonized for 1 to 3 h under 700 to 1000 DEG C at a nitrogen or argon protection atmosphere; and (3) the obtained composite material is immersed by dilute hydrochloric acid for 5 to 24 h, filtering and drying are carried out, and a porous nitrogen-doped carbon / carbon nanotube compositematerial is acquired. Through adjusting process parameters, the high-specific surface area porous nitrogen-doped carbon / carbon nanotube composite material can be acquired. The process is simple, thecost is low, and industrial production is easy.

Owner:ZHONGBEI UNIV

Method for synthesizing particle reinforced aluminum-based composite under high-intensity ultrasonic field and pulsed electric field

The invention relates to the technical field of the preparation of the particle reinforced metal-based composite, in particular to a method for synthesizing a particle reinforced aluminum-based composite under a high-intensity ultrasonic field and a pulsed electric field. The method is mainly characterized in that when the melt direct reaction method is adopted to perform the in-situ reaction of the particle reinforced aluminum-based composite, the high-intensity ultrasonic field and pulsed electric field are both applied on the reaction melt. The parameters of the high-intensity ultrasonic field are as follows: the frequency is 22-30kHz and the intensity is 1-10W / cm<2>. The parameters of the pulsed electric field are as follows: the peak density of current is 0.1-10A / cm<2> and the pulse frequency is 0.1-10Hz. The method has the significant advantage of the coupling of the high-intensity ultrasonic field and the pulsed electric field, thus the thermodynamics and kinetics of the in-situ particle formation reaction can be improved, the mixing of the reactant and the melt can be improved and the shape and size of particles in micron-scale / nanoscale can be controlled; and the dispersion effect of particles in the melt can be controlled, and the method is suitable for the preparation of the high performance micron-nano particle reinforced composite.

Owner:NANTONG UNIVERSITY

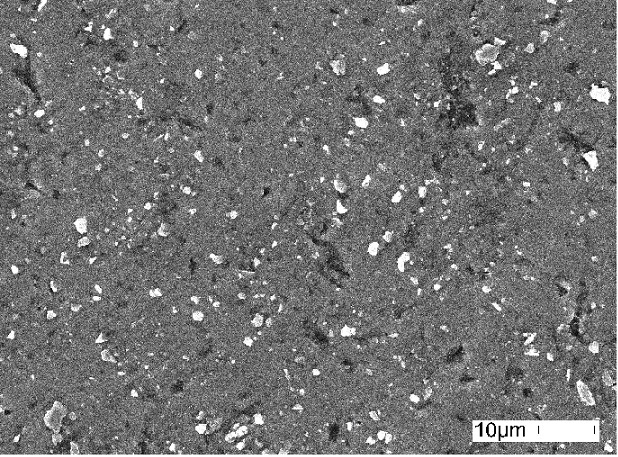

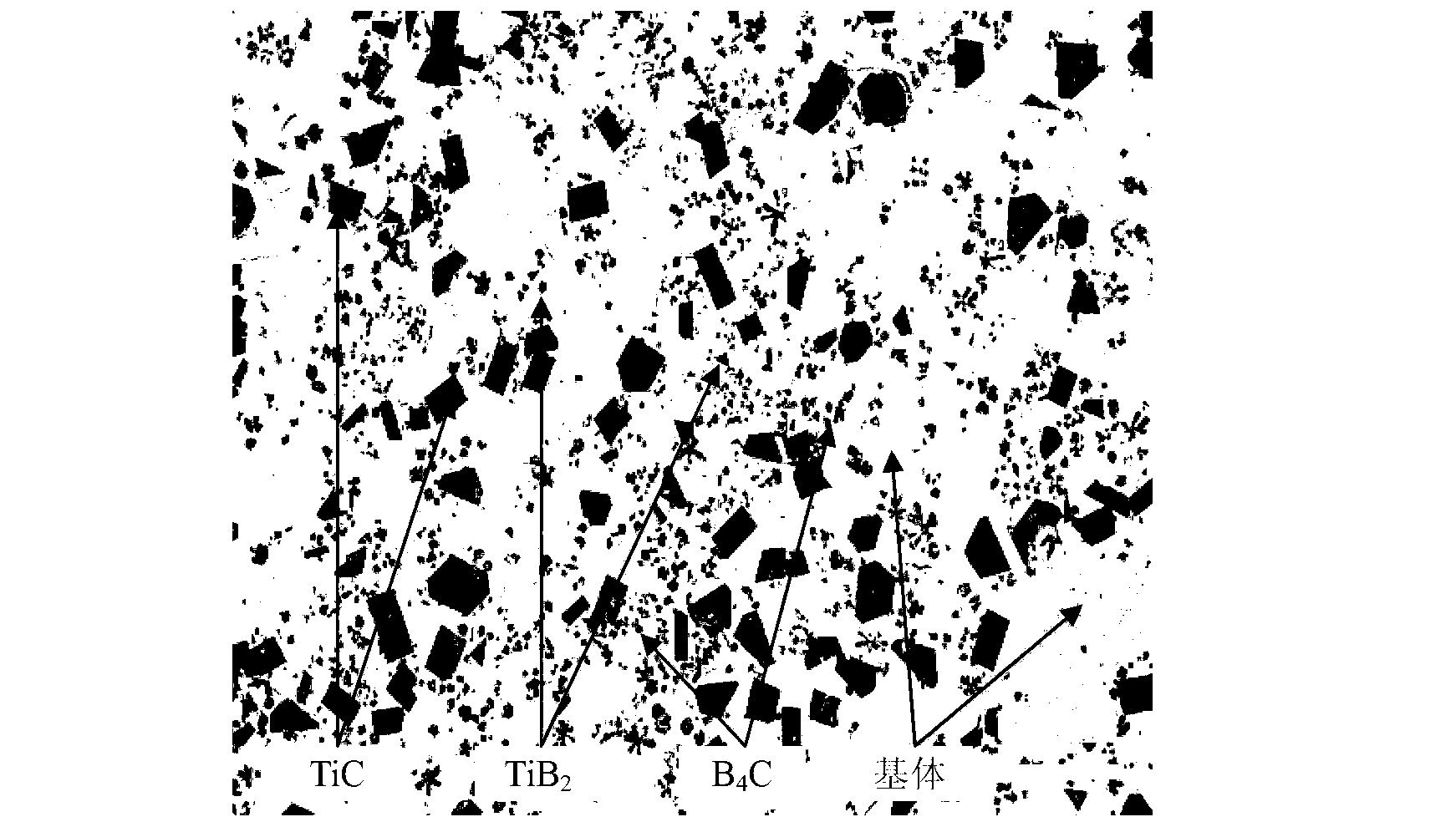

Laser cladding in-situ synthesis ceramic phase reinforced Fe-base cladding layer and preparation method thereof

InactiveCN103290406ADense tissueHigh microhardness valueMetallic material coating processesAlloyPre treatment

The invention relates to a laser cladding in-situ synthesis ceramic phase reinforced Fe-base cladding layer and a preparation method thereof, and belongs to the technical field of laser cladding. In-situ synthesis ceramic hard phases mainly comprise TiC, TiB2 and B4C. The coating is prepared according to the following steps of: firstly pretreating a base body; then proportioning alloy power in proportion by adopting a synchronous powder delivery laser cladding mode, and then sufficiently mixing and drying to use as a cladding material; regulating the process parameters of laser cladding in the presence of argon, wherein the cladding material carries out in-situ reaction under the irradiation of laser energy to generate a ceramic hard phase and shows good metallurgical bonding with the base body. The coating disclosed by the invention is compact in tissue without pores or cracks, achieves the large microhardness value more than 1000 HV and has very good application prospect in the field of laser surface modification.

Owner:BEIJING UNIV OF TECH

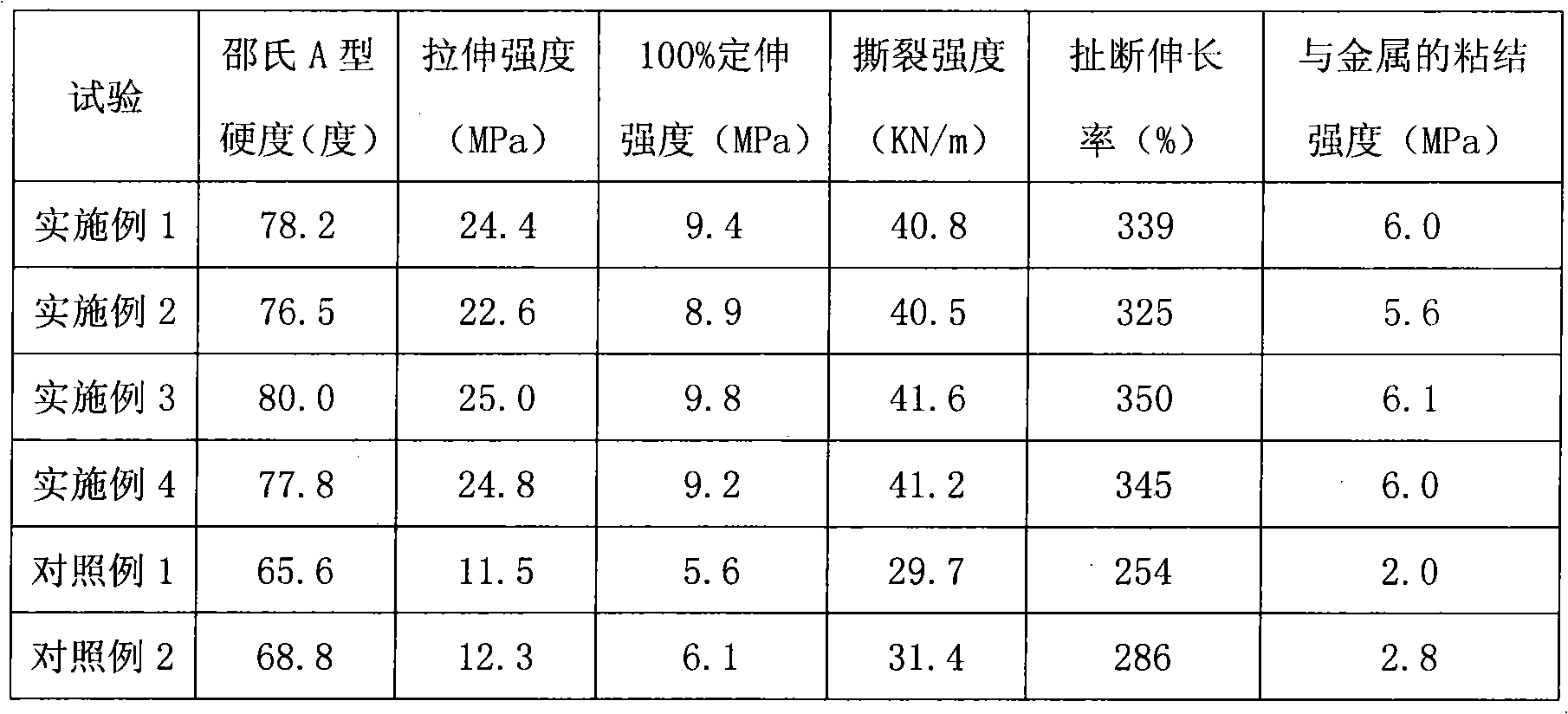

Unsaturated carboxylic acid metal salt modified ethylene-propylene-diene monomer (EPDM) and preparation method thereof

ActiveCN103131088ANo pollution in the processSimple preparation processSuperoxideEthylene-propylene-diene-monomer

The invention discloses unsaturated carboxylic acid metal salt modified ethylene-propylene-diene monomer (EPDM) and a preparation method thereof. Carbon black, metallic compound, stearic acid, accelerant, inert filler, sulphur, superoxide and unsaturated carboxylic acid are added in the EPDM, then mixing treatment and sulfidizing are conducted, and therefore the unsaturated carboxylic acid metal salt modified EPDM is obtained. According to the unsaturated carboxylic acid metal salt modified EPDM and the preparation method thereof, unsaturated carboxylic acid metal salt in in-situ reaction is used for modifying the EPDM, preparation process is simple, modification effect is good, the prepared modified rubber has good physical mechanical performance and especially has good bonding strength with metal, and the application range is wide.

Owner:TIANJIN XINZHONGHE RUBBER IND

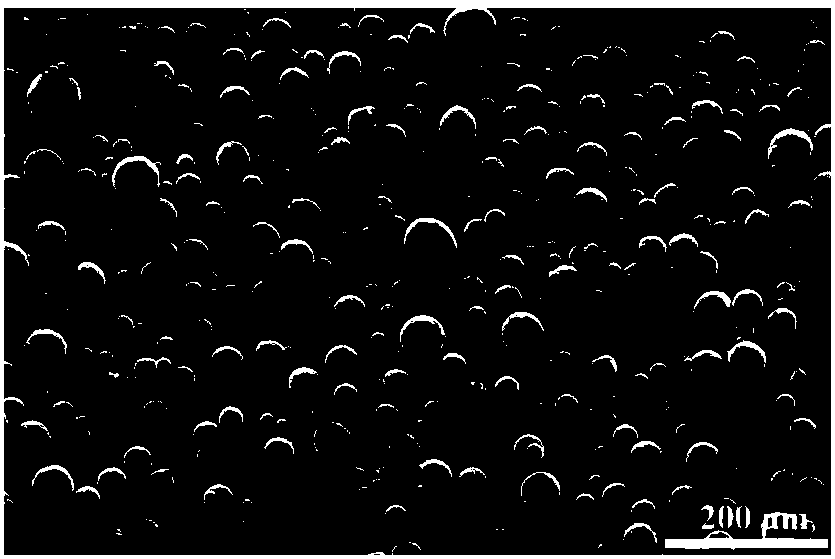

In-situ nanocomposite ceramic-reinforced aluminum alloy powder for 3D printing and preparation method thereof

InactiveCN107760933AHigh sphericityUniform particle size distributionAdditive manufacturing apparatusNanoparticleNanometre

The invention belongs to the technical field of preparation of reinforced materials, and relates to in-situ nanocomposite ceramic-reinforced aluminum alloy powder and a preparation method thereof, inparticular to in-situ nanocomposite ceramic-reinforced aluminum alloy powder for 3D printing and a preparation method thereof. Through combination of an in-situ reaction and an atomization powder preparation technology, special Al2O3 phase and TiB2 ceramic phase-reinforced aluminum alloy powder for 3D printing is prepared in site. The nanoparticle-reinforced aluminum alloy powder prepared by the preparation method provided by the invention has excellent overall performance, uniform particle size distribution, high sphericity, high bulk density, excellent fluidity, excellent metal / ceramic interface bonding performance and the like, and can fully meet requirements of different 3D printed aluminum alloy components.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

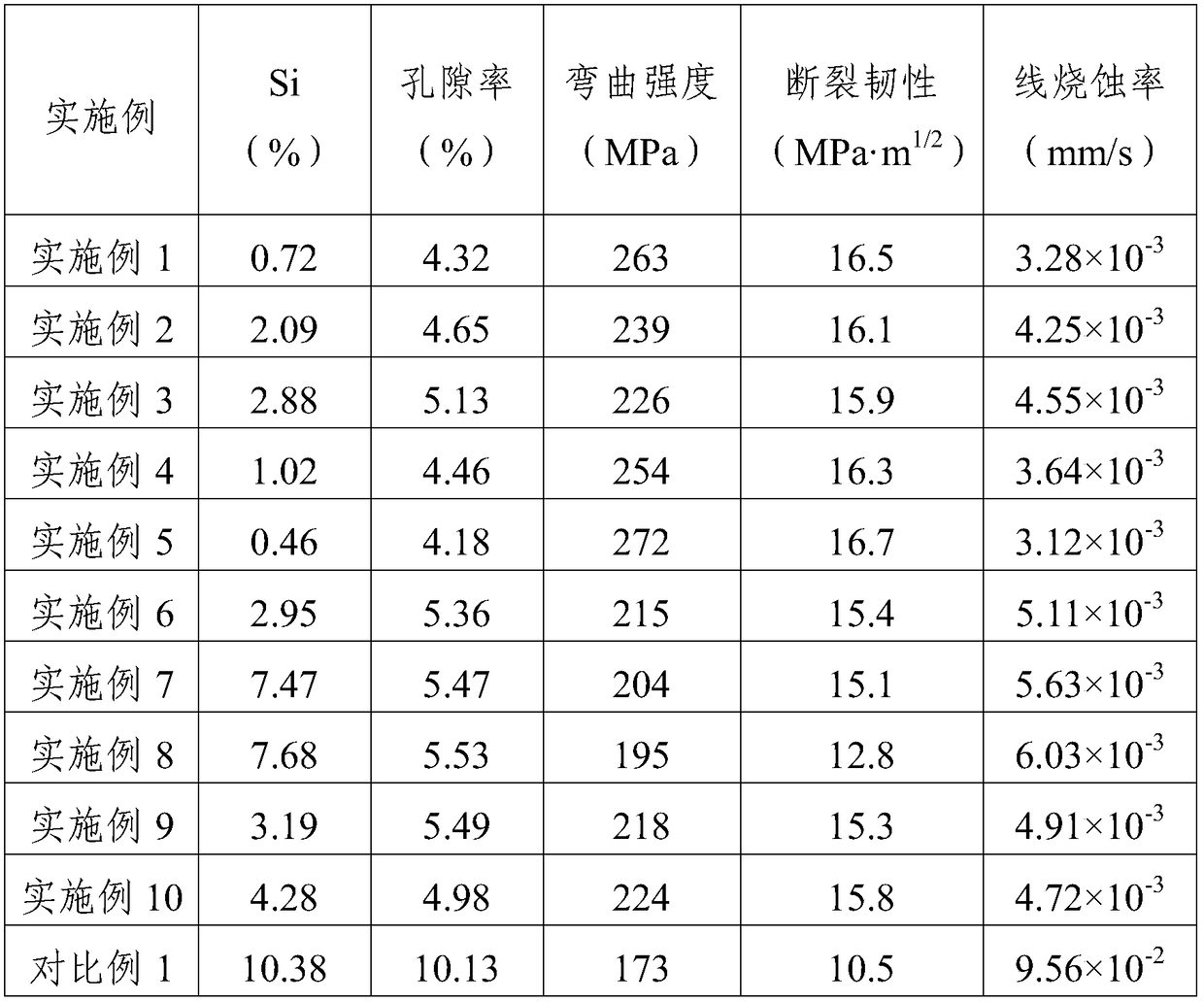

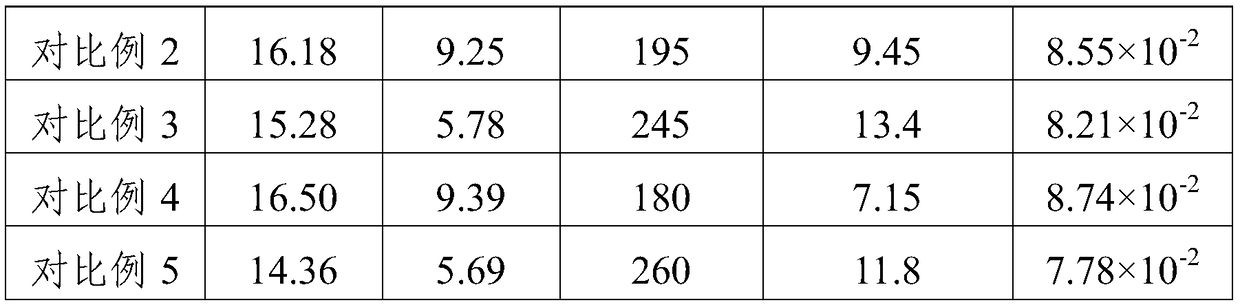

Fiber reinforced carbon-silicon carbide ceramic matrix composite material and preparation method thereof

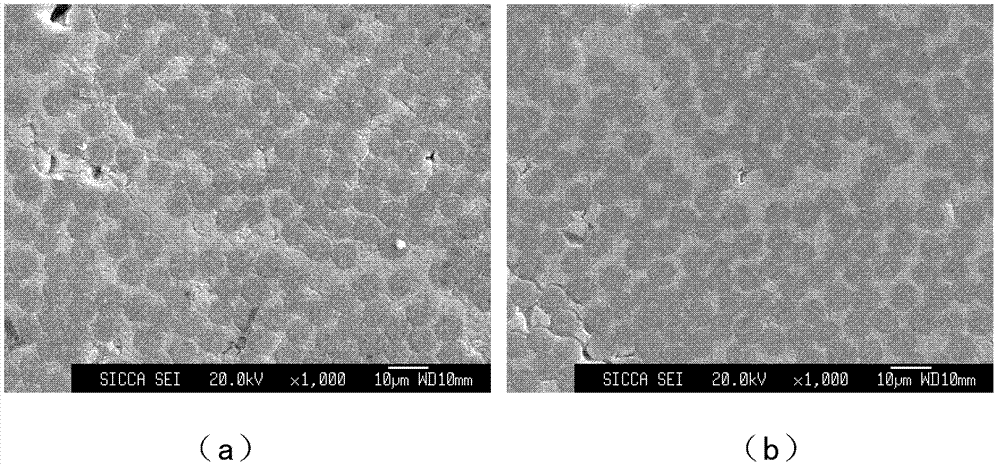

ActiveCN109293383AAvoid damageRealize anti-oxidation functionMechanical propertyTemperature treatment

The invention relates to a fiber reinforced carbon-silicon carbide ceramic matrix composite material and a preparation method thereof. The method includes: (1) preparing a pyrolytic carbon layer and asilicon carbide layer on the surface of a fiber preform in order to obtain a modified fiber preform; (2) impregnating the modified fiber preform with a resin solution containing silicon powder, phenol-formaldehyde resin and an organic solvent, and then conducting curing and cracking steps on the impregnated modified fiber perform in order; (3) repeating the step (2) at least one time to obtain afiber reinforced carbon-silicon ceramic matrix composite material; and (4) subjecting the fiber reinforced carbon-silicon ceramic matrix composite material to high temperature treatment at 1350-1550DEG C for 0.5-2h, thus obtaining the fiber reinforced carbon-silicon carbide ceramic matrix composite material. The method provided by the invention can realize uniform distribution of silicon and carbon in the composite material and generation of silicon carbide by in-situ reaction, can reduce the content of free silicon in the composite material, and improves the mechanical properties and ablationresistance of the composite material.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com