Stud welding mixed connection node of rectangular concrete filled steel tubular column and H-shaped steel girder

A technology of concrete columns and rectangular steel pipes, which is applied in the direction of construction and building structure, can solve problems such as affecting aesthetics and home layout, steel layering or brittle damage, affecting concrete pouring in pipes, etc., to avoid adverse effects and high prefabrication rate. , the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

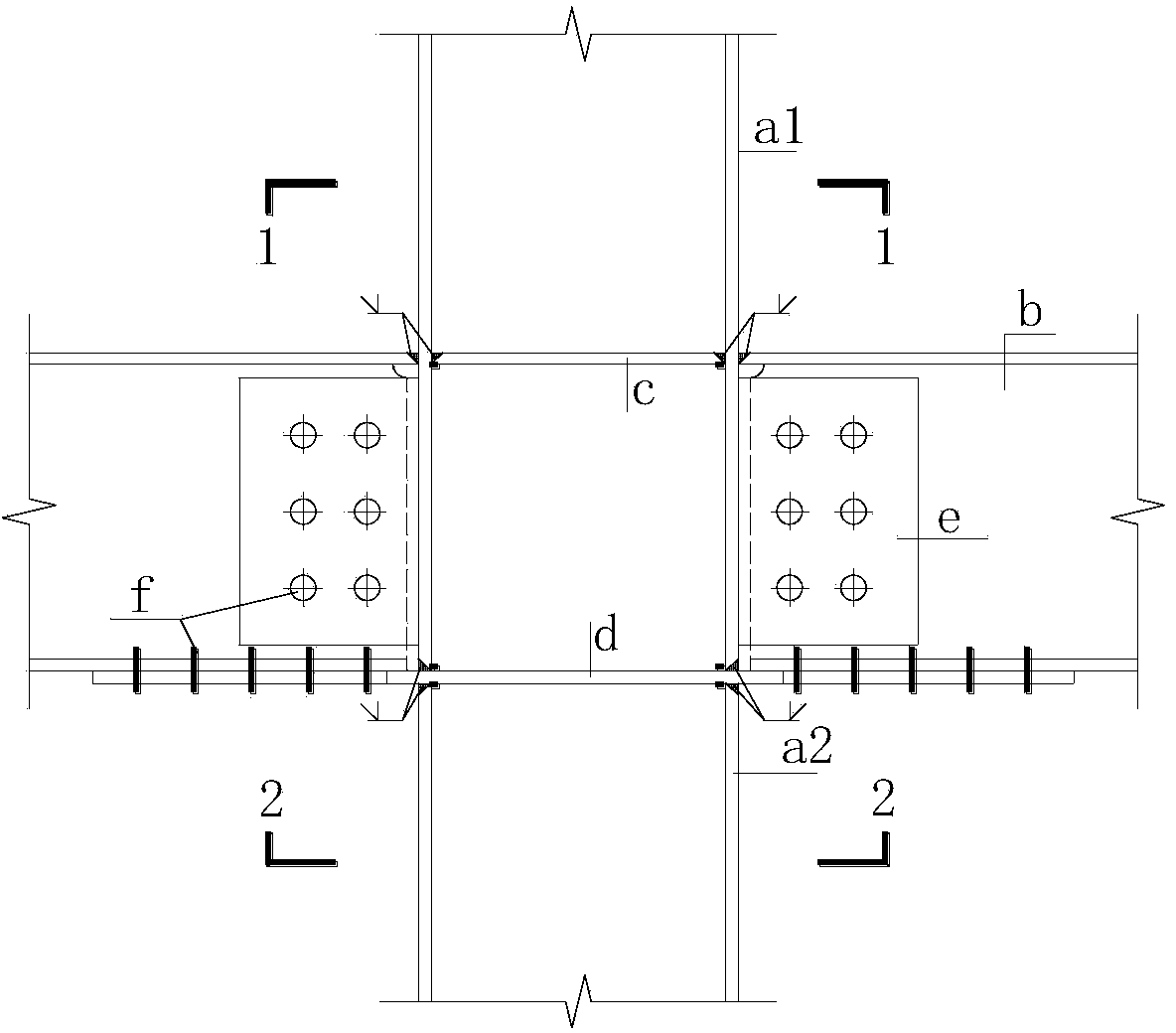

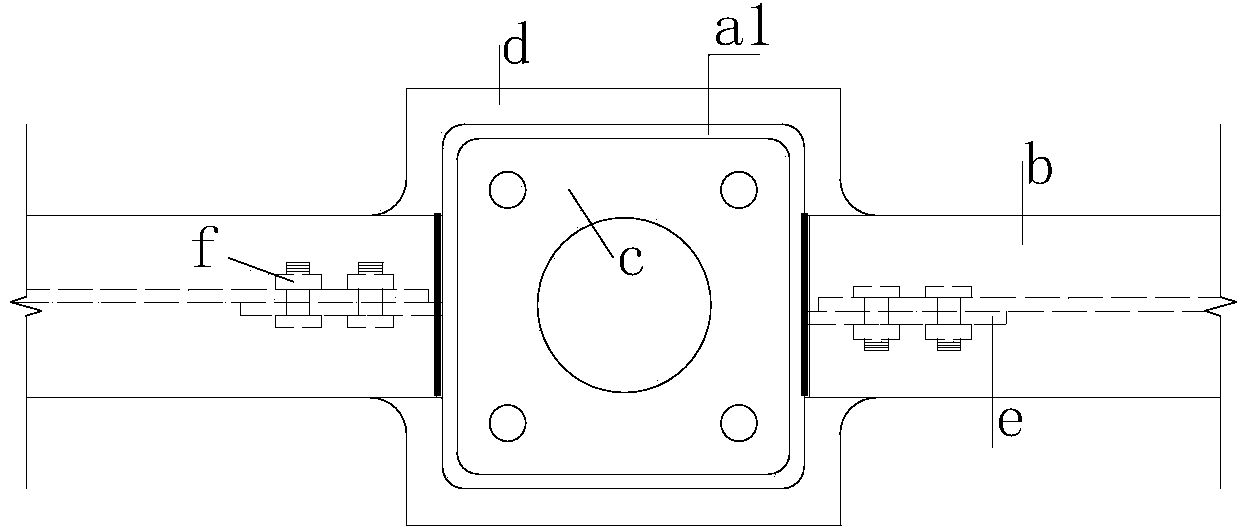

[0034] see Figure 1 ~ Figure 3 , the through partition d is located below the lower flange, and the through partition d is connected to the lower flange by high-strength bolts f.

[0035] The construction method of this embodiment:

[0036] 1) Process the inner partition c and the through partition d according to the size of the rectangular concrete-filled steel tube column. Under the premise of meeting the structural requirements, the through partition is provided with arc chamfering so that the wider middle body of the through partition is narrower. The overhanging section transitions, the overhanging section is as wide as the lower flange, and the radius of the arc chamfer is not less than 25mm.

[0037] 2) Bolt holes are reserved on the through partition d, the diameter of which is slightly larger than the diameter of the high-strength bolt f, and the number of reserved holes is calculated by the bending moment borne by the beam flange;

[0038] 3) Weld the inner partit...

Embodiment 2

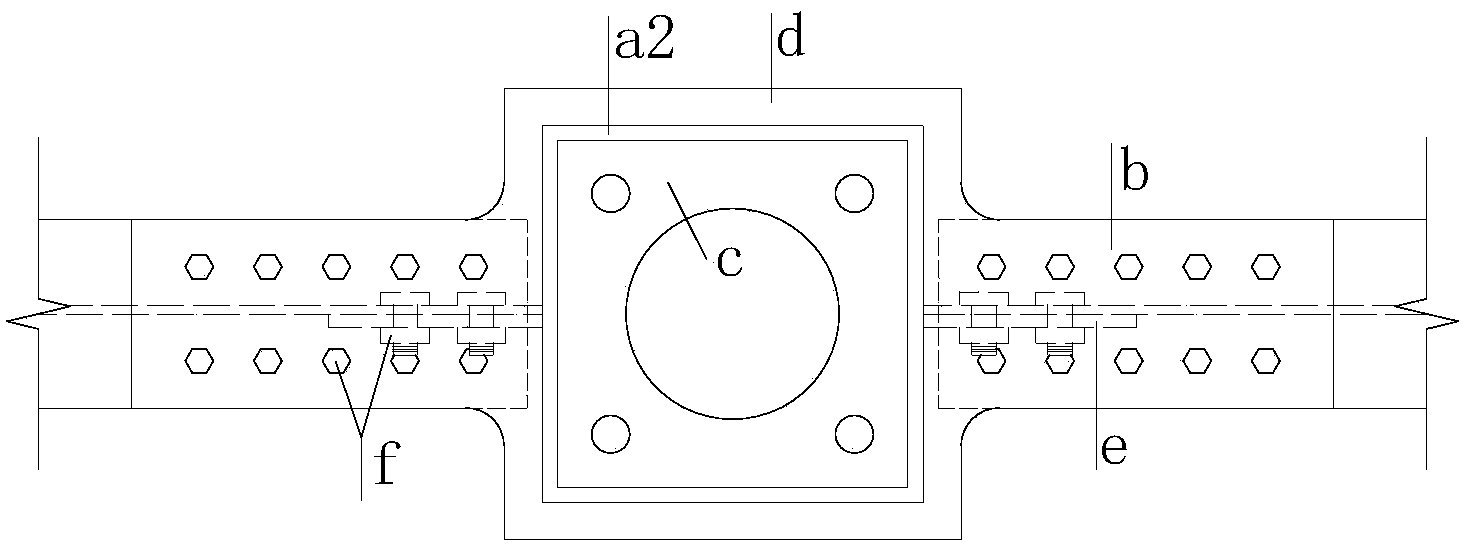

[0043] see Figure 4 ~ Figure 6 , the lower flange is opposite to the through partition d, and the lower flange is welded to the through partition d.

[0044] The construction method of this embodiment:

[0045] 1) Process the inner partition c and the through partition d according to the size of the rectangular concrete-filled steel tube column. Under the premise of meeting the structural requirements, the through partition is provided with arc chamfering so that the wider middle body of the through partition is narrower. The overhanging section transitions, the overhanging section is as wide as the lower flange, and the radius of the arc chamfer is not less than 25mm.

[0046] 2) Bolt holes are reserved on the through partition d, the diameter of which is slightly larger than the diameter of the high-strength bolt f, and the number of reserved holes is calculated by the bending moment borne by the beam flange;

[0047] 3) Weld the inner partition c into the upper steel pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com