Patents

Literature

827results about How to "Good thermal conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

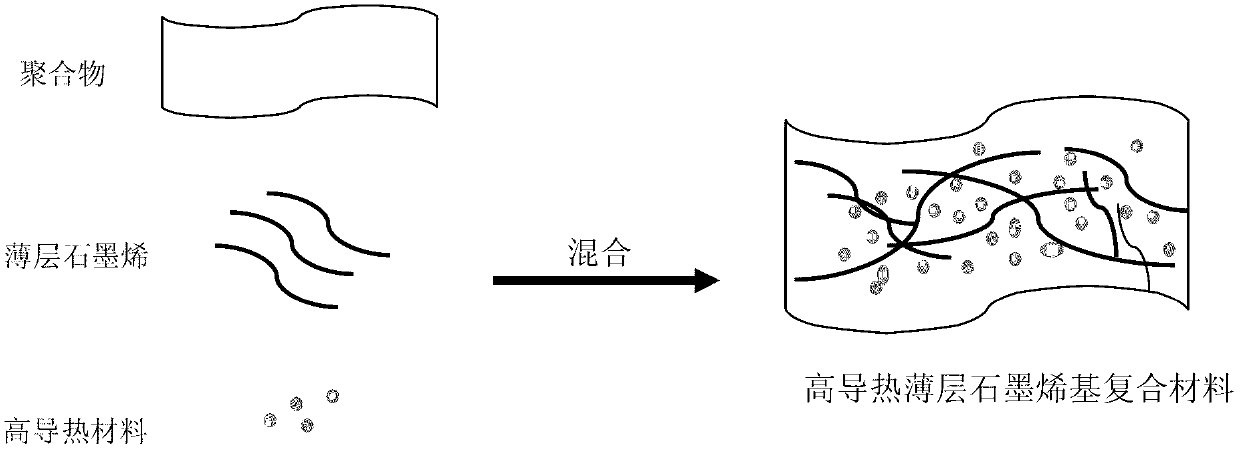

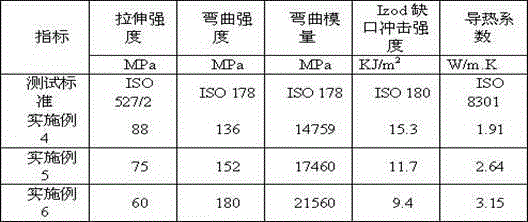

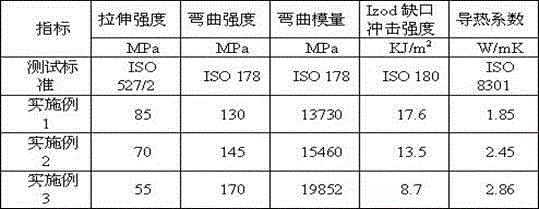

High heat-conducting thin graphene-based composite material, as well as preparation method and application thereof

InactiveCN103122075AGood thermal conductivityExcellent MechanicsHeat-exchange elementsCvd grapheneElectrospinning

The invention discloses a high heat-conducting thin graphene-based composite material, as well as a preparation method and an application thereof. The composite material comprises a base body component and a packing component, wherein the base body component and the packing component respectively include thin graphene, polymer and / or polymer monomer and a high heat-conducting material; the preparation method comprises a step of compounding the base body component with the packing component; the compounding method comprises fusing, ball-milling, solution blending, electrostatic spinning, solution spinning, melt-spinning, extruding by double screws, mixing by an open mill or powder metallurgy. The polymer, the thin graphene, the traditional high heat-conducting material and the like are compounded by a simple process, so as to form the product with excellent heat conducting property, and good mechanical and electrical properties. Therefore, the process is easy to perform and control, and cost is low; and the obtained product has a wide application prospect in the aspects such as efficient heat conduction and radiation.

Owner:苏州格瑞丰纳米科技有限公司

Thermal conductive molding compound and preparation method thereof

The invention discloses a thermal conductive molding compound and a preparation method thereof. The thermal conductive molding compound consists of the following components by weight percent: 15-40% of thermal conductive filler A, 10-30% of thermal conductive filler B, 1-5% of thermal conductive filler C, 5-15% of reinforcing component, 0.05-0.5% of surface modifier and 0-2% of other additives. The preparation method comprises the following steps: adding the thermal conductive filler B in a mixer, adding the surface modifier for mixing, and then adding the thermal conductive filler C for further mixing to obtain a mixture I; adding the thermal conductive filler A in a high-speed mixer, and adding the surface modifier for mixing to obtain a mixture II; after uniformly mixing a plastic matrix with other additives, adding the mixture of the plastic matrix and other additives from the main feeding port of a twin-screw extruder; adding the mixture I and the mixture II from the main feeding port or a feeding port on one side downstream of the extruder; independently adding the reinforcing component from a feeding port on the other side downstream of the extruder; and obtaining the thermal conductive molding compound from the twin-screw extruder. The thermal conductive molding compound has excellent thermal conductivity and good mechanical property.

Owner:KINGFA SCI & TECH CO LTD +1

Composite amorphous phase-change heat storage material and preparation method thereof

InactiveCN103525373AReduce leakageLeakage is not easy to happenHeat-exchange elementsActive agentHeat conducting

The invention relates to a composite amorphous phase-change heat storage material and a preparation method thereof, and belongs to the technical field of composite materials. The composite material is prepared from a porous material used as a support material and an inorganic hydrous salt used as a phase-change material in manners of absorbing the inorganic hydrous salt into a porous structure of the support material by virtue of the capillary adsorption action of the porous material, and self-assembly of a surfactant. The method comprises the following steps: firstly, emulsifying and dispersing the molten inorganic hydrous salt phase-change material such as calcium chloride hexahydrate by the emulsifying dispersion effect of the surfactant under an ultrasonic condition, so as to form a stable emulsion; adding expanded graphite to the emulsion to evenly disperse; putting the mixture into a vacuum oven, vacuumizing and keeping in a constant state for 30 minutes at room temperature, so as to prepare a novel composite amorphous phase-change heat storage material which is high in phase-change latent heat, good in heat-conducting property, and low in cost.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

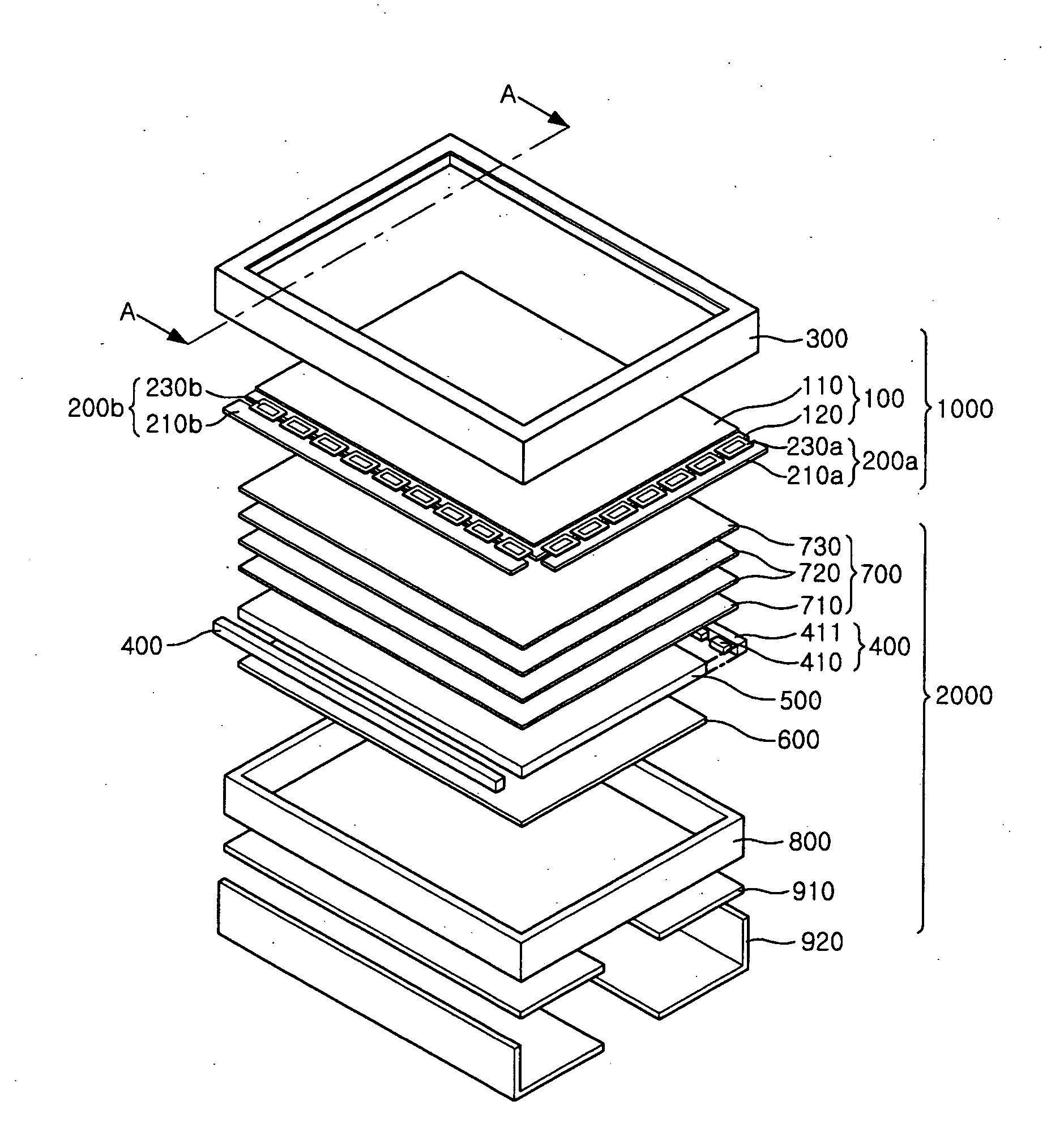

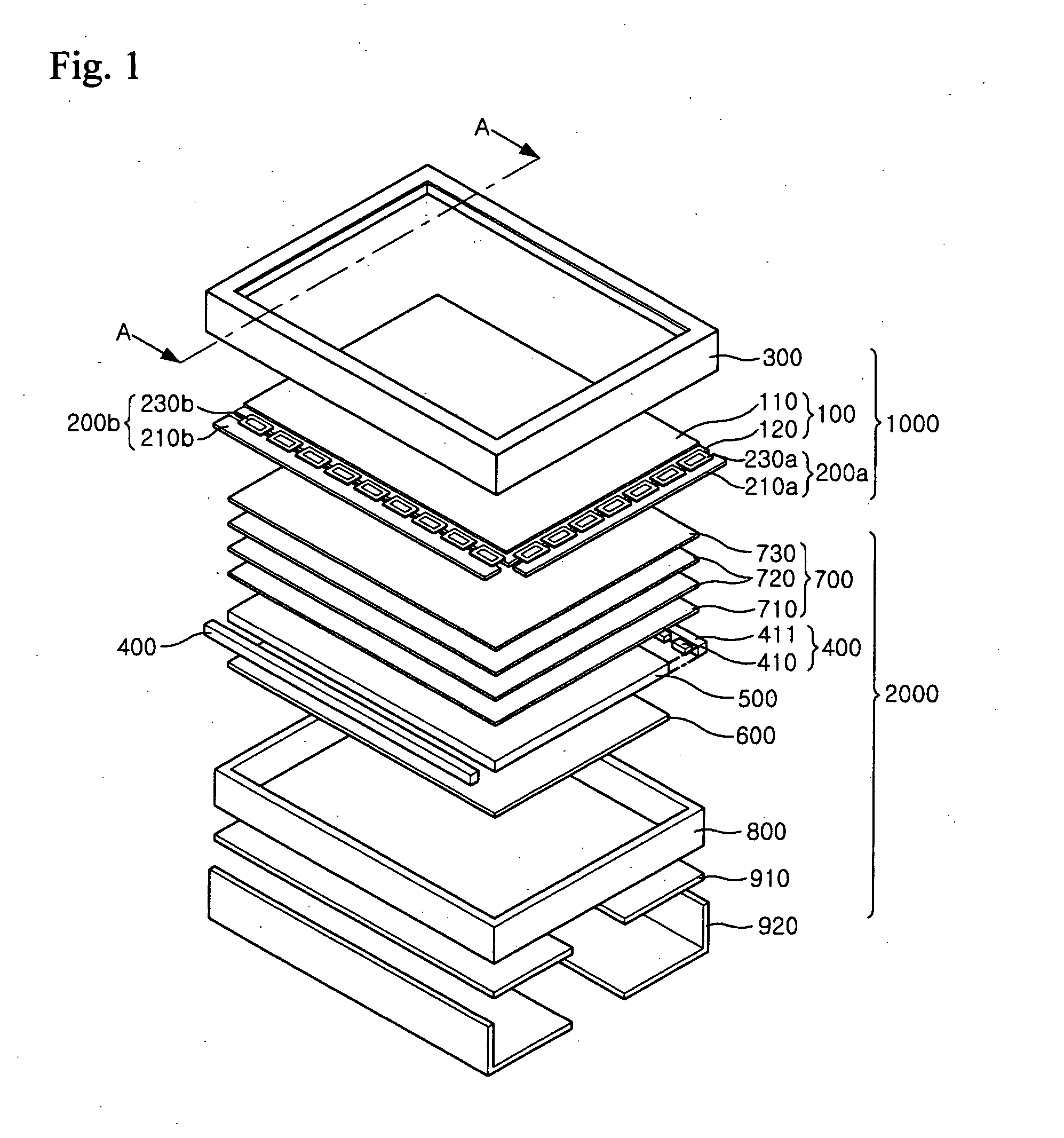

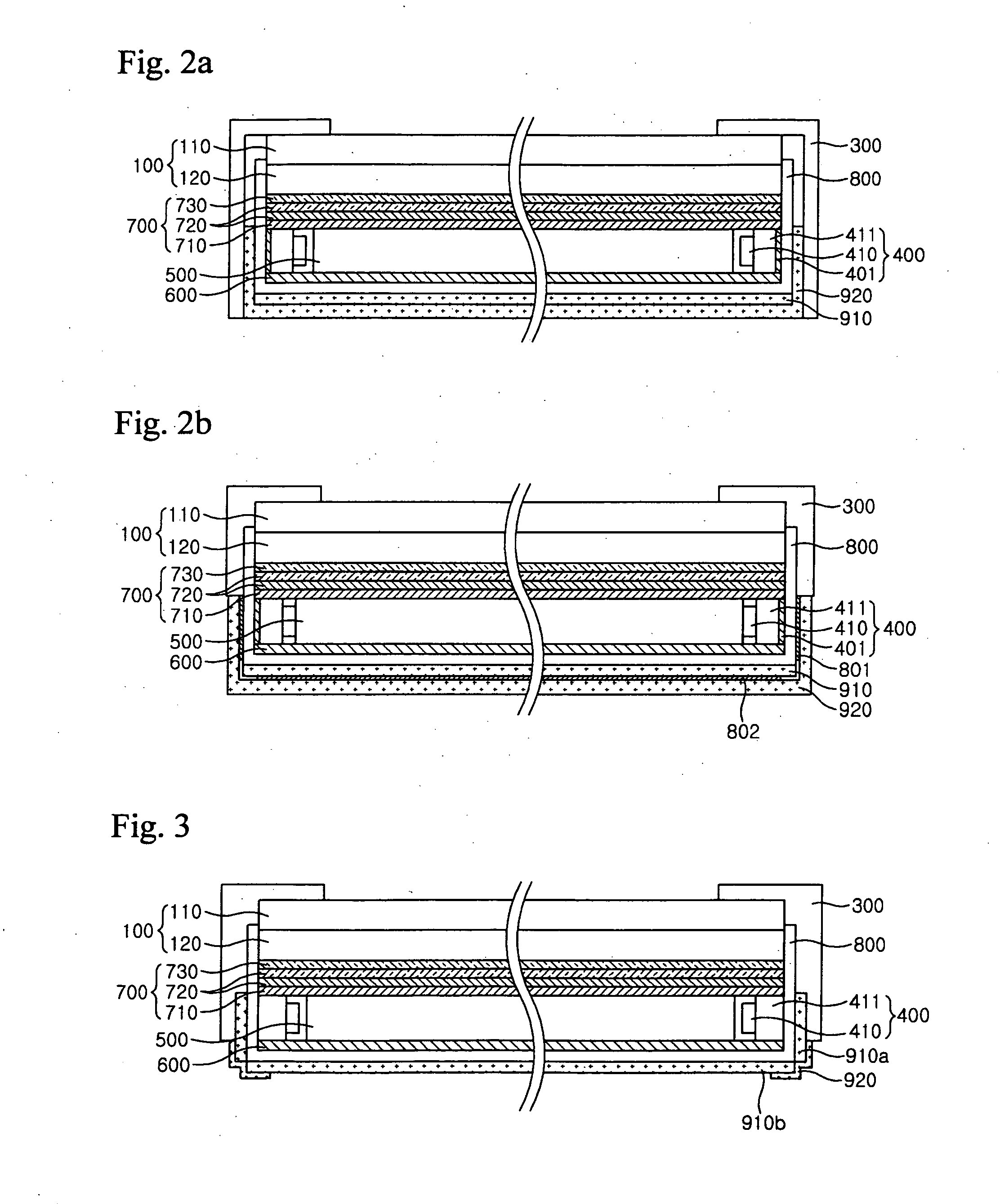

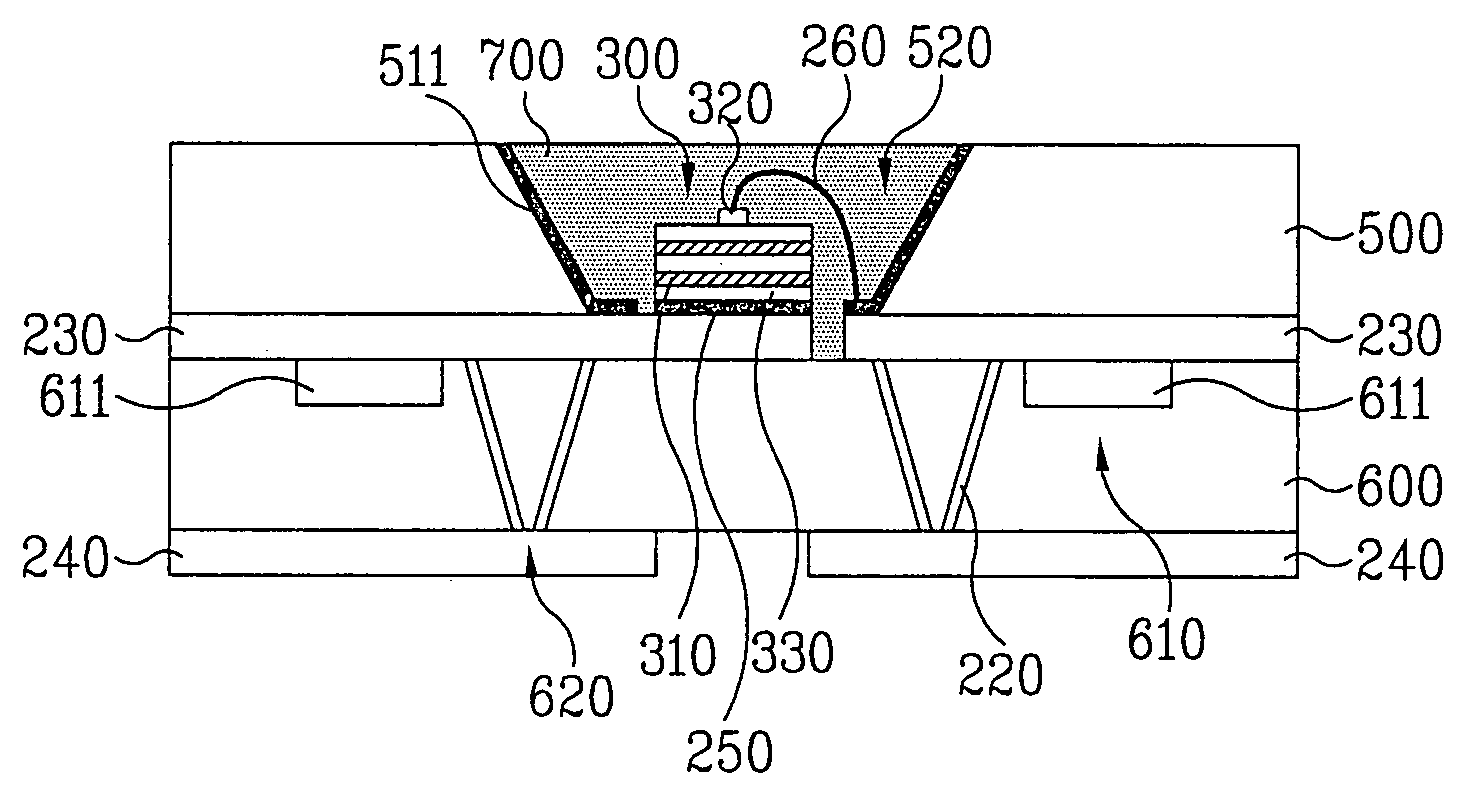

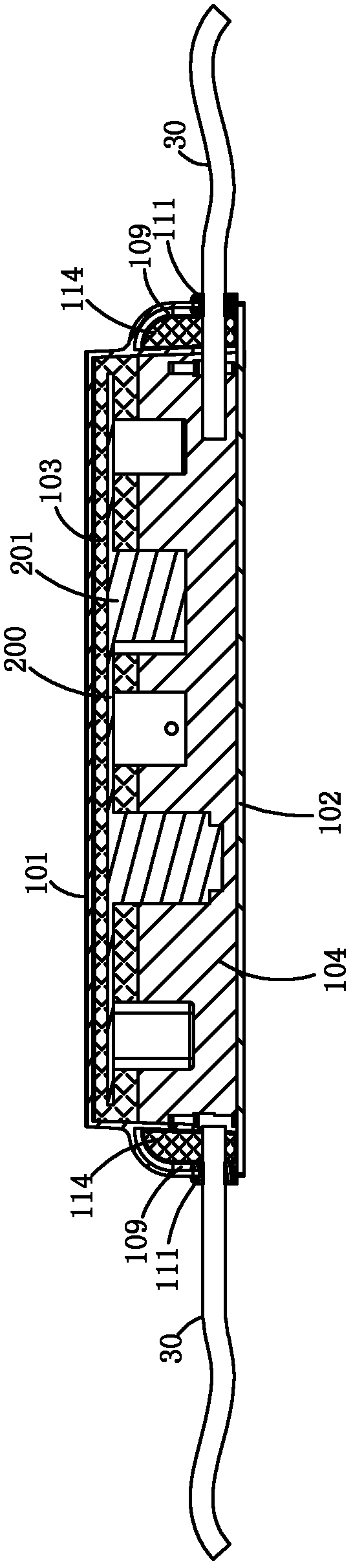

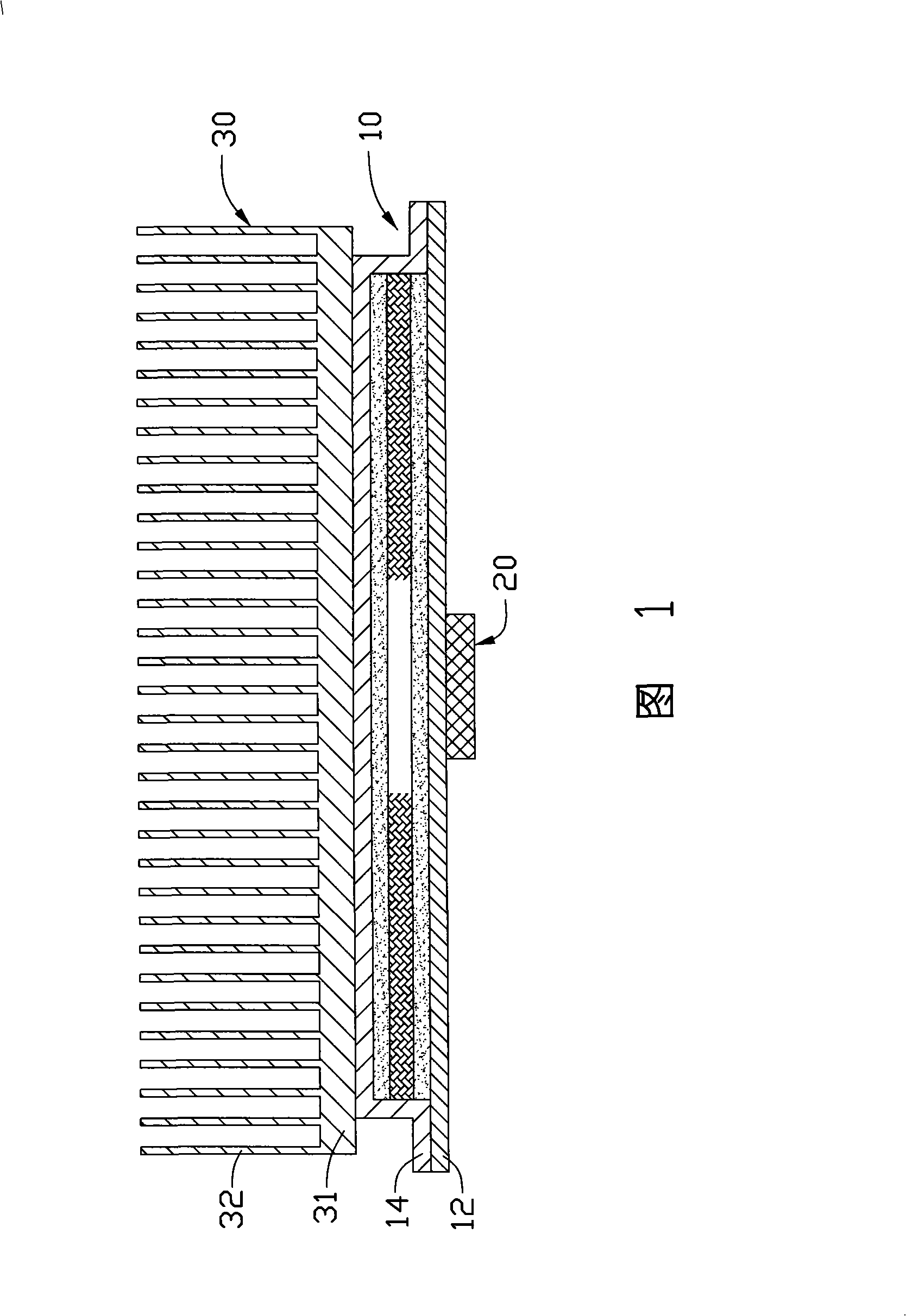

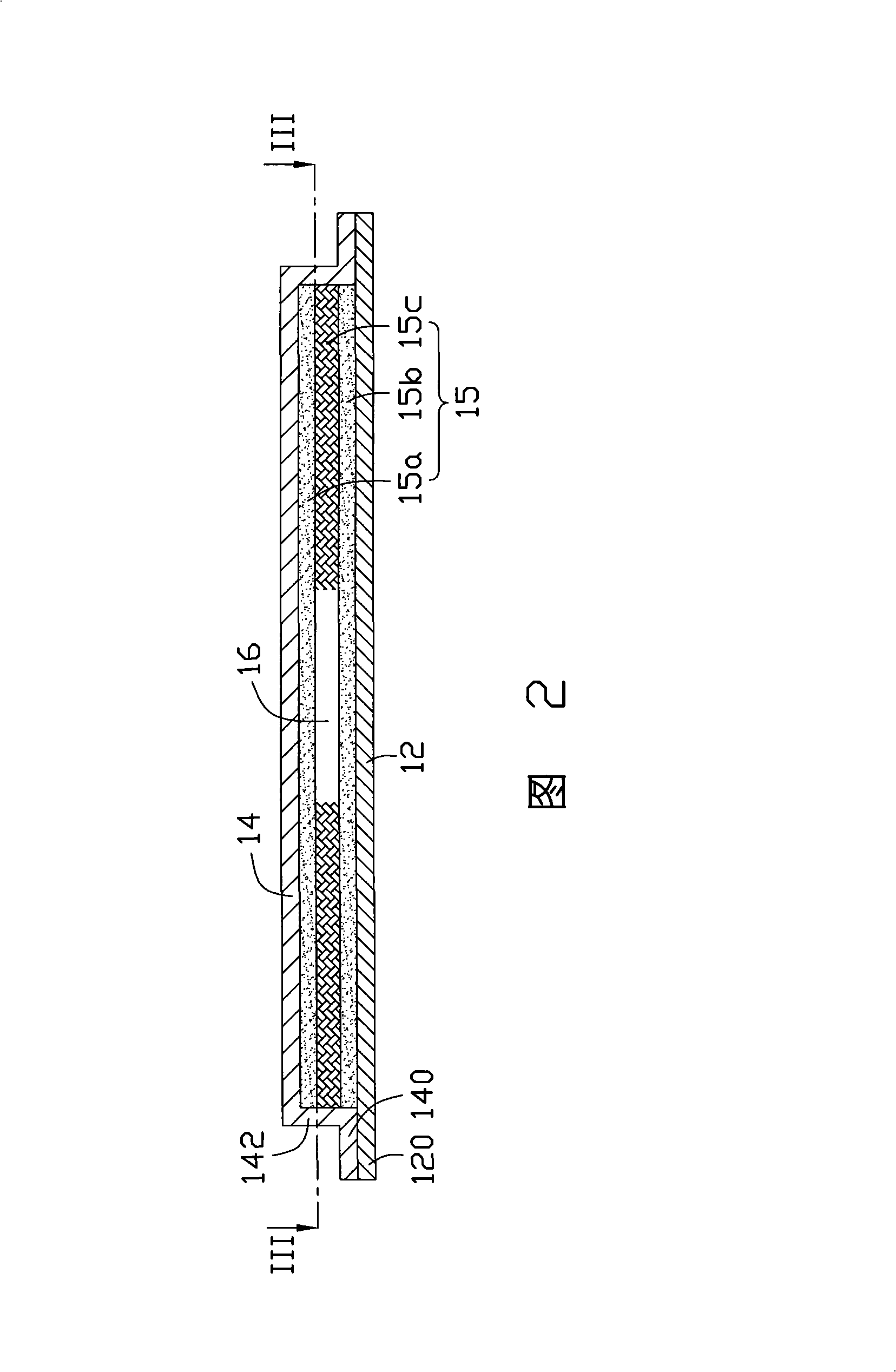

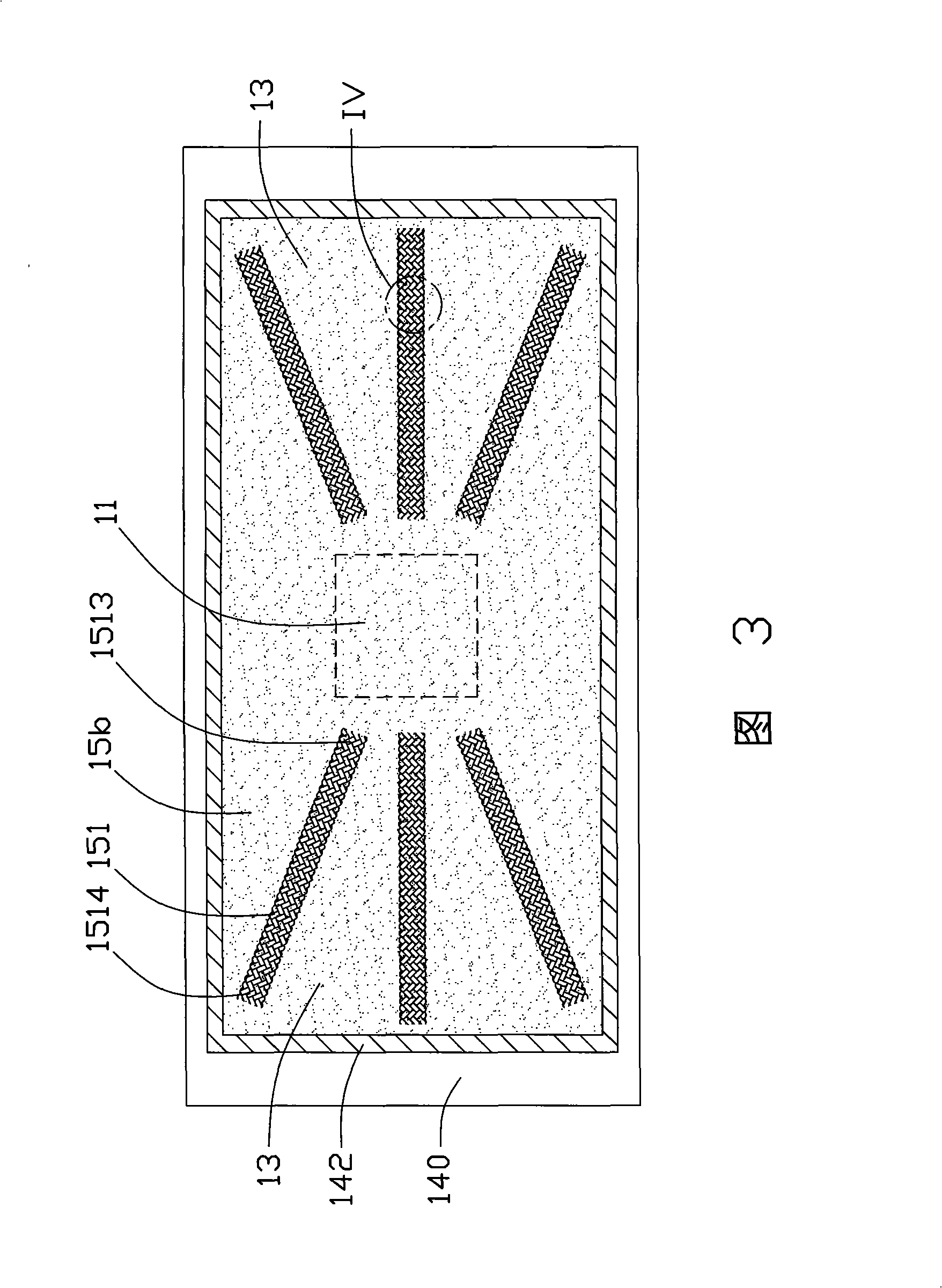

Backlight assembly and liquid crystal display device using the same

ActiveUS20060285362A1Good thermal conductivityShow cabinetsImpedence networksThermal conductivityLiquid-crystal display

A backlight assembly and a liquid crystal display device can discharge heat from the lamp unit to the outside or effectively dissipate the heat. The backlight assembly of the present invention includes a lamp unit, a receiving member for receiving the lamp unit, a first heat dissipation member disposed below the receiving member, and a second heat dissipation for wrapping around a lateral side of the receiving member and the first heat dissipation member. The lamp unit is disposed on an area corresponding to the lateral side of the receiving member. In one embodiment, the first heat dissipation member is a flat plate made of graphite and disposed on an outer side of the bottom of the receiving member. The second heat dissipation member is metal with good thermal conductivity in close contact with the first heat dissipation member and the lateral side of the receiving member where the lamp unit is disposed. Thus, the heat discharged from the lamp unit can be distributed uniformly over the entire area of the receiving member. In addition, the lateral side of the receiving member where the lamp unit is disposed can be replaced with the second heat dissipation member.

Owner:SAMSUNG DISPLAY CO LTD

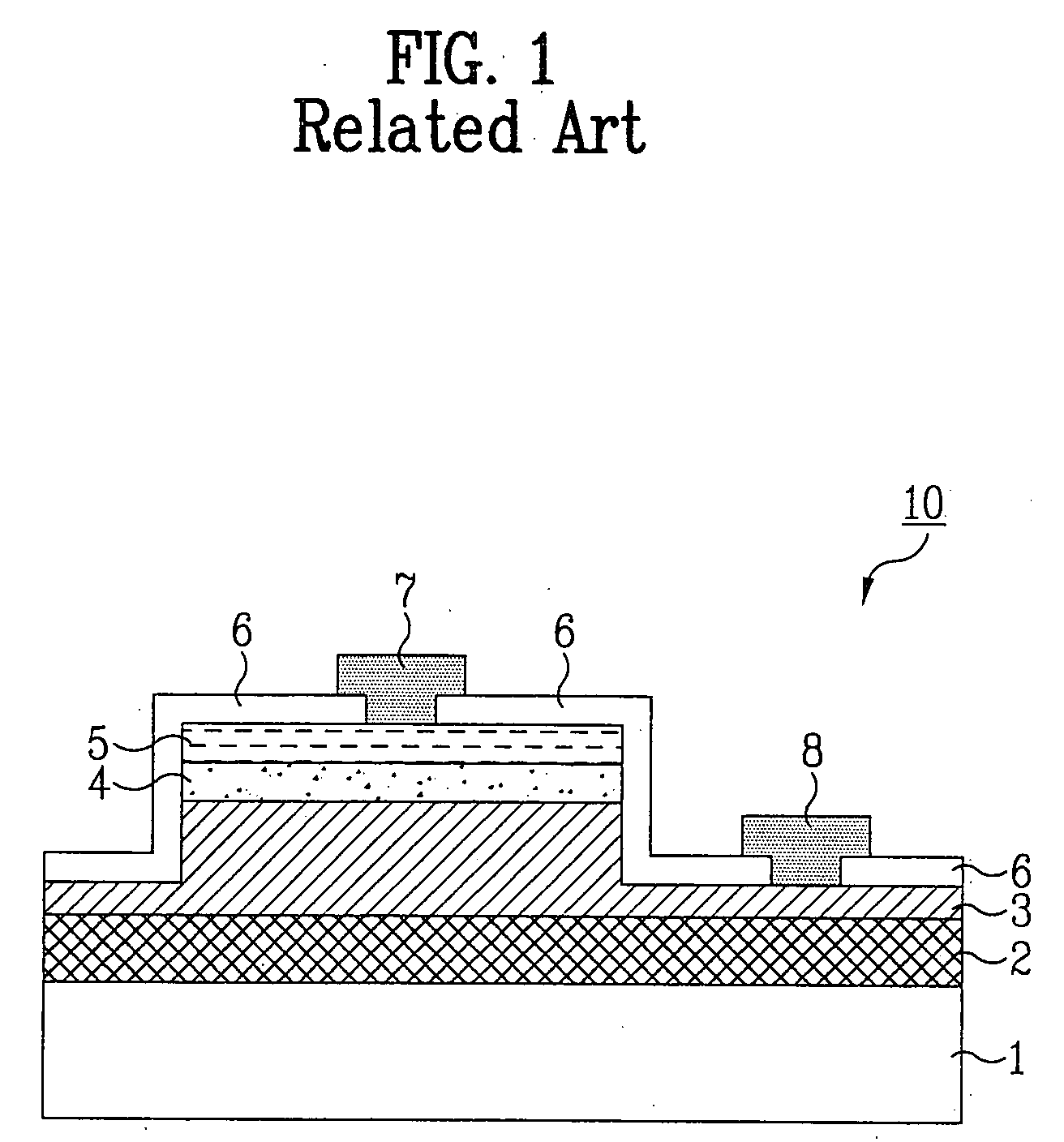

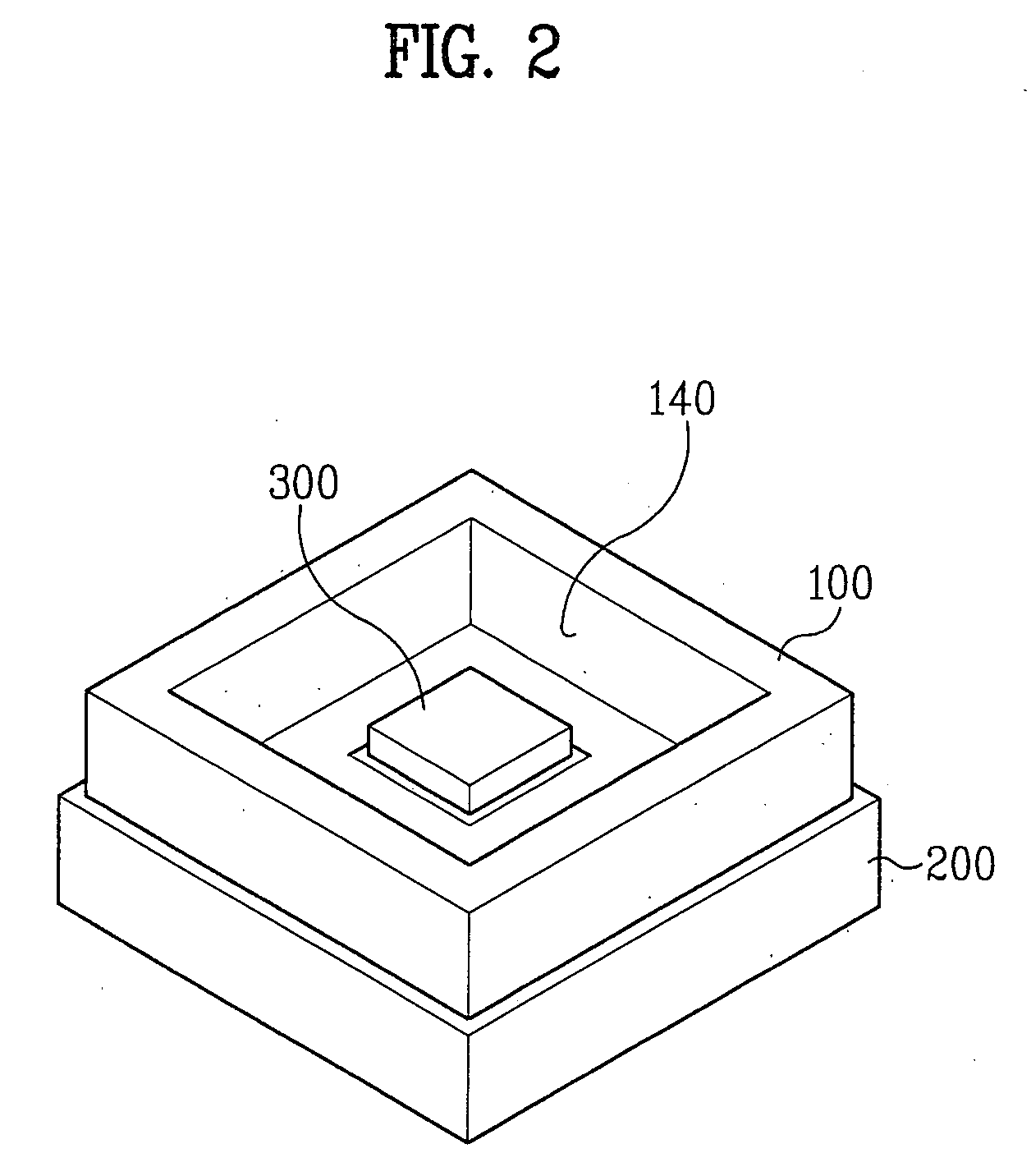

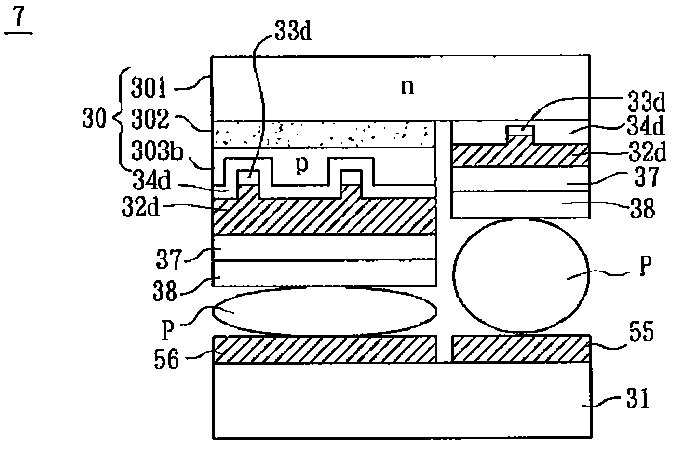

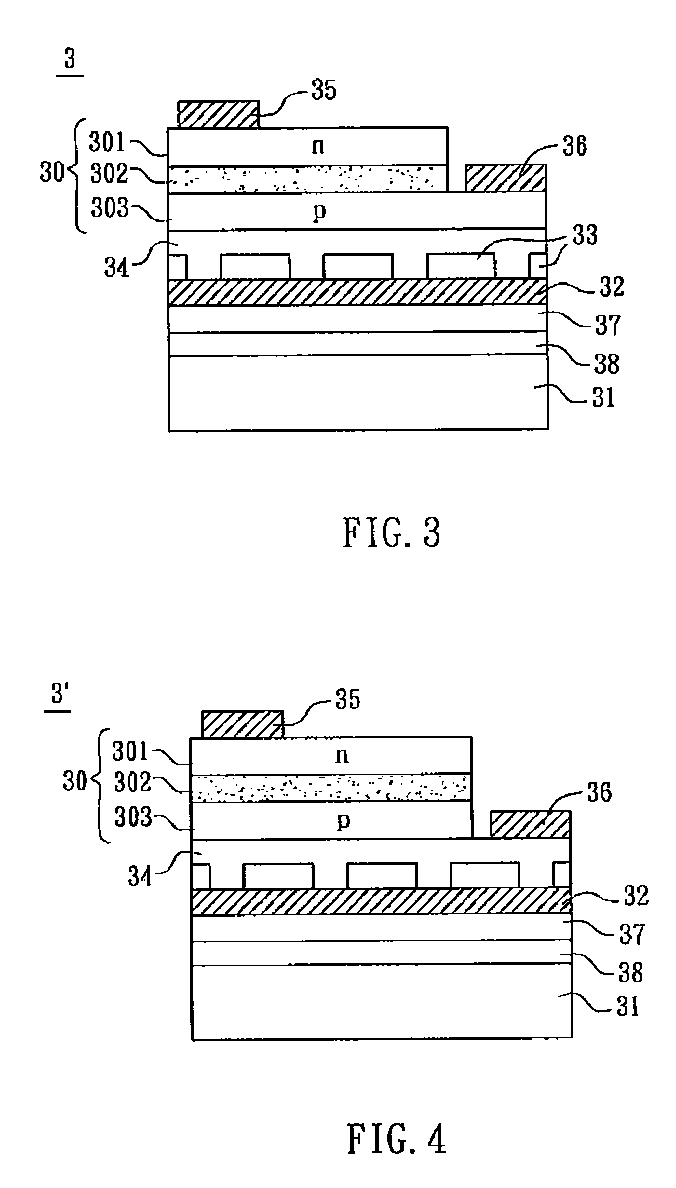

Light emitting device package and method for manufacturing the same

ActiveUS20080149962A1Improving voltage withstanding characteristicGood thermal conductivityDischarge tube luminescnet screensSemiconductor/solid-state device detailsLight emissionMetal

A light emitting device package capable of achieving an enhancement in light emission efficiency and a reduction in thermal resistance, and a method for manufacturing the same are disclosed. The method includes forming a mounting hole in a first substrate, forming through holes in a second substrate, forming a metal film in the through holes, forming at least one pair of metal layers on upper and lower surfaces of the second substrate such that the metal layers are electrically connected to the metal film, bonding the first substrate to the second substrate, and mounting at least one light emitting device in the mounting hole such that the light emitting device is electrically connected to the metal layers formed on the upper surface of the second substrate.

Owner:SUZHOU LEKIN SEMICON CO LTD +1

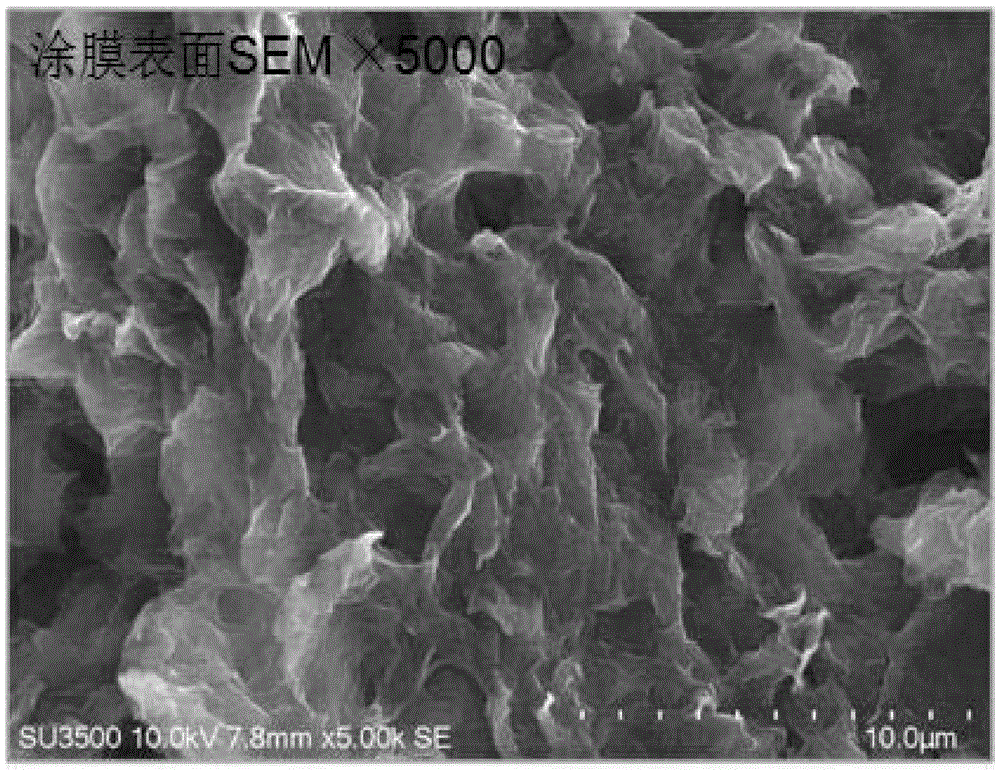

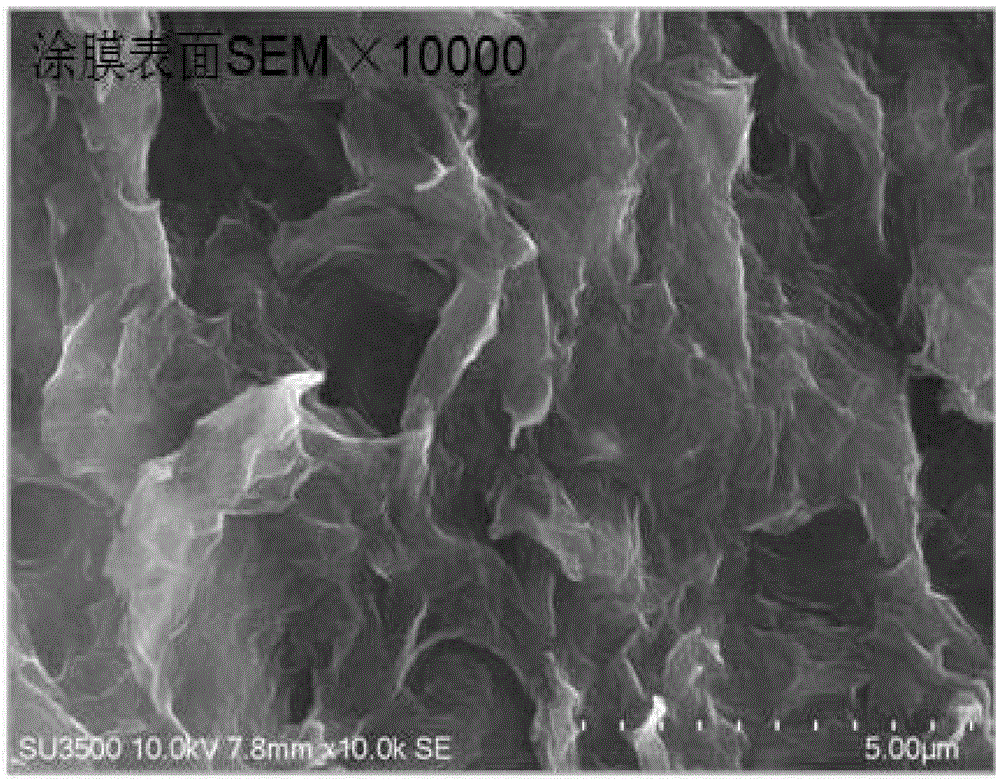

Preparation method of graphene-containing water-based electrothermal film

ActiveCN105906832AHigh viscosityImprove conductivityPolyurea/polyurethane coatingsHeating element materialsWater basedHydrophilization

The invention discloses a preparation method of graphene-containing water-based electrothermal film. The method comprises the following steps of: (1) carrying out hydrophilization treatment on graphene, then adding solutions of cellulose derivatives as a dispersing agent and a thickening agent, and carrying out pre-dispersion; (2) adding an auxiliary agent into the pre-dispersed graphene, and dispersing to obtain homogeneous dispersion liquid; (3) adding an adhesive into the homogeneous dispersion liquid, and mixing to obtain graphene-containing electrothermal film slurry; and (4) coating a film formation carrier with the graphene-containing electrothermal film slurry to form a graphene conducting layer, and drying to obtain the graphene-containing electrothermal film formed by the graphene conducting layer and the film formation carrier. After the preparation method is adopted, a heating body having excellent heat conduction and electric conduction properties can be prepared.

Owner:四川烯材科技有限公司

Aqueous coating with high heat-dissipation performance and preparation method thereof

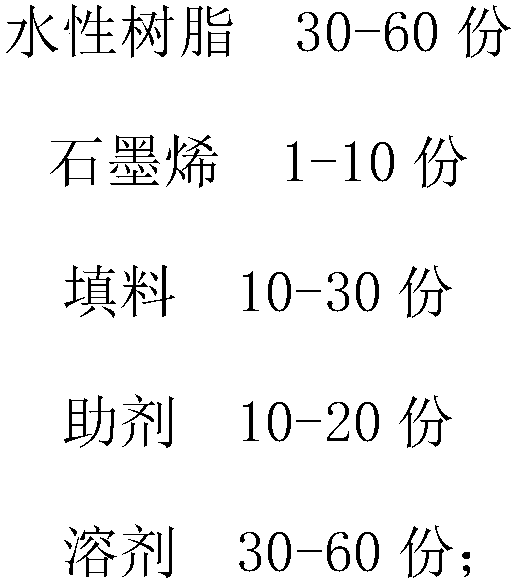

InactiveCN107760128ALow densityGood thermal and electrical conductivityAnti-corrosive paintsEpoxy resin coatingsSolventChemistry

The invention relates to the technical field of novel coating preparation and in particular relates to an aqueous coating with high heat-dissipation performance which comprises the following components: 30-60 parts of aqueous resin, 1-10 parts of graphene, 10-30 parts of packing, 10-20 parts of an aid and 30-60 parts of a solvent, wherein the radial size of the graphene is 1-100 microns; and the graphene consists of 1-3 layers. The high heat-dissipation performance aqueous coating provided by the invention is good in heat dissipation effect, environmentally friendly and low in cost.

Owner:CHANGZHOU XICAI CARBON MATERIAL TECH CO LTD

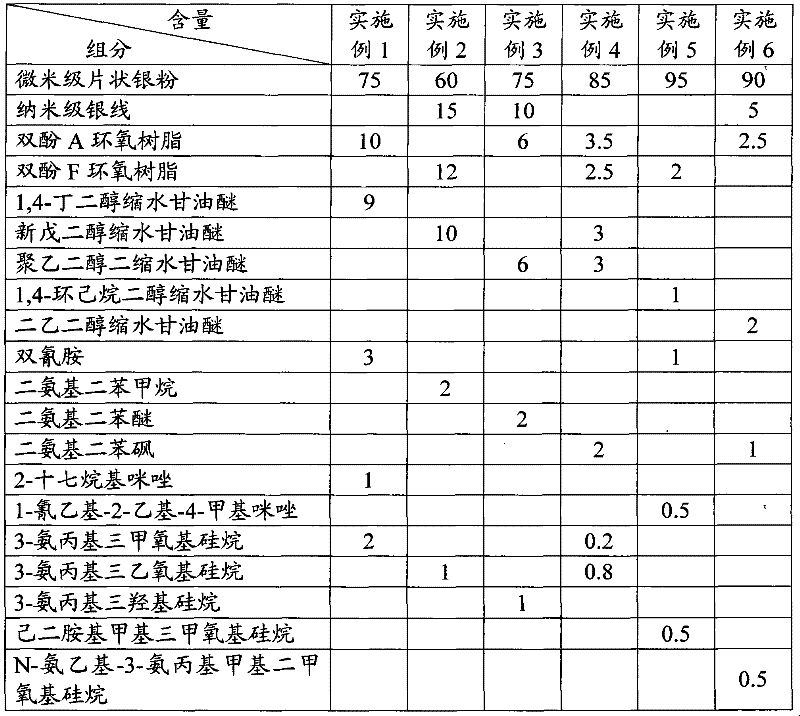

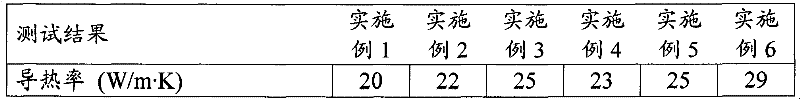

Conductive adhesive for LED (light emitting diode) packaging and preparation method of conductive adhesive

InactiveCN102174306ASuperior performanceGood thermal conductivityModified epoxy resin adhesivesSemiconductor devicesChemistryAdhesive

The invention discloses a conductive adhesive for LED (light emitting diode) packaging. The conductive adhesive consists of the following raw materials in percentage by weight: 75 to 95 percent of conductive powder, 2 to 12 percent of epoxy resin, 1 to 10 percent of epoxy diluting agent, 1 to 3 percent of curing agent, 0 to 1 percent of curing accelerator, and 0.5 to 2 percent of coupling agent. The LED conductive adhesive provided by the invention has superior performance and good heat conduction and electric conduction effects and can fully meet operating requirements of a high-brightness high-power LED chip.

Owner:YANTAI DARBOND TECH

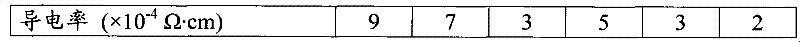

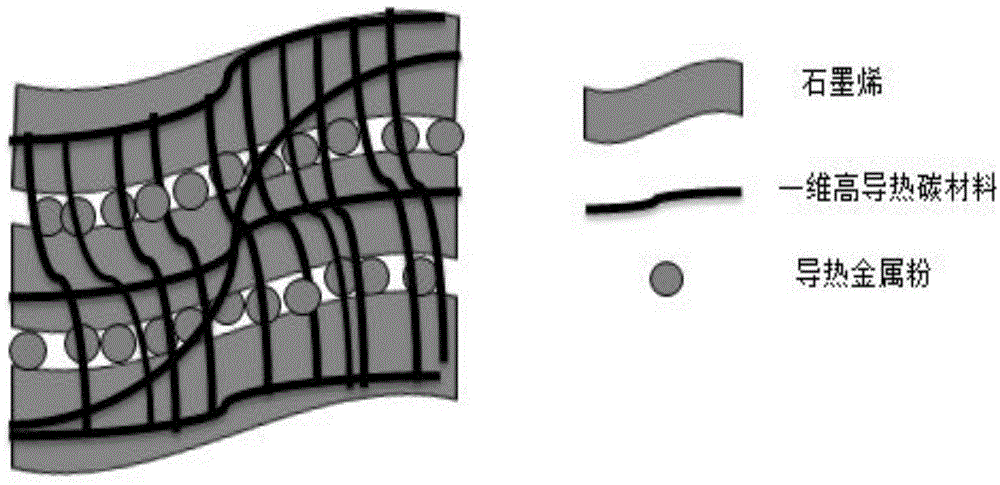

Graphene heat radiation paint, preparation method and applications

ActiveCN105273540ALight in massHigh film strengthEpoxy resin coatingsPolyester coatingsSolventRadiation

The invention discloses graphene heat radiation paint. The graphene heat radiation paint comprises the following ingredients, by weight, 40-80 parts of high-molecular resin, 5-15 parts of graphene, 1-8 parts of one-dimensional nanomaterials, 1-8 parts of heat conduction metal powder, 0.5-5 parts of dispersing agents, 0.5-5 parts of antifoaming agents and 100-200 parts of inert solvent. The heat conduction metal powder is at least one selected from silver powder, copper powder and aluminum powder and the granularity is 1-20 micrometers. The above paint has good heat radiation and heat conduction functions. The invention also discloses a preparation method for the graphene heat radiation paint. The preparation method mainly comprises processes of stirring, grinding and reblending. Operation is simple, and the cost is low. The graphene heat radiation paint is mainly applied in heat radiation of daily electronic products and also can be applied in spaceflight electronic devices with high requirements because of good heat conduction and heat radiation functions.

Owner:SHENZHEN GUOCHUANG JIAWEI GRAPHENE TECH CO LTD

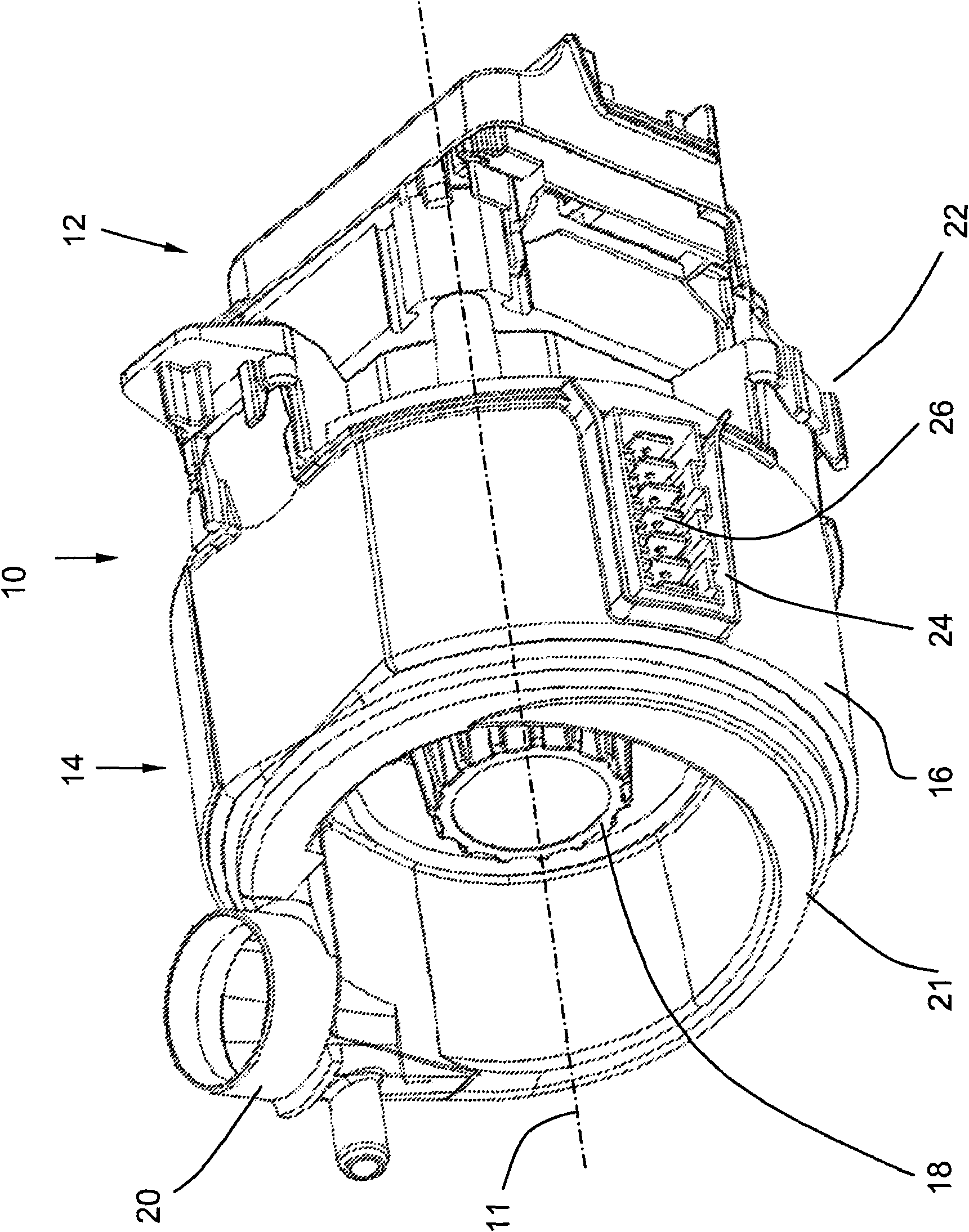

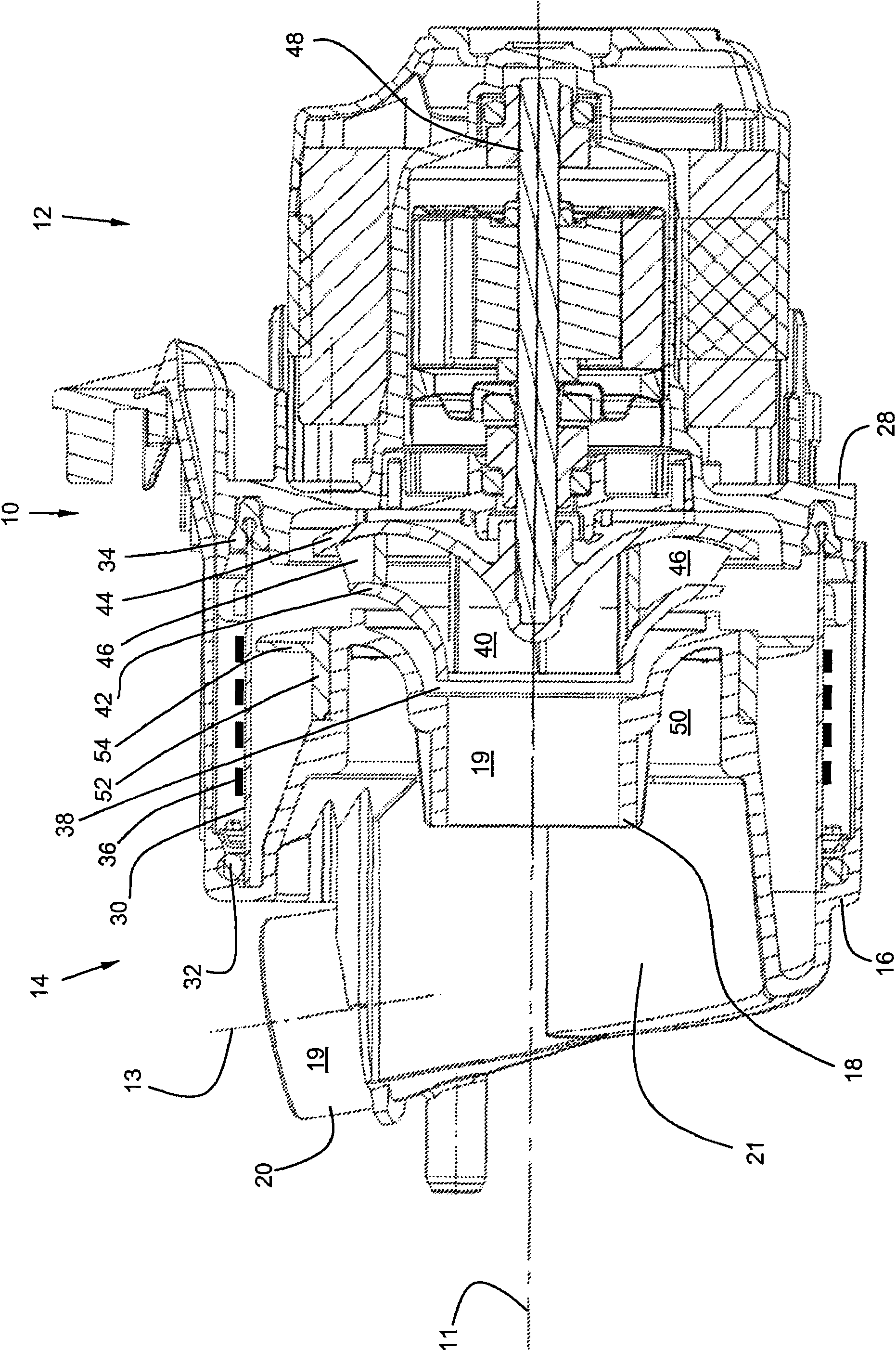

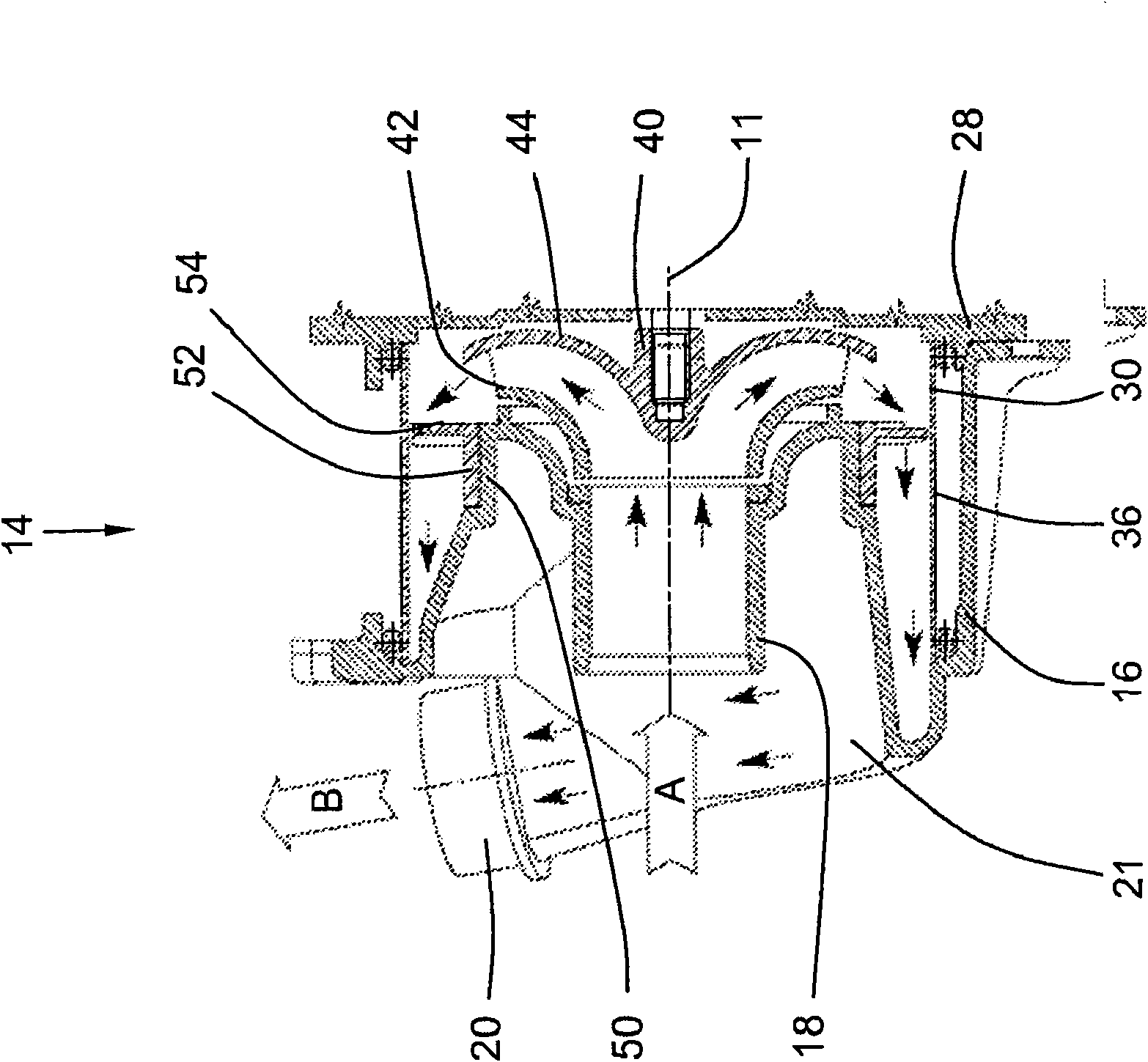

Pump having a heating device

ActiveCN101657137AHeating evenlyEasy to replaceTableware washing/rinsing machine detailsPump componentsImpellerDevice form

The present invention relates to a pump (10, 110), particularly for dishwashers, comprising a housing made of a housing bottom (28, 128), a housing cover (16, 116), and a heating device (30, 130, 36,136) disposed in between the bottom and cover for heating a washing fluid, the device forming a ring-shaped side wall of the housing, further comprising an impeller (40, 140) arranged in the housing,an intake connection (18, 118) arranged axially in the housing cover (16, 116) relative to the axis of rotation of the impeller (40, 140), and a pressure connection (20, 120), wherein the pressure connection (20, 120) is arranged in the housing cover (16, 116).

Owner:BOSCH SIEMENS HAUSGERATE GMBH

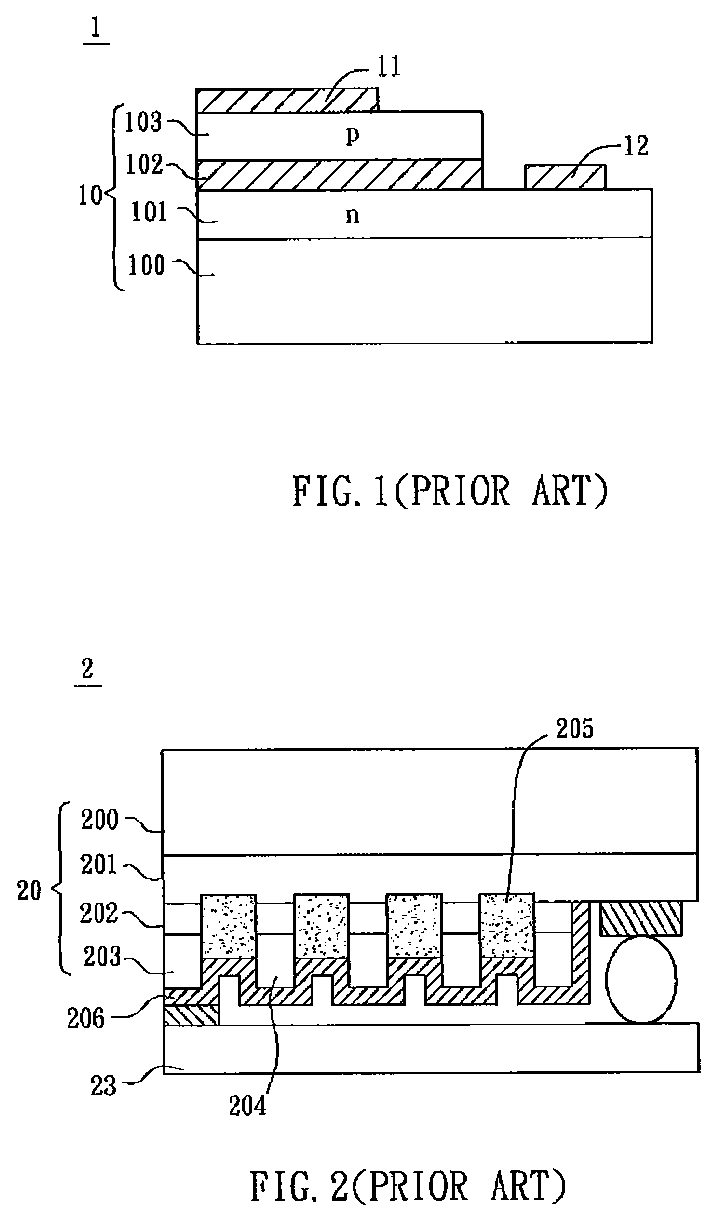

Light emitting diode apparatus

InactiveUS20080237620A1Good thermal conductivityHigh opto-electronic conversion efficiencySemiconductor devicesElectrical conductorReflective layer

A light emitting diode apparatus includes a heat dissipating substrate, a composite layer, an epitaxial layer, a first electrode and a second electrode. The composite layer includes a reflective layer, a transparent conductive layer and a patterned insulating thermoconductive layer, which is disposed between the reflective layer and the transparent conductive layer. The composite layer is disposed between the heat dissipating substrate and the epitaxial layer and allows currents to concentrate to the reflective layer or the transparent conductive layer and then to be diffused evenly through the transparent conductive layer. The epitaxial layer includes a first semiconductor layer electrically connected with the first electrode, an active layer and a second semiconductor layer electrically connected with the second electrode.

Owner:DELTA ELECTRONICS INC

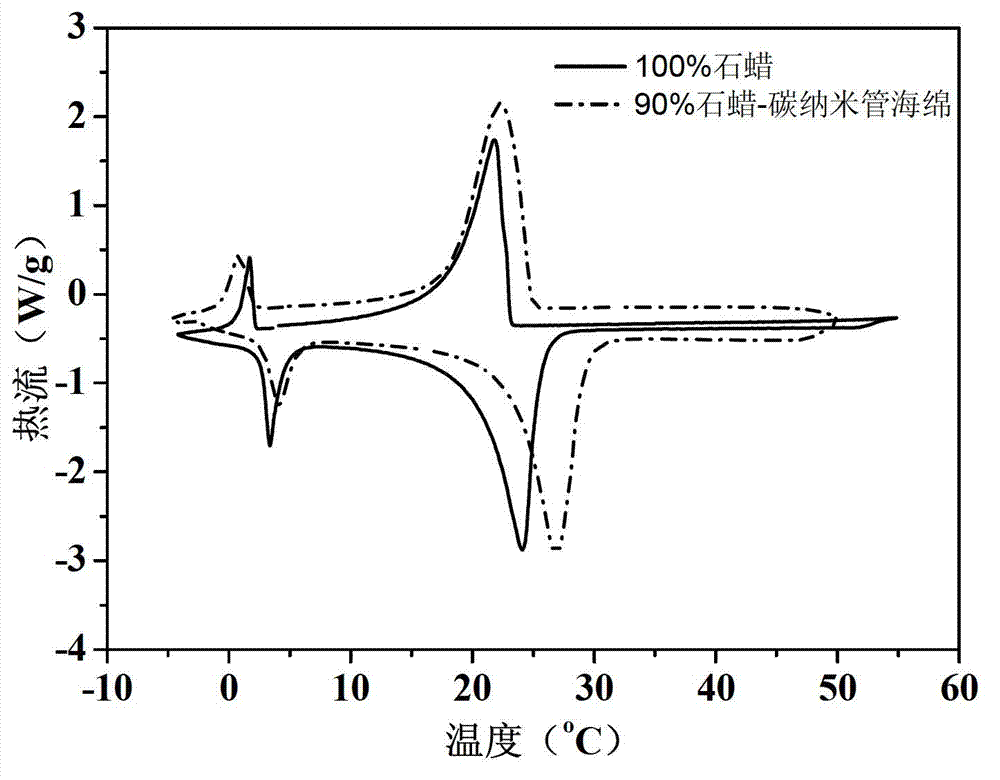

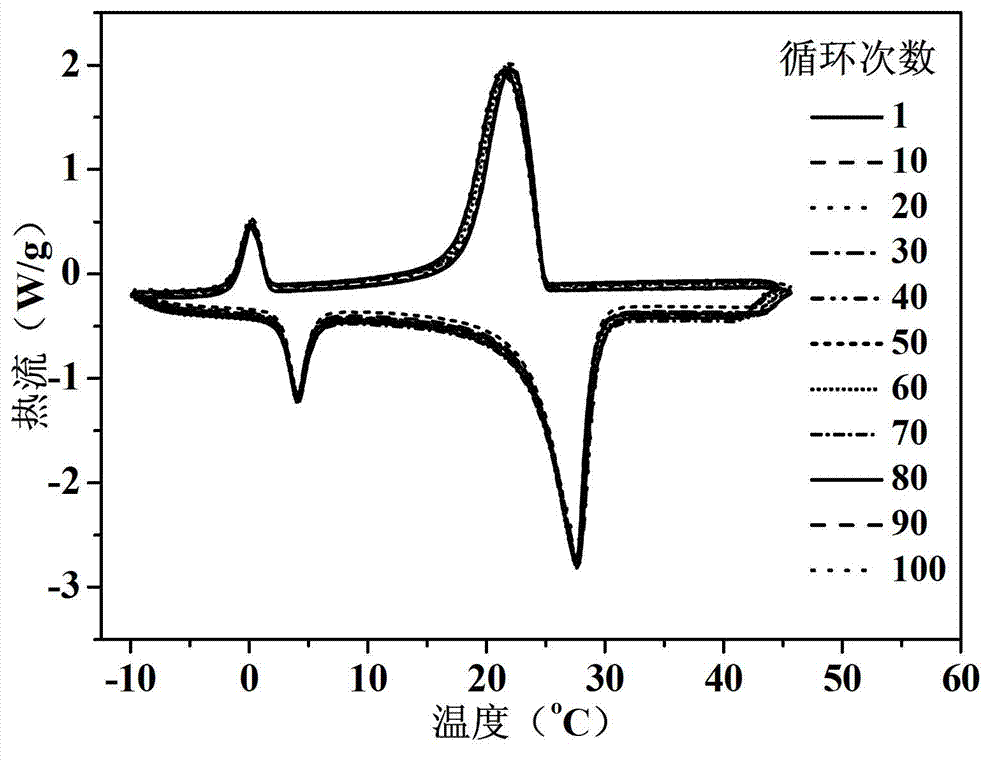

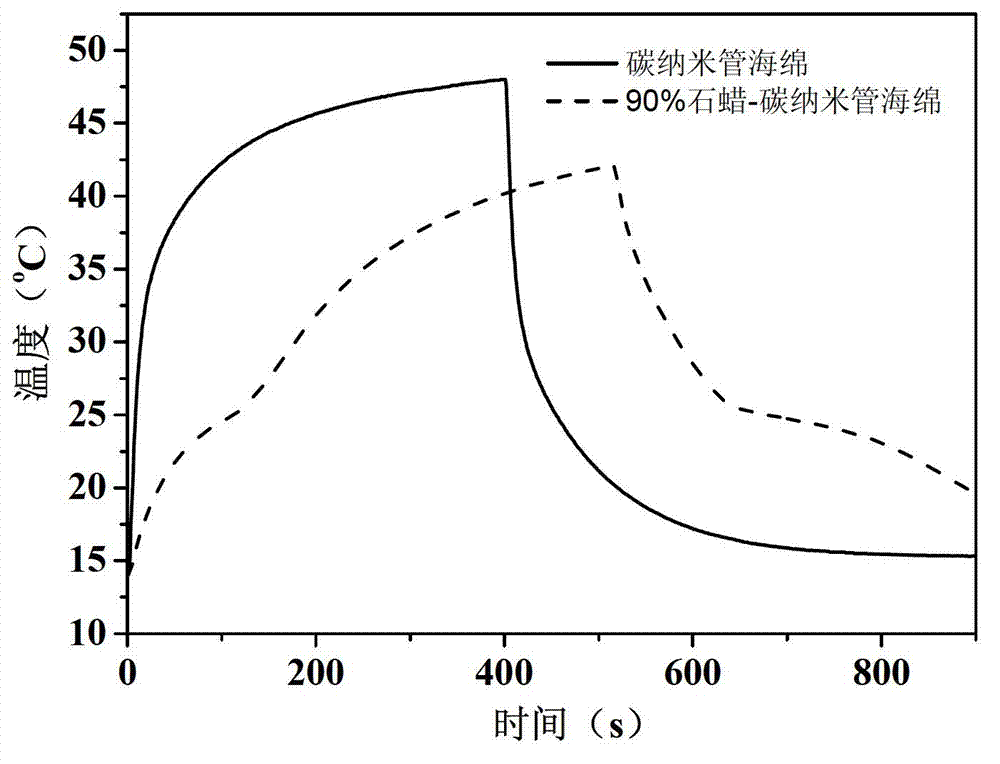

Composite shape-stabilized phase change material with light absorption and conductive properties and preparation method thereof

InactiveCN103087682AGood thermal conductivityGood light absorption performanceChemical industryHeat-exchange elementsHeat transfer efficiencyThermal energy storage

The invention provides a composite shape-stabilized phase change material with light absorption and conductive properties and a preparation method thereof. The material consists of 5-15 percent of porous carbon material and 85-95 percent of organic phase change material distributed in the porous carbon material, wherein the organic phase change material is distributed in the porous carbon material. The method comprises the following steps of: preparing a carbon material with the three-dimensional communicating porous property; heating and fusing the organic phase change material and casting the organic phase change material on the porous carbon material; shocking the mixture at the temperature of 100-120 DEG C for a certain time so as to uniformly distribute the organic phase change material in the porous carbon material; and grinding the mixture at room temperature, and pressing and forming the material in a die. The composite shape-stabilized phase change material has high heat conduction, light absorption and conductivity; the heat transfer efficiency of the phase change material can be obviously improved; and meanwhile, the solar energy and electric energy can be converted into heat energy at high efficiency and are stored in the phase change material, and the material is a photoelectric composite shape-stabilized phase change material.

Owner:PEKING UNIV

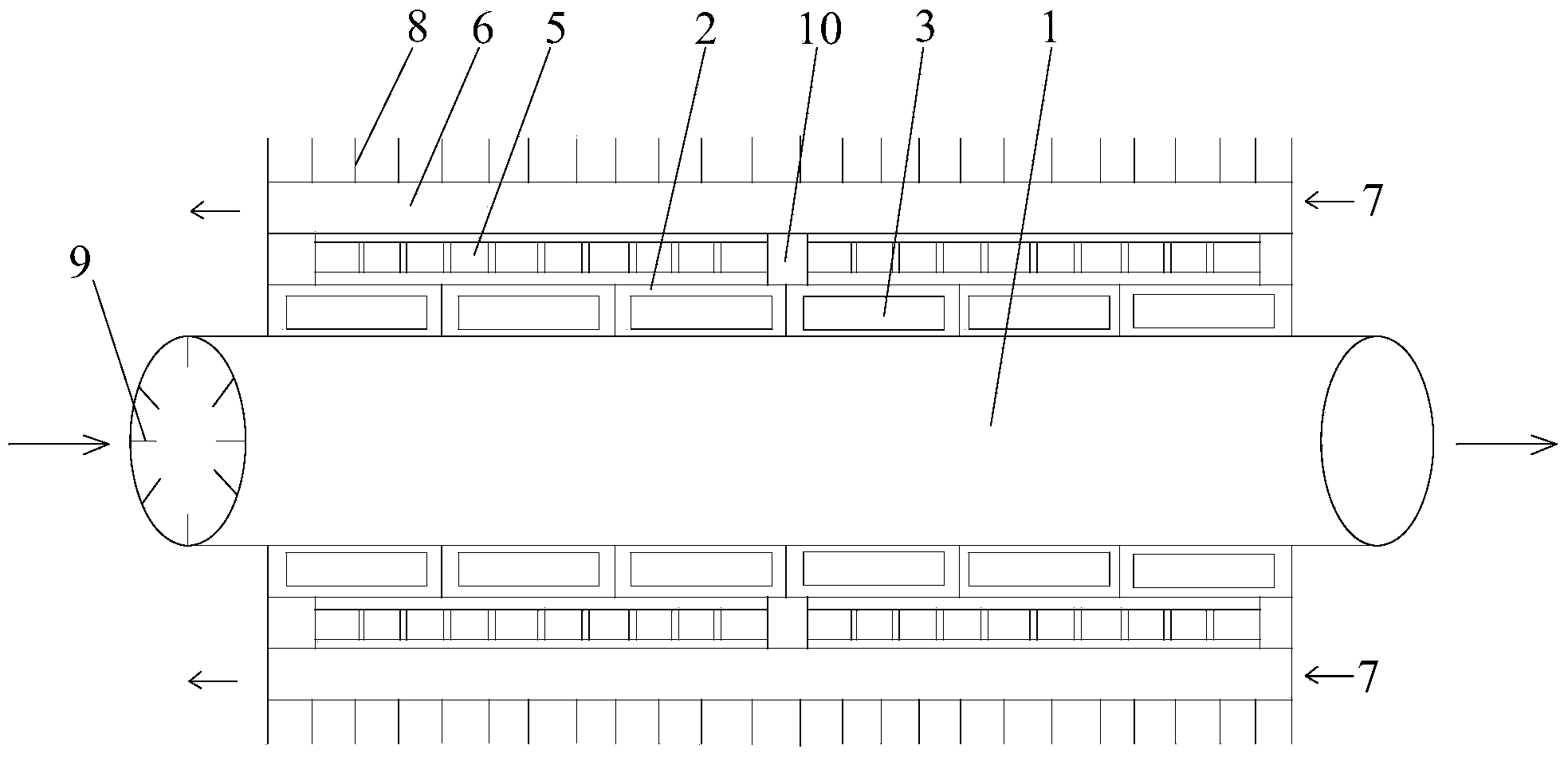

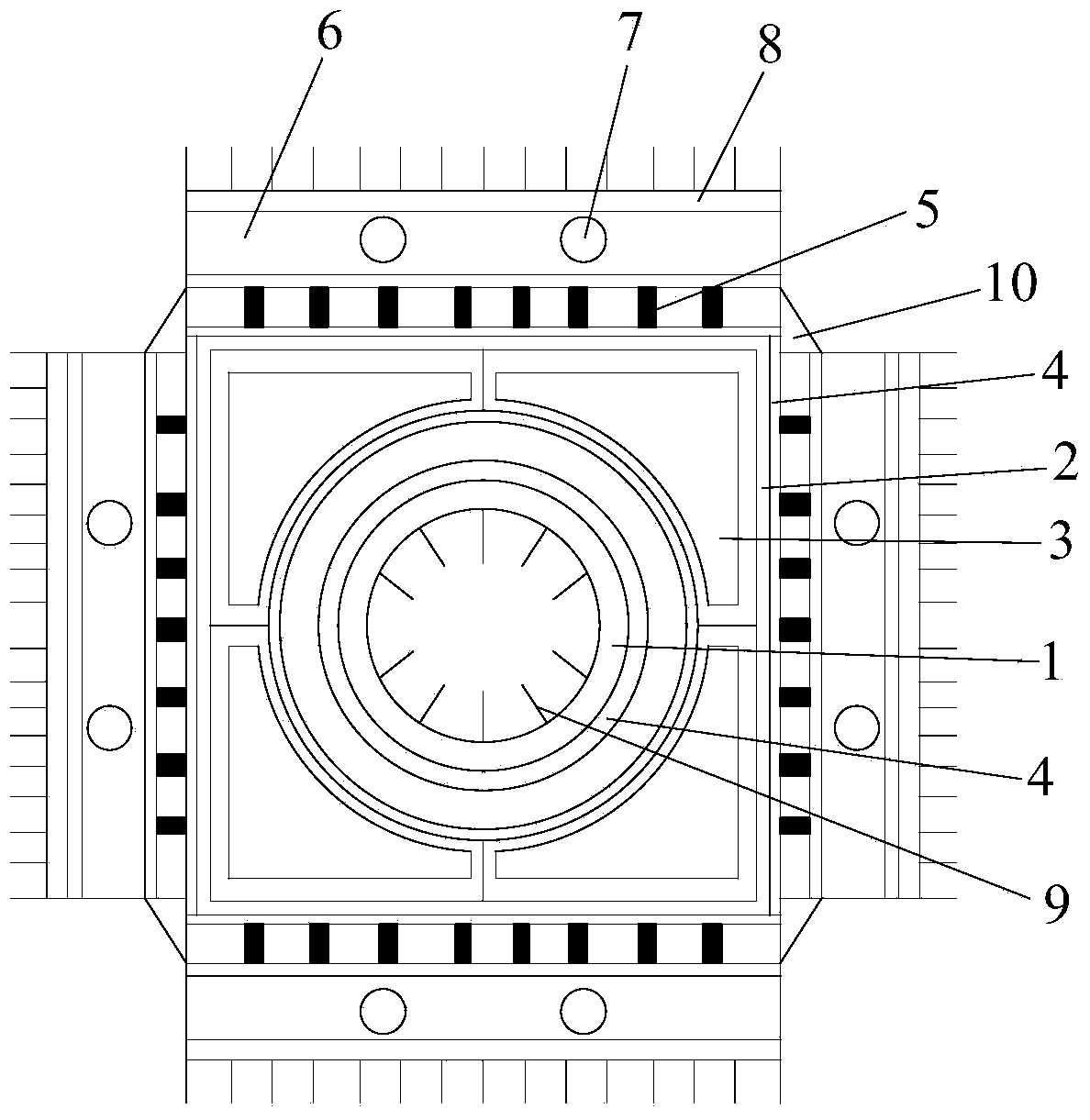

Foam metal composite phase change material heat storage temperature-difference power generation device

InactiveCN104135191AGood thermal conductivityFast heat storage and heat releaseGenerators/motorsExhaust gasComposite phase change material

The invention relates to a foam metal composite phase change material heat storage temperature-difference power generation device. The device comprises a plurality of small separated sealed containers arranged on the outer wall of a high-temperature flue gas pipeline in a sleeved mode. The small separated sealed containers are filled with foam metal composite phase change materials. The outer sides of the small separated sealed containers are closely connected with the hot end of a temperature-difference thermoelectric power generation module through a thermally-conductive adhesive. The shape of the inner sides of the small separated sealed containers is the same as the shape of the outer wall of the high-temperature flue gas pipeline, and the inner sides of the small separated sealed containers make close contact with the outer wall of the high-temperature flue gas pipeline; the outer sides of the small separated sealed containers are planes connected with the hot end of the temperature-difference thermoelectric power generation module, and the cold end of the temperature-difference thermoelectric power generation module is connected with a radiating block. The radiating block is filled with circulating cooling water, and the outer side of the radiating block is connected with radiating fins. According to the device, the foam metal composite phase change heat storage materials are combined with temperature-difference thermoelectric power generation devices to generate power, and therefore the efficiency of temperature-difference thermoelectric power generation can be effectively improved. The device can be conveniently installed on a boiler pipeline or an automobile exhaust pipeline and is reliable in power generation performance.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Resin composition with high-heat, high-glass transition temperature for printed circuit board, prepreg and coating substance

InactiveCN101343402AImprove heat resistanceImprove flame resistanceSynthetic resin layered productsCircuit susbtrate materialsEpoxyProcedure Agents

The invention relates to resin combination with high thermal conductivity and glass transition temperature used for a printed circuit board. According to the weight percentage, the resin combination comprises brominated epoxy resin occupying 20 percent to 70 percent, hardening agent occupying 1 percent to 10 percent, accelerating agent occupying 0.1 percent to 10 percent, inorganic powder occupying 0 percent to 20 percent, high heat conducting powder occupying 5 percent to 85 percent, and processing auxiliary agent occupying 0 percent to 10 percent. The resin combination has the advantages of high glass transition temperature and heat conducting performance, excellent thermal resistance and flame resistance, which can be applied to the heat conducting insulating layer of the printed circuit board after being made into a high heat conducting preimpregnated body through a containing and soaking way or into a high heat conducting coating through a coating way, thus the printed circuit board has high heat conducting performance, and the heat quantity generated by the operation of the electronic elements on the printed circuit board can be rapidly dissipated to enhance the service life and the stability of the electronic elements.

Owner:NANYA PLASTICS CORP

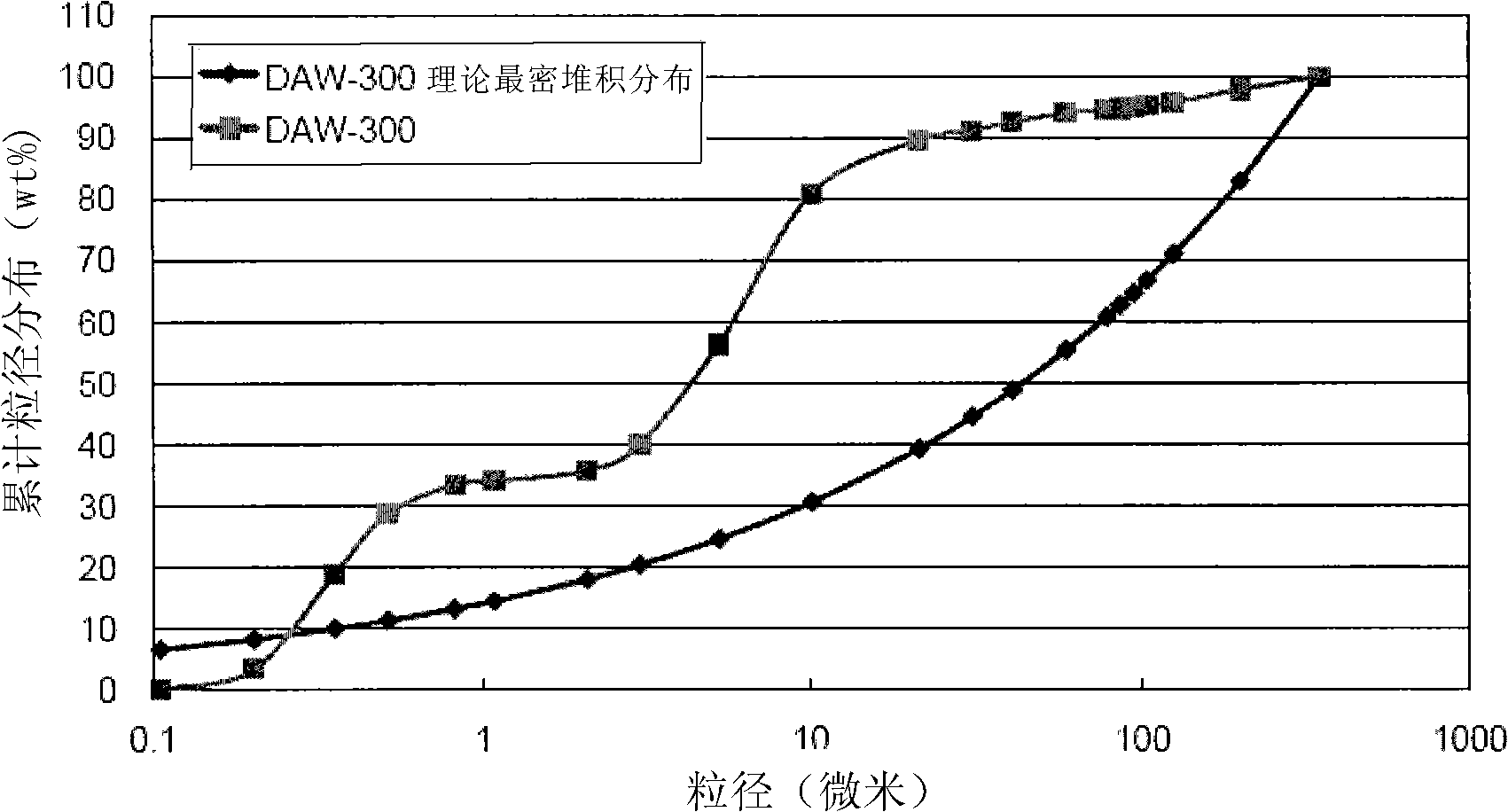

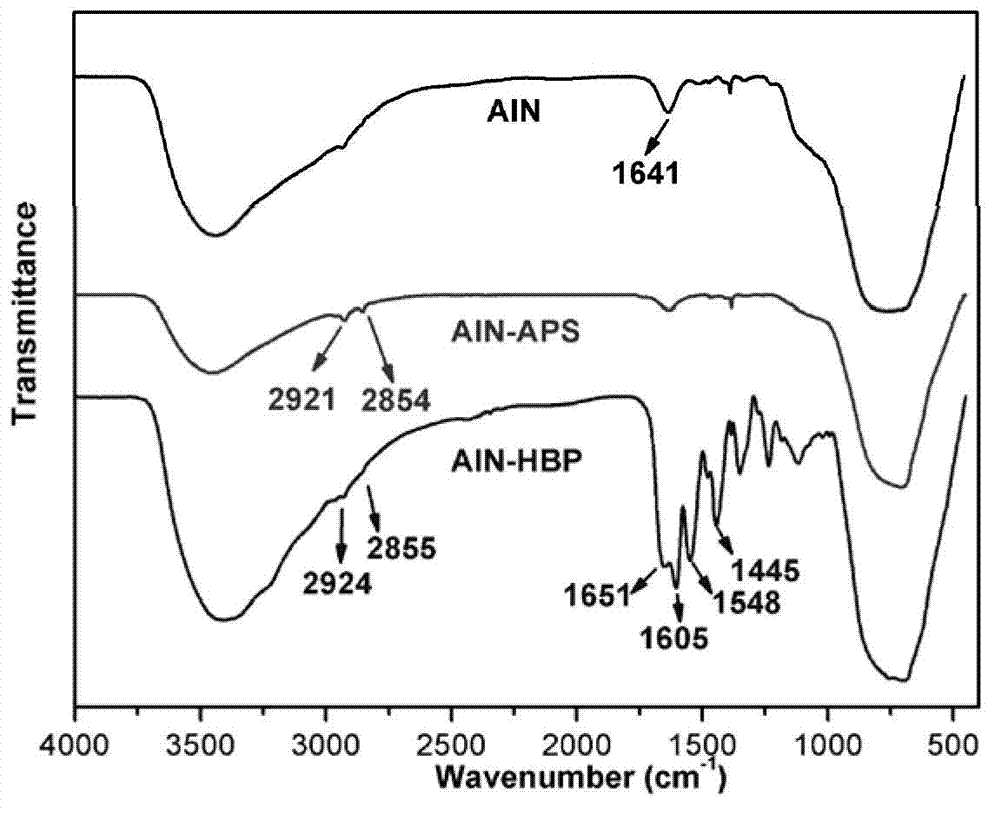

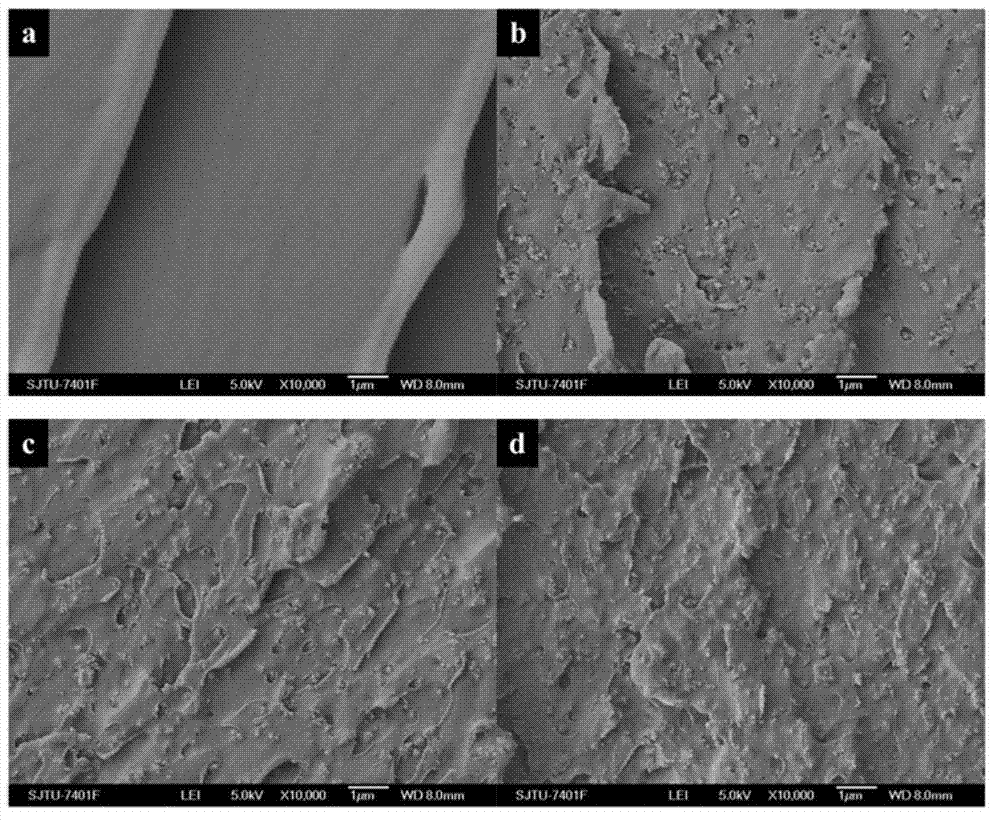

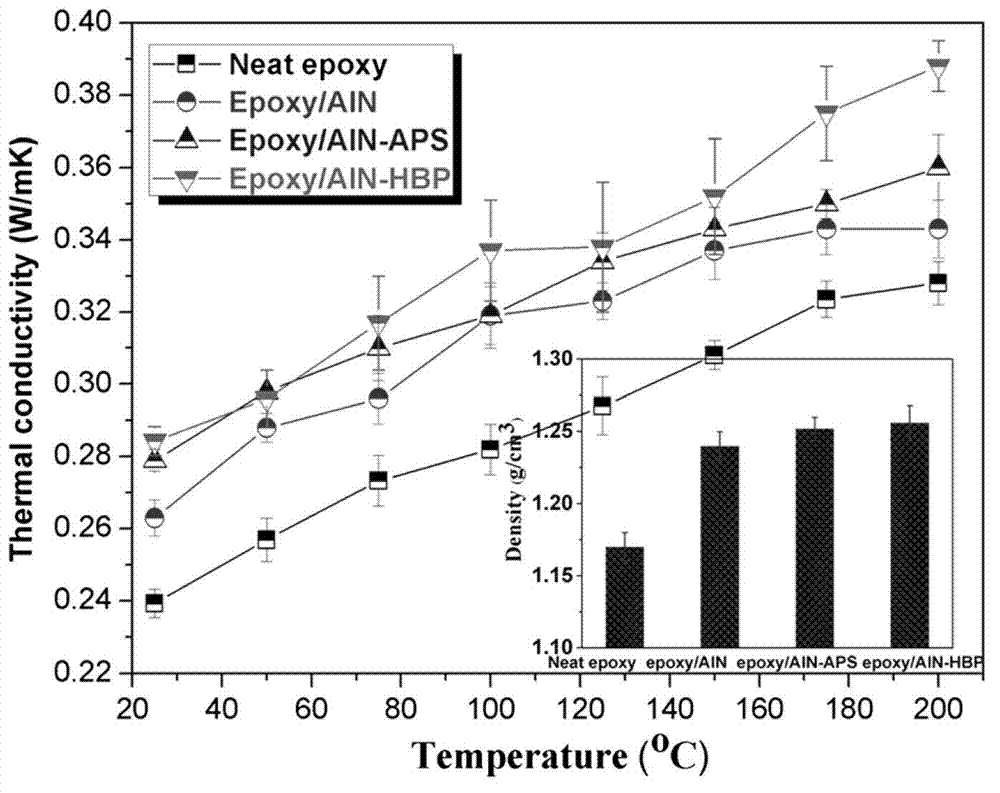

High thermal-conductivity polymer composite material and preparation method thereof

The invention discloses a high thermal-conductivity polymer composite material. The high thermal-conductivity polymer composite material comprises the following components in percentage by weight: 60%-95% of epoxy resin and 5%-40% of hyperbranched polyaryl amide grafted ceramic thermal-conductivity filler particles. The invention further discloses a preparation method of the high thermal-conductivity polymer composite material. According to the high thermal-conductivity polymer composite material and the preparation method thereof disclosed by the invention, the hyperbranched polyaryl amide grafted ceramic thermal-conductivity filler particles and the epoxy resin are used materials to obtain the high thermal-conductivity functional ceramic thermal-conductivity filler / epoxy resin polymer composite material; and the composite material has high thermal conductivity, and higher thermal conductivity and heat engine performances in comparison with the conventional filler direct blending process. The polymer composite material disclosed by the invention has excellent thermal conductivity and can be used for greatly improving the thermal conductivity and mechanical performances of the polymer matrix under low thermal-conductivity filler mixing amount, and therefore, the polymer composite material has an extensive application value in the fields of machinery, electronics, chemical engineering and the like. The preparation method disclosed by the invention is simple and easy to operate, strong in controllability and capable of realizing large-scale production.

Owner:SHANGHAI JIAO TONG UNIV

Low-density thermal conductive silicone pad and preparation method thereof

InactiveCN107057371AGood thermal conductivityExcellent flame retardant and mechanical propertiesThermal conductivityChemistry

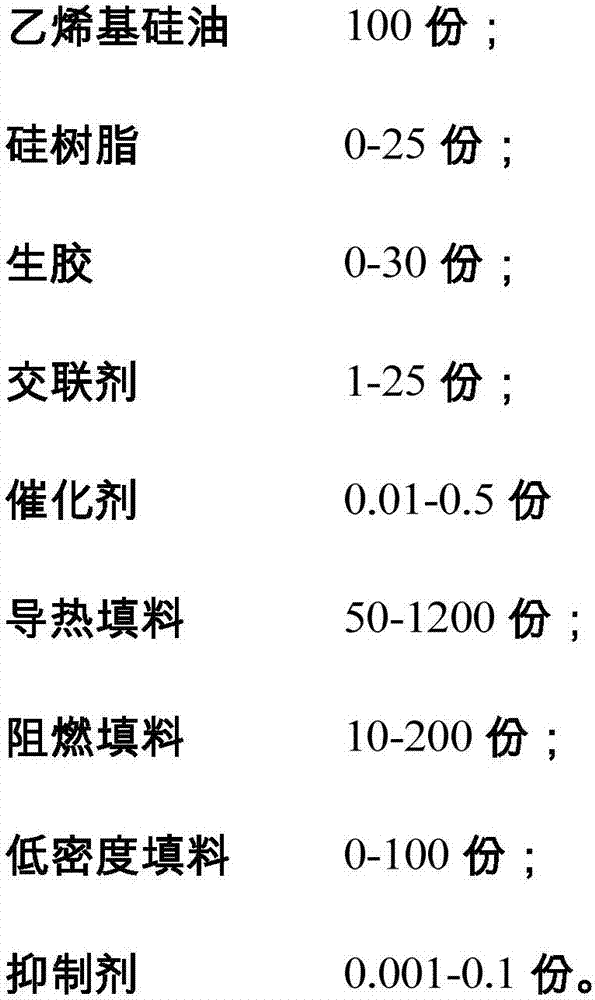

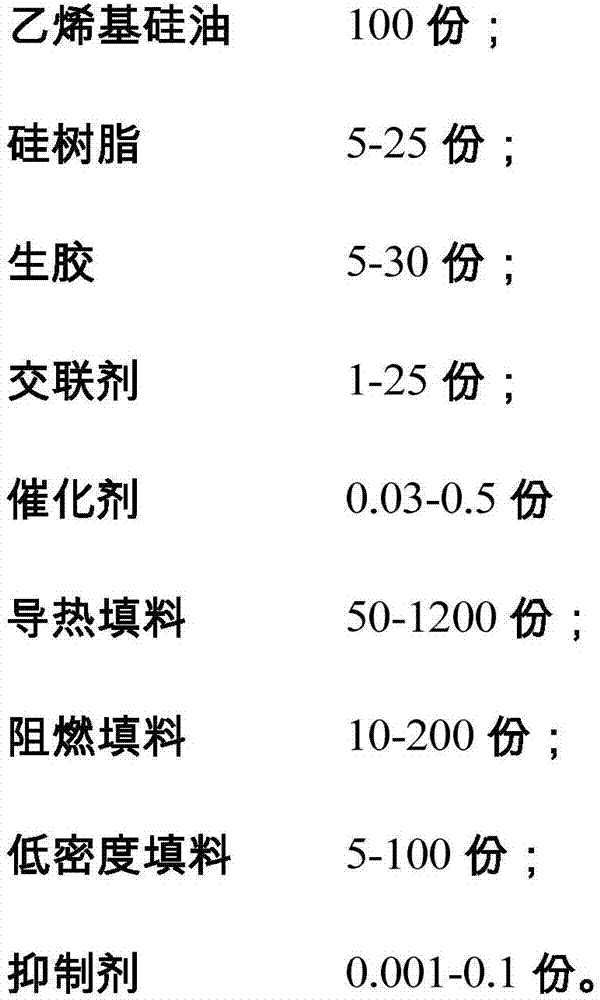

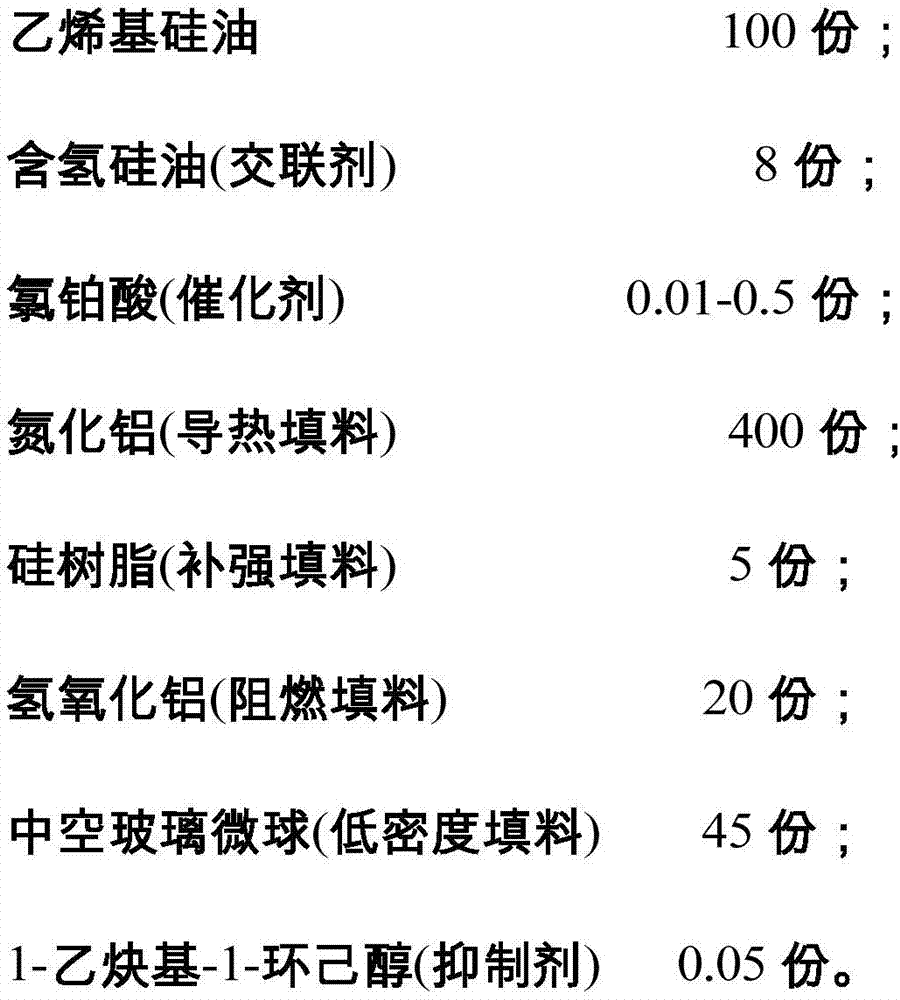

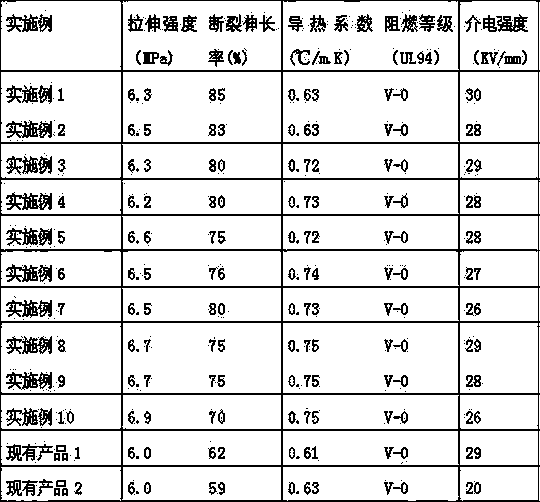

The invention discloses a low-density thermal conductive silicone pad and a preparation method thereof. The low-density thermal conductive silicone pad is prepared from the following components: 100 parts of vinyl silicone oil, 0-25 parts of silicon resin, 0-30 parts of crude rubber, 1-25 parts of a cross-linking agent, 0.01-0.5 part of a catalyst, 50-1,200 parts of a thermal conductive filler, 10-200 parts of a flame-retardant filler, 0-100 parts of a low-density filler and 0.001-0.1 part of an inhibitor. As a proper amount of the low-density filler is contained, together with the proper amounts of the thermal conductive filler, a reinforcing filler, the flame-retardant filler and other fillers, the thermal conductive silicone pad with good thermal conductivity, excellent flame-retardant and mechanical property and low density is prepared; compared with a common thermal conductive silicone pad at present, the low-density thermal conductive silicone pad has the advantages that the density is reduced by about 60%, the battery weight of an electric vehicle can be remarkably reduced, and application of the low-density thermal conductive silicone pad in the field of electric vehicles is greatly improved.

Owner:深圳市德镒盟电子有限公司

Halogen-free flame retardant heat conduction polyurethane pouring sealant and preparation method thereof

InactiveCN103524698ALow environmental impactGood thermal conductivityNon-macromolecular adhesive additivesOther chemical processesIsocyanateDefoaming Agents

The invention relates to the technical field of a polyurethane pouring sealant, and particularly relates to a halogen-free flame retardant heat conduction polyurethane pouring sealant. The halogen-free flame retardant heat conduction polyurethane pouring sealant is formed by uniformly mixing 100 parts by mass of component A and 15-25 parts by mass of component B, wherein the component A comprises 30-45 parts by mass of polymer polyhydric alcohol, 15-25 parts by mass of halogen-free flame retardant, 40-55 parts by mass of heat conducting filler, 0.1-2 parts by mass of defoaming agent and 0.1-2 parts by mass of catalyst, the component B is isocyanate, and the polymer polyhydric alcohol is one of or a mixture of castor oil and polyether polyol. The halogen-free flame retardant heat conduction polyurethane pouring sealant does not contain halogen and has high conductivity of heat, high flame resistance and strong mechanical property. Meanwhile, the invention also discloses a preparation method of the halogen-free flame retardant heat conduction polyurethane pouring sealant. The preparation method is simple in process and has strong operability.

Owner:FUJIAN RUISEN CHEM

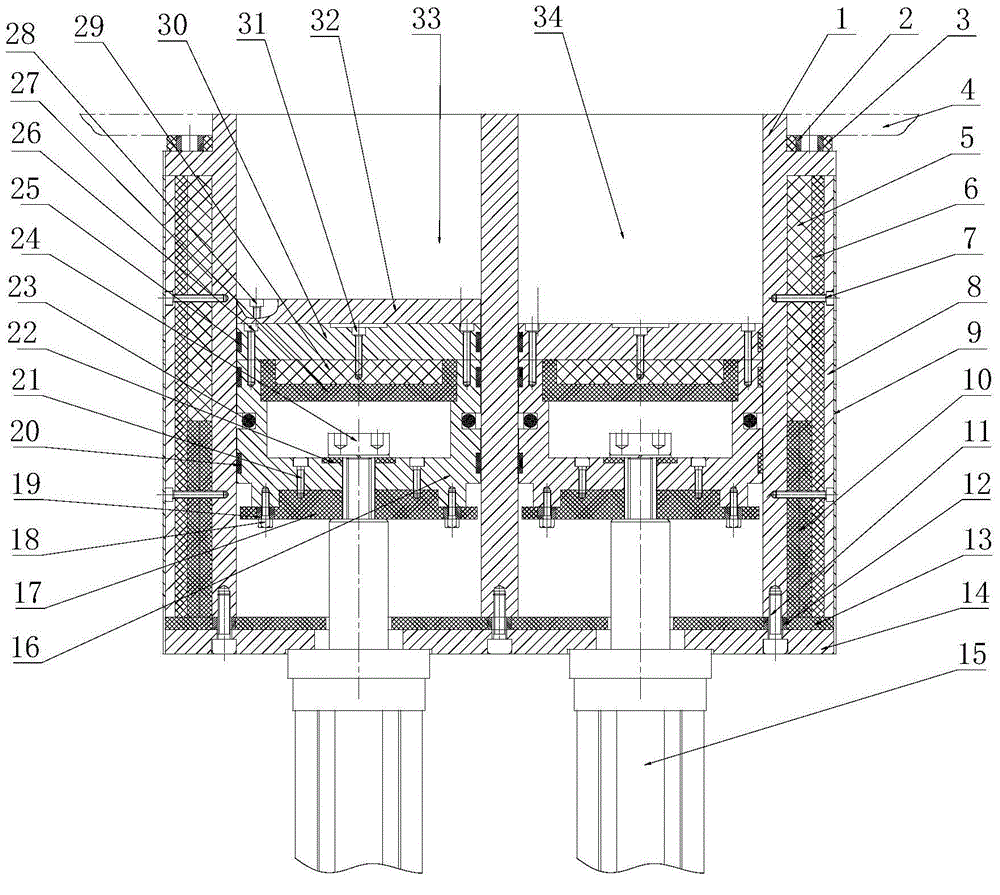

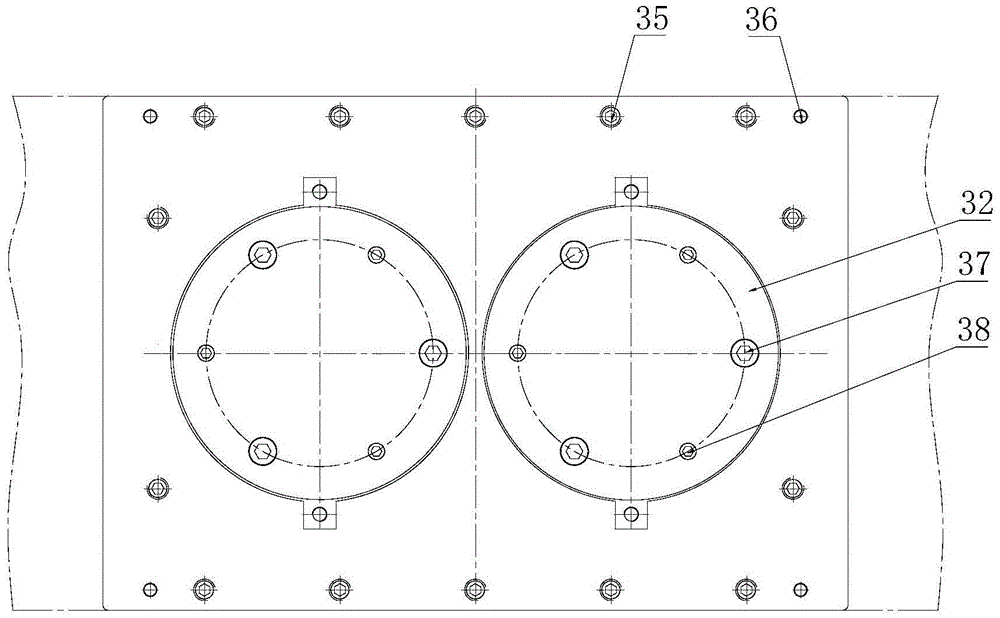

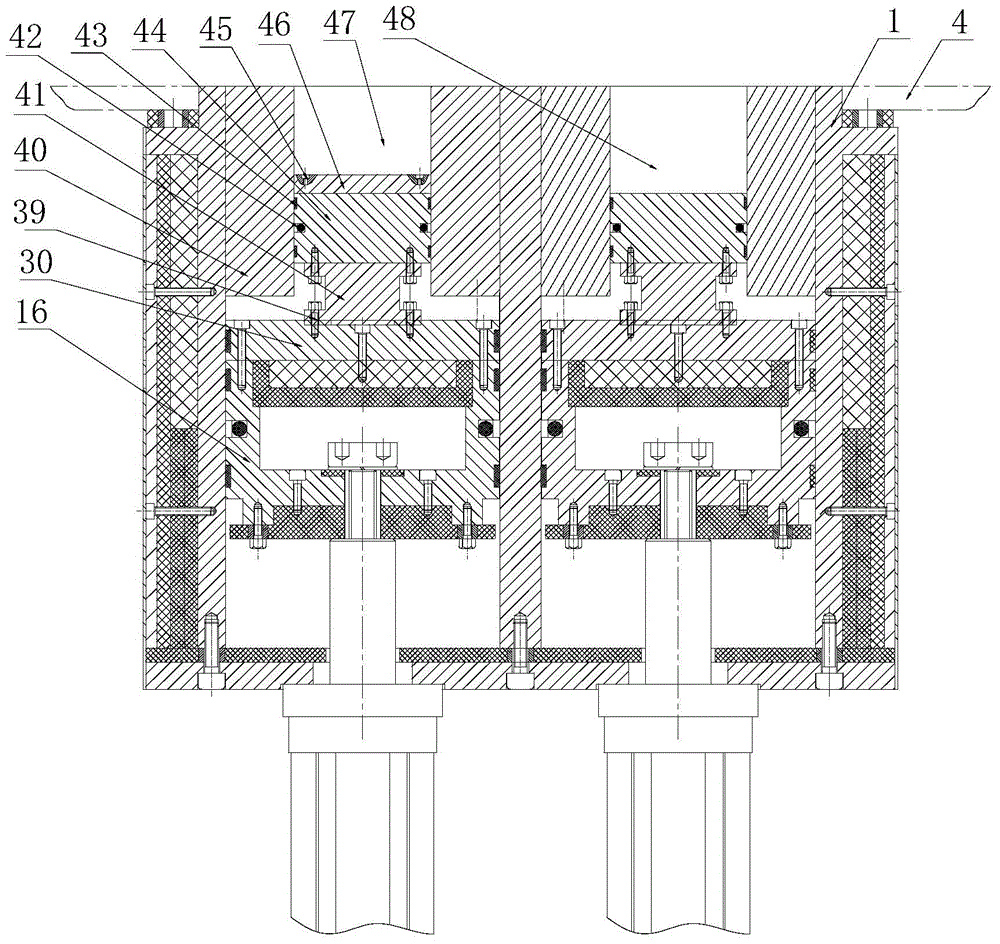

Metal laser selective melting forming double-piston controllable preheating powder cylinder

ActiveCN105014071AAvoid wastingAvoid errorsAdditive manufacturing apparatusCylinder blockMetal powder

The invention discloses a metal laser selective melting forming double-piston controllable preheating powder cylinder capable of respectively working in two states of single piston and double pistons. When the powder cylinder works in the state of single piston, firstly, a large piston basal plate in a forming cylinder is leveled; and then, the periphery of a cylinder body is heated by using a cylinder body heating ring, and a piston heating plate is used for heating a piston cover plate to realize indirect heating of a forming cylinder and metal powder in a powder feeding cylinder. When the powder cylinder works in the state of double pistons, firstly, a small piston basal plate is leveled; and then, powder in a small piston forming cylinder and a small piston powder feeding cylinder is uniformly heated by using the cylinder body heating ring and the piston heating plate. The powder cylinder adopts an integrated double-piston design; a small piston can be replaced and disassembled to realize the laser forming of metal components with different sizes; powder is saved; and meanwhile, the powder cylinder can be heated in all directions, so that the controllable powder preheating is realized, the powder heating is uniform, the temperature gradient is improved, and the deformation and the split of the components are reduced.

Owner:XI AN JIAOTONG UNIV

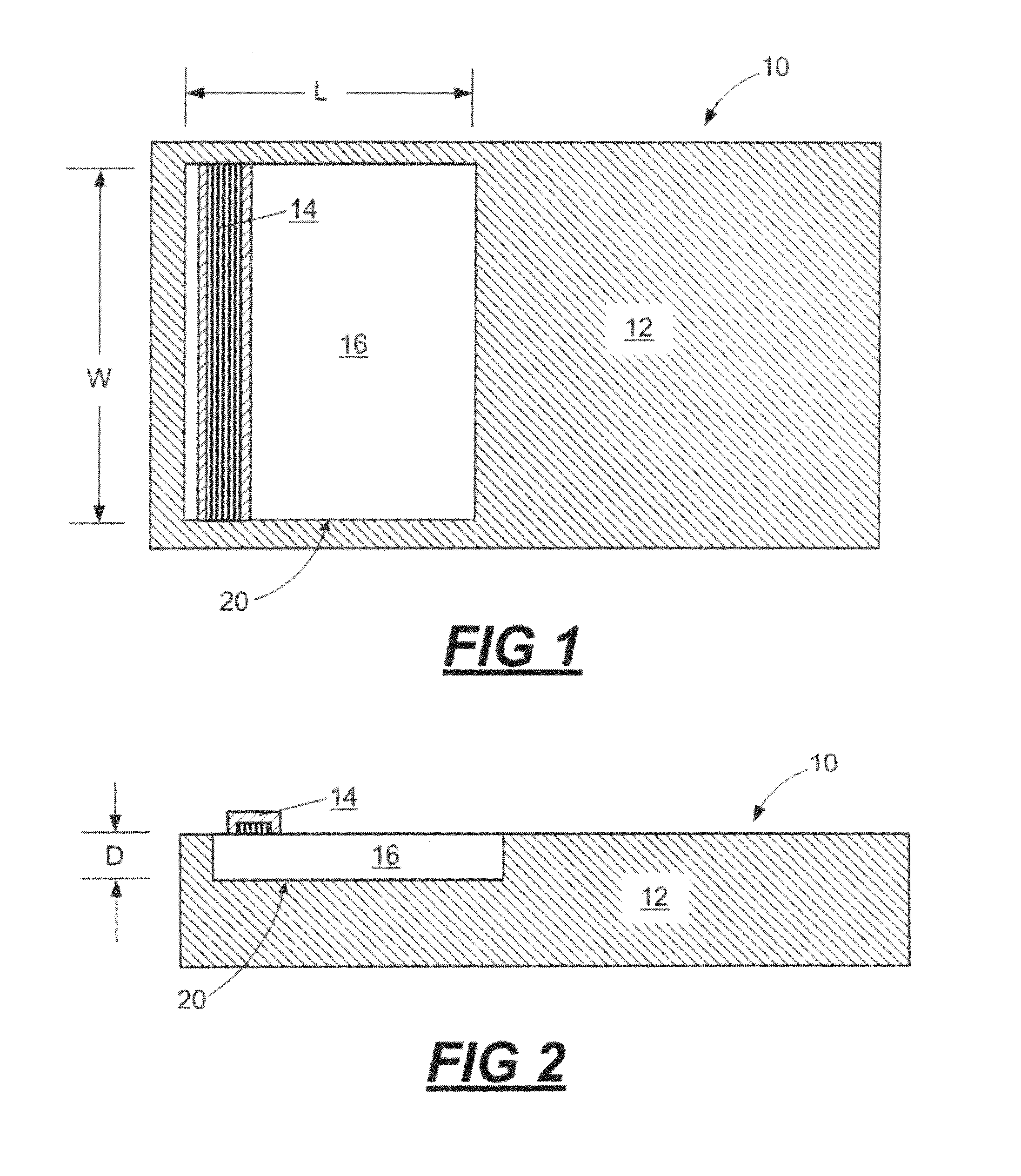

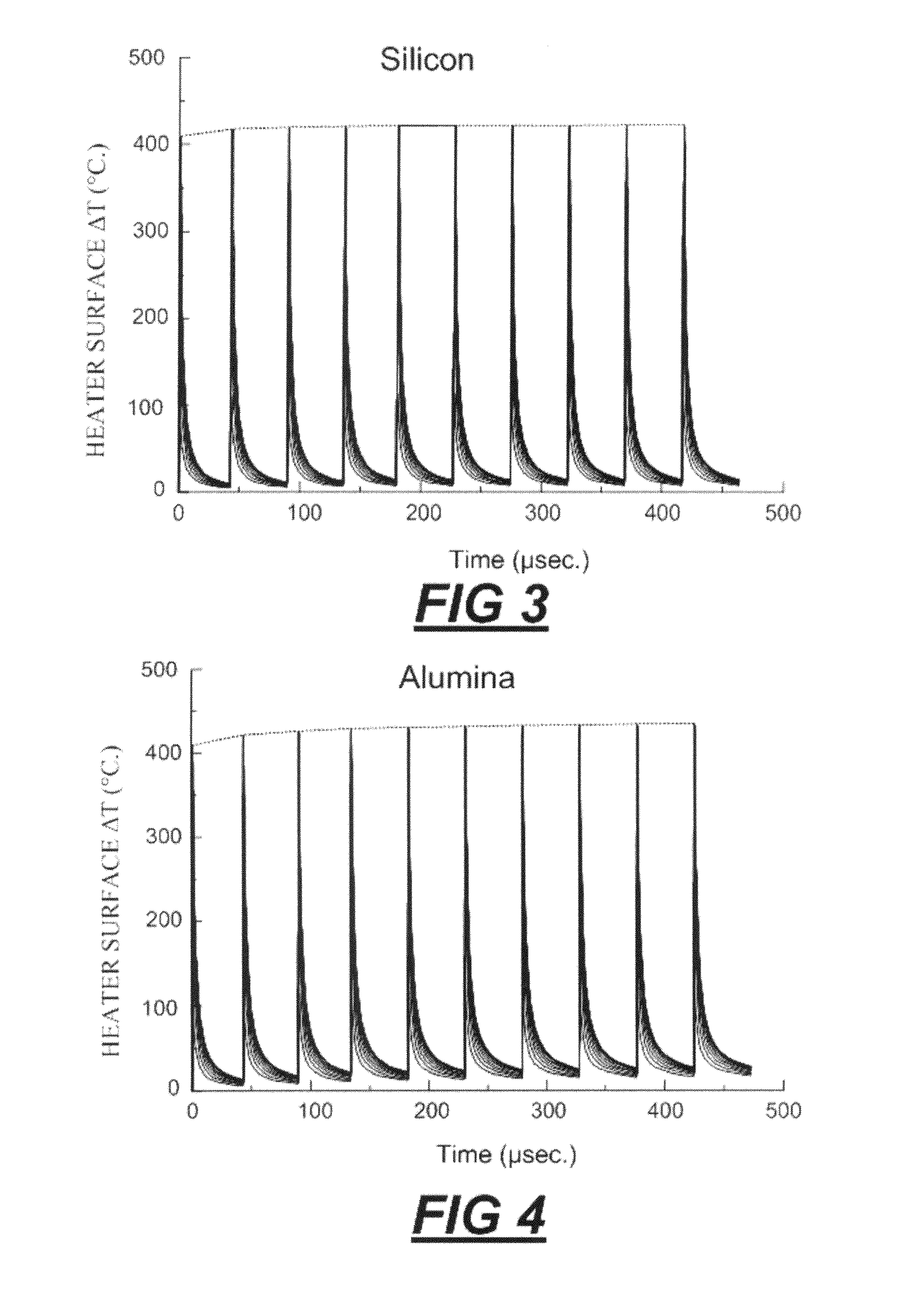

Method for Improving Thermal Conductivity in Micro-Fluid Ejection Heads

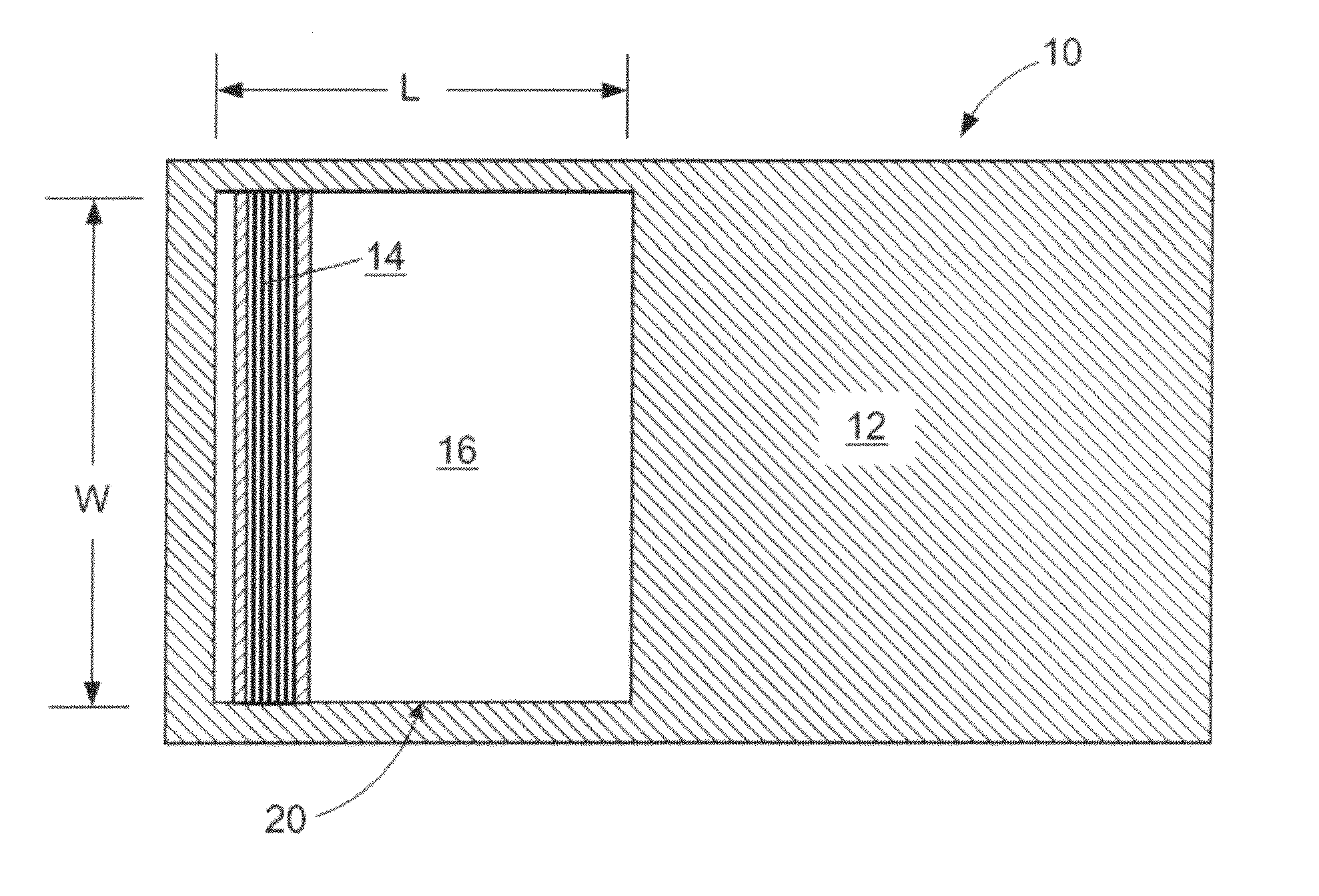

InactiveUS20080079779A1Improve thermal conductivity characteristicDissipate heatPrintingThermal conductivityMaterials science

Methods for improving the thermal conductivity of a substrate for a micro-fluid ejection head and micro-fluid ejection heads are provided. One such head includes a substrate having a thermal conductivity ranging from about 1.4 W / m-° C. to about 148 W / m-° C., a fluid ejection actuator, and a thermal bus thermally adjacent to the substrate and configured to dissipate heat associated with the operation of the actuator. Exemplary modified substrates have improved thermal conductivity characteristics as compared to a corresponding substrate not modified to include the thermal bus.

Owner:LEXMARK INT INC

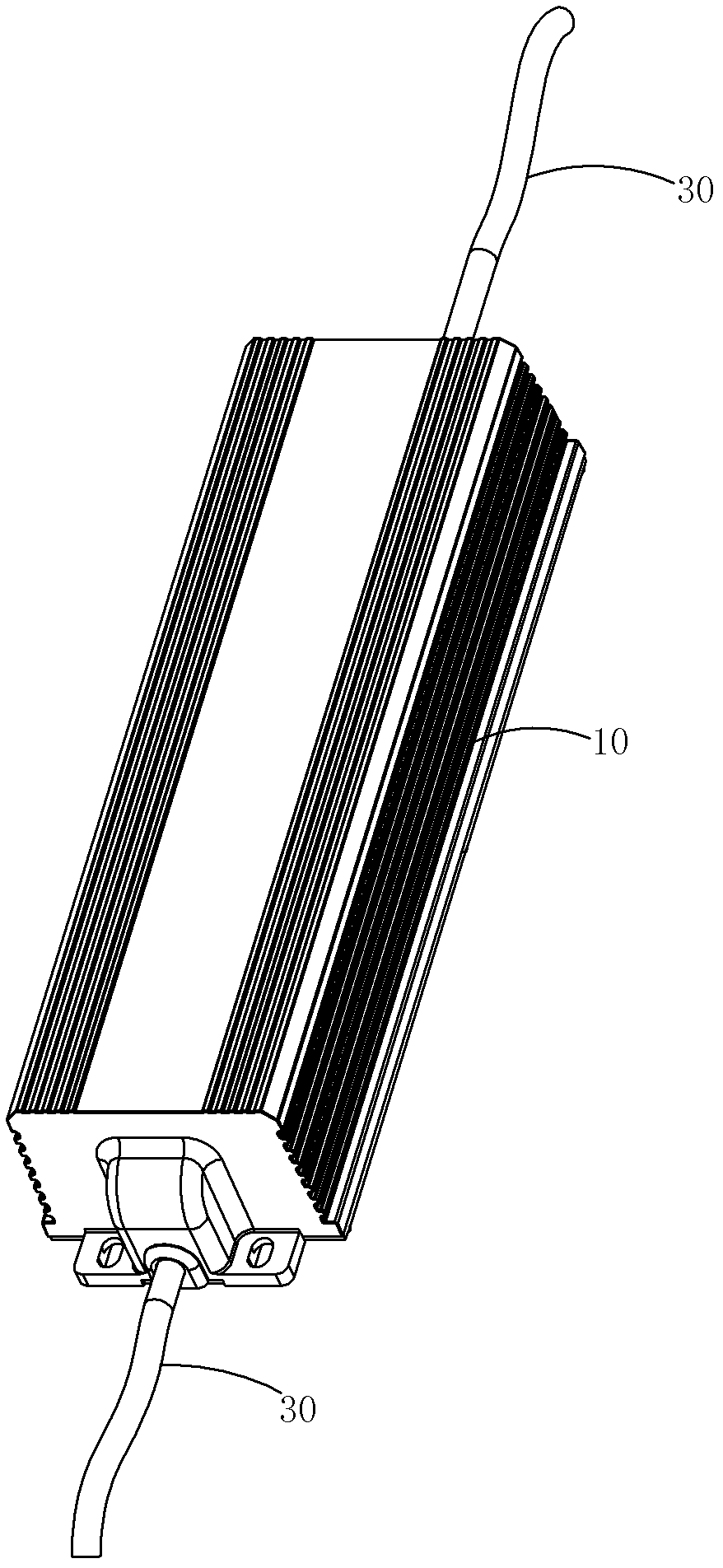

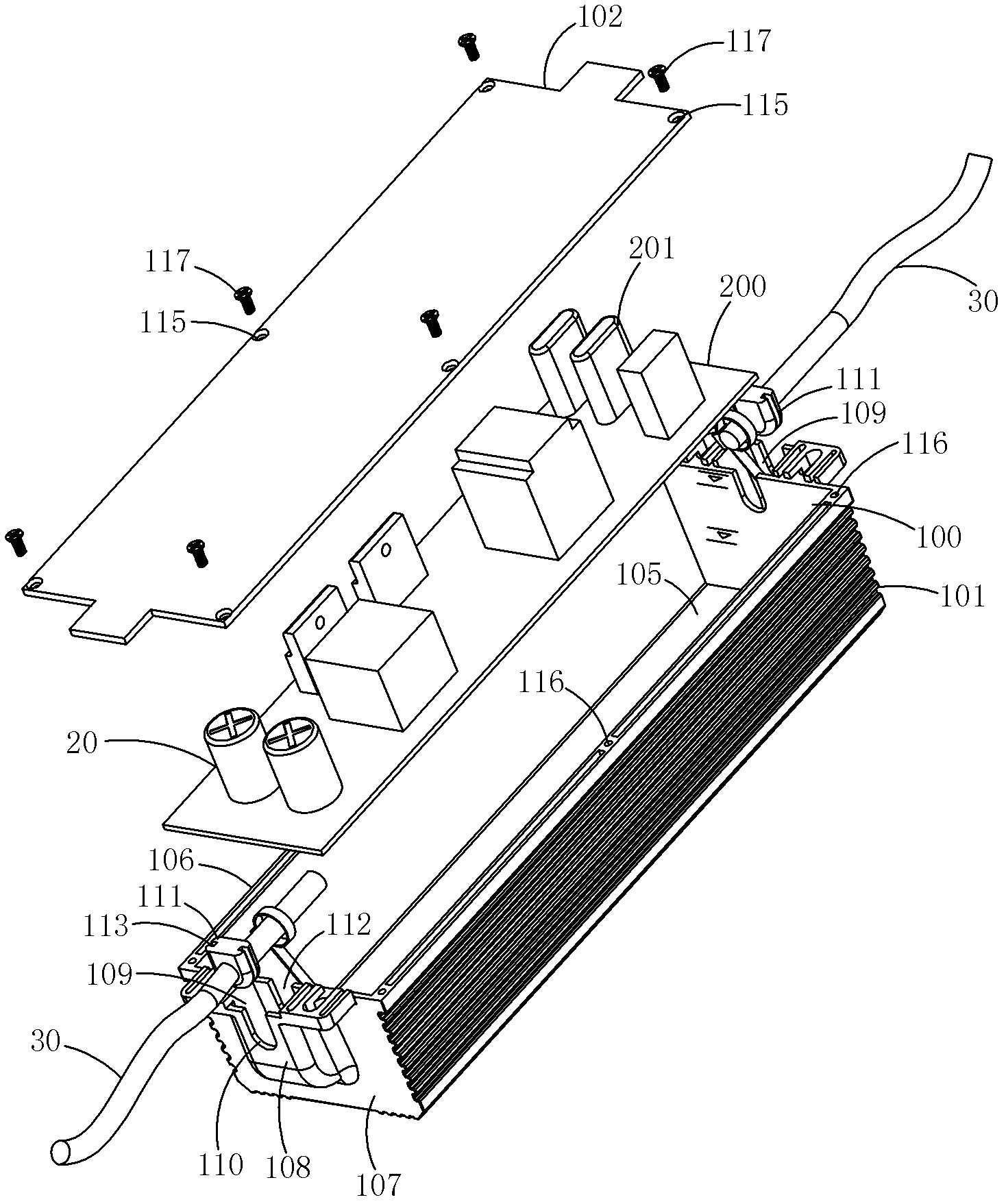

Electronic equipment sealing structure, electronic power supply and encapsulation method for electronic power supply

InactiveCN102548313AGood thermal conductivityImprove cooling effectHermetically-sealed casingsEngineeringElectrical and Electronics engineering

The invention discloses an electronic equipment sealing structure which comprises a shell, wherein a circuit board with an electronic element is arranged in the shell; wire rods are introduced into the shell respectively from two ends of the shell and electrically connected with the circuit board; the shell comprises an upper shell and a cover board; an opening is formed on the bottom surface of the upper shell, and the cover board is covered at the opening of the upper shell; a soft encapsulation glue layer is encapsulated on the upper part of the inner cavity of the upper shell, and at least wraps a board body of the circuit board; and a hard encapsulation glue layer is encapsulated below the soft encapsulation glue layer. According to the electronic equipment sealing structure, a phenomenon of stress damage, caused by encapsulation glue, to the electronic element can be avoided. The invention also discloses an electronic power supply with the electronic equipment sealing structure, and an encapsulation method for the electronic power supply.

Owner:惠州茂硕能源科技有限公司

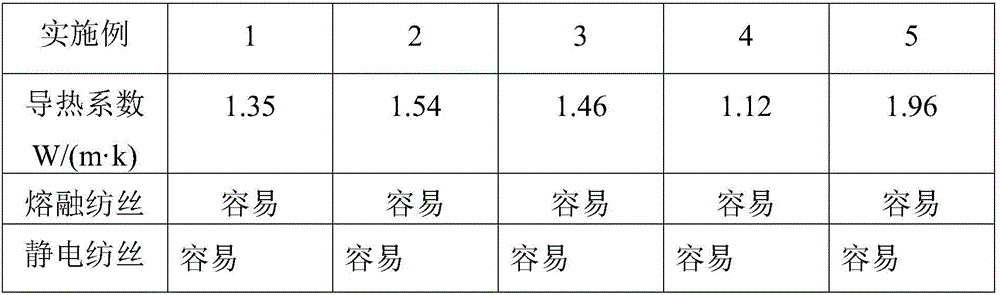

In-situ polymerization preparation method of spinning-level high-heat-conductivity graphene/nylon composite material

ActiveCN105949760AGood thermal conductivityExcellent spinnabilityGrapheneCvd grapheneElectrospinning

The invention relates to an in-situ polymerization preparation method of a spinning-level high-heat-conductivity graphene / nylon composite material, belonging to the field of high-polymer composite materials. The in-situ polymerization preparation method comprises the following steps: diluting and dispersing a graphene oxide concentrated solution and water, and carrying out ultrasonic oscillation to obtain a graphene oxide dispersion solution; adding the graphene oxide dispersion solution into a nylon monomer, heating and uniformly mixing, and carrying out stepwise heating polymerization; and carrying out after-treatment to obtain the graphene / nylon composite material. The in-situ polymerization method is adopted to solve the problems of poor dispersity and high aggregation tendency of the graphene in the nylon monomer, and the nylon monomer and the oxygen-containing functional group of the graphene oxide can form a firm chemical bond. The synthesized graphene / nylon composite material has favorable heat conductivity, and the heat conductivity coefficient is 0.23-6.12 W / (m.K). Besides, the graphene / nylon composite material has favorable spinning properties, and can be used for spinning by melt spinning, electrostatic spinning or any other spinning process.

Owner:BEIJING UNIV OF CHEM TECH

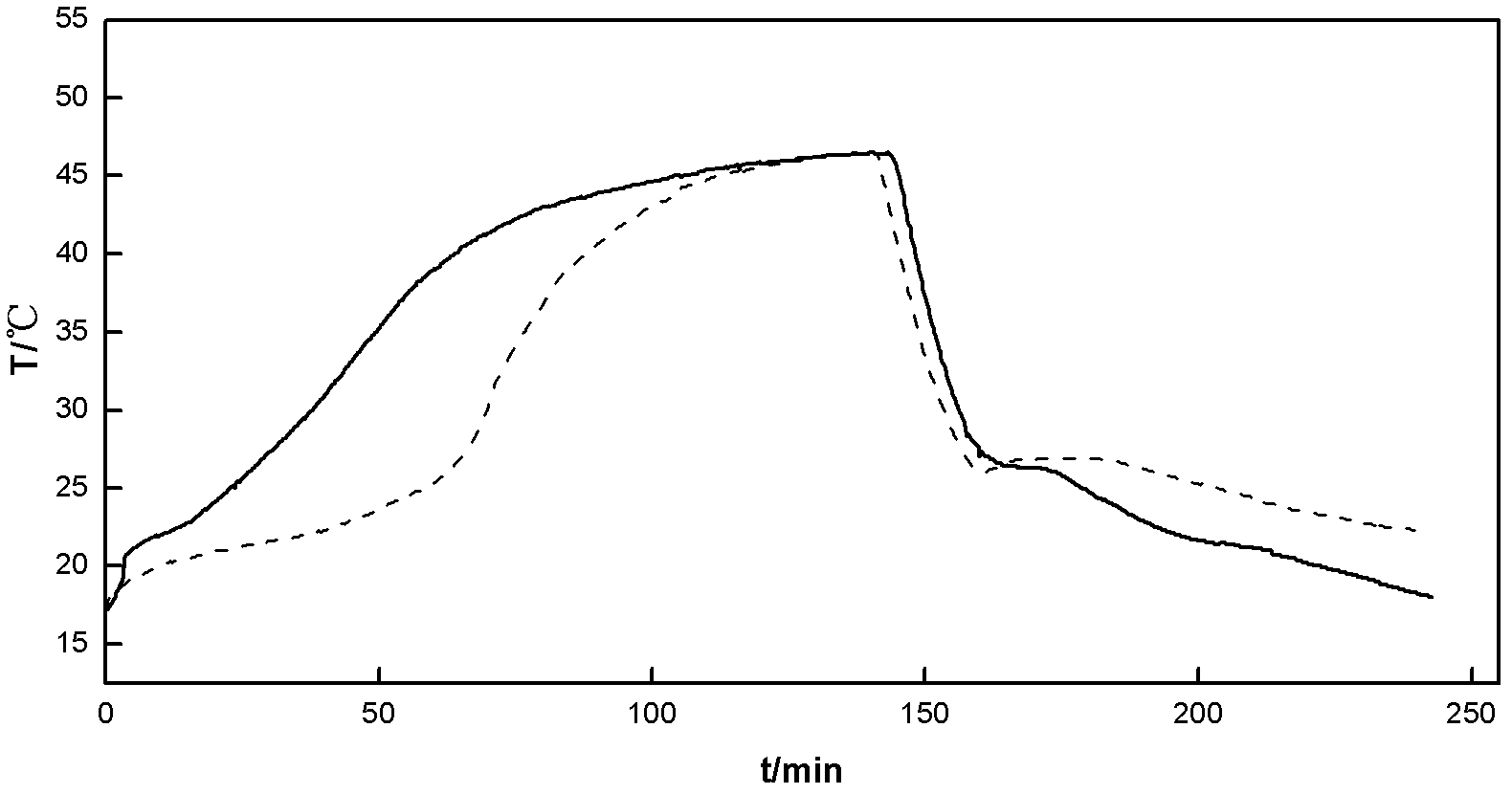

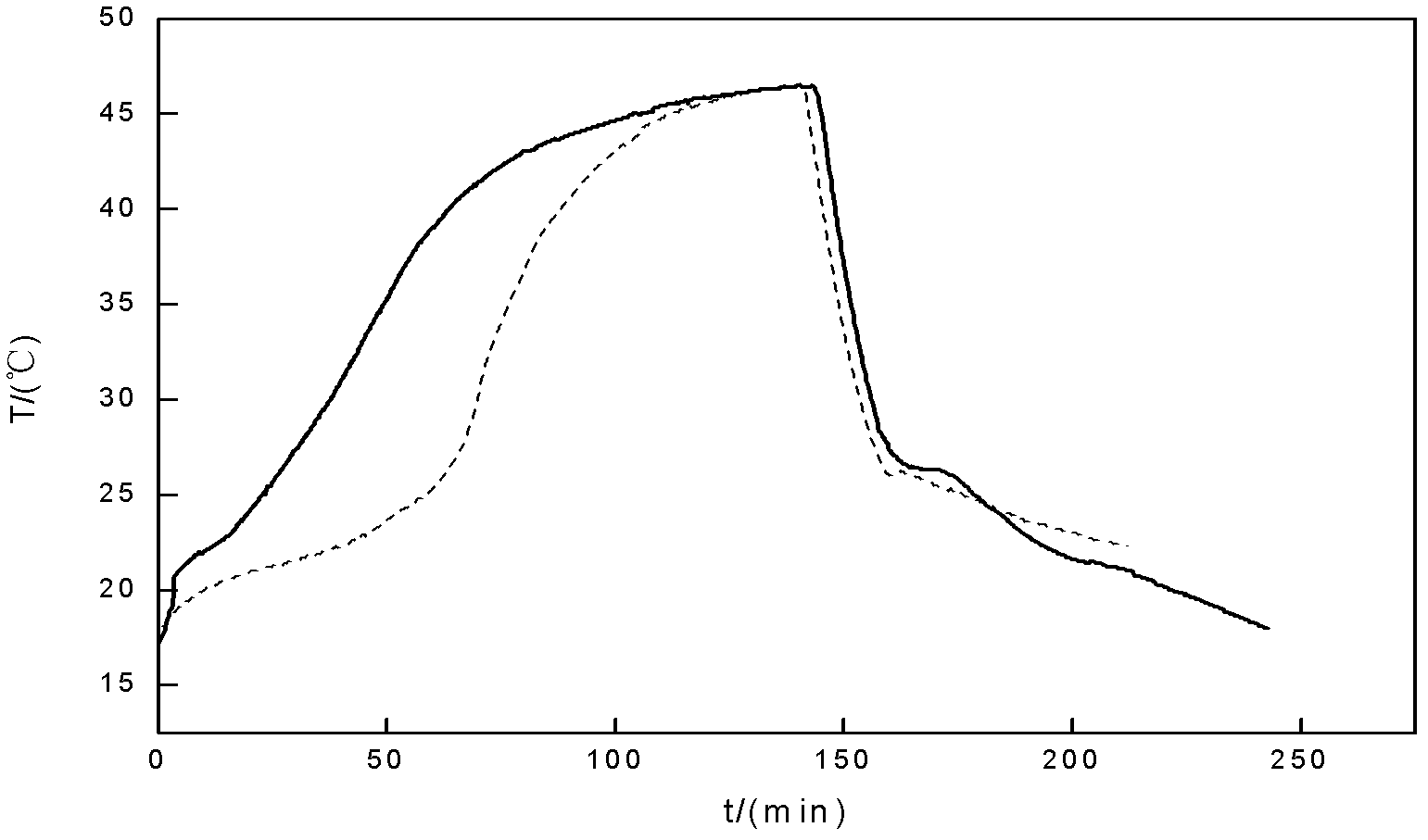

Shape-stabilized phase change energy storage material for building and preparation method thereof

InactiveCN102432258AGood thermal conductivityHigh thermal conductivityHeat-exchange elementsGypsumBuilding material

The invention relates to a shape-stabilized phase change energy storage material for building and a preparation method thereof. The material provided by the invention comprises components of: by weight, 70-85% of a composite phase change energy storage material with its melting point being 18-30 DEG C and 15-30% of gesso. The composite phase change energy storage material with its melting point being 18-30 DEG C is composed of a porous matrix and a mixed fatty acid phase change material, wherein the mass ratio of the porous matrix to the mixed fatty acid phase change material is 1:4-1:6. At the temperature of 60-80 DEG C, the porous matrix is added in the molten lauric acid-capric acid mixed fatty acid to prepare a composite phase change material. Then, gesso is mixed with the composite phase change material to prepare a shape-stabilized fatty acid phase change energy storage material with a more stable adsorption property. The prepared shape-stabilized phase change energy storage material has good thermal conductivity, good adsorption stability and good material plasticity, will not cause seepage at high temperature, is easy to mix with a building material, and has a good application prospect.

Owner:NANJING UNIV OF TECH +1

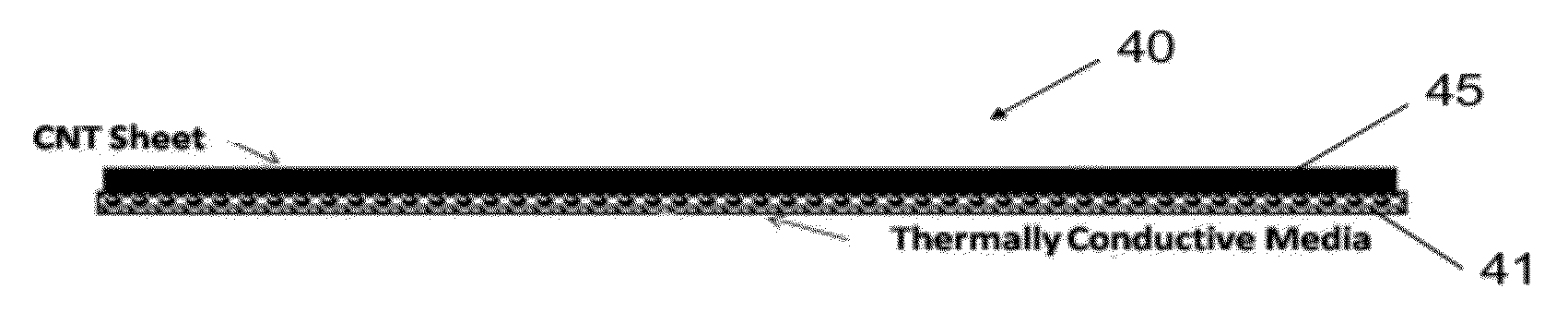

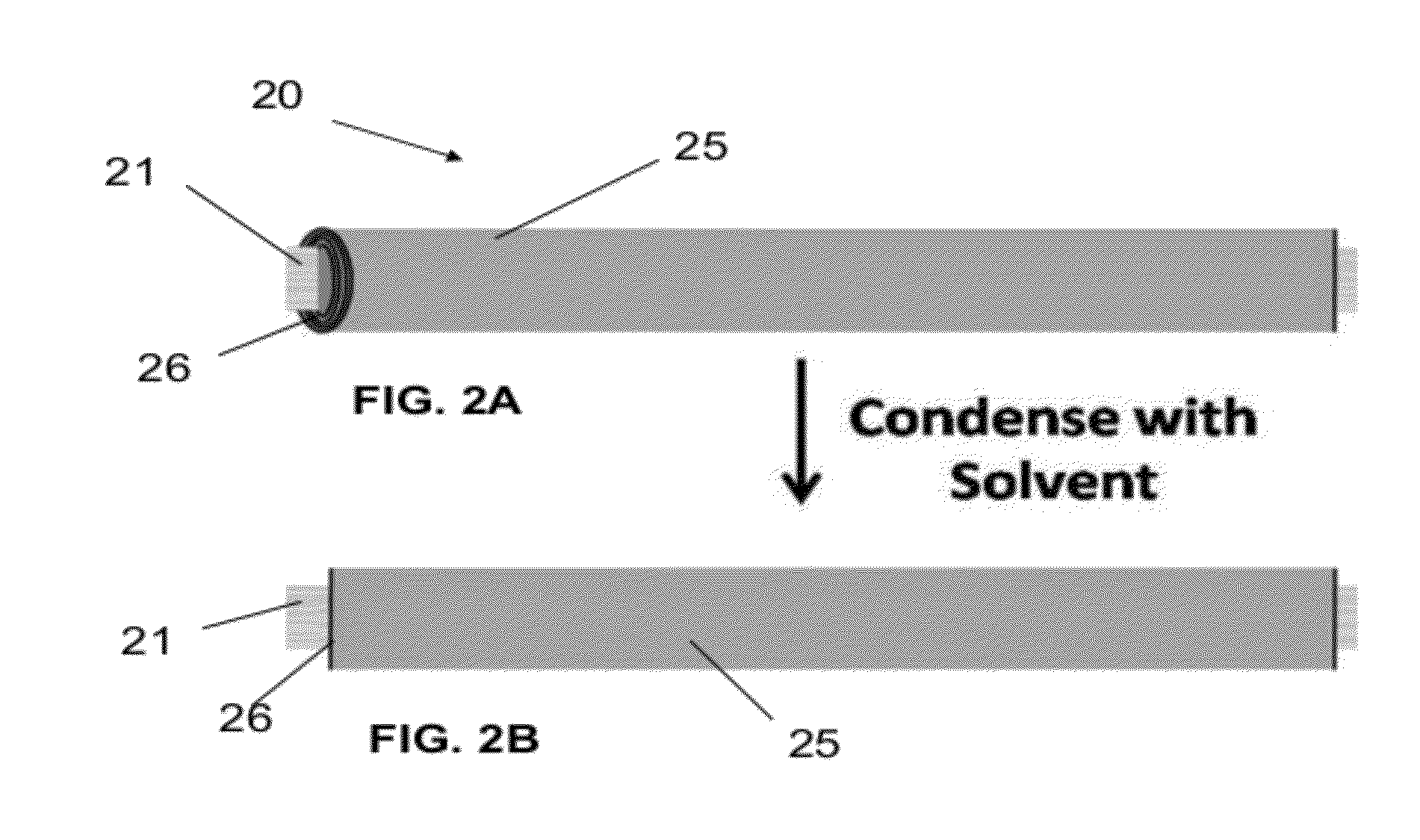

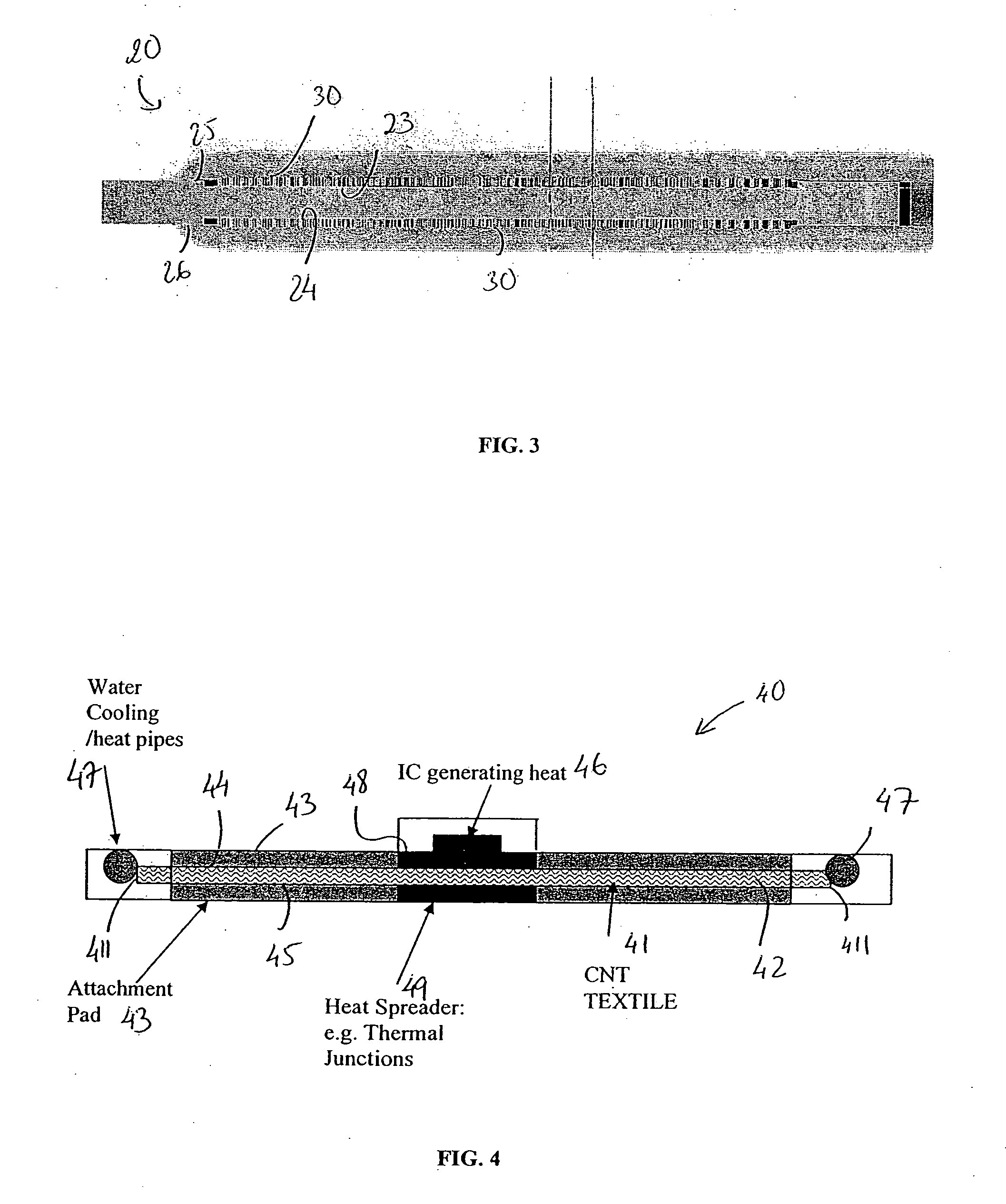

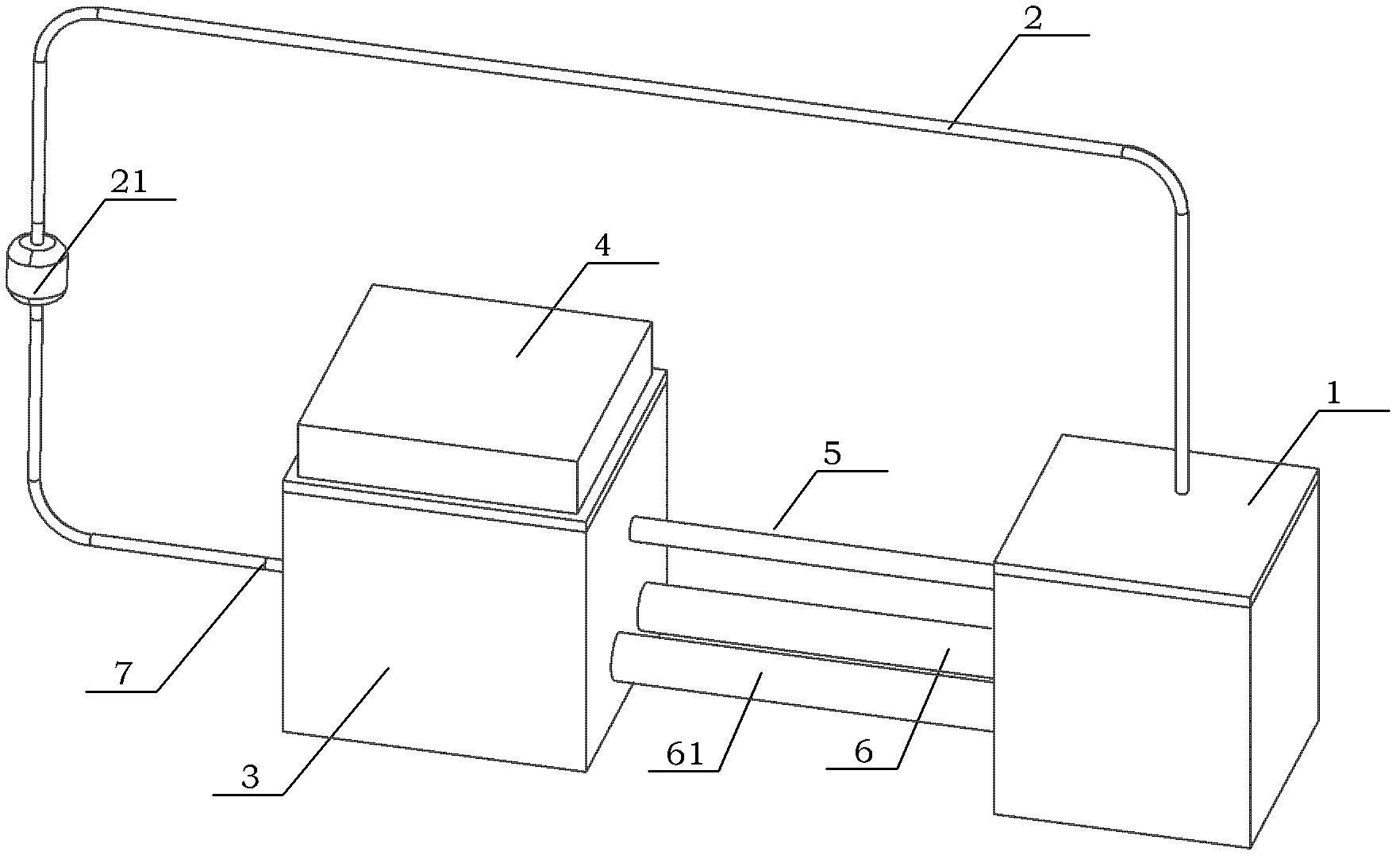

Systems and methods for thermal management of electronic components

InactiveUS20120118552A1Easy transferImprove cooling effectInsulated cablesHeat exchange apparatusElectrical resistance and conductanceCarbon nanotube

The device for extracting heat from carbon nanotubes wires or cables used under high power applications is provided. The device can include a thermally conductive member for placement against a heat source and for directing heat away from the heat source to a heat dissipating medium. The device can further include an electrically conductive member positioned on the thermally conductive member and made from a layer of carbon nanotubes, to reduce electrical resistance along the electrically conductive member. A geometric pattern can be imparted to the electrically conductive member to enhance dissipation of heat away from the thermally conductive member and the heat source.

Owner:NANCOMP TECHNOLOGIES INC

Even heating board and heat radiating device

InactiveCN101309573ASolve the cooling problemGood heat distributionSemiconductor/solid-state device detailsSolid-state devicesWorking fluidEngineering

The invention relates to a heat soaking plate, which comprises a base plate and a cover plate, wherein, a chamber is hermetically formed between the base plate and the cover plate, working fluid is filled in the chamber, at least a vessel extending from the central area of the heat soaking plate to the circumferential edge part of the heat soaking plate is arranged in the chamber, a central through hole is formed at the center of the vessel, a multi-orifice structure used for performing capillary force on the working fluid is formed on the wall of the vessel, the multi-orifice structure is communicated with the central through hole. The heat soaking plate utilizes the vessel of the heat soaking plate to provide the capillary force to strengthen the back flow of the working fluid after being condensed, so as to reach the better purpose of heat soaking distribution, and to effectively solve the heat radiating problem of the electronic element with high heat productivity. The invention also provides a heat radiating device which is formed by assembling the head radiator and the heat soaking plate.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

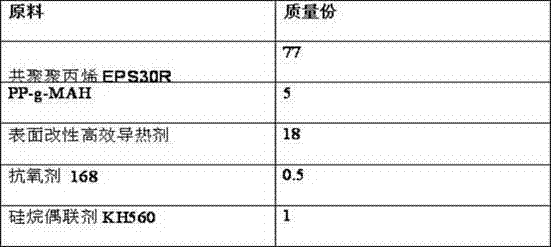

High-thermal-conductivity PP (polypropylene)-based composite material and preparation method thereof

The invention discloses a high-thermal-conductivity PP-based composite material, which comprises 60% to 80% of PP, 1% to 20% of surface-modified efficient thermal conduction agents, 1% to 5% of compatilizers, 0.5% to 1% of antioxidants and 0.5% to 1% of coupling agents in percentage by weight. The preparation method of the high-thermal-conductivity PP-based composite material comprises steps of mixing materials uniformly, then placing the mixed materials in an extruder, fusing and extruding, and granulating the extruded materials. According to the high-thermal-conductivity PP-based composite material and the preparation method thereof, a product has good thermal conductivity and can be applied to cooling components of lighting and communication systems.

Owner:GUANGDONG HIGH & NEW ENG PLASTICS

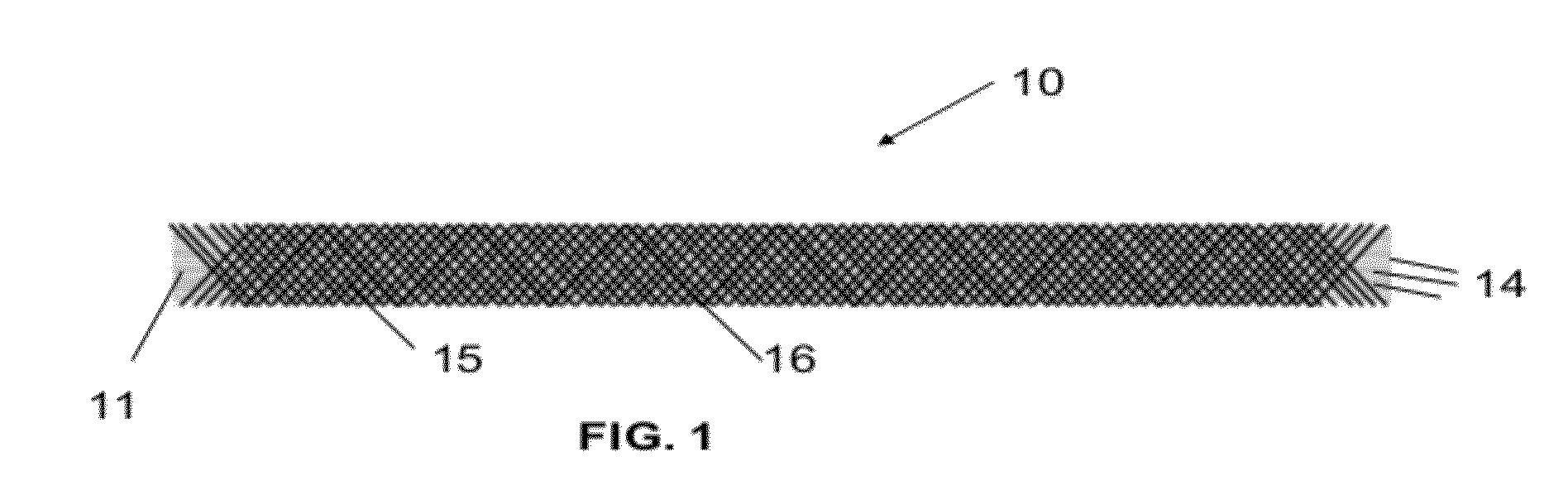

Systems and methods for thermal management of electronic components

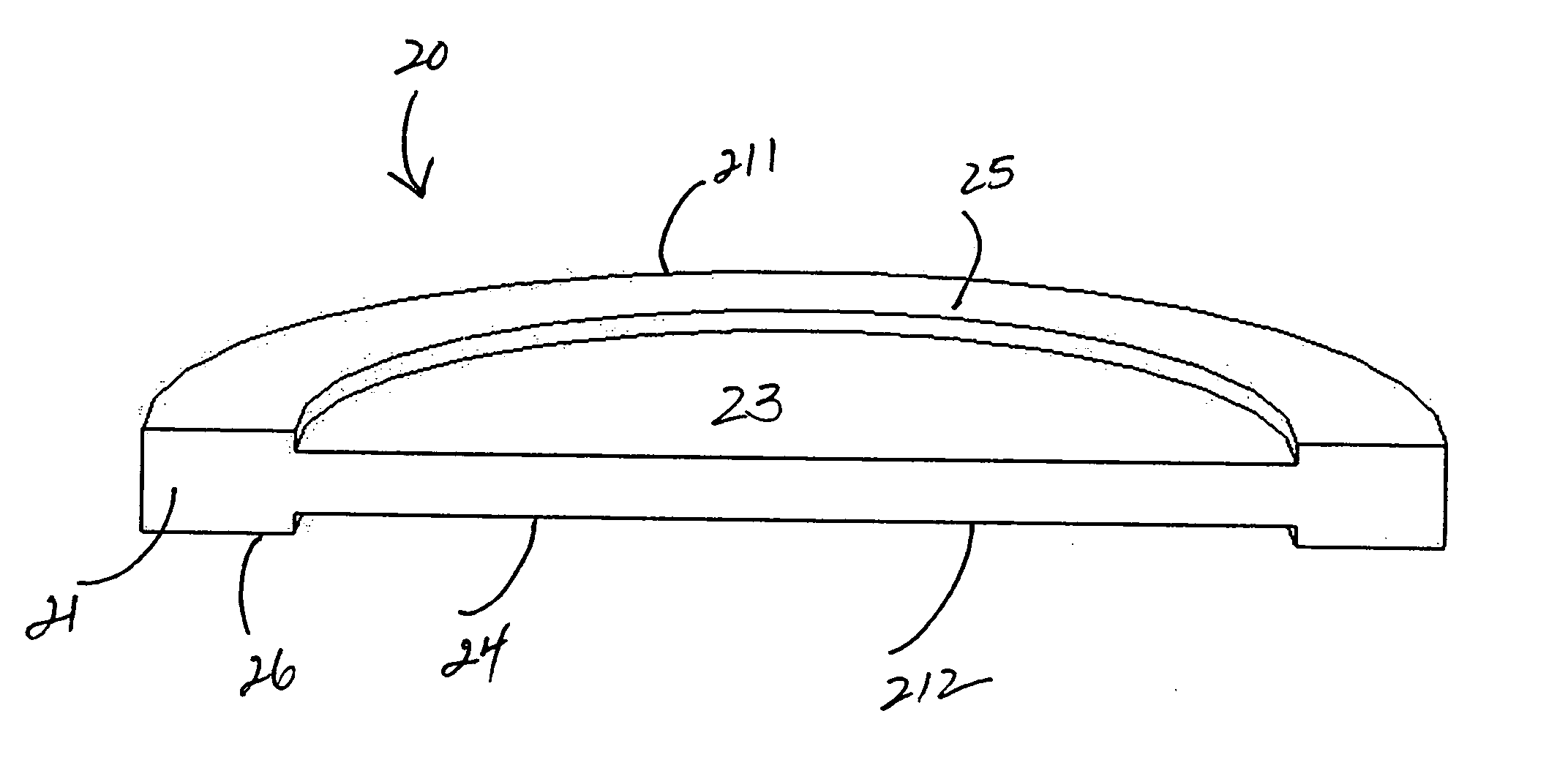

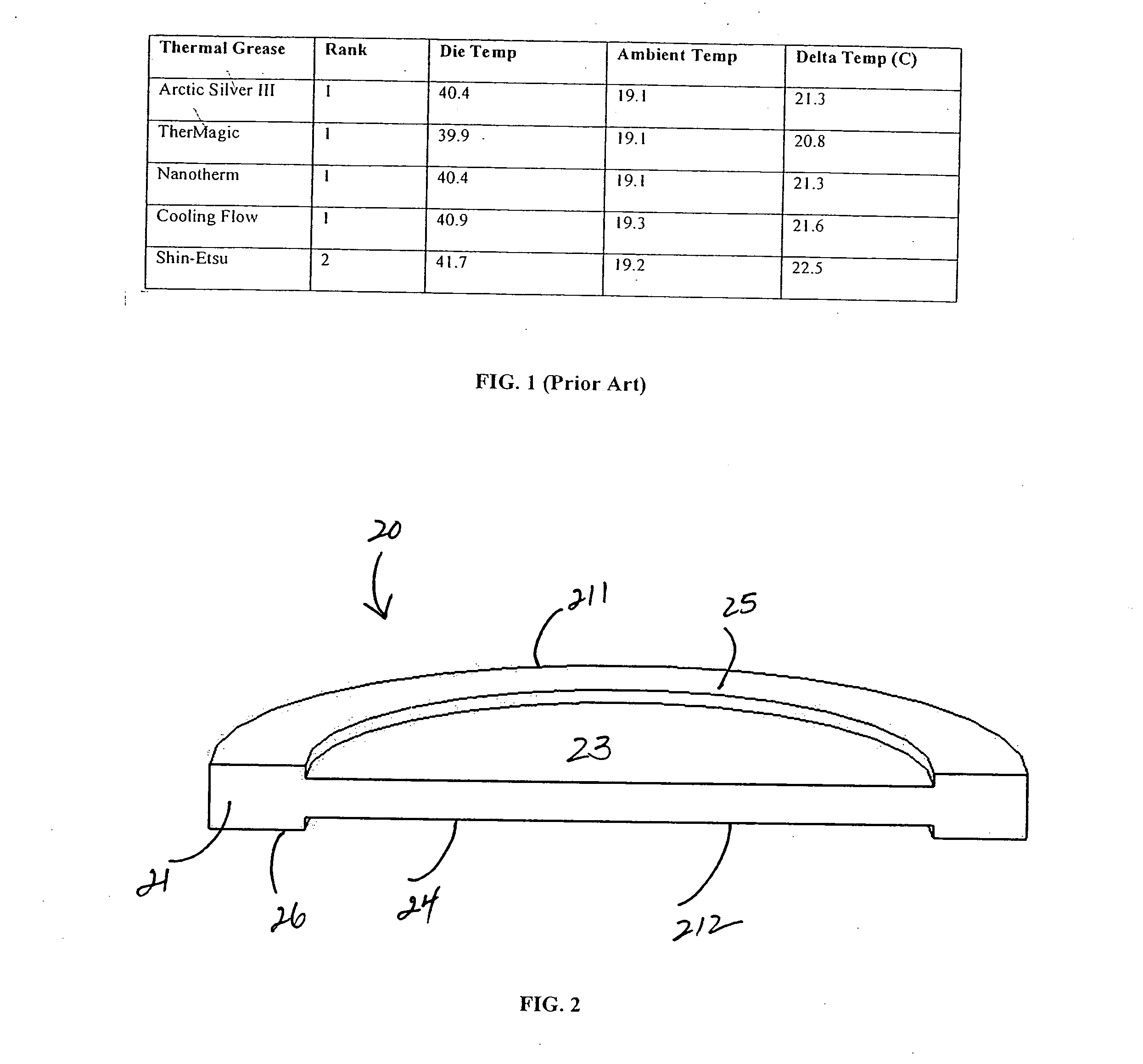

ActiveUS20060269670A1Minimize amountHigh thermal conductivityLayered productsSemiconductor/solid-state device detailsHeat spreadingThermal conductivity

A heat-conducting medium for placement between a heat source and heat sink to facilitate transfer of heat from the source to the sink is provided. The heat-conducting medium can include a disk having relatively high thermal conductivity and heat spreading characteristics. The heat-conducting medium also includes a first recessed surface and an opposing second recessed surface. Extending from within each recessed surface is an array of heat conducting bristles to provide a plurality of contact points to the heat source and heat sink to aid in the transfer of heat. The recessed surfaces may be defined by a rim positioned circumferentially about the disk. The presence of the rim about each recessed surface acts to minimize the amount of pressure that may be exerted by the heat sink and the heat source against the bristles. A method for manufacturing the heat-conducting medium is also provided.

Owner:NANCOMP TECHNOLOGIES INC

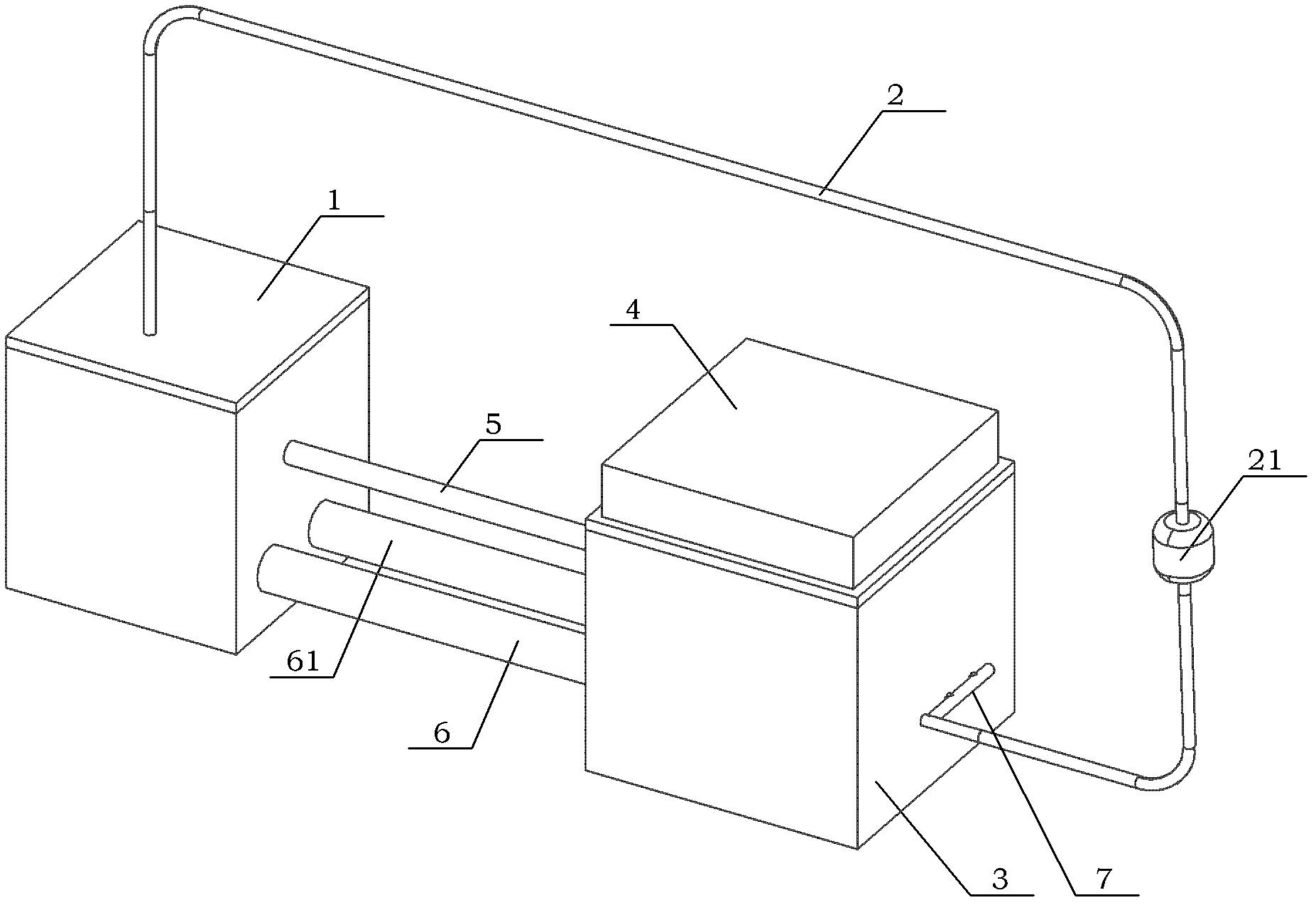

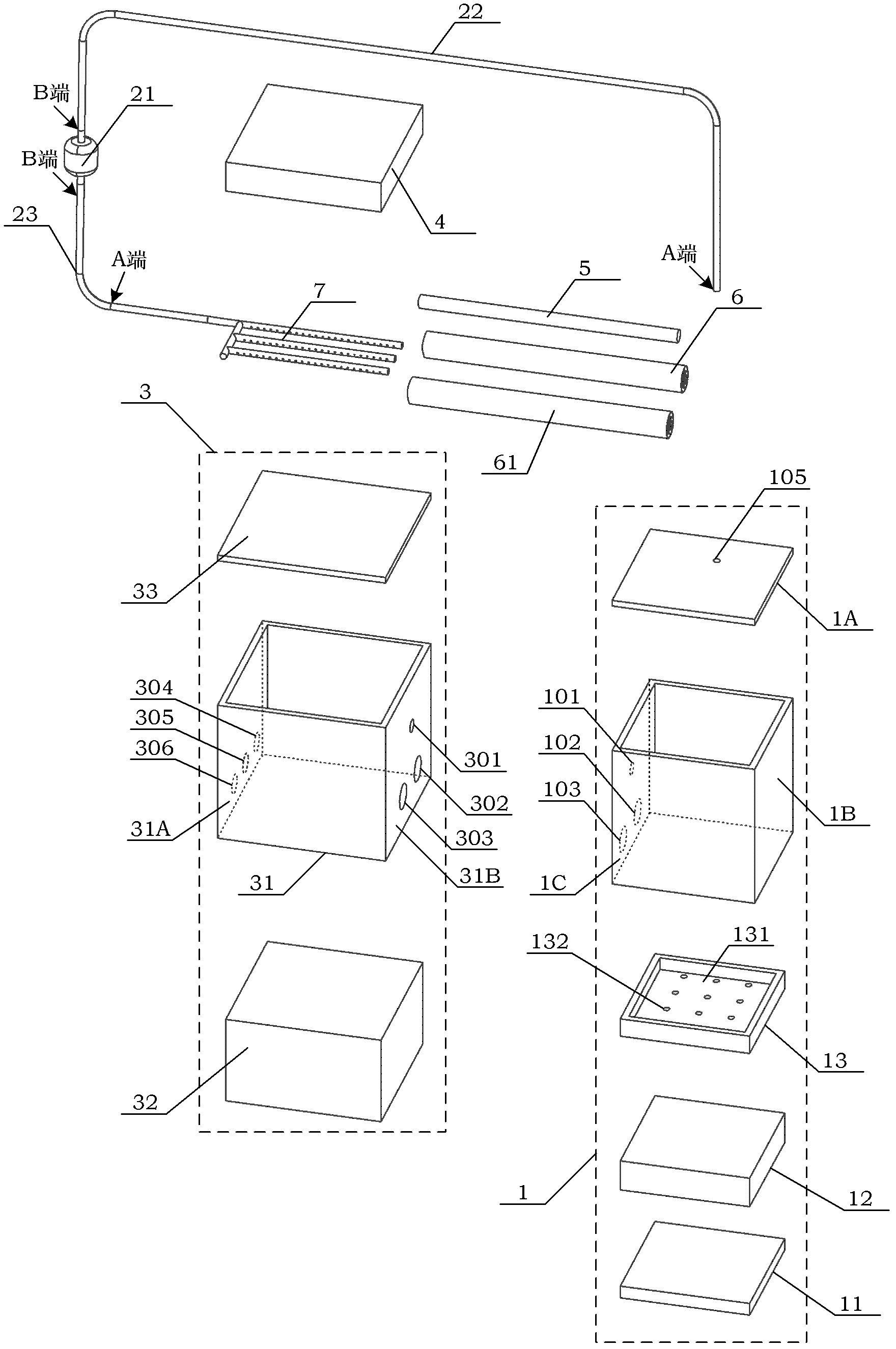

Microgravity environment-based spray cooling loop device

InactiveCN102514733ARealize the collectionAchieve cycleCosmonautic vehiclesCosmonautic partsDiaphragm pumpEvaporation

The invention discloses a microgravity environment-based spray cooling loop device. According to the device, a heat sink is arranged on a liquid storage component; a hydraulic driving pipeline is provided with a micro high pressure diaphragm pump; two ends of the hydraulic driving pipe are communicated with a liquid collector and a spray component respectively; three hole drain pipes of the liquid collector are inserted into a second capillary core of the liquid storage component; and the spray component and the liquid storage component are connected through a steam collecting pipeline, a first liquid collecting pipeline and a second liquid collecting pipeline. The device generates high-speed atomized liquid drops under high pressure impact, and the high speed atomized liquid drops impact the surface of the first capillary core connected with a heat source to take away heat generated by the heat source in heat transfer modes such as forced convection, boiling, evaporation phase change and the like. By the capillary characteristics of the capillary core, the device collects and circulates the liquid under microgravity environment; and moreover, a steam collector, a steam condenser and the liquid collector are integrated into a unit, so the volume is reduced.

Owner:BEIHANG UNIV

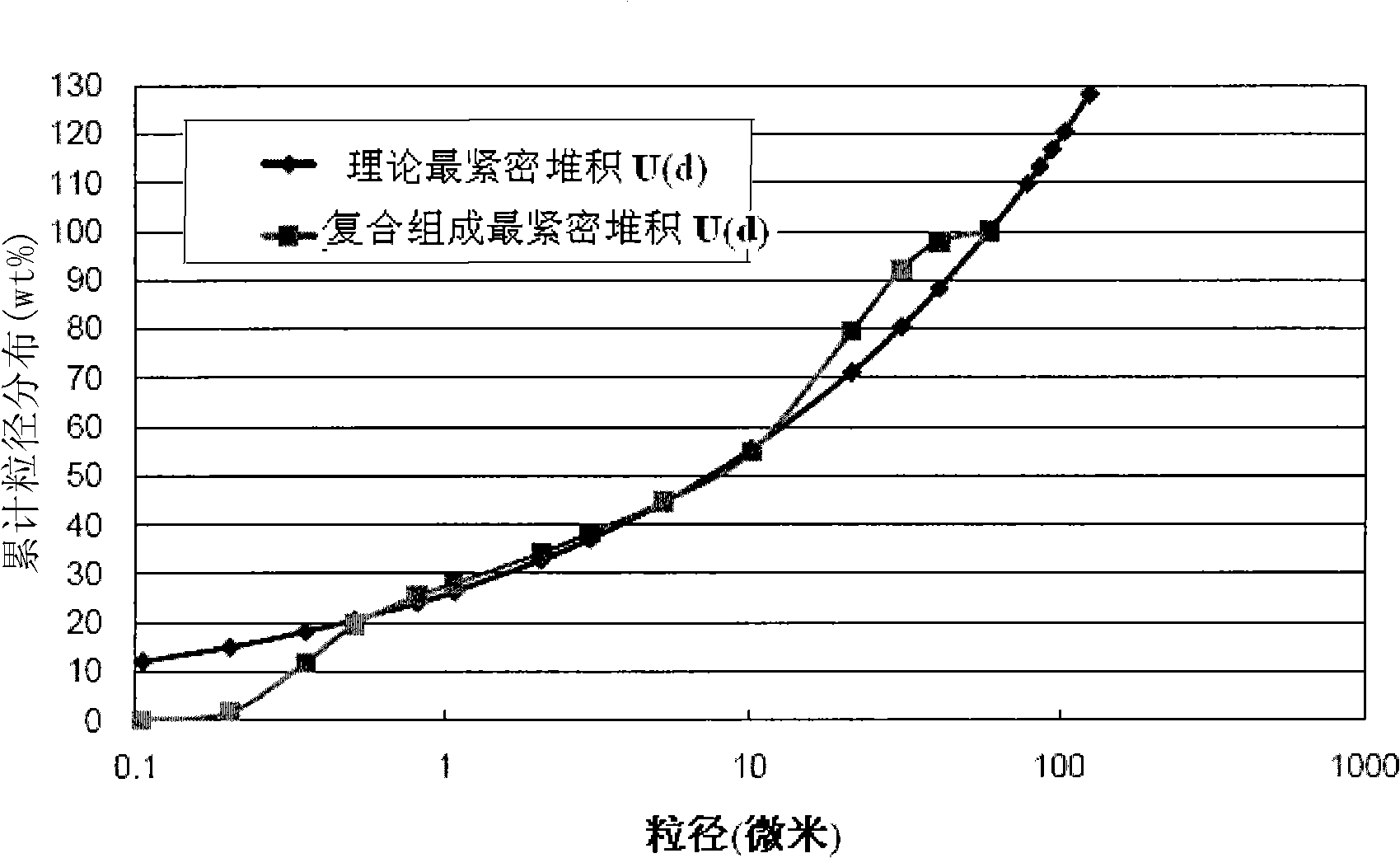

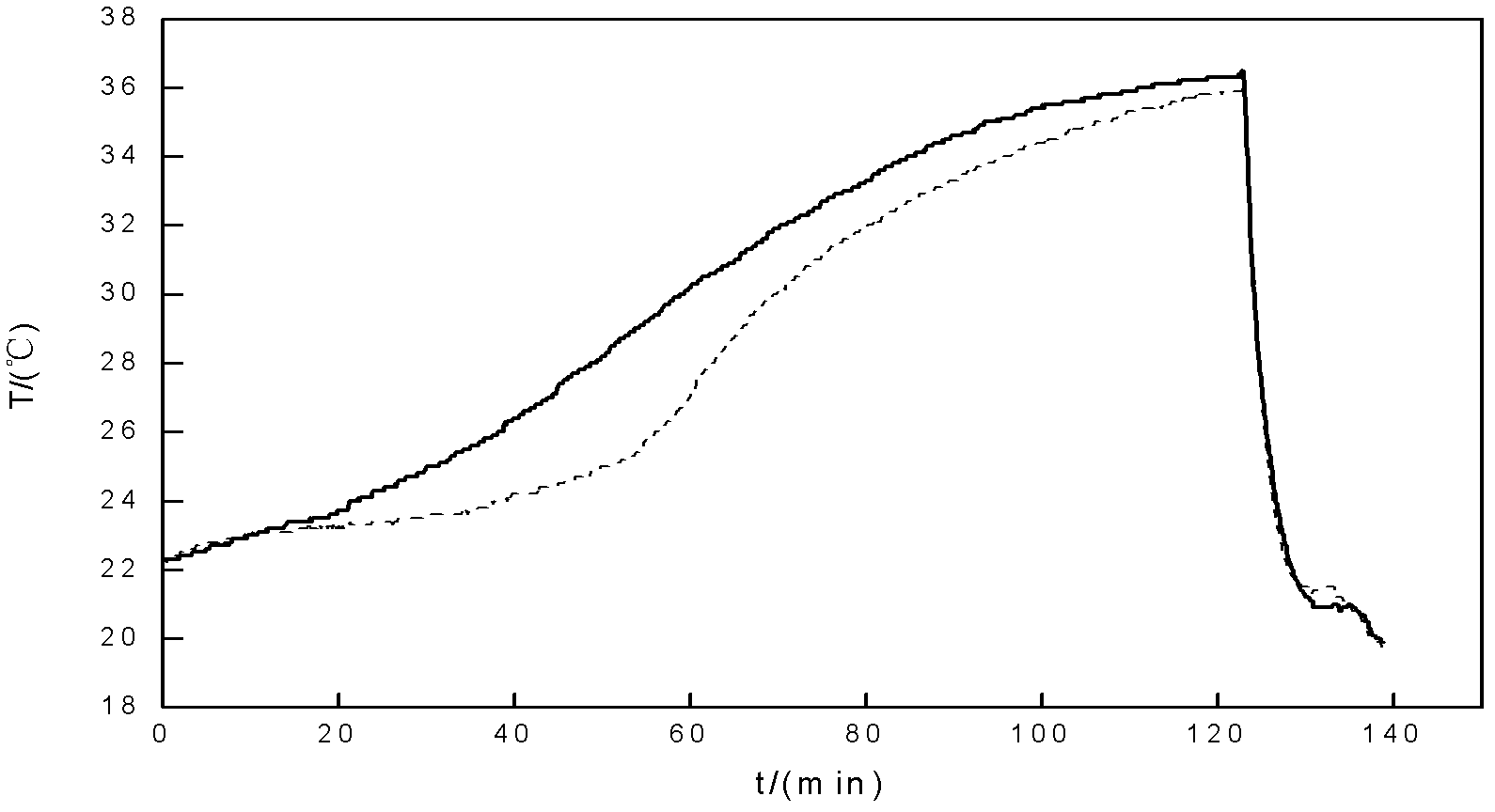

Concrete materials having functions of heat conduction and heat storage, and preparation method thereof

ActiveCN104386981AGood thermal conductivityConsistent granularityHeat-exchange elementsMicroballoon preparationHeat conductingGraphite

The invention discloses a concrete material having the functions of heat conduction and heat storage, and a preparation method thereof, and belongs to the technical field of building materials. The concrete material having the function of heat conduction and heat storage, disclosed by the invention, comprises 15-25 parts of cement, 15-25 parts of quartz sand, 15 -25 parts of natural pebbles, 10-15 parts of graphite, 20-30 parts of water, 1-3 parts of water reducing agents, 1-3 parts of expanding agents, 5-10 parts of phase-change polyethylene microcapsules and1-5 parts of aramid fibers. The preparation method comprises three steps: step 1) preparing cement slurry and performing the heat conduction on the cement slurry; step 2) preparing hot concrete slurry; step 3) pouring concrete. The working procedures are simple. Through the adoption of the concrete material and the preparation method, disclosed by the invention, the double purposes of good heat conducting effect and good heat storing effect for the concrete material having the functions of heat conduction and heat storage can be realized.

Owner:MAANSHAN NBWAVE HEAT ENERGY SCI

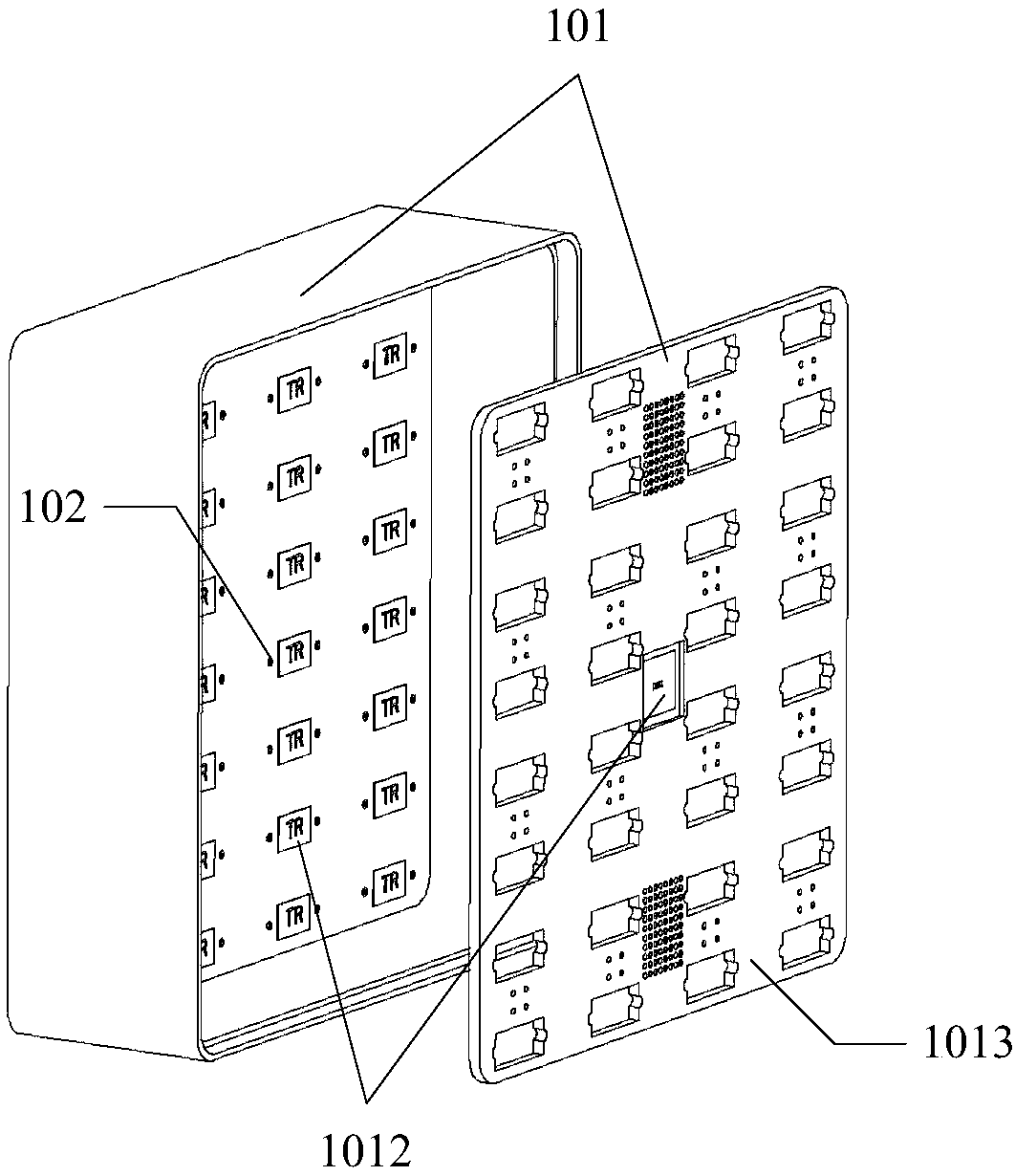

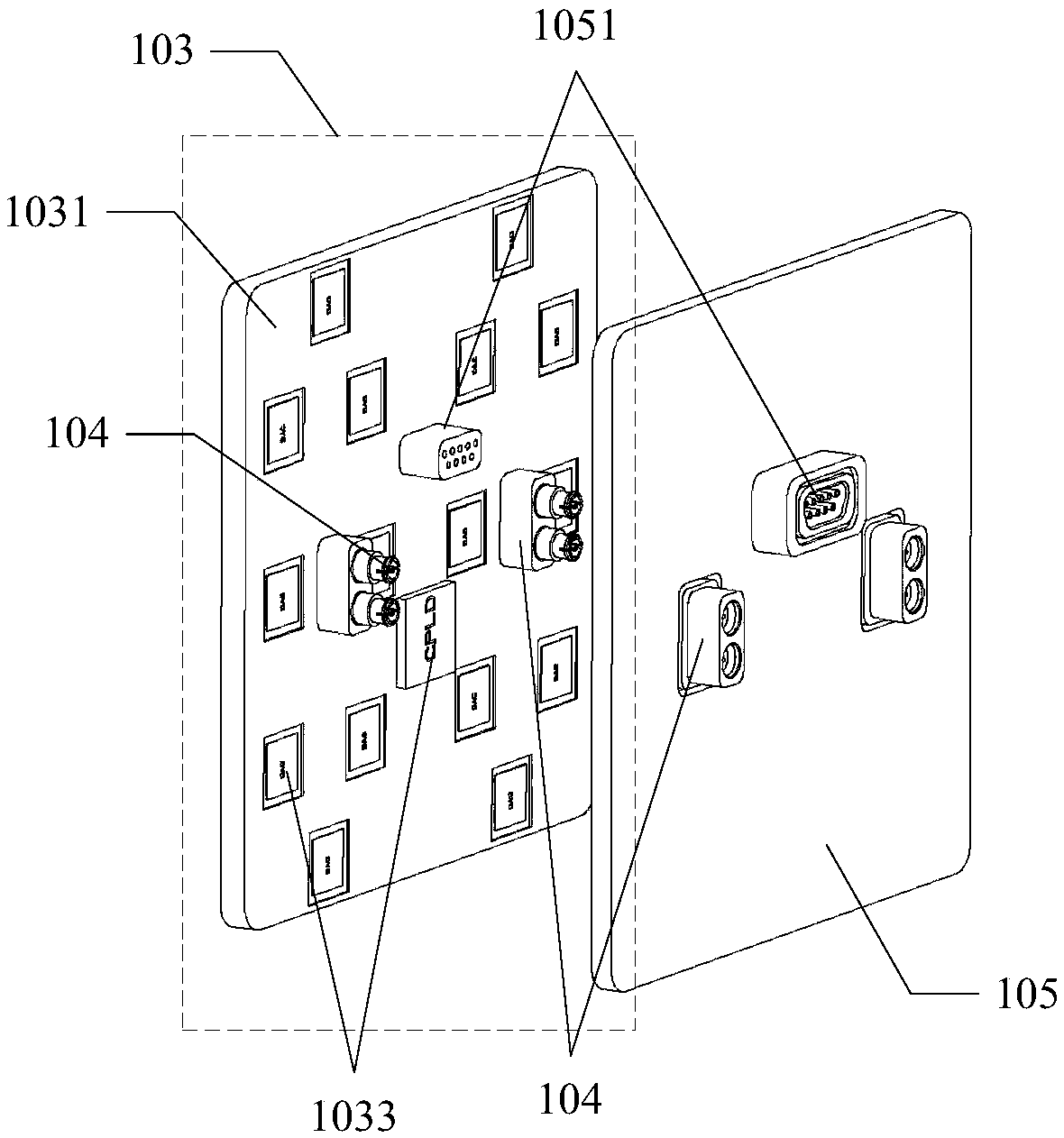

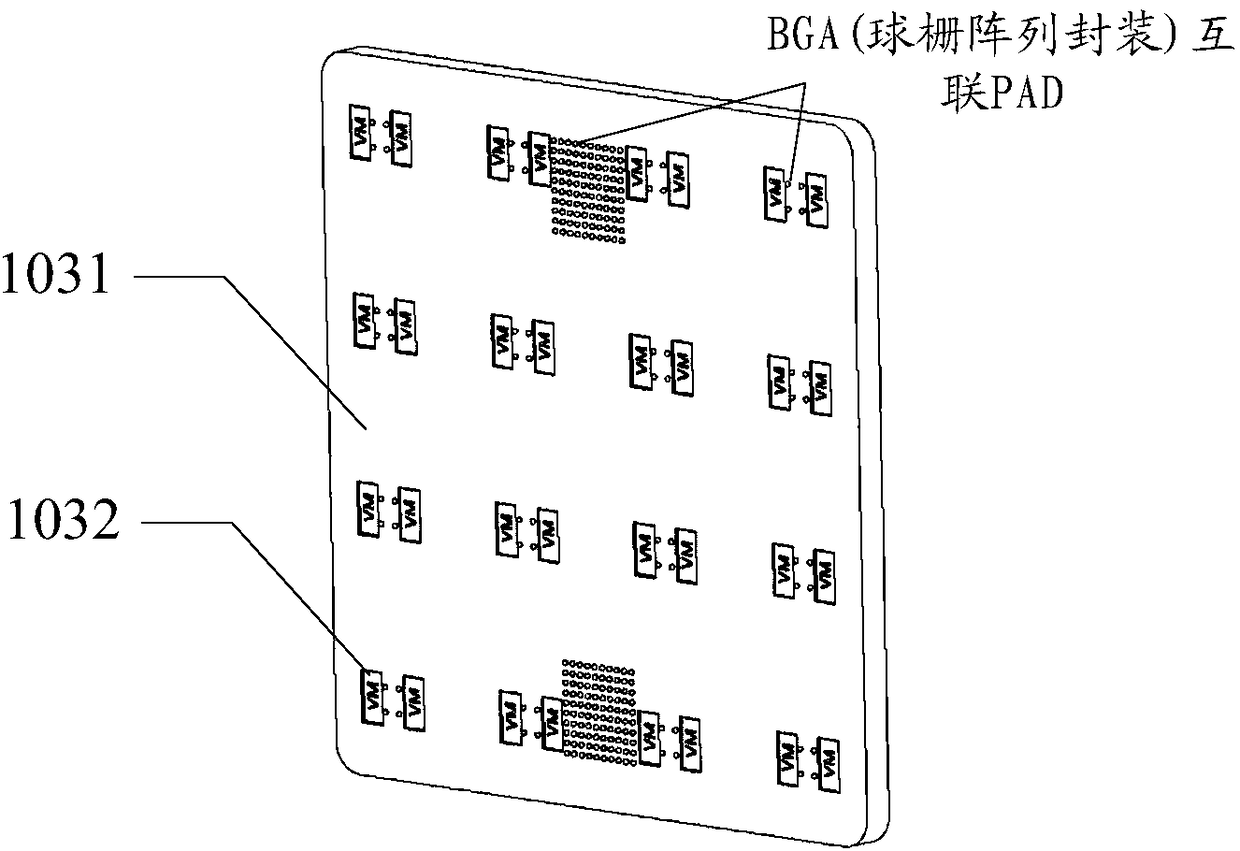

Multi-beam tile type TR component

The invention discloses a multi-beam tile type TR component, which can separately set an amplification processing module and a multi-beam amplitude-phase modulation module in a TR component, and thencan integrate a multi-beam forming function and an amplitude-phase modulation function through the multi-beam amplitude-phase modulation module. Thereby, the miniaturization and high-level integrationof a multi-beam phased array TR component can be achieved; and meanwhile, as a multi-beam vector modulation chip in the technical scheme of the embodiment of the application can perform independent amplitude modulation and phase modulation on multi-beam signals, great flexibility and scalability can be brought to the design of the multi-beam TR component, the size, weight and versatility of TR component application system equipment can be adjusted according to actual needs, and the technical effects of very extensive application values and applicability can be achieved in the field of microwave and millimeter wave radar communication with strict requirements for the above applications.

Owner:CHENGDU T-RAY TECH CO LTD

Preparation method of low stress state composite substrate for GaN growth

ActiveCN105514224AReduced stress stateImproving epitaxial growth qualitySemiconductor devicesComposite substrateDielectric layer

The invention discloses a preparation method of a low stress state composite substrate for GaN growth. The preparation method comprises that a GaN monocrystal epitaxial layer is prepared on a sapphire substrate; a stress compensation layer is deposited at the back side of a thermally and electrically conductive transfer substrate of high welding point; bonding dielectric layers of high welding point are prepared at the surfaces of a GaN epitaxial wafer and the transfer substrate respectively; the GaN epitaxial wafer is bonded to the thermally and electrically conductive substrate by the high-temperature diffusion bonding technology; and the composite substrate with high temperature stability and low stress state for GaN growth is obtained. According to the composite substrate of the invention, homoepitaxy can be realized and a vertical structural device can be directly prepared as a traditional composite substrate, the low stress state and high-temperature stability can be also realized, and the quality of subsequent GaN epitaxial growth and chip preparation can be effectively improved.

Owner:SINO NITRIDE SEMICON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com