Patents

Literature

1331results about How to "Improve coating efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

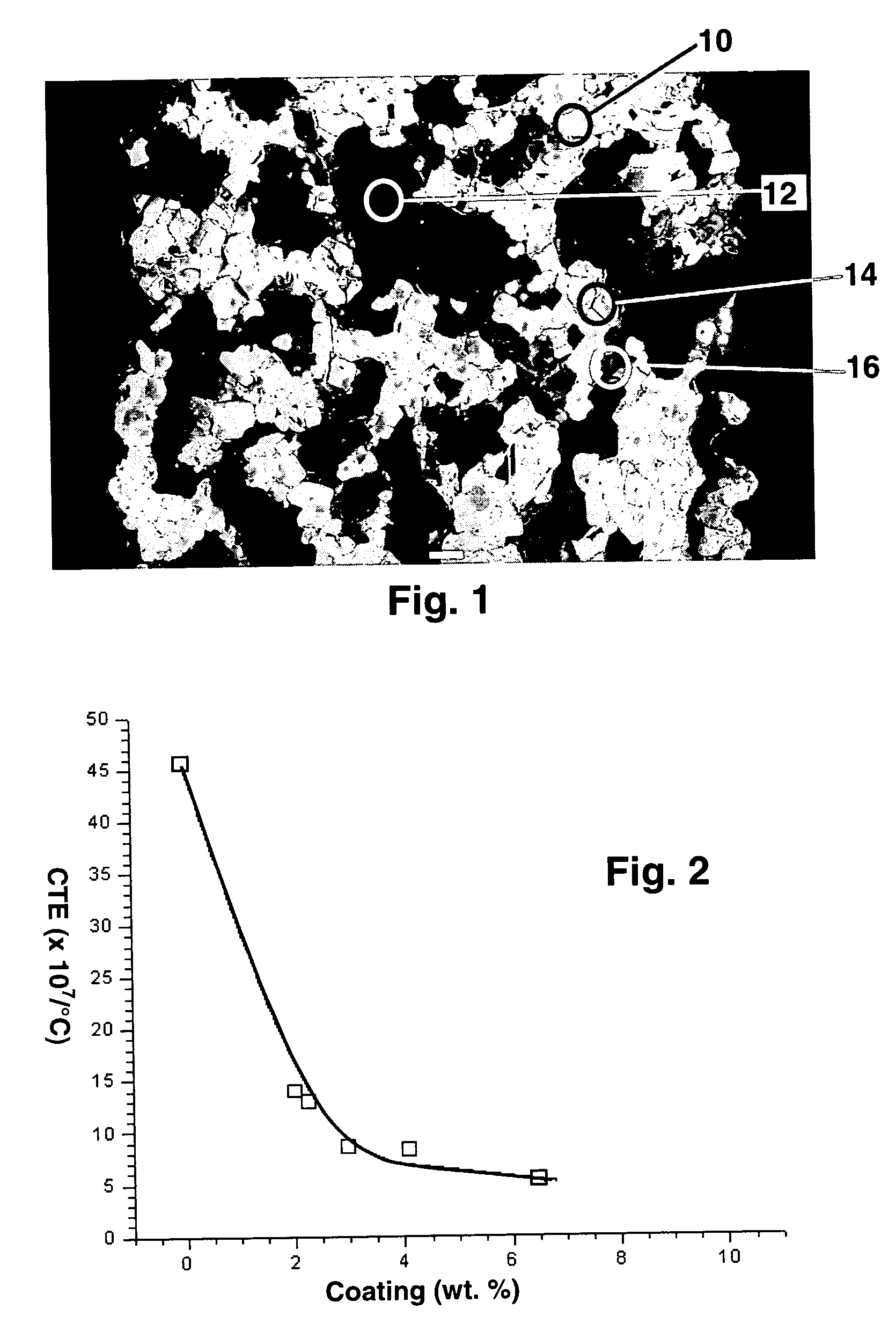

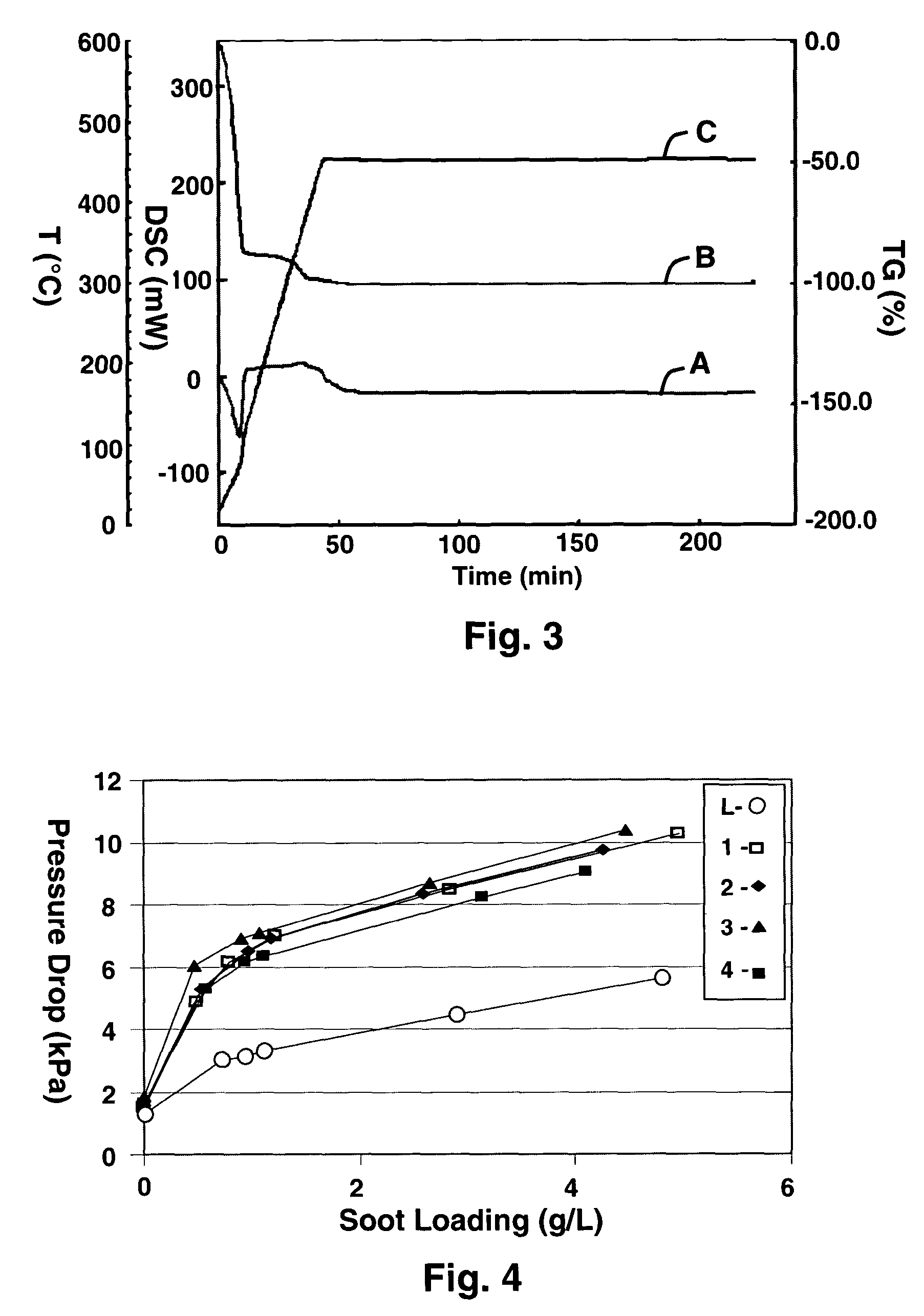

Porous ceramic filters with catalyst coatings

ActiveUS20050037147A1Easy to disassembleHigh porosityDead plant preservationArtificial flowers and garlandsNanoparticleBiological activation

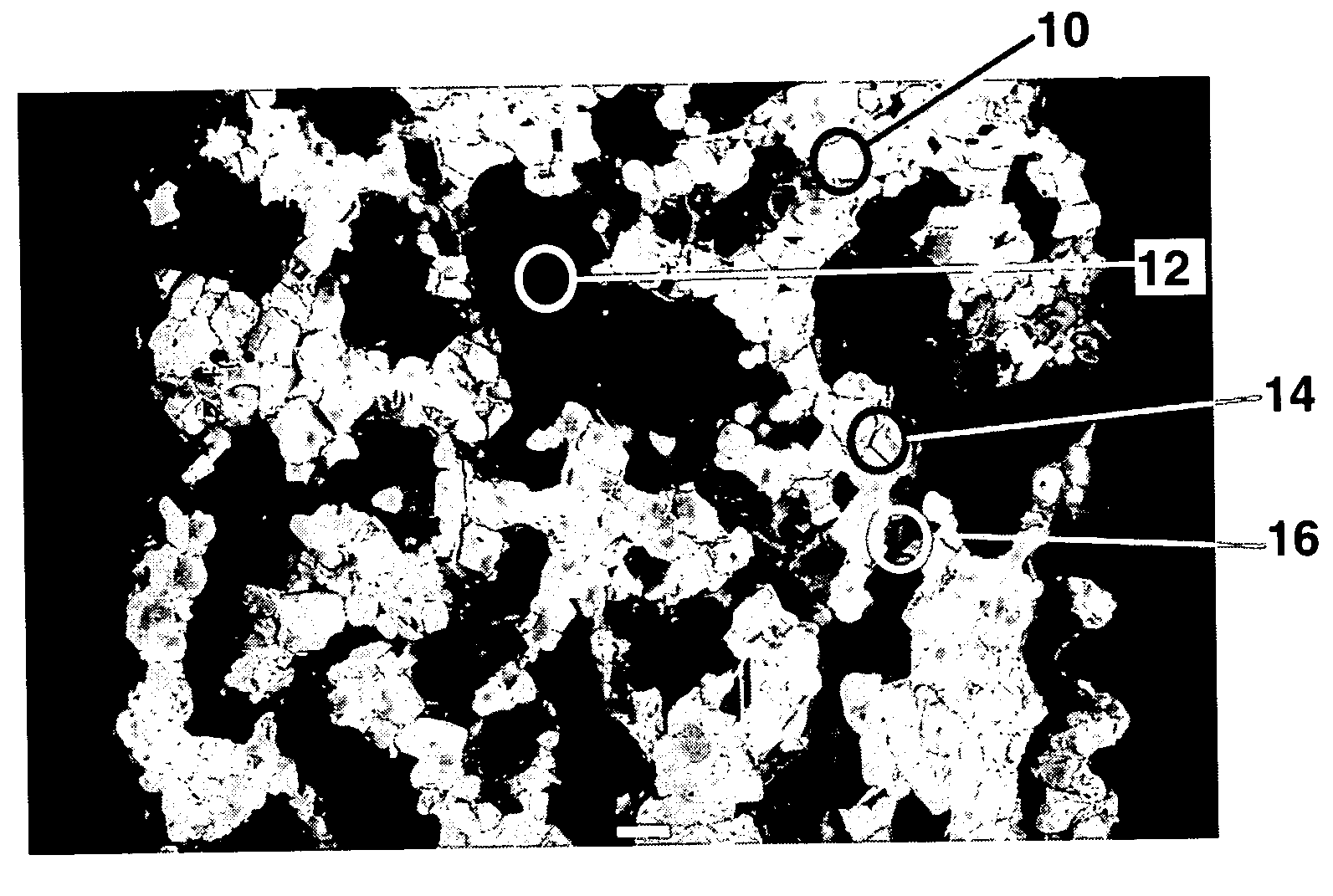

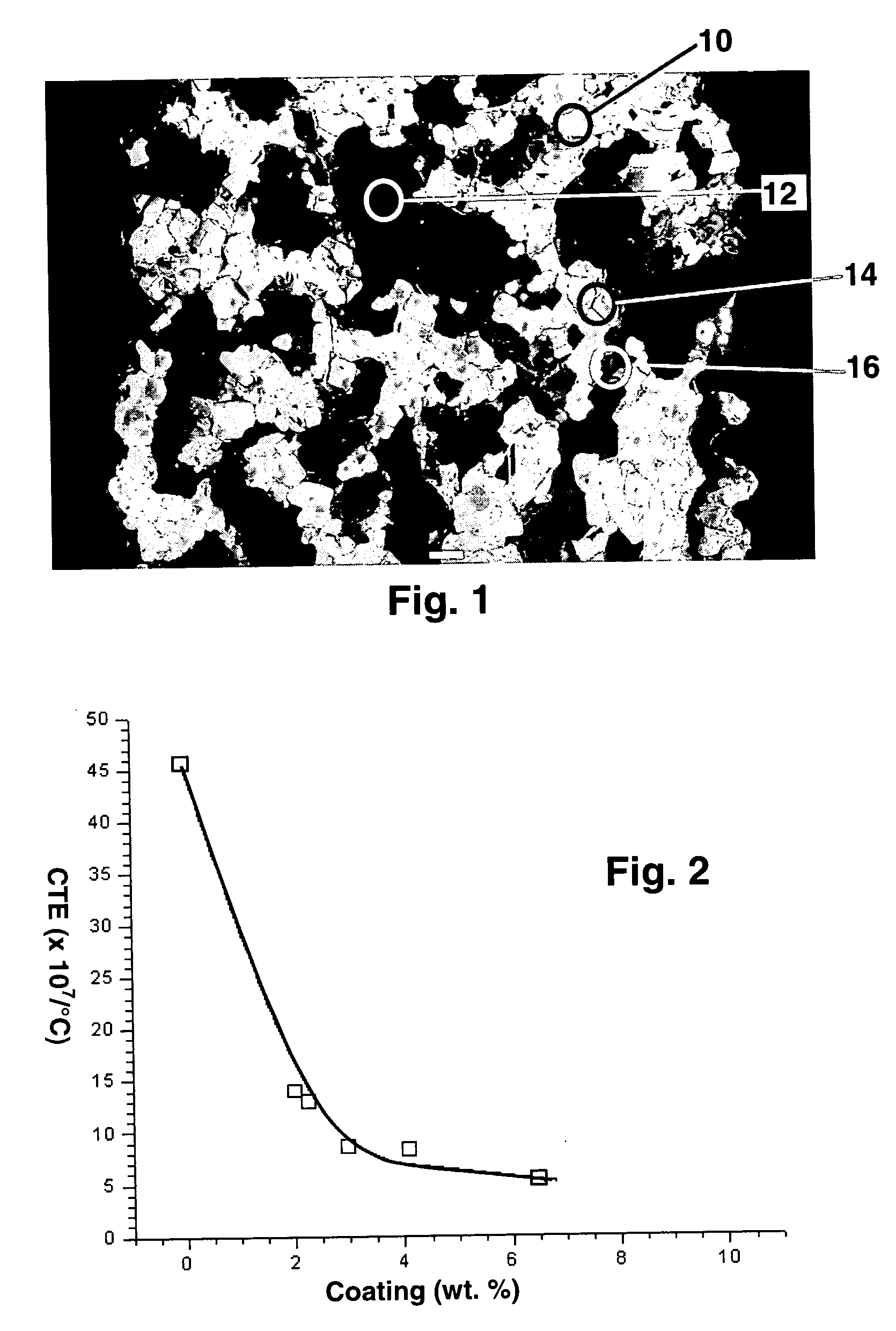

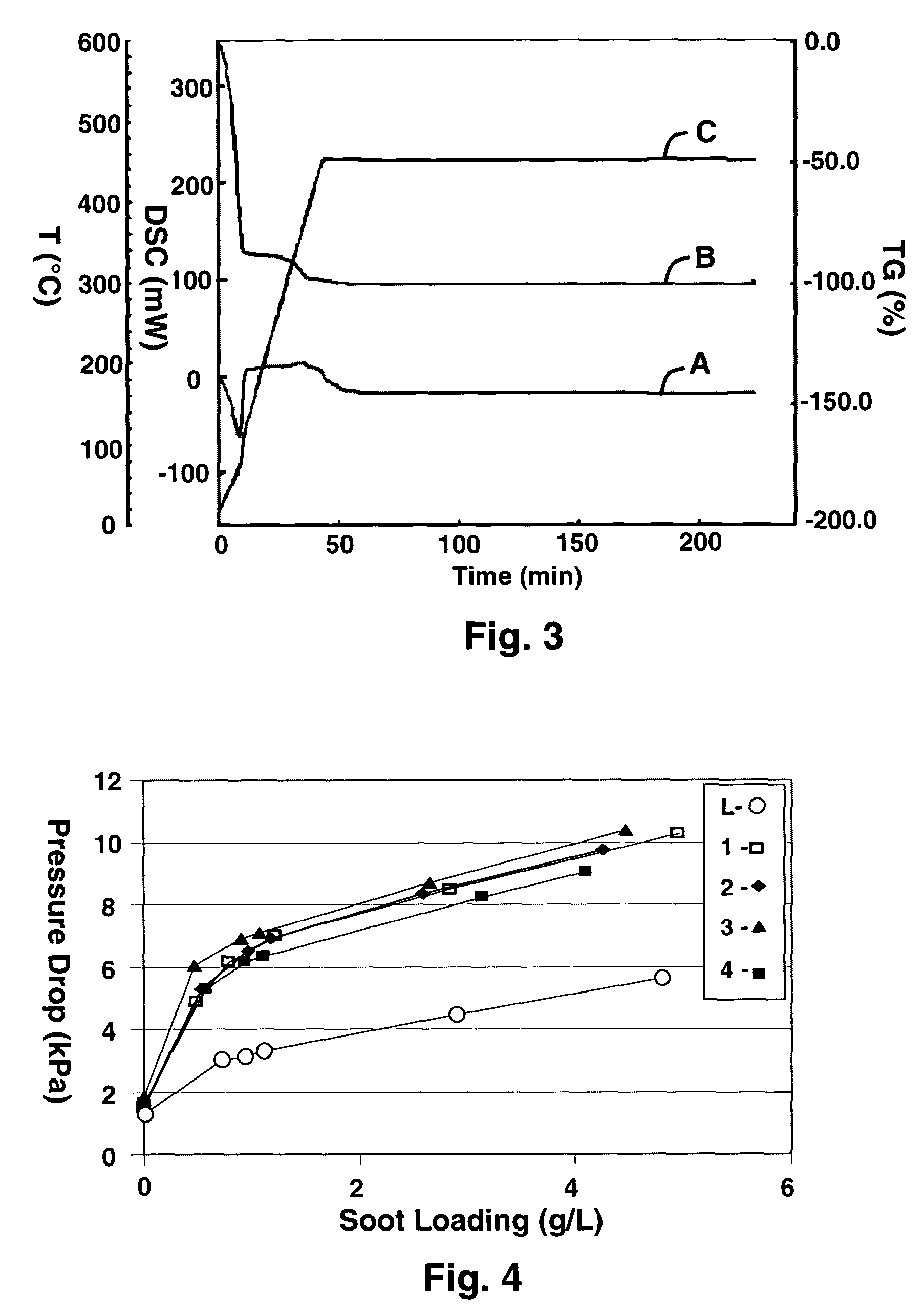

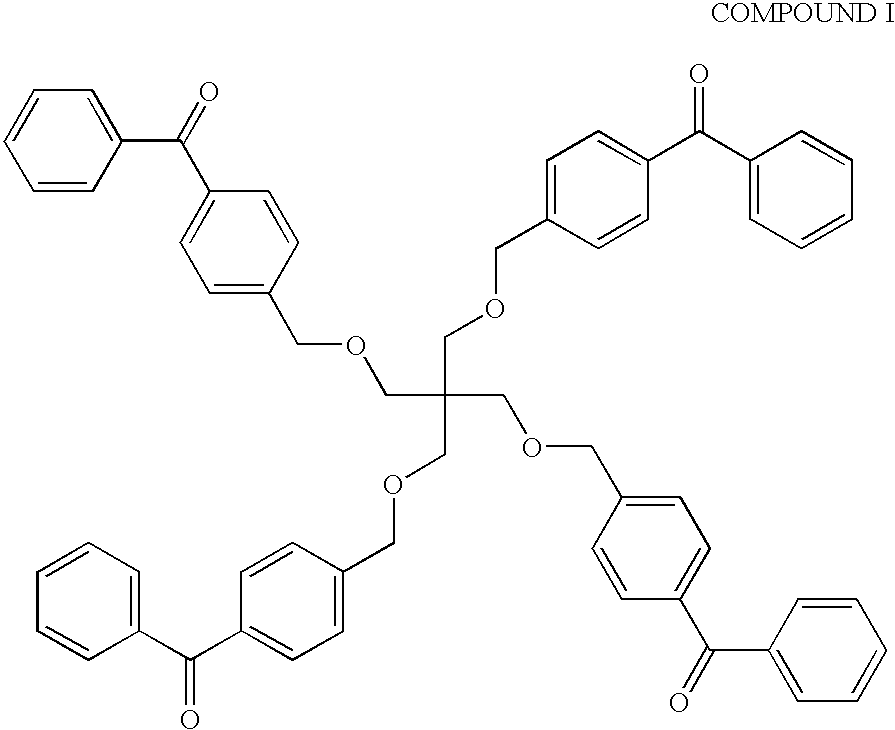

Porous ceramic catalyst supports or filters to be provided with catalyst coatings via oxide washcoating processes are pre-coated with polymer barrier layers to prevent washcoat nanoparticle intrusion into the microcracked and / or microporous surfaces of the ceramics, the barrier coatings being formed of hydrocarbon polymers that are soluble or dispersible in polar media, capable of forming neutral or hydrophilic surfaces on porous ceramic supports, and completely vaporizable at moderate washcoat stabilization or catalyst activation temperatures.

Owner:CORNING INC

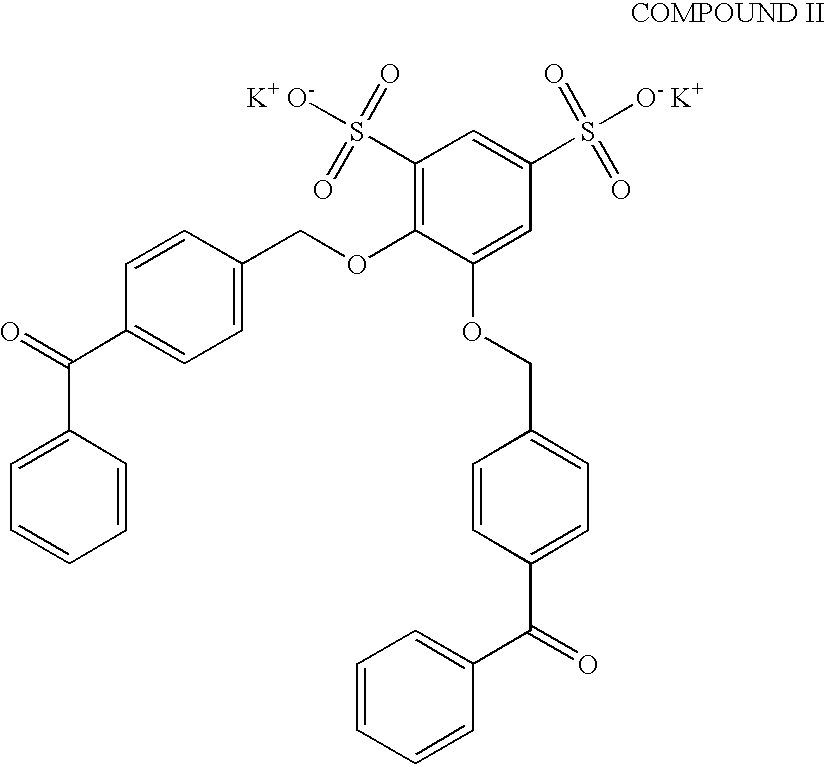

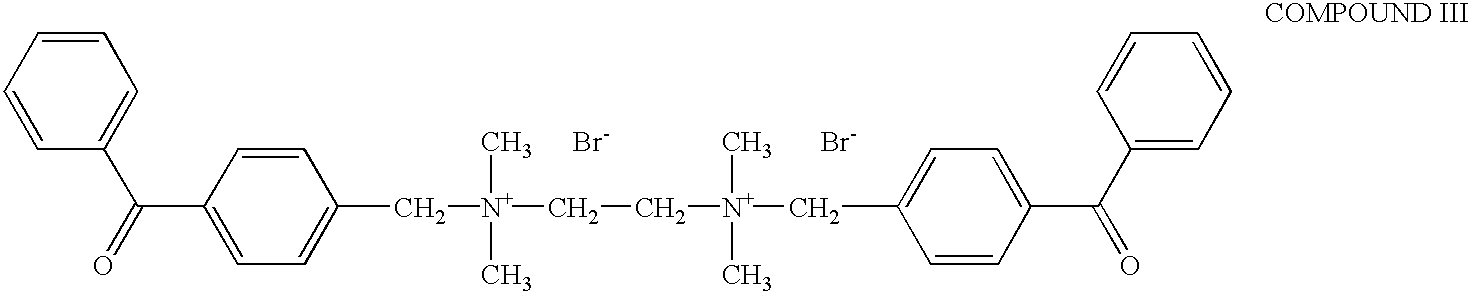

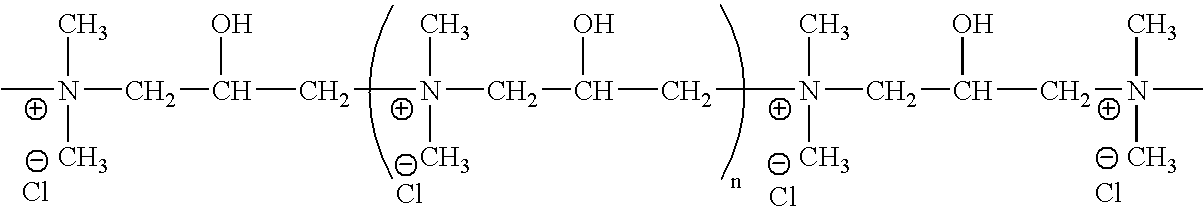

Reagent and method for providing coatings on surfaces

InactiveUS20030165613A1Easy to controlImprove coating efficiencyMaterial nanotechnologySurgeryPorosityBiological activation

A grafting reagent and related method of using the reagent to form a polymeric layer on a support surface, and particularly a porous support surface, in a manner that provides and / or preserves desired properties (such as porosity) of the surface. The reagent and method can be used to provide a thin, conformable, uniform, uncrosslinked coating having desired properties onto the surface of a preformed, and particularly a porous, polymeric substrate. The method includes the steps of a) providing a porous support surface, b) providing a nonpolymeric grafting reagent comprising a photoinitator group, c) providing one or more polymerizable monomers adapted to be contacted with the surface, in the presence of the grafting reagent, and to be polymerized upon activation of the photoinitiator; and d) applying the grafting reagent and monomer(s) to the surface in a manner, and under conditions, suitable to coat the surface with the grafting reagent and to cause the polymerization of monomers to the surface upon activation of the grafting reagent.

Owner:SURMODICS INC

Thin and thermal insulation inner wall paint, preparation method and construction method thereof

ActiveCN101085892AImprove the decorative effectLow costFireproof paintsEmulsion paintsPolymer scienceMicrosphere

The invention discloses a kind of thin thermal insulating inner wall paint. The comprised components and their weight proportion are as follows: styrene-acrylic emulsion 28- 35%, titanium dioxide 8- 13%, fillings 10- 18%, borosilicate hollow microsphere 6- 12%, water- brone nanometer anti- pollution agent 0.5- 2%, defoaming agent 0.3- 0.5%. Said hollow microsphere is hollow white spherical powder with thin wall, the main component is silicon dioxide and diboron trioxide, the real density is small and heat conductive coefficient is 0.04- 0.08 w / m.k. The invention aslo discloses the preparation and construction method for said paint. It employs high pressure airless painting process for construction, the aperture of employed gunjet nozzle is 0.6- 0.8 mm, atomization pressure is 15- 18 Mpa, and when the coating layer is 0.3- 1.0 mm, the coating layer is homogeneous and tight, and the thermal insulating effect is good. The paint is especially suitable for building inner wall and ceiling painting.

Owner:上海秀珀化工有限公司

Preparation method of high-reaction-activity hydroxyl acrylic resin

InactiveCN103130944AImprove molecular structureHigh glass transition temperaturePolyurea/polyurethane coatingsAcrylic resinSolvent

The invention relates to a preparation method of high-reaction-activity hydroxyl acrylic resin. According to the invention, a solvent in a reactor is heated to a preset temperature under the protection of an inert gas; a mixture of a monomer component A with hard monomer as a main component (and comprising a small amount of soft monomer, hydroxyl monomer and carboxyl monomer) and an initiation agent is slowly added; a reaction is carried out for a certain period of time with maintained temperature; a mixture of a monomer component B with soft monomer as a main component (and comprising a small amount of hard monomer, hydroxyl monomer and carboxyl monomer) and an initiation agent is slowly added; and reaction is carried out for a certain period of time with maintained temperature, such that acrylic resin comprising hydroxyl is obtained. The invention has the characteristic that common monomers are adopted, and only the synthesis process is changed wherein monomer dropping sequence is changed, such that resin molecular structure is substantially changed, and the synthesized hydroxyl acrylic resin shows high reaction activity during a curing reaction. The method provided by the invention also has the advantages of low cost, simple process, and suitability for industrialized productions.

Owner:XI AN JIAOTONG UNIV +1

Porous ceramic filters with catalyst coatings

ActiveUS7132150B2Improve washcoating characteristicEasy to disassemblePretreated surfacesLight effect designsNanoparticleNanometre

Porous ceramic catalyst supports or filters to be provided with catalyst coatings via oxide washcoating processes are pre-coated with polymer barrier layers to prevent washcoat nanoparticle intrusion into the microcracked and / or microporous surfaces of the ceramics, the barrier coatings being formed of hydrocarbon polymers that are soluble or dispersible in polar media, capable of forming neutral or hydrophilic surfaces on porous ceramic supports, and completely vaporizable at moderate washcoat stabilization or catalyst activation temperatures.

Owner:CORNING INC

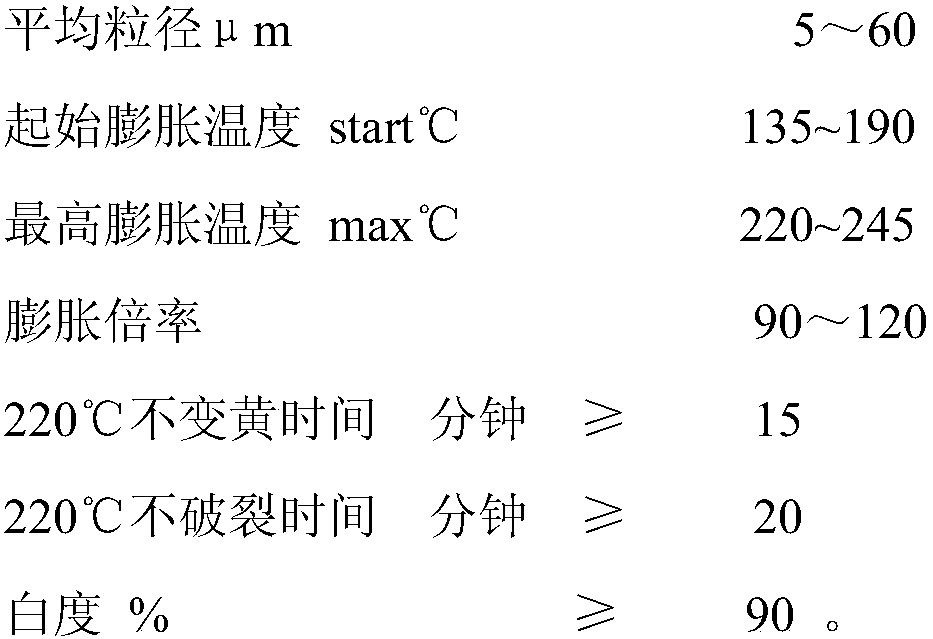

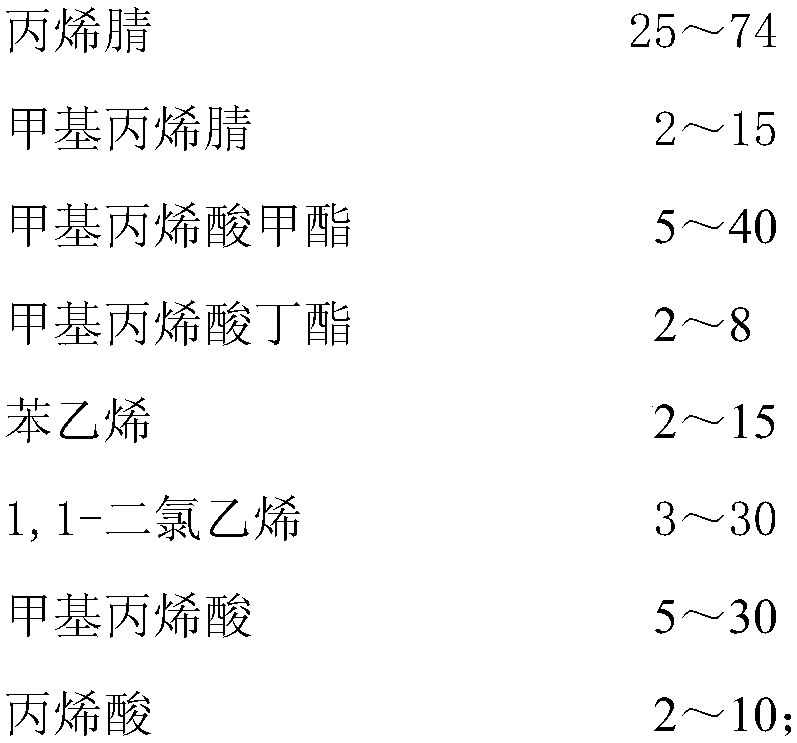

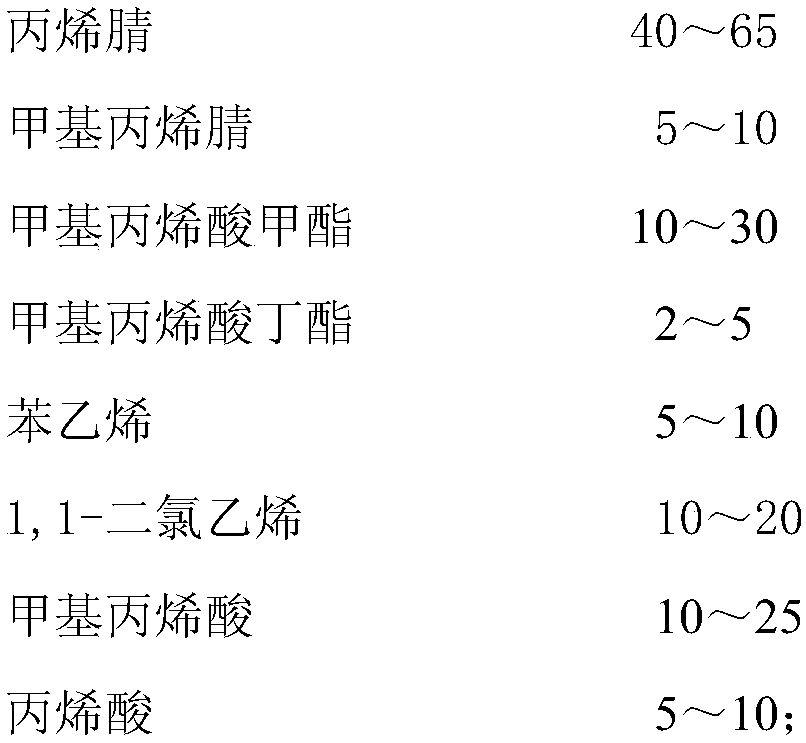

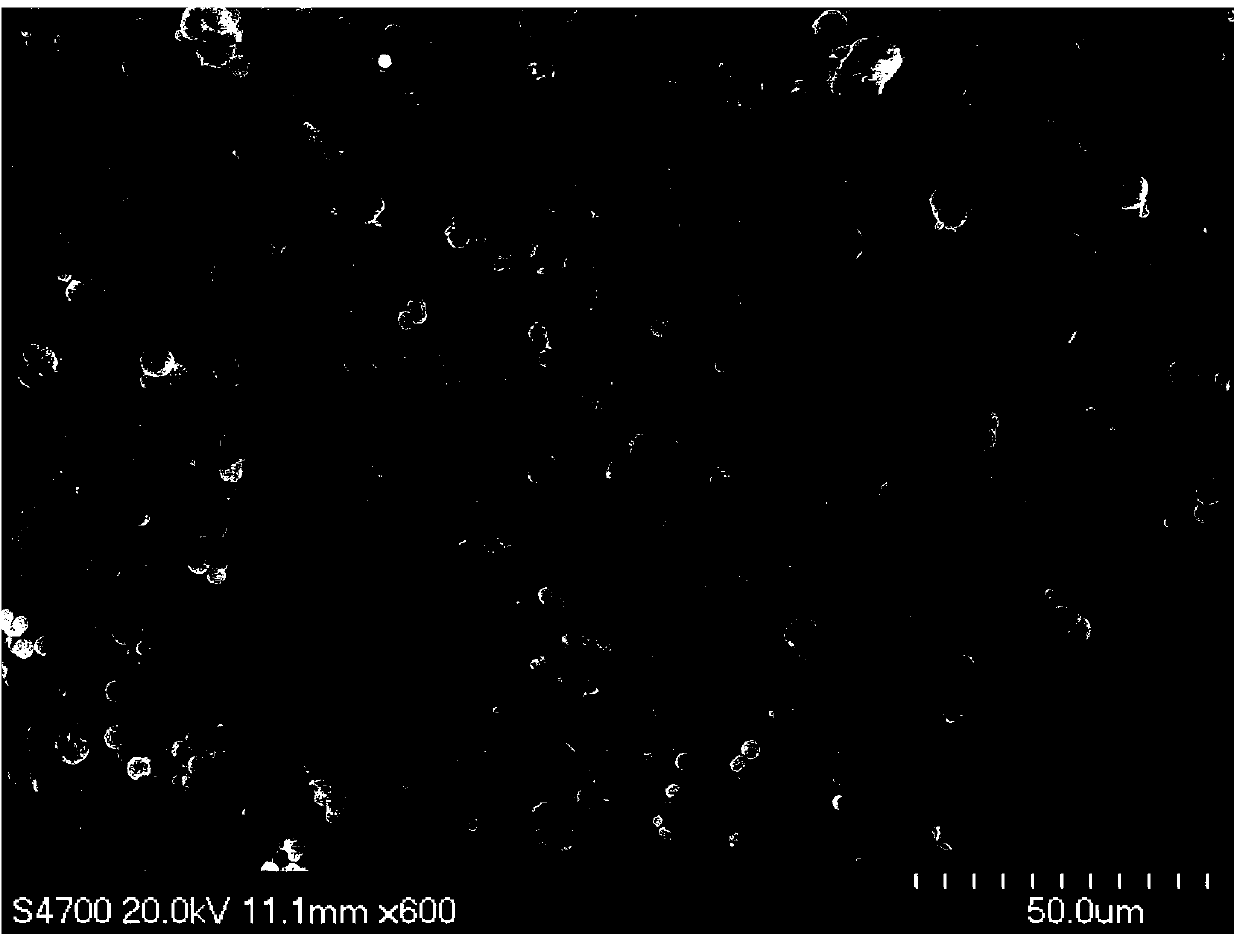

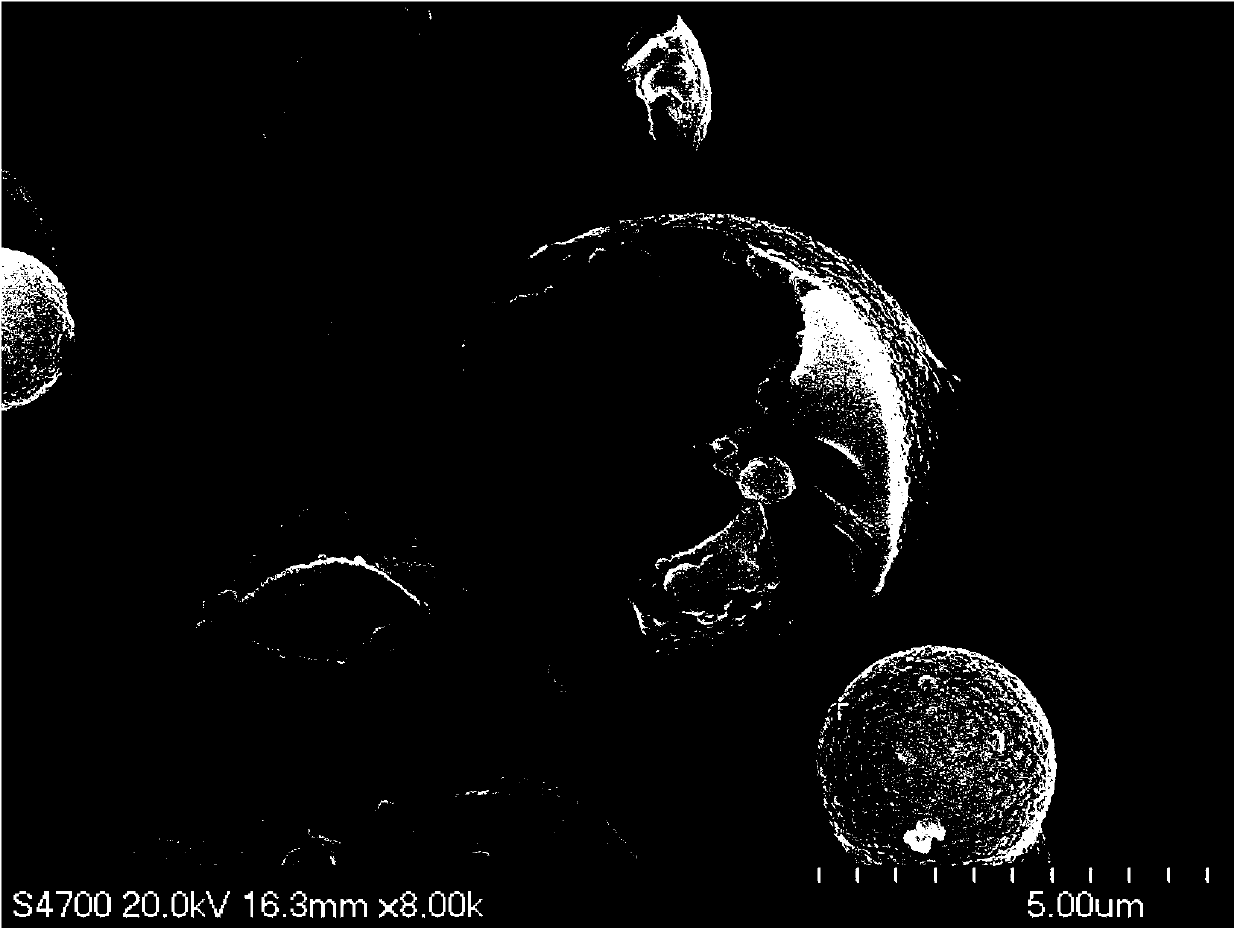

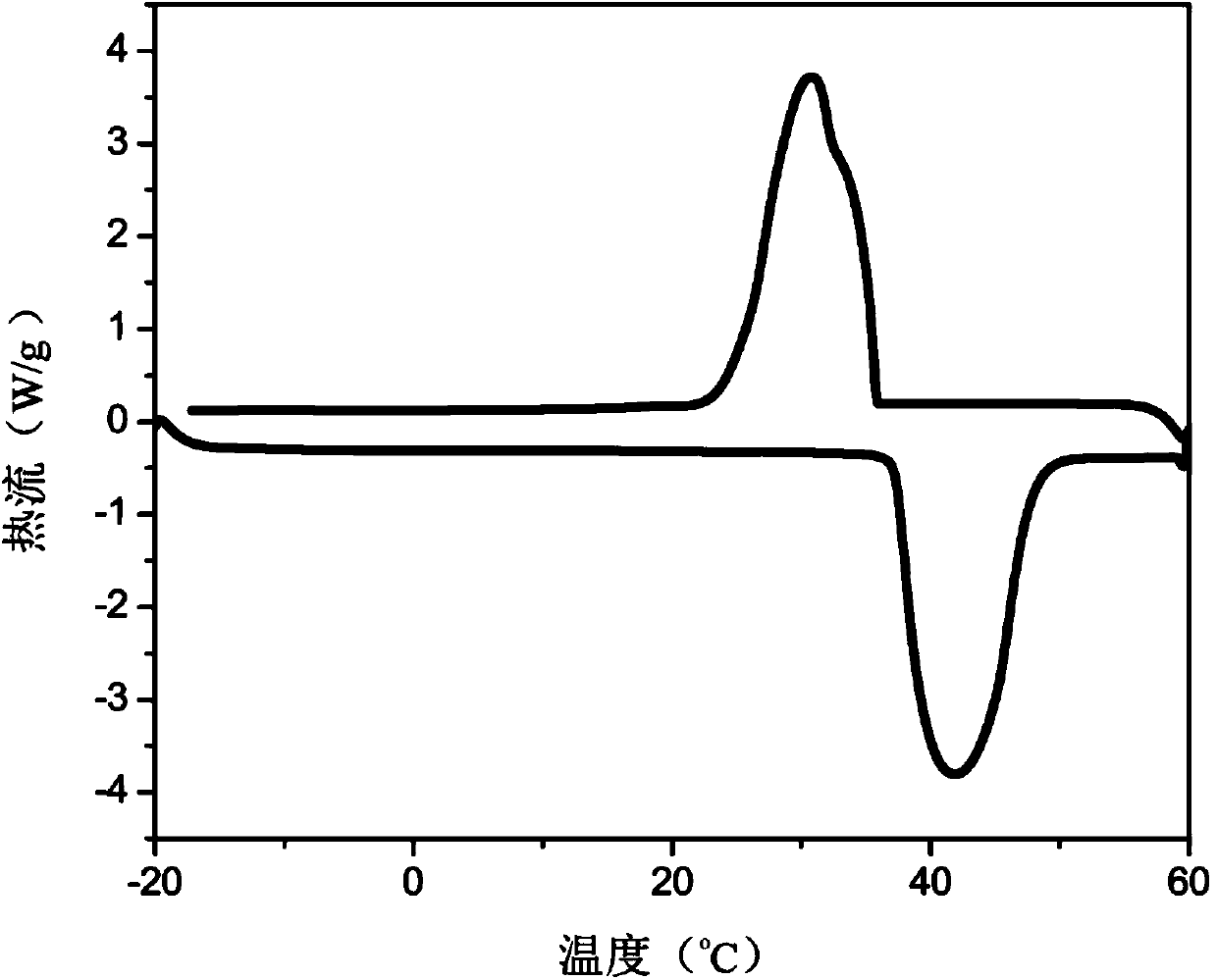

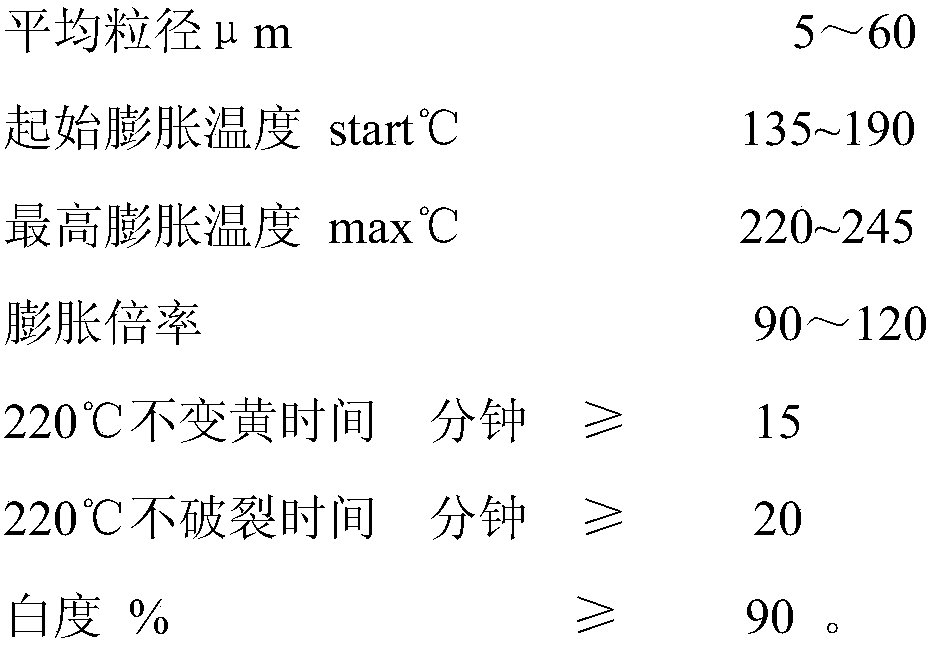

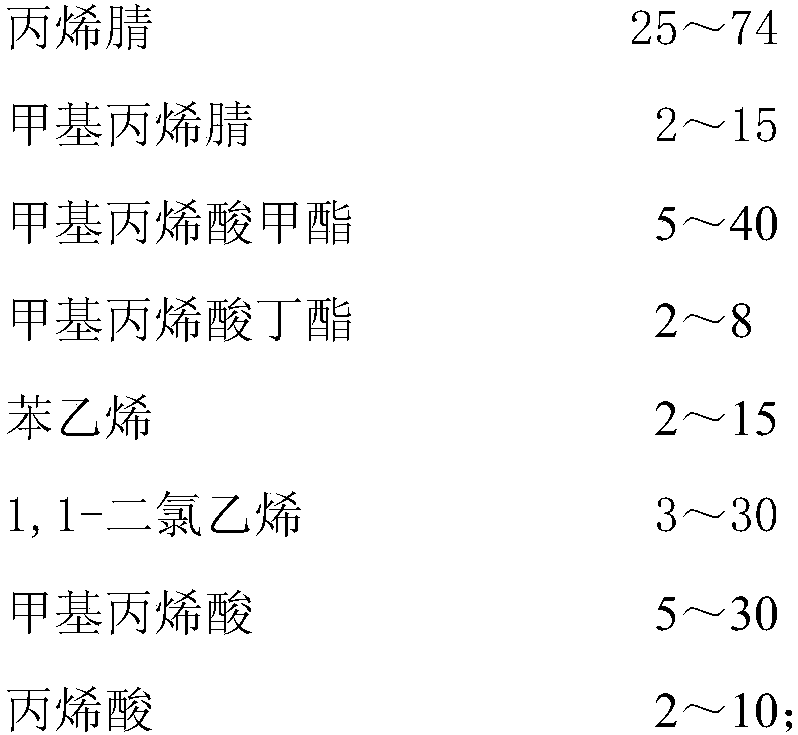

High-temperature expanded polymer microspheres and preparation method thereof

The invention provides high-temperature expanded polymer microspheres and a preparation method thereof and belongs to expandable particles. The high-temperature expanded polymer microspheres are prepared from a thermoplastic resin shell body and a foaming agent packaged in the shell body, wherein an oil-phase composition composed of a polymerizable monomer and a crosslinking agent can be dispersedinto a water-phase dispersed composition; in the presence of the foaming agent, the polymer microspheres coated with the foaming agent are directly prepared through carrying out suspension polymerization reaction and coating the foaming agent in situ; the high-temperature expanded polymer microspheres are characterized in that the oil-phase composition contains the polymerizable monomer and the crosslinking agent, and also comprises a silane coupling agent; the foaming agent is a mixture of isopentane, isooctane and n-octane; the high-temperature expanded polymer microspheres provided by theinvention have the advantages of complete core-shell structure, uniform grain diameter distribution, high foaming agent coating efficiency, good heat resistance of a shell-layer polymer, relatively high initial temperature in an expansion process, relatively high highest expansion temperature and high foaming ratio, have a relatively wide foam stabilizing temperature range, and are suitable for being applied to a thermoplastic resin, rubber or thermoplastic elastomer foaming and processing technology.

Owner:SHANDONG RUIFENG CHEM

Magnetic microencapsulated phase change energy storage material and preparation method thereof

ActiveCN103992774AUniform particle size distributionAchieve dual functionHeat-exchange elementsMicroballoon preparationThermal energyThermal energy storage

The invention discloses a magnetic microencapsulated phase change energy storage material with magnetic and thermal energy storage functions and a preparation method thereof. A wall material of microcapsules is a magnetic ferrite / silica inorganic hybrid material with the magnetic function and a core material can be paraffin and a higher fatty alcohol, acid and ester type organic phase change energy storage material. The preparation method of the magnetic microencapsulated phase change energy storage material disclosed by the invention comprises the steps of firstly synthesizing magnetic ferrite nanoparticles and further assembling the magnetic ferrite nanoparticles in a solvent to the surfaces of suspended oil droplets of the organic phase change energy storage material through a Pickering emulsion technology; finally forming silica gel on the surface of the phase change energy storage material through an interfacial polymerization technology to fix the magnetic ferrite nanoparticles on the surfaces of the oil droplets of the organic phase change energy storage material so as to form the microcapsules using the magnetic ferrite / silica hybrid wall material to coat the phase change energy storage material.

Owner:上海弈峋科技有限公司

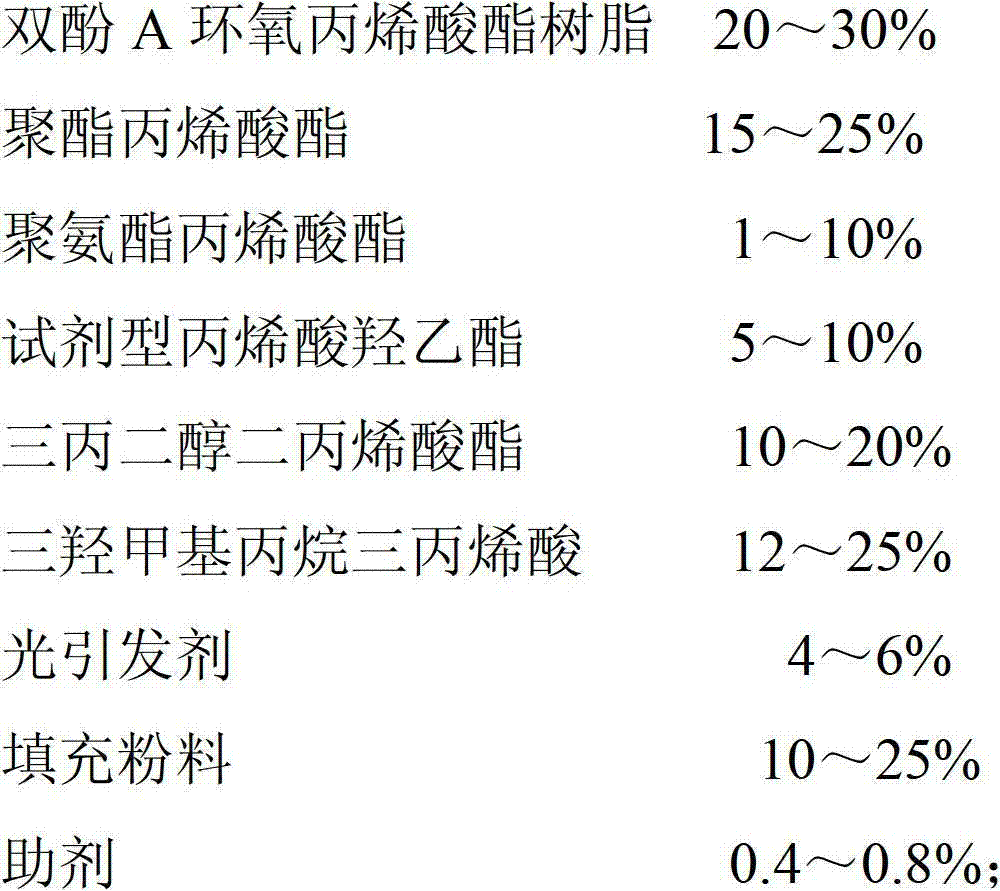

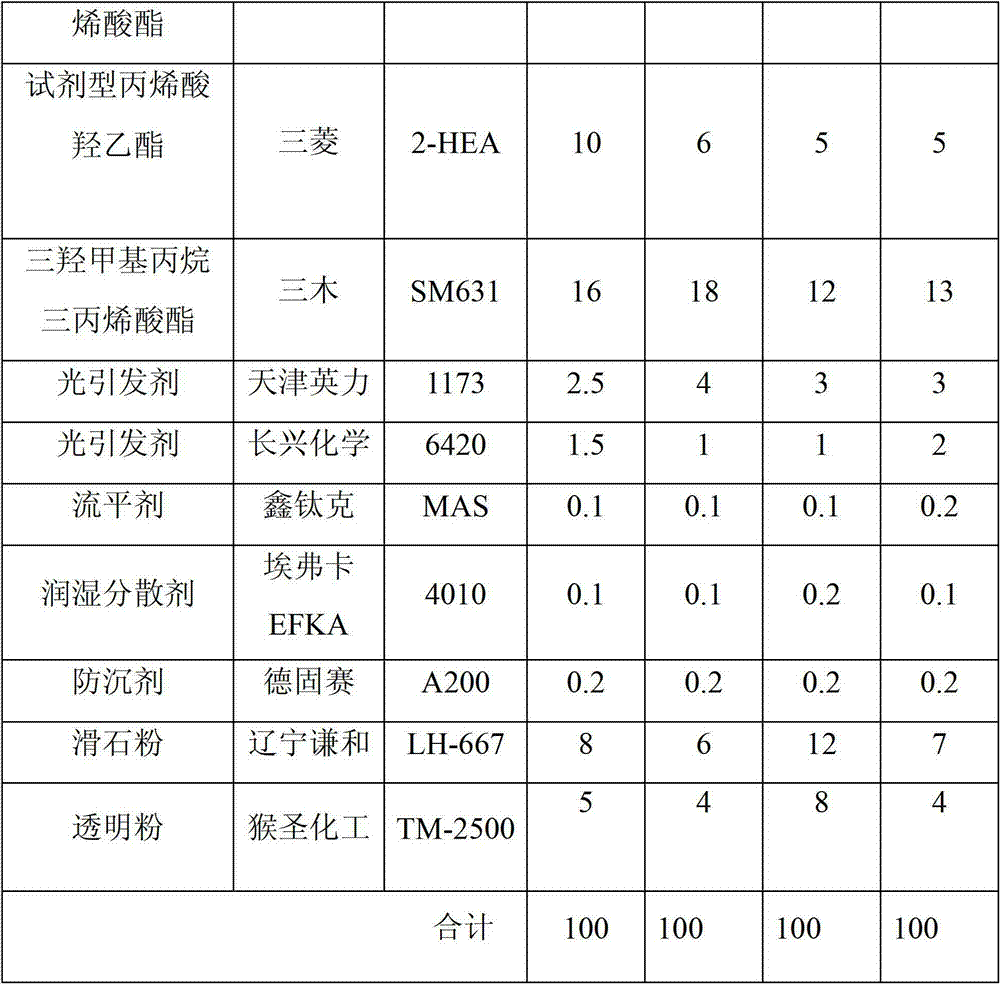

Ultraviolet light curing transparent priming paint and preparation method and use method thereof

ActiveCN102952455AReduce lossImprove product qualityPolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycolPolyester

The invention discloses an ultraviolet light curing transparent priming paint and a preparation method and a use method thereof. The ultraviolet light curing transparent priming paint comprises the following components in percentage by weight: 20-30% of bisphenol A epoxy acrylate resin, 15-25% of polyester acrylate, 1-10% of urethane acrylate, 5-10% of reagent type hydroxyethyl acrylate, 10-20% of tripropylene glycol diacrylate, 12-25% of trimethylolpropane triacrylate, 4-6% of photoinitiator, 10-25% of filling powder and 0.4-0.8% of promotor. The ultraviolet light curing transparent priming paint is suitable for laser roller construction, has good grittiness and transparency, has the characteristics that sanding is not needed for semi-curing recoating between film layers and the like, and has thick coating performance and the performance that the surface is similar to a mirror surface, and compared with conventional roller coating, the coating weight is greatly increased, roller coating processes are saved, the priming paint is sanded by a sanding machine without large pressure and with a small number of sanded films, a workpiece has no bright spots, the fullness of a product is guaranteed, the product quality is improved, the loss of the machine is smallreduced, and the use amount of sanding belts is greatly reduced.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Anti-reflective coating for photovoltaic glass panel

InactiveUS20080241373A1Accelerate the application processReduction in undesirable evaporation of solventPretreated surfacesCoatingsAnti-reflective coatingSilicic acid

A method of making an anti-reflective film comprises preparing a liquid composition with specific amounts of tetraethyl orthosilicate, polyethylene glycol, HCl, ethanol and at least one alcohol having a higher boiling point than ethanol and miscibility with both ethanol and water; applying the liquid composition onto a surface of a substrate to form a liquid film; evaporating the ethanol and the at least one alcohol from the liquid film to form a solid film; and heating the solid film to form a silica film.

Owner:AGC FLAT GLASS NORTH AMERICA INC

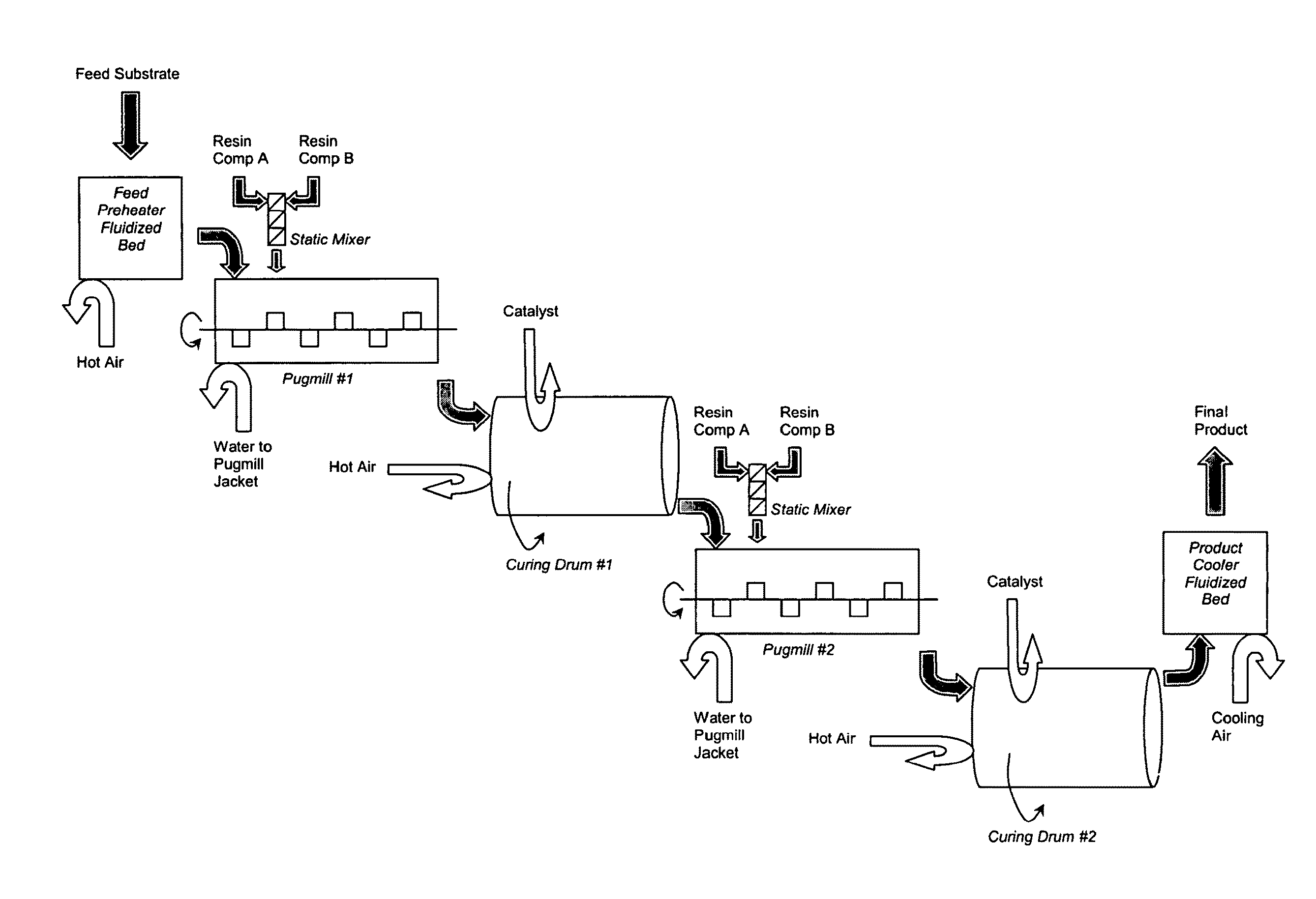

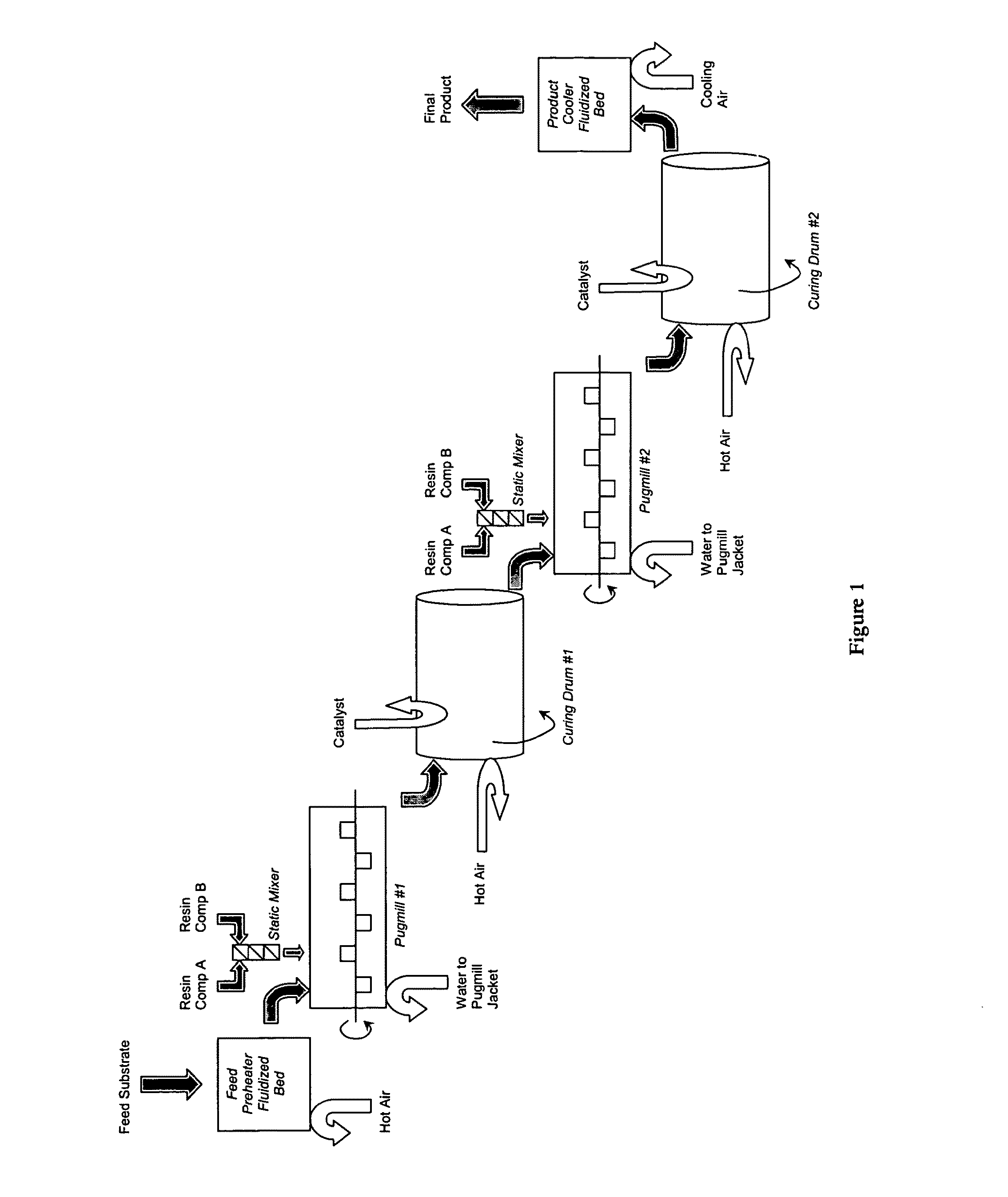

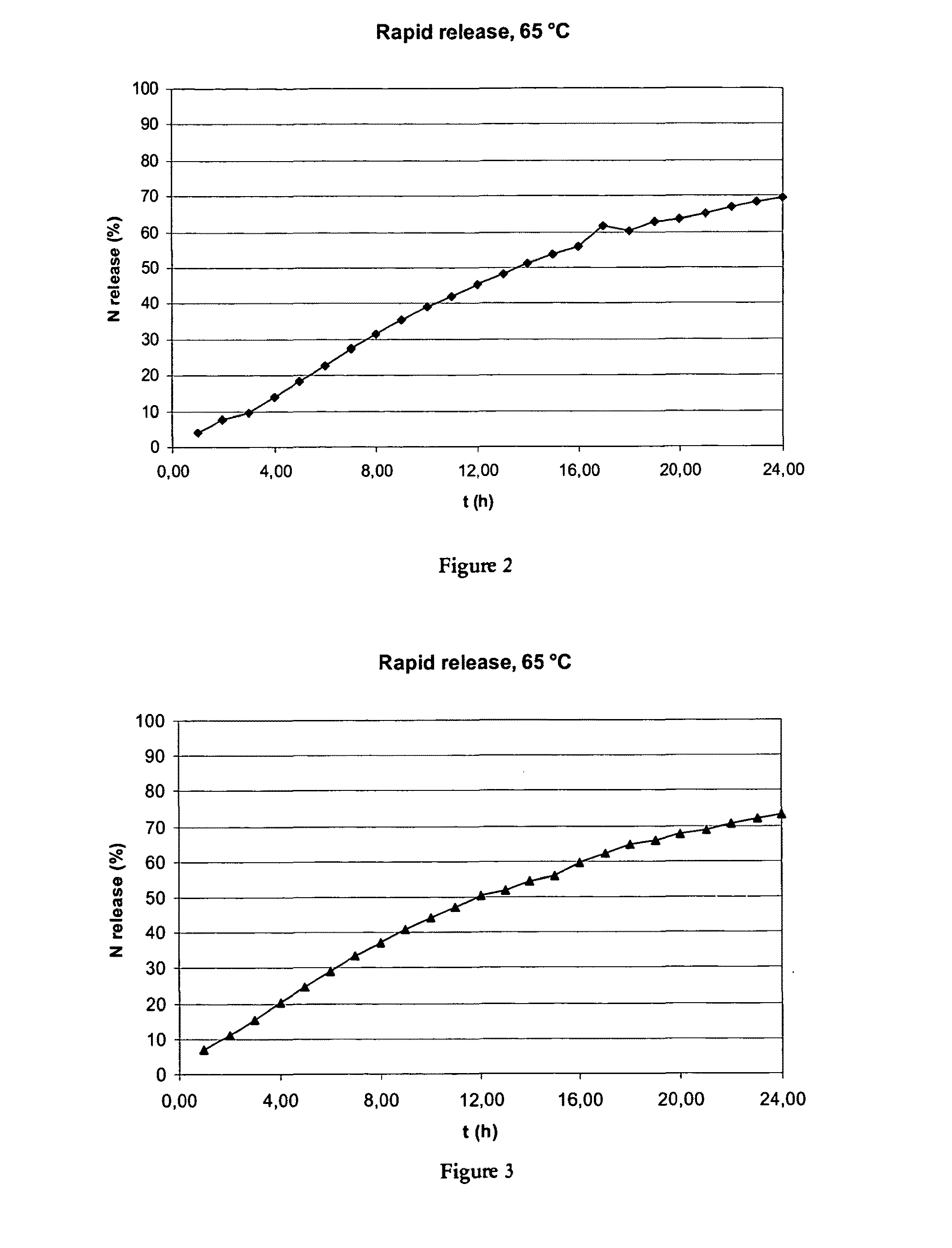

Methods and systems for coating granular substrates

ActiveUS20140033779A1Easy to controlReduce the possibilityBiocideRotating receptacle mixersEngineeringCoating

Owner:EVERRIS INT

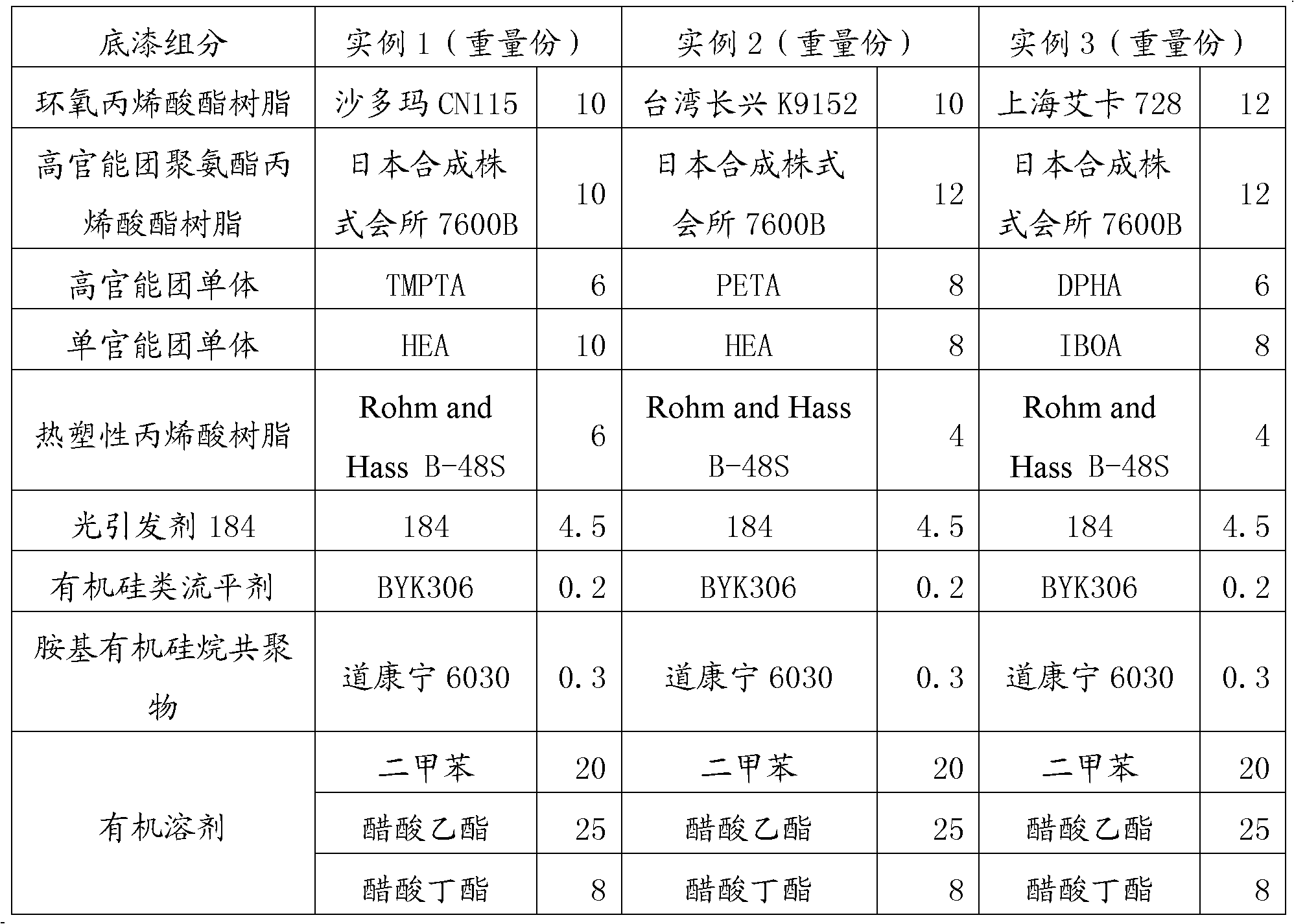

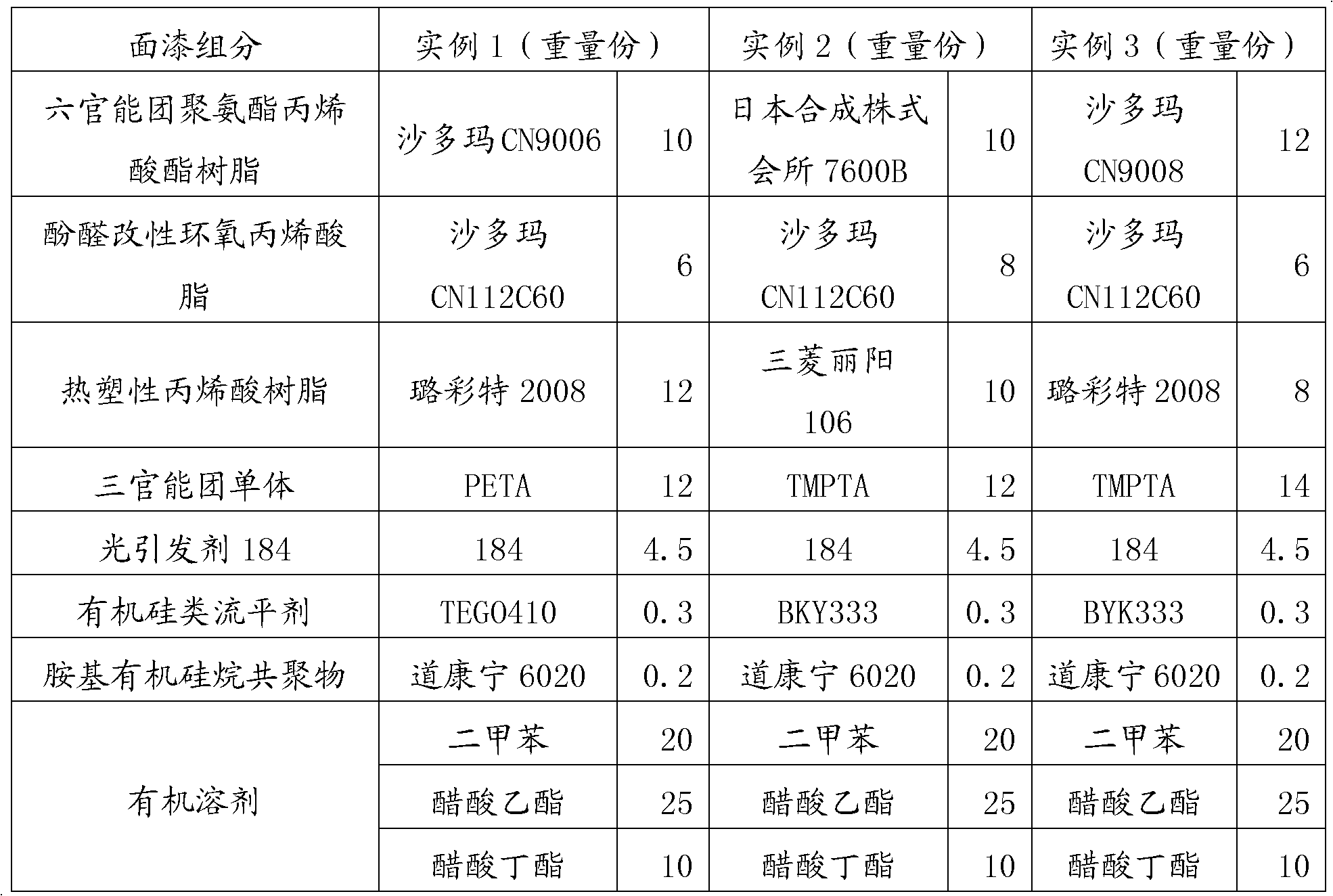

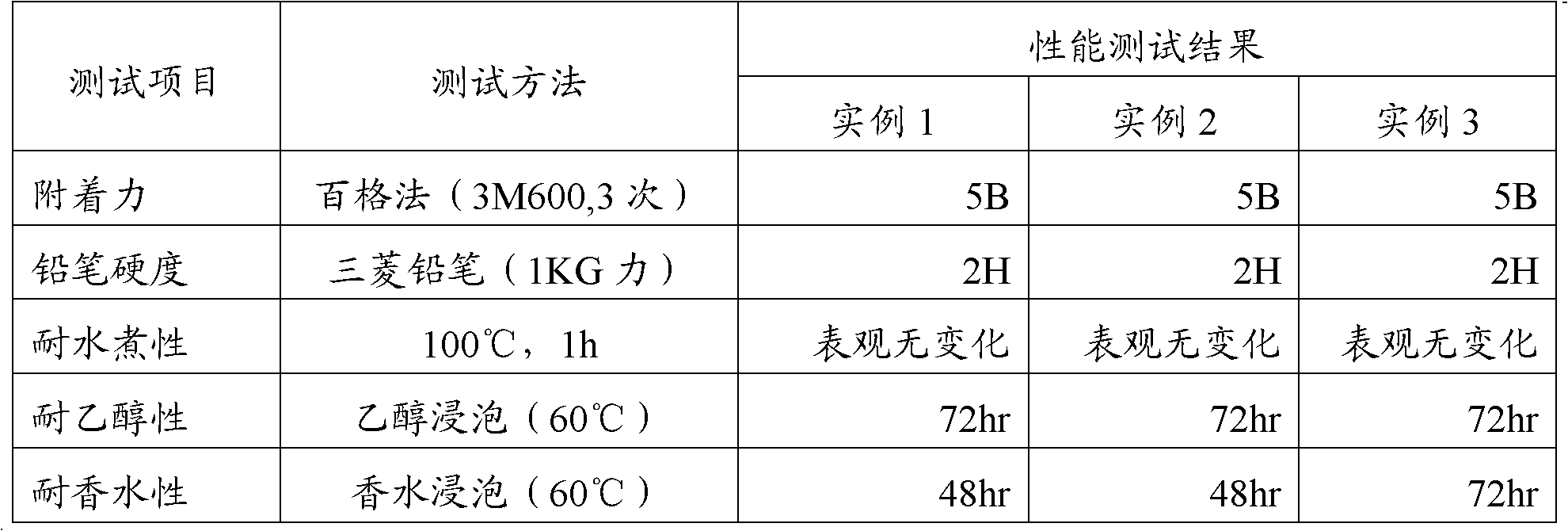

UV (ultraviolet)-curing glass coating paint

ActiveCN102134437AFast curingImprove boiling resistancePolyurea/polyurethane coatingsEpoxy resin coatingsOrganic solventAcrylic resin

The invention discloses a UV (ultraviolet)-curing glass coating paint which comprises a primer and a finish, wherein the primer comprises epoxy acrylate resin, high-functional-group polyurethane-acrylate resin, high-functional-group monomer, single-functional-group monomer, thermoplastic acrylic resin, photoinitiator 184, organosilicon leveling agent, amido-organosilane copolymer and organic solvent; and the finish comprises six-functional-group polyurethane-acrylate resin, phenolic modified epoxy acrylate, thermoplastic acrylic resin, three-functional-group monomer, photoinitiator 184, organosilicon leveling agent, amido-organosilane copolymer and organic solvent. The plating bottom surface coat of the paint has the advantages of high curing speed, higher crosslinking density during construction, high boiling resistance, high ethanol resistance and high perfume resistance.

Owner:ZHEJIANG UVCHEM SPECIAL COATINGS CO LTD

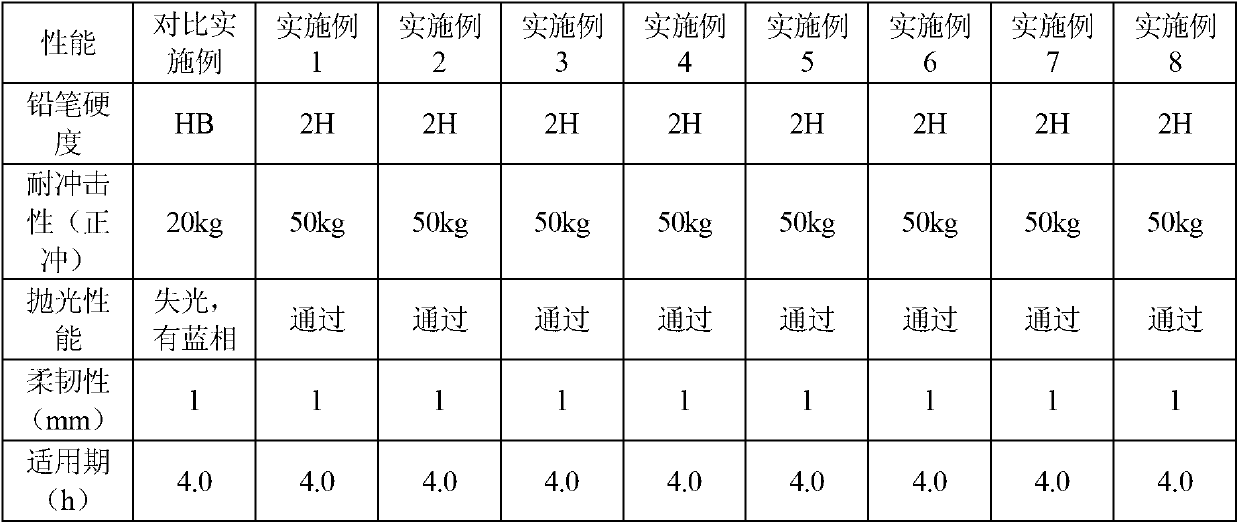

Double-component polyurethane coating and production method and construction method

InactiveCN101457120AShorten the coating production cycleHigh fullnessPretreated surfacesPolyurea/polyurethane coatingsLacquerPolyurethane coating

The present invention discloses a bicomponent polyurethane paint and preparation method and execution method thereof, wherein the bicomponent polyurethane paint includes primer, primer fluidifying agent and bicomponent polyurethane PU varnish lacquer that matched with the primer. The bicomponent polyurethane PU paint can be used on HIPS plastic rubber case with complicated structure, and can improve productivity effect and save energy sources, have appearance with high lustrousness and high fullness; the preparation method provides simple producing process and the execution method provides convenient painting.

Owner:DONGGUAN JIAZHUOCHENG CHEM TECH

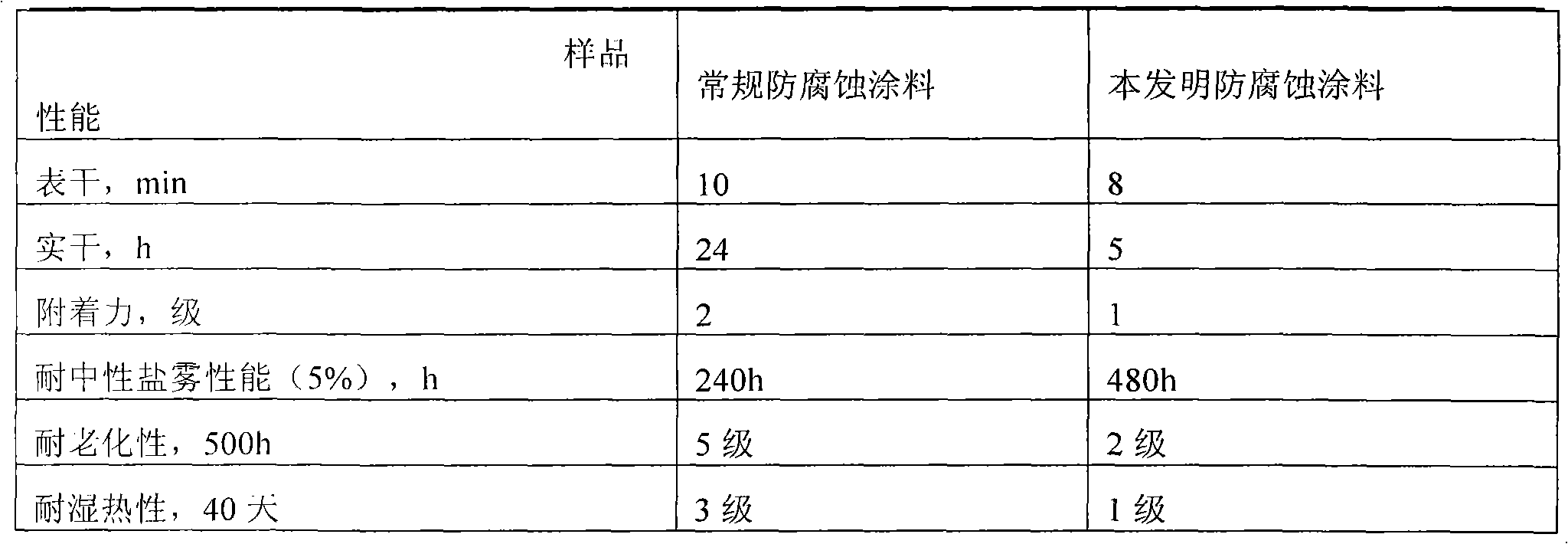

Anticorrosive paint for weather-resistant corrosion-resistant steel pipe outer wall

ActiveCN102120909AFast dryingDry fastGeneral water supply conservationAnti-corrosive paintsEpoxyWeather resistance

The invention relates to an anticorrosive paint for a weather-resistant corrosion-resistant steel pipe outer wall, which is prepared from 30-50 parts of alkyd resin, 2-5 parts of epoxy resin, 10-15 parts of terpene resin, 30-50 parts of hydrocarbon solvent, 3-8 parts of anticorrosive agent and 1-3 parts of drying agent. The paint provided by the invention can be applied by brushing, spraying, dipcoating, curtain coating or the like, and is naturally dried at normal temperature. The terpene resin adopted in the invention has high stability for oxygen, heat and light, and has excellent ageing resistance, so that the paint has excellent weather resistance. The rust inhibitor adopted in the invention can form a compact protective layer with high adhesive force on the surface of a steel pipe,and thus, prevents or slows the permeation of oxygen and water in the environment under the isolation action, thereby inhibiting the generation of corrosion microcells and performing a favorable anticorrosive protection function.

Owner:TIANJIN COLOROAD COATING & CHEM

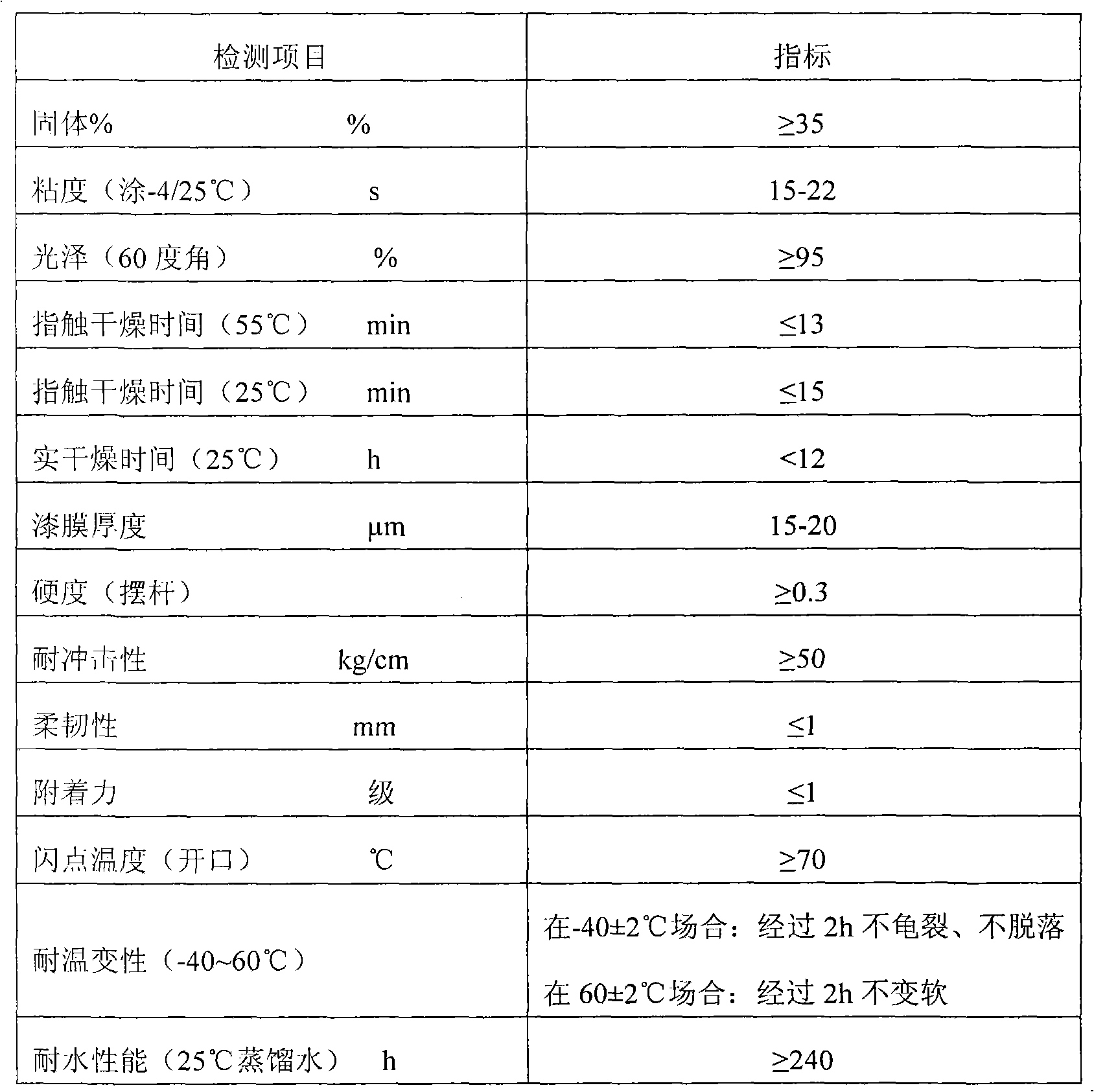

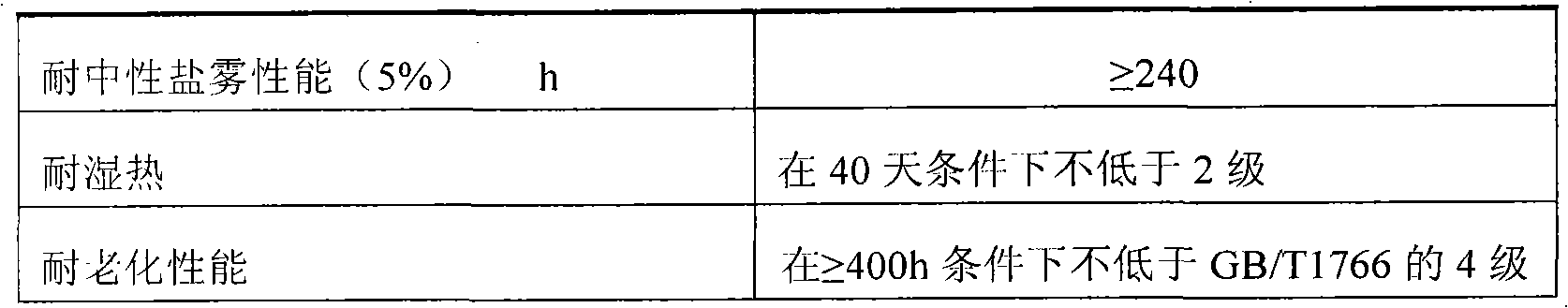

Water-based photo-cured elastomeric paint

InactiveCN102127362AImprove coating efficiencyReduce environmental pollutionPolyurea/polyurethane coatingsPolyether coatingsMonomerUltraviolet

The invention discloses a water-based photo-cured elastomeric paint, which consists of the following components in percentage by weight: 60-80 percent of water-based UV (Ultra Violet) elastic resin, 5-20 percent of water-based UV curing monomer, 1-8 percent of water-based initiator, 0.2-1 percent of water-based flatting agent, 0.2-1 percent of water-based dispersant, 3-9 percent of flatting silica and 1-10 percent of elastic powder. A coating is a water-based UV photo-cured elastomeric paint. Compared with a bi-component coating in the conventional elastic hand paint, the water-based photo-cured elastomeric paint has the advantages of fast curing, high coating efficiency and low environmental pollution.

Owner:ZHEJIANG UVCHEM SPECIAL COATINGS CO LTD

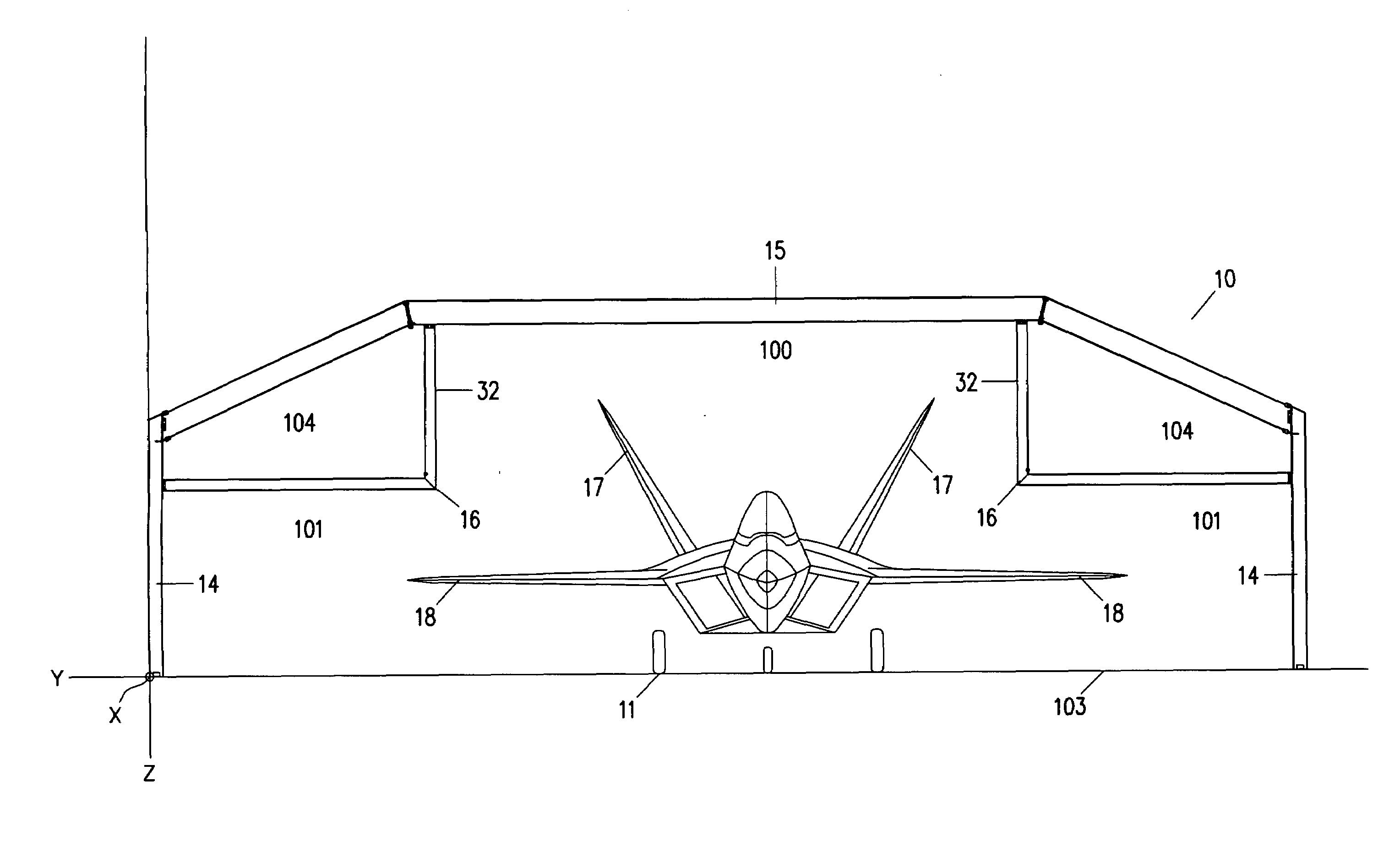

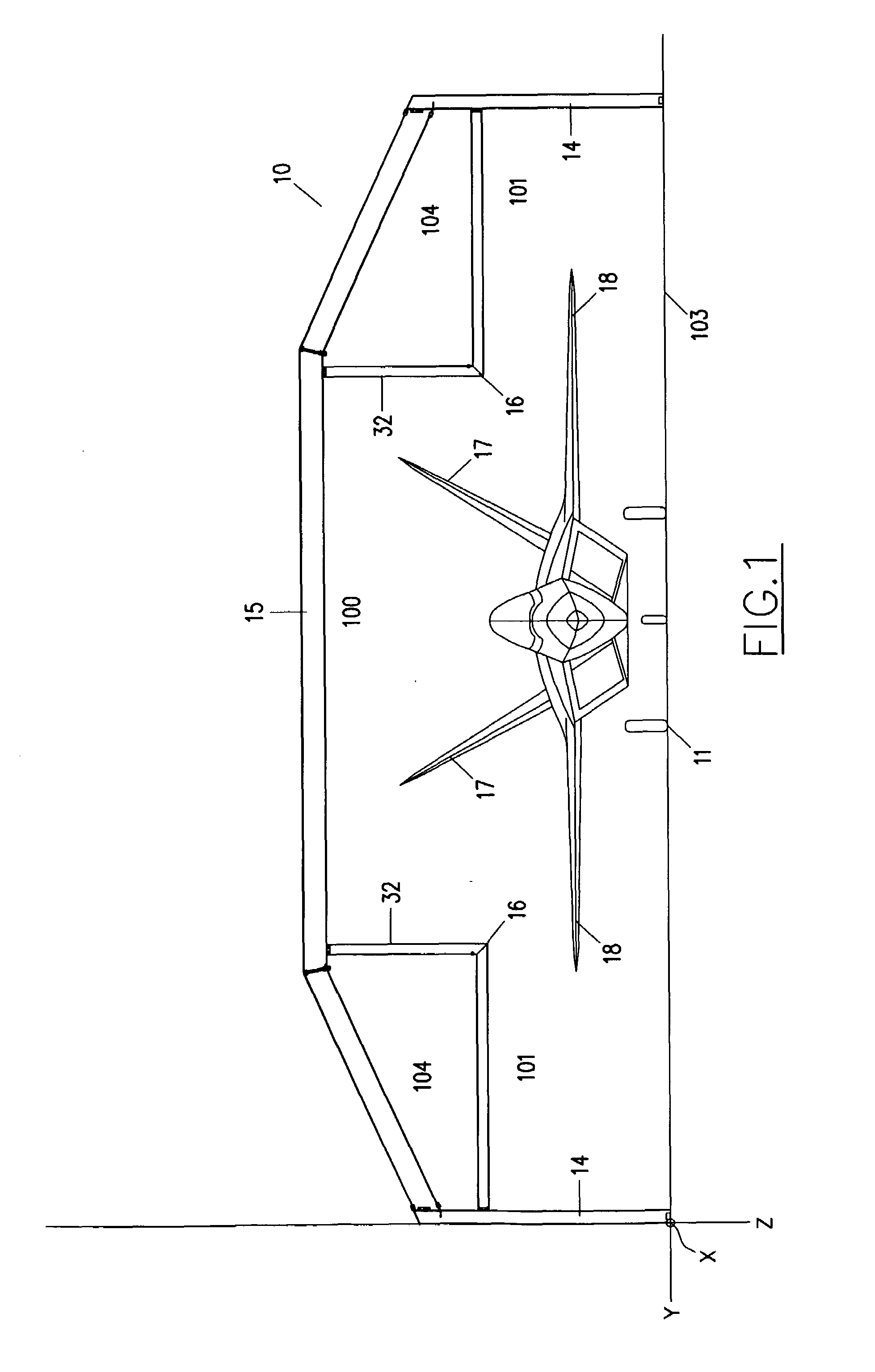

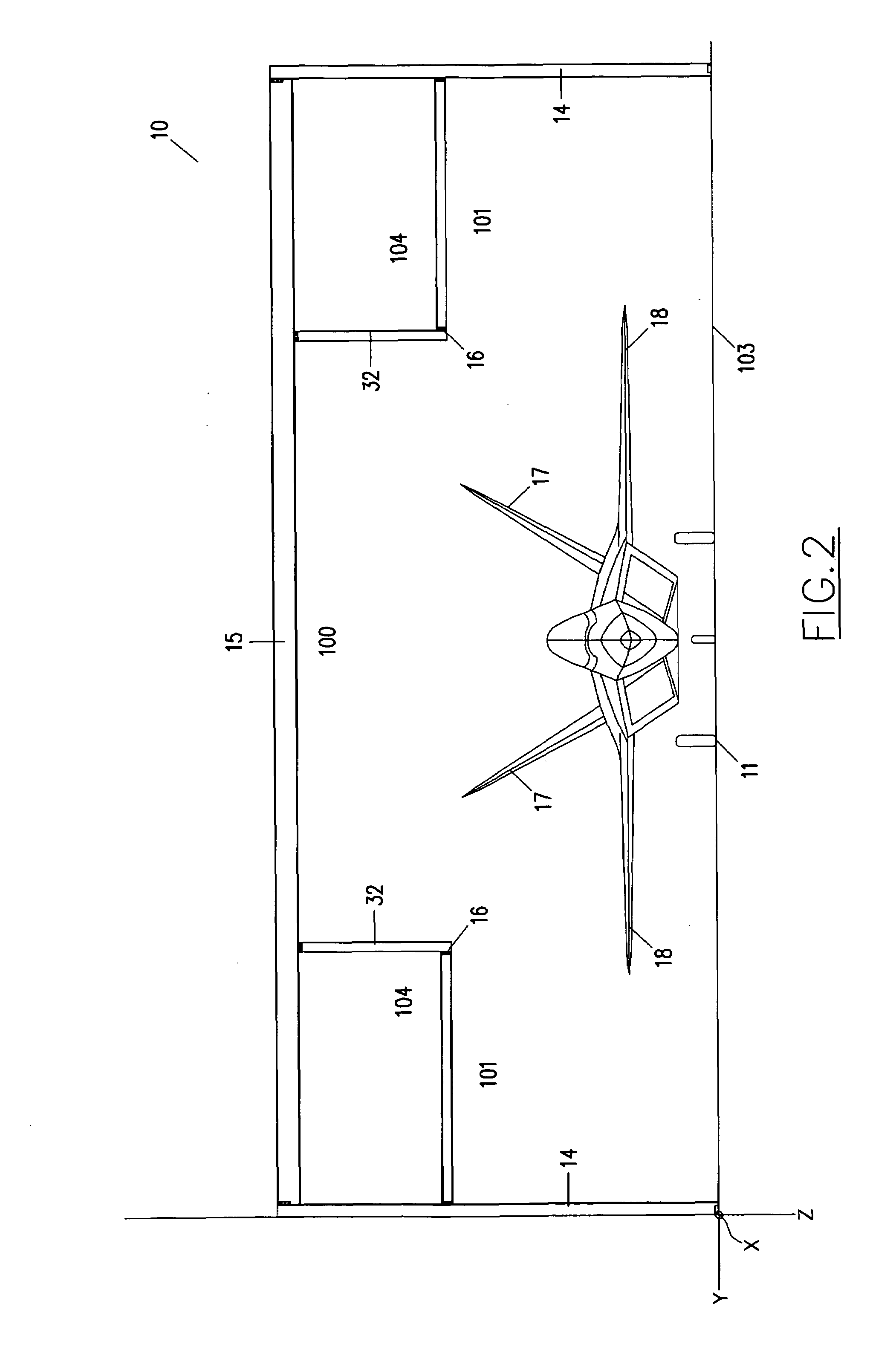

Paint booth arrangement and method for directing airflow

ActiveUS7666077B1High degree of structural strengthSmall additional costDucting arrangementsLiquid surface applicatorsAirflowEngineering

A paint booth arrangement maximizes floor space and efficiency of a painting operation. The arrangement comprises an equipment enclosing structure and certain air handling equipment specifically configured within the structure. The structure comprises forward and rearward sections, opposed wall sections, a centralized roof section, and opposed wall-to-roof sections, which sections define open space having varied elevation for receiving paintable equipment. The air handling equipment comprises an air intake and exhaust assemblies and an air replacement system. The air intake and exhaust assemblies extend coextensively intermediate the wall sections at the rearward section and function to support portions of the air replacement system. The air replacement system comprises conduit extending intermediate the forward and rearward sections as defined by the wall-to-roof sections. The air intake assembly communicates with the conduit for directing inlet airflow to the open space, and the air exhaust assembly comprises exhausts airflow from the open space.

Owner:GLOBAL FINISHING SOLUTIONS

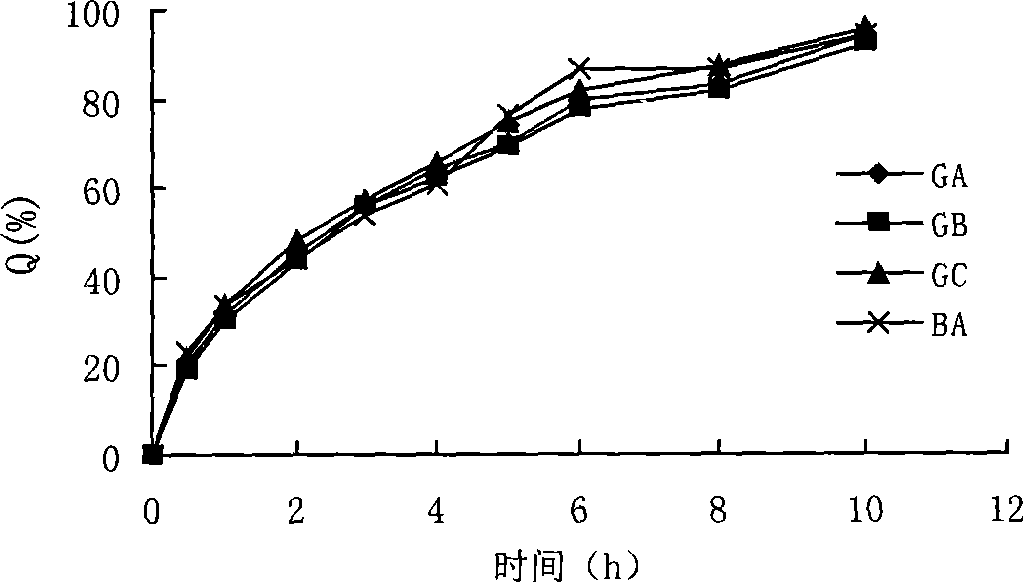

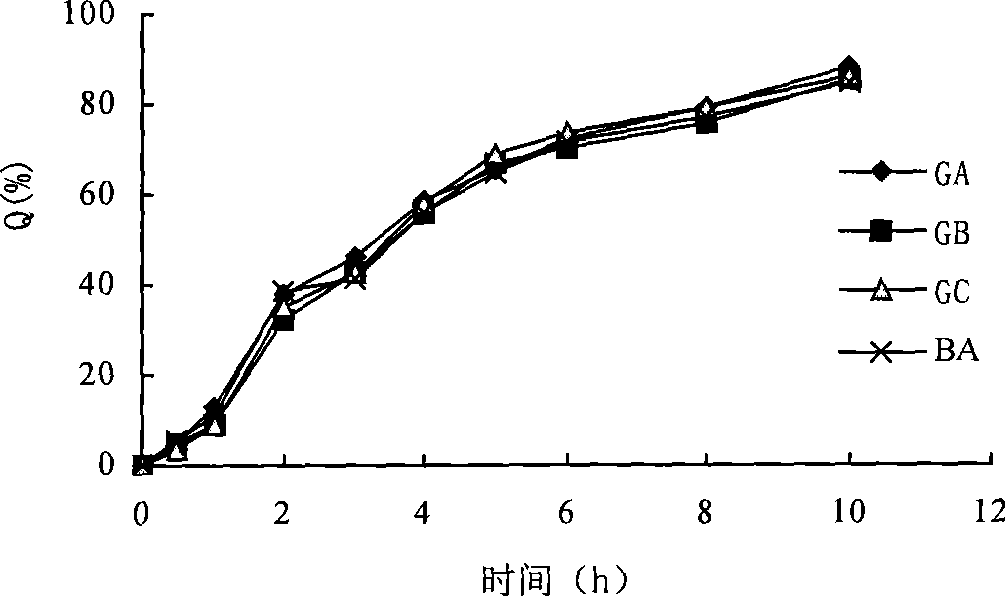

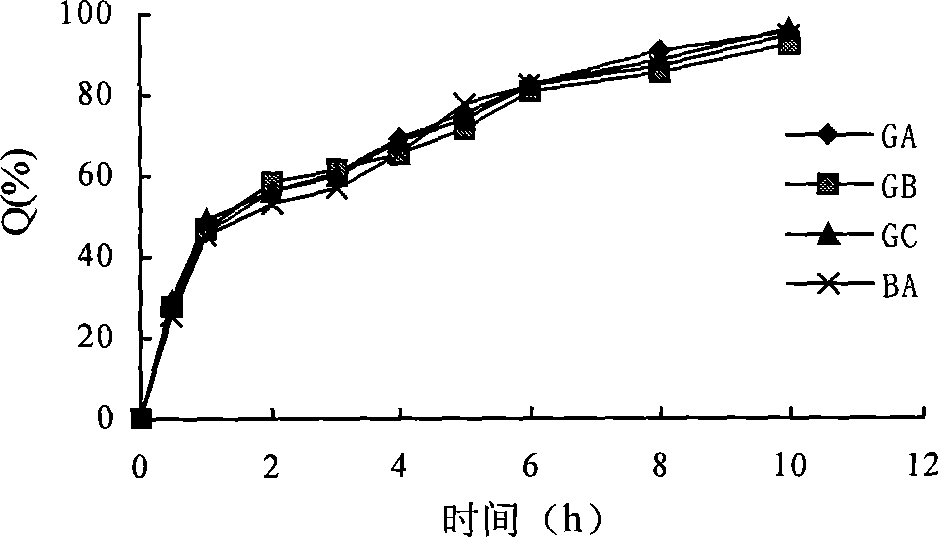

Slow/controlled release pellet composition containing ginkgo leaf extracts and preparation method thereof

InactiveCN101375869ASmall toxicityStable blood concentrationGranular deliveryGinkgophyta medical ingredientsSustained release pelletsHard Capsule

The invention belongs to the field sustained / controlled-release preparations, in particular to an oral sustained / controlled-release pellet combination containing ginkgo biloba extract and a preparation method. The oral sustained / controlled-release pellet combination is composed of (A) a core containing a pill; (B) an insulating coating layer; (C) a sustained-release coating layer; (D) and an enteric-coated coating layer. The invention is the traditional Chinese medicine multi-component sustained-release pellet combination which is taken once by 24 hours and the multi-unit sustained-release pellet combined preparation with the different drug release systems, the core containing the pill is prepared by adopting the extrusion pill rolling method, a novel sustained-release multi-layer coating technology and a fluidized bed are utilized for coating the sustained-release pellet, the rapid-release part and the sustained-release part of the coated pellet are mixedly filled into a hard capsule or pressed into a pellet tablet. The sustained-release pellet has stable coating process and good reproducibility, thereby being applicable to the industrial mass production; and the drug quality of the preparation is stable through the long-term storage. The in vitro release test shows that the multiple components of the traditional Chinese medicine can achieve the sustained-release role, the sustained-release preparation can significantly increase the transmembrane absorption and the stability of various effective active ingredients by oral drug administration, the curve of plasma drug concentration in vivo is smooth, and the design purpose of 24-hour sustained-release is achieved.

Owner:CHINA PHARM UNIV

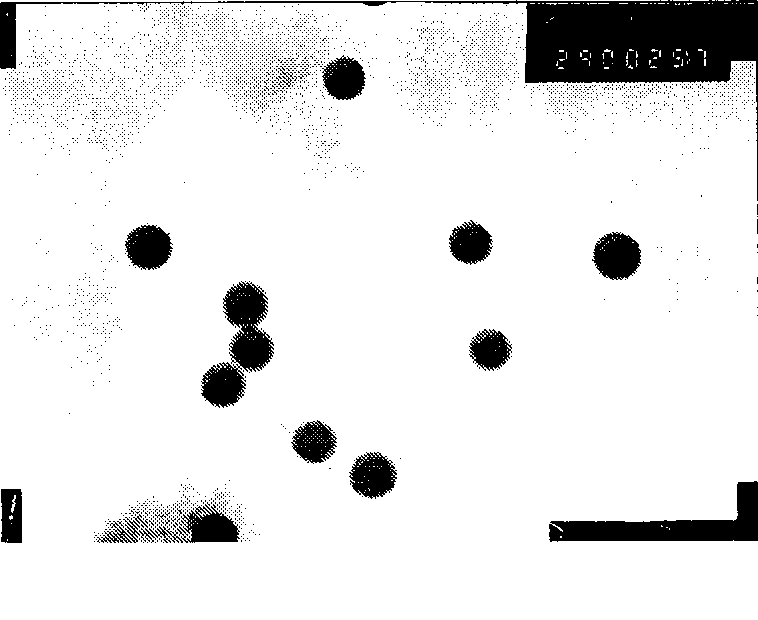

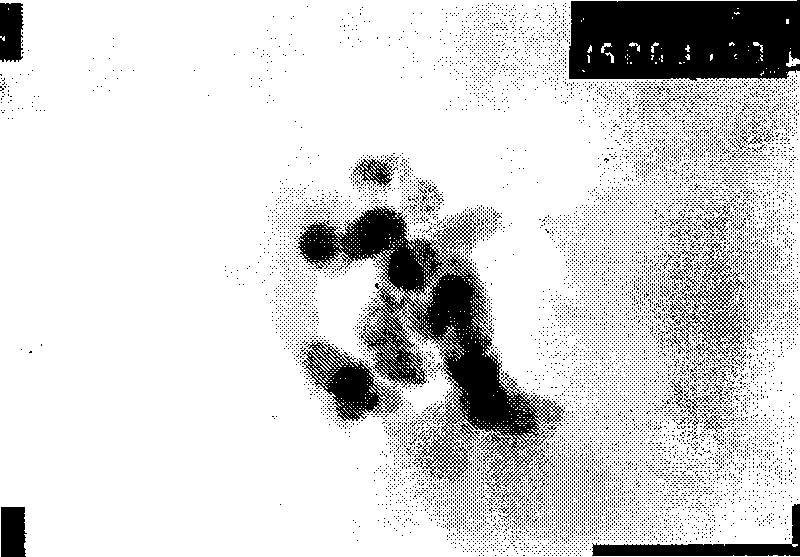

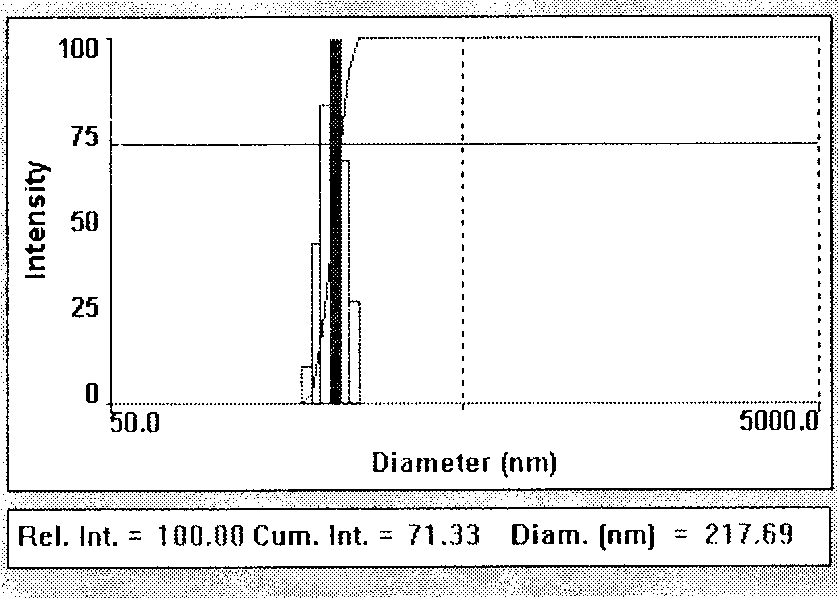

Nano-zinc oxide/acrylic ester grafting composite emulsion and preparation thereof

InactiveCN101372527AUniform particle sizeImprove coating efficiency and grafting rateNano zinc oxideNanometre

The invention relates to the manufacturing field of nano composite emulsion materials, in particular to graft nano zinc oxide / polyacrylate composite emulsion and a manufacturing method thereof. Firstly an initiator azobisisovaleric acid is anchored on the surface of nano zinc oxide particles, two portions of hexadecane are added to 100 portions of mixed monomers, and 5 portions of nano ZnO particles anchoring the azo initiator are added and ultrasonically oscillated for 20 minutes to form an oil phase pre-dispersion solution. The pre-dispersion solution is added to an emulsifier aqueous solution and dispersed by a high-shear dispersion homogenizer at high speed for 30 minutes to form a mini-emulsion. The mini-emulsion is transferred to a reactor, heated to the temperature of 75 DEG C, with polyreaction initiated for 3 hours, and then heated to the temperature of 85 DEG C, polymerized for 2 hours, cooled to room temperature and discharged. The invention solves the problems of high cost and poor stability of the nano composite emulsion prepared by coupling agents, and low encapsulation efficiency and graft ratio of nano polymer composite particles. The composite emulsion has the advantages of simple preparation process, low cost, even particle size, good performance, high encapsulation efficiency and graft ratio of the nano-particles, forms nano monodisperse state in the polymer, and is suitable for the fields of coating materials, leather finishing materials, adhesives and functional plastics.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

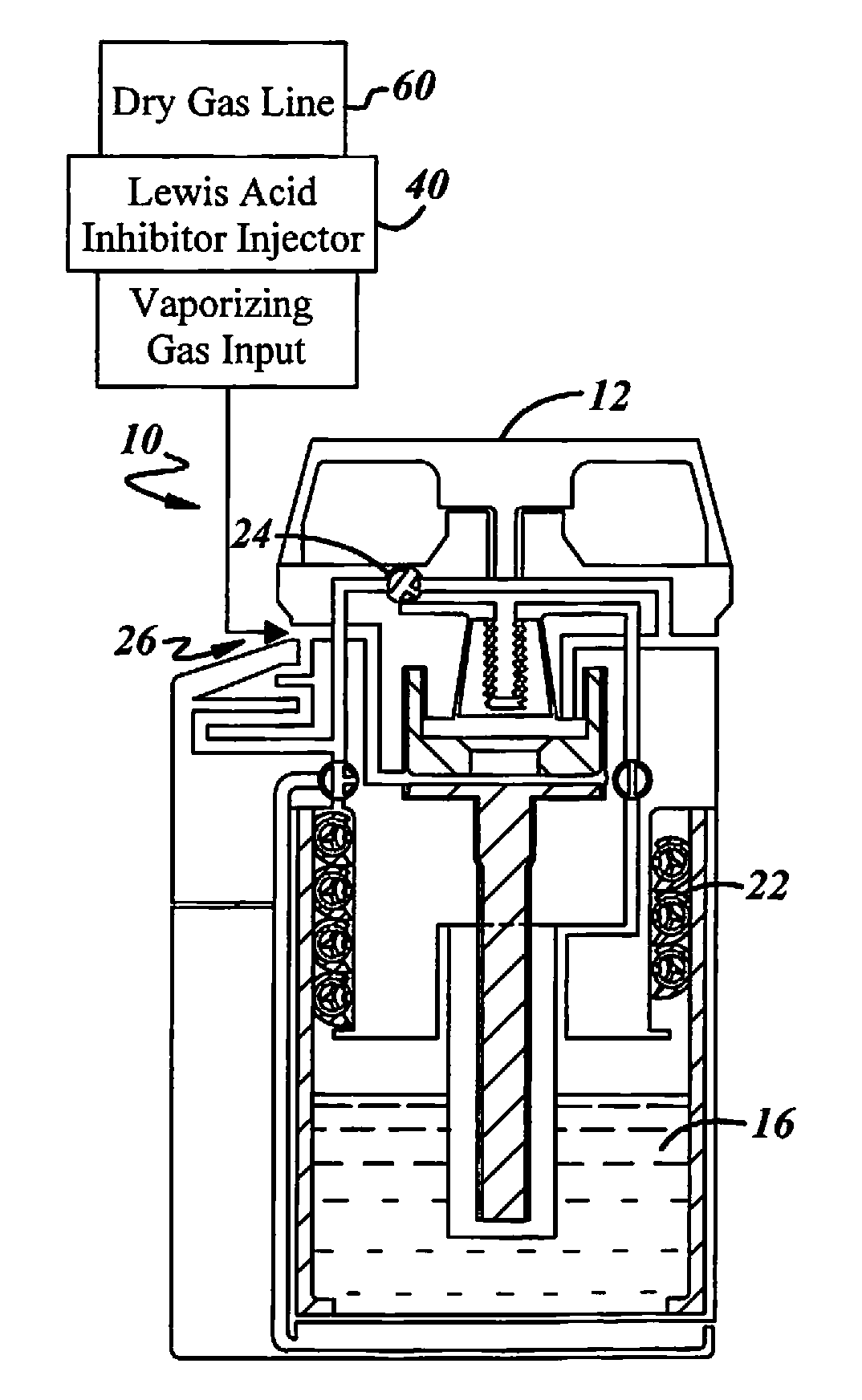

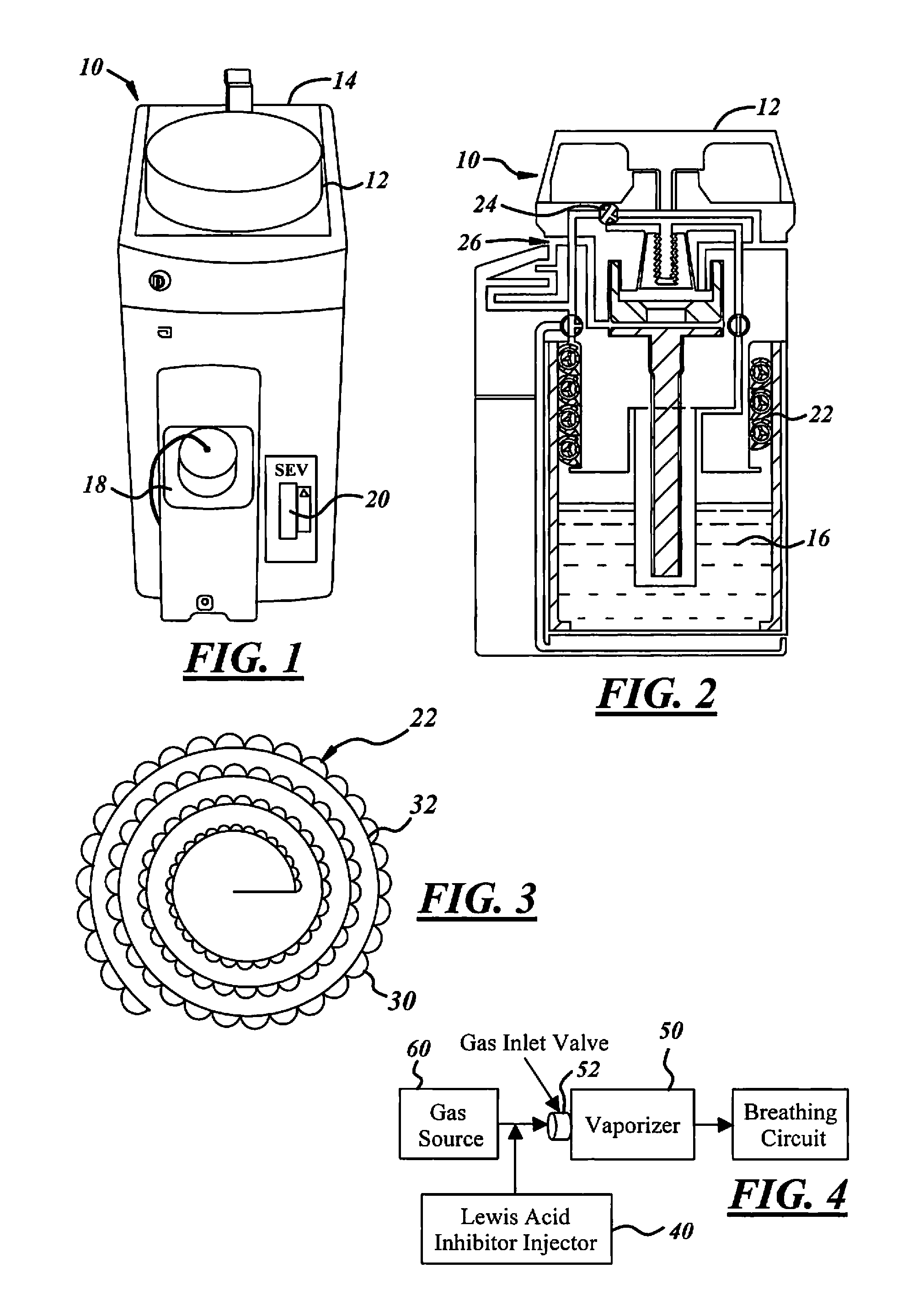

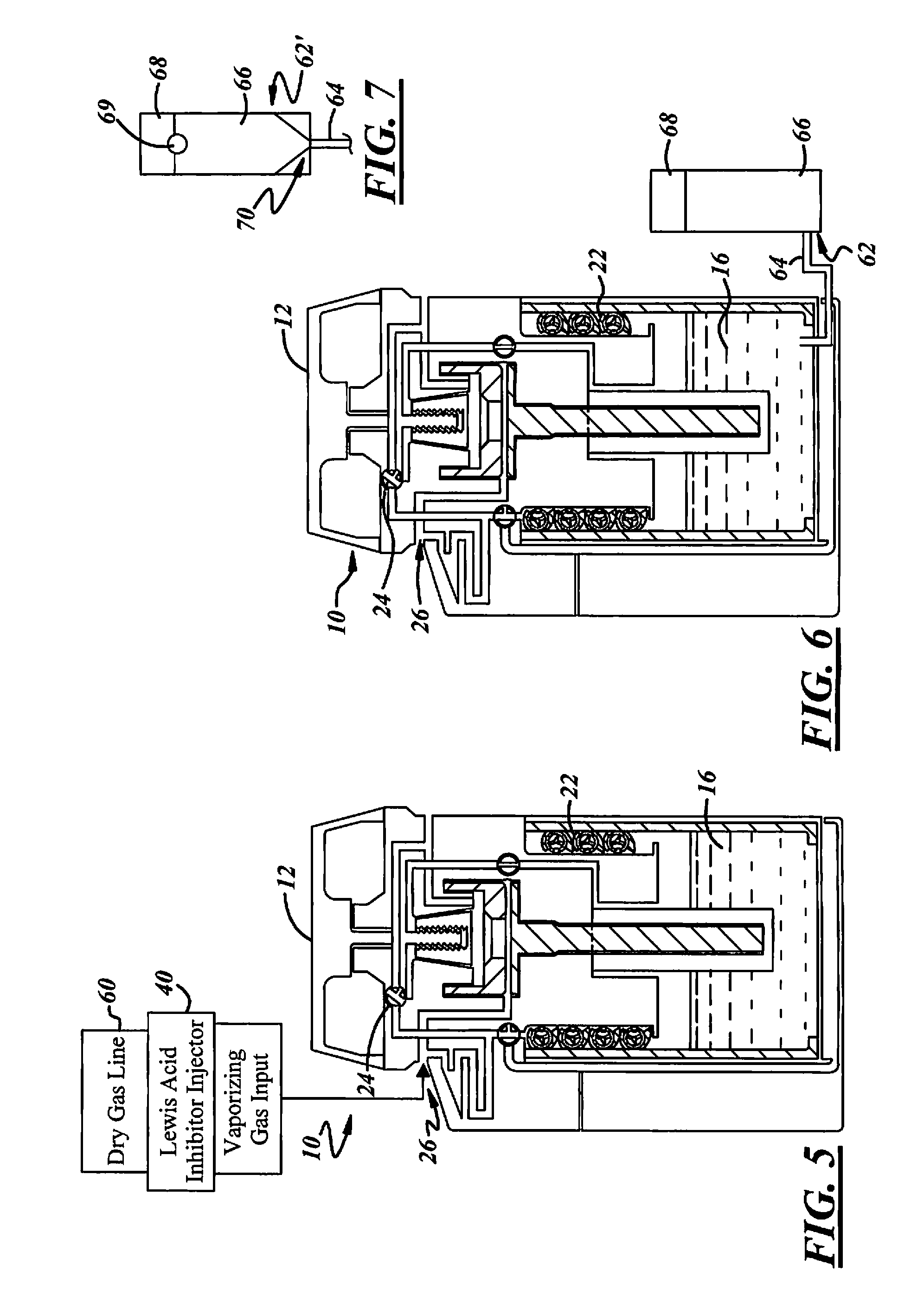

Apparatus for and related method of inhibiting lewis acid degradation in a vaporizer

InactiveUS20080087283A1Reduce the amount requiredImprove coating efficiencyRespiratorsInhalatorsEvaporatorAnesthesia vaporizer

The present invention relates to an anesthesia vaporizer, more particularly, a vaporizer for use in administering anesthesia wherein the vaporizer is designed to inhibit the degradation of anesthesia that is contained within the vaporizer. The invention further provides a method of preparing a vaporizer to inhibit the degradation of anesthesia.

Owner:ABBOTT LAB INC

Coated particulate preparation method

The invention discloses a coated particulate preparation method, comprising the following steps: firstly, particulates in movement are coated with coating solution to cure the solution to form films; the coating rate and curing rate are controlled to ensure that the particulates reach the designed coating quantity while avoiding accumulation; then, the organic polymer films outside the coating films of particulates in movement are cured; inert organic substance is added to form continuous inert liquid membranes outside the organic polymer films before the particulates are likely to accumulate on the adopted coating film curing process conditions; then, the organic polymer films outside the particulates are continuously cured to lose autohension or so that the whole coating films are cured fully; and finally, the particulates coated films are cooled to the room temperature to obtain the coated particulates. The preparation method of the invention has high coating efficiency and good coating integrity and coating process.

Owner:NANJING UNIV OF SCI & TECH

Thermally-expandable polymer microsphere special for polyvinyl chloride resin foaming and preparation method thereof

The invention relates to a thermally-expandable polymer microsphere for polyvinyl chloride resin foaming and a preparation method thereof, and belongs to the field of expandable particles. The thermally-expandable polymer microsphere consists of a thermoplastic resin shell and a foaming agent encapsulated in the shell; an oil phase composition composed of a polymerizable monomer and a crosslinkingagent is dispersed in an aqueous phase dispersion composition; and in the presence of the foaming agent, the foaming agent is coated in situ through a suspension polymerization reaction to directly prepare the polymer microsphere coated with the foaming agent. The thermally-expandable polymer microsphere is characterized in that the oil phase composition comprises a silane coupling agent in addition to the polymerizable monomer and the crosslinking agent, and the foaming agent is a mixture of isopentane, isooctane and n-octane. The invention provides a thermally-expandable polymer microspherewhich has the advantages of complete core-shell structure, uniform particle size distribution, high foaming agent coating efficiency, good heat resistance of a shell polymer, high initial temperatureduring expansion, high maximum expansion temperature, high foaming ratio, and wide foam stabilizing temperature range, and is special for foaming polyvinyl chloride resin.

Owner:SHANDONG RUIFENG CHEM

UV (Ultraviolet) curing white primer for laser roller painting of woodware and preparation and application methods thereof

InactiveCN103694862AReduce lossReduce usagePretreated surfacesPolyurea/polyurethane coatingsPolyesterUltraviolet

The invention discloses a UV (ultraviolet) curing white primer for laser roller painting of woodware, which has high coating quantity and flat and bright coated surface. The UV curing white primer comprises 15-25 percent of bisphenol A epoxy acrylate, 15-25 percent of polyester acrylate, 1-10 percent of polyurethane acrylate, 8-15 percent of tripropylene glycol diacrylate, 3-8 percent of reagent type hydroxyethyl acrylate, 10-25 percent of trimethylolpropane triacrylate, 5-8 percent of photoinitiator, 0.2-0.4 percent of wetting dispersant, 0.2-0.4 percent of anti-settling agent, 8-15 percent of talcum powder and 10-20 percent of titanium dioxide. The UV curing white primer has the characteristics that after laser roller painting construction is ended, the coating amount is capable of reaching 35-45g / m<2>, the coated surface is flat and bright, the covering power is stronger than that of a common roller painting UV white primer, and the semi-curing repainting between paint films is not required to be ground, and the like. When being used for performing coating, the UV curing white primer has the advantages of time and labor saving, high fullness of products, and less loss of a machine.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

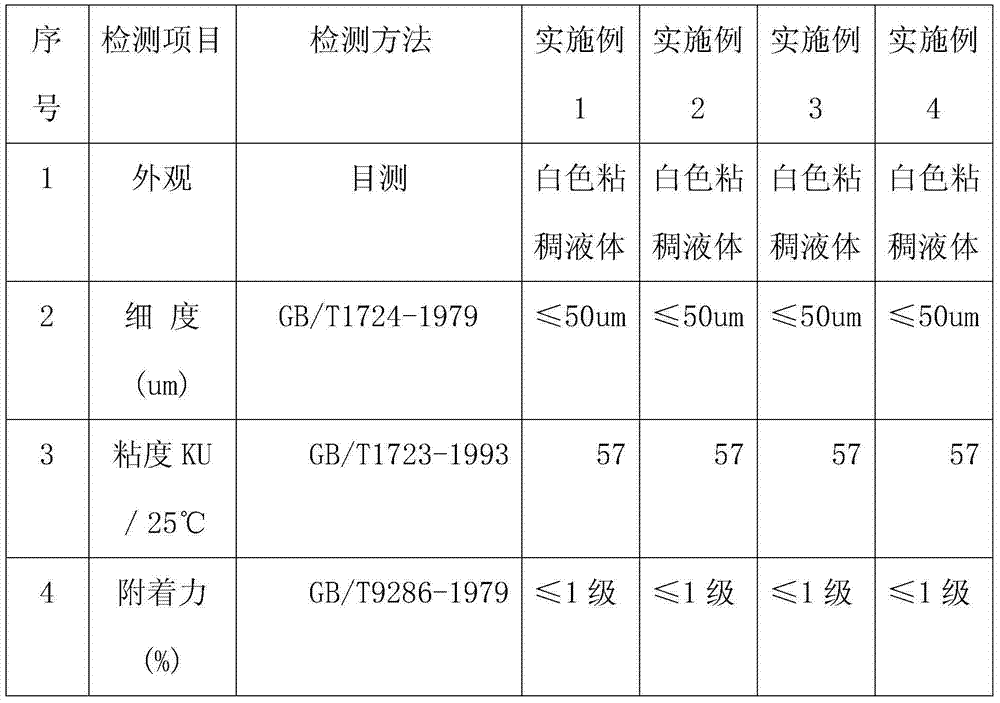

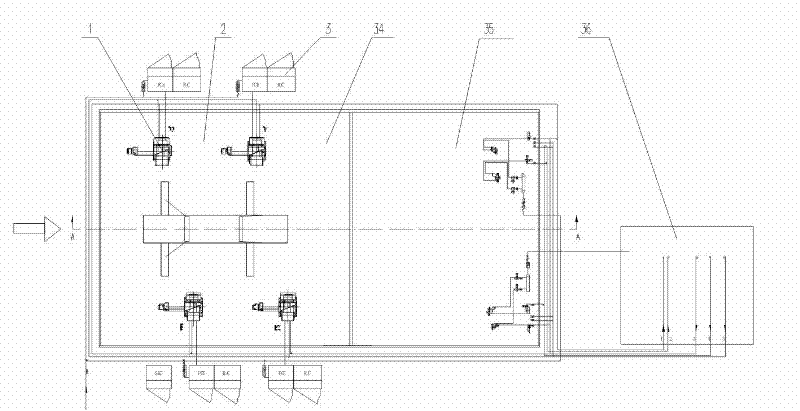

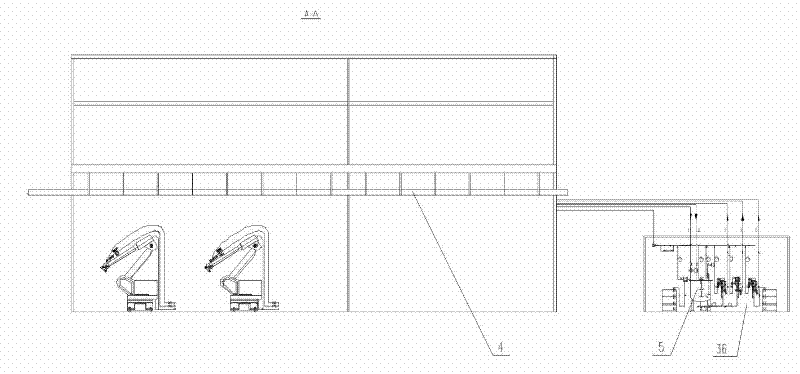

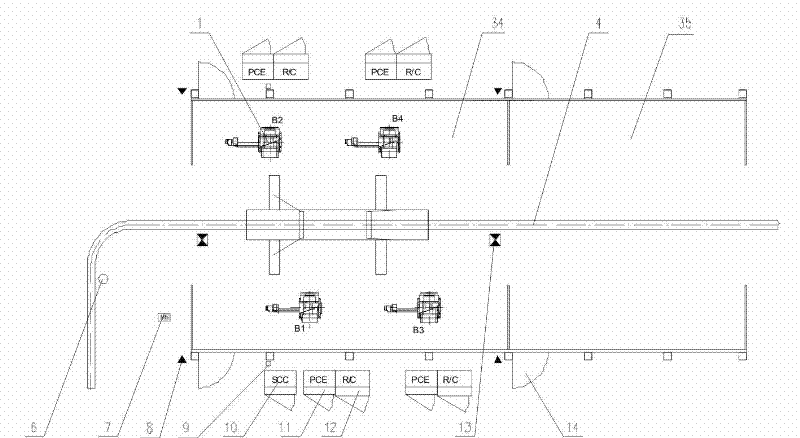

Flexible high-efficiency automatic spray-coating system and spray-coating process of big wheel tractor chassis

InactiveCN102371220AImprove the overall coating levelHigh strengthLiquid surface applicatorsSpraying apparatusControl systemWorking environment

The invention discloses a flexible high-efficiency automatic spray-coating system of a big wheel tractor chassis. The system comprises a spray-coating robot system, a mixed gas spray-coating system, a top-supply and bottom-water-absorption rotary paint spraying room, a wide push rod underslung power and free chain and a control system. During spray-coating operation, the top-supply and bottom-water-absorption rotary paint spraying room can ensure an appropriate working environment of a spray-coating robot; the wide push rod underslung power and free chain is used for conveying parts of the big wheel tractor chassis to the spray-coating robot and tracking and interlocking the big wheel tractor chassis; and an automatic mixed gas spray gun at the front end of an arm of the spray-coating robot moves according to the demonstrating track and optimized process parameters and works together with the robot to complete the spray-coating work. The flexible high-efficient automatic spray-coating system of the big wheel tractor chassis has the advantages of intelligence, high efficiency, low pollution and high coating utilization rate, can ensure the consistency of the spray-coating operation and can flexibly change the spray-coating track according to different workpieces.

Owner:FIRST TRACTOR

Coating process applying water-based paint to metal parts of construction machinery

InactiveCN102974520AMeet the use requirementsGood lookingAnti-corrosive paintsPolyurea/polyurethane coatingsProcess engineeringMechanic - metal

The invention discloses a coating process applying water-based paint to metal parts of construction machinery. The coating process is characterized in that water-based anti-corrosion priming paint and waterborne polyurethane texture finish paint are combined and used on base materials of the metal parts of the construction machinery. The coating process applying the water-based paint to the metal parts of the construction machinery enables the water-based paint to be correctly used for the coating of the metal parts of the construction machinery, not only solves harm and potential safety hazards brought about by a traditional coating process to a forklift, but also improves the protecting performance and the physical and chemical performance of the coating process, and prolongs the service life of the forklift.

Owner:GUANGZHOU QINGTIAN INDAL +1

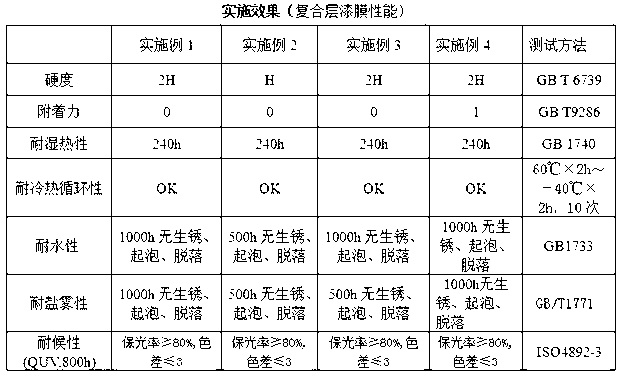

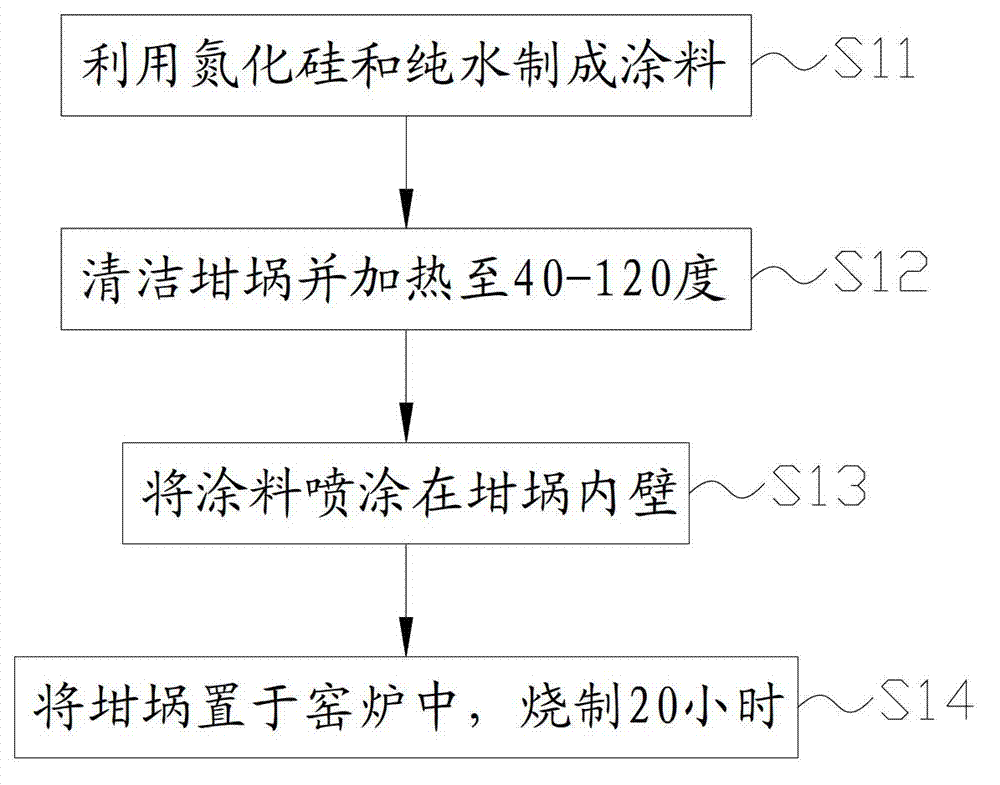

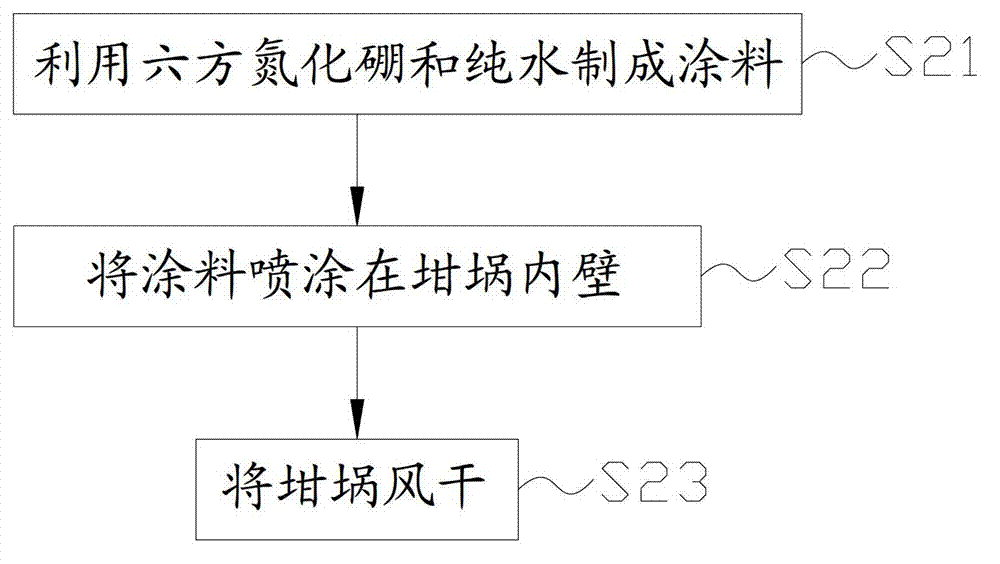

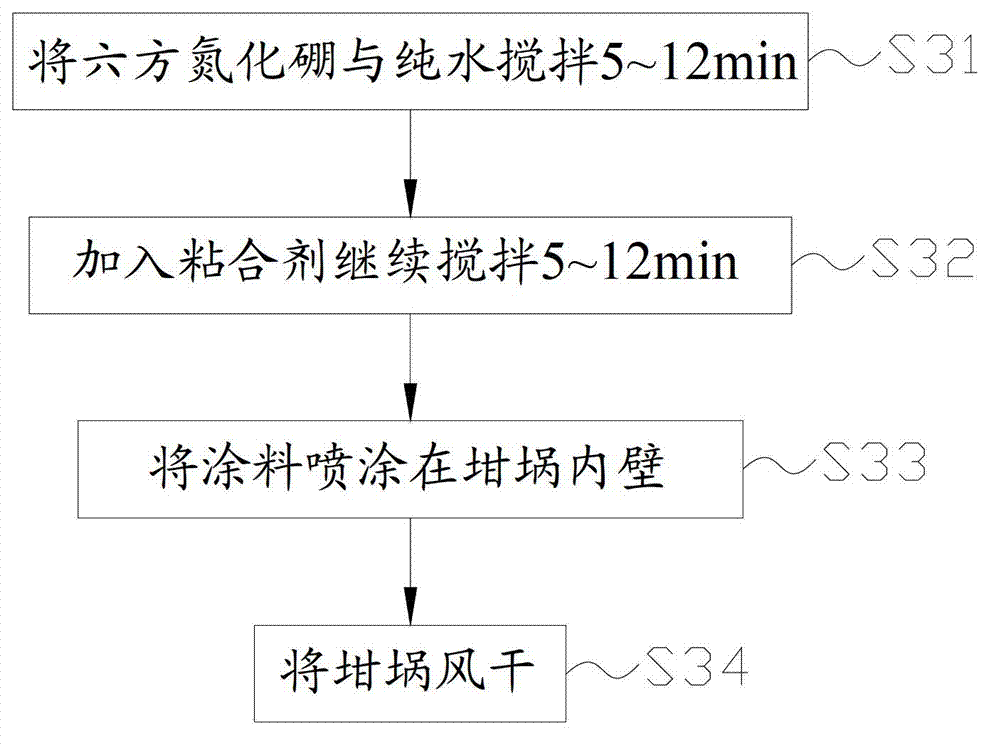

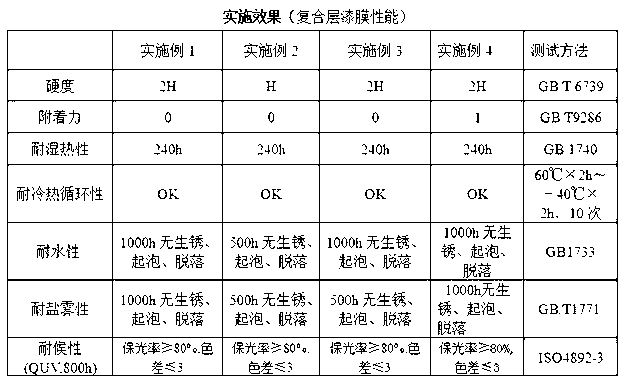

Crucible and coating method thereof

InactiveCN103084325AImprove coating efficiencyIncrease productivityAfter-treatment apparatusPretreated surfacesHexagonal boron nitrideCrucible

The invention discloses a crucible and a coating method of the crucible. The disclosed coating method of the crucible comprises the following steps: coating paint is manufactured, and the coating paint comprises hexagonal boron nitride and pure water; the coating paint is coated on the inner wall of the crucible in a spraying mode; and the crucible is aired to be dry. The possibility of the reaction between the crucible and the hexagonal boron nitride is small, silicone material is not prone to stick to the crucible, the possibility of occurrence of leakage is obviously lowered, and therefore the safety and reliability in the process of production of the silicone material are improved. Meanwhile, a coating is poor in wettability with liquid silicone and is not prone to stick to the silicone materials under the condition of carrying the liquid silicone. In addition, due to the fact that the hexagonal boron nitride has good wettability, demolding of a silicone ingot is good. The coating enables the heat conduction to be more uniform in the growth process of the silicone ingot, so that the interior quality of the silicone ingot is improved. Therefore, the coating method of the crucible is capable of reducing the sticking and permeation between the crucible and the liquid silicone material, plays a role in a protective layer, has the functions of lubrication and demolding, and improves the production quality of the silicone material and production efficiency.

Owner:TIANJIN YINGLI NEW ENERGY RESOURCES

Coating process applying water-based paint to cast iron parts

InactiveCN102974518AMeet the use requirementsGood lookingPretreated surfacesAnti-corrosive paintsCast ironCoating

The invention discloses a coating process applying water-based paint to cast iron parts. The coating process is characterized in that water-based anti-corrosion priming paint and waterborne polyurethane texture finish paint are combined and used on base materials of the cast iron parts of machinery. The coating process applying the water-based paint to the cast iron parts enables the water-based paint to be correctly used the coating of the cast iron parts of the machinery, and not only solves harm and potential safety hazards brought about by a traditional coating process to a forklift, but also improves the protecting performance and the physical and chemical performance of the coating process, and prolongs service life of the forklift.

Owner:GUANGZHOU QINGTIAN INDAL +1

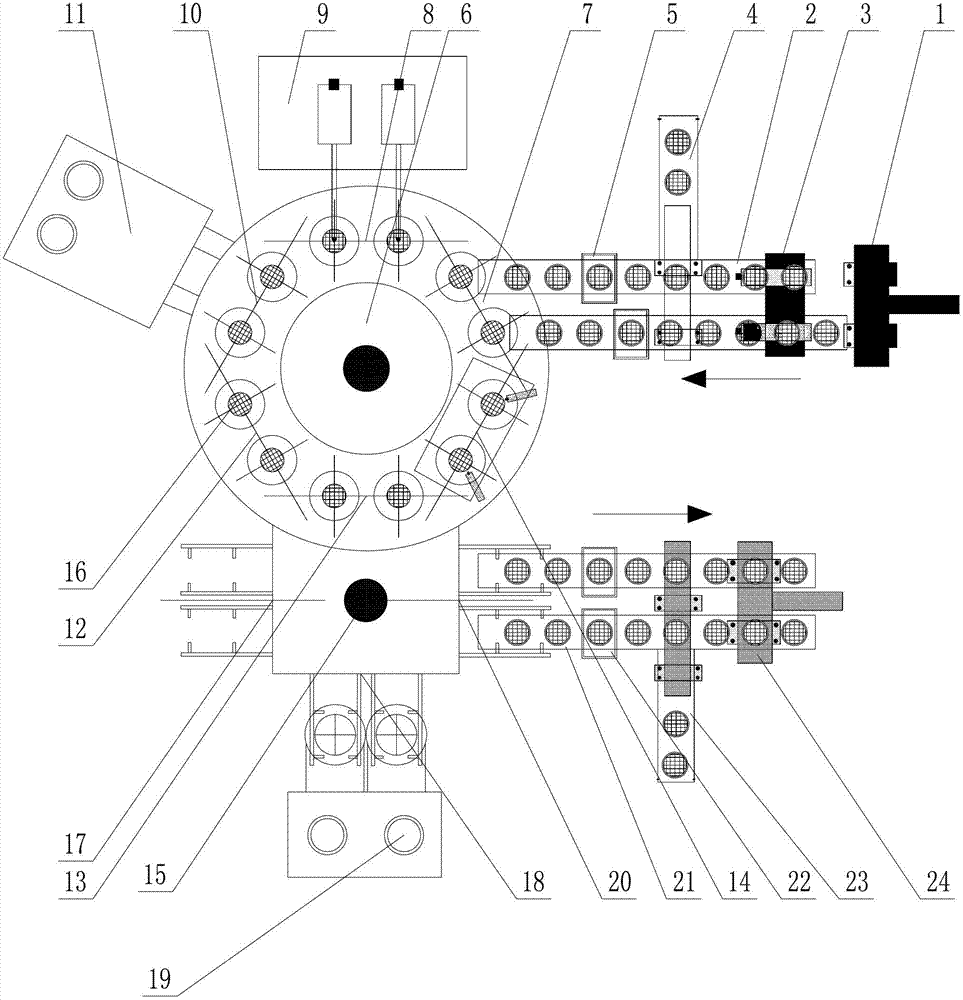

Full-automatic quantitative honeycomb carrier catalyst coating device

ActiveCN103157521ABroad applicable industrial fieldBroad industrial fieldCatalyst activation/preparationHoneycombEngineering

The invention relates to a full-automatic quantitative honeycomb carrier catalyst coating device. The full-automatic quantitative honeycomb carrier catalyst coating device comprises a large turnplate and is characterized in that the large turnplate is orderly provided with a first work position, a second work position, a third work position, a forth work position, a fifth work position and a sixth work position along a counter-clockwise direction; the first work position is connected to one end of a feeding conveyor belt and the other end of the feeding conveyor belt is a feeding end; the feeding end is provided with a feeding device; the feeding end of the feeding conveyor belt is provided with an ink-jet printing machine; the second work position of the large turnplate is provided with a spraying device; the third work position of the large turnplate is provided with a first suction device; the fifth work position of the large turnplate is provided with a turnable small turnplate; the periphery of the turnable small turnplate is provided with an overturn work position, a suction work position and a discharge work position along a counter-clockwise direction; an overturn cylinder is installed at the overturn work position; a second suction device is installed at the suction work position; and the discharge work position is connected to a discharge conveyor belt. The full-automatic quantitative honeycomb carrier catalyst coating device has a high automation degree and high coating efficiency and guarantees product quality.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

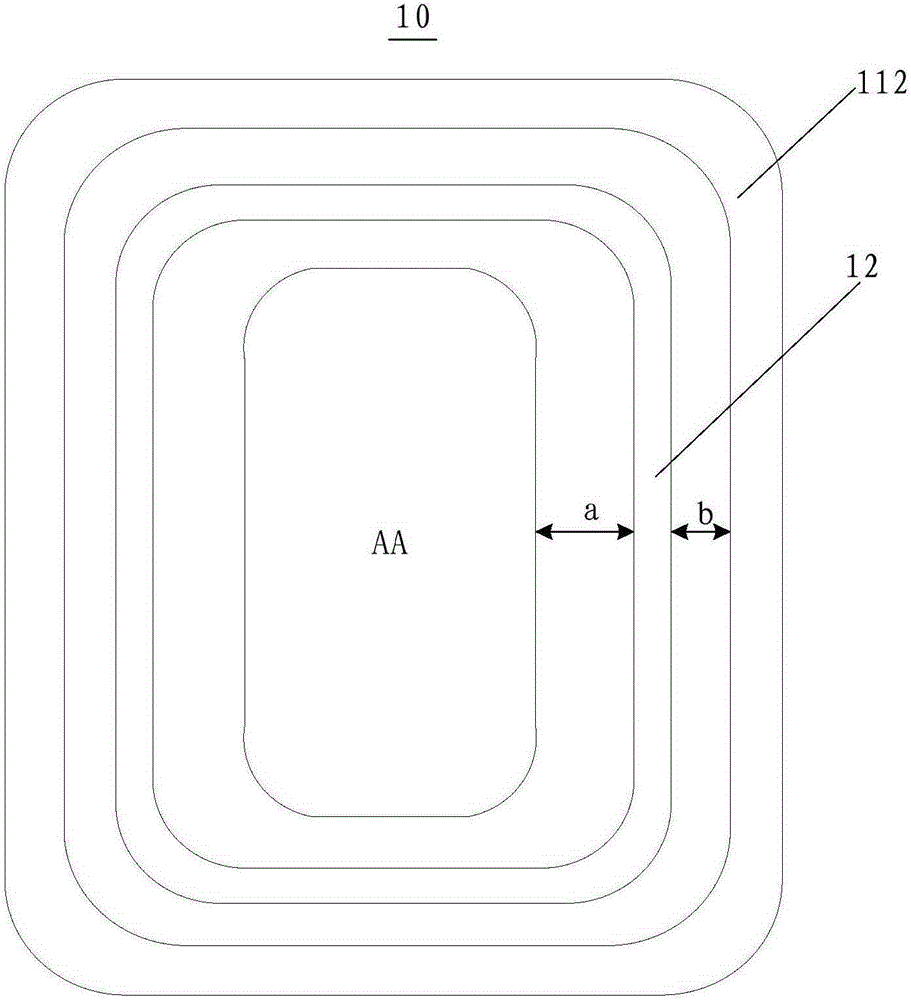

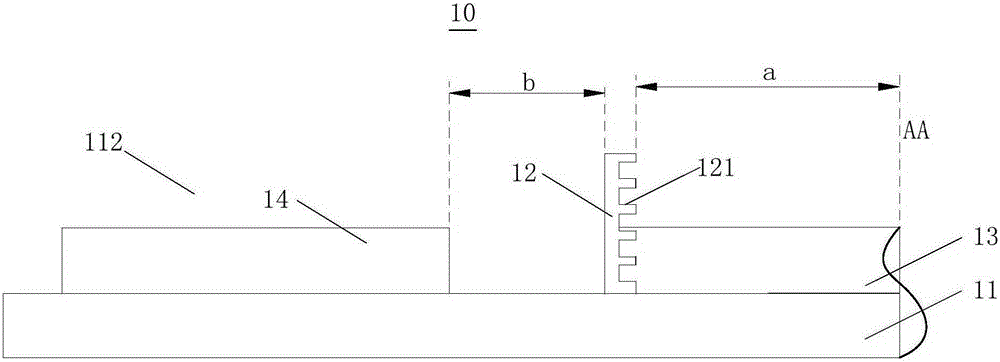

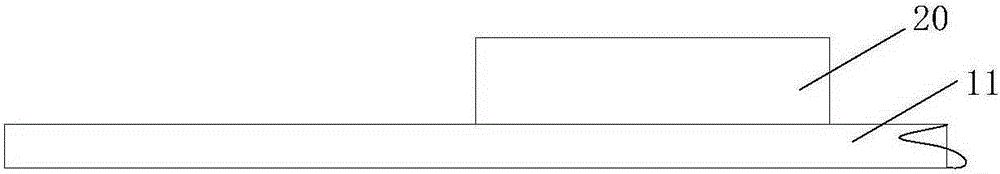

Liquid crystal display panel and display device

ActiveCN105204237AIncrease contact areaReduce impactNon-linear opticsLiquid-crystal displayEngineering

The invention discloses a liquid crystal display panel and a display device. The liquid crystal display panel comprises a substrate and a stopping wall, wherein the substrate comprises a display area used for displaying and a sealing area used for sealing, and the stopping wall is formed on the substrate and located between the sealing area and the display area. A coarse structure is arranged on the lateral side, near the display area, of the stopping wall. In this way, by means of the liquid crystal display panel and the display device, the impact force of alignment liquid to the stopping wall can be reduced through the coarse structure of the lateral side of the stopping wall in the coating process of an alignment film; meanwhile, the adhesive force of the alignment liquid to the stopping wall is increased, and therefore the problem that as the alignment liquid refluxes to the display area, the thickness of the alignment film is uneven is solved. In addition, the coating accuracy and the coating efficiency of the alignment film can be improved by arranging the stopping wall, and then the product yield of the liquid crystal display panel is increased.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

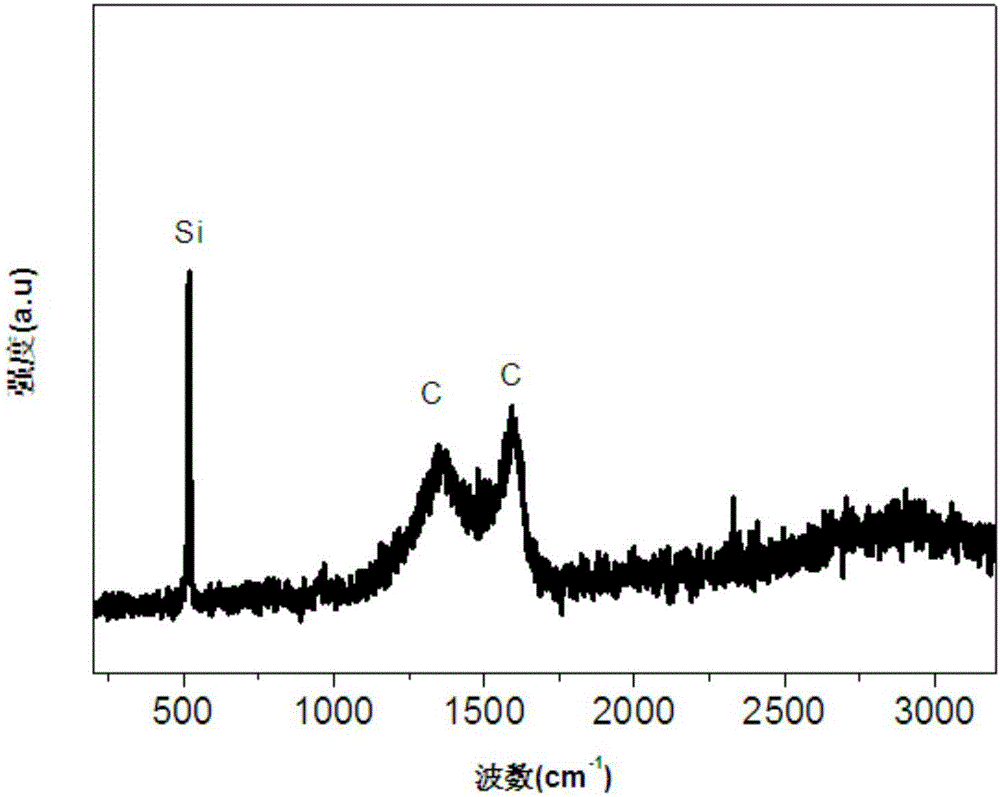

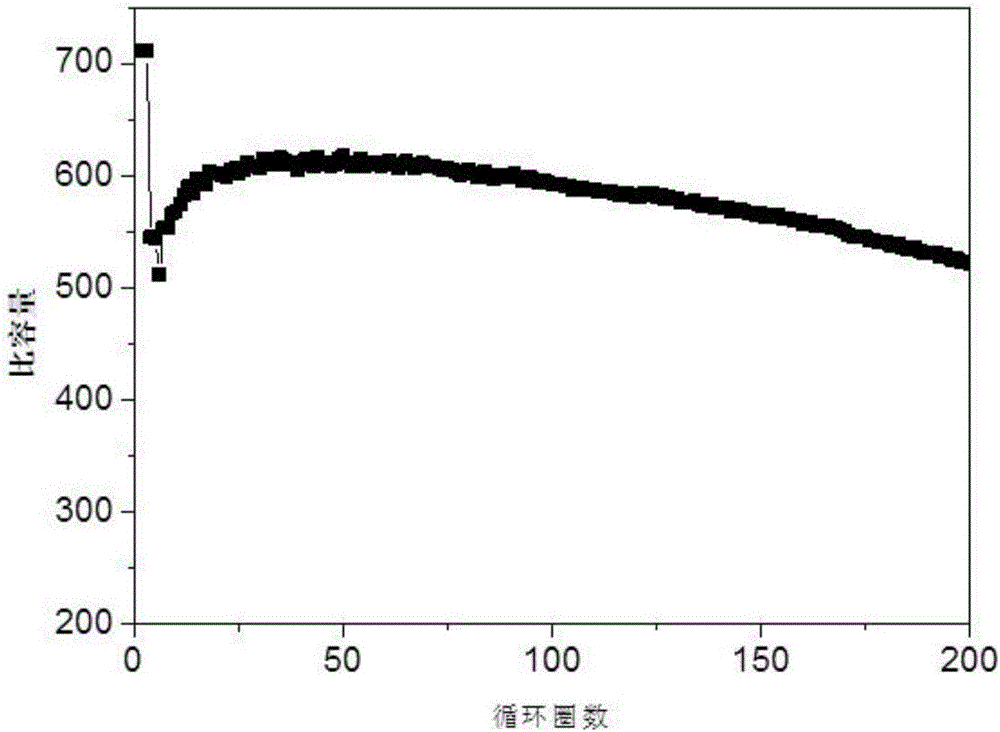

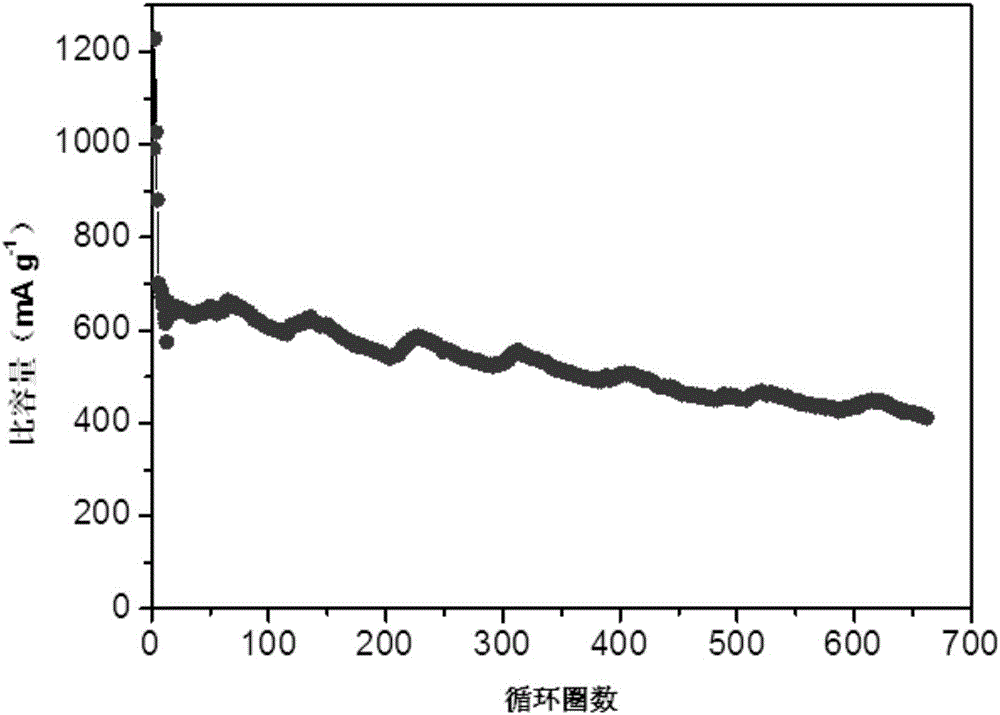

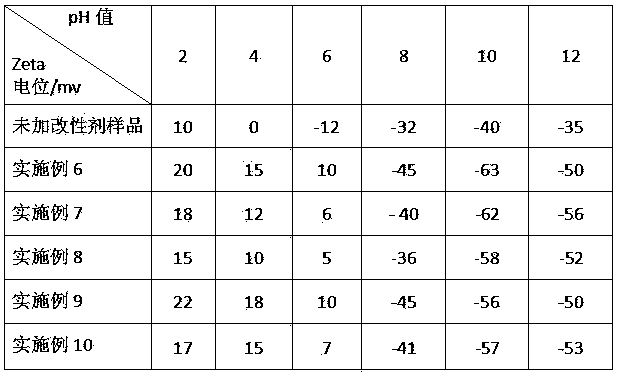

Preparation method and application of silicon-carbon composite material

InactiveCN106549149AImprove coating efficiencyUniform adhesionCell electrodesSecondary cellsCarbon coatingCarbon composites

The invention discloses a preparation method and application of a silicon-carbon composite material, belonging to the technical field of preparation of composite materials. The preparation method comprises the following steps of: (1), grinding silicon-based alloy into powder, and performing acid pickling to obtain a porous silicon material; and (2), mixing the porous silicon material with an organic polymer carbon source and a solvent, performing ball-milling to obtain a homogenate type mixture, and performing thermal treatment after drying so as to obtain the silicon-carbon composite material. According to the preparation method and application disclosed by the invention, when carbon coating is carried out, the organic polymer carbon source (such as polyvinylidene fluoride) having high viscosity is mixed with a little solvent, so that thick colloid is prepared; then, matched with ball-milling, the organic polymer carbon source is adhered to the surface of porous silicon effectively and uniformly; the carbon coating efficiency is relatively high; in addition, the use amount of the organic solvent is low; energy consumed by solvent evaporation is saved; therefore, the production cost is reduced; the preparation process is simple, and suitable for large-scale production; the silicon-carbon proportion in the prepared silicon-carbon composite material is reasonable; the volume strain capacity is better; and the electrochemical performance of a lithium ion battery is improved.

Owner:TIANNENG SAFT ENERGY JOINT CO

Surface modification method of silicon carbide micropowder

The invention relates to a surface modification method of silicon carbide micropowder. Two modifying agents are adopted to perform two-step dry modification of the silicon carbide micropowder. The surface modification method comprises steps of: preparing an ethanol solution of a silane coupling agent and an aqueous solution of water-soluble polymer, preheating the silicon carbide micropowder at 30-70 DEG C for 20-60 min, spraying the ethanol solution of the silane coupling agent in a form of mist into the silicon carbide micropowder stirred at a high speed, stirring and drying at 110-150 DEG C for 0.5-3 h, spraying the aqueous solution of the water-soluble polymer preheated to 30-80 DEG C in a form of mist into the silicon carbide micropowder stirred at a high speed, and stirring and drying at 110-150 DEG C for 0.5-3 h to obtain surface modified silicon carbide micropowder. The surface modification method aims at dry-method modification of the silicon carbide micropowder, and is capable of effectively solving the dispersibility problem of the dispersibility, and improving the uniformity and increasing the powder yield of granulation of the silicon carbide micropowder.

Owner:连云港海蓝研磨材料有限公司 +1

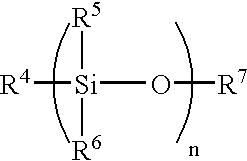

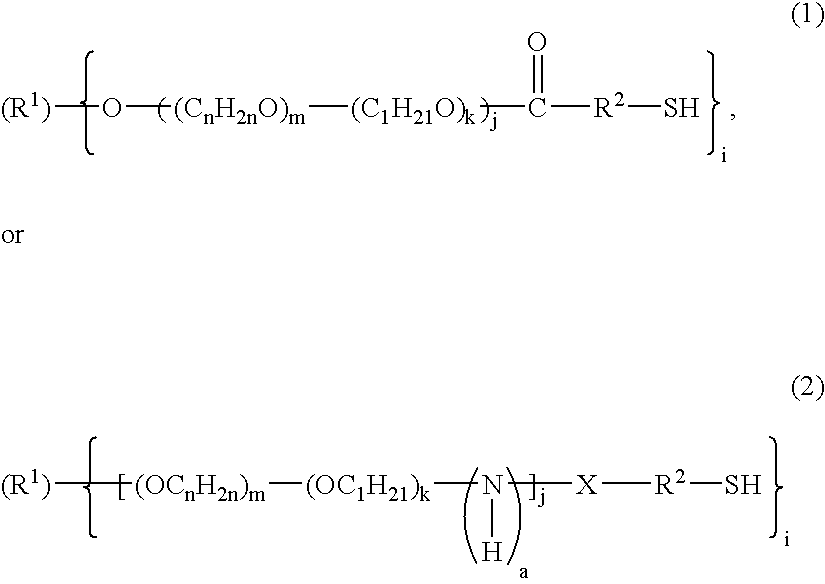

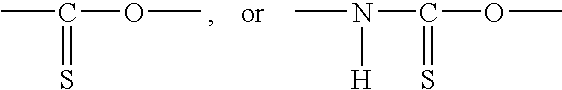

(POLY)oxyalkylene block silyl ester copolymer, antifouling coating composition, antifouling coating formed from antifouling coating composition, antifouling method using antifouling coating composition and hull or underwater structure covered with antifouling coating

InactiveUS6828030B2Reduce usageImprove performanceAntifouling/underwater paintsPretreated surfacesSilyleneHydrolysis

A (poly)oxyalkylene block silyl ester copolymer comprising silyl ester copolymer block units (A) and block units (B), the block units (a) comprising (a) component units derived from a polymerizable unsaturated carboxylic acid silyl ester, and (b) polymerizable unsaturated monomer units other than the component units (a), the block units (B) derived from particular mercapto compounds, and an antifouling paint comprising the (poly)oxyalkylene block silyl ester copolymer. The copolymer enables the formation of an antifouling coating film which exhibits less cracking tendency, excellent adherence, less peeling tendency and controlled hydrolysis rate resulting in excellent antifouling performance and properties.

Owner:CHUGOKU MARINE PAINTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com