Display device and manufacturing method thereof

A technology for a display device and a manufacturing method, which is applied in optics, instruments, nonlinear optics, etc., can solve problems affecting display quality, uneven bonding pressure spacing, and increased production costs, so as to improve display quality and product yield, The thickness of the box remains uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

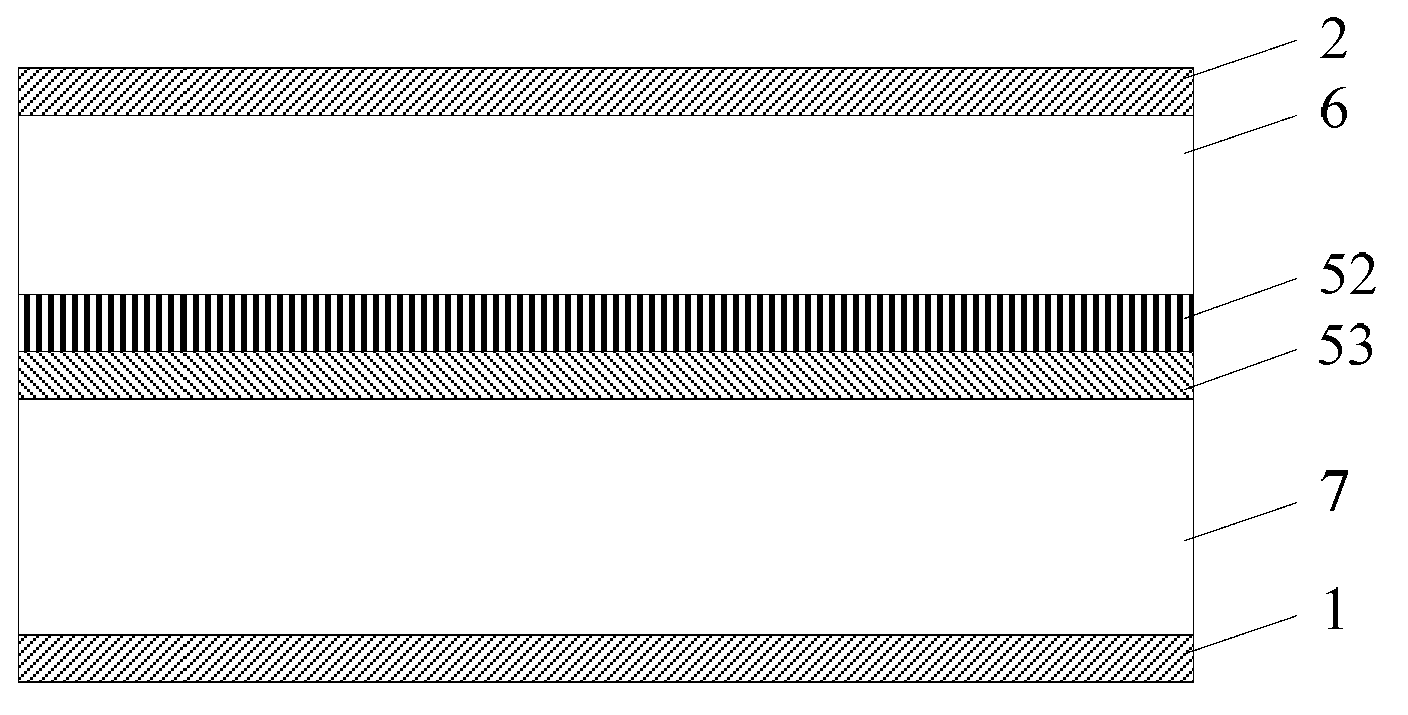

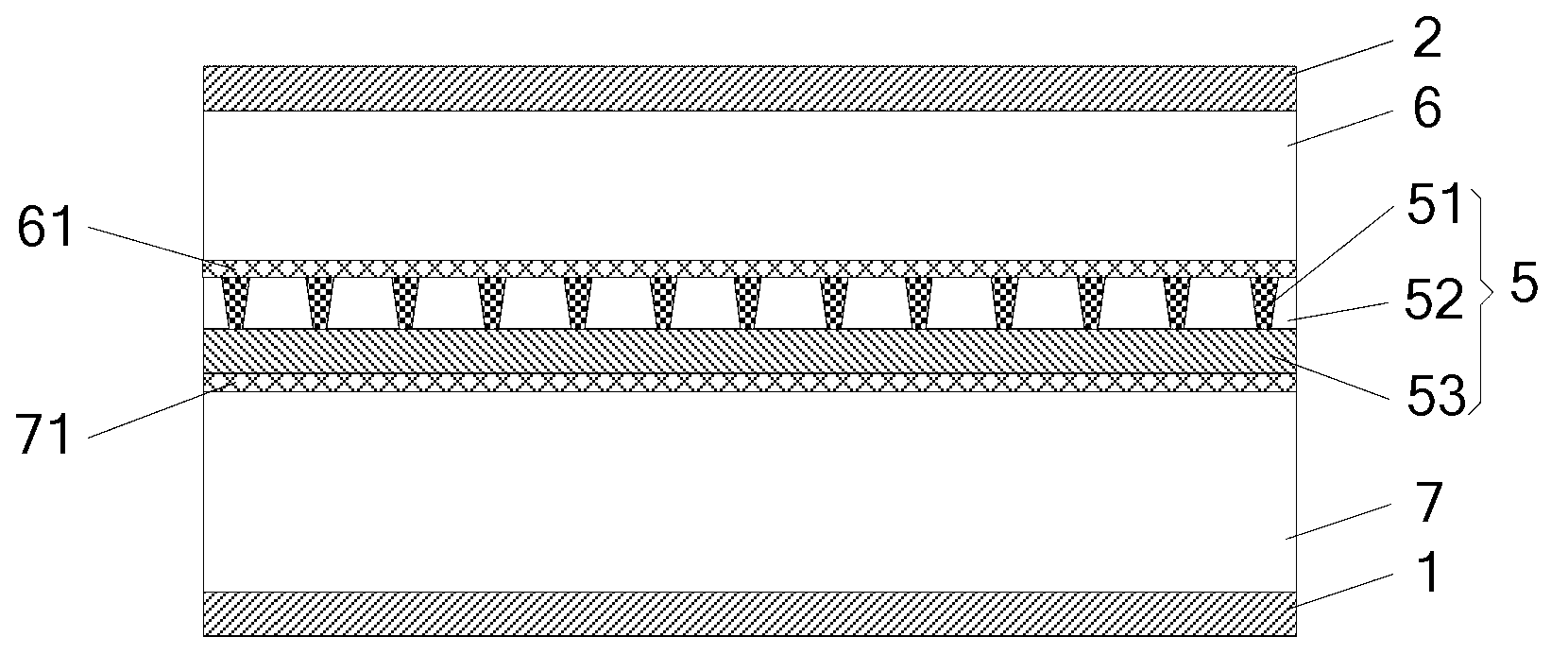

[0058] In the liquid crystal display device provided in Embodiment 1 of the present invention, the cell-thick support layer only includes one layer of support body, and the inter-cell polarizer can be installed on the upper surface of the substrate of the display panel and the lower surface of the lower substrate of the liquid crystal grating. The upper surface of the upper substrate of the selected display panel in the inter-cell polarizer can be arranged as the inter-cell polarizer, and the supporting body can form a surface including the lower surface of the lower substrate of the liquid crystal grating and the upper surface of the inter-cell polarizer (that is, non-bonding side of the polarizer in the box). Combine below figure 2 The structure of the liquid crystal display device provided by Embodiment 1 of the present invention will be described in detail.

[0059] like figure 2 As shown, the liquid crystal display device in this embodiment includes a first polarizer ...

Embodiment 2

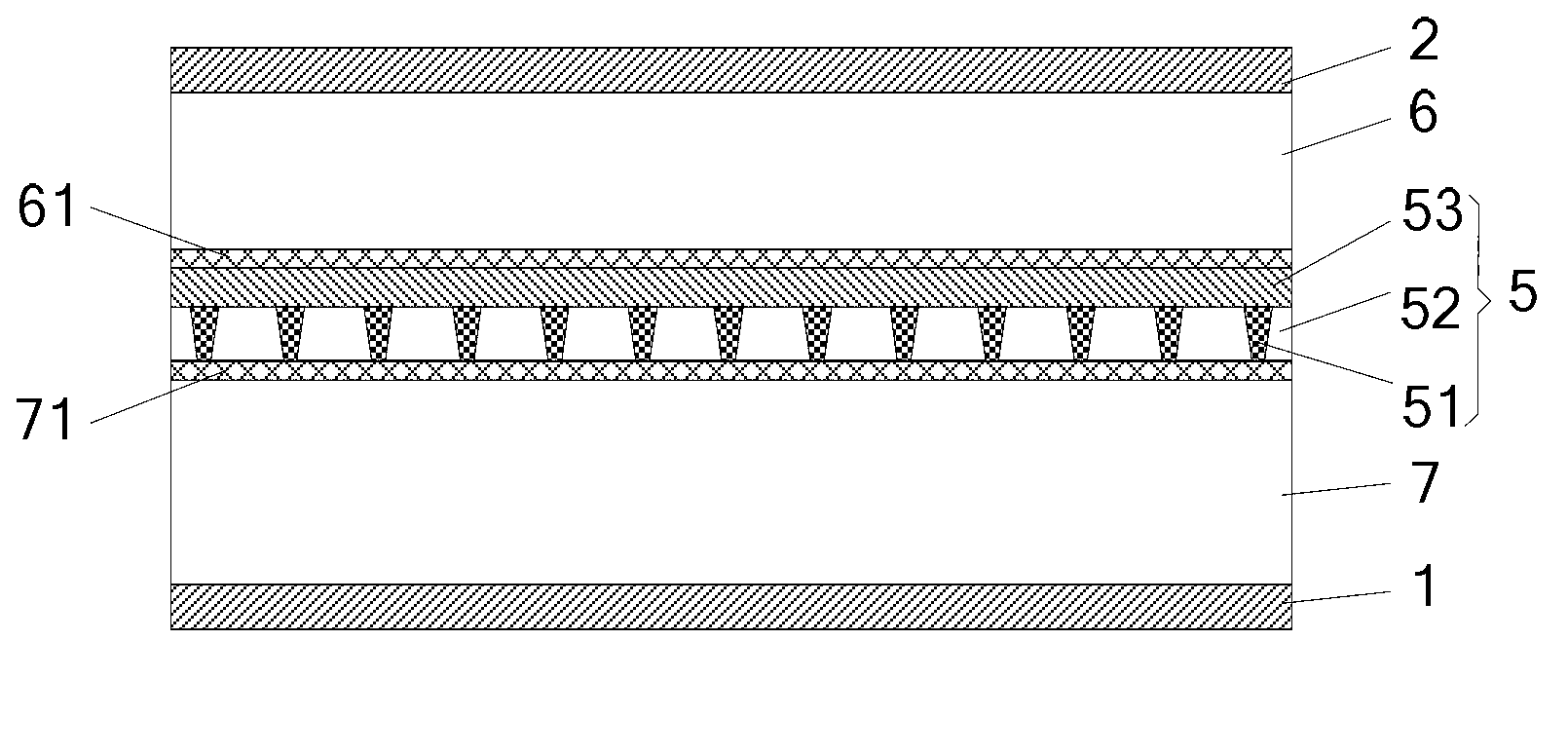

[0063] In the liquid crystal display device provided in Embodiment 2 of the present invention, the cell-thick support layer only includes one layer of support body, and the inter-cell polarizer can be arranged on the upper surface of the substrate of the display panel and the lower surface of the lower substrate of the liquid crystal grating. The setting surface of the polarizer is selected as the lower surface of the lower substrate of the liquid crystal grating, and the surface on which the support body can be formed includes the upper surface of the upper substrate of the display panel and the lower surface of the inter-cell polarizer. Combine below image 3 The structure of the liquid crystal display device provided by Embodiment 2 of the present invention will be described in detail.

[0064] like image 3 As shown, the liquid crystal display device provided by Embodiment 2 of the present invention also includes a first polarizer 1, a display panel 7, a cell thickness su...

Embodiment 3

[0067]In the liquid crystal display device provided in Embodiment 3 of the present invention, the cell-thick support layer includes a layer of spacer substrate and two layers of support bodies, the support body located below the spacer substrate is called the first layer of support body, and the support body located above the spacer substrate It is called the second layer of support; the inter-cell polarizer can be arranged on the surface including the upper surface of the upper substrate of the display panel, the lower surface of the lower substrate of the liquid crystal grating, the lower surface and the upper surface of the spacer substrate; the inter-cell polarizer is selected as The upper surface of the upper substrate of the display panel; the surface on which the support can be formed includes the lower surface and the upper surface of the spacer substrate, the lower surface of the lower substrate of the liquid crystal grating, and the upper surface of the inter-cell pola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com