Patents

Literature

193results about How to "Shorten the lifting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

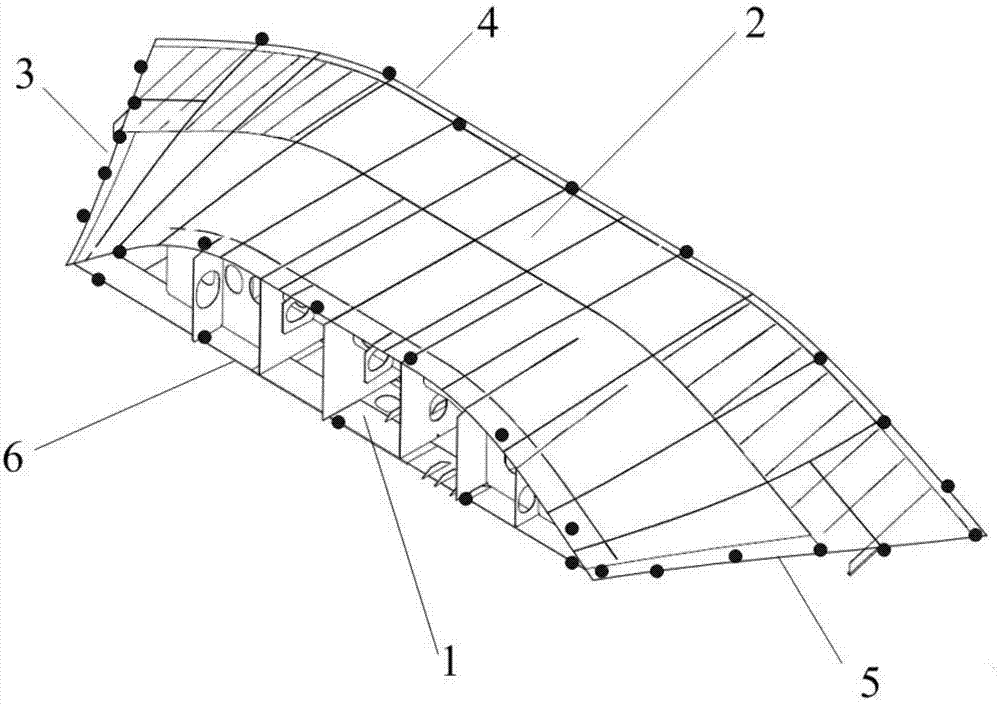

Production technology of hatch coaming and hatch cover

InactiveCN101362505AReduce the number of liftingReduce workloadHull decksVessel hatches/hatchwaysManufacturing technologyHydraulic equipment

Owner:江苏熔盛重工有限公司 +1

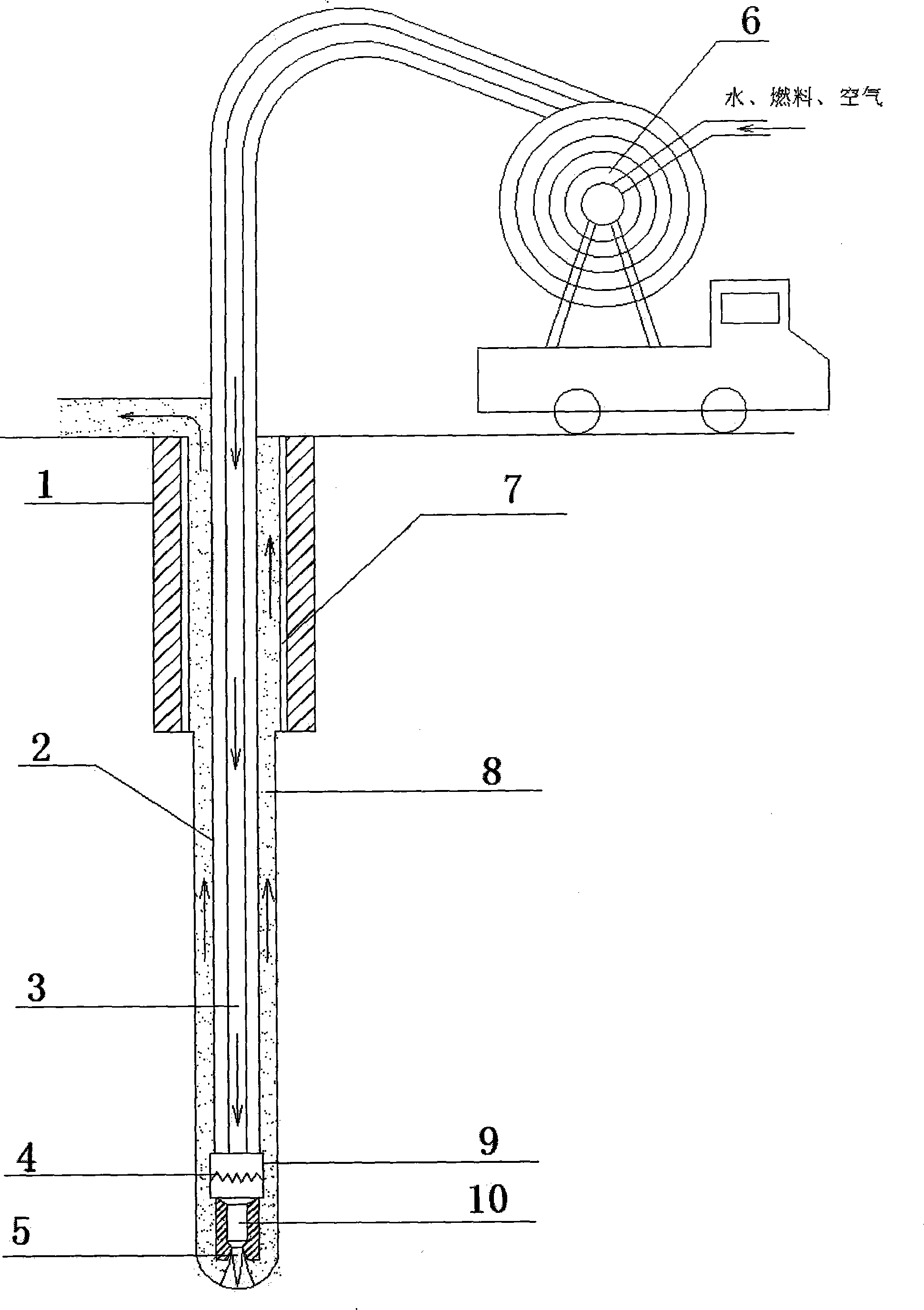

New well drilling method for efficient rock breaking by means of heating power jet flow

ActiveCN103790516AEfficient rock breakingIncrease profitLiquid/gas jet drillingElectric cablesHeating power

The invention relates to a new welling drilling method for efficient rock breaking by means of heating power jet flow, and a complete set of construction scheme. According to the system composition, a continuous coil tubing unit, an electric measuring instrument truck, a cable, an air injection pipeline, a fuel injection pipeline, a fuel reaction cavity, a heating power jet flow nozzle, a ground pump set and the like are included. According to the technology, on the basis of the principle that the continuous heated surfaces of rocks crack until the rocks are decomposed in a splitting mode, the heating power jet flow acts on the rocks on the deep well hard formation, the non-contact efficient rock breaking is achieved under heat transfer and impact force of high-temperature and high-pressure fluid media, and the energy utilization rate of the well bottom is improved; the technological process is simple, the continuous oil tube well drilling technology is combined, a drill bit does not need to be replaced, the time of the tripping operation is shortened, abrasion to a tubular column is reduced, and the cost of the drilling operation is reduced. According to the new welling drilling method for efficient rock breaking by means of heating power jet flow, the heating power jet flow technology is creatively guided into the continuous oil tube well drilling, popularization and application of the continuous tube technology are facilitated, and oil and gas resources are efficiently exploited.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

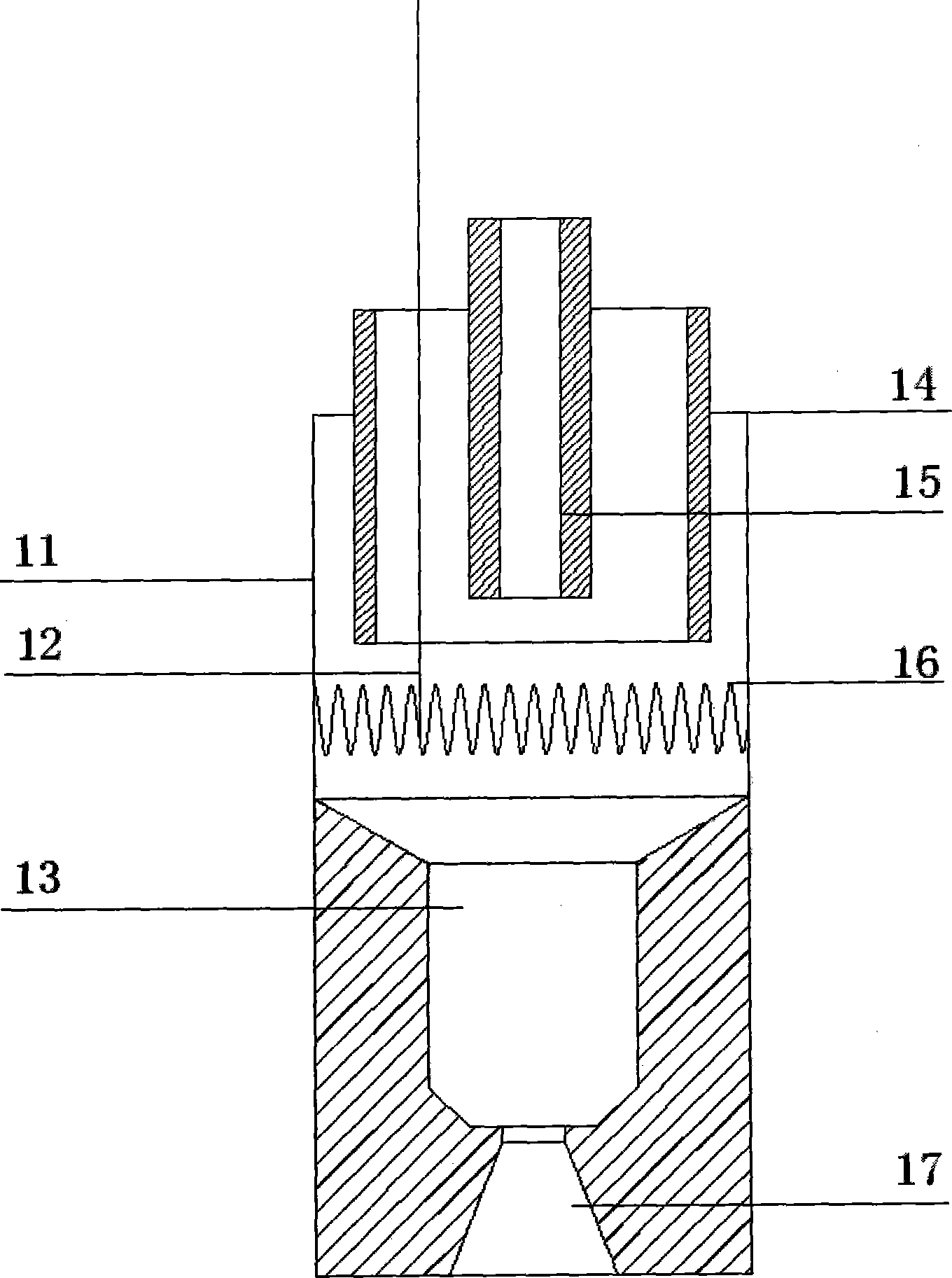

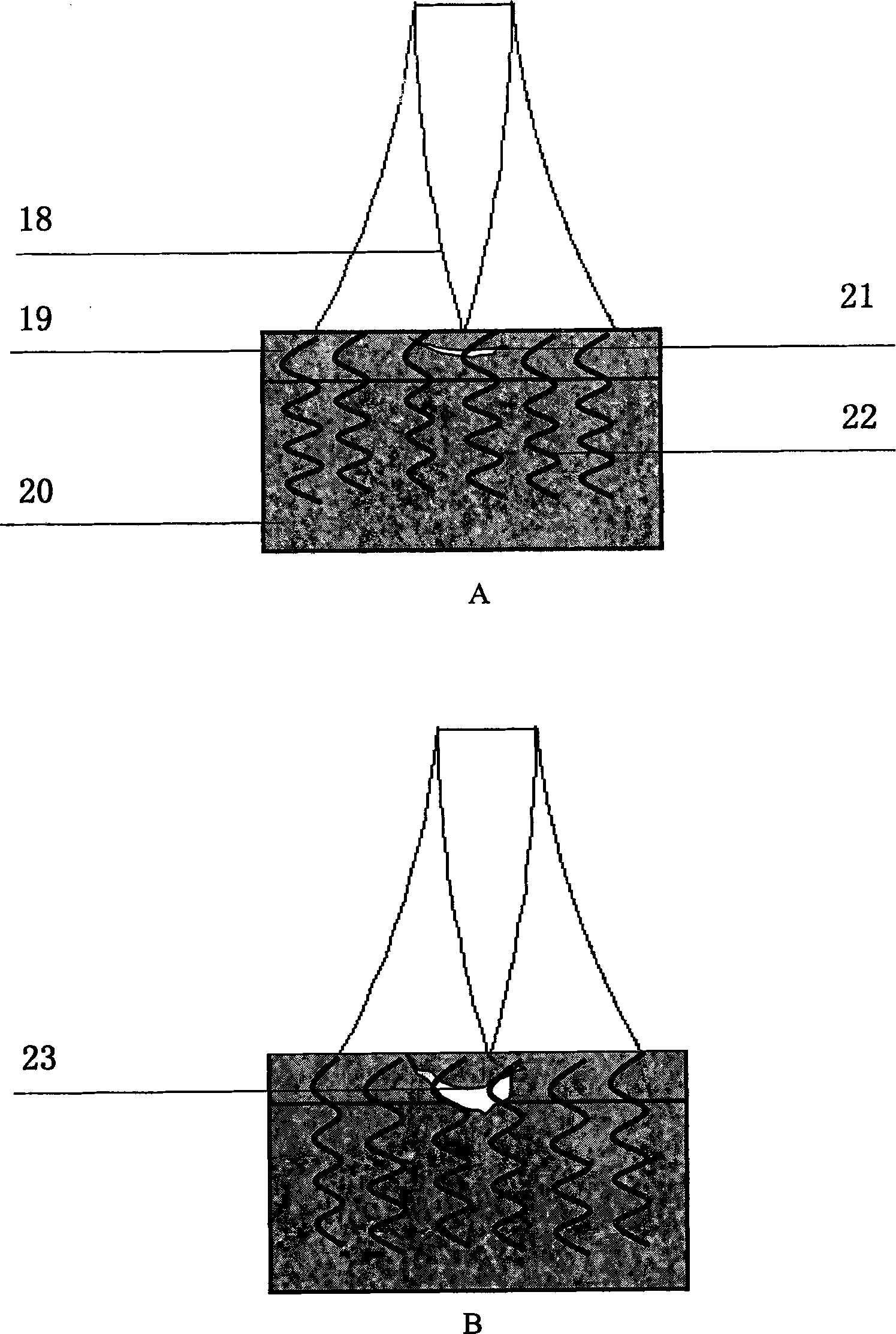

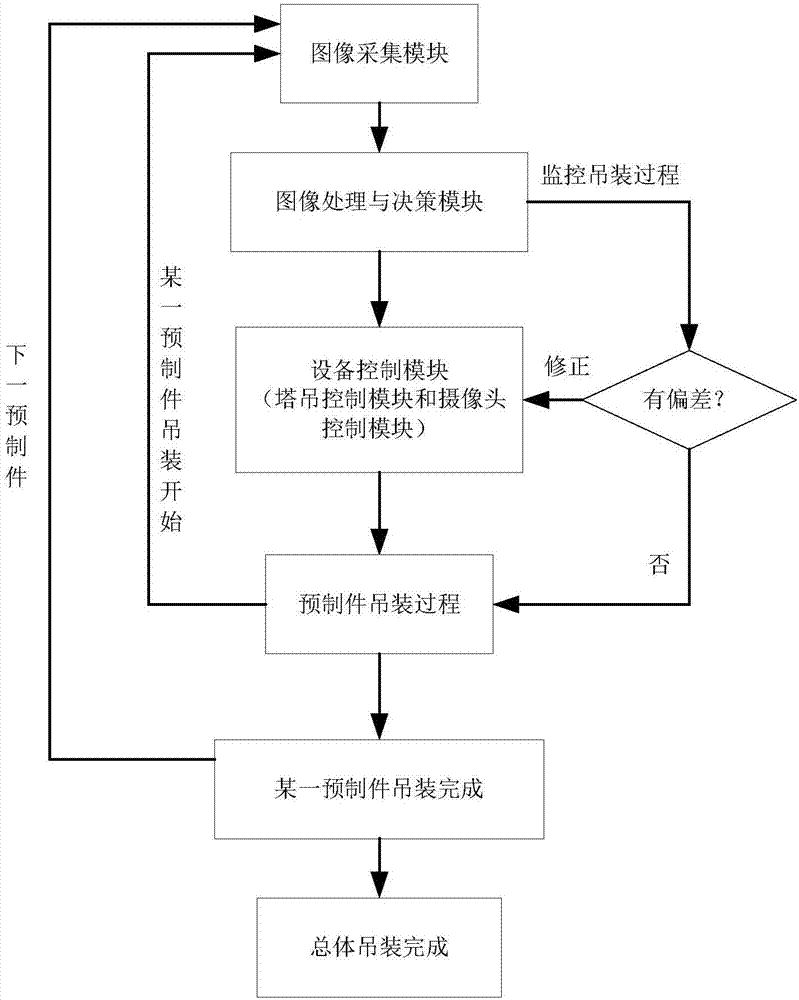

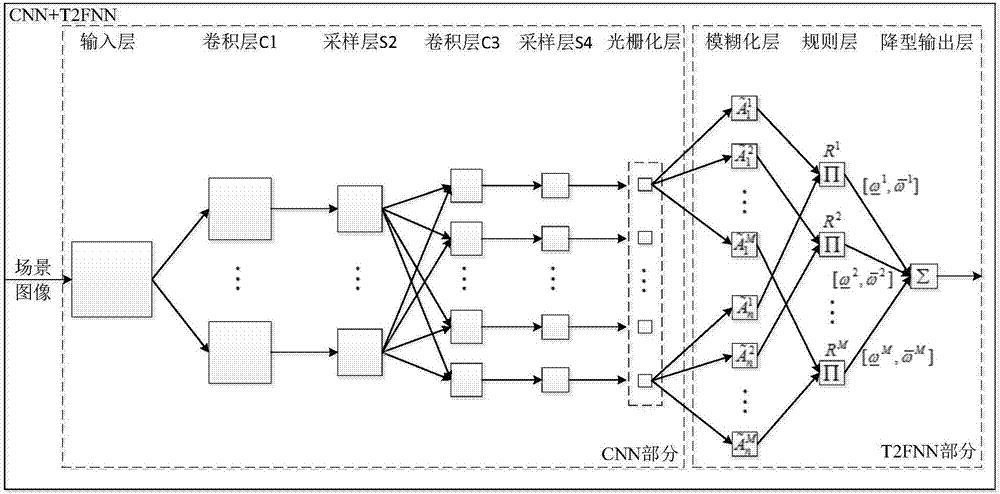

Fabricated type building intelligent hoisting method and system based on machine vision

ActiveCN106966298AImprove hoisting efficiencyImprove accuracyImage enhancementImage analysisIntelligent lightingMachine vision

The invention discloses a fabricated type building intelligent hoisting method and a system based on machine vision. The fabricated type building intelligent hoisting system based on the machine vision comprises an image gathering module, an image processing and decision module and a device control module, the image processing and decision module and the image gathering module are communicated, and the device control module and the image processing and decision module are communicated. According to the fabricated type building intelligent hoisting method and the system based on the machine vision, the machine vision replaces the reliance on human vision in the hoisting process of the fabricated type building. Obstacle recognition is conducted in a complex fabricated scene through a deep learning model of a convolutional neural network and a type-II fuzzy neural network by using the machine vision, prefabrication hoisting path planning is conducted by using ant colony algorithm, and consequently, the movement of equipment on the scene is controlled according to the decision result. The fabricated type building intelligent hoisting method and the system based on the machine vision analyze and obtain the best scheme from the complex scene by using the camera instead of the human eye, can better plan the prefabrication hoisting path, greatly improve the hoisting efficiency and accuracy of the fabricated type building, realize the intelligent hoisting of the fabricated type building, and improve the shortcomings of artificial hoisting.

Owner:日照安泰科技发展有限公司

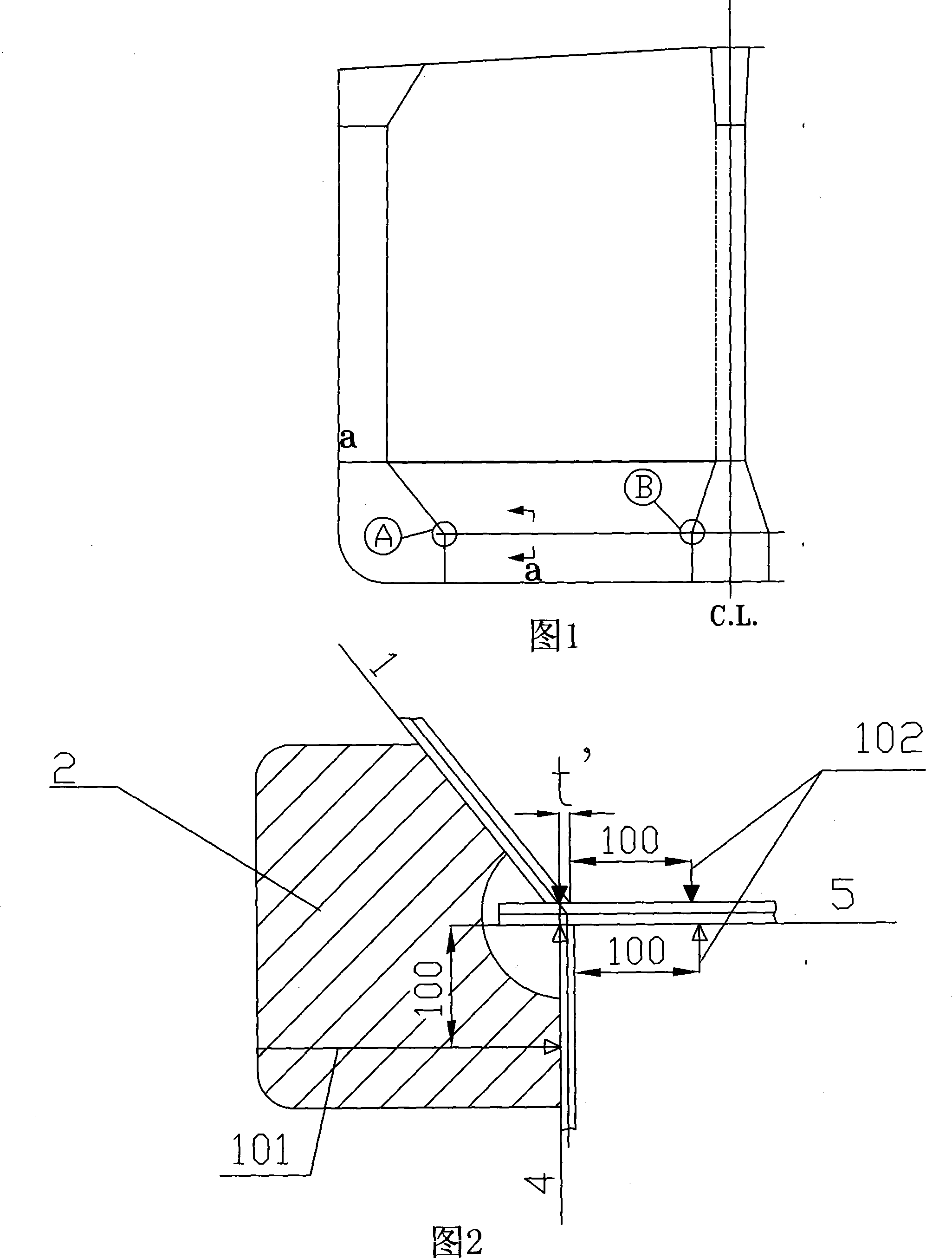

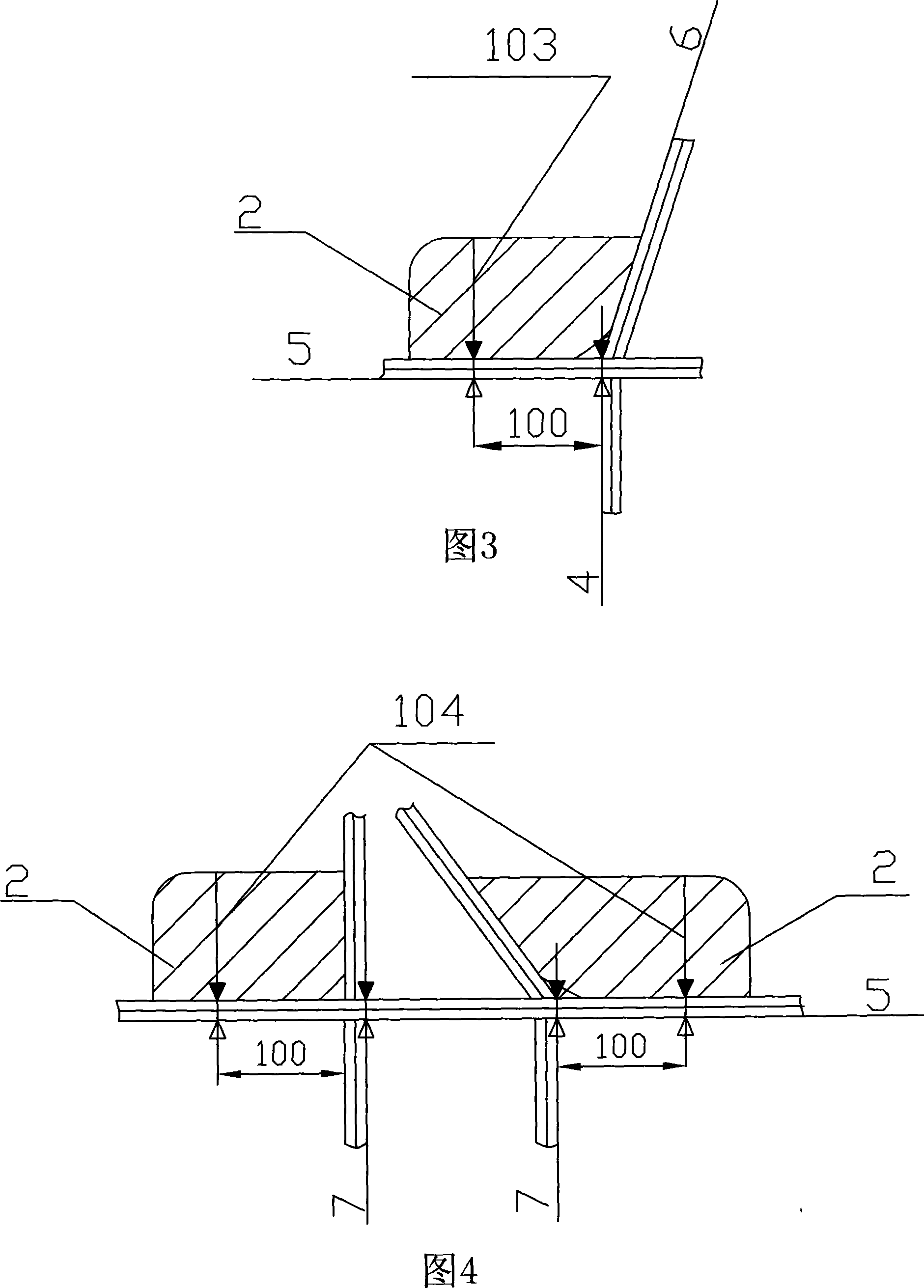

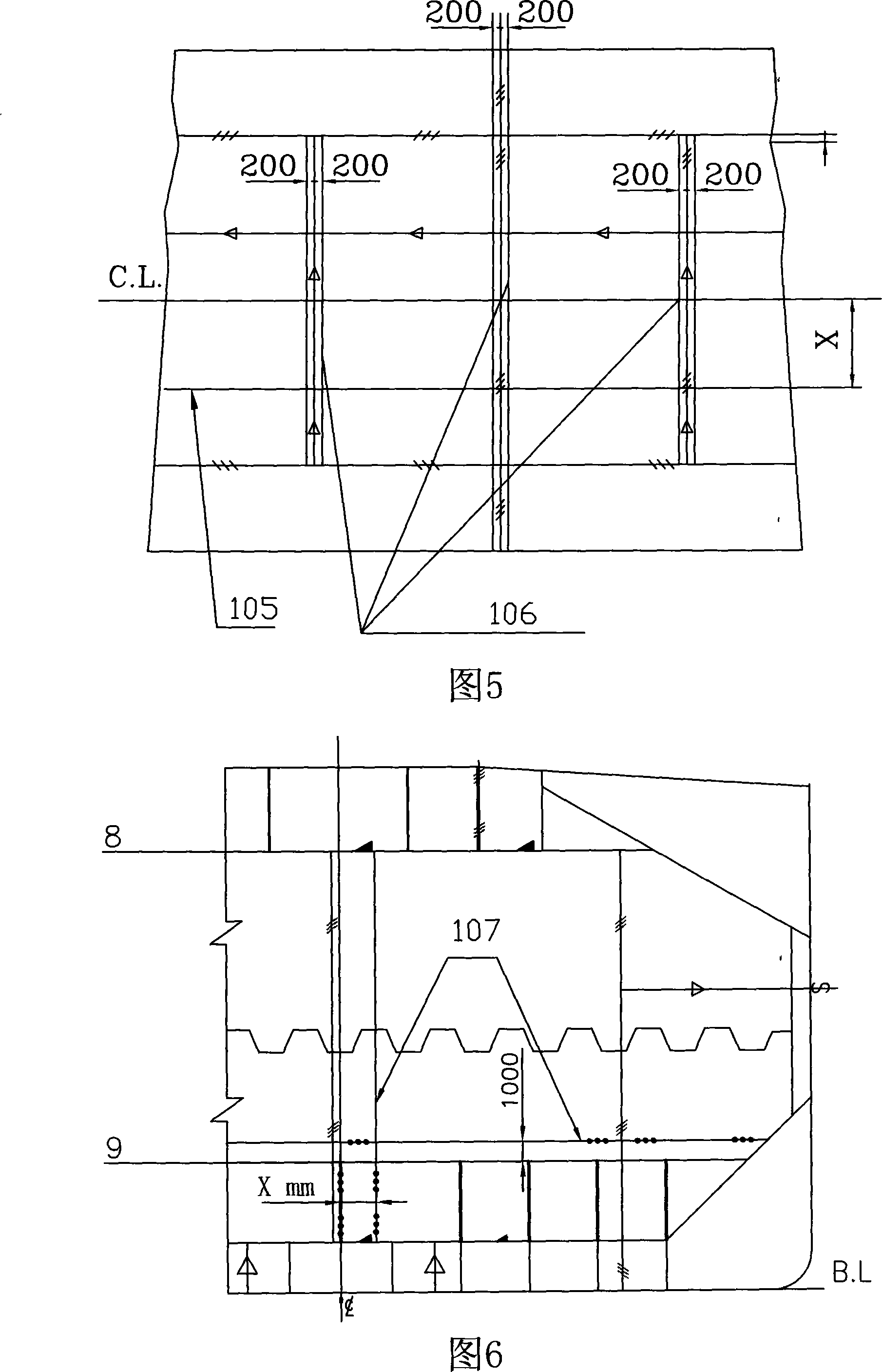

Method for rapidly detecting accuracy of position seaming in shipbuilding process

The invention discloses a method of rapid detection of precision of the position and closure in the process of ship building, which is mainly used to detect the structure and the closure precision of block assembly, and the steps include: before the closure, presetting an assembly position line which is used for ensuring the position of closure on to-be-assembled plates or a truss; before position closure, arranging an another reference line parallel to the assembly position line on one side of the assembly position line on assembled plates or the truss via equidistance; when positioning to assemble, detecting the location precision of the reference line. The invention increases the precision and speed of the block assembly and position closure through the arrangement and application of the reference line (check line), thereby reducing the workload of trimming. Experiments have proved the invention, such as that in the sectioned position closure of vertical wall and horizontal wall of each ship body, the hoisting time of the method is saved by nearly one hour, and the trimming rate of 60% in the existing implementing method is reduced to 20%.

Owner:DALIAN SHIPBUILDING IND

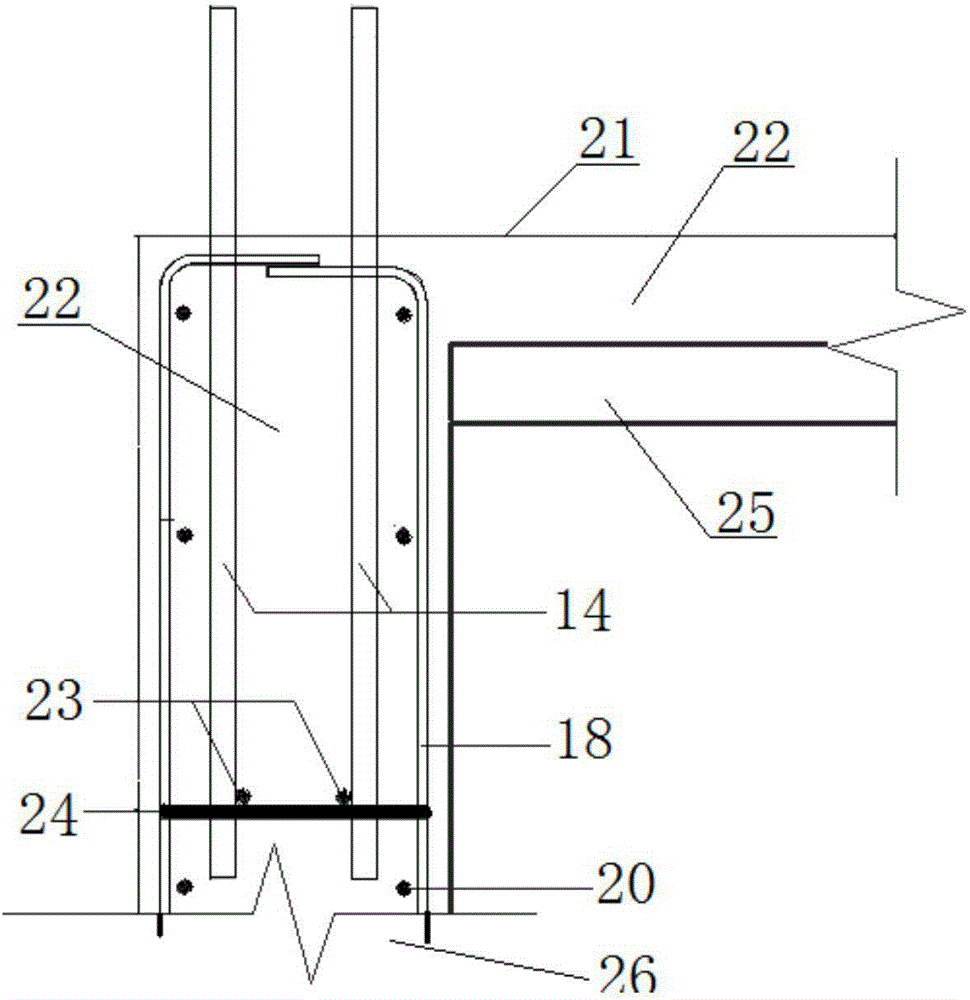

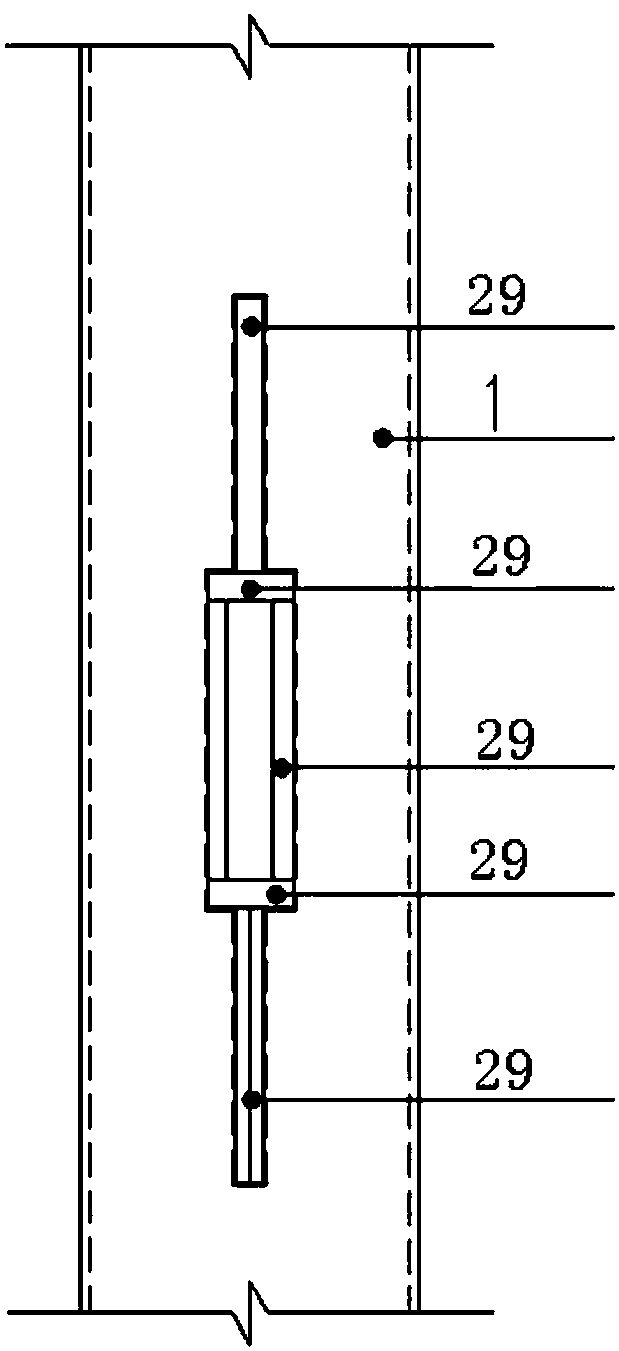

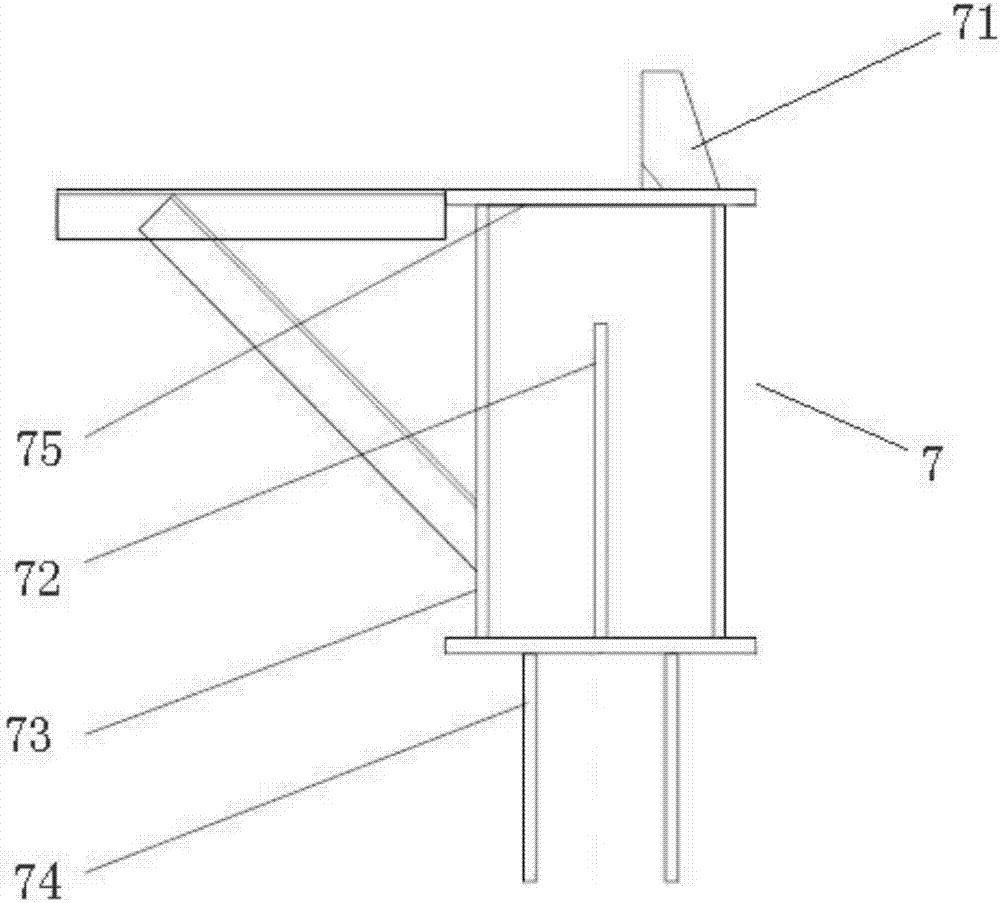

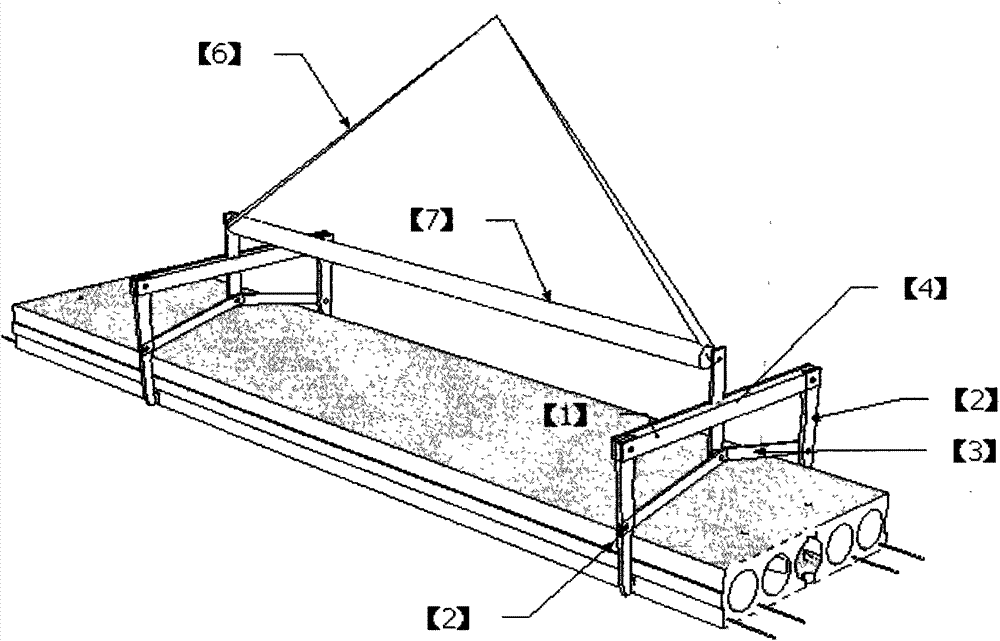

Positioning and reinforcing system and method for assembly type building cast-in-place connection layer reserved reinforcing steel bar

ActiveCN106639327ANo waste of materialSimple and efficient operationBuilding material handlingRebarShear wall

The invention discloses a positioning and reinforcing system and method for an assembly type building cast-in-place connection layer reserved reinforcing steel bar. The system comprises an axial positioning and detecting device and an anti-deflection reinforcing device. The axial positioning and detecting device is used for detecting and positioning the reserved reinforcing steel bar before casting, and the anti-deflection reinforcing device is used for reinforcing the positioned reserved reinforcing steel bar and preventing the reserved reinforcing steel bar from deflecting and inclining in the casting process. Positioning precision of the reserved reinforcing steel bar and non-deflection during concrete casting are guaranteed, cyclic and repeated use can be achieved, energy conservation and environmental protection are achieved, materials are not wasted, connection modes are all physical connection, operation is easy and quick, subsequent installation of a pre-cast shear wall is benefited, time for hoisting the wall in place is shortened, installation precision of the wall is improved, the installation quality is guaranteed, the construction cost is effectively reduced, and the construction period is shortened.

Owner:CHINA FIRST METALLURGICAL GROUP

Method for drawing hull section margin line

ActiveCN104724250AReduce breakageShorten the manufacturing cycleVessel partsMarine engineeringTotal station

The invention relates to the technical field of ship machining, in particular to a method for drawing a hull section margin line. The method includes the following steps of conducting calculation, wherein the theoretical data values of required points are found out on a hull section; arranging a station, wherein a total station is erected; drawing a frame line; drawing points, wherein the actual positions of the required points on the hull section are found out through the total station and connecting the points into a line, wherein all the points found out on the hull section are connected in a smooth mode. By means of the method, drawing of the section margin line can be finished quickly, and meanwhile the hoisting time is reduced.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Technology for hoisting LNG liquefied gas transport ship liquid tanks to hold

The invention relates to a technology for hoisting LNG liquefied gas transport ship liquid tanks to a hold. The hoisting technology can hoist a first liquid tank and a second liquid tank successivelyafter parts on a hull are closed to form a whole body. The hoisting technology includes the following steps: (1) performing preparation; (2) cleaning a surface of the first liquid tank; (3) trying hoisting the first liquid tank; (4) horizontally putting the first liquid tank to a guide device; (5) putting the first liquid tank in a saddle and pressing a die; (6) pouring epoxy resin to the saddleand a wood block; (7) finishing the operation; and (8) preparing to hoist the second liquid tank. The advantages of the invention are that the hoisting difficulty is lowered, and the positioning precision of liquid tank hoisting and the hoisting efficiency can be improved; the whole hoisting technology optimizes tool use and labor arrangement during a transport ship liquid tank hoisting process; the safety can be ensured; and safe and reliable operation for hoisting the liquid tanks to the hold can be ensured.

Owner:南通中集太平洋海洋工程有限公司

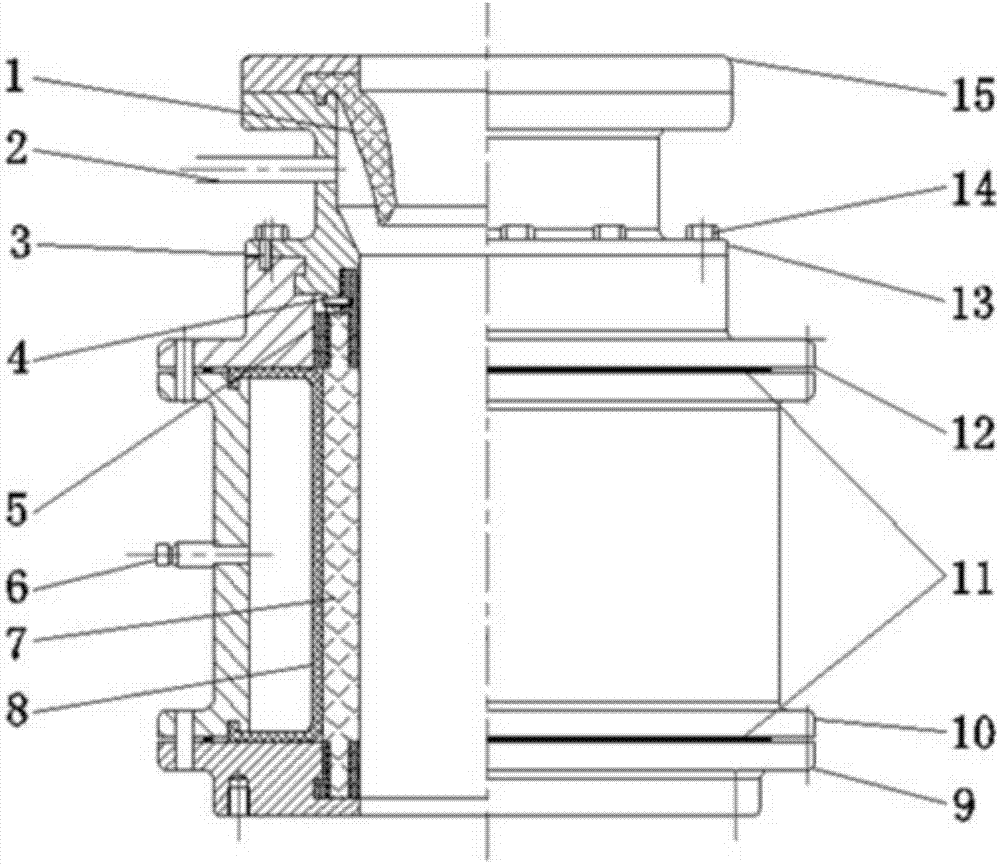

Annular blowout preventer

The invention discloses an annular blowout preventer. The annular blowout preventer comprises a first shell body, a gas bag and a gas inflating opening. According to the technical schemes of the annular blowout preventer, gas serves as a power medium to push the gas bag to embrace an oil tube tightly, the gas is inflated between the first shell body and the gas bag through a gas inflating valve, the gas bag is deformed and embraces the oil tube tightly, so that annular sealing between the oil tube and a sleeve tube is achieved; when the oil tube is needed to be lifted upwardly during minor repairing operation, due to the fact that compressibility of the gas is good, the gas bag can be squeezed by an oil tube coupling, the gas located between the gas bag and the first shell body is squeezed and deformed, so that space in the middle of the gas bag allows the oil tube coupling to pass through directly; and compared with the prior art, time for waiting opening and closing of a hydraulic annular blowout preventer is saved, so that oil tube uplifting time in minor repairing operation is shortened, and time of minor repairing operation is reduced accordingly, the efficiency of minor repairing operation is improved, and reservoir in non-well killing operation is protected.

Owner:CHINA UNITED COALBED METHANE +1

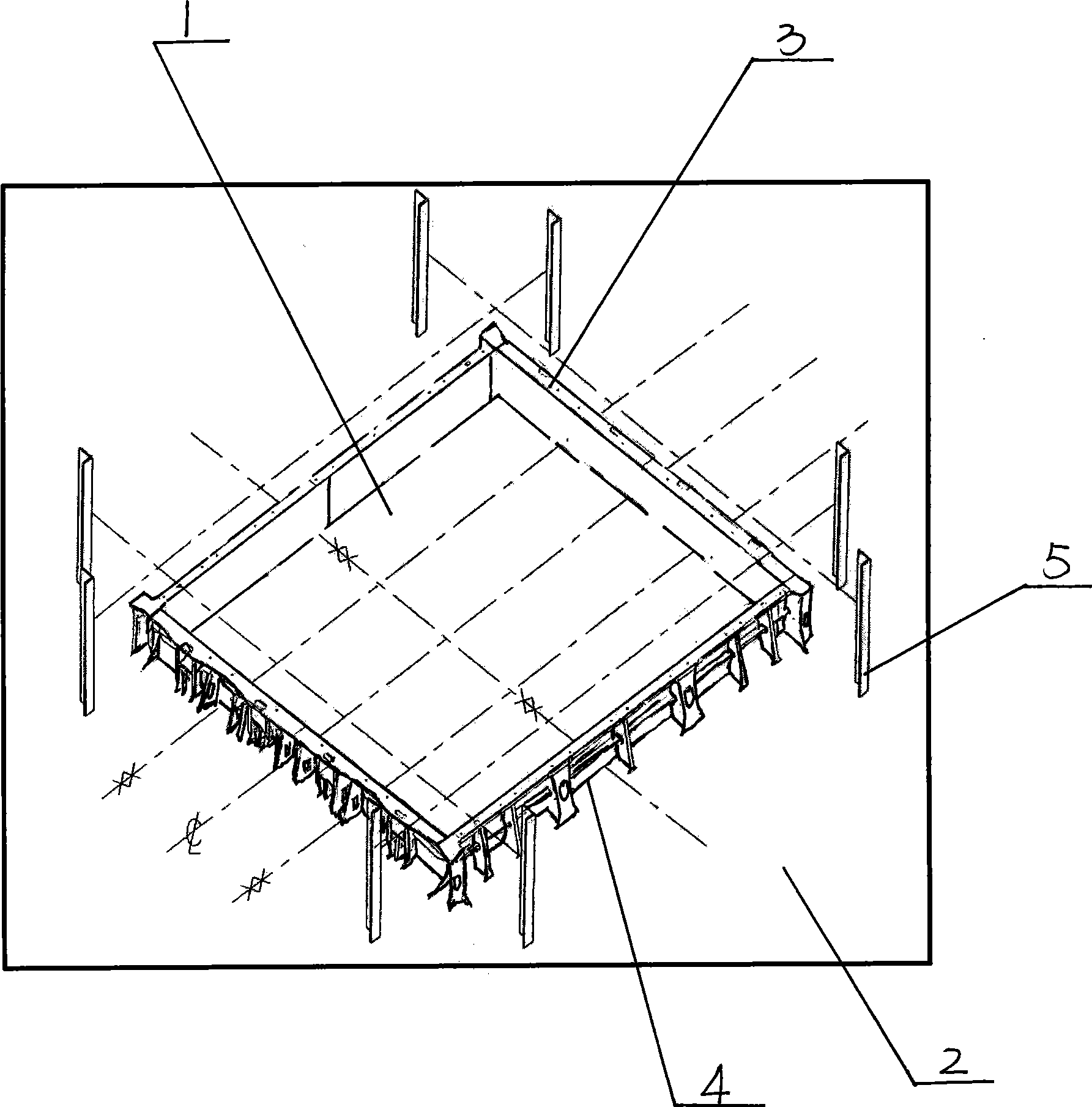

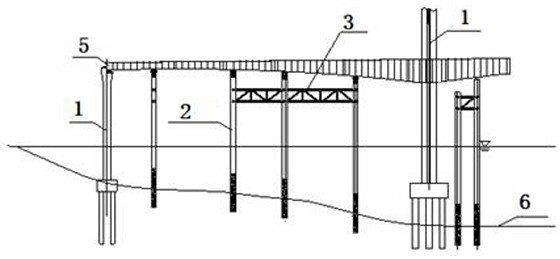

Grid-type formwork supporting and operating platform for construction of water tank on top of inverted-cone water tower

ActiveCN103291116AEasy to buildSave construction and maintenanceForms/shuttering/falseworksTowersSupporting systemArchitectural engineering

The invention relates to a construction device, in particular to a grid-type formwork supporting and operating platform for construction of a water tank on the top of an inverted-cone water tower. The grid-type formwork supporting and operating platform is characterized in that a steel-pipe derrick is erected at the center of a cylinder of the water tower, a girder of the derrick is 5 m higher than the top of the water tank of the water tower, an inverted-cone steel grid is mounted around a ring joist of the water tank, suspending ends of a main truss of the grid are connected with a ring beam outside the girder of the derrick through steel wire ropes, and thus, the stable and safe overhead cast-in-situ water tank formwork supporting system and operating platform are formed. By the grid-type formwork supporting and operating platform which is mainly used for construction of the water tank on the top of the inverted-cone water tower, difficulty in construction of the inverted-cone water tower is overcome, and problems of long construction period, low construction efficiency, high equipment investment cost and the like in the prior art are solved.

Owner:CHINA NO 15 METALLURGICAL CONSTR GRP

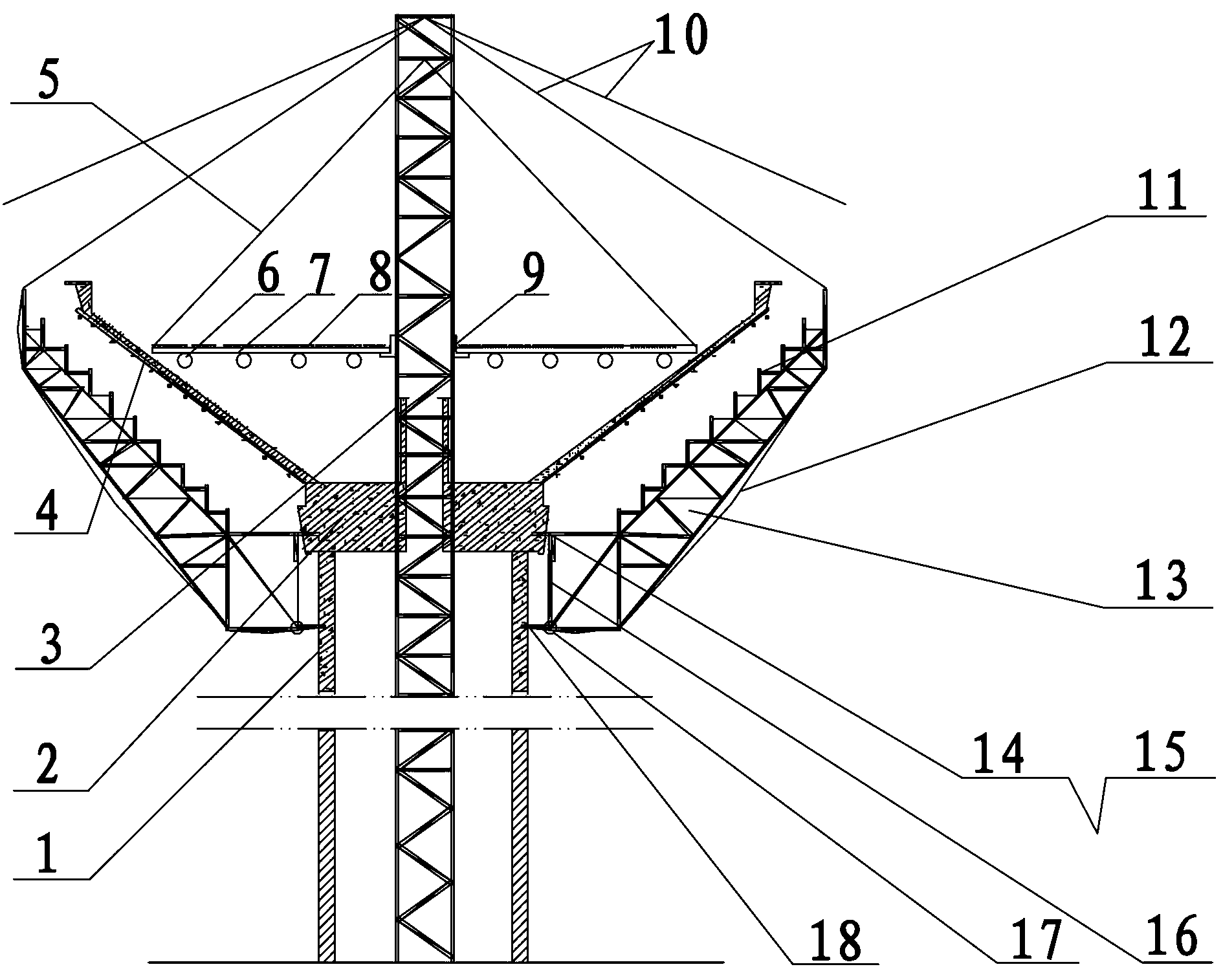

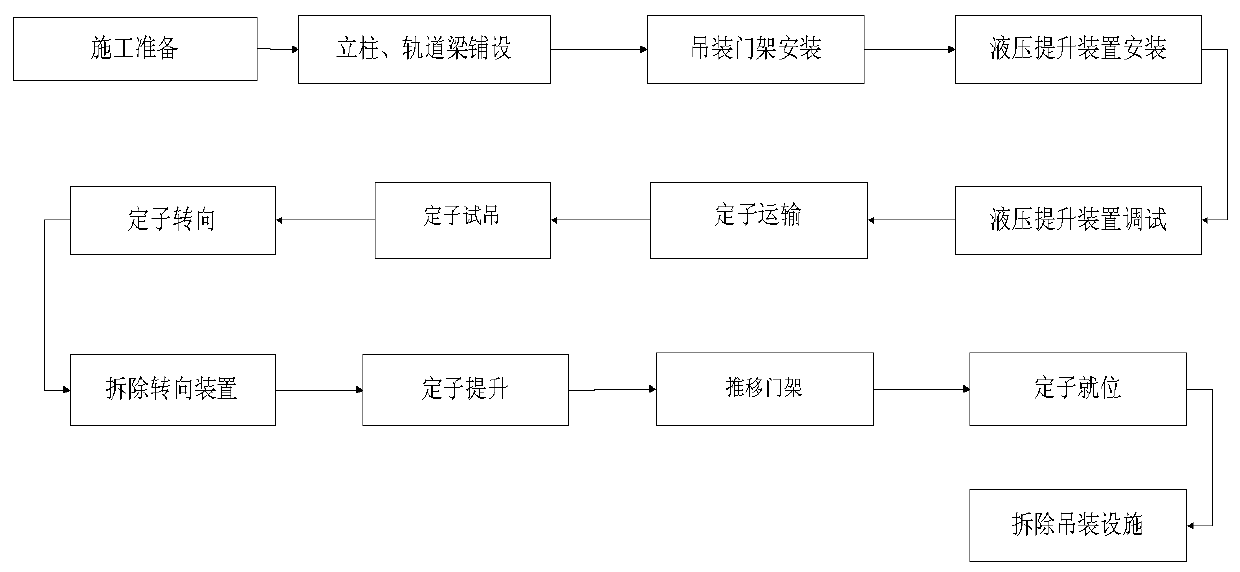

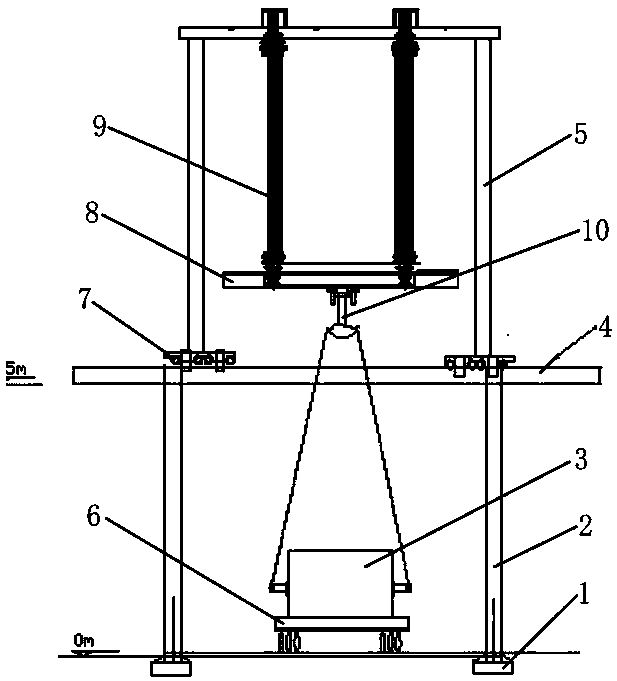

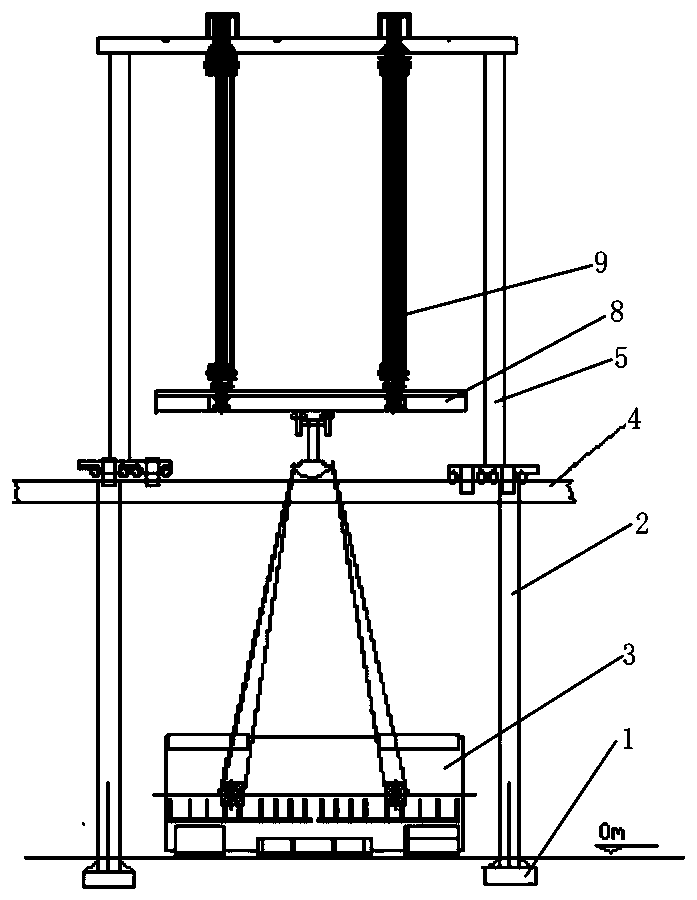

Construction method for hoisting novel phase modifier based on portal frame and Laoxinge device

ActiveCN110407097AChange widthAchieve migrationManufacturing dynamo-electric machinesLoad-engaging elementsButtressEngineering

The invention discloses a construction method for hoisting a novel phase modifier based on a portal frame and a Laoxinge device. Construction preparation and basic treatment are conducted; track beamsupports are arranged and reinforced; track beams are placed; the track beams are arranged in two columns on steel buttresses and fixed through bolts; a portal frame traveling mechanism is placed, anda portal frame is mounted; a hydraulic hoisting device is mounted and arranged; a hoisting device is perfected and debugged; a stator is unloaded and steered; the hydraulic hoisting device is arranged again; the stator is hoisted in position; and hoisting equipment is dismounted. The track beams are laid between a phase modifier base platform and a hoisted object, the Laoxinge device are matchedwith the portal frame to travel on the track beams, the effect that heavy objects are hoisted in position in factories without heavy hoisting equipment in a narrow space is achieved, vertical lifting,lowering, back-and-forth movement and rotation operation of the heavy objects can be completed, and the problems that in the prior art, assembled operation equipment is adopted for operation, the operation steps are cumbersome and complicated, the workload and labor intensity of personnel are increased, and the burden on enterprises is increased are solved.

Owner:POWER CHINA HENAN ENG CO LTD

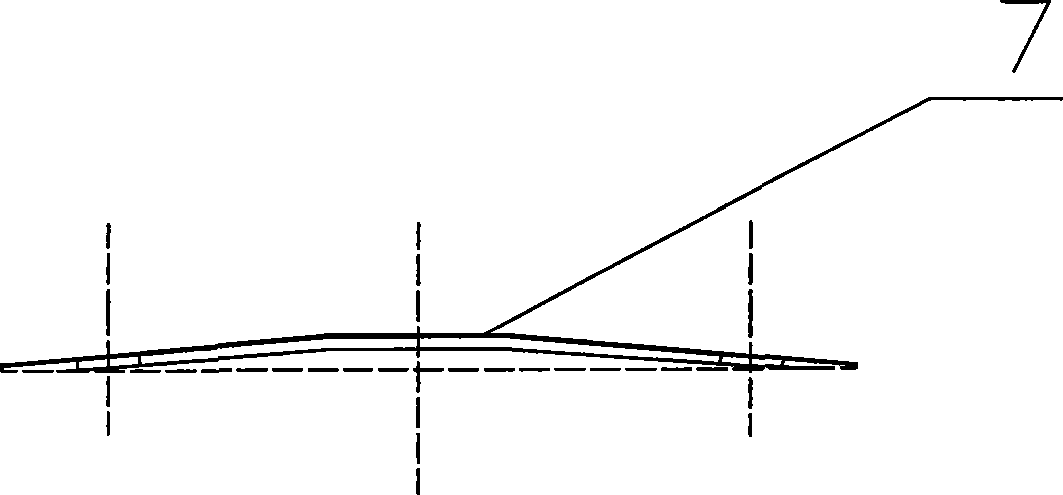

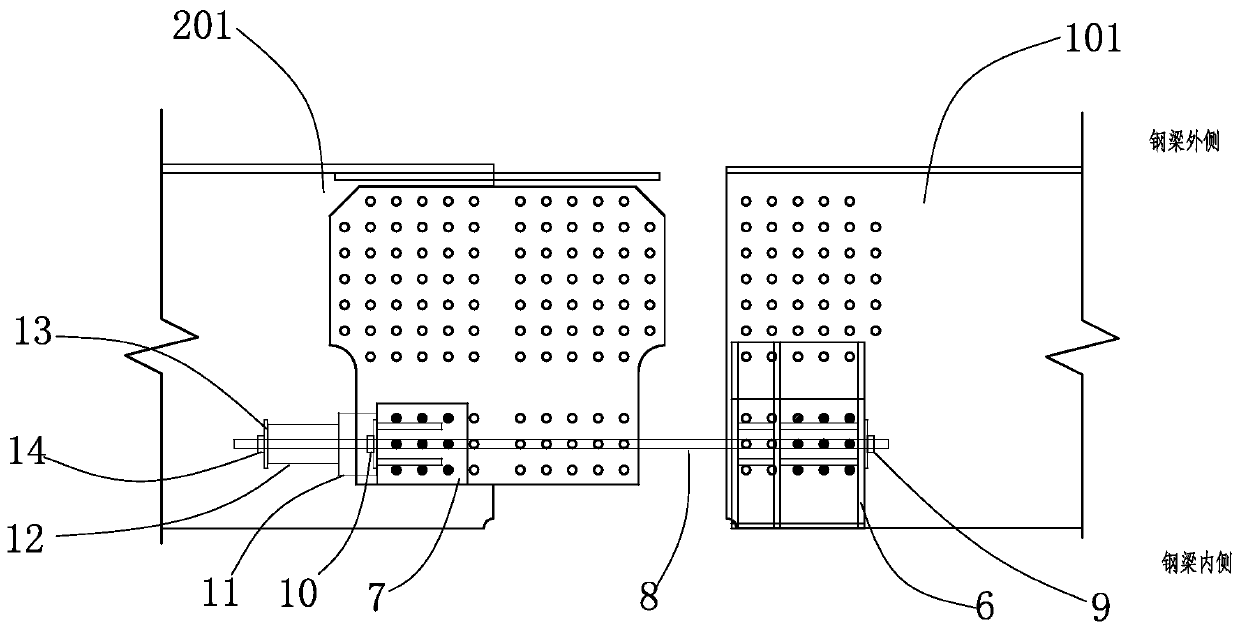

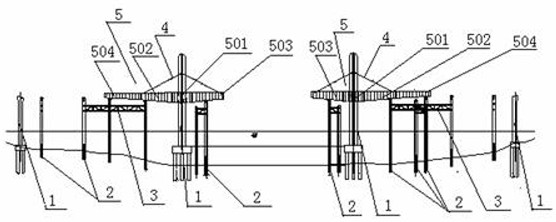

Precise aerial alignment system and method of suspension bridge steel bridge

PendingCN109914253AShorten the lifting timeReduce construction costsSuspension bridgeBridge erection/assemblyControllabilityCounterforce

The invention provides a precise aerial alignment system and method a suspension bridge steel bridge. A fixing rack and a counterforce rack are respectively mounted on two steel beam alignment end topchords to be aligned; the fixing rack is connected with the counterforce rack through a pull rod; the pull rod is fastened by using a screw nut at a fixing rack end; an auxiliary screw nut is screwedat a counterforce rack end, sequentially penetrates through a box type pushing bracket, a jack and a pad plate and is screwed and fastened; two steel beams are mutually approached and aligned by using the jack through a traction pull rod; chain blocks are mounted on lugs on both sides of the top surface of a steel beam; each chain block is connected with an opposite lug on the other steel beam ina diagonal manner through a steel wire rope; and the steel wire ropes are constantly tightened in the alignment process to prevent wind loads. By adopting the system, precise aerial alignment of steel beams can be rapidly achieved by virtue of stroke controllability of the jack, transverse stability of a longitudinal cross-pulling device and effectiveness of a transverse wind resistant device, the hoisting time of steel beams is shortened, and the construction cost can be reduced.

Owner:ROAD & BRIDGE INT +1

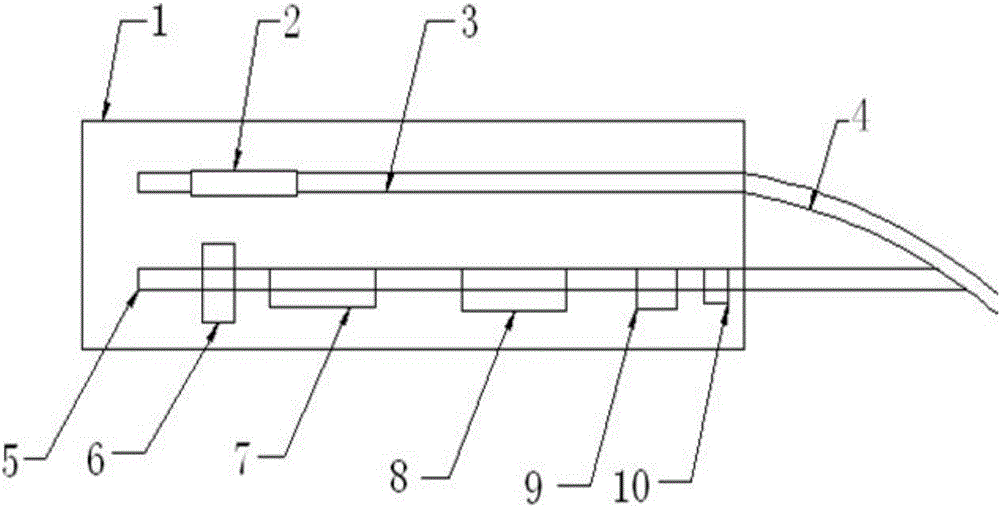

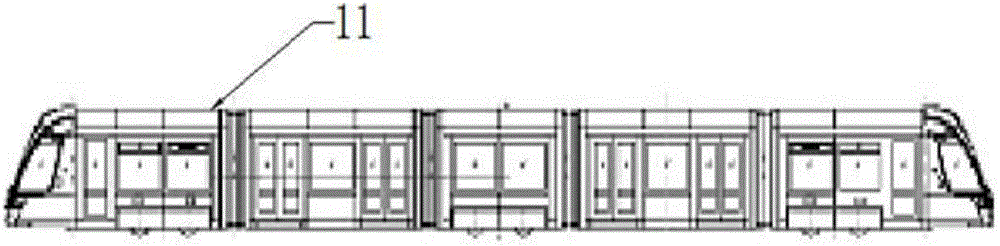

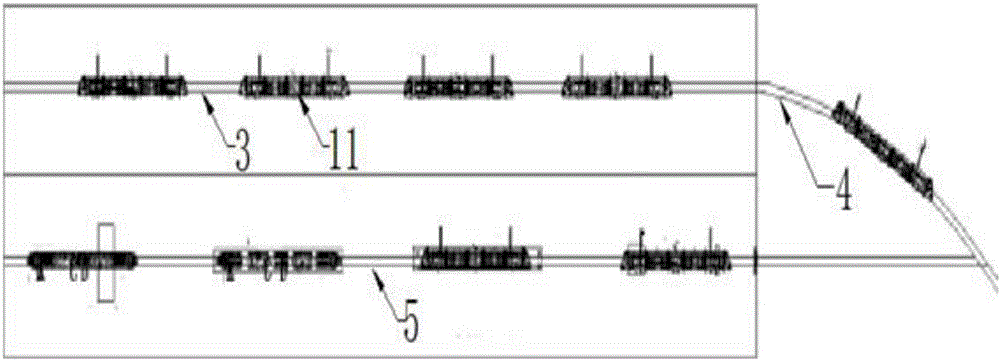

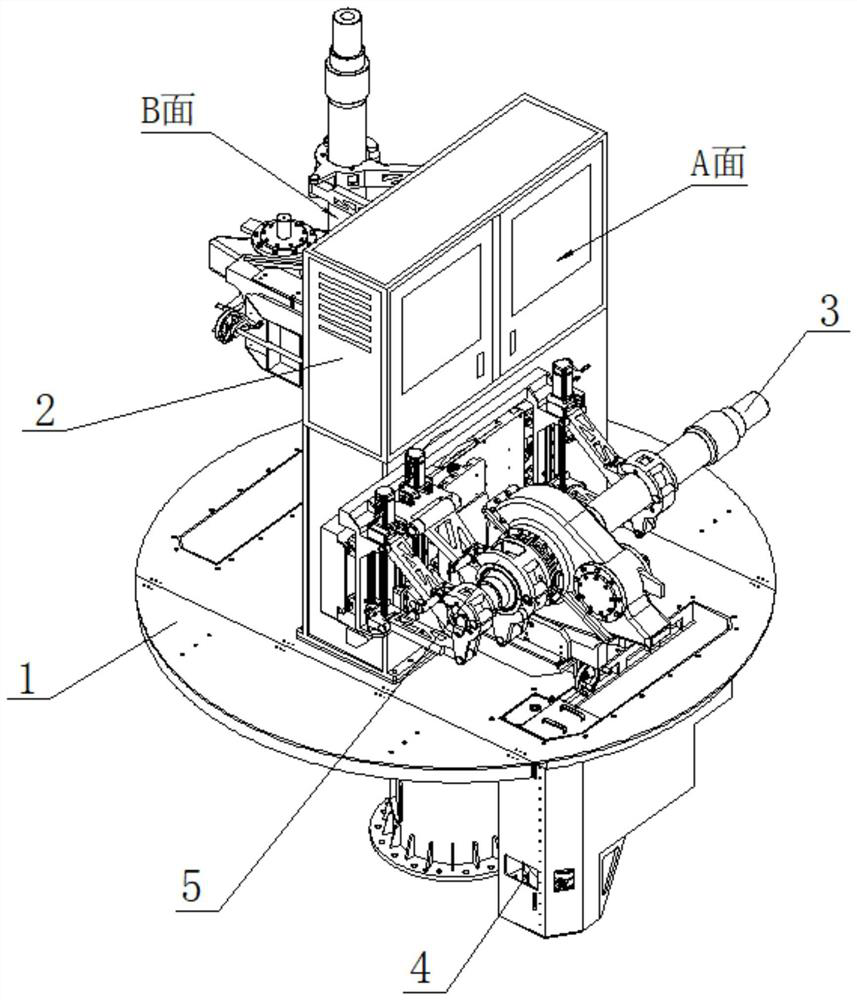

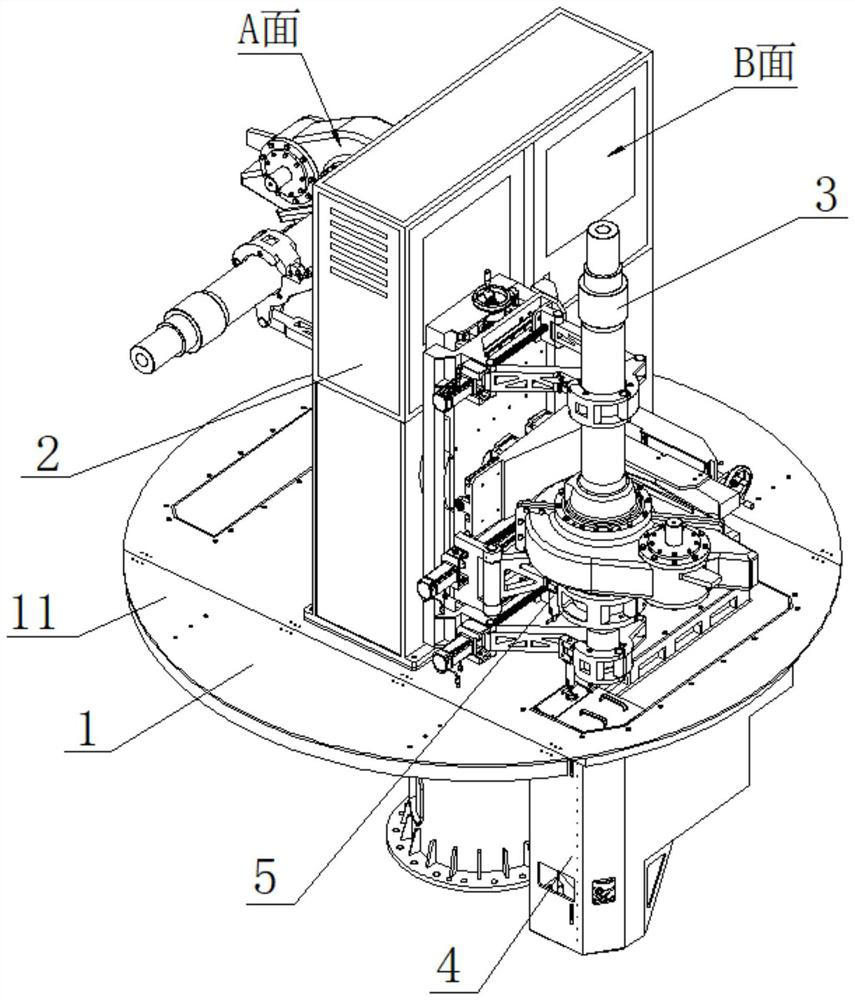

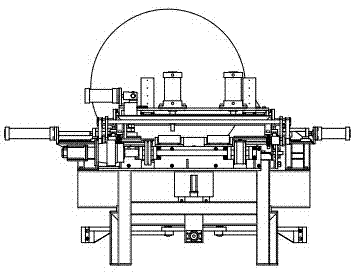

System and method used for integrating routine tests of railway vehicles

ActiveCN106383036AShorten lifting timeShorten the lifting timeRailway vehicle testingAutomotive engineeringTest line

The invention discloses a system and method for integrating routine tests of railway vehicles. The system comprises a static debugging workshop and a railway vehicle, and is characterized in that the static debugging workshop is internally provided with a static debugging test line and a cut-through test line, the static debugging test line and the cut-through test line are connected through a dynamic debugging test line, the railway vehicle is stopped at the upper ends of the static debugging test line and the cut-through test line, and routine test railway vehicles comprise subway A-type vehicles, subway B-type vehicles, 100% low-floor tramcars, 70% low-floor tramcars and the like. The system and method used for integrating routine tests of railway vehicles have the beneficial effects that working procedures between completion of a vehicle and entrance to static debugging are organically integrated together after a cut-through line is built, a lot of vehicle handling time is saved, and vehicle transfer is not required.

Owner:成都长客新筑轨道交通装备有限公司

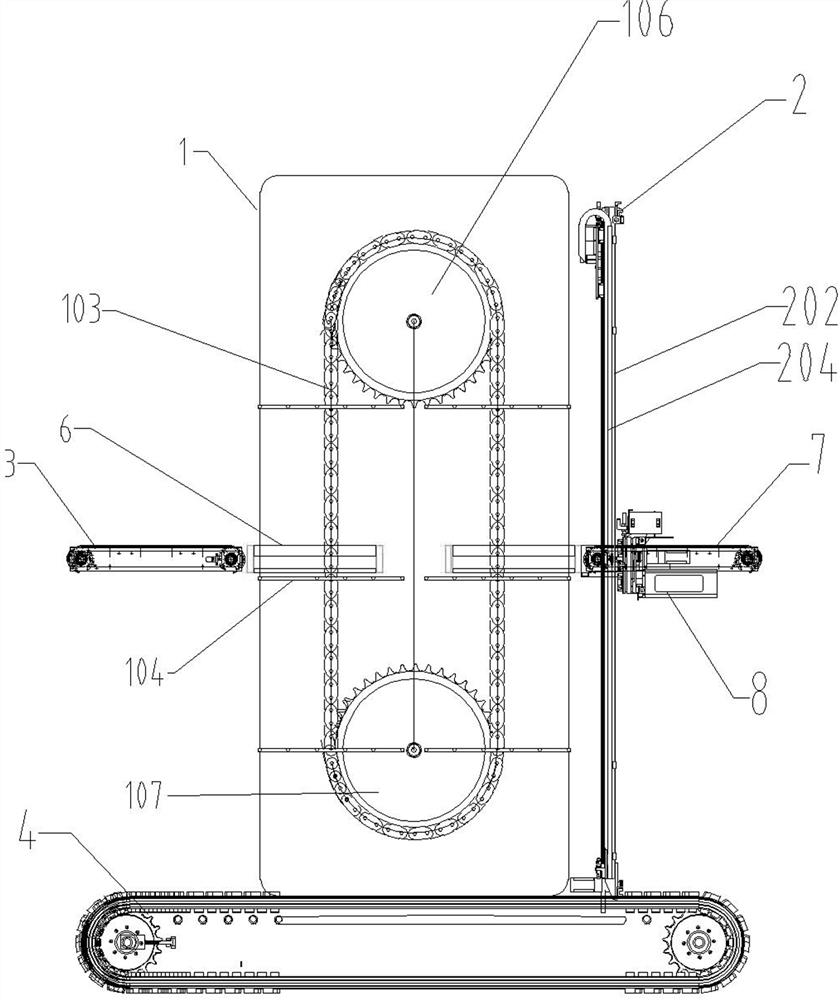

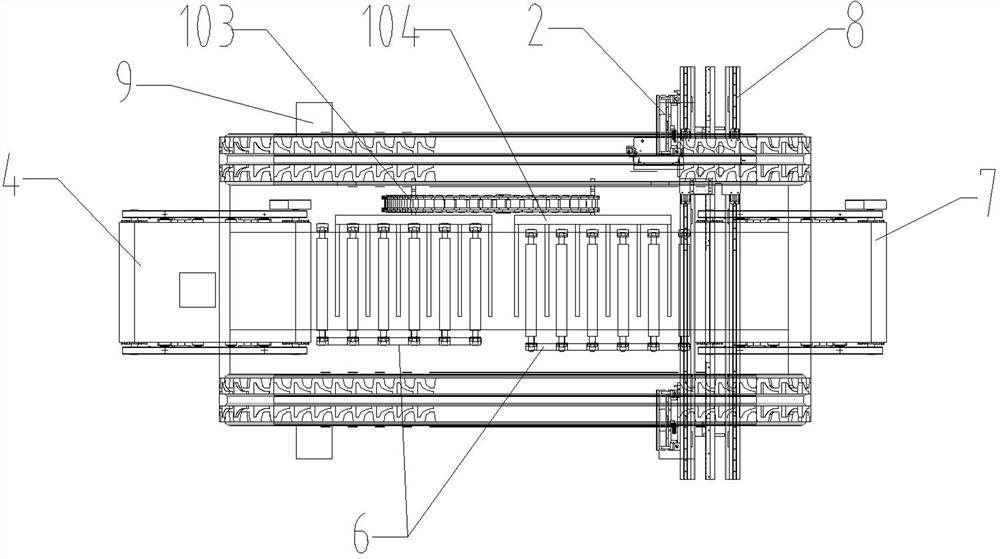

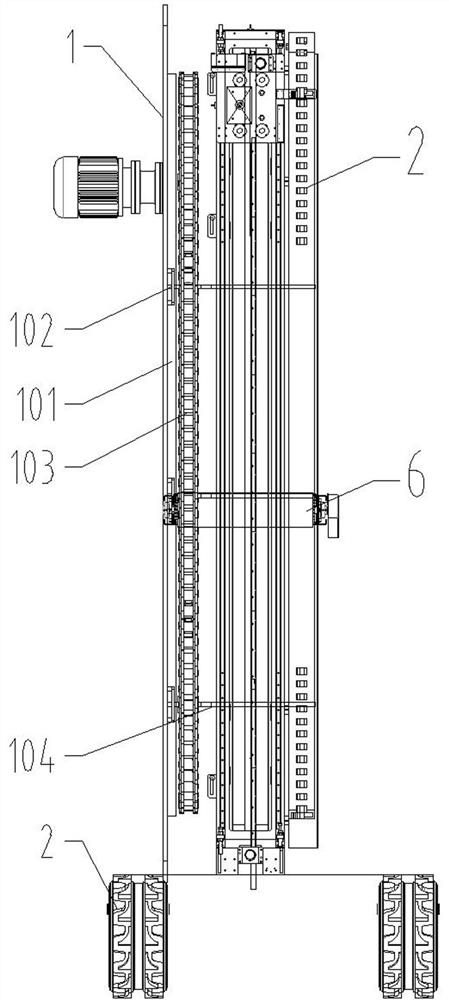

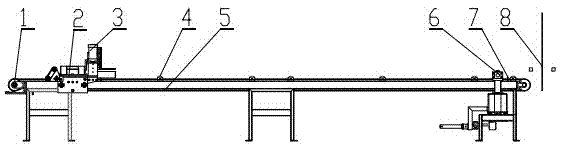

Automatic loading device

PendingCN113200373AMeet the requirements of stackingShorten the lifting timeControl devices for conveyorsStacking articlesControl engineeringMachine

The invention relates to an automatic loading device, and belongs to the field of automatic stacking and loading. According to the technical scheme, a circulating lifting conveyor and a material taking and placing elevator are arranged on the rear portion of a main conveyor. The circulating lifting conveyor comprises a long-circle-shaped vertical circulating rail, a chain lifting structure running along the circulating track and a circulating operation table, the long-circle-shaped end of the rail is provided with a semicircular rerail with the same radius as the long circle, the rerail communicates with the track, a plurality of vertical sliding blocks moving along the rail are arranged on a chain, and the vertical sliding blocks are provided with at least two sets of idler wheels. The two idler wheels move in the circulating rail and the rerail and are kept in a vertical state, and a circulating operation table is further arranged on the vertical sliding blocks. Materials on the conveyor are transferred to a stacking and lifting mechanism through the circulating lifting mechanism, and the stacking and lifting mechanism can move left and right along with a lifting machine and the materials can be placed at the required position, so that the requirement of stacking is met.

Owner:三维汉界机器(山东)股份有限公司

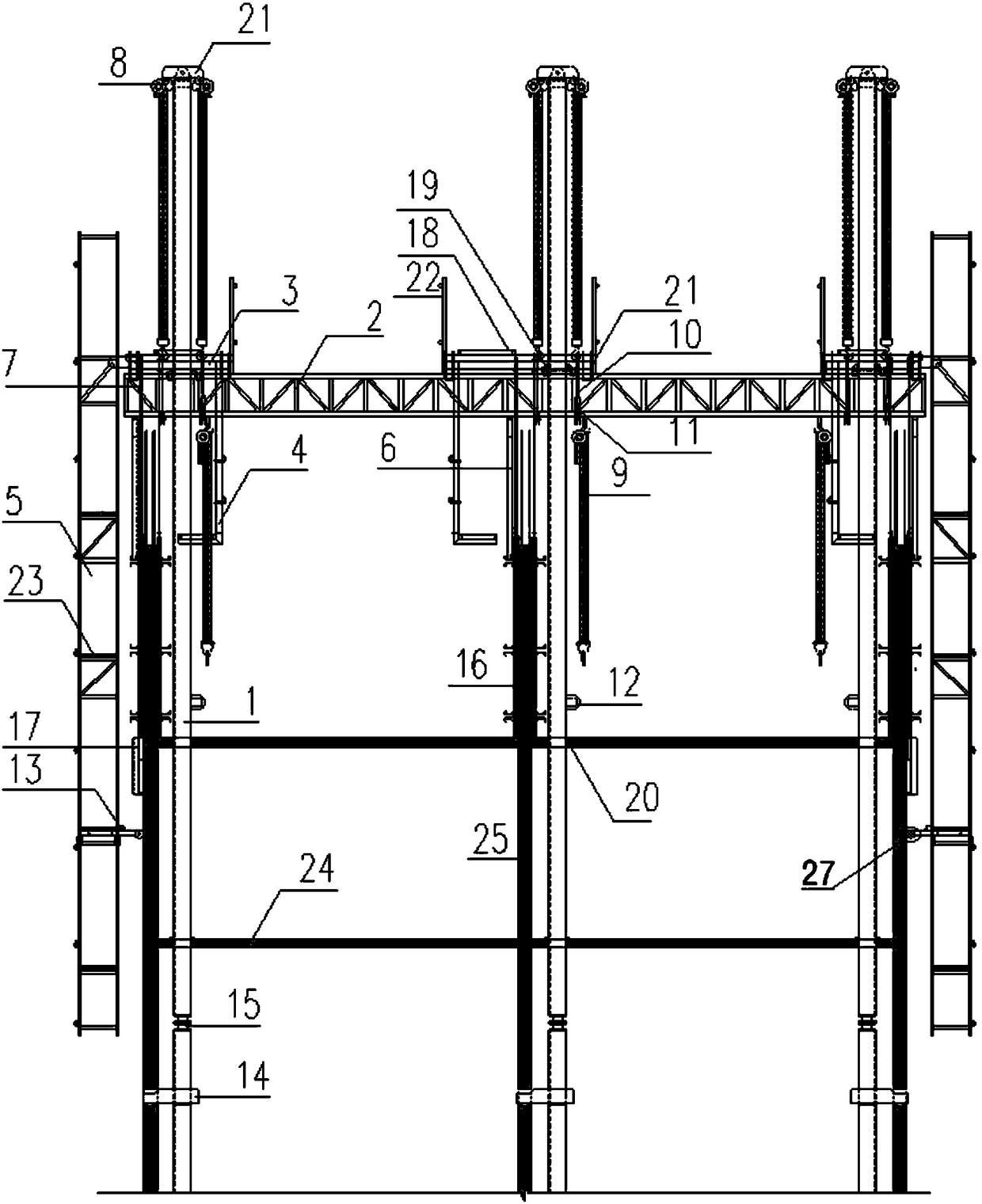

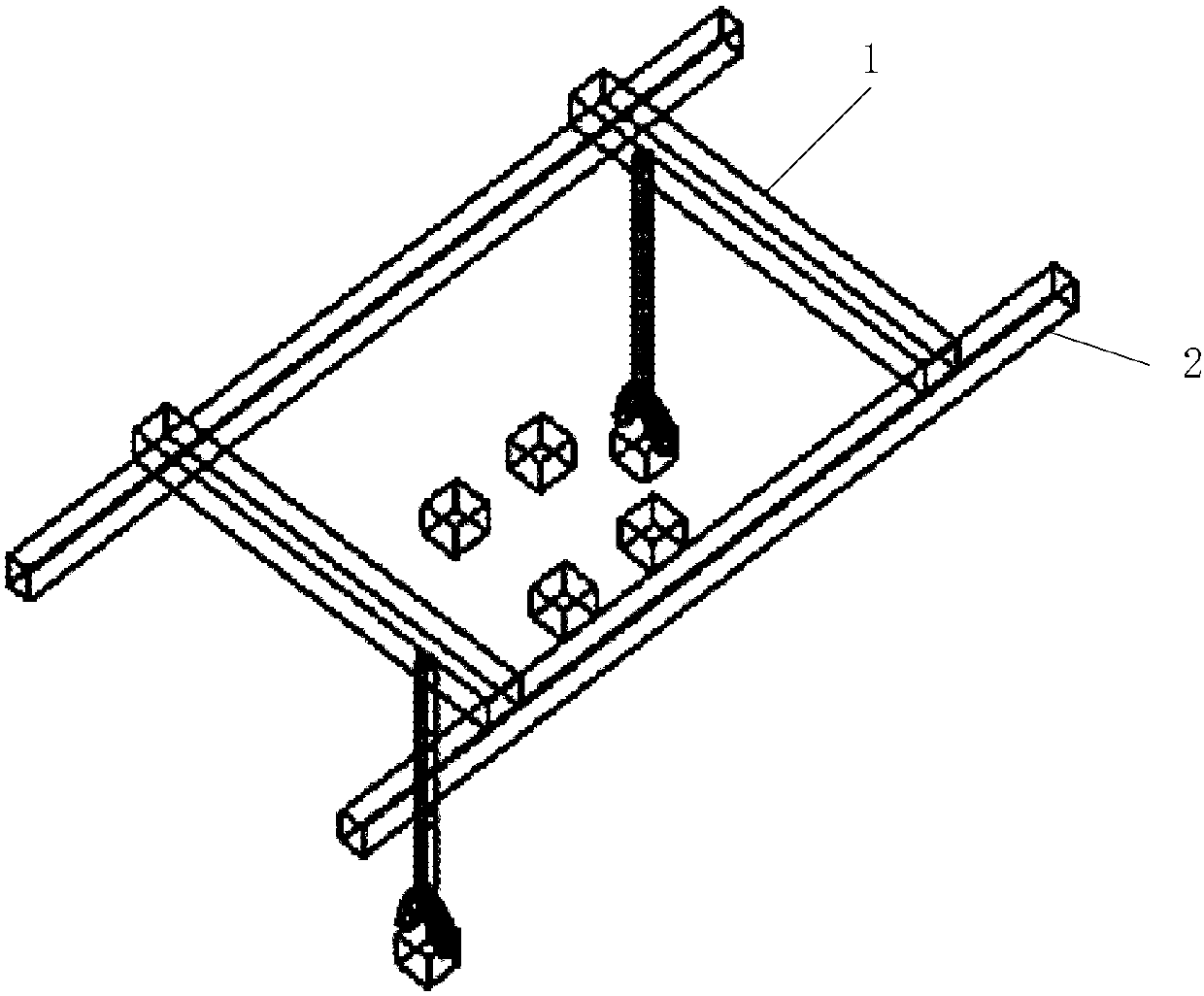

High-rise building construction steel formwork and operation frame integral lifting platform device

ActiveCN108979131AShorten the lifting timeReduce labor costsForms/shuttering/falseworksSteel platesBeam shape

The invention belongs to the technical field of buildings, and particularly discloses a high-rise building construction steel formwork and operation frame integral lifting platform device. The devicecomprises a truss main beam, auxiliary beams shaped like the Chinese character 'mu', supporting columns, inner hanging frames, outer hanging frames and hanging skirt plates. The lower ends of the supporting columns are installed on a concrete wall body, upper electric hoists are arranged at the top ends of the supporting columns, and the truss main beam is connected with the supporting columns through the upper electric hoists; the truss main beam is connected with lower electric hoists; the auxiliary beams shaped like the Chinese character 'mu' are connected with the truss main beam through U-shaped clamps, and modular steel plate nets are arranged on the auxiliary beams shaped like the Chinese character 'mu'; the outer hanging frames are hung on the auxiliary beams shaped like the Chinese character 'mu' along the outer wall of a building, the inner hanging frames are fixed to the auxiliary beams shaped like the Chinese character 'mu' through the U-shaped clamps, and the steel formwork is hung on the auxiliary beams shaped like the Chinese character 'mu' through hanging ropes at the top end of the steel formwork; the steel formwork, the inner hanging frames and the outer hanging frames ascend along with lifting of the platform device. External large equipment is not needed, and manpower and cost are greatly saved.

Owner:惠玉清

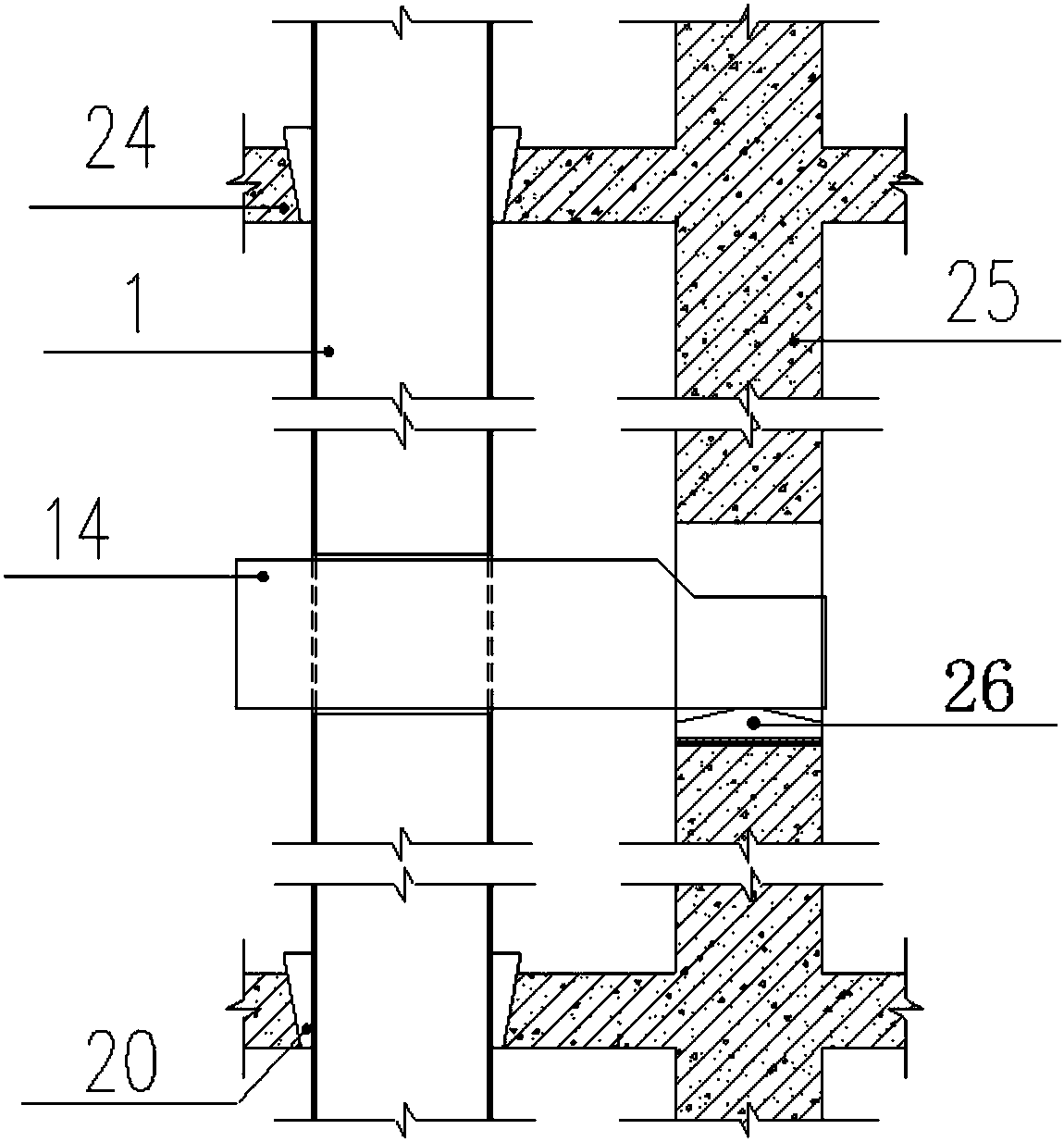

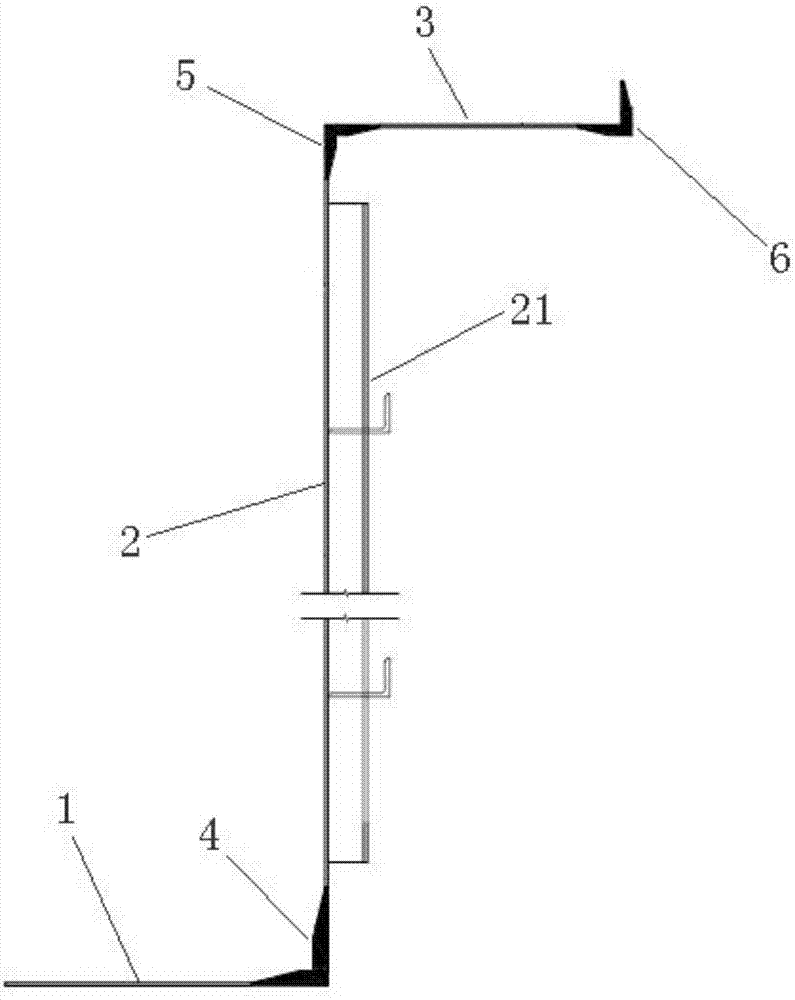

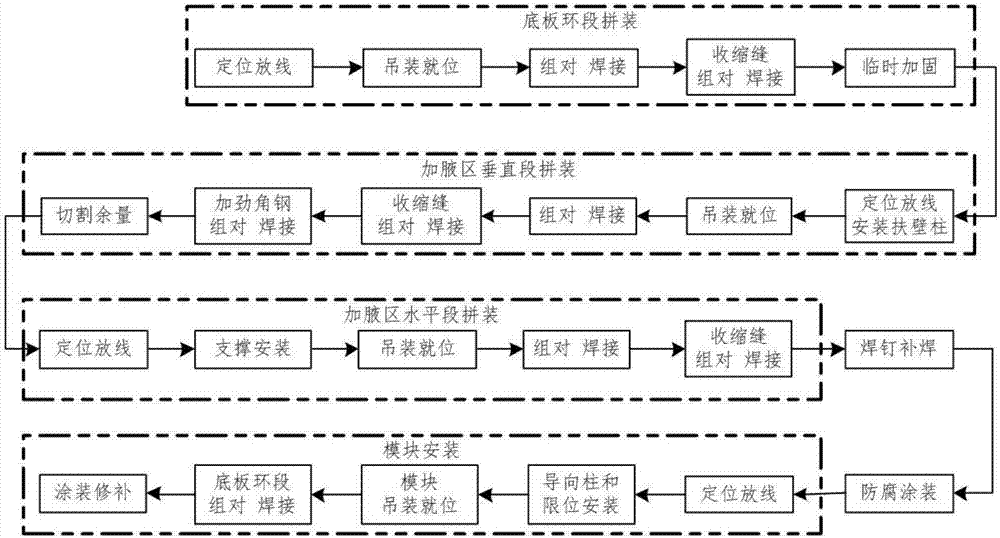

Integrated connection module structure of nuclear power station safe shell steel lining and mounting method thereof

ActiveCN107545937ASimple and efficient operationLower working heightNuclear energy generationContainmentWall plateNuclear power

The invention discloses an integrated connection module structure of a nuclear power station safe shell steel lining. The structure comprises a baseplate ring segment, a haunching area wall plate anda horizontal segment, the baseplate ring segment and the horizontal segment are both horizontally arranged, and the haunching area wall plate is vertically arranged; the baseplate ring segment is fixedly connected with the lower end of the haunching area wall plate, the upper end of the haunching area wall plate is fixedly connected with one end of the horizontal segment, and a first reinforcing joint is arranged on the connection portion of the baseplate ring segment and the haunching area wall plate; a second reinforcing joint is arranged on the connection portion of the haunching area wallplate and the horizontal segment, a third reinforcing joint is arranged at the end, away from the haunching area wall plate, of the horizontal segment, and the baseplate ring segment, the haunching area wall plate, the horizontal segment, the first reinforcing joint, the second reinforcing joint and the third reinforcing joint are integrally assembled into an entirety and then fixedly connected with the lowest layers of the baseplate ring segment and a nuclear power station safe shell steel lining cylinder. The integrated connection module structure has the advantages that module assembly is conducted on an assembly field, hoisting in position at a time is achieved, and the intersecting construction time of construction with an inner shell is reduced.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

LNG storage tank in-tank pipeline mounting method

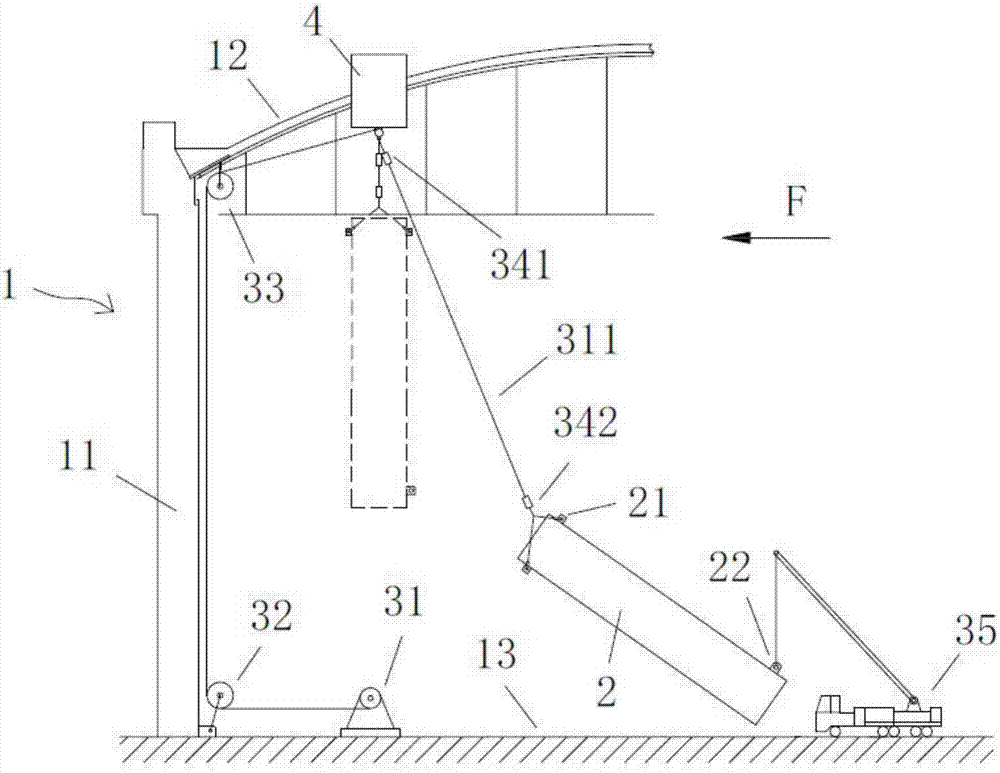

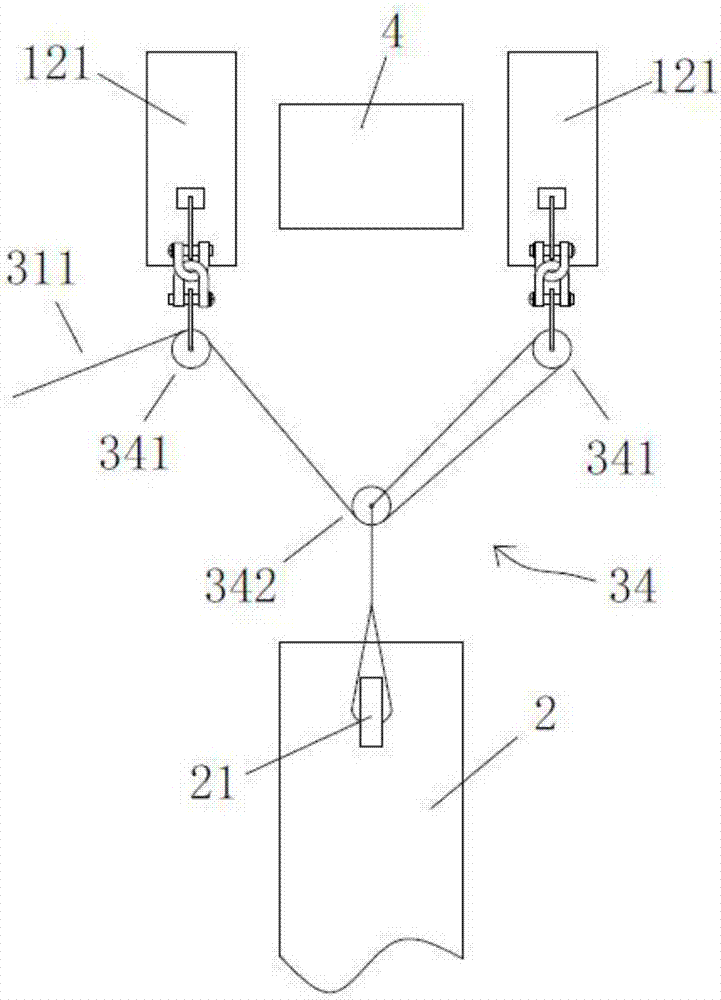

ActiveCN106927353AAvoid security risksLower the altitudeWinding mechanismsLoad-engaging elementsWinchIndustrial engineering

The invention belongs to the field of LNG storage tank construction, and particularly relates to an LNG storage tank in-tank pipeline mounting method. In order to solve the problems that in the prior art, when an LNG storage tank in-tank pipeline is lifted, construction time is long, construction cost is high, and aerial work risks exist, the invention discloses the LNG storage tank in-tank-pipeline mounting method. The LNG storage tank in-tank pipeline mounting method comprises the steps of prefabricating of an in-tank pipeline in a storage tank, mounting and arranging of a lifting device and lifting of the in-tank pipeline through a winch. According to the LNG storage tank in-tank pipeline mounting method, aerial lifting work risks on the outer portion of the storage tank can be avoided, safety in the lifting process can be improved, through arrangement of a lifting device in the storage tank, one-time lifting of the in-tank pipeline can be achieved, the lifting time can be shortened, and lifting construction cost can be reduced.

Owner:CHINA NUCLEAR IND FIFTH CONSTR CO LTD

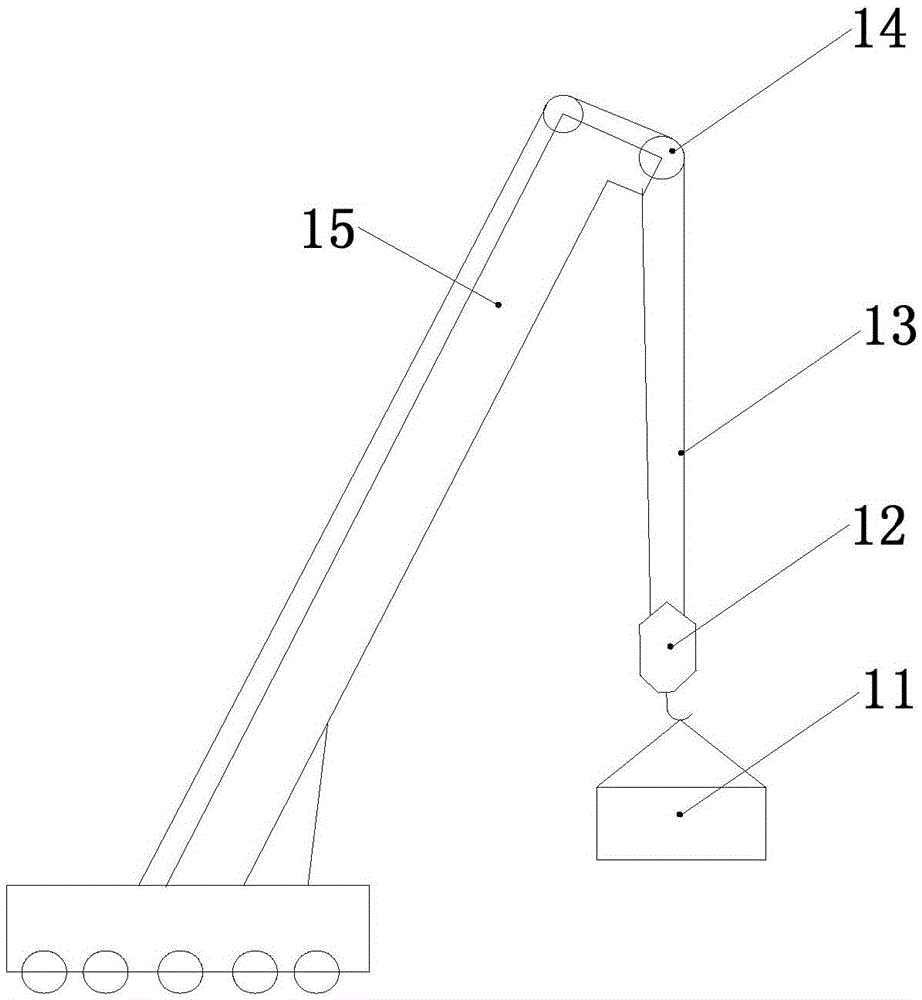

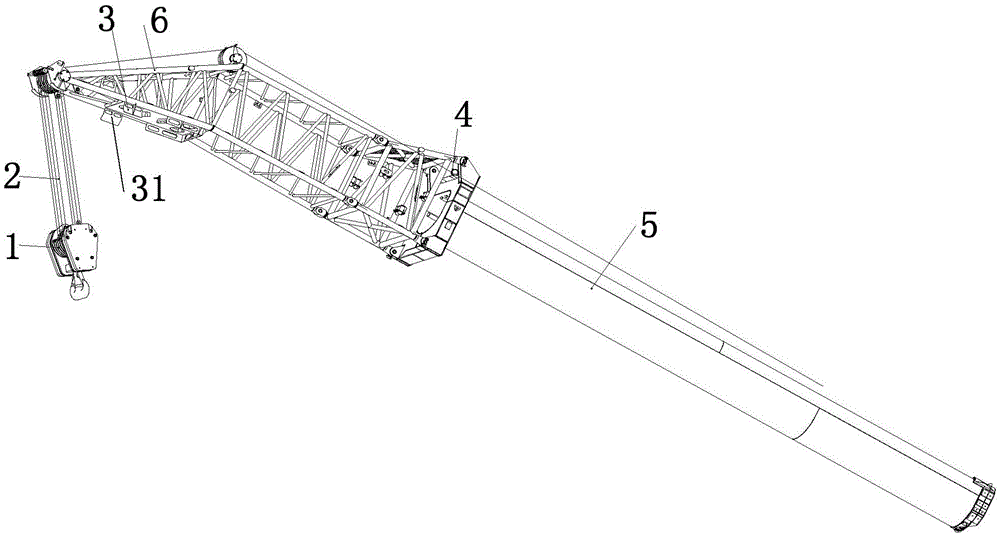

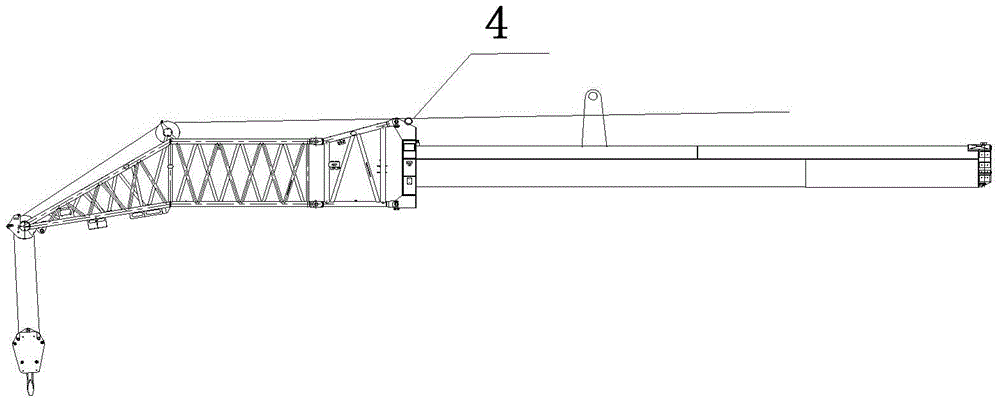

Lifting hook maintaining structure, crane and lifting hook fixing method

ActiveCN105565146AShorten the lifting timeLoad-engaging elementsCranesIndustrial engineeringMechanical field

The invention discloses a lifting hook maintaining structure, a crane and a lifting hook fixing method and relates to the field of engineering machines. By the adoption of the lifting hook maintaining structure, the crane and the lifting hook fixing method, the lifting efficiency of the crane is improved, and the lifting cost is reduced. The lifting hook maintaining structure comprises an arm frame, an arm head, a lifting hook and a lifting hook maintaining assembly, wherein the arm frame is rotatably connected with the arm head. When the arm head rotates to the position above the arm frame, the lifting hook is fixed by the lifting hook maintaining assembly. In this way, by the adoption of the technical scheme, in the process that the crane is transferred to another place after lifting is completed, the lifting hook can be automatically and stably kept above the arm frame, the lifting hook does not need to be dismantled, a steel wire rope does not need to be taken up, the crane can be transferred to another placed by carrying the lifting hook, and the lifting time is shortened.

Owner:XUZHOU HEAVY MASCH CO LTD

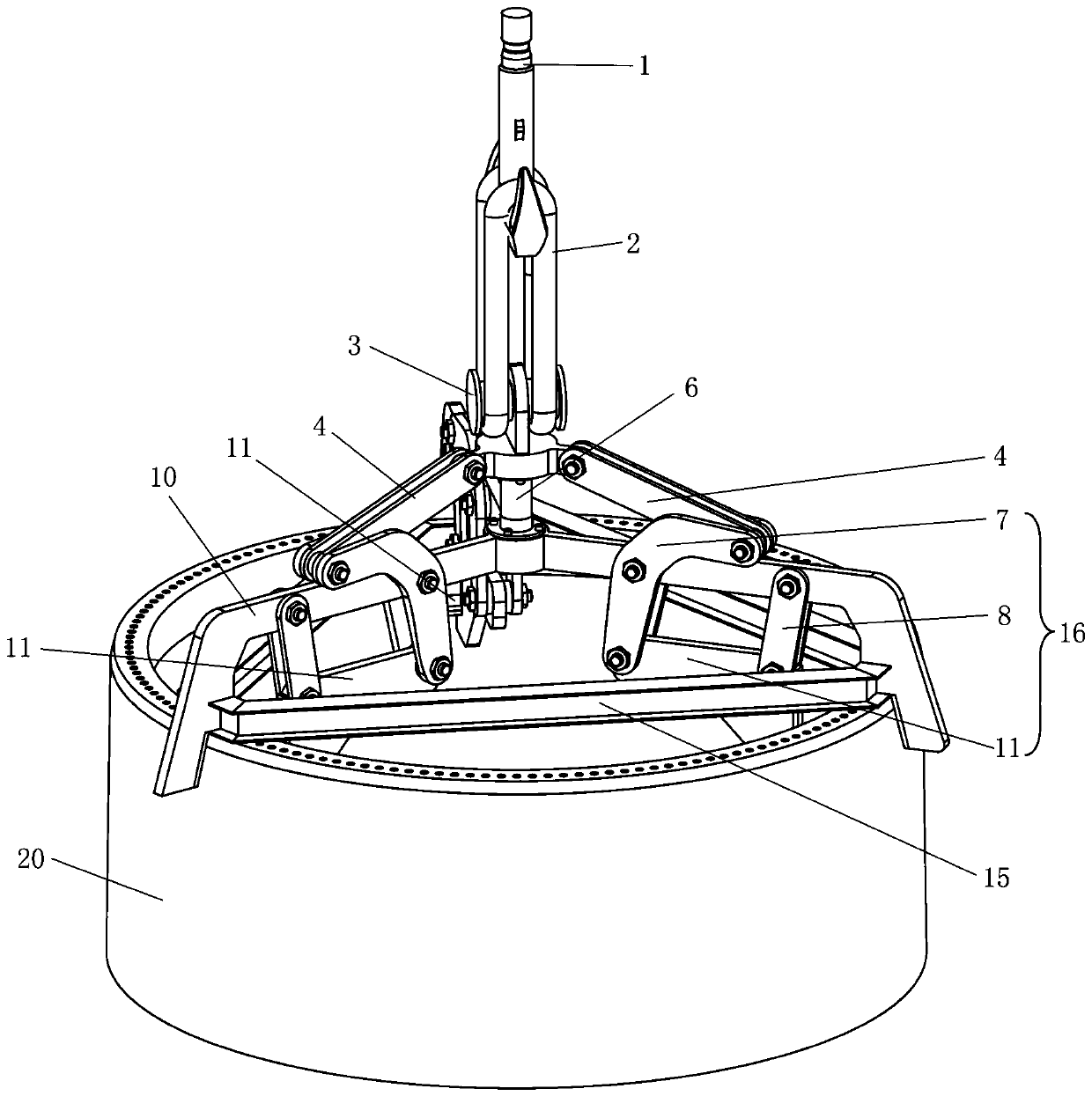

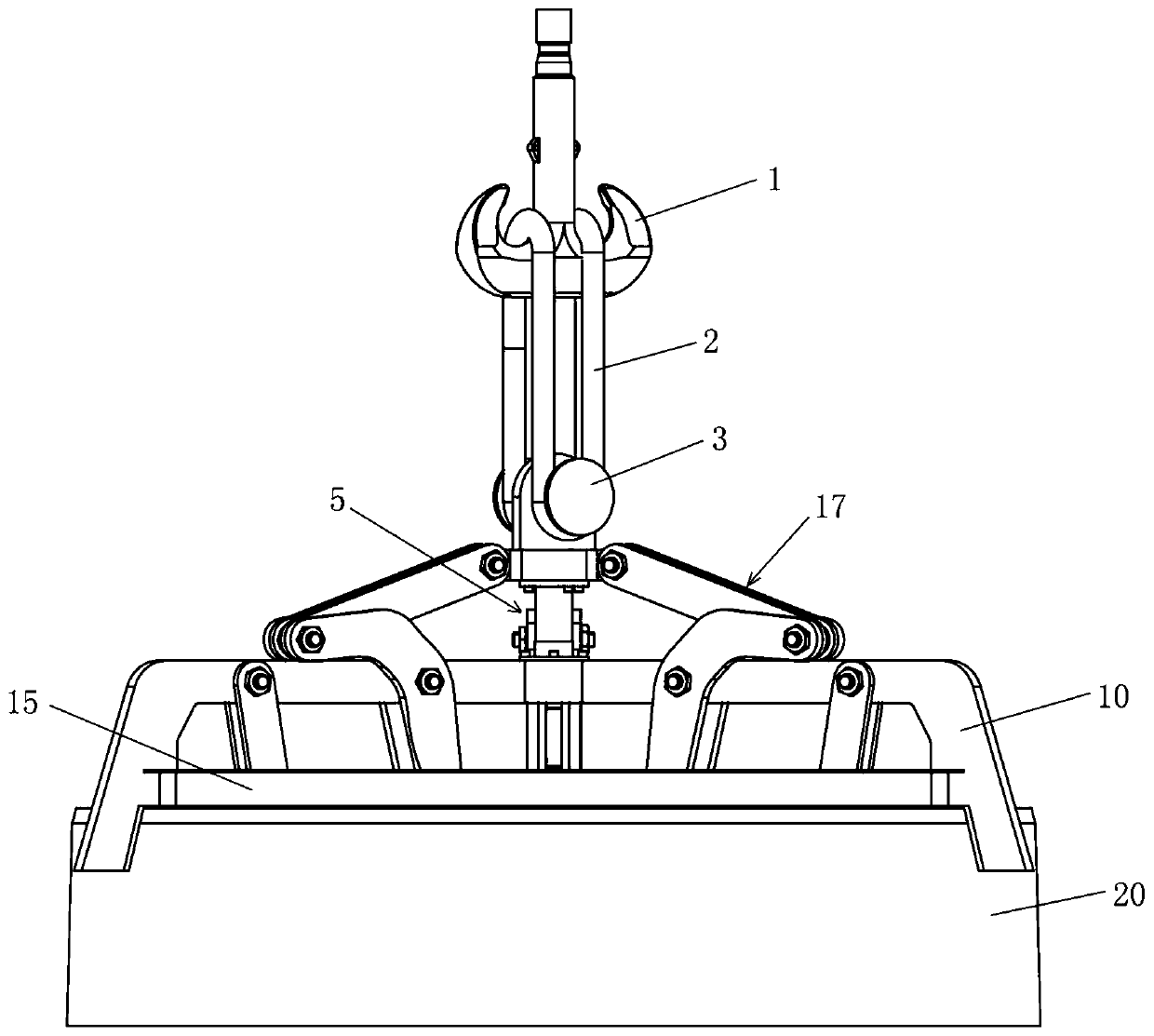

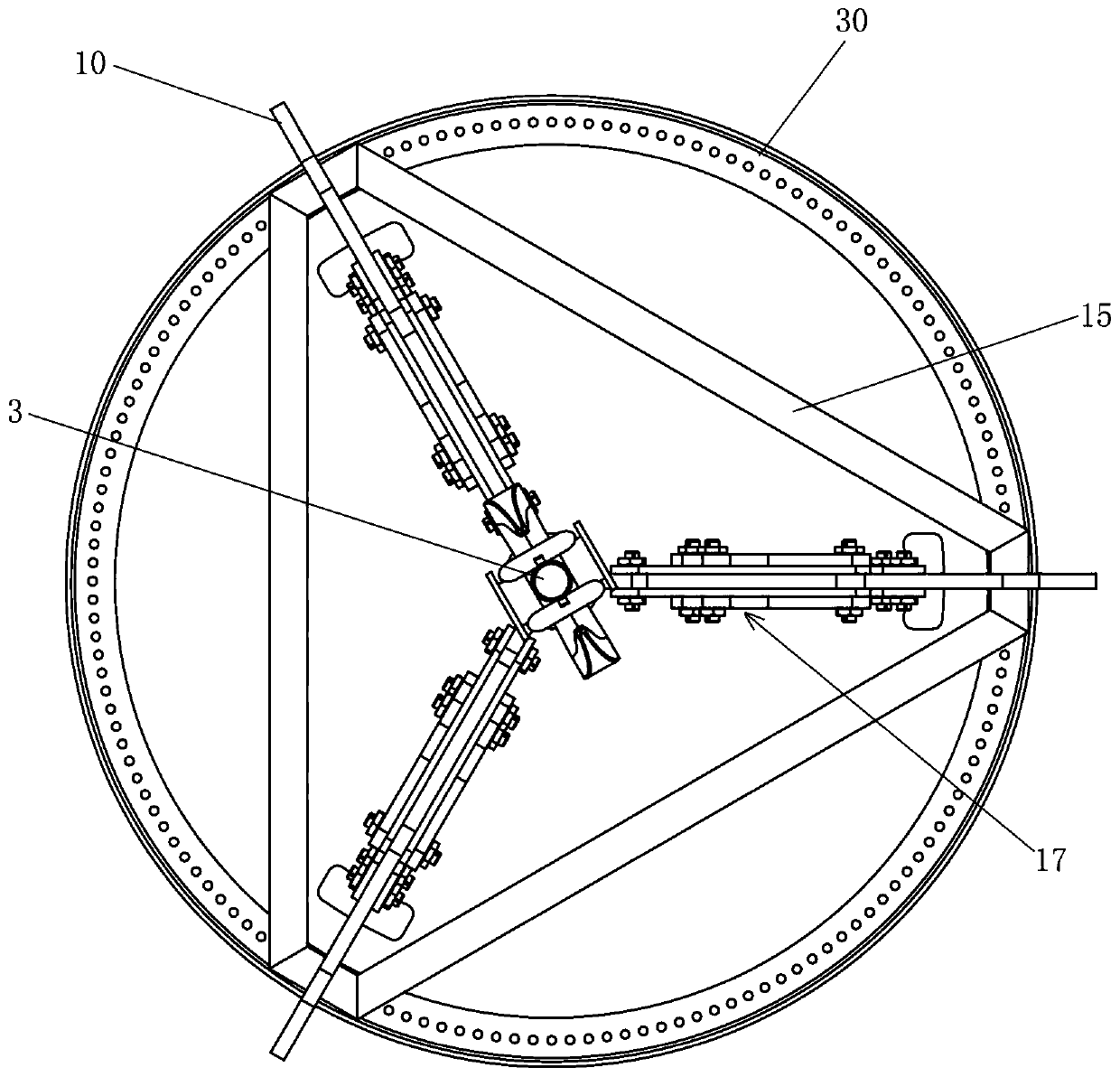

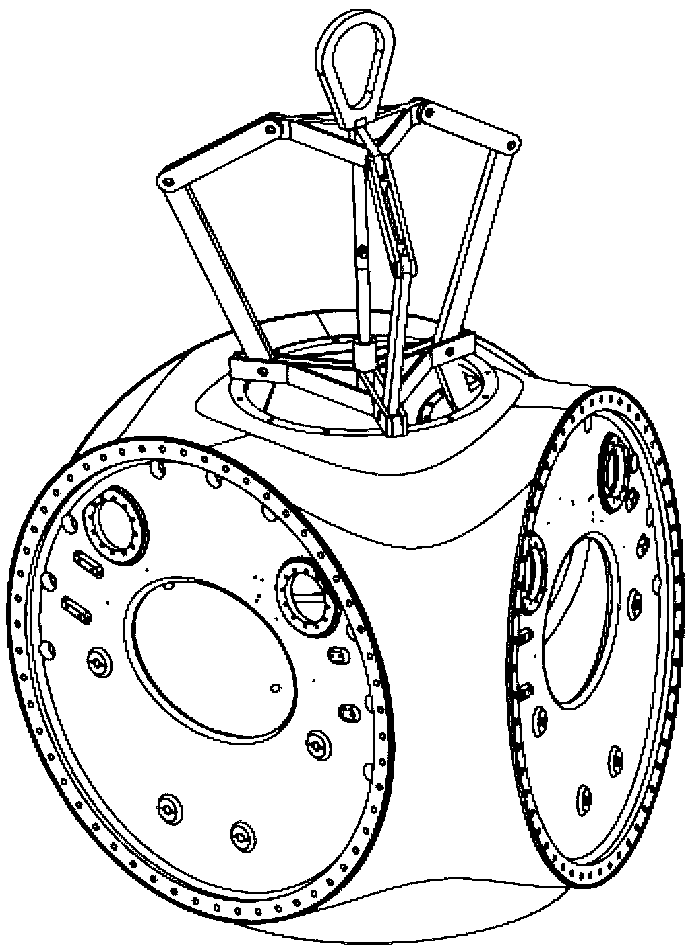

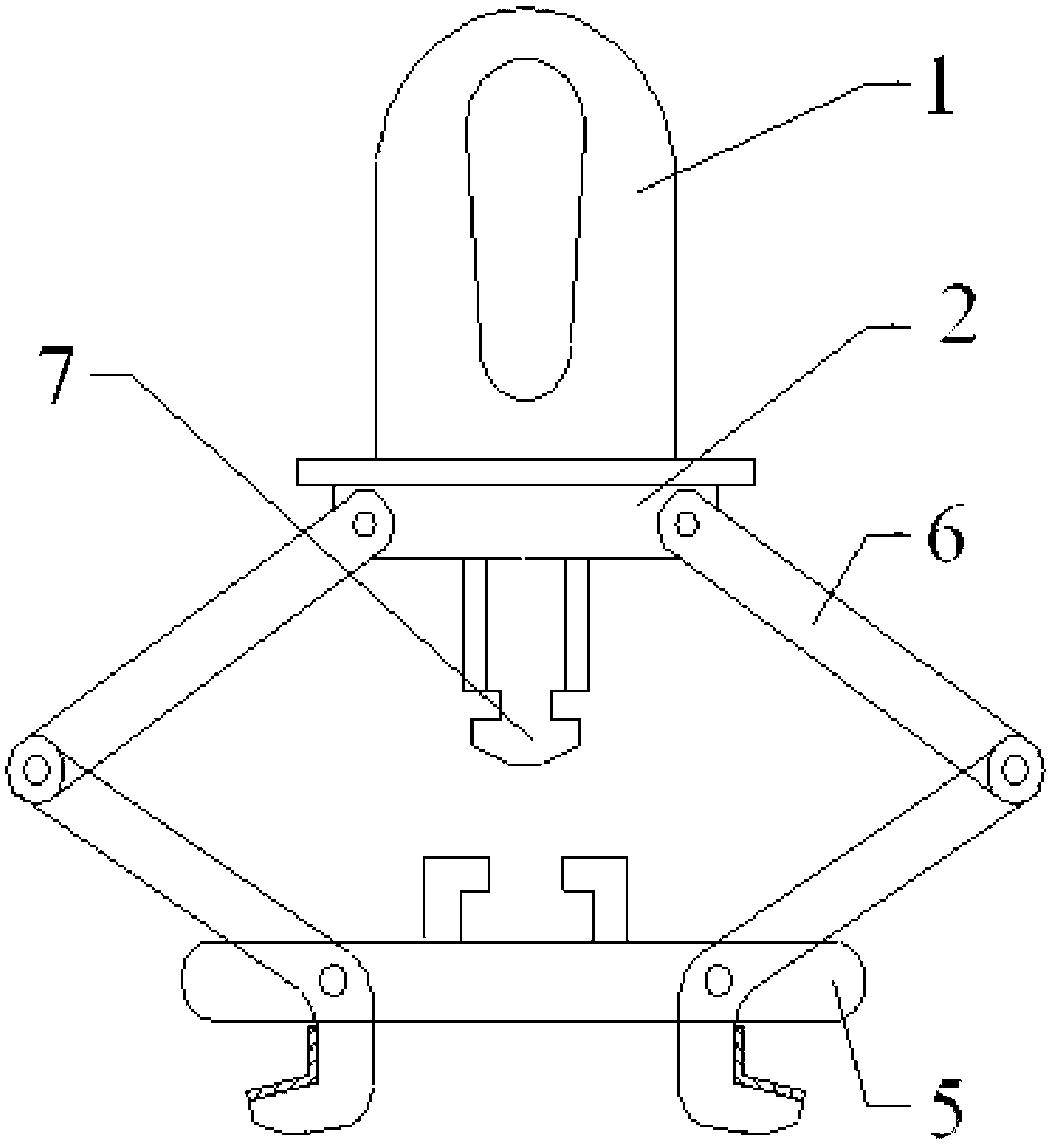

Tower drum lifting appliance

The invention provides a tower drum lifting appliance. The tower drum lifting appliance comprises a lifting seat, a fixing frame, at least two clamping arms and a locking structure, wherein the fixingframe is located below the lifting seat; at least two clamping arms are hinged to the hanging seat and the fixing frame in a radial mode according to a preset angle interval, so that the clamping arms can move relative to the fixing frame to clamp or loosen the flange of a tower drum; and the locking structure can lock the lifting seat to the fixing frame or unlock the fixing frame. According tothe tower drum lifting appliance, the tower drum lifting appliance can be locked and unlocked, vertical hoisting of tower drums with various diameters can be met, the production cost is saved, and thehoisting efficiency is improved.

Owner:FUJIAN GOLDWIND SCI TECH CO LTD

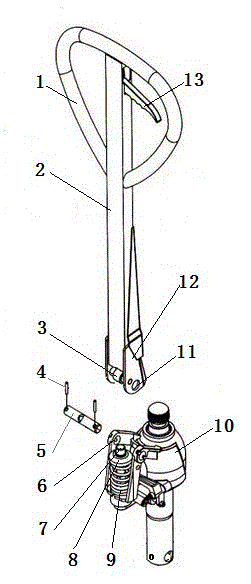

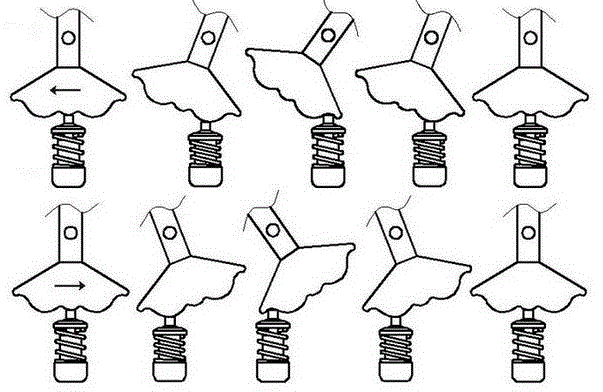

Control handle for hand hydraulic carrier

The invention discloses a control handle for a hand hydraulic carrier. The control handle for the hand hydraulic carrier comprises a rod body and an annular handle connected to the rod body. A pinching handle is installed on the rod body and connected with a hydraulic lifting device of the hand hydraulic carrier through a transmission element. The rod body is connected with a pump body of the hydraulic lifting device through a pin shaft. The rod body is composed of a press rod part and a swing part which are movably connected. Lug plates on the two sides of the press rod part are connected with the pump body through pin shafts. The swing part is provided with a swing rod body and a sector block fixedly connected with the lower end of the swing rod body into a whole. A driving piece and a driven piece of a cam mechanism are composed of the sector block and a pump core of the pump body. In the cam mechanism, the sector block swings leftwards and rightwards, and the corresponding pump core moves downwards to supply oil or moves upwards to absorb oil. By the adoption of the control handle, carrier lifting time is shortened and meanwhile the operation range is reduced.

Owner:SHANDONG JIANZHU UNIV +1

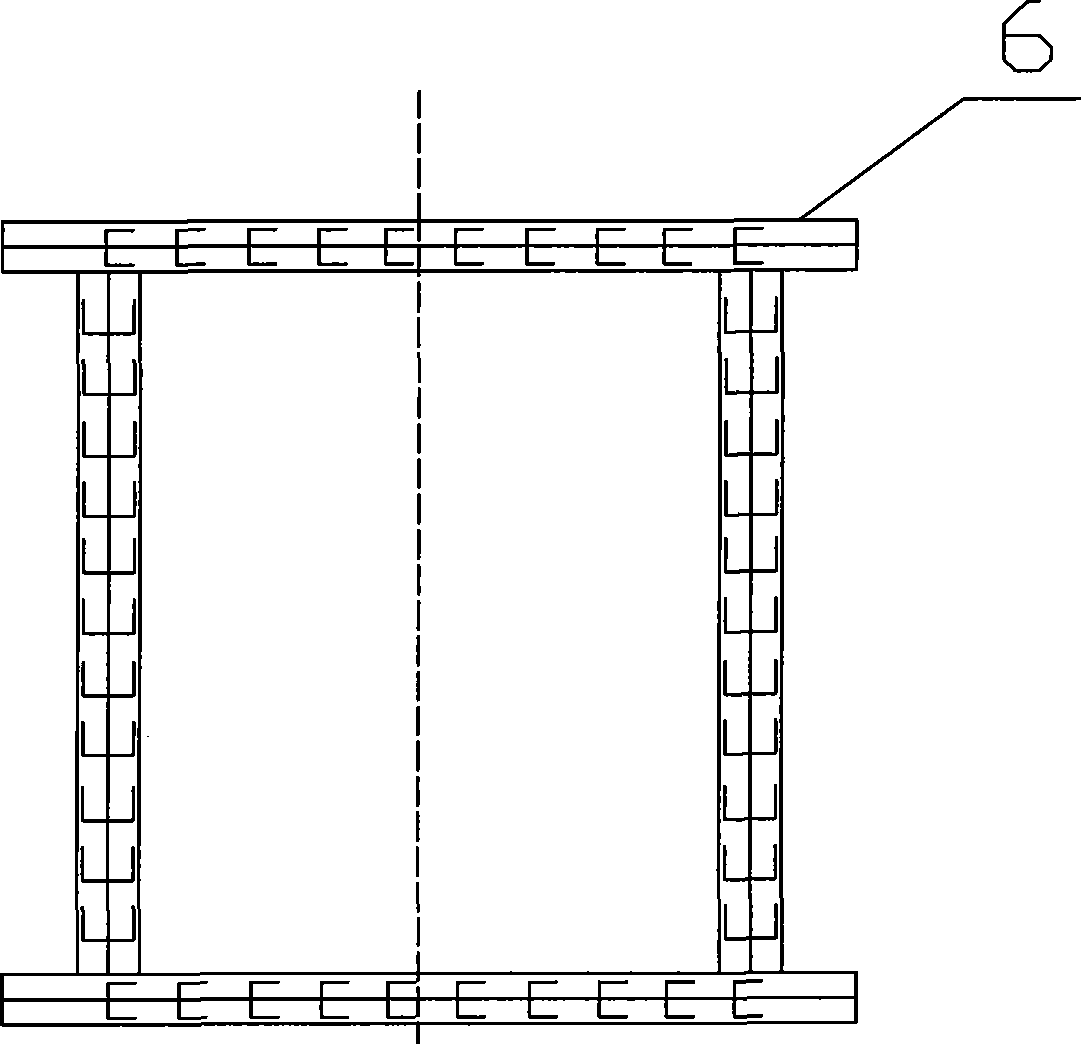

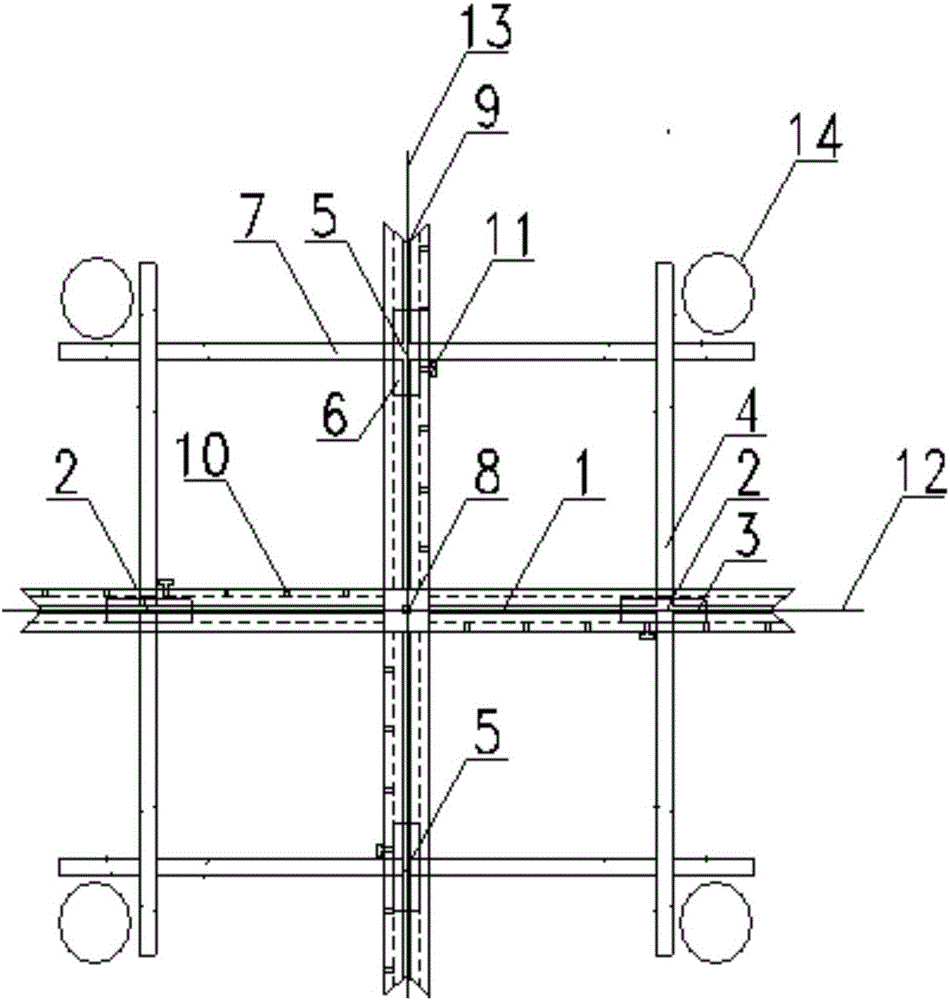

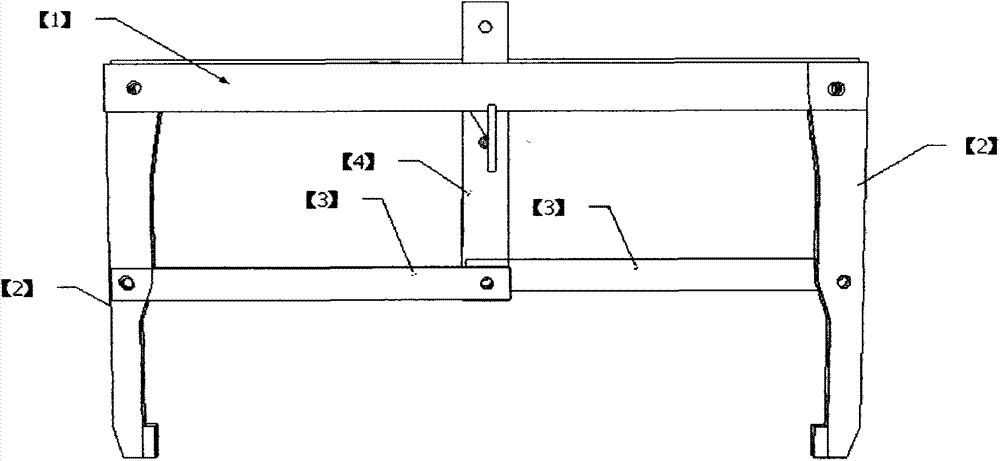

Jig frame tooling component for longitudinal bulkhead segmented general assembling construction

ActiveCN101898622AShorten the lifting timeImprove crane efficiencyVessel partsEngineeringStandardization

The invention discloses a jig frame tooling component for longitudinal bulkhead segmented general assembling construction. The jig frame tooling component comprises a rectangular bottom plate, wherein both longitudinal sides of the middle part of the plate surface of the bottom plate are vertically welded with a large baffle plate and a small baffle plate respectively; a reinforcing plate is vertically welded with the larger baffle plate, the small baffle plate and the bottom plate respectively; the bottom of the reinforcing plate is correspondingly provided with concave holes; the large baffle plate is in a bending structure and is reversely arranged on the bottom plate; a notch on the lower part of the large baffle plate is opposite to the small baffle plate, and the height of the small baffle plate is lower than that of the notch; and the inside of the upper part of the large baffle plate is provided with a round hole. The jig frame tooling component has the advantages of loosing hooks by only slightly adjusting when a crane is positioned, greatly reducing hoisting time, and improving the efficiency of the crane, the standardization degree of buttresses of the general assembling construction and the utilization rate of fields. In addition, tooling devices for the jig frame tooling component can be universal and can be reused, so that the cost can be reduced, and the component can be used simply and conveniently.

Owner:DALIAN SHIPBUILDING IND

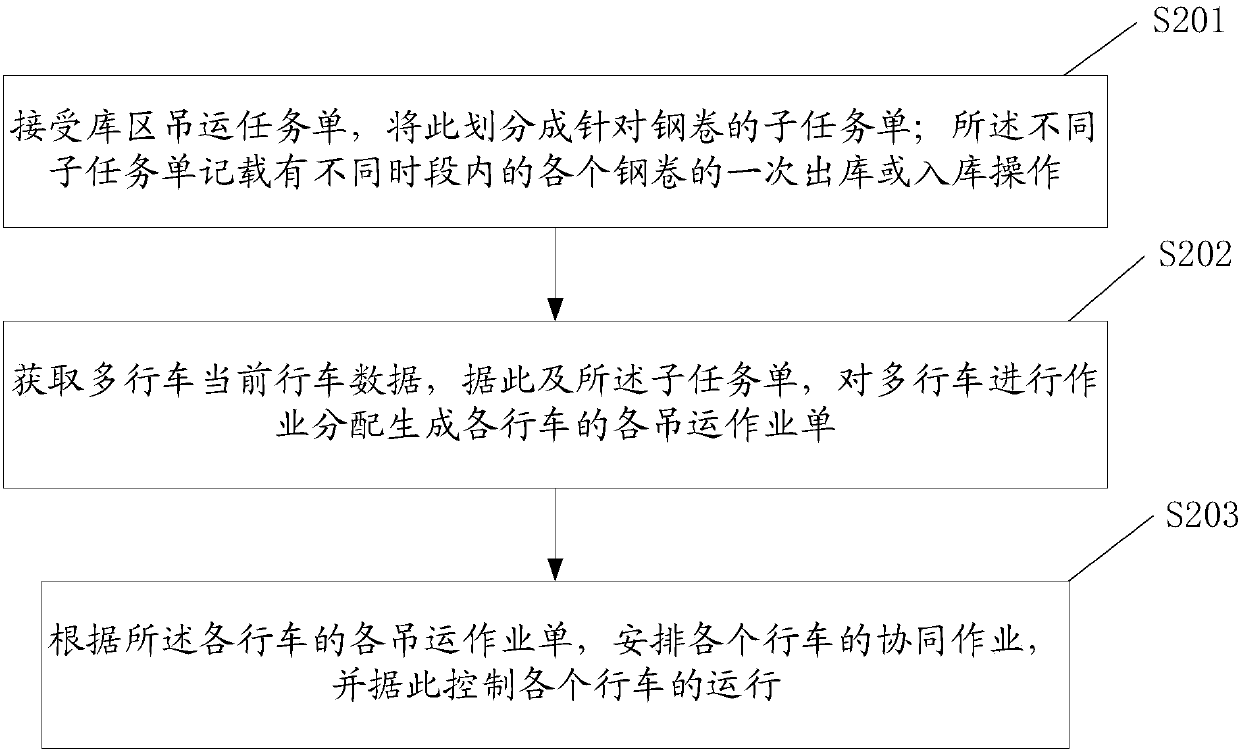

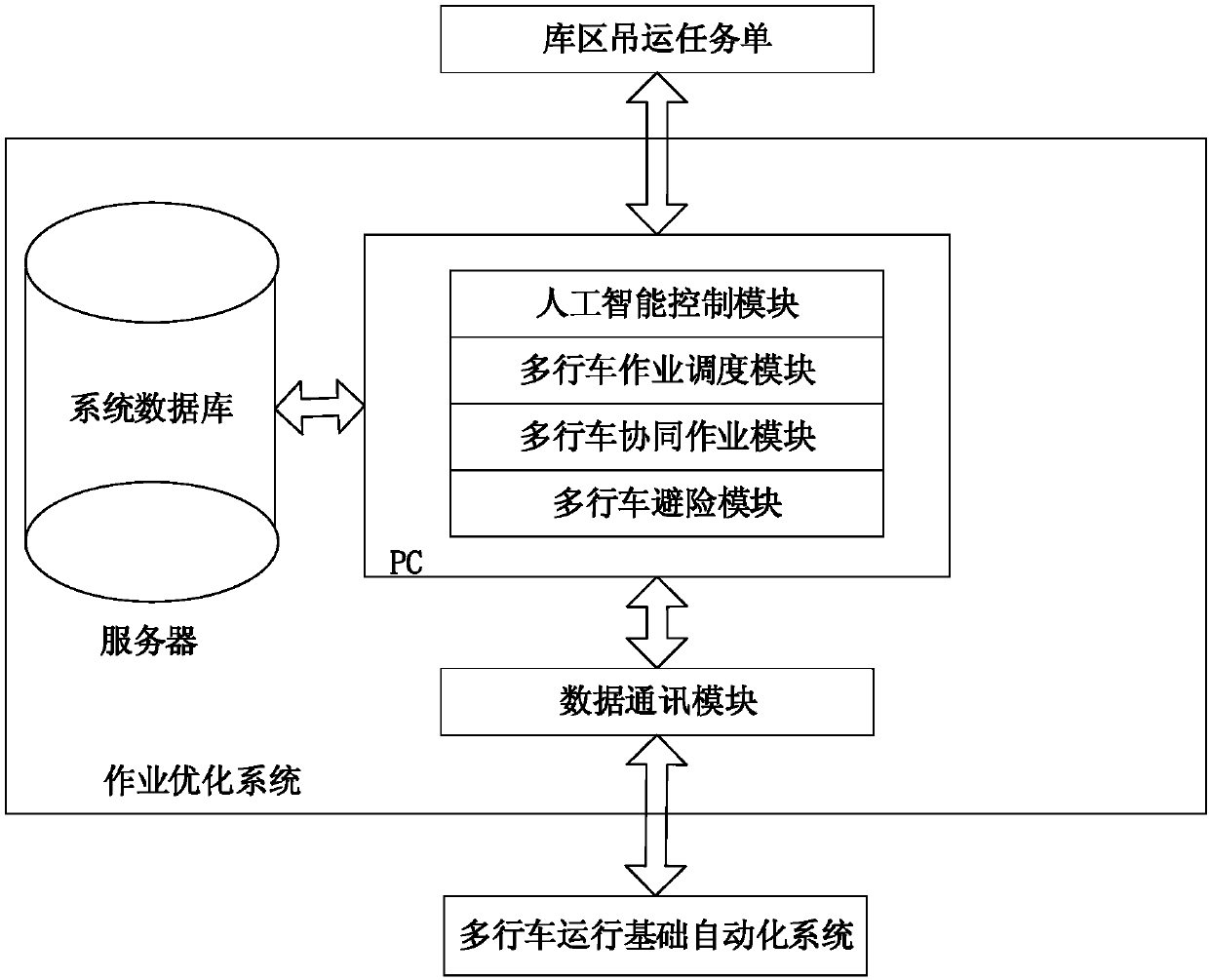

Optimization method and system of collaborative operating of multiple common-rail unmanned running vehicles of steel coil post-rolling storehouse area

ActiveCN108280529AReduce walking distanceImprove lifting efficiencyForecastingResourcesCommon railComputer science

The embodiment of the invention discloses an optimization method and system of collaborative operating of multiple common-rail unmanned running vehicles of a steel coil post-rolling storehouse. The method comprises the steps of: A, accepting a storehouse area hoisting transportation task order, and dividing the same into sub-task-orders for steel coils, wherein the different sub-tasks-orders record one-time warehouse-out or warehouse-in operations of all the steel coil in different time periods; B, acquiring current running-vehicle data of the multiple running vehicles, and carrying out job assignment on the multiple running vehicles according to the same and the sub-task-orders to generate all hoisting transportation job orders of all the running vehicle; and C, arranging cooperative jobsof all the running vehicles according to all the hoisting transportation job orders of all the running vehicles, and controlling running of all the running vehicles according to the same. Therefore,the embodiment of the invention facilitates reducing of running-vehicle avoidance.

Owner:BEIJING BESTPOWER INTELCONTROL TECH CO LTD

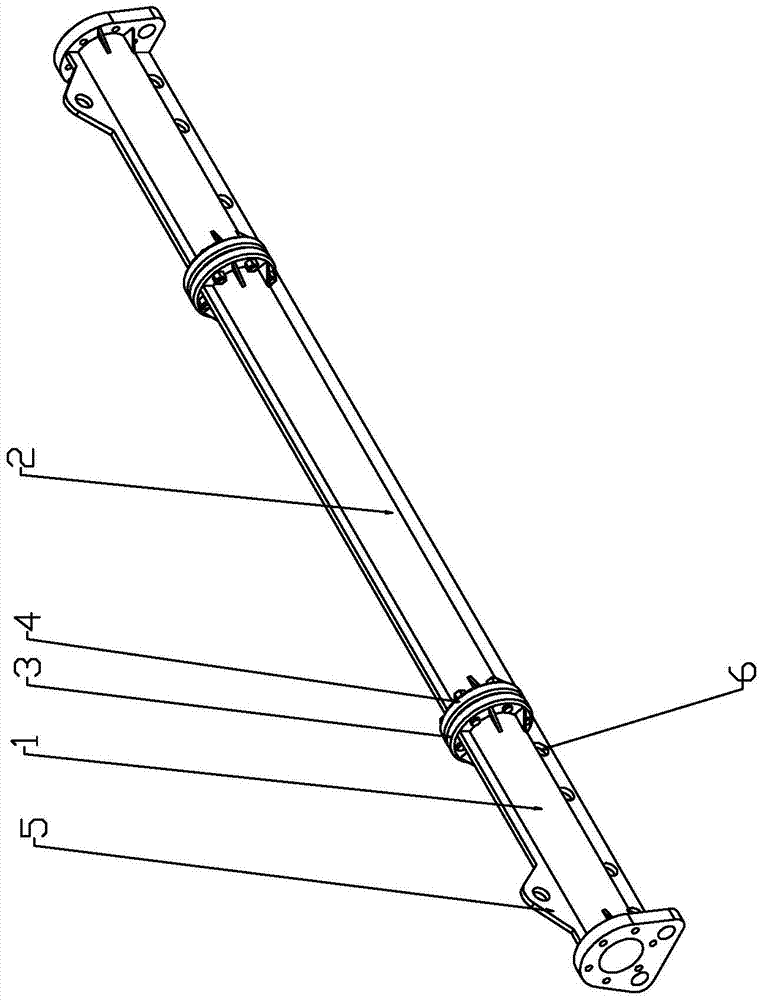

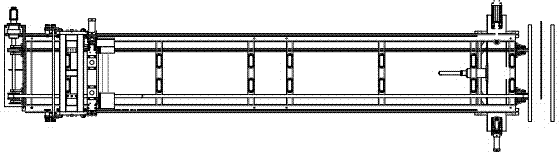

Adjustable hoisting beam

The invention belongs to the technical filed of hoisting equipment, and relates to a hoisting beam, in particular to an adjustable hoisting beam. The adjustable hoisting beam comprises two end beams, wherein a plurality of sequentially connected intermediate beams are arranged between the two end beams; the two end beams and the intermediate beams are connected through flanges; the plurality of intermediate beams are connected through flanges; and an upper hoisting lug is arranged at the upper part of each end beam, and a lower hoisting lug is arranged at the lower part of each end beam. According to the adjustable hoisting beam, the hoisting beam length can be freely adjusted according to different specifications of goods, so that the hoisting beam with the length corresponding to the specification lengths of goods is not required to be customized, the hoisting time is saved when goods with different specification lengths are hoisted, the work efficiency is improved, and the hoisting cost is saved.

Owner:无锡市新华起重工具有限公司

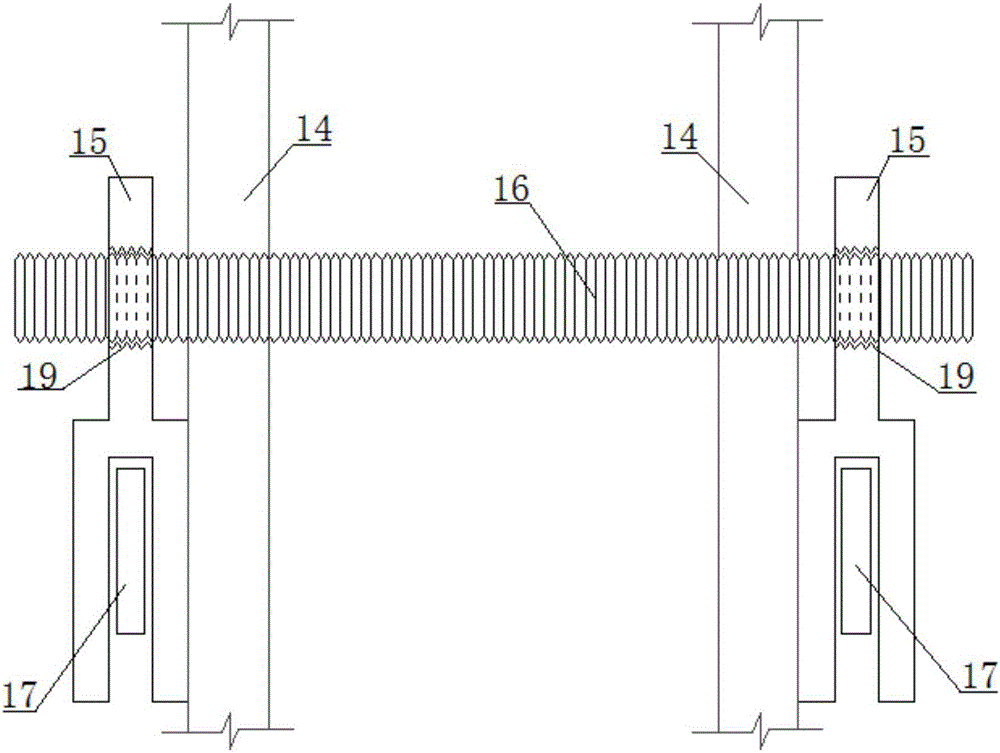

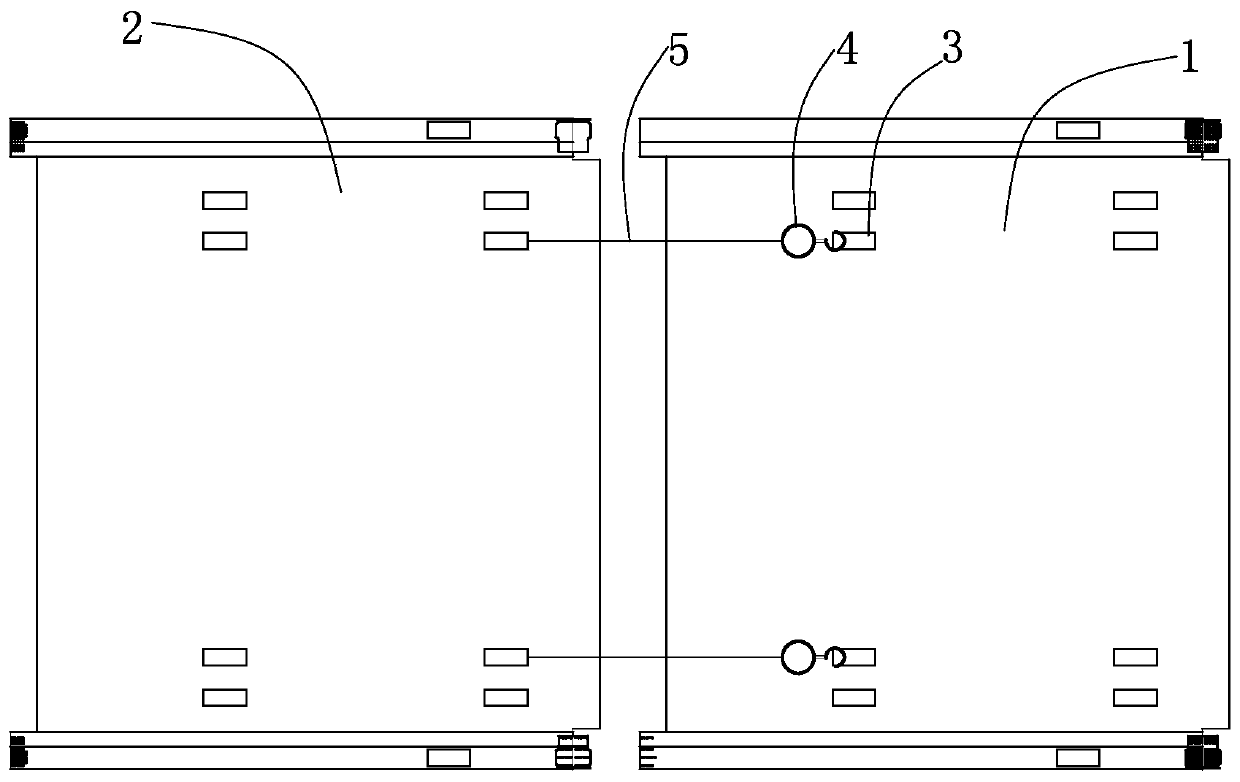

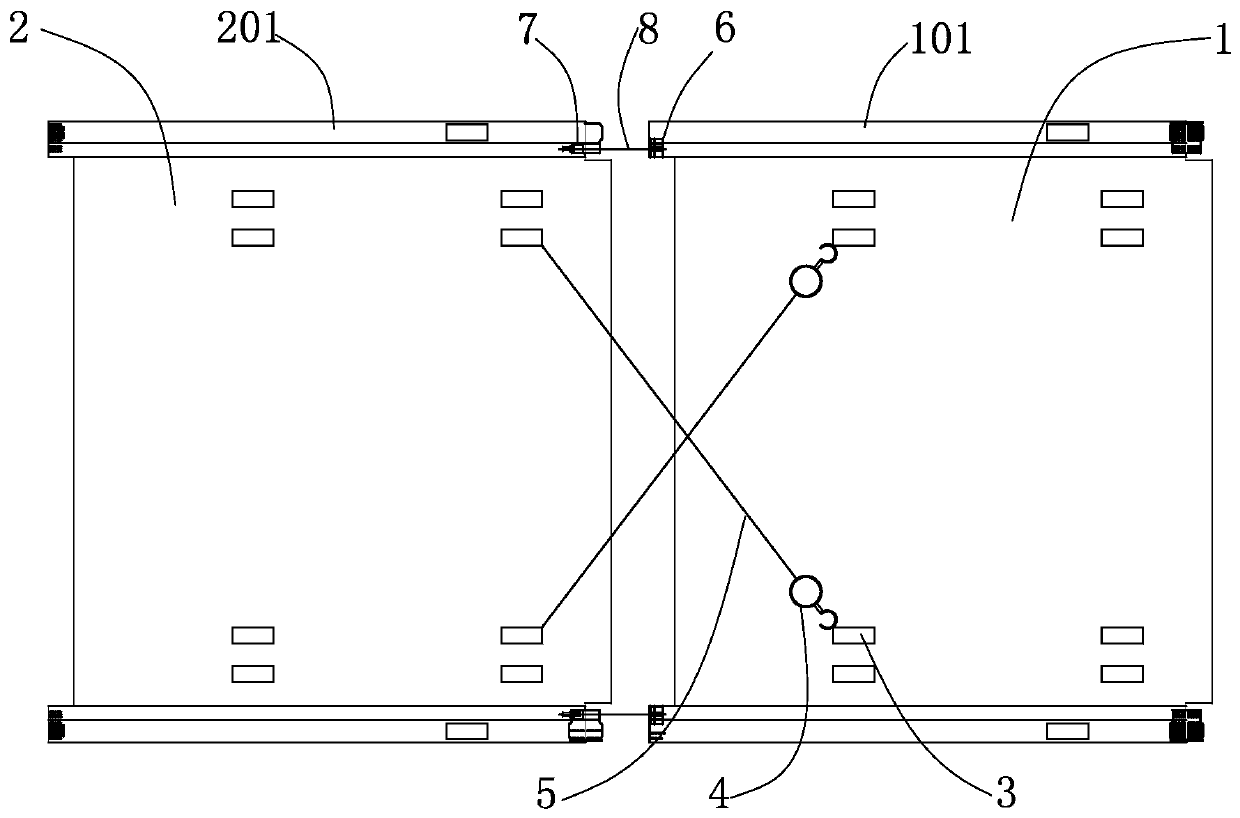

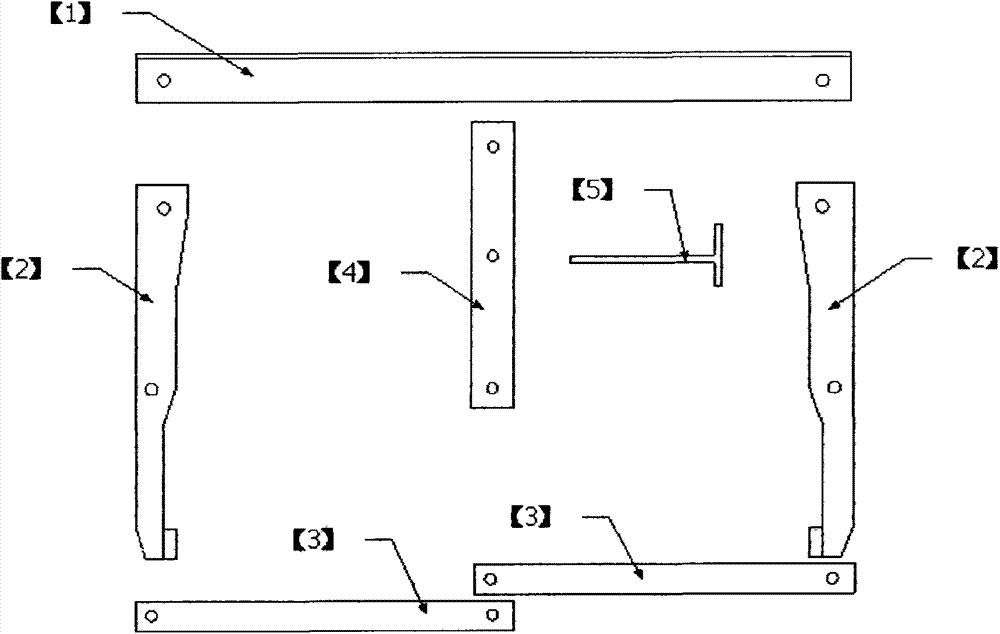

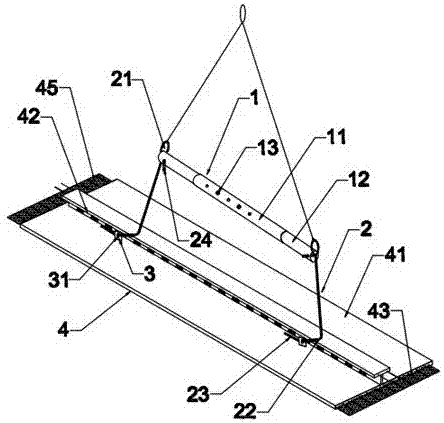

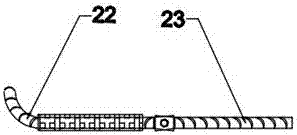

Horizontal hoisting clamp for wallboard

ActiveCN103395689AImplementing Fixture ProblemsSimple structureLoad-engaging elementsEngineeringWall plate

The invention provides a horizontal hoisting clamp for a wallboard. The horizontal hoisting clamp comprises five parts, respectively a hoisting clamp cross beam (1), hoisting clamp arm locks (2), arm lock connecting rods (3), a hoisting rod (4) and a bolt (5), wherein the hoisting clamp arm locks (2) are respectively downwards arranged at two ends of the hoisting clamp cross beam (1), the two arm lock connecting rods (3) which are connected are arranged between the hoisting clamp arm locks (2), and places in which the two connecting rods (3) are connected are simultaneously connected with the hoisting rod (4) upwards penetrating through the cross beam and provided with a bolt hole. The upper end of the hoisting rod (4) is hung on a hoisting hook by a hook, a rope sling or hoisting frame, and when the wallboard is hoisted, the hoisting rod (4) upwards pulls the connecting rods (3), and the connecting rods (3) pull the arm locks (2) to move inwards. After the arm locks (2) firstly clamp the wallboard, the wallboard moves upwards along with the upwards movement of the hoisting rod (4), and thus the purpose of hoisting is achieved. When the wallboard is placed down, after the wallboard falls to the ground, the hoisting hook continues move downwards, the hoisting rod is pressed to be below the cross beam to expose the bolt hole, and the arm locks are released so that the wallboard is placed down. After the bolt (5) is inserted into the bolt hole, the hoisting hook moves upwards, the bolt (5) on the hoisting rod (4) lifts up the cross beam, and the clamp naturally moves out from the wallboard. Therefore, the hoisting clamp provided by the invention can be used for conveniently and rapidly hoisting various kinds of plate type objects with greater strength.

Owner:邯郸市丛台区宗楼建筑有限公司

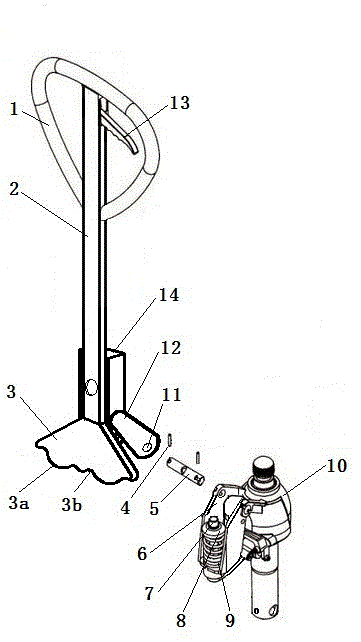

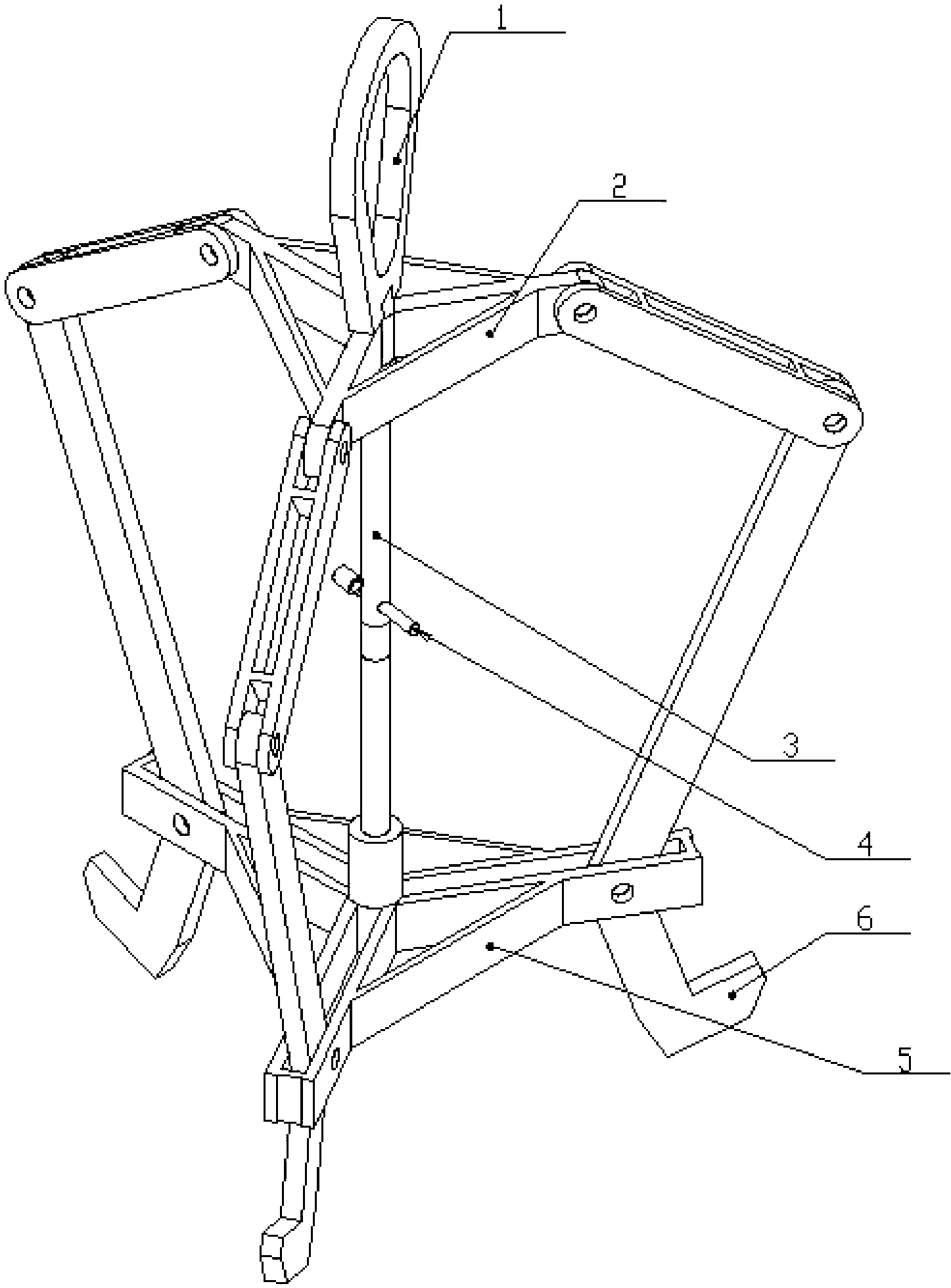

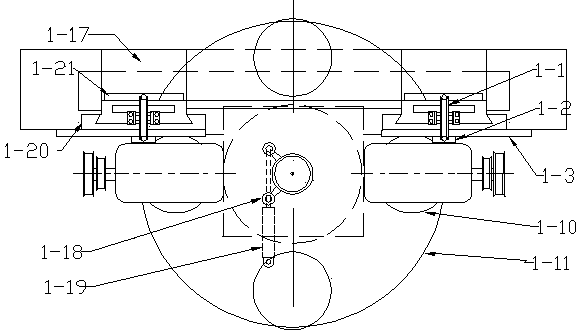

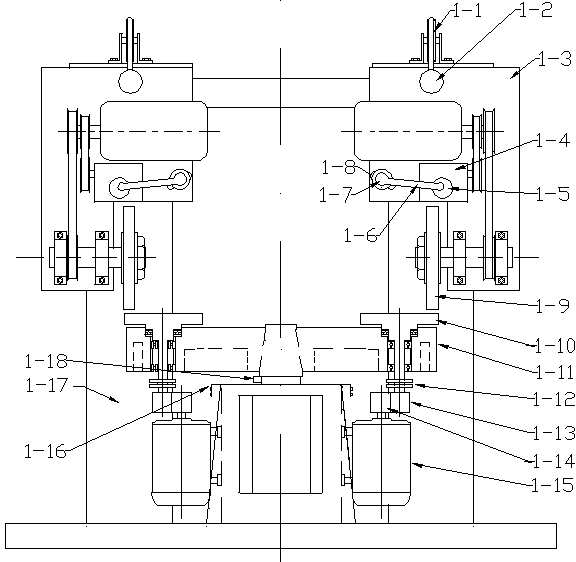

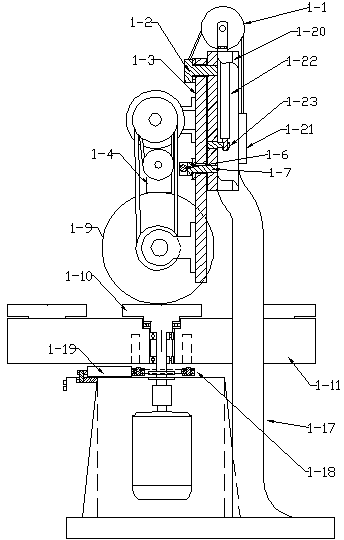

Fan hub hanger with rotational locking mechanism and using method thereof

ActiveCN103010932AAvoid safety hazardsLow costLoad-engaging elementsEngineeringElectrical and Electronics engineering

The invention discloses a fan hub hanger with a rotational locking mechanism and a using method thereof. The fan hub hanger with the rotational locking mechanism comprises a ring, an upper connection module, an intermediate connection module, a lower connection module, a claw module and a rotational locking mechanism, wherein the ring is fixed right above the upper connection module which is connected with the intermediate connection module; the intermediate connection module is connected with the claw module which is fixed on the lower connection module; the rotational locking mechanism is mounted right below the upper connection module; and a slot matched with the rotational locking mechanism is formed on the upper surface of the lower connection module. The invention further discloses a using method for the fan hub hanger with the rotational locking mechanism. The fan hub hanger has the advantage that a worker does not need to ascend to transport a hub.

Owner:CRRC WIND POWER(SHANDONG) CO LTD

Double-station edging machine

The invention relates to machining equipment, in particular to saw blade edging equipment, and provides a double-station edging machine. The double-station edging machine comprises a machine frame provided with a base, a circular work table is arranged on the machine frame and uniformly provided with four small rotary tables, saw blades to be machined are arranged on the small rotary tables, each small rotary table serves as one station, grinding wheels used for grinding the saw blades and feed control devices used for driving the grinding wheels are arranged above the work table, the grinding wheels are arranged on grinding wheel supporting devices and lifting devices, the work table is provided with two machining stations and two stations to be machined, the machining stations are arranged on the two sides of the work table and are provided with two sets of the independent grinding wheels and the grinding wheel feed control devices, the grinding wheel supporting devices and the lifting devices are of gantry type frame structures, two stations carry out abrasive machining at the same time, and the other two stations carry out feeding and blanking processes simultaneously. The double-station edging machine is stable in structure, is provided with two machining stations, and greatly improves work efficiency.

Owner:SHANDONG GOLD GRP CHANGYI MINING

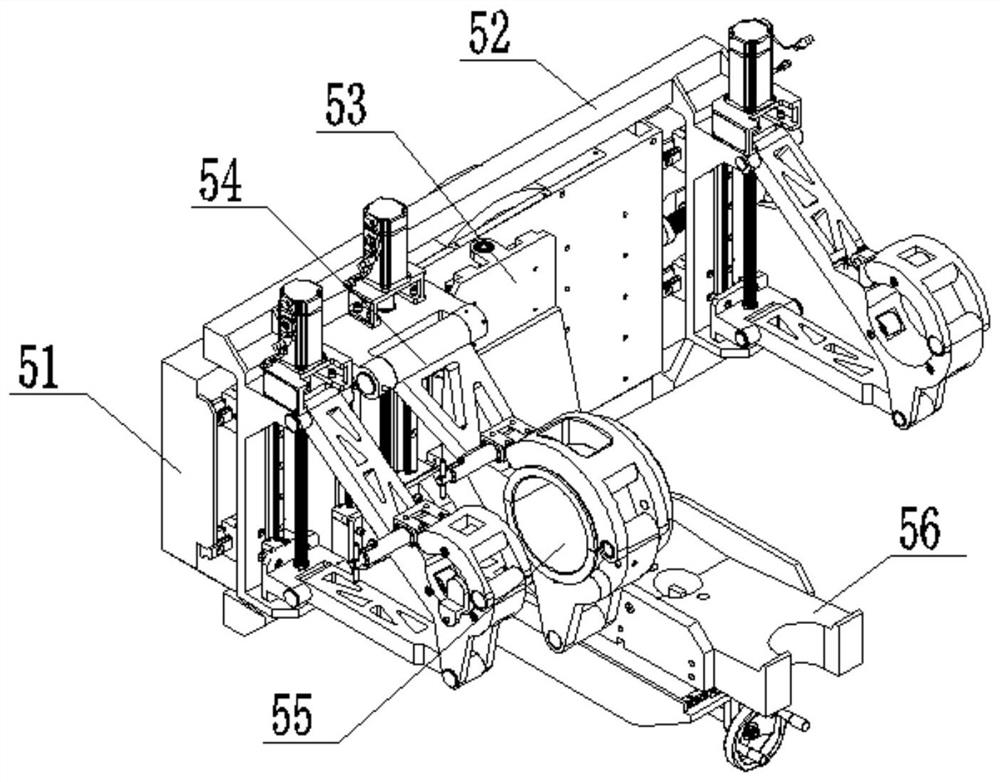

Clamping method and system for overhauling short shaft side gearbox of motor train unit based on AGV (Automatic Guided Vehicle)

PendingCN114516005AShorten the lifting timeSave manpower and material resourcesWork holdersElectric/hybrid propulsionGear wheelMachine

The invention discloses an AGV-based motor train unit short shaft side gear box overhauling and clamping method and system. The method comprises the steps that a turnover machine and a gear box positioning and clamping unit return to zero for self-inspection; the AGV conveys the gear box workpiece on the short shaft side to a box closing operation station and takes the gear box workpiece in place; the robot presses the torque value on the short shaft side end face of the gearbox and then returns to the zero position; a gearbox vertical lifting unit is installed on the short shaft side of a gearbox workpiece and fixed, a transverse moving unit is started to eliminate the gap value between a box body on the short shaft side of the gearbox workpiece and the gearbox vertical lifting unit, and a gearbox positioning and clamping unit on the short shaft side is controlled to rotate anticlockwise so that the gearbox workpiece can be in a vertical posture; the automatic jacking unit assists in adjusting the large gear bearing clearance of the gear box workpiece until the gear box workpiece is qualified; after the small gear enters the box and the clearance of the small gear is measured, the short shaft side gear box positioning and clamping unit is controlled to rotate clockwise, so that a gear box workpiece is in a horizontal posture; and through integrated and automatic operation, the workpiece hoisting cost is saved, and the working efficiency is improved.

Owner:LOTEEM BEIJING RAIL TRANSIT TECH CO LTD

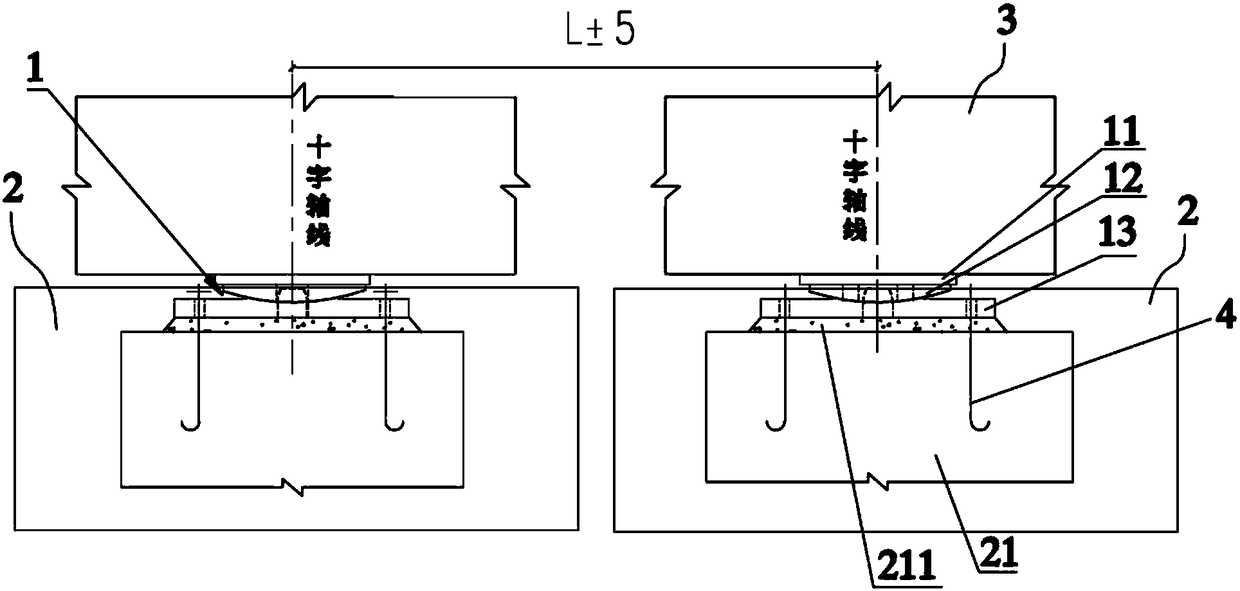

Large-span steel cross-beam hoisting construction method for crossing existing line portal pier

InactiveCN108374345AEffective control of measurement dataGuaranteed construction accuracyBridge erection/assemblyEngineeringSpandrel

The invention discloses a large-span steel cross-beam hoisting construction method for crossing an existing line portal pier. The method comprises the following steps: step S1: according to a set position, installing a temporary support on a temporary padstone installed on the portal pier; step S2: according to a design position, accurately setting out a cross-shaped axis of a steel cross beam onthe pier top of the portal pier, and correspondingly setting out a cross-shaped axis on the steel cross beam, which is used for the installing and positioning of the steel cross beam; step S3: hoisting the steel cross beam by using a hoisting machine, in a positioning process, adjusting the position of the exterior of the steel cross beam by using a crowbar, and adjusting the position of the interior of the steel cross beam by using a chain block, until the cross-shaped axis on the steel cross beam is completely aligned with the cross-shaped axis on the pier top, and completing the beam fall;and step S4: welding a bottom plate of the steel cross beam and the temporary support. Through the alignment of cross curves, the construction precision is guaranteed, each item of the measured data of the hoisted steel cross beam is effectively controlled to be within a deviation area of the design requirements, a good effect is achieved, the hoisting time is shortened at the same time, and construction speed is rapid.

Owner:中铁二十一局集团第五工程有限公司

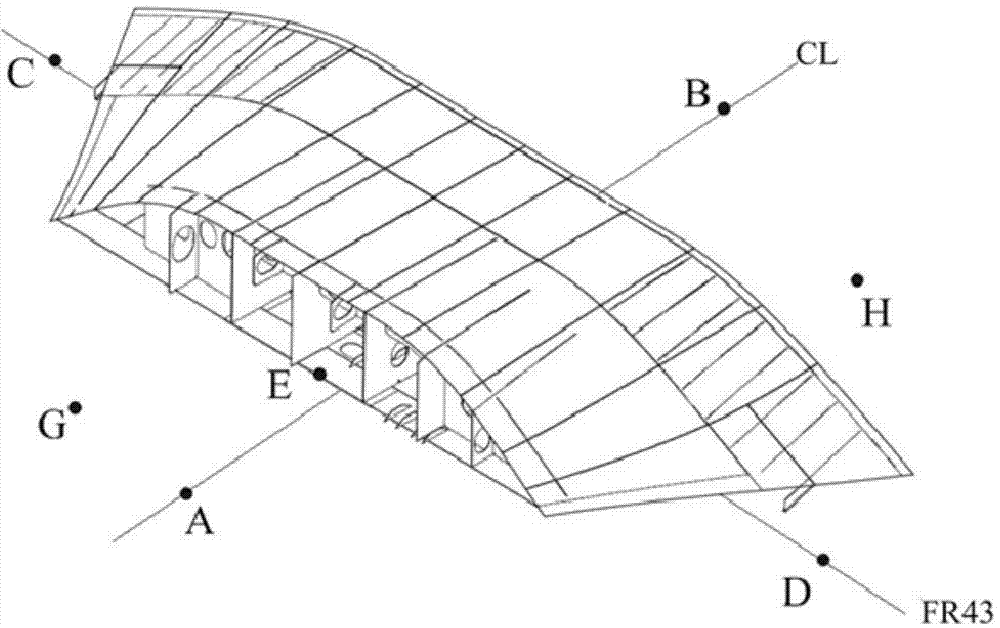

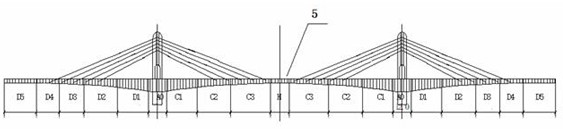

Asymmetric installation and construction method for straddle type light rail special steel box extradosed cable-stayed bridge

ActiveCN111622116AReduce build timeImprove manufacturing precisionCable-stayed bridgeBridge structural detailsArchitectural engineeringLight rail

The invention discloses an asymmetric installation construction method for a straddle type light rail special steel box extradosed cable-stayed bridge. The method comprises the steps of dividing a full-bridge steel box girder into a plurality of girder sections, and then conducting asymmetric installation according to the hoisting sequence of a side span section D1, a middle span section C1, a side span section D2, a middle span section C2,..., a side span section Dn, a side span section D<n+2>, a side span closure section,..., a middle span section Cn and a middle span closure section H. According to the method, steel pipe supports do not need to be arranged in the mid-span section, and channel requirements can be met to the maximum extent.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

Steel grating through-type drifting clamping feeding mechanism

InactiveCN106862988ADesign scienceReasonable designMetal sawing accessoriesMetal working apparatusGratingEngineering

The present invention relates to a steel grating through-type drifting clamping feeding mechanism. The problems to be solved are poor procedure continuity, time waste, labor waste, and low production efficiency due to that a welded steel grating may not be directly delivered to a pit-saw cutting table. The technical solution employed to solve the technical problems has the following key points: a servo drive mechanism drives a feeding trolley to move backward and forward along a feeding platform; a rollgang is disposed on the feeding platform; a steel grating clamping mechanism on the feeding trolley consists of horizontal U-shaped clamps on both sides, and a lower clamping plate of each U-shaped clamp is lower in position than the upper tangent-plane of the rollgang so that the conveyed steel grating can pass through the U-shaped clamp. The U-shaped clamps are controlled by power to clamp and fix up and down. The steel grating through-type drifting clamping feeding mechanism is applicable to steel grating production.

Owner:YANTAI XINKE STEEL STRUCTURE

Construction method of PK prestressed concrete overlapping slabs

ActiveCN107130720AAdvantages of construction methodOptimize stacking methodFloorsBuilding material handlingElectricityPre stress

The invention discloses a construction method of PK prestressed concrete overlapping slabs. The construction method comprises the following steps: S1, according to the requirements of a design drawing, preparing corresponding PK slabs, conveying to a construction site, and stacking by batches; S2, according to designed locations of the PK slabs in the drawing, setting up support frames with adjustable height at the corresponding locations, so as to press the PK slabs onto transverse rods in the support frames; S3, enabling lifting equipment to lift the PK slabs to the corresponding locations, and simultaneously paving the PK slabs one by one until fully paving; S4, according to the design requirements of the drawing, reserving a water and electricity pipeline mounting hole in the corresponding PK slab; S5, sealing at a connecting part of each PK slab and a beam and column formwork; S6, arranging a reinforcing bar and a pipeline on each PK slab; S7, casting concrete on each PK slab; S8, detaching the support frames and the beam-column formwork set up in step 2. The construction method of the PK prestressed concrete overlapping slabs has the advantages that the PK slabs are lifted by a self-made lifting tool, the lifting time is shortened, and the lifting procedure is simplified.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com