Patents

Literature

533results about How to "Improve hoisting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production technology of hatch coaming and hatch cover

InactiveCN101362505AReduce the number of liftingReduce workloadHull decksVessel hatches/hatchwaysManufacturing technologyHydraulic equipment

Owner:江苏熔盛重工有限公司 +1

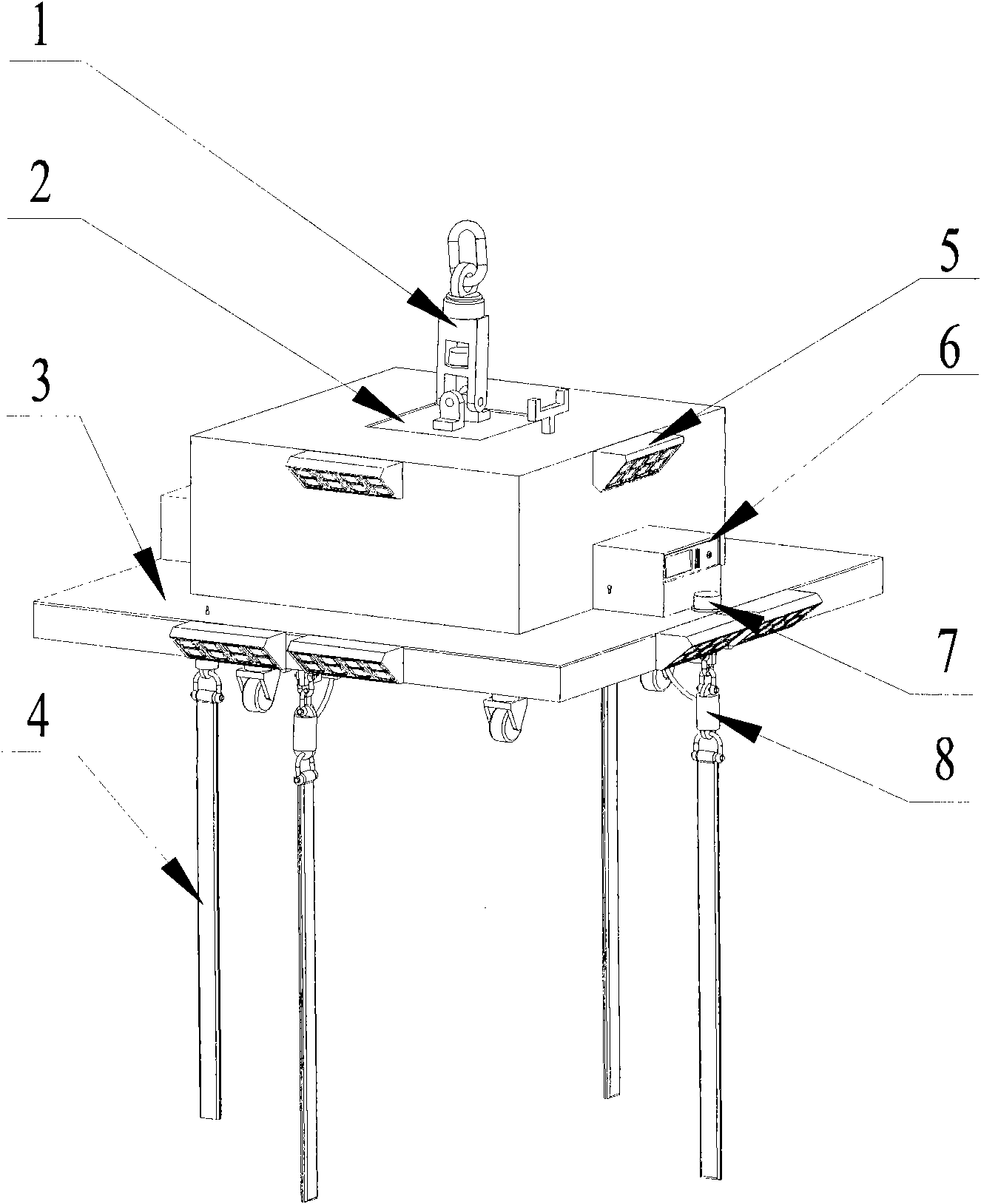

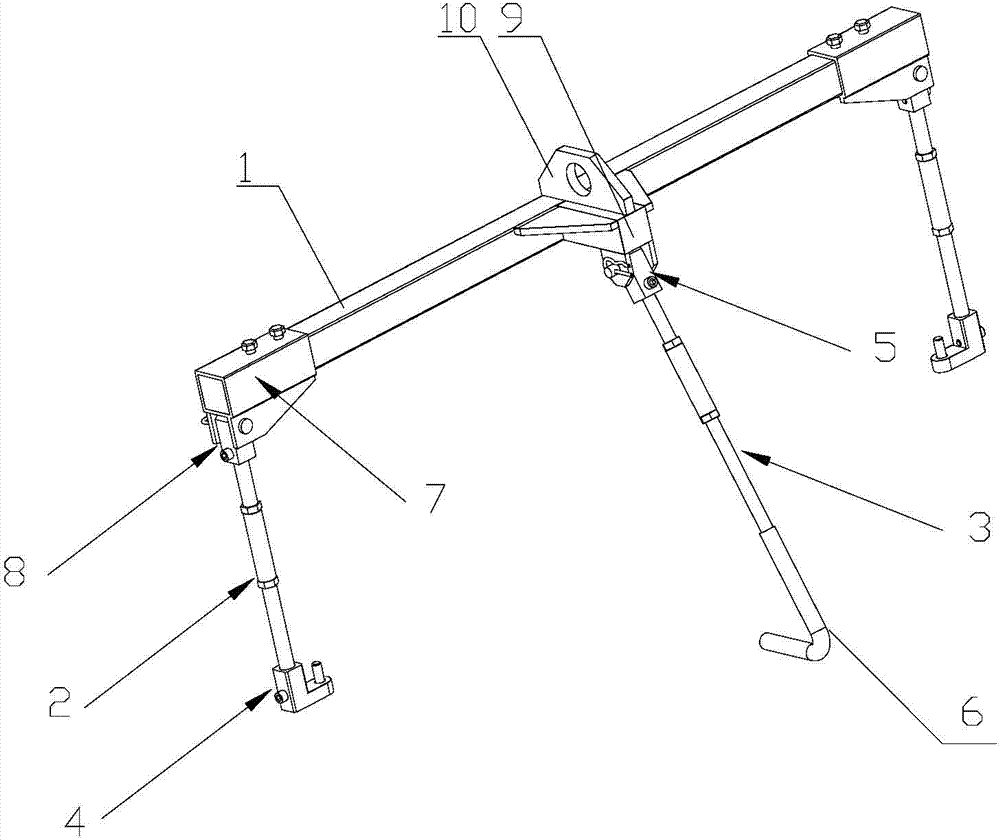

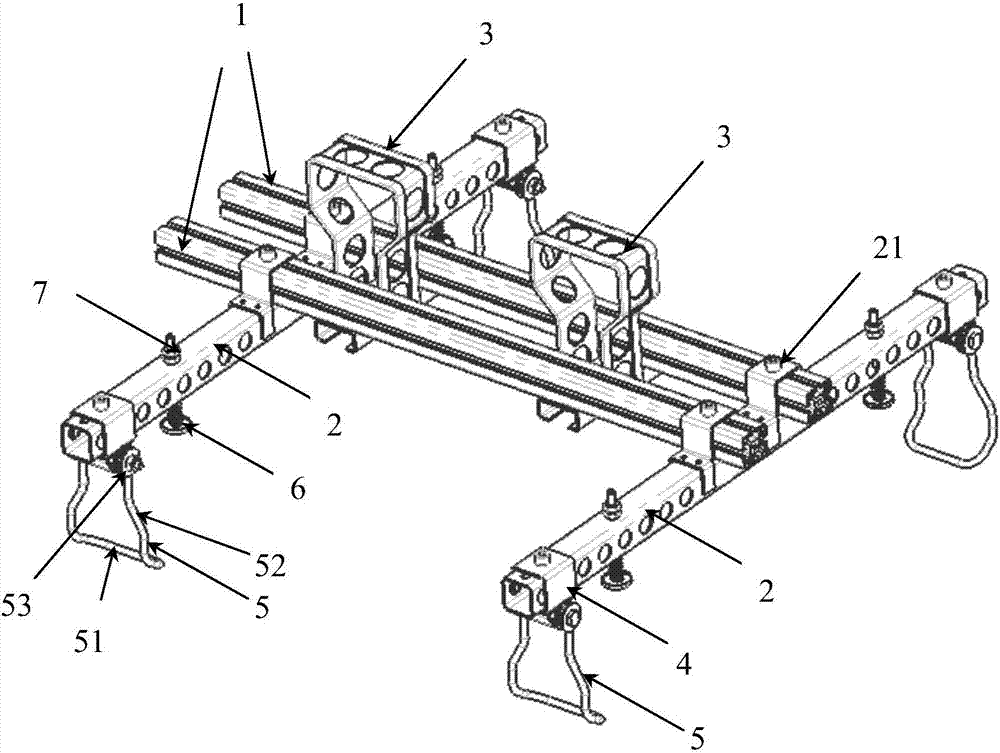

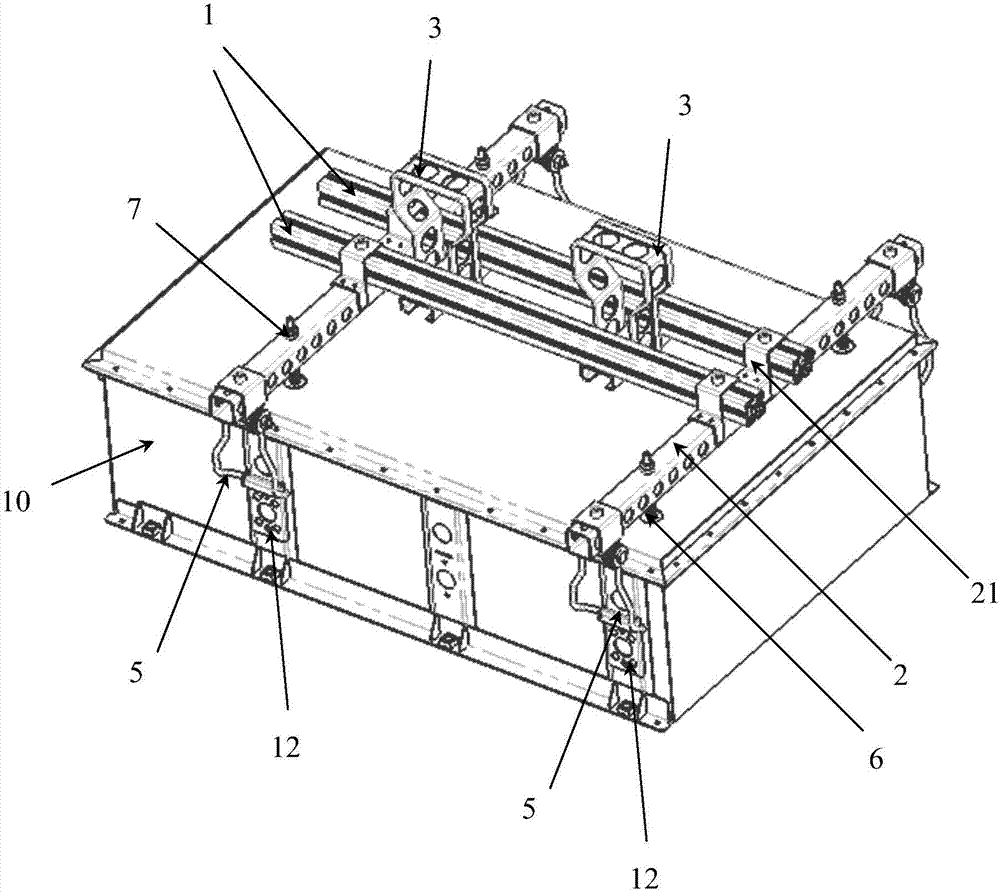

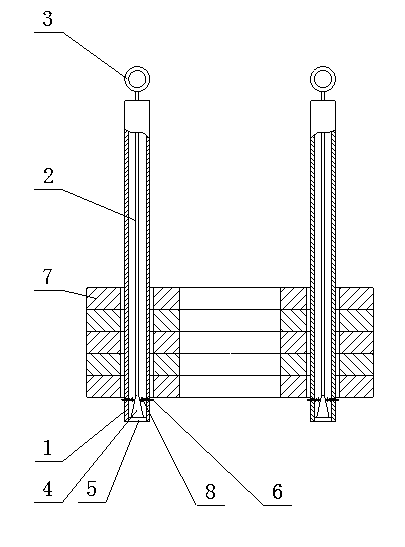

Horizontal adjusting sling for spacecraft

ActiveCN102556831AReduce labor intensityOvercome the problem of automatic level adjustmentLoad-engaging elementsUniversal jointEngineering

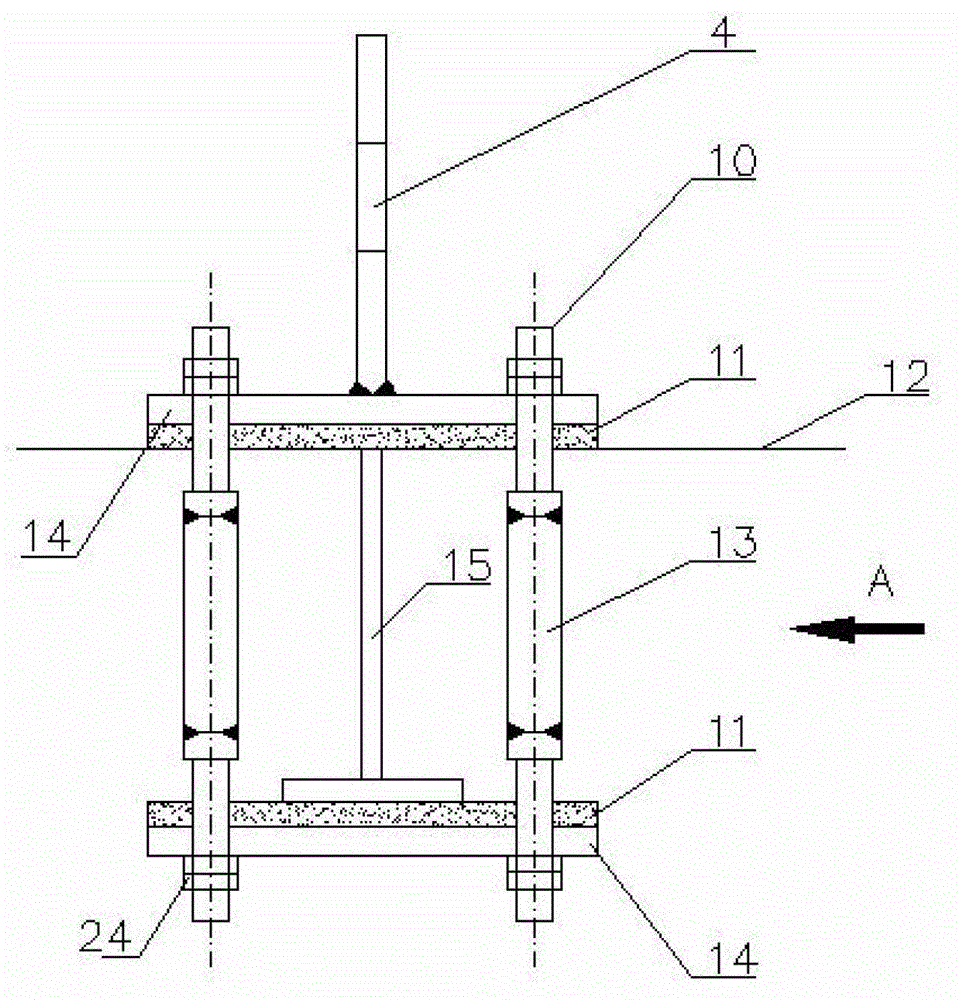

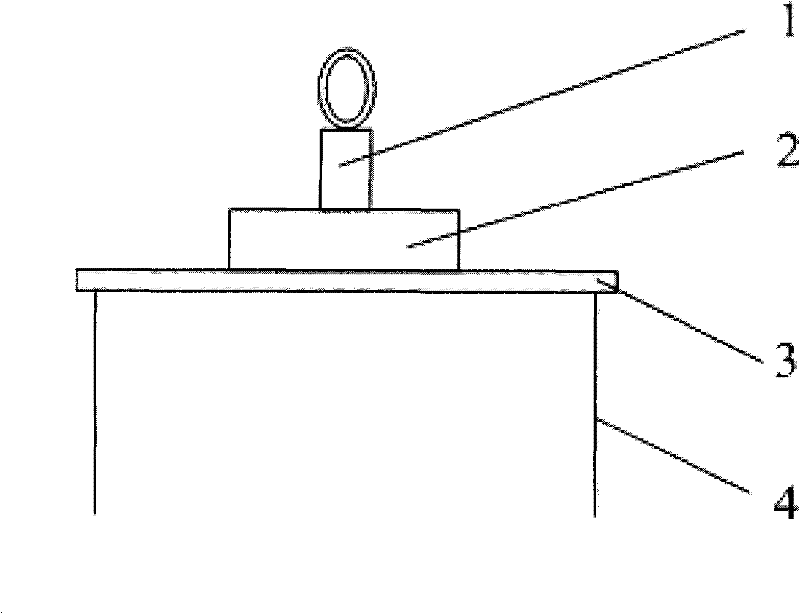

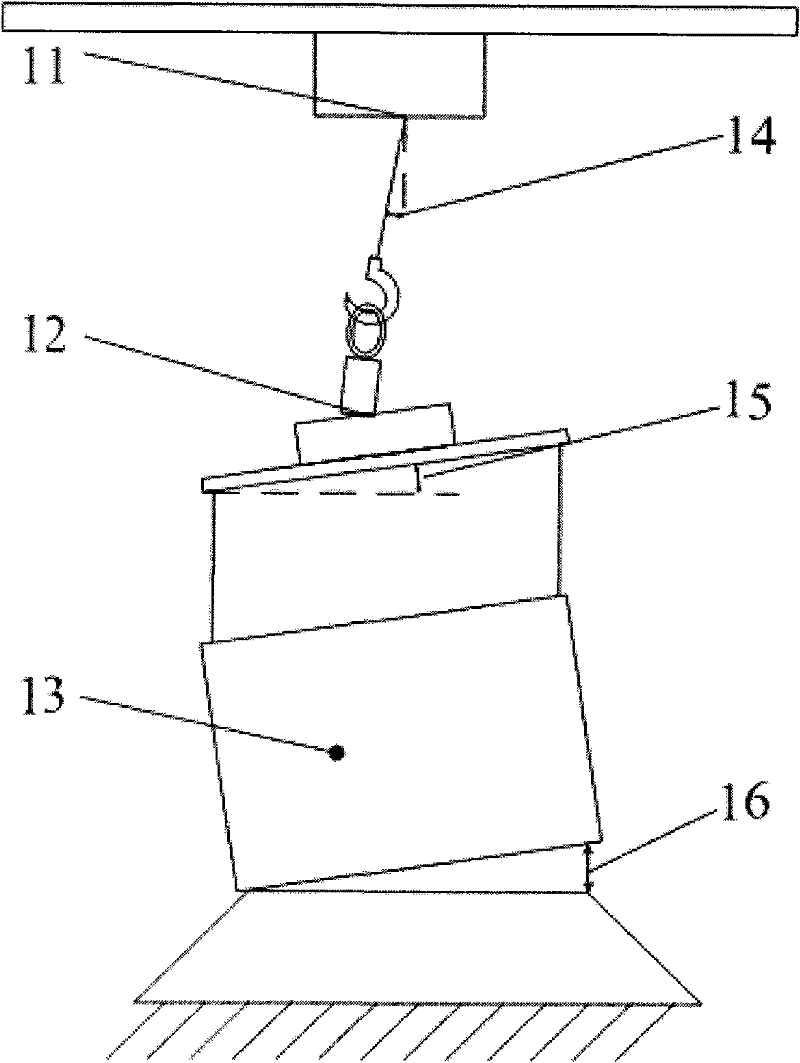

The invention provides a horizontal adjusting sling for a spacecraft, which comprises a hoisting ring component, an XY workbench, a hoisting beam and straps, wherein the XY workbench is arranged on the hoisting beam; the top center of the XY workbench is hinged with the hoisting ring component through a universal joint; four straps are arranged below the hoisting beam; the XY workbench comprises an X workbench and a Y workbench; the X workbench slides on the Y workbench through a slide rail along the X direction; the Y workbench slides on the hoisting beam through a slide rail in the Y direction; and the hoisting ring component comprises a hoisting ring connected with a hook of a crane, a middle bearing structure and a two-dimensional inclination sensor b for measuring the angle of inclination of the hook relative to the crane. Compared with the prior art, the horizontal adjusting sling for hoisting the spacecraft solves the problem that automatic horizontal adjustment cannot be implemented in a two-dimensional plane, the digitization and automation in the measuring and adjusting process are achieved, the hoisting accuracy and hoisting efficiency are improved and the labor intensity of operators is reduced.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

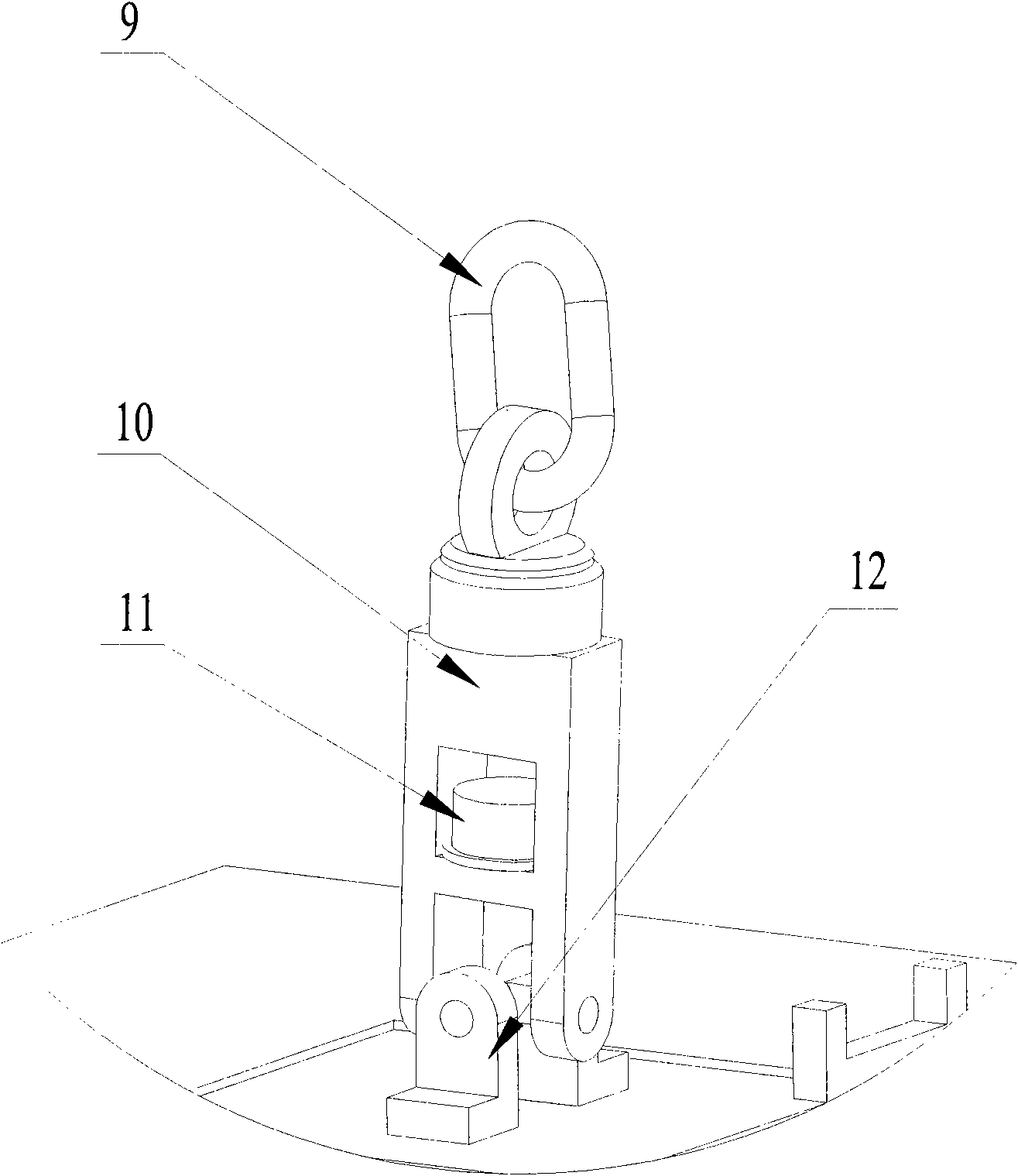

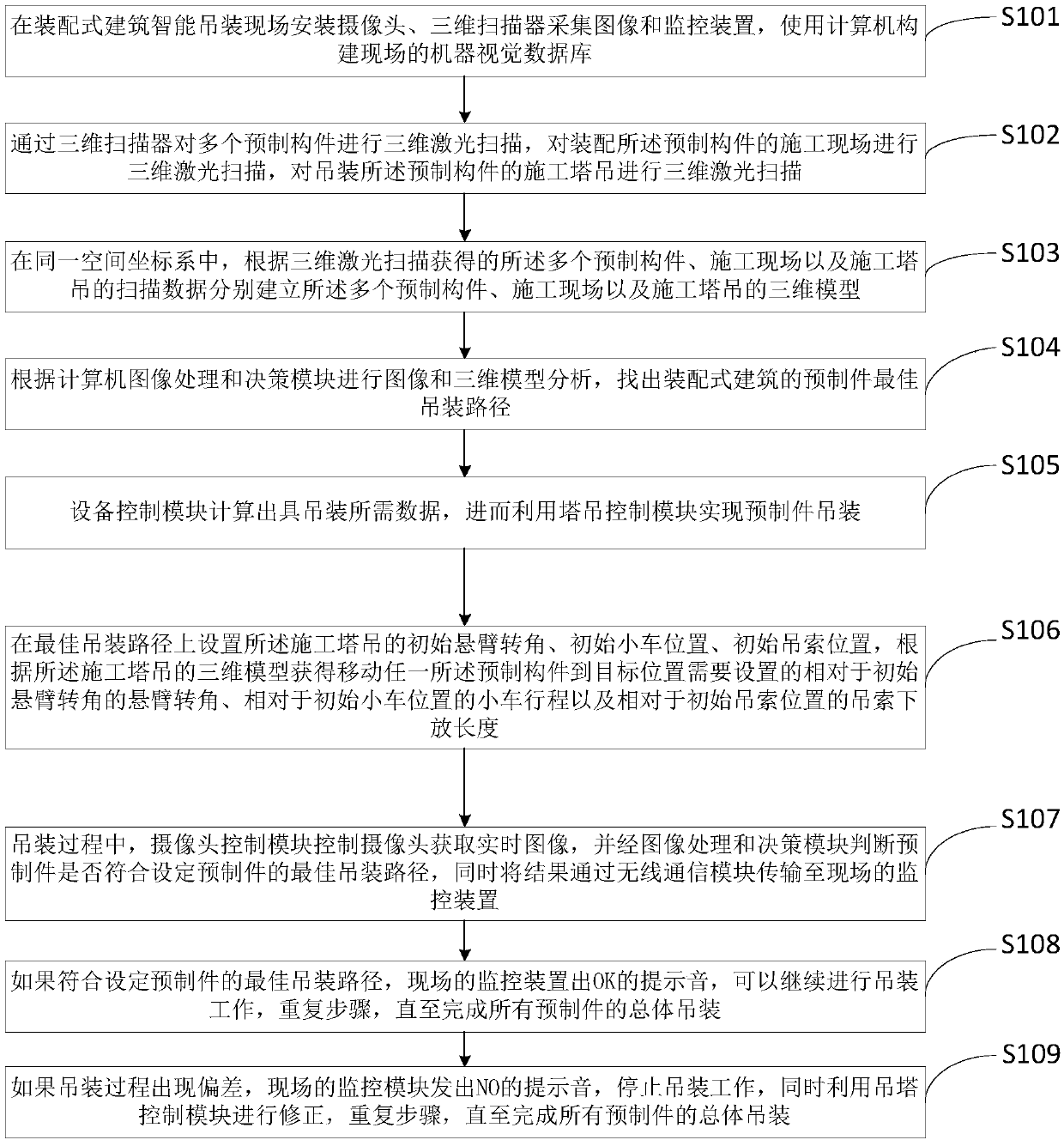

Intelligent assembled building hoisting method based on robot machine vision

InactiveCN107720552AEasy to planImprove hoisting efficiencyImage analysisCharacter and pattern recognitionMachine visionLaser scanning

The invention belongs to the technical field of building hoisting, and discloses an intelligent assembled building hoisting method based on robot machine vision. A camera is utilized for replacing human eyes to analyze a complex scheme and obtain the optimal scheme, the prefabricated part hoisting path can be better planned, the assembled building hoisting efficiency and accuracy are greatly improved, and assembled building hoisting intelligence is achieved. The character of high precision of the three-dimensional laser scanning technology is utilized for obtaining the three-dimension accuratesize of a prefabricated component, a construction site and a construction tower crane, and high precision of construction is guaranteed. Finally, an operator of the construction tower crane conductsoperation through the obtained tower crane parameters, a field monitoring device can be utilized for visually judging whether the hoisting path requirement is met or not, and the defect that a personis needed for commanding in a traditional hoisting method and the defect that repeated hoisting is conducted for installing precision adjustment are overcome. By means of the intelligent assembled building hoisting method based on robot machine vision, the hoisting accuracy can be improved, the hoisting efficiency is improved, the construction time is shortened, and the labor force is relieved.

Owner:XIHUA UNIV

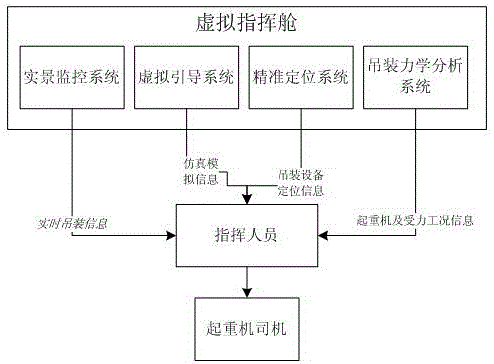

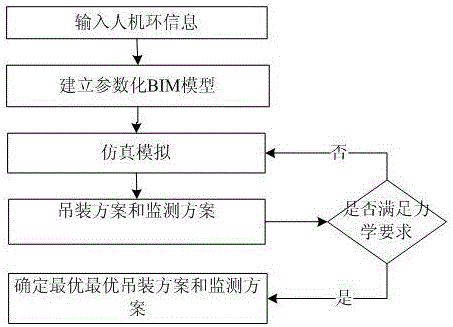

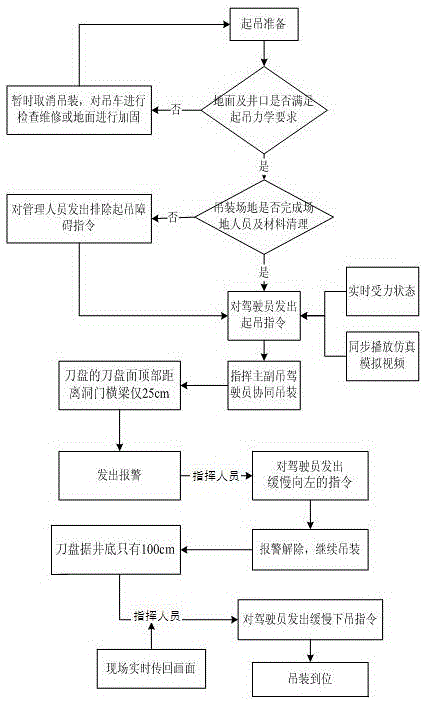

Virtual command module for large lifting operations and working method of virtual command module

ActiveCN105819339ASimple structureEasy to operateLoad-engaging elementsInformatizationDriver/operator

The invention belongs to the field of safety control on lifting operations and provides a virtual command module for large lifting operations and a working method of the virtual command module. The module comprises a live-action monitoring system, a virtual guiding system, a precise positioning system and a lifting mechanical analysis system. Visualization of global field monitoring of a lifting site can be realized, a virtual lifting rehearsal model is constructed on the basis of a BIM (building information model), and simulation and route optimization of a lifting process are realized through setting of working conditions and lifting parameters, so that lifting risks are mastered in advance, and a lifting scheme conforming to actual requirements is made; besides, through precise positioning and lifting mechanical analysis, automation and informatization of collision prevention and safety control on lifting are realized, accurate and direct early-warning information is provided for front-line commanders, unified and standard lifting commands are given to crane drivers, the crane drivers are assisted in completing lifting operations smoothly and safely, and the safe, real-time and effective technical support is provided for the large lifting operations.

Owner:HUAZHONG UNIV OF SCI & TECH

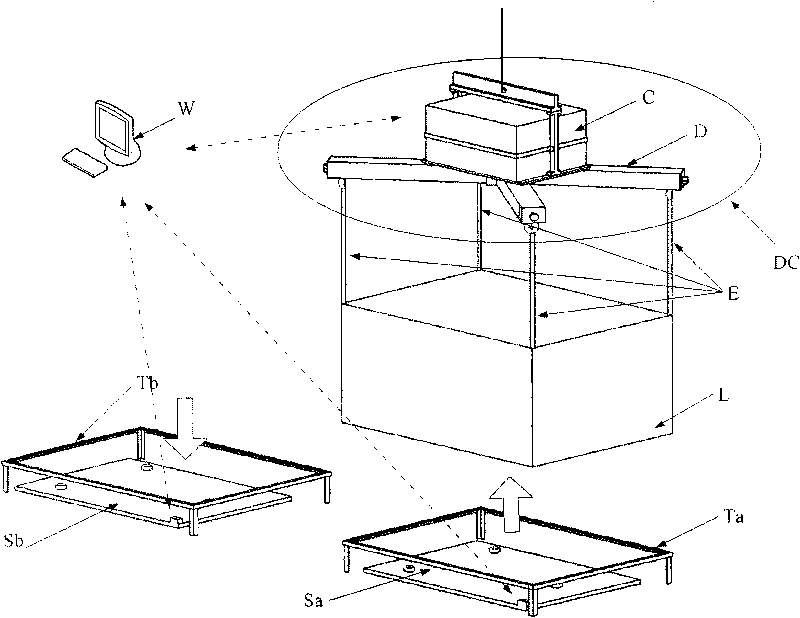

Single counterweight type automatic levelling spreader and using method thereof

InactiveCN101759092AEasy to adjust the position of the hanging pointEasy to adjustTravelling cranesLoad-engaging elementsButt jointControl signal

The invention relates to a single counterweight type automatic levelling spreader and a using method thereof, belonging to the technique of loading-unloading winching device. The single counterweight type automatic levelling spreader comprises a bearing spreader, an automatic levelling device, an initial bottom surface distance measurer, a target bottom surface distance measurer and a computer, wherein the automatic levelling device is mounted on the bearing spreader and is provided with counterweight blocks; the initial bottom surface distance measurer and the target bottom surface distance measurer are respectively located below an initial bearing bracket and a target bearing bracket; the computer communicates with both the bottom distance measurers, calculates the leveling inclination angle of the loading butt joint surface according to information measured by the initial bottom surface distance measurer and the target bottom surface distance measurer and based on the input structural size of the loading butt joint surface, calculates control signals, transmits the control signals to the automatic levelling device, controls the position of the counterweight block in the automatic levelling device and keeps the initial bearing bracket and horizontal target bearing bracket of the loading butt joint in the horizontal state so as to realize precise and easily damaged hoisting. The invention has the advantages of high precision, fast speed, safety and reliability.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

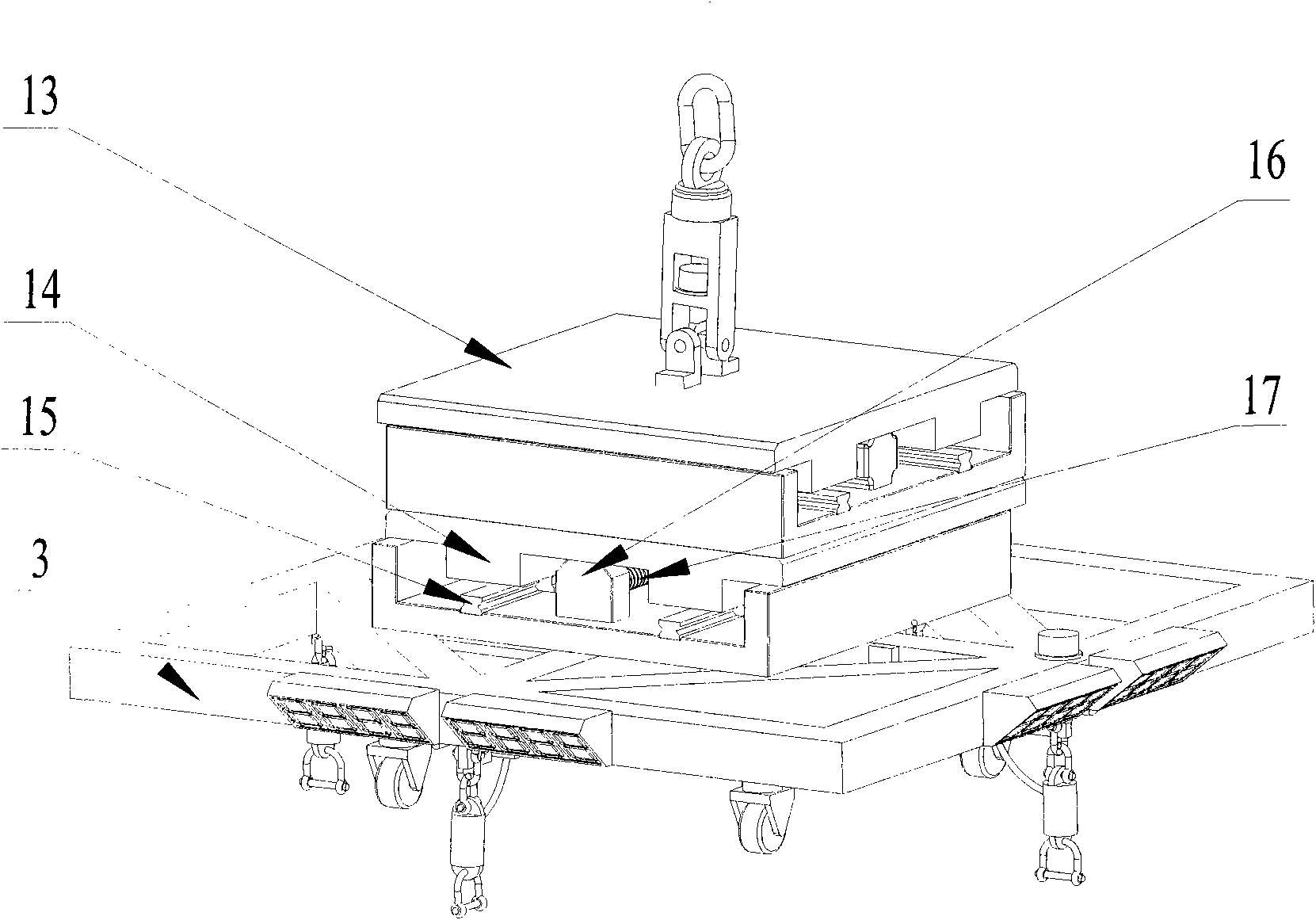

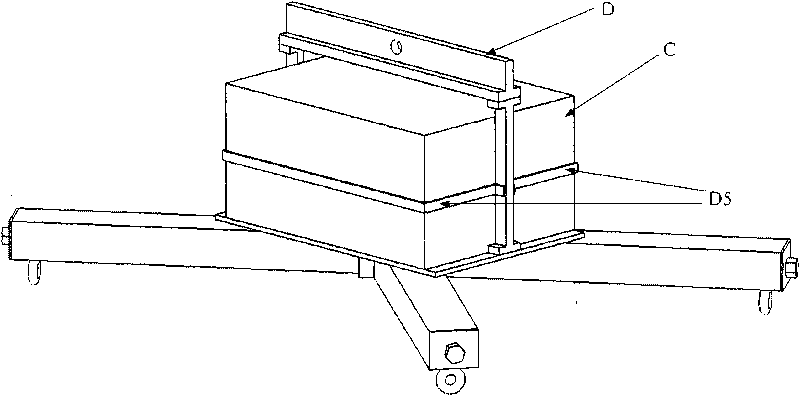

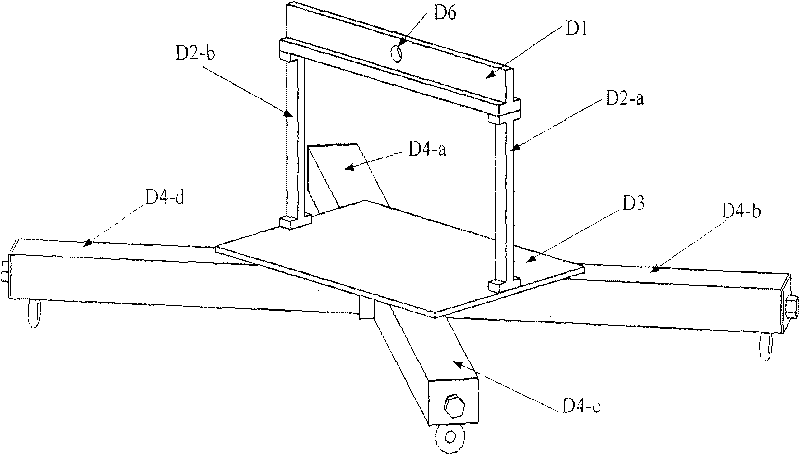

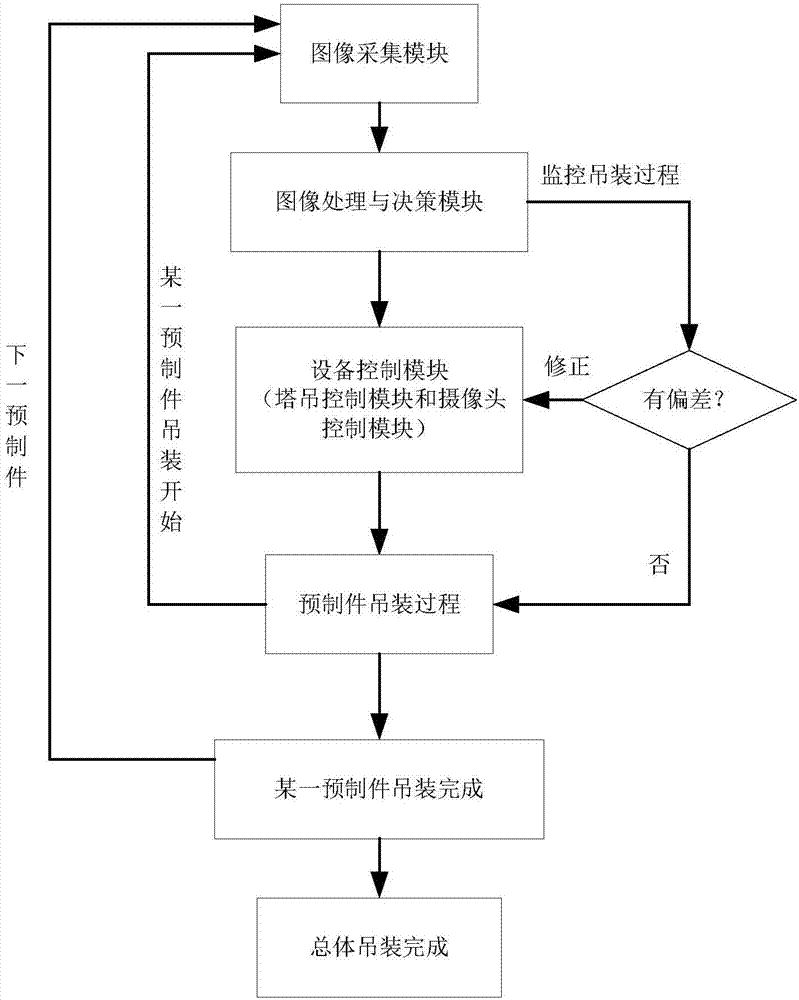

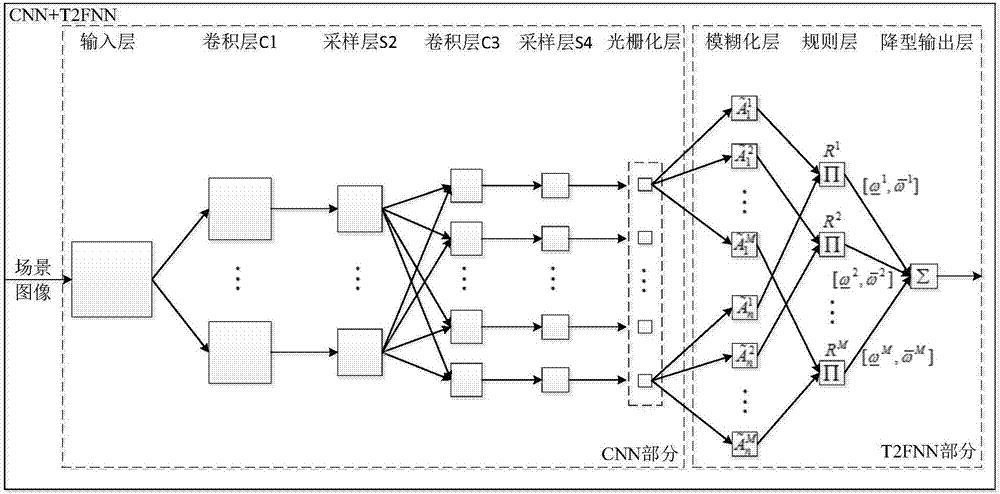

Fabricated type building intelligent hoisting method and system based on machine vision

ActiveCN106966298AImprove hoisting efficiencyImprove accuracyImage enhancementImage analysisIntelligent lightingMachine vision

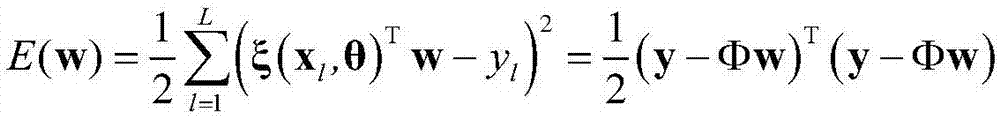

The invention discloses a fabricated type building intelligent hoisting method and a system based on machine vision. The fabricated type building intelligent hoisting system based on the machine vision comprises an image gathering module, an image processing and decision module and a device control module, the image processing and decision module and the image gathering module are communicated, and the device control module and the image processing and decision module are communicated. According to the fabricated type building intelligent hoisting method and the system based on the machine vision, the machine vision replaces the reliance on human vision in the hoisting process of the fabricated type building. Obstacle recognition is conducted in a complex fabricated scene through a deep learning model of a convolutional neural network and a type-II fuzzy neural network by using the machine vision, prefabrication hoisting path planning is conducted by using ant colony algorithm, and consequently, the movement of equipment on the scene is controlled according to the decision result. The fabricated type building intelligent hoisting method and the system based on the machine vision analyze and obtain the best scheme from the complex scene by using the camera instead of the human eye, can better plan the prefabrication hoisting path, greatly improve the hoisting efficiency and accuracy of the fabricated type building, realize the intelligent hoisting of the fabricated type building, and improve the shortcomings of artificial hoisting.

Owner:日照安泰科技发展有限公司

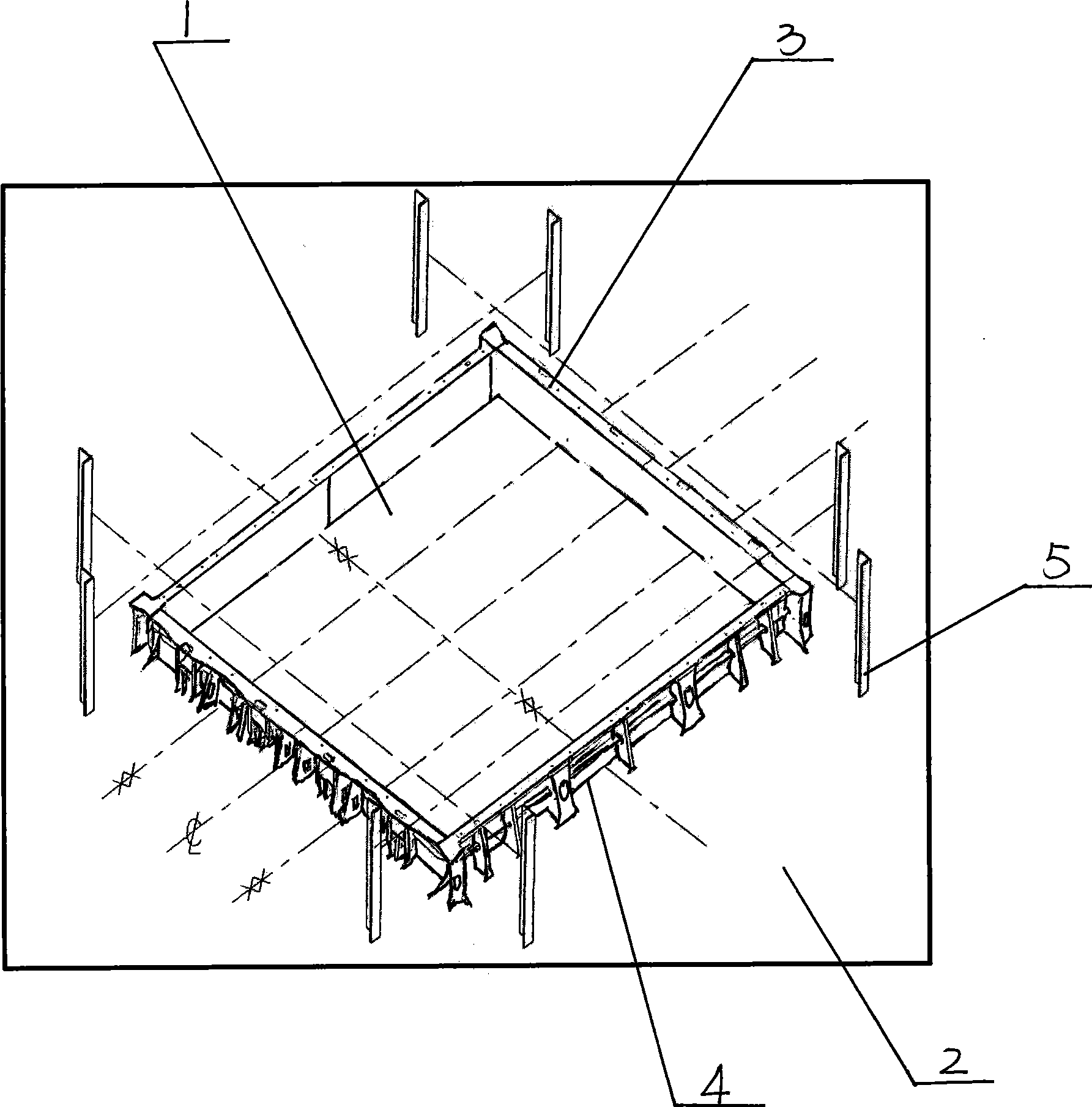

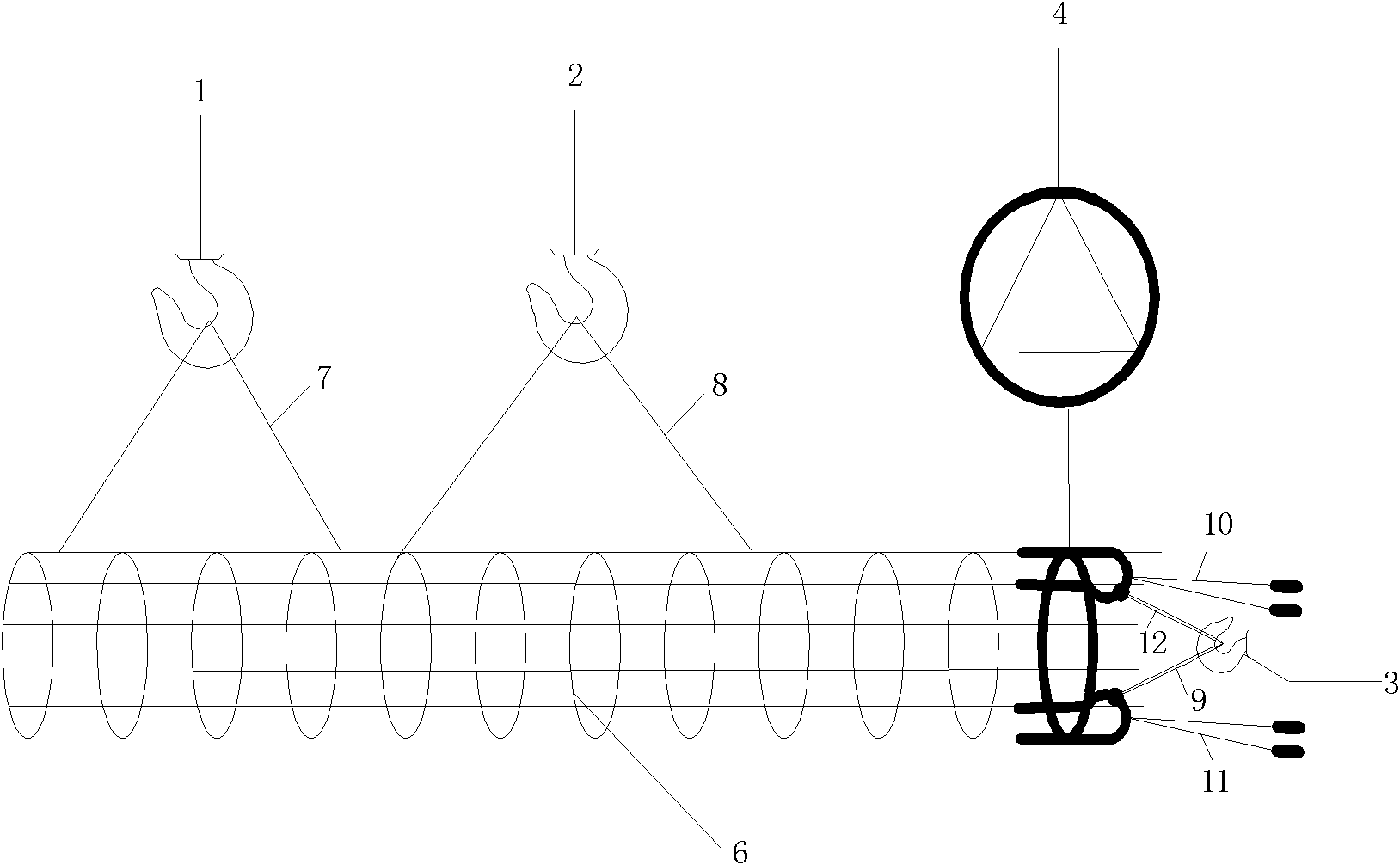

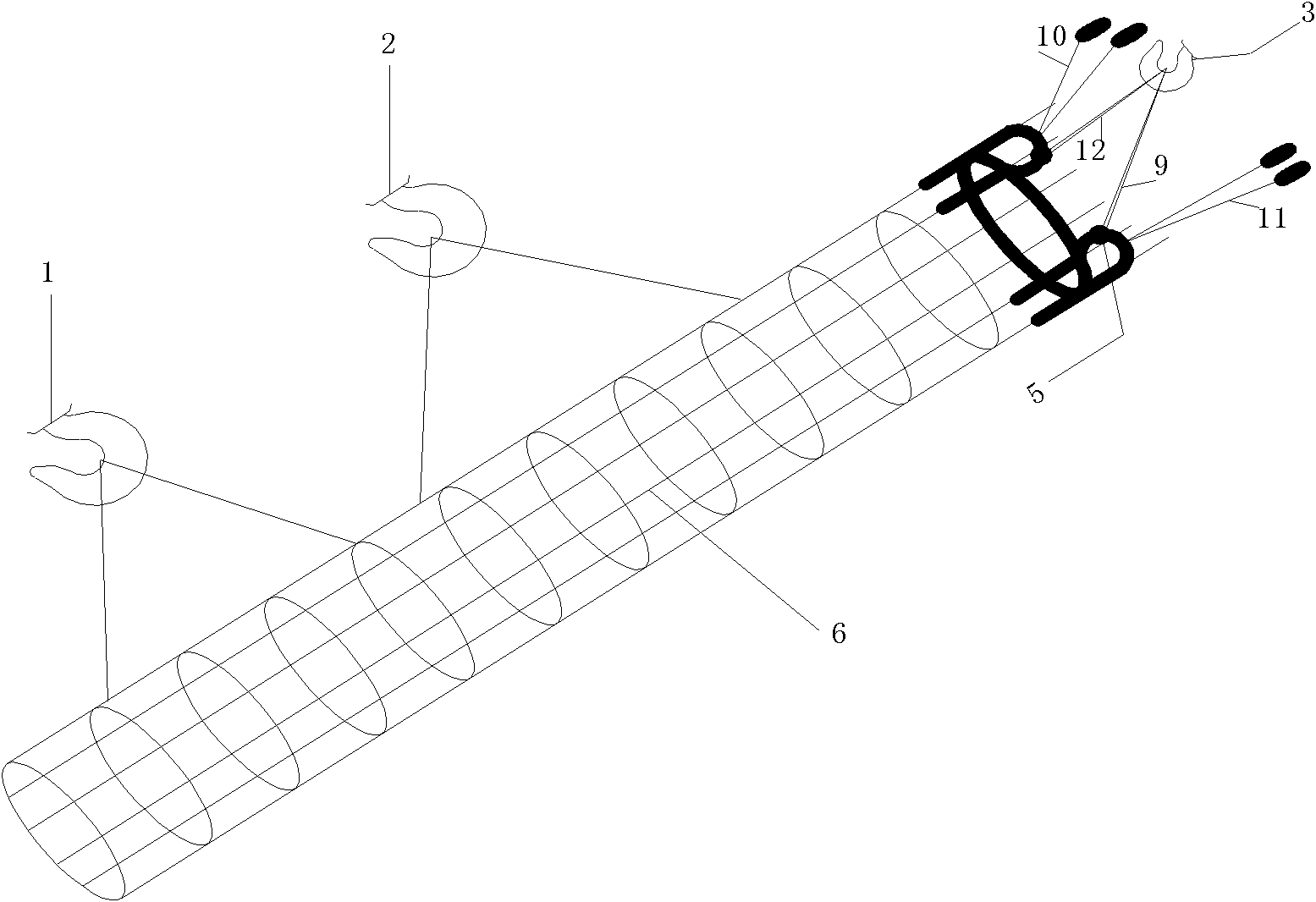

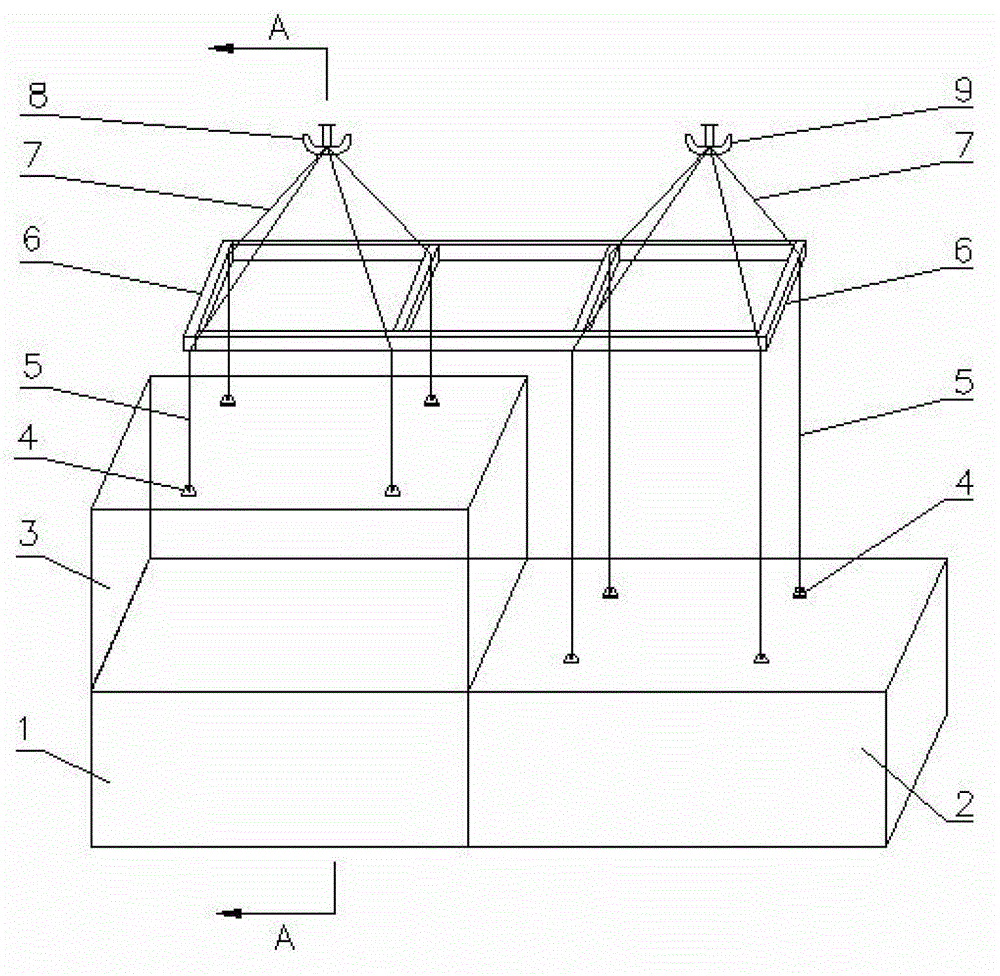

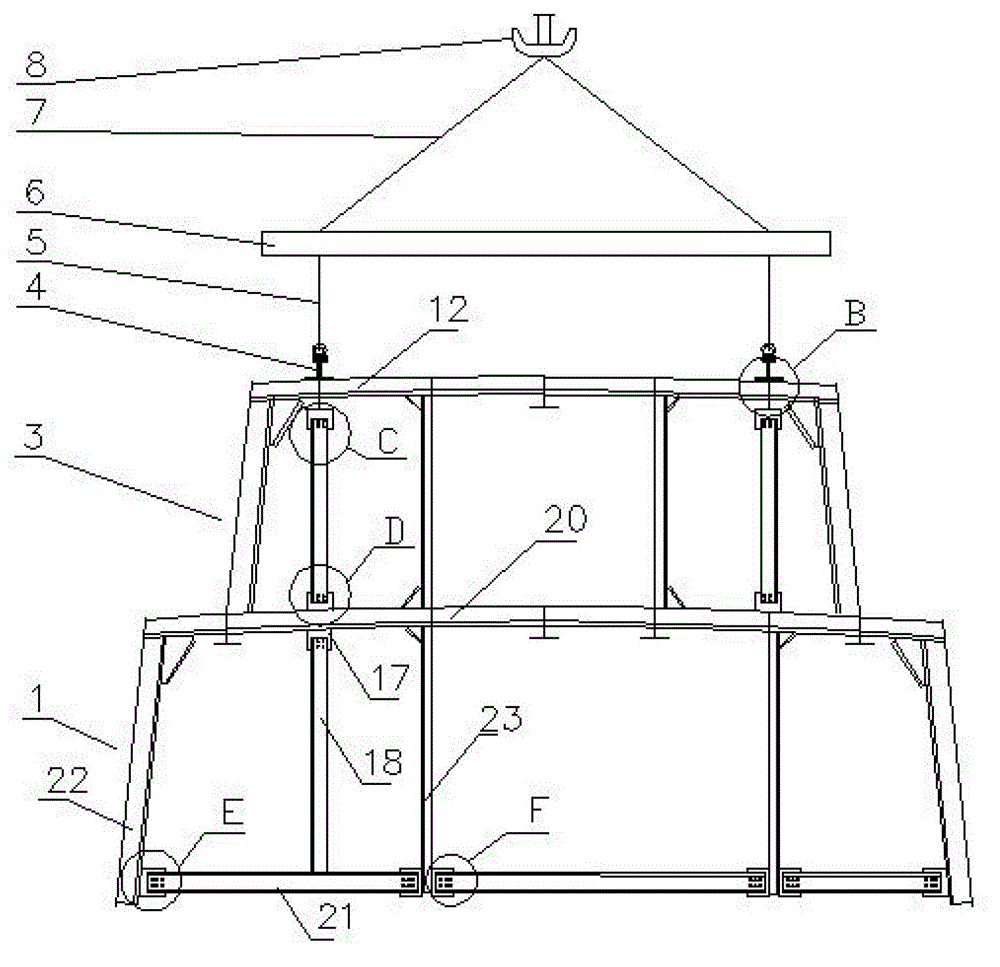

Device and method for hoisting entire oversized steel reinforcement cage in one step

InactiveCN102328881AGuaranteed deformationGuaranteed deformation controlCranesLoad-engaging elementsOperabilityRebar

The invention discloses a method for hoisting an entire oversized steel reinforcement cage in one step. The method mainly comprises the steps of: binding a steel reinforcement cage; arranging hoisting points and configuring a crane; connecting a main hoisting hook with the hoisting points; completing horizontal hoisting of the steel reinforcement cage; converting the steel reinforcement cage froma horizontal state to a vertical state; and directly hoisting the steel reinforcement cage in the vertical standing state to be in place by using a third crane. According to the invention, by jointlyhoisting the oversized steel reinforcement cage by using three hoisting equipment and by skillfully transforming the hoisting points in the angle transformation from the horizontal state to the vertical state, the oversized steel reinforcement cage is hoisted in one step without segmentation and structural variation, so that the efficiency in hoisting operation is increased, in addition, concretecan be poured, so that the advantages of construction safety, operability, capability of meeting construction period requirement and increased efficiency are achieved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

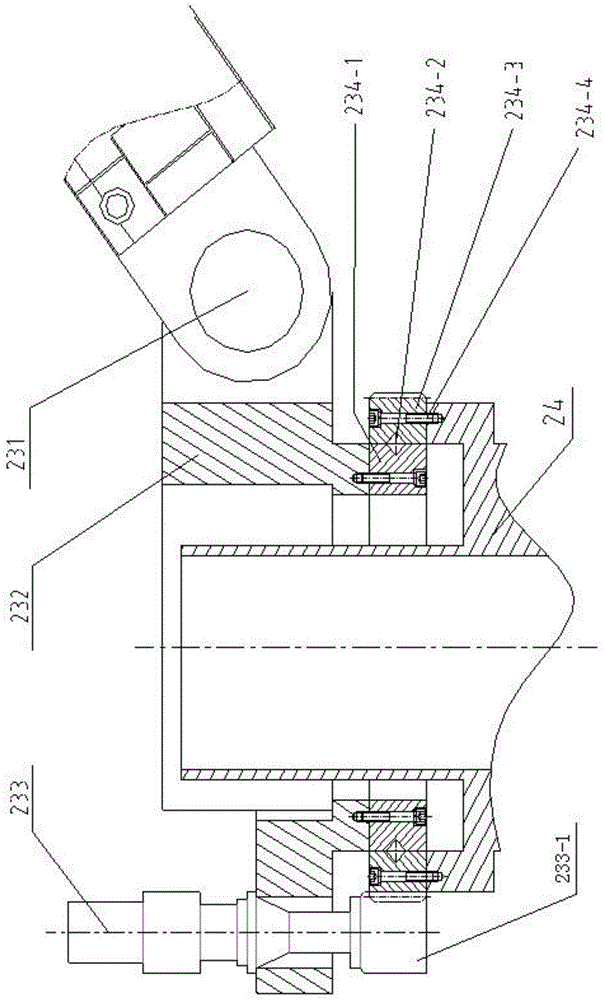

Sucker hoisting device and plate welding conveying system

ActiveCN103111778AImprove processing efficiencyTailor welding is convenient and reliableWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining process

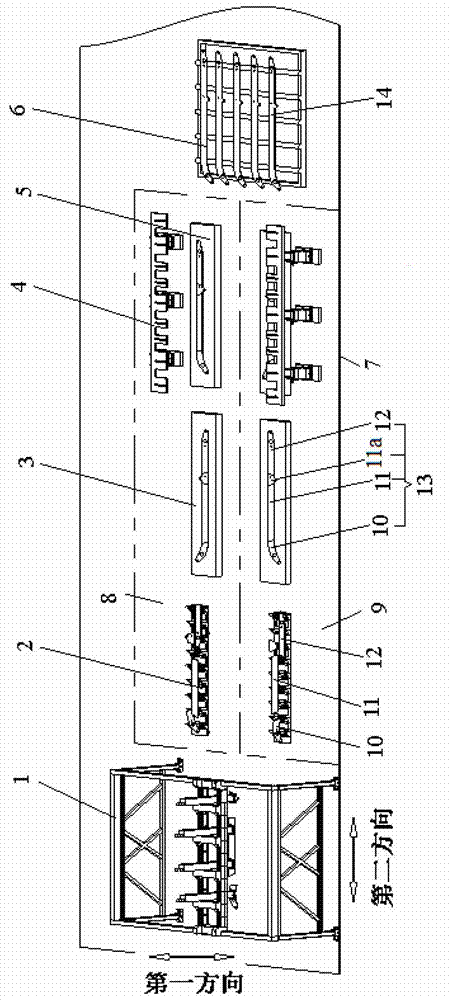

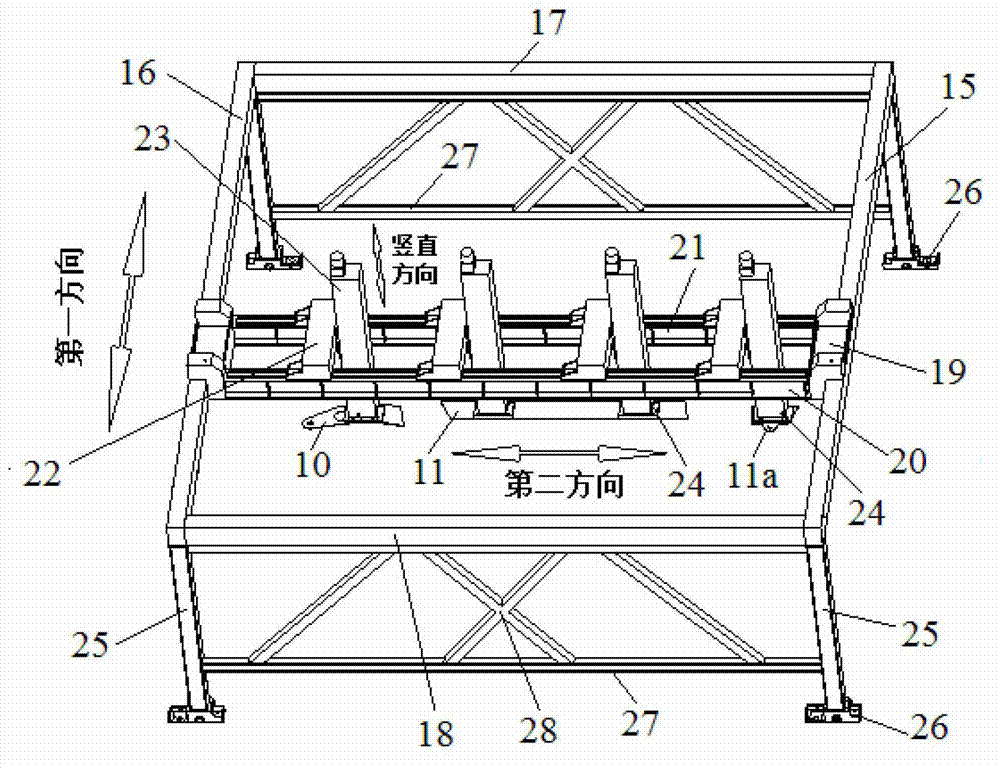

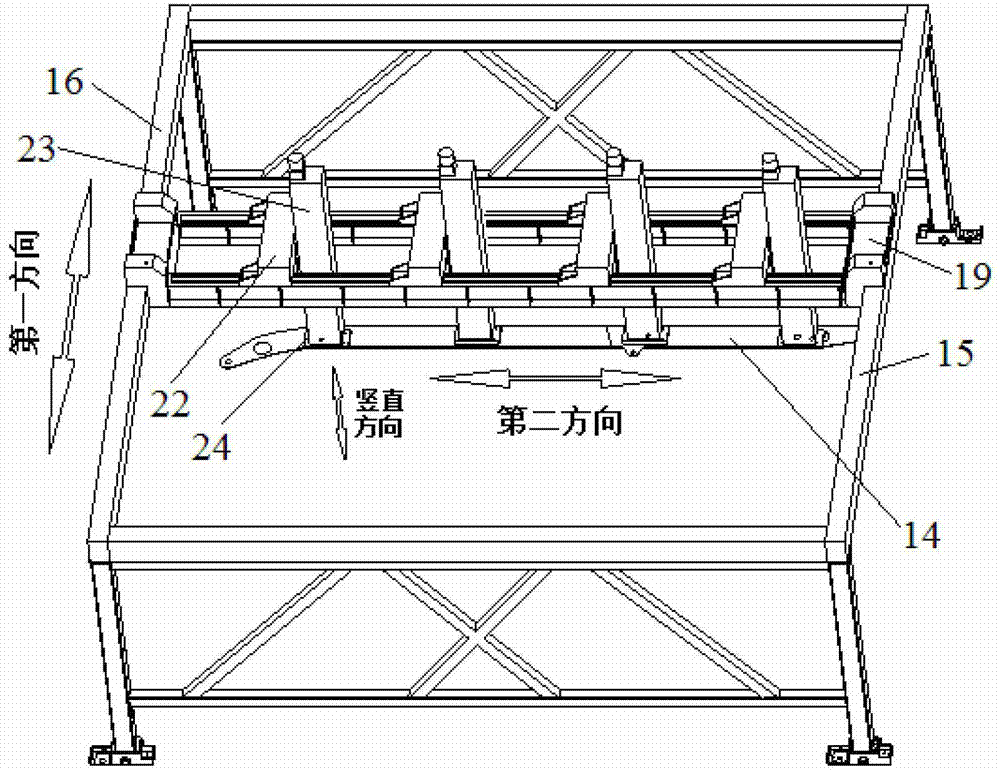

A sucker hoisting device comprises a main bearing frame, a moving bearing beam (19) and a plurality of lifting device assemblies. The main bearing frame at least comprises a first guide rail beam and a second guide rail beam (15 and 16) which extend along a first direction and are spaced and parallel to each other. The moving bearing beam is movably installed on the first guide rail beam and the second guide rail beam and is capable of moving back and forth along the first direction. The plurality of lifting device assemblies are sequentially and movably installed on a guide rail of the moving bearing beam (19), and the lower ends of lifting devices (23) of the lifting device assemblies are respectively provided with an electromagnet sucker (24). Besides, the invention further provides a plate welding conveying system including the sucker hoisting device. The plate welding conveying system including the sucker hoisting device is capable of conveniently hoisting plates, especially long and narrow plates, operation is stable and reliable, and security coefficient is high. Therefore, plates with different lengths can be conveyed conveniently during a plate welding process, and plate welding is convenient and reliable.

Owner:ZOOMLION HEAVY IND CO LTD

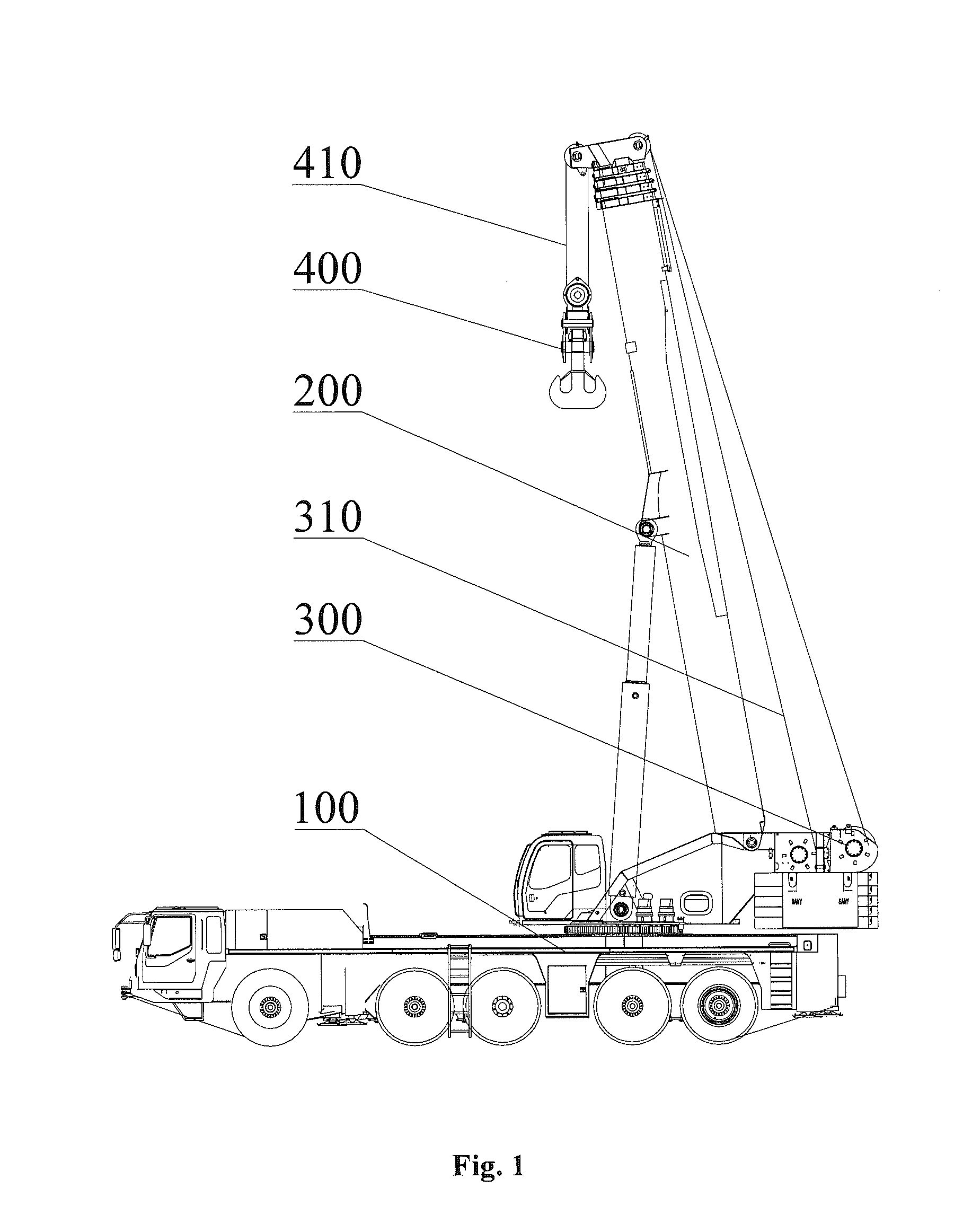

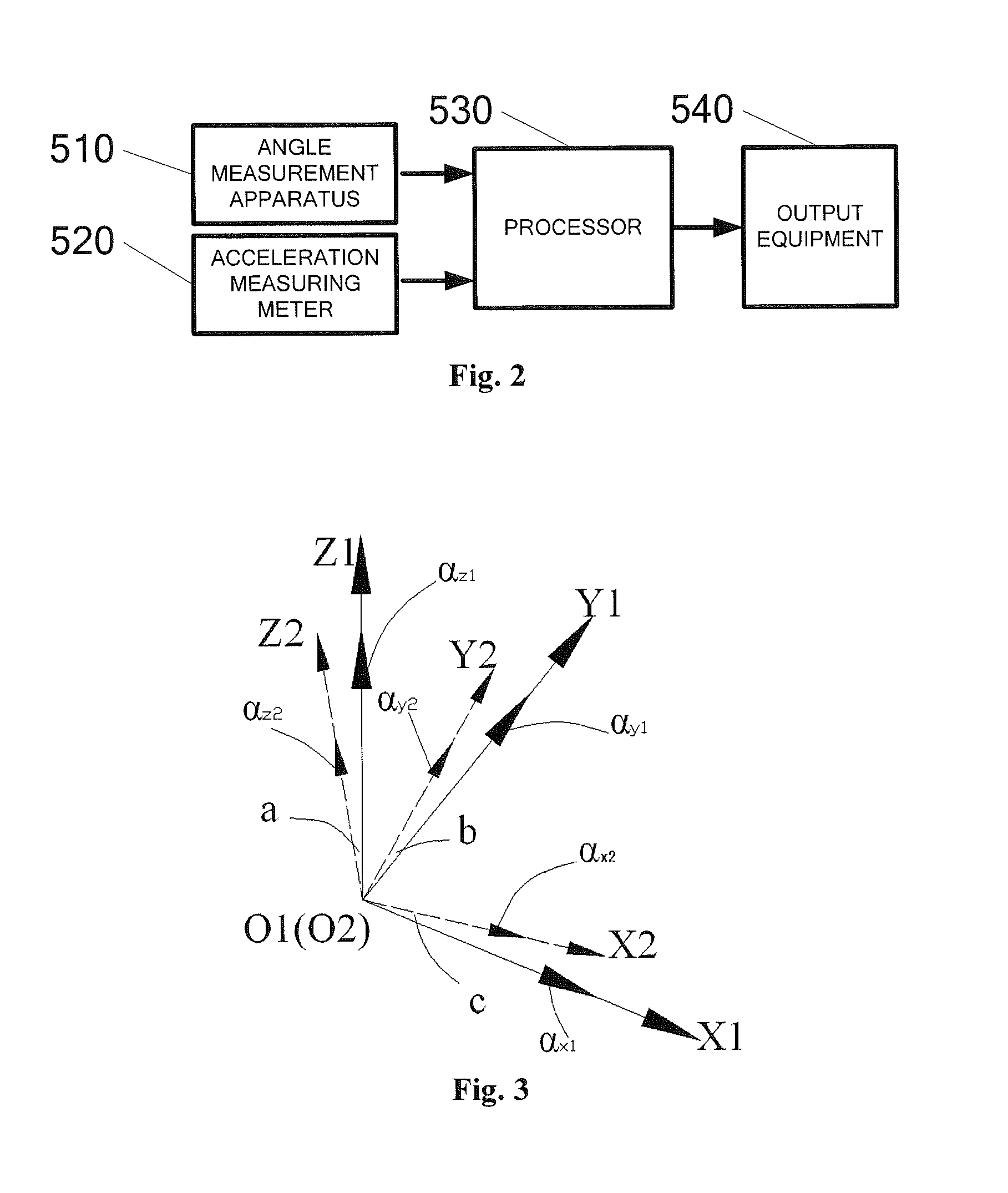

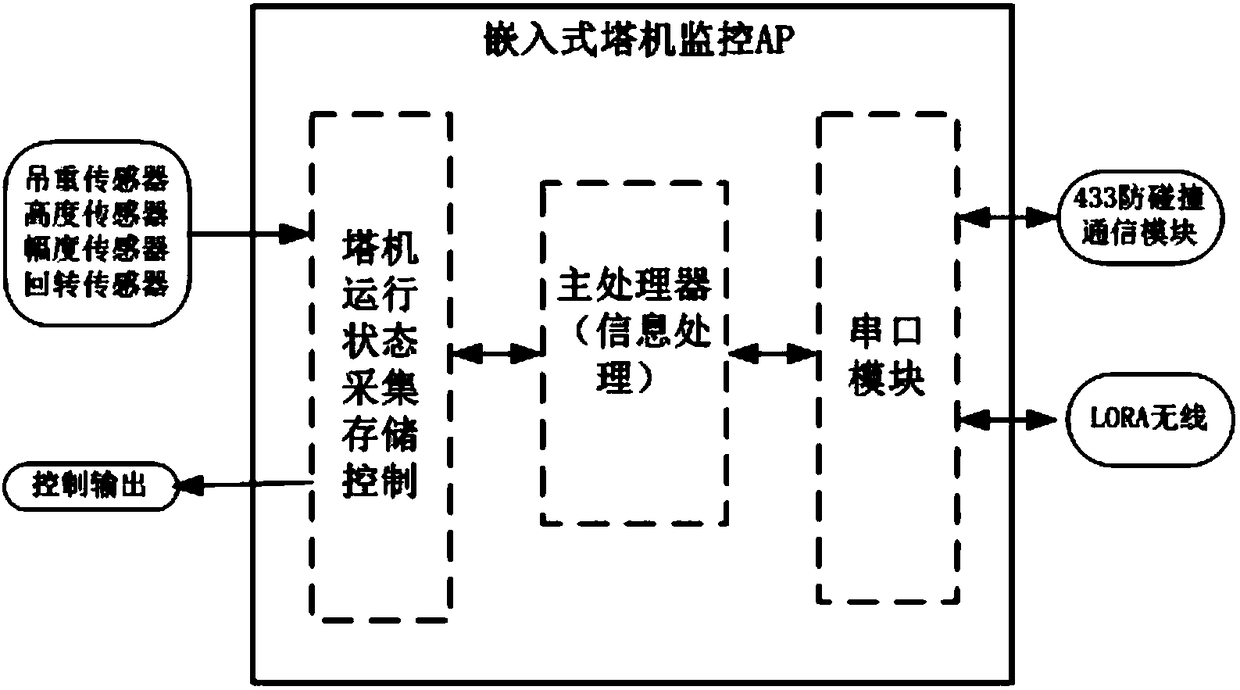

Hook pose detecting equipment and crane

InactiveUS20120255188A1Improve hoisting efficiencySafety accident is reduced and avoidedAcceleration measurement using interia forcesDrilling/boring measurement devicesAngular degreesEngineering

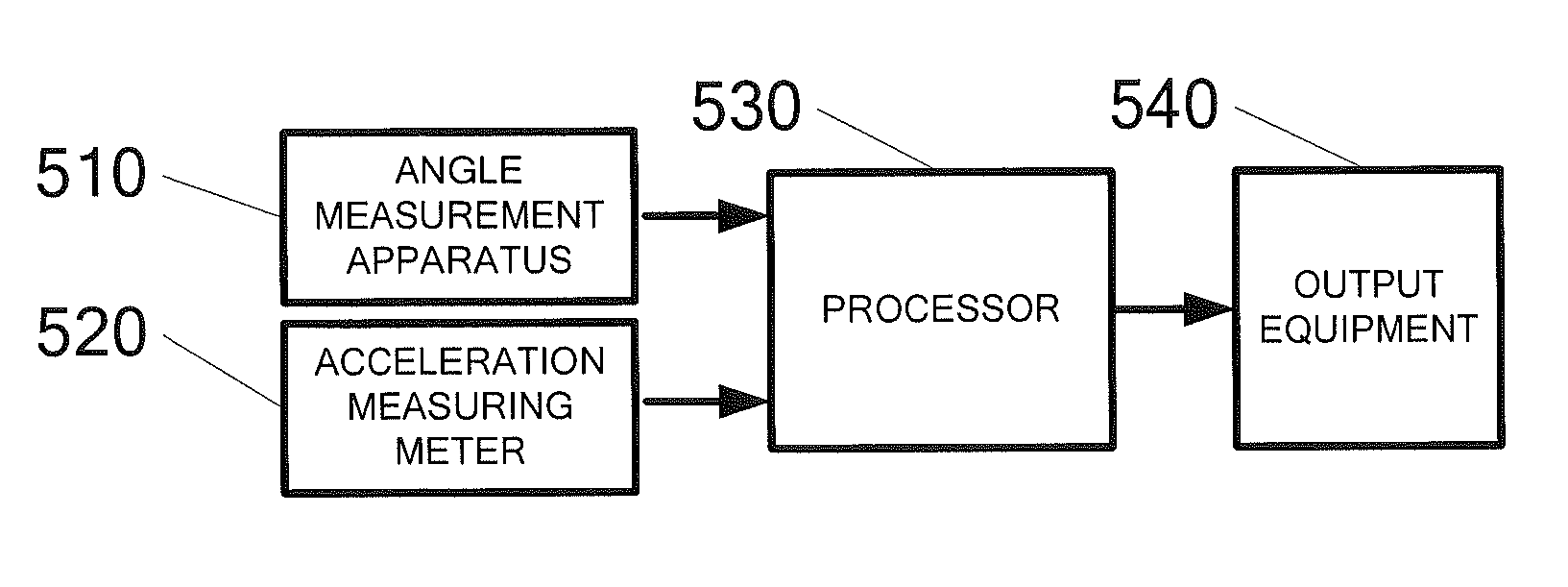

A hook pose detecting equipment and a crane with the hook pose detecting equipment, in which the hook pose detecting equipment comprises an angle measuring apparatus for obtaining the angle between an axis in a second coordinate system and the corresponding axis in a first coordinate system, an acceleration measuring meter for obtaining the acceleration of the hook in a predetermined direction, a processor for building the first coordinate system and the second coordinate system, and an output equipment. The first coordinate system is relatively fixed with a predetermined location, and the second coordinate system is relatively fixed with the hook. The processor obtains the pose parameters of the hook in the first coordinate system according to the angle obtained by the angle measuring apparatus and the acceleration obtained by the acceleration measuring meter. The operator is able to take appropriate hook-stabilizing measures according to the pose parameters, and thus the efficiency of lifting work is increased.

Owner:HUNAN SANY INTELLIGENT CONTROL EQUIP +1

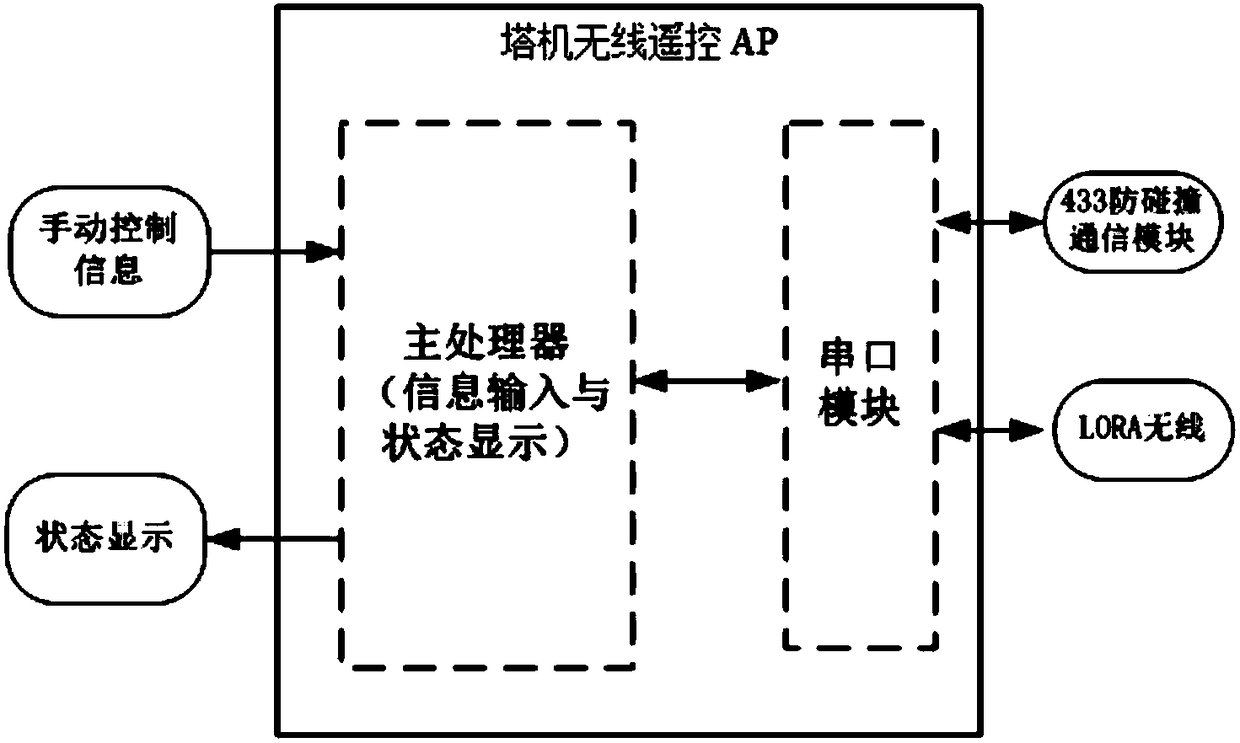

Tower group smart accurate hoisting control method based on Internet of Things

ActiveCN108163718AGuaranteed positioning accuracyReduce safety incidentsCranesLoad-engaging elementsRemote controlThe Internet

The invention discloses a tower group smart accurate hoisting control method based on the Internet of Things. The method comprises the steps that (1) an ith tower crane wireless remote control Api applies a hoisting request for a centralized dispatcher AP; (2) the centralized dispatcher AP performs tower crane dispatching according to the hoisting application; (3) the tower crane wireless remote control Api starts the hoisting task; (4) an embedded tower crane monitor unit APk performs path planning and starts a smart cruise; (5) the embedded tower crane monitor unit APk starts a remote control mode and performs accurate positioning, and loading is conducted; (6) the embedded tower crane monitor unit APk starts the smart cruise state again; (7) after an executive tower crane k arrives at the target position, the tower crane wireless remote control Api remotely controls the executive tower crane k for accurate positioning again, and unloading is completed; and (8) the tower crane wireless remote control Api sends a hoisting ending command to the centralized dispatcher AP, the centralized dispatcher AP enables the executive tower crane k to be in an idle state, and so far, the wholehoisting process is completed. The method achieves smart control over hoisting of a tower group.

Owner:XIAN UNIV OF TECH +1

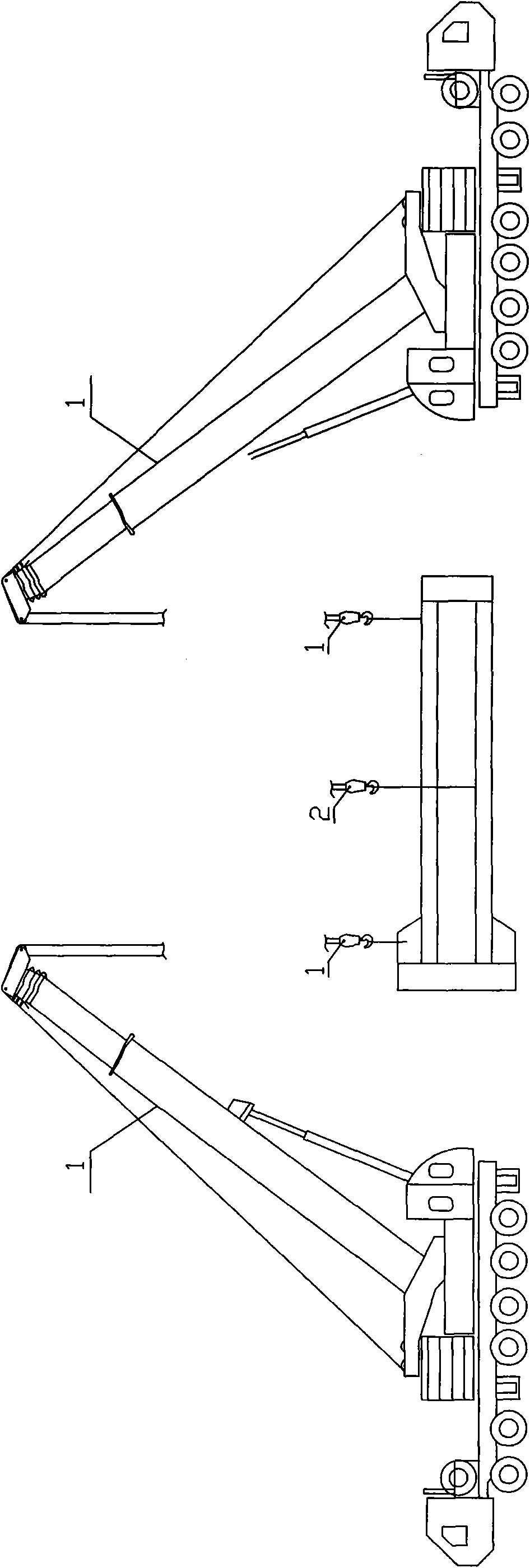

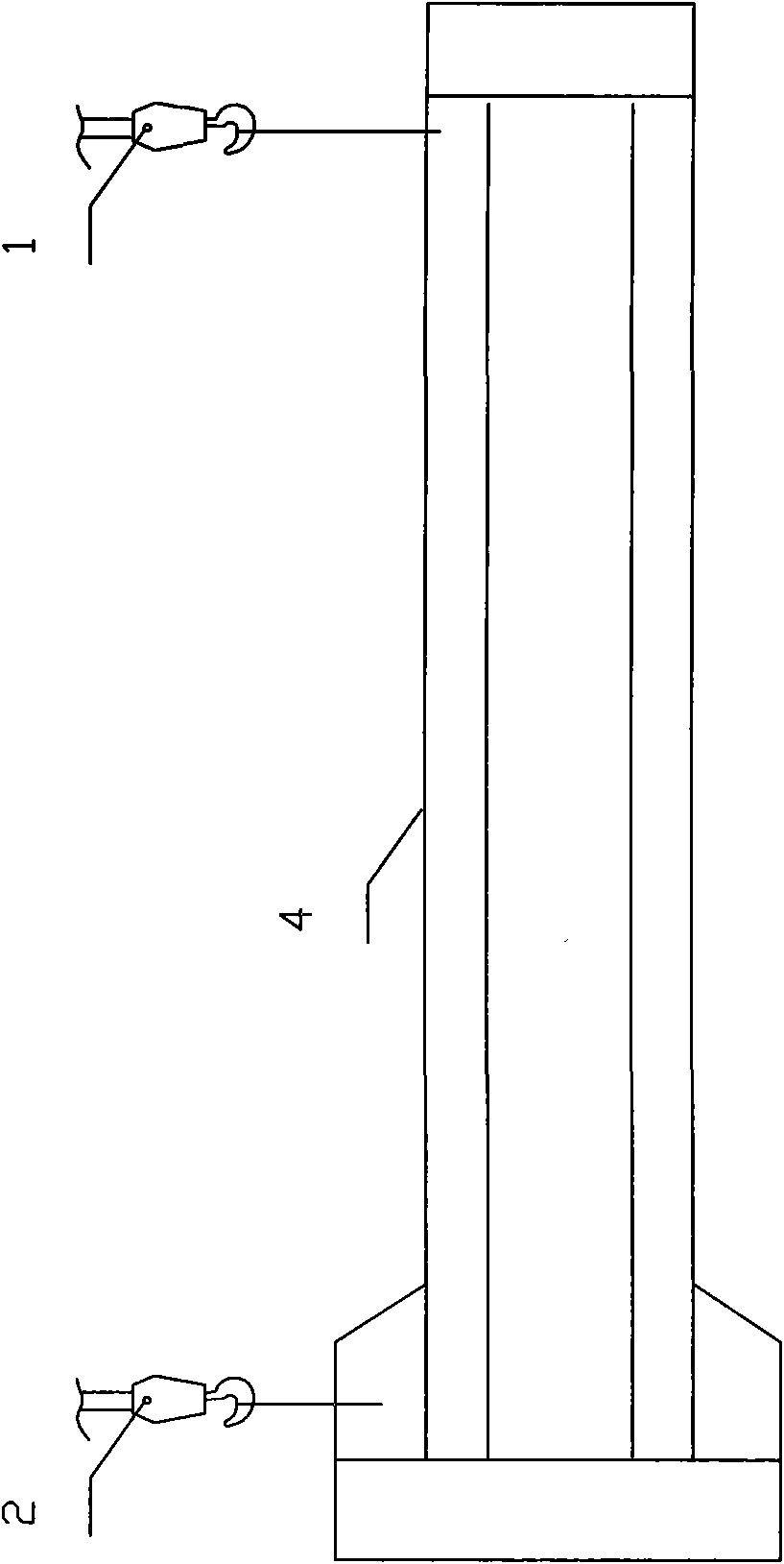

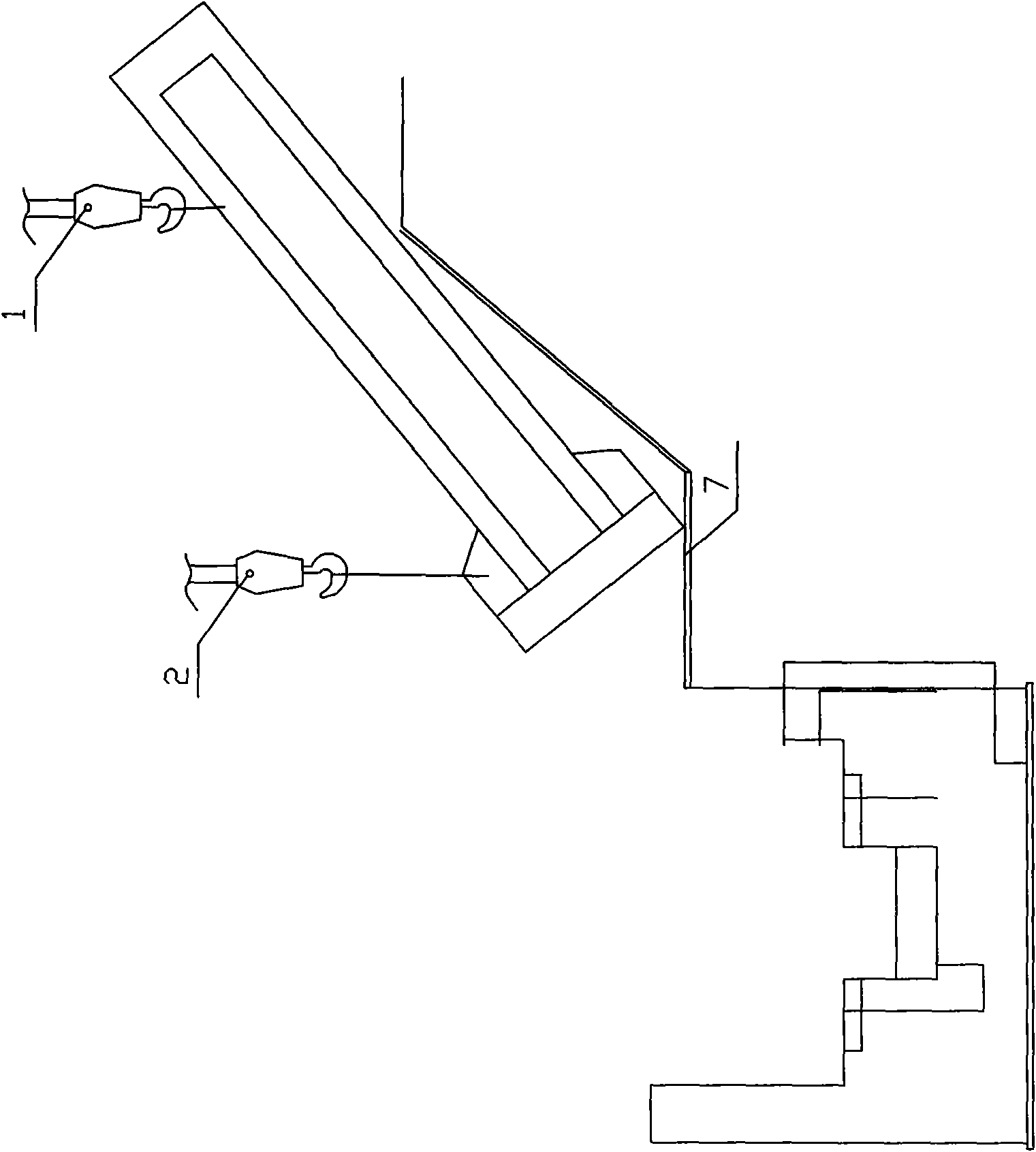

Method for hoisting ultra-high overweight equipment in closed workshop and special sling

InactiveCN101549836AEasy to installSimple structureTravelling cranesLoad-engaging elementsLifting capacityBridge type

The present invention relates to a method for hoisting ultra-high overweight equipment in closed workshop and a special sling. The hoisting method includes steps as follows: constructing an inclined slope near an equipment installing base; turning the equipment for making the installing direction in a right direction; parallel moving the equipment to a place near the inclined slope; placing the equipment on the inclined slope; raising up the equipment slowly and placing on the inclined slope bottom platform; hoisting the equipment in position cooperating with the special sling; the special sling includes a first girder, a second girder, a hanging ear, the first girder connects with the second girder showing included angle, one side of the first girder far from the second girder is equipped with a first girder hanging ear, two sides of the second girder are equipped with a second girder hanging ear. The method uses two hydrostatic triggers, a bridge type hoisting engine in workshop and the sling for cooperating lifting the ultra-high overweight equipment which can solve problem of insufficient weight-lifting capability; the inclined slope for storing equipment temporarily near the equipment base which can solve defect of limited workshop beam orbital height by ultra-high.

Owner:CHINA FIRST METALLURGICAL GROUP

Lifting appliance of automobile auxiliary frame

ActiveCN103523650ANot easy to shakeGuaranteed stabilityLoad-engaging elementsVehicle frameIndustrial engineering

Owner:CHERY AUTOMOBILE CO LTD

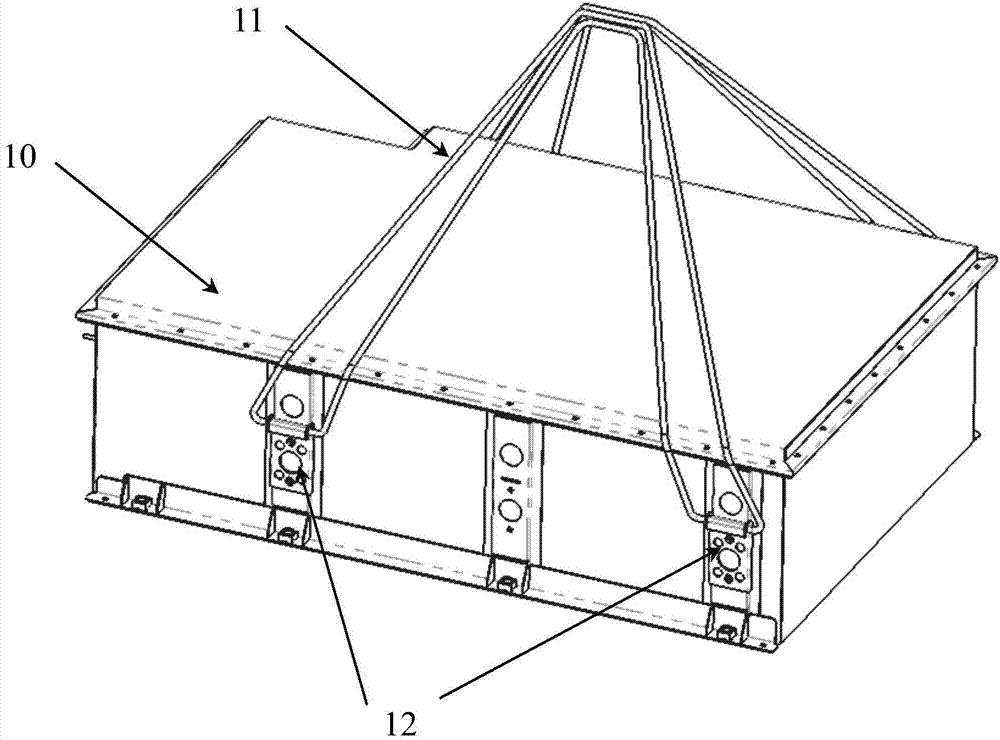

Aluminum alloy superstructure block hoisting method

The invention provides an aluminum alloy superstructure block hoisting method, which comprises the following steps of (1) determining the quantity of multiple hoisting points, positions of multiple hoisting points and an integral hoisting method of an aluminum alloy superstructure block according to the weight of the aluminum alloy superstructure block, a structural form and a gravity core; (2) producing a hoisting bracket for hoisting the aluminum alloy superstructure block; (3) designing and installing temporary reinforcement onto the aluminum superstructure block according to the integral hoisting method; (4) installing one hoisting hanger on each position of multiple hoisting points; and (5) vertically joining the hoisting hangers with the hoisting bracket through a wire cable, and utilizing the hoisting bracket to carry out the multipoint vertical hoisting. According to the hoisting method, not only can the deformation control problem for hoisting the aluminum superstructure block be solved and sectional construction of the aluminum alloy superstructure block be realized, but also the hoisting hangers and the temporary reinforcement for the hoisting are convenient to disassemble, and the block hoisting time can be shortened.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

Adjusting method for level adjustment of hanging tool for spacecraft

ActiveCN102530726AReduce labor intensityGo digitalLoad-engaging elementsUltimate tensile strengthIndustrial engineering

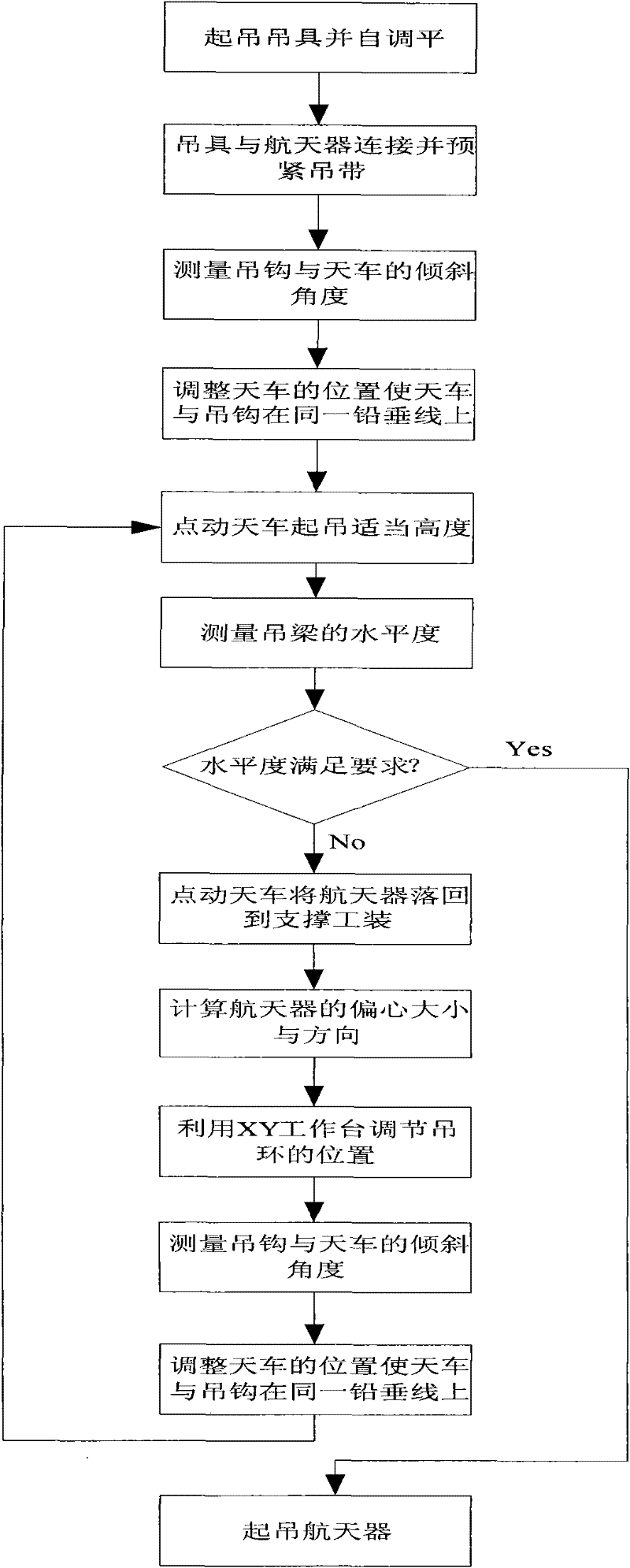

The invention discloses an adjusting method for level hanging adjustment for a hanging tool based on hanging point adjustment. The adjusting method mainly comprises the following steps of hanging adjustment processes, such as level adjustment of the hanging tool per se, centering of a hanging hook (or a hanging ring of the hanging tool) with a crown block, levelness measurement and position adjustment, wherein a measurement value of an obliquity sensor on a hanging ring assembly is used as a reference for judging the centering of the crown block with the hanging hook; a measurement value of an obliquity sensor on a hanging beam is used as a criterion for judging the hanging levelness; position adjustment of the hanging points of the hanging tool is realized through the movement of a worktable XY in a plane; and on the premise of ensuring the centering between the crown block and the hanging hook, the hanging points of the hanging tool are adjusted to proper positions, so that two-dimensional levelness adjustment of the spacecraft in the hanging process is realized. According to the adjusting method for high-precision level hanging, disclosed by the invention, the levelness is less than 4.1 mm / m, and the level adjustment process can be completed within 180 s, so that digitalization and automation of measurement and adjustment processes are realized, the hanging precision and hanging efficiency are improved, the labor intensity of operating personnel is lowered, and the application value is remarkable.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

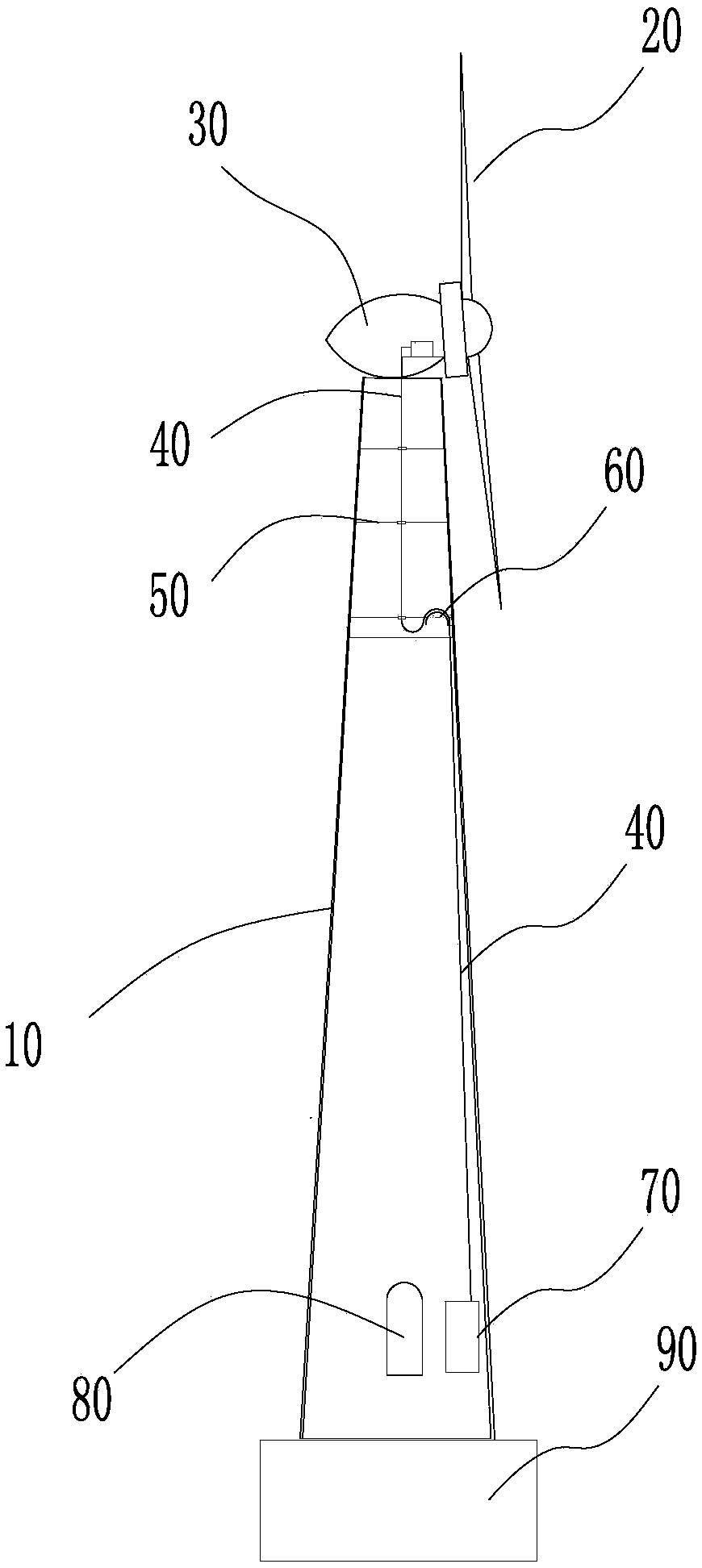

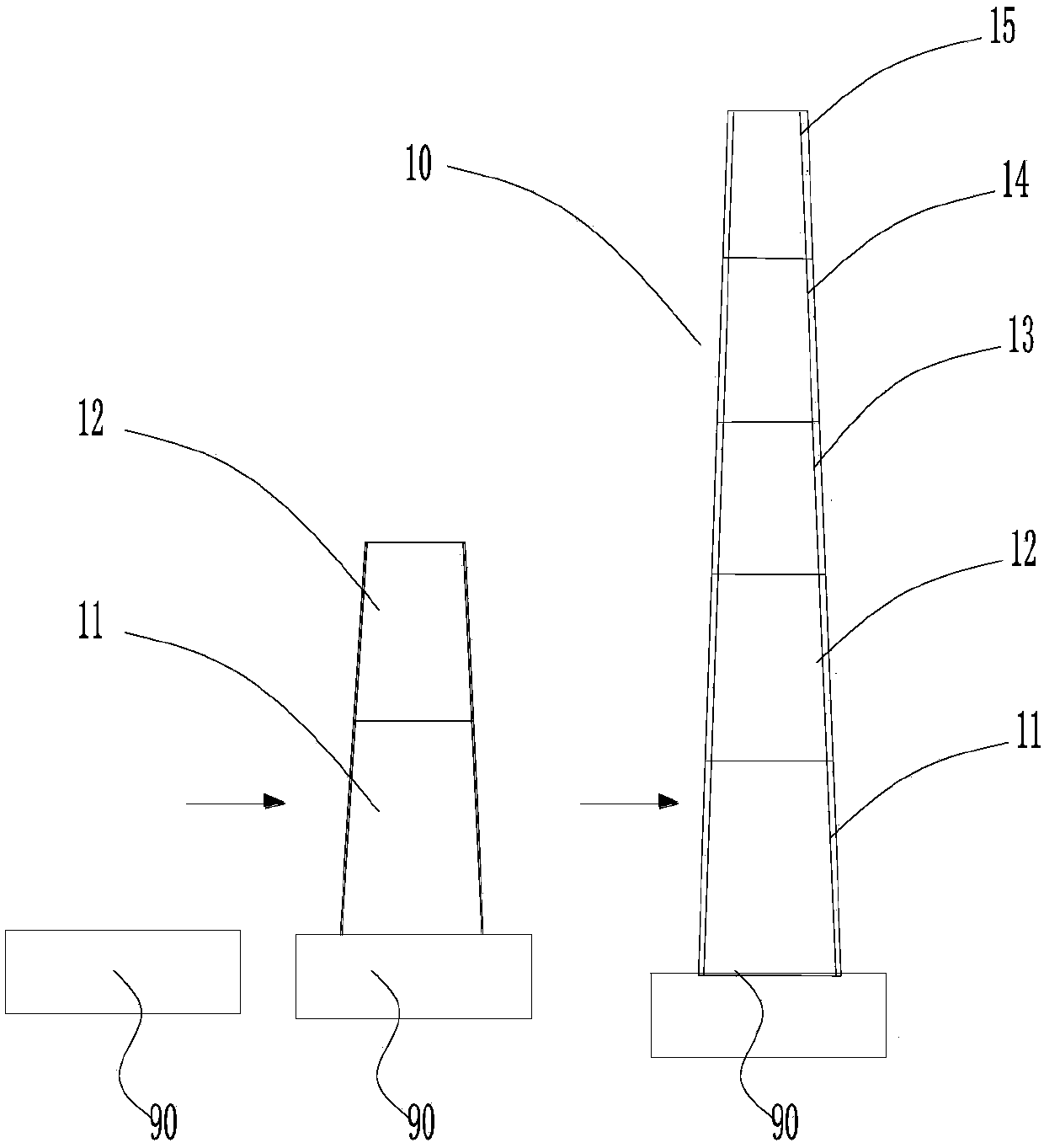

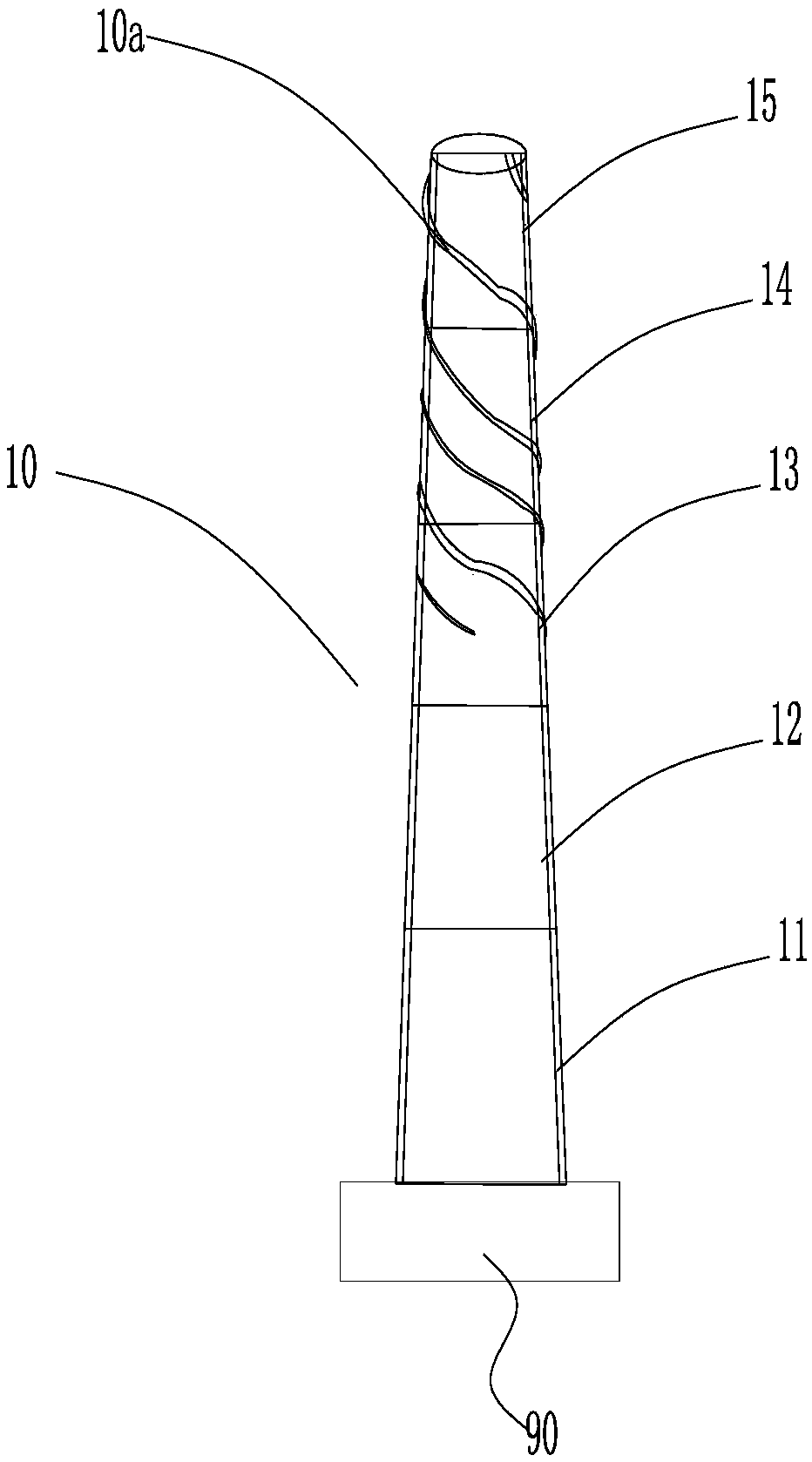

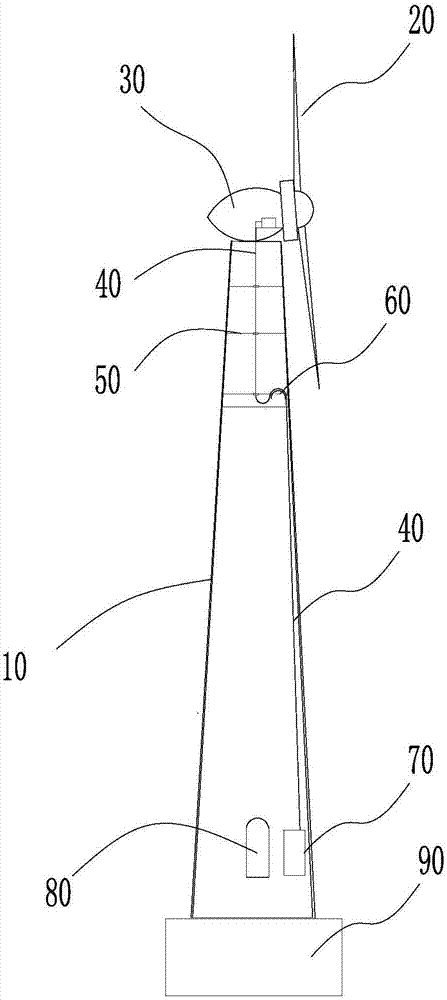

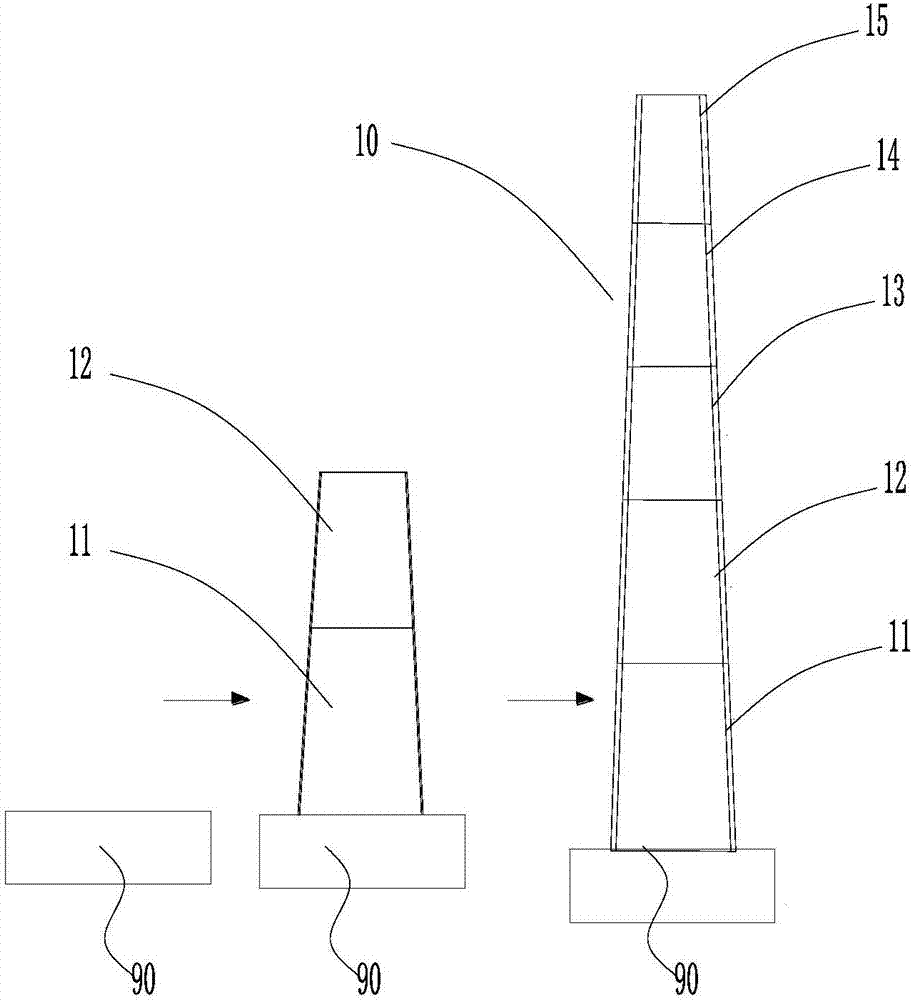

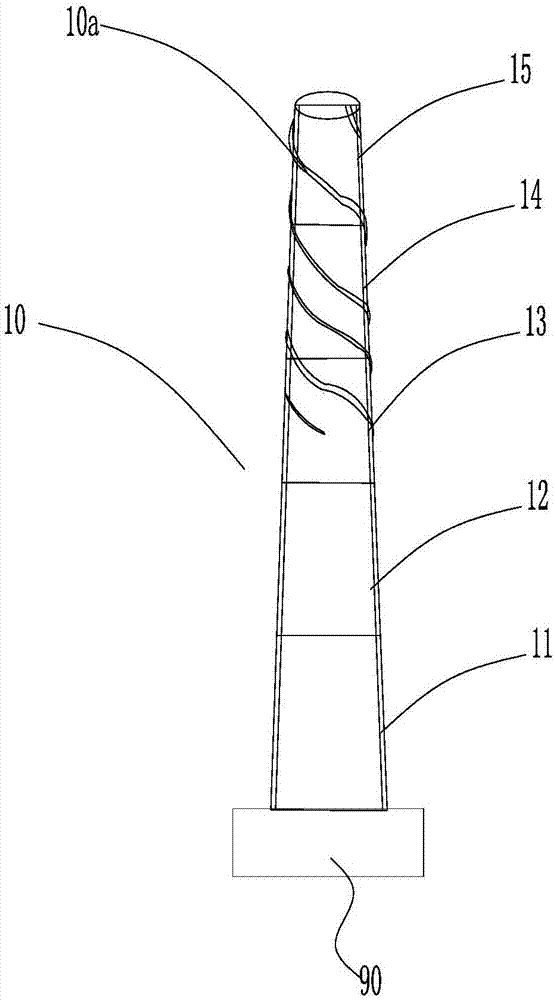

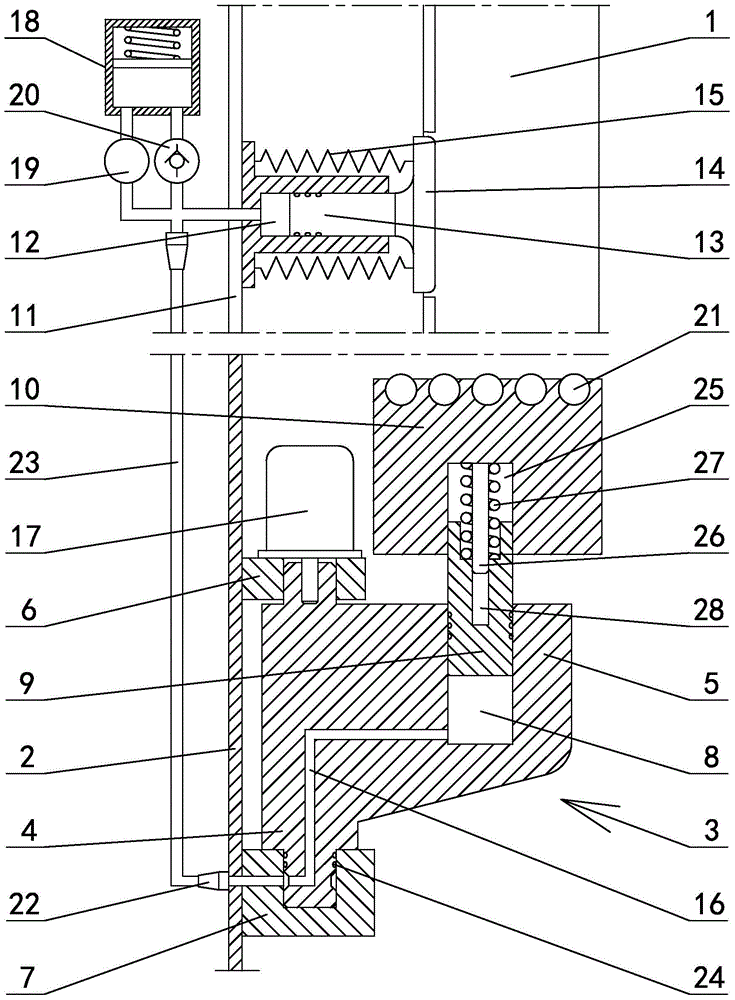

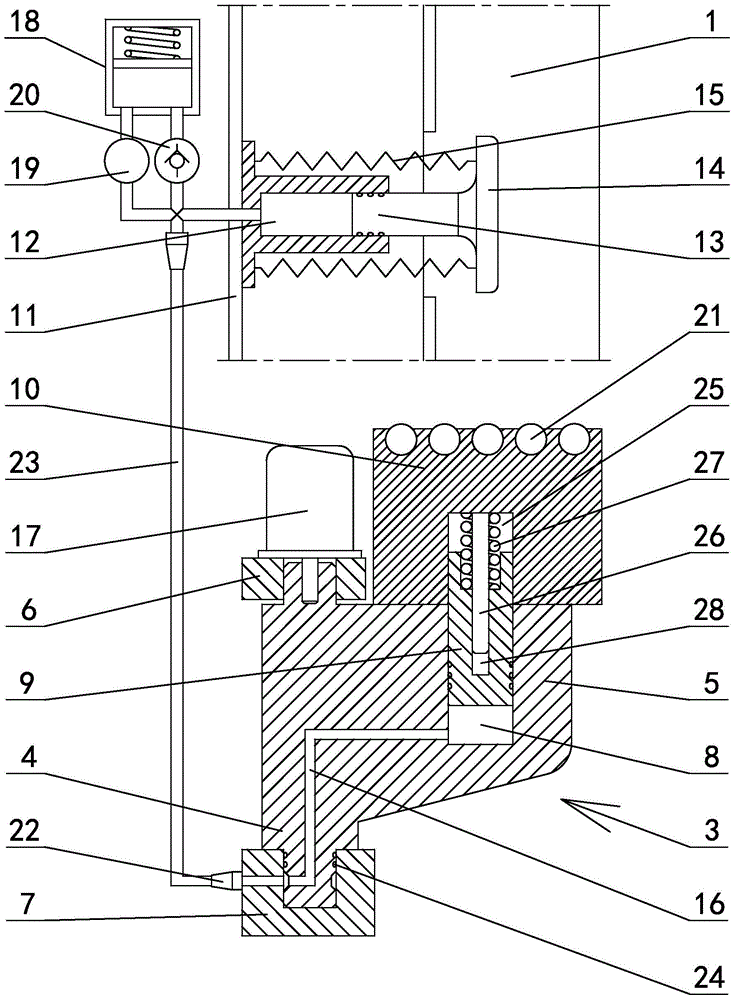

Surrounding body device and method for inhibiting vibration of retaining structure

ActiveCN107740752ASolve the damageSolve hidden dangersWind motor assemblyWind motor supports/mountsStructure of the EarthEngineering

The invention discloses a surrounding body device and method for inhibiting vibration of a retaining structure. The device comprises a surrounding body capable of surrounding the retaining structure.The surrounding body is further provided with a lifting device. The lifting device is provided with an air inlet runner and an exhaust runner. The lifting device drives the surrounding body to float vertically through exhausting of the exhaust runner. Due to the fact that the lifting device drives the surrounding body to sweep vertically, the attack angle and the pneumatic appearance of tower sections at different heights can be changed continuously in a floating height range, formation of vortexes on the two sides behind a tower is hindered, the consistency of the disengaging frequency of upper and lower vortexes of the tower is disorganized, and generation of vortex-induced vibration is inhibited. In addition, when the surrounding body floats and sinks vertically, the surrounding body can also swing and collide with the outer wall of the tower to damage boundary layer stream around near the tower, formation of vortexes can also be hindered, and vibration is inhibited.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Enclosure structure with vibration suppression function and method for suppressing vibration of enclosure structure

ActiveCN107956650ALow densityDownwind shock reductionWind motor supports/mountsMachines/enginesEngineeringStructural vibration

The invention discloses an enclosure structure with a vibration suppression function and a method for suppressing vibration of the enclosure structure. The outer surface of the enclosure structure isprovided with heat sources. The heat sources are used for heating an airflow boundary layer at the position of the outer surface of the enclosure structure, and through heating, the density of the airflow boundary layer rho can be lowered, the amplitude is reduced, and transverse vibration is suppressed; the airflow boundary layer at the position of the windward surface of the enclosure structureis heated, the airflow boundary layer density is lowered, and equivalently an airflow buffer layer is arranged at the windward surface; and when the windward incoming flow meets the airflow buffer layer, the turbulence can be weakened, the pulsatility is lowered, and the following wind impact on the enclosure structure is reduced, so that the following wind vibration of the enclosure structure canbe suppressed.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

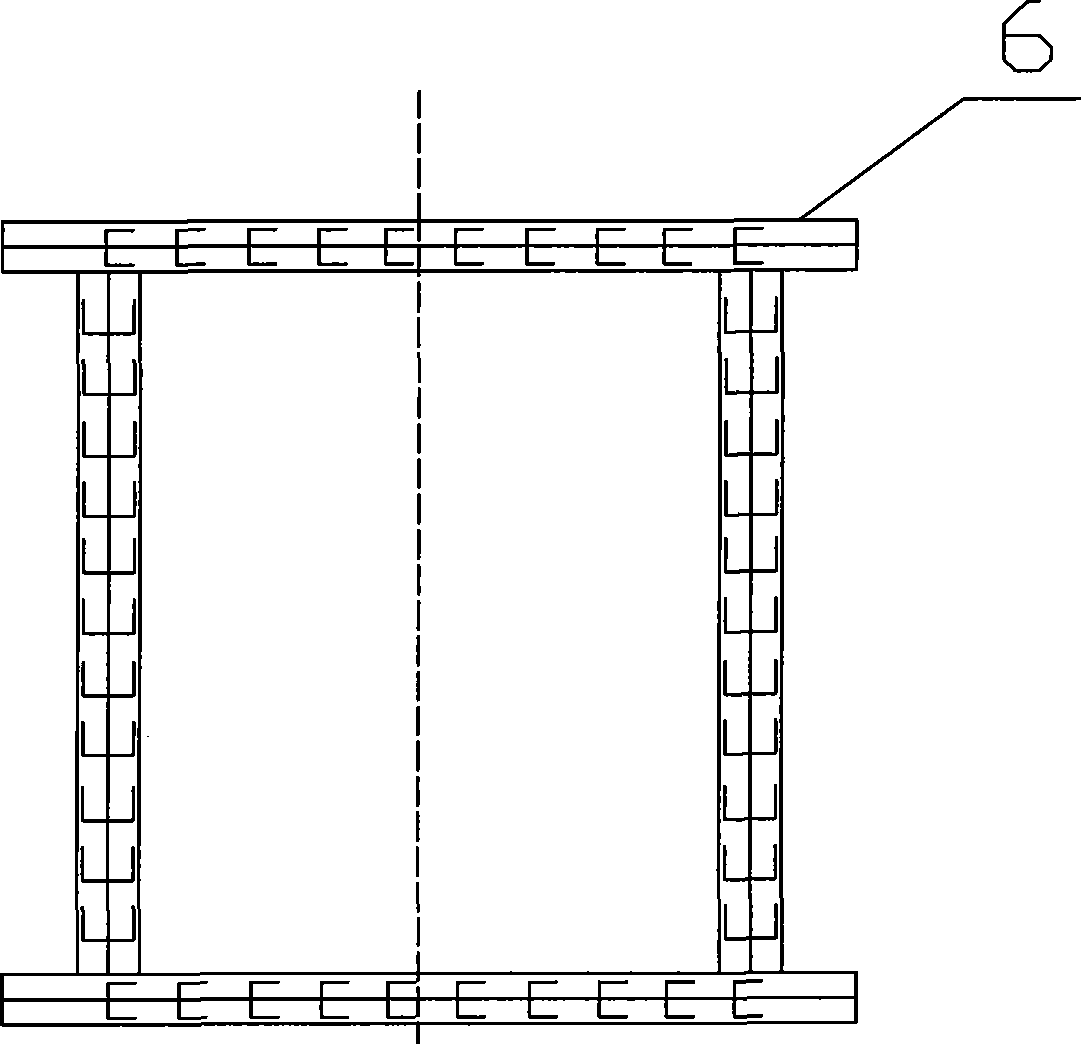

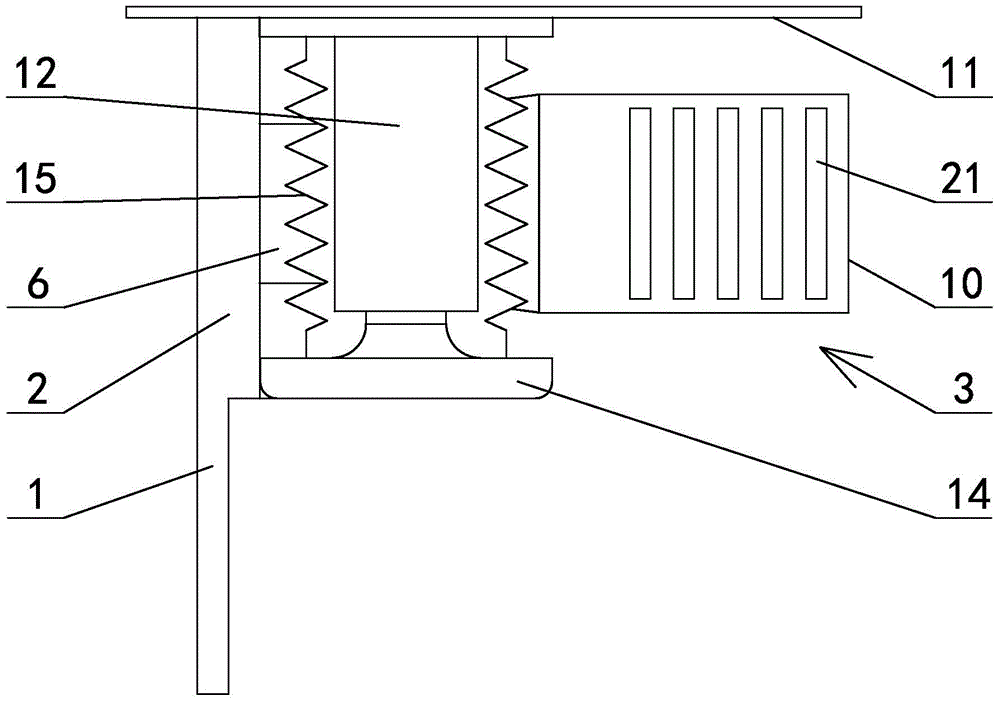

Container positioning guide rail device for ships

The invention discloses a container positioning guide rail device for ships. The container positioning guide rail device comprises four guide rail racks in long strip shapes, wherein 2-4 corbel supports are arranged on each guide rail rack; the corbel supports on different guide rail racks are arranged on the same horizontal plane; each corbel support comprises a pivot shaft which is parallel to the guide rail rack, and a supporting body arranged on one side of the pivot shaft; an upper pivot base connected with the pivot shaft, and a lower pivot base connected with the pivot shaft are connected with each guide rail rack; a lower oil cylinder of which the axis is parallel to the guide rail rack is arranged in each supporting body; the upper end of a lower oil cylinder piston is connected with a supporting block; an upper oil cylinder of which the axis is perpendicular to the surface of a cabin wall is arranged on the cabin wall above each corbel support; the outer end part of an upper oil cylinder piston is connected with a top block; a tension spring is arranged between each top block and the upper oil cylinder; the bottom of each lower oil cylinder is communicated with the corresponding upper oil cylinder through a hydraulic pipeline; the corbel supports on different guide rail racks and at the same height take synchronous action. The container positioning guide rail device effectively solves the problems that containers in the prior art are easy to shift, so that the positioning effects of the containers are influenced, or guide rails on cabin walls are damaged; therefore, the container positioning guide rail device has a high practical value.

Owner:ZHEJIANG ZENGZHOU SHIPBUILDING +1

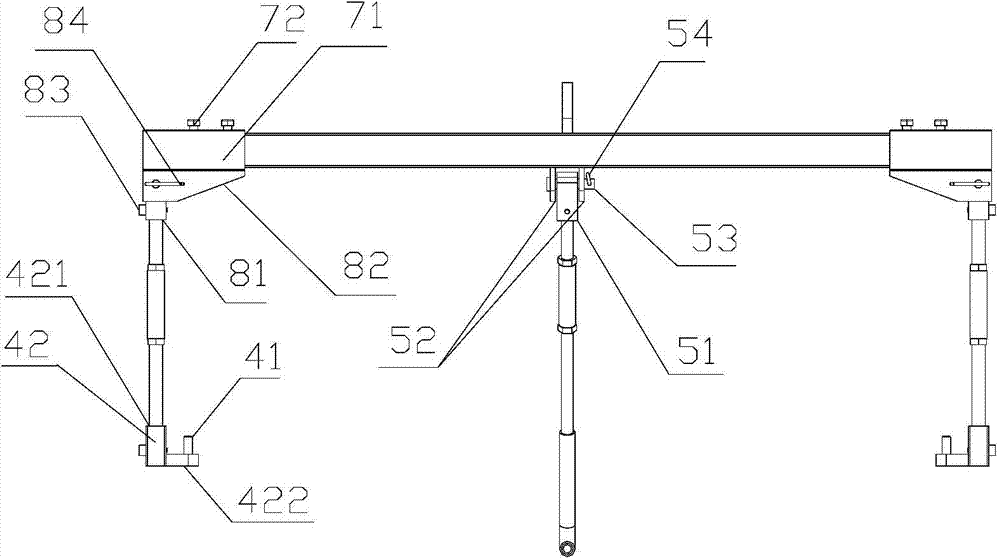

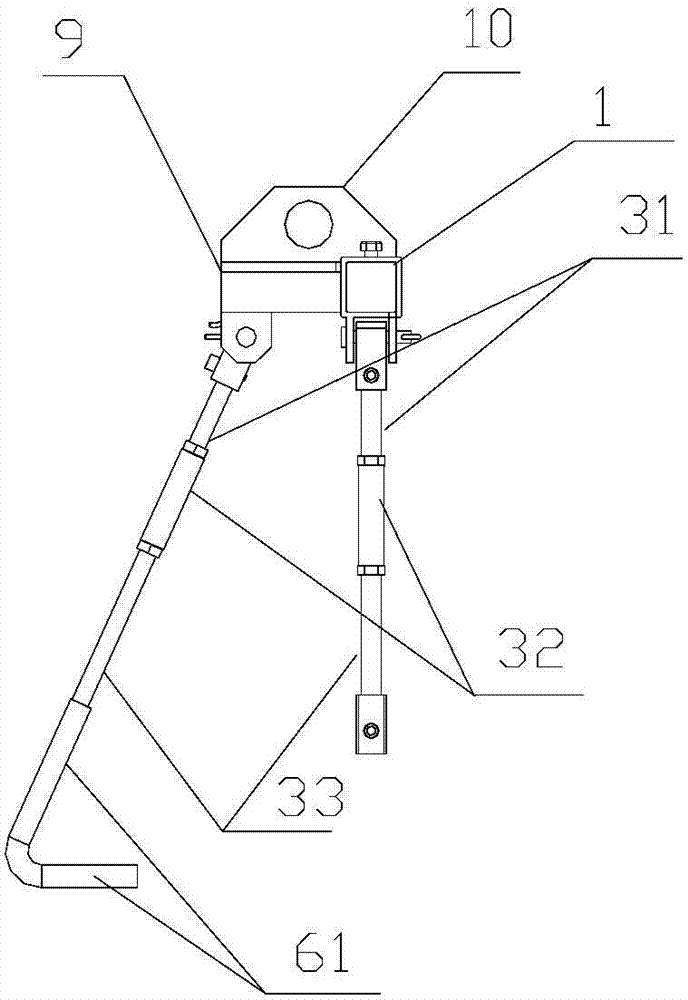

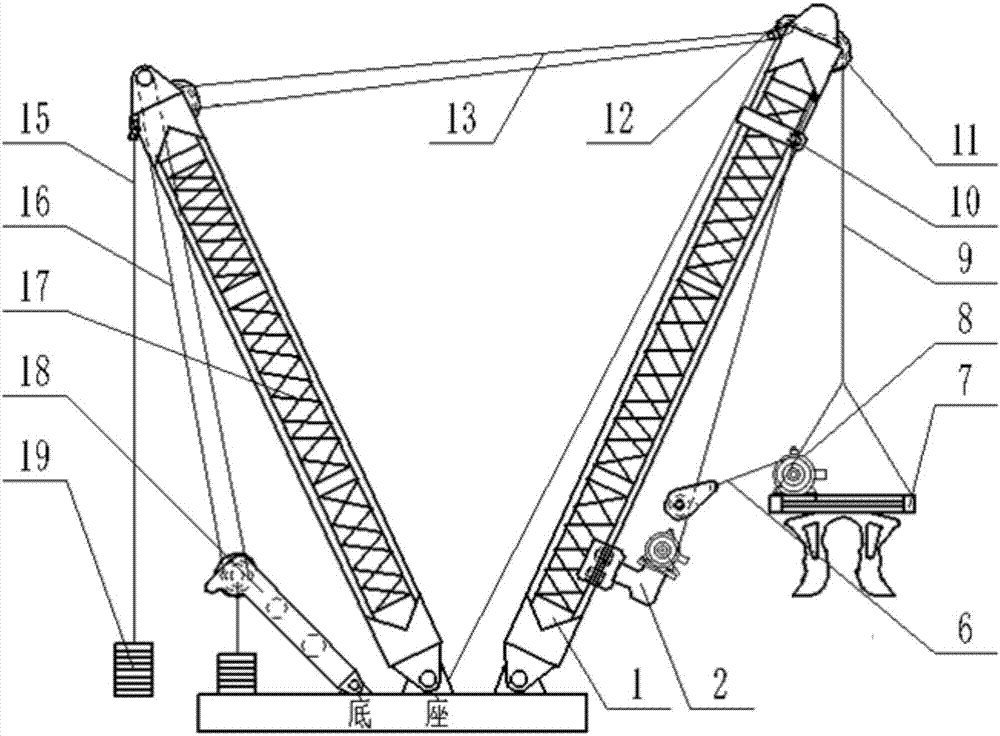

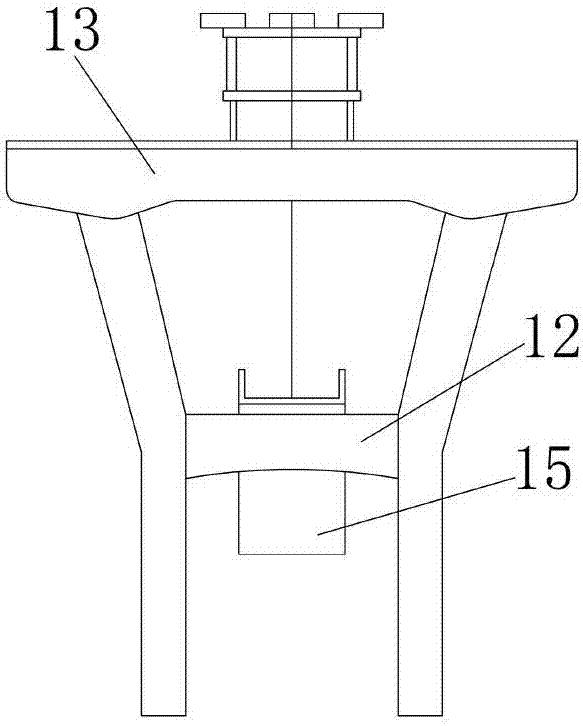

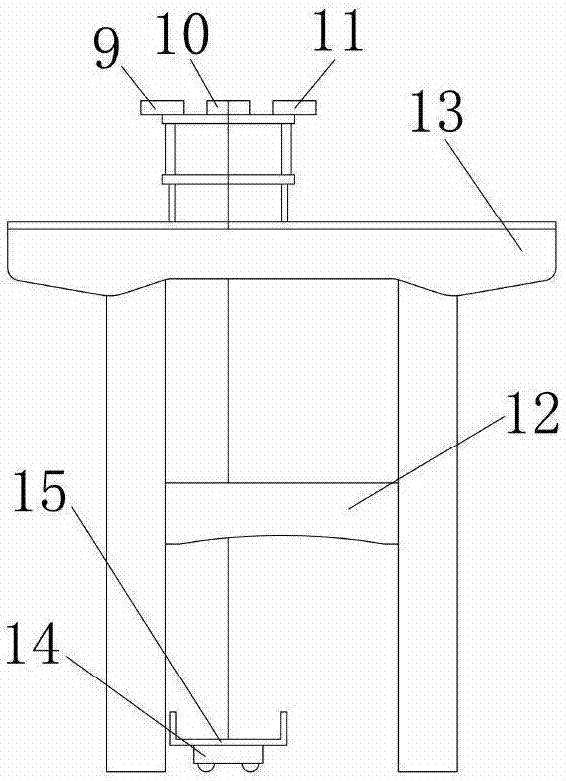

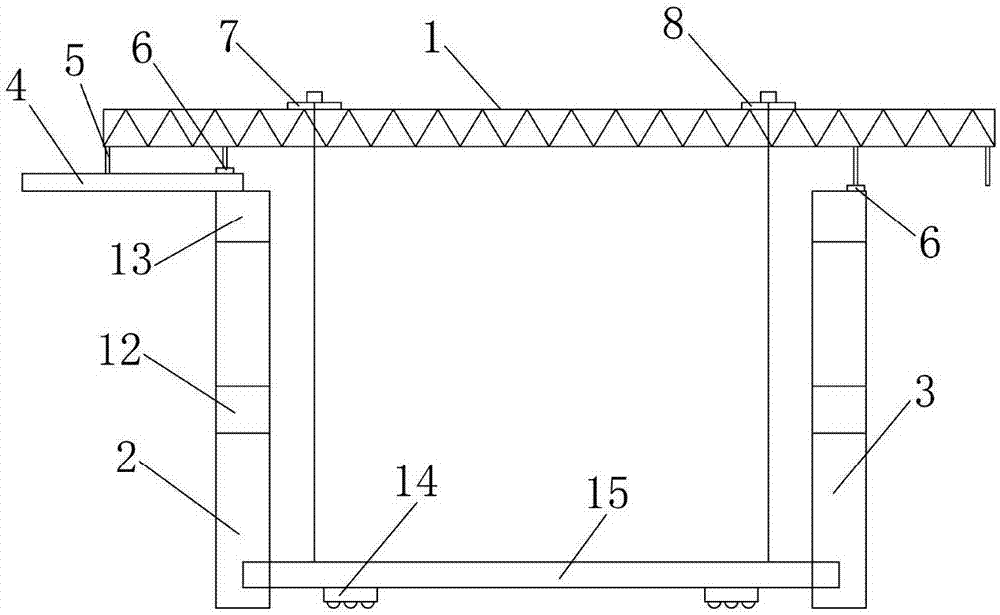

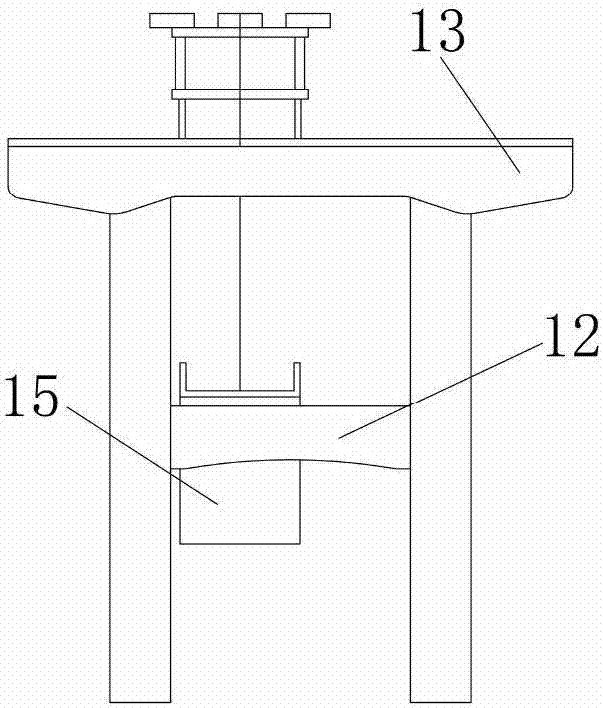

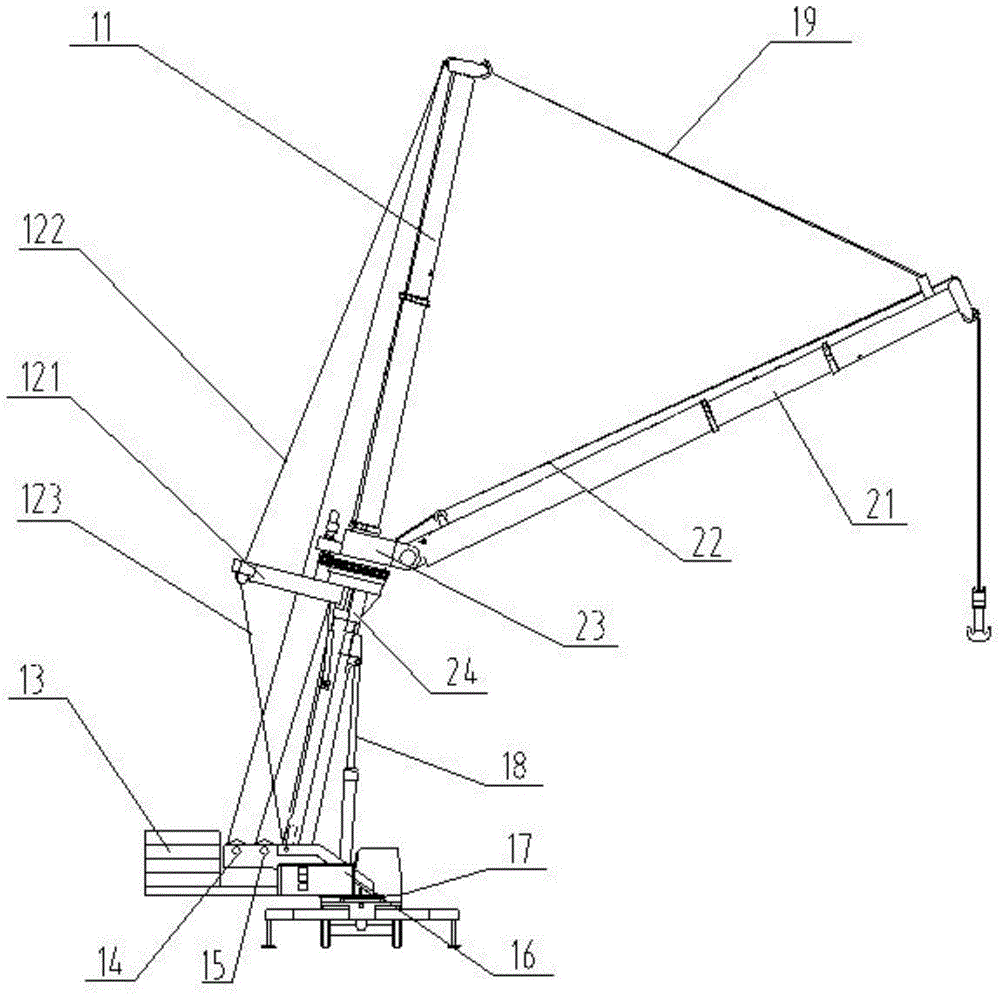

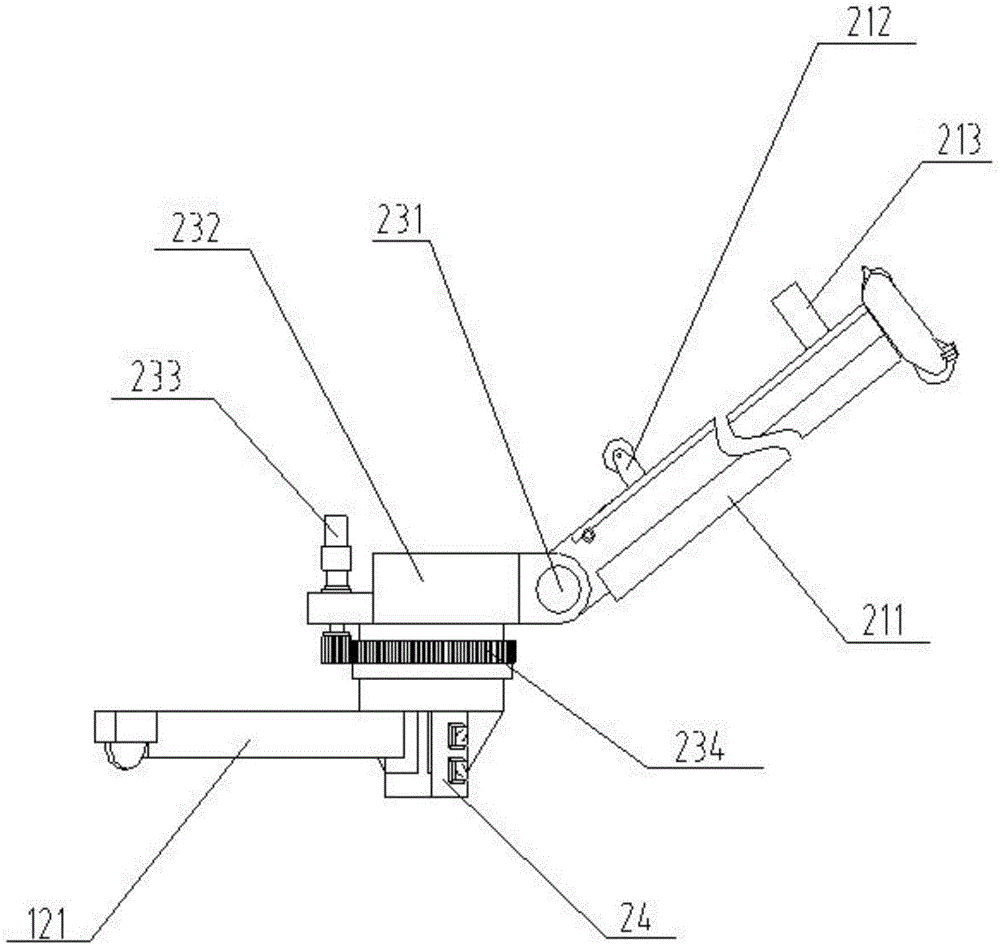

Large commonly-used hoisting stabilizing device and method for restraining heavy objects from swinging and rotating

The invention discloses a large commonly-used hoisting stabilizing device for restraining heavy objects from swinging and rotating. The large commonly-used hoisting stabilizing device comprises a base unit, a main arm unit, a heavy object lifting unit, a heavy object clamping unit and a heavy object stabilizing unit. The bottom of the main arm unit is in hinge joint with the base unit. The heavy object lifting unit and the heavy object stabilizing unit are arranged on the main arm unit. The heavy object clamping unit is connected with the heavy object lifting unit through a heavy object pulling rope. The heavy object stabilizing unit is connected with the heavy object clamping unit through a heavy object stabilizing rope. The heavy object hoisting stability control device disclosed by the invention does not depend on certain specific hoisting equipment, the hoisting stabilizing device can be installed on most of upper air jack-up hoisting equipment for performing stability control over the hoisted heavy objects, and the universality is high. The large commonly-used hoisting stabilizing device is simple in structure, low in manufacturing cost, convenient to operate and high in practicability. The professional requirement for operators is low, and the hoisting stabilizing device can perform heavy object hosting stability control in various complicated environments.

Owner:CHINA UNIV OF MINING & TECH

Battery box hoisting device

Owner:WUHAN LISHEN POWER CELL SYST TECH CO LTD

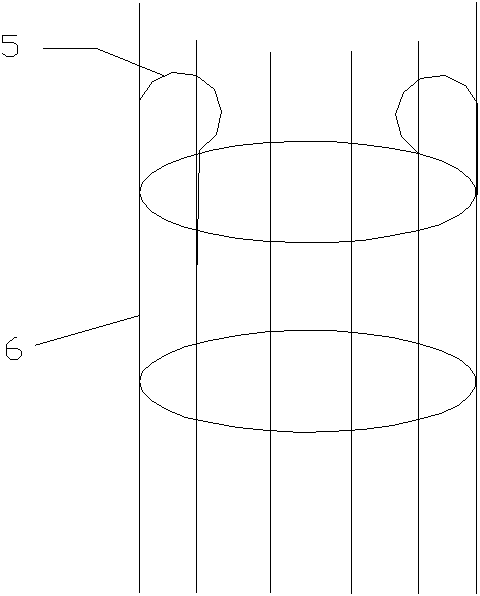

Wind power flange supporting-expanding-type lifting appliance

InactiveCN103640964AImprove hoisting efficiencyQuick installationLoad-engaging elementsElectricityEngineering

The invention relates to a wind power flange supporting-expanding-type lifting appliance. The wind power flange supporting-expanding-type lifting appliance is characterized by comprising casing pipes, wherein lifting rods which are coaxial with the casing pipes are inserted into the casing pipes; the upper ends of the lifting rods are provided with lifting rings, and the lower ends of the lifting rods are connected with conical column pushing blocks; the lower parts of the conical column pushing blocks are connected with cylindrical spacing blocks; the diameters of the cylindrical spacing blocks are greater than the bottom surface diameters of the conical column pushing blocks; the parts of the casing pipes, which correspond to the conical column pushing blocks, have at least two radial through holes; the lifting rods the lower ends of which push and press the outer periphery surfaces of the conical column pushing blocks are inserted into the radial through holes; the axes of the lifting rods are perpendicular to the axes of the lifting rods. The wind power flange supporting-expanding-type lifting appliance has the advantages of simple structure, convenience in using, time and labor conservation and capability of improving the lifting efficiency.

Owner:天津市盛佳怡电子有限公司

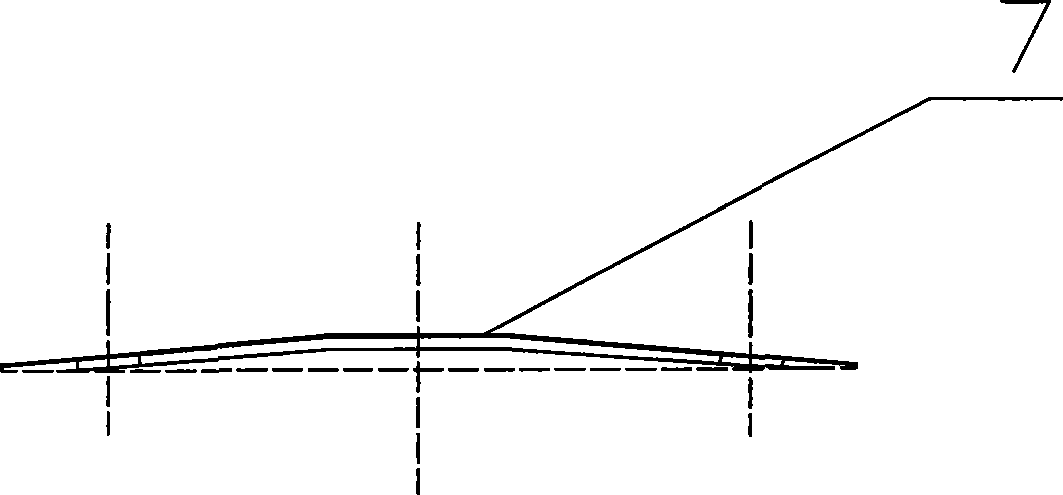

Method for hoisting steel dome of nuclear power plant in balance-keeping manner

The invention discloses a method for hoisting a steel dome of a nuclear power plant in a balance-keeping manner. The method is realized by cooperation of a balance hosting device of the steel dome of the nuclear power plant and hoisting machinery and comprises the steps of assembling in place, trial hoisting, hoisting and the like. A plurality of adjustments are carried out in each step to stress related components in a balance-keeping manner, so that the stability of the hoisting process is ensured. The method can ensure the balance of multi-point hoisting stress and accuracy of levelness of a lower opening of the dome, is applicable to hoisting and mounting of the dome of a containment of the nuclear power plant, is used for ensuring the balance of hoisting stress and accuracy of levelness of the lower opening of the dome, and is also applicable to the hoisting process of other spherical segment and spherical coronary objects.

Owner:中国电建集团河北工程有限公司

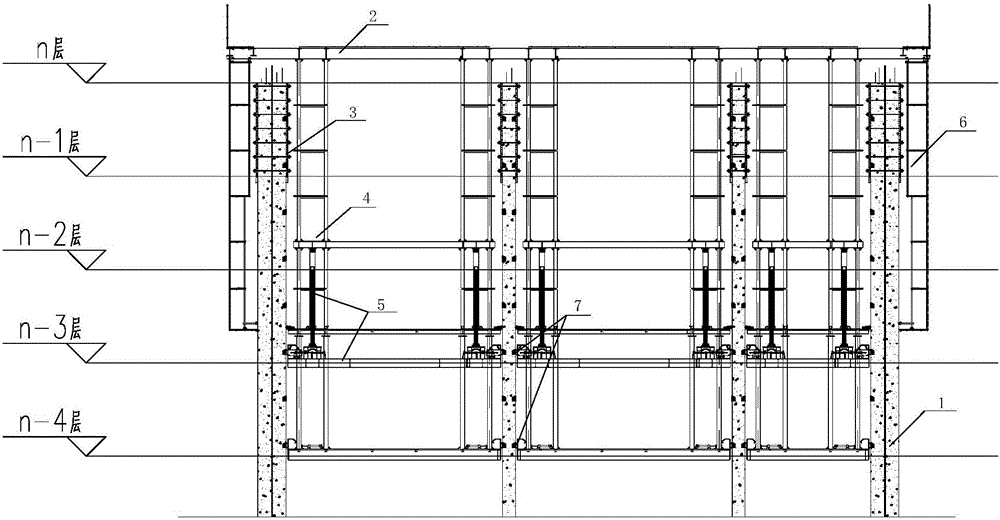

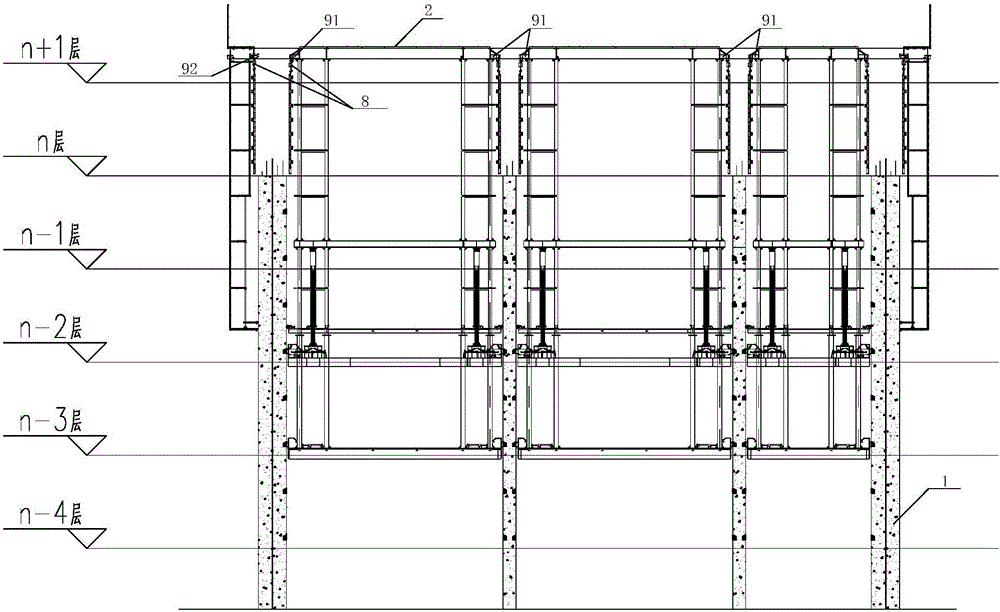

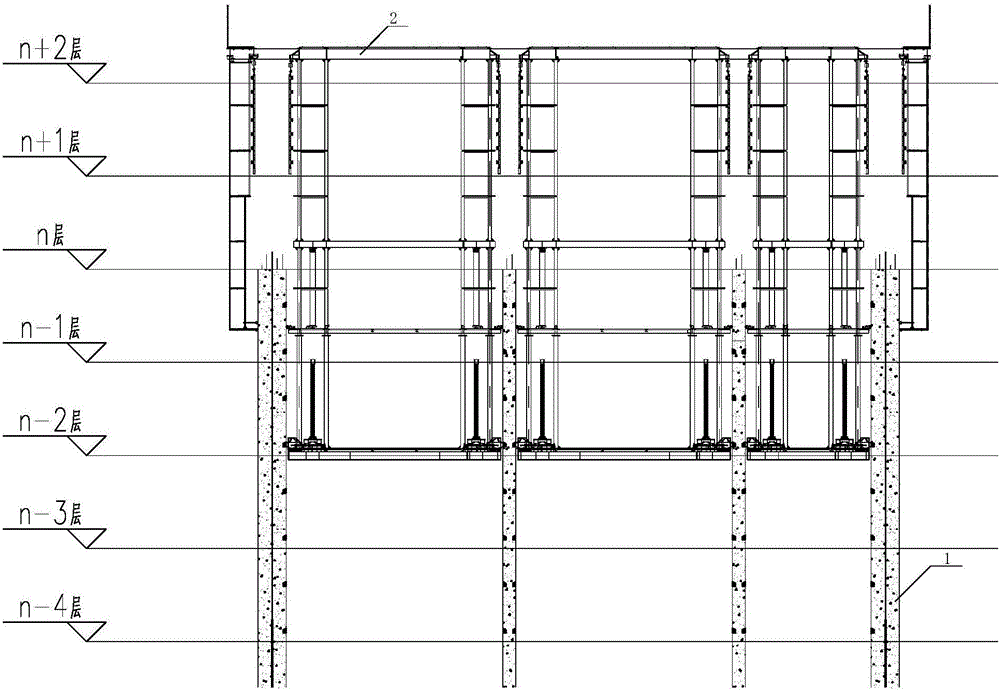

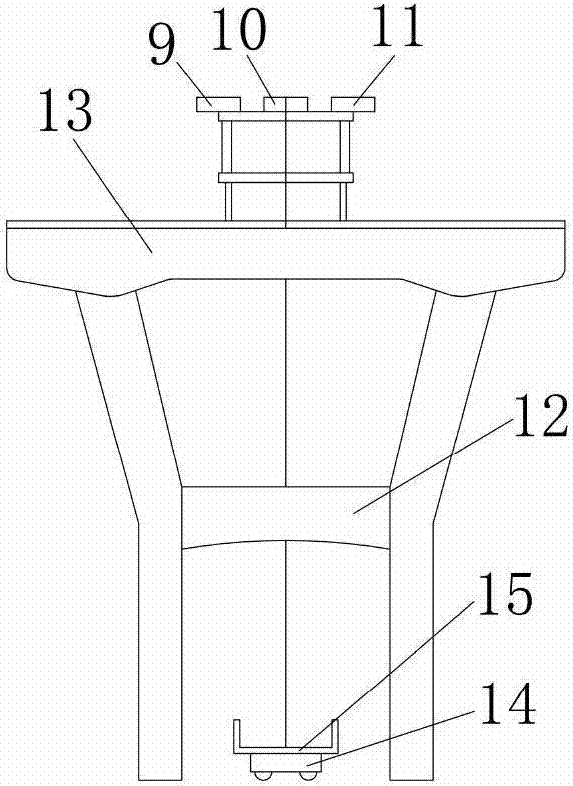

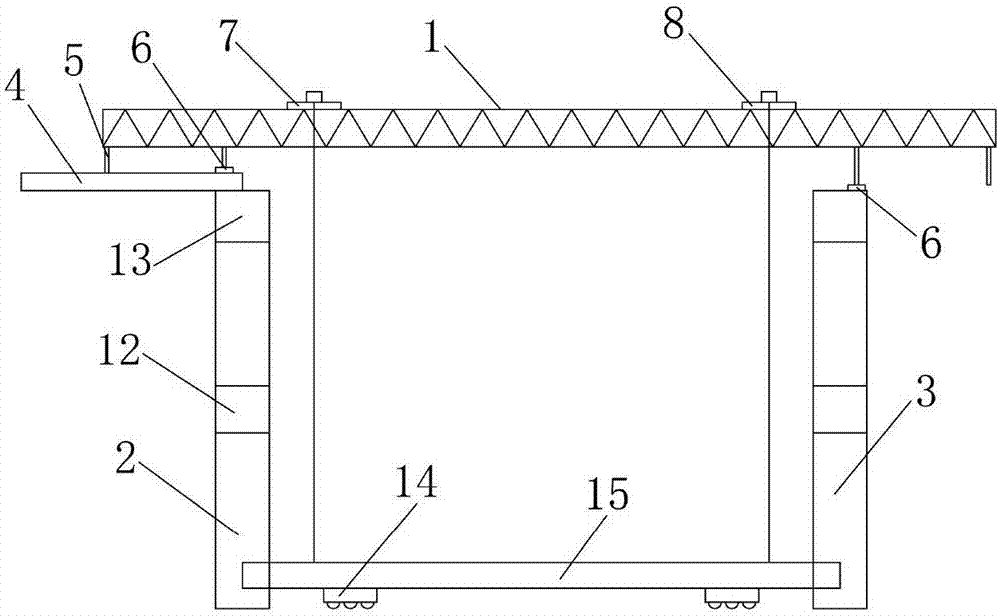

Construction method for cylindrical frame supporting type hydraulic-climbing integral steel platform formwork shear steel plate layer

PendingCN106592826AReduce the number of liftingSpeed up hoisting and construction efficiencyWallsForms/shuttering/falseworksSteel platesRebar

The invention provides a construction method for a cylindrical frame supporting type hydraulic-climbing integral steel platform formwork shear steel plate layer, and belongs to the technical field of building construction. The construction method is used for solving the problems that construction of traditional integral formwork shear steel plate layers is low in efficiency and poor in safety. The construction method includes the following steps that firstly, cylindrical frame supporting type hydraulic-climbing integral steel platform formwork equipment is located at the top of a core tube wall which is just poured, and templates are fixed to the core tube wall through fixing parts; secondly, the fixing parts are removed, the templates are fixed to the lower end of a steel platform beam by means of a chain block through a template hoisting point arranged on the steel platform beam; thirdly, an integral steel platform formwork continuously climbs by the height of two storeys; fourthly, a shear steel plate is hoisted and mounted; fifthly, first frame steel bars are bound, the template is placed in position, and concrete pouring and curing are conducted; sixthly, second frame steel bars are bound, the other template is placed in position, and concrete pouring and curing are conducted; and seventhly, the first step to the sixth step are repeated till all shear steel plates are constructed.

Owner:SHANGHAI CONSTRUCTION GROUP

Y-shaped highway and railway dual-purpose bridge deck slab lifting device and method

The invention provides a Y-shaped highway and railway combined bridge deck slab lifting device and method and belongs to the technical field of road bridge construction. The device comprises two girders and two crossbeams. The girders are fixedly connected through the crossbeams. The girders stretch across two adjacent piers. The first pier is arranged below the left side of the girders. The second pier is arranged below the right side of the girders. A highway bridge deck is arranged above the first pier. A hydraulic tail landing leg and a girder movement mechanism are arranged at the positions, above the highway bridge deck, on the girders. A girder movement mechanism is arranged at the position, above the second pier, on the girders. A front joist barrow and a rear joist barrow are further arranged between the two girders. When railway bridge deck slabs are laid, a first channel girder is lifted and placed on an upper bent cap of the piers, the lifting space large enough is saved for lifting a second channel girder, and the second channel girder is convenient to lift. After the second channel girder is aligned to the position and falls, the first channel girder is aligned to theposition and falls.

Owner:ZHEJIANG ZHONGJIAN ROAD & BRIDGE EQUIP

H-shaped combined highway and railway bridge deck slab lifting device and method

ActiveCN108004929AReduce hoisting spaceEasy to operateBridge erection/assemblyBridge deckEngineering

The invention provides an H-shaped combined highway and railway bridge deck slab lifting device and method and belongs to the technical field of road bridge construction. The device comprises two girders and two crossbeams. The girders are fixedly connected through the crossbeams and stretch across two adjacent piers. The first pier is arranged below the left side of the girders. The second pier is arranged below the right side of the girders. A highway bridge floor is arranged above the first pier. A hydraulic tail supporting leg and a girder moving mechanism are arranged above the highway bridge floor and on the girders. A girder moving mechanism is arranged above the second pier and on the girders. A front traveling crane and a rear traveling crane are further arranged between the two girders. When railway bridge deck slabs are laid, a beam channel is obliquely lifted, and the needed lifting space of the beam channel is greatly reduced. Operation is convenient in the whole lifting process, lifting efficiency is high, the construction workload and construction cost are reduced, and the paving schedule is quickened.

Owner:ZHEJIANG ZHONGJIAN ROAD & BRIDGE EQUIP

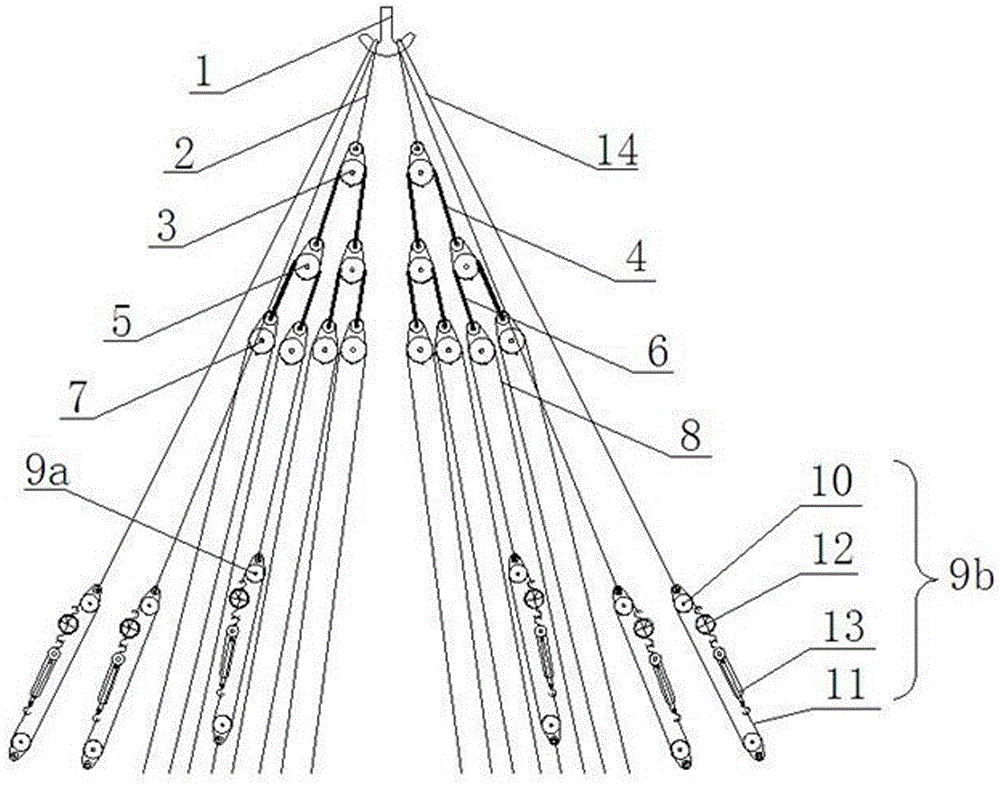

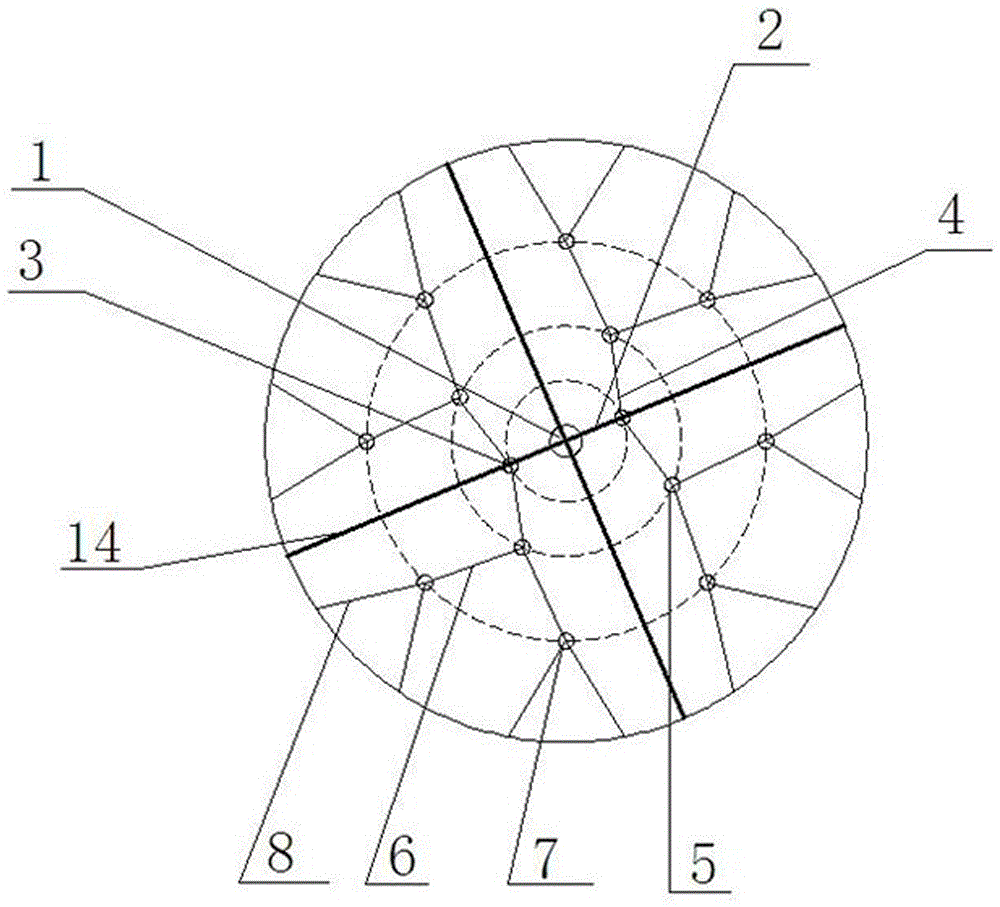

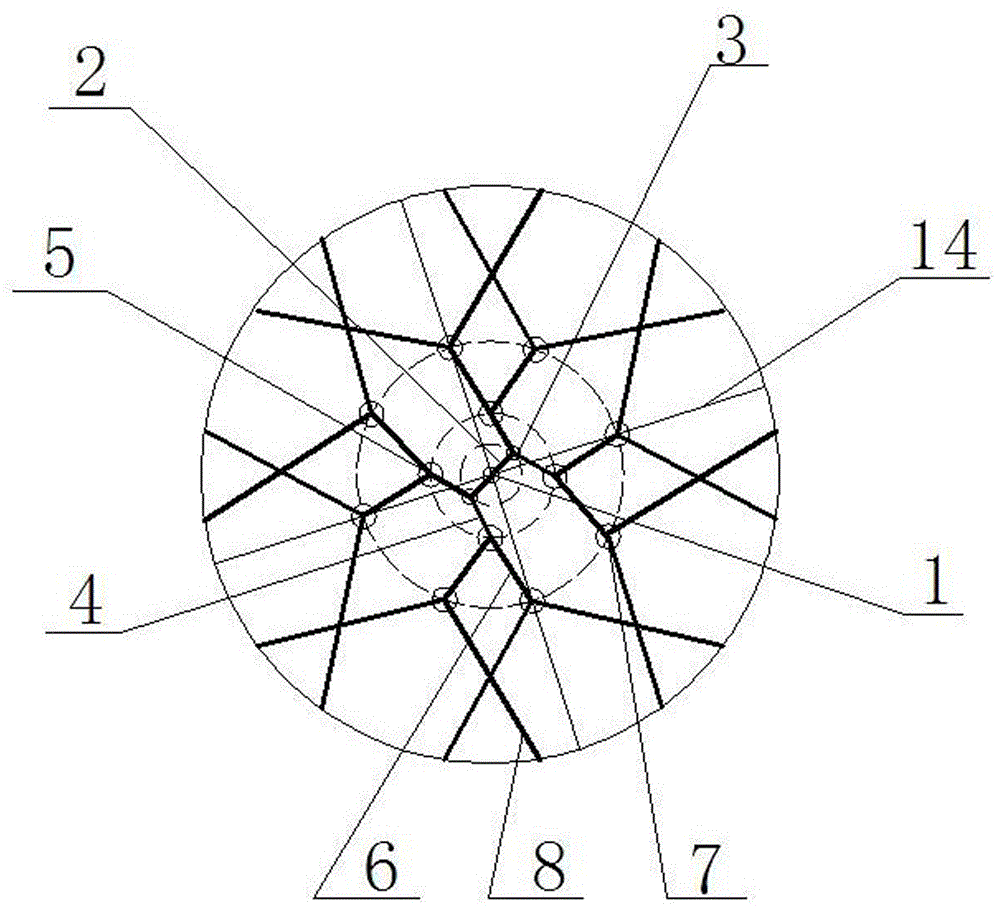

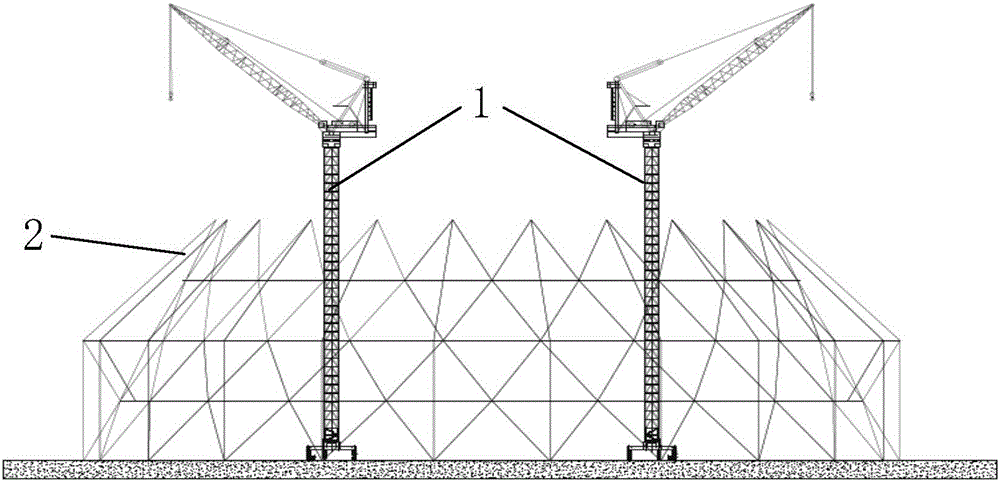

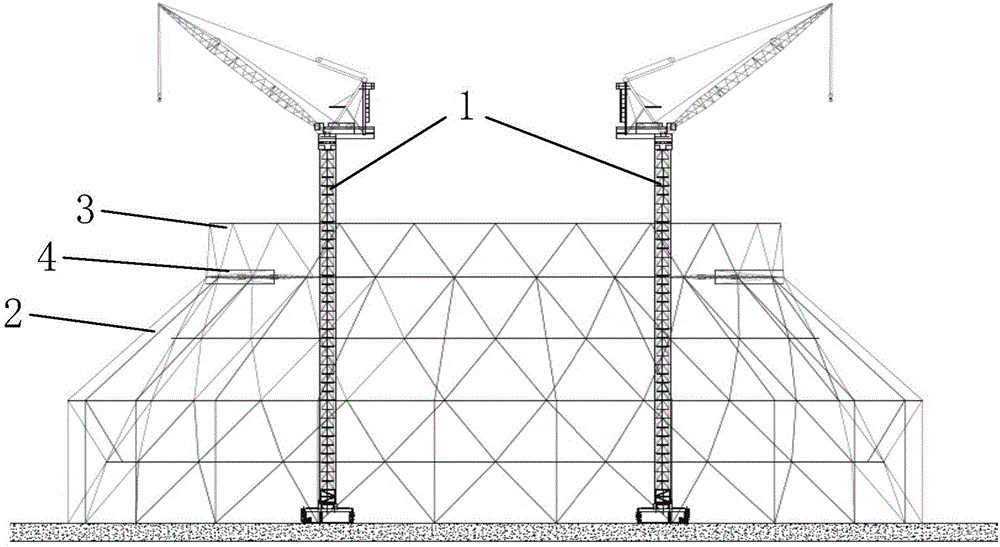

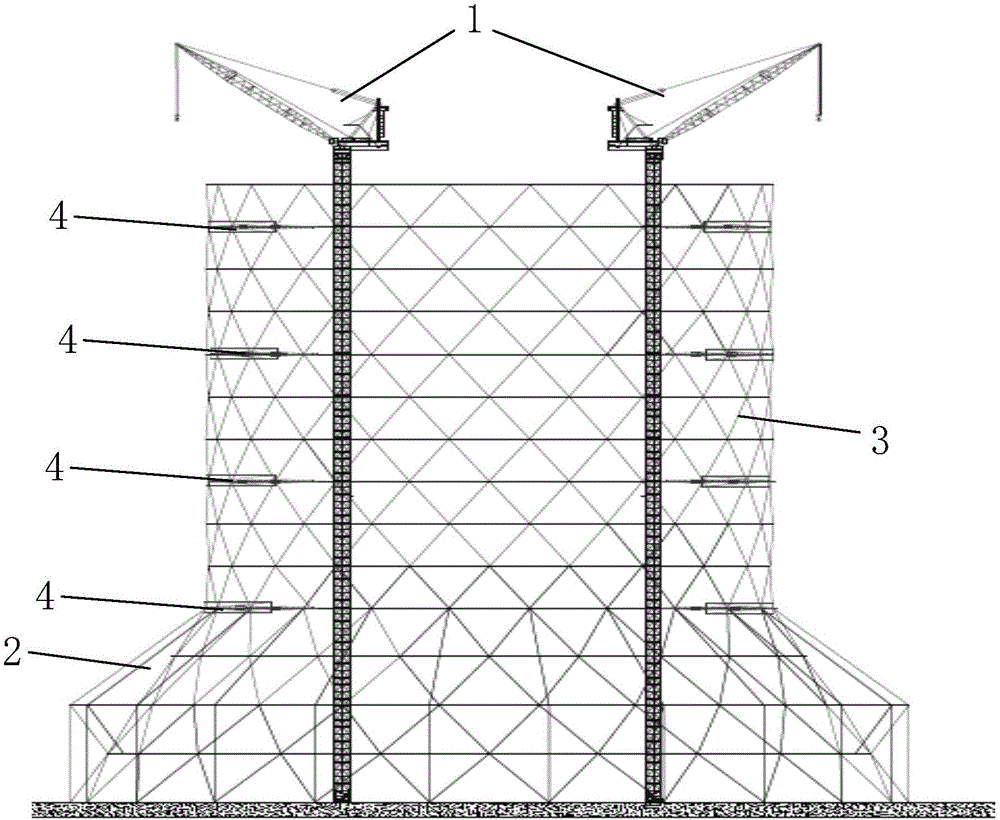

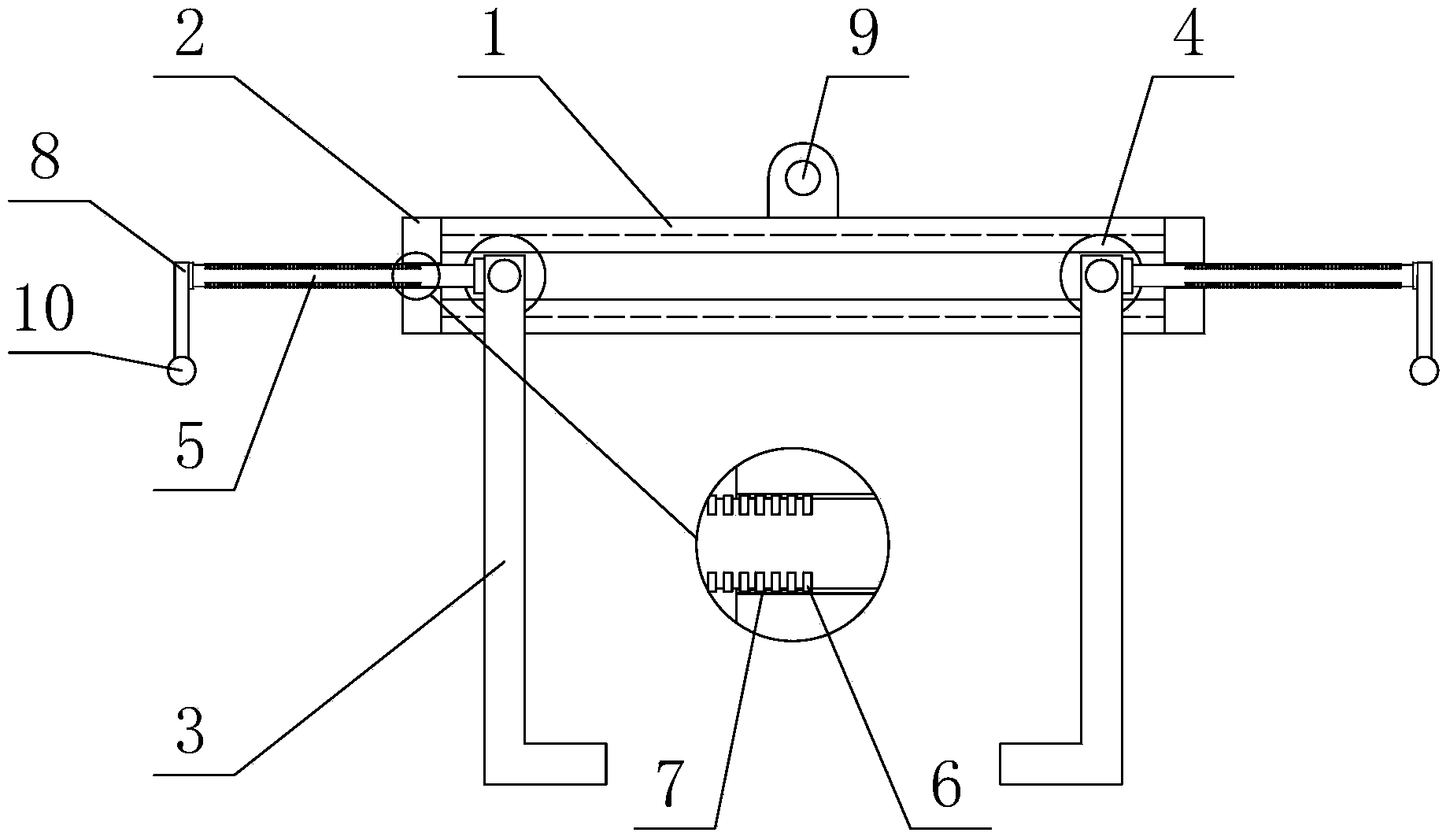

Tower crane construction method of large steel structural air cooling tower

ActiveCN106759883AIncrease construction heightLarge operating radiusBuilding constructionsLoad-engaging elementsCooling towerTower crane

The invention provides a tower crane construction method of a large steel structural air cooling tower. The tower crane construction method comprises the following steps that (S1) two tower cranes are provided and located in an area of the air cooling tower; (S2), linear movement of the tower cranes is achieved through a rail type moving support, further hoisting of a triangular hoisting unit of a circular tapered section is conducted through linear movement and hoisting action of the tower cranes, the two tower cranes conduct symmetrical hoisting, and finally hoisting construction of the circular tapered section is completed; (S3), the positions of the tower cranes are fixed, further hoisting of a triangular hoisting unit of a cylinder section is conducted through action of the tower cranes, the two tower cranes conduct symmetrical hoisting, and after hoisting every layer of the cylinder section is finished, and hoisting of a triangular hoisting unit of an reinforcing ring corresponding to the layer is conducted through action of the tower cranes, so that the reinforcing ring is connected to the inner side of the cylinder section through quick positioning nodes, and the two tower cranes conduct symmetrical hoisting; and finally hoisting construction of the cylinder section is completed.

Owner:SHANGHAI MECHANIZED CONSTR GRP

Steel coil hoisting tool

InactiveCN103626022AHoisting process safetyImprove hoisting efficiencyLoad-engaging elementsPush pullEngineering

The invention relates to a steel coil hoisting tool which comprises two parallel hoisting beams and end plates, wherein the end plates are used for connecting the two hoisting beams and are respectively positioned at both ends of the hoisting beams; each hoisting beam is a c-shaped steel with a long slot; the long slots of the two hoisting beams are opposite; two L-shaped hangers are arranged between the two hoisting beams; the L-shaped hangers are mounted between the two hoisting beams through rollers respectively embedded in the long slots of the two hoisting beams; two rollers are coaxial; through holes are respectively formed in the two end plates; push-pull rods in parallel to the hoisting beams are respectively inserted in the through holes; a plurality of latches are uniformly distributed on the push-pull rods in the axial direction; clamping grooves matched with the latches are formed in the inner sides of the through holes; the two push-pull rods are respectively connected with the two L-shaped hangers; handles perpendicular to the push-pull rods are mounted at the end parts outside the push-pull rods. The steel coil hoisting tool has the advantages of simple structure, convenience in use, firm structure, avoidance for damage to a steel coil, improvement on hoisting efficiency and elimination for potential safety hazards.

Owner:TIANJIN JINWANFANG STEEL STRUCTURE

Central cable surface steel box girder integral type bridge deck crane

PendingCN108439206AImprove stabilityAvoid interference problems that hinder the movement of support trussesBase supporting structuresBraking devices for hoisting equipmentsBridge deckEngineering

The invention relates to the technical field of bridge construction, in particular to a central cable surface steel box girder integral type bridge deck crane. The central cable surface steel box girder integral type bridge deck crane comprises a sliding rail, a supporting truss and hoisting equipment, wherein a sliding device which is slidably connected to the sliding rail is arranged at the lower end of the supporting truss, and a pushing oil cylinder used for pushing the supporting truss to move in the clockwise bridge direction is arranged between the sliding device and the sliding rail; and the crane further comprises a distribution device which is located between the sliding rail and the supporting truss and can rotate around a vertical shaft in the axial direction, the distributiondevice is supported on the lower end of the supporting truss to form a cushion beam structure the width of which is larger than the width of the supporting truss in the transverse direction of a bridge is formed at the lower end of the supporting truss when the distribution device rotates to the transverse direction of the bridge, and the distribution device is suspended on the lower end of the supporting truss and does not influence the moving of the supporting truss in the axial direction of the bridge. According to the integral type bridge deck crane, the structure is simple, operation is convenient to operate, the hoisting efficiency of a steel box girder is improved to a great extent, the problem that the central cable surface is prone to interference of the bridge deck crane transferis solved, the construction time is saved, and great popularization value is achieved.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES

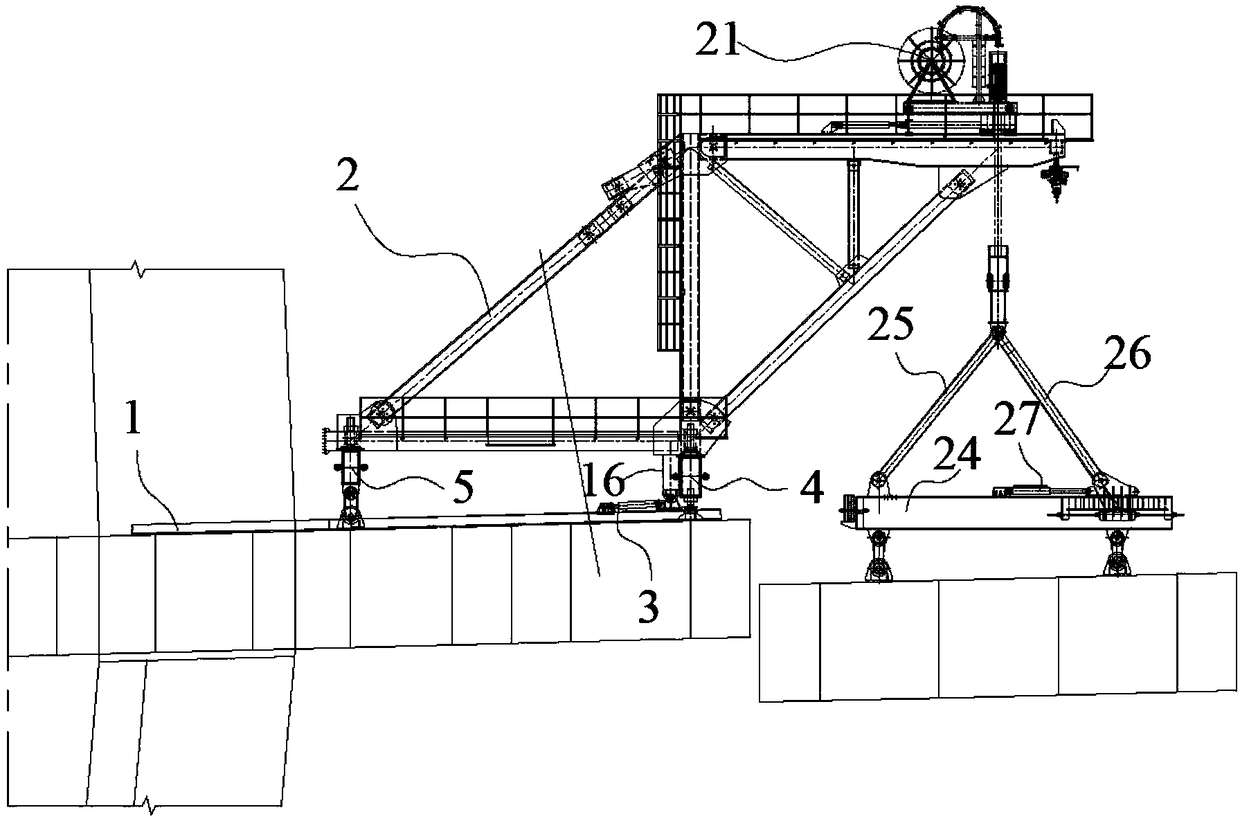

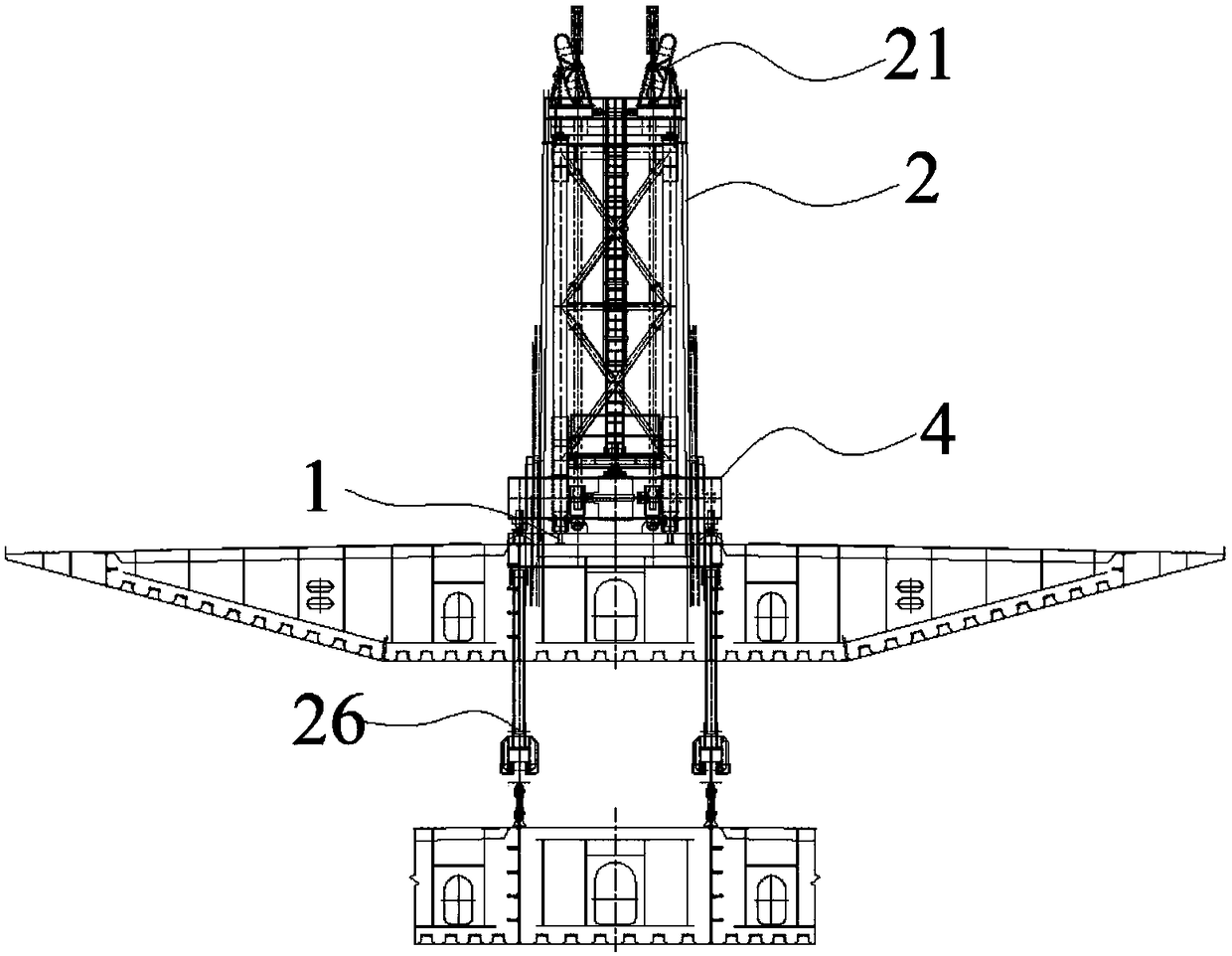

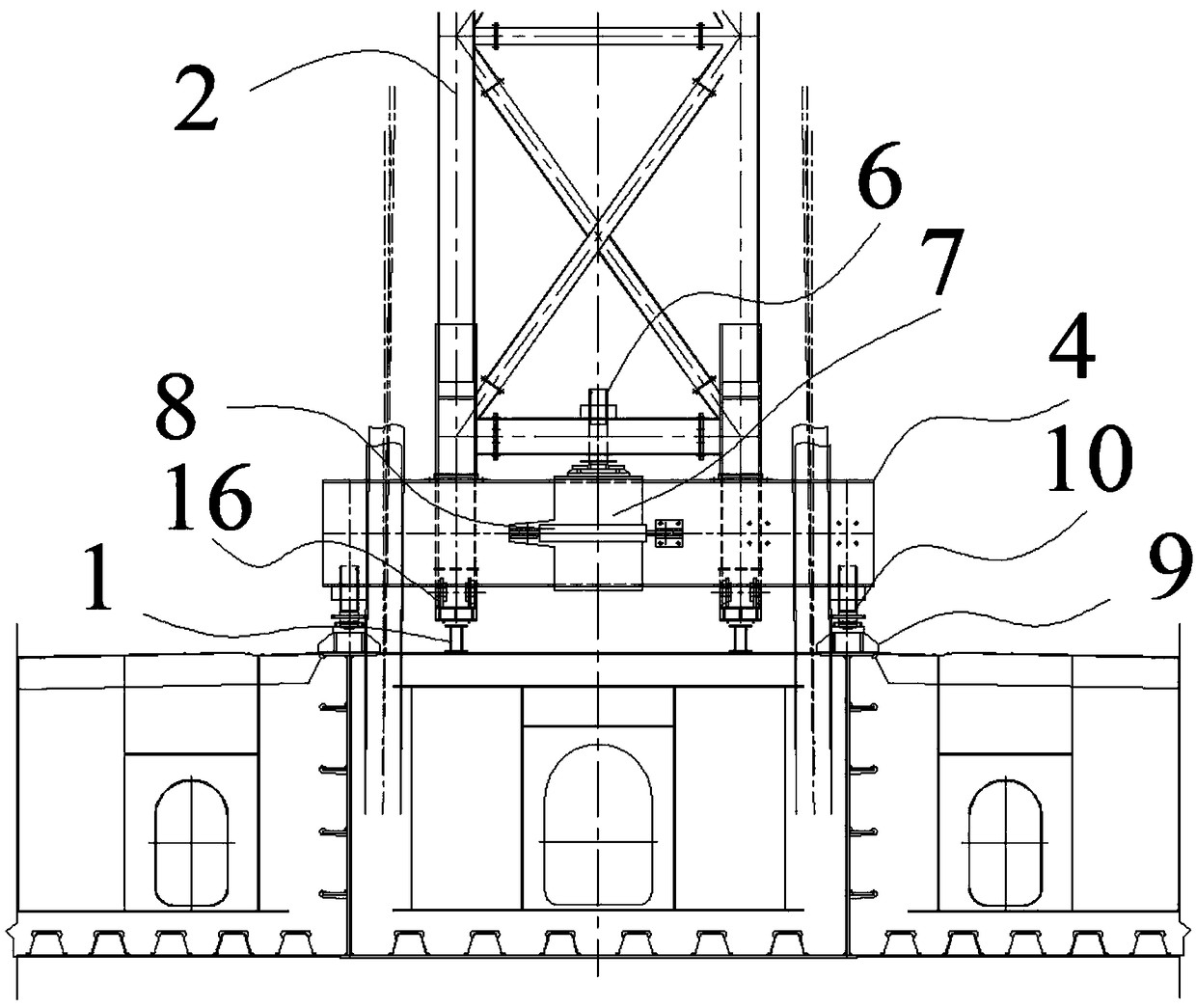

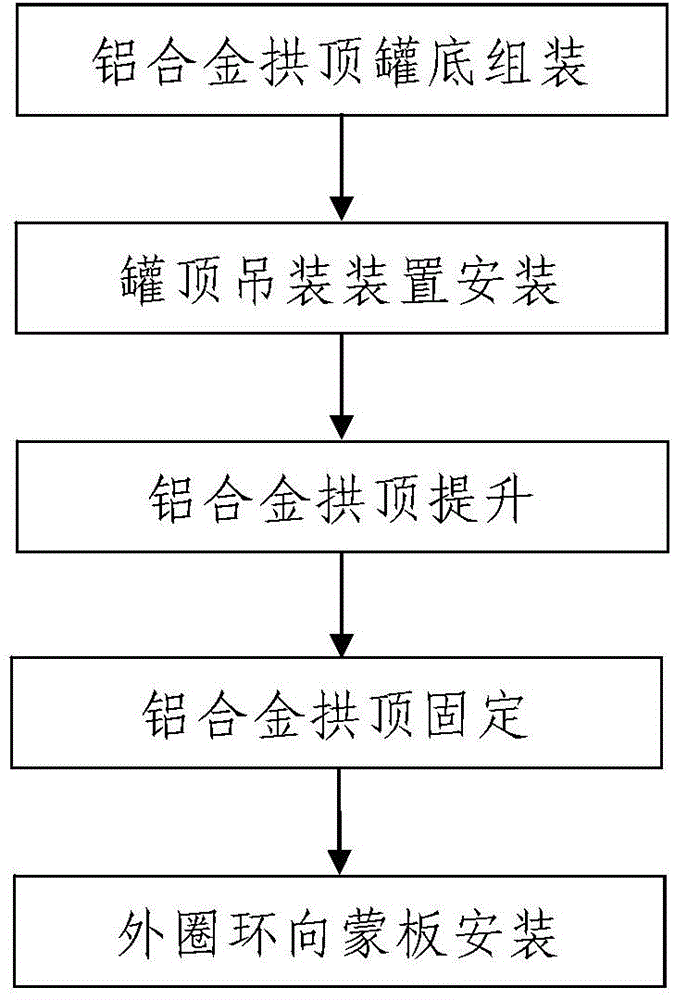

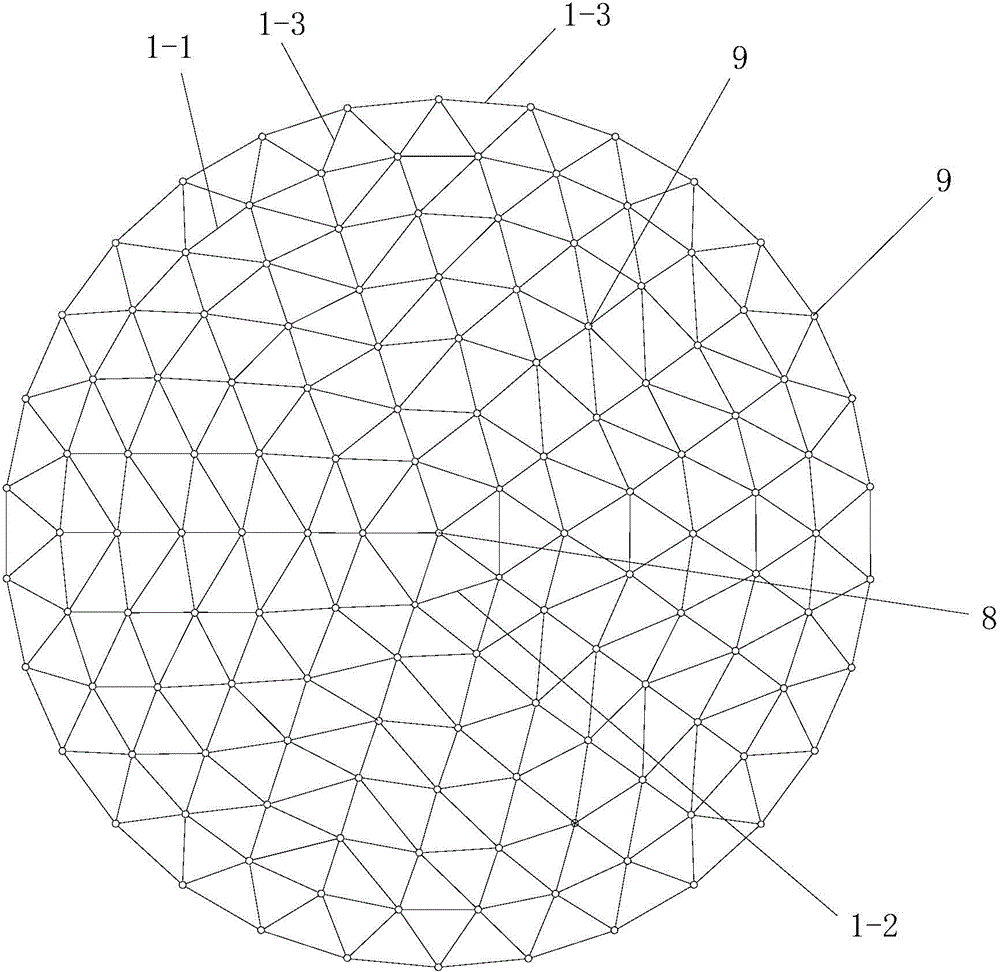

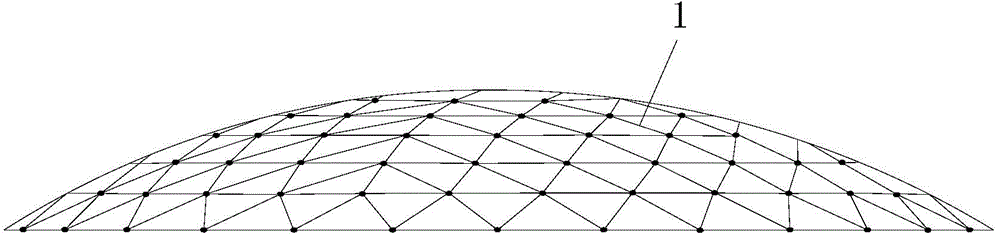

Construction method for single-piece hoisting of aluminum alloy vault of large vertical storage tank

InactiveCN104675171AThe method steps are simpleReasonable designBulk storage containerClerestoryMaterials science

The invention discloses a construction method for single-piece hoisting of an aluminum alloy vault of a large vertical storage tank. The aluminum alloy vault is fitted to the top of the large vertical storage tank in a covering manner; the aluminum alloy vault comprises a support frame and an outer mask covering the support frame; the support frame comprises a central connector and a plurality of ring beams distributed outside the central connector from inside to outside; the outer mask comprises a middle mask and a plurality of circumferential masks; the outermost one of the circumferential masks is an outer circular mask. The construction method includes: 1, assembling the aluminum alloy vault and a tank bottom; 2, mounting a tank top lift, namely, mounting the lift used for hoisting the required vault, outside the upper portion of the tank which is cylindrical; 3, hoisting the aluminum alloy vault; 4, fixing the aluminum alloy vault; 5, mounting the outer circular mask. The construction method has the advantages that steps are simple, the design is reasonable, construction is easier, construction is efficient, construction effect is good and the aluminum alloy vault can be hoisted to the large vertical storage tank simply and quickly.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

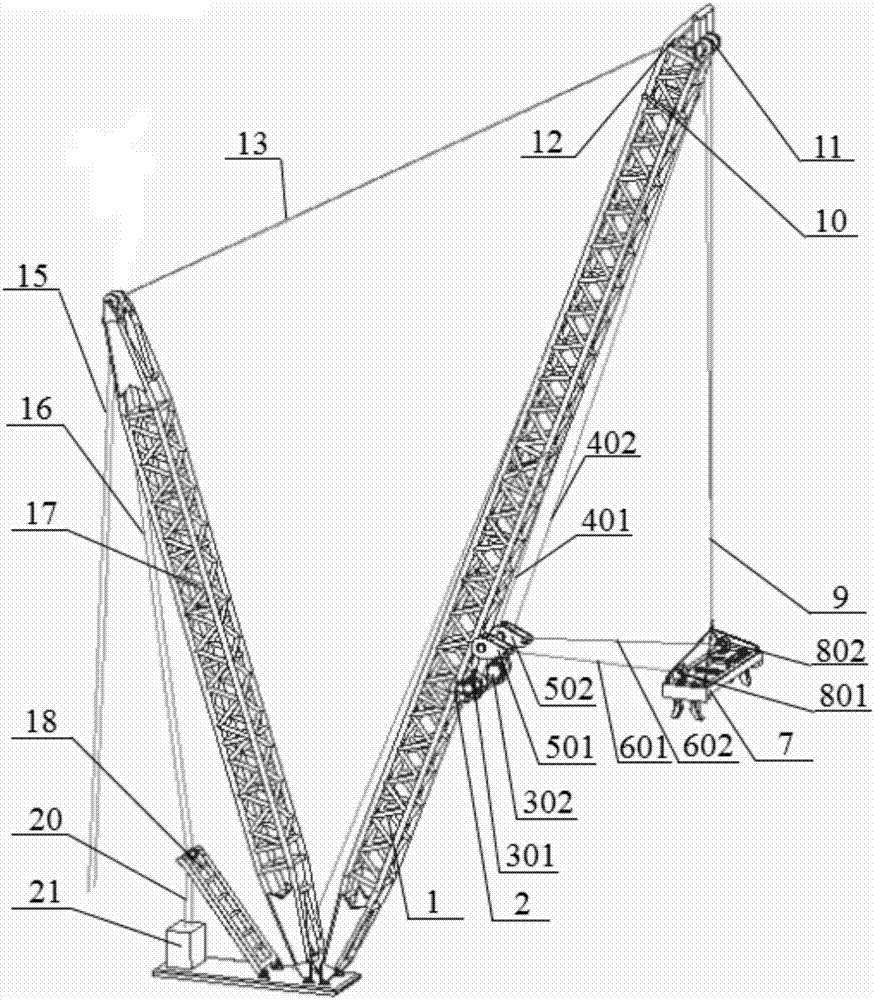

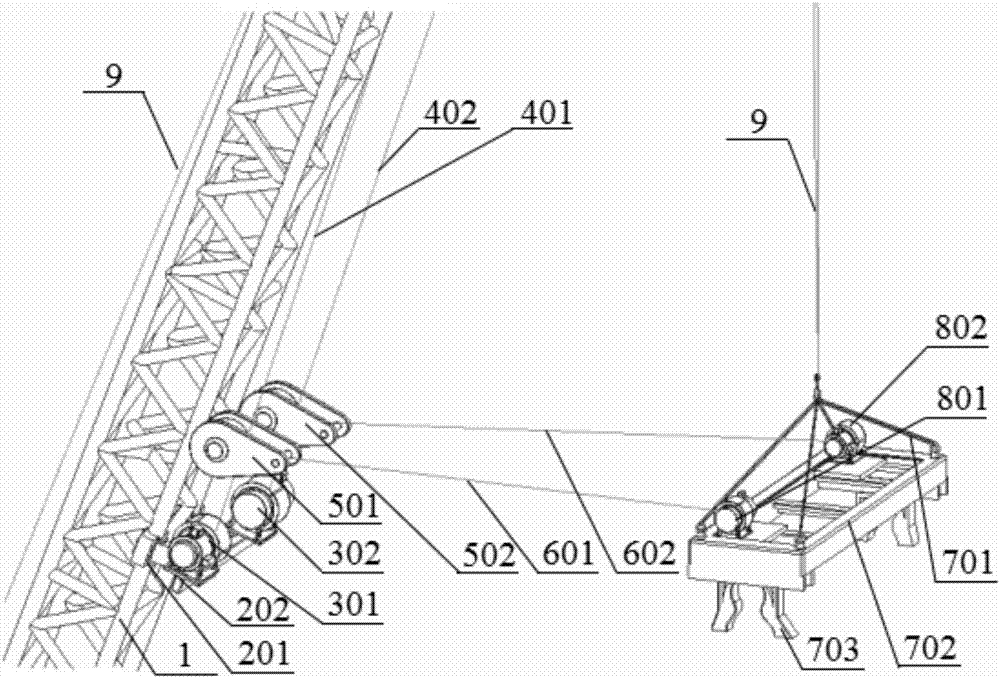

Auxiliary slinging device and method through combination process of a plurality of cranes

The invention discloses an auxiliary slinging device and method through combination process of a plurality of cranes. The auxiliary slinging device comprises an auxiliary winch, an elastic auxiliary suspension arm, an auxiliary suspension rope, a turnable auxiliary rotation support, a connecting base and a connecting device for the cranes, wherein the connecting base is connected with main suspension arms of the cranes; the auxiliary rotation support is connected with the connecting base, and the arm tail of the auxiliary suspension arm is hinged to the auxiliary rotation support; the auxiliary wince is arranged on a rotary table of each crane, the auxiliary suspension rope winds the auxiliary winch , and the auxiliary suspension rope winds around the arm head of the auxiliary suspension arm; the main suspension ropes of the cranes wind around the arm head of the main suspension arm to be connected with the auxiliary suspension arm; the connecting device for the cranes is connected with the connecting base, and the auxiliary hoisting method adopts the auxiliary slinging device to sling heavies. The auxiliary slinging device and method, disclosed by the invention, can realize hoist in a large working space for the cranes under the condition of not enlarging the length of an elevating arm, so that the destabilizing resistance and the hoisting stability of the cranes are improved, and the hoisting efficiency is improved.

Owner:CHINA UNIV OF MINING & TECH

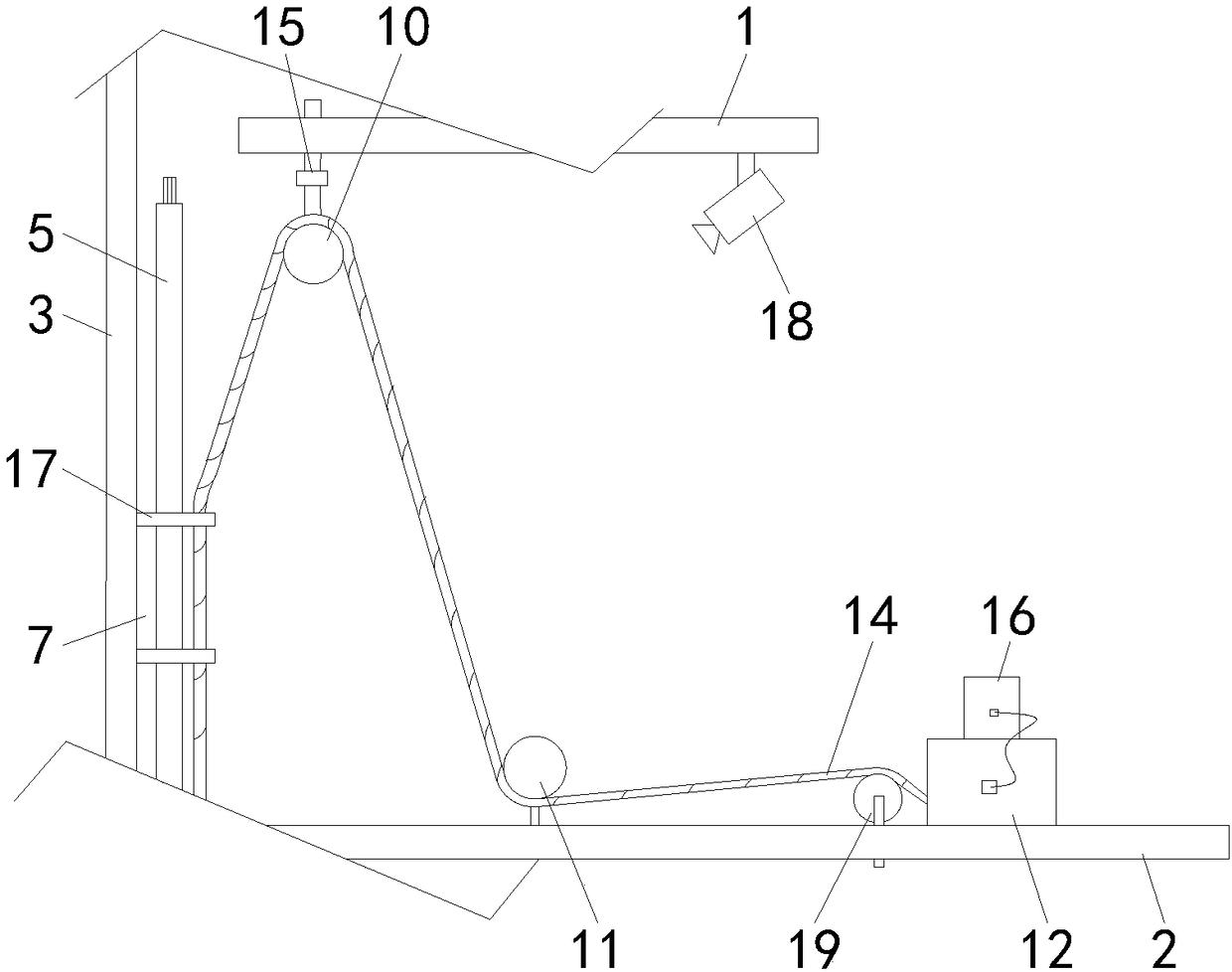

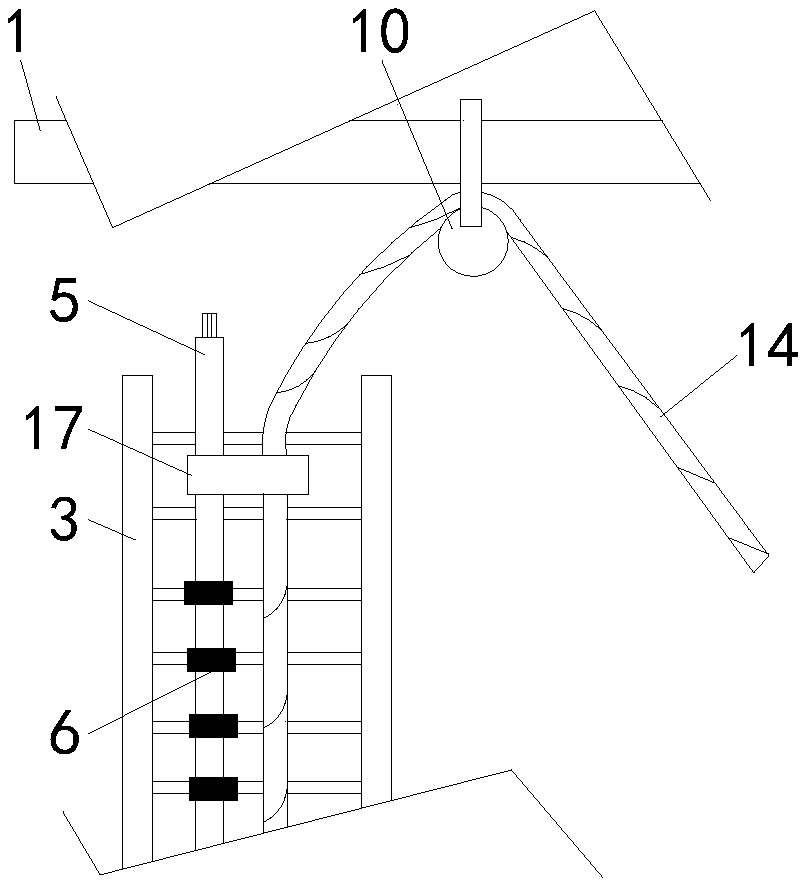

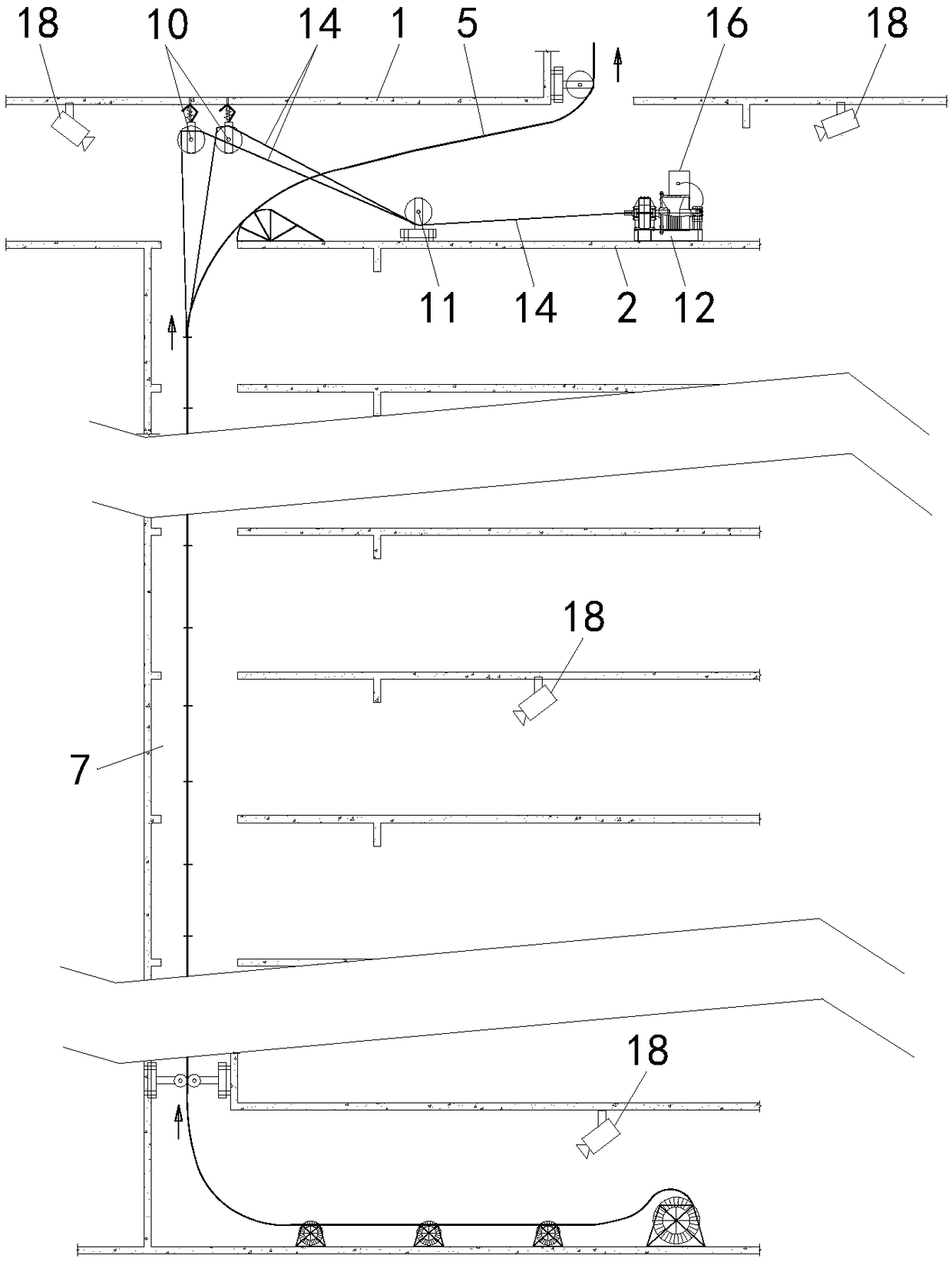

Wirerope-accompanying cable vertical hoisting system and construction method thereof

PendingCN108516464AIncreased breaking stressAvoid breakingPortable liftingSafety gearEngineeringHigh pressure

A wirerope-accompanying cable vertical hoisting system and a construction method thereof relate to the technical field of hoisting equipment. Due to lack of monitoring or intelligent spacing measuresin a traditional hoisting mode of high voltage cables in existing super high-rise buildings, critical engineering accidents are caused and high voltage cable laying is difficult. In allusion to the above problems, the wirerope-accompanying cable vertical hoisting system of the invention comprises a first pulley, a second pulley, a hoist, a weight sensing device, a gravity stopper and a controller,wherein the first pulley is close to a cable well and installed at the bottom of a top floor; the second pulley is installed at the bottom flour and is arranged in a staggered manner with the first pulley; the hoist is fixed at the bottom floor and is arranged at interval with the second pulley, and a wire rope of the hoist successively winds second and first pulleys and is arranged in parallel with and fixedly connected with the high voltage cable; the weight sensing device is installed at the top of the first pulley and is used for converting a tension signal of a wire rope carrying the high voltage cable during the hoisting process into an electrical signal; the gravity stopper is disposed at the bottom floor and is used for cutting off power of the hoist; and the controller is respectively in signal connection with the hoist, the weight sensing device and the gravity stopper.

Owner:SHANGHAI INSTALLATION ENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com