Stress relieving device for thin-wall cylindrical part

A technology of thin-walled cylinder and stress relief, which is applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problems of low aging temperature, high stress relief temperature, reduced strength and elongation, etc., to improve reliability and product quality, Solve the effect of large residual stress and avoid instability deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

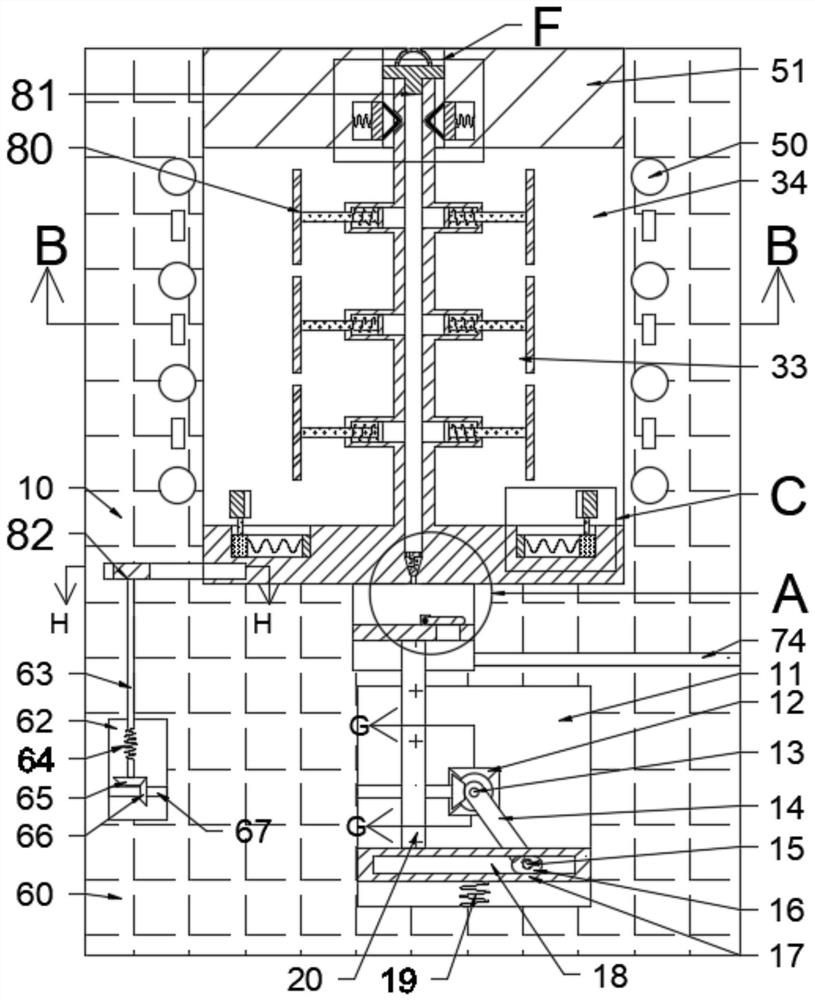

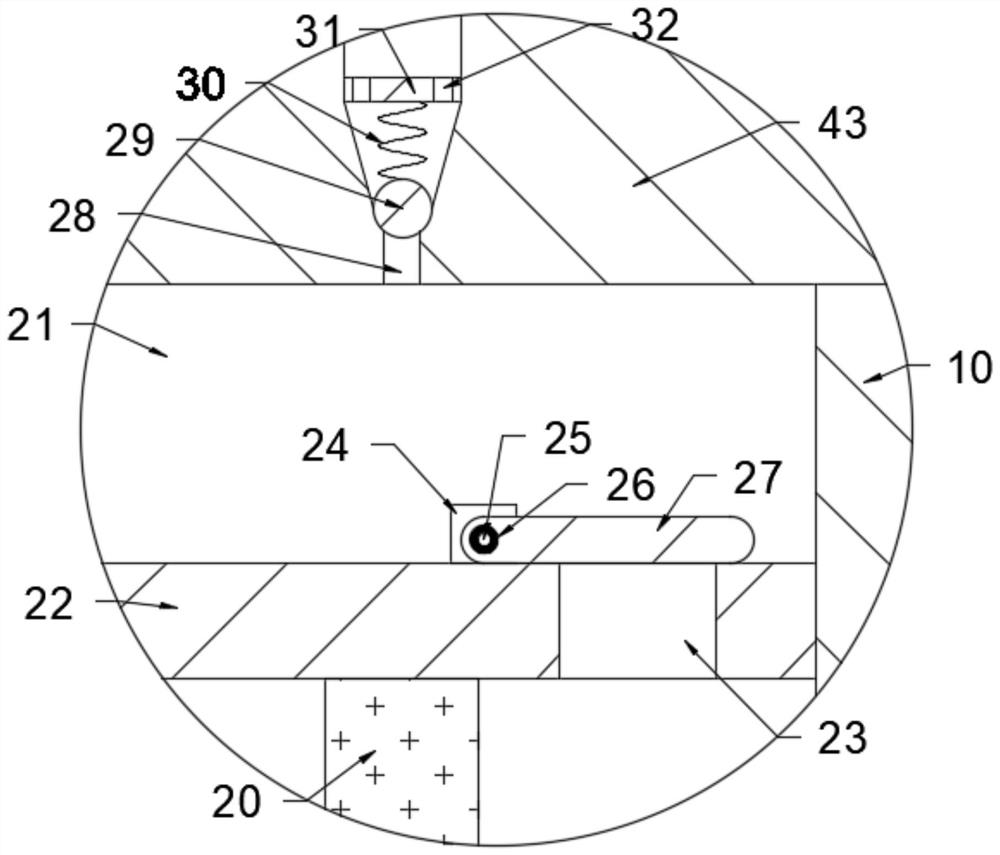

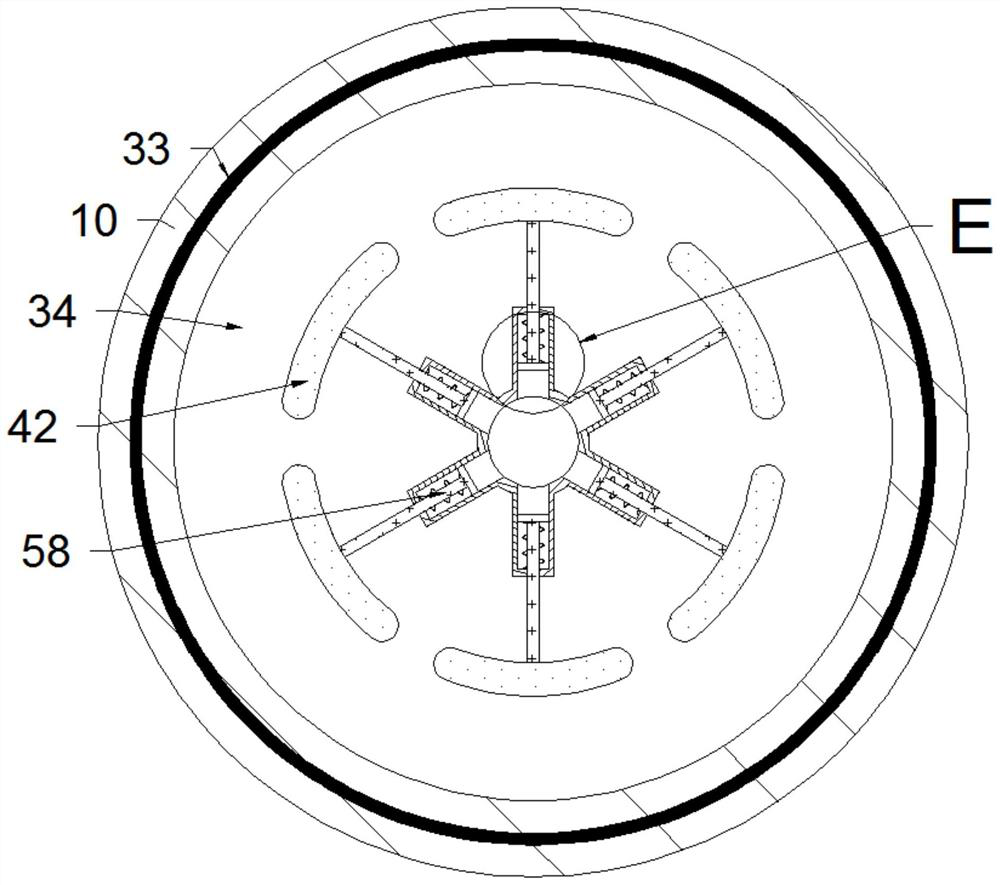

[0023] Combine below Figure 1-9 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0024] combined with Figure 1-9 The stress relief device for a thin-walled cylindrical part includes a placement block 10, a first transmission chamber 11 is arranged inside the placement block 10, a radial fixing mechanism 80 is arranged inside, and the radial fixing mechanism 80 includes a drive motor 12 fixed on the rear inner wall of the first transmission chamber 11, a first rotating shaft 13 is fixed on the front end of the driving motor 12, and a first connecting rod is fixed on the first rotating shaft 13 14. The first connecting rod 14 is rotated with a second rotating shaft 15, the second rotating shaft 15 is fixed with a first slider 16, and the first transmission chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com