Patents

Literature

34results about How to "Uniform box thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

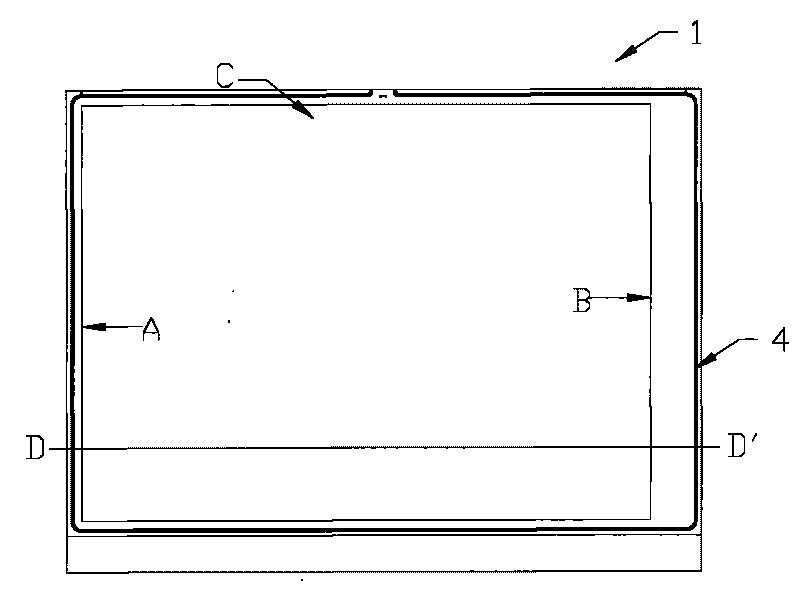

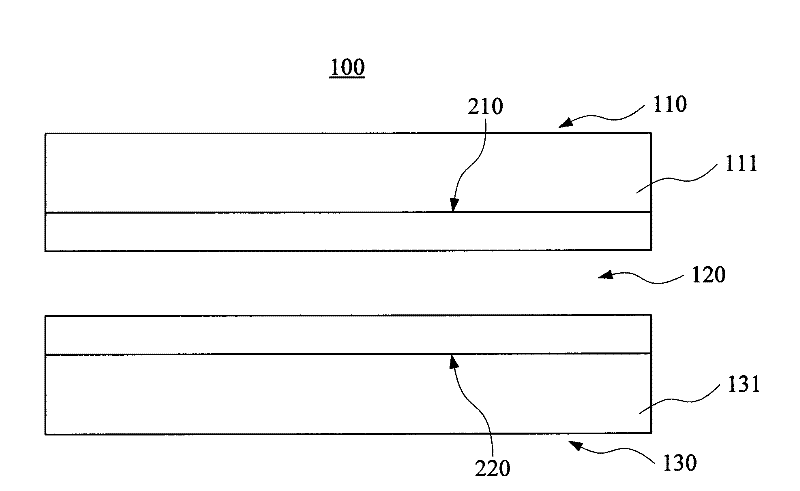

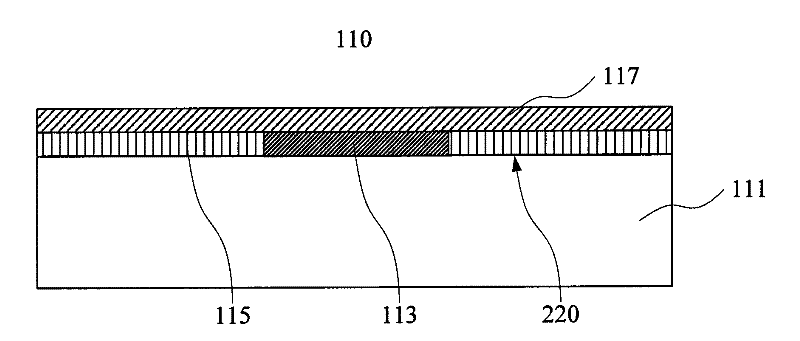

Mother board of liquid crystal panel and manufacturing method thereof

InactiveCN102012576AUniform box thicknessImprove flatnessStatic indicating devicesNon-linear opticsLiquid-crystal displayColor film

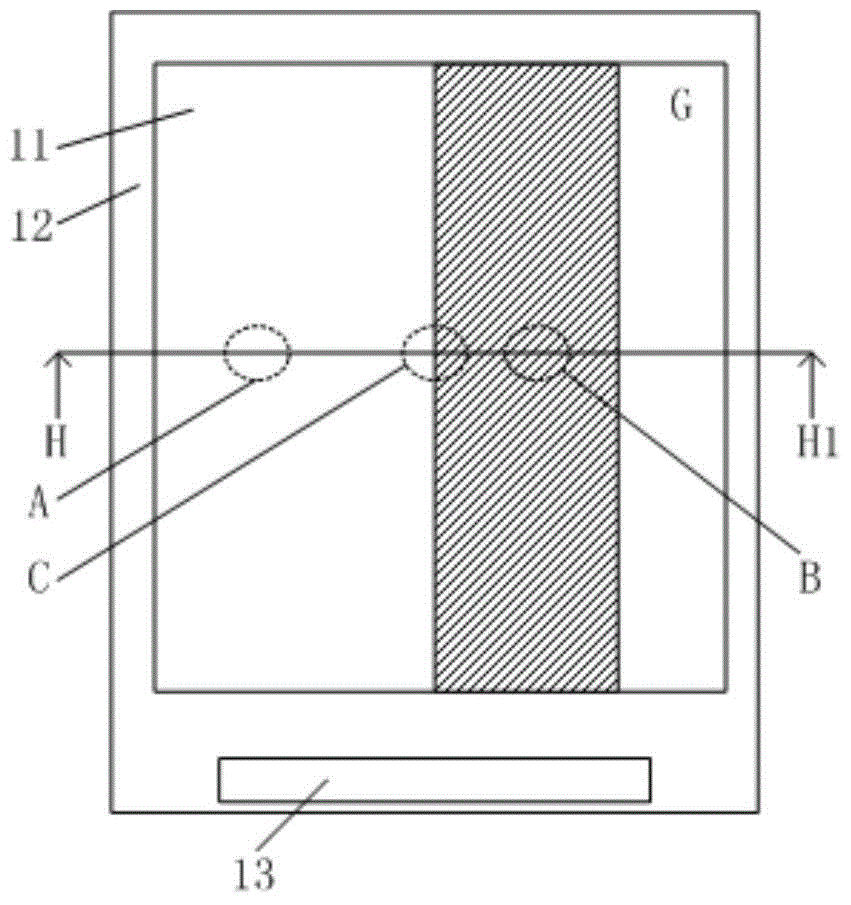

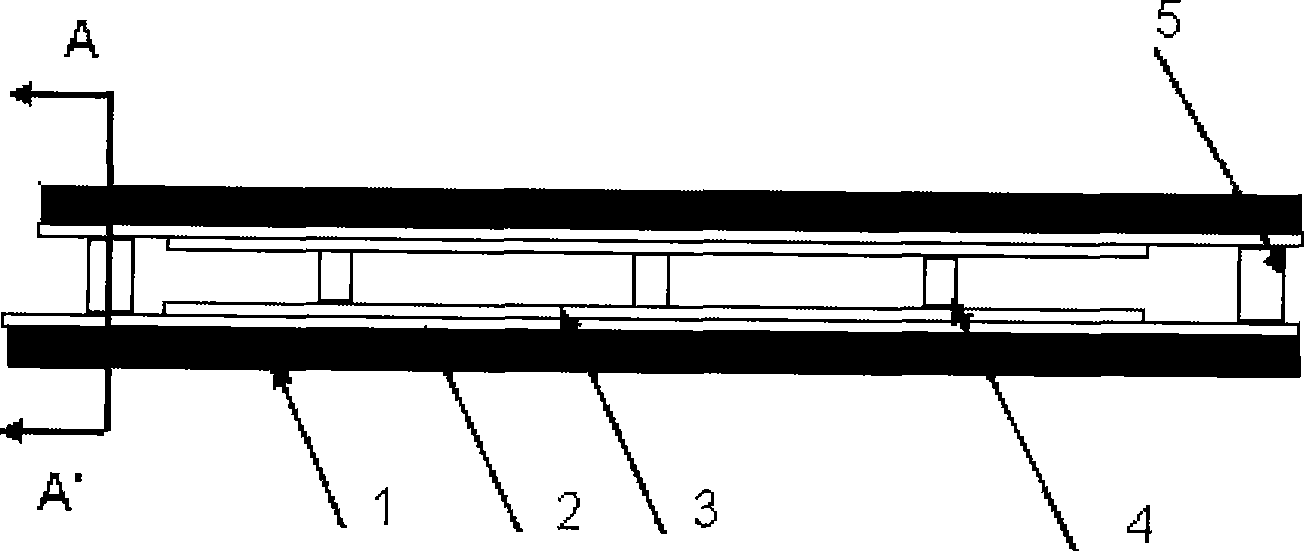

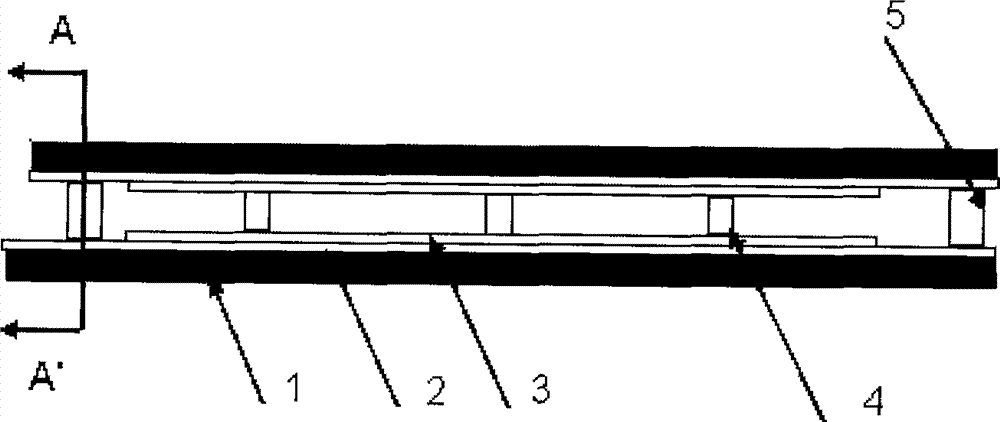

The embodiment of the invention discloses a mother board of a liquid crystal panel and a manufacturing method thereof, relating to the technical field of liquid crystal display. The invention can keep uniform box thickness between a color film base plate and an array base plate in the vacuum box folding process. The mother board of the liquid crystal panel comprises the color film base plate, the array base plate, a main frame sealing glue, an auxiliary frame sealing glue, a main partition substance and an auxiliary partition substance, wherein the array base plate is opposite to the color film base plate; the main frame sealing glue and the auxiliary frame sealing glue are formed between the color film base plate and the array base plate; liquid crystals are filled in an area encircled by the main frame sealing glue; the auxiliary partition substance and the main partition substance have different heights, and the distances between the color film base plate and the array base plate, which are kept after the auxiliary partition substance and the main partition substance respectively support against structural layers of the color film base plate and the array base plate, are equal. The mother board of the liquid crystal panel and the manufacturing method thereof are suitable for manufacturing any liquid crystal display device.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

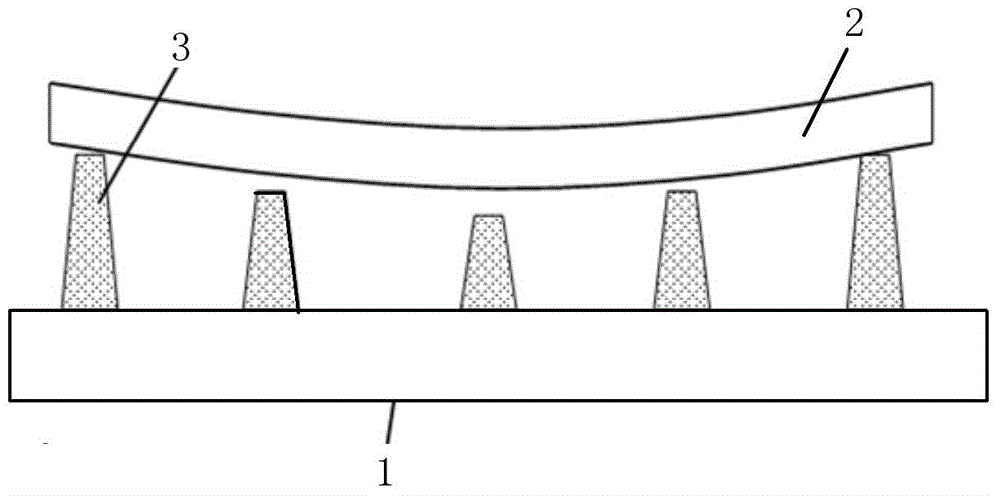

Liquid crystal display panel, manufacturing method thereof, and liquid display device

ActiveCN104460121AImprove display unevennessUniform box thicknessNon-linear opticsConvex structureDisplay device

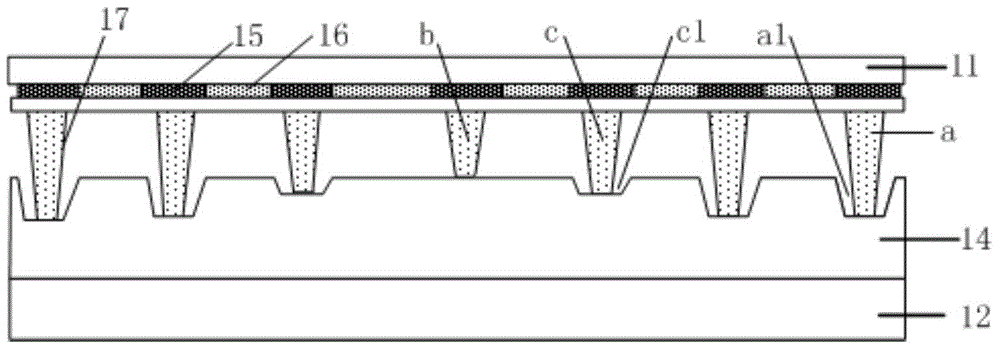

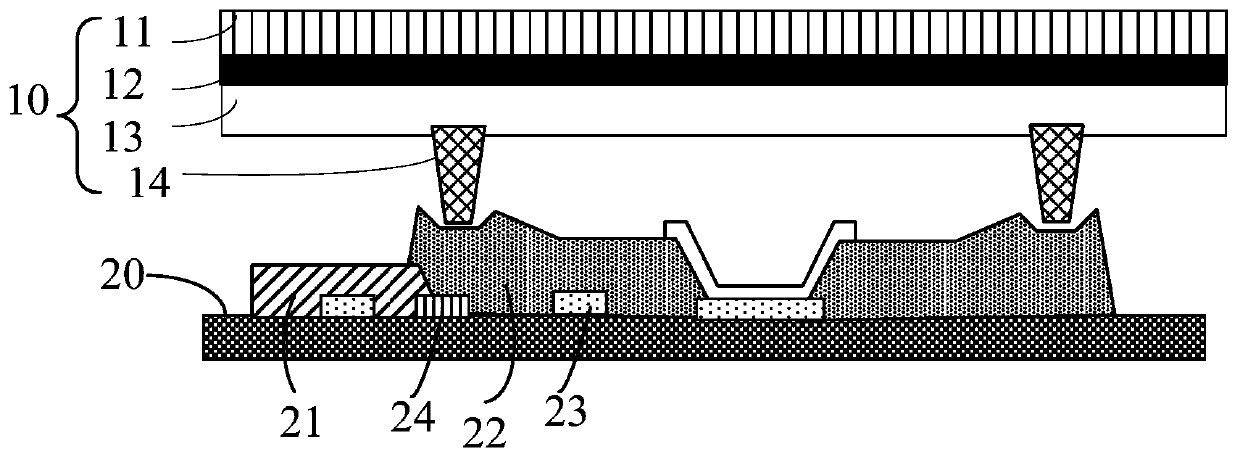

The invention discloses a liquid crystal display panel, a manufacturing method of the liquid crystal display panel and a liquid display device. The liquid crystal display panel comprises a first substrate, a second substrate, a plurality of supporting pillars and a film structure, wherein the first substrate and the second substrate are arranged oppositely, the multiple supporting pillars are arranged between the first substrate and the second substrate, the first end of each supporting pillar is connected with the first substrate, the film structure is arranged on the second substrate, a concave-convex structure is arranged on the surface of the film structure, and the surface of the film structure makes contact with the second ends of the supporting pillars so that the distances between the first ends of the supporting pillars and the side, far away from the supporting pillars, of the second substrate are the same. The second ends of the supporting pillars are near the film structure. The thickness of a liquid crystal box of the liquid crystal display device is uniform, the light transmitting rate is uniform, and the phenomenon of non-uniform display of the liquid crystal display device is further solved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS +1

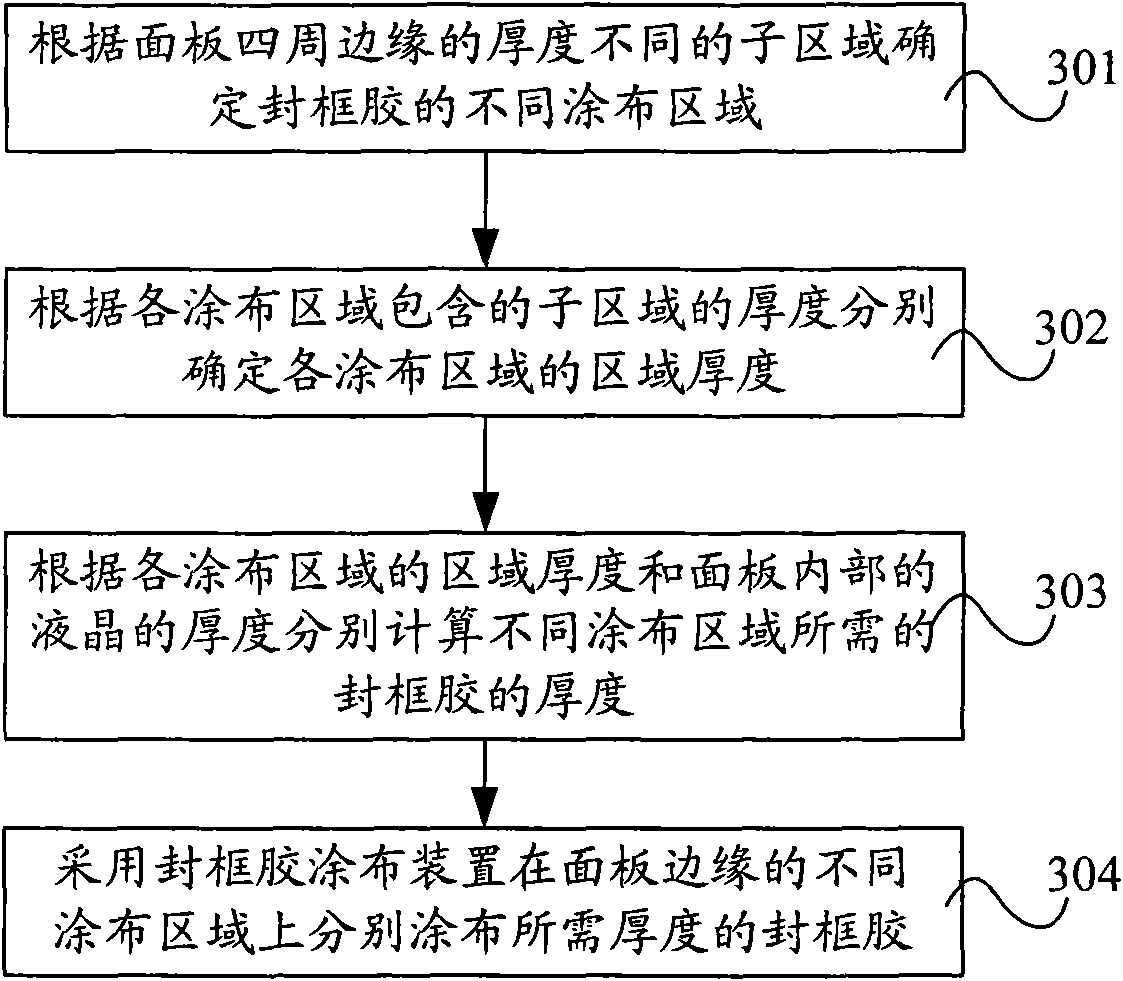

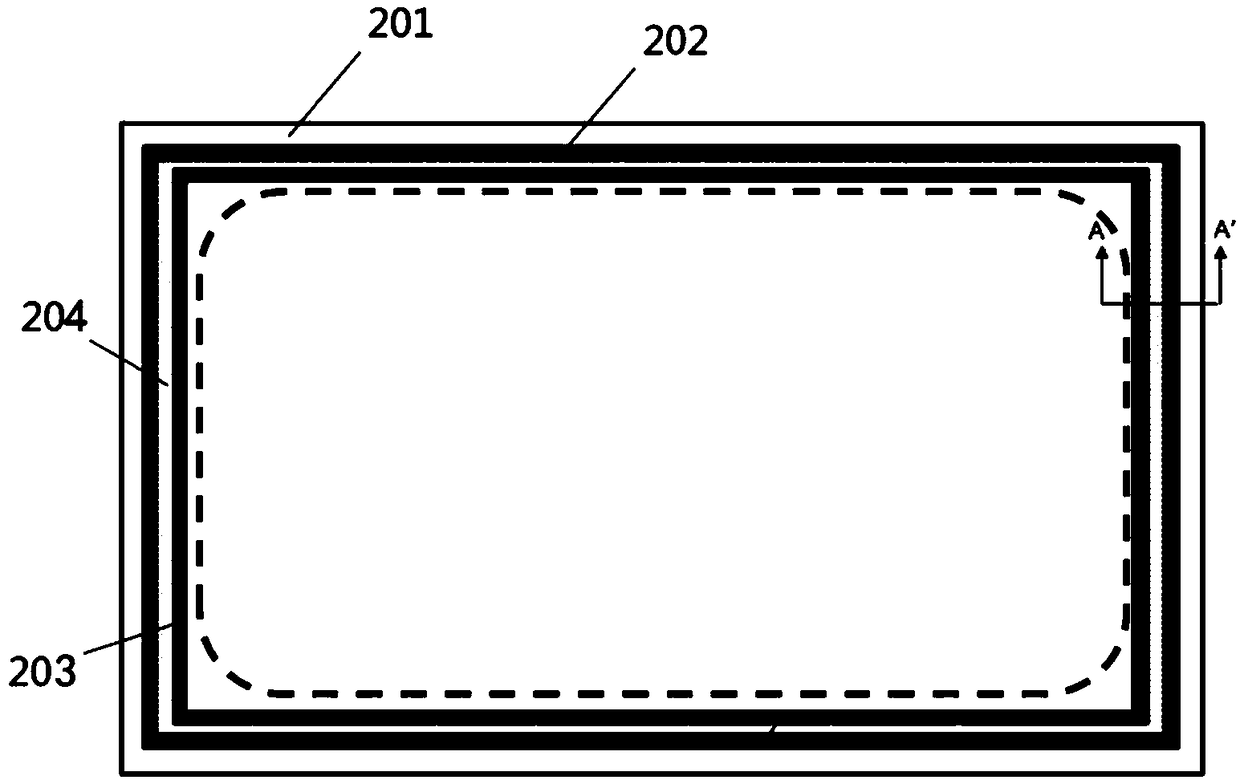

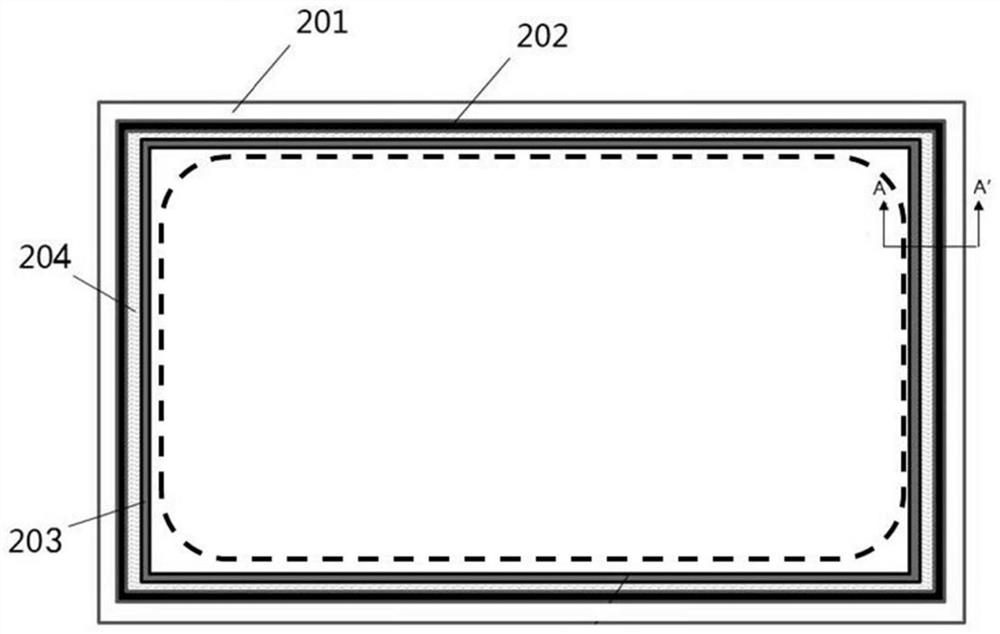

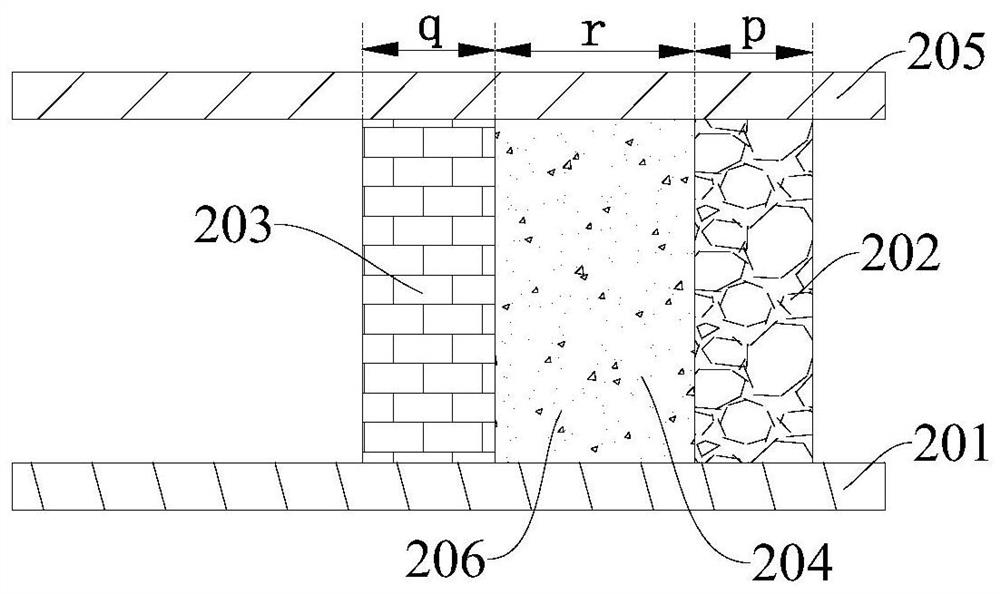

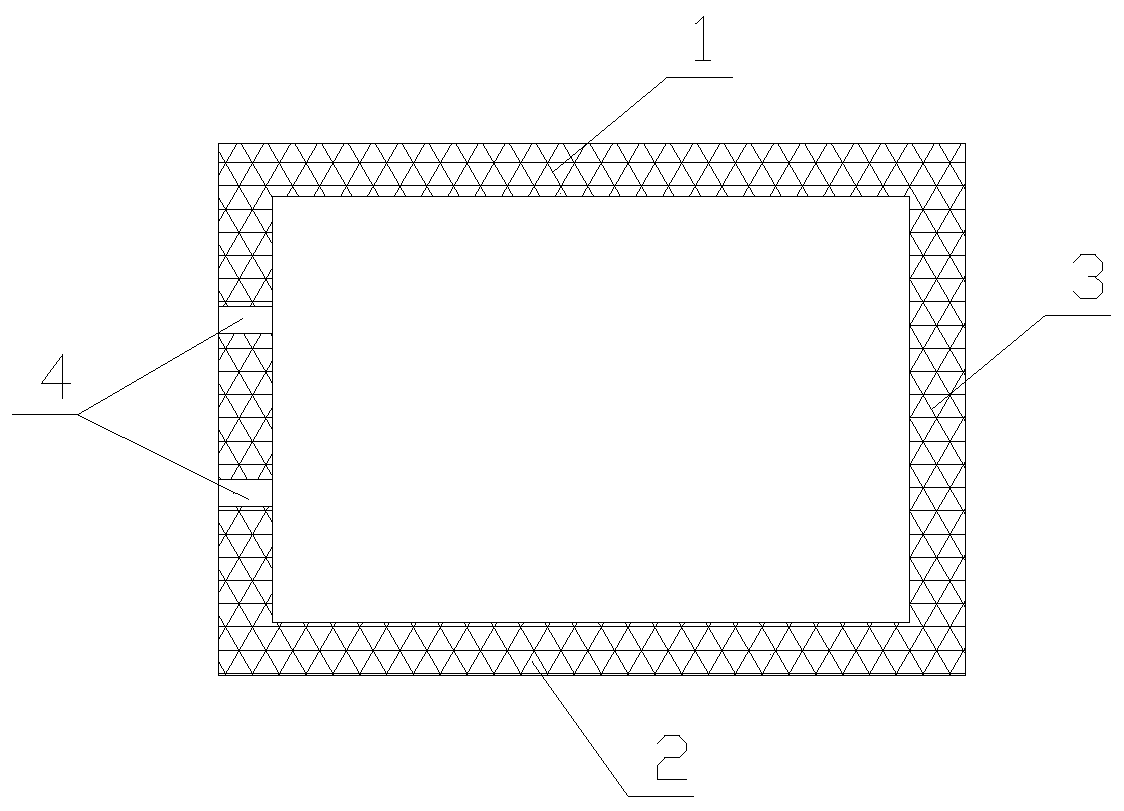

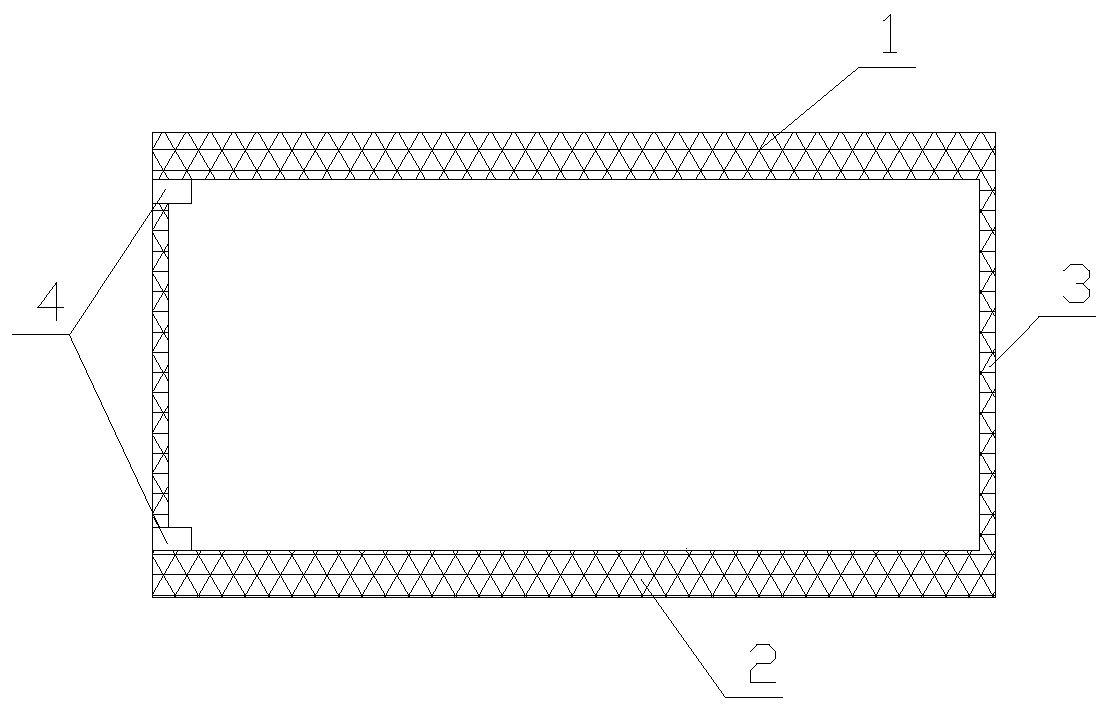

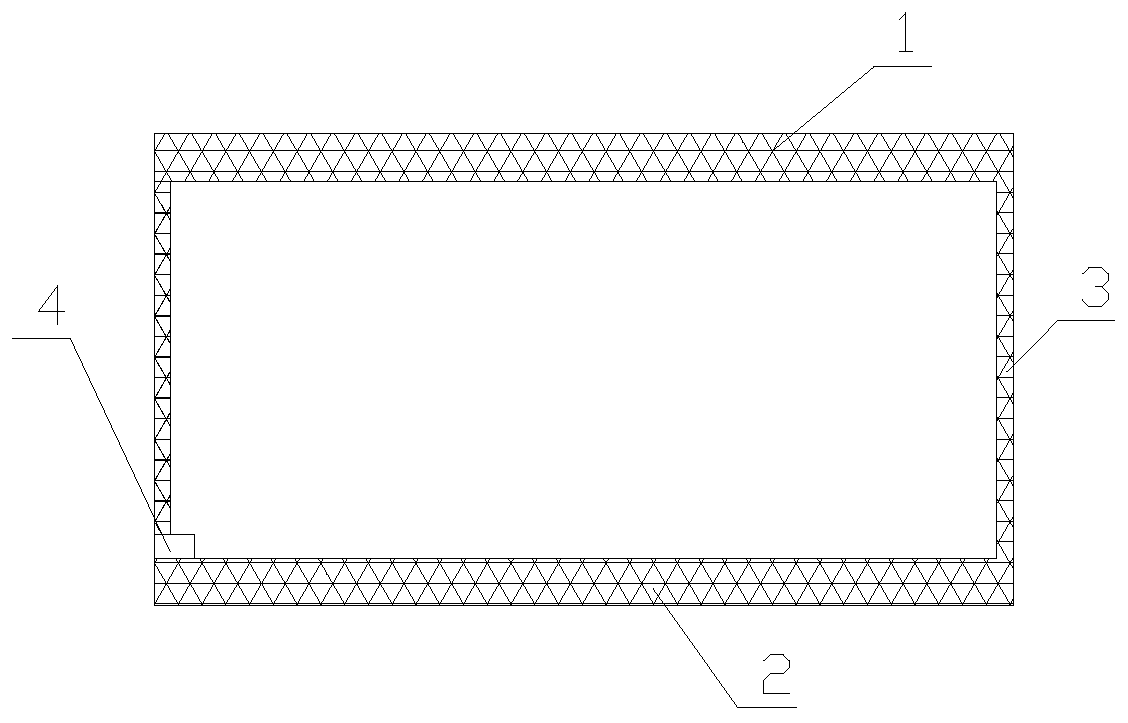

Frame-sealing glue coating method of liquid crystal display panel and liquid crystal display panel

InactiveCN101846836AUniform box thicknessConsistent box thicknessNon-linear opticsLiquid-crystal displayLiquid crystal

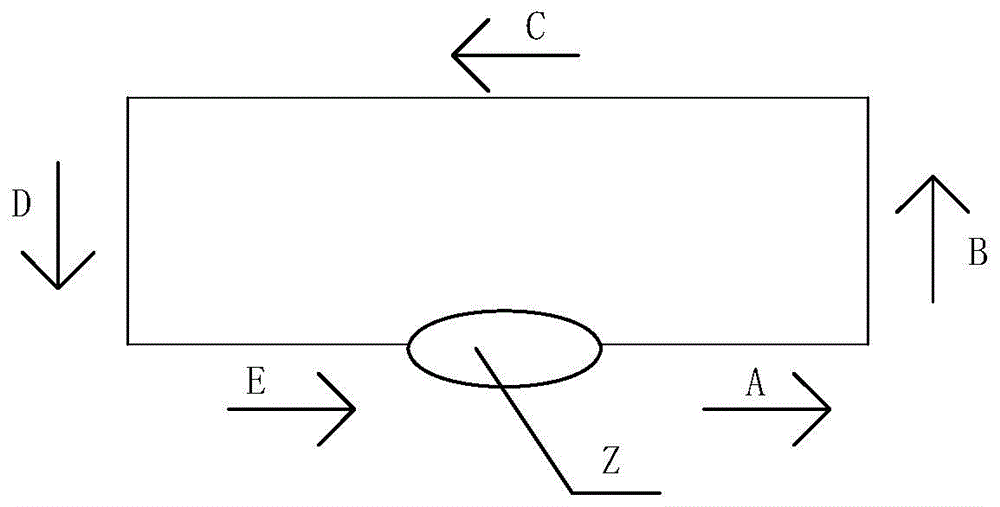

The invention discloses a frame-sealing glue coating method of a liquid crystal display panel and the liquid crystal display panel. The frame-sealing glue coating method of the liquid crystal display panel comprises the following steps: determining different coating regions of the frame-sealing glue according to the sub regions with different thicknesses at the edges of the periphery of the panel; respectively determining the region thicknesses of the coating regions according to the thicknesses of the sub regions contained by the coating regions; respectively calculating the thickness of the frame-sealing glue needed by the coating regions according to and the region thickness of the coating regions and the thickness of liquid crystal in the interior of the panel; and respectively coating the frame-sealing glue with needed thickness on the different coating regions at the edges of the panel by adopting a frame-sealing glue coating device. The invention also provides the liquid crystal display panel. The invention enables the thicknesses of the coating regions in different positions to be equal after the coating regions are coated frame-sealing glue, and enables the thickness of the frame of the periphery of the panel to be uniform. Since the box thickness of the edge of the panel and the box thickness of the interior of the panel are constant, negative phenomena of the periphery, which are caused by the nonuniform thickness of the frame-sealing glue, and the display effect is greatly improved.

Owner:BOE TECH GRP CO LTD +1

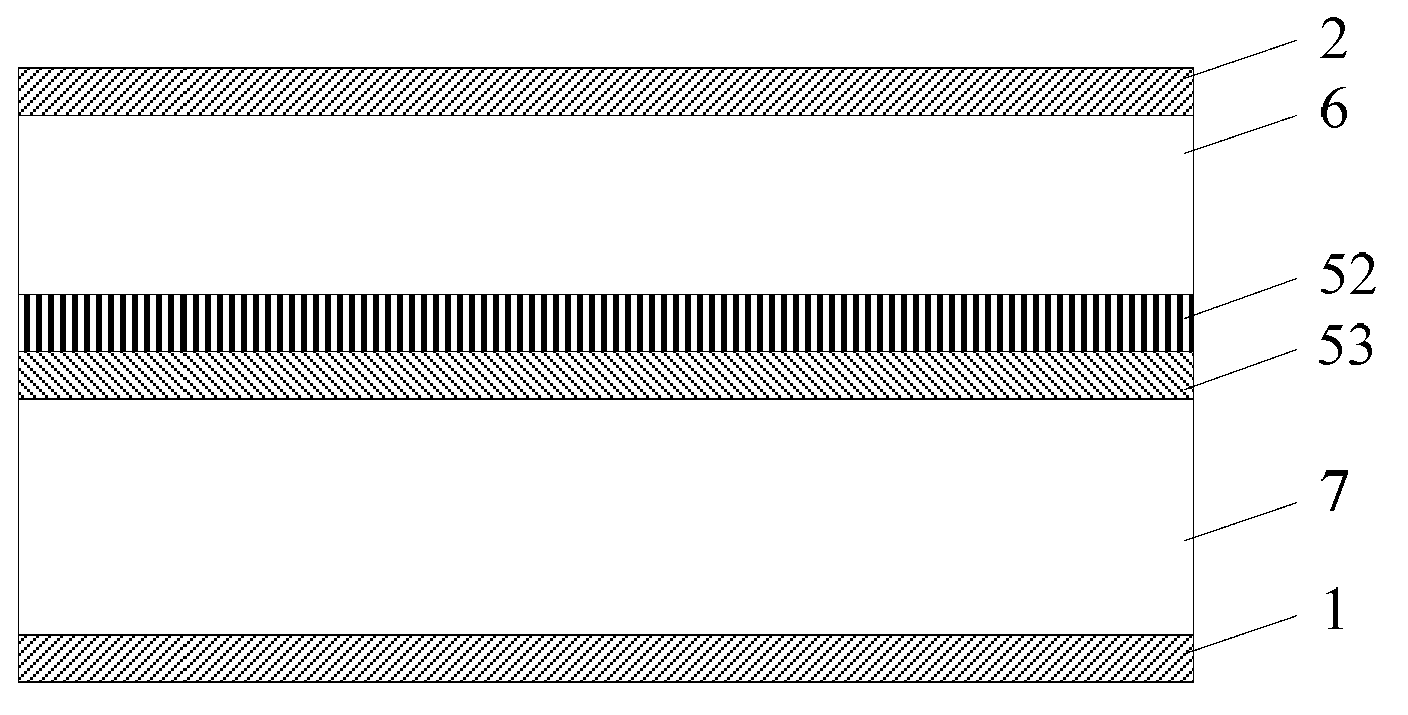

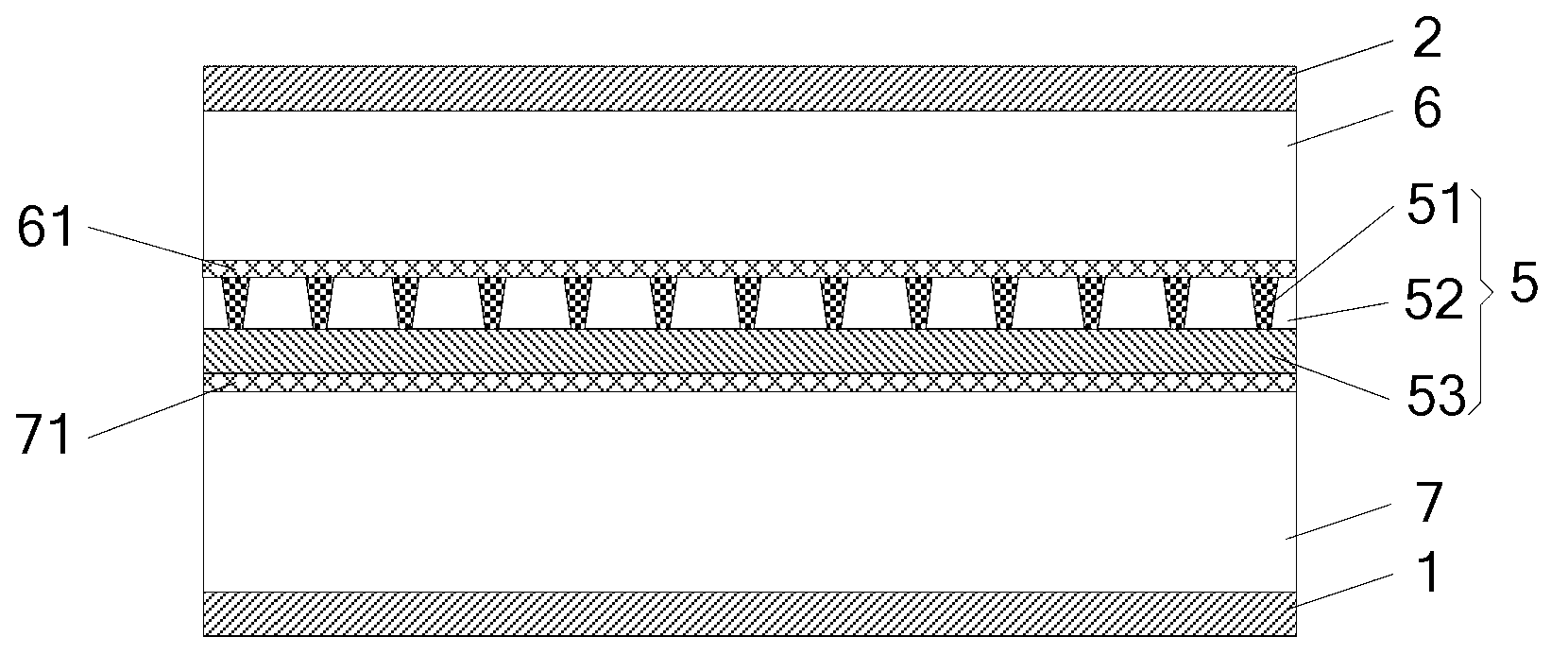

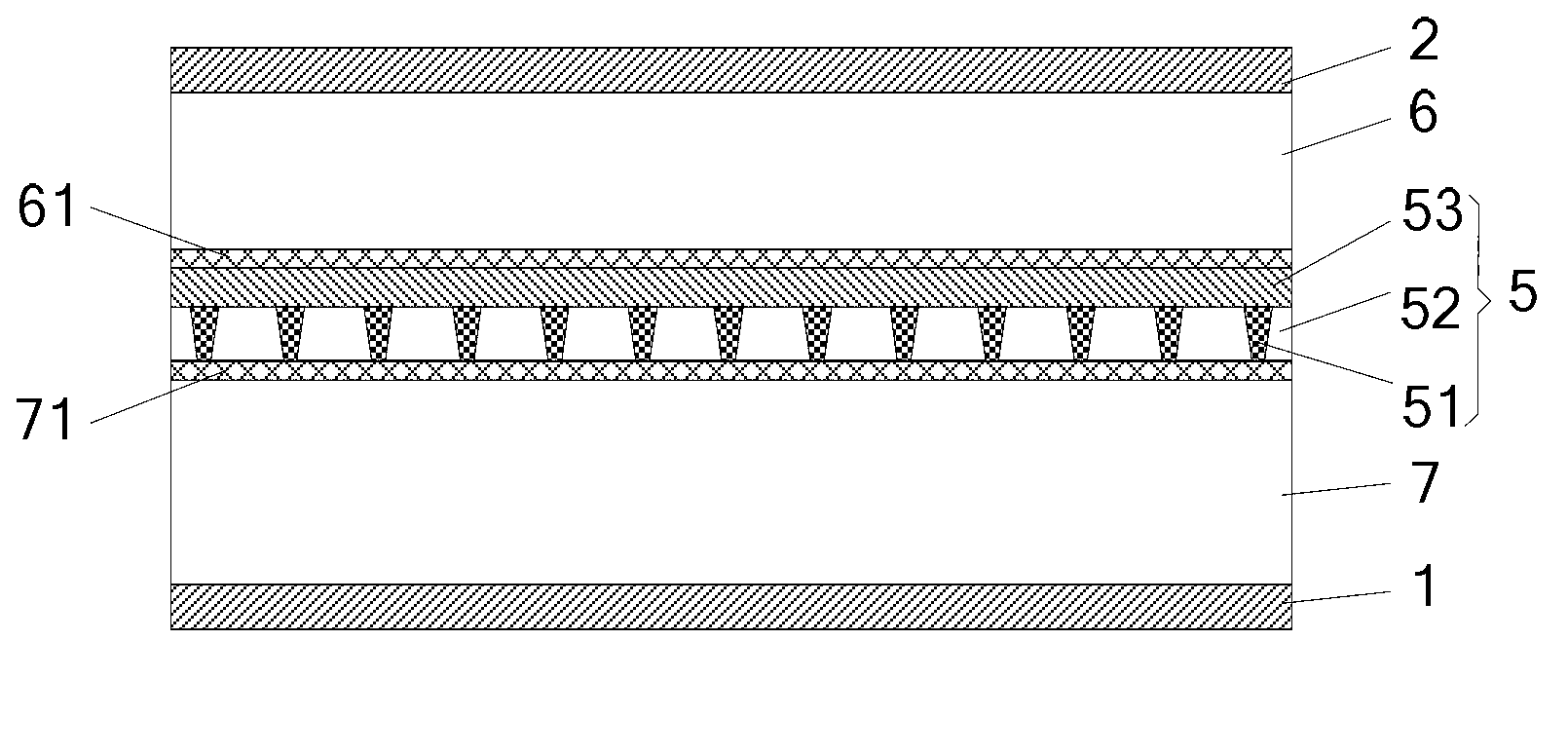

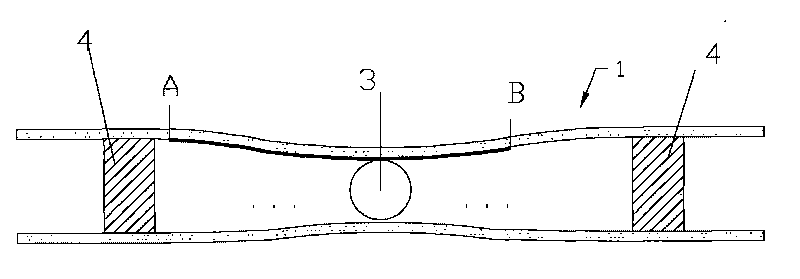

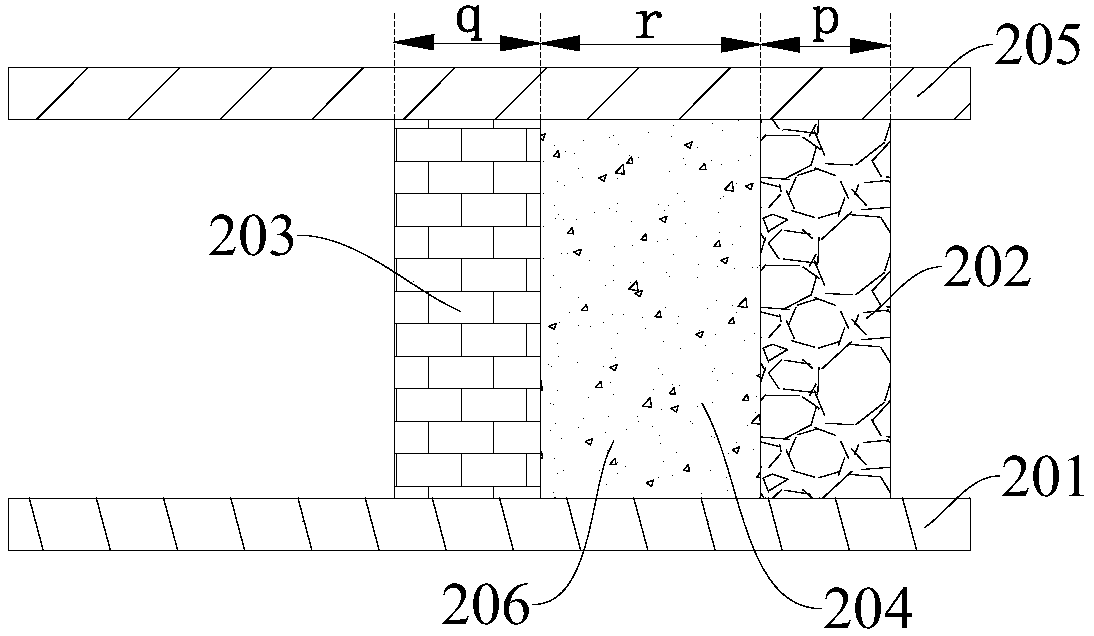

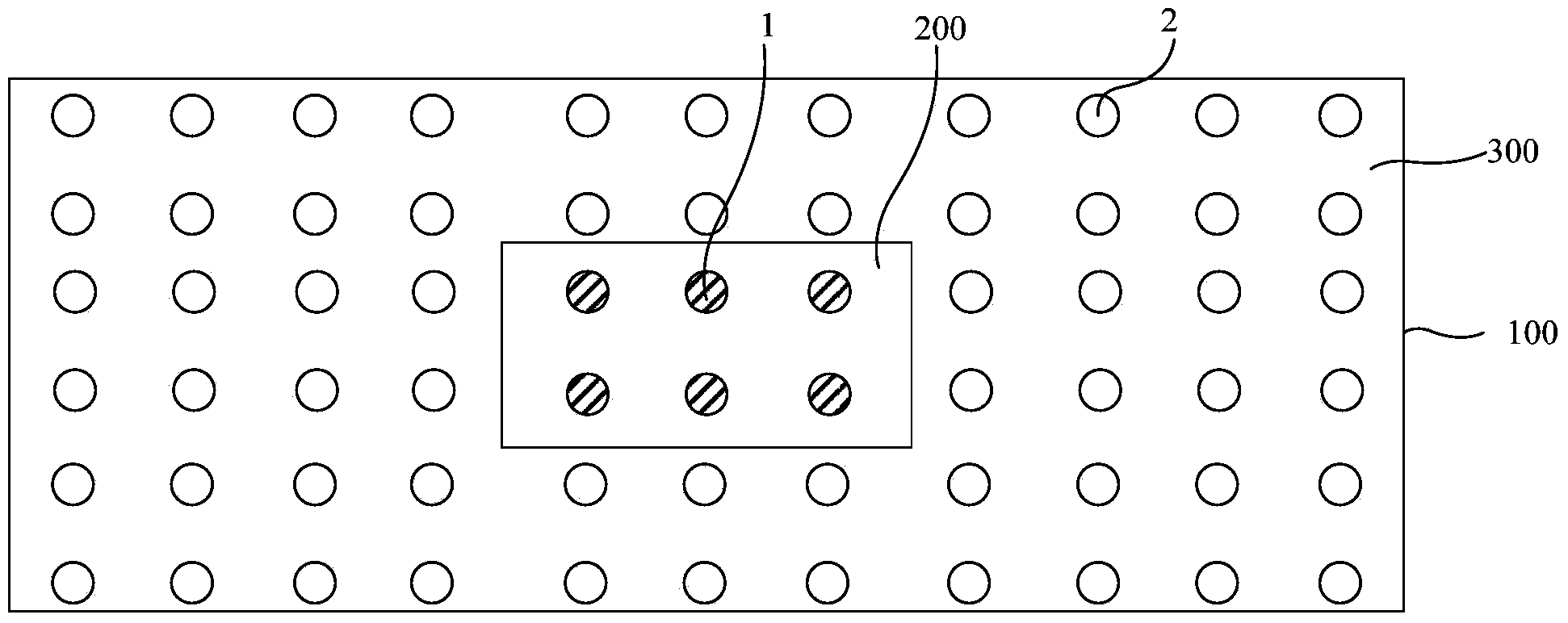

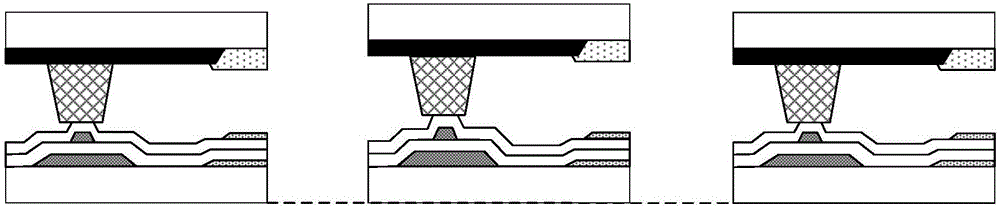

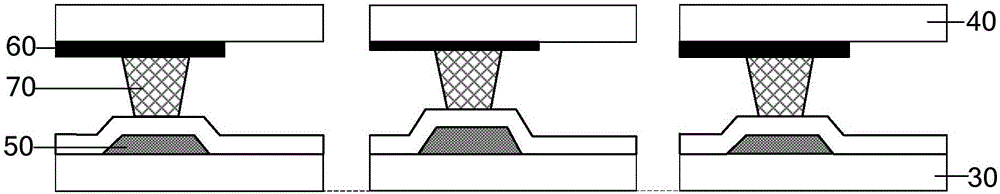

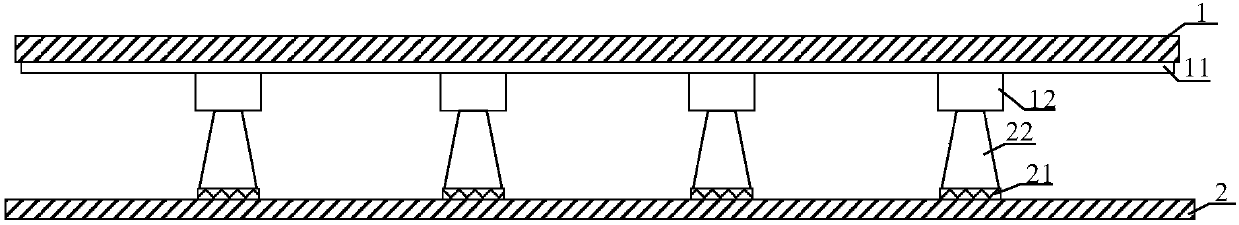

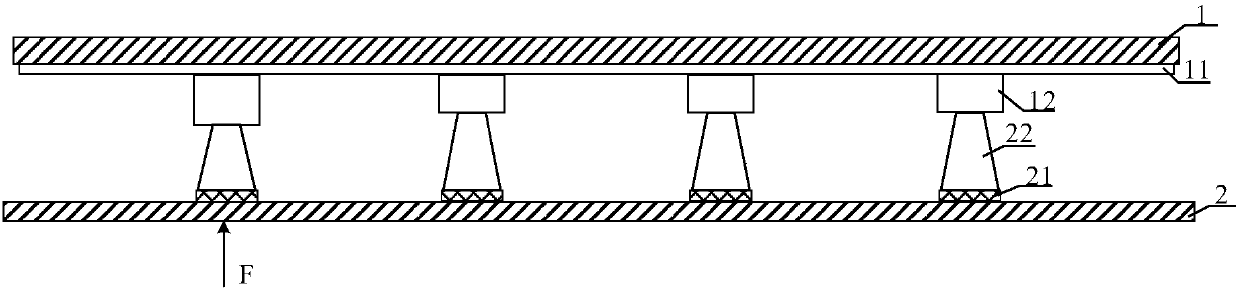

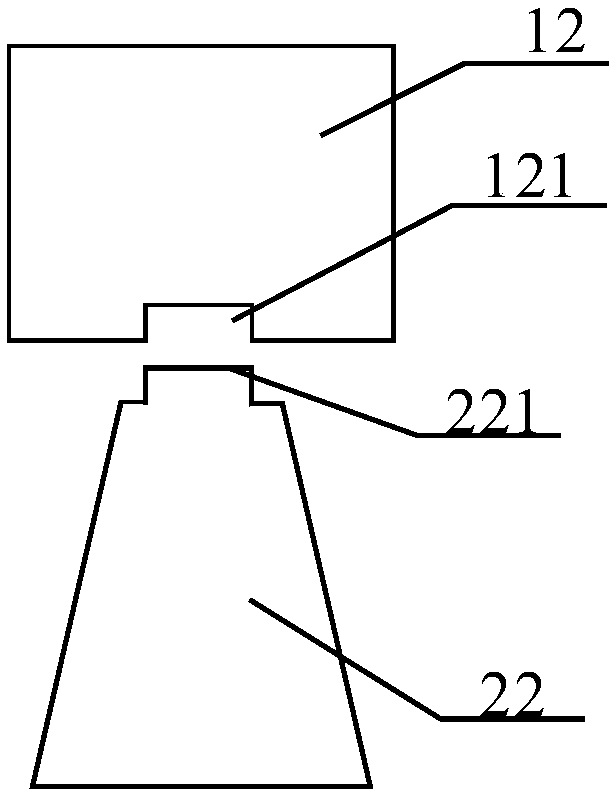

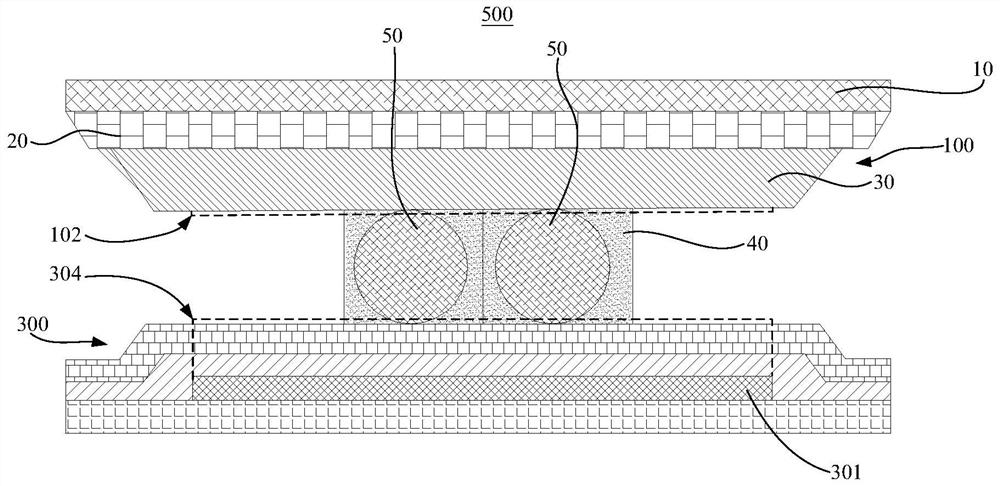

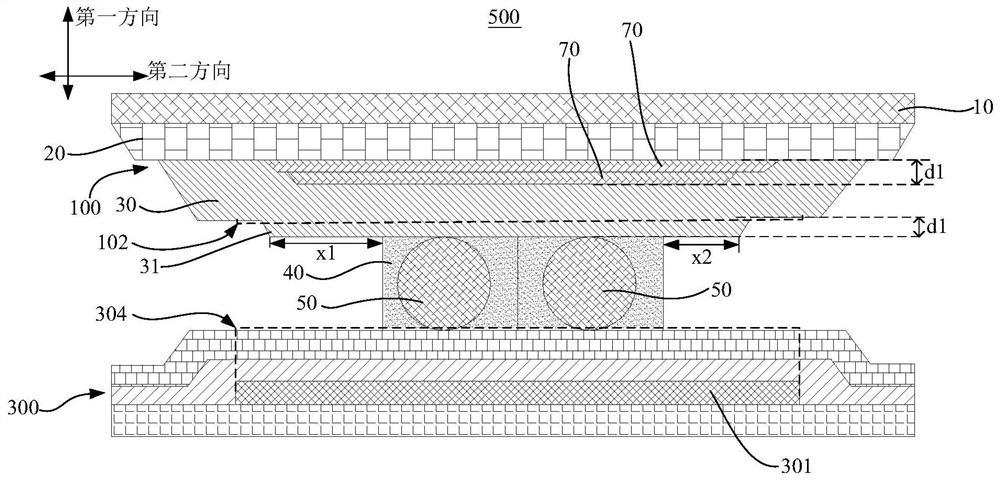

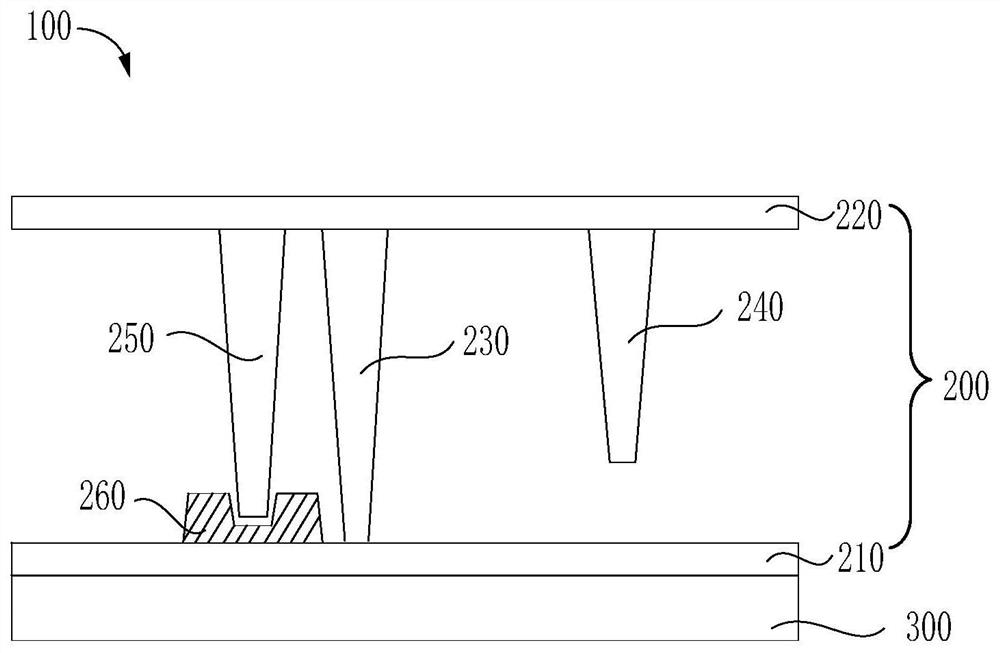

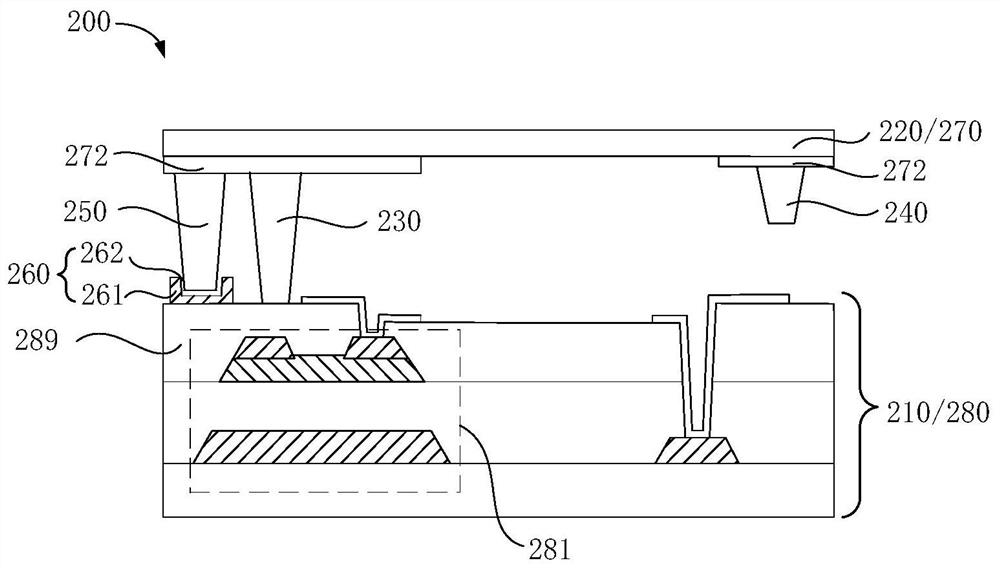

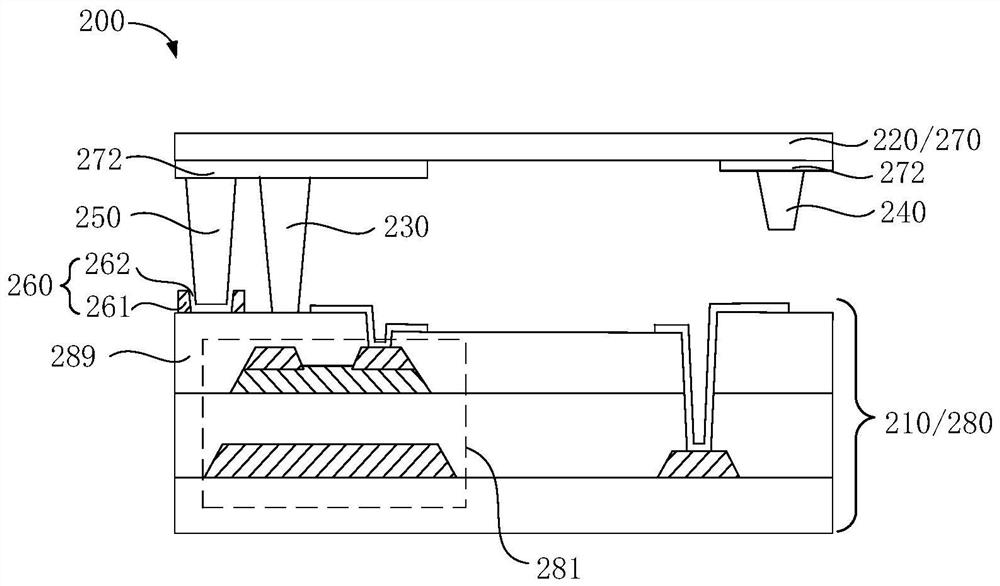

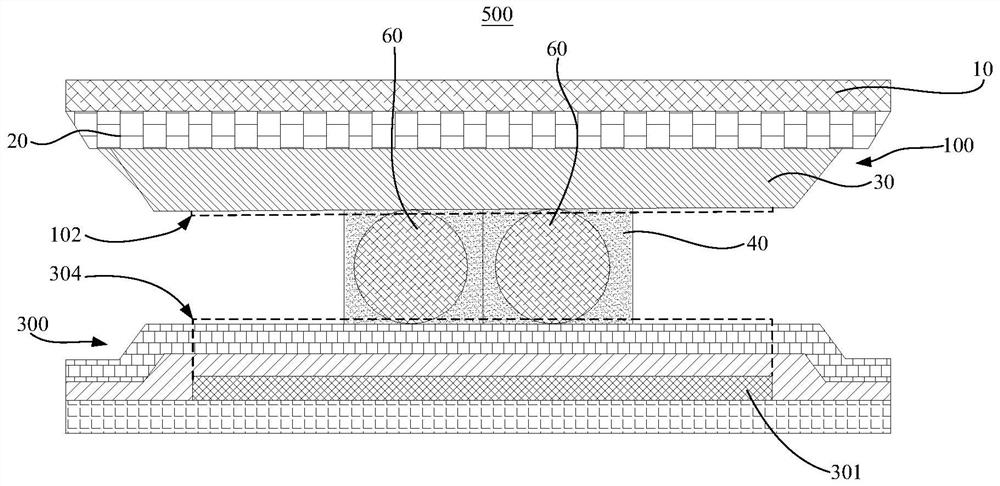

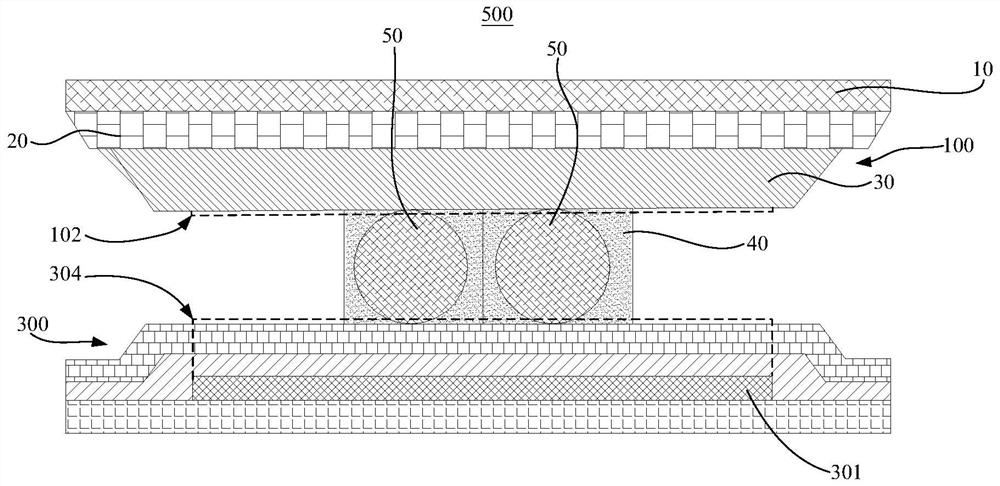

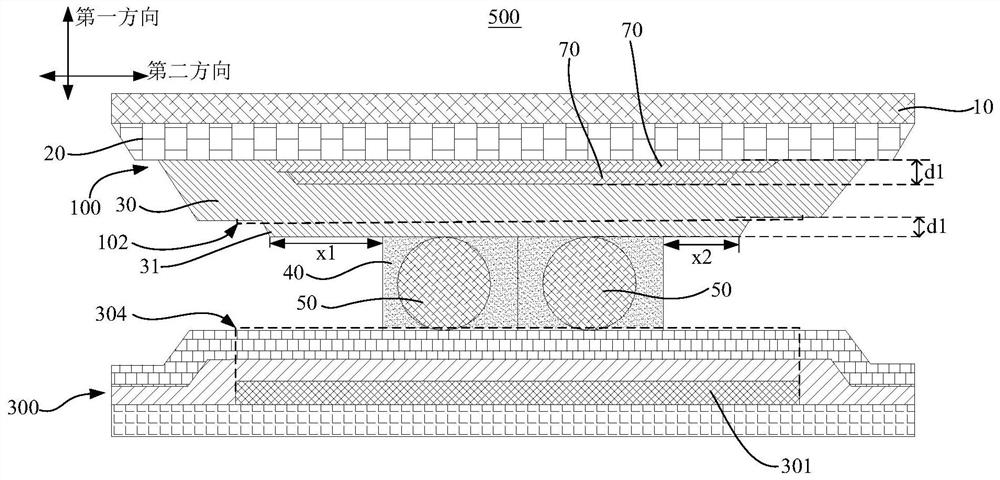

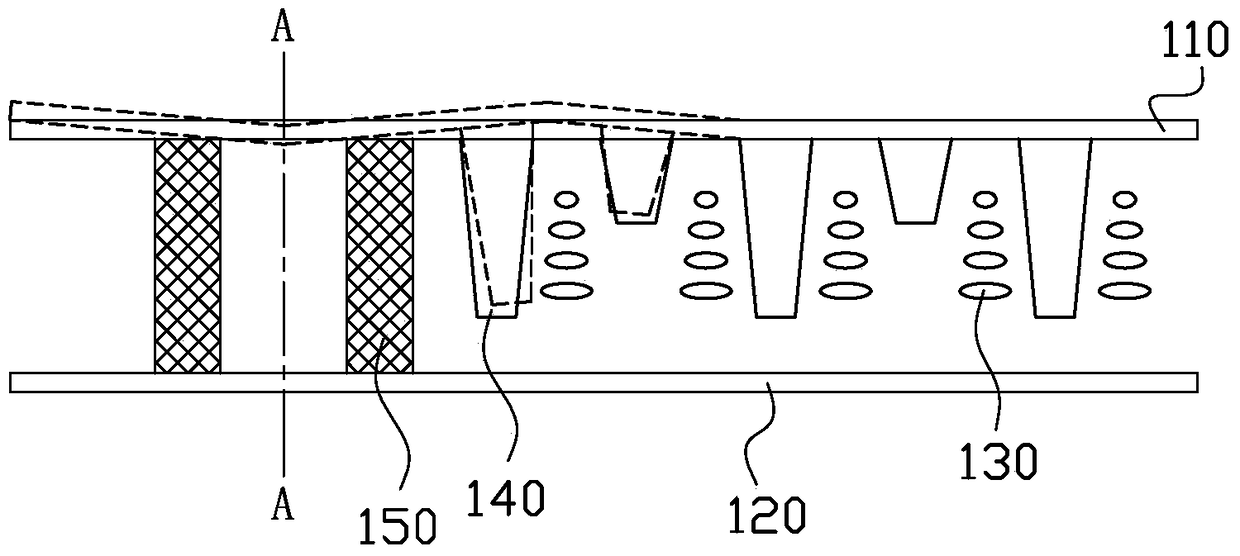

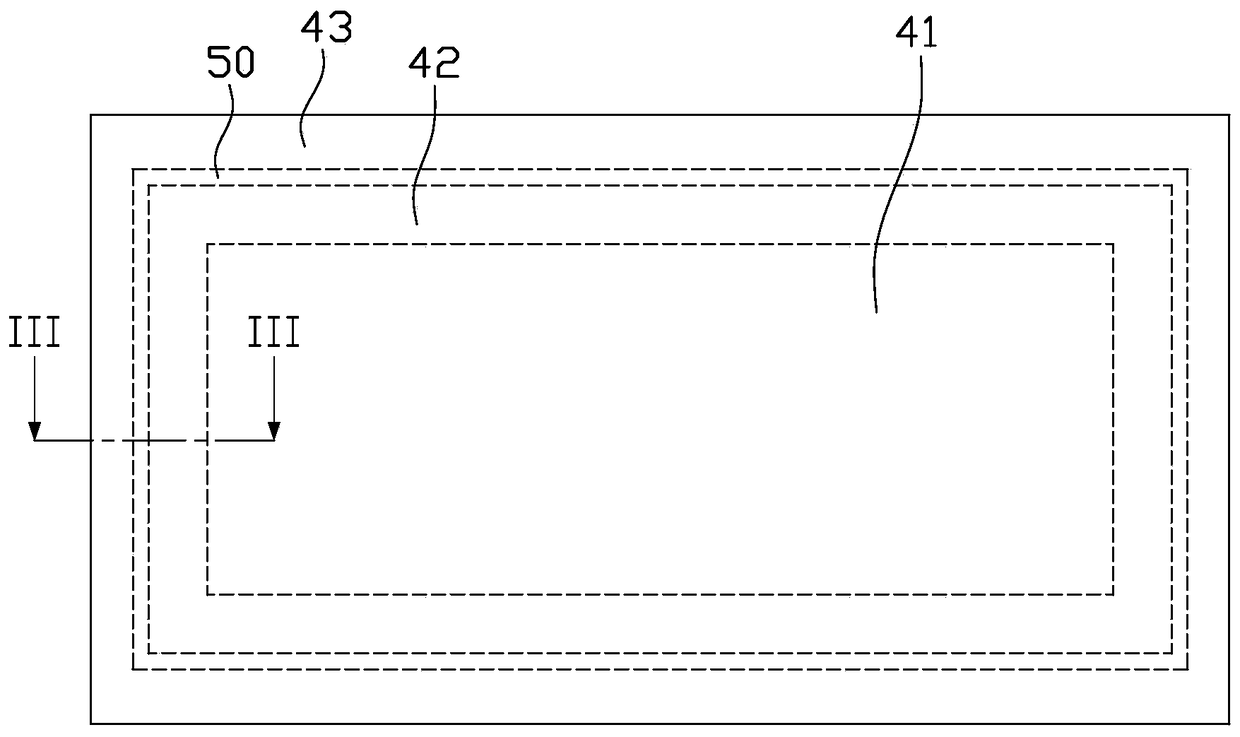

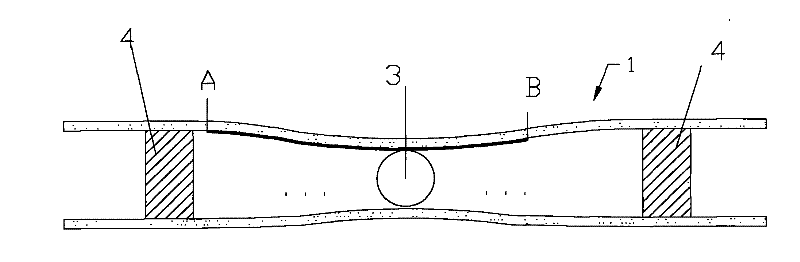

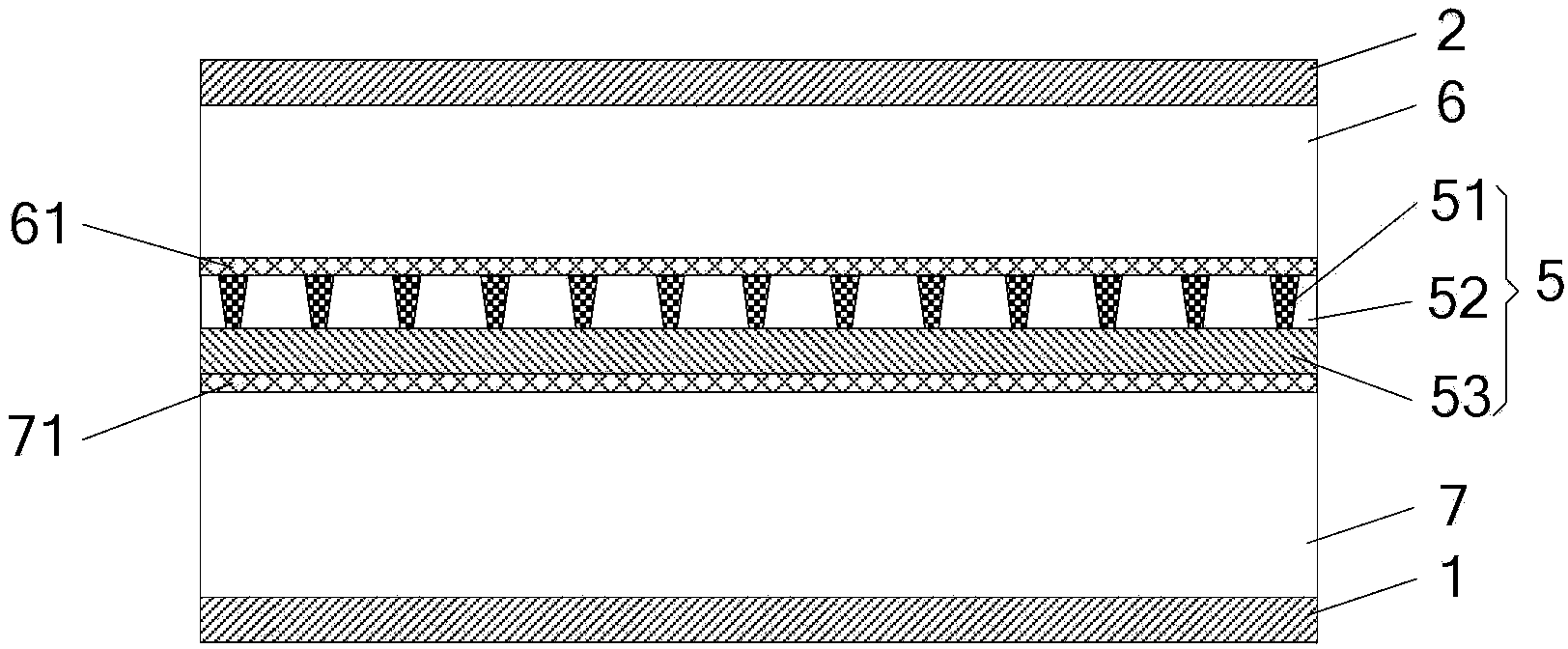

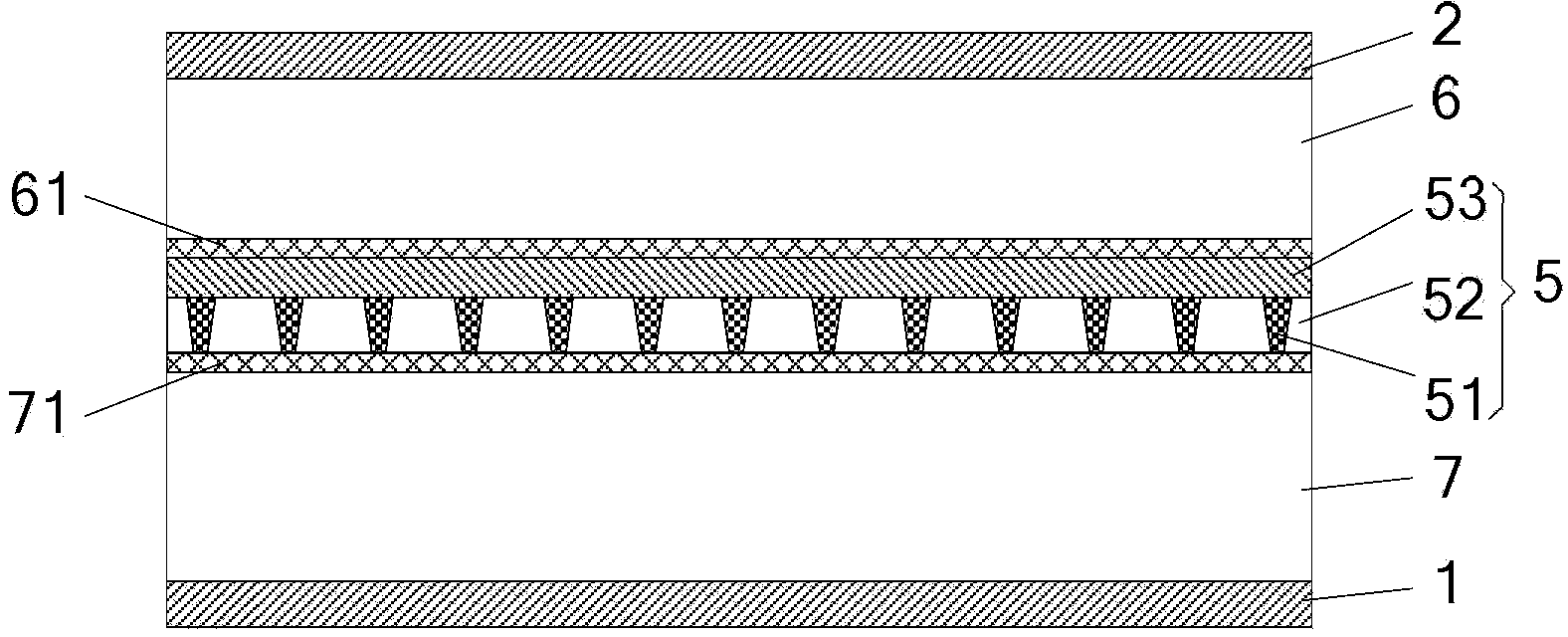

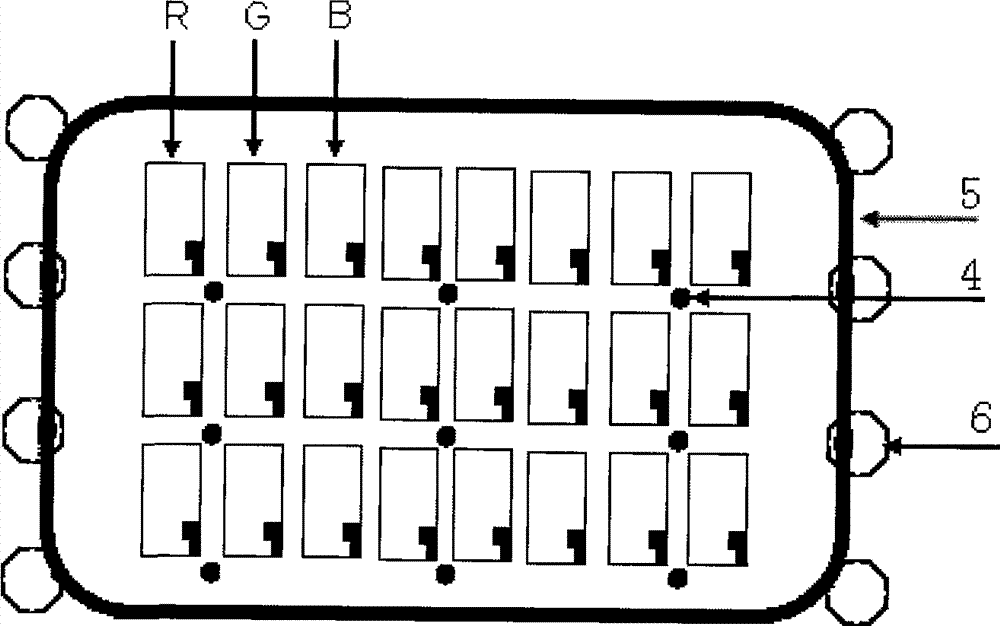

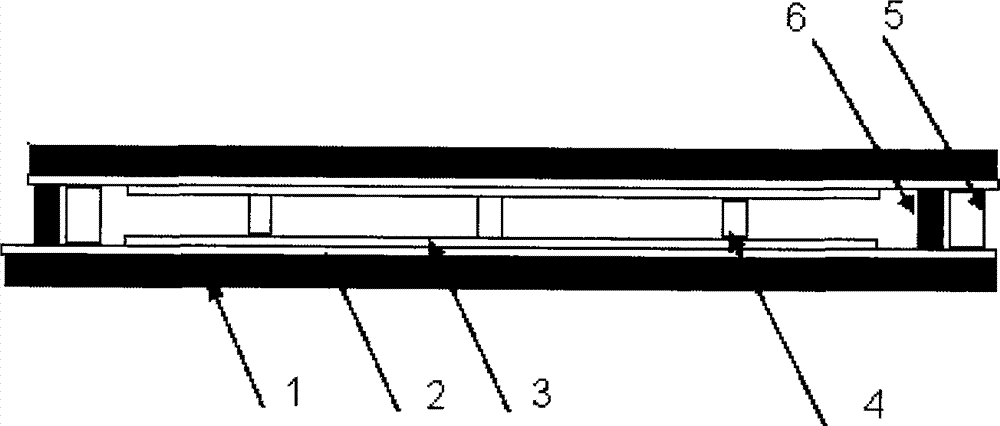

Display device and manufacturing method thereof

ActiveCN102854628AImprove display quality and product yieldBox thickness remains uniformNon-linear opticsOptical elementsSurface plateVertical distance

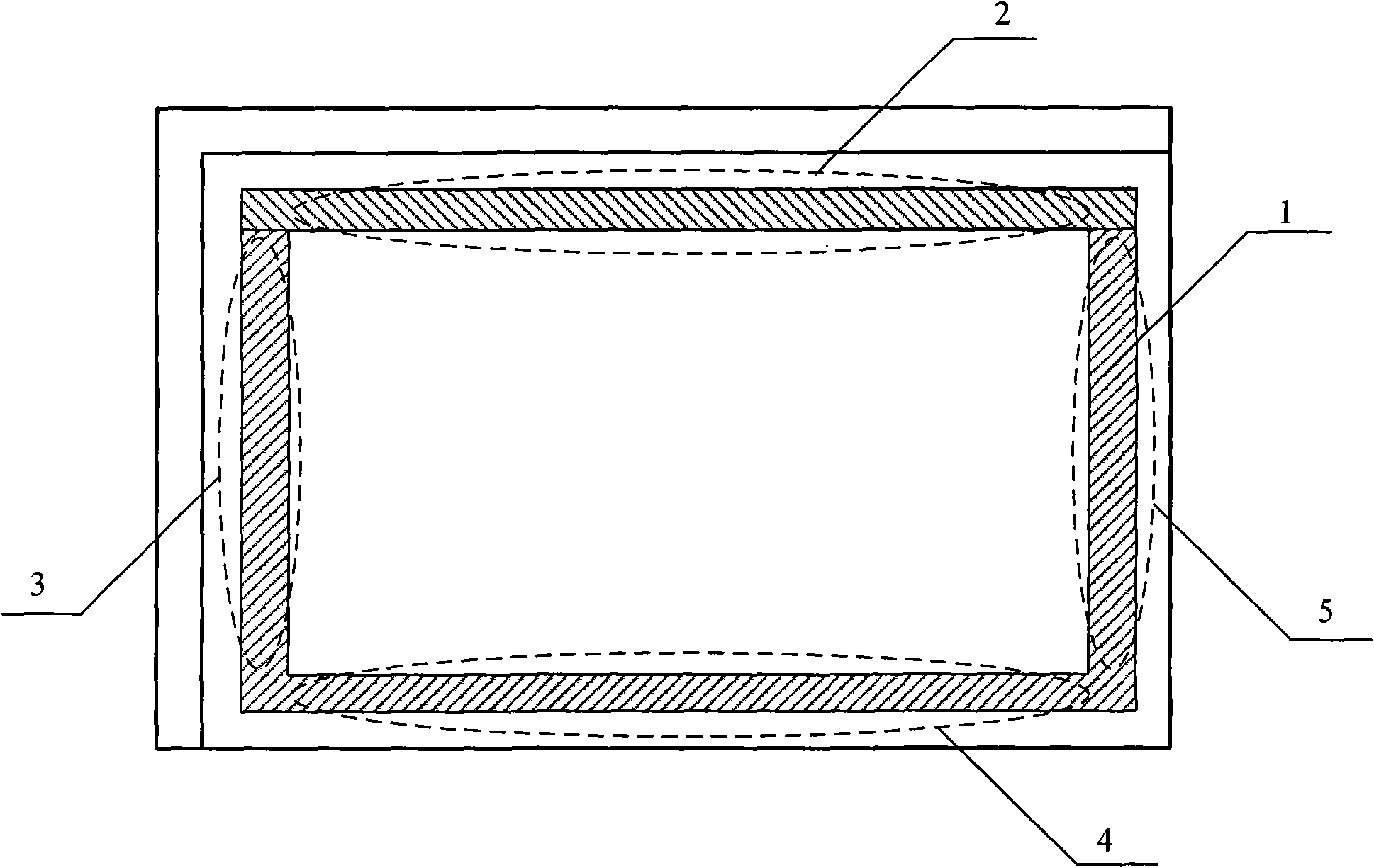

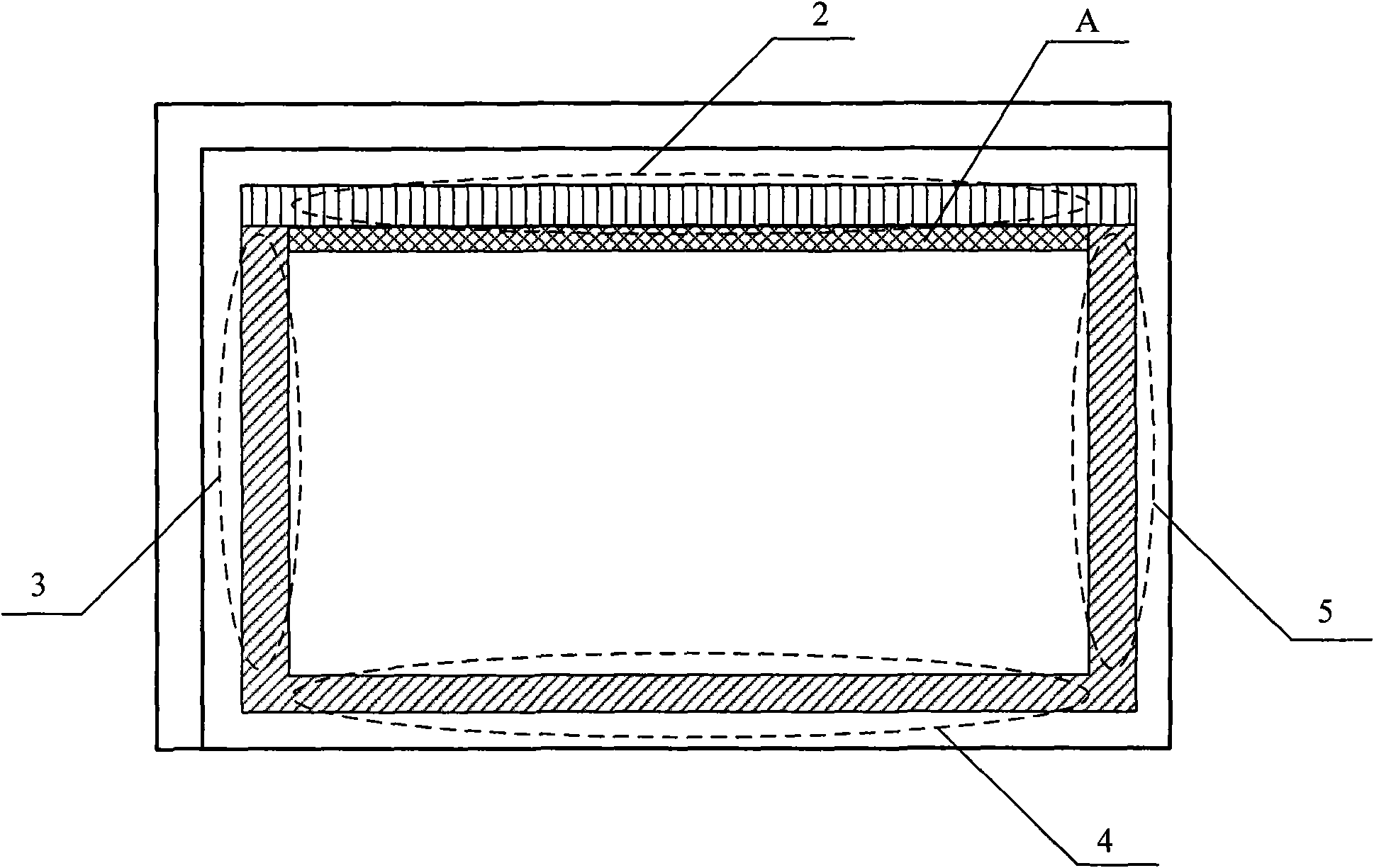

The invention provides a display device and a manufacturing method thereof. The display device comprises a display panel and a grating arranged on the light-emitting side of the display panel. The upper surface of the display panel and the lower surface of the grating are parallel to each other and are arranged adjacently. Box-thickness supporting layers are overlaid between the upper surface of the display panel and the lower surface of the grating and comprise at least one layer of support bodies. For each layer of support bodies, adhesion agents are filled in gaps between the support bodies, and the heights of the support bodies positioned at different positions are equal, so that the vertical distances from different position points on the upper surface of the display panel to the lower surface of the grating are equal. According to the display device and the manufacturing method of the display device, the space between the grating and the display device can be kept uniform, and accordingly the display quality of the display device and the product yield are improved.

Owner:BOE TECH GRP CO LTD

Single-polarizer liquid crystal dimming automotive rearview mirror

InactiveCN102331643AReduce dosageLow costNon-linear opticsOptical viewingIndium tin oxideEngineering

The invention discloses a single-polarizer liquid crystal dimming automotive rearview mirror. A layered structure of the rearview mirror comprises a front polarizer, a front substrate, a front substrate electrode, a front direct action membrane, a liquid crystal layer, a rear direct action membrane, a rear substrate electrode and a rear substrate with a reflector from front to back in turn, wherein the front substrate electrode and the rear substrate electrode respectively comprise an ion infiltration-preventing SiO2 film and an indium tin oxide (ITO) transparent conductive film; and the product of the birefraction rate of the liquid crystal and the thickness of the liquid crystal layer is more than 0.2 and less than 1.6mu m. Compared with the prior art, the single-polarizer liquid crystal dimming automotive rearview mirror has better dimming effect and temperature characteristic, good reflectivity in a bright state and a dark state, and low cost, and is easy to popularize.

Owner:DALIAN DKE LCD CO LTD

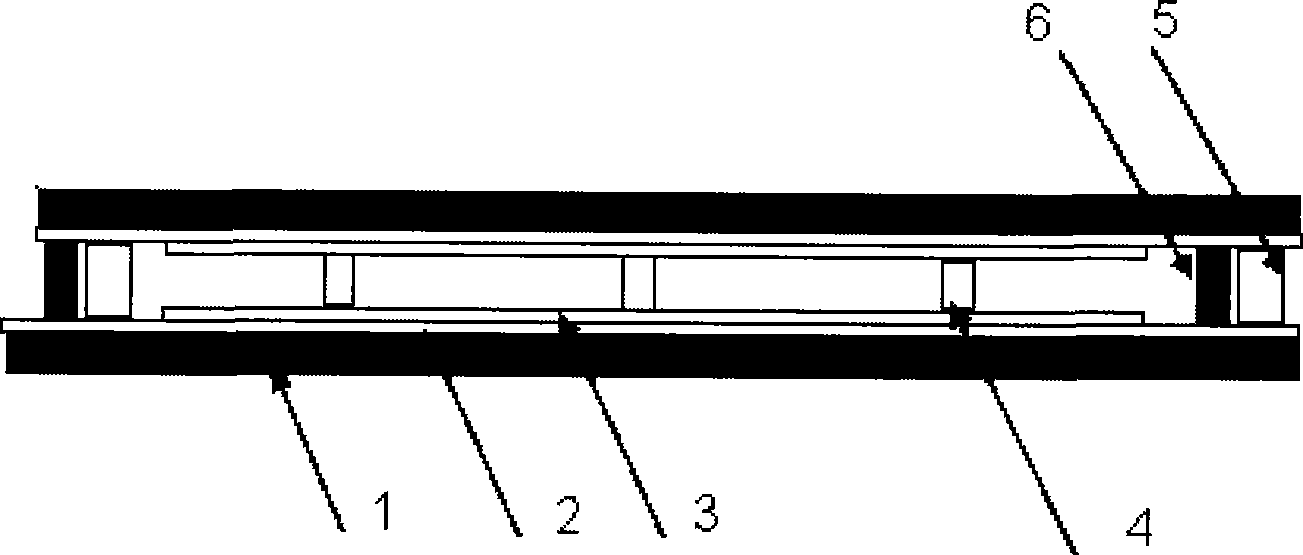

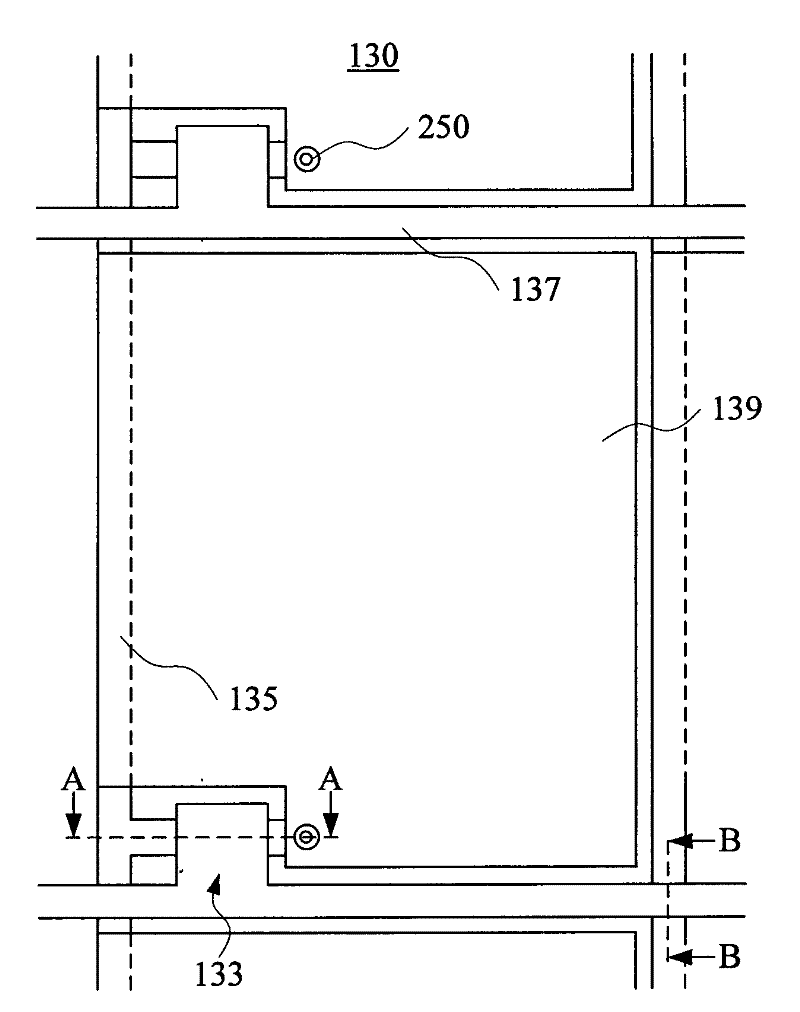

Liquid crystal display panel structure and manufacturing method thereof

ActiveCN101546069AImprove support strengthImprove conductivityNon-linear opticsLiquid-crystal displayAdhesive

The invention discloses a liquid crystal display panel structure and a manufacturing method thereof, belonging to the technical field of the liquid crystal displays and being invented aiming to improve the display quality of the liquid crystal display. The liquid crystal display panel structure comprises a color film substrate and an array substrate which are oppositely arranged, supporting spacers are evenly distributed in a display area at one side of the color film substrate relative to the array substrate, the edge at one side of the color film substrate relative to the array substrate is stuck with the edge at one side of the array substrate relative to the color film substrate through frame sealing adhesive to form a closed area, and the closed area is filled with liquid crystals; a conducting spacer is arranged on the edge at one side of the color film substrate relative to the array substrate and is embedded in the frame sealing adhesive, and both ends of the conducting spacer are respectively in contact with the two substrates to realize the electric connection between the two substrates; and the conducting spacer has good supporting strength and good electric conductivity. The invention is suitable for improving the display quality of the liquid crystal display.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

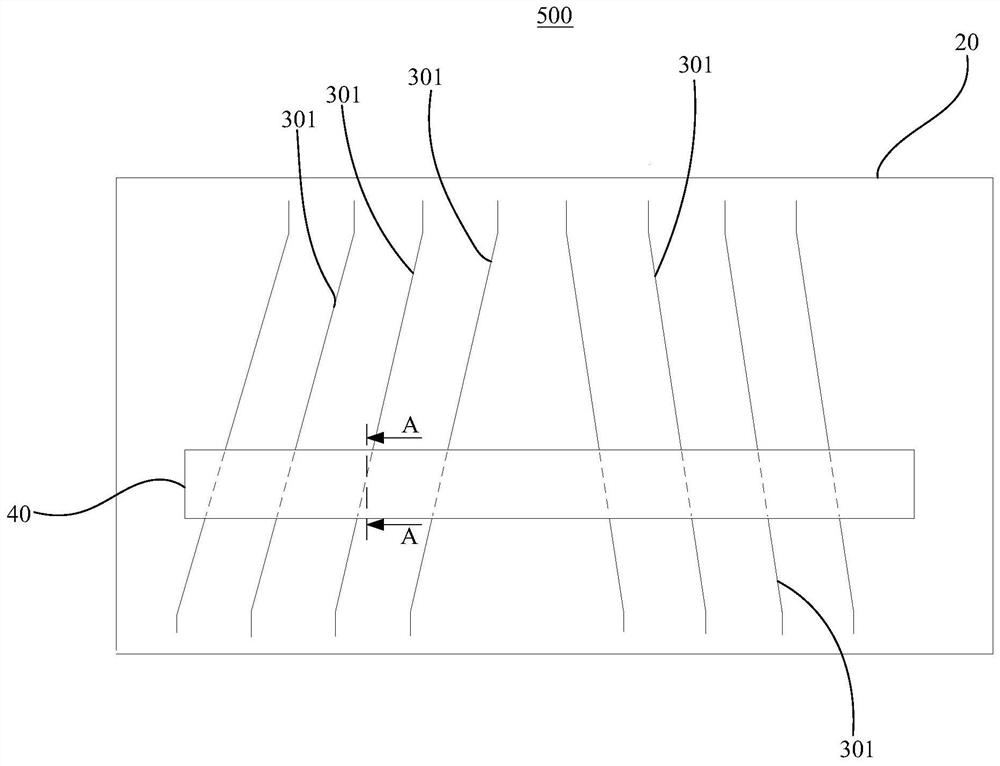

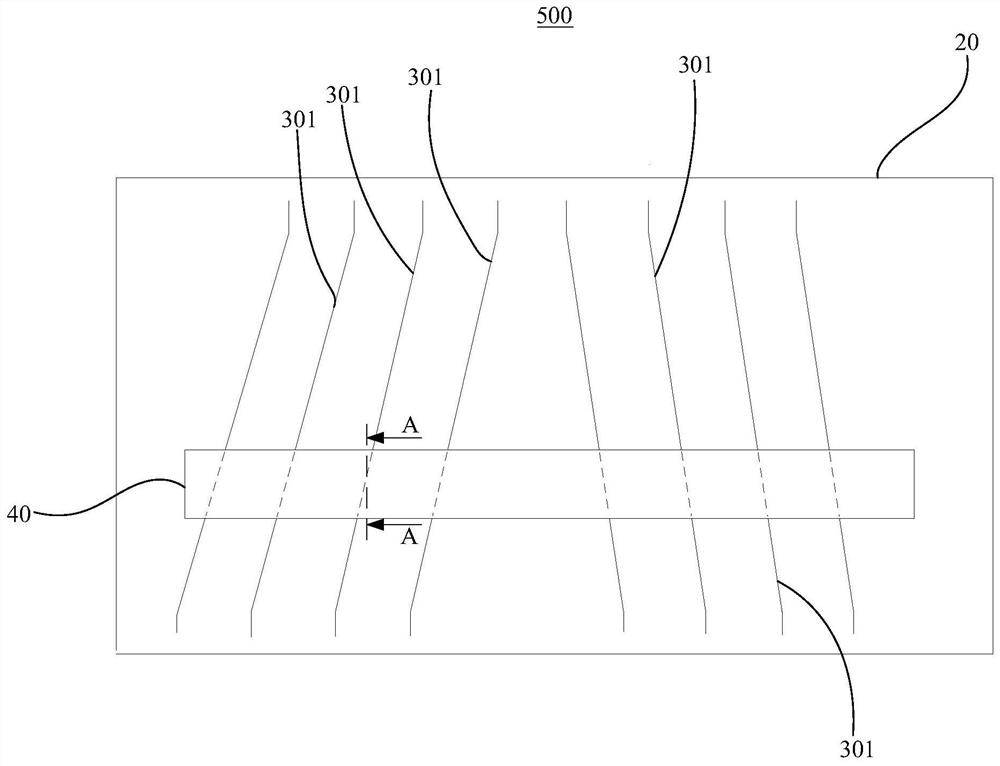

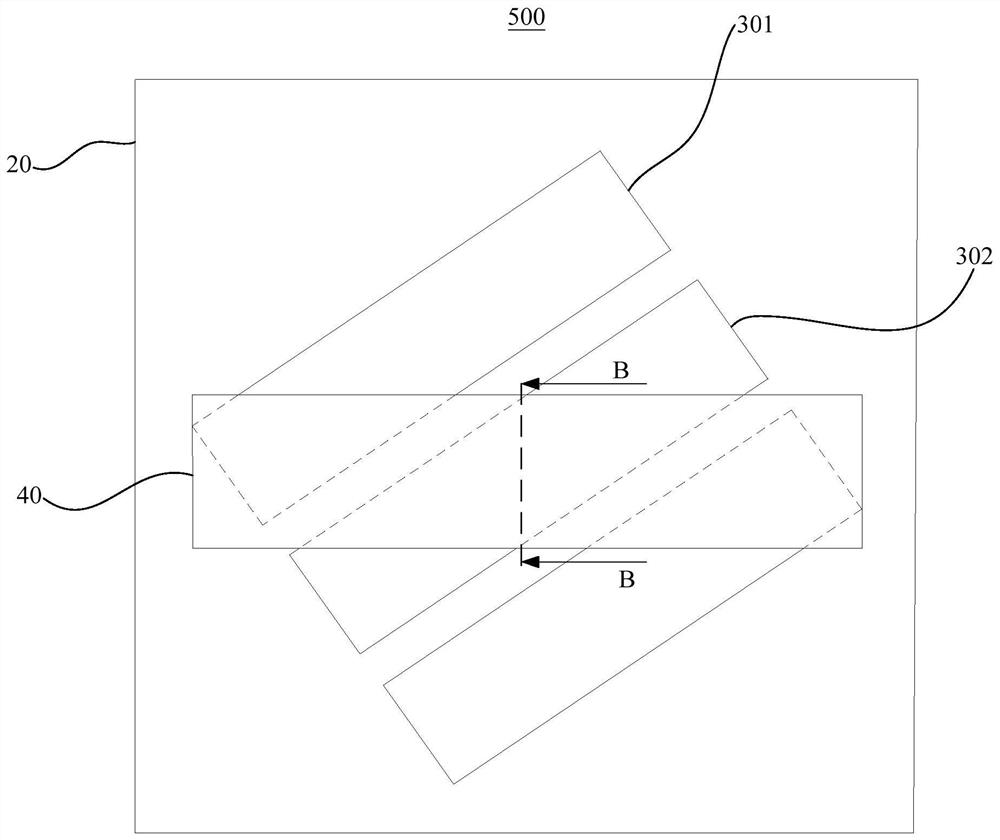

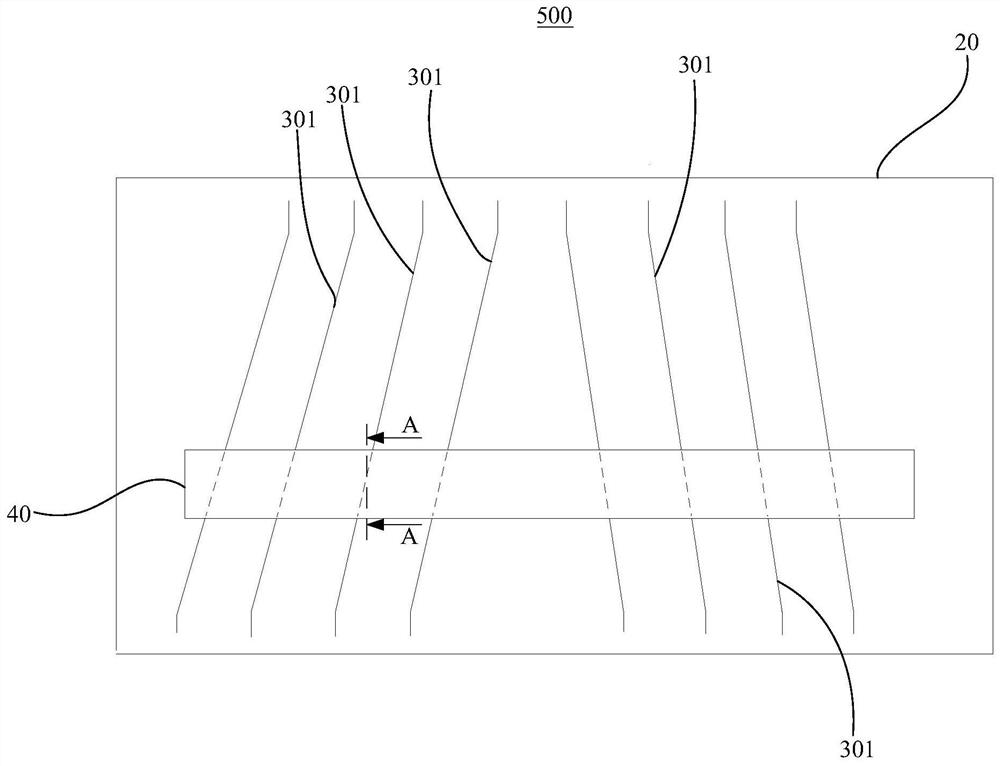

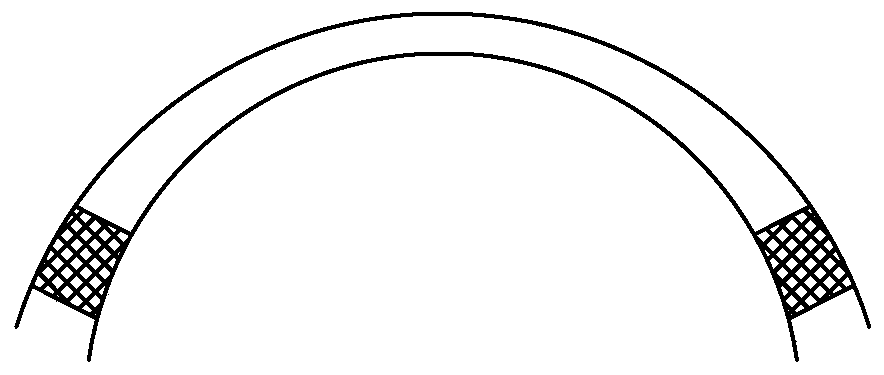

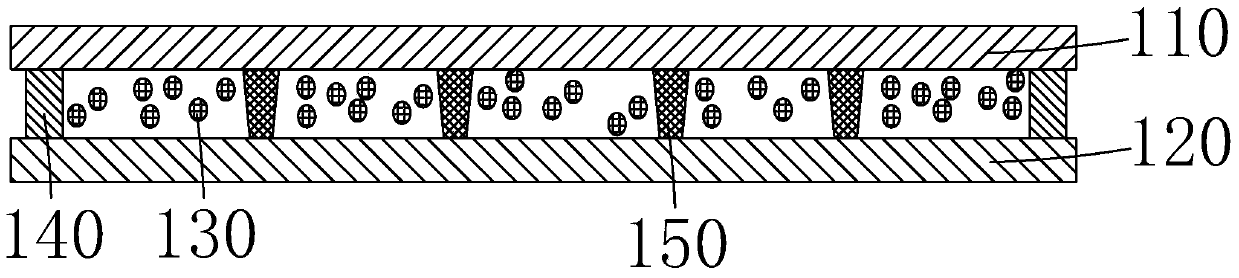

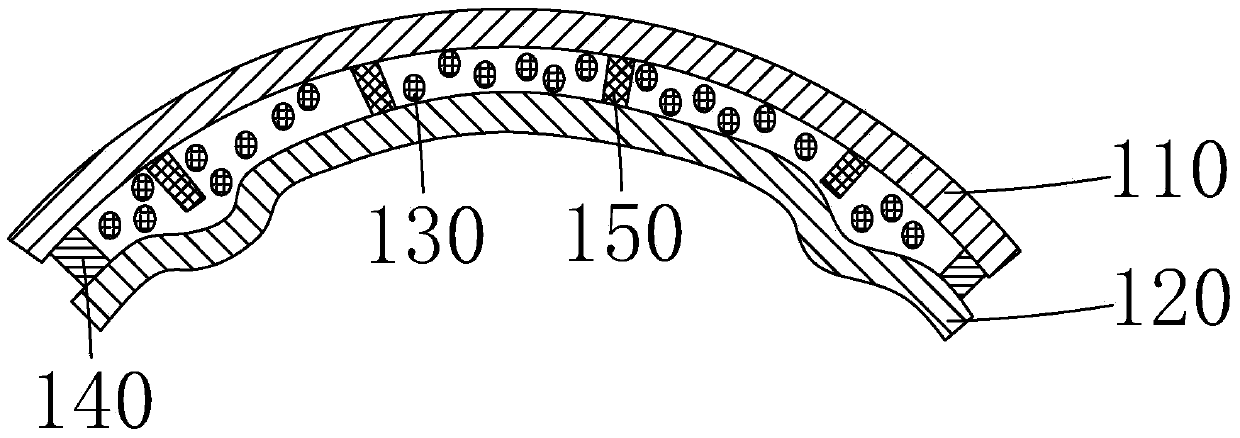

Curved-surface display panel and curved-surface display device

ActiveCN107656403AUniform box thicknessImprove the display effectNon-linear opticsIdentification meansSurface displayEngineering

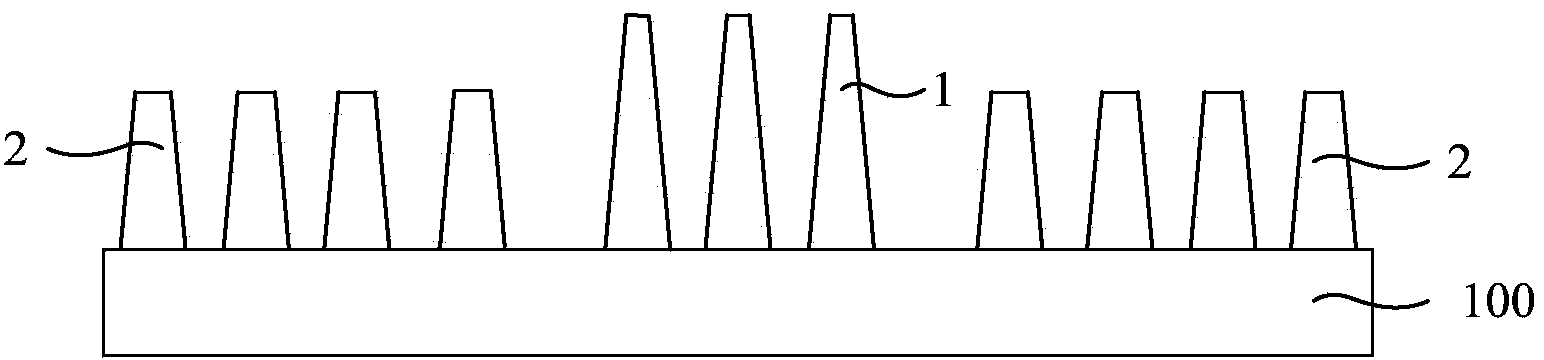

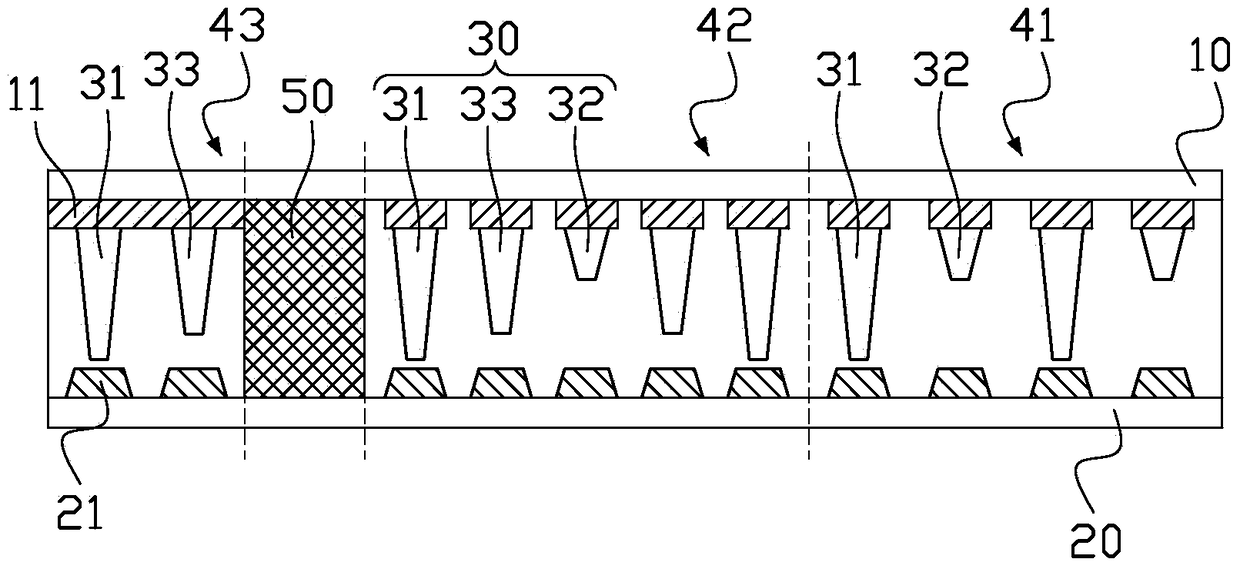

The embodiment of the invention provides a curved-surface display panel and a curved-surface display device, and relates to the technical field of displaying. In the prior art, when an array substrateof the curved-surface display panel or a spacer on a box alignment substrate is prepared, the area of the top is smaller than the area of the bottom, so that the supporting force applied by the spacer to the array substrate and the support force applied by the spacer to the box alignment substrate are different, the thickness of a liquid crystal box is uneven, the image display quality of the display panel is affected, and such problem is solved by the curved-surface display panel and the curved-surface display device. The curved-surface display panel includes a first substrate, a second substrate and a liquid crystal layer, wherein the first substrate and the second substrate are subjected to box alignment mutually, and the liquid crystal layer is arranged in a gap between the first substrate and the second substrate, and a spacer layer is arranged in the first substrate and the second substrate and used for supporting the first substrate and the second substrate so as to form a gap.The spacer layer includes several spacer sets, and the spacer set includes a first spacer and a second spacer, the first spacer is arranged on the first substrate and the second spacer is arranged onthe second substrate, and the supporting area, on the first substrate, of the spacer set is equal to the supporting area, on the second substrate, of the spacer set.

Owner:BOE TECH GRP CO LTD +1

Liquid crystal display panel and liquid crystal display

ActiveCN101726929AImprove uniformityQuality improvementNon-linear opticsLiquid-crystal displayEngineering

The invention provides a liquid crystal display panel and a liquid crystal display. The liquid crystal display panel comprises a first substrate, a second substrate, a liquid crystal layer between the two substrates and main frame glue sealing the liquid crystal layer, wherein the main frame glue is basically arranged along the edge of the liquid crystal display panel and at least comprises a first sub section and a second sub section. The liquid crystal display panel has a display area which at least comprises a first edge and a second edge, wherein the first edge corresponds to the first sub section of the main frame glue; the second edge corresponds to the second sub section of the main frame glue; the distance between the first edge and the first sub section is smaller than the distance between the second edge and the second sub section; and at least a section of auxiliary frame glue is arranged between the second edge and the second section. In liquid crystal display panel of the invention, under the condition of not influencing the characteristics of TFT-LCD, the auxiliary frame glue is added in a proper area in the two substrates to overcome the drawback of uneven box thickness and further improve the display effect of the liquid crystal display considerably.

Owner:TRULY SEMICON

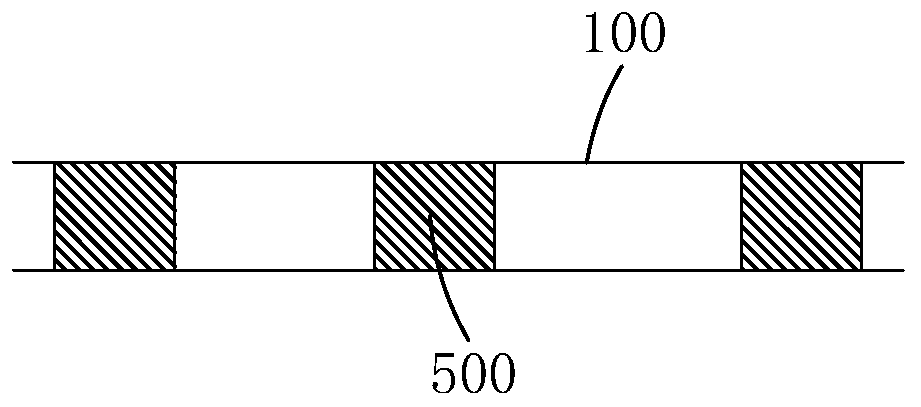

Display panel, display device and production method of display panel

ActiveCN108490699AUniform box thicknessImprove picture qualityNon-linear opticsDisplay deviceColor film

The invention provides a display panel, a display device and a production method of the display panel. The display panel includes an array substrate, a color film substrate, frame sealing glue and a baffle wall; the baffle wall is arranged between the array substrate and the color film substrate, is in contact with the array substrate and the color film substrate, is located at the inner side of the frame sealing glue and surrounds a display area of the display panel, wherein containing space between the baffle wall and the frame sealing glue is filled with liquid crystal. The baffle wall of the display panel plays the effect of secondary sealing, and the liquid crystal fills the gap between the baffle wall and the frame sealing glue and further plays the effect of sealing; the display panel has excellent leakproofness; periphery blackening and a Mura phenomenon which are caused by interference of external gas and impurities on the interior of the display panel can be prevented when the frame sealing glue cracks or is not well painted; the box thickness is uniform, the picture quality is good, and the stability and the display quality are high.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

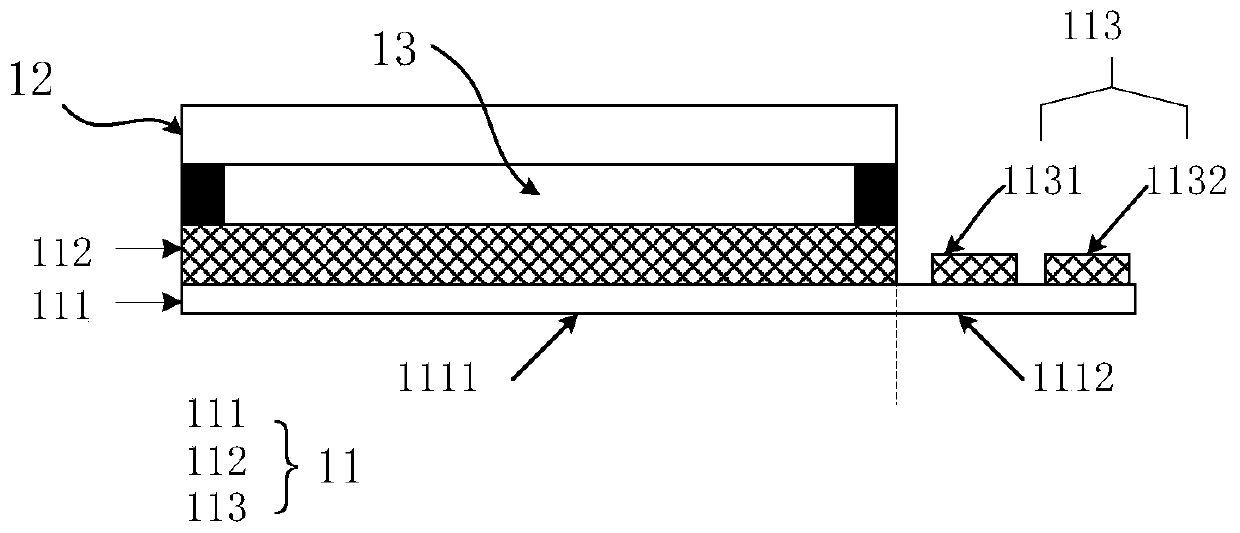

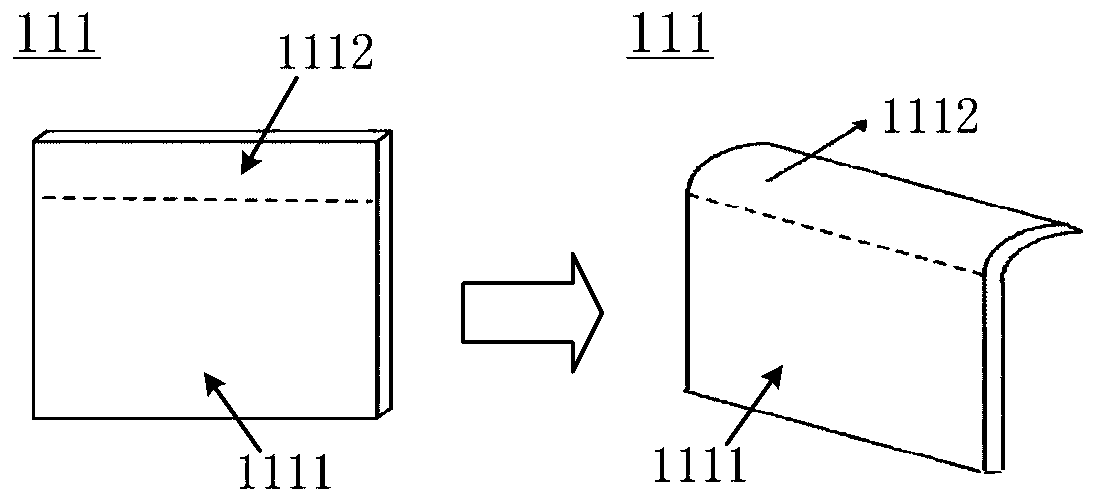

Narrow-frame display panel, preparation method thereof and narrow-frame display device

ActiveCN110426877AImprove flexibilityImprove rigidityStatic indicating devicesFinal product manufacturePolymer resinLight irradiation

The invention discloses a narrow-frame display panel, a preparation method thereof and a narrow-frame display device. The flexibility and rigidity conversion of a substrate base plate can be realizedby selecting a flexible photosensitive hardening polymer resin material with high light transmittance and carrying out selective light irradiation treatment. The bending area of the substrate base plate is flexible and can be bent and hidden to the back of the substrate base plate, so that the narrow frame of the panel is realized; and the planar area of the substrate base plate is rigid and can maintain a stable cell thickness when bent.

Owner:SUZHOU CHINA STAR OPTOELECTRONICS TECH CO LTD

Flexible liquid crystal display panel and manufacturing method thereof

InactiveCN107844007AImprove deformation resistanceImprove the narrow viewing angle problemNon-linear opticsLiquid-crystal displayEngineering

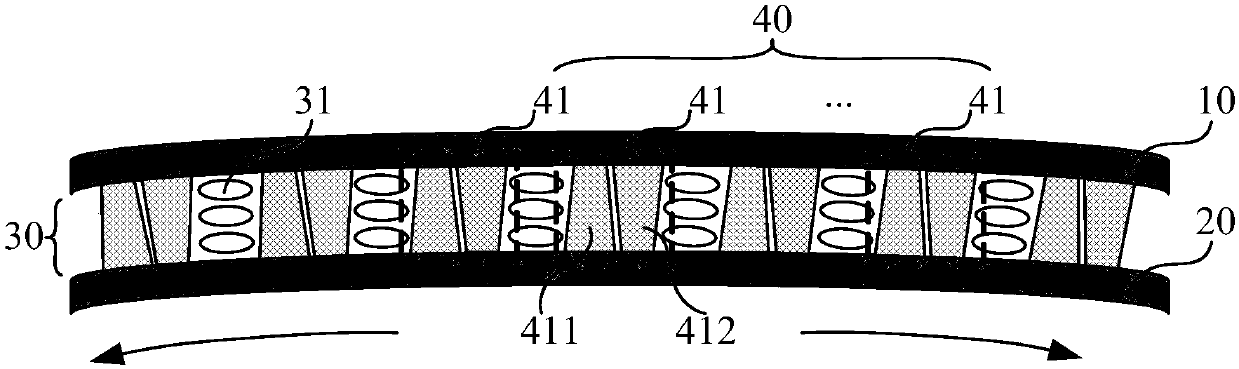

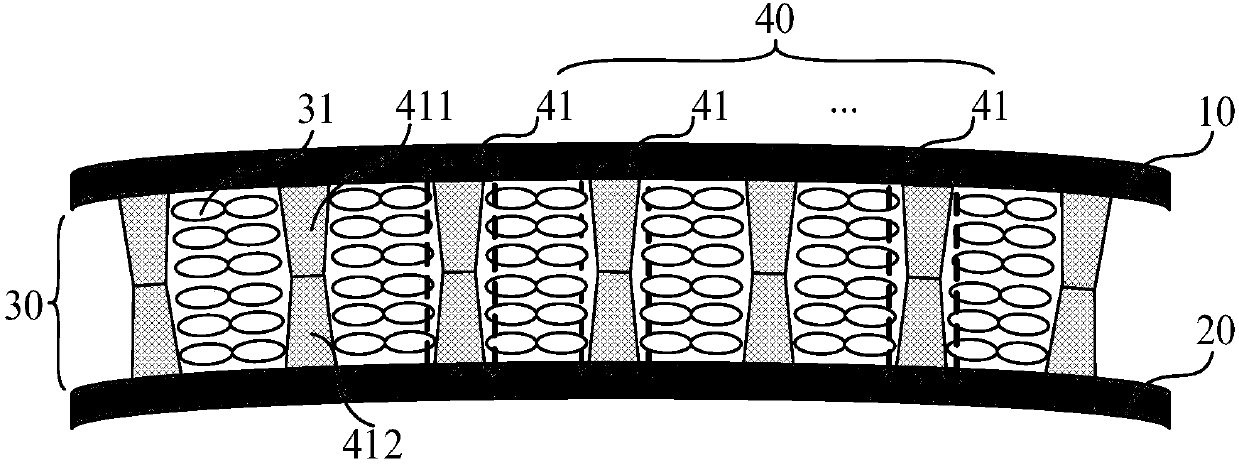

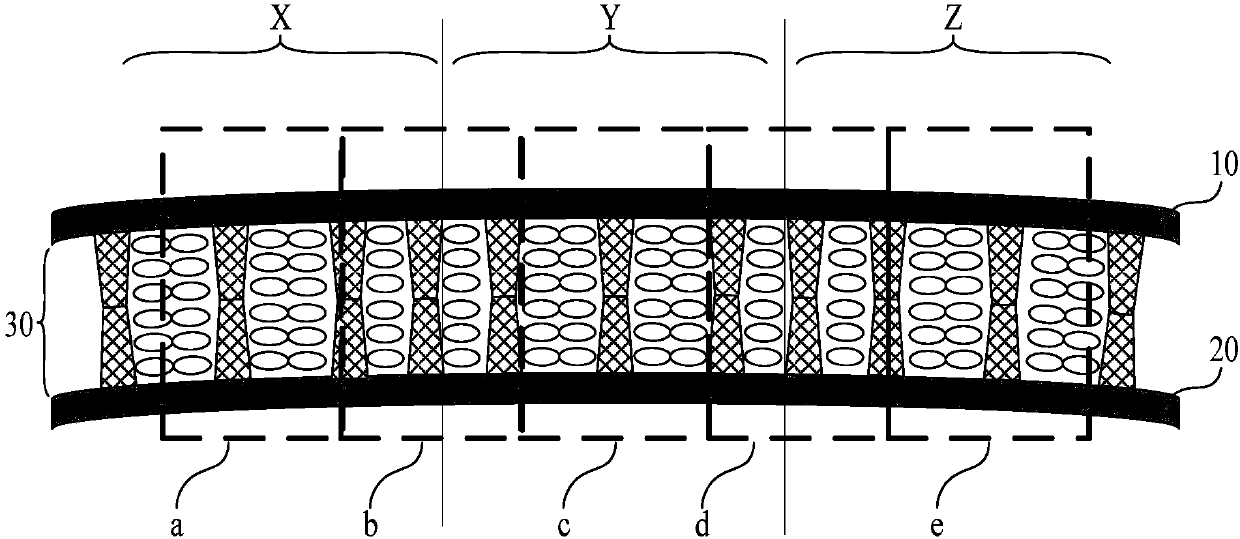

The invention discloses a flexible liquid crystal display panel and a manufacturing method thereof. The flexible liquid crystal display panel comprises a first flexible substrate, a second flexible substrate, liquid crystals, a plurality of spacer columns and encapsulation glue, wherein the liquid crystals are arranged between the first flexible substrate and the second flexible substrate, the spacer columns are arranged between the first flexible substrate and the second flexible substrate at intervals, and the encapsulation glue is arranged between the first flexible substrate and the secondflexible substrate so as to encapsulate the liquid crystals and the spacer columns. The two ends of each spacer column abut against the inner surface of the first flexible substrate and the inner surface of the second flexible substrate respectively, and sub-spacers are wrapped in the encapsulation glue. In the flexible liquid crystal display panel and the manufacturing method thereof, the encapsulation glue and the spacer columns can be made from the same encapsulation materials, and the encapsulation glue and the spacer columns can not only have encapsulation capacity but also have supporting capacity, so that the gap cell uniformity of the flexible liquid crystal display panel can be kept after the flexible liquid crystal display panel is bent; besides, the spacer columns in the middleare arranged in an array mode, so that the overall deformation resistance of the flexible liquid crystal display panel is improved, and the narrow-visual-angle problem of a flexible liquid crystal panel and the tearing risk of the encapsulation materials can be ameliorated.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Array baseplate and manufacturing method thereof as well as display panel using same

InactiveCN102315214APrevent display defectsAvoid faultSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringTransistor

The invention relates to the technical field of flat-plate display, in particular to an array baseplate, which comprises a second transparent substrate, a plurality of thin-film transistors and a plurality of data wires, wherein the second transparent substrate is provided with a third surface for forming a plurality of receiving spaces, and the thin-film transistors and the data wires are formed on the second transparent substrate; and each thin-film transistor comprises a source electrode and a drain electrode, and the source electrodes of the thin-film transistors positioned on the same column are connected with a same data wire and are received in the receiving spaces together with the drain electrodes of the thin-film transistors. In addition, the invention also provides a manufacturing method of the array baseplate and a display panel using the array baseplate.

Owner:SHENZHEN LAIBAO HI TECH

Substrate, liquid crystal display panel and display device

InactiveCN103869553AUniform box thicknessReduce height differenceNon-linear opticsLiquid-crystal displayLiquid crystal

The invention, which relates to the field of the liquid crystal display technology, discloses a substrate for liquid crystal display panels, a liquid crystal display panel and a display device. The substrate is provided with a plurality of spacers, the spacers are second spacers and first spacers, the first spacers are closer to the gravity center of the substrate than the second spacers, and the height of the first spacers is greater than the height of the second spacers. Consequently, under the effect of the own weight of the display panel, the compression of the first spacers closer to the gravity center of the substrate is greater than the compression of the second spacers, as a result, the difference between the height of the first spacers and the height of the second spacers is reduced to be within a preset threshold, and thereby the uniformity of the cell thickness of the liquid crystal panel is ensured.

Owner:BOE TECH GRP CO LTD +1

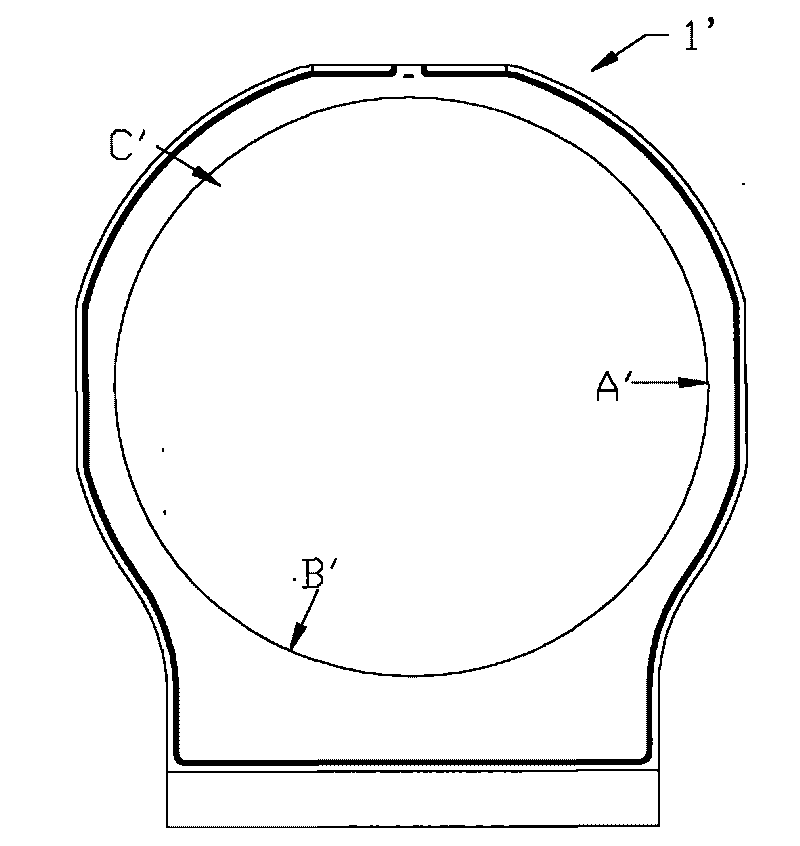

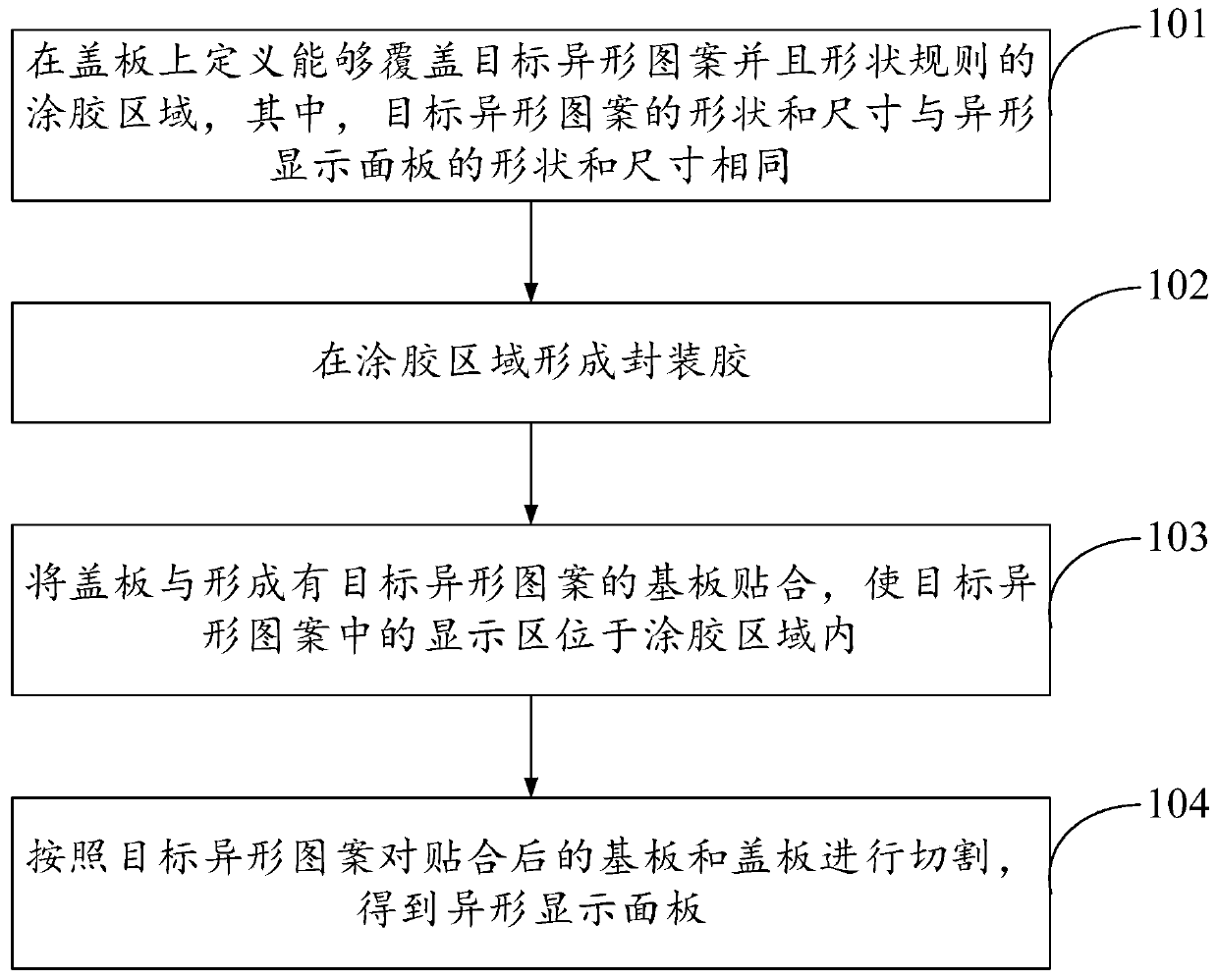

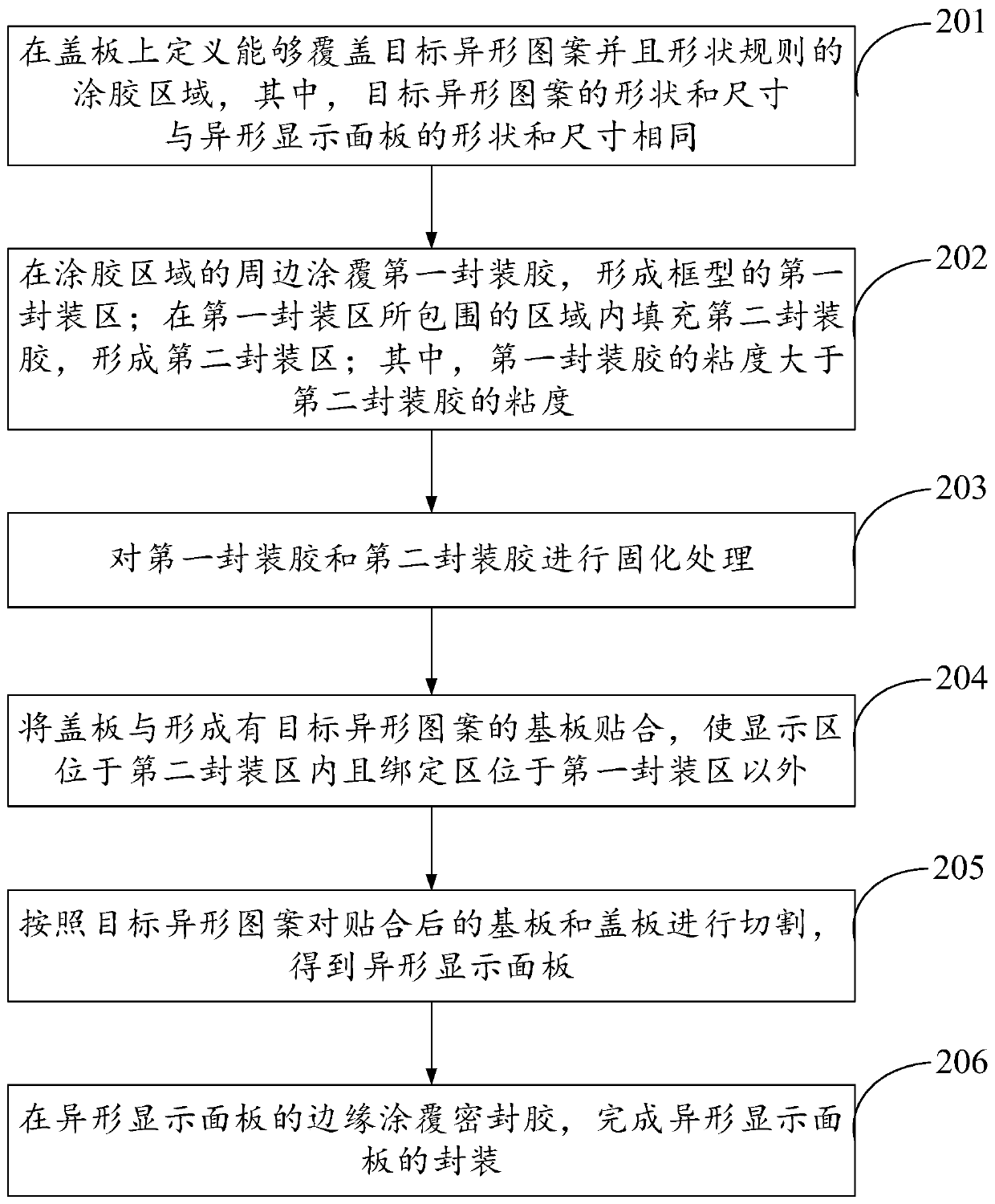

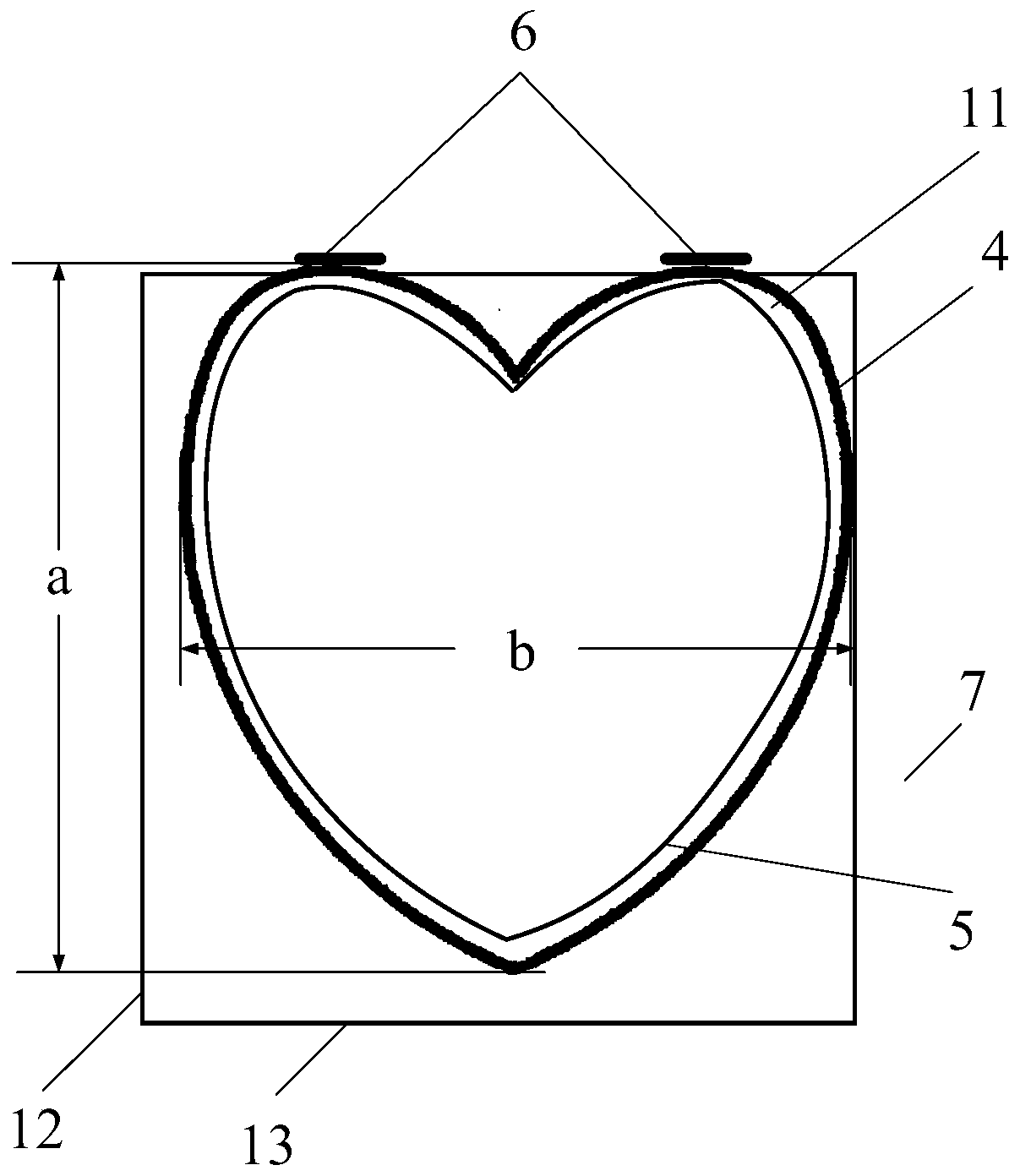

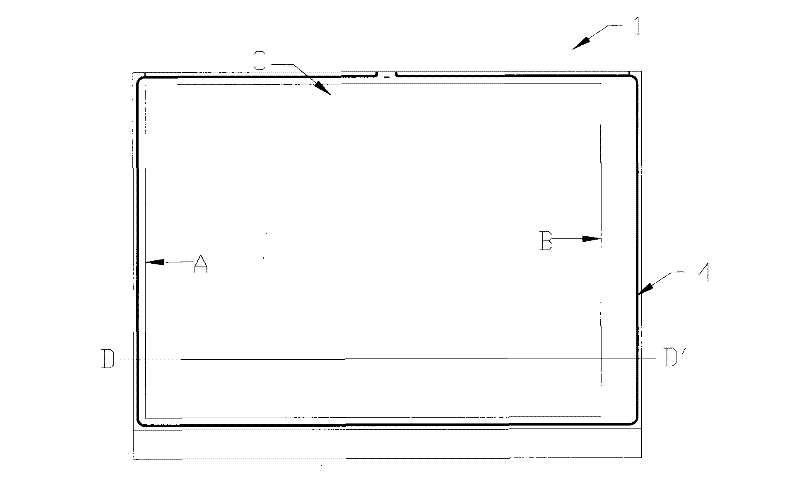

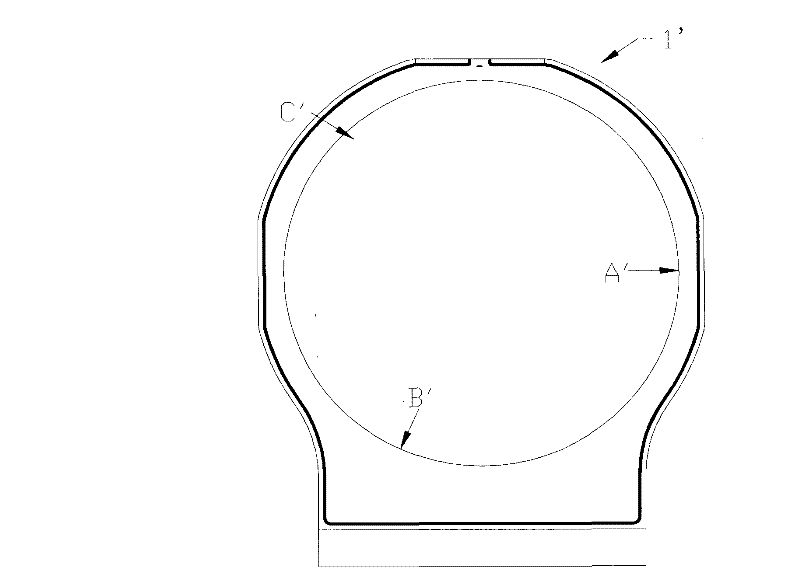

Packaging method of special-shaped display panel, special-shaped display panel and display device

PendingCN111477770AImprove qualityAvoid breakingSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveDisplay device

The invention discloses a packaging method of a special-shaped display panel, the special-shaped display panel and a display device. The packaging method comprises the steps of defining a gluing areawhich can cover a target special-shaped pattern and is regular in shape on a cover plate, wherein the shape and size of the target special-shaped pattern are the same as those of the special-shaped display panel; forming a packaging adhesive in the gluing area; attaching the cover plate to the substrate with the target special-shaped pattern, so that a display area in the target special-shaped pattern is located in the gluing area; and cutting the laminated substrate and cover plate according to the target special-shaped pattern to obtain the special-shaped display panel. The packaging methodis simple in process and can be suitable for special-shaped display panels of different shapes and sizes. The display area in the target special-shaped pattern after attachment can be completely filled with colloid, and uniform box thickness is kept. The problem of non-uniform display is solved, and the display effect is improved.

Owner:HEFEI BOE ZHUOYIN TECH CO LTD +1

Display panel and preparation method thereof

InactiveCN106324895AUniform box thicknessImprove picture qualitySolid-state devicesNon-linear opticsLiquid-crystal displayCell assembly

An embodiment of the invention provides a display panel and a preparation method thereof, relates to the technical field of display and guarantees a uniform cell gap of a liquid crystal display panel. The display panel comprises a first substrate and a second substrate which are arranged in a cell assembly manner, wherein a metal layer, a black matrix and spacers are arranged between the first substrate and the second substrate; orthographic projection of any two of the spacers, the black matrix and the metal layer on the first substrate at least overlaps partially; the thickness sum of any spacer, the metal layer and the black matrix is identical in a position corresponding to the spacer in the direction perpendicular to the first substrate. The invention is used for preparing the display panel.

Owner:BOE TECH GRP CO LTD +1

Display panel and display device

The invention discloses a display panel and a display device. The display panel comprises a first substrate and a second substrate which are arranged oppositely. The first substrate comprises a firstelectrode layer and an electrostriction structure formed o the first electrode layer; the second substrate comprises a second electrode layer and a spacer formed on the second electrode layer; a plurality of overlapping regions are formed on the second electrode layer and the first electrode layer, the electrostriction structure is arranged on the overlapping region, the electrostriction structurecorresponds to the spacer one to one, and the end face, facing the spacer, of the electrostriction fits the end face, facing the electrostriction structure, of the spacer; the display panel further comprises a control module, and the control module is connected with the first electrode layer and the second electrode layer respectively, is used for determining the position of the electrostrictionstructure corresponding to a force bearing point, changing the voltage of the first electrode layer and the second electrode layer corresponding to the electrostriction structure corresponding to theforce bearing point and controlling the electrostriction structure corresponding to the force bearing point to stretch and retract after the display panel bears external force.

Owner:BOE TECH GRP CO LTD +1

Color film substrate, manufacturing method of color film substrate and display panel

The invention discloses a color film substrate, a manufacturing method of the color film substrate and a display panel, the color film substrate is provided with a display area and a non-display areasurrounding the display area, and the non-display area is defined to comprise a first non-display area right opposite to a double-layer metal wiring area of an array substrate and a second non-displayarea right opposite to a single-layer metal wiring area of the array substrate. The color film substrate further comprises a substrate body; a black matrix layer which is arranged on one surface of the substrate body; a raising layer which is arranged on the surface, deviating from the substrate body, of the black matrix layer and located in the second non-display area; and a conducting layer which is arranged on one side, deviating from the substrate, of the black matrix layer, and is jacked by the two lifting layers to form a convex part. According to the technical scheme, when the particlesize of the gap supporting ball is calculated according to the longitudinal sections of the first non-display area and the second non-display area, the particle size of the gap supporting ball is uniform, and then it is guaranteed that the box thickness of the display panel is uniform.

Owner:HKC CORP LTD

Display panel and display device

InactiveCN113741101AImprove stabilityGuaranteed opening rateNon-linear opticsDisplay deviceEngineering

The invention discloses a display panel and a display device. The display panel comprises a first substrate, a second substrate, a main spacer and an auxiliary spacer. The first substrate and the second substrate are arranged in a box-to-box mode, the main spacer and the auxiliary spacer are arranged between the first substrate and the second substrate, the height of the main spacer is larger than that of the auxiliary spacer, one end of the main spacer is arranged on the second substrate, the other end of the main spacer abuts against the first substrate, and the display panel further comprises a limiting spacer and a limiting structure; the limiting spacer is arranged between the first substrate and the second substrate, is arranged at an interval with the main spacer, and is positioned in the same shading area; the limiting structure is arranged on the side, close to the second substrate, of the first substrate, corresponds to the limiting spacer and limits sliding of the limiting spacer. In this way, the shock insulator is prevented from sliding, and abnormal display of the display panel is avoided.

Owner:HKC CORP LTD

Color film substrate, manufacturing method of color film substrate and display panel

The invention discloses a color film substrate, a manufacturing method of the color film substrate and a display panel, the color film substrate is provided with a display area and a non-display areasurrounding the display area, and the non-display area is defined to comprise a first non-display area right opposite to a double-layer metal wiring area of an array substrate and a second non-displayarea right opposite to a single-layer metal wiring area of the array substrate. The color film substrate further comprises: a substrate body; a black matrix layer which is arranged on one surface ofthe substrate body, wherein a first receding groove is formed in the surface, deviating from the substrate body, of the black matrix layer, and the first receding groove is located in the first non-display area; and a conducting layer which is arranged on the side, deviating from the substrate, of the black matrix layer, wherein at least part of the conducting layer is sunken in the first recedinggroove to form a second receding groove. According to the technical scheme, when the particle size of the gap supporting ball is calculated according to the longitudinal sections of the first non-display area and the second non-display area, the particle size of the gap supporting ball is uniform, and then it is guaranteed that the box thickness of the display panel is uniform.

Owner:HKC CORP LTD

Display panel, display device and method for manufacturing display panel

ActiveCN108490699BUniform box thicknessImprove picture qualityNon-linear opticsColor filmDisplay device

The present invention provides a display panel, a display device, and a method for manufacturing the display panel. The display panel includes: an array substrate, a color film substrate, a sealant, and a retaining wall. The retaining wall is arranged between the array substrate and the color film. Between the substrates, it is in sealing contact with the array substrate and the color filter substrate, and is located inside the sealant to enclose the display area of the display panel, wherein, between the retaining wall and the sealant The containing space is filled with liquid crystal. The retaining wall of the display panel acts as a secondary seal, and the liquid crystal fills the gap between the retaining wall and the frame sealant, which further acts as a seal. It has excellent airtightness and can prevent the sealant from breaking or poor coating When the external gas and impurities interfere with the inside, the peripheral blackening and Mura phenomenon are caused, and the box thickness is uniform, the stability is strong, the picture quality is good, and the display quality is high.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

Color filter substrate, manufacturing method of color filter substrate, and display panel

Owner:HKC CORP LTD

Liquid crystal panel and liquid crystal display device

ActiveCN105116628BUniform box thicknessEliminate peripheral chromatic aberrationNon-linear opticsColor gelEngineering

The invention provides a liquid crystal display panel which comprises a color filter substrate, an array substrate and a liquid crystal layer arranged between the color filter substrate and the array substrate in a filling mode. The liquid crystal display panel comprises an active area and a dummy area located between frame sealing glue and the active area. The active area and the dummy area between the color filter substrate and the array substrate are provided with main photo spacers and sub photo spacers. The height of the main photo spacers is larger than that of the sub photo spacers. The dummy area is further provided with transition photo spacers. The height of the transition photo spacers is lower than that of the main photo spacers but larger than that of the sub photo spacers. By means of the liquid crystal display panel and a liquid crystal display device, when the action force borne by the dummy area is larger than that of the active area, the transition photo spacers can offset the difference value between the action force borne by the dummy area and the action force borne by the active area through compression of the transition photo spacers, the cell thickness of the liquid crystal display panel is made to be even, and the peripheral color difference is eliminated.

Owner:KUSN INFOVISION OPTOELECTRONICS

Liquid crystal display panel and liquid crystal display

ActiveCN101726929BImprove uniformityQuality improvementNon-linear opticsLiquid-crystal displayEngineering

Owner:TRULY SEMICON

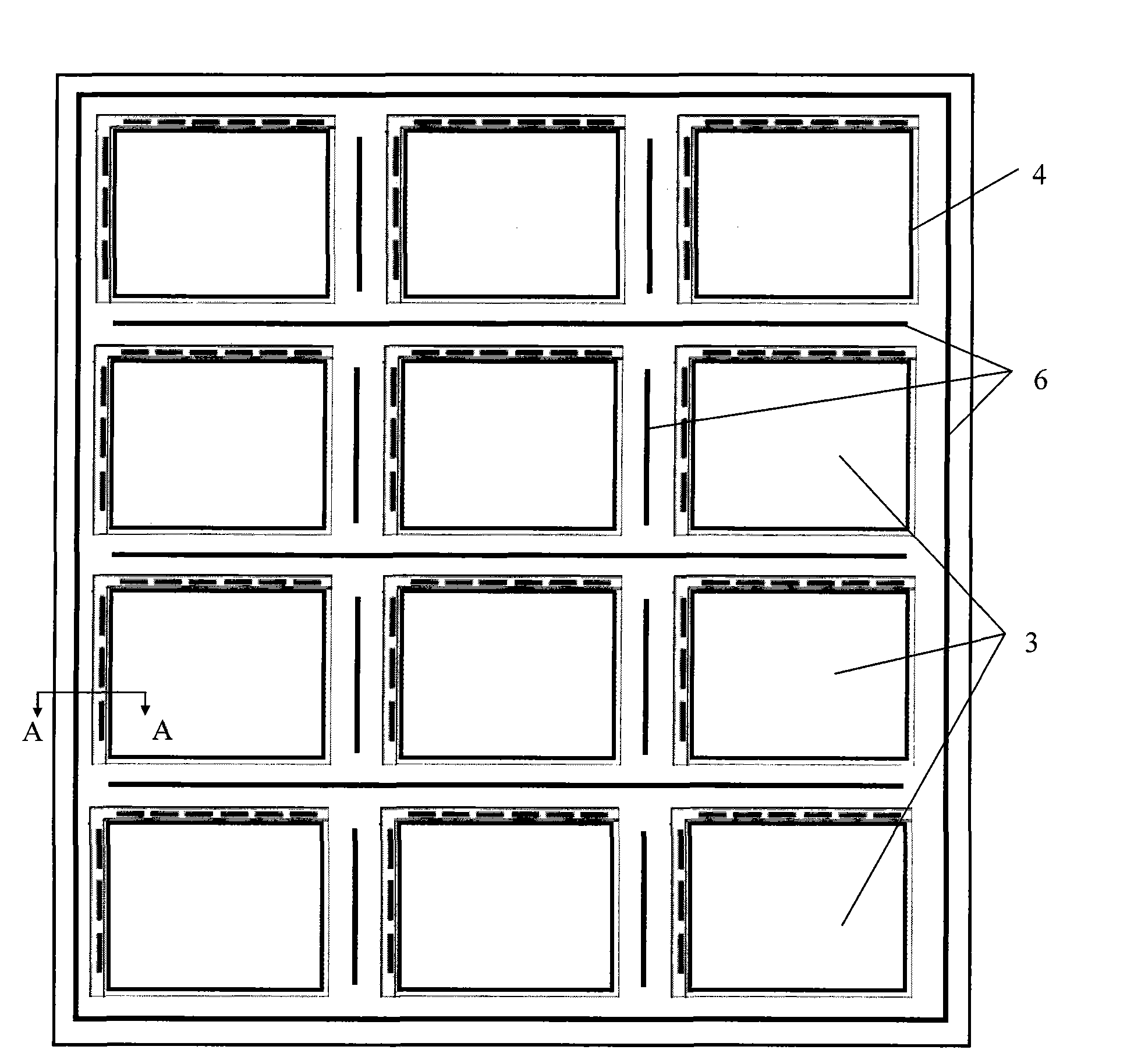

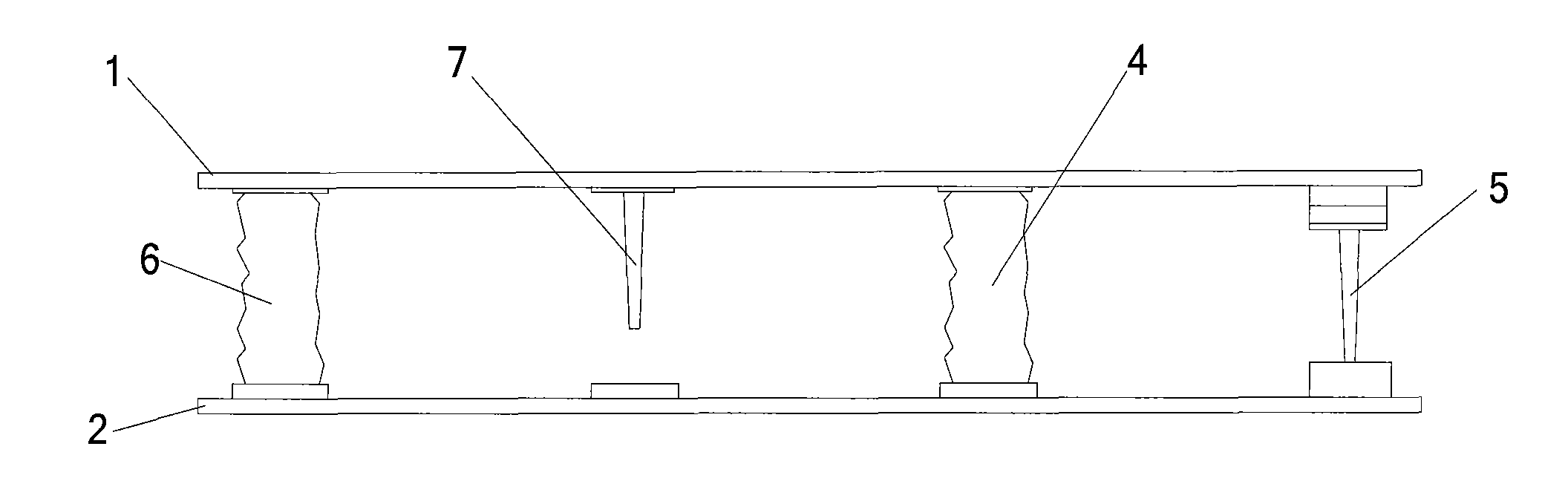

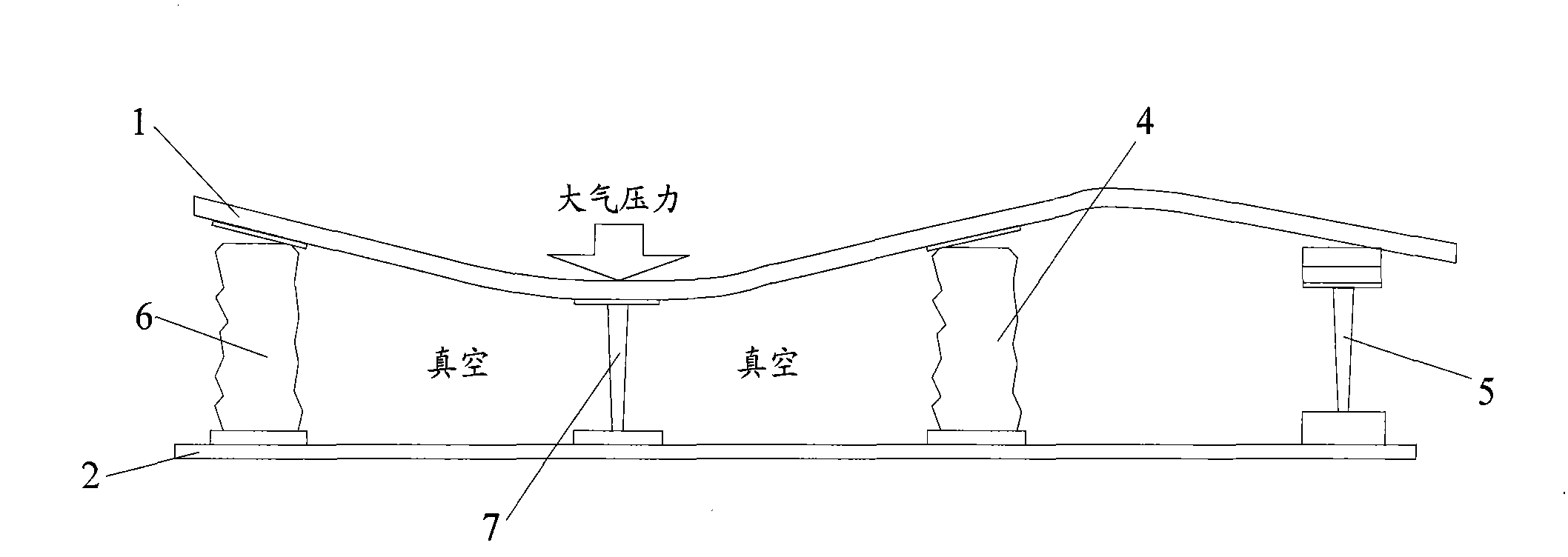

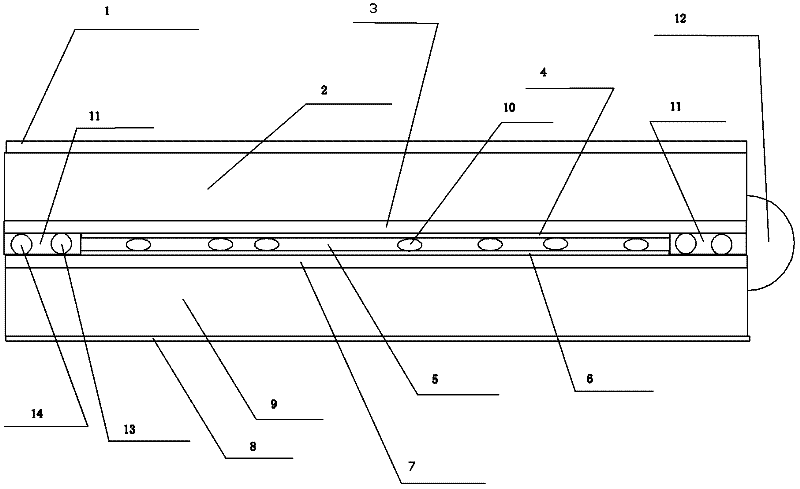

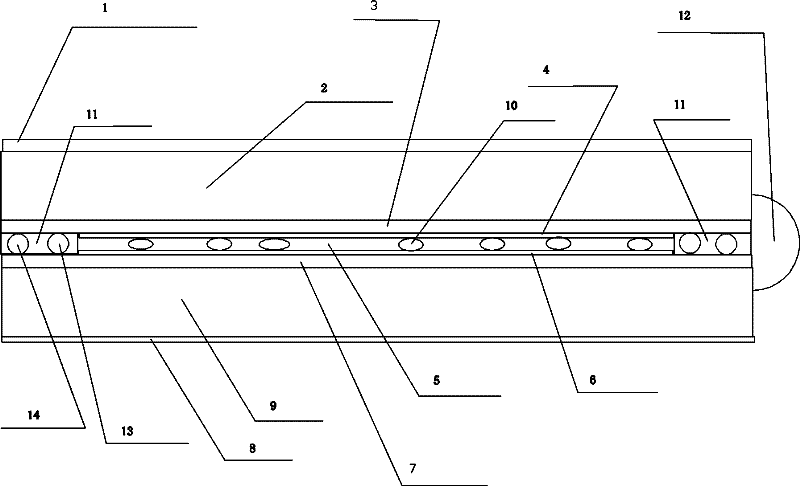

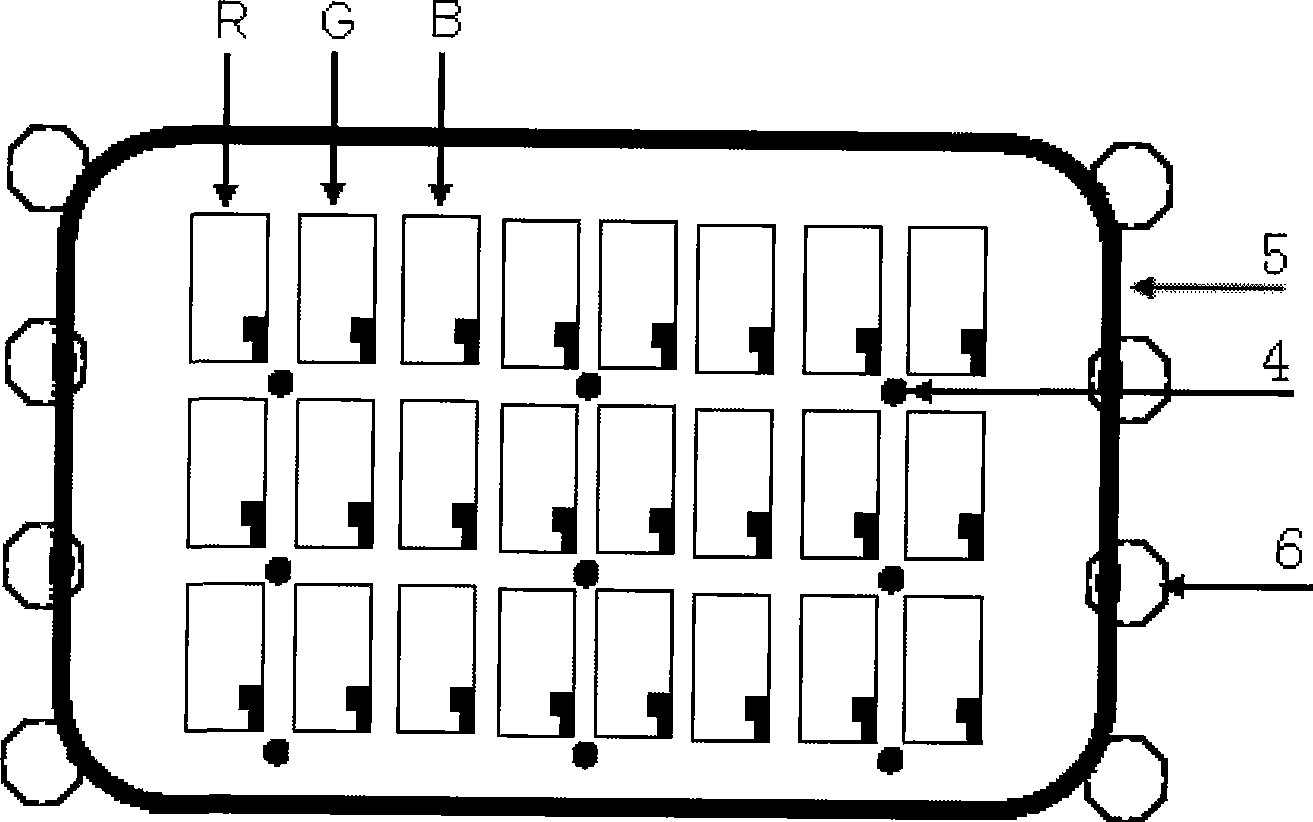

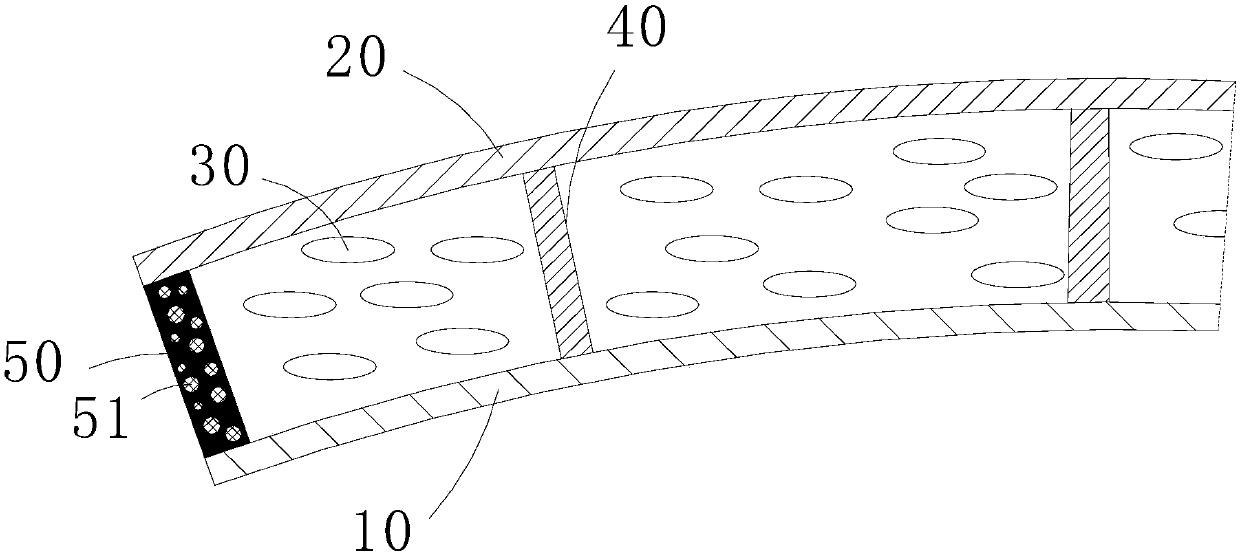

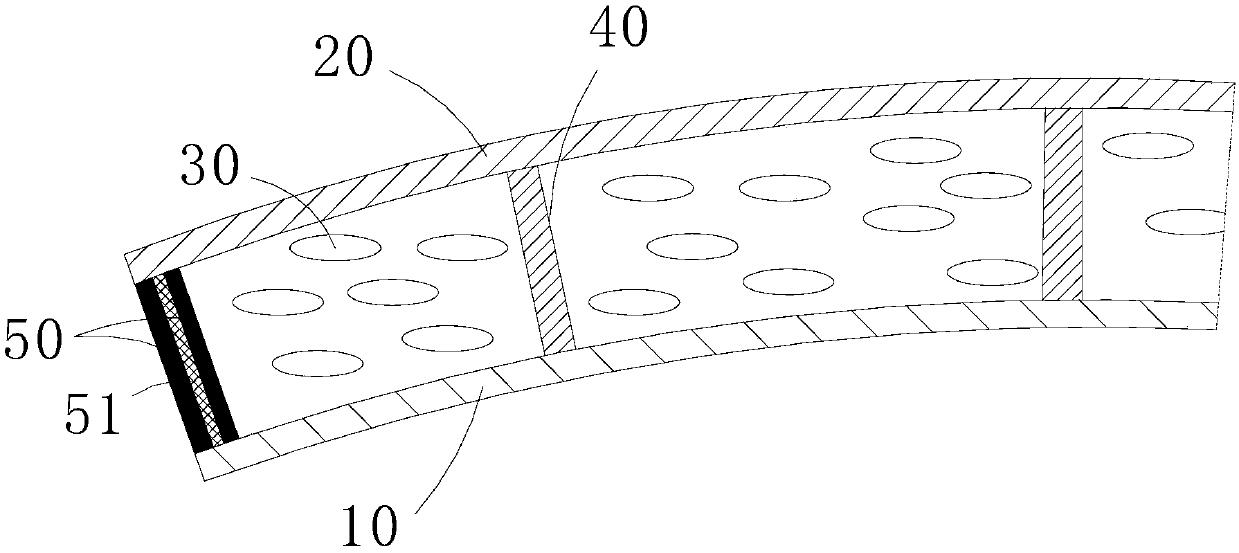

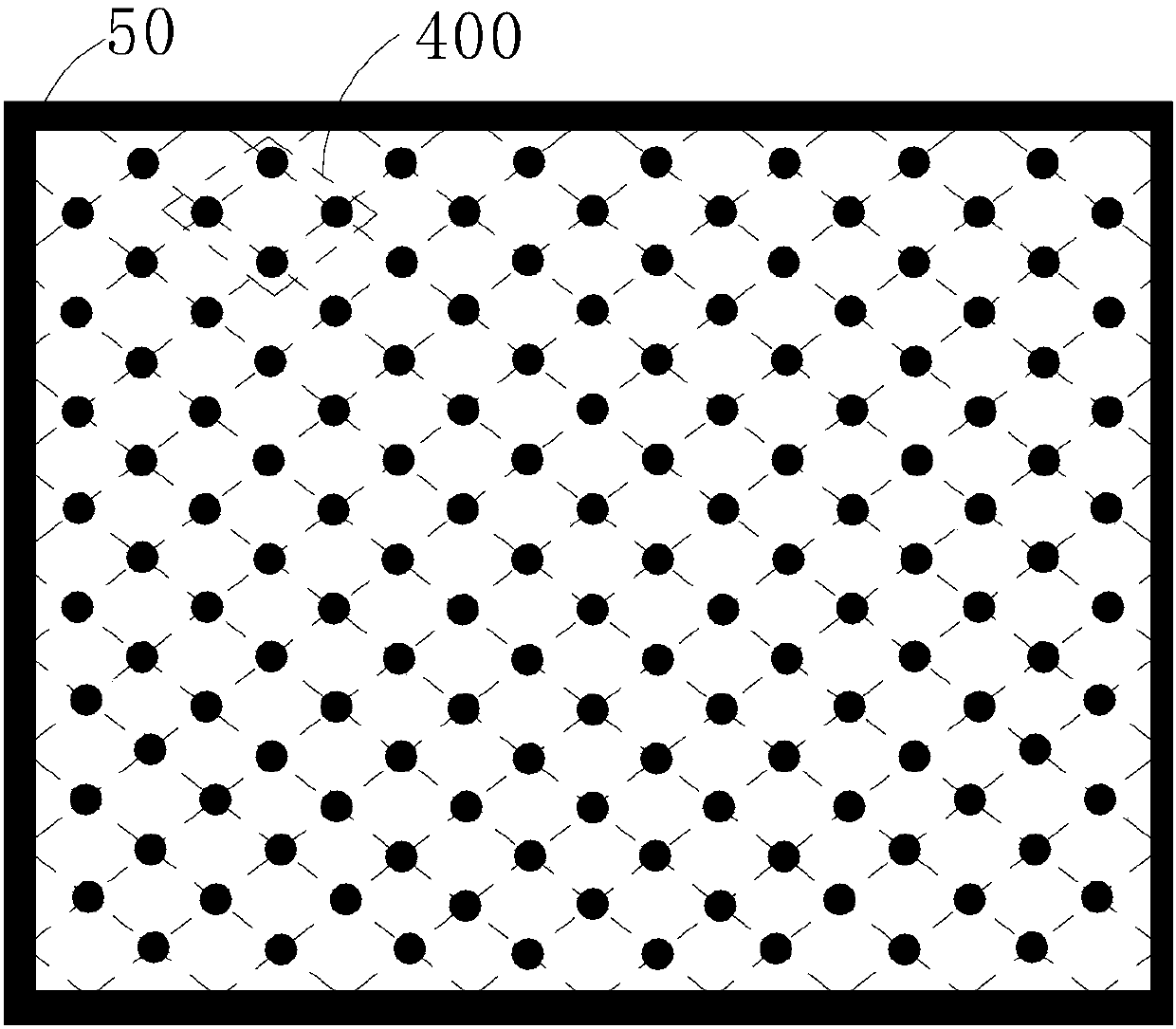

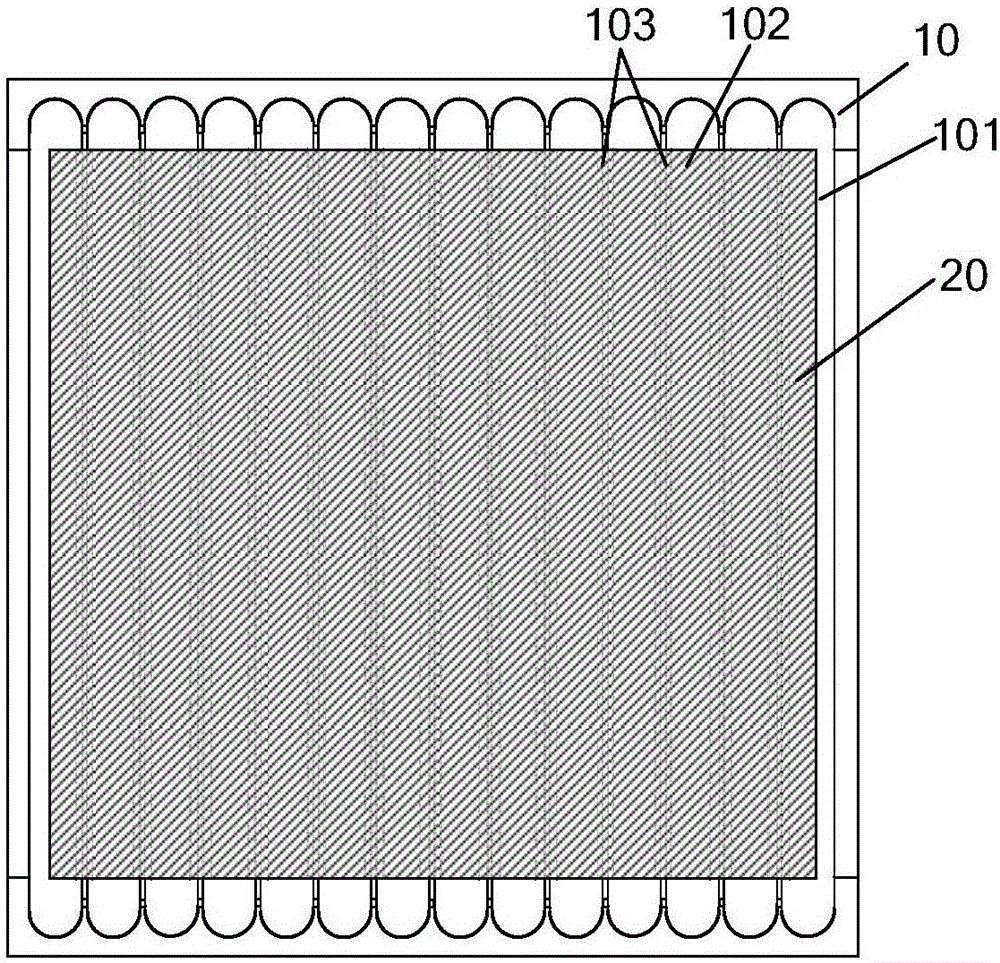

Splicable large-size liquid crystal display device and process method thereof

Provided in the invention is a splicable large-size liquid crystal display device comprising an upper frame, a lower frame and a side frame. The side frame serves as a splicing side frame of the display device and is used for transverse splicing of a plurality of display devices, wherein the width of the splicing side frame ranges from 0.6 mm to 0.8 mm; the upper frame and the lower frame or one of the upper frame and the lower frame is a conductive side frame, wherein the width of the conductive side frame is 1.5-2.0 mm. And a liquid crystal filling port of each display device is arranged atthe edge of the spliced side frame and is adjacent to the conductive side frame. In-box lining materials of a liquid crystal box of each display device are evenly distributed in the density range of 30 to 50 pieces per square millimeter, and the lining materials in the liquid crystal box are formed by mixing 5.0-5.5 microns of white silicon ball hard powder and 5.5-6.0 microns of black plastic soft powder. The width of the splicing side is very small, and the splicing side can be transversely and seamlessly spliced for use; and meanwhile, the position of the filling port is redesigned to adaptto the width of the splicing side. And the large-size liquid crystal display also enables a problem of non-uniform bottom color caused by overall change of the box thickness when the outdoor temperature is changed to be solved.

Owner:亚世光电(集团)股份有限公司

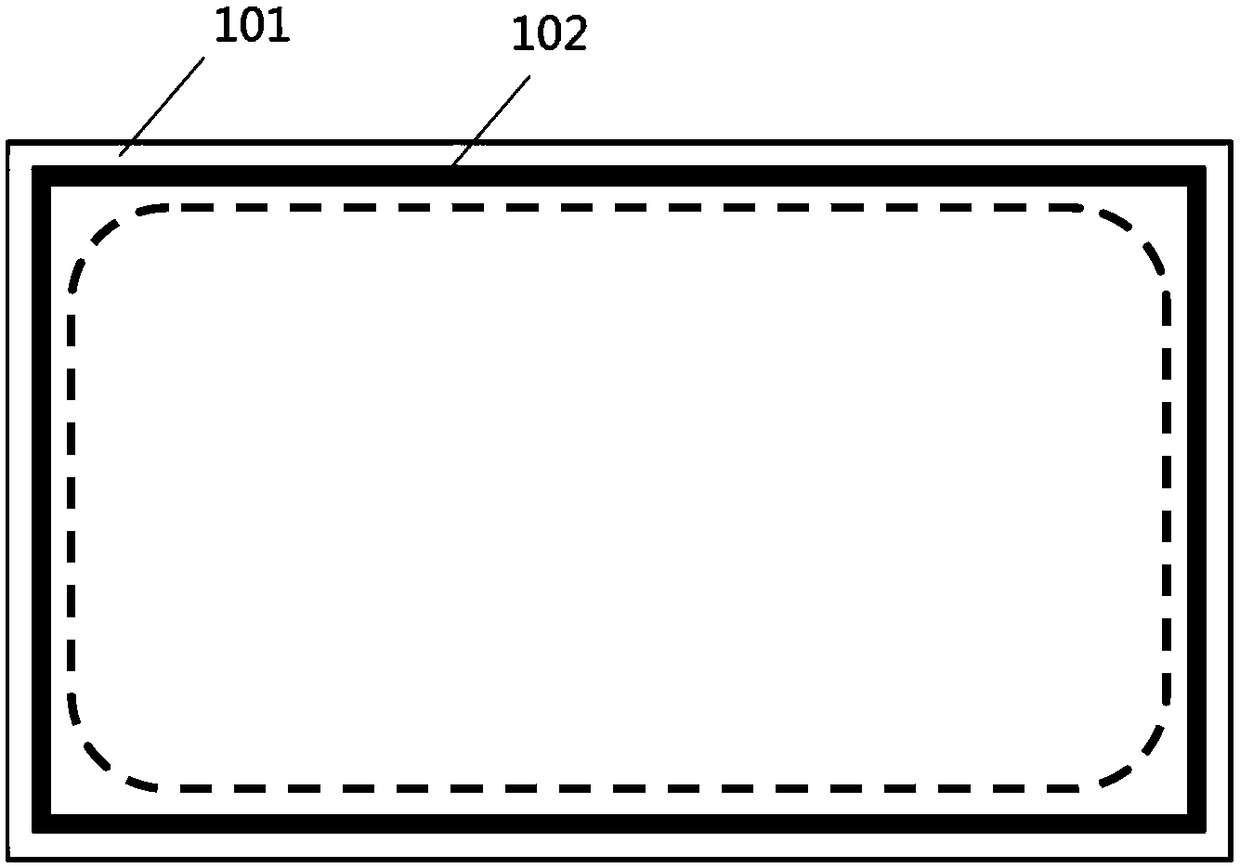

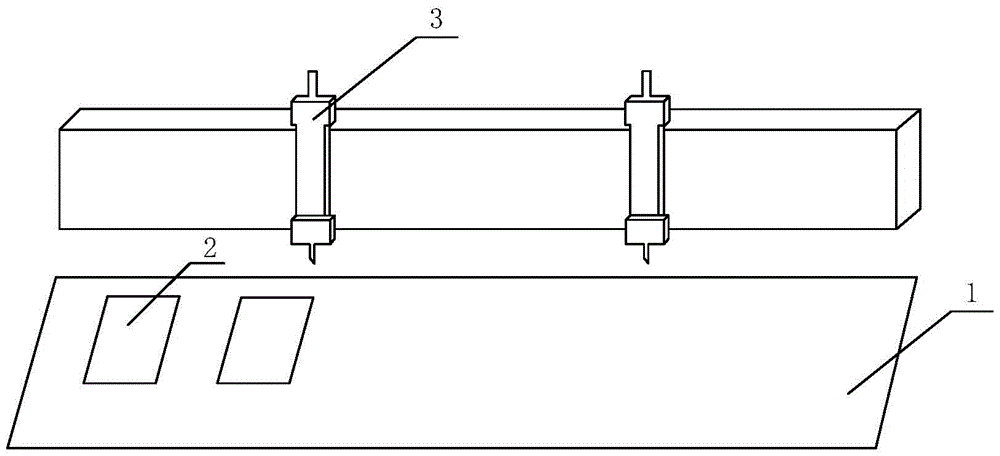

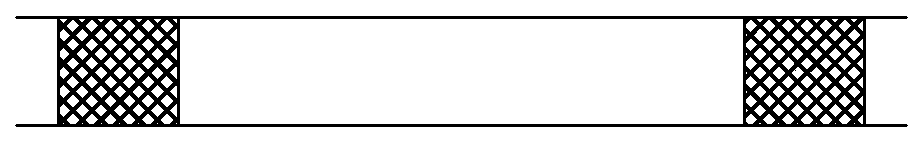

Coating method of border glue and substrate mother board

InactiveCN104007582BImprove coating efficiencyUniform box thicknessNon-linear opticsEngineeringMotherboard

The invention discloses a frame glue coating method and a substrate mother board, which belong to the field of display technology. The coating method comprises: coating equipment adopts a one-stroke continuous coating method to apply frame glue to a plurality of first substrates; When the equipment moves from one corner of the first substrate to one corner of the adjacent first substrate, the coating line is a broken line. The technical solution of the present invention can set the position of the intersection point of the sealant at the corner of the first substrate, so that Effectively reduces the mura problem caused by the non-uniform thickness of the box. At the same time, the coating method provided by the invention is also suitable for coating the first substrate with special typesetting on the substrate motherboard, so it can effectively reduce the coating on the substrate motherboard. The time it takes for the cloth to seal the frame.

Owner:BOE TECH GRP CO LTD +1

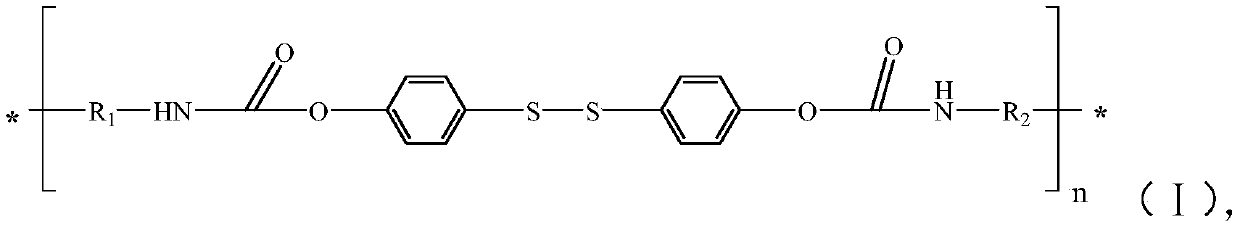

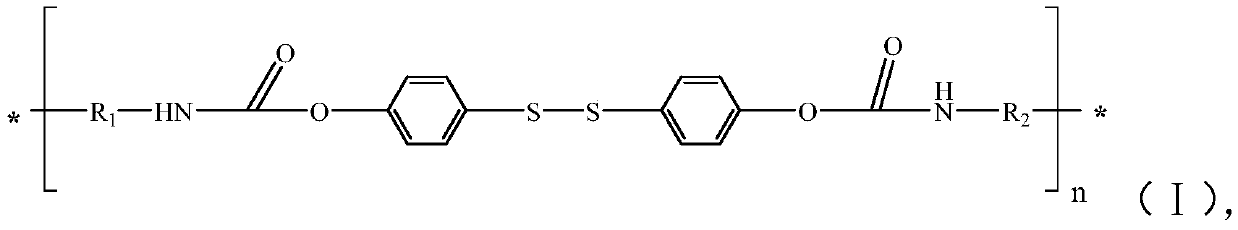

A kind of photosensitive resin composition and its preparation method and application

ActiveCN109100918BIncrease elasticityStable structurePhotosensitive materials for photomechanical apparatusPolymer sciencePhotoinitiator

The invention provides a photosensitive resin composition for a light spacer, which comprises a photopolymerization monomer, a resin composition, an auxiliary agent, a photoinitiator and a solvent ina specific ratio, wherein the resin composition comprises a modified polyurethane of a specific structure, an alkali-soluble resin, an acrylate resin and an epoxy acrylate resin, and the modified polyurethane has self-healing property. A light spacer film layer formed from the photosensitive resin composition can have good elastic recovery and strong adhesion to the substrate. The obtained opticalspacer film scrapes in the process of large curvature bending, which can also recover quickly and reduce the risk of the optical spacer pattern fracture. The invention also provides a preparation method and an application of the photosensitive resin composition.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

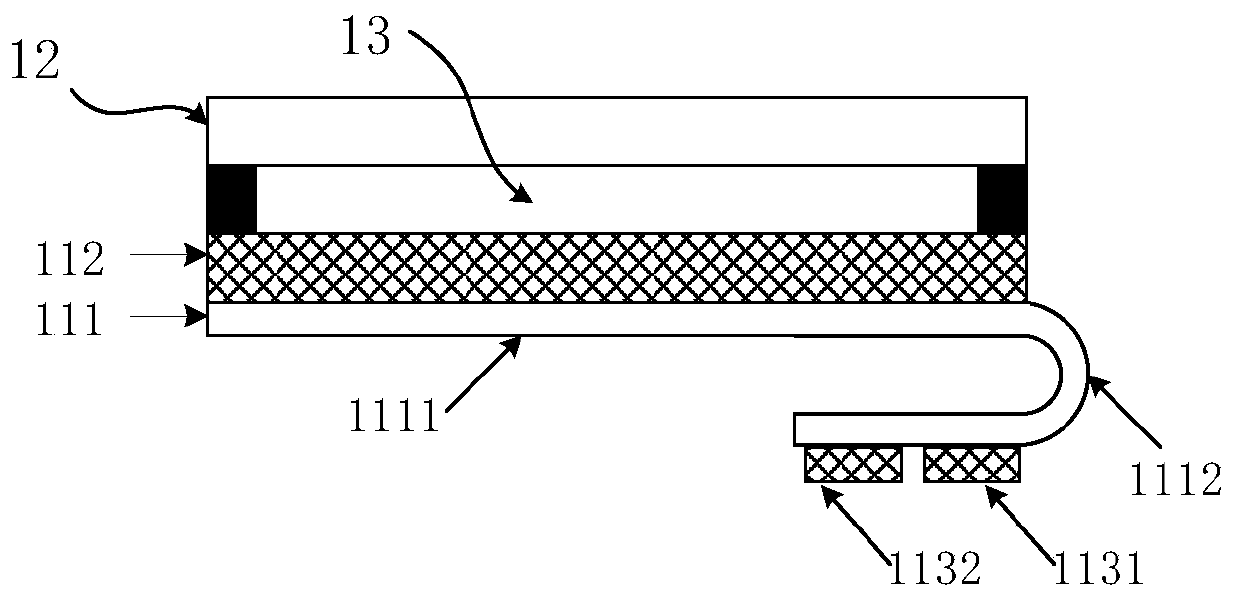

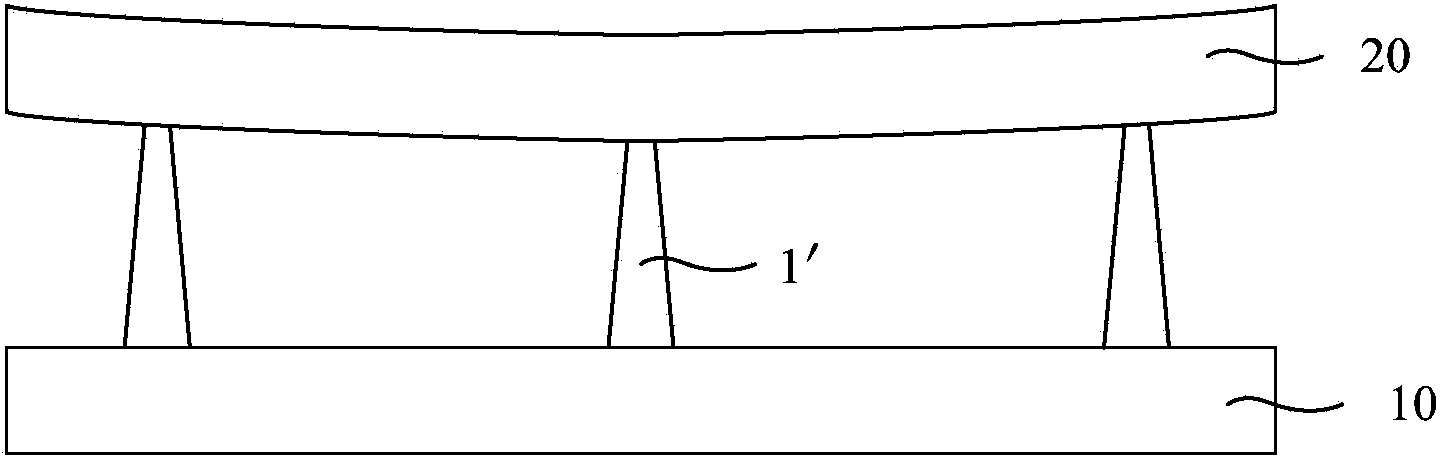

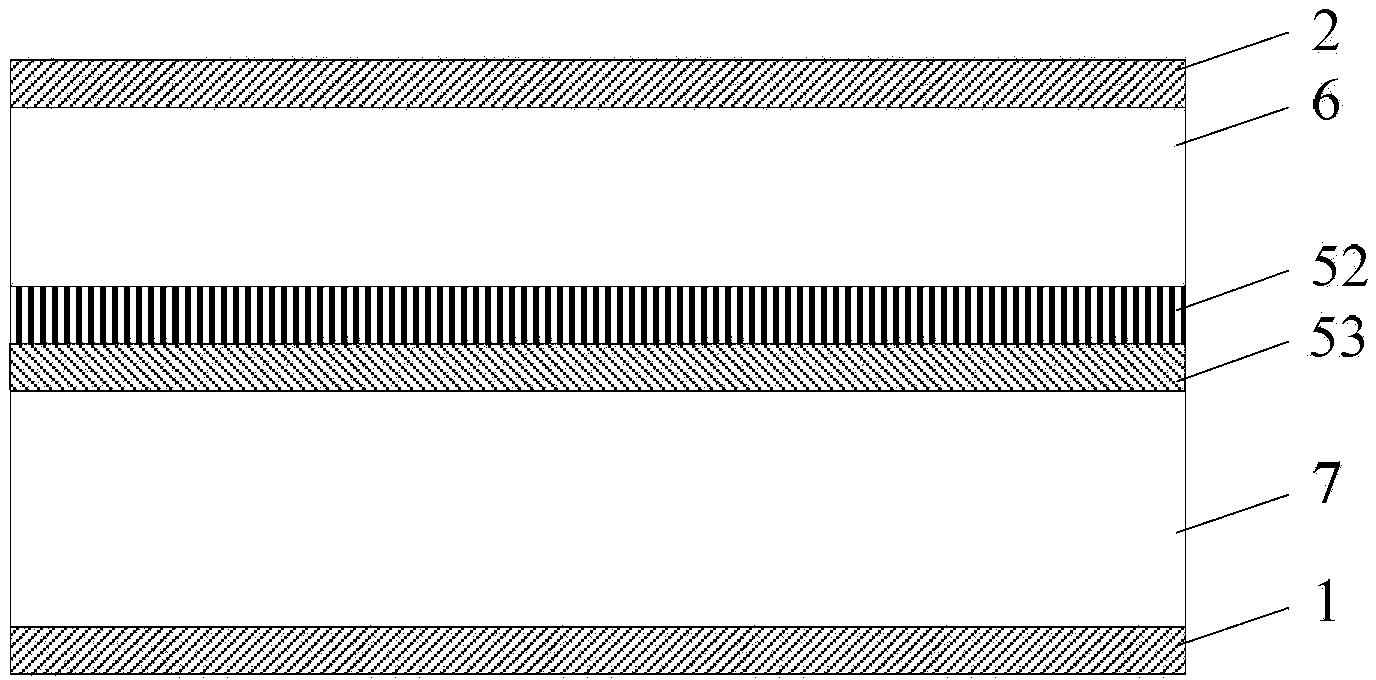

Liquid crystal display and manufacturing method thereof

ActiveCN108153063BUniform box thicknessFacilitate the realization of flexible displayNon-linear opticsLiquid-crystal displayDisplay device

The invention provides a liquid crystal display and a manufacturing method thereof. The manufacturing method of the liquid crystal display includes the steps: providing an upper substrate and a lowersubstrate; arranging a spherical shock insulator between the upper substrate and the lower substrate; connecting the shock insulator to the upper substrate and the lower substrate in a chemical bond mode or physical adhesion mode. By the manufacturing method, when the manufactured liquid crystal display deforms in a bending manner, the shock insulator cannot be broken or break away from the substrates, the thickness of a liquid crystal box is uniform, flexible display can be implemented, and the quality and the production yield of the flexible liquid crystal display are improved. The liquid crystal display manufactured by the manufacturing method has the advantages that the shock insulator cannot be broken or break away from the substrates, the thickness of the liquid crystal box is uniform, and flexible display can be implemented.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

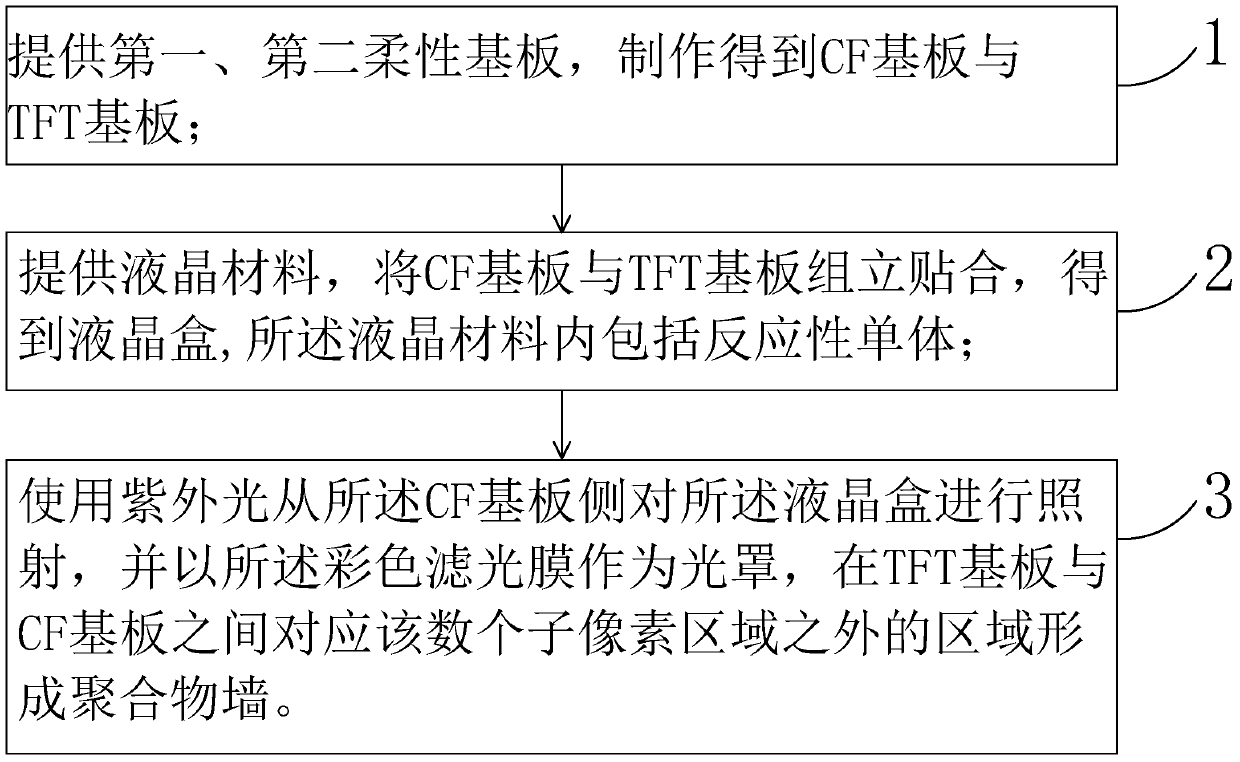

Manufacturing method of flexible liquid crystal display panel

The invention discloses a production method of a flexible liquid crystal display panel. Ultraviolet light is used to irradiate a liquid crystal box from a CF substrate, a color filter film of the CF substrate is utilized as a photomask, as a plurality of filter units which are formed on the color filter film corresponding to a plurality of sub-pixel areas have a shielding function to the ultraviolet light, under the irradiation of the ultraviolet light, reactive monomers mixed in liquid crystal materials correspondingly form a polymer wall in an area between a TFT (Thin Film Transistor) substrate and the CF substrate except for the plurality of sub-pixel areas, the polymer wall can surround liquid crystal molecules to prevent liquid crystal from flowing when the liquid crystal display panel is bent, so that the liquid crystal display panel can be maintained at a more uniform box thickness when being bent, the use of an additional photomask is saved, the production method is simple, and the production cost is low.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Display device and manufacturing method thereof

ActiveCN102854628BUniform box thicknessImprove display qualityNon-linear opticsOptical elementsGratingDisplay device

The invention provides a display device and a manufacturing method thereof. The display device comprises a display panel and a grating arranged on the light-emitting side of the display panel. The upper surface of the display panel and the lower surface of the grating are parallel to each other and are arranged adjacently. Box-thickness supporting layers are overlaid between the upper surface of the display panel and the lower surface of the grating and comprise at least one layer of support bodies. For each layer of support bodies, adhesion agents are filled in gaps between the support bodies, and the heights of the support bodies positioned at different positions are equal, so that the vertical distances from different position points on the upper surface of the display panel to the lower surface of the grating are equal. According to the display device and the manufacturing method of the display device, the space between the grating and the display device can be kept uniform, and accordingly the display quality of the display device and the product yield are improved.

Owner:BOE TECH GRP CO LTD

Liquid crystal display panel structure and manufacturing method thereof

ActiveCN101546069BImprove support strengthImprove conductivityNon-linear opticsLiquid-crystal displayAdhesive

The invention discloses a liquid crystal display panel structure and a manufacturing method thereof, belonging to the technical field of the liquid crystal displays and being invented aiming to improve the display quality of the liquid crystal display. The liquid crystal display panel structure comprises a color film substrate and an array substrate which are oppositely arranged, supporting spacers are evenly distributed in a display area at one side of the color film substrate relative to the array substrate, the edge at one side of the color film substrate relative to the array substrate isstuck with the edge at one side of the array substrate relative to the color film substrate through frame sealing adhesive to form a closed area, and the closed area is filled with liquid crystals; aconducting spacer is arranged on the edge at one side of the color film substrate relative to the array substrate and is embedded in the frame sealing adhesive, and both ends of the conducting spacerare respectively in contact with the two substrates to realize the electric connection between the two substrates; and the conducting spacer has good supporting strength and good electric conductivity. The invention is suitable for improving the display quality of the liquid crystal display.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com