Patents

Literature

30results about How to "Reduced stress state" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

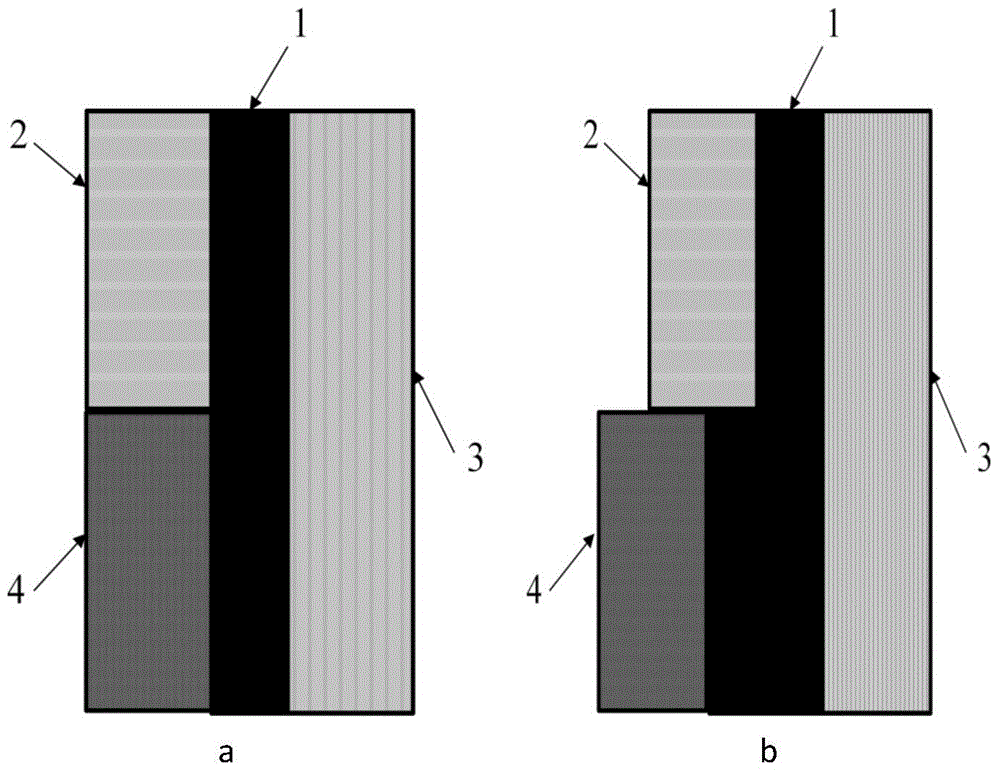

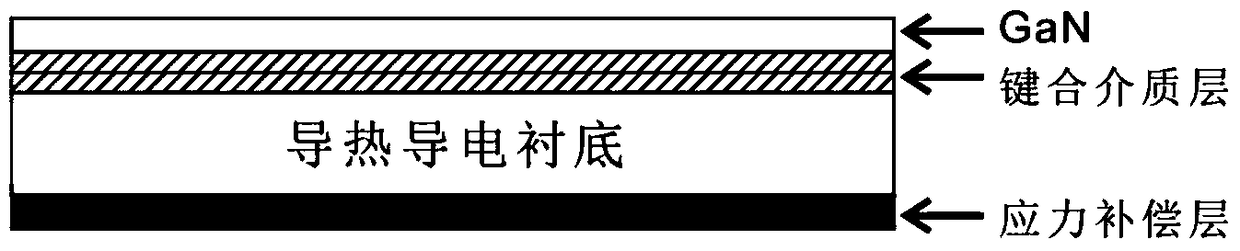

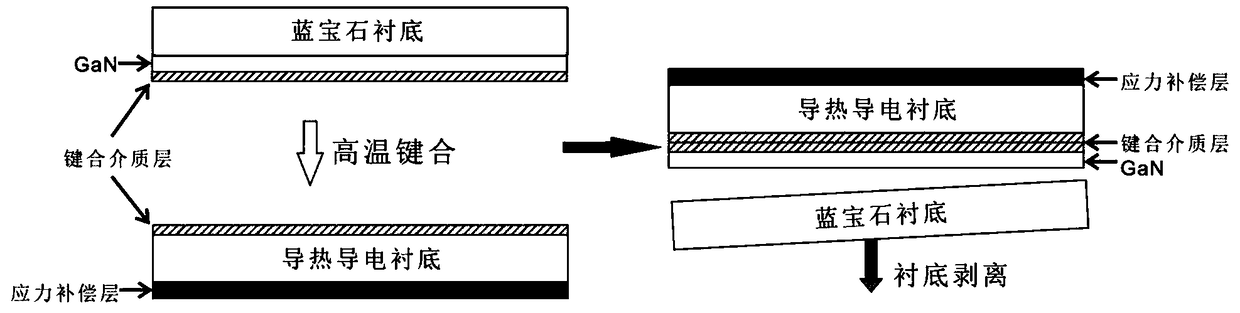

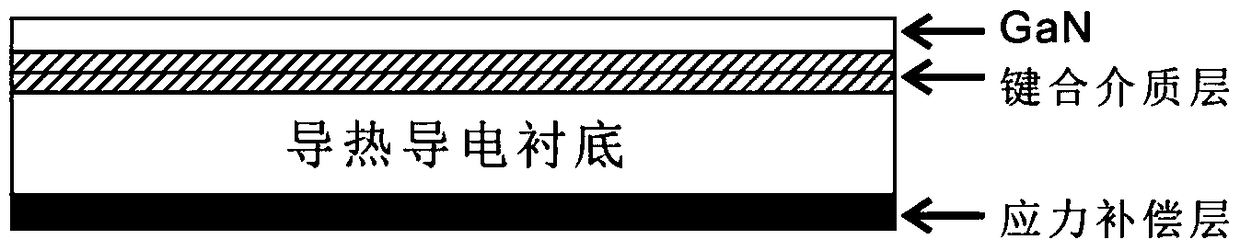

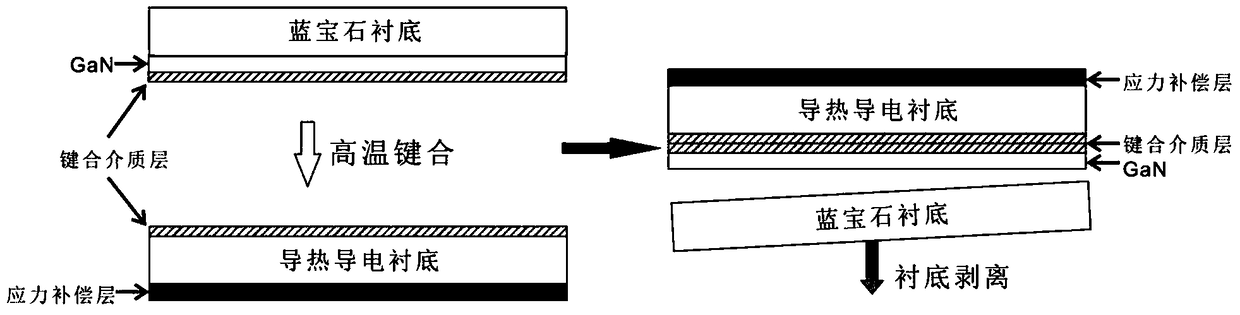

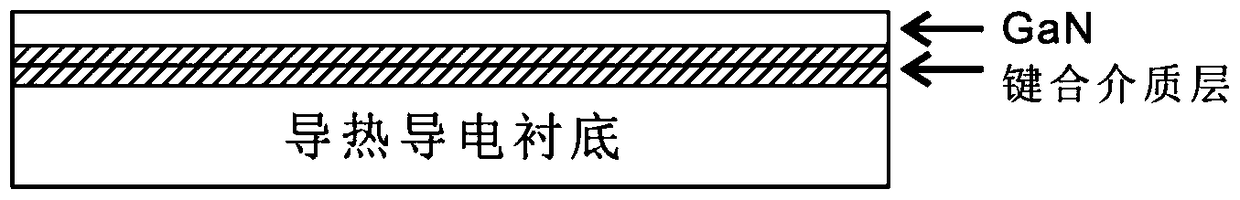

Preparation method of low stress state composite substrate for GaN growth

ActiveCN105514224AReduced stress stateImproving epitaxial growth qualitySemiconductor devicesComposite substrateDielectric layer

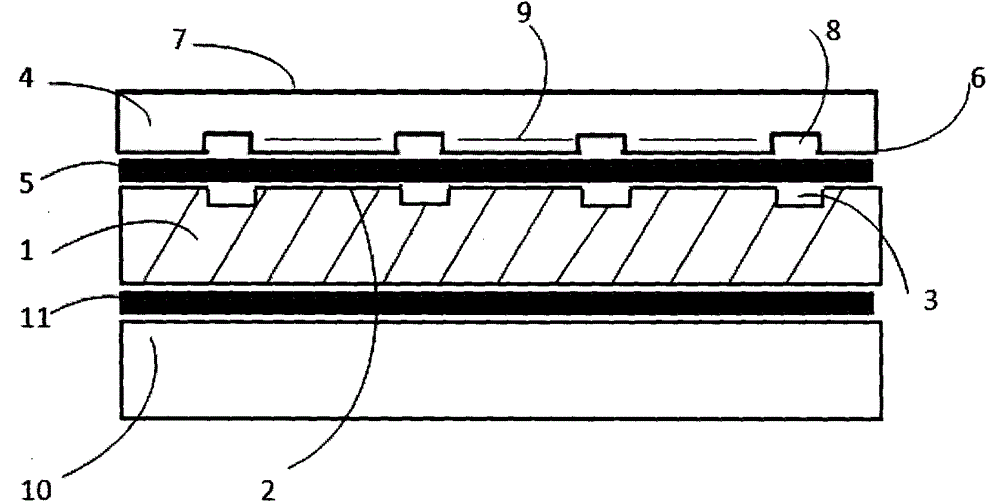

The invention discloses a preparation method of a low stress state composite substrate for GaN growth. The preparation method comprises that a GaN monocrystal epitaxial layer is prepared on a sapphire substrate; a stress compensation layer is deposited at the back side of a thermally and electrically conductive transfer substrate of high welding point; bonding dielectric layers of high welding point are prepared at the surfaces of a GaN epitaxial wafer and the transfer substrate respectively; the GaN epitaxial wafer is bonded to the thermally and electrically conductive substrate by the high-temperature diffusion bonding technology; and the composite substrate with high temperature stability and low stress state for GaN growth is obtained. According to the composite substrate of the invention, homoepitaxy can be realized and a vertical structural device can be directly prepared as a traditional composite substrate, the low stress state and high-temperature stability can be also realized, and the quality of subsequent GaN epitaxial growth and chip preparation can be effectively improved.

Owner:SINO NITRIDE SEMICON

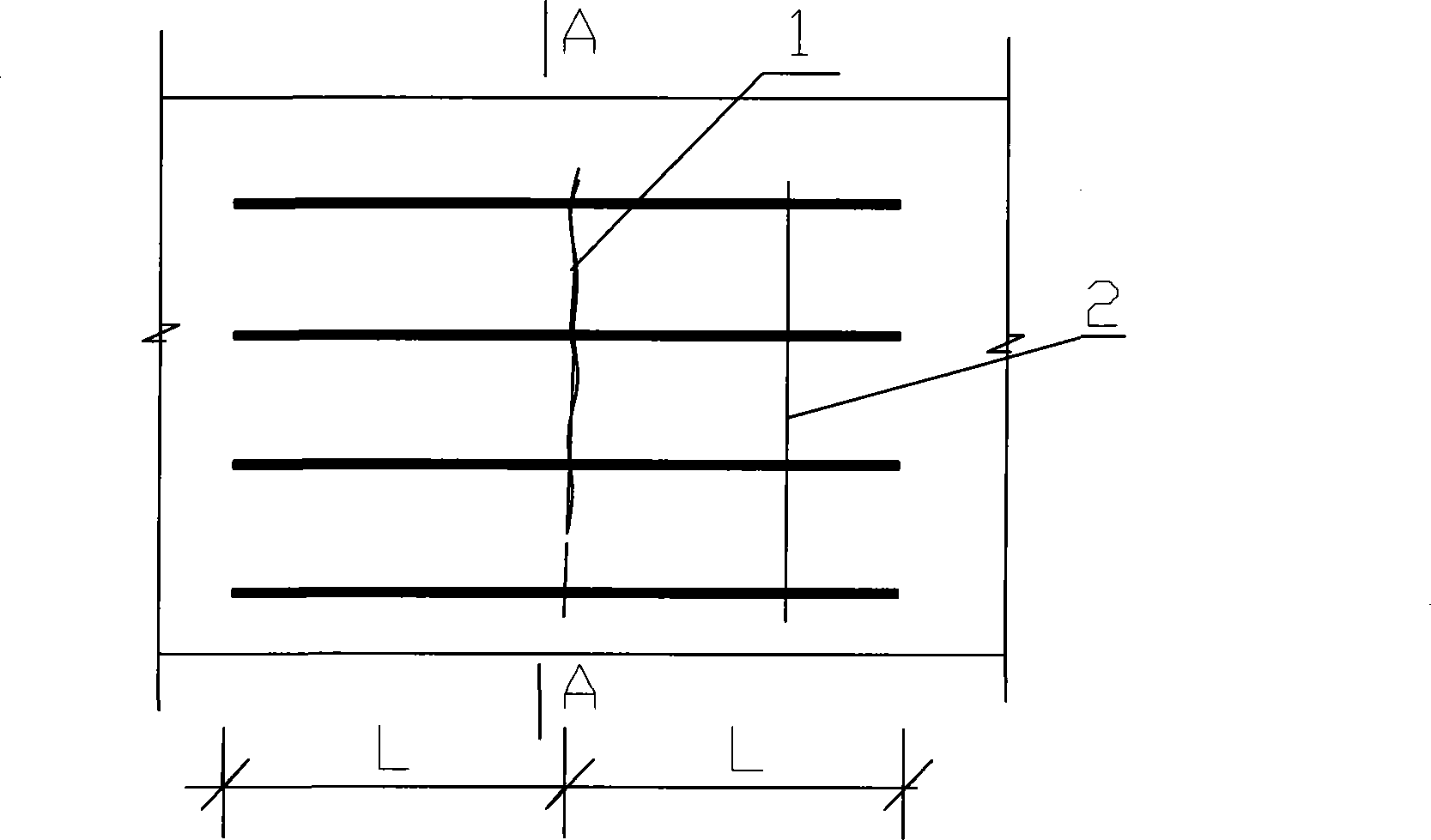

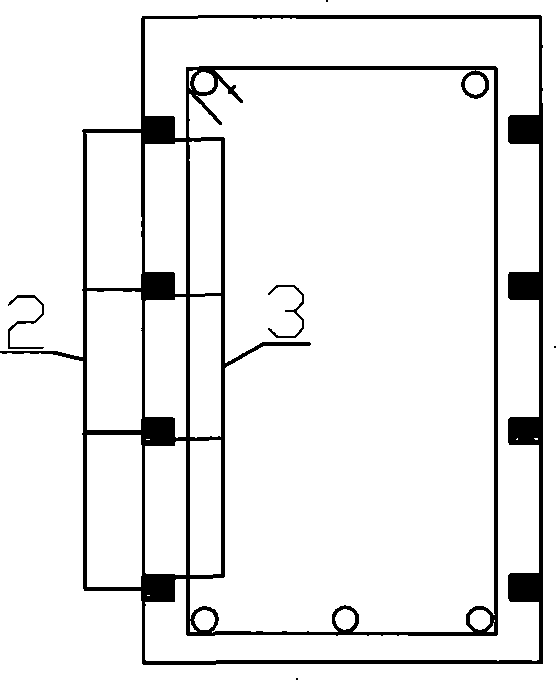

Inner binding outer cramping method architecture structural crack comprehensive processing method

InactiveCN101240662AIncreased resistance to crackingReduces the possibility of crackingBuilding repairsBuilding insulationsInner boundSteel bar

The present invention provides a reinforcing method for treating the concrete and masonry structural crack, according to the concrete condition of the crack, a self-pressure crack processor or air compressor is adopted for assorting the pressure generated by equipments of a slurry storing pot and the like, the corresponding grouting material is pressed into the existing crack, after the hardening of the grouting agent the concrete or masonry at the two sides of the crack can be adhered from the inner side namely inner adhering; the high-technique materials of FRP board, sheet material, rod material and the like or the ordinary materials of reinforcing steel bar, steel plate and the like is selected for adhering across the crack or a groove is cut for anchoring, the concrete at the two sides of the crack is connected from the outside namely exterior cramping. The adopting of the method can thoroughly settle the problem of the building structural crack.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES

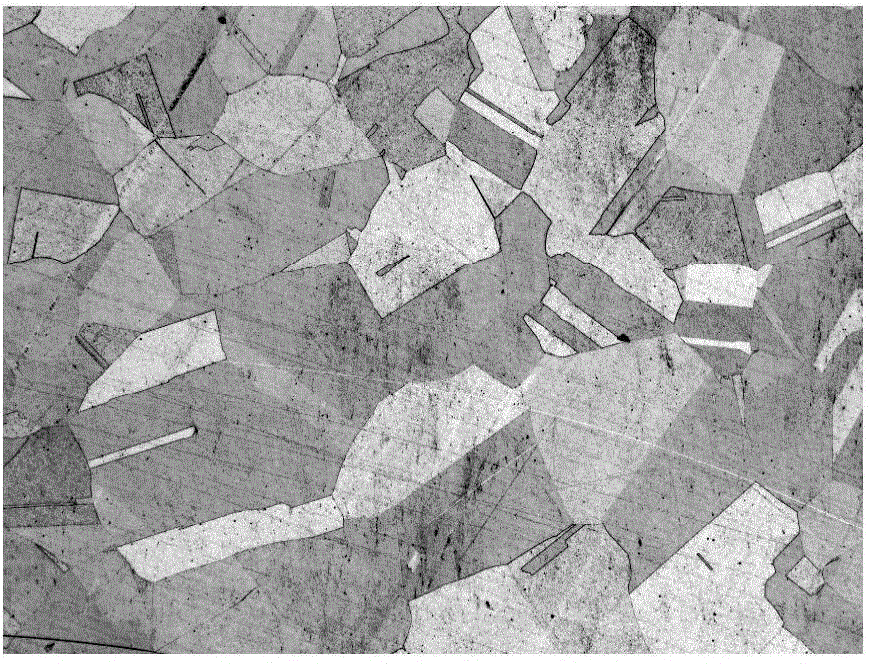

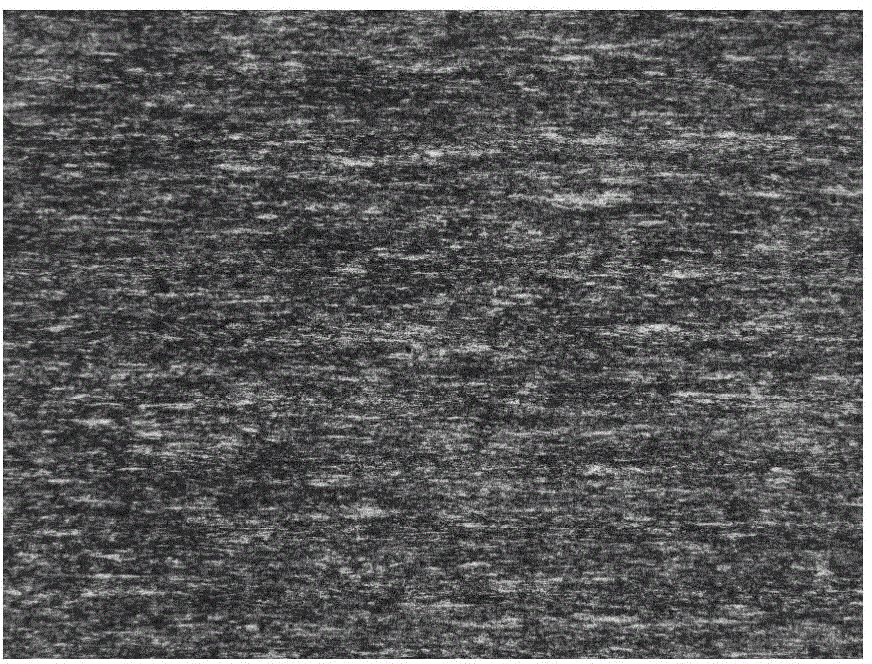

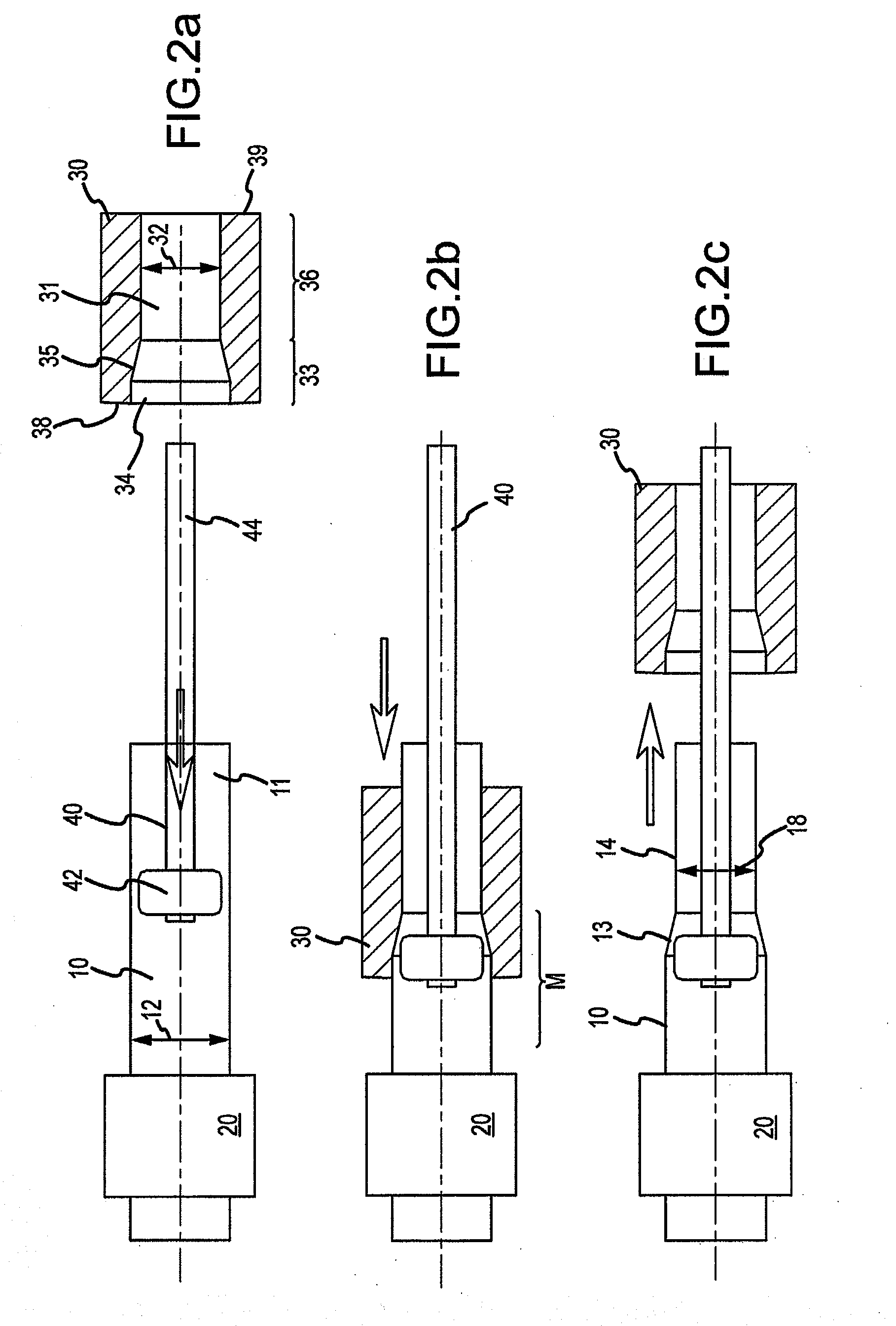

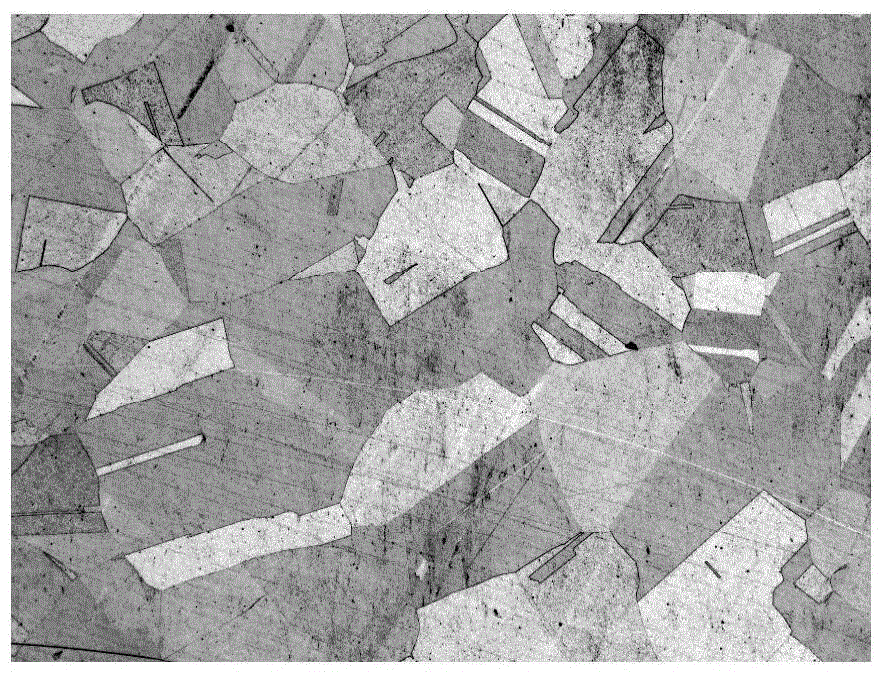

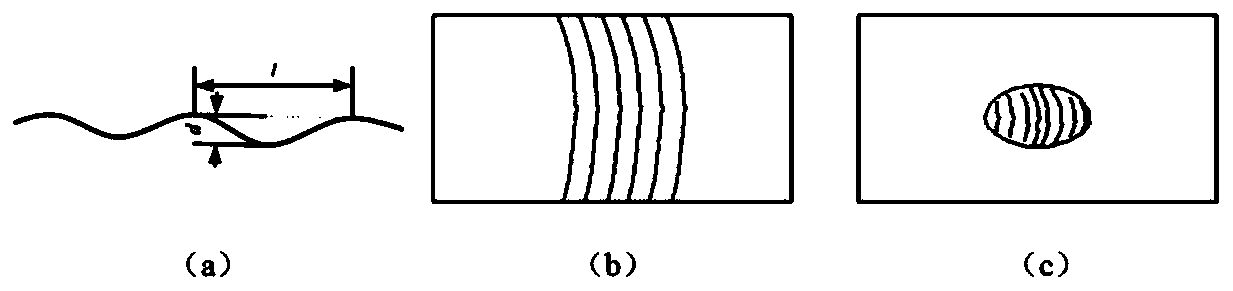

Deep overcooling treatment method for fine grain copper alloy shaped charge liner

The invention provides a preparation method of a fine grain copper alloy shaped charge liner. The preparation method of the fine grain copper alloy shaped charge liner comprises the following steps: carrying out compound cold extrusion plastic deformation, carrying out deep overcooling treatment, and carrying out recrystalization annealing, wherein the compound cold extrusion plastic deformation comprises the steps of putting a blank into a mould cavity of a preformed blank forming mould, carrying out forward extrusion forming to obtain a designed copper alloy preformed blank under the actions of three-dimensional compressive stress and deformation rate and then putting the preformed blank into a mould cavity of a shaped charge liner forming mould and gradually forming the shaped charge liner preformed blank by carrying out gradual-pass diameter-expanded extrusion plastic deformation, thus obtaining the shaped charge liner blank of a required shape structure; the deep overcooling treatment comprises the step of carrying out heat preservation on the shaped charged liner blank for 2-4 hours at the temperature ranging from -196 DEG C to 130 DEG C; and the recrystallization annealing comprises the step of carrying out heat preservation on the shaped charge liner (subjected to deep overcooling treatment) for 5-15 minutes at the temperature of 450-550 DEG C in a protective atmosphere, thus obtaining a shaped charge liner component. The preparation method of the fine grain copper alloy shaped charge liner has the advantages that strict requirements of the shaped charge liner on grain structure homogeneity, consistency of performance and stress state and distribution can be met, and quality of the shaped charge liner can be improved.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

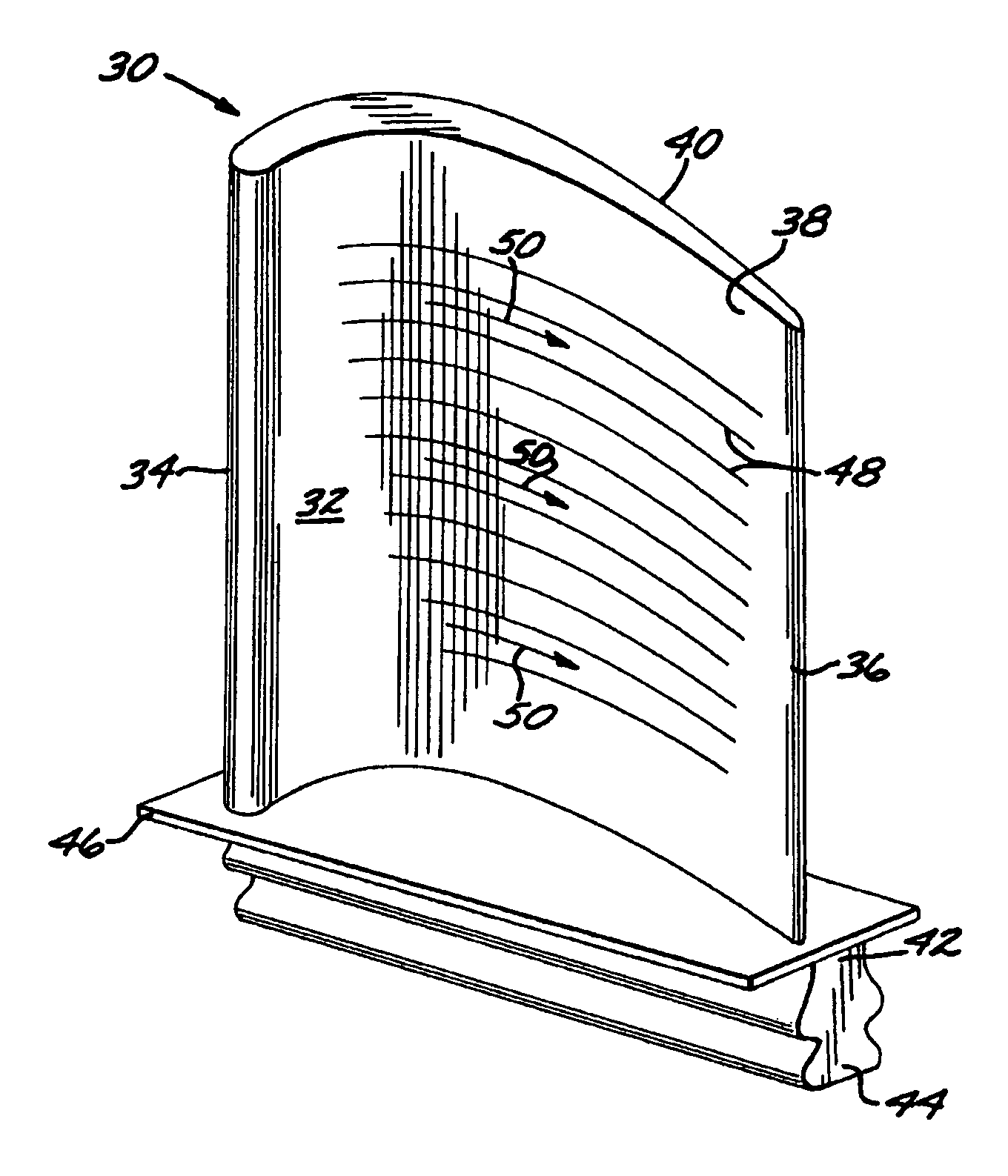

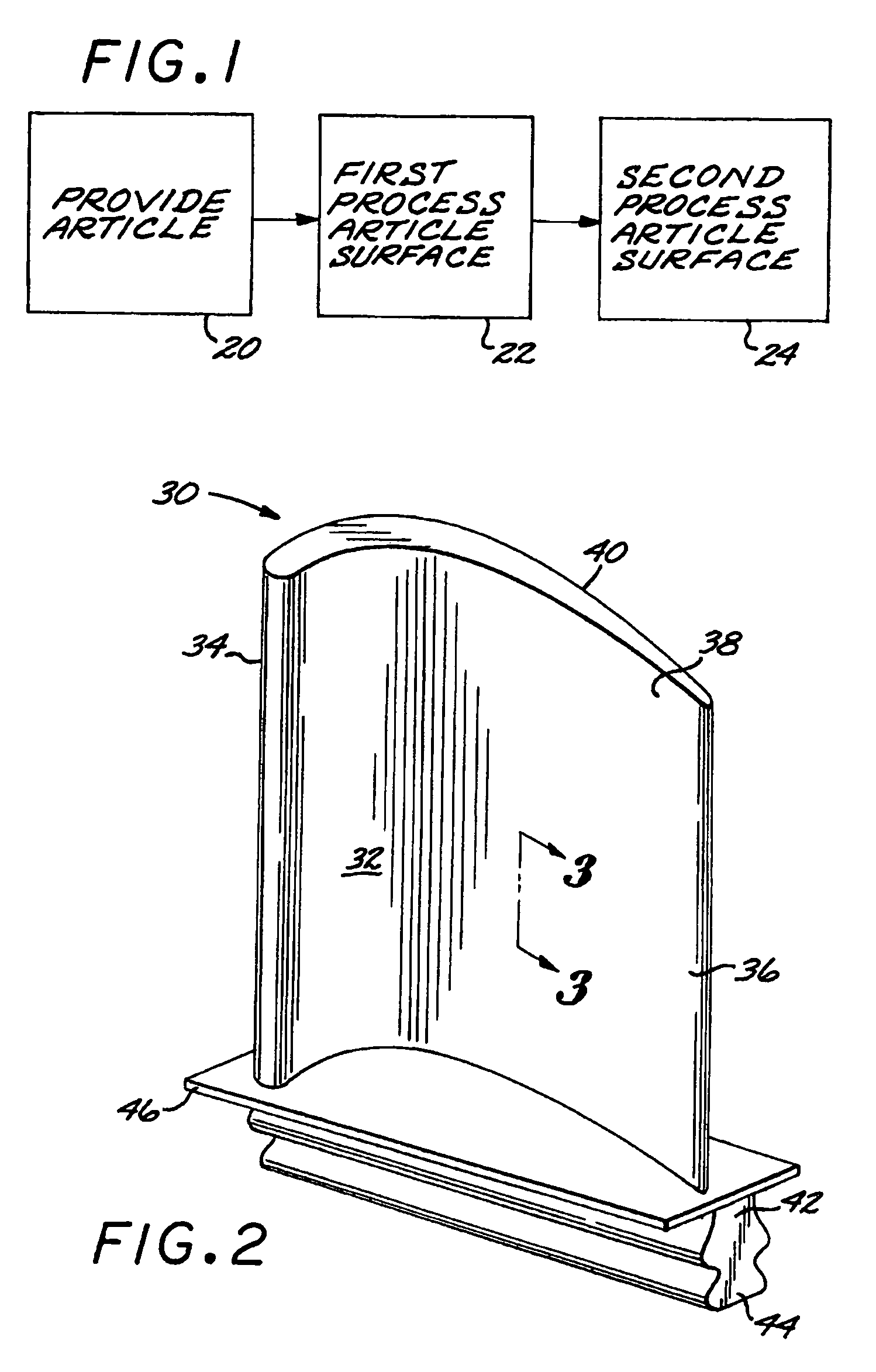

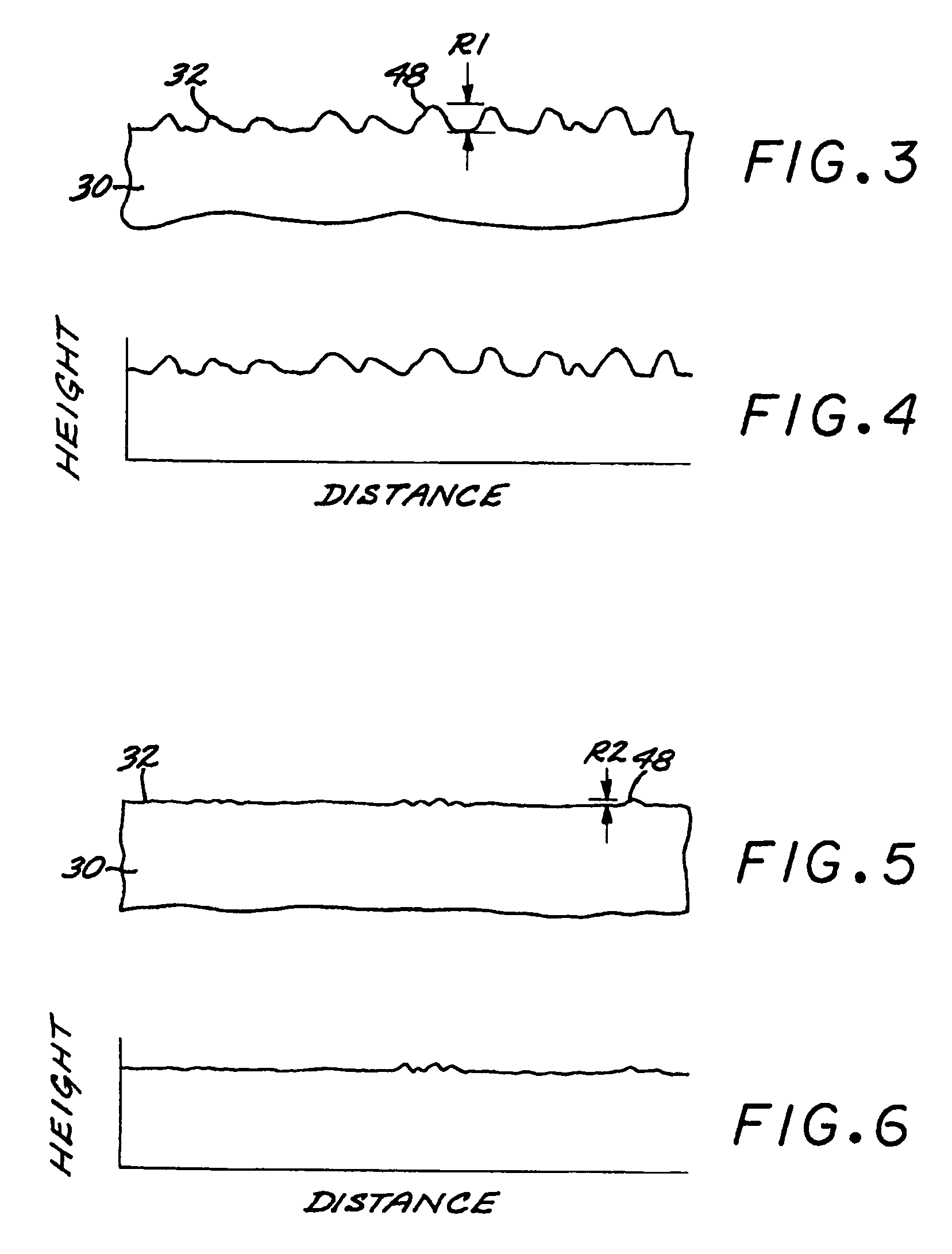

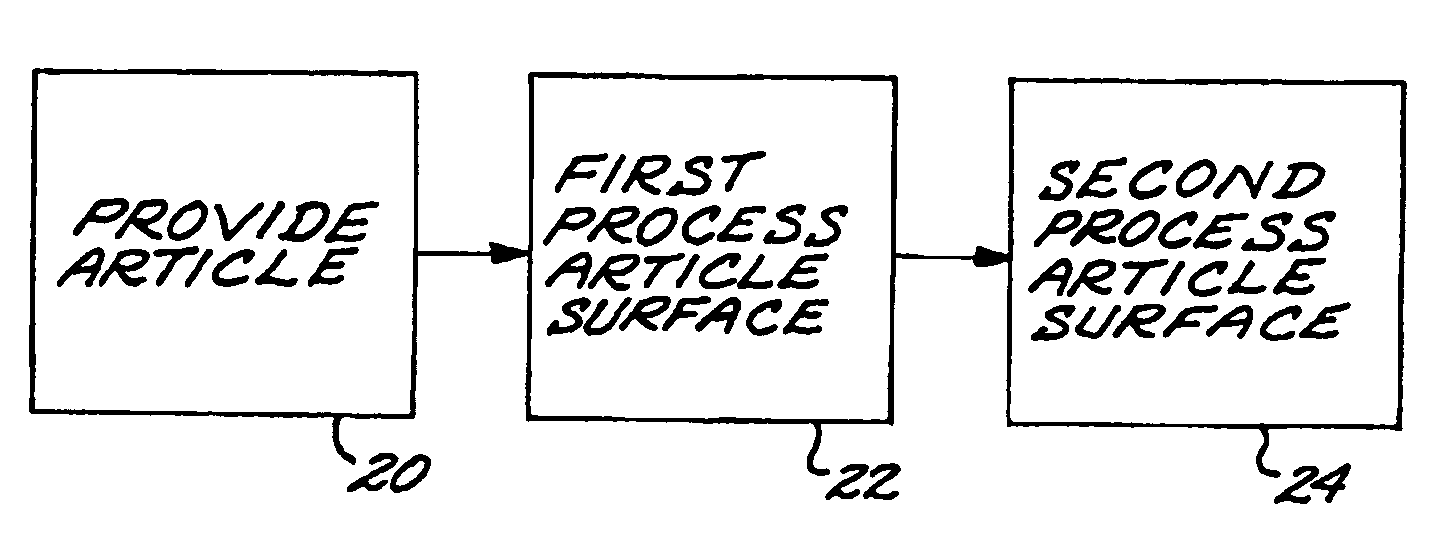

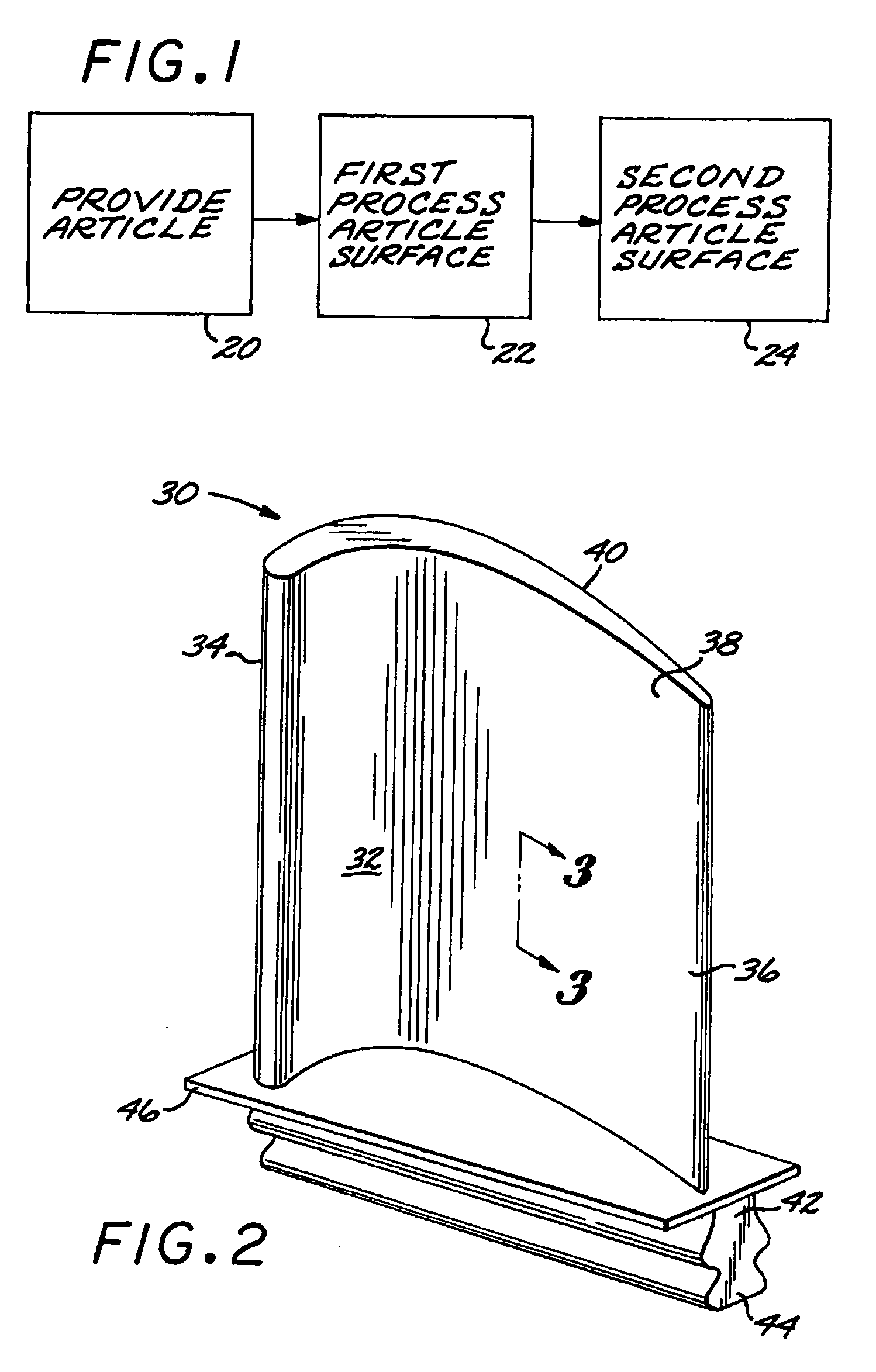

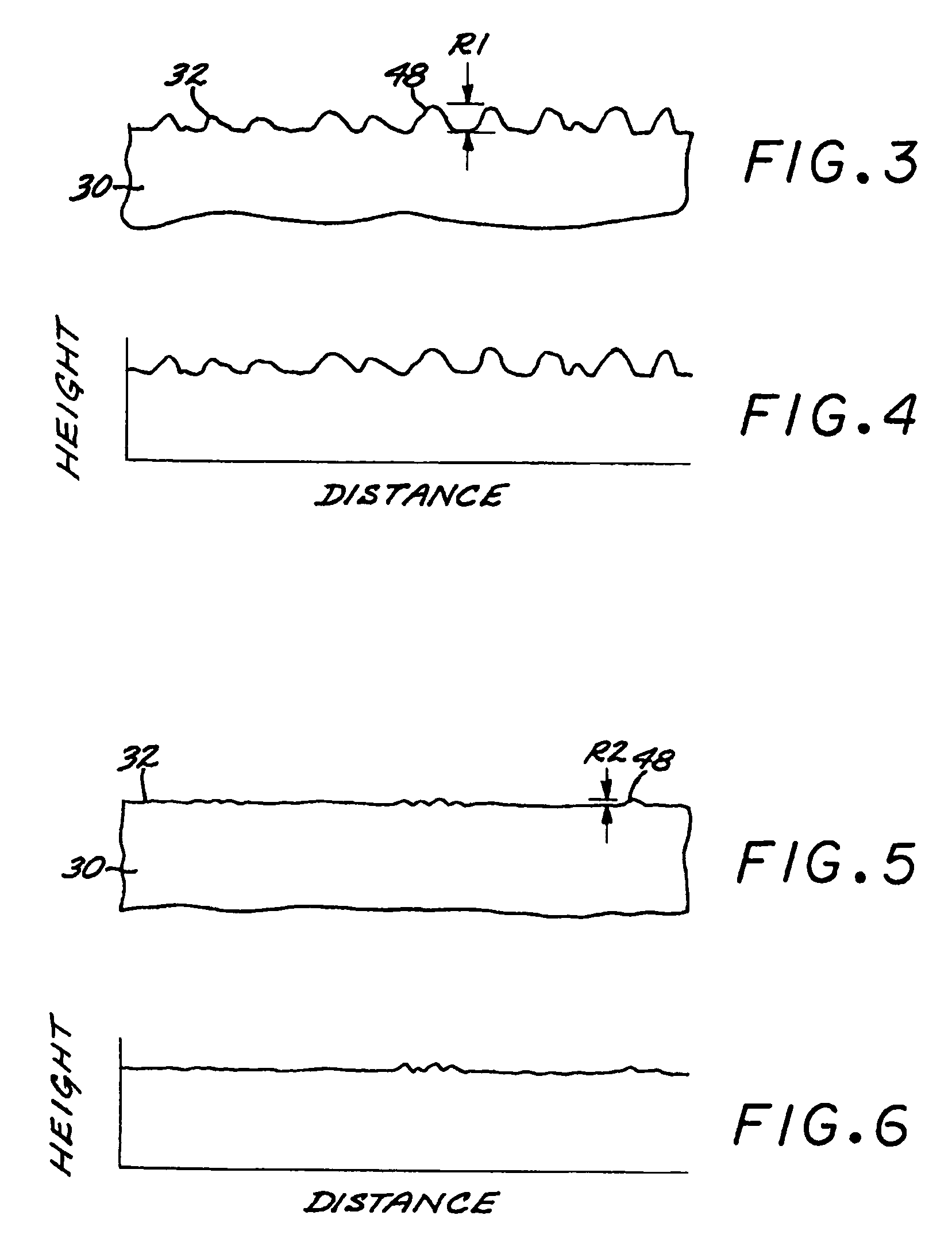

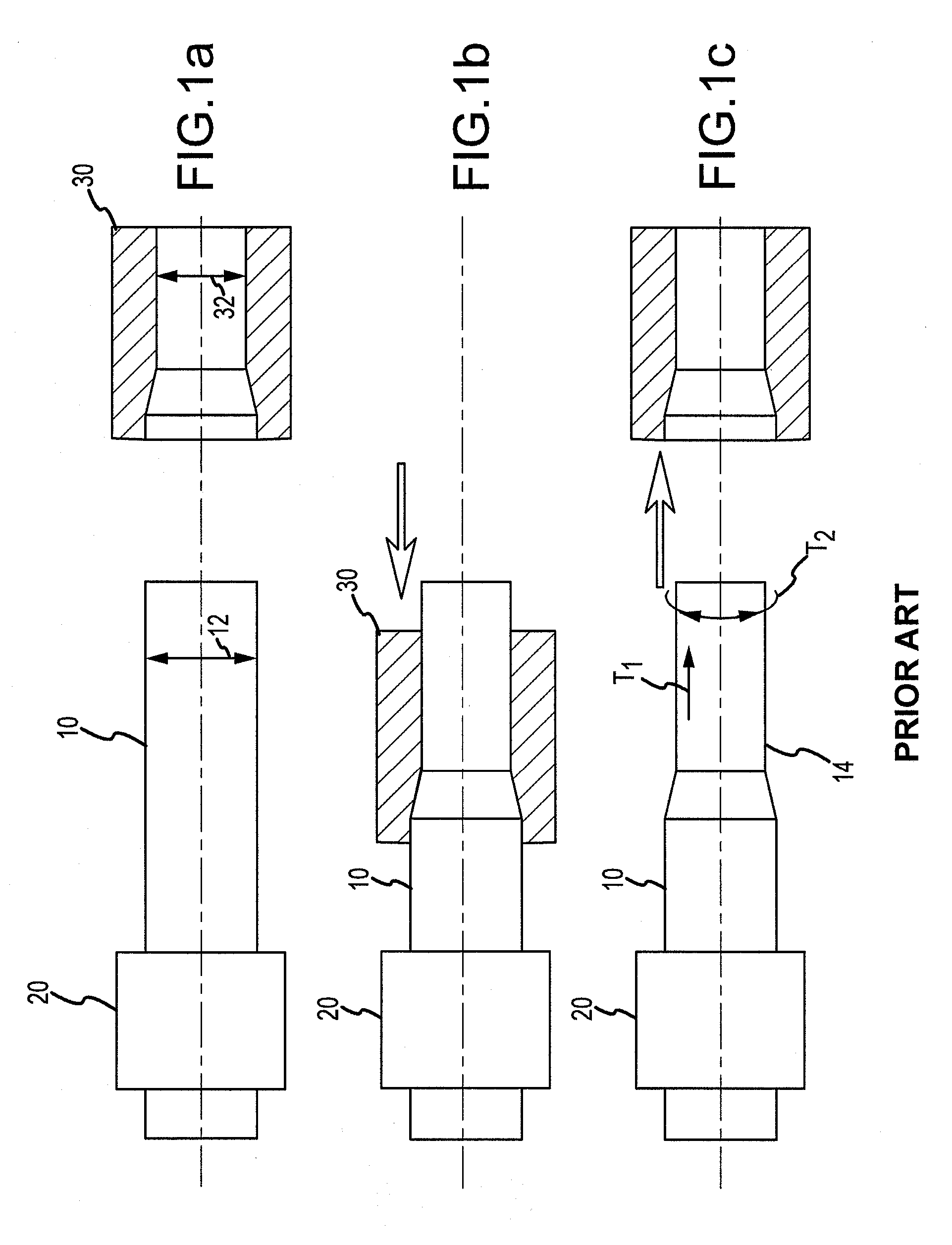

Preparation of an article surface having a surface compressive texture

ActiveUS8024846B2Reduce surface roughnessSmooth surface finishEngine manufactureBlade accessoriesSurface roughnessMaterials science

A method for preparing a surface includes providing an article having an article surface, thereafter first processing the article surface to establish a first residual compressive stress state and a first surface roughness in the article surface, and thereafter second processing the article surface by surface compressive texturing to establish a second residual compressive stress state and a second surface roughness in the article surface. The second surface roughness is quantitatively less than the first surface roughness, and substantially no material is removed from the article surface in the step of second processing.

Owner:GENERAL ELECTRIC CO

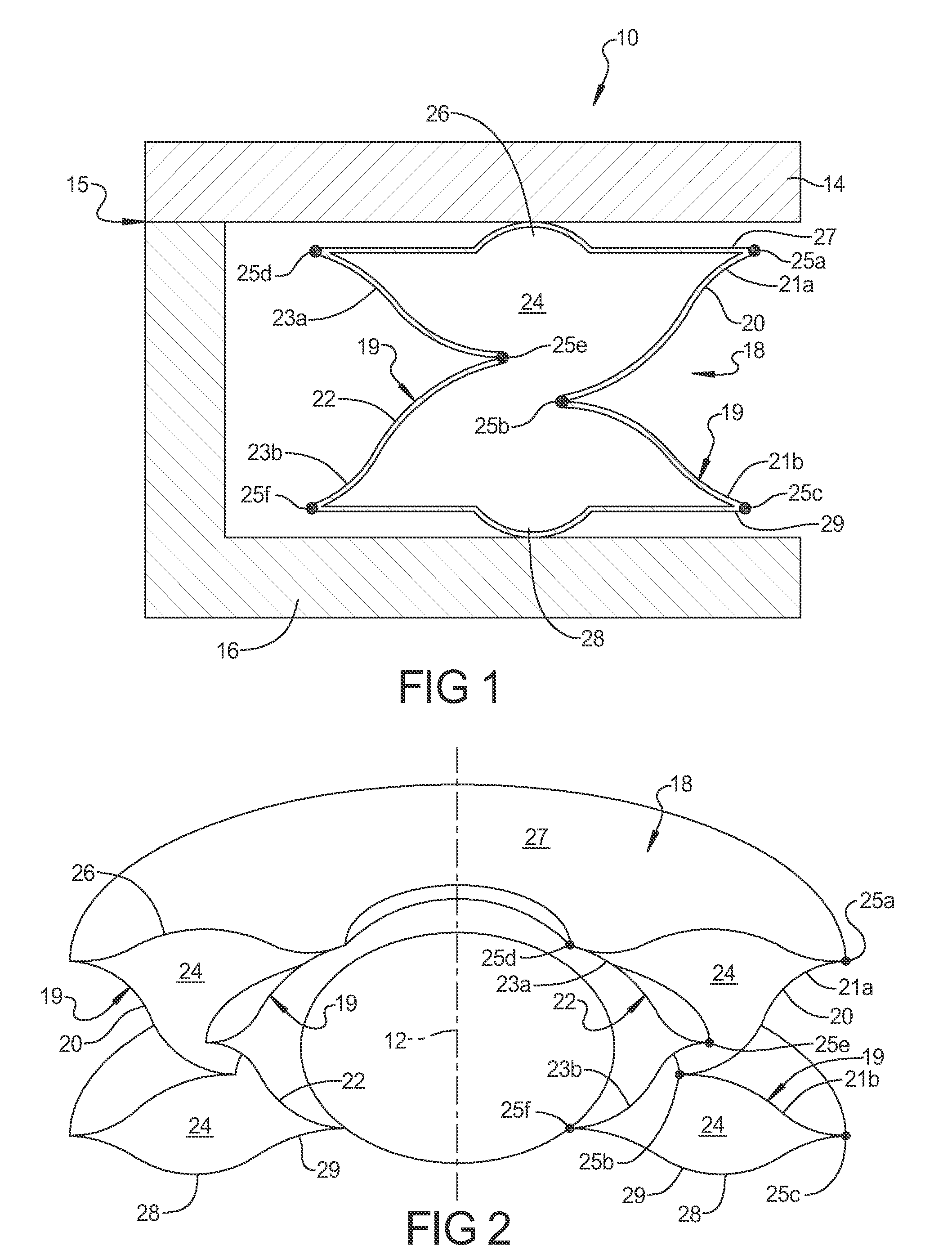

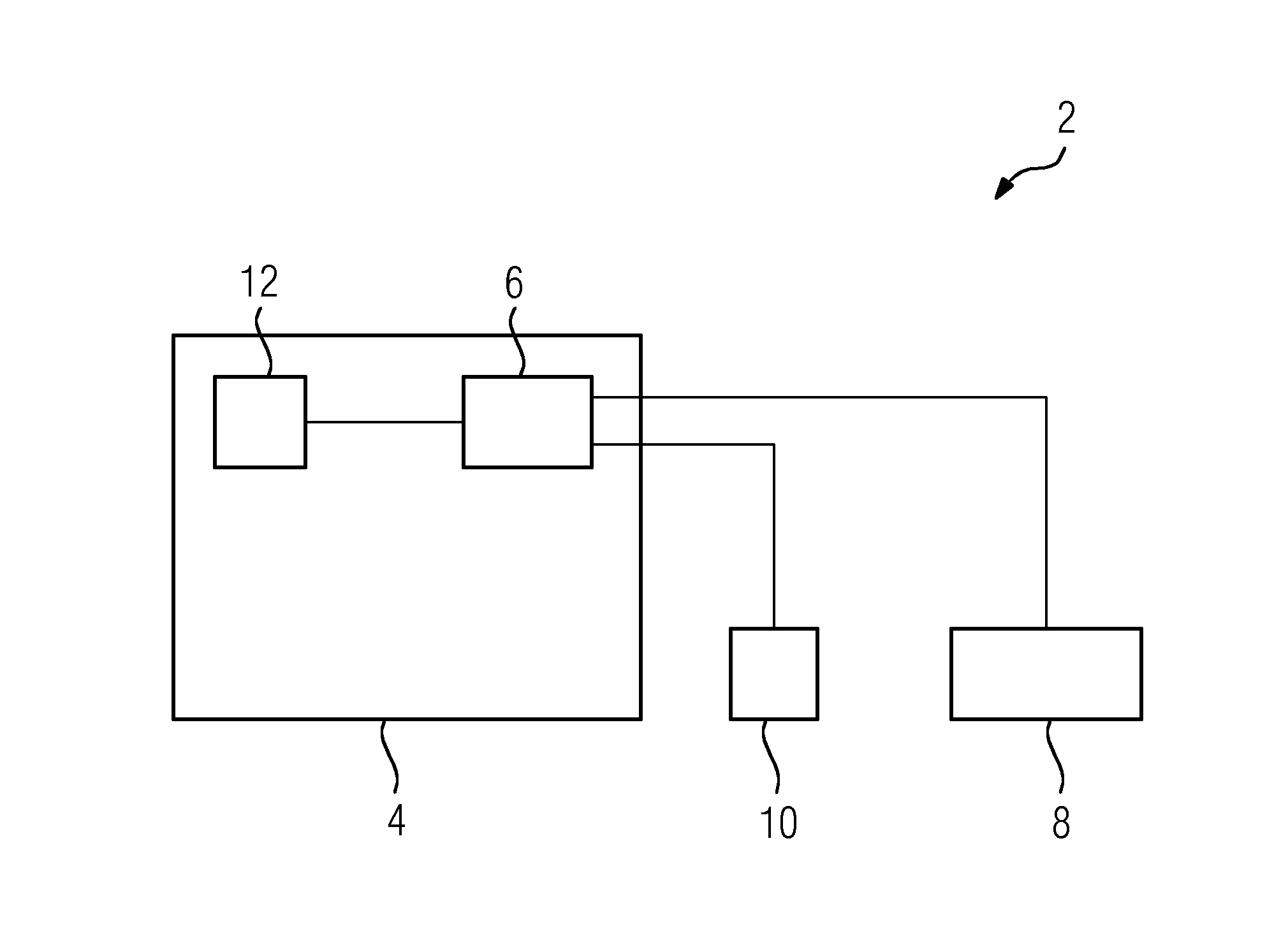

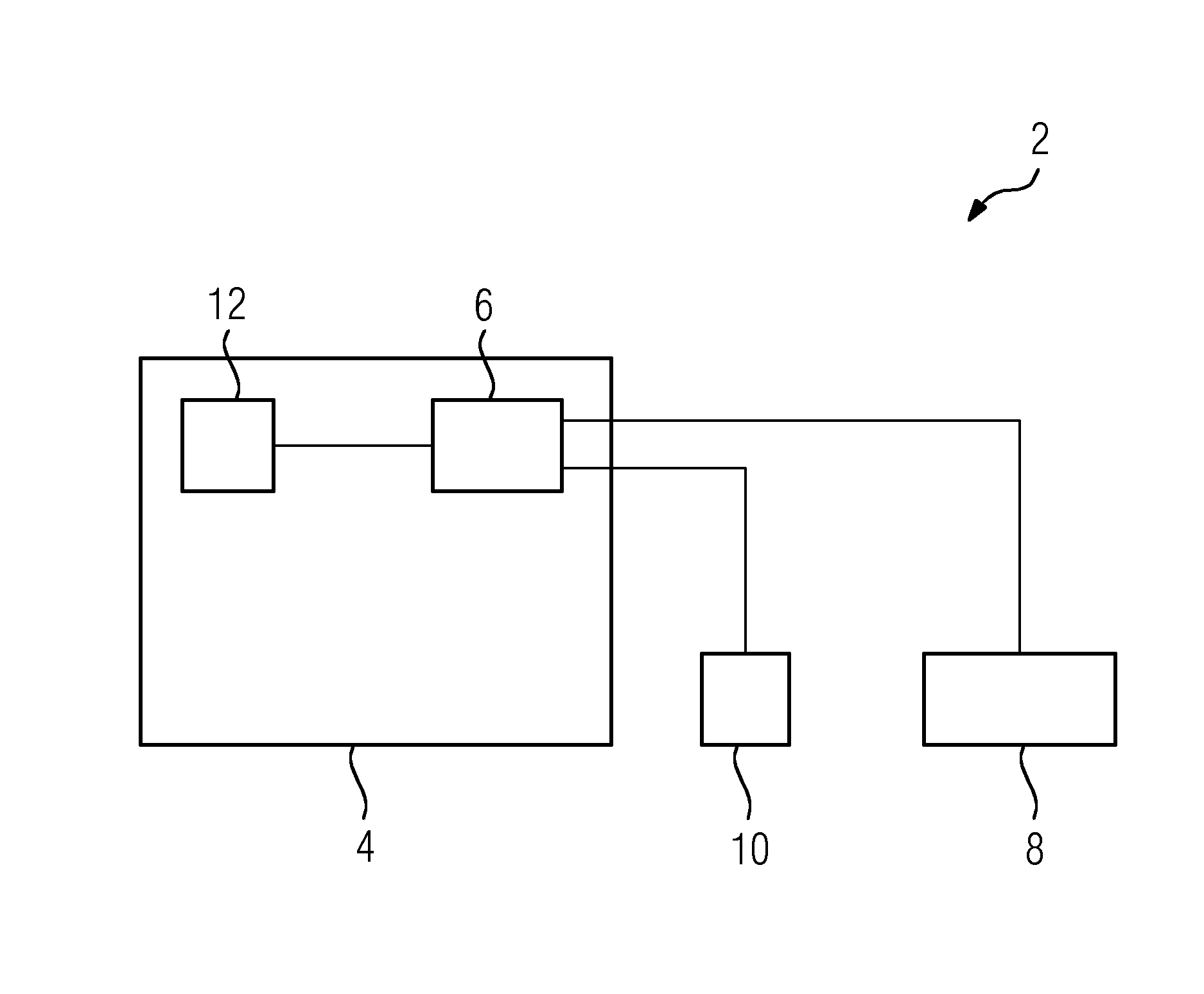

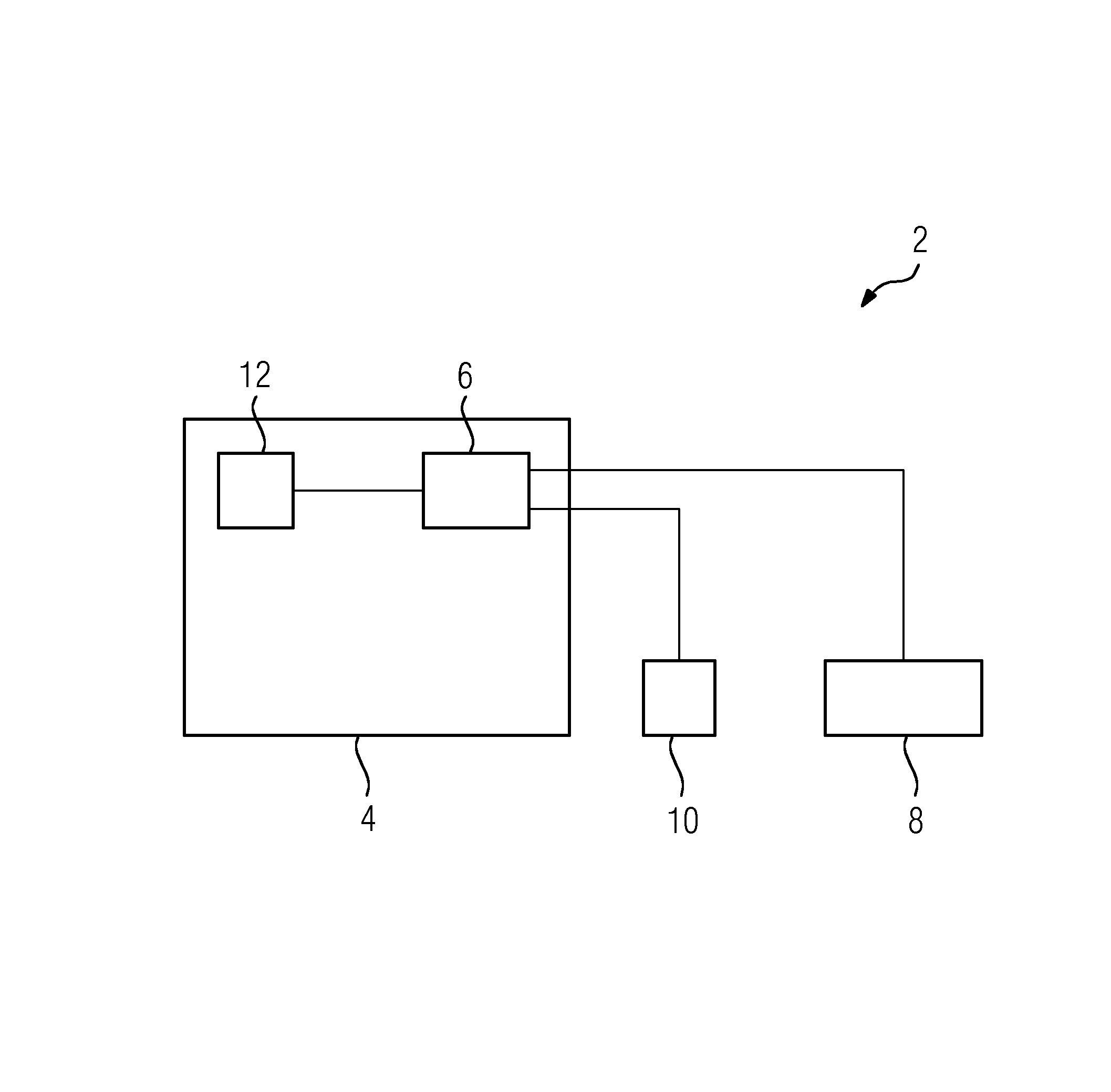

Biofeedback method and apparatus

InactiveUS20080071137A1Improve performanceManage stressSurgeryMedical devicesRegimenAuditory display

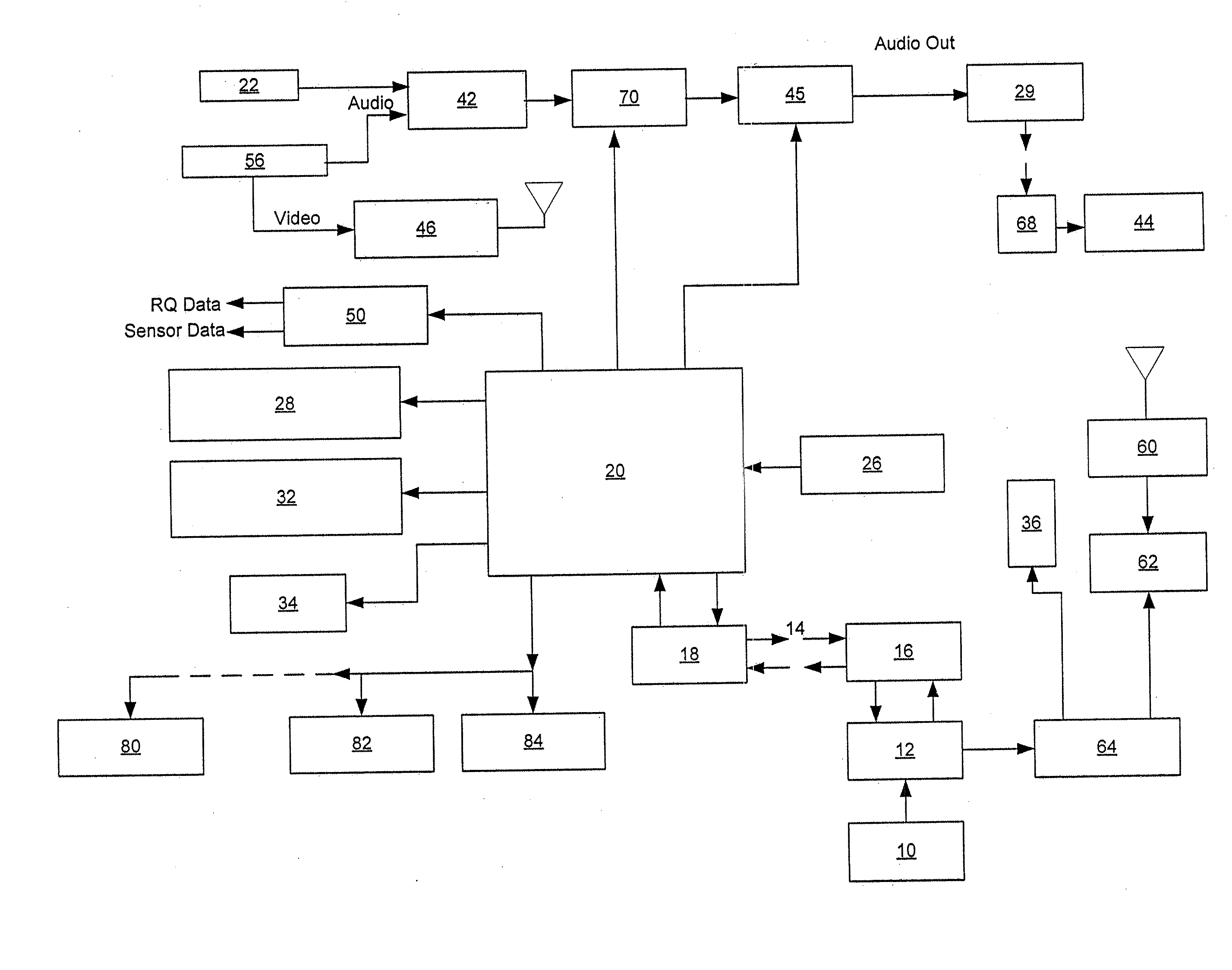

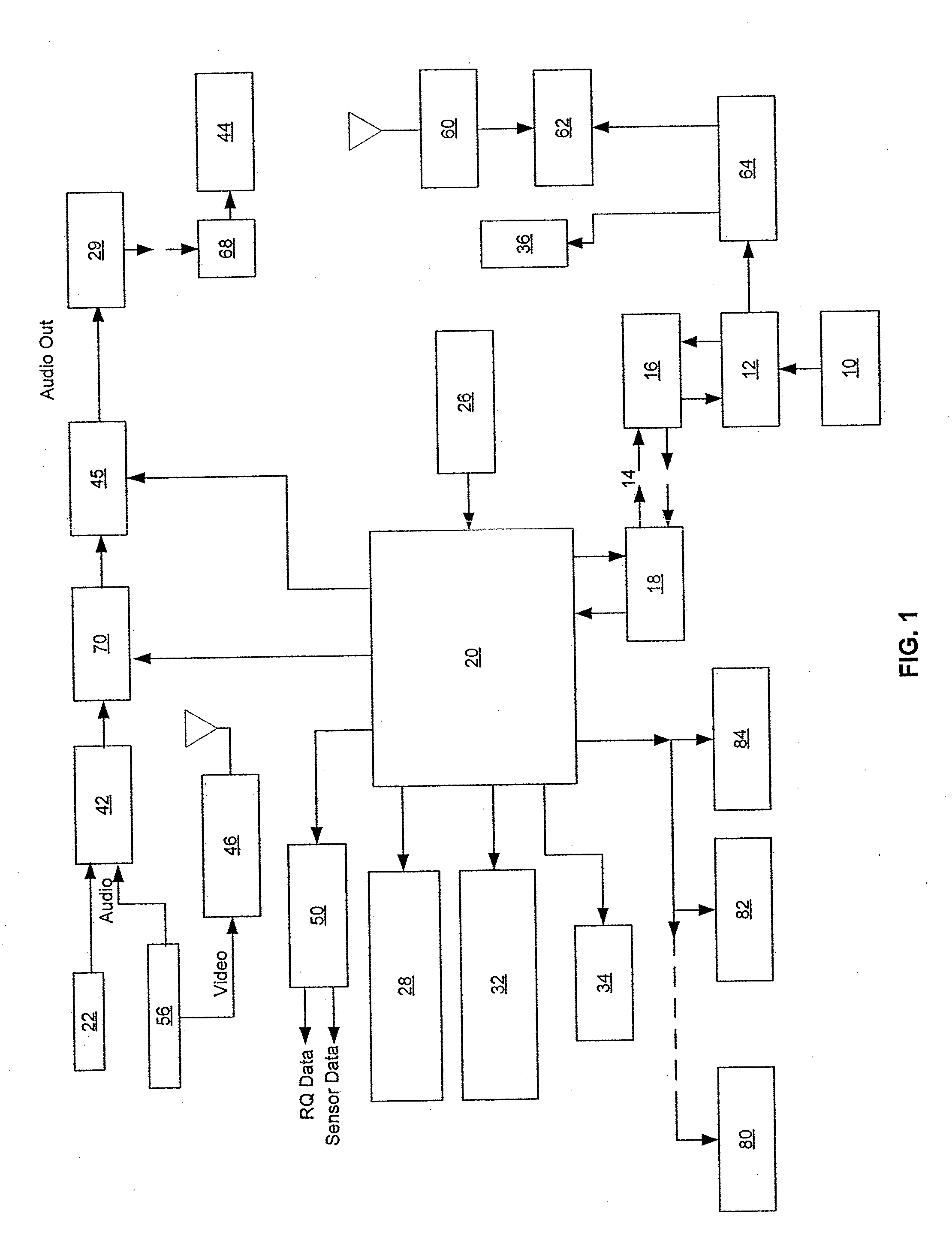

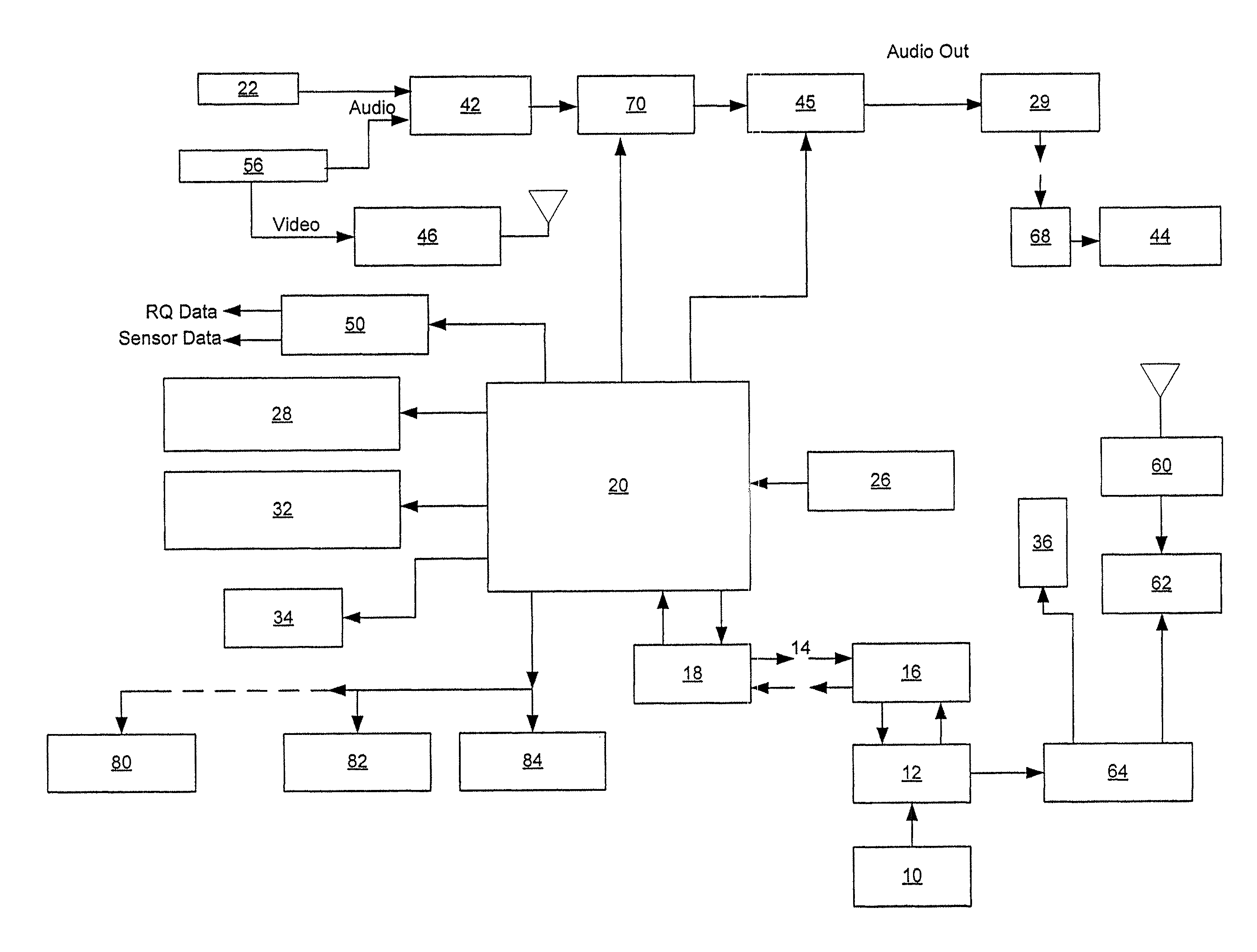

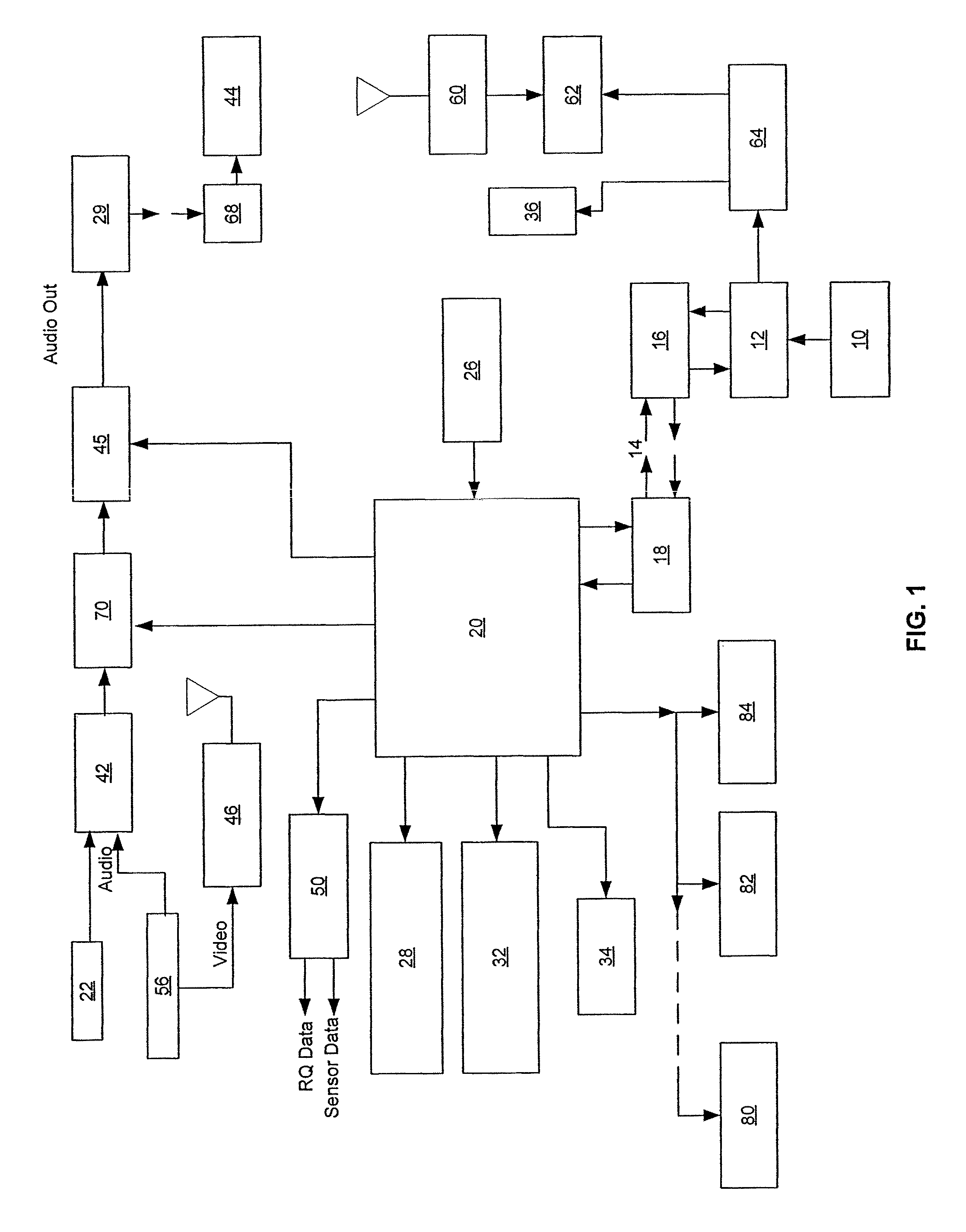

The invention is directed to a method and apparatus for relieving stress using biofeedback techniques. In embodiments, the method and system are used according to a specified regimen to enable a user to achieve a relaxed state. The apparatus comprises a sensor 10 wirelessly connected to a CPU 20, which processes signals from the sensor 10 to produce a visual display 36 and / or auditory display 44 that is representative of the relaxation state of the user.

Owner:THETA TECH

Biofeedback method and apparatus

InactiveUS7785249B2Reduced stress stateImprove athletic performanceSurgeryMedical devicesRegimenAuditory display

The invention is directed to a method and apparatus for relieving stress using biofeedback techniques. In embodiments, the method and system are used according to a specified regimen to enable a user to achieve a relaxed state. The apparatus comprises a sensor 10 wirelessly connected to a CPU 20, which processes signals from the sensor 10 to produce a visual display 36 and / or auditory display 44 that is representative of the relaxation state of the user.

Owner:THETA TECH

Preparation of an article surface having a surface compressive texture

ActiveUS20070175030A1Reduce surface roughnessSmooth surface finishEngine manufactureBlade accessoriesSurface roughnessMaterials science

A method for preparing a surface includes providing an article having an article surface, thereafter first processing the article surface to establish a first residual compressive stress state and a first surface roughness in the article surface, and thereafter second processing the article surface by surface compressive texturing to establish a second residual compressive stress state and a second surface roughness in the article surface. The second surface roughness is quantitatively less than the first surface roughness, and substantially no material is removed from the article surface in the step of second processing.

Owner:GENERAL ELECTRIC CO

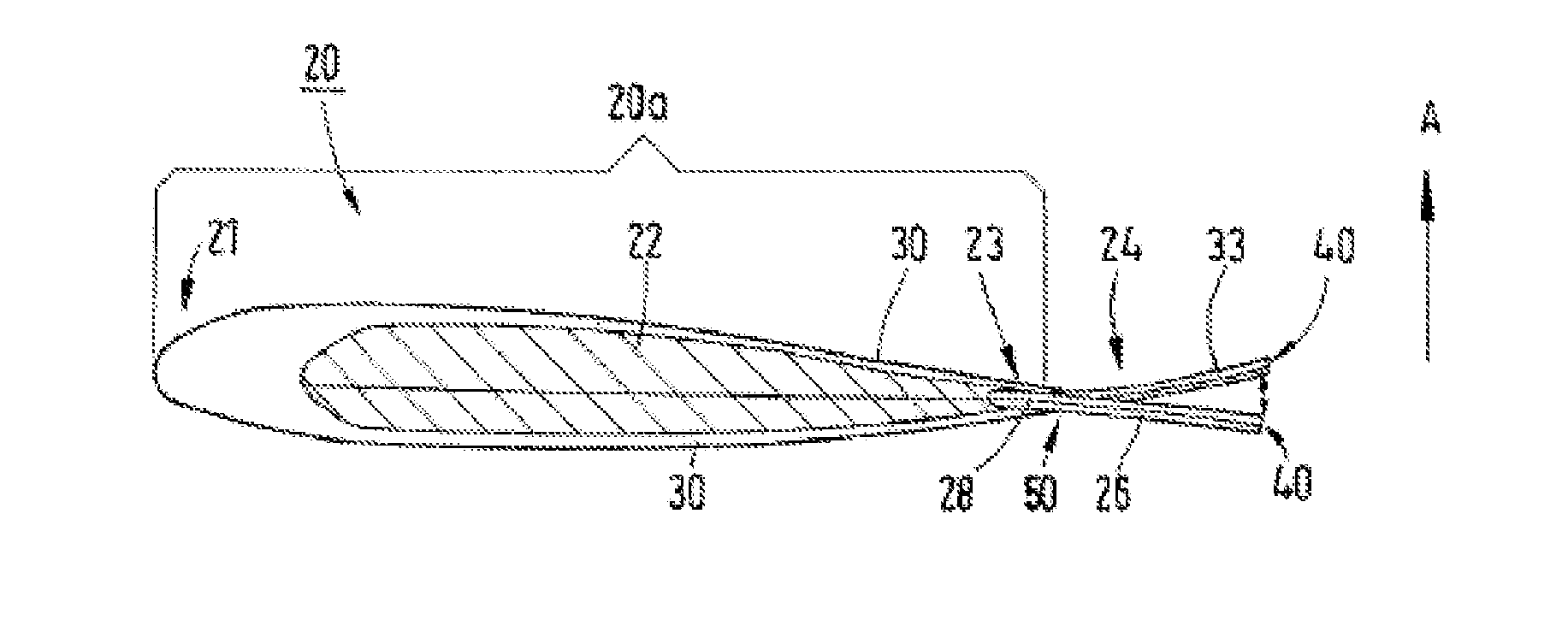

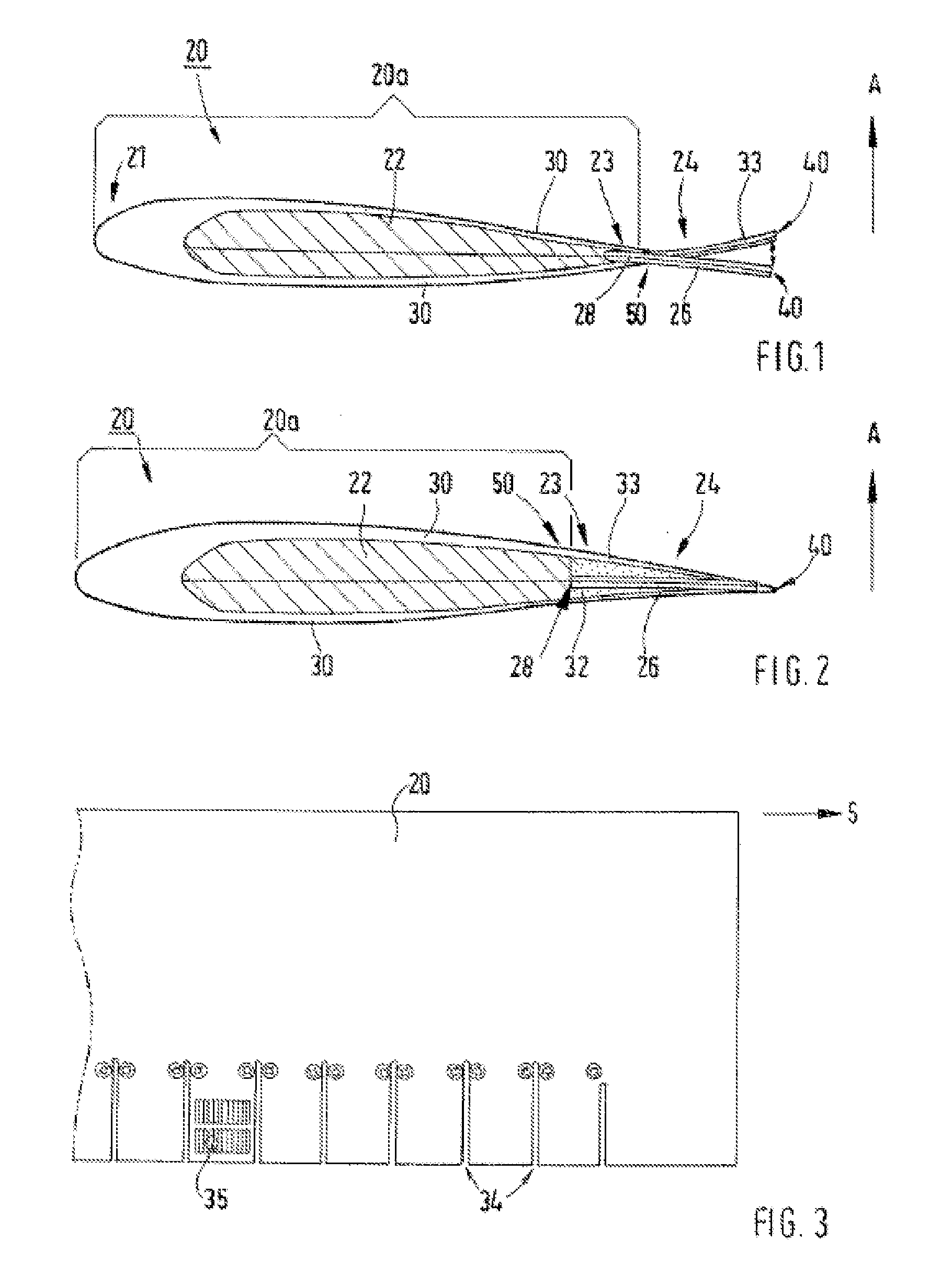

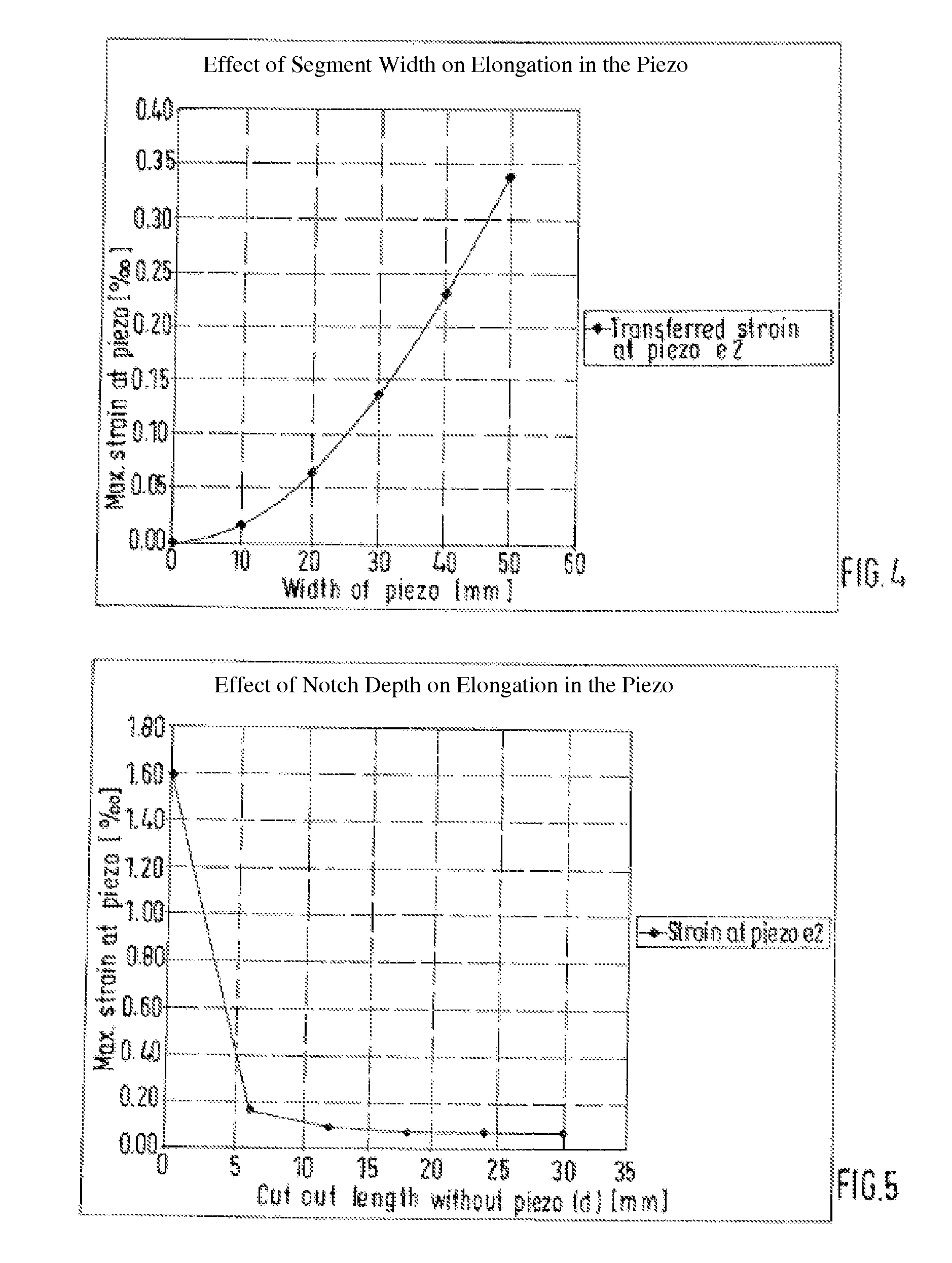

Rotor blade for a rotary wing aircraft

InactiveUS20100181415A1Reduced stress stateImparts further flexibilityPropellersPump componentsEngineeringActuator

The invention relates to a rotor blade (20), especially for a rotary wing aircraft. The invention is characterized in that an aerodynamically effective rotor blade profile with a profile nose region (21), a profile base body (20a) with a profile core, an upper and lower cover skin (30) that envelops the profile core (22), and a profile rear edge region (23) with a rear edge (40) and a reversibly bendable supporting member (26) that can be attached with the first end to the end region of the profile base body (20a) pointing toward the rear edge (40) and projects with the second end freely out of the profile base body (20a) and its end region toward the rear edge (40) and forms a movable rotor blade flap (24), and several actuators (35) that are dynamically connected to the projecting second end of the reversibly bendable supporting member (26) and an arc-shaped flap deflection can be initiated via the change in length of the actuators, the second end of the reversibly bendable supporting member (26) that forms the rotor blade flap (24) viewed in the direction of the span (S) being divided by notches (34) into several segments to which at least one actuator (35) at a time is assigned.

Owner:EUROCOPTER DEUT GMBH

Fabricated self-resetting concrete frame soft steel energy dissipation composite joint

InactiveCN110258787AImprove energy consumptionReduce pollutionProtective buildings/sheltersShock proofingReinforced concrete columnEarthquake intensity

The invention discloses a fabricated self-resetting concrete frame soft steel energy dissipation composite joint. The fabricated self-resetting concrete frame soft steel energy dissipation composite joint includes a prefabricated reinforced concrete column, a prefabricated reinforced concrete beam, soft steel dampers, a pre-stressed steel strand, embedded high-strength bolts and anchored steel bars, wherein the prefabricated reinforced concrete beam is provided with a beam end embedded steel sleeve, and a column end embedded steel plate is arranged at the butt-joint position between the prefabricated reinforced concrete column and the beam end embedded steel sleeve; the pre-stressed steel strand penetrates through a pre-stressed steel strand hole channel of the prefabricated reinforced concrete column, a pre-stressed steel strand opening of the column end embedded steel plate, a pre-stressed steel strand opening of the beam end embedded steel sleeve and the pre-stressed steel strand channel of the prefabricated reinforced concrete beam in sequence, so that the prefabricated reinforced concrete column and the prefabricated reinforced concrete beam are spliced together; and the soft steel dampers are arranged on both sides of a web plate of the section steel part of the beam end embedded steel sleeve. The fabricated self-resetting concrete frame soft steel energy dissipation composite joint enables the prefabricated concrete frame structure to have excellent seismic performance and self-resetting ability under high earthquake intensity.

Owner:南京毕慕智能建筑科技有限公司

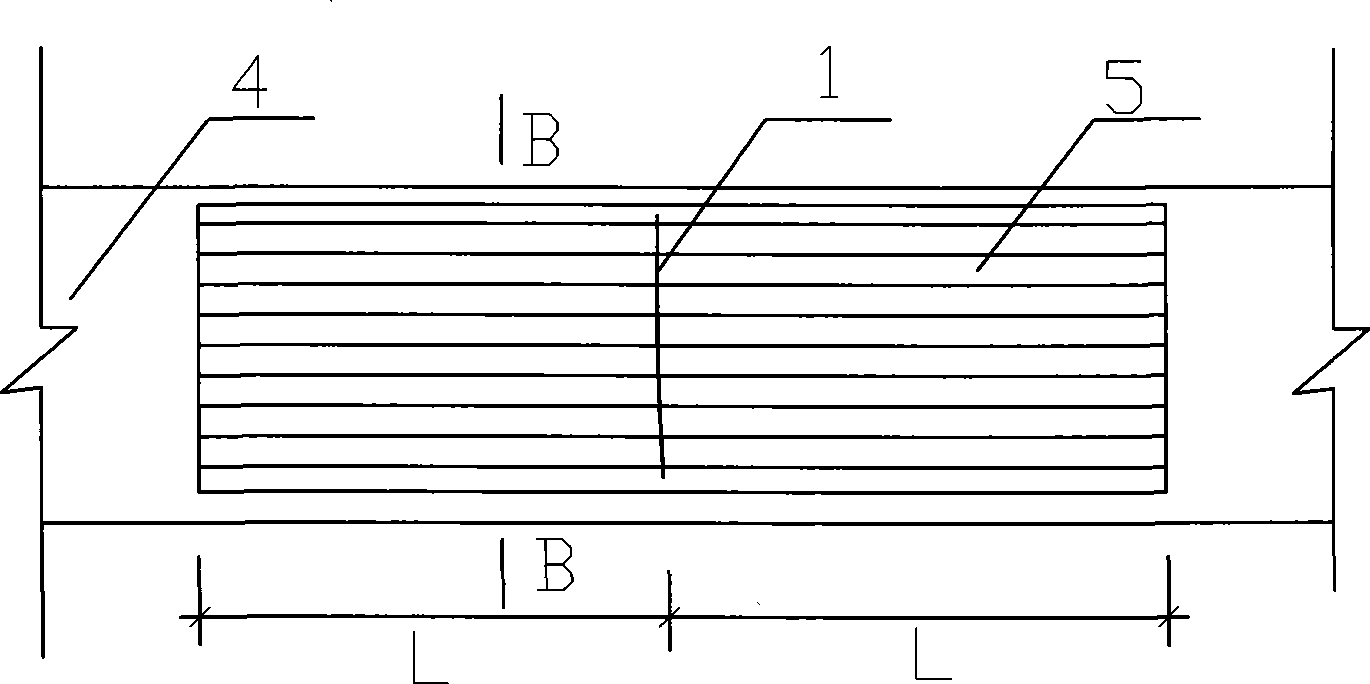

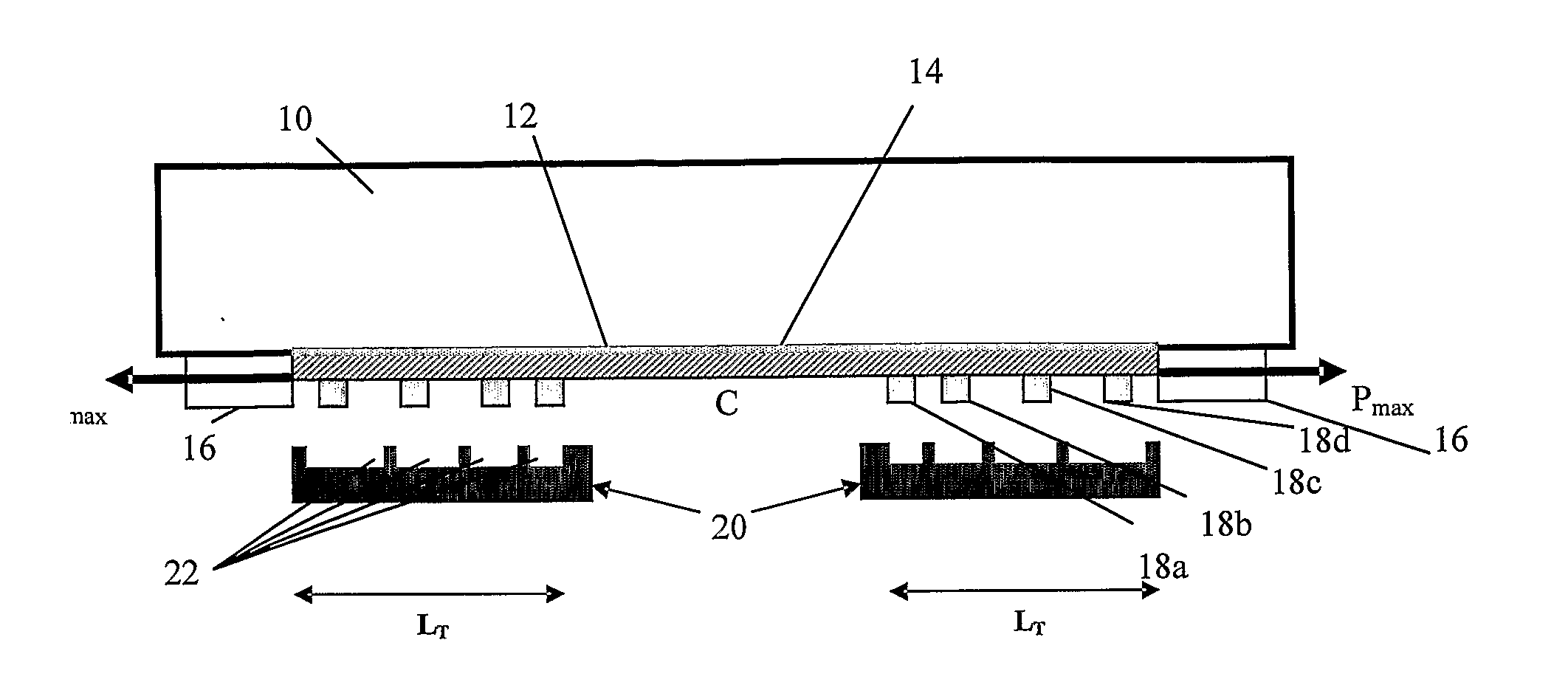

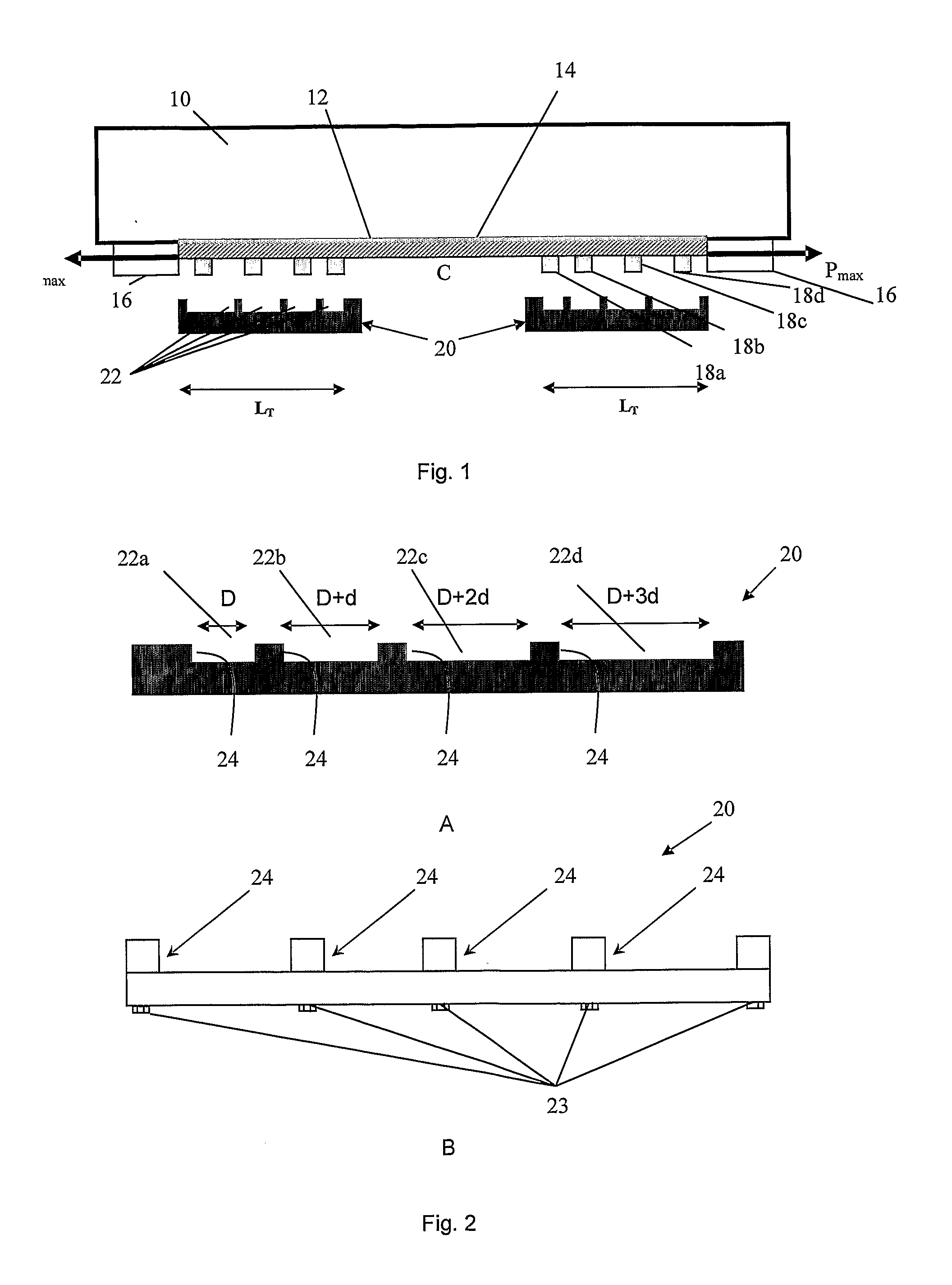

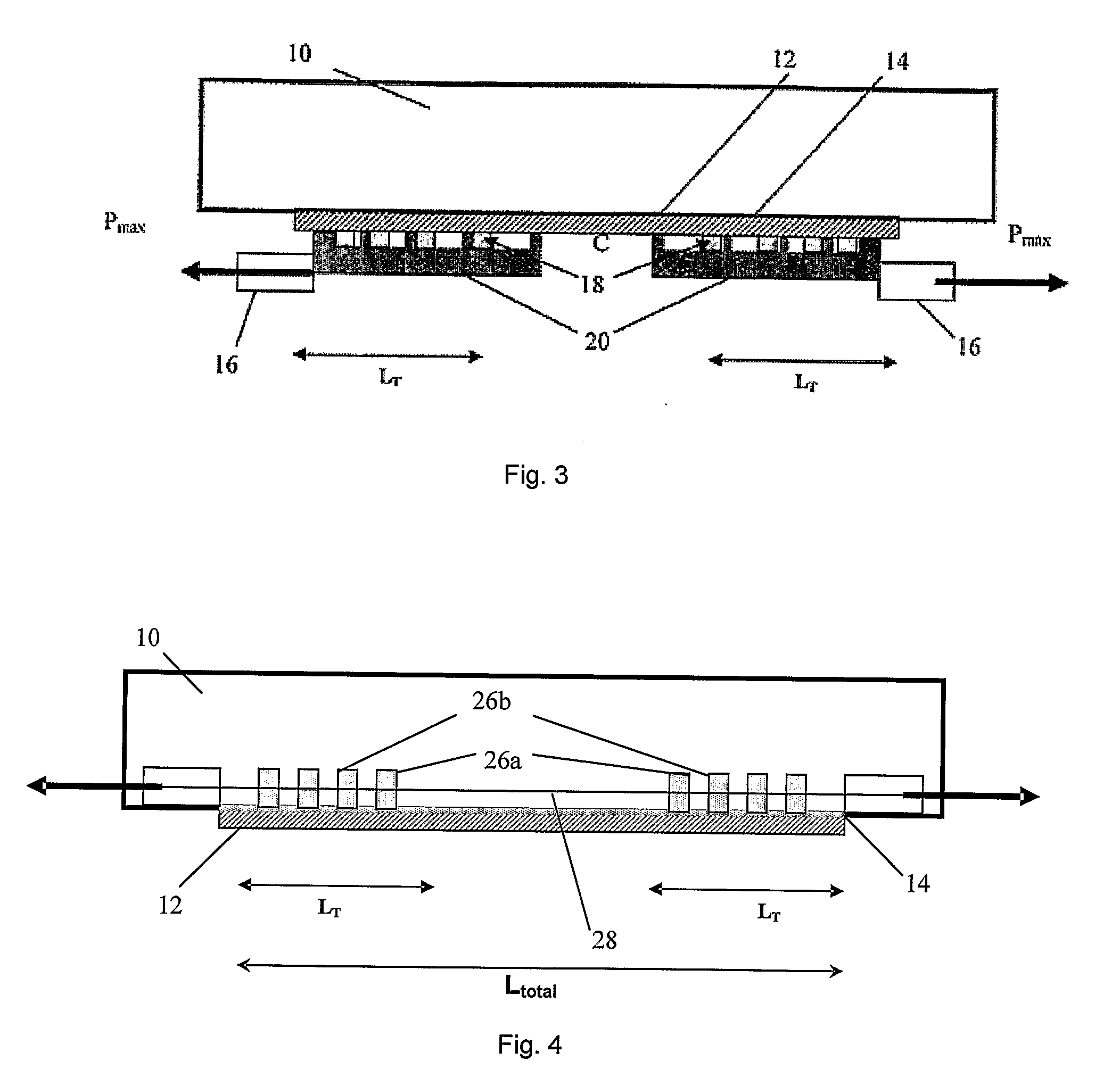

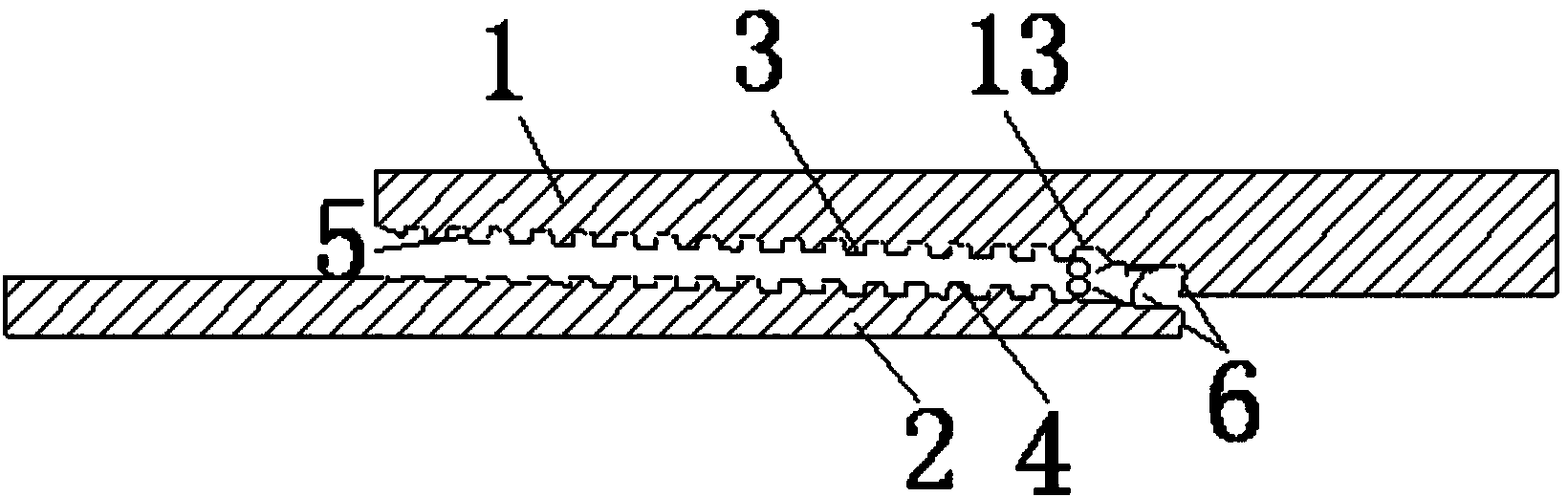

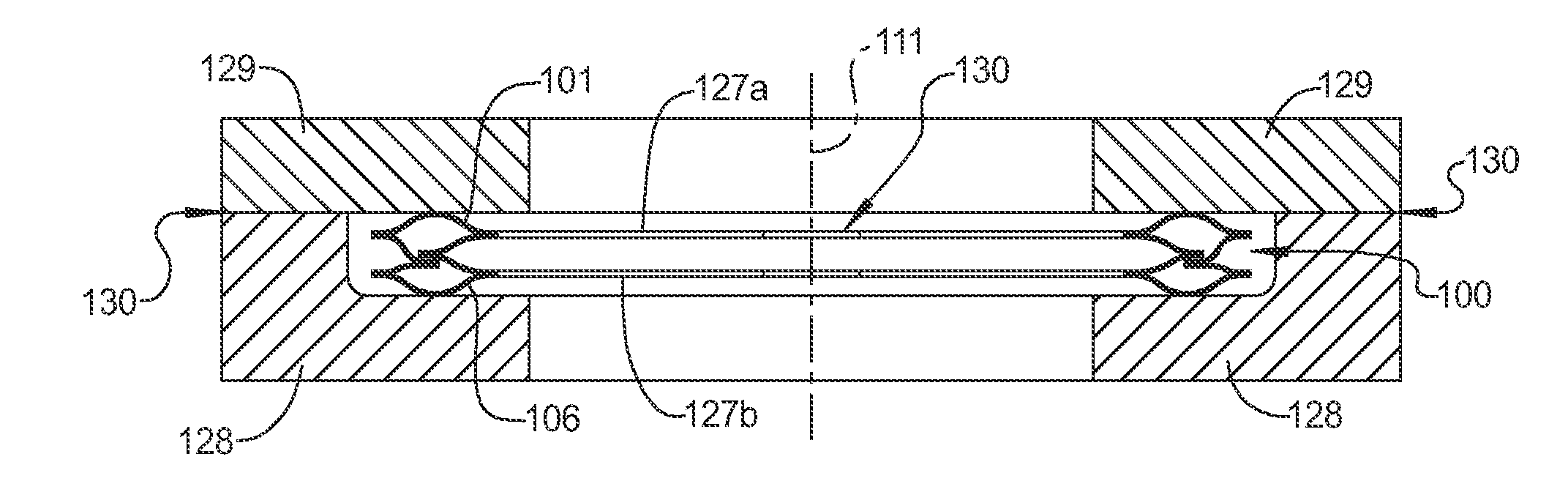

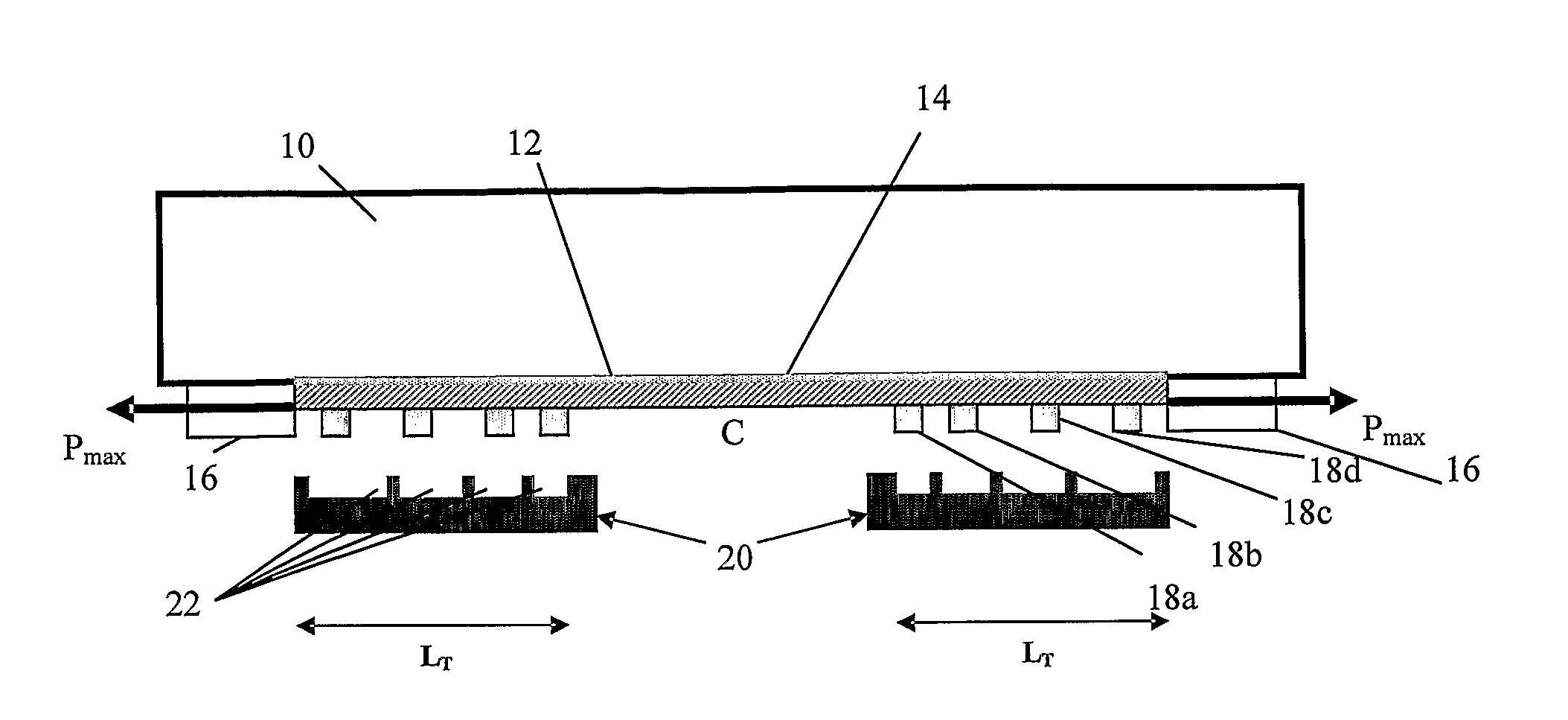

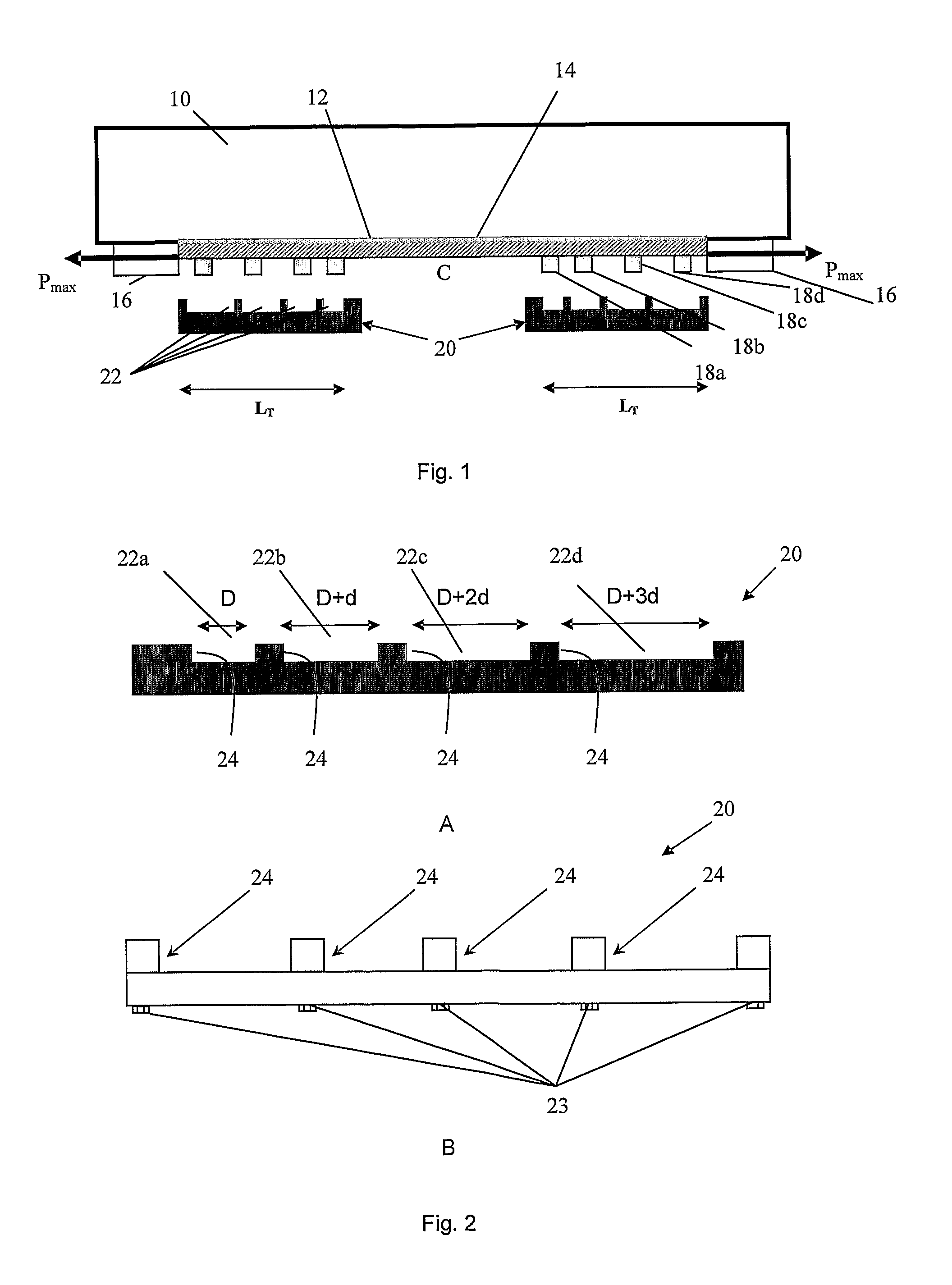

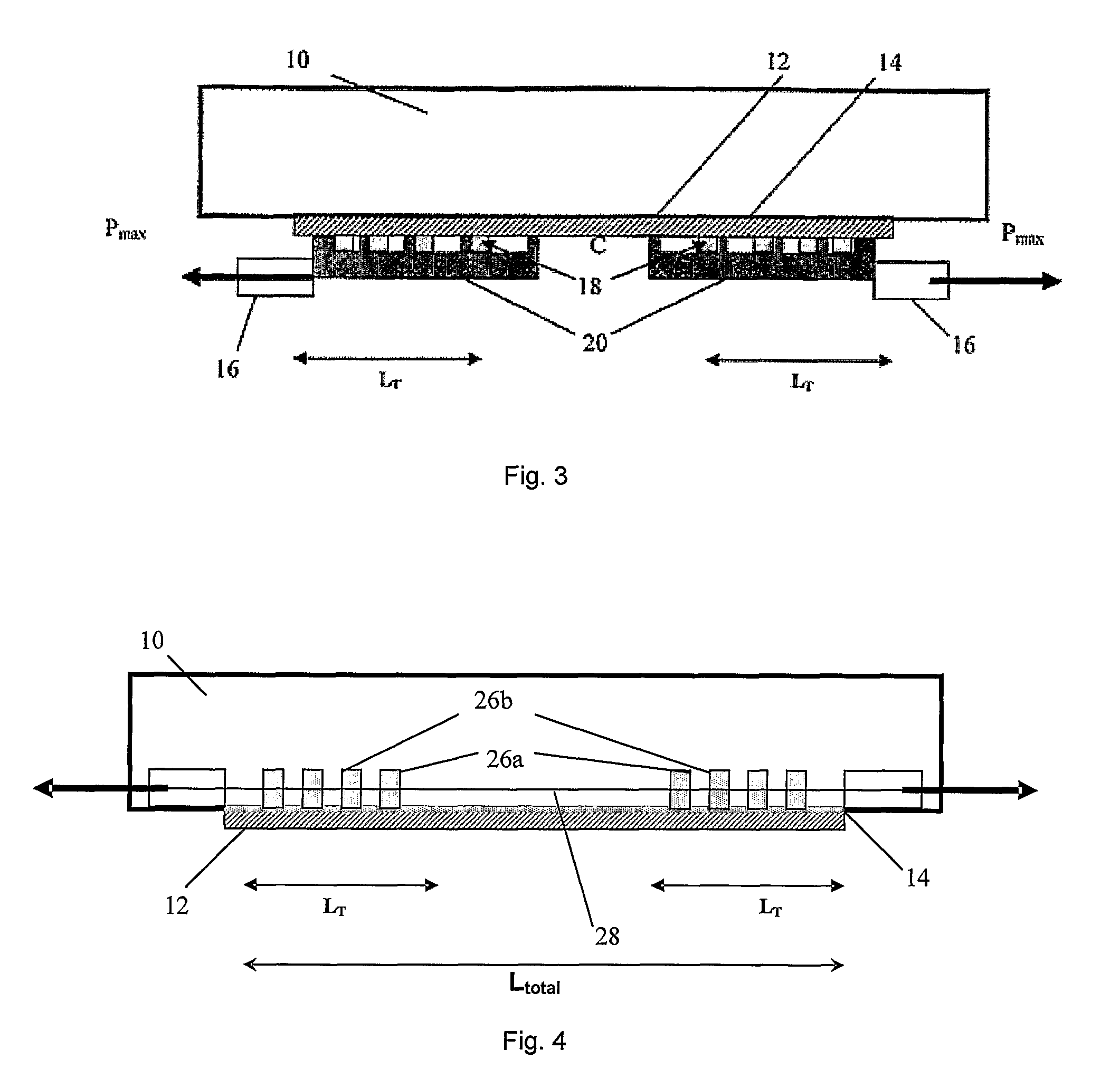

Method

InactiveUS20110000606A1Increase workSupport function be reduceCovering/liningsWallsPre stressingGrout

Method for applying a reinforced composite material, such as a fibre reinforced polymer (FRP) laminate or a steel reinforced polymer (SRP) laminate or a steel reinforced grout (SRG) composite, to a structural member. The method comprises the steps of: applying a curable adhesive to a surface of the structural member and / or a surface of the reinforced composite material, and bringing said surfaces into contact. A pre-stressing force, Pmax, is directly or indirectly applied to the reinforced composite material. The pre-stressing force, Pmax, to which a treatment length, LT, of the reinforced composite material is subjected is then decreased so that the reinforced composite material along the treatment length, LT, will be less pre-stressed than the reinforced composite material adjacent to the treatment length, LT, when the adhesive has cured.

Owner:AL EMRANI MOHAMMAD +2

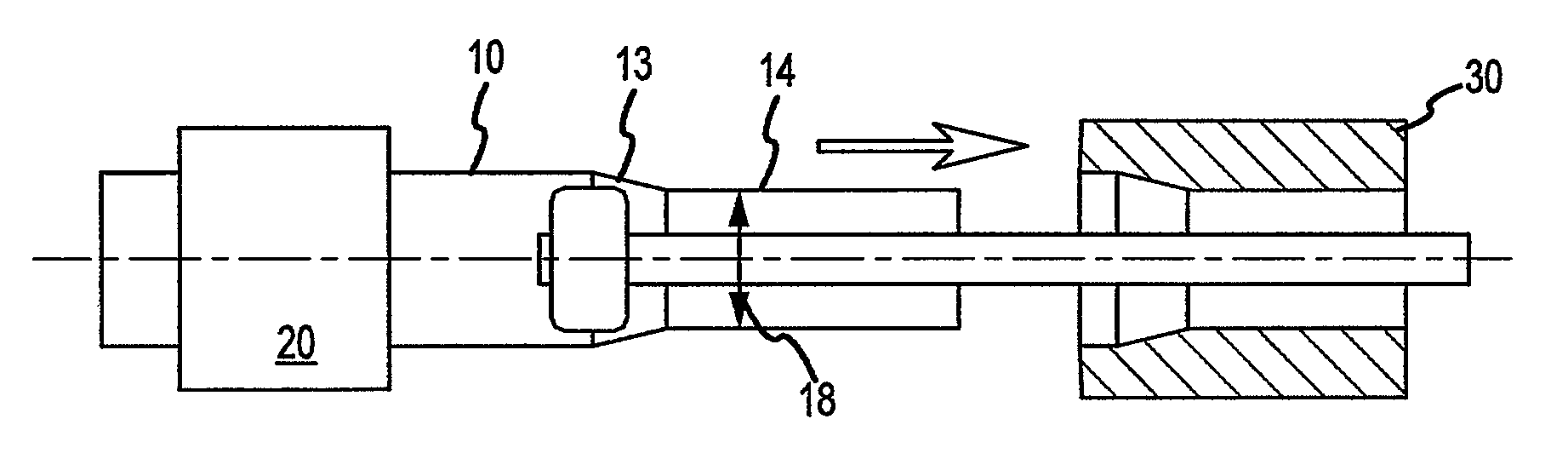

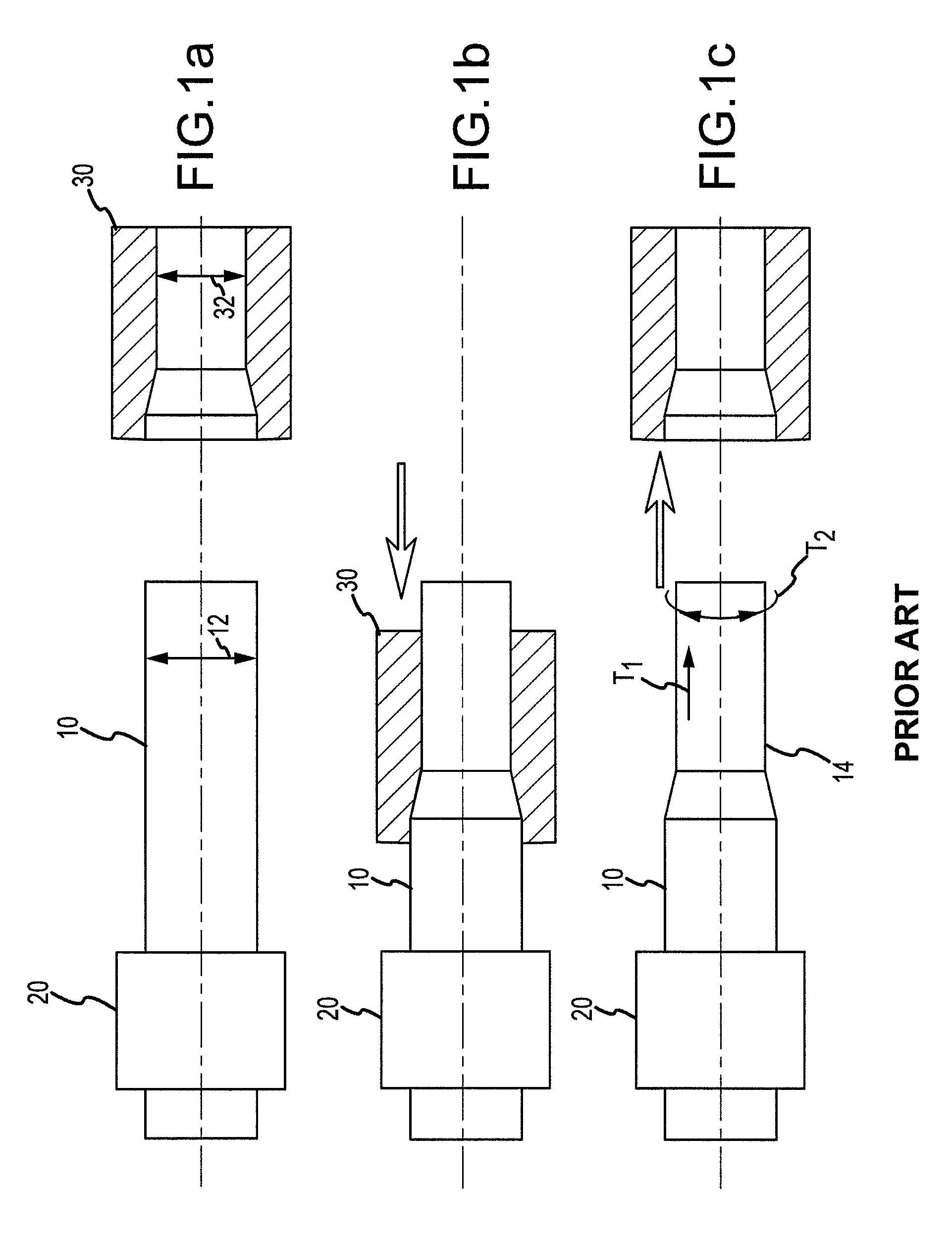

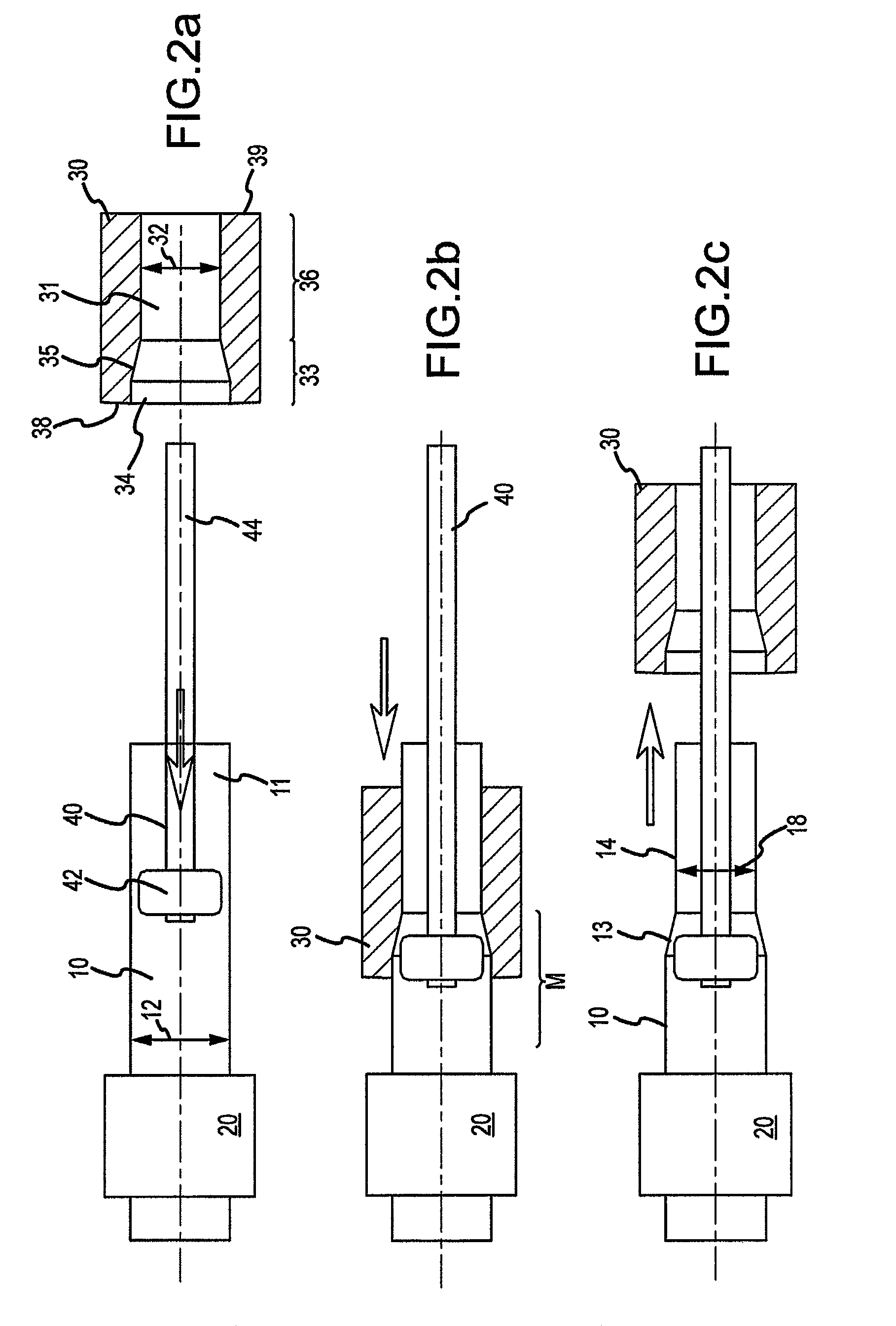

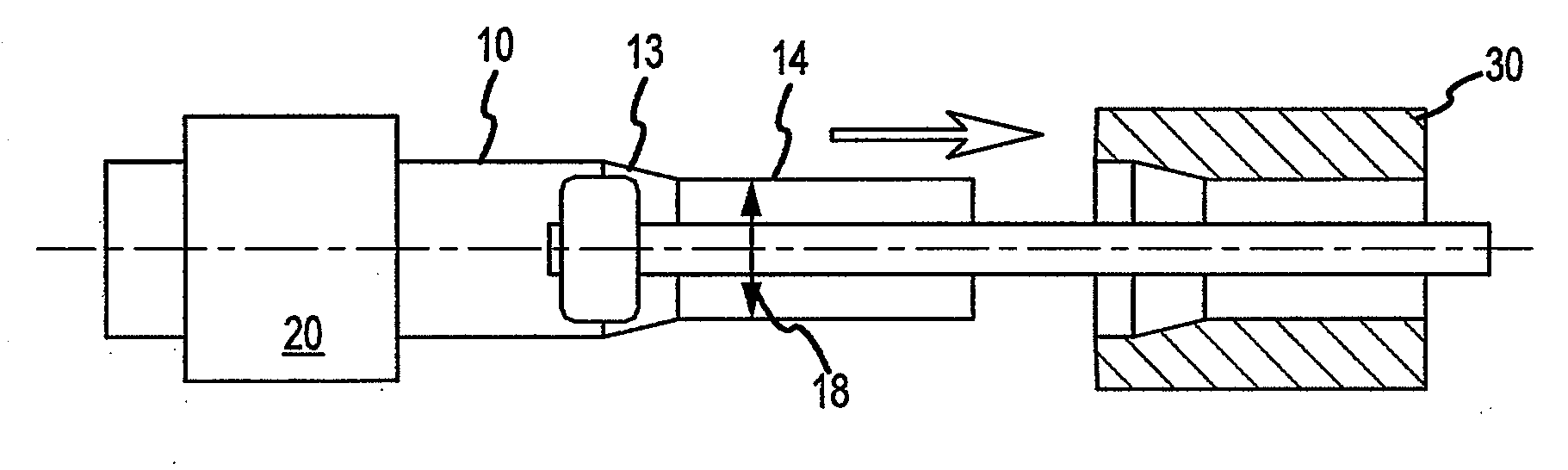

Methods and systems for reducing tensile residual stresses in compressed tubing and metal tubing products produced from same

ActiveUS7895875B2Reduced stress stateRestricted and no loss of mechanical strengthEngine componentsHollow articlesStressed stateMetal

Methods and systems for reducing the stress state of compressed ends of compressed tubes are disclosed. The methods and systems may provide a reduced tensile residual stress state, or even a compressive residual stress state. Tube products produced from the same are also provided.

Owner:ARCONIC TECH LLC

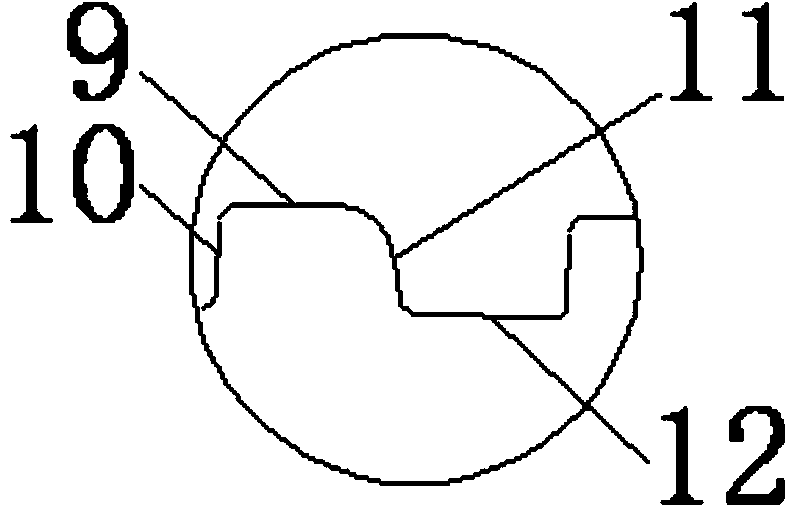

Multistage sealing anti-sticky buckle type thread for titanium alloy oil casing

InactiveCN103527110AImprove airtight reliability performanceReduced stress stateDrilling rodsDrilling casingsButtressCoupling

The invention relates to a multistage sealing anti-sticky buckle type thread for a titanium alloy oil casing. The multistage sealing anti-sticky buckle type thread comprises an oil casing coupling and an oil casing tube end, the oil casing coupling is provided with a standard API buttress internal thread which is sequentially connected with a tool withdrawal groove, a cone surface to cone surface first stage sealing structure, a cylinder surface to cylinder surface second stage sealing structure and a negative angle torque circular bead, wherein the cone surface to cone surface first stage sealing structure and the cylinder surface to cylinder surface second stage sealing structure are in transition through chambering, and the negative angle torque circular bead is connected with the standard API buttress internal thread through a transitional angle. The multistage sealing anti-sticky buckle type thread for the titanium alloy oil casing has the advantages that two stages of metal sealing and one negative angle torque circular bead sealing are added based on the improved buttress thread, the reliability of the air tightness of a thread connector is improved through the design of multistage sealing, meanwhile, the stress state of the thread connector is reduced by changing a thread parameter, the performance of an anti-sticky buckle is improved, and machining and detecting are convenient.

Owner:XIAN SANHUAN TECH DEV GENERAL

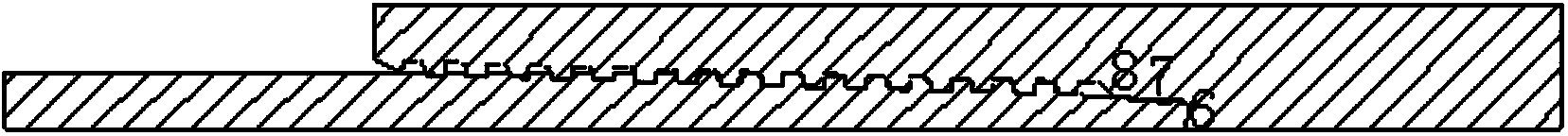

Gob-side entry retaining method

InactiveCN107083959AGuaranteed ventilation effectReduced stress stateUnderground chambersUnderground miningEngineeringCoal mining

The present invention relates to the field of coal mining technology, in particular to a method for retaining roadways along gobs, comprising the following steps: S1, excavating a first roadway on the side adjacent to the second mining face on the first mining face, The roadway is supported, and at the same time, the side of the first roadway close to the second mining face is prefabricated; S2, before the mining of the first mining face, the roof of the first mining face is prefabricated with cracks; S3, at the Excavate the second roadway on the side near the side of the roadway on the secondary mining face, and support the second roadway. The invention solves the problems of high pressure, high stress and serious deformation of the concrete wall in the commonly used gob-side retaining roadway. During the excavation of the previous working face, the concrete wall of the gob-side retaining is prefabricated in advance, and the process during the mining of the working face is reduced. The degree of complexity increases the recovery speed of the previous working face, and the secondary roadway of gobside retaining often needs to be repaired, which requires a large amount of work and high difficulty. The present invention is a new roadway for the next working face, so there is no need for roadway repair.

Owner:TIANDI SCI & TECH CO LTD +1

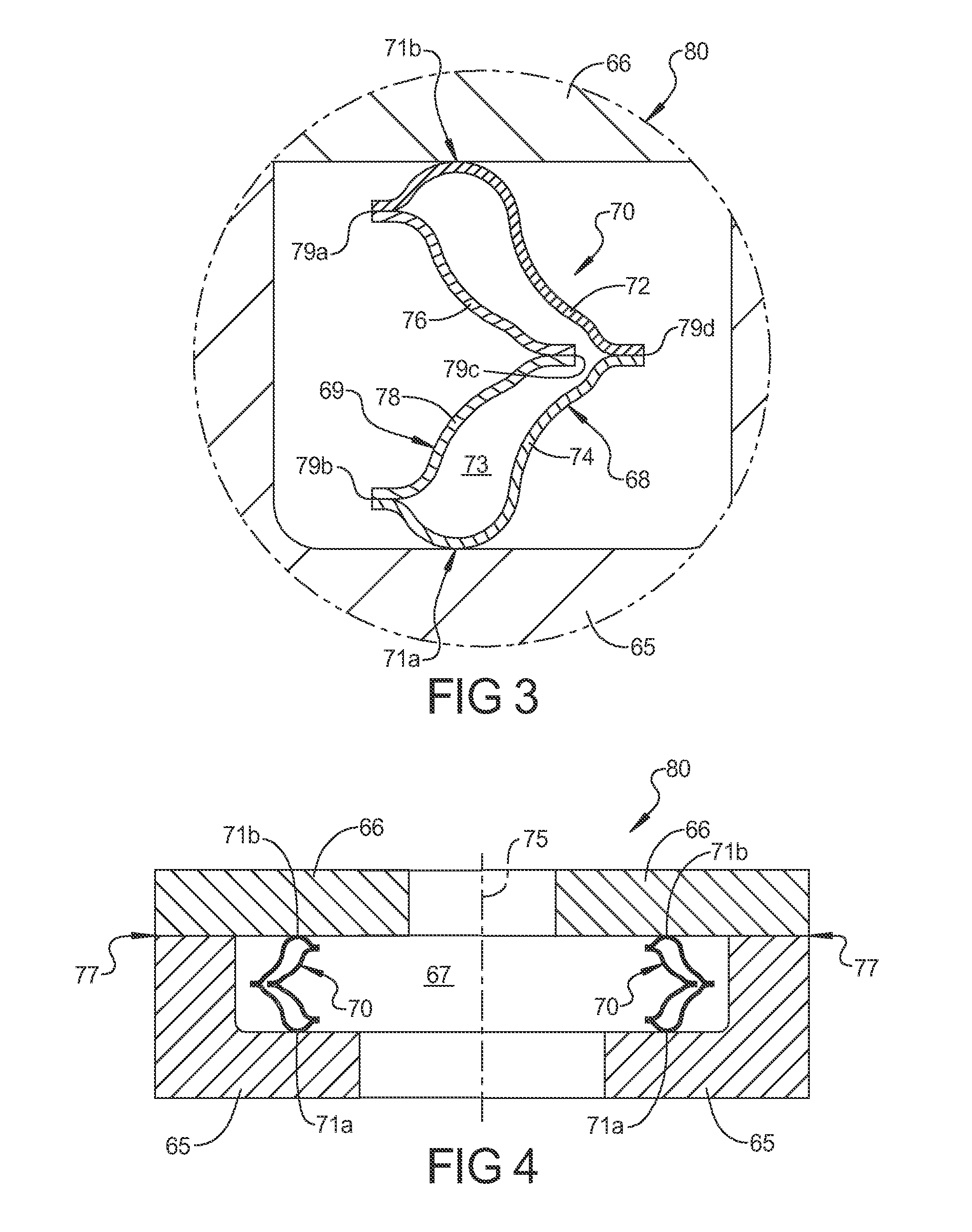

Resilient seal having a pressurized bellows spring

InactiveUS20130228980A1Increase sealing forceIncrease temperatureEngine sealsMetal working apparatusJet engineMechanical components

An increased resilience seal utilizing a sealed gas filled inner chamber in a bellows spring that functions as both a mechanical spring and a gas spring to provide a more constant level of separation force between two face plates to provide a seal between two mechanical components such as those found in an aircraft jet engine. The bellows spring is made of a plurality of walls that are joined together in a pressurized chamber that is filled with a gas, such as an inert gas. In alternative embodiments, the bellows spring is made of walls that are shaped and oriented to optimize the operating characteristics of the bellows spring when the pressure is increased in a sealed inner chamber in response to elevated temperature. In one embodiment, the walls forming a portion of the chamber overlap to optimize the geometry of the bellows spring.

Owner:EATON CORP

Methods and systems for reducing tensile residual stresses in compressed tubing and metal tubing products produced from same

ActiveUS20080053183A1Reduced stress stateRestricted and no loss of mechanical strengthEngine componentsHollow articlesStressed stateMaterials science

Methods and systems for reducing the stress state of compressed ends of compressed tubes are disclosed. The methods and systems may provide a reduced tensile residual stress state, or even a compressive residual stress state. Tube products produced from the same are also provided.

Owner:ARCONIC TECH LLC

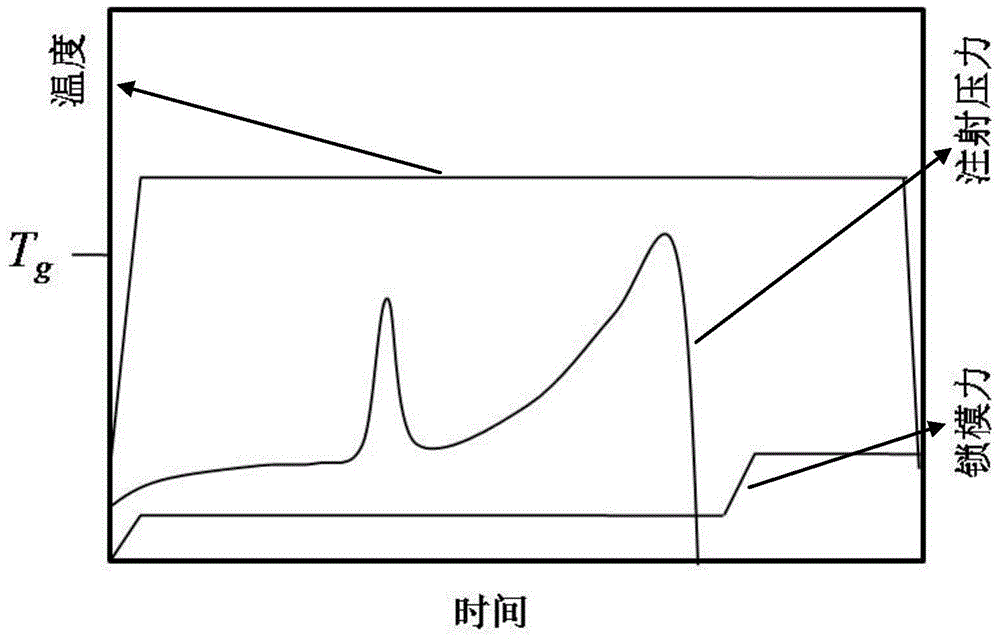

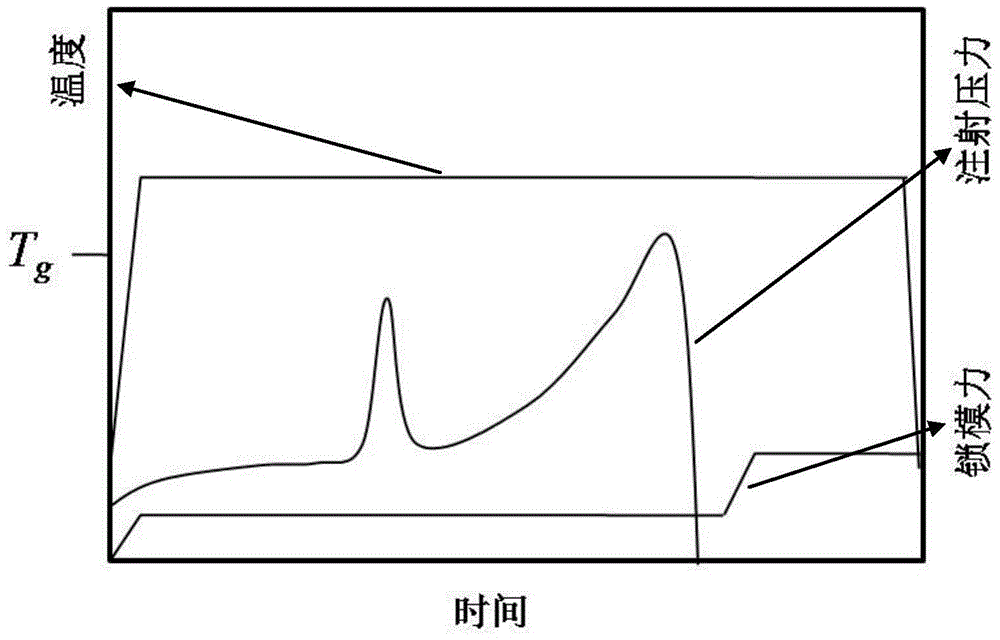

Method for manufacturing variable-thickness cambered transparent workpiece

ActiveCN104552740AHigh dimensional accuracyGuaranteed surface qualityOptical articlesTemperature controlVariable thickness

The invention belongs to the technical field of injection forming and relates to a method for manufacturing a variable-thickness structural transparent workpiece, and particularly relates to a method for manufacturing a high-accuracy variable-thickness cambered transparent workpiece. The method disclosed by the invention carries out forming processing on a variable-thickness workpiece by adopting a primary integral injection compression and secondary differential expansion injection compression combined injection forming method, thereby effectively controlling the surface quality and retracting warpage of the workpiece in areas with different thicknesses; in addition, the method disclosed by the invention carries out forming by selecting a polycarbonate material with excellent impact resistant property, thereby ensuring the characteristics of light weight and transparency of the workpiece. According to the method, the mould temperature is controlled to be higher than plastic glass transition temperature in a stage of filling a cavity through a fusant by applying a dynamic variable-mould temperature control technology, and after expansion and compression are finished, the mould temperature is fast reduced to sufficiently cool a shaped workpiece, so that the surface quality of the workpiece is ensured, the forming period is shortened, and the production cost is reduced. The workpiece manufactured by adopting the method disclosed by the invention can achieve the light transmittance of more than 75%, and the optical distortion of an effective area can be controlled to be less than 1 / 10.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method for applying a reinforced composite material to a structural member

InactiveUS8349109B2Simple and reliable and cost-effectiveShort timeCovering/liningsWallsPre stressAdhesive

Method for applying a reinforced composite material, such as a fibre reinforced polymer (FRP) laminate or a steel reinforced polymer (SRP) laminate or a steel reinforced grout (SRG) composite, to a structural member. The method comprises the steps of: applying a curable adhesive to a surface of the structural member and / or a surface of the reinforced composite material, and bringing said surfaces into contact. A pre-stressing force, Pmax, is directly or indirectly applied to the reinforced composite material. The pre-stressing force, Pmax, to which a treatment length, LT, of the reinforced composite material is subjected is then decreased so that the reinforced composite material along the treatment length, LT, will be less pre-stressed than the reinforced composite material adjacent to the treatment length, LT, when the adhesive has cured.

Owner:AL EMRANI MOHAMMAD +2

A deep subcooling treatment method for fine-grained copper alloy liner

ActiveCN104789911BFacilitate stacking misalignmentGrain refinementExplosive chargesShaped chargeGrain structure

The invention provides a preparation method of a fine grain copper alloy shaped charge liner. The preparation method of the fine grain copper alloy shaped charge liner comprises the following steps: carrying out compound cold extrusion plastic deformation, carrying out deep overcooling treatment, and carrying out recrystalization annealing, wherein the compound cold extrusion plastic deformation comprises the steps of putting a blank into a mould cavity of a preformed blank forming mould, carrying out forward extrusion forming to obtain a designed copper alloy preformed blank under the actions of three-dimensional compressive stress and deformation rate and then putting the preformed blank into a mould cavity of a shaped charge liner forming mould and gradually forming the shaped charge liner preformed blank by carrying out gradual-pass diameter-expanded extrusion plastic deformation, thus obtaining the shaped charge liner blank of a required shape structure; the deep overcooling treatment comprises the step of carrying out heat preservation on the shaped charged liner blank for 2-4 hours at the temperature ranging from -196 DEG C to 130 DEG C; and the recrystallization annealing comprises the step of carrying out heat preservation on the shaped charge liner (subjected to deep overcooling treatment) for 5-15 minutes at the temperature of 450-550 DEG C in a protective atmosphere, thus obtaining a shaped charge liner component. The preparation method of the fine grain copper alloy shaped charge liner has the advantages that strict requirements of the shaped charge liner on grain structure homogeneity, consistency of performance and stress state and distribution can be met, and quality of the shaped charge liner can be improved.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

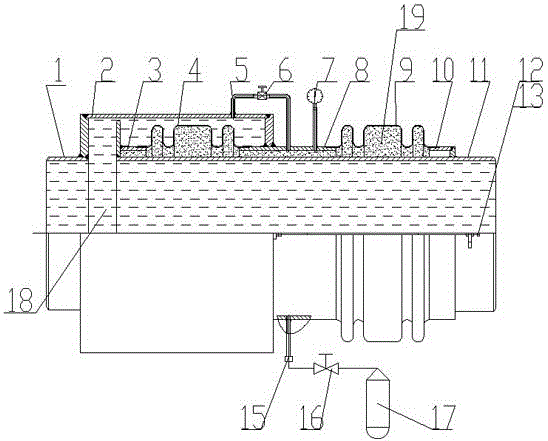

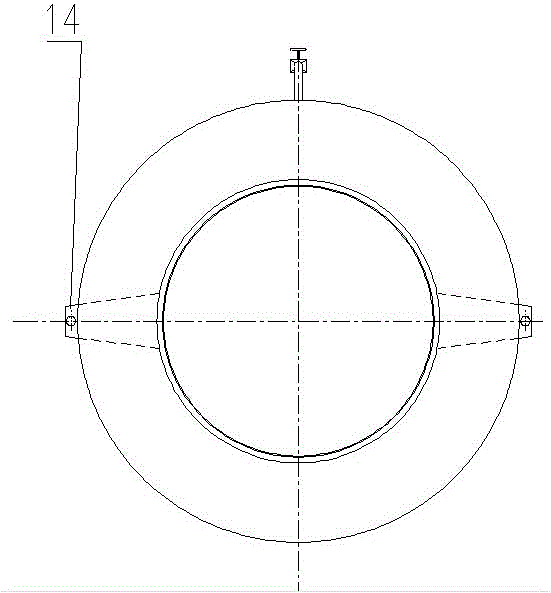

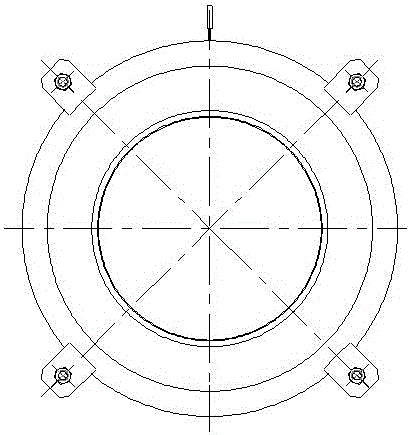

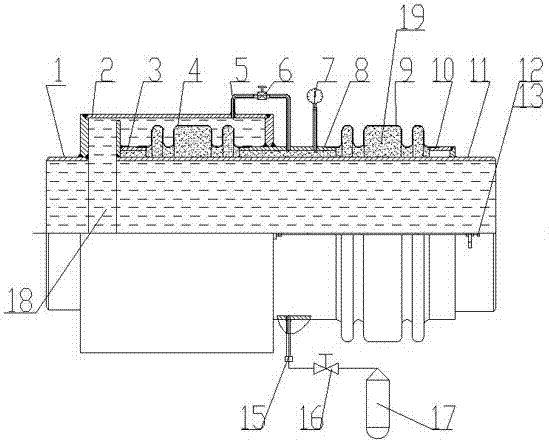

Pipeline-used expansion joint with second-level pressurization structure

ActiveCN105864554AMeet temperature compensation requirementsReduce work stressPipeline expansion-compensationEngineeringExpansion joint

The invention relates to a pipeline-used expansion joint with a second-level pressurization structure. The pipeline-used expansion joint comprises a working corrugated pipe used for compensating expansion and contraction of a pipeline; the working corrugated pipe is connected to the pipeline and bears the internal pressure applied by a fluid medium inside the pipeline to the inner wall of the working corrugated pipe, or the working corrugated pipe is arranged inside the pipeline and bears the external pressure applied by the fluid medium inside the pipeline to the outer wall of the working corrugated pipe; the outside or the inside of the working corrugated pipe is provided with a pressurization medium used for applying the pressure opposite to the pressure of the fluid medium to the working corrugated pipe; and the pressurization medium communicates into a protective corrugated pipe. By means of the pipeline-used expansion joint with the second-level pressurization and alarm structure, the working stress state of each corrugated pipe can be lowered; the temperature compensation requirement of the pipeline is met; the service life of each corrugated pipe is prolonged; and the requirement of safe use is met.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

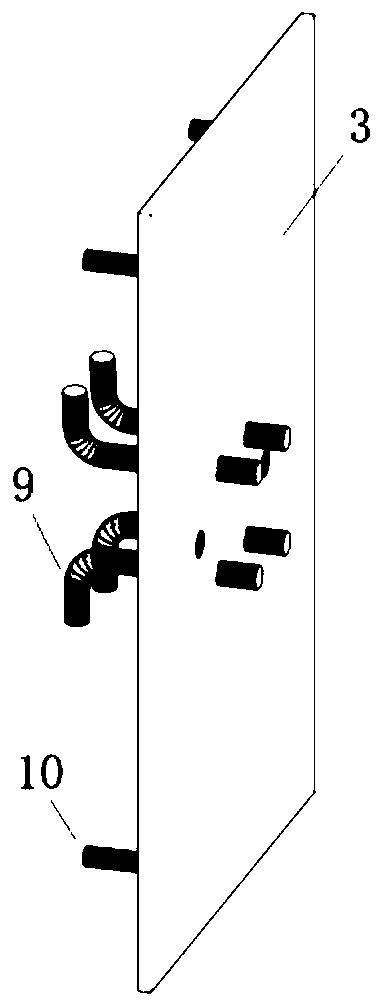

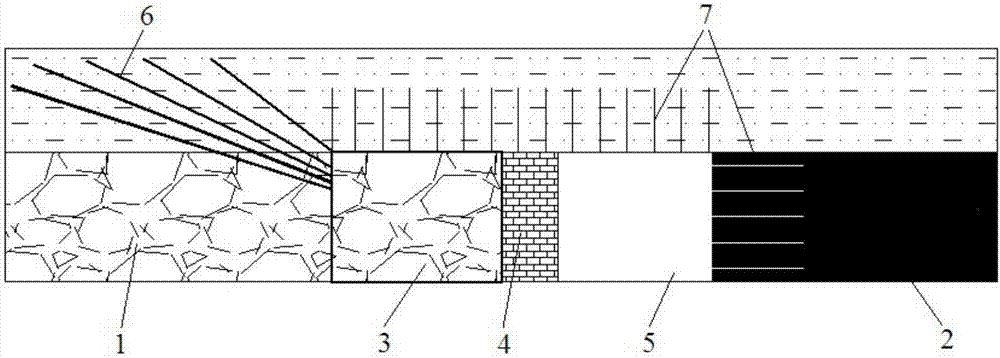

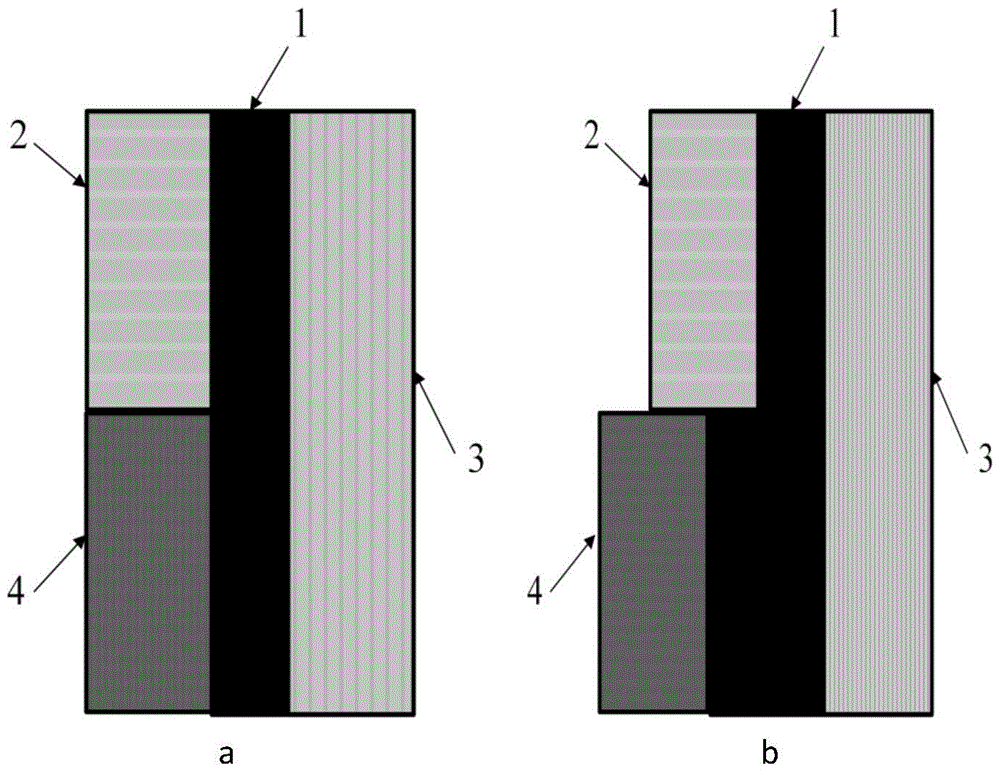

Stress-reducing laser chip structure and heat sink structure and preparation method thereof

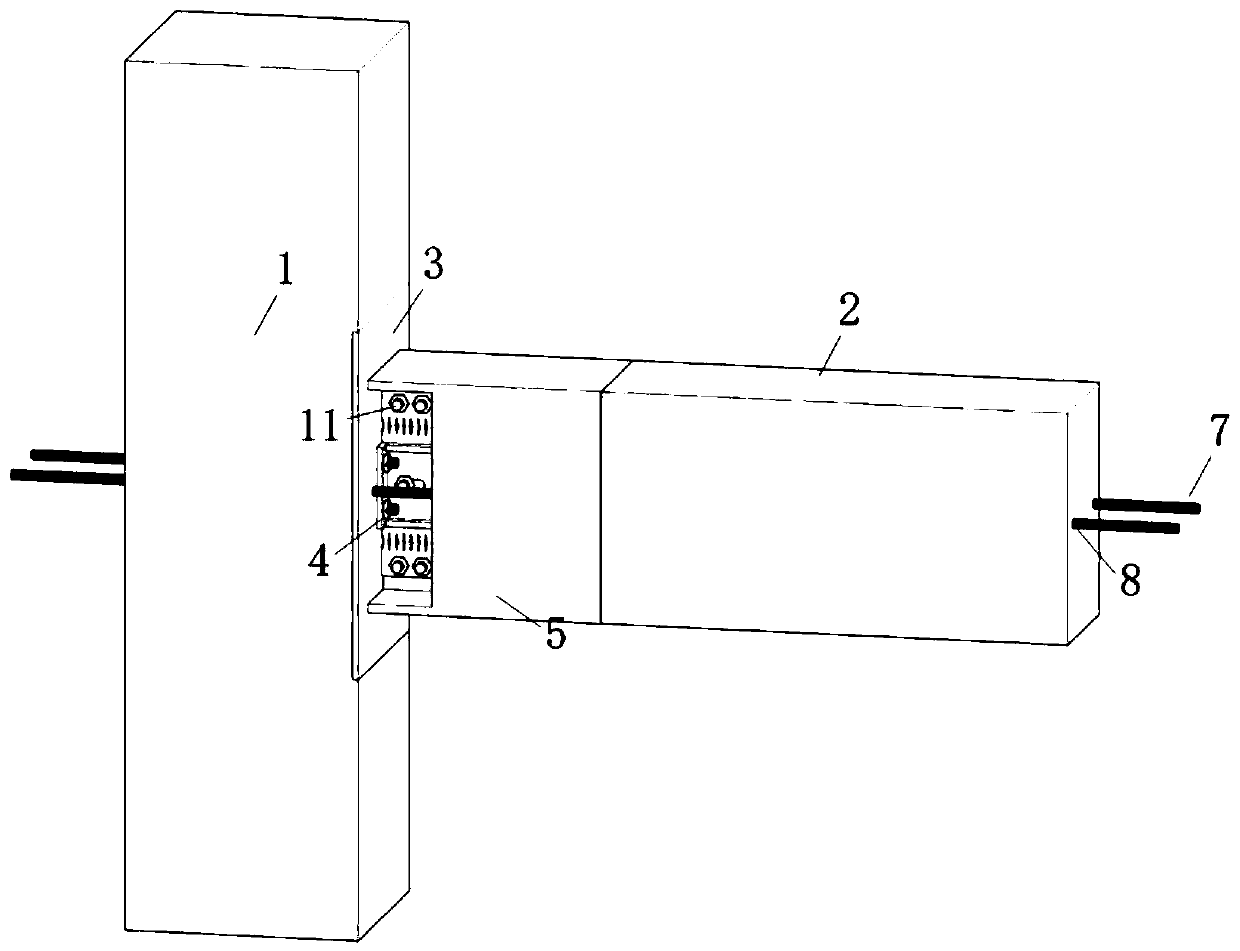

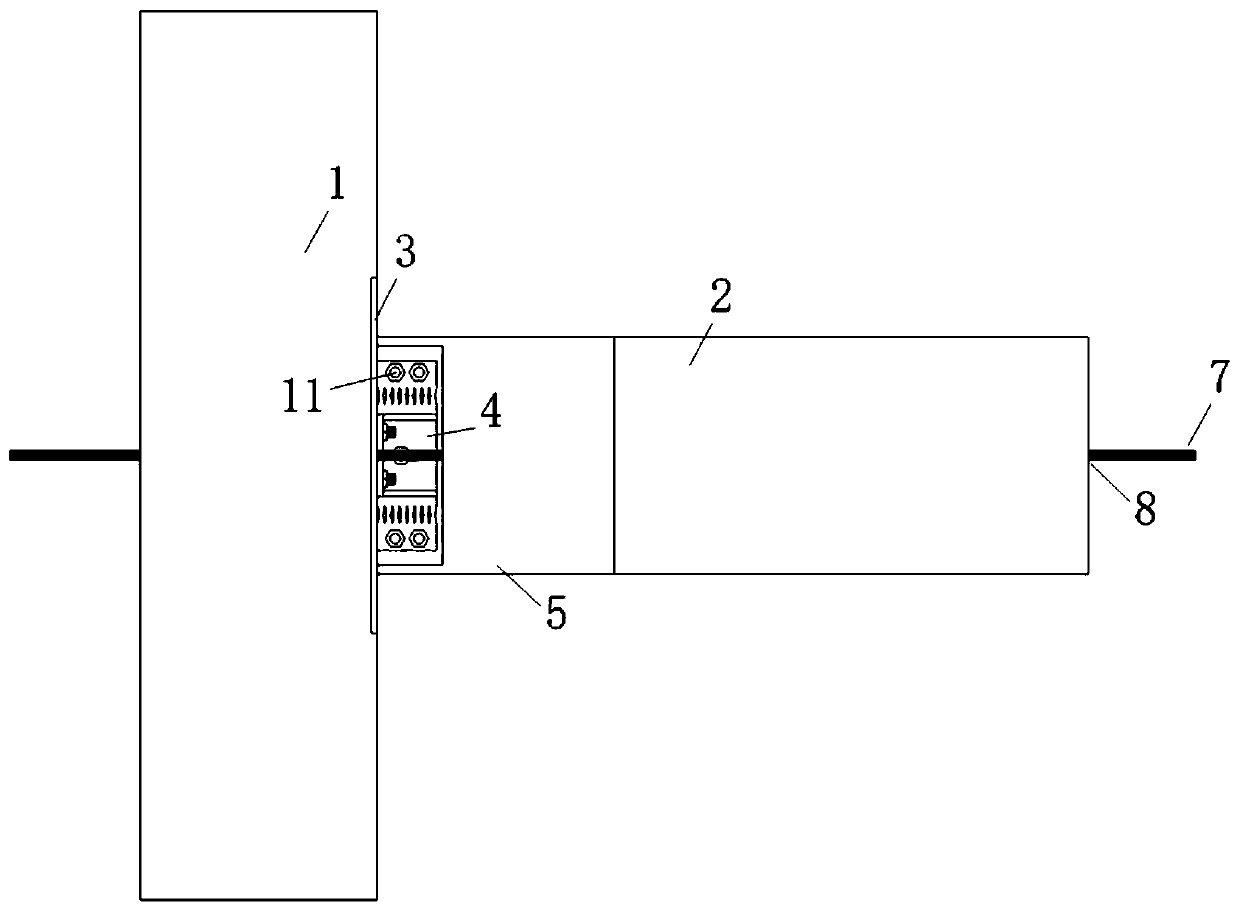

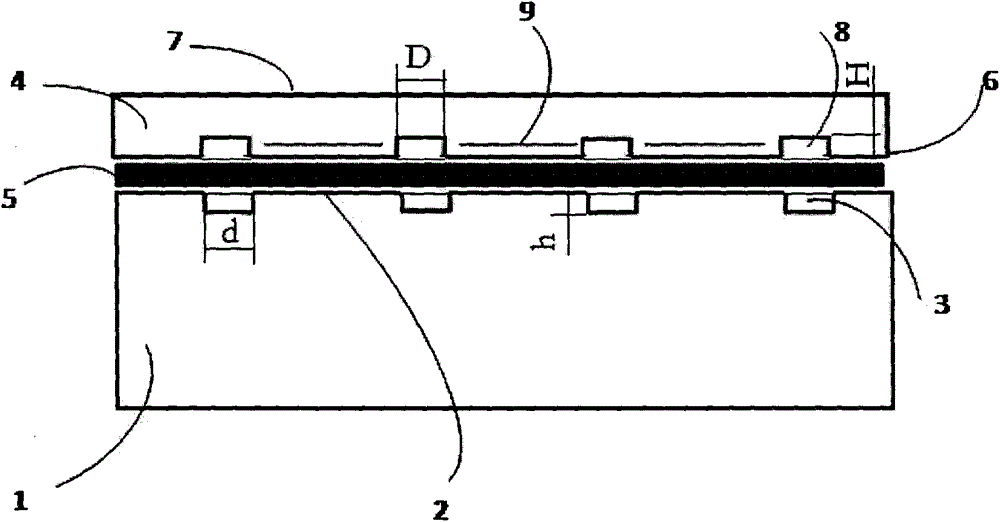

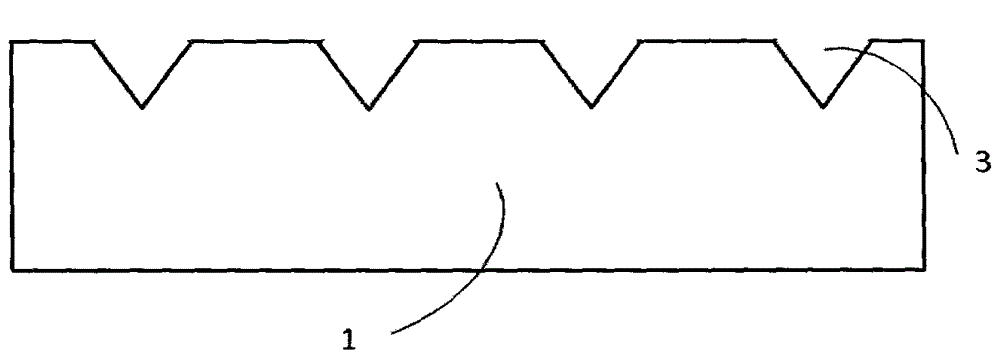

ActiveCN103427330BReduce curvatureReduced stress stateLaser detailsSemiconductor lasersEngineeringHeat sink

A stress-reducing laser chip structure comprises a laser chip body (4), the laser chip body (4) is provided with a positive pole (6) and a negative pole (7) that is electrically connected to an external electrode, a plurality of light-emitting portions (9) is disposed on the positive pole (6), and a first groove (8) is disposed between the light-emitting portions (9). The laser chip structure further comprises a heat sink structure, the heat sink structure comprises a heat sink body (1), a front surface (2) of the heat sink body (1) is welded to the positive pole (6) of the laser chip body (4) by using a solder layer (5), a portion, corresponding to the first groove (8) of the laser chip body (4), of the heat sink body (1) is provided with a second groove (3), and the second groove (3) corresponds to the first groove (8) one by one. The laser chip structure has a low stress state and a low curvature, can implement low-stress or "stress-free" packaging without affecting a thermal conduction capability of a laser, and can ensure long-time working of the laser.

Owner:WUHU ANRUI LASER TECH CO LTD

Control unit and medical examination apparatus

InactiveUS20130109955A1Improve coordinationCritical situationSurgeryCatheterDiagnostic Radiology ModalityMeasurement device

A control unit for an equipment arrangement is provided. The control unit includes an imaging modality, a measurement device for measuring a control variable and a controllable injection device for a regulatory substance influencing the control variable, wherein the injection rate of the injection device may be varied during a data acquisition such that a proposed value for the control variable is reached.

Owner:SIEMENS HEALTHCARE GMBH

A method for preparing a low-stress state composite substrate for gan growth

ActiveCN105514224BReduced stress stateImproving epitaxial growth qualitySemiconductor devicesComposite substrateDielectric layer

The invention discloses a preparation method of a low stress state composite substrate for GaN growth. The preparation method comprises that a GaN monocrystal epitaxial layer is prepared on a sapphire substrate; a stress compensation layer is deposited at the back side of a thermally and electrically conductive transfer substrate of high welding point; bonding dielectric layers of high welding point are prepared at the surfaces of a GaN epitaxial wafer and the transfer substrate respectively; the GaN epitaxial wafer is bonded to the thermally and electrically conductive substrate by the high-temperature diffusion bonding technology; and the composite substrate with high temperature stability and low stress state for GaN growth is obtained. According to the composite substrate of the invention, homoepitaxy can be realized and a vertical structural device can be directly prepared as a traditional composite substrate, the low stress state and high-temperature stability can be also realized, and the quality of subsequent GaN epitaxial growth and chip preparation can be effectively improved.

Owner:SINO NITRIDE SEMICON

A pipeline expansion joint with its own secondary pressure charging

ActiveCN105864554BMeet temperature compensation requirementsReduce work stressPipeline expansion-compensationInternal pressureEngineering

The invention relates to an expansion joint for a pipeline with self-contained secondary pressure, which includes a working bellows for compensating the expansion and contraction of the pipeline. Internal pressure, or set inside the pipeline to withstand the external pressure exerted by the fluid medium in the pipeline on its outer wall; the outside or inside of the working bellows is provided with a pressurized medium for applying an opposite pressure to the fluid medium on the working bellows. The pressure medium is connected to a protective bellows. The pipeline expansion joint with a secondary pressure charging alarm structure of the present invention can not only reduce the working stress state of the bellows, meet the temperature compensation requirements of the pipeline, improve the service life of the bellows, and meet the requirements of safe use.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

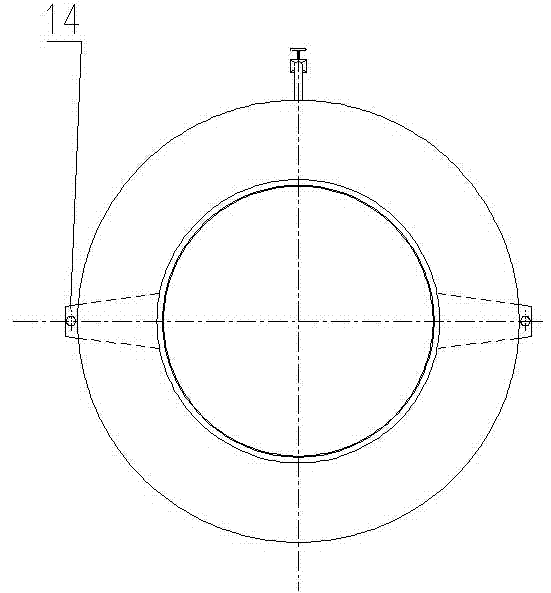

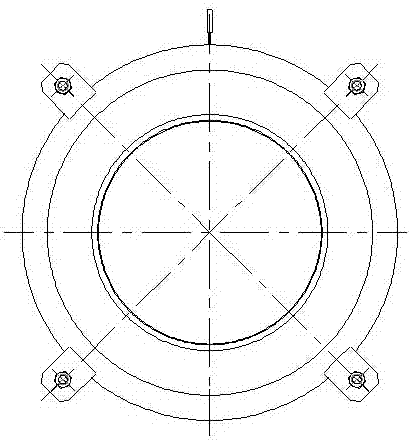

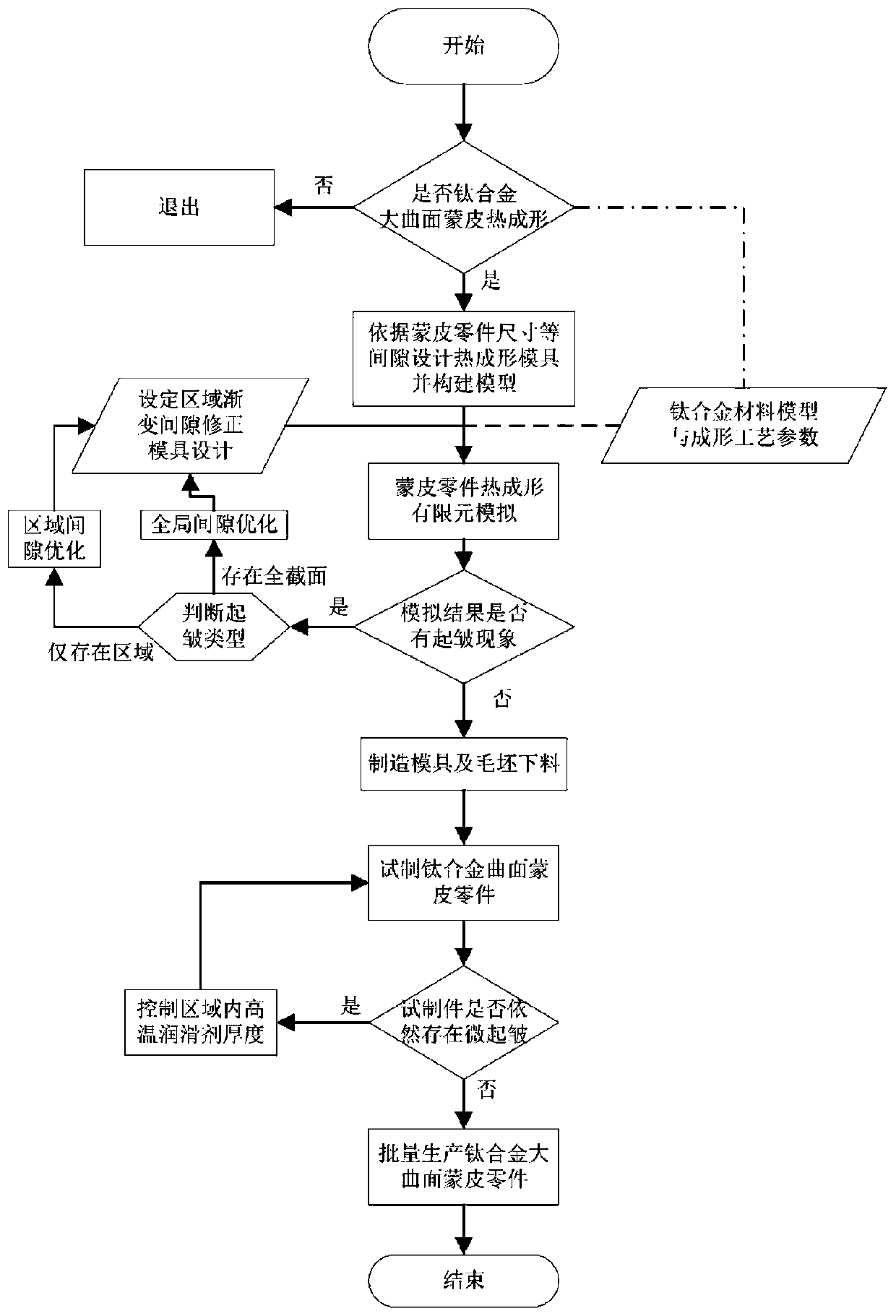

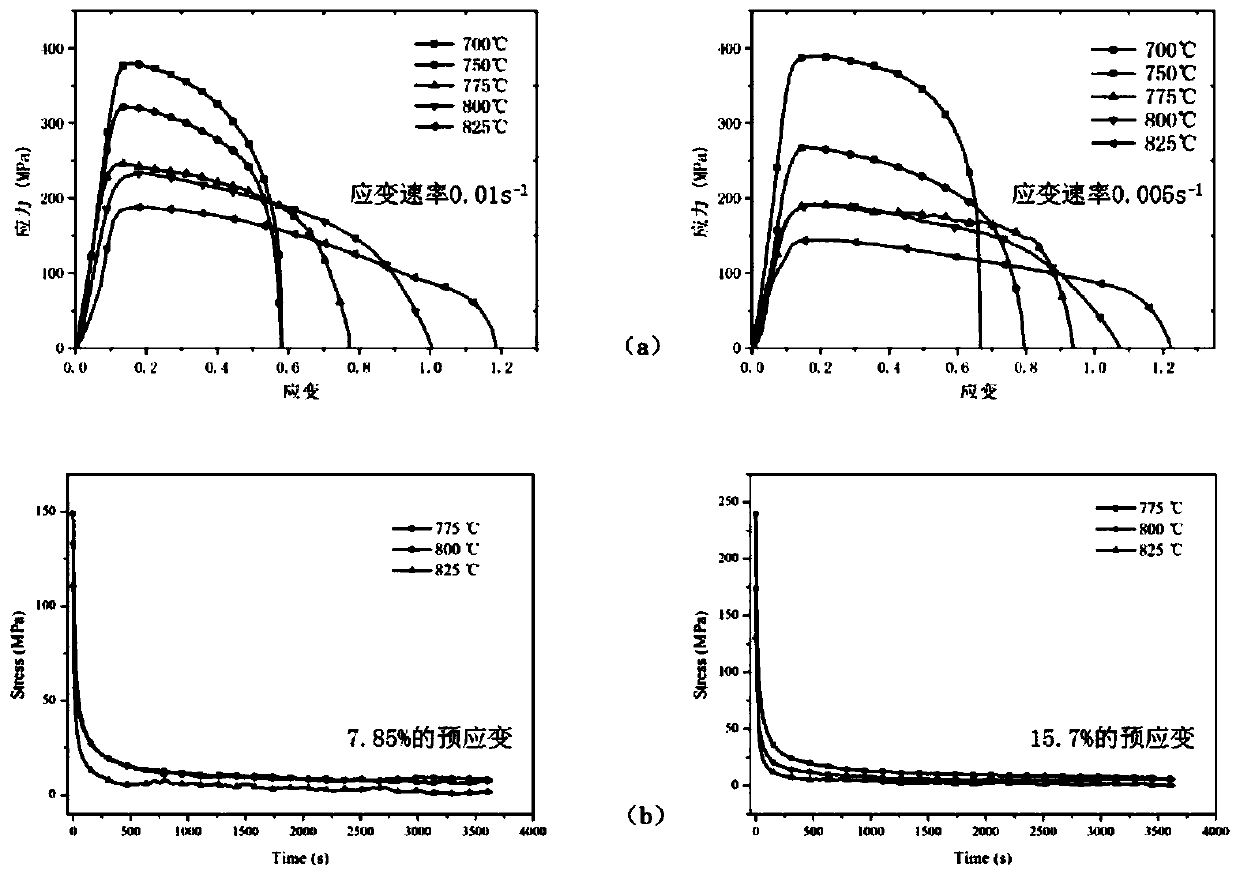

A Method of Eliminating Wrinkling of Large Curved Surface Based on Gradient Gap Die

The invention discloses a method of eliminating skin wrinkles of a large surface based on a gradient gap die and belongs to the field of techniques of removing skin formation wrinkles. Batch production of high-quality skin can be implemented herein by optimally designing die gaps and manufacturing; the method herein is applicable to the formation of skin parts of various high-intensity materials,particularly manufacturing of titanium alloy skin parts; pressure-pressure stress state is a main cause to wrinkling; gaps are reasonably designed, gradient frictional resistance is utilized to form acontrollable resistance field, and therefore, mobility during plate forming process is limited, the pressure-pressure stress state in plates is reduced, wrinkle removal is achieved, and high-qualityparts with corrugation meeting technical requirements are met. The method herein may be used as a new method to eliminate wrinkles in thermal formation of titanium alloy large-surface skin so as to obtain high-quality parts.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A low stress state composite substrate for gan growth

ActiveCN105514231BReduced stress stateImproving epitaxial growth qualitySemiconductor devicesComposite substrateDielectric layer

Owner:SINO NITRIDE SEMICON

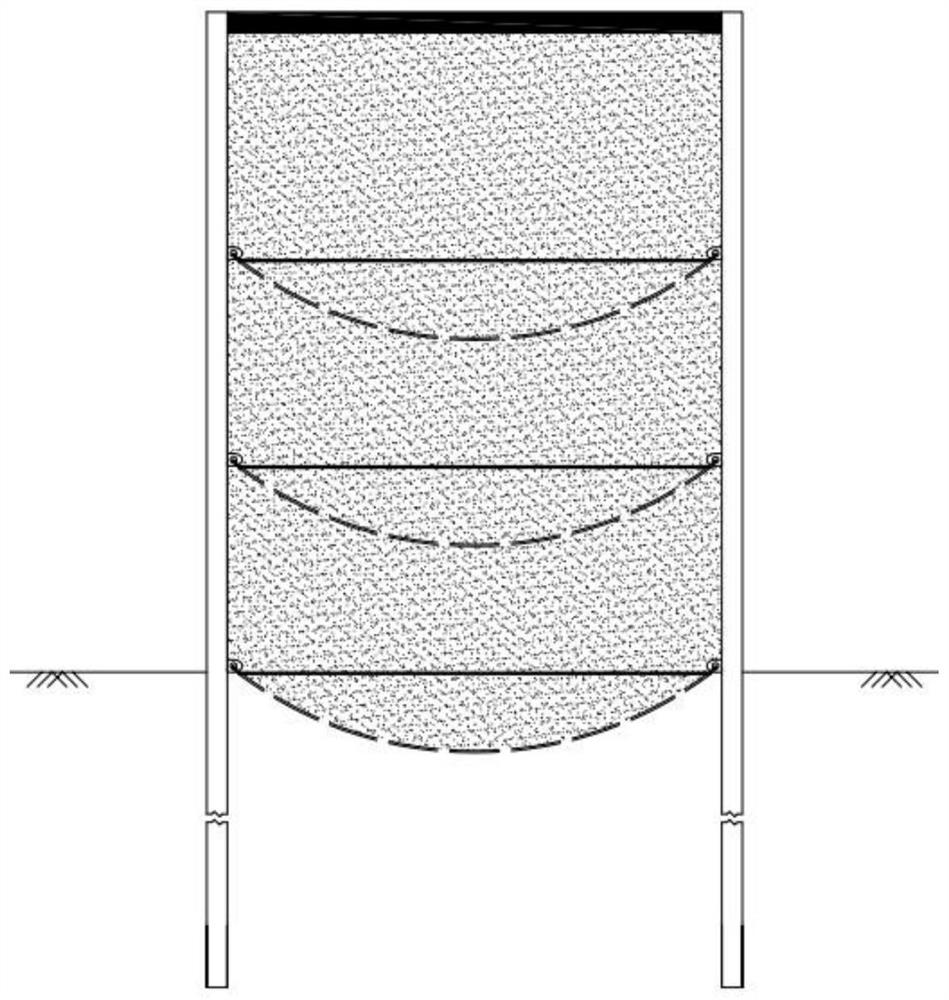

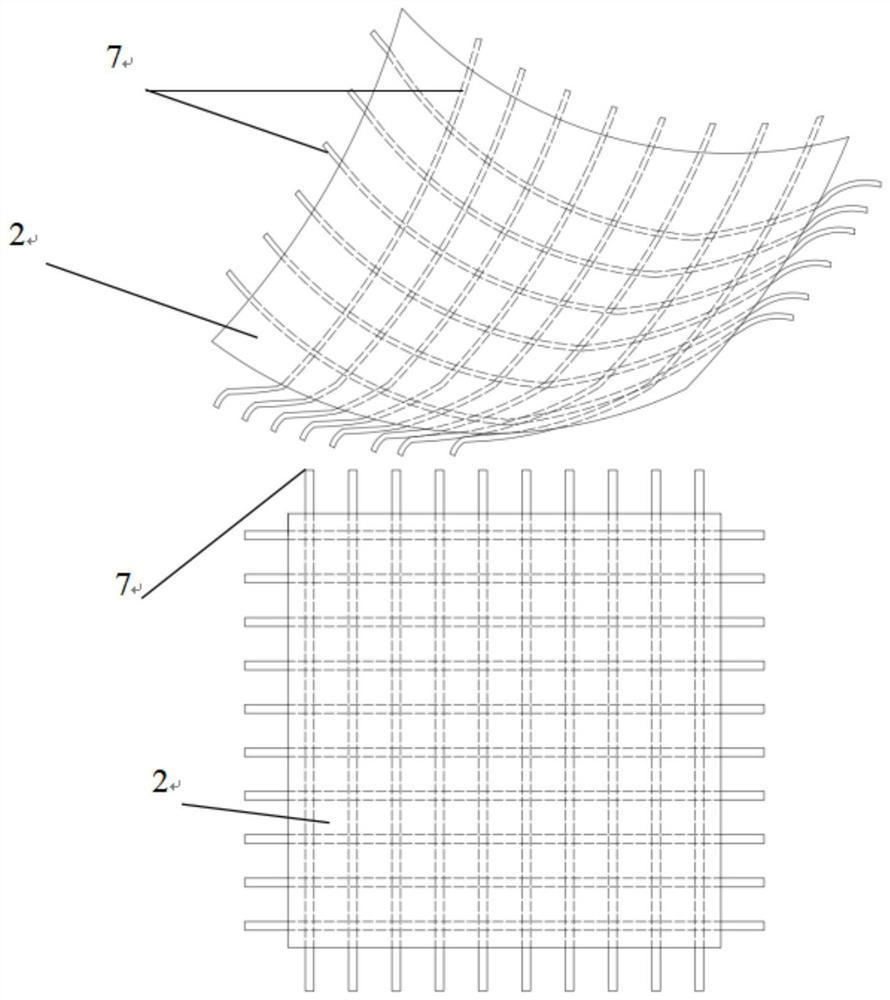

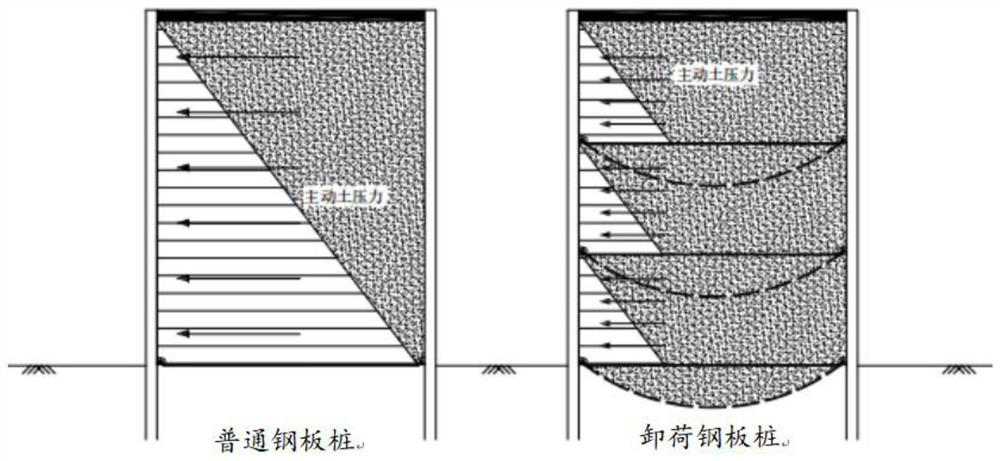

Double-row sheet pile decompression self-unloading method and double-row pile structure thereof

ActiveCN114197445AImprove integrityIncrease stiffnessGeometric CADDesign optimisation/simulationSoil scienceSoil stress

The decompression self-unloading method comprises the design and installation process of self-unloading double-row sheet piles and the mechanical calculation optimal process of the self-unloading double-row sheet piles, a double-row sheet pile structure can be obtained through design of the method, the double-row sheet piles comprise the double-row sheet piles, unloading geotechnical cloth, filling soil, anchoring rings and top supports, the double-row sheet piles are vertically inserted into a soft soil foundation of a to-be-constructed area; the top supporting cross bars are arranged at the top positions of the double-row sheet piles; a plurality of anchoring rings are arranged on the inner sides of the double-row sheet piles, unloading soil cloth is hung on the anchoring rings, and the space defined by the double-row sheet piles is divided into a plurality of layers. And the filling soil is filled on the unloading geotechnical cloth until the enclosed space is full. The self weight of the filling soil on the unloading geotechnical cloth is shared through the unloading geotechnical cloth, so that the soil stress in the filling soil is greatly reduced, and the soil pressure load of the filling soil on the double-row sheet piles is also greatly reduced.

Owner:TONGJI UNIV

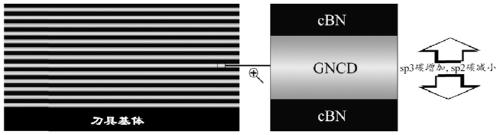

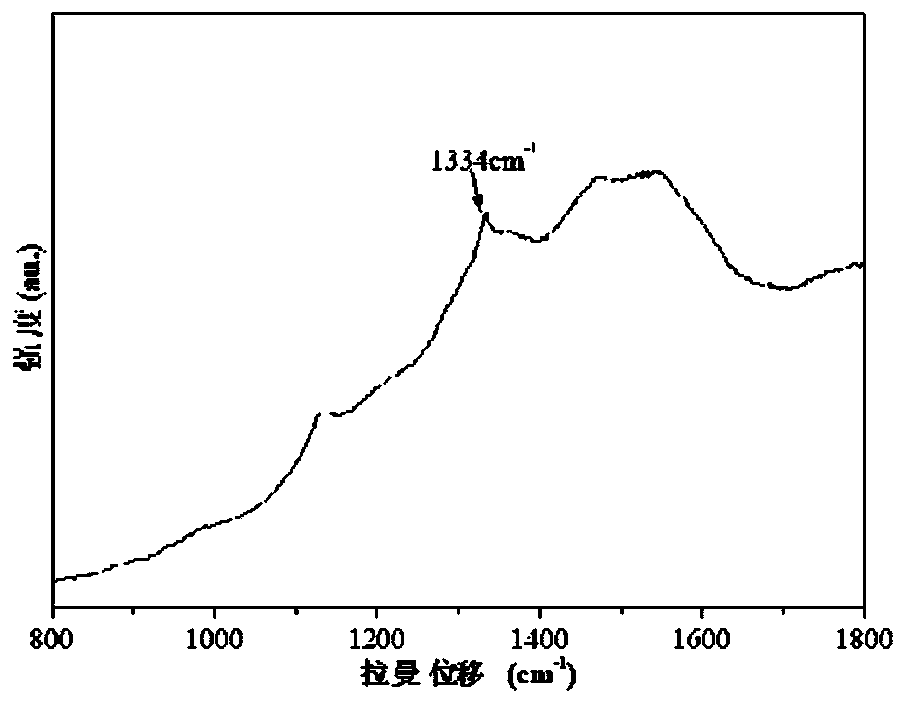

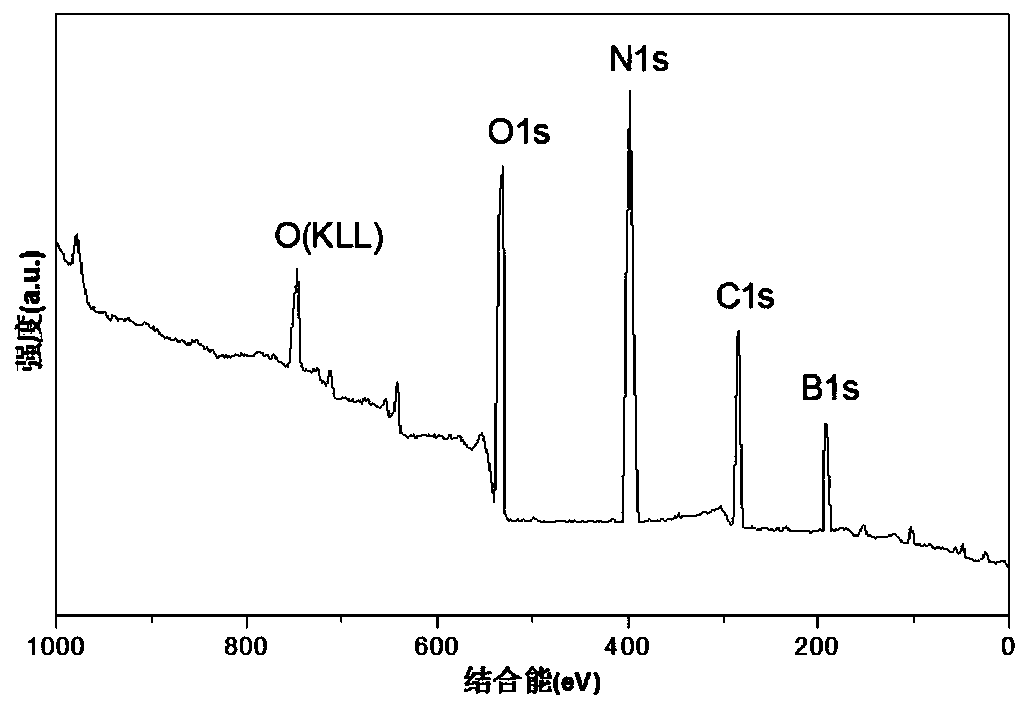

Preparation method of GNCD-CBN nanocomposite multi-layer coating tool with toughening mechanism

ActiveCN108220916BReduce processing costsImprove efficiencyVacuum evaporation coatingSputtering coatingBoron nitrideSuperalloy

The invention provides a preparation method of a nano composite GNCD-cBN multilayer coated cutter having toughening mechanism, wherein the composite coating is formed through alternate growth of gradient nano-crystalline diamond (GNCD) and cubic boron nitride (cBN). The GNCD coating is a gradually-varying coating layer, wherein the internal structure of the GNCD coating is in a gradient arrangement of high-content sp3 carbon + high-content sp2 carbon + high-content sp3 carbon. The coating has the hardness of the cBN and can be used for cutting ferrous metal material such as high-temperature alloy and high-strength steel; by means of the GNCD, thickness of the coating layer can be increased, and toughness of the coating during cutting process can be improved and strength and anti-impact performance of the coating are totally improved. The method significantly improves wear resistance of the coating cutter and prolongs the service of the cutter.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Control unit and medical examination apparatus

InactiveUS8886285B2Improve coordinationCritical situationSurgeryMedical devicesDiagnostic Radiology ModalityMeasurement device

A control unit for an equipment arrangement is provided. The control unit includes an imaging modality, a measurement device for measuring a control variable and a controllable injection device for a regulatory substance influencing the control variable, wherein the injection rate of the injection device may be varied during a data acquisition such that a proposed value for the control variable is reached.

Owner:SIEMENS HEALTHCARE GMBH

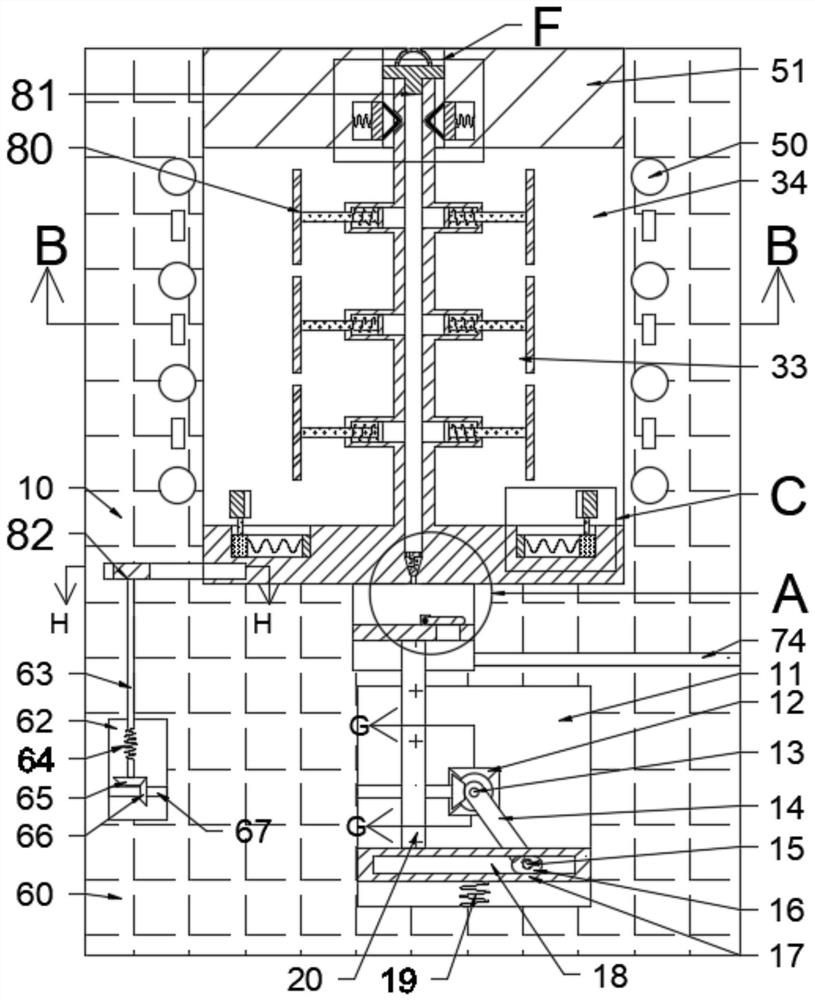

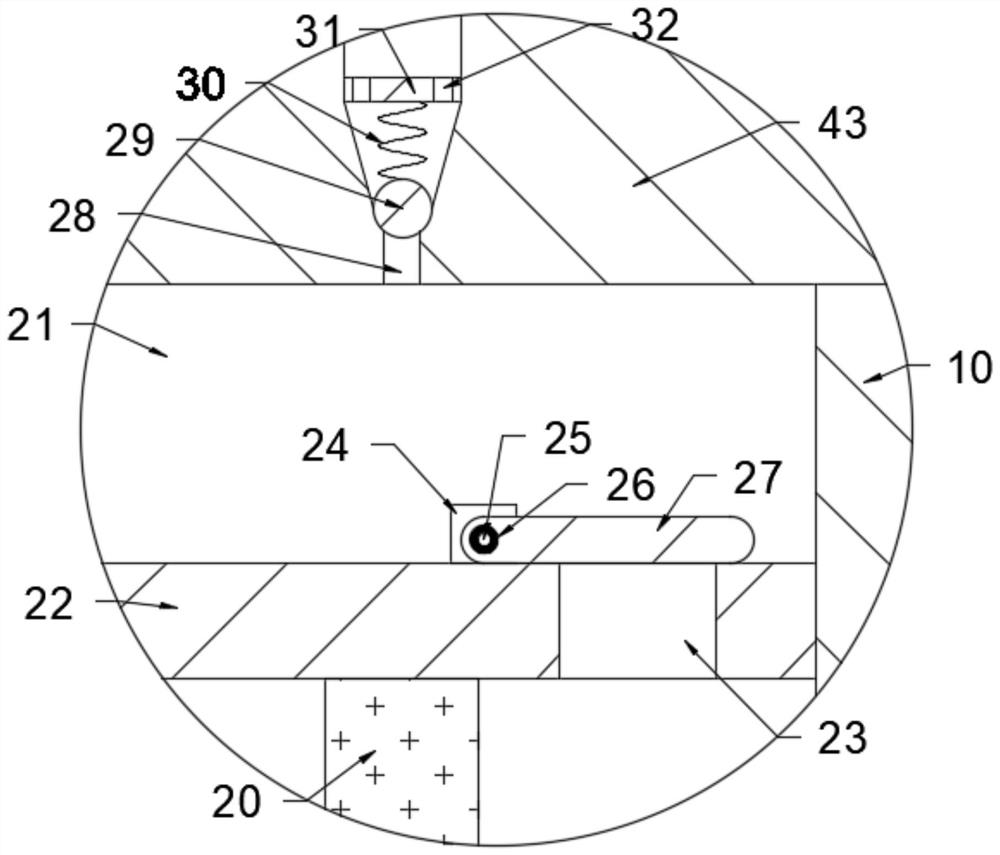

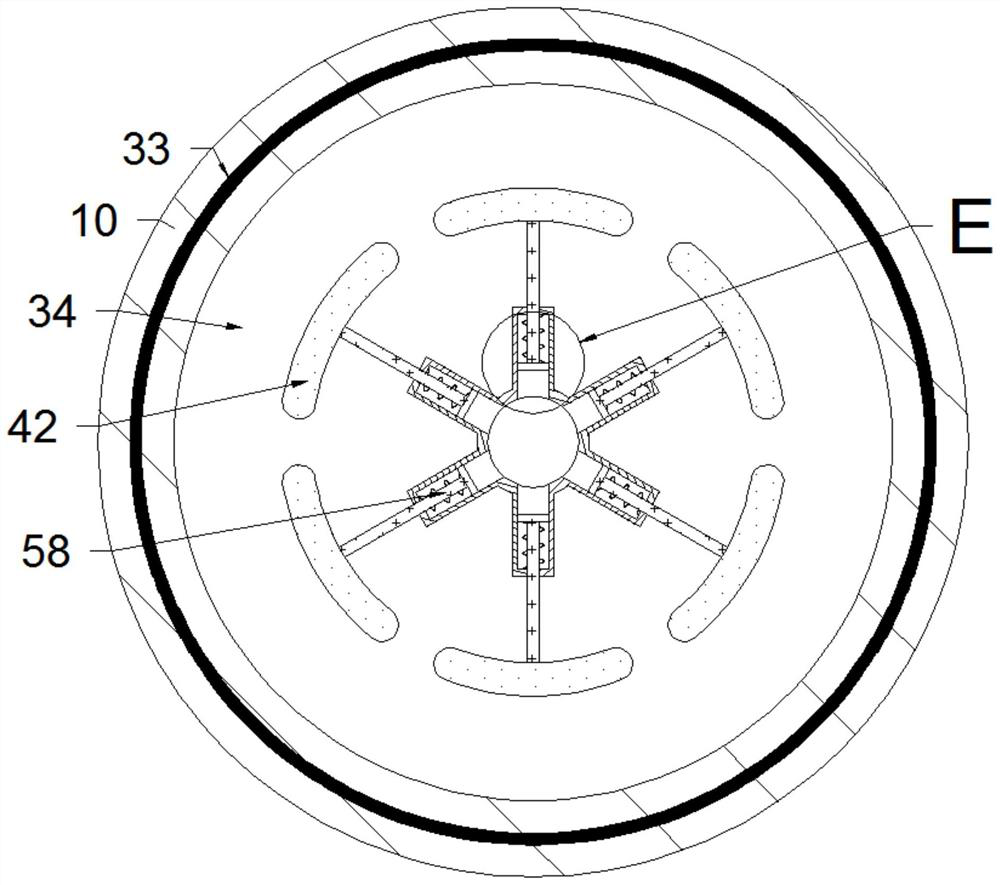

Stress relieving device for thin-wall cylindrical part

InactiveCN113005271AAddress stressSolve problems such as easy deformationFurnace typesHeat treatment furnacesStress relievingElectric machinery

The invention discloses a stress relieving device for a thin-wall cylindrical part. The stress relieving device comprises a placement block, wherein a first transmission cavity is formed in the placement block; a radial fixing mechanism is arranged in the first transmission cavity; and the radial fixing mechanism comprises a driving motor which is fixedly arranged on the inner wall of the rear side of the first transmission cavity. According to the stress relieving device disclosed by the invention, the thin-wall cylindrical part is radially fixed through a clamping block and an inflation pushing silica gel strip, so that clamping processing is convenient, and the problem of instability and deformation is completely avoided; and meanwhile, a method for relieving stress by cold and hot alternation is adopted for the thin-wall cylindrical part through a high-temperature pipe and a low-temperature pipe, so that the thin-wall cylindrical part generates pressure stress or tensile stress under continuous cold and hot alternation, the pressure stress or the tensile stress is counteracted with machining stress, the stress state of the part is reduced, the problems of large residual stress, easiness in deformation and the like in a processing process of the thin-wall cylindrical part are effectively solved, and the processing reliability and the product quality of the thin-wall cylindrical part are improved.

Owner:南京瑟朗图汽车用品有限公司

A method for manufacturing a curved surface transparent part with variable thickness

ActiveCN104552740BHigh dimensional accuracyGuaranteed surface qualityOptical articlesVariable thicknessMetallurgy

The invention belongs to the technical field of injection forming and relates to a method for manufacturing a variable-thickness structural transparent workpiece, and particularly relates to a method for manufacturing a high-accuracy variable-thickness cambered transparent workpiece. The method disclosed by the invention carries out forming processing on a variable-thickness workpiece by adopting a primary integral injection compression and secondary differential expansion injection compression combined injection forming method, thereby effectively controlling the surface quality and retracting warpage of the workpiece in areas with different thicknesses; in addition, the method disclosed by the invention carries out forming by selecting a polycarbonate material with excellent impact resistant property, thereby ensuring the characteristics of light weight and transparency of the workpiece. According to the method, the mould temperature is controlled to be higher than plastic glass transition temperature in a stage of filling a cavity through a fusant by applying a dynamic variable-mould temperature control technology, and after expansion and compression are finished, the mould temperature is fast reduced to sufficiently cool a shaped workpiece, so that the surface quality of the workpiece is ensured, the forming period is shortened, and the production cost is reduced. The workpiece manufactured by adopting the method disclosed by the invention can achieve the light transmittance of more than 75%, and the optical distortion of an effective area can be controlled to be less than 1 / 10.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com