Composite shape-stabilized phase change material with light absorption and conductive properties and preparation method thereof

A technology for shaping phase change materials and properties, applied in heat exchange materials, chemical instruments and methods, climate sustainability, etc., can solve problems that have not been discussed, and achieve excellent electrical conductivity, good light absorption performance, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

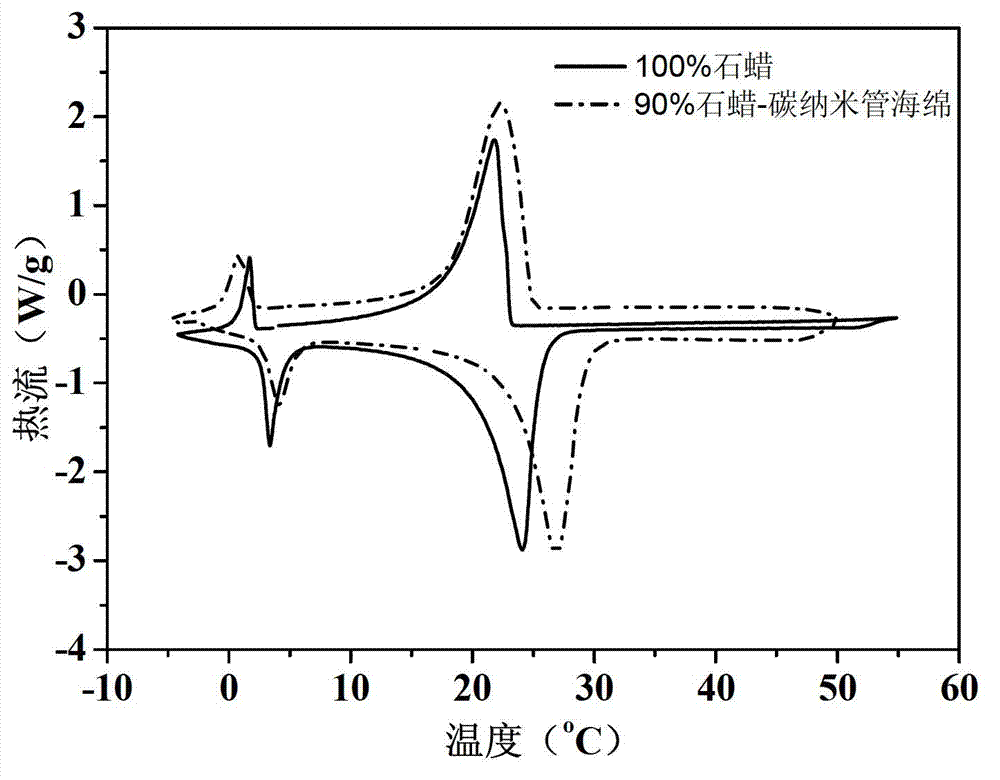

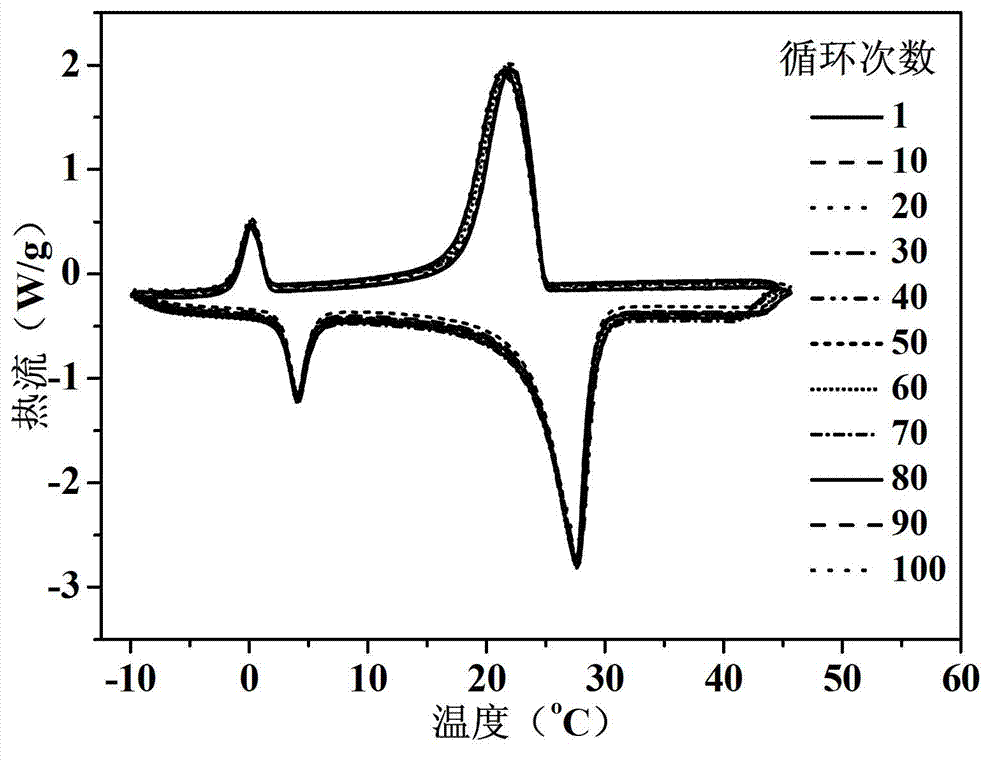

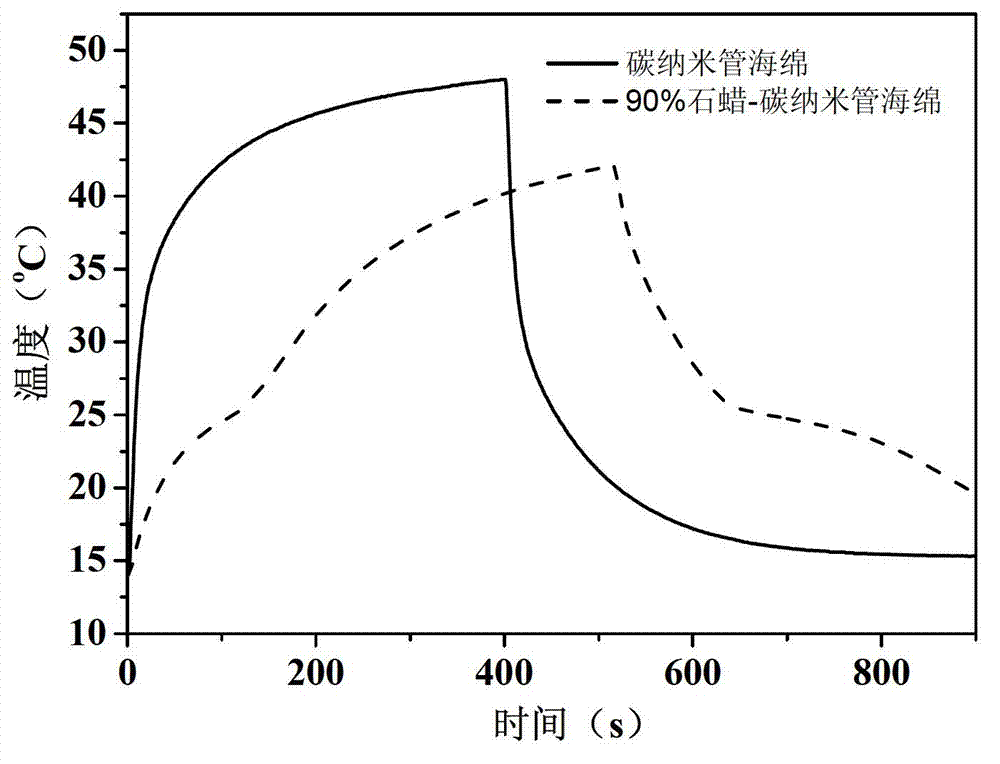

Embodiment 1

[0031] Carbon nanotube sponge, a new type of carbon material with three-dimensional connected porous properties, was prepared by chemical vapor deposition. The specific steps were to dissolve ferrocene in 1,2-dichlorobenzene and make the concentration 0.06g / mL, and then in At 860°C, the 1,2-dichlorobenzene solution of ferrocene was injected into the reaction tube through a syringe pump, and at the same time, hydrogen and helium were fed at a rate of 300mL / min and 2000mL / min respectively, and the reaction lasted for 12 hours to obtain carbon nanotube sponge. Take 0.9g of paraffin wax with a melting point of 20.3°C and a phase transition enthalpy of 136.1J / g and heat it to melt until the temperature reaches 100°C, and slowly pour the paraffin wax in liquid state onto 0.1g of carbon nanotube sponge. Keep the mixture at 100°C for half an hour under vibration, use a grinder to grind the mixture at room temperature, place the ground mixture in a mold and press it under a pressure of...

Embodiment 2

[0038]Carbon nanotube arrays, a new type of carbon material with three-dimensional connected porous properties, were prepared by chemical vapor deposition. The specific steps were to dissolve ferrocene in xylene to a concentration of 0.06 g / mL, and then dissolve The toluene solution was poured into the reaction tube through a syringe pump, and at the same time hydrogen and helium were fed at a rate of 300mL / min and 2000mL / min, respectively, and the reaction lasted for 12 hours to obtain a carbon nanotube array. Take 0.9g of paraffin wax with a melting point of 35.7°C and a phase transition enthalpy of 231J / g and heat it to melt until the temperature reaches 100°C, and slowly pour the liquid paraffin on 0.1g of carbon nanotube arrays. Keep the mixture at 100°C for half an hour under vibration, use a grinder to grind the mixture at room temperature, place the ground mixture in a mold and press it under a pressure of 1 MPa to obtain a mass fraction of 90%. Composite shape-setting...

Embodiment 3

[0041] First prepare graphene gel according to the literature method, add 110mL concentrated sulfuric acid to the ice-water bath beaker at a constant temperature of 0°C and stir, add 5g flake graphite powder, and then add 2.5g NaNO 3 , slowly add 15gKMnO 4 and stirred for 1.5 hours. After raising the temperature to 35°C and stirring for 30 minutes, while stirring at about 70°C, slowly add 220mL of deionized water, and then slowly add 137.83mL of 5% hydrogen peroxide. Finally, 500 mL of HCl was added to the above solution and allowed to stand until the layers were separated. After adding 2000mL to wash, until neutral after several times. Take 0.9g of stearyl alcohol with a melting point of 57°C and a phase transition enthalpy of 239J / g and heat it to melt until the temperature reaches 120°C. Slowly pour the stearyl alcohol in liquid state onto 0.1g of graphene gel. Keep the mixture at 120°C for half an hour under vibration, use a grinder to grind the mixture at room temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com