Coating process applying water-based paint to metal parts of construction machinery

A technology for construction machinery and metal parts, applied in the field of coating technology, can solve the requirements of construction machinery anti-corrosion, the corrosion resistance is not easy to achieve, the technology is immature, etc., to achieve good construction performance, improve surface aesthetics, good appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

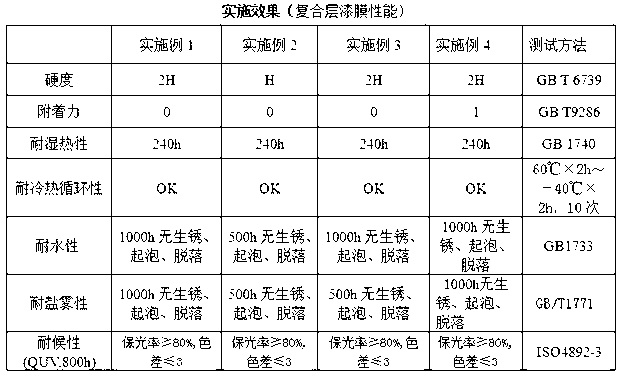

Examples

Embodiment 1

[0032] Shot blasting of cast iron substrates in construction machinery to remove oil and rust from component surfaces. Then, post-treatment is carried out by brushing the water-based rust-bearing paint to remove floating rust on the surface of the base material of the component. Then spray water-based epoxy zinc-rich primer (the main component and ratio are water-based epoxy resin: zinc powder = 20:80, and the ratio of water-based polyamine to curing agent is 5:1), and the wet film thickness is about 60~ 120 microns, dry at room temperature for more than 0.5 hours. After the surface of the paint film is dry, spray the water-based polyurethane texture topcoat (its main component and ratio are water-based polyurethane resin: weather-resistant coloring pigment: auxiliary agent: water = 40:30:5:15, and the combination of polyurethane curing agent Ratio is 6:1), after leveling for 15-30 minutes, spray the topcoat again, the wet film thickness is controlled at 100-200 microns, and ...

Embodiment 2

[0034] Sand blasting of hot-rolled sheet substrates for construction machinery to remove oil and rust from component surfaces. Then, post-treatment is performed with an aqueous rust-carrying paint to remove floating rust on the surface of the base material of the component. Then spray water-based epoxy ester anti-corrosion primer (the main components and ratio are water-based epoxy ester resin: anti-rust pigments and fillers: additives: water = 40:25:5:30, the wet film thickness is about 60-100 Micron, dry at room temperature for more than 0.5 hours. After the paint film is surface-dry, spray water-based polyurethane texture topcoat (its main component and proportion are water-based polyurethane resin: weather-resistant coloring pigment: additive: water = 50:30:3: 15. The ratio with the polyurethane curing agent is 6:1, the wet film thickness is controlled at 60-140 microns, and then dried at room temperature. The total dry film thickness of the composite coating is about 80-2...

Embodiment 3

[0036] Grinding and derusting the hot-rolled plate substrates of construction machinery to remove oil and rust on the surface of the components. Then, post-treatment is carried out by brushing the water-based rust-bearing paint to remove floating rust on the surface of the base material of the component. Then spray water-based epoxy anti-corrosion primer (the weight ratio of its main components is water-based epoxy resin: anti-rust pigment: auxiliary agent: water=50:30: 5: 15 and water-based polyamine curing agent, the proportion is 8:1, the wet film thickness is about 60-100 microns, bake at 80°C for 30 minutes, inspect the appearance and performance of the coating film, and finally spray the water-based polyurethane texture topcoat (the main component and ratio are water-based polyurethane resin: weather-resistant type Coloring pigments: additives: water = 50:25:4:20, the ratio of polyurethane curing agent is 6:1, the wet film thickness is controlled at 60-140 microns, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com