Patents

Literature

182results about How to "Improve prefabrication rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

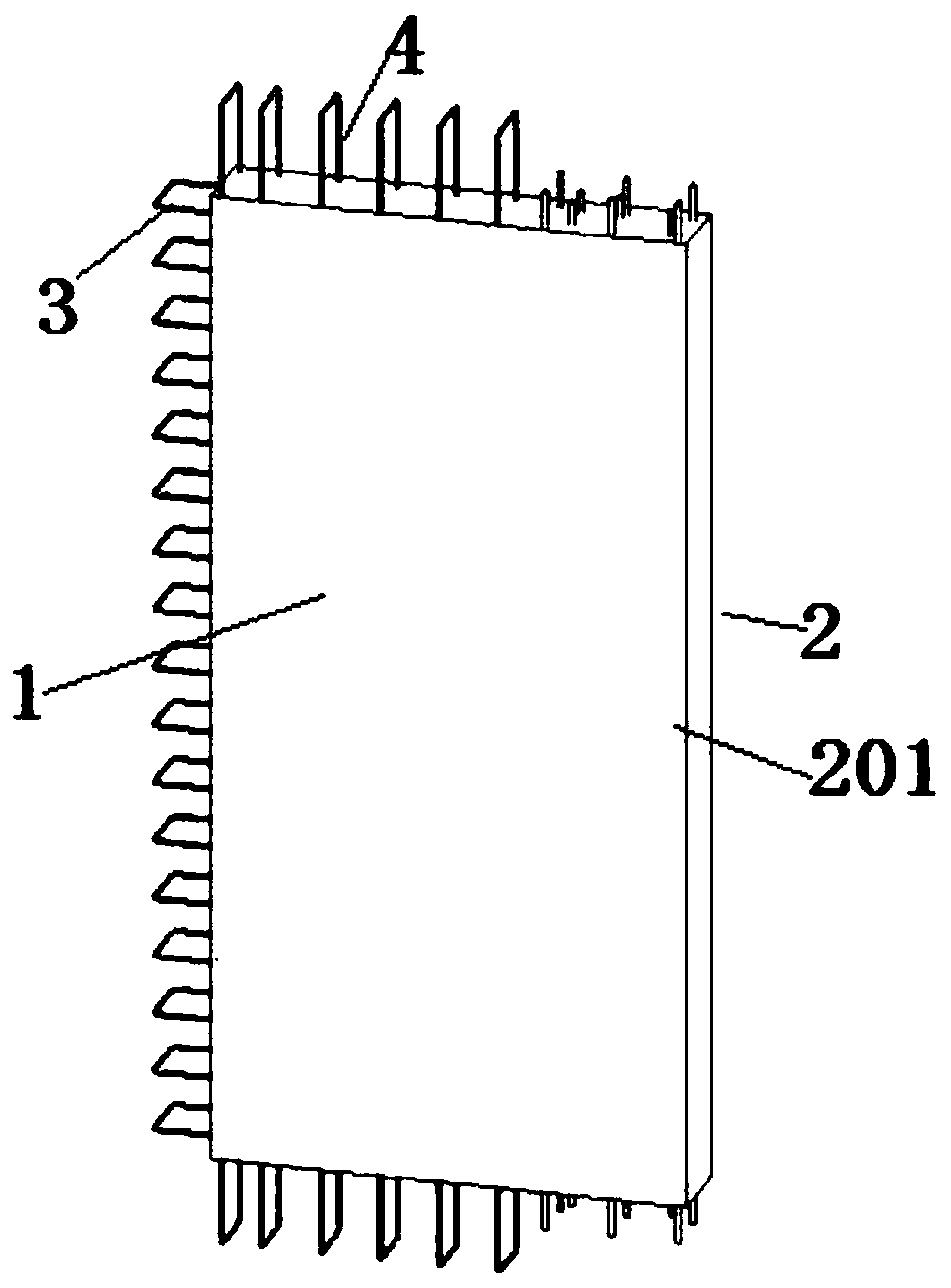

DGC modular fabricated building system and building method thereof

Provided are a DGC modular fabricated building system and a building method thereof. Wallboards are composite boards prefabricated in a factory. Light steel profiles and light steel keels are connected through self-tapping screws. The corners of the light steel profiles with grooves in frames are connected through self-tapping screws and light steel keel connecting pieces. The interiors of the wallboards are filled with heat preservation materials. Pouring layers of modified cement mortar or light aggregate concrete materials are arranged on the outermost sides of the wallboards. Floors are composite boards prefabricated in the factory, and each composite board is a foundation bottom plate or a floorboard or a roof panel of the DGC modular fabricated building system. The wallboards are connected through board connecting pieces, the wallboards and the floors are connected through board connecting pieces, and the floors are connected through board connecting pieces. The DGC modular fabricated building system is simple in structure, convenient to mount and low in cost, the construction period can be saved, and therefore the defects that an existing fabricated building is single in structure, complex in mounting process and high in manpower cost are overcome.

Owner:江苏保力装配式住宅工业有限公司

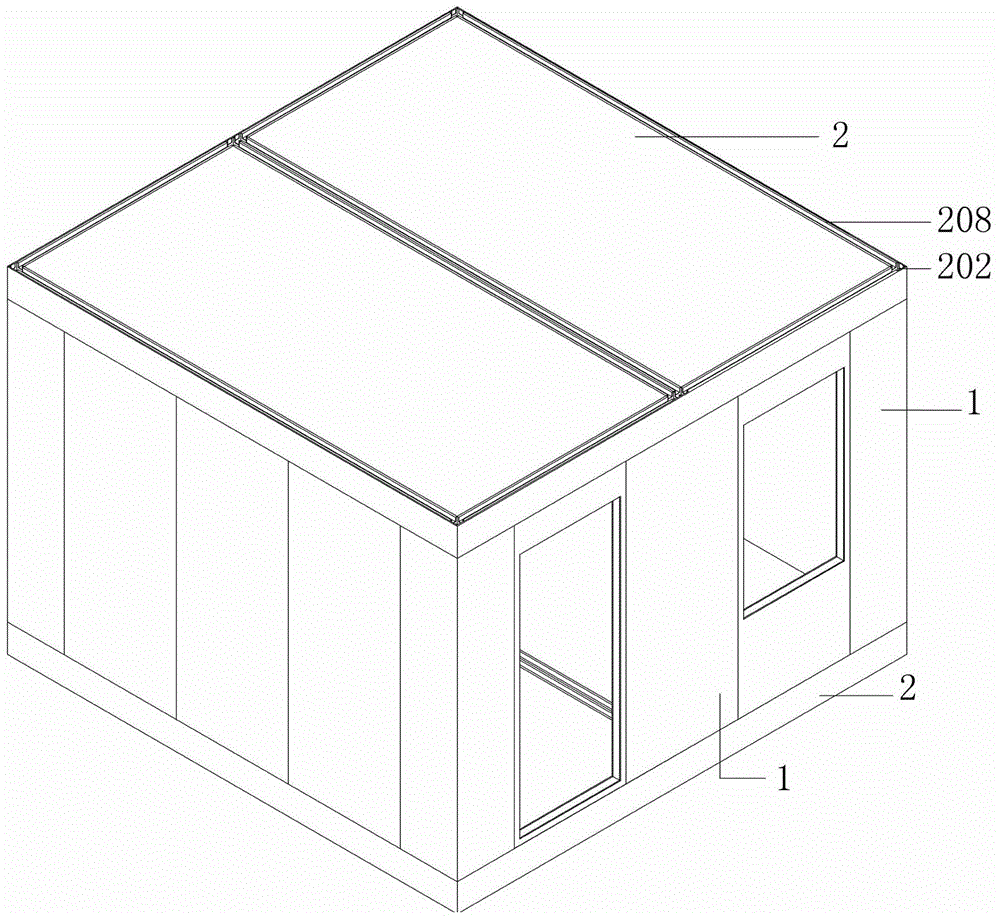

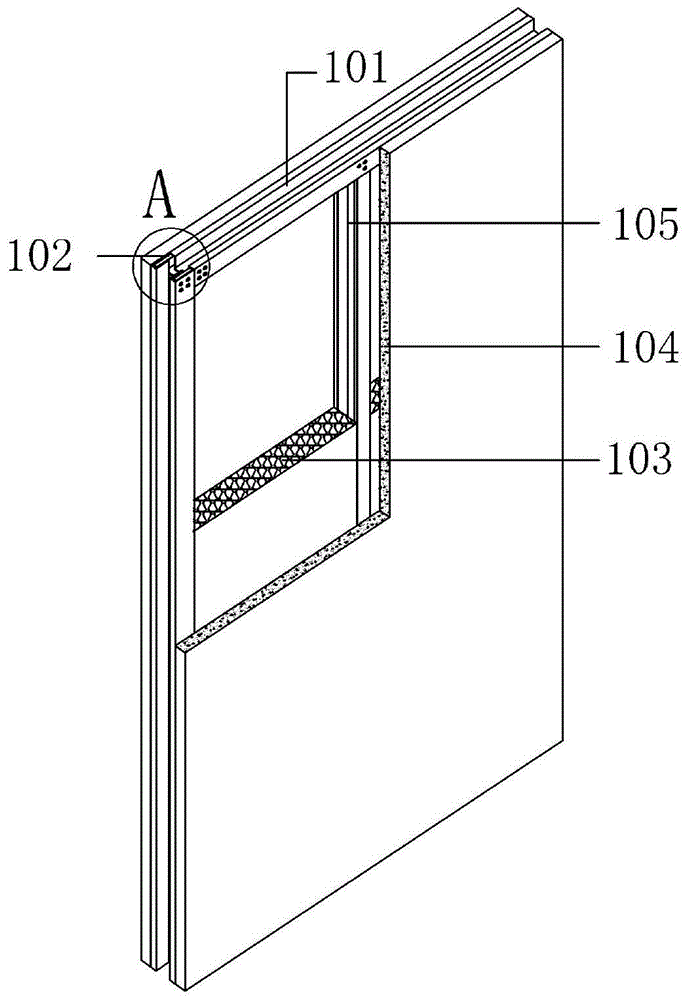

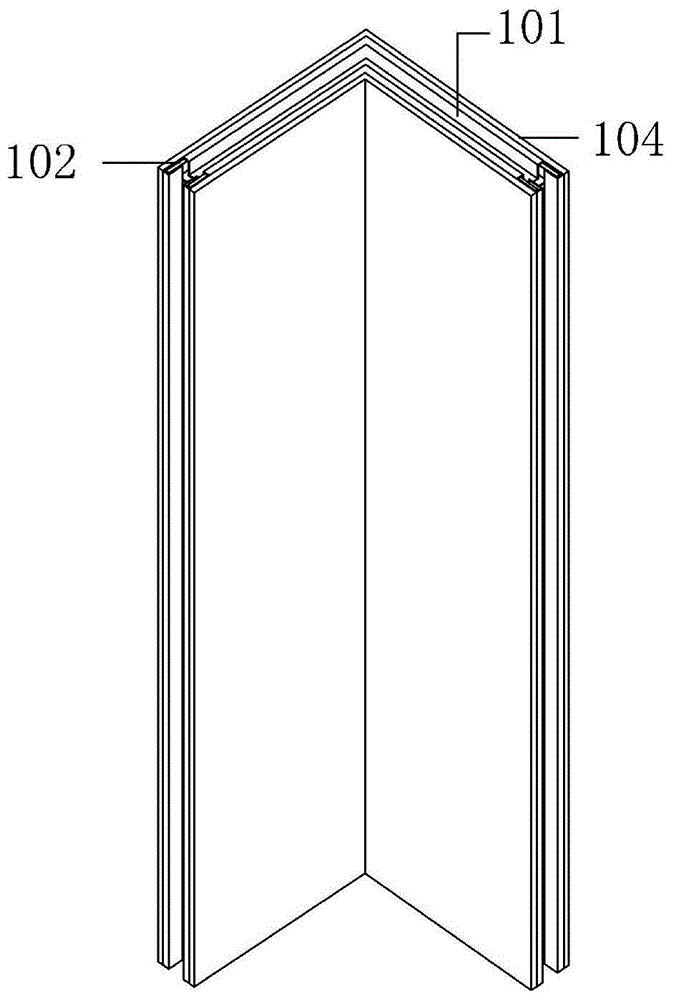

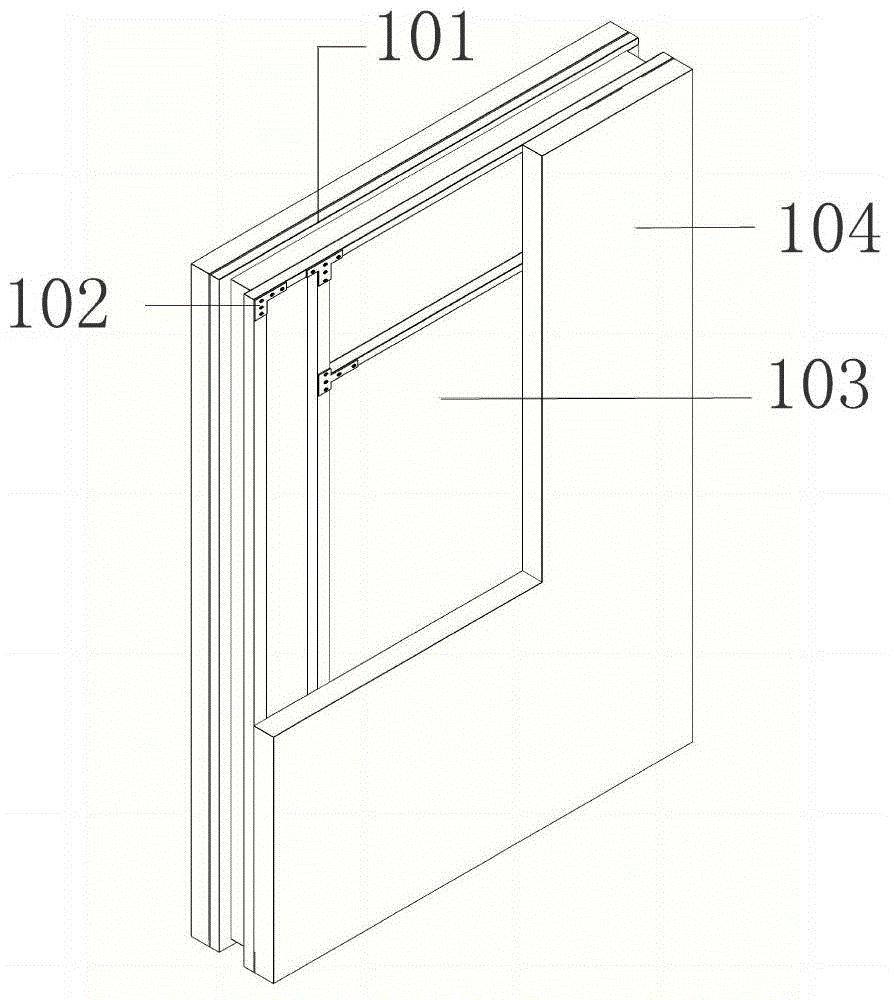

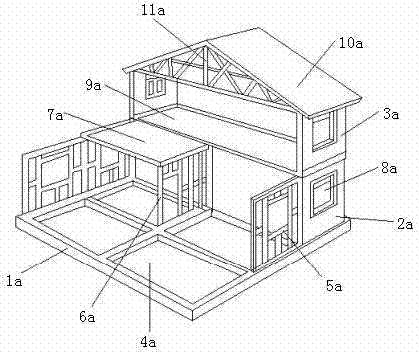

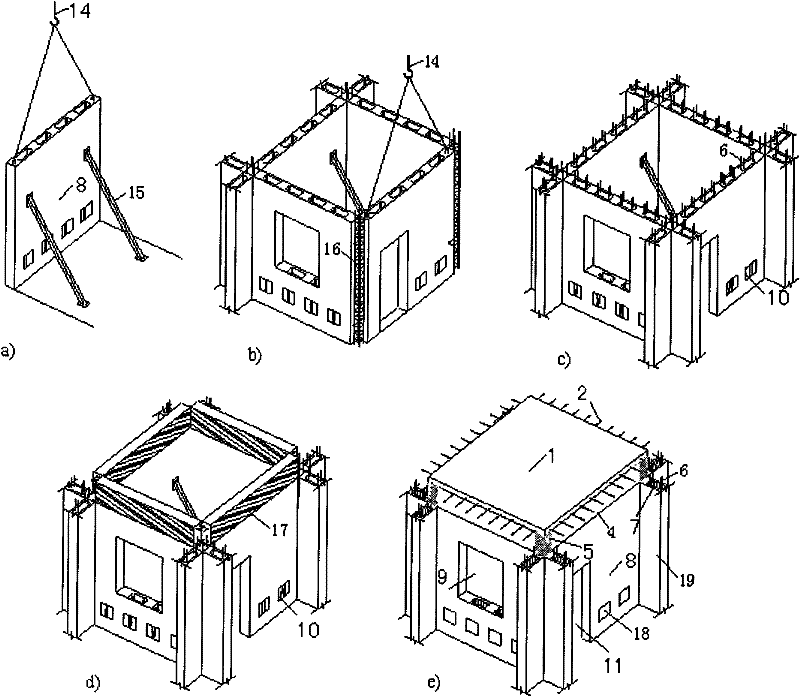

Simply-built green light steel fabricated building and installation method

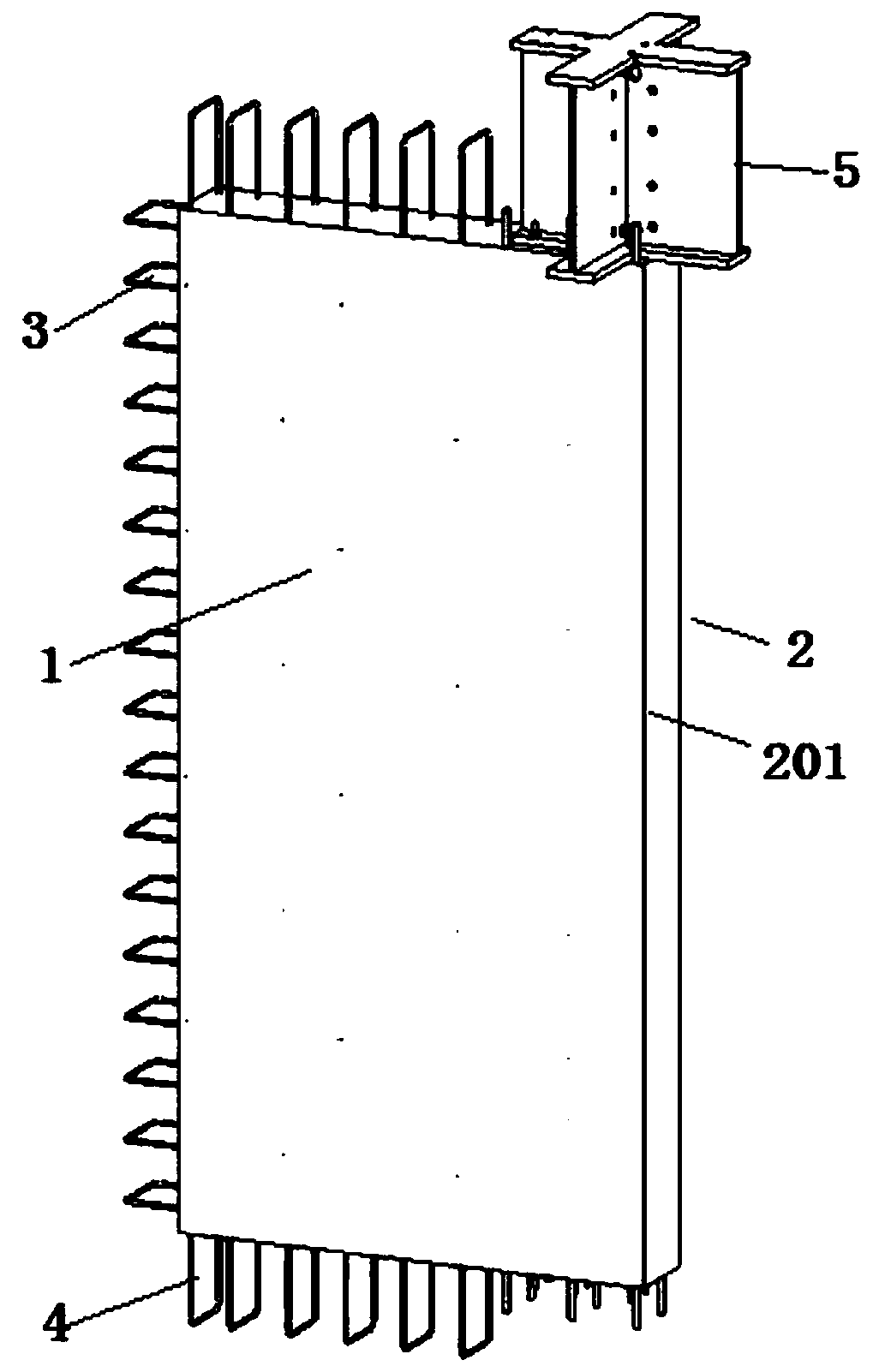

ActiveCN104947792AImprove prefabrication rateEnsure structural safetyBuilding componentsBuilding material handlingPollutionPrefabrication

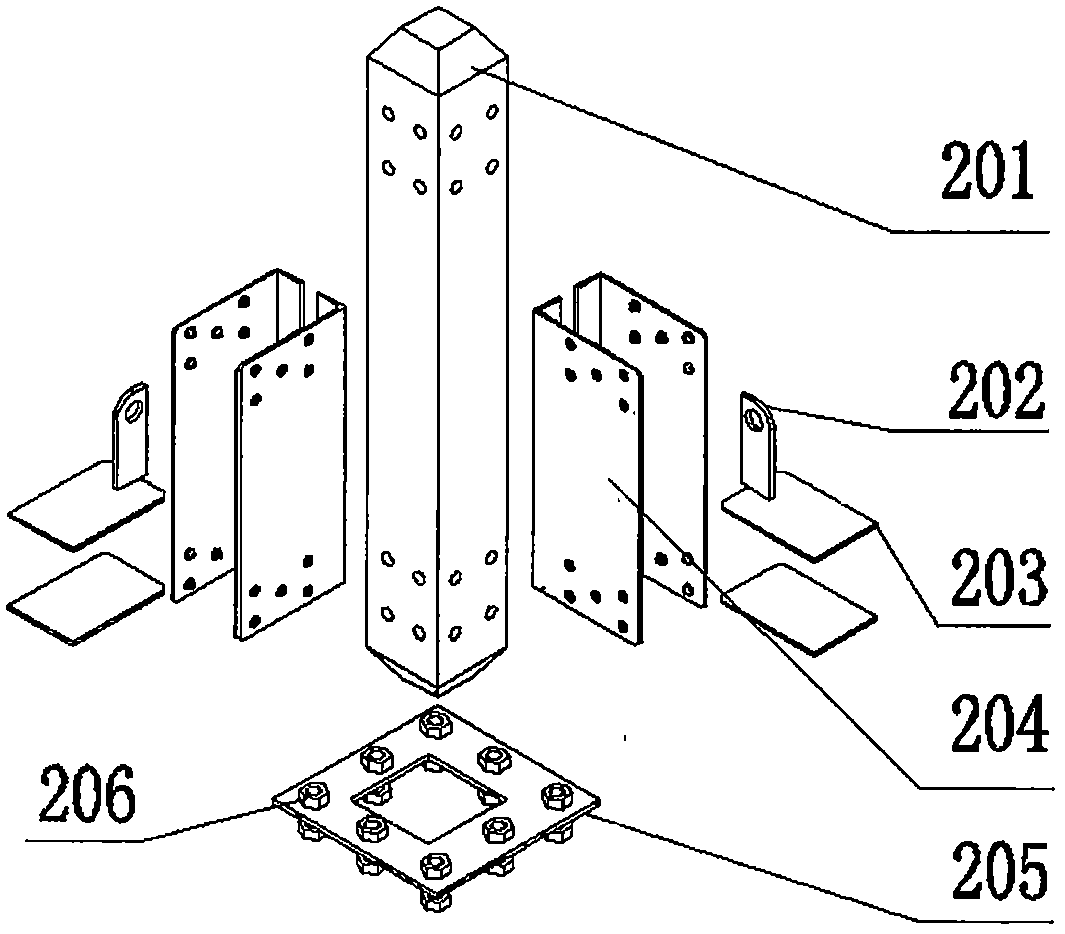

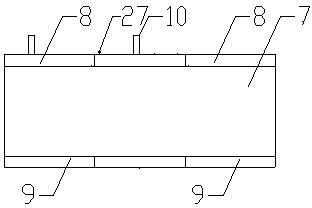

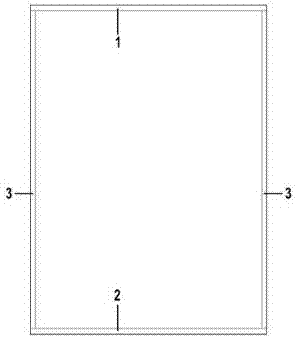

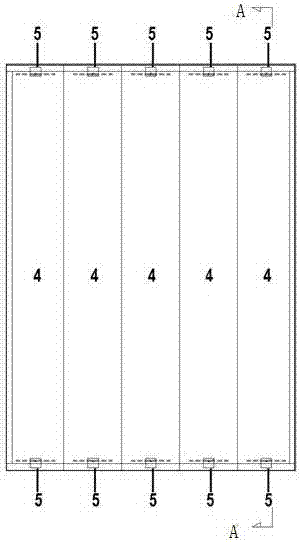

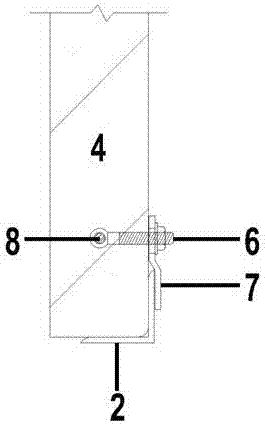

The invention provides a simply-built green light steel fabricated building and an installation method. The fabricated building comprises wall plates, main plates, composite frame columns and main connection pieces. The two wall plates are connected by means of the corresponding main connection pieces through self-tapping screws. The composite frame columns and the wall plates are connected by means of the corresponding main connection pieces through self-tapping screws. In the connection process, firstly the main connection pieces abut against the composite frame columns, the self-tapping screws are screwed into the composite frame columns to fix the composite frame columns, the wall plates are then arranged in place, and the main connection pieces are clamped into lateral side grooves of the wall plates. The main boards are connected with the composite frame columns, and body column sleeves of the portions, on the top layers of the main plates, of the composite frame columns are inserted in upwards-exposed tenon columns in a sleeved mode and are then fixed through bolts. By means of the full industrialized prefabrication of the wall plates and the main plates, the prefabrication rate of main components of the building is greatly increased, and therefore the structure safety and quality of the building are better facilitated, site workloads are reduced, the construction environment pollution is reduced, the construction period is shortened, and cost is saved.

Owner:江苏保力装配式住宅工业有限公司

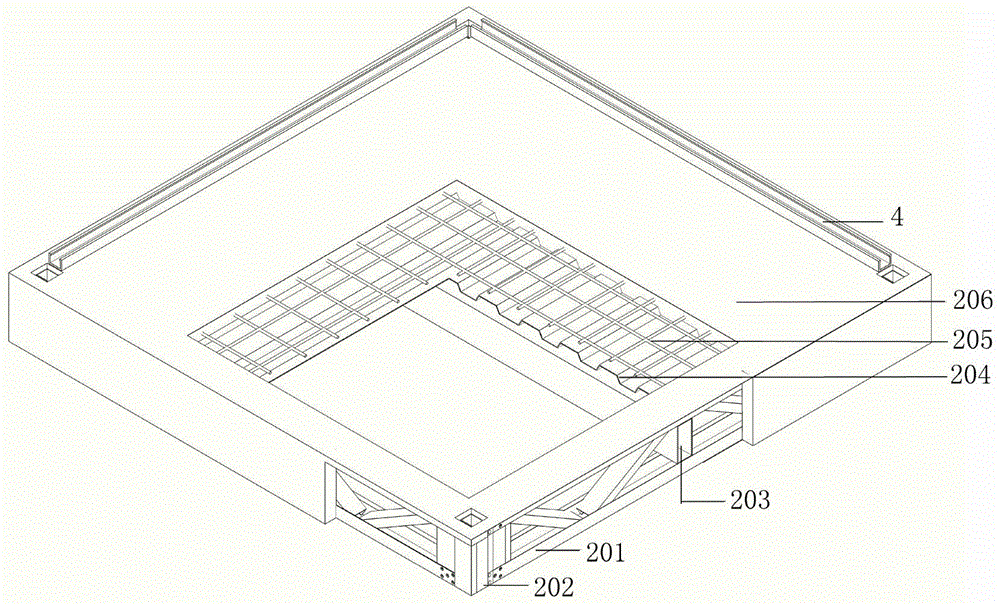

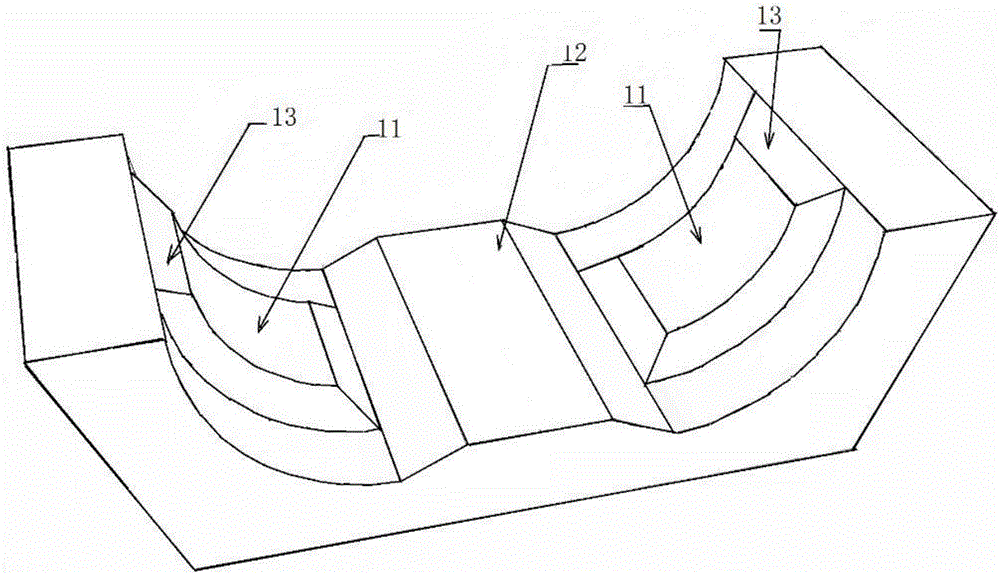

Assembly-type building bottom-layer composite floor and connection mode thereof

PendingCN107780576AImprove prefabrication rateReduce pollutionFloorsGirdersReinforced concreteMortise and tenon

Provided are an assembly-type building bottom-layer composite floor and a connection mode thereof. Factory-fabricated reinforced concrete with embedded parts is used as independent basis, square headshort columns are factory-prefabricated connection components and connected with upper chord members and lower chord members of main beams through pulling rivets to form outer frames of floors; on thebasis of the outer frames, secondary beams, profiled steel sheets and reinforcing meshes are laid horizontally, a surface course is poured, a decorative layer is attached to the surface course, and thus a mortise and tenon joint type connection mode of the floors and basic nodes is formed by combing insertion, pulling rivet connection and flange connection. According to the assembly-type buildingbottom-layer composite floor and the connection mode, the building mode of a traditional bottom-layer floor can be changed, the assembly type can be achieved, and the defects of poor vibration performance and soundproof effect and the like of an assembly-type light steel composite floor can also be overcome; meanwhile, the assembly-type building bottom-layer composite floor also has the advantages that the floor is assembled rapidly and subjected to industrial production easily and is high in strength and high in production speed, and has large actual project significance and market values topromotion and development of assembly-type buildings.

Owner:谢志强 +1

Butt joint connecting structure of precast concrete components

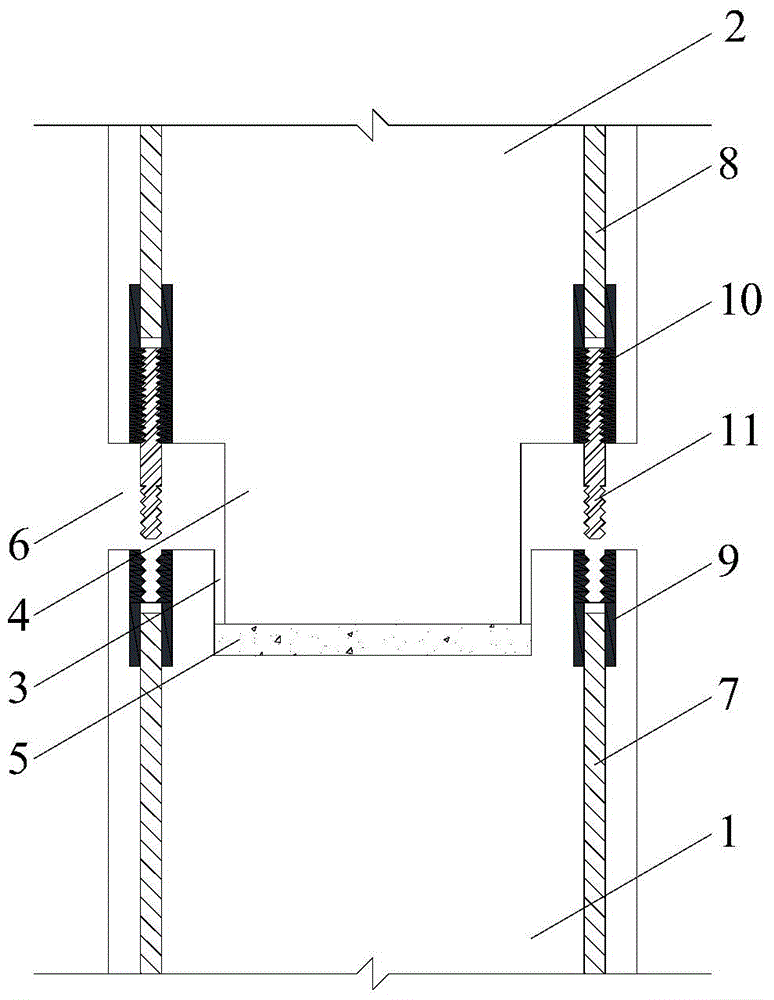

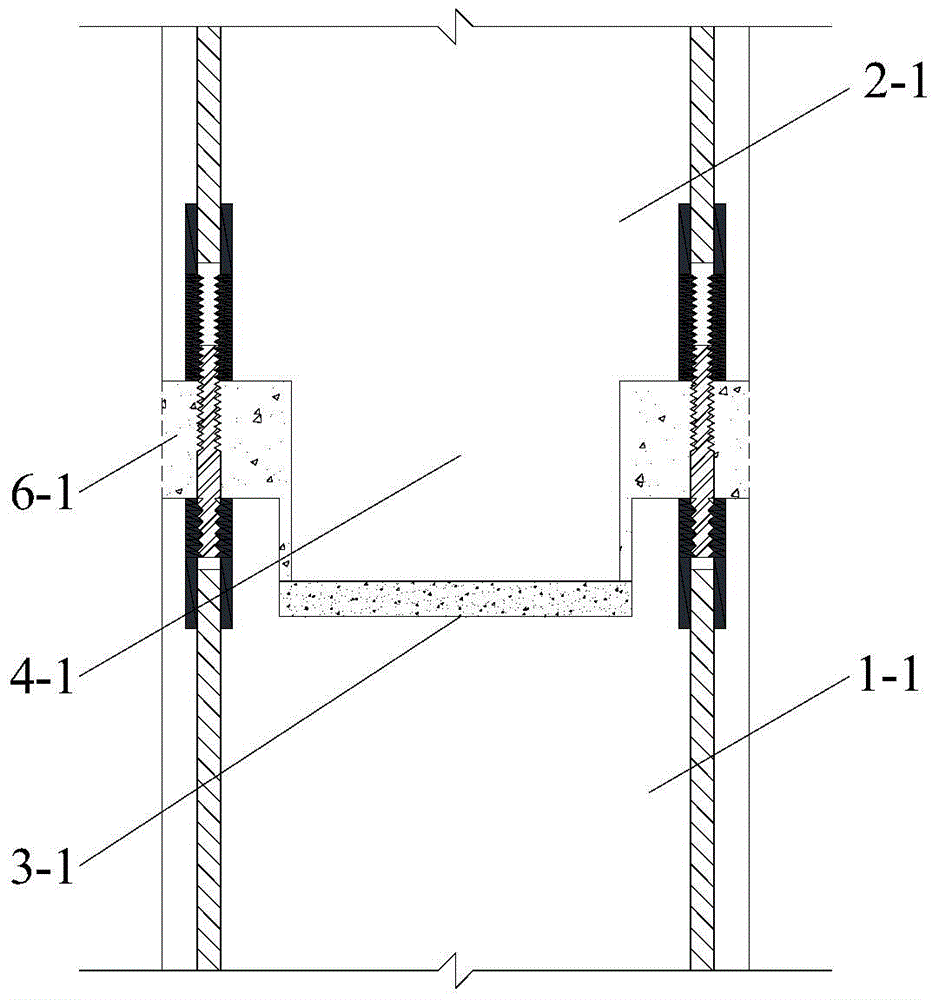

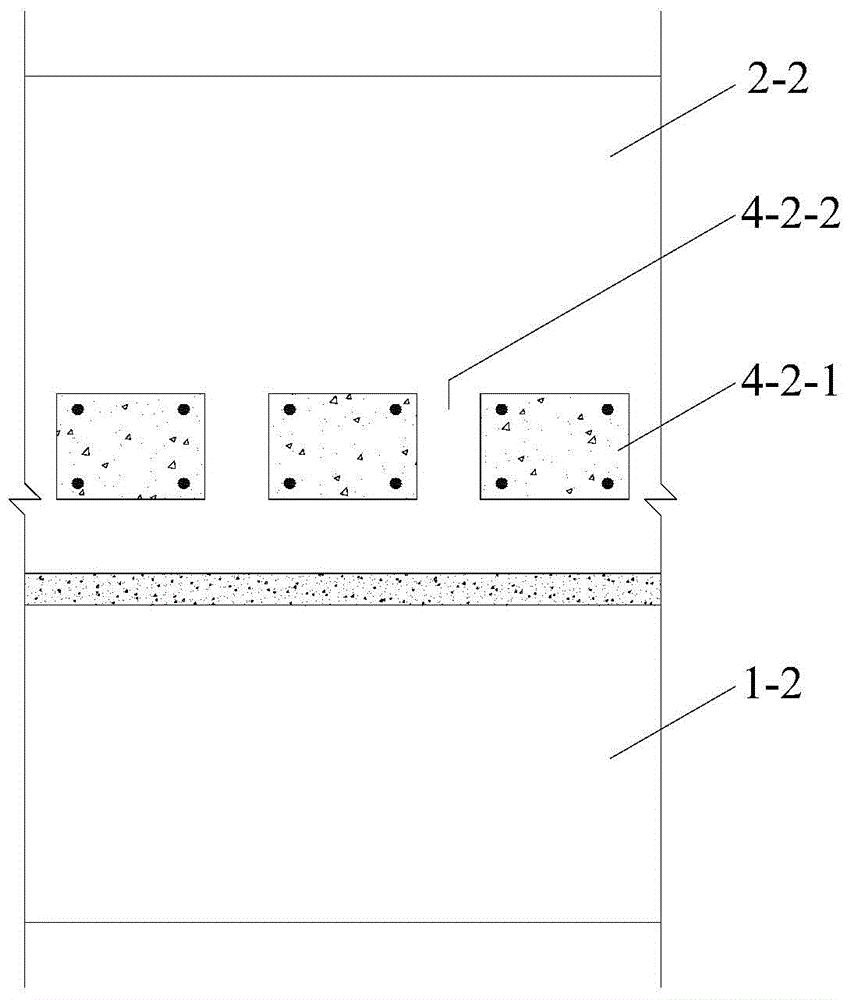

InactiveCN104975652AShorten the construction periodSmall diameterBuilding constructionsCOMPONENT IIGrout

The invention discloses a butt joint connecting structure of precast concrete components. The connecting objects are a component I and a component II which are closely connected with each other through a concave pit / a groove and a protrusion which are matched with each other in shape and size and paved with a cushion ply, and meanwhile a rear sealing troughed belt is formed between the two precast concrete components; a connecting mode of 'a longitudinal bar-a sleeve-a connecting rod-a sleeve-a longitudinal bar' is adopted for longitudinal bar connection, connection between the connecting rod and sleeves at the two ends can achieve a prestressed connection effect through a difference between pitches at the two ends. According to the butt joint connecting structure of the precast concrete components, the problems that in existing cast-in-place connection and bed mortar connection, time for forming bearing capacity on the joint is too long, assembly schedule is affected, the difficulty for transporting and protecting longitudinal bars to be connected is great, and minimum clear distance of grout sleeves and thickness of a protection layer is difficult to be guaranteed are solved, and meanwhile the prestressed connection is achieved.

Owner:CHINA UNIV OF MINING & TECH

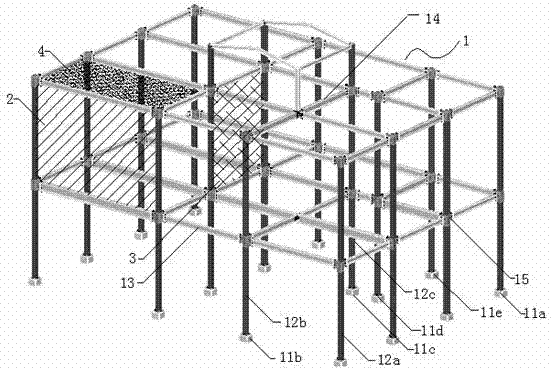

Light-weight steel structure house and construction method thereof

ActiveCN106948472AFast adjustmentEasy to adjustFloorsFoundation engineeringNoise reductionUltimate tensile strength

The invention relates to a light-weight steel structure house and a construction method thereof. The light-weight steel structure house comprises a house frame, double-layer outer wall plates, inner wall plates and lightweight floor plates. The house frame comprises a foundation, supporting upright columns, truss beams and cross sleeve connecting pieces; the supporting upright columns comprise four corner supporting upright columns, a plurality of outer supporting upright columns and a plurality of inner supporting upright columns; each supporting upright column is of an I-shaped steel structure; and the supporting upright columns are mounted on the foundation in mutually-parallel mode. The double-layer outer wall plates are arranged between every two adjacent outer supporting upright columns or between the adjacent corner supporting upright columns and the outer supporting upright columns. The inner wall plates are arranged between every two adjacent inner supporting upright columns or between the adjacent inner supporting upright columns and the outer supporting upright columns. The lightweight floor plates are parallelly arranged between every two adjacent truss beams. The light-weight steel structure house and the construction method thereof have the advantages that by means of the house frame, the double-layer outer wall plates, the inner wall plates and the lightweight floor plates and adjustment of connection of all the structures, the house is convenient for correction, effective heat dissipation and noise reduction are achieved, and meanwhile the overall strength of the house is guaranteed.

Owner:西藏藏建科技股份有限公司

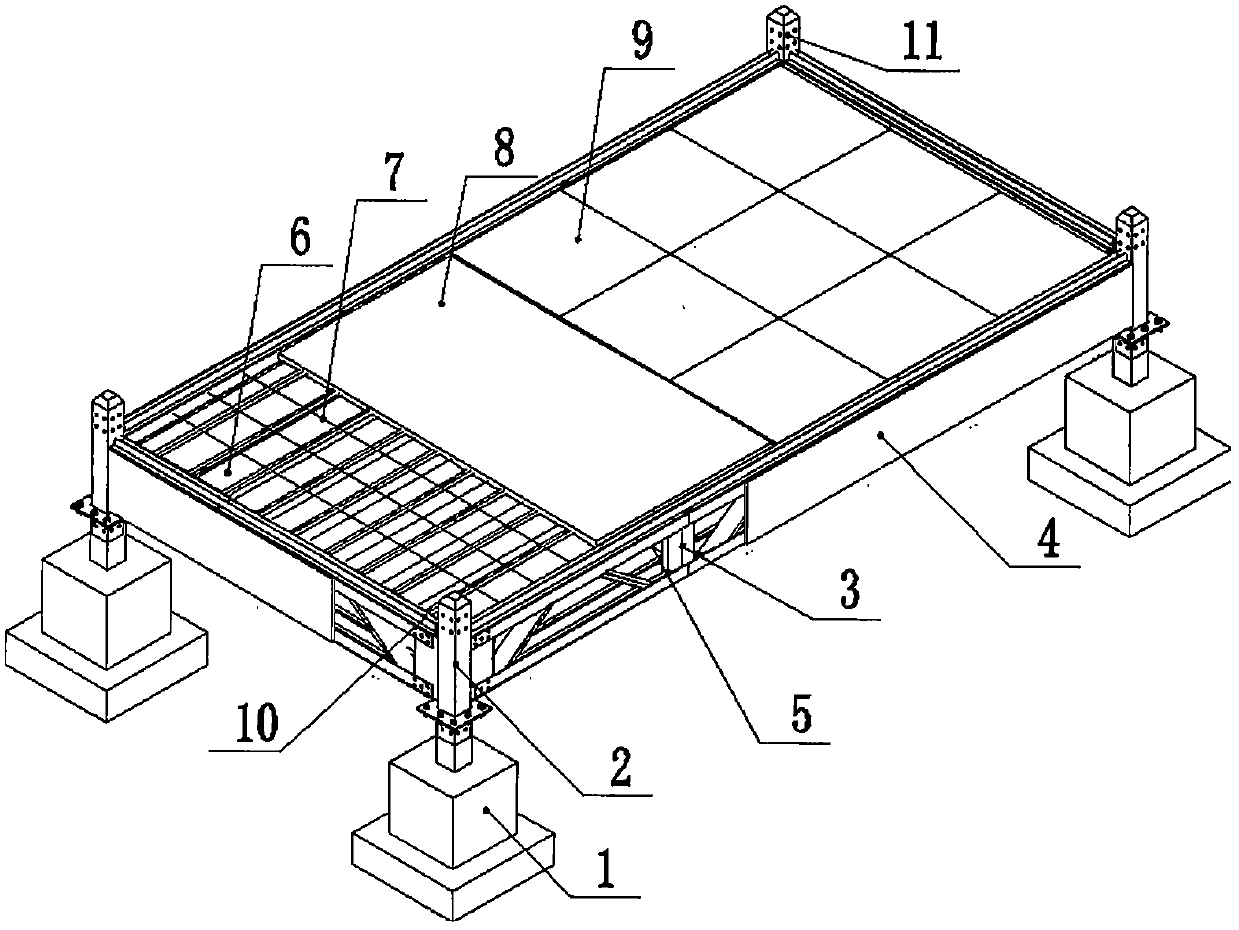

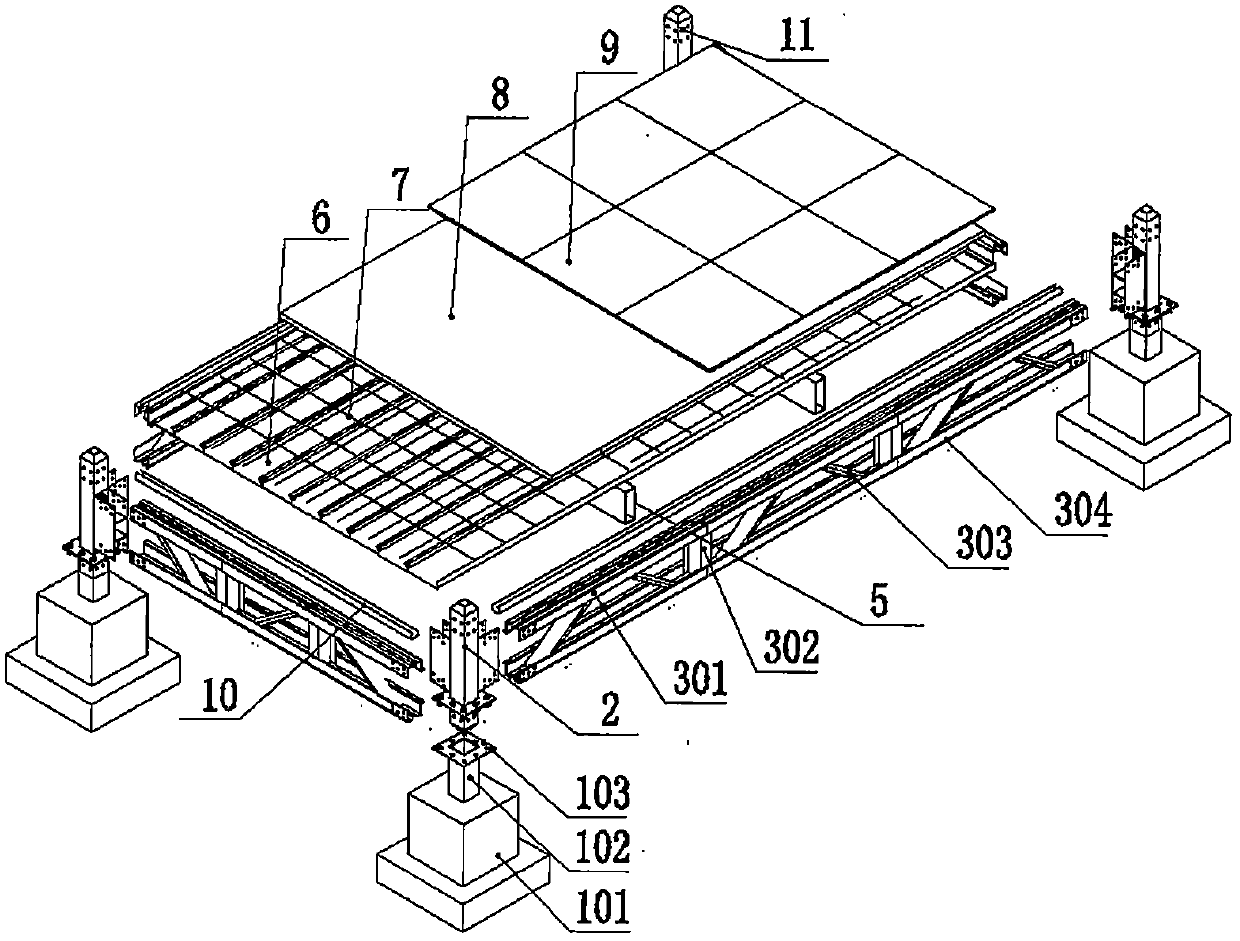

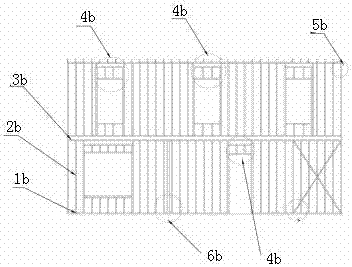

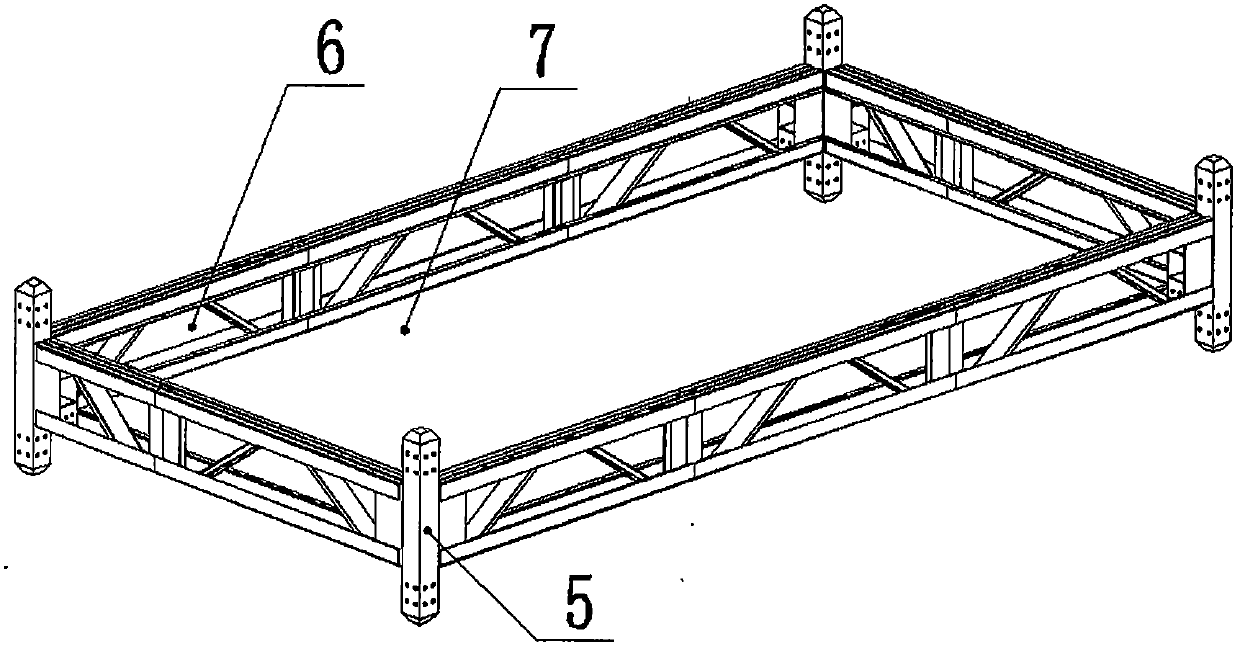

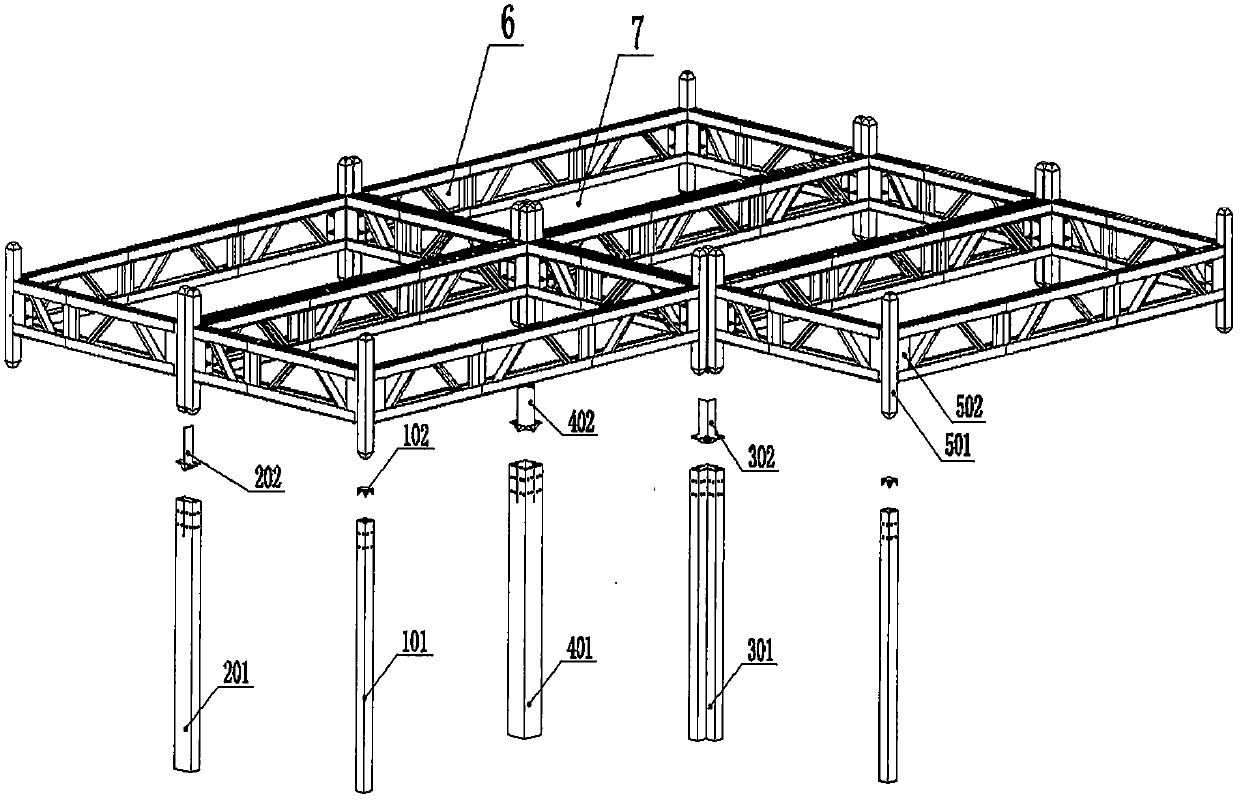

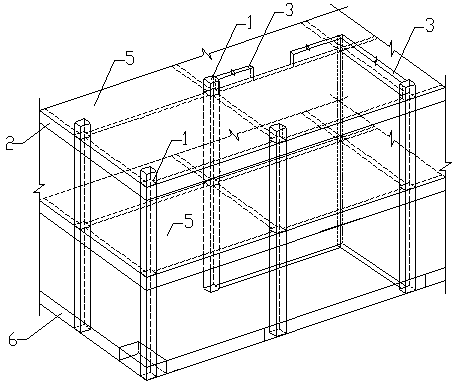

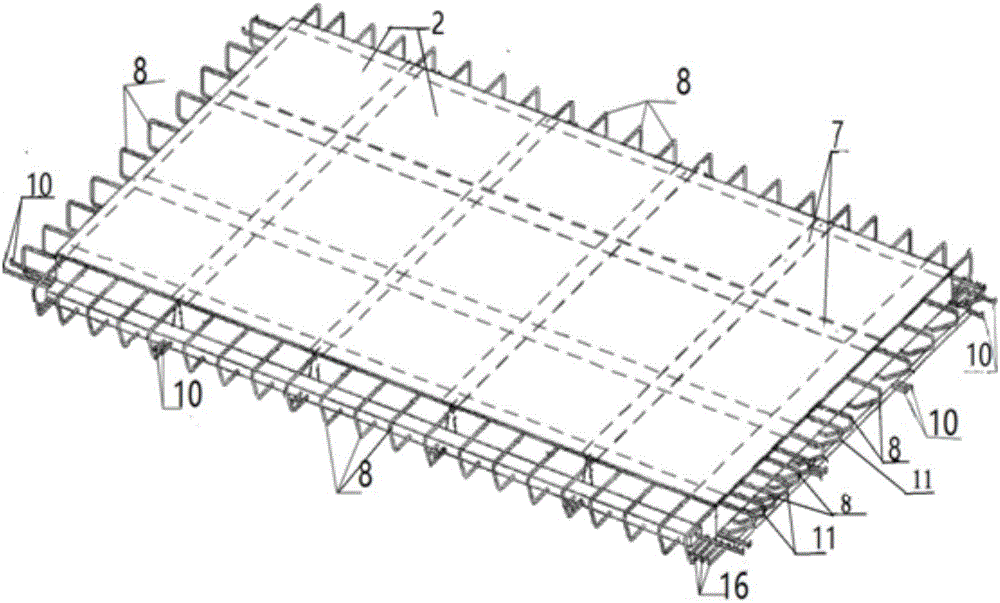

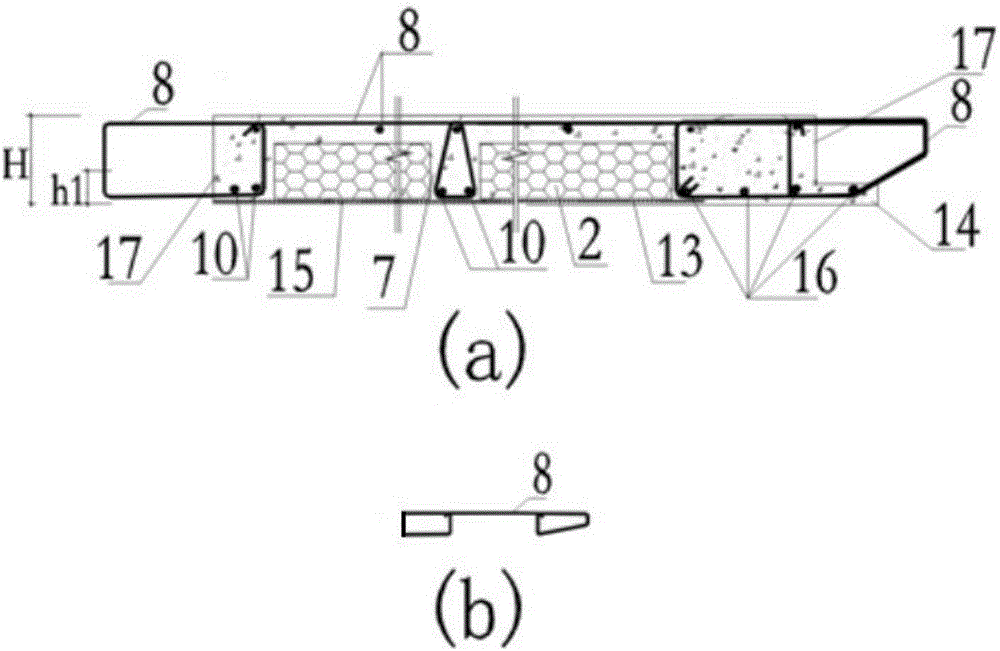

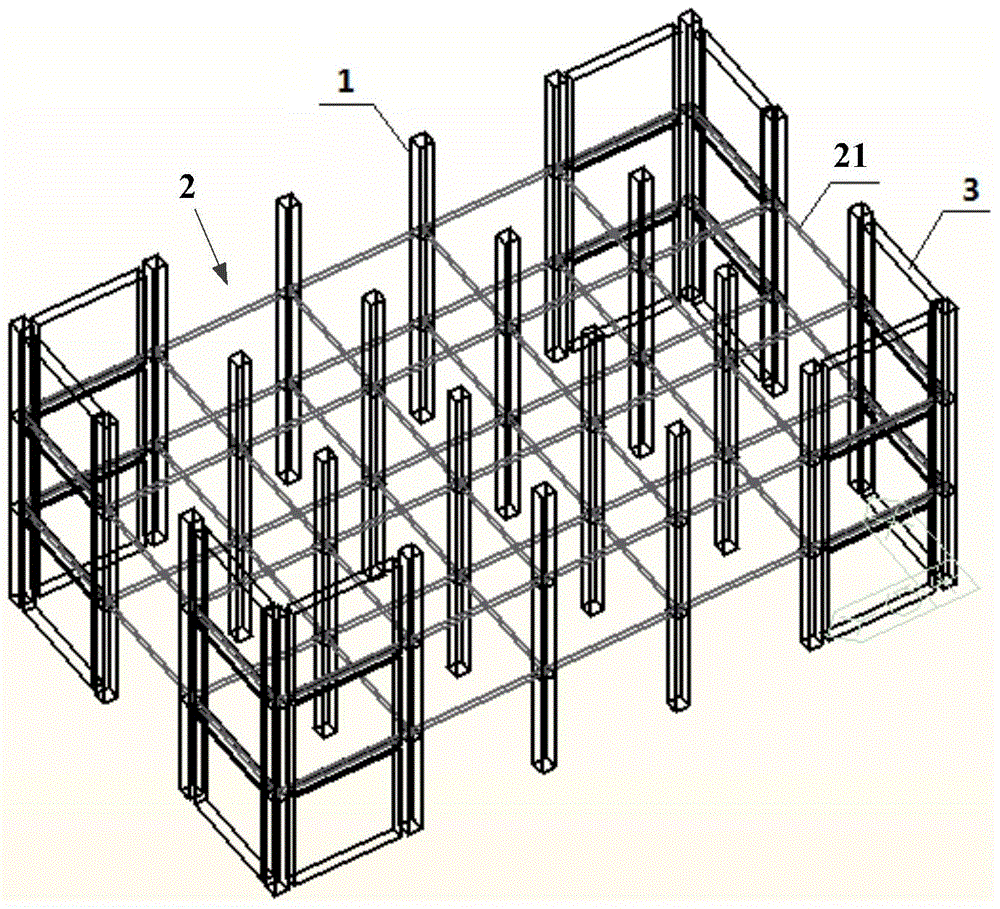

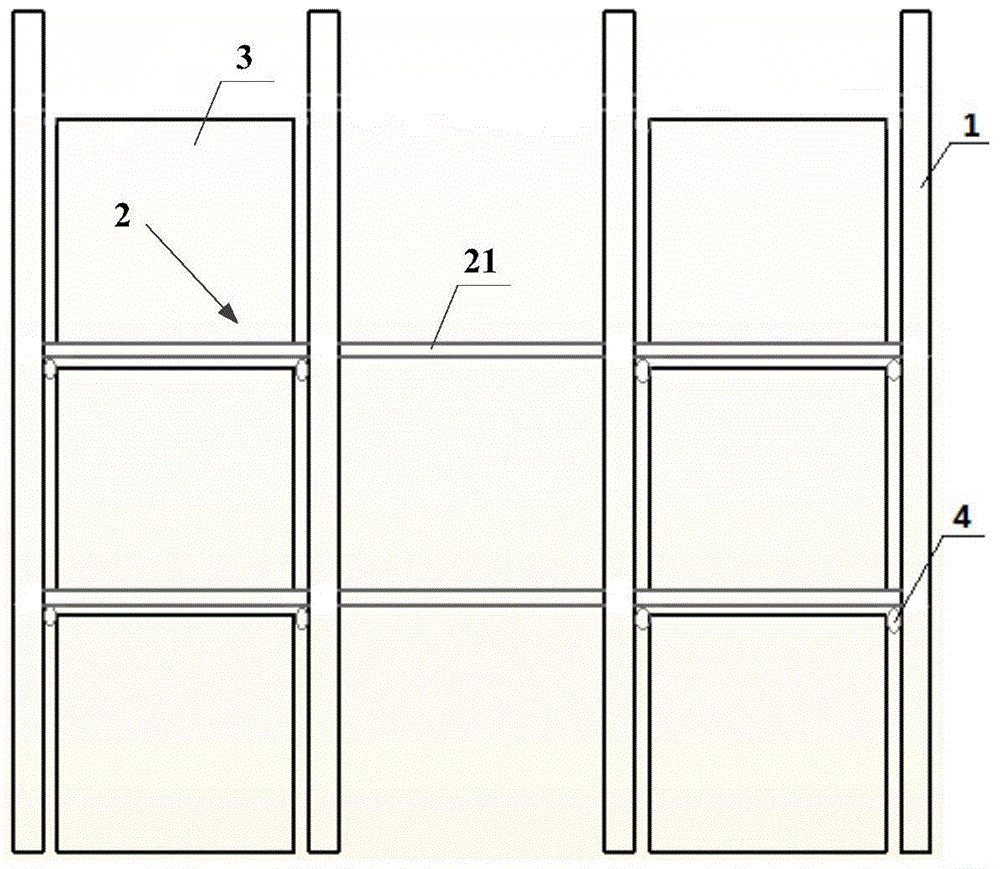

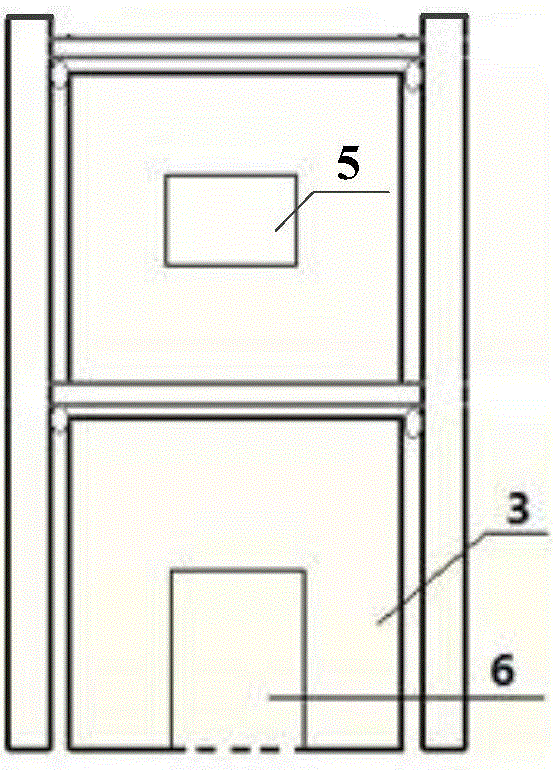

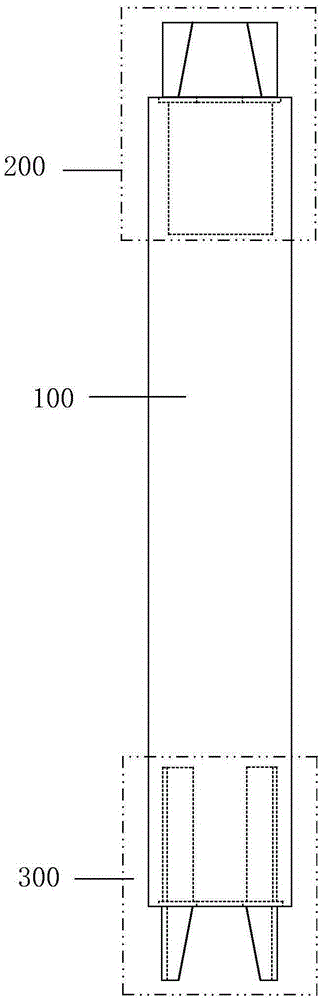

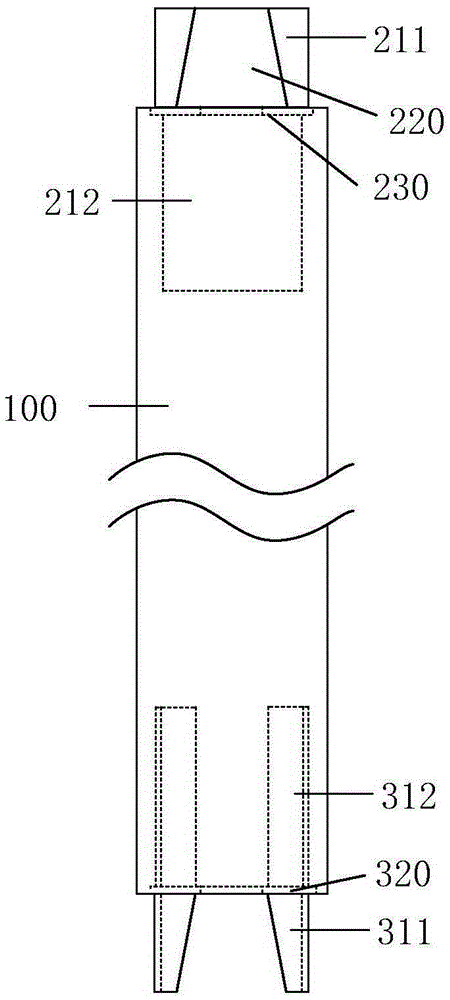

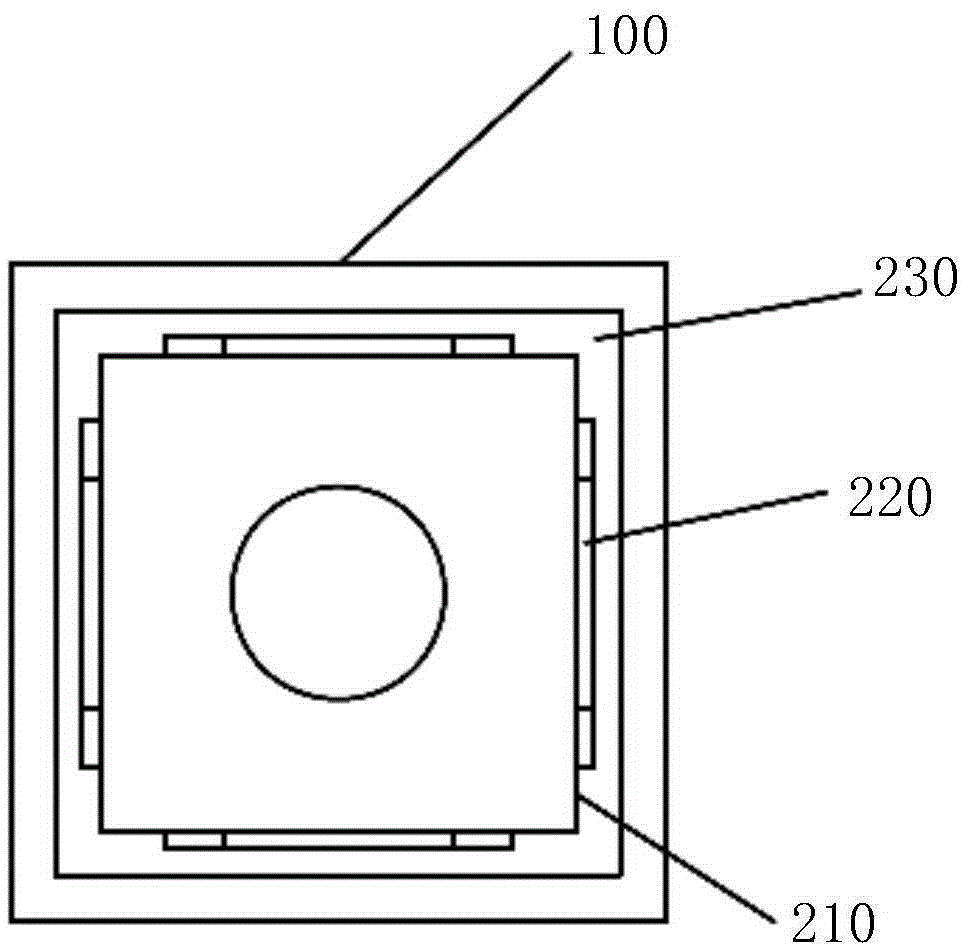

Prefabricated cold-formed thin-walled steel plate column structure tenon and mortise connection system and construction method thereof

InactiveCN107795013AImprove prefabrication rateEnsure structural safetyStrutsPillarsCold formedHouse building

The invention relates to a prefabricated cold-formed thin-walled steel plate column structure tenon and mortise connection system and a construction method thereof, and belongs to the technical fieldof structural engineering. Single-hole columns, double-hole columns, three-hole columns and four-hole columns are support columns of the system. A floor module is the main structure of the system. Theconnection mode between the floor and the columns is the connection mode between the support columns and the main structure of the system. The single-hole columns and the double-hole columns are respectively arranged at joint connection support parts at the bottom of the floor module. The three-hole columns are arranged at corner support parts at the bottom of the floor module. The four-hole columns are located at center cross support parts at the bottom of the floor module. Through the method of optimizing the light steel plate column structure system by implanting beam-column joints in thefloor, the structure is allowed to bear the force more reasonably, the consumption of building materials and the amount of construction work at a construction site are greatly reduced, and a rapid green construction is truly realized. The whole building is sturdy and durable, thermal-insulating, lightweight, energy-saving, environmentally friendly, suitable for all kinds of housing construction and highly applicable, and will bring good economic and social benefits.

Owner:谢志强 +1

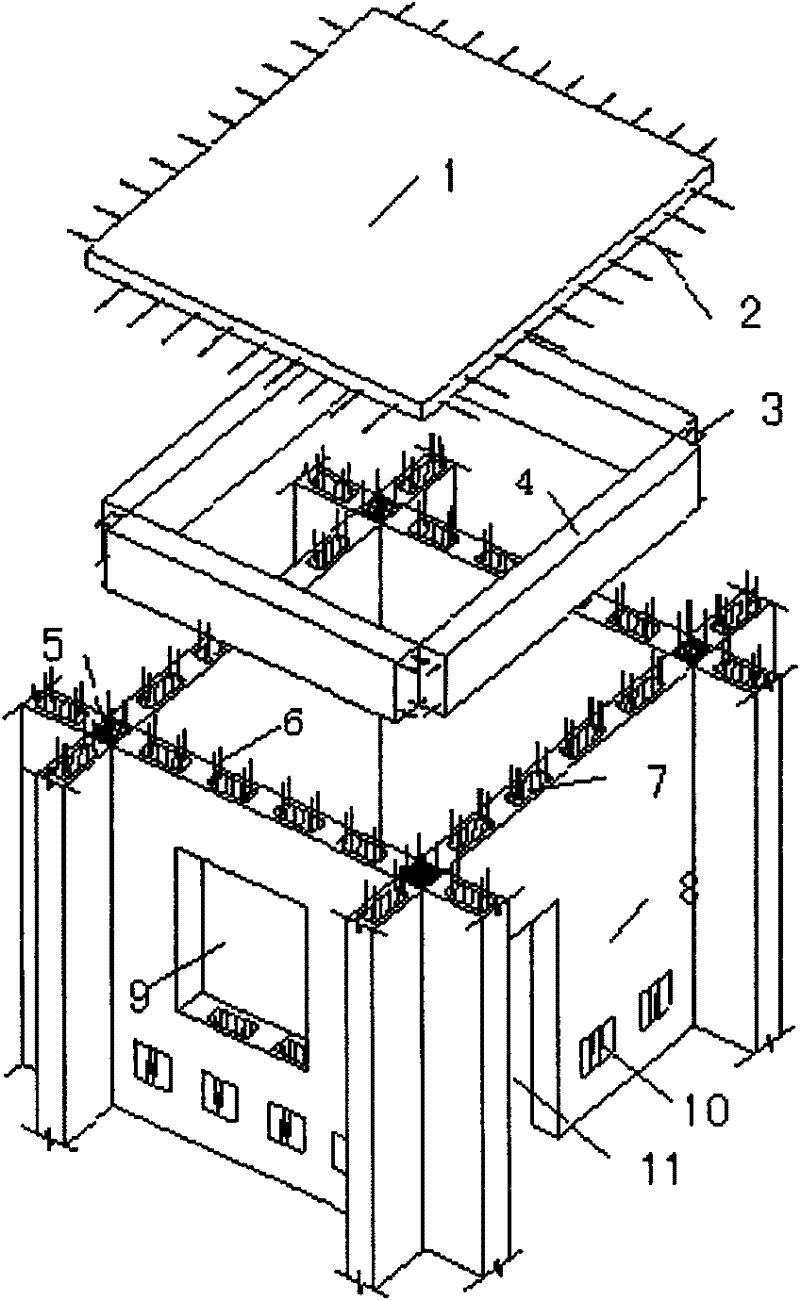

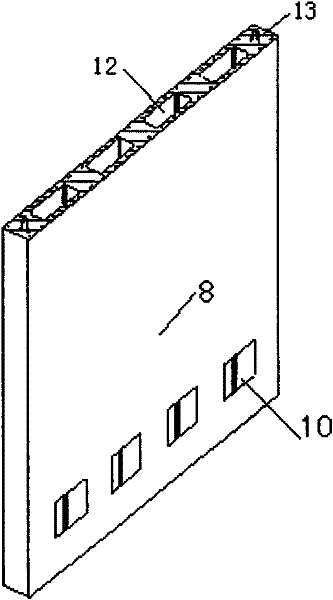

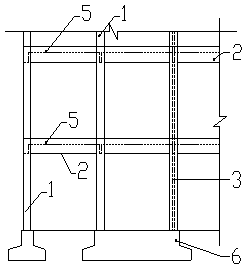

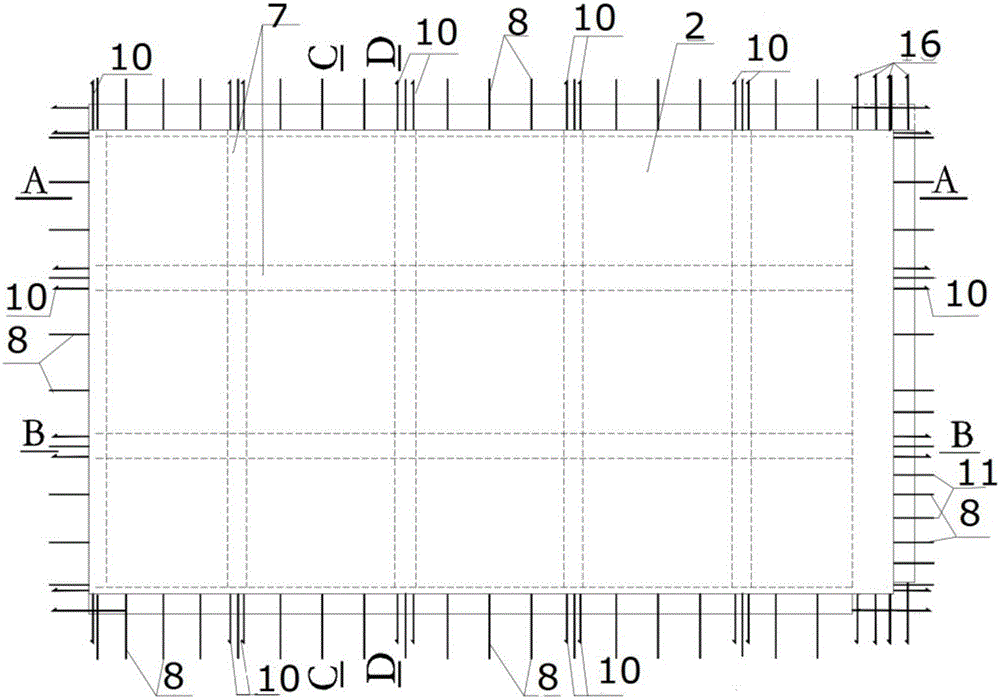

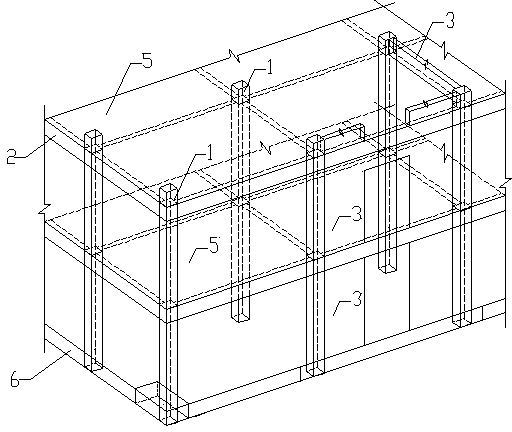

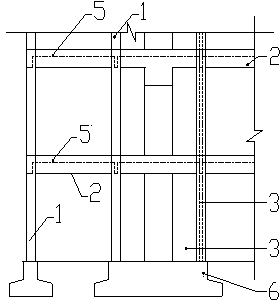

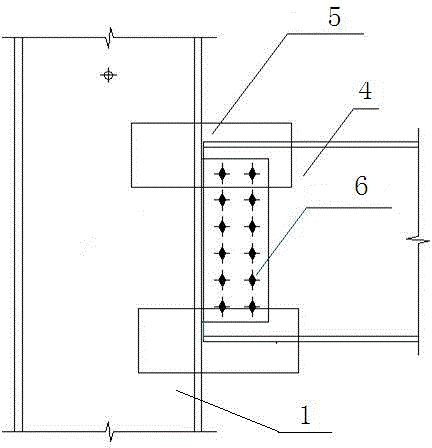

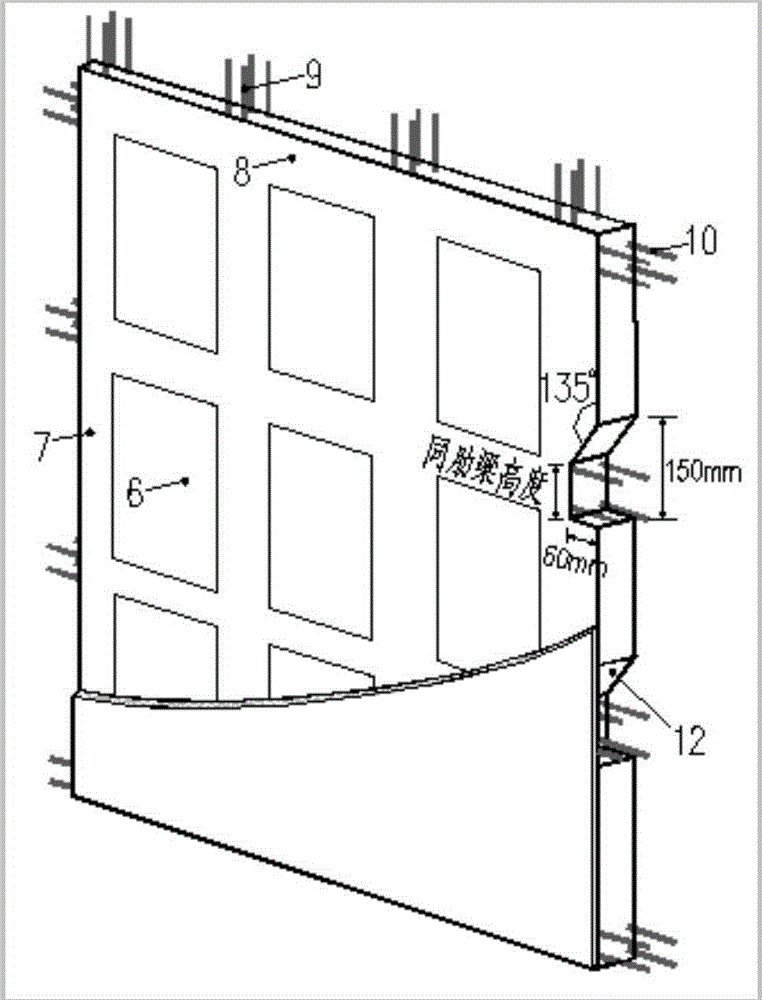

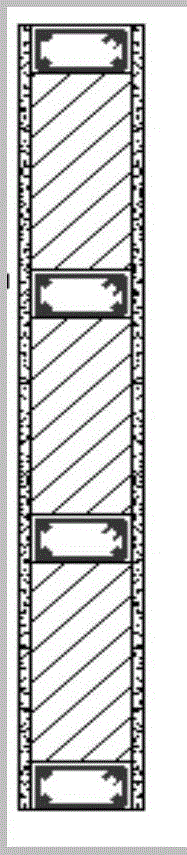

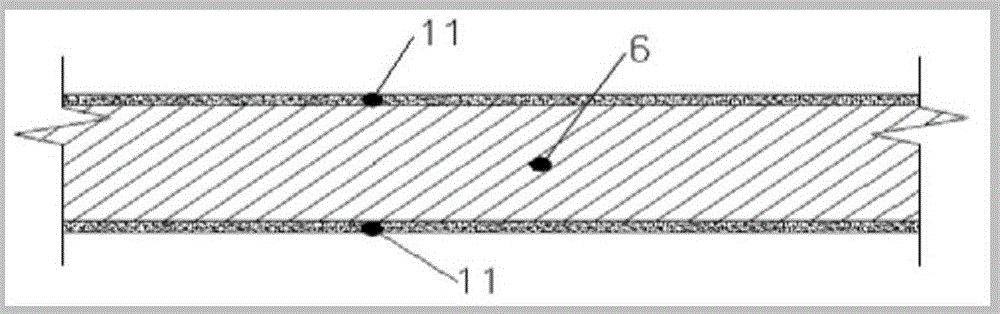

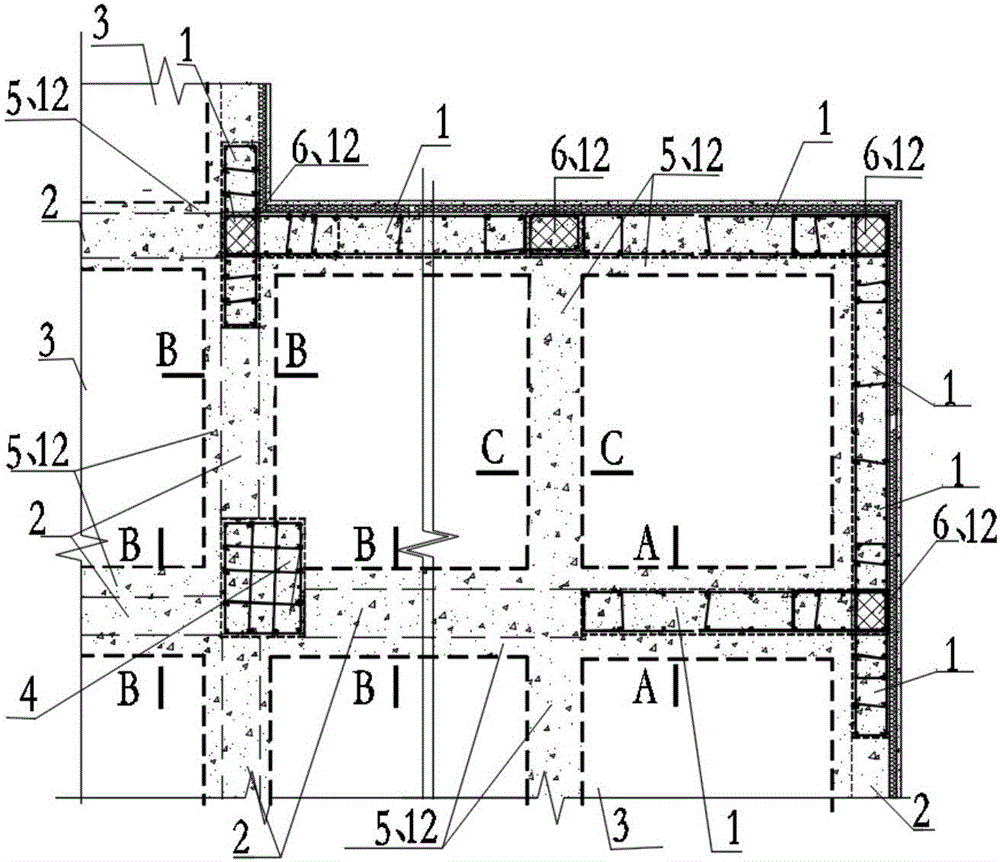

An assembly-cast-in-place dense column structure for residential buildings with shear wall system

InactiveCN102261189AImprove prefabrication rateOvercome defectsCovering/liningsWallsStructure of the EarthEngineering

The invention belongs to the field of construction engineering, and relates to construction technology of building structures, in particular to the technology of adopting the construction method of assembly-cast-in-place to realize the dense column structure used in residential buildings with shear wall system. It is suitable for multi-storey and small high-rise residential buildings with shear wall system, and can also be used for shear wall structures of other industrial and civil buildings. In the present invention, dense columns (7) are arranged in the cavity of the prefabricated building hollow wall formwork (8) and connected with cast-in-place corner columns (5), cast-in-place beams (4), floor slabs (1) and other components to form an assembled-on-site Poured dense column structure. Adopting the assembly-cast-in-place dense column structure with good structural performance of the present invention, in the construction of multi-storey and small high-rise residential buildings of the shear wall system, the cast-in-place concrete wall does not need traditional wall formwork, which improves the assembly-type concrete structure. The prefabrication rate of the structure realizes the industrialized operation on the construction site, which can be used in the construction of industrialized houses, and effectively overcomes the defects of the current prefabricated concrete structure.

Owner:应惠清 +2

Shock-proof prefabricated steel tube shear wall mixed structural building

ActiveCN103388357ABolt-and-solder connections for easy connectionHigh compressive strengthWallsShock proofingFloor slabSteel columns

The invention relates to a shock-proof prefabricated steel tube shear wall mixed structural building which belongs to the field of buildings. The building is provided with a foundation, wherein the foundation is respectively connected with the lower ends of shear walls and steel columns; the upper ends of the shear walls and the steel columns are connected with steel beams; the shear walls and the steel beams are connected with composite floor slabs; single shear walls on a plane are combined and connected together to form a shear wall barrel body; a vertical upper section of shear walls is connected with a vertical lower section of shear walls; stair treads are connected with supporting beams; and self-bearing masoning filler walls and main body structural components are connected together. The integrity and vibration strength of the connected structural components are reliable, so that the building is safe, economic and durable; steel structural components and steel concrete combined components have good connecting performances, so that the working environment of the operating personnel is improved to the maximum extent, the construction period is shortened, and the construction cost is lowered; and moreover, the structural components of the building are made by steel materials with higher strength, so that a large span is realized, and the building is easy to reconstruct and update after a plurality of years and has high durability.

Owner:INSTALLATION BRANCH WEIHAI CONSTR GRP CO LTD

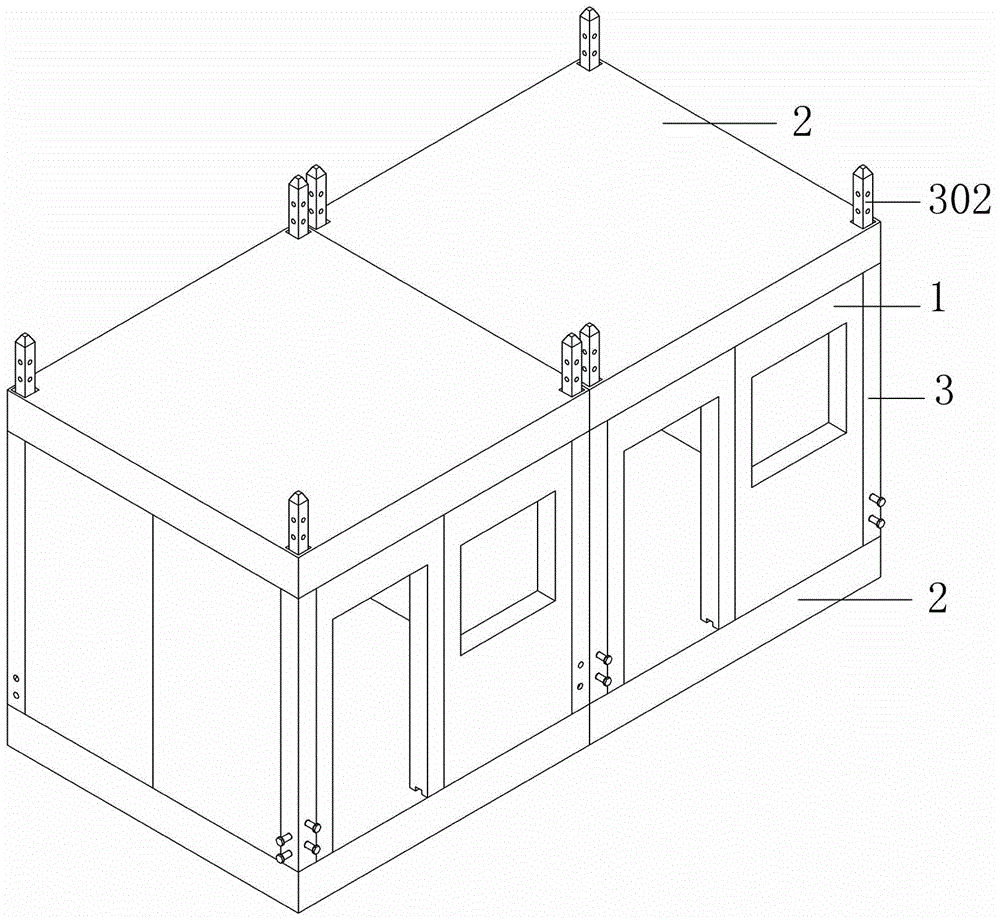

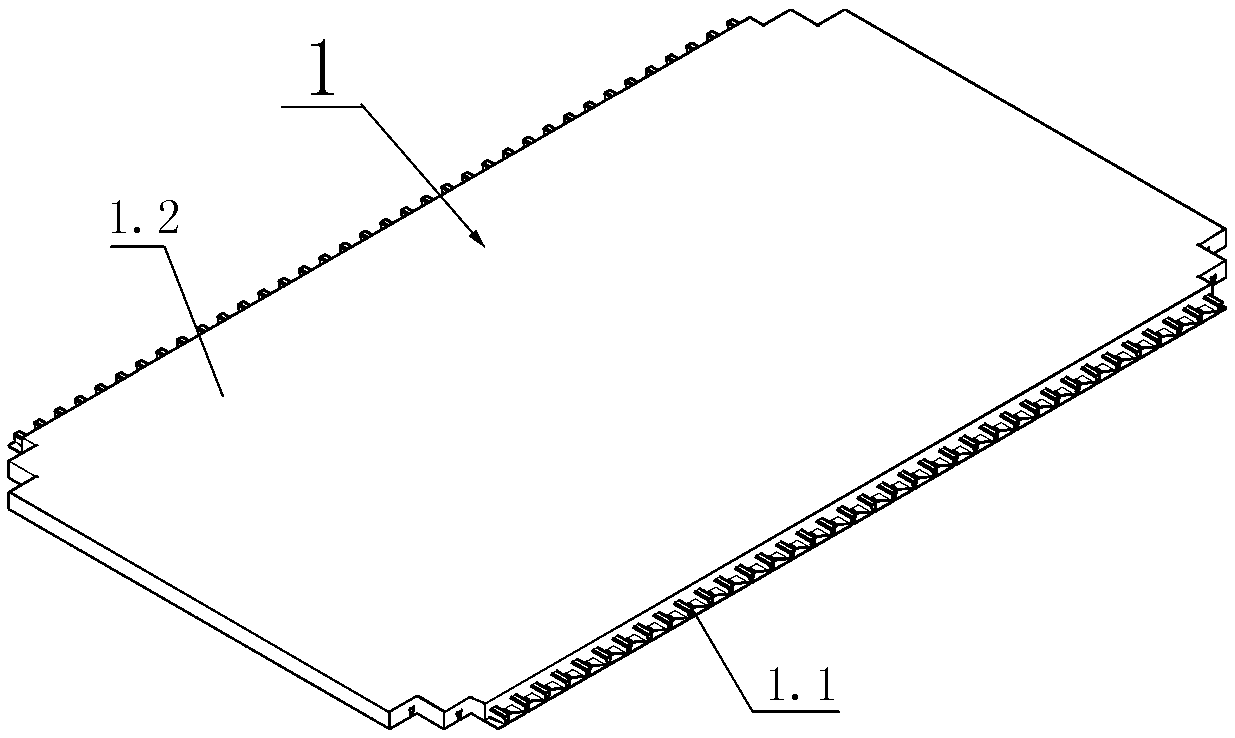

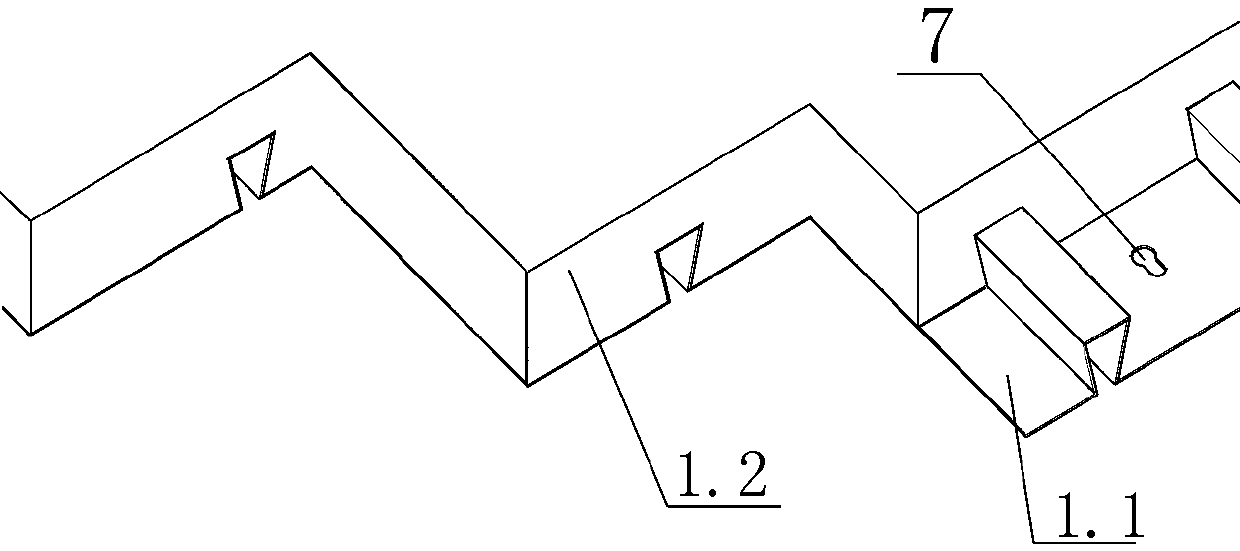

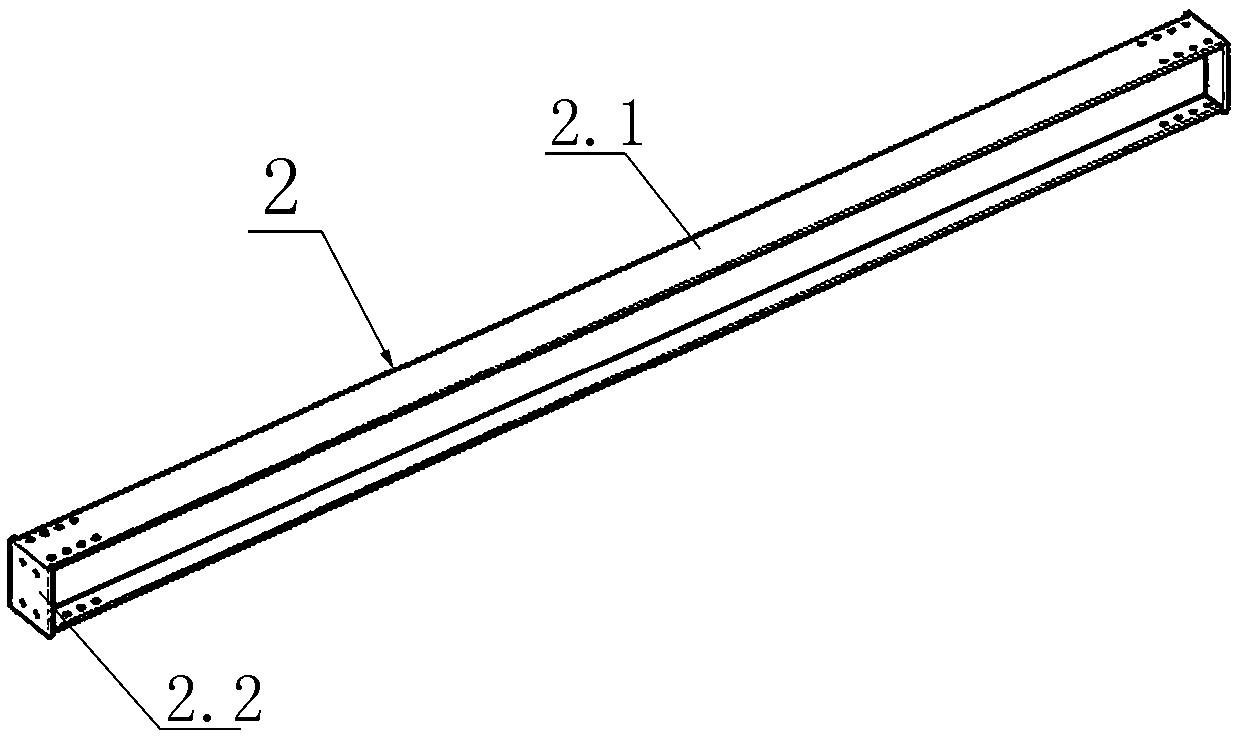

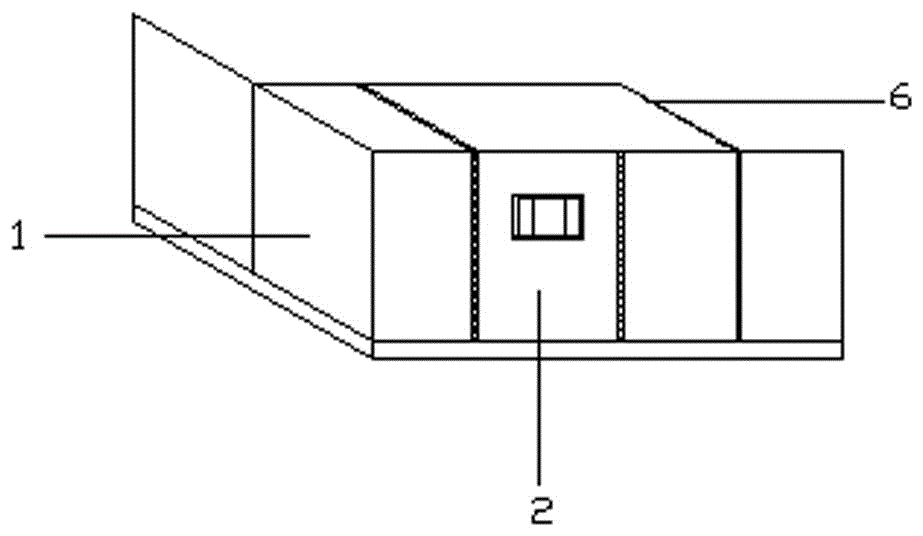

DGC board-type assembled house system and construction method and manufacturing method thereof

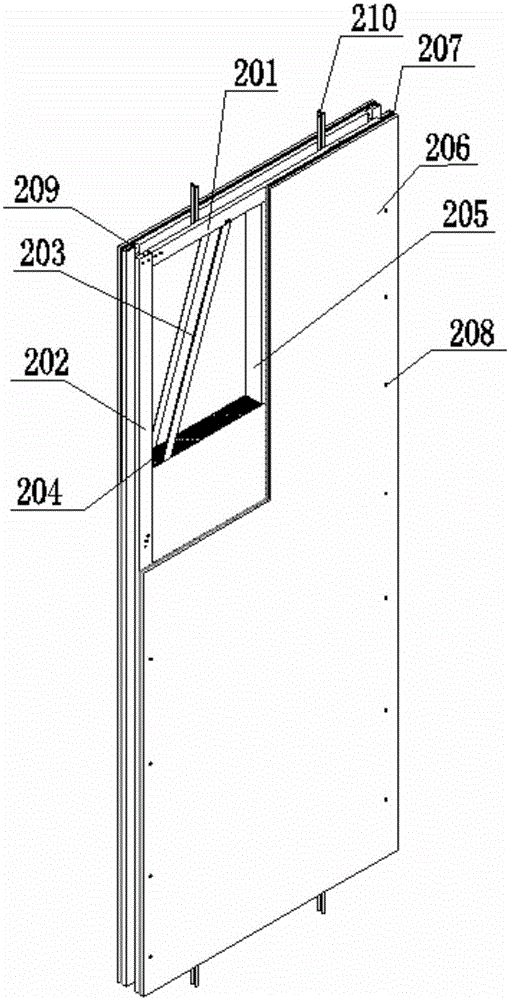

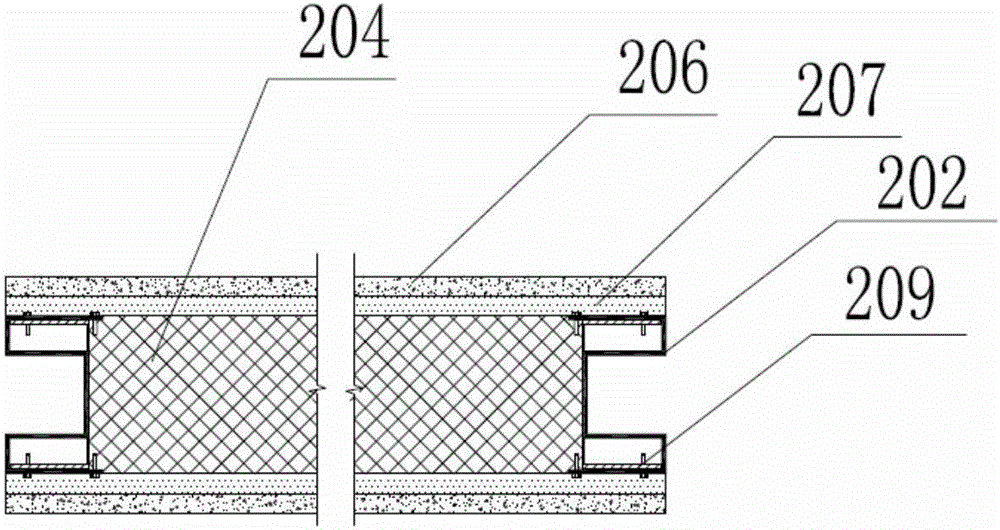

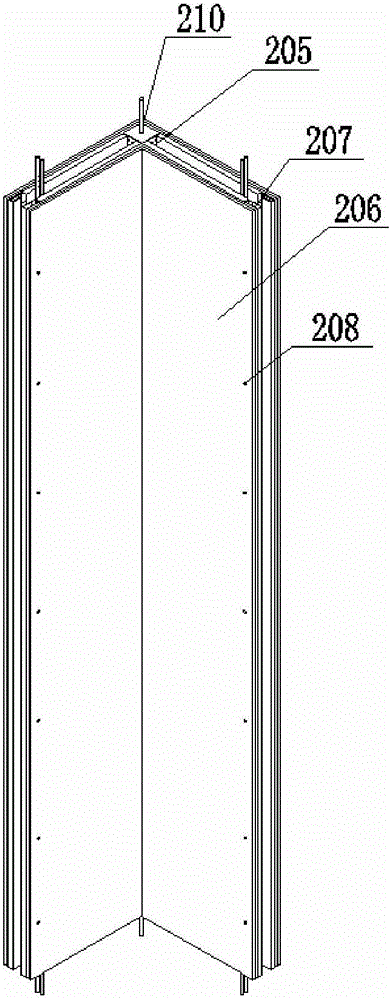

InactiveCN105804233AImprove prefabrication rateEnsure structural safetyWallsFloorsModular compositionInsulation layer

The invention discloses a DGC board-type assembled house system and a construction and a manufacturing method thereof. A basic unit of the system is formed by floor slabs and wallboards which are combined and assembled in a modularized manner; the wallboards are prefabricated composite boards, each wallboard mainly consists of a light-steel frame, a peripheral guard board, a sandwich insulation layer, a heat insulating layer and turnbuckles, and different wallboard standard modules such as in-line wallboards, L-shaped wallboards, T-shaped wallboards and cross-shaped wallboards are adopted and freely combined; the floor slabs are prefabricated composite boards, the floor slabs are used as foundation slabs, floor slabs or roof slabs of the DGC board-type assembled house system, and vertical connection between the floor slabs and the wallboards in the system consists of combined connection of lateral connection of horizontal M-shaped steel, M-shaped chord members and square steel pipes through tapping screws and vertical connection of the turnbuckles in trusses. According to the DGC board-type assembled house system and the construction method and the manufacturing method thereof, the structure is simple, the construction speed is fast, the construction period is reduced, the cost is low, and the defects of single structure, complex installation process and high labor cost of the existing assembled house structure can be overcome.

Owner:江苏保力自动化科技有限公司

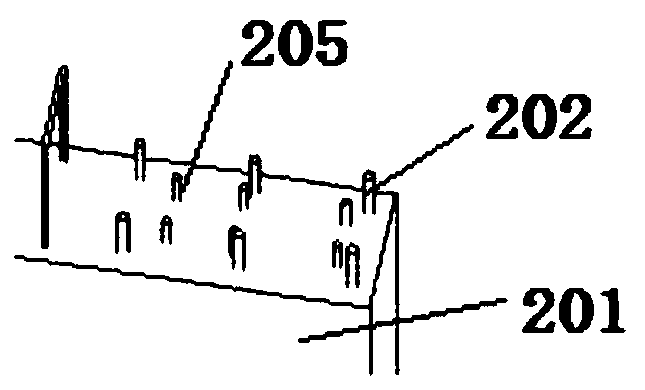

Connecting node of assembled whole thick prefabricated slab unit and slab unit thereof

The invention discloses a connecting node of an assembled whole thick prefabricated slab. Connecting steel bars are reserved on the connecting surface of a prefabricated slab unit in the mode, the exposed parts of the connecting steel bars are ' '-shaped, and the exposed parts and the connecting surface form a closed polygon. In the connecting mode for the prefabricated slab unit and a beam or a wall, the connecting steel bars of the prefabricated slab unit are inserted with steel bars configured for the beam or the wall together at the connecting positions in a penetrating mode. Viewing from the cross section of the whole connecting node, the connecting steel bars and the steel bars configured for the beam or the wall form a single closed stirrup or a composite stirrup, and longitudinal bolt steel bars penetrate into the inner corner position of the single closed stirrup or the composite stirrup. The connecting node of the whole thick prefabricated slab unit can achieve the equivalent performance as a prefabricated slab connecting nodes and a cast-in-place concrete structure while achieving higher prefabrication rate and assembly rate. The invention further provides the whole thick prefabricated slab unit for achieving the connecting mode.

Owner:刘祥锦

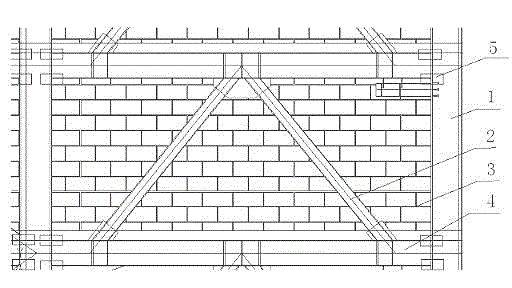

Building adopting aseismatic precasted reinforcing steel truss shear wall composite structure

ActiveCN103397696ABolt-and-solder connections for easy connectionHigh compressive strengthStrutsWallsFloor slabSteel frame

The invention relates to a building adopting an aseismatic precasted reinforcing steel truss shear wall composite structure, and belongs to the architectural field. The building adopts the scheme that reinforcing steel truss concrete shear walls provided with steel frames and composite floor slabs with prestressed concrete sheets are precasted; a foundation is connected with steel columns and the shear walls; the steel columns are connected with steel beams; the steel beams are connected with the composite floor slabs and the shear walls; the shear walls are connected with the composite floor slabs; an upper section of each shear wall is connected with the lower section of each shear wall; the steel columns are connected with the shear walls; the steel beams are combined and connected with the shear walls. According to the invention, the safety, economy and durability of the building can be ensured in virtue of the reliable integrity and seismic resistance of the connection between the structural elements; the steel structural elements and the steel concrete composite members have favorable connection performance, the labor environment for operators is improved, the construction period is shorted and the construction cost is reduced furthest; besides, the large span can be realized as the building structural elements are made of steel materials with higher strength, so that the building is easy to refit and renovate after several years, and the high durability is realized.

Owner:INSTALLATION BRANCH WEIHAI CONSTR GRP CO LTD

NALC (N autoclaved lightweight concrete) large slab component

PendingCN107130757ASave mechanical shiftsSave time for coordinationCovering/liningsSlagStructural engineering

The invention discloses an NALC (N autoclaved lightweight concrete) large slab component. The large slab component is characterized by comprising multiple NALC slabs, wherein slag joints between the adjacent NALC slabs are treated with a crack sealer, angle steel components are arranged around the NALC slabs, mounting joints are arranged at the two ends of the NALC slabs, and the NALC slabs are fixed through fixing components. The technical scheme is compact and ingenious in structural design and high in prefabricating rate and assembling rate, and the whole NALC large slab composite exterior decoration is completely manufactured in a factory; all manufacturing procedures are performed on the ground, so that aloft work is reduced, and the construction risk is lowered.

Owner:南京旭建新型建材股份有限公司

Multi-storey and high-rise steel structure house integrated system with pillars and walls in equal thickness

InactiveCN104481170AReduce labor intensityReduce transport volumeHeat proofingSound proofingThermal insulationEngineering

The invention relates to a multi-storey and high-rise steel structure house integrated system with pillars and walls in equal thickness. According to a structural scheme of rectangular steel tube concrete pillars, a steel framework beam and a steel support adopted by the invention, an outer wall, a separating wall, a core tube wall and a firewall are arranged in the steel structure framework, and indoor partitioning walls are arranged in rooms; floors and stairs are arranged between each layer of the steel framework beams. The multi-storey and high-rise steel structure house integrated system with equal-thickness pillars and walls is characterized in that the width of the pillars is 180mm-200mm, an inner partition plate and a transverse partition plate are not arranged inside each pillar, and the width of an outer ring beam combined with each pillar is limited to be within 200mm; inner beams of the steel structure house adopt small steel beams; after fireproof paint and a screeding layer are sprayed, the beam width is controlled to be within the width of the partition walls, the wall plates adopt composite wall plates with good thermal insulation performance and good fireproof soundproof performance, and using area of a house is increased according to the thicknesses of the walls. The multi-storey and high-rise steel structure house integrated system with pillars and walls in equal thickness has the advantages of reasonable layout, low cost, high prefabricating efficiency, good anti-seismic performance and capacity of increasing the using area of the house.

Owner:HANG XIAO STEEL STRUCTURE (INNER MONGOLIA) CO LTD

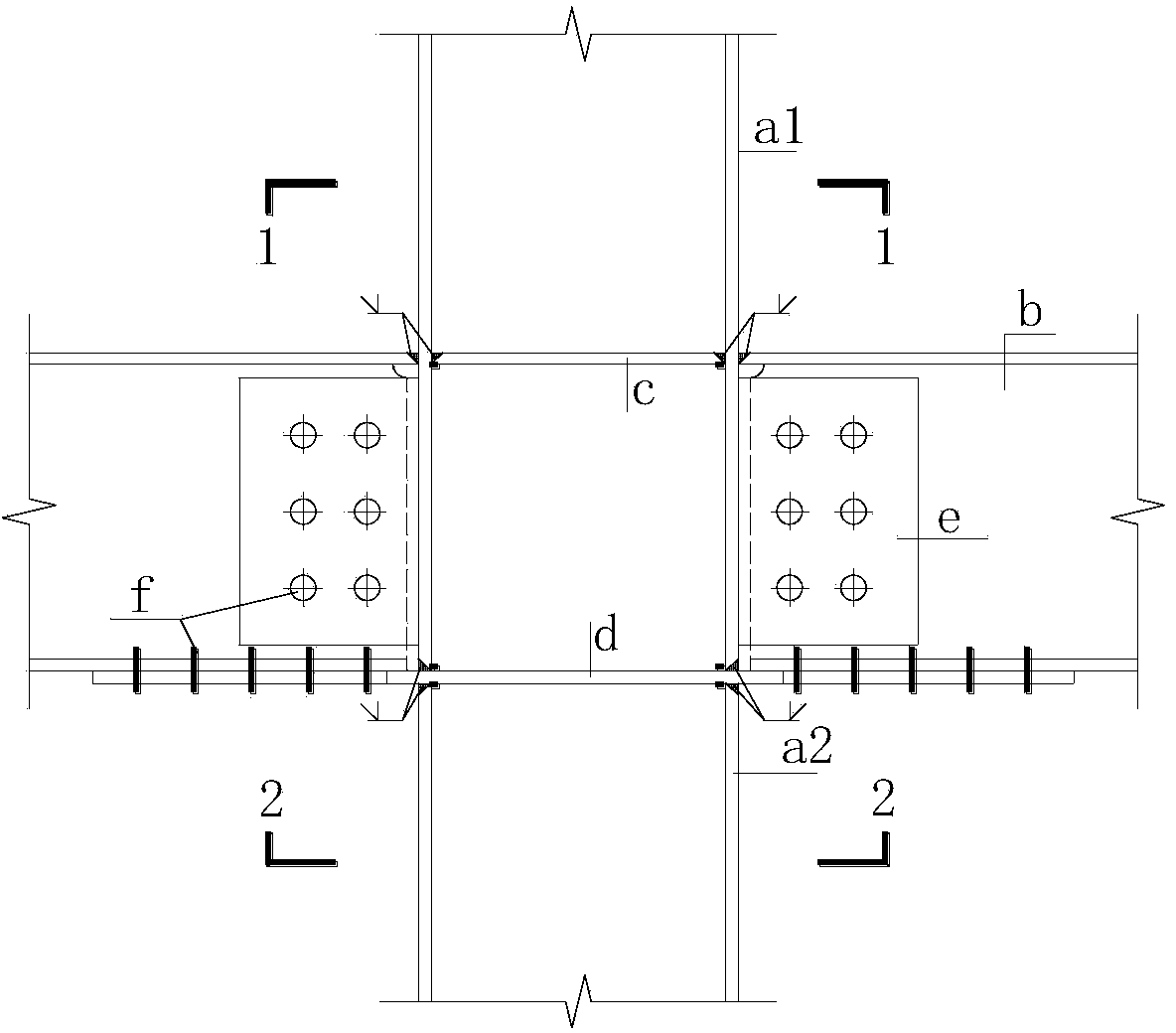

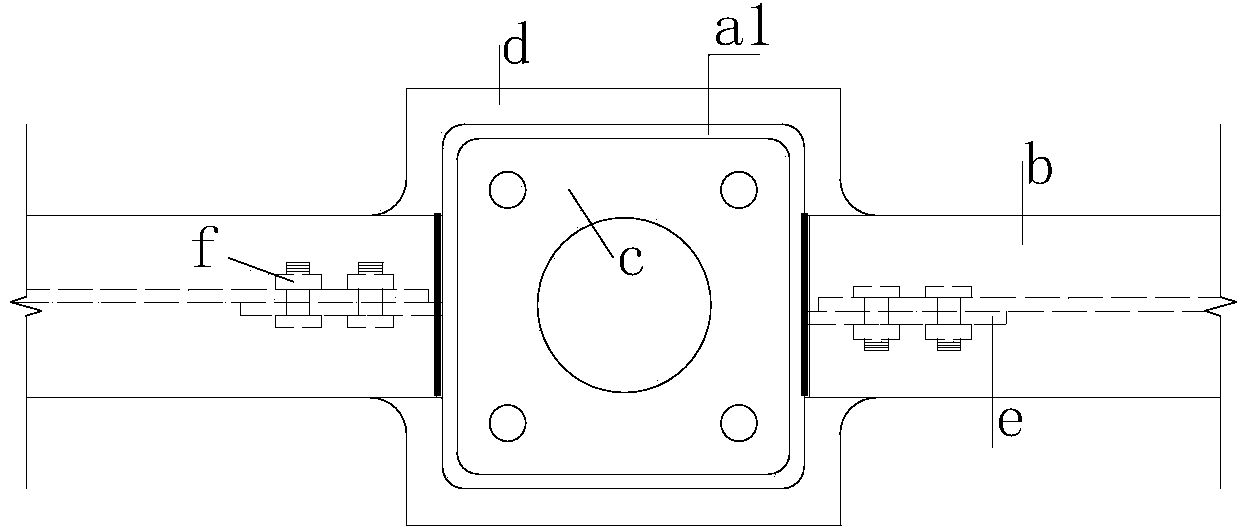

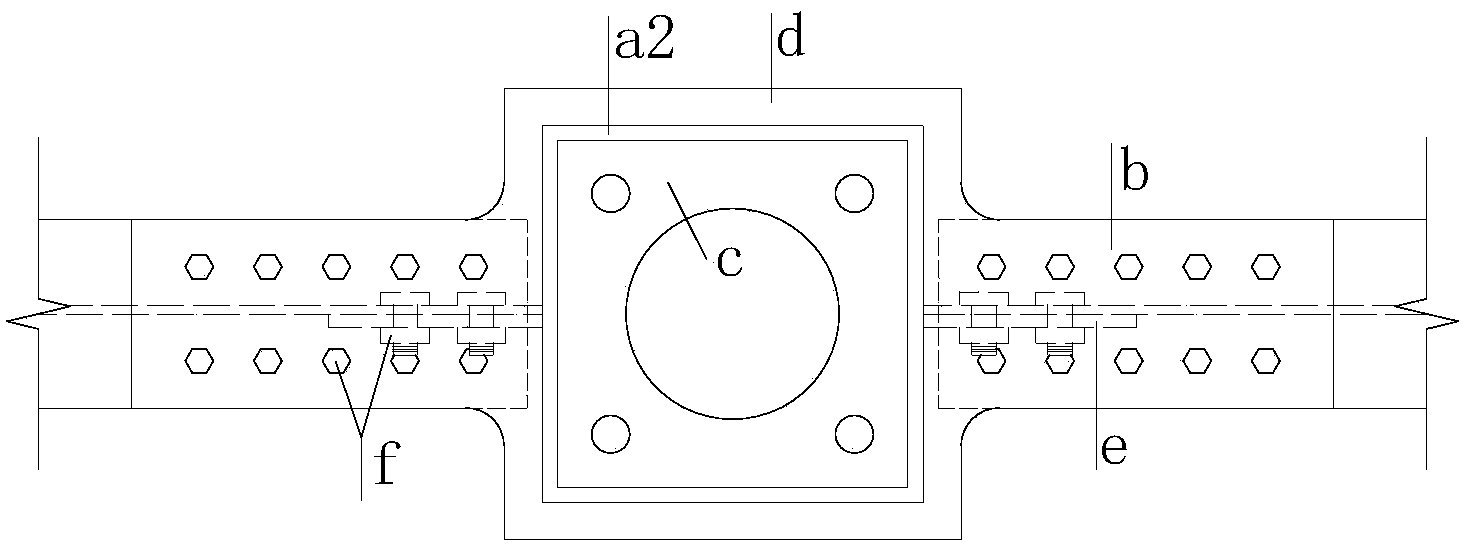

Stud welding mixed connection node of rectangular concrete filled steel tubular column and H-shaped steel girder

InactiveCN103967133AAddress stressImprove prefabrication rateBuilding constructionsArchitectural engineeringEngineering

The invention discloses a stud welding mixed connection node of a rectangular concrete filled steel tubular column and an H-shaped steel girder. The H-shaped steel girder comprises an upper flange, a web and a lower flange, wherein the upper flange, the web and the lower flange are formed together. The rectangular concrete filled steel tubular column comprises an upper steel tube and a lower steel tube which are vertically arranged adjacently. The node comprises an inner separating board welded to the bottom in the upper steel tube, a through separating board welded to the bottom end of the upper steel tube and a vertical connecting board welded to the side of the bottom of the upper steel tube. The top end of the lower steel tube is welded to the lower surface of the through separating board. The upper flange is opposite to the inner separating board and welded to the upper steel tube. The web is connected with the vertical connecting board through high strength bolts. The lower flange is fixedly connected with the through separating board. According to the node, stud welding mixed connection is adopted, the node can be fast installed in the position in a field, a construction period can be obviously shortened, and the assembly process is facilitated. Meanwhile, due to the arrangement of the through separating board, a girder-end plastic hinge is moved outwards, the steel girder is damaged before the node, and safety of the node is guaranteed.

Owner:TIANJIN UNIV

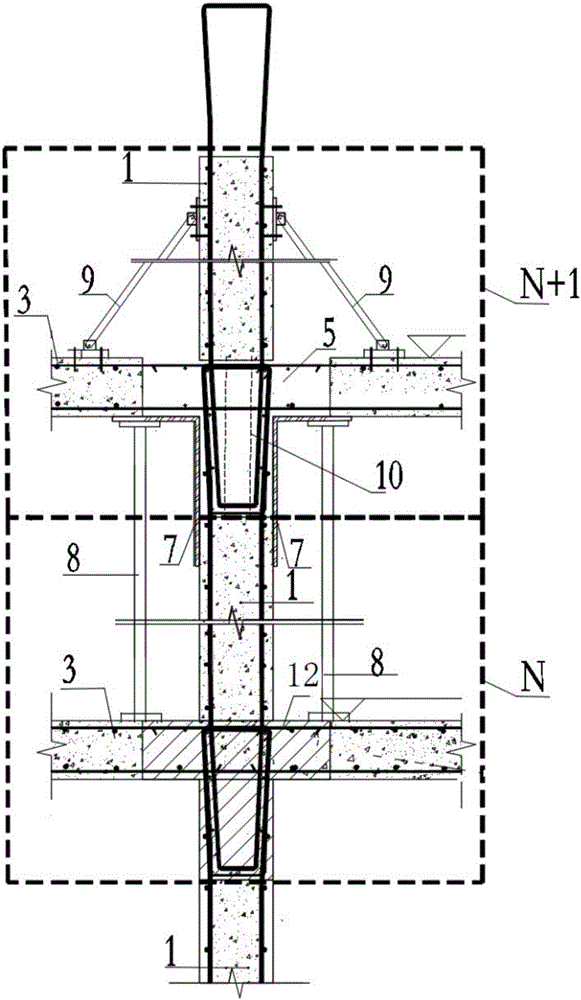

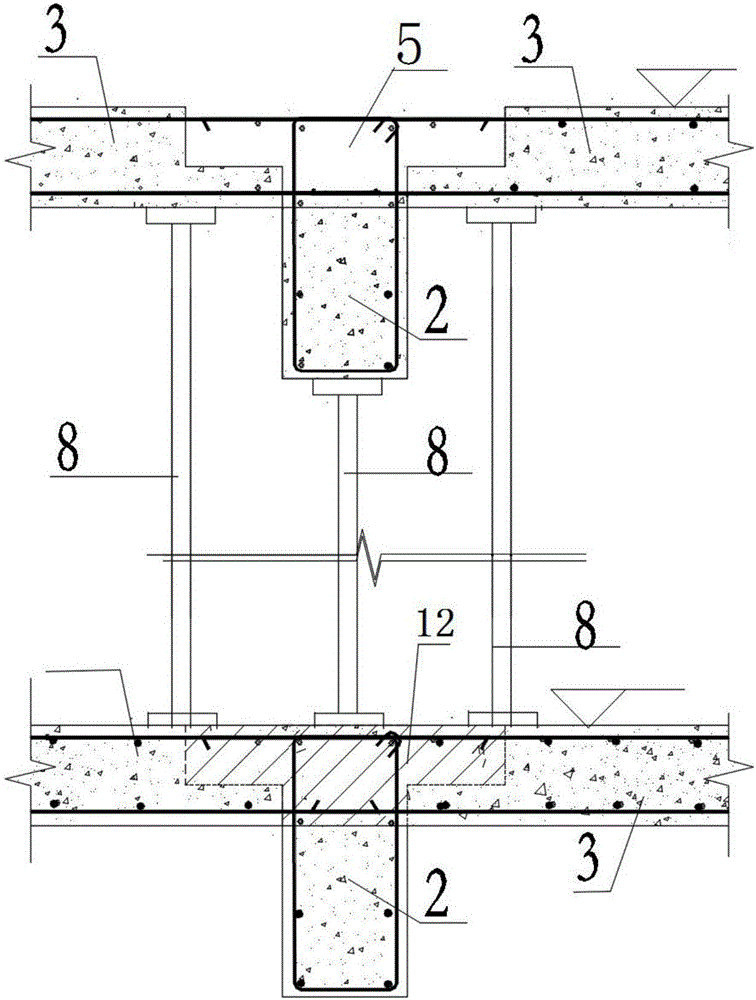

Prefabricated steel joint concrete slab-column structure and hoisting method thereof

ActiveCN104895229AThe force is clear and directSimple forceFloorsShock proofingPrefabricationBuilding construction

The invention provides a prefabricated steel joint concrete slab-column structure and a hoisting method thereof. The prefabricated steel joint concrete slab-column structure comprises a concrete slab, concrete piles, energy dissipation support units and a plurality of deformation energy dissipation devices, wherein the bottom end of any one of the concrete piles is fixed on the ground foundation or the top end of the next concrete pile, the bottom end of any one of the concrete piles is fixed on the ground foundation or the concrete slab and arranged between every two adjacent concrete piles, and deformation joints are formed between the concrete slab at the top end and any one adjacent concrete pile; the deformation energy dissipation devices are arranged in the deformation joints and at two vertex angles of any one of the energy dissipation support unit. The steelwork joints are arranged at the joint of the concrete piles and the ground foundation or the concrete slab. Prefabrication efficiency is improved, anti-seismic function is realized, construction procedures are simplified, and construction cost is reduced.

Owner:SHANGHAI MECHANIZED CONSTR GRP +1

Total-prefabricated rural residential class composite wall structure system and construction method thereof

ActiveCN106522359ASolve the compactness problemImprove integrityWallsProtective buildings/sheltersFloor slabReinforced concrete

Provided is a total-prefabricated rural residential class composite wall structure system, comprising prefabricating a construction main body bearing component and prefabricating an accessory component. The method comprises the steps of when a factory prefabricates a construction main body bearing component and prefabricates an accessory component, pre-burying construction equipment pipelines; during construction on spot, achieving the connection between wallboards by conducting pouring on reinforced concrete connecting columns with small cross sections, and achieving the connection between the wallboards and composite floor slabs by conducting pouring on reinforced concrete constraint hidden beams with small cross sections. All components of the total-prefabricated rural residential class composite wall structure system are produced by prefabrication technology in workshops, which effectively ensures the quality and trait of the components; professional construction installation team command hoisting installation and construction at the construction site, meanwhile little wet connection is adopted and little concrete is poured only at the component key connecting portions and floor slab super-position layers, the overall stability and anti-seismic property of the building is ensured, construction and operation area on spot is saved, meanwhile the main body structure of a set of rural residence can be finished by hoisting installation only in a few days, and the construction period is greatly shortened.

Owner:西咸新区矩阵实业有限公司

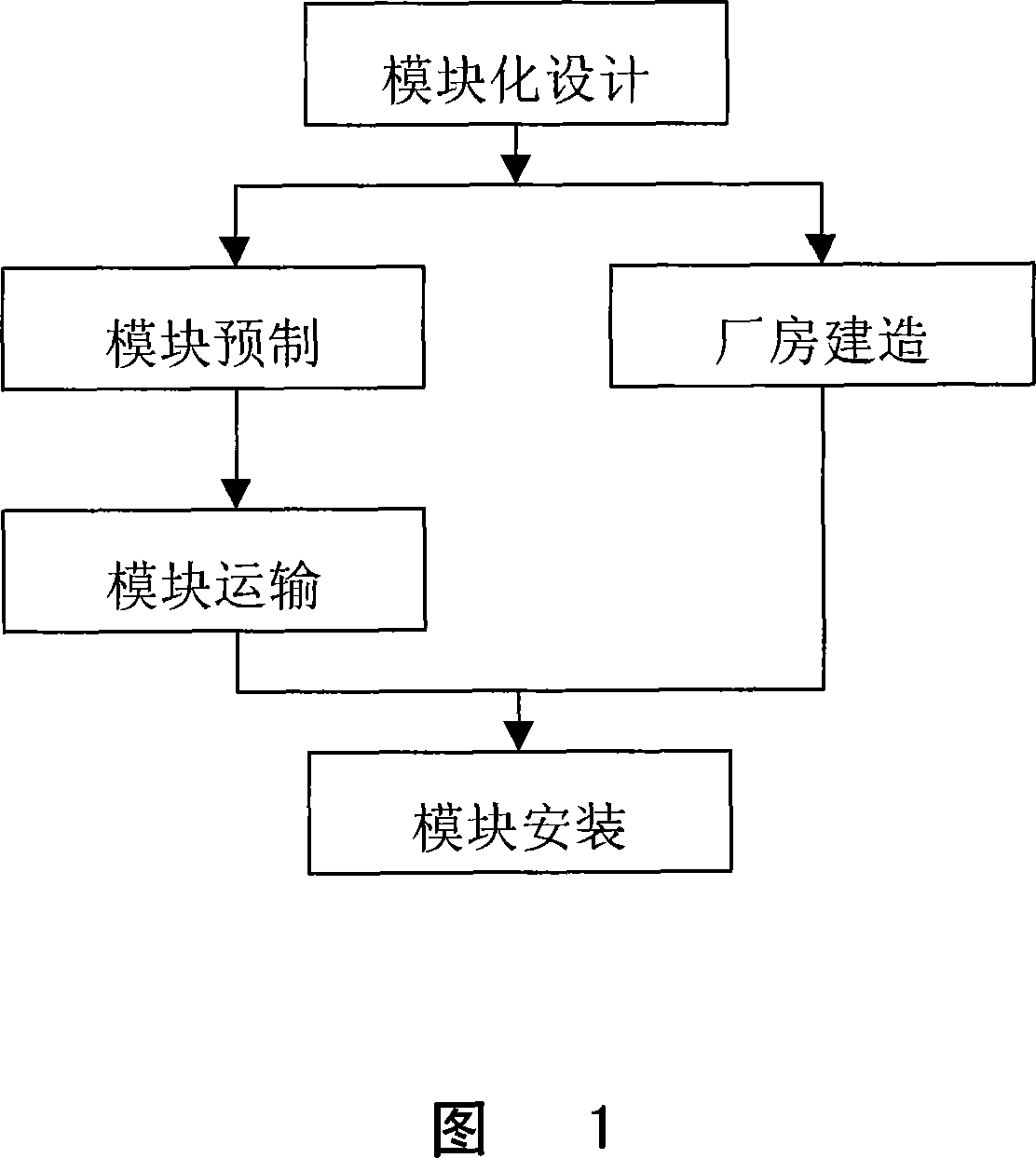

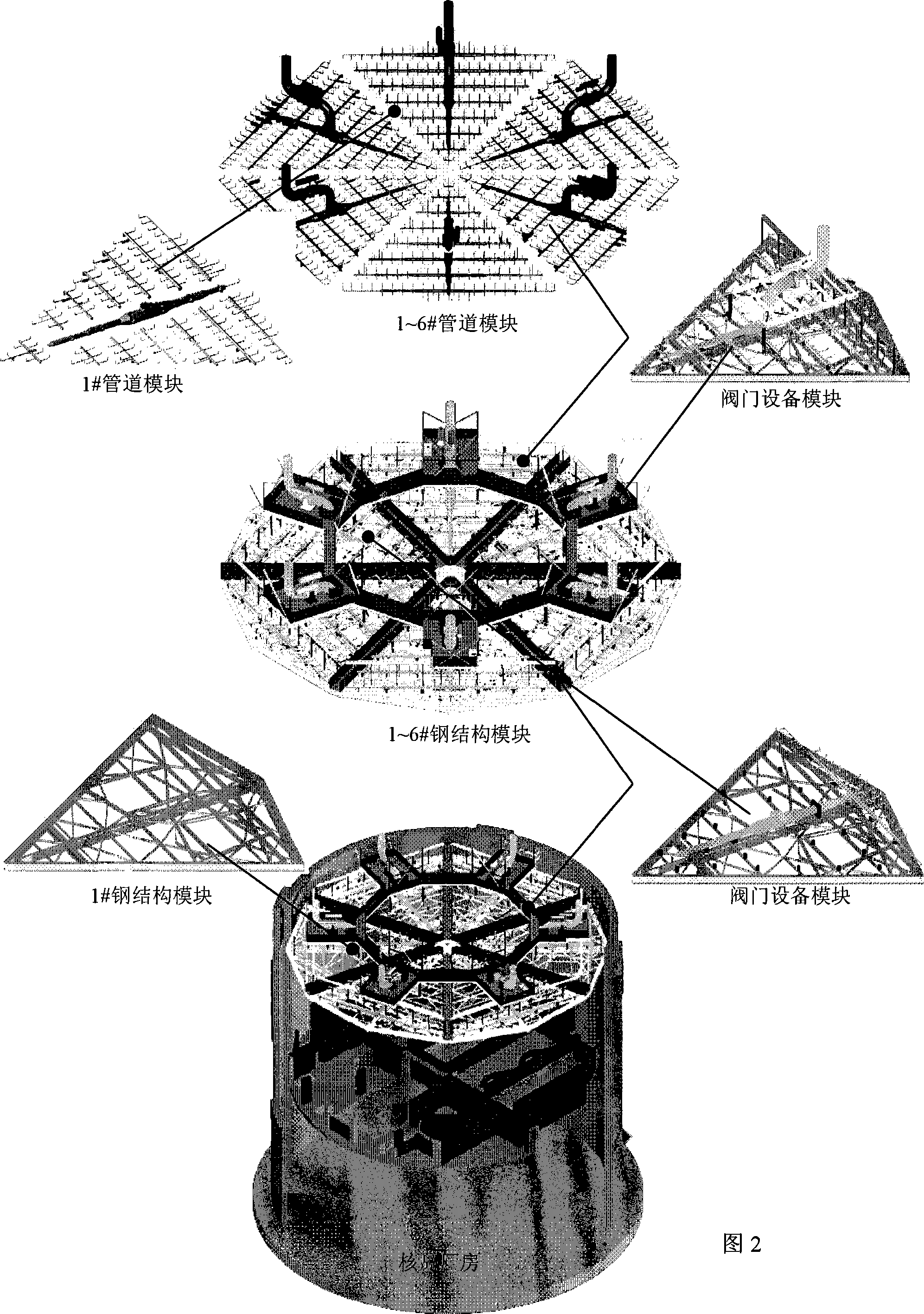

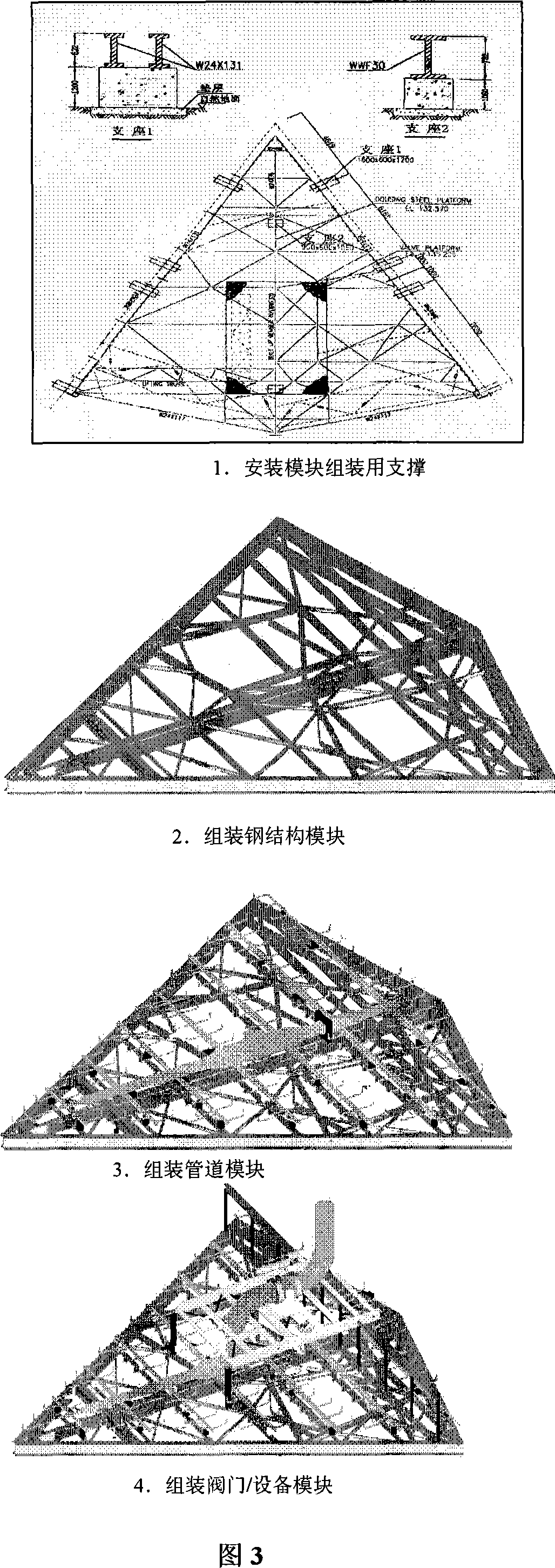

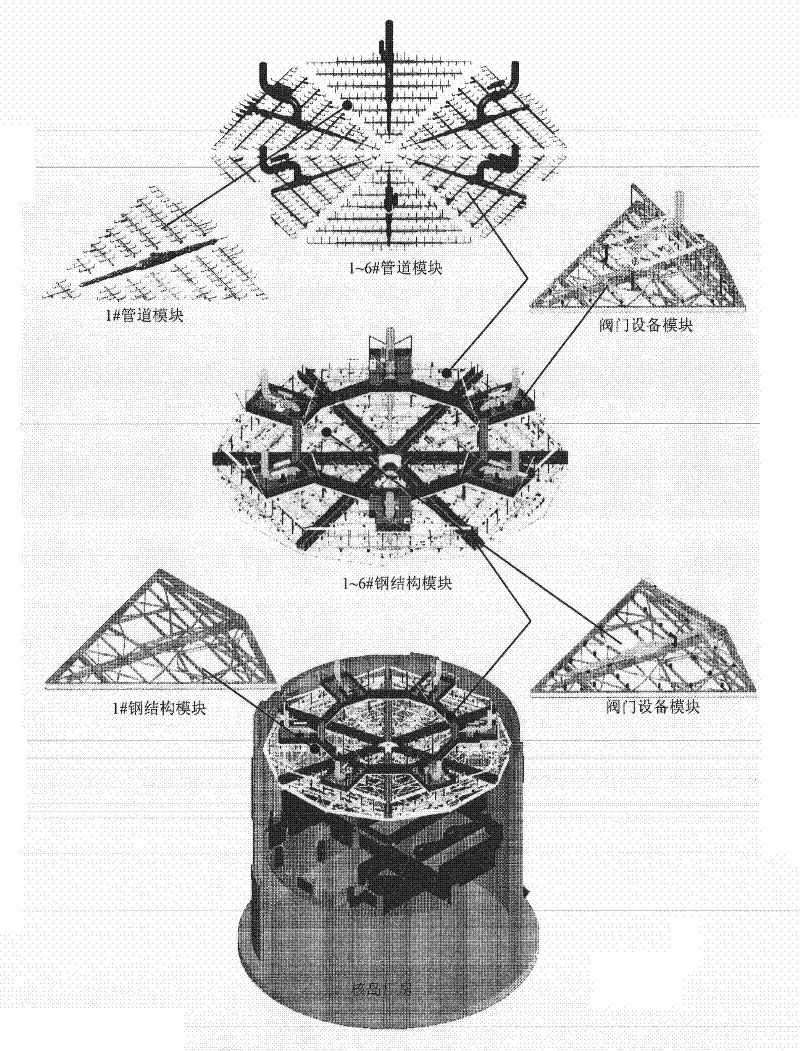

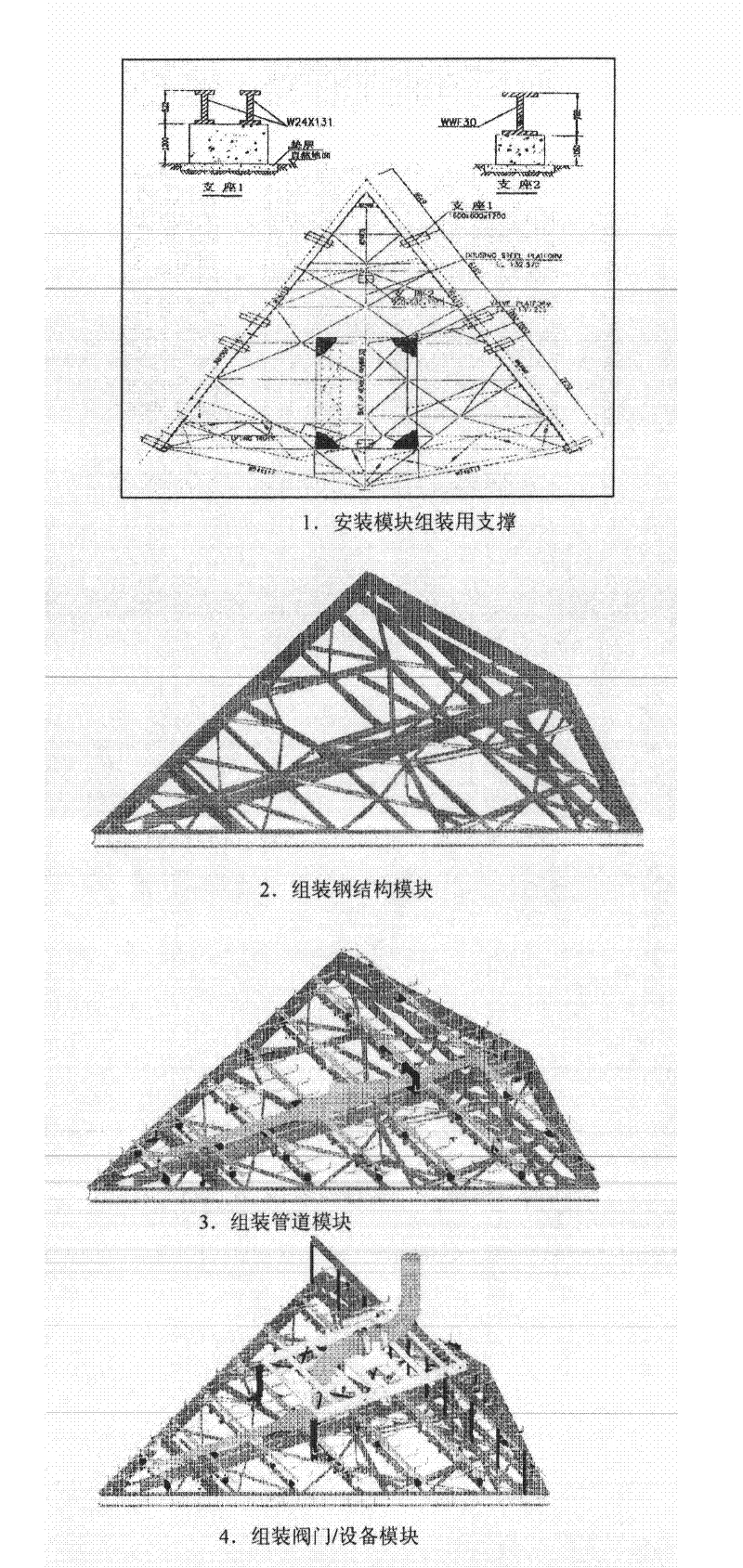

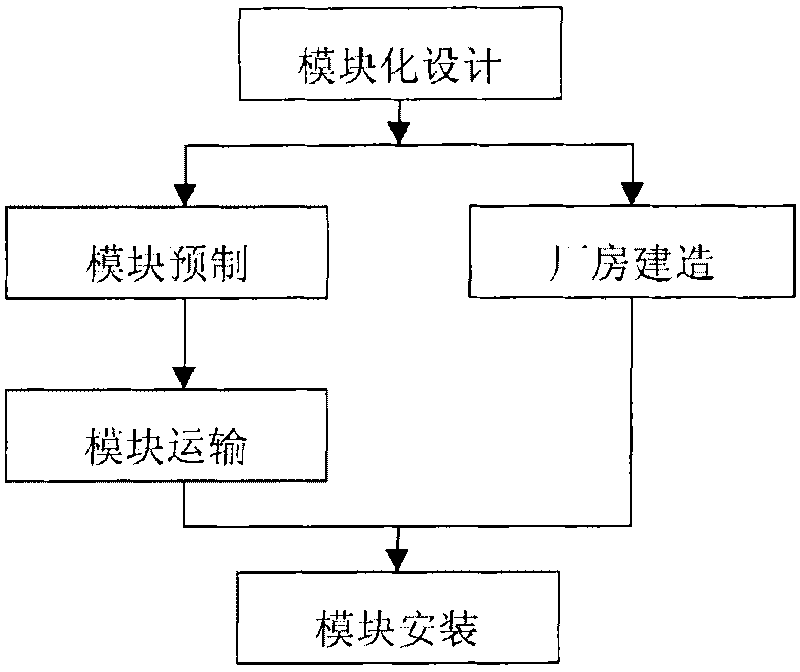

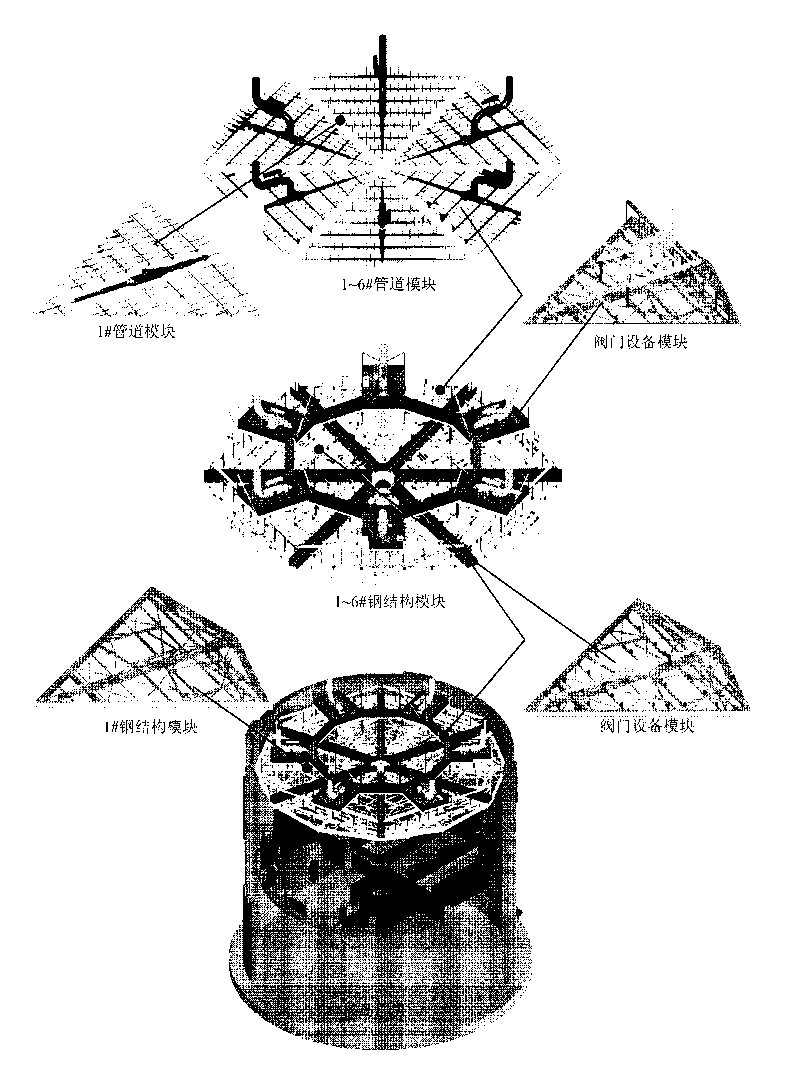

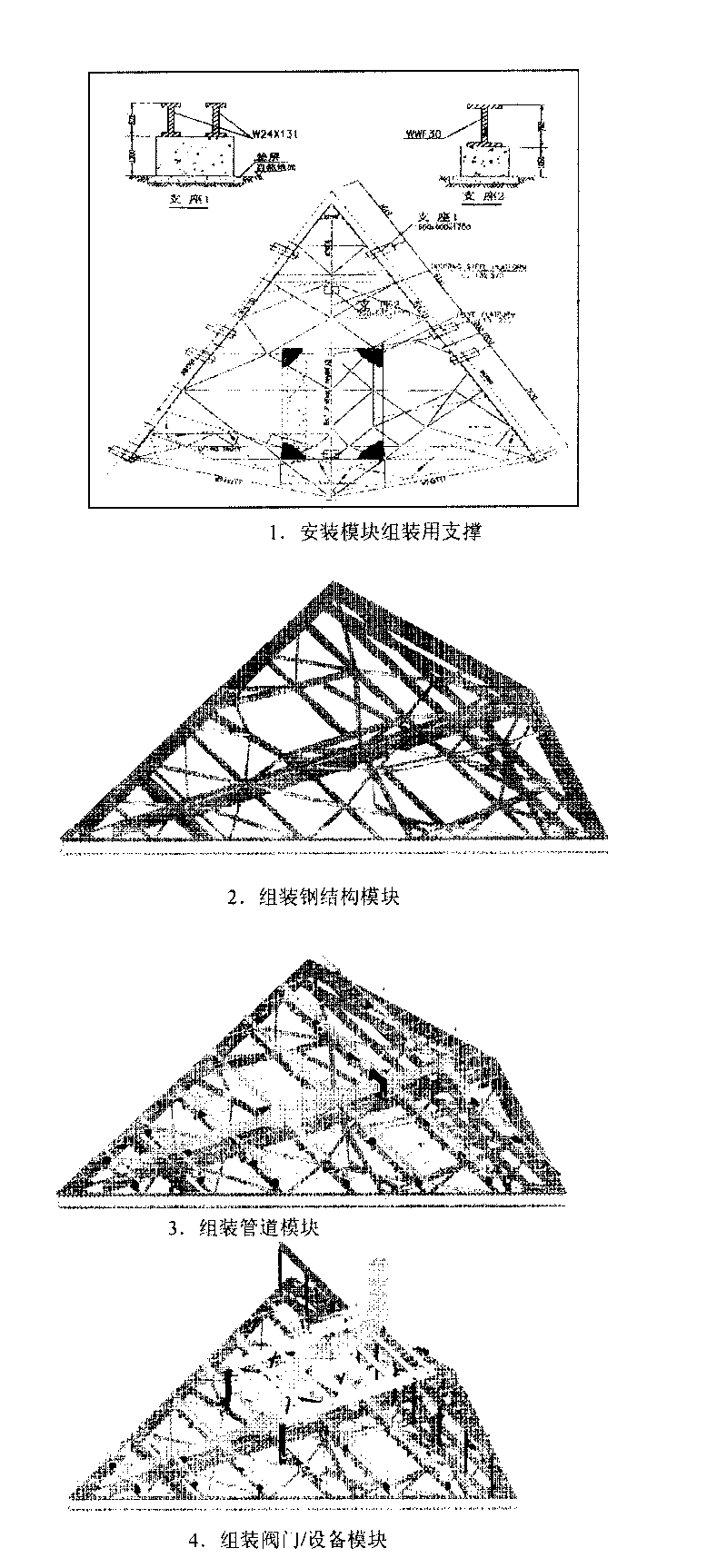

Modularize building method for nuclear reactor of nuclear plant

InactiveCN101136259AImprove construction qualityGuarantee the construction qualityNuclear energy generationNuclear power plant detailsNuclear plantNuclear reactor core

The modularized building method for nuclear island of nuclear power plant includes: modularized designing the upstream engineering of a nuclear island of nuclear power plant to divide and / or combine multiple units in the nuclear island into connection units among multiple modules, connection units between modules and connection units between module and exterior; prefabricating module by factory producing mode; building workshop by roof-opening construction mode; mounting the prefabricated module onto preset design position of the workshop. Advantage: raised prefabrication rate and constriction quality, increased engineering speed and low building cost.

Owner:CHINA NUCLEAR IND 23 CONSTR

Prefabricated reinforced concrete shear wall convenient to install and construction method

PendingCN111424849AReduce usagePrecise positioningWallsBuilding material handlingReinforced concreteFloor slab

The invention discloses a prefabricated reinforced concrete shear wall convenient to install and a construction method. The prefabricated reinforced concrete shear wall comprises a concrete wall body,wherein an edge component is arranged on the side face of the concrete wall body, and longitudinal ribs vertically protrude out of the end face of the concrete wall body; a steel beam connecting piece is arranged at one end of the edge component; and the steel beam connecting piece comprises two flange plates, and a web is arranged between the two flange plates. The construction method comprisesthe following steps that stirrups and the longitudinal ribs are bound in a horizontal connecting area, supporting pieces and the steel beam connecting piece are arranged on the shear wall, and the steel beam connecting piece is fixed to anchor bolts; hidden beam steel bars and hidden beam stirrups are arranged in a vertical connecting area; hidden column longitudinal ribs are connected through longitudinal rib connectors, and the stirrups are inserted into stirrup penetrating holes; the steel beam connecting piece is connected with a steel beam; and a laminated slab or a floor support plate islaid on the steel beam, floor slab steel bars are bound, concrete is poured, and the wall body is obtained through maintenance. The prefabricated reinforced concrete shear wall has the advantages ofbeing low in manufacturing cost and good in fireproof performance.

Owner:THE ARCHITECTURAL DESIGN & RES INST OF ZHEJIANG UNIV

Prefabricated concrete column in butting connection by steel nodes

InactiveCN105239723AQuick fit connectionFit connection stableStrutsPillarsReinforced concrete columnRebar

The invention discloses a prefabricated concrete column in butting connection by steel nodes. The prefabricated concrete column comprises a prefabricated concrete column body, a first steel node positioned at one end of the prefabricated concrete column body, and a second steel node positioned at the other end of the prefabricated concrete column body, wherein the first and second steel nodes are matched. As the first steel node and the second steel node are additionally arranged at the two ends of the prefabricated concrete column body, two sections of prefabricated concrete columns can be quickly matched and connected by using a principle of mutual matching of the first and second steel nodes; and then, the matched place is fixed through electric welding, so that the butting connection between the two sections of prefabricated concrete columns can be guaranteed, the traditional scene butting wet operation of prefabricated concrete columns is prevented, and the construction efficiency is quickened. The prefabricated concrete column is simple in structure and low in cost; and after the steel nodes are used for connecting, the node stress and the node ductility are improved.

Owner:SHANGHAI MECHANIZED CONSTR GRP

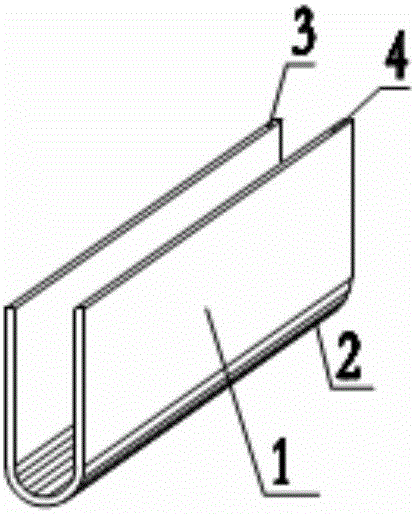

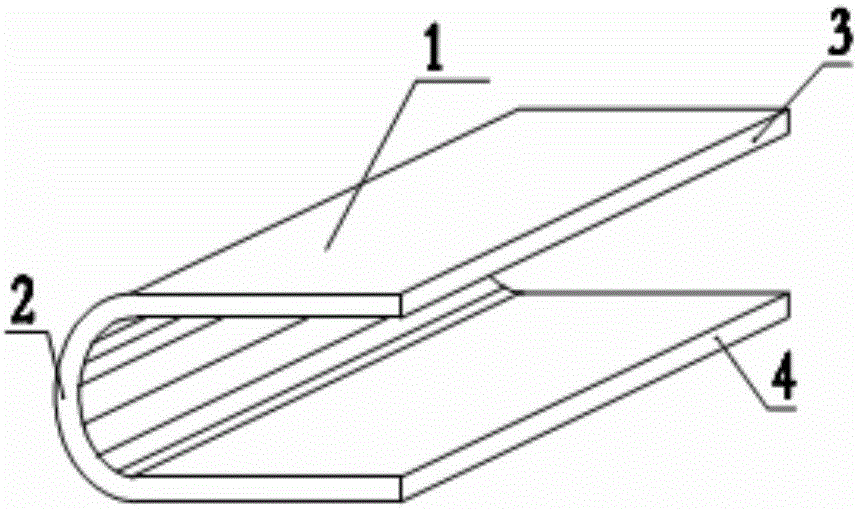

Steel bar connecting piece, connecting method, connecting connector and special extrusion die

ActiveCN106151186ASimple production processEasy qualityRod connectionsFriction grip releasable fasteningsSheet steelArchitectural engineering

The invention discloses a steel bar connecting piece, a connecting method, a connecting connector and a special extrusion die. The connecting piece comprises an arc steel plate section, a first steel plate section and a second steel plate section, wherein the first steel plate section and the second steel plate section are connected to two arc edges of the arc steel plate section correspondingly. The connecting connector comprises connecting ends of a steel bar A and a steel bar B and connecting pieces wrapping the connecting ends of the steel bar A and the steel bar B, wherein the connecting ends lean against each other in parallel, and a lap joint overlapping section is formed; and the inner surfaces of the connecting pieces and protruding ribs on the surfaces of the steel bars are closely engaged together, and contact faces between the steel bar A and the steel bar B are pressed mutually and engaged. The steel bar connecting piece, the connecting method, the connecting connector and the special extrusion die are supplementation of the steel bar connecting technology, and application of the steel bar connecting piece, the connecting method, the connecting connector and the special extrusion die to connection of the steel bars has the beneficial effects that safe reliability of high connecting strength is achieved, the economical efficiency of low construction difficulty and time and labor saving during operation is achieved, and the application range is wide.

Owner:刘祥锦

Assembled concrete structure construction method

ActiveCN106193623AIncrease stiffnessReduce supportBuilding material handlingEngineeringStructure system

The invention discloses an assembled concrete structure construction method. According to the construction method, a reversed construction procedure is adopted for installation of a vertical component of a currently constructed floor, that is, before connection assembly of a horizontal component of the currently constructed floor, the vertical component connected to the upper portion of the horizontal component is hoisted firstly, and finally connection concrete is poured at a time to connect the horizontal component with the vertical component of the currently constructed floor into a whole. The construction method adopts the reversed construction procedure, so that construction links are reduced, and the construction period is shortened; the method is suitable for assembled concrete building construction for structure systems such as precast shear walls, composite wallboards and frameworks, and has the advantages of convenient construction, time saving, economy, environment friendliness and the like; and meanwhile, the requirement for identical performance as a cast-in-place structure is met.

Owner:刘祥锦

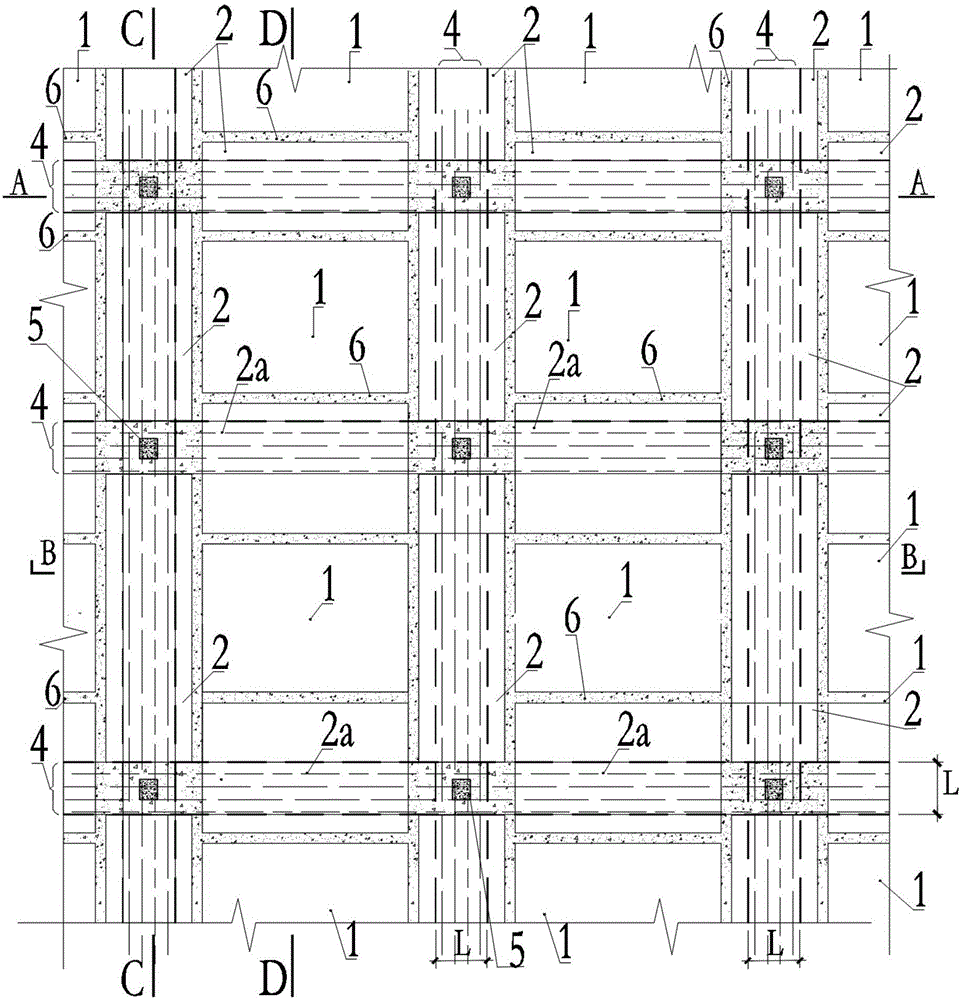

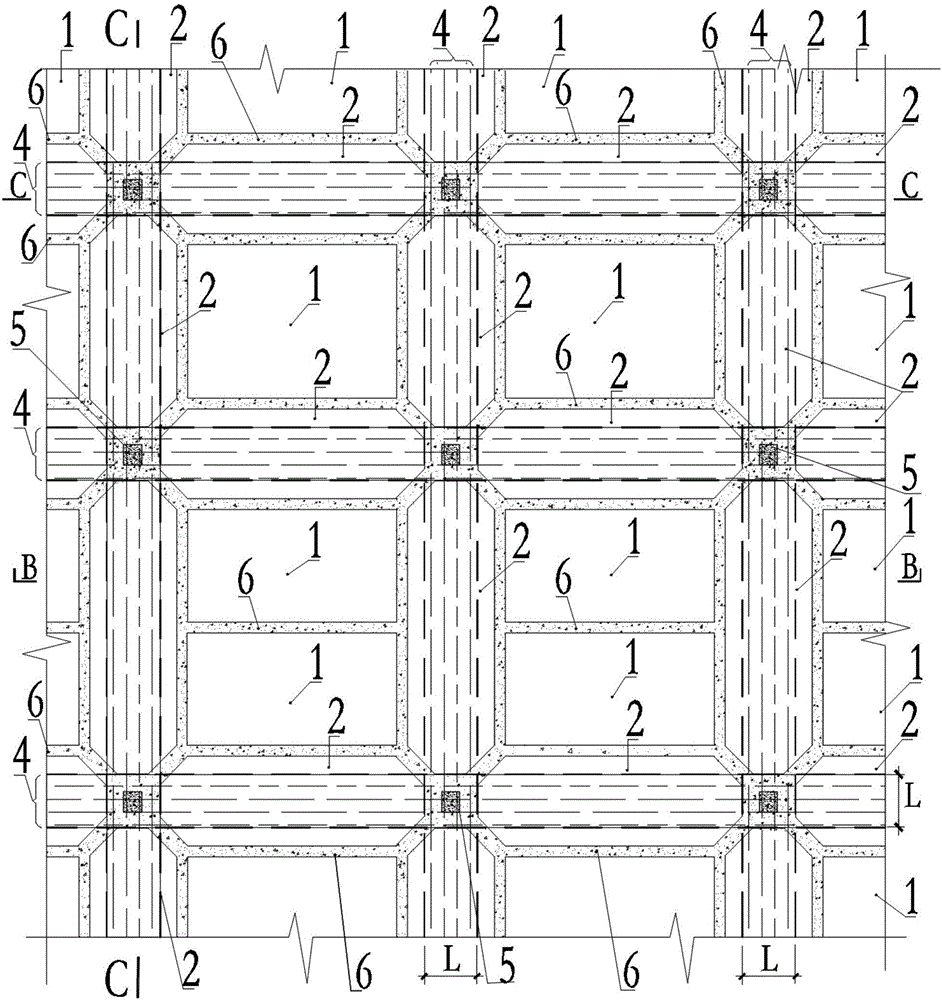

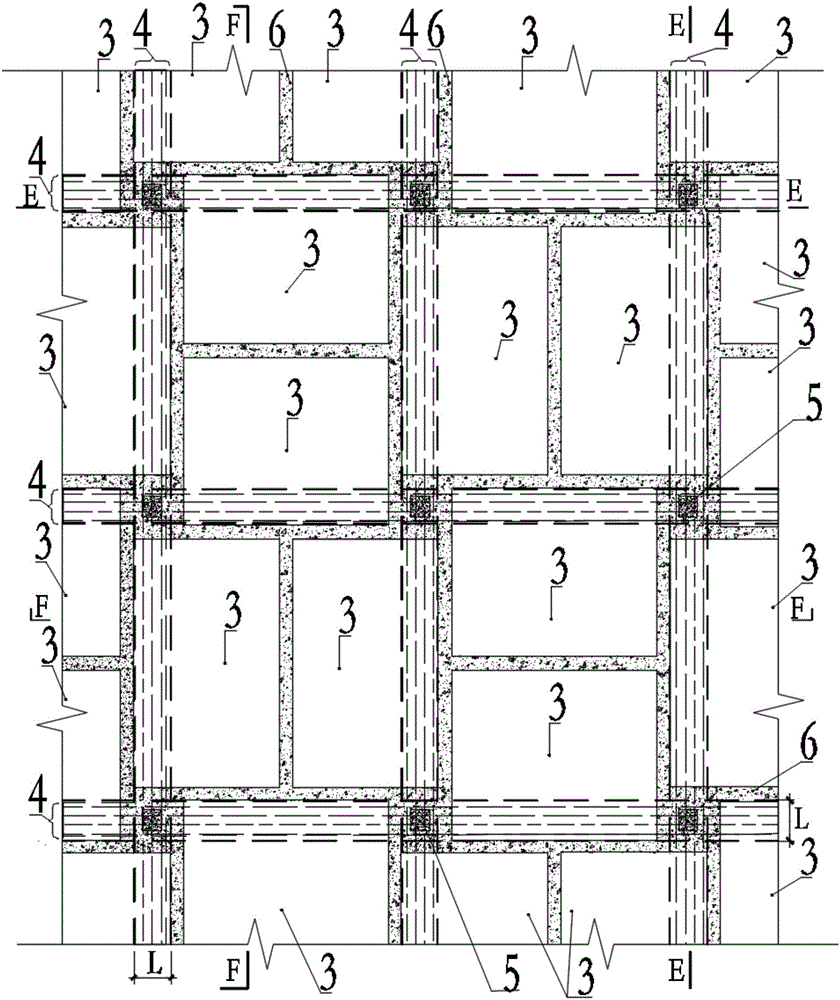

Assembled board-column structure floor slab, dividing method thereof, and floor slab unit components

ActiveCN106522552AImprove reliabilityHigh costFloorsBuilding material handlingAgricultural engineeringFloor slab

The invention discloses an assembled board-column structure floor slab, a dividing method thereof, and floor slab unit components. The assembled board-column structure floor slab comprises the multiple prefabricated floor slab unit components comprising adjacent column connection board belts, or the assembled board-column structure floor slab comprises the multiple prefabricated floor slab unit components comprising the adjacent column connection board belts, and the multiple conventional prefabricated floor slab unit components. The adjacent column connection board belts in the prefabricated floor slab unit components comprising the adjacent column connection board belts are long-strip-shaped belt boards integrally stretching across every two adjacent columns. The connection line of section centroids of the two adjacent structure columns connected through each adjacent column connection board belt serves as a reference line of the adjacent column connection board belt, and the width of each adjacent column connection board belt is larger than or equal to the longest side length of the connection sides of the two adjacent structure columns connected through the adjacent column connection board belt. The adjacent column connection board belts are provided with direct-through bottom reinforcing bars in the span direction. By the adoption of the technical scheme, cost can be reduced, construction is convenient, and safety and reliability of the board-column structure of the prefabricated floor slab can be improved at the same time.

Owner:刘祥锦

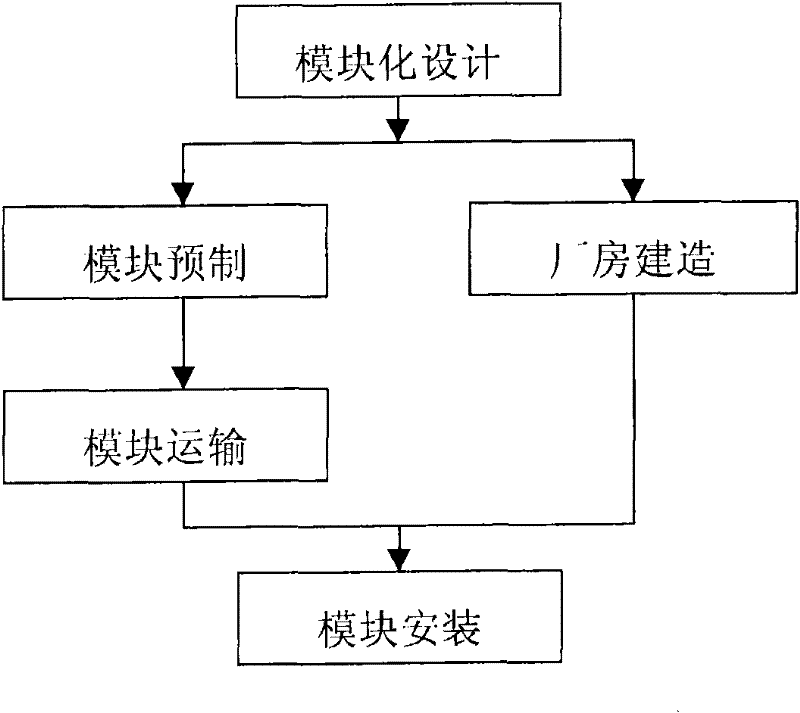

Modularization construction method for nuclear power station nuclear island

InactiveCN101748915AImprove construction qualityGuarantee the construction qualityIndustrial buildingsNuclear powerWorkshop building

The invention discloses a modularization construction method for a nuclear power station nuclear island, comprising the following steps: a modularization design step, carrying out the modularization design on an upstream engineering design of the nuclear power station nuclear island so as to divide and / or combine a plurality of units in the nuclear power station nuclear island into a plurality of modules and connecting units among the modules and between the modules and the outside; a module prefabrication step, prefabricating each module in a workshop manufacturing manner; a workshop building step, building workshops of a nuclear island building by an open-top construction method; and a module installation step, installing the prefabricated modules at the pre-designed positions of the workshops. The invention greatly improves the prefabrication rate of workshop manufacture of the nuclear power station nuclear island engineering, improves the construction quality of the nuclear island engineering, accelerates the engineering progress and achieves the purpose of reducing the whole construction cost.

Owner:CHINA NUCLEAR IND 23 CONSTR

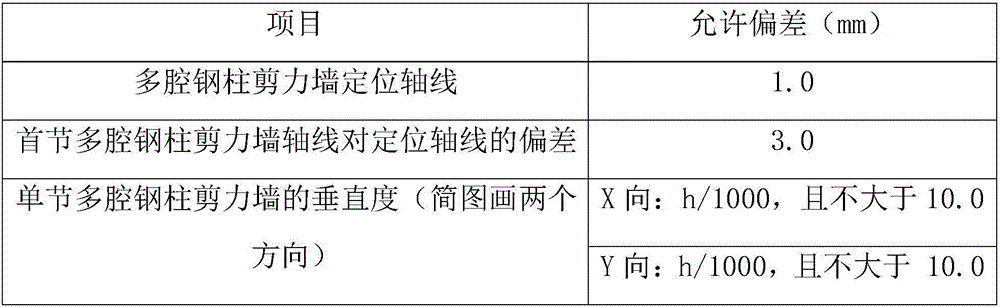

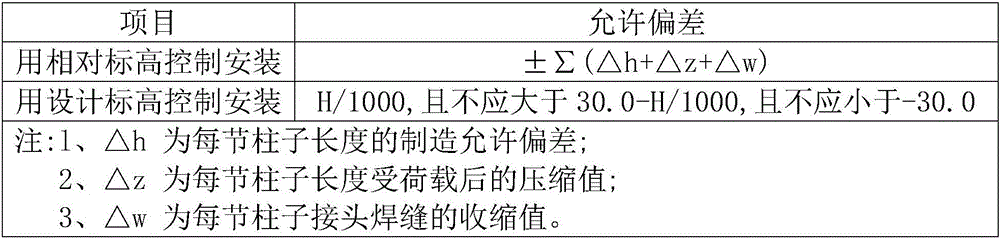

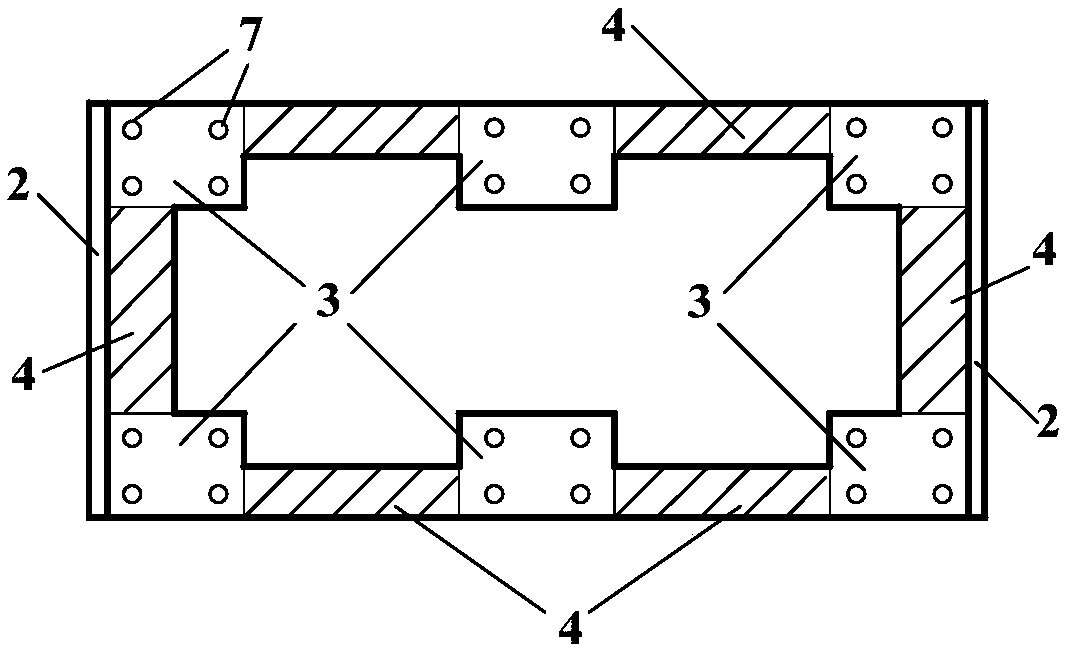

Installation method for multi-cavity steel column shear wall composite structure building system

The invention relates to a shear wall composite structure, in particular to an installation method for a multi-cavity steel column shear wall composite structure building system. The installation method comprises the following steps of 1, base and supporting surface setting, 2, installing and correcting, 3, multi-cavity steel column shear wall internal concrete engineering, and 4, completing and acceptance of parts of construction of a steel structure. According to the shear wall composite structure installation method, the structure is compact, usable areas are increased, and the quality is ensured.

Owner:潮峰钢构集团有限公司

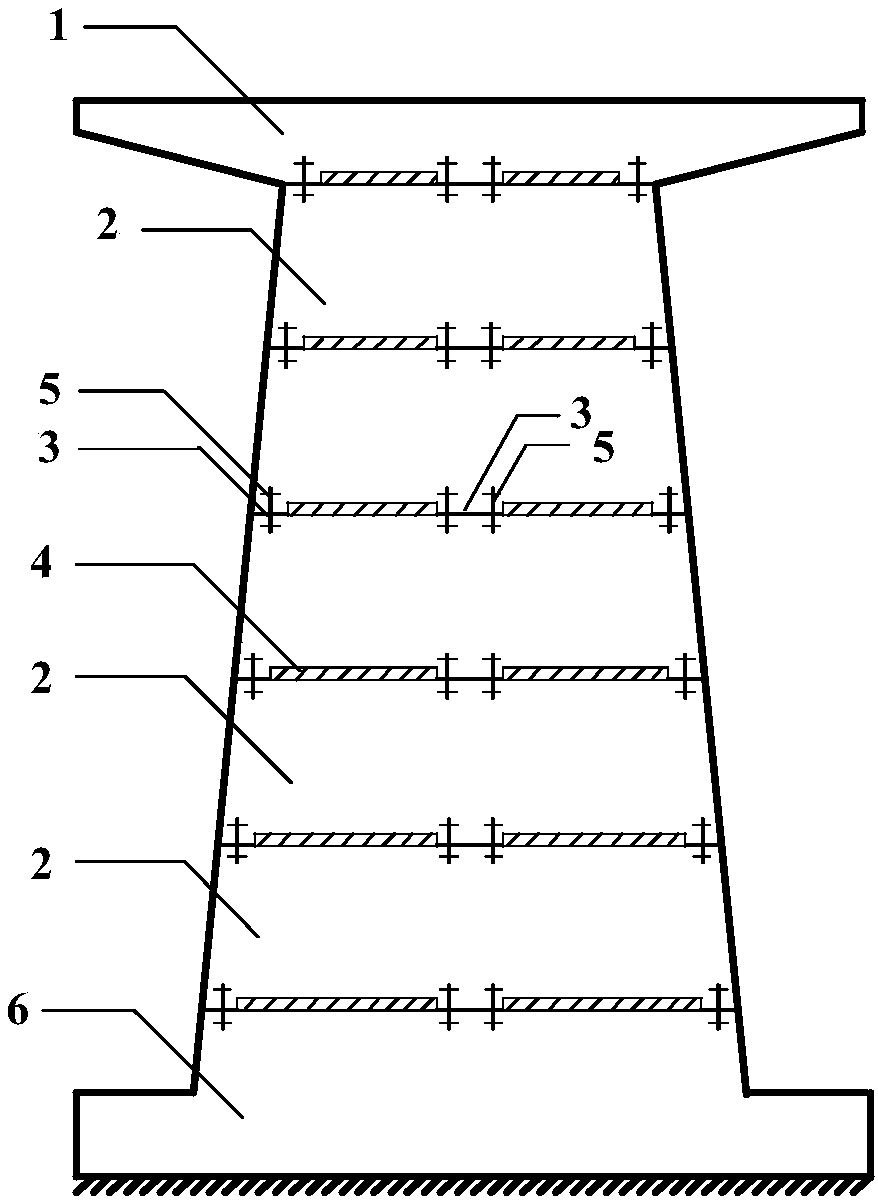

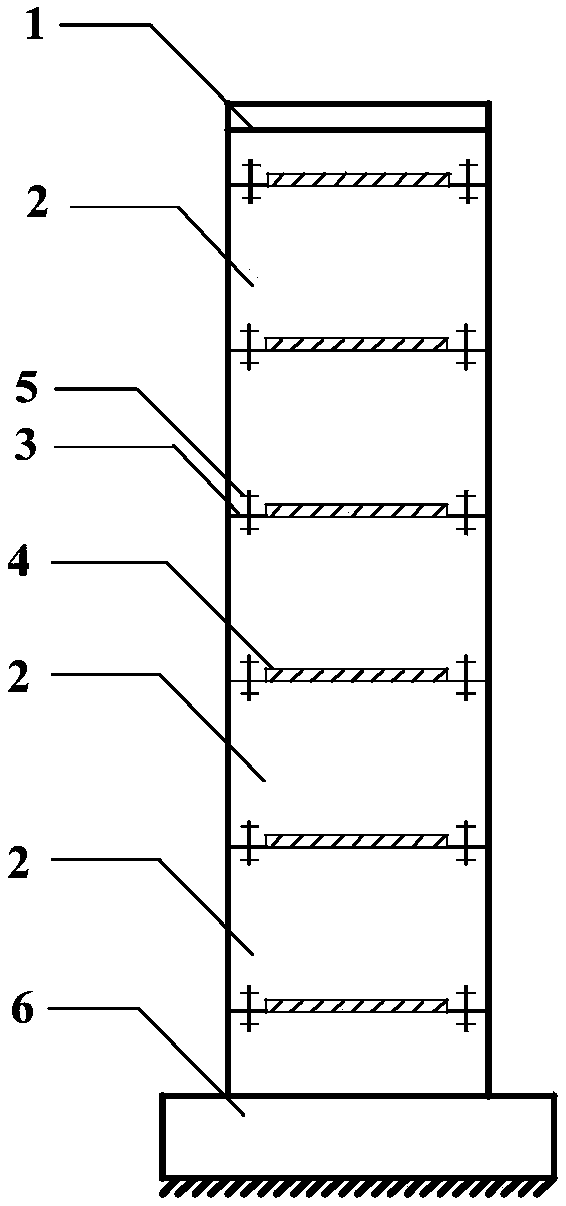

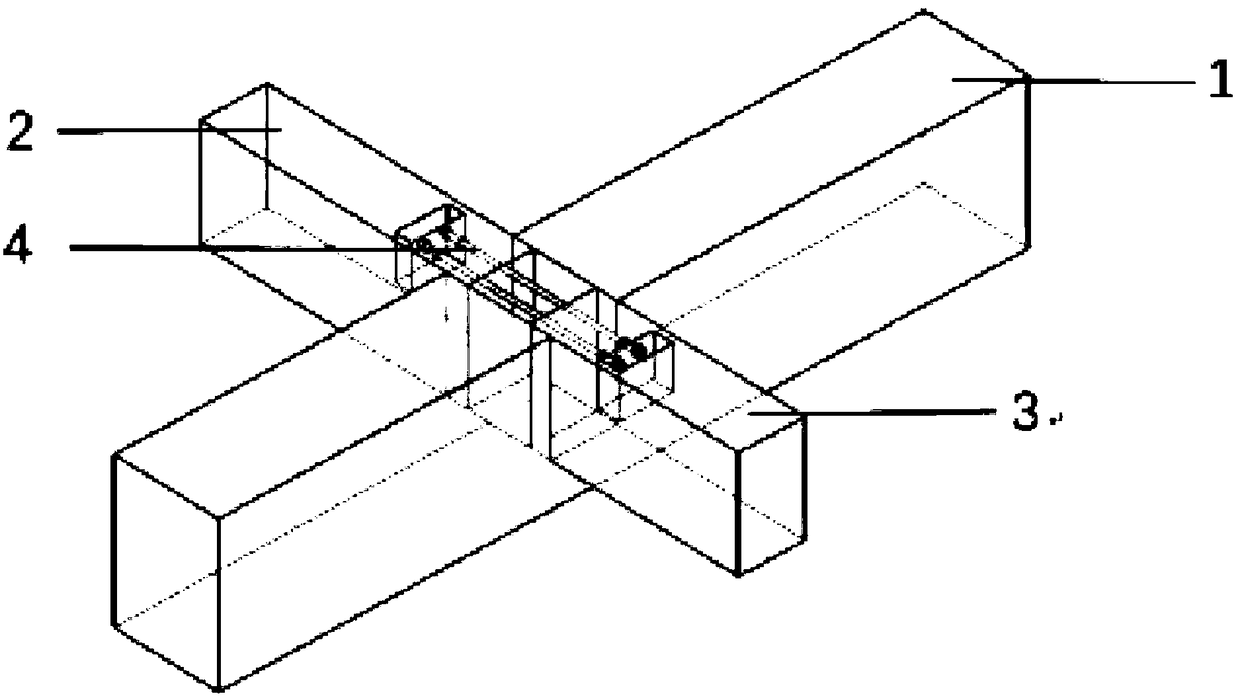

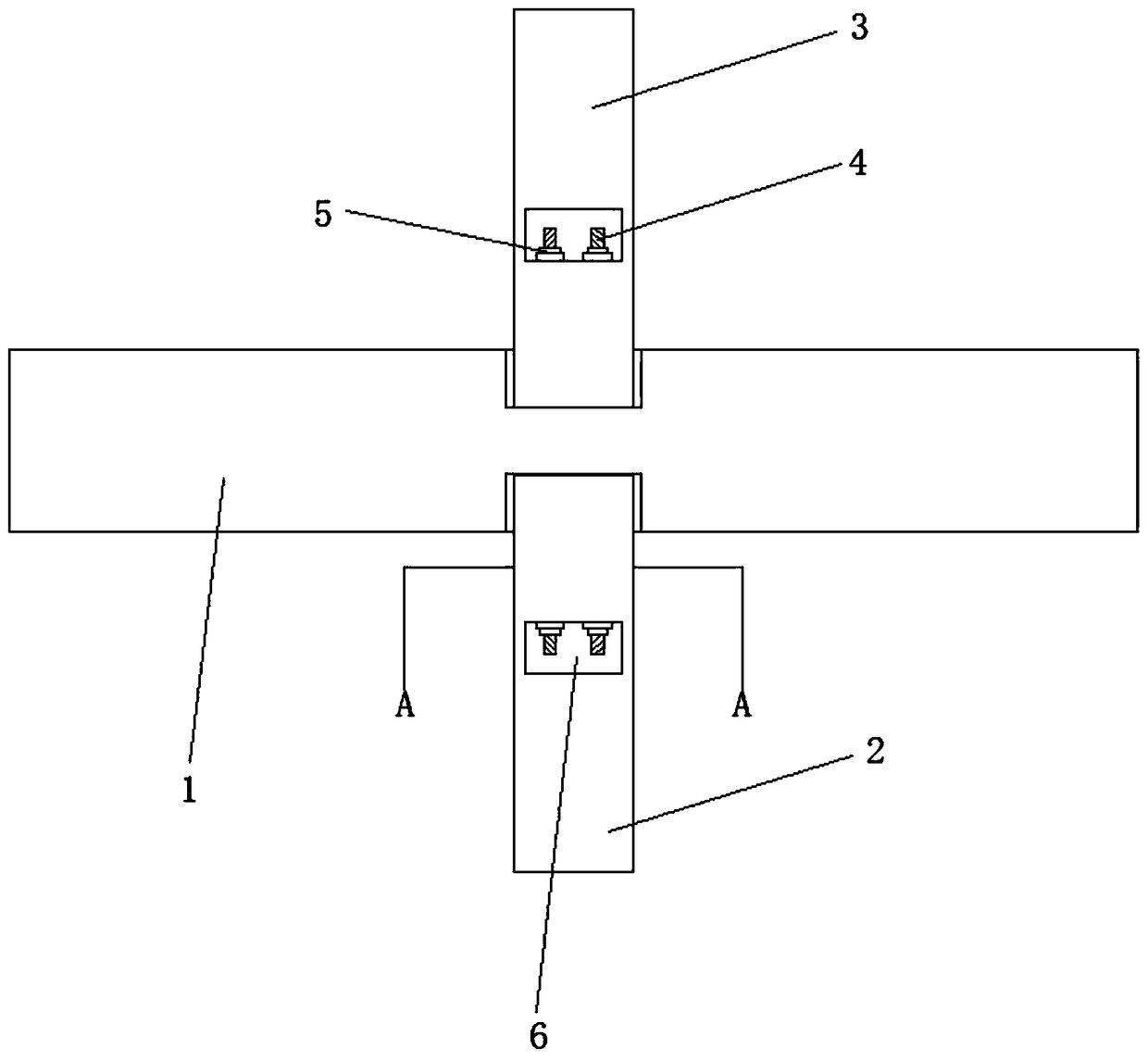

Segmental prefabricated assembled pier and construction method thereof

PendingCN108425317AImprove prefabrication rateImprove construction qualityBridge structural detailsBridge erection/assemblyEngineeringMechanization

The invention provides a segmental prefabricated assembled pier and a construction method thereof. A bent cap and a pier are divided into a plurality of standard segments; joint connection between every two standard segments comprises fixed connection for two parts, i.e., dry joint operation surfaces and wet joint operation surfaces; and all the standard segments are prefabricated in a factory andthen assembled on site. After being solidified, wet joint concrete bears load along with the dry joint operation surfaces, increasing the integrity of the pier; after the wet joint concrete is solidified, the assembling construction of the next segment can be immediately carried out, and therefore the curing period of the wet joint concrete is shortened. The segmental prefabricated assembled piernot only has all the advantages of a prefabricated assembled structure, such as high construction quality, less on-site operating personnel, high mechanization degree, low energy consumption and environment-friendliness, but also has the advantage of the dry joint operation surface, i.e., convenience and rapidness in construction, the advantages of a wet joint, i.e., good integrity, high anti-shearing capability, and the like. On the other hand, the invention further provides a construction method for the segmental prefabricated assembled pier.

Owner:CENT SOUTH UNIV +2

Novel fabricated primary and secondary beam connecting node and connecting method thereof

PendingCN108999297AImprove prefabrication rateImprove assembly rateBuilding material handlingMechanical engineeringPrefabrication

The invention discloses a novel fabricated primary and secondary beam connecting node and a connecting method thereof, which comprises a primary beam. Two sides of the middle position of the primary beam are respectively provided with beam grooves. Two sides of each beam groove are uniformly provided with connecting jacks. A first secondary beam and a second secondary beam are respectively arranged in the beam grooves. The middle positions of the first secondary beam and the second secondary beam are respectively provided with a mounting groove. The inside of one side, close to the primary beam, of each of the first secondary beam and the second secondary beam are uniformly provided with bolt jacks. One end of each bolt jack penetrates the corresponding mounting groove. A bolt penetrates each bolt jack. The middle position of each bolt penetrates the corresponding connecting jack. Two ends, located in the corresponding mounting groove, of each bolt are in threaded connection with nuts.The invention relates to the technical field of building beams. According to the novel fabricated primary and secondary beam connecting node and the connecting method thereof, the purpose of improving the bearing capacity and integrality thereof, improving the primary and secondary beam node connecting efficiency, further improving the prefabrication rate and fabrication rate of the connecting node, and promoting modernization development of the construction industry.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Modular construction method for nuclear island of nuclear power station

InactiveCN101736925AImprove construction qualityGuarantee the construction qualityNuclear energy generationNuclear power plant detailsNuclear powerComputer module

The invention discloses a modular construction method of a nuclear island of a nuclear power station, which comprises: a modular design step, which is to modularly design an upstream project of the nuclear island of the nuclear power station to divide a plurality of units in the nuclear island of the nuclear power station and / or combine the plurality of units to form a plurality of modules and connecting units between the modules and between the modules and the outside; a module prefabrication step, which is to prefabricate the modules in an industrial manufacturing mode; a plant building construction step, which is to construct plant buildings in the nuclear island in an open-top-method construction mode; and a module installation step, which is to install the prefabricated modules on preset design positions of the plant buildings. The method greatly increases the prefabrication rate of the industrial manufacturing of the project of the nuclear island of the nuclear power station, improves the construction quality of the project of the nuclear island, accelerates the construction process of the project and reduces overall construction cost.

Owner:CHINA NUCLEAR IND 23 CONSTR

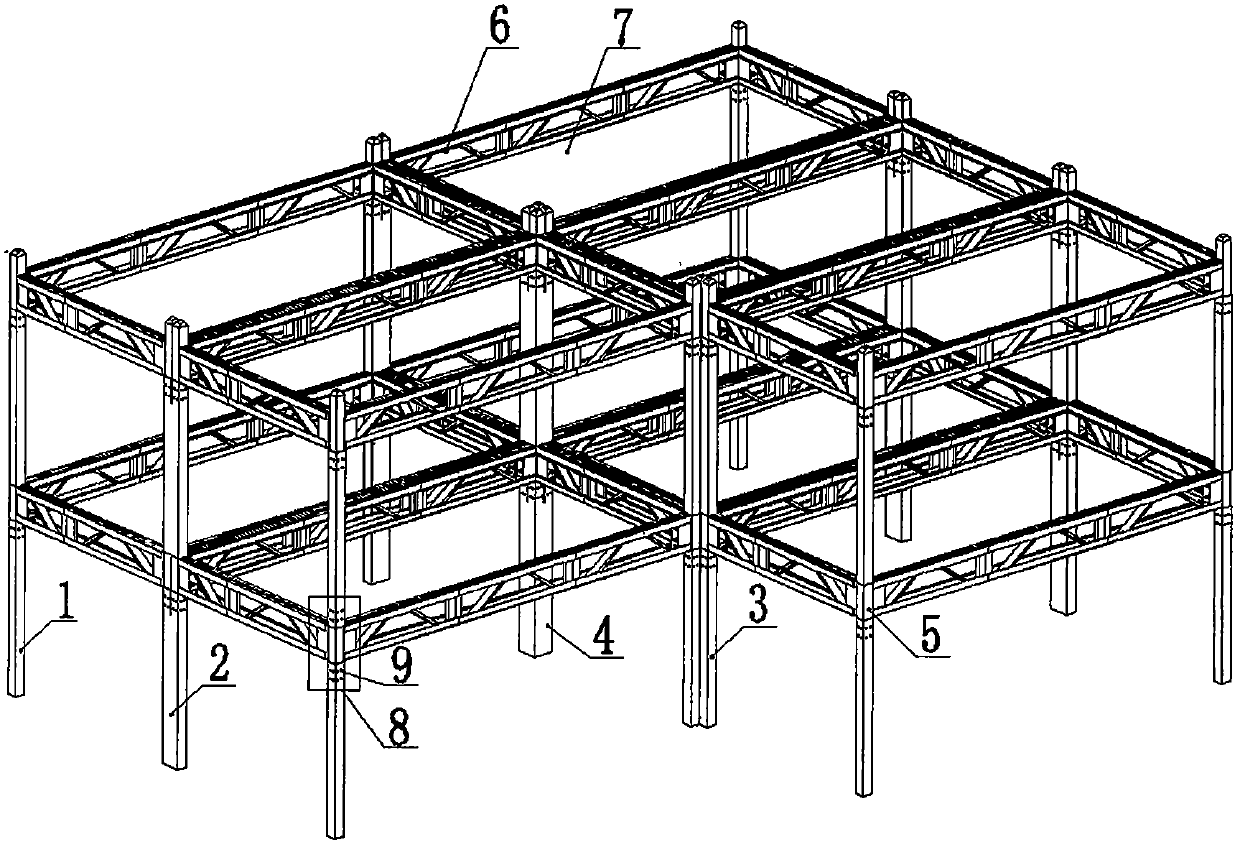

Assembly type steel reinforced concrete framework spatial module structure and system and construction method

PendingCN107605038AImprove prefabrication rateImprove hoisting efficiencyBuilding material handlingReinforced concreteFloor slab

The invention provides an assembly type steel reinforced concrete framework spatial module structure and system and a construction method. The spatial module structure comprises a bell-shaped five-face spatial modular structure composed of four prefabricated walls, section steel columns, section steel beams, section steel longitudinal beams and a steel concrete composite floor slab; the prefabricated wall comprises a rectangular wall panel main body and section steel rods which are detachably connected to two sides of the wall panel main body; the section steel columns are detachably connectedwith two adjacent prefabricated walls; the section steel beams are detachably connected to tops of the transverse prefabricated walls; the section steel longitudinal beams are detachably connected totops of longitudinal prefabricated walls; shear resistant connecting members are connected with intervals to tops of the section steel longitudinal beams in the long axis direction; the steel concrete composite floor slab is detachably connected to the section steel beams and the section steel longitudinal beams. The invention solves the technical problems that the prior assembled building structural system has the problems of low assembly rate, poor anti-seismic performance, large workload of hoisting on site and complex site construction.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

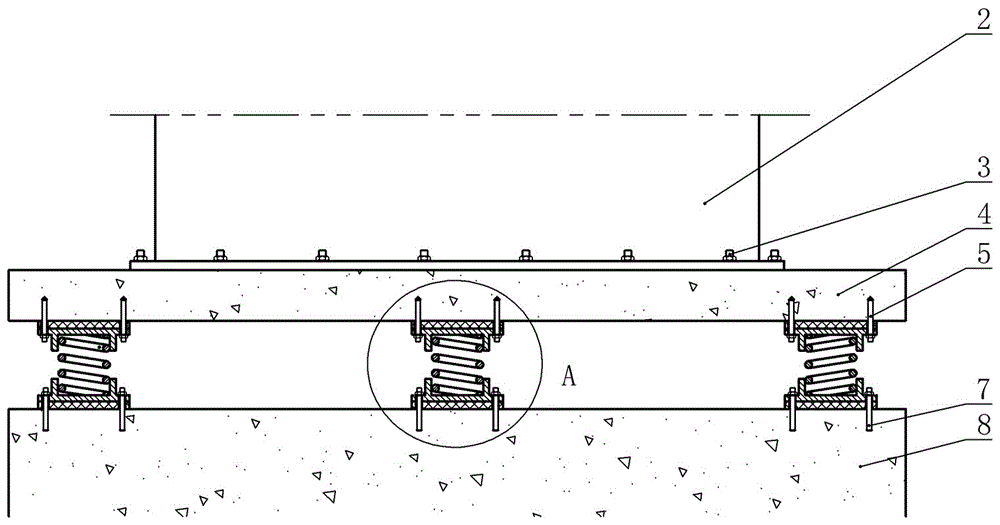

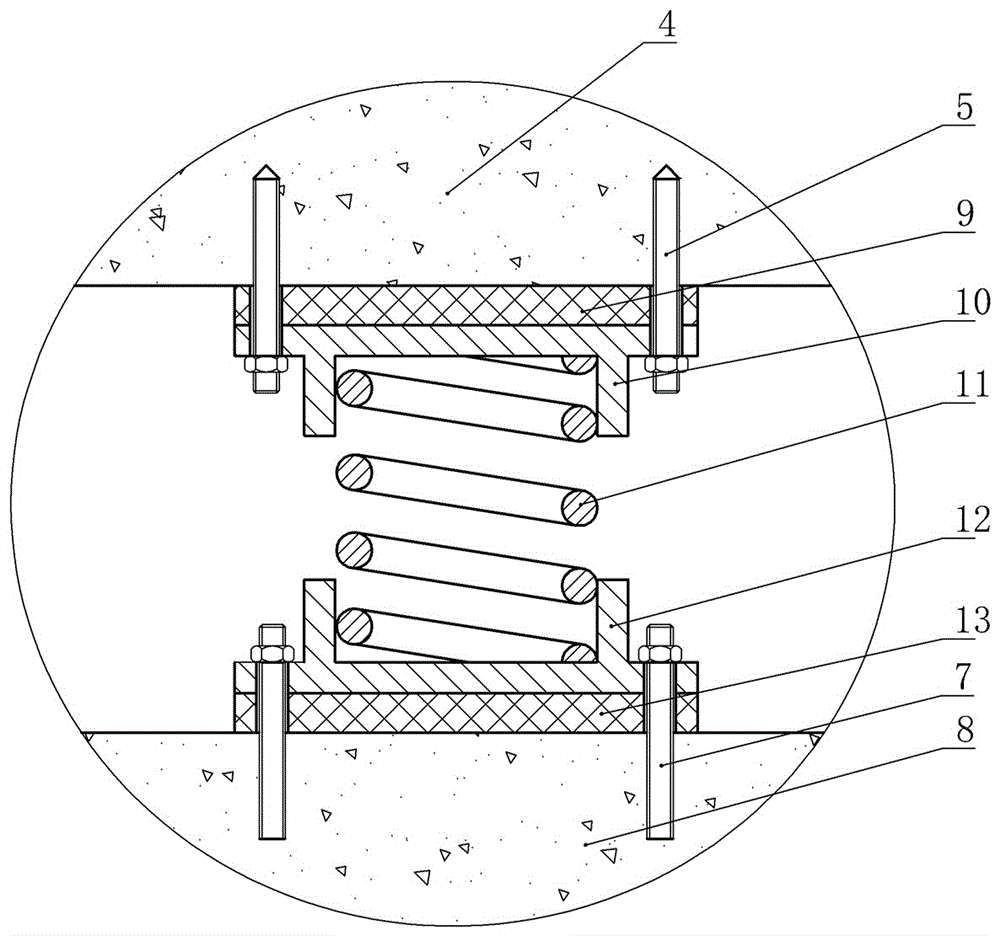

Assembled integrated house component device

InactiveCN106013459AReduce varianceImprove performanceProtective buildings/sheltersShock proofingWastewaterEconomic benefits

The invention relates to an assembled integrated house component device, which comprises a foundation, a main wallboard, a floor deck, an external wallboard and a door / window plate, wherein the main wallboard is fixedly arranged on the foundation through L-shaped connecting pieces and first embedded bolts; the external wallboard is fixedly arranged on the outer side of the main wallboard; a sound insulation and heat preservation layer is arranged between the external wallboard and the main wallboard; the foundation comprises a foundation bed, a base and multiple seismic stabilizer brackets; the main wallboard is fixedly arranged on the upper surface of the base; the seismic stabilizer brackets are uniformly arranged between the foundation bed and the base at intervals; each seismic stabilizer bracket comprises a damping spring and upper and lower vibration isolation cushions; the upper ends of the damping springs are fixedly arranged on the lower surface of the base through upper spring seats, and the lower ends of the damping springs are fixedly arranged on the foundation bed through lower spring seats. The assembled integrated house component device is high in prefabrication rate and overall house performance, less in field wet operation, rapid in construction, easy to operate, low in labor intensity of a worker, material-saving and labor-saving, and has remarkable economic benefits, the quality of a building is improved, production of a large amount of construction waste and wastewater is avoided, noise pollution is reduced, and consumption is reduced.

Owner:HENAN GUOLONG IND

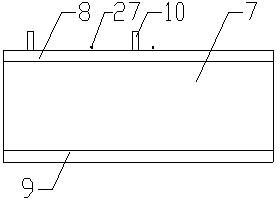

Precast concrete monolithic ground floor for kitchen and toilet and installation method

InactiveCN108442595APut an end to common quality problems that are easy to leakImprove prefabrication rateFloorsSpecial buildingFloor slabEconomic benefits

The invention discloses a precast concrete monolithic ground floor for a kitchen and toilet. The precast concrete monolithic ground floor comprises a kitchen and toilet bottom plate, guide walls are laid on the periphery of the kitchen and toilet bottom plate, the guide walls and the kitchen and toilet bottom plate are formed integrally. The guide walls are directly installed on a structural beamor part of the guide walls is installed on the structural beam or all of the guide walls are not installed on the structural beam. A groove is formed in the middle of the outer side of the guide wallin a surrounding mode, the groove is in a trapezoid shape, inward slope toes are arranged on the root portions of the outer side surfaces of the guide walls, annular anchoring stirrups and longitudinal reinforcements are reserved on the peripheries of the guide walls, and door hole openings are formed in the middles of one sides of the guide walls. The precast concrete monolithic ground floor forthe kitchen and toilet is simple and reasonable in technological structure, convenient to operate and easy to control, the construction speed is high, common quality problems of leakage of a common cast-in-place structural floor usually occur in kitchen and bathroom parts are completely eliminated, the problem that prefabricated buildings cannot use precast concrete fabricated parts in water roomsuch as the kitchen and toilet is solved, and economic benefits are remarkable.

Owner:JIANGSU NANTONG SANJIAN CONSTRUCTION GROUP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com