Simply-built green light steel fabricated building and installation method

A prefabricated, light-steel technology, used in buildings, building components, building structures, etc., can solve the problems of heavy workload of light-steel rib keel composite structures, self-heavy concrete materials, and single installation methods, and achieve rapid The effect of green construction, reducing the consumption of building materials and improving the prefabrication rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments of the description.

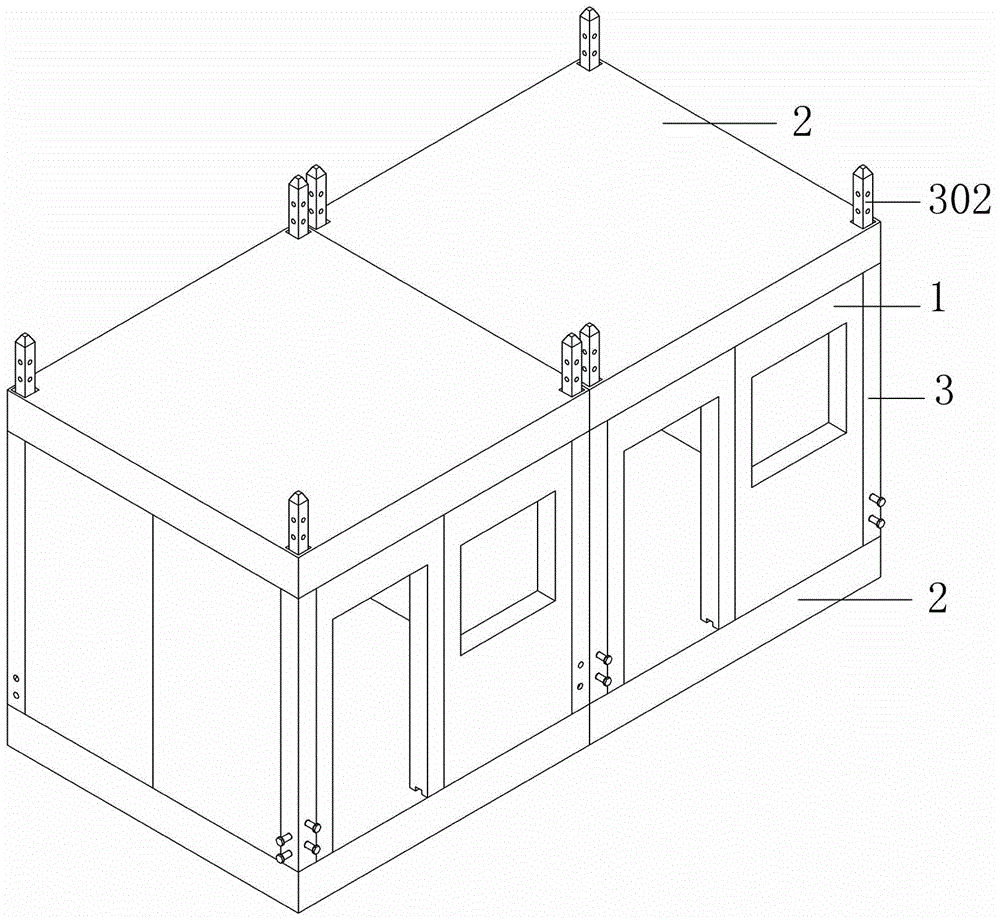

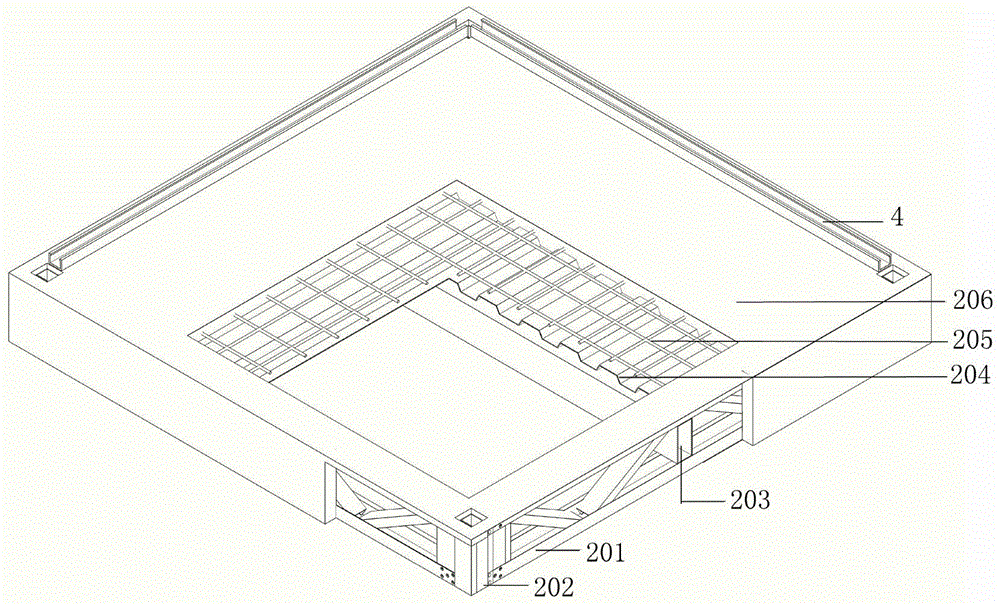

[0046] A green light-steel prefabricated house of simple construction, the house comprises a wall panel (1), a main board (2), a composite frame column (3) and a main connector (4).

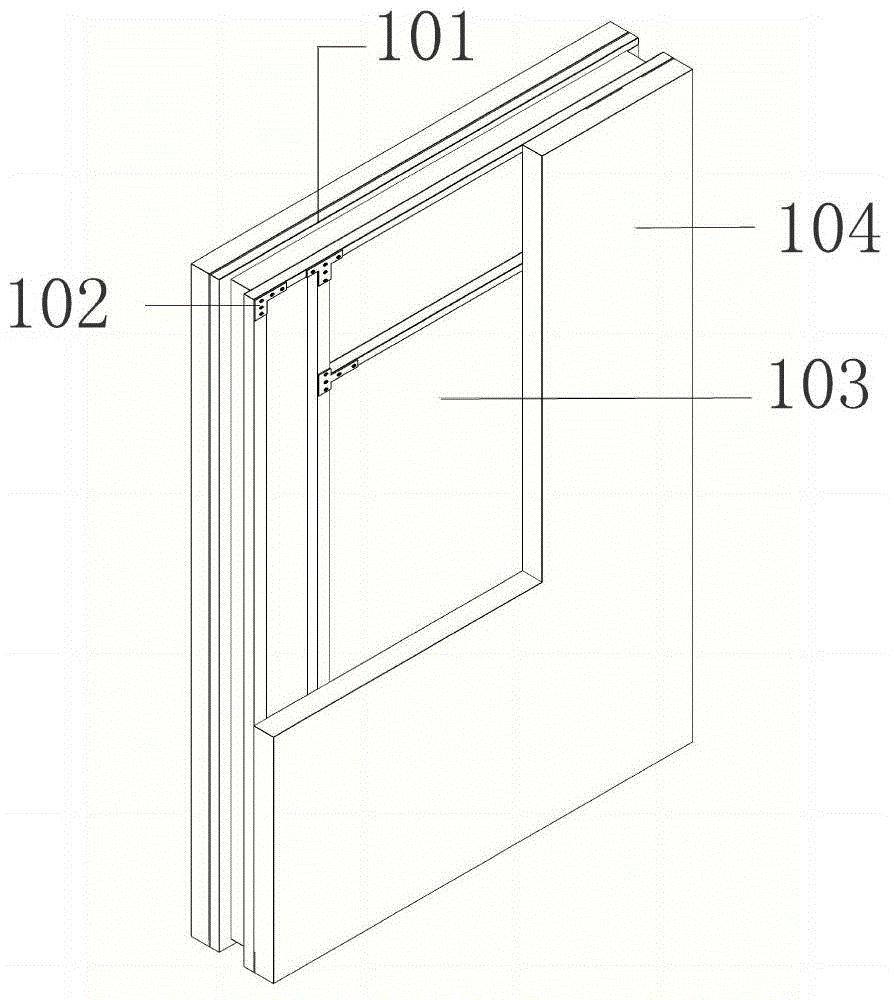

[0047] refer to figure 2 As shown, the wall panel (1) is a prefabricated composite panel, and the wall panel (1) includes a light steel profile (101) with a concave groove on the frame, a connector a (102), and an insulating material (103). , pouring layer (104), light steel keel; the section of light steel profile (101) and light steel keel is M type or hat type or C shape. The light steel profile (101) and the light steel keel are connected to each other through the connector a (102) with self-tapping screws. The middle of the wallboard (1) is filled with thermal insulation material (103); the outermost side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com